Construction process for rock enlarged toe anchor pile foundation of overhead power transmission line

A technology for power transmission lines and construction techniques, which is applied in infrastructure engineering, construction, etc., and can solve problems such as long construction time, reduced rock pullout resistance, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

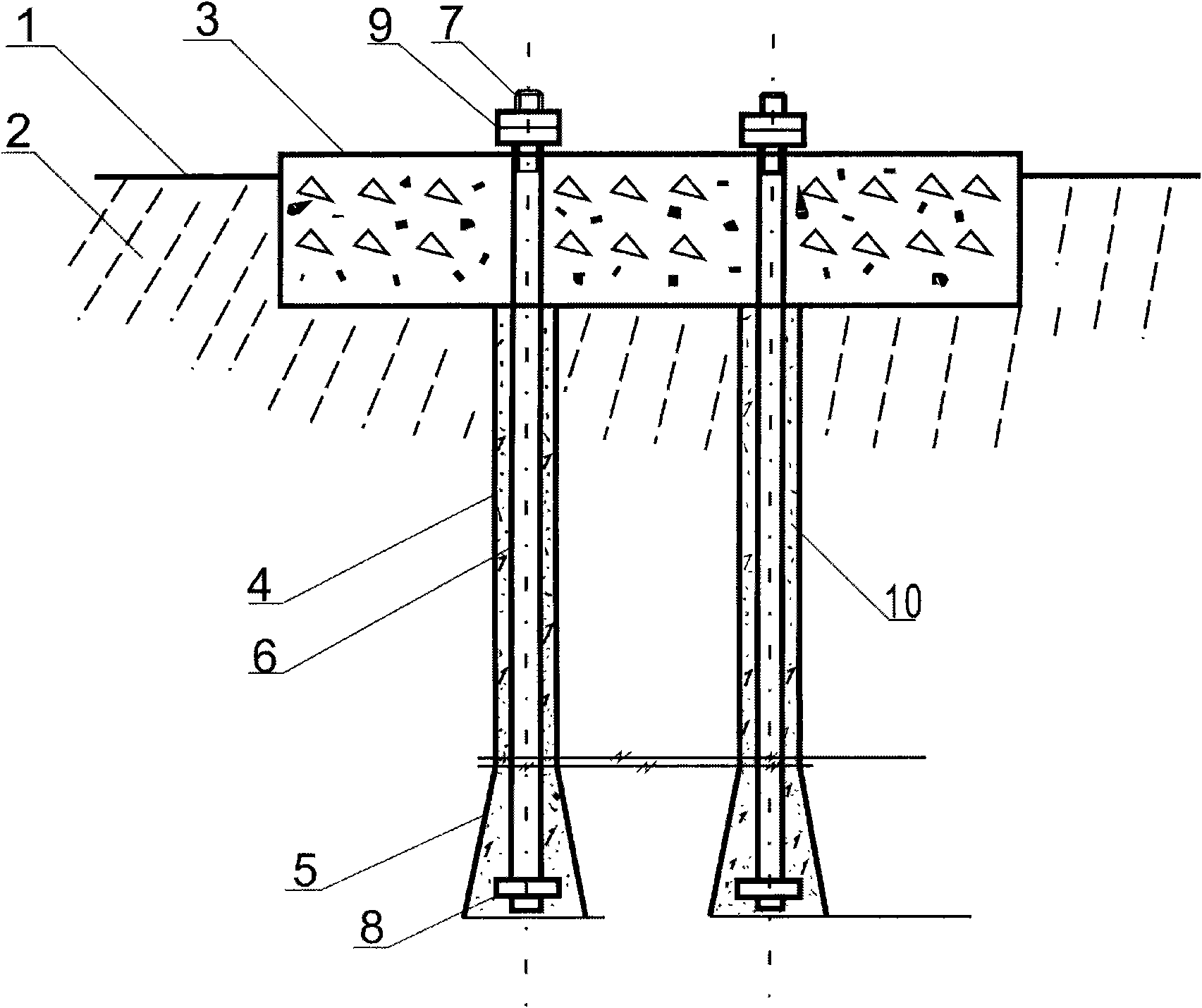

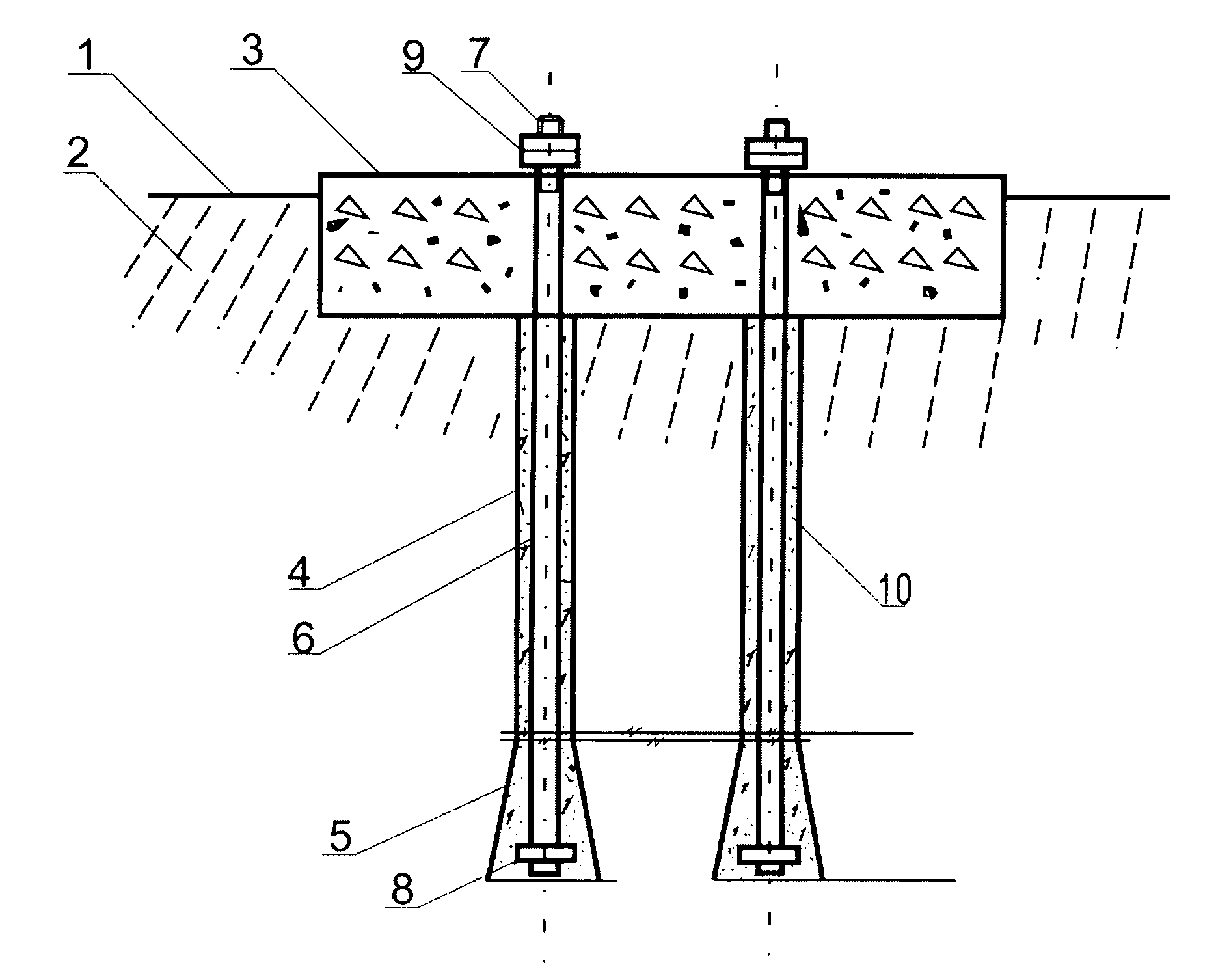

[0007] Attached below figure 1 And figure 2 The technical features of the present invention are further explained.

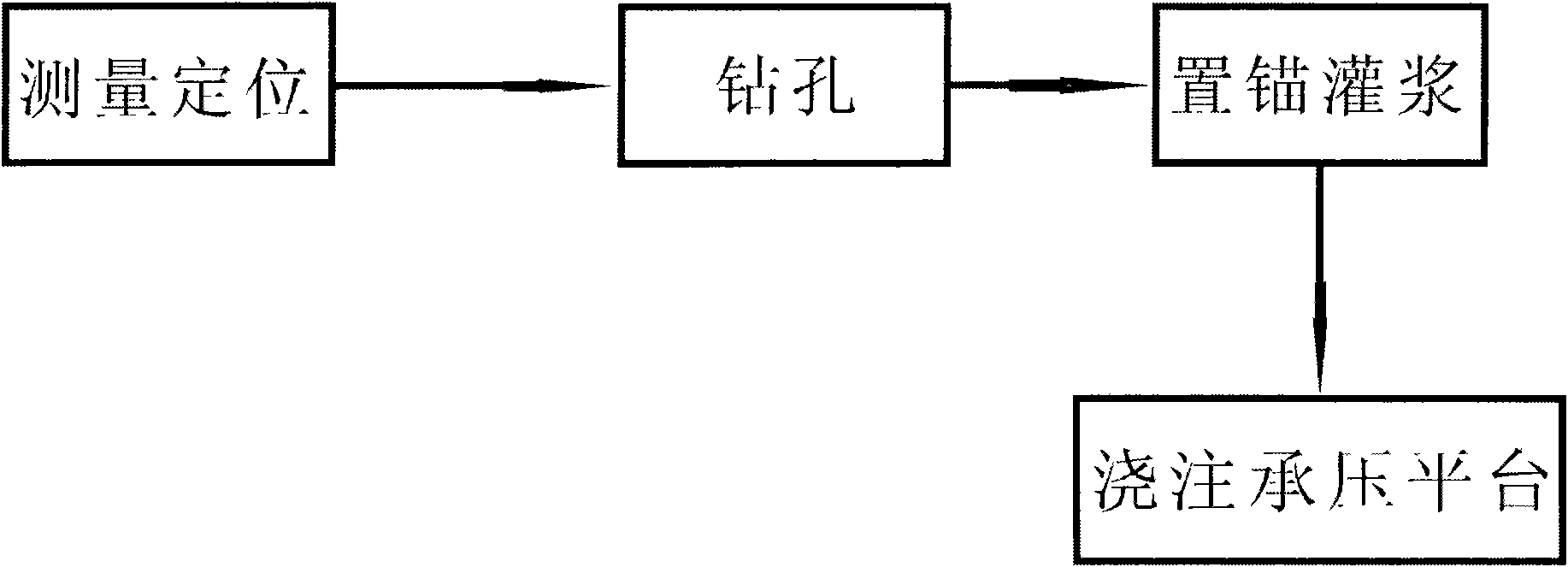

[0008] (1) Measurement positioning: After determining the position of the tower foot, first remove the surface debris or the rock surface of the weathered layer to expose the hard rock surface (1), and determine the pressure platform (3) on the rock surface (1) according to actual needs. Determine the position of the tower foot within the contour of the pressure-bearing platform (3) based on the shape, area and height of the pressure-bearing platform (3), and locate the base point of the anchor bolt (7) based on this; (2) Drilling: the base point of the anchor bolt (7) After determining, use a tubular drill to drill a straight hole (4) into the rock layer (2). When the required depth of the bolt (6) is drilled (the inner diameter and depth of the straight hole are determined by the outer diameter of the bolt and the length of the bolt), Use an eccentric drill bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com