Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

An anti-hydrogen sulfide and stress corrosion technology is applied in the field of round steel for large-scale oil well drilling tools and its manufacturing. and other problems, to achieve the effect of good shape, high strength and good plasticity of non-metallic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

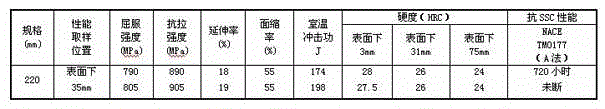

[0035] The diameter of the round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance involved in this embodiment is 220 mm, and its chemical composition is calculated by mass percentage: C: 0.26%, Si: 0.23%, Mn: 0.50%, P: 0.005 %, S: 0.002%, Cr: 1.00%, Mo: 0.72%, Ni: 0.06%, Cu: 0.06%, Al: 0.06%, V: 0.042%, Nb: 0.0294%, N: 0.00568%, B: 0.0025 %, the balance is iron and unavoidable impurity elements.

[0036] The manufacturing process of the above-mentioned round steel for drilling tools is that the smelting raw materials are configured according to the above-mentioned chemical composition, followed by KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain molten steel with high purity. Feed silicon-calcium wire for calcium treatment to make inclusions spheroidized and evenly distributed; molten steel is poured into continuous casting round billets with argon protection at a low superheat of 20°C, and t...

Embodiment 2

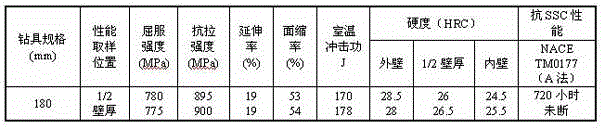

[0040] The diameter of the high-strength and toughness-resistant hydrogen sulfide stress corrosion-resistant drill tool round steel involved in this embodiment is 180mm, and its chemical composition is calculated by mass percentage: C: 0.24%, Si: 0.24%, Mn: 0.490%, P: 0.006 %, S: 0.003%, Cr: 1.00%, Mo: 0.74%, Ni: 0.06%, Cu: 0.06%, Al: 0.054%, V: 0.035%, Nb: 0.0313%, N: 0.00859%, B: 0.0026 %, the balance is iron and unavoidable impurity elements.

[0041] The manufacturing process of the above-mentioned round steel for drilling tools is to configure the smelting raw materials according to the above-mentioned chemical composition, and then carry out KR molten iron pretreatment, electric furnace smelting, LF refining, and VD degassing to obtain molten steel with high purity. Calcium-iron wire is added for calcium treatment, so that the inclusions are spheroidized and distributed evenly; molten steel is poured into continuous casting round billets with argon protection at a low su...

Embodiment 3

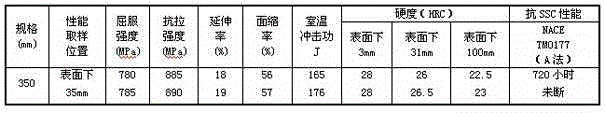

[0045] The diameter of the round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance involved in this embodiment is 350mm, and its chemical composition is calculated by mass percentage: C: 0.26%, Si: 0.25%, Mn: 0.50%, P: 0.005 %, S: 0.002%, Cr: 1.20%, Mo: 0.90%, Ni: 0.03%, Cu: 0.03%, Al: 0.058%, V: 0.045%, Nb: 0.0305%, N: 0.00543%, B: 0.0026 %, the balance is iron and unavoidable impurity elements.

[0046] The manufacturing process of the above-mentioned round steel for drilling tools is that the smelting raw materials are configured according to the above-mentioned chemical composition, followed by KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain molten steel with high purity. Feed silicon-calcium wire for calcium treatment, so that the inclusions are spheroidized and distributed evenly; molten steel is poured into continuous casting round billets with argon protection at a low superheat of 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com