Patents

Literature

134results about How to "Uniform heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

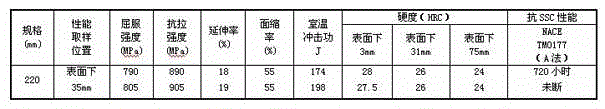

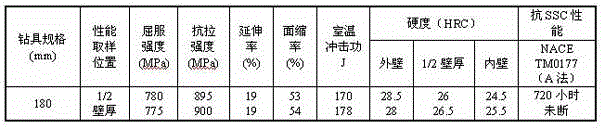

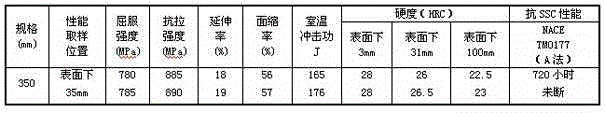

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

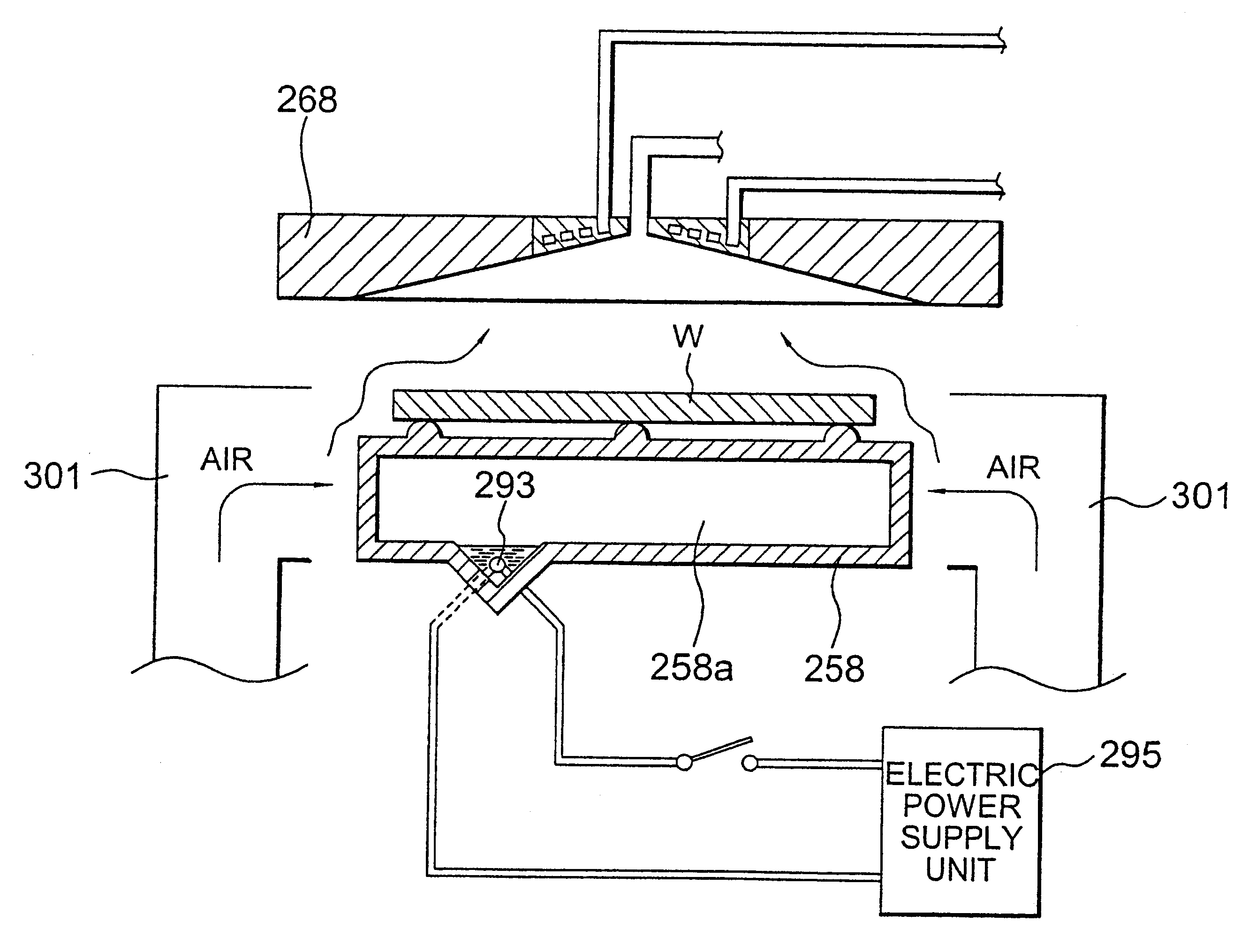

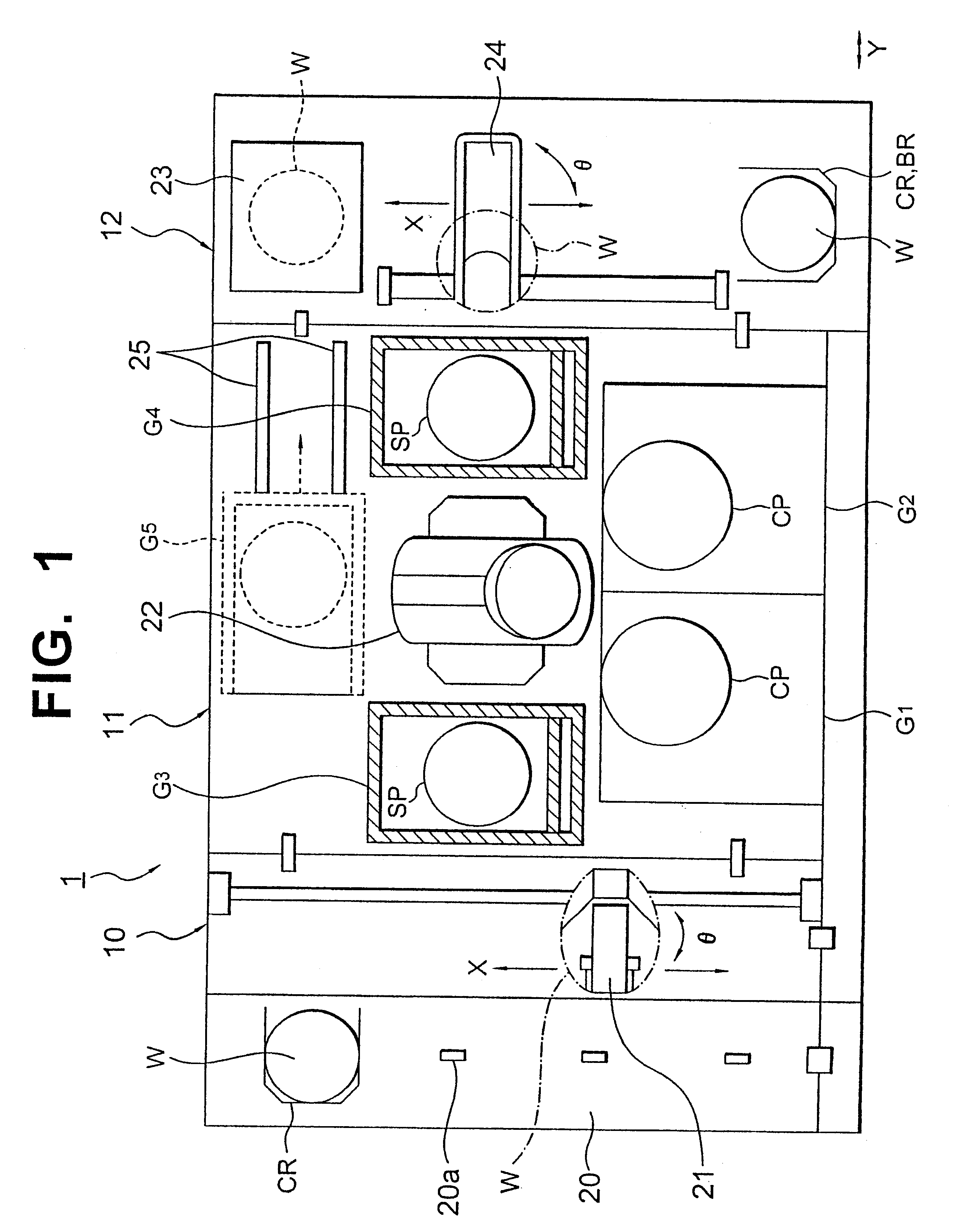

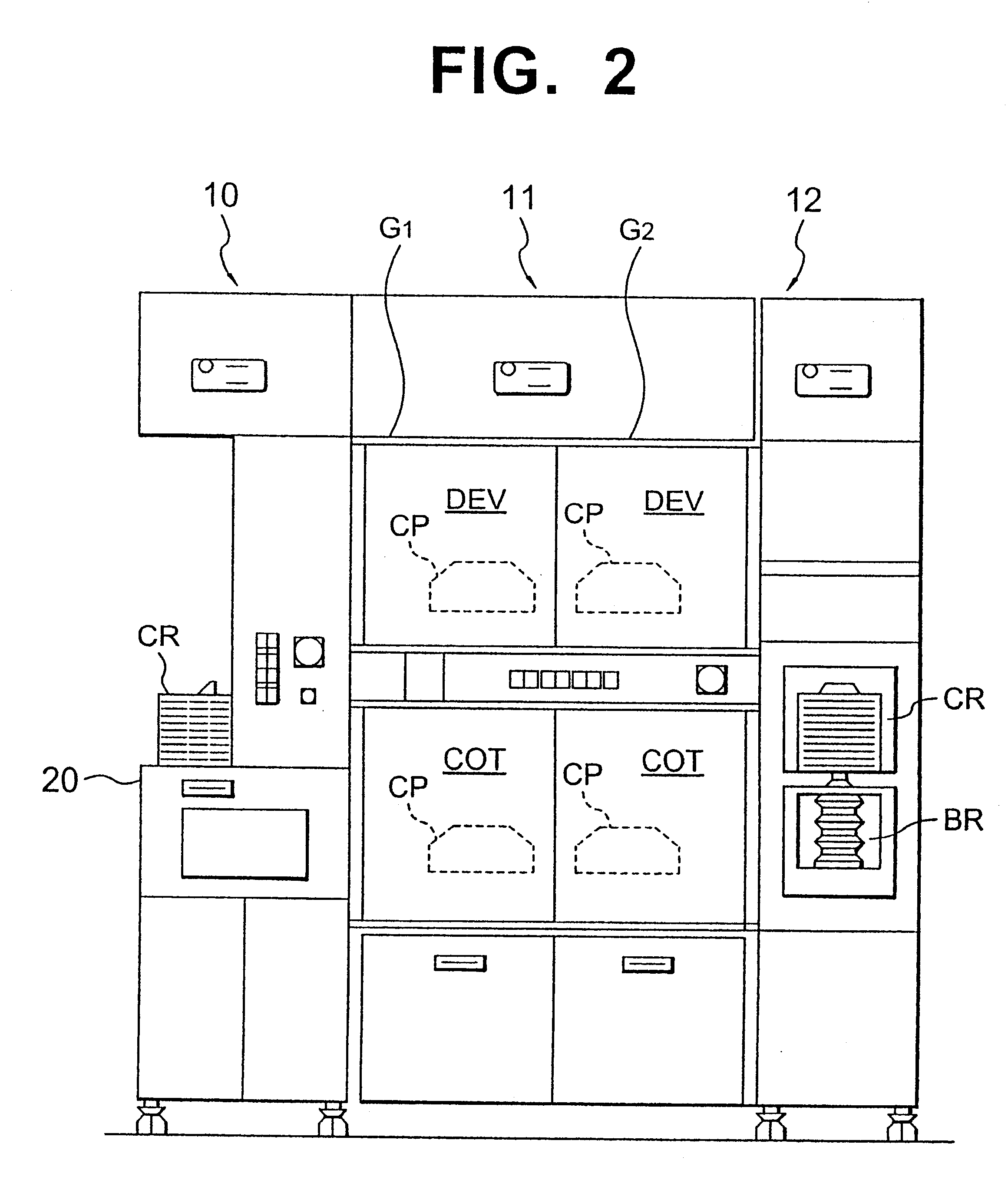

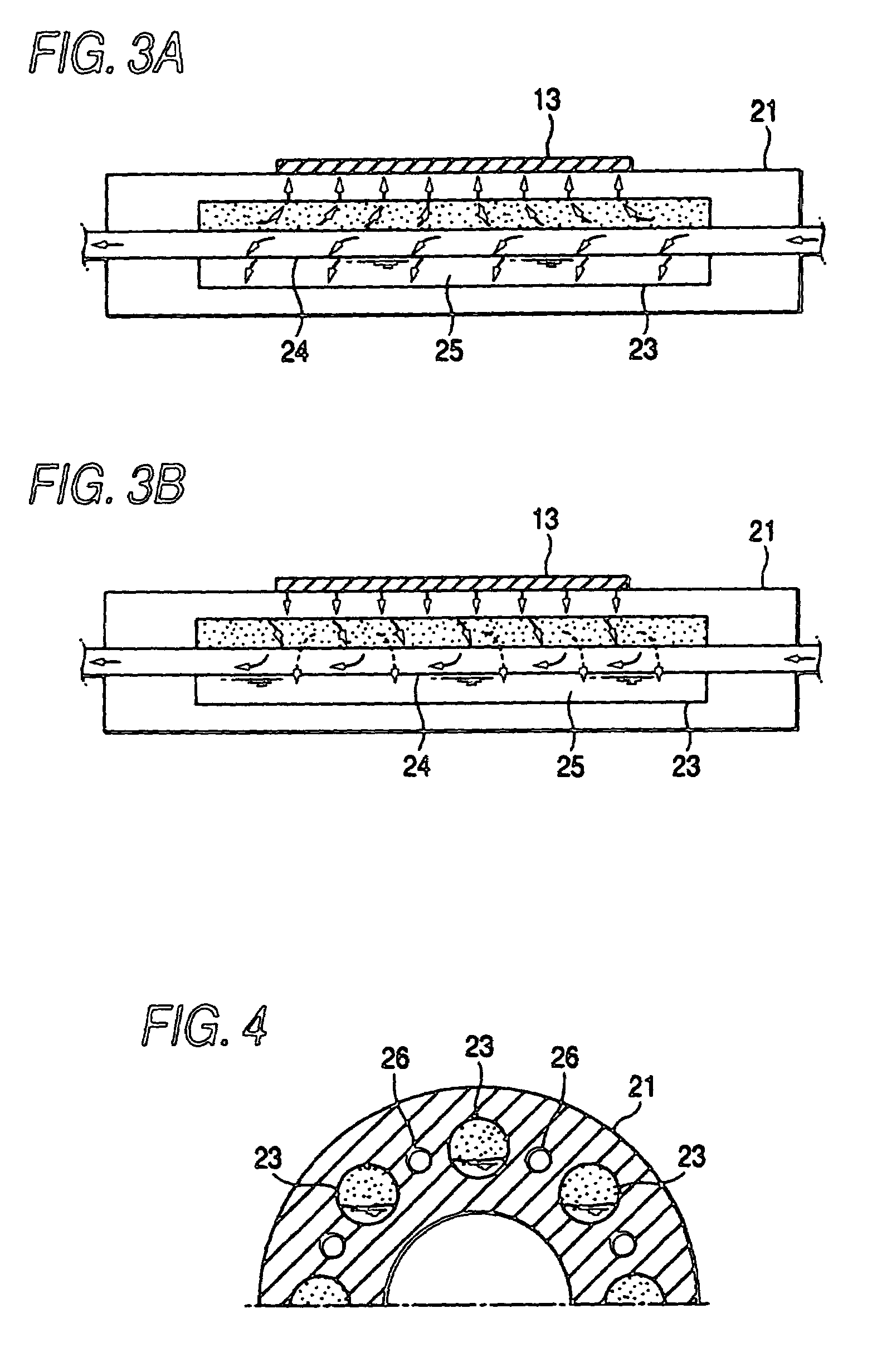

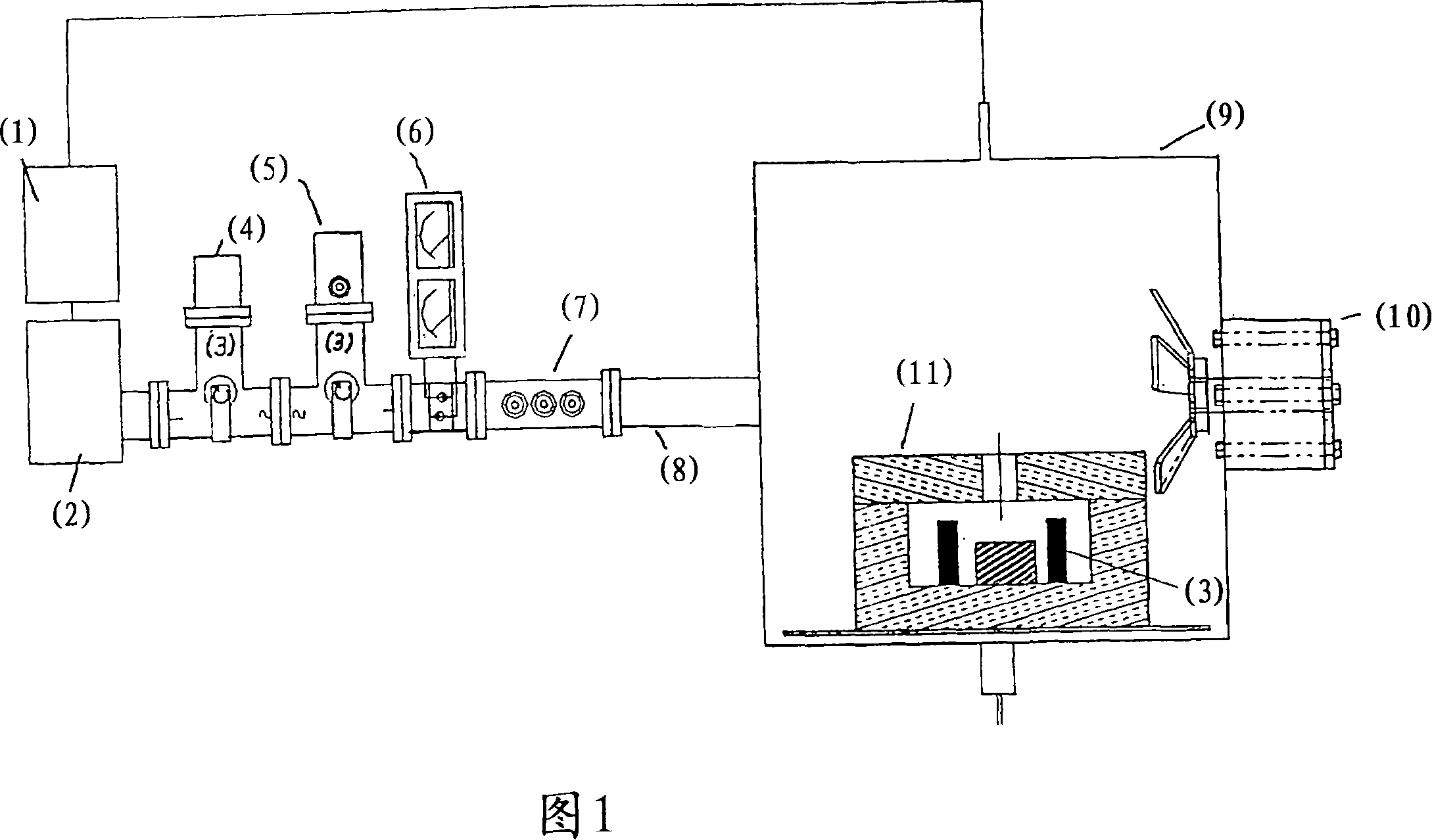

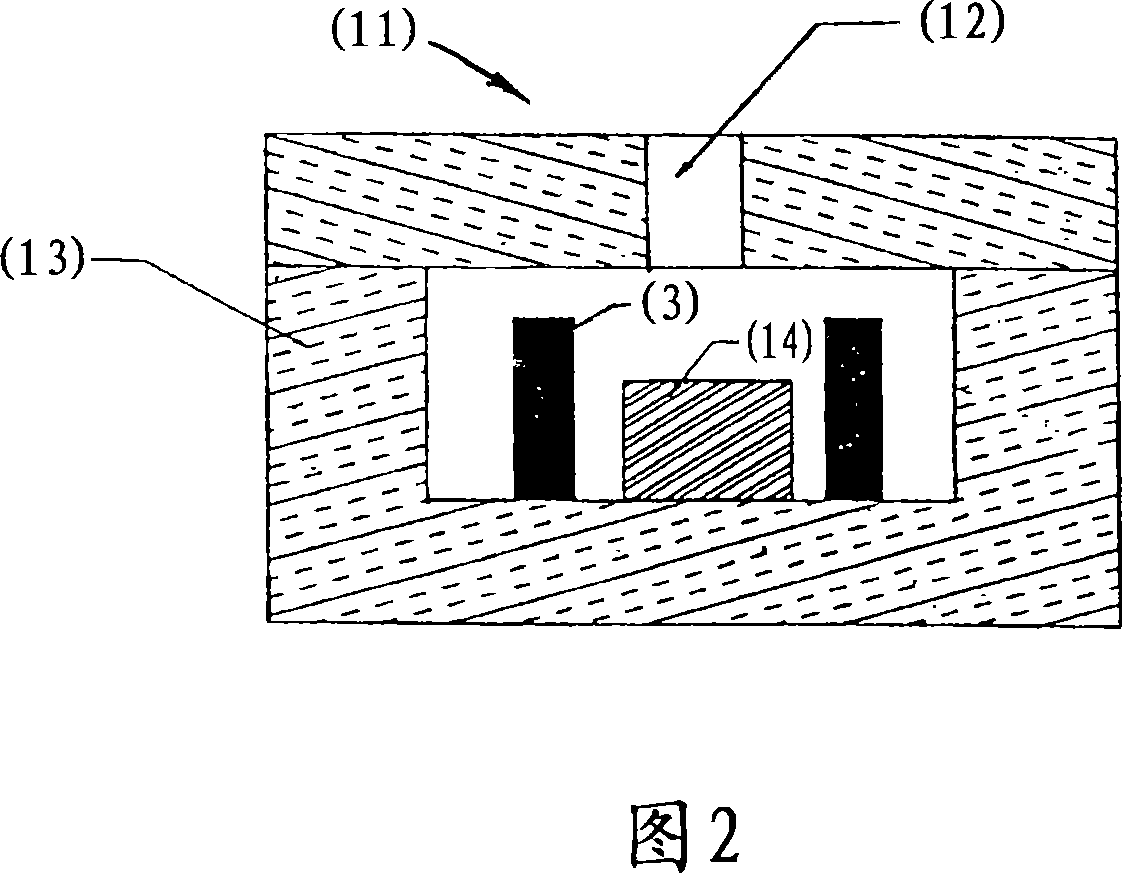

Heat treatment apparatus

InactiveUS6450803B2Uniform heat treatmentEasy to controlSpadesMuffle furnacesEngineeringHeat treated

A heat treatment table is divided into two or more regions, a heater is disposed for each region. On a predetermined portion of the heat treatment table, a plurality of sensors are disposed separately each other. A relation between temperatures of the respective portions on the heat treatment table and temperatures detected by the sensors is grasped in advance, thereby enables to surmise a temperature of the respective portion of the heat treatment table from the temperature detected by the sensors. In the case of an wafer being actually treated by placing on the heat treatment table, the temperatures detected by the sensors are observed, from these detected temperatures, the temperatures of the respective portions on the heat treatment table, that is, temperatures affecting the wafer, are surmised.

Owner:TOKYO ELECTRON LTD

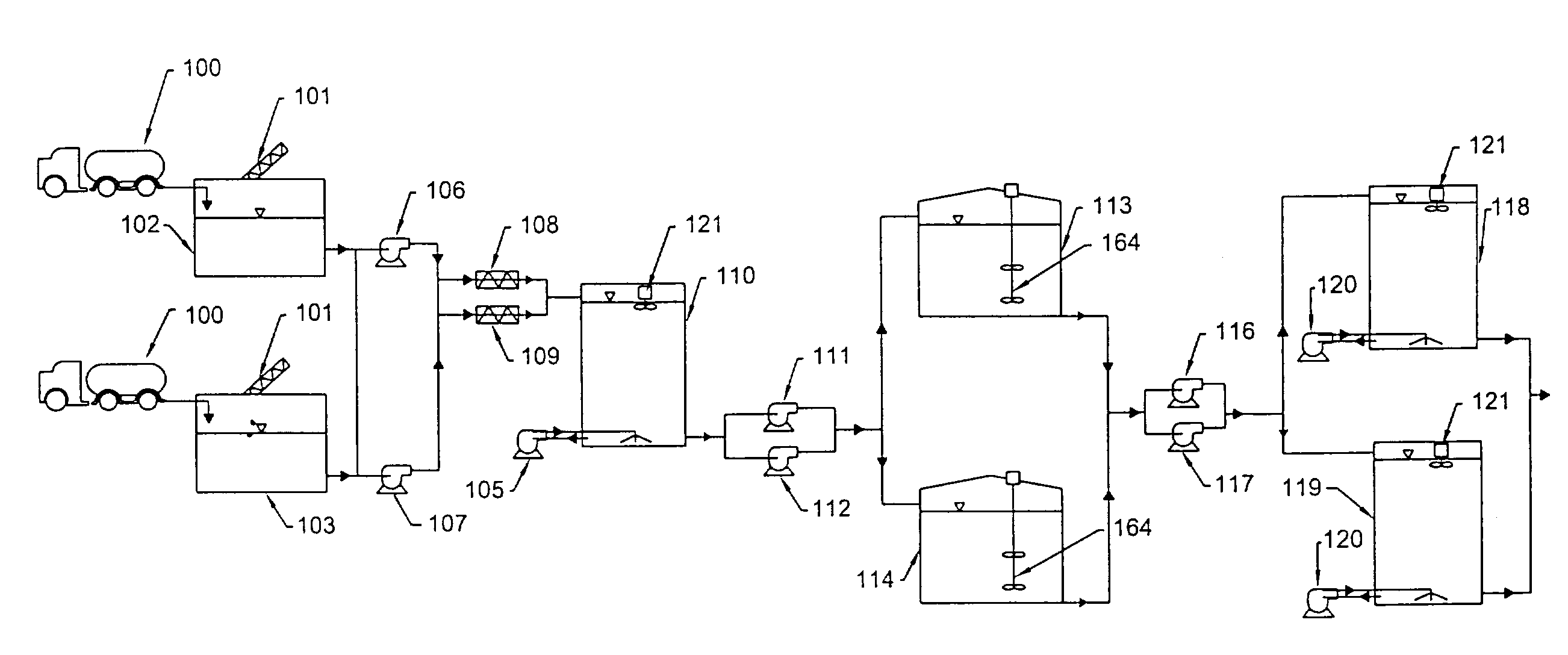

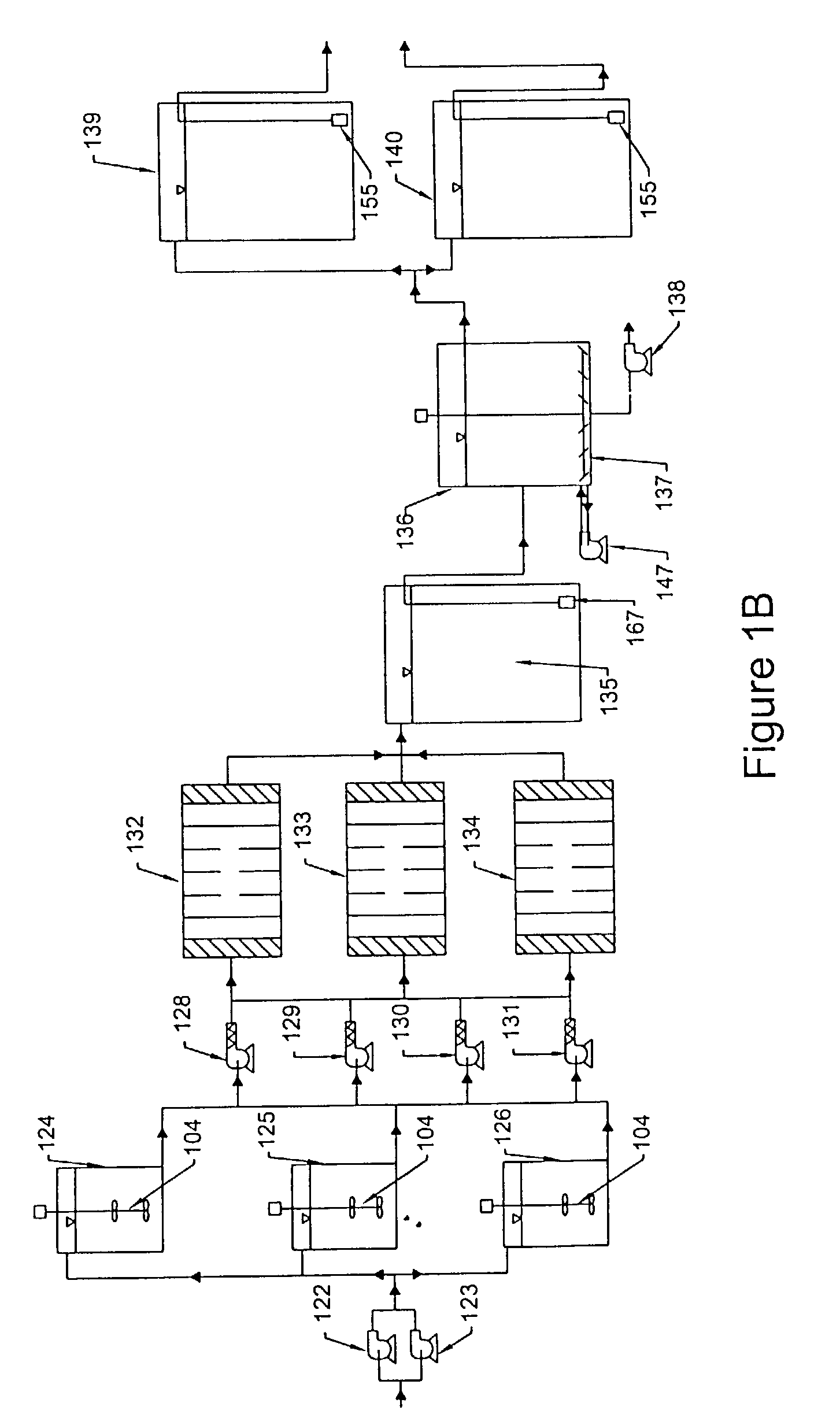

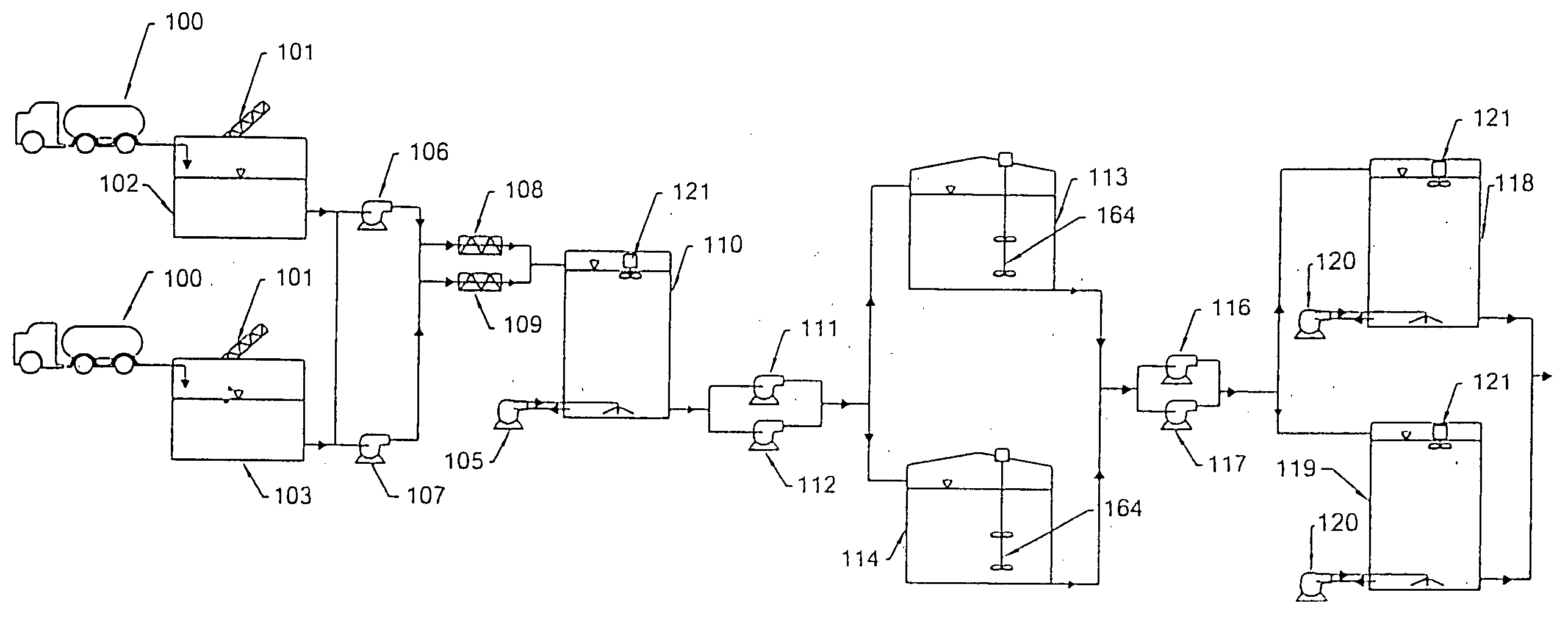

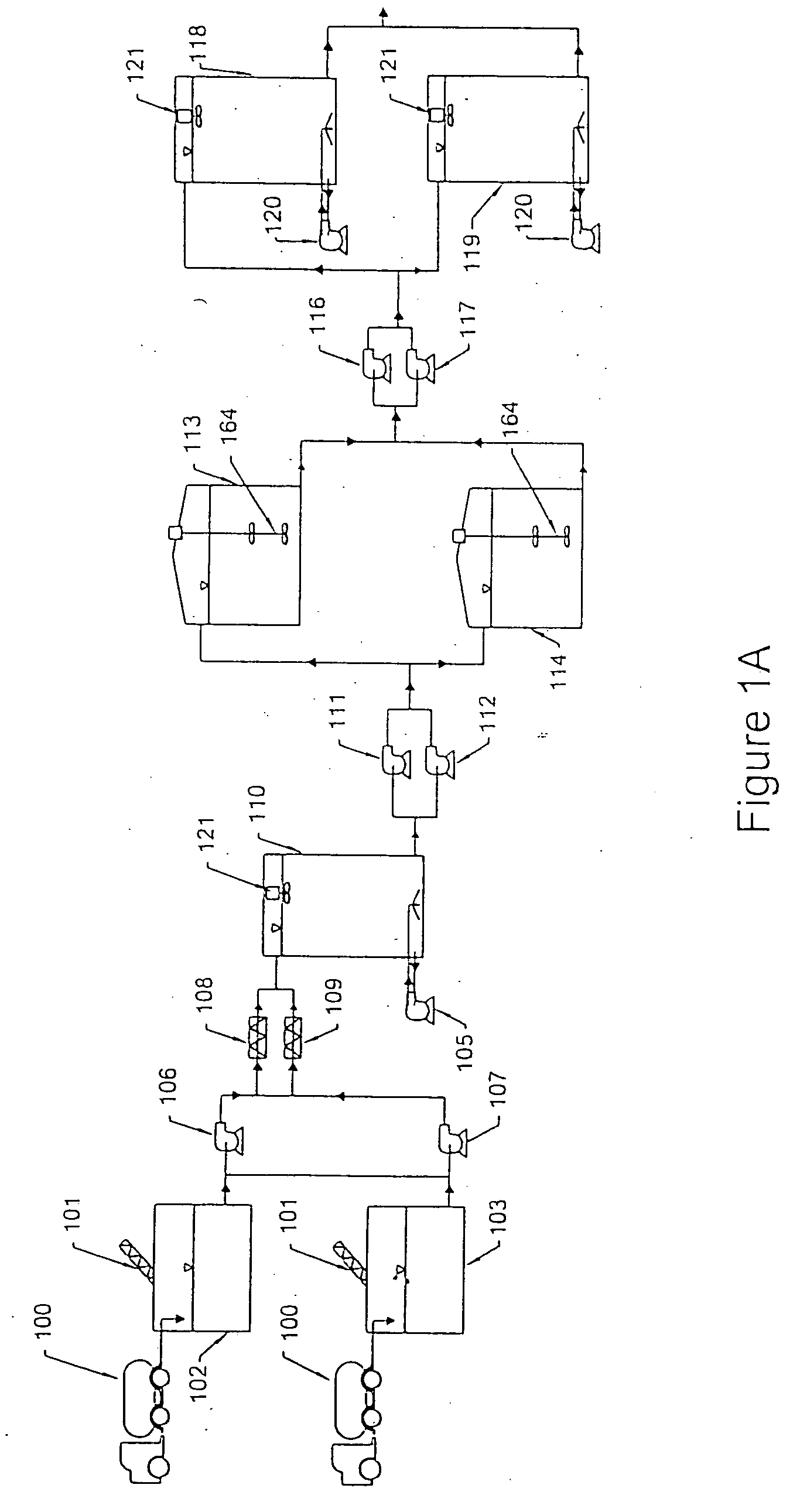

Process for treating septage

InactiveUS7070693B2Easy to dehydrateQuality improvementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSolid fractionPasteurization

A process and apparatus for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process will convert the septage into Biosolids (sludge) and water dischargeable to the environment. The treated septage achieves pathogen reduction, and reduced vector attraction. Treatment of septage by pasteurization causes the destruction of harmful pathogens. Pasteurization of septage having high water content provides for even temperature elevation and distribution of heat within the thermal mass of the septage allowing for consistent pathogen destruction. An alkaline compound is utilized to form a filter cake from the solids fraction of the pasteurized septage preventing vector attraction, while producing a beneficial bio-solid. The liquid fraction of the septage is treated by biological process allowing for its discharge into the environment.

Owner:KELLY ROBERT J

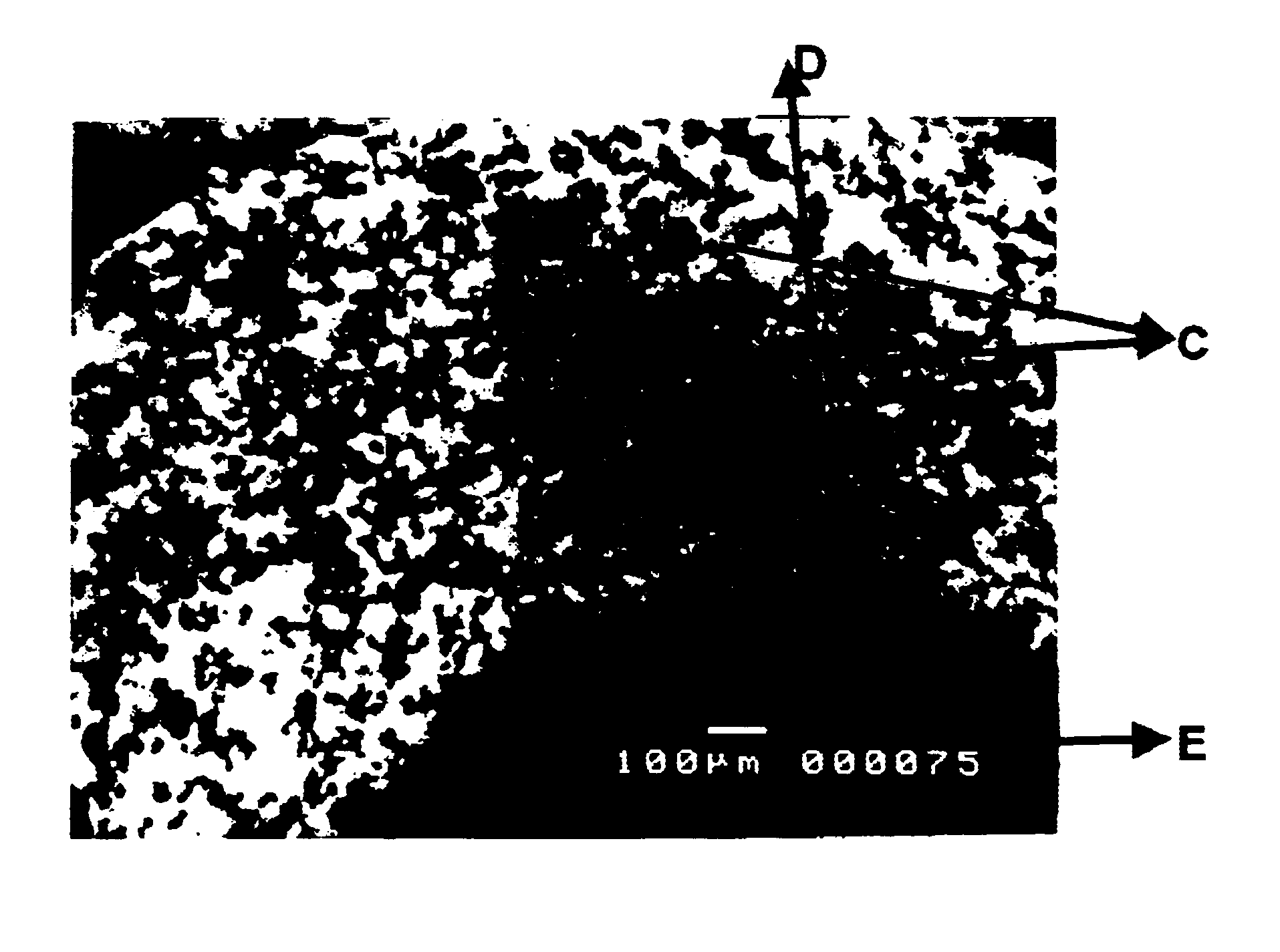

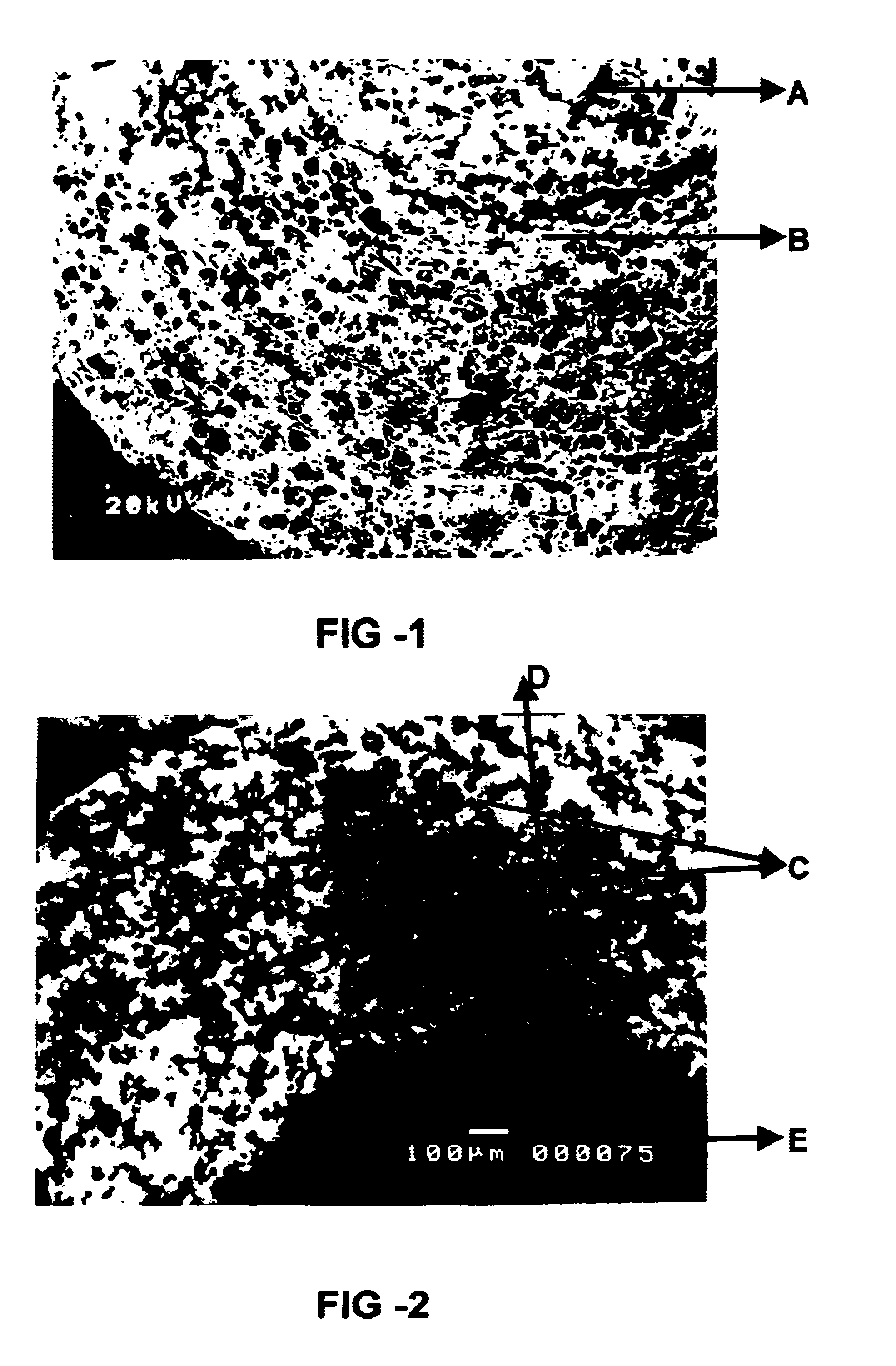

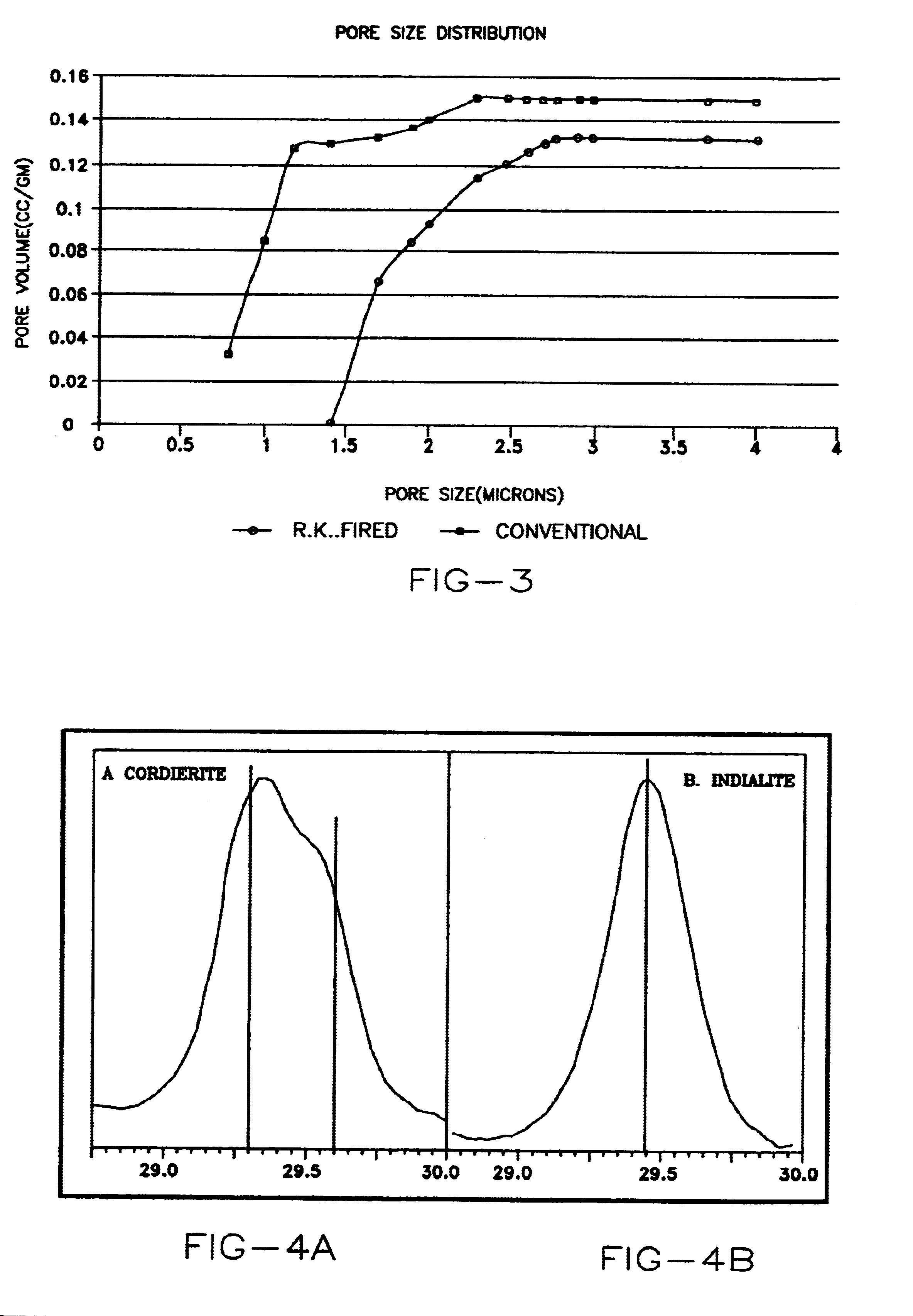

Process for making macro porous ceramic spheres

InactiveUS6616873B1High compressive strengthUniform heat treatmentCeramic shaping apparatusCeramicwareBrickCooling down

Process for making thermally stable macro porous spheres with or without central core cavity includes steps of homogenizing dry pulverized selective constituents with or without burnable core particles and with <25% combustibles; sprinkling over pan pelletizer wetted with PVA aqua sol binder and rolling to form spheres having <25% moisture and dry compacting in pelletizer before oven drying at 90-100° C. until moisture and core particles are partially destroyed and sintering under rotary motion of the spheres for 45-60 minutes at 1350-1380° C. before being rapidly cooled down to ambient temperature and sieving and recovering therefrom low-to-high temperatures >90% loose fill macro porous spheres for catalyst and moulded bricks / monoliths forming refractory insulation applications.

Owner:THE ASSOC CEMENT CO LTD

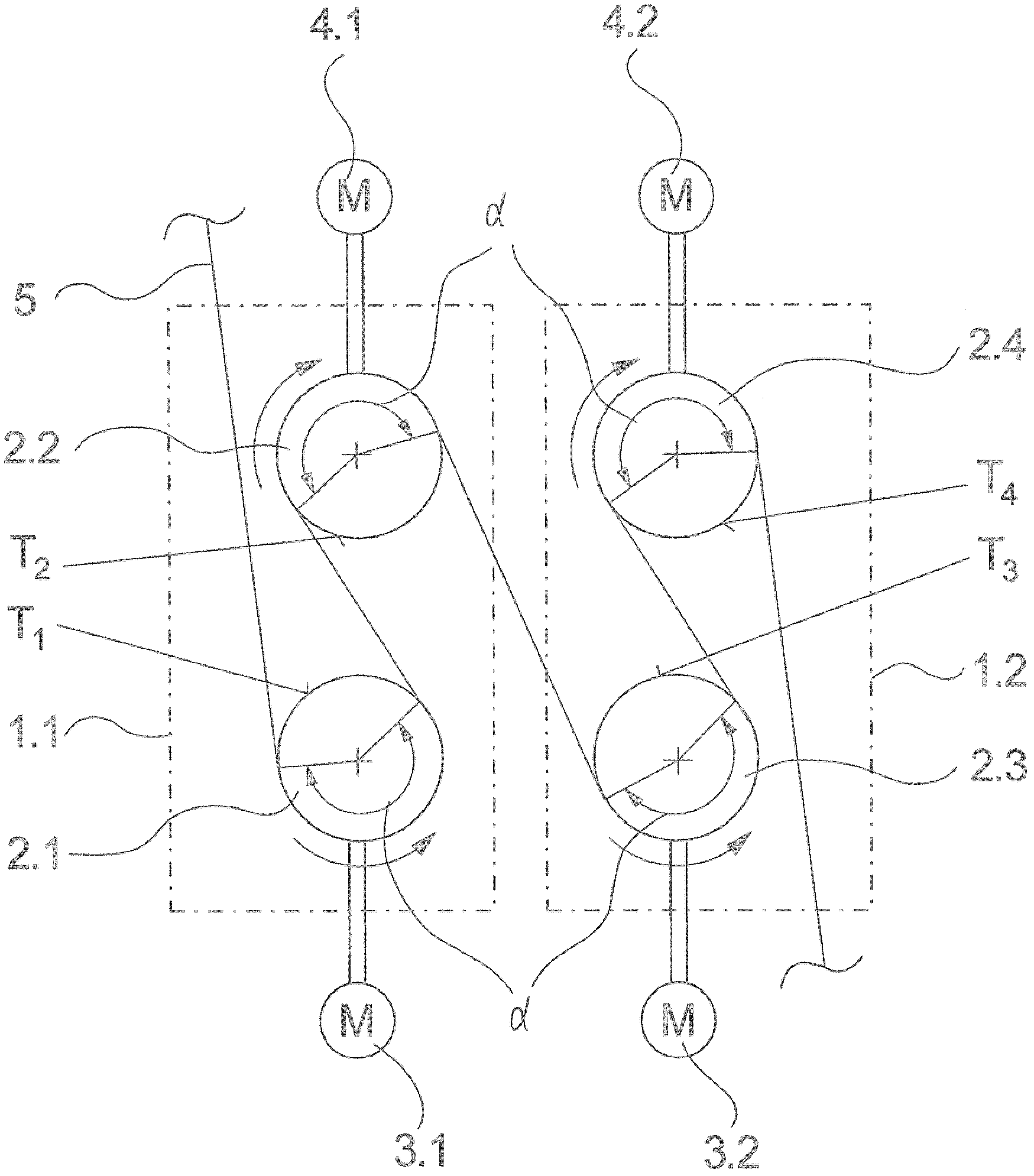

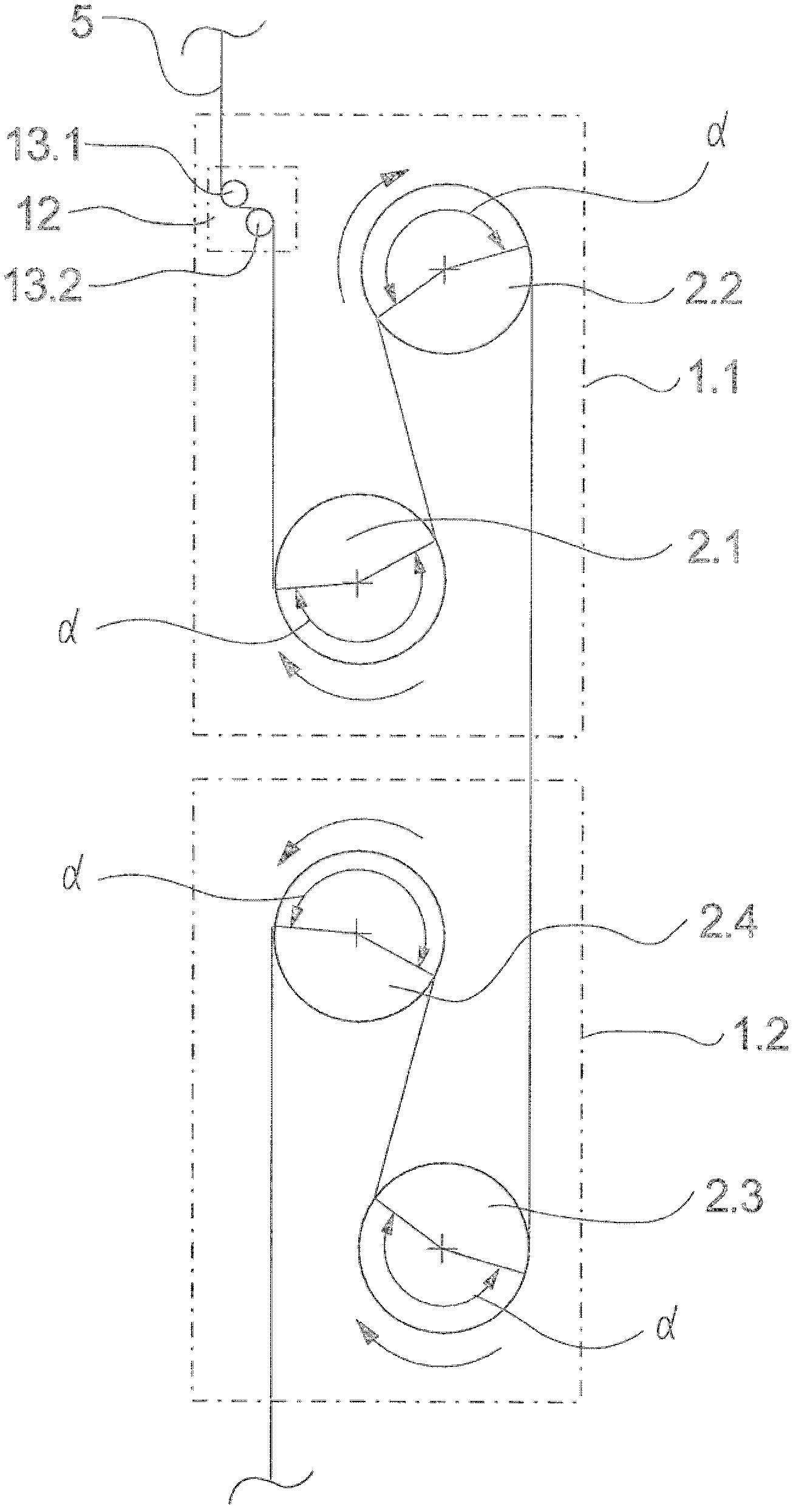

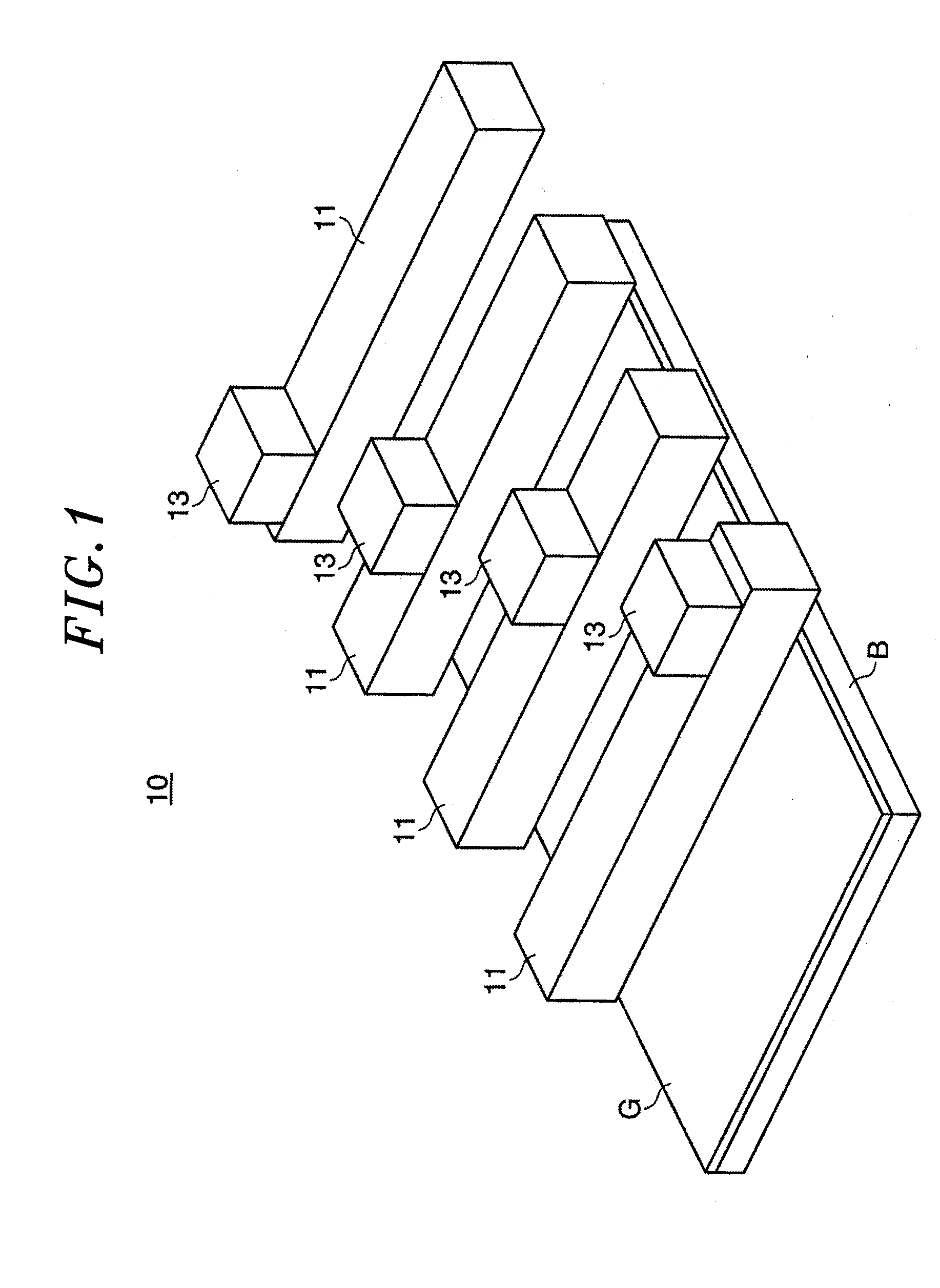

Method for removing and drawing a synthetic thread and a device for performing the method

ActiveCN102471935AHeating evenlyAchieve uniformityArtificial filament heat treatmentStretch-spinning methodsSpinningSingle filament

The invention relates to a method and a device for removing and drawing a synthetic thread to form a fully drawn yarn. The thread is formed by joining a plurality of extruded filaments and is guided by contact on the circumference of heated guide jackets of several driven galette pairs. In order to obtain a gentle and highly homogenized treatment of the filaments, the thread is guided in an S-shaped or Z-shaped thread course by a first galette pair having two guide jackets driven in opposite directions during the removal from a spinning zone and before the drawing. Thus, both sides of the thread can be brought directly into circumferential contact with the guide jackets for in order to heat the thread.

Owner:OERLIKON TEXTILE GMBH & CO KG

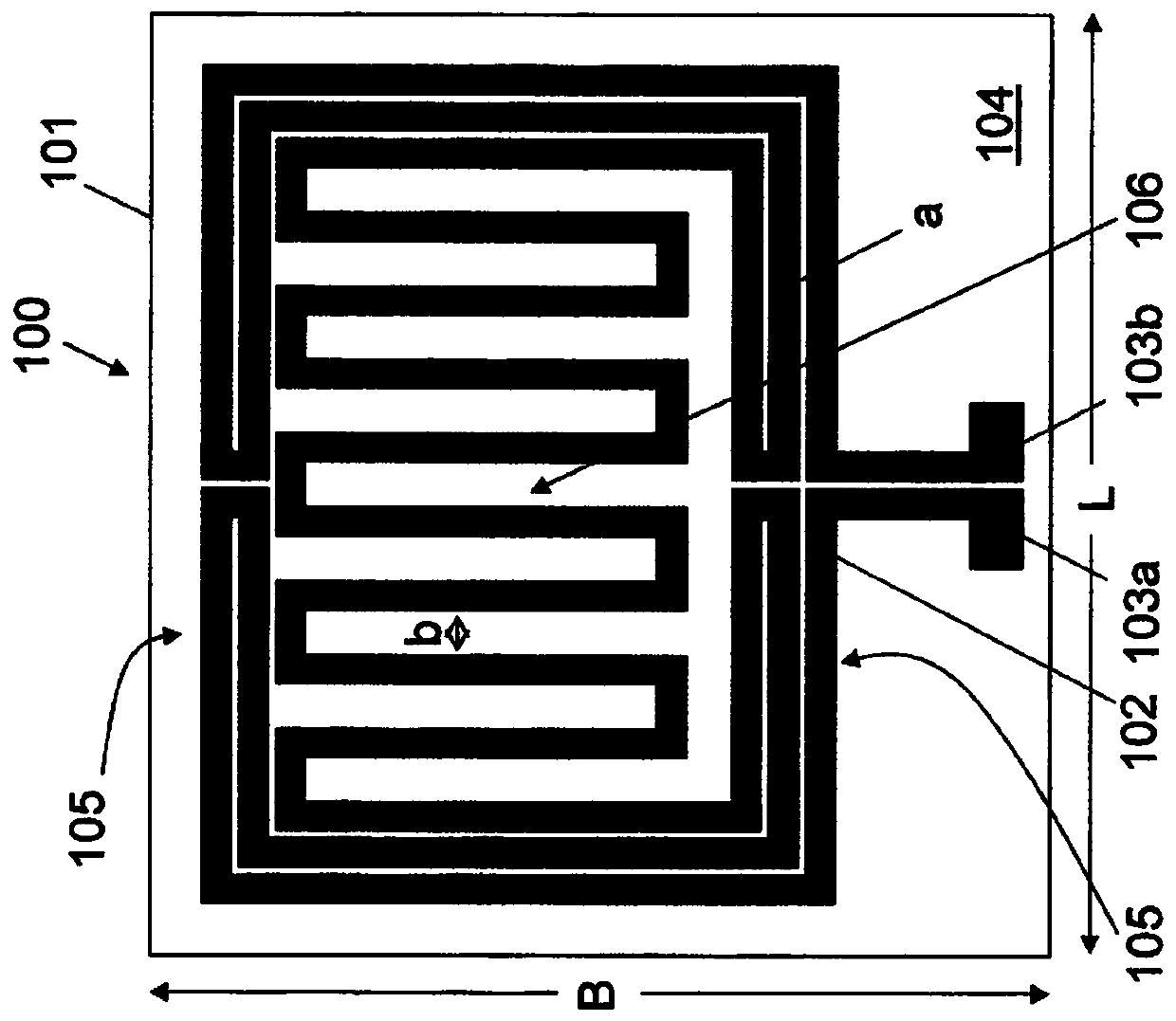

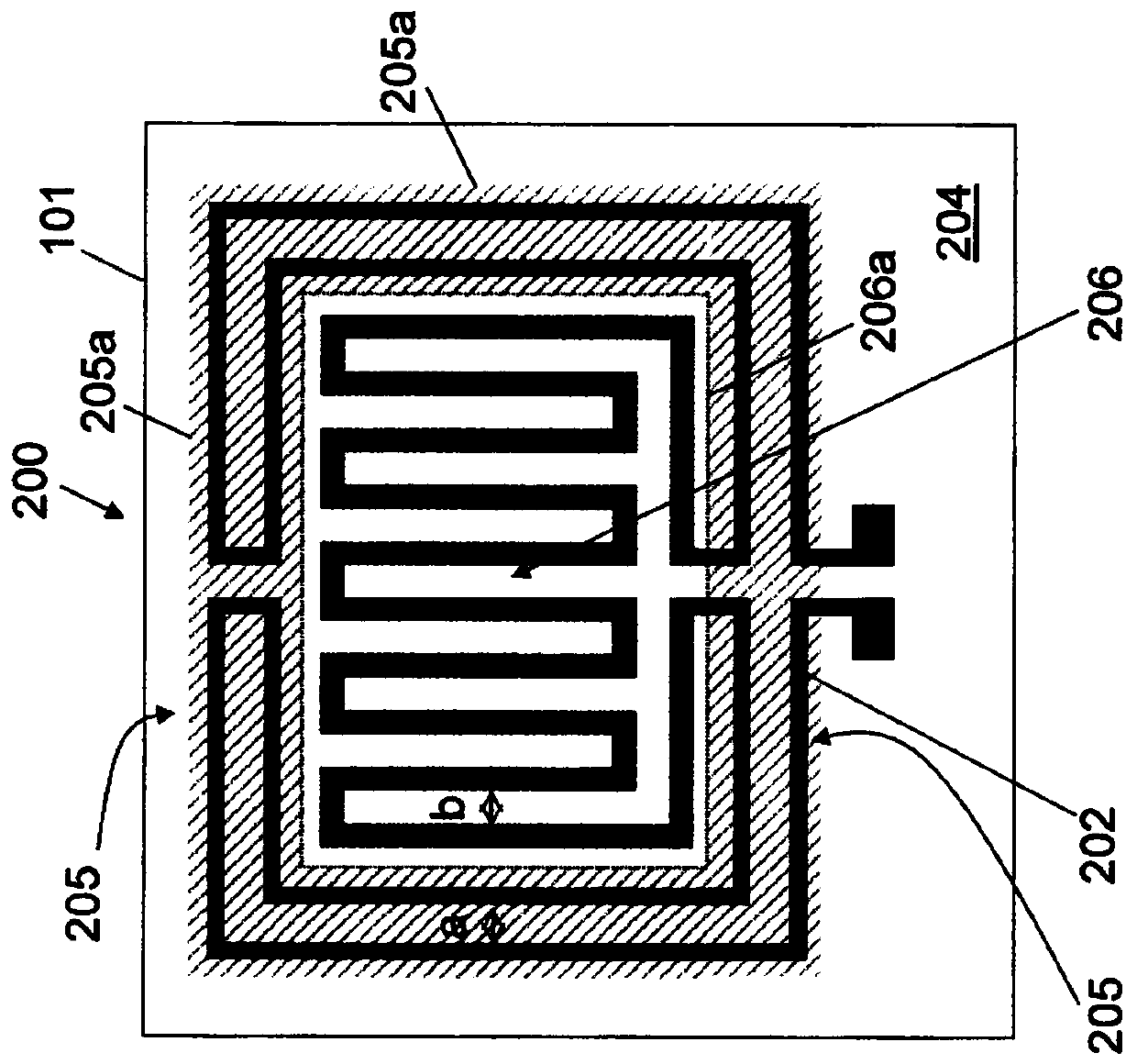

Infrared surface emitter

InactiveCN109716858AUniform irradiation intensityUniform heat treatmentSemiconductor/solid-state device manufacturingOhmic-resistance heatingEngineeringElectrical conductor

Known infrared surface emitters comprise a carrier with a heating surface and with a conductor track applied to a conductor track covering surface of the carrier and consisting of an electroconductiveresistive material that generates heat as a current flows through, the conductor track comprising a first conductor track section for producing a first surface output and a second conductor track section for producing a second surface output different from the first surface output. The aim of the invention is to provide an infrared surface emitter with a high level of irradiation, designed to emit radiation with an irradiation strength that is as homogeneous as possible. To this end, the carrier contains a composite material comprising an amorphous matrix component and an additional componentin the form of a semiconductor material, and the first conductor track section and the second conductor track section are connected in series and differ from each other in terms of the covering density thereof and / or the conductor cross-section thereof.

Owner:HERAEUS NOBLELIGHT LTD

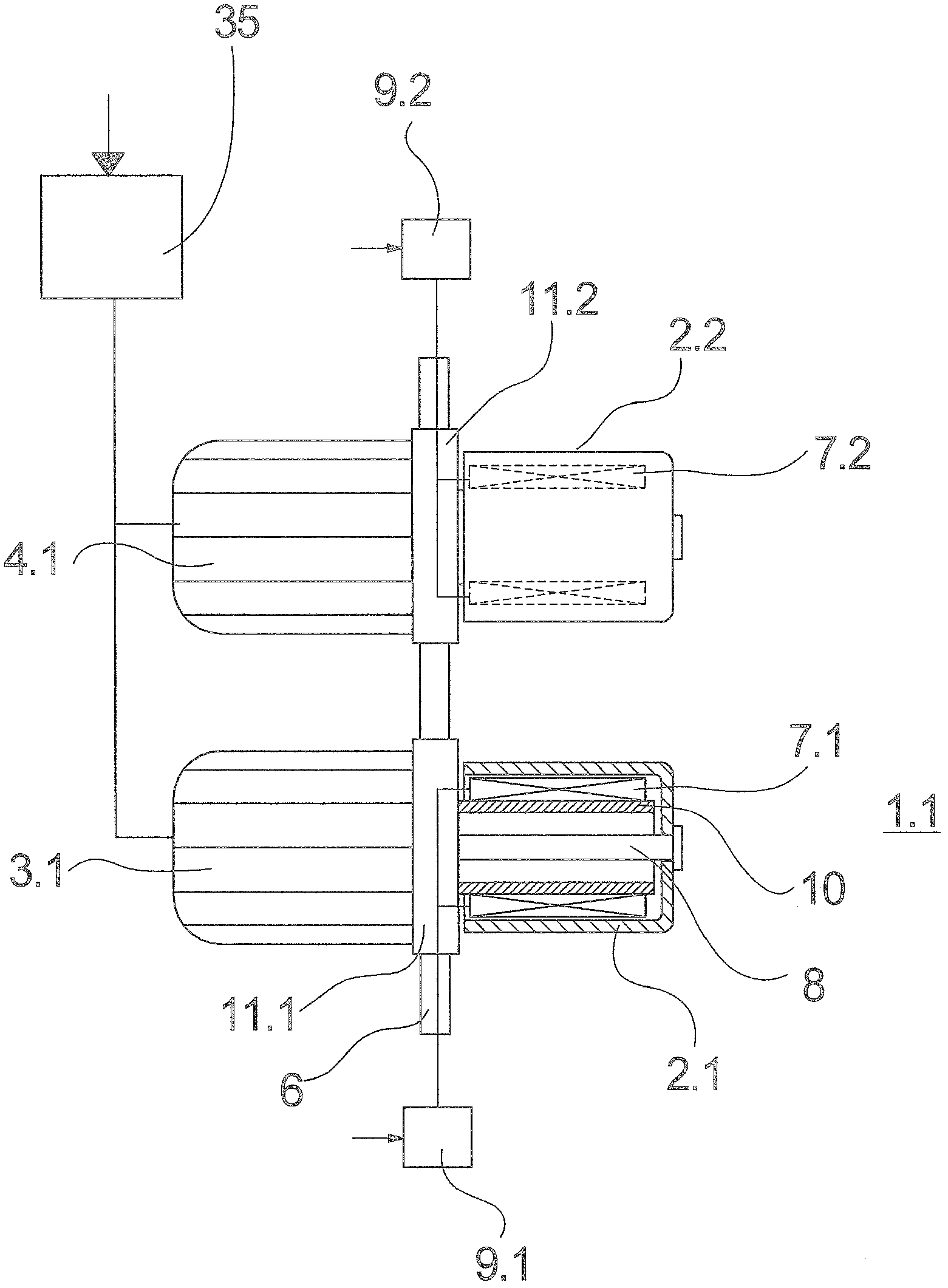

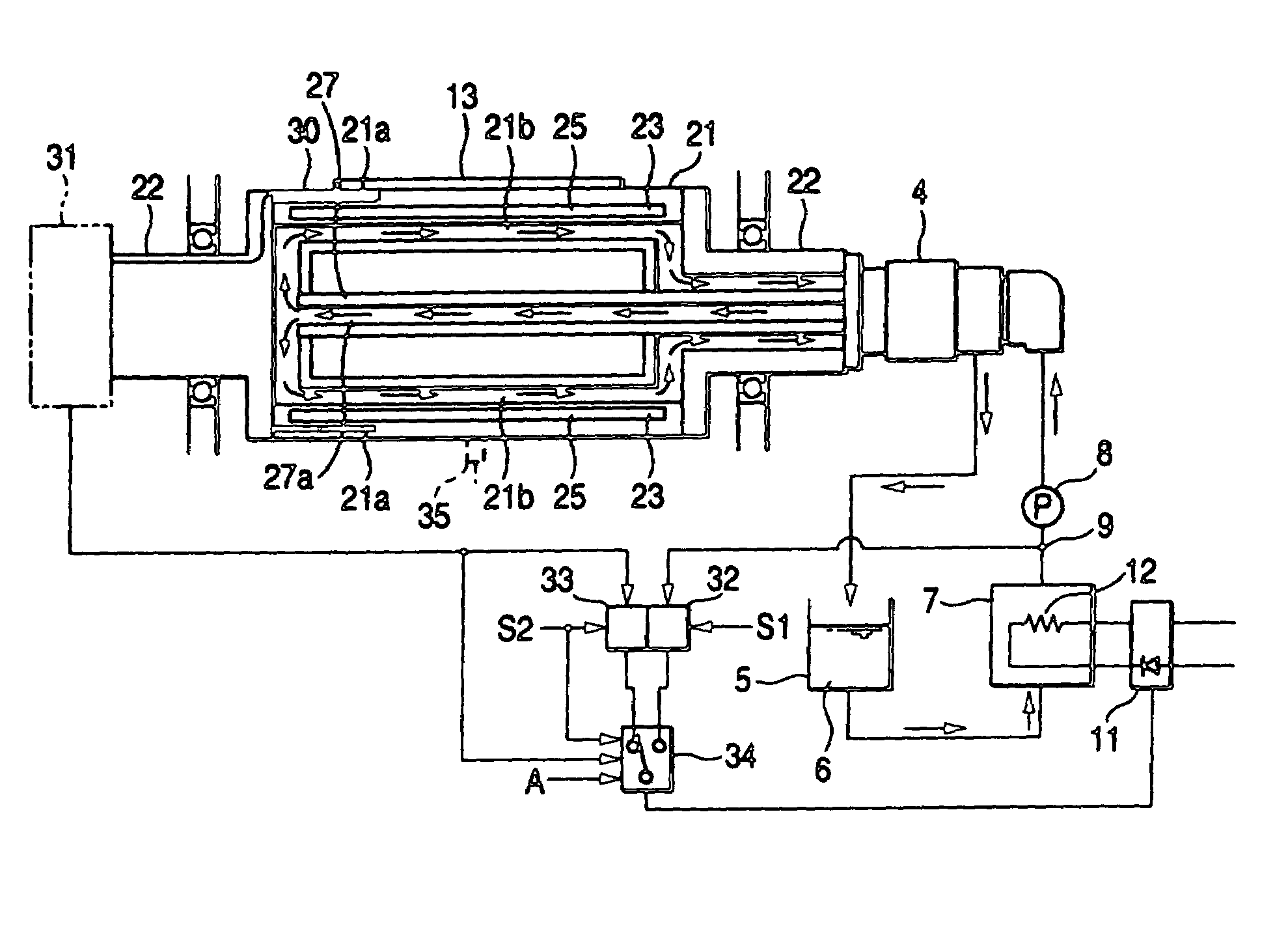

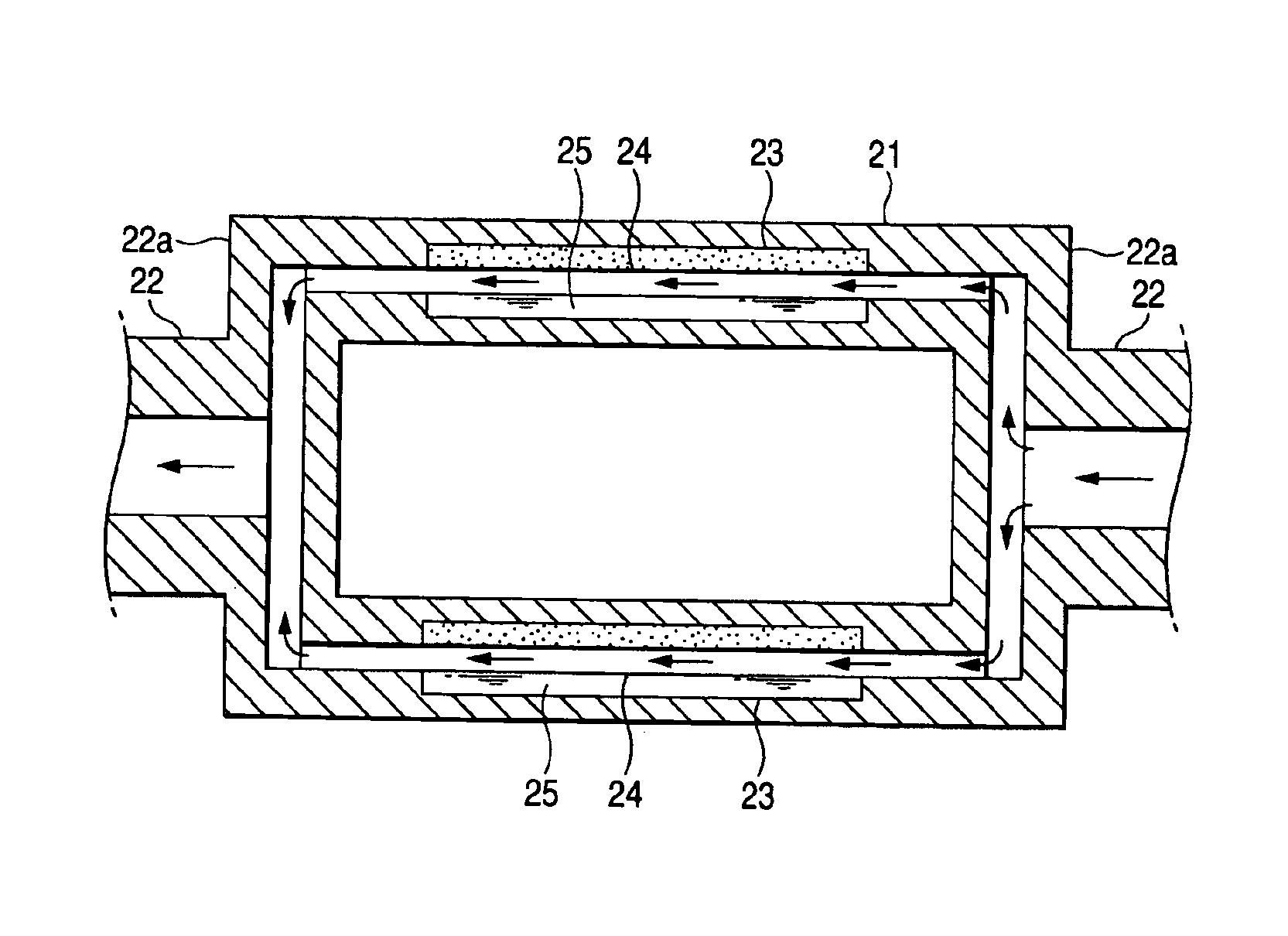

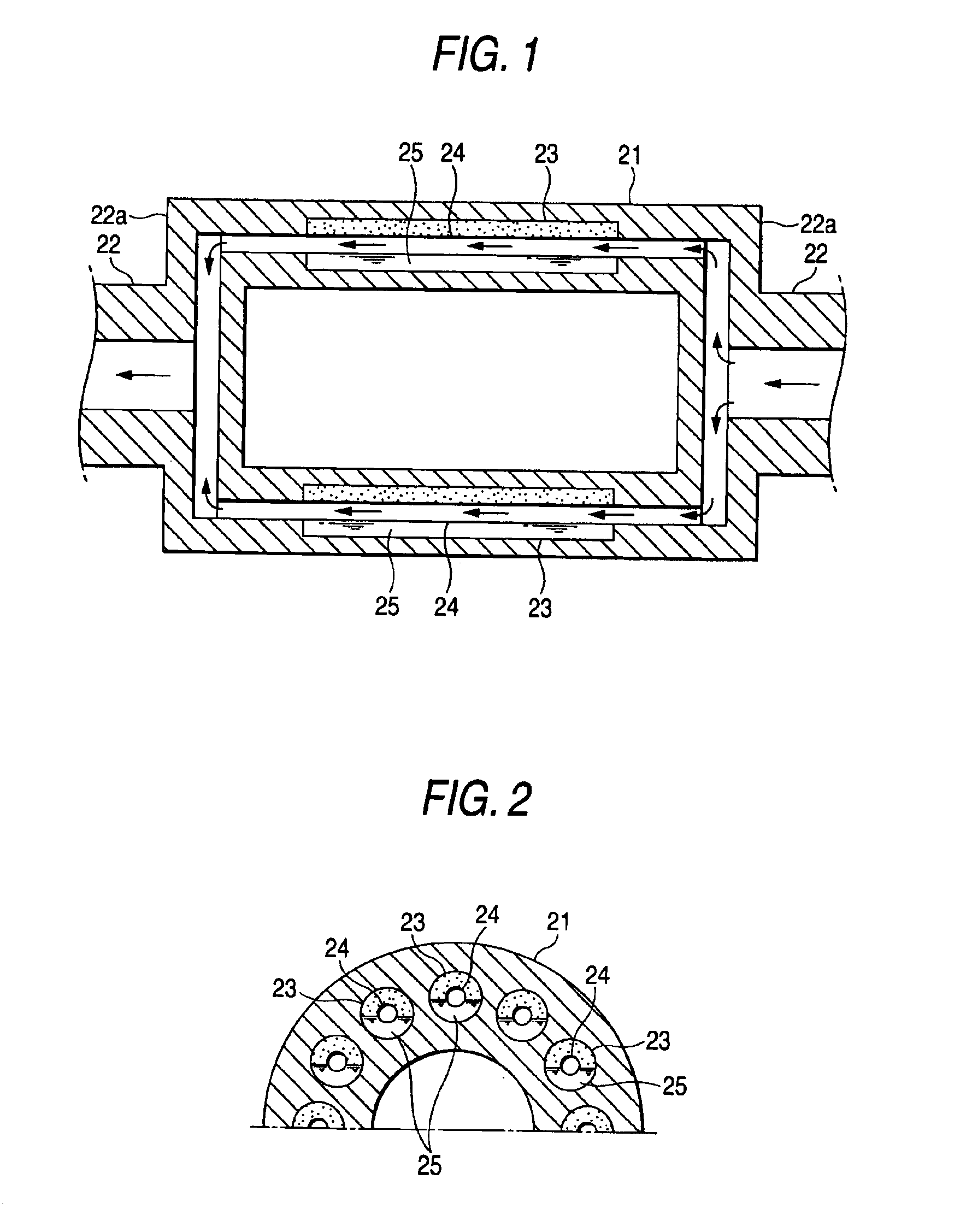

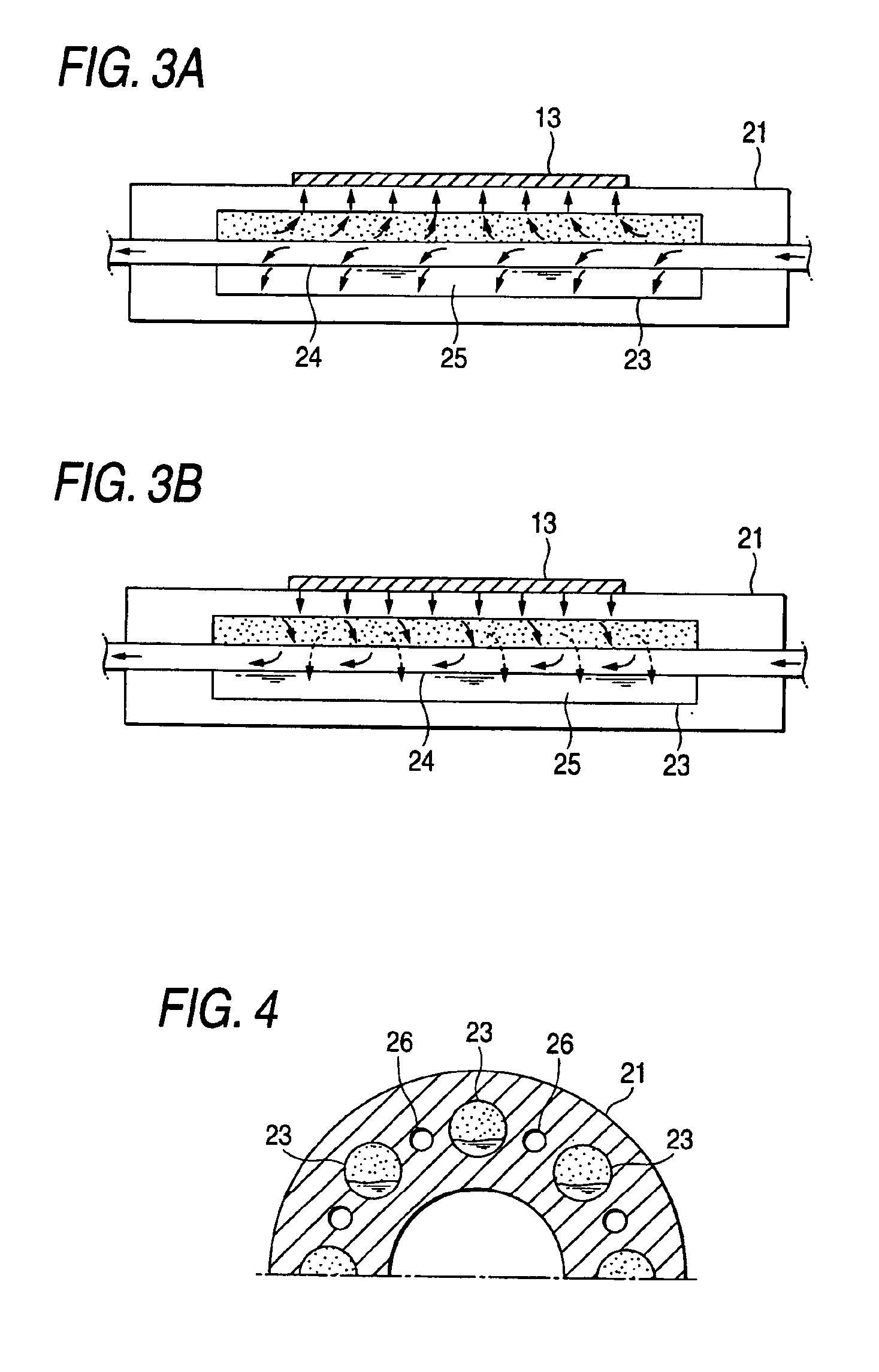

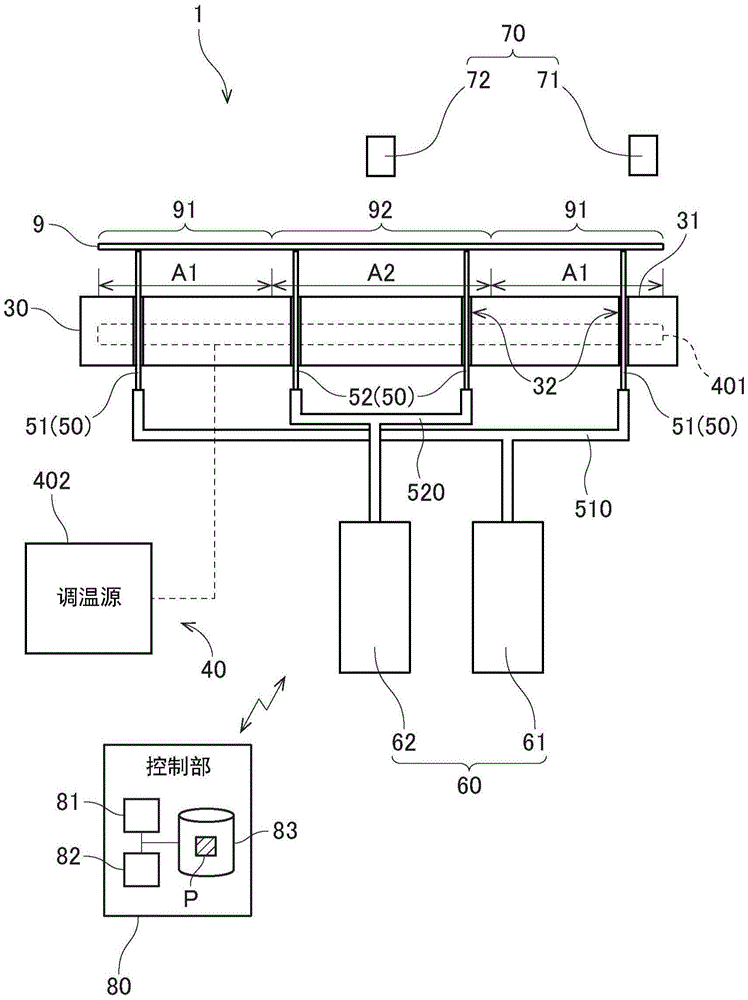

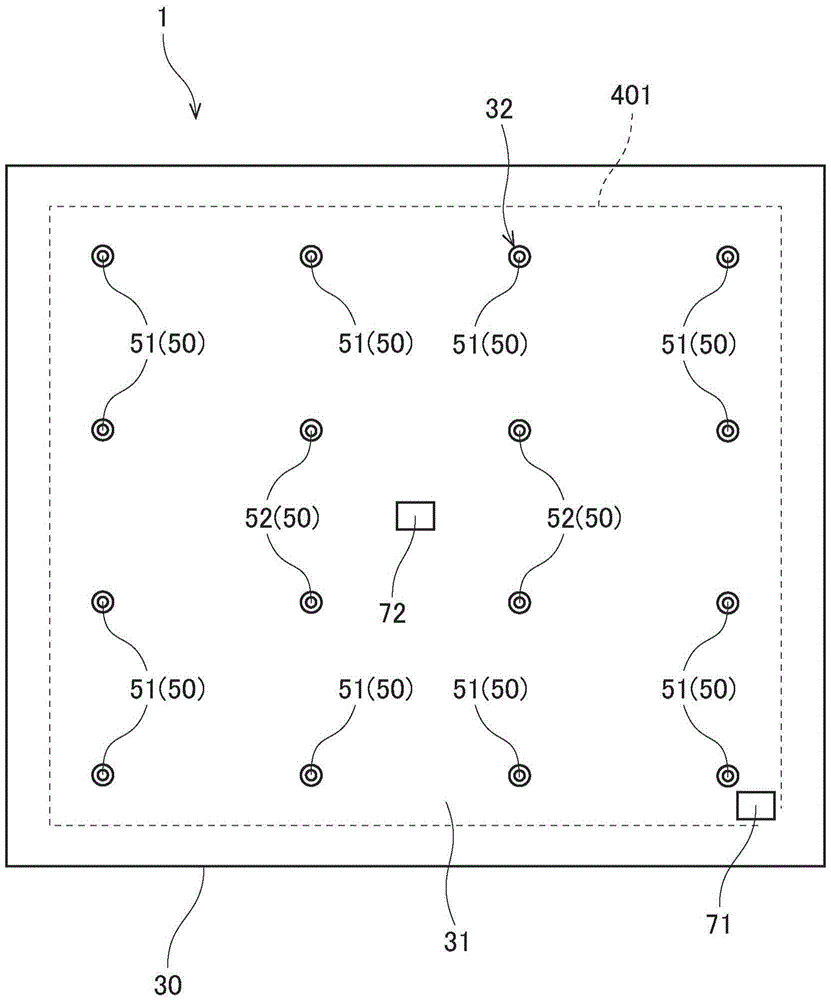

Thermal processing roller and temperature control apparatus for roller

InactiveUS7420141B2Uniform heat treatmentIncrease flow rateOhmic-resistance heating detailsRollsVapor liquidTemperature control

A thermal processing roller includes a heat transfer medium flowing path therein and heats a member to be processed abutting against a surface of the roller or absorbs heat therefrom by heat transfer fluid flowing through the heat transfer medium flowing path, wherein a sealed chamber extending in a longitudinal direction of the roller and in which heat transfer medium of vapor-liquid two phases is sealed is formed within a thick portion of the roller.

Owner:TOKUDEN CO LTD

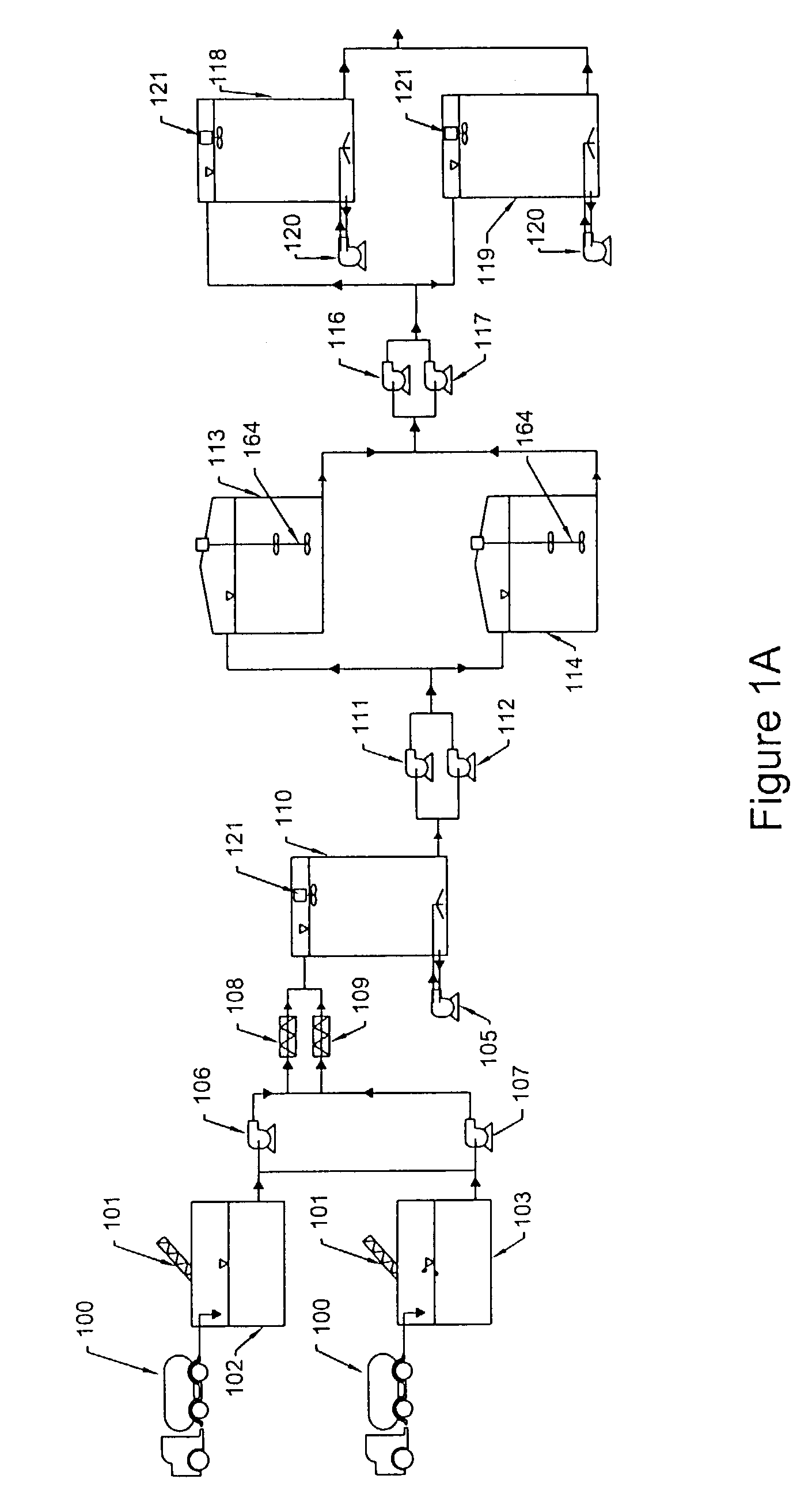

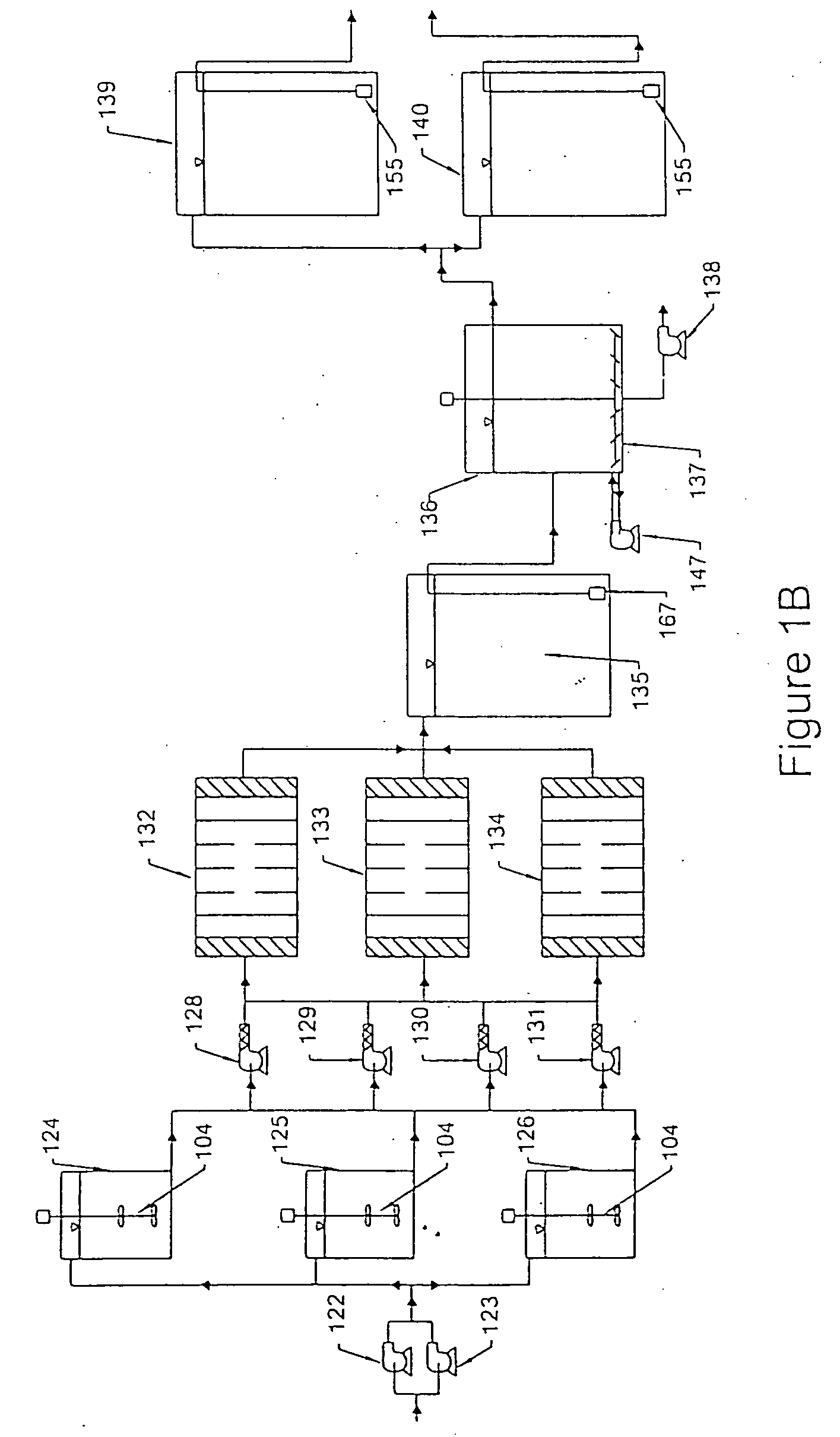

Process for treating septage to extract a bio-fuel

InactiveUS20070056902A1Uniform and thorough heat treatmentGreat pathogen reductionSludge treatmentOther chemical processesAlternative fuelsBiofuel

A process for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process converts septage into sludge usable as a bio-fuel. The conversion of the septage makes it desirable as an alternative fuel source, as the sludge has a high BTU value due to the large percentage of grease in the septage.

Owner:KELLY ROBERT J

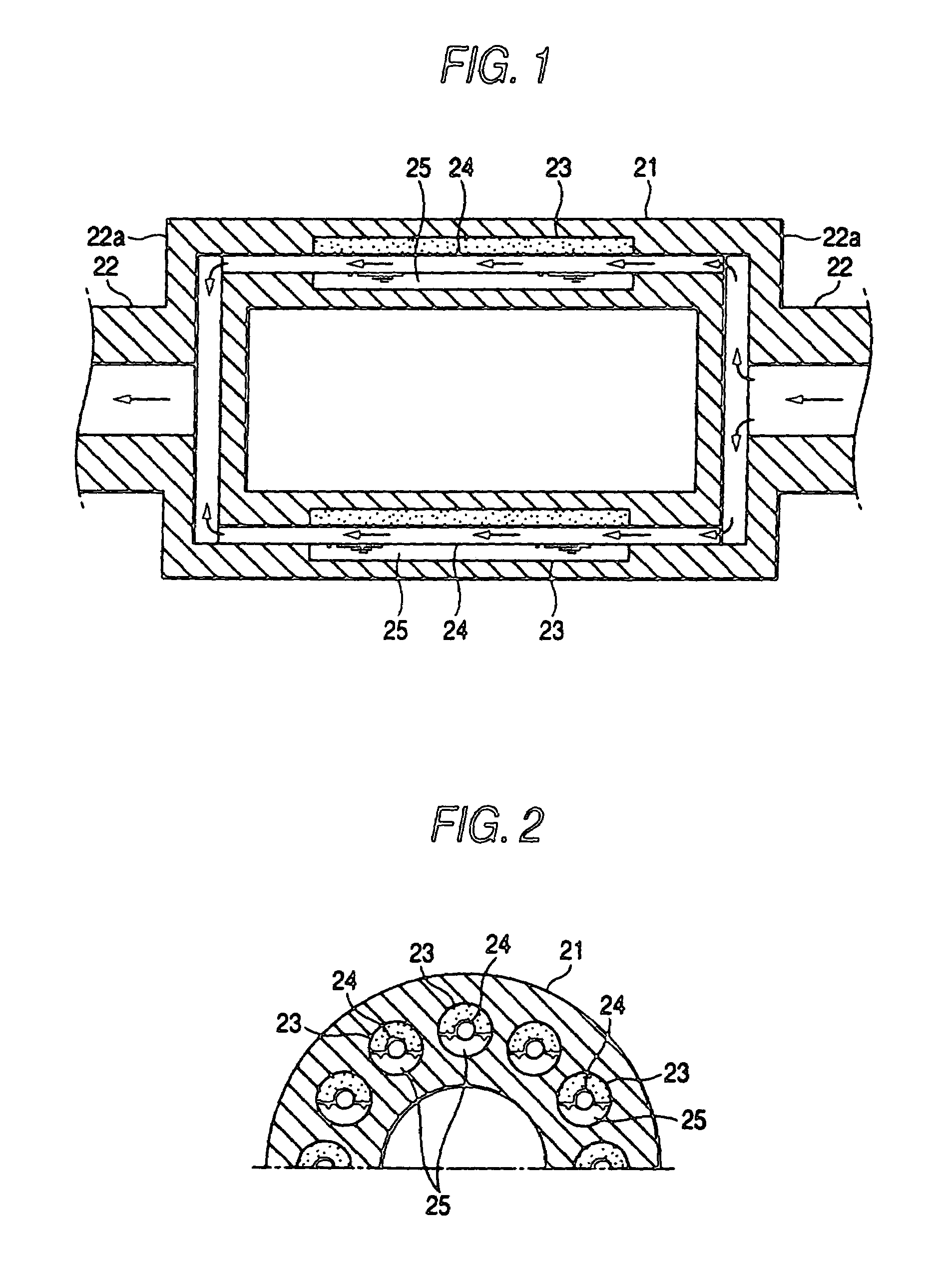

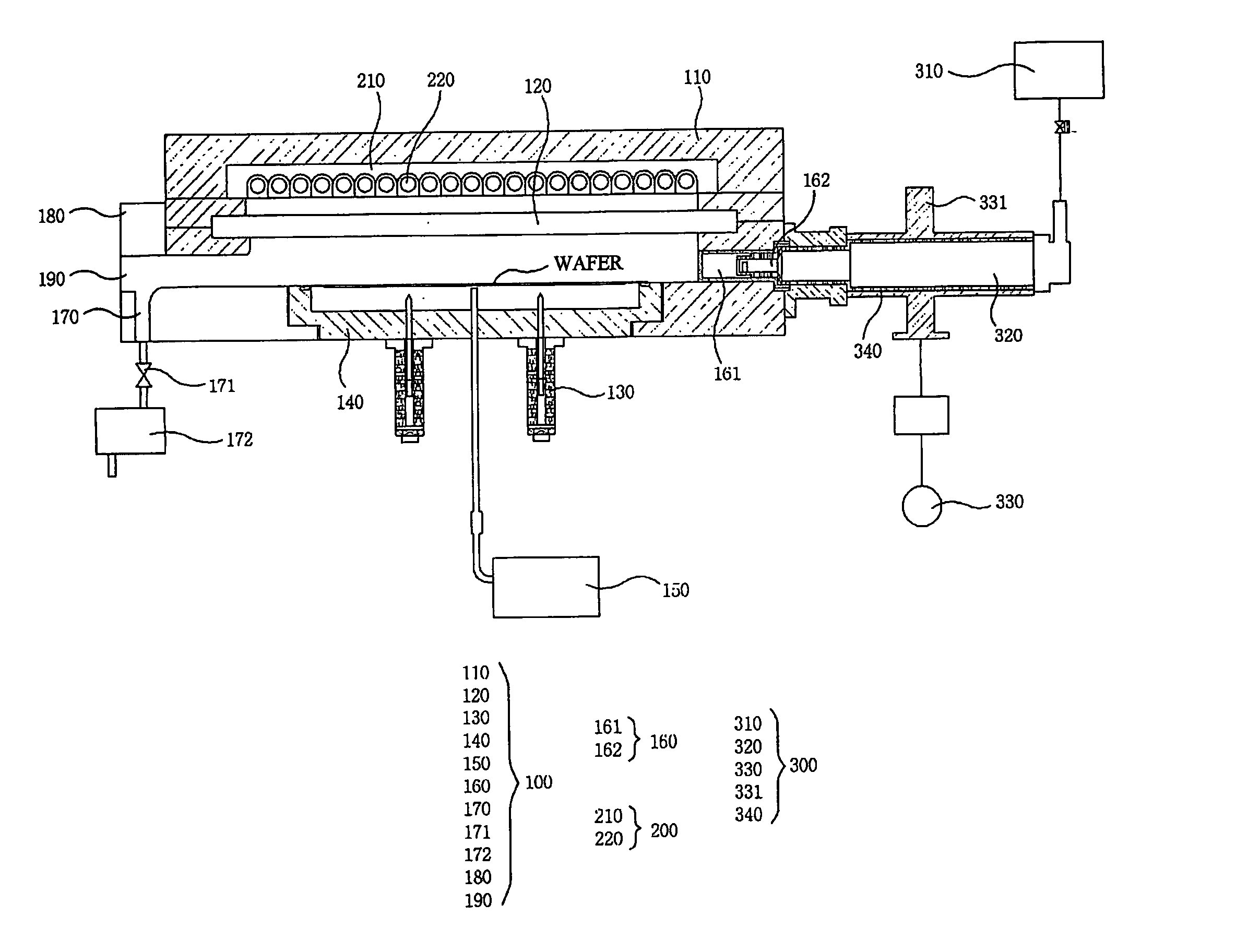

Heat-treating method for substrate and heat treating furnace

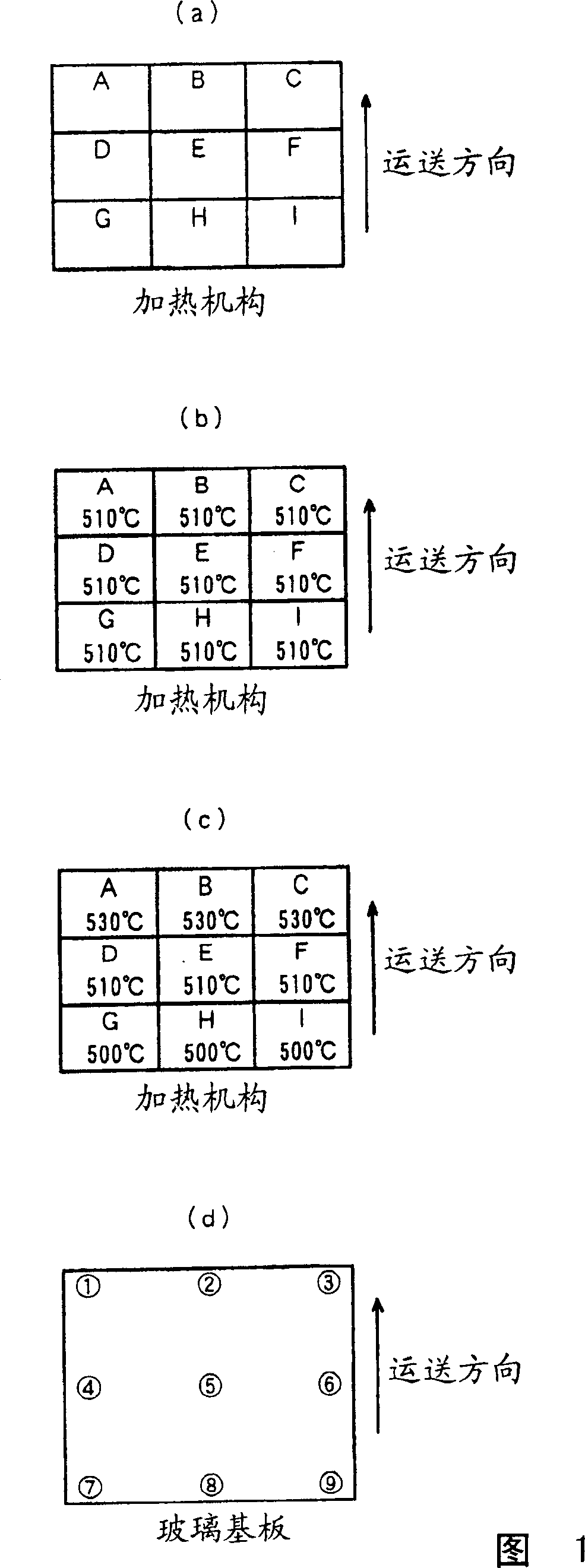

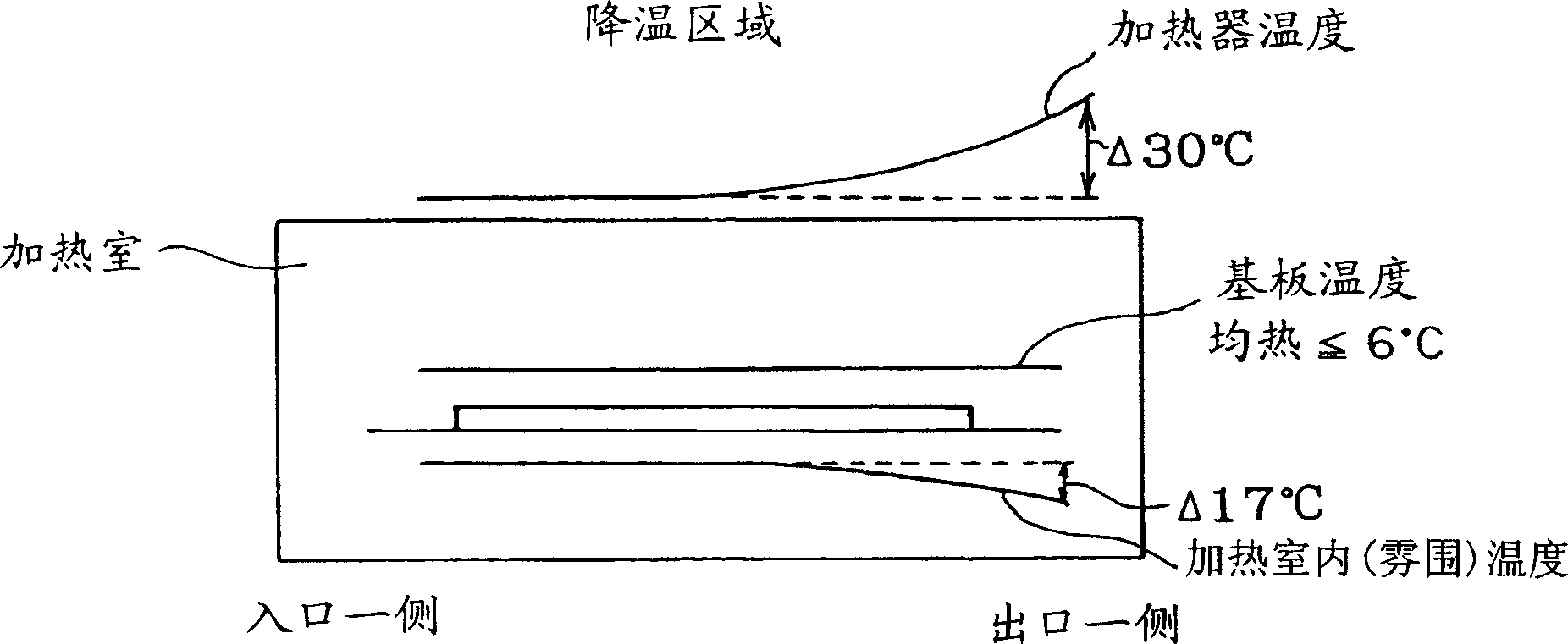

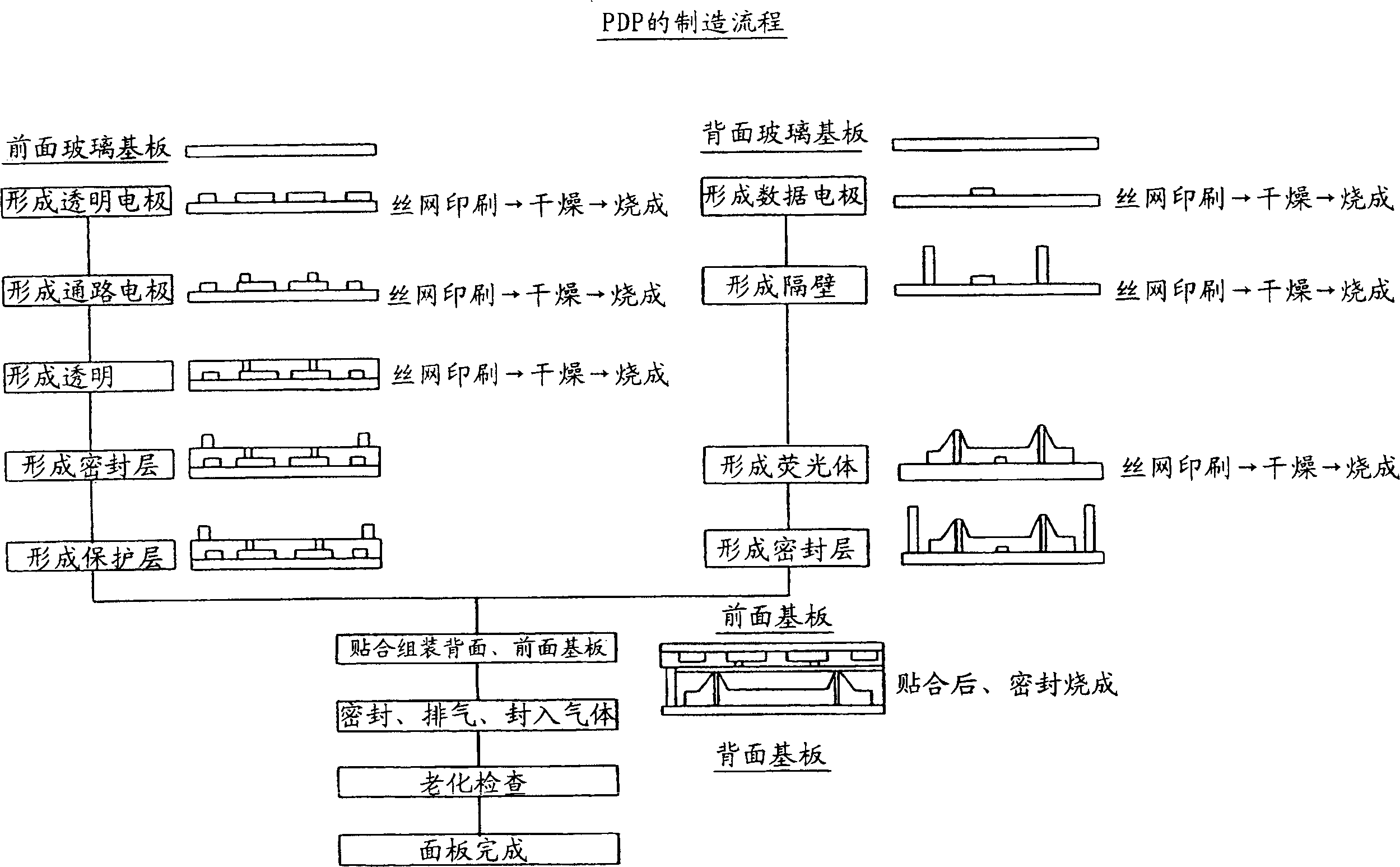

InactiveCN1517962AUniform heat treatmentFast shippingStatic indicating devicesVessels or leading-in conductors manufactureTemperature controlThermal effect

Provided is a method of heat-treating a substrate and a heat treatment furnace capable of uniformly heat treating the entire part of the substrate by suppressing the occurrence of temperature distribution in the substrate by thermal effect thereon from the other adjacent heating chamber with a different average indoor temperature from that in a heating chamber when heat-treating the substrate including a film formation material is performed in the heating chamber of a furnace. In the heating chamber with the different average indoor temperature from that in at least one chamber of the plurality of heating chambers (25, 26, 27) divided in the carrying direction of a heat-treated body, the set temperatures of electric heaters (14) for heating installed in the heating chambers are controlled so as to be different in the carrying direction of the heat treated body (22). In the heating chamber, temperatures at the inlet and outlet of the heat treated body (substrate) (22) in the carrying direction are maintained to have a distribution larger than a target temperature distribution in the substrate (22) so that the substrate (22) can be uniformly heat-treated.

Owner:NGK INSULATORS LTD

Bake-hardenable cold rolled steel sheet with superior strength and aging resistance, gal-vannealed steel sheet using the cold rolled steel sheet and method for manufacturing the cold rolled steel shee

ActiveCN101310031AHigh strengthImprove anti-agingFurnace typesHeat treatment furnacesSheet steelRoom temperature

A bake-hardenable cold rolled steel sheet with high strength and superior aging resistance used for outer panels of an automobile body, a galvannealed steel sheet using the cold-rolled steel sheet, and a method for manufacturing the cold-rolled steel sheet are disclosed. The steel sheet comprises, by weight%, C: 0.0016-0.0025%, Si: 0.02% or less, Mn: 0.2-1.2%, P: 0.05-0.11%, S: 0.01% or less, Sol. Al: 0.08-0.12%, N: 0.0025% or less, Ti: 0-0.003%, Nb: 0.003-0.011%, Mo: 0.01-0.1%, B: 0.0005-0.0015%, the balance of Fe and other unavoidable impurities. The steel sheet has superior bake hardenability, aging resistance at room temperature, and secondary work embrittlement resistance.

Owner:浦项股份有限公司

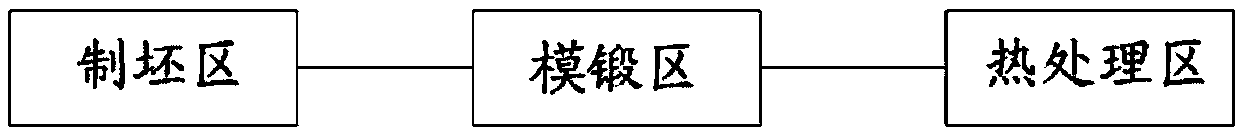

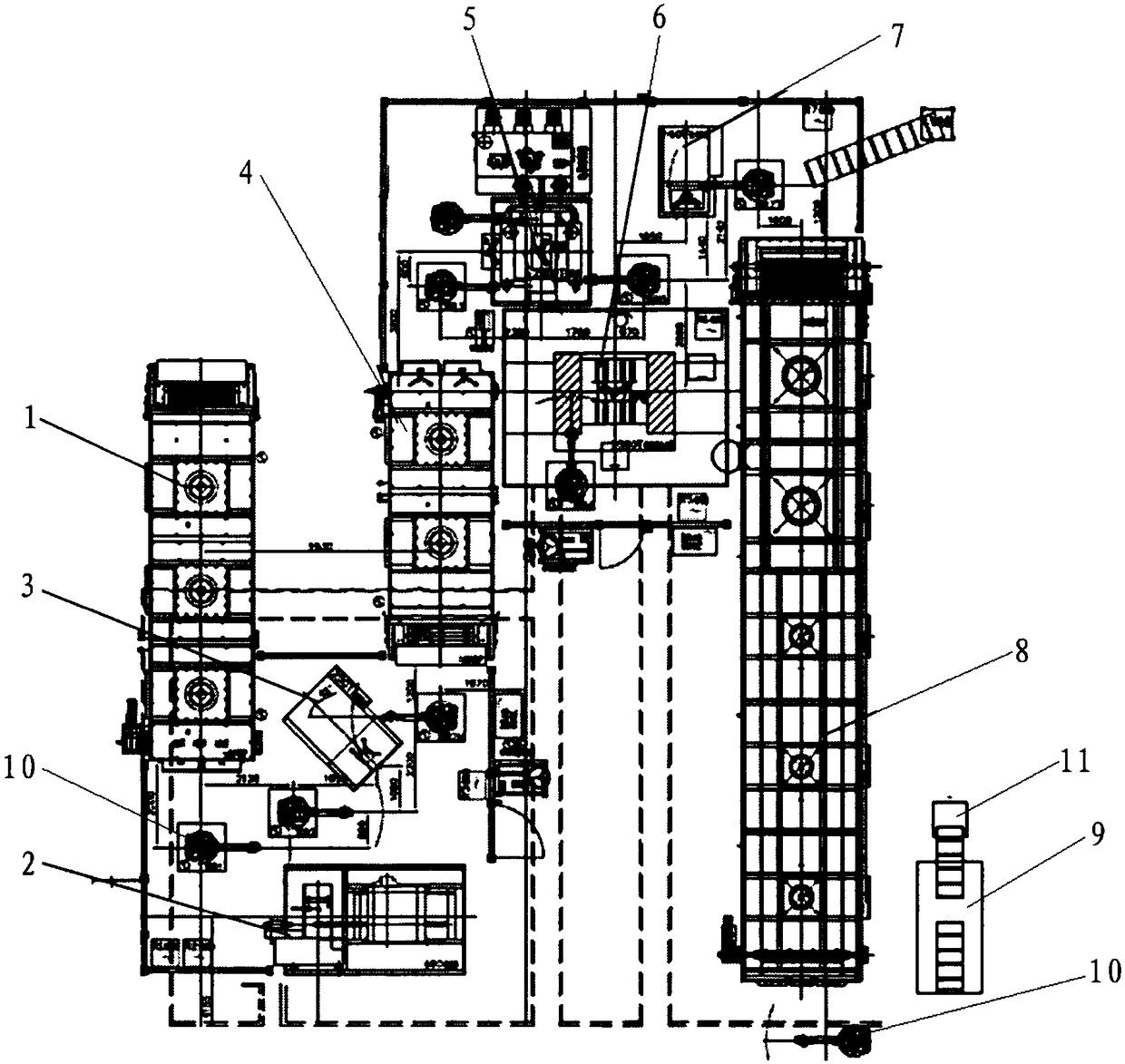

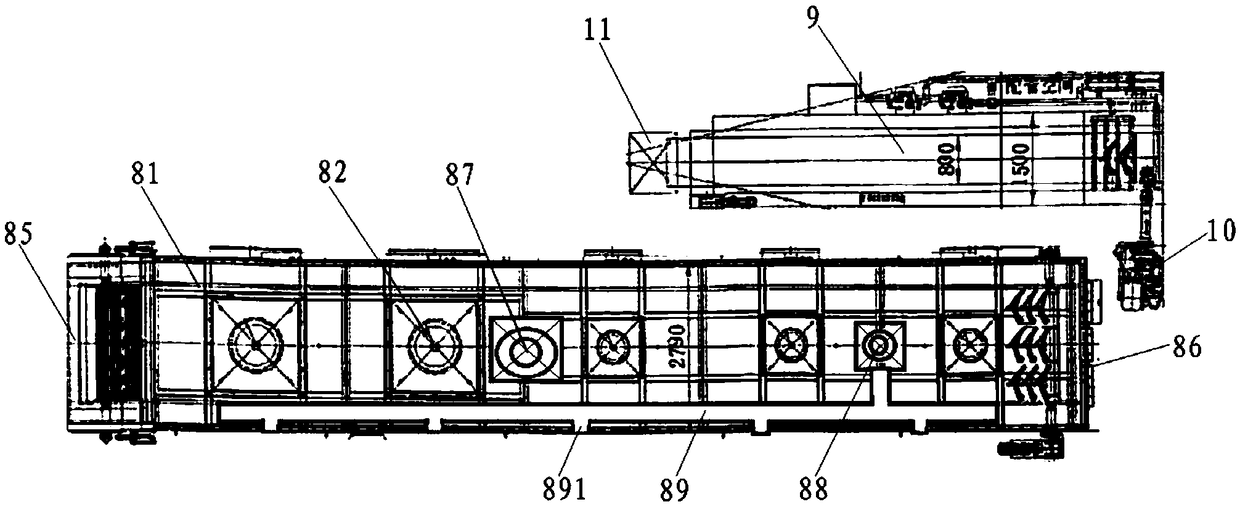

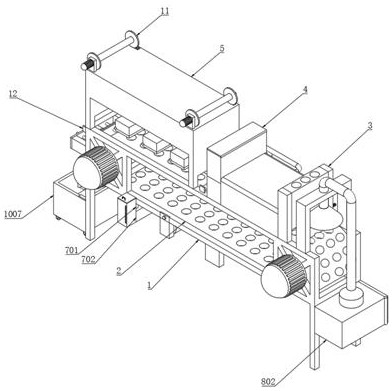

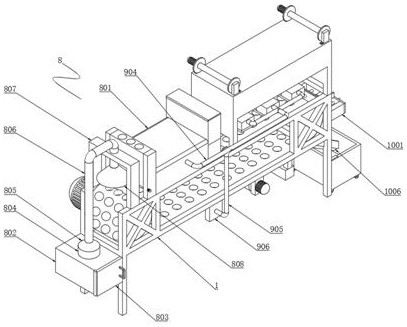

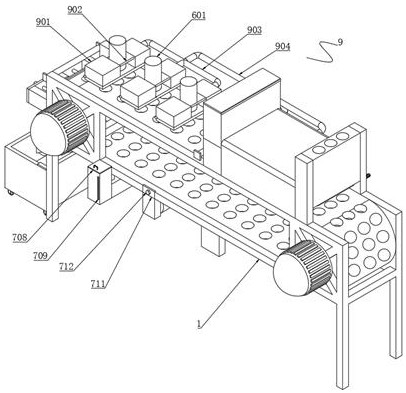

Automobile control arm forging production line and forging forming technology

PendingCN108817307AReduce labor intensityImprove working environmentRailway componentsForging/hammering/pressing machinesSolution treatmentProduction line

The invention discloses an automobile control arm forging production line. The production line comprises a blank making area, a die forging area and a heat treatment area which are sequentially arranged according to a production technology. A plurality of mechanical arms used for conveying workpieces are arranged among the areas. The blank making area comprises a first heating furnace and a rollerforging machine. The die forging area comprises a second heating furnace and a die forging press machine set, the die forging press unit is used for forging forming of a blank obtained after secondary heating, and the workpieces are conveyed to the heat treatment area through the mechanical arms. The heat treatment area comprises a solution treatment furnace and a cooling device, the solution treatment furnace is used for carrying out solution treatment on the forged workpieces, the workpieces are conveyed to the cooling device through the mechanical arms, and a finished product bin is connected to a discharge port of the cooling device. The automobile control arm forging production line is reasonable in layout, high in automation degree and good in stability; the heat treatment area is additionally arranged, so that the production time is shortened, and the production efficiency is improved; and the heating process adopts jet flow heating, so that the heating speed and heating uniformity of the blank are improved, and the product quality is effectively improved.

Owner:海安金锻工业有限公司

Thermal processing roller and temperature control apparatus for roller

ActiveUS6992272B2Uniform heat treatmentIncrease flow rateOhmic-resistance heating detailsRollsTemperature controlVapor liquid

Owner:TOKUDEN CO LTD

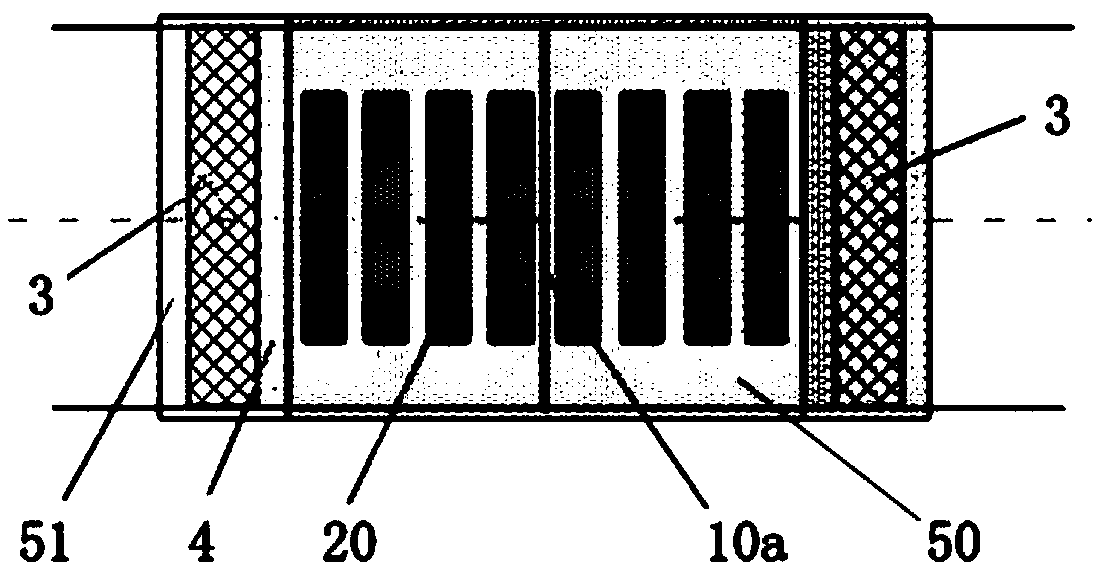

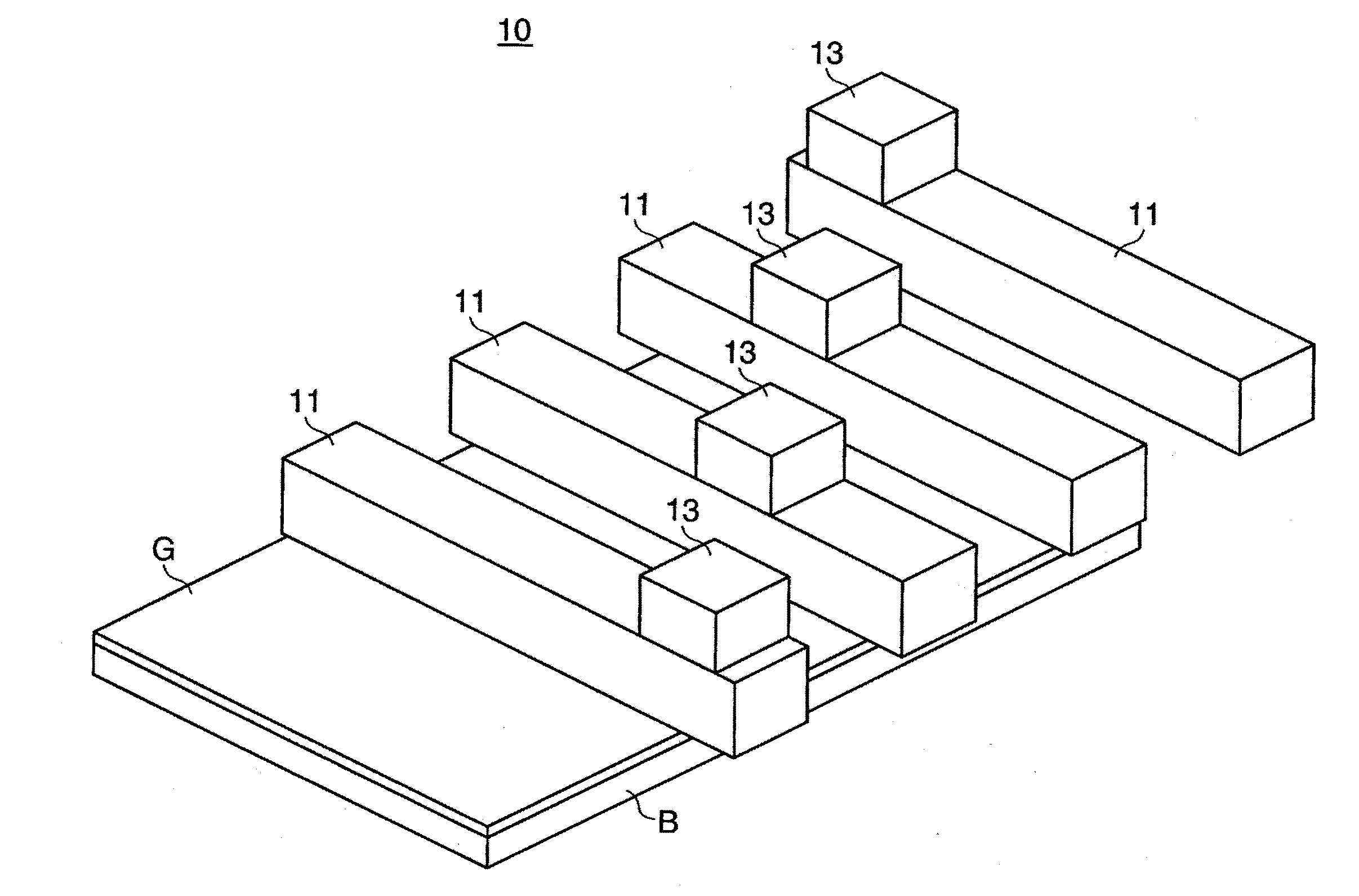

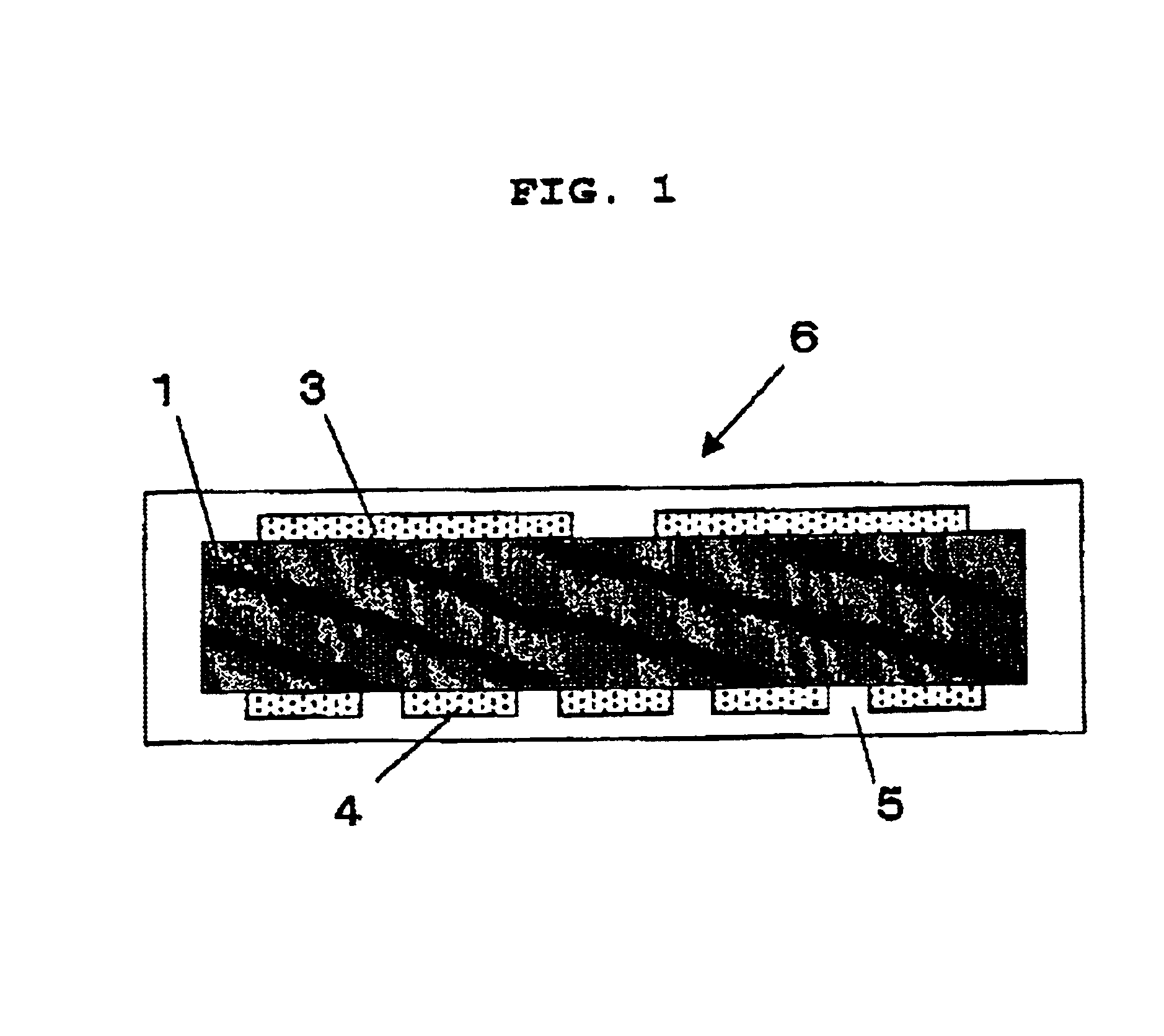

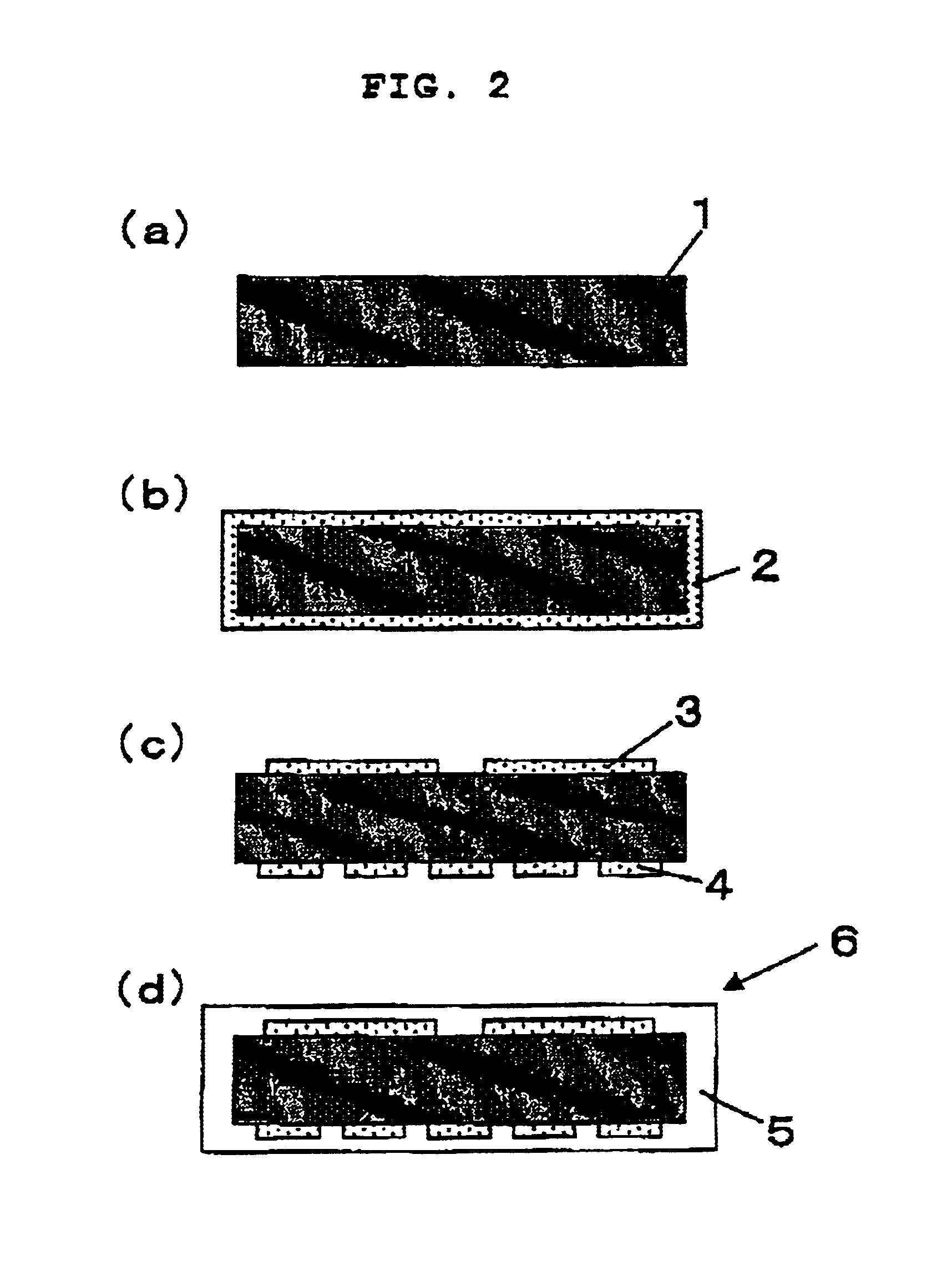

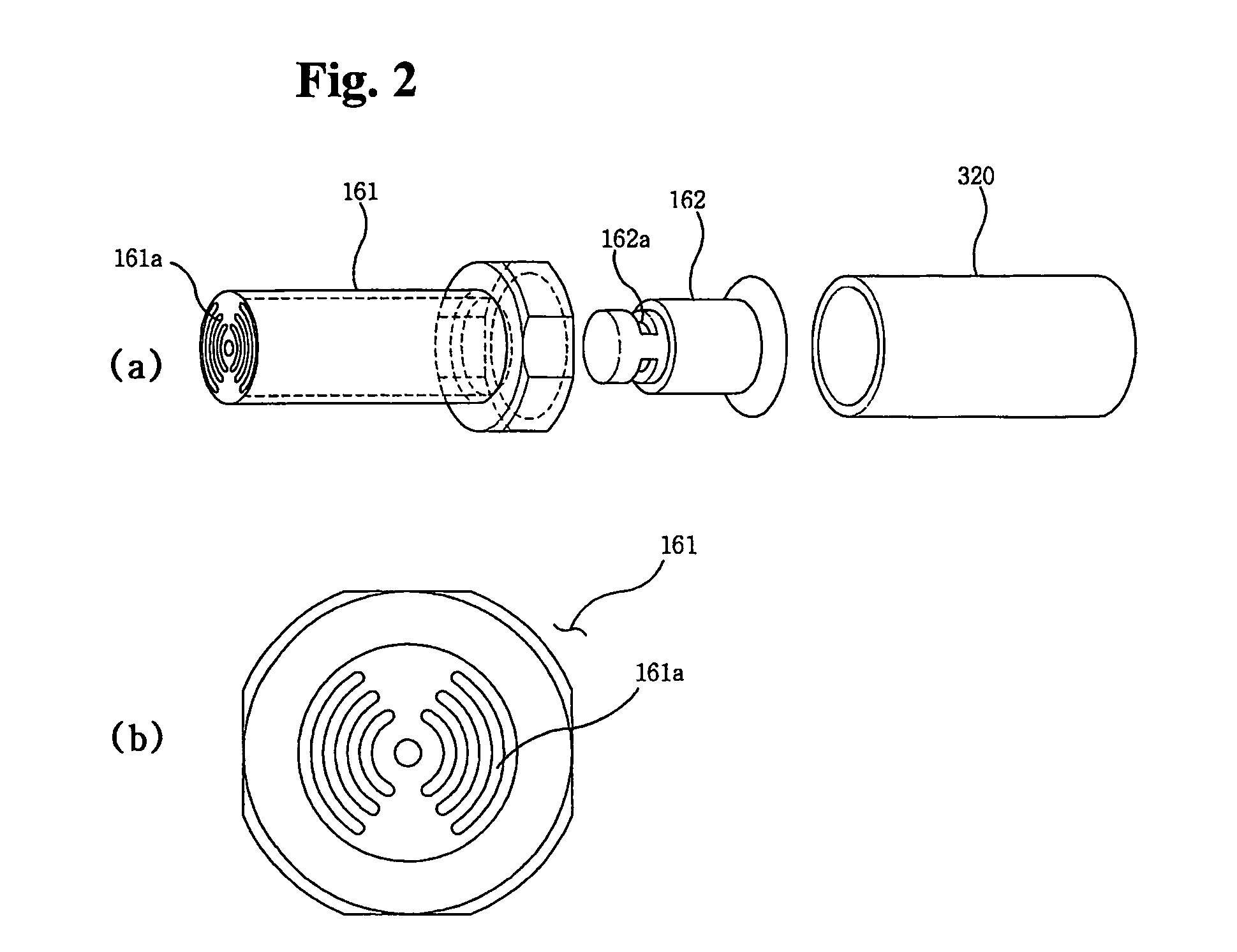

Gas adsorbing device and vacuum insulation panel provided with same

ActiveUS20130305928A1Good gas adsorption performanceEasy to confirmGas treatmentElectric discharge tubesNitrogenEngineering

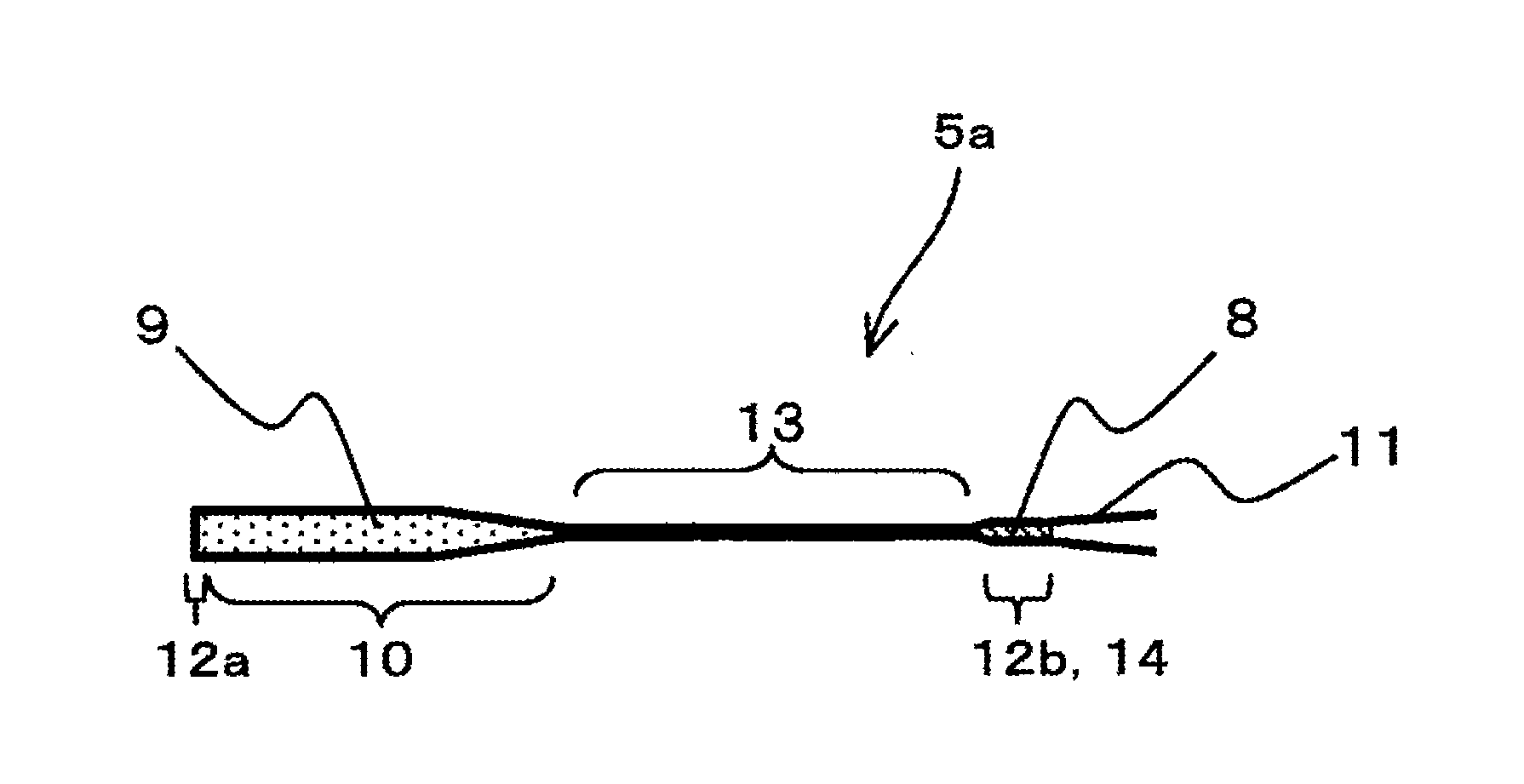

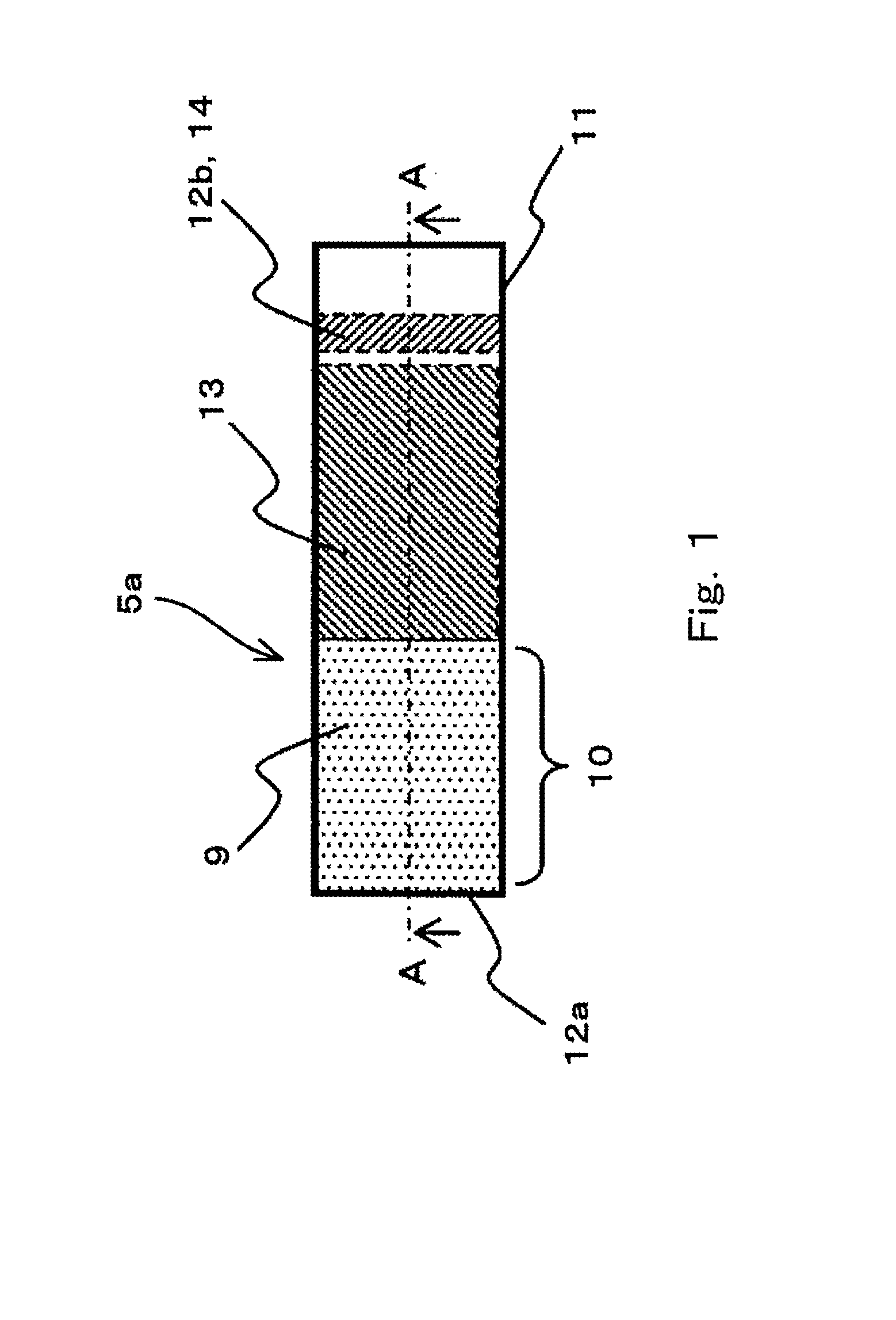

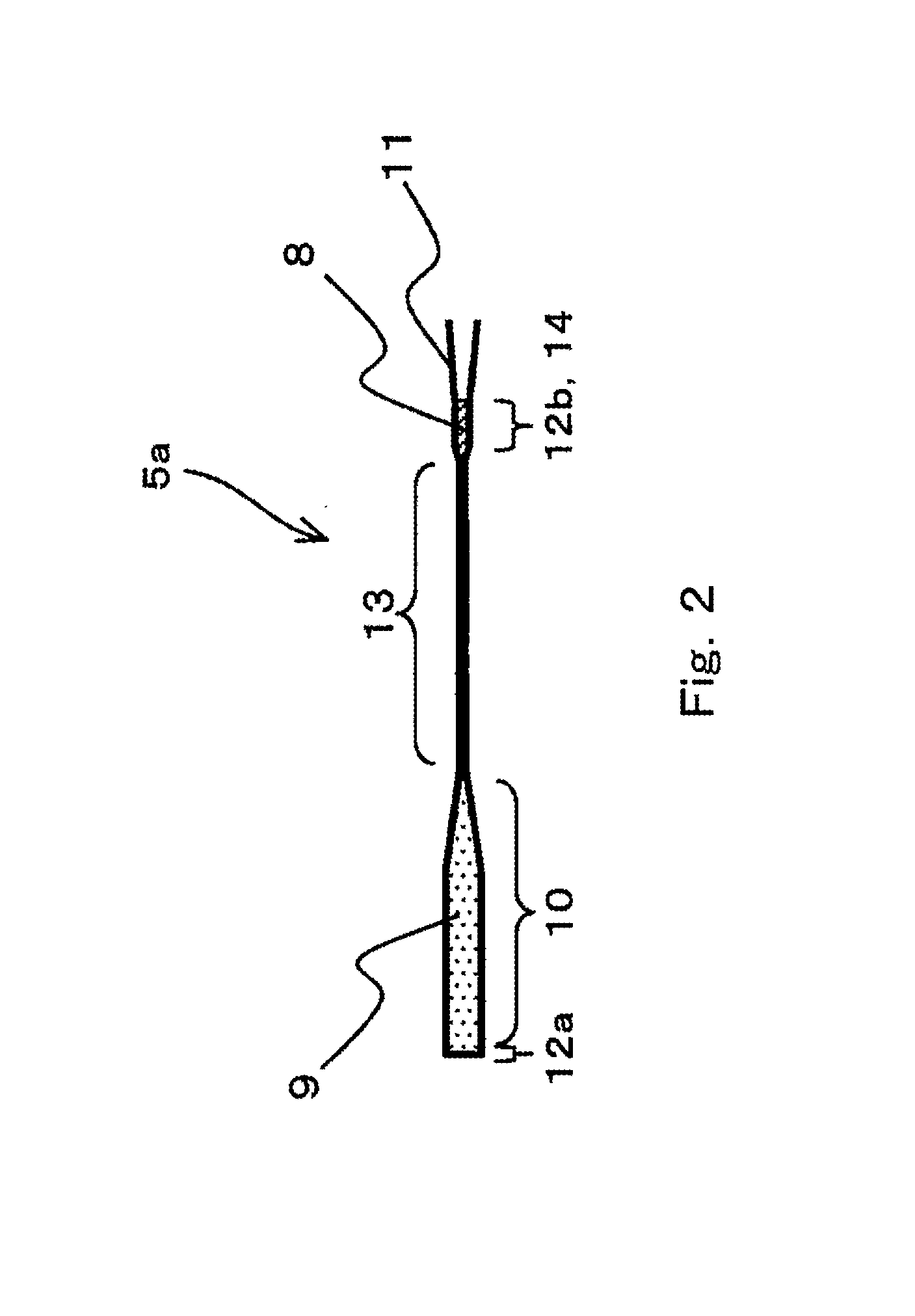

A gas adsorbing device (5a) according to the present invention includes a gas adsorbing material (9) that adsorbs at least nitrogen and a housing container (11) that has a long, thin, flat, tubular shape and is made of metal and in which both sides of a housing portion (10) configured to house the gas adsorbing material (9) under reduced pressure are sealed. A contact portion (13) where opposing inner surfaces of the housing container (11) are in close contact with each other is located between at least one of seal portions (12a and 12b) of the housing container (11) and the housing portion (10).

Owner:PANASONIC CORP

Crushing, melting and extruding integrated equipment for plastic production

The invention relates to crushing, melting and extruding integrated equipment for plastic production. The crushing, melting and extruding integrated equipment for the plastic production comprises a main barrel, a vertical knife, a connecting block, an inlet and a blocking ball. A motor is arranged on the middle portion above the main barrel, and a first rotary shaft is arranged under the motor. Afeed inlet penetrates through the left side of the upper portion of the main barrel. A hydraulic cylinder is arranged on the lower portion of the left side of the main barrel, and a push plate is fixed to the right side of the hydraulic cylinder. A hinge is installed on the left side of the main barrel, and a barrel door is arranged on the left side of the hinge. A main crushing knife with an arc-shape pointed structure is arranged, plastic can be crushed, and thus the melting speed of the plastic is accelerated, the working efficiency is improved. Through the arrangement of a secondary crushing knife and the vertical knife, the degree of plastic crushing can be improved. A filter plate with hollowed-out structure can block the unbroken plastic to ensure that the plastic volume passing through the filter plate conforms to the melting standard, and secondly, a stirring rod is arranged in a saw tooth structure.

Owner:ANHUI WANSHUN PIPE IND

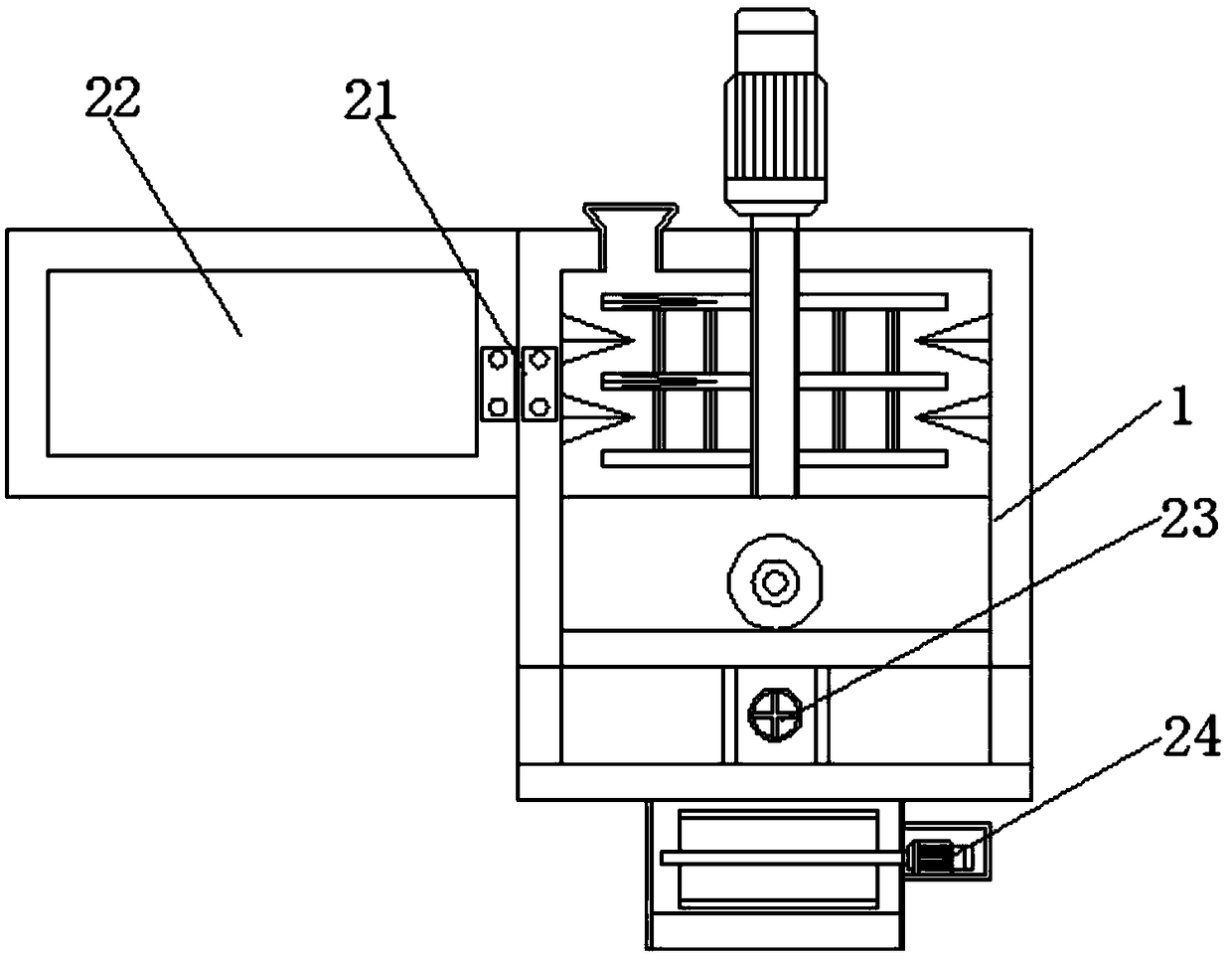

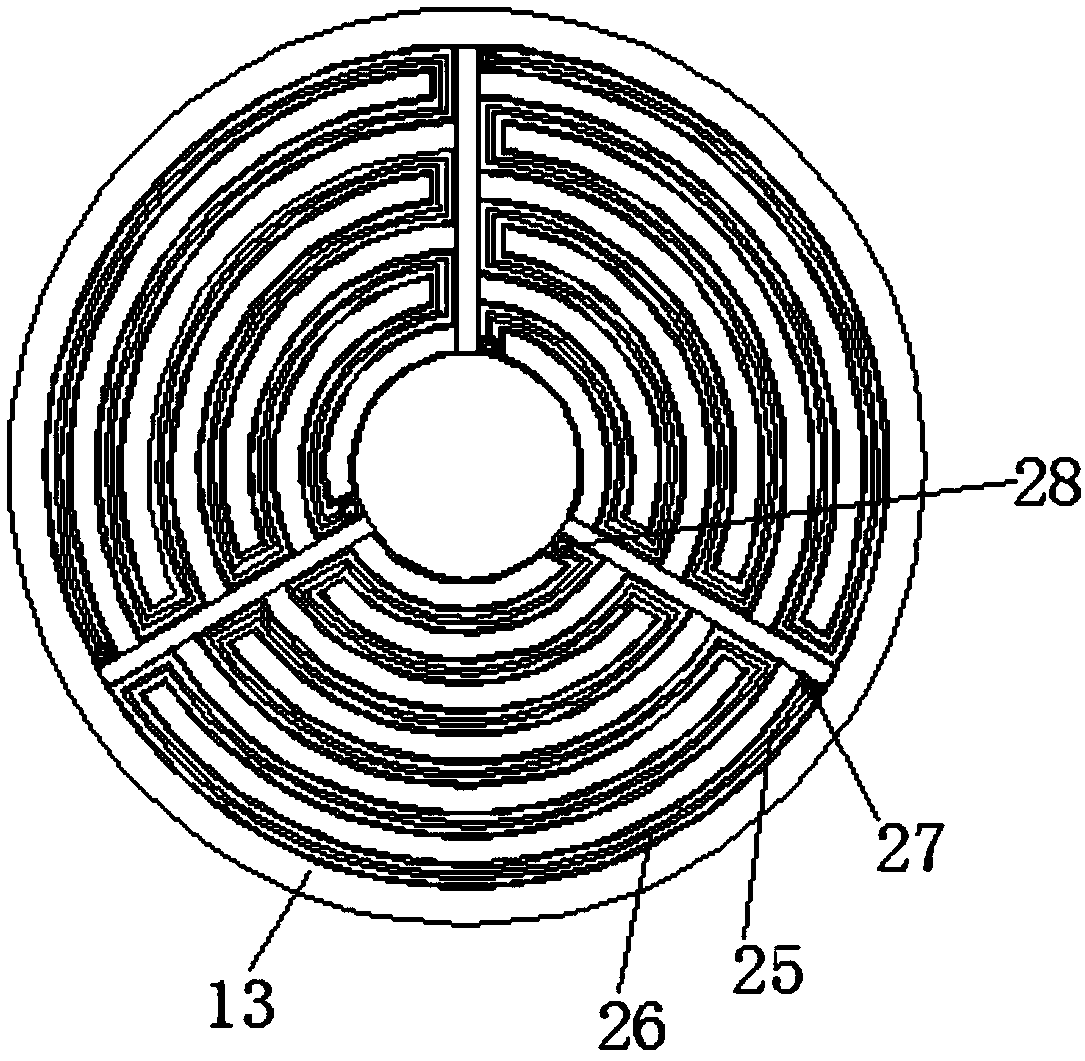

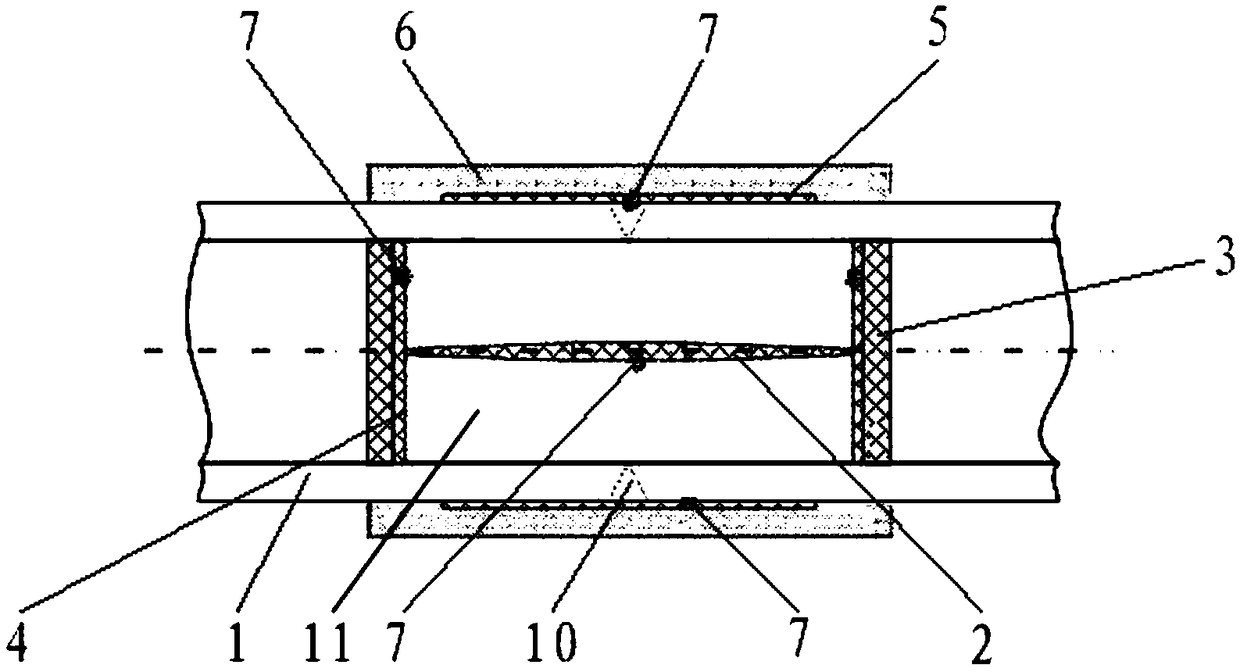

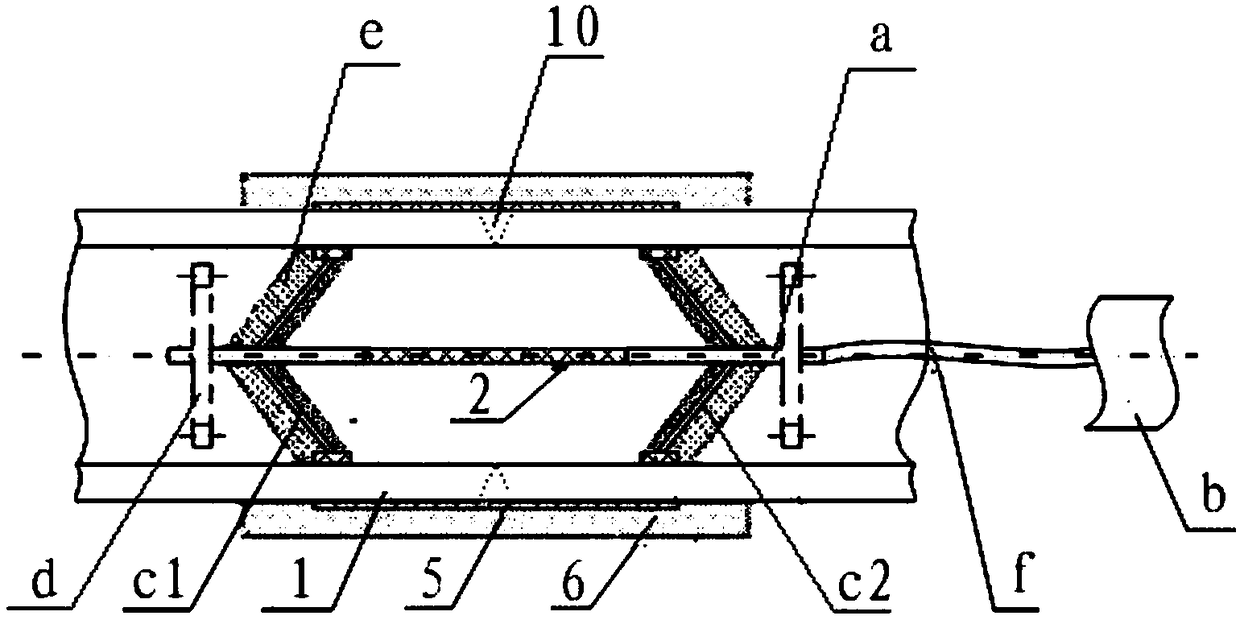

Heat treatment device and heat treatment method for corrugated pipe with complex contour

ActiveCN112063822AEfficient electromagnetic induction heating technologyGuaranteed continuityFurnace typesIncreasing energy efficiencyThermodynamicsEngineering

The invention provides a heat treatment device for a corrugated pipe with a complex contour. The heat treatment device is characterized in that an induction heating mechanism, a quenching cooling unitassembly, a rotating lifting platform and a bottom plate are sequentially arranged from top to bottom; in the induction heating mechanism, shells of servo motors are fixedly connected with the innerside of a fixing ring, the output ends of the servo motors are fixedly connected with the input ends of worms, and a circular induction coil is connected with the inner sides of opposite rotating typeworm gears; and the opposite rotating type worm gears comprise magnetizers and non-magnetizers, the magnetizers and the non-magnetizers account for half of the opposite rotating worm gears correspondingly, and the opposite rotating type worm gears are arranged on the circular induction coil in a circumferential array mode. According to a heat treatment method, the principle that the magnetizers can change the magnetic flux density and direction is applied, and the rotating speed and the rotating angle of the opposite rotating type worm gears are adjusted and controlled in real time accordingto the heated contour shape of the sinusoidal corrugated pipe, so that uniform heat treatment of the sinusoidal corrugated pipe is achieved, and the continuity of a hardening layer is guaranteed; andmeanwhile, the heat treatment device and heat treatment method are suitable for sinusoidal corrugated pipes with different corrugated periods and wave crest heights.

Owner:江苏日升科技实业有限公司

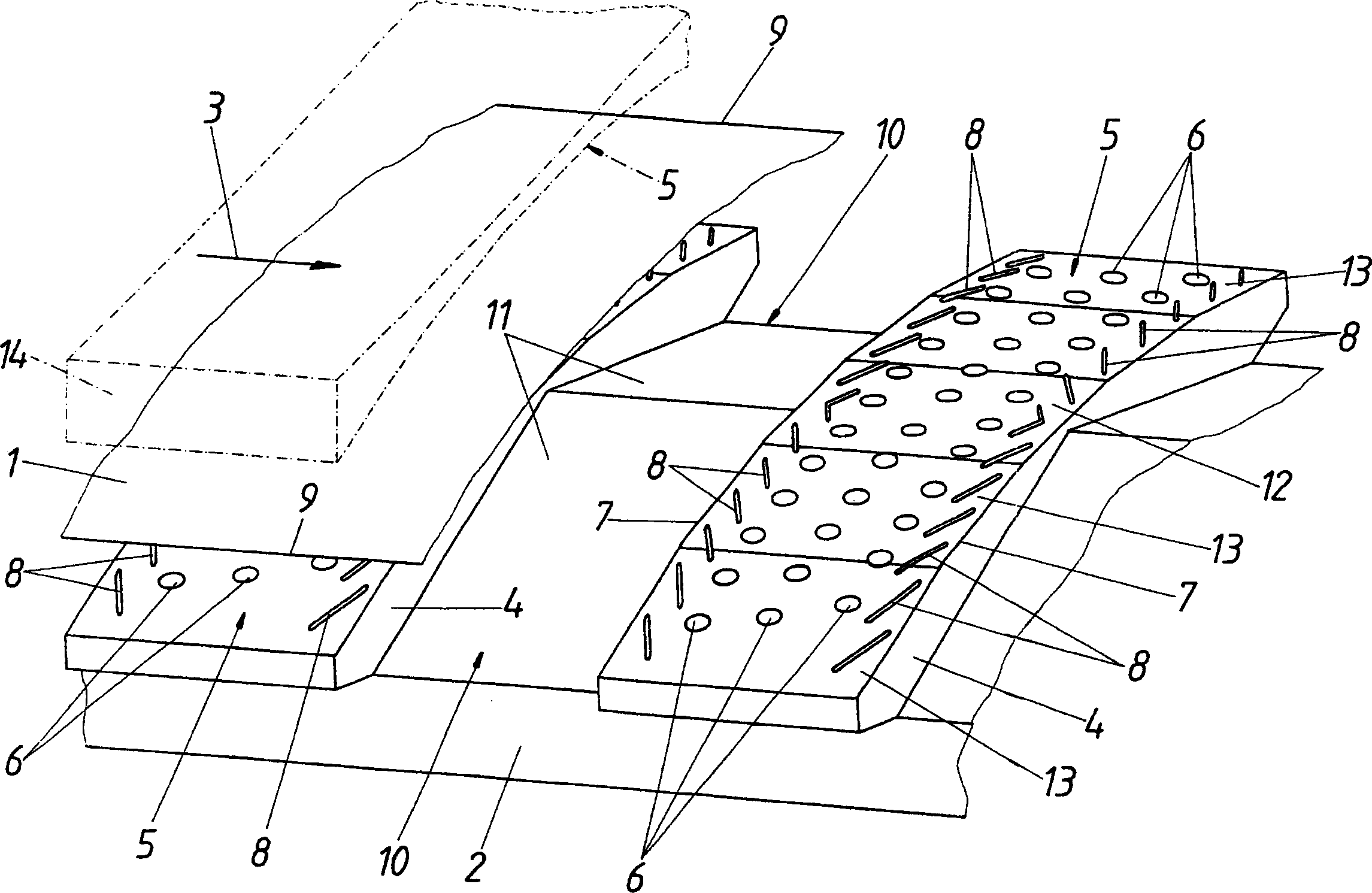

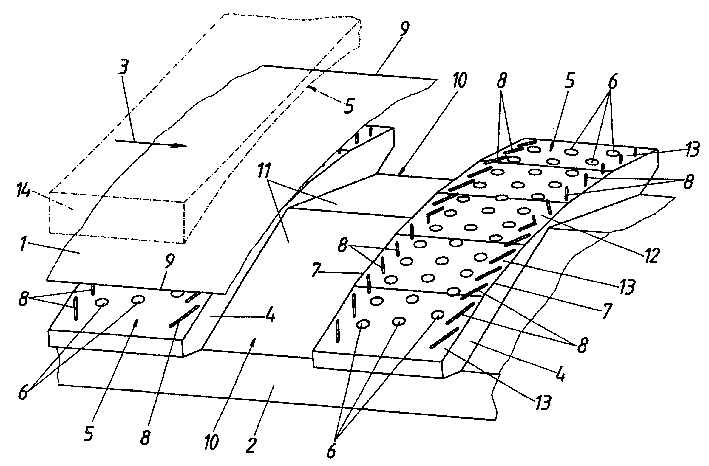

Device for guiding metal strip on gas cushion

InactiveCN1440360AUniform distanceSpeed up preparationFurnace typesHeat treatment furnacesEngineeringMetal

An apparatus is described for guiding a metal band (1) on a gas cushion with blowing boxes (4) which are disposed one after the other in the longitudinal direction (3) of the band and which comprise nozzle fields (5) which extend transversally to the longitudinal direction (3) of the band and comprise hole-type nozzles (6) distributed over the field surface area. In order to provide advantageous constructional conditions it is proposed that the nozzle fields (5) are provided with a convex basic shape through field sections (1, 3) which slope in at least one end section at either side transversally to the longitudinal direction of the band.

Owner:彼得・埃布纳

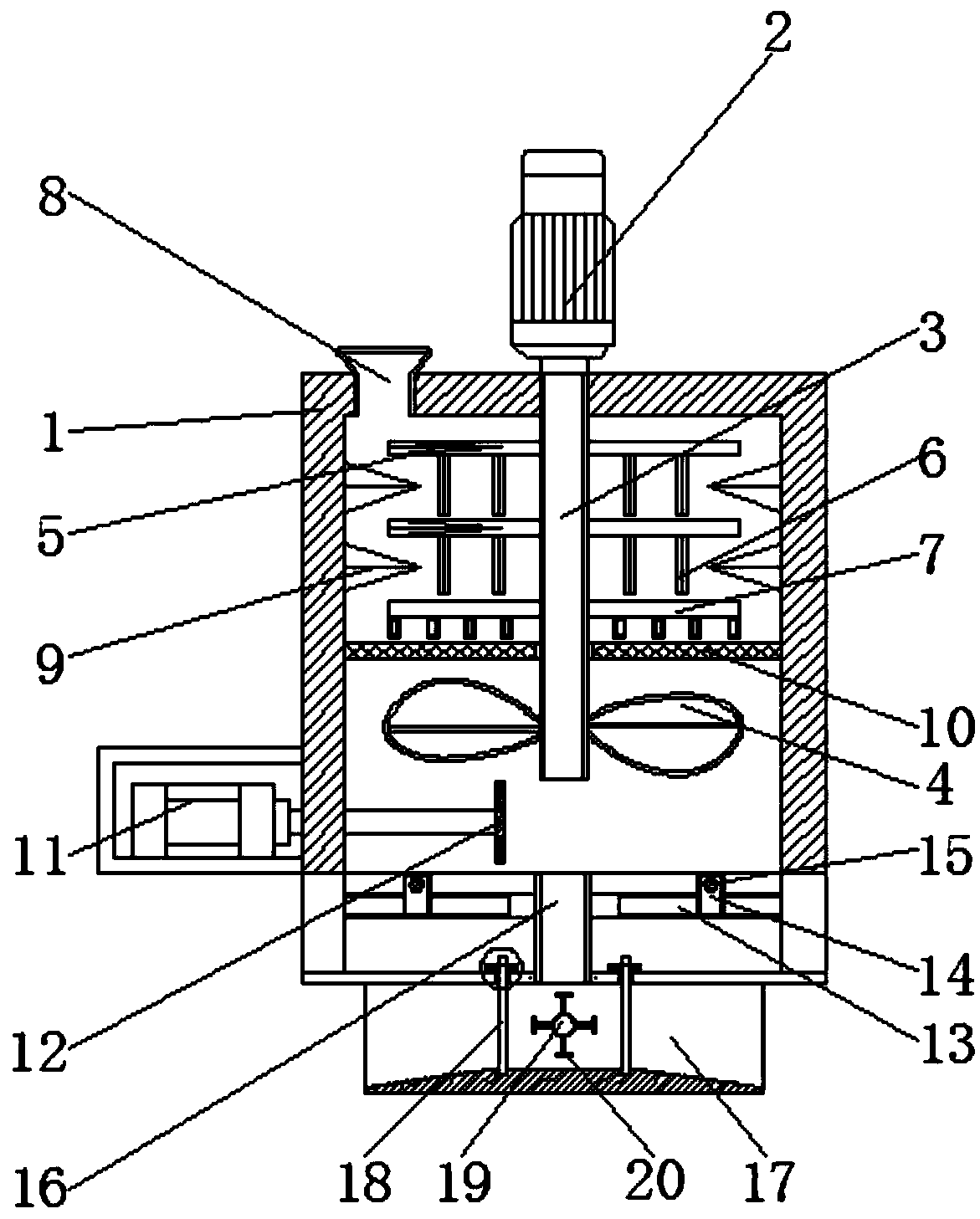

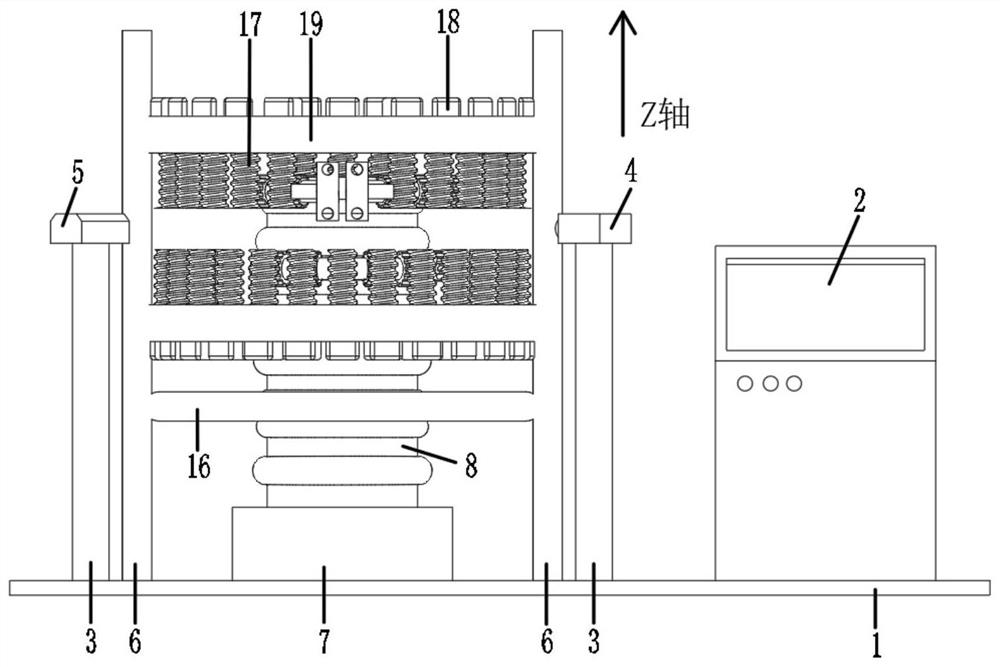

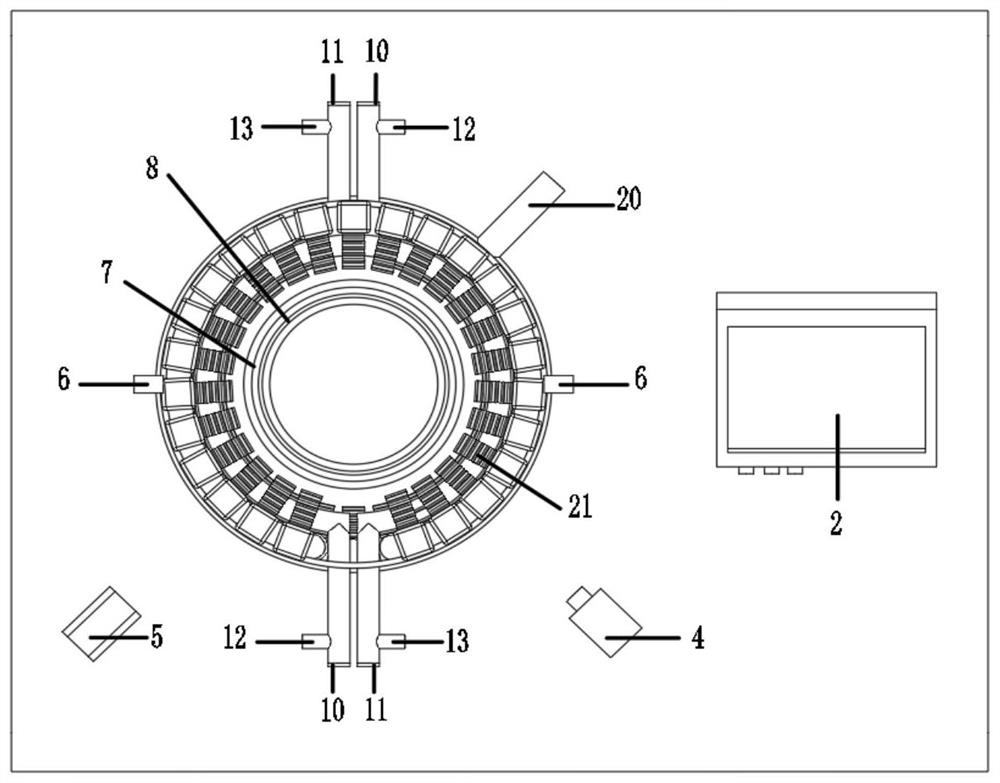

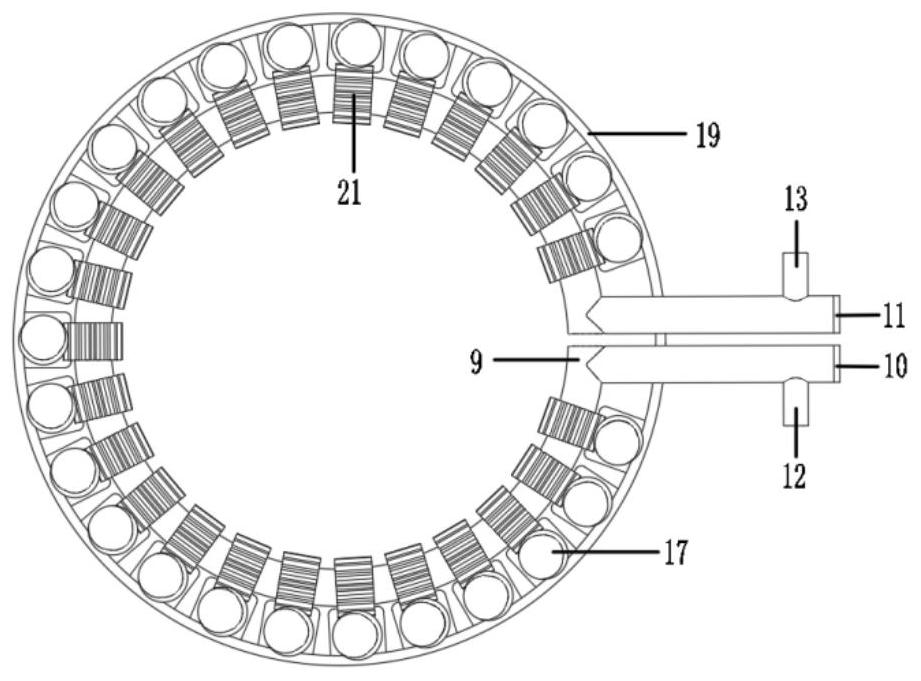

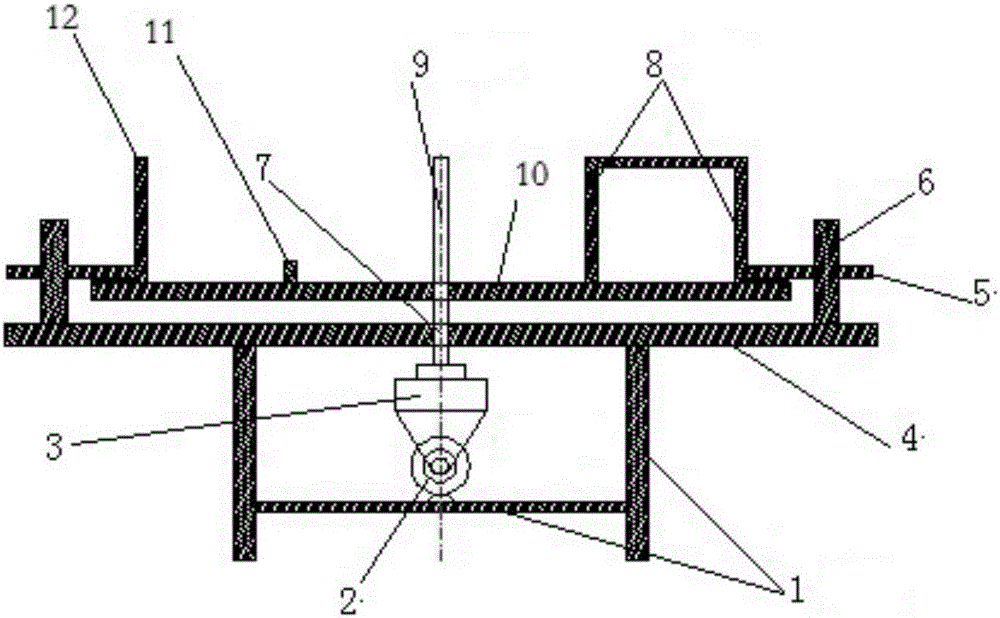

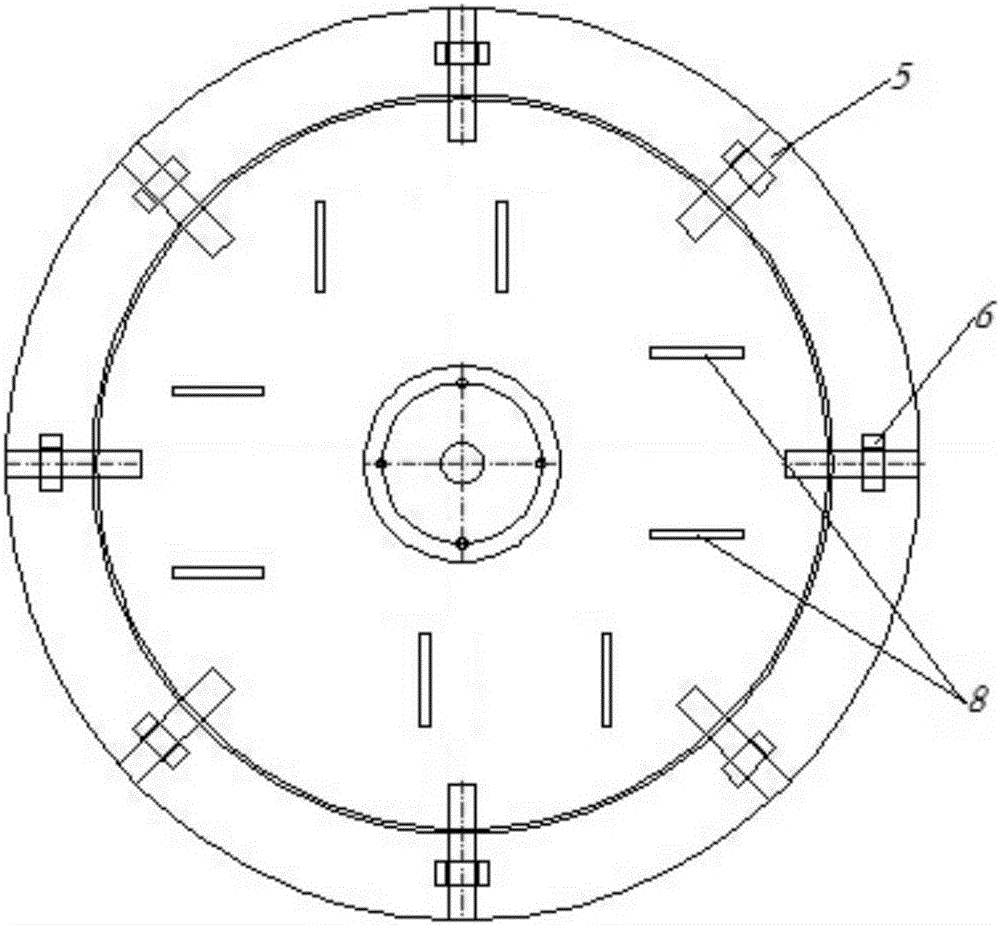

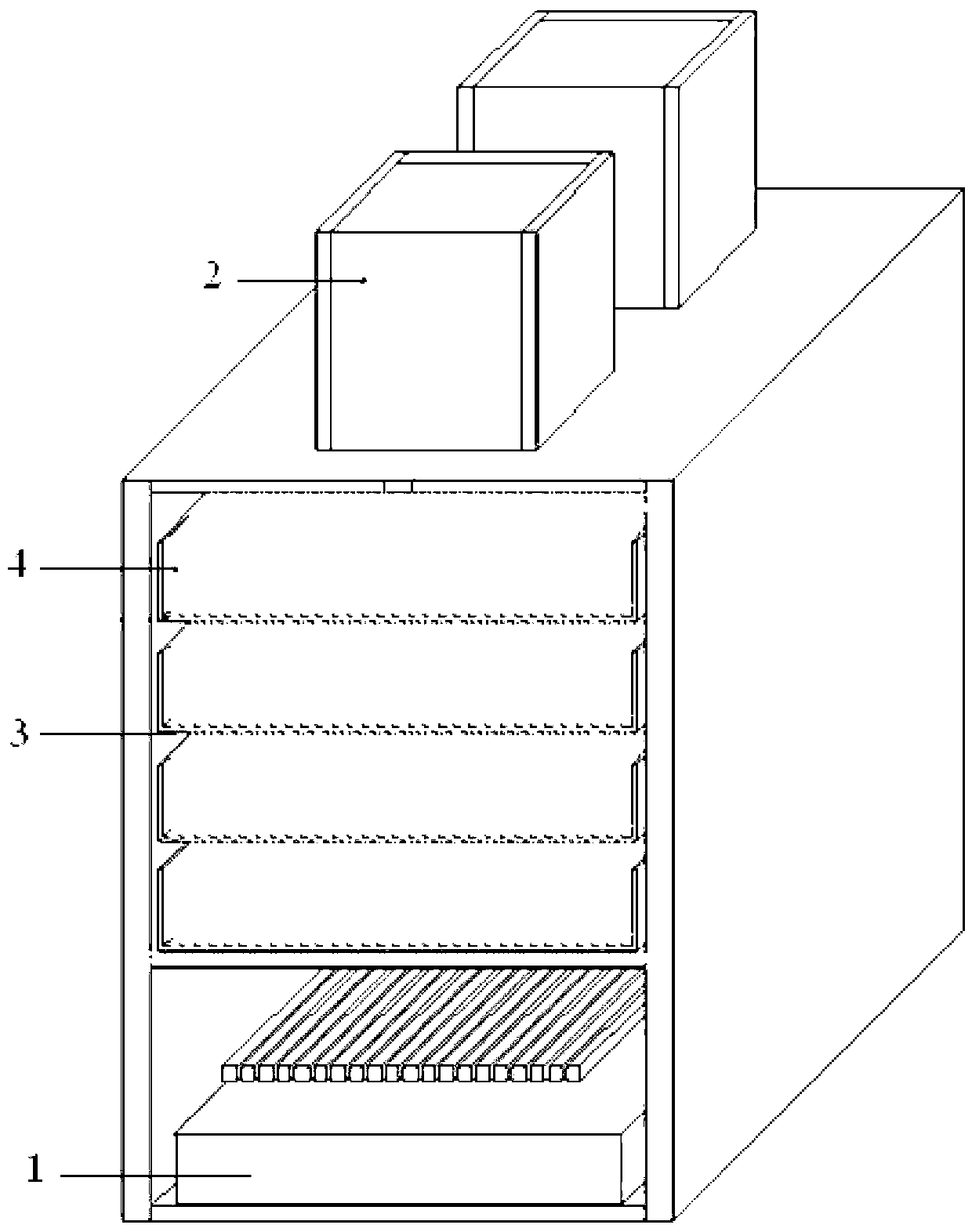

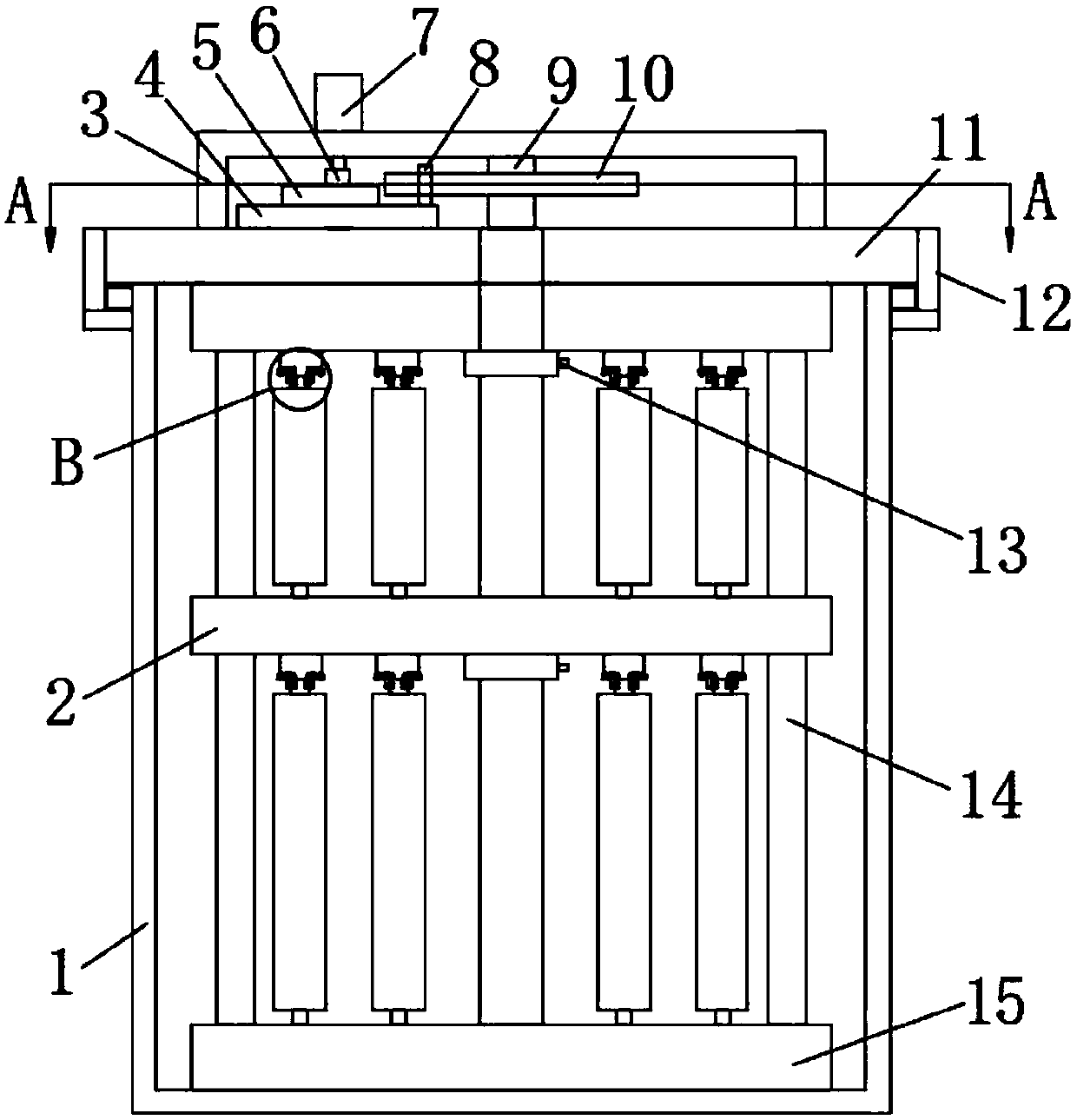

Rotary type thermal treatment working platform

ActiveCN105132647AUniform heat treatmentExtended service lifeQuenching devicesDrive shaftElectric machine

The invention discloses a rotary type thermal treatment working platform, and belongs to the field of thermal treatment. The rotary type thermal treatment working platform comprises a bracket (1), a working platform (4), and a rotary plate mechanism. The rotary type thermal treatment working platform is characterized in that the working platform (4) is arranged above the bracket and is fixedly connected with the bracket; the rotary plate mechanism comprises a rotary drive device, a rotary plate (10) and a roller device which is arranged at the periphery of the rotary plate (10); the rotary drive device comprises a motor (2), a transmission device and a drive shaft (9); the motor (2) is arranged on the bracket and positioned below the working platform (4); the drive shaft (9) passes through a positioning hole (7) in the working platform (4) and then is connected with the rotary plate (10) for driving the rotary plate (10) to rotate; and a plurality of groups of supporting workpiece devices (8) are arranged on the working surface of the rotary plate (10). The rotary type thermal treatment working platform can save labor power and can be used for quickly placing high-temperature discharge casting pieces, is uniform in quenching, and accurate in positioning, so that the production cost is reduced, the qualified rate of product thermal treatment is increased and production benefits are increased.

Owner:MAANSHAN HUADONG WEAR RESISTING ALLOY

Method for guaranteeing uniformity of heat treatment of large-diameter thick-wall pipe weld

ActiveCN108866314AImprove performanceImprove the problem of poor heat treatmentFurnace typesHeat treatment process controlWelding residual stressTemperature difference

The invention relates to a method for guaranteeing the uniformity of heat treatment of a large-diameter thick-wall pipe weld. The method comprises the following steps: heating the pipe cavity of a pipe located at a weld position when heating the outer wall of the pipe located at the weld position, and then heating the inner wall of the pipe. Through the heat treatment process for simultaneously heating the inner wall and the outer wall, the temperature difference between the inner wall and the outer wall of the large-diameter thick-wall pipe weld can be reduced; the purpose of eliminating thewelding residual stress through heat treatment and improving the welding joint performance can be fulfilled; the problem about the poor heat treatment of the inner wall of the pipe can be solved; thepurpose of the uniform heat treatment of the weld can be integrally fulfilled; and especially, the heat treatment effect on a thick-wall pipe weld can be more obvious. The method is obvious, simple and economical; and furthermore, the method is strong in real-time performance and easy to operate on site.

Owner:SUZHOU NUCLEAR POWER RES INST +2

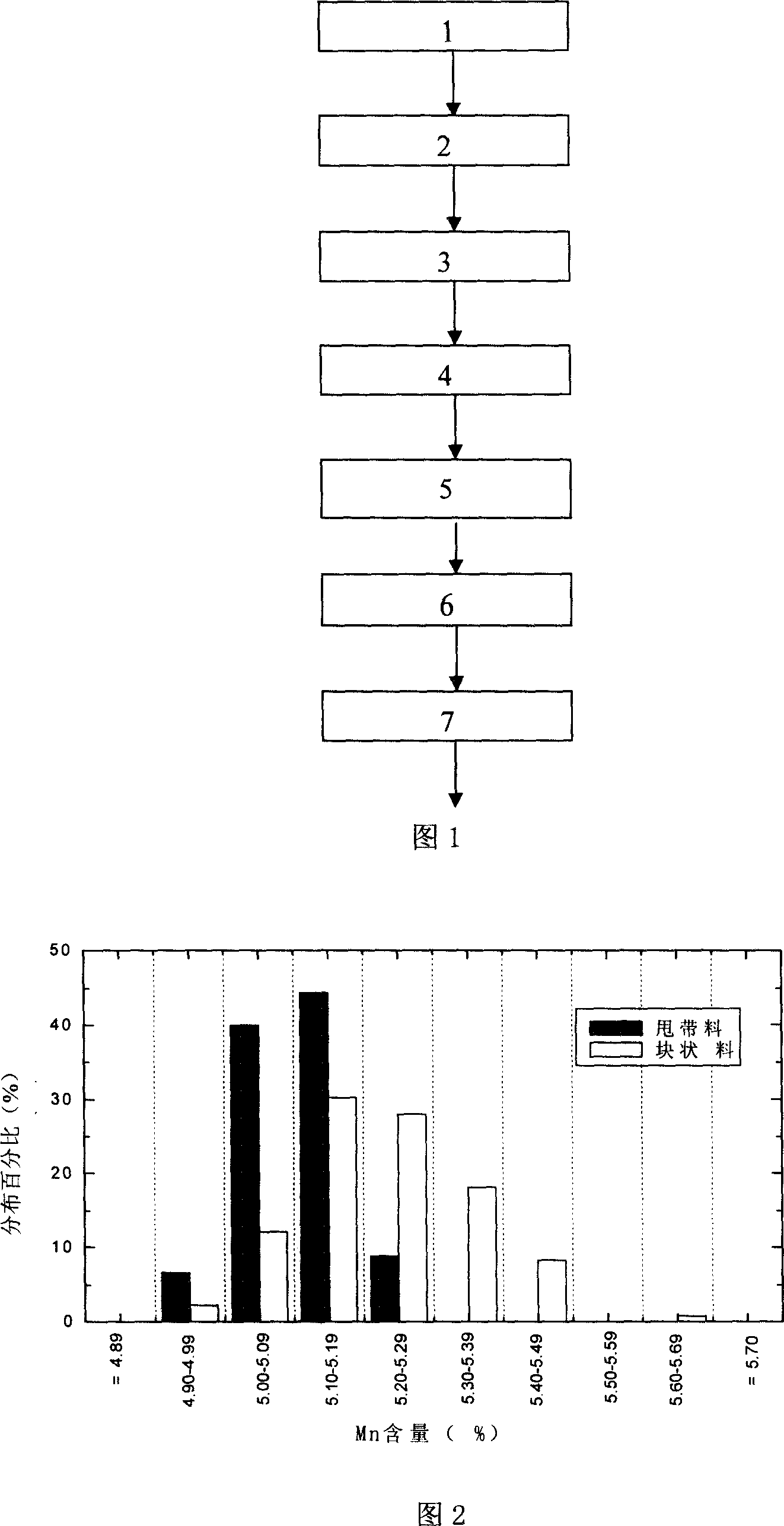

Method for preparing uniform heat treatment wood by stacking

The invention relates to a preparation method of uniform heat treatment wood, and in particular relates to a method for preparing the uniform heat treatment wood by stacking, aiming at solving the problems that the existing prepared heat treatment wood is not even in carbonization, obvious in wood color difference and high in cost. The method comprises the steps of: 1. selecting a wood board, and drying; 2. stacking; 3. carrying out heat treatment; and 4. cooling. The heat treatment medium needed by the method is low in cost; and the prepared heat treatment wood is balanced in carbonization inside and outside and even in wood color. The method is used for preparing the uniform heat treatment wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

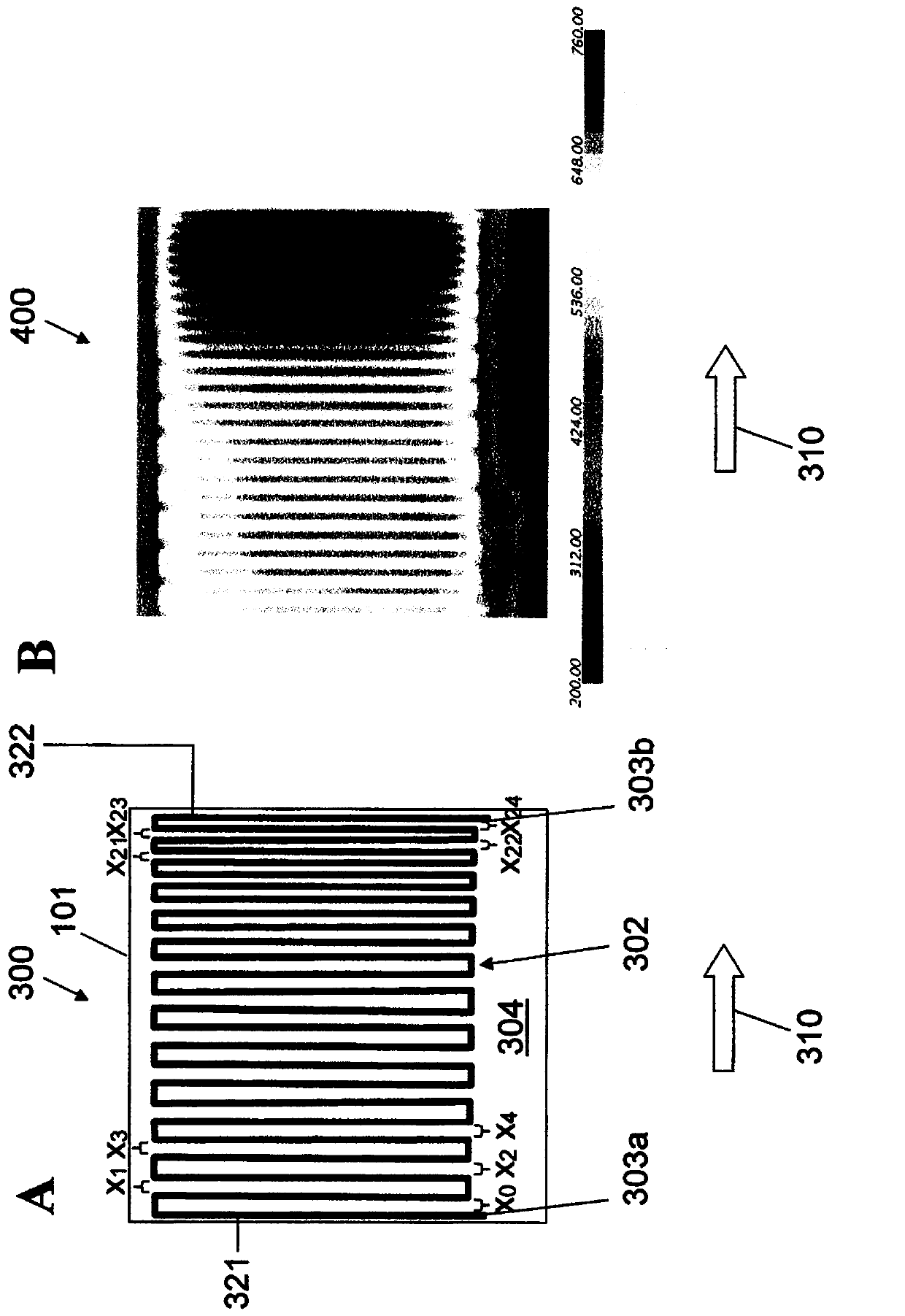

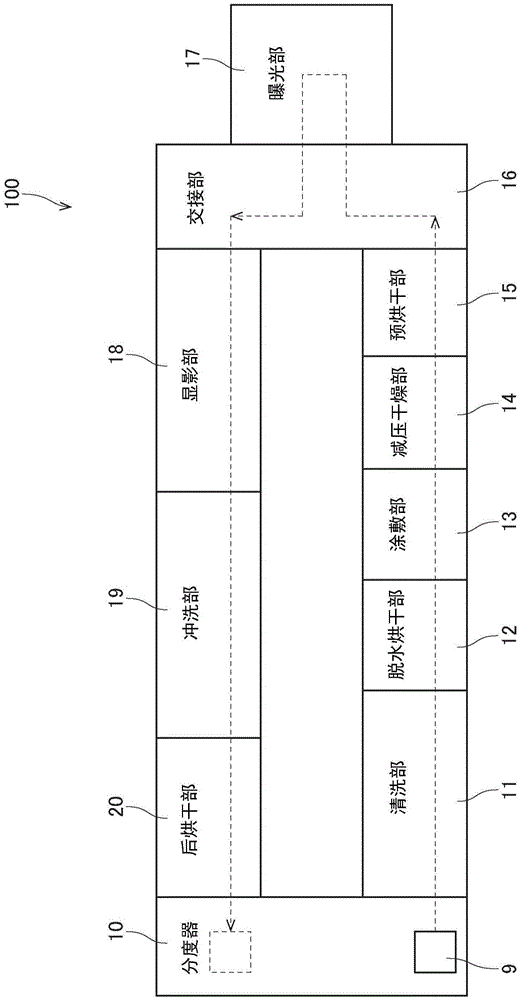

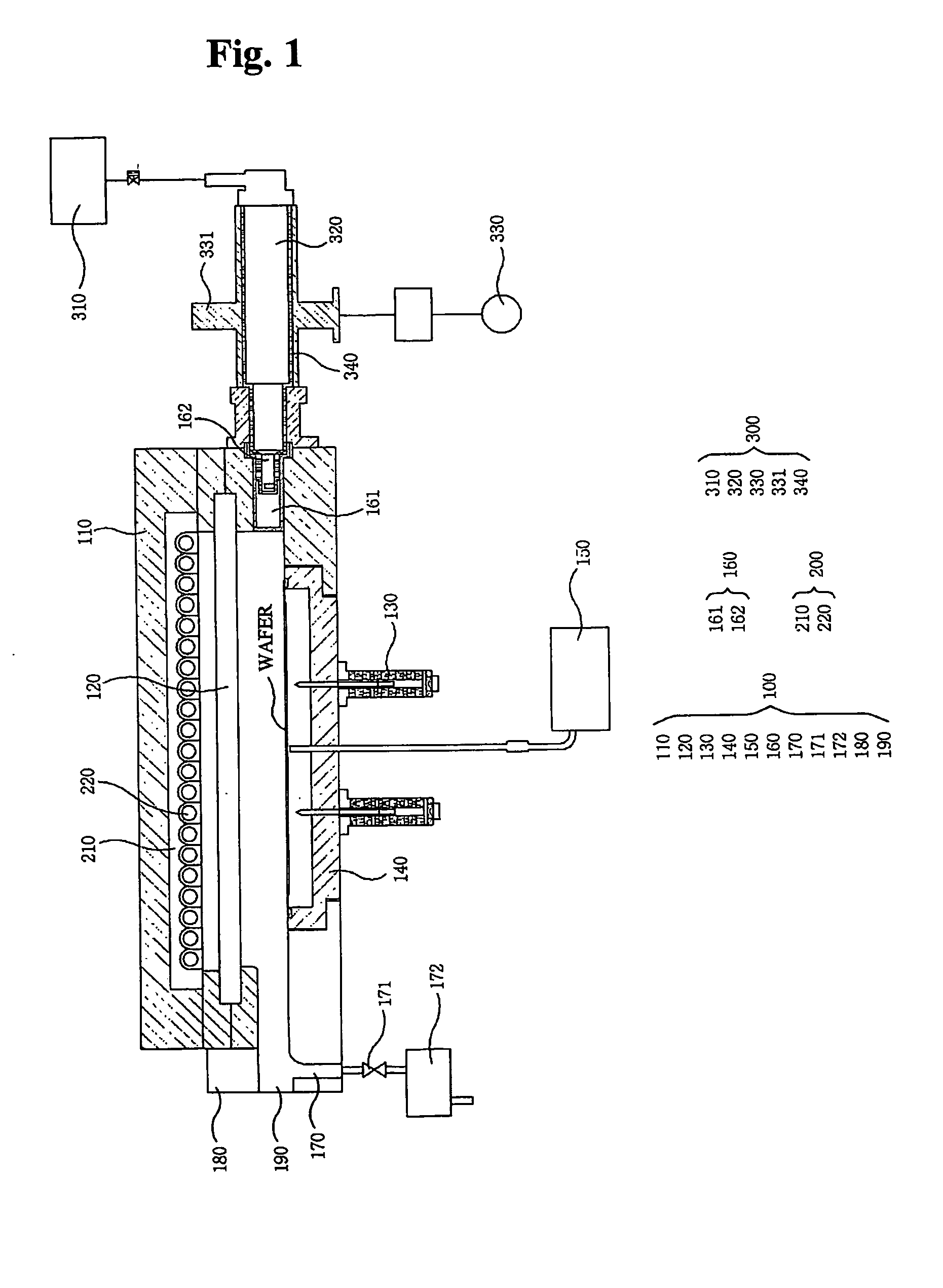

Heat treatment apparatus and heat treatment method

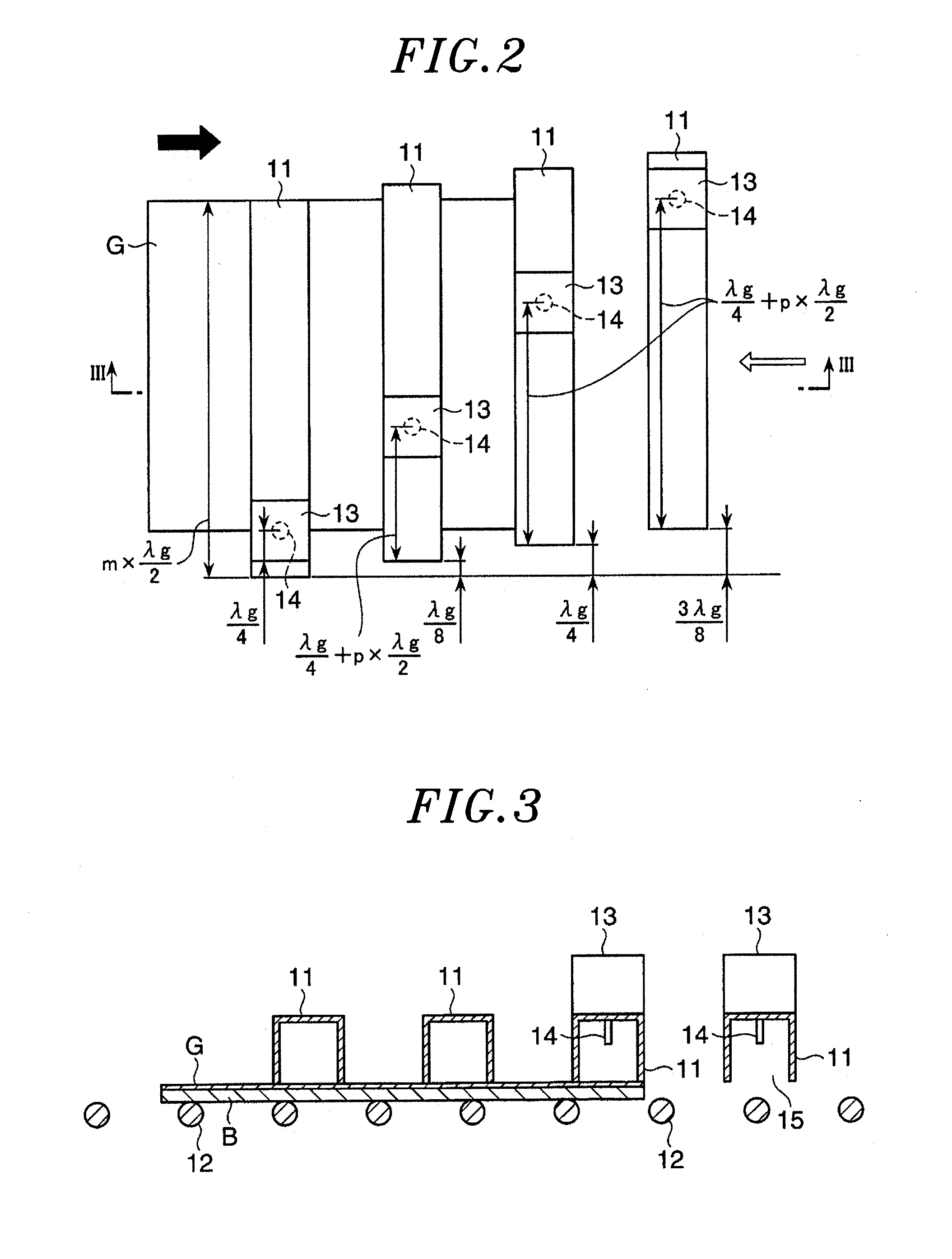

InactiveUS20160013056A1Uniform heat treatmentSemiconductor/solid-state device manufacturingMicrowave heatingLength wavePerpendicular direction

A heat treatment apparatus includes processing chambers into which microwaves with an effective wavelength of λg are introduced. The processing chambers are arranged parallel to each other. The length from an inner wall surface of one end of each processing chamber in the lengthwise direction to an inner wall surface of the other end thereof is m×λg / 2 (m being a positive integer). An antenna sending microwave oscillation into the processing chambers is separated by λg / 4+p×λg / 2 (p being a positive integer including 0) from the inner wall surface of the end part in the lengthwise direction of each processing chamber. The processing chambers are disposed to be offset by λg / (2×n) (n being the number of the processing chambers) from each other in the lengthwise direction, when the processing chambers are seen to overlap with each other in a perpendicular direction to the lengthwise direction of each processing chamber.

Owner:TOKYO ELECTRON LTD

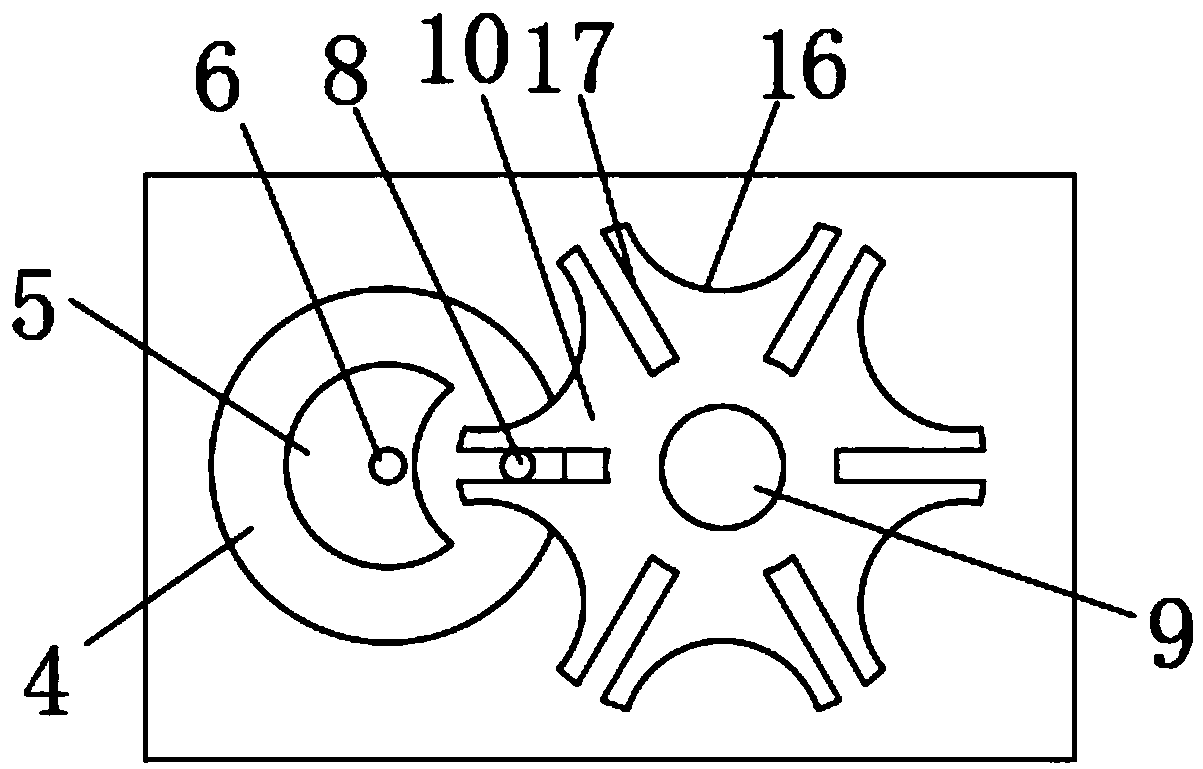

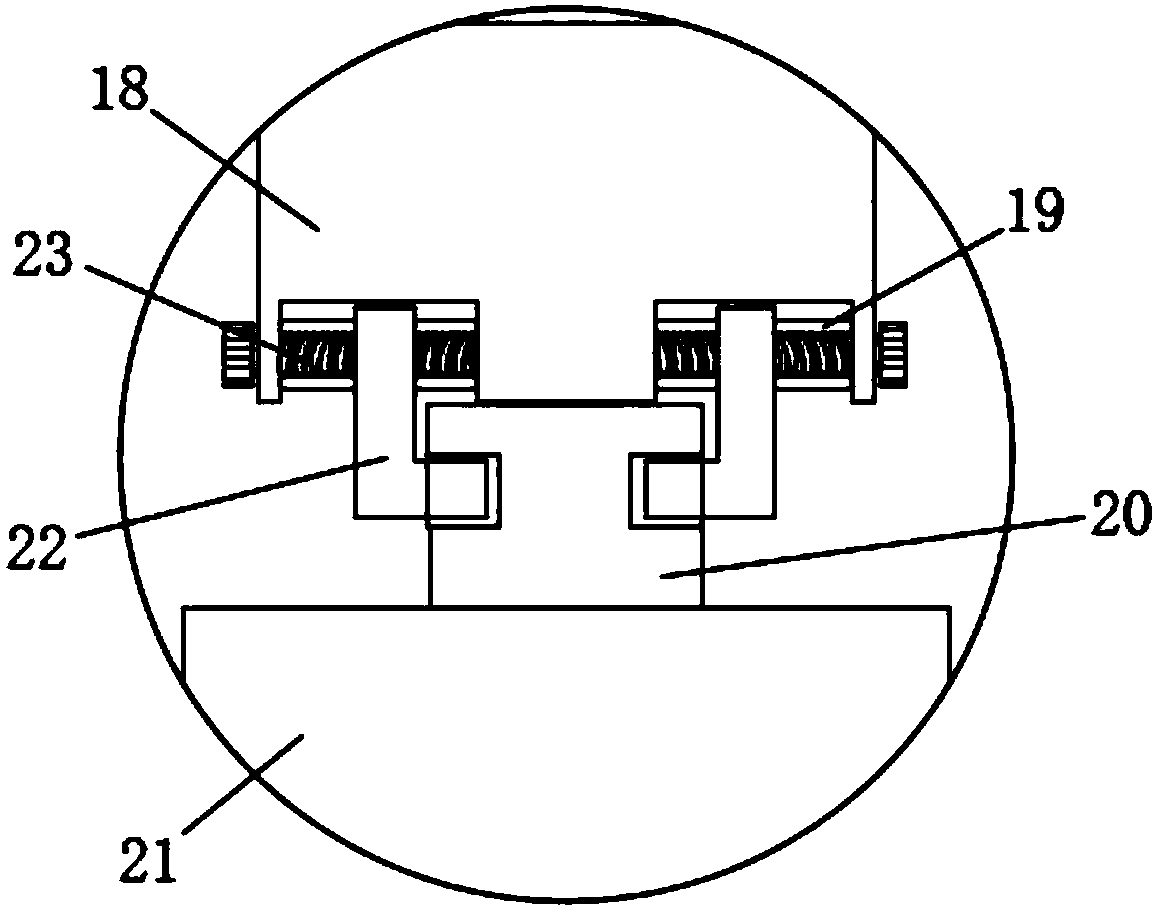

Power equipment mechanical industry heat treatment device

InactiveCN107723444AUniform heat treatmentFast loadingFurnace typesHeat treatment furnacesAgricultural engineeringEngineering

The invention discloses a heat treatment device in the electric power equipment machinery industry, which comprises a furnace body, a furnace cover is arranged on the upper end of the furnace body, a mounting frame is installed on the upper end of the furnace cover, and a second Rotating shaft, the second rotating shaft is rotatably connected to the furnace cover, the upper end of the second rotating shaft is rotatably connected to the mounting frame, and a ratchet is fixedly sleeved on the second rotating shaft, and the ratchet is located between the mounting frame and the furnace cover , the upper end of the furnace cover is rotatably connected with a first rotating shaft, the upper end of the mounting frame is equipped with a driving device, the end of the output shaft of the driving device passes through the mounting frame and is connected to the first rotating shaft, on the first rotating shaft A turntable and a shift block are fixedly sleeved, and a shift lever is arranged at the edge of the turntable. The invention has simple structure and convenient operation, can realize rapid loading and unloading of materials, improves production efficiency, can perform uniform heat treatment on materials, and has good heat treatment effect.

Owner:CHENGDU LEYE TECH CO LTD

Hot treatment device and method

ActiveCN106024672AUniform heat treatmentSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringHeat treated

Owner:DAINIPPON SCREEN MTG CO LTD

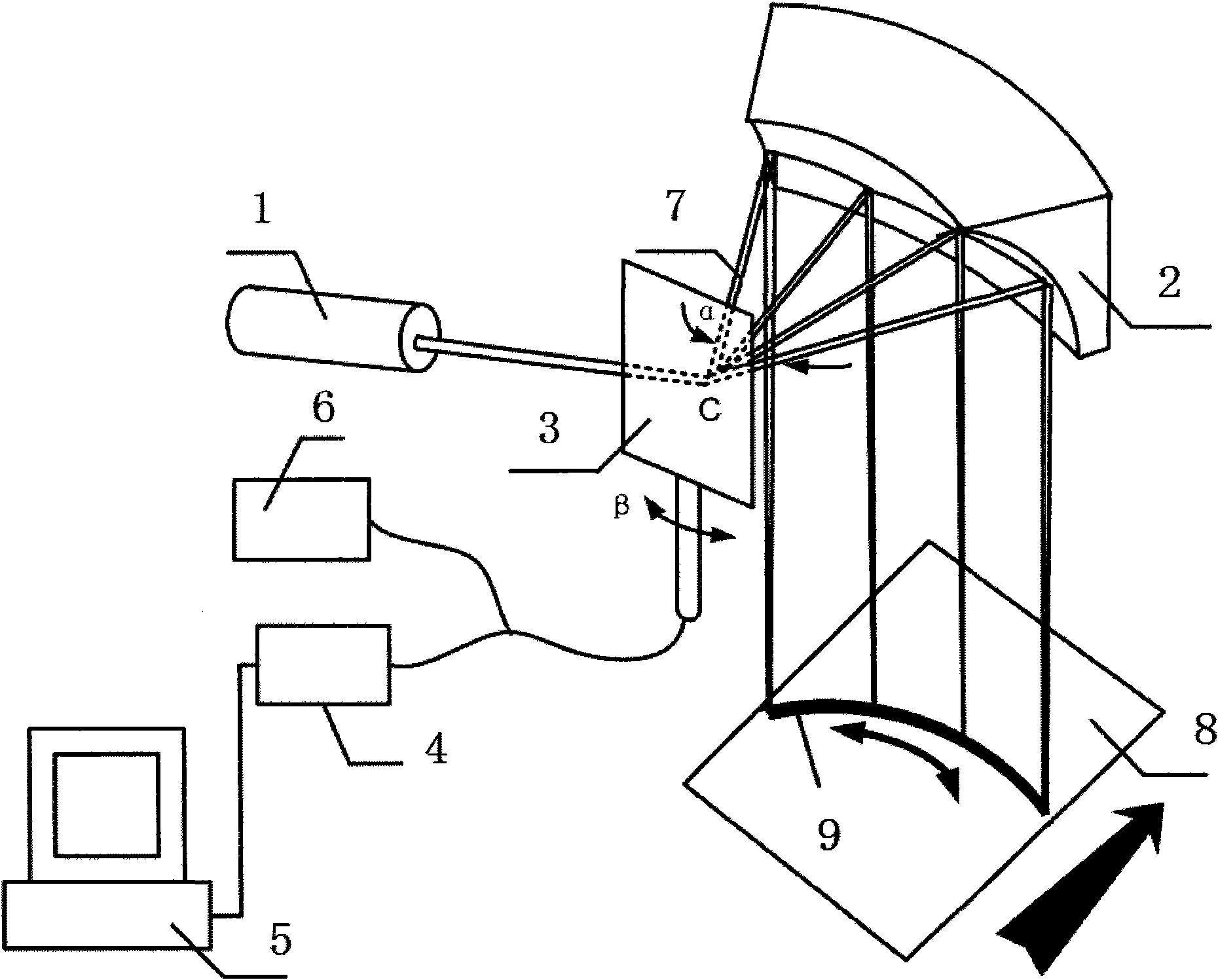

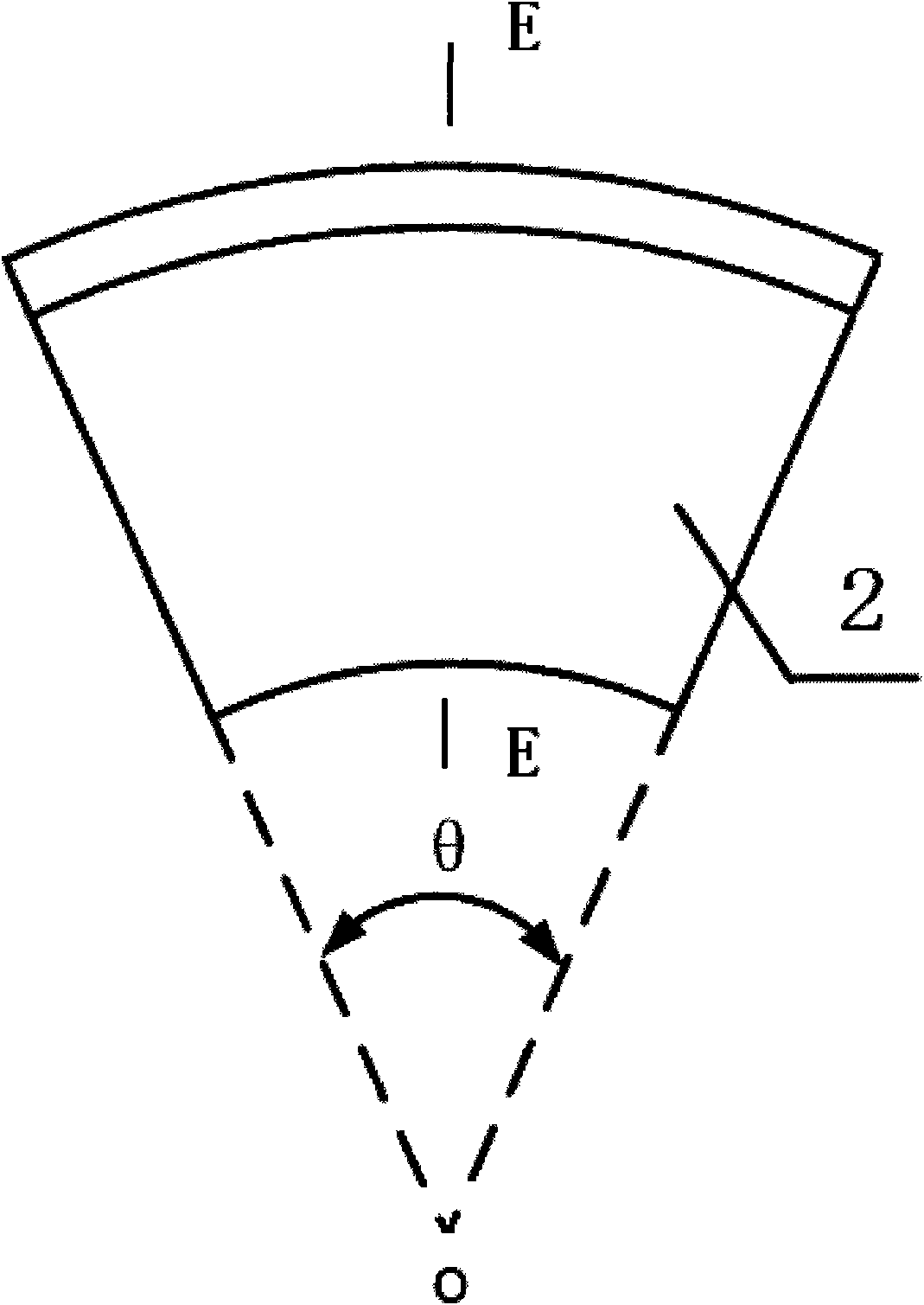

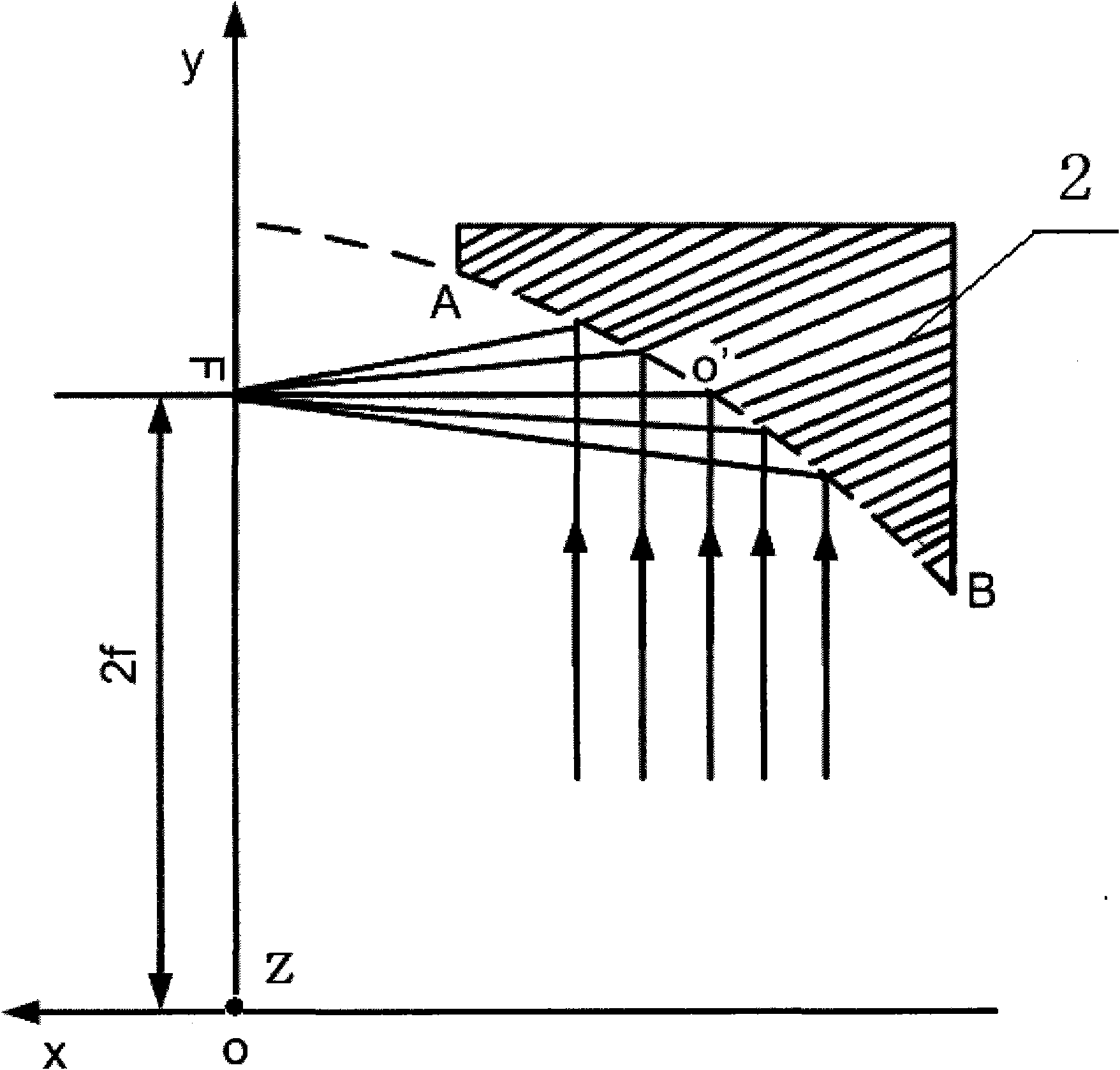

Widening device of high-power laser beam and method thereof

InactiveCN101666911AUniform effectSimple device structureLaser beam welding apparatusOptical elementsHigh power lasersOptoelectronics

The invention discloses a widening device of a high-power laser beam and a method thereof. The device comprises a continuous laser, a sector reflection focusing lens, a deflection-type oscillating mirror, a high-speed motor and a computer. One side of the deflection-type oscillating mirror is connected with a rotation shaft of the high-speed motor. The high-speed motor is connected with the computer. The deflection-type oscillating mirror and the sector reflection focusing lens are placed oppositely. The laser beams emitted by the continuous laser are homocentric with a turning center O of thesector reflection focusing lens at a reflecting point C of the deflection-type oscillating mirror. The method causes the continuous laser beam output by the continuous laser to form continuous scanning beams in the sector region with a certain scanning angle alpha after being reflected by the deflection-type oscillating mirror rotating at high speed, wherein the scanning beams form continuous arcscanning focusing light bands on the surface of the processed work piece after being reflected and focused by the sector reflection focusing lens. Compared with the prior art, the device can widen the high-power laser beam in a wider range (20-500mm) and the widened width is continuously controllable.

Owner:苏州市博海激光科技有限公司

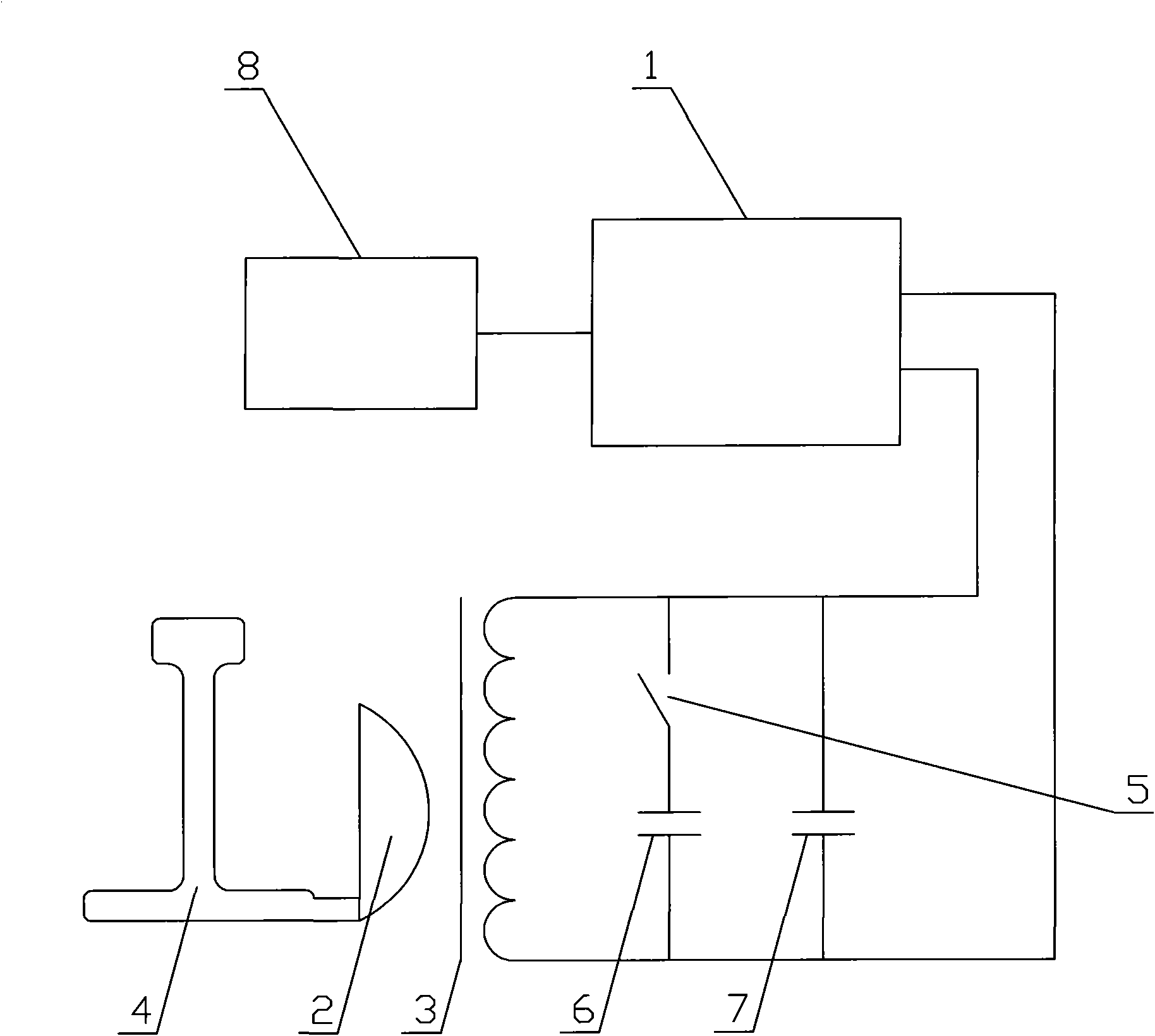

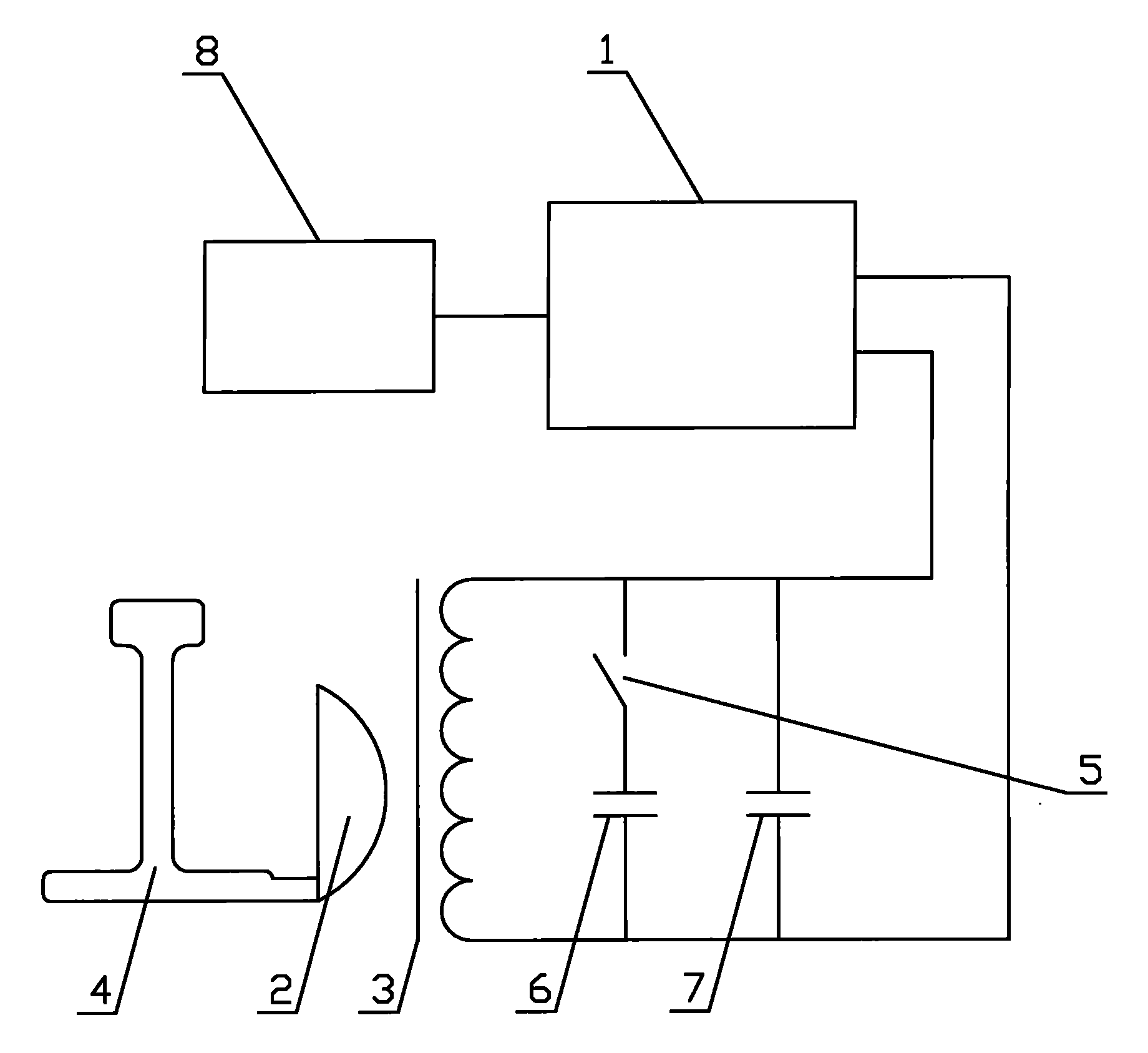

Double-frequency equipment and process for normalizing rail welding seams

The invention discloses a double-frequency process for normalizing rail welding seams. The process comprises the following production steps: (1) low-frequency heating: setting the power and frequency of normalizing equipment to 60kW-80kW and 800Hz-1200Hz respectively, and heating rail welding seams; and (2) high-frequency heating: setting the power and frequency of the normalizing equipment to 60kW-70kW and 2000Hz-2800Hz respectively, heating the rail welding seams, and detecting whether the temperature of the rail welding seams reaches a preset value, thus completing the normalizing process. The process has the following advantages: the temperature range can be randomly adjusted according to different rail types and rail profiles, thus completely solving the uniformity problem of the normalizing temperature of the rail welding seams; and the technology can ensure special-shaped steel to be subjected to uniform heating. The highest temperature of the rail bottom angles of the rail welding seams in the normalizing process reaches 900 DEG C, so the normalizing process is suitable for normalizing the welding seams of rails with weight of 50kg / m, 60kg / m, 68kg / m and 75kg / m.

Owner:中国铁路呼和浩特局集团有限公司焊轨段

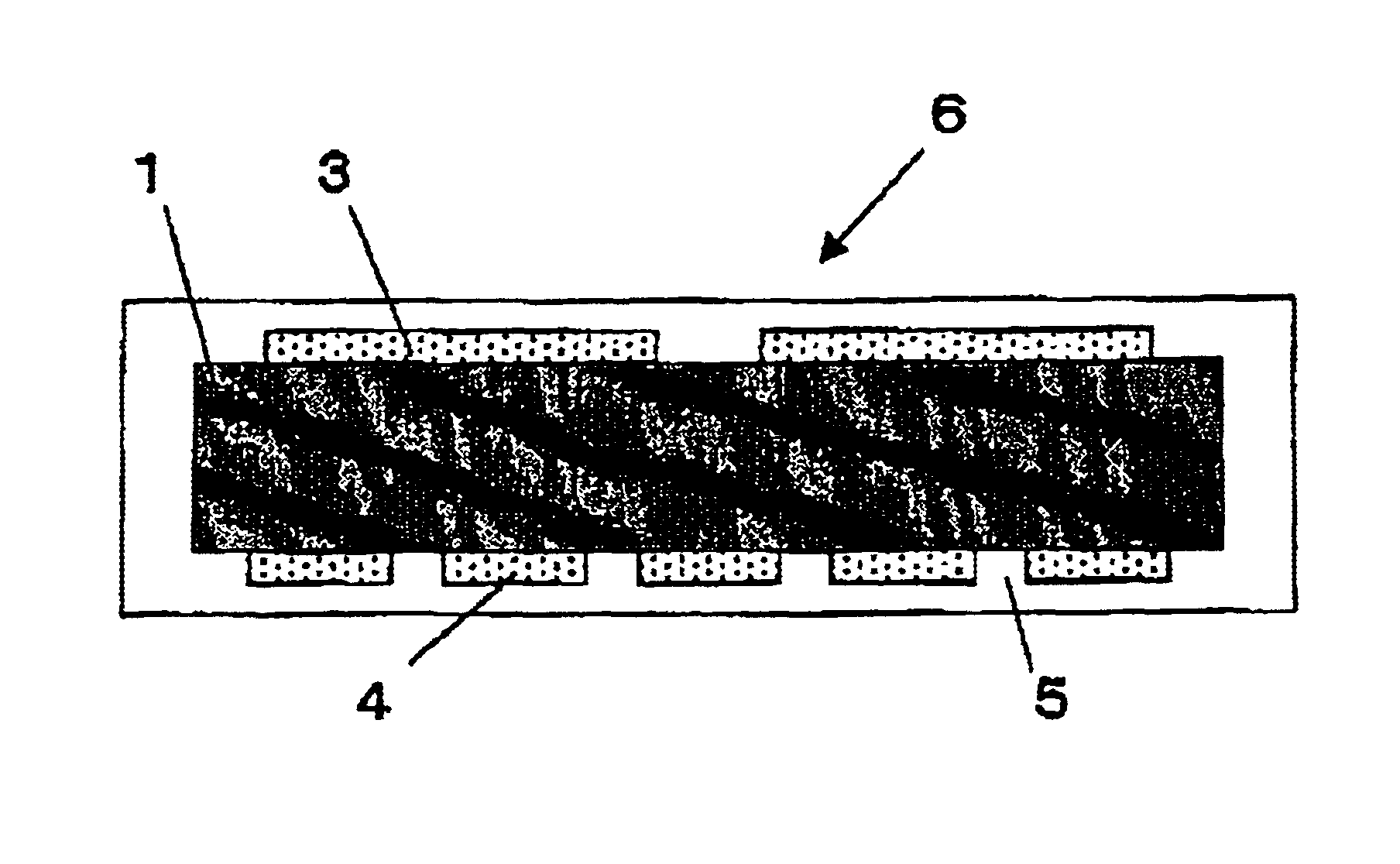

Method for preparing hydrogen storing alloy powder

The invention relates to the making of stored hydrogen alloy powder. It is cheap, with great improvement in discharge capacity, recycling life and high power discharge feature. It pretreats the material with polishing and drying machines, smelting the material to form into alloy thin plate and annealing, powdering the alloy in inert atmosphere to get the alloy powder. It is easy to adjust the grain, suitable for big current discharge.

Owner:XTC HYDROGEN ENERGY SCI & TECH (XIAMEN) CO

Heating apparatus which has electrostatic adsorption function, and method for producing it

ActiveUS6953918B2Improve temperature distributionImprove temperature uniformityHeater elementsDielectric heating electrodesEngineeringHeat treated

There is disclosed a heating apparatus which has an electrostatic adsorption function and which comprises at least a supporting substrate, an electrode for electrostatic adsorption formed on a surface of one side of the supporting substrate, a heating layer formed on a surface of the other side of the supporting substrate, and an insulating layer formed so that it may cover the electrode for electrostatic adsorption and the heating layer wherein a volume resistivity of the insulating layer is varied in a plane. Thus, there can be provided a heating apparatus which has an electrostatic adsorption function wherein uniformity of a temperature distribution in a plane of the wafer when the wafer is heated can be improved, and the wafer can be heat-treated uniformly.

Owner:SHIN ETSU CHEM IND CO LTD

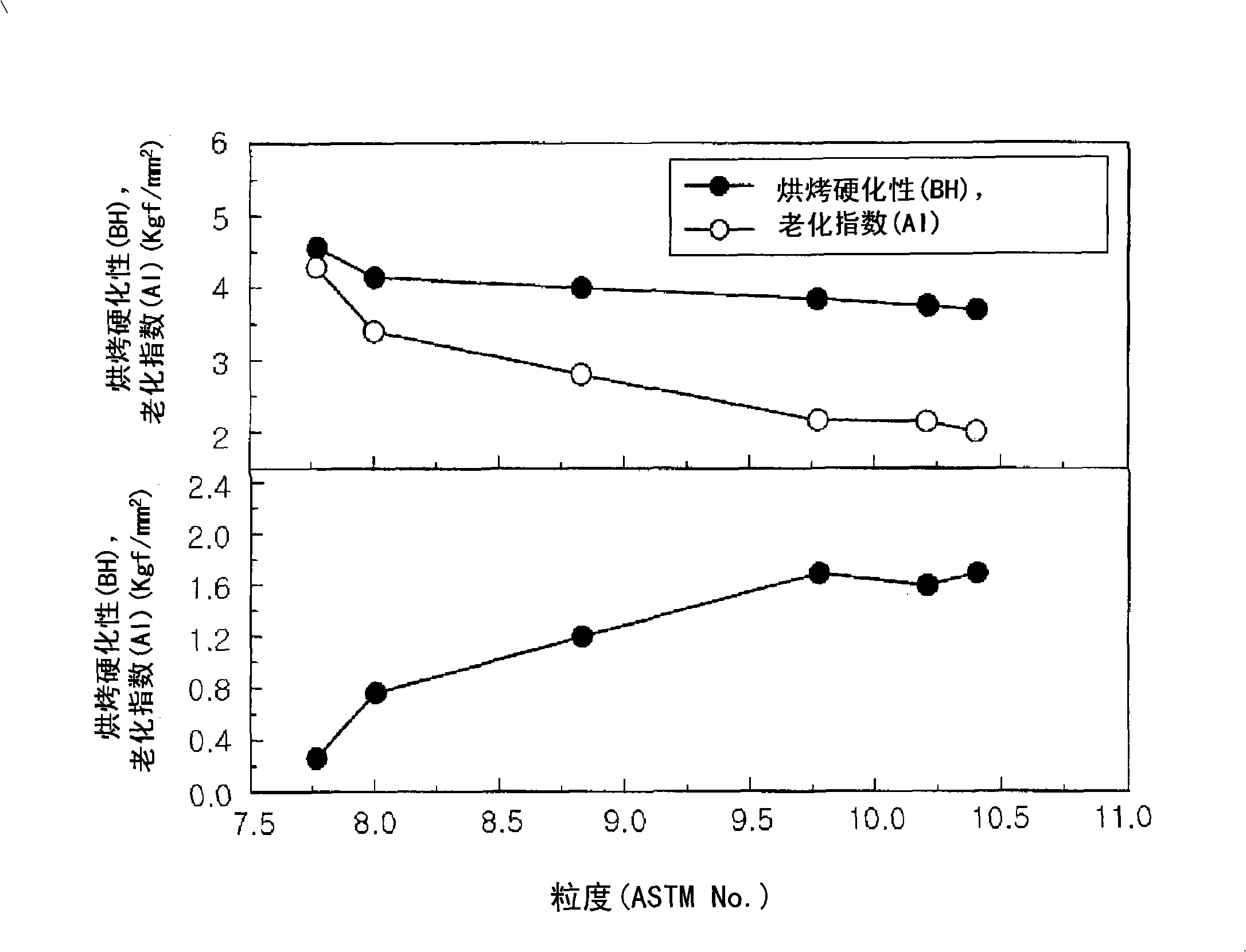

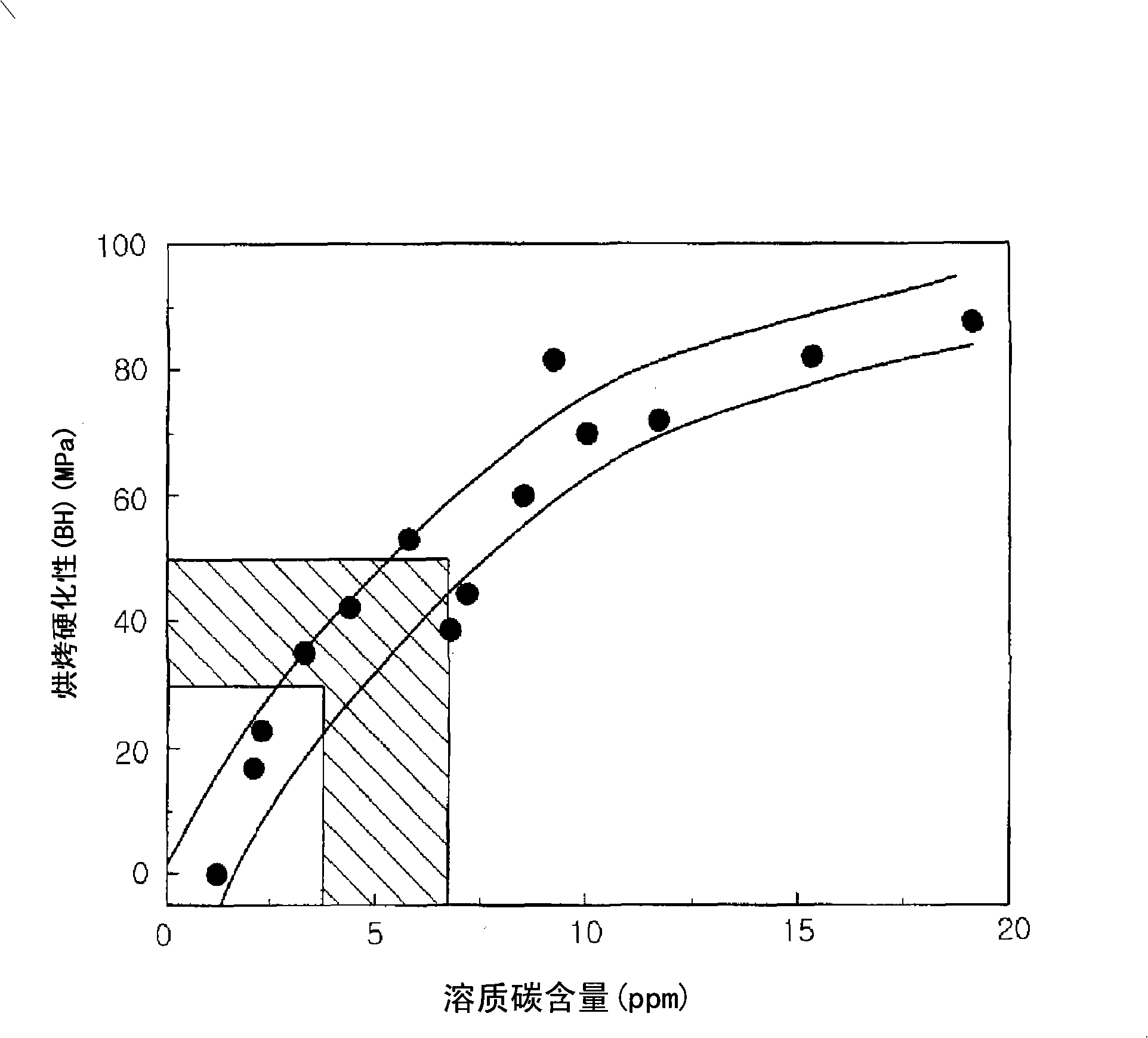

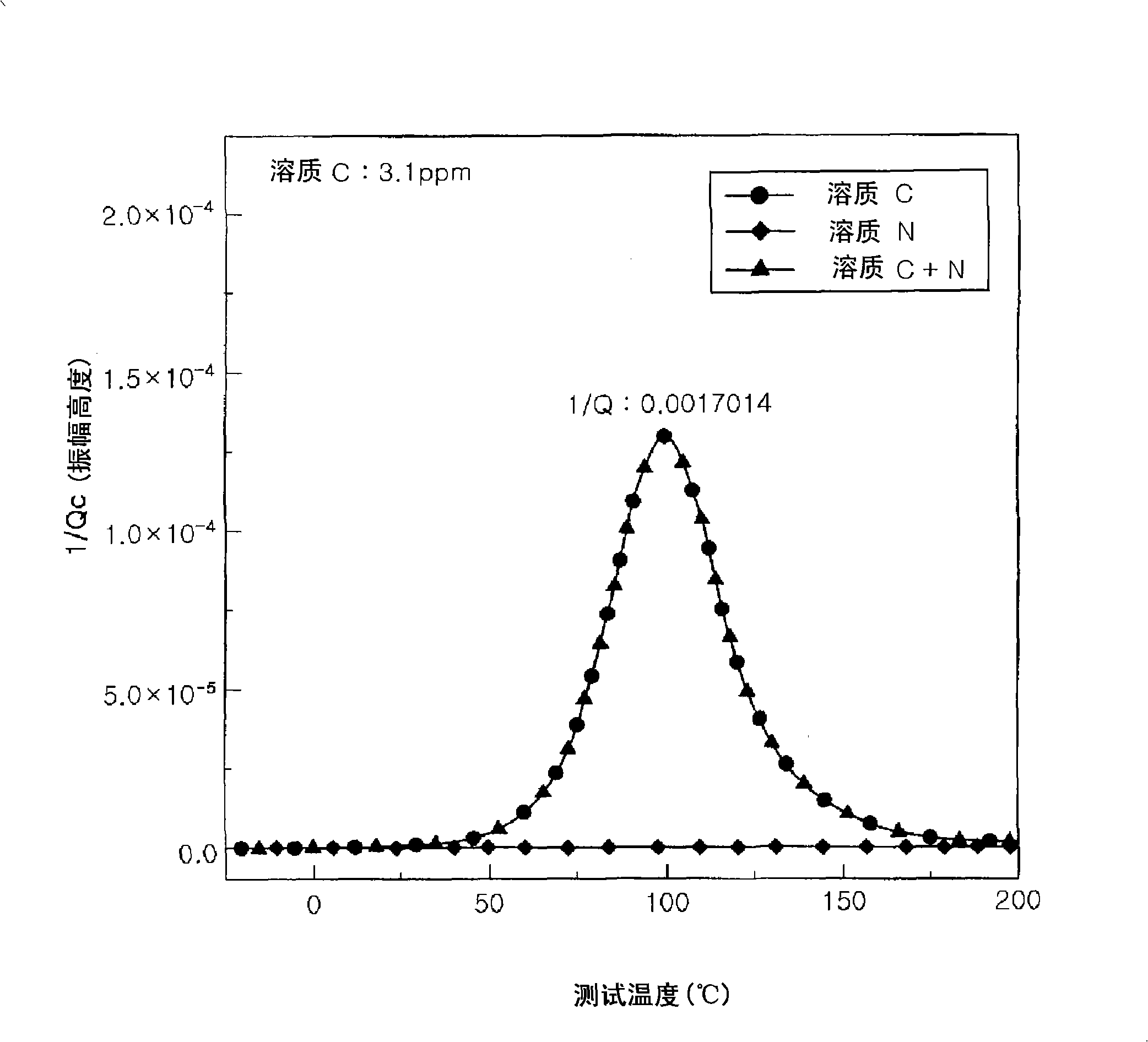

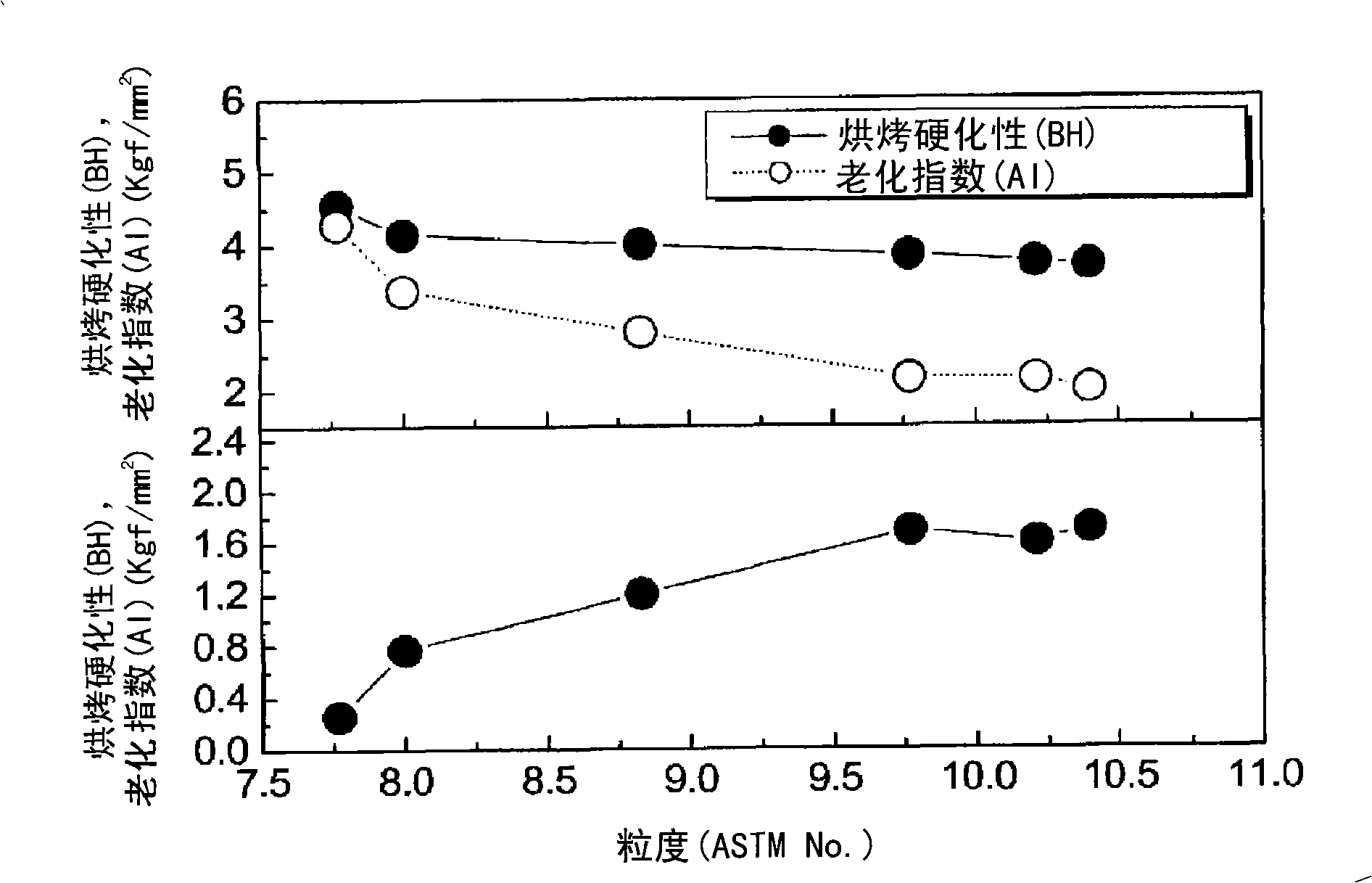

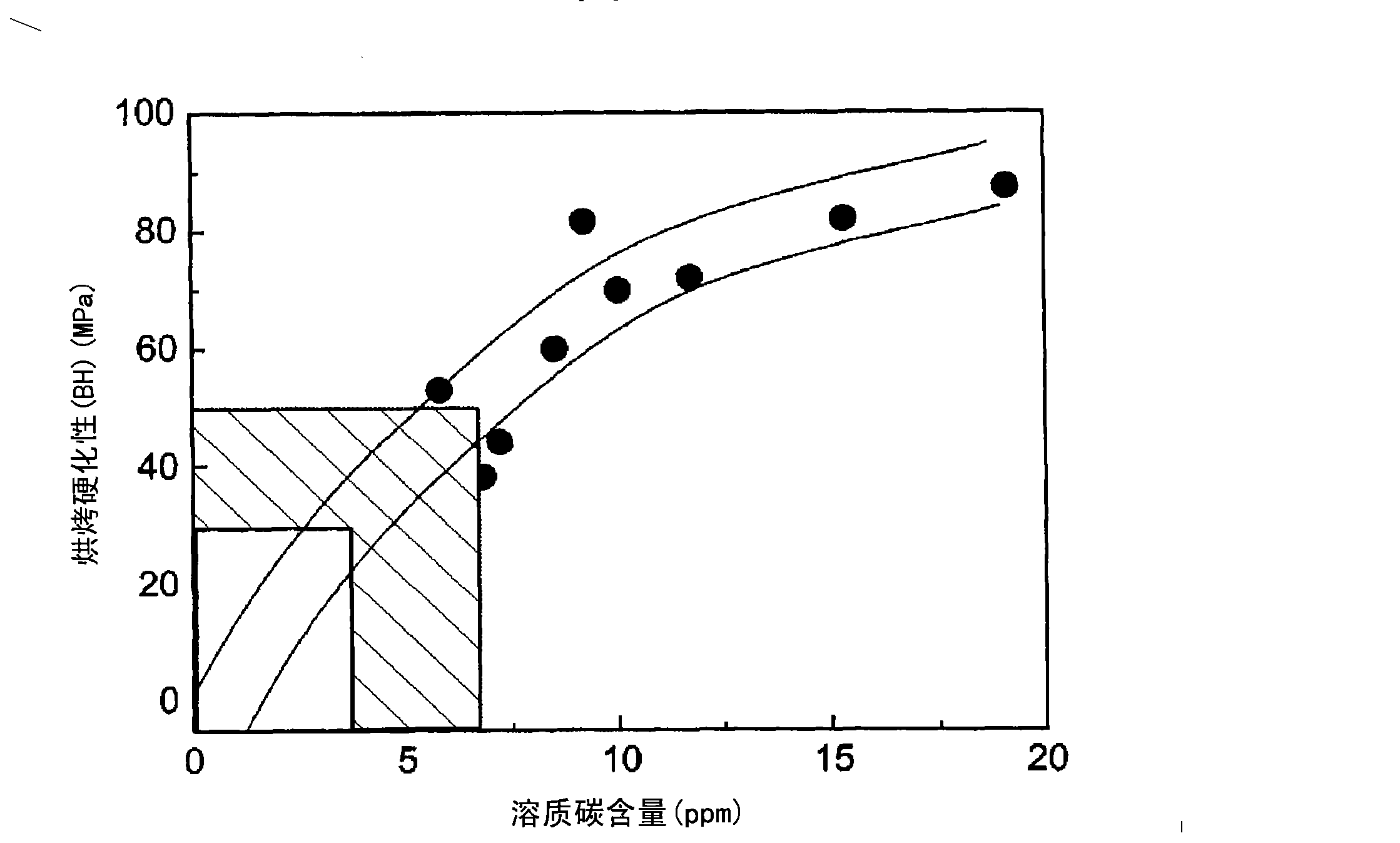

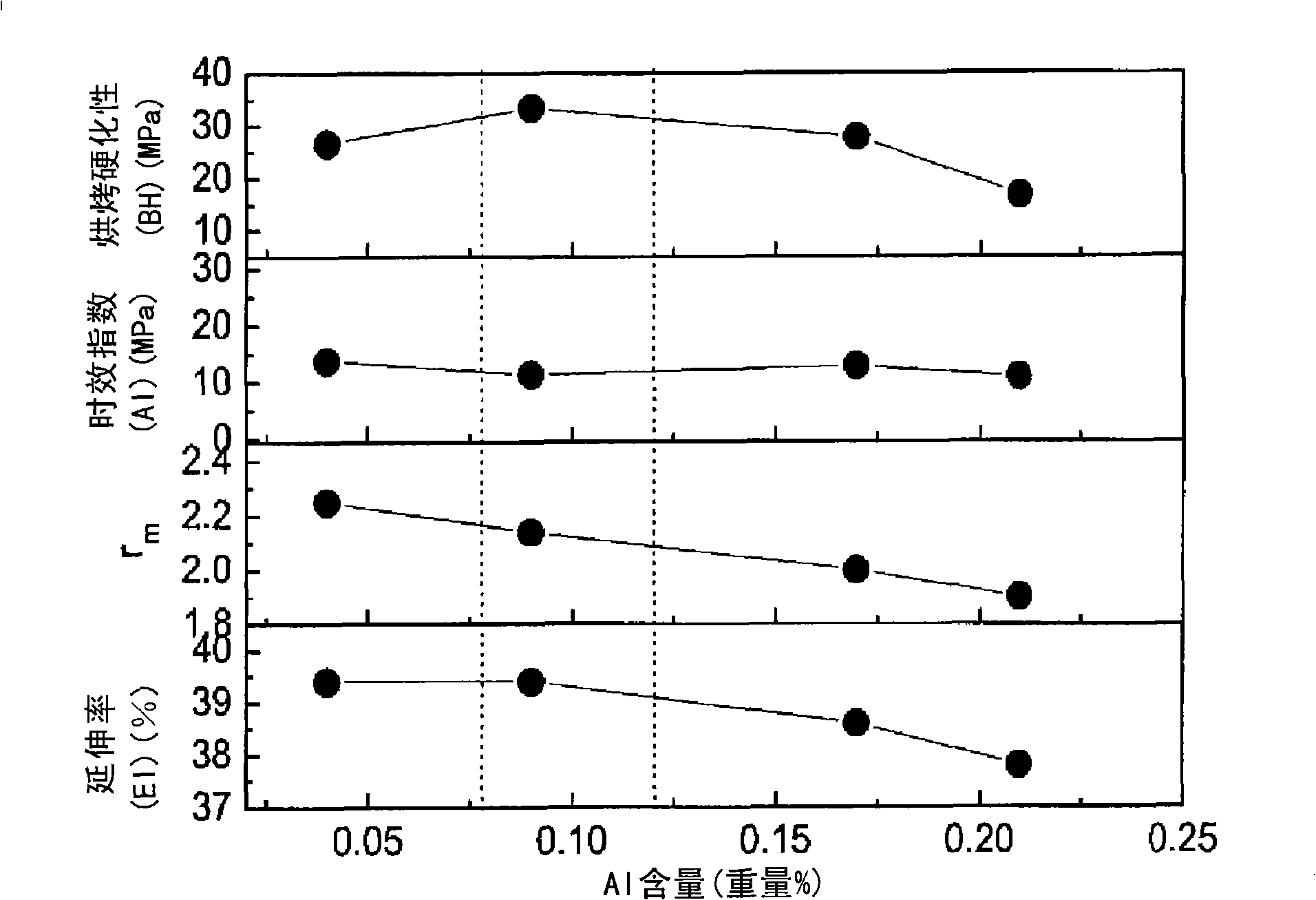

Bake-hardenable cold rolled steel sheet with superior strength, galvannealed steel sheet using the cold rolled steel sheet and method for manufacturing the cold rolled steel sheet

ActiveCN101310032AUniform heat treatmentExcellent bake hardenabilityFurnace typesHeat treatment furnacesSheet steelRoom temperature

A cold-rolled steel sheet for outer panels and the like of an automobile body, a galvannealed steel sheet using the cold-rolled steel sheet, and a method for manufacturing the same are disclosed. It is an object of the present invention to provide a high strength cold-rolled steel sheet, which has superior bake hardenability, aging resistance at room temperature and secondary work embrittlement resistance, and a method for manufacturing the same. The steel sheet has a grain size of ASTM No. of 9 or more after annealing, a BH of 30 MPa or more, an AI of 30 MPa or less, and a tensile strength of 340-390 MPa through appropriate control of solute elements in steel by addition of a small amount of Ti, addition of Al and Mo, and control of manufacturing conditions, and refinement of crystal grains after annealing. The cold-rolled steel sheet and the galvannealed steel sheet produced using the cold-rolled steel sheet have the superior bake hardenability, aging resistance at room temperature, and secondary work embrittlement resistance.

Owner:浦项股份有限公司

Rapid and homogenous heat treatment of large metallic sample using high power microwaves

InactiveCN101151395AUniform heat treatmentRapid heat treatmentMuffle furnacesRetort furnacesFiberSusceptor

A system for heat treatment of large metal specimens (14), comprising a microwave heating device having a waveguide (8), a device for monitoring and measuring temperature and a device for holding the metal specimen (14) The holding device, wherein the holding device includes a box (11) structure, which is made of low-density alumina fiber board (13) and wrapped with low-density alumina fiber material to define a cavity, and along the inner wall of the cavity Equipped with receptors.

Owner:BHARAT HEAVY ELECTRICALS LIMITED

Plasma rapid thermal process apparatus in which supply part of radical source is improved

InactiveUS20070032090A1Low thermal budgetUniform thermal processingElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringHeat treated

Owner:KORNIC SYST

Uniform heat conduction system for jelly sealing machine and temperature control method

ActiveCN111846318AEasy extractionEasy to filterCleaningPackaging protectionTemperature controlHydraulic cylinder

The invention discloses a uniform heat conduction system for a jelly sealing machine and a temperature control method. The uniform heat conduction system comprises a fixing frame. A conveying belt isfixedly arranged on one side of the fixing frame. The edge portion of the top end of the fixing frame is provided with a shell placing block. A feeding groove is formed in a position, corresponding toone side of the shell placing block, of the top end of the fixing frame. The edge portion of top end of the fixing frame is provided with a sealing block. A heat conducting mechanism is fixedly arranged at the bottom end of the sealing block and comprises a hydraulic cylinder, a pressing plate, an oil outlet pipe, an oil via pipe, an oil pump, a through pipe, an oil pipe and a filtering box. According to the uniform heat conduction system for the jelly sealing machine and the temperature control method, through cooperation of the heat conducting mechanism, a cleaning mechanism, a dustproof mechanism and an energy-saving mechanism, optimization is conducted on the pressing plate and pressing block uniform heat conducting process, the heat recycling process and the sterilization process; and meanwhile, through a material collecting mechanism, the difficulty of collecting jelly products by workers is reduced, the sealing efficiency of the jelly sealing machine is effectively improved, and the jelly sealing machine is more efficient and energy-saving.

Owner:LABIXIAOXIN (FUJIAN) FOOD INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com