Patents

Literature

530results about How to "Short construction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of anti-plastering putty for concrete structure wall

InactiveCN101363269AThin thickness and small weightLight weightCovering/liningsResource consumptionPutty

The invention discloses a construction method of a wall putty of a plaster-free concrete structure. The construction method comprises the following steps: construction preparation, base course treatment, concave-convex line construction, a first full application of wall putty, flattening, a second full application of wall putty and flattening. The construction method has the advantages of less workload, short construction time, little resource consumption, no hollow drum and crack of the floated coat, no crack at the joint of the primary structure and the secondary structure.

Owner:中建五局第三建设有限公司 +1

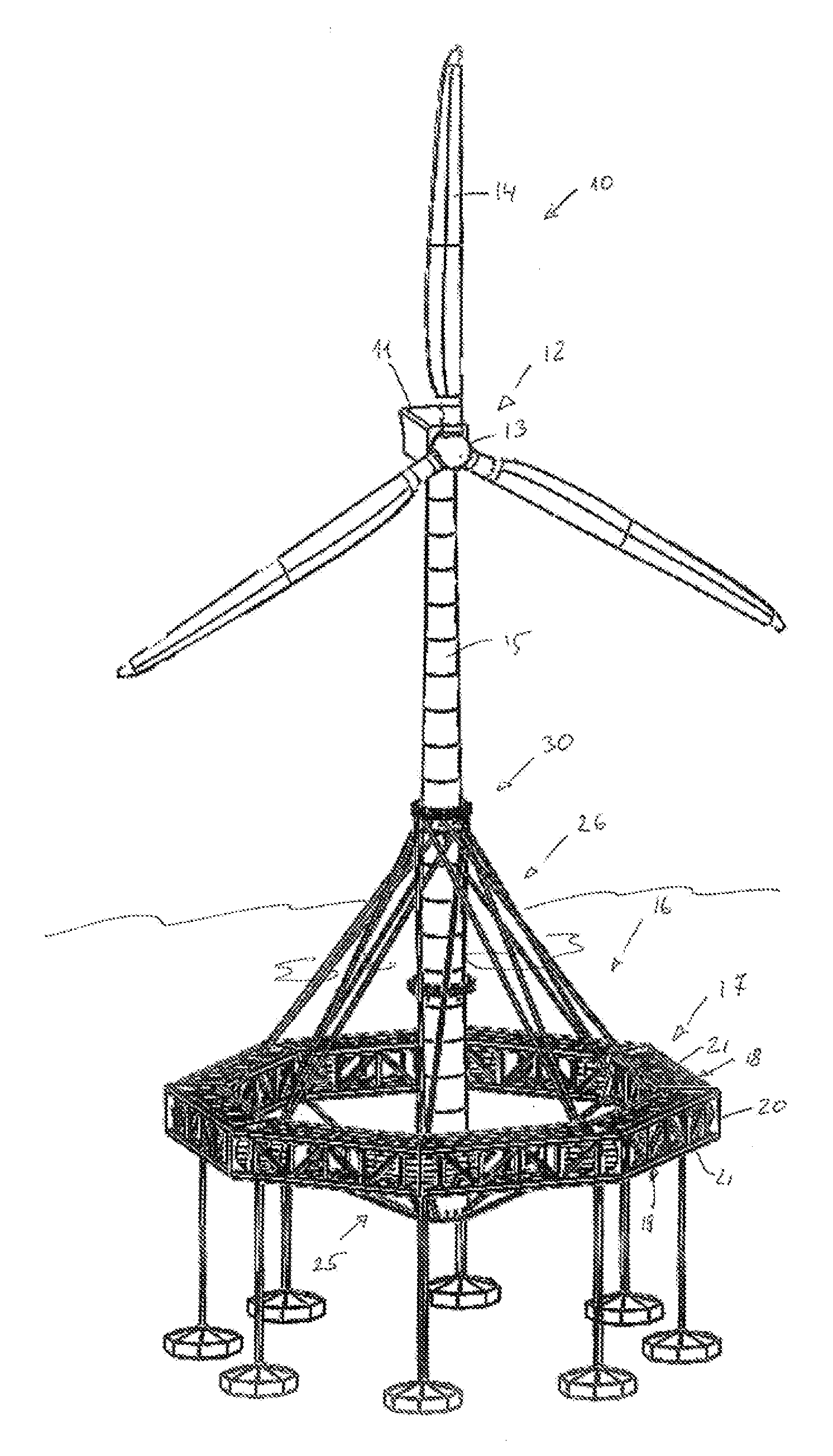

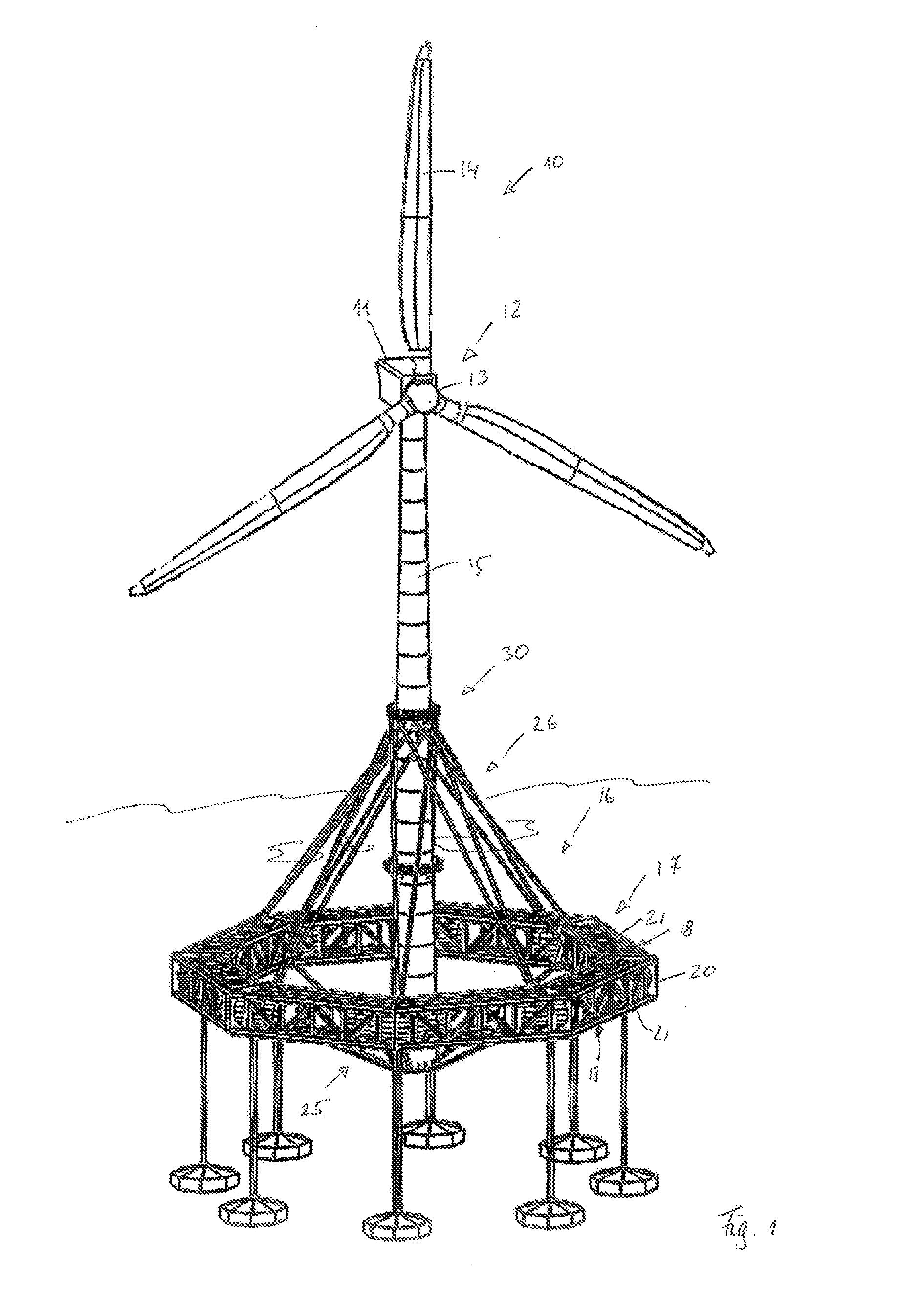

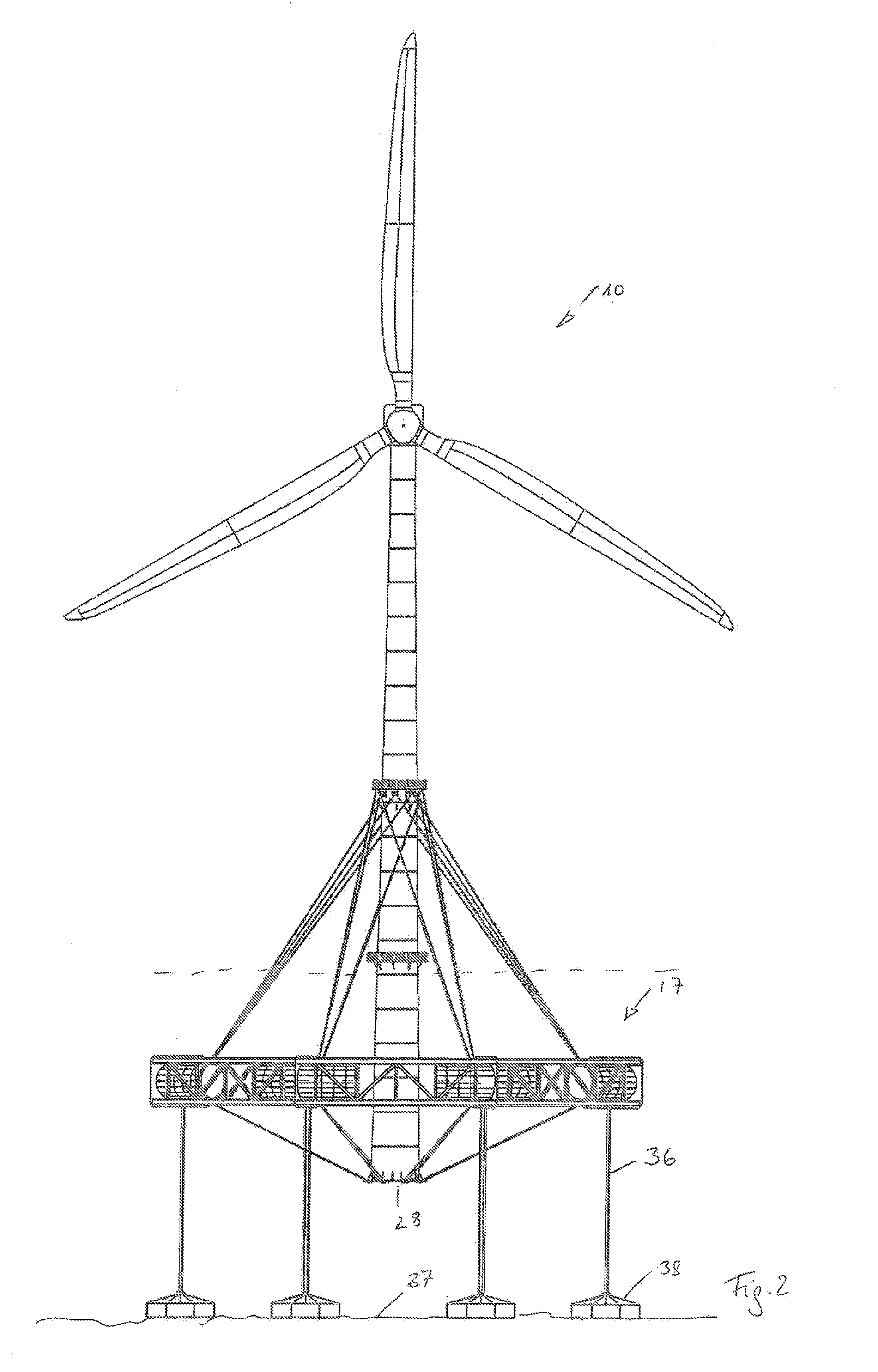

Floating Foundation for Mass Production

InactiveUS20130019792A1Reduce expenditureEasy constructionFinal product manufactureWind motor supports/mountsOcean bottomEngineering

A floating structure has an annular support as an underwater support with a buoyant body. A tower penetrates the annular support centrally and is connected to the annular support at a location underneath the annular support by slantedly outwardly ascending tension spokes and at a location above the annular support by slantedly outwardly descending tension spokes. Anchors on the ocean floor are connected by tension elements with the annular support. The structure is built by the steps of supporting by auxiliary devices the annular support on a floor of a basin that can be flooded; positioning the tower at the center of the annular support in vertical position; attaching the tension spokes at the annular support and at the tower; flooding the basin; towing the structure to its desired final position; and lowering and anchoring the structure in a submerged floating position.

Owner:JAHNIG GMBH FELSSICHERUNG & ZAUNBAU

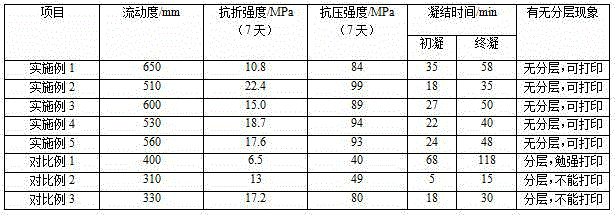

High-performance powder concrete for 3D (three-dimensional) printing

The invention relates to high-performance powder concrete for 3D (three-dimensional) printing. The concrete is prepared from the following raw materials in parts by weight: 500-900 parts of ordinary Portland cement, 250-350 parts of active mineral admixture, 800-1,300 parts of inert filler, 10-20 parts of composite efficient water reducing agent powder, 2-5 parts of thickener, 4-10 parts of self-curing agent, 2-10 parts of fast setting time regulator, 145-230 parts of water, 3 parts of organic fiber and 40-200 parts of copper plated fiber. The concrete material for 3D printing has the characteristics of ultrahigh strength and toughness, good durability, long full life cycle, high curing rate, good flowing property and easiness in pumping and lifting and is suitable for constructing 3D-printed building structural materials in all kinds of engineering.

Owner:黄贺明

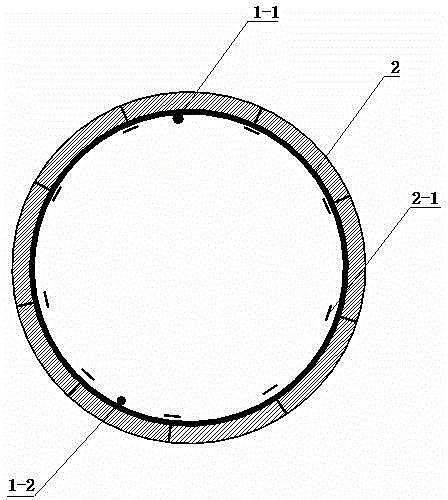

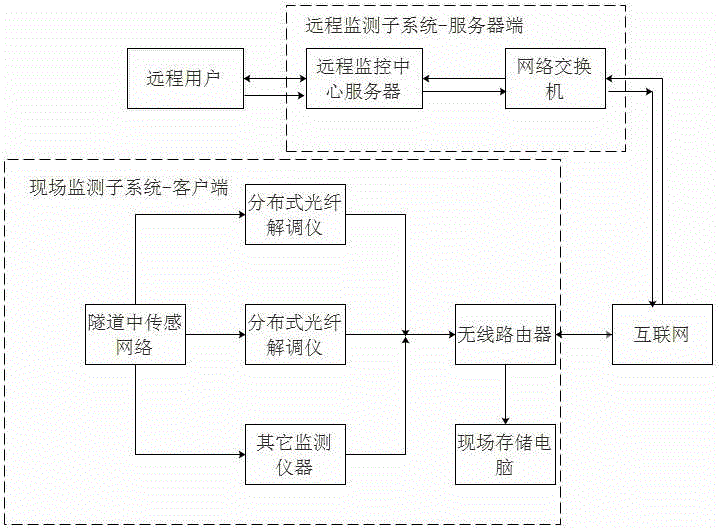

Tunnel structure monitoring system and tunnel structure monitoring method based on distributed long-gauge fiber bragg grating

The invention discloses a tunnel structure monitoring system and a tunnel structure monitoring method based on a distributed long-gauge fiber bragg grating. The system comprises distributed long-gauge fiber bragg grating sensors which are comprehensively distributed in a monitored range along the axial direction and the cross section of a tunnel; and longitudinal sedimentation of the tunnel and change conditions of various ring joints of the shield tunnel are monitored. The method comprises the following steps of arranging the distributed long-gauge fiber bragg grating sensors; and acquiring, transmitting and processing data. By the tunnel structure monitoring system and the tunnel structure monitoring method based on the distributed long-gauge fiber bragg grating, full-life monitoring on a tunnel structure in a construction period and a running period can be carried out, and longitudinal sedimentation, convergence deformation, joint deformation, duct piece internal force, strain and the like of the tunnel structure are dynamically monitored in real time.

Owner:SOUTHEAST UNIV +2

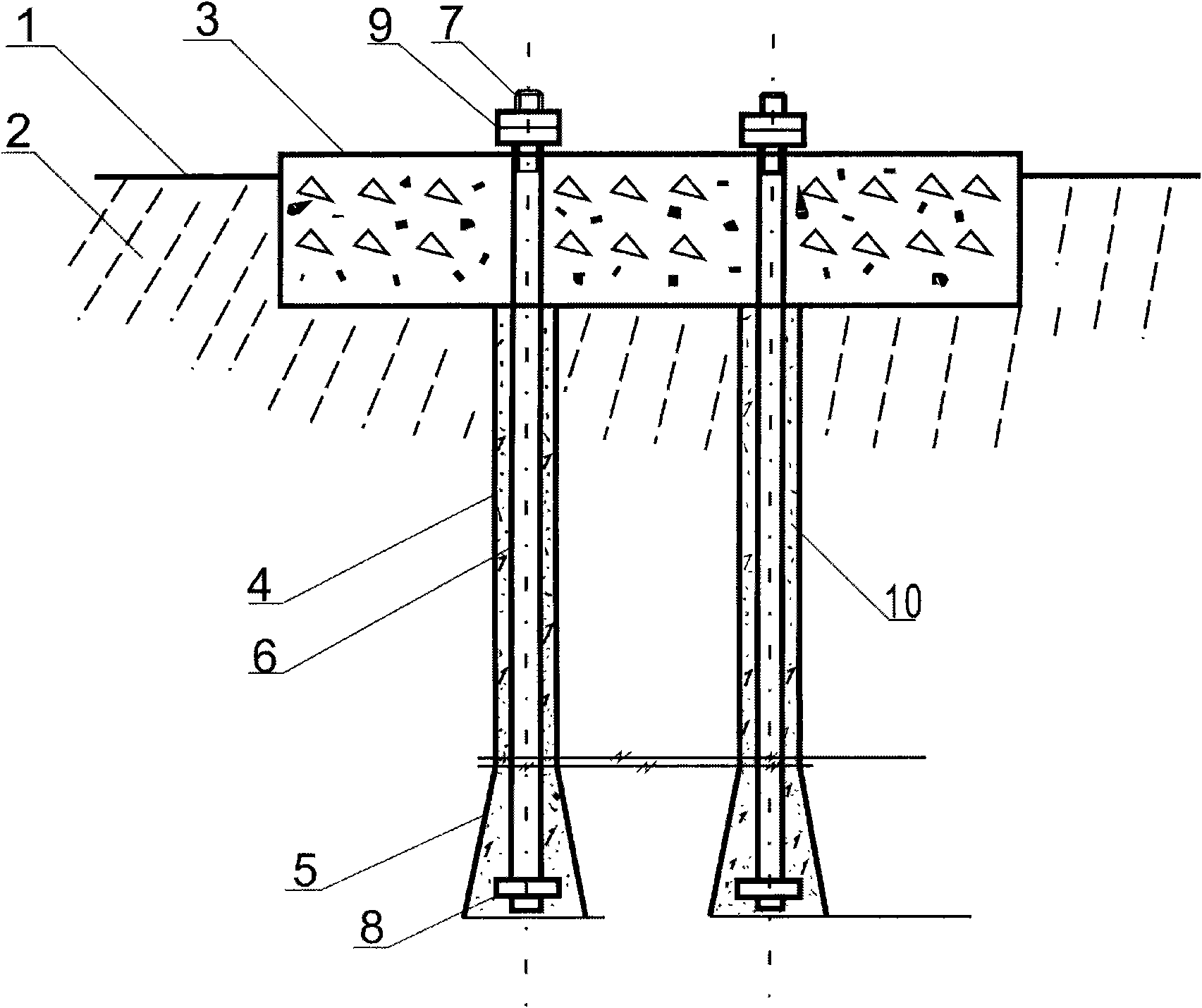

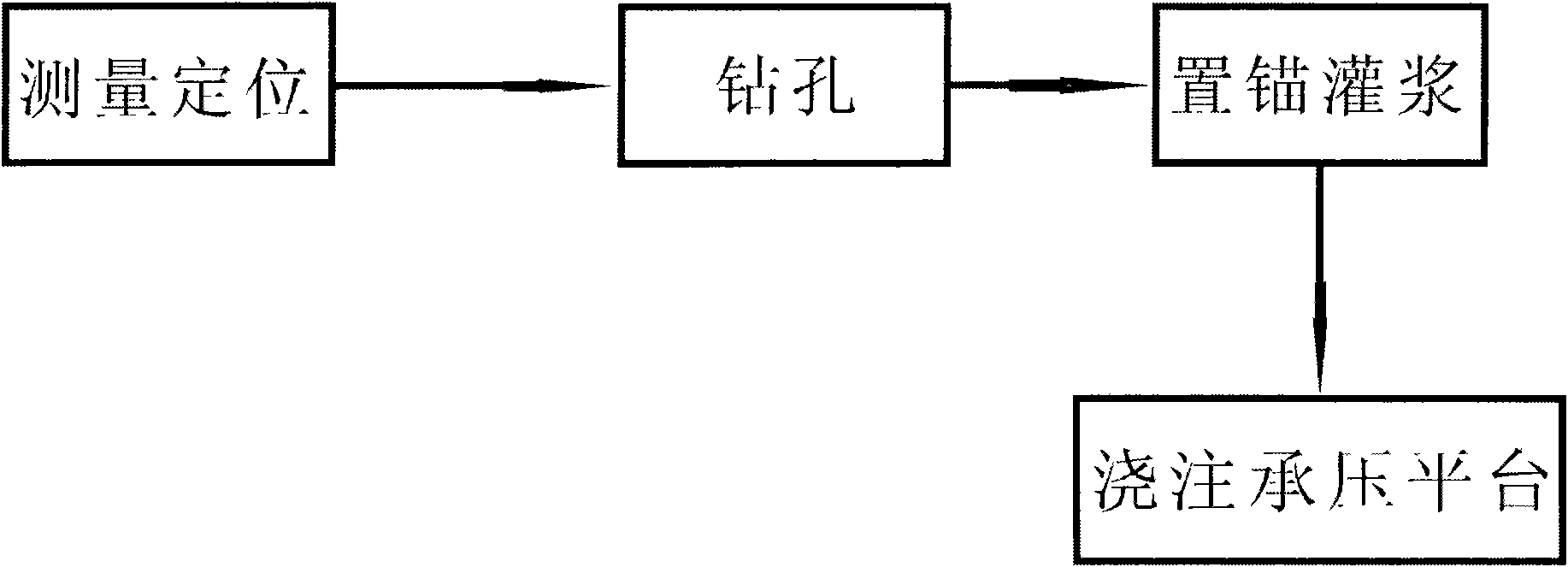

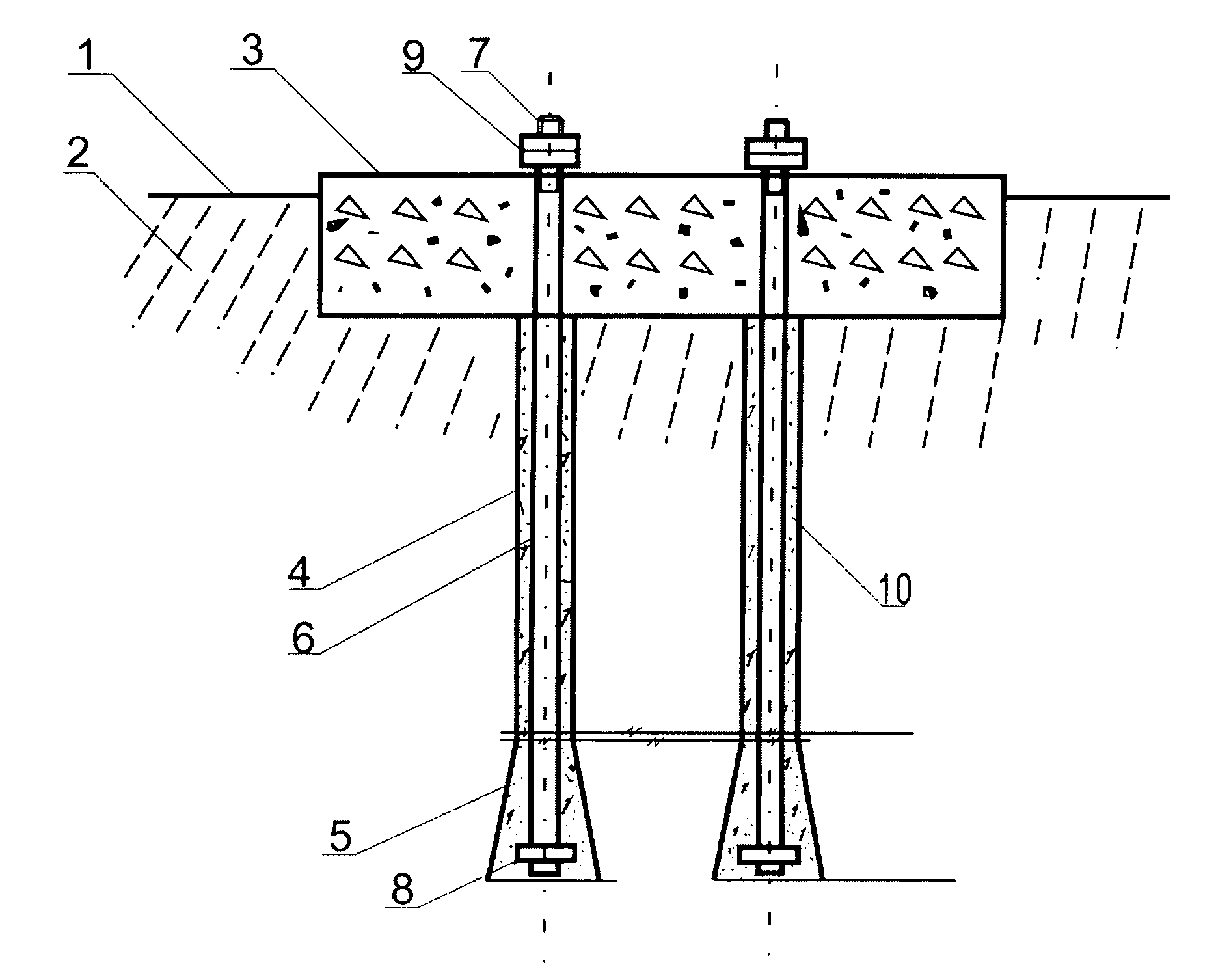

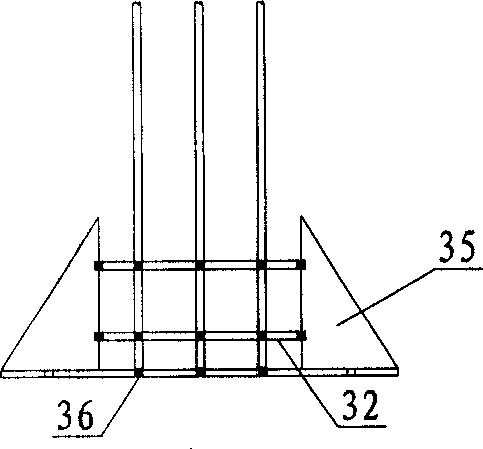

Construction process for rock enlarged toe anchor pile foundation of overhead power transmission line

The invention discloses a construction process for a rock enlarged toe anchor pile foundation of an overhead power transmission line. The construction process comprises the following steps of: (1) measuring and positioning, namely measuring a tower foot position and removing a rock surface to determine a foundation bolt base point; (2) drilling, namely drilling a straight hole at the base point by using a tubular drill until the drilling is finished, and enlarging the bottom of the straight hole by replacing a deviation bit to form a taper hole, wherein the aperture and the depth of the straight hole are determined according to the external diameter and the length of an anchor rod; the taper angle is controlled by controlling the drill bit sinking and the deviation speed; the lower bottom surface of the taper hole is coincided with the bottom of the straight hole; the taper height is determined according to the actual demand; the taper hole is coaxial with the straight hole; the upper bottom of the taper hole is the section of the straight hole; the diameter of the straight hole is 8 to 10cm more than the external diameter of the anchor rod; and the taper angle is 30 to 40 degrees; (3) placing an anchor and grouting, namely placing the anchor rod into the hole to insert a foundation nut and a part of rod body into the taper hole and grouting a CGM30 grout into the hole until the grout reaches the rim of the hole, wherein the anchor rod and the straight hole are coaxial; and (4) pouring a bearing platform, namely pouring the anchor rod which is exposed out of the straight hole into the bearing platform by using high-standard cement, wherein the foundation nut and a foundation bolt are protruded out of the surface of the bearing platform.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

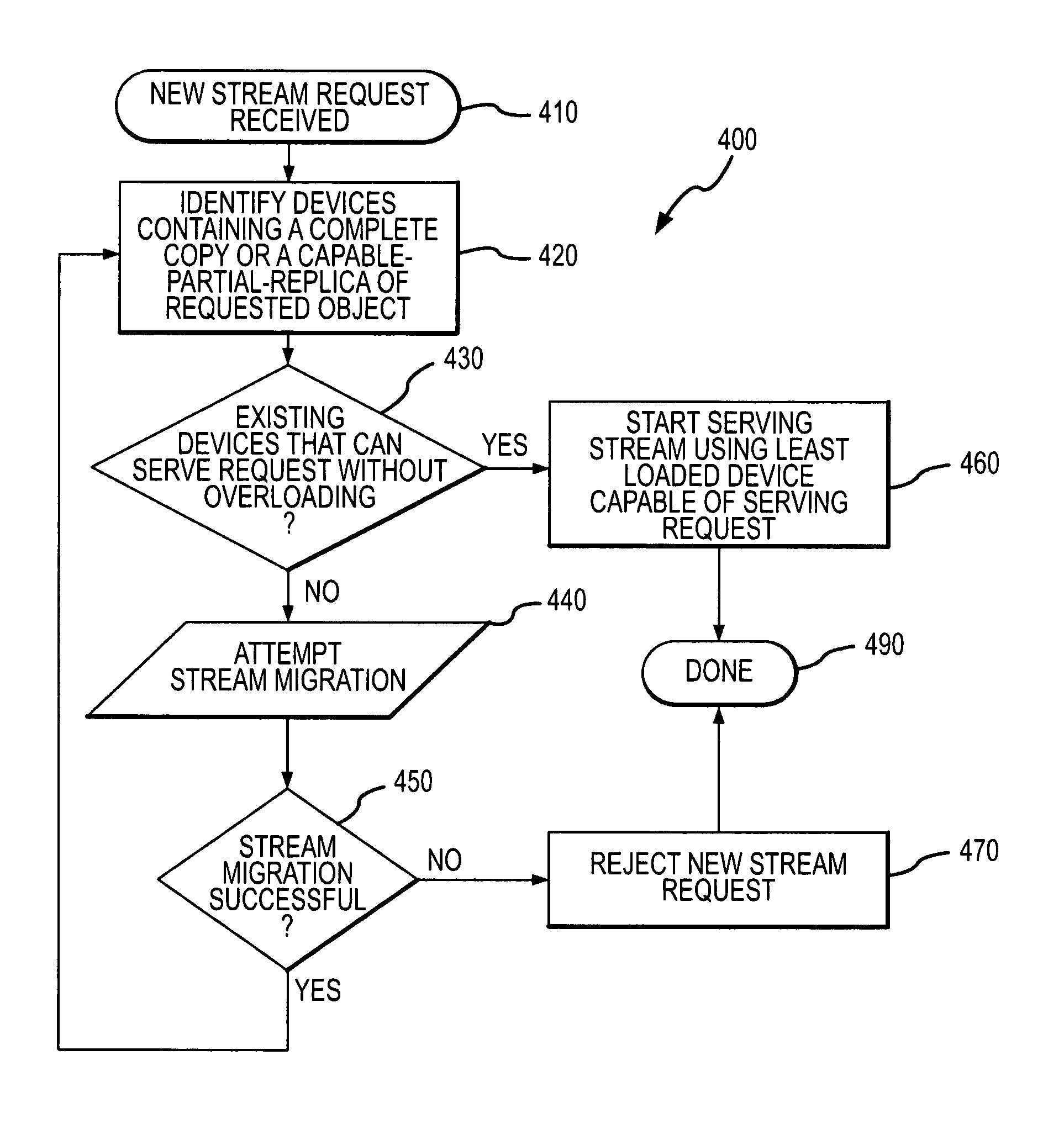

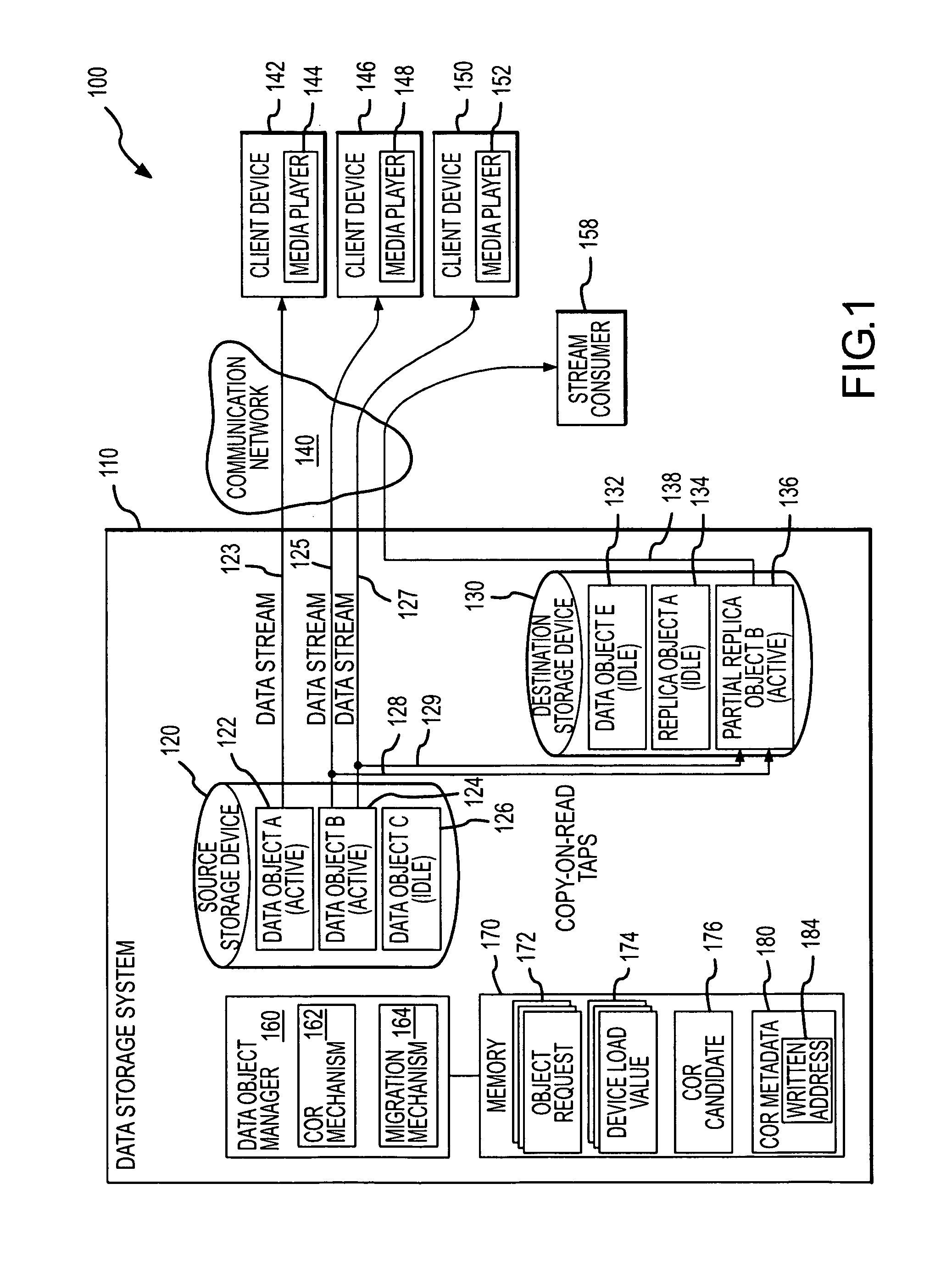

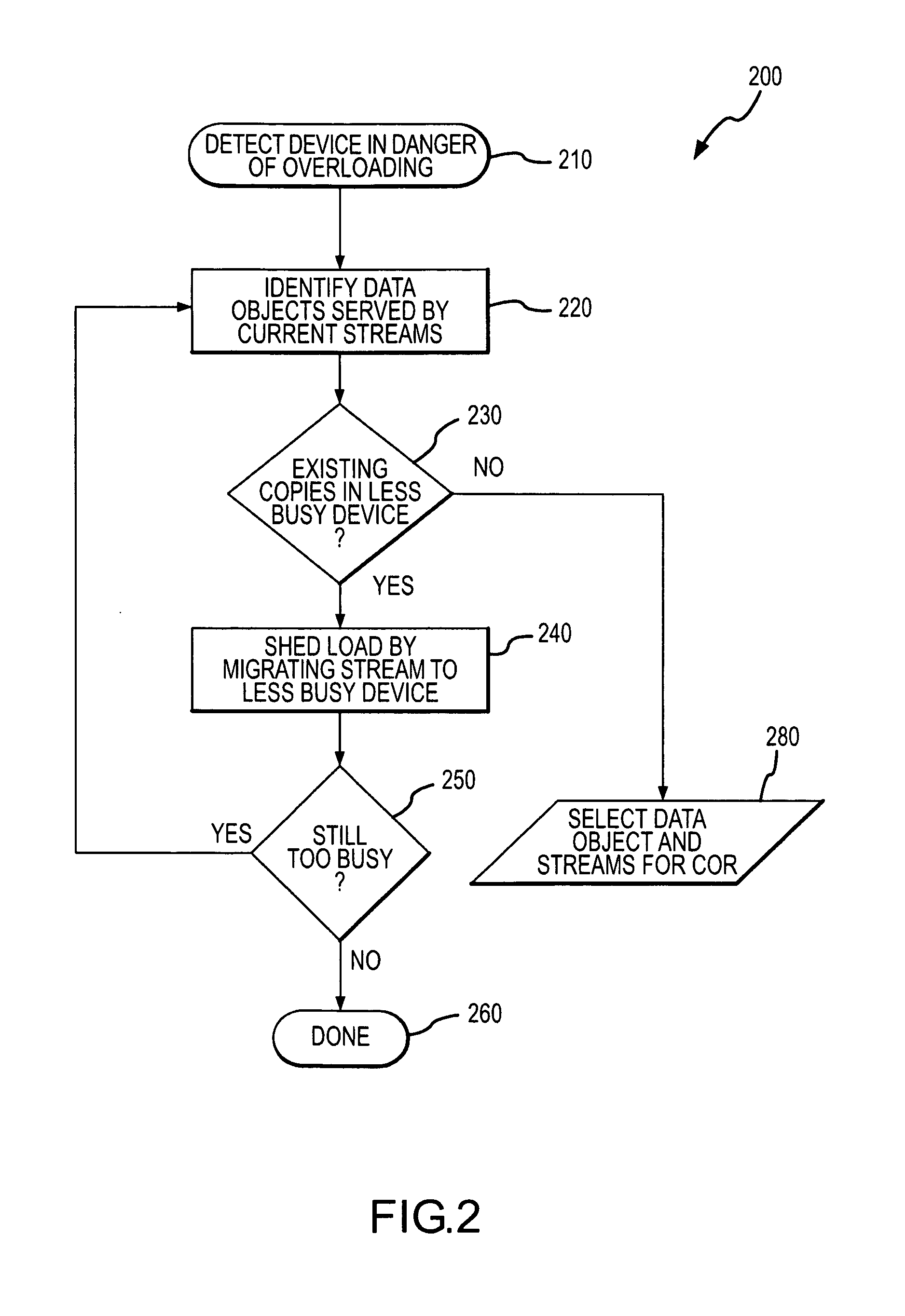

Dynamic creation of replicas of streaming data from a storage device without added load

ActiveUS8458125B1Improve writing efficiencyImprove distributionDigital data processing detailsTransmissionStreaming dataData stream

A method, and corresponding system, is provided for generating replicas or copies of data objects that are used to serve data streams. The method includes determining one of the storage devices is operating at a load above a predetermined overload value. The method continues with identifying the data objects being served by data streams from the near overload storage device and then, selecting one of these served data objects for replication. To create a replica, the method includes writing data from the selected data object to another less busy one of the data storage devices, with the writing being done using data from one or more of the streams being served from the selected data object on the near-overload storage device. During replica creation, one or more streams from the selected data object provide data concurrently to a stream consumer or client device and to the replica.

Owner:ORACLE INT CORP

Organosilicon superhydrophobic nano-composite coating, and preparation method and use thereof

ActiveCN102963087ASimple recipeImprove general performanceSynthetic resin layered productsCoatingsResin coatingOrganosilicon

The invention discloses an organosilicon superhydrophobic nano-composite coating with ultra-low inorganic powder content. The composite coating sequentially comprises a base material, an organosilicone resin coating which contains inorganic powder and serves as an inner coating, and an organosilicone resin coating which does not contain the inorganic powder and serves as an outer coating, or the composite coating sequentially comprises the base material, an organosilicone resin coating which does not contain the inorganic powder and serves as the inner coating and an organosilicone resin coating which contains the inorganic powder and serves as the outer coating. A method for forming the coating on the base material by a two-step coating method is also provided by the invention. The composite coating provided by the invention can be used for long-term hydrophobisation, ice prevention and weather resistance in the fields of inner and outer walls of outdoor buildings, automobile bodies, ship bodies, various pipelines, electric and electronic devices, toys, plastic products, glass products and the like. The preparation method provided by the invention has the advantages of simple process, short flow, strong generality, strong environmental suitability and the like, and is easy to construct.

Owner:STATE GRID CHONGQING ELECTRIC POWER +1

Integral assembling type building system and installing method

InactiveCN105649360AImprove quality controlEasy to installBuilding material handlingDwelling buildingTime of usePrecast concrete

The invention belongs to the technical field of building engineering and particularly relates to an integral assembling type building system and an installing method. The integral assembling type building system is characterized by comprising prefabricated steel reinforced concrete combination columns, prefabricated steel reinforced concrete combination beams, prefabricated reinforced concrete slabs, a prefabricated light integral inner wall and a prefabricated concrete heat preservation outer wall which are assembled together. The building system has the beneficial effects that all the members are prefabricated in a factory, quality is controlled conveniently, and the construction difficulty caused by outdoor weather changes can be reduced. Moreover, splicing is carried out on site, and installing is safe, fast and convenient. The recycle rate of formworks is high, work for the formworks and frame pipes on site is avoided, the number of times of use and consumption of the formworks and frame pipes are reduced, on-site labor is saved, the on-site dust raise phenomenon is improved substantially, the influence on the environment is small, and environmental pollution is reduced.

Owner:SHANDONG YUANBO BUILDING TECH CO LTD

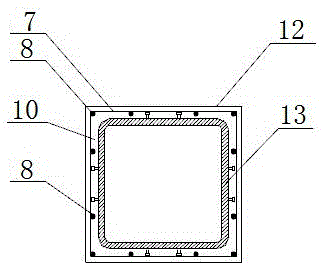

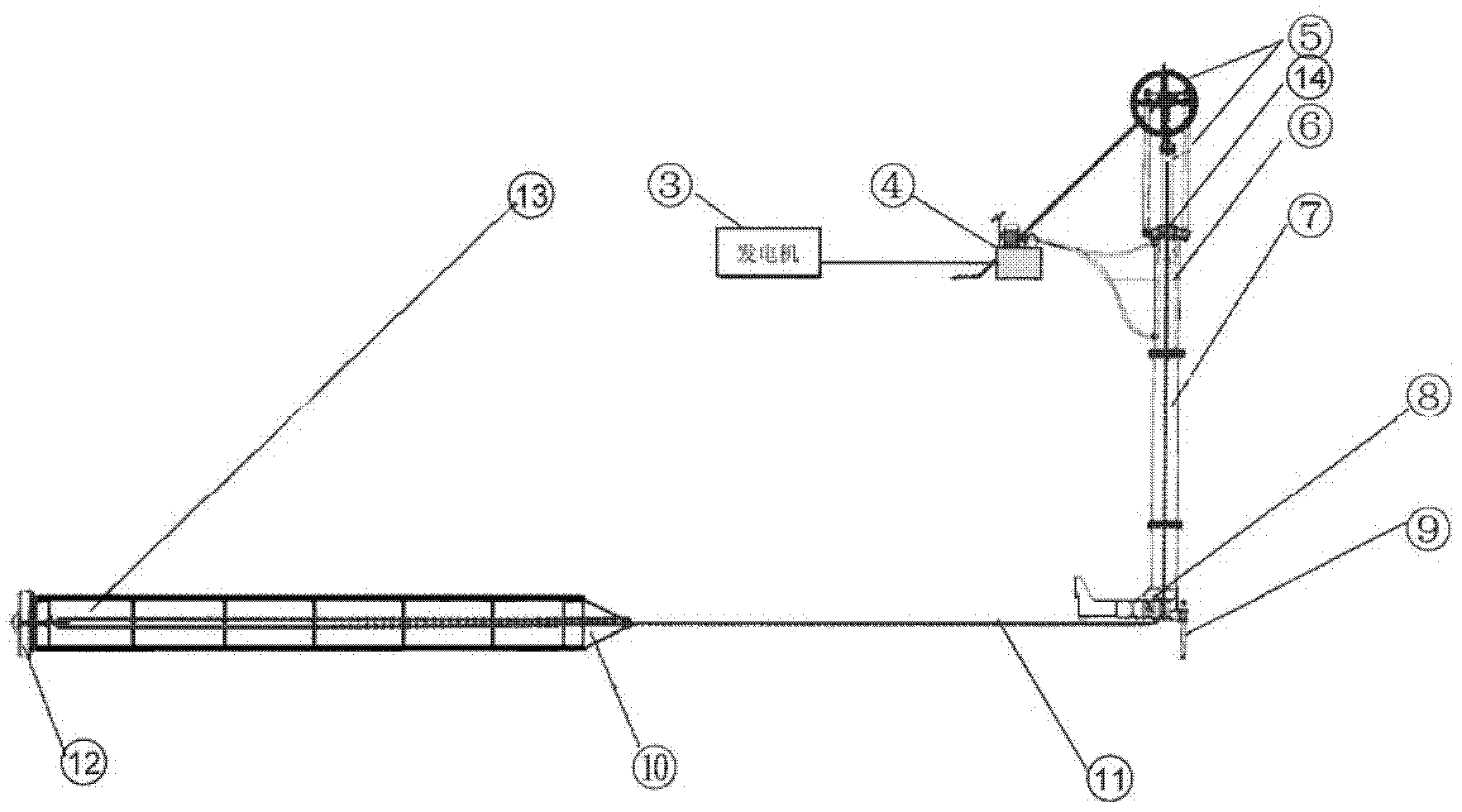

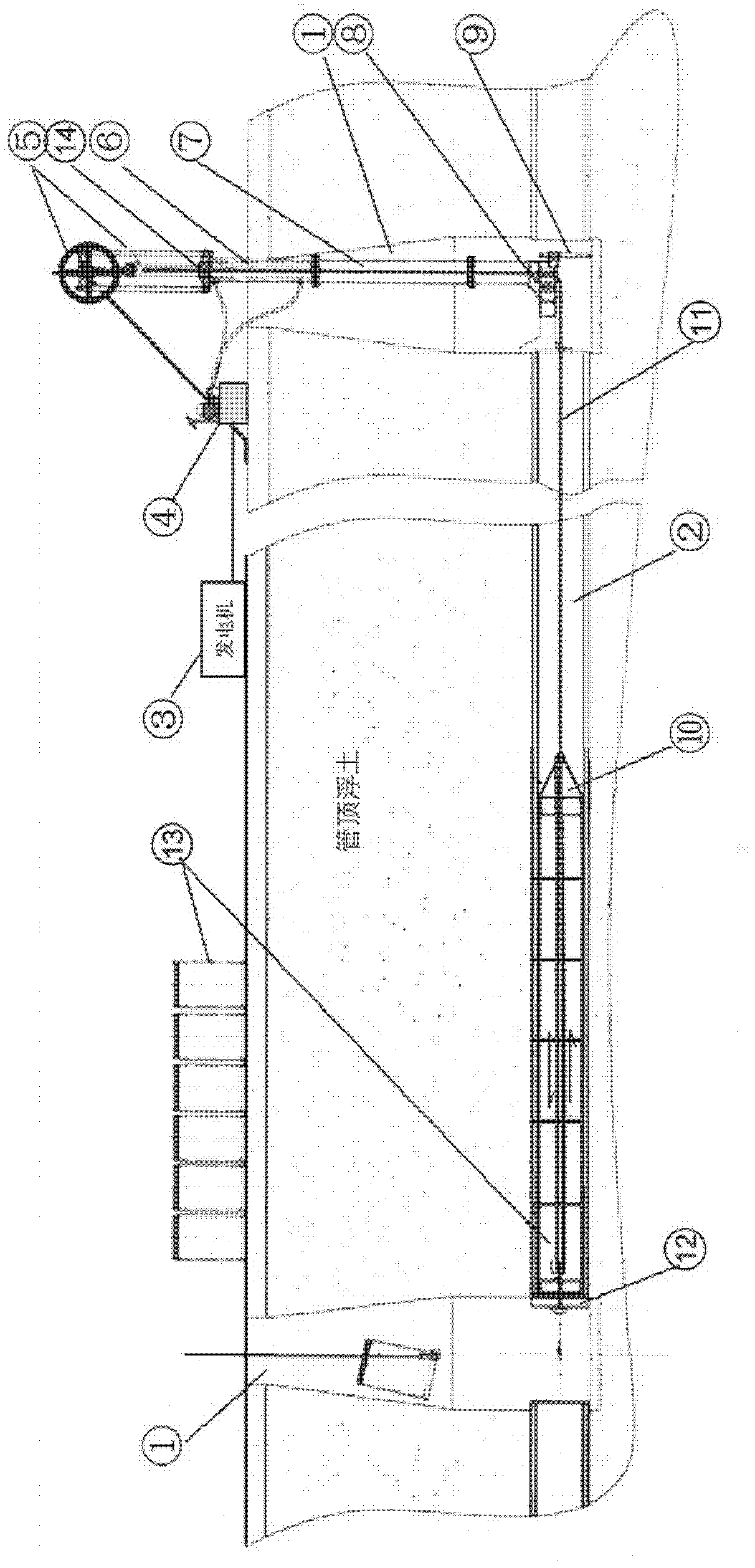

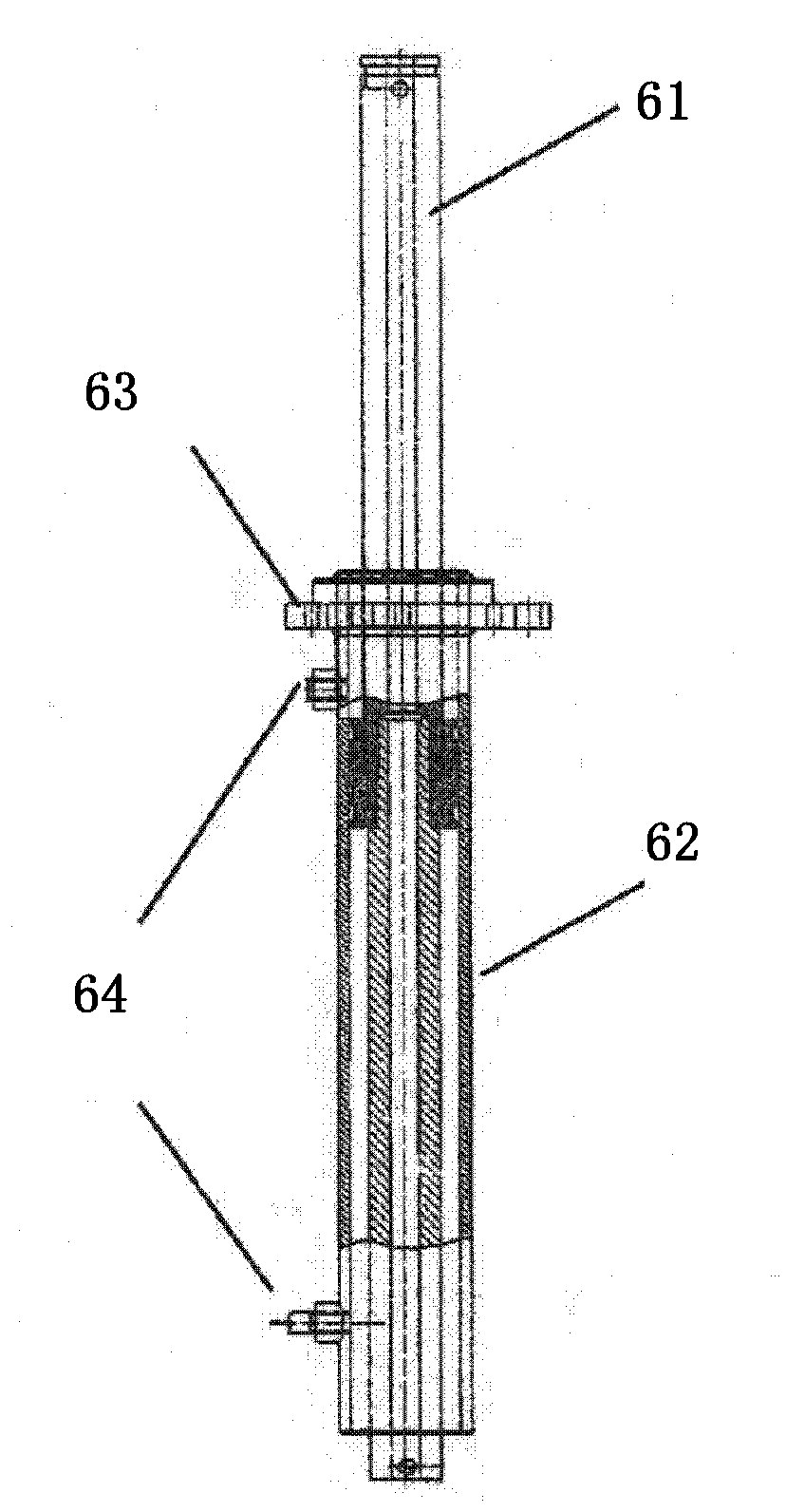

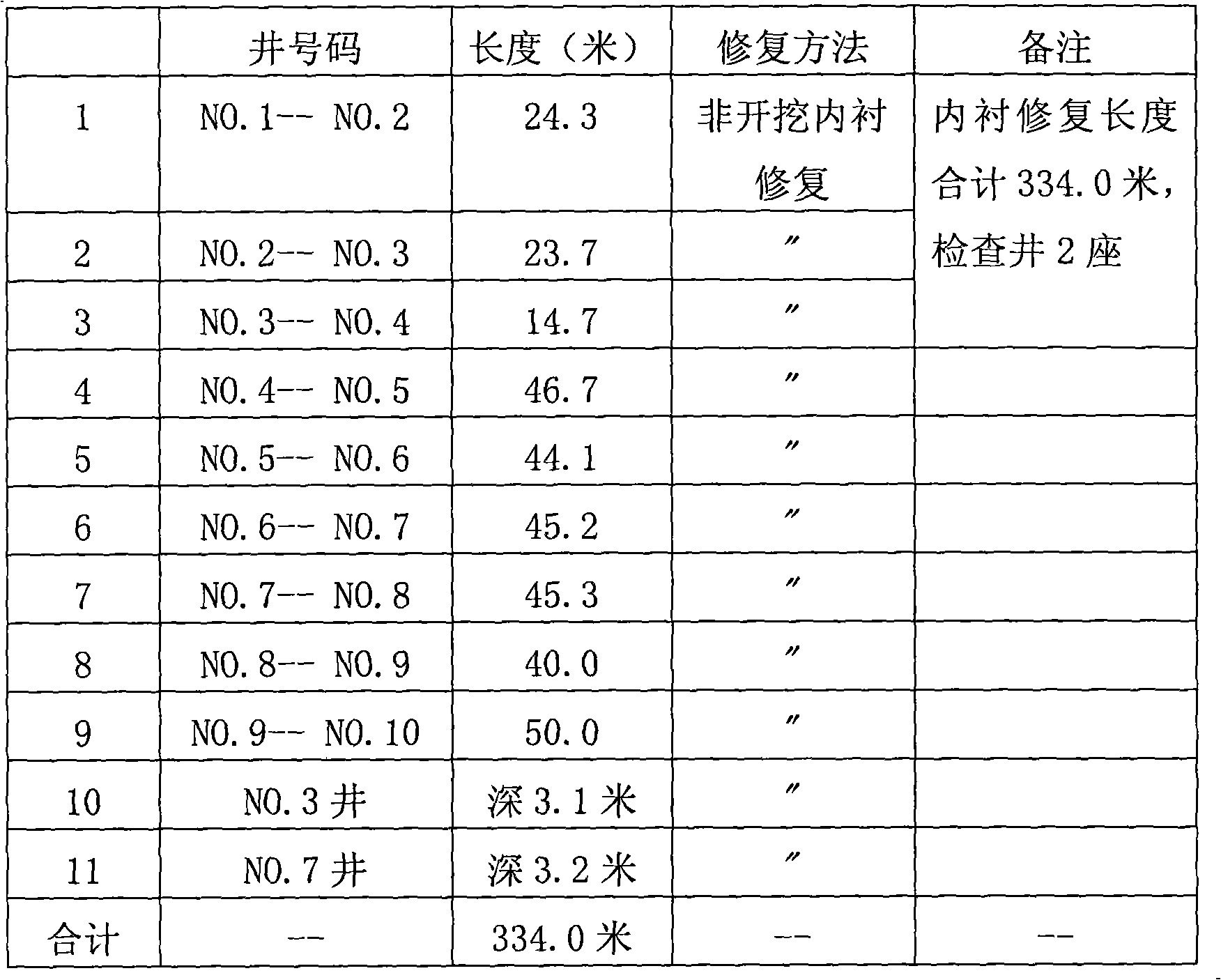

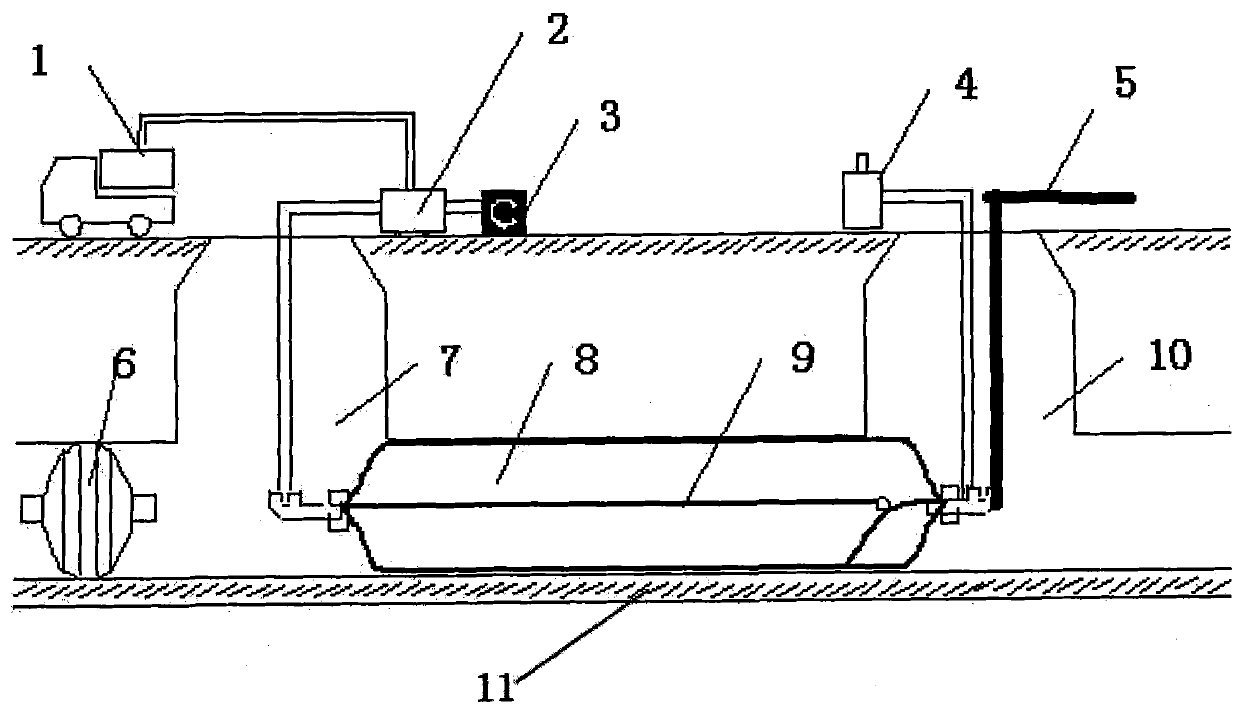

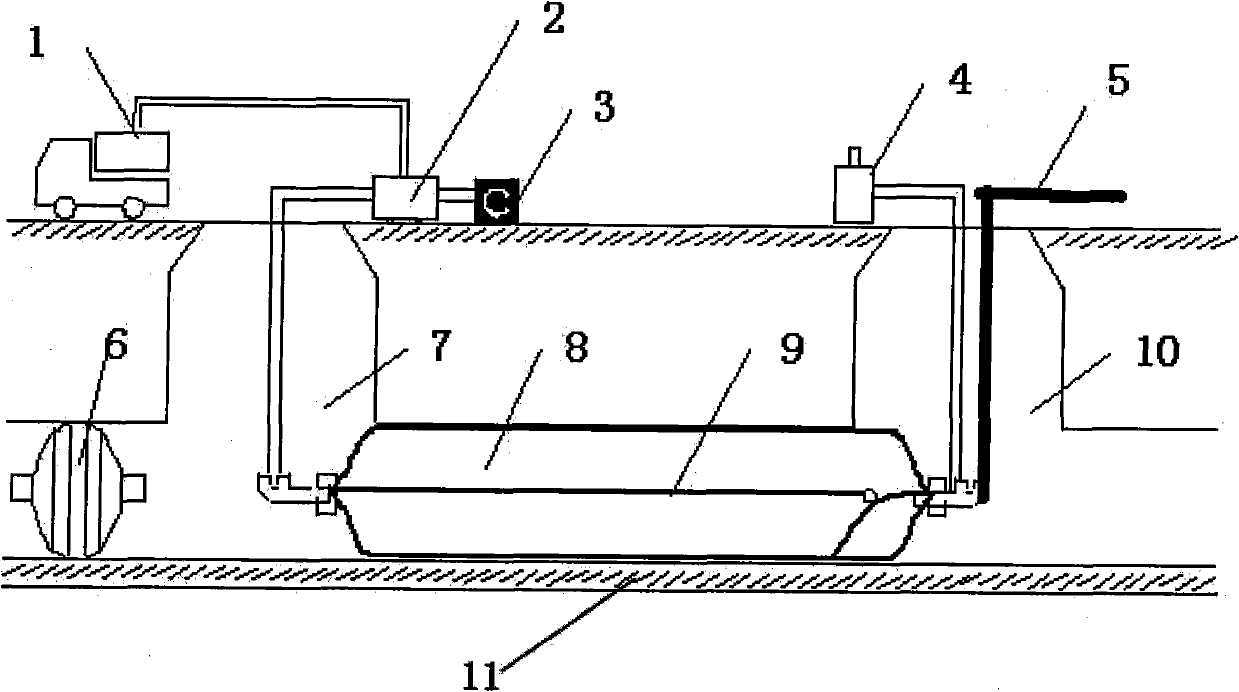

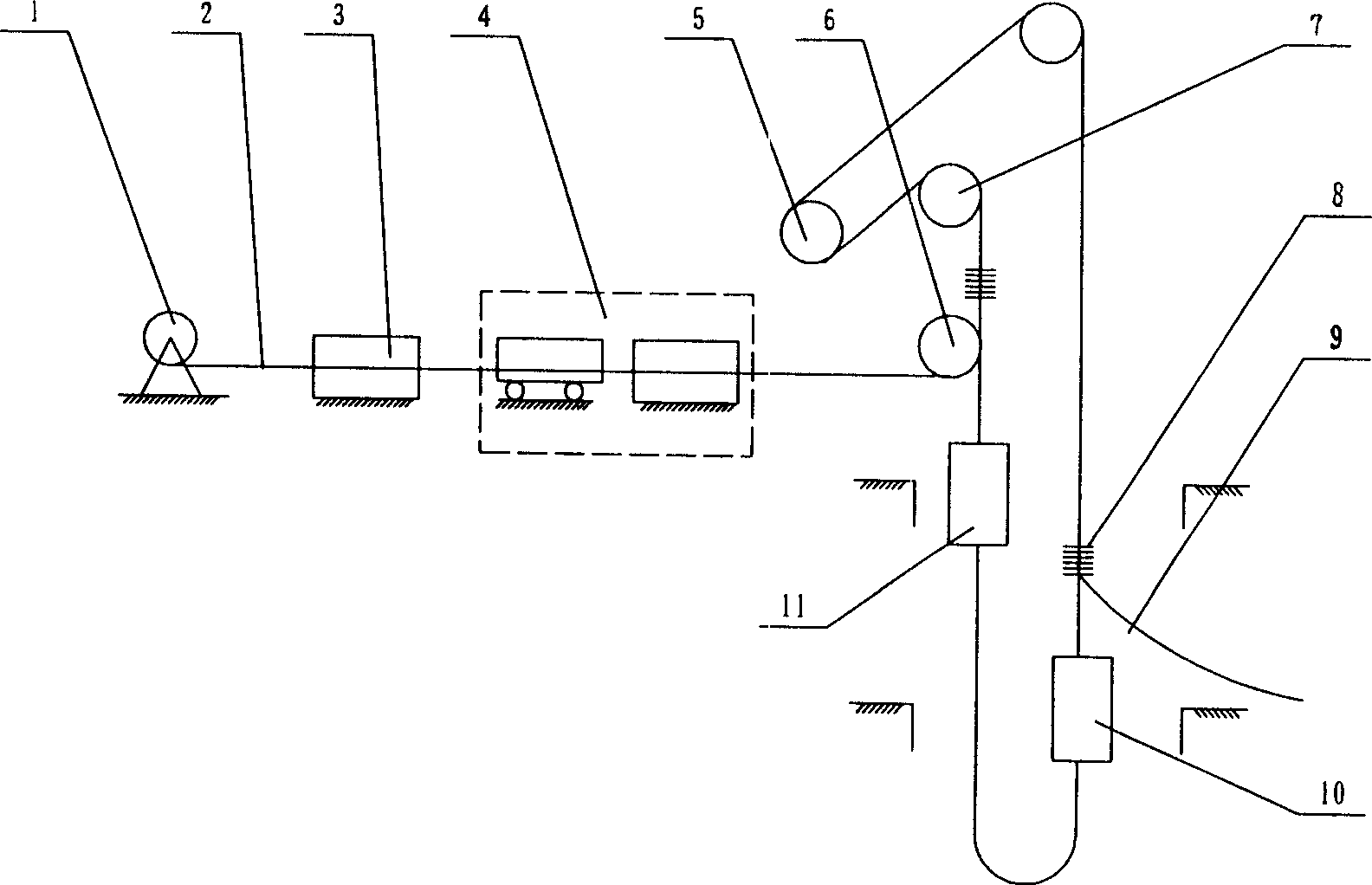

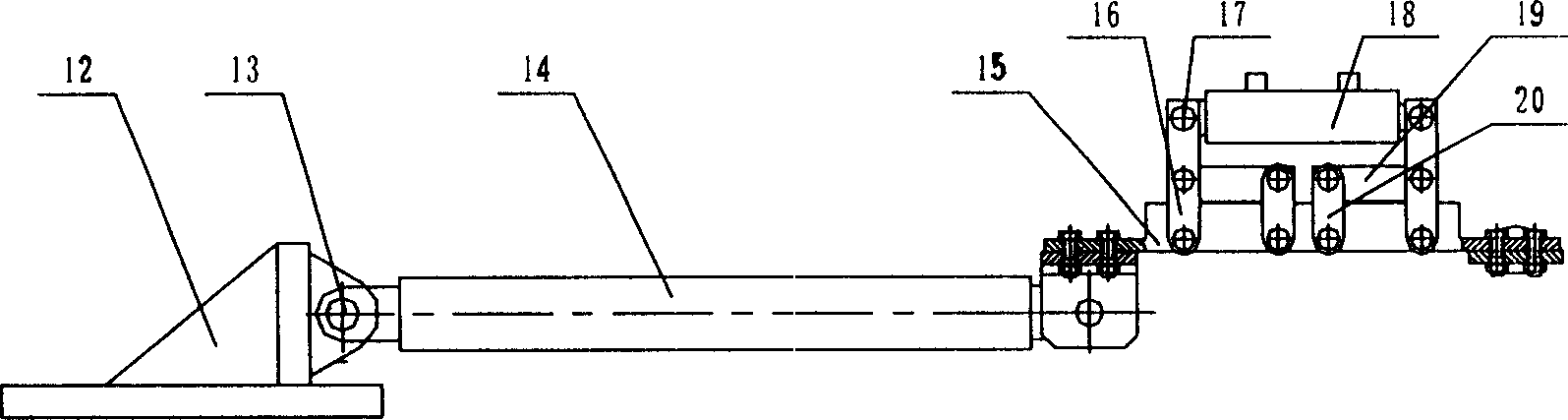

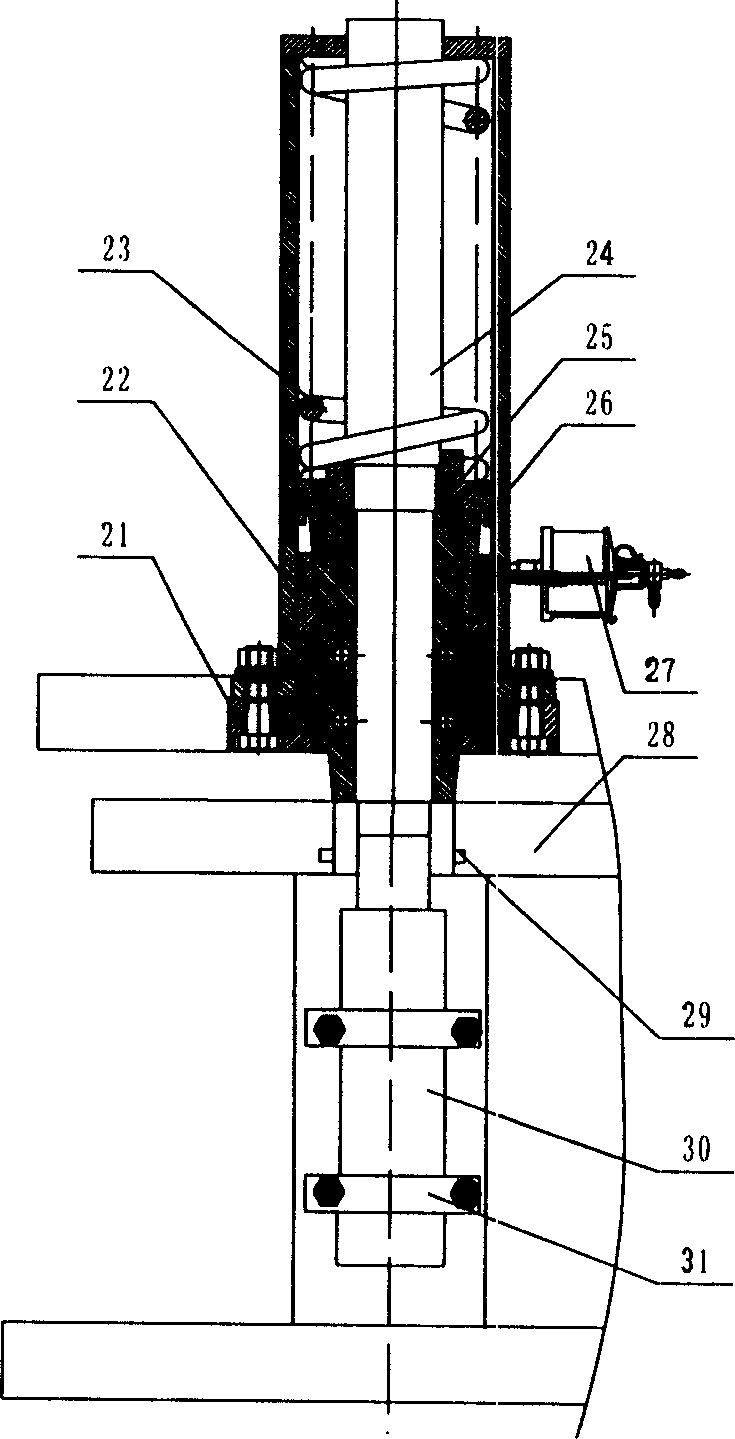

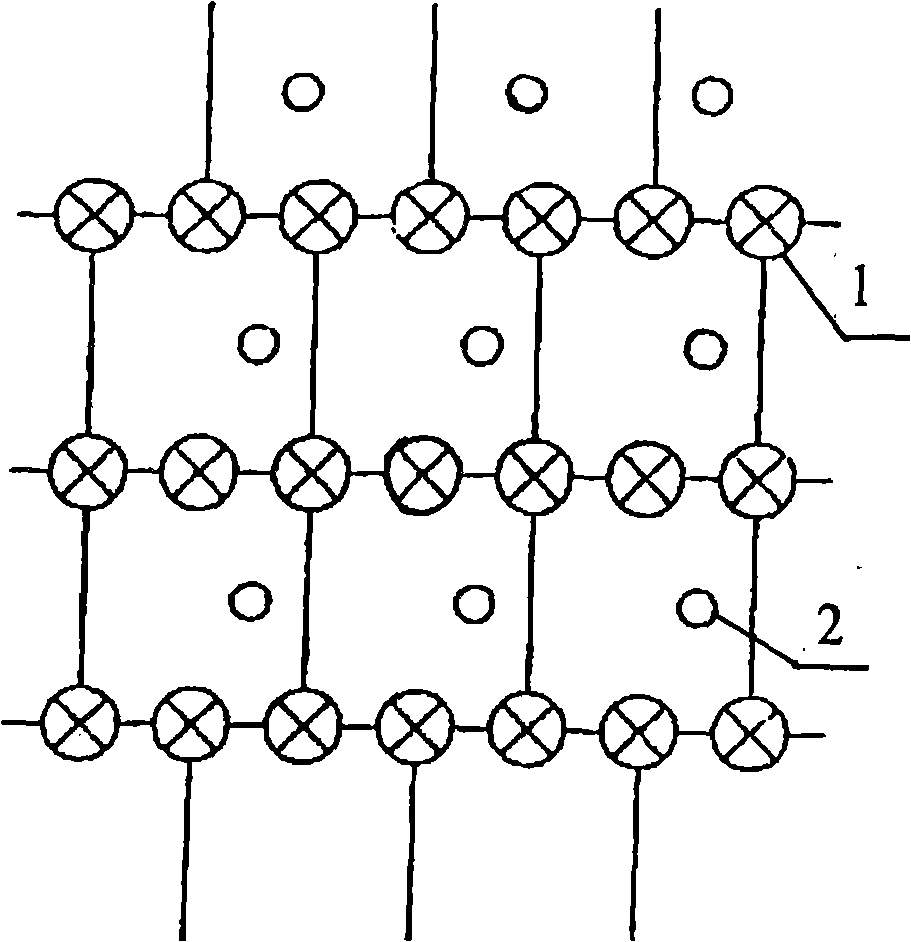

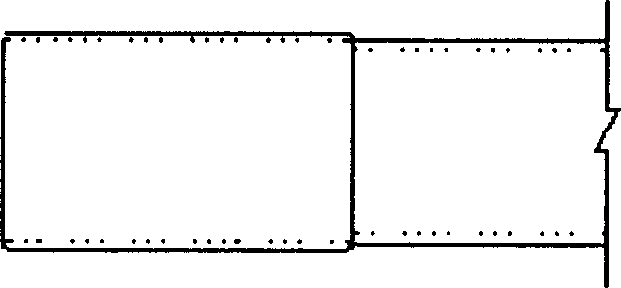

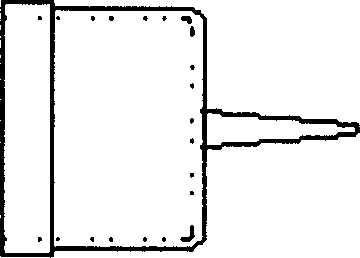

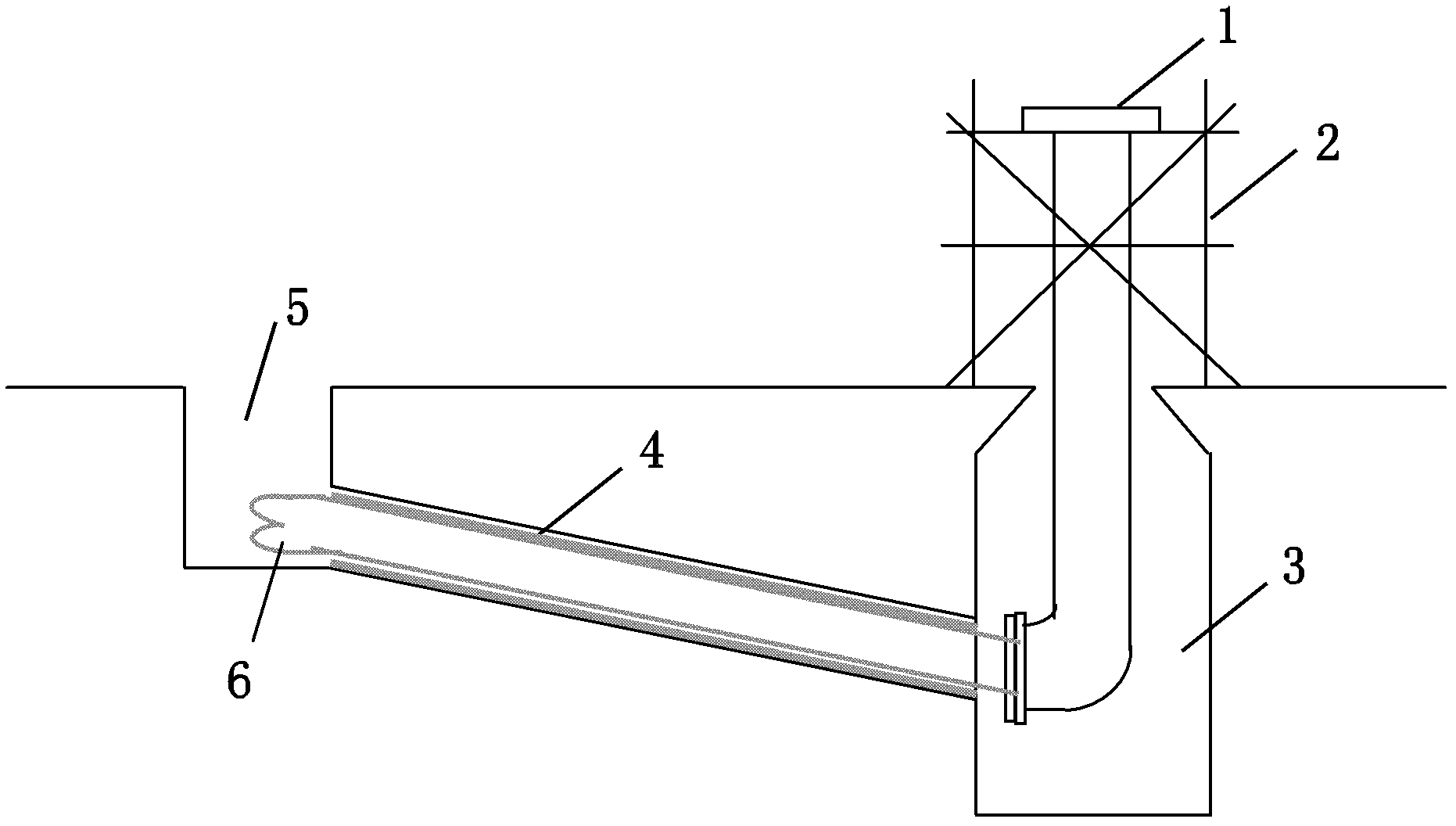

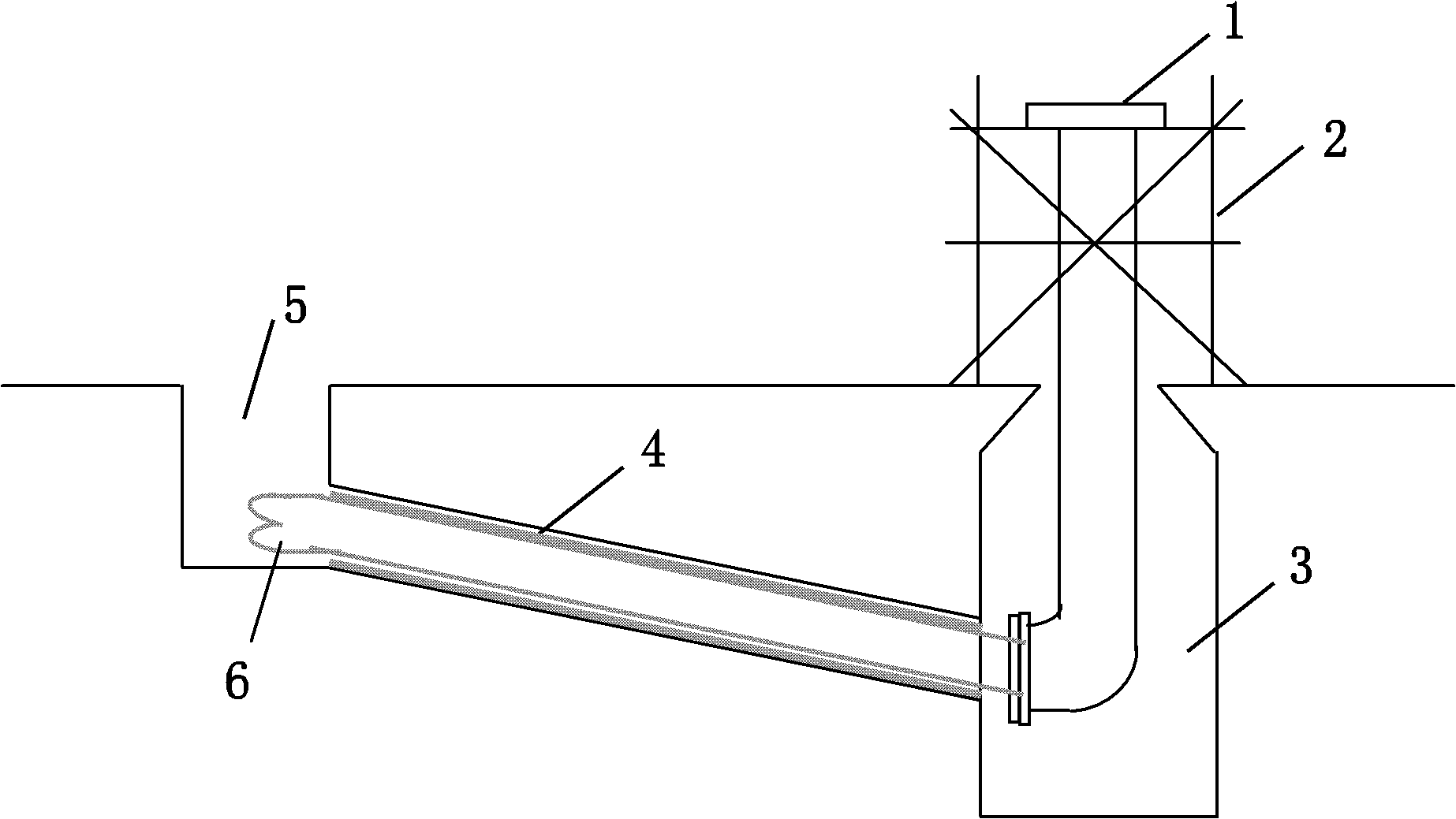

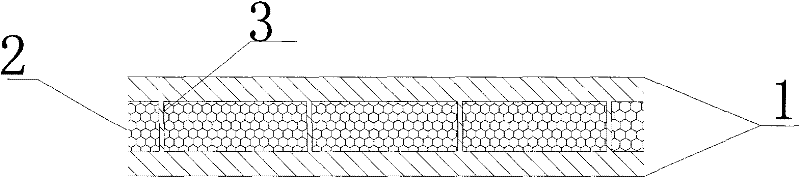

Trenchless built-in sleeve pipeline repairing equipment and method

ActiveCN102518907AShort construction timeReduce project costPipe elementsEngineeringTrenchless technology

The invention discloses a trenchless built-in sleeve pipeline repairing method and equipment. The method includes utilizing two adjacent inspection shafts as operation space under the condition that the road surface is not excavated, adopting a pipeline to be repaired as a carrier, conveying short pipes into the pipeline to be repaired, dragging the short pipes to advance via a traction device, gradually completing hitting combination and connection between a latter short pipe and a former short pipe in an advancing process, realizing assembly of the short pipes in the pipeline to be repaired and finally forming a new pipeline; and then filling a gap between the new pipeline and the pipeline to be repaired in a grouting manner, leading the sleeved-in new pipeline to be stabilized and to be closely combined with the pipeline to be repaired to realize common pressure resistance strength, and accordingly realizing repair to the pipeline to be repaired. The equipment comprises a mechanical traction system and a hydraulic power system. The trenchless built-in sleeve pipeline repairing method and the equipment completely realize the trenchless technology, and have the advantages that continuousness is realized when the pipeline to be repaired crosses a road, construction time is short, engineering comprehensive manufacturing cost is low, influence to traffic is quite low, and the like.

Owner:北京创安亚非开挖工程技术有限公司 +1

Construction method for mine shaft through multilayer goaf

ActiveCN102071940AShorten the construction periodCompletely closedUnderground miningSurface miningSpontaneous combustionBedrock

The invention particularly discloses a construction method for a mine shaft through multilayer goaf, which solves the problem of blankness of the construction method for the conventional mine shaft through goaf. The method comprises the following steps that: 1) the ground and the underground space of the goaf are detected; 2) mechanical analysis is performed on a rock stratum of the goaf; 3) a goaf filling range and filler mechanical property are determined; 4) bedrock is tunneled; 5) a related underground chamber which is integrally connected with a shaft is constructed; and 6) the goaf is filled and reinforced. The construction method fills the blank of the construction method for the shaft through goaf; back filling injection, filling and reinforcing technology is used during the construction of a through goaf of a vertical shaft; the construction method has an advanced, economic and rational technology; the goaf can be completely closed; return current is prevented from entering the goaf, so a coal seam of the goaf has a tendency to spontaneous combustion; thus safe and reliable use of the shaft is guaranteed.

Owner:DATONG COAL MINE GRP

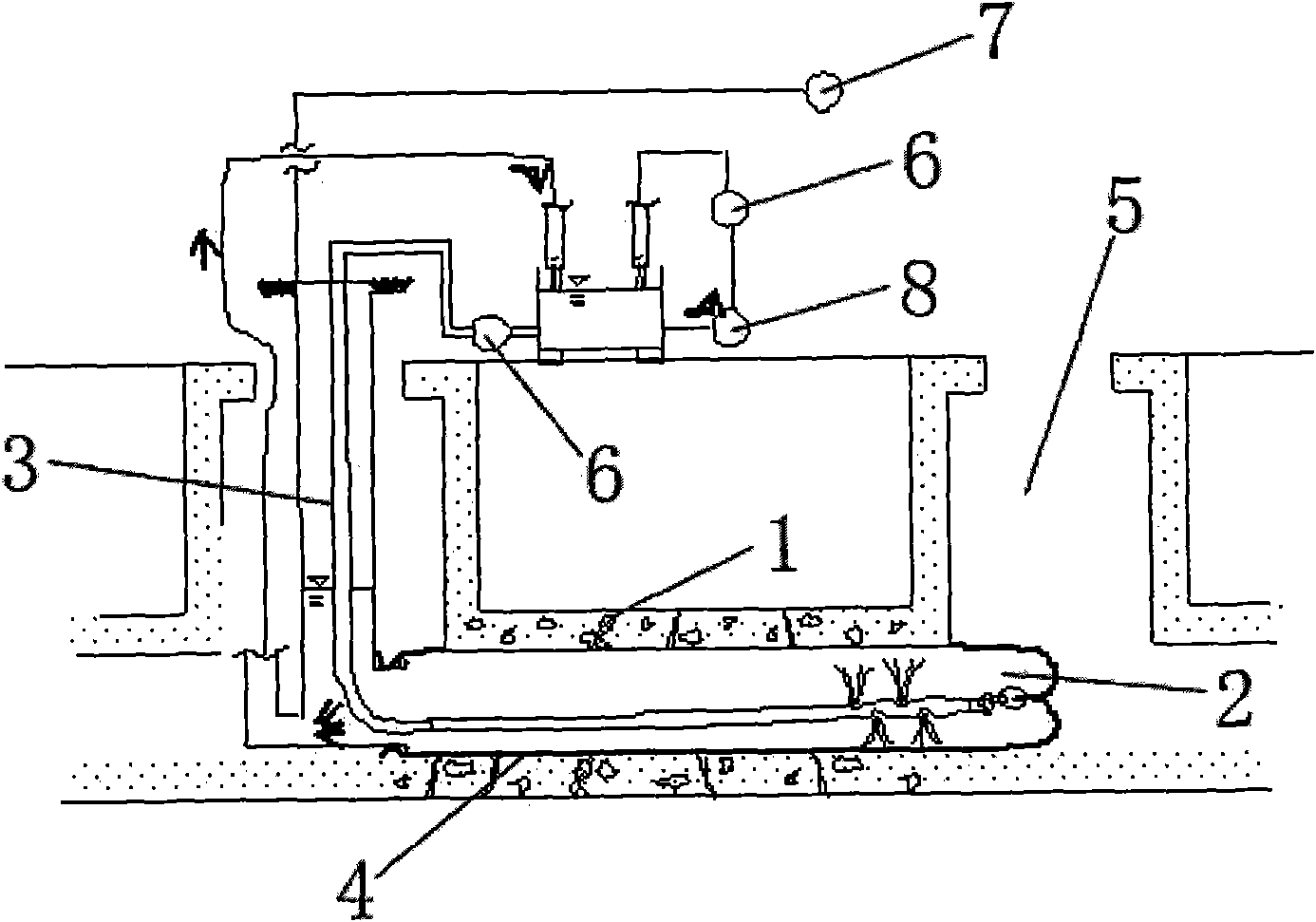

Method for repairing underground pipeline without digging

InactiveCN101649944AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a method for repairing an underground pipeline without digging, which comprises the following steps: (1) blocking and cleaning an old sewage pipeline needing repair and usingclosed circuit TV system (CCTV) equipment to detect the inner part of the pipeline; (2) delivering a waterproof barrel-shaped auxiliary lining hose pipe into the pipeline and injecting thermosetting resin to form a resin hose pipe; (3) turning over and inserting the resin hose pipe and a warm water delivery pipe for heating into the waterproof barrel-shaped auxiliary lining hose pipe; (4) expanding the resin hose pipe with water and compressed air so that the resin hose pipe is tightly attached to the inner wall of an old pipe, circularly heating by warm water and hardening and molding the thermosetting resin hose pipe so that the inner wall of the old pipe forms a new lining pipe with high strength; (5) opening pipe openings at both ends of the new lining pipe by cutting to smooth the pipeline; and (6) cutting at the extending positions of the pipe openings of the new lining pipe, which are positioned in the well wall of a check well. The method can prevent leakage, protect the pipe openings, prevent the thermosetting resin injected into the lining hose pipe from being mixed with underground water and prevent a poor phenomenon of lining material part hardening.

Owner:管丽环境技术(上海)有限公司 +1

Trenchless repairing method of underground pipeline with drawing-type liner pipe

InactiveCN101907213AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a trenchless repairing method of an underground pipeline with a drawing-type liner pipe. The method comprises the following steps of: (1) blocking and cleaning a worn sewage pipeline and detecting the interior of the pipeline; (2) drawing a watertight cylindrical auxiliary liner hose in the worn pipeline, preliminarily impregnating thermosetting resin in a non-woven hose to form a resin hose and well turning the resin hose; (3) drawing the well-turned resin hose and a warm water conveying pipe for heating in the watertight cylindrical auxiliary liner hose which is already arranged in the worn pipeline; and (4) expanding the resin hose by adopting compression air to tightly attach to the worn pipe, directly adding hot water to the resin hose to harden and form the thermosetting resin hose in the worn pipe and forming a new high-strength liner pipe on the inner wall of the worn pipe. The invention solves limitation caused by a construction site when repairing an underground pipeline through liner by using a turning method, solves the problem of uneven resin curing strength, simplifies the process flows of on-site construction and has the advantages of easy and simple operation, time saving and damage resistance.

Owner:管丽环境技术(上海)有限公司 +1

Fast rope changing device of floor type multirope friction elerator

A quick replacement of multi-cable friction elevator achieves reducing of replacement time and labor intensity, and fsafety. Its apparatus consists of a stepped replacing mechansm, a cable-off preventing unit, and an automatic monitor. The stepped replacing mechansm comprises a stepping cylinder, a clamp, and a basement. The cable-off preventing unit comprises a sleeve, a cable going-through unit, a press cap, a wedge, a spring and a spring base, a hydraulic cylinder, an installing rack, pins, U-shaped clips, needle oil cups, and H-shape steel. The automatic monitor comprises a pressure monitoring alarm which includes an A / D converter, a pressure sensor, PLC, relays, and pressure modules, and a cable-off monitoring alarm which includes a tachogenerator, solenoid valves, an A / D converter, PLC and relays.

Owner:山西潞安矿业(集团)有限责任公司常村煤矿 +1

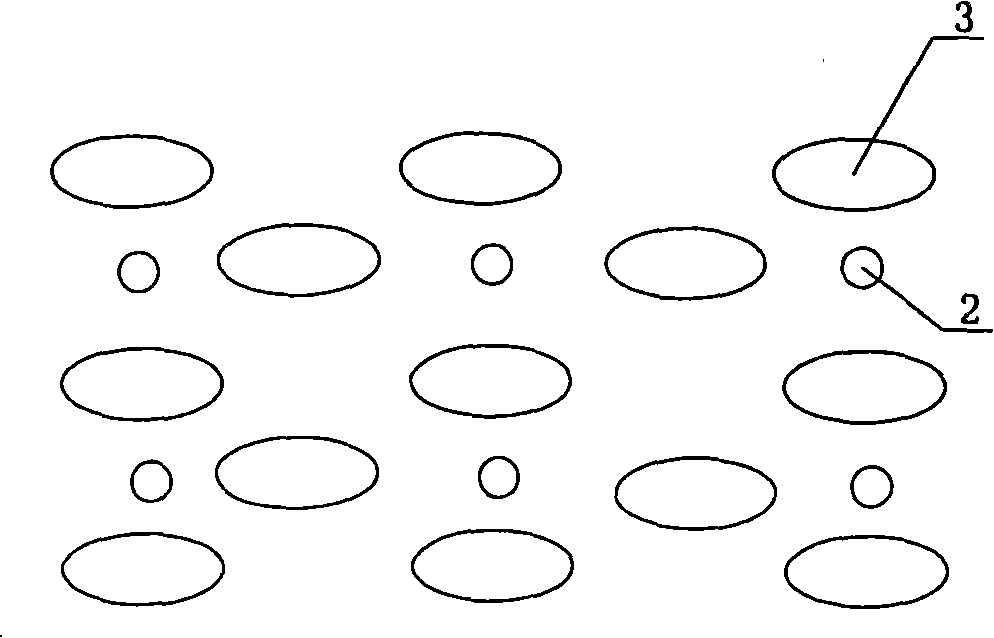

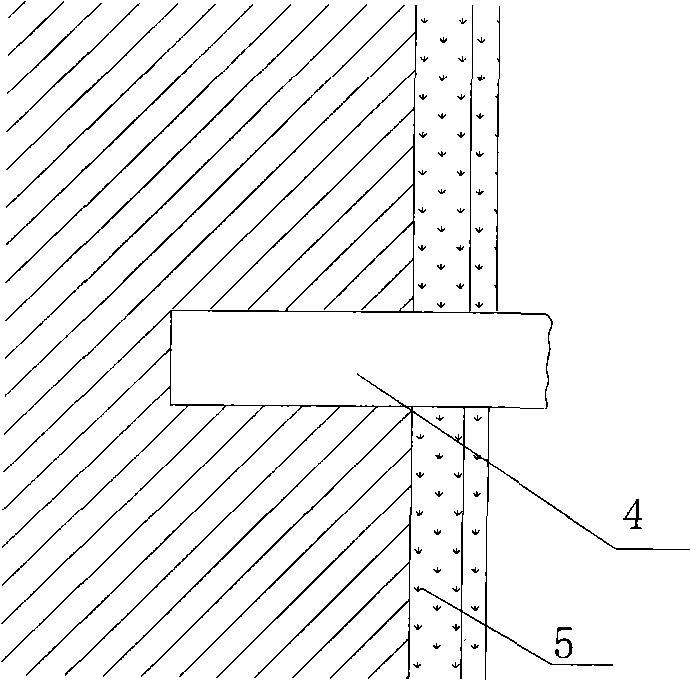

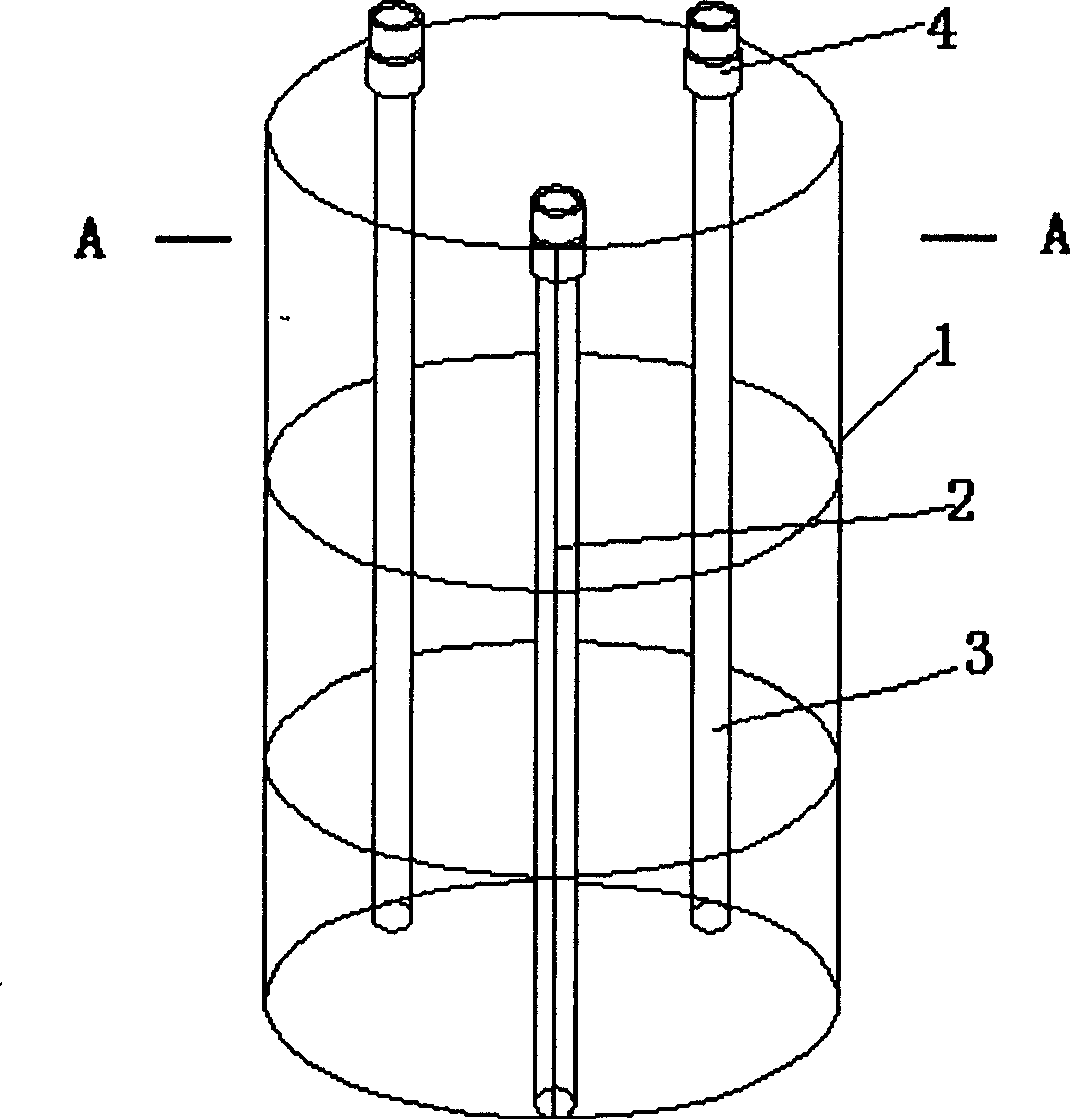

Blast furnace pressing-in grouting and lining-making construction method

InactiveCN101289698AGuarantee normal productionImprove maintenance efficiencyBlast furnace componentsBlast furnace detailsSlurryMaterials science

A blast furnace pressing-in grouting lining making construction method comprises the following: a first step of drilling grouting holes (2) in a furnace casing (5) of the damaged part of the blast furnace, inserting a grouting short pipe (4) with a valve (9) into each hole, and then welding the grouting short pipe (4) and the furnace casing (5) together; a second step of butting the output pipe of a pulp press and the grouting short pipe with the valve (9) on the furnace casing together; a third step of pressing stirred slurry (12) into the blast furnace through the pulp press, after reaching the preset slurry amount, the pulp press stopping pressing, opening the feedback valve of the pulp press, and then disassembling an output pipe (8) of the pulp press from the grouting short pipe (4) after closing the valve (9) of the grouting short pipe (4); a fourth step of circulating the second step until grouting is finished for all grouting holes. The blast furnace pressing-in grouting lining making construction method not only improves the efficiency and quality of blast furnace maintenance but also achieves good maintenance effect under both the delay status of the blast furnace and the non-delay status of the blast furnace.

Owner:WUHAN HONGCHENG METALLURGICAL MATERIAL

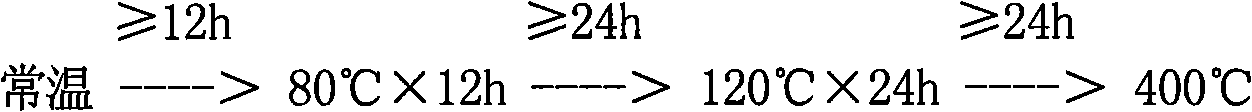

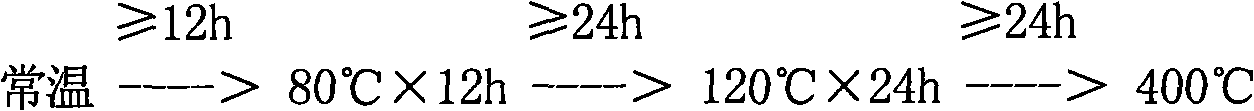

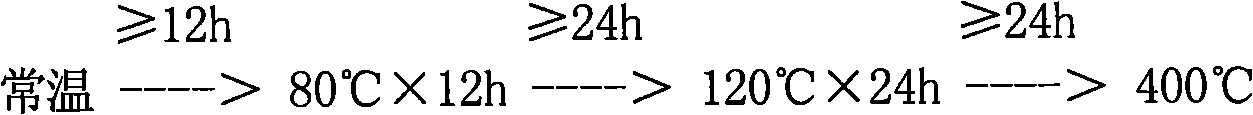

Spray repair method for lining of kiln firebrick

ActiveCN101660869AExtended service lifeGood cavitation environmentLinings repairChemical industryHigh pressure

The invention mainly relates to a spray repair method for the lining of a kiln firebrick in smelting and chemical industries and the like, comprising technical processes such as scene pretreatment, spray repair, maintaining and scene heat treatment. Aiming at the damaged firebrick linings of inner walls of a roasting kiln, a sulfur kiln and a waste heat boiler in smelting and chemical industries and the like, powder-shaped high temperature fireproof material is sent to a spray pipe by directly utilizing an air compressor and an injector and then sprayed on the firebrick or a steel board needing repairing by high pressure after mixed with a certain proportion of water in a transfer piping. The method is a recovery repair technology, and is characterized in that thorough repair treatment canbe carried out on line as long as the spraying pipe can be stretched to the position needing repairing in the premise of no need for removing or bricking again; and the method has simple and effective procedure, short construction time and low repair cost, thereby effectively repairing the firebrick lining dropping from the inner part of the kiln, prolonging the service life of the kiln and guaranteeing long-term normal operation of equipment.

Owner:甘肃中顺石化工程装备有限公司

Construction method for installing plastic sounding pipe

ActiveCN1755016ASimple construction processImprove construction qualityFoundation testingBulkheads/pilesEngineeringRebar

The invention discloses a construction method of plastic acoustic pipe fixation, which comprises the following steps: first, connecting the plastic acoustic pipe as long as reinforcement cage with the major steel of reinforcement cage; second, connecting the roll end with the last acoustic pipe end and one end of joining member with the other end of acoustic pipe by binder; then, dragging the drilling; putting down the reinforcement cage; injecting water in the acoustic pipe; putting down the second reinforcement cage in connection with the former cage; connecting the acoustic pipe with the inner acoustic pipe of previous reinforcement cage by joining member and binder; filling the acoustic pipe with clean water until the last pipe according to the analogy; binding the roll end and the top of acoustic pipe by binder; finally, casting concrete. This method has the following characteristics: simple construction process; low strength construction for workers; low cost and so on, which can be set in the filling plastic acoustic pipe.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

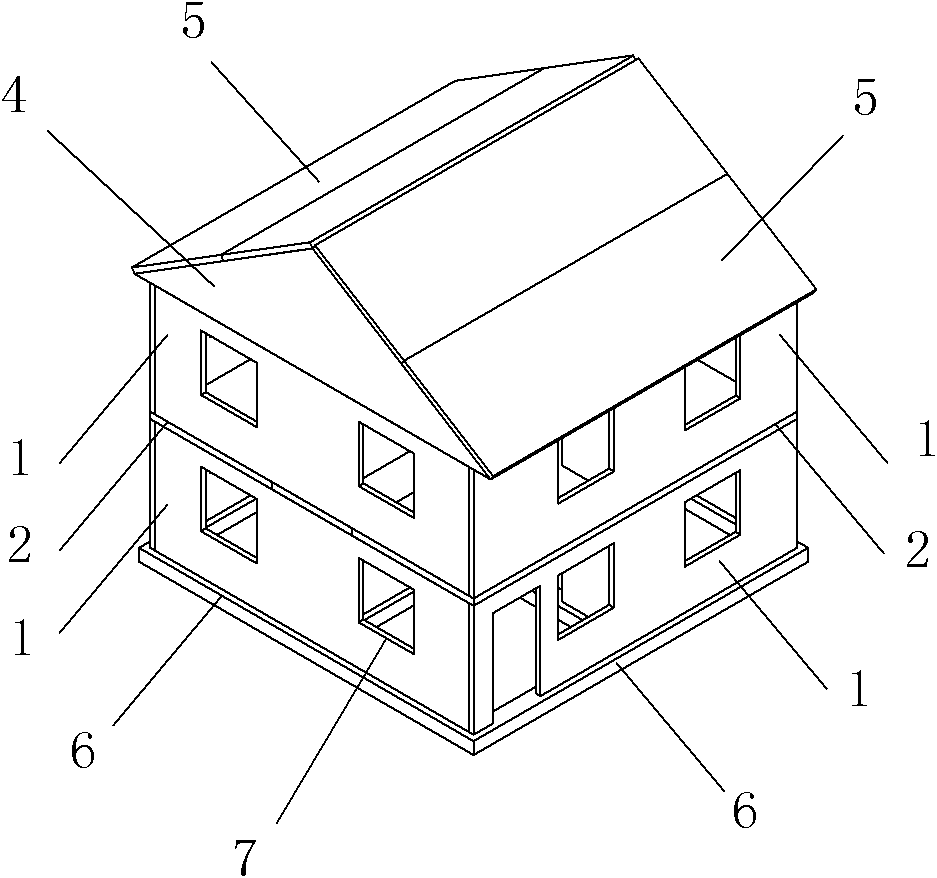

Energy Saving House

An energy-saving house, has a main frame, an enclosed wall, a floor cover plate, a top cover plate, a separation wall, a bathroom, and stairs. The enclosed wall is assembled from multiple integral composite prefabricated external wallboards and fixed on the main frame via an energy-dissipating connector. The bathroom and the stair are integrally prefabricated and directly installed. The energy-saving house features low power consumption, high construction efficiency, short construction time, low noise, low dust, light weight, good anti-seismic performance, and small thermal conductivity and is applicable to multi-floor houses and high rise buildings.

Owner:HUANG ZHENXI

Compensation method for roadbed settlement

InactiveCN102322008AShort construction timeLittle traffic disturbanceRoadwaysArchitectural engineeringRoad surface

The invention provides a compensation method for roadbed settlement, which comprises the steps that: when in a roadbed construction process, on a road section which can easily settle and deform after being open to traffic, when a roadbed is filled to a height which is 30cm to 200cm from the top surface, retaining walls are built on both sides of the roadbed; bagged lime is uniformly paved on the inner sides of the retaining walls within the full-width range of the roadbed on different layers; a rubber pipe is pre-reserved on each lime bag to the outer side of the roadbed as a water injection channel in a later period; the bottom surfaces of the retaining walls are 20cm to 100cm lower than the bottom surfaces which are paved from the bagged lime, and the top surfaces of the retaining wallsare in alignment with the top surface of the roadbed; and when the roadbed settles, the water is injected into the lime bags through the pre-reserved rubber pipe, the lime absorbs the water, swells and jacks a road surface structure up. The compensation method for roadbed settlement completes the water injection on the outer side of the roadbed, has a short construction time, does not interrupt the traffic during the construction process and has little interference to the traffic; and the construction is not restricted by the weather and the environment, the settlement can be handled at any time when being found, and the construction process is controllable.

Owner:广东大象交通科技有限公司

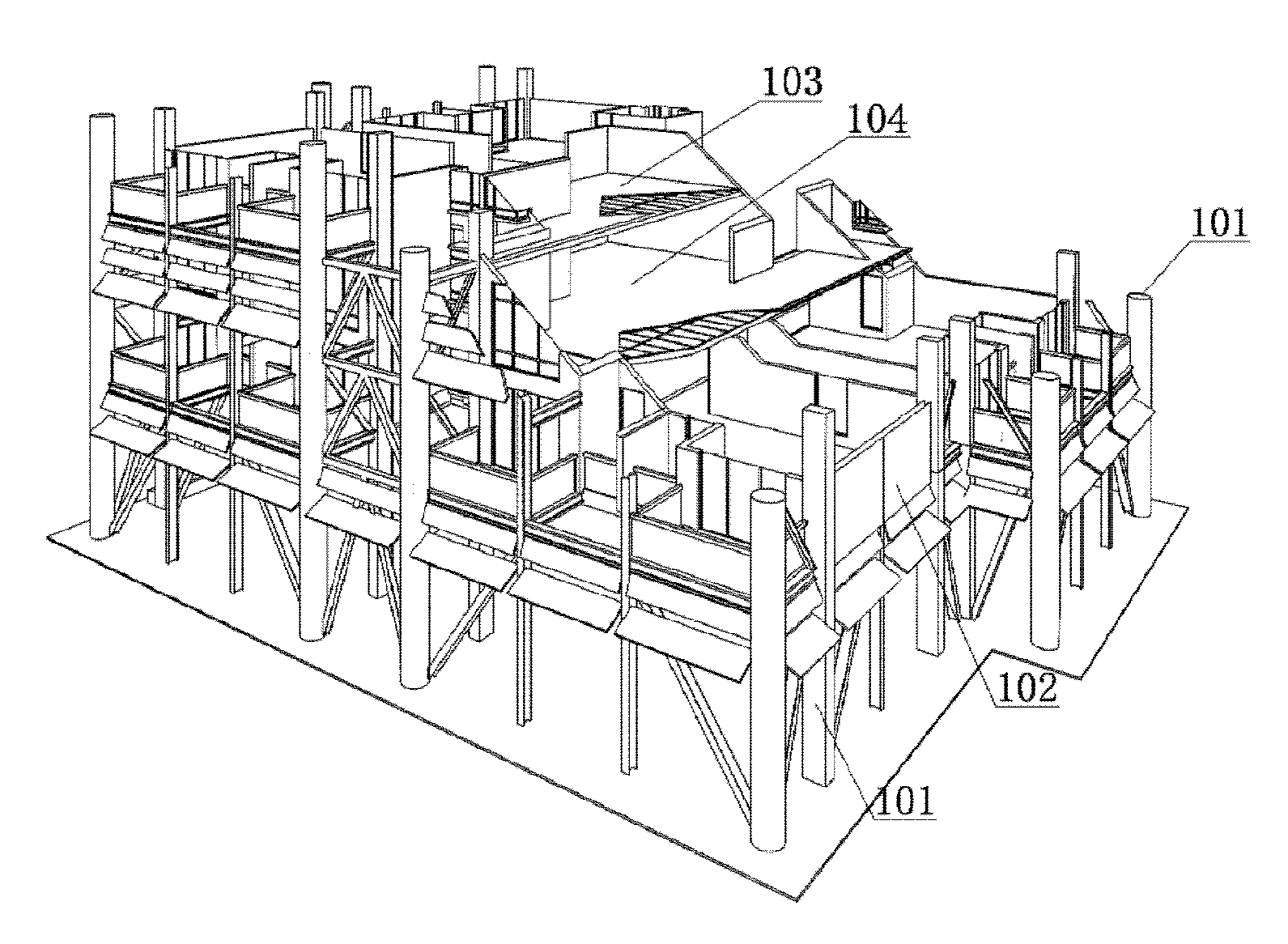

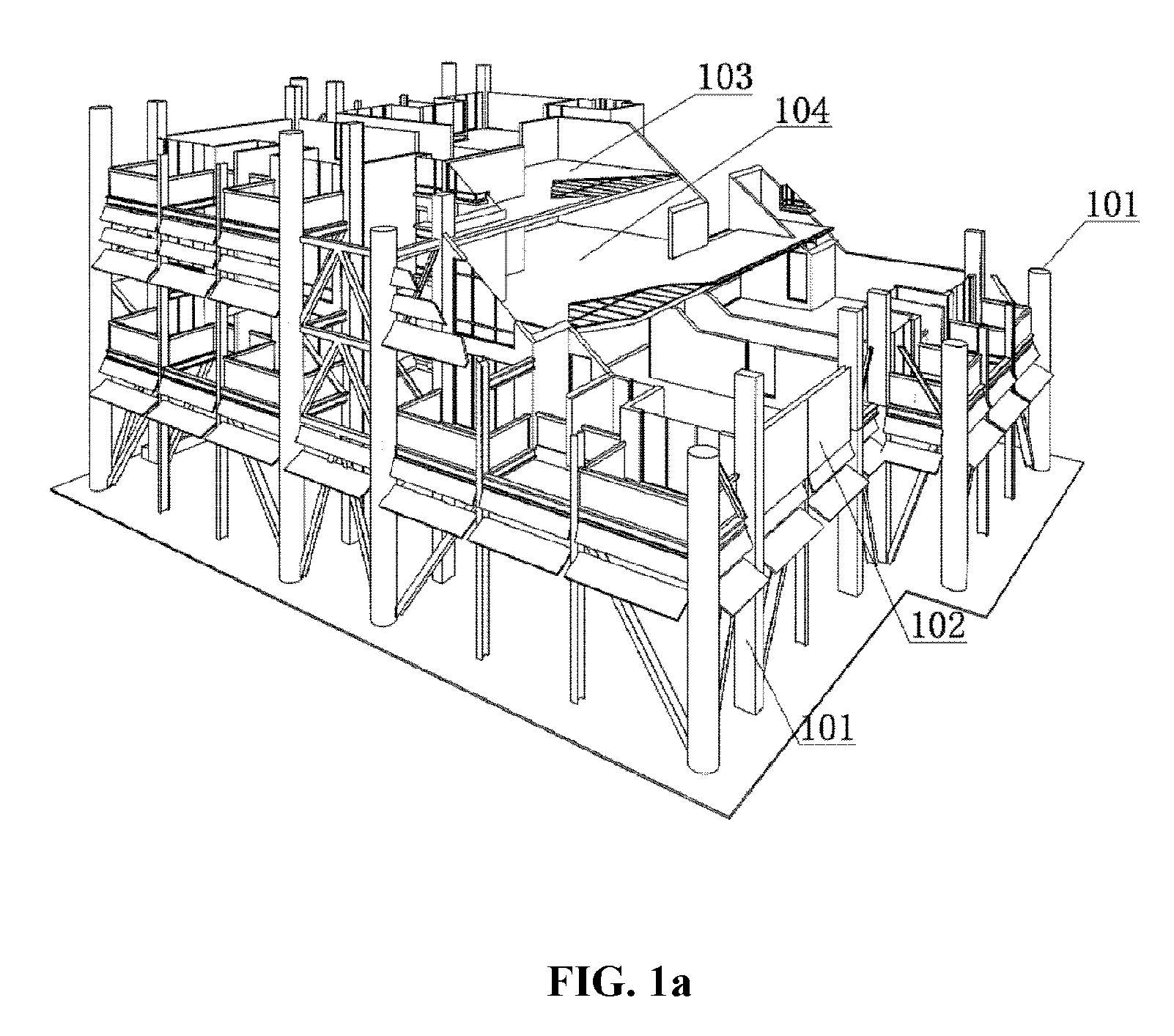

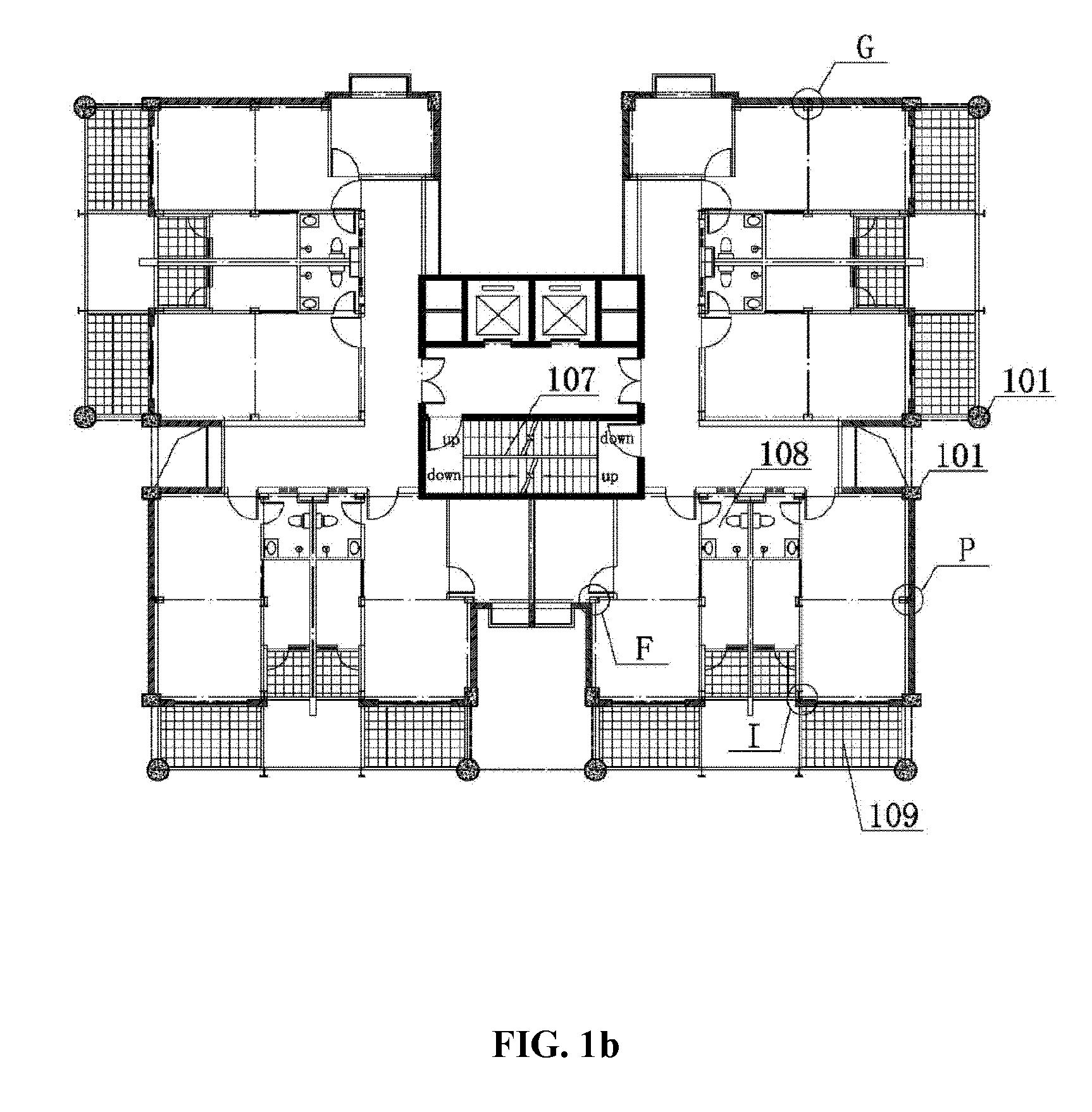

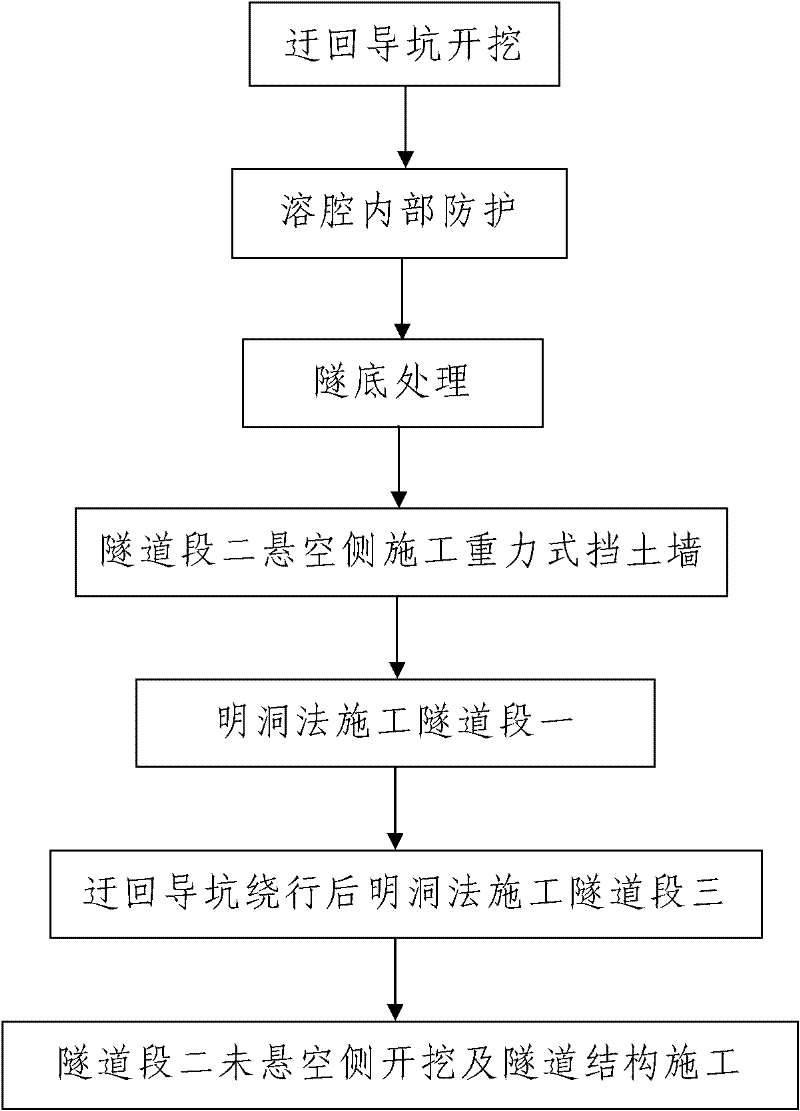

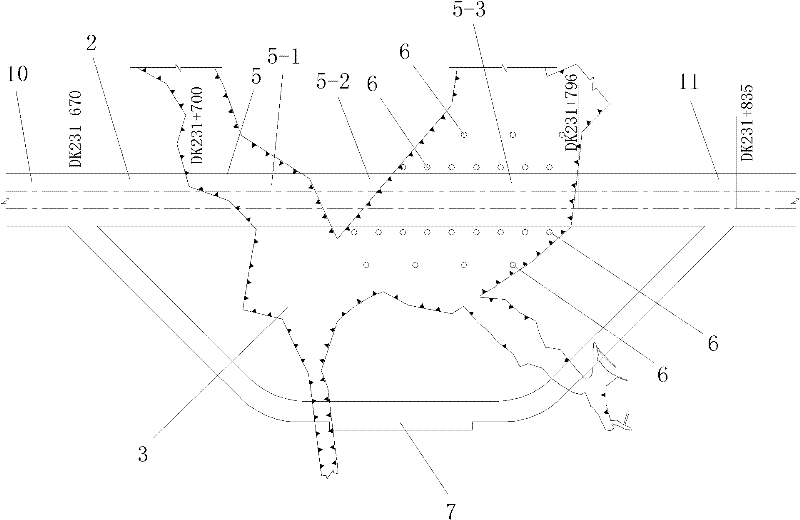

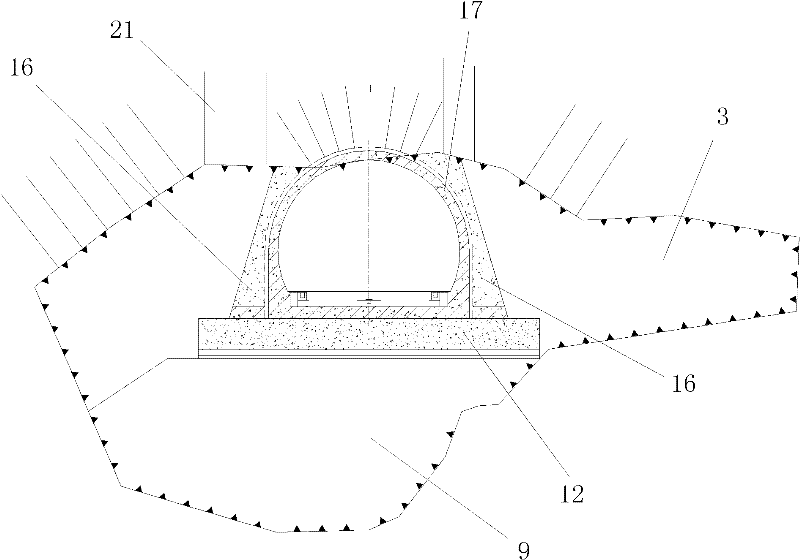

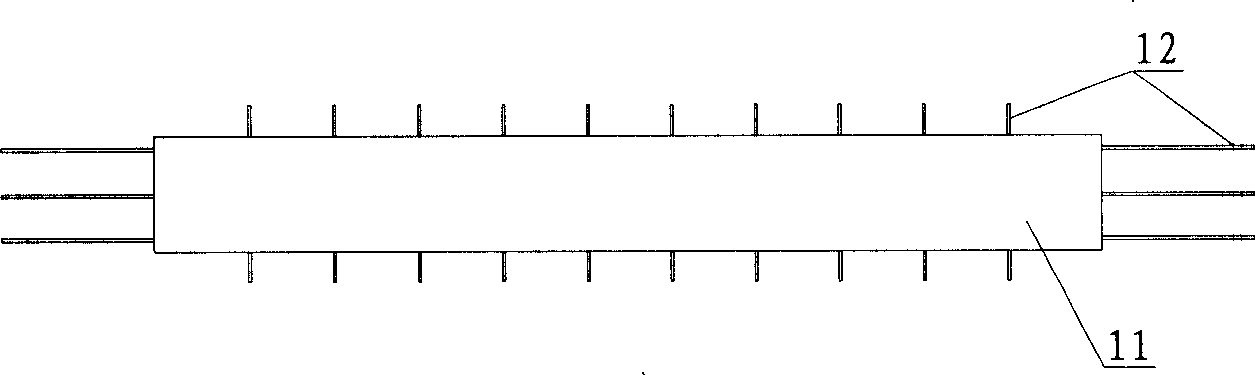

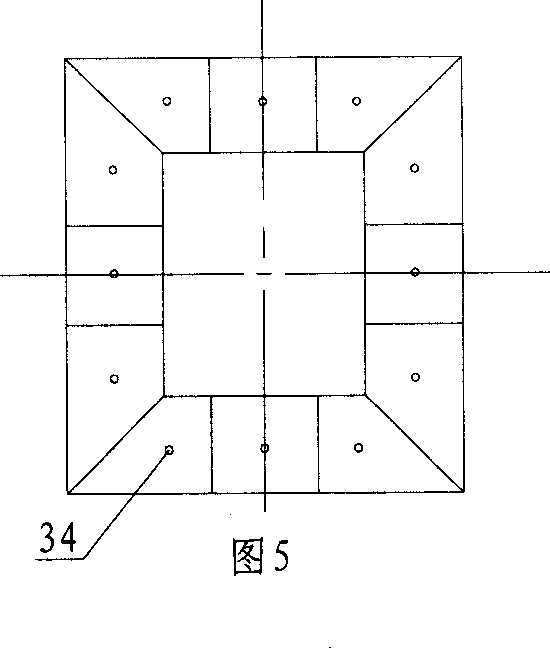

A large-scale solution cavity treatment method for karst tunnels

ActiveCN102296961AReasonable designSimplify construction stepsUnderground chambersTunnel liningLarge distanceKarst tunnel

The invention discloses a karst tunnel large-scale cavern processing method. A cavern traversing tunnel section penetrating through a cavern comprises a tunnel section I, a tunnel section II and a tunnel section III according to the distribution positions, wherein two sides of the tunnel section I are suspended in midair and the top of the tunnel section I is at a smaller distance away from a cavern top plate, one side of the tunnel section II is suspended in midair, and two sides of the tunnel section III are suspended in midair and the top of the tunnel section III is at a larger distance away from the cavern top plate. The processing method comprises the steps of: 1, excavating a bypass pilot tunnel; 2, protecting inside of the cavern; 3, processing the bottom of the tunnel: filling the cavern below the tunnel section I with rock residues and grouting for reinforcing, and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section III with concrete and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section II with hard fillers; 4, constructing a gravity retaining wall at the suspending side of the tunnel section II; 5, constructing the tunnel section I with an open cut tunnel process; 6, constructing the tunnel section III with the open cut tunnel process after the bypass pilot tunnel bypasses; and 7, constructing the tunnel section II. The karst tunnel large-scale cavern processing method has the advantages of reasonable design, convenience for construction, safe and reliable construction process and short construction period, good processing effect on the large-scale cavern.

Owner:CHINA RAILWAY 20 BUREAU GRP

Prefabricated component for residenter house, prefabricated component house and its construction method

InactiveCN101368428AShort construction timeImprove performanceStrutsConstruction materialEarthquake resistanceInsulation layer

Prefabricated pieces for residential houses, a prefabricated house and a construction method thereof are disclosed. Crossbeams, wall boards, support posts are prefabricated according to design sizes; above prefabricated pieces are designed into different shapes according to needs; all the prefabricated pieces are provided with reinforced heads in advance, so during construction, the prefabricated house can be formed only by welding the reinforced heads of the prefabricated pieces arranged in advance, thus realizing the fabrication of a building in a factory; and the finished building is a frame structure and has earthquake-resistance. The house adopts a double-layer wall board; a heat insulation layer is arranged between the two layers of the wall board, so the house is cool in summer and warm in winter. The prefabricated pieces, the prefabricated house and the construction method thereof can greatly reduce construction period, save manpower and reduce fabrication cost.

Owner:徐尉

A non-excavation lining repair method for the repair of drainage branch pipes under urban roads

A non-excavation lining repair method for the repair of lower drainage branch pipes of urban roads, comprising: (1) cleaning and testing the lower drainage branch pipes; - 0.5mm polyester film, the inside of which is made of polyester non-woven fabric and filled or impregnated with unhardened thermosetting resin; (3) After cutting the resin hose to the same length as the drainage branch pipe, Flip inside and outside on the ground and drag it into the drainage branch pipe; (4) Send a pressure bag into the resin hose, and pressurize it with water or air to make the resin hose expand and stick to the inner wall of the lower drainage branch pipe; (5) Warm water circulation heating is carried out in the pressure bag, and a hardened high-strength lining new pipe is formed on the inner wall of the drainage branch pipe to be repaired; (6) The air and water in the pressure bag are removed and taken out from the new lining pipe. According to the present invention, the pressure pack can be reused, and the drainage branch pipe can be repaired without excavation on the road surface when the size of the rainwater grate is very small and the end cutting cannot be performed.

Owner:管丽环境技术(上海)有限公司 +1

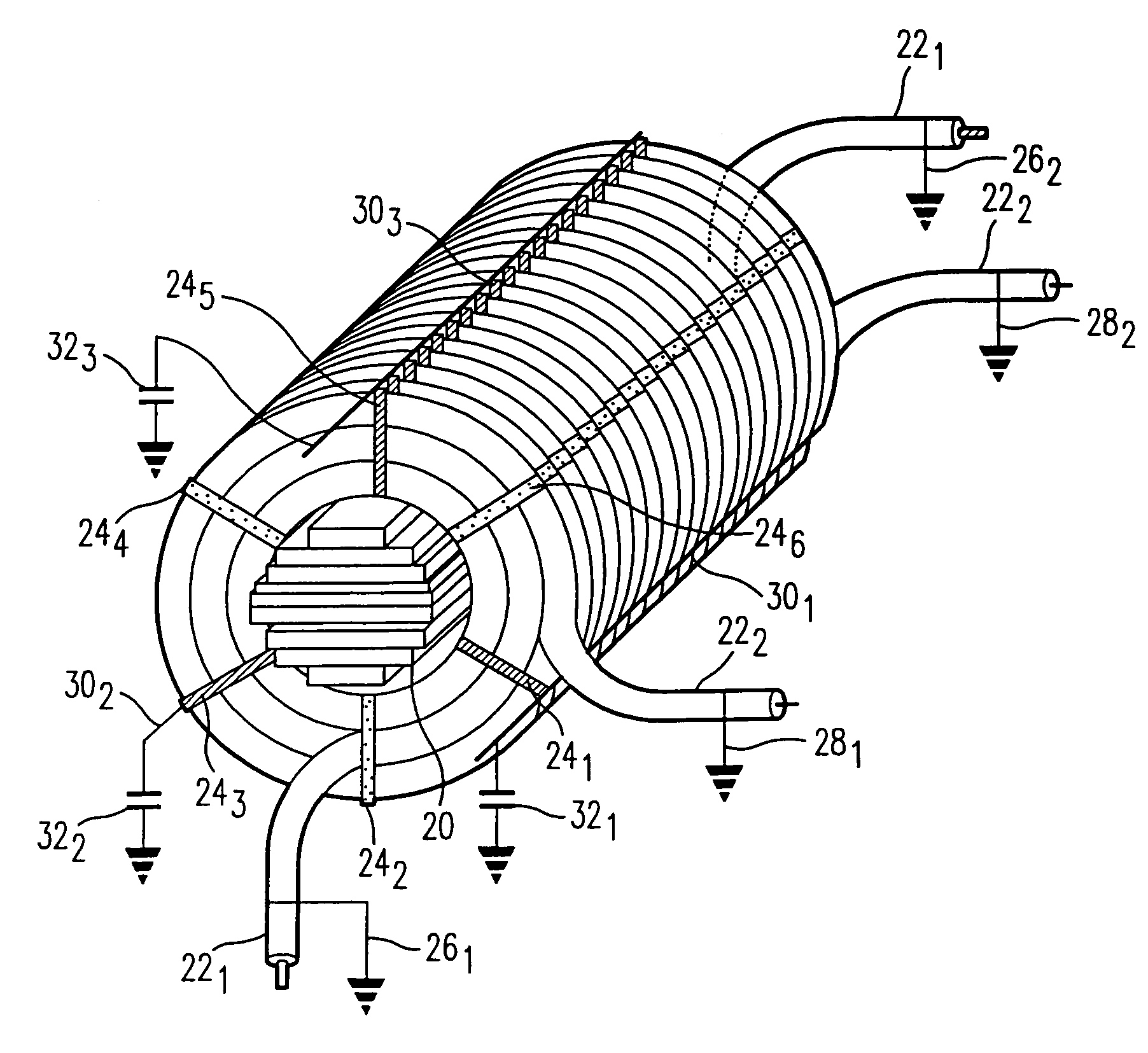

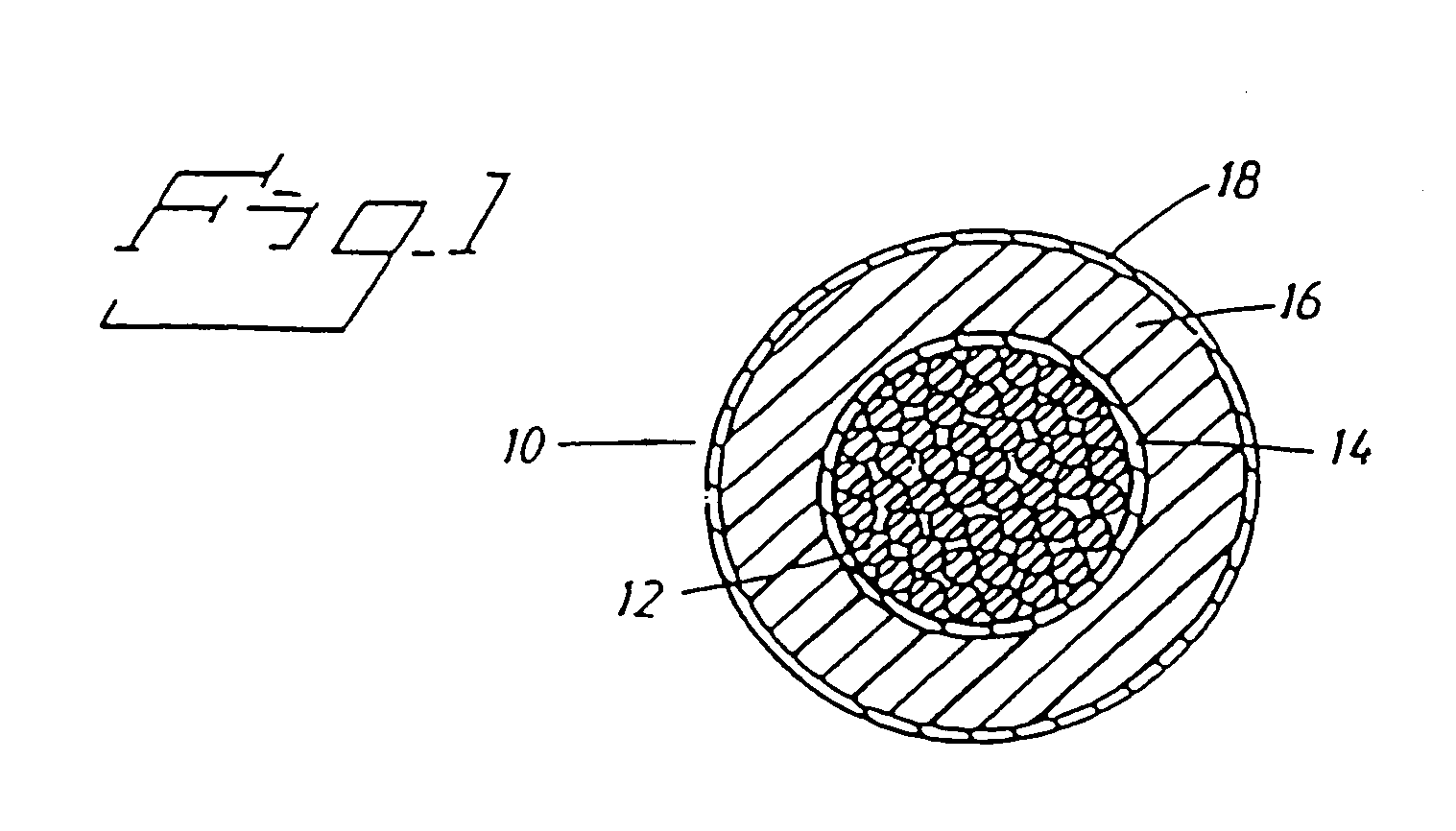

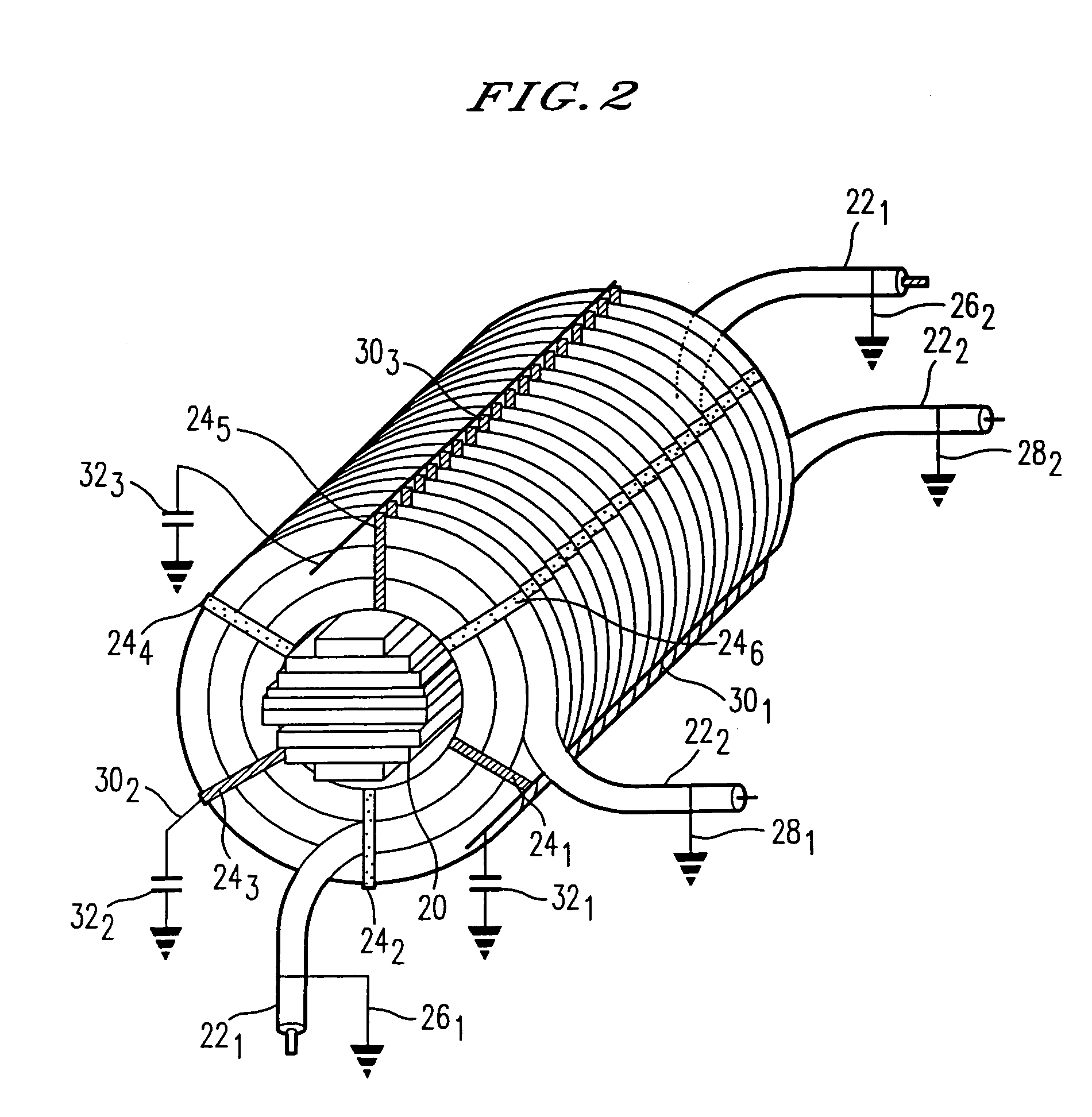

Power transformer/inductor

InactiveUS7046492B2Short construction timeShort timeEmergency protective circuit arrangementsTransformers/inductances coils/windings/connectionsElectrical conductorTransformer

A power transformer / inductor includes at least one winding. The winding is made of a high voltage cable that includes an electric conductor, and around the electric conductor is arranged a first semiconducting layer, around the first semiconducting layer is an insulating layer, and around the insulating layer is a second semiconducting layer. The second semiconducting layer is directly earthed at both ends of the winding and furthermore at least at two points per turn of every winding such that one or more points are indirectly earthed.

Owner:ABB (SCHWEIZ) AG

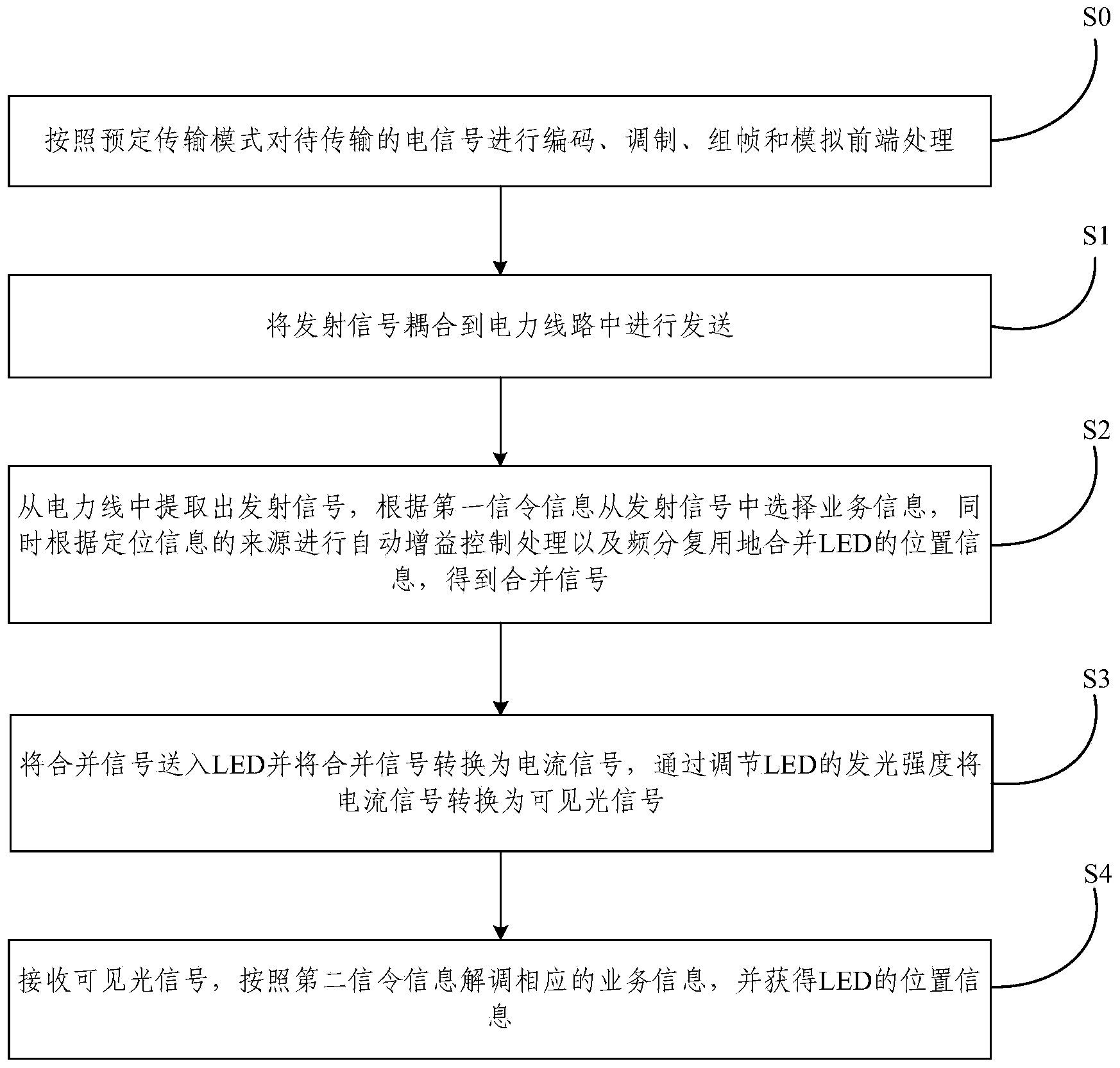

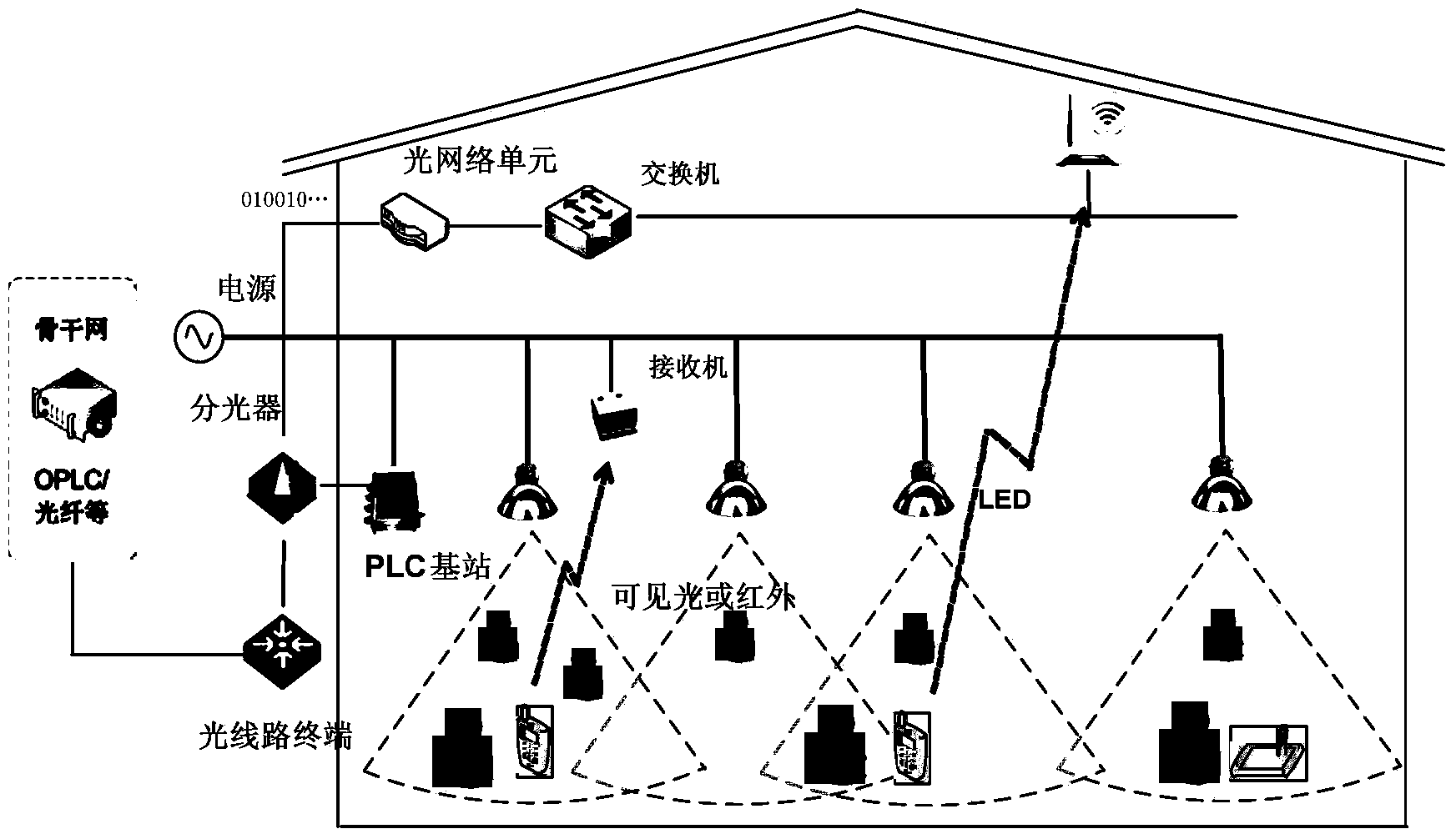

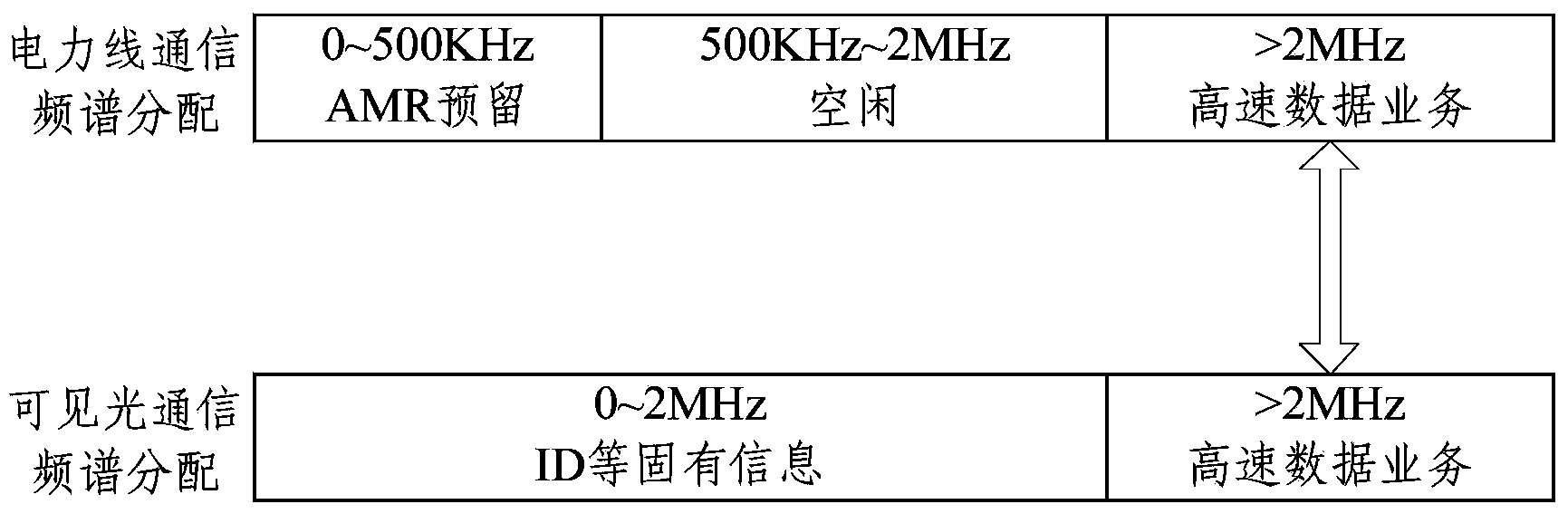

Visible light and power line communication method and device supporting data transmission and positioning

ActiveCN104301010AAchieve seamless integrationReduce construction costsPower distribution line transmissionClose-range type systemsLuminous intensitySmart grid

The invention discloses a visible light and power line communication method and device supporting data transmission and positioning. The visible light and power line communication method comprises the steps that emission signals are coupled to a power line to be transmitted; the emission signals are extracted, service information is selected from the emission signals according to first signaling information, automatic gain control is conducted according to the source of positioning information, pieces of position information of an LED are combined in a frequency division multiplexing mode, and then a combination signal is obtained; the combination signal is fed into the LED and converted into a current signal, and the current signal is converted into a visible light signal by adjusting the luminous intensity of the LED; the visible light signal is received, corresponding service information is demodulated according to second signaling information, and the LED position information is obtained. By the adoption of the visible light and power line communication method and device supporting data transmission and positioning, electrical signals transmitted by a power line are directly emitted out through the LED in a visible light communication mode, and data transmission and positioning application are considered. The visible light and power line communication method and device supporting data transmission and positioning have the advantages that the network establishment cost is low and construction time is short. The visible light and power line communication method and device supporting data transmission and positioning can be applied to the fields such as smart power grids, digital families and pubic security monitoring.

Owner:TSINGHUA UNIV

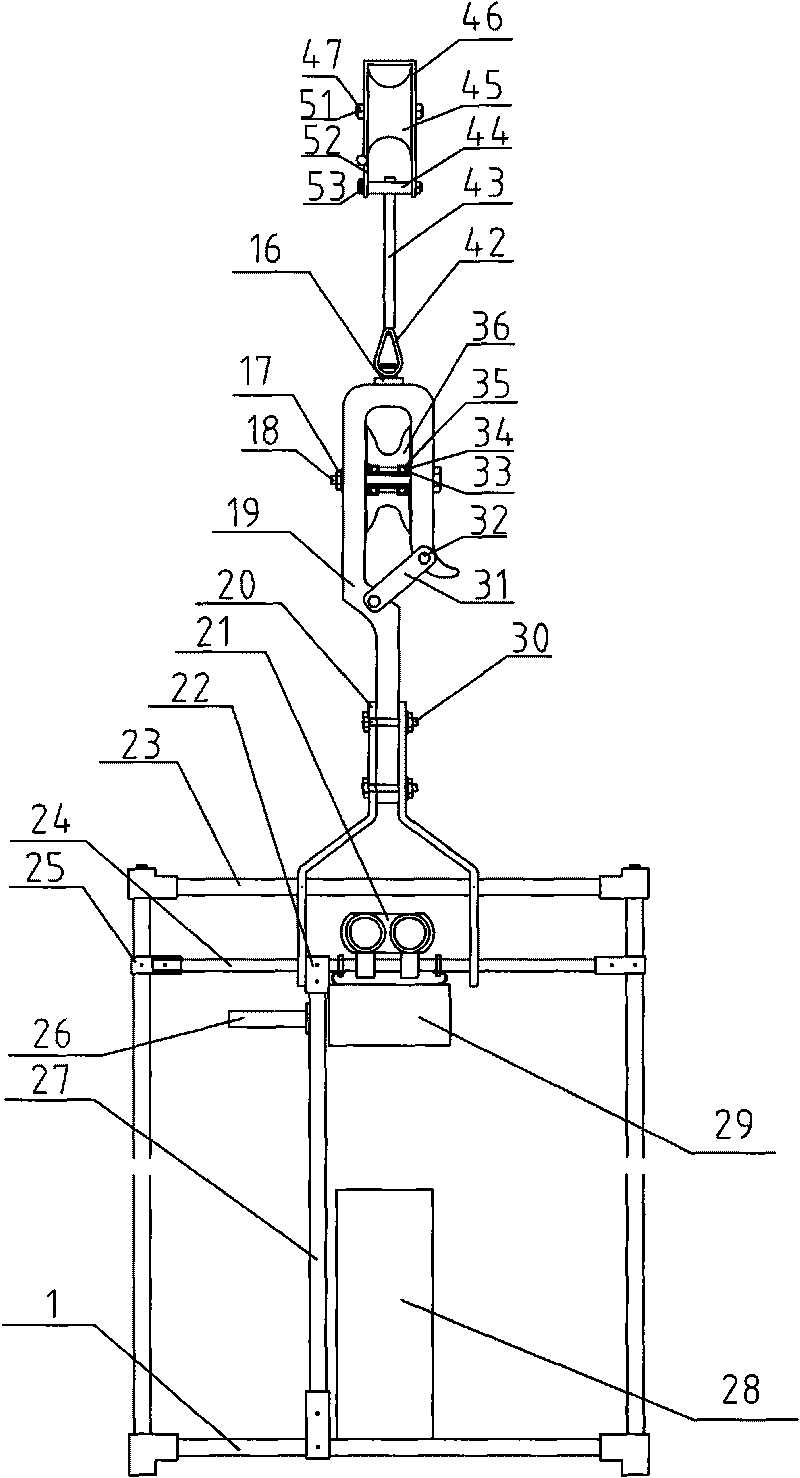

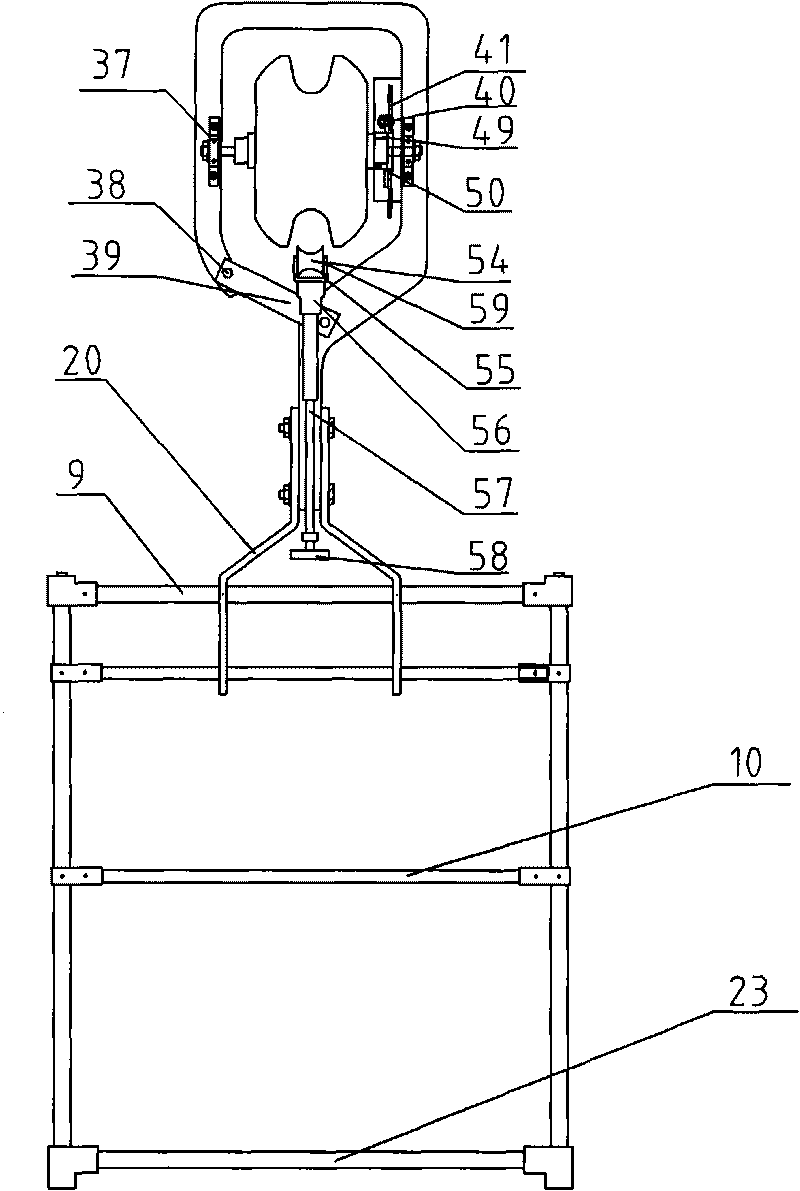

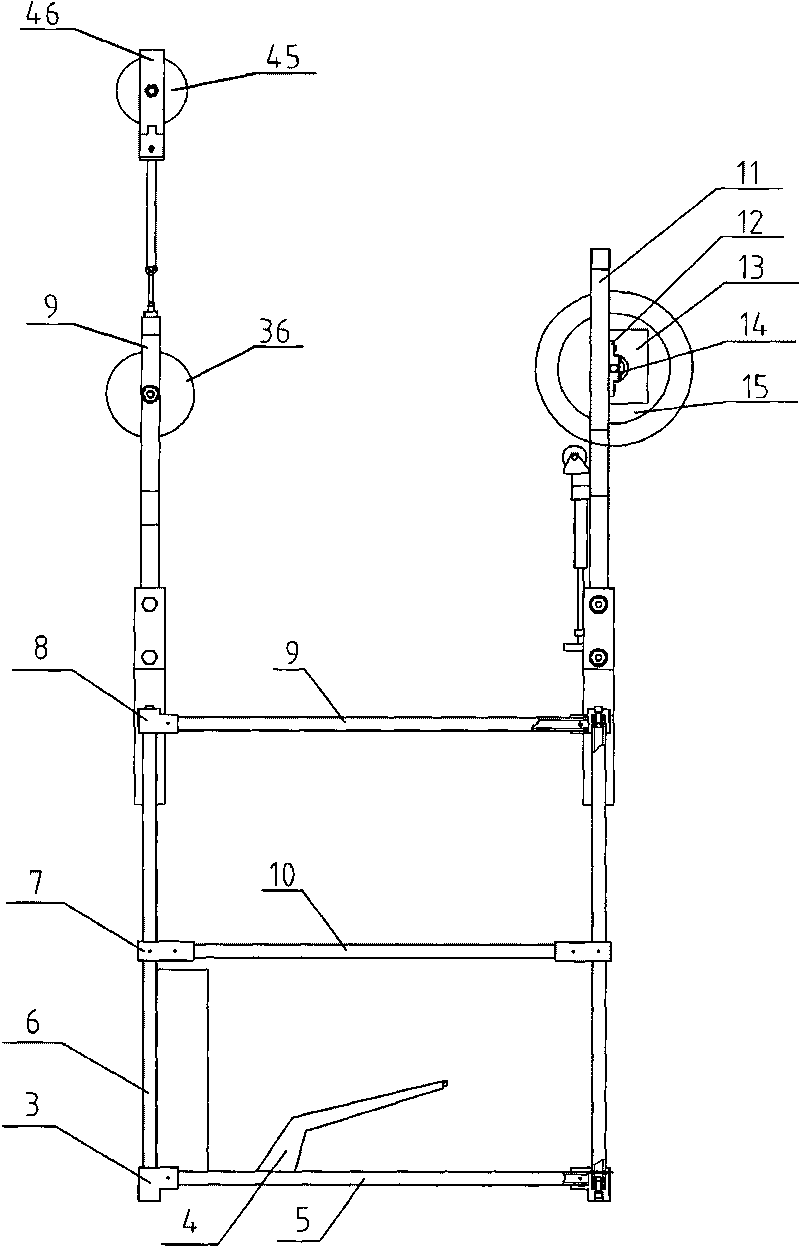

Walking-type hanging basket for transmission line

ActiveCN101764375AReduce labor intensityTaxiing fastApparatus for overhead lines/cablesDrive wheelEngineering

The invention relates to a walking-type hanging basket for transmission line, which comprises a basket base frame formed by the assembly of a cross beam at the basket lower part, a longitudinal beam at the basket lower part and a three-way joint at the basket lower part, a basket top frame formed by the assembly of a cross beam at the basket upper part, a longitudinal beam at the basket upper part and a three-way joint at the basket upper part, a basket upright column is provided with a basket thin two-way joint, the basket thin two-way joint is connected to a cross beam at the basket middle part, the cross beam at the basket middle part on one side and the cross beam at the basket upper part are provided with a driving wheel support, and the driving wheel support is provided with a driving wheel device and an auxiliary tensioning wheel support, the auxiliary tensioning wheel support is provided with an auxiliary tensioning wheel device; the cross beam at the basket middle part on the other side and the cross beam at the basket upper part are provided with a driven wheel support, and the driven wheel support is provided with a driven wheel device. The invention adopts electric power drive and has providing quick sliding speed, thereby shortening construction period, improving efficiency, enabling operators to construct in standing manner.

Owner:STATE GRID CORP OF CHINA +2

CIPP overturning liner pipeline repairing device

The invention discloses a CIPP overturning liner pipeline repairing device, comprising the following steps: pipeline dredging: reducing a water level of a pipeline to be repaired to a lowest point, and after pulling chamber dredging is adopted to remove most deposits, performing high pressure cleaning work and comprehensive water plugging; adopting a special water plugging device and a large power sewage pump to perform water plugging and water transferring on an upstream and a downstream of the pipeline, and cleaning the pipeline; and enabling a high pressure water cleaning vehicle to enter from an upstream well mouth to move to a downstream well mouth for repeated cleaning till the pipeline meets the repairing requirement, and meanwhile, enabling a CCTV detecting device to enter from the upstream well mouth to monitor among the pipelines to be repaired and to match with the high pressure cleaning work. The CIPP overturning liner pipeline repairing device adopts a non-excavation technology and is short in construction time, site operation is finished in 24 hours generally, construction devices have a small floor area, a liner pipe and an old pipe are tightly combined, the strength is high, the service life can reach 50 years at most, and the CIPP overturning liner pipeline repairing device has small influence on traffic and is less affected by the environment, and thus the construction cost is reduced.

Owner:WENZHOU FUCHENG CONSTR ENG CO LTD

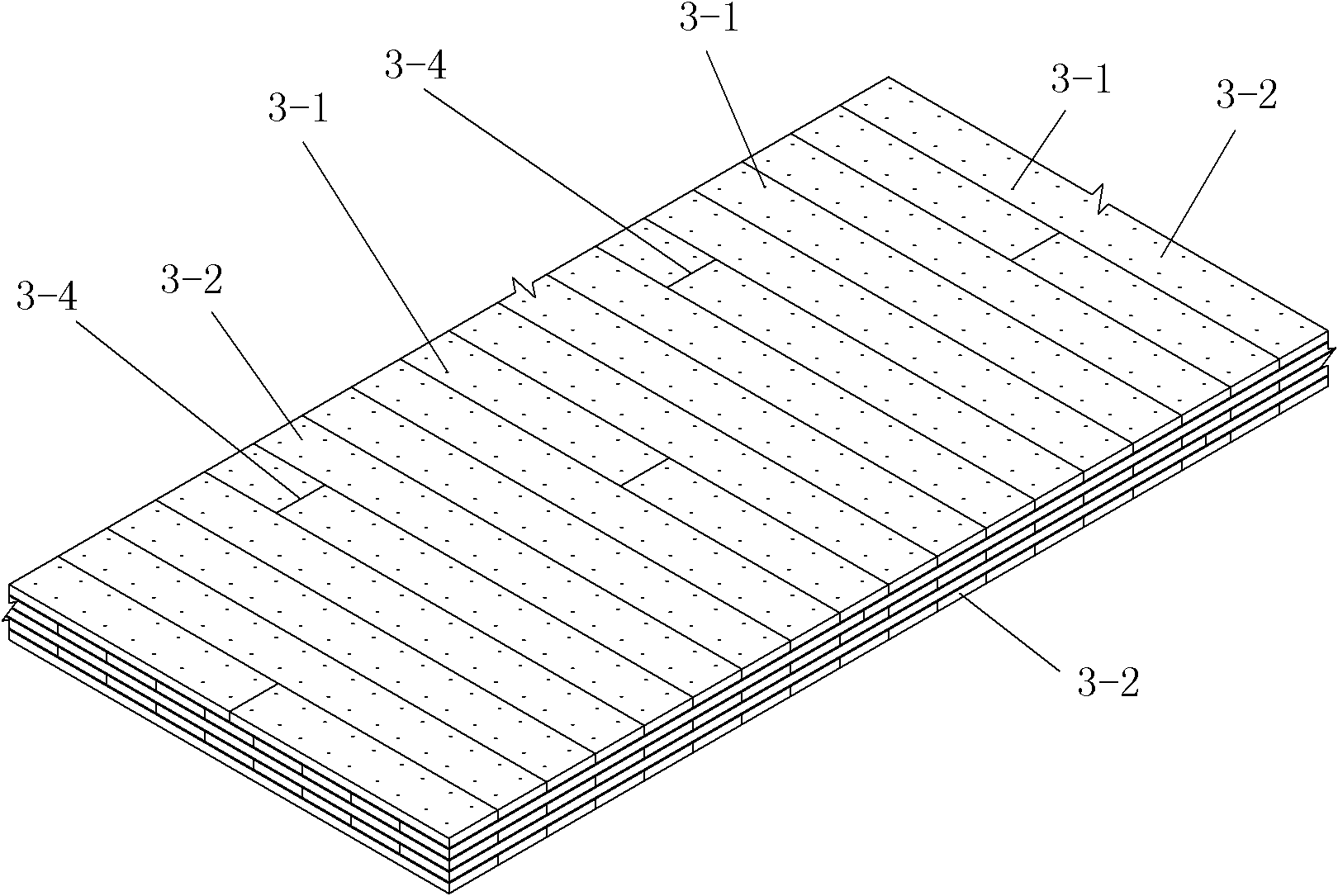

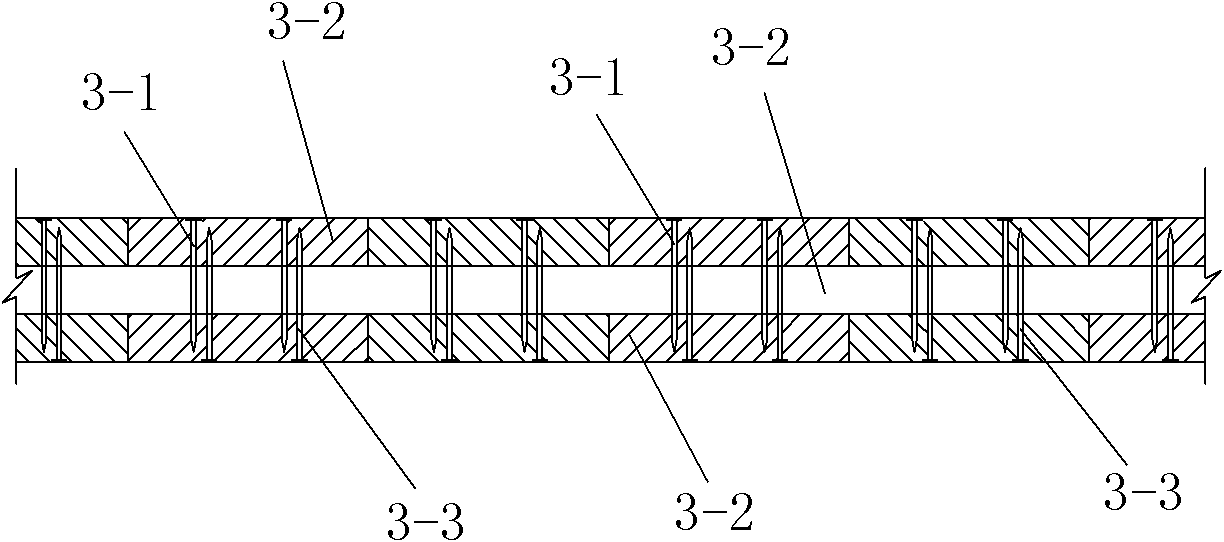

Wooden structure house and building process thereof

InactiveCN102174859ASimple structureClear mechanical propertiesRoof covering using slabs/sheetsBuilding roofsBasementOn board

The invention discloses a wooden structure house and a building process thereof. The wooden structure house comprises a house main body structure and a roof structure, wherein every floor of the house main body structure comprises a plurality of wall bodies 1; the adjacent floors are separated by a floor plate; the wall bodies 1 and the floor plate are an integrated composite board or are formed by splicing a plurality of composite boards arranged on the same plane; the integrated composite board is formed by piling a plurality of layers of wooden boards with same shapes and sizes; and the wooden board is formed by splicing a plurality of wooden plate strips which are arranged on the same plane. The building process comprises the following steps of: 1, on-site constructing foundation and basement, factory-prefabricating and transporting the integrated composite boards; and 2, using the prefabricated composite boards to assemble the wooden structure house on the spot. The wooden structure house in the invention is simple in construction process, controllable in construction quality, low in input investment, rational in structural stress of the built house, beautiful in shape, wide in application range and convenient for prefabricating the integrated boards and suspending on the spot.

Owner:杨岳华

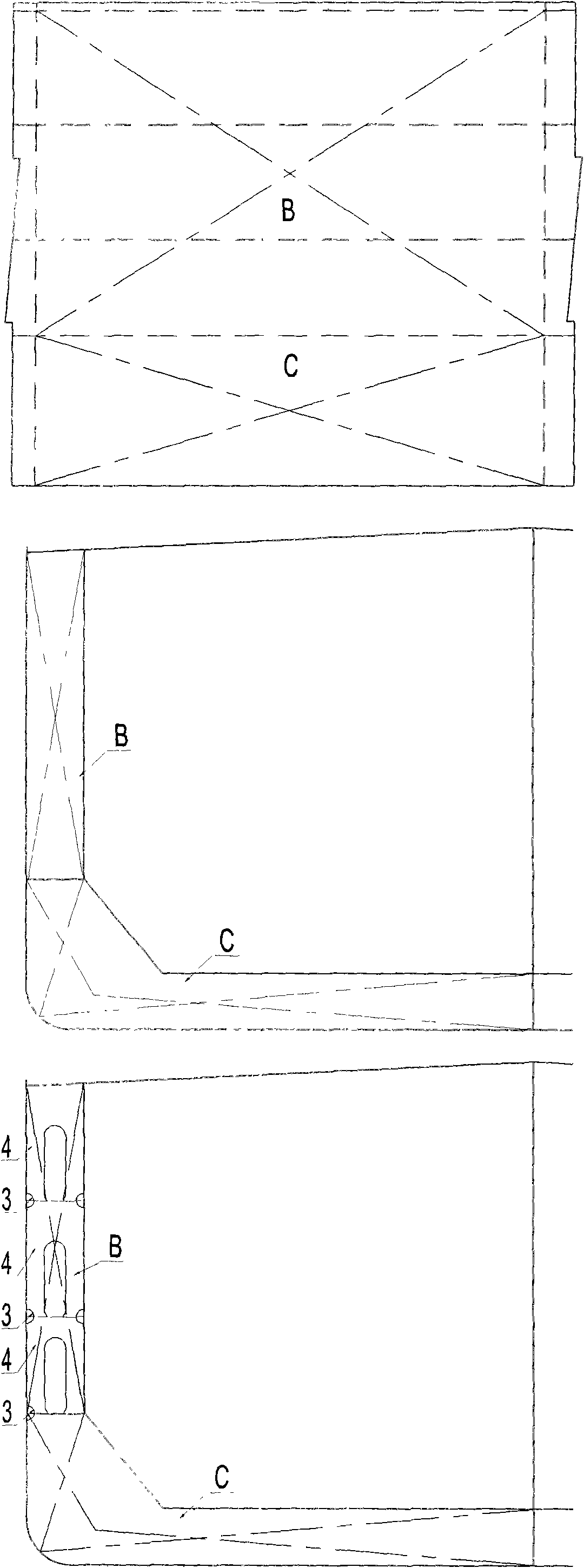

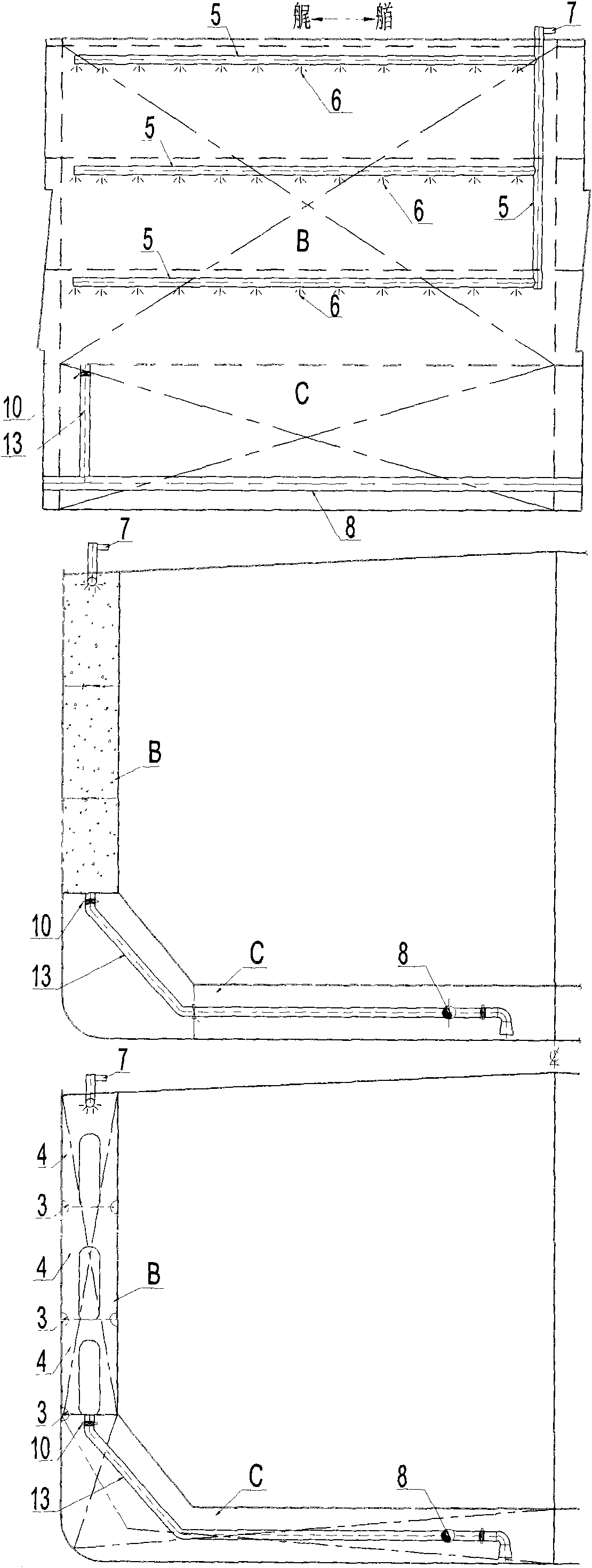

Device and method for preventing sediment deposition and treating sediment in ballast tank of ship

The invention relates to a device and a method for preventing the sediment deposition and treating the sediment in a ballast tank of a ship. The traditional L-shaped ballast tank is divided into a topside ballast tank and a bottom ballast tank, wherein the topside ballast tank structure is provided with sediment outlet holes, and the shape and the size of the drain holes are optimized. During ballasting in the water area with a large sediment charge, only the topside ballast tank is ballasted, and the bottom ballast tank is in the void state, so that the ship can achieve the draught and the stability for safe sailing; and when the ship drives away from water field containing the sediment, the bottom ballast tank is ballasted, and the sediment in the topside ballast tank is discharged by a pump or gravity. For the conversion of the traditional ship, the invention has the advantages of slight change to the ship structure and the ballast piping, short construction time, convenient operation flow and lower cost; and for a newly-made ship, the invention has the advantage that the effect of preventing the sediment can be achieved as long as increasing less design and manufacturing cost, thereby achieving huge practical meanings and extensive application prospects.

Owner:COSCO SHIPYARD GROUP +1

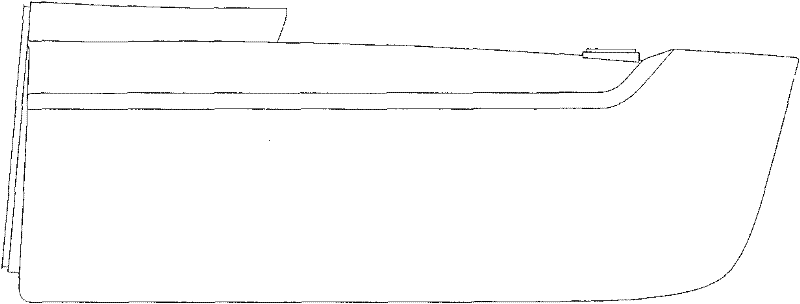

Manufacturing method of sandwich-structure glass steel cabin cover

InactiveCN102189690AReduce thicknessImprove stress resistanceOther domestic articlesGlass fiberThermal insulation

The invention discloses a manufacturing method of a sandwich-structure glass steel cabin cover. The method comprises the following steps: paving glass fibers, a foam board and glass fibers on a mold; paving a demolding cloth layer on the surface of the glass fibers; paving a diversion net layer on the demolding cloth; paving a diversion pipe on the diversion net; paving a vacuum bag on the diversion pipe; starting a vacuum system which exhausts air in the mold cavity so as to form a negative pressure with vacuum degree of 90% in the mold cavity; introducing special resin into vacuum by means of the negative pressure, and pressing the resin into the fiber layer through the pre-paved diversion pipe, so that the entire mold is fully filled with the resin soaked and reinforced material; curing the cabin cover; removing the vacuum bag; and demolding the cabin cover from the mold. The method disclosed by the invention has the advantages of simple manufacturing process, low cost and short construction time, improves the pressure resistance and toughness of the cabin cover, enhances the thermal insulation performance, and prolongs the service life, thereby achieving high social and economic benefits.

Owner:无锡利保科技发展有限公司

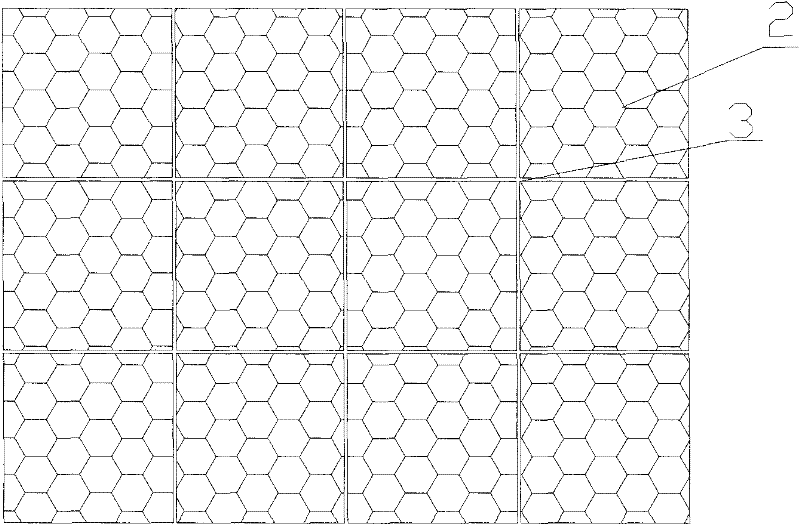

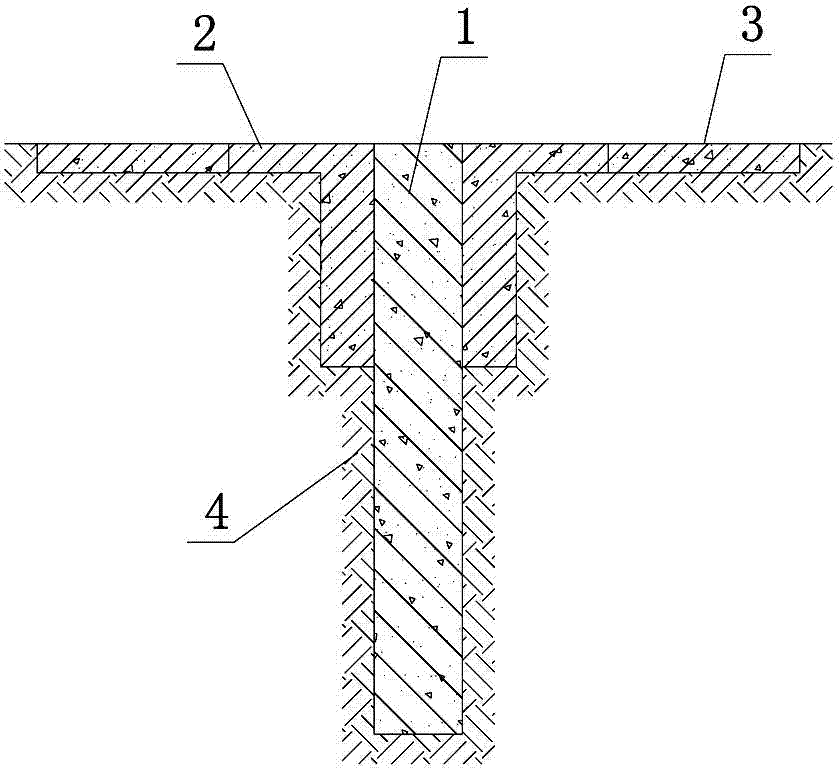

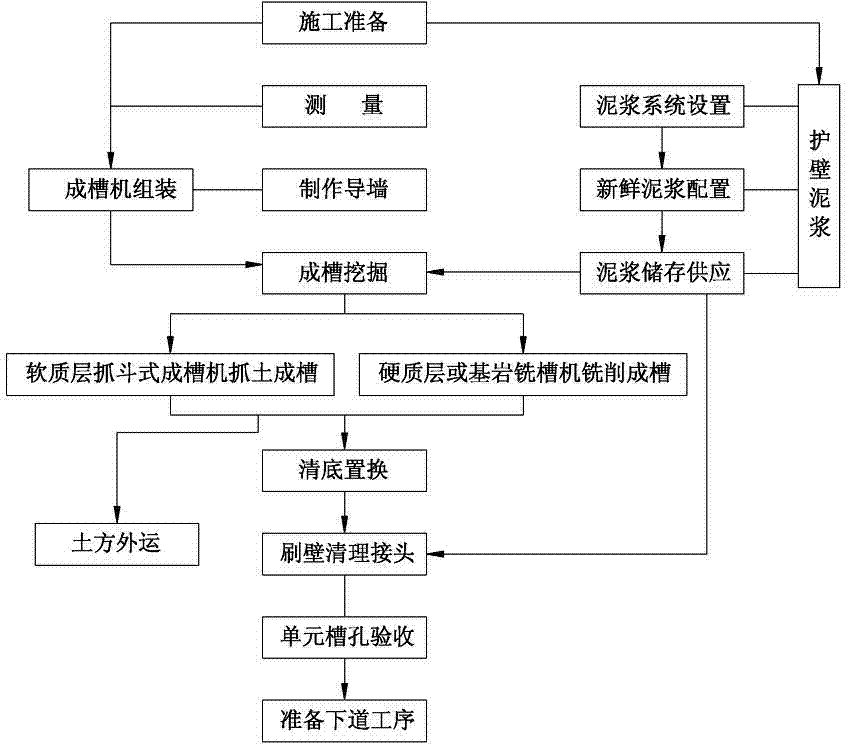

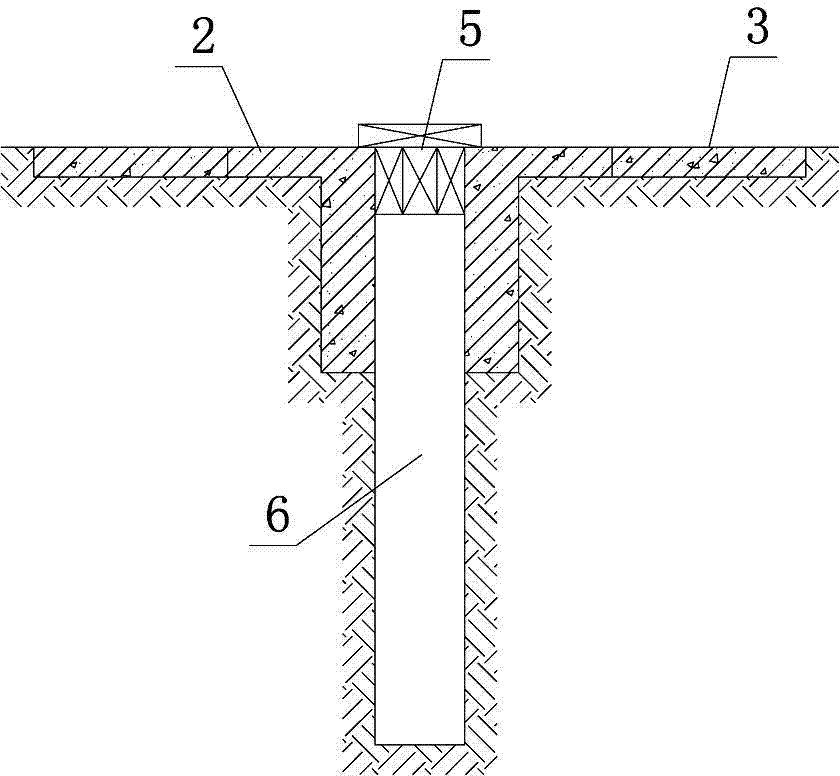

Super-deep underground continuous wall and construction method thereof

The invention relates to a super-deep underground continuous wall which comprises an underground continuous wall body. Guide walls are symmetrically arranged on the two sides of the wall body, the cross sections of the guide walls are in the shape of an L, the lower ends of the guide walls are located on underground rock-soil, and the lug edges of the guide walls are connected with a concrete pavement. The invention further discloses a construction method of the super-deep underground continuous wall. The method includes the following steps of construction preparation, measuring, guide wall manufacturing, wall protection slurry manufacturing, grooving construction, bottom-clearing replacement, connector cleaning through wall brushing and unit slot section inspection, wherein a grabbing-milling integrated grooving method is used in the grooving construction. The method is high in grooving efficiency, short in construction time and short in groove wall soaking time, the grabbing-milling integrated grooving method is used in the grooving construction, technologies can be changed timely according to different stratum hardness situations, the characteristics that a grab bucket is high in digging speed at the soft soil layer and milling wheel can achieve rapid milling and digging footage at a hard soil layer or bed rod with standard penetration test blow count exceeding 45 are fully used, and therefore rapid and efficient grooving of the whole wall can be achieved.

Owner:ZHONGDING INT ENG

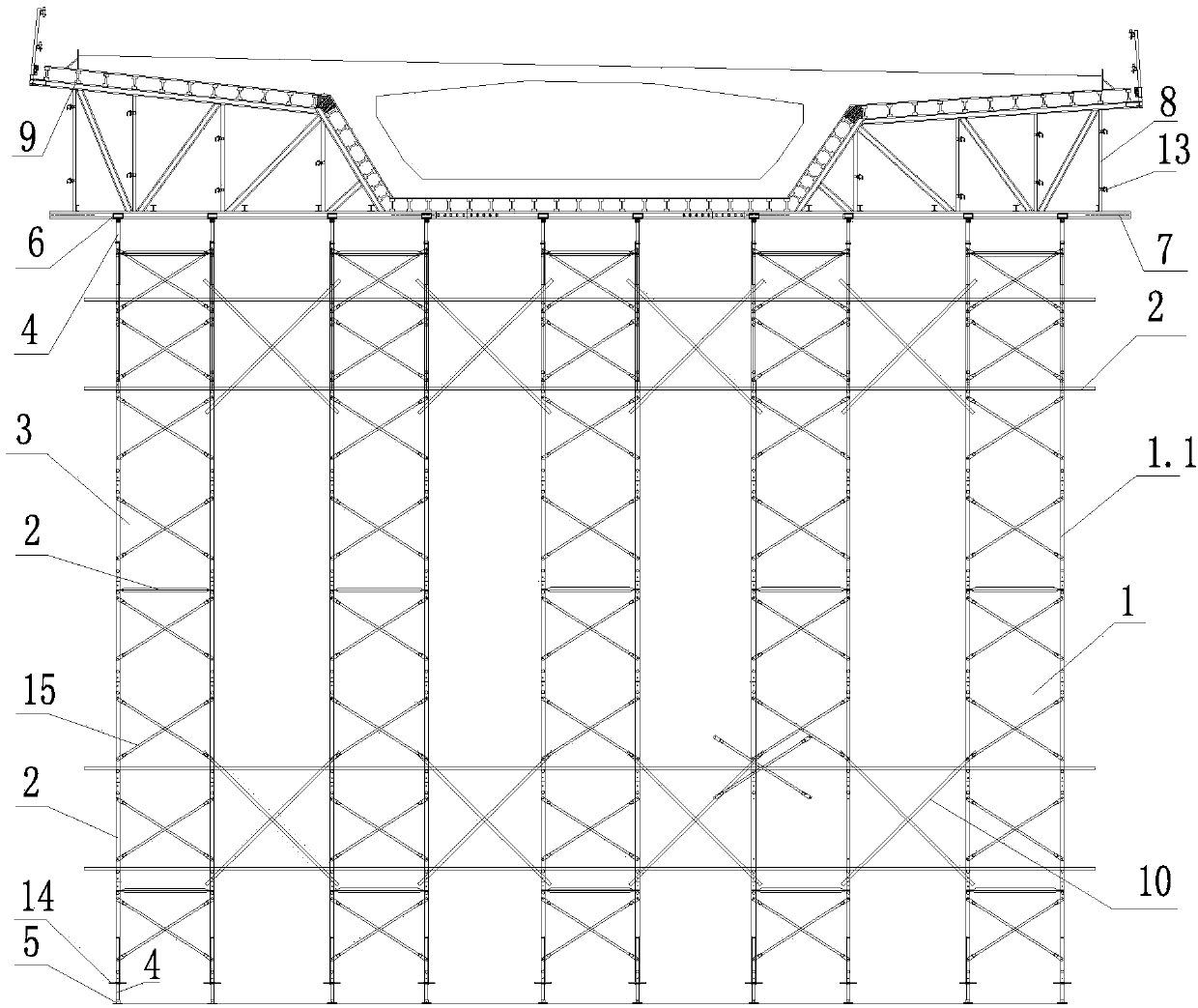

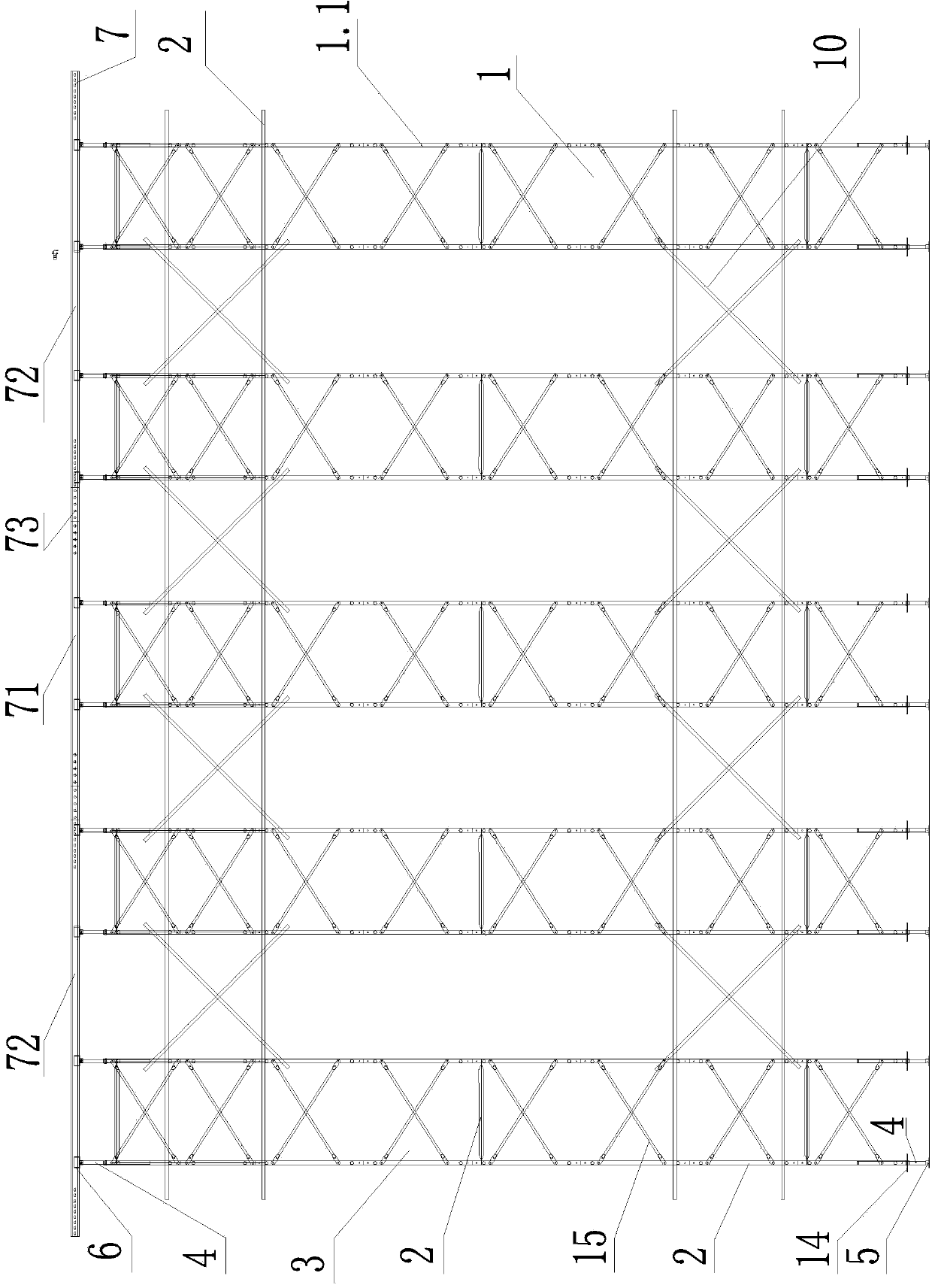

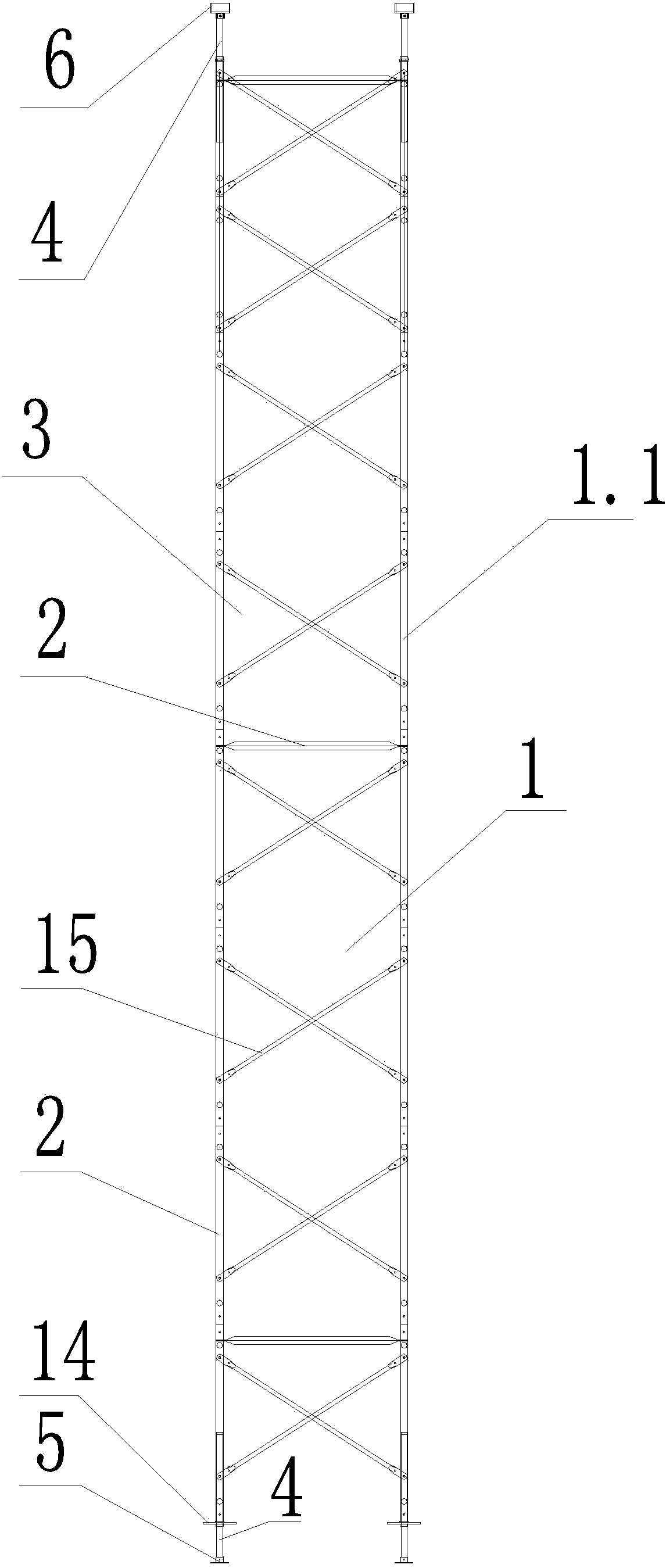

Overhead cast-in-place box beam pressure-bearing strut and construction technology thereof

ActiveCN103437279AImprove construction efficiencyEasy to install and disassembleBridge structural detailsBridge erection/assemblyFalseworkArchitectural engineering

The invention discloses an overhead cast-in-place box beam pressure-bearing strut and relates to overhead concrete box beam hole-by-hole casting construction work. The overhead cast-in-place box beam pressure-bearing strut comprises a support body (1), a reinforced support (2) and a crossed support (10). The support body (1) is composed of a plurality of scaffolds (3). A supporting base (5) and a bracket (6) are arranged at the top end and the bottom end of a vertical supporting rod (1.1) respectively. The bracket (6) is provided with distribution beams (7) in an overlapped mode, and the distribution beams (7) comprise a first distribution beam (7.1) placed in the middle and second distribution beams (7.2) placed on two sides. The second distribution beams (7.2) are provided with wing plate supports (8) in an overlapped mode, and the first distribution beam (7.1) and the wing plate supports (8) are provided with formworks (9) in an overlapped mode. The overhead cast-in-place box beam pressure-bearing strut is convenient to assemble and disassemble, high in mechanical degree, quick in transferring, and capable of improving construction efficiency of cast-in-place box beams. According to the overhead cast-in-place box beam pressure-bearing strut, overlapping accuracy of the support body can be controlled easily, cost performance is high, construction time is short, and modern construction demands can be met. The invention further discloses a construction technology of the overhead cast-in-place box beam pressure-bearing strut.

Owner:CCCC SHEC FIRST HIGHWAY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com