Patents

Literature

3262results about How to "Reasonable ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power having nutrition of paddy, bean, fruit, vegetables and tea with the functions of equalizing the nutrition, losing weight and reducing blood sugar

ActiveCN101116510ABalanced nutritionHave weight lossPre-extraction tea treatmentMetabolism disorderFiberGlucose polymers

The present invention provides a low-lipid, high-fiber, balanced-nutritional, instant-taking and instant-resolving powder made from all natural components including corn, bean, flower, vegetable, fruit, tea and bi-usage plants for both food and medication. The nutritional powder provided by the present invention has not only the functions to balance the nutrition, but also the effect to decrease the body weight, lower the blood glucose, and effectively prevent and treat the diabetes.

Owner:湖南湘泉药业股份有限公司

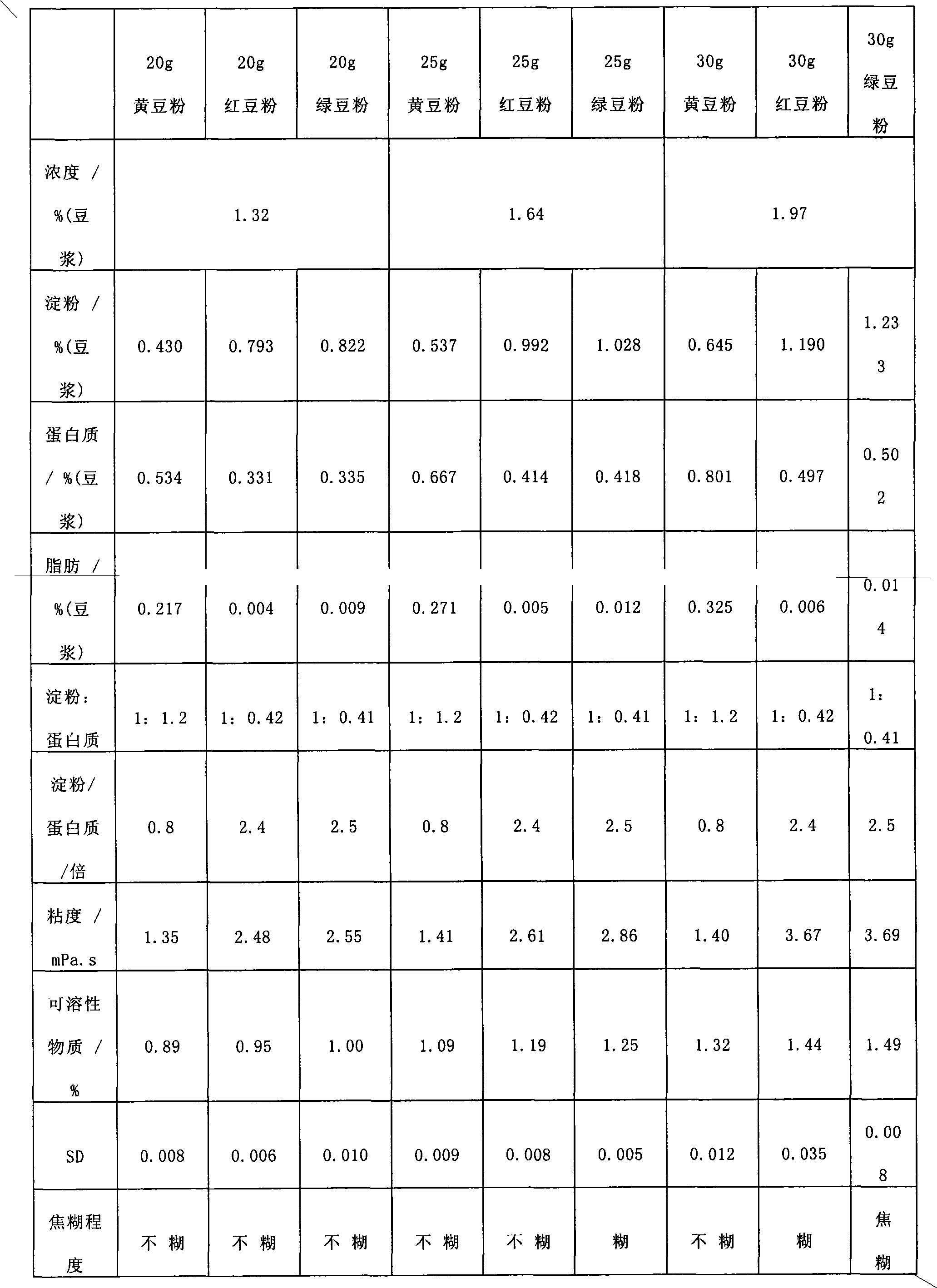

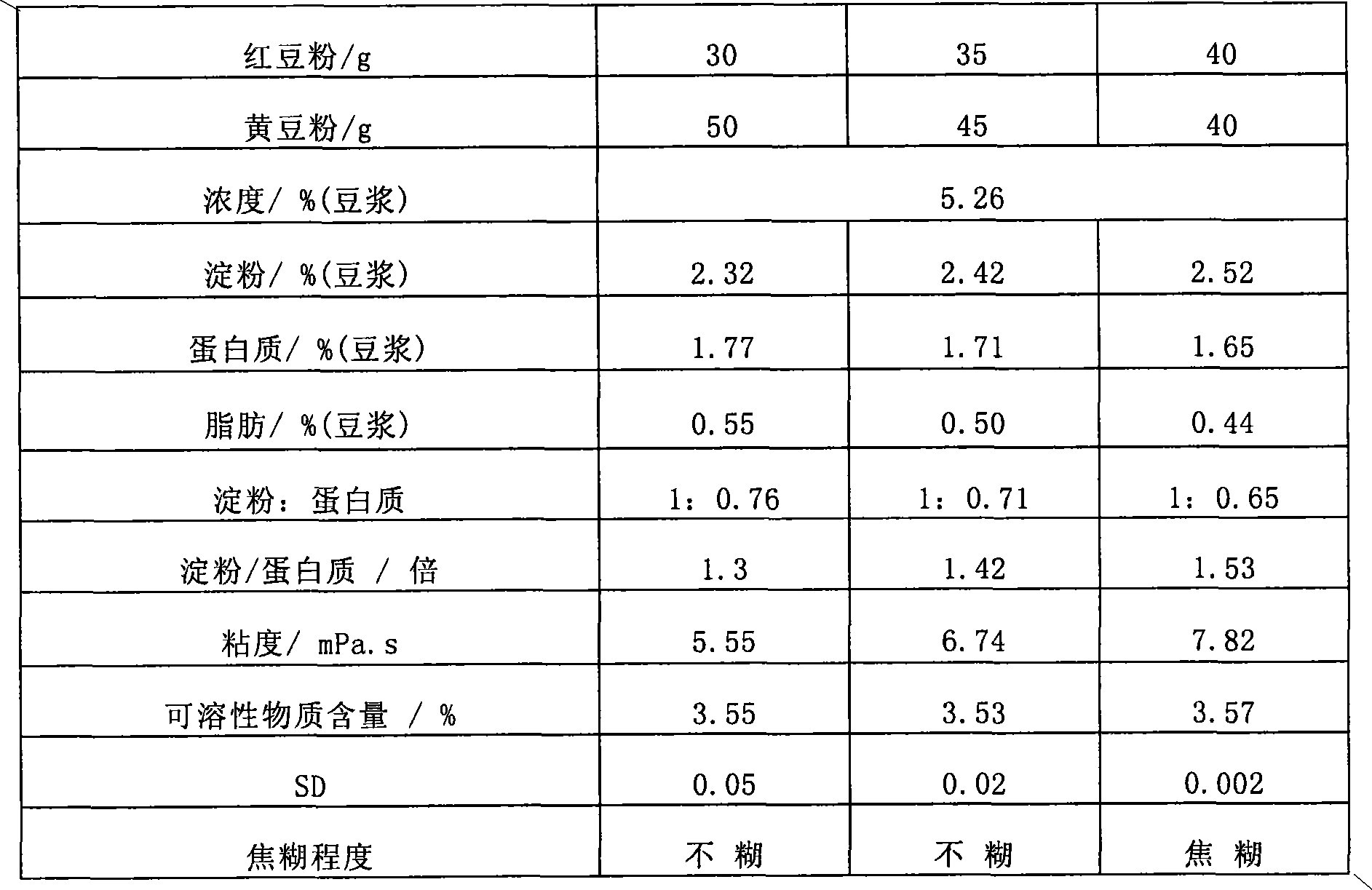

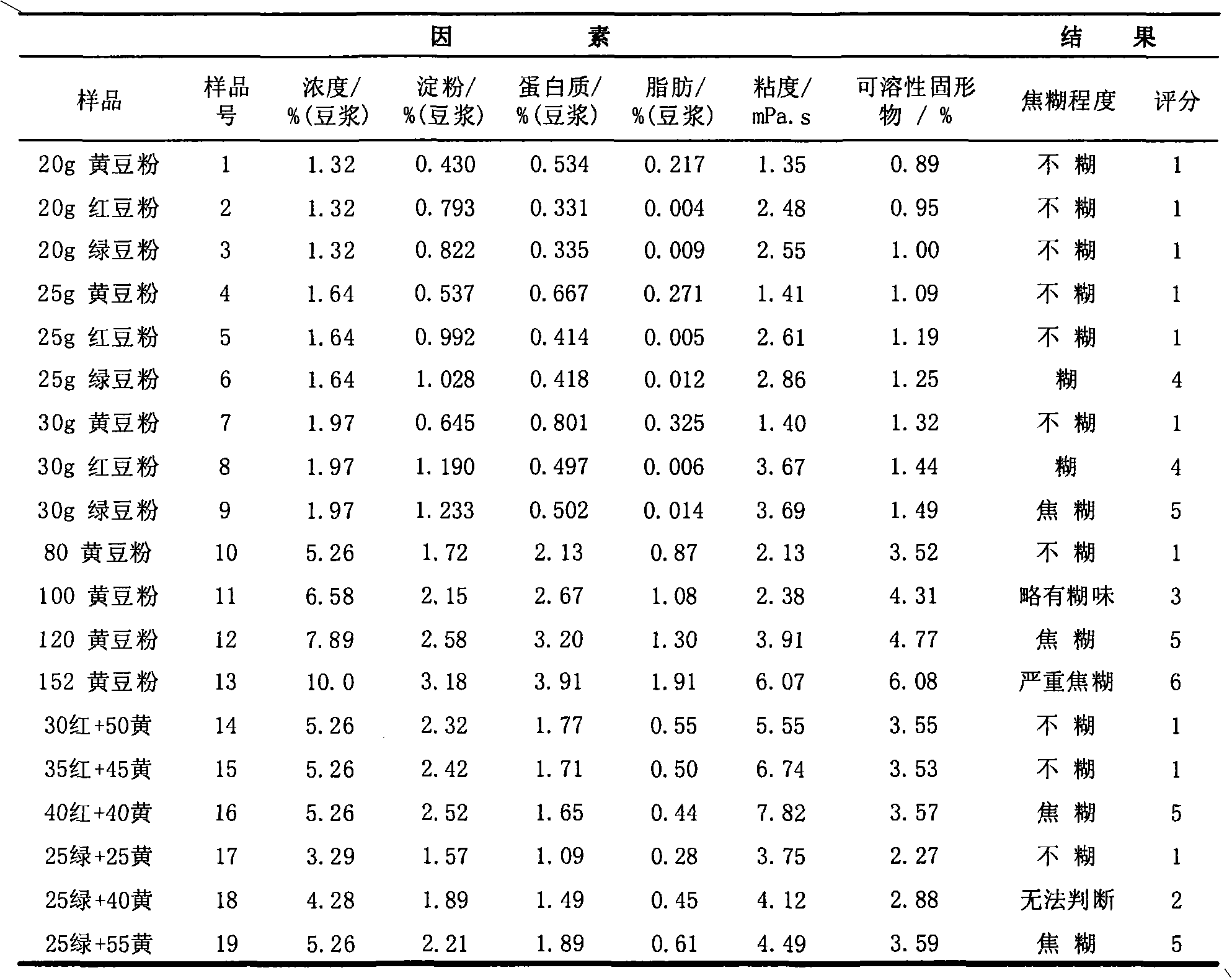

Raw material for making soybean milk and preparation method thereof

ActiveCN101884402AReasonable proportionIncrease nutritionFood preparationMilk substitutesSoybean mealSoybean oil

The invention discloses a raw material for making soybean milk and a preparation method thereof. Based on the total weight of the raw material and water, the raw material accounts for less than or equal to 6 weight part.

Owner:秦皇岛金海食品工业有限公司

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

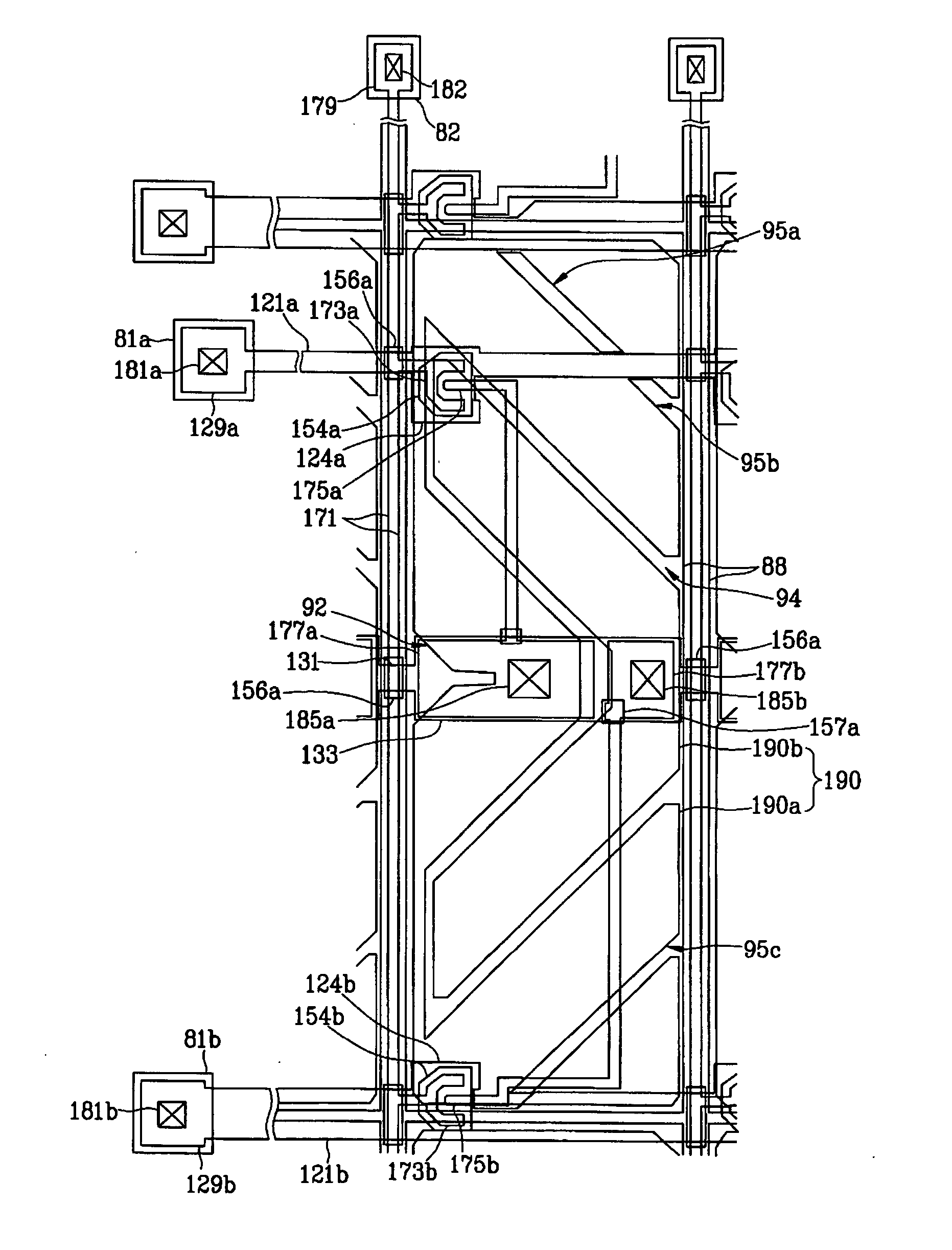

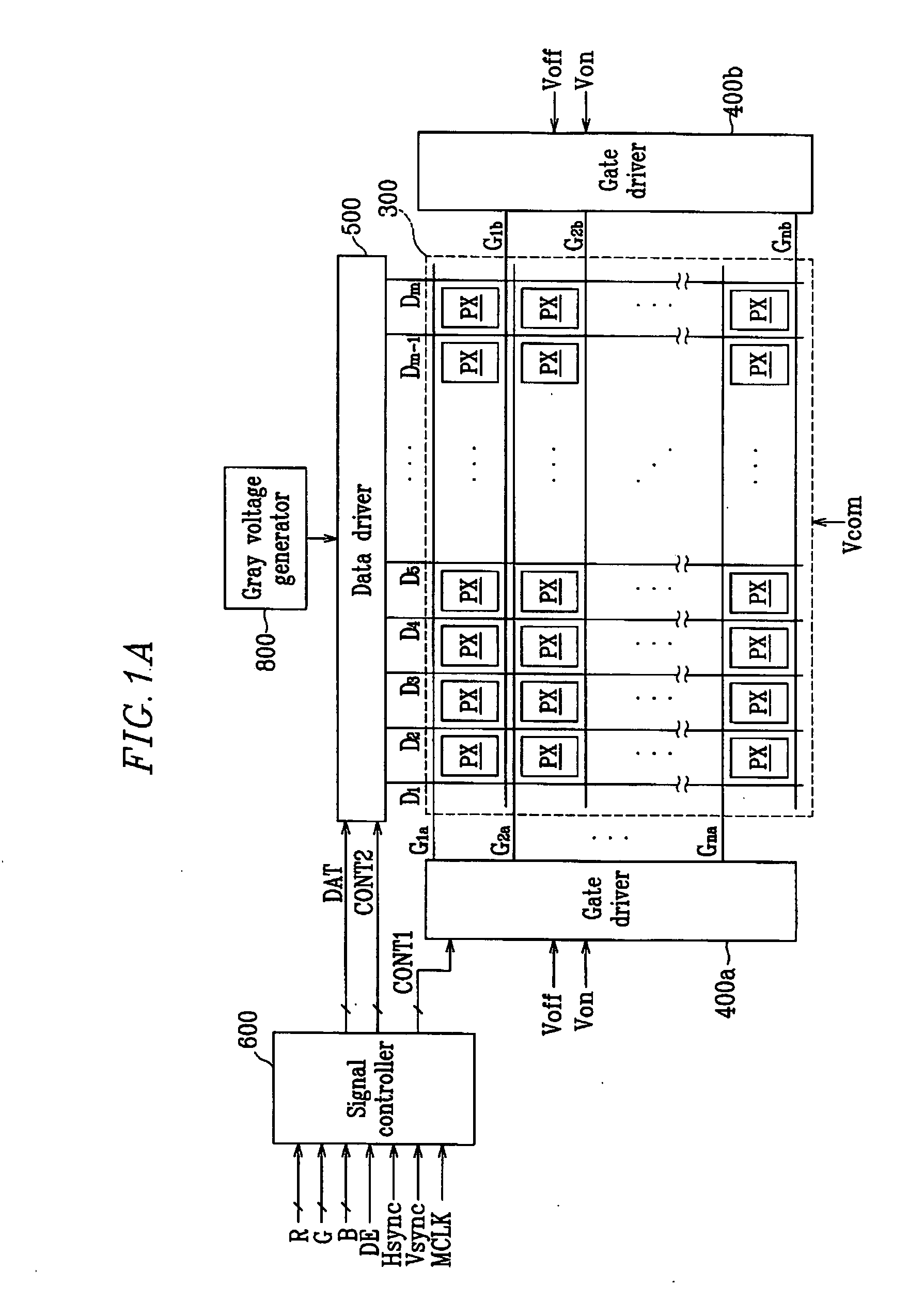

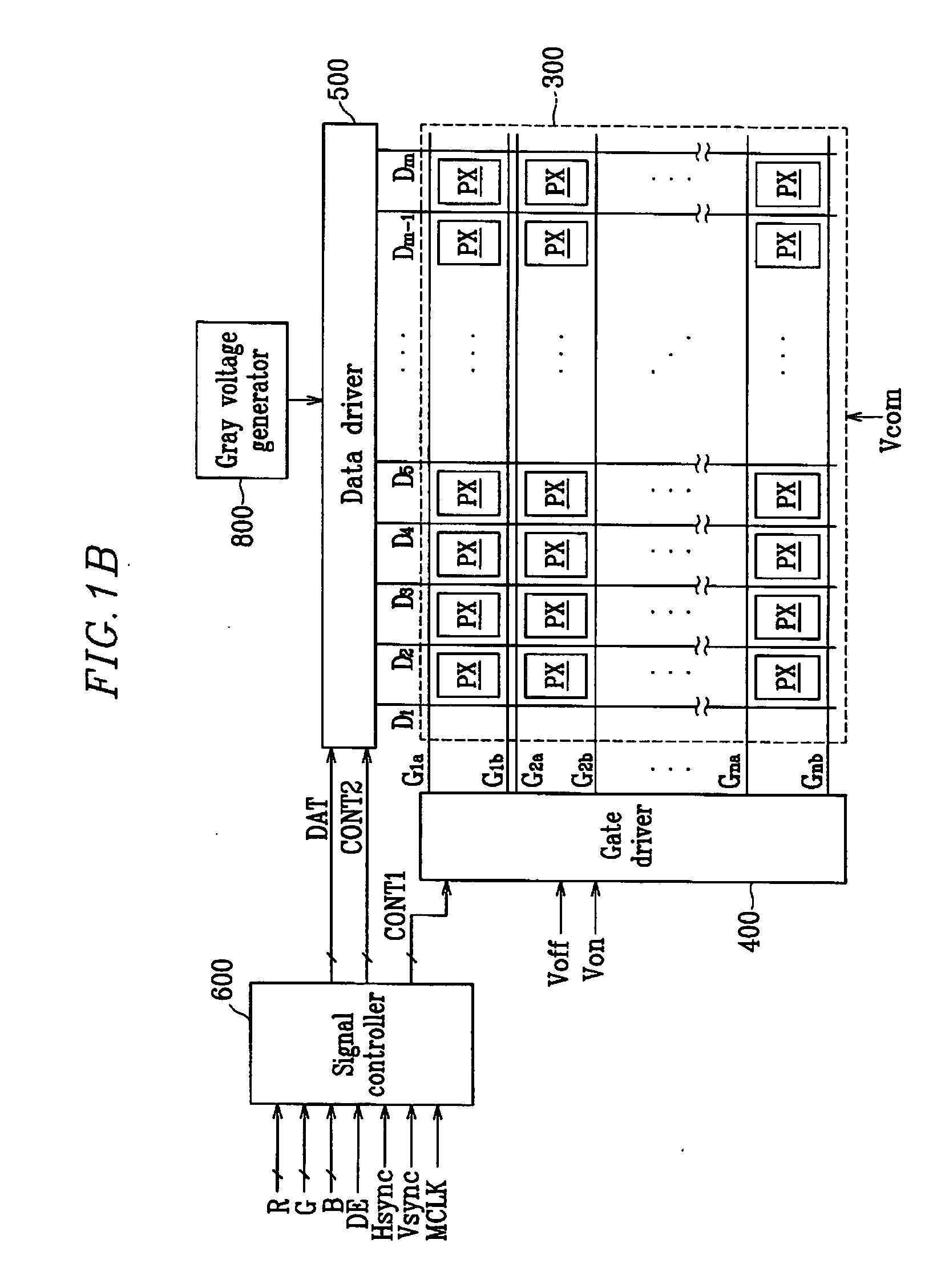

Liquid crystal display

InactiveUS20060231838A1Enhancing lateral side visibilityIncrease the areaStatic indicating devicesSolid-state devicesLiquid-crystal displayVoltage

A liquid crystal display includes an array of pixels. Each pixel is divided into a first sub-pixel and a second sub-pixel, and different data voltages are separately applied to (or evolved at) the two sub-pixels, thereby enhancing the lateral side visibility. Each sub-pixel includes a sub-pixel electrode (connected to the drain electrode of a sub-pixel's switching element) overlapped with the sub-pixel's storage electrode. A first predetermined voltage is applied to the first sub-pixel and second predetermined voltage is applied the second sub-pixel, and thus the first sub-pixel electrode may receive a voltage lower than the voltage of the second sub-pixel electrode. The first sub-pixel electrode may be larger in area than the second sub-pixel electrode. The overlapping area between the first drain electrode and the storage electrode of a first sub-pixel may be larger than the overlapping area between the drain electrode and the storage electrode of a second sub-pixel. Thus the kickback voltage of the first sub-pixel may be substantially the same as the kickback voltage of the second sub-pixel.

Owner:SAMSUNG DISPLAY CO LTD

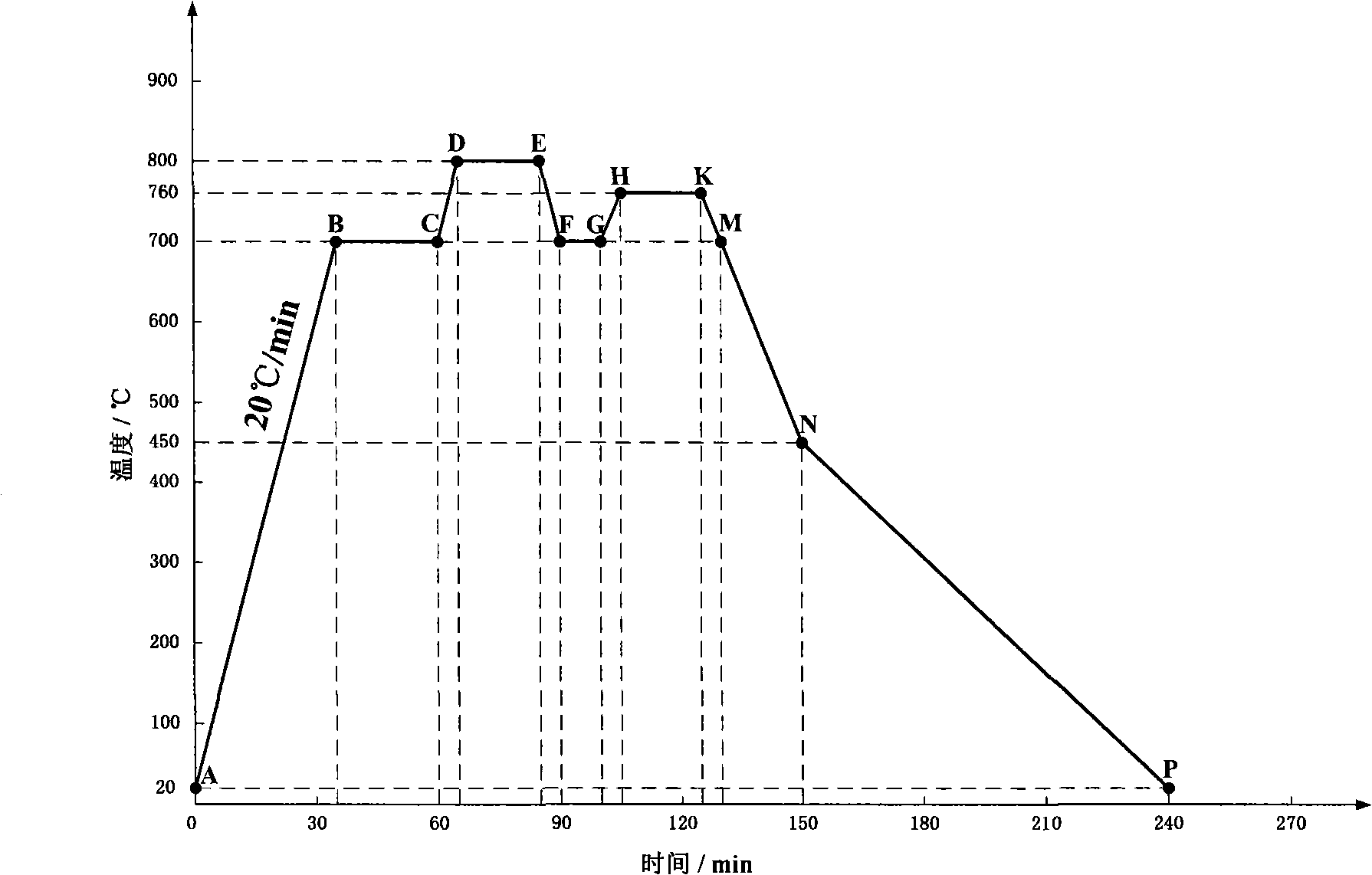

Electrothermal film and manufacturing method thereof

ActiveCN101668359ASimple processEfficient processHeating element materialsResistors adapted for applying terminalsTitanium chlorideMetallurgy

The invention relates to an electrothermal film and a manufacturing method thereof, belonging to the technical field of semiconductor heating. The electrothermal film is mainly prepared by adopting stannic chloride, titanium tetrachloride, stannic chloride, titanium trichloride, ferric chloride, antimony trichloride, calcium chloride, potassium chloride, cadmium chloride, stannic dioxide, stannictetroxide, hydrofluoric acid, boric acid, ethanol, isopropyl alcohol and inorganic water. By adopting the above formula, the mixture is mixed, stirred and heated to prepare into electrothermal film treating fluid, a semi-finished product of the electrothermal film is obtained by spraying the electrothermal film treating fluid at negative pressure on the electrothermal film carrier, and then silveroxide slurry is coated on the semi-finished product of the electrothermal film for baking to form a finished product of the electrothermal film. The electrothermal film has reasonable proportion andsimple manufacturing process, can be manufactured into various electrothermal film heating devices, has a working temperature capable of being up to 500 DEG C, and has wider application range. The electrothermal film of the invention also has the function of far infrared radiation, can play a role of physical therapy and health care to human body, and can help improve the quality and output of agricultural products.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

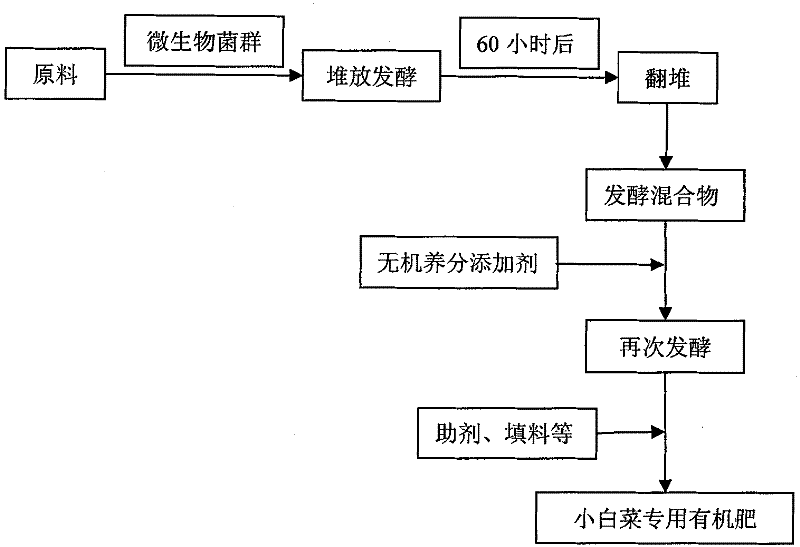

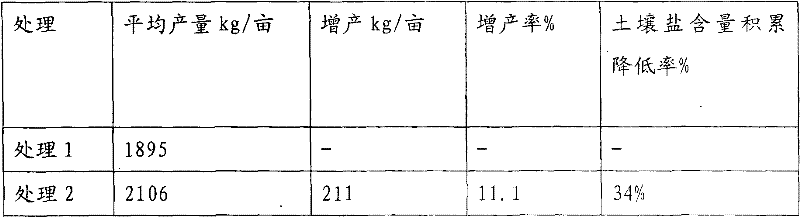

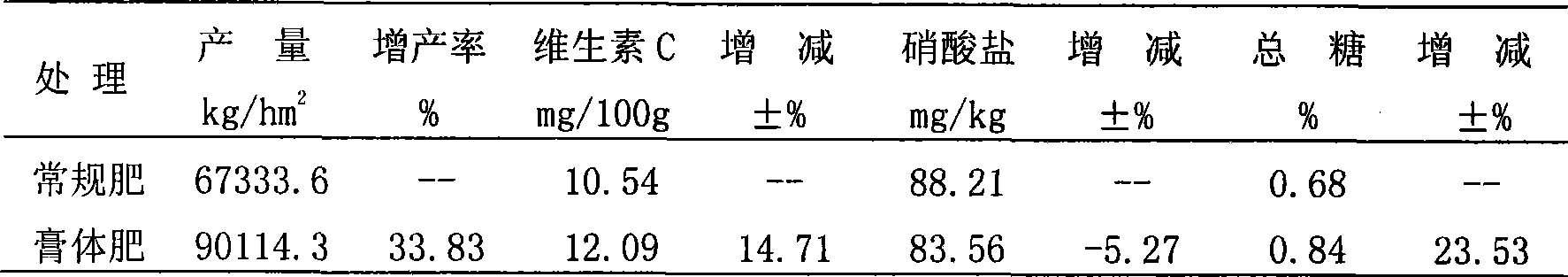

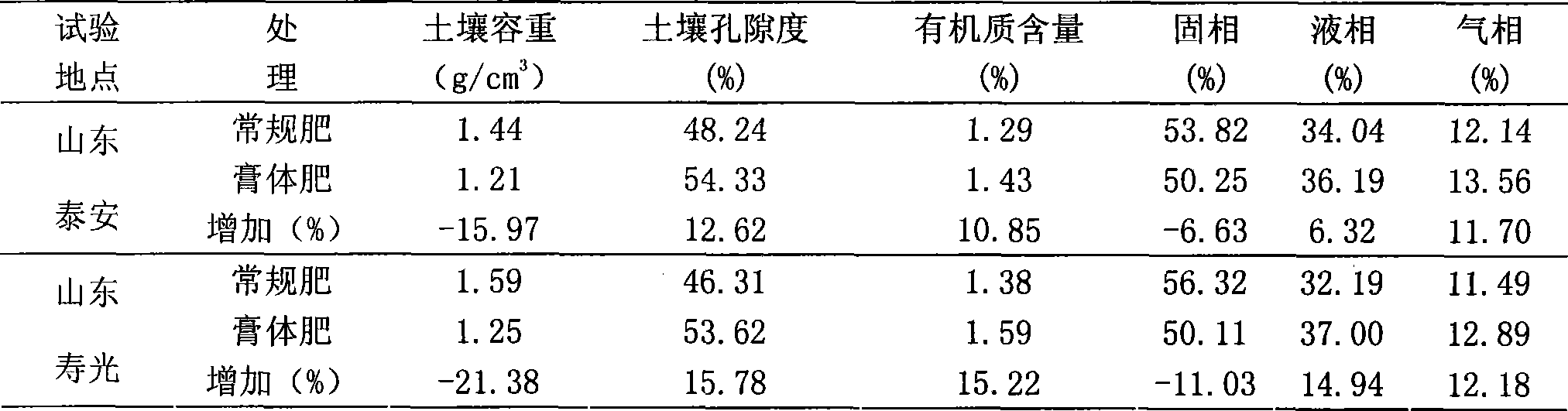

Pakchoi organic composite fertilizer

ActiveCN102351596AReasonable ratioFully absorb and utilizeBio-organic fraction processingOrganic fertiliser preparationSoil typeEffective microorganism

The invention relates to pakchoi organic composite fertilizer. The pakchoi organic composite fertilizer is characterized in that medium and trace elements needed by multiple plants are mixed with inorganic fertilizer and organic fertilizer; and simultaneously, auxiliary agents capable of improving an absorption and utilization rate for a plant and increasing fertilizer slow-release performances and effective microorganisms are added into the mixture to be prepared into specialized composite fertilizer particles through proper fermentation and processing. The pakchoi organic composite fertilizer has the advantages that scopes of suitable regions and soil types are wide; base fertilizer one-step application can be realized in fertilizer application and topdressing can be carried out later according to needs; pakchoi growth needs are satisfies; and effects of yield increase and harvest increase are realized.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

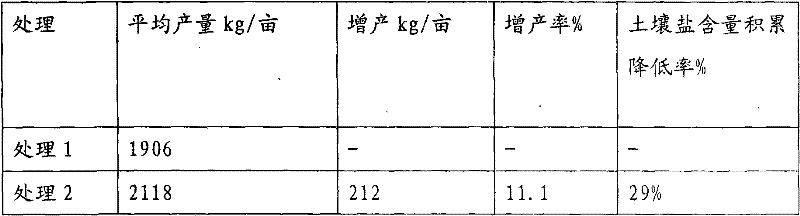

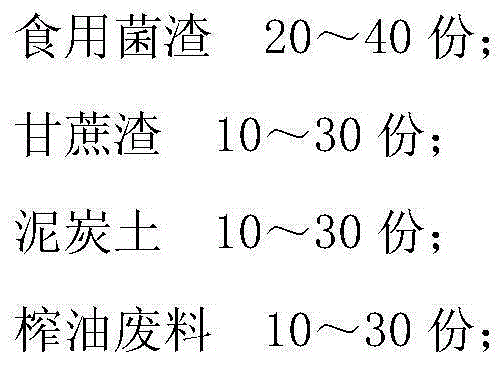

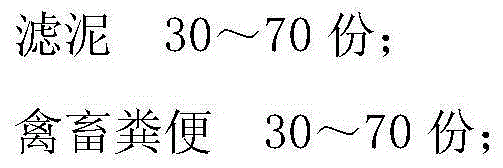

Microbial ecological organic fertilizer and preparation method thereof

InactiveCN105218254AWide variety of sourcesSimple structureBio-organic fraction processingOrganic fertiliser preparationHigh absorptionMicrobial agent

The invention discloses microbial ecological organic fertilizer and a preparation method thereof. The organic chemical fertilizer comprises the following components: edible mushroom dregs, sugarcane dregs, peat soil, oil squeezed waste, filter sludge, livestock and poultry manure and a microbial agent, wherein the microbial agent comprises bacillus subtilis, saccharomycetes, aspergillus niger, guanyloribonuclease, trichoderma, lactobacillus, photosynthetic bacteria, actinomycetes and streptomyces microflavus. The prepared organic fertilizer has advantages of wide raw material source, low cost, high absorption utilization rate, comprehensive nutrients, low dosage, no odor, fast fertilizer effect, various bacteria types, high content, capability of preventing injurious pests, simple preparation method and the like.

Owner:广西多得乐生物科技有限公司

Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

The invention discloses a compound liquid fertilizer with high suspension degree, and a preparation method and an application thereof, and belongs to the liquid fertilizer industry field. The preparation method comprises the steps: adding macromolecule organic sugar into a clay material to be used as a basal suspending agent I, and carrying out first suspension chelation of a major element and a trace element at the temperature of 40-60 DEG C; followed by controlling the temperature at 20-30 DEG C, slowly adding a plant growth regulator and a surface active material, fully mixing uniformly, finally adding macromolecule cellulose and an analog thereof as a suspending agent II, carrying out second suspension chelation, and fully stirring to obtain the compound liquid fertilizer with high suspension degree. The prepared compound liquid fertilizer with high suspension degree has comprehensive nutrients, high content, low cost, good liquidity, good stability and good dissolvability, and is beneficial for crops to efficiently absorb and utilize. The preparation method is simple in process and easy to implement. The compound liquid fertilizer is an ideal fertilizer source for water and fertilizer integration for drip irrigation, sprinkler irrigation, water flushing and the like.

Owner:SOUTH CHINA AGRI UNIV +1

Grain flavouring milk comprising nut granule and production method thereof

The invention discloses a cereal flavoring milk containing nut particles and process for preparation, wherein the milk comprises the following constituents (by weight portions): milk 75-95, nuts particles 1-15, cereal 0.05-10, sugar 3-12, stabilizing agent 0.1-1, edible flavoring essence 0.05-0.2.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

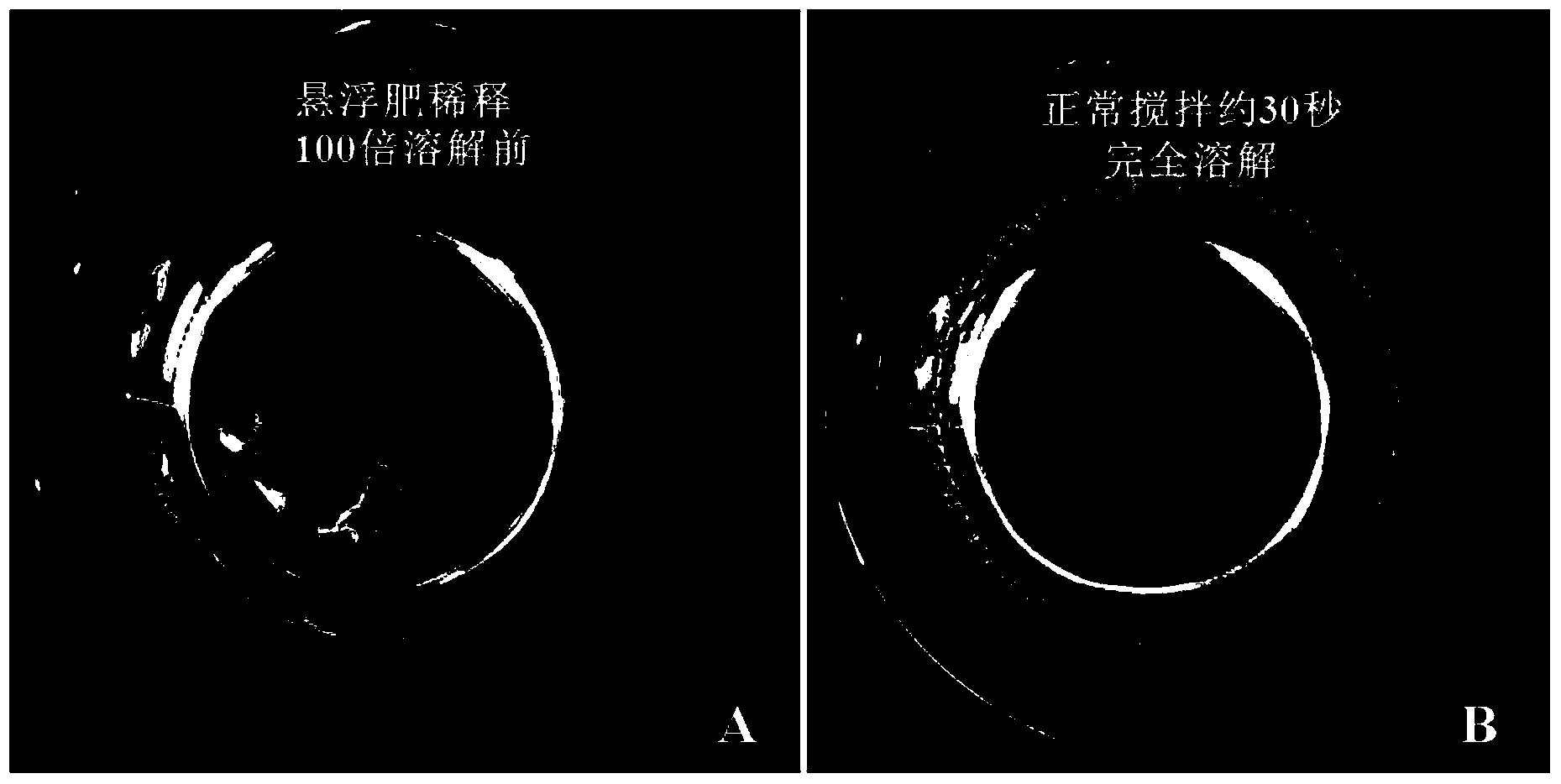

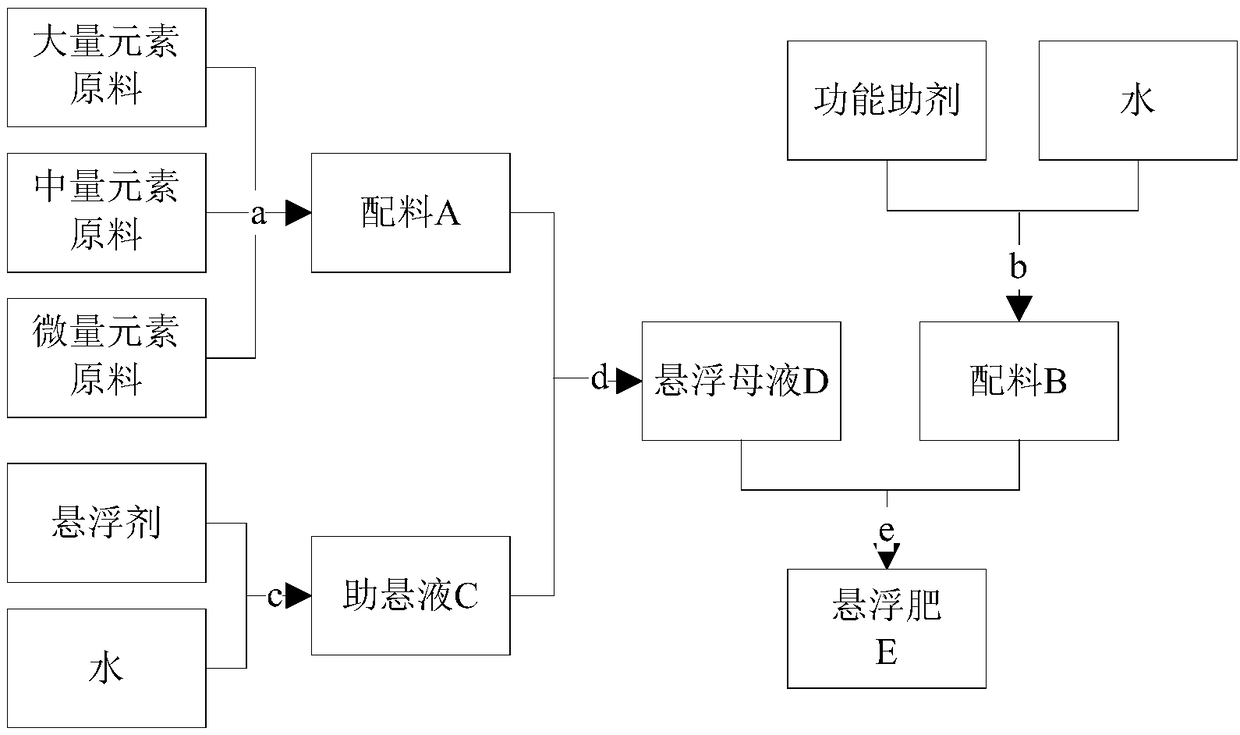

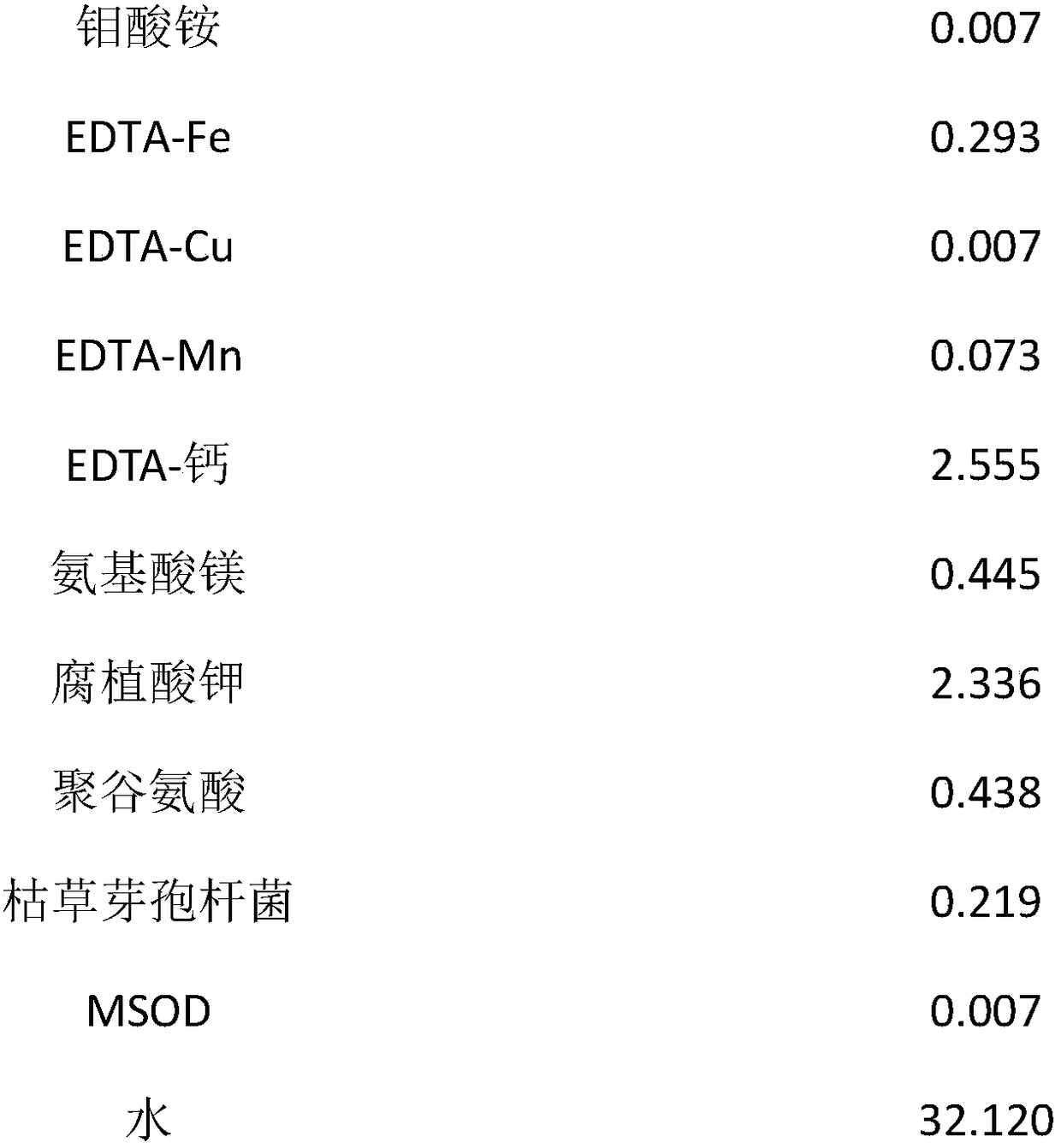

High-concentration full-nutrition functional suspension liquid fertilizer and preparation method thereof

InactiveCN108440146APromote physiological metabolismSimple structureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersHigh concentrationPotassium

The invention discloses high-concentration full-nutrition functional suspension liquid fertilizer and a preparation method thereof. 1-5 parts of functional additive, 40-60 parts of major element fertilizer, 1-5 of medium element fertilizer, 0.5-2.5 parts of trace element fertilizer, 0.5-2.5 parts of suspension agent and 20-40 parts of water are homogeneously emulsified and evenly mixed in a specific order to prepare the product. The obtained suspension liquid fertilizer is rich in nitrogen, phosphorus, potassium and medium and trace elements and has comprehensive nutrients and a reasonable ratio, and sufficient nutrients can be provided for different stages of plant growth. The functional additive contained in the product has the functions of positively promoting the plant growth and conditioning the soil, the physiological metabolism of plants can be stimulated, the stress resistance can be enhanced, the body immunity can be improved, the soil structure can be improved, the utilization rate of various nutrients by the plants can be increased, the yield of crop products is increased, and the quality of the crop products is improved. The fertilizer is fully water-soluble, good in fluidity and suitable for an integrated irrigation system of water-soluble fertilizer; the fertilizer is produced under normal temperature and normal pressure, the equipment is simple, large-scale production is easily achieved, and the labor degree is reduced.

Owner:YUNNAN YUNTIANHUA

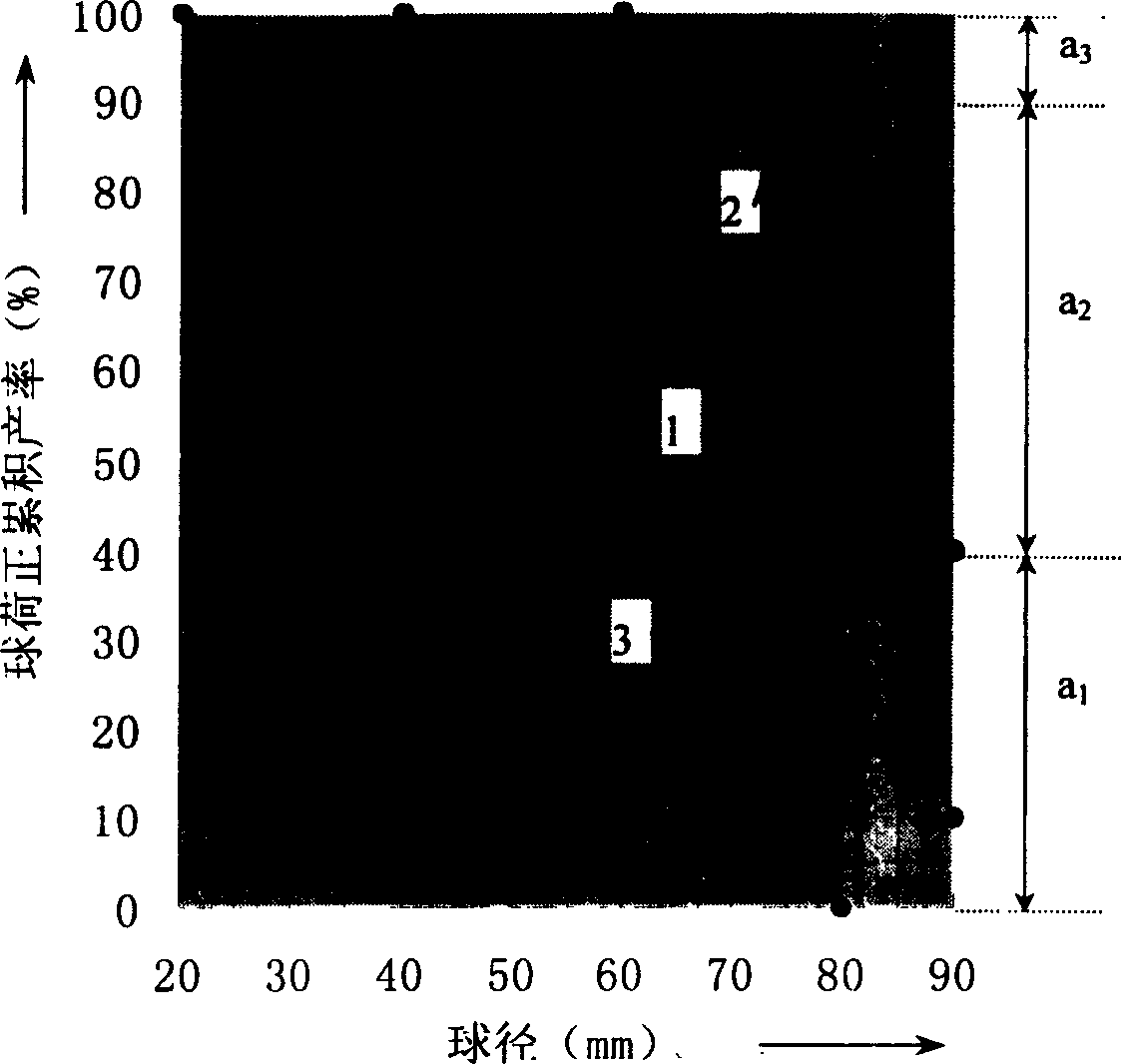

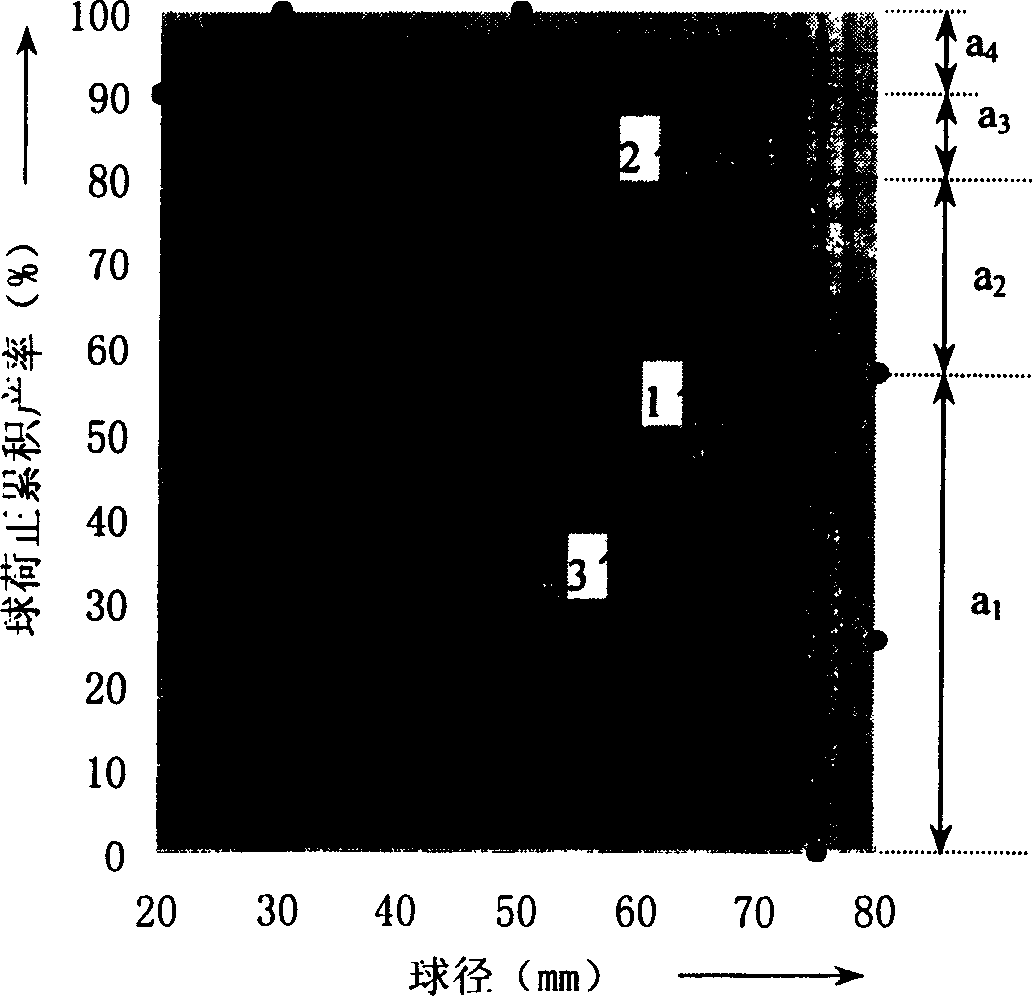

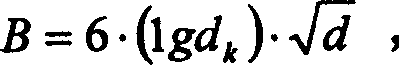

Ball grinder accurate ball loading method

The invention is a method for ball mill to recuperate balls precisely, which belongs to ore pulverizing, grinding technology field. The method includes: measures the mechanical parameter of ore; sifts and analyzes the mill ore and back sands, calculates the ore particle components and groups them; calculates the particle radius value according to ball radius haft theory formula; determines the ball ratio of the mill according to the ore particle and the needed ball radius; paints the ball particle accumulating curve, thus acquires the radius and recuperating ratio precisely. The proportion is reasonable, the method is simple, the productivity is upgraded greatly, and the quality is improved.

Owner:KUNMING UNIV OF SCI & TECH +2

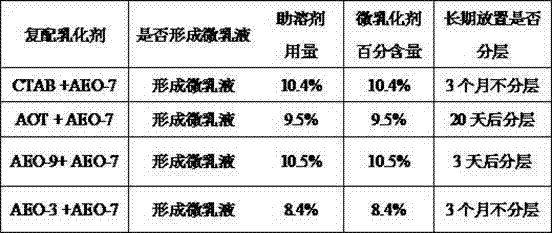

Micro-emulsion biodiesel and preparation method thereof

The invention discloses a micro-emulsion biodiesel and a preparation method thereof. The formula of the micro-emulsion biodiesel comprises the following components in mass percentages: 65-90% of biodiesel, 2-12% of complex emulsifier, 3-8% of cosolvent and 5-15% of water. The micro-emulsion biodiesel disclosed by the invention has reasonable proportion and has the characteristics of clearness, transparency, uniform dispersion, rather stable thermodynamics, storage and conveyance facilitation, no lamination and the like. The micro-emulsion biodiesel disclosed by the invention can exert the advantages of the biodiesel as a reproducible energy source, can also reduce the exhaust of harmful gas NOx and carbon smoke in the process of the combustion of the biodiesel, has low cost and can be stably stored and conveyed for a long time. The micro-emulsion biodiesel disclosed by the invention has a simple preparation method and does not cause pollution to the environment during preparation.

Owner:国家石油石化产品质量监督检验中心(广东)

Diamond bead string and manufacturing method thereof as well as rope saw without base body supporting layer

ActiveCN102825254AReasonable ratioSmall kerfMetal sawing toolsStone-like material working toolsHot pressWire rope

The invention discloses a diamond bead string and a manufacturing method thereof as well as a diamond bead string rope saw without a base body supporting layer. The manufacturing method of the diamond bead string comprises the following steps of: uniformly mixing metal powder, diamond and an organic binding agent; manufacturing a rough blank of the diamond bead string through a pre-hot-pressing modeling or metal injection molding (MIM) process; and obtaining a finished product of the diamond bead string by placing the rough blank in a high-temperature furnace for one-step sintering modeling process after degreasing. The manufacturing method of the diamond bead string provided by the invention can be used for sintering the rough blank in one step to form an entire cylindrical bead string without a bead string base body layer; the external diameter of the bead string becomes smaller, so that the bead string can be directly stringed into a steel wire rope to obtain a diamond rope saw with a smaller external diameter; the bead string is molded through one step without a last-stage permeation process, so that the production cost of the diamond bead string is greatly reduced. Furthermore, the diameter of the diamond rope saw is smaller, and a cutting seam of a stone material to be cut is smaller, so that the yield of rough stone block is improved. The manufacturing method of the diamond bead string is beneficial to large-range popularization and utilization of the diamond rope saw.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

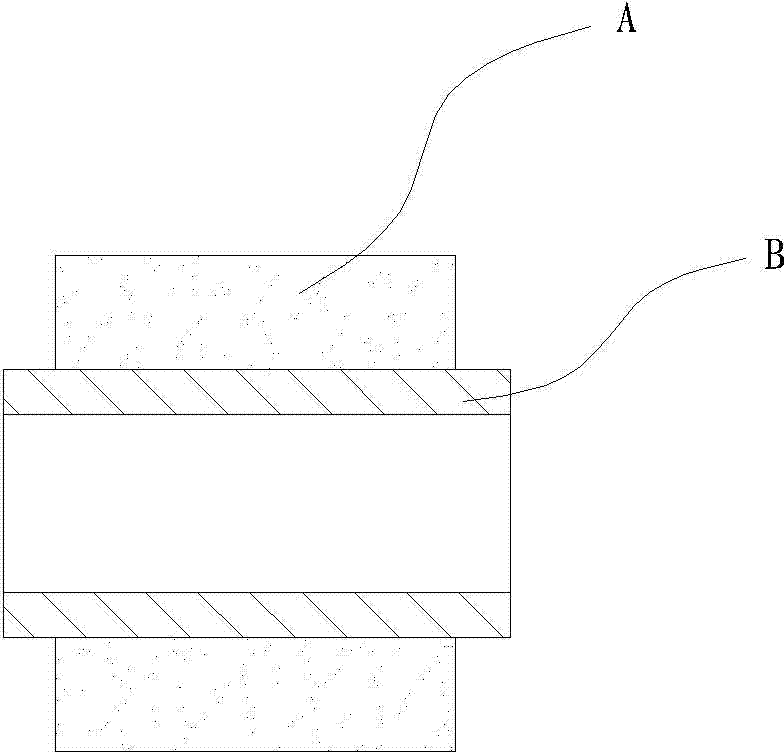

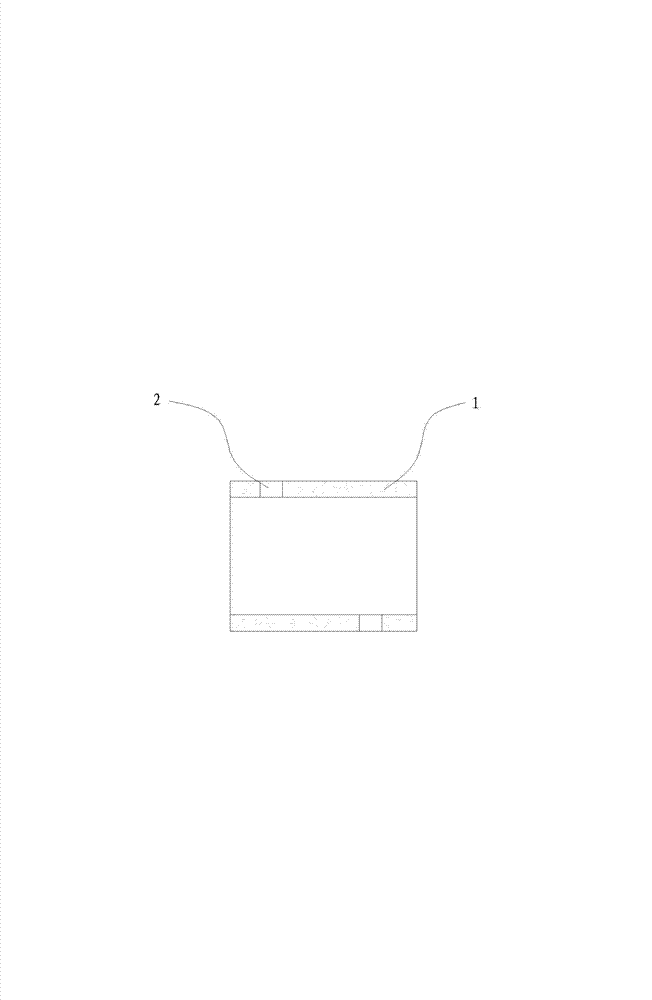

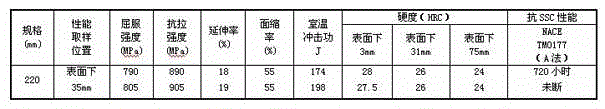

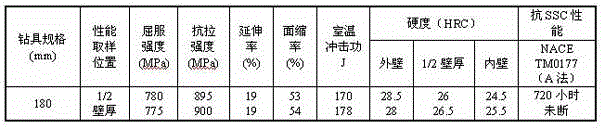

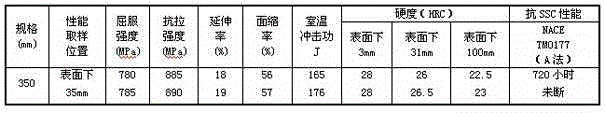

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

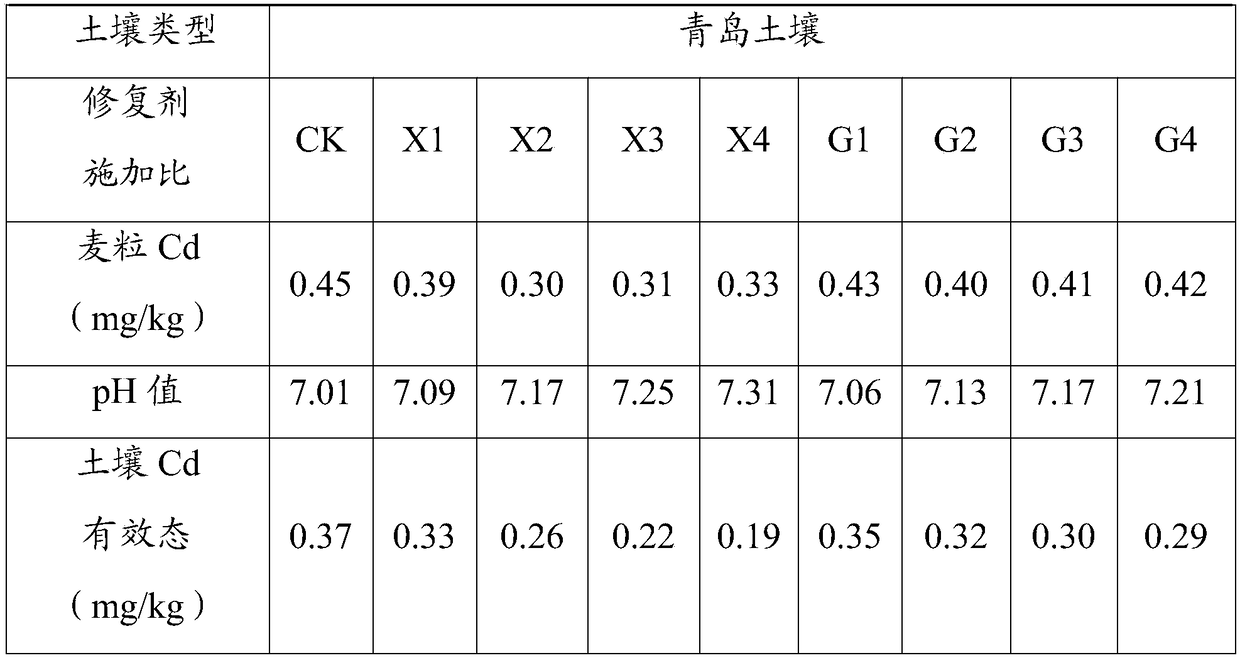

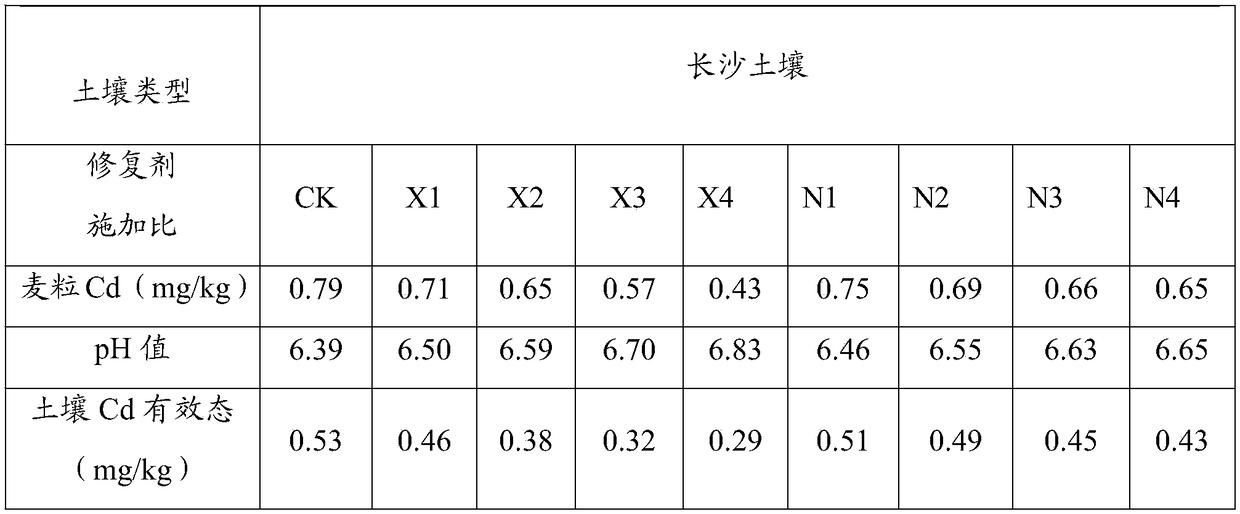

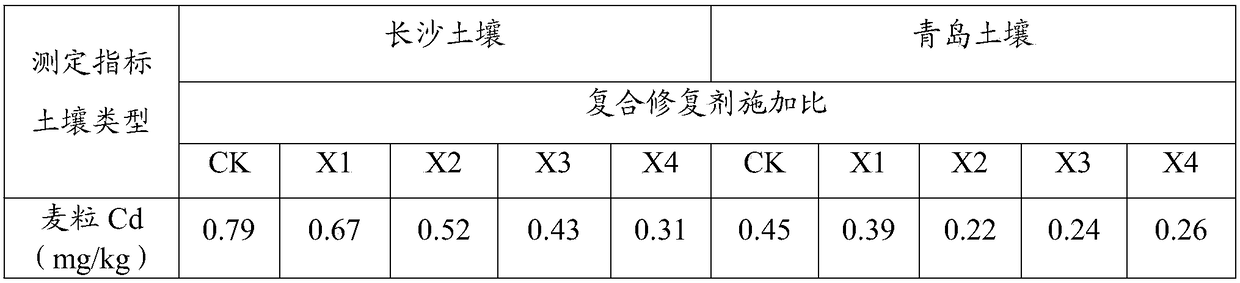

Composite repair agent for soil heavy metal pollution and application thereof

InactiveCN108085010AWide variety of sourcesImprove efficiencyContaminated soil reclamationOrganic fertilisersSodium BentoniteOyster

The invention provides a composite repair agent for soil heavy metal pollution as well as a preparation method and application thereof, and belongs to the technical field of soil improvement and environmental protection. A composite repair agent for soil cadmium pollution is prepared from the following components in parts by weight: 10 to 30 parts of sodium bentonite, 5 to 15 parts of bone powder,5 to 25 parts of chitosan, 5 to 30 parts of oyster shell powder, 10 to 40 parts of graphene-modified crop straw biochar, 10 to 30 parts of bio-organic fertilizer, 15 to 45 parts of sodium silicate, 1to 15 parts of nano-FeO, 1 to 8 parts of carbon nanotubes, and 1 to 10 parts of microbial inoculants. The number of each 10 mg colonies of rhodotorula mucilaginosa OP11 in the microbial inoculum is 2.25*10 <8> to 2.5*10<9> CFU; the preservation number of the rhodotorula mucilaginosa OP11 is CGMCC No. 13540. The application of the composite repair agent is in remediation of heavy metal contaminated soil.

Owner:QINGDAO AGRI UNIV +1

Mirco algal food nutrient intensifying agent prescription and its preparing process

InactiveCN1653938ABalanced nutritionReasonable ratioAnimal feeding stuffAccessory food factorsShrimpAdditive ingredient

The present invention is one kind of nutrient reinforcing agent for artificial fry raising of marine animal, and relates to the recipe and preparation process of micro algae bait nutrient reinforcing agent. The microalgae bait nutrient reinforcing agent consists of several kinds of micro algae containing different nutritious components and has grain size of 5-20 microns. It contains great amount of DHA, ARA and natural astaxanthin, and can raise the immunity and survival rate of raised marine animal. It can meet the requirement of hatched fries of fishes, shrimps and shells in feed. For example, when the microalgae bait nutrient reinforcing agent is used in raising turbot, it can raise the survival rate and lower the albinism rate greatly.

Owner:QINGDAO SAMUELS INDAL & COMML

Silicon carbide carbonized complex phase ceramic sealing material and preparation method thereof

InactiveCN101591169AImproved dry friction propertiesGood self-lubricating performanceWater basedHigh density

The invention relates to a silicon carbide carbonized complex phase ceramic sealing material, which comprises the following component in portion by weight: 100 portions of silicon carbide powder, 0.1 to 1 portion of boron carbide, 5 to 30 portions of carbon powder, 0.5 to 3 portions of binding agent PVA, and 0.5 to 1.5 portions of dispersing agent. A preparation method comprises the following steps in turn: (1) blending the raw materials in proportion and then adding the mixture into deionized water, and after ball milling and mixing, preparing the mixture into a water-based silicon carbide composite slurry of which the solid phase weight content is between 40 and 60 percent; (2) adopting a spraying granulating process to perform spray drying on the slurry to obtain silicon carbide granulated powder; (3) adopting a two-step mode of 140 MPa dry pressing pre-compaction and 200 MPa isostatic cool pressing final compaction to carry out forming on the granulated powder to obtain a high-density sealing material blank; and (4) putting the blank into a vacuum pressureless sintering furnace, raising the temperature to between 2,000 and 2,100 DEG C, keeping the temperature for 1 to 1.5 hours, and sintering the blank to obtain the silicon carbide carbonized complex phase ceramic sealing material.

Owner:东新密封有限公司

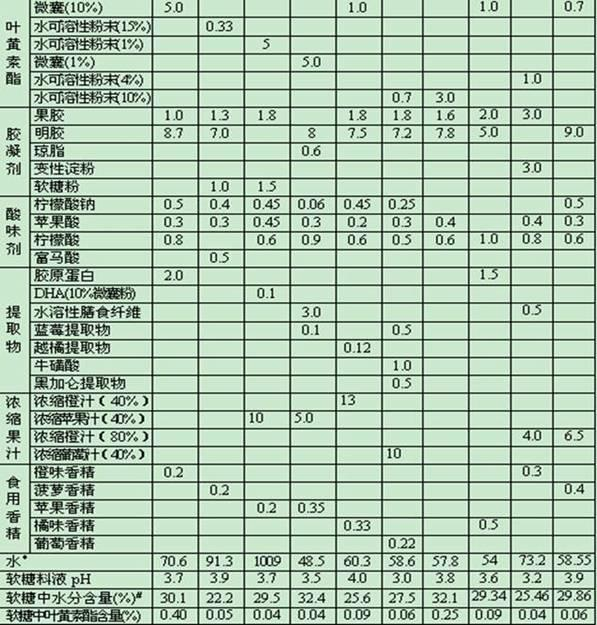

Lutein ester soft sweet and preparation method thereof

ActiveCN102578346AReasonable ratioMade in the right wayConfectionerySweetmeatsChaptalizationSnack food

The invention relates to a lutein ester soft sweet and a preparation method of the lutein ester soft sweet. The soft sweet comprises 60-90% of sweet material, 0.01-10% of lutein ester micro-capsule or water soluble powder, 0.1-15% of gelling agent, 0.01-5% of sour agent, 0-10% of extract, 0-30% of concentrated juice, 0-0.5% of food flavor and 5-34% of water. The preparation method of the lutein ester soft sweet comprises the following steps of: a. sugaring off; b. gelling; c. mixing sugar liquid with gel liquid or gel peptone; d. adding lutein ester, the extract, the concentrated juice, the flavor and the sour agent into the mixed liquid; and e. preparing a finished product. The lutein ester soft sweet has health care functions of relieving visual fatigue, improving eyesight, preventing age related macular degeneration (AMD), and is good in mouthfeel, not glutinous, chewable and palatable in sour and sweet, thus being a healthy snack food; and the preparation method of the lutein ester soft sweet is simple, easy to operate and suitable for industrial production.

Owner:华北制药河北华维健康产业有限公司

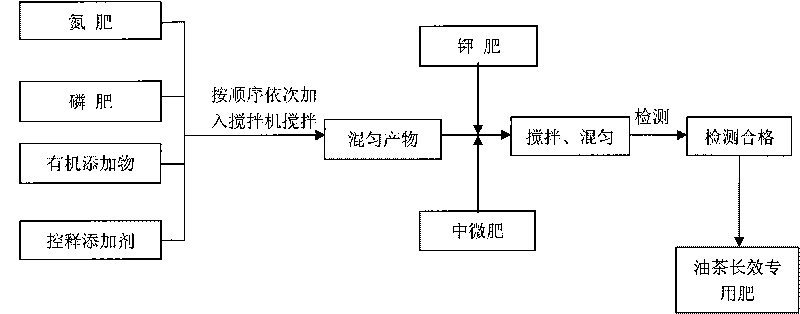

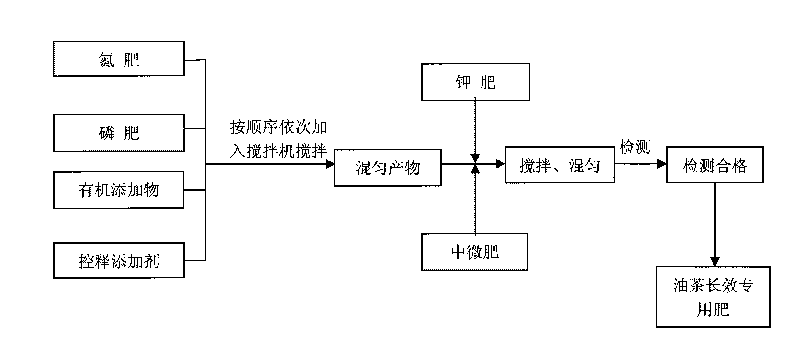

Long-acting special fertilizer for oil-tea camellia and preparation method thereof

ActiveCN101696138AExtend the fertilizer periodImprove Nutrient Utilization EfficiencyFertilizer mixturesLong actingNutrient

The invention relates to a long-acting special fertilizer for oil-tea camellia and a preparation method thereof. The long-acting special fertilizer is characterized in that: the fertilizer is prepared from the following raw materials in percentage by weight: 31.3 to 42.9 percent of nitrogen fertilizer, 8.5 to 8.7 percent of phosphate fertilizer, 26.7 to 32.0 percent of potassic fertilizer, 2.6 to 5.1 percent of medium-micro fertilizer, 10 to 15 percent of organic additive and 4 to 19.4 percent of controlled release additive. The special fertilizer for the oil-tea camellia is produced according to the absorption characteristics of the oil-tea camellia on N, P and K, is suitable for the absorption of N, P and K by the oil-tea camellia, has reasonable proportion and long fertilizer efficiency period, can be used as base fertilizer and additional fertilizer, has high nutrient utilization rate, and is safe and environment-friendly; the special fertilizer can remarkably improve the utilization rate of nitrogen, the increasing range is over 8 percent, and the fertilizer efficiency period is as long as 90 to 150 days; and under the same nutrient condition, the special fertilizer can increase the yield of oil-tea camellia fruits by about 10 percent, can remarkably promote the quality of the oil-tea camellia fruits, and promotes the oil content by over 0.6 percent.

Owner:广东新大地生物科技股份有限公司 +1

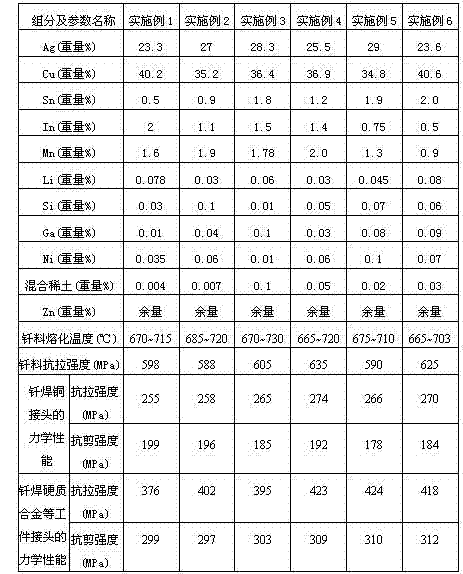

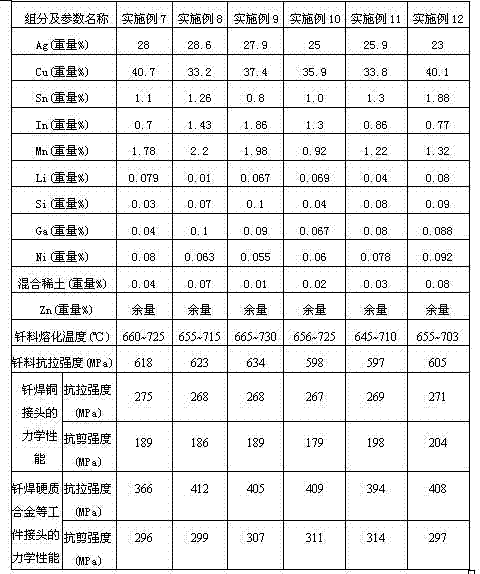

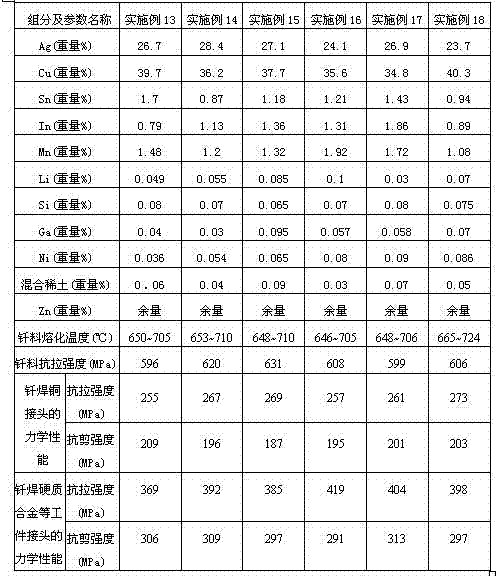

Multielement rare-earth silver solder

InactiveCN102240870AReduce contentImprove plasticityWelding/cutting media/materialsSoldering mediaIndiumRare earth

The invention relates to a multielement rare-earth silver solder which contains elements, such as manganese, indium, tin and the like. The multielement rare-earth silver solder is suitable for soldering metallic materials, such as red copper, brass, carbon steel, hard alloy, stainless steel and the like. The multielement rare-earth silver solder consists of the following components in percentage by weight: 23-29 wt% of Ag, 32-42 wt% of Cu, 0.5-2 wt% of Sn, 0.5-2.0 wt% of In, 0.5-2.2 wt% of Mn, 0.01-0.1 wt% of mischmetal, 0.01-0.1 wt% of Si, 0.01-0.1 wt% of Ni, 0.01-0.1 wt% of Li, 0.01-0.1 wt% of Ga and the balance of Zn. The multielement rare-earth silver solder has the advantages of high cost performance, capability of replacing BAg50CuZnSnNi and BAg50CuZnCd, exclusion of cadmium (Cd), lower melting temperature and good soldering property.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

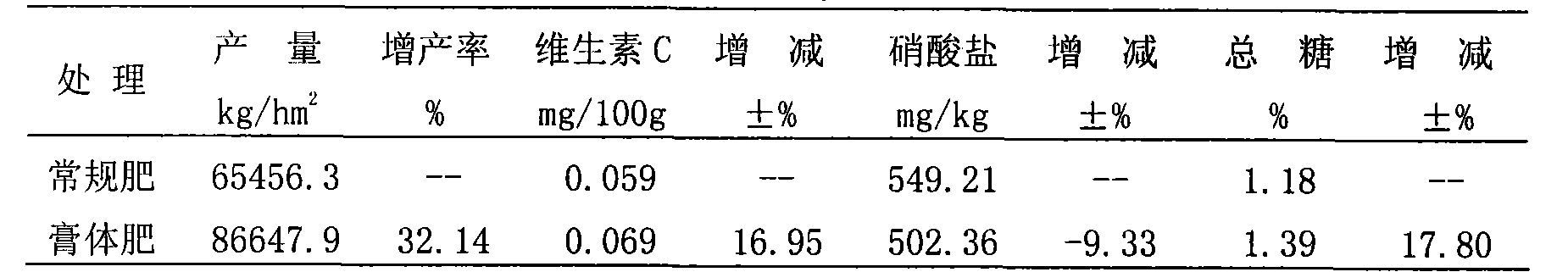

Fermented liquid pasty fertilizer and preparation method thereof

InactiveCN101544522AFull of nutritionReasonable ratioBio-organic fraction processingClimate change adaptationSolubilityLivestock manure

The invention discloses fermented liquid pasty fertilizer which relates to the technology of utilizing fermented liquid for producing pasty and organic compound fertilizer, in particular to a method mixing fermented liquid of livestock manure with humic acid raw materials to prepare the pasty fertilizer and the application of the method, belonging to the technical field of novel organic fertilizer and the cyclic utilization of the resource of agricultural wastes. The pasty fertilizer includes the main component of fermented liquid, and is additionally provided with carbamide, diammonium phosphate, lemery, aminated wood coal, thickening agent and other additives; and the carbamide, the diammonium phosphate, the emery, the aminated wood coal, the thickening agent and the other additives are added to and uniformly mixed and stirred with the fermented liquid, and the mixture is pulverized to form a pasty shape. The invention which utilizes the fermented liquid to prepare the pasty fertilizer turns the wastes into resources, the preparation method is easy, and required equipment is simple, thereby the invention is easy to be easily popularized and applied to the fertilizer industry. The pasty fertilizer has the advantages of favorable dissolvability, full nutrition and obvious effect of yield and quality improvement and can be widely applied to vegetables, fruits, foodstuffs, forests and various cash crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

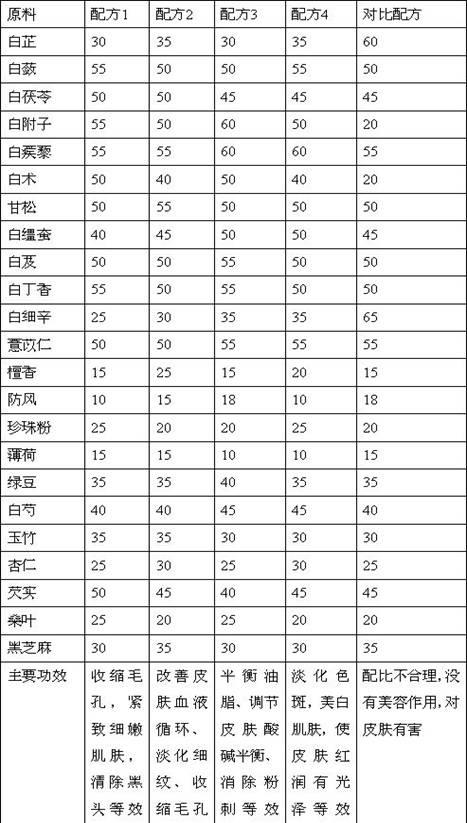

Traditional Chinese medicine beauty mask

InactiveCN102525870AImprove microcirculationTo promote metabolismCosmetic preparationsToilet preparationsFine lineBletilla striata

The invention provides a traditional Chinese medicine beauty mask which is prepared from the following raw materials in parts by weight radix angelicae, ampelopsis japonica, Indian buead, giant typhonium rhizome, tribulus terrestris, white atractylodes rhizome, rhizoma nardostachyos, white silkworm, bletilla striata, white lilac, white asarum, semen coicis, sandalwood, divaricate saposhnikovia root, pearl powder, mint, mung bean, radix paeoniae alba, radix polygonati officinalis, almond, gorgon fruit, folium mori and semen sesami nigrum. The raw materials are crushed into powder and mixed uniformly. The powder prepared from the raw materials is uniformly blended with egg white and then applied to the face, various traditional Chinese medicine components in the mask enter the human body through skin and pores, and active components of the raw materials interact so as to improve the blood circulation of skin, eliminate fine lines, contract the pores, tighten skin, remove color mottles and nourish skin, after being used for a long time, the beauty mask has beautifying and anti-aging functions and can remove blackheads and acne. The traditional Chinese medicine beauty mask is reasonable in proportioning and has no side effect on the skin of people.

Owner:李进

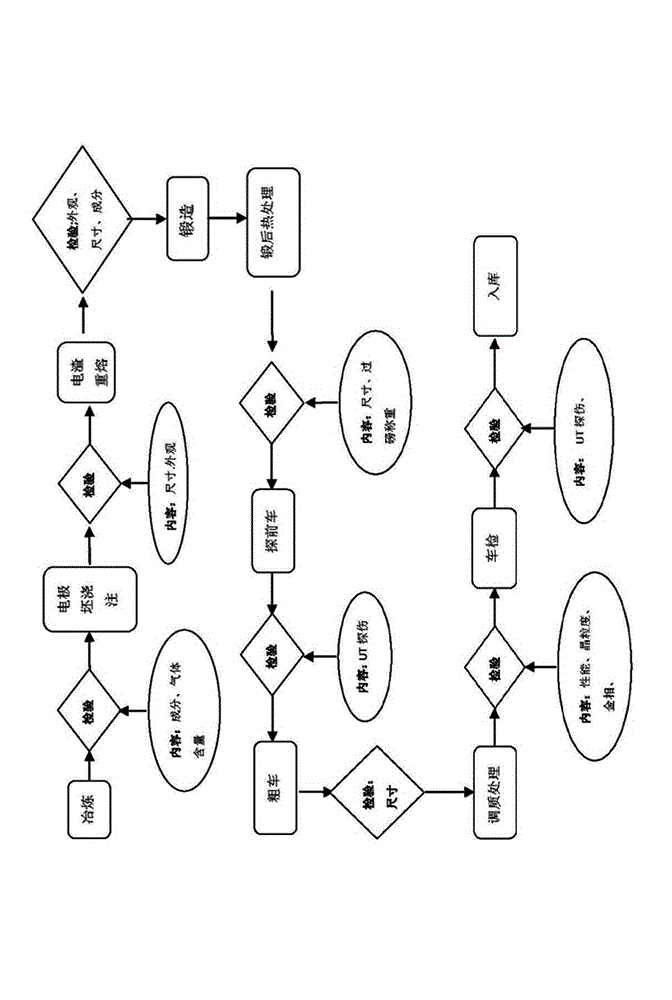

Wheel disc forging and manufacturing method thereof

ActiveCN102719761AReasonable ratioImprove purityMetal-working apparatusProcess efficiency improvementForgingSmelting

The invention discloses a wheel disc forging and a manufacturing method thereof and belongs to the technical field of mechanical manufacture. The manufacturing method further optimizes material components, controls the upper limits of C and Mn content, improves Ni content, reduces content of harmful P and S, reduces Si content and temper brittleness of Mn, utilizes an electroslag remelting process so that the purity of molten steel is improved, and utilizes post-forging heat treatment comprising two normalizing processes so that materials are further homogenized and grains are fined. Raw materials adopted by the manufacturing method comprise C, Mn, Si, P, S, Cr, Ni, Al, Cu and Fe. The manufacturing method comprises the following steps of electrode blank smelting, electroslag remelting smelting, steel ingot annealing, steel ingot forging, post-forging heat treatment, property heat treatment, and property and microstructure examination. The wheel disc forging obtained by the manufacturing method and the manufacturing method have the advantages that a ratio of chemical components is reasonable; material purity is high; forging effects on the core are good; density of the metal microstructure is good; and the problems that a wheel disc forging obtained by the existing manufacturing method is unqualified in the forging flaw detection and a mechanical property especially such as a material ductile-brittle transition temperature does not satisfy the requirement are solved.

Owner:TONGYU HEAVY IND

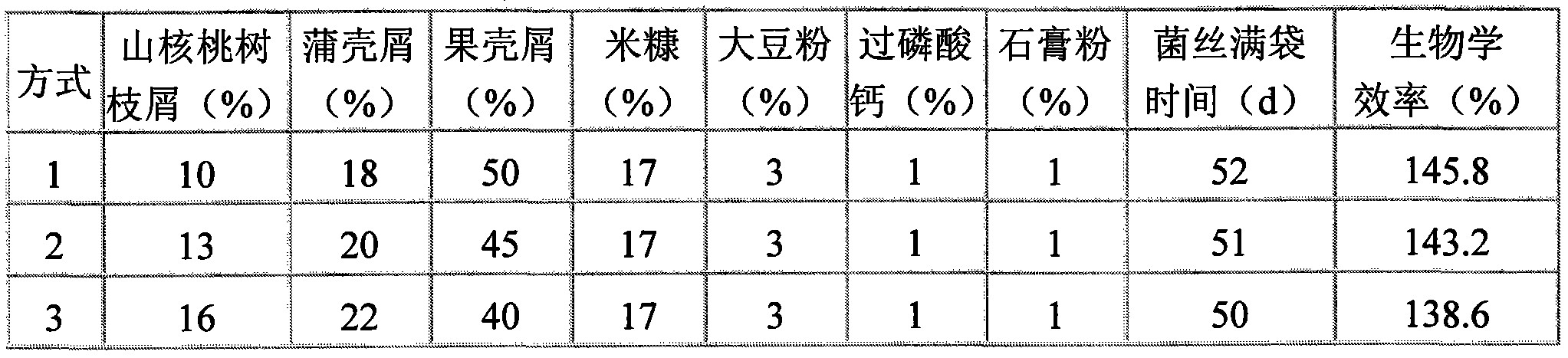

Method for utilizing hickory producing and processing waste to prepare black mushroom cultivation material

InactiveCN103508811AReasonable ratioGood fruiting performanceBio-organic fraction processingOrganic fertiliser preparationShiitake mushroomsMacromolecular Substances

The invention discloses a black mushroom cultivation material. The cultivation material is characterized by using hickory branch chips, nutshell chips and husk chips as main raw materials, and using bran, bean cake, calcium superphosphate, gypsum powder and the like as auxiliaries, wherein the water content is 63-65%. The invention further discloses a manufacturing method of the cultivation material. The manufacturing method and the cultivation material have the following advantages: 1, the hickory branch chips, the nutshell chips and the husk chips are insolate by sunshine, secondarily fermented or piled up to be aged, so that the toxic bacteriostats are degraded, and the macromolecular substances such as lignin and cellulose are decomposed to simple substances which are beneficial to absorb by black mushroom hypha, and the growth of the black mushroom hypha can be promoted; 2, the cultivation material proportion is reasonable, the bacterial material is good in breathability, the water-retaining property is strong, the effective mushroom quantity is a lot, the yield is high, and the biological efficiency is up to 130.3-142.6%; 3, the preparation method provides a solution for innocent treatment of hickory branch, nutshell and husk, and provides a new substrate for cultivating the black mushroom.

Owner:邬方成

Flavouring milk and preparing method

ActiveCN101023761AFix stability issuesStable and good suspensionMilk preparationFood preparationSugarCow milk

The present invention discloses a flavoured milk and its preparation method. Said flavoured milk includes the following components: (by weight portion) 75-95 portions of milk, 1-20 portions of grain granules, 2-15 portions of sugar, 0.1-0.8 portion of stabilizing agent and 0.05-0.2 portion of edible essence. Said preparation method includes the following steps: (1), weighing raw materials according to the formula; (2), preparing material: adding partial milk into sugar-melting pot, heating to 30-60 deg.C, adding partial sugar and stabilizing agent into the sugar-melting pot, stirring, then continuously heating to 62-85 deg.C, stirring, adding residual sugar, stirring until the above-mentioned materials are be completely molten, then pouring the above-mentioned molten mixture into the mixing vat in which the residual milk is held; (3), preheating; (4), homogenizing; (5), pasteurizing; (6), adding edible essence and grain granules; (7), sterilizing so as to obtain the invented flavoured milk containing grain granules.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Healthy crawfish feed and preparation method

InactiveCN103229911AGrow vigorouslyImprove the survival rate of breedingAnimal feeding stuffBiotechnologyFish Flavor

The invention relates to a healthy crawfish feed and a preparation method. The healthy crawfish feed is prepared by selecting various organic raw materials according to a formula, thus providing feed base for producing high-quality crawfish; especially, natural fish meal, earthworm meal, silkworm chrysalis meal, spiral shell meal and bone tankage are added to provide a high-quality animal protein source for the high-quality crawfish, thus enabling the nutrition ingredients of the feed to be more reasonable; due to addition of Chinese herbal medicines, the immunocompetence of the high-quality crawfish is favorably enhanced, the fish flavor of the crawfish is improved, the disease infection possibility can be reduced, and the shell powder can provide calcium for manufacturing crawfish shells; the feed prepared by adopting the formula is complete in nutrition, good in palatability, easy to digest, and fast to absorb, and the crawfish is hale and healthy to grow, strong in disease prevention capability, and high in culture survival rate; and the preparation method is wide in raw material sources, simple and convenient as well as easy to operate, reasonable in formula, and low in cost.

Owner:杨成胜

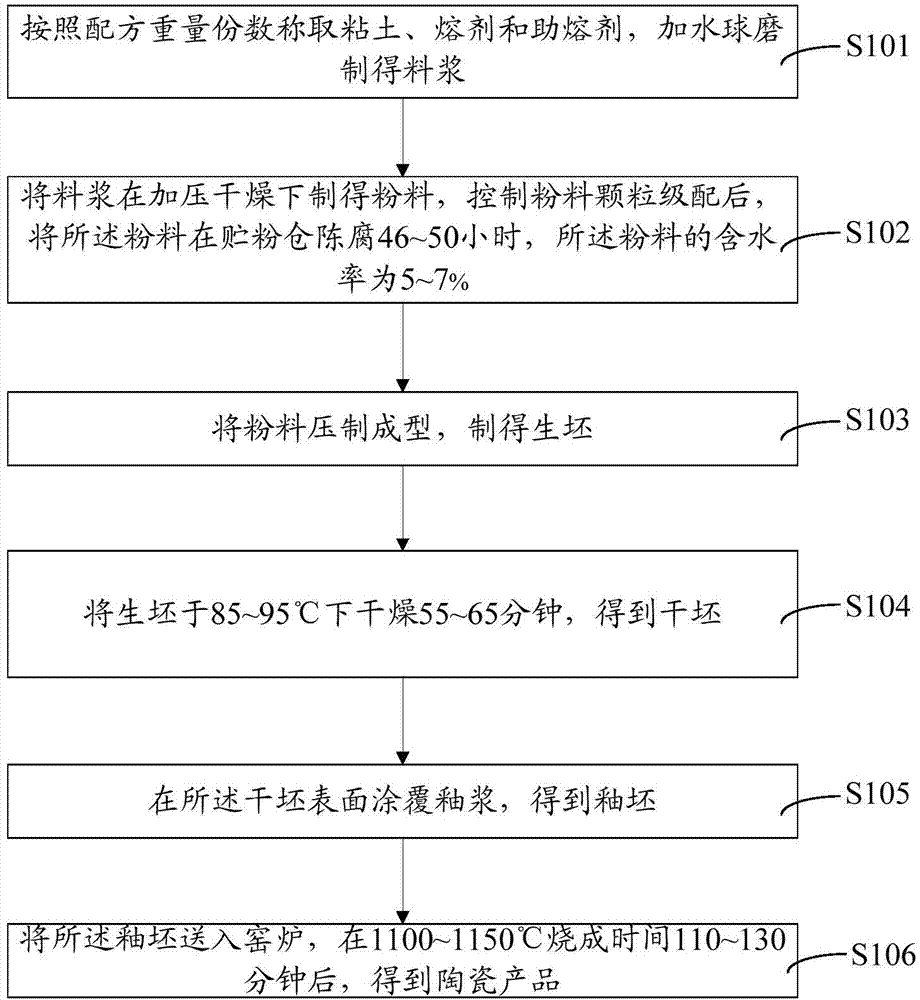

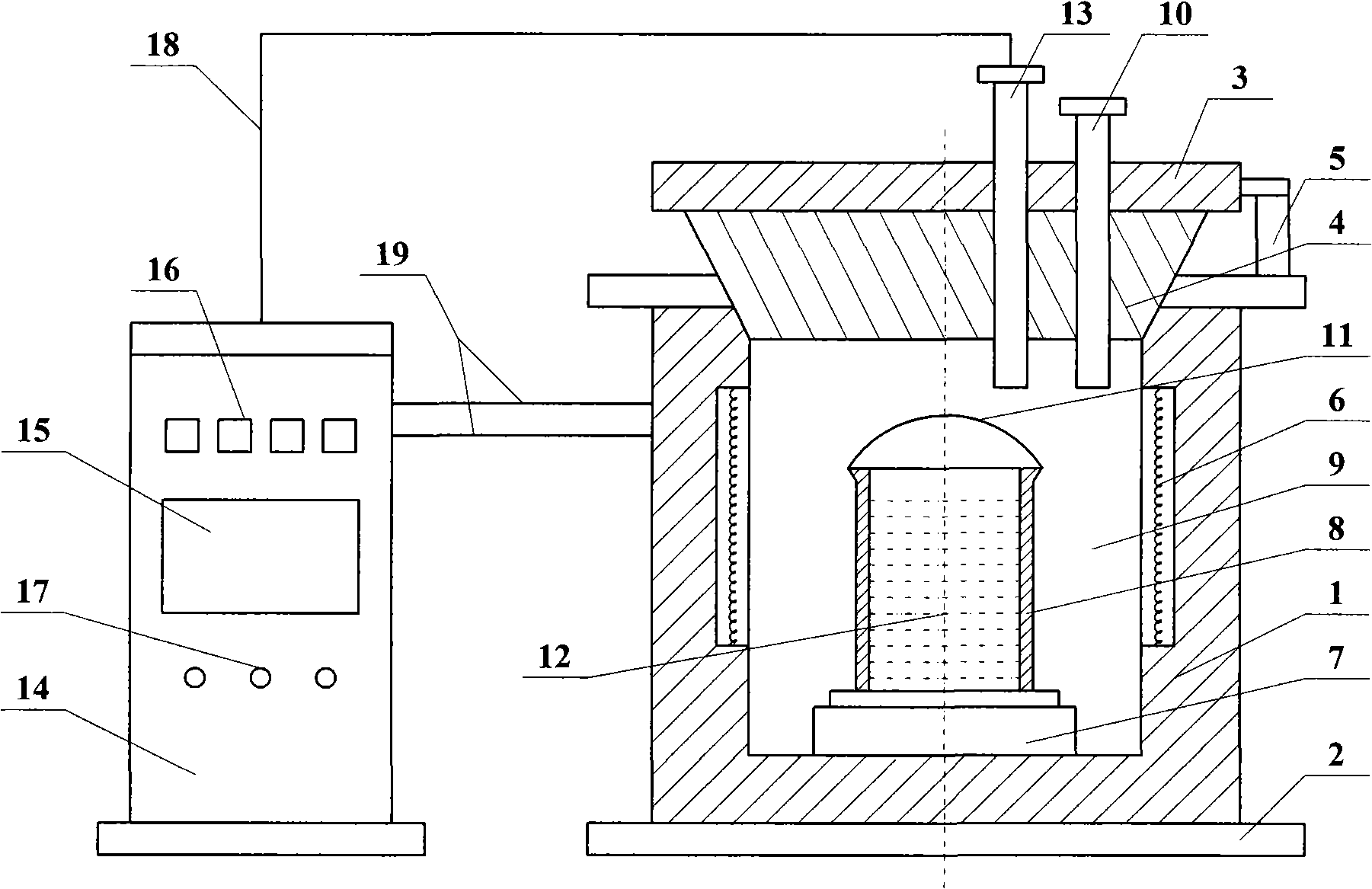

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

Low-sugar flavorful jam and preparation method thereof

InactiveCN102370125APromote absorptionImprove immunityFood preparationVitamin CIsomaltooligosaccharide

The invention discloses a low-sugar flavorful jam and a preparation method thereof which belong to the field of functional food. The jam is prepared with the following materials in percentage by weight: 5 to 35 percent of isomaltooligosaccharide, 1 to 20 percent of polydextrose, 0.01 to 0.5 percent of xanthan gum, 0.5 to 2 percent of pectin, 0 to 2 percent of dextrose, 0.05 to 0.15 percent of vitamin C, 0 to 0.15 percent of stevioside, 0.5 to 1.5 percent of other auxiliary materials and the balance of water. The jam is suitable for peoples in various classes and ages, particularly the group of people wanting to control weight and diabetics, the jam does not contain medicines, the materials can be easily obtained, the jam cannot be limited by regions and seasons, the equipment and the process are simple, and the cost is low.

Owner:CHINA AGRI UNIV

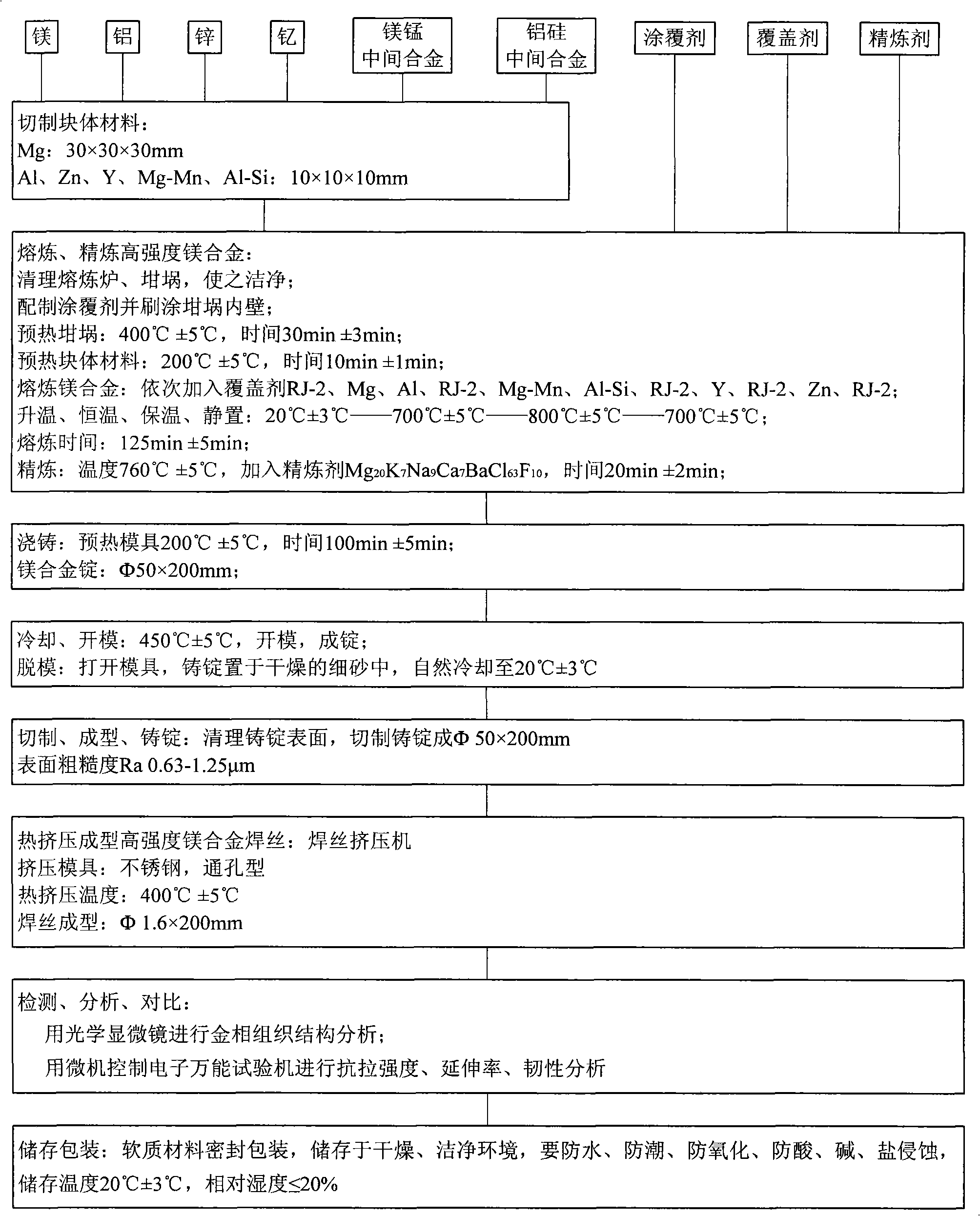

Method for manufacturing high-strength magnesium alloy solder wire

InactiveCN101269449AImprove toughnessImprove solderabilityWelding/cutting media/materialsSoldering mediaRare-earth elementManganese

The invention relates to a preparation method of a high-intensity magnesium alloy soldering wire, which adopts alloy agent magnesium, aluminum, zinc, yttrium, magnesium-manganese intermediate alloy and aluminium-silicon intermediate alloy as raw materials. In a vertical melting furnace, through being melted at 700 DEG C, rare-earth element yttrium is added at 800 DEG C and is refined at 760 DEG C, with a covering agent and a refine agent being added, through constant temperature, thermal retardation and stewing, then magnesium alloy molten liquid is made; through casting a mould, magnesium alloy ingot is made; through cooling, cutting and forming, and then thermoplastic extruding, in the end, the high-intensity magnesium alloy soldering wire is made; the yttrium element, the magnesium-manganese intermediate alloy and aluminium-silicon intermediate alloy can greatly improve the intensity, the malleability and the solderability of the magnesium alloy soldering wire; the preparation technology is refined, the mixture ratio is reasonable, the environment pollution does not exist; the outcome of a magnesium alloy soldering wire metallic phase has uniform structure and good compactability, the average grain size is 25microns, the tensile strength can reach 330MPa, the elongation percentage can reach 25 percent and can be improved by 18 to 28 percent compared with the prior art, and the solderability is good.

Owner:TAIYUAN UNIV OF TECH

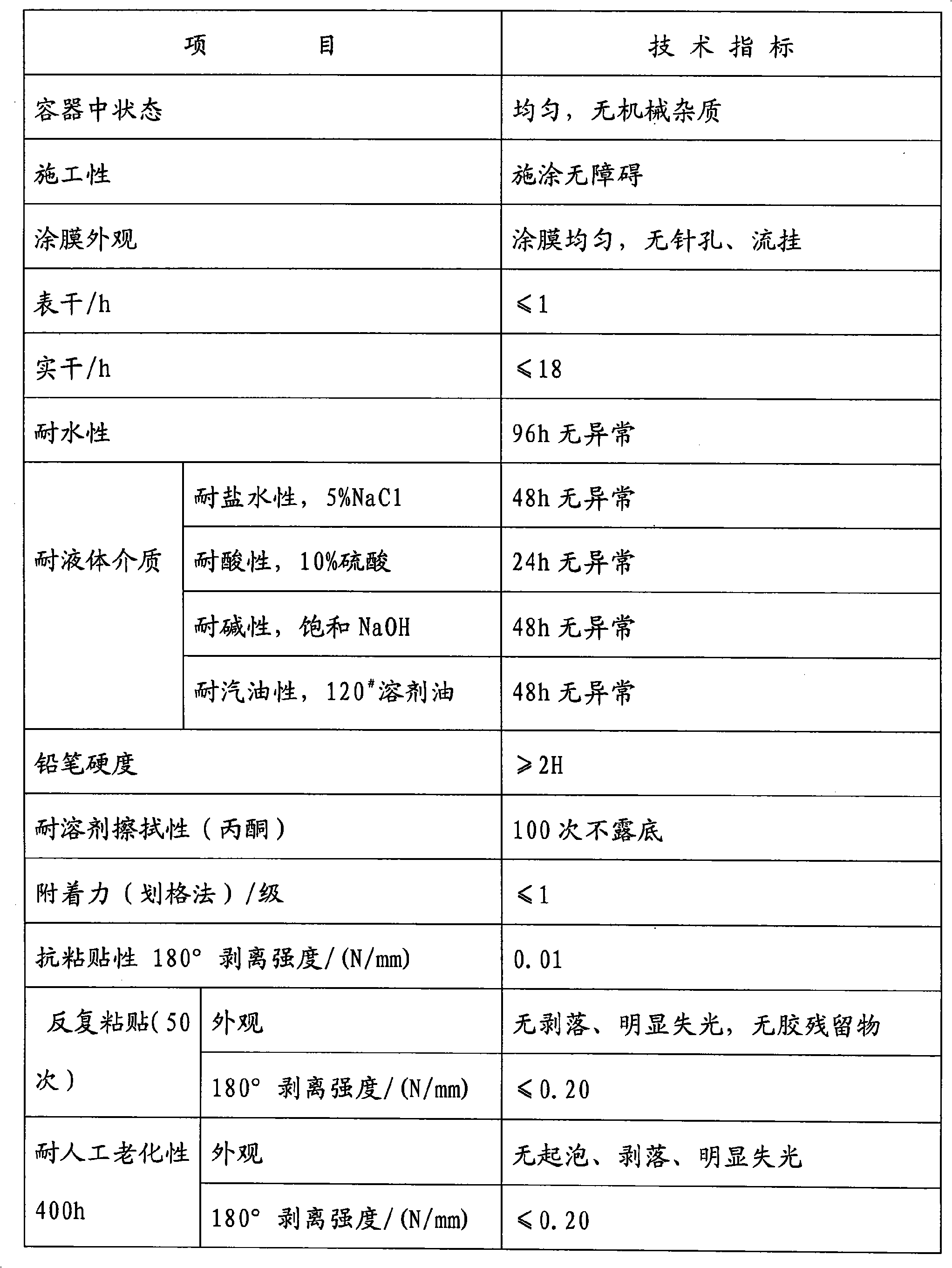

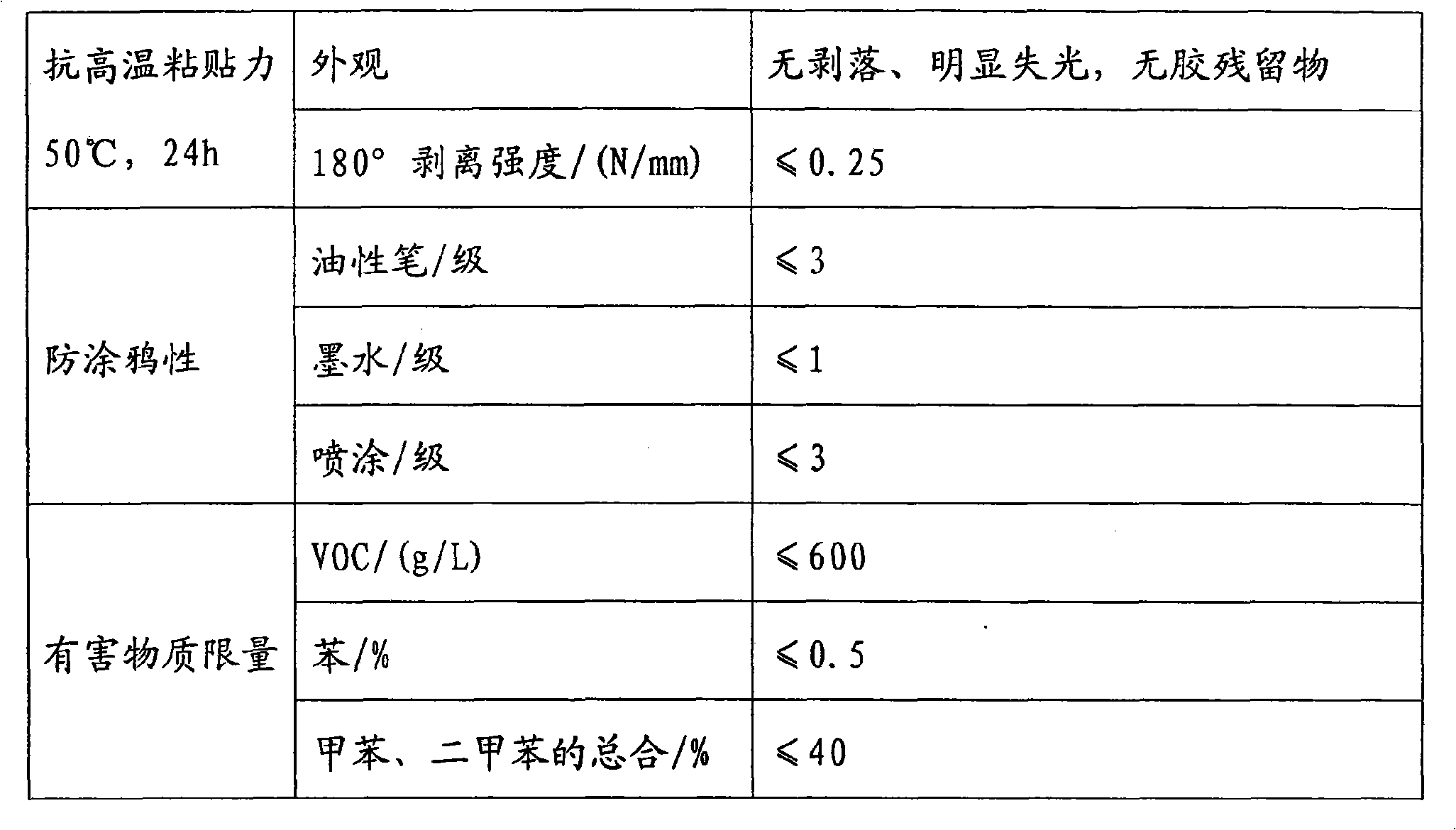

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com