Patents

Literature

4114results about How to "Shorten construction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

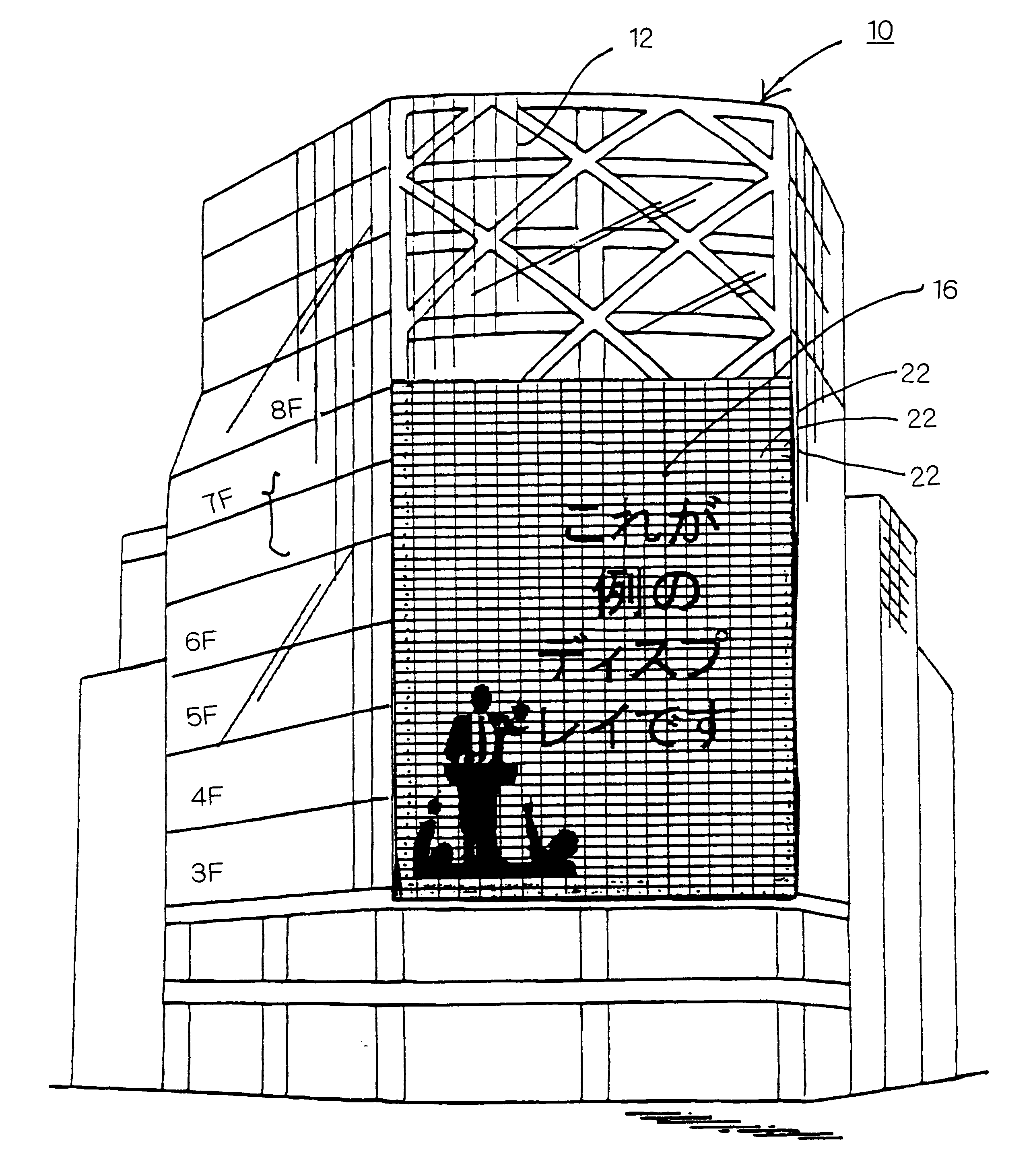

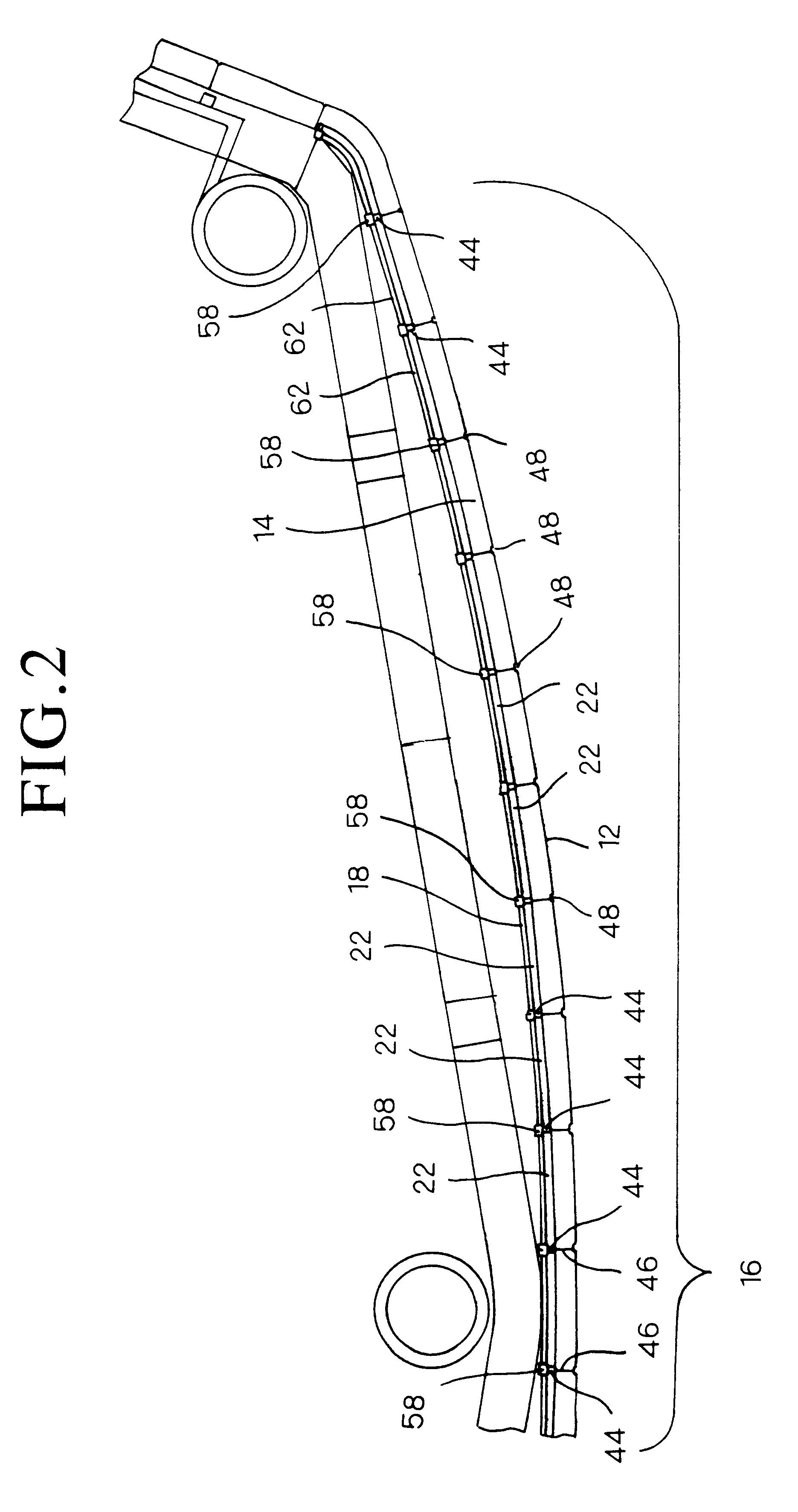

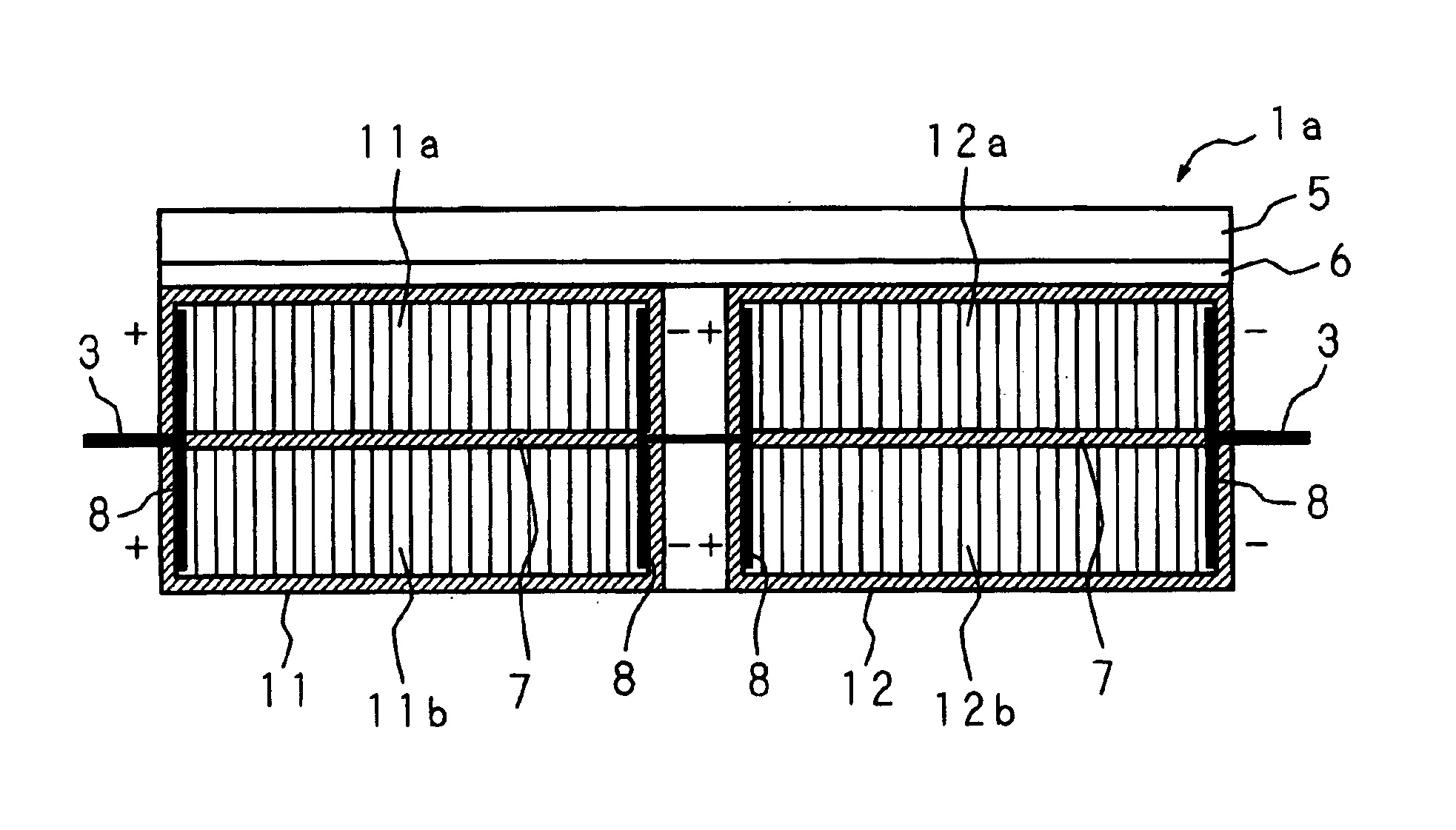

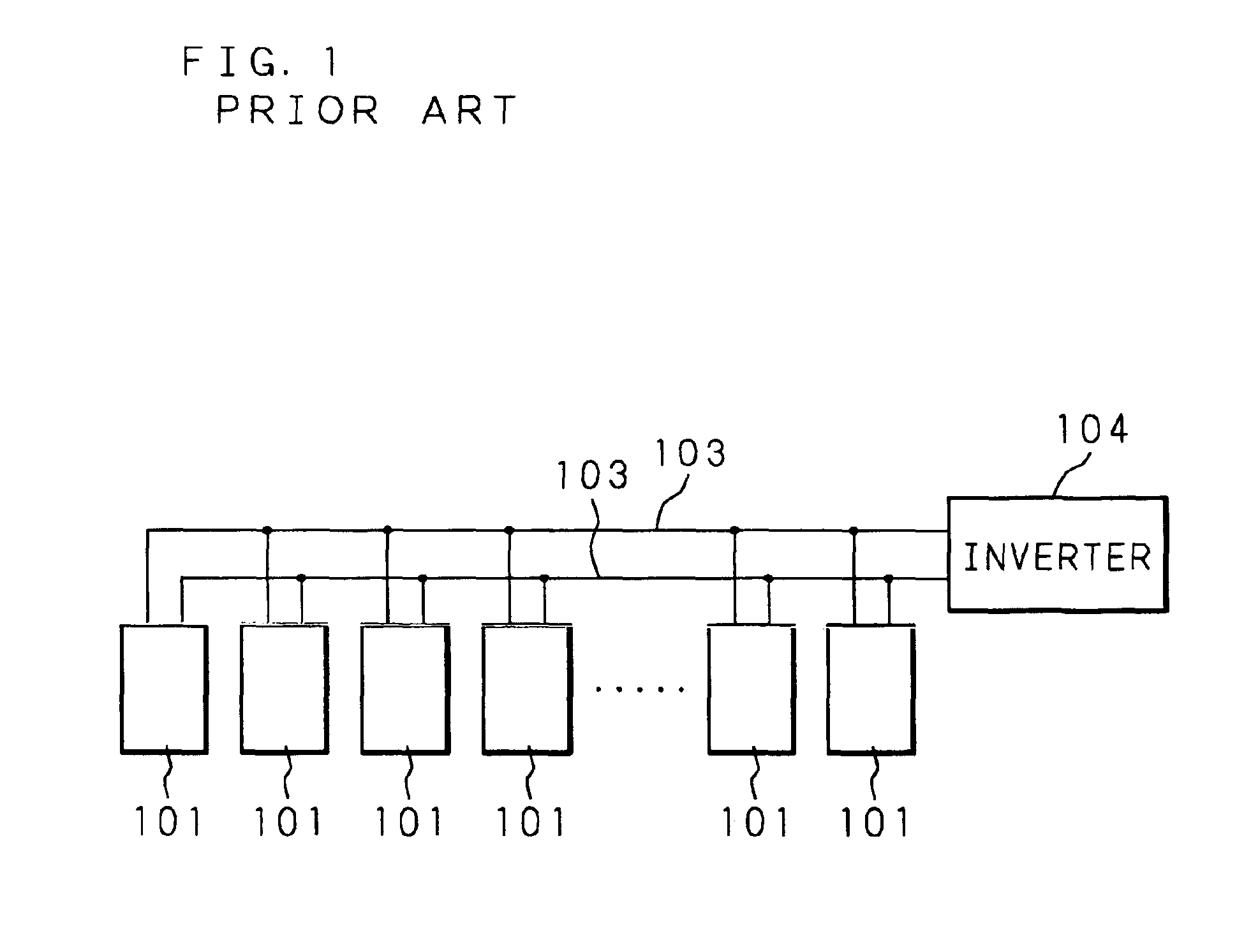

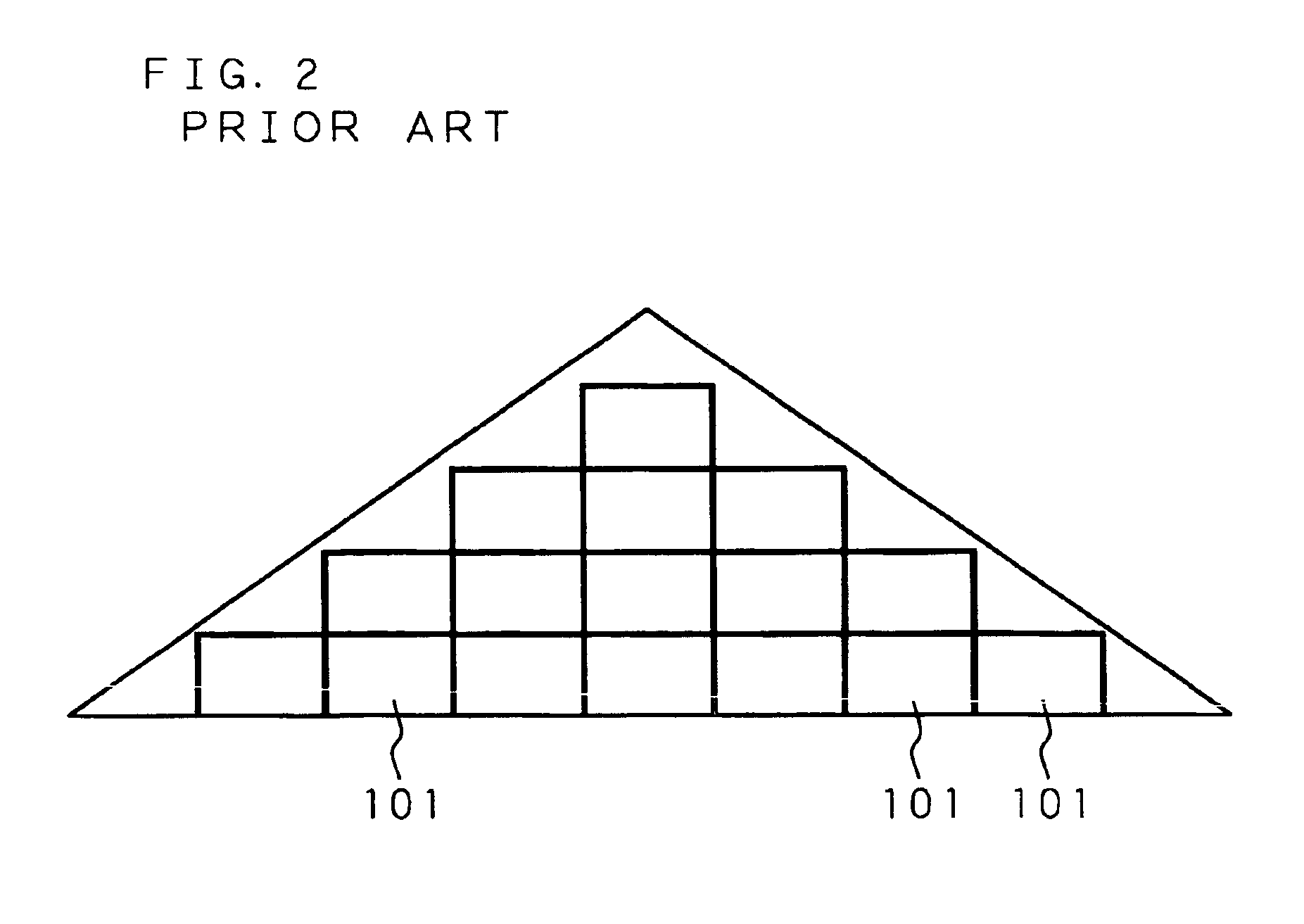

High-rise building with large scale display device inside transparent glass exterior

InactiveUS6237290B1Easy to carryImprove device performanceStampsPublic buildingsFloor slabWindow shutter

A high-rise building with a large scale dot-matrix display device is disclosed. The glass panels arranged in rows and columns form a curtain wall structured transparent outer wall 12 extending over an exterior of a building 10. Each panel is installed apart from end portions of floor slabs to form a void space therebetween. A plurality of louver structured modules 22 are arranged within the void space in rows and columns to form a large scale display area. Each module 22 has a louver-like structure formed of a plurality of posts 24 arranged in substantially parallel relationship and a plurality of parallel, uniformly spaced beams 26 connecting said adjacent posts 24. A plurality of LED combination lamps 28 are mounted on each beam 26 at uniform pitches as those between the adjacent beams 26. The LEDs are driven by drive circuits disposed in each beam 26. The vertical guide members 44 are fixed to the end portions of the floor slabs 20. The guide members 44 are arranged substantially in parallel relationship so that the modules 22 are supported between the adjacent guides 44 at the both lateral sides thereof. A plurality of vertical mullion members 48 fixed to the vertical guide members 44 as spaced apart from each of the vertical guides 44, so that the glass panels 12 are supported therebetween.

Owner:AVIX

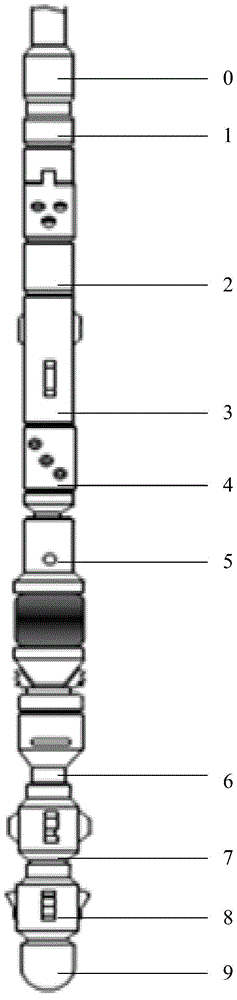

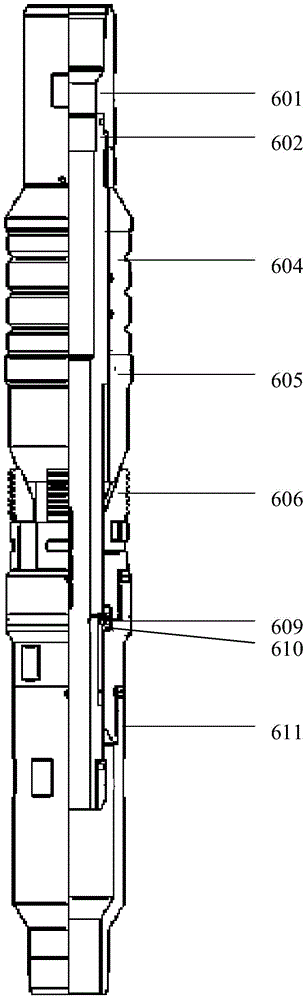

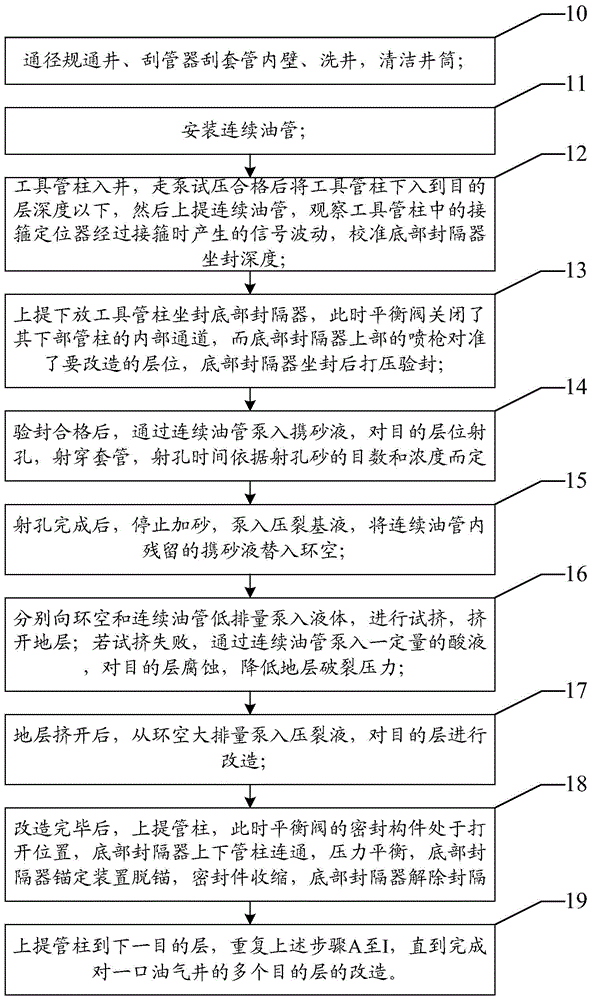

Multistage fracturing tool pipe column of continuous oil pipe and construction method

InactiveCN104563998AShorten construction timeShorten the time of fracturing and acidizingFluid removalEngineeringCoiled tubing

The embodiment of the invention discloses a multistage fracturing tool pipe column of a continuous oil pipe and a construction method. A contact, a releasing sub, a centralizer, a spray gun, a balance valve, a bottom packer, a friction pup joint, a collar locator and a guiding shoe are connected to form the tool pipe column, wherein the contact and a connecting oil pipe are connected and are positioned on the top end of the whole tool pipe column; the spray gun and the balance valve are positioned above the bottom packer; when the tool pipe column is subjected to setting, the internal channels of the upper pipe column and the lower pipe column of the bottom packer are packed by the balance valve; when the tool pipe column is lifted, the balance valve is used for communicating the internal channels of the upper pipe column and the lower pipe column of the bottom packer. Since the balance valve and the bottom packer are arranged, after the modification of one target layer is finished, a sealing construction member of the balance valve is positioned on an opening position when the fracturing tool pipe column is lifted, the upper pipe column and the lower pipe column of the bottom packer are communicated, pressure is balanced, and construction time is shortened.

Owner:JEREH ENERGY SERVICES

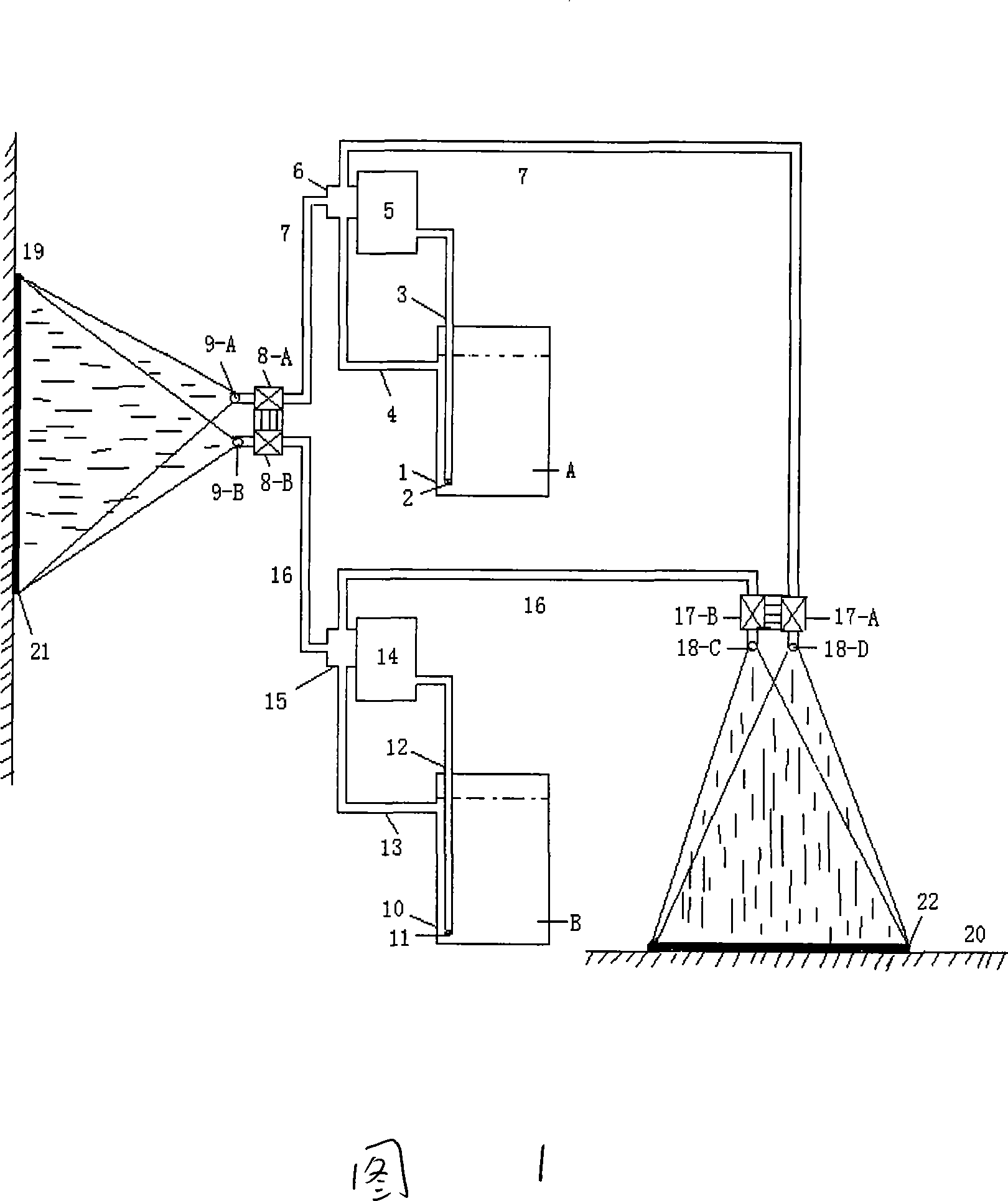

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

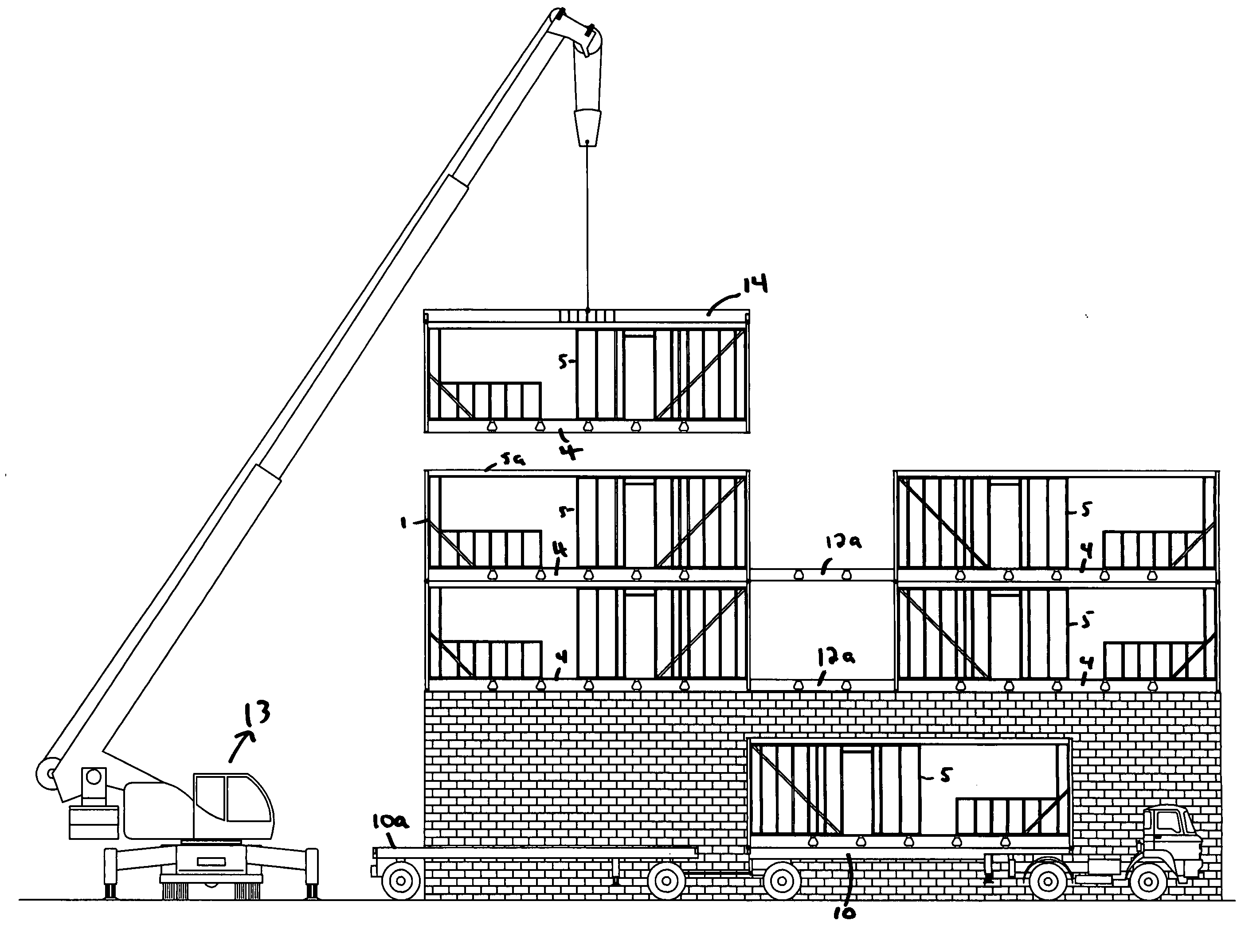

Load-bearing construction pod and hybrid method of construction using pods

InactiveUS20110056147A1Reduce construction costsQuality improvementPublic buildingsSpecial buildingArchitectural engineeringLaundry

Off-site load-bearing construction pod (module) that incorporate the vertical structure to carry similar pods placed on top of it and part of the on-site structure built around and above these pods. Hybrid method of construction where buildings are erected by combining standardized pods which incorporate smaller, most labor-intensive rooms and components of the edifice to conventional methods of construction for larger, less labor-intensive rooms and components. The very same mass-manufactured pod that incorporates kitchen, bathrooms, laundry room and most of the plumbing and the electric system of a dwelling can be used to build the top floor of a skyscraper or a single-family house.

Owner:BEAUDET PATRICE

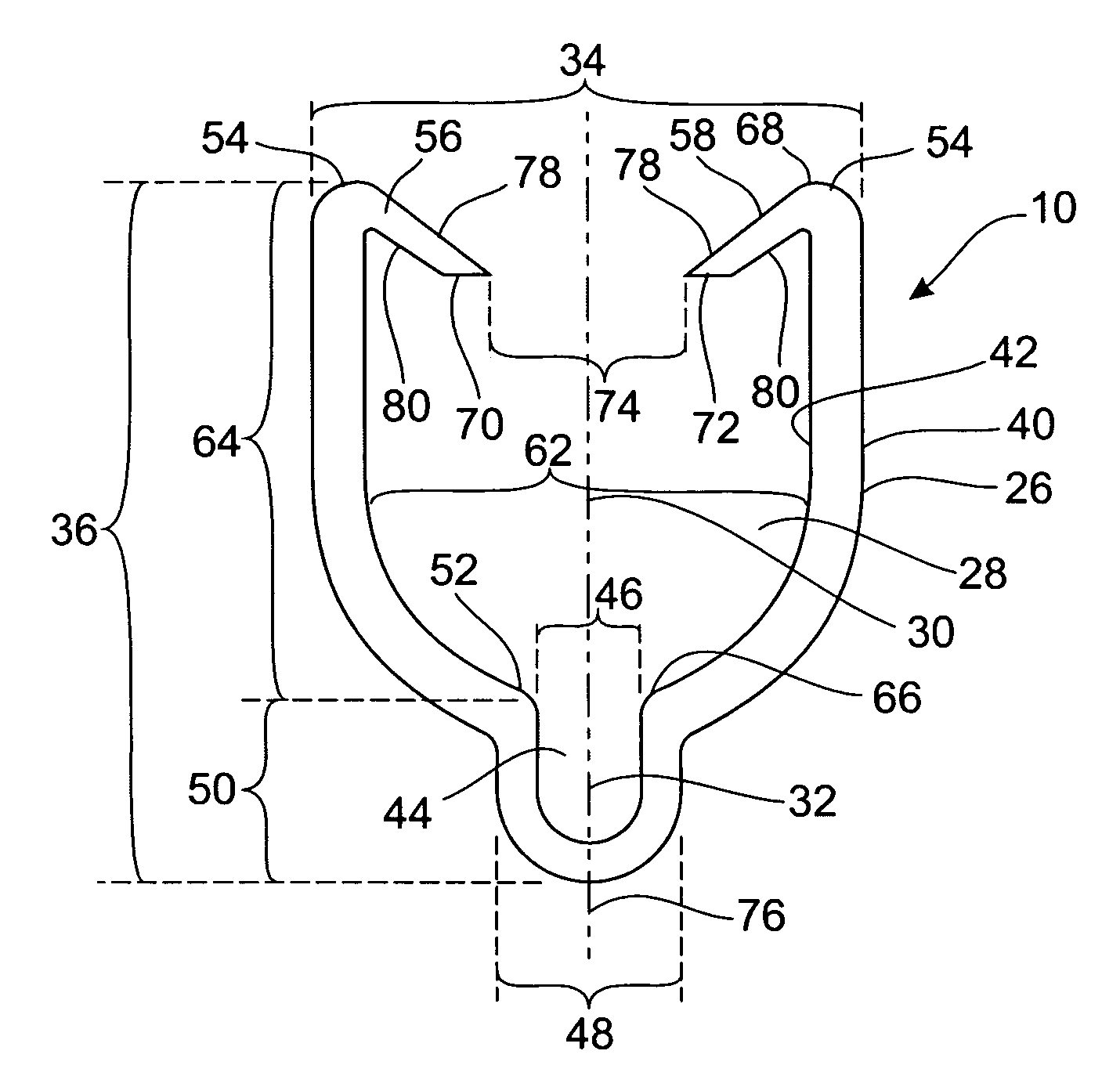

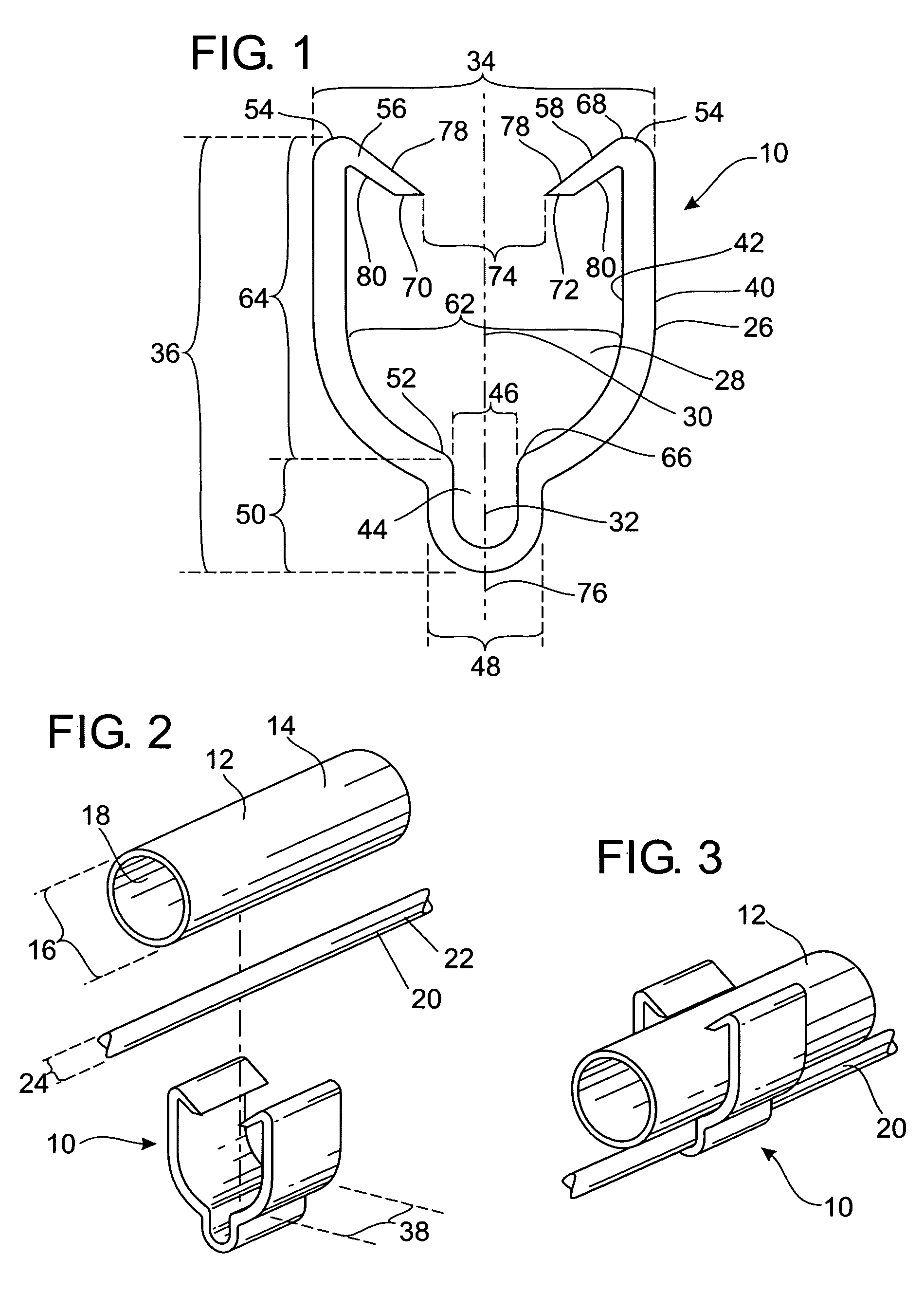

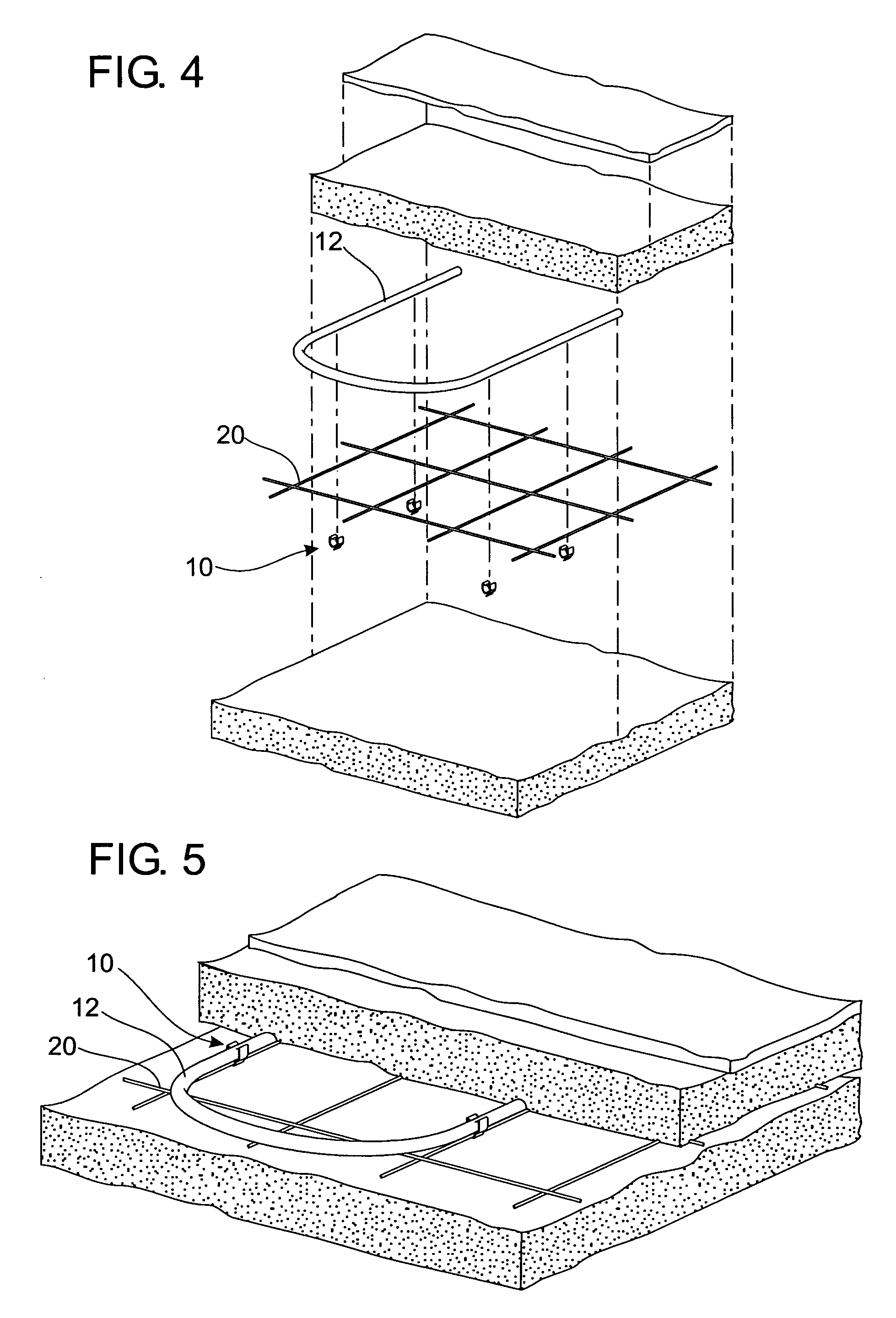

Radiant floor heating and cooling system clip

ActiveUS6969832B1Durable and reliable constructionLower sales pricePipe supportsLighting and heating apparatusMain channelEngineering

A radiant heating and cooling system clip for positioning a tube and construction support wire with one hand comprising an interior having a main channel for positioning a tube with a narrowing second channel within said main channel for positioning a wire.

Owner:MEYER ENTERPRISES

Method of installing solar cell modules, and solar cell module

InactiveUS6914182B2Reducing time and cost of photovoltaicEffective installationPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringSolar cell

Two types of solar cell modules having an equal output voltage and different sizes are used, and a plurality of solar cell modules of these two types are installed so that they are connected in parallel. The size of a solar cell module having two solar cell sub-modules is two times larger than the size of a solar cell module including one solar cell sub-module. By connecting two power generating regions of each of the solar cell sub-modules of the former solar cell module in parallel, connecting adjacent two solar cell sub-modules in series and connecting two power generating regions of the solar cell sub-module of the latter solar cell module in series, an equal output voltage is obtained from both of the solar cell modules.

Owner:SANYO ELECTRIC CO LTD

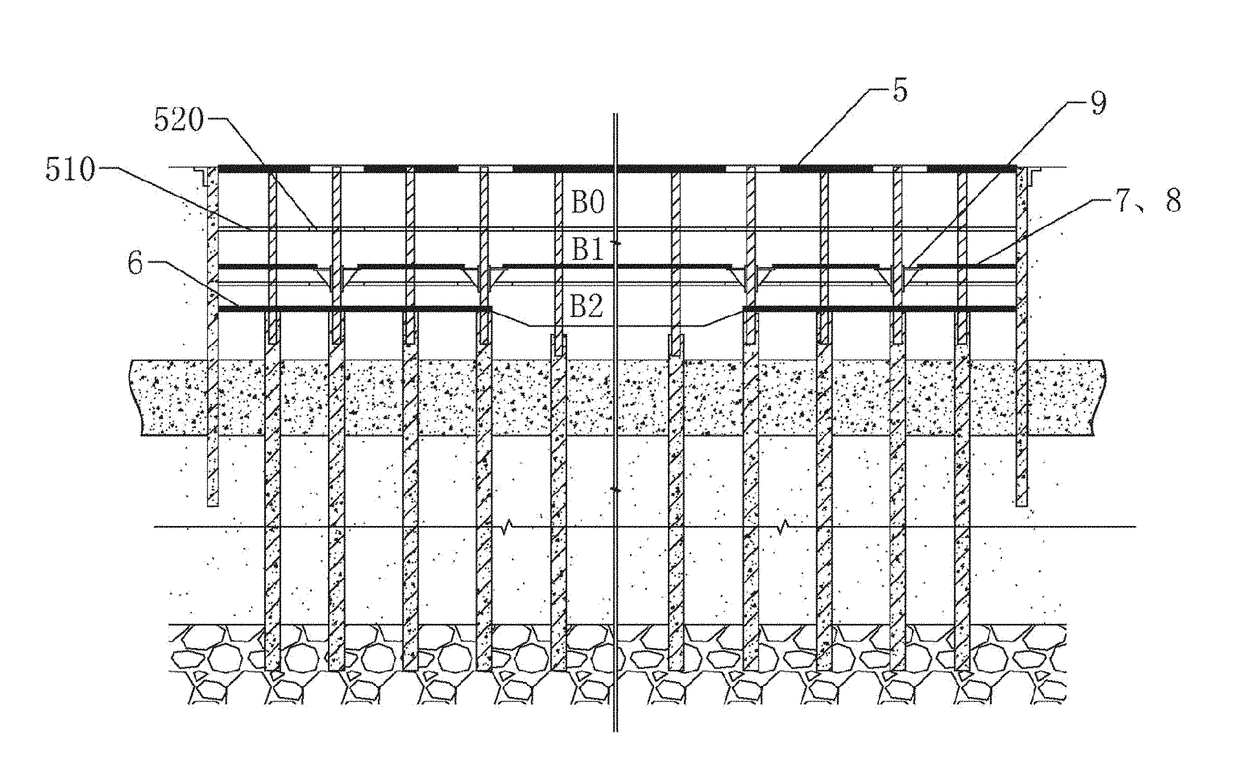

Inverse construction method for deep, large and long pit assembling structure of suspension-type envelope enclosure

ActiveUS20180044907A1Improve soil excavation efficiencyShortens pit construction timeConstruction materialFloorsBasementEngineering

The present invention relates to the field of construction of underground buildings, specifically to an inverse construction method for a deep, large and long pit assembling structure of a suspension-type envelope enclosure. A method includes design and calculation; engineering construction of foundation piles; control over underground water; construction of a pit enclosure; building of a basement reinforcing and anti-seeping layer; inverse construction; and floor structure construction. By the inverse construction method for a deep, large and long pit assembling structure of a suspension-type envelope enclosure of the present invention, the pit construction quality is easily controlled, the basement is well waterproofed and easily monitored, and the quality control, service and maintenance are easy.

Owner:WUHAN ZHIHE GEOTECHNICAL ENG CO LTD

Dried hanging thermal insulation decorative curtain wall and mounting process thereof

InactiveCN101302782AReduce construction costsShorten construction timeCovering/liningsWallsThermal insulationKeel

The invention discloses a dry-hanging curtain wall for thermal insulation and decoration and an installation technique thereof, which essentially comprises a 'duplex F' shape installation hanging part; the radial frameworks and the zonal frameworks of the 'duplex F' shape installation hanging part are vertically arranged; a first layer of the radial frameworks with two or more than two layers is level to the zonal frameworks and the radial framework at the last layer is at a certain distance from the tail end of the zonal framework; the width and thickness of the radial frameworks at every layer can be equal or not. Insulation boards can be fixed in a point-typed installation and location method by the installation hanging part, thus overcoming the defects of the prior art, providing an installation technique of the thermal insulation and decoration curtain wall without installing the horizontal and the vertical joist, simplifying the installation procedure, saving the installation raw materials and cost and overcoming the defect that the rain leakage is easy to happen in the splicing seam of the insulation board adopting the traditional method.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

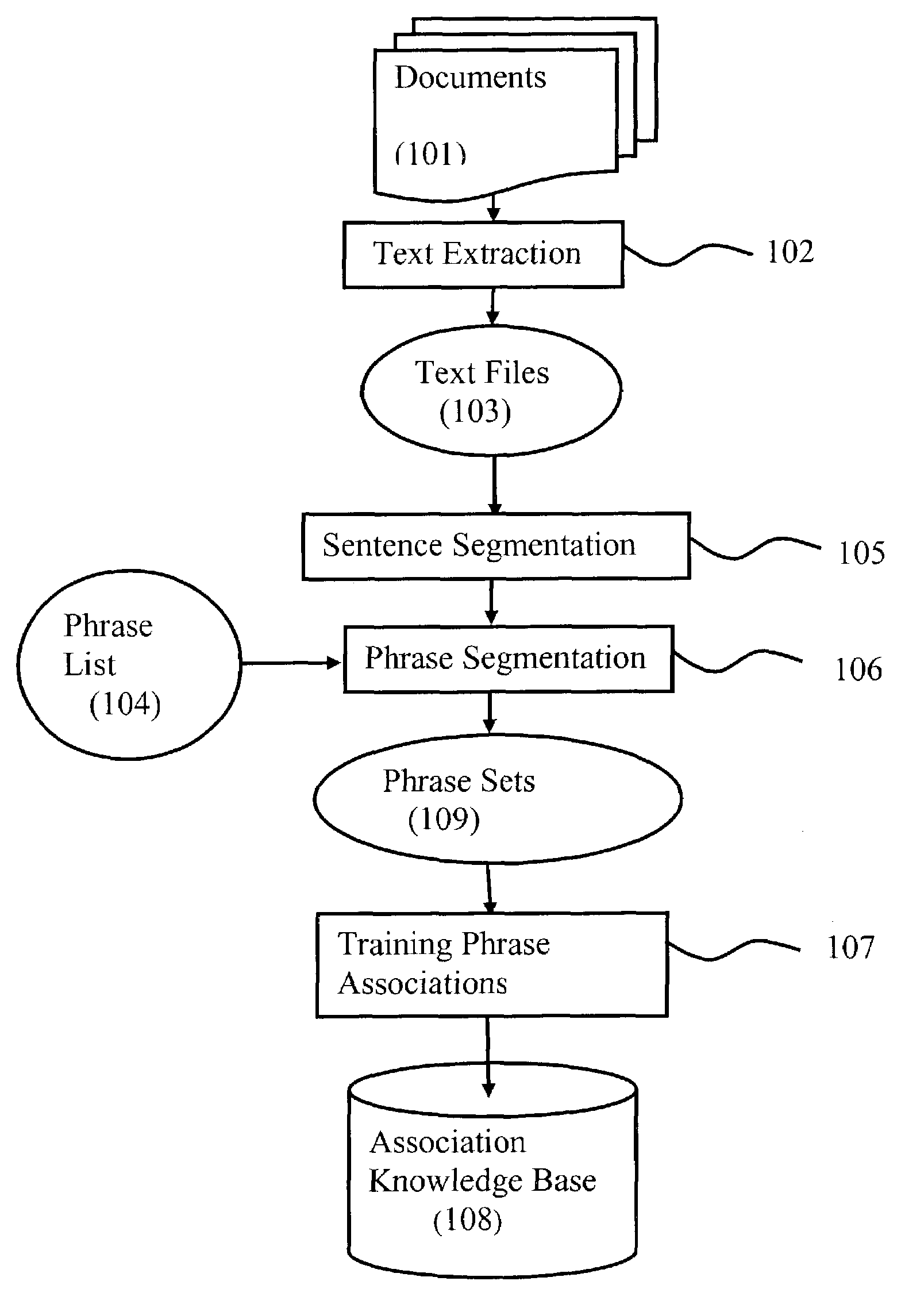

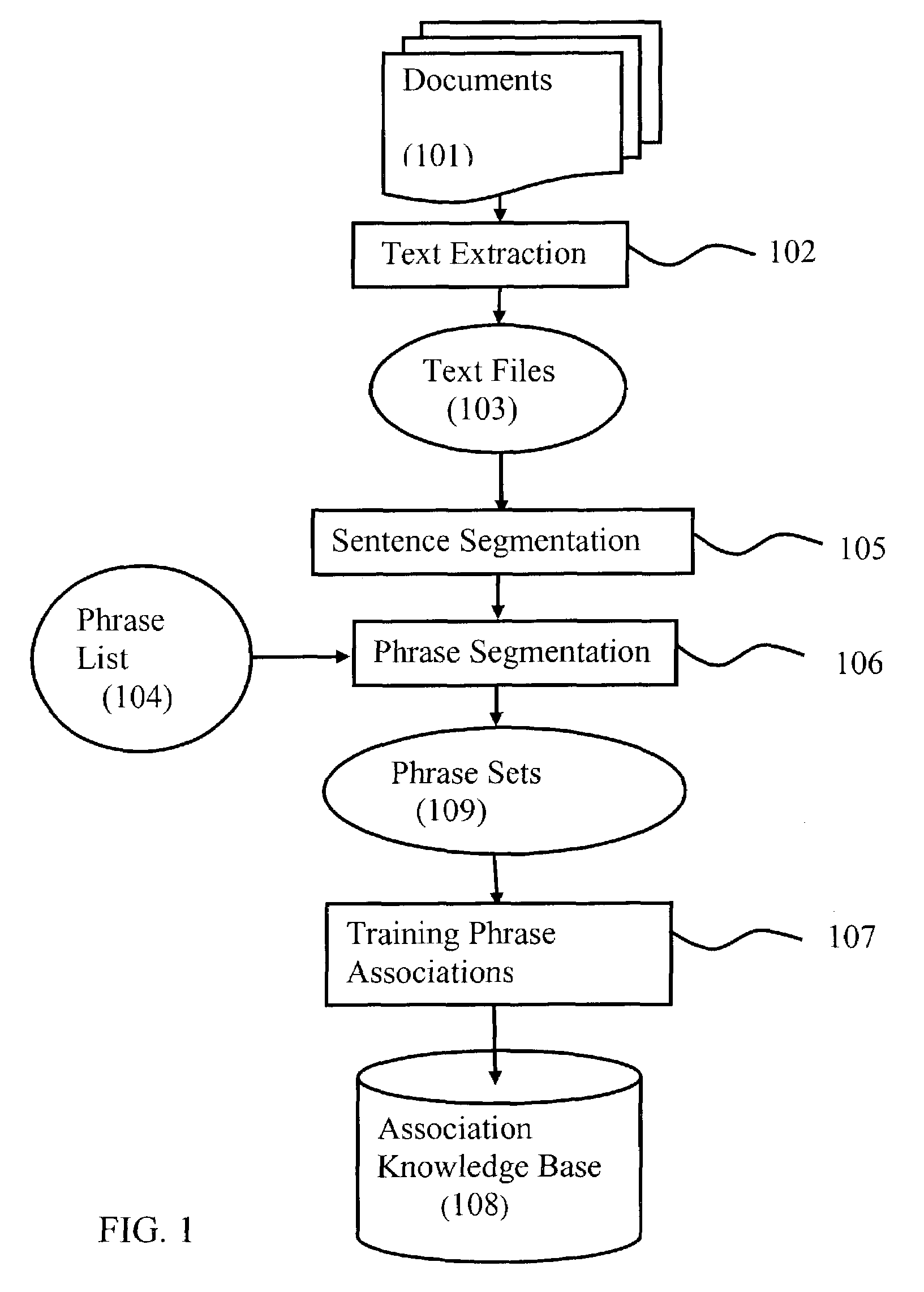

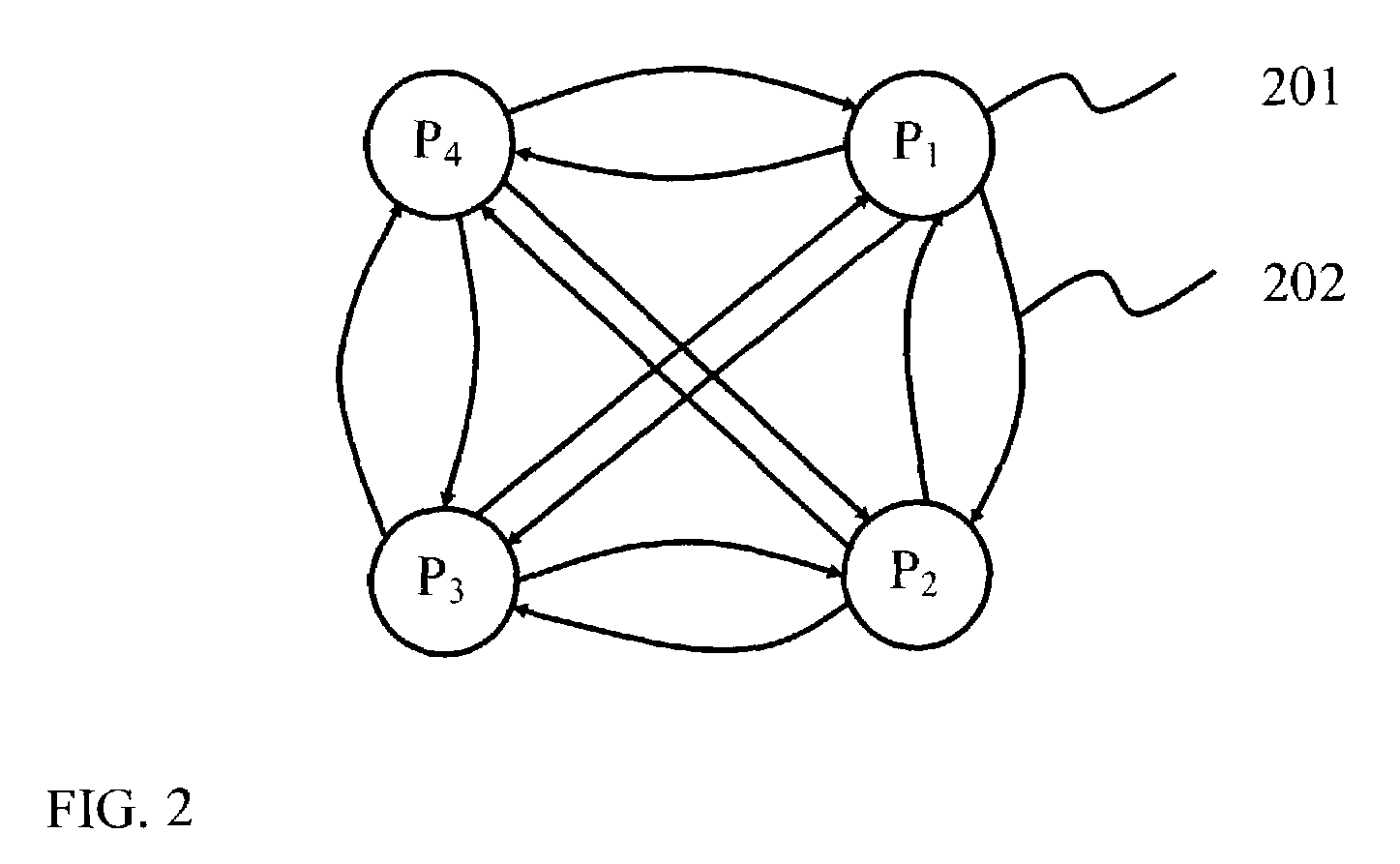

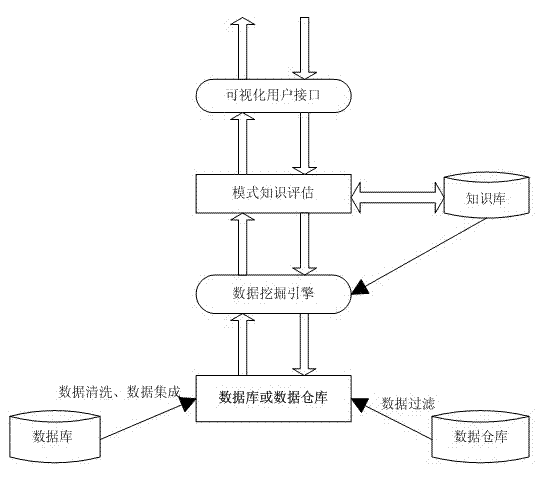

Method and system of knowledge based search engine using text mining

ActiveUS7257530B2Shorten construction timeEasy maintenanceDigital data information retrievalNatural language data processingIntranetWeb page

A method of text mining is disclosed for automatically building text knowledge base. First, the text mining is applied to the web pages downloaded from internet / intranet or other text documents to extract phrases information. Then, the phrases are classified using automatic classification method or using existed classification information. In addition, the weights between the phrases are trained by using the text information in the web pages or the documents. A knowledge base system is built using the text mining results. The knowledge base is used to directly provide knowledge for a search. Also, the knowledge base helps search engine refine search results.

Owner:RPX CORP

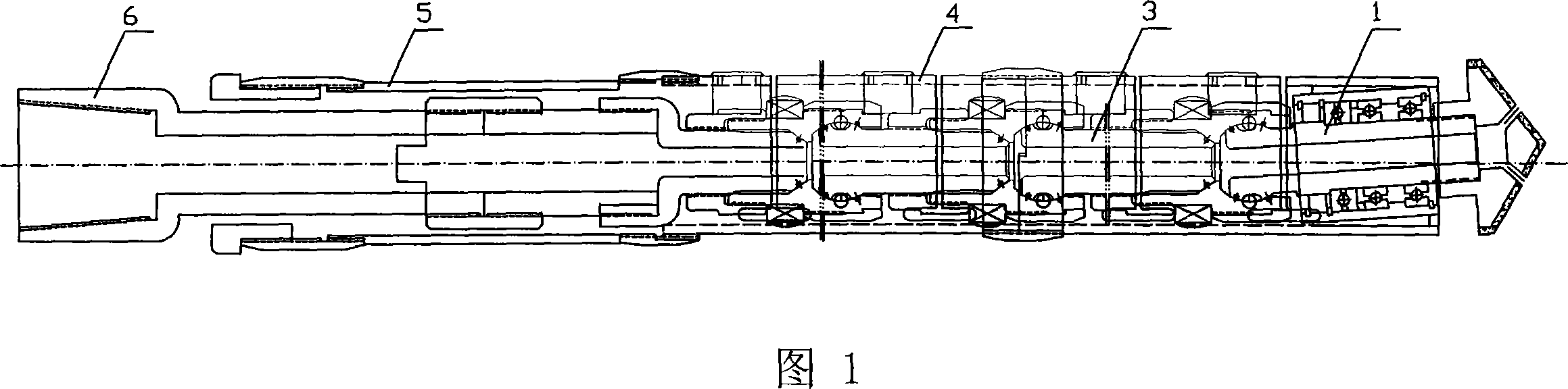

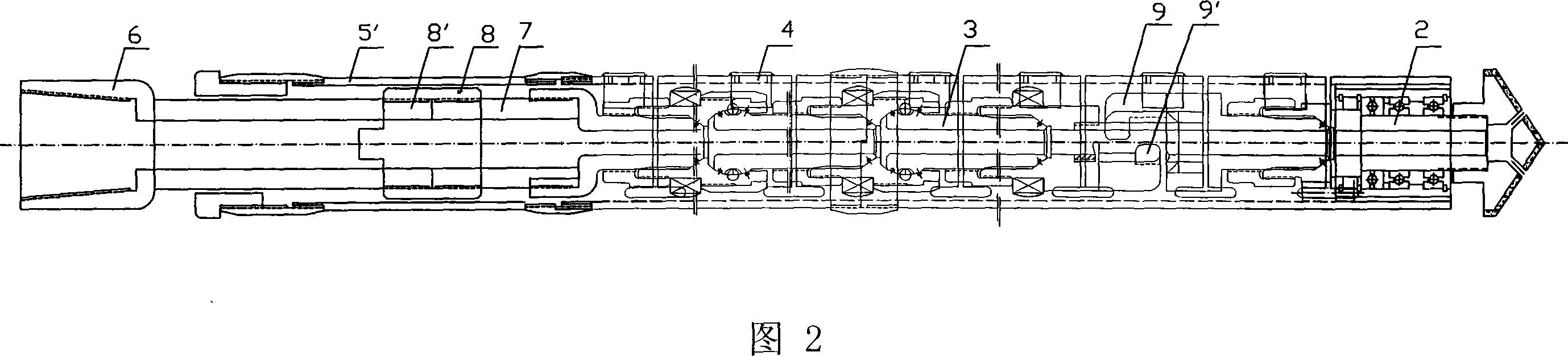

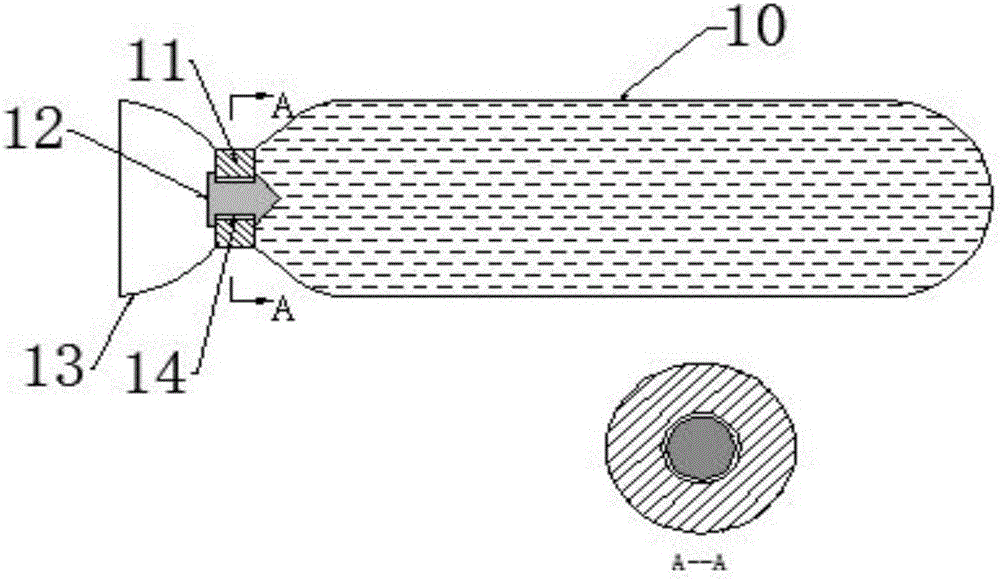

Ultra-short radius radial horizontal well drilling, completion tool and technique thereof

InactiveCN101078335AEasy maintenanceHigh strengthDrilling rodsDirectional drillingCouplingWell drilling

Owner:BEIJING WANWEI YITONG TECHNOLOGICAL DEV

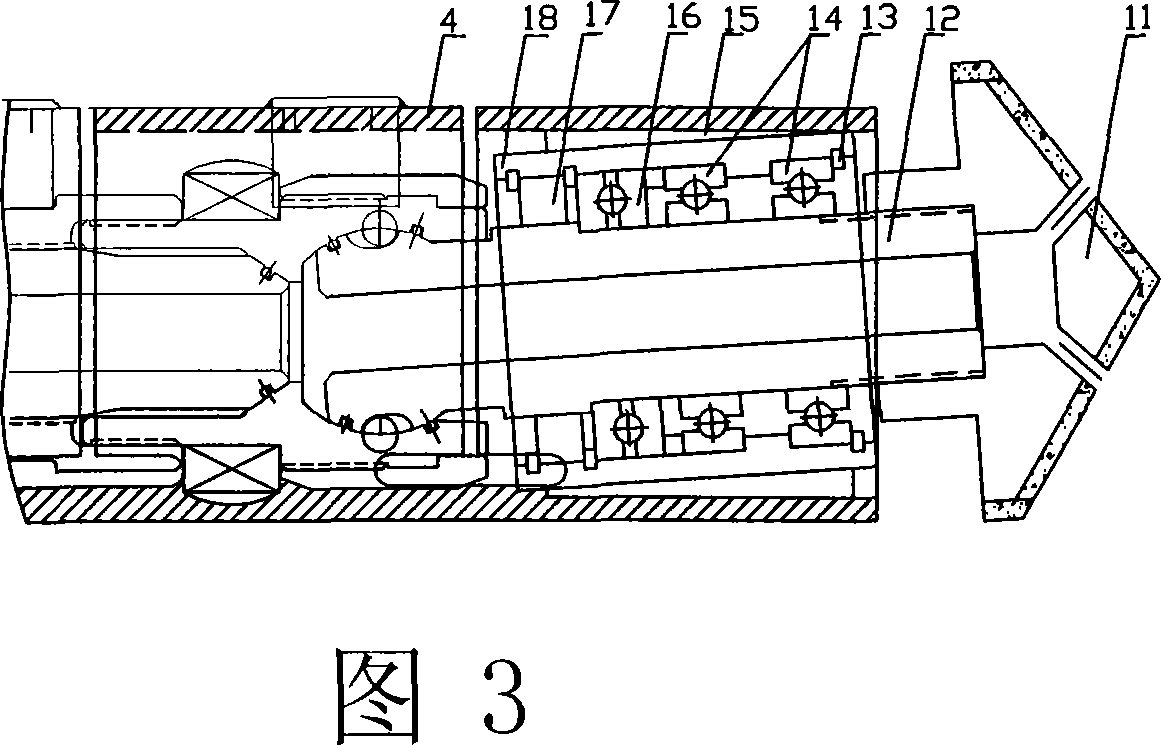

Method for constructing engineering pile by combining rotary drilling rig with manual pile base chambering

InactiveCN102425160AGuarantee the construction qualityImprove construction qualityBulkheads/pilesRebarDrill

The invention relates to a method for constructing an engineering pile by combining a rotary drilling rig with manual pile base chambering, which comprises the following steps: (1) preparation work before construction, including field leveling; (2) pile lofting; (3) pile casing embedding; (4) rig installation and rotary drilling; (5) manual pile base chambering; (6) rotary drilling drill quality detection; (7) reinforcement cage manufacturing; (8) reinforcement cage installation; (9) preparation before casting, mainly including hole cleaning, final hole acceptance check, and pump concrete casting quality safeguard measure; and (10) concrete casting, mainly including guide pipe installation, concrete casting and sampling for test and pile forming. In the method for constructing the engineering pile by combining the rotary drilling rig with the manual pile base chambering, the high efficiency of the rotary drilling rig is fully utilized, and the manual pile base chambering is utilized, the advantages of the rotary drilling rig and the manual pile base chambering are combined to make up the defects of the rotary drilling rig and the manual pile base chambering. The construction steps are detailed; the process flow is clear and definite; the construction quality of the engineering pile is ensured through an effective detail measure; the construction process of the rotary drilling rig and the process step of the manual pile base chambering are combined as a whole to realize the effective allocation of a construction field, a construction machine and construction time; and when the construction quality is ensured, the construction efficiency of a digging pile is greatly increased, thereby, the construction time of the engineering pile can be greatly saved, and the construction period requirement of the project is met.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

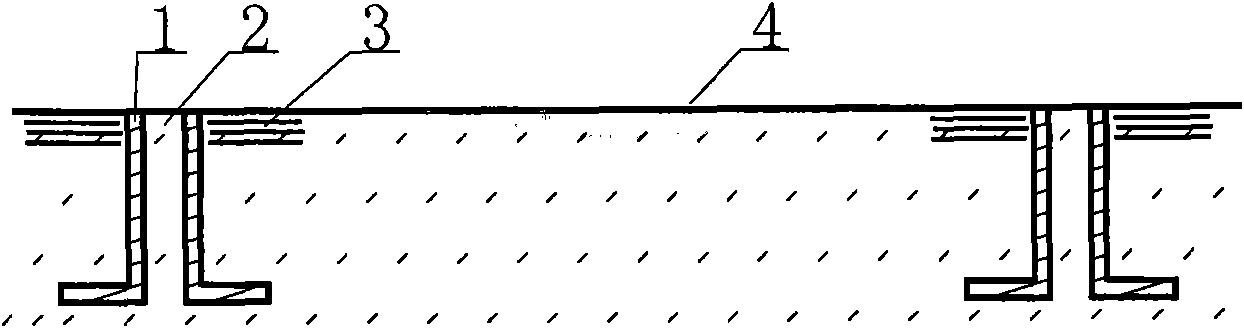

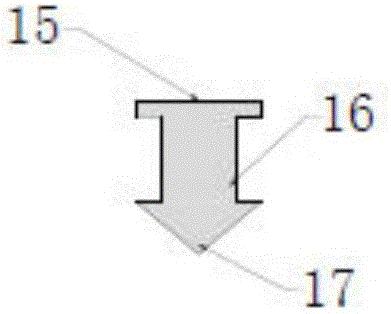

Method for connecting slotted sections in underground construction of diaphragm wall

The invention discloses a method for connecting slotted sections in underground construction of diaphragm wall of 'deep wall, large thickness and needing rock-socketed' applied to large acale bridges and construction foundation pit excavation. The method comprises the following steps: establishing a guide wall and a construction platform; constructing I phase slotted section of the diaphragm wall; constructing of a slotted eye of II phase slotted section of the diaphragm and jagged section surface of the I phase slotted section; forming an underground diaphragm wall; cleaning and brushing the wall of the II phase slotted section repeatedly up and down by a special steel brush carried by a hydraulic grab, until the steel brush does not have obvious spare, deposit on the bottom of the eye does not increase; releasing a reinforcing cage and casting concrete so as to complete the connection of I phase slotted section and II phase slotted section after the II phase slotted section is completed; forming a complete diaphragm wall after connection. After the method is adopted, the progress of the construction of the underground diaphragm wall is greatly improved; construction cost is saved; construction problems, such as concrete circumferential motion prevention, water seepage in seam and the like can be completely solved by the jagged connection section so as to improve construction quality and safety reliability.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

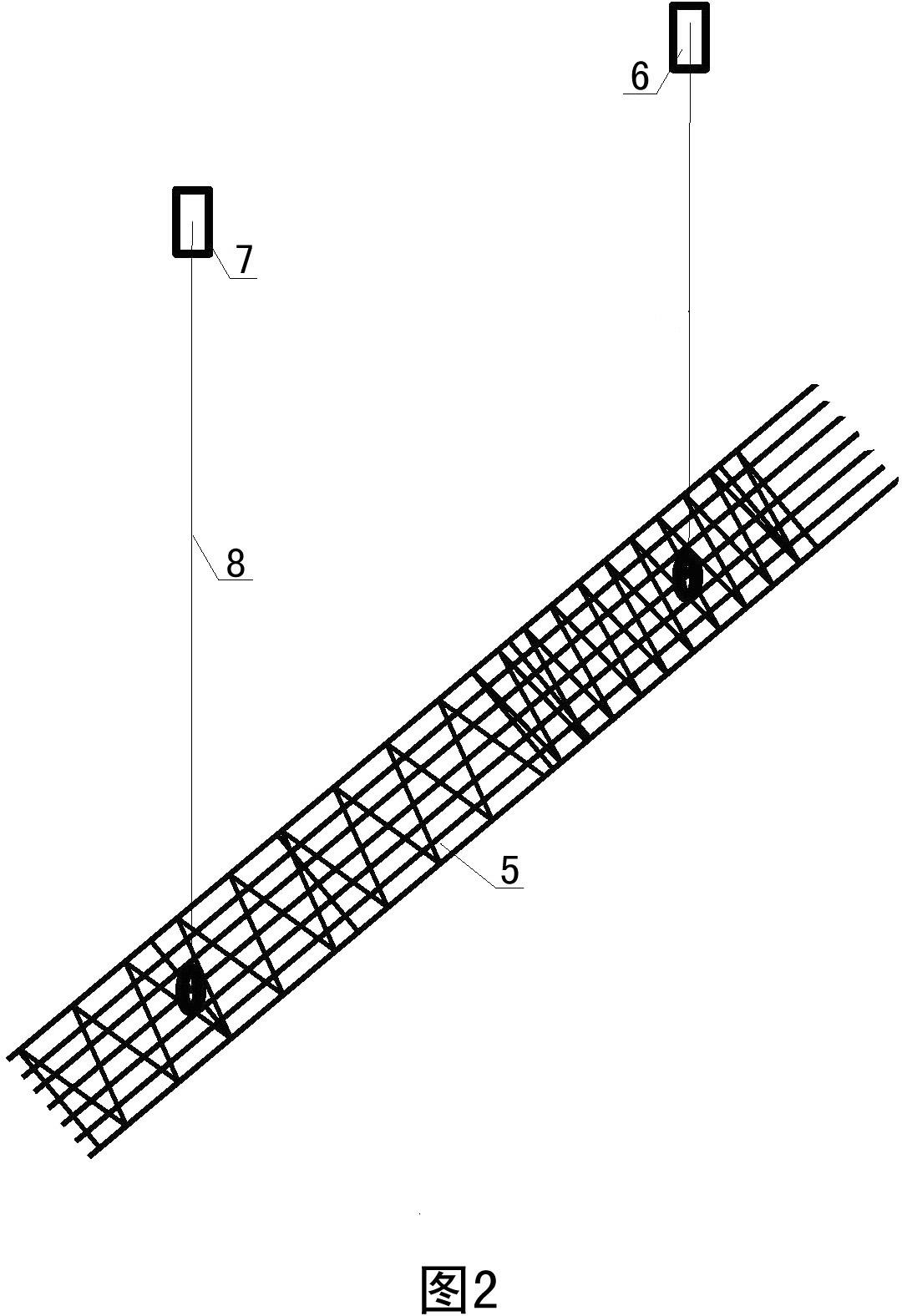

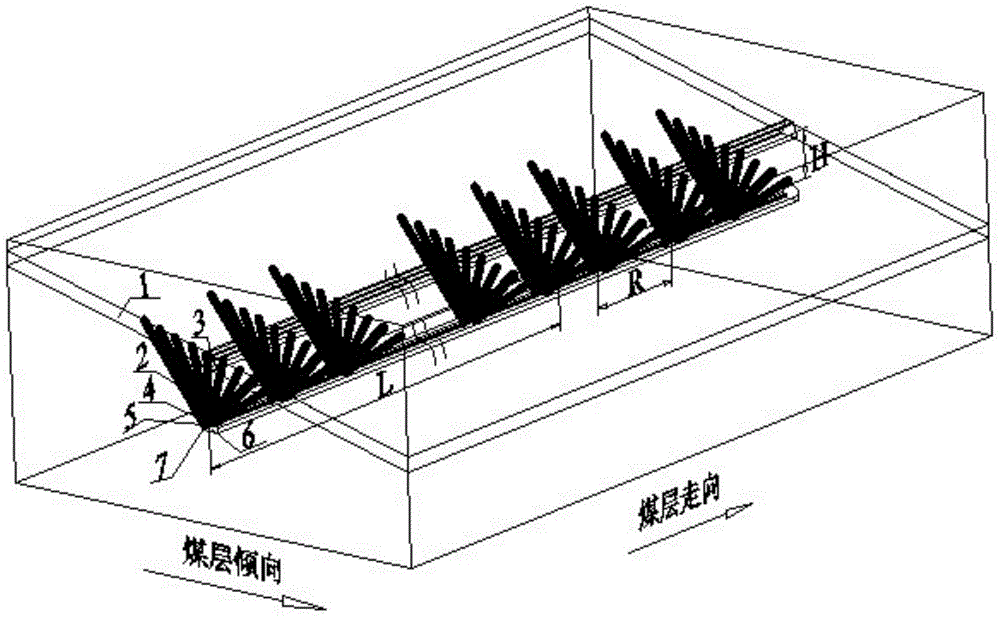

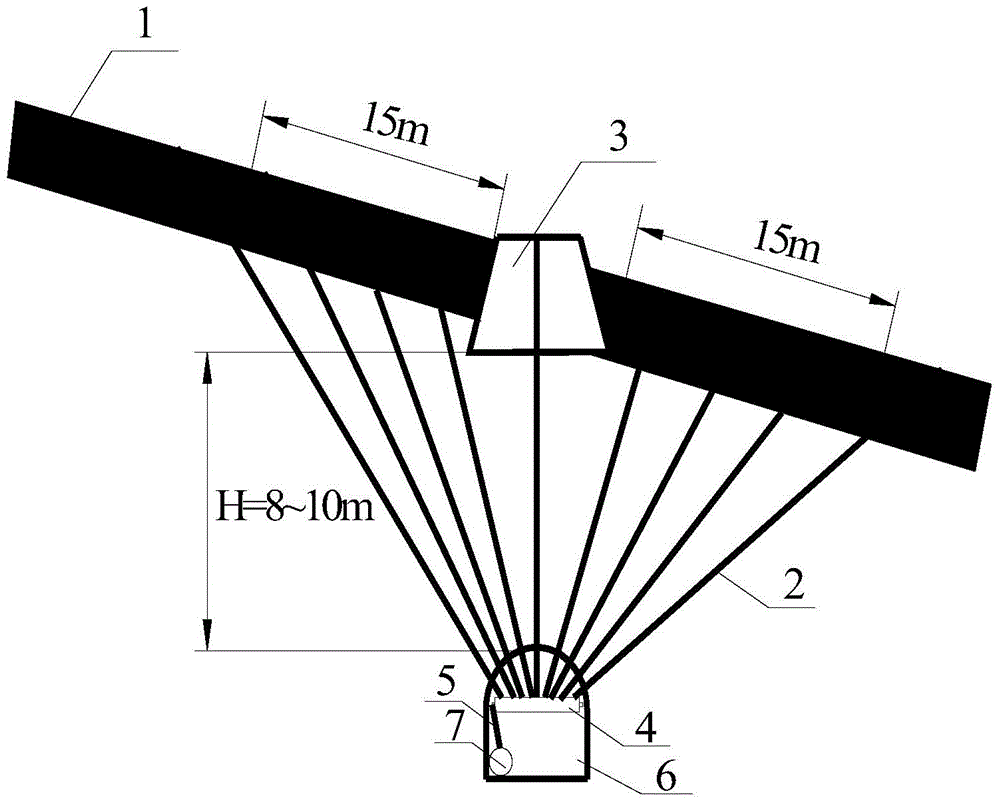

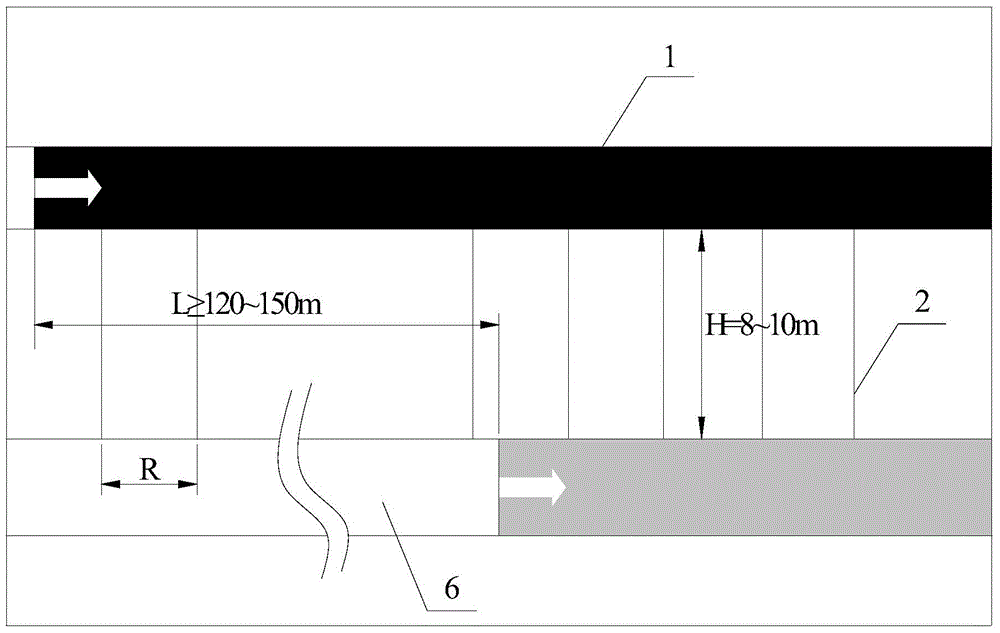

Method for extracting coalbed gases from coal mines by upper and lower combination

The invention relates to coalbed gas mining technology, in particular to a method for extracting coalbed gases from coal mines by upper and lower combination. The method solves the problem of poor gas drainage effects through surface well drilling and hole drilling in the coalbed. The method comprises the following steps: constructing extraction drilled wells on the surface, constructing underground directional long drilled holes in the coalbed, crosslinking the fracture areas of the extraction drilled wells with the drainage areas of the underground directional long drilled holes, then effectively sealing the underground directional long drilled holes in the coalbed, then utilizing fracturing equipment on the surface to fracture the drainage areas drilled on the surface and the drainage areas of the long drilled holes in the coalbed via the extraction drilled wells and finally carrying out extraction. The method has the advantages of improving the extraction rate and efficiency of the coalbed gases and shortening the construction period of the coalbed gas extraction engineering.

Owner:山西蓝焰煤层气集团有限责任公司

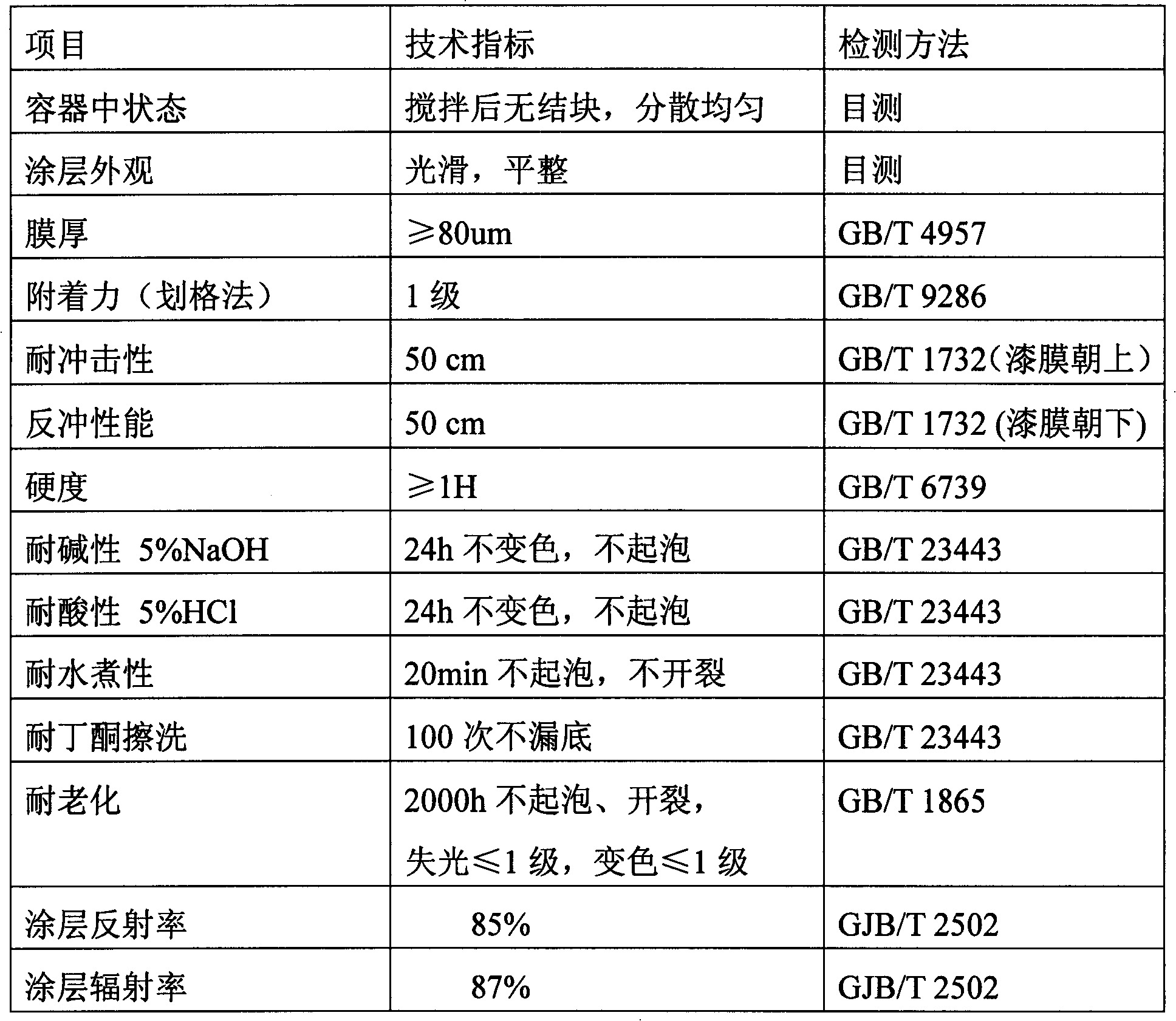

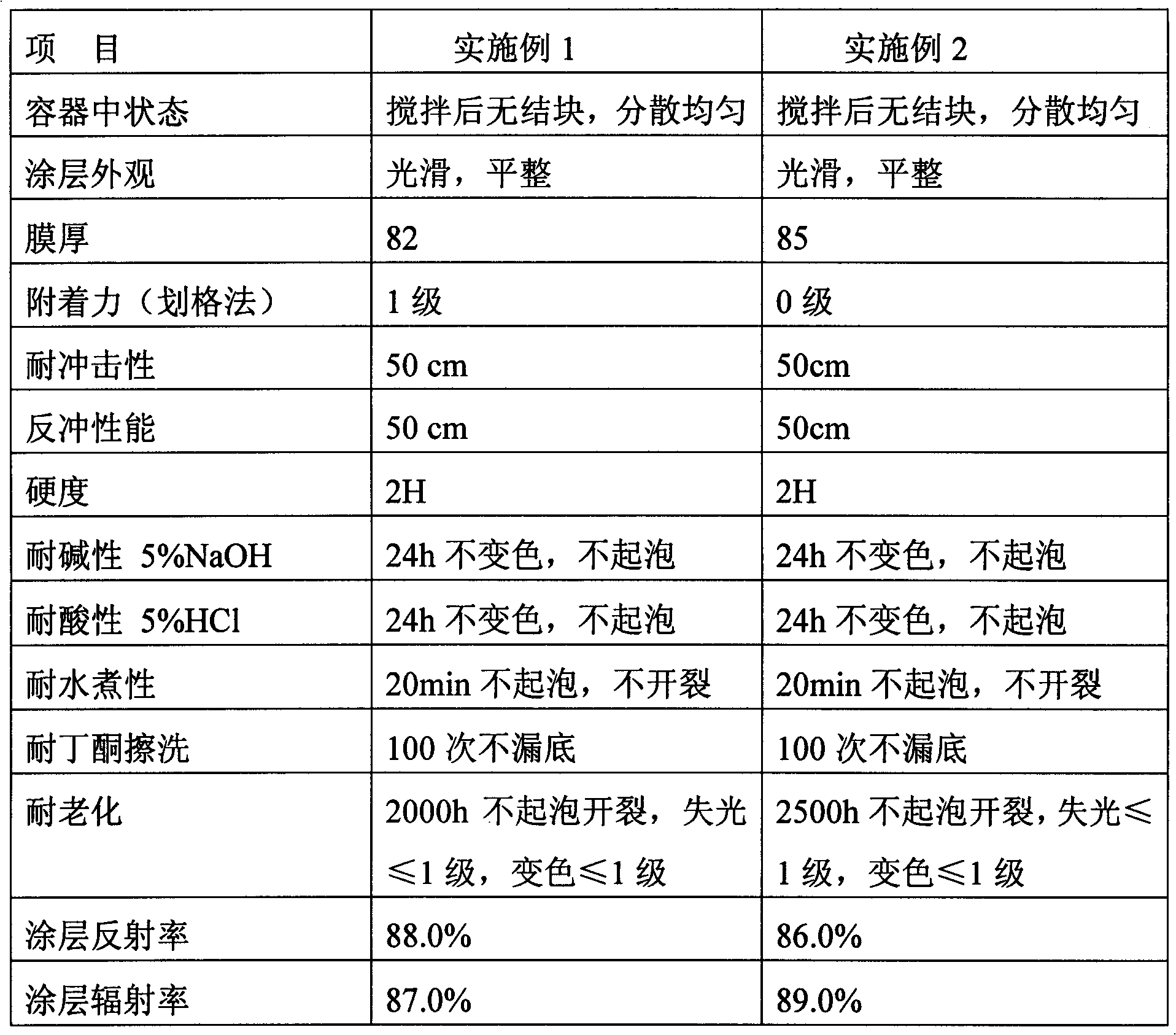

Ultrathin metal plate heat-insulation reflection coating and its preparation method

InactiveCN102876181AThe overall thickness is thinSuitable for paintingEpoxy resin coatingsPolyester coatingsSolventPigment

The invention relates to an ultrathin metal plate heat-insulation reflection coating and its preparation method. The coating comprises a priming paint and a finish. The preparation method which adopts two coats comprises the following steps: coating the priming paint on a metal plate, and then coating the finish. The priming paint comprises the following components, by weight, 40-60 parts of a film forming resin, 20-30 parts of a pigment, 0-10 parts of a filler, 2-5 parts of auxiliary agents, 5-20 parts of a solvent, and 5-15 parts of a curing agent; and the finish comprises the following components, by weight, 40-60 parts of the film forming resin, 20-30 parts of the pigment, 2-10 parts of the filler, 2-5 parts of the auxiliary agents, 5-20 parts of the solvent, and 5-15 parts of the curing agent. Compared with coatings prepared through the prior art, the coating provided by the invention has the advantages of thin coat thickness, wide application range, convenient construction and the like.

Owner:SHANGHAI DATONG HIGH TECH MATERIALS

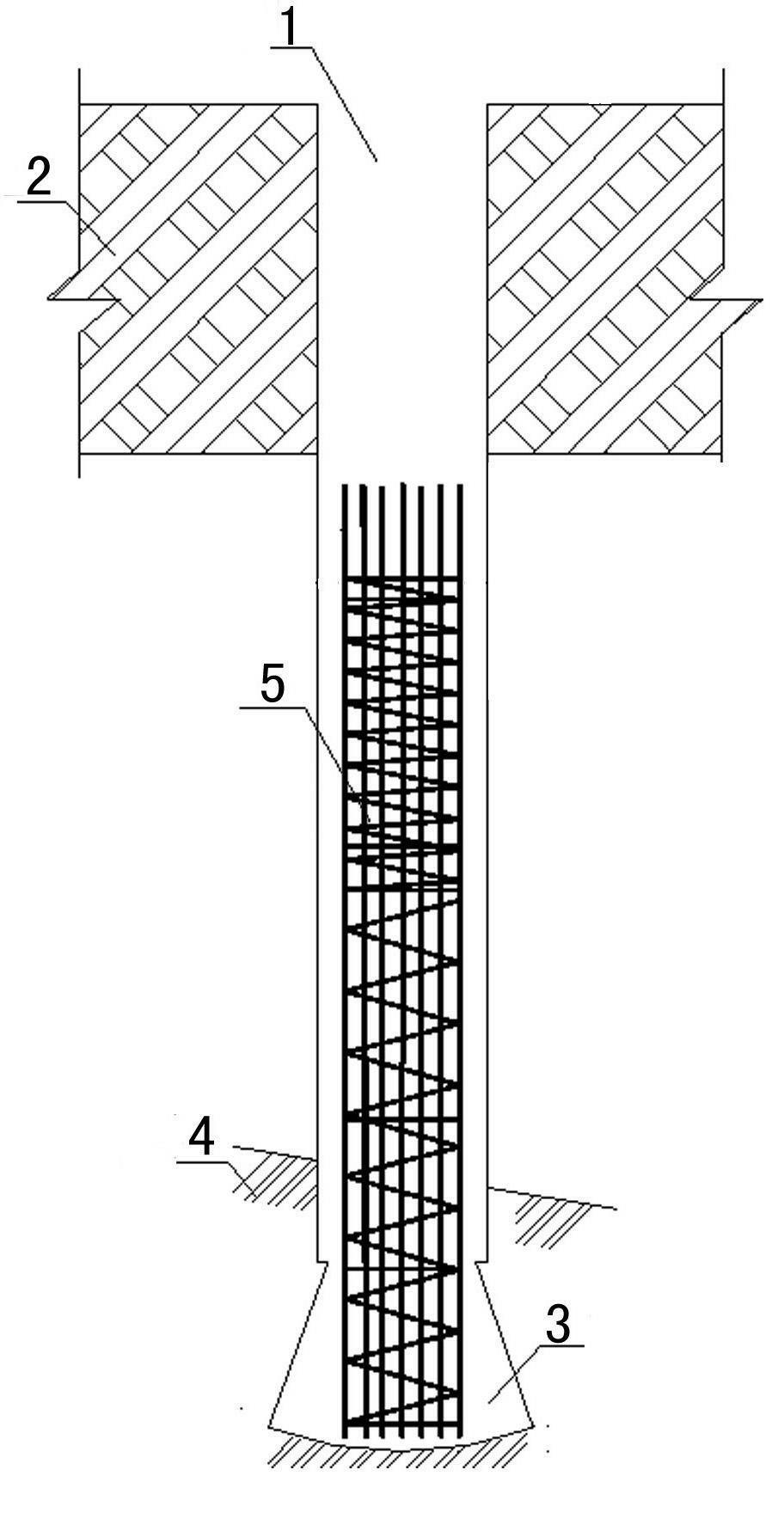

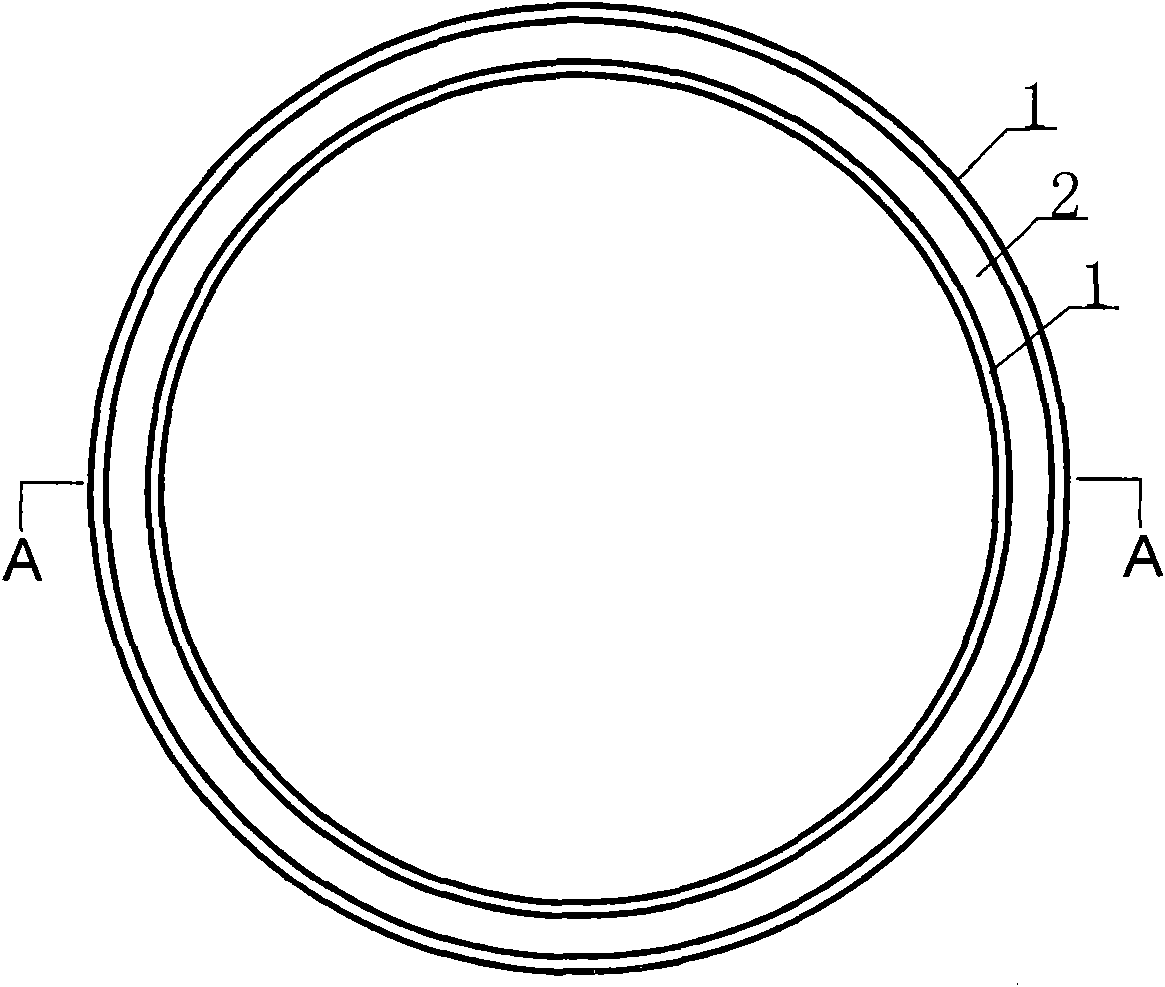

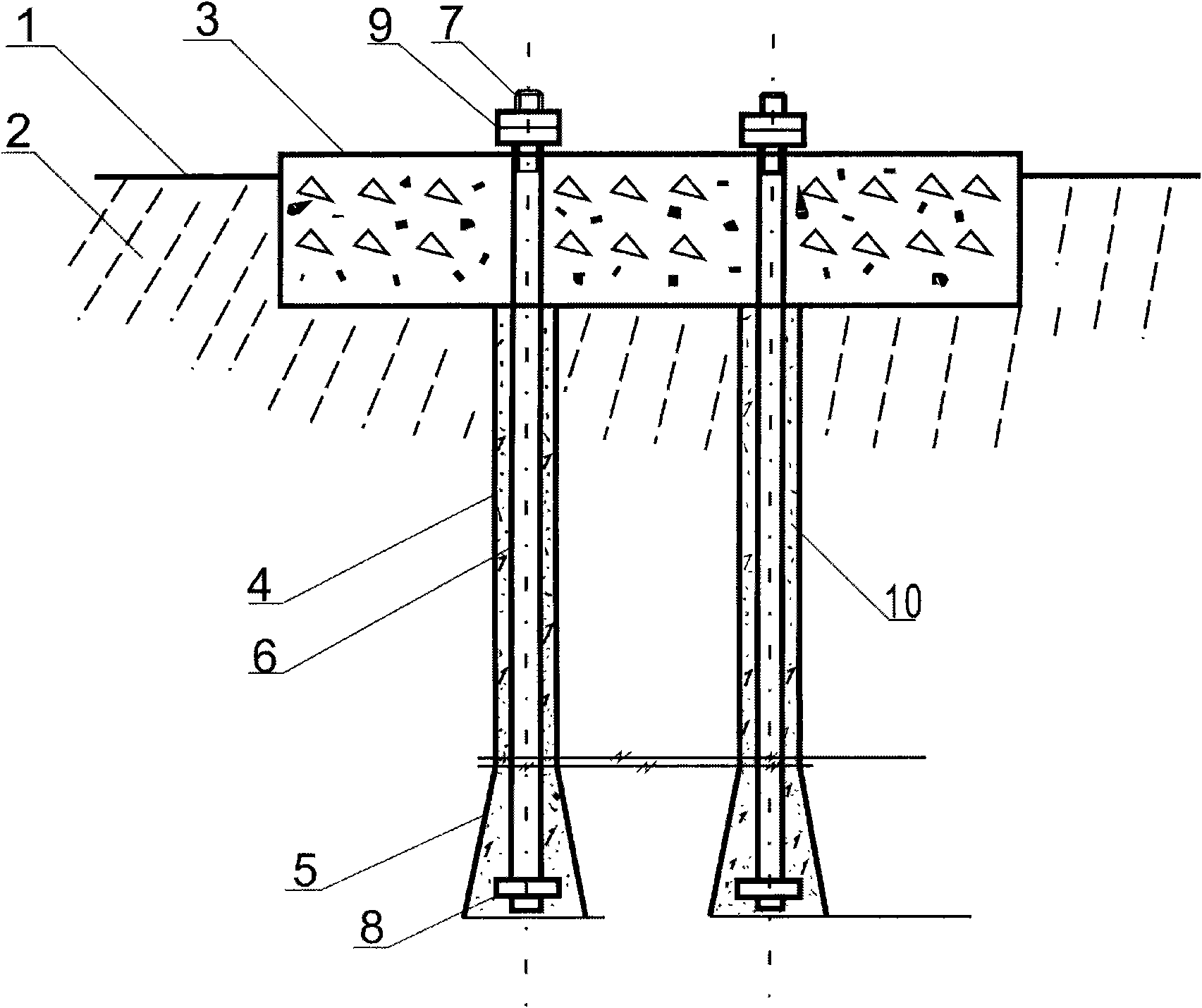

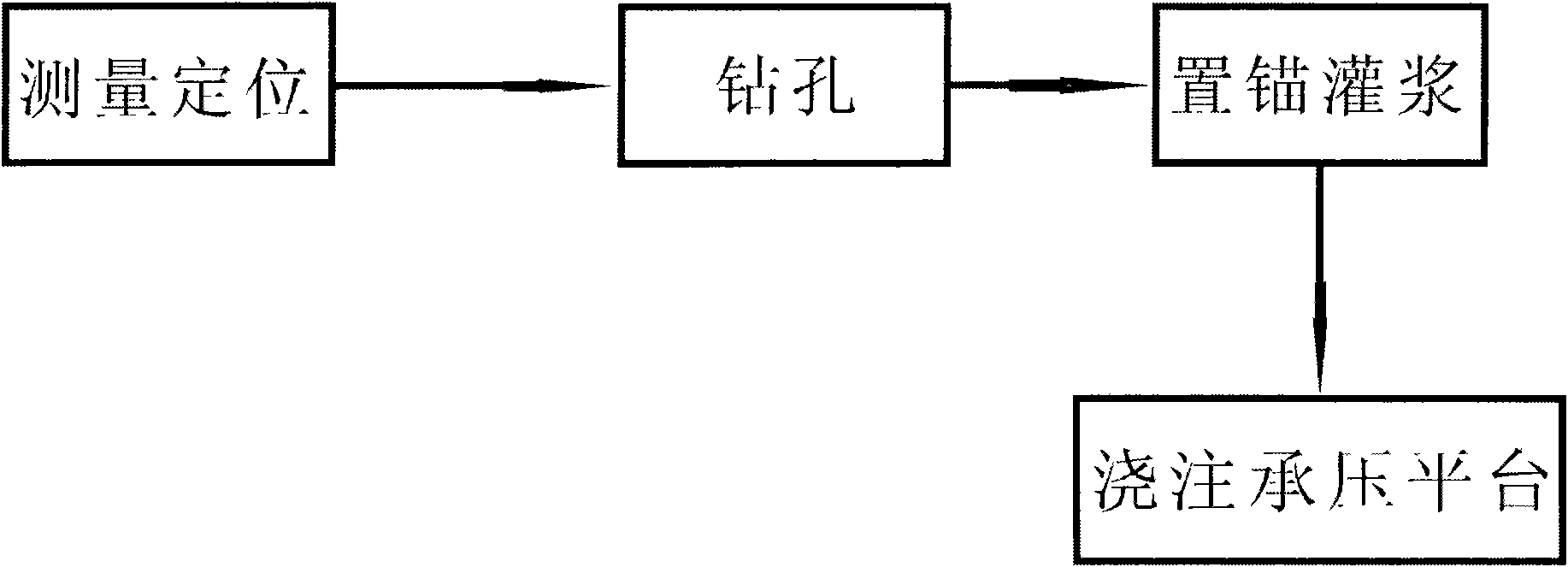

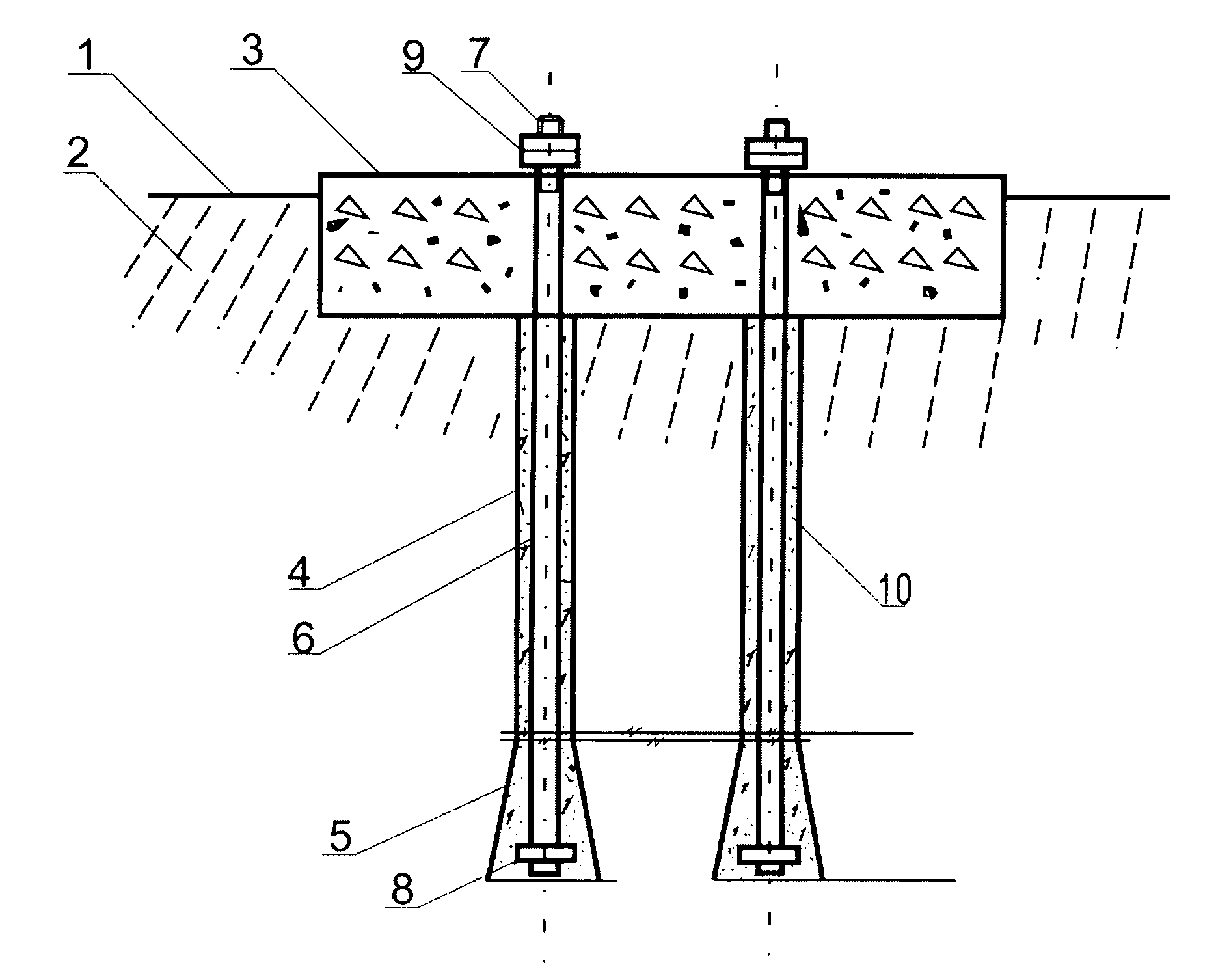

Construction process for rock enlarged toe anchor pile foundation of overhead power transmission line

The invention discloses a construction process for a rock enlarged toe anchor pile foundation of an overhead power transmission line. The construction process comprises the following steps of: (1) measuring and positioning, namely measuring a tower foot position and removing a rock surface to determine a foundation bolt base point; (2) drilling, namely drilling a straight hole at the base point by using a tubular drill until the drilling is finished, and enlarging the bottom of the straight hole by replacing a deviation bit to form a taper hole, wherein the aperture and the depth of the straight hole are determined according to the external diameter and the length of an anchor rod; the taper angle is controlled by controlling the drill bit sinking and the deviation speed; the lower bottom surface of the taper hole is coincided with the bottom of the straight hole; the taper height is determined according to the actual demand; the taper hole is coaxial with the straight hole; the upper bottom of the taper hole is the section of the straight hole; the diameter of the straight hole is 8 to 10cm more than the external diameter of the anchor rod; and the taper angle is 30 to 40 degrees; (3) placing an anchor and grouting, namely placing the anchor rod into the hole to insert a foundation nut and a part of rod body into the taper hole and grouting a CGM30 grout into the hole until the grout reaches the rim of the hole, wherein the anchor rod and the straight hole are coaxial; and (4) pouring a bearing platform, namely pouring the anchor rod which is exposed out of the straight hole into the bearing platform by using high-standard cement, wherein the foundation nut and a foundation bolt are protruded out of the surface of the bearing platform.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

Sol combined fire resistant repair material and repair method

The invention relates to the technical field of a refractory material, in particular to a sol-bonded refractory repair material and a repair method thereof. In order to overcome the disadvantages that the prior refractory repair material is low in high-temperature bonding strength, slow to solidify, difficult to bake fast, easy to fall off, poor in anti-erosion capability, and so on, and the invention provides the sol-bonded refractory repair material, consisting of a repair material matrix, silicon carbide, silicon oxide or alumina micropowder, sol and promoting coagulant. Compared with the prior art, the refractory repair material can increase the bonding strength of the repair material with a furnace lining of a main channel, a slag groove, a hot metal ladle, a torpedo tank or other place, has good durability, prolongs the service life of the furnace lining, decreases repair time, simultaneously raises the anti-erosion capability of the furnace lining, and reduces the refractory material consumption of iron systems.

Owner:武钢集团有限公司

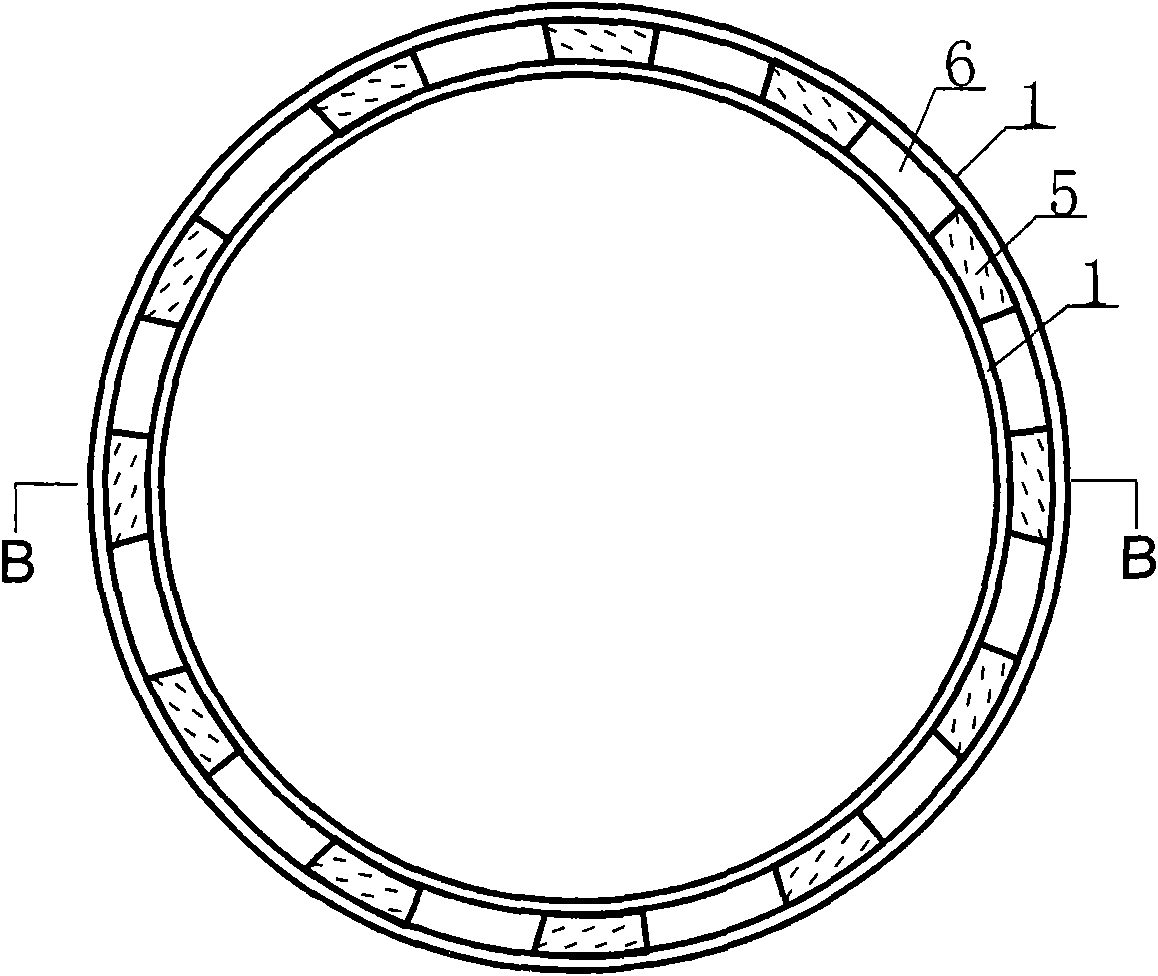

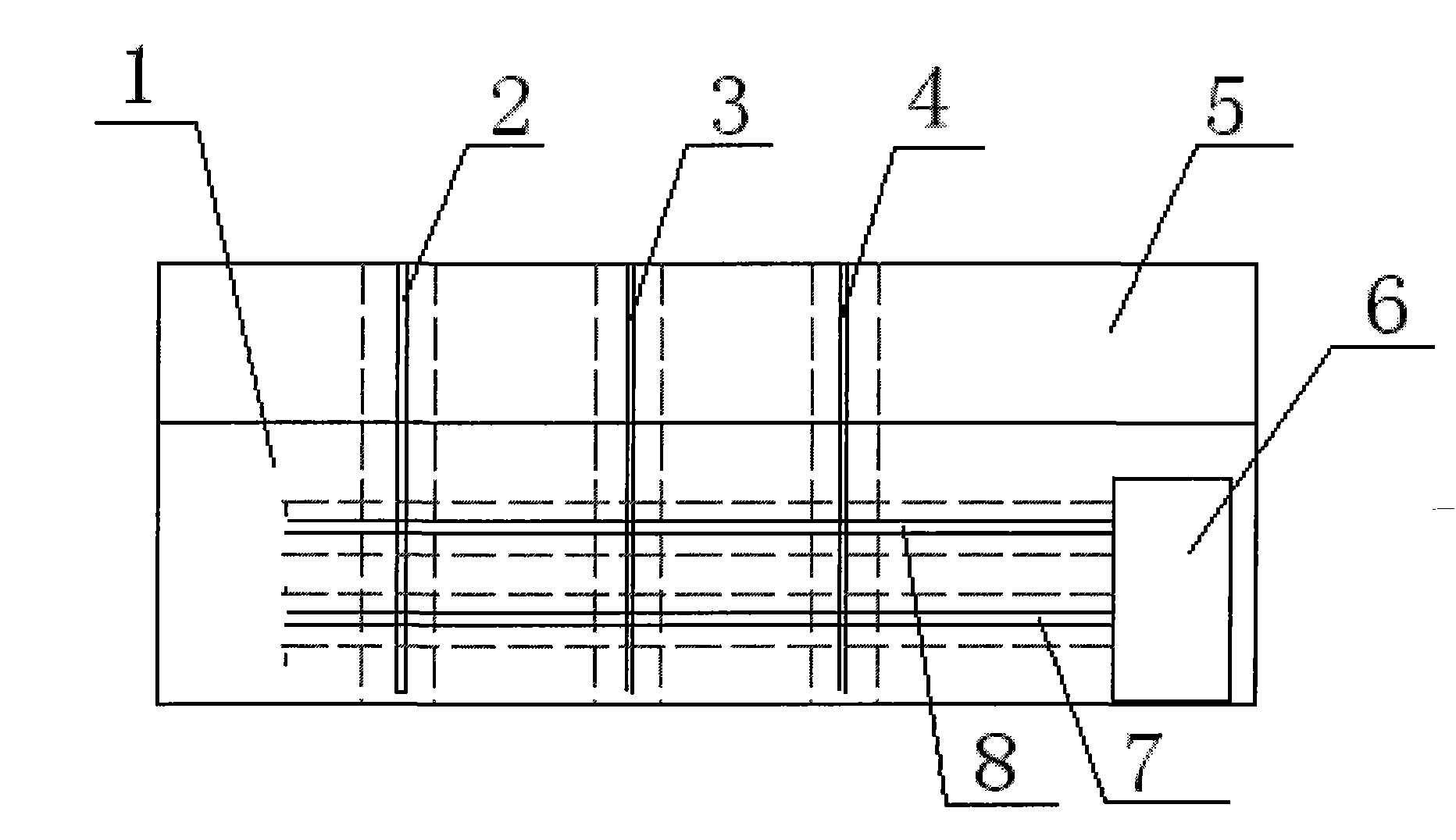

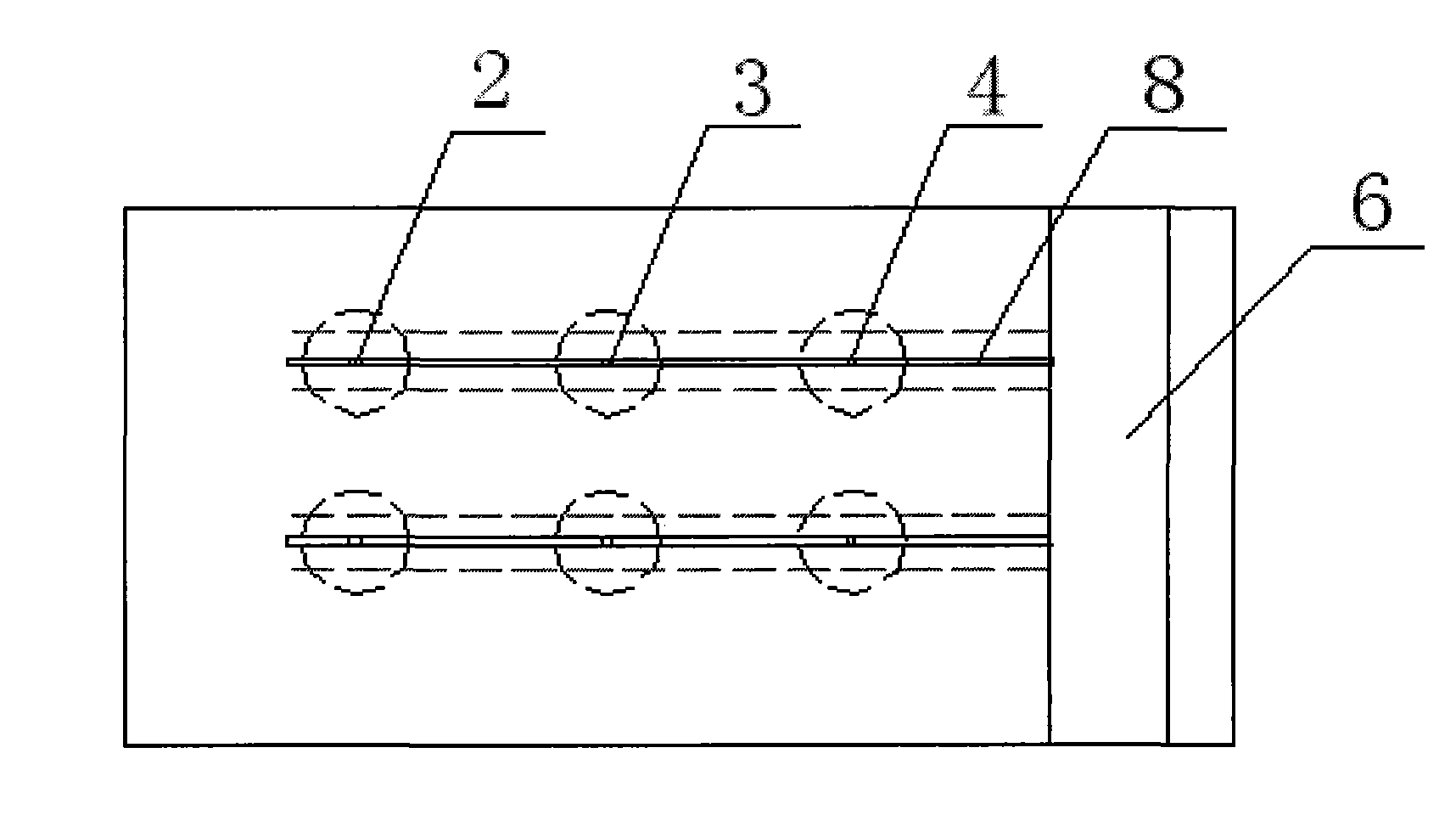

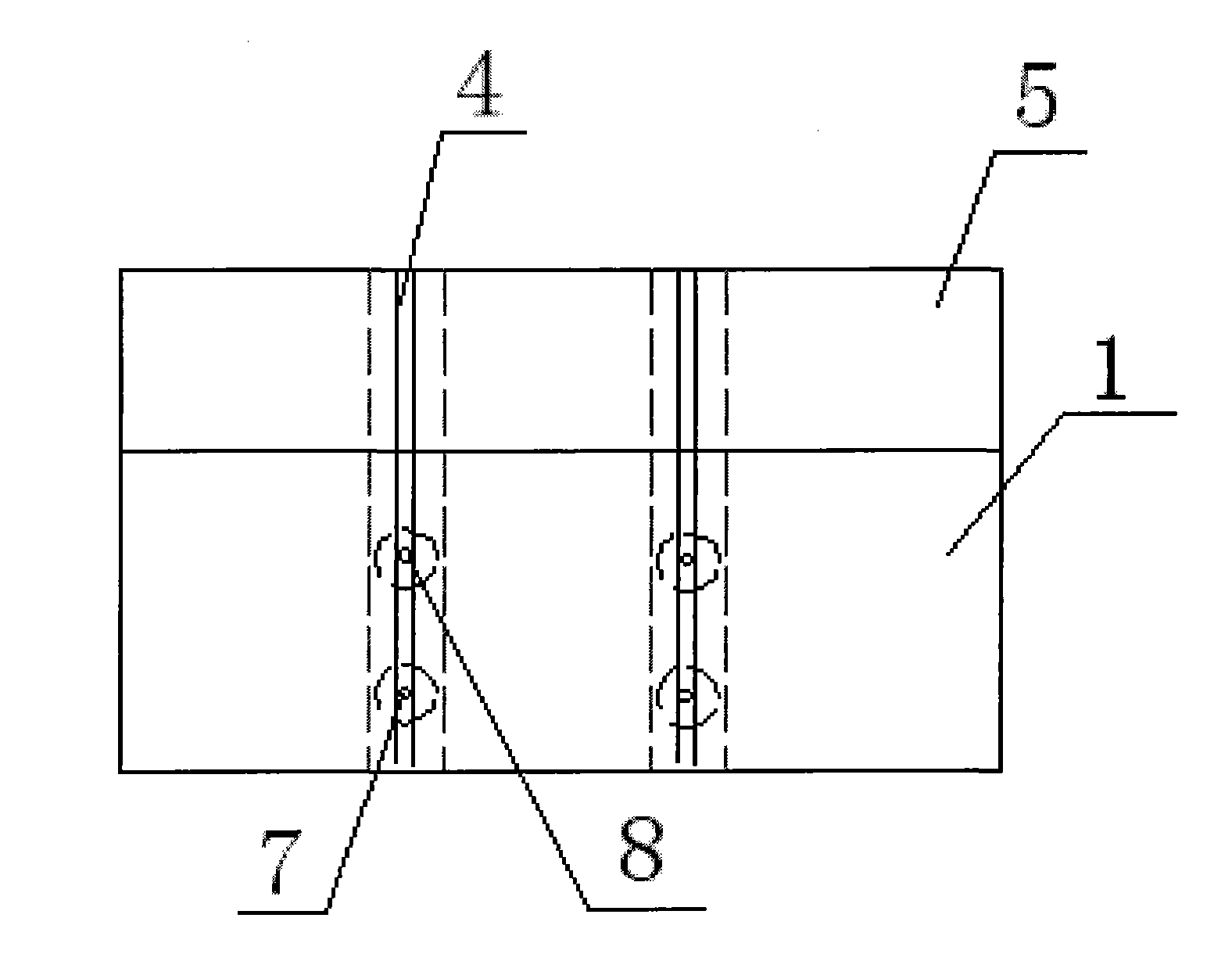

Wheeltrack magnetic levitation universal technology

InactiveCN101481893AReduce construction landReduce engineering costsRailway tracksCommunications systemTrackway

The invention relates to a general technology of wheeltrack magnetic suspension, belonging to the technical field of earthbased track traffic. The general technology of wheeltrack magnetic suspension mainly comprises a wheeltrack magnetic suspension dualpurpose trackway, an electromagnetic trackway, an electromagnetic switching turnout, a suspension-oriented technology and a matched train, and is characterized in that the wheeltrack magnetic suspension dualpurpose trackway can be mutually connected with a pure suspension trackway and a common wheeltrack trackway to form a trafficable trackway communication system; the corresponding position relationship of a long stator winding and a suspension trackway which are arranged in the pure magnetic suspension trackway is consistent with the position relationship of the long stator winding and the suspension trackway which are arranged in the wheeltrack magnetic suspension dualpurpose trackway; and the track space of two steel rails in a common wheeltrack trackway is equal to the track space of two steel rails in the wheeltrack magnetic suspension dualpurpose trackway. The general technology of wheeltrack magnetic suspension combines the wheeltrack technology with the magnetic suspension technology, is used for meeting the requirement of the long-distance high-speed transportation, and has the advantages of low construction cost, high versatility, energy saving, and environmental protection, etc.

Owner:李葛亮

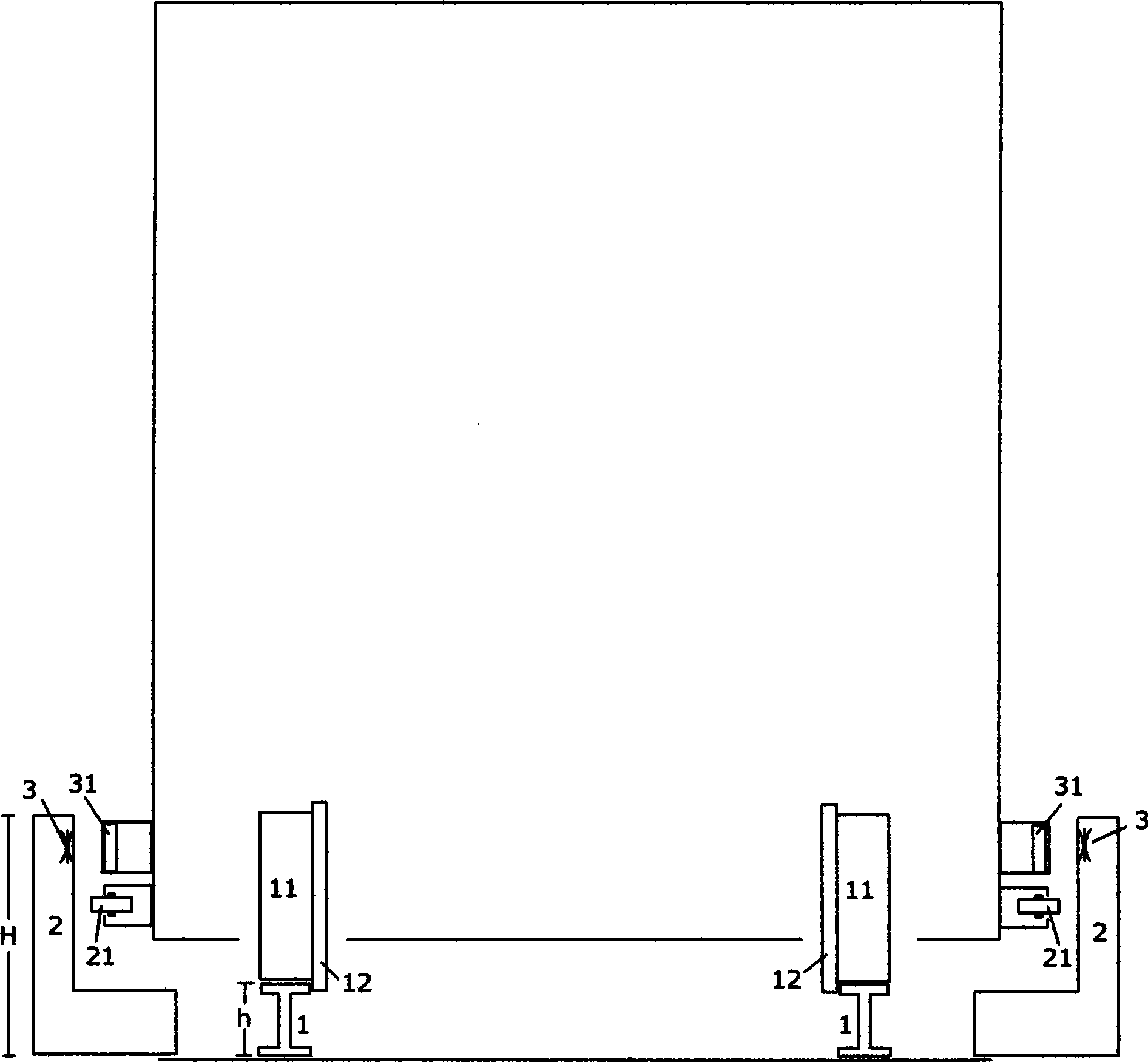

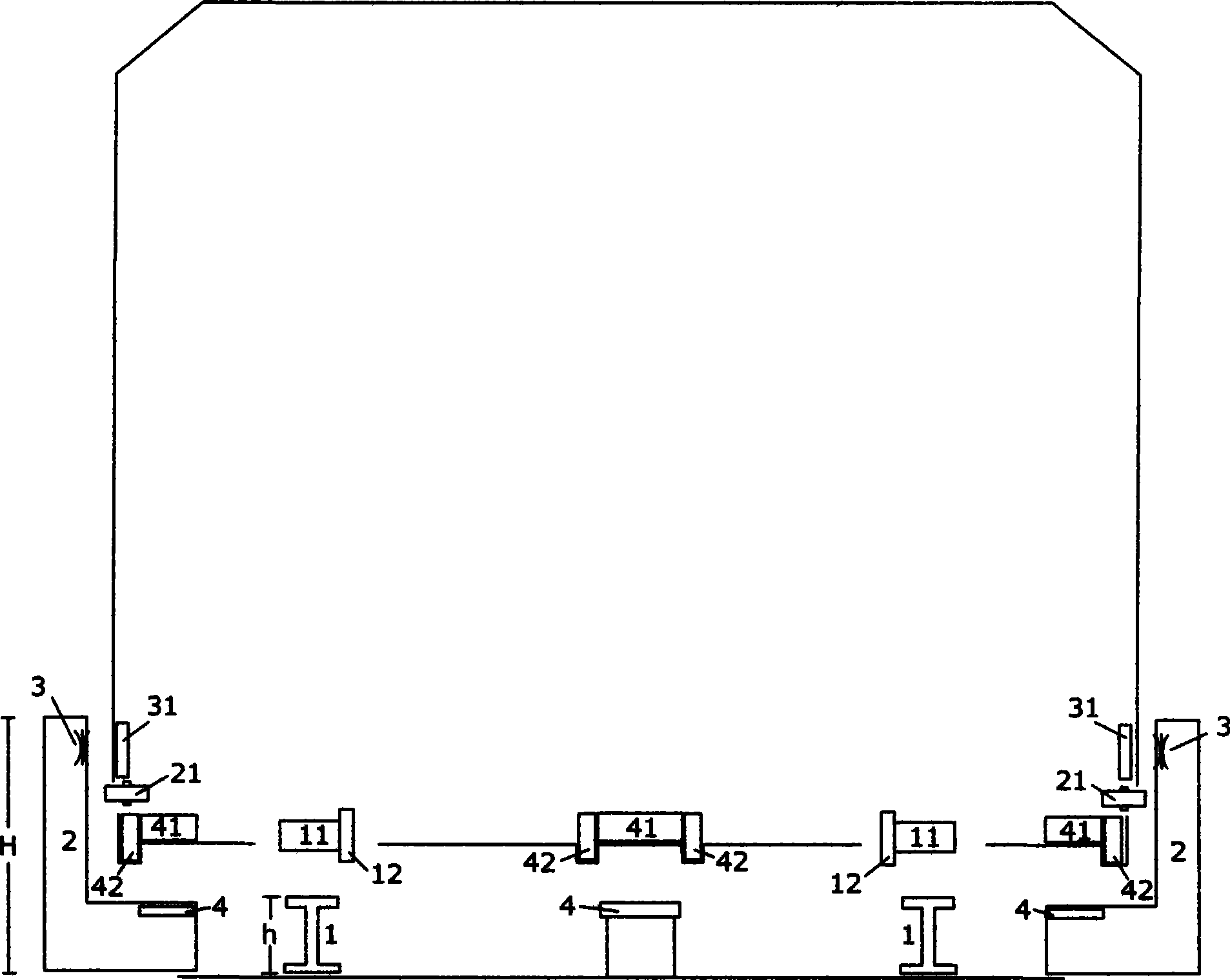

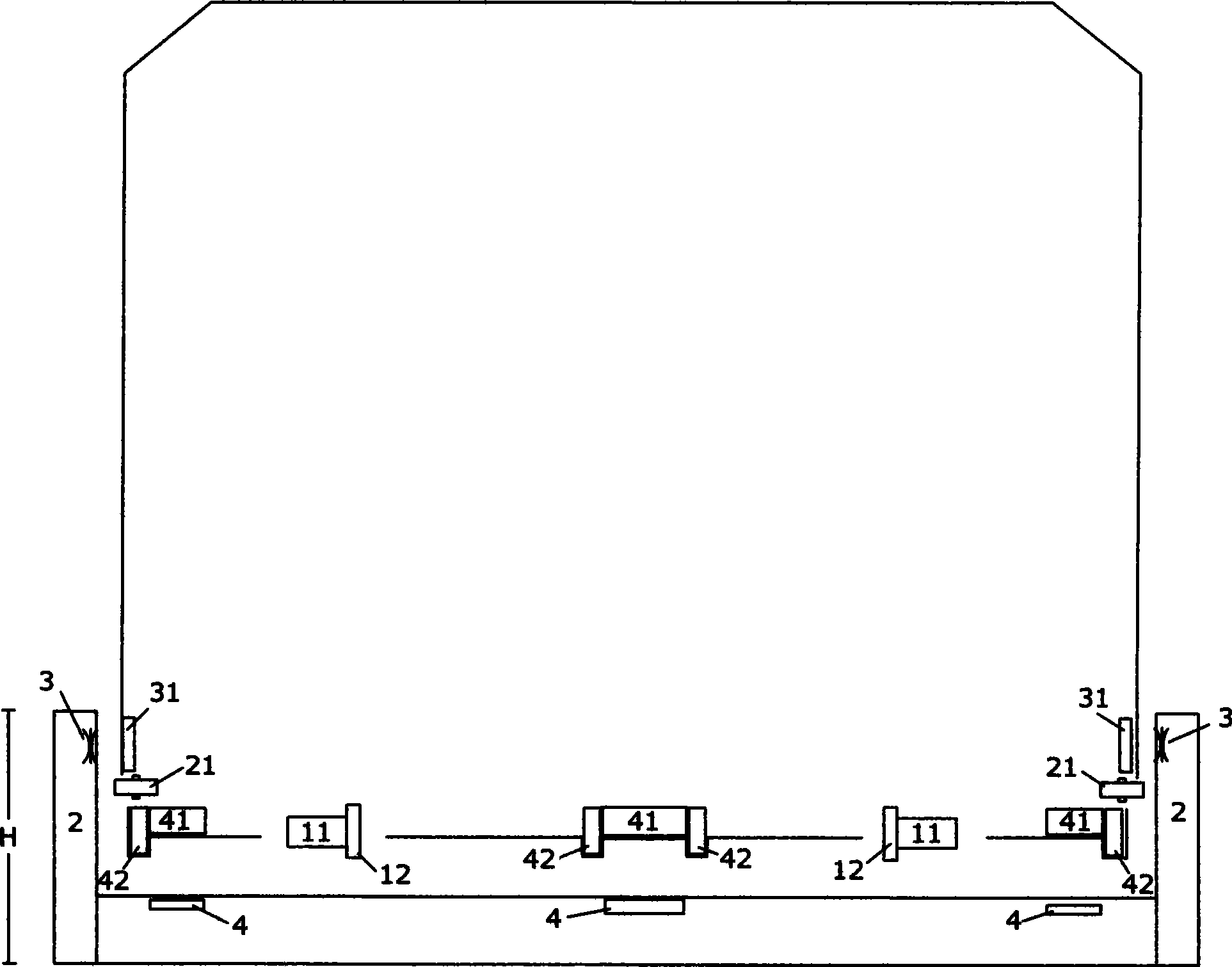

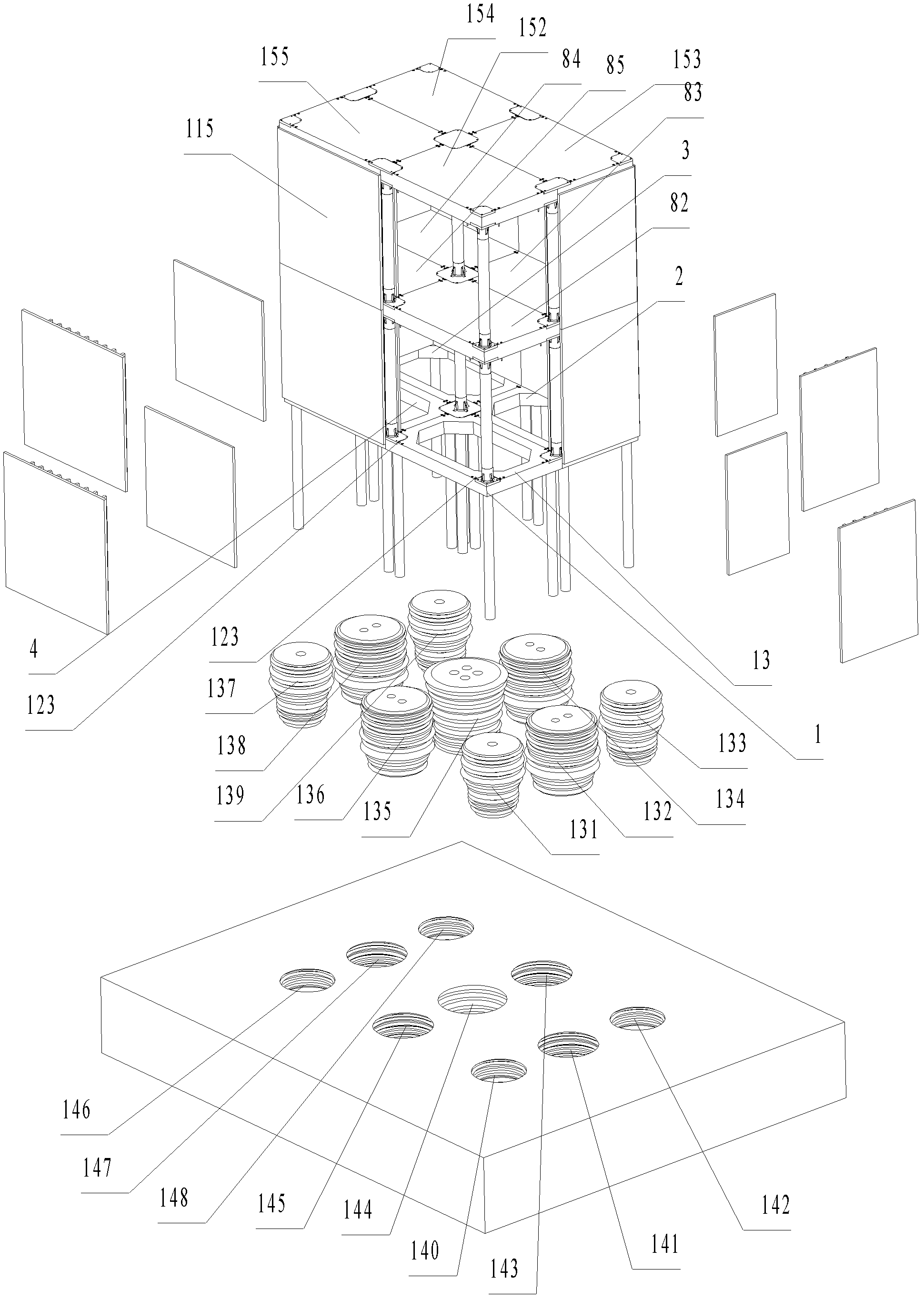

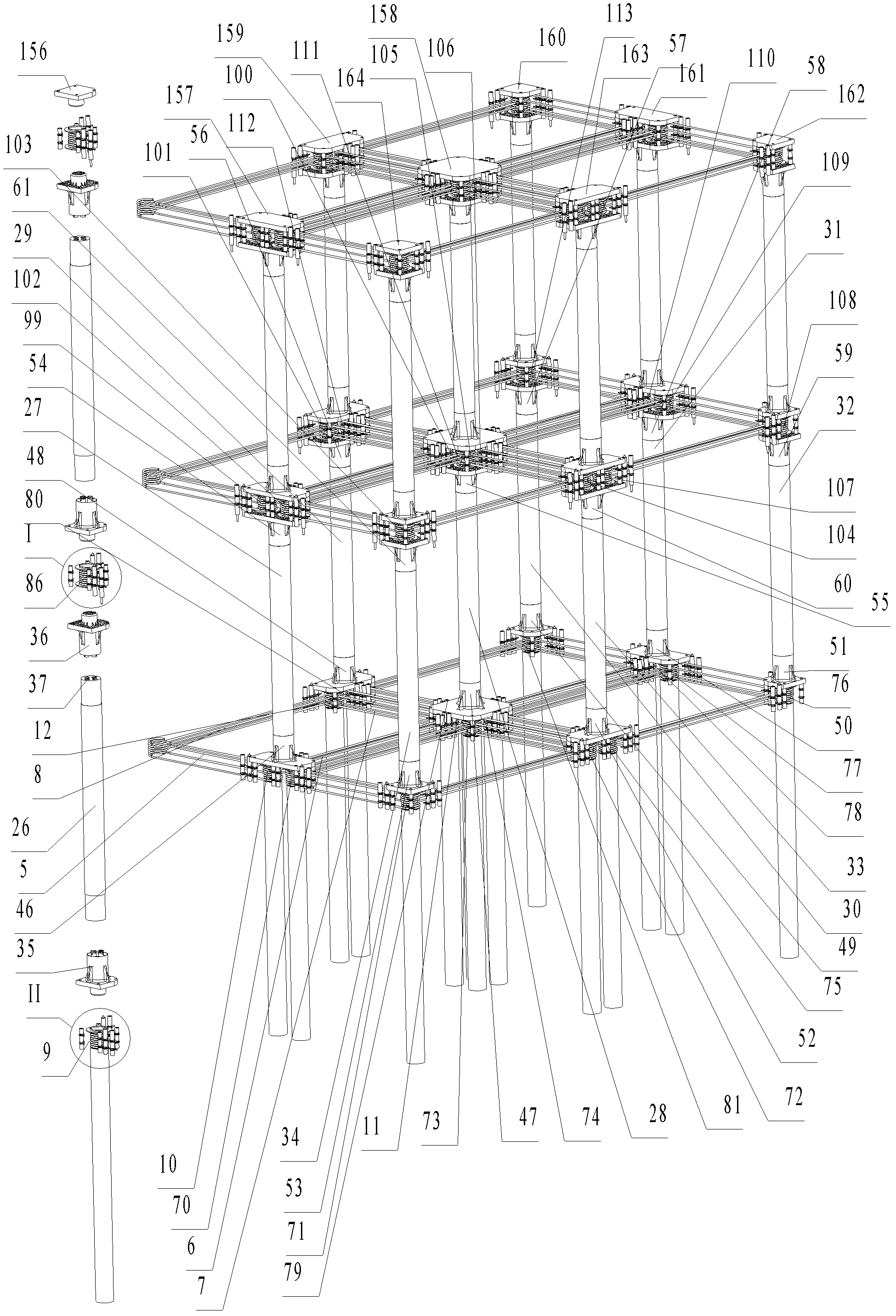

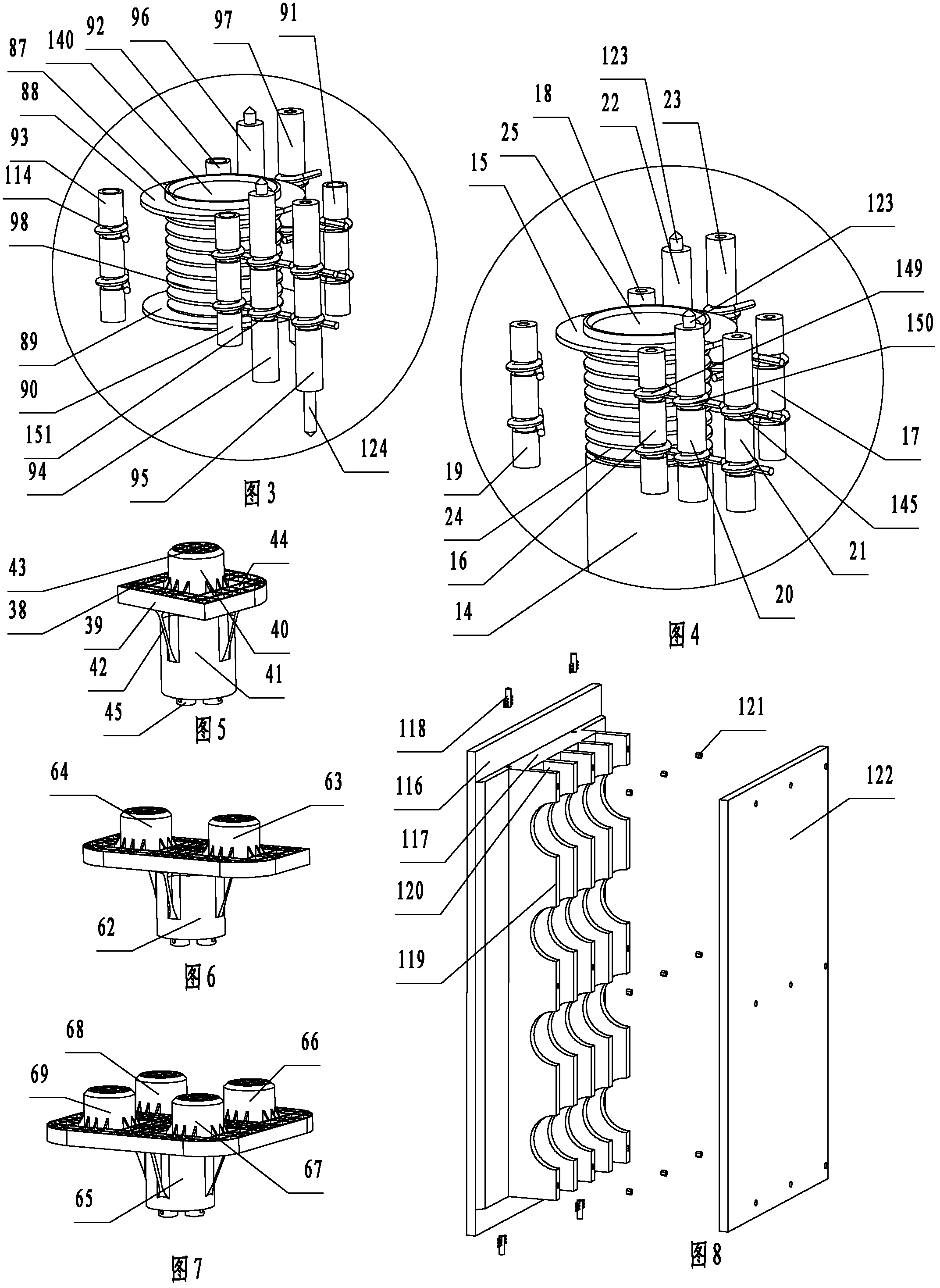

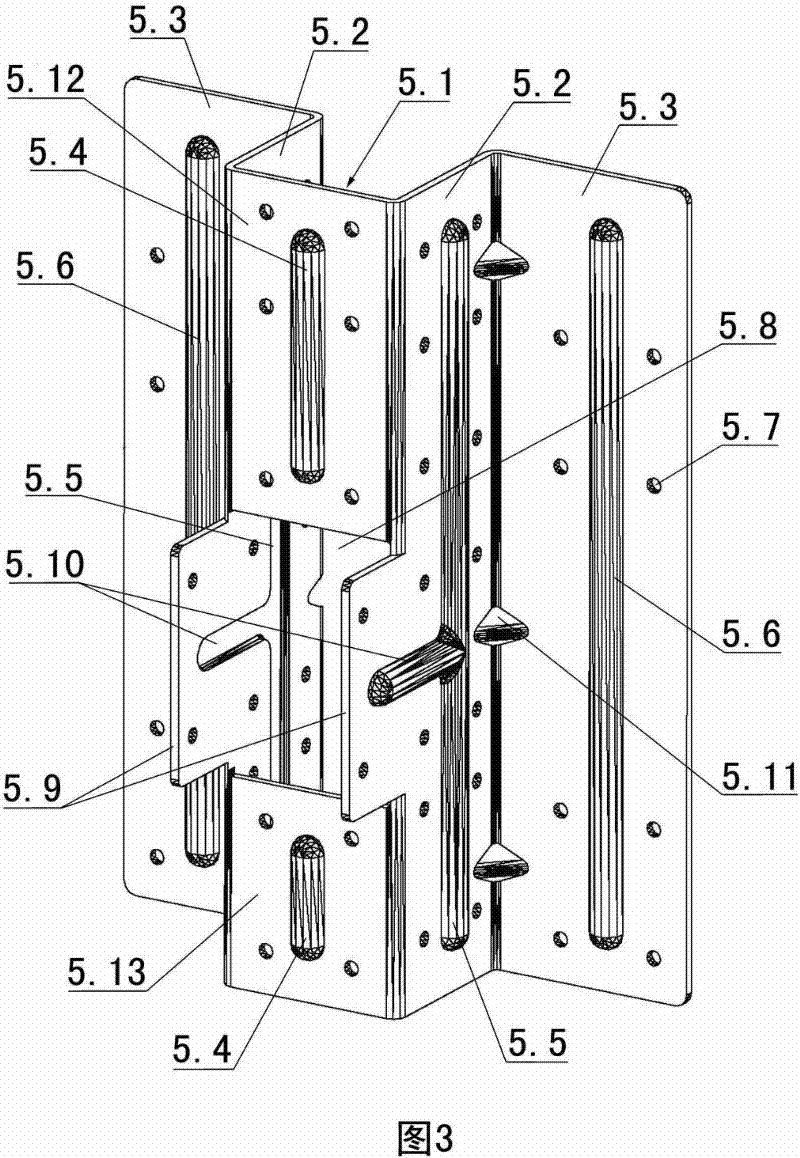

Building structure and construction method

Disclosed are a building structure and a construction method. The building structure comprises upright columns, prefabricated plates or prefabricated frames and columnar connecting parts. Each prefabricated plate or prefabricated frame comprises reinforced beams or section crossbeams and embedded connecting parts, wherein the reinforced beams or section crossbeams are embedded in the prefabricated plates or prefabricated frames, and the embedded connecting parts are arranged at connecting joints for connecting the reinforced beams or section crossbeams; the columnar connecting parts are mounted at connecting joints of the prefabricated plates or prefabricated frames; the number of the columnar connecting parts is smaller than or equal to that of the embedded connecting parts; each embedded connecting part comprises a first positioning mechanism; each columnar connecting part comprises one to four second positioning mechanisms matching with the corresponding first positioning mechanisms in a one-to-one correspondence manner; and the first positioning mechanisms and the corresponding second positioning mechanisms are vertically connected in an inserted manner, and the columnar connecting parts are fixed with the one to four embedded connecting parts at the connecting joints. The building structure and the construction method have the advantages that various portions of the building structure can be mechanically assembled and disassembled, can be reused, and are convenient in assembly and disassembly, and the connecting joints are firm and reliable in connection and fine in load-carrying capability.

Owner:杨东佐

Foam concrete

The invention discloses a foam concrete, which comprises admixture, cementing material and chemical auxiliary agent, wherein the weight percentage of the admixture in the foam concrete is 25-40%, the weight percentage of the cementing material in the foam concrete is 45-75%, the weight percentage of the chemical auxiliary agent in the foam concrete is 5-25%, the cementing material comprises cement clinker, calcium oxide and bone gelatin powder, and the mass ratio of the three ingredients in the cementing material is 2: 2: 1. The invention further discloses a preparation method of the foam concrete. The preparation method comprises the following steps: foam technology, slurry processing, chemical auxiliary agent processing, mixing, shaping and curing. The foam concrete has the advantages that the cementing material is made of cement clinker, calcium oxide and bone gelatin powder and the use of a great amount of cement is avoided, so that the coal resources required for producing cement is reduced, which not only relieves the tension of energy utilization, but also can improve the compressive strength, leakage resistance, sound insulation effect of the foam concrete.

Owner:王寿光

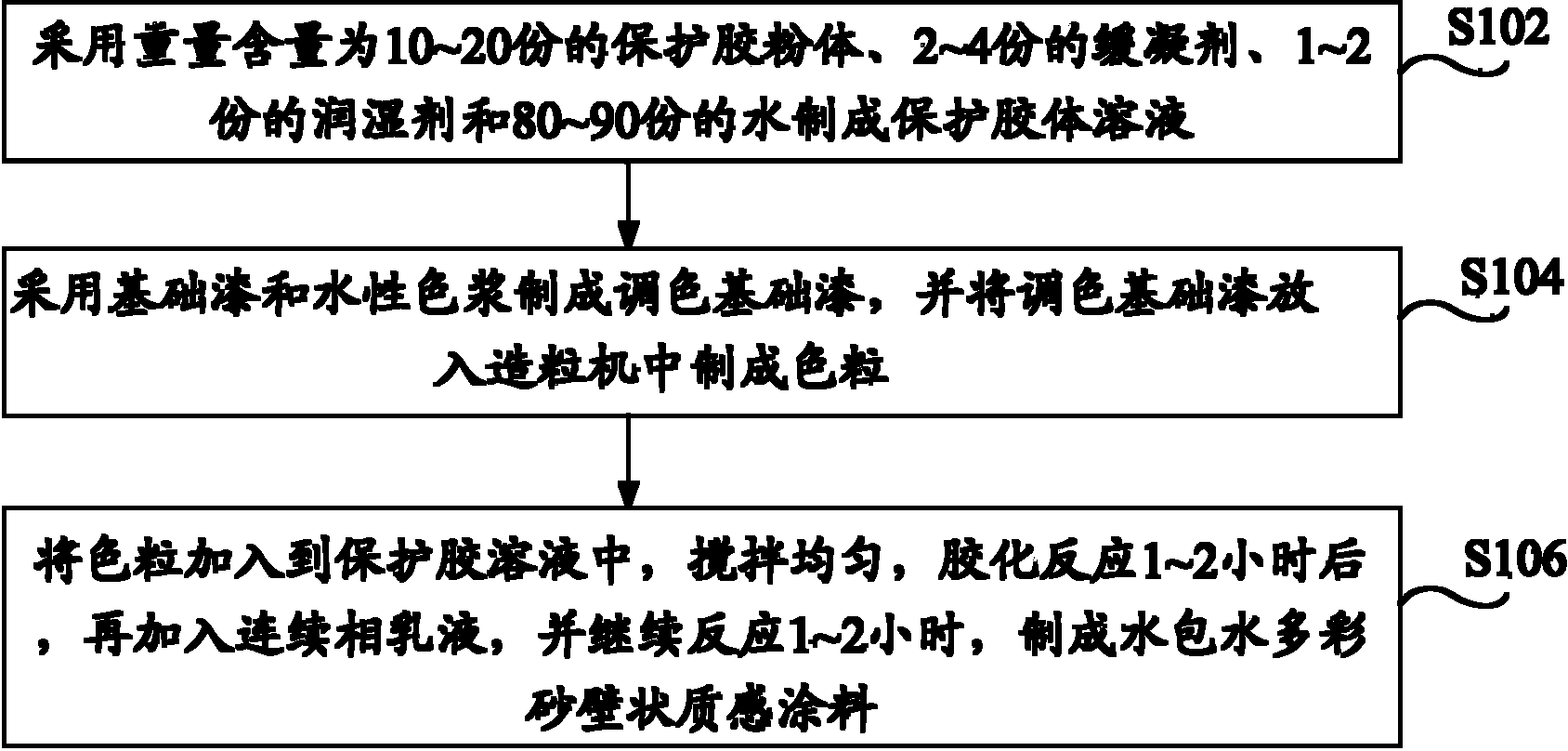

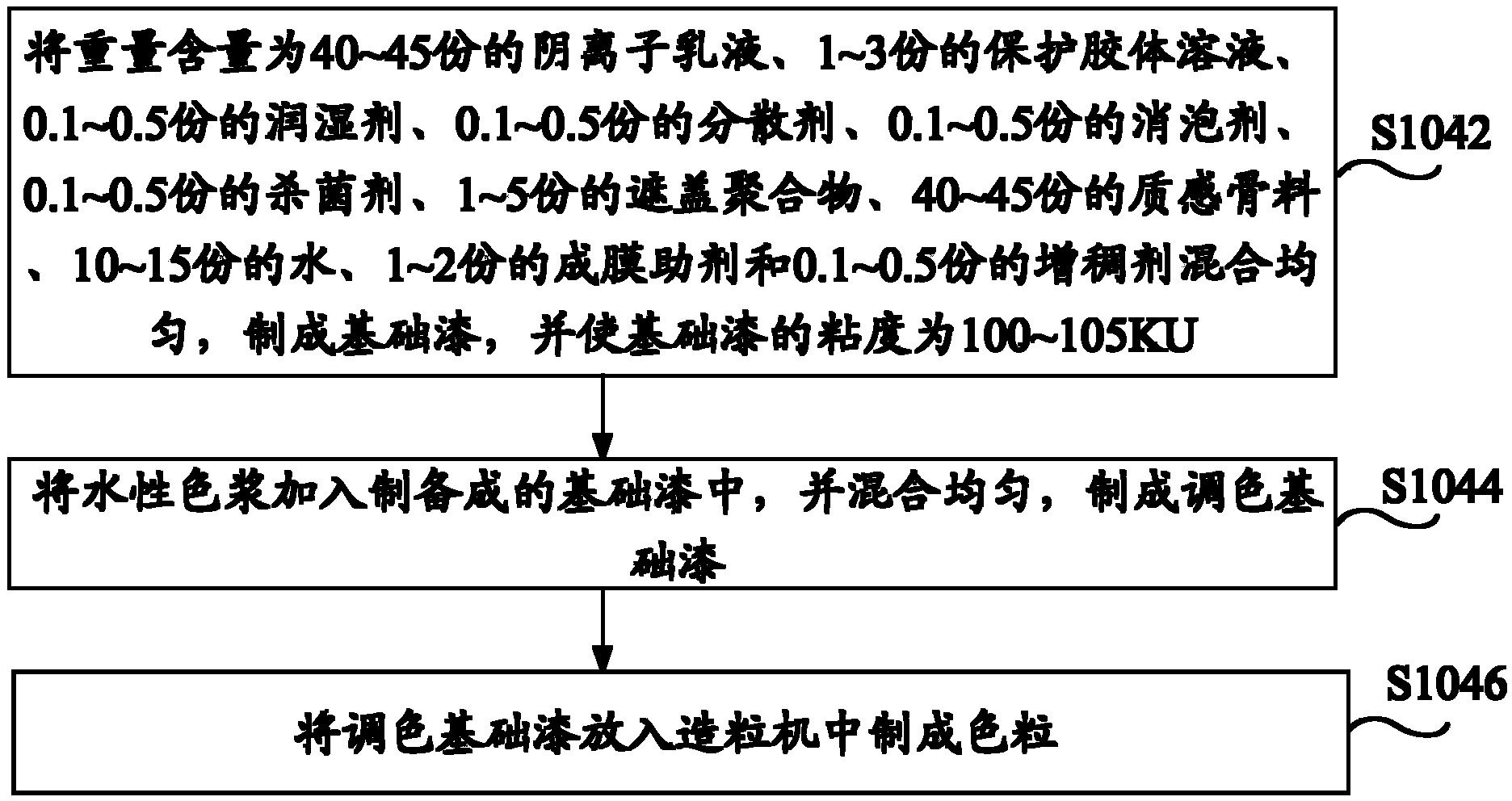

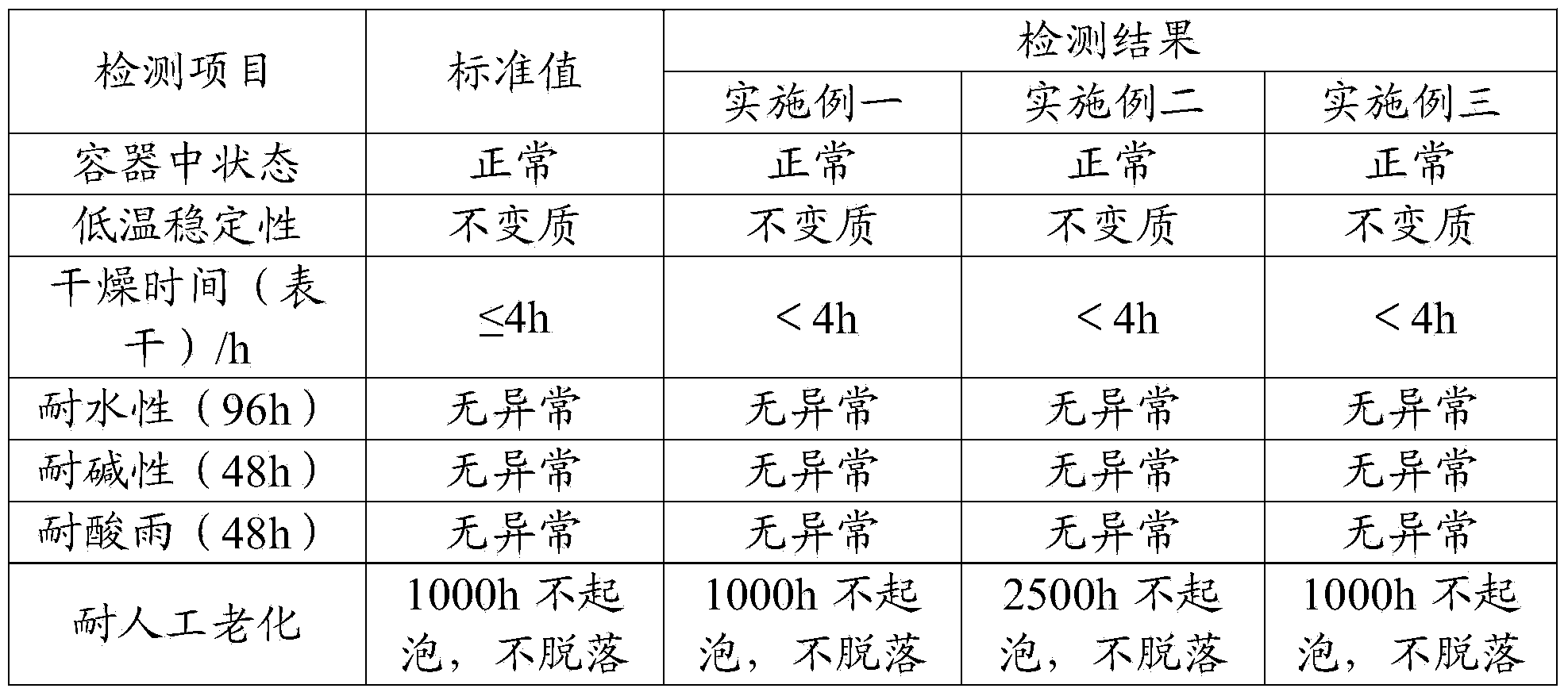

Water-in-water colored sand wall texture coating and preparation method thereof

ActiveCN104231818ARequire stabilityHigh volume solidsAntifouling/underwater paintsPaints with biocidesColloidal SolutionCoating

The invention provides a water-in-water colored sand wall texture coating and a preparation method thereof. The water-in-water colored sand wall texture coating comprises the following components in parts by weight: 30-40 parts of toning basic paint, 30-40 parts of a protective colloid solution and 20-40 parts of continuous phase emulsion. The water-in-water colored sand wall texture coating provided by the invention is an all-water-based product; the product performance accords with the standard of HG / T4343-2012 water-based colored building coatings; the texture coating is low in VOC, APEO-free, green, environment-friendly and free of irritant smell; a coating which contains multiple colors and has a rough-surface granite imitation effect can be obtained through one-time spraying; the water-in-water colored sand wall texture coating is an ideal substitute of decorative stones such as marble and granite, the construction is simple, and the construction cost is reduced.

Owner:ASIA PAINT SHANGHAI

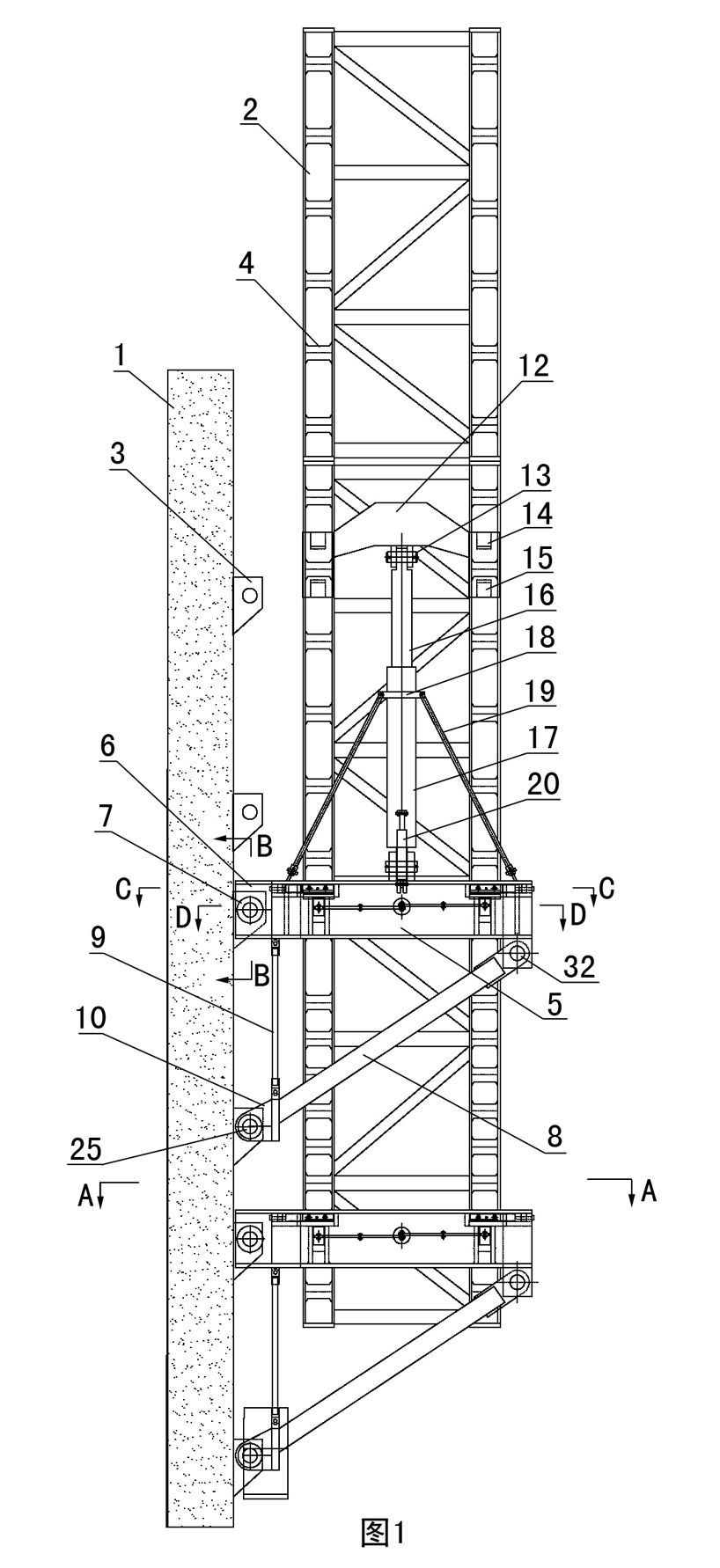

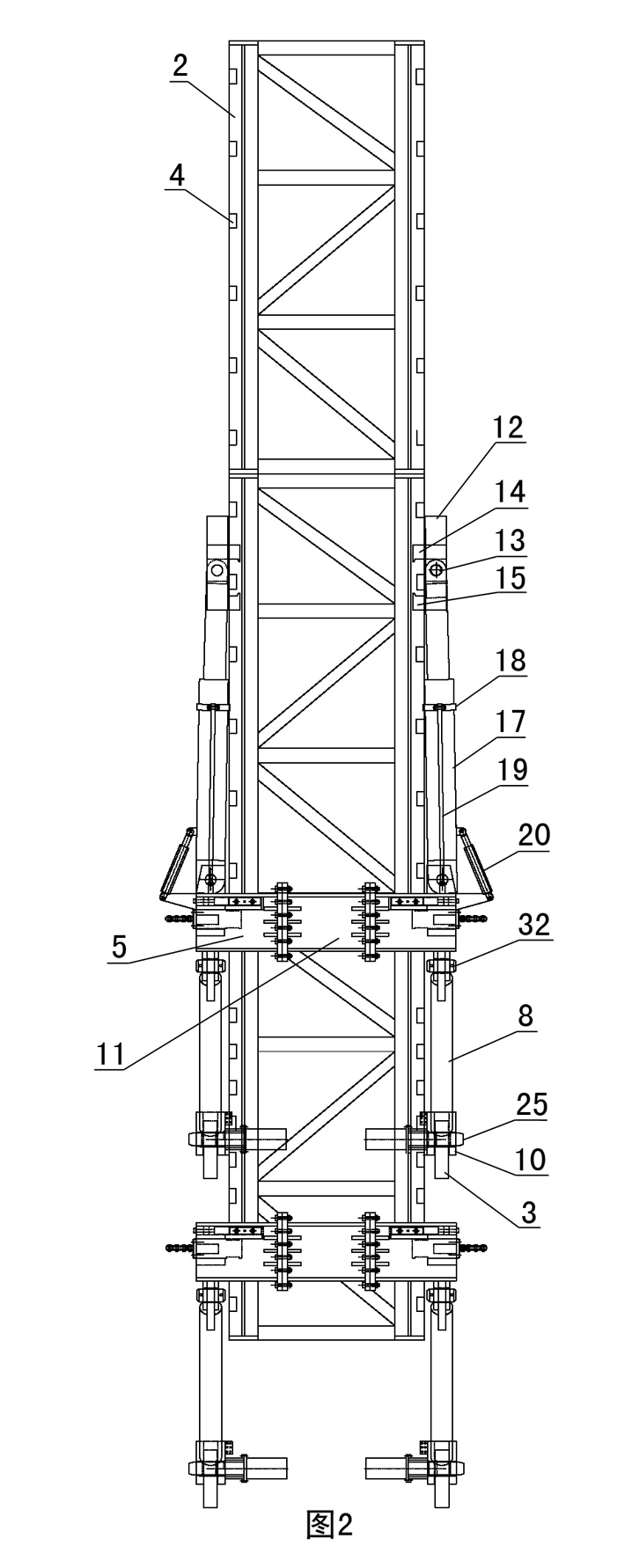

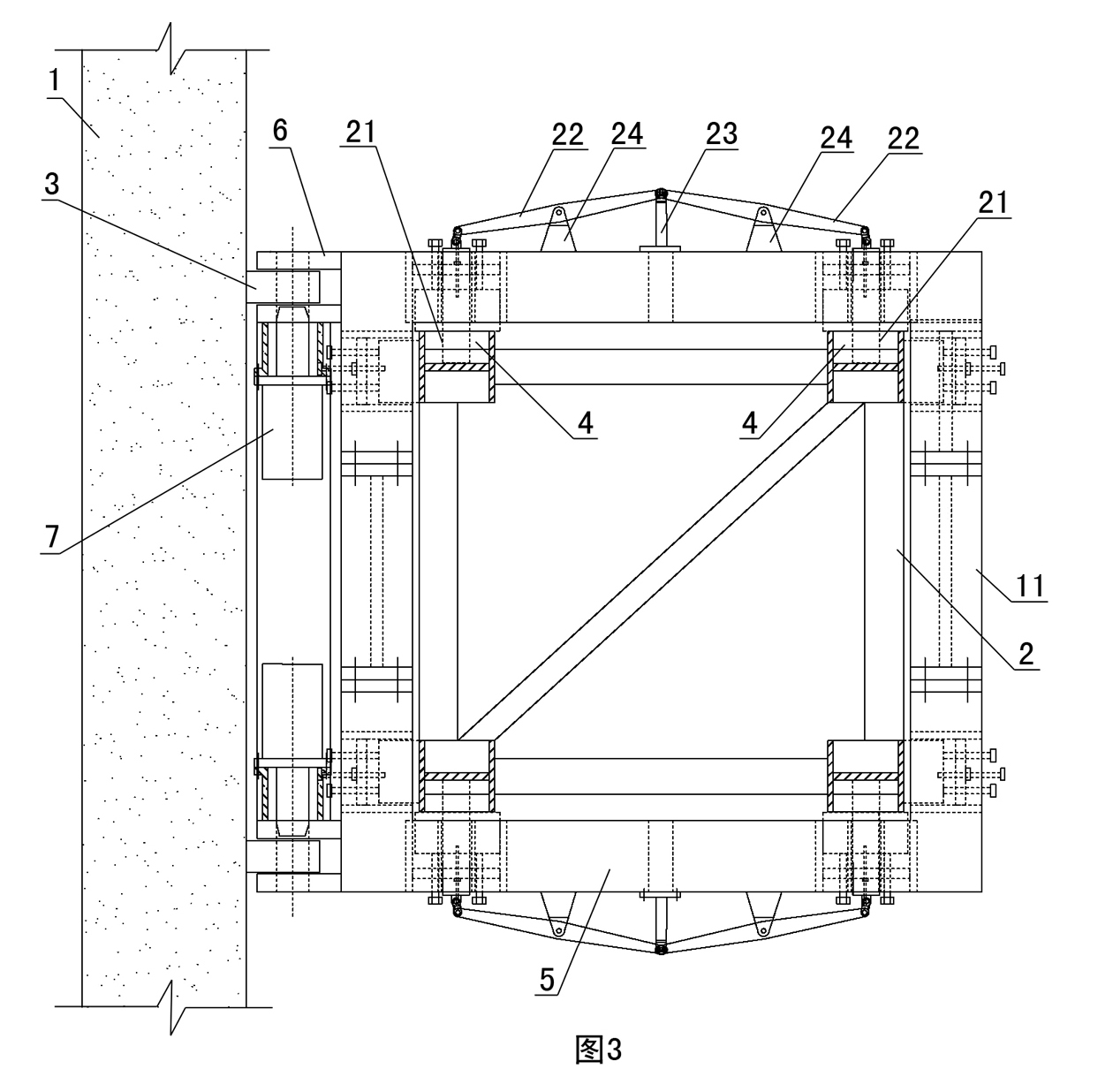

Hydraulic climbing system for wall-attached support frame

ActiveCN102071798AImprove construction efficiencyReduce construction costsForms/shuttering/falseworksScaffold accessoriesSupporting systemArchitectural engineering

The invention discloses a hydraulic climbing system for a wall-attached support frame. The system comprises a support upright post, a support frame device and a hydraulic jacking device, wherein the support frame device is detachably connected with a bracket which is fixed on a core barrel concrete wall and at least comprises an upper support frame device and a lower support frame device; both the upper support frame device and the lower support frame device are provided with upright post supporting devices and upright post clamping devices; climbing step blocks are vertically distributed at intervals on a column of the support upright post; and the support upright post is supported on the upright post supporting device through the climbing step blocks and is connected with the upper support frame device and the lower support frame device through the upright post clamping devices in a clamping way. In the system, an overall elevating template system, a construction steel platform system, a tower crane support system and the like are automatically elevated entirely along with the height increase of a building main body. The system has high safety, short climbing time and high construction efficiency, and can be used repeatedly in different projects.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

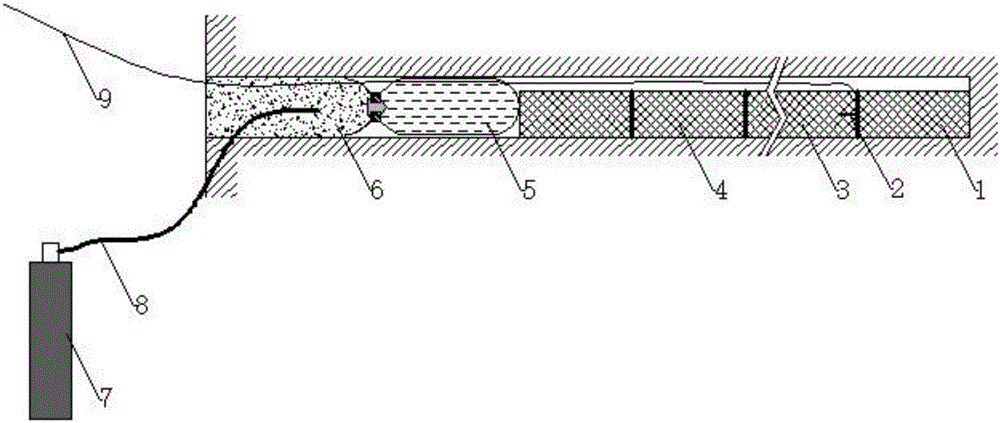

Mine water stemming bag and application of mine water stemming bag in borehole blockage

ActiveCN105066804AConvenient and fast blocking effectEfficient and reliable blocking effectBlastingCombined useSelf locking

The invention provides a mine water stemming bag and an application of the mine water stemming bag in borehole blockage. By means of the mine water stemming bag, local self-locking can be achieved, and leakage of a bag opening can be prevented reliably. By applying the mine water stemming bag to borehole blockage and combining with polyurethane expansion foam composites, a convenient, quick, efficient and reliable borehole blockage effect can be achieved, labor intensity of manual borehole blocking is relieved, construction time is shortened, work efficiency is improved, and the forced mining and forced excavation technical requirements of underground metal mines are met on the premise that the blasting effect is guaranteed.

Owner:HUNAN CHENZHOU MINING CO LTD +1

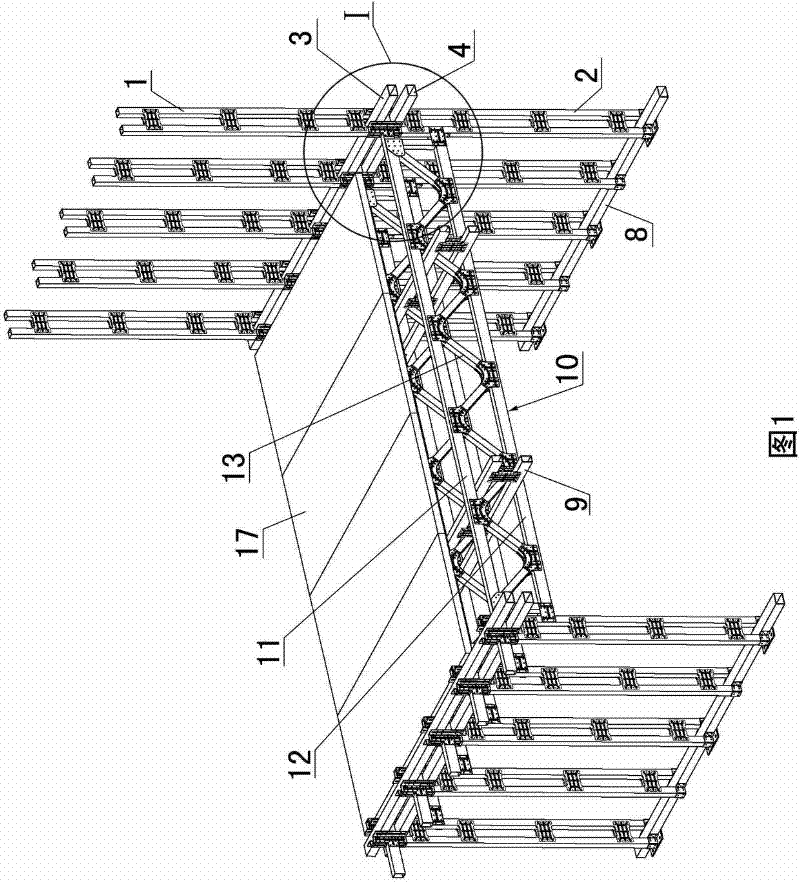

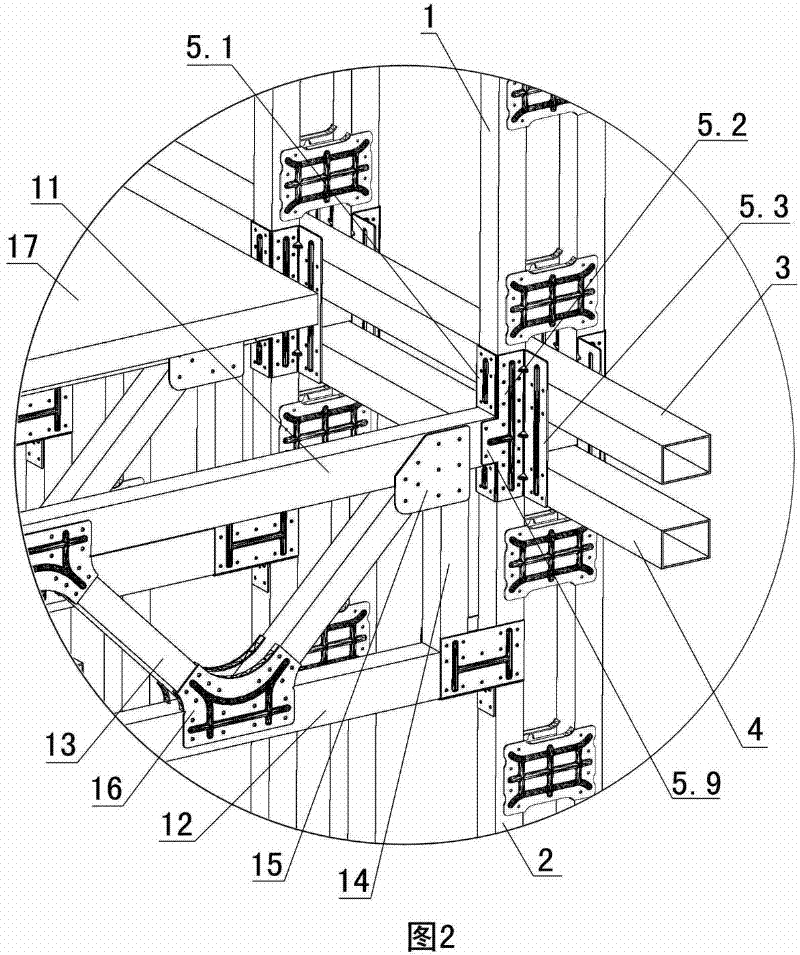

Truss combined beam and upper and layer connected light steel structure and construction method thereof

InactiveCN102359180ATroubleshoot simultaneous connectionsSolve the shortcomings that the pressure is not easy to meet the force requirementsGirdersJoistsRear quarterKeel

The invention discloses a truss combined beam and upper and layer connected light steel structure and a construction method thereof. The light steel structure comprises upper wall sheet columns distributed at intervals, lower wall sheet columns distributed at intervals, upper wall sheet column lower connecting pipes connected among the lower parts of the upper wall sheet columns, lower wall sheet column upper connecting pipes connected among the upper parts of the lower wall sheet columns, and truss combined beams connected between the upper wall sheet columns and the lower wall sheet columns through upper and lower connectors, wherein the upper and lower connectors are beam passing buckles, the web plates of the beam passing buckles consist of upper web plates and lower web plates, a square connecting port is formed between the upper web plates and the lower web plates, upper chord member connecting plates are extended from the left and right sides of the square connecting ports, and the upper chord member connecting plates and side plates of the beam passing buckles are positioned in the same plane. Through the light steel structure, the structural stability of a light steel keel house system is enhanced, and the floor surface beams, the connecting pipes and the floor panels do not easily vibrate.

Owner:筑巢(北京)科技有限公司

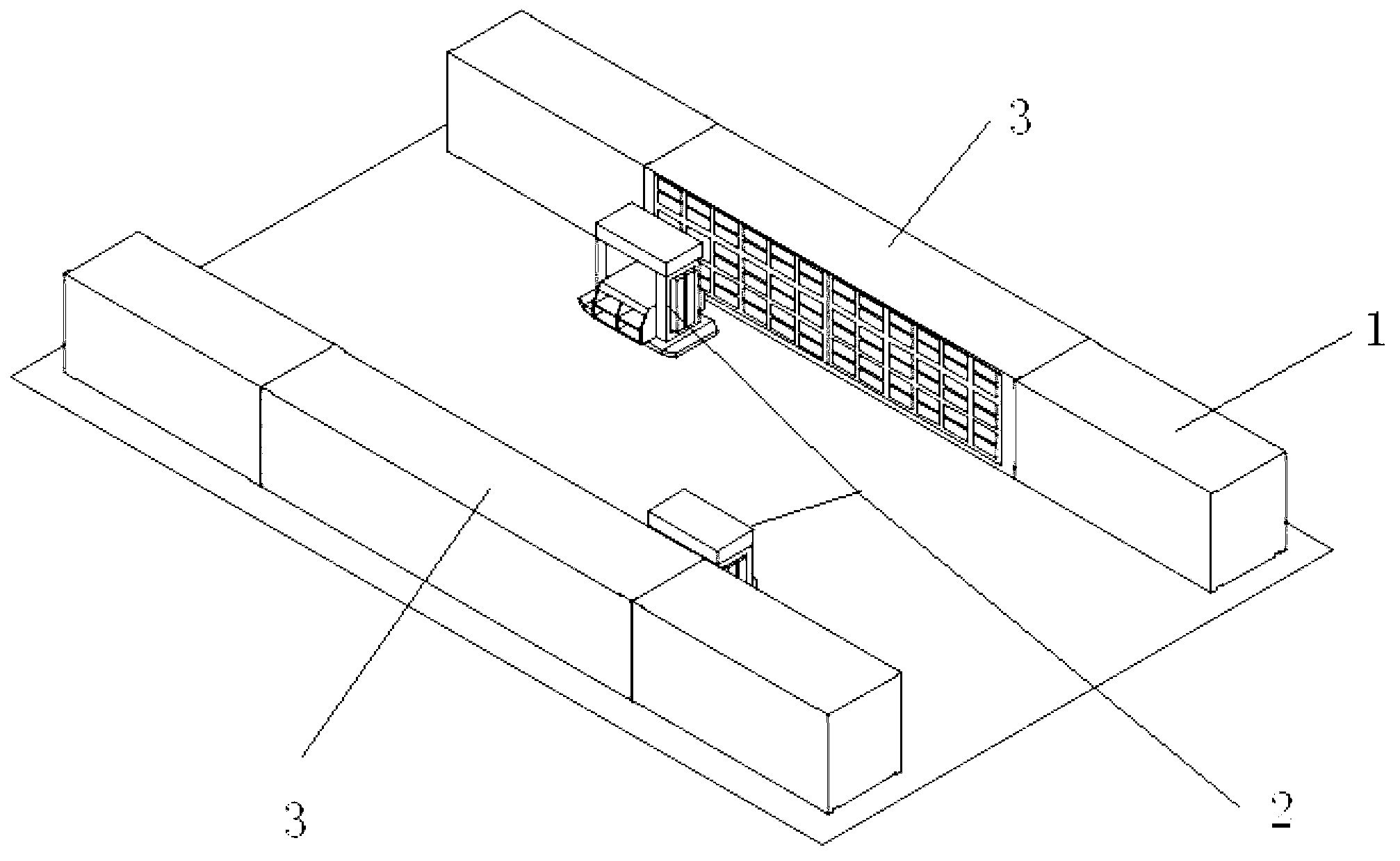

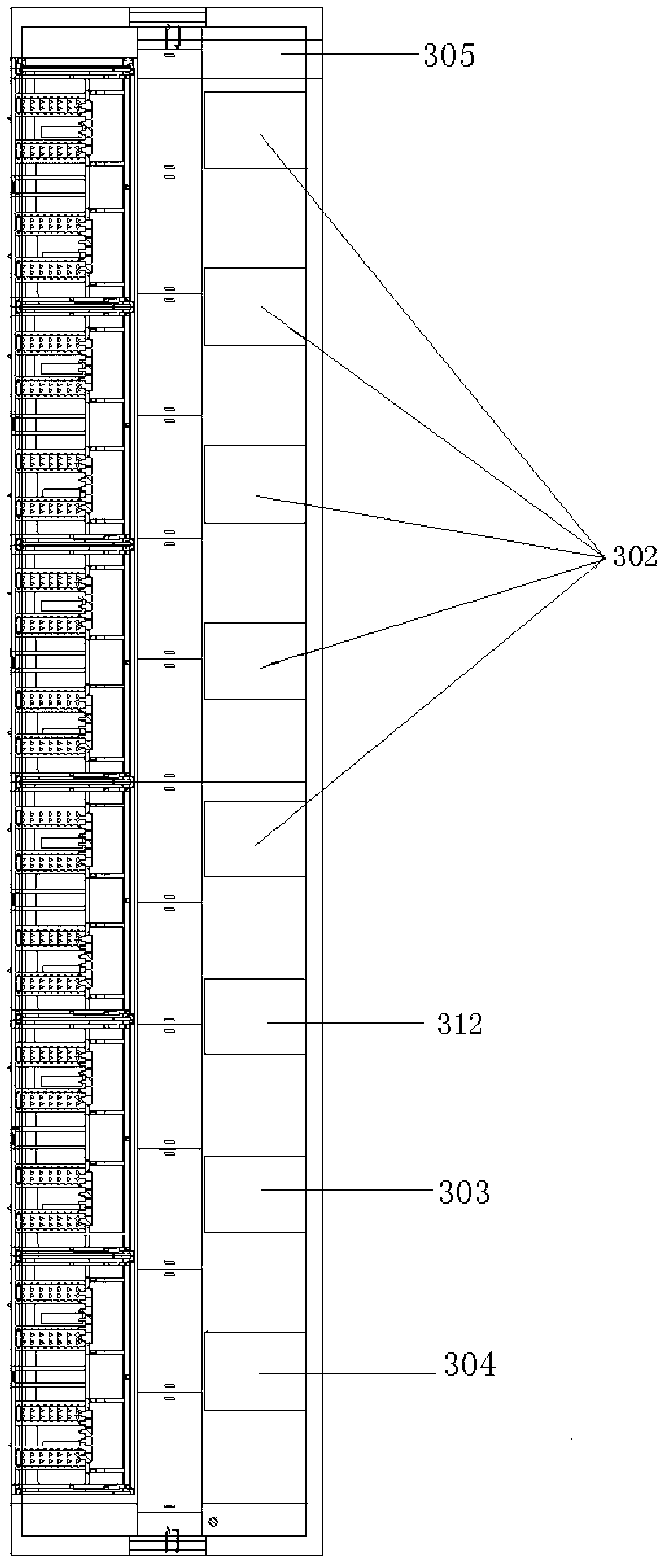

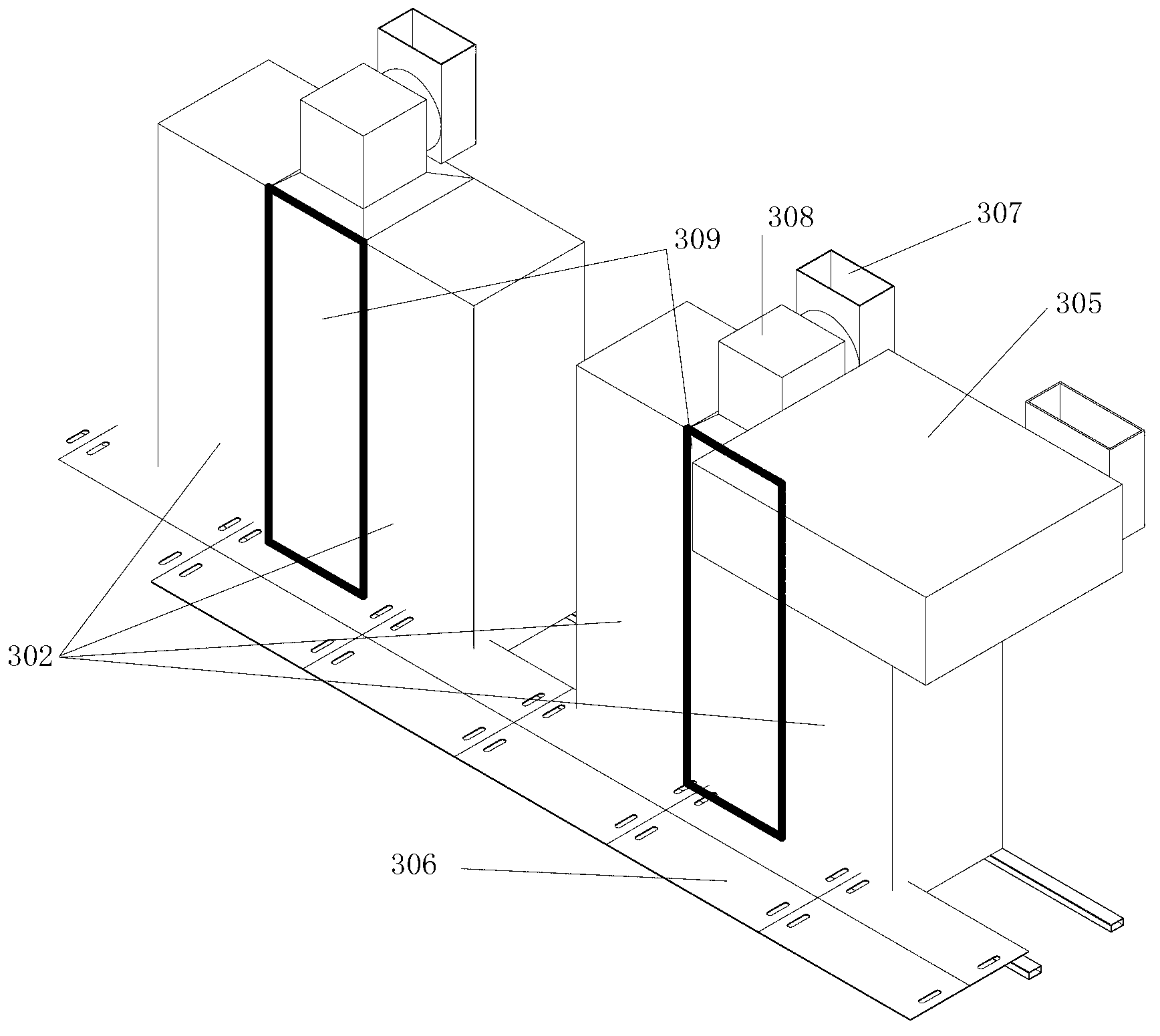

Modularized box type charging and battery swapping station

ActiveCN102923099AAdaptableFlexible configurationVehicle servicing/repairingSmall footprintEngineering

The invention provides a modularized box type charging and battery swapping station used for replacing a battery of an electric car. The charging and battery swapping station comprises a central monitoring room 1, a battery swapping robot 2 and a charging and battery swapping box 3, wherein the central monitoring room 1 is used for monitoring the charging and battery swapping station, the battery swapping robot 2 is located between the charging and battery swapping circuit 3 and the electric cars provided with batteries to be replaced, and the battery between the electric cars provided with batteries to be replaced can be replaced; and a battery storage rack 301, a battery charger cabinet 302, a monitoring cabinet 303, a distribution cabinet 304, a temperature control system 305 and an access path 306 are arranged in the charging and battery swapping box 3. The modularized box type charging and battery swapping station, provided by the invention, has the advantages of strong adaptability, flexible configuration and expansibility, small floor space, high working efficiency, short construction period, benefit for large-scale popularization and construction, high automation degree, smaller device maintenance amount, simple structure and low fault rate.

Owner:BEIJING STATE GRID PURUI EXTRA HIGH VOLTAGE POWER TRANSMISSION TECH CO LTD +1

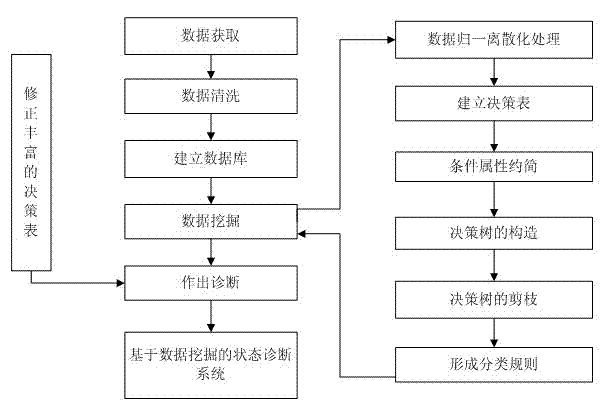

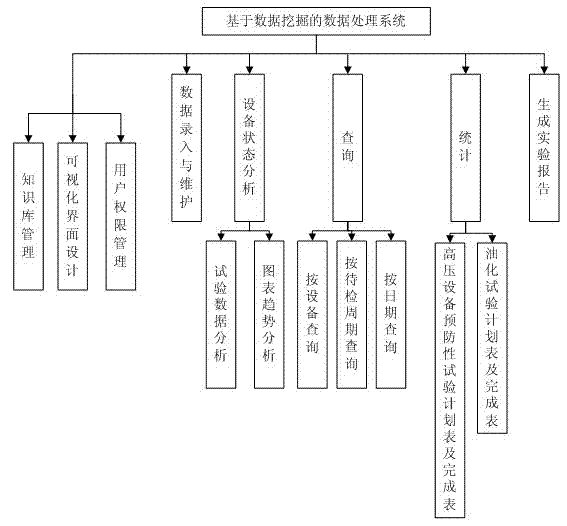

Electrification detection data processing method based on data mining technology

InactiveCN103902816AAchieve loose couplingImprove execution efficiencySpecial data processing applicationsAnalytic modelTransformer

The invention belongs to the technical field of data mining in information technologies, and relates to an electrification detection data processing method based on a data mining technology, in particular to a state analysis technology and method for a transformer, a breaker, an arrester and others in electrical equipment. The processing method includes the steps that according to maintenance lag existing in traditional state maintenance of the electrical equipment and redundant work of overmuch planned maintenance, and a data mining state analyzing model with a rough set and a decision-making tree combined is built and combined with an existing electrical equipment state maintenance system to build the electrification detection data processing system based on the data mining technology. The rough set and the decision-making tree fusion technology is applied to state data analysis of the electric equipment, according to existing state judgment standards, state data of an over 35 KV transformer, an SF6 breaker and other electric equipment are preprocessed, Gini coefficient indexing, attribute reduction, threshold value selection and other steps are performed on attributes, state analysis is performed on the basis, meanwhile a work state table is formed, and a corresponding processing scheme is given.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

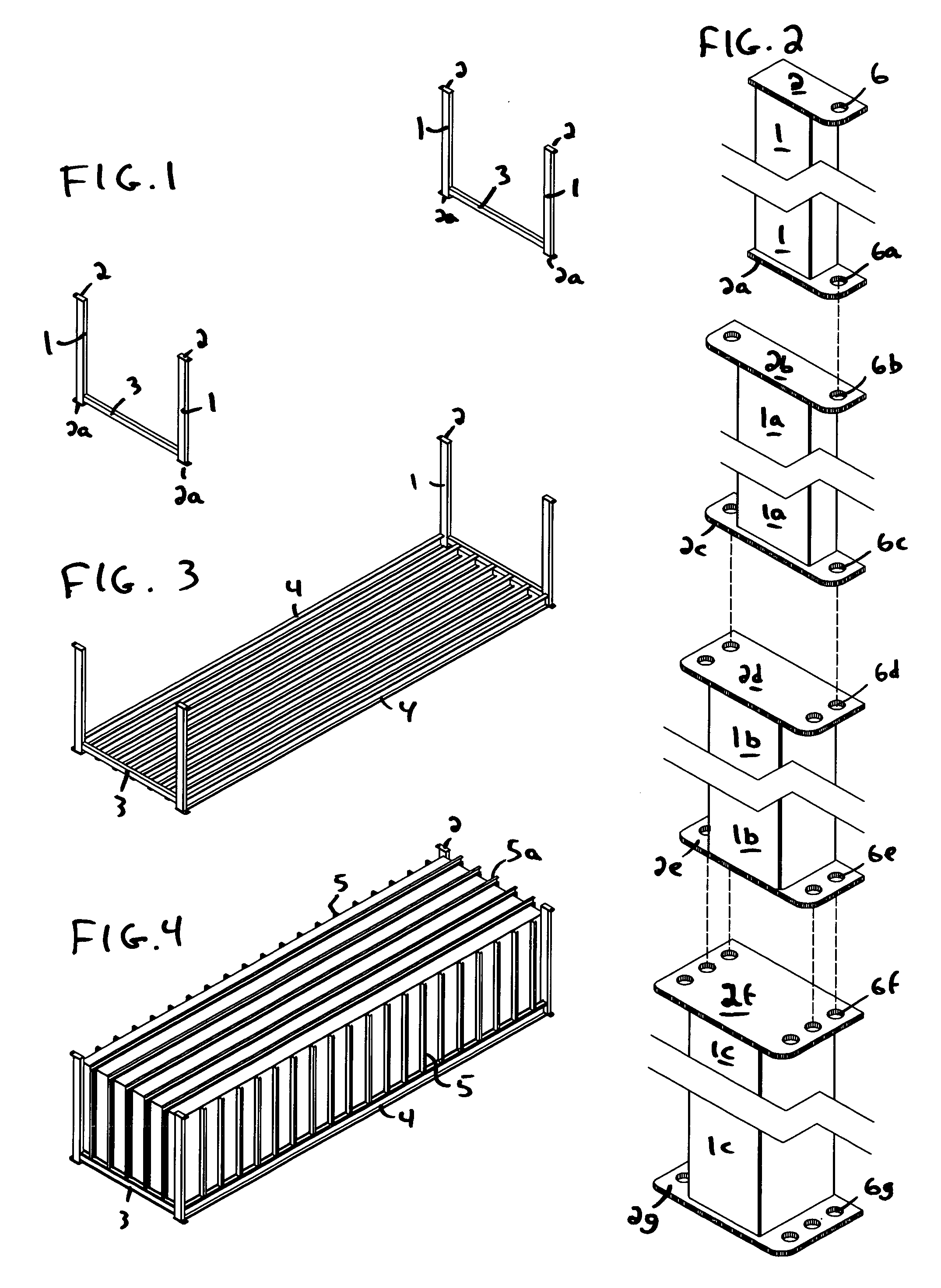

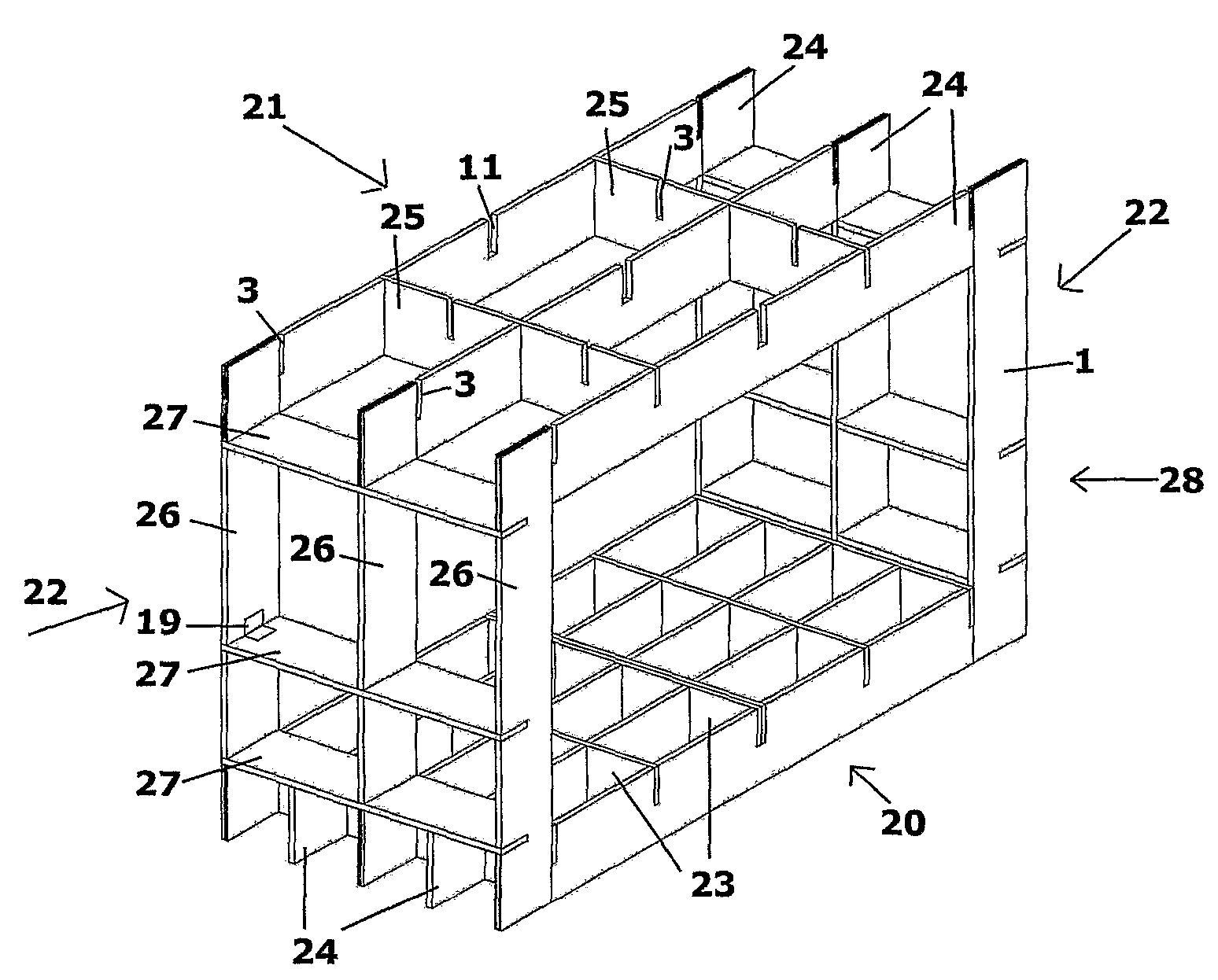

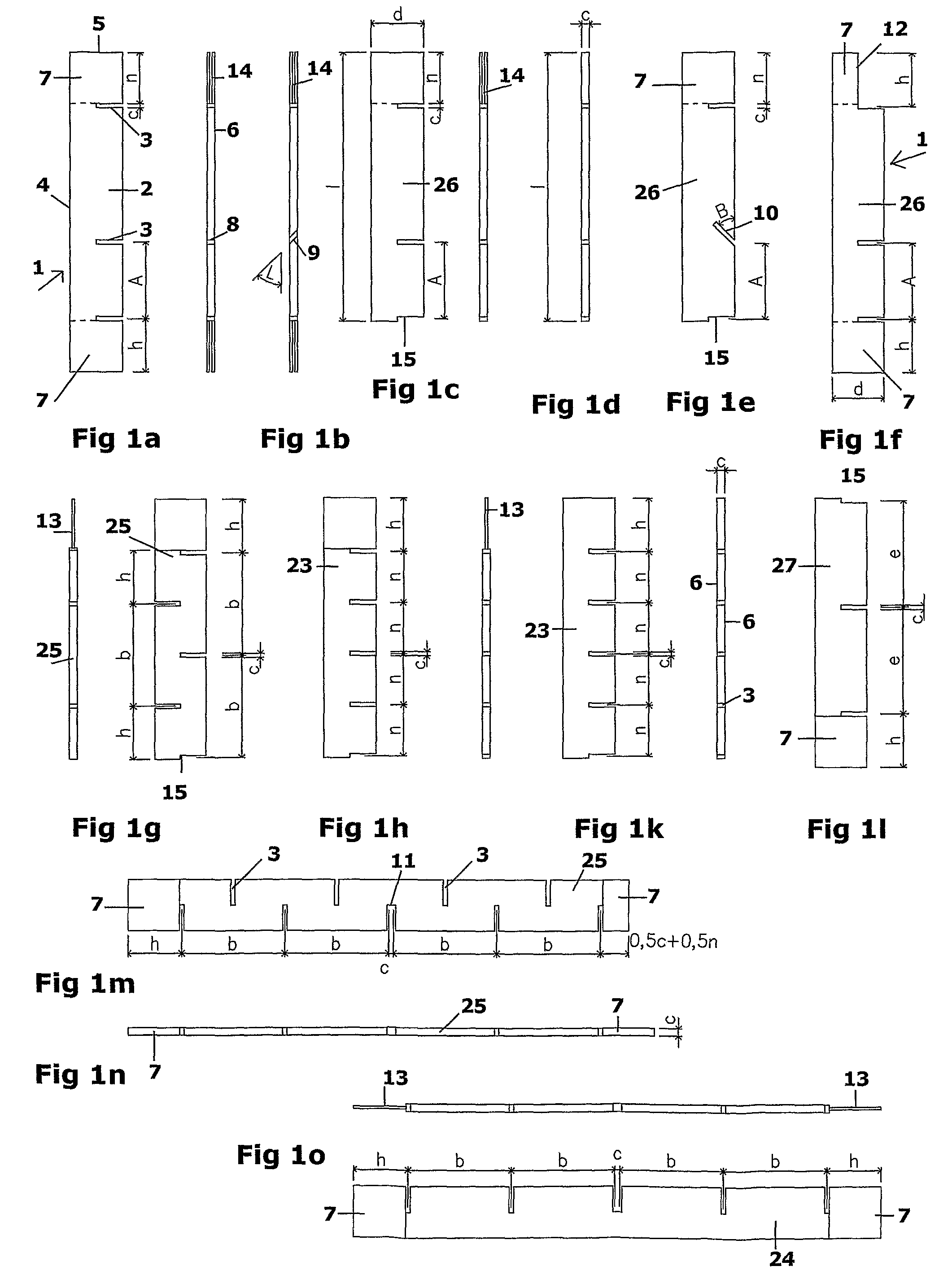

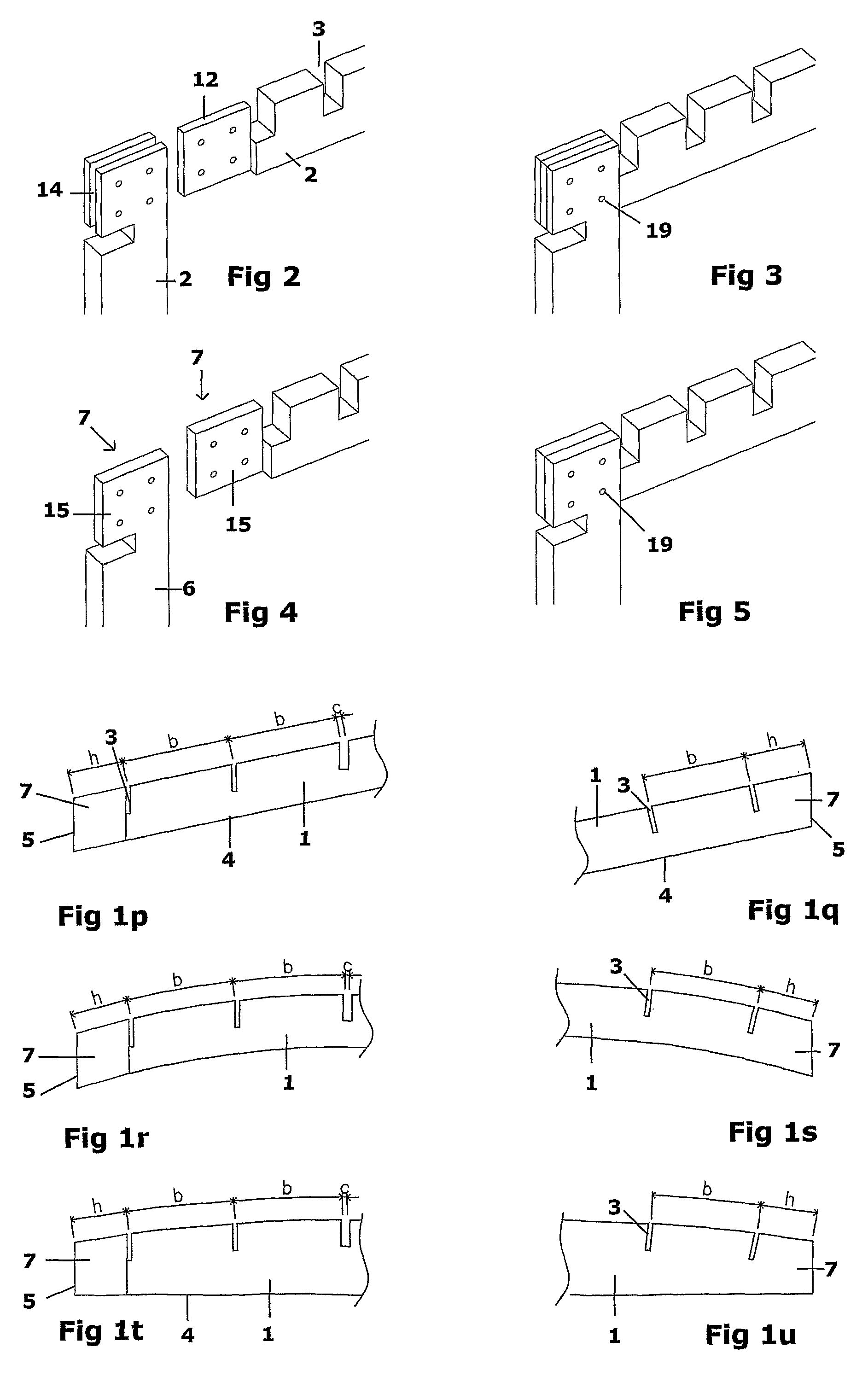

Modular building construction

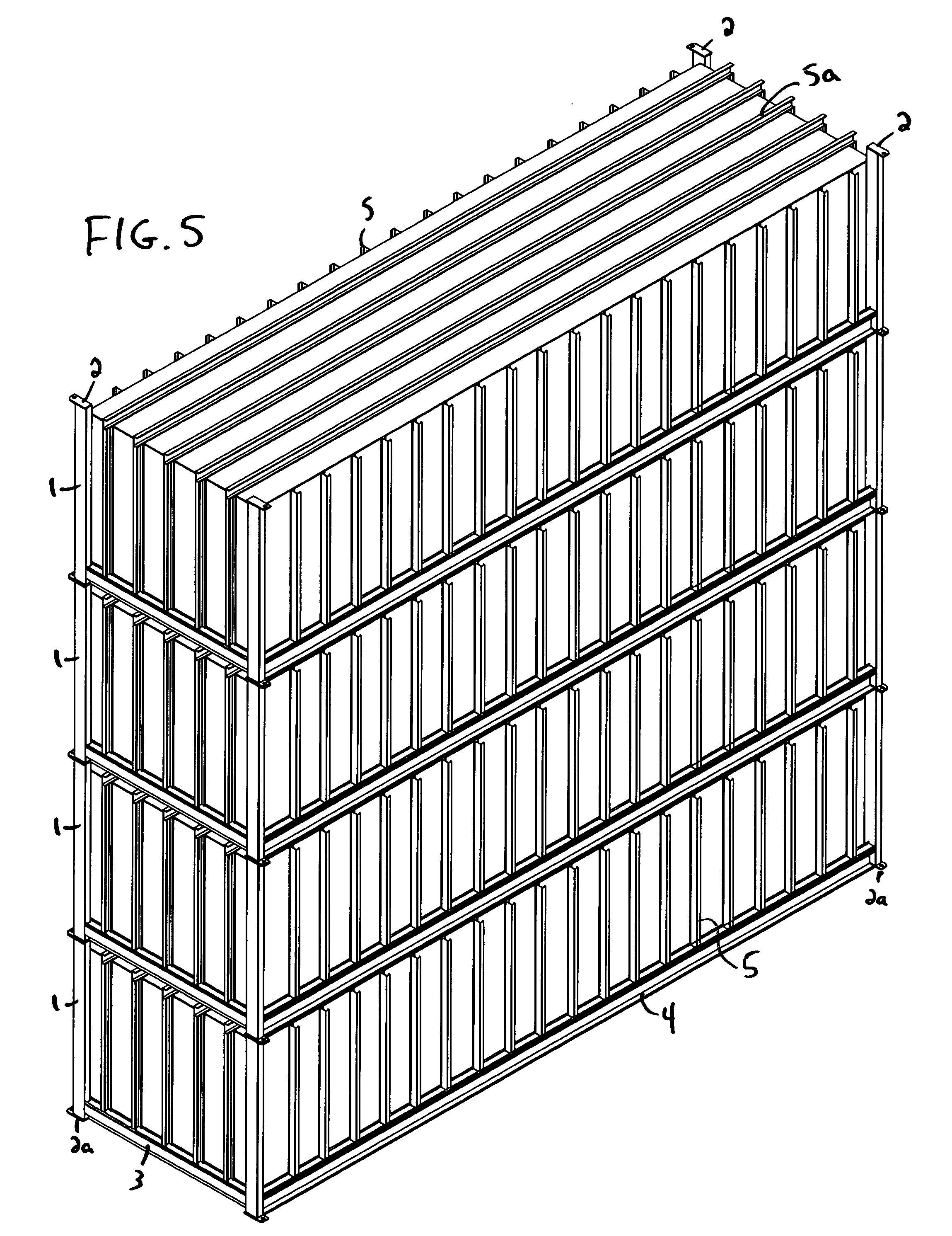

InactiveUS8458980B2Quick installationImprove rigidityDollsPublic buildingsArchitectural engineeringStructural system

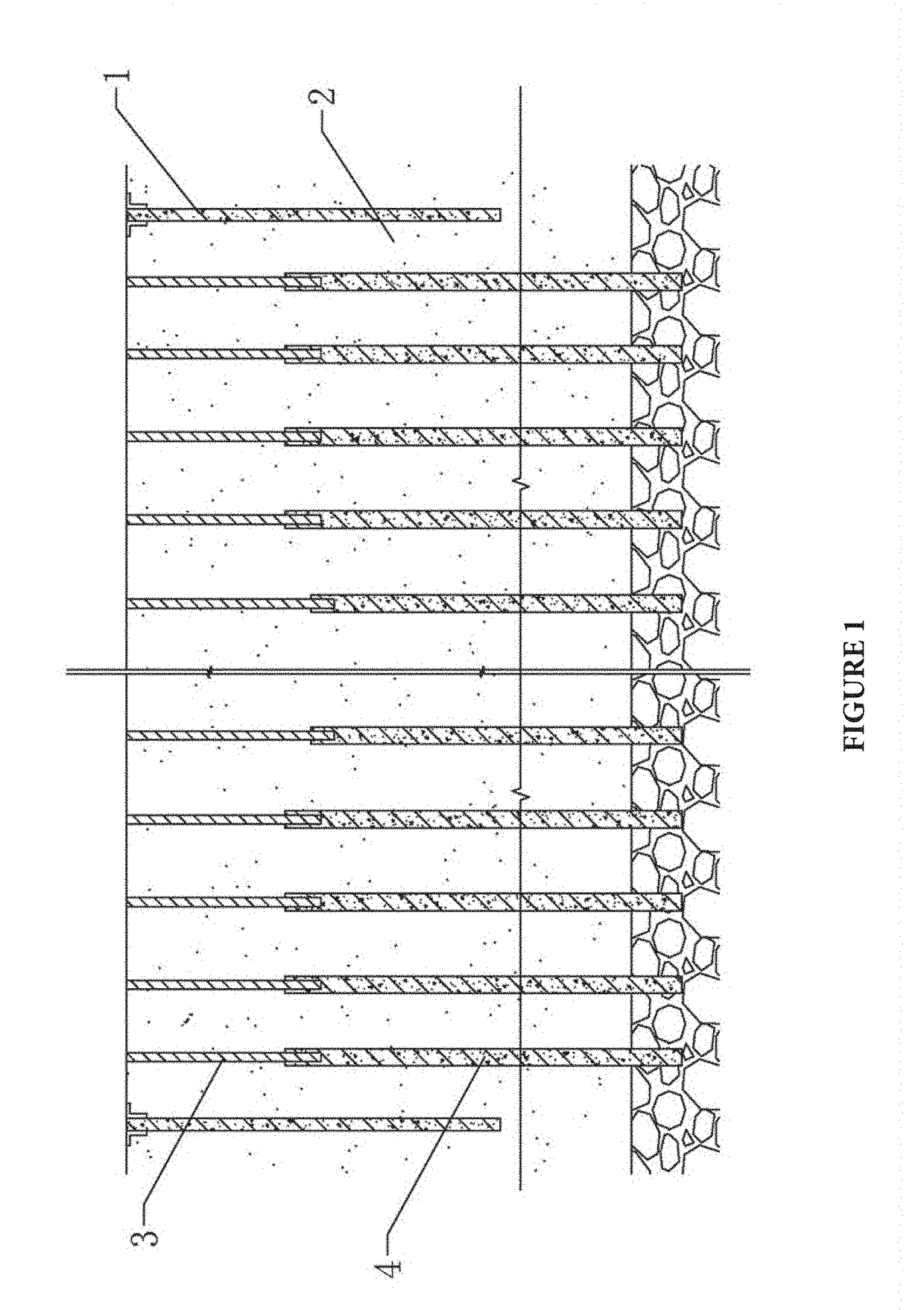

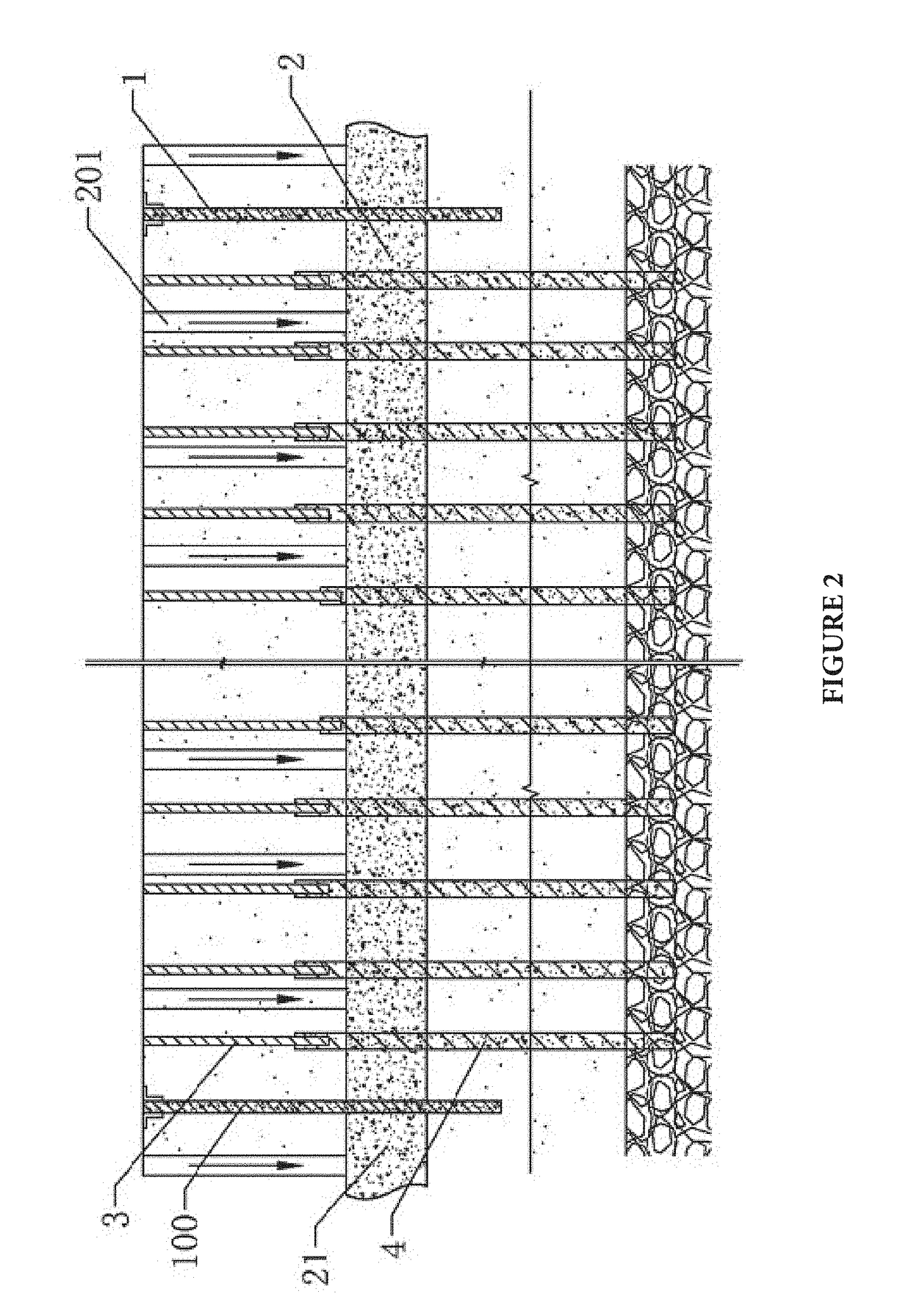

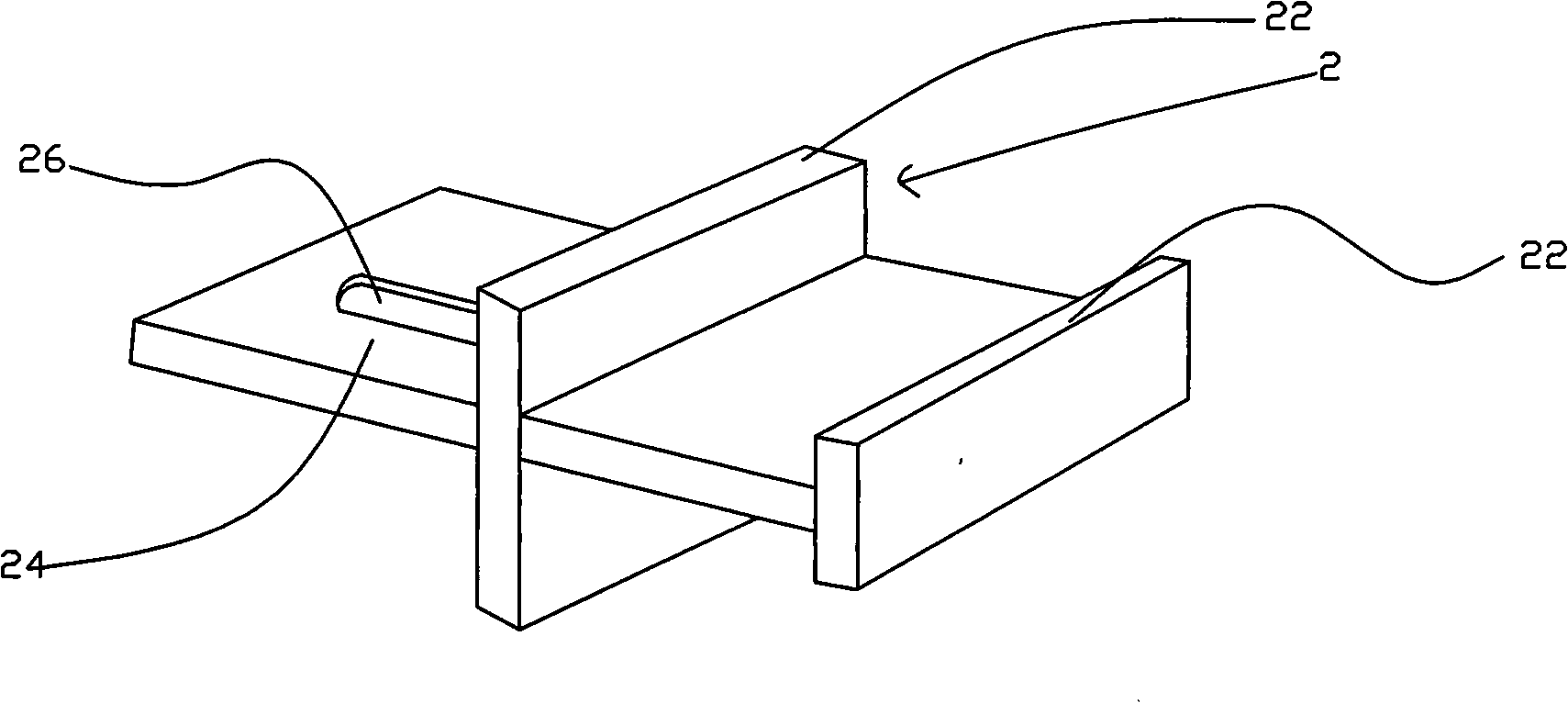

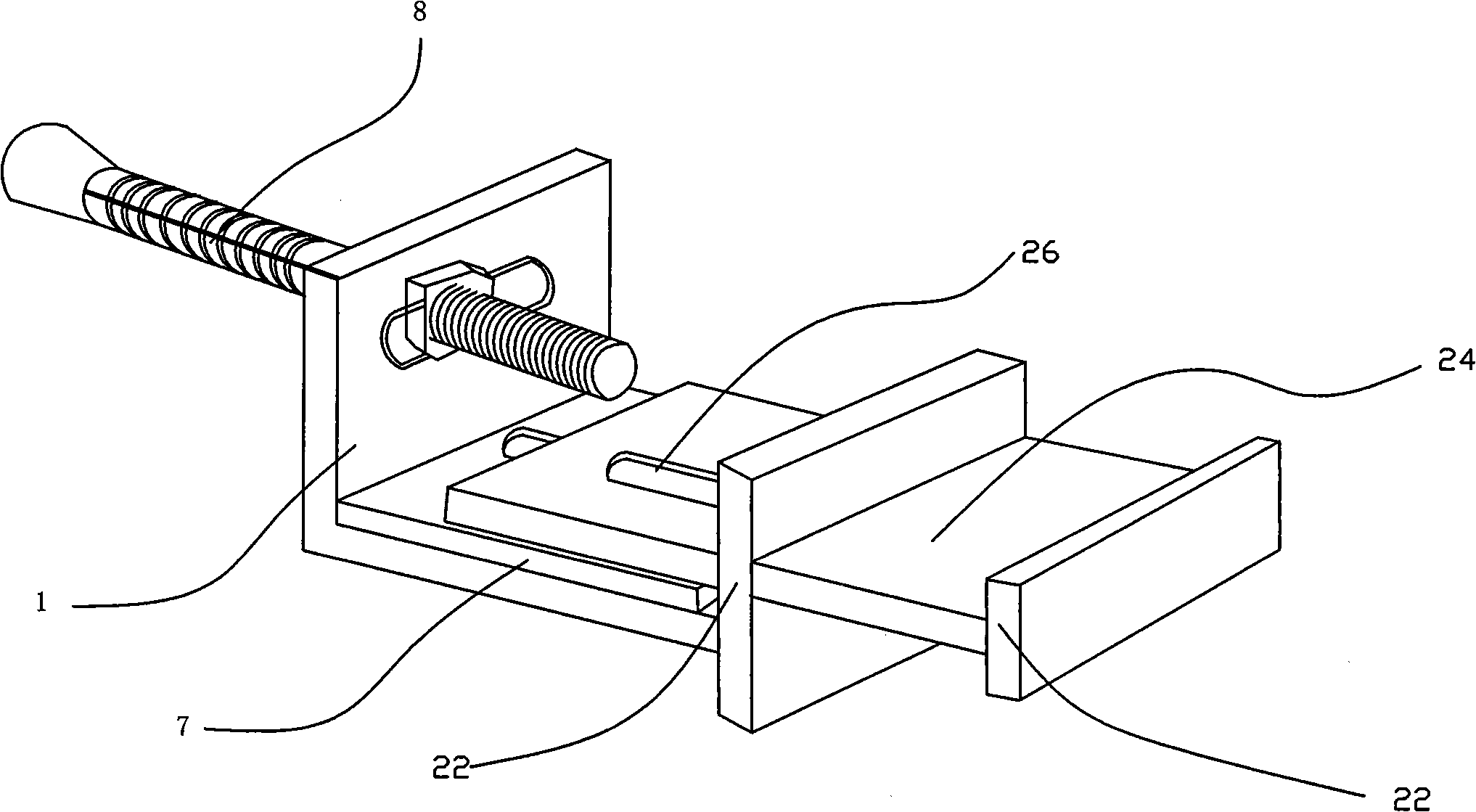

The invention relates to the field of construction and in particular to a modular construction system used for building of construction modules. The construction system comprises plurality of flat elements (1) with identical thickness C and having slots (3) on at least one of its long sides (4), as the slots (3) are located at a distance from each other so that the flat elements (1) can intersect each other through their slots (3) in order to form a grid. The elements (1) of the system have slots (3) located at equal distances n or b from each other where the ratio n:b is within the range from 1:1 to 1:10. The building construction module is made as three-dimensional frame structure shaped like polyhedron including a floor (20), a ceiling (21) and at least two walls (22) grids connected together. The grids are made by intersecting through slots (3) flat elements (1).

Owner:IVANOV NIKOLAY VASKOV

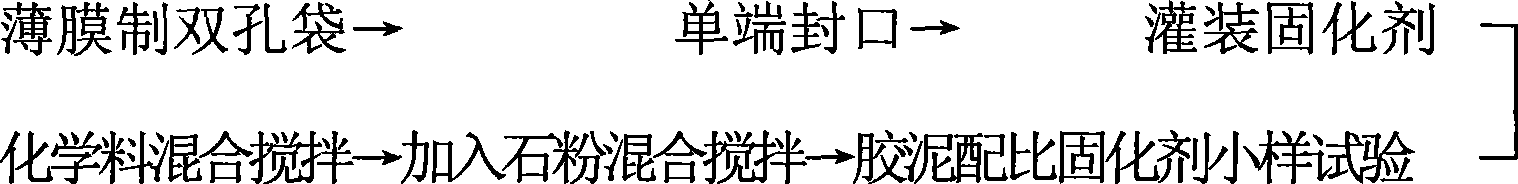

Resin mastic cement for anchorage agent and anchorage agent thereof

InactiveCN101508540AReduce consistencyHigh compressive strengthAnchoring boltsDimethylaniline N-oxideCompressive strength

The invention relates to an anchoring agent, which is resin mortar for an anchoring agent and the anchoring agent, and is used for anchoring large-diameter anchor cables used in the construction of the support of coal mine roadways and the protection of underground engineering. The resin mortar comprises the following compositions in portion by mass: 800 to 1,200 portions of MG unsaturated polyester resin, 4,000 to 6,000 portions of limestone powder, 3 to 10 portions of dimethylaniline, and 6 to 12 portions of white carbon black, wherein the particle size of the limestone powder is between 80 and 120 meshes. The resin mortar and a curing agent form a bi-component anchoring agent. The anchoring agent can effectively reduce the consistency of the resin mortar, and improve the compressive strength after the solidification of the anchoring agent, thereby realizing the effects during the use such as high adhesive force, low stirring resistance and the like; and the anchoring agent meets the requirement of using large-diameter and high-strength anchor cables in the support of the coal mine roadways, reduces anchoring length, construction time and construction personnel, and improves the production efficiency.

Owner:晋城宏圣科威矿用材料有限公司

Shale gas horizontal well proppant in-crack shielding and temporary plugging staged fracturing process

ActiveCN106223922ASolve complex problems such as inability to downloadStable and reliable perforationFluid removalPressure riseSand blasting

The invention discloses a shale gas horizontal well proppant in-crack shielding and temporary plugging staged fracturing process. The process includes following steps: lowering a continuous oil pipe and a sand blasting perforation tool a layer section needing fracturing modification, performing multi-cluster perforation, and lifting up the continuous oil pipe and the perforation tool; setting highest safe pumping pressure on the ground, and conducting main fracturing to promote a reservoir to generate a size crack; after injection liquid quantity reaches 1600-1800m3, pumping a proppant section plug for temporary plugging; after the section plug used for sand filling enters a stratum hole, lowering injection displacement until a sand plug completely enters a stratum; if shaft pressure rises to the highest safe pumping pressure set on the ground, showing that shielding and plugging are successful; lowering the continuous oil pipe for multi-cluster perforation and main fracturing of the next section until fracturing of all sections is completed. Multi-cluster sand blasting perforation of the continuous oil pipe is combined with in-crack sand filling temporary plugging staged fracturing, so that the complex problems that a mechanical bridge plug and a perforation tool cannot be lowered due to casing deformation and hole shrinkage and the like can be solved effectively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

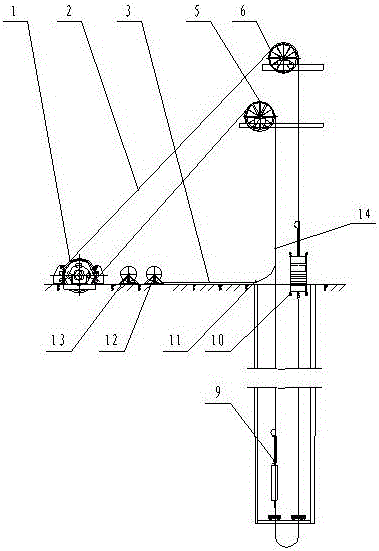

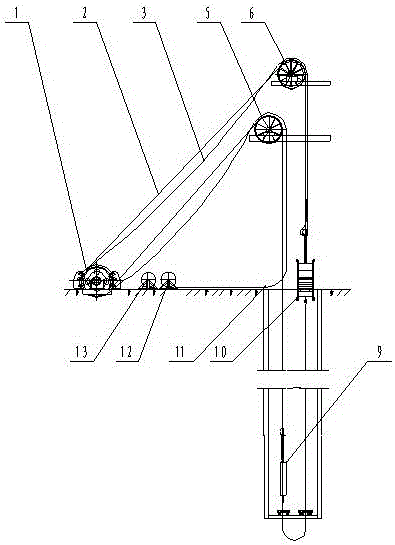

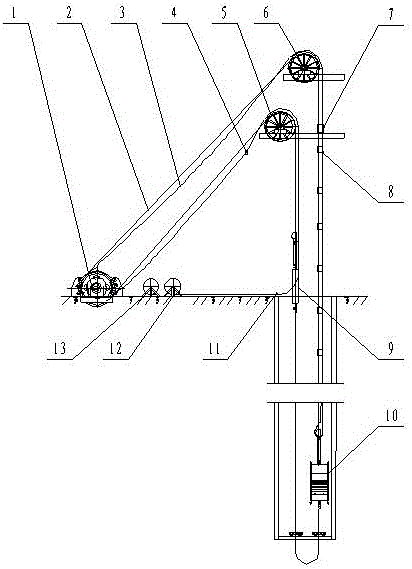

Replacement process for lifting steel wire rope of vertical shaft multi-rope friction lifter

The invention discloses a replacement process for a lifting steel wire rope of a vertical shaft multi-rope friction lifter. The replacement process comprises the following steps: (1) placing a new rope plate and an old rope receiving plate at proper positions at the balance hammer side of an upper shaft mouth, and stopping a tank cage at the position of the upper shaft mouth; (2) at the upper shaft mouth, connecting a traction rope with new and old ropes by the rope head of the new rope via a guide wheel at the balance hammer side; (3) starting a lifter to descend the tank cage by a hoist at the speed of 0.4m / s; (4) respectively clamping the new rope at a hoist house, an upper hoisting sheave and a lower hoisting sheave by compound board cards and then lifting the new rope, and dismounting the traction rope for connecting the new rope with the old rope; (5) reversely driving the hoist at the speed of 0.4m / s, and lifting the tank cage to the upper shaft mouth; (6) arranging an anti-running device and a rope tightener, and descending the tank cage until the balance hammer is lifted to the upper shaft mouth; (7) dismounting the anti-running device and the rope tightener, and mounting a rope clamper; (8) cutting off the old steel wire rope below a hoist roller, and replacing the old rope with the new rope; and (9) after the tank cage is lifted to the upper shaft mouth, mounting the rope clamper, connecting the new rope with a wedge-shaped rope, regulating the rope length, dismounting the rope clamper, and implementing pilot run after the rope replacing process is completed.

Owner:XUZHOU JOY TECH

Coal road stripe region burst-preventing method

InactiveCN104314610AImprove breathabilityReduce the amount of drilling workGas removalCoalBuilding construction

The invention discloses a coal road stripe region burst-preventing method which comprises the following steps: enabling a to-be-dug coal road to be directly positioned in a pressure relieving region of a pre-digging bottom plate rock gangway and performing stripe-drilling on drawing-out coal bed gas, namely, pre-digging the bottom plate rock gangway along a trend just below the to-be-dug coal road coal bed, performing pressure relief on the to-be-dug coal road on the bottom rock gangway, and performing gas drawing-out on the upper edge and the lower edge of the to-be-dug coal road by adopting stripe-drilling. According to the coal road stripe region burst-preventing method, the purposes of relieving pressure of the to-be-dug coal road stripe coal bed, increasing the breathability, and improving the gas extraction effect can be realized. The coal road stripe region burst-preventing method has the characteristics of improving the safety and reliability of stripe-drilling construction, reducing the burst-preventing project, shortening the construction time, and improving the burst-preventing effect of the coal road stripe region.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com