Spray repair method for lining of kiln firebrick

A refractory brick lining and repair method technology, applied in the direction of lining repair, etc., can solve the problems of repair, time-consuming, falling off, etc., achieve the effect of simple and effective procedures, ensure normal operation, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

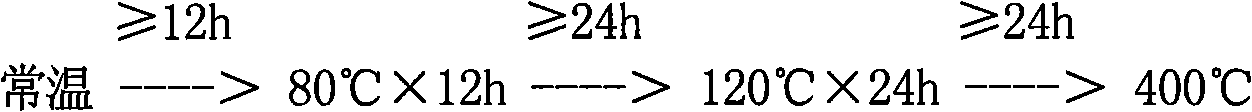

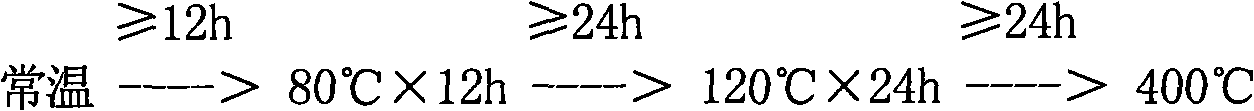

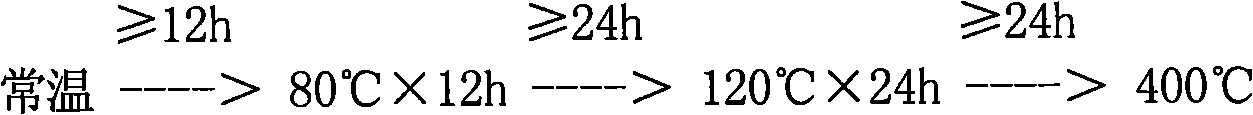

Method used

Image

Examples

specific example

[0024] Specific example: Diameter φ = 10500mm, height H = 16000mm, bottom area 600m 2 , the temperature at the bottom is 600°C, and the temperature at the outlet of the flue gas is 900°C.

[0025] The internal structure of the equipment is three layers, the first layer is refractory bricks, built with mud, the second layer is insulation bricks, and the third layer is steel shell. At present, the steel shell of the furnace body is red and deformed, and the refractory brick lining has cracks and some parts fall off. The area to be repaired is 400m 2 about.

[0026] Due to the shedding phenomenon of the refractory brick (high alumina brick) lining of the roasting furnace, it is analyzed that the iron, aluminum, silicon, oxygen and other substances contained in the high alumina brick and masonry mortar are related to the sulfur, copper, lead, and other substances contained in the ore. The result of chemical reactions of zinc, molybdenum, gold, cobalt, molybdenum and other substa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com