Infrared surface emitter

A radiator and outer panel technology, applied in the field of infrared panel radiators, can solve problems such as the influence of temperature distribution on heating surface temperature distribution, high conductor circuit layout density, and no longer free choice of conductor circuit design, etc. The effect of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

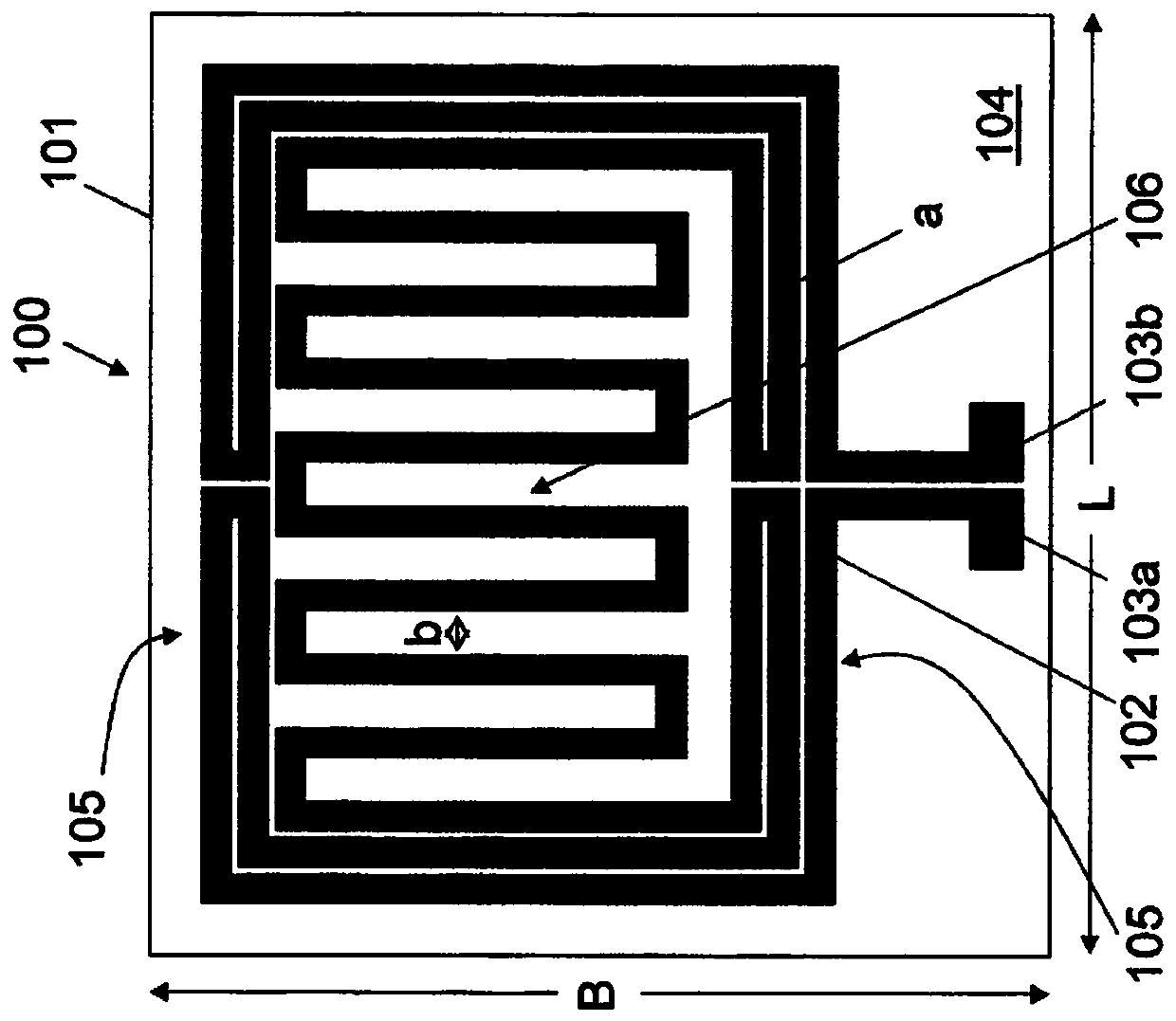

[0084] figure 1 A top view of a first embodiment of an infrared panel radiator according to the invention is shown, which is generally assigned the reference number 100 . The infrared panel radiator 100 is suitable for use in an apparatus for producing flexible printed electronics (not shown). It comprises a plate-shaped substrate (which is a carrier within the scope of the invention) 101 , a conductor track 102 applied to the substrate 101 , and two conductor tracks 103 a , 103 b for electrical contacting of the conductor track 102 .

[0085] The plate-shaped substrate 101 is made of quartz glass having a chemical purity of 99.99% and a cristobalite content of 0.25%, to which elemental silicon is added in an amount of 5% of the total mass. The elemental silicon phase is homogeneously distributed in the quartz glass in the form of non-spherical domains. The largest average size (median) of the Si phase domains is in the range of about 1 μm to 10 μm. The density of the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com