Touch screen sensing component and production method thereof

A technology for sensing components and manufacturing methods, applied in the direction of instruments, electrical digital data processing, and input/output processes of data processing, etc., can solve jagged and irregular lines, cannot meet the design requirements of narrow-frame touch screens, and has poor process stability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

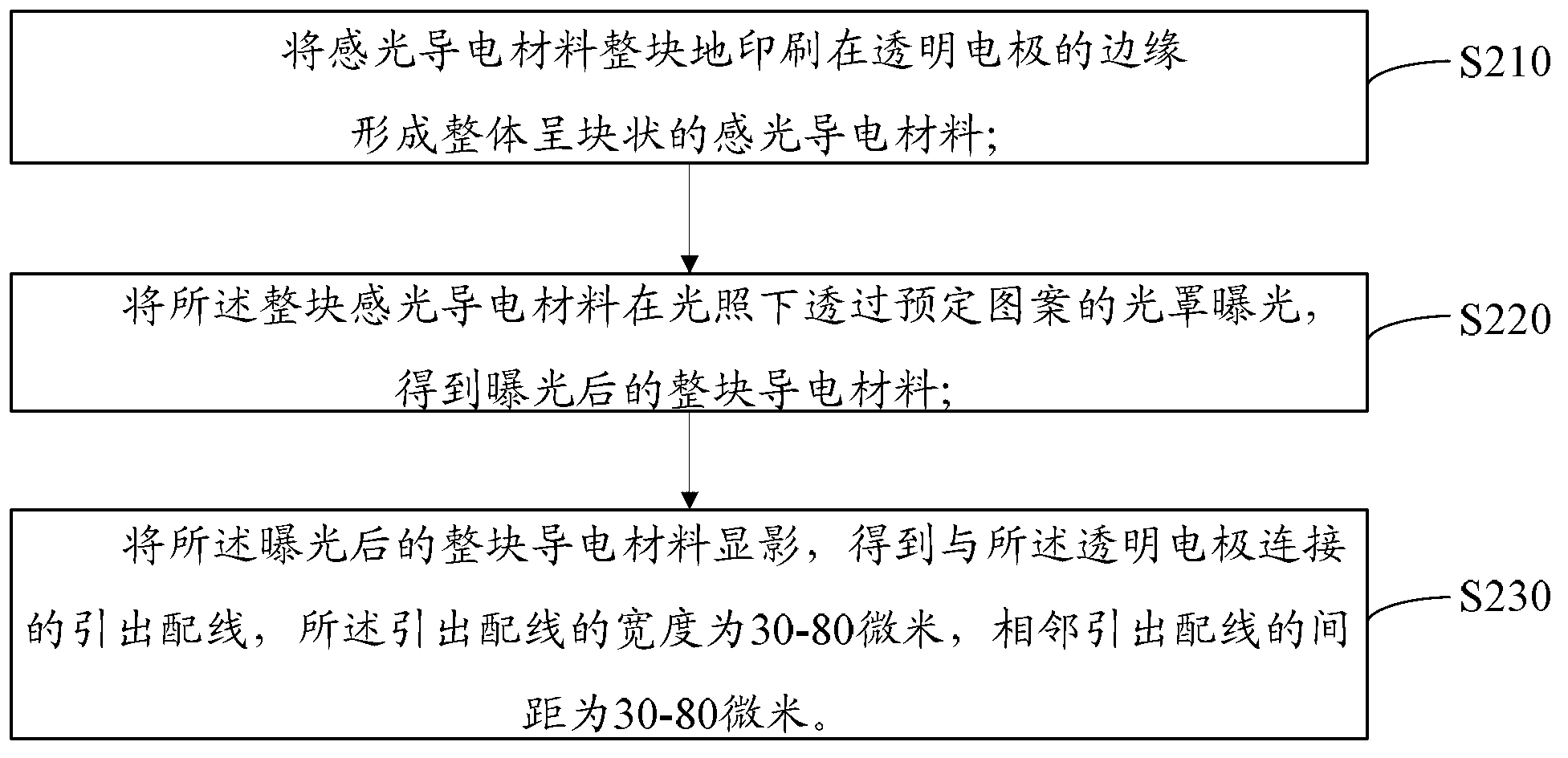

[0026] Such as figure 2 As shown, a manufacturing method of a touch screen sensing component in an embodiment includes the following steps:

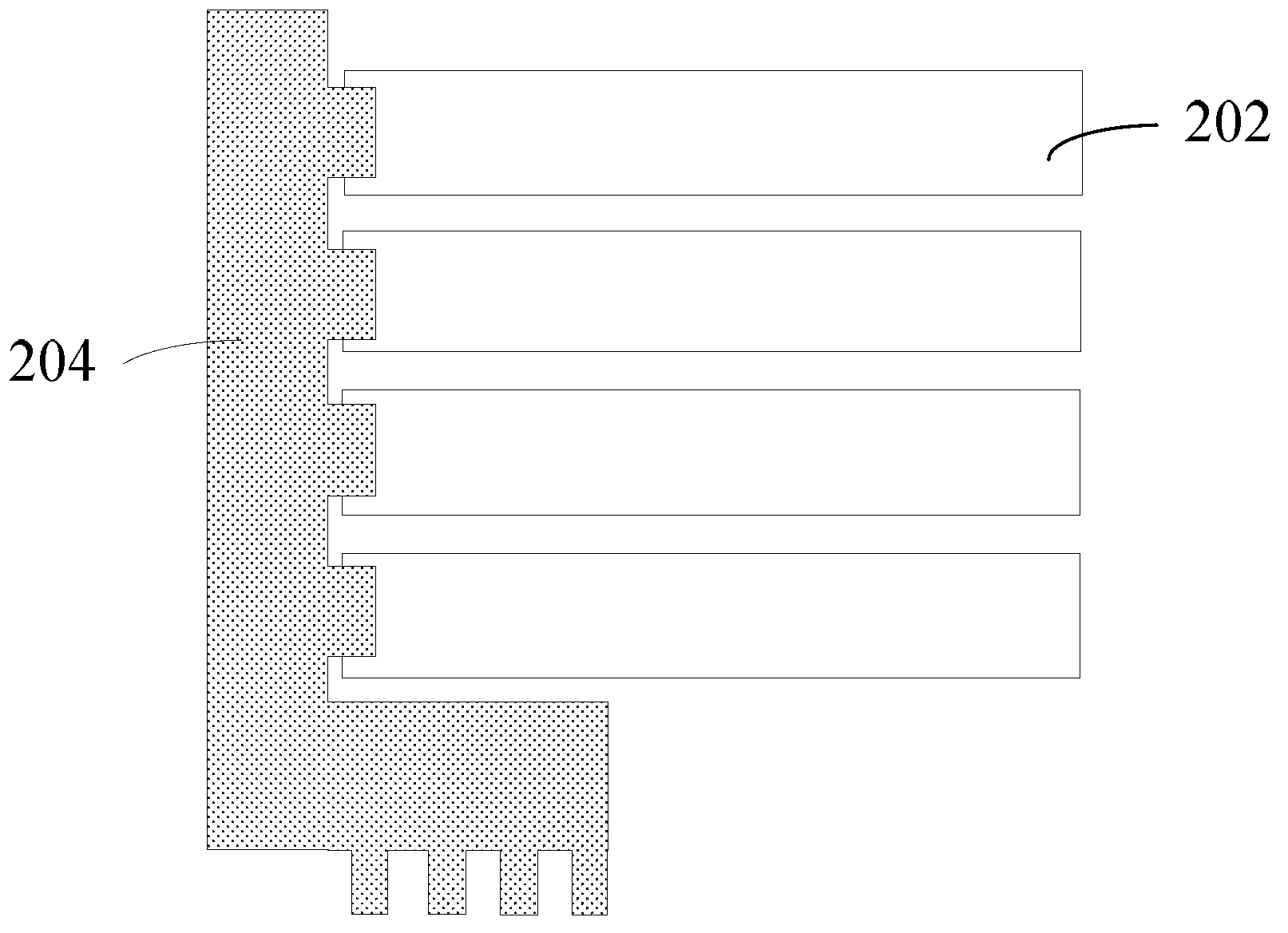

[0027] Step S210, printing the photosensitive conductive material on the edge of the transparent electrode to form a bulk photosensitive conductive material as a whole. The photosensitive conductive material is printed on the edge of the transparent electrode. At this time, the photosensitive conductive material can be just in contact with the edge of the transparent electrode, or can cover a part of the edge of the transparent electrode. In this embodiment, the photosensitive conductive material covers a small portion of the edge of the transparent electrode 202 , so that the formed lead wire 208 is better connected to the transparent electrode 202 and improves the stability of the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com