Reinforcing steel climbing frame for tunnel waterproof and drainage board paving trolley

A technology of waterproof and drainage boards and climbing frames, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as low construction efficiency, affecting construction progress, and affecting project progress, so as to speed up the installation of steel bars, shorten construction time, and speed up construction. The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

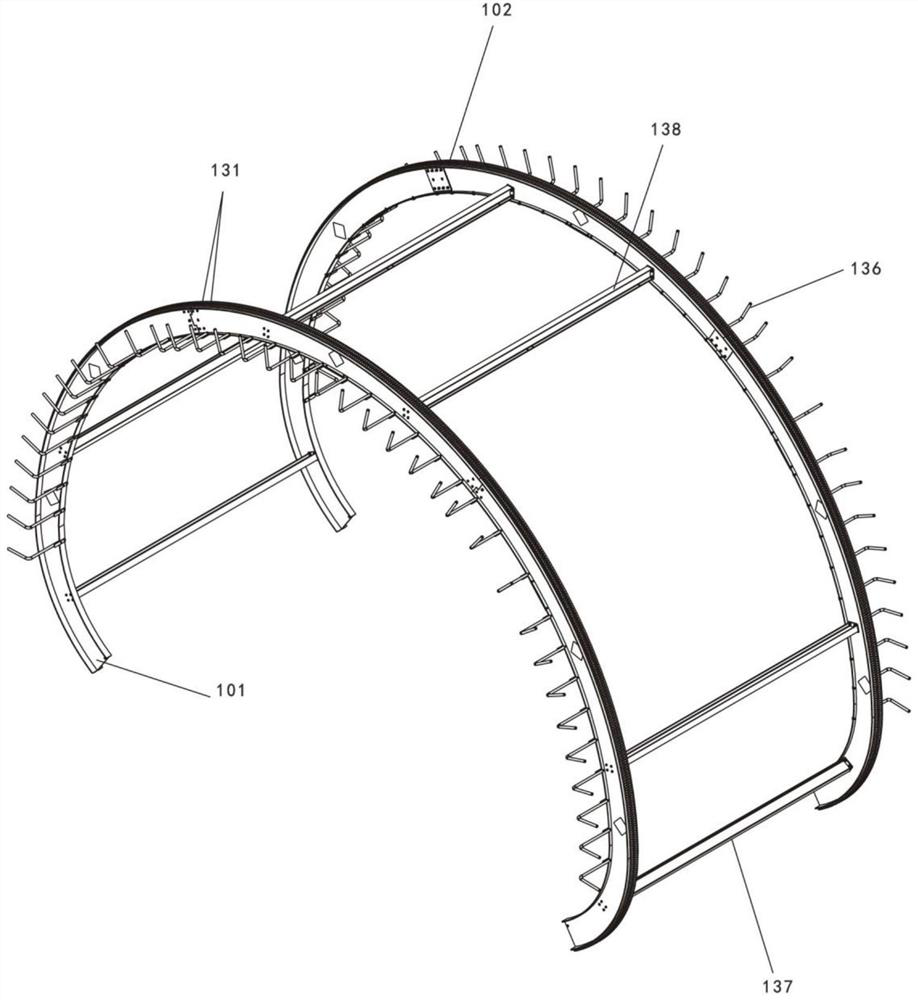

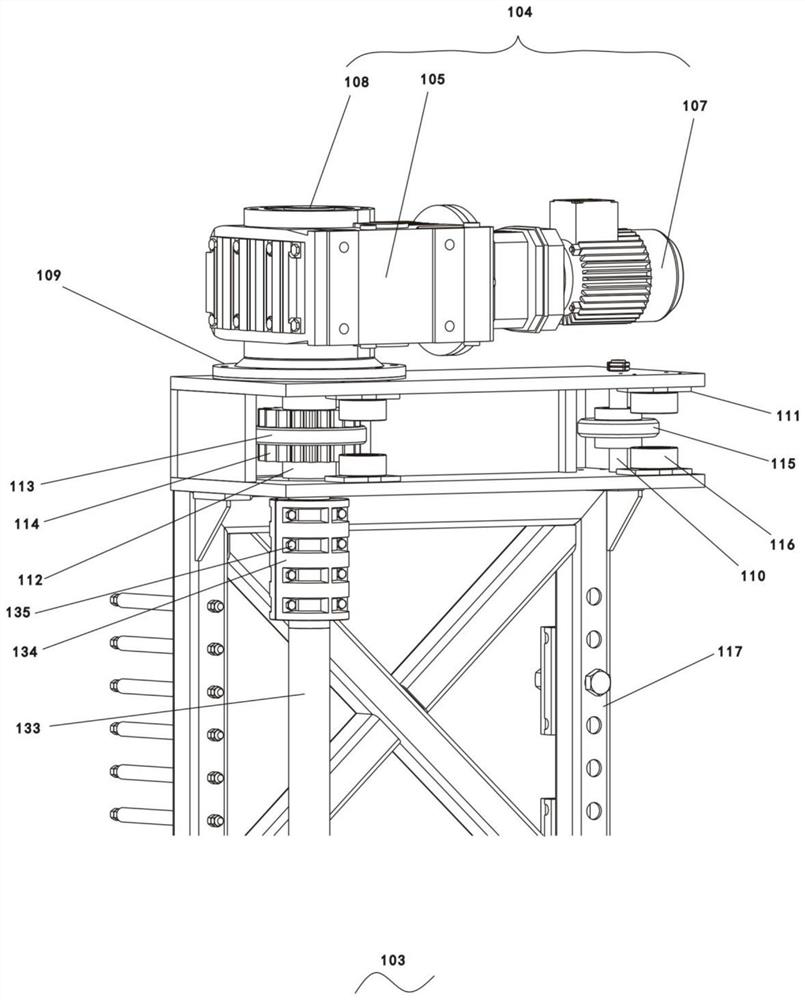

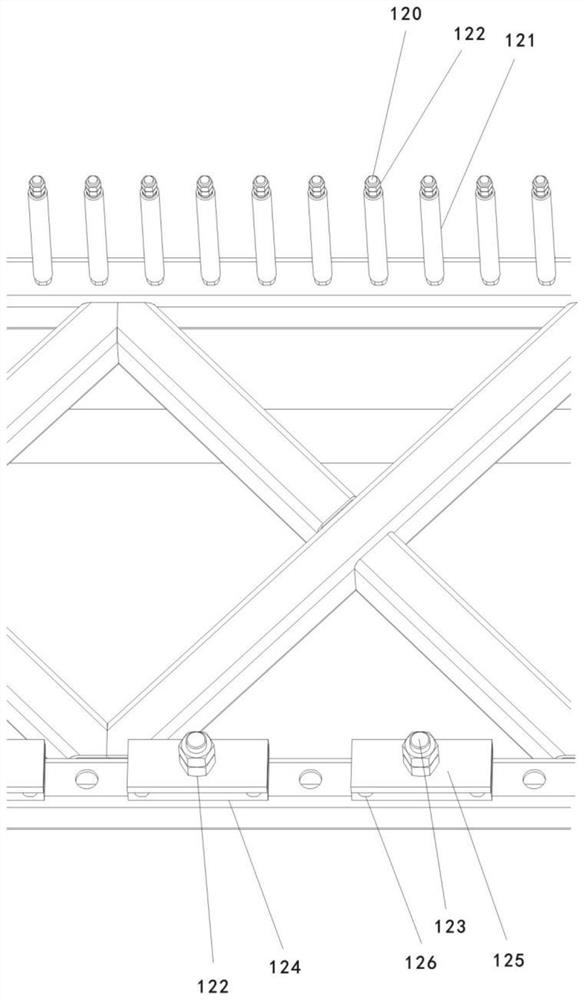

[0025] As an embodiment of the steel bar climbing frame for the tunnel waterproof and drainage board paving trolley of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes two sets of support rings 101, two sets of ring gears 102, two steel bar climbing frames 103 and two sets of first drive motor sets 104, and the first drive motor sets 104 are arranged on two sides of the steel bar climbing frames 103. On the side, the first driving motor unit 104 includes a first hollow shaft 105 and a first motor 107, the first hollow shaft 105 is provided with a first hollow shaft 108, and the first hollow shaft 108 is provided with a first Flange 109, the first flange 109 is connected on the steel climbing frame 103, the steel climbing frame 103 is arranged on the supporting ring 101, and the ring gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com