Nitrogen-doped three-dimensional bicontinuous porous carbon and graphene composite electrode as well as preparation and application thereof

A composite electrode and bi-continuous technology, applied in the field of capacitor electrodes, can solve the problems of poor electrode conductivity, low energy density, and poor cycle performance, and achieve the effects of increasing the contact area, simple preparation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

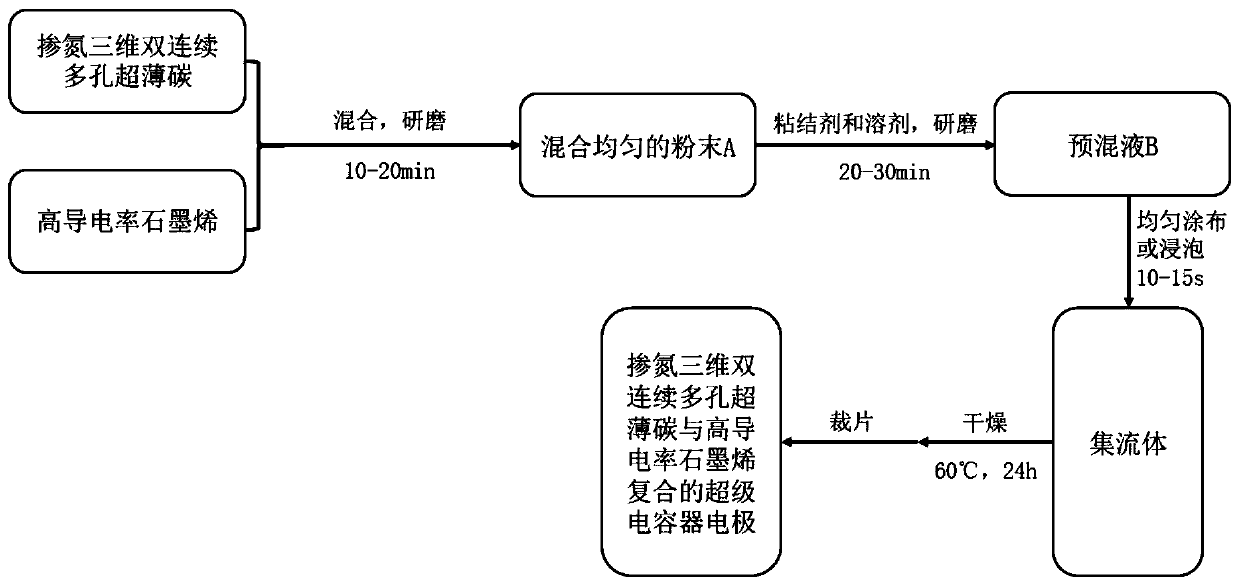

[0035] figure 1 It is a process flow diagram for the implementation of the present invention. The preparation of nitrogen-doped three-dimensional double-continuous porous ultra-thin carbon can refer to the Chinese patent publication number CN106517133B. The three-dimensional double-continuous porous ultra-thin carbon is formed by low-temperature pyrolysis of shrimp shells and urea, which can expand to three dimensions. Ultrathin porous carbon with interconnected pores. Mix nitrogen-doped three-dimensional bicontinuous porous ultra-thin carbon with high-conductivity graphene, grind for 10-20 minutes to obtain a uniformly mixed powder, add PVDF to the powder as a binder, and NMP as a solvent, and continue grinding for 20-30 minutes to obtain Premix solution; then evenly coat the premix solution on stainless steel foil, dry at 60°C for 24 hours, and cut into pieces to obtain the final nitrogen-doped three-dimensional double-continuous porous ultra-thin carbon and high-conductivi...

Embodiment 2

[0037] Mix nitrogen-doped three-dimensional bicontinuous porous ultra-thin carbon with high-conductivity graphene, grind for 10-20 minutes to obtain a uniformly mixed powder, add PVDF to the powder as a binder, and NMP as a solvent, and continue grinding for 20-30 minutes to obtain Premix solution; then immerse the pre-cut nickel foam discs in the premix solution for 10-15s, remove, dry at 60°C for 24 hours, and press into tablets to obtain the final nitrogen-doped three-dimensional double continuous porous ultra-thin Electrodes for supercapacitors composited with carbon and high-conductivity graphene. Electrode loadings of 1.5-3 mg / cm were achieved 2 .

Embodiment 3

[0039] Mix nitrogen-doped three-dimensional bicontinuous porous ultra-thin carbon and high-conductivity graphene, and grind for 10-20 minutes to obtain a uniformly mixed powder. Add Nafion to the powder as a binder, and a mixed solution of isopropanol and water as a solvent. Continue Grind for 20-30 minutes to obtain the premix; then evenly coat the premix on stainless steel foil, dry at 60°C for 24 hours, and cut into pieces to obtain the final nitrogen-doped three-dimensional double continuous porous ultra-thin carbon and high-conductivity graphite Alkene-composite supercapacitor electrodes. Obtained electrode loadings of 0.8-1.5 mg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com