Patents

Literature

1876results about How to "Reduce repair costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

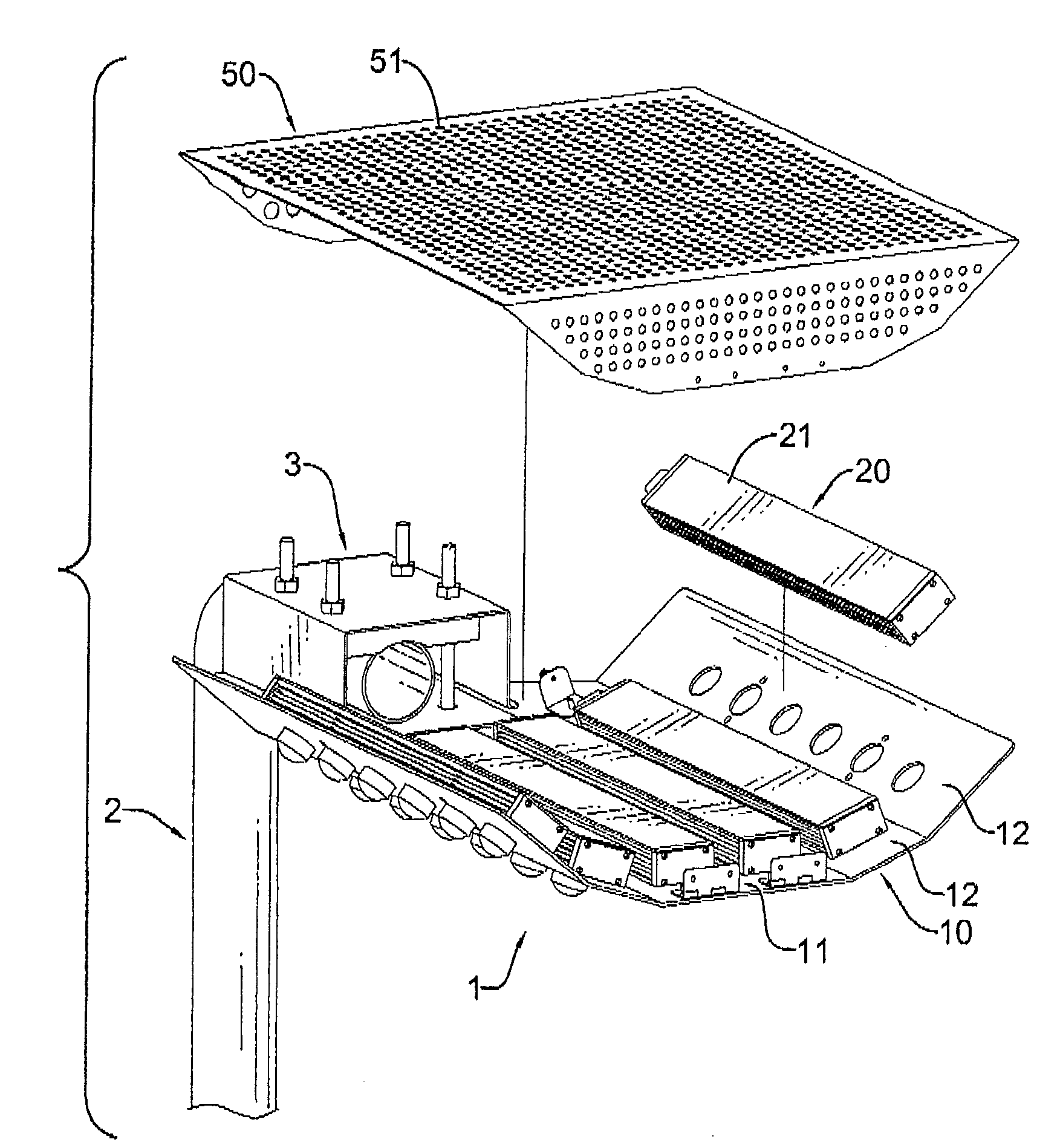

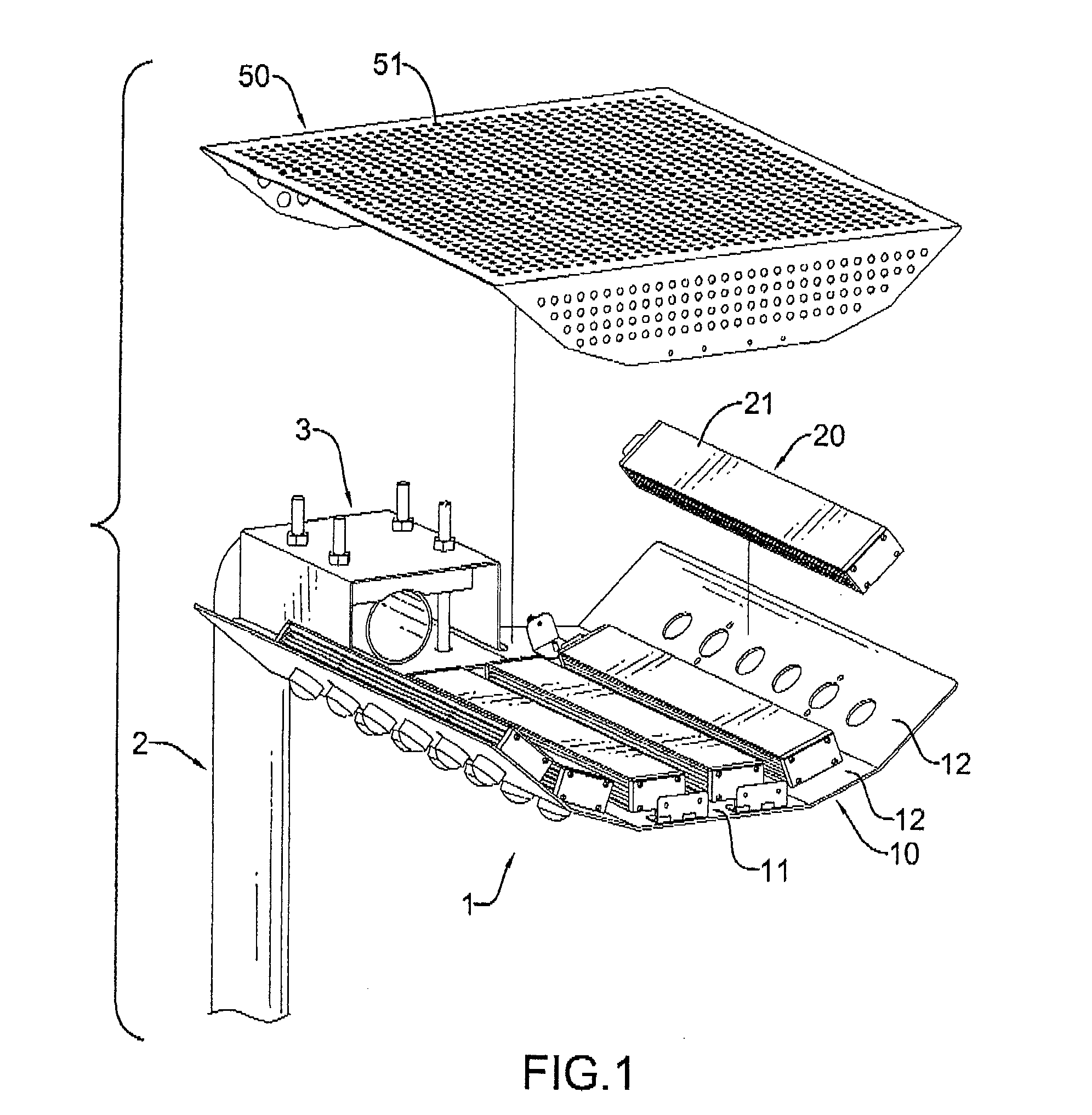

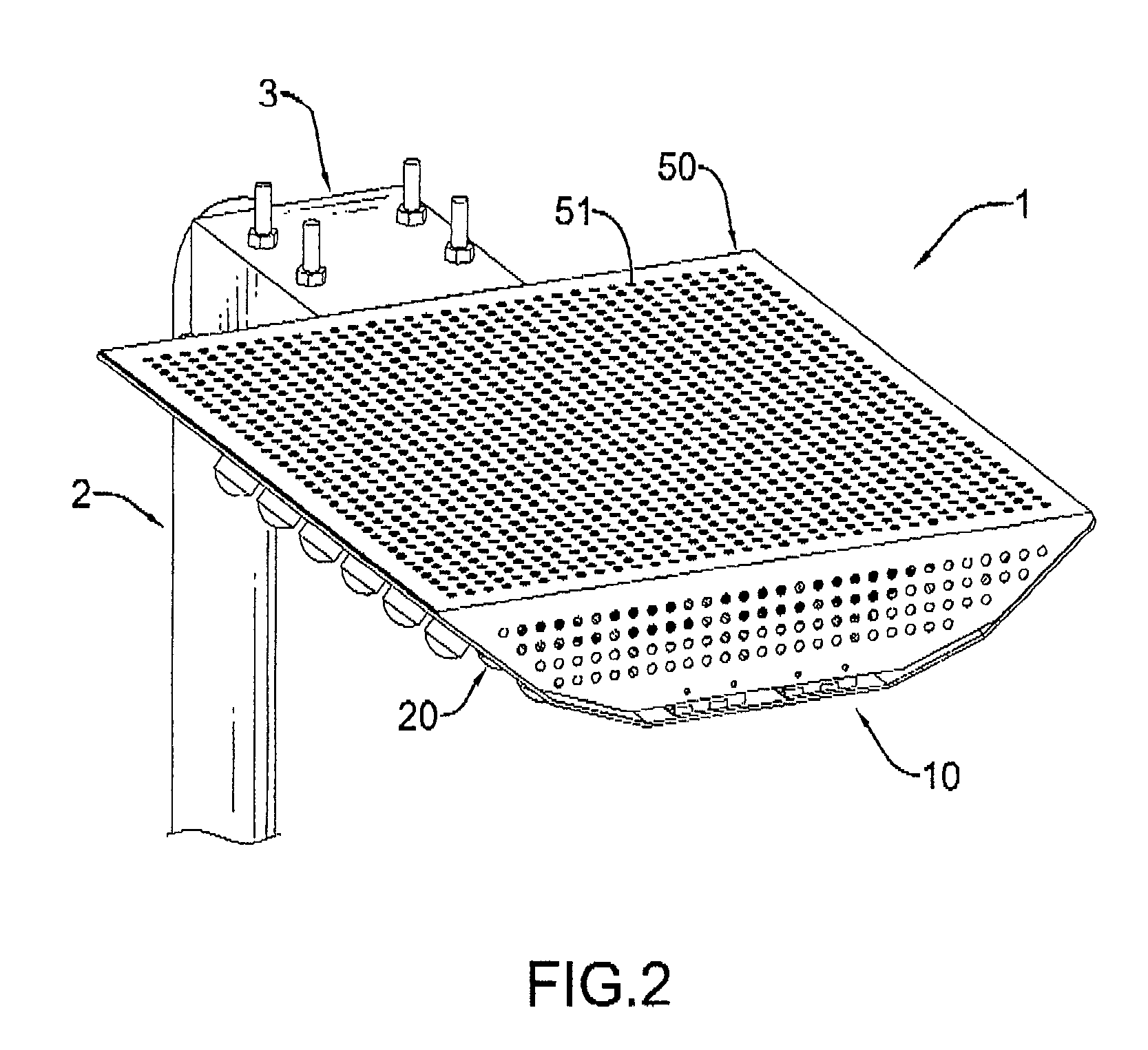

Lighting device having LED light bars

InactiveUS20090185374A1Easy maintenanceEffective coolingMechanical apparatusPoint-like light sourceElectricityComputer module

A lighting device has a light-bar mount and multiple light bars. The light-bar mount is integrally formed from a board. The light bars are mounted on the light-bar mount and each light bar has a heat sink, a circuit board and multiple high-power LED modules. The heat sink is detachably mounted in the light-bar mount. The circuit board is mounted in the heat sink. The high-power LED modules are mounted on the heat sink and electrically connected to the circuit board for providing outward illumination.

Owner:ANTEYA TECH CORP

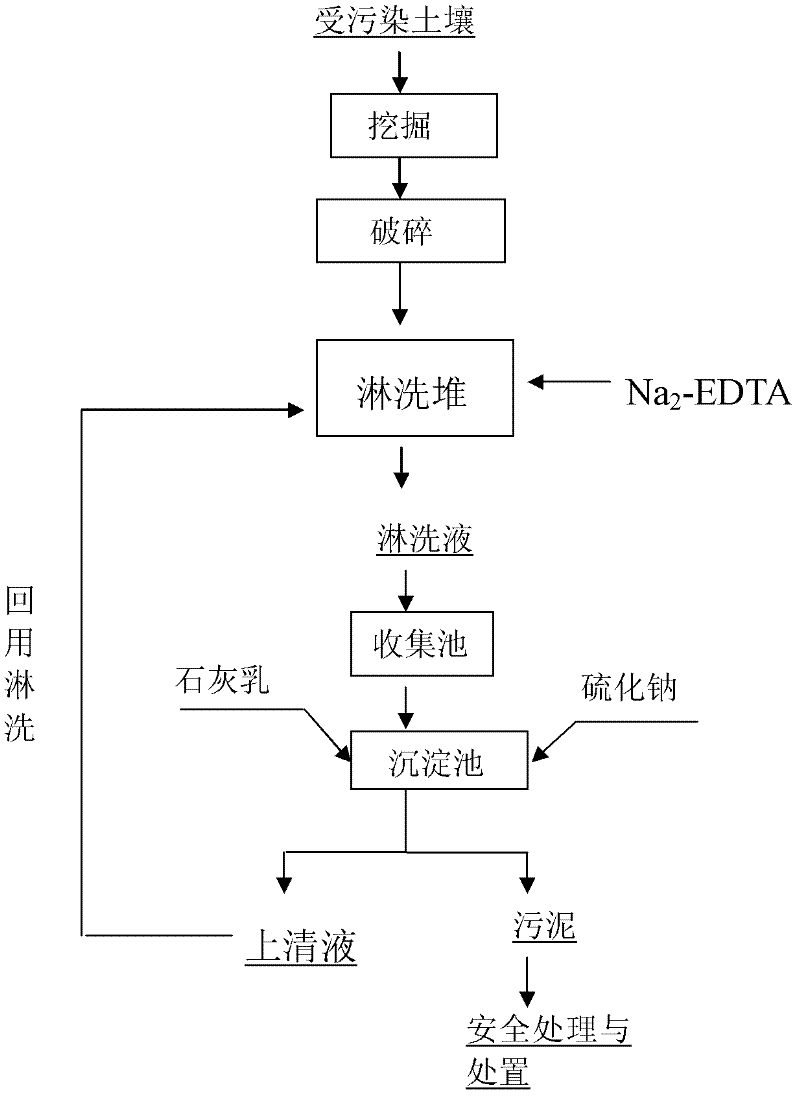

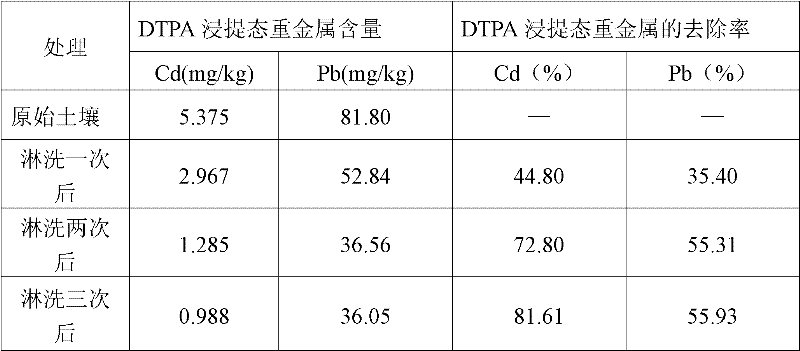

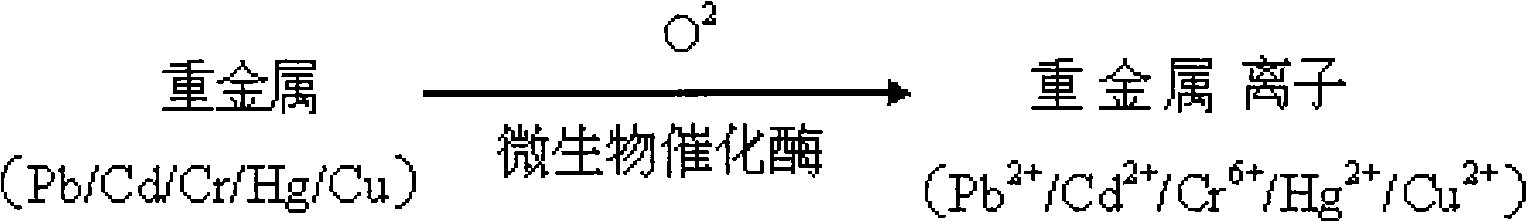

Chemical leaching restoring method for soil polluted by heavy metals

ActiveCN102500612AReduce Na

<sup>+</sup>

contentReduce operating costsContaminated soil reclamationPollution soilCadmium Cation

The invention discloses a chemical leaching restoring method for soil polluted by heavy metals. Na2EDTA solution is utilized to perform leaching to the soil polluted by the heavy metals, available cadmium and lead in the soil are effectively removed, Na2S.9H2O is utilized to precipitate the heavy metals in filtrate, Na2EDTA is released again, and repeated recycling of the Na2EDTA solution is achieved. After recycling, the Na2EDTA solution carries out leaching to the soil polluted by the heavy metals, the removing rate of available Cd in the polluted soil reaches 81.6-81.8%, and the removing rate of available Pb reaches 55.9-60.1%. The chemical leaching restoring method for the soil polluted by the heavy metals overcomes the shortcomings that an existing method for the Na2EDTA solution to perform leaching to the soil polluted by the heavy metals causes chemical cost to be large, generated filtrate is much, and the follow-up treatment is troublesome. Simultaneously, the chemical leaching restoring method for the soil polluted by the heavy metals has the advantages of being simple in process, becoming effective quickly, enabling a leaching agent to be reused, and enabling the heavy metals to be effectively eliminated.

Owner:CENT SOUTH UNIV +1

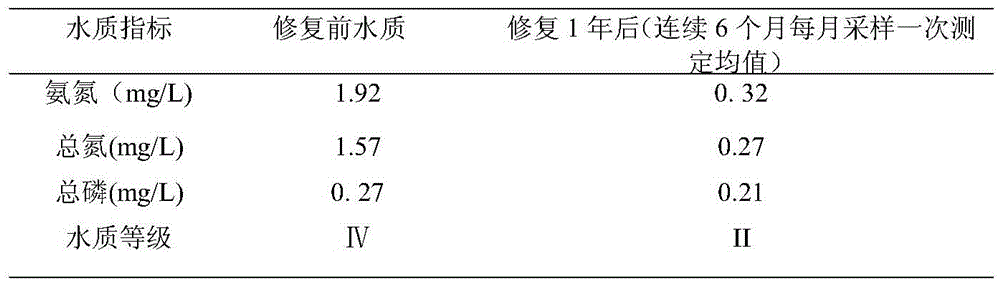

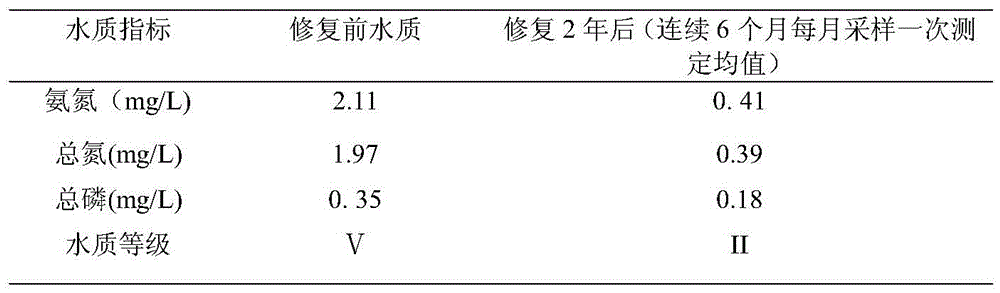

Ecological restoration method for city watercourse

InactiveCN103882828AHas the ability to resist external interferenceEasy to viewWater resource protectionStream regulationEcological environmentRestoration method

The invention relates to an ecological restoration method for a city watercourse. The ecological restoration method for the city watercourse is characterized in that the polluted city watercourse is comprehensively restored with the combination of physical, biological and ecological technologies, the ecological theory is used for reference in the treatment process, the ecological idea is used as the guiding thought, a complex water ecosystem structure is constructed and restored, the original natural state of the watercourse is restored, the self-cleaning capacity of a river system is improved, the environment is beautified, and the local city microclimates are improved at the same time. The ecological restoration method mainly comprises the steps of (1) controlling a pollution source, (2) modifying the river bank, (3) optimizing the environment of the river bottom, (4) modifying the watercourse, (5) conducting aeration and oxygenation, (6) constructing an aquatic plant community, (7) constructing a fish and macrobenthos community, and (8) maintaining the system. The watercourse ecological system restored through the ecological restoration method has the certain anti-interference capacity, on the premise that a large amount of exogenous pollution is cut off, the certain-strength interference can be resisted, and the good ecological environmental effect is obtained. After one-time input, the better ecological benefit can be obtained only with a small number of maintenance costs.

Owner:深圳市益水生态科技有限公司

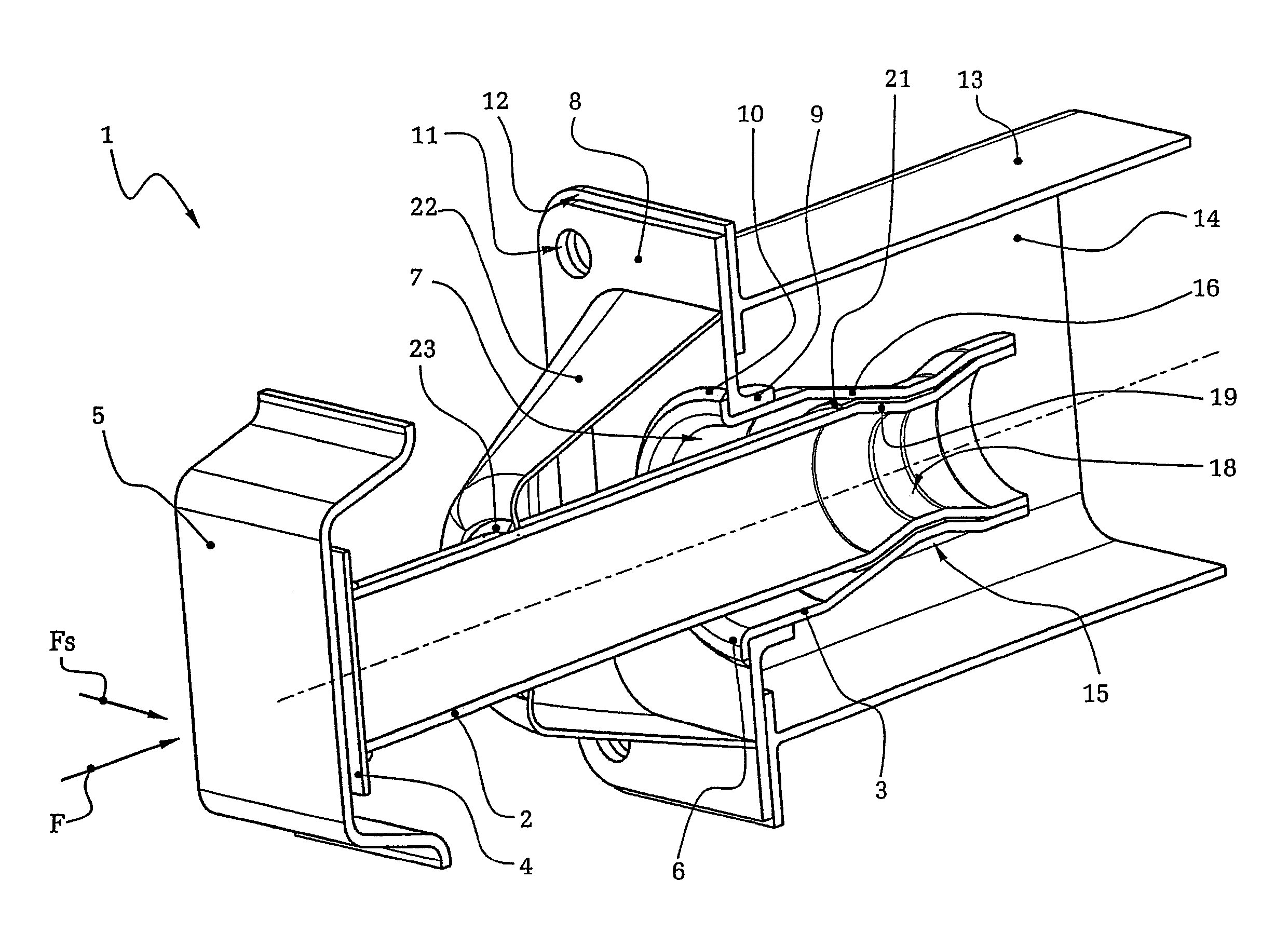

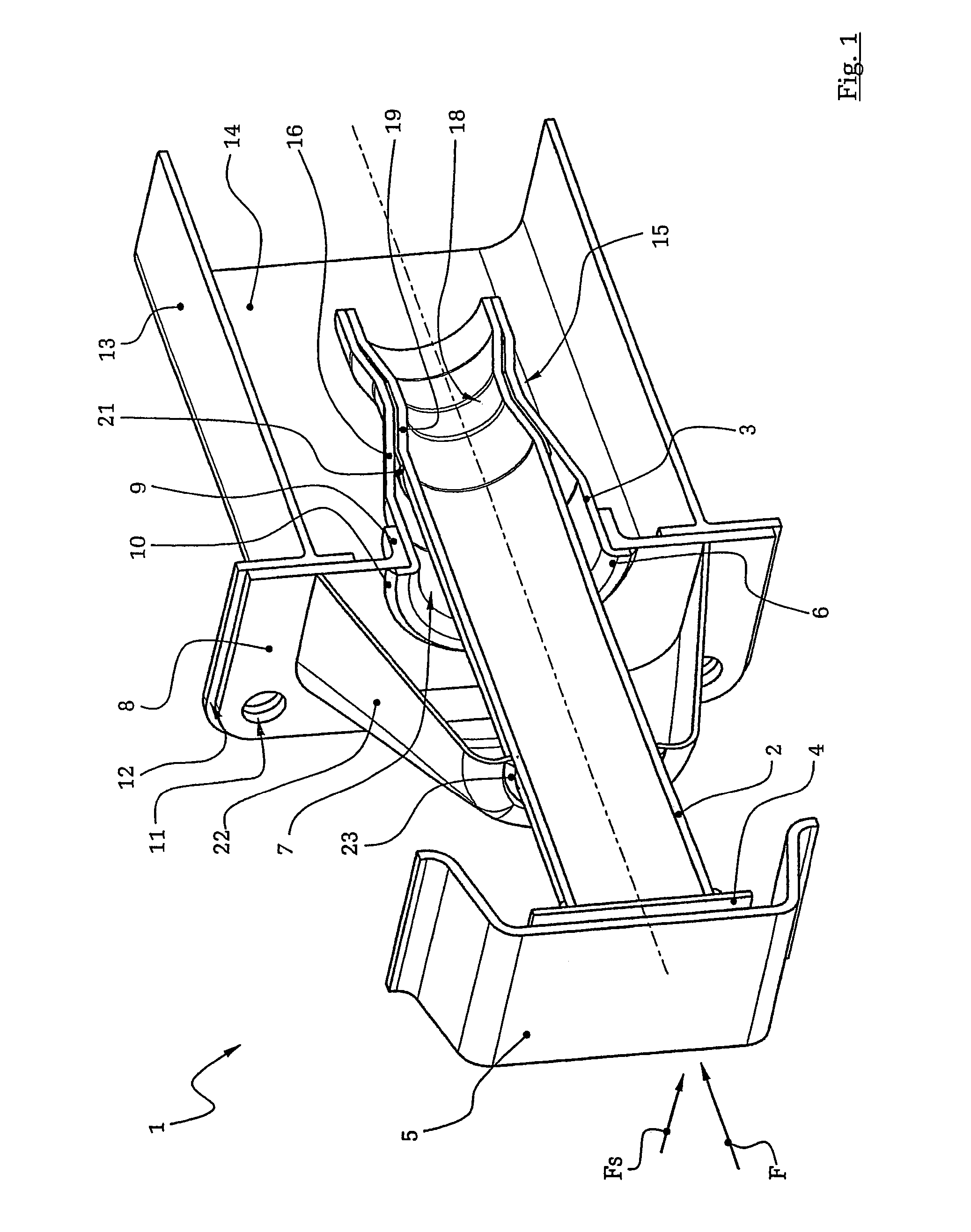

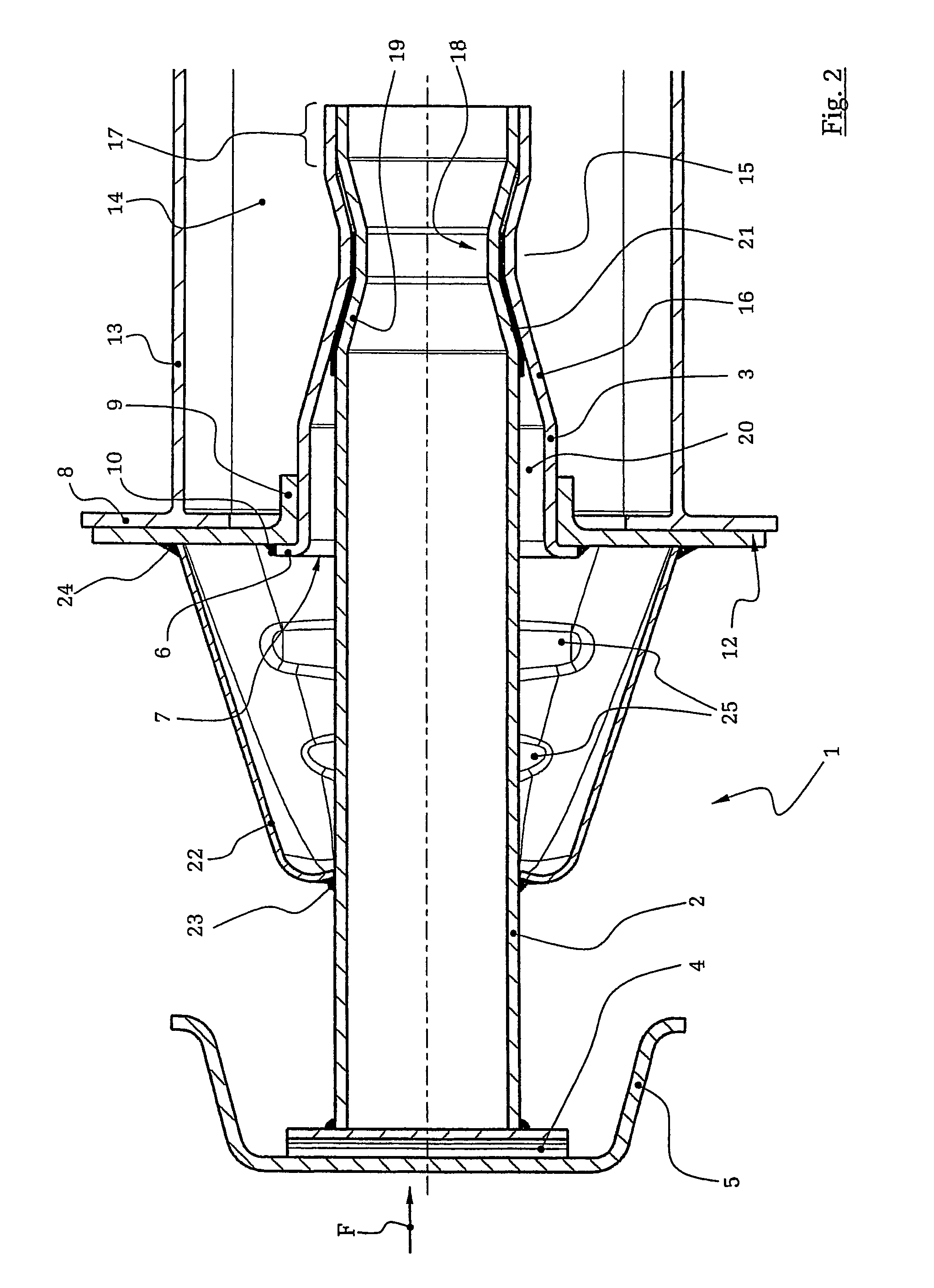

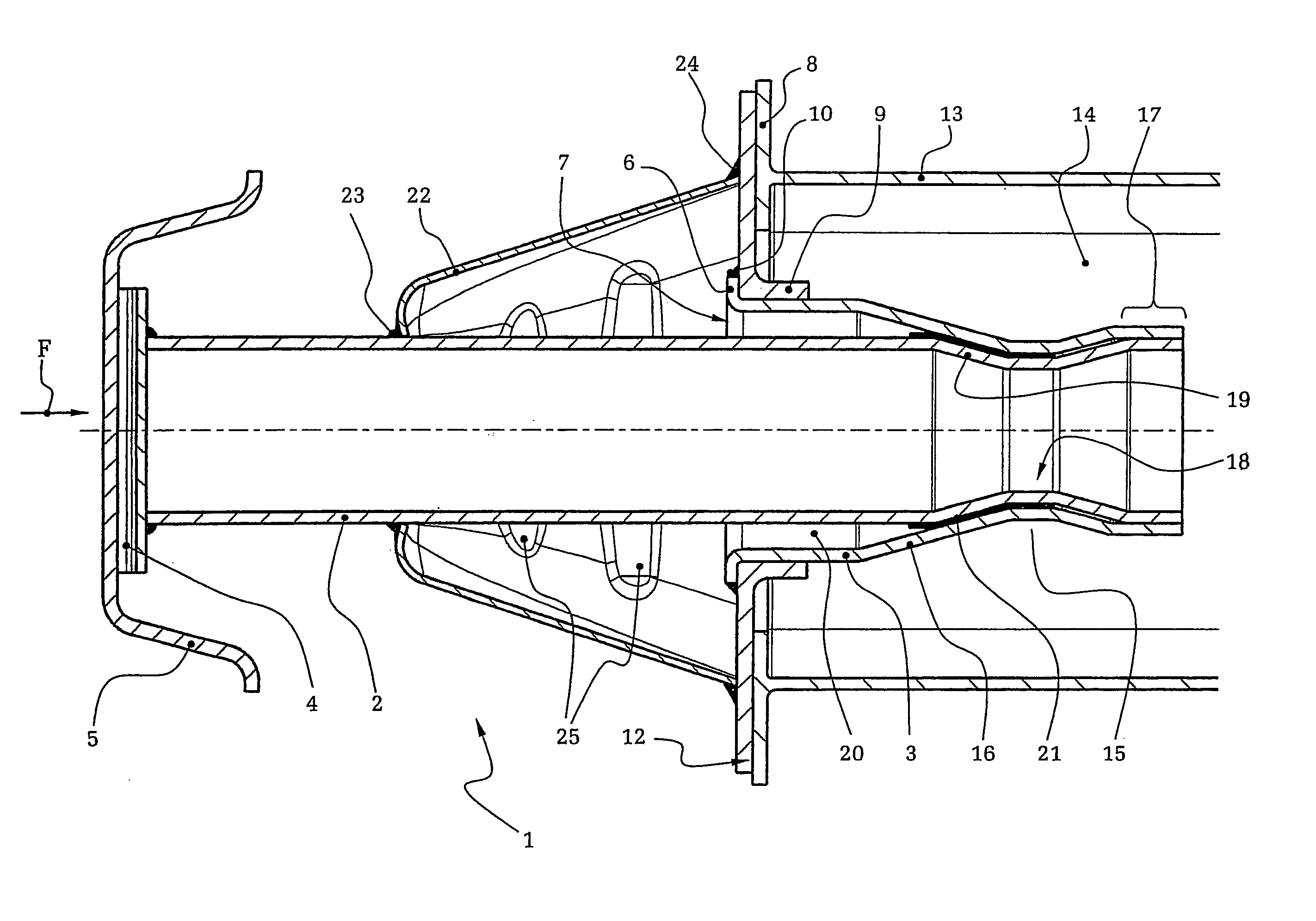

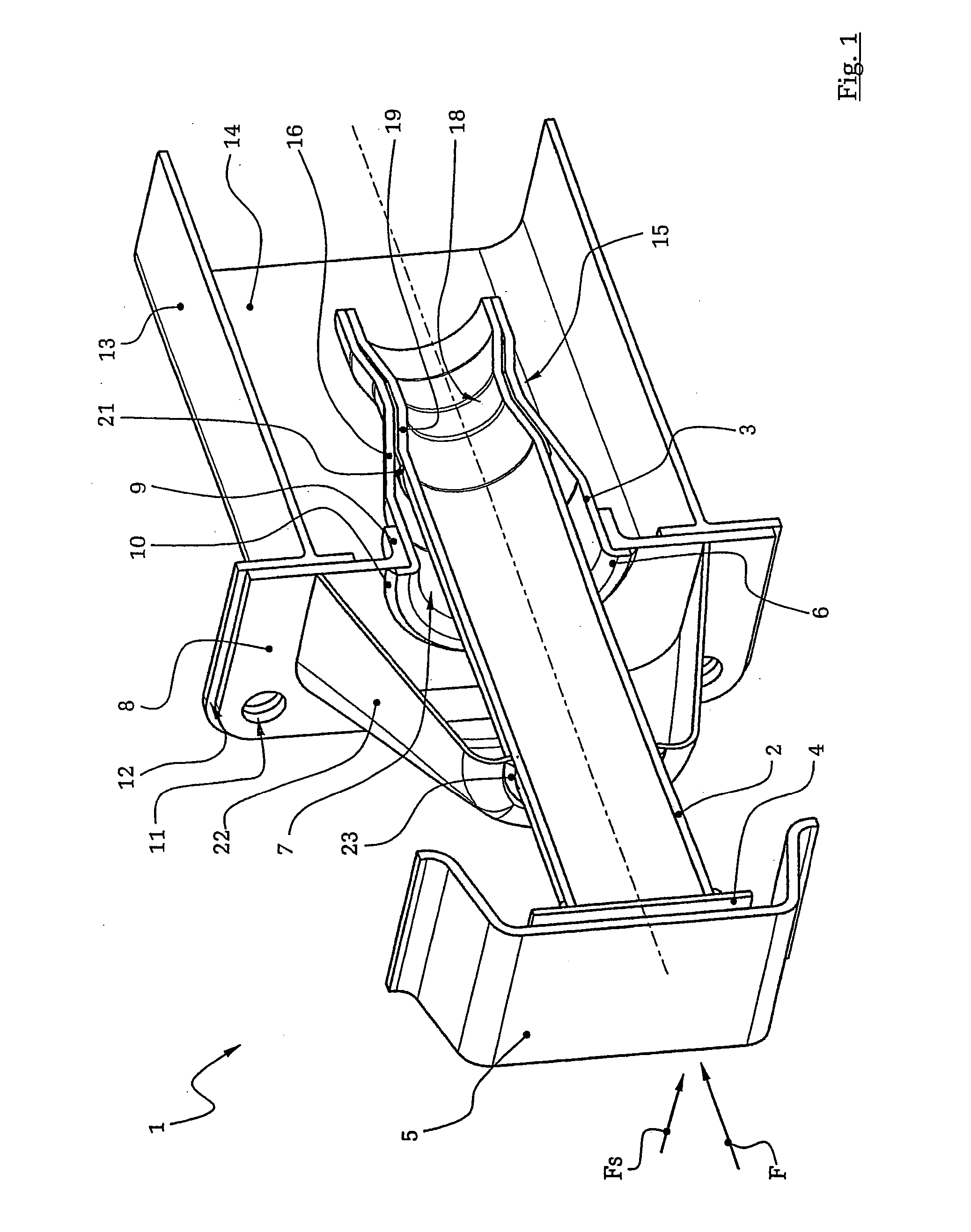

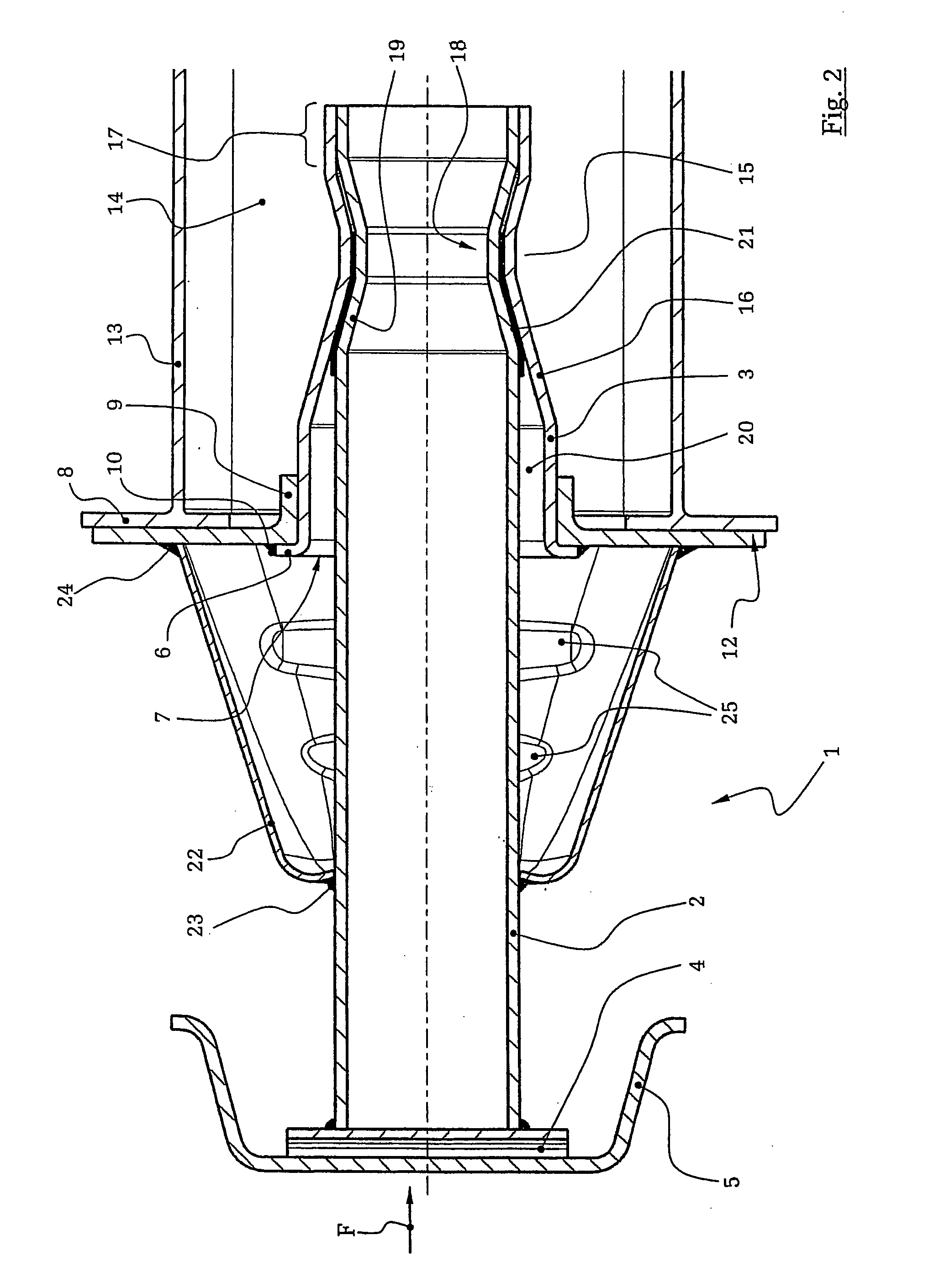

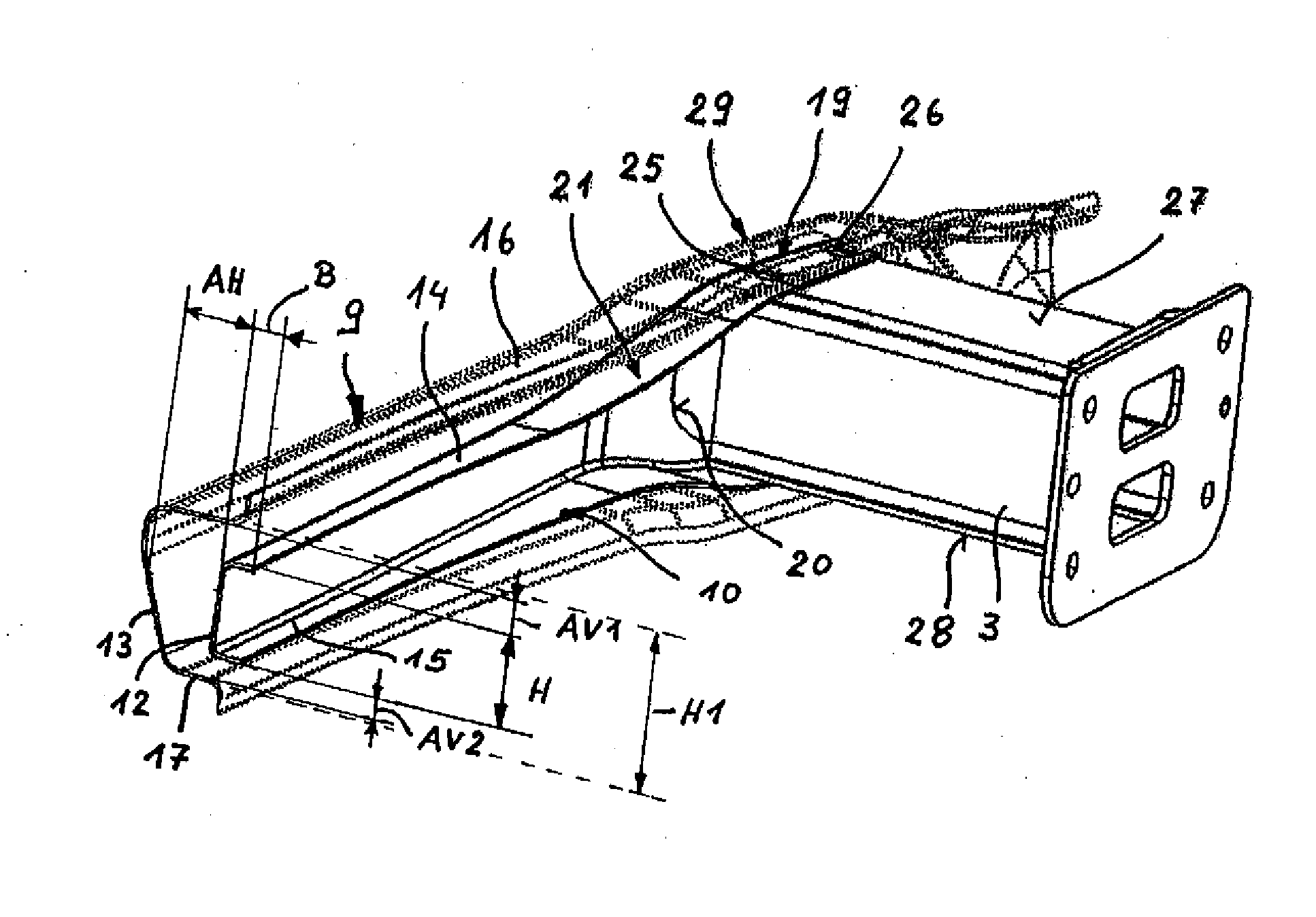

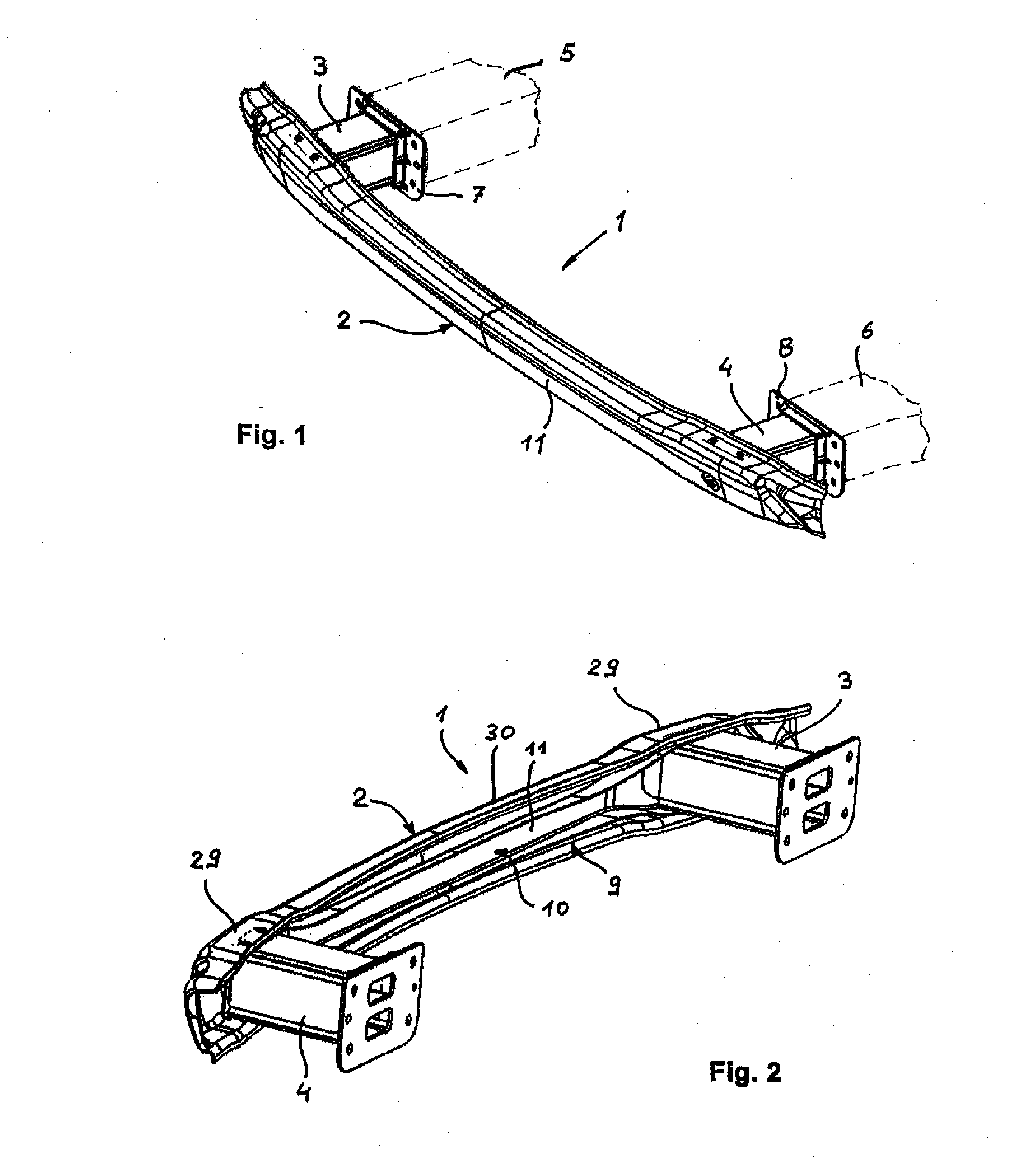

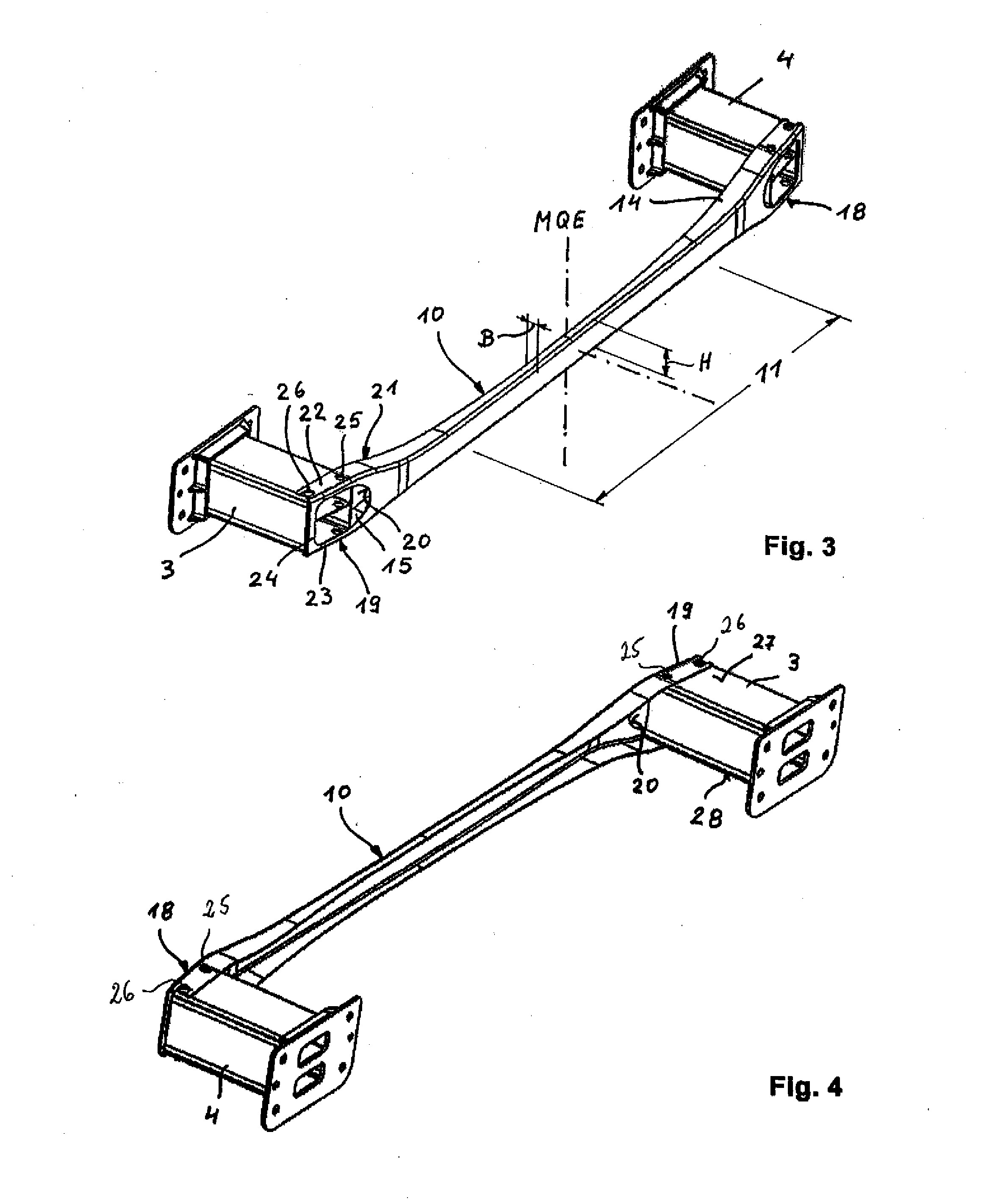

Impact damper assembly for an automobile

InactiveUS7192067B2Improve securityPrevent deformation or damageVehicle seatsPedestrian/occupant safety arrangementEngineeringChassis

Impact damper assembly for an automobile, in particular for supporting a bumper 5 on an automobile chassis, with an inner tube 2 movably arranged in an outer tube 3, wherein both tubes 2, 3 have an approximately mutually parallel taper 16, 19, wherein the taper 19 of the inner tube 2 is encompassed by the taper 16 of the outer tube 3, and wherein at least one of the two tubes 2, 3 can be deformed during the movement by the taper 16, 19 of the two tubes. The invention is characterized in that the impact damper assembly includes an additional deformable stiffening element 22.

Owner:ZF FRIEDRICHSHAFEN AG

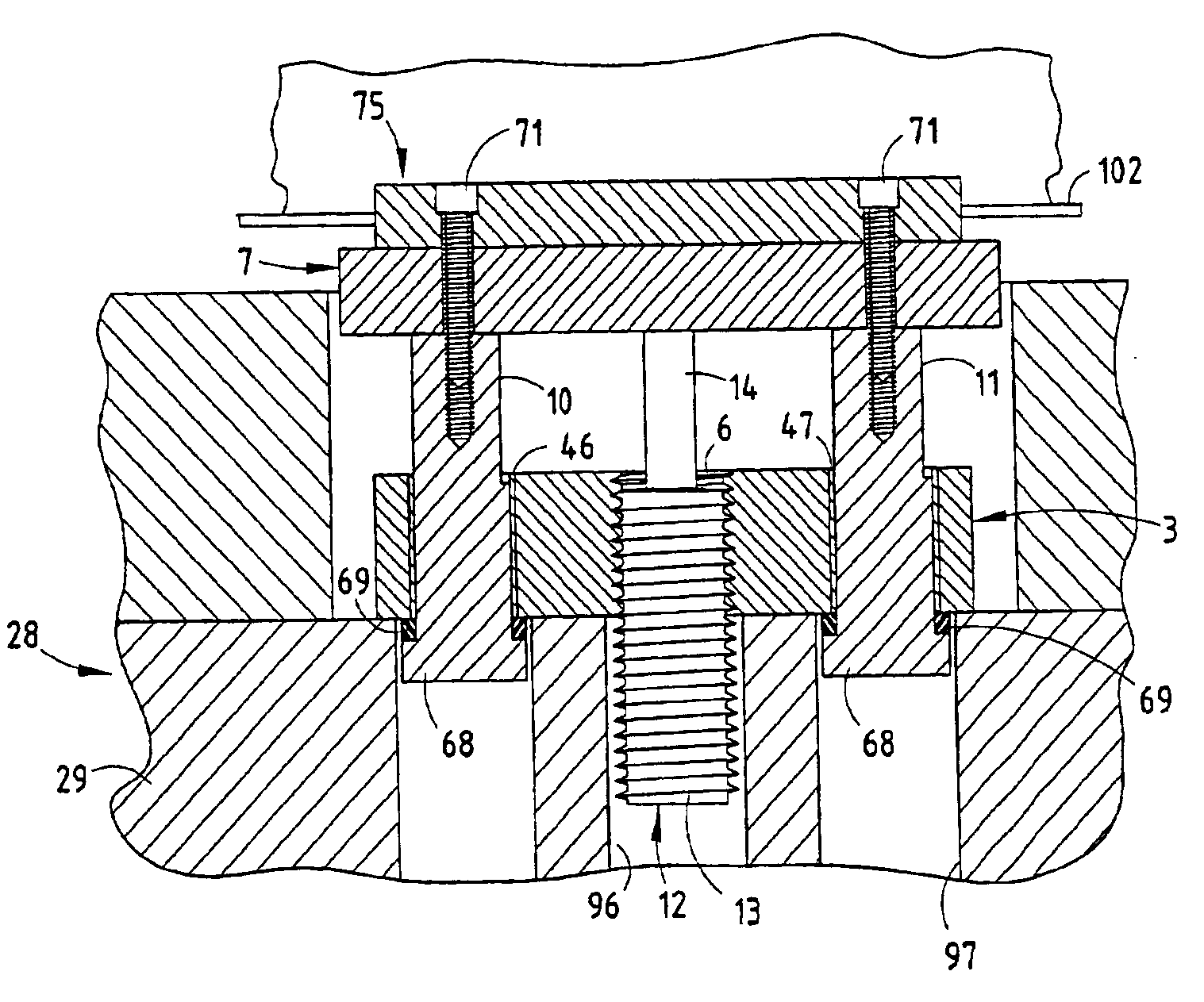

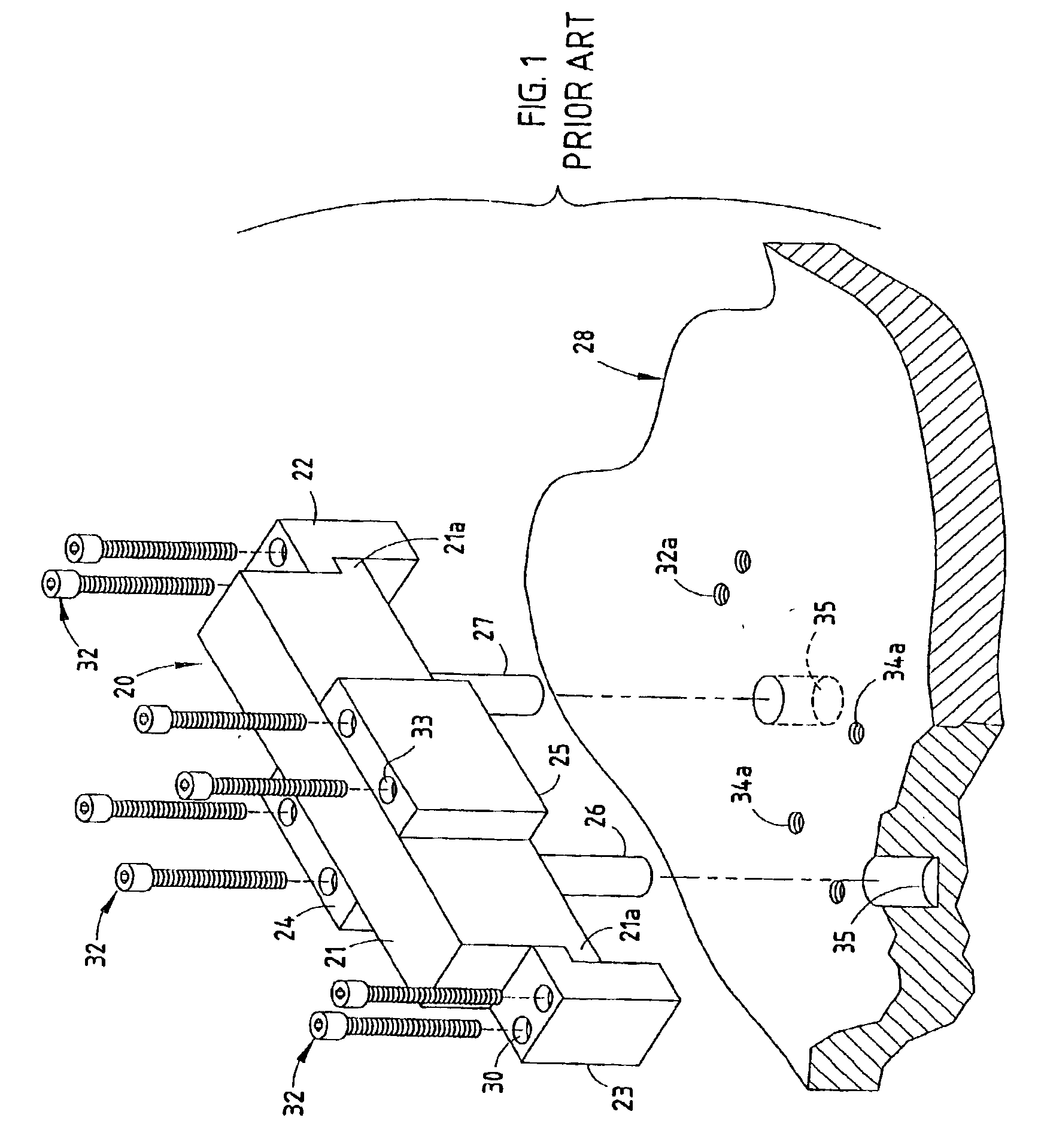

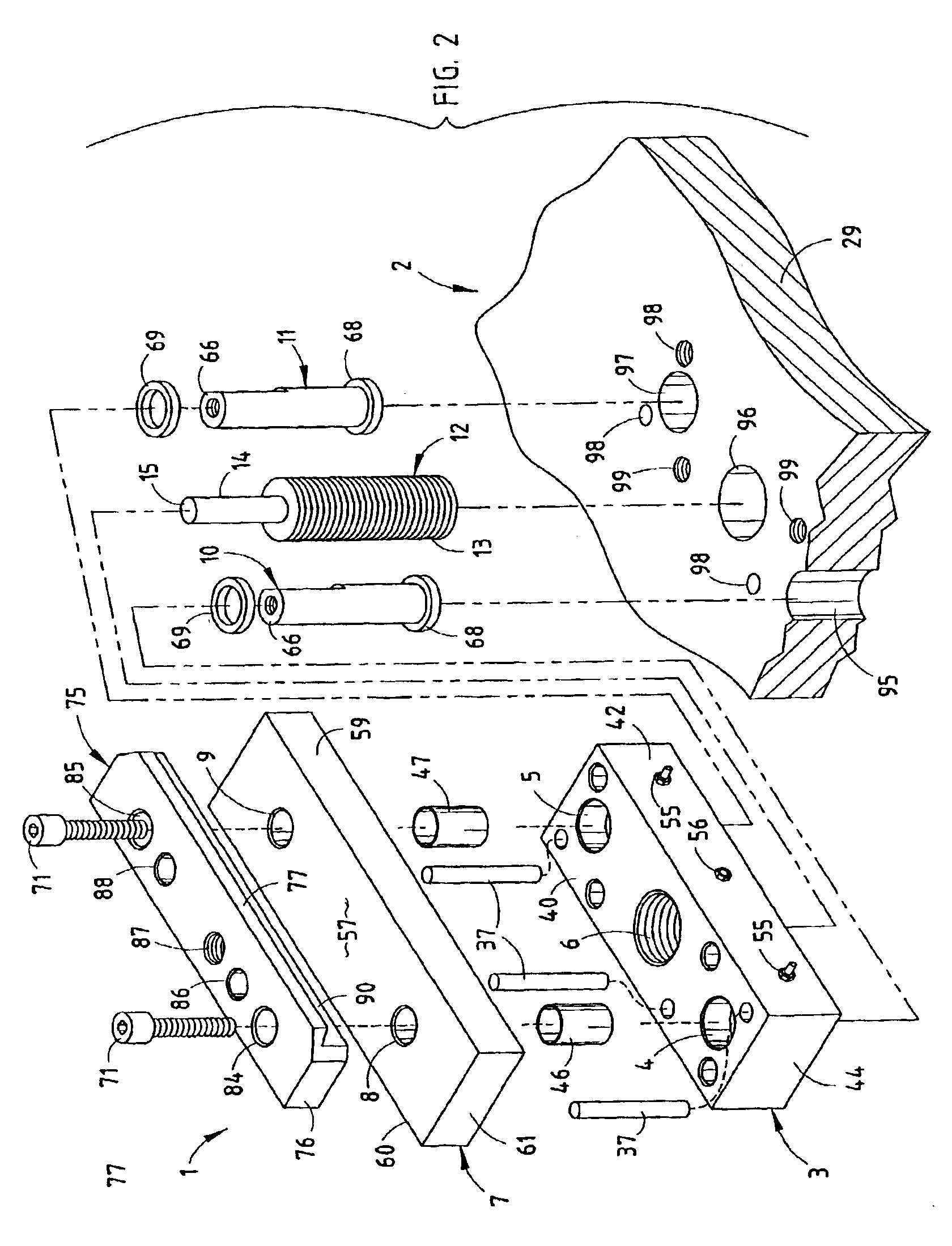

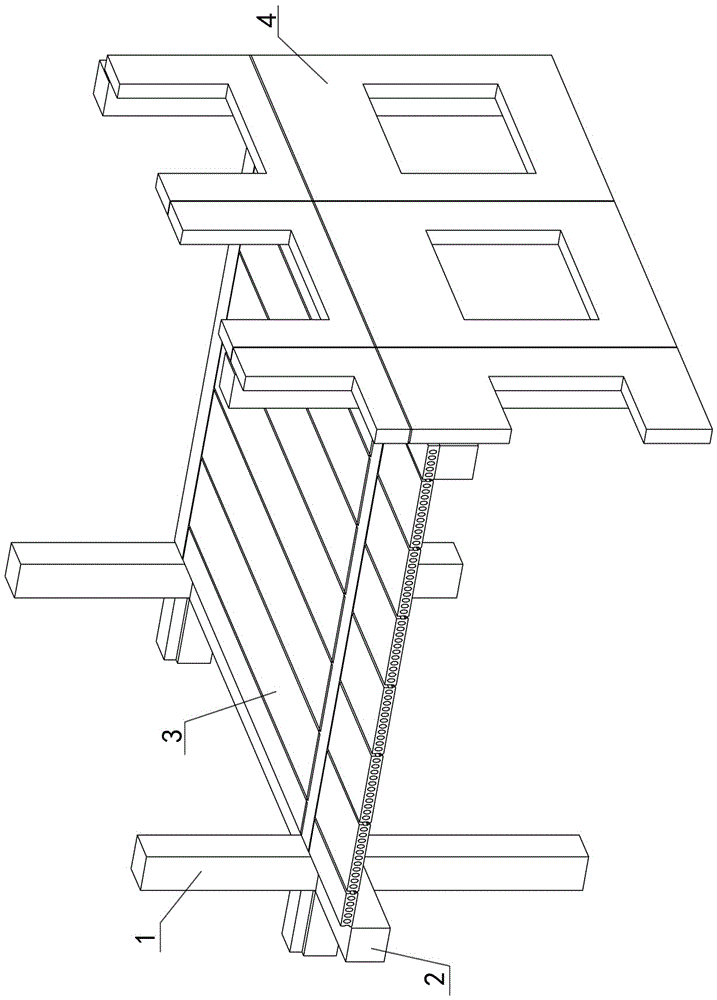

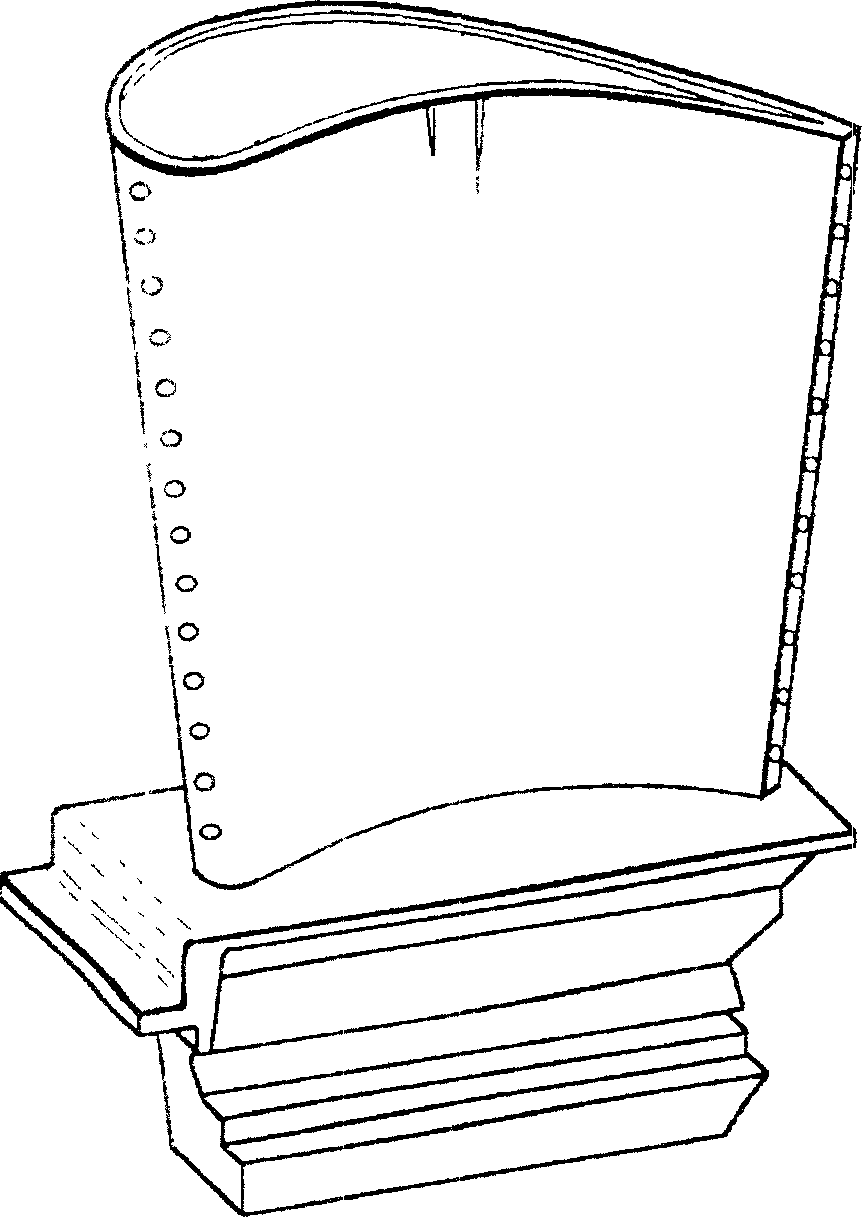

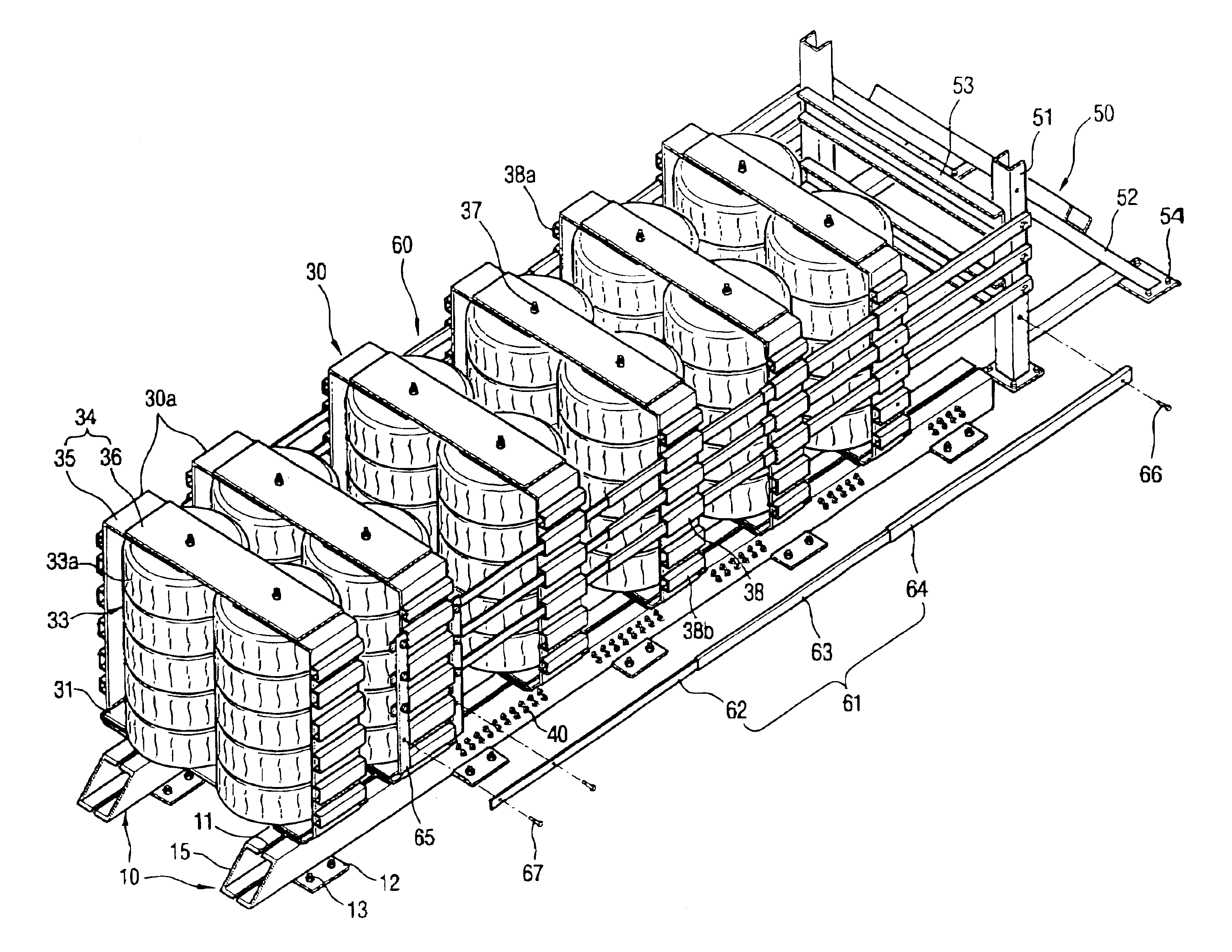

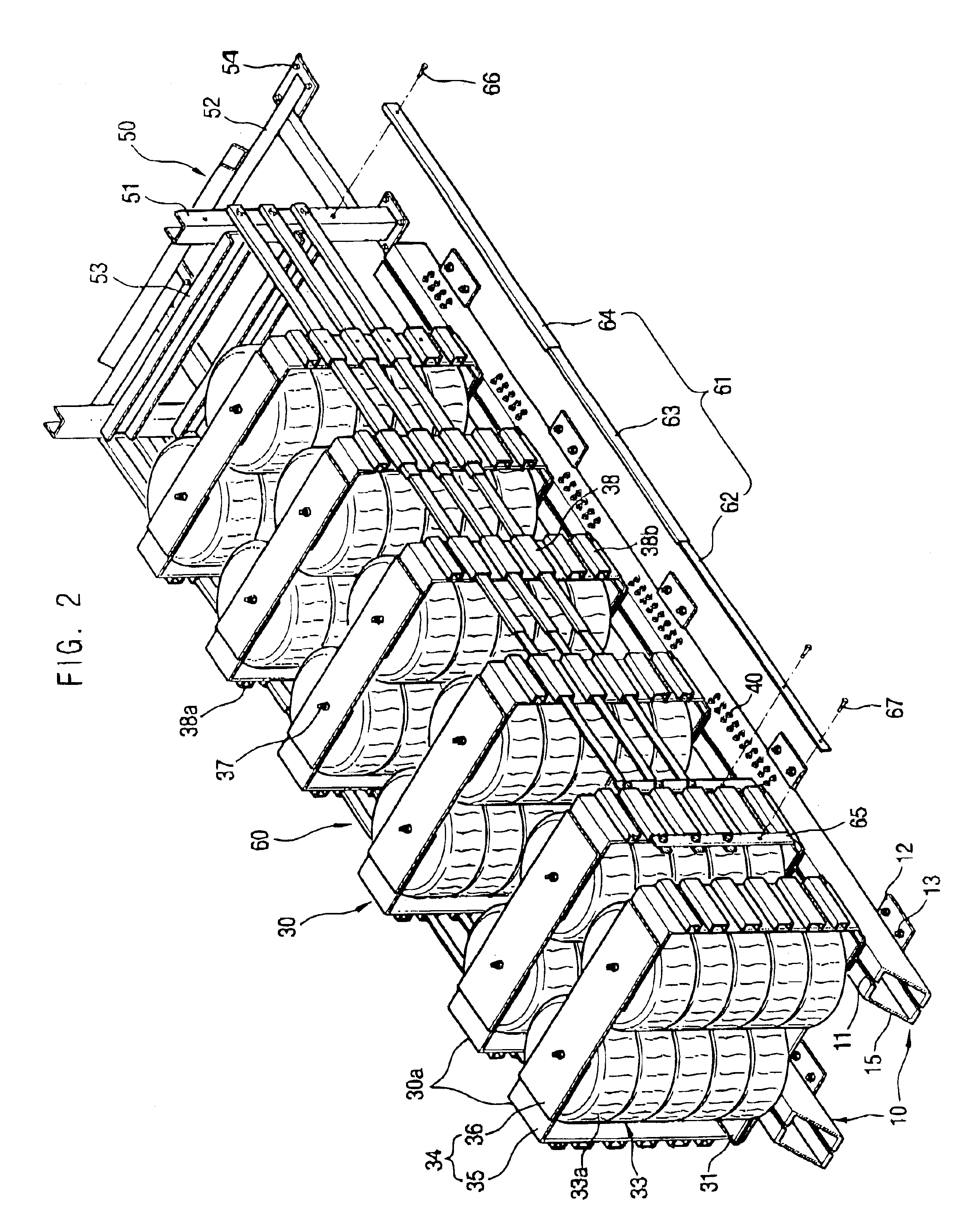

Stock lifter for metal forming dies and method for making the same

InactiveUS6848290B2Reduce design costReduce manufacturing costShaping toolsMetal-working feeding devicesMetal formingReciprocating motion

A self-contained stock lifter is particularly adapted for use in multiple station, progressive metal forming dies and the like, and includes a base plate with two vertical through holes adjacent opposite sides, and a vertical spring unit aperture located between the through holes. The stock lifter also includes a lifter bar having two vertical through holes in vertical registry with the base plate through holes. Two rigid guide shafts are mounted in the base plate through holes to permit the lifter bar to reciprocate in a manner which selectively lifts stock in the die to permit longitudinal shifting of the stock along the multiple die stations. A spring unit has a base retained in the spring unit aperture, and a reciprocating rod biased outwardly, with a free end abutting a central portion of the lifter bar to shift the lifter bar to an extended position, thereby defining a fully self-contained unit that can be readily mounted in and removed from the die to reduce manufacturing and repair costs.

Owner:PYPER TOOL & ENG

Slow release fertilizer having soil remediation function and soil contamination remediation method

ActiveCN101928179AReduce the frequency of fertilizationImprove repair efficiencyContaminated soil reclamationFertilizer mixturesBiologyNutrients substances

The invention discloses a slow release fertilizer having a soil remediation function. The slow release fertilizer is prepared by mixing fully-biodegradable polyhydroxyalkanoates and organic and inorganic nutrient substances. The fully-biodegradable polyhydroxyalkanoates is slowly degraded under the actions of soil microorganisms to provide nutrient substances needed by the growth of the soil microorganisms so as to promote the ionization effects of the soil microorganisms on heavy metals and release the organic and inorganic nutrient substances by slow degradation so as to promote durable and rapid growth of plants and improve soil remediation efficiency. The invention also discloses a soil contamination remediation method for using the slow release fertilizer. High-efficiency, environmentally-friendly and durable remediation of heavy metal-contaminated soil is realized by planting plants having hyper-accumulation capability to absorb and extract the heavy metals in the soil to which the slow release fertilizer is applied.

Owner:SHENZHEN ECOMANN BIOTECH

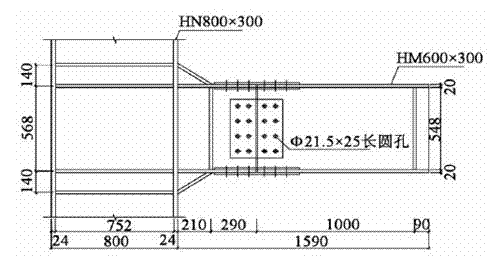

High-ductility steel structure beam column node in angle steel connection and construction method of high-ductility steel structure beam column node

ActiveCN102363979AIncreased ductile deformation capacityImprove energy consumptionBuilding material handlingShock proofingHigh intensitySteel columns

The invention relates to a high-ductility steel structure beam column node in angle steel connection and a construction method of the high-ductility steel structure beam column node. The invention is characterized in that: upper and lower flange plates of an H-shaped steel beam are respectively connected with a steel column by using flange angle steel, a flange steel cushion plate and a friction type high-strength bolt; a web plate of the H-shaped steel beam is connected with the steel column by using web plate angle steel, a web plate steel cushion plate and the friction type high-strength bolt; bolt holes in a flange angle steel branch and a web plate angle steel branch, which are connected with the H-shaped steel beam, are long circular holes; horizontal reinforcing ribs are arranged, at a joint of the steel column and the H-shaped steel beam, inside the steel column; and a gap is reserved between an end head of the H-shaped steel beam and the steel column. The high-ductility steel structure beam column node has quite high ductile deformation capacity and excellent energy-dissipation capacity; and connection welded beams are not formed on beam column members, so that the brittle failure of the steel beam or the steel column in a node area under the action of a seldom-occurring earthquake is avoided. Furthermore, the high-ductility steel structure beam column node has the advantages of convenience for construction, simple and quick in repair operation after the earthquake, low in repair cost and the like.

Owner:FUZHOU UNIV

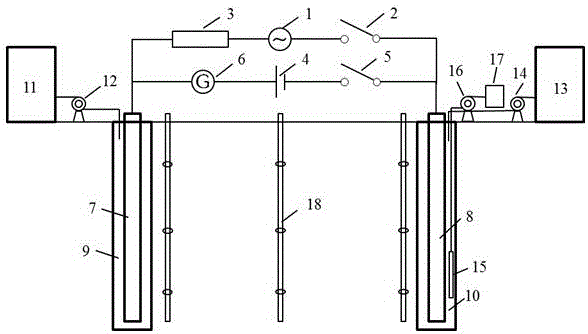

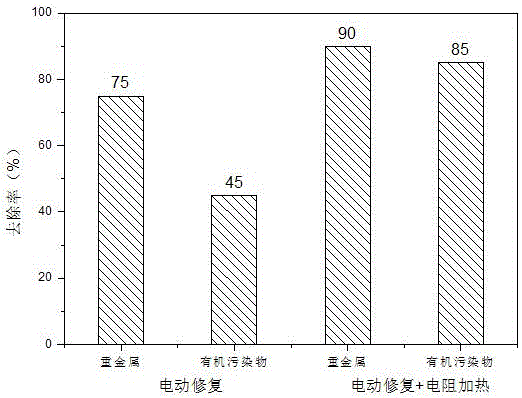

In-situ remediation method of heavy metal-organic combined pollution soil

InactiveCN106269843ATo achieve an organic combinationAchieve migrationContaminated soil reclamationEngineeringAlternating current

The invention relates to an in-situ remediation method of heavy metal-organic combined pollution soil. According to the method, a set of electrokinetic remediation device is added with a power switching system, an electrode heating technology is combined with the electrokinetic remediation and chemical oxidization technology, namely, the direct current power is utilized firstly, sodium persulfate used as the oxidizing agent is migrated to soil through electric process, meanwhile, migration and removal of heavy metal ion in the soil are realized. Then the alternating current power is switched, and soil is heated to a certain temperature through the electrode heating method so as to activate the sodium persulfate migrated to soil, and thereby realizing the in-situ degradation of organic pollutant in the soil. The method applies electrode to the electrode heating system and the electrokinetic remediation device at the same time, simplifies the remediation device and saves the system energy consumption while solves the difficulty that oxidant cannot migrate and activate in the soil and improves the remediation efficiency; the method is a combined soil remediation technology with prospect of application and promotion.

Owner:中建中环新能源有限公司 +1

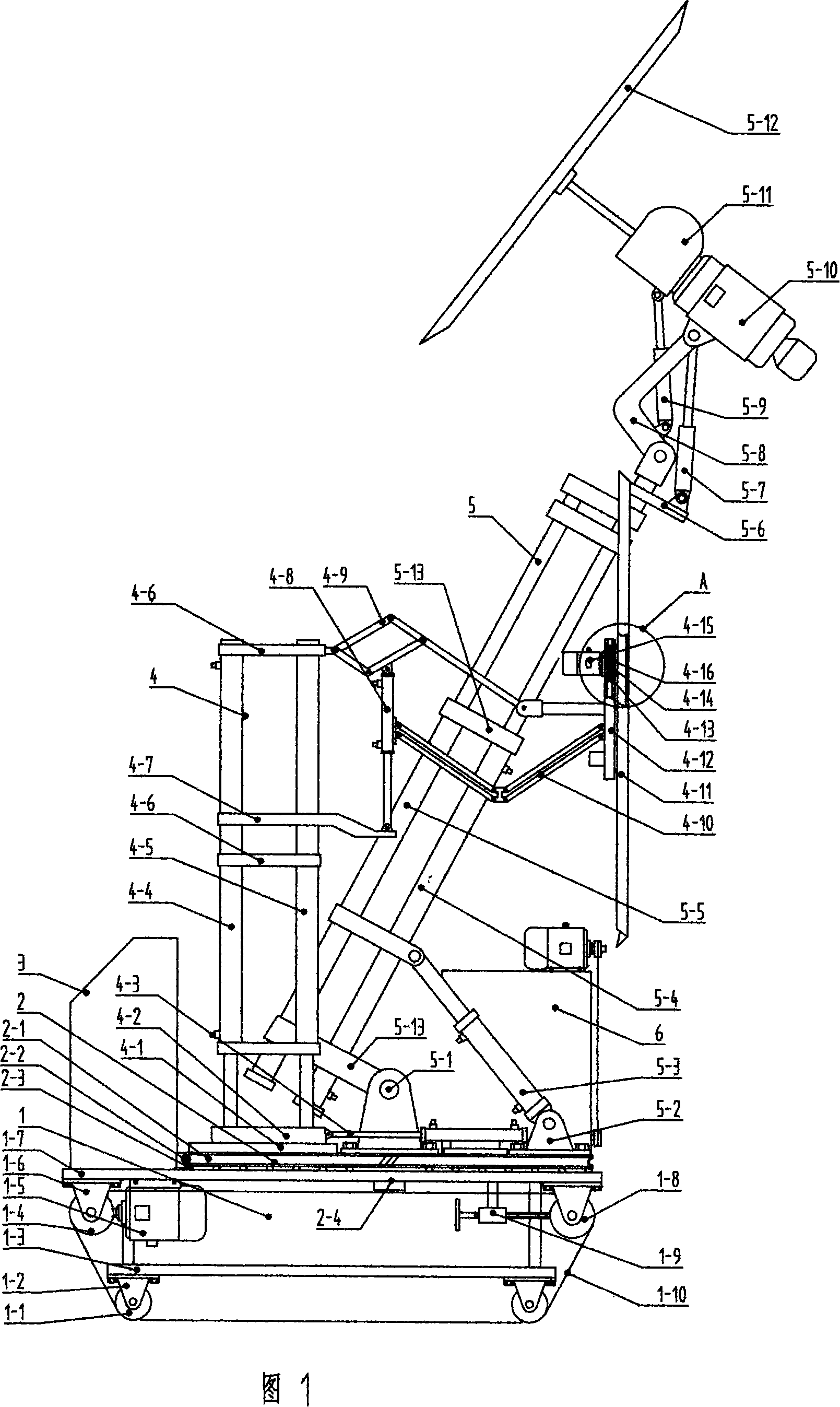

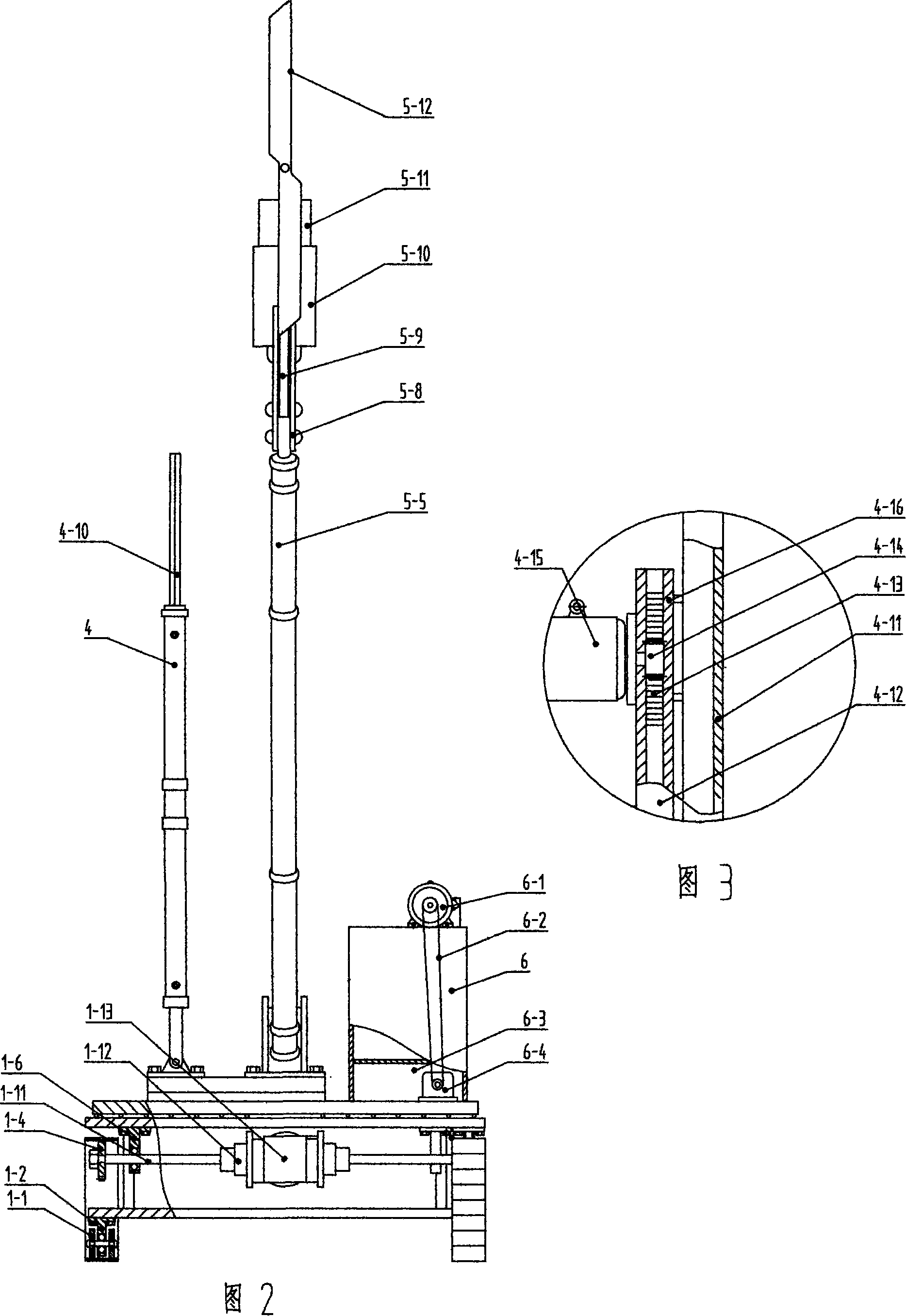

Wall rendering robot

InactiveCN101144324AStraightness is easy to guaranteeQuality improvementBuilding constructionsElectromagnetic clutchDrivetrain

The invention relates to an improved equipment on the basis of an original patent wall side plastering machine (the patent number: ZL01218090.4), and the invention is that two groups of mutually independent plane plastering devices and reentrant and outside corners plastering devices are arranged on the revolution support of a crawler belt chassis. Improvement is done to a power driving system of the crawler belt chassis, and a half axis and an electromagnetic clutch are added. The revolution support adopts a gear worm to drive. The weight of a complete machine is reduced, in order to ensure that the whole mechanization is realized for the work of the complete machine such as the plastering, the roughening, the treatment of the reentrant and outside corners during the construction, the labor strength is greatly reduced, the production efficiency is improved, and the maintenance expense is reduced, as well as the service life is prolonged.

Owner:赵呈为 +1

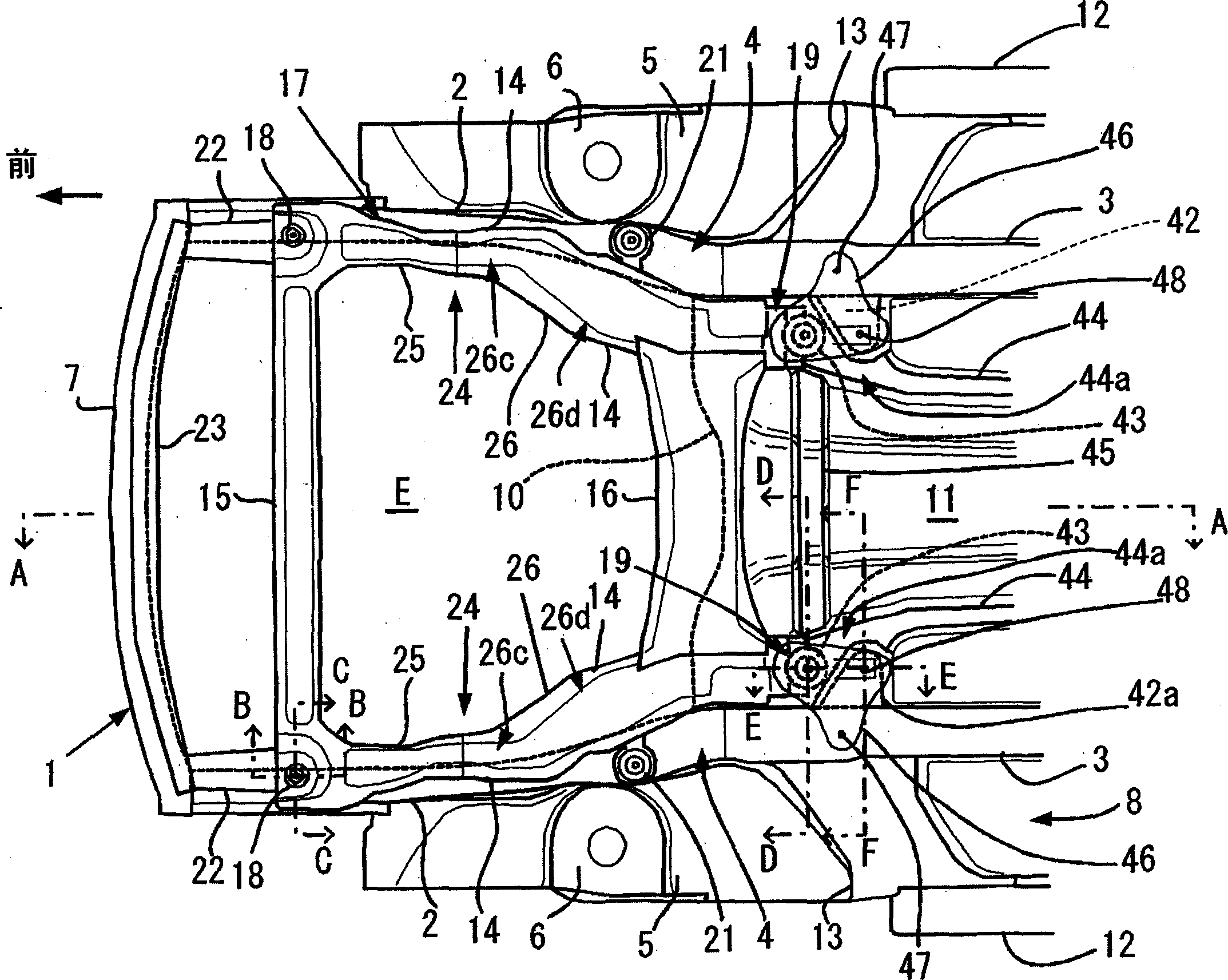

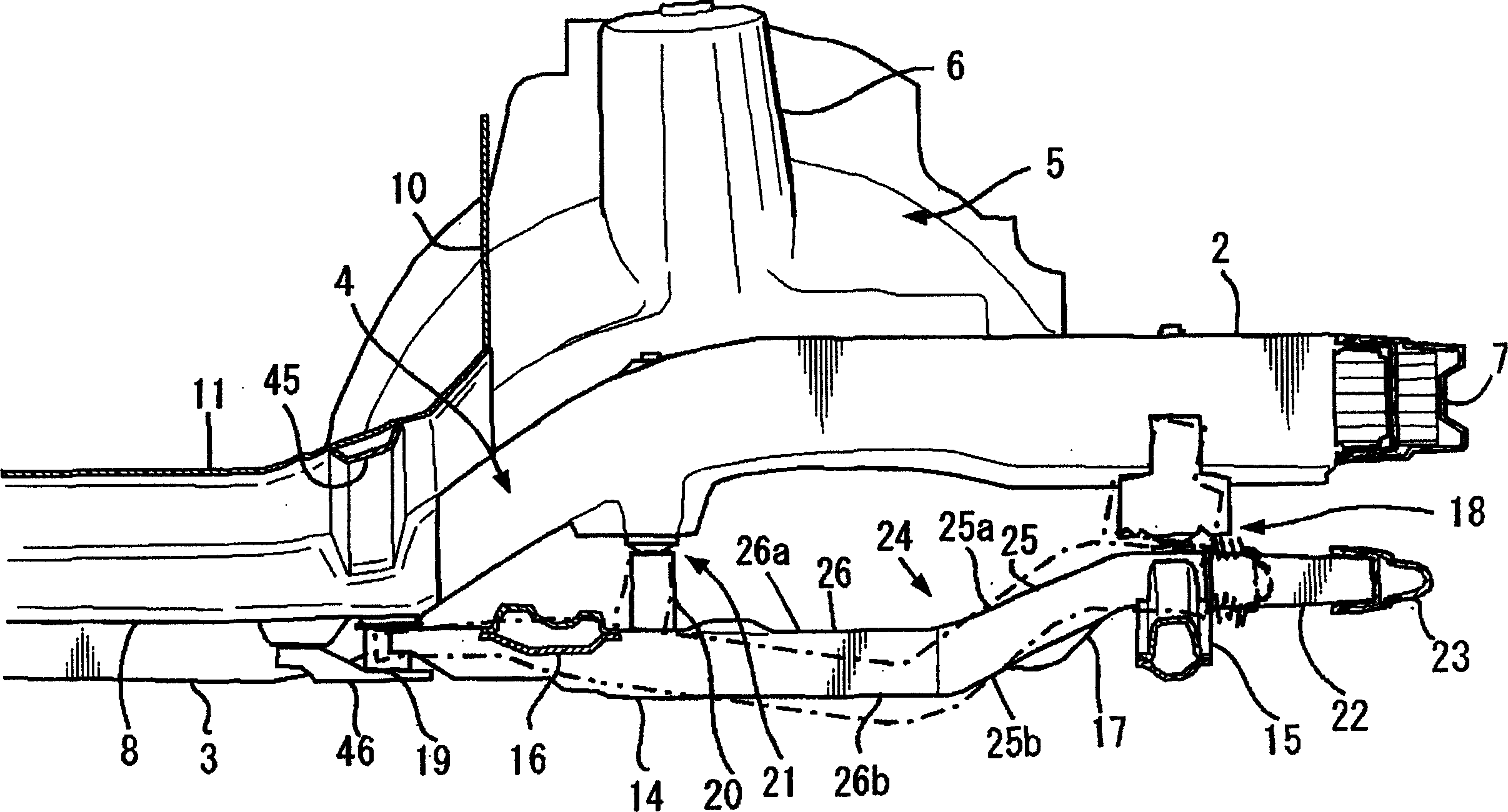

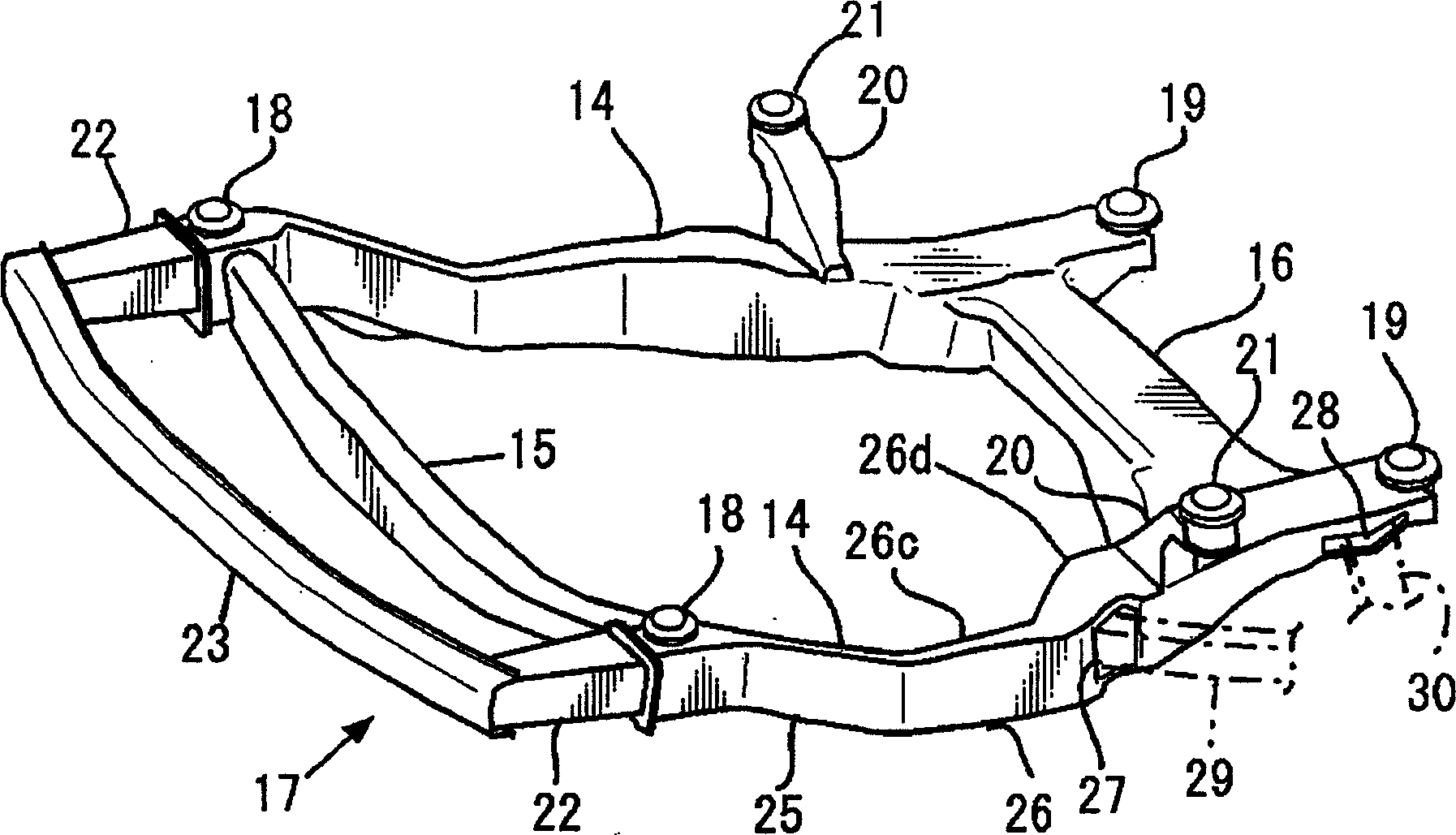

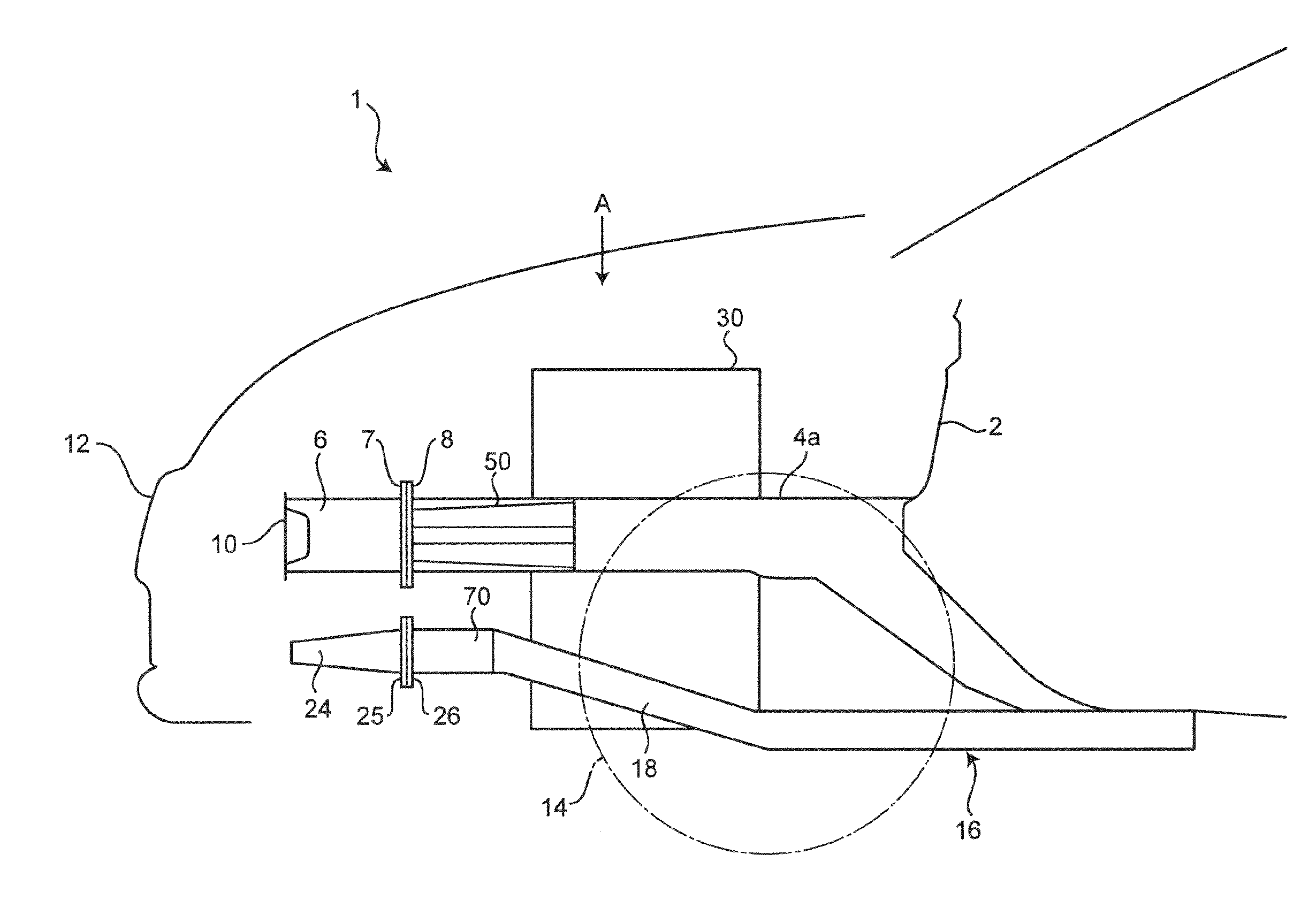

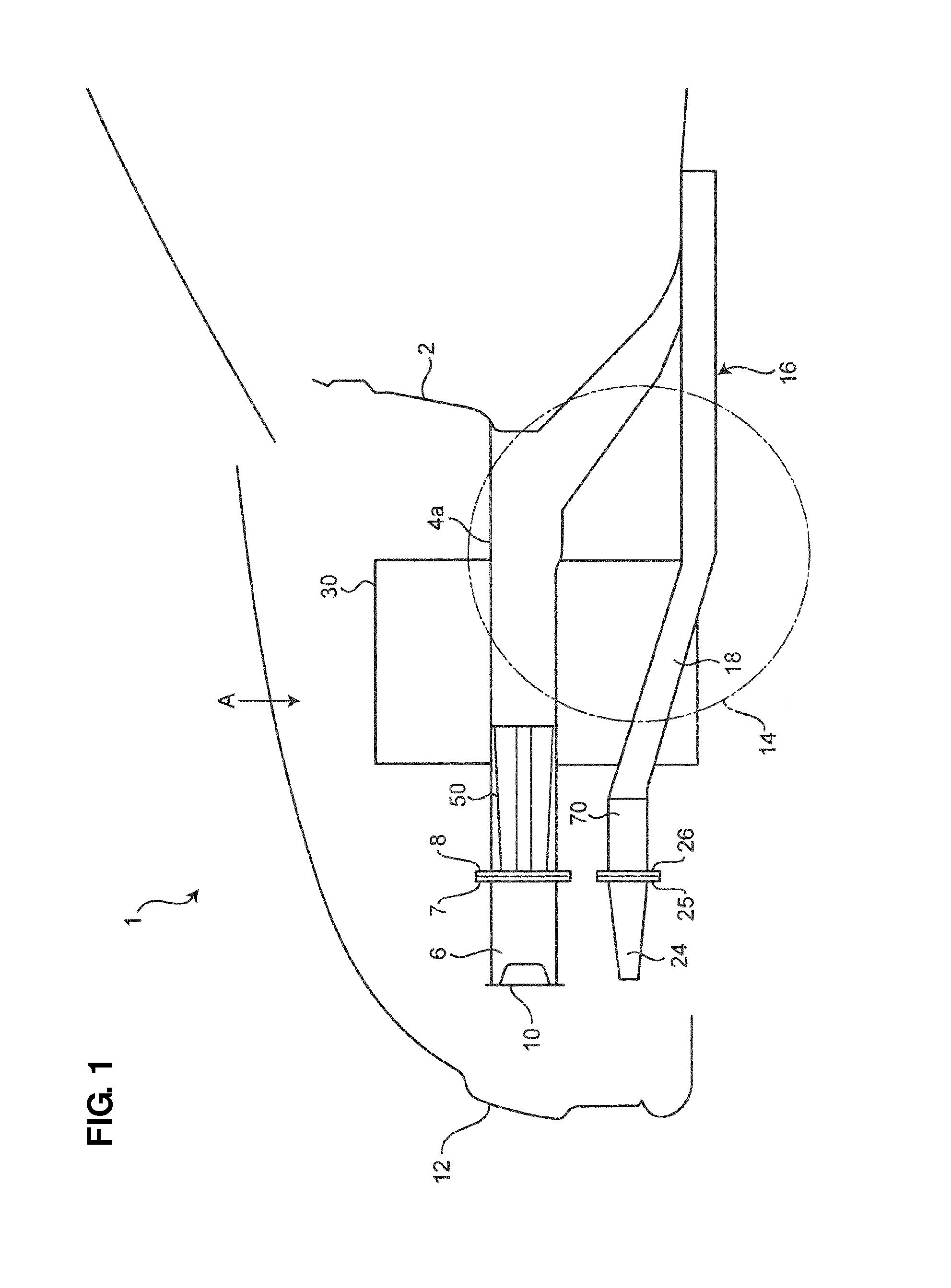

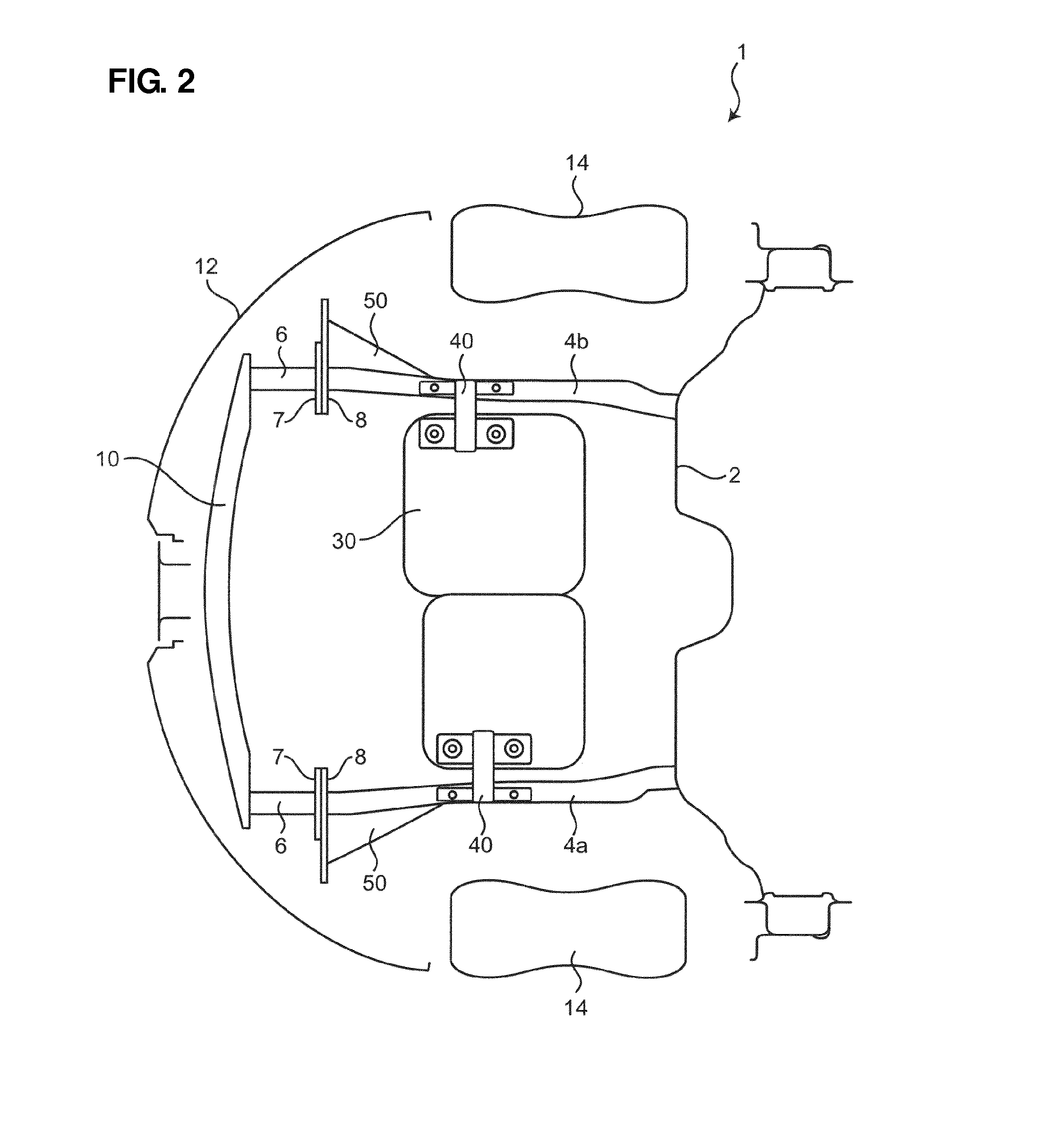

Vehicle front-part structure

An automobile front-part structure is provided in which an impact-absorbing member can absorb the impact energy that is given by a bump, whatever bump it is, such as an offset collision and a pole bump. This automobile front-part structure including: a pair of vehicle-body frames which extends in the front-and-rear directions along both sides of a vehicle, and whose front-end parts extend up to the front part of an automobile; and a front sub-frame which is supported with the vehicle-body frames in the front part of the vehicle, and is disposed below the vehicle-body frames, in which the front sub-frame includes: a front sub-frame main-body which has, a pair of right and left side frames which extends in the front-and-rear directions of the vehicle, and a cross member which is formed by a reinforcement and bridges the front parts of the side frames; a pair of right and left impact absorbing members which is formed by a crush pipe, is disposed at the front-end parts of the side frames in the front sub-frame main-body and absorbs impact energy from ahead; and a reinforcement which bridges the front ends of both impact absorbing members.

Owner:MAZDA MOTOR CORP

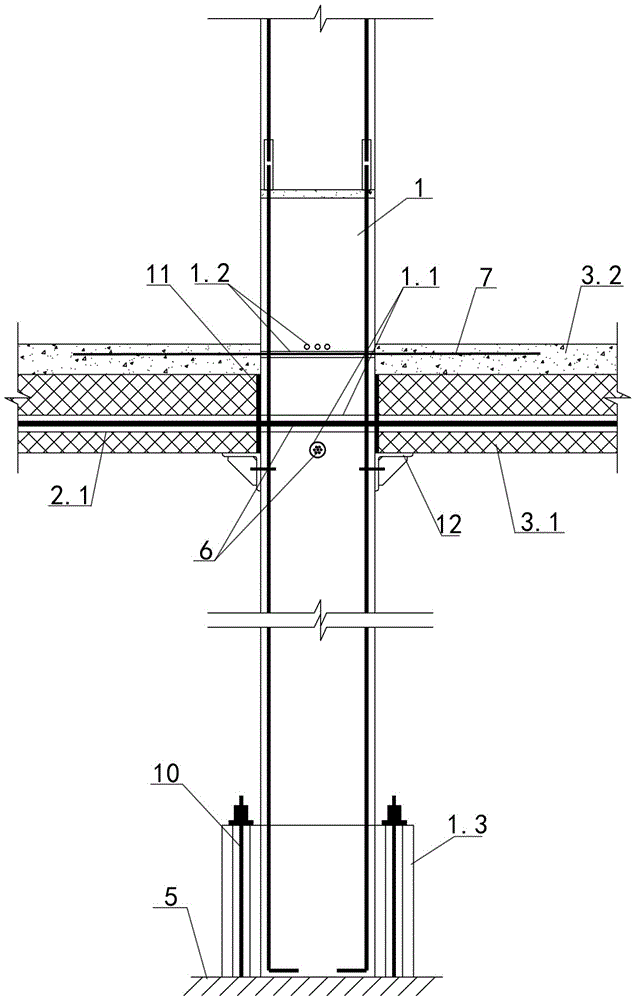

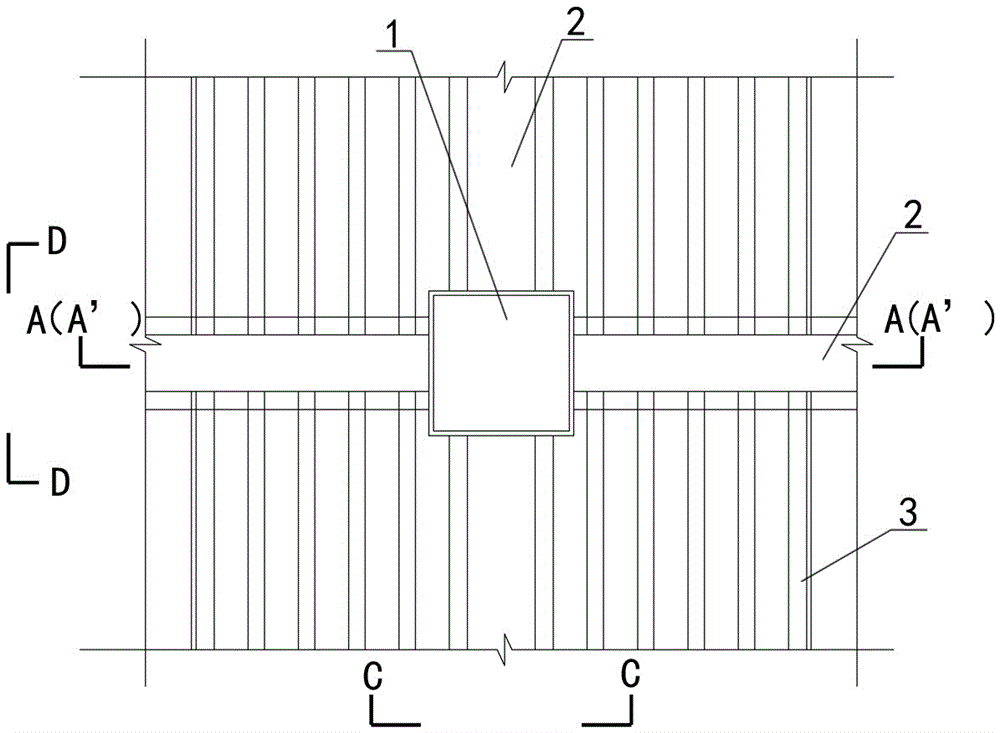

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

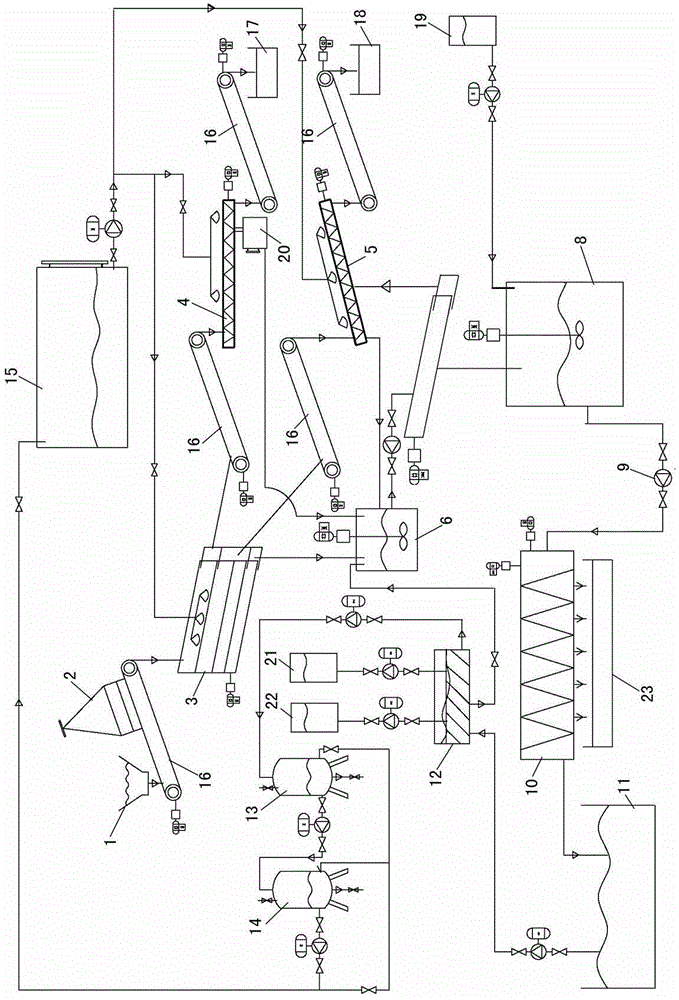

Soil washing restoration system based on reduction concentration design concept and method thereof

ActiveCN104475441AShort stayImprove production efficiencyContaminated soil reclamationSoil washingCompound (substance)

The invention discloses a soil washing restoration system based on a reduction concentration design concept and a method thereof. The washing restoration system comprises the following four module units which are sequentially connected with one another: a feeding and screening unit, an ore washing unit, a sludge dewatering unit and a tail-end sewage treatment recycling unit. The pollutants on the surface of coarse particles are eluted, transferred and concentrated into the filter-pressed mud cake by virtue of washing, so that pollutant-containing fine particles in contaminated soil can be effectively separated from crude particles such as gravel and grit. The repaired and discharged clean gravel and grit can be directly recycled to serve as building material. According to the system, purified water serves as a washing solution, so that secondary pollution caused by addition of a chemical washing agent is avoided, and the washing solution is treated by a tail-end sewage treatment system so as to be recycled. The reduction of remediation of contaminated soil is realized, the comprehensive repair cost is greatly reduced, the washed and discharged materials can be recycled, the contaminated soil is repaired, and a novel profit point is created.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

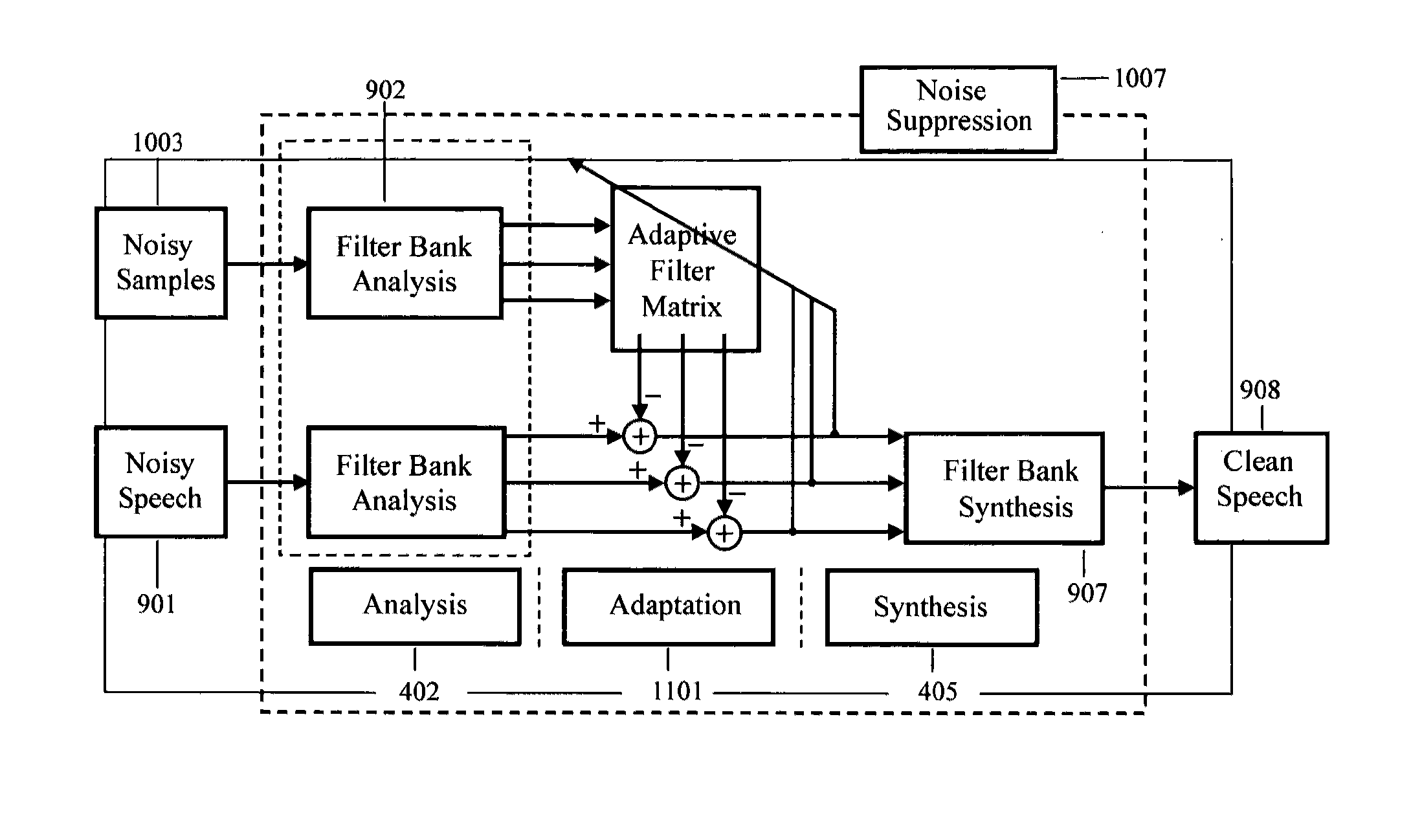

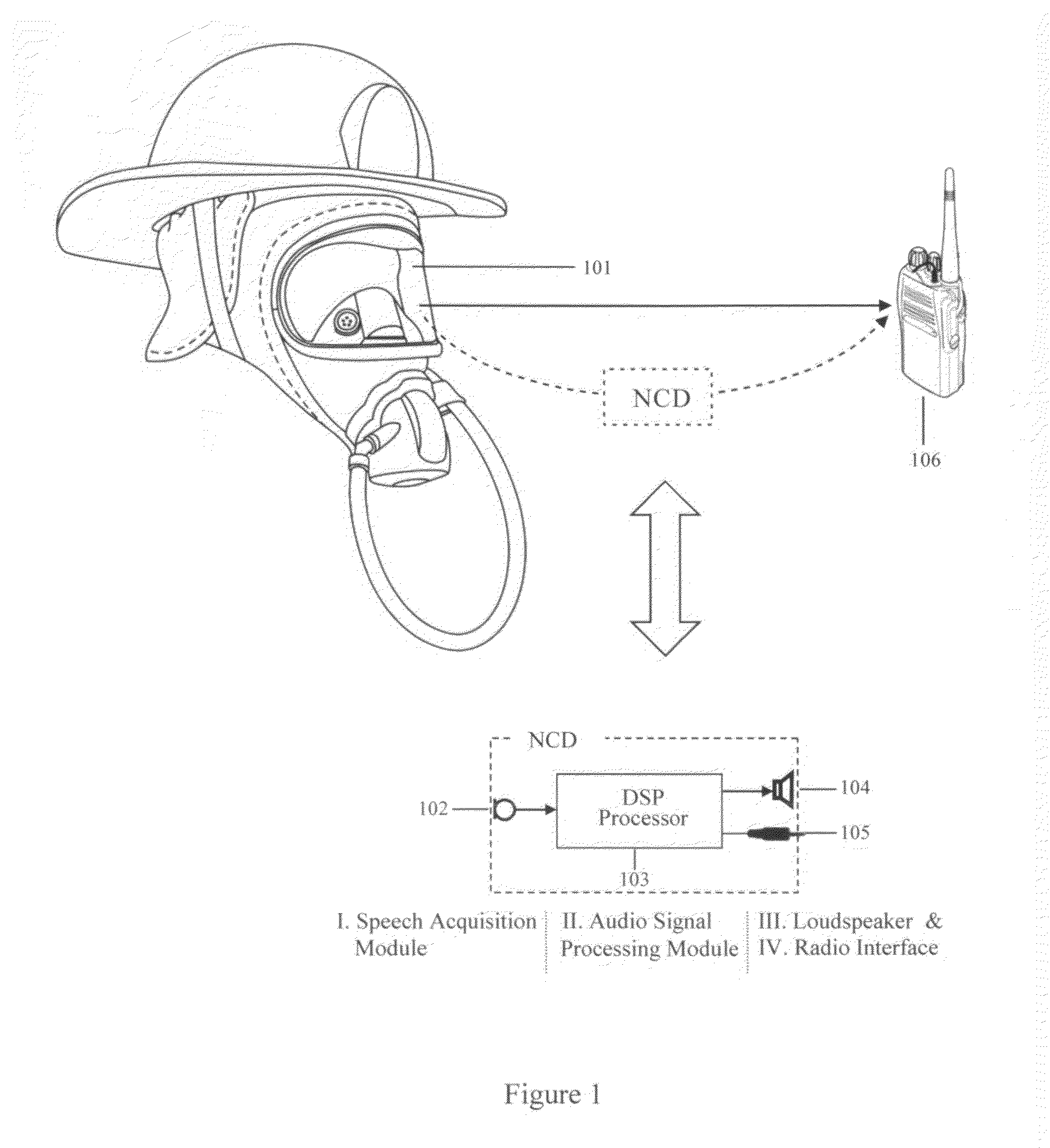

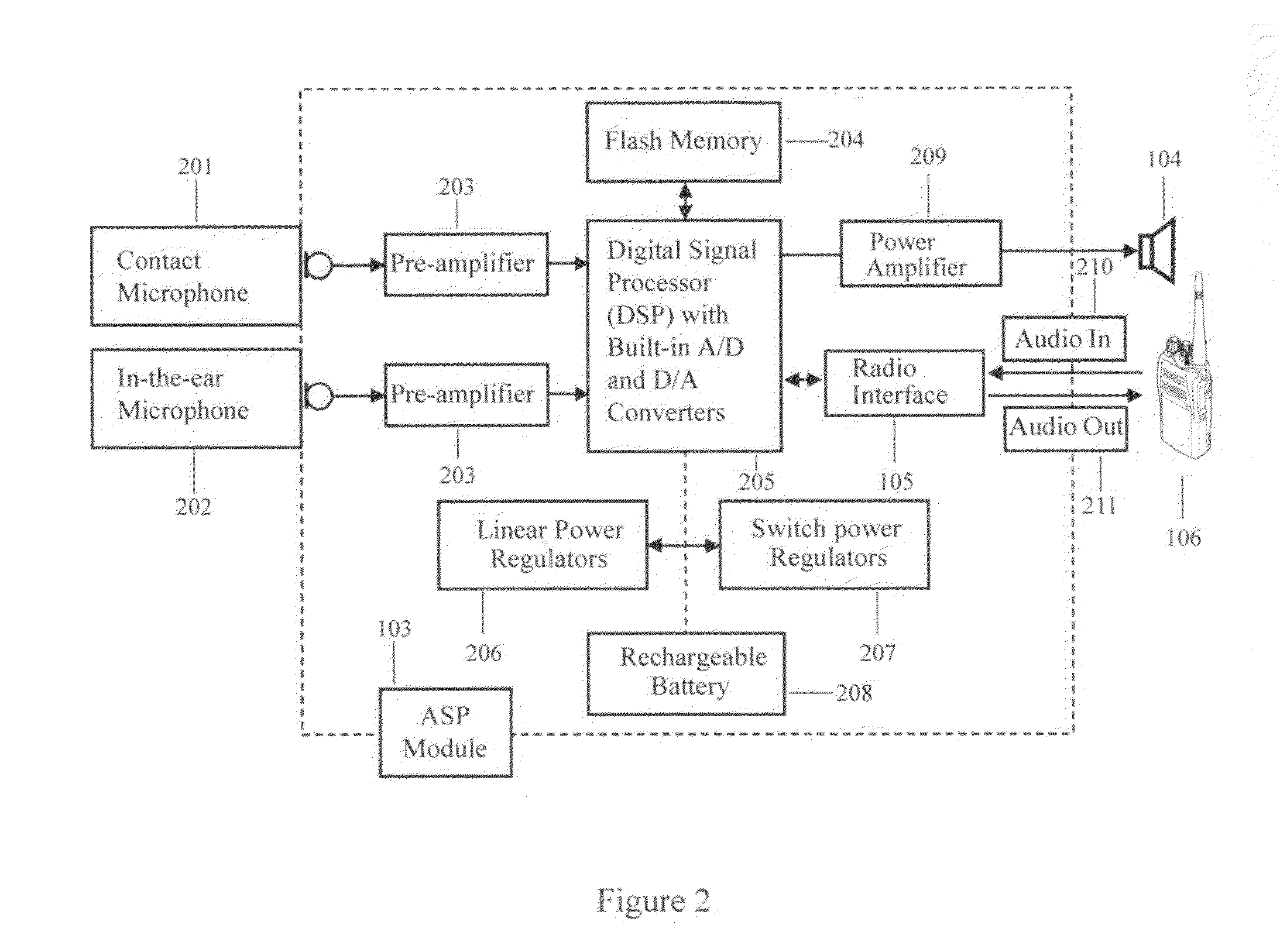

Noise cancellation device for communications in high noise environments

ActiveUS20120084084A1Novel noise cancellationEasy to useSpeech recognitionSignal-to-noise ratio (imaging)Engineering

This invention presents a noise cancellation device for improved personal face-to-face and radio communications in high noise environments. The device comprises speech acquisition components, an audio signal processing module, a loudspeaker, and a radio interface. With the noise cancellation device, the signal-to-noise ratio can be improved by as much as 30 dB.

Owner:LI CREATIVE TECH

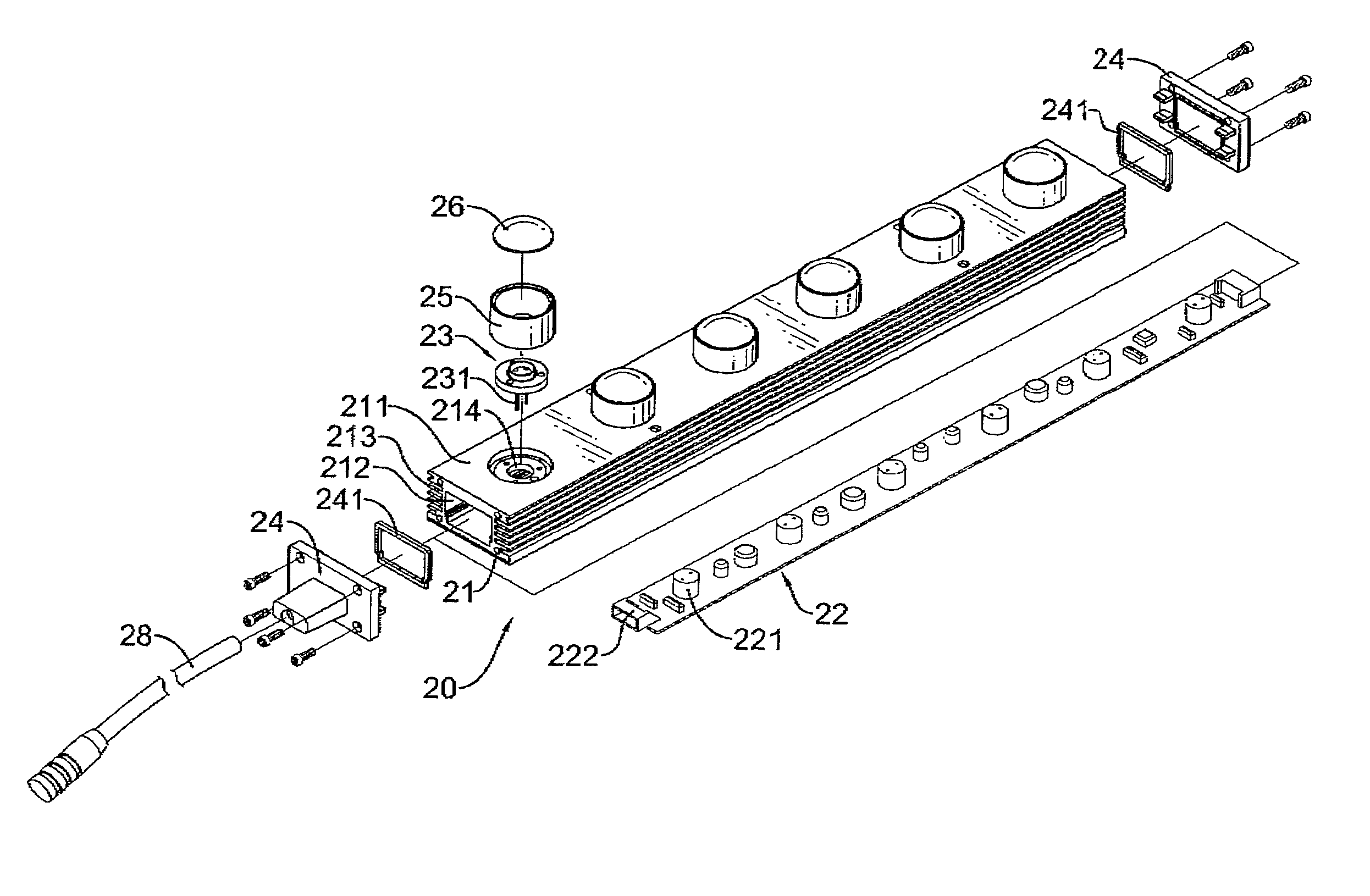

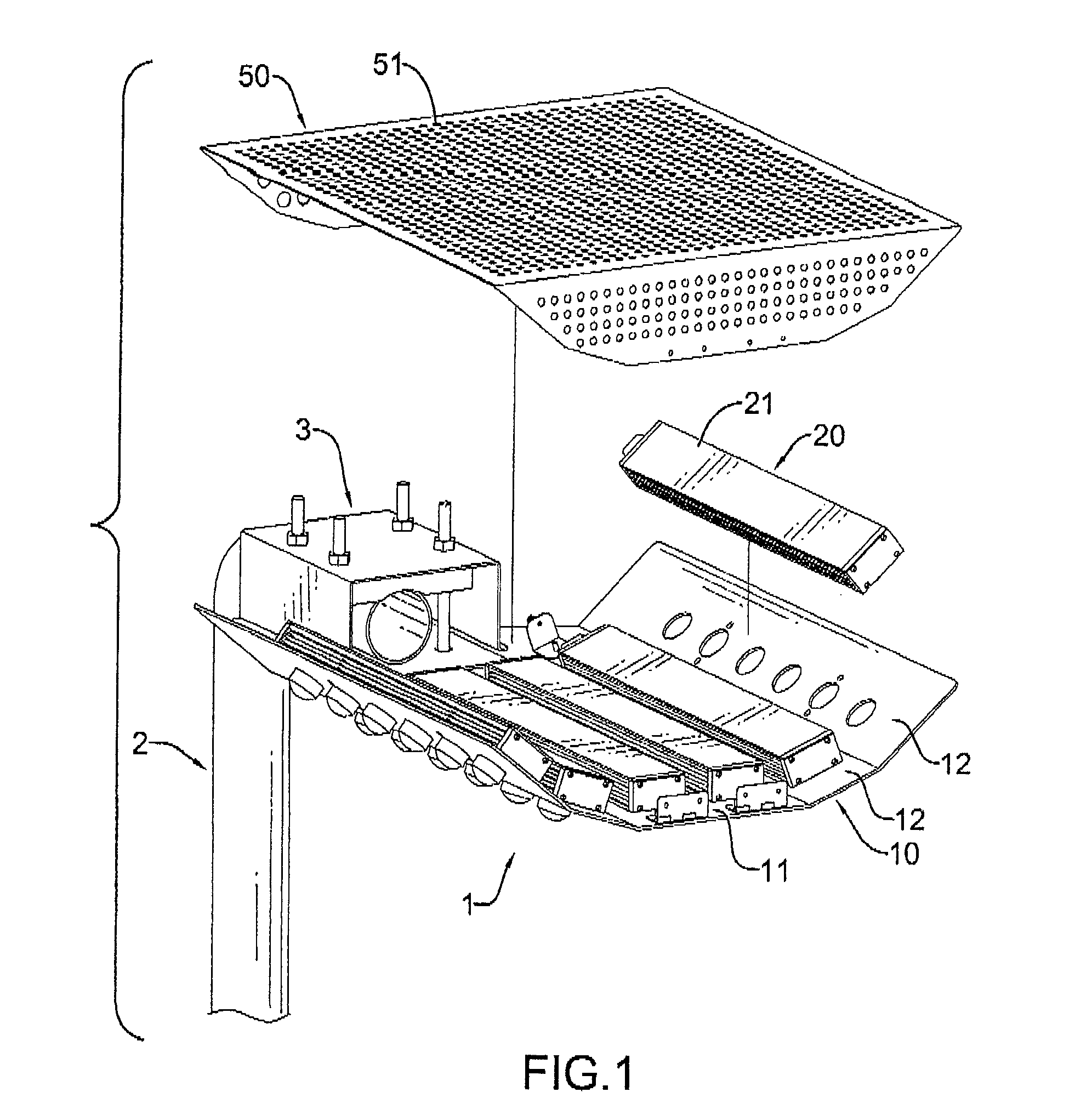

Lighting device having LED light bars

InactiveUS8007128B2Easy maintenanceEffective coolingMechanical apparatusLighting support devicesElectricityEffect light

A lighting device has a light-bar mount and multiple light bars. The light-bar mount is integrally formed from a board. The light bars are mounted on the light-bar mount and each light bar has a heat sink, a circuit board and multiple high-power LED modules. The heat sink is detachably mounted in the light-bar mount. The circuit board is mounted in the heat sink. The high-power LED modules are mounted on the heat sink and electrically connected to the circuit board for providing outward illumination.

Owner:ANTEYA TECH CORP

Impact damper assembly for an automobile

InactiveUS20060022473A1Reduce harmImprove vehicle safetyPedestrian/occupant safety arrangementBumpersEngineeringChassis

Impact damper assembly for an automobile, in particular for supporting a bumper 5 on an automobile chassis, with an inner tube 2 movably arranged in an outer tube 3, wherein both tubes 2, 3 have an approximately mutually parallel taper 16, 19, wherein the taper 19 of the inner tube 2 is encompassed by the taper 16 of the outer tube 3, and wherein at least one of the two tubes 2, 3 can be deformed during the movement by the taper 16, 19 of the two tubes. The invention is characterized in that the impact damper assembly includes an additional deformable stiffening element 22.

Owner:ZF FRIEDRICHSHAFEN AG

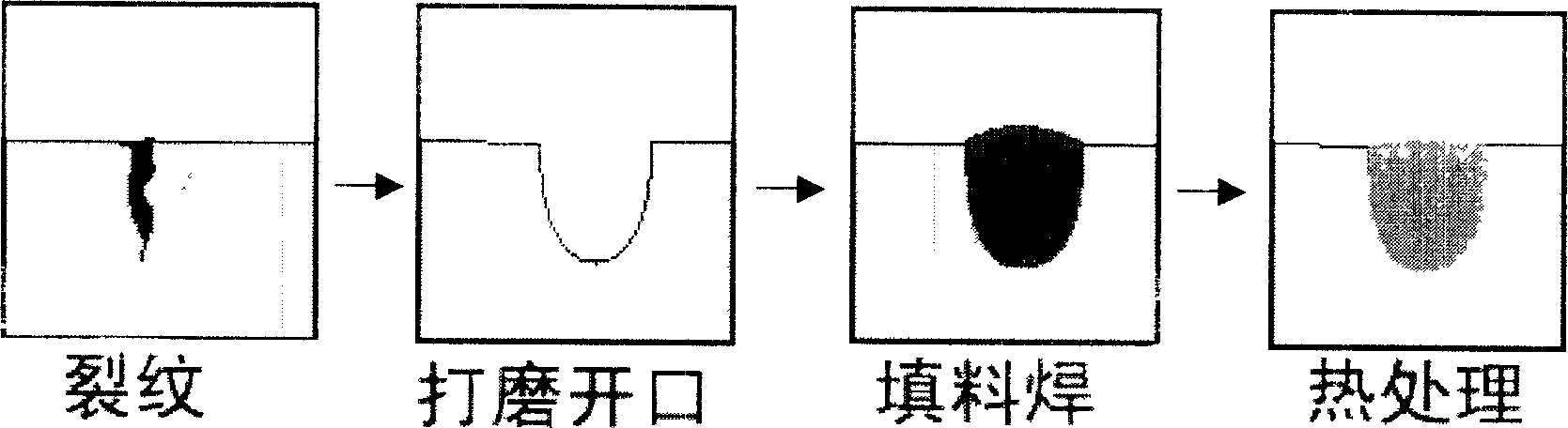

Crack repair process for high-pressure turbine blade tip in gas turbine

The present invention belongs to the metal surface crack repairing method, meaning the tip crack repairing method of a gas-turbine engine high-pressure turbine blade. The method comprises polishing apertures for complete crack removal based on the crack conditions of the gas-turbine engine high-pressure turbine blade tip, carrying out surfacing welding in the repair welding zone using low-heat input welding technology and implementing heat treatment process to the repaired blade. The present invention has the virtues of simple process, needing no vacuum or preheating, small damage to blade base materials, realizing loss-free repair to the high-pressure turbine blade tip cracks and reducing repair cost. The invention can be used to repair both the gas-turbine engine high-pressure turbine blade tip cracks and steam turbine, smoke turbine and other turbine mechanisms high-pressure or low-pressure blade tip cracks. And the aircraft engine high-pressure turbine blade repaired with the method has passes 368h long-term bench trial check.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Bumper for a motor vehicle

A bumper for a motor vehicle includes a cross member which is disposed transversely to side rails of a motor vehicle frame and connected to the side rails via crash boxes. The cross member has a C-shaped cross section and includes an outer shell member and an inner shell member. The inner shell member is constructed as tension link which is made of a material having a tensile strength that is greater than the tensile strength of a material of the outer shell member.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

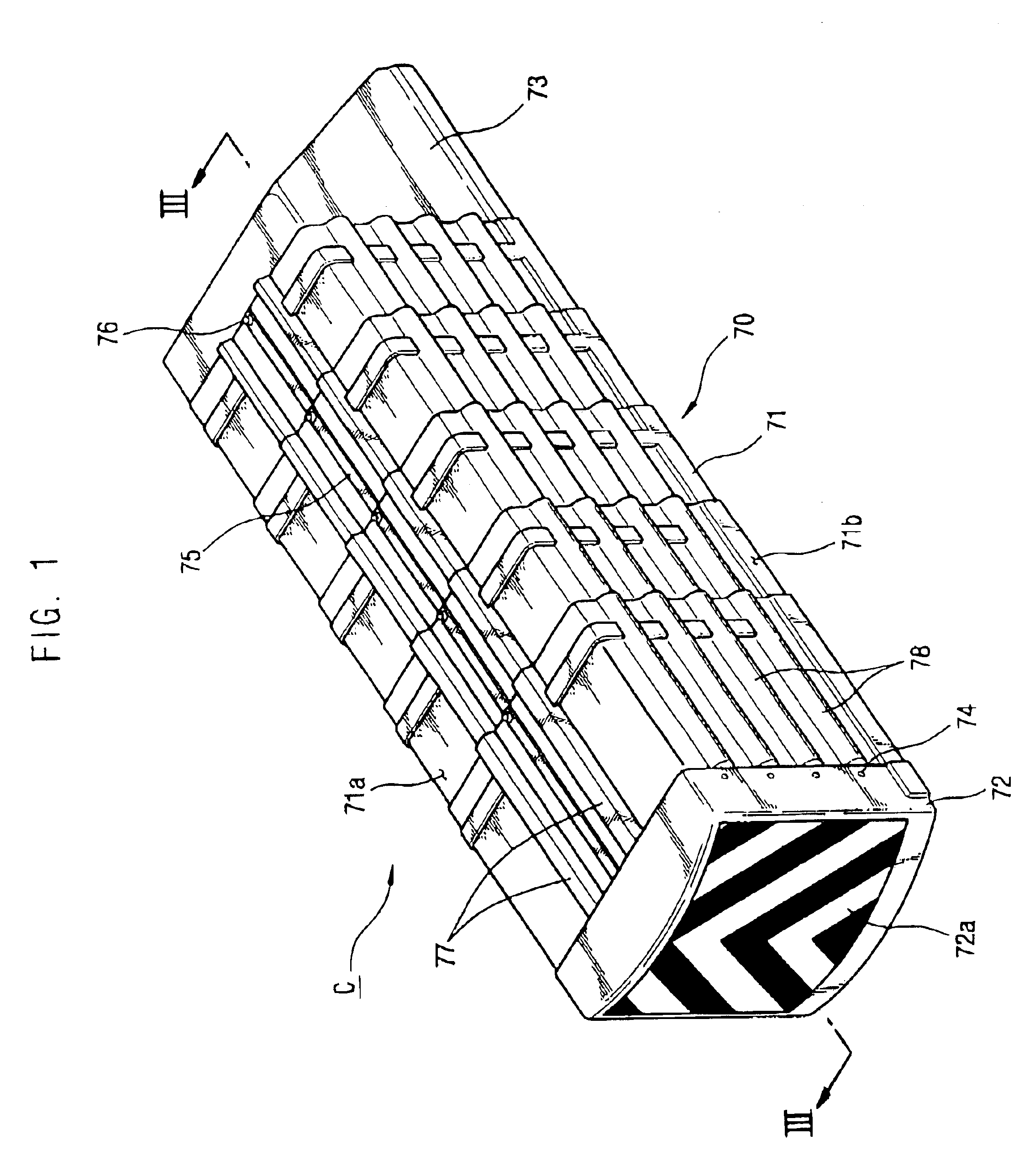

Vehicular impact absorbing apparatus having cushion pins

InactiveUS6905281B2Impact energy absorptionPrevent springbackRefuge islandsTraffic signalsEngineeringGuide tube

A vehicular impact absorbing apparatus includes a pair of tubular guide rails having a guide slit longitudinally formed at the upper part of each guide rail fixed to the ground. Sliders are movably mounted in the guide rail at predetermined intervals, the upper part of each slider is laid on the upper part of the guide rail through the guide slit. Cushion units are mounted on the upper part of each slider. Each cushion unit is elastically deformed by vehicular impact while retracting along the guide rail. Cushion pins are mounted across the guide rails at predetermined intervals between the sliders that also absorb the kinetic energy of an impact by being broken by the rearward retracting slider. A stopper is installed around the rear end of the guide rail for stopping the retracting cushion units. A successive cushion and deceleration of the impact is possible in this arrangement.

Owner:KANG SUNG KU

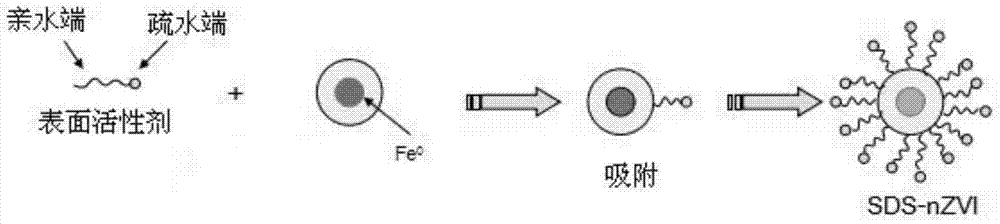

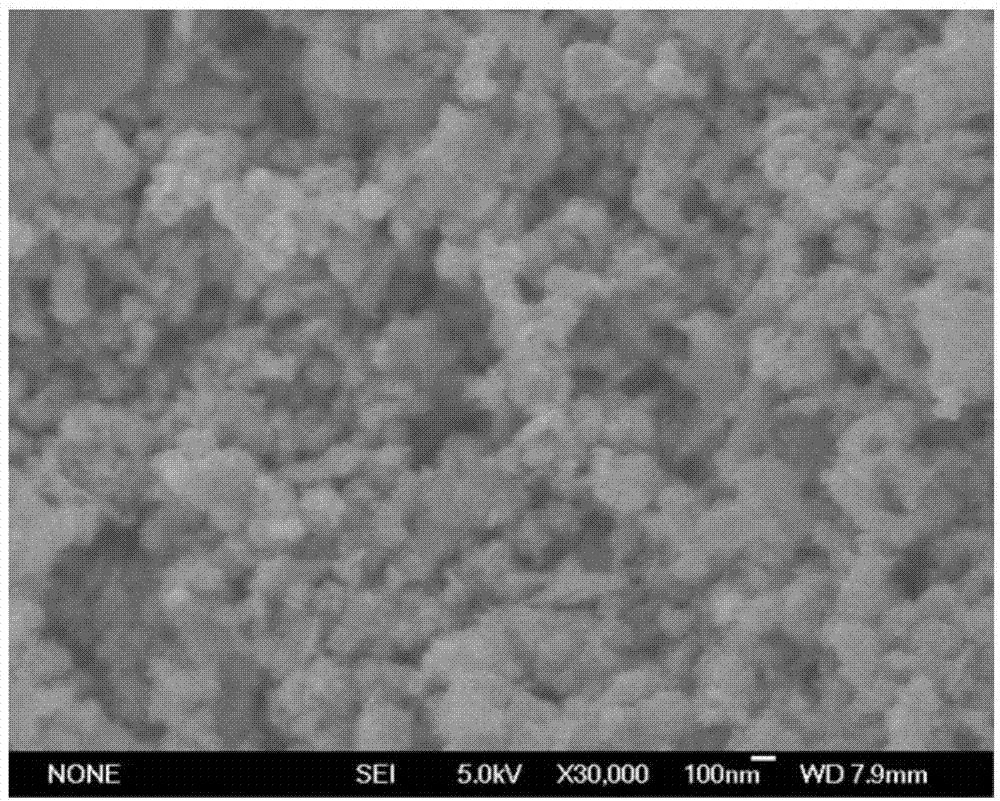

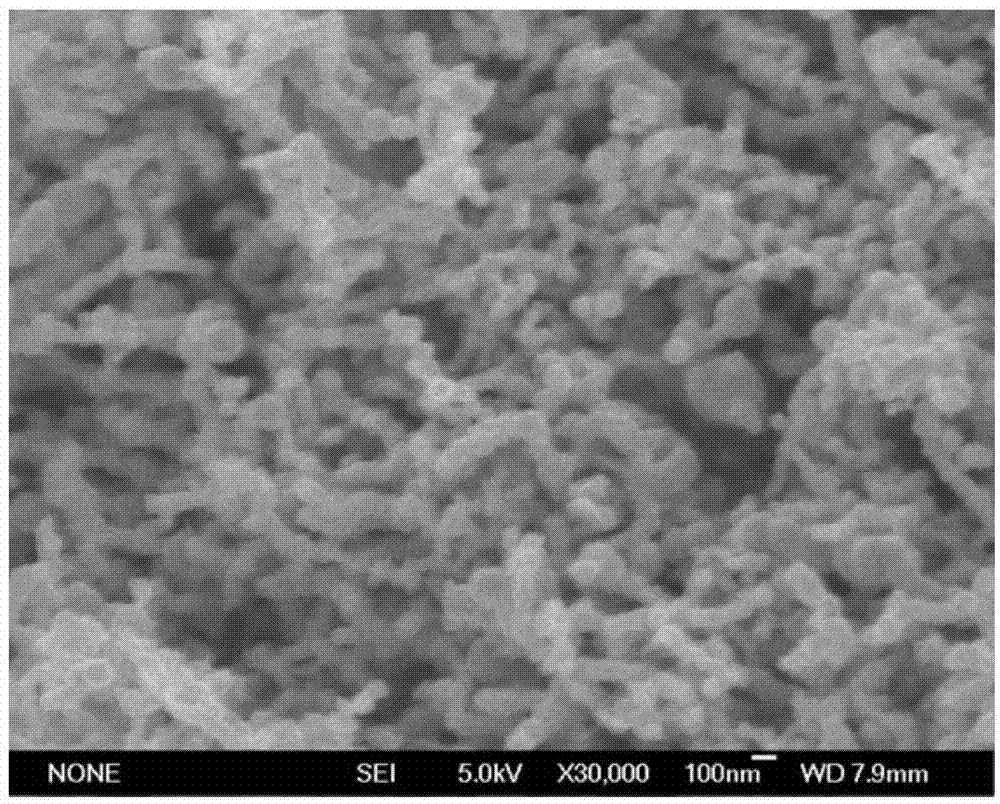

Modified nanoscale zero-valent iron and preparing method thereof

InactiveCN104226987AGood dispersionImprove stabilityMaterial nanotechnologySludge treatmentSodium sulfateNanometre

The invention discloses modified nanoscale zero-valent iron and a preparing method thereof. The modified nanoscale zero-valent iron comprises nanoscale zero-valent iron and lauryl sodium sulfate. The lauryl sodium sulfate is wrapped on the surface of the nanoscale zero-valent iron, and the mass ratio of the lauryl sodium sulfate and the nanoscale zero-valent iron is 0.01-0.07. The preparing method of the modified nanoscale zero-valent iron comprises the following steps that nanoscale zero-valent iron particles are dispersed in a lauryl sodium sulfate solution through ultrasound, and the modified nanoscale zero-valent iron is obtained. According to the modified nanoscale zero-valent iron and the preparing method thereof, the lauryl sodium sulfate is used for modifying the nanoscale zero-valent iron, through a steric-hinerance effect, nano materials are stabilized, and the advantages of being good in dispersing performance, good in stability, high in reactivity and the like are achieved.

Owner:HUNAN UNIV

Vehicle-body front structure of vehicle

ActiveUS20130256051A1Reduce repair costsAppropriate design flexibilityElectric devicesPedestrian/occupant safety arrangementLow speedEngineering

A first projection portion projecting outward, in a vehicle width direction, from a front side frame is provided. A front end of the first projection portion is located at the same position, in the vehicle longitudinal direction, as a connection portion of a crash can to the front side frame or located in back of the connection portion. An outward side face of the first projection portion is configured to slant rearward and inward in a plan view. The first projection portion and a power unit are arranged to overlap each other in the vehicle longitudinal direction. Accordingly, an impact transmitted to a vehicle-compartment side in a small overlap collision can be reduced, restraining repair costs of the crash can broken in a low-speed collision as well as maintaining appropriate design flexibility of a vehicle-body front portion.

Owner:MAZDA MOTOR CORP

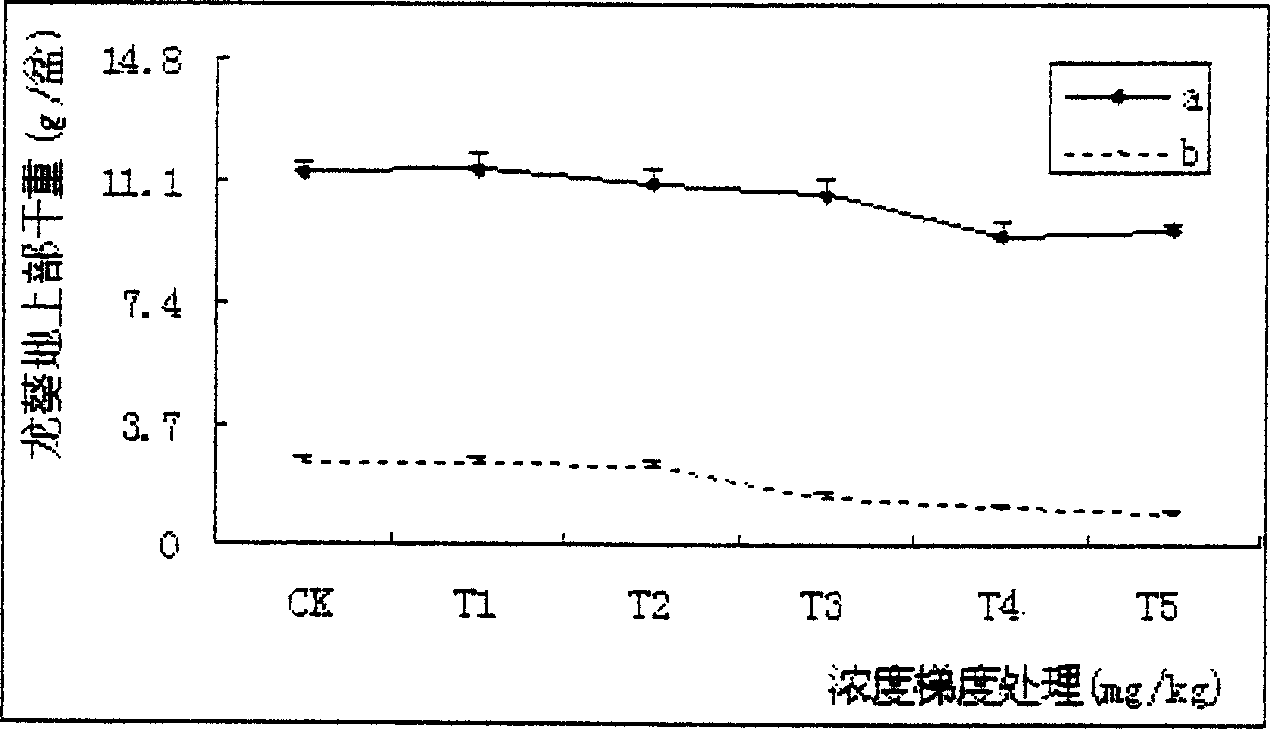

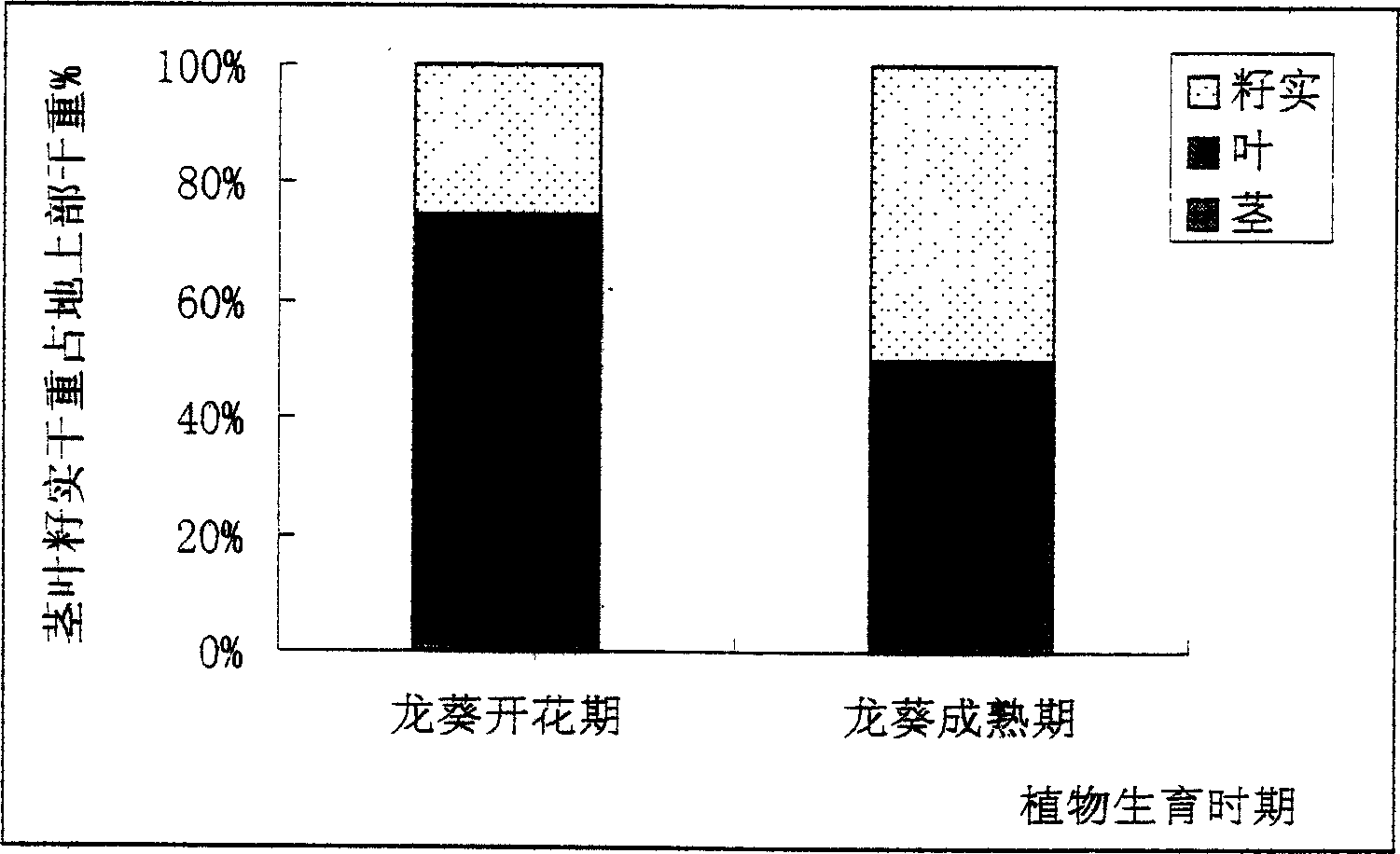

Method for repairing soil of cadmium polluted by solanaceae plant

InactiveCN1724184APrevent water erosionReduce water erosionContaminated soil reclamationPollution soilInflorescence

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

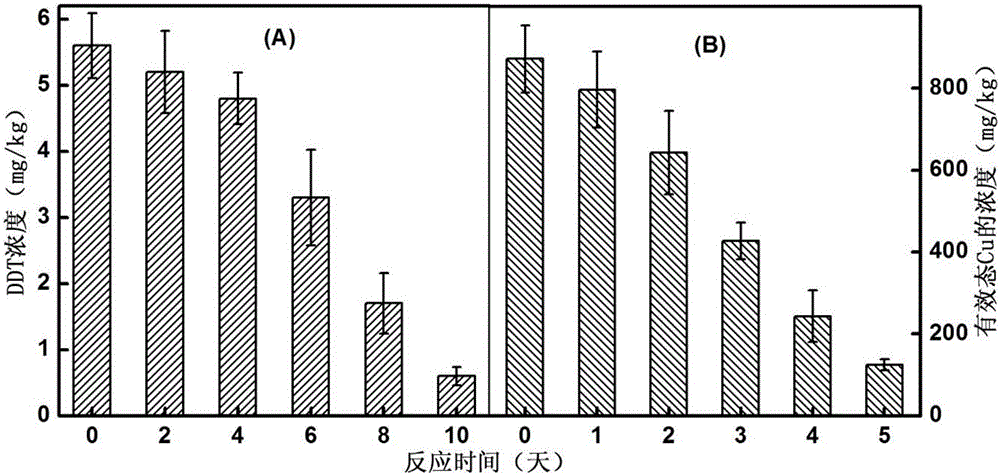

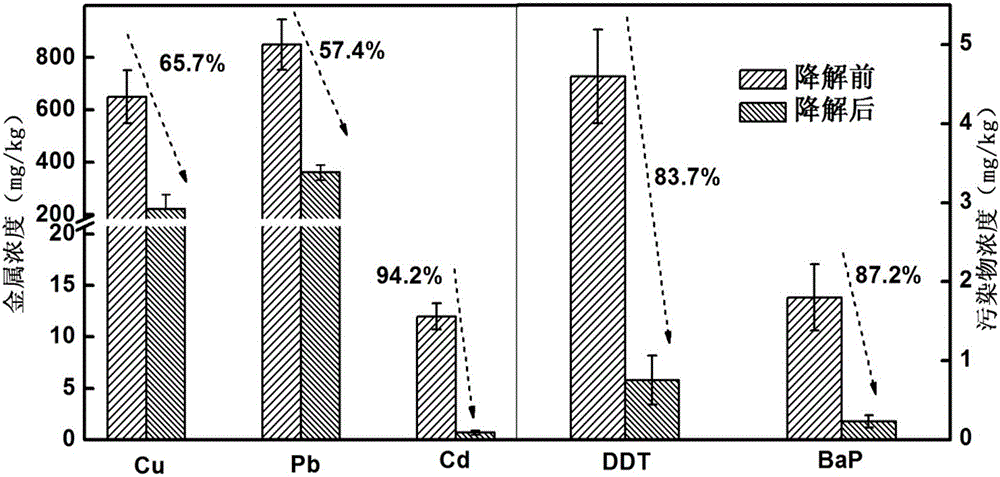

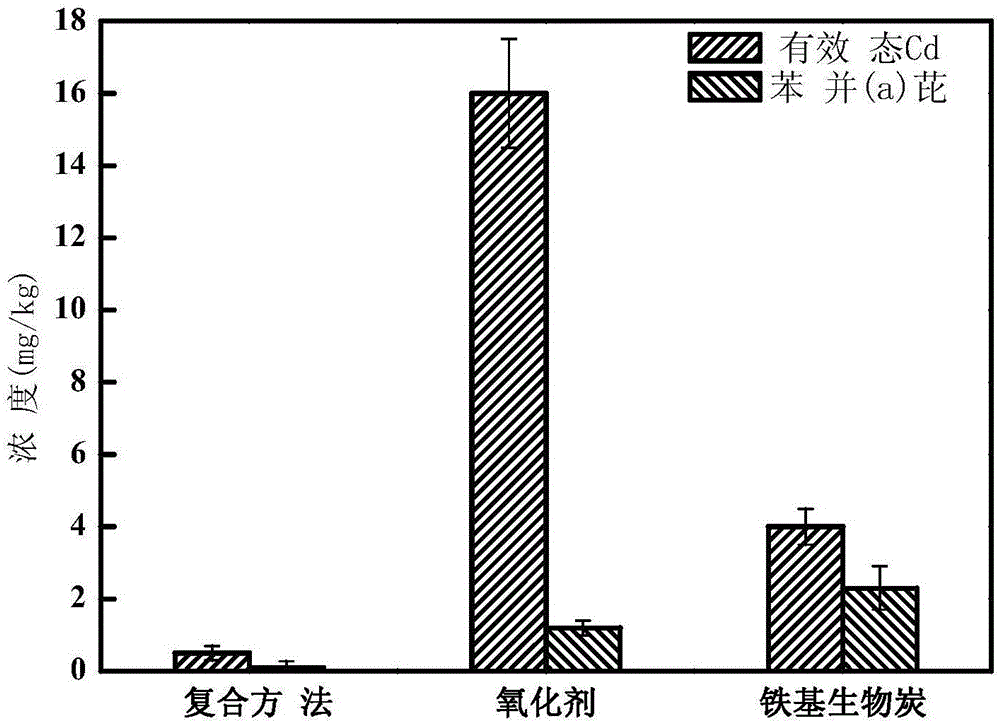

Remediation method of organic contaminant-heavy metal compound contaminated soil

ActiveCN106623380AEfficient repairReduce repair costsContaminated soil reclamationHeavy metal compoundPersulfate

The invention discloses a remediation method of organic contaminant-heavy metal compound contaminated soil. The remediation method comprises the following steps: adding persulfate into organic matter-heavy metal compound contaminated soil, and on the basis of effective oxidative degradation of organic contaminant, further using iron-based biochar for passivating heavy metals after playing an activating effect so as to achieve effective remediation of the organic matter-heavy metal compound contaminated soil. Compared with the method for remedying contaminated soil with single contamination by using the biochar or the persulfate, the remediation method provided by the invention has the advantages as follows: two methods are combined for remedying organic matter-heavy metal compound contamination, the persulfate is used for oxidizing organic matters and can fully mineralize the organic matters; for heavy metal contaminated soil, the persulfate can oxidize the heavy metals, and reduces the pH of the soil to cause an increase in the concentration of effective-state metal; the biochar fixes the heavy metals to the surface through adsorption, so that the bioavailability of the heavy metals is reduced.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Technology for repairing surfacing of piston rod of super large marine diesel engine

InactiveCN101444881ALow roughness requirementsLow cleanliness requirementsArc welding apparatusRoom temperatureEngineering

The invention discloses a technology for repairing surfacing of a piston rod of a super large marine diesel engine, and the technology can carry out the deep repair of the surface of the piston rod. The adopted surfacing process is as follows: flaw detection and straightening are carried out on the piston rod, turning machining is carried out on the surface of the piston rod to remove a defect layer, and individual deeper cracks are manually removed by grinding; fire whirl is used for heating the piston rod twice, the first heating is carried out till 200 DEG C-250 DEG C, the heating is stopped, the race rotation is carried out for 30 minutes, the second heating is further carried out after the temperature difference between the interior and the exterior is reduced, and a surfacing machine tool is rotated after reaching 250 DEG C-300 DEG C; submerged arc welding is used for rotating dual heads of the surfacing machine tool and a 2Cr13 flux-cored welding wire for carrying out the simultaneous surfacing, and asbestos cloth is used for wrapping and keeping the temperature during the welding process; the piston rod wrapped by the asbestos cloth for slow cooling after the surfacing achieves the size requirement, when the temperature is decreased to be lower than 100 DEG C, the piston rod wrapped by the asbestos cloth is vertically placed till the temperature is decreased to the room temperature, and then the temperature-keeping cloth is removed. The surface of the piston rod after the repair by employing the method has no weld defects, the piston rod fully meets the performance requirements, and the cost is only about one fifth of the cost for fabricating a new piston rod.

Owner:DALIAN XINZHONG GRP +1

Agent for phytoremediation of soil polluted by heavy metals using the waste active Sludge as the original material and the method of the phytoremediation of soil polluted by heavy metals

InactiveCN101036917AThe enrichment effect is obviousRealize ecological restorationContaminated soil reclamationActivated sludgePhosphoric acid

Provided is a heavy metal pollution soil repairing agent using excess activated sludge as the rawmaterial, a method of extraction and a method for repairing the heavy metal pollution soil, which relates to a heavy metal pollution soil repairing agent and a method thereof and a method for repairing the heavy metal pollution soil, and solves the problems of high cost, easily secondary pollution and complex operation existing in the repair of the heavy metal pollution soil. The heavy metal pollution soil repairing agent is composed of amylose, protein, nucleic acid, phosphoric acid, amino acid, humic acid compound, uronic acid and the organic substance required for cell lifecycle. The method for distilling the heavy metal pollution soil repairing agent is as follows: the wastewater treatment excess activated sludge reacts under the condition of 80-120 KPa and 60-100 DEG for 8-20 minutes; then centrifuges for 8-20 min at the rotating speed of 5000-7000r / min. The invention adopts the home position repairing or the heterotopia repairing to repair the heavy metal pollution. The invention has low cost and no secondary pollution, simple operation, short repairing period, strong activity and wide range of application.

Owner:HARBIN INST OF TECH

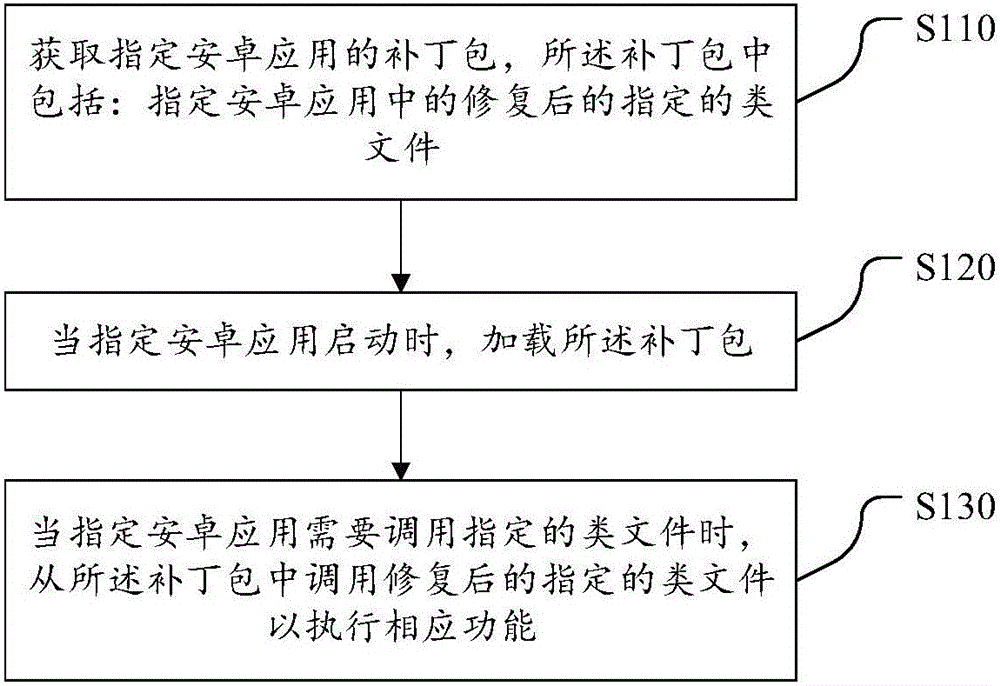

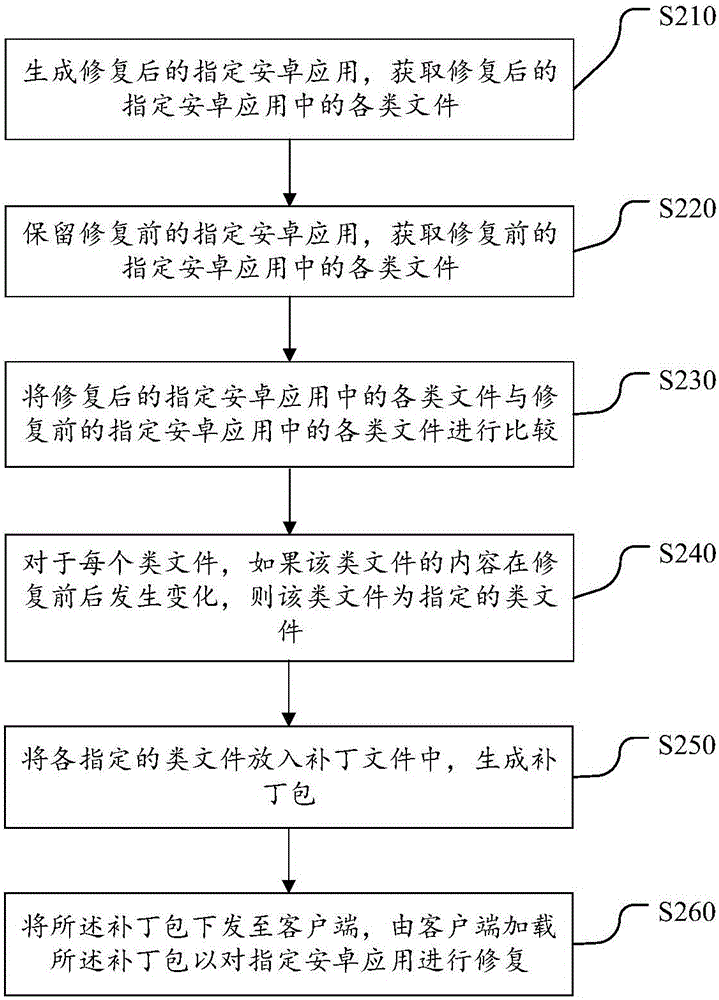

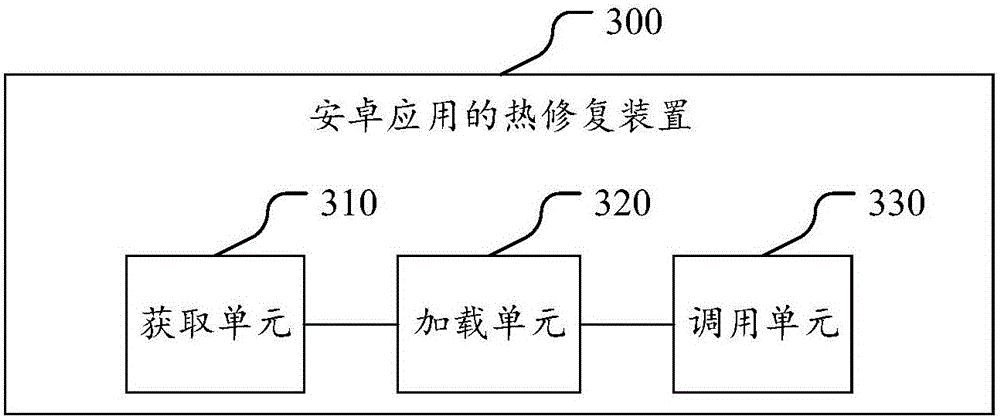

Thermal repair method, device, server and system for Android application

InactiveCN106095502AAchieve normal operationImplement hotfixNon-redundant fault processingProgram loading/initiatingSoftware engineeringAndroid app

The invention discloses a thermal repair method, device, server and system for an Android application. The method includes the steps that a patch pack of the designated Android application is acquired, wherein the patch pack includes a repaired designated class file in the designated Android application; when the designated Android application is started, the patch pack is loaded; when the designated Android application needs to call a designated class file, the repaired designated class file is called from the patch pack to perform corresponding functions. Thus, compared with the prior art, according to the scheme, a series of steps of repacking a designated Android application, conducting testing, exchanging packs to various application markets and channels, reminding a user to conduct upgrading, reminding the user to conduct downloading, conducting coverage installation of the Android application with a new installation pack and the like by a publisher are not needed in the repair process, thermal repair of the Android application can be achieved through one patch pack without changing the original Android application, and thus the repair cost of the Android application is greatly reduced.

Owner:BEIJING QIHOO TECH CO LTD +1

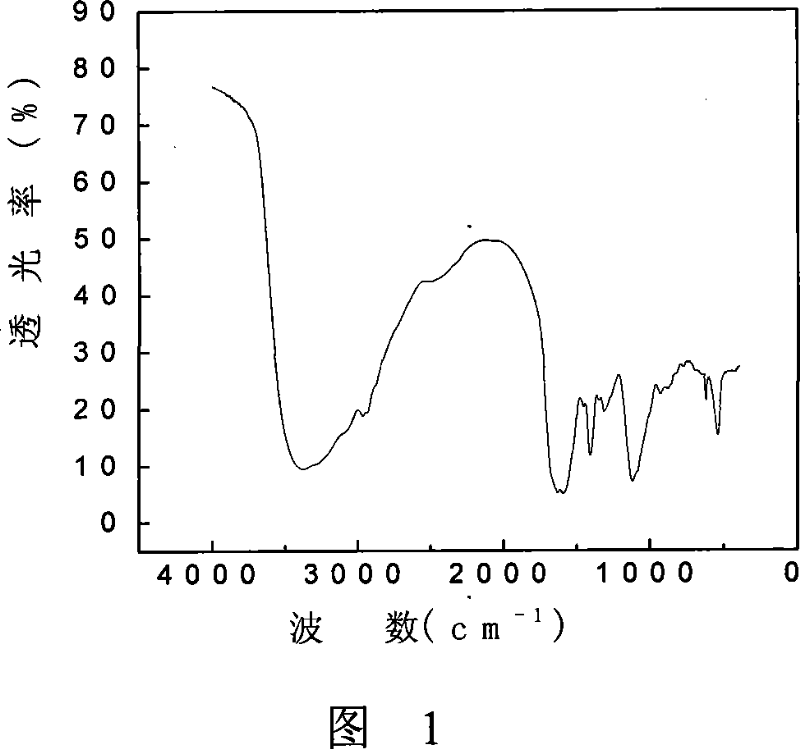

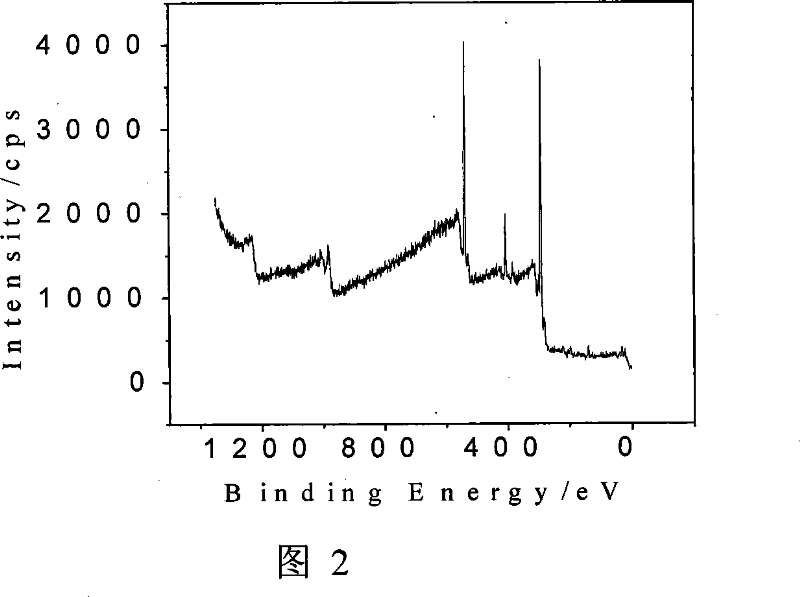

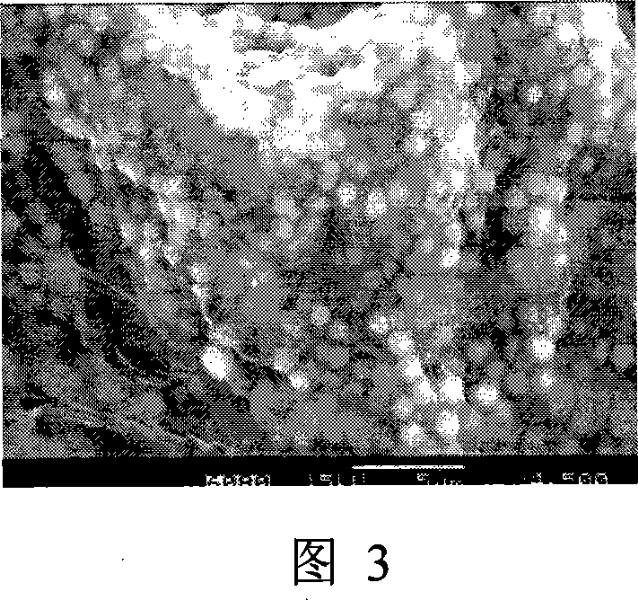

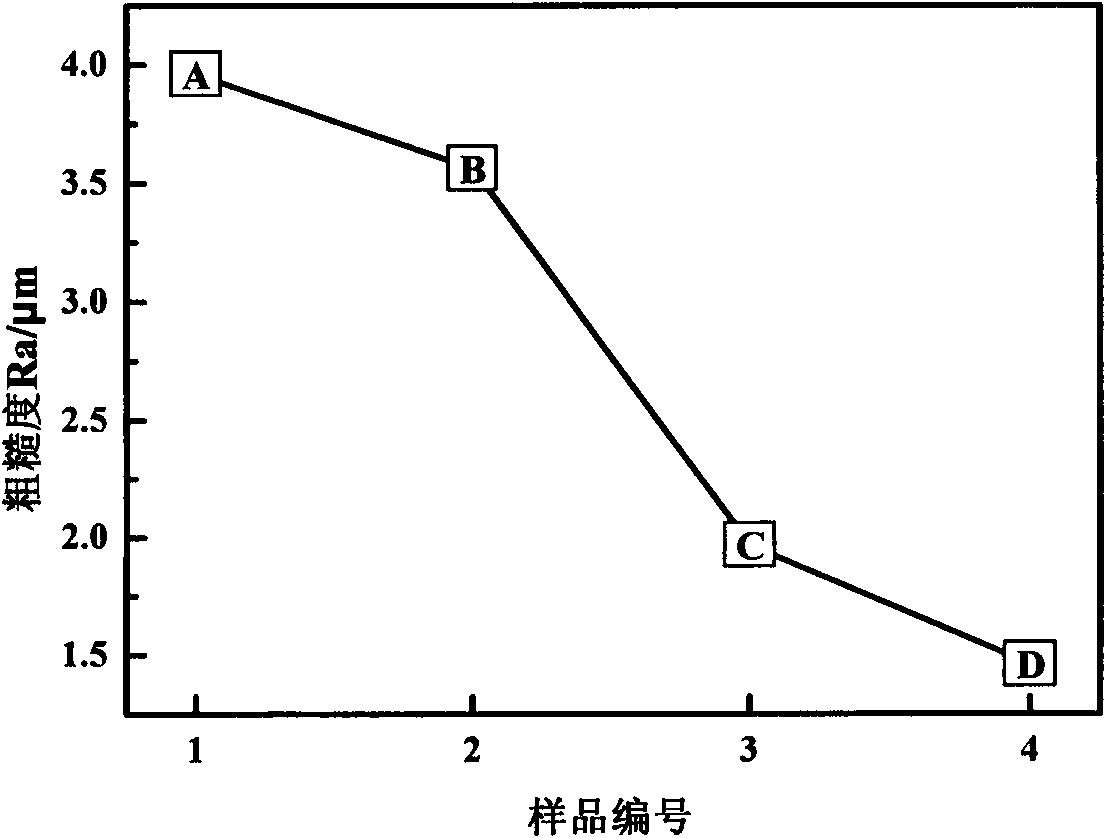

Method for surface pre-treatment of titanium electrode substrate

InactiveCN101565834AOptimal Preprocessing ParametersEnhanced electrocatalytic activity for oxygen evolutionElectrodesTitanium electrodeMetallic materials

The invention belongs to the field of metal material and relates to a method for surface treatment of a titanium electrode substrate. The service life and the electrocatalysis performance of the titanium electrode are greatly increased by the abrasive blasting pretreatment to the substrate. The abrasive blasting treatment is carried out on the titanium substrate; the nozzle pressure of an abrasive blasting machine is 0.3-0.5MPa; the Al2O3 grinding medium of 70-90 meshes is adopted; the blasting angle is 45-90 degrees; the distance from the nozzle to a workpiece is 1-2cm; the coarsening time is 15-30s; the titanium substrate is then pickled for pickling treatment in a 10wt.% of oxalic acid solution for 1.5-2.5 hours at the temperature of 90-95 DEG C; a Ti / IrO2.Ta2O5 oxide coating electrode is prepared on the obtained substrate by a thermal decomposition method, wherein the Ir is chloro-iridic acid, Ta is tantalum pentachloride and the molar ratio of Ir to Ta is 7:3; a coating solution is uniformly coated on the pre-treated titanium substrate by a soft hair brush; the titanium substrate is dried for 10min at the temperature of 120 DEG C, is subsequently arranged in a box-type resistance furnace and sintered for 10min at the temperature of 450 DEG C; the above operations of coating, drying and sintering are repeatedly carried out by 5-20 times; and the final sintering is carried out for 1h at the temperature of 450 DEG C. The method provides optimum pretreatment parameters, greatly prolongs the service life of the titanium electrode, effectively improves the electrocatalytic activity and greatly reduces the running and repairing cost for the electrode.

Owner:UNIV OF SCI & TECH BEIJING

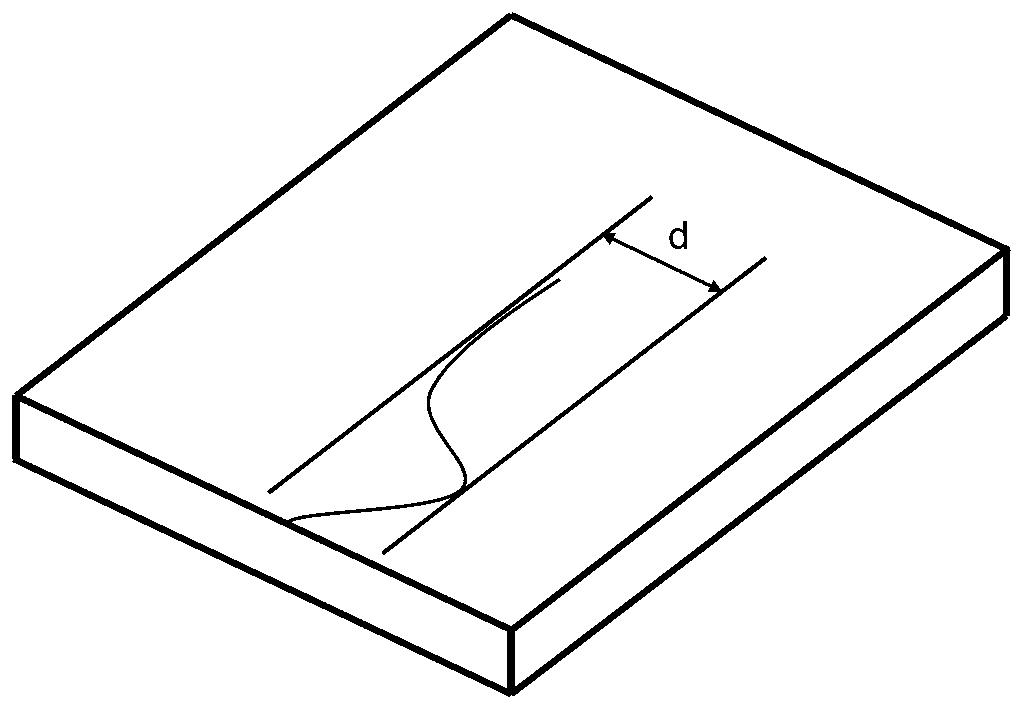

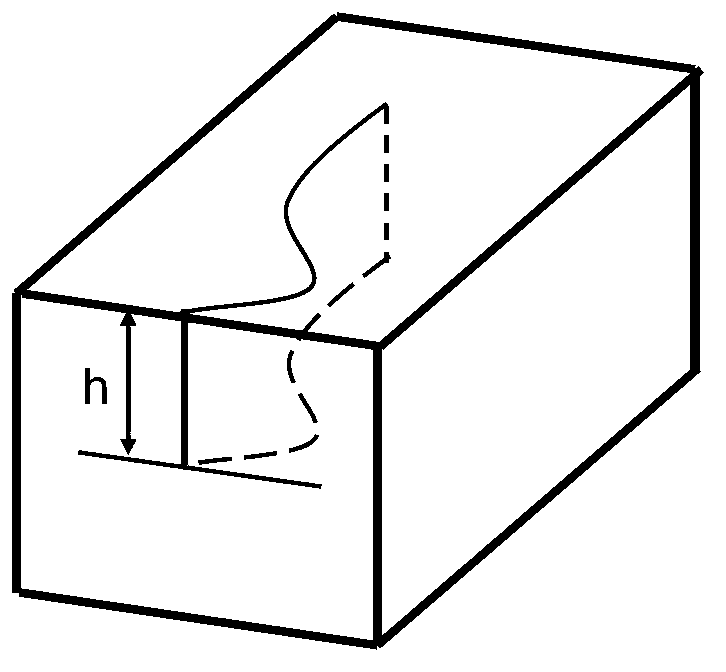

Stirring-friction-based crack repair method

InactiveCN103212778AReduce distortionReduce stressNon-electric welding apparatusUltimate tensile strengthAstronautics

The invention relates to a stirring-friction-based crack repair method which mainly is used for solving the problems in the prior art that the repair cost is high, the repair quality is poor and cracks appear repeatedly. The method is applied to the repair of surface cracks and through cracks of plate-shell metal structures, so as to enable cracked workpieces to meet reuse requirements. The method comprises the following specific steps of designing and manufacturing a friction repair tool according to the position and size of a crack, a material to be repaired, structural characteristics and the like; and realizing the friction between a shaft shoulder and the surface of the material to be repaired through the rotation of the repair tool so as to enable metal of a repair area to reach a thermoplastic state under the action of frictional heat, and realizing the flowing transfer and dynamic recrystallization of thermoplastic metal around the crack by using the rotating and upsetting action of the shaft shoulder of the repair tool, thereby realizing the filling repair of the crack. The method has the advantages that the method is simple, the damage to base metal is little, the quick, equal-strength and in-situ repair of engineering cracks can be realized, and the repair process is economical and environment-friendly. The method can be applied to the crack repair in fields, such as aeronautics and astronautics, shipbuilding, automobiles and rail transportation and has broad application prospects.

Owner:SHENYANG AEROSPACE UNIVERSITY

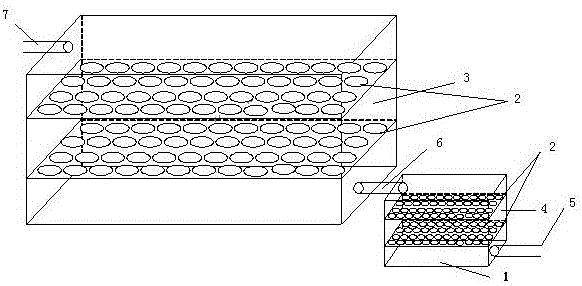

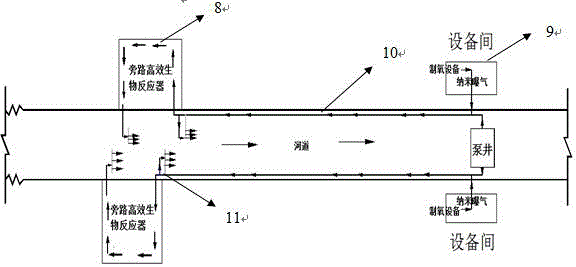

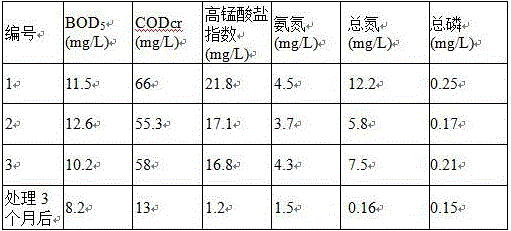

Black and odorous water/eutrophicated water treatment method and device, and application thereof

InactiveCN106348548AReduce volumeReduce weightTreatment using aerobic processesSpecific water treatment objectivesEutrophicationRestoration method

The invention provides a black and odorous water / eutrophicated water treatment method and device, and application thereof. The method mainly comprises the following steps: (1) treating river course sediment; (2) treating by a bypass high-efficiency bioreactor; (3) oxygenating the river course; and (4) adding a microbial inoculant and a stimulant. The external sources are controlled: the upstream uncontrollable pollution source or severe black and odorous / eutrophicated water is pretreated by a bypass high-efficiency bioreactor, and the microbial-ecological restoration measures are taken to effectively control the black and odorous / eutrophicated water pollution sources. The black and odorous / eutrophicated water sediment is digested to reduce the endogenous pollution. The bypass high-efficiency bioreactor technique and the oxygenation technique are combined, so that the quality of the black and odorous / eutrophicated water is maintained; and the self-purification capacity of the water is enhanced, thereby providing a feasible restoration method for treating the black and odorous / eutrophicated water.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

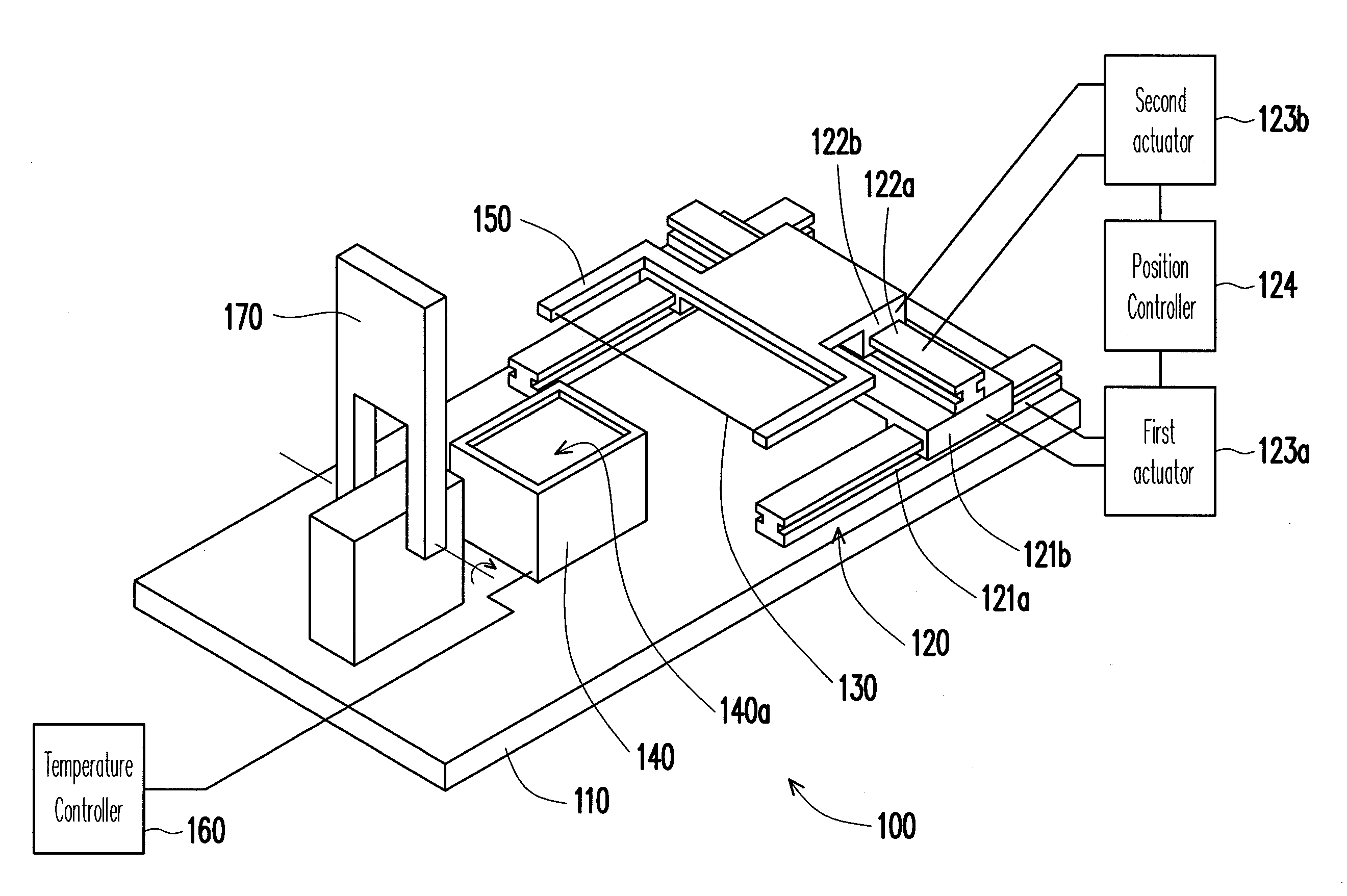

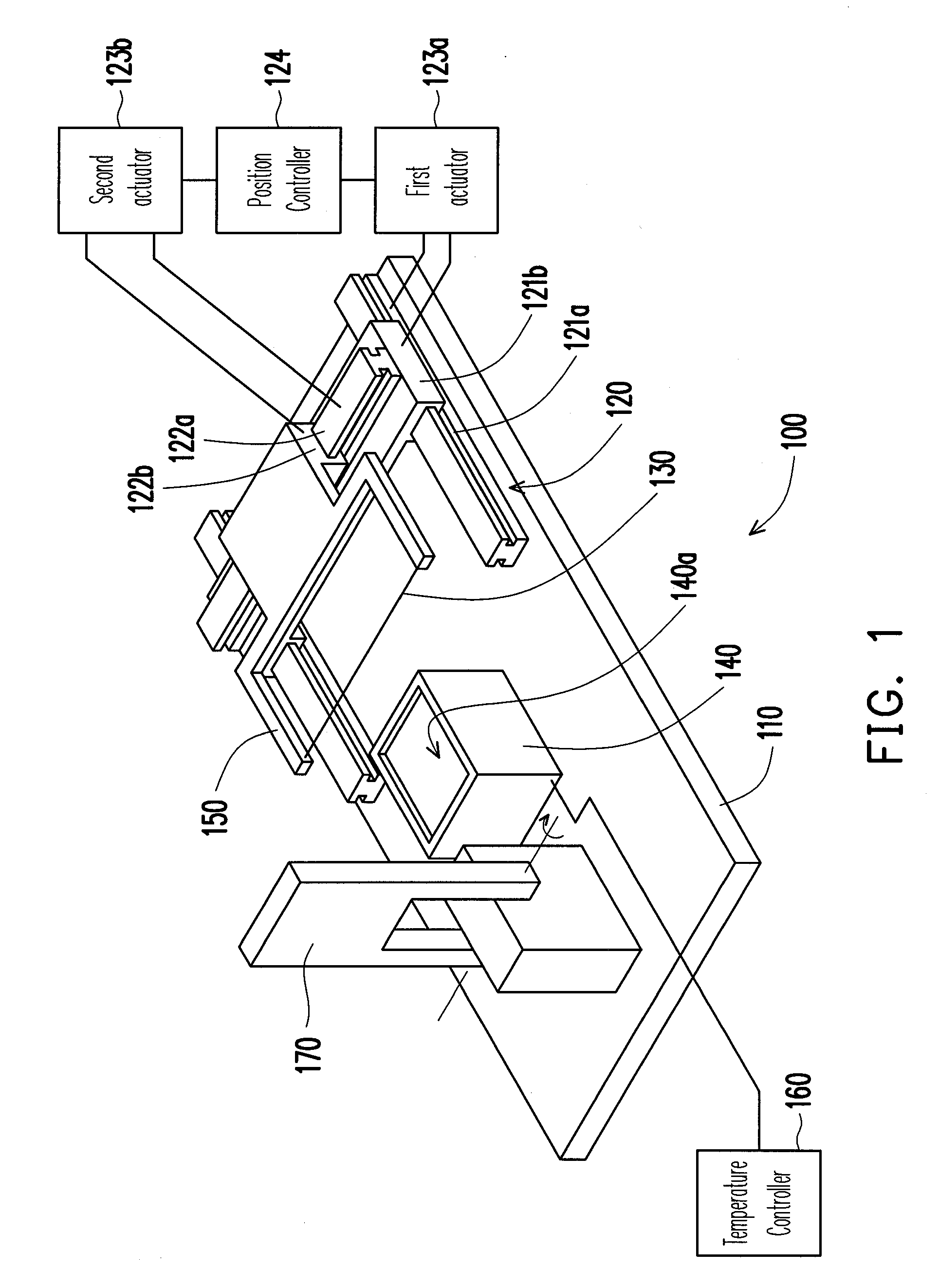

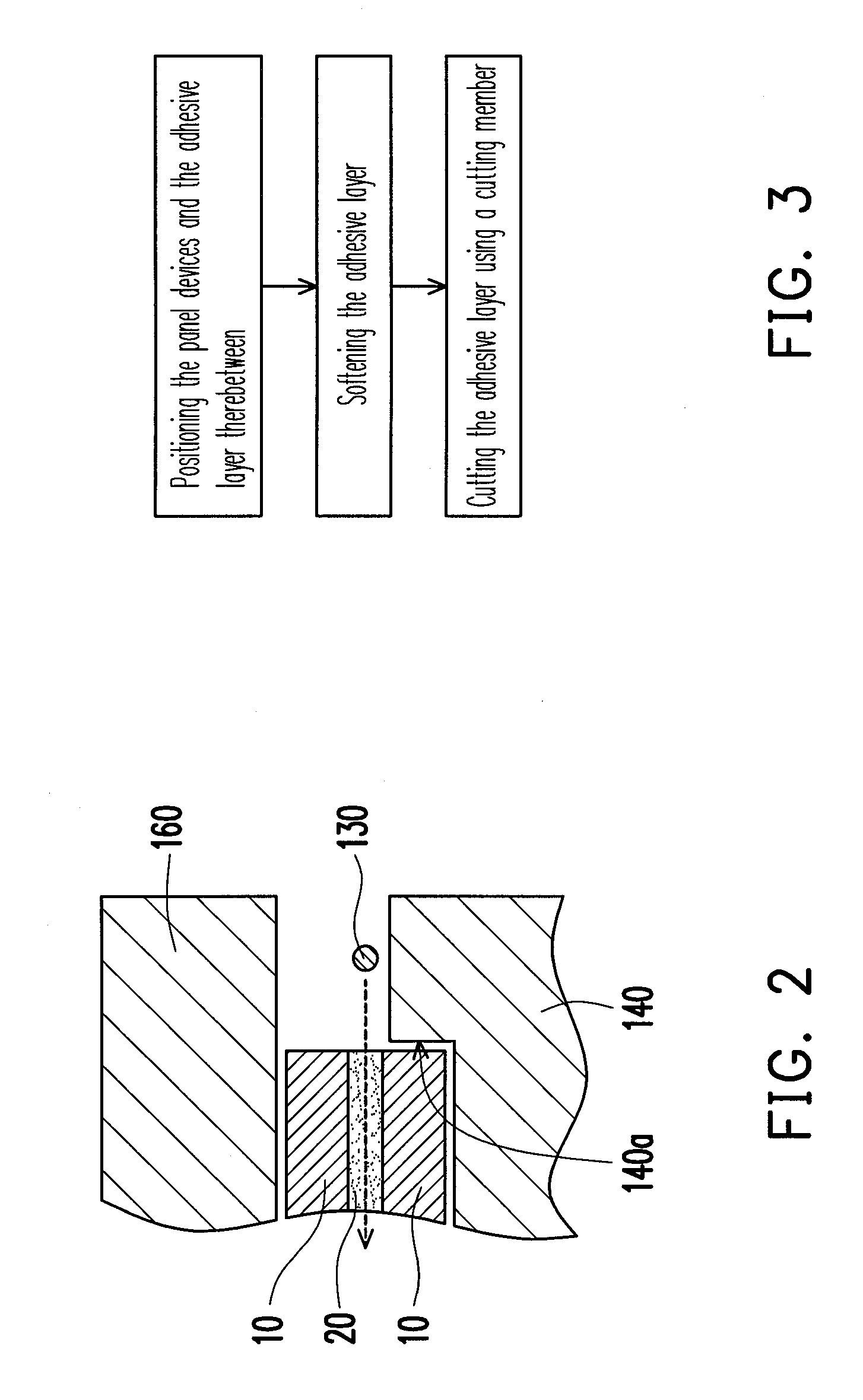

Separation apparatus and separation method

ActiveUS20100107834A1Reduce repair costsReduce rework costsMetal sawing devicesCross-cut reciprocating sawsEngineeringMechanical engineering

A separation apparatus for separating two planar devices bonded together by an adhesive layer is provided. The separation apparatus includes a base, a sliding module, a cutting member, and a positioning stage. The sliding module is mounted on the base. The cutting member is connected to the sliding module and is moveable in a two-dimensional plane with respect to the base by the sliding module for cutting the adhesive layer. The positioning stage is mounted on the base for positioning the planar devices and the adhesive layer therebetween on the base.

Owner:HTC CORP

A benthonic animal-algae-aquatic plant-fish based river water ecological environment self-remediation method

ActiveCN105523637AControl quantityControl concentrationSustainable biological treatmentBiological water/sewage treatmentEcological environmentIndividual animal

The invention relates to a benthonic animal-algae-aquatic plant-fish based river water ecological environment self-remediation method. The method is to overcome problems of river water ecological environment remediation methods at present, namely short effect duration, high costs and easy generation of secondary pollution. The method includes 1) evaluating the degree of pollution of a river, 2) planting reed and seeding algae, 3) throwing in plankton and benthic mollusks, 4) planting submerged plants, 5) throwing in shrimps, herbivorous fishes, omnivore fishes and filter-feeding fishes, 6) throwing in carnivorous fishes, and 7) harvesting the reed and the submerged plants before the reed and the submerged plants die, catching the benthic mollusks and the shrimps, and catching the fishes after two years. The method is long in effect duration, low in cost and free of secondary pollution and is applied for the field of river water pollution remediation.

Owner:JIAYING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com