Patents

Literature

6748 results about "Shrimp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term shrimp is used to refer to some decapod crustaceans, although the exact animals covered can vary. Used broadly, shrimp may cover any of the groups with elongated bodies and a primarily swimming mode of locomotion – most commonly Caridea and Dendrobranchiata. In some fields, however, the term is used more narrowly and may be restricted to Caridea, to smaller species of either group or to only the marine species. Under the broader definition, shrimp may be synonymous with prawn, covering stalk-eyed swimming crustaceans with long narrow muscular tails (abdomens), long whiskers (antennae), and slender legs. Any small crustacean which resembles a shrimp tends to be called one. They swim forward by paddling with swimmerets on the underside of their abdomens, although their escape response is typically repeated flicks with the tail driving them backwards very quickly. Crabs and lobsters have strong walking legs, whereas shrimp have thin, fragile legs which they use primarily for perching.

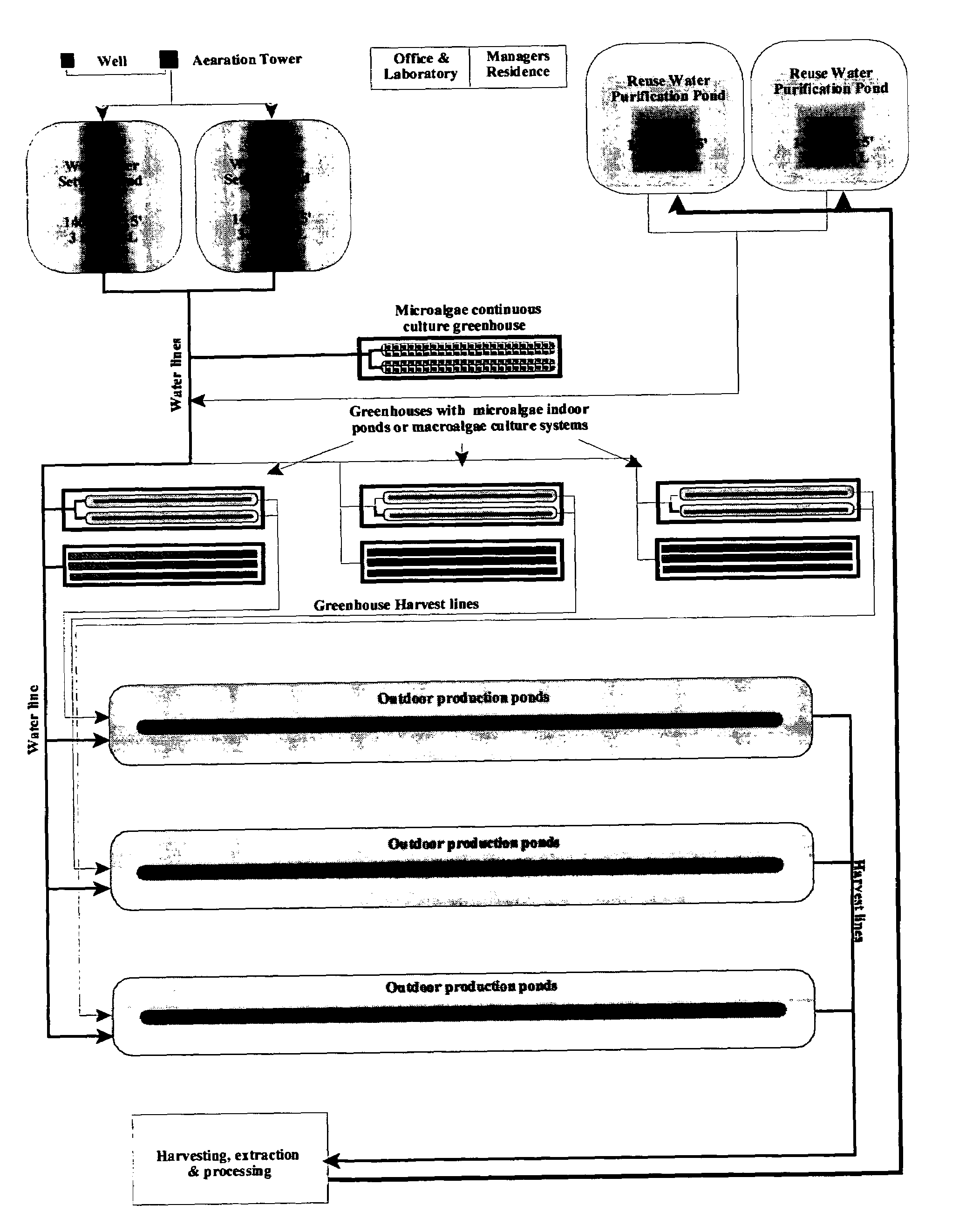

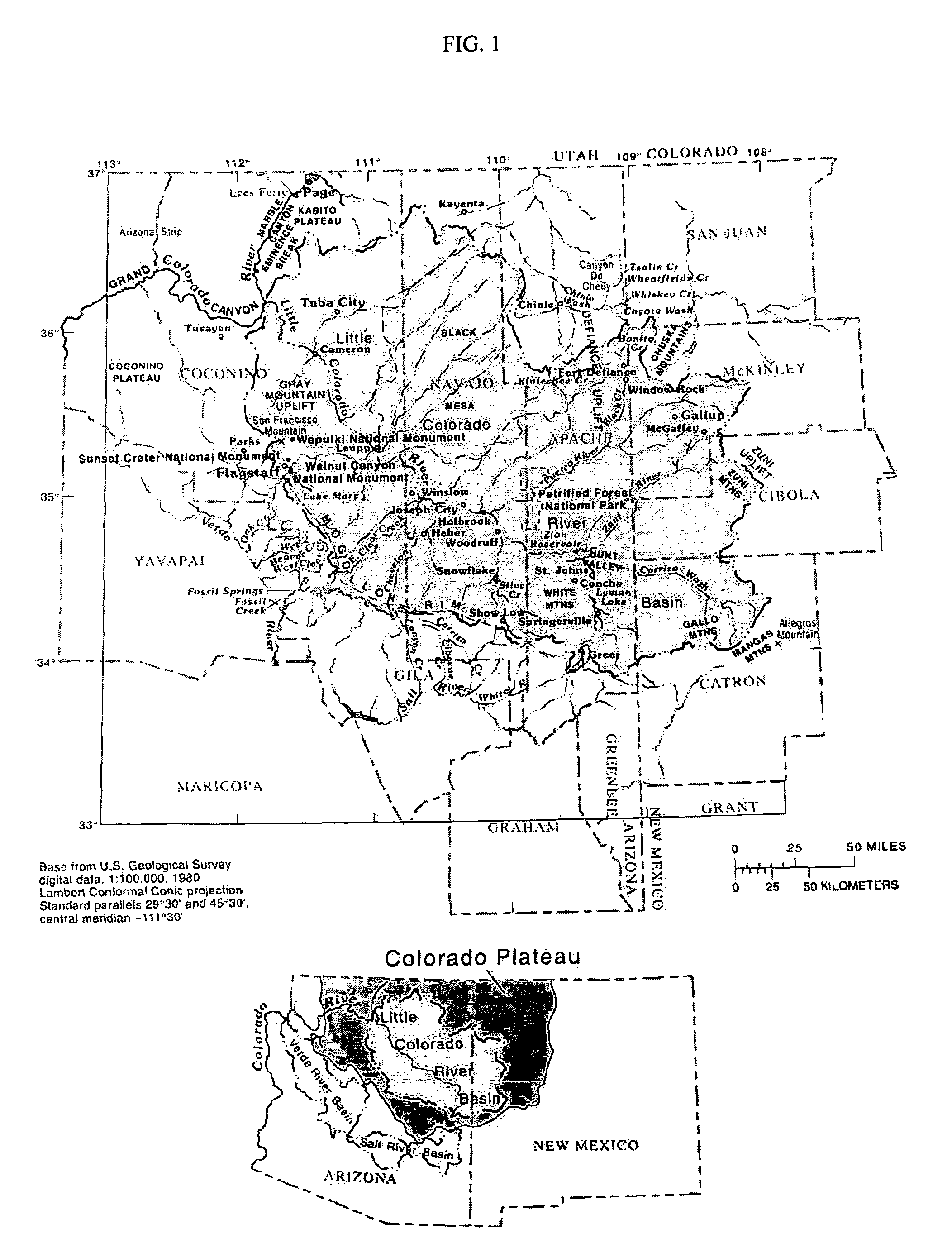

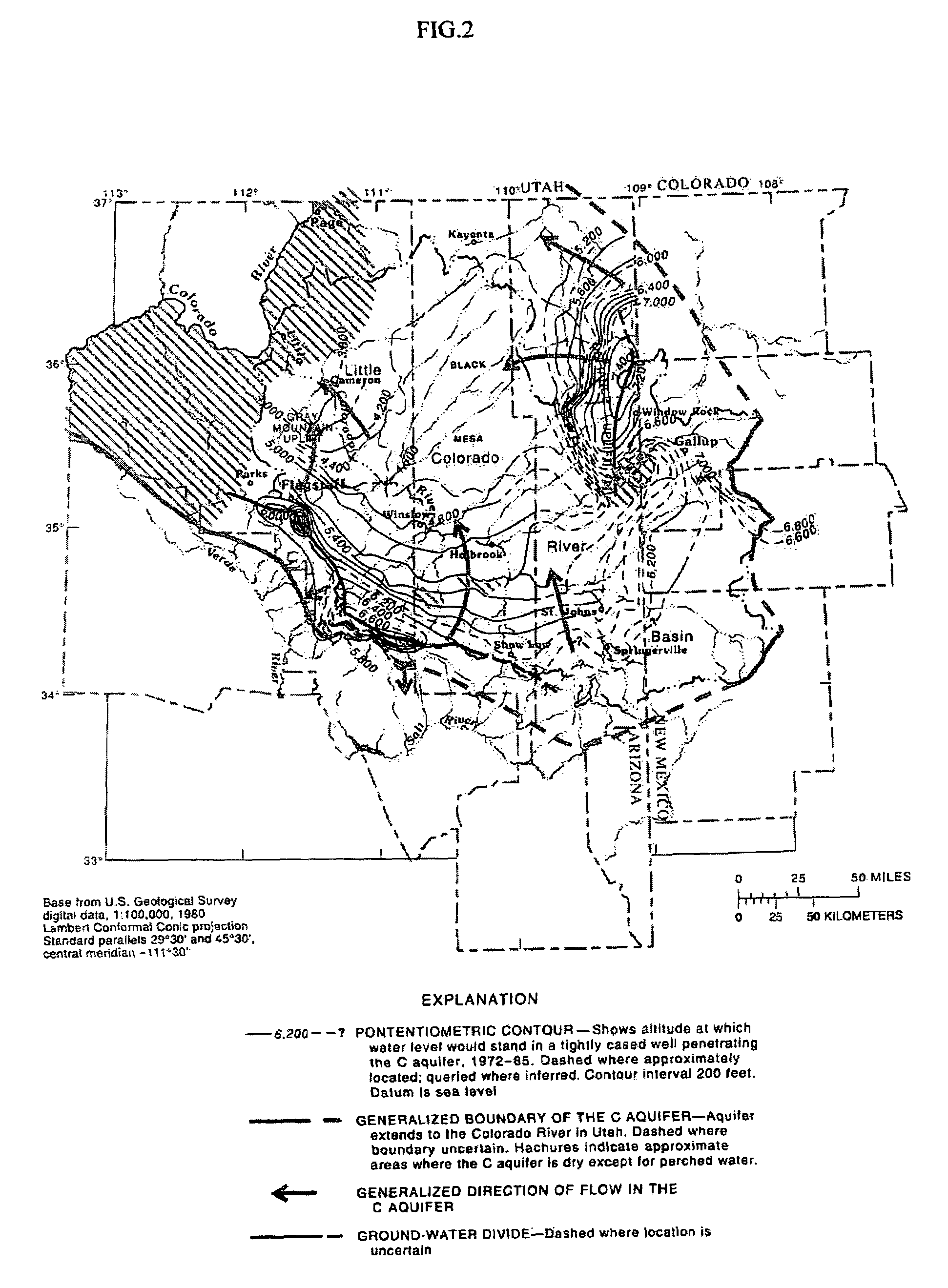

Inland aquaculture of marine life using water from a saline aquifer

InactiveUS6986323B2Overcome disadvantagesClimate change adaptationPisciculture and aquariaInland saline aquacultureWater layer

A method and system for the inland aquaculture of marine species using water from a saline aquifer having a heavy metals content within the acceptable limits of the EPA guidelines for drinking water. The aquifer is preferably the Coconino aquifer located in Arizona and New Mexico. The system can be used to culture microalgae, macroalgae, fish, shrimp and many other marine species. Nutrients and fertilizers can be added to the water to optimize culture conditions for particular species. Useful products can be isolated from the marine species or the cultured marine species can be harvested as useful products themselves.

Owner:ALGAE BIOSCI

Dietetic nutritive powder

InactiveCN1647696APrevent cancerPromote absorptionUnknown materialsFood preparationWheat germPowder mixture

The diatotherapeutic nutritive powder as a kind of health food is powdered mixture produced with over forty kinds of grains, vegetable, fruit, sea food material and Chinese medicinal materials, including rice, red bean, peanut, Chinese cabbage, apple, shelled fresh shrimp, glossy ganoderma, lily, etc. It has comprehensive, balanced and reasonable nutritive components.

Owner:孙天福

Marine product meat sausage and making method thereof

The invention discloses a marine product meat sausage and a making method thereof. The marine product meat sausage is characterized by comprising the following raw materials proportioning by weight: 30-85 portions of marine product, 0-30 portions of edible meat, 10-30 portions of edible water, 1-12 portions of edible vegetable oil, 2-6 portions of soybean protein isolate, 0.5-1.6 portions of saltand 2.0-7.5 portions of starch; the marine product meat sausage is prepared according to the steps of raw material processing, twisting, chopping, stirring, filling, sterilizing and packaging. The invention is prepared by adopting the marine products (scallop muscle, oyster meat, sleeve-fish meat, salmon meat, shrimp meat, trepang, abalone, yellow croaker meat, hairtail meat, fish seeds, ling meat, waste fish meat and the like) or adding the edible meat (chicken, pork, mutton, beef and the like) as the main raw materials, has abundant and balanced nutrition, meets the requirement of a consumeron the marine products and increases the appetite, and the product has strong seafood taste and unique flavor, does not contain nitrite, is beneficial to health, is packaged in vacuum, has unique appearance and is ready to be enjoyed when a bag is opened.

Owner:青岛农博农食品科技有限公司

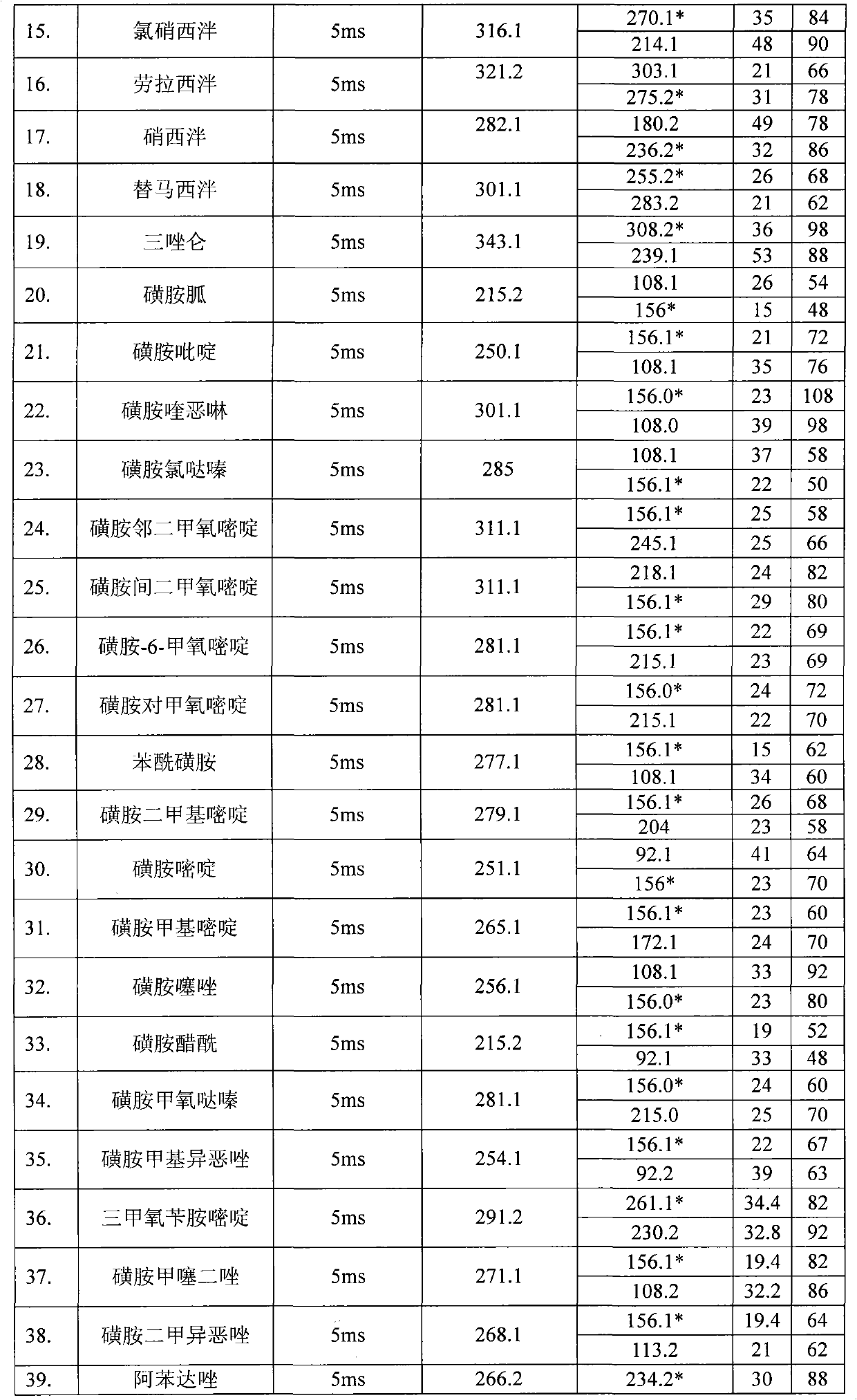

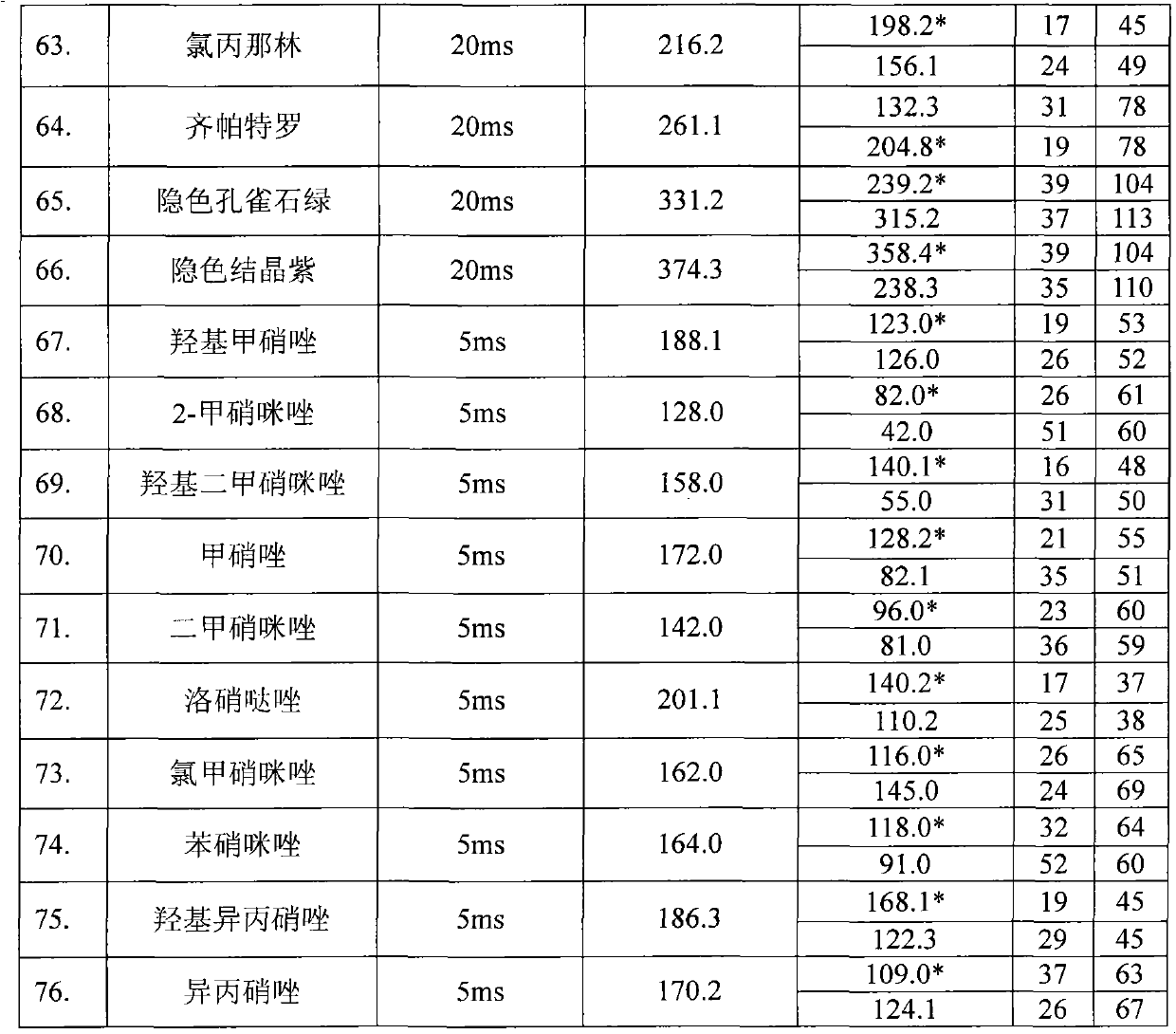

Method for detecting residual quantity of multiple alkaline drugs in animal derived food

The invention relates to the fields of analytical chemistry and food safety, in particular to a method for detecting the residual quantity of multiple alkaline drugs in animal derived food. Based on the vortex mixed extracting of acetonitrile, isopropanol and citric acid buffer solutions, the purification of a hydrophilic polystyrene-divinylbenzene solid phase extraction column and a cation exchange solid phase extraction column and the liquid phase chromatography-mass spectra determination, the method can detect the residual quantity of multiple alkaline drugs in pork, pork liver, eggs, shrimps and milk, such as beta-receptor agonists,sulfonamides, benzodiazepines, nitroimidazoles, benzimidazoles and triphenylmethanes. The method has the advantages of simple operation, fast and accurate detection and high efficiency.

Owner:SHANGHAI ANPEL SCI INSTR +1

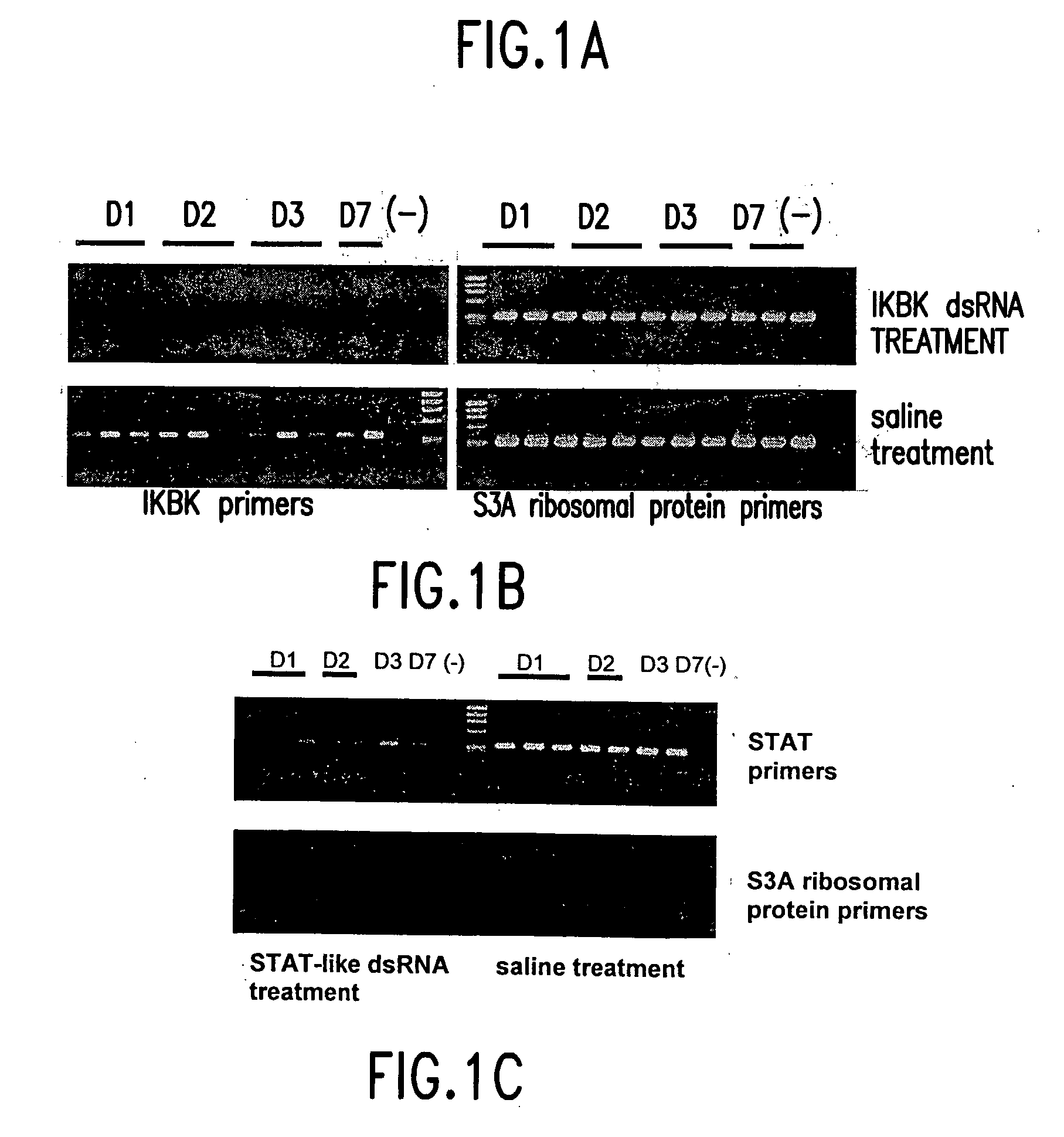

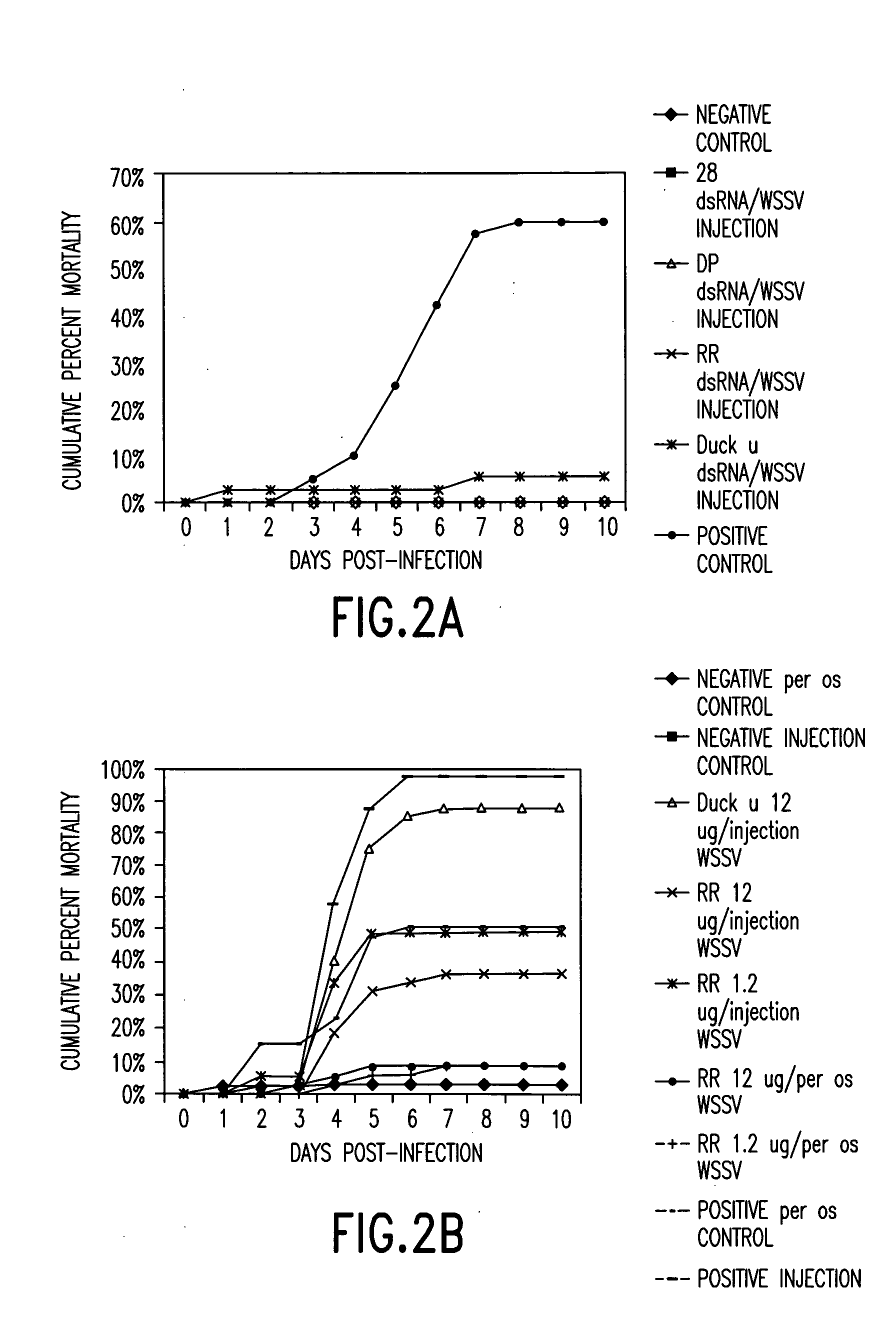

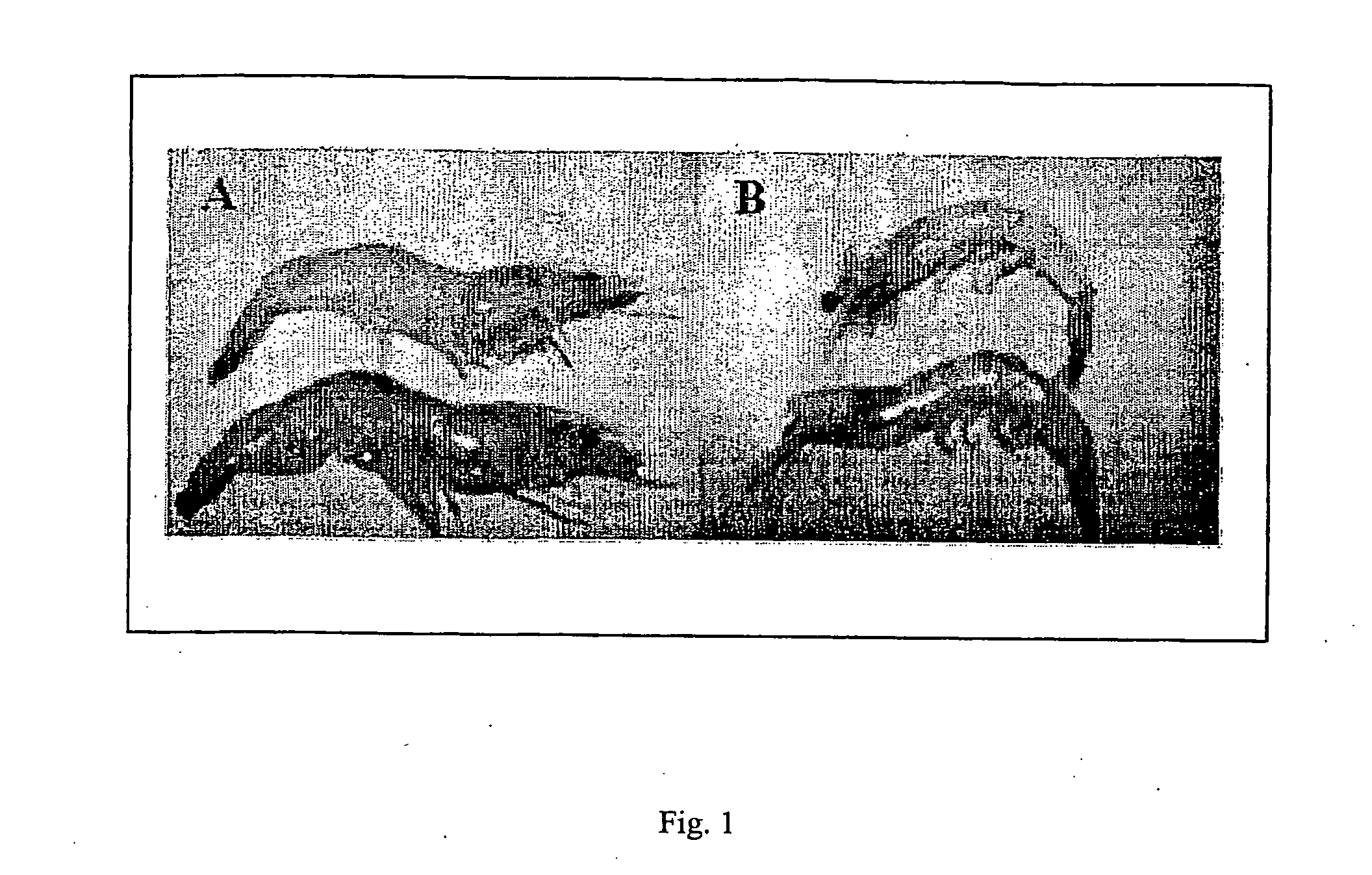

dsRNA induced specific and non-specific immunity in crustaceans and other invertebrates and biodelivery vehicles for use therein

InactiveUS20050080032A1Easy to understandGood curative effectAntibacterial agentsAntimycoticsWhole bodyMarine invertebrates

Methods for inducing systemic, non-specific and / or sequence specific immune responses in invertebrates, e.g., marine invertebrates such as mollusks, porifera, ctenophora, echinodermas, marine worms, cnideria and preferably crustaceans, by the administration of at least one dsRNA, that confers immunity against a pathogen, or modulates expression of gene that affects growth, reproduction, and general health or "robustness" are provided. Also provided are methods of identifying invertebrate genes, e.g., crustacean genes, the expression of which is involved in the induction of non-specific (systemic) immune responses against pathogens. Also disclosed are preferred delivery systems and methods for stably administering at least one dsRNA to a crustacean whereby the dsRNA is administered via injection, immersion, in a feed or nutrient medium or comprised in a microorganism, e.g., yeast or microalgae, that expresses said dsRNA and is ingestible by said crustacean, e.g., a shrimp.

Owner:MUSC FOUND FOR RES DEV

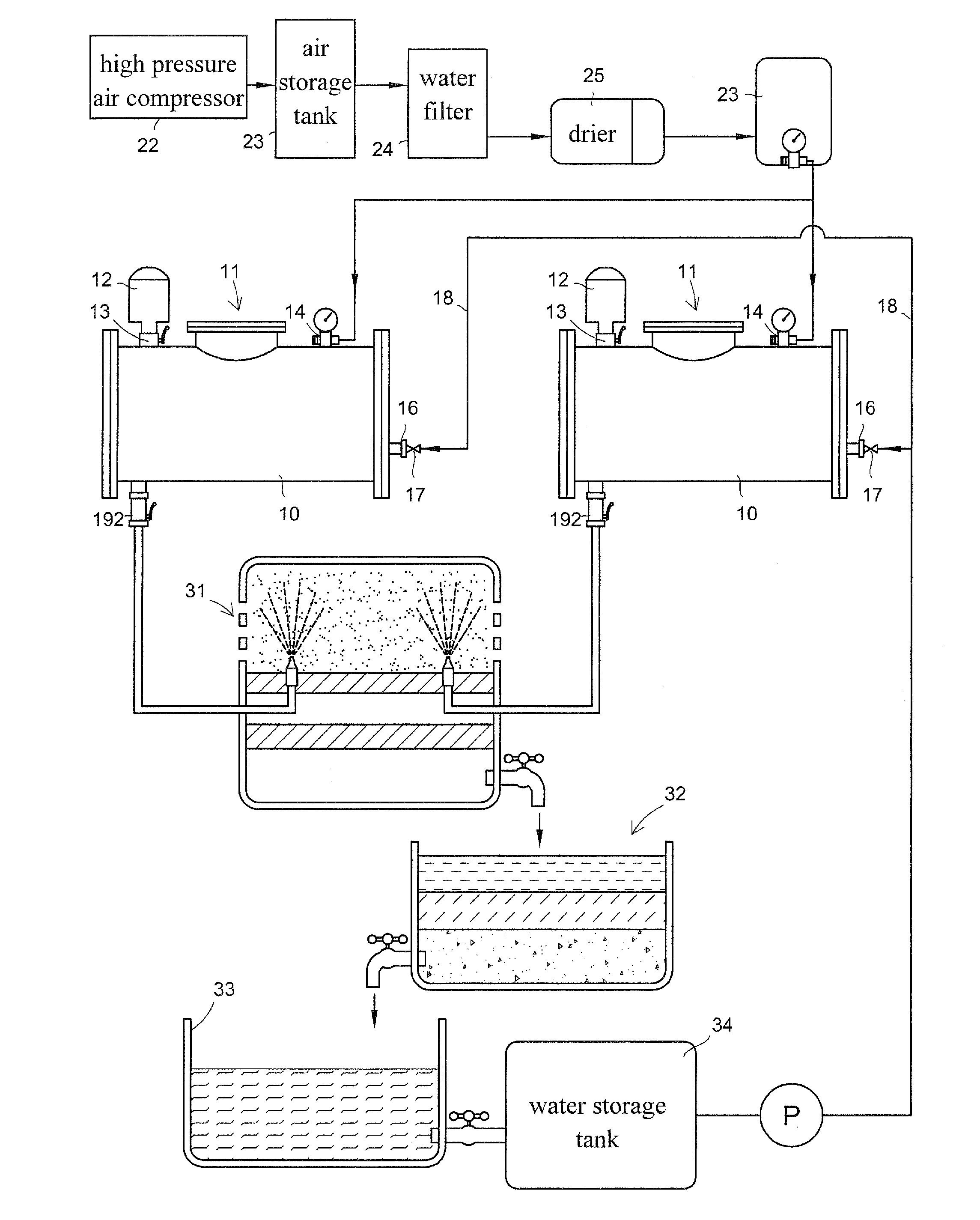

Method of aquaculture

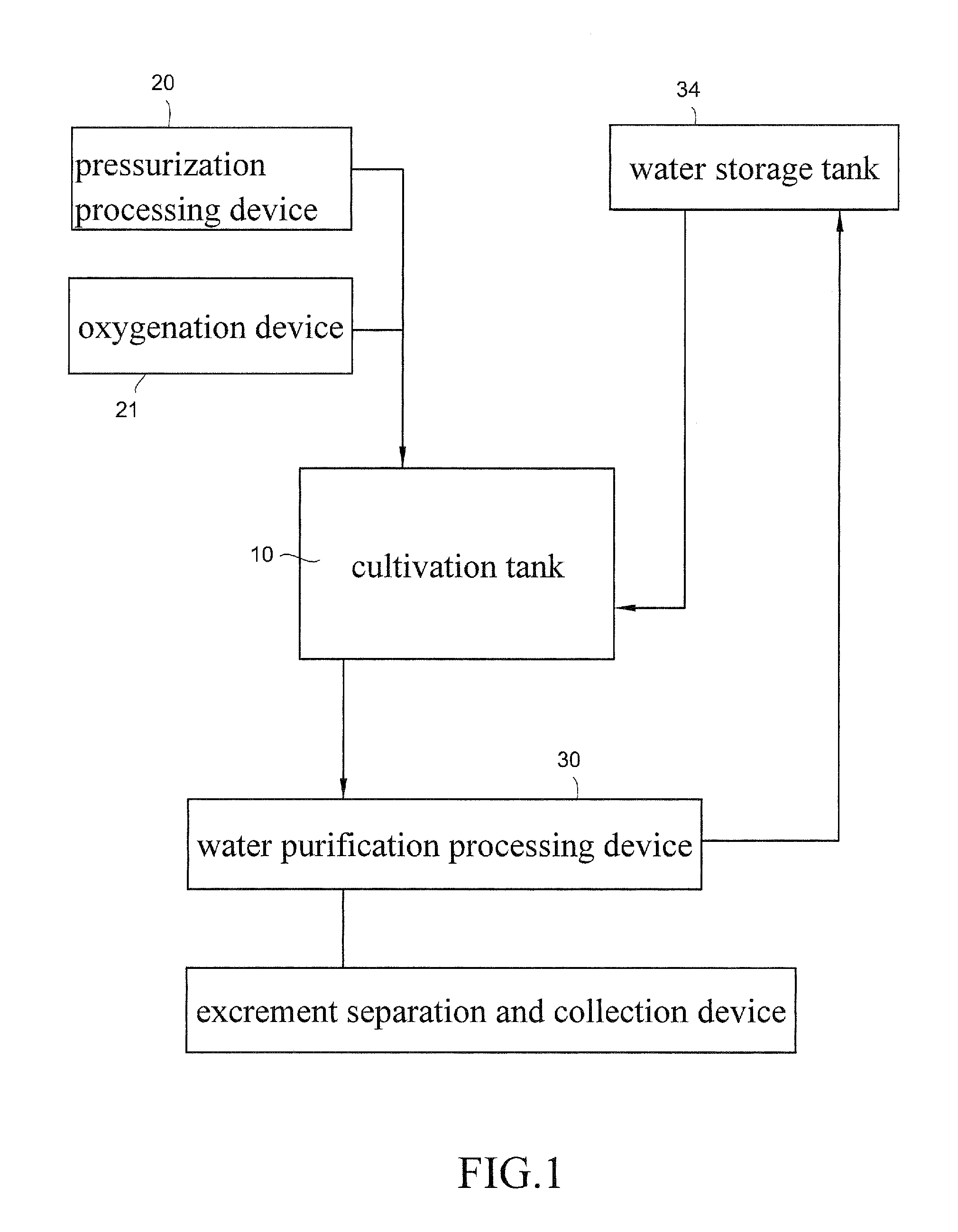

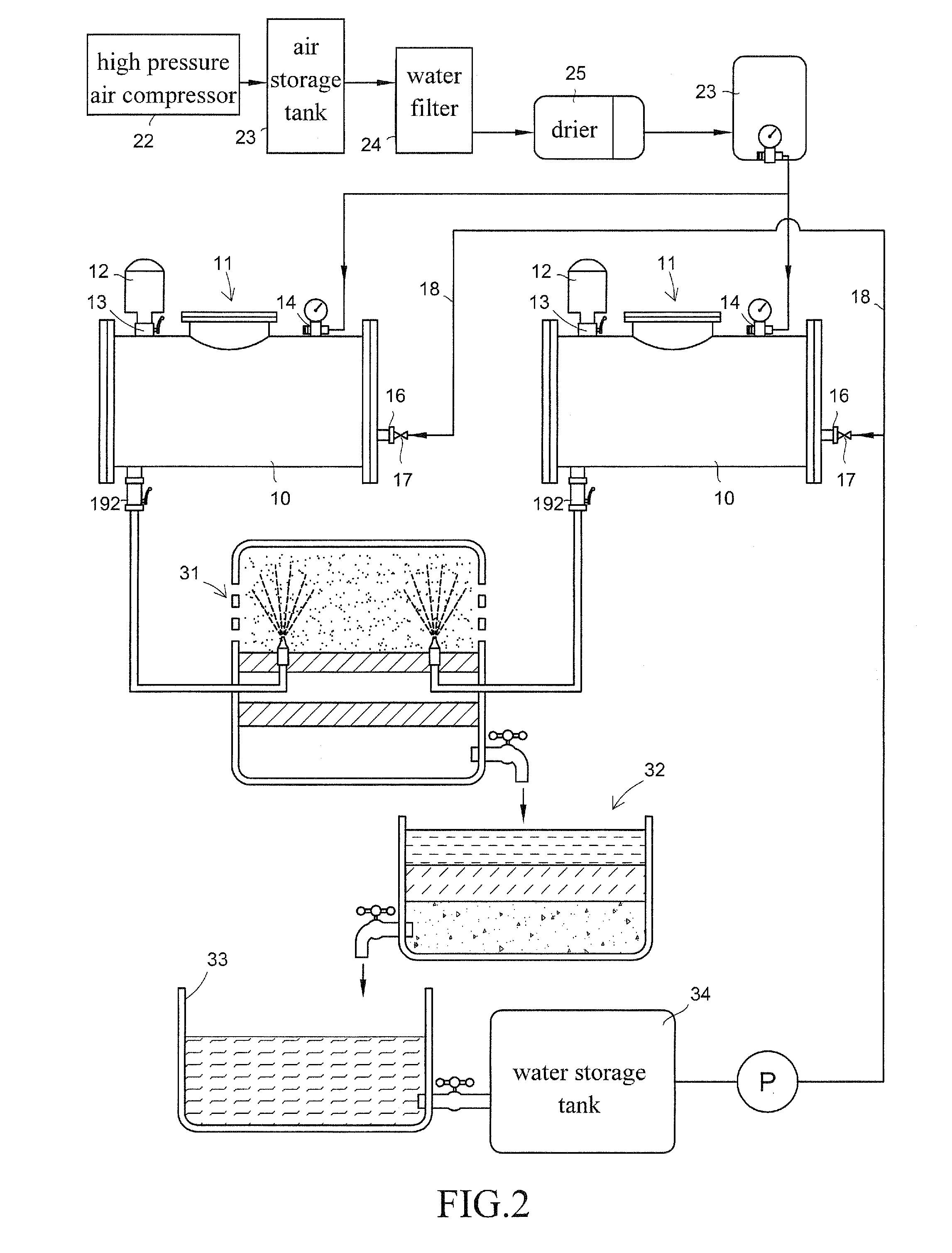

ActiveUS20100269761A1Increase fishery productionHigh economic valueClimate change adaptationPisciculture and aquariaSiphonFiltration

A method of aquaculture is applicable to a novel culture arrangement for diversified farming of generally deep sea fin fishes, shrimps, and shellfishes. A pre-manufactured enclosed cultivation tank is provided and air compressor facility is included for pressurization and oxygenation so as to make the interior of the cultivation tank a pressurized water environment of predetermined high pressure. A low pressure siphon tube is included for sucking and removing excrements from the cultivation tank and to realize water replacement in a natural manner thereby providing a deep sea mimicked clean cultivation environment. The drained water is subjected to multiple steps of filtration and purification for separating the excrements from the water and for purifying water to allow cyclic use of the water. An arrangement of multiple cultivation tanks allows for diversified and multi-species cultivation of fishery products and deep sea fishes.

Owner:NIEN TE CHIH

Fucoidin ester as antiviral immunoregulator and its prepn

InactiveCN1344565AHigh yieldSimple and fast operationPharmaceutical non-active ingredientsImmunological disordersShrimpReverse osmosis

Owner:汤洁 +1

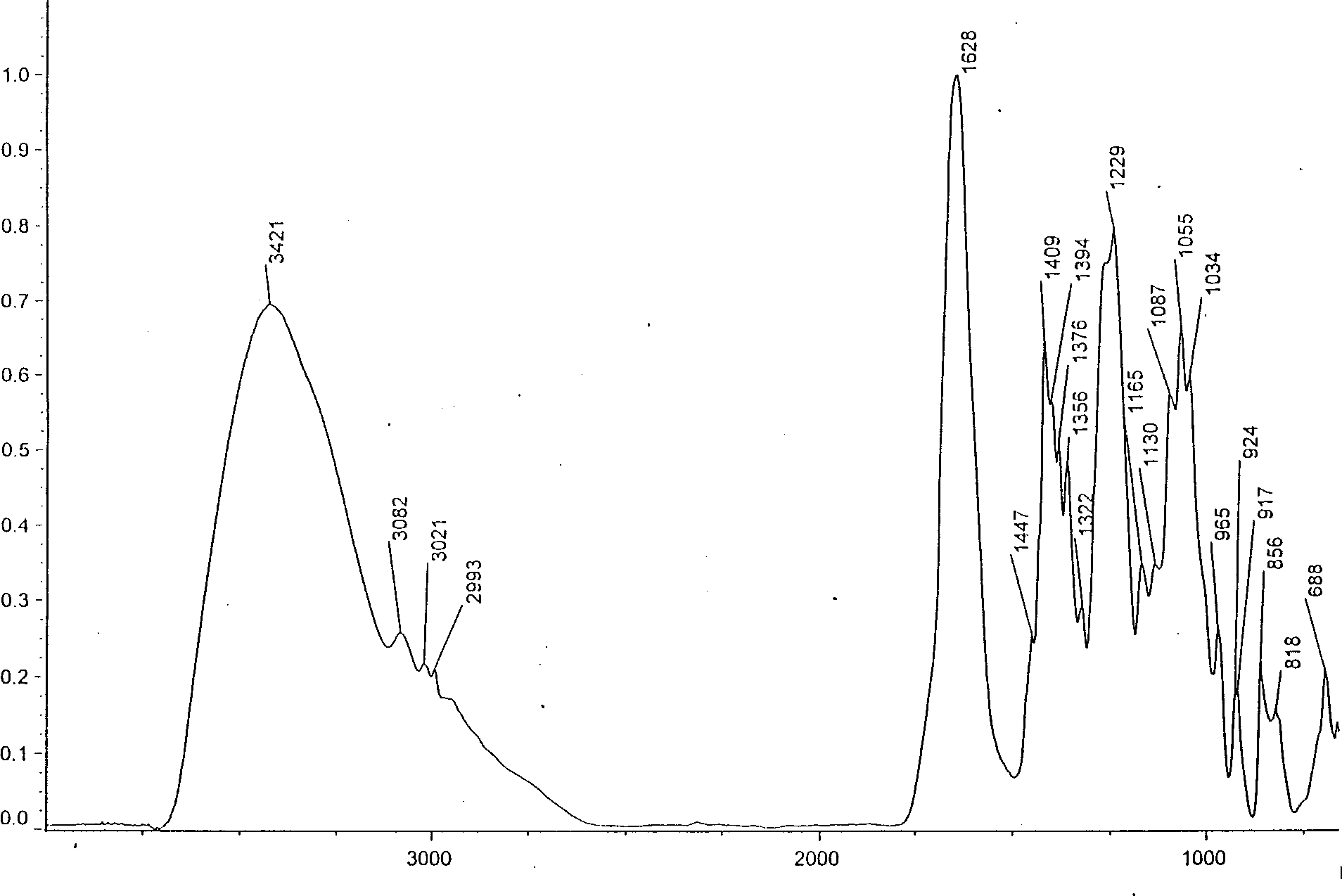

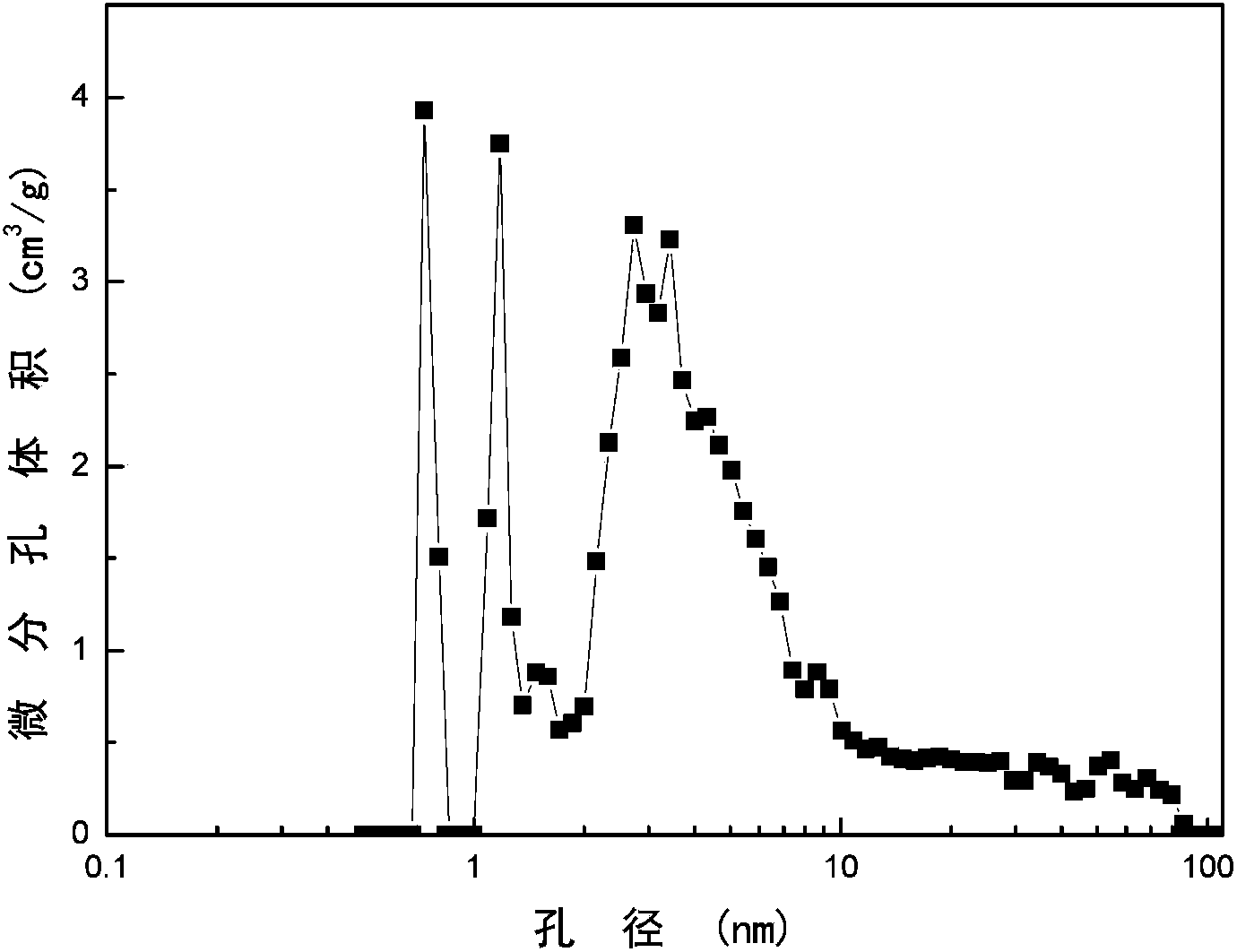

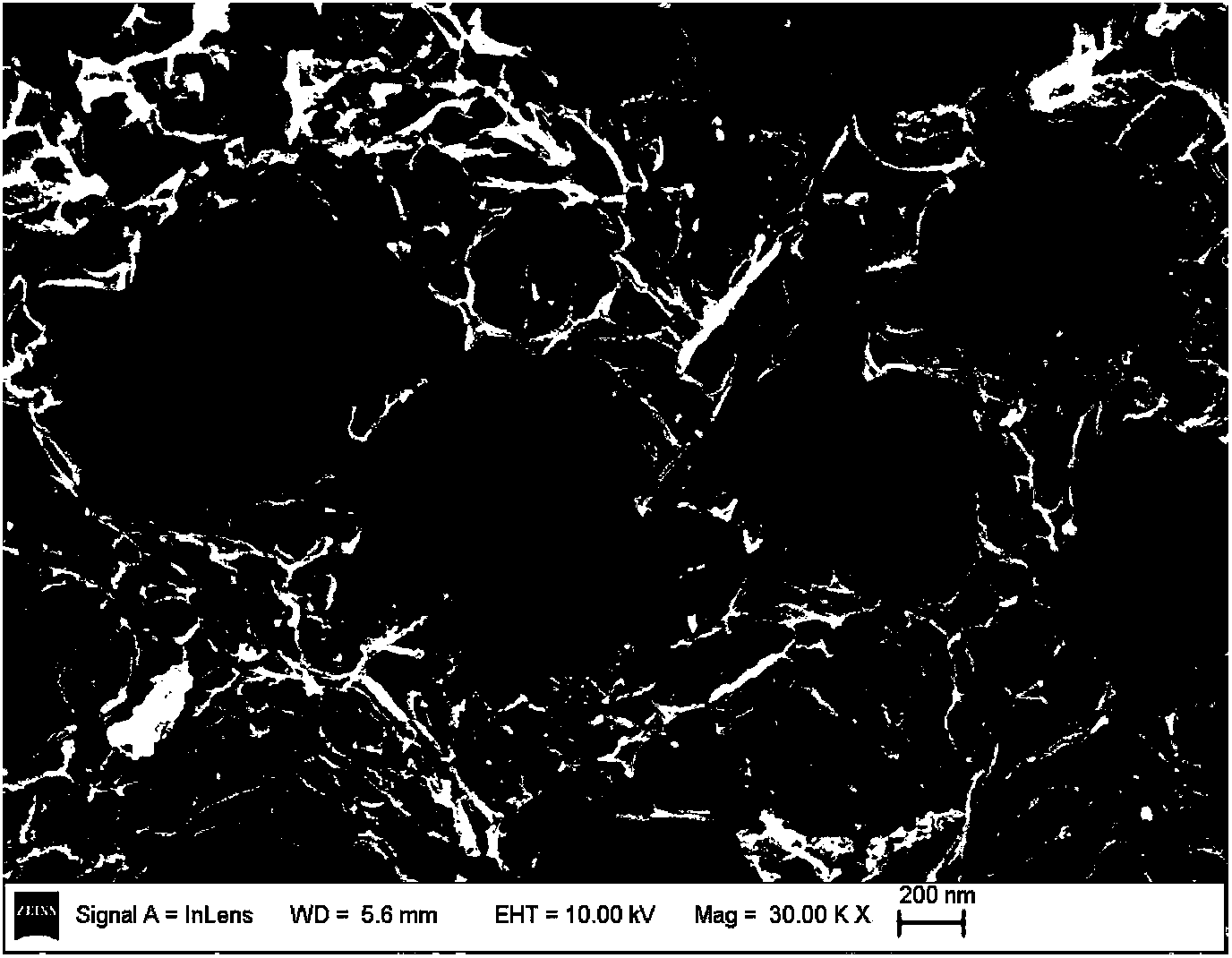

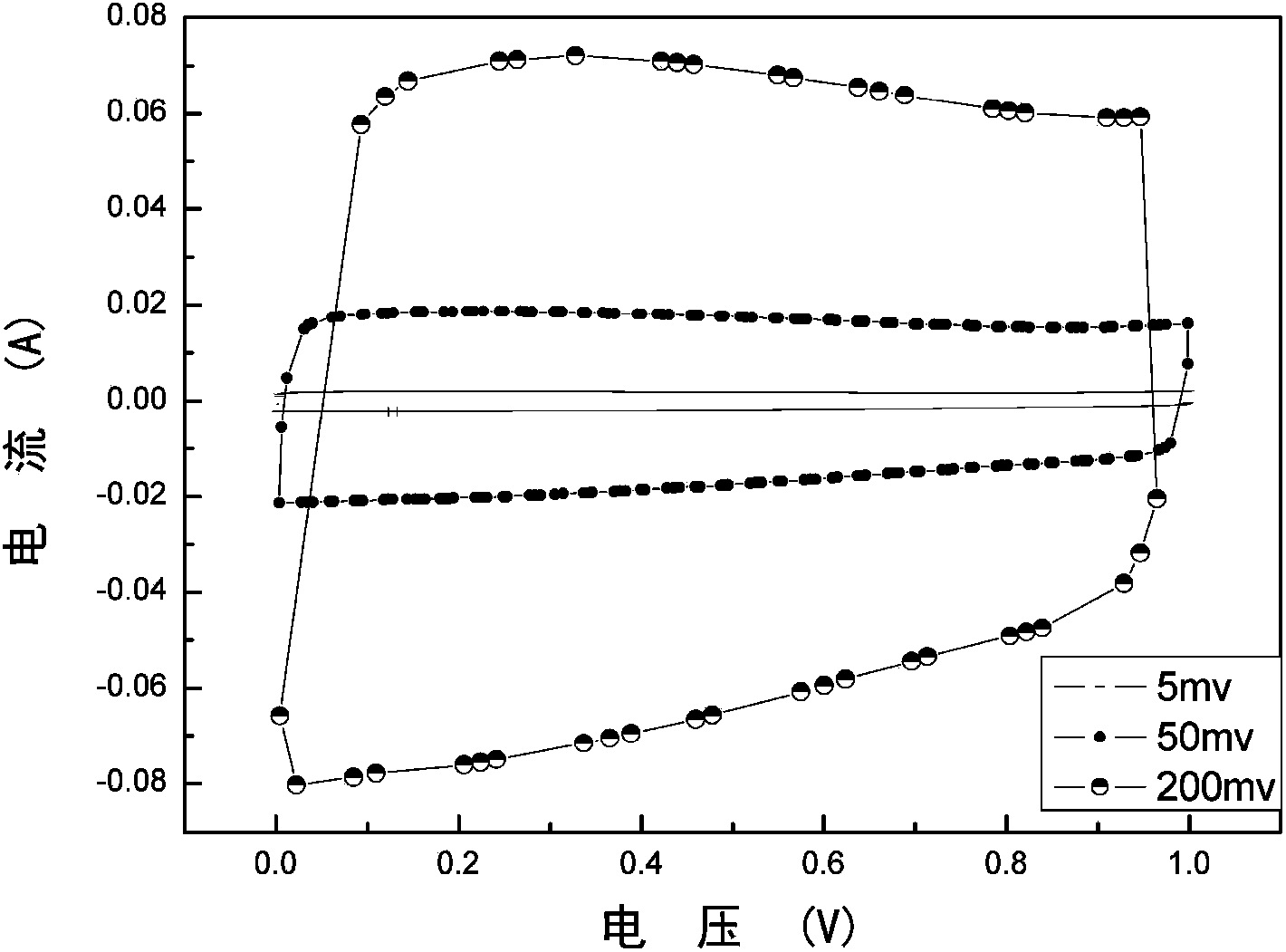

Porous carbon material and preparation method and application thereof

InactiveCN103420353AReduce manufacturing costReduce dosageElectrolytic capacitorsCell electrodesDecompositionPorous carbon

The invention relates to a porous carbon material and a preparation method and application thereof. Organic and inorganic materials in shrimp shell and crab shell are used as carbon sources and natural templates, meanwhile the pore formation effect of template structures during high temperature decomposition is utilized, and a proper activator is mixed to produce the porous carbon material. The difficulties of methods those in the prior art in a preparation process, preparation of templates is needed, carbon precursors need to be soak in the templates, and the like, are overcome; and the nitrogen-containing carbon material with multistage pore structures is prepared by using the characteristic that the carbon sources themselves contain nitrogen element. The preparation method of the porous carbon material is simple, is low in cost, is strong in process controllability, and is suitable for industrial production, the porous carbon material shows very good application effects in electrochemical capacitors and secondary cells, and the porous carbon material not only provides a new material for the new energy, but also opens up a new way for the effective use of waste, namely the shrimp shell and crab shell in aquatic products industry.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing thermal reaction type shrimp tasted seasoning by utilizing shrimp or shrimp leftovers as raw materials

The invention relates the method for preparation of hot reaction shrimp quelite, using shrimp or leftover bits and pieces as raw material. The method comprises the following steps: using shrimp or leftover bits and pieces as raw material, adding water to confect serous fluid, carrying out enzymolysis with proteinase, after sterilizing and removing leavings, adding deacidizing sugar, amino acid and other accessory materials. The method has the advantages of short production circle, low cost, and stable quality.

Owner:JIANGNAN UNIV

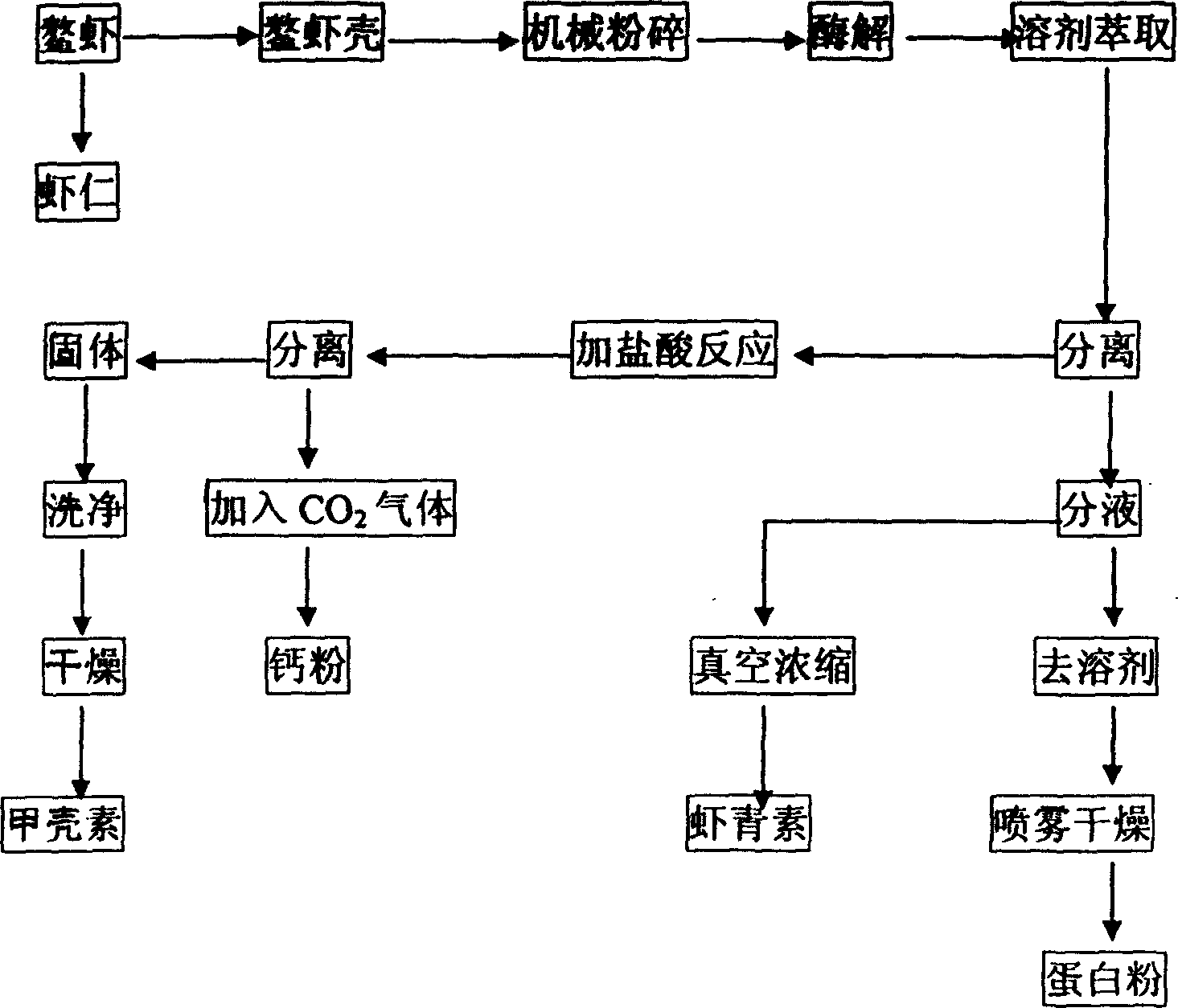

Method for producing chitin, astaxanthin, protein, calcium powder and biological fertilizer from shrimp shell

ActiveCN1715255AReduce pollutionGood effectAnimal corpse fertilisersClimate change adaptationBetaxanthinsPhytic acid

The method of producing chitin, astaxanthin, protein, calcium powder and biofertilizer with shrimp shell includes the following technological steps: crushing shrimp shell, enzymolysis with composite enzyme, extracting with organic solvent, reaction and separating liquid from solid; separating the liquid into hydrolysis liquid and organic liquid ; vacuum concentrating the organic liquid to obtain coarse astaxanthin; eliminating organic solvent from hydrolysis liquid, vacuum concentrating and spray drying to obtain protein powder; soaking the solid in 3 % concentration hydrochloric acid and rinsing to obtain chitin; introducing CO2 gas to the waste acid solution and filtering to obtain active calcium powder; ultrafiltering the coarse astaxanthin liquid to obtain astaxanthin; adding phytic acid and active oligose into the effluent to obtain nutritious liquid as biofertilizer.

Owner:林大昌

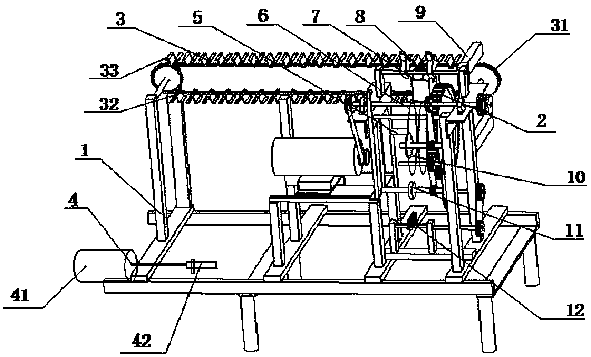

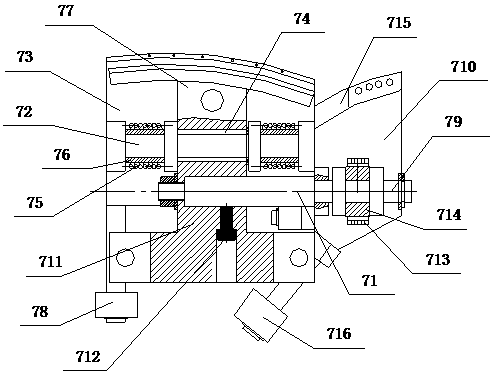

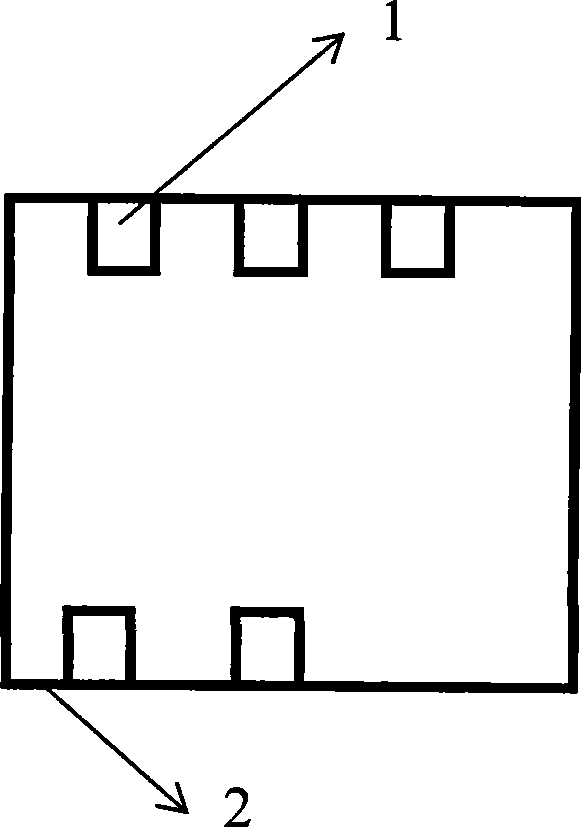

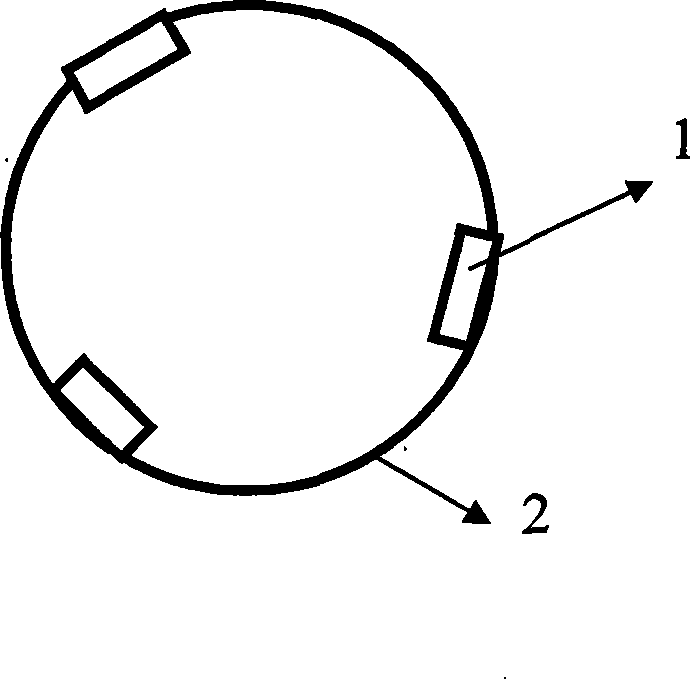

Automatic shrimp peeling machine

The invention provides an automatic shrimp peeling machine. The automatic shrimp peeling machine is characterized by comprising a frame, a main drive gear, a conveying device, a transmission gear, a cam system and a water spray system which are mounted on the frame, wherein the main drive gear is arranged on a main transmission shaft in a sleeving manner; two corresponding plane cams are further arranged on the main transmission shaft in a sleeving manner; a plurality of large / small jaw clamping devices and final-stage separation devices are arranged around the circumferences of the plane cams; the conveying device, a guide pinch roller device, a blade assembling unit, an intestine-removing brush, an in-vivo long-needle assembling unit and a shrimp shell cleaning brush are sequentially arranged along the working track for mounting the raw material shrimp outside the circumferences of the large / small jaw clamping devices. The automatic shrimp peeling machine disclosed by the invention can eliminate the accumulative error generated in the machine operation process, lower the accumulative error to be minimal, and ensure that the single deheaded shrimp holding position of the circulating jaw in the positioning holding device is correct, so as to enable the working stations of back opening, peeling, and removal of shrimp line to be kept correctly and ensure the peeling quality of the shrimp.

Owner:南通宝泰机械科技有限公司

Element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles

InactiveCN102400238AMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentTextile fiberSlurry

The invention relates to element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles. The invention belongs to the technical field of textile fiber fabric production of vehicle-use nano-grade decorative fabric with functions of refreshing and air-purifying. The fabric is a nano-grade functional healthy textile. The nano-grade fabric provided by the invention is produced form chitosan, which is a natural high polymer extracted from shells of shellfishes, crabs and shrimps; a natural antibiotic humectant SCJ-920; a high-efficiency mite-preventing antibacterial agent SCJ-998; nano-grade negative-ion powder SCJ-900; negative-ion far infrared healthcare slurry 700; a fire retarding finishing agent ATF; an aromatic finishing agent SCM; electromagnetic-wave-preventing ferrites Fe2O3, Fe3O4, and Fe; substances such as TiO2, Al2O3, and ZnO used for providing far infrared radiation; an Ag-embedded nano-TiO2 (AT) antibacterial agent; nano-grade selenium or organic selenium which is rare on earth; organic germanium, Chinese herbal medicines, essential oil, maifanite, tourmaline nano-grade powder and other materials. A mixture of the materials is added to cotton, linen, wool, silk, polyamide fiber, acrylic fiber, terylene or viscose fiber spinning liquid, and the nano-grade fabric is produced through weaving.

Owner:丁一

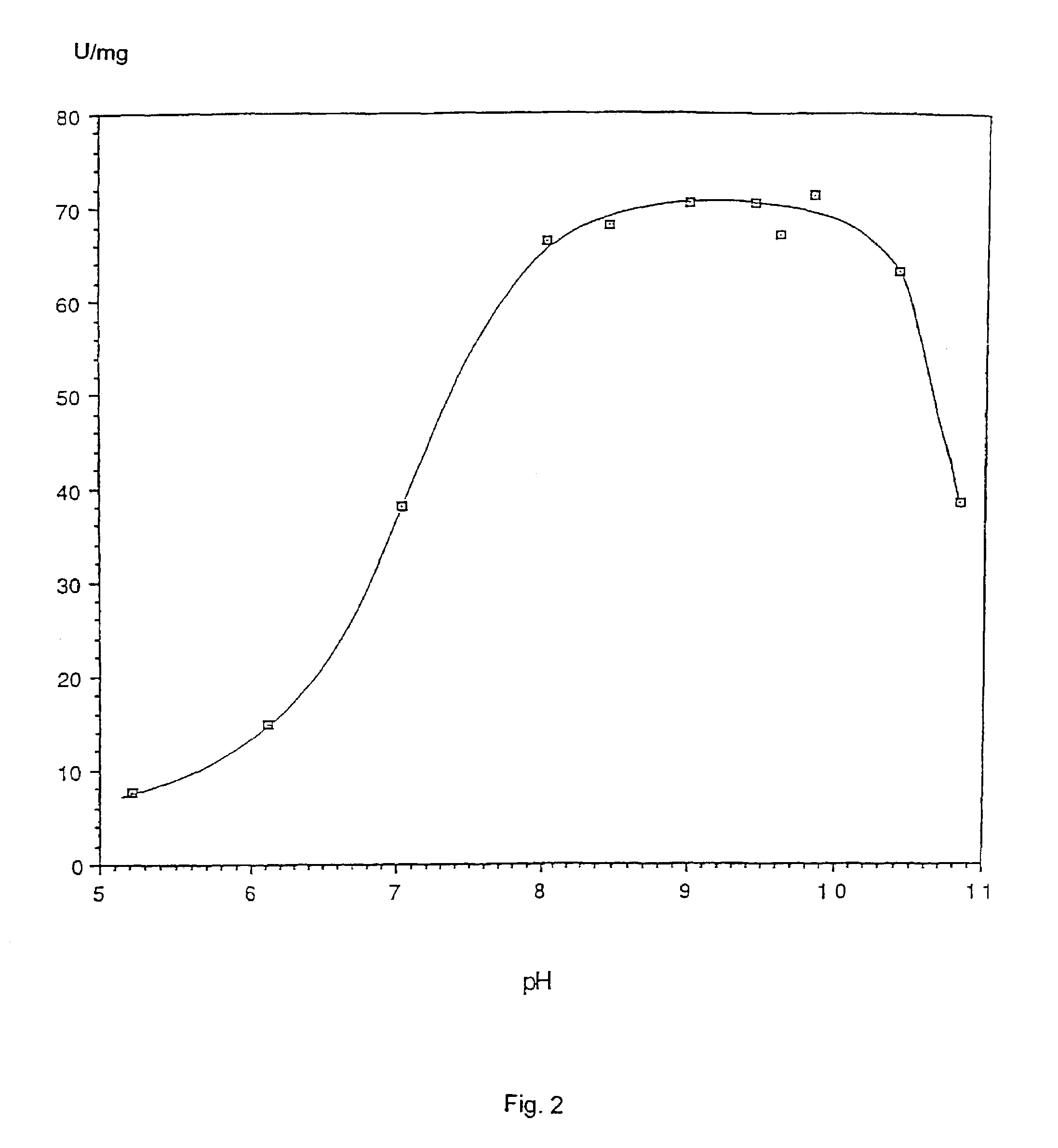

Protein hydrolysates produced with the use of cod proteases

InactiveUS7070953B1Increase contentCosmetic preparationsHydrolysed protein ingredientsProtein materialsFood flavor

The invention relates to a method for enzymatically obtaining protein hydrolysates for human consumption, animal feed and cosmetics. The process involves the use of a proteolytic composition derived from fish, such as Cod (Gadus morhua), to obtain hydrolysates which have a non-bitter taste and retain the flavor and aroma of the protein-containing material which is hydrolyzed: e.g. when hydrolyzing protein-containing material from marine organisms or parts thereof, such as fish, shrimp, lobster or other seafood according to the invention, a protein hydrolysate is produced that has a characteristic natural flavor of the organism Also provided are food products comprising the hydrolysates of the invention, such as soup, sauce, cheese, HVP, meat extract and flavoring agent, broth, paté, mousse, frying dough, orly dough, and pastries.

Owner:NORDUR EHF

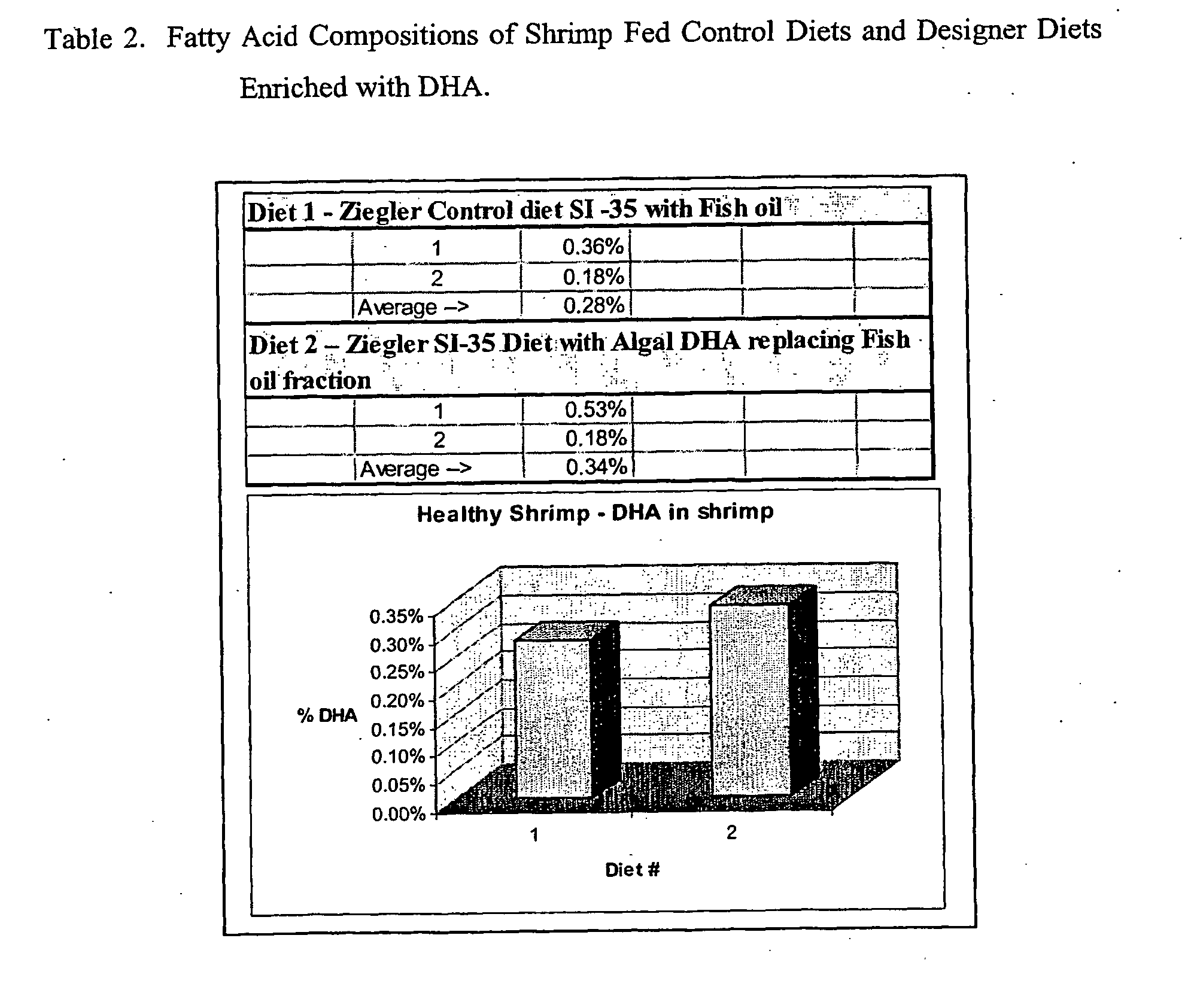

Shrimp and the production thereof

This invention is directed to compositions comprising improved edible shrimp and other crustaceans. The shrimp or other crustaceans are enriched with one or more components that provide benefits, such as improved taste and / or appearance, or improved health benefits for humans consuming them. The invention also relates to methods of producing such shrimp and other crustaceans, and methods of making a feed to feed the shrimp and other crustaceans.

Owner:ADVANCED BIONUTRITION CORP

Bioactive food complex, method for making bioactive food complex product and method for controlling disease

InactiveUS20040009160A1Growth inhibitionPromote absorptionBiocideBacteria material medical ingredientsDiseaseAdditive ingredient

A bioactive food complex product, method for preparing a bioactive food complex product and method for controlling disease using probiotics and quorum sensing inhibitors such as inhibitory furanones and other bioactive compounds included in both the continuous and dispersed phases of a bioactive food complex product. The product is comprised of a solids-in-oil or an oil-in-solids emulsion forming a first emulsion that is itself emulsified in polymer forming oil-in-polymer or solids-in-polymer emulsion complex. The bioactive complex is formed of two emulsions with the first emulsion comprising the dispersed phase and a hydrocolloid polymer serving as the continuous phase. The second emulsion complex is then crosslinked to form a physically stable matrix. The bioactive food complex or the first emulsion of the bioactive food complex then serve to deliver different bioactive components including probiotic bacteria and quorum sensing inhibitor molecules to the digestive tract and environment of animals such as shrimp or fish or other livestock raised commercially to effectively control bacterial disease by a novel combination of mechanism including: competitive exclusion, direct inhibit, digestion of cell-to-cell signaling molecules and direct inhibition of homoserine lactone and (acyl) homoserine lactone regulated processes of pathogenic bacteria. Thus, effective disease prevention and control is accomplished through the novel combined delivery and use of probiotic bacteria and quorum sensing inhibitory furanones.

Owner:ACUABIOTEC

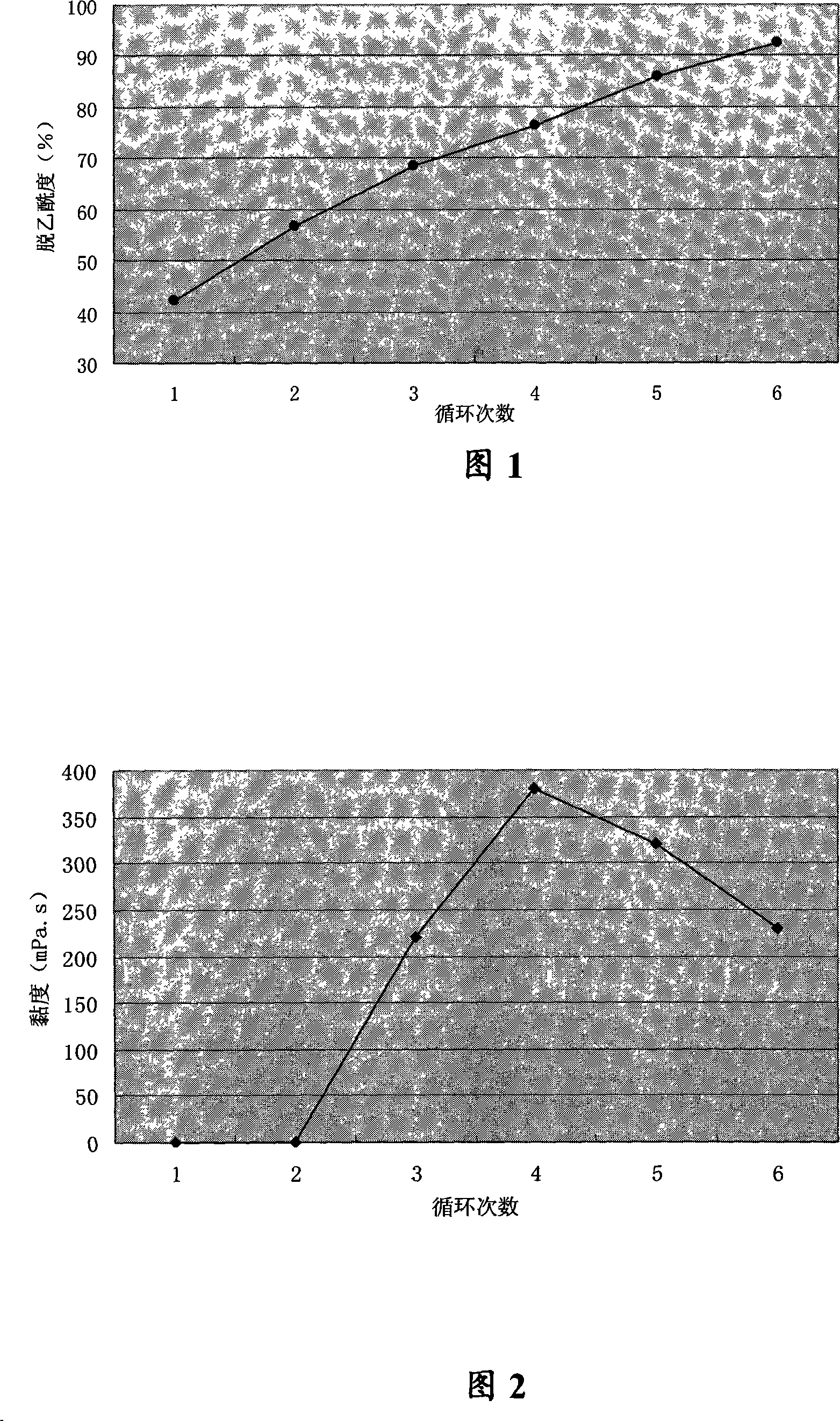

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097ATake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effect is attained.

Owner:重庆百奥帝克微生态科技有限公司

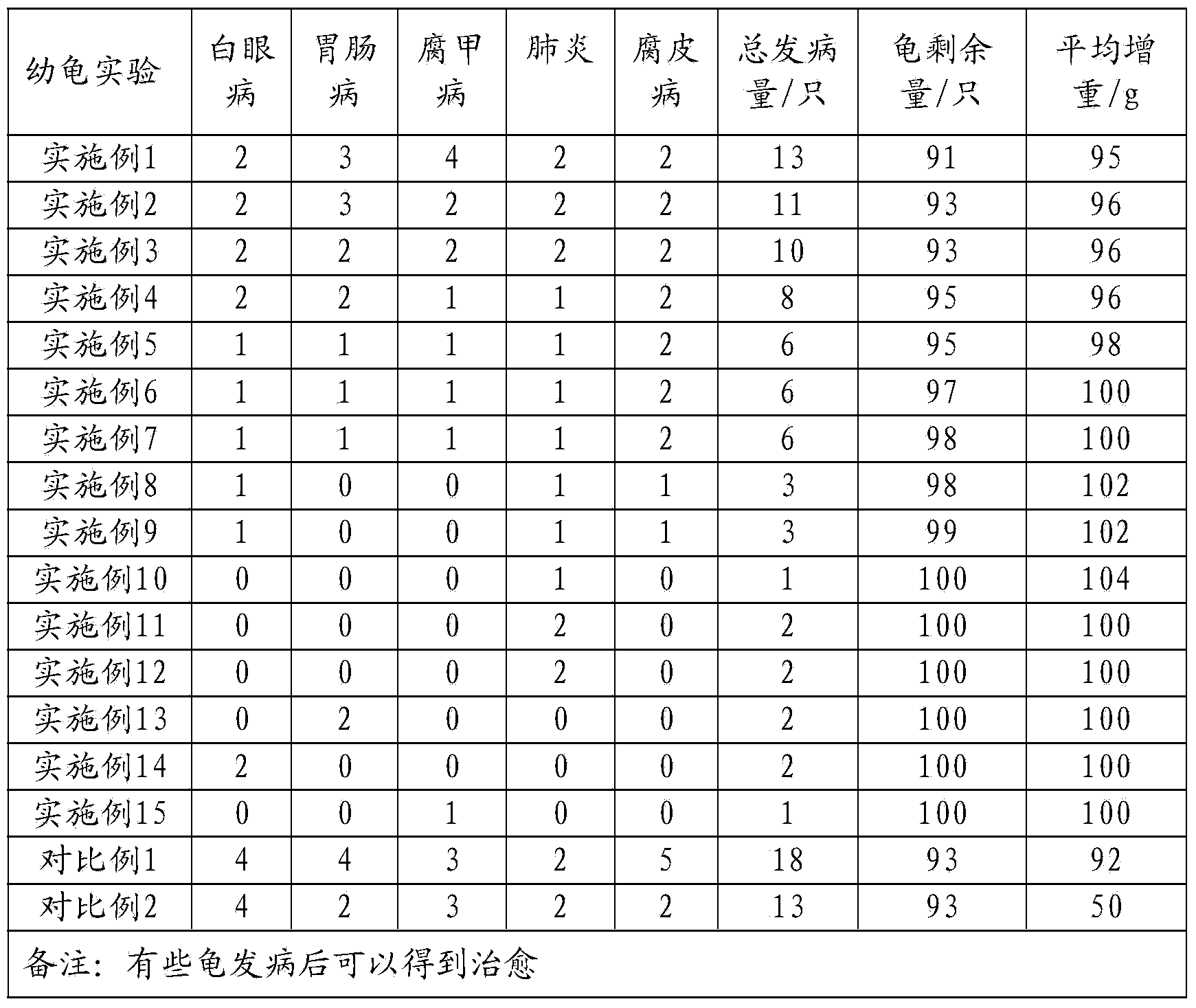

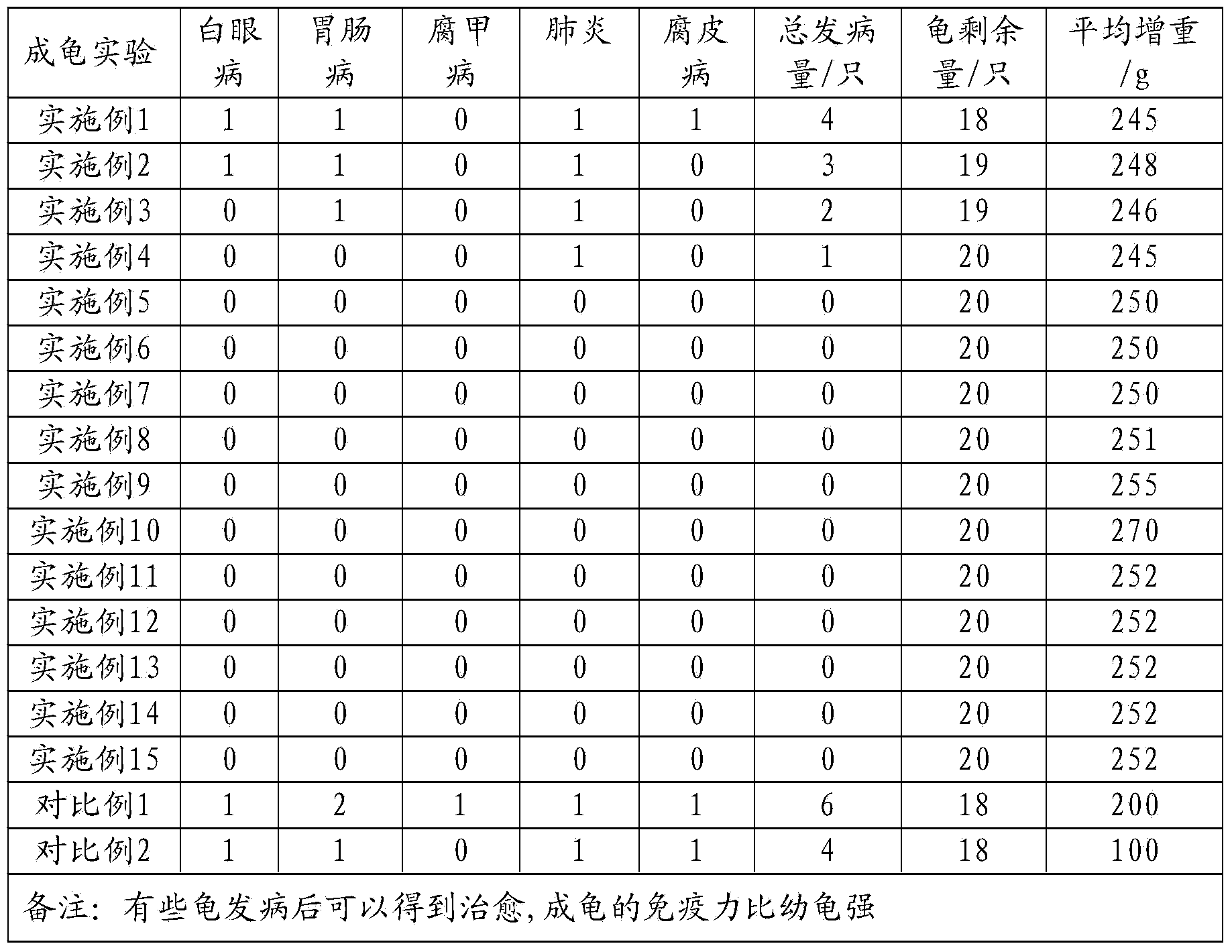

Turtle feed and preparation method thereof

InactiveCN103766591AImprove survival rateAdequate and reasonable nutritional contentClimate change adaptationAnimal feeding stuffWeight gainingAdditive ingredient

The invention discloses a turtle feed and a preparation method of the turtle feed. The turtle feed comprises the following components by weight ratio: 30-40% of imported fish meal, 25-35% of bean pulp, 10-20% of shrimp meal, 6-10% of beer yeast powder, 2-4% of fish oil, 0.4-0.6% of choline chloride, 0.4-0.6% of lysine, 0.4-0.6% of multivitamin, 0.4-0.6% of multimineral, 12-16% of high protein flour and 6-10% of Chinese herbal medicine. The compound feed is prepared by mixing, super micro-grinding, screening, mixing for a second time, granulating by expansion, drying, cooling and packaging. The turtle feed does not contain antibiotics, is complete in nutritional ingredients and high in palatability, and has the functions of preventing diseases of turtles in the feeding process, reducing the probability of disease occurrence, increasing the survival rate of baby turtles and being beneficial to growth of the baby turtles and weight gain of adult turtles.

Owner:XIAMEN FUYIN BIOLOGICAL FEED CO LTD

Method for extracting phospholipid-enriched krill oil from Antarctic krill

InactiveCN102071101ARich sourcesSafe storageFatty-oils/fats productionDocosahexaenoic acidPhospholipid

The invention discloses a method for extracting phospholipid-enriched krill oil from Antarctic krill. The method comprises the following steps: using Antarctic krill as the raw material and using the autologous protease to decompose the Antarctic krill and release lipids, quickly heating to inactivate the enzymes in the krill, drying at low temperature, and extracting krill oil with rich eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) phospholipids at low temperature by using low carbon alcohol as the solvent. The method disclosed by the invention is simple to operate, has the advantages of clear process and high input-output ratio; and compared with other organic solvents, ethanol or isopropanol is safer for storage, transportation and use, has abundant sources, and has obvious advantages of being used as the solvent for extracting oil of krill type crustacean.

Owner:SHANDONG KERUIER BIOLOGICAL PRODS

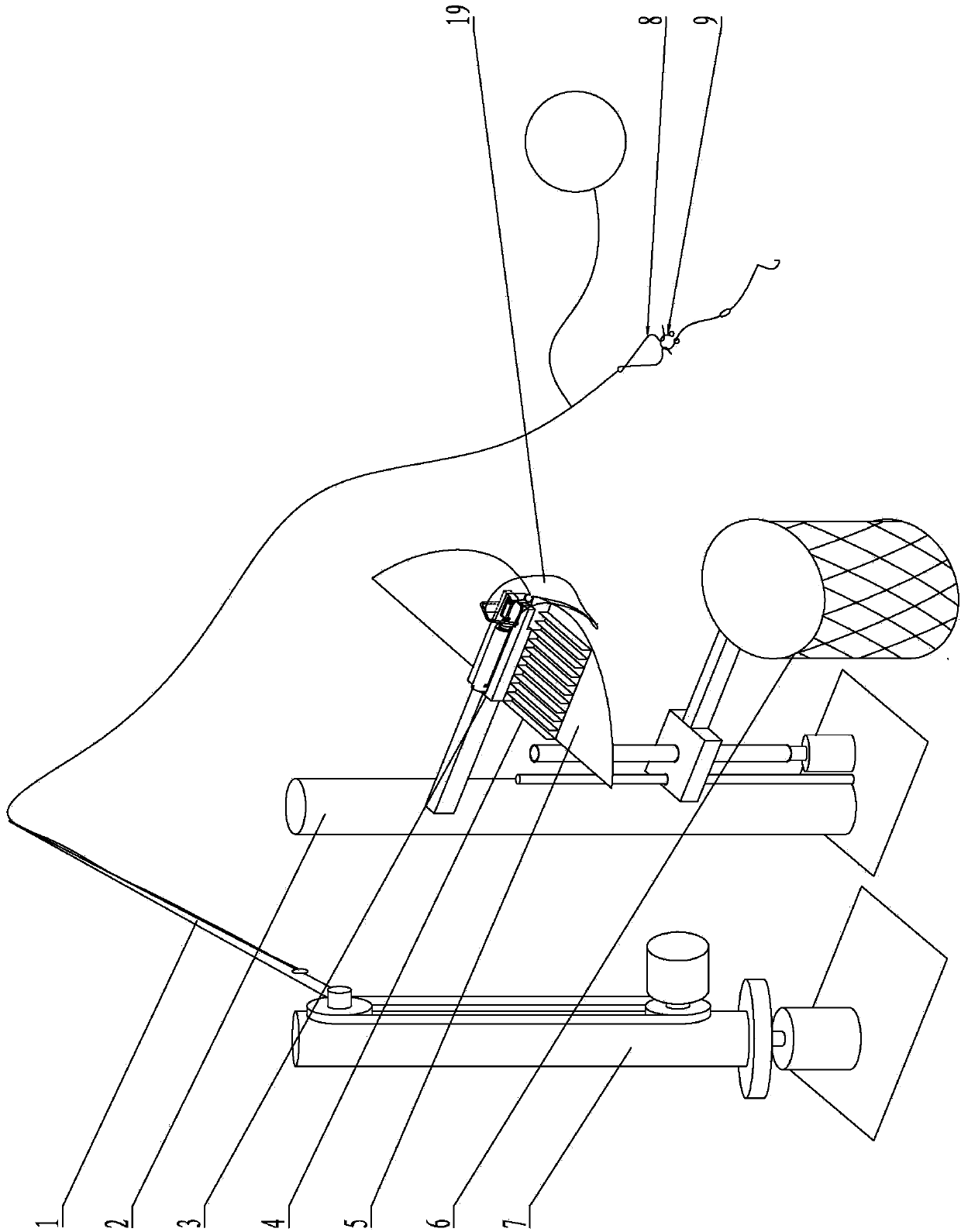

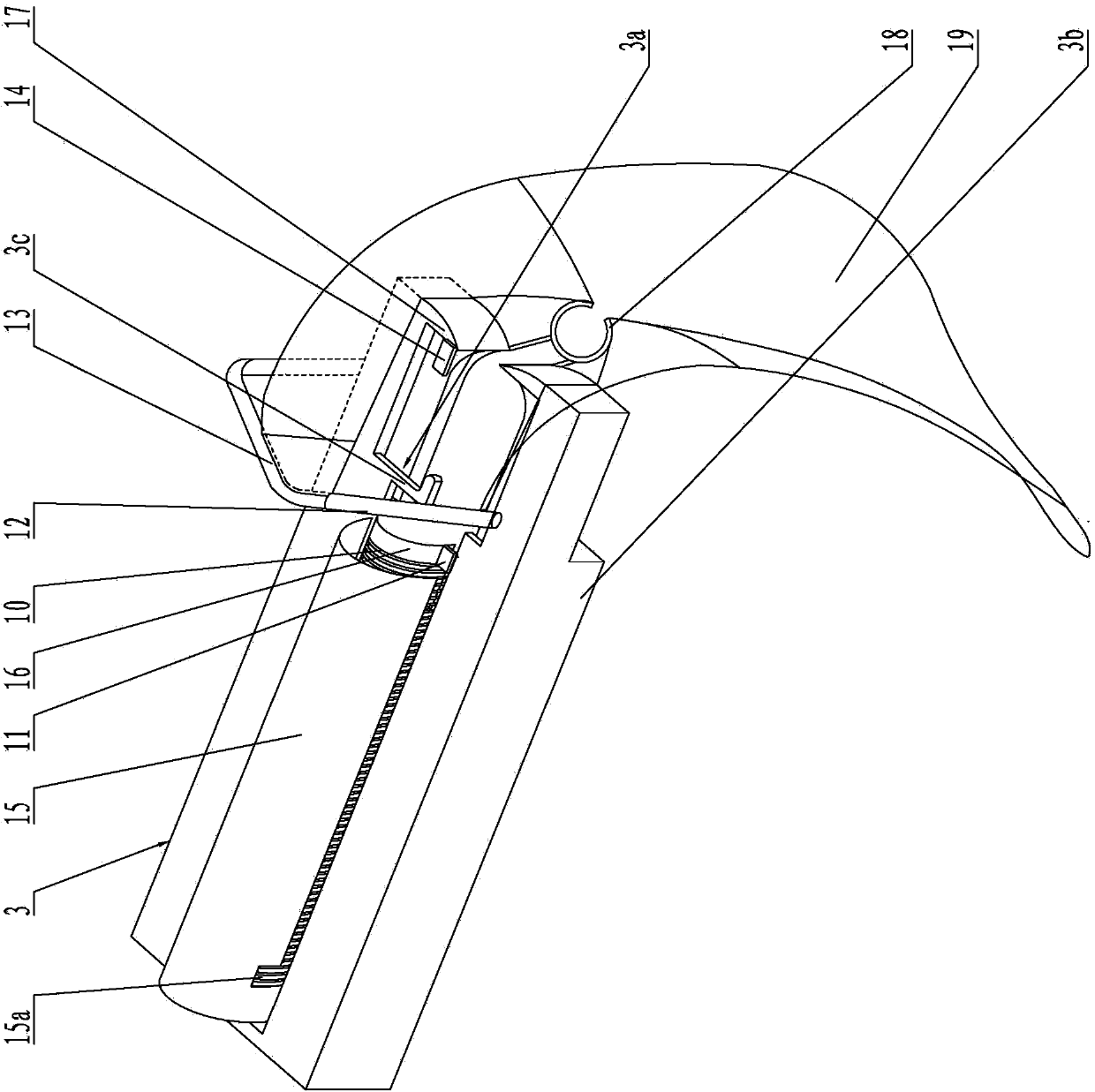

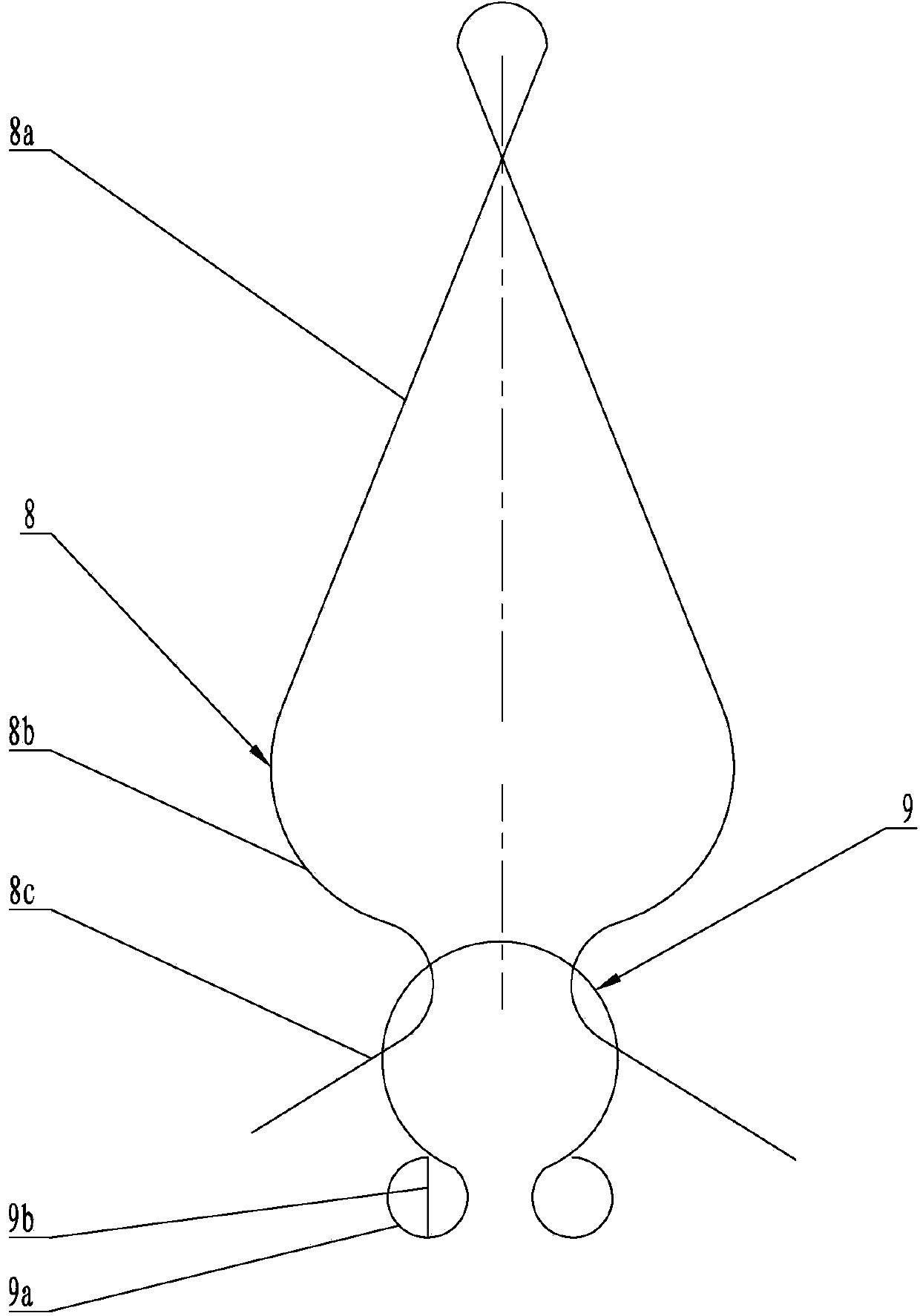

Non-contact bait-changing fish-taking shrimp-taking fishing equipment

The invention discloses non-contact bait-changing fish-taking shrimp-taking fishing equipment. A fishing line is broken into a fishing line upper section and a fishing line lower section; the lower end of the fishing line upper section is connected with a hook capable of being squeezed left and right to be deformed; the upper end of the fishing line lower section is connected with a hanging ring; the hanging ring is movably sleeved with the hook; the non-contact bait-changing fish-taking shrimp-taking fishing equipment also comprises a horizontally arranged bait changing box; the bait changing box is provided with a passage in the front and rear direction; a compression spring of which the center line is coincided with that of the passage is arranged on the bait changing box; when the hanging ring is placed in the passage, the compression spring is abutted against the hanging ring forwards; a clamp ring of which the front end is open is fixed at the lower part of the front part of the bait changing box. According to the invention, due to adoption of the structure, combinations of the hanging ring, the fishing line lower section and a fishhook are rapidly replaced by the bait changing box, so that operations of taking fishes, taking shrimps and changing baits are relatively convenient and rapid to carry out; the non-contact bait-changing fish-taking shrimp-taking fishing equipment has the characteristics of convenience for use, ingenious design, simple structure, easiness for production and the like.

Owner:淮北辰威科技有限公司

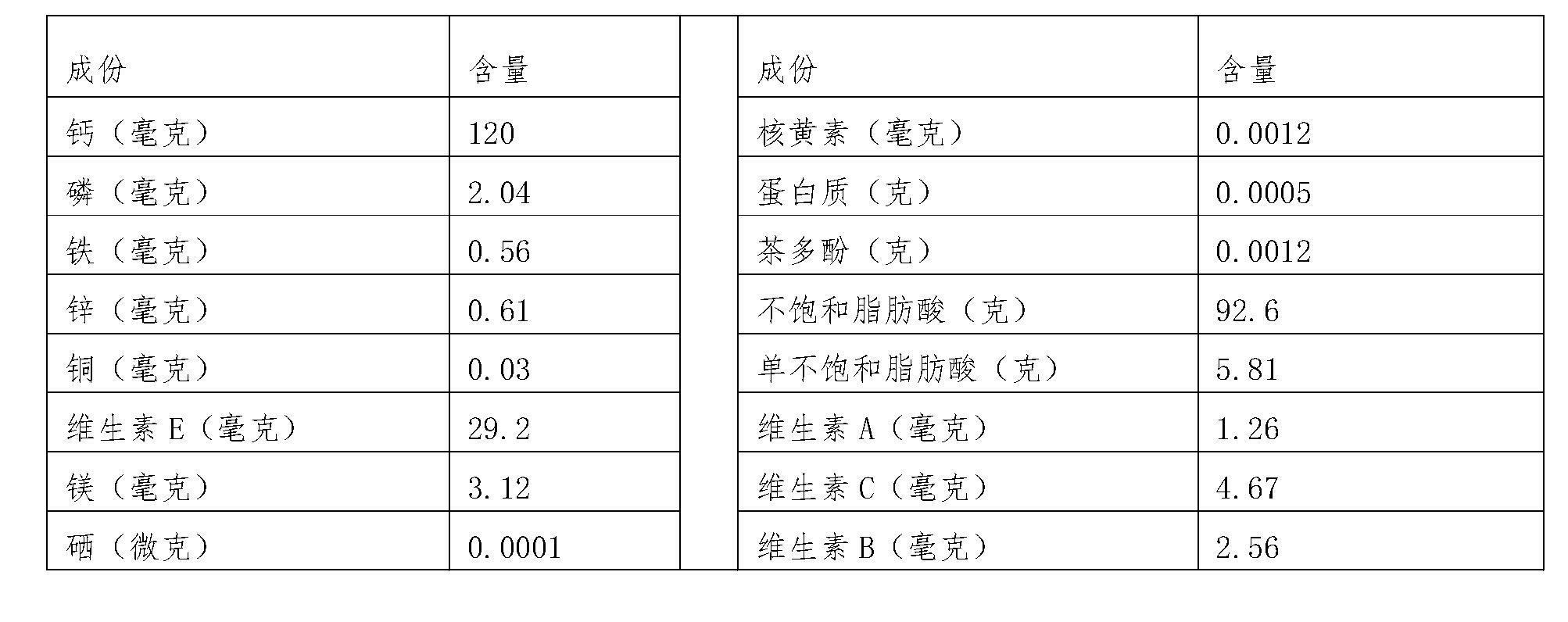

Calcium supplement health-care tea oil

InactiveCN102669309ANutritional diversityEdible oils/fats production/working-upCalcium in biologyShrimp

The invention discloses calcium supplement health-care tea oil, relating to the field of biomedical technology. The calcium supplement health-care tea oil is prepared from tea oil, dried small shrimp and calcium carbonate. Specially, the preparation method comprises the steps of: auxiliary material pretreatment, auxiliary material retreatment, auxiliary material mixing, mixed auxiliary material treatment, extraction, purification and filtering. The calcium supplement health-care tea oil has the characteristics of complete nutrition, capability of supplementing calcium, and the like, not only can be suitable for the calcium-deficient crowds to eat, but also can be suitable for children and the old to eat.

Owner:管天球 +1

A feedstuff for marine lives and pre-maturation process

InactiveCN1961714AGood food attractantReduce the impactFood processingClimate change adaptationMaltoseMarine life

The invention provides an aquatic feed which is prepared from soybean waste, steam heated fish meal, fish meal, brewer's yeast, squid meal, shrimp shell powder, choline chloride, flour, calcium dihydrogenphosphate, scallop powder, Ulva lacbuca Linnaeus powder, glutelin powder, phosphatidy icholine, fish oil, palmitic oil, maltose dextrin, amino acid fish grout, vitamins for shrimps, microelements, immunological polysaccharides, copper-methionine and complex enzyme. The invention also discloses the pre-maturing process for the aquatic feed.

Owner:JIANGSU TIANFULAI GROUP

Instant noodle seasoning packet and manufacturing method thereof

The invention provides an instant noodle seasoning packet and a manufacturing method thereof, which mainly takes fresh beef, pork, entire chicken, fresh shrimp, seasonal fresh vegetables, shrimpbran, kelp, mushroom, shallot, ginger, and the like as the main materials, takes spice powder, salt, sugar, monosodium glutamate, and the like as flavoring additives and accessories, adopts the brand-new technical conception which combines stewing with frying as well as combines enzymolysis with fining to convert the nutrition components of poultry with fresh vegetables into amino acids which are easily absorbed by human bodies, and implements seasoning based on the steps to manufacture the flavoring additives with more familization as well as excellent color, fragrance and taste, changes the fixed modes of the original instant noodles including powder packet, sauce packet and vegetable packet, and recommends the brand-new three-packet seasoning combination of brand-new soup packet, oil packet and vegetable packet, thus effectively improving the defects of less vegetables and high fats of the instant noodle seasoning packet, and being more beneficial to the body health of people. The seasoning adopts scientific and precise mixture ratio, which has the advantages of simple manufacturing technique and high production efficiency, thus greatly simplifying the traditional production technique of the instant noodle seasoning packet.

Owner:ANHUI XIN JINFENG ENTERPRISE INVESTMENT GROUP

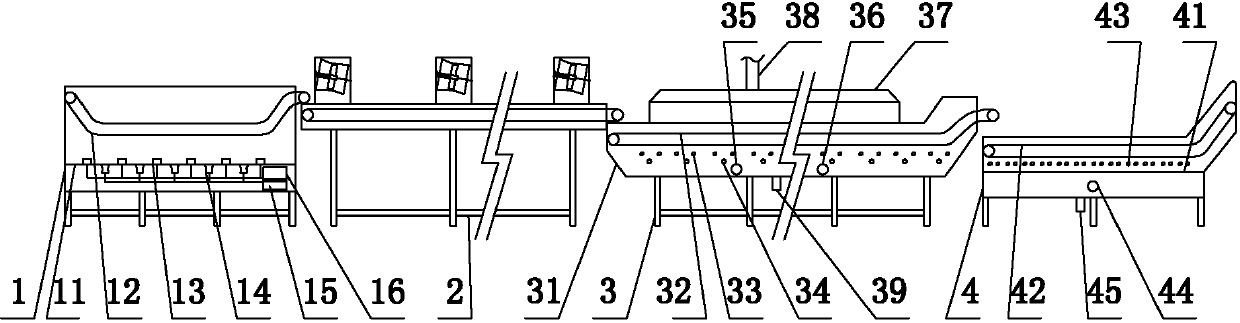

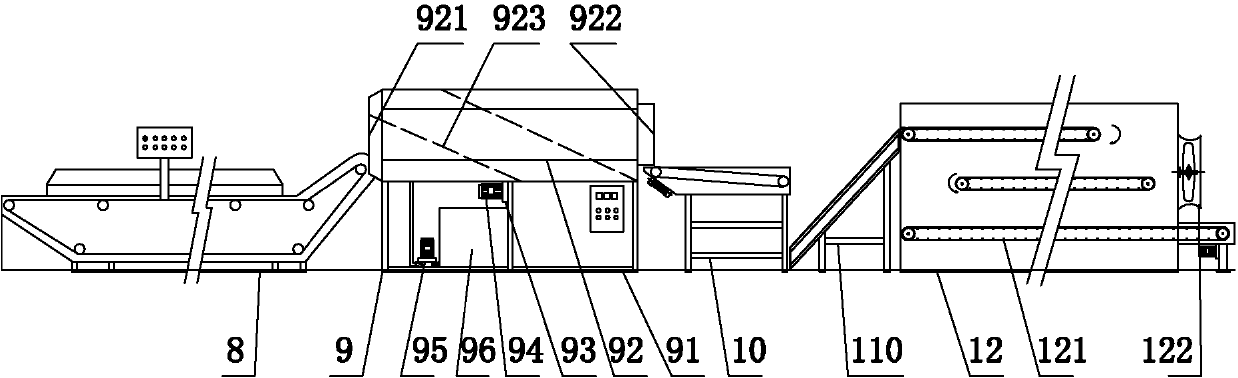

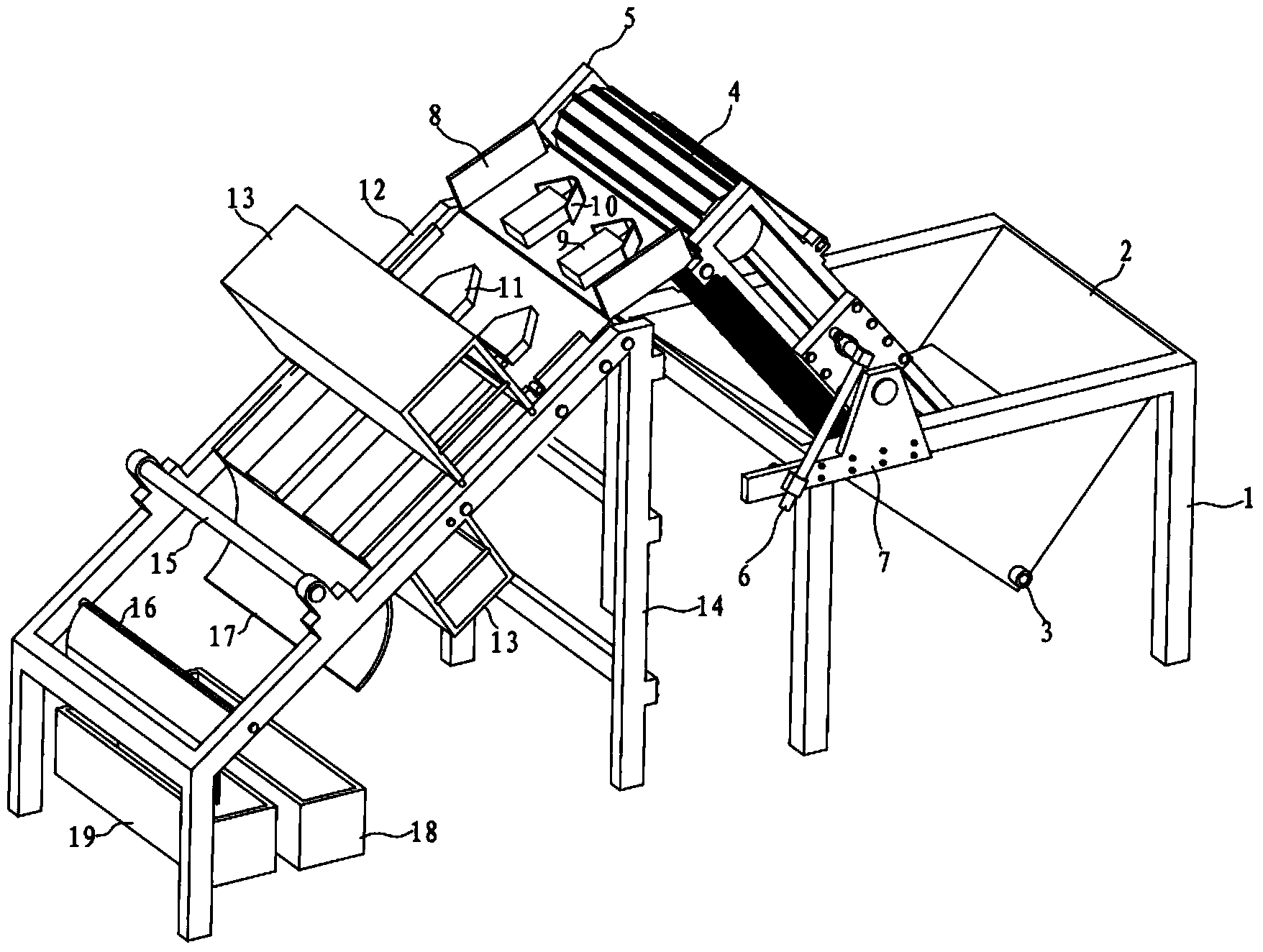

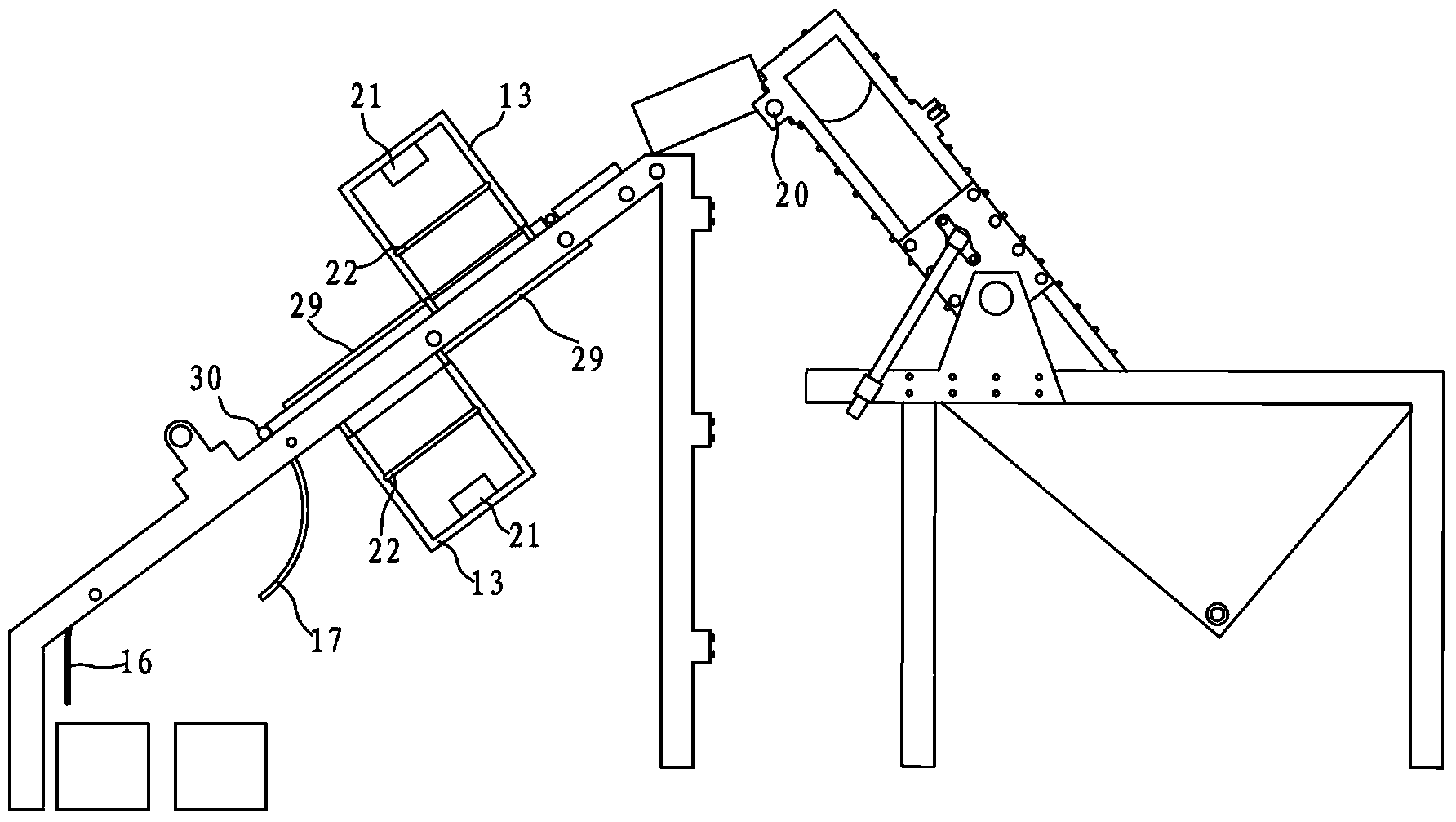

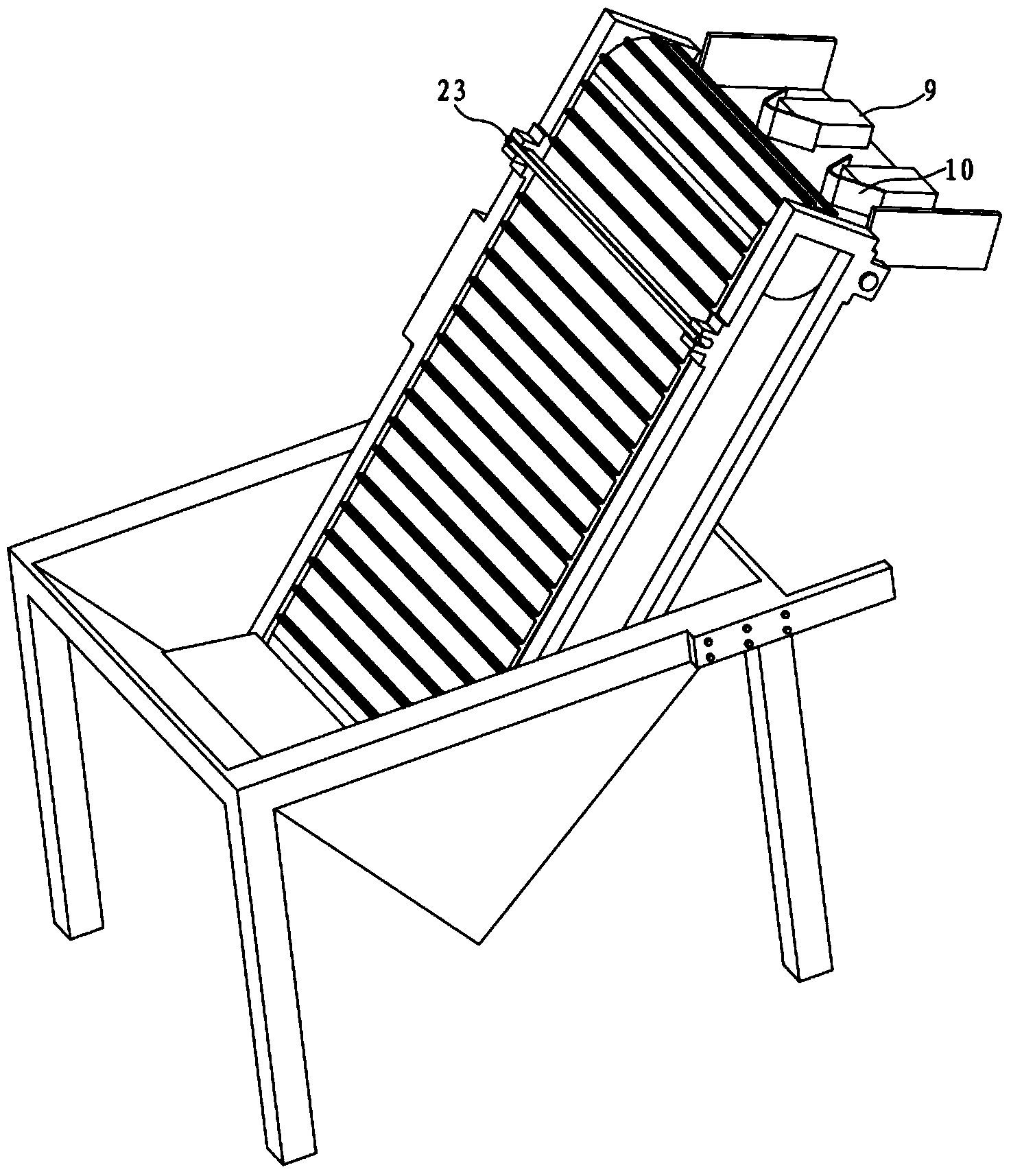

Crayfish food as well as preparation method and production equipment thereof

InactiveCN103960697AGood health effectSilky meatWater/sewage treatmentOil/fat bakingVegetable oilAdditive ingredient

Crayfish food comprises ingredients in parts by weight as follows: 100 parts of crayfish, 50 parts of vegetable oil, 10.6-15.2 parts of spice, 0.3-0.5 parts of transglutaminase, 0.3-0.5 parts of nisin, 0.2-0.5 parts of konjac glucomannan, 0.2-0.4 parts of chitosan, 0.4-0.5 parts of lecithin and 0.08-0.16 parts of delta-gluconolactone. According to the crayfish food, crayfish balls are used for preparing instant food, crayfish shells are used for preparing chitosan, and raw materials are sufficiently utilized; transglutaminase in the raw materials prompts crosslinking of crayfish meat protein crosslinking amino acid, tenderness of a product is improved, natural food antiseptics such as nisin and the like meet requirements of people for food health, and at the same time, the guarantee period of the crayfish food is prolonged to 12 months; and defects that crayfish products which can be stored at the normal temperature are less, the guarantee period is short and the like are overcome, and the crayfish food has good market prospect.

Owner:顾炎林

Hongze lake steamed crab feed and preparation method thereof

The invention discloses a Hongze lake steamed crab feed and a preparation method thereof. The feed is composed of the following components according to mass percent: 31.00% of wheat, 15.00% of bean pulp, 10.00% of fresh dried fish, 10.00% of cotton seed meal, 8.00% of rice bran, 8.00% of rapeseed meal, 5.70% of spiral shell meat, 3.00% of corn protein powder, 2.00% of shrimp meal, 1.60% of squid meal, 1.00% of soybean oil, 1.00% of zeolite powder, 1.00% of phosphoric acid single calcium, 1.00 %of phospholipid oil, 0.25% of choline, 0.05% of salt, 1.00% of premix compound, 0.40% of Chinese medicinal herb additive, thus 100% in total. According to the physiological characteristics, life habit and natural law of the Hongze lake steamed crab, the invention achieves high yield of the Hongze lake steamed crab under large-scale artificial culturing by optimizing feed components, adding Chinese medicinal herb in the feed and changing the traditional processing method of crab feed; and the Hongze lake steamed crab has the natural characteristics of large size, haleness, puffy crab cream, natural and fresh taste, high nutrient value and the like.

Owner:江苏华威农牧发展有限公司

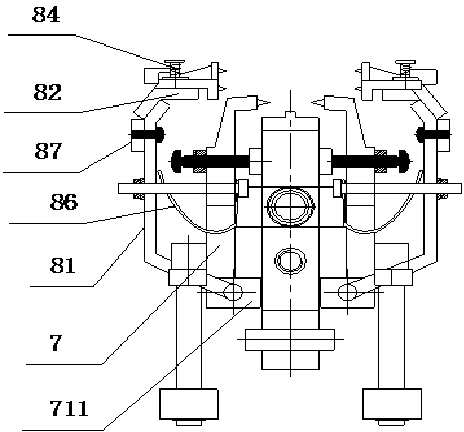

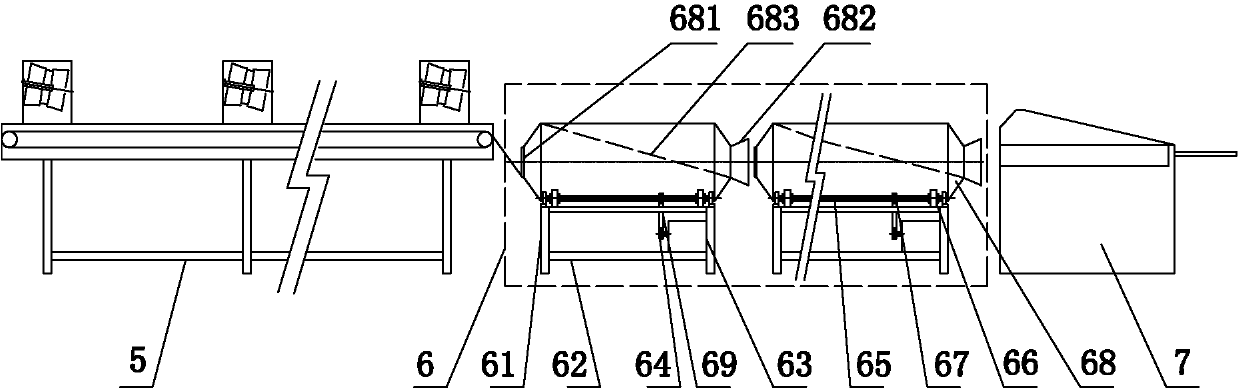

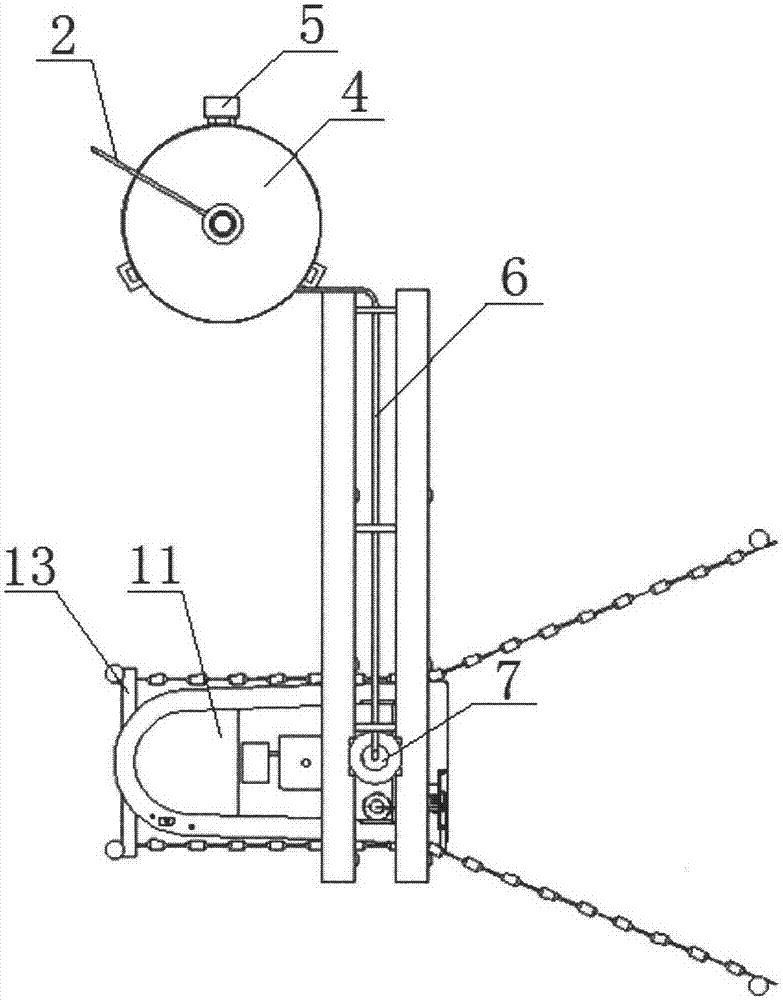

Method and device for automatically carefully sorting and grading shrimps

ActiveCN103801520ANot easy to damageAdjustable to adapt to changes in the detection objectSortingImaging processingShrimp

The invention discloses a device for automatically carefully sorting and grading shrimps. The device comprises a feeding system, a sorting channel, an image collecting system, a grading system and an image processing system; the feeding system is used for outputting to-be-sorted shrimps to the sorting channel in a single row; the sorting channel consists of a buffering channel and a sampling channel which are sequentially connected, the sampling channel is divided into a plurality of single-row channels, the buffering channel is internally provided with a plurality of direction adjusters, and used for separating raw material shrimps, output by the feeding system, into singles, and adjusting the posture of each raw material shrimp entering single-row channel; the image collecting system is used for collecting images of the raw material shrimps; the grading system comprises spray nozzles corresponding to single-row channels, and the spray nozzles are controlled by the image processing system and used for blowing the shrimps to enter different receiving tanks; the image processing system is used for analyzing the images, grading the image of each shrimp, and emitting the signal for controlling the grading system according to the graded results. The invention further discloses a method for automatically carefully sorting and grading shrimps.

Owner:ZHEJIANG UNIV

Sturgeon feed and preparation method thereof

InactiveCN101642199AStrong disease resistanceReduce the cost of farmingFood processingClimate change adaptationDiseaseShrimp

The invention belongs to the technical field of feed, and particularly relates to sturgeon feed and a preparation method thereof. The sturgeon feed is prepared from the following materials by weight percentage: 12wt% to 25wt% of soya bean meal, 15wt% to 25wt% of flour, 25wt% to 35wt% of fish meal, 5wt% to 10wt% of meat meal, 6wt% to 10wt% of refined fish oil, 5wt% to 8wt% of shrimp meal, 0.1wt% ofvitamin complexes, 0.2wt% to 0.4wt% of composite trace elements, 0.2wt% to 0.4wt% of salt, and 0.2wt% to 0.4wt% of choline. The preparation method comprises the following steps: weighing the materials by the formula; mixing all the materials except the refined fish oil to form a mixture; micro-grinding the mixture; concocting the ground materials, puffing and granulating; oven-drying, cooling andscreening the products; and post-spraying the oil to obtain the sturgeon feed. The sturgeon feed of the invention has the advantages that the time for solution is as long as about 45 minutes; the digestibility is high; the ratio between feed and meat reaches 1.2-1.5:1 and the disease-resisting rate of sturgeon eating the feed is high.

Owner:北京汉业科技有限公司

Mirco algal food nutrient intensifying agent prescription and its preparing process

InactiveCN1653938ABalanced nutritionReasonable ratioAnimal feeding stuffAccessory food factorsShrimpAdditive ingredient

The present invention is one kind of nutrient reinforcing agent for artificial fry raising of marine animal, and relates to the recipe and preparation process of micro algae bait nutrient reinforcing agent. The microalgae bait nutrient reinforcing agent consists of several kinds of micro algae containing different nutritious components and has grain size of 5-20 microns. It contains great amount of DHA, ARA and natural astaxanthin, and can raise the immunity and survival rate of raised marine animal. It can meet the requirement of hatched fries of fishes, shrimps and shells in feed. For example, when the microalgae bait nutrient reinforcing agent is used in raising turbot, it can raise the survival rate and lower the albinism rate greatly.

Owner:QINGDAO SAMUELS INDAL & COMML

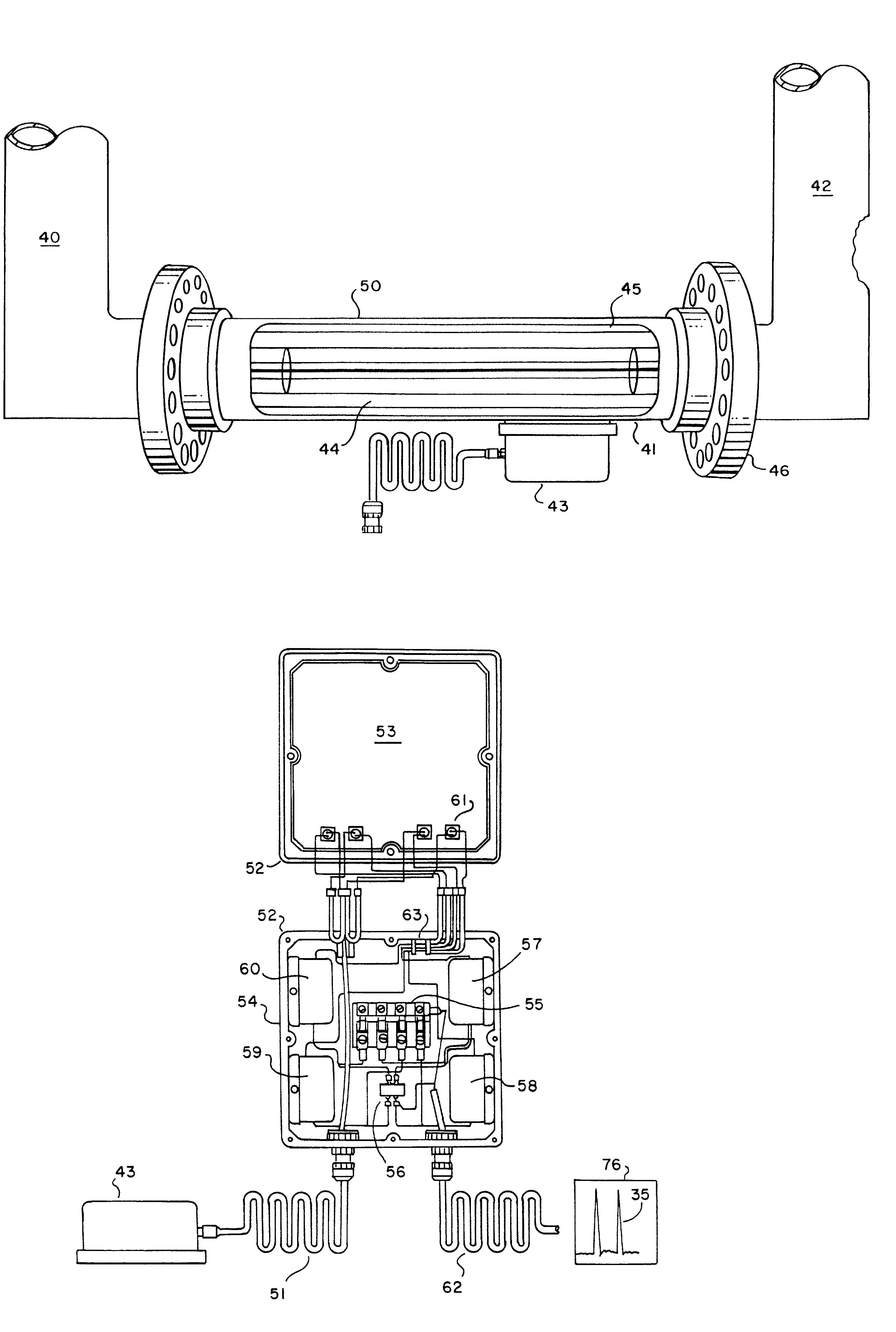

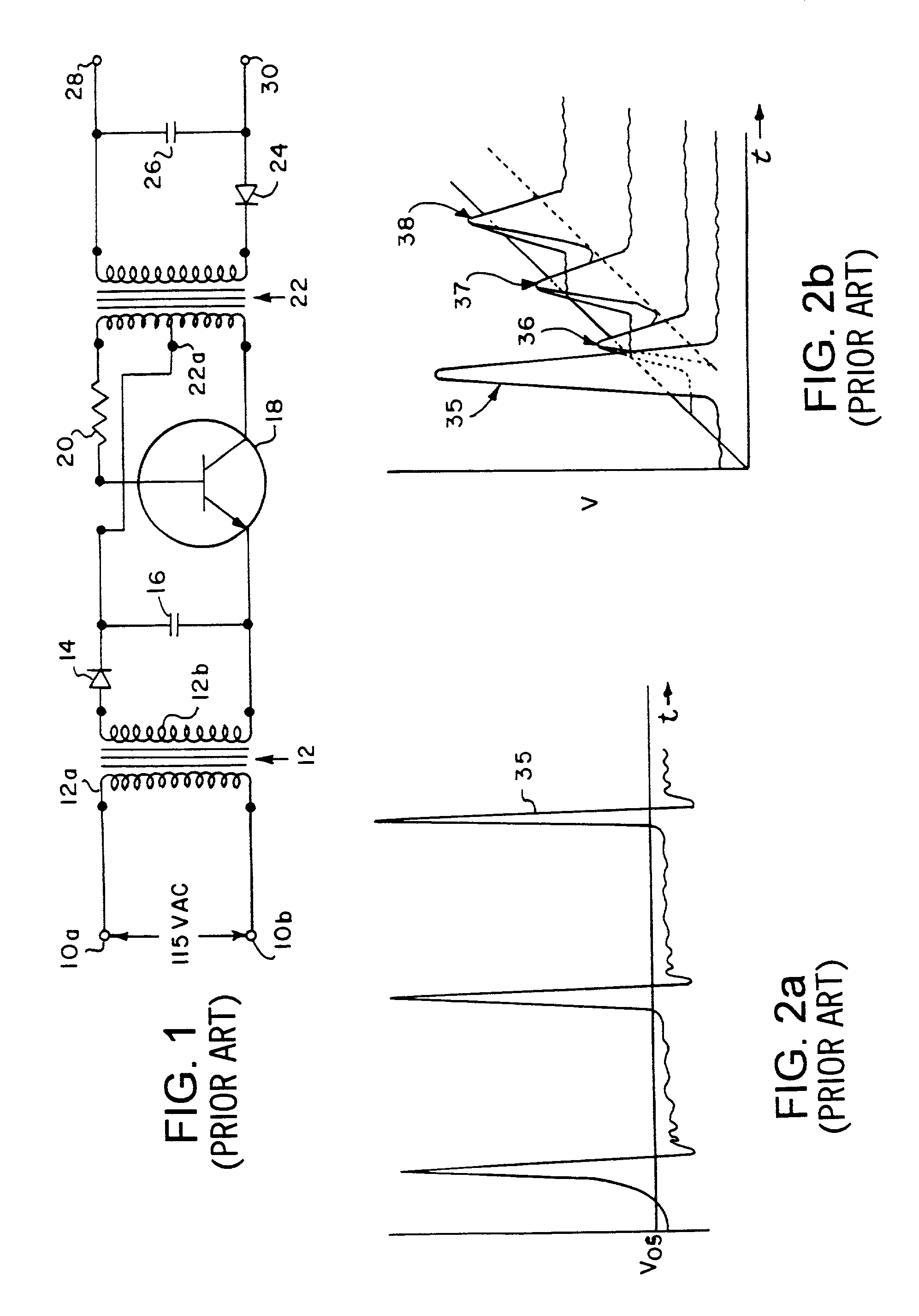

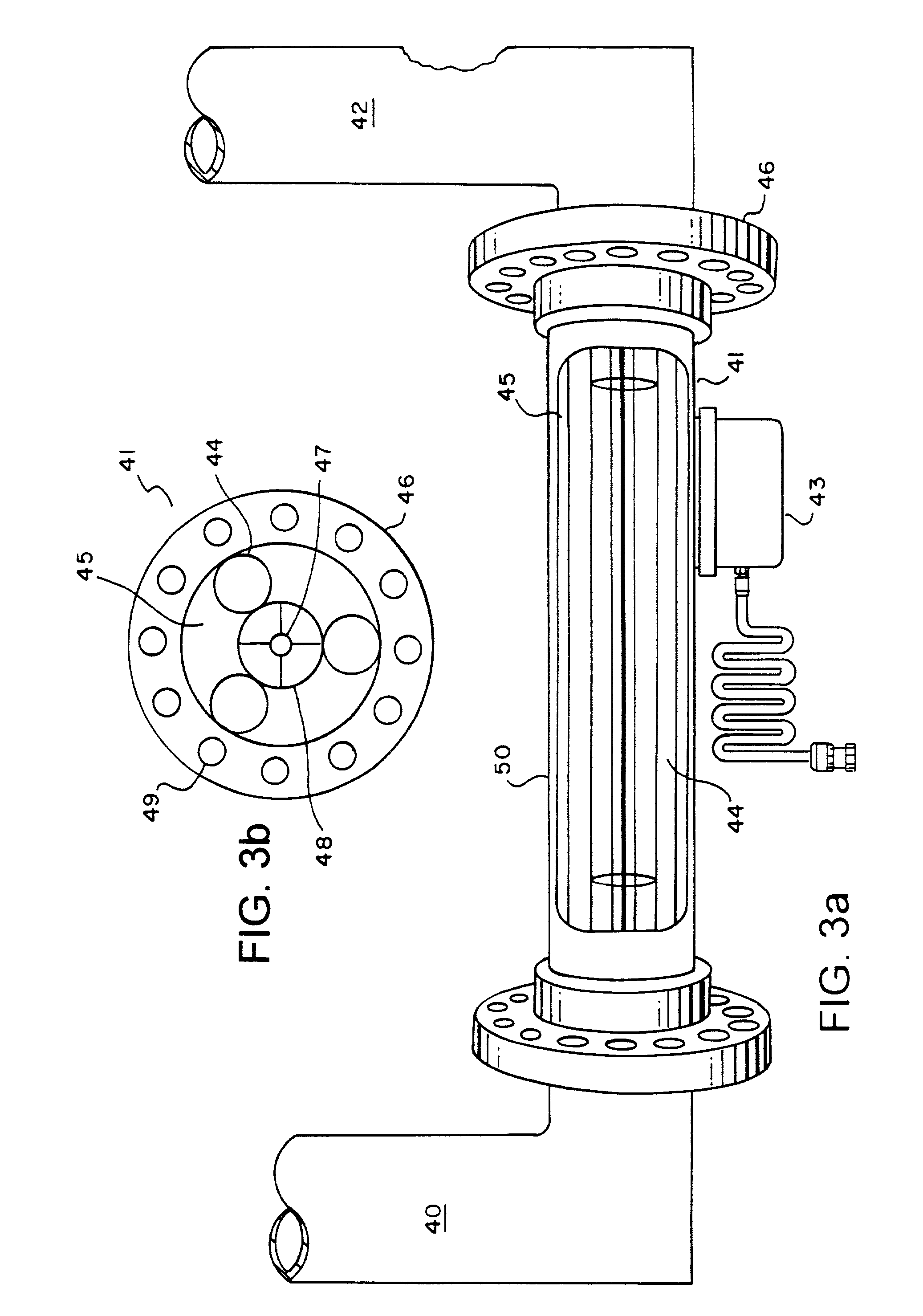

Methods of preparing and using electrostatically treated fluids

InactiveUS6974561B1Measurably betterIncrease crop yieldElectrolysis componentsLiquid separation by electricityWater basedVoltage spike

The present invention includes an improved electrostatic device for energizing fluids, in particular water based fluids, which will be used to provide a benefit to living organisms, machinery, processes and substances. The improved device of the invention will include an electrostatic voltage spike signal generator, two or more radio frequency signal generators, one or more antennas, optional one or more signal boosters and a fluid conduit. When fluid is treated with the improved device of the invention, the fluid will become energized and can be used to provide significant benefits in applications such as milk production, flower production, fruit production, crop production, vegetable production, shrimp production, egg production, meat production, gasoline combustion, waste fluid combustion, scale removal, water purification, fluid tracking, fluid sterilization and more.

Owner:COMPLETE WATER SYST L L C

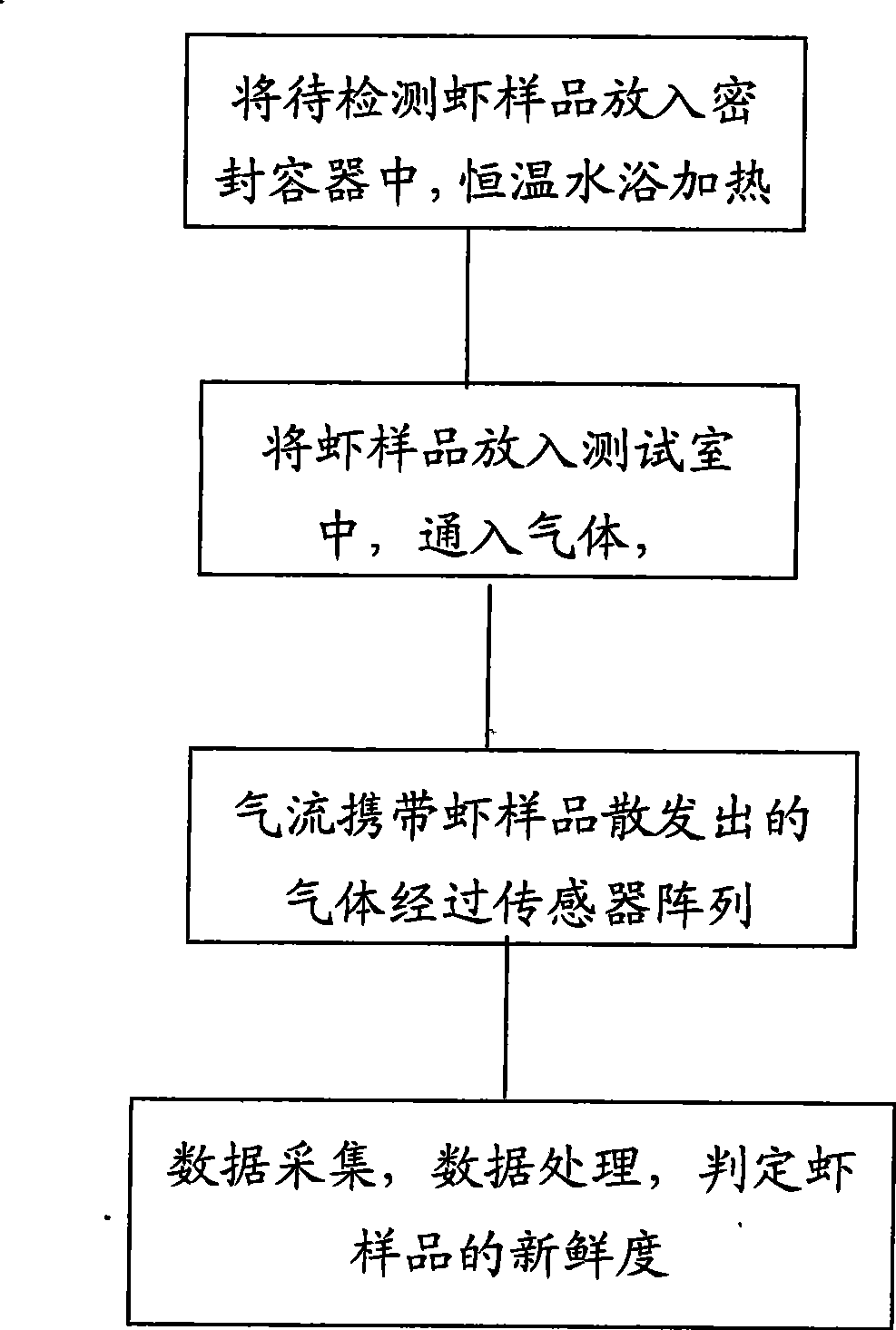

Method for detecting fresh degree of shrimp by electronic nose

InactiveCN101382531AReduce dosageEasy pretreatmentPreparing sample for investigationTesting foodSensor arrayShrimp

The invention discloses a method for detecting the freshness of shrimps by using an electronic nose, and aims at providing a quick and convenient method which uses the electronic nose to detect the freshness of shrimps and has the advantages of convenient usage, objective and reliable detection result and reducing the influence of the storage condition on the detection result. The method comprises the steps: the shrimp samples to be tested are put into a sealed container and heated in thermostatic waterbath; the gas with stable flow speed is passed into a testing room, the heated shrimp samples are put into the testing room, the smell emitted by the samples is carried by the airflow to pass through an array being composed of five different types of gas sensors for detection; the data obtained by the gas sensor array is collected and carried out data processing, and the freshness of the shrimps is evaluated according to the data processing result. The detection method adopts the electronic nose being composed of five different types of sensors to detect the shrimp samples, thus having objective, accurate and quick detection result, and good repetitiveness.

Owner:TIANJIN UNIV OF COMMERCE

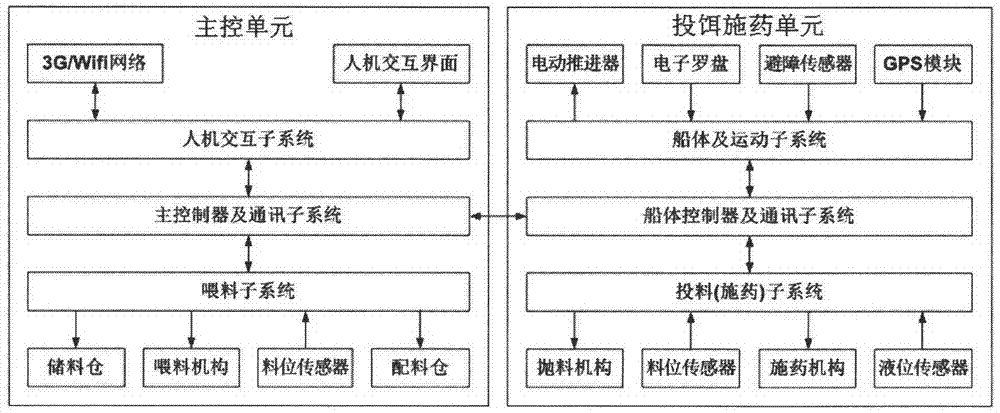

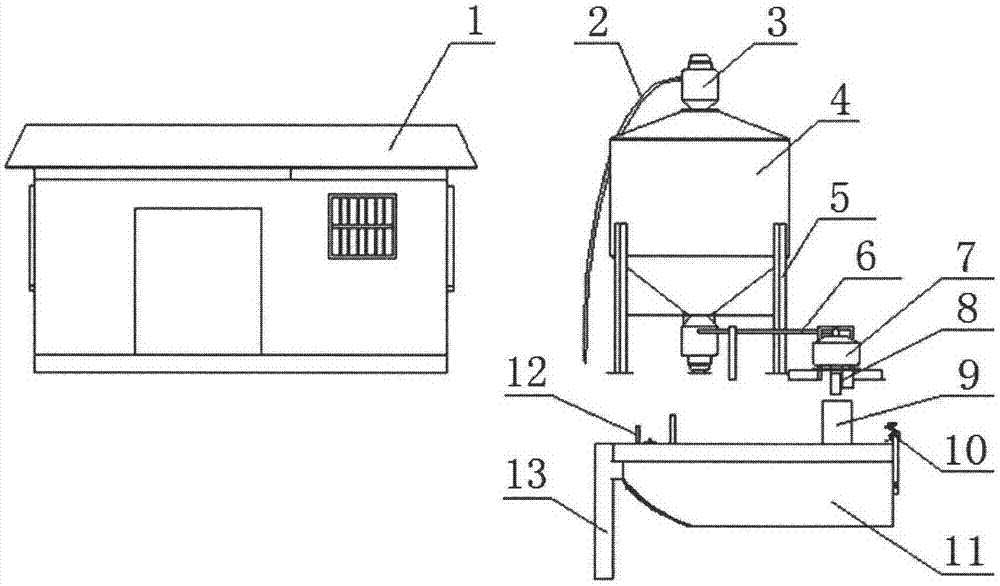

GPS (global positioning system) navigation based intelligent feeding and spraying system and device

InactiveCN103918596AReduce labor intensitySplash evenlyPisciculture and aquariaVeterinary instrumentsShrimpGps navigation

The invention discloses a GPS (global positioning system) navigation based intelligent feeding and spraying system and device, and belongs to the field of aquaculture equipment. A main controller receives a task and an instruction inputted by a man-machine interaction subsystem, and controls a feed subsystem to execute feed action; the feed subsystem feeds back feed information to the main controller, and the feed information is displayed to the man-machine interaction subsystem; a hull controller receives hull movement information inputted by a hull and a movement subsystem and controls the hull to move, and a feeding (spraying) subsystem executes feeding (spraying) action under an instruction of the hull controller; the feeding (spraying) subsystem feeds back feeding (spraying) information to the hall controller; the main controller and the hull controller are wirelessly connected through a communication subsystem. Labor intensity of aquaculture farmers is lowered greatly, accurate feeding of feed and uniform spraying of medicine are realized, use efficiency of the feed and medicine is improved, impact of aquaculture on the environment is reduced, and the system and device is particularly applicable aquaculture of shrimps and crabs.

Owner:常州智能农业装备研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com