Patents

Literature

349 results about "Wire width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The standard defines the width of the wire diameter using a series of numbers. 0000 is the smallest gauge at 0.46 inches (11.684 mm) and the largest is 40 at .00314 inches (0.0799 mm). The larger the number, the smaller the diameter of the wire. The smallest sizes are 0000, 000, 00 and 0. The wire size is typical written as n AWG, for example 1 AWG.

Timing optimization in presence of interconnect delays

InactiveUS6553338B1CAD circuit designSoftware simulation/interpretation/emulationWire widthParallel computing

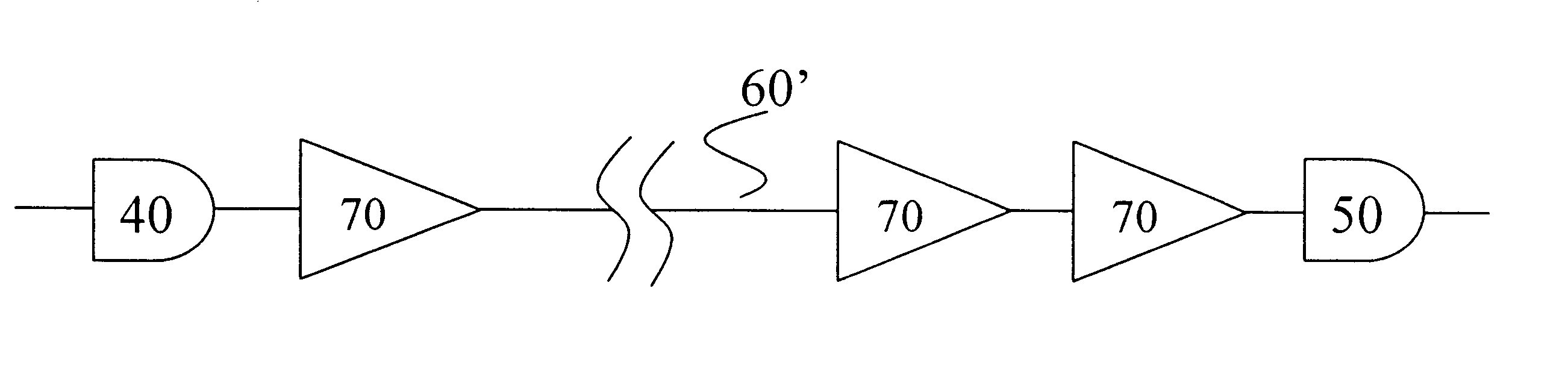

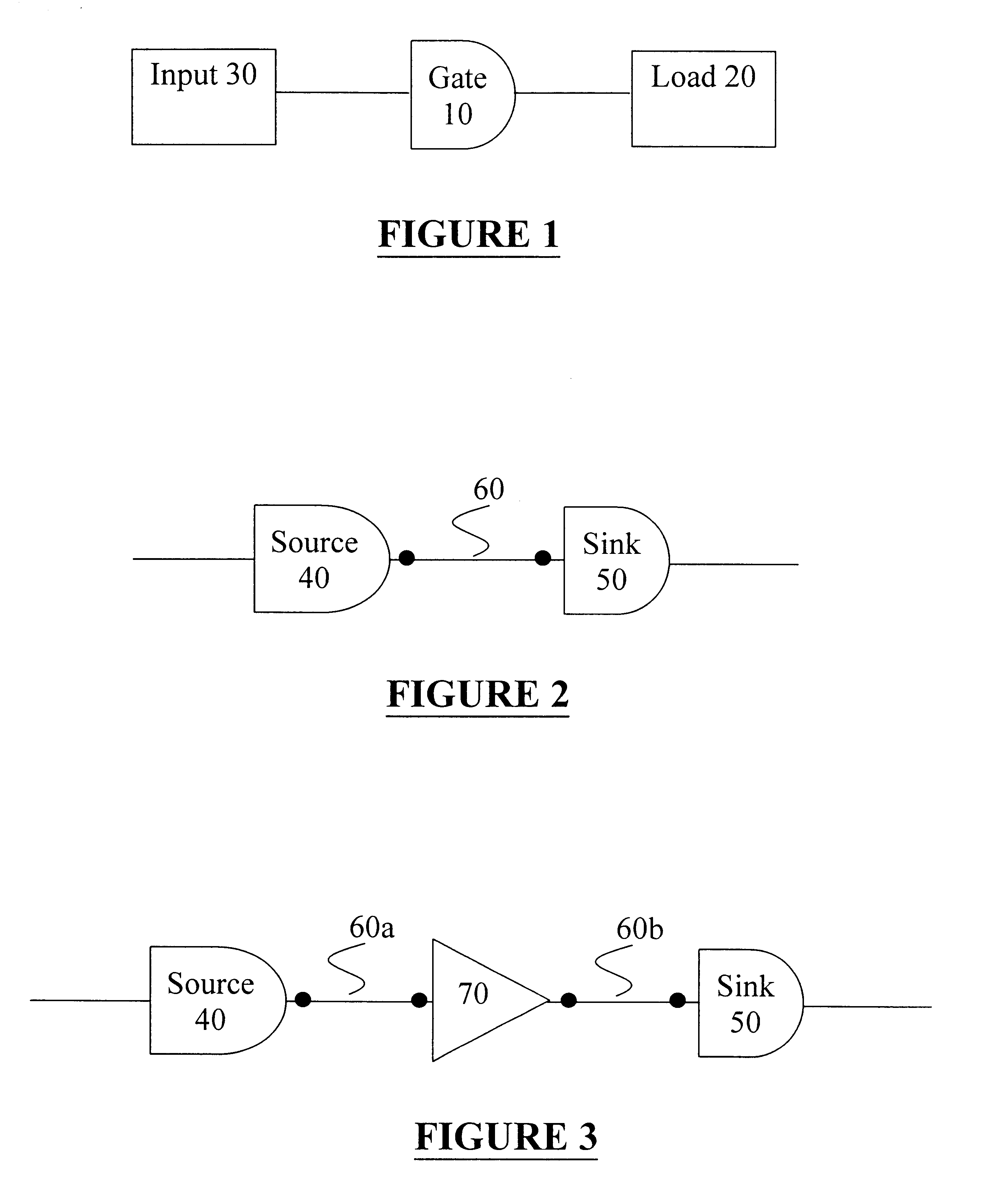

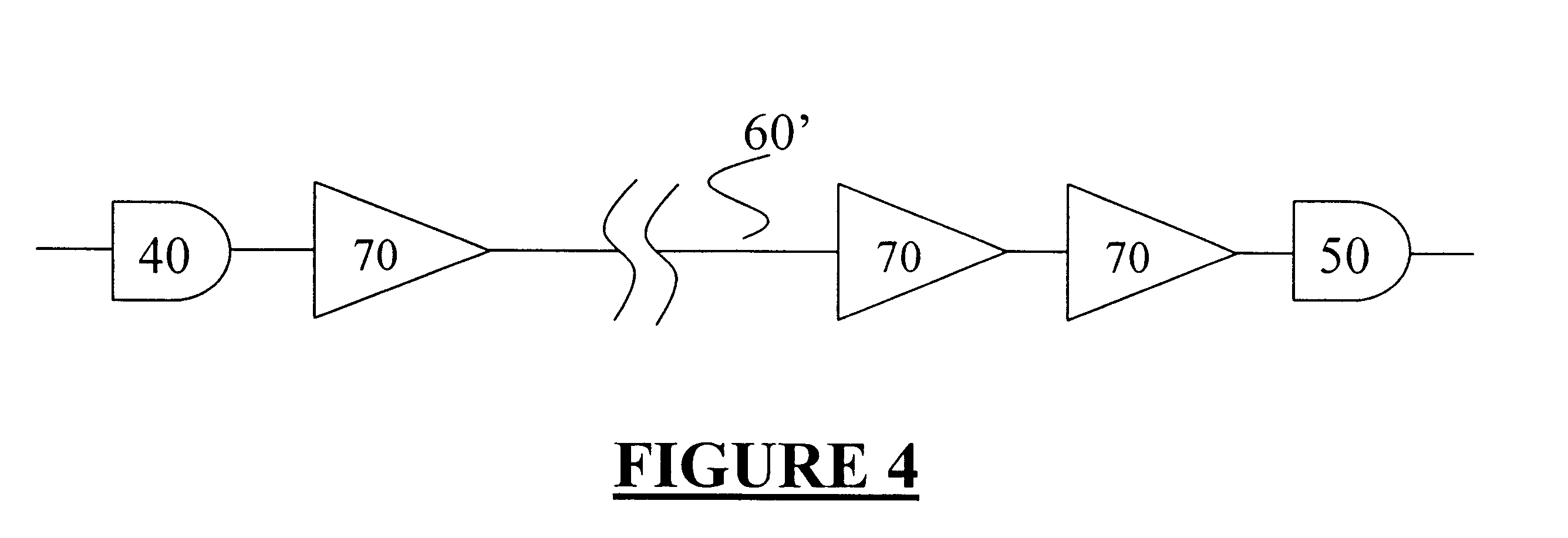

A strategy for optimal buffering in the case of an infinitely long wire buffered with an arbitrary number of equally spaced single-size buffers is presented. A simple but efficient technique is proposed using this to choose a buffer size and determine a good inter-buffering distance up front, thus enabling fast, efficient buffer insertion. The analysis also allows representing delays of long wires as a simple function of the length and buffer and wire widths. Based on this, a novel constant wire delay approach is proposed where the proposed wire delay model is used for fairly accurate prediction of wire delays early in the design process and these predictions are later met via buffer insertion and wire sizing.

Owner:MAGMA DESIGN AUTOMATION

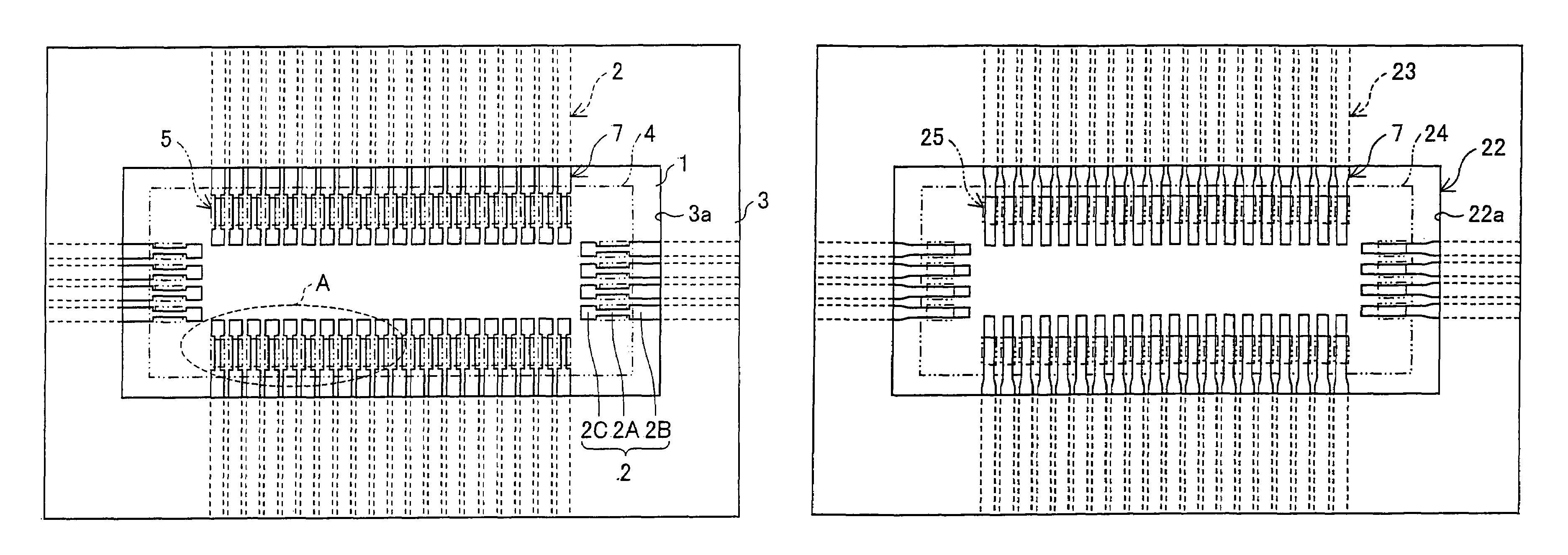

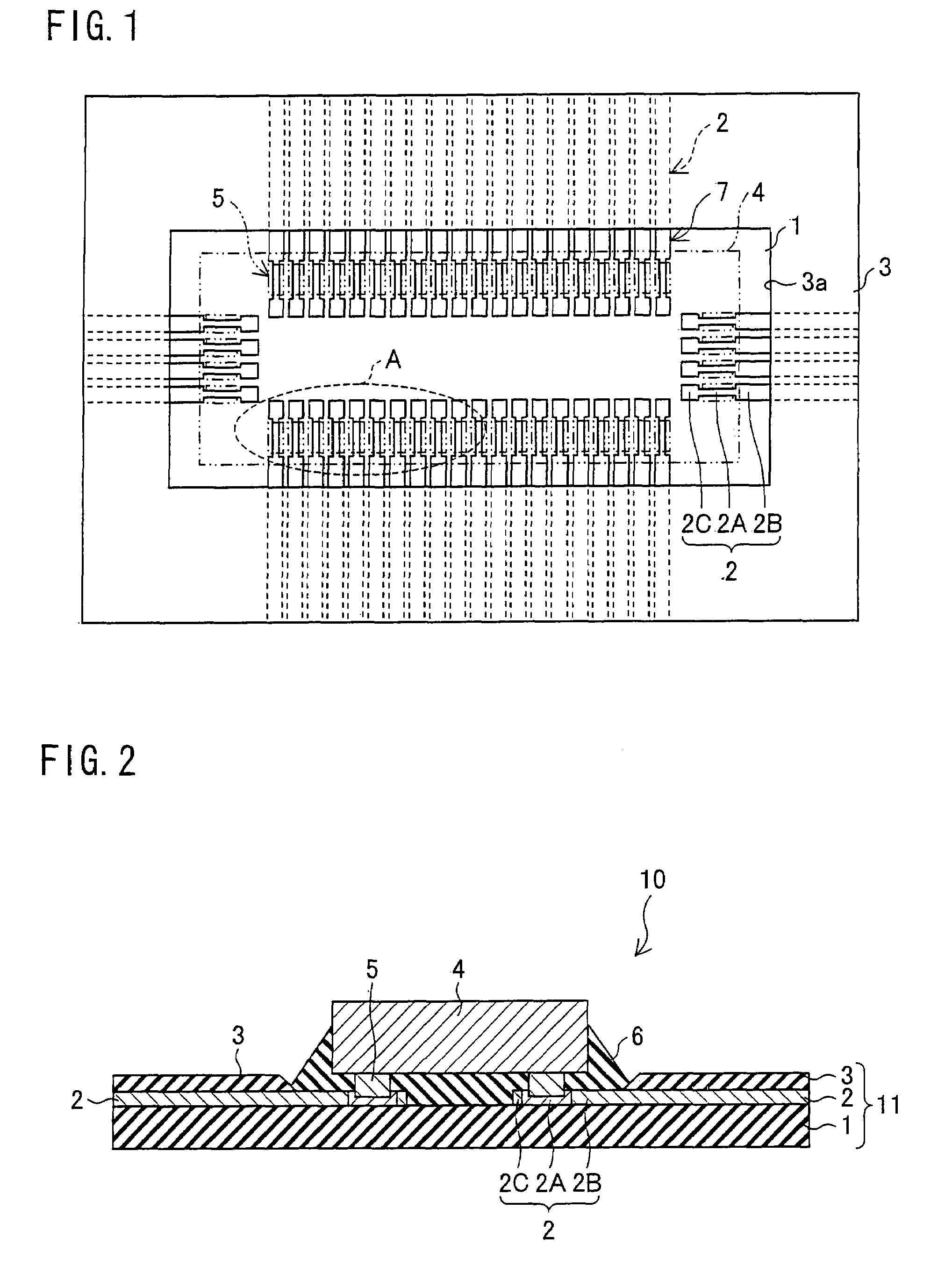

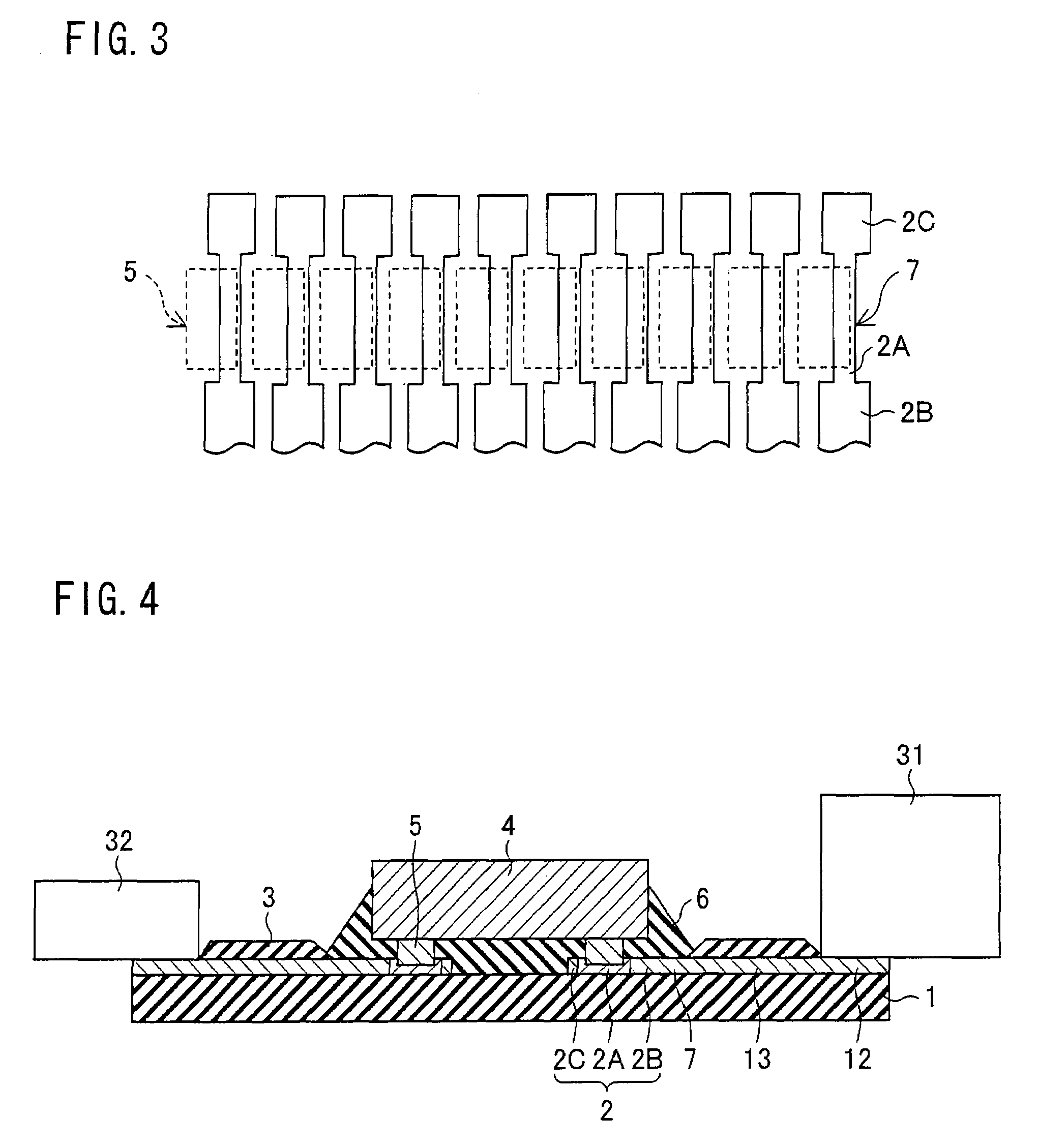

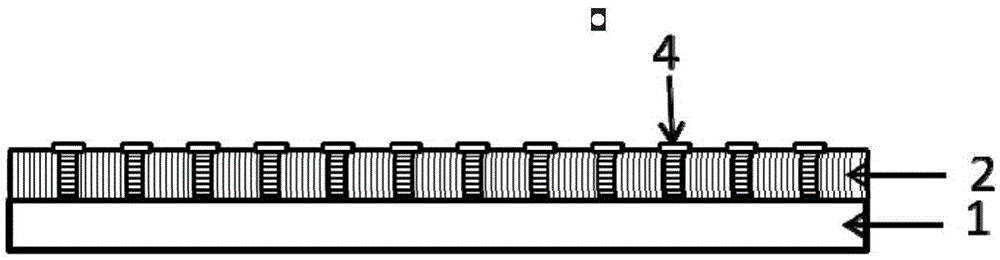

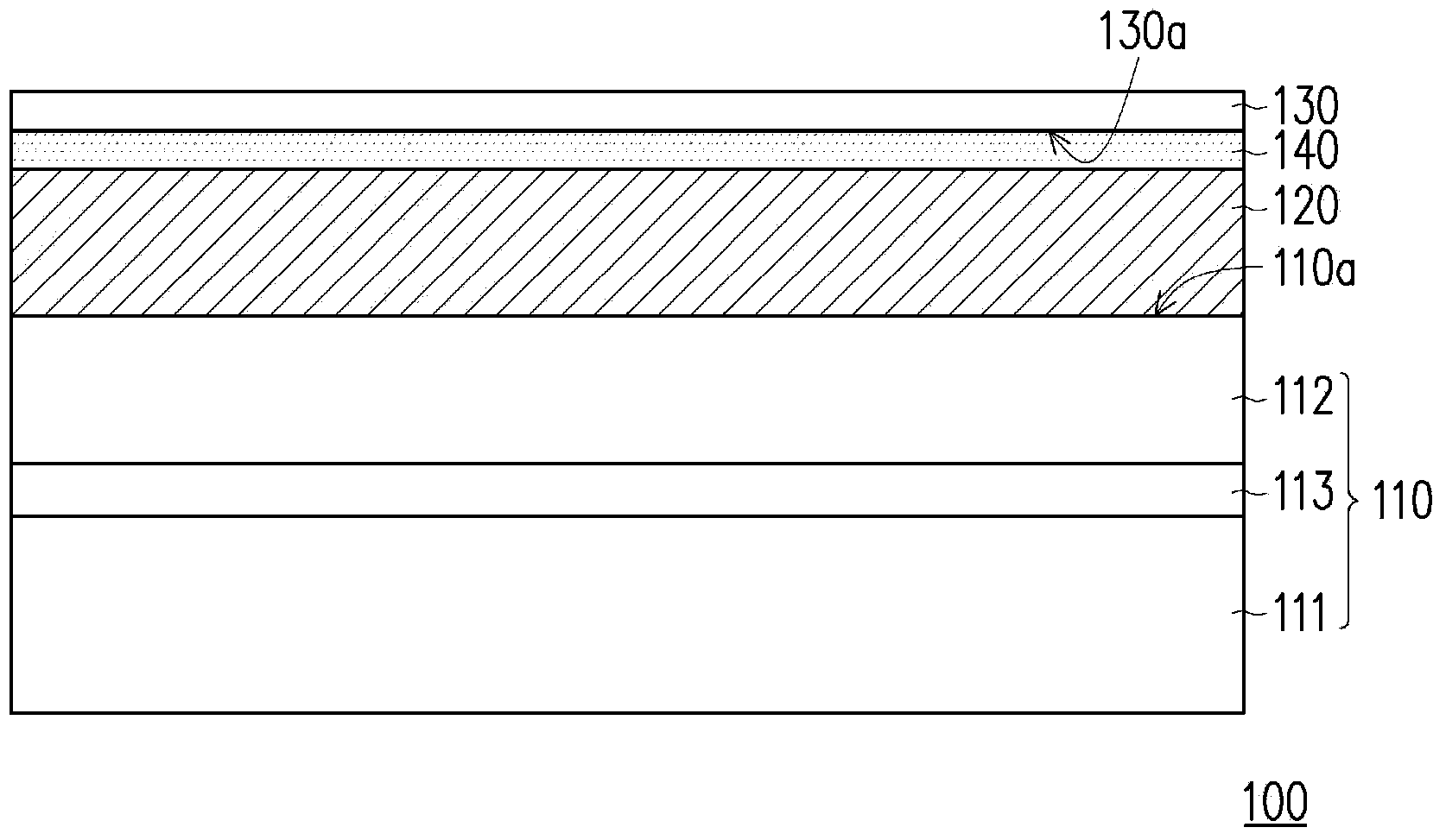

Tape carrier, semiconductor apparatus, and semiconductor module apparatus

ActiveUS7671454B2Prevent peelingAvoid defectsFinal product manufactureSemiconductor/solid-state device detailsWire widthEngineering

A tape carrier of the present invention includes an insulating tape and a wiring pattern formed on the insulating tape. The wiring pattern includes a connecting section via which the wiring pattern is connected to a bump electrode. The connecting section is provided at a part of an overlap part of the wiring pattern, which overlap part overlaps a semiconductor device when the semiconductor device is mounted on the wiring pattern. The connecting section of the wiring pattern is smaller in wiring width than the remaining part of the overlap part, which remaining part is other than the connecting section.

Owner:SHENZHEN TOREY MICROELECTRONIC TECH CO LTD

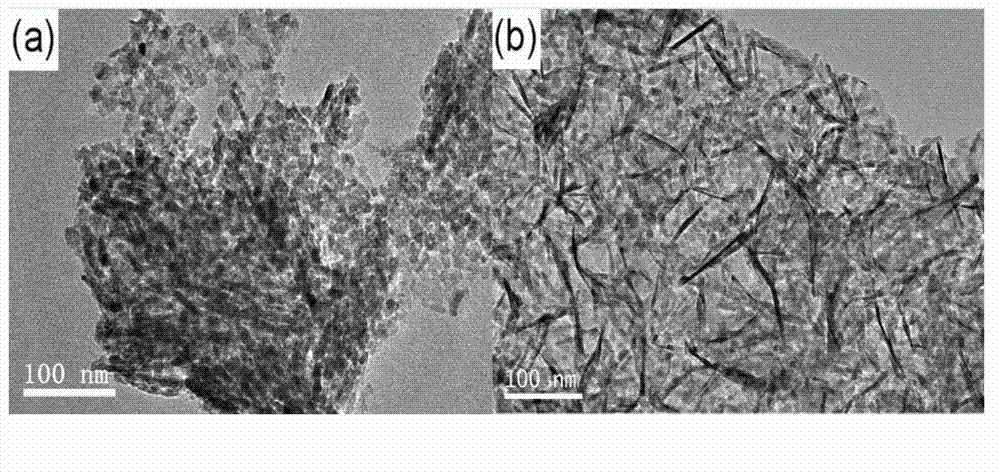

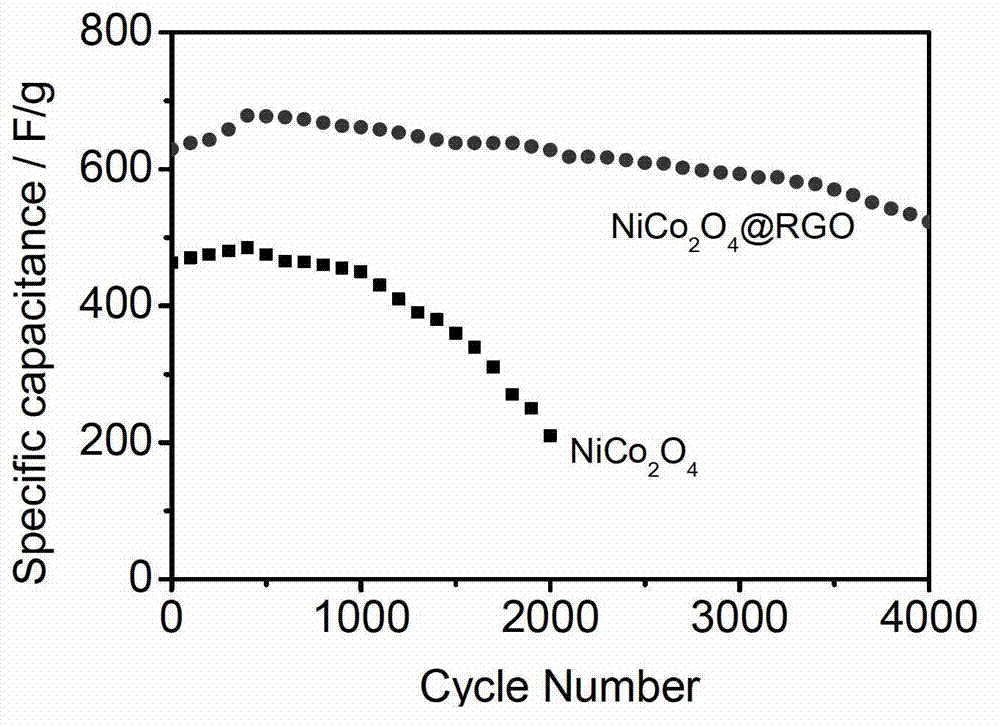

Nickel cobaltate-graphene composite material and application and preparation method thereof

InactiveCN102891016ASmall sizeLarge specific surface areaElectrolytic capacitorsCapacitanceNickel salt

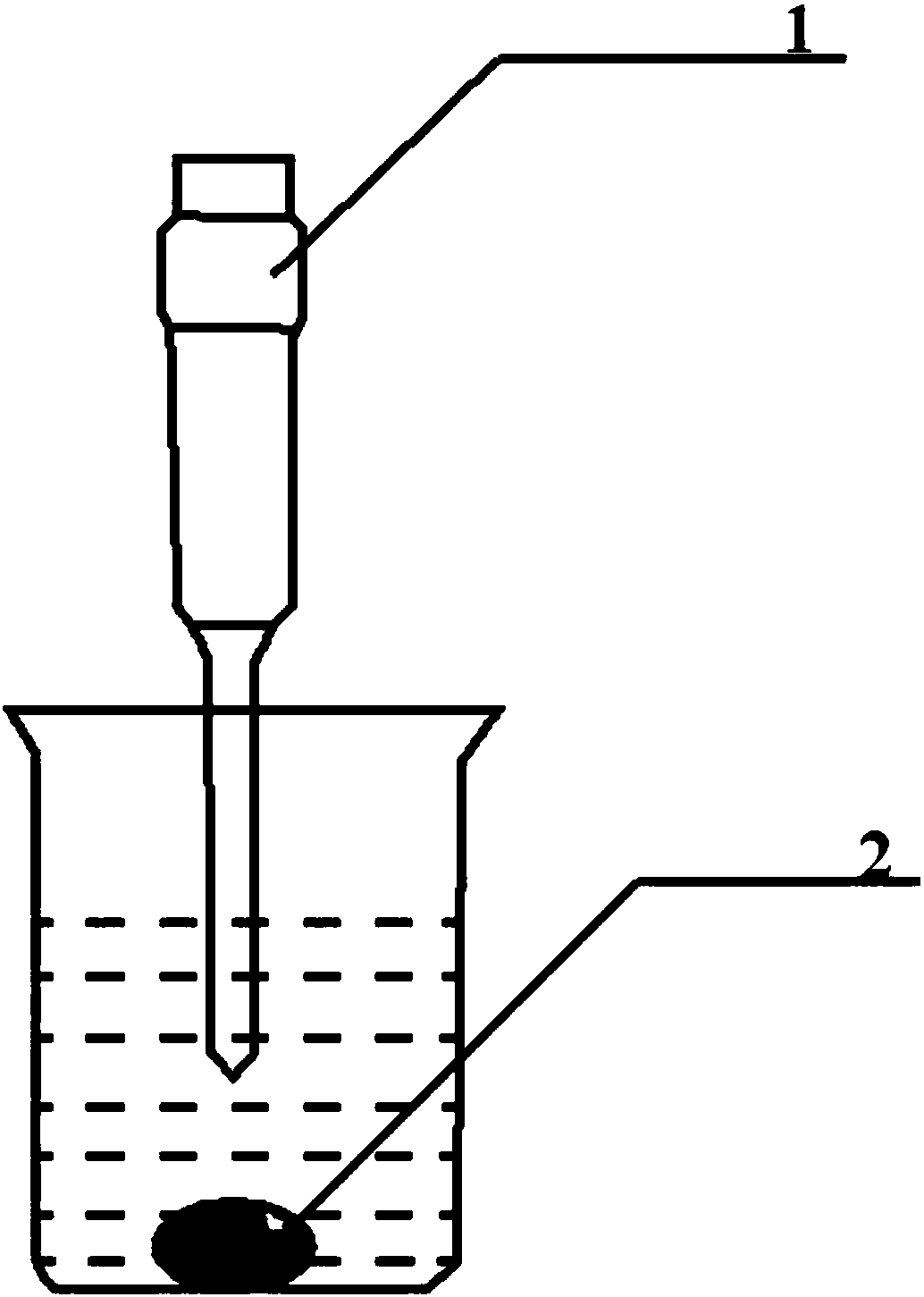

The invention relates to a nickel cobaltate-graphene composite material and a preparation method thereof. The composite material comprises graphene and nickel cobaltate, wherein nickel cobaltate nanowires are uniformly grown on a graphene sheet, the wire length of the nickel cobaltate nanowires is 50-300nm, and the wire width is 5-30nm. The preparation method comprises the following steps of: taking a graphene oxide water solution and a cobalt salt and nickel salt water solution which are dispersed in an ultrasonic manner, mixing, further adding a precipitator, uniformly stirring and mixing, transferring into a high-temperature reaction kettle, performing hydro-thermal reaction for a certain period of time, filtering, washing and drying an obtained product, and further performing thermal treatment so as to obtain the nickel cobaltate nanowire-graphene composite material. The nickel cobaltate nanowire-graphene composite material prepared by the method disclosed by the invention has the advantages of high single-electrode capacitance and good cycle performance, and is suitable for being used as an electrode material of a super-capacitor.

Owner:CHANGZHOU UNIV

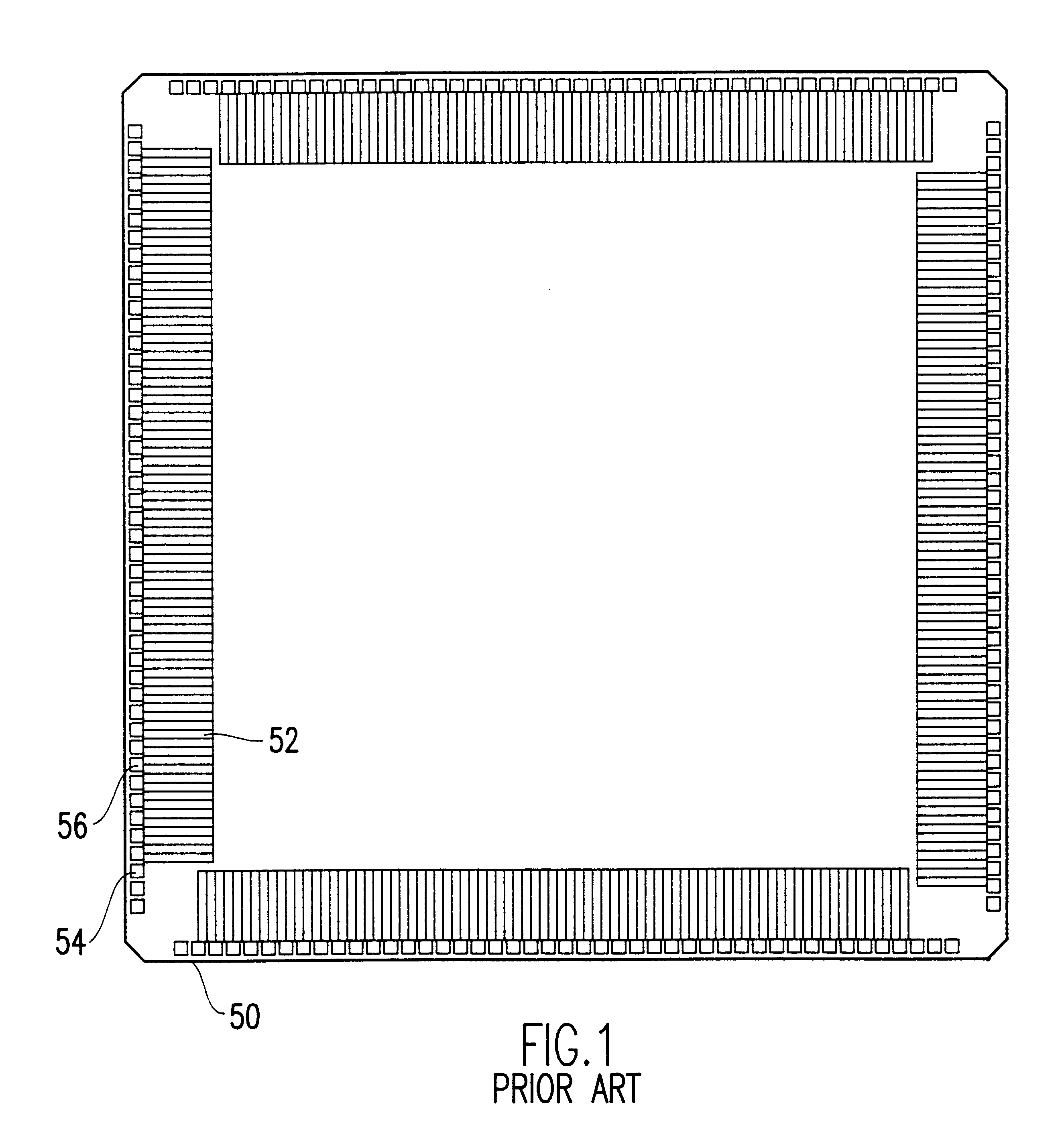

Method of automated ESD protection level verification

InactiveUS6086627AComputer aided designSoftware simulation/interpretation/emulationWire widthElectrical resistance and conductance

A integrated circuit (IC) chip with ESD protection level and the system and method of wiring the IC chip. Minimum wire width and maximum resistance constraints are applied to each of the chip's I / O ports. These constraints are propagated to the design and array pads are wired to I / O cells located on the chip. Thus, wiring is such that wires and vias to ESD protect devices are wide enough to provide adequate ESD protection level. The design is then verified by first identifying the chip pads, I / O cells and ESD protect devices. Connections between these three structures are verified. Wires between the ESD protect devices and the chip pads and I / O cells are shrunk such that unsuitable connections becomes opens (disconnected) and are found in subsequent checking. Finally connections to guard rings are checked. Power rails are checked in a similar manner.

Owner:GLOBALFOUNDRIES INC

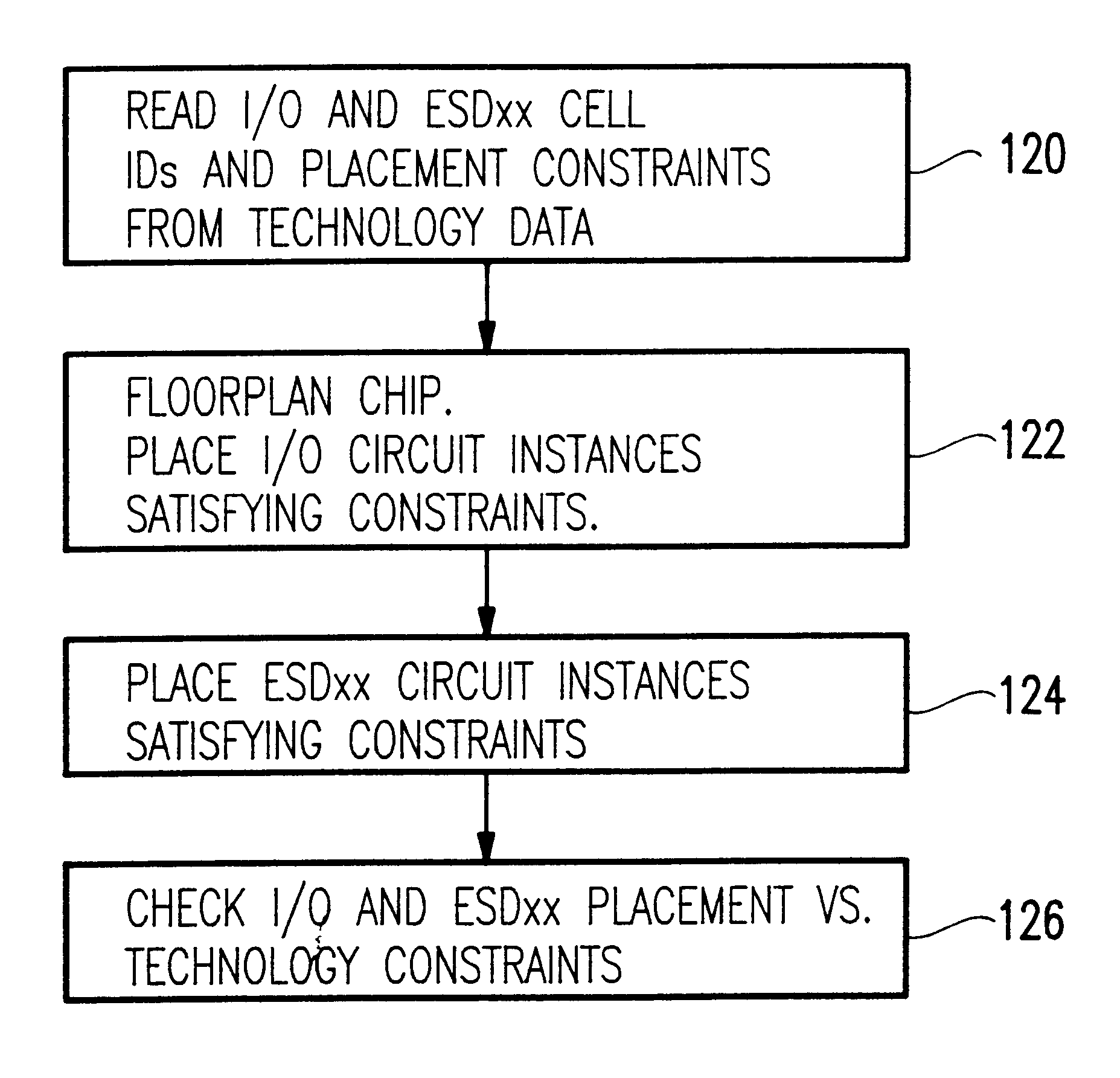

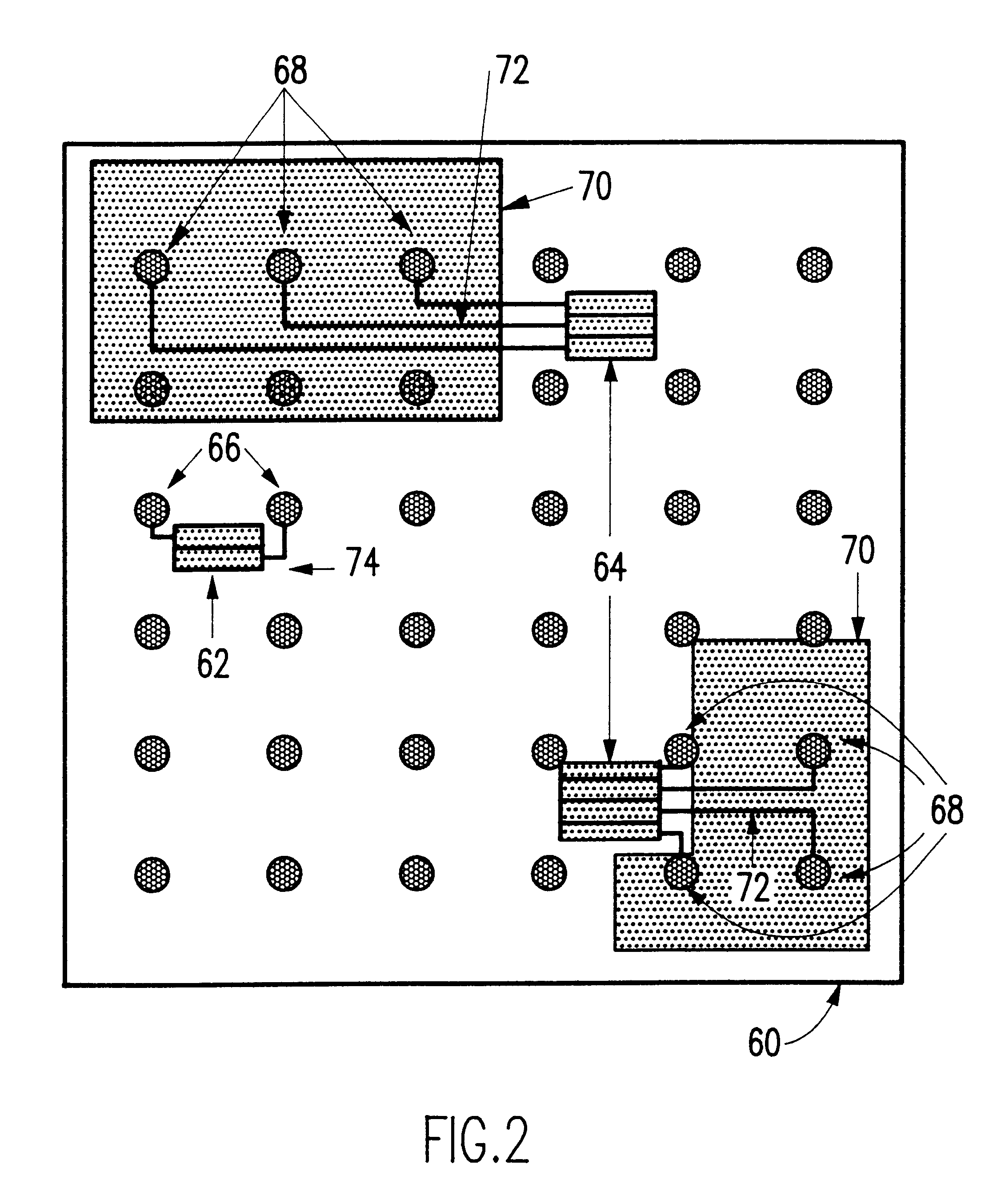

Method of automated design and checking for ESD robustness

InactiveUS6725439B1CAD circuit designSpecial data processing applicationsElectrical resistance and conductanceWire width

A integrated circuit (IC) chip with ESD robustness and the system and method of wiring the IC chip. Minimum wire width and maximum resistance constraints are applied to each of the chip's I / O ports. These constraints are propagated to the design. Array pads are wired to I / O cells located on the chip. Unused or floating pads may be tied to a power supply or ground line, either directly or through an electrostatic discharge (ESD) protect device. A multi-supply protect device (ESDxx) coupled between pairs of supplies and ground or to return lines is also included. Thus, wiring is such that wires and vias to ESD protect devices are wide enough to provide adequate ESD protection. Robust ESD protection is afforded all chip pads. The design may then be verified.

Owner:GLOBALFOUNDRIES INC

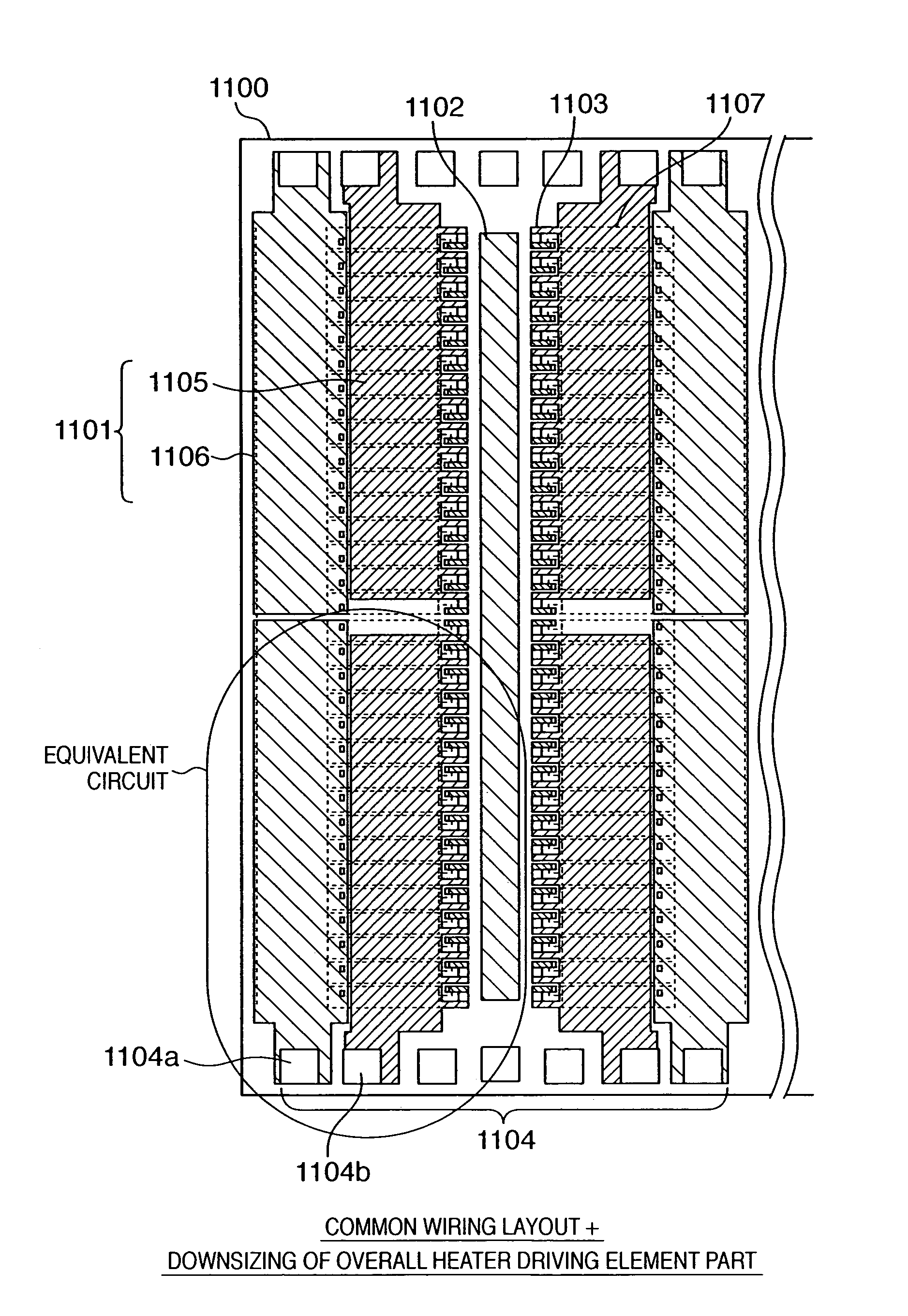

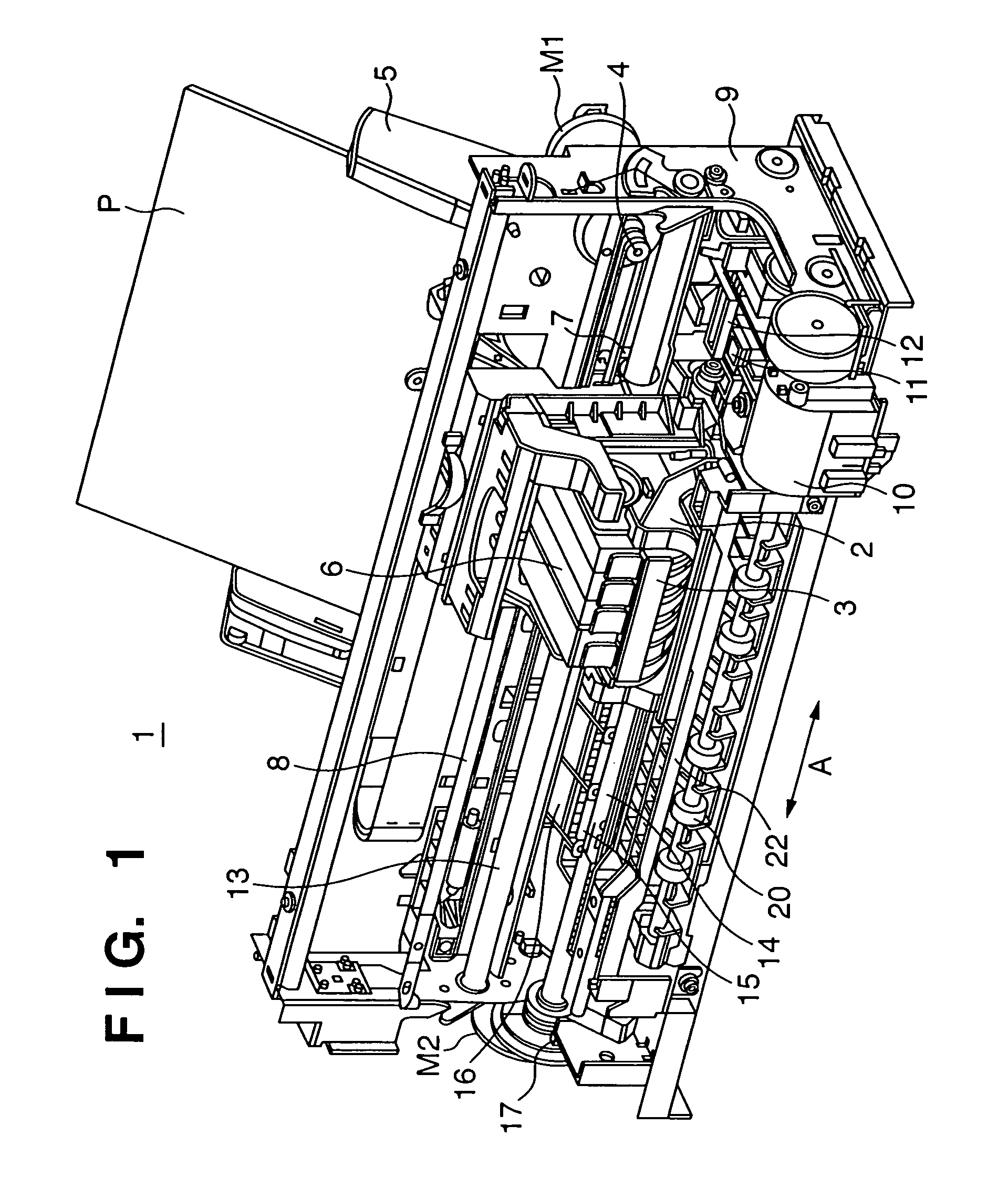

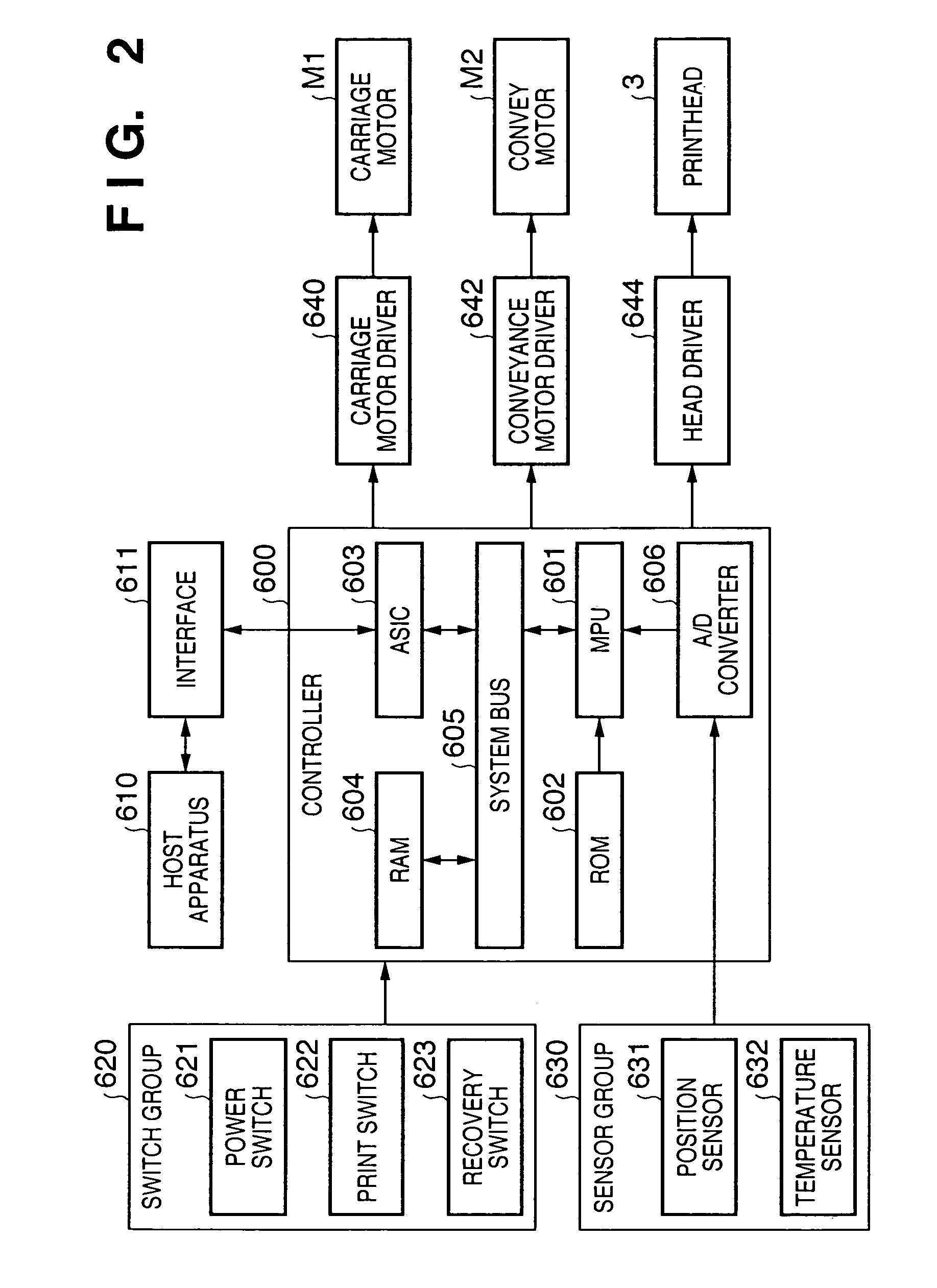

Method of driving a printhead using a constant current and operating MOS transistor in saturation region

InactiveUS7216960B2Increase line widthIncrease the number ofPrintingElectrical resistance and conductanceWire width

This invention relates to a printhead substrate capable of suppressing an increase in wiring width and an increase in the size of a substrate formed by a film forming process while increasing the number of simultaneously driven printing elements in order to improve the printing performance, a printhead using the substrate, and a printing apparatus using the printhead. The wiring lines of the substrate are formed into a common wiring line, and energy applied to a heating resistance element is prevented from deviating from a stable ink discharge range owing to the difference in the number of simultaneously driven heating resistance elements. For this purpose, a driving element is greatly downsized in comparison with a conventional one, and the operation region of a MOS transistor is shifted from the non-saturation region to the saturation region.

Owner:CANON KK

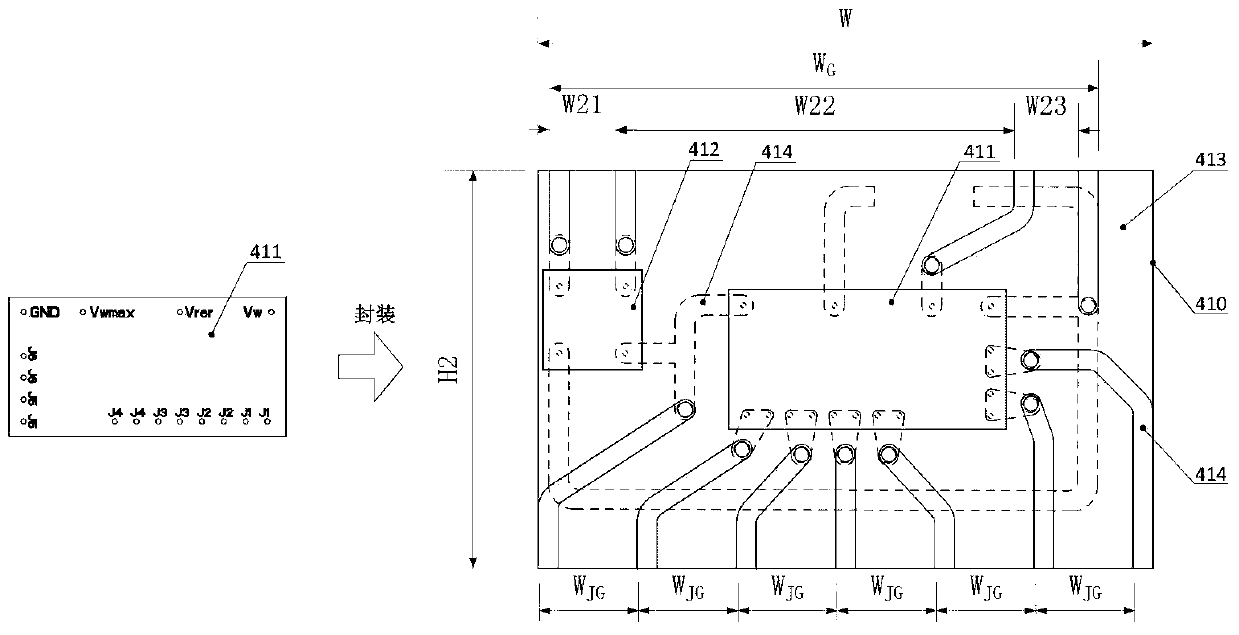

LED (light emitting diode) driving power supply large chip

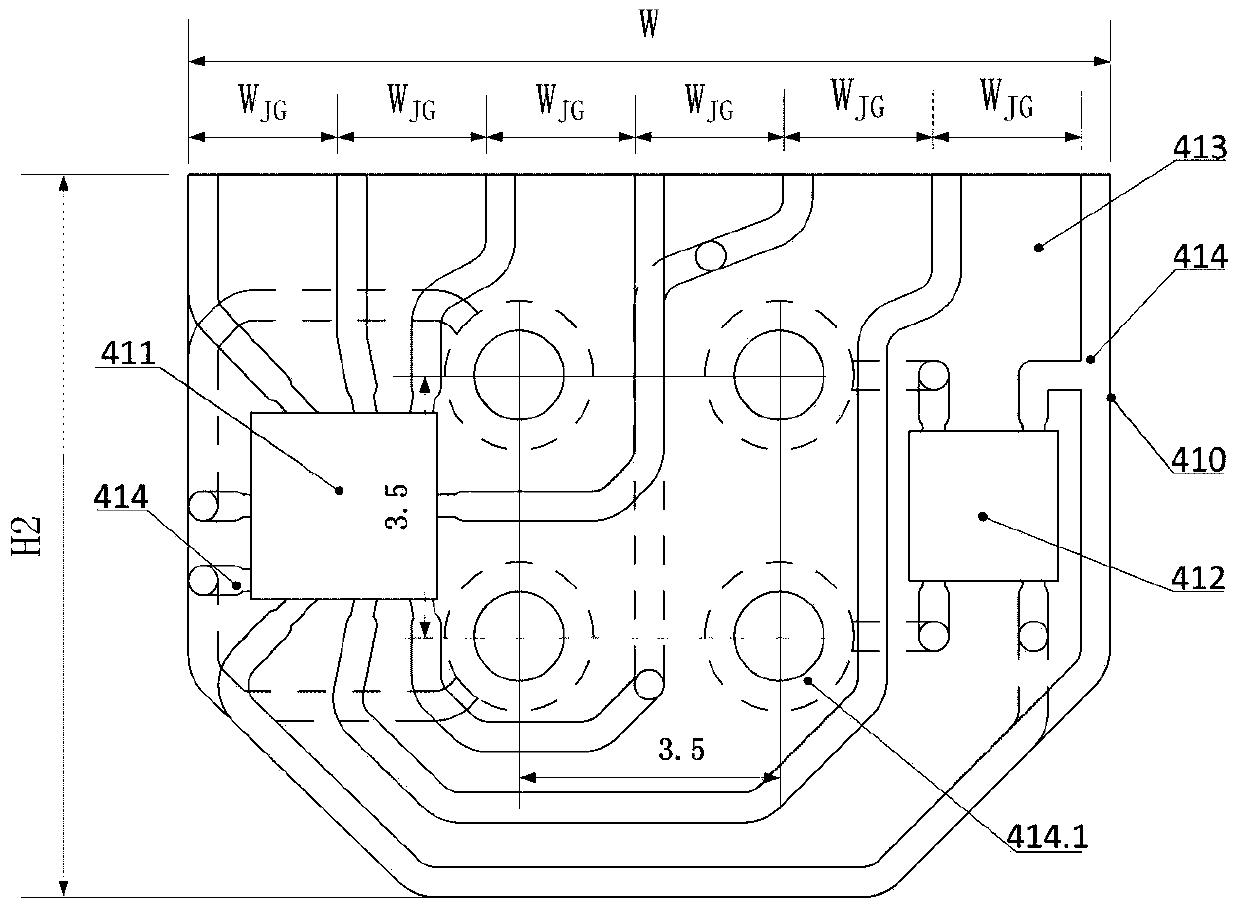

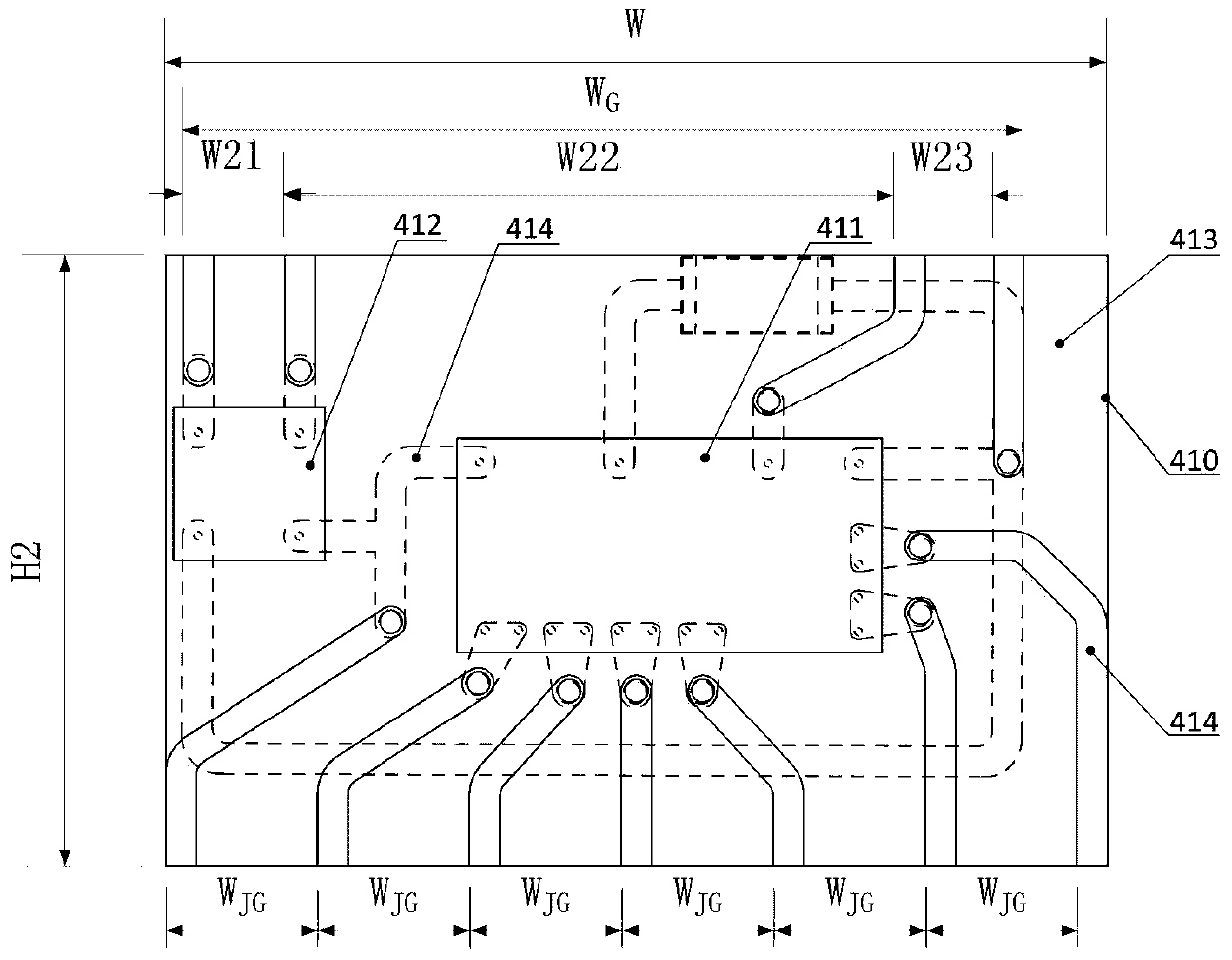

ActiveCN103953902ALow costReduce volumePoint-like light sourceElectric circuit arrangementsWire widthSlurry

The invention discloses an LED (light emitting diode) driving power supply large chip, which comprises transparent base plates (413) with the width constantly being W, wherein a second transparent base plate (413) is printed with a silver slurry circuit, and an interface conducting wire is formed on the silver slurry circuit and is provided with an input end and an output end; the width of the input end is identical to the width WG of a conducting wire input end of a light machine template (43), or the input end is provided with a welding disc connected with an electric connector; N+1 parallel interface conducting wires are arranged on the silver slurry circuit arranged at the output end, and the space WJG of the two adjacent interface conducting wires can be obtained through dividing the difference value of W and the width of the interface conducting wire by N; an unencapsulated power supply driving wafer level chip (411) and a rectifier bridge wafer level chip (412) are firstly pasted on the second transparent base plate (413), and then, the unencapsulated power supply driving wafer level chip (411) and the rectifier bridge wafer level chip (412) are welded onto the second transparent base plate (413).

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

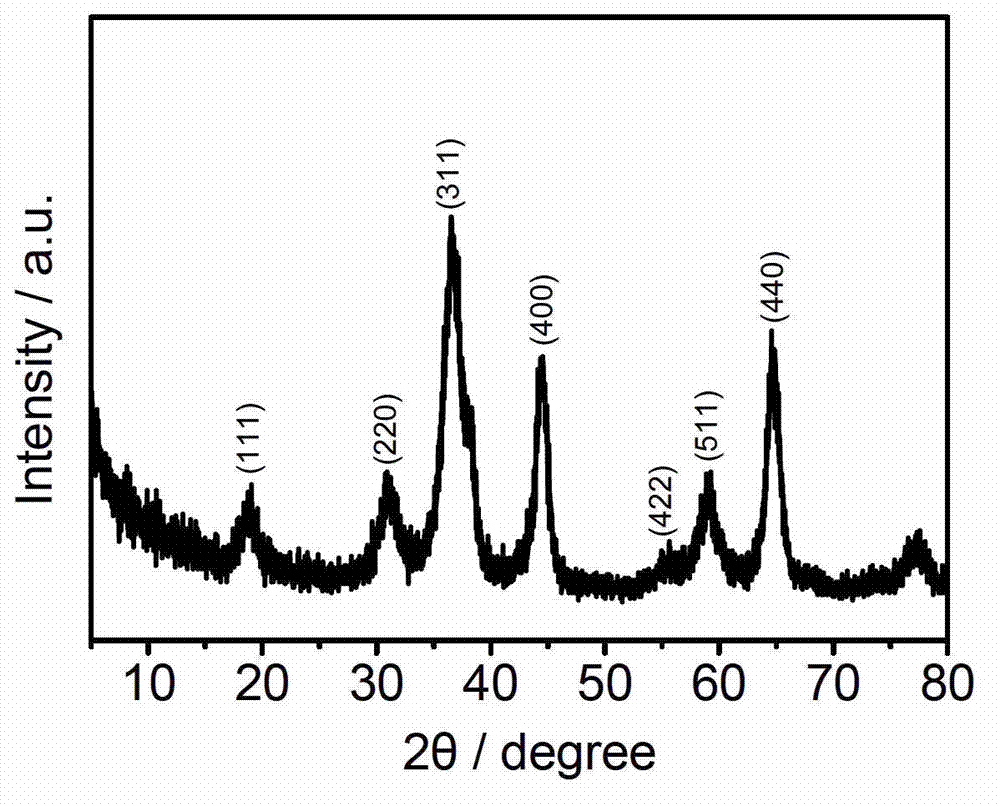

Super low-loss and small-line width microwave ferrite material and preparation method for microwave ferrite material

The invention relates to a super low-loss and small-line width microwave ferrite material and a preparation method for the microwave ferrite material and belongs to the field of microwave communication and magnetic materials. The main phase of the material is of a johnstonotite structure, and the chemical formula of the material is Y3-2x-yCa2x+yFe5-x-y-zVxZryAlzO12, wherein x is not less than 0.02 but is not more than 0.25, y is not less than 0.05 but is not more than 0.25, and z is not less than 0.01 but is not more than 0.25. The preparation method comprises the following steps of: calculating according to chemometry and weighing a raw material, vibratory milling, presintering, vibratory grinding and coarse crushing, sanding fine crushing, spray granulation, compression moulding and sintering. Proved by testing, the ferromagnetic resonance line width deltaH of the obtained material is not more than 1.27KA / m, the dielectric loss tgdeltae is not more than 0.5*10-4, and the insertion loss of an assembled microwave device is not more than 0.21dB, and thereby, the stability and the reliability of the obtained material are greatly enhanced, and the application range is broadened. The manufactured microwave ferrite device has the advantages of wide working band and low insertion loss.

Owner:TDG HLDG CO LTD

Flexible stretchable conductive circuit and preparation method and use thereof

InactiveCN108668431AReduce dosageAchieve mass productionLithography/patterningConductive pattern formationWire widthImage resolution

The invention provides a flexible stretchable conductive circuit, a preparation method and use thereof. The invention also provides double-sided wiring, multilayer board, flexible display, flexible electronics, and / or sensor comprising the flexible stretchable circuit described above. The method for preparing flexible stretchable conductive circuit provided by the invention is simple and rapid, and is generally applicable to various substrate materials, the liquid metal is used in a small amount, does not require additional external force, and the pattern does not generate cracks, the wire width is controllable, has a high resolution and it's very suitable for mass production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

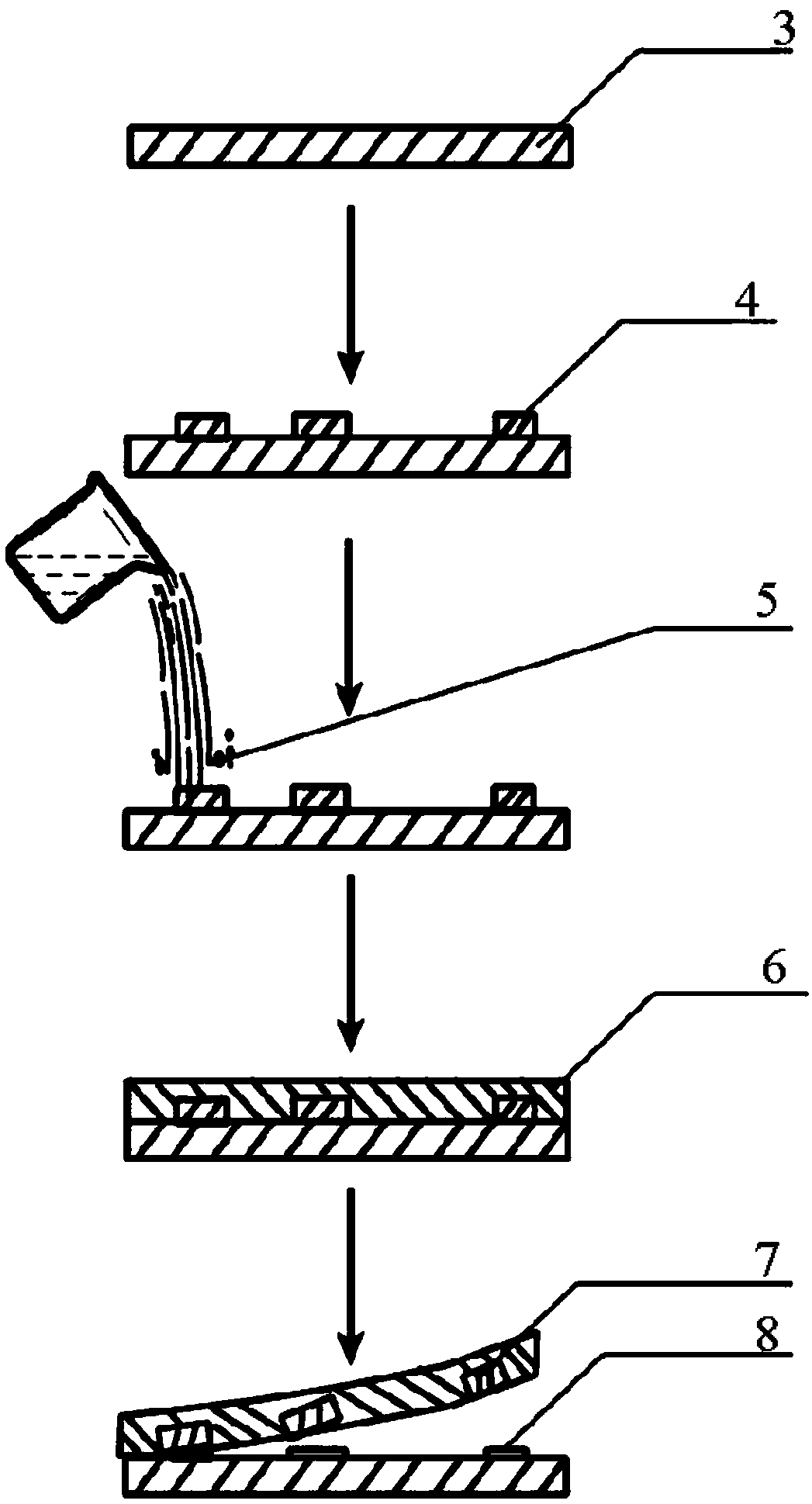

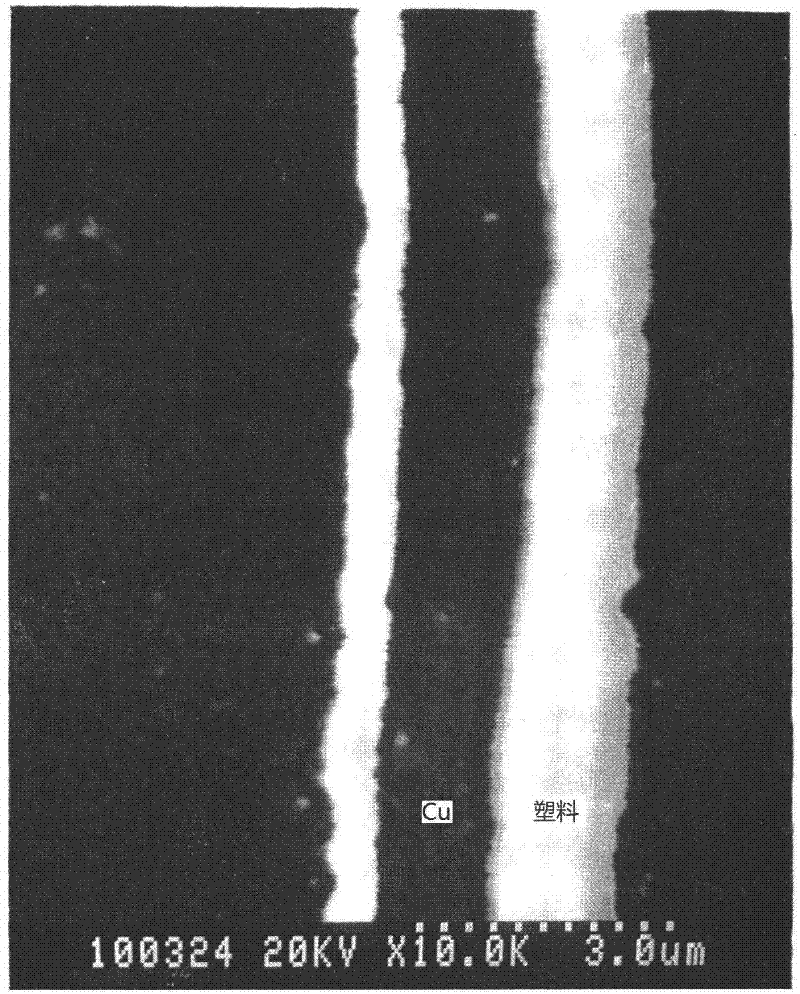

Preparation method of flexible copper electrode pattern in micron level wire width

InactiveCN102400115AImprove conductivityGood adhesionLiquid/solution decomposition chemical coatingCopper platingCopper electrode

The invention belongs to the field of microelectronic material, and relates to a preparation method of a flexible copper electrode pattern in a micron level wire width. The preparation method provided by the invention is a ''whole addition'' method, which means that metal copper only precipitates on a predetermined position on a plastic substrate. A specific process comprises steps of plastic substrate cleaning, drying, surface modification, ultraviolet irradiation under a photomask and chemical coppering, etc. The flexible copper electrode pattern prepared by the invention has the following advantages that (1) precision of the electrode pattern is determined by the photomask to reach a micron level wire width; (2) most of the process is carried out in solution, so the process does not require large-scale apparatus equipment and rigorous environment of anultraclean chamber and is suitable for low cost and large scale production; (3) the electrode pattern and the plastic substrate are firmly bonded, can stand repeat folding and have long service life and high reliability; (4) the electrode pattern has good conductivity and is beneficial for reducing energy consumption during usage. The flexible copper electrode pattern prepared by the invention can be widely applied to industrial fields of flexible transistor, flexible solar cell and flexible luminescent device, etc.

Owner:FUDAN UNIV

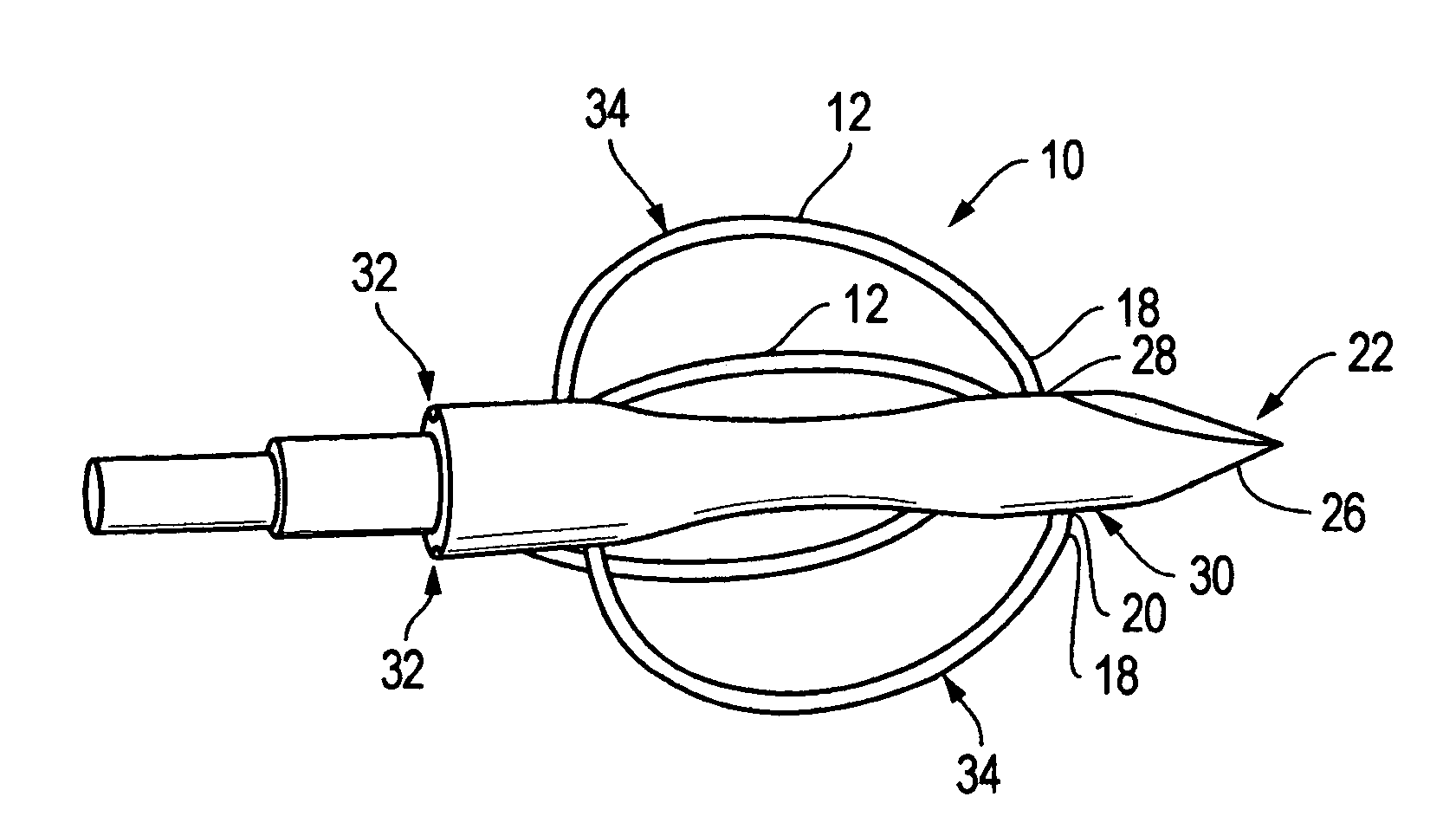

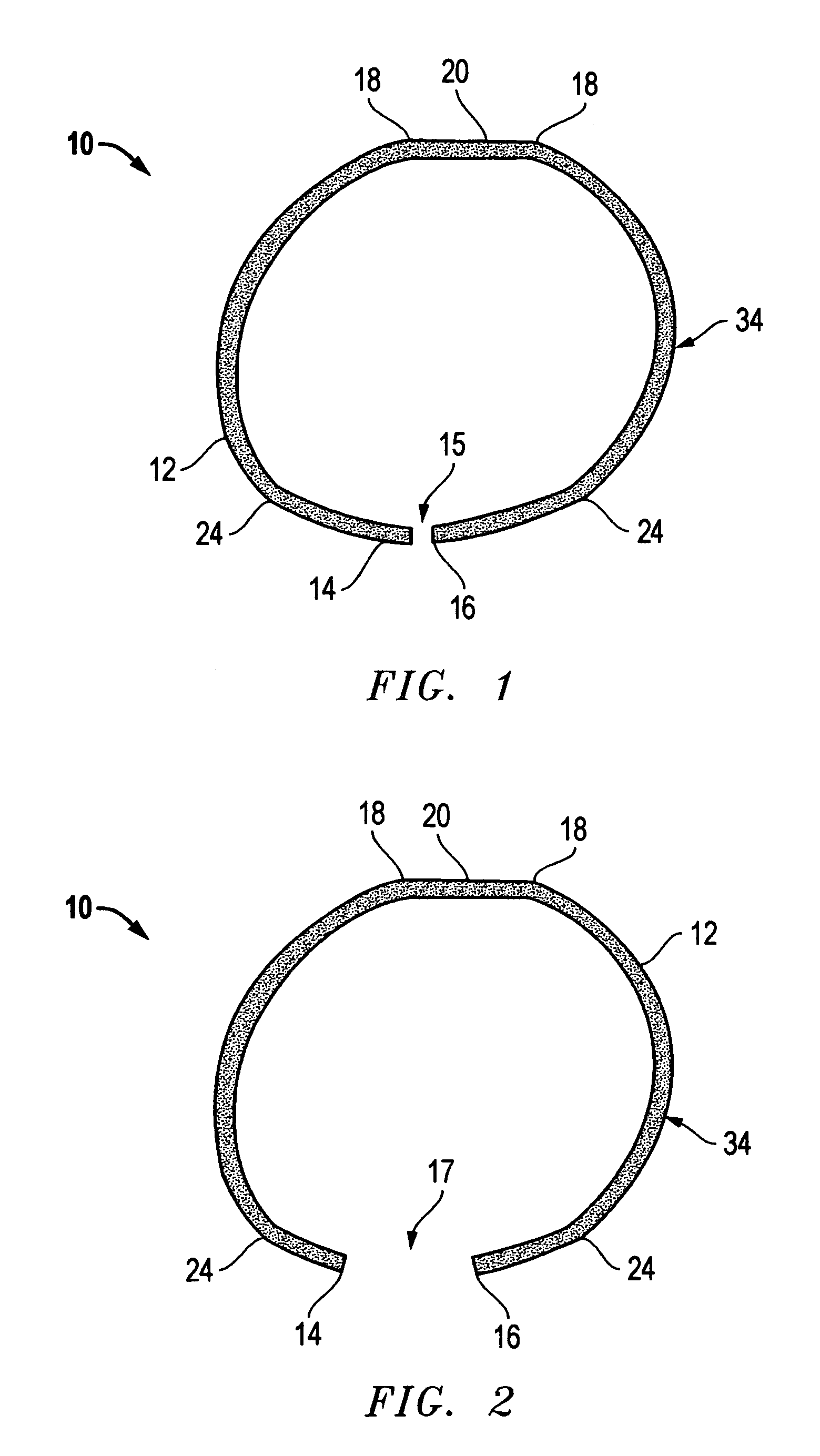

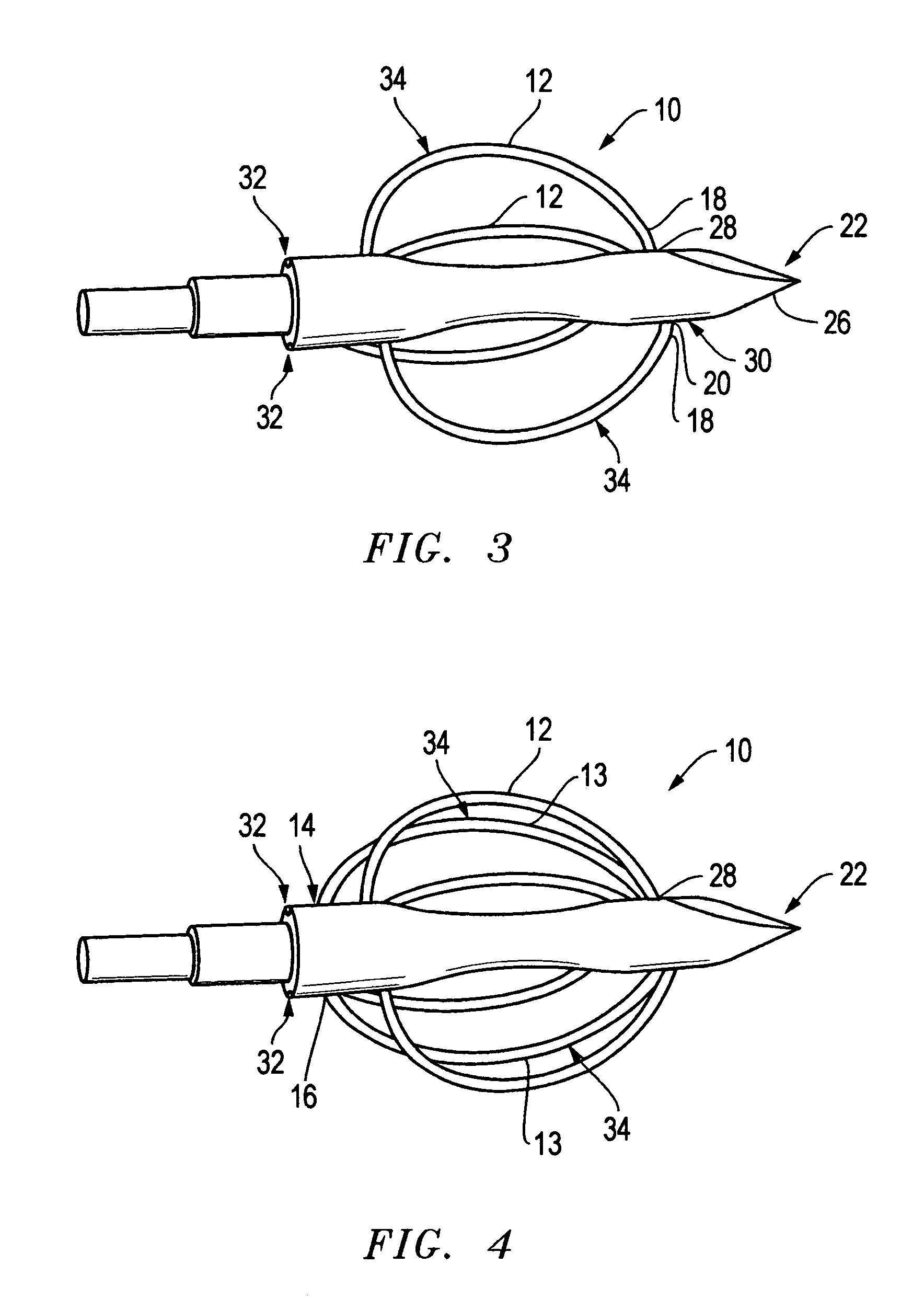

Wire broadhead apparatus and method

InactiveUS7311622B1Minimal cross sectional surface areaMaximum cutting widthThrow gamesArrowsEngineeringMechanical engineering

Owner:ARROWDS LLC

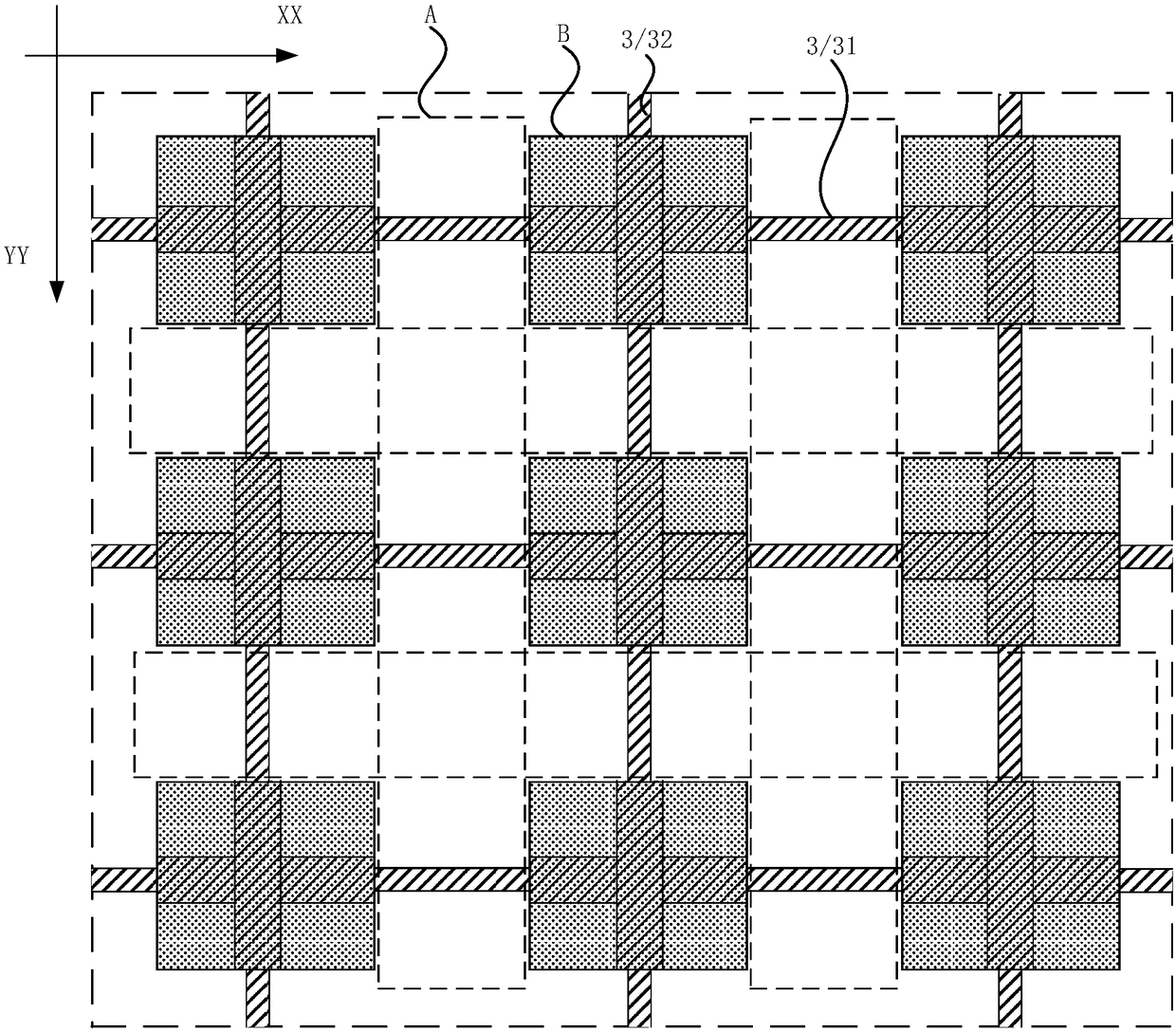

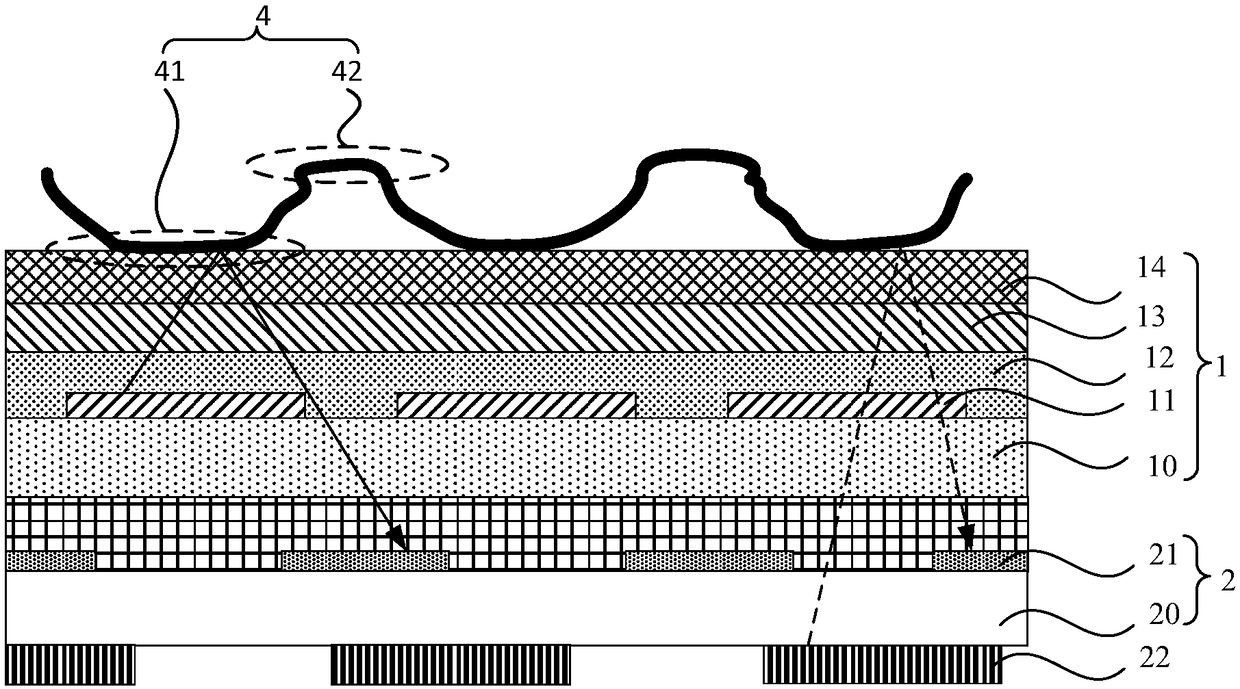

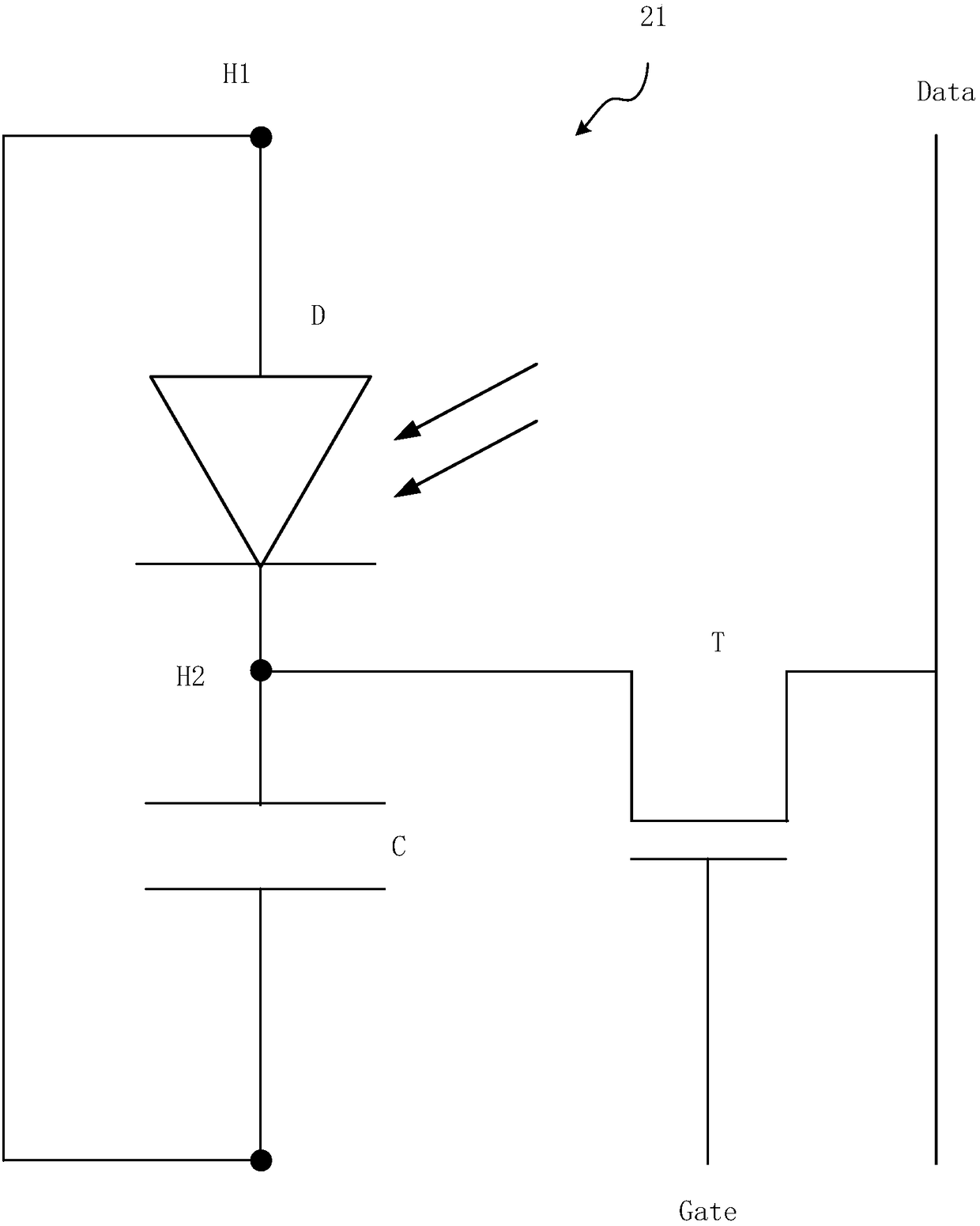

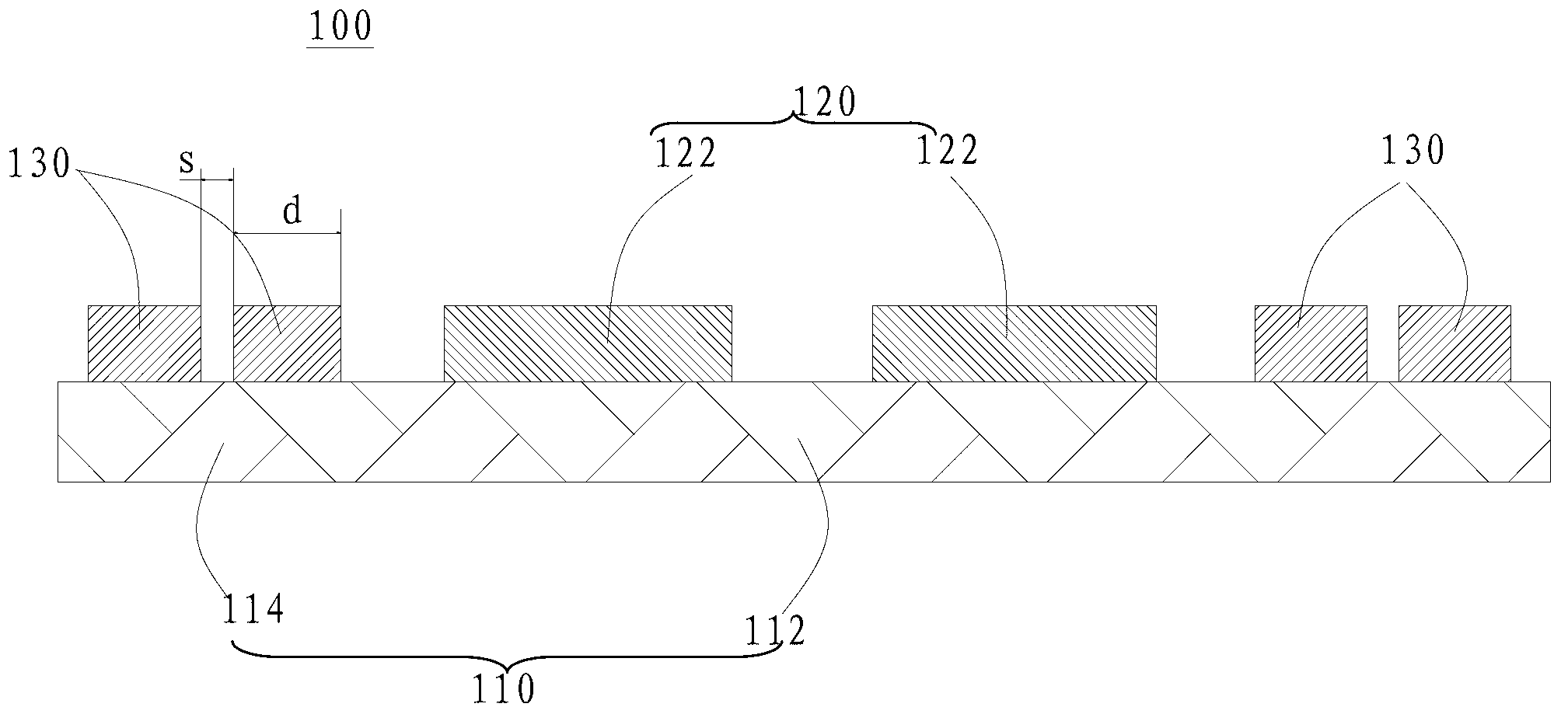

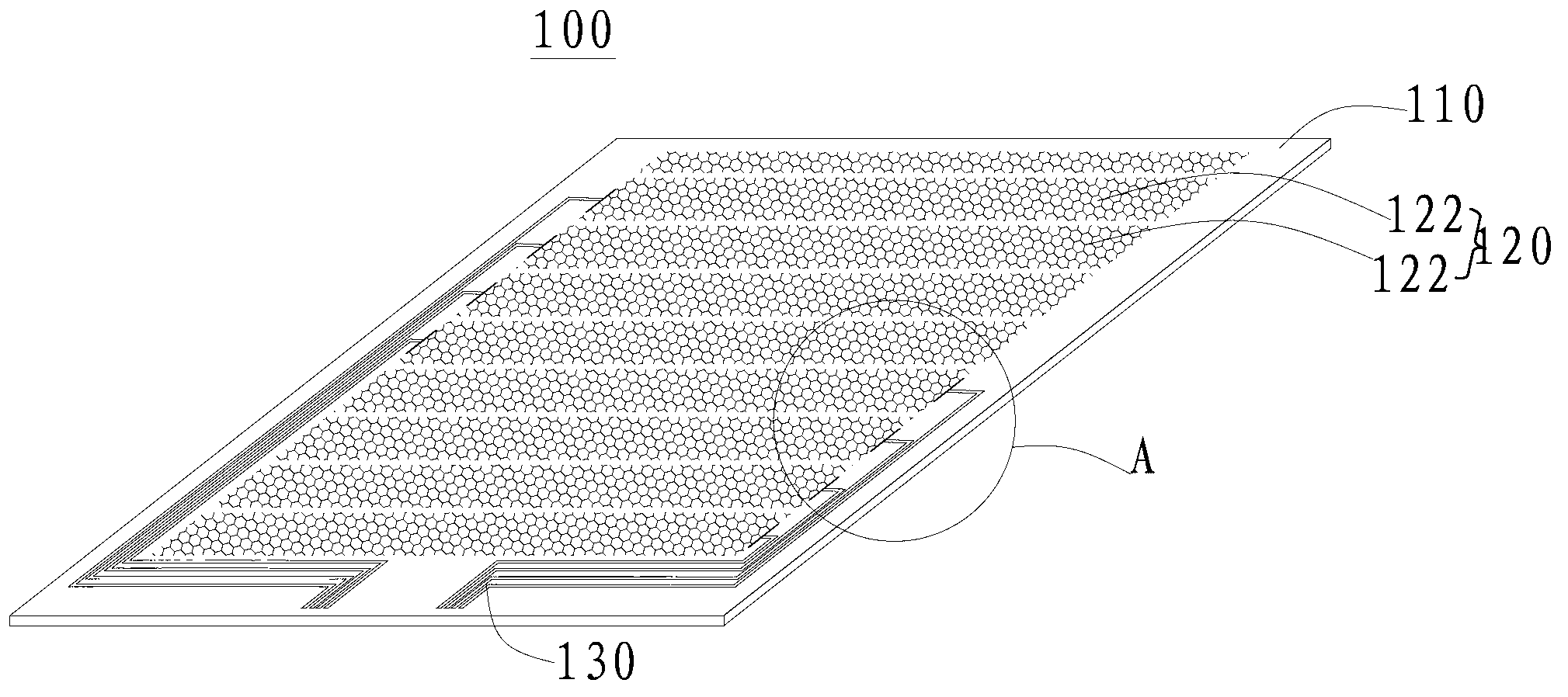

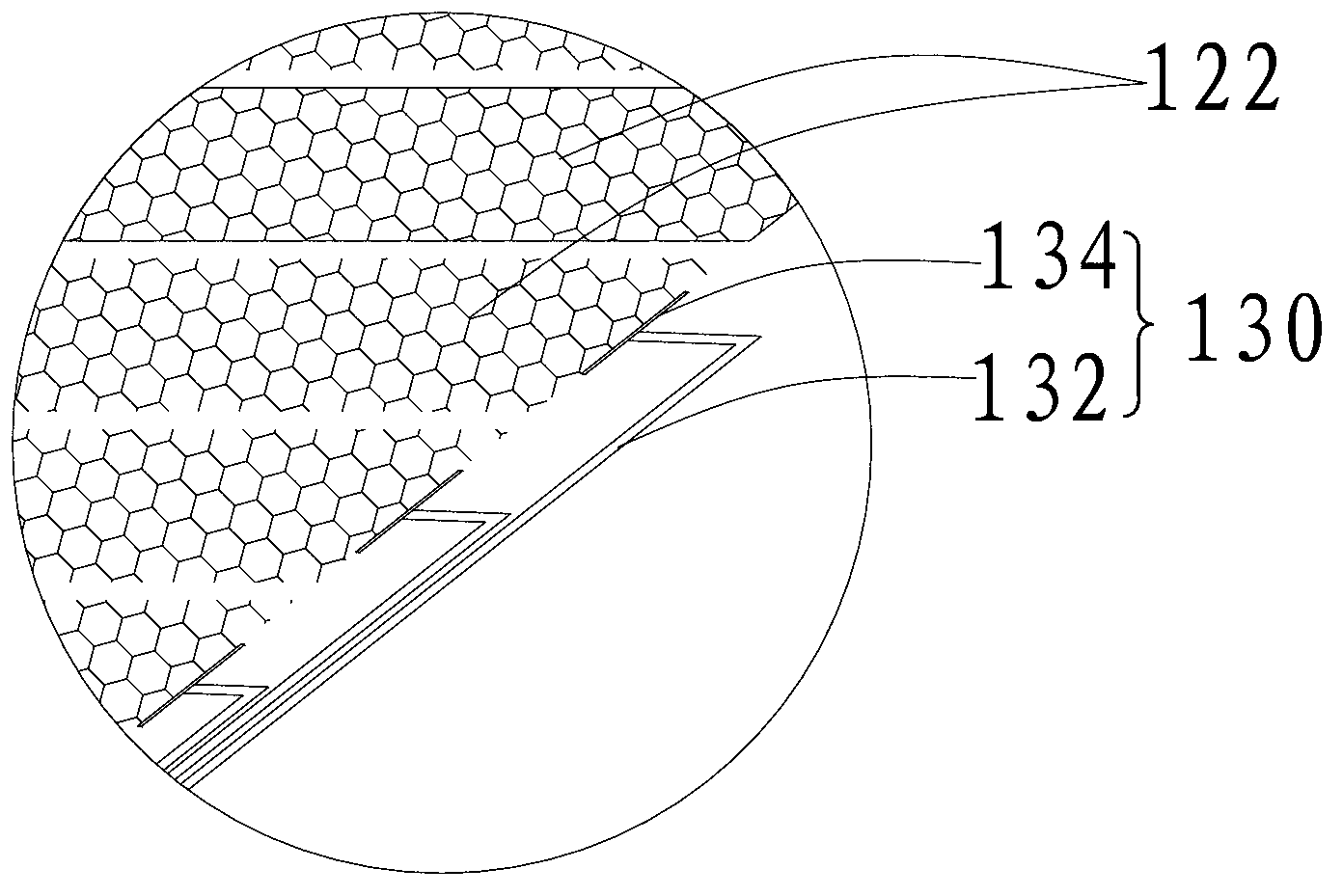

Display panel and display device

PendingCN108269503AReduce occlusionHigh light transmittancePrint image acquisitionNon-linear opticsWire widthDisplay device

The invention discloses a display panel and a display device. The display panel comprises a display module and a fingerprint recognition module, wherein the display module comprises an array base plate and a plurality of pixel units positioned on the array base plate; the fingerprint recognition module is positioned at one side, far away from the pixel units, of the array base plate; the fingerprint recognition module comprises a first base plate and at least one fingerprint recognition unit positioned on the first base plate; the fingerprint recognition unit is used for performing fingerprintrecognition according to light rays reflected to the fingerprint recognition unit through a touch main body; the array base plate comprises a plurality of light transmission regions and a plurality of non-light transmission regions; the array base plate also comprises a plurality of metal wires; the ratio of the wire width of at least one metal passing wire corresponding to at least one light transmission region to the wire width corresponding to the arrangement part of the non-light-transmission region is smaller than 1. By using the technical scheme, compared with the prior art, the displaypanel and the display device have the advantages that the wire width of the at least one metal passing wire corresponding to at least one light transmission region is reduced; the fingerprint recognition signal quantity of the fingerprint recognition unit is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Method for manufacturing anode screen plate for improving solar cell silicon sheet conversion rate

Owner:SUZHOU OUFANG ELECTRONICS TECH

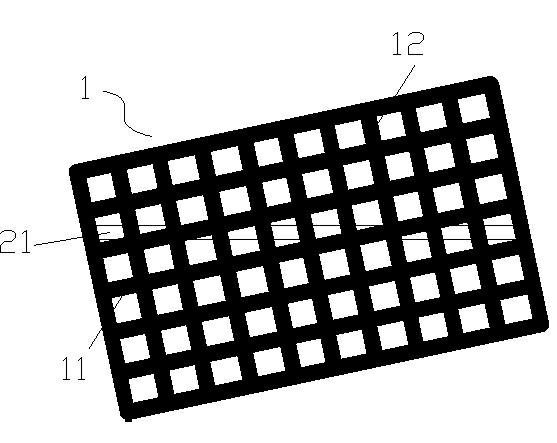

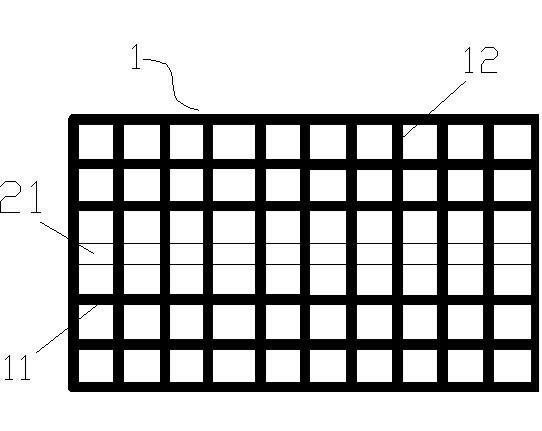

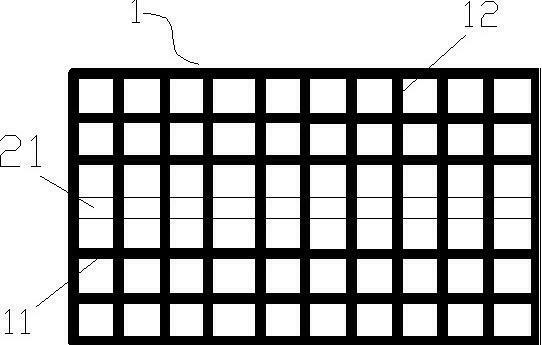

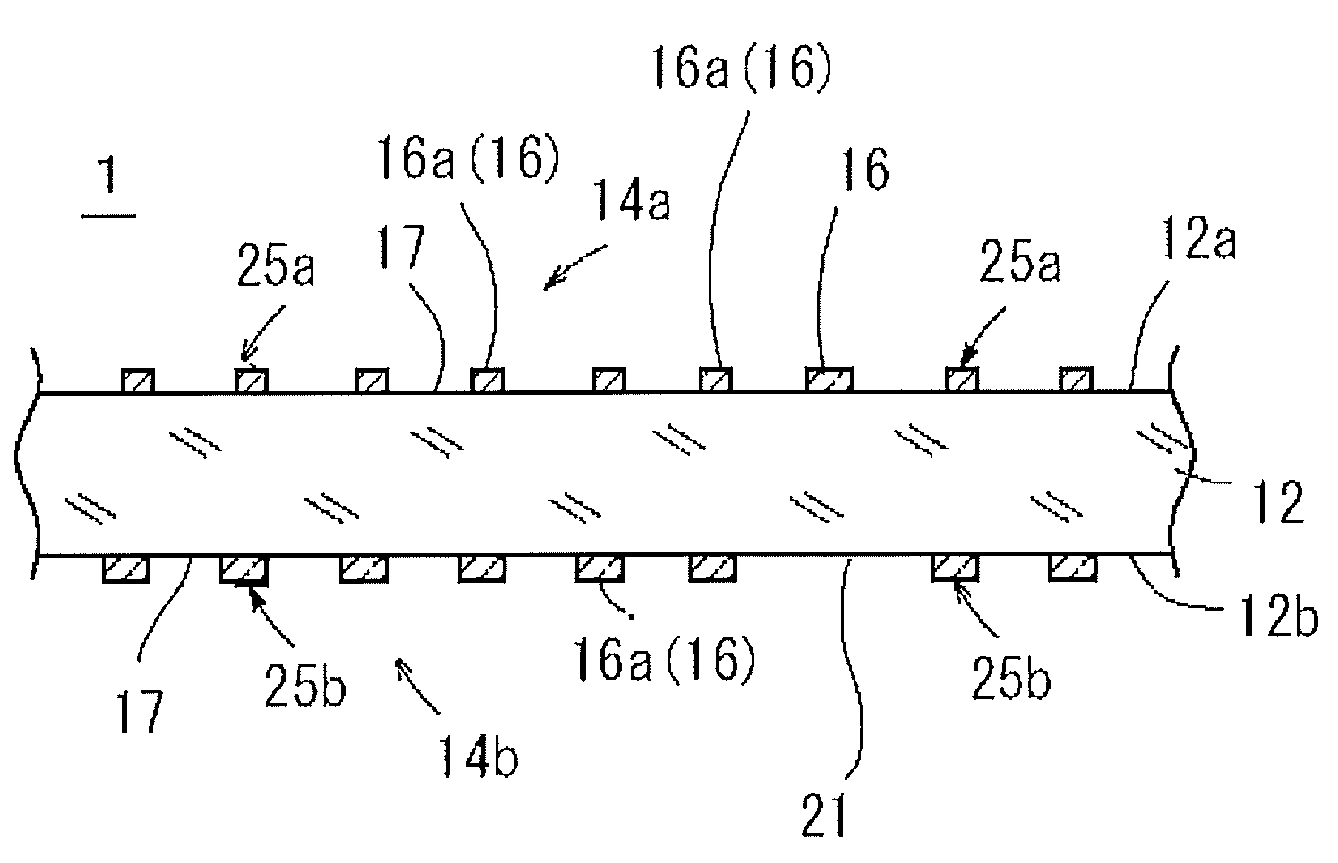

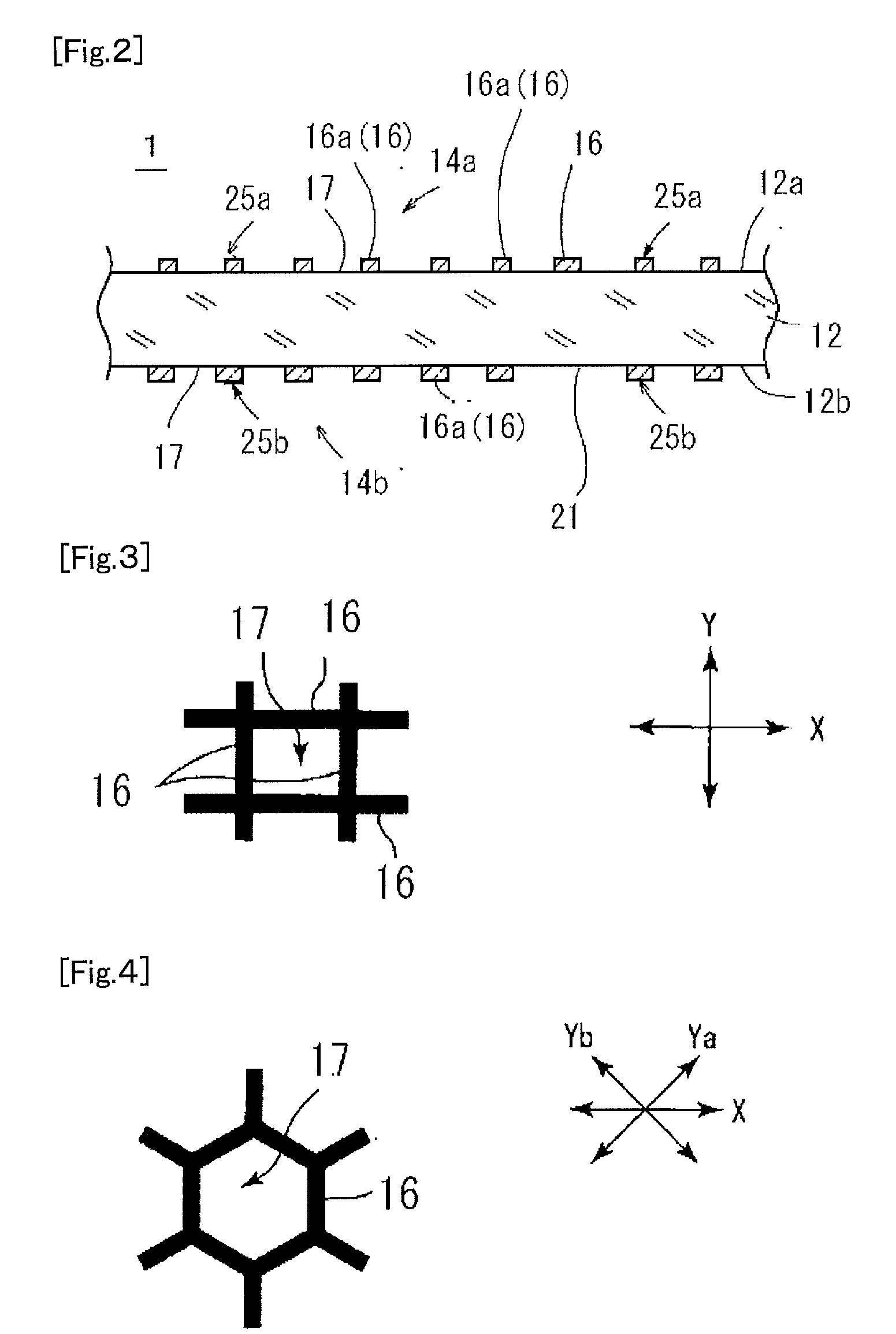

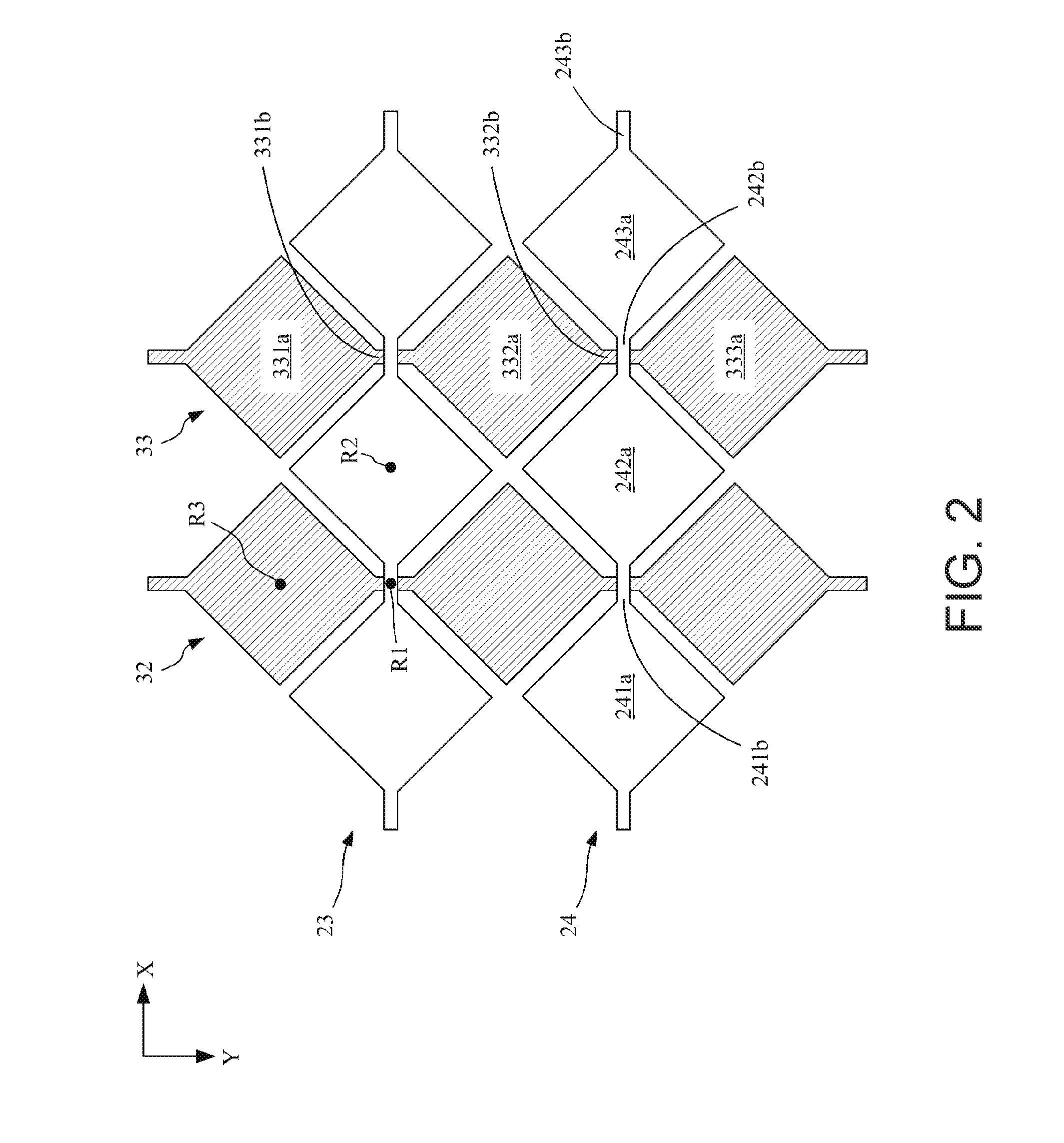

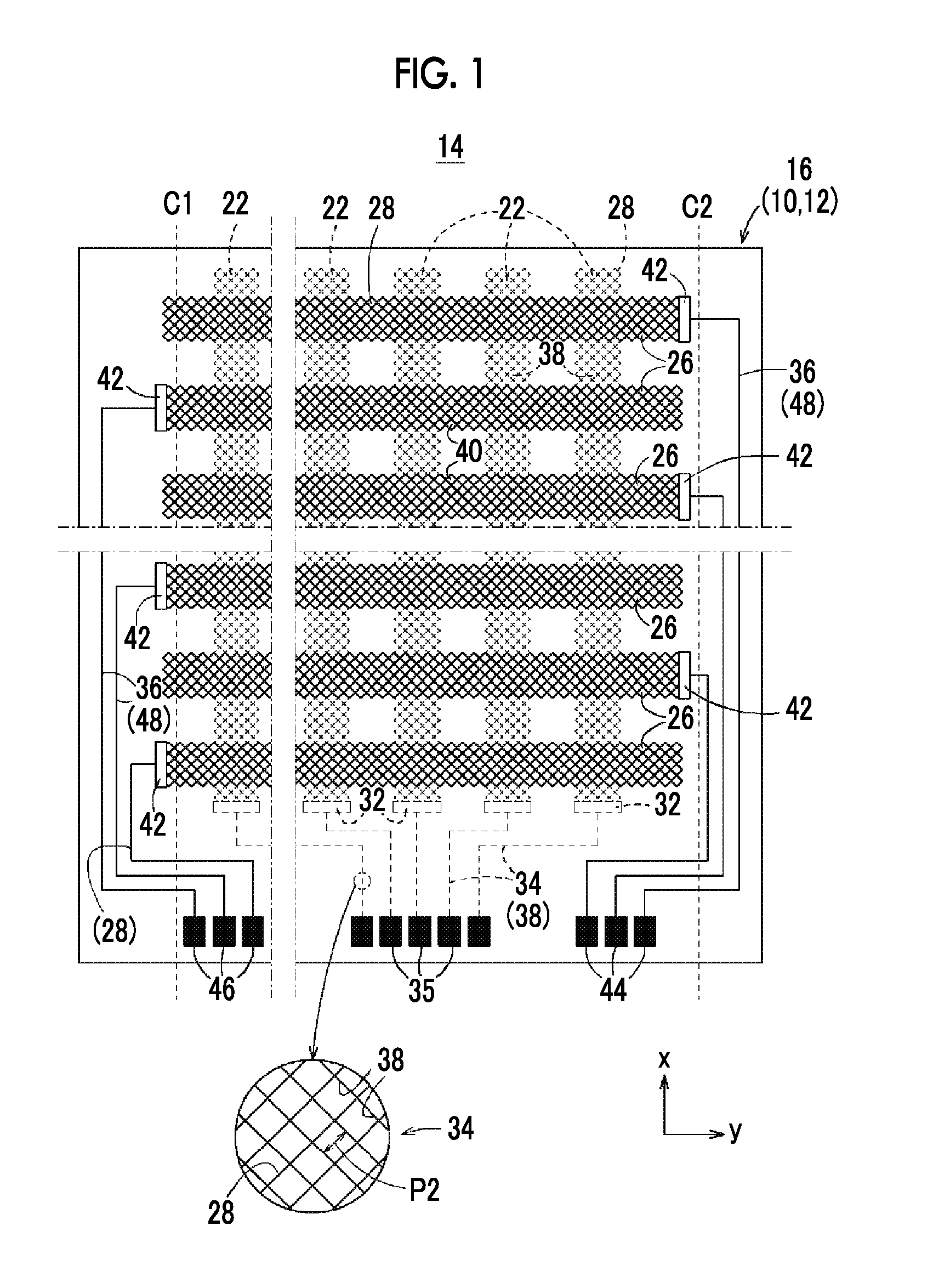

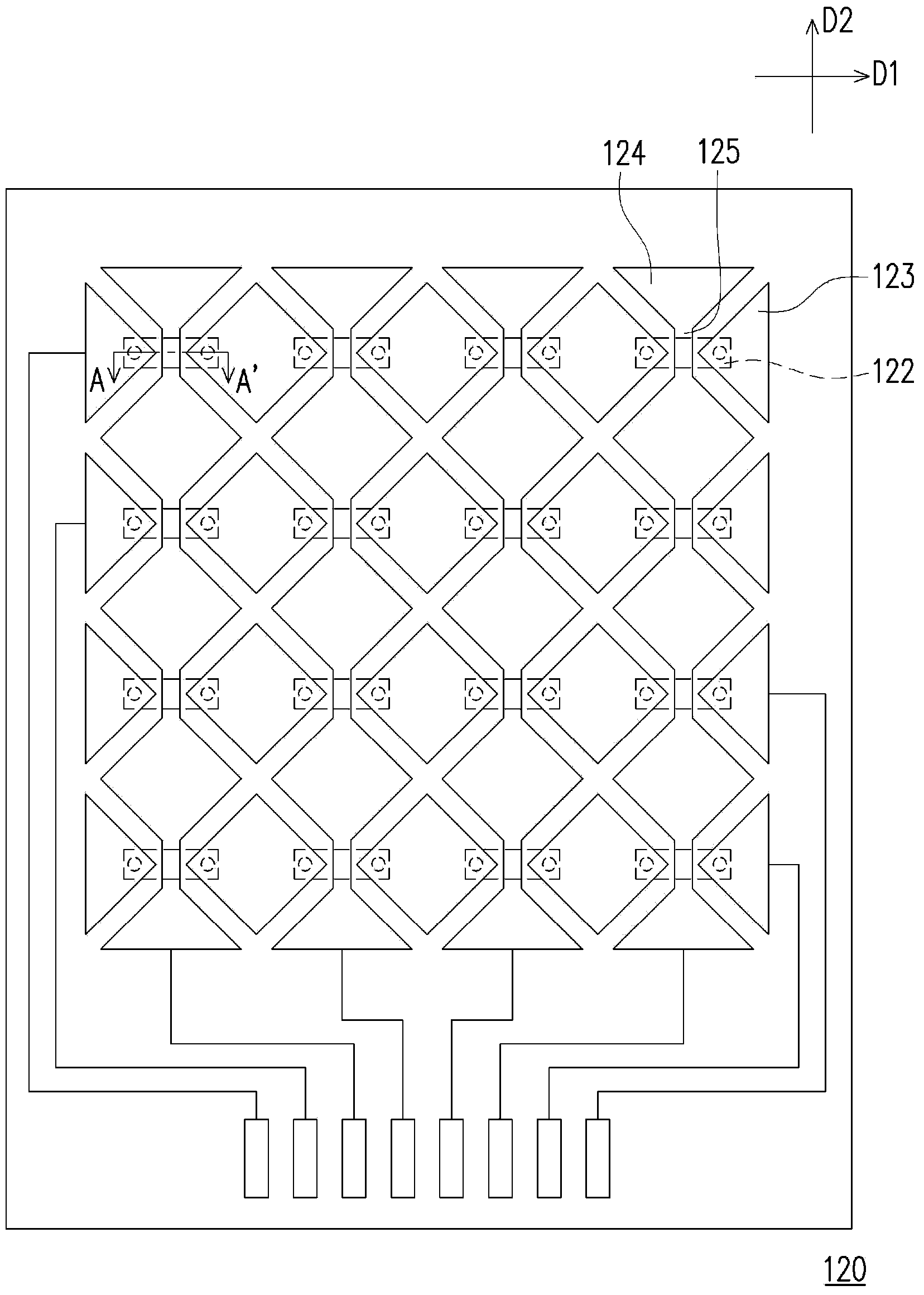

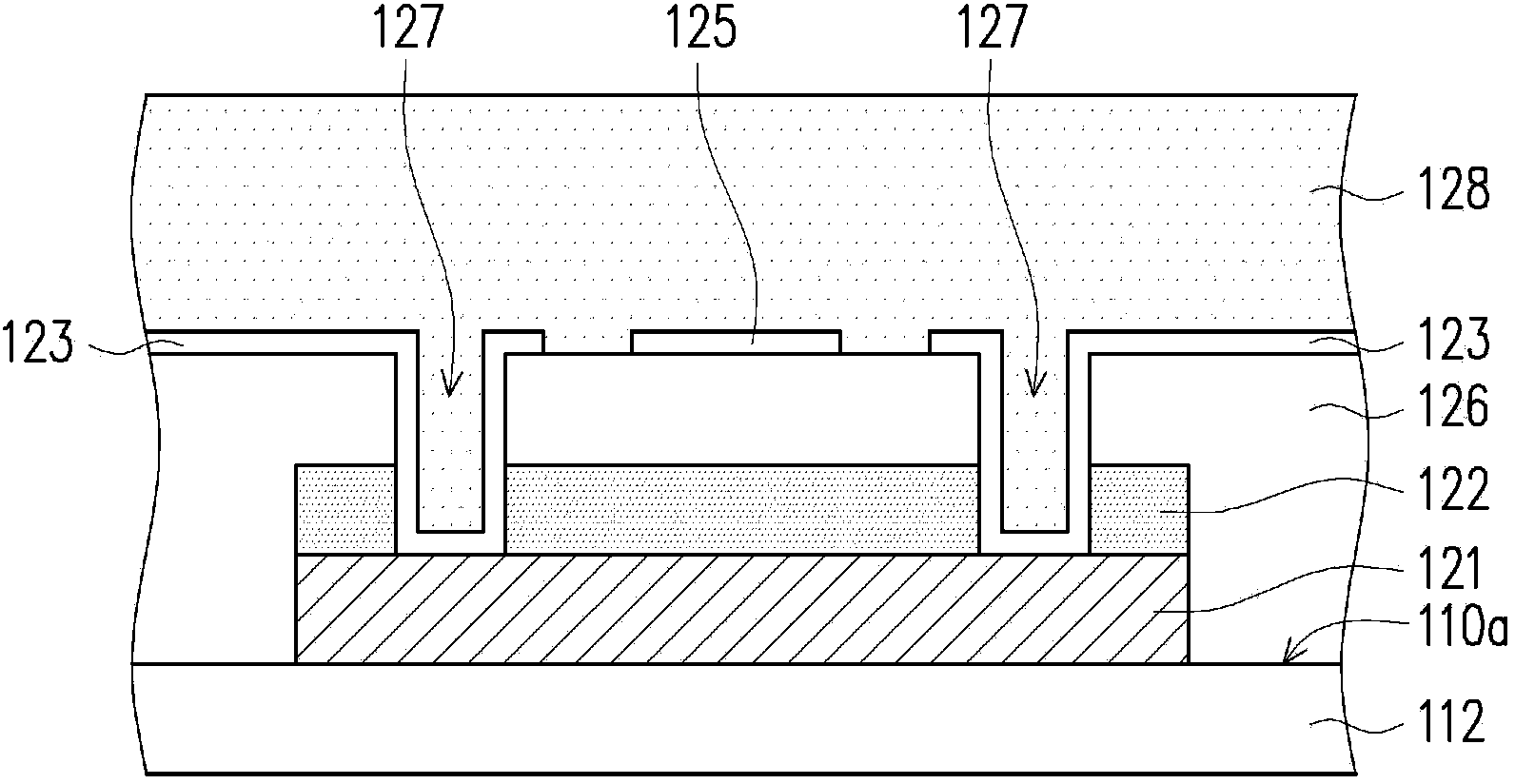

Electrode sheet for capacitance-type touch panel

ActiveUS20160370916A1High transparencyInput/output processes for data processingWire widthCapacitance

A first electrode pattern 25a and a second electrode pattern 25b, each composed of an opaque conductive fine line and a blank part 17 partitioned by the conductive fine line, have line segments 16a of the conductive fine lines 16, that face each other across a substrate 12, and the conductive fine line 16 in one of the first electrode pattern 25a and the second electrode pattern 25b is formed narrower in line width than that in the other of the first electrode pattern 25a and the second electrode pattern 25b only at the facing line segment 16a, thereby designed to have a non-uniform width.

Owner:NISSHA PRINTING COMPANY

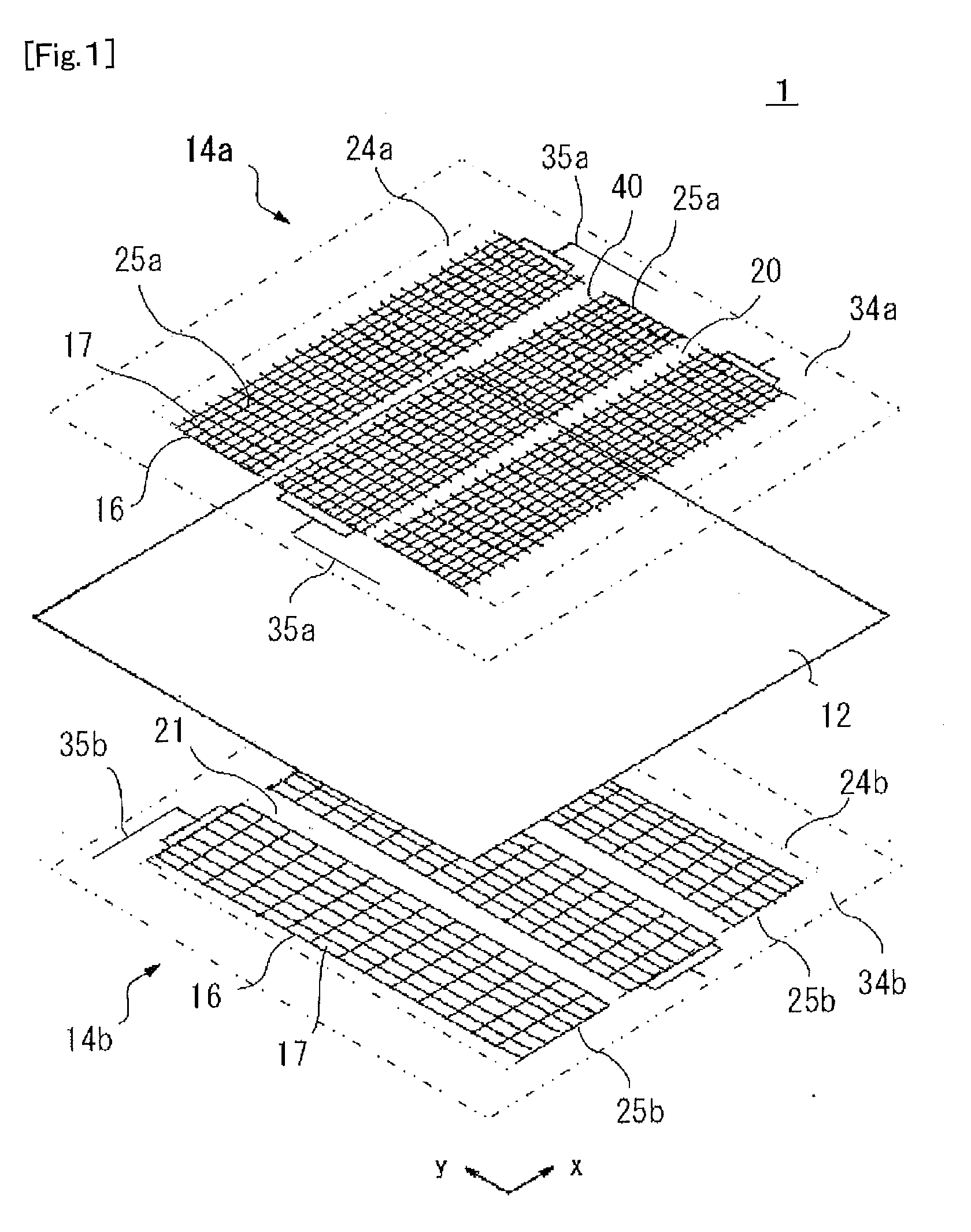

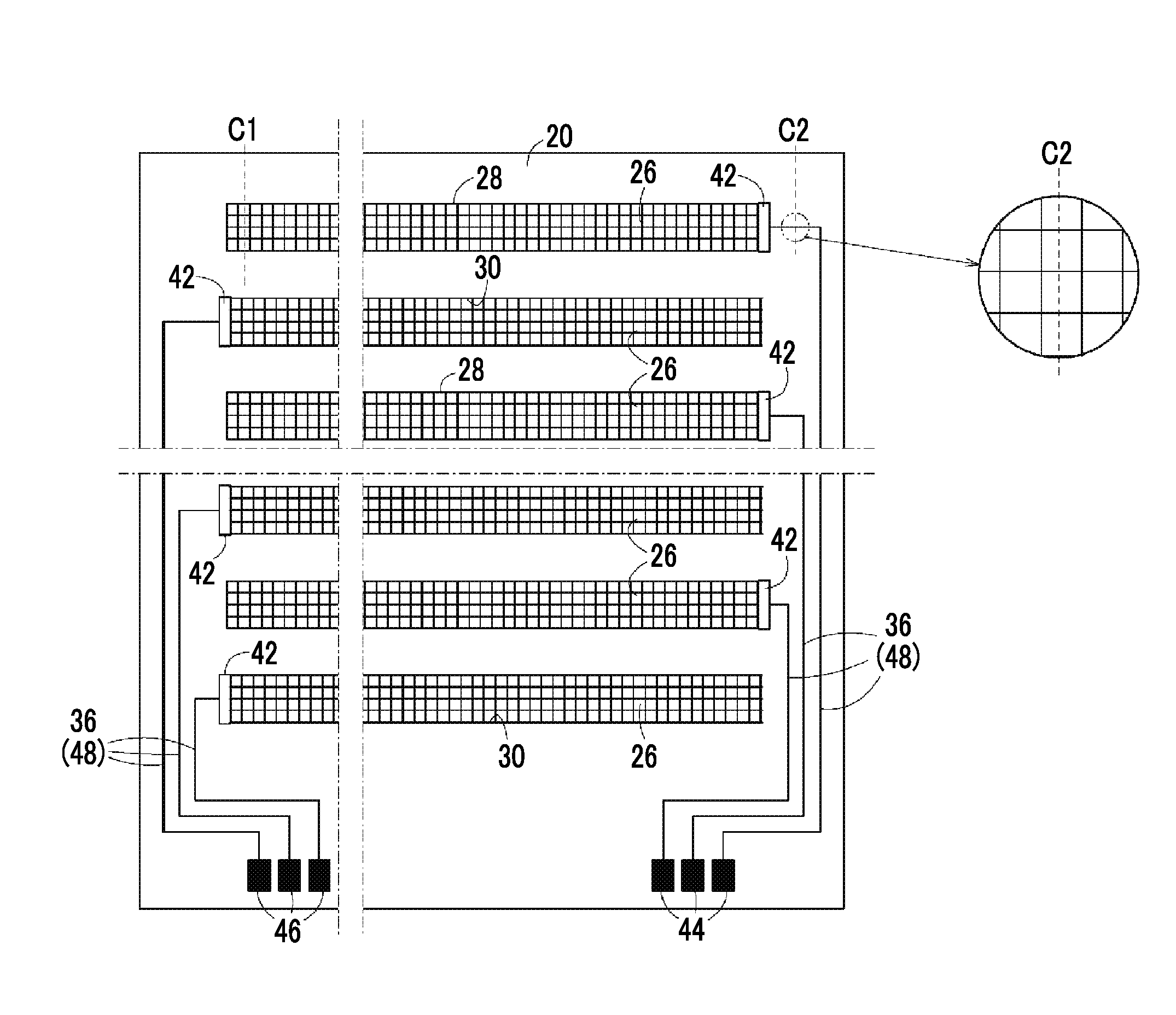

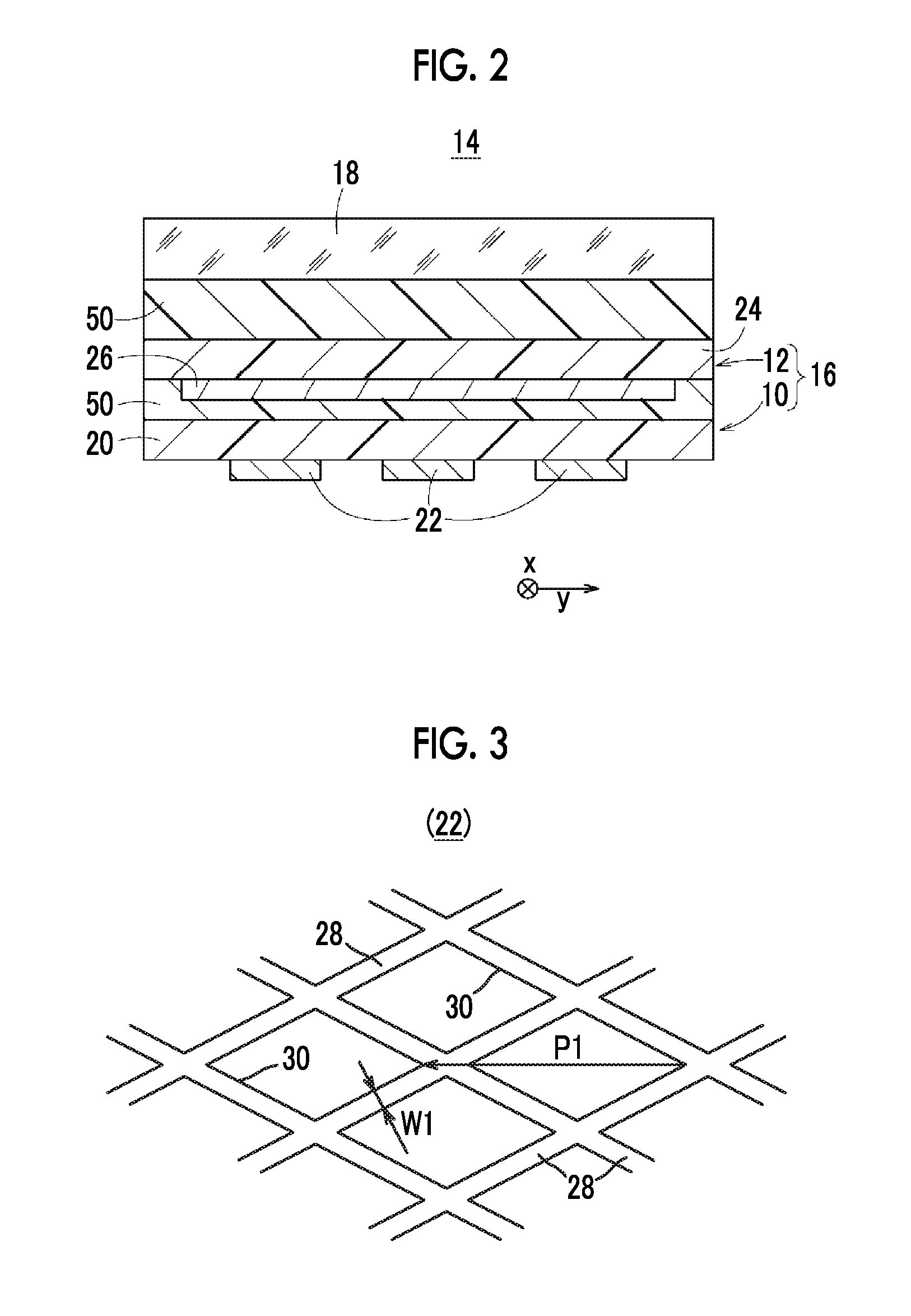

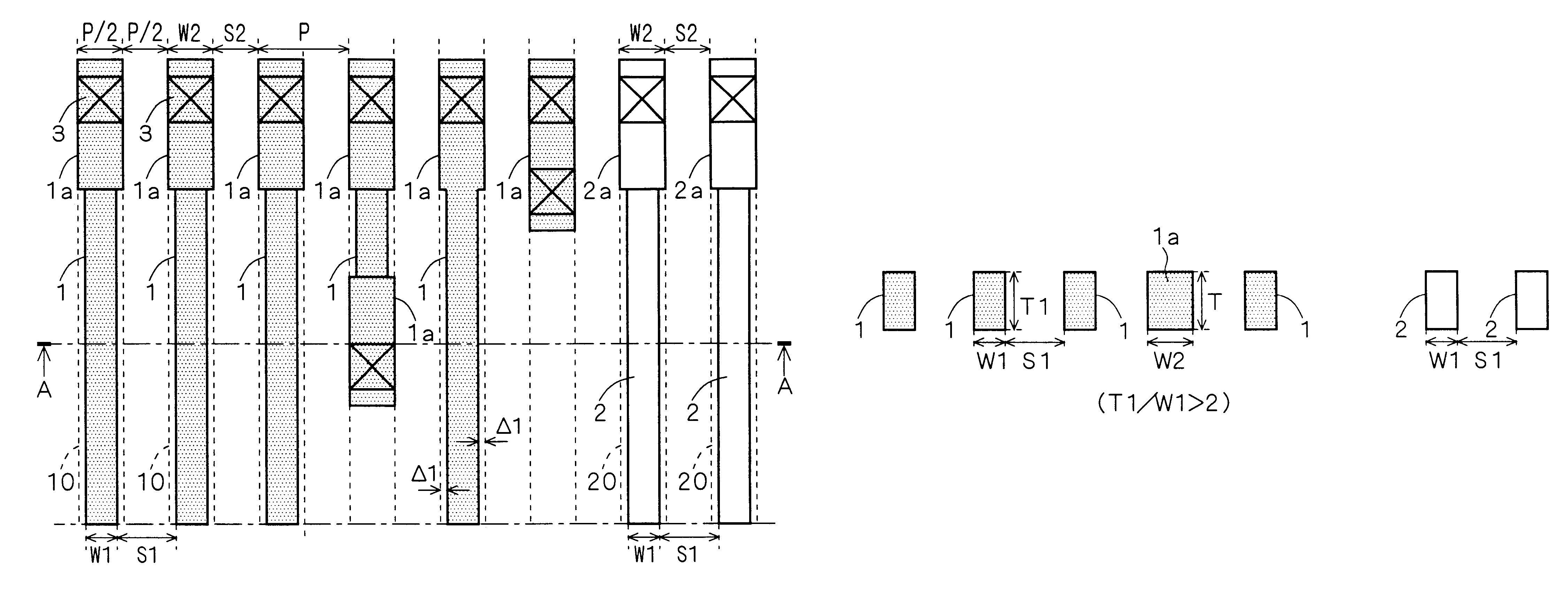

Conductive sheet, touch panel device, display device, and method for manufacturing conductive sheet

InactiveUS20160231861A1Improve visibilityAvoid interferenceInput/output processes for data processingWire widthDisplay device

A touch panel includes: a substrate; an X axis direction electrode part; and a Y axis direction electrode part. The X axis direction electrode part includes a plurality of fine metal wires formed on one main surface (a first main surface) of the substrate. The Y axis direction electrode part includes a plurality of fine metal wires formed on another main surface (a second main surface) of the substrate. In bridge regions in which the X axis direction electrode part and the Y axis direction electrode part overlap in a plan view, the wiring pattern of the plurality of the fine metal wires included in the X axis direction electrode part is identical to the wiring pattern of the plurality of the fine metal wires included in the Y axis direction electrode part. In the bridge regions, the wire width of the fine metal wires included in the X axis direction electrode part is larger than the wire width of the fine metal wires included in the Y axis direction electrode part.

Owner:SHARP KK

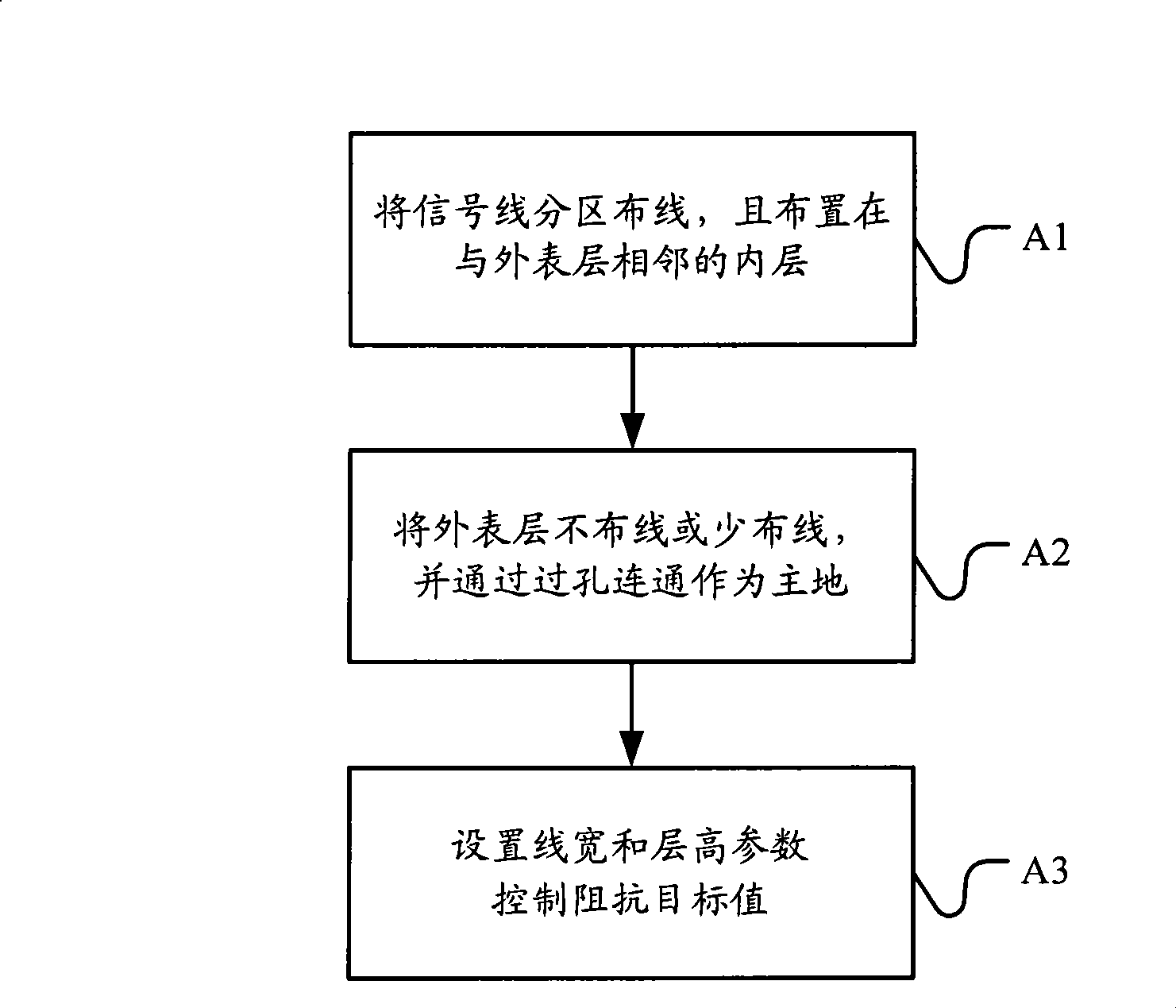

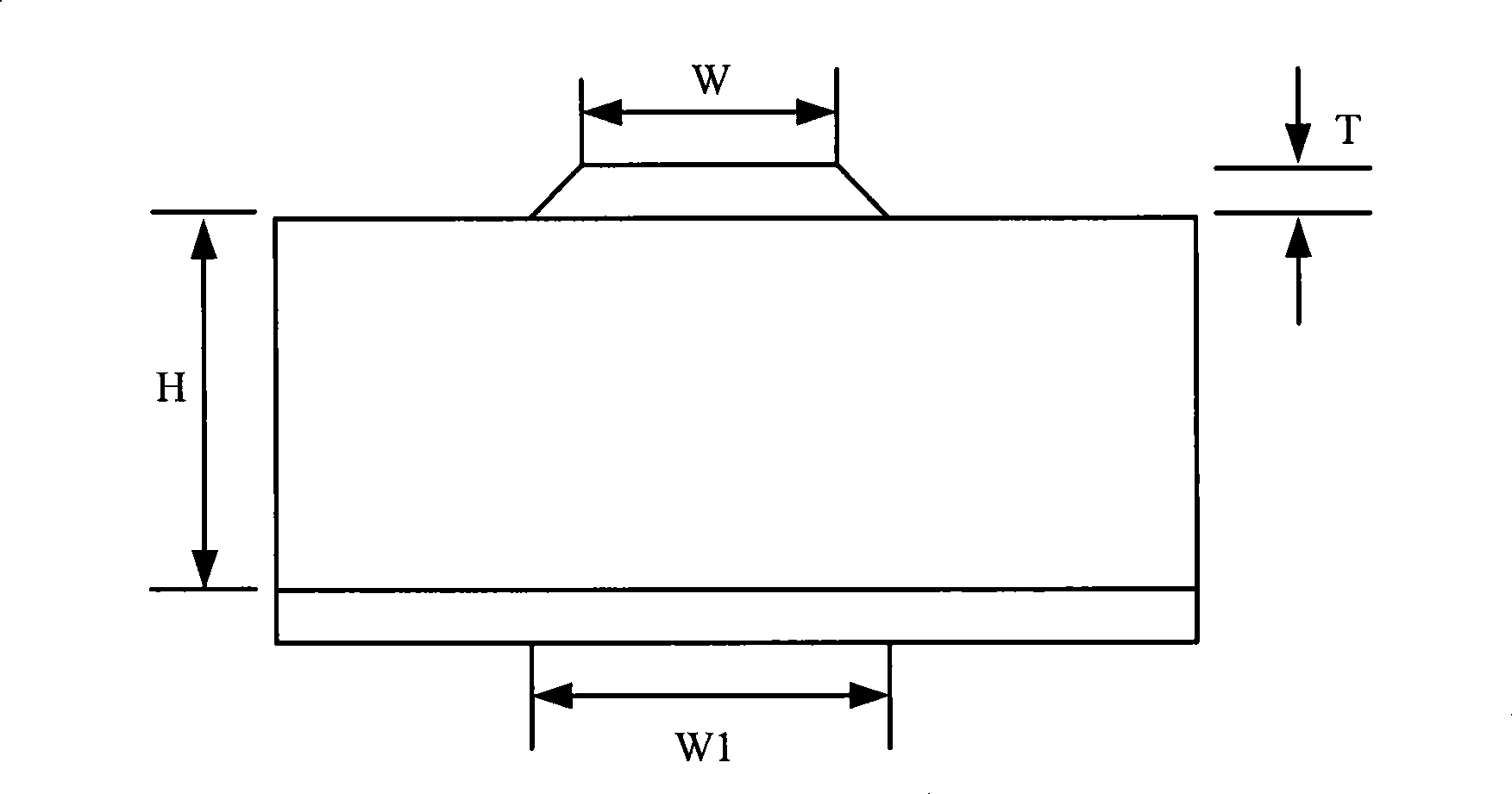

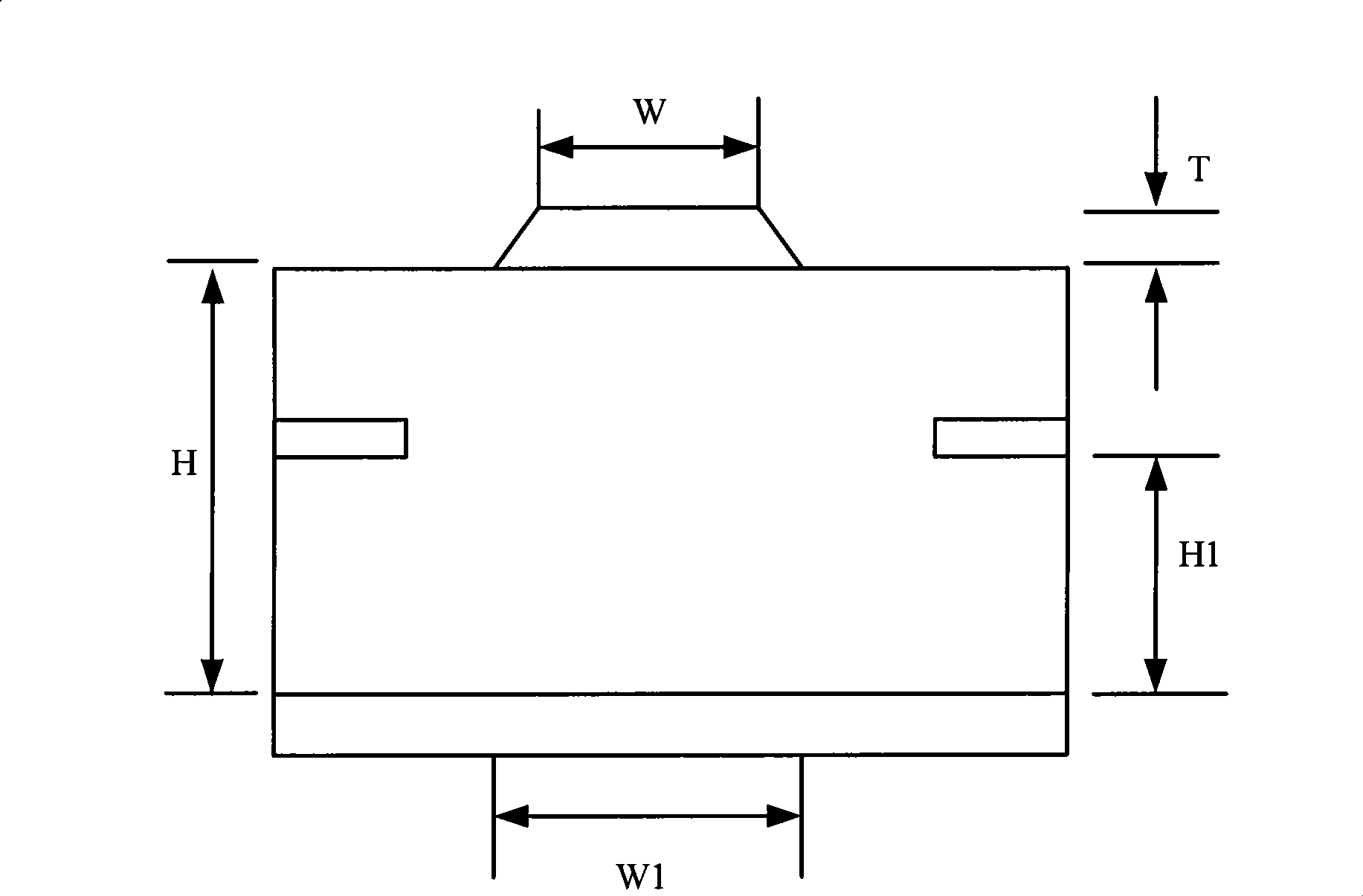

Printed circuit board, design method thereof and terminal product main board

ActiveCN101365291AGuaranteed basic performanceGuaranteed performanceCross-talk/noise/interference reductionPrinted circuit aspectsWire widthSurface layer

The embodiment of the invention discloses a design method of a printed circuit board. The method comprises the following steps of laying a signal wire on inner layers next to an outer surface layer by zones; not wiring the outer surface layer or laying less wire on the outer surface layer which is used as a main area communicated through a hole; and setting wire width and layer height parameters to control an impedance target value. Correspondingly, the embodiment of the invention provides the printed circuit board, which comprises the out surface layer, and two inner layers positioned between the surface layers. The inner layers next to the out surface layer are used for laying signal wires by zones. Few wires or no wire is laid on the out surface layer and the outer surface layer is used as the main area communicated through the hole. The invention also discloses a terminal product main board using the printed circuit board. The technical proposal provided by the embodiment of the invention can reduce the cost and improve the reliability by layer reduction design under the condition that the basic properties of the original multi-layer printed circuit board is kept.

Owner:HUAWEI TECH CO LTD

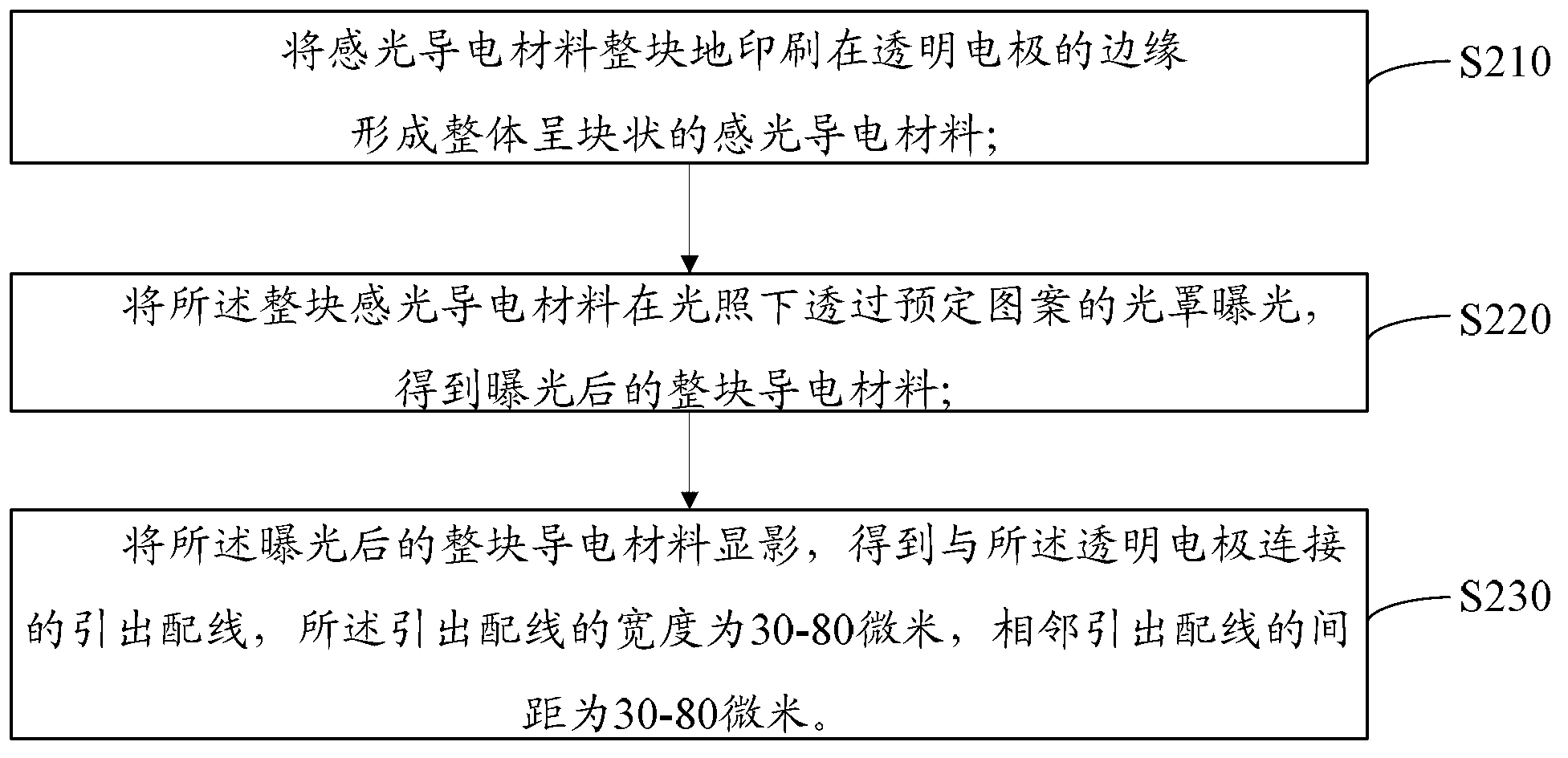

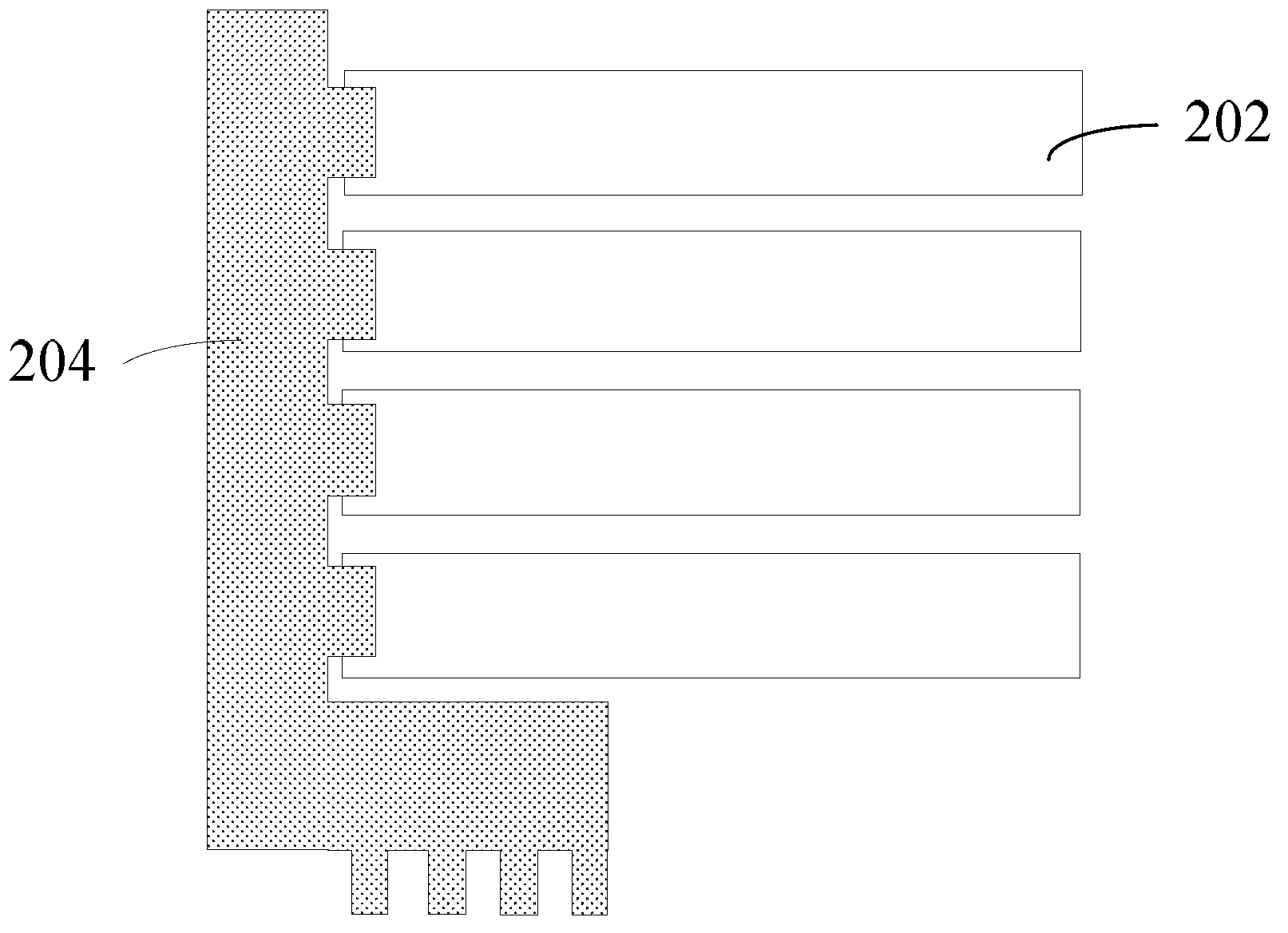

Touch screen sensing component and production method thereof

InactiveCN103268180ANeat lineMeet design needsInput/output processes for data processingWire widthFine line

The invention discloses a touch screen sensing component and a production method thereof. The production method includes the steps of printing a sheet of photosensitive conductive material on the side of a transparent electrode to obtain a photosensitive conductive sheet; and exposing the photosensitive conductive sheet to light under a photomask with a preset pattern, and developing to obtain an outgoing wire of the transparent electrode. The production method has the advantages that the outgoing wire is made of the photosensitive conductive material, the traditional printing is combined with exposure and development; and accordingly, fine lines are generated by the exposure and development, the complex process of metal film evaporation and etching and photoresist stripping is avoided, and the production cost of fine wires is reduced. The outgoing wires of the touch screen sensing component produced by the method are 30 micrometers / 30 micrometers in wire width / wire spacing, and the touch screen sensing component meets the design requirement of market for narrow-frame touch screens.

Owner:SUZHOU O FILM TECH

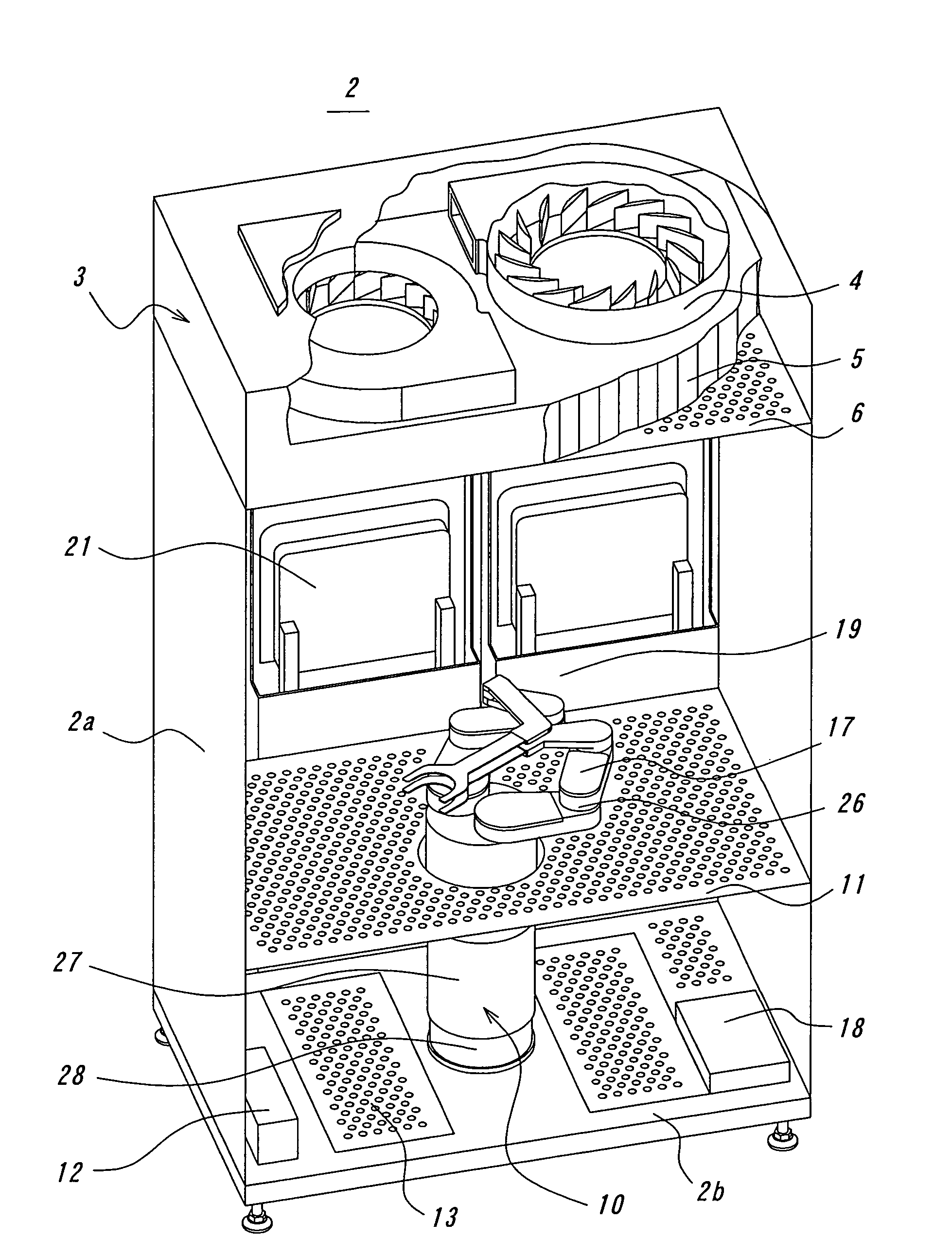

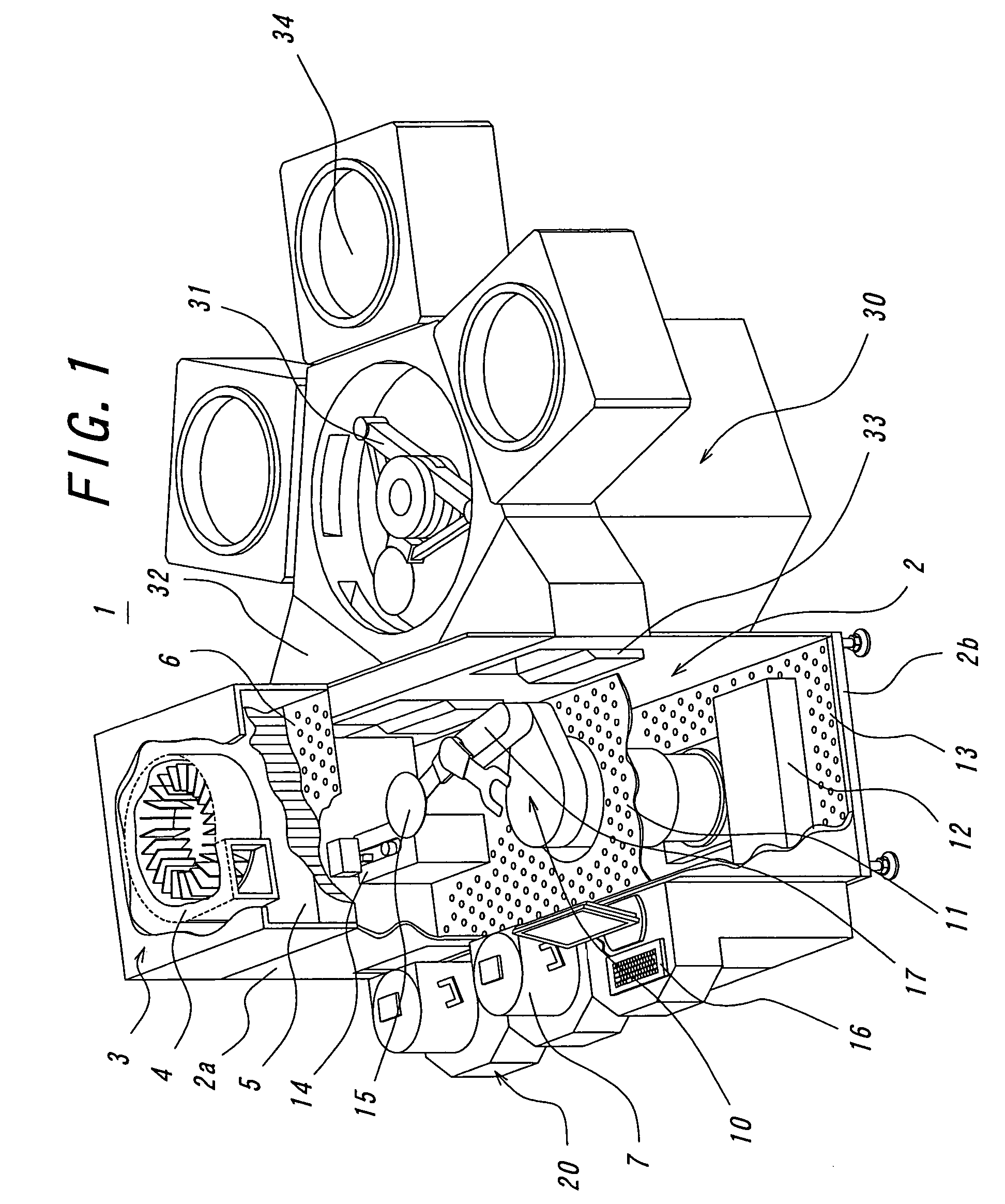

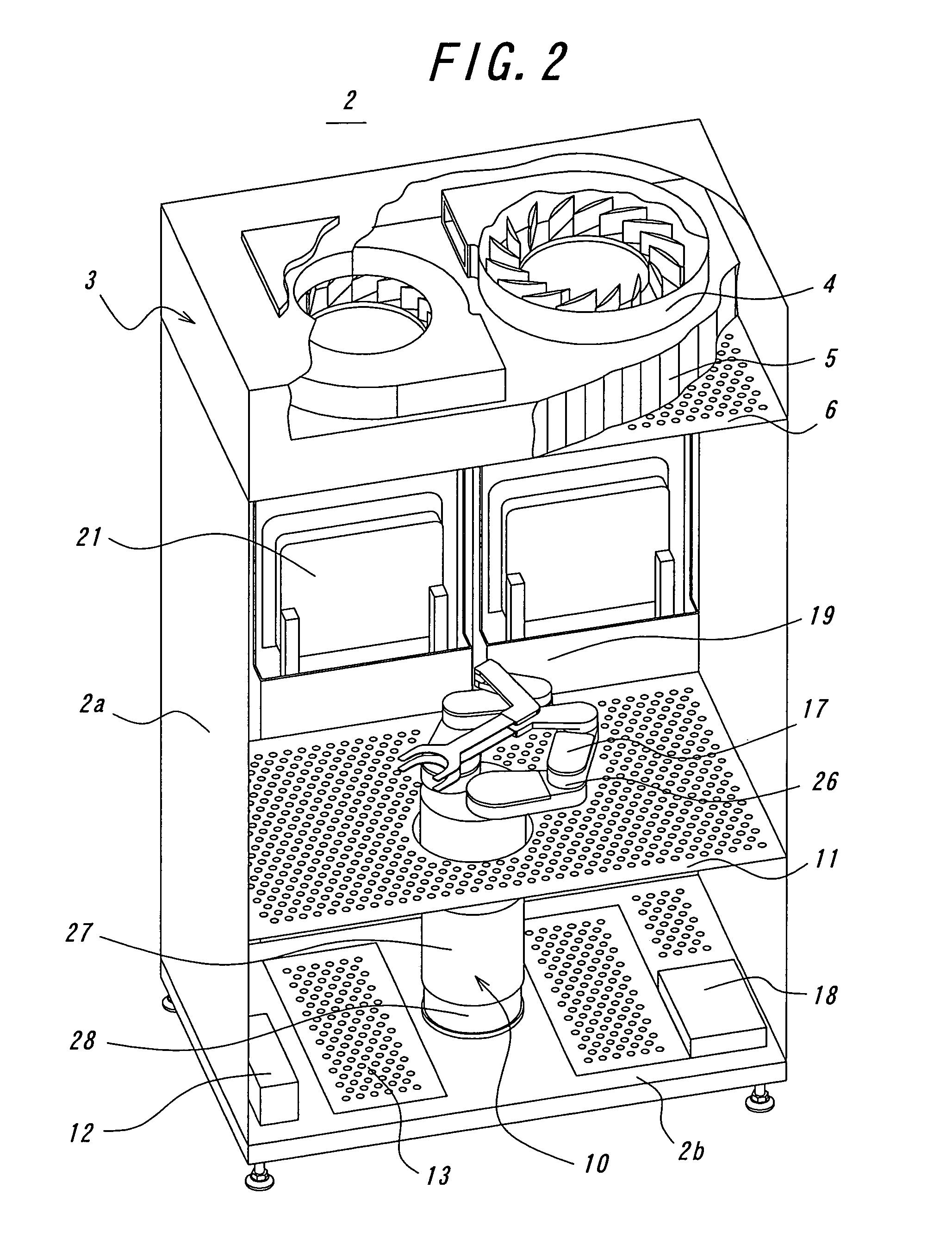

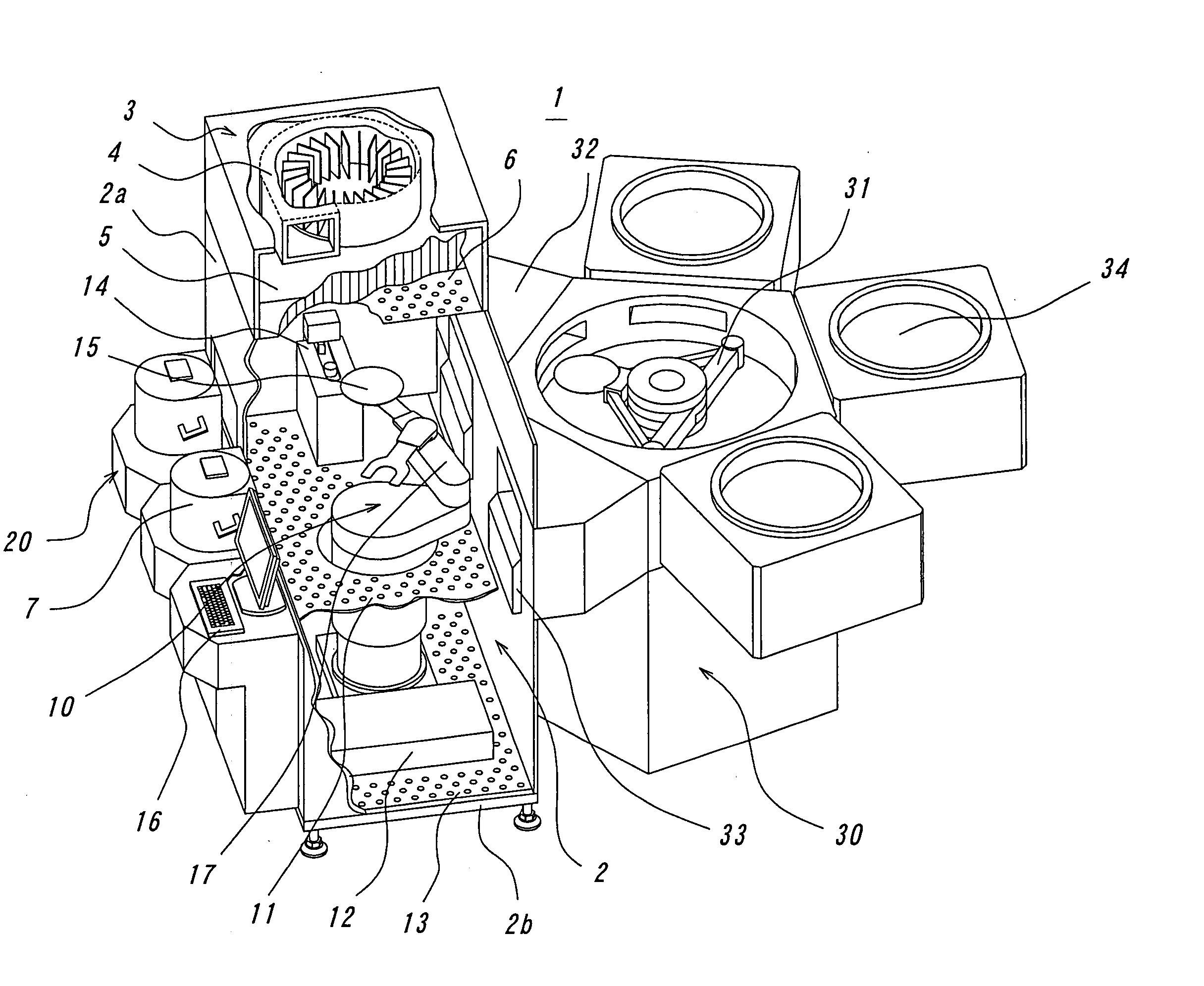

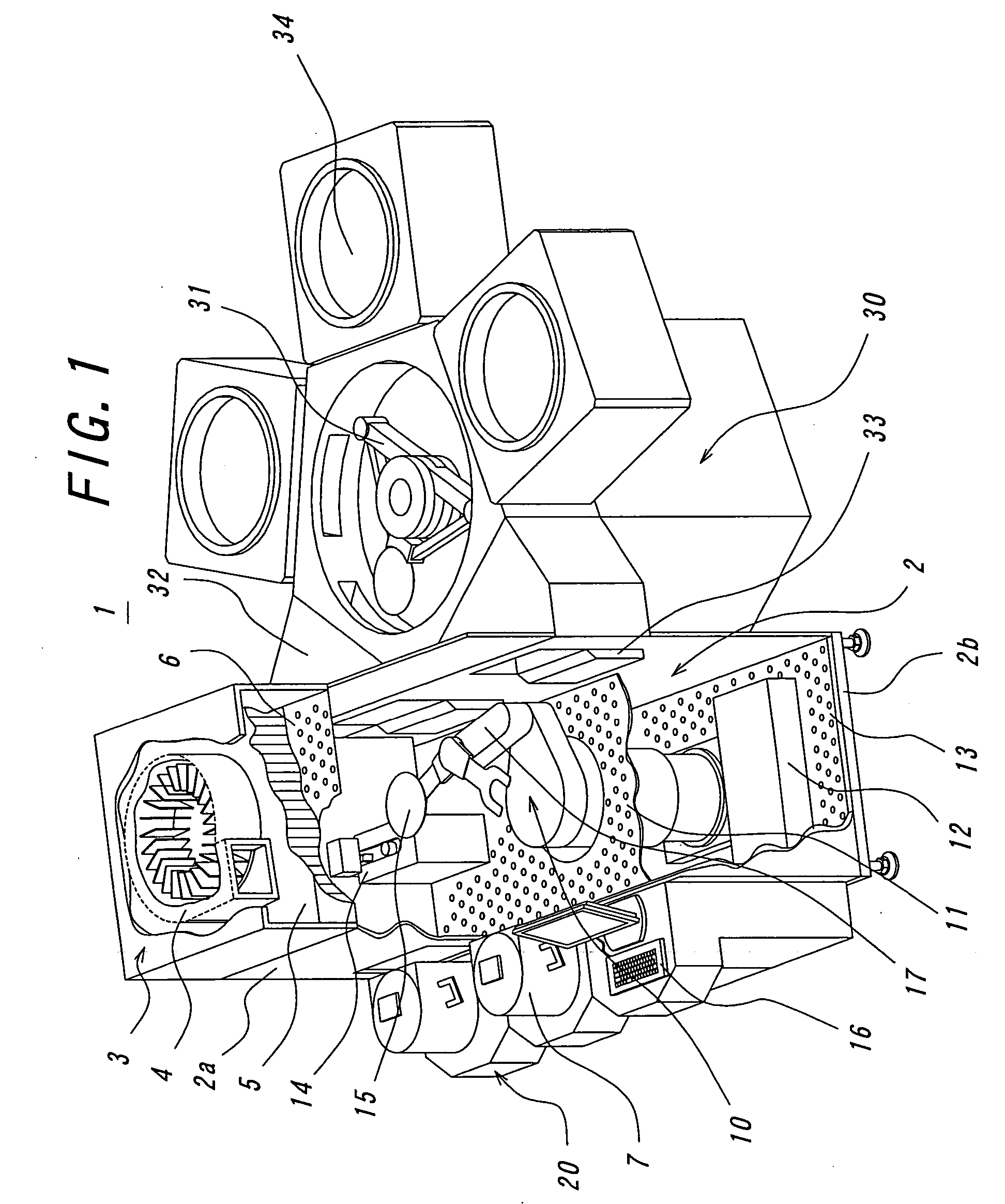

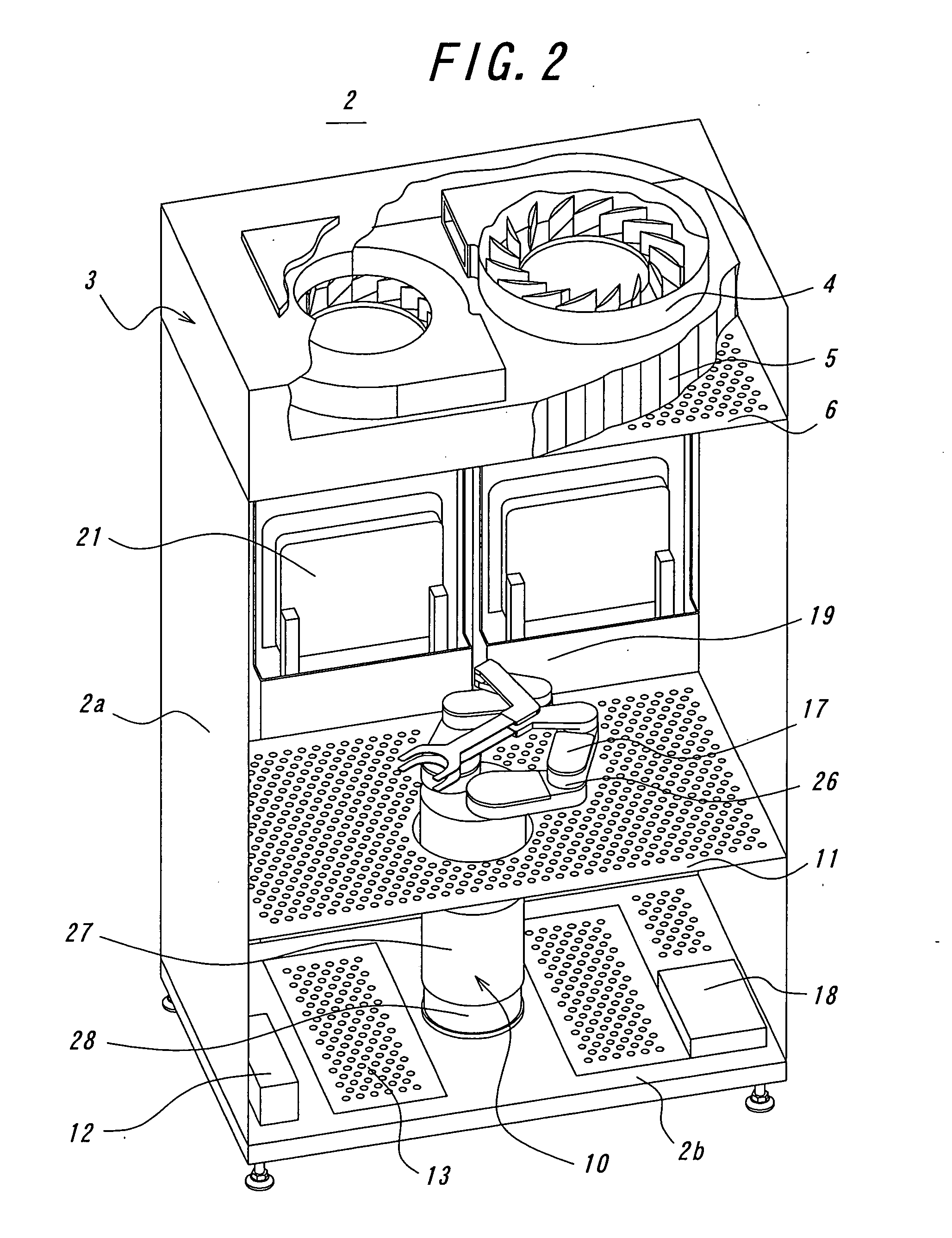

Sheet-like electronic component clean transfer device and sheet-like electronic component manufacturing system

InactiveUS7635244B2Improve cleanlinessSuppress air pressure fluctuationsSemiconductor/solid-state device manufacturingCharge manipulationWire widthPunching

When a first floor (11) which is formed of a punching plate or the like and through which air passes is provided immediately below an arm (17) at a middle height part of a conveying robot (10) in a casing (2a) of a clean transfer device (2) and a degree of opening of a casing bottom part frame (2b), which supports a base part of the conveying robot (10), with respect to the outside is restricted, a class 1 can be maintained. Here, when a second floor (13) formed of a punching plate or the like is used on the casing bottom part frame (2b), a class 0 state can be realized under specific conditions, thereby enabling production of a semiconductor having a wire width of 0.1 μm. As a result, the device can cope with the unexpectedly high degree of cleanliness of 0.1 μm particle class 1, which cannot be realized in the prior art, requested also for the transfer device according to a reduction in wire width on a highly integrated semiconductor wafer.

Owner:RORZE CORP

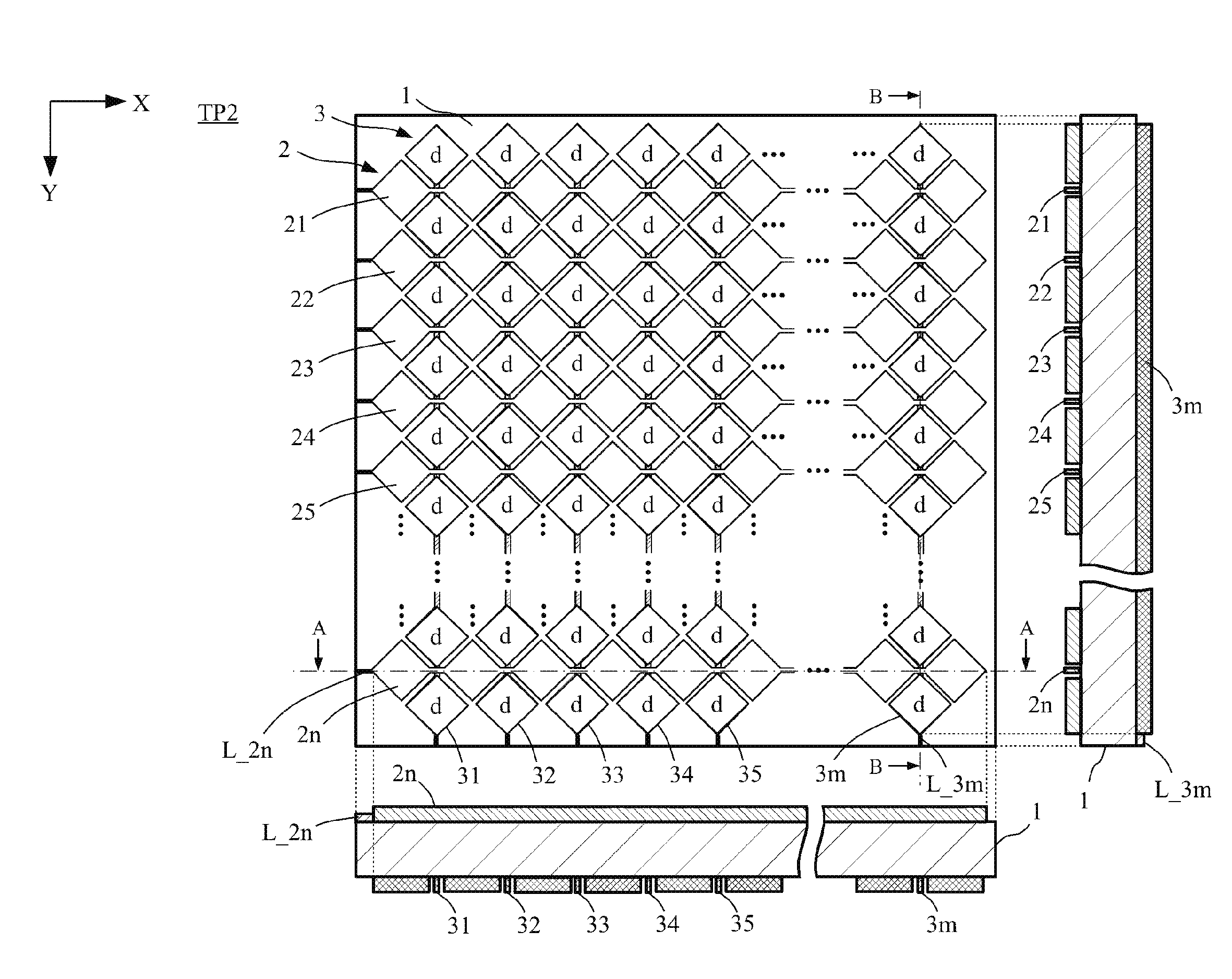

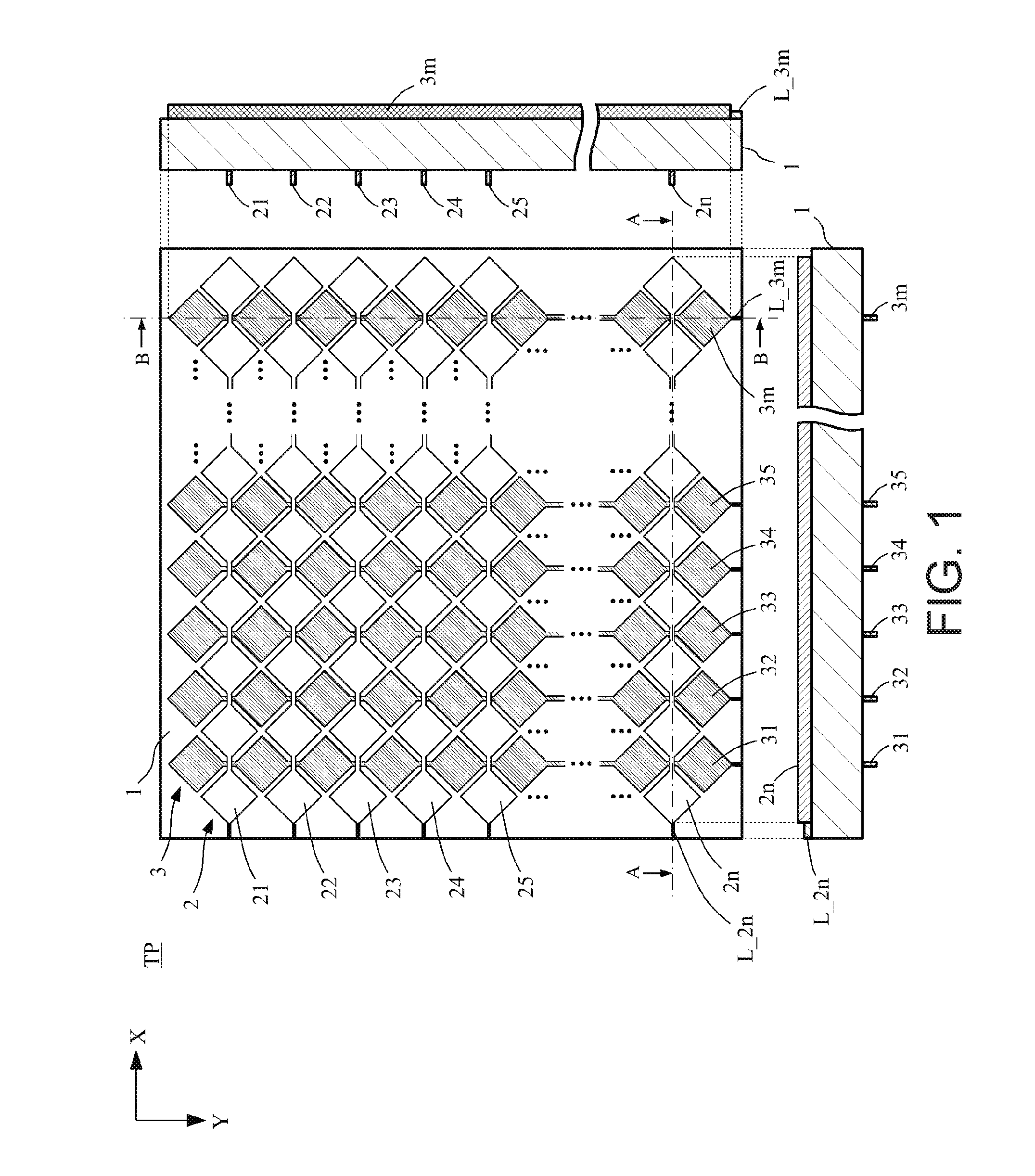

Conductive sheet for touch panel and capacitive touch panel

ActiveUS20170010720A1Good followabilityAvoid disconnectionInput/output processes for data processingWire widthTouchscreen

In a second-conductive-sheet for a touch-panel, a plurality of upper-detection-electrodes disposed in a detection region and a plurality of second terminal wiring portions disposed in a peripheral wiring region to electrically connect the upper-detection-electrodes to second terminal portions and are formed. Each of the upper-detection-electrodes is made of a mesh-patterned first metal mesh having intersecting thin conductive metal wires, and each of the second terminal wiring portions is made of a mesh-patterned second metal mesh having intersecting thin conductive metal wires made of the same material as the thin conductive metal wires constituting each of the upper detection electrodes. The wire width of the first metal mesh is set to be equal to or less than 5 μm, and the extension direction of the thin conductive metal wires constituting the first metal mesh and the second metal mesh is inclined with respect to a bending line direction of a bent portion of a second-resin-film.

Owner:FUJIFILM CORP

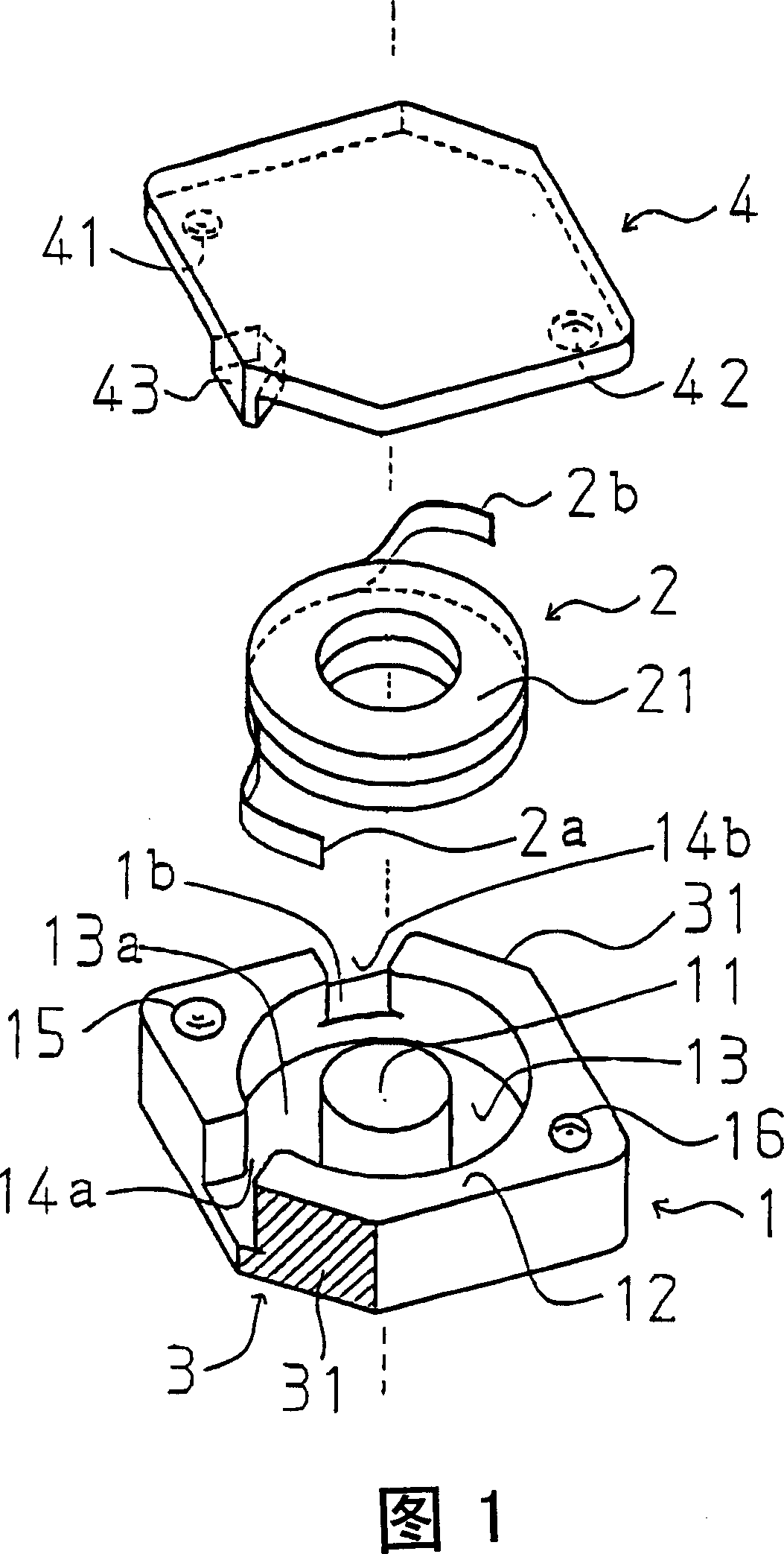

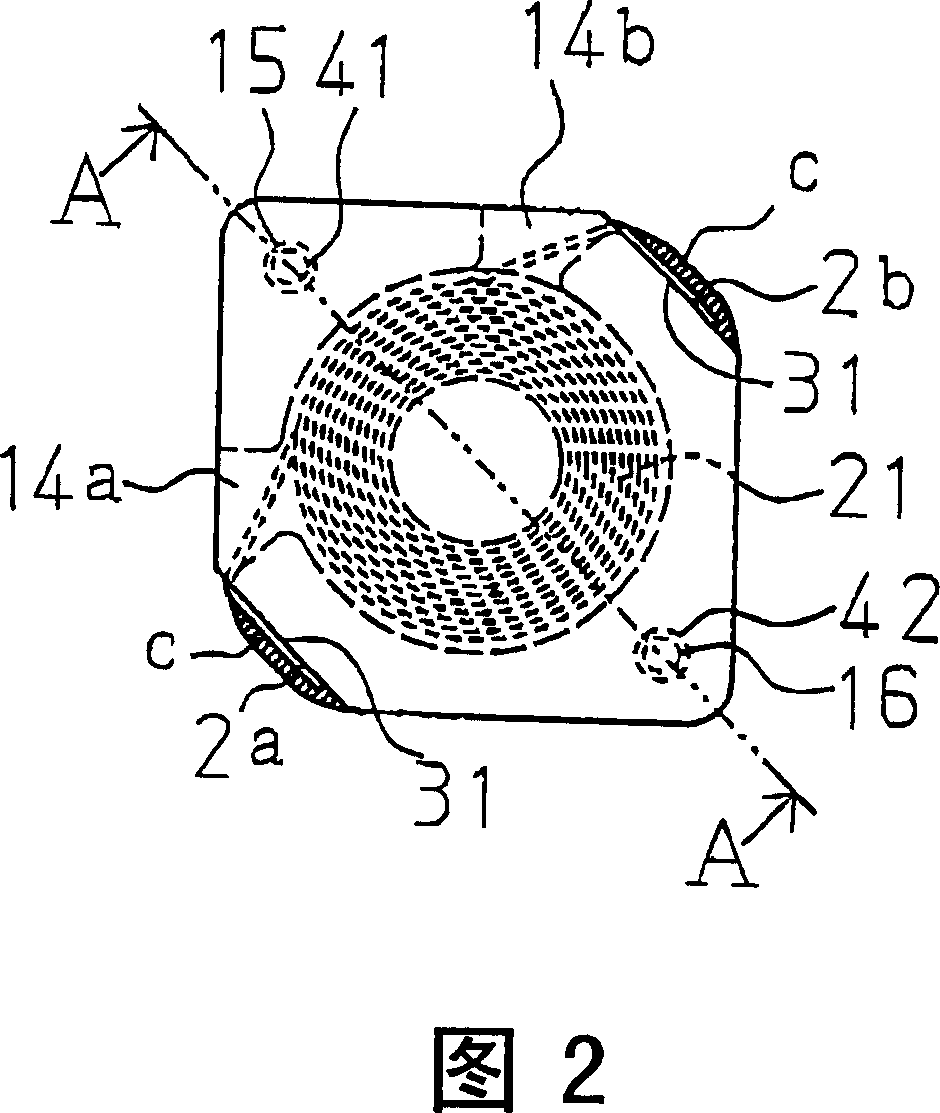

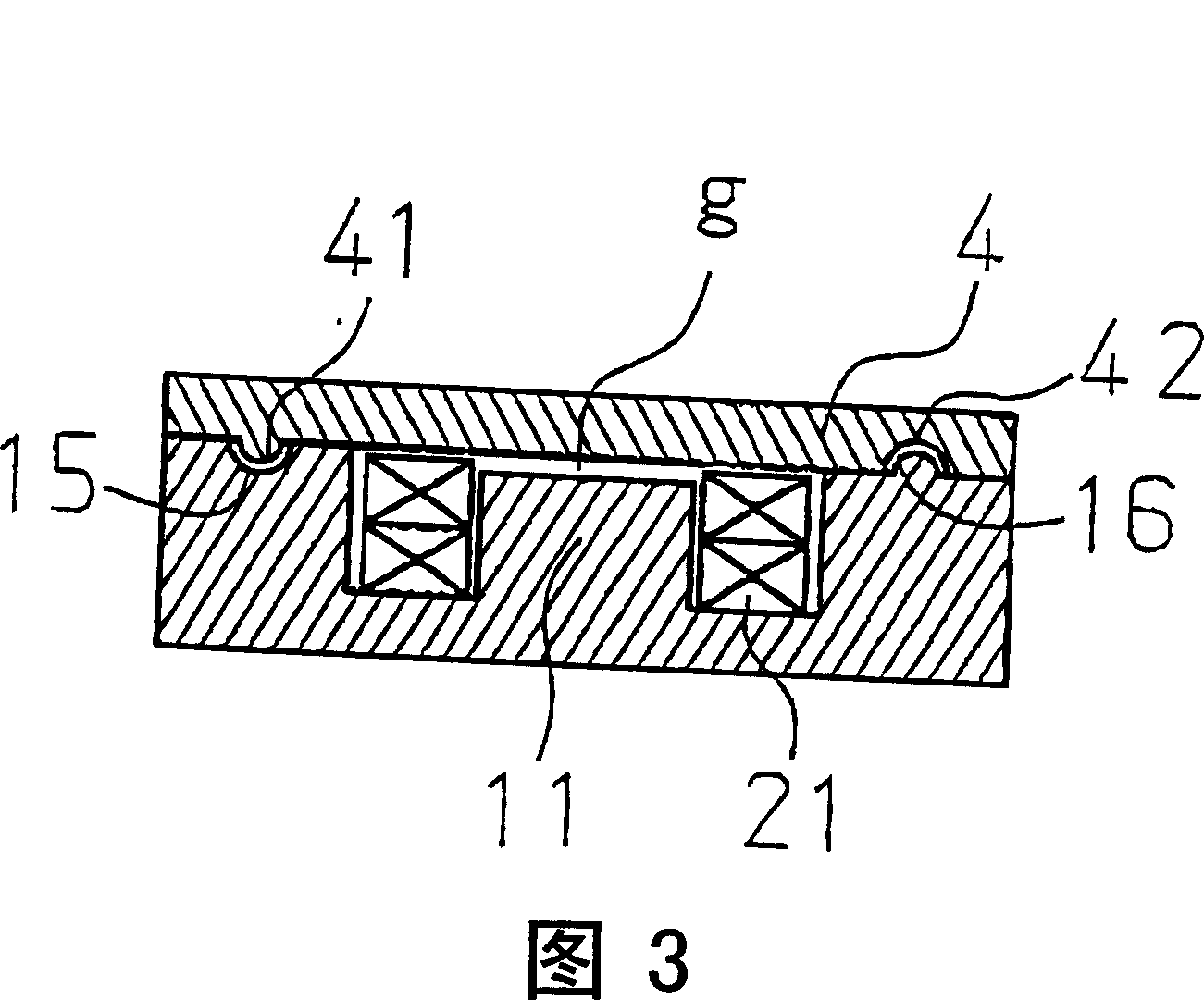

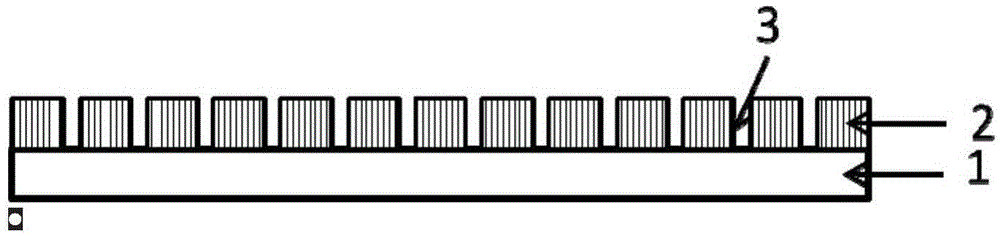

Surface installation inductor

InactiveCN1941227AHigh positioning accuracyImprove work efficiencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresWire widthSurface mounting

The present invention provides a surface-mounting inductor resolving the requirement for downsizing and a low profile having good assembling workability, an improved electrical characteristic, and no leakage magnetic flux. The surface-mounting inductor comprises a pot-type core having an external wall, a rectangular coil fixed to the pot-type core, a pair of electrodes provided on an outer periphery surface of the pot-type core, and a cover core for closing an opening end of the pot-type core. The pot-type core comprises a positioning mechanism for positioning with the cover core at the opening end, and two U shape windows having an open space adjacently over the electrode. The height of the bottom face of one U shape window is higher than that of the other U shape window by the width of a rectangular wire, and a protruding portion (43) having a height corresponding to the wire width of the rectangular coil is provided to the part of the cover core (4) corresponding to the other window (14a).

Owner:TOKYO PARTS IND CO LTD

Touch screen electrode and manufacturing method thereof

InactiveCN103294276AEasy to operateLow costInput/output processes for data processingElectricityWire width

A touch screen electrode comprises a substrate, a conducting layer and light-sensitive silver paste electrode leads. The substrate comprises a display area and a frame area. Under a yellow light condition, through coating, exposure, development treatment, etching and peeling procedures, the conducting layer with a plurality of conducting pattern regions is formed in the display area of the substrate, an exposure developing mode is directly carried out on the frame area through silk-screen light-sensitive silver paste, the conducting pattern regions in the display area are obtained to form the conducting layer, the frame area is provided with the light-sensitive silver paste electrode leads with small wire widths and spacing, and the light-sensitive silver paste electrode leads are electrically connected with the conducting pattern regions to form a loop. Due to the fact that the light-sensitive silver paste electrode leads are obtained through the exposure developing mode, and therefore the wire widths and spacing can be reduced; the manufacturing method has simple procedures, reduces cost, and meanwhile avoids the bad phenomena of ink penetration-out, adhesion, jaggy edges and the like.

Owner:NANCHANG O FILM TECH CO LTD

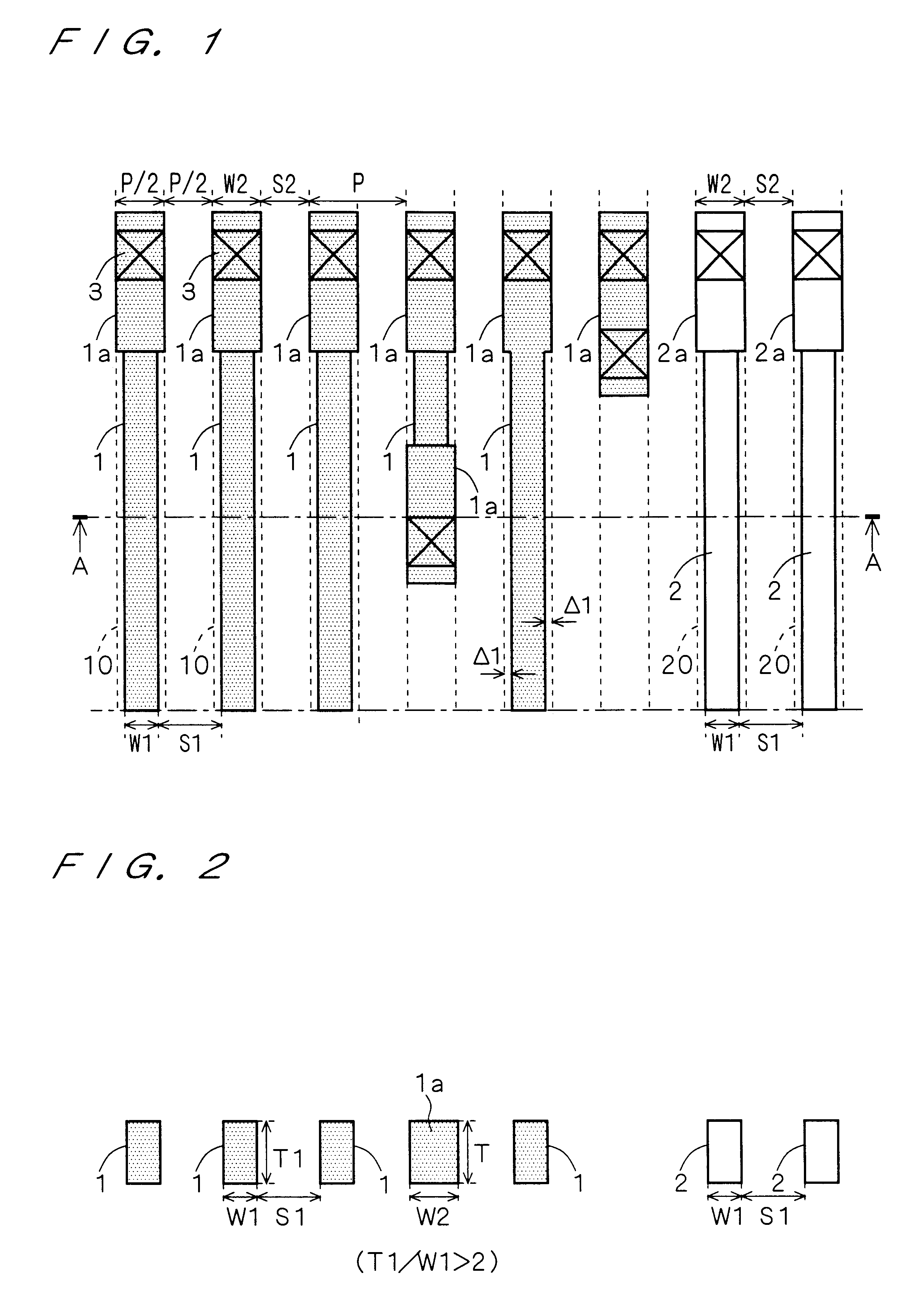

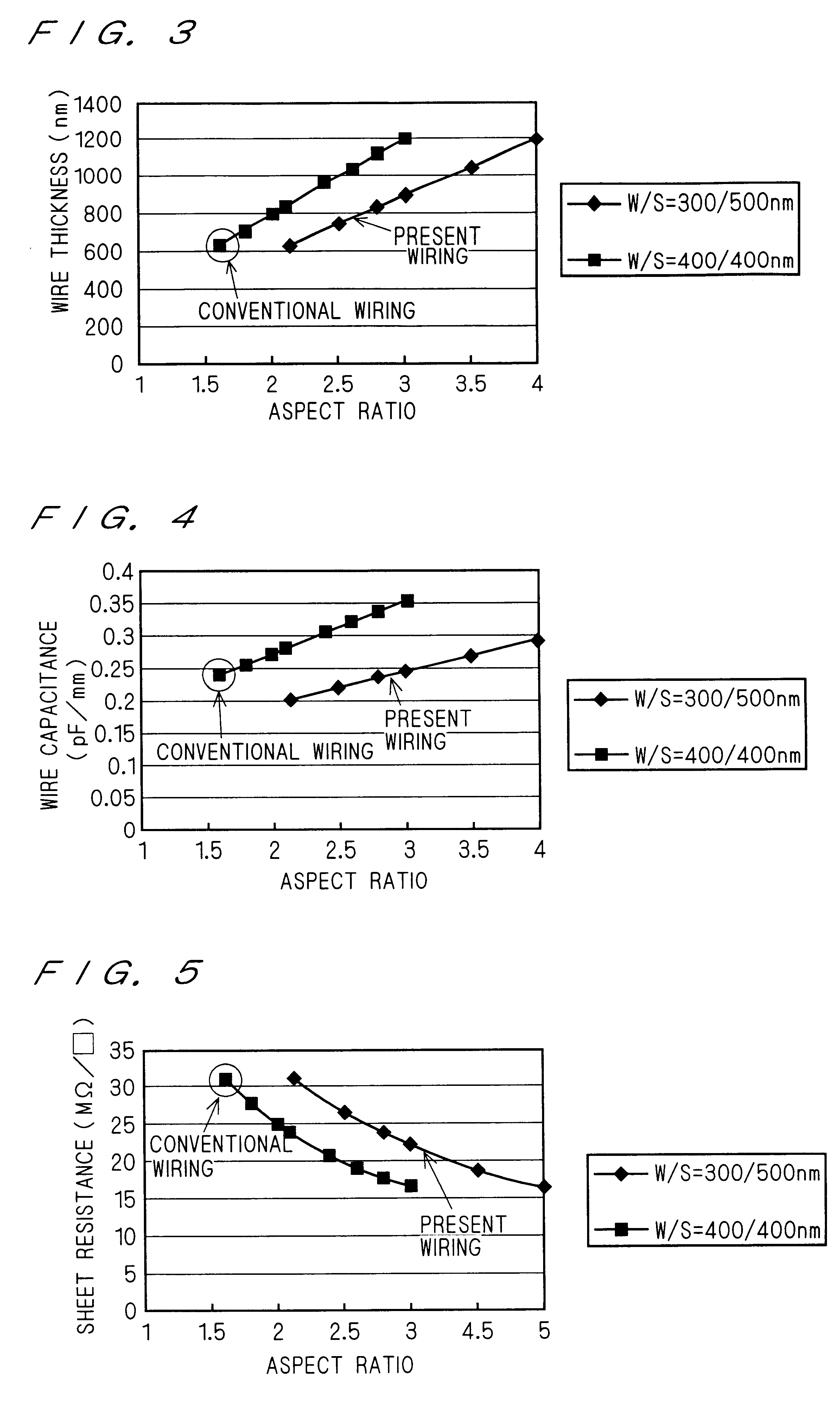

Wiring structure for an integrated circuit

InactiveUS6664641B2Semiconductor/solid-state device detailsSolid-state devicesWire widthIntegrated circuit

Owner:RENESAS TECH CORP

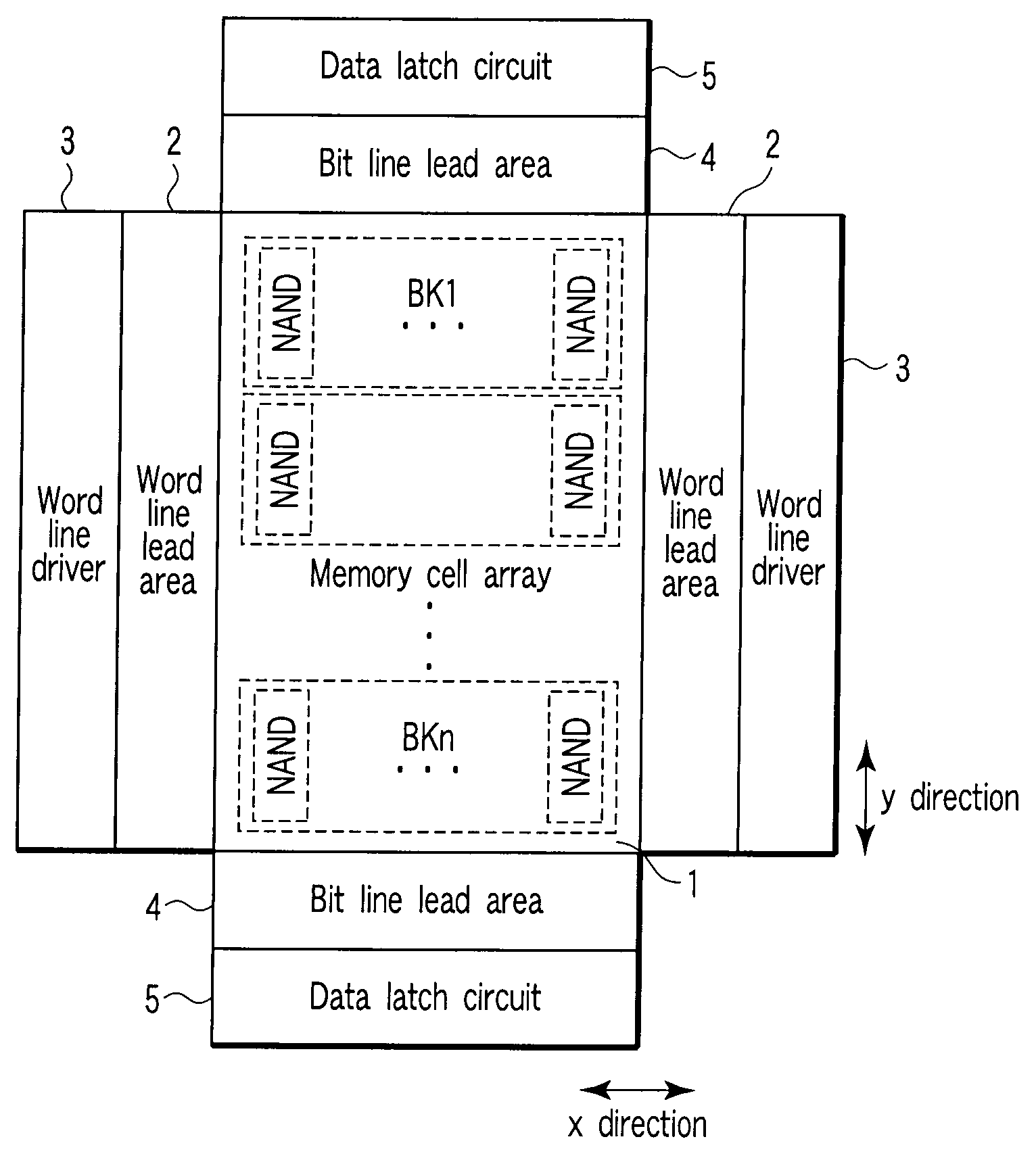

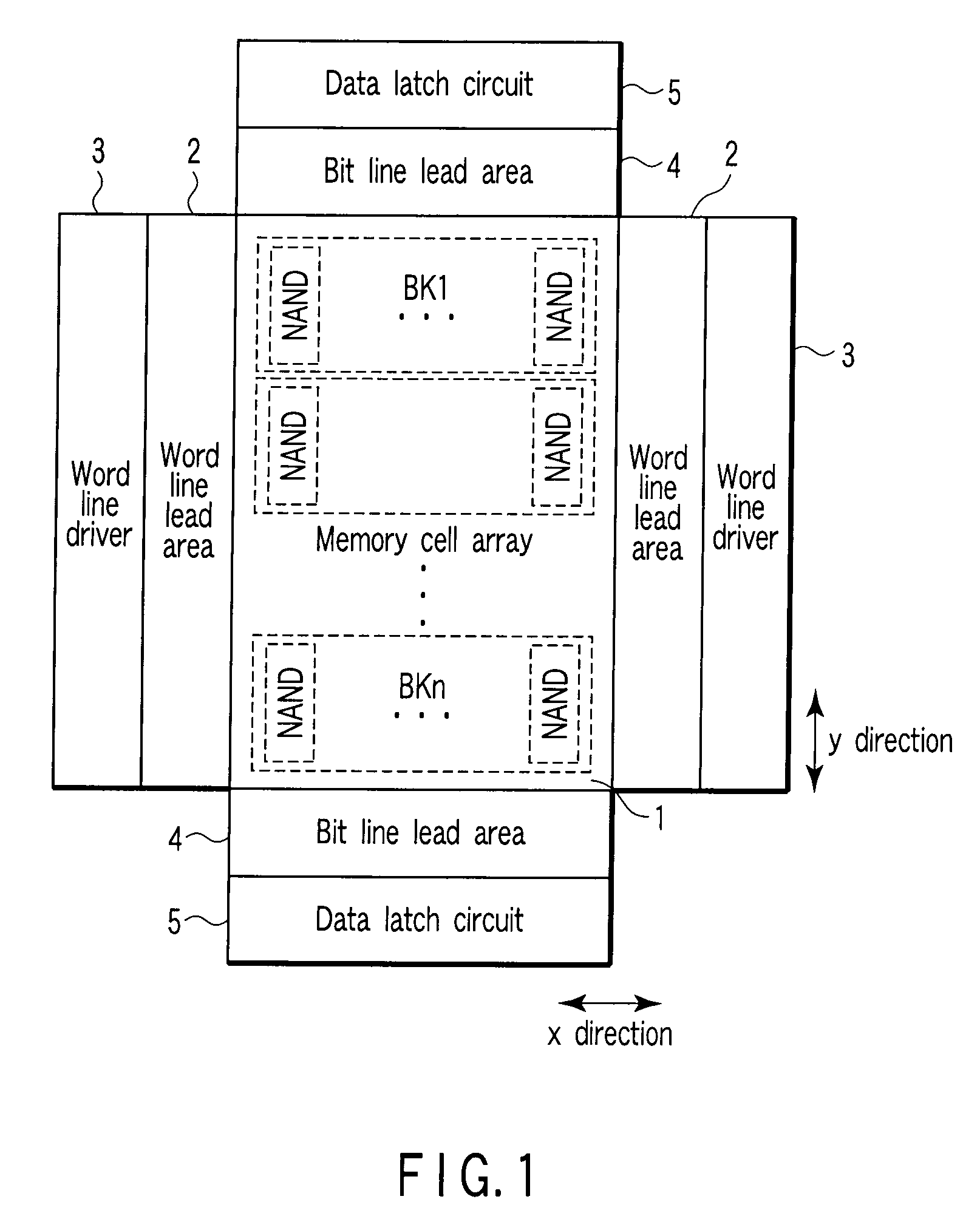

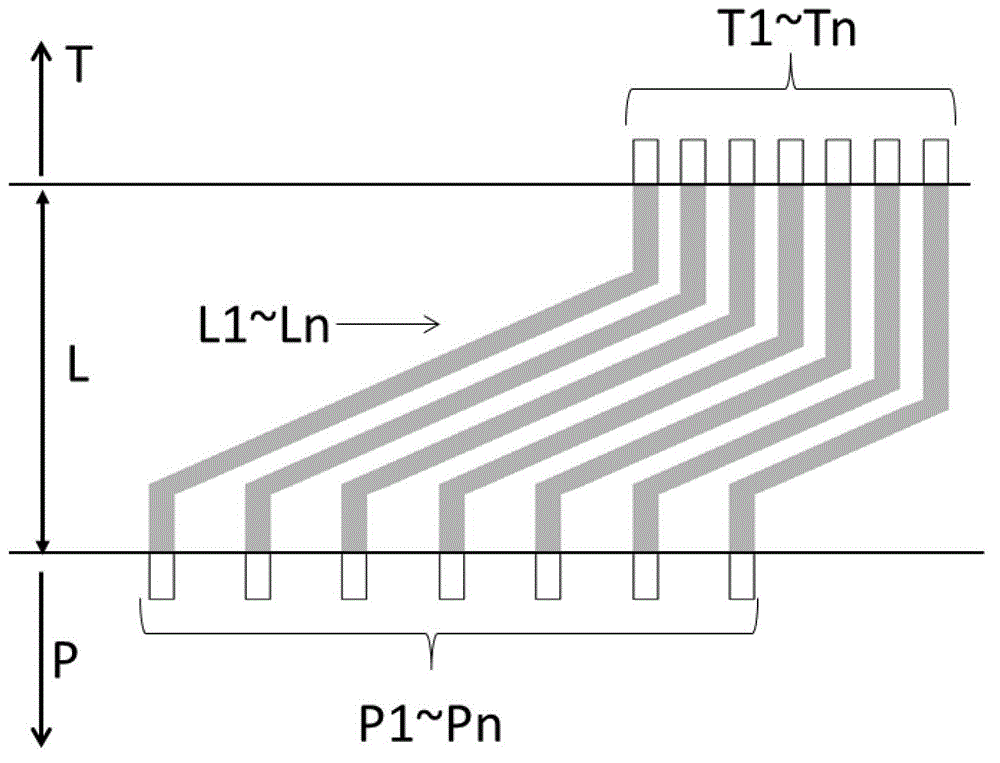

Semiconductor integrated circuit

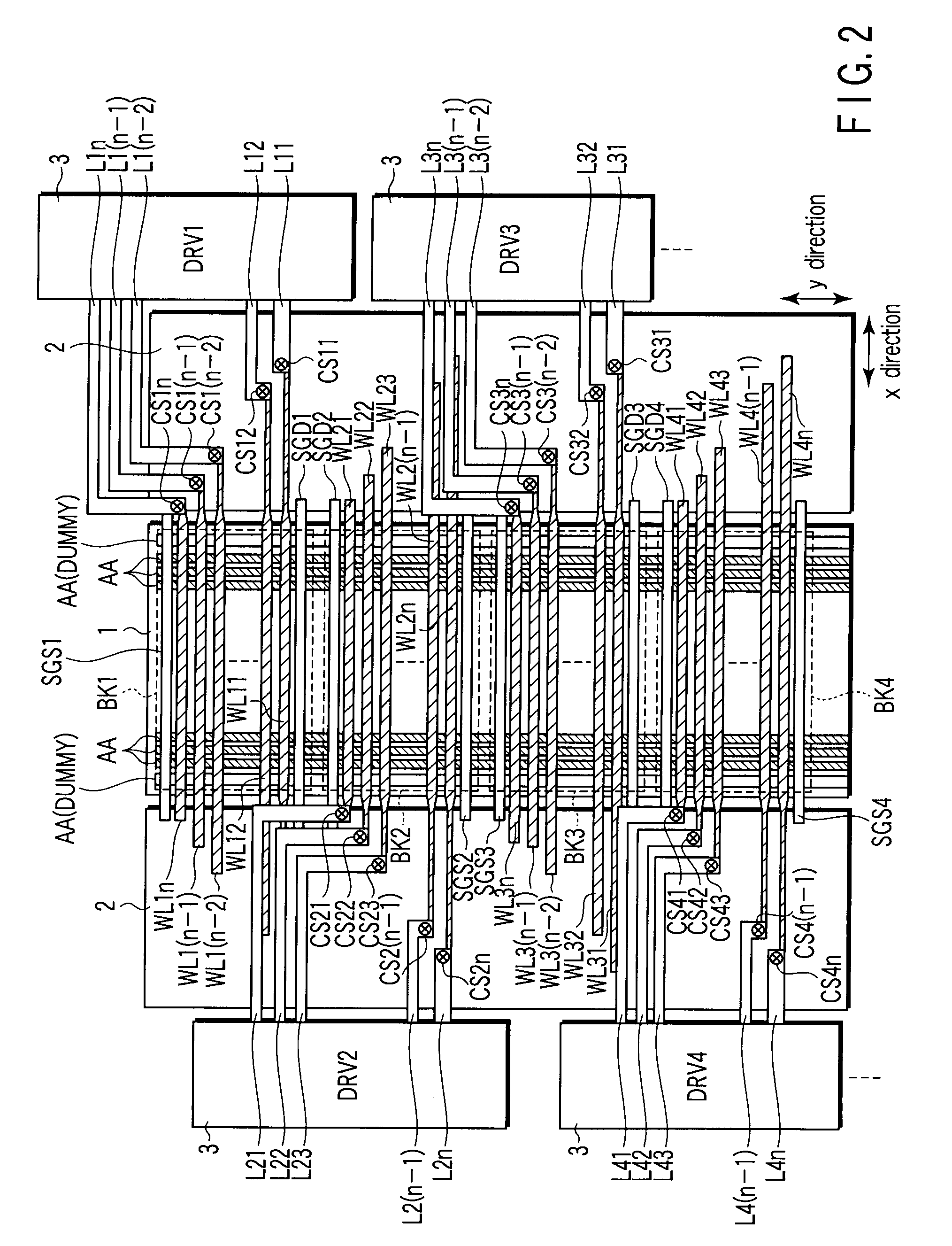

ActiveUS20080073672A1Increase distanceSemiconductor/solid-state device detailsSolid-state devicesWire widthSemiconductor

A nonvolatile semiconductor memory concerning an example of the present invention comprises a cell array, a plurality of conducting wires extending from the cell array to a lead area, and a plurality of contact holes to arranged in the lead area so that a distance from the end of the cell array sequentially increases from one to the other of the plurality of conducting wires, each of the plurality of conducting wires having a first conducting wire portion having a first conducting wire width, a second conducting wire portion connected to the contact hole and having a second conducting wire width smaller than the first conducting wire width, and a third conducting wire portion electrically connecting the first conducting wire portion to the second conducting wire portion.

Owner:KIOXIA CORP

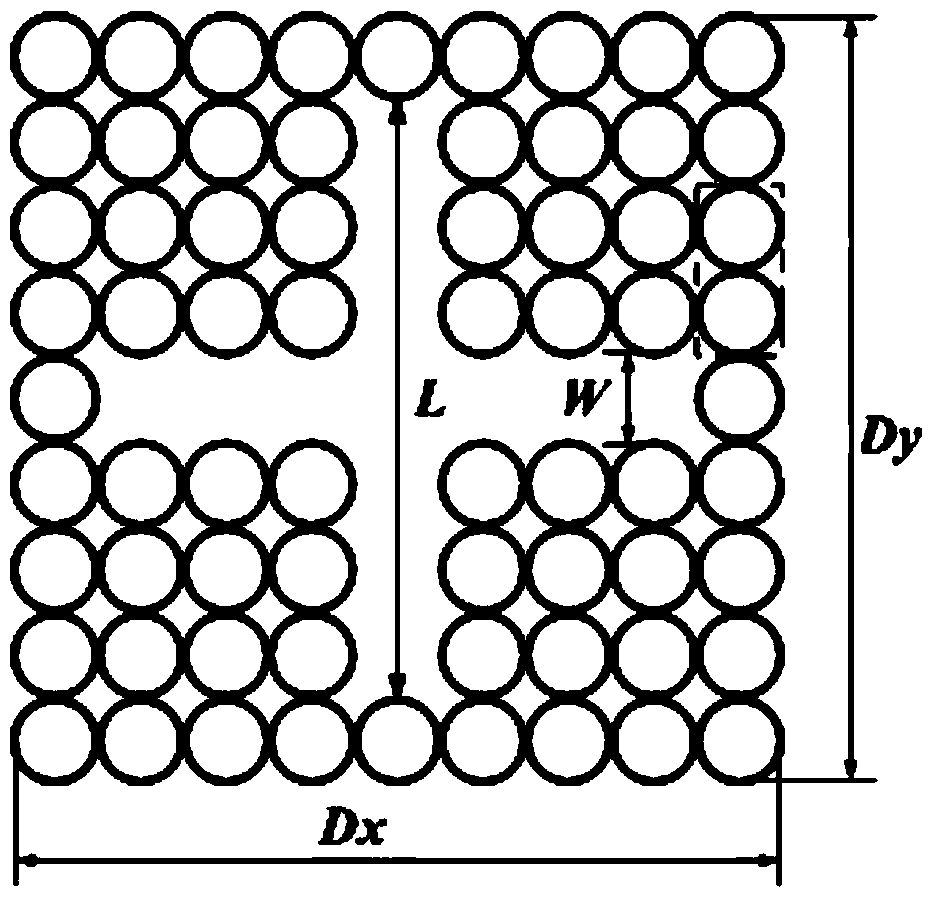

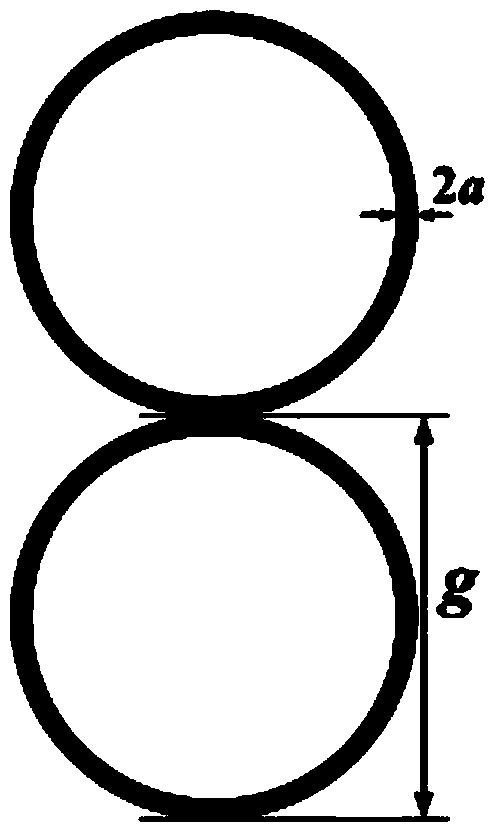

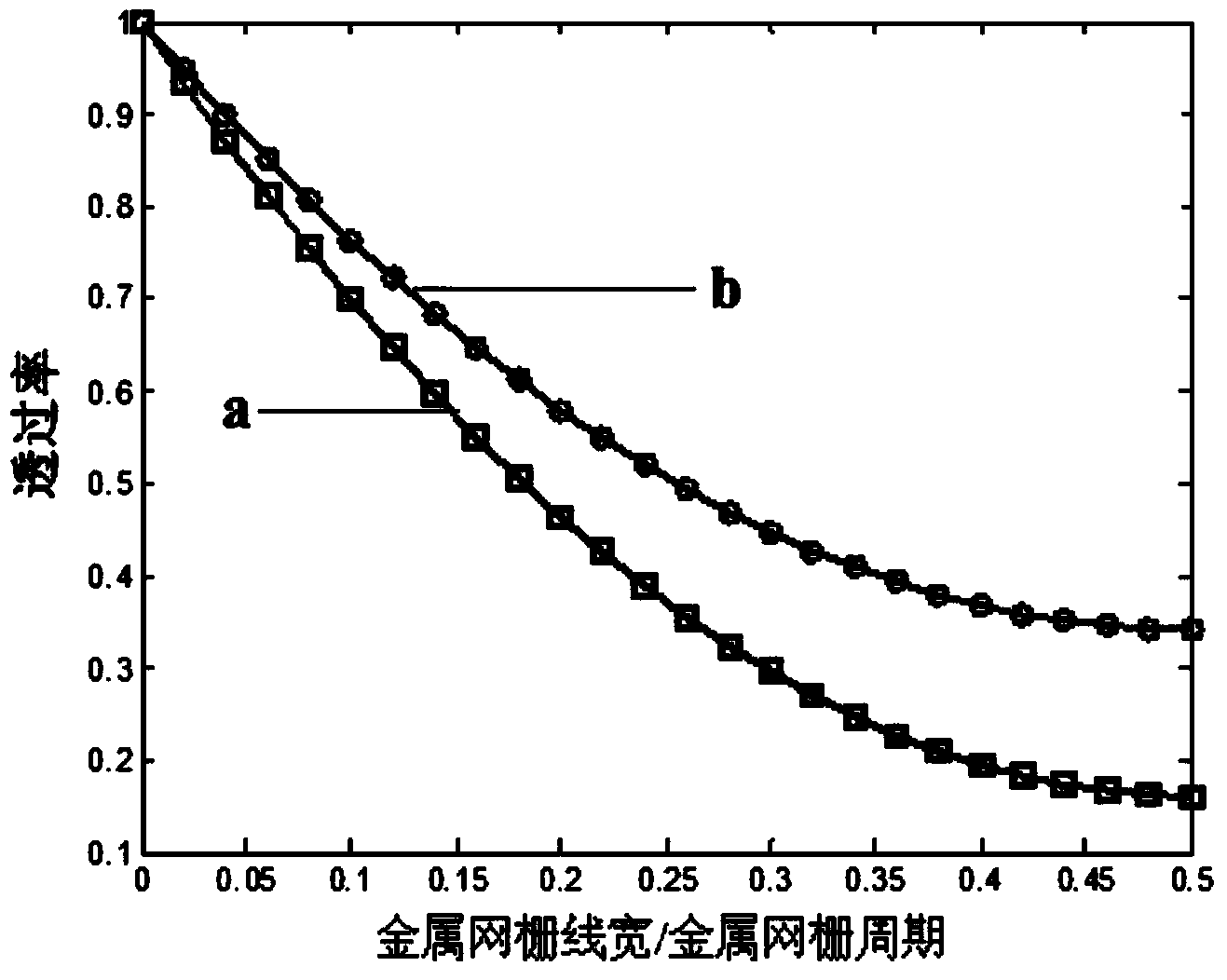

Radar/infrared two-waveband frequency selective surface

ActiveCN103487860AHigh optical transmittanceUniform distribution of diffracted light intensityDiffraction gratingsWaveguide type devicesWire widthRadar

The invention discloses a radar / infrared two-waveband frequency selective surface which solves the technical problems that a latticed metal mesh FSS in the prior art cannot further improve optical transmittance, the distribution of stray light is centralized, and the application in high-precision detection and imaging observation is not facilitated, and belongs to the technical field of electromagnetic shielding. The radar / infrared two-waveband FSS is a cross-hole-shaped periodic array on a metal mesh, the metal mesh is a round-hole-shaped metal mesh or a hexagonal metal mesh, the periods of cross hole shapes are the integer multiples of the period of the metal mesh, and each cross hole shape meets the two following constraint conditions that the slit width of the cross hole shapes is the integer multiples of the period of the metal mesh minus the wire width of the metal mesh; the difference between the slit length of the cross hole shapes and the slit width of the cross hole shapes is the even times of the period of the metal mesh. The radar / infrared two-waveband FSS is higher in optical transmittance, more even in diffraction light distribution and capable of effectively restraining the stray light.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Sheet-like electronic component clean transfer device and sheet-like electronic component manufacturing system

ActiveUS20050191155A1Improve cleanlinessSuppress air pressure fluctuationsSemiconductor/solid-state device manufacturingCharge manipulationWire widthPunching

When a first floor (11) which is formed of a punching plate or the like and through which air passes is provided immediately below an arm (17) at a middle height part of a conveying robot (10) in a casing (2a) of a clean transfer device (2) and a degree of opening of a casing bottom part frame (2b), which supports a base part of the conveying robot (10), with respect to the outside is restricted, a class 1 can be maintained. Here, when a second floor (13) formed of a punching plate or the like is used on the casing bottom part frame (2b), a class 0 state can be realized under specific conditions, thereby enabling production of a semiconductor having a wire width of 0.1 μm. As a result, the device can cope with the unexpectedly high degree of cleanliness of 0.1 μm particle class 1, which cannot be realized in the prior art, requested also for the transfer device according to a reduction in wire width on a highly integrated semiconductor wafer.

Owner:RORZE CORP

Fabrication method of flexible nanowire gate-type transparent conductive electrode

ActiveCN105405752AImprove conductivityLow square resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesWire widthNanowire

The invention discloses a fabrication method of a flexible nanowire gate-type transparent conductive electrode. Compared with the prior art, a conductive wire gate structure of the flexible transparent electrode fabricated by the method selectively grows in an electrodeposition process; the minimum wire width can reach dozens of nanometers, but a nanowire gate formed by electrodeposition is relatively high in conductivity, so that a relatively low sheet resistance value can still be ensured even if the width and the thickness of the wire gate are only dozens of nanometers. According to the fabrication method of the flexible transparent electrode disclosed by the invention, a single-function electrode can be fabricated; and a multi-layer composite electrode can be fabricated by depositing different material layers on the surface of a nano transfer mold through multiple transferring processes, or the transparent electrode with different conductive function regions can be fabricated.

Owner:SUZHOU UNIV +1

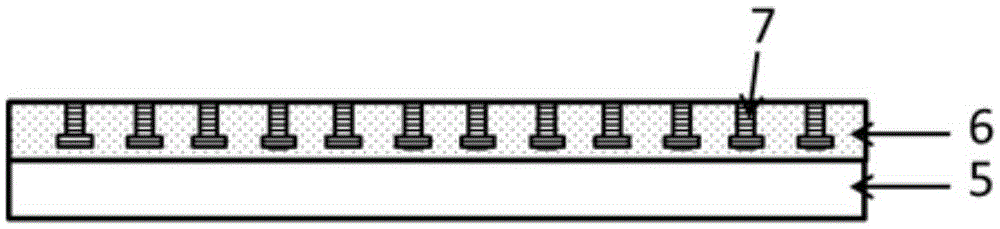

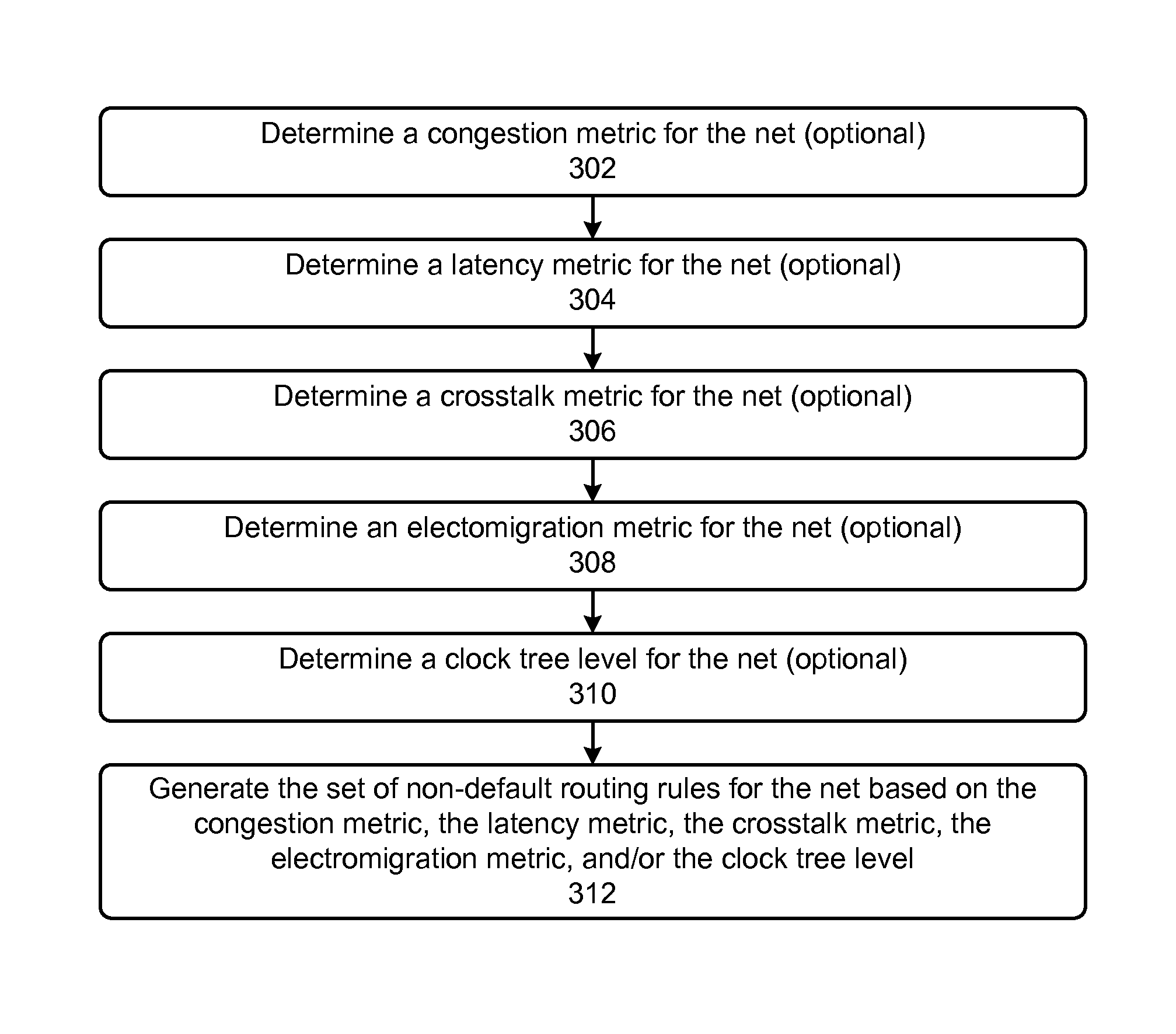

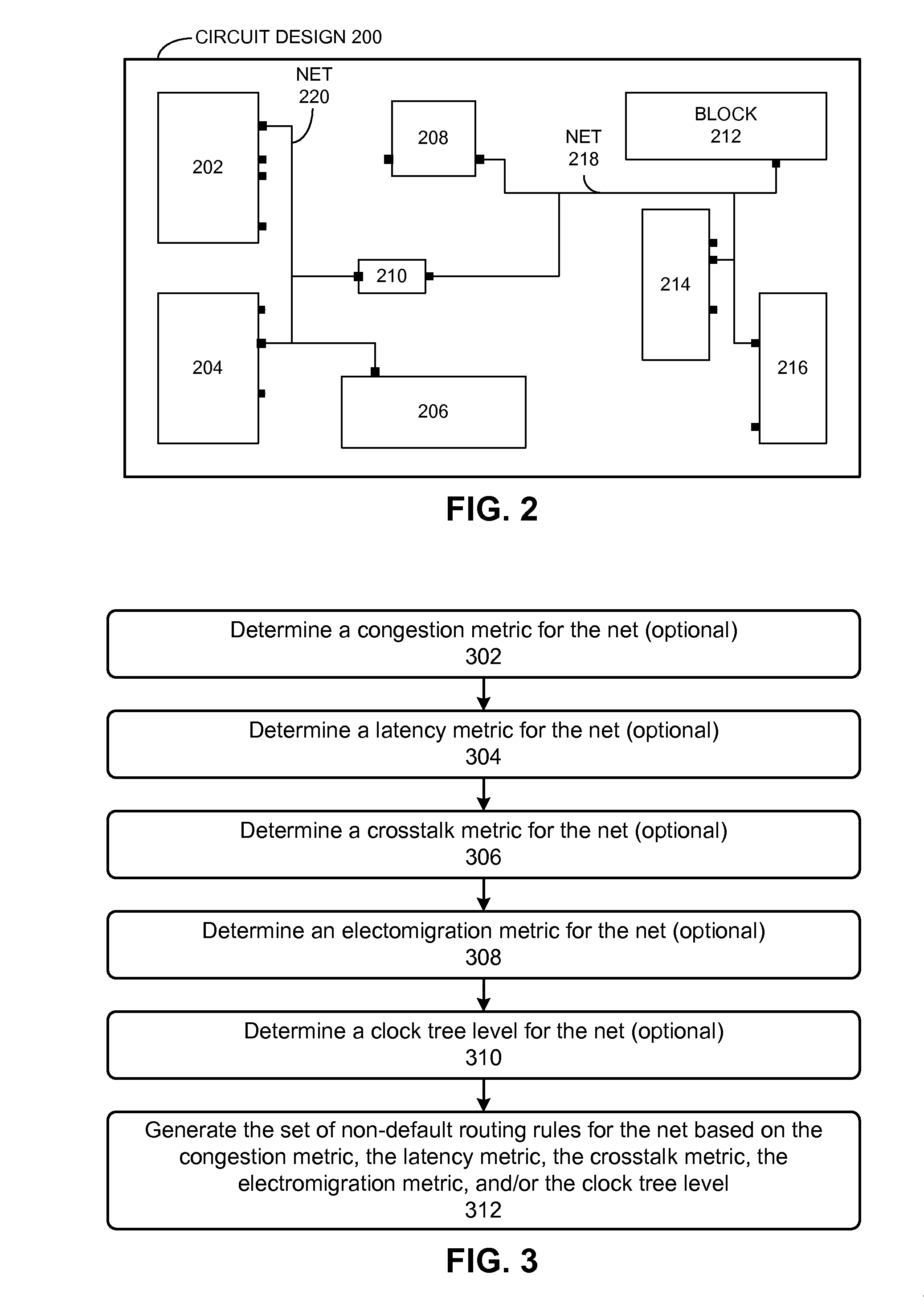

Automatic clock tree routing rule generation

ActiveUS9009645B2Computer aided designSoftware simulation/interpretation/emulationWire widthClock tree

Systems and techniques are described for automatically generating a set of non-default routing rules for routing a net in a clock tree based on one or more metrics. The metrics can include a congestion metric, a latency metric, a crosstalk metric, an electromigration metric, and a clock tree level. Next, the embodiments can generate the set of non-default routing rules for routing the net based on one or more metrics. A routing rule can specify how wide the wires are supposed to be and how far apart adjacent wires are to be placed. A non-default routing rule can specify a wire width that is different from the default width and / or specify a spacing (i.e., the distance between two wires) that is different from the default spacing.

Owner:SYNOPSYS INC

Capacitive touch control display panel, capacitive touch panel and manufacturing method thereof

InactiveCN103885659ADoes not reduce display aperture ratioImprove visual experienceInput/output processes for data processingVertical projectionCapacitance

The invention discloses a capacitive touch control display panel, which comprises a display panel and a capacitive touch control element. The capacitive touch control element is arranged on the display surface of the display panel. The capacitive touch control element comprises at least one non-transparent bridging wire and at least one low-reflective pattern layer. The non-transparent bridging wire is provided with a first wire width, and two first main borders are arranged at the two sides of the non-transparent bridging wire. The low-reflective pattern layer is arranged at the other side of the non-transparent bridging wire relative to the display panel. The low-reflective pattern layer is provided with a second wire width. The two sides of the low-reflective pattern layer are provided with two second main borders. The low-reflective pattern layer is superposed with the non-transparent bridging wire in the vertical projection direction. The first wire width is slightly equal to the second wire width and the first main boards are slightly aligned with the second main borders. The invention also discloses a capacitance type touch control panel and a manufacturing method thereof.

Owner:AU OPTRONICS CORP

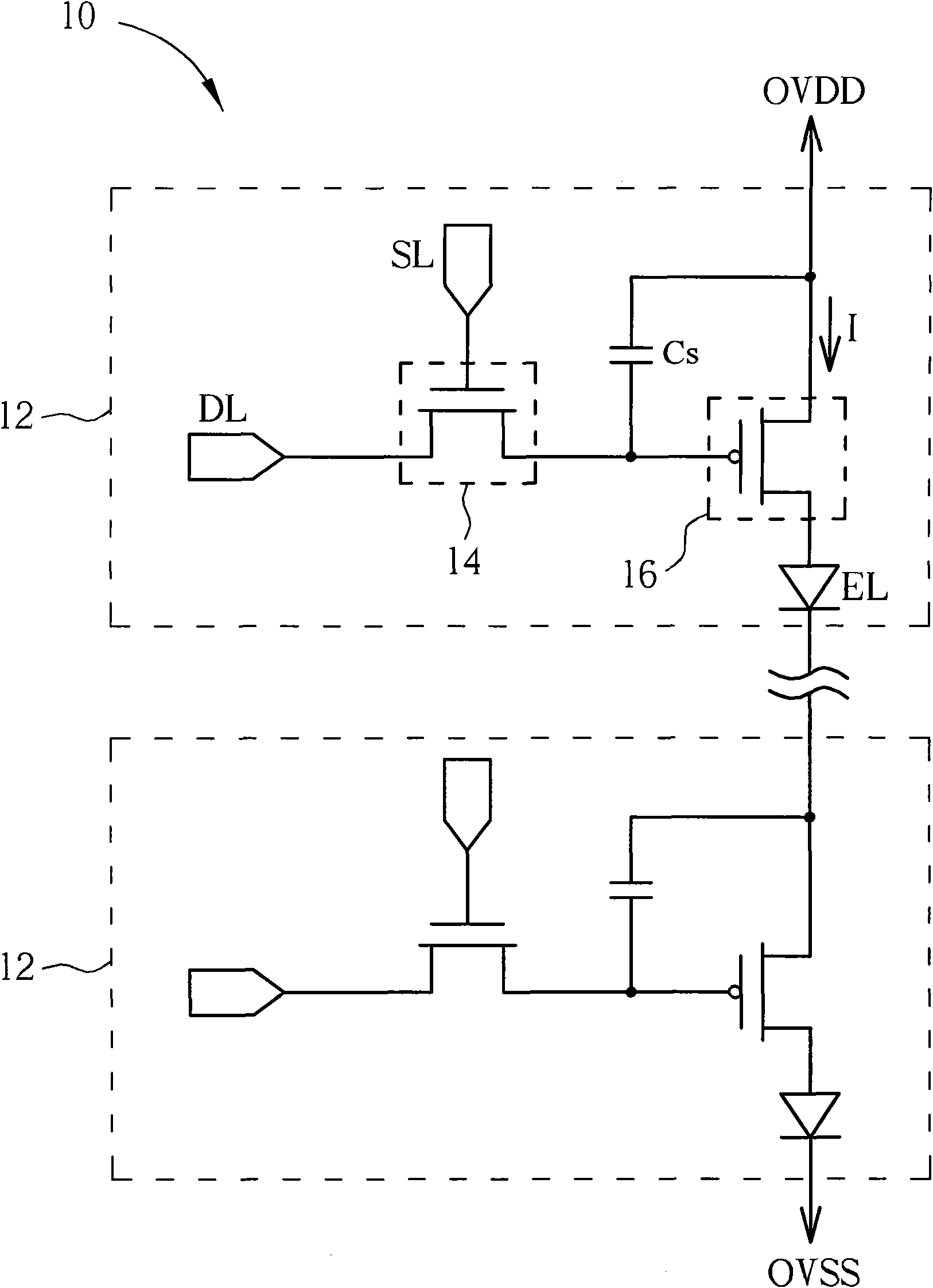

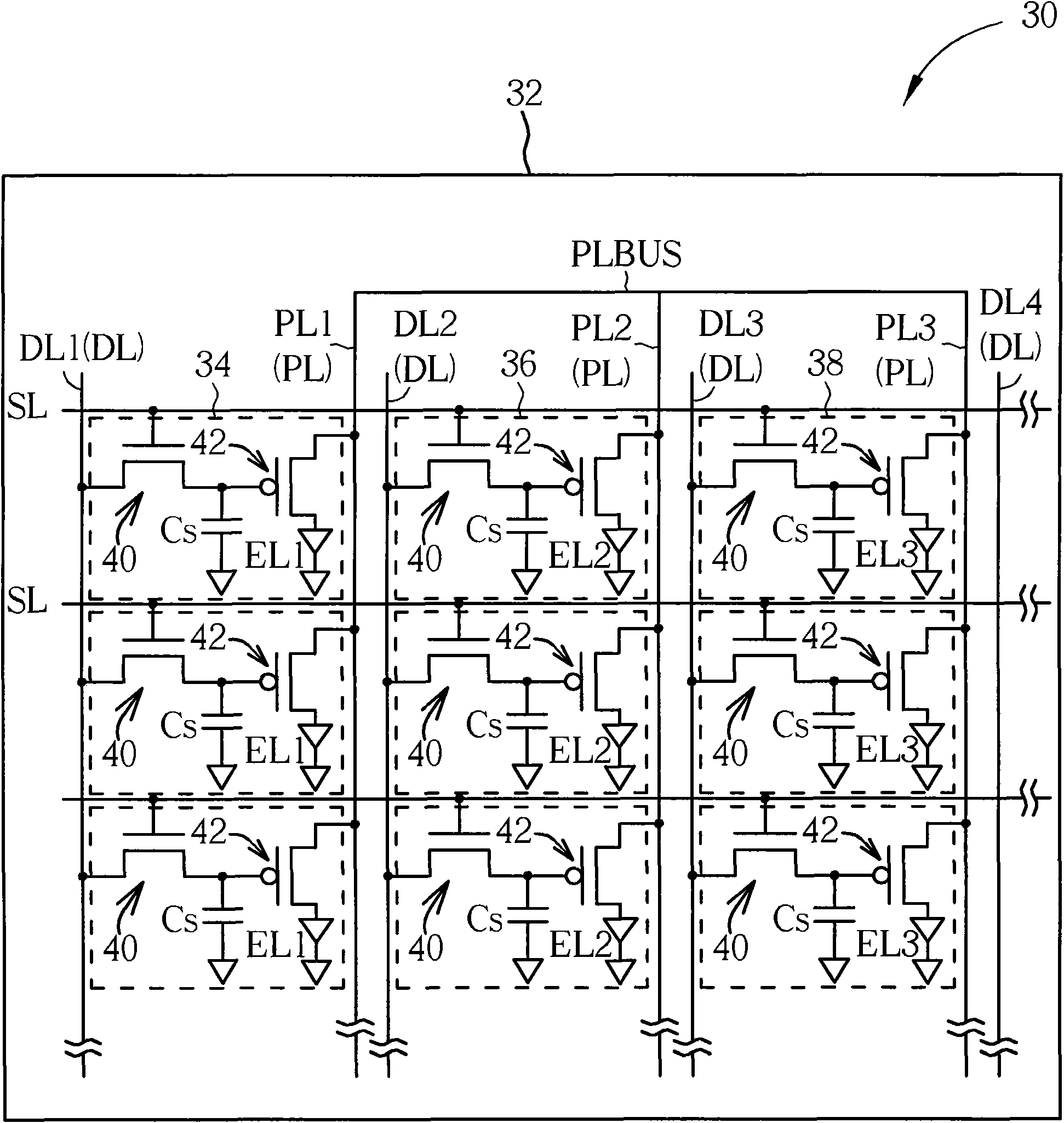

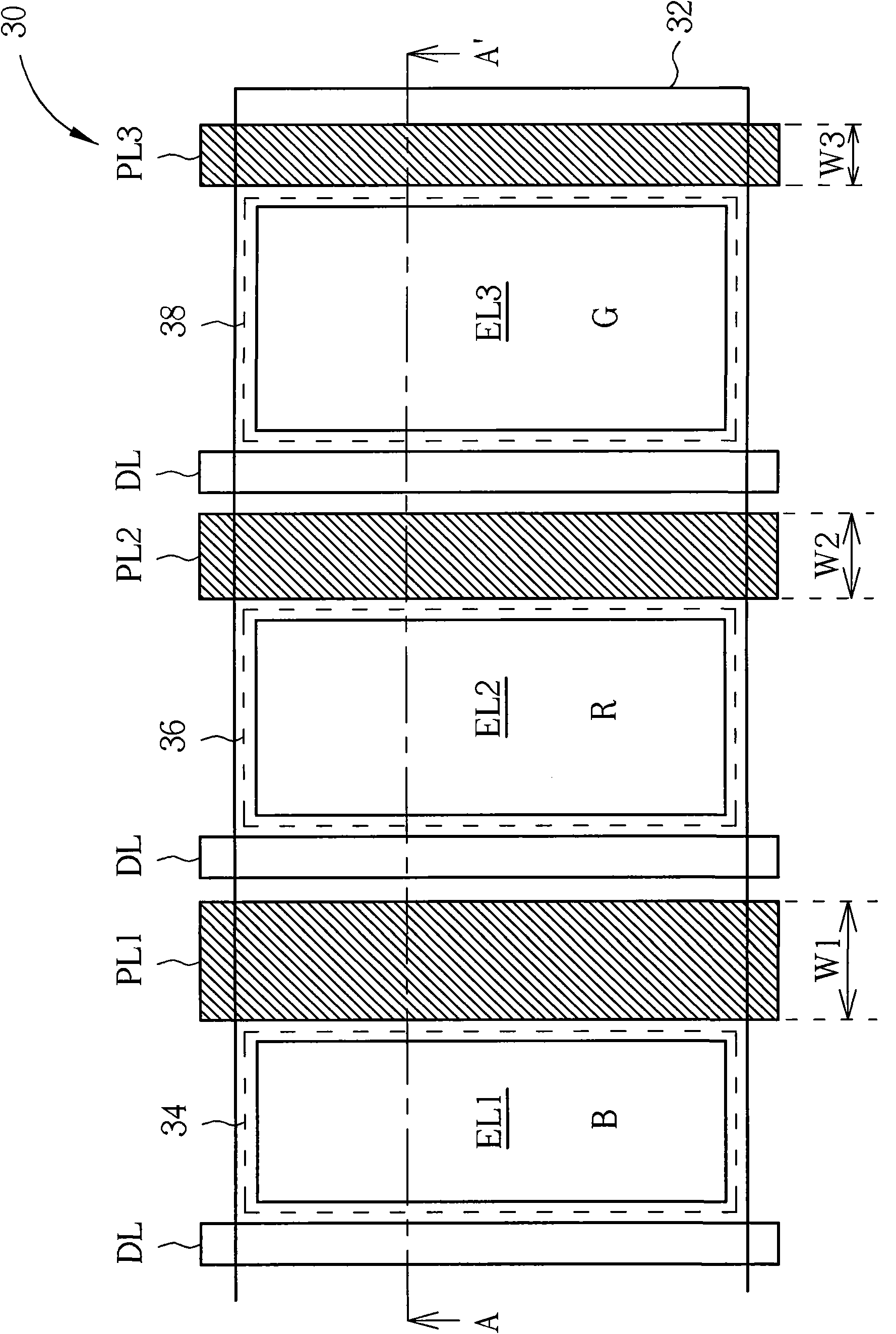

Electroluminescent display panel and pixel structure thereof

InactiveCN101894860ASmall pressure dropDoes not affect aperture ratioSemiconductor/solid-state device detailsSolid-state devicesWire widthElectroluminescent display

The invention discloses an electroluminescent display panel, which comprises a blue electroluminescent element, a red electroluminescent element, a green electroluminescent element, a first power line electrically connected with the blue electroluminescent element, a second power line electrically connected with the red electroluminescent element, and a third power line electrically connected with the green electroluminescent element. The first power line has a first wire width, the second power line has a second wire width, the third power line has a third wire width, wherein the first wire width is greater than the second wire width, and the first wire width is greater than the third wire width. The invention also discloses a pixel structure of the electroluminescent display panel.

Owner:AU OPTRONICS CORP

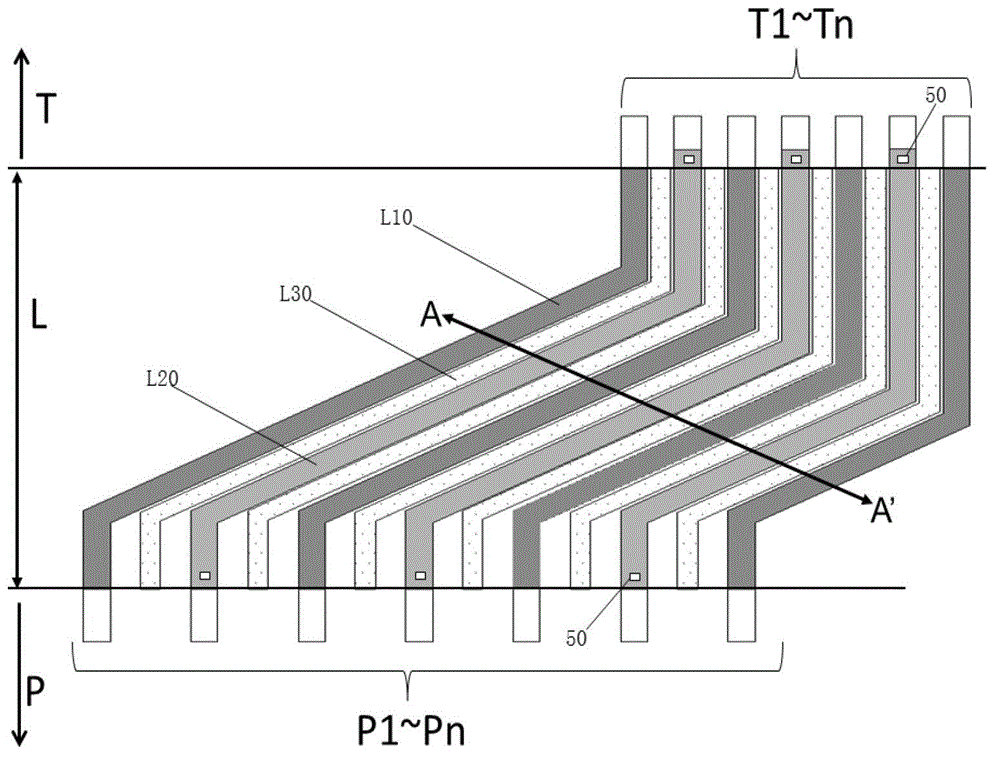

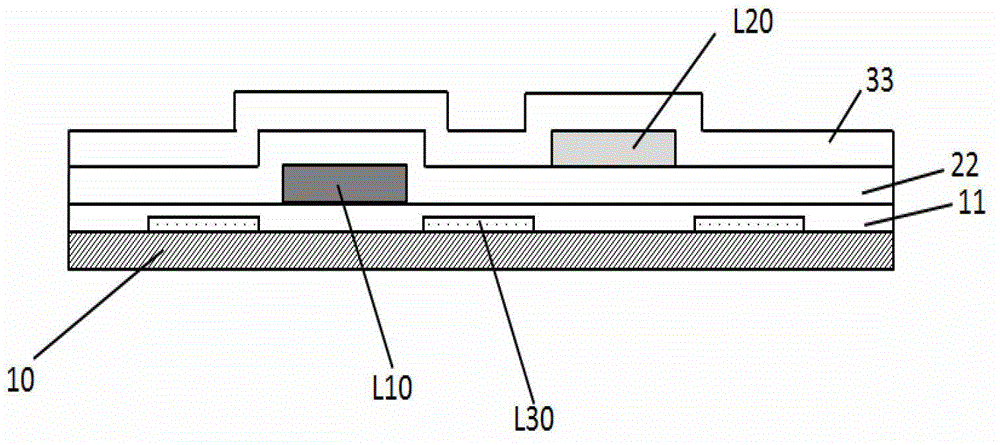

Wiring structure

ActiveCN103336395ASolve the problem of line width and line spacing that is easy to encounterSolve the problem that signal interference affects display qualityNon-linear opticsWire widthIndium tin oxide

The invention discloses a wiring structure, which is applied to TFT-LCD (thin film transistor liquid crystal display) array substrate, wherein the substrate has a pixel region, a wiring region, a terminal region and a TFT array; the pixel region is limited crossly by a plurality of scanning lines and a plurality of data signal lines; the wiring region and the terminal region are arranged on the outer side of the pixel region; the TFT array is formed on the substrate and is arranged in the pixel region; the wiring region comprises a plurality of first wires formed by first wiring layers and a plurality of second wires formed by second wiring layers; the first wires and the second wires are alternatively configured, and a shielding electrode is arranged between each first wire and each second wire; the first wires and the second wires electrically connect a plurality of pixel terminals with a plurality of signal terminals. Through the scheme of the invention, the problem of wire width and wire distance easily generated in a single-layer metal wire is solved through the double-layer wire; meanwhile, an ITO (indium tin oxide) transparent electrode arranged between the two adjacent wires is used for isolating signal interference, so that the problem that the display quality is influenced by the signal interference between the two layers of wires is solved.

Owner:NANJING CEC PANDA LCD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com