Patents

Literature

2781 results about "Beam column" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beam column. A structural member subjected simultaneously to axial load and bending moments produced by lateral forces or eccentricity of the longitudinal load.

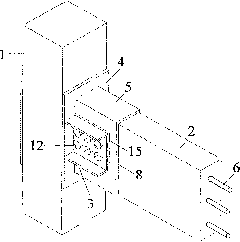

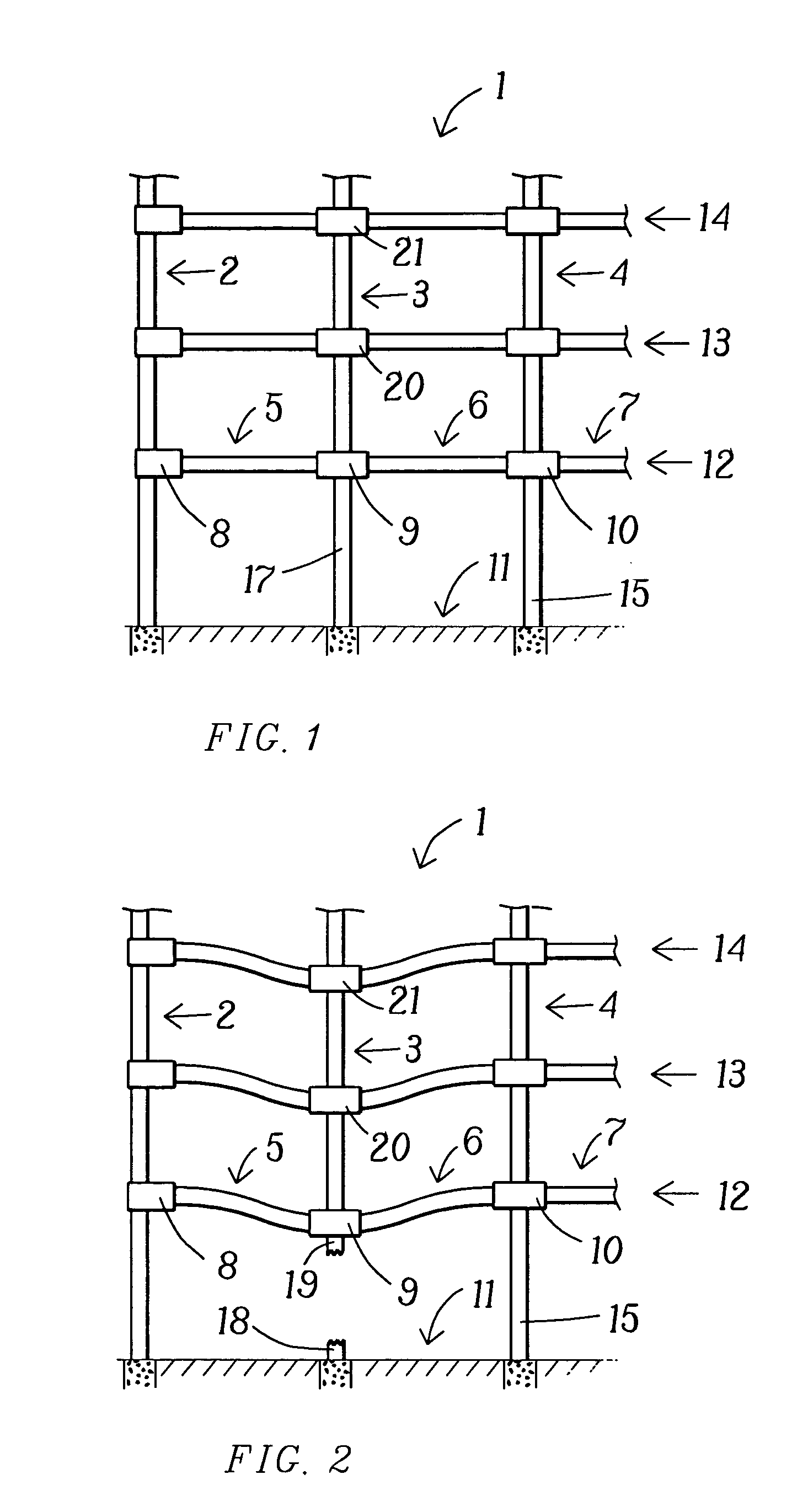

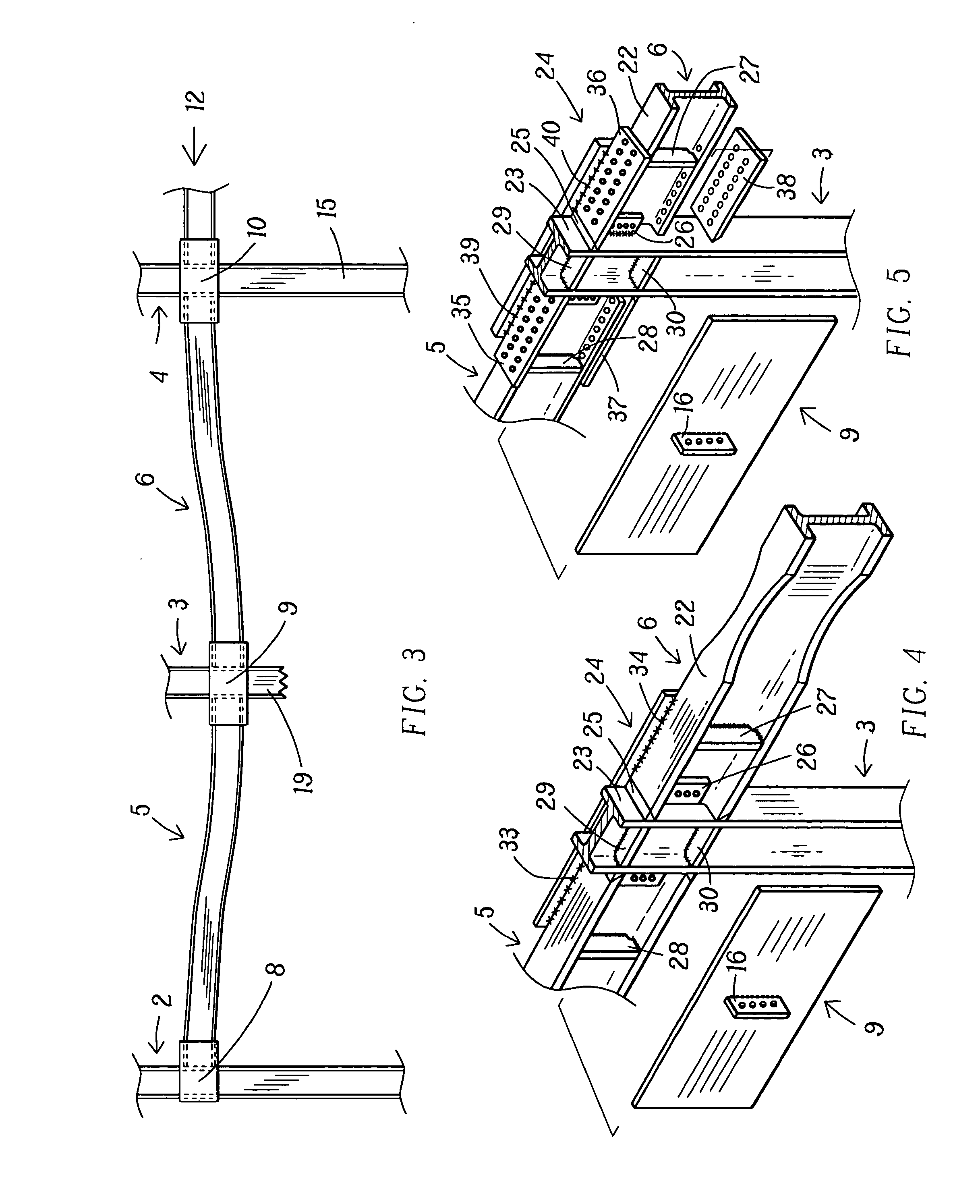

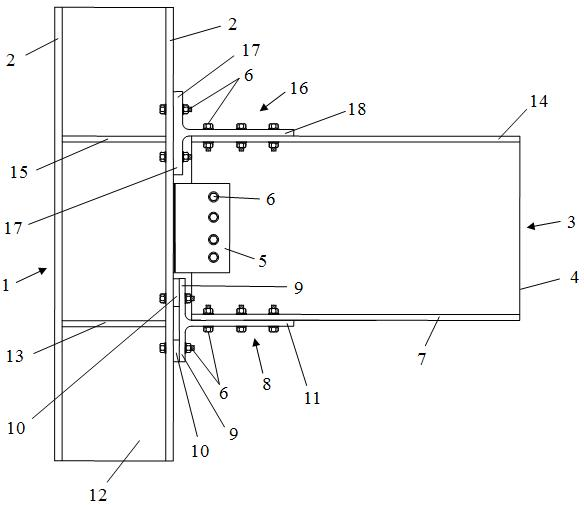

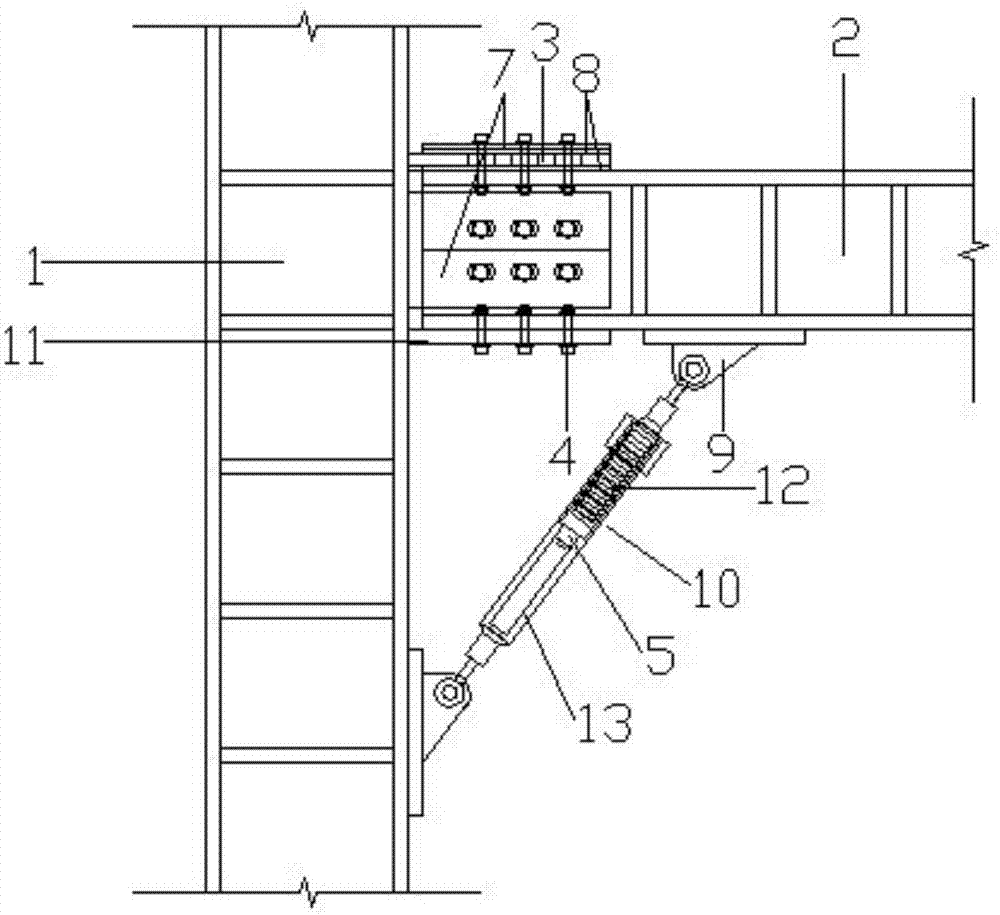

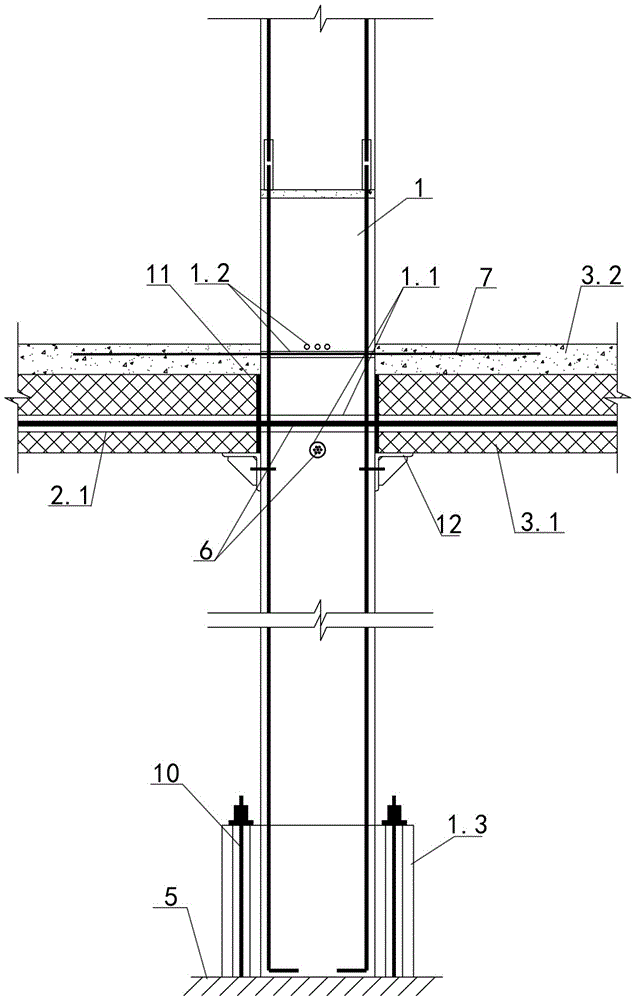

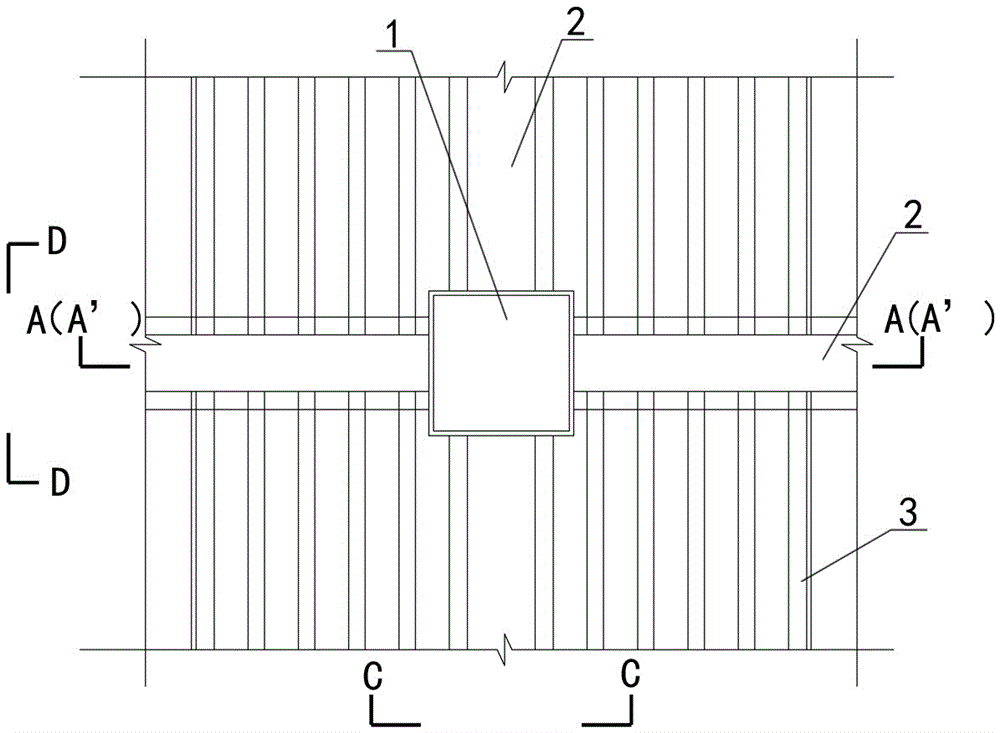

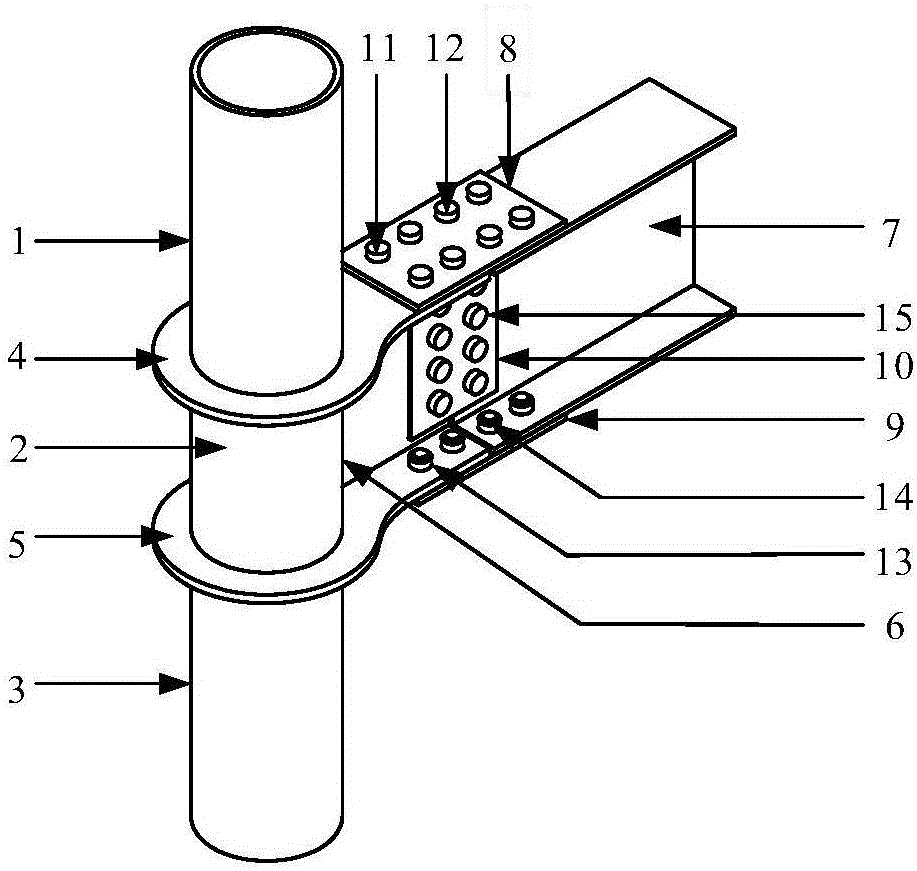

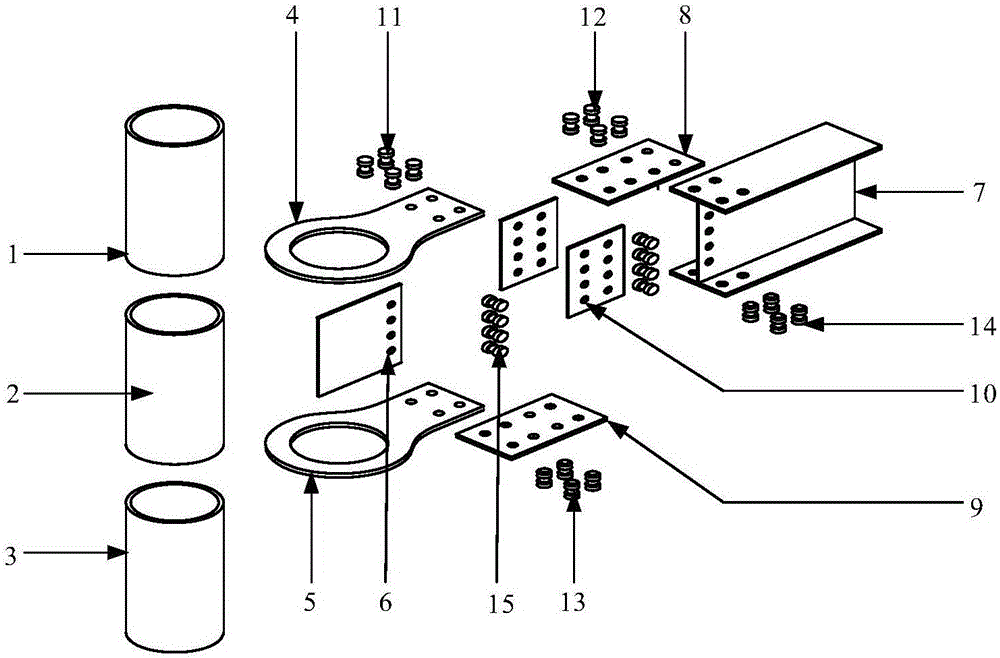

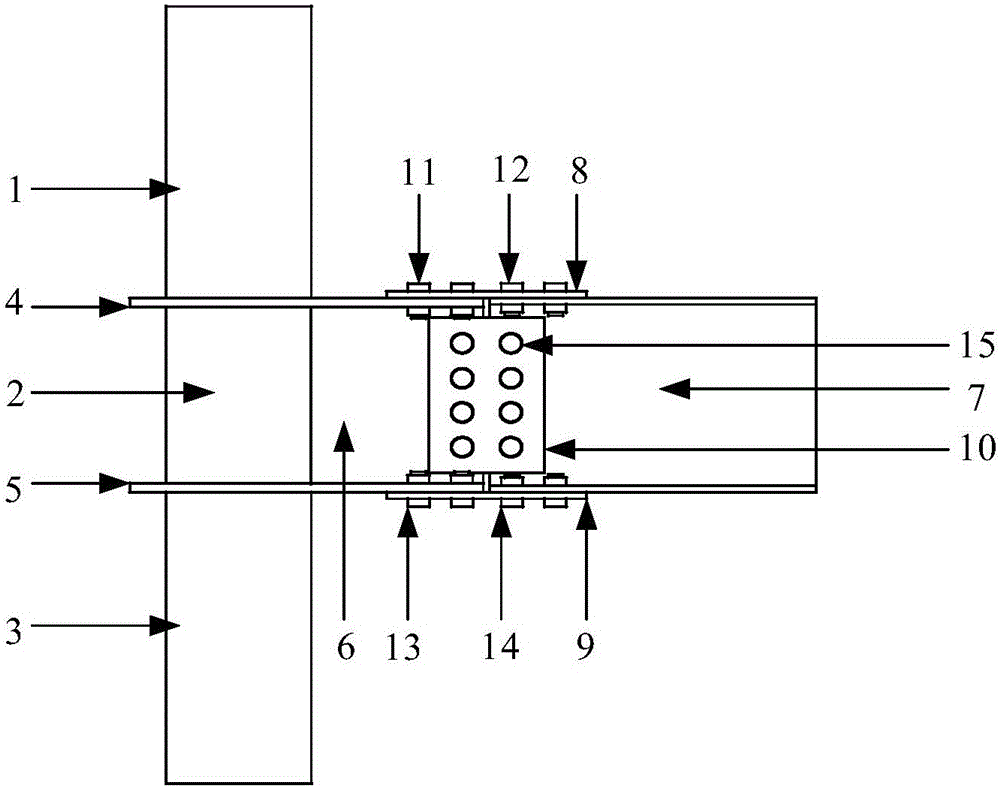

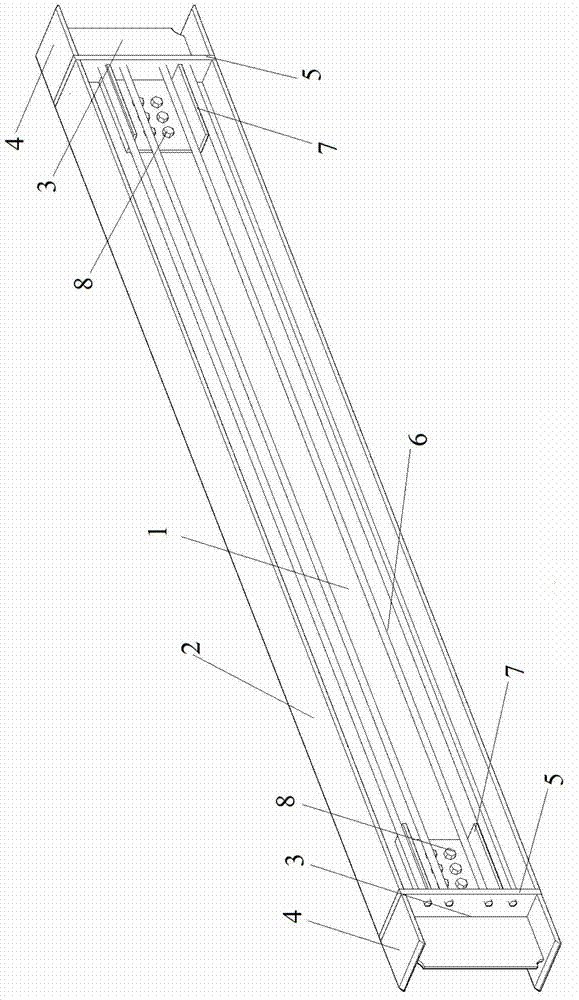

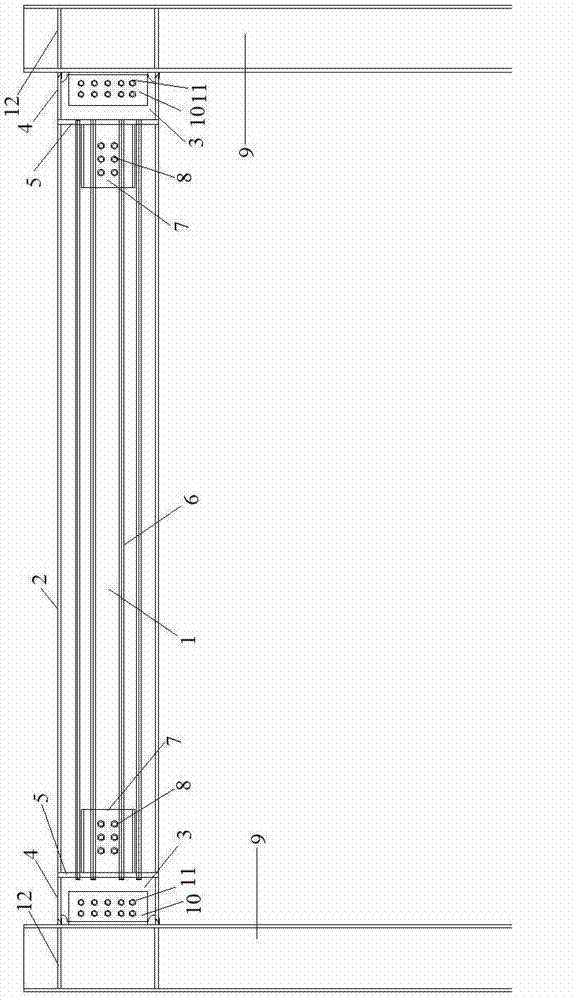

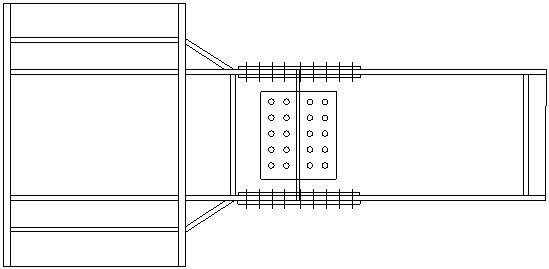

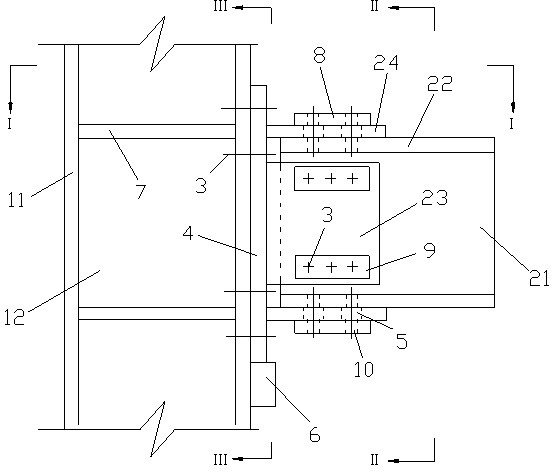

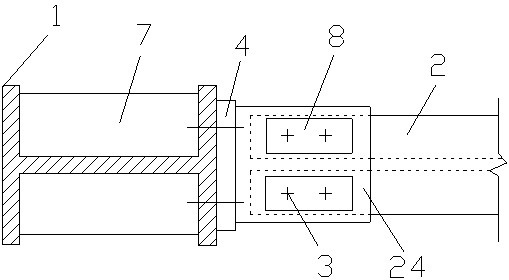

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

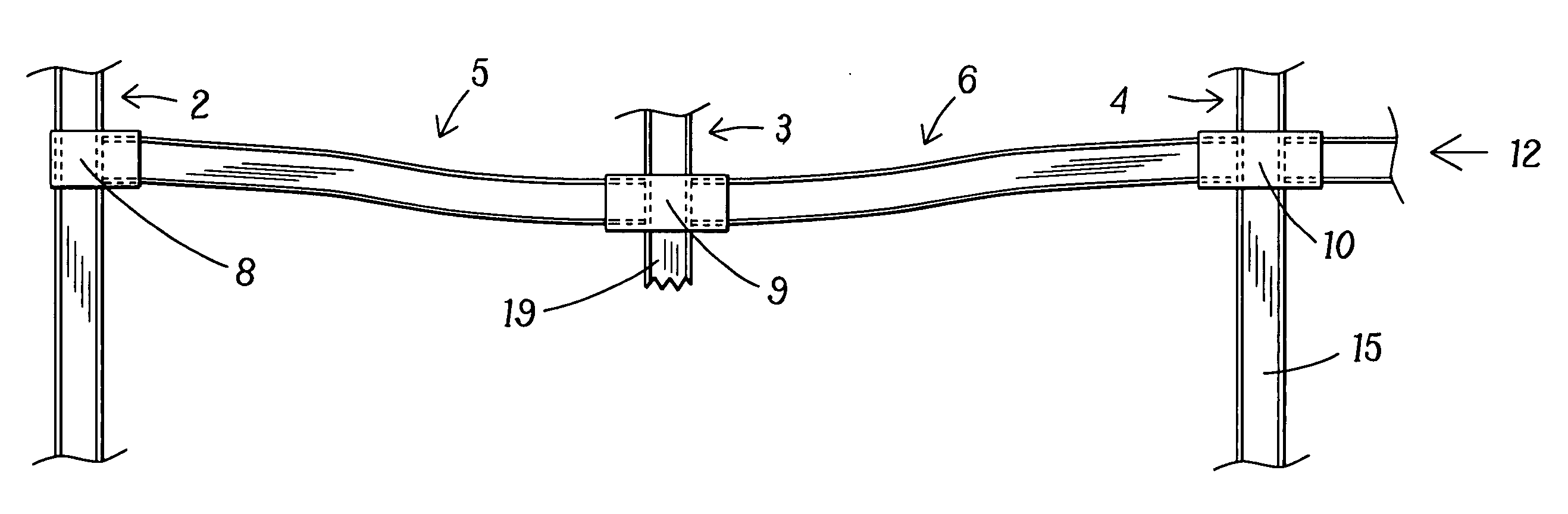

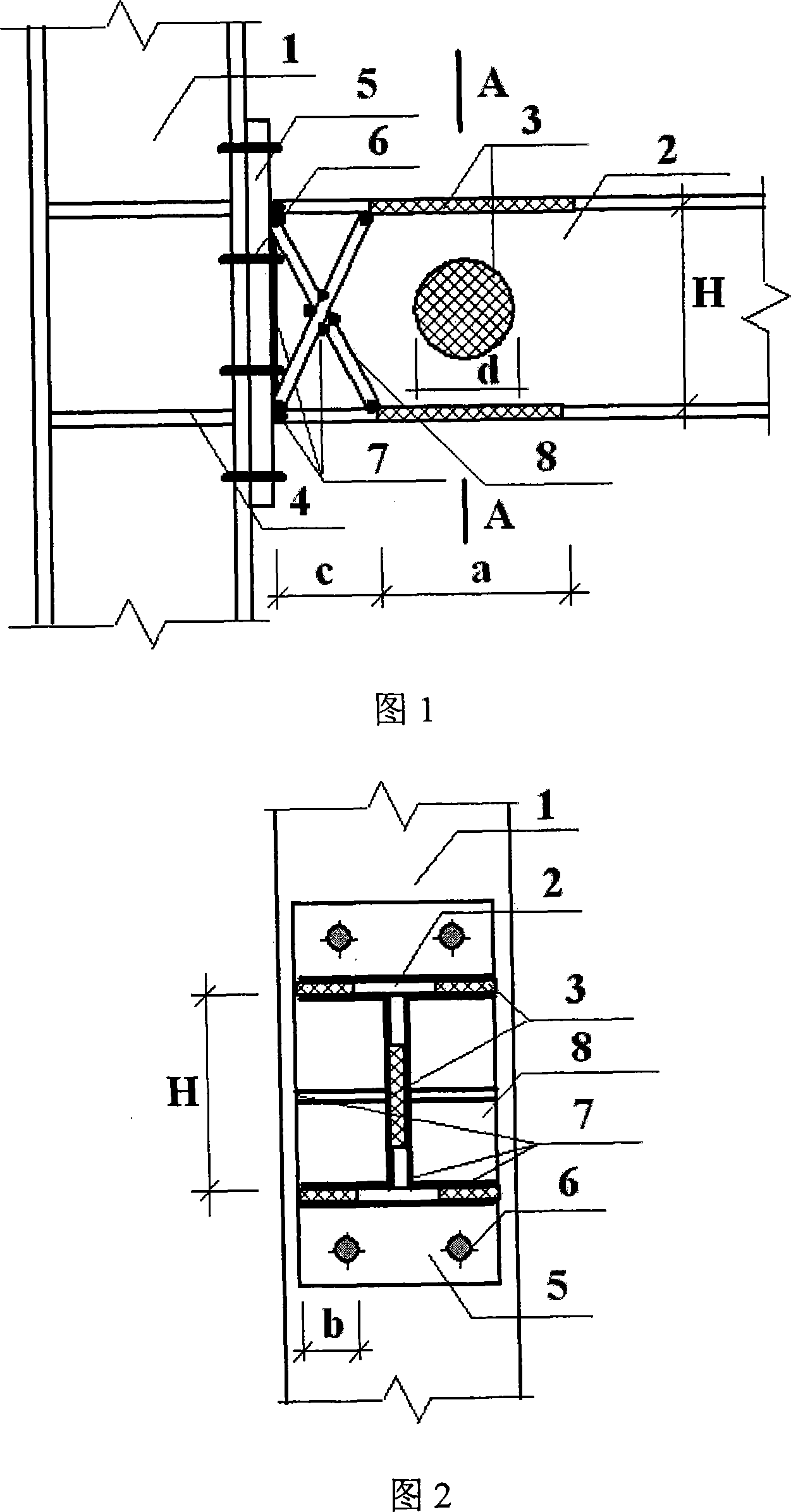

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

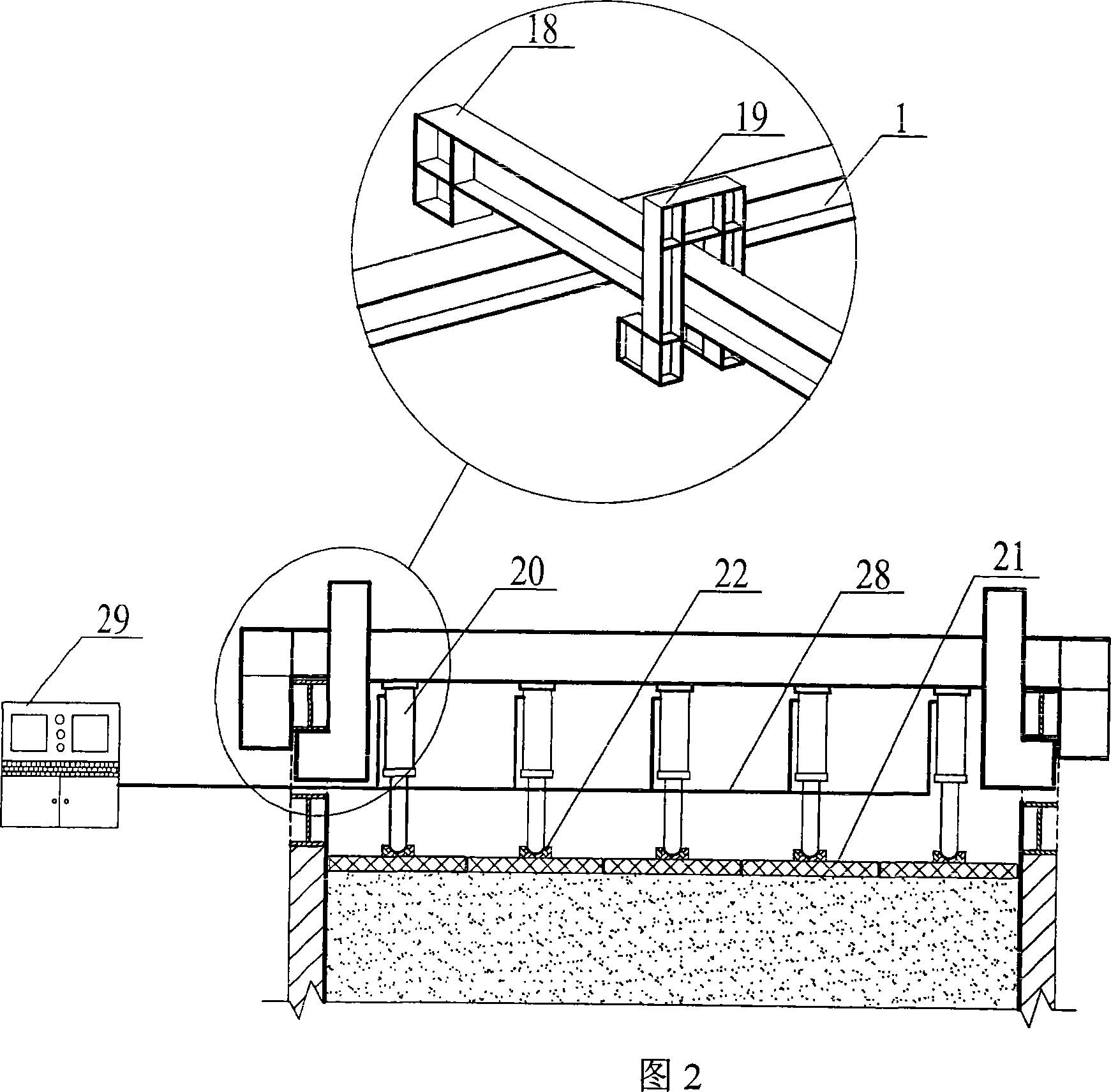

Foundation and slope engineering model test platform

InactiveCN101086494ASoil conditions are controllableControllable groundwater levelFoundation testingMaterial analysisVacuum extractionPore water pressure

The invention relates to a testing platform with ground and slope engineering module. Long edge at one side of the main structure side steel plate has an instrument burying hole and data leading out hole, the other side having viewing window, bottom of the rectangular structural module slot rubble and sand cushion having water pipe supply net that connects with the water tank and vacuum extraction device, one side of the short edge of the main body structural side steel plate having discharge hole, two sides of the main structural beam post overpass the latched the reverse beam, whose lower end having hydraulic jack, ball hinges and bearing plate formed servo bearing system, displacement sensor, sand pressure sensor and gap water pressure connected to form the monitoring system. It can be deployed to prevent disasters.

Owner:ZHEJIANG UNIV

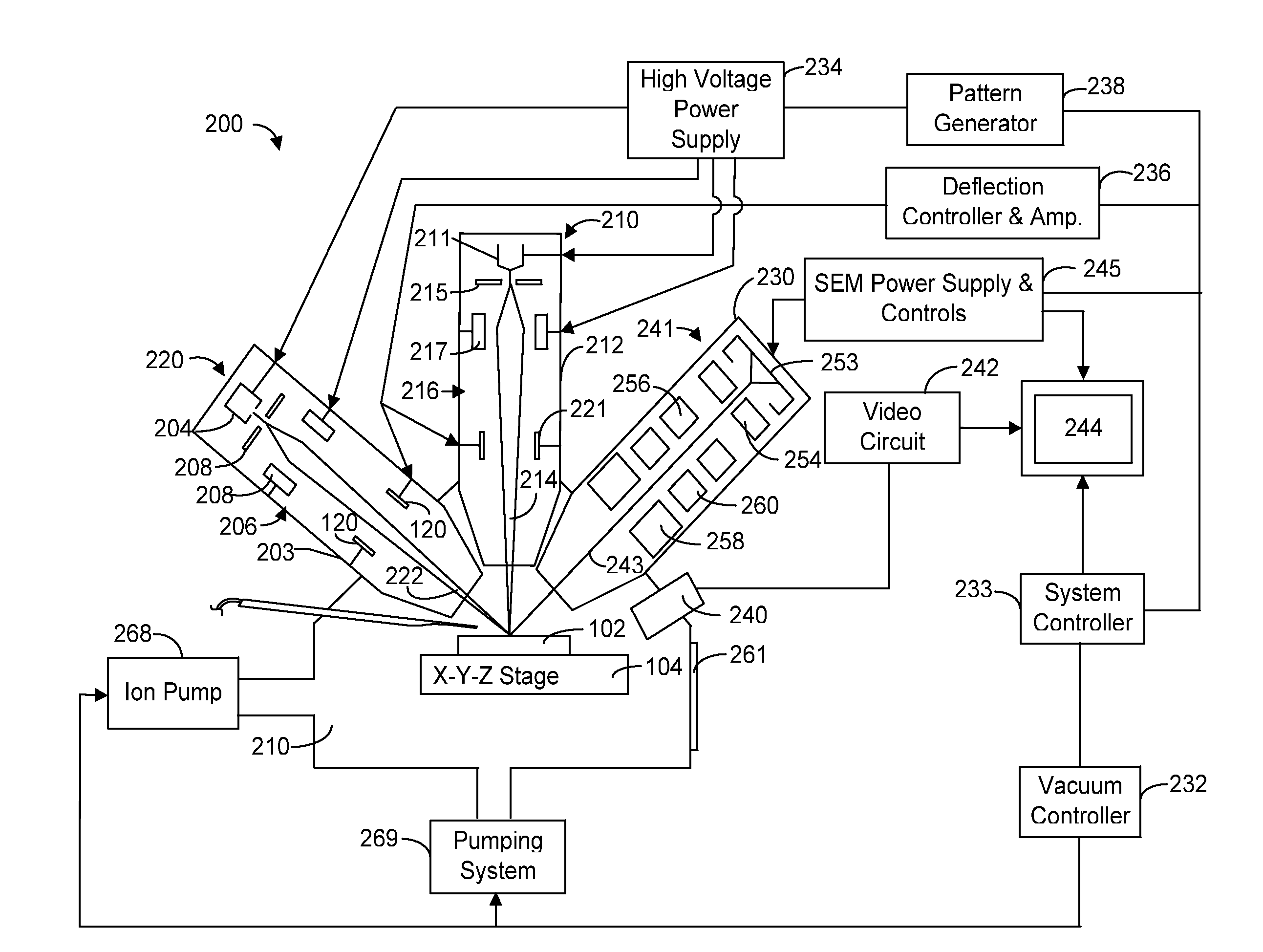

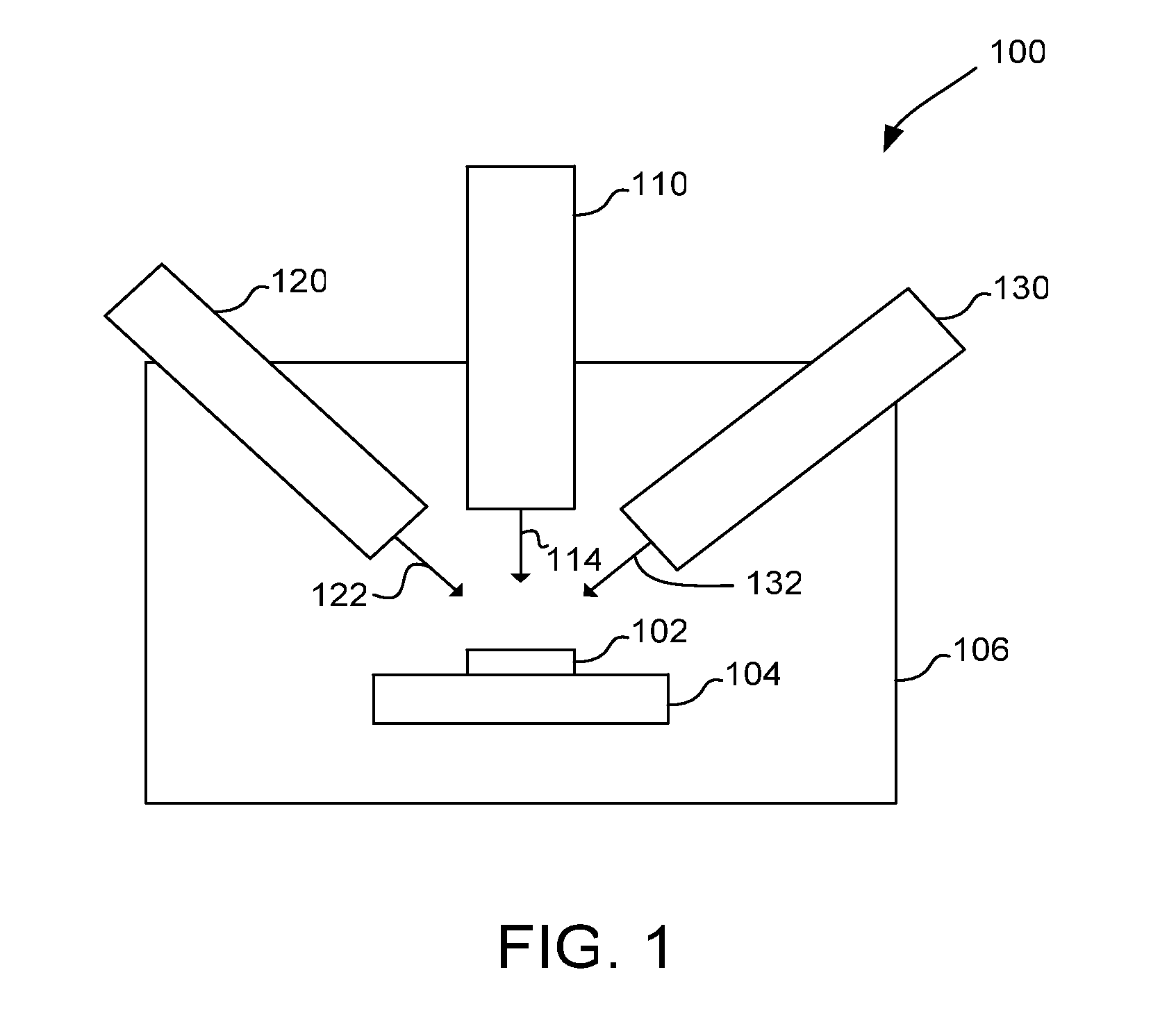

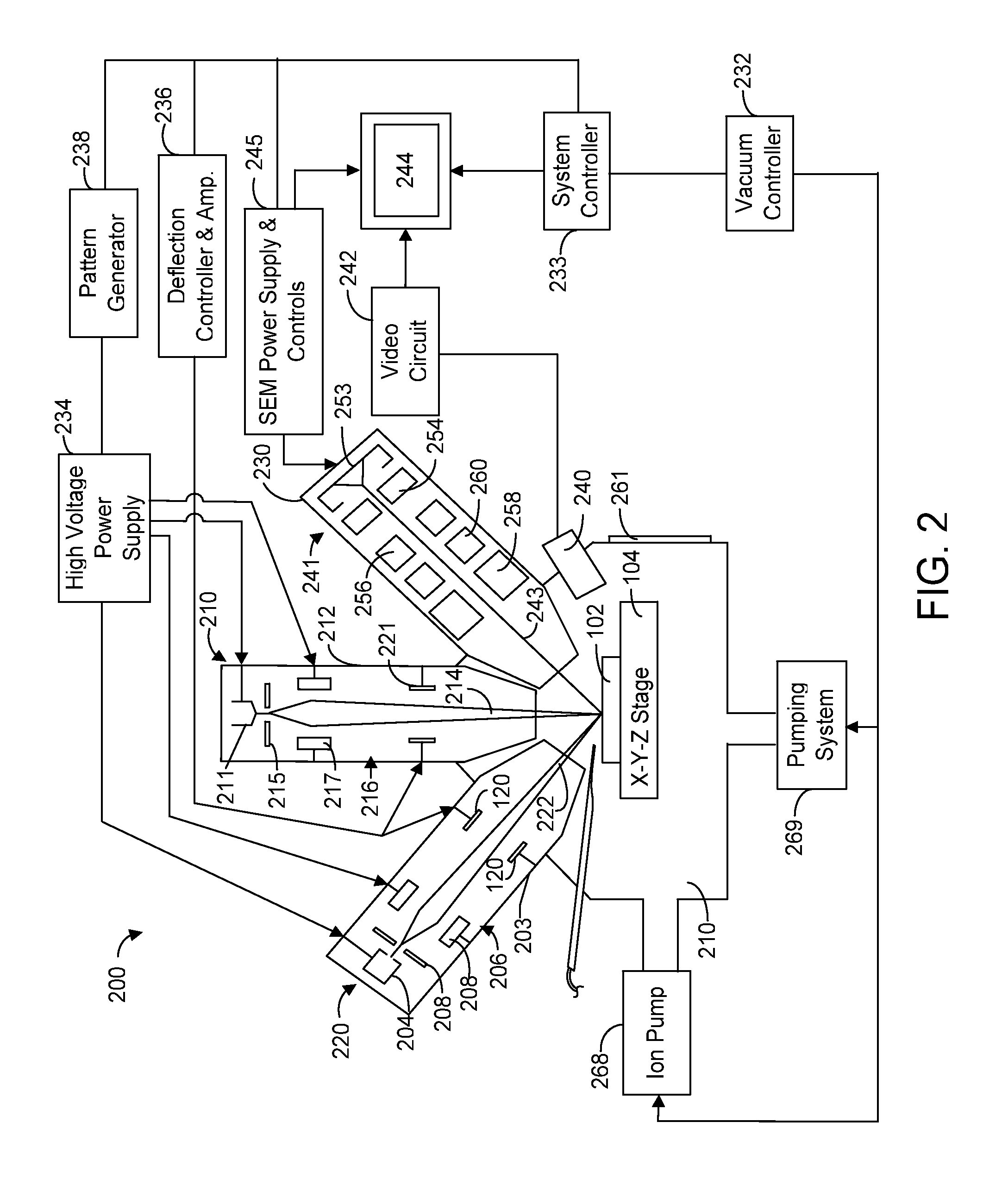

Multibeam System

A multibeam system in which a charged particle beam and one or more additional beams can be directed to the target within a single vacuum chamber. A first beam colunm preferably produces a beam for rapid processing, and a second beam column produces a beam for more precise processing. A third beam column can be used to produce a beam useful for forming an image of the sample while producing little or no change in the sample.

Owner:UTLAUT MARK +6

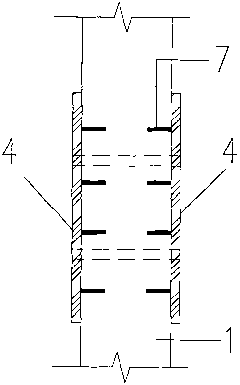

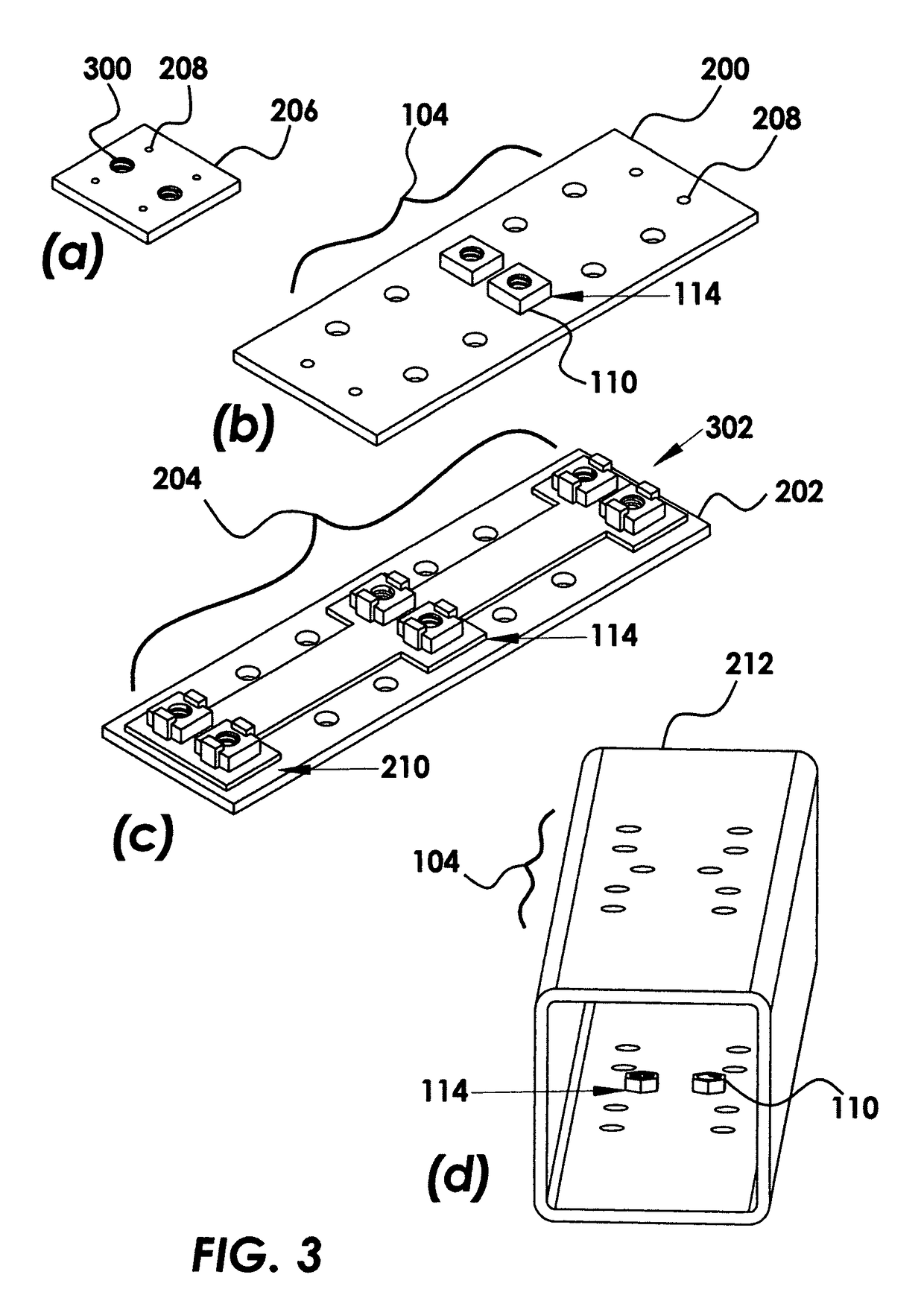

Flexible vibratory micro-electromechanical device

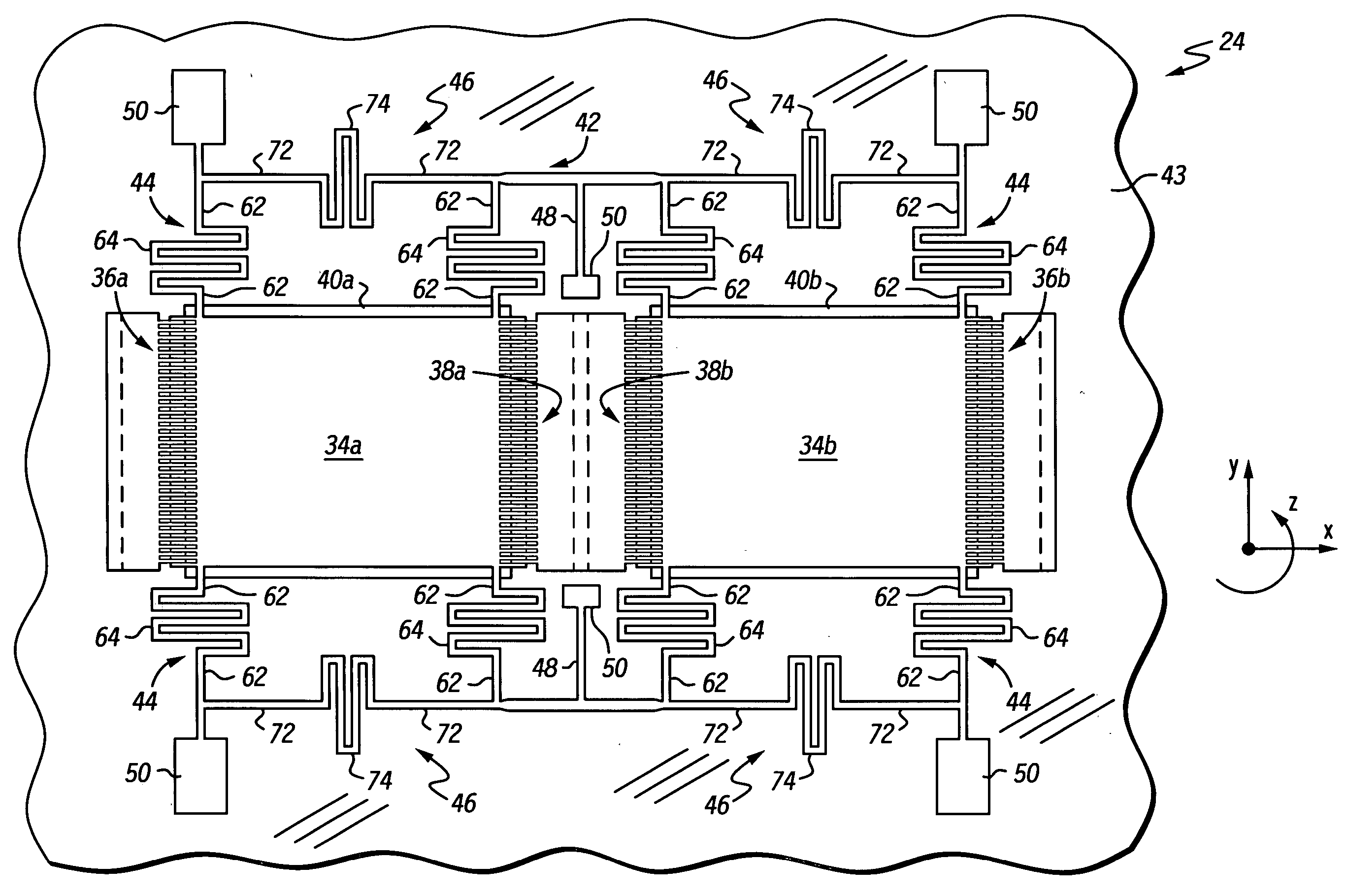

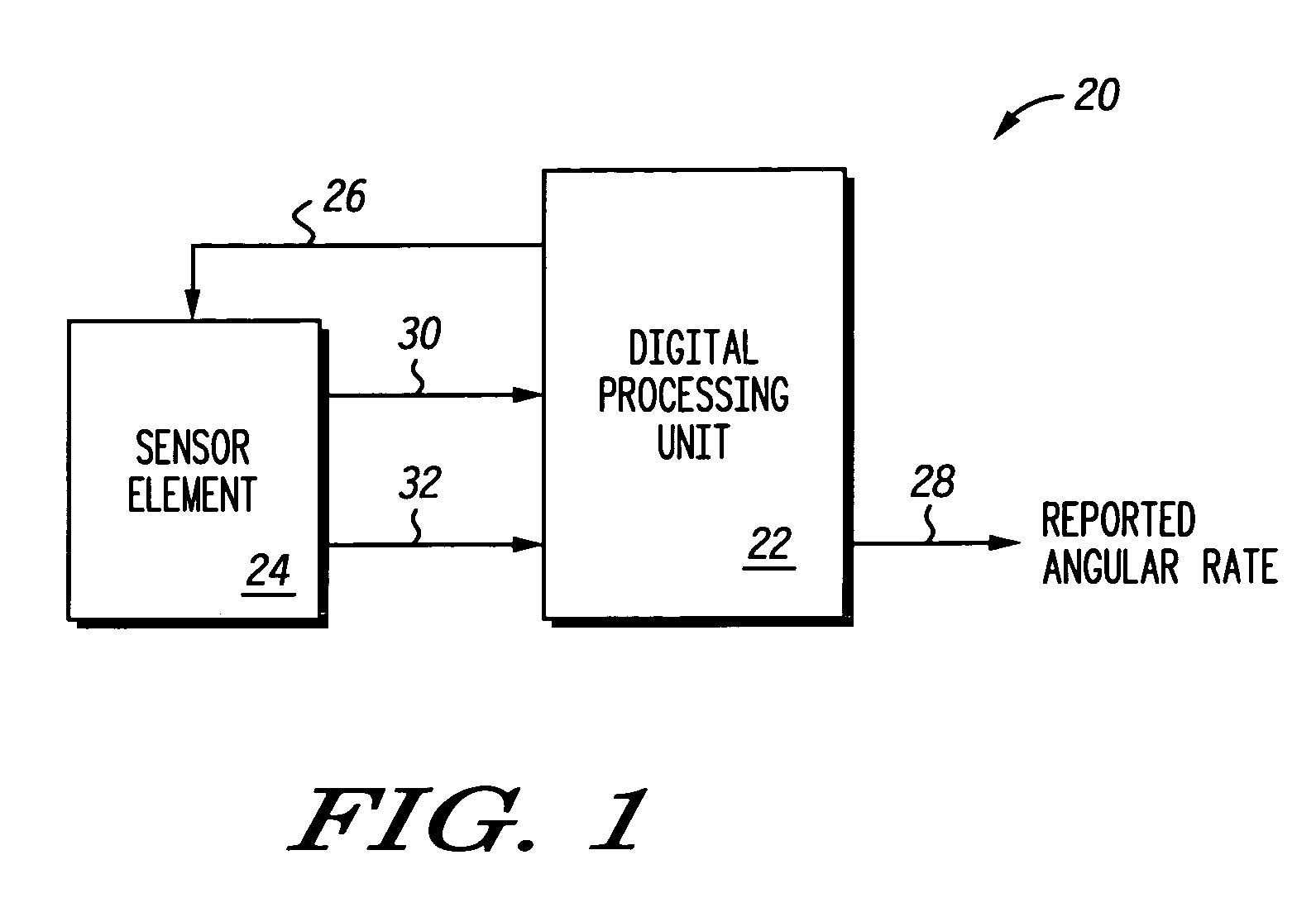

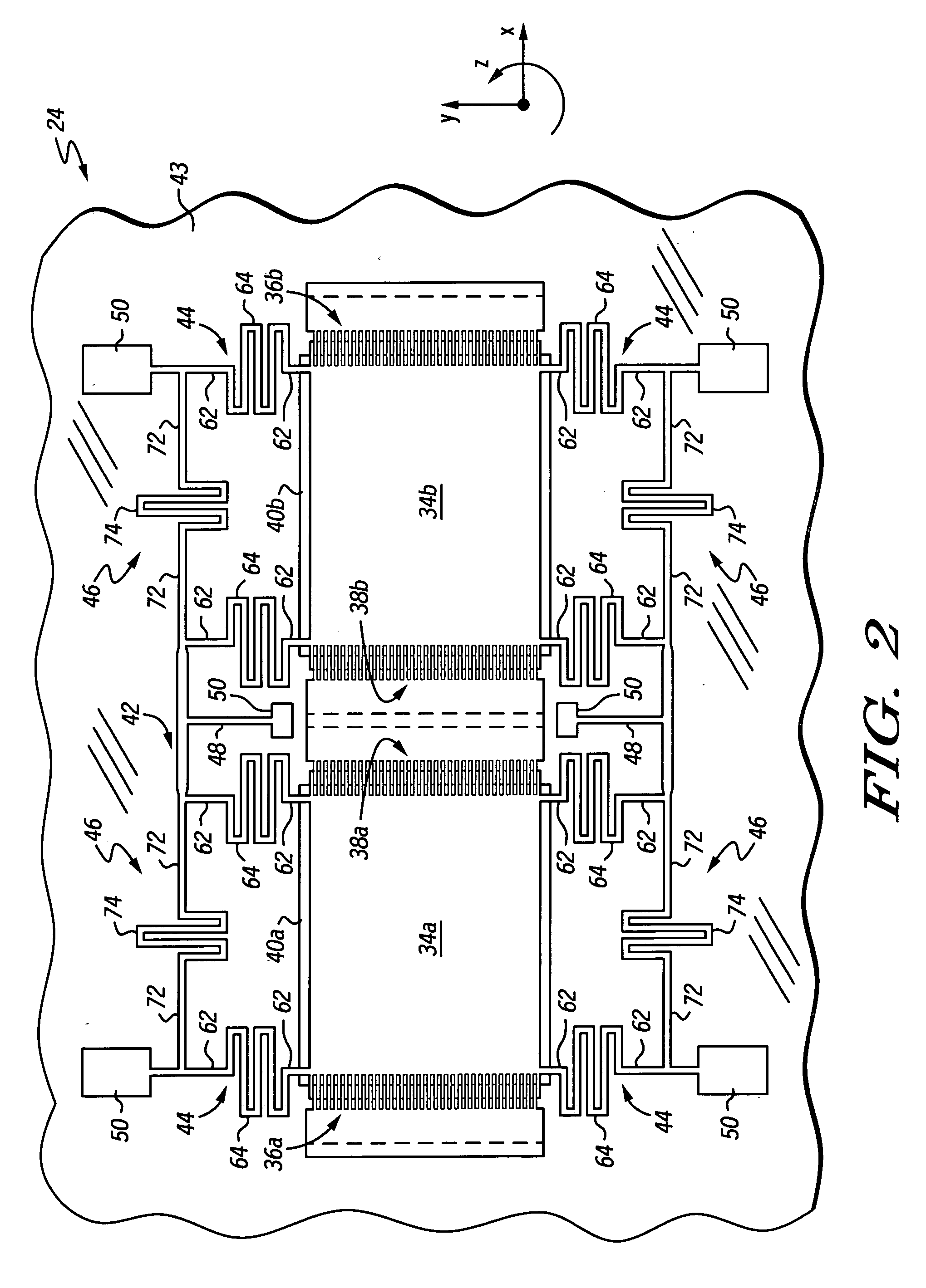

InactiveUS6843127B1Television system detailsAcceleration measurement using interia forcesMechanical engineeringAnchor point

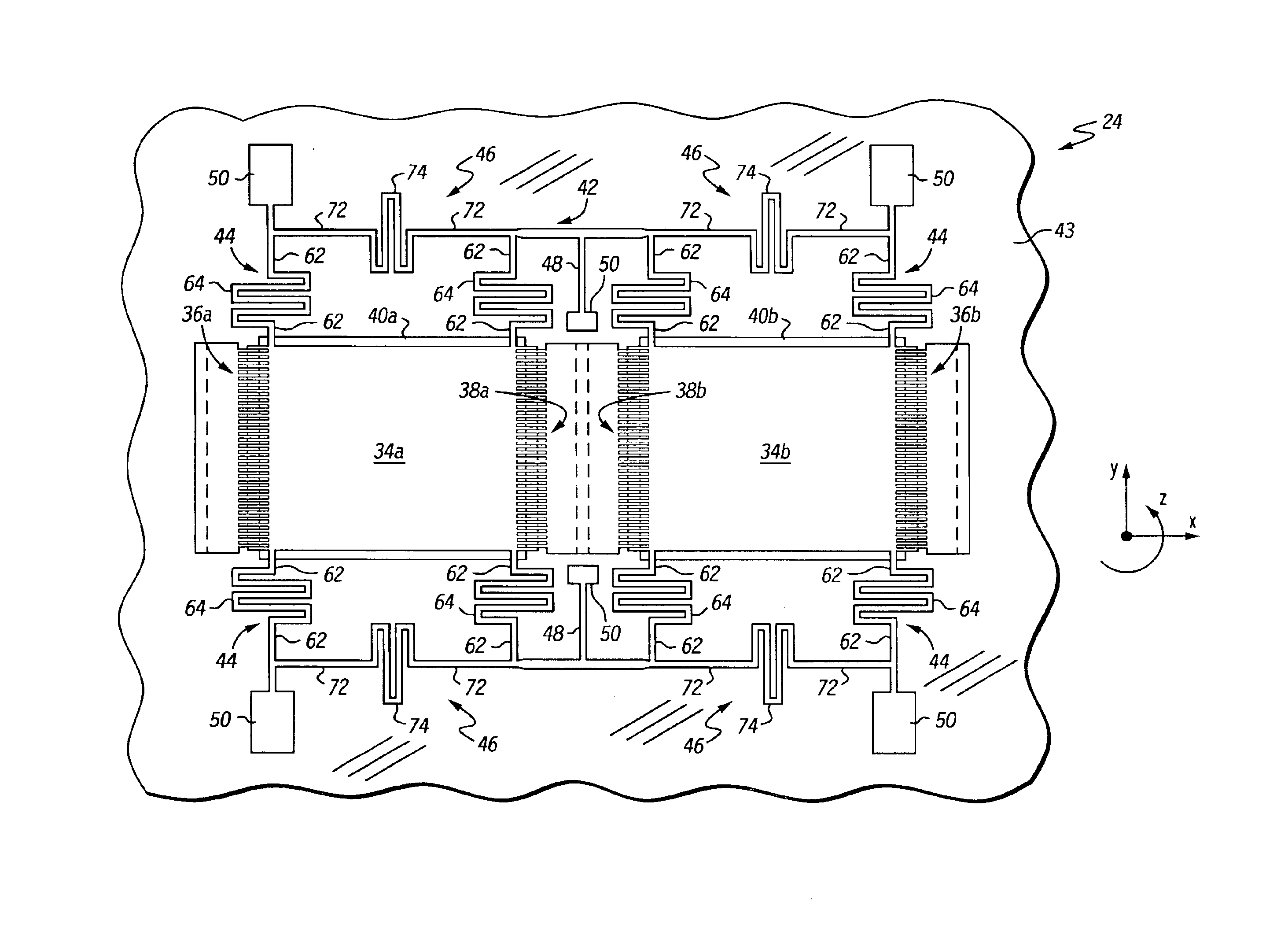

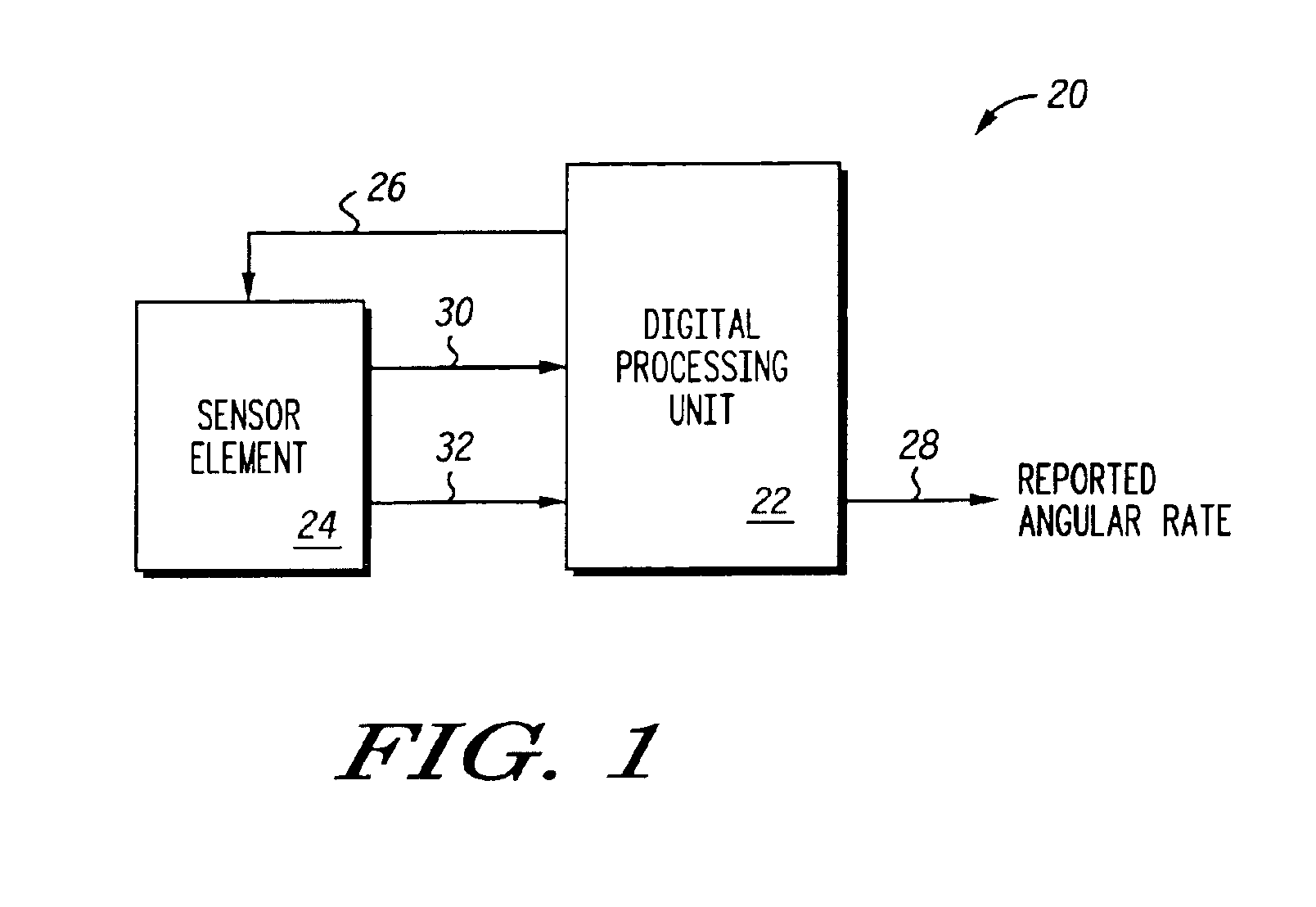

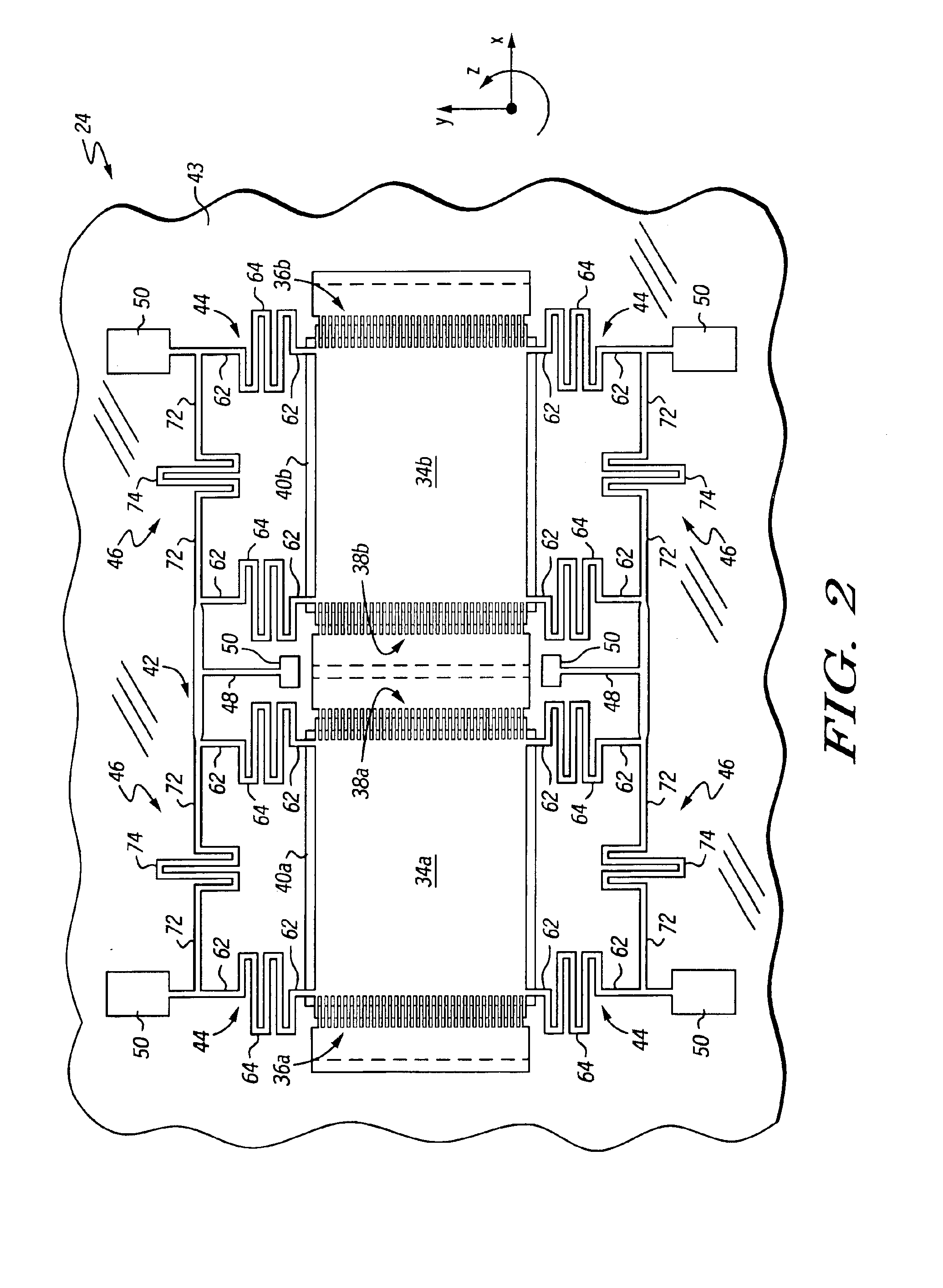

There is a sensor element (24) for an electronic sensor device (20). The sensor element (24) may have a substrate (43), a pair of proof masses (34a, 34b), a set of drive beams (44), and at least one base beam (46). The pair of proof masses (34a, 34b) are suspended above the substrate (43) and attached to the substrate (43) at fixed anchor points (50). The set of drive beams (44) are positioned between the proof masses (34a, 34b) and the anchor points (50). Each drive beam (44) has a first longitudinal body portion (62) that extends in a first direction and a first flexible spring member (64) that extends along a second direction. The base beam (46) interconnects the set of drive beams (44) and has a second longitudinal body portion (72) and a second flexible spring member (74). The second longitudinal body portion (72) extends along the second direction and the second flexible spring member (74) extends along the first direction. The first and second flexible spring members (64, 74) may be serpentine in shape, such as folded beam-columns or wrinkle springs.

Owner:TEMIC AUTOMOTIVE OF NORTH AMERICA

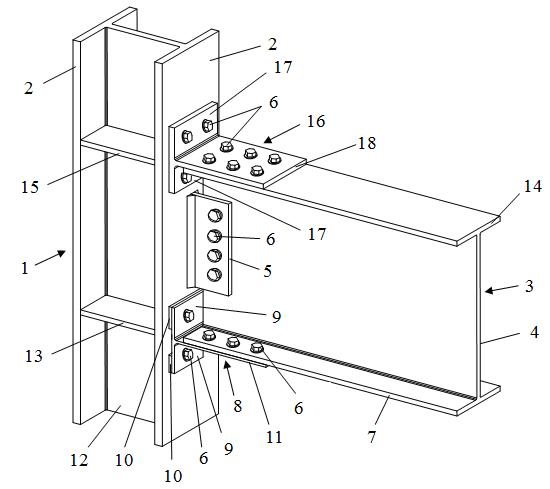

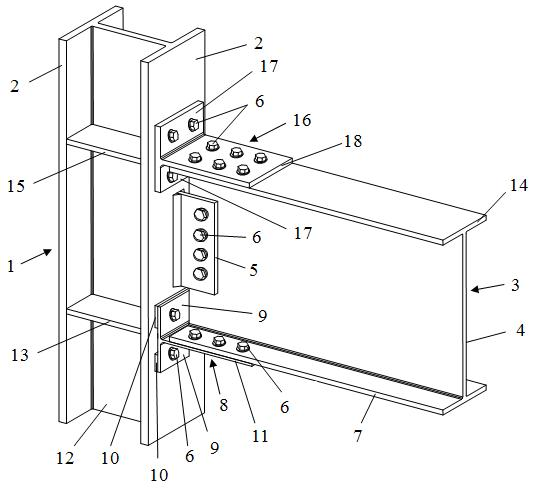

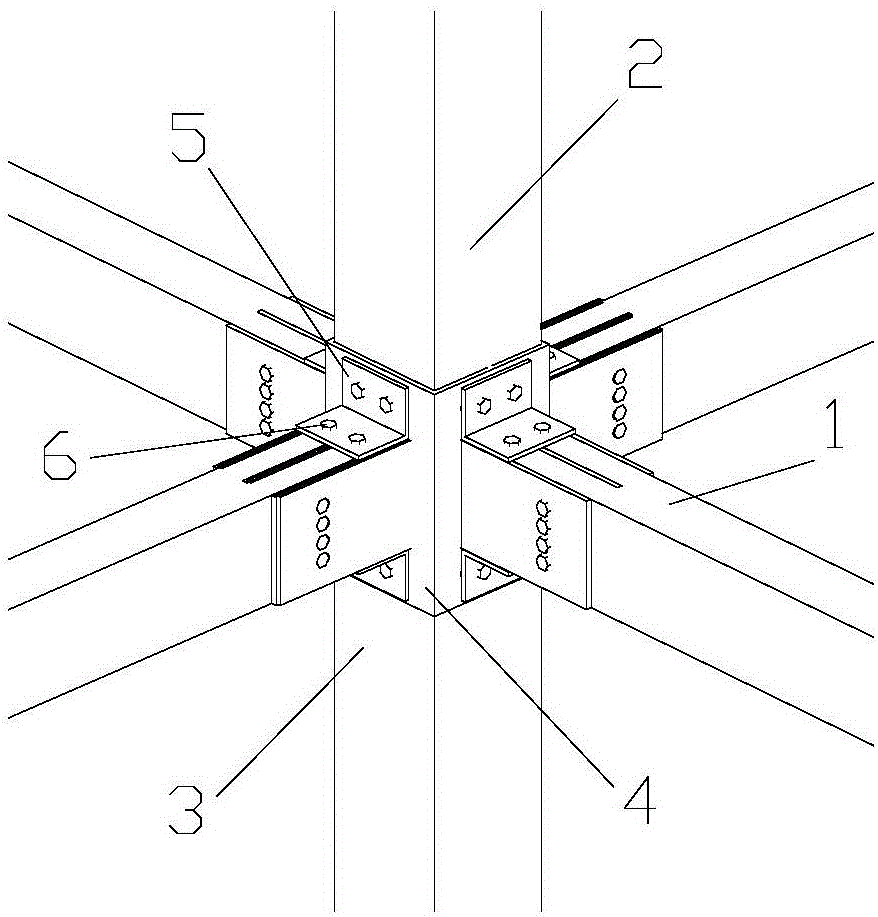

Structural joint connection providing blast resistance and a beam-to-beam connection resistant to moments, tension and torsion across a column

ActiveUS20050204684A1Mitigates likelihood of progressive collapseTremendous tensile pull and vertical moment demandBuilding roofsFloorsGusset plateEngineering

At a beams-to-column joint connection of two beams to a column, in which the joint connection comprises both a gravity load-carrying connection and a moment-resisting connection, there is added a beam-to-beam connection across the column, using two gusset plates, facing each other, on opposite sides of the joint connection. The gusset plates, which are not connected to the column in a moment-resisting connection, connect the two beams, in a tension and moment-resisting connection with respect to each other, by longitudinal welds between the gusset plates and the beams, and provide the capability of withstanding disastrous events, including loss of column support and / or loss of integrity of the beams-to-column joint connection and severe torsional and lateral inelastic deformation due to direct blast pressure. When subjected to such violent conditions and upon loss of column support, and, the likely loss of integrity of the beams-to-column joint connection, the two beams and two gusset plates provide independent beam-to-beam structural continuity, causing the two beams to act as one long beam, or, in other words, a “double-span” condition is created. Such beam-to-beam connection is capable of carrying the tension, torsional and moment loads placed upon the beams, to the ultimate capacity of the beams. Inasmuch as a gusset plate is disposed on each side of the beams-to-column joint connections, substantial shielding of those connections against blast and impact forces is also achieved.

Owner:MITEK HLDG INC

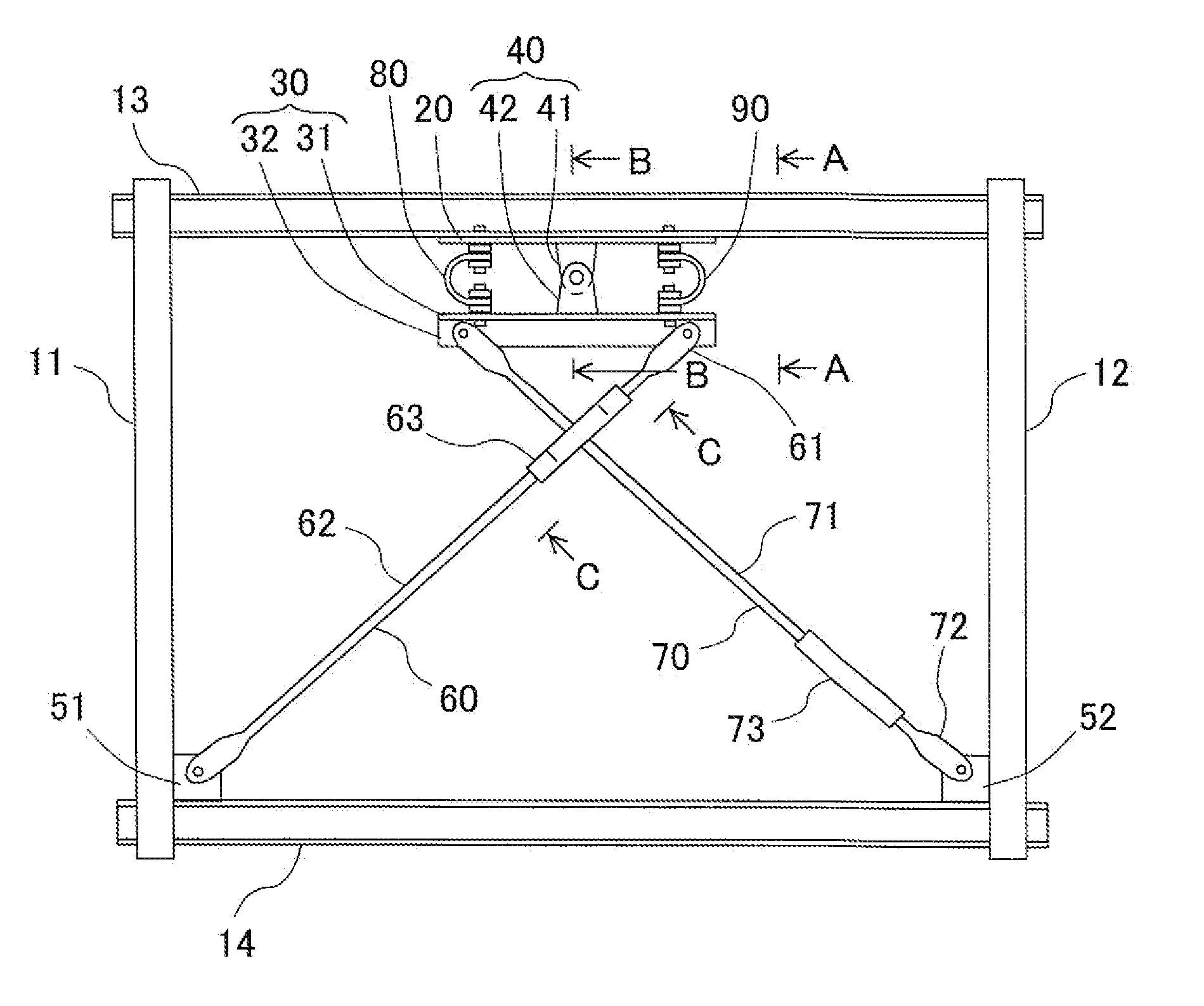

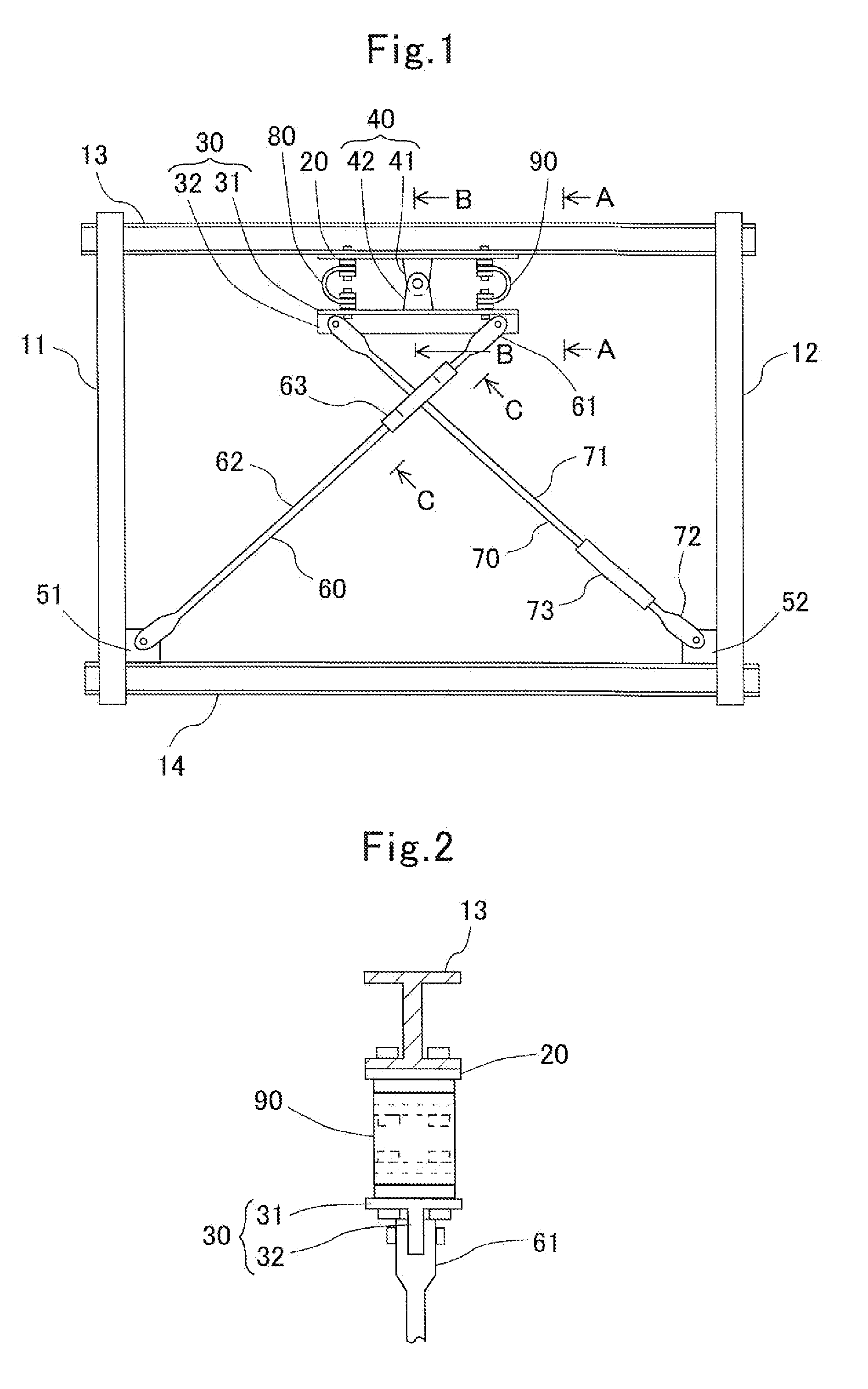

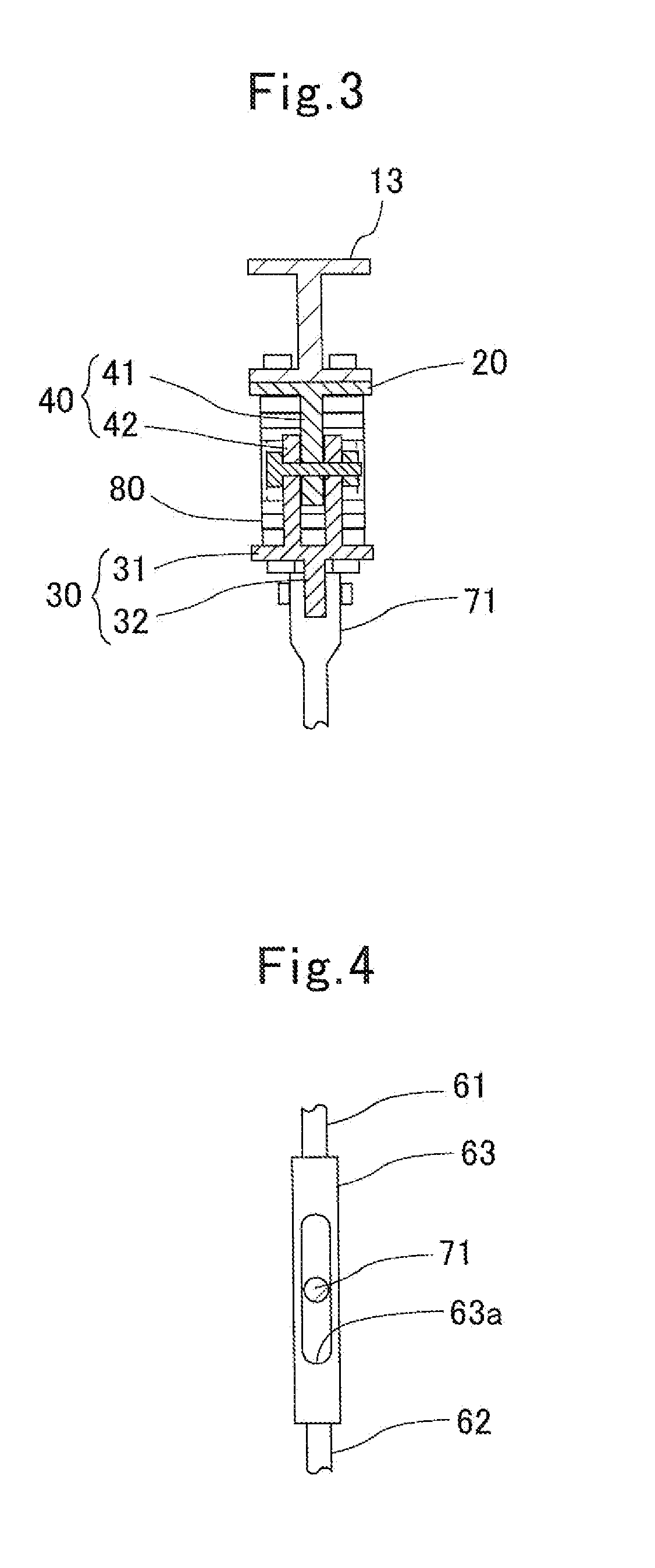

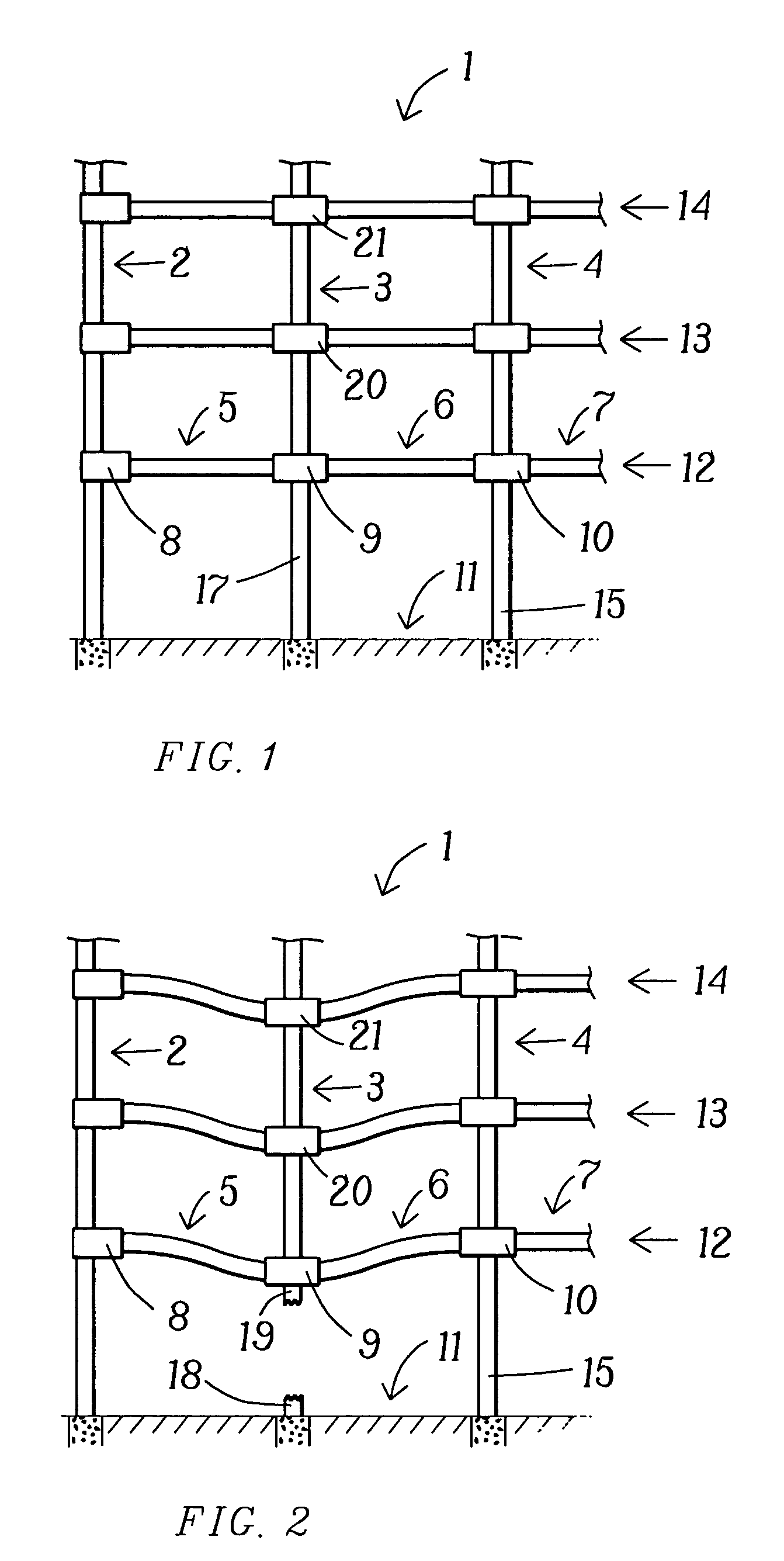

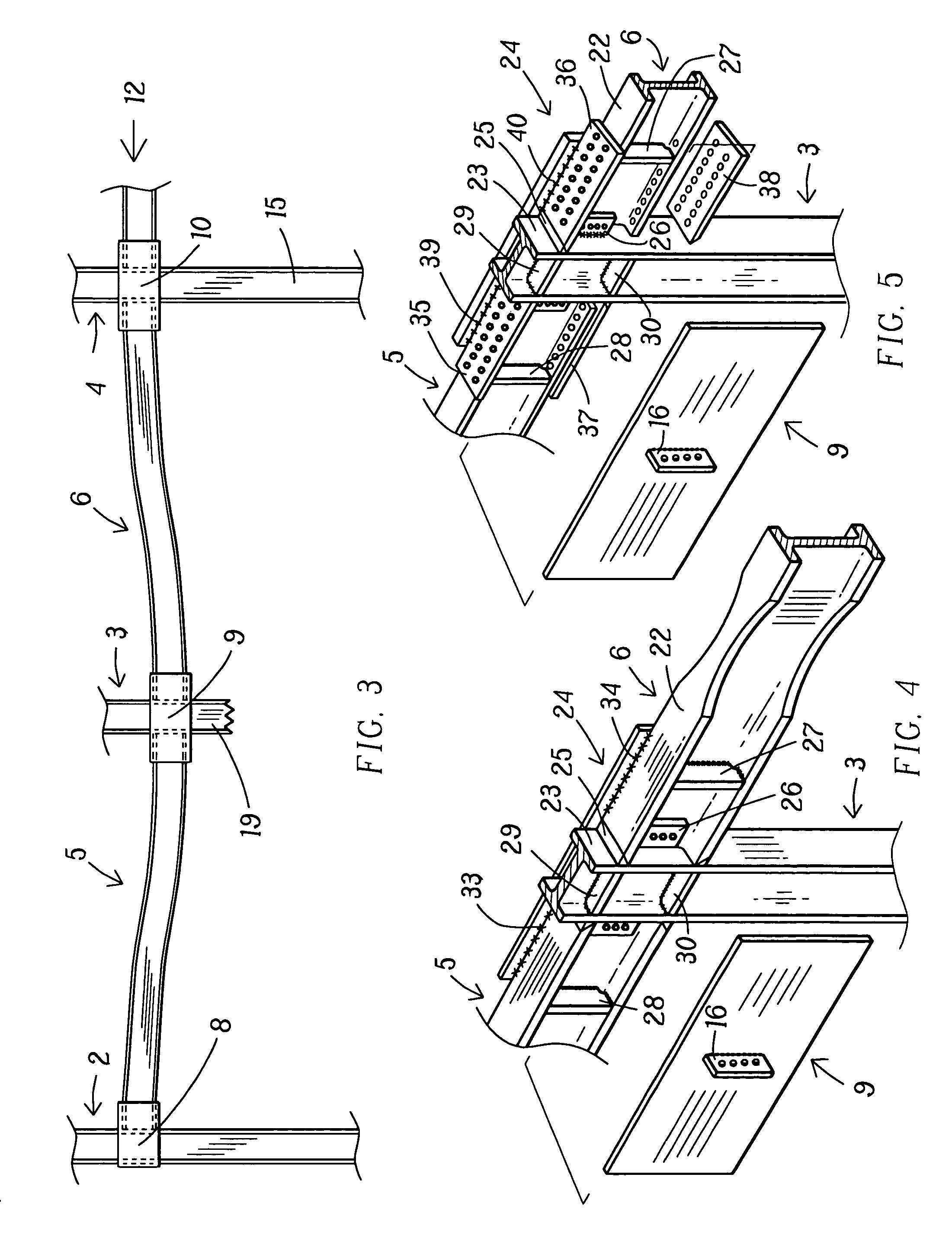

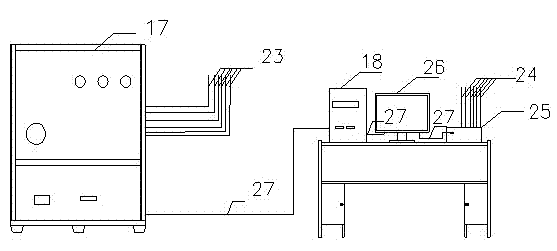

Vibration control device for beam-and-column frame

ActiveUS20120038091A1Improve rigidityPortable framesNon-rotating vibration suppressionVibration controlEngineering

To set up such a constitution that no compression forces act on braces, alternatively, to set up a constitution that makes it possible to make compression forces to be applied to braces smaller extremely; and to provide a vibration control device for beam-and-column frame that can demonstrate high vibration control performance.A rotary supporting member 40 supports a parallel member 30 rotatably with respect to an upper beam 13. A first brace 60 connects an opposite-end side of the parallel member 30 with an opposite-end side of a lower beam 14. A second brace 70 connects another opposite-end side of the parallel member 30 with another opposite-end side of the lower beam 14. An intersection position of the first brace 60 with the second brace 70 is positioned more adjacent to a side of the upper beam 13 than where an intermediate position between the upper beam 13 and the lower beam 14 is present. The resulting vibration control device includes damper members (80, 90) being disposed respectively so as to be interposed between the parallel member 30 and the upper beam 13, connecting the parallel member 30 with the upper beam 13, and being disposed to make a pair at least on both sides each of which is separated away from the rotary supporting member 40 to interpose the rotary supporting member 40 therebetween.

Owner:NAGOYA UNIVERSITY +1

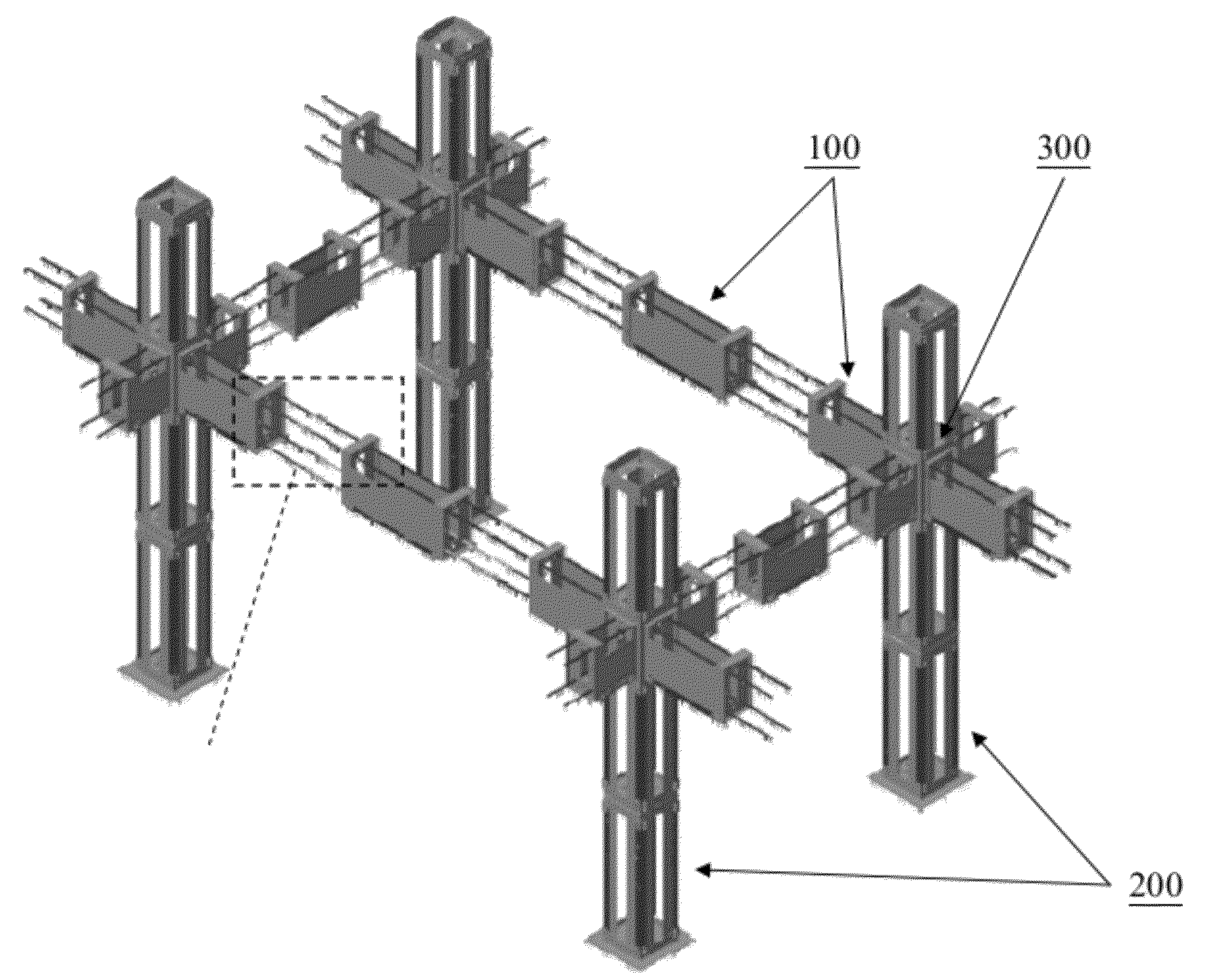

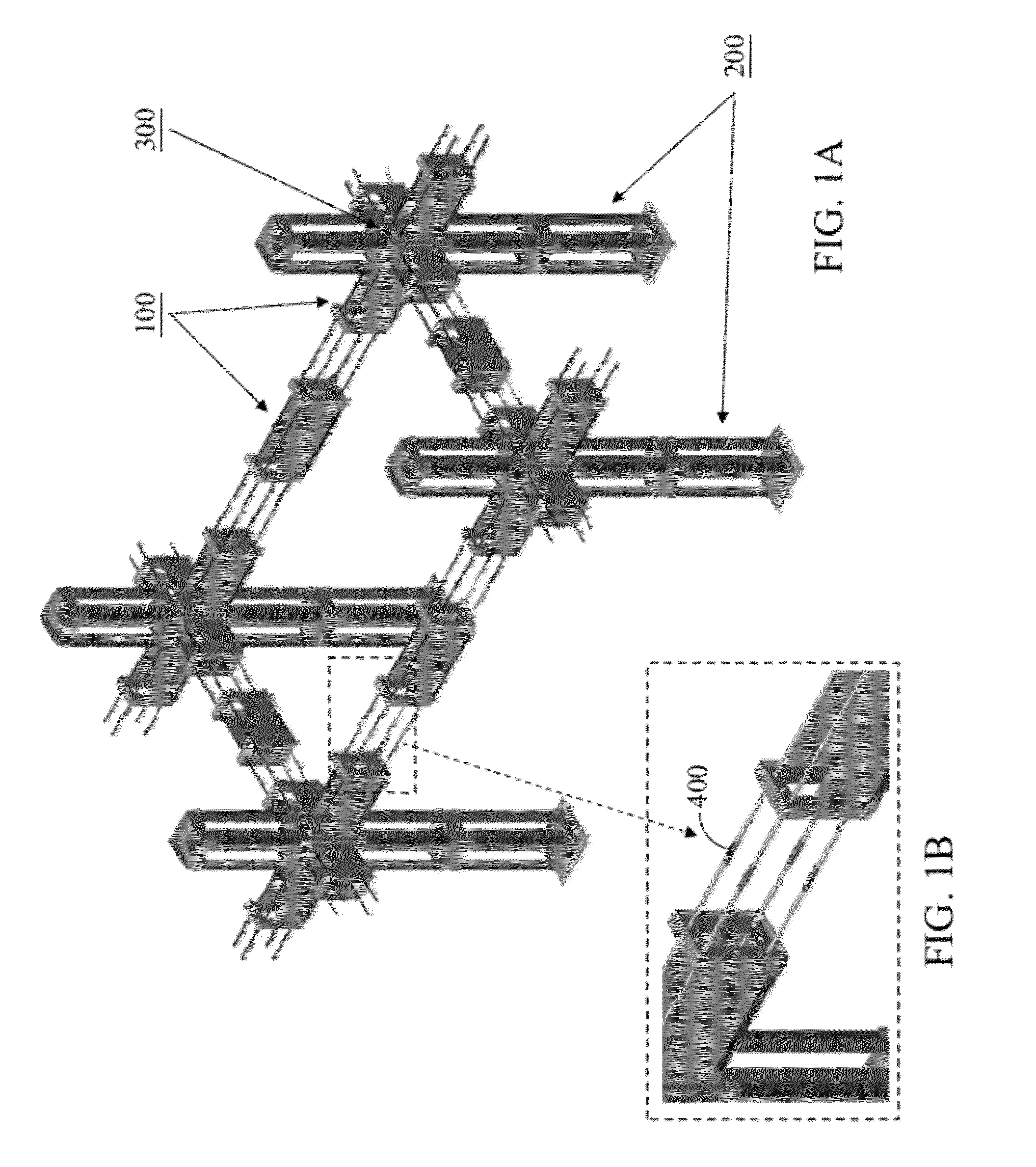

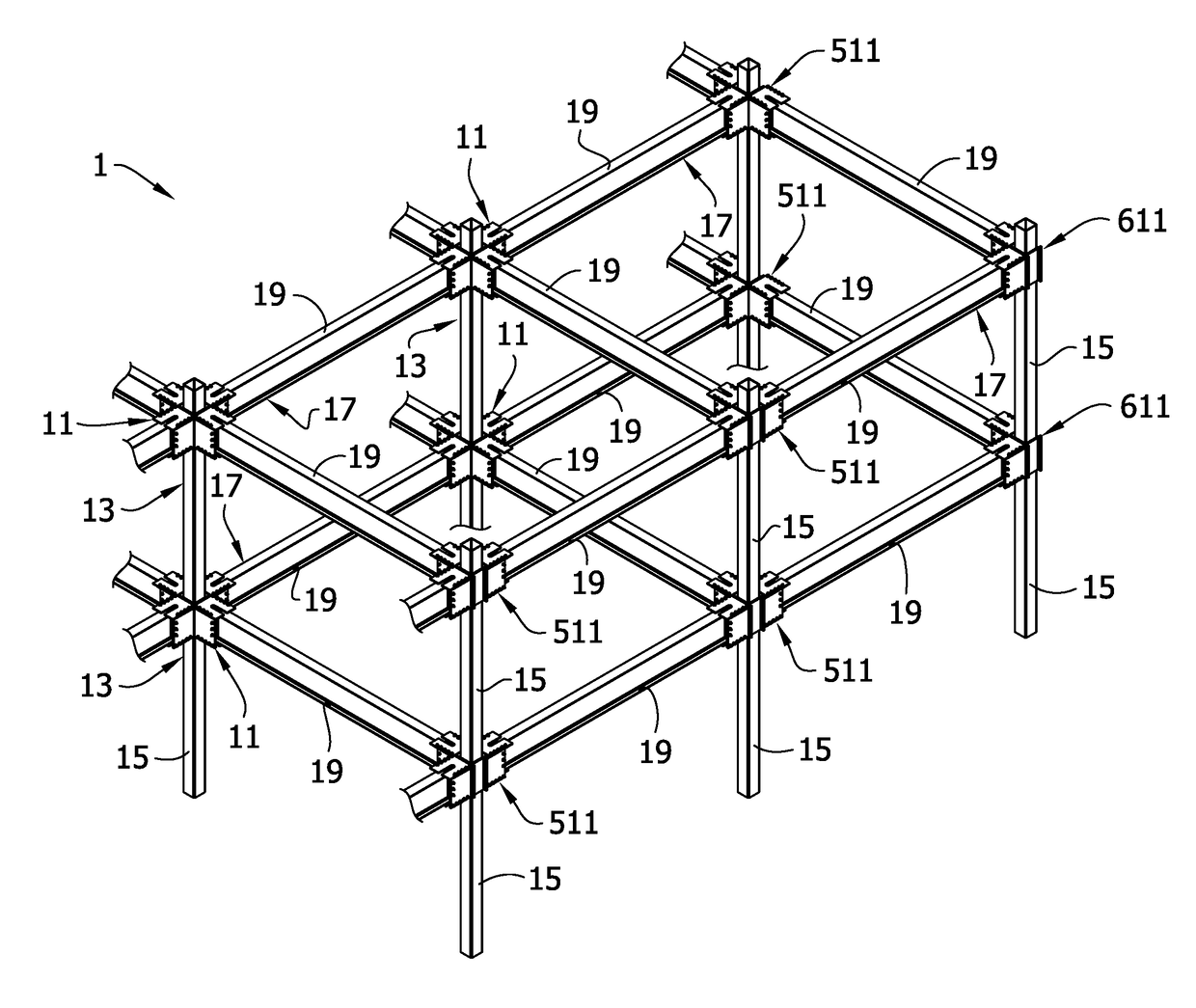

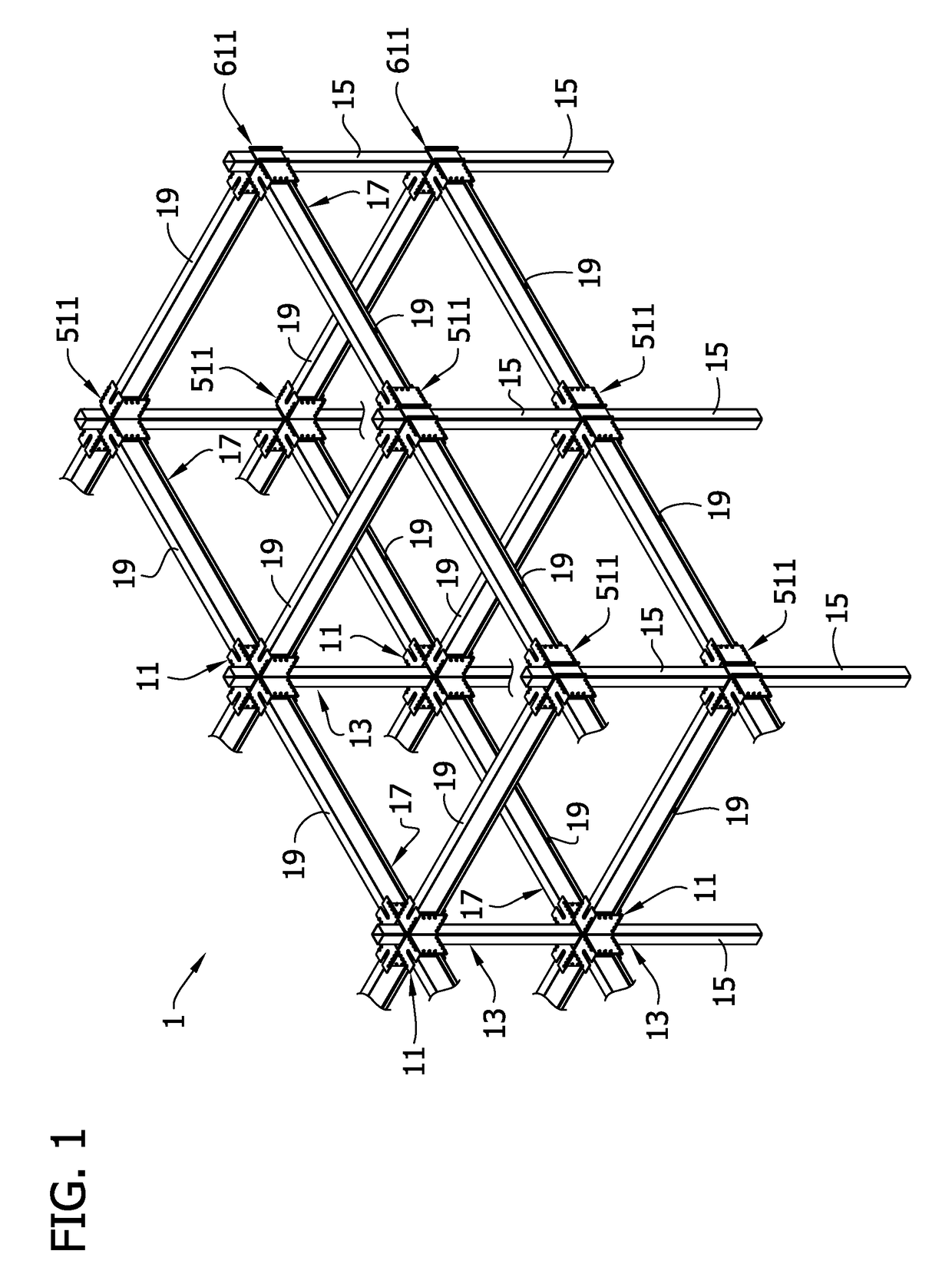

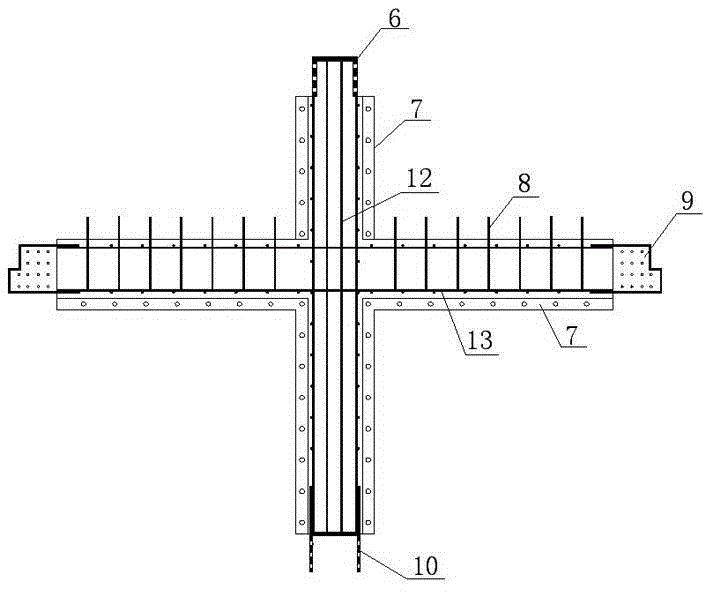

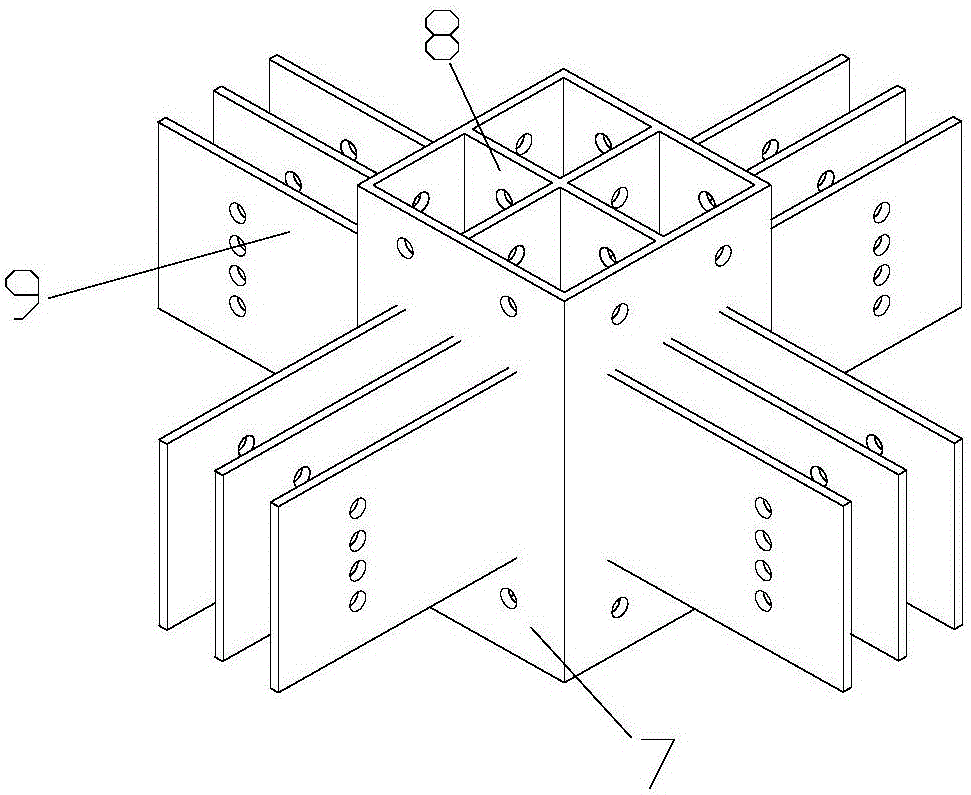

Architectured reinforcement structure

InactiveUS20120304584A1Easy constructionReduced isolationTowersBuilding constructionsReinforced concreteHoneycomb

This invention presents a modified reinforced concrete structure, which has a steel structure composed of a beam steel box unit, column steel box unit, and beam-column joint steel box unit with lap jointing reinforced steels. The side plate and / or end plate of the steel box has through holes for concrete flowing therebetween. In this way, the workability of concrete grouting and tamping are improved, and the phenomena of hive, segregation, or floating can be avoided. It can also enhance the performance of beam-column joints (e.g. with better confinement ability, etc.). Applying the invention, the efficiency and accuracy of constructing beam-column joints can be increased, and in addition to better ensure the structural safety, it can also reduce construction manpower and schedule.

Owner:NAT TAIWAN UNIV OF SCI & TECH

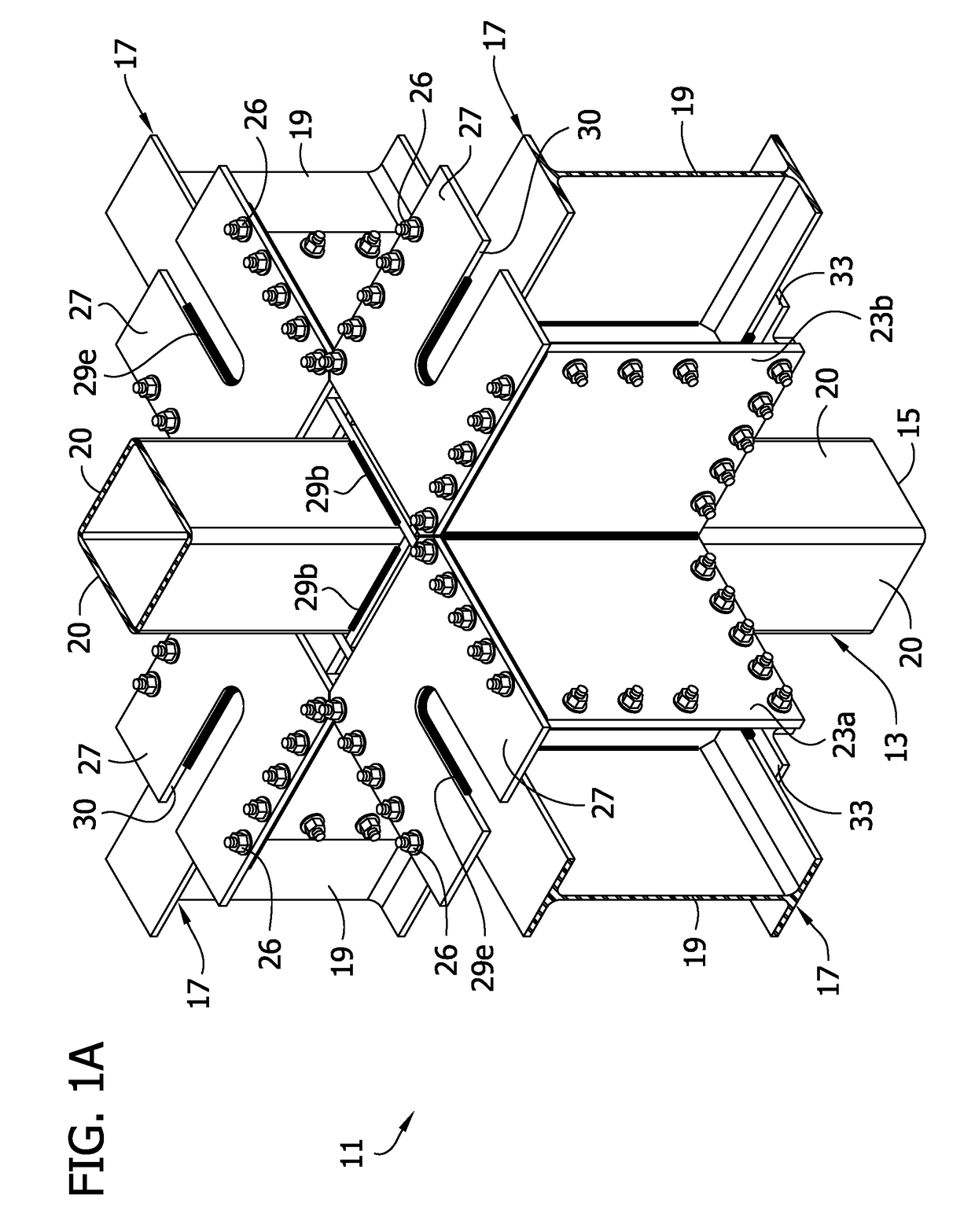

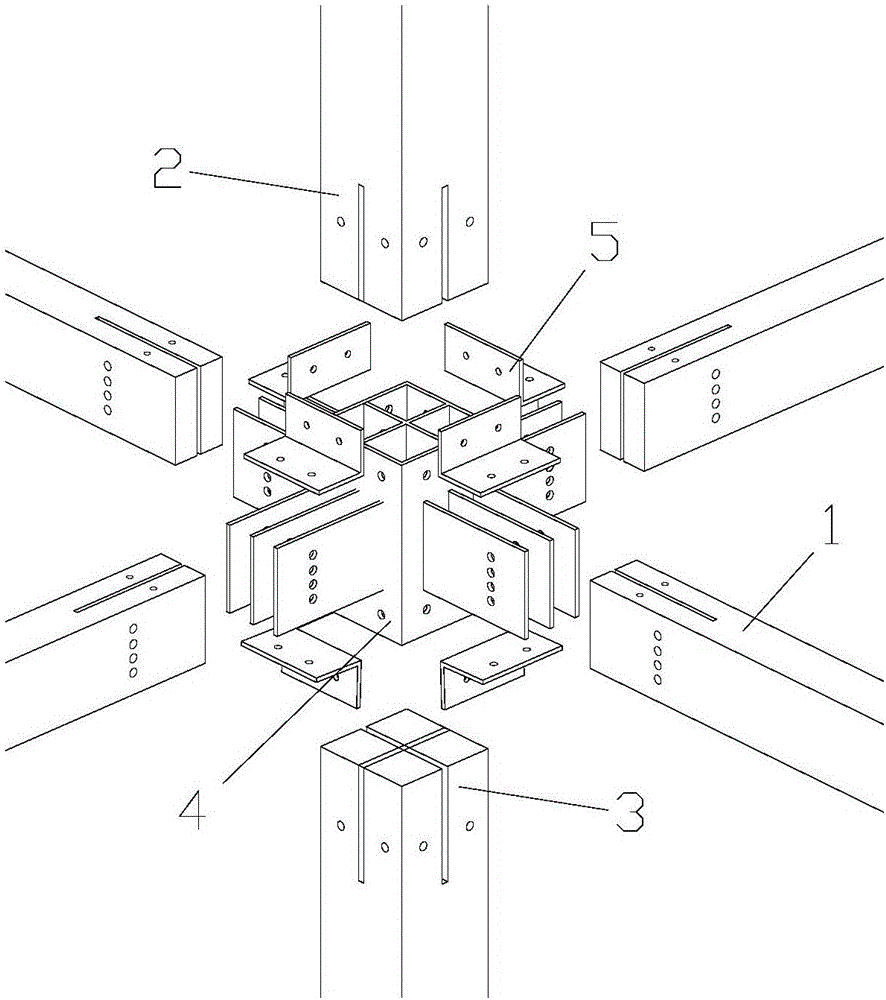

Moment resisting bi-axial beam-to-column joint connection

InactiveUS20170314254A1Building constructionsWelding/soldering/cutting articlesGusset plateAxial joints

A prefabricated column assembly includes a hollow tubular column having a longitudinal axis. A gusset plate assembly includes a plurality of gusset plates connected to the column and extending laterally outward from the column in planes generally parallel to the longitudinal axis of the column. A first pair of the gusset plates extends laterally outward from the column along a first axis and defines a space for receiving an end portion of a first beam for mounting the first beam on the first pair of gusset plates. A second pair of the gusset plates extends laterally outward from the column along a second axis that is nonparallel and non-coincident with the first axis. The second pair of gusset plates defines a space for receiving an end portion of a second beam for mounting the second beam on the second pair of gusset plates to provide a bi-axial joint connection.

Owner:MITEK HLDG INC

Structural joint connection providing blast resistance and a beam-to-beam connection resistant to moments, tension and torsion across a column

ActiveUS7178296B2Tremendous tensile pull and vertical moment demandBuilding roofsFloorsGusset plateEngineering

Owner:MITEK HLDG INC

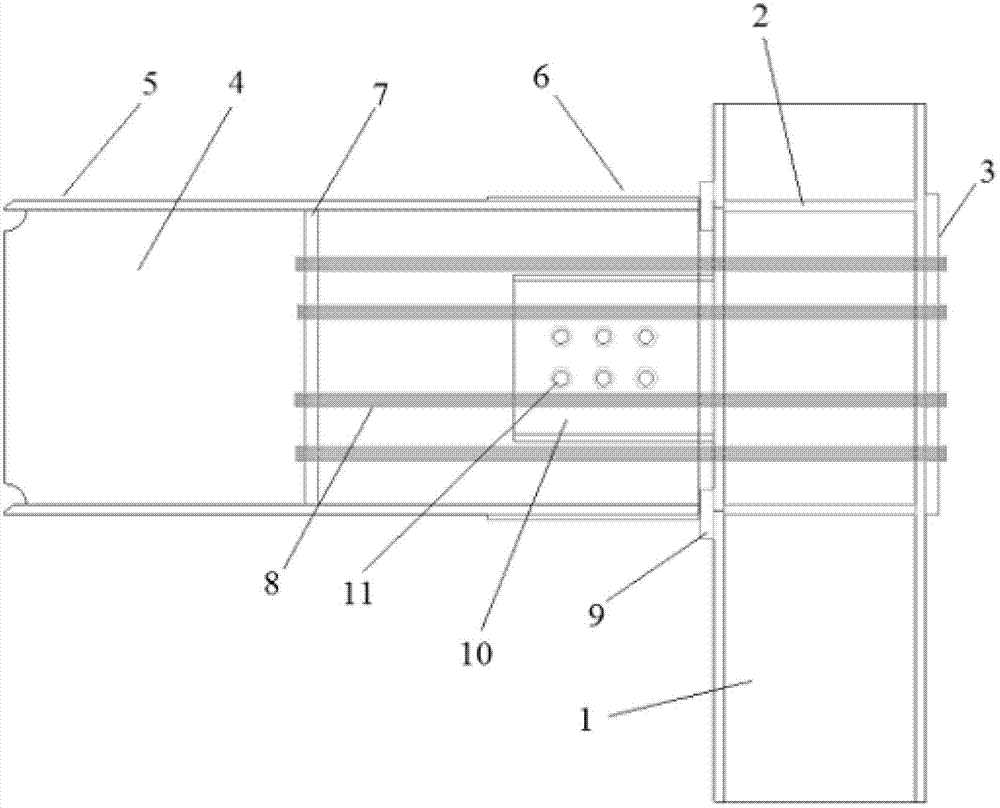

Easily repaired steel-structure beam-column node

InactiveCN101812872ASolve the lack of ductilitySolve the problem prone to brittle failureShock proofingHigh intensitySteel columns

The invention relates to an easily repaired steel-structure beam-column node, in particular to an easily repaired steel-structure beam-column node which is applied in the field of structural engineering and particularly used in high-intensity earthquake-proof areas. The node comprises an upright H-shaped steel column and an H-shaped steel beam of which the end part is vertically connected on a side wing plate of the H-shaped steel column, and is characterized in that: connecting ends of a belly plate of the H-shaped steel beam and the side wing plate of the H-shaped steel column are connected by a reinforced connecting plate closely contacted with the belly plate of the H-shaped steel beam and high-strength bolts penetrating the reinforced connecting plate, the reinforced connecting plate is in welding connection with the side wing plate of the H-shaped steel column, and both sides of the connecting end of a bottom side wing plate of the H-shaped steel beam are in locked connection with the H-shaped steel column by a T-shaped connecting plate and penetrating high-strength bolts respectively; and the T-shaped connecting plate is transversely arranged, upper and lower ends of the T-shaped connecting plate in the vertical direction are in locked connection with the side wing plate of the H-shaped steel column by a washer and the penetrating high-strength bolts respectively, a transverse plate of the T-shaped connecting plate is supported on the lower part of the bottom side wing plate of the H-shaped steel beam and locked by the penetrating high-strength bolts. The structure can effectively avoid brittle failure, has good ductile fracture characteristic, and can be widely applied to structures of earthquake areas, particularly the high-intensity earthquake-proof areas; and the easily repaired steel-structure beam-column node of the invention also has the advantages of convenient construction and convenient after-earthquake repairing.

Owner:FUZHOU UNIV

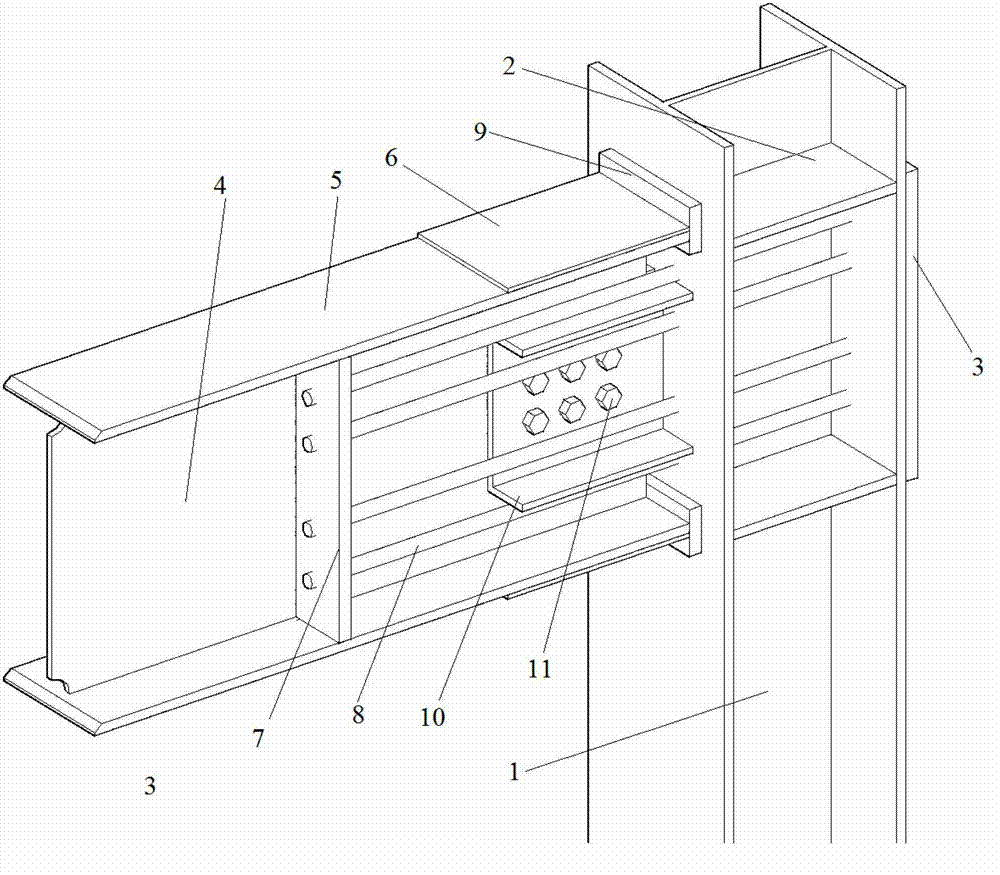

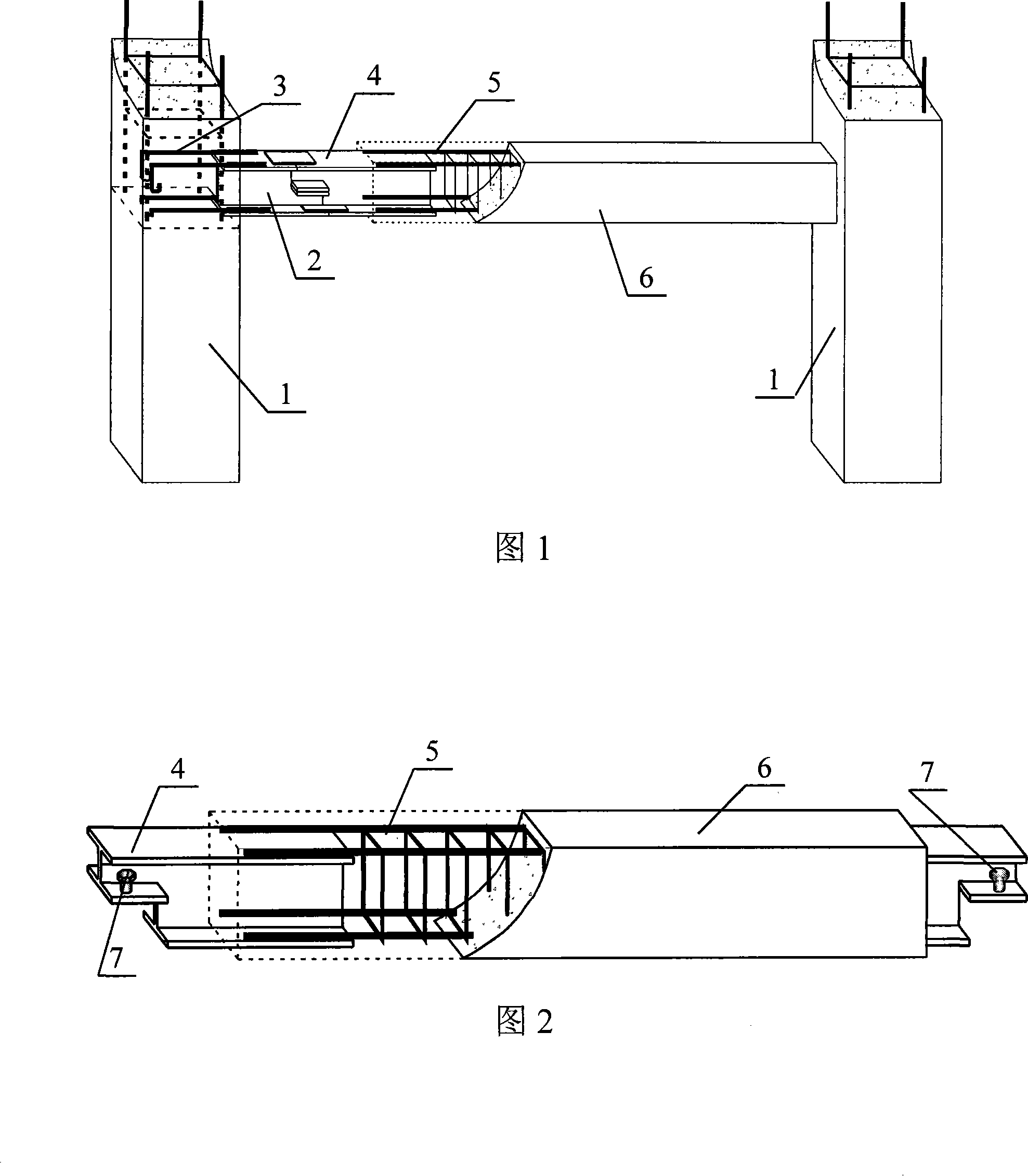

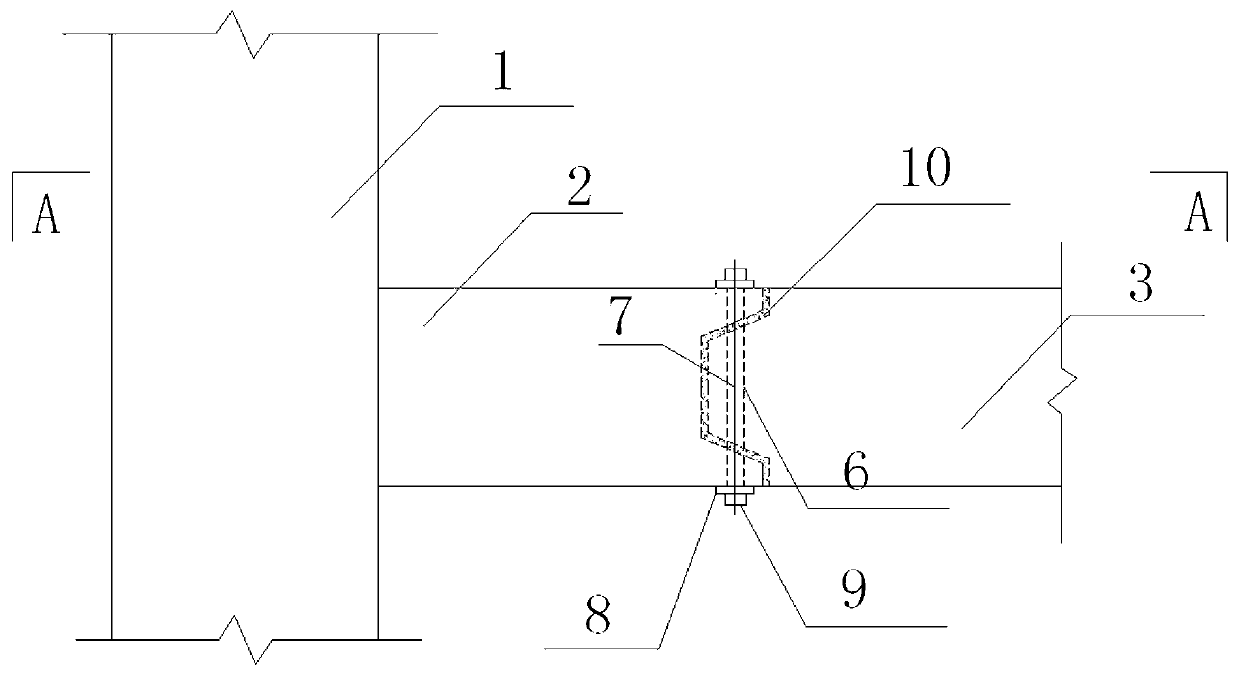

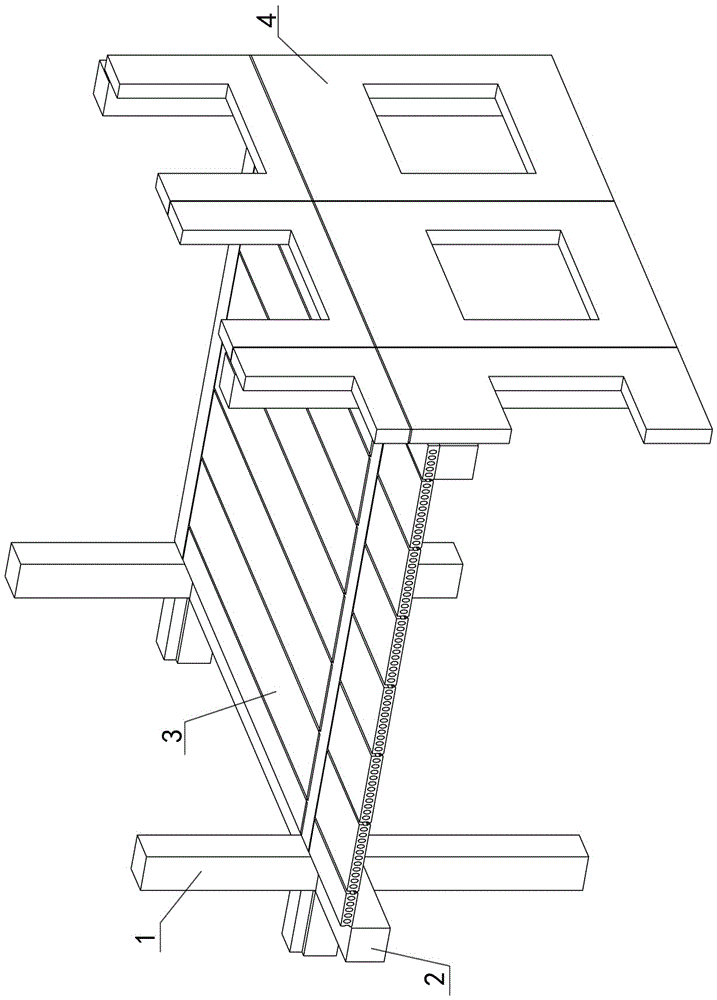

Steel frame precast prestressed beam column joint with post-earthquake recovering function

InactiveCN102817413AEasy constructionImprove construction qualityBuilding material handlingShock proofingPre stressSteel frame

The invention relates to a steel frame precast prestressed beam column joint with a post-earthquake recovering function. The joint comprises a steel frame column, a short beam section, a beam column connection device and an energy consumption device, wherein the steel frame column comprises a steel column, a column reinforced rib and a column reinforced plate; the short beam section comprises a short beam section web, a short beam section flange and a short beam section flange reinforced plate; the beam column connection device comprises a short beam section web reinforced rib, a prestressed cable and a beam end top plate; the energy consumption device comprises two channel steels and a high-strength bolt; and the two short beams are integrally connected with the column in a factory through a tension prestressed cable and two short beam section web reinforced ribs. When the earthquake action achieves a certain degree, the contact surface of the beam and the column is opened; the high-strength bolt is in friction energy dissipation so as to avoid destroying main components, such as beams and columns After the earthquake, the beams can be recovered to the former vertical position under the action of the prestress.

Owner:BEIJING UNIV OF TECH +1

High-ductility steel structure beam column node in angle steel connection and construction method of high-ductility steel structure beam column node

ActiveCN102363979AIncreased ductile deformation capacityImprove energy consumptionBuilding material handlingShock proofingHigh intensitySteel columns

The invention relates to a high-ductility steel structure beam column node in angle steel connection and a construction method of the high-ductility steel structure beam column node. The invention is characterized in that: upper and lower flange plates of an H-shaped steel beam are respectively connected with a steel column by using flange angle steel, a flange steel cushion plate and a friction type high-strength bolt; a web plate of the H-shaped steel beam is connected with the steel column by using web plate angle steel, a web plate steel cushion plate and the friction type high-strength bolt; bolt holes in a flange angle steel branch and a web plate angle steel branch, which are connected with the H-shaped steel beam, are long circular holes; horizontal reinforcing ribs are arranged, at a joint of the steel column and the H-shaped steel beam, inside the steel column; and a gap is reserved between an end head of the H-shaped steel beam and the steel column. The high-ductility steel structure beam column node has quite high ductile deformation capacity and excellent energy-dissipation capacity; and connection welded beams are not formed on beam column members, so that the brittle failure of the steel beam or the steel column in a node area under the action of a seldom-occurring earthquake is avoided. Furthermore, the high-ductility steel structure beam column node has the advantages of convenience for construction, simple and quick in repair operation after the earthquake, low in repair cost and the like.

Owner:FUZHOU UNIV

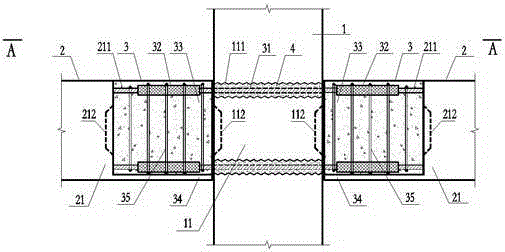

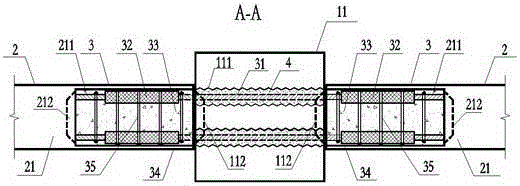

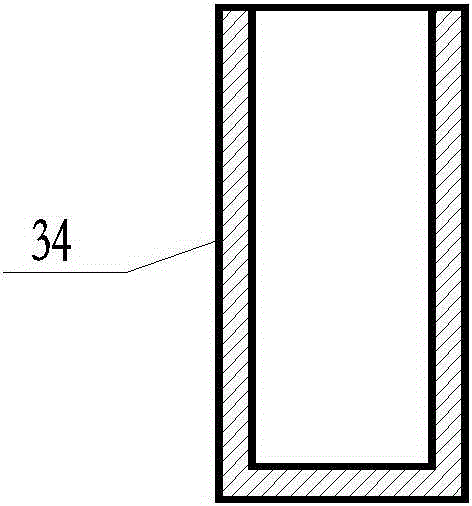

Pre-stressing-force fabricated concrete-frame-joint connecting structure and construction method thereof

PendingCN107165272AImprove integrityImprove energy consumptionGirdersProtective buildings/sheltersFloor slabPre stress

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Combination beam

InactiveCN101215855AImprove integrityEasy to make nodesBuilding constructionsReinforced concreteMaterial consumption

The invention discloses a composite beam, which comprises reinforcement concrete prefab beam and section steel joints, wherein both ends of reinforcements of the reinforcement concrete prefab beam are connected with section steels, one end of section steel joint is pre-imbedded into the wall pier concrete and is connected to the reinforcement inside the wall pier, the other end of the section steel joint is remained outside the wall pier, both ends of section steel of the prefab beam and the section steel joints are connected to form the composite prefab beam. Due to the composite beam, the section steel joints and the wall piers are integrated with good connection integration property of the beams and simple process, wherein both ends of the section steel is connected with the section steel joints of the prefab beam to form composite beam, the connection between the prefab beam end and the section steel joints adopts welding, bolt connection type, and the like, the composite beam production can be industrialized, needs no framework, has small materials consumption and rapid construction progress.

Owner:吴方伯

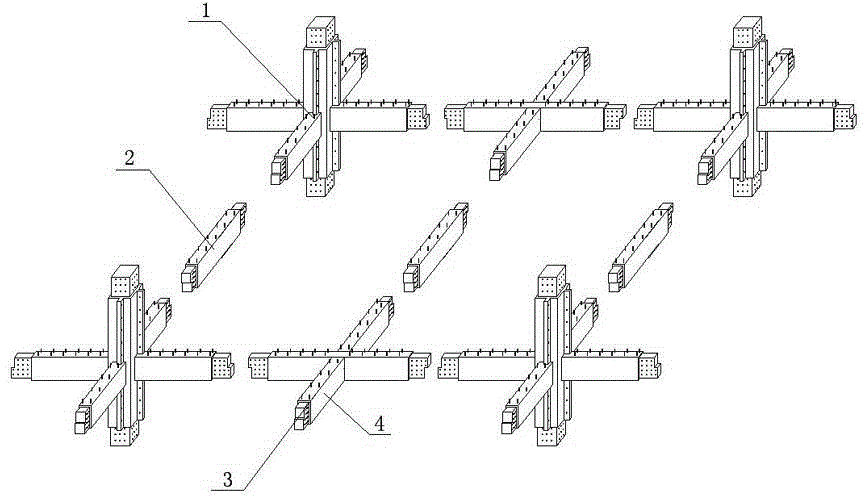

Dry type joggle frame structure

The invention relates to a dry type joggle frame structure. The structure comprises beam node components, each beam node component comprises a prefabricated column and a prefabricated beam which are cast into one piece, the prefabricated column and the prefabricated beam are prefabricated reinforced concrete components, the upper and lower ends and the column connection points of the prefabricated column are provided with reserved steel bars, the upper-end column connection point is provided with a column head, the lower-end column connection point is provided with a column cap in cooperation muff-coupling with the column head, the column head and the column cap are connected with the preserved steel bars; two ends of the prefabricated beam and the beam connection points are provided with joggle heads which are connected with the steel bar in the prefabricated beam. During the assembly process, the dry type joggle frame structure is environmentally friendly, and the construction noise and the building dust can be effectively reduced. The economic performance is excellent, the man power, materials and time are saved, the application range is wide, and the dry type joggle frame structure can be used both in industrial and civil buildings.

Owner:HUAIHAI INST OF TECH

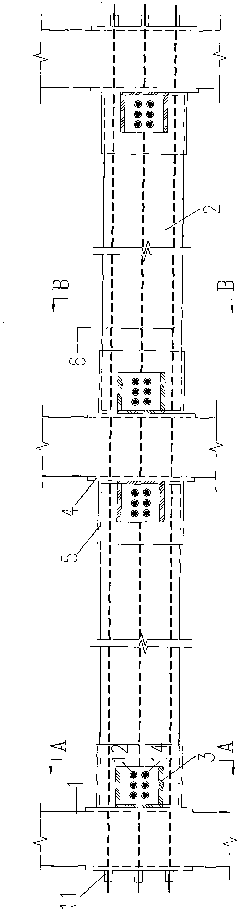

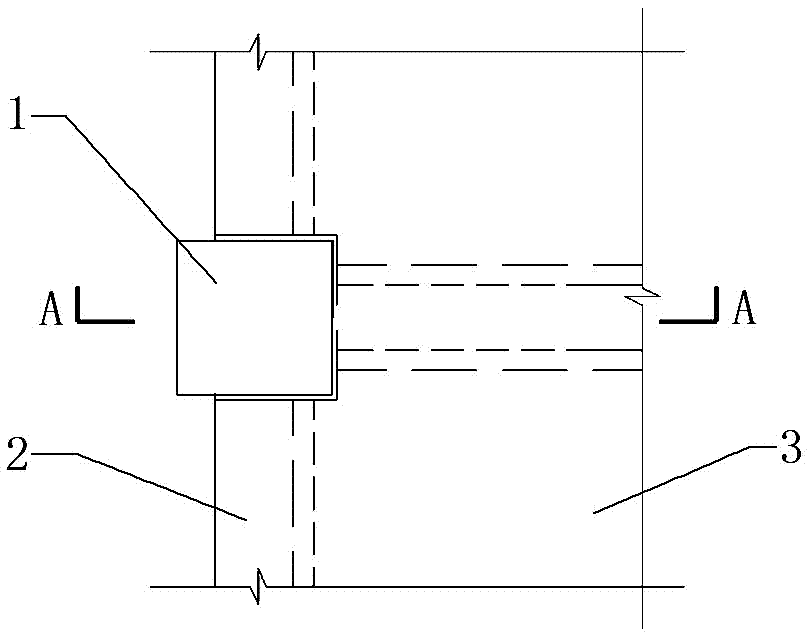

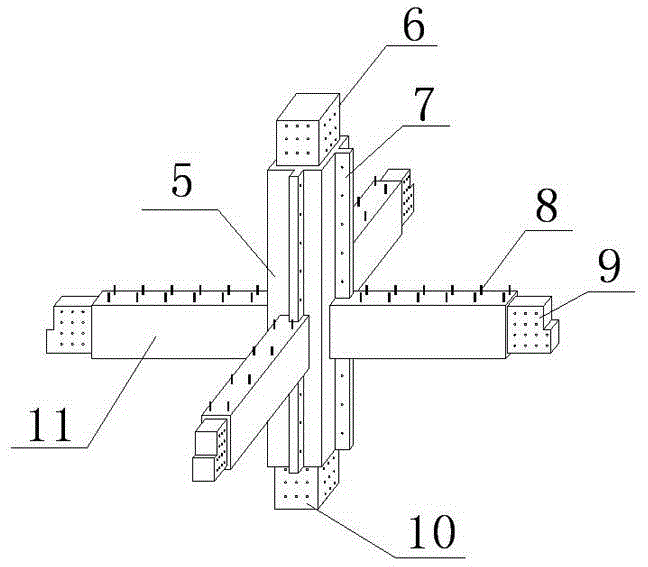

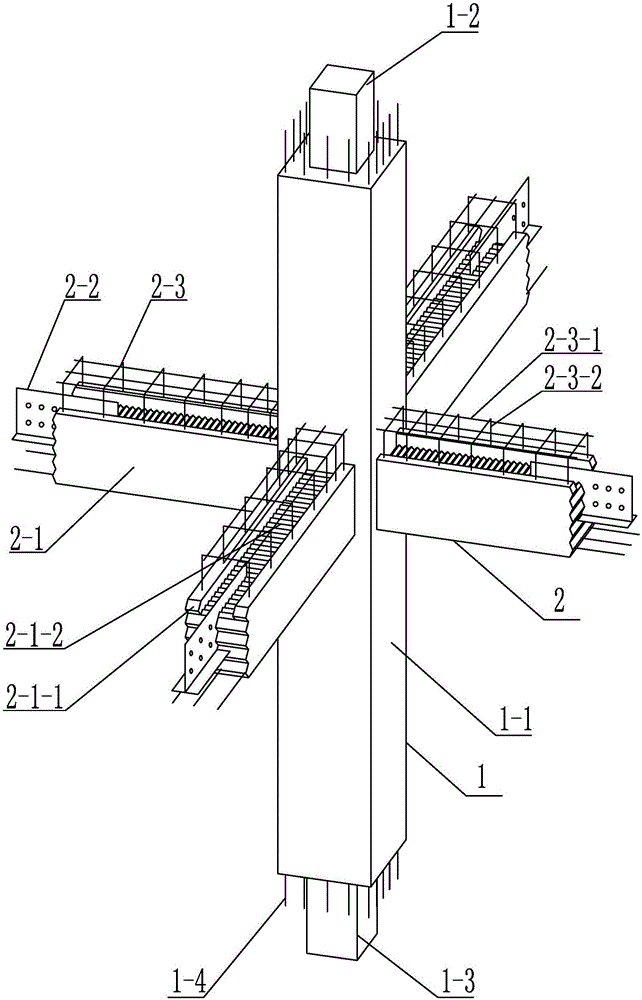

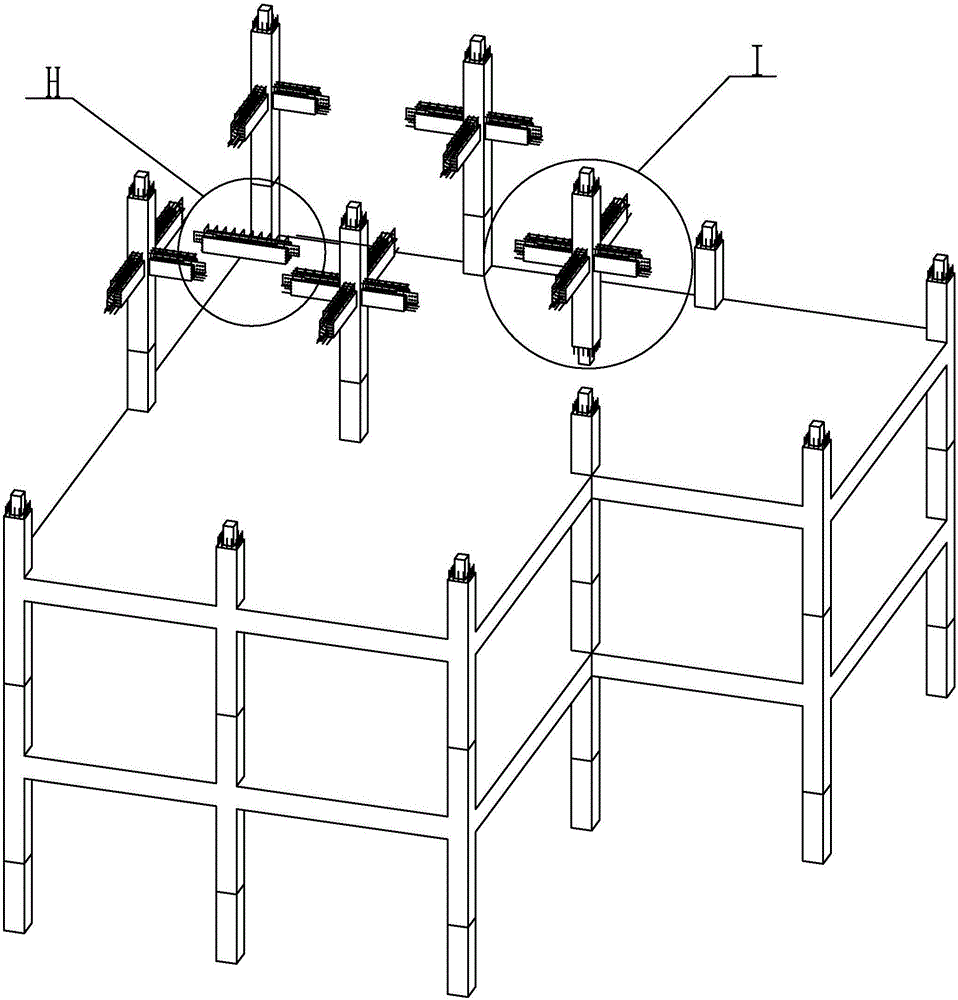

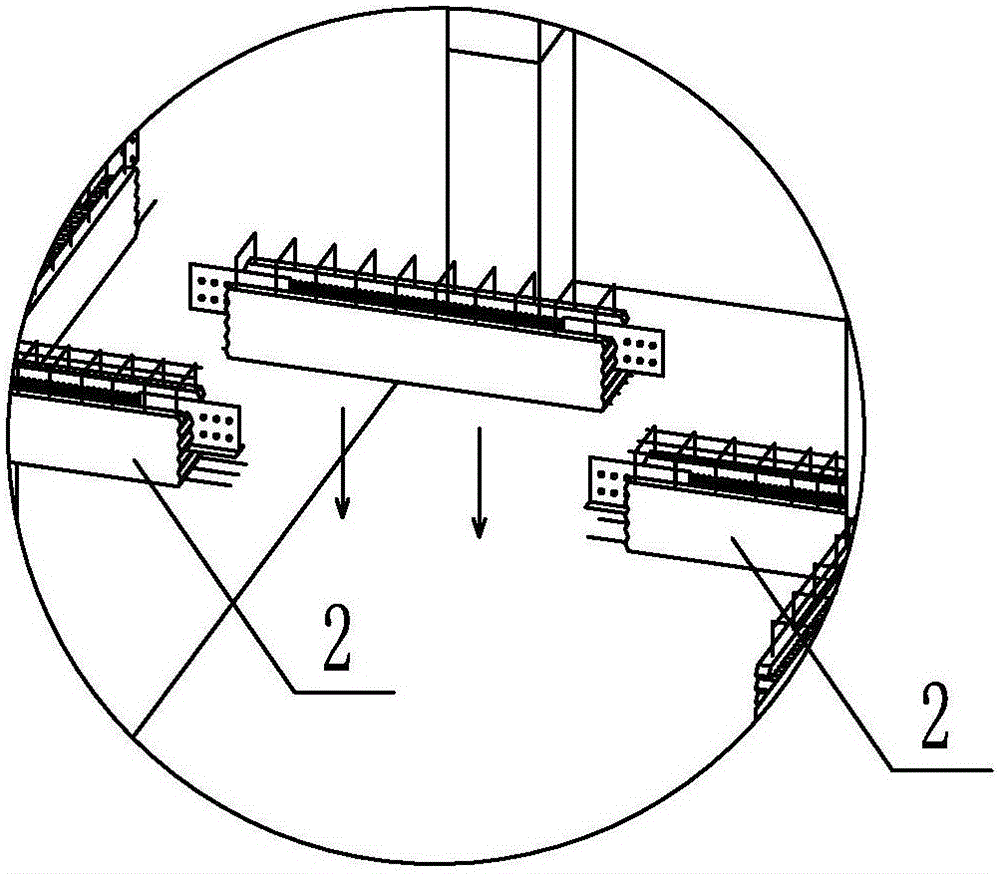

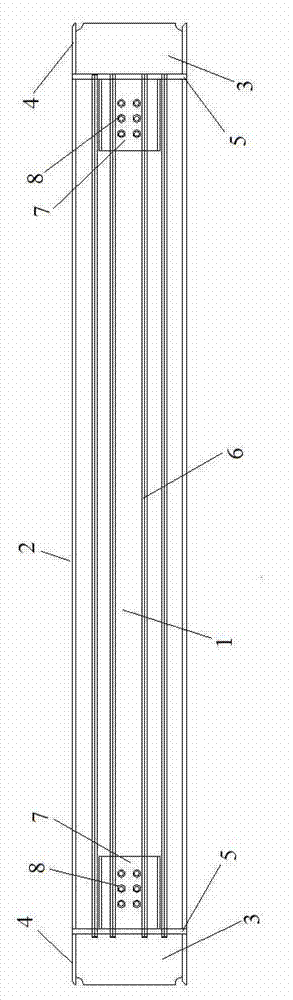

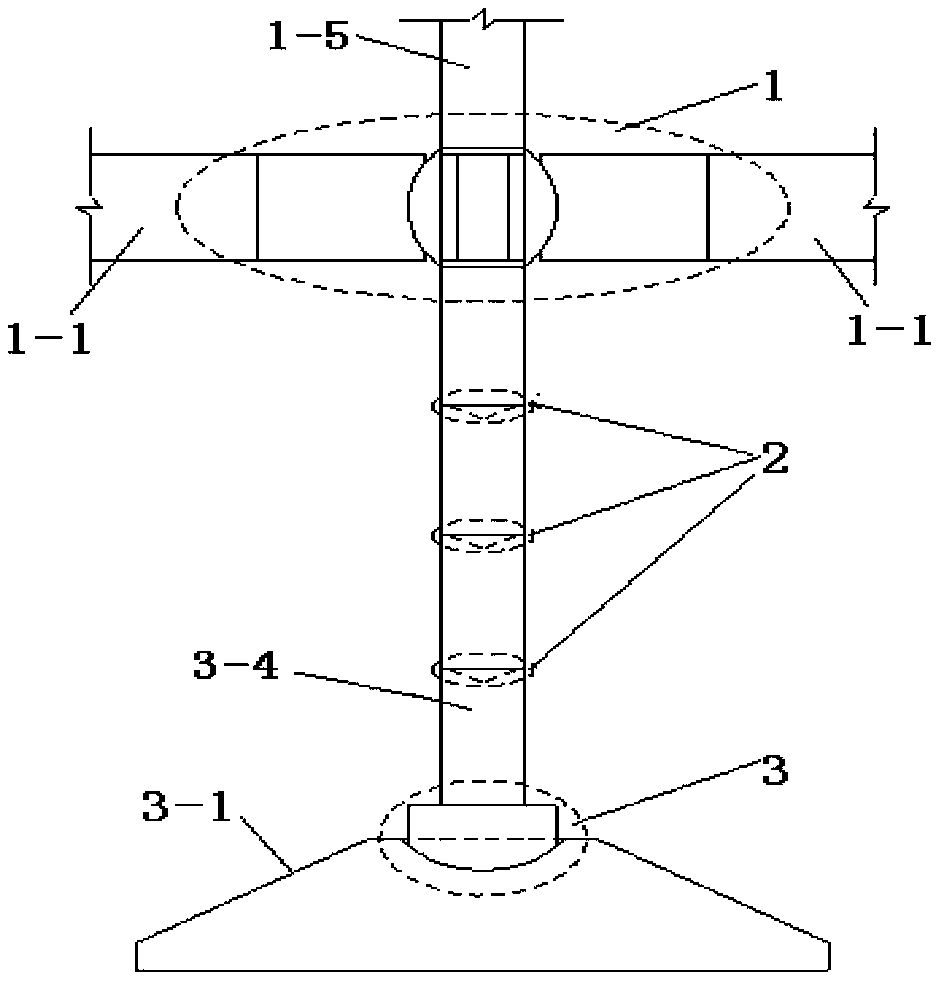

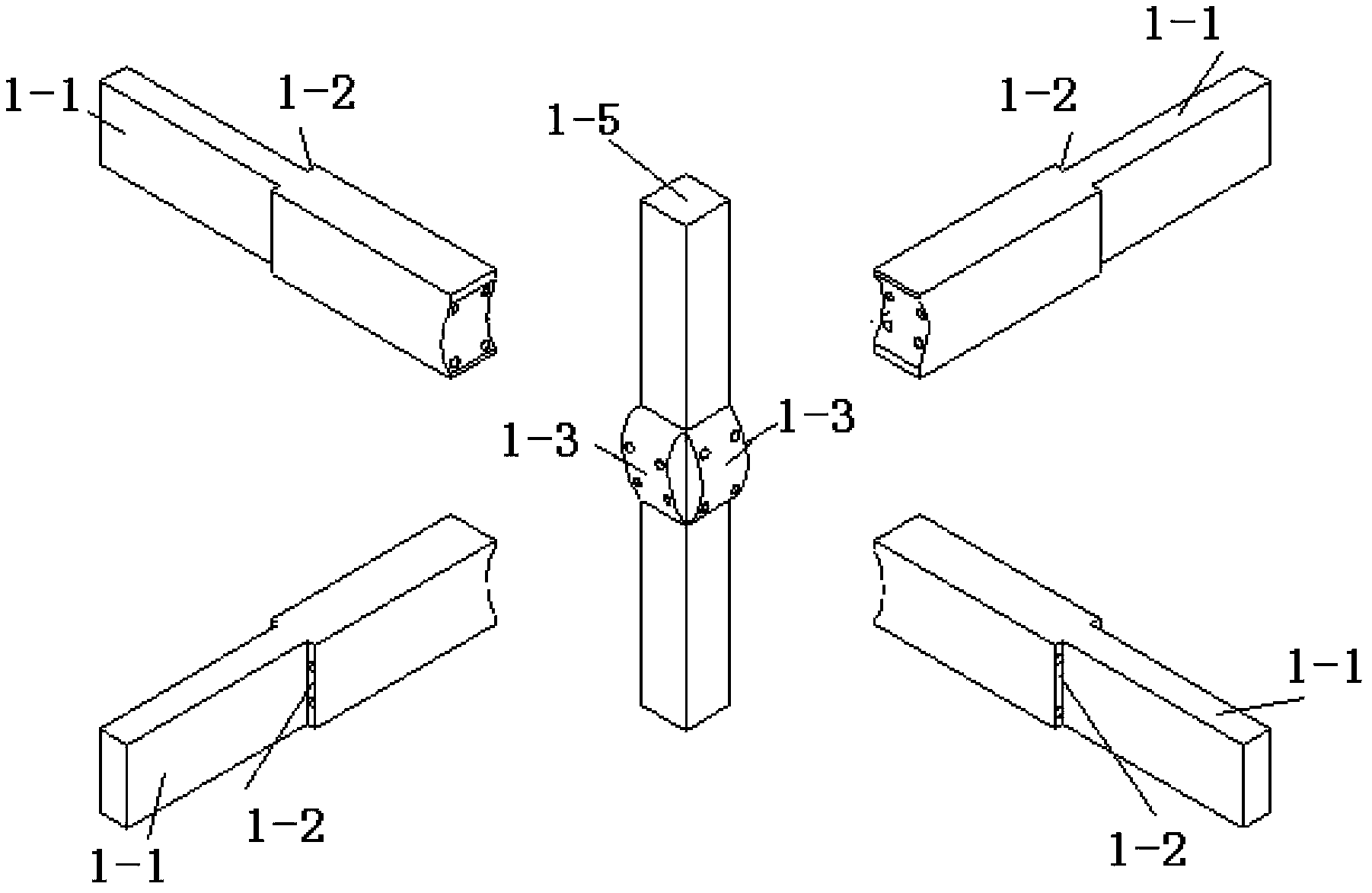

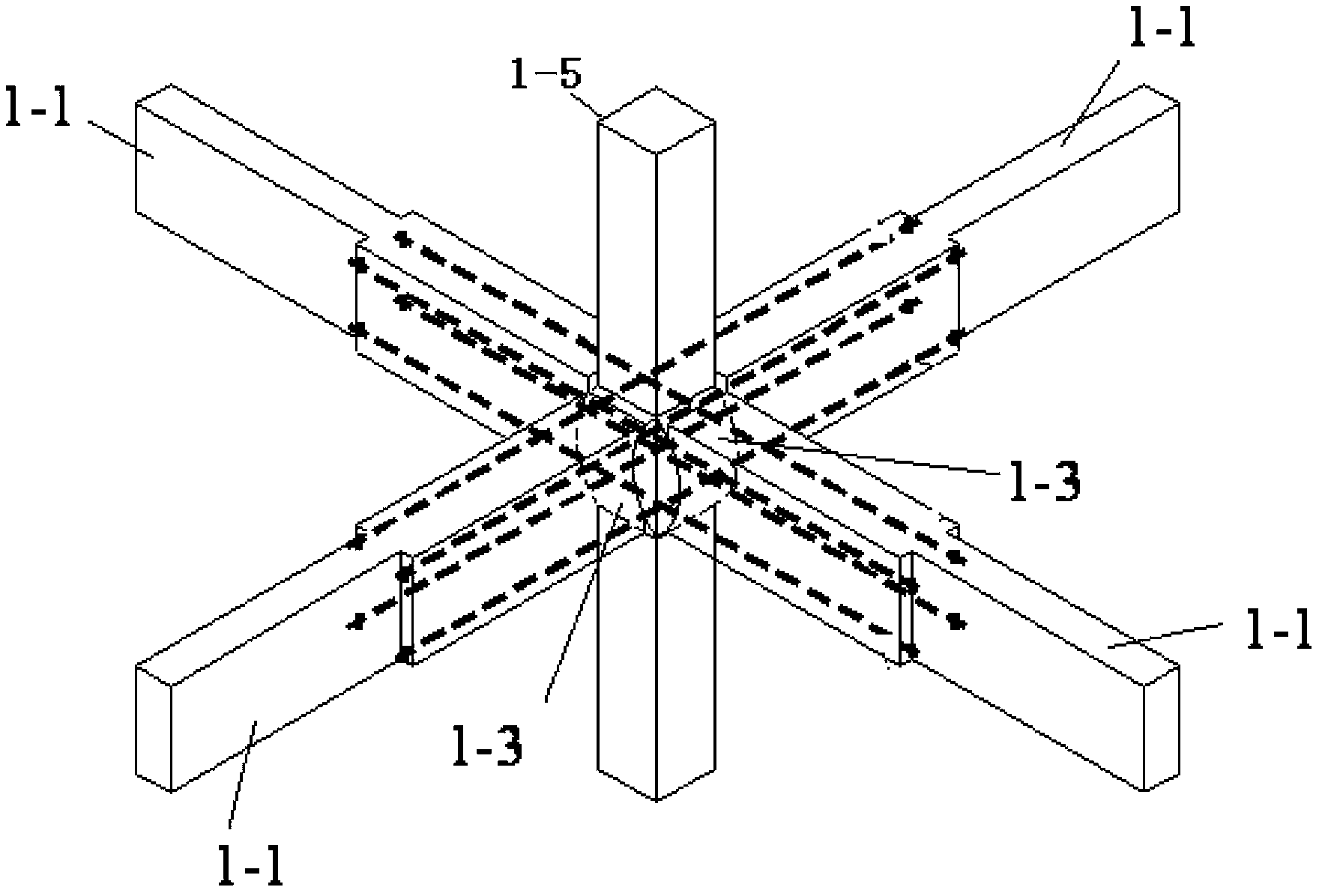

Single-layer prefabricated assembly type reinforced concrete beam-column joint

The invention relates to a prefabricated reinforced concrete beam-column joint, in particular to a single-layer prefabricated assembly type reinforced concrete beam-column joint. In order to solve the problem that the connection integrity of existing prefabricated beams and prefabricated columns is hard to guarantee, the prefabricated joint for one-piece casting manufacturing of a column section and part of beam sections is provided according to the concept of the point of inflection. The single-layer prefabricated assembly type reinforced concrete beam-column joint is formed by overall manufacturing of a vertical column section (1) and joint superposed beam sections (2) in a factory for prefabrication. A manufacturing method comprises the steps of beam-column longitudinal bar and stirrup binding, connector pre-burying, formwork erecting and concrete pouring and curing. The height of the vertical column section (1) of the joint is 1 / 2 of the storey height, and the length of each joint superposed beam section (2) is 1 / 3 of the span of adjacent columns. The vertical column section (1) comprises a pouring section (1-1), a concrete filled steel tube connector (1-2), a steel tube connector (1-3) and column section longitudinal bars (1-4). Each joint superposed beam section (2) comprises a groove-shaped pouring section (2-1), inverted-T-shaped structural steel connectors (2-2) and a reinforcement cage framework (2-3). The single-layer prefabricated assembly type reinforced concrete beam-column joint is applied to the construction industry.

Owner:HARBIN INST OF TECH

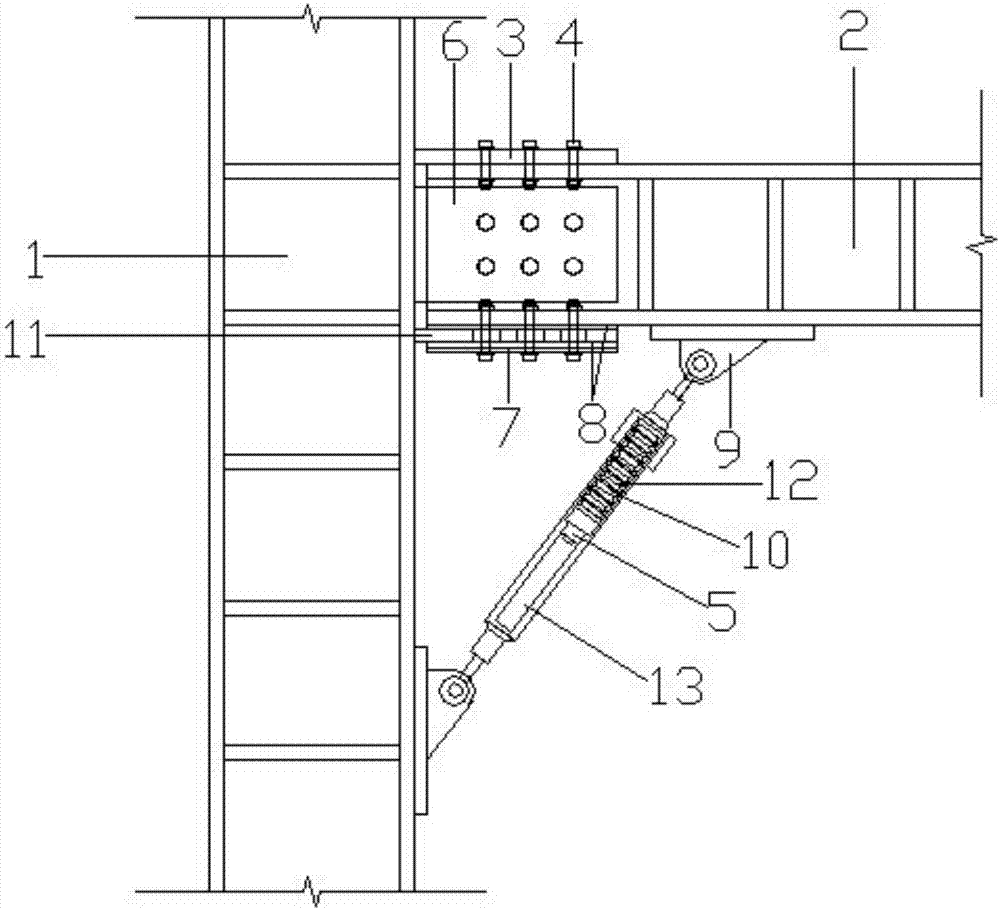

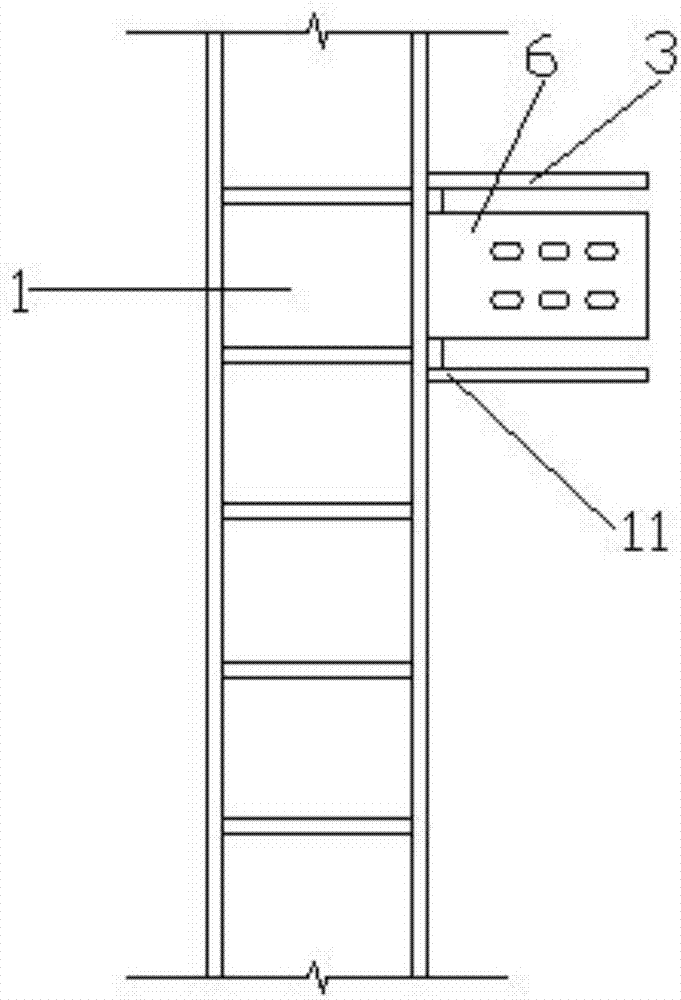

Self-reset beam column friction energy consumption node

InactiveCN107268825ASimple structureEasy constructionProtective buildings/sheltersShock proofingEngineeringSteel frame

The invention discloses a self-reset beam column friction energy consumption node which comprises an upper flange plate, a lower flange plate, a web and a self-reset angle brace. One end of the upper flange plate, one end of the lower flange plate and one end of the web are all fixedly connected to the side face of a steel frame column to form a connecting short beam. One end of the connecting short beam is connected to the steel frame column, and the other end is connected with a steel frame beam. The joint of the connecting short beam and the steel frame beam can generate left-right displacement when bearing external force. The self-reset angle brace is connected with the steel frame column and the steel frame beam through ear plates at the two ends respectively. Through the sliding friction of a friction base plate at the upper flange plate or the lower flange plate or the web and the self-reset angle brace at the lower flange position of the steel frame beam, earthquake energy is consumed, and the node can automatically restore the initial state after an earthquake. The self-reset beam column friction energy consumption node is simple in structure and convenient to construct and can be widely applied to various steel structure buildings.

Owner:陈云

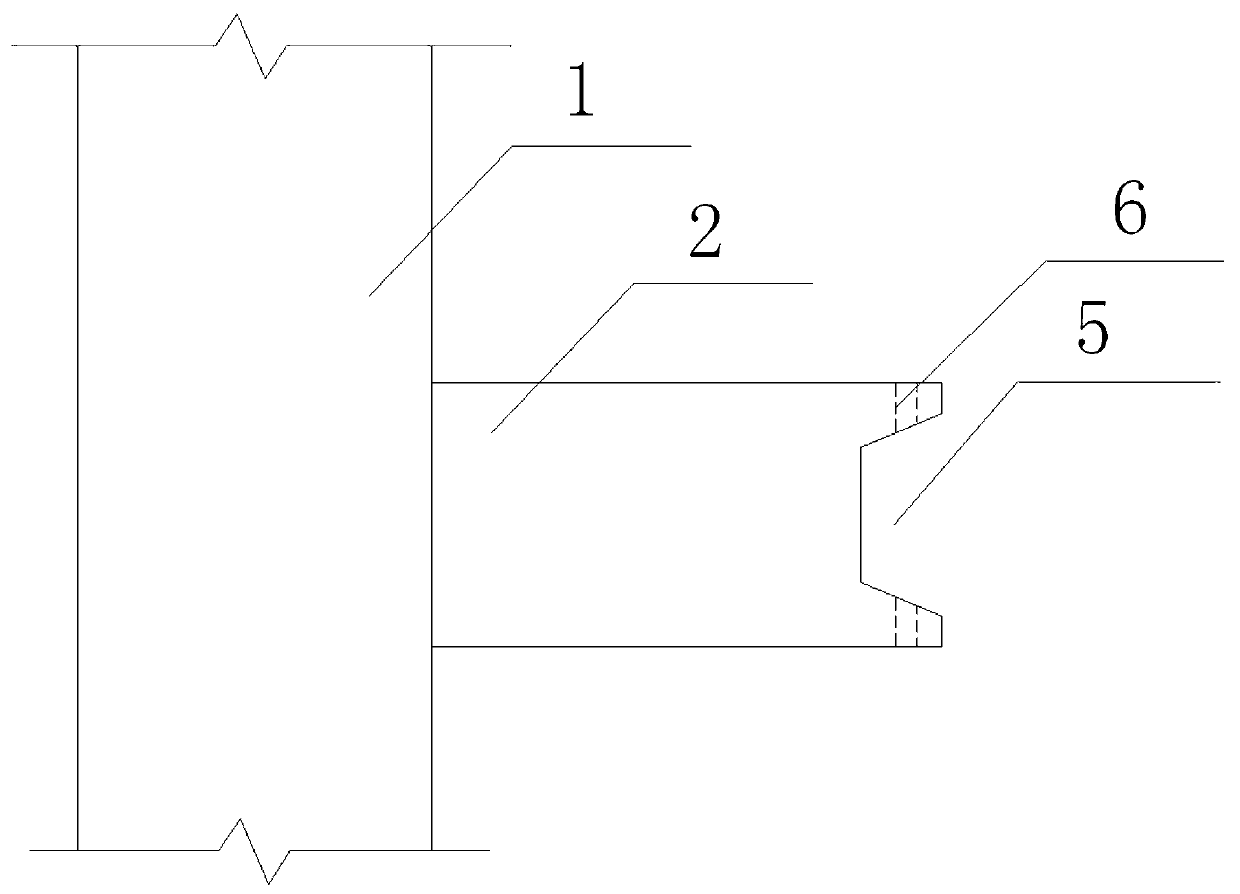

Assembled framework beam-column joint adopting vertical connection and construction method thereof

InactiveCN103104040AFlat sectionDoes not affect the spaceBuilding material handlingReinforced concreteRebar

The invention relates to an assembled reinforced-concrete framework beam-column joint adopting vertical bolt connection. The joint comprises a corbel of a precast column and a precast beam, wherein the end face of the corbel and the end face of the precast beam are respectively provided with a concave groove and a convex block which are matched with each other and are respectively provided with a vertical corbel bolt hole and a vertical precast beam bolt hole; and the corbel is matched with the precast beam along the length direction of the precast beam in an embedded fixing manner, bolt cushion plates are arranged at the upper and lower sides of the corbel and the precast beam after the corbel and the precast beam are fixed in an embedding manner, and a bolt vertically penetrates through the bolt cushion plates, the corbel bolt hole and the precast beam bolt hole so as to carry out fixing. A corresponding construction method comprises the steps of precasting, mounting and filling mortar in gaps. The joint and the corresponding construction method have the advantages that the smoothness of force transmission between the precast beam and the precast column is achieved, the joint is reliable in connection and simple in structure, the construction process is simplified, the on-site assembling time is saved, and the production efficiency can be effectively increased.

Owner:ZHENGZHOU UNIV

Prefabricated beam-column connection in prefabricated concrete buildings and construction method thereof

InactiveCN105155683ASimple structureImprove integrityBuilding material handlingVertical barAgricultural engineering

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

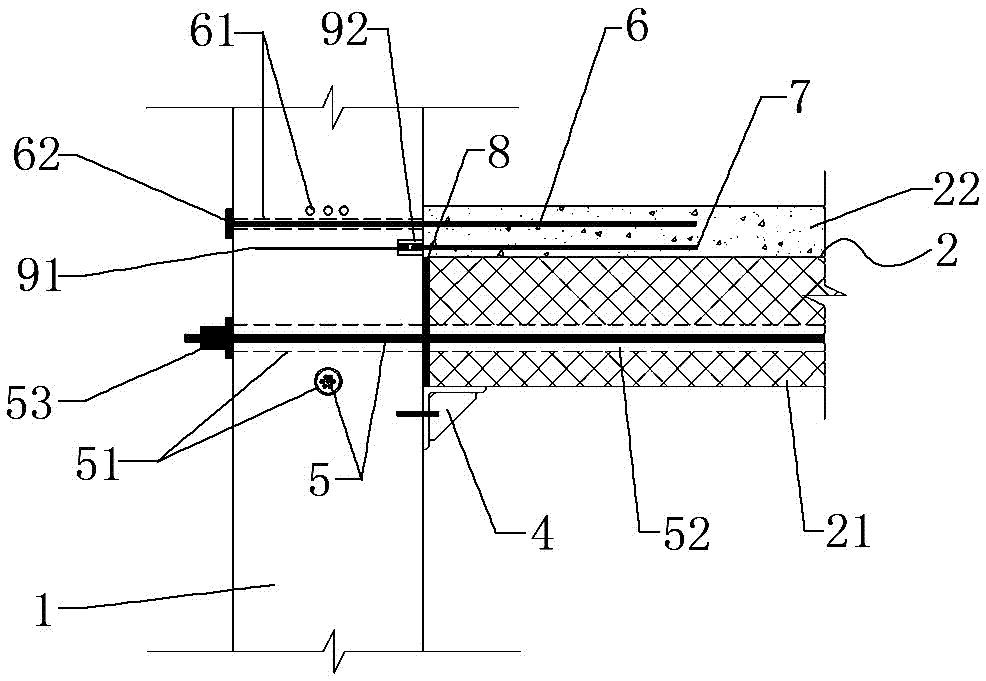

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

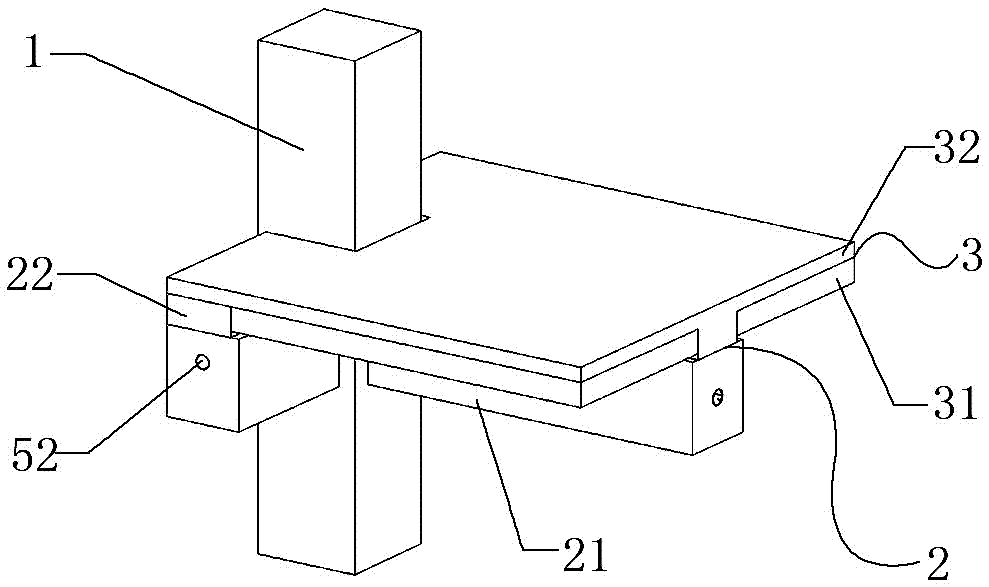

Assembly type beam-column node connection device with function recovery effect

ActiveCN105735472AImprove control accuracyQuality is easy to controlBuilding constructionsEngineeringWeld seam

The invention relates to an assembly type beam-column node connection device with a function recovery effect, and belongs to the field of structure engineering. The assembly type beam-column node connection device with the function recovery effect consists of a round steel pipe column with a cantilever beam section, a general beam section and a connection device for the round steel pipe column and the general beam section. According to the node connection device, welded parts are all finished in a factory, so that the weld seam quality and the machining precision can be more easily controlled; the round steel pipe column with the cantilever beam section and the general beam section are assembled by adopting a high-strength bolt and a connection plate on site, so that the construction speed is greatly increased and the construction quality is greatly improved; meanwhile, the general beam section can be arranged on the connection plate at the lower part of the cantilever beam section, so that the difficulty in construction is lowered and the field assembly and positioning are easy; a node is used for both beam end reinforcement and cover plate connection weakening; through reasonable parameter design, double energy consumption of frictional sliding of the bolt and plastic deformation of the connection plate and the bolt can be realized and a plastic hinge can be transferred to the connection plate; and the function of the structure can be recovered only by replacing the connection plate after earthquake.

Owner:BEIJING UNIV OF TECH

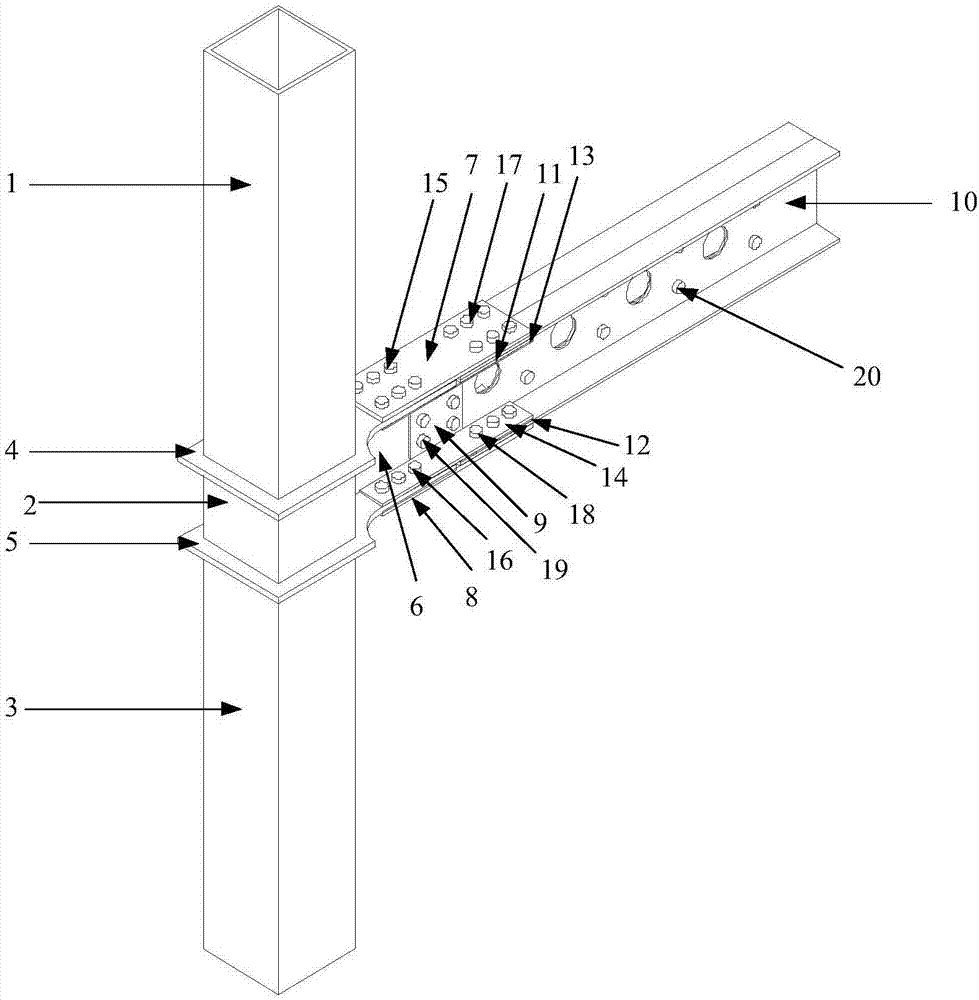

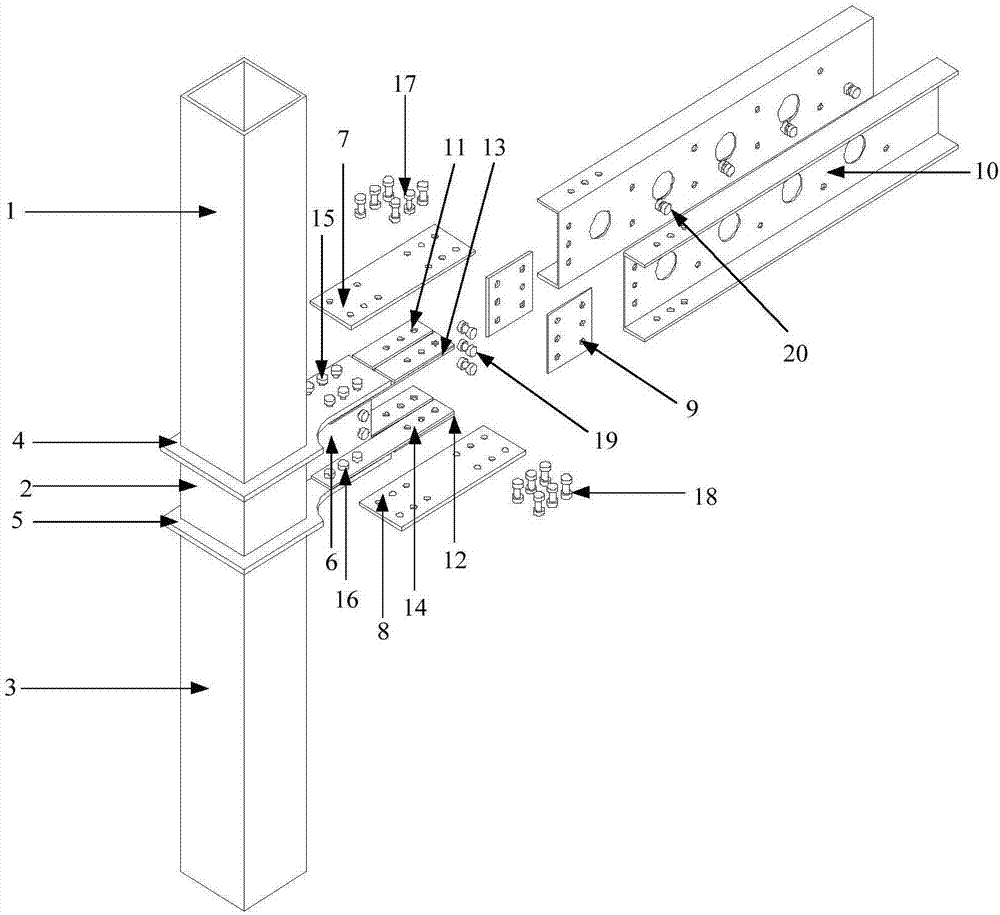

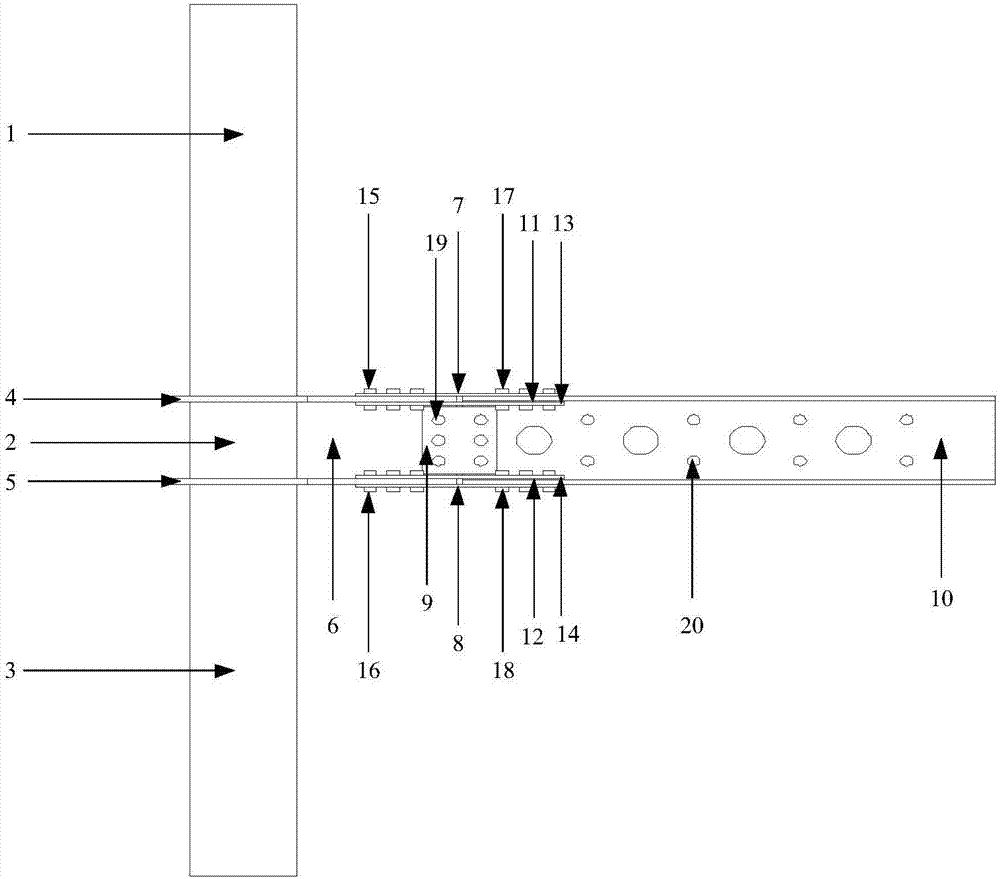

Assembly channel steel punching beam column joint connecting device capable of achieving function recovery

InactiveCN106869325AAvoid complex stress fieldsReduce construction difficultyFloorsFloor slabPunching

The invention relates to an assembly channel steel punching beam column joint connecting device capable of achieving function recovery and belongs to the field of structural engineering. The assembly channel steel punching beam column joint connecting device capable of achieving function recovery is composed of a square steel pipe column with a cantilever beam section, a channel steel punching beam section and a connecting device of the cantilever beam section and the channel punch beam section. All welding parts of the joint connection device are all finished in a factory, so that precision and quality of welds are easier to control. Construction speed is greatly increased and construction quality is greatly improved, and a spatial structure of the channel punch beam section of the channel is conducive to pipeline penetration; the channel steel punching beam and a floor can be assembled and molded in the factory to form modular assembly units. Then all the modular assembly unit and the square steel pipe column with the cantilever beam section achieve assembly connection through the channel steel punching beam. Joints of the connection device can be used for both of beam end reinforcing and cover plate connection weakening. A multi-energy dissipation mechanism can be realized, a plastic hinge is transferred to a cover plate and a connecting plate. The function of structures can be recovered only by replacing the connecting plate after an earthquake.

Owner:BEIJING UNIV OF TECH

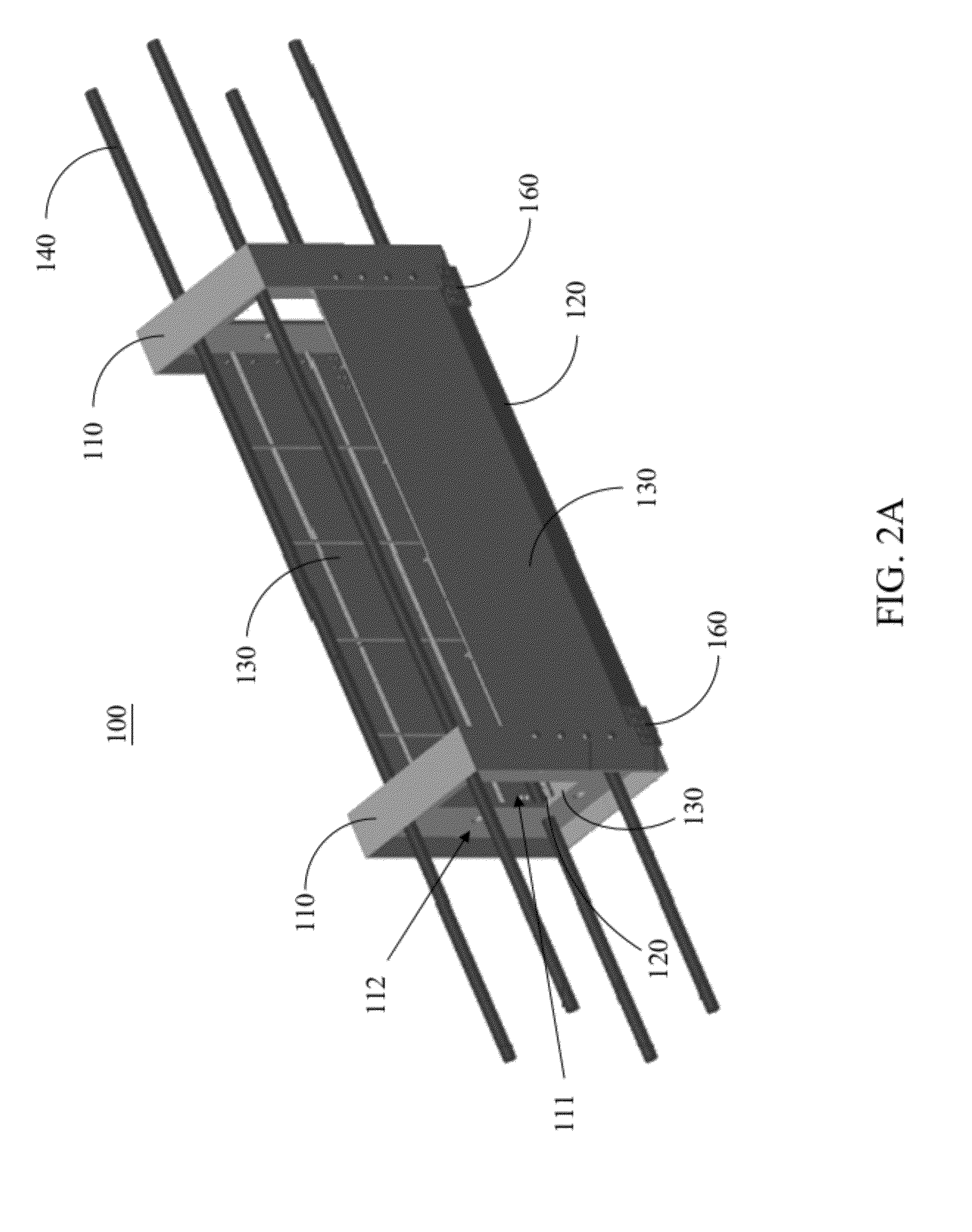

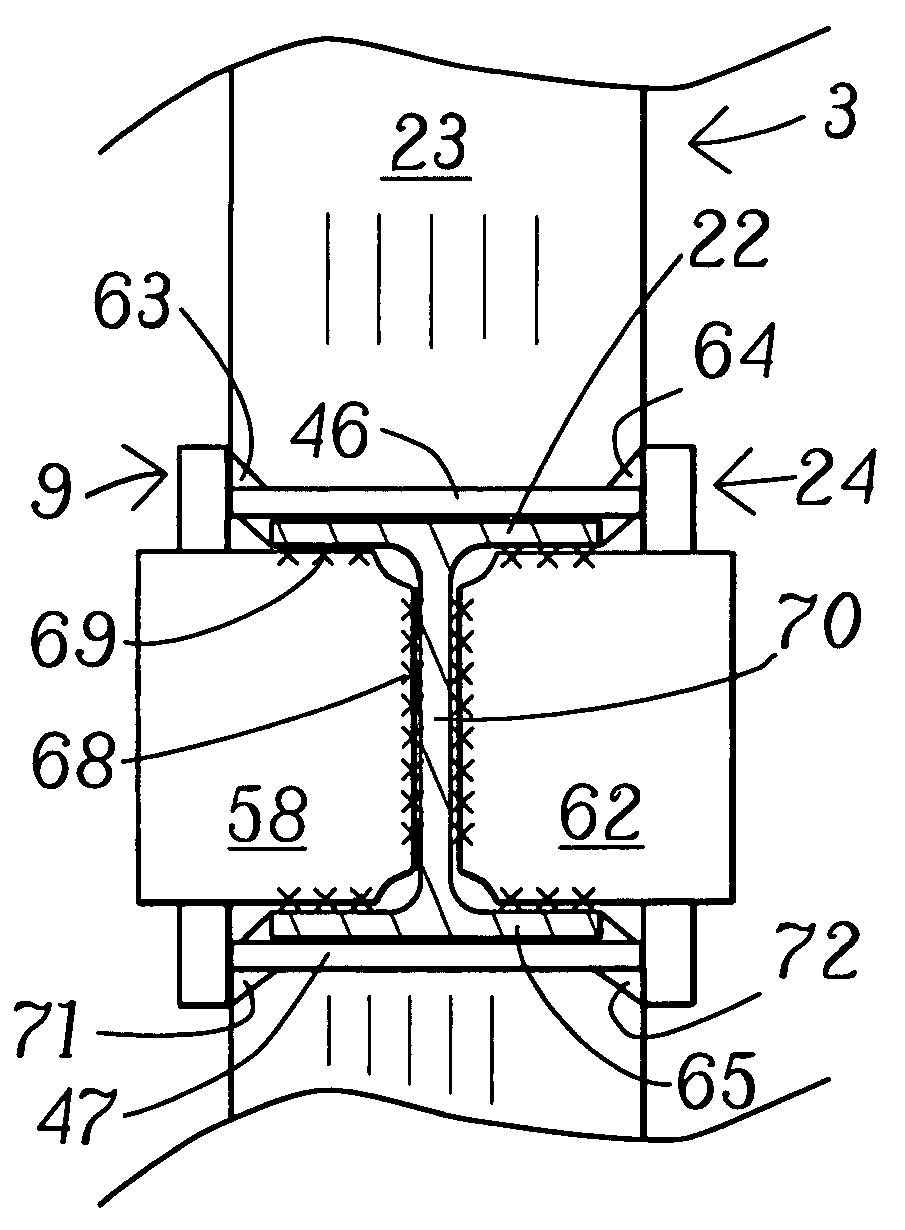

Flexible vibratory micro-electromechanical device

InactiveUS20050024527A1Television system detailsAcceleration measurement using interia forcesEngineeringAnchor point

There is a sensor element (24) for an electronic sensor device (20). The sensor element (24) may have a substrate (43), a pair of proof masses (34a, 34b), a set of drive beams (44), and at least one base beam (46). The pair of proof masses (34a, 34b) are suspended above the substrate (43) and attached to the substrate (43) at fixed anchor points (50). The set of drive beams (44) are positioned between the proof masses (34a, 34b) and the anchor points (50). Each drive beam (44) has a first longitudinal body portion (62) that extends in a first direction and a first flexible spring member (64) that extends along a second direction. The base beam (46) interconnects the set of drive beams (44) and has a second longitudinal body portion (72) and a second flexible spring member (74). The second longitudinal body portion (72) extends along the second direction and the second flexible spring member (74) extends along the first direction. The first and second flexible spring members (64, 74) may be serpentine in shape, such as folded beam-columns or wrinkle springs.

Owner:TEMIC AUTOMOTIVE OF NORTH AMERICA

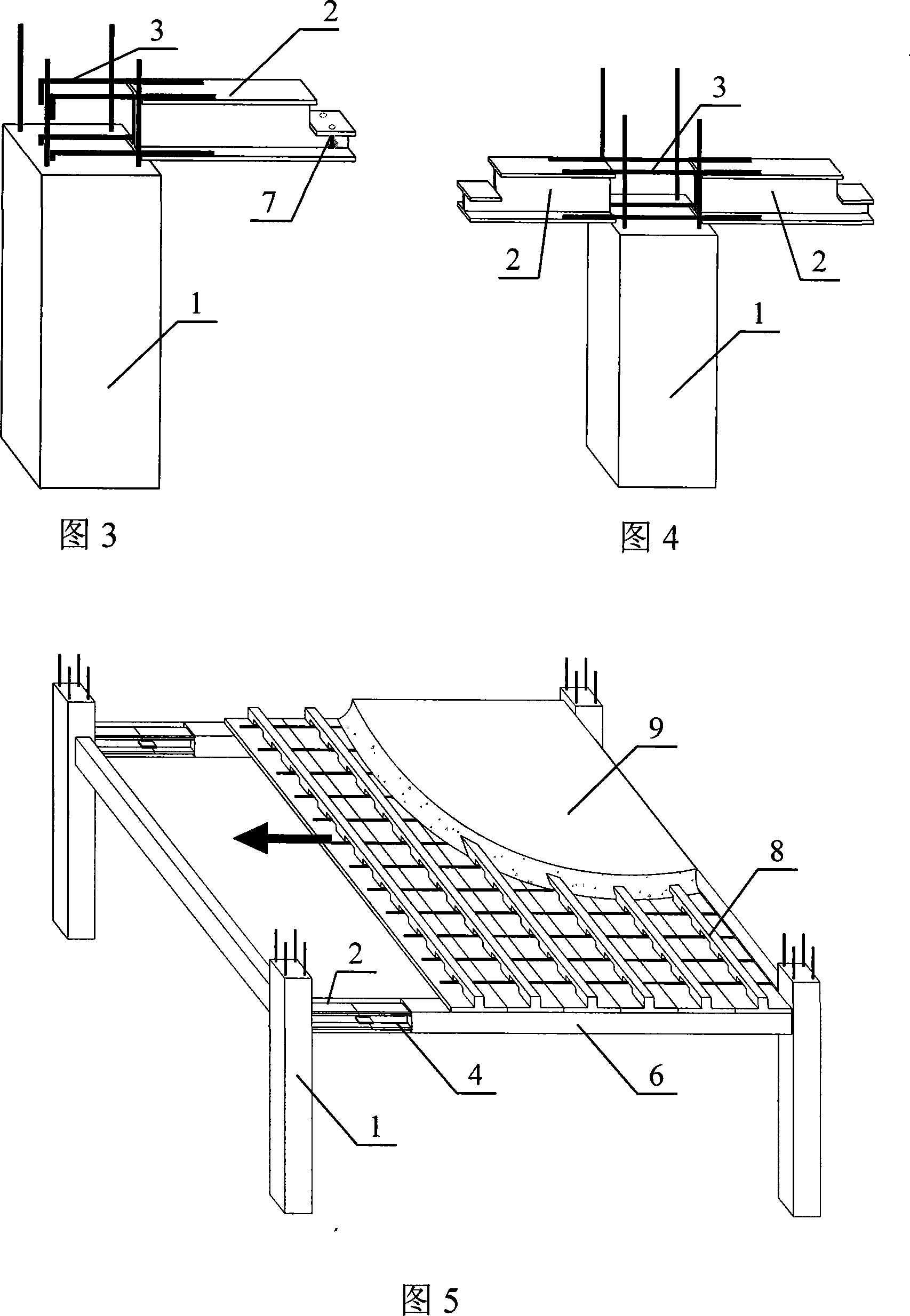

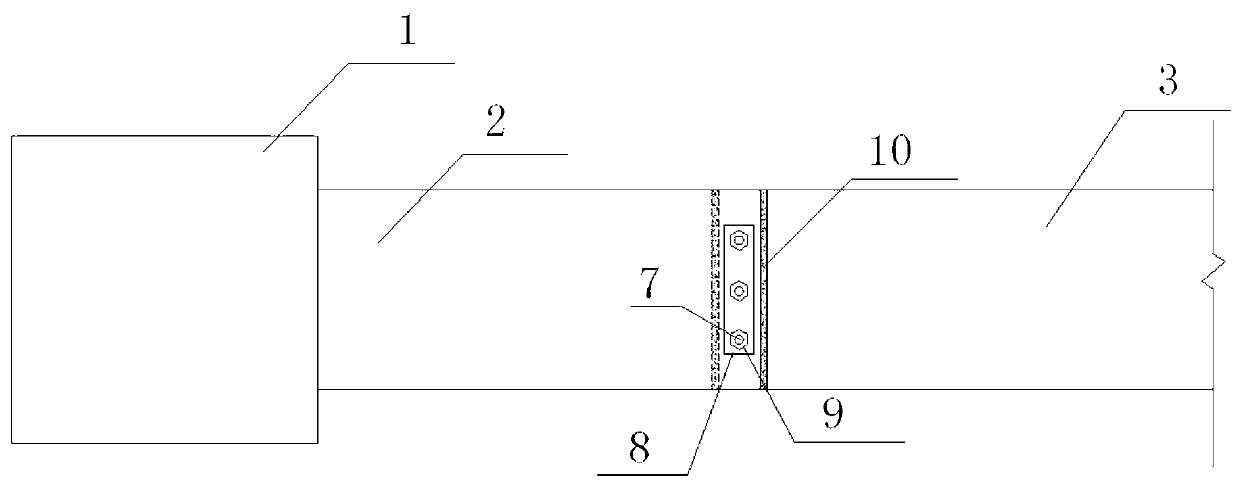

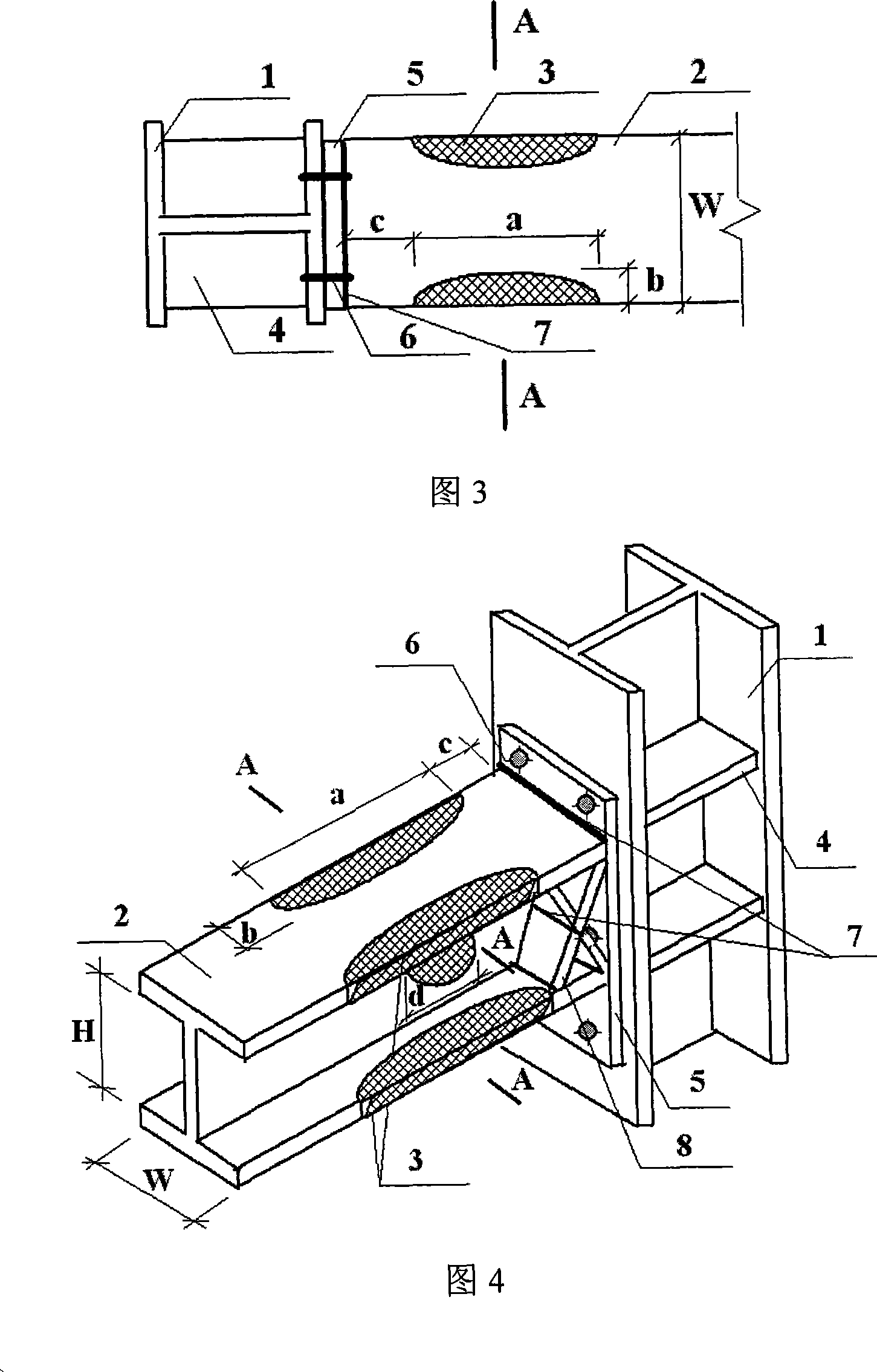

Precast prestressed steel girder with post-seismic restorable function

InactiveCN102758499AEasy constructionImprove construction qualityGirdersJoistsPre stressHigh intensity

The invention discloses a precast prestressed steel girder with a post-seismic restorable function, which belongs to the field of building structures. The steel girder comprises an intermediate girder section, short girder sections, a connecting device and an energy dissipation device, wherein the short girder sections are arranged at the two ends of the intermediate girder section; the intermediate girder section comprises an intermediate girder section web and an intermediate girder section flange connected to the edge of the intermediate girder section web; each short girder section comprises a short girder section web and a short girder section flange connected to the edge of the short girder section web; the connecting device is used for connecting the intermediate girder section and the short girder section, and comprises a connecting vertical plate and a prestressed guy cable; and the energy dissipation device comprises U-bars (arranged on both sides of the intermediate girder section web) and high-strength bolts. When the seismic effect achieves to a certain extent, the intermediate girder section is separated from the contact surface of the connecting vertical plate, and the high-strength bolts consume energy through friction, thereby avoiding the damages to main members such as girders and columns and the like. After the seismic effect is completed, the structure is restored to the original vertical position under the action of a prestressing force.

Owner:BEIJING UNIV OF TECH +1

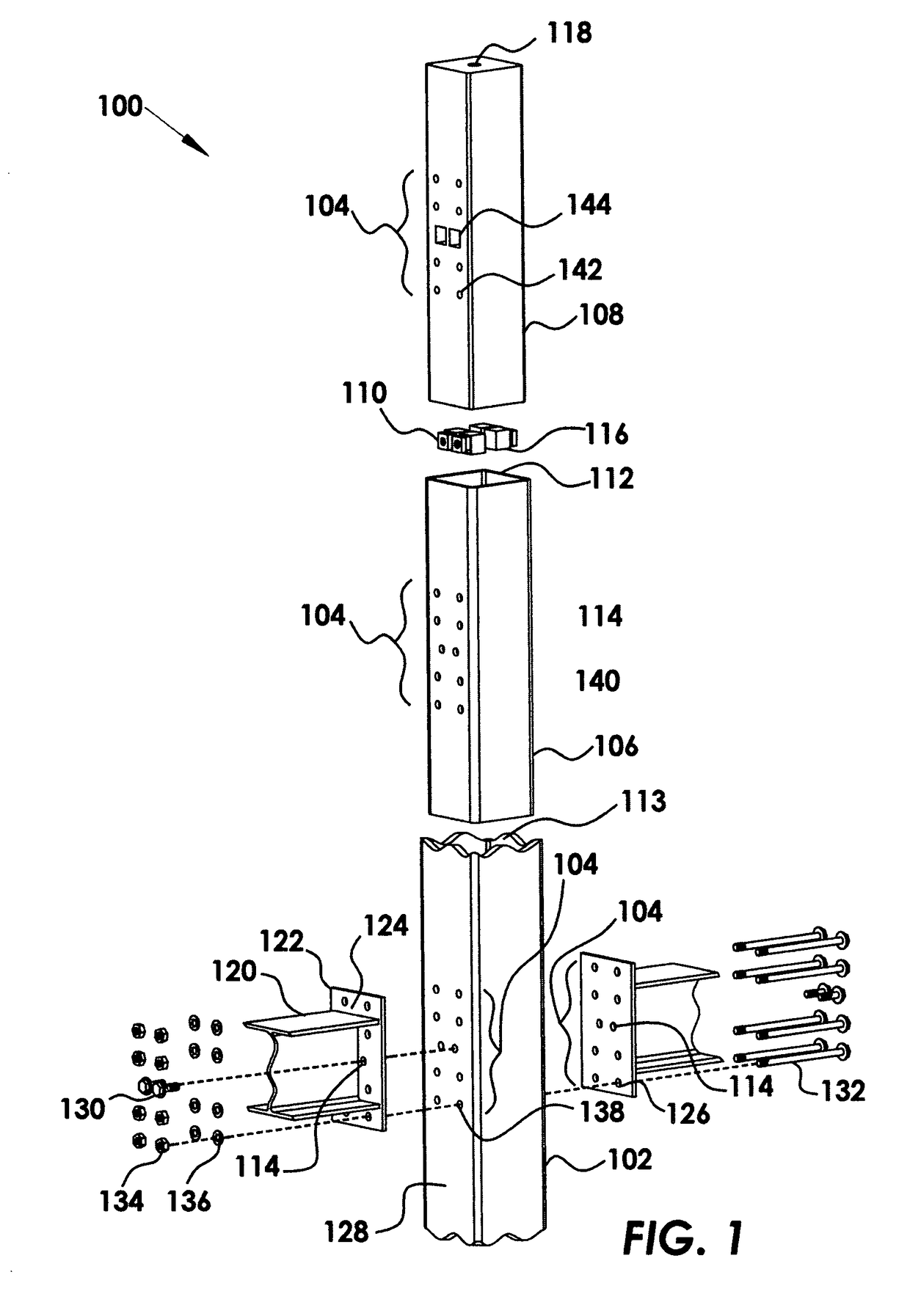

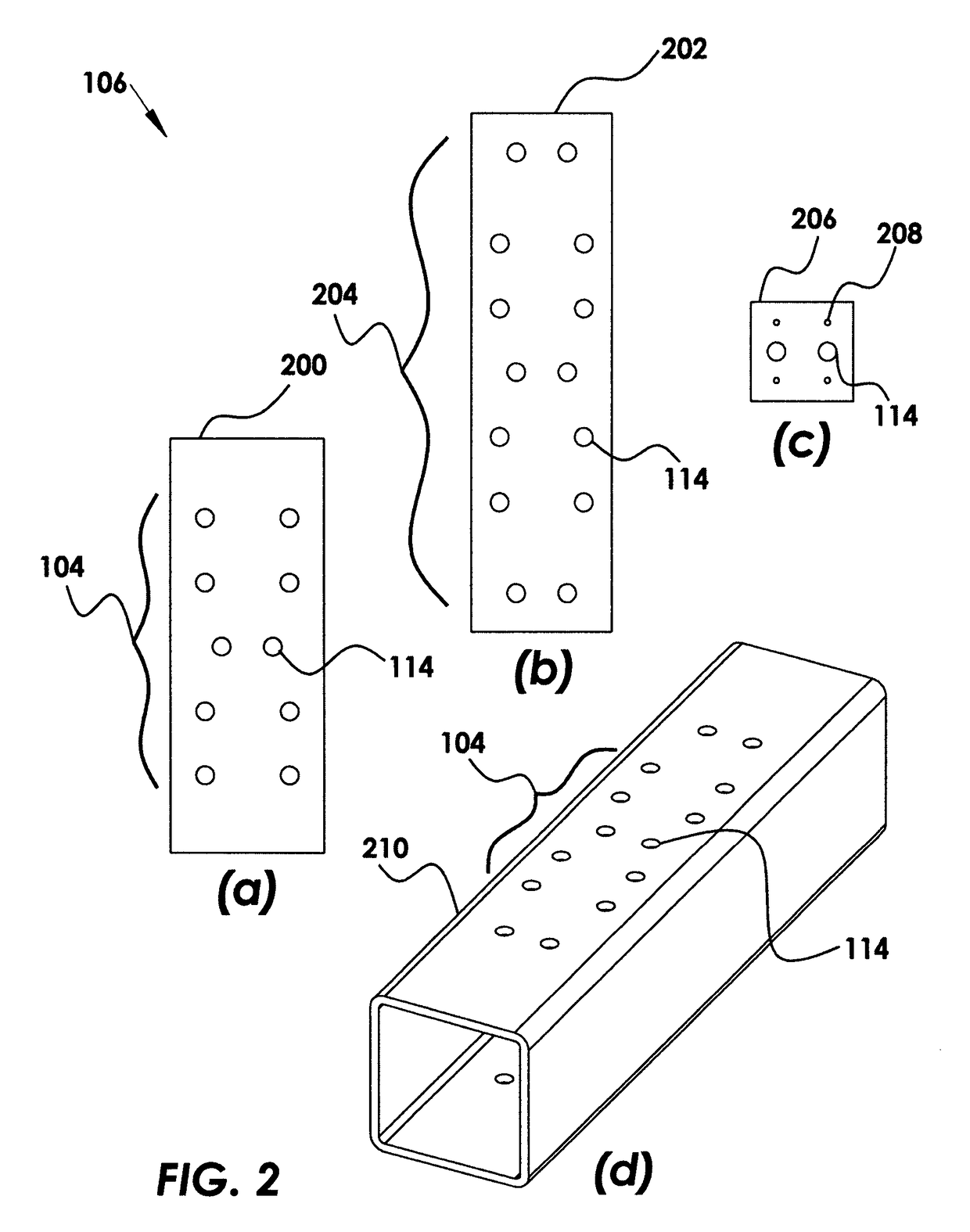

Moment resistant building column insert system and method

InactiveUS8468775B2Easy to assembleHigh strengthBuilding roofsFloorsUltimate tensile strengthMechanical engineering

A moment resistant building column insert system is provided that enables the erection of beams to columns, and the installation and pretension of connection bolts possible in a single stop to each beam-column joint in the field. Included is a building column insert with pre-hardened structural filler inside, and a pattern of through-holes transverse to the insert length, where the insert has threaded elements disposed inside and concentric to erection holes in the pattern. The insert is disposed inside a building column. Erection bolts installed to the erection holes to hold the beam in place against the column with the holes in the beam mounting plate, the column and insert aligned. Connection through-bolts are installed and pretensioned to provide the connection strength needed to make a beam-column moment joint rigid. Without the pre-hardened structural filler in the insert the column would deform or crush due to the bolt pretensioning.

Owner:VAUGHN WILLAIM B

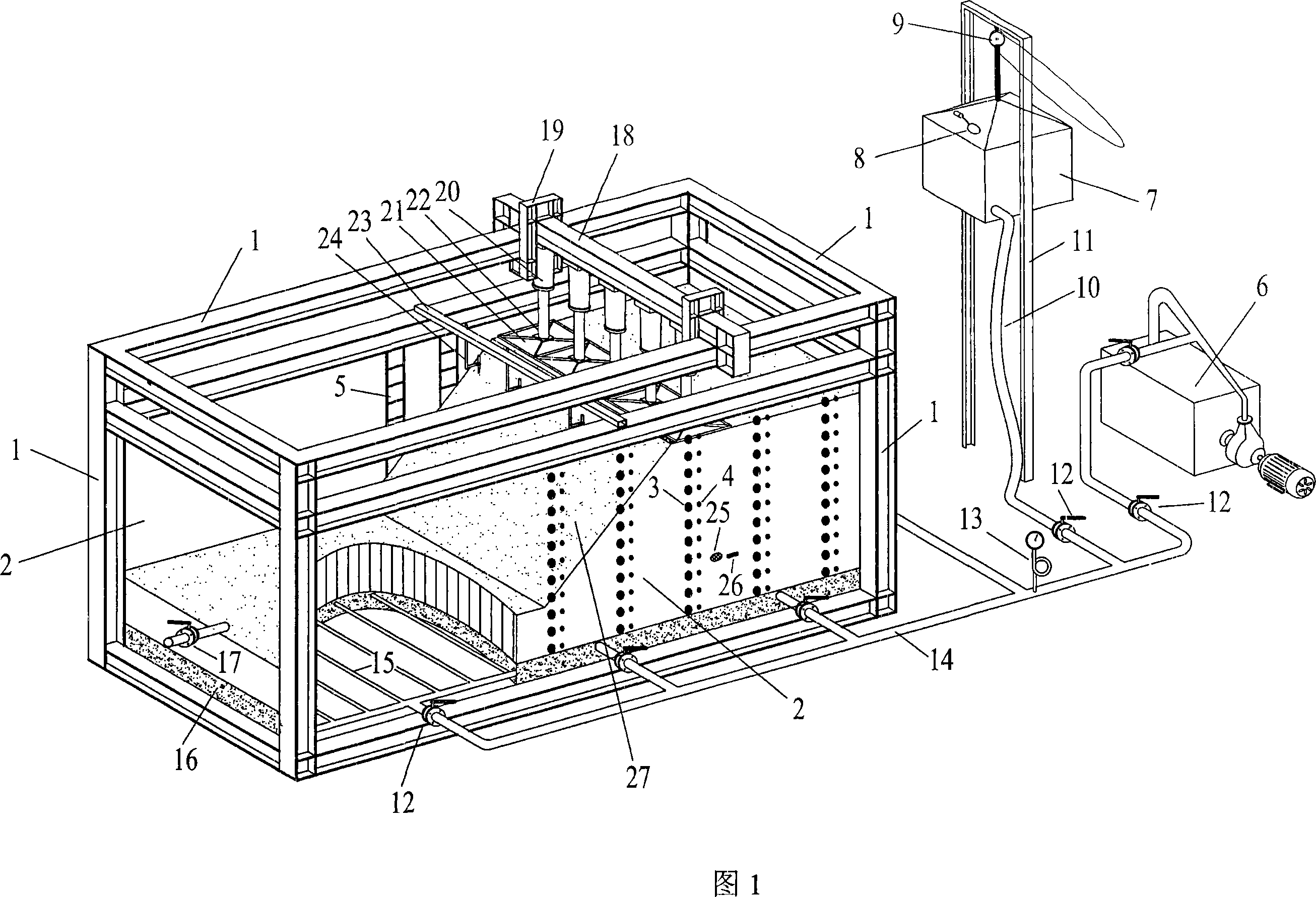

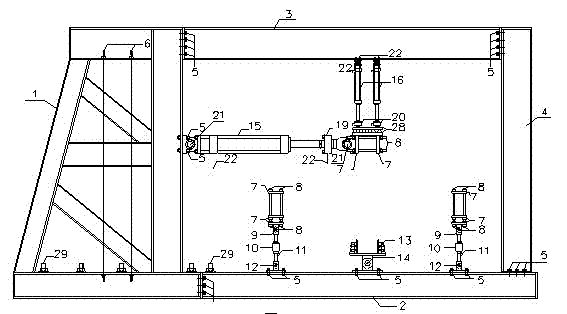

Portable performance test device for automatic control of combined action of bidirectional load of beam-column joint and determination method

InactiveCN103076192AFlexible stroke adjustmentPrevent movementStructural/machines measurementShaped beamAutomatic control

The invention discloses a portable performance test device for automatic control of a combined action of a bidirectional load of a beam-column joint and a determination method. The test device comprises an outer frame fixing device, a test piece fixing device, a test piece loading device and a data acquisition system, wherein the outer frame fixing device comprises a trapezoidal horizontal counter-force frame, an I-shaped girder bearing platform, an I-shaped beam, an I-shaped upright and a prestress wire rope; the test piece loading device comprises a horizontal actuator, two vertical actuators, a hydraulic oil source, a horizontal load sensor and a vertical load sensor; the test piece fixing device comprises two steel splints, an anchor bolt rod, a column fixing base and a column bottom hinge support; and the data acquisition system comprises a controller, a multi-channel strain collector and a computer. The device, provided by the invention, has the advantages of simple structure, convenience for assembly and disassembly, and few required materials, and is suitable for testing hysteretic behavior of a node test piece at scientific research and construction sites.

Owner:HOHAI UNIV +1

Prestress assembly frame structure

InactiveCN103362210ARealize low carbonizationDoes not affect layoutBuilding constructionsDistribution methodPre stress

The invention discloses a prestress assembly frame structure which comprises floor beams, a floor post and a foundation, wherein the floor post is formed by connecting a plurality of floor post units in sequence from top to bottom, one floor post unit connected with the floor beams is a top post, one floor post unit connected with the foundation is a bottom post, a connecting point between the top post and the floor beams is a beam-post node, a connecting point between two adjacent floor post units is a post-post node, and the connecting point between the bottom post and the foundation is a post-foundation node. Through the improvement on the beam-post node, the post-post node and the post-foundation node, the problems that in a conventional prestress assembly frame structure, the beam-post node and the post-foundation node cannot consume energy effectively under major earthquake, and cannot provide pressed protection for concrete on a pressed area of an interface, and the tendon distribution method is unreasonable are solved, and meanwhile, the problems that the post-post node is inconvenient to accomplish, and an anti-shearing weak part is formed on a connection interface are solved.

Owner:CHINA UNIV OF MINING & TECH

Beam end weakened replacement type steel frame beam shock proof node

InactiveCN101100877AEnsure safetyTo achieve reinforcementShock proofingMetallic materialsSteel frame

This is an anti-knock node for steel frame beam. It is by substituting traditional steel material on the beam end and web by an metal of strong endergonic ability, and adding X shape low carbon armor plate to the beam end to form an endergonic plasticity node.

Owner:BEIJING UNIV OF TECH

Assembly type wood frame structure beam-column joint with sleeve

InactiveCN106368315AAvoid weakeningIncrease profitBuilding constructionsAgricultural engineeringUltimate tensile strength

The invention discloses an assembly type wood frame structure beam-column joint with a sleeve. The assembly type wood frame structure beam-column joint comprises an upper wood column, a lower wood column, wood beams, a sleeve joint and reinforcing corner pieces. A middle vertical inserting groove is formed in the end of each wood beam. A cross-shaped inserting groove is formed in the upper end of the lower wood column, and a cross-shaped inserting groove is formed in the lower end of the upper wood column. The sleeve joint is provided with a column sleeve; a cross-shaped sleeve longitudinal rib plate and a sleeve middle transverse partition plate are arranged in the column sleeve; and wing type sleeve connecting plates are arranged outside the column sleeve. The column sleeve is arranged at the upper end of the lower wood column in a sleeving mode; the lower end of the upper wood column is inserted into the column sleeve; the ends of the wood beams are inserted into the wing type sleeve connecting plates; and the upper side and the lower side of each wood beam are each provided with a reinforcing corner piece. The reinforcing corner pieces, the sleeve joint, the wood beams and the wood columns are connected through bolts. The assembly type wood frame structure beam-column joint is little in wood consumption, low in manufacturing cost, high in connection strength, easy to manufacture, convenient to construct, definite in stress, and beneficial to the population and the application of assembly type wood frame structures.

Owner:TIANJIN UNIV

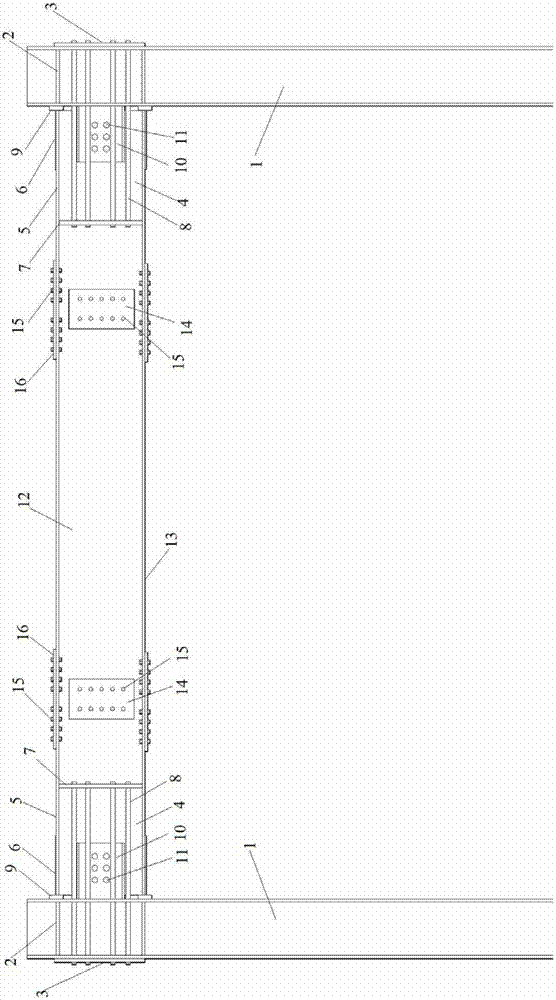

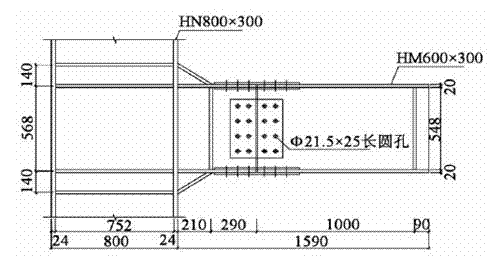

Reamed steel structure beam-column joint connected via end plate and construction method for same

ActiveCN102444211AStrong ductile deformation abilityImprove energy consumptionBuilding material handlingShock proofingSteel columnsBeam column

The invention relates to a reamed steel structure beam-column joint connected via an end plate and a construction method for the same. The reamed steel structure beam-column joint connected via an end plate comprises a steel column and an H-section steel beam, which is characterized in that: a steel column flange is connected with the end plate via a friction-type high-strength bolt; the end plate is connected with a steel beam web via a steel beam web connection plate; the end plate is connected with an upper steel beam flange and a lower steel beam flange via a steel beam flange connection plate; the steel beam web connection plate and the steel beam flange connection plate are welded on the end plate via groove full penetration welds; oblong holes are disposed on the steel beam web connection plate and the steel beam flange connection plate; the steel beam web connection plate and the steel beam flange connection plate are connected with the steel beam web and the steel beam flange via friction-type high-strength bolts; and the steel column flange is provided with a shear-resisting support plate on the bottom of the end plate. The reamed steel structure beam-column joint connected via an end plate and the construction method for the same disclosed by the invention can remarkably enhance the ductile deformability and energy dissipation capability of the joint under the function of a rare earthquake, and have the advantages of being convenient in construction, easy to repair after an earthquake etc.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com