Device and method for preventing sediment deposition and treating sediment in ballast tank of ship

A ballast tank and sediment technology, applied in ship safety, transportation and packaging, ships, etc., can solve the problems of intensified corrosion of ship components, consumption of manpower and material resources, reduction of ship cargo capacity, etc., and achieve small design and manufacturing. Cost, construction time is short, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, this technology is described in further detail:

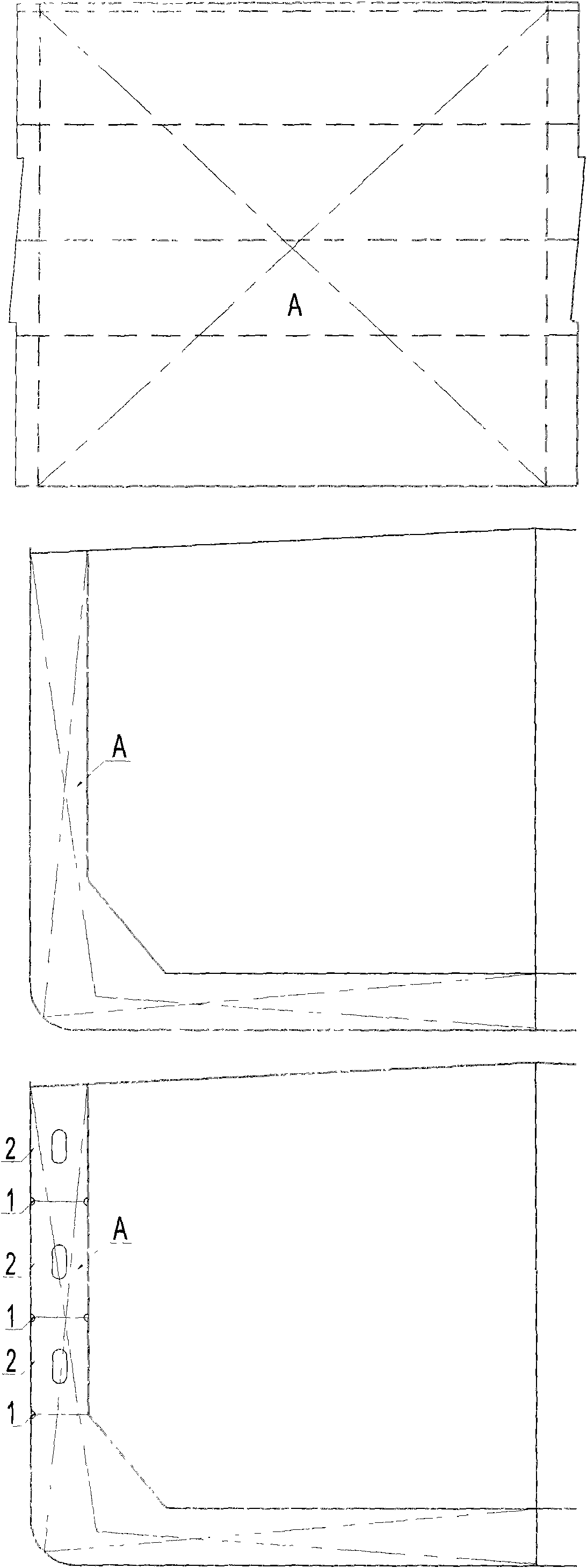

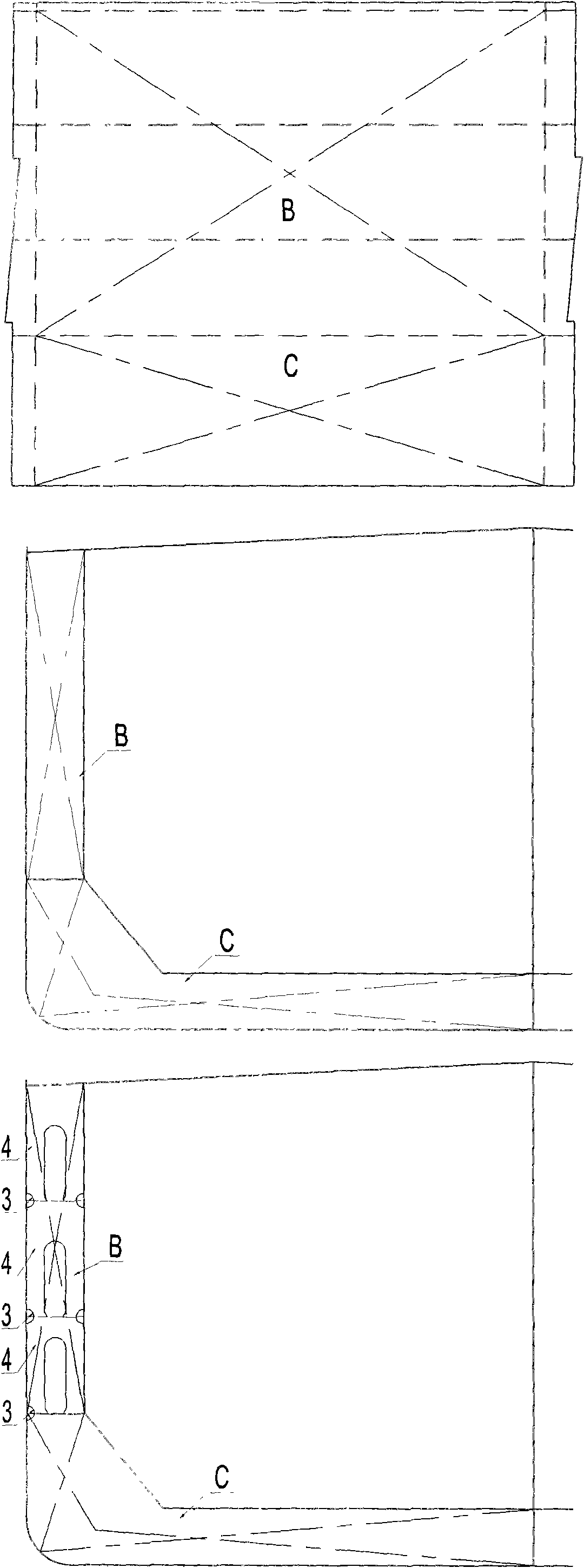

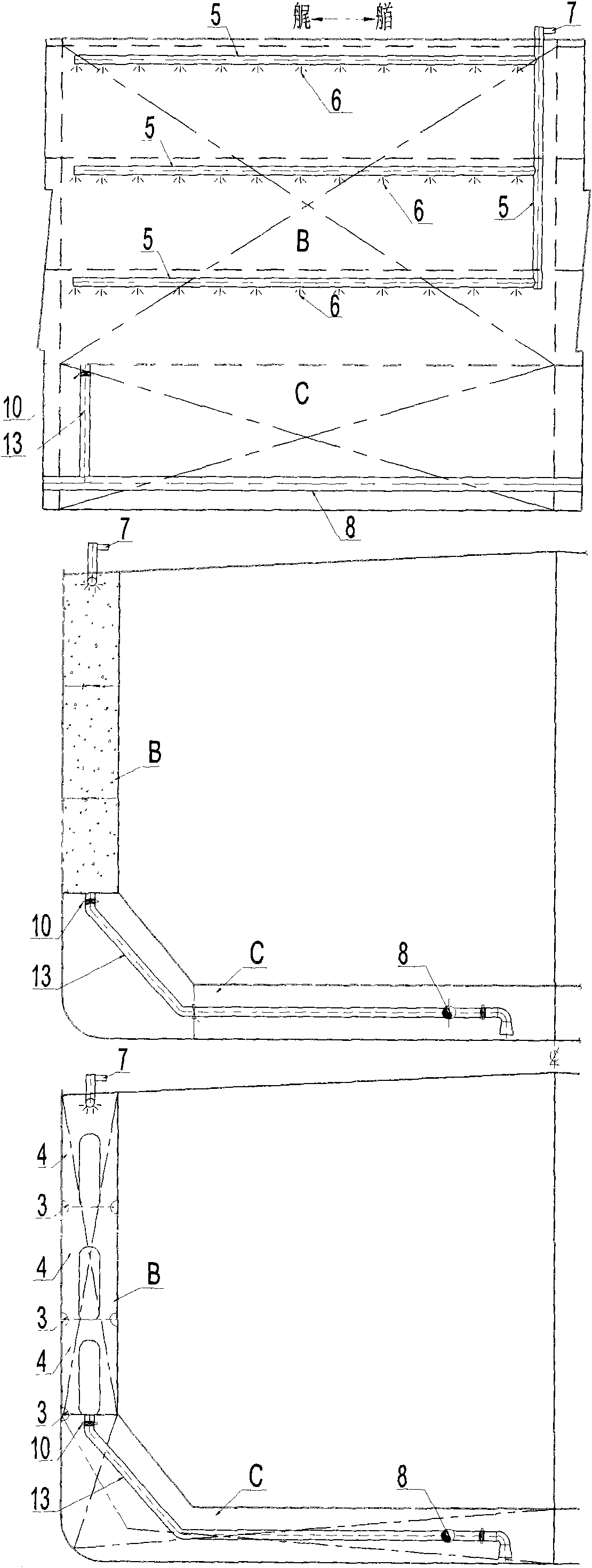

[0019] Such as figure 1 Shown, traditional ballast tank is L type, and the present invention divides it into top edge ballast tank B and bottom ballast tank C, see figure 2 , the division position of ballast tanks of different ship types shall be determined according to the overall performance calculation to meet the ship stability and minimum draft requirements for coastal navigation, and the ballast water containing sediment can only be injected into the top side ballast tank B, Bottom ballast tank C can only be filled with ballast water without sediment; open non-dense floor water holes 3 are provided at the lower corners of the open non-dense floor plate 4; the radius of the open non-dense floor flow hole 3 It is R150mm to facilitate sediment discharge and prevent sediment deposition; flushing main pipe 5 is arranged on the main deck in the ballast tank B on the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com