Patents

Literature

97results about How to "Flat section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

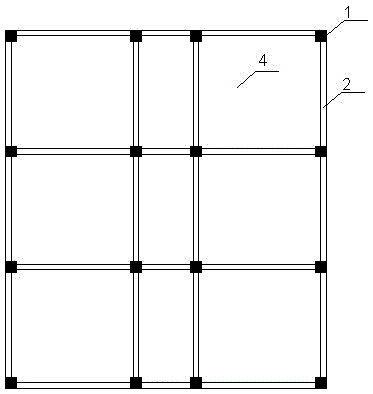

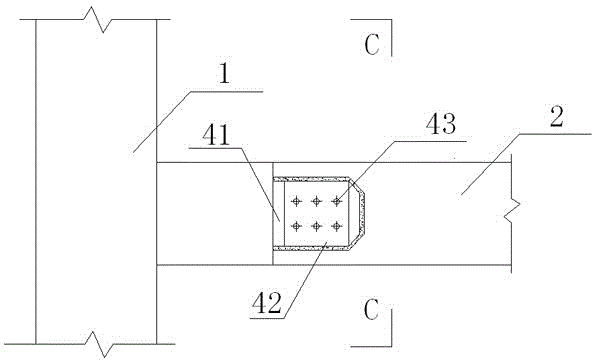

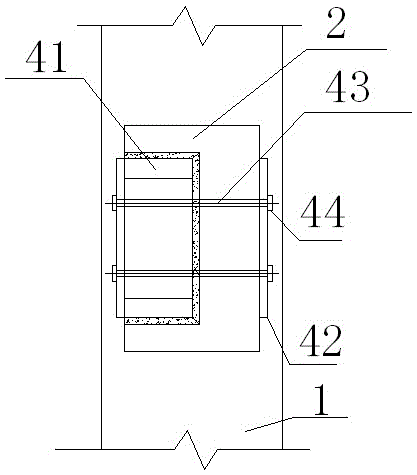

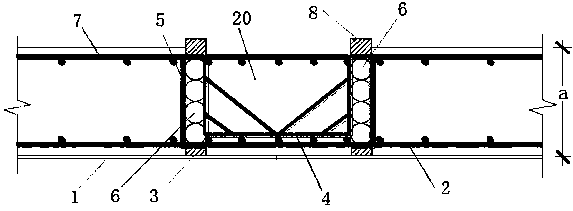

Assembled framework beam-column joint adopting vertical connection and construction method thereof

InactiveCN103104040AFlat sectionDoes not affect the spaceBuilding material handlingReinforced concreteRebar

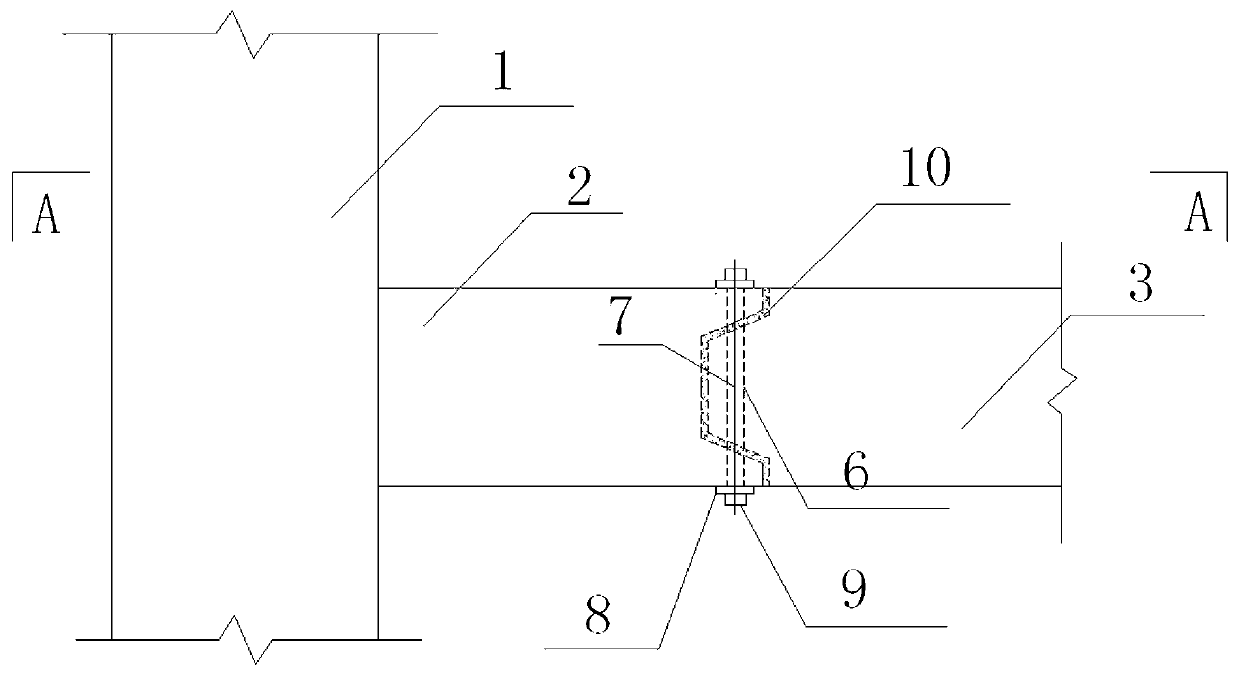

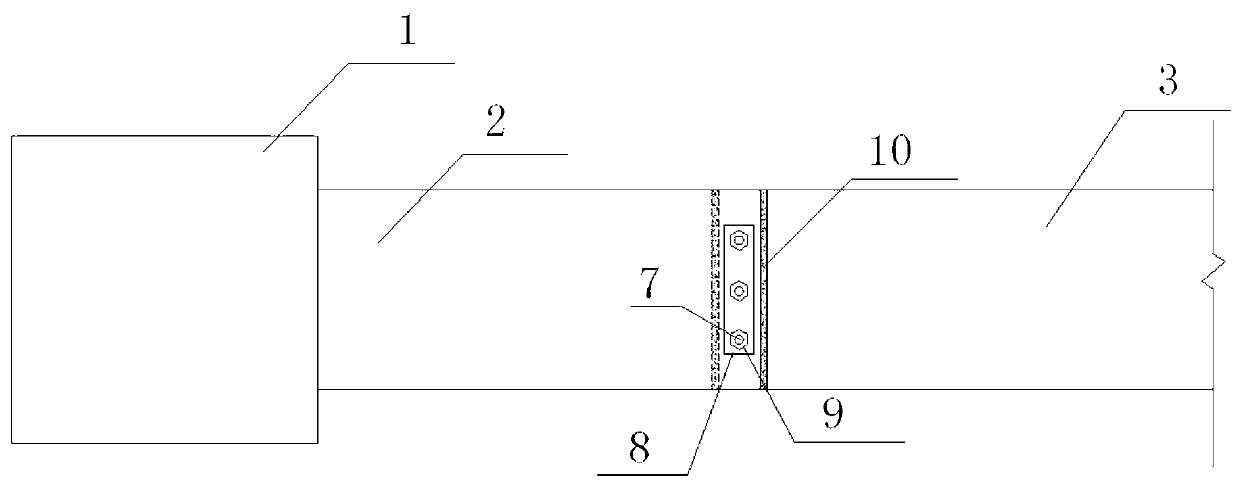

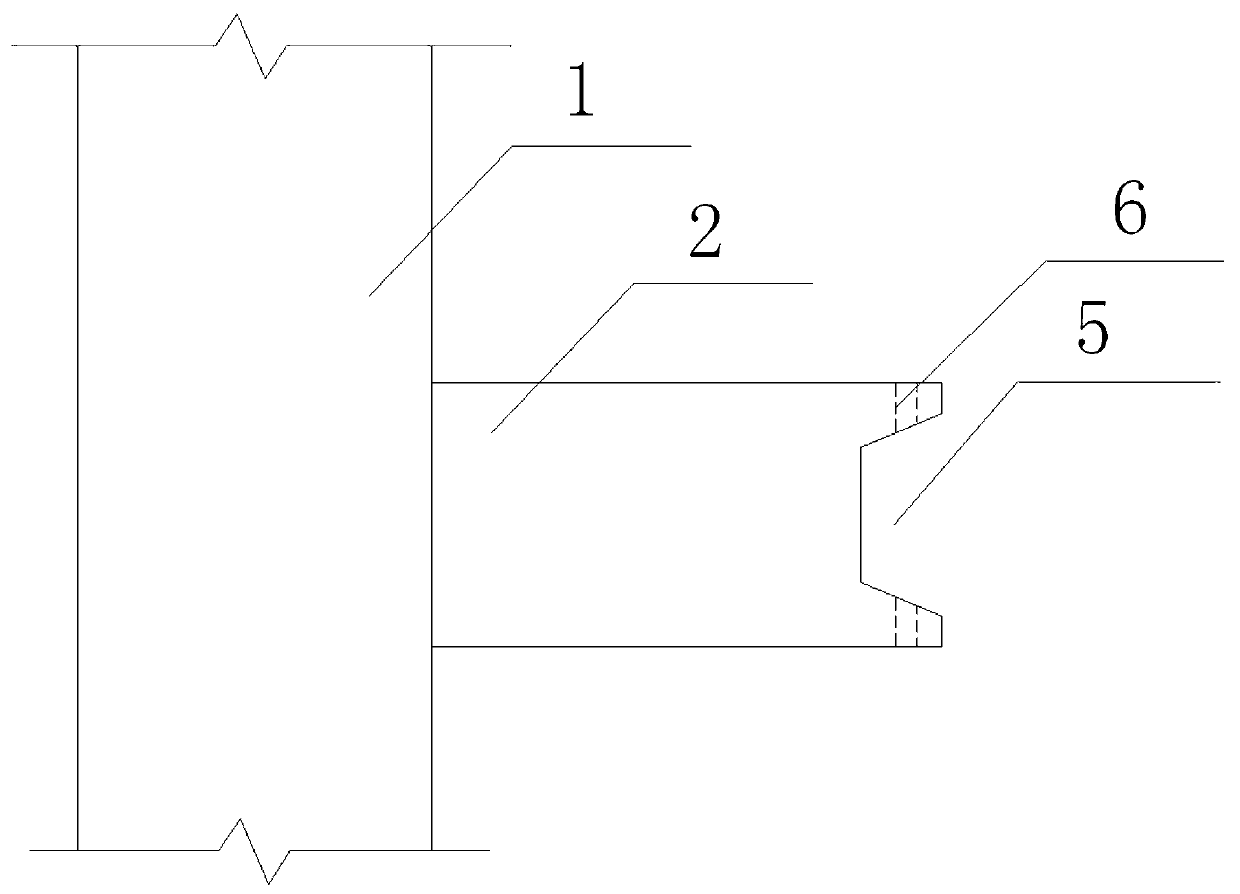

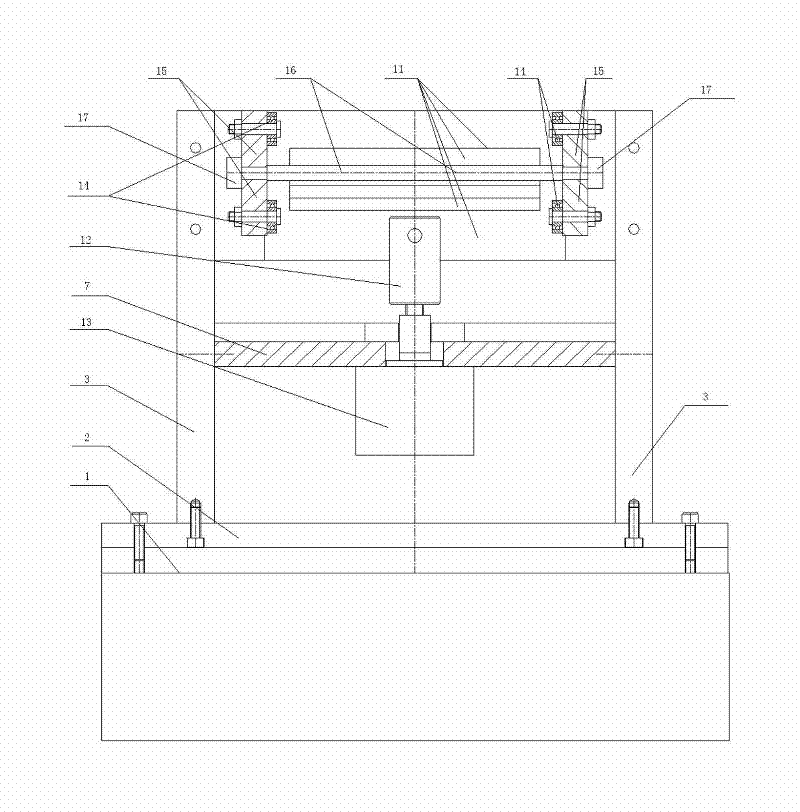

The invention relates to an assembled reinforced-concrete framework beam-column joint adopting vertical bolt connection. The joint comprises a corbel of a precast column and a precast beam, wherein the end face of the corbel and the end face of the precast beam are respectively provided with a concave groove and a convex block which are matched with each other and are respectively provided with a vertical corbel bolt hole and a vertical precast beam bolt hole; and the corbel is matched with the precast beam along the length direction of the precast beam in an embedded fixing manner, bolt cushion plates are arranged at the upper and lower sides of the corbel and the precast beam after the corbel and the precast beam are fixed in an embedding manner, and a bolt vertically penetrates through the bolt cushion plates, the corbel bolt hole and the precast beam bolt hole so as to carry out fixing. A corresponding construction method comprises the steps of precasting, mounting and filling mortar in gaps. The joint and the corresponding construction method have the advantages that the smoothness of force transmission between the precast beam and the precast column is achieved, the joint is reliable in connection and simple in structure, the construction process is simplified, the on-site assembling time is saved, and the production efficiency can be effectively increased.

Owner:ZHENGZHOU UNIV

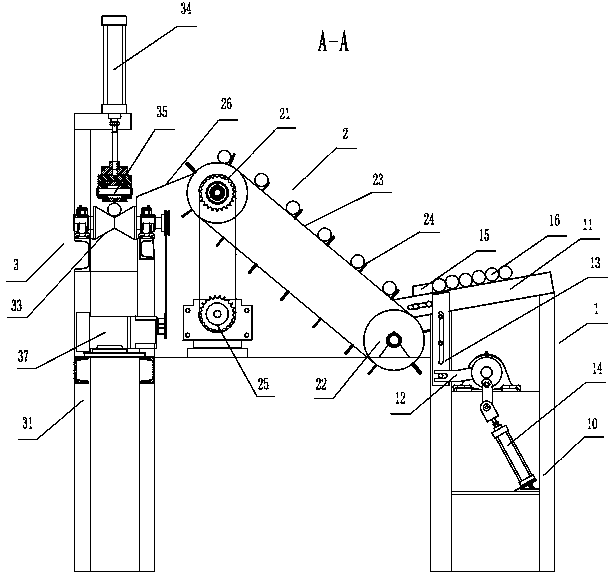

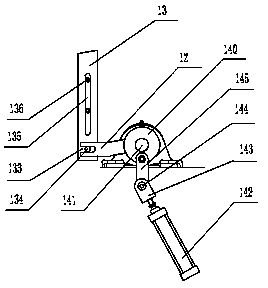

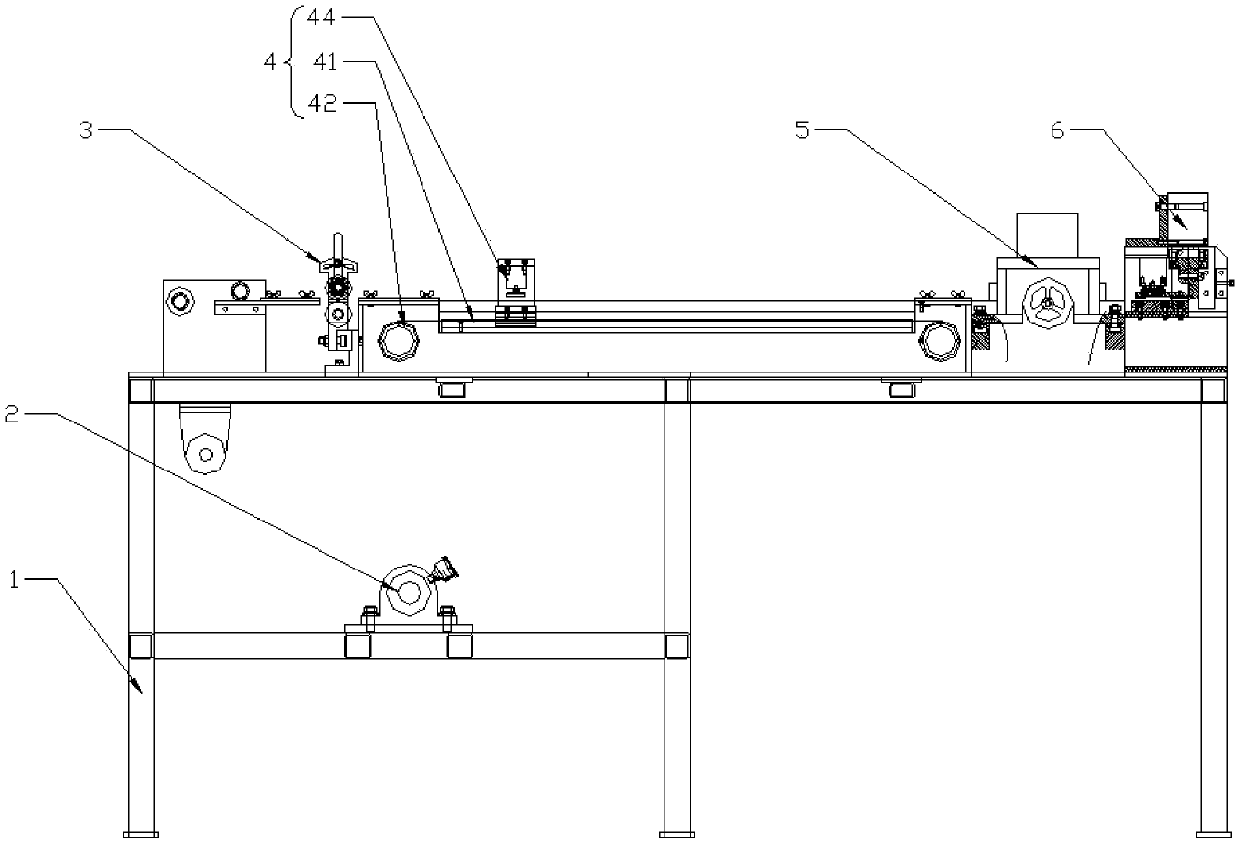

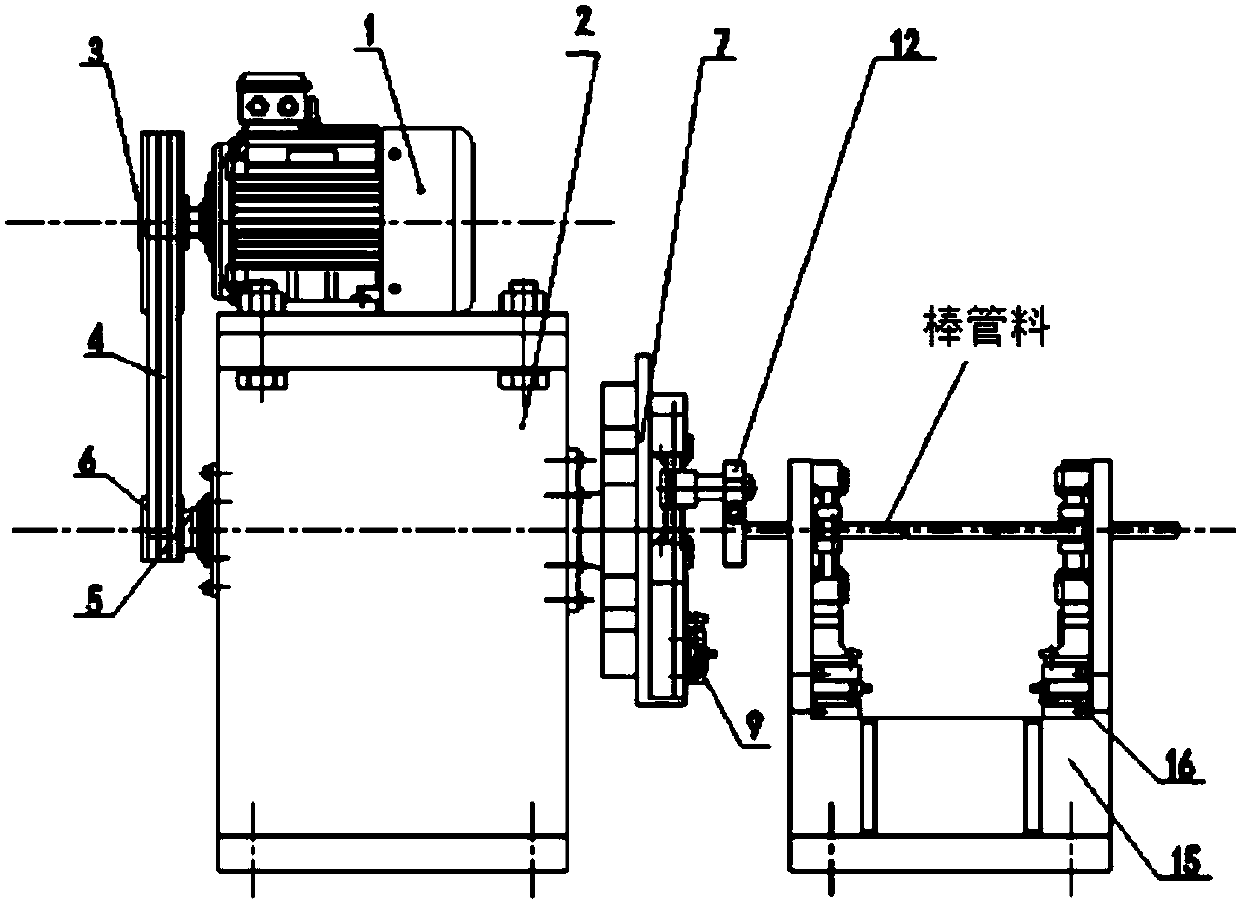

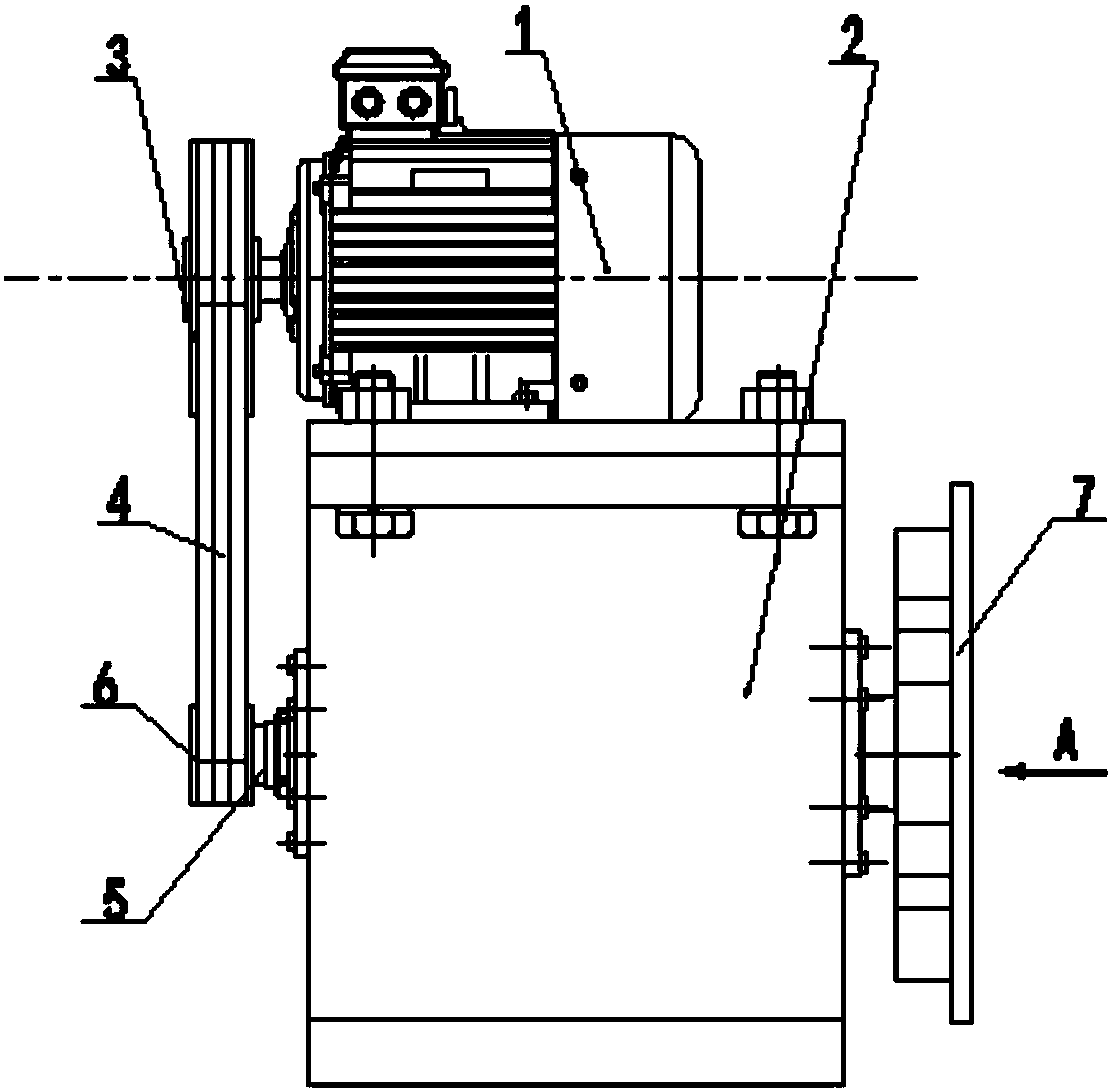

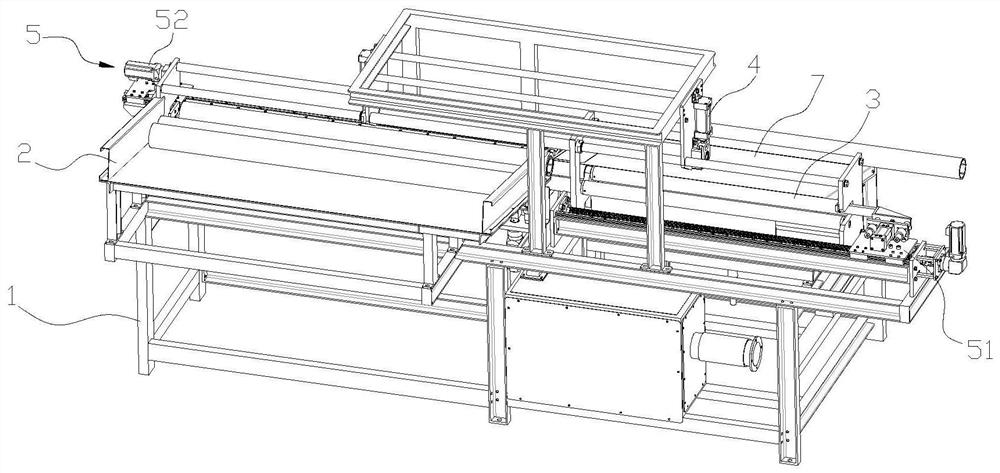

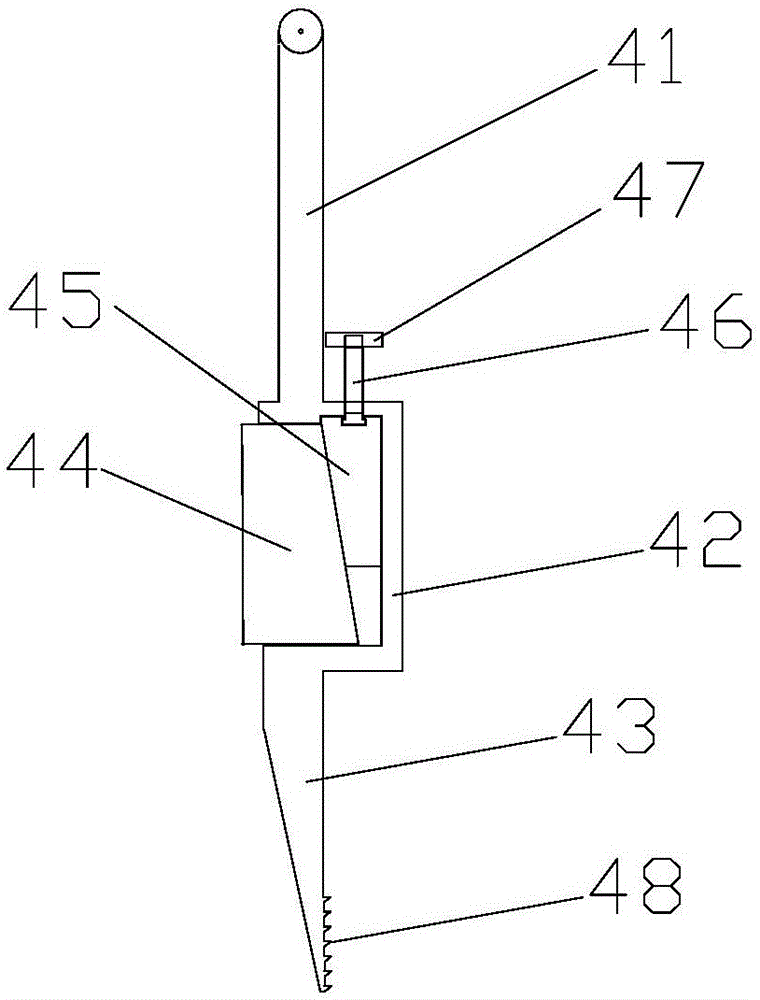

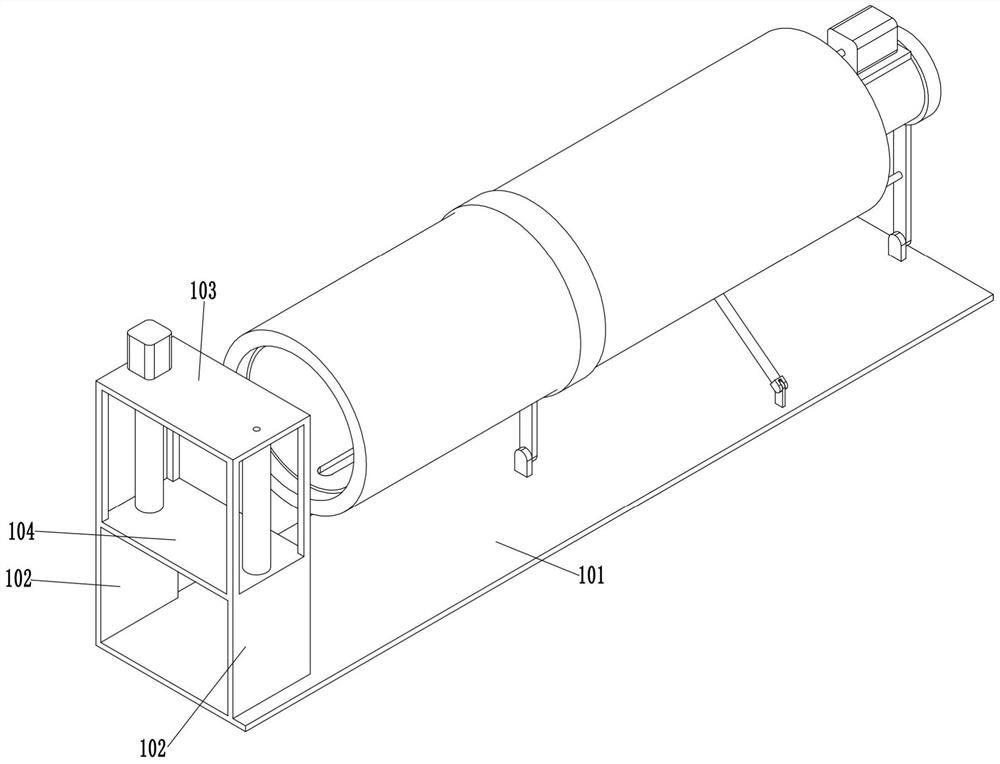

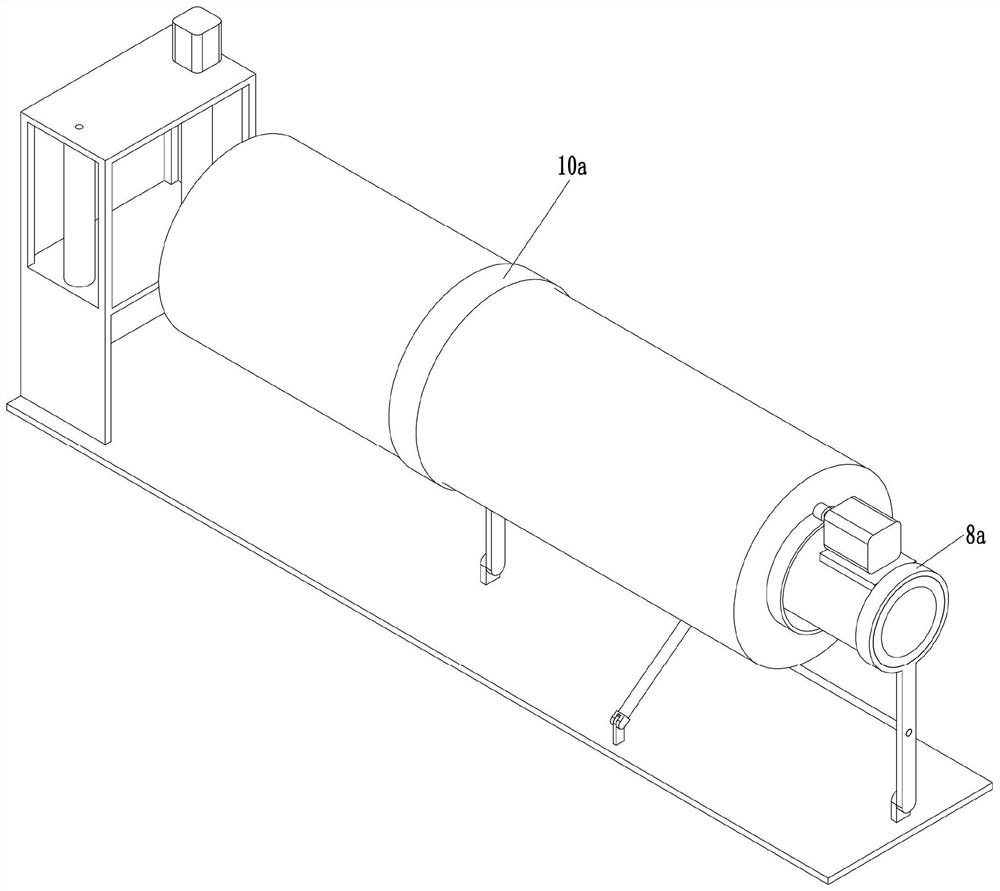

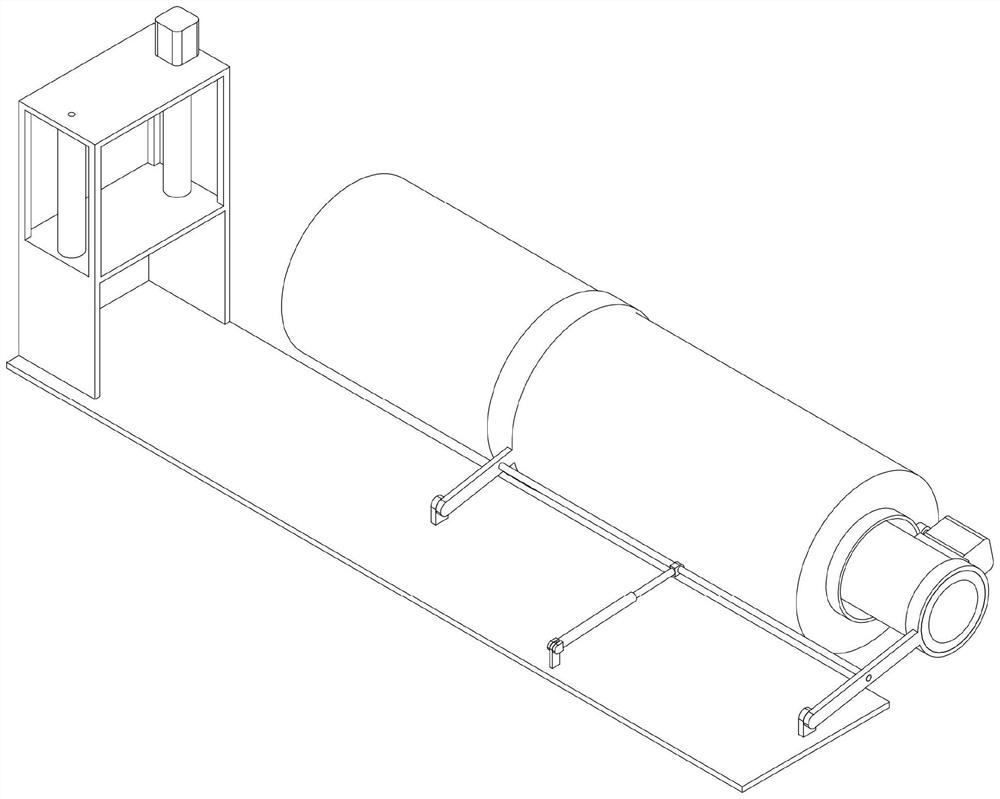

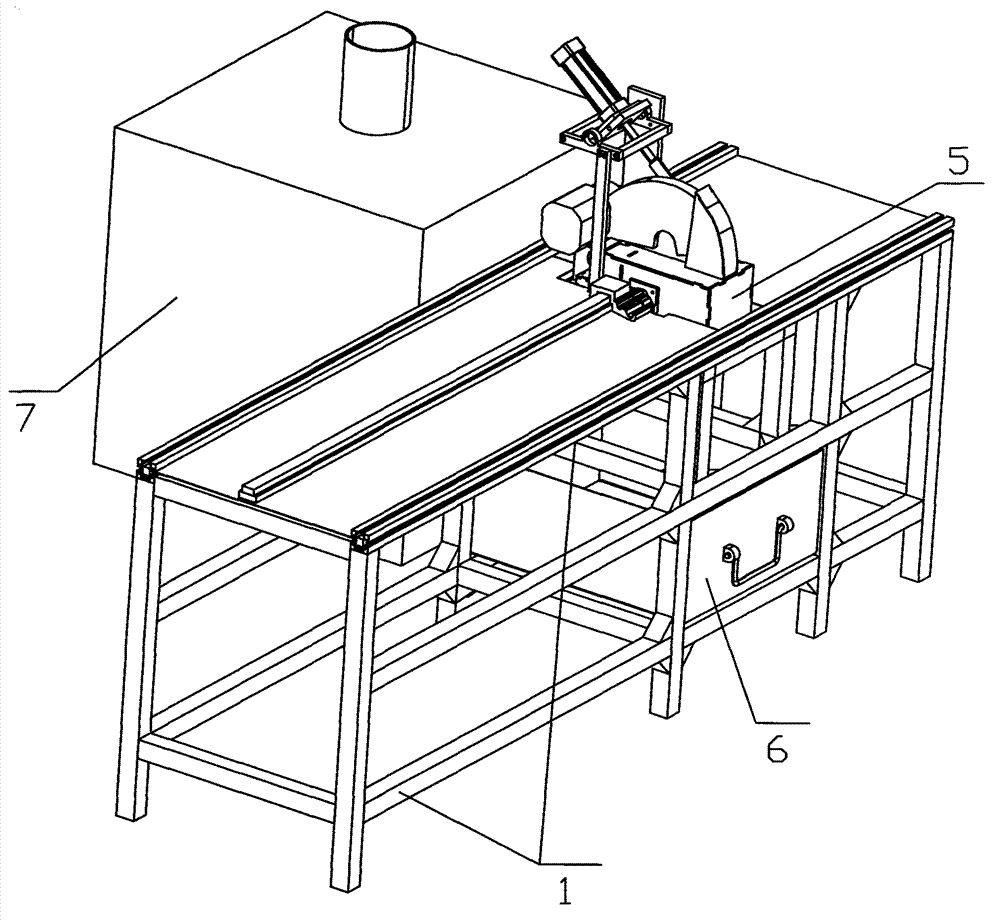

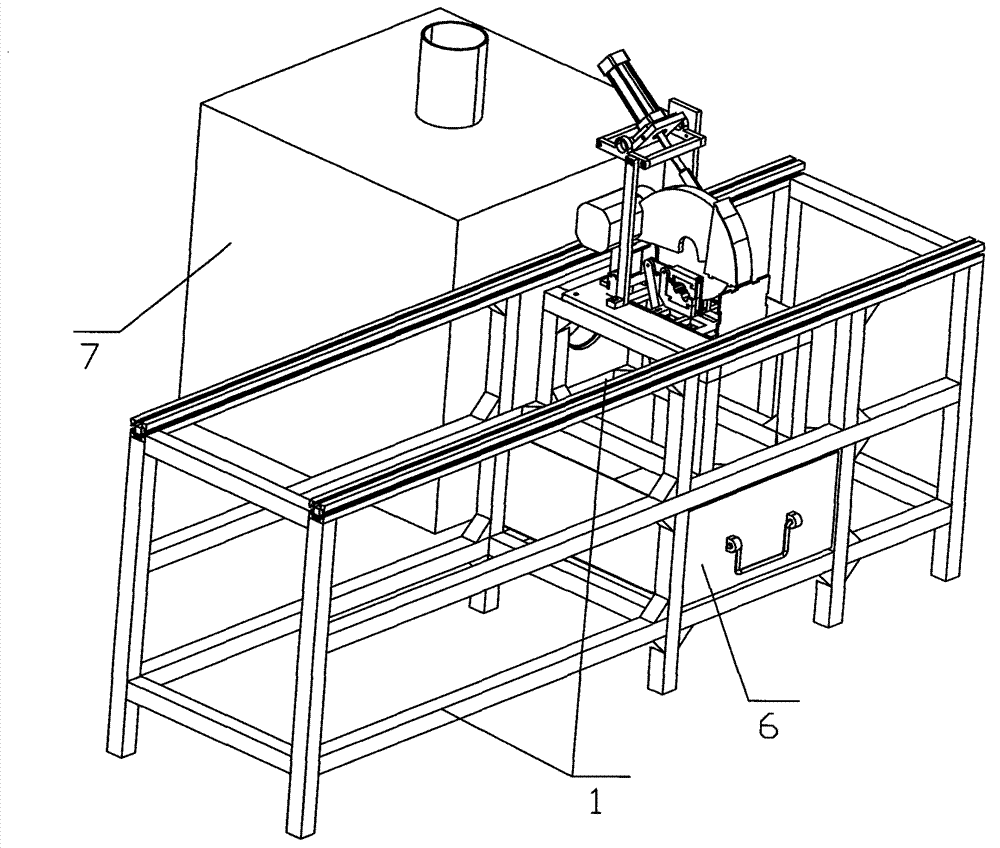

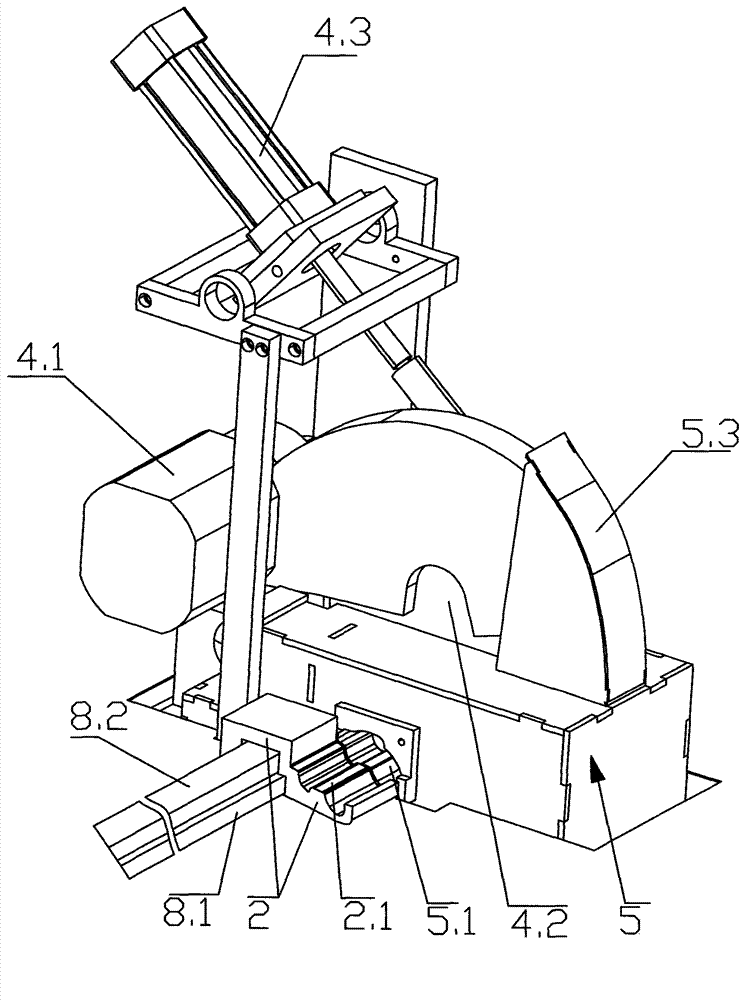

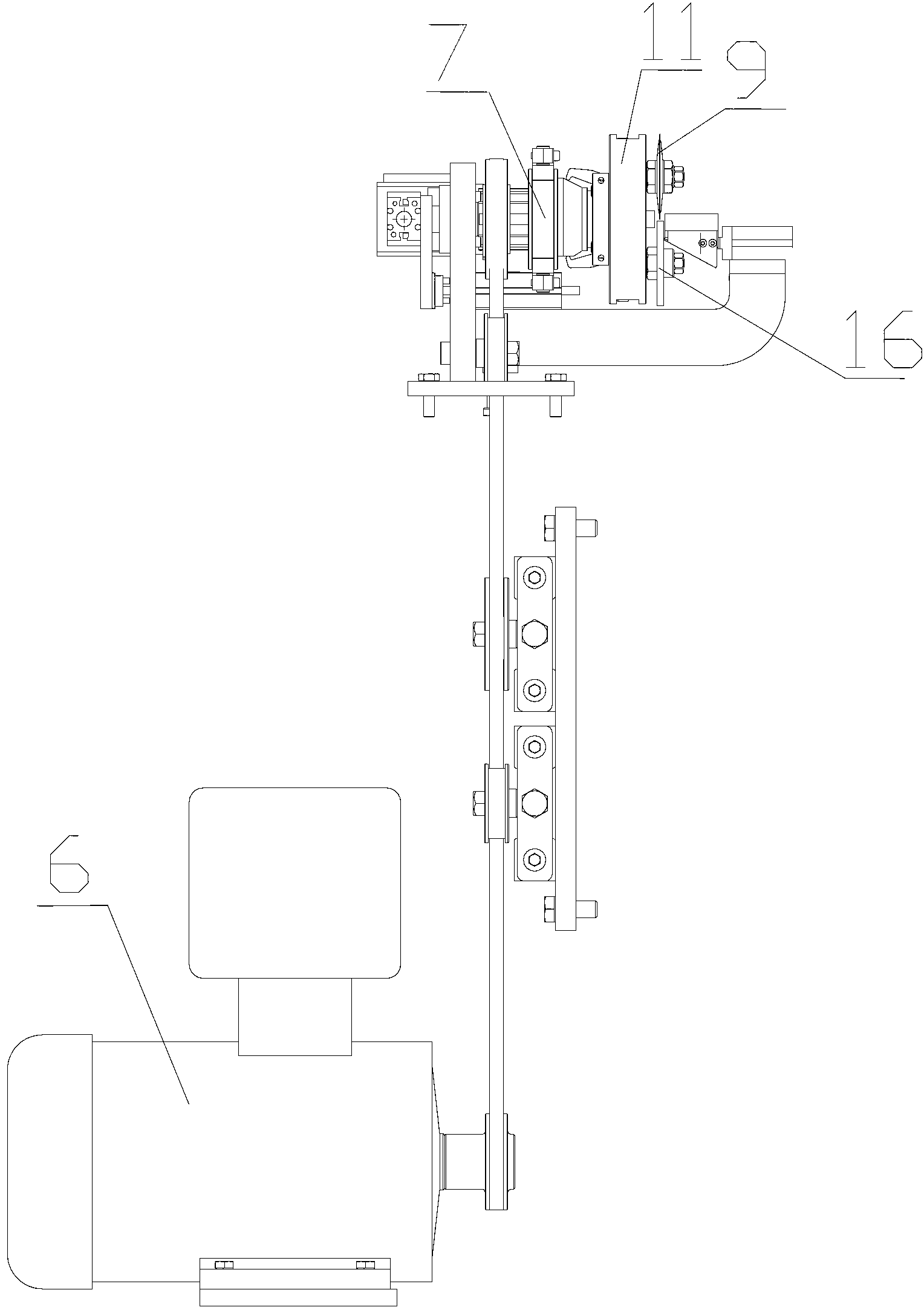

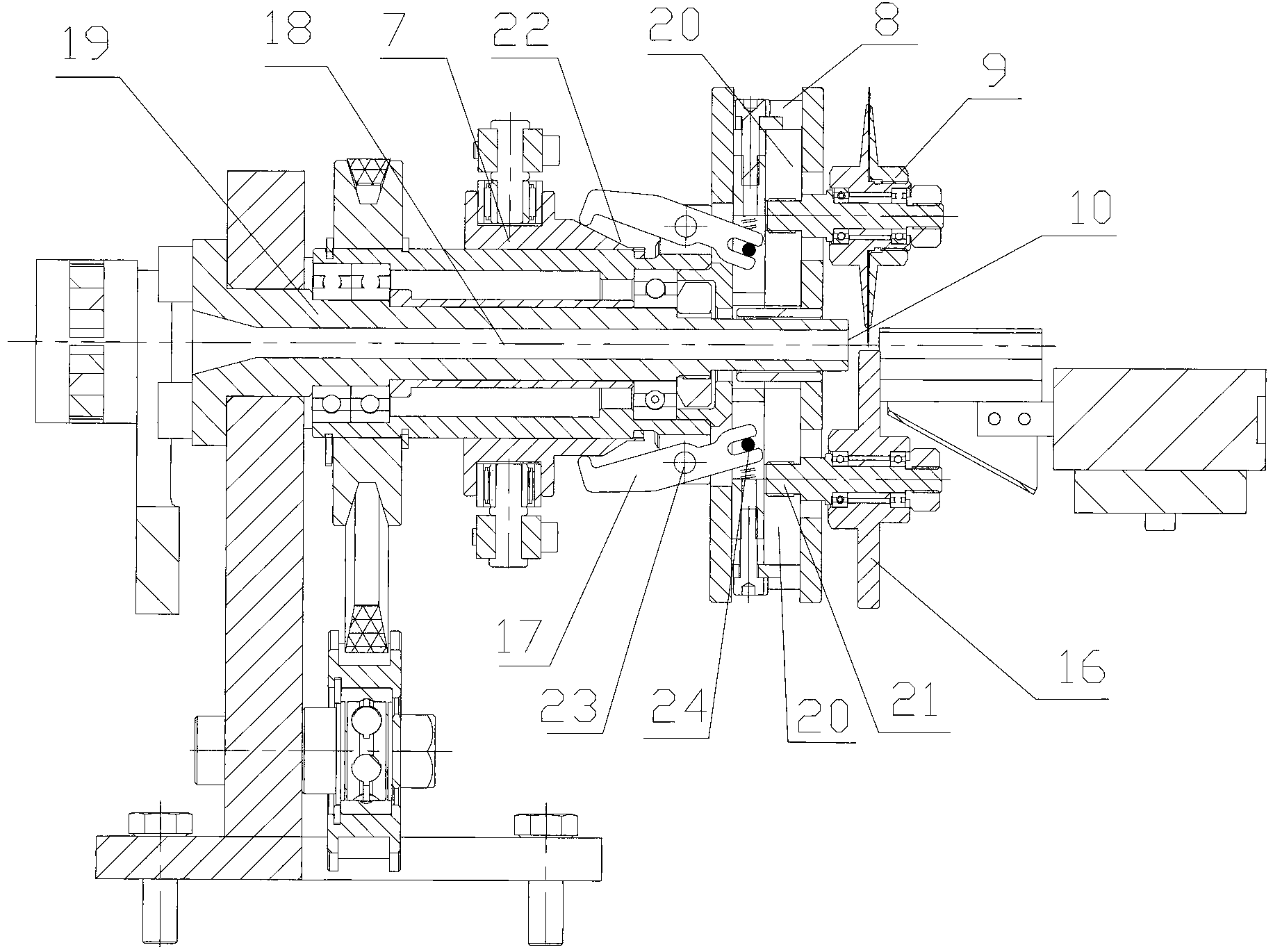

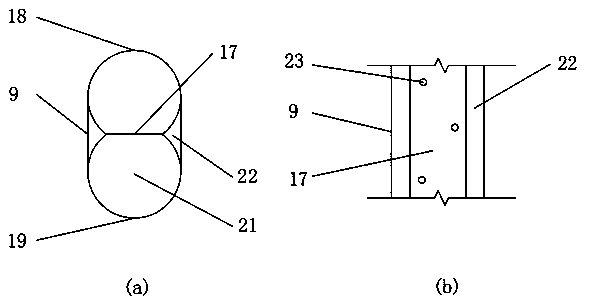

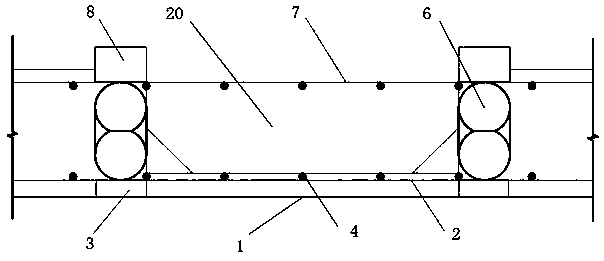

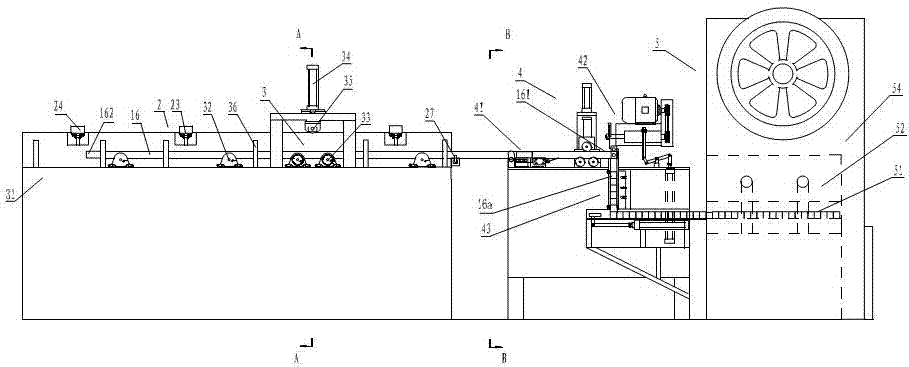

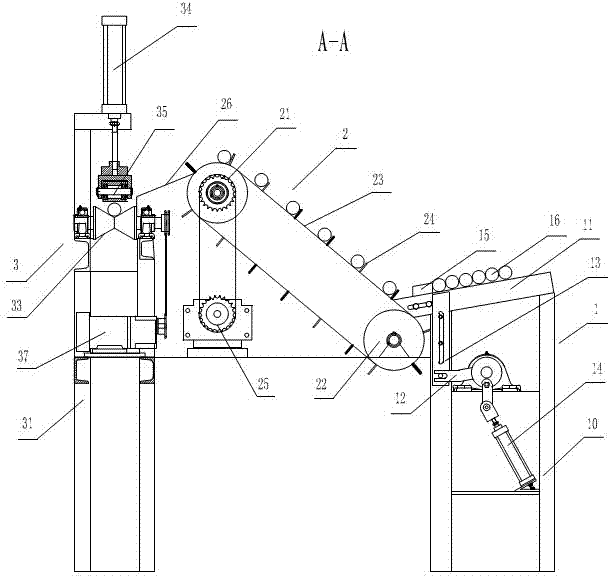

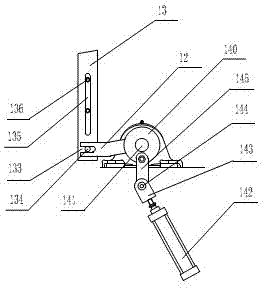

Equipment for automatically lifting, continuously feeding, sawing and heating bars

ActiveCN103447825AReduce labor intensitySame lengthOther manufacturing equipments/toolsMetal working apparatusProduction linePunch press

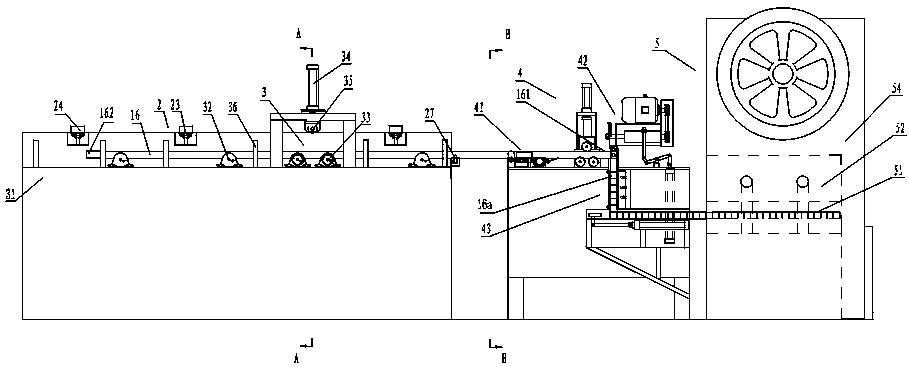

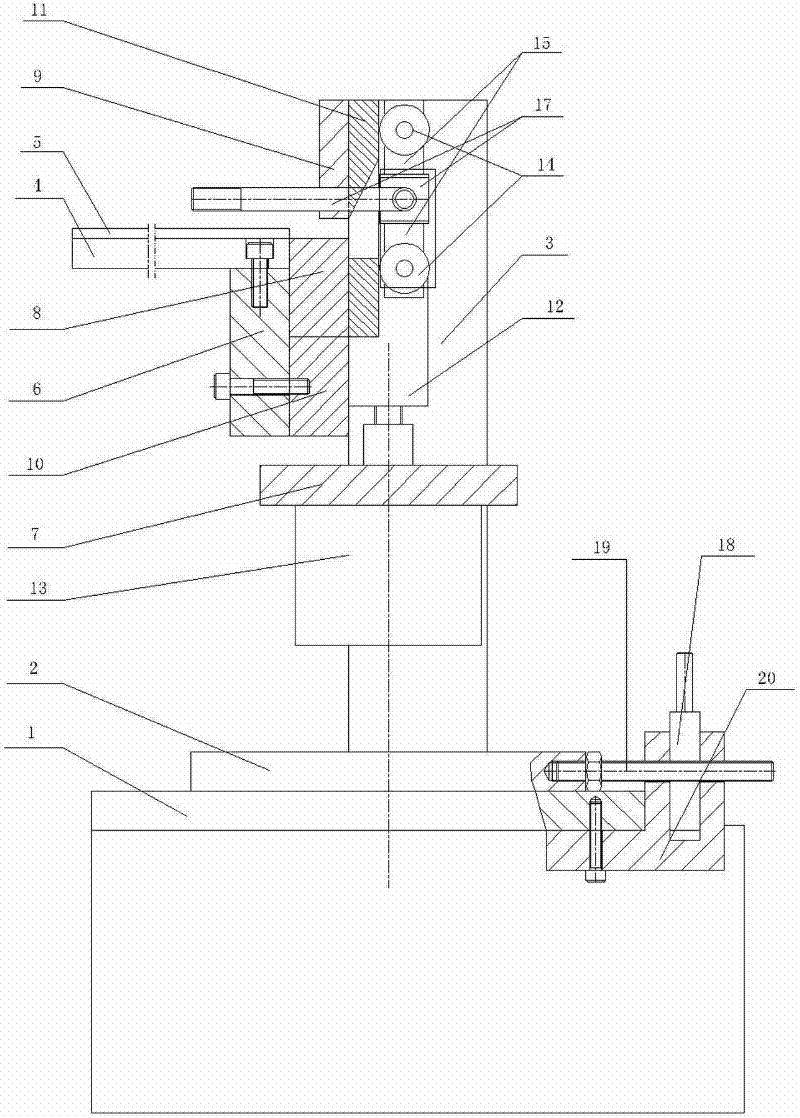

The invention relates to equipment for automatically lifting, continuously feeding, sawing and heating bars. The equipment comprises a loading device, a lifting device, a feeding device, a blanking device and a heating hot punching device, wherein the loading device comprises a loading frame, a loading platform, an ejector rod, a linkage rod, a driving wheel and an ejector cylinder; the lifting device comprises a lifting chain, a chain wheel, a driving chain wheel and a lifting motor; the feeding device comprises a feeding frame, a V-shaped wheel, a compression cylinder, a compression guide wheel and a feeding limit switch; the blanking device comprises a guide mechanism, a saw-cutting mechanism and a material rotating mechanism; and the heating hot punching device comprises a heating groove, a heating furnace, a blanking guide groove and a punch press. A fully-automatic production line of lifting, feeding, blanking and heating hot punching is manufactured and formed on a valve shell, so full-automatic control is realized, production efficiency is improved, energy consumption is saved, workers are protected from directly operating beside the heating furnace, scalding and sunstroke accidents are avoided, labor intensity is reduced, and the automatic level is increased and product quality is improved.

Owner:NINGBO JIEKELONG PRECISION MFG +1

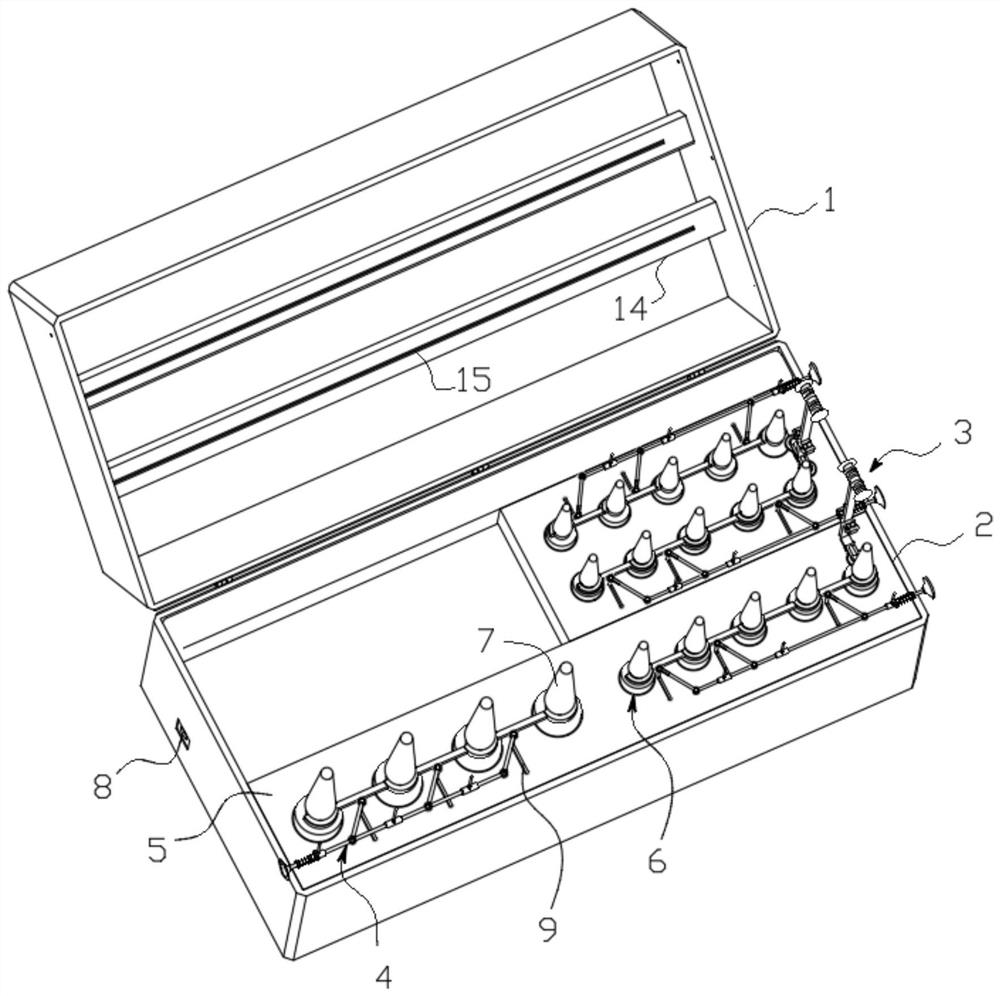

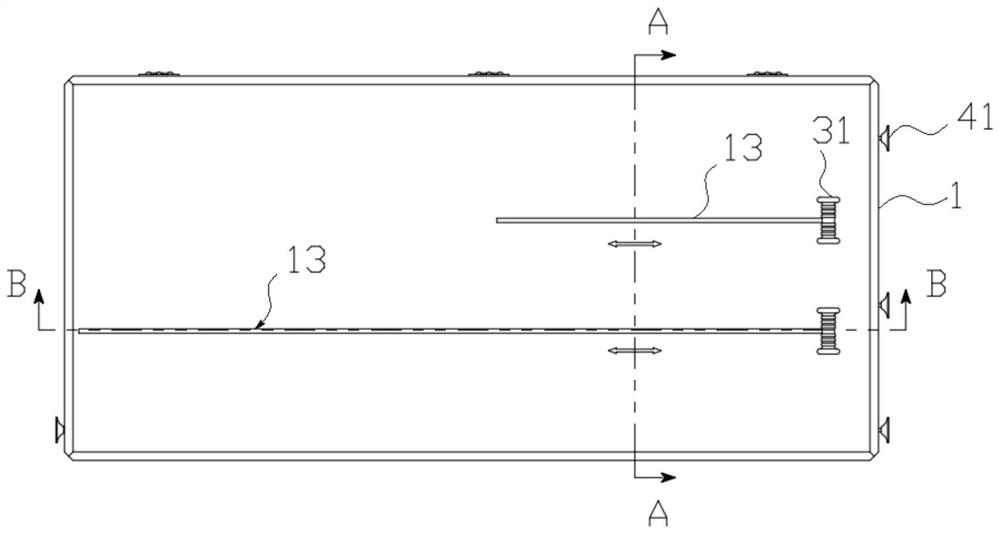

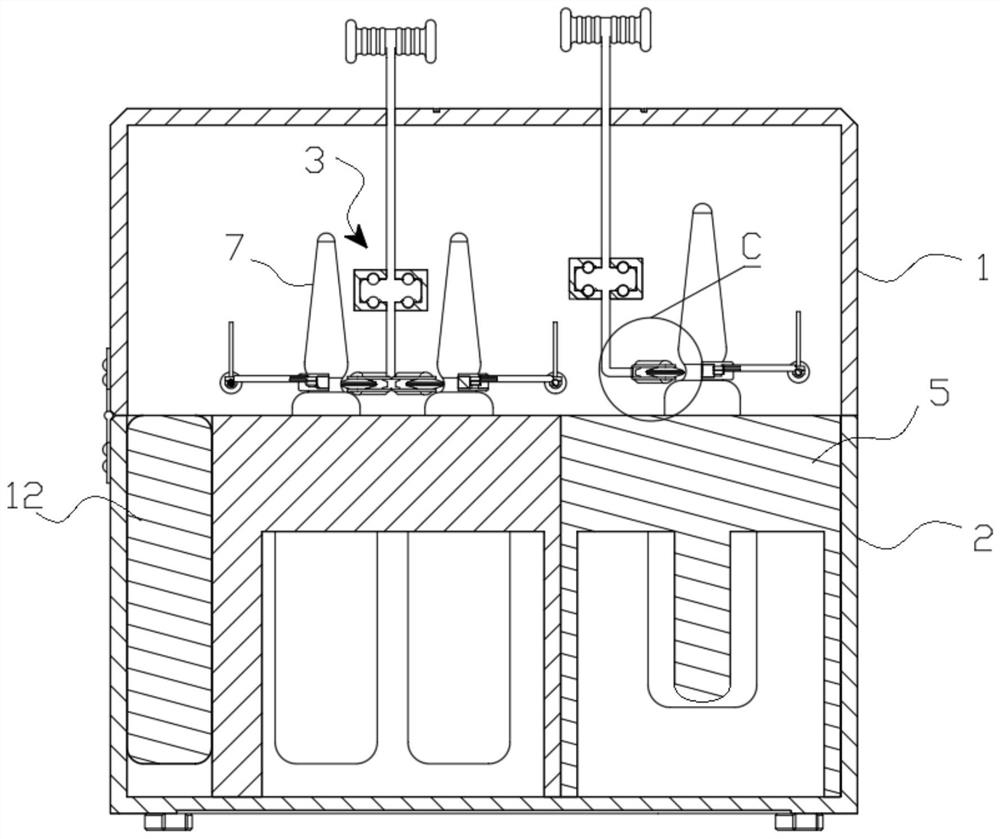

Ampoule bottle opener

ActiveCN111977590ASolve pollutionEasy to operateBottle/container closurePower operated devicesBottle neckControl circuit

The invention discloses an ampoule bottle opener. The ampoule bottle opener comprises an upper box body and a lower box body which can be opened and closed through hinging, wherein a supporting platform is arranged in the lower box body; accommodating holes with various dimensions and used for placing ampoule bottles are formed in the supporting platform; a tray capable of freely rotating, a control circuit board, a lithium battery electrically connected with the control circuit board and a power supply port used for charging are arranged on the bottom of any accommodating hole; a cutting mechanism for forming physical scratches on bottle necks of the ampoule bottles and a heating mechanism are arranged in the upper box body; and the heating mechanism is powered and heated through the control circuit board. According to the ampoule bottle opener disclosed by the invention, tensile stress is formed on a specified position of each ampoule bottle through cutting, heating and cooling, so that the ampoule bottles can be broken by applying relatively small shearing stress by hands, and broken sections are flat, uniform and smooth; and the problems that medicament and liquid medicine arewasted as the whole ampoule bottles are broken, and potential safety hazards are caused to medical staff are fundamentally solved.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Amorphous refractory and corrosion resistant material for inert anode aluminum cells and manufacturing method thereof

The invention relates to an amorphous refractory and corrosion resistant material for inert anode aluminum cells and a manufacturing method thereof. The preparation of the material is characterized by employing sintered tabular corundum particles as the aggregate, powder selected from several of sintered tabular corundum fine powder, magnesia-alumina spinel fine powder, multi-peak sintered alumina micropowder with different particle size distributions, activated alumina micropowder, activated Rho-Al2O3 micropowder, dispersion alumina micropowder and pure calcium aluminate cement as the substrate, fiber as the reinforcing and toughening agent for mixing. Able to well resist electrolyte atmosphere corrosion, the amorphous refractory and corrosion resistant material of the invention has the advantages of high hot strength, good thermal shock resistance, easy implementation, long service period, relative low cost, etc. The material provided in the invention is suitable for heat preservation and sealing of industrial inert anode aluminum cells, especially the upper parts of cells, and can be used to directly face a fused electrolyte liquid surface and areas with invaded by an electrolyte atmosphere.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

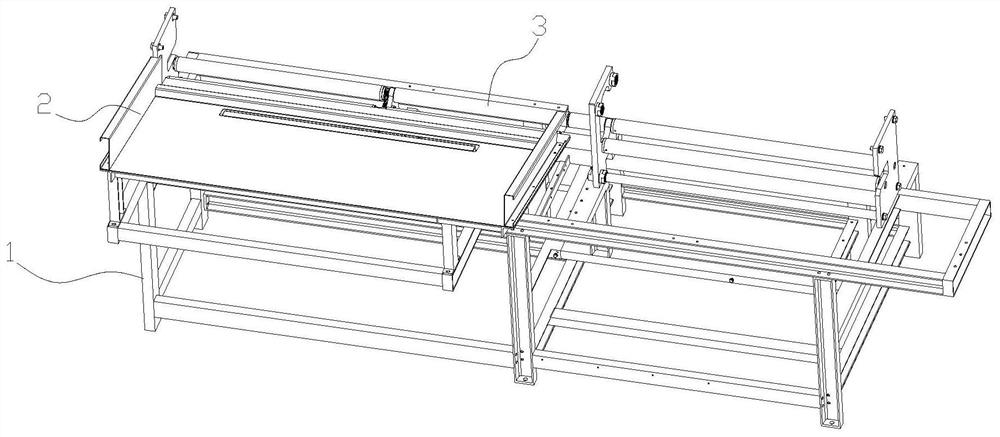

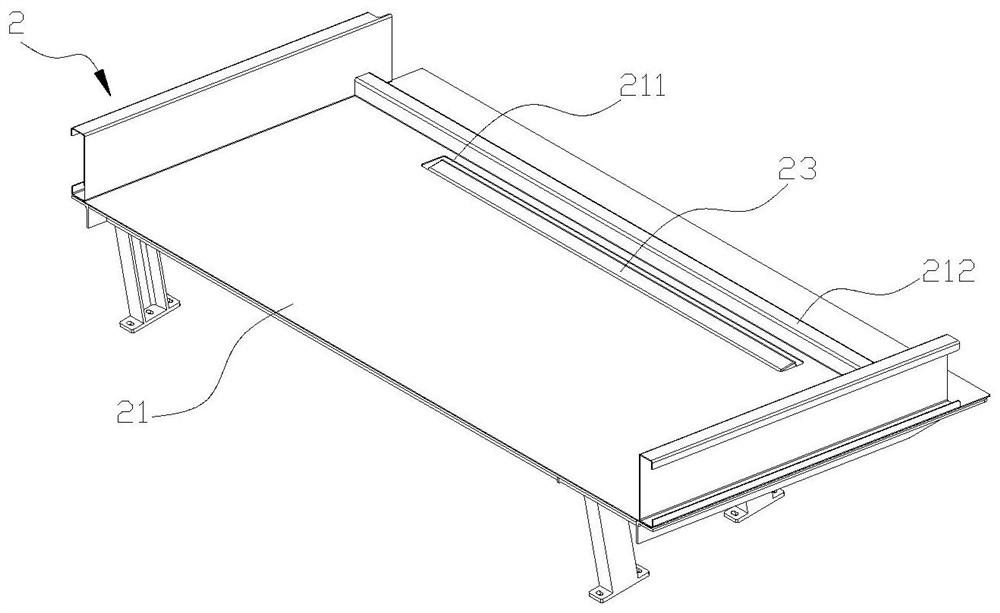

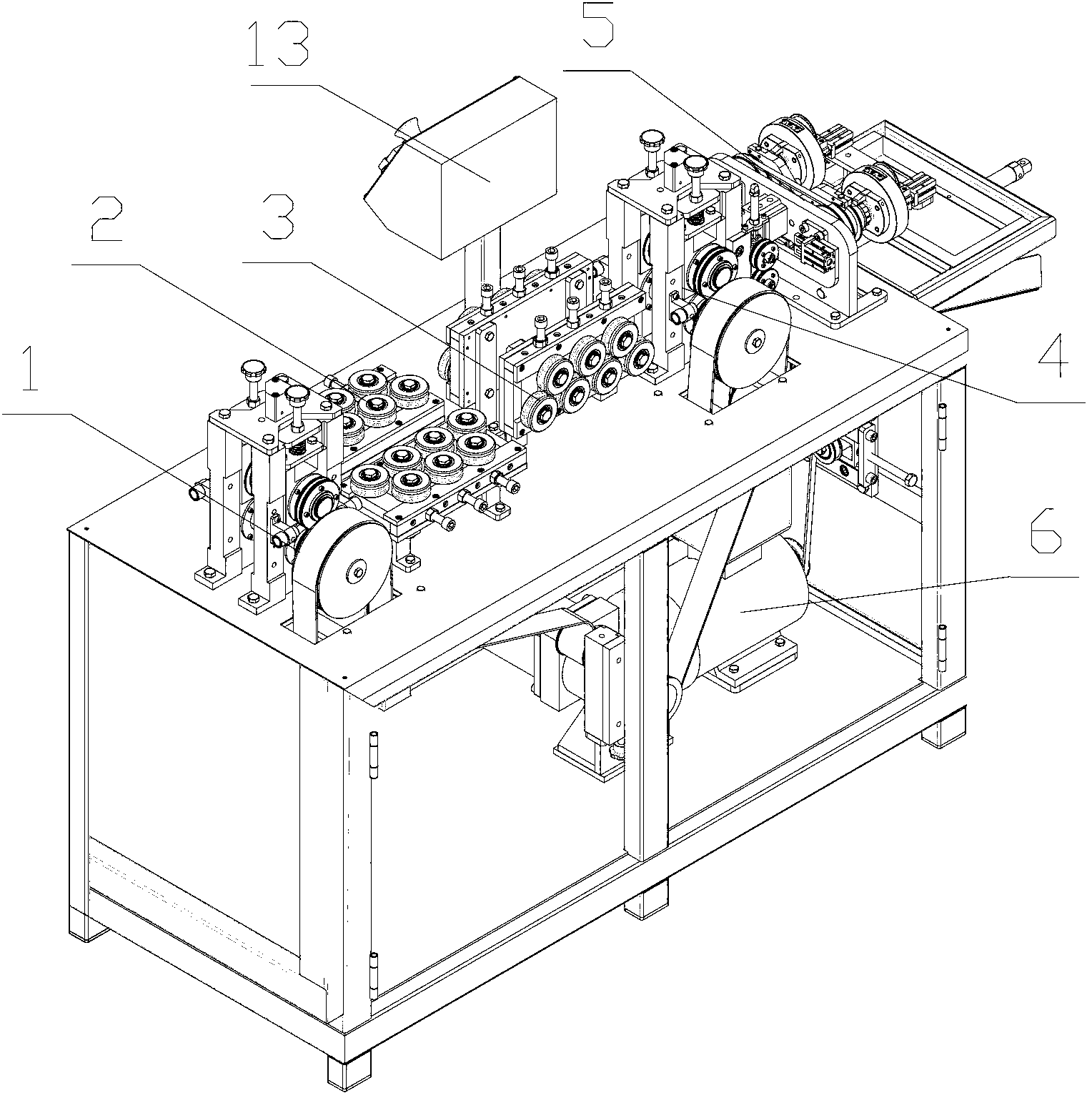

Insulation paper forming machine

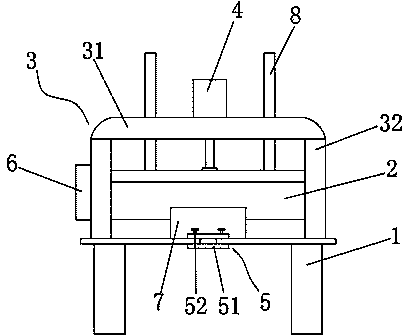

The invention relates to the technical field of power capacitors and provides an insulation paper forming machine high in production efficiency and capable of effectively guaranteeing product qualityin order to overcome the defects that when workers conduct indentation, angle cutting and cutting on insulation paper at present, obtained insulation paper finished products of various specificationsare poor in size accuracy consistency and low in production efficiency. The insulation paper forming machine comprises a machine frame, a material shaft, an indentation mechanism, a conveying device,an angle cutting mechanism and a cutting-off mechanism, wherein the material shaft, the indentation mechanism, the conveying device, the angle cutting mechanism and the cutting-off mechanism are fixedly installed on the machine frame in sequence in the moving direction of insulation paper; the material shaft is used for holding insulation paper rolls; the indentation mechanism is used for pressingfolding marks on insulation paper; the conveying device is used for providing power for forward moving of insulation paper; the angle cutting mechanism is used for cutting angles of insulation paperaccording to actually needed shapes of edges of insulation paper; and the cutting-off mechanism is used for cutting off continuous insulation paper obtained after indentation and angle cutting.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

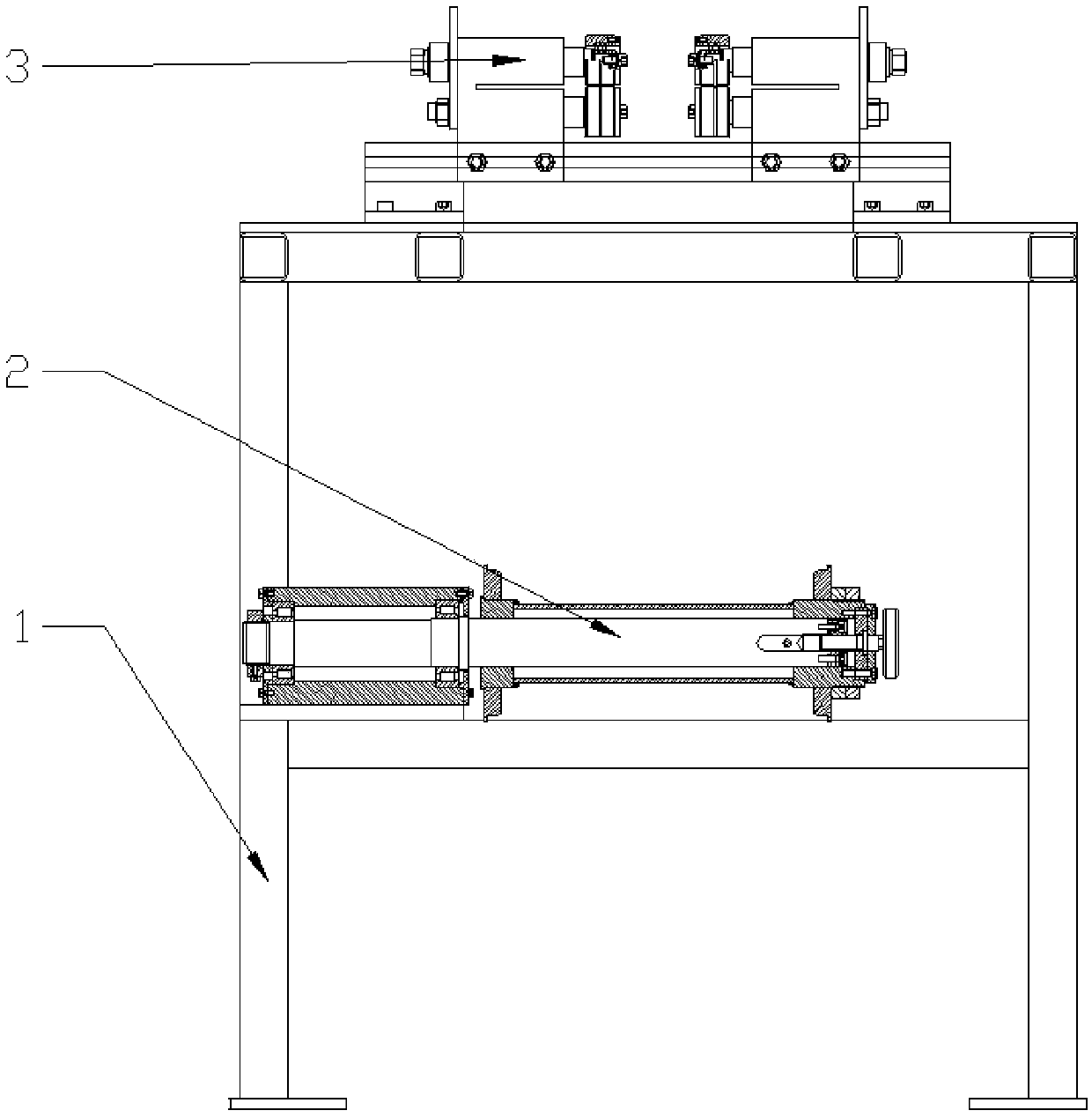

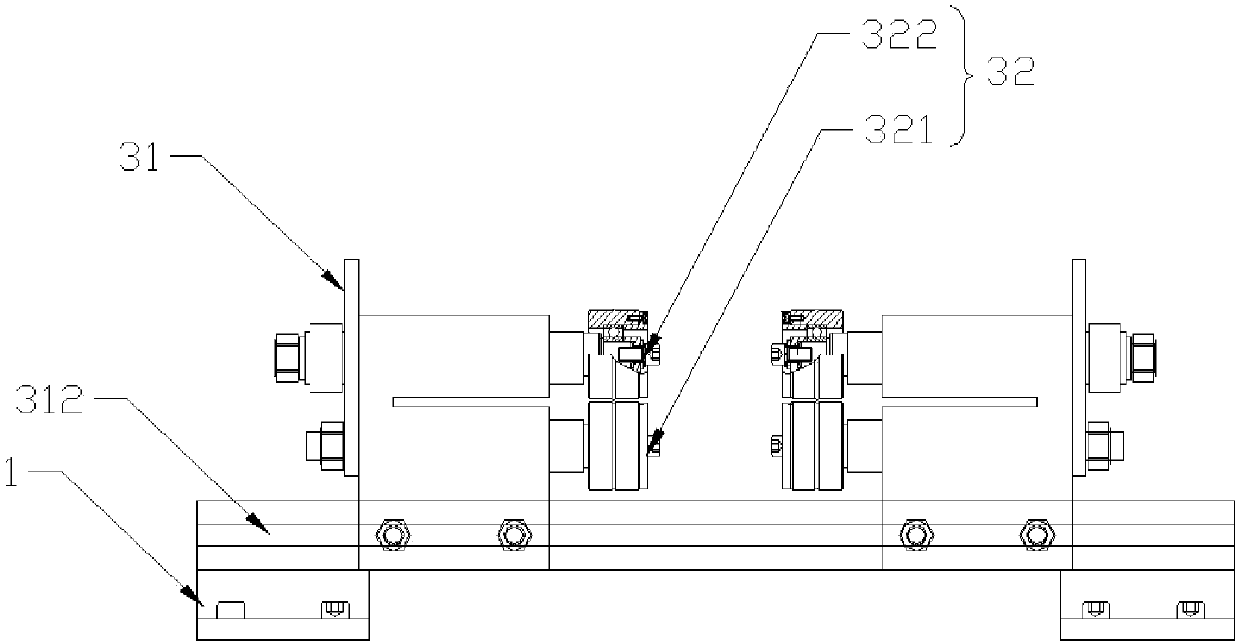

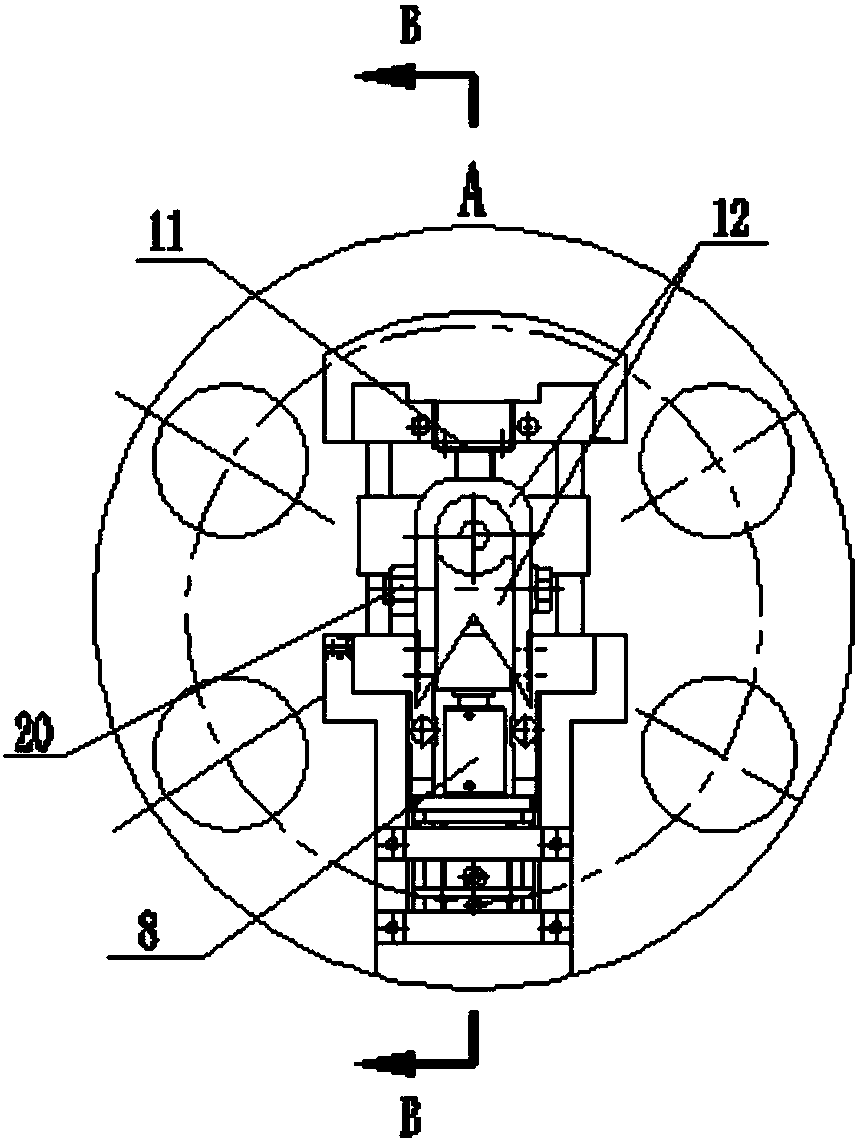

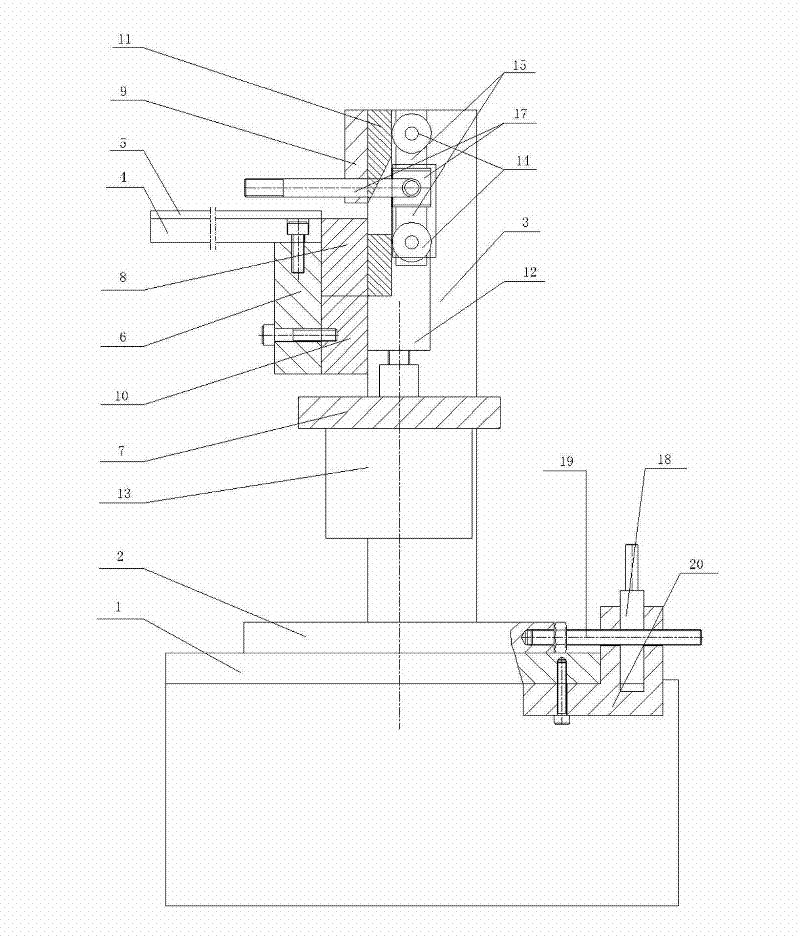

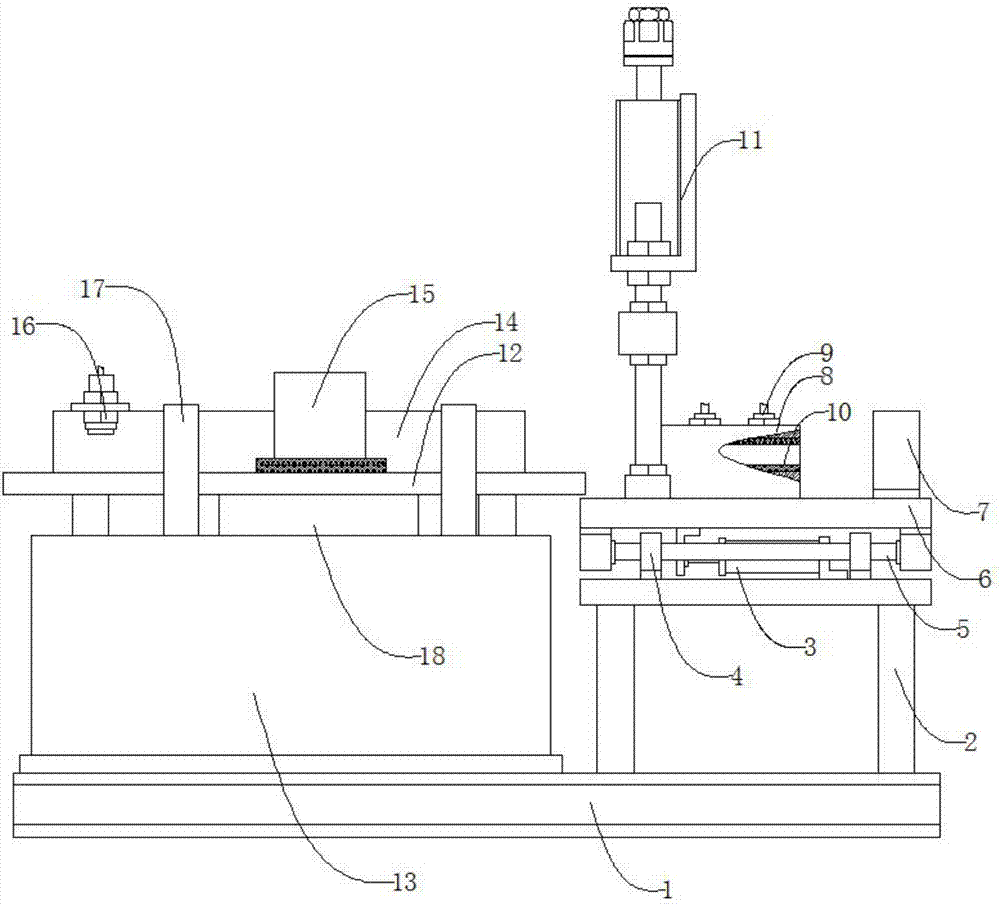

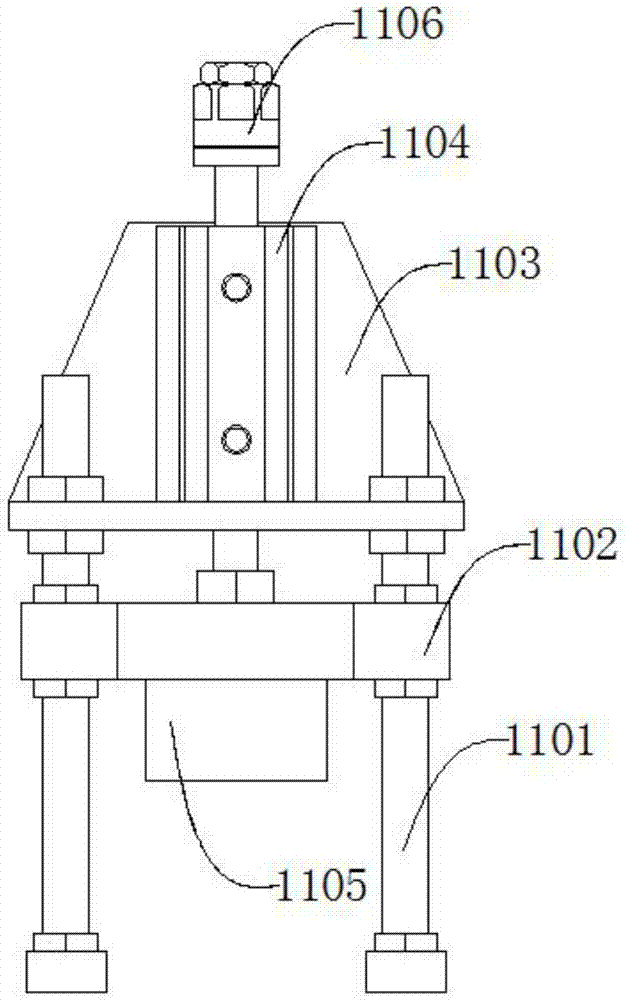

Fatigue break feeding machine for fixed workpiece fatigue load circumferential cyclic loading

ActiveCN108043946ASimple structureImprove efficiencyMetal-working feeding devicesPositioning devicesMotor driveFatigue loading

The invention discloses a fatigue break feeding machine for fixed workpiece fatigue load circumferential cyclic loading. A loading frequency regulating and controlling mechanism comprises a main shaftand a rotating chuck connected with the main shaft; a fatigue load loading mechanism comprises a first servo motor and a lead screw which are arranged on the rotating chuck, the first servo motor drives the lead screw to rotate, a nut is vertically installed on the lead screw, and a feeding die is movably installed on the nut; a workpiece clamping mechanism comprises a feeding opening and a discharging opening, the locations of the feeding opening and the discharging opening are separately provided with clamping assemblies, second servo motors of the clamping assemblies drive two-way lead screws to rotate, and each two-way lead screw is provided with two clamping pieces. A fatigue break principle is used, so that multiple fatigue crack sources are generated at the prefabricated stress gaps of rod and tube materials to enable the crack to quickly extend, and quick feeding of the rod and tube materials is achieved; and sections are kept smooth, end portions are free of deformation, wherein the fatigue load loading mechanism controls the displacement of the lead screws by the servo motors, and radial real-time adjustment of displacement amount is achieved.

Owner:XIAN UNIV OF TECH

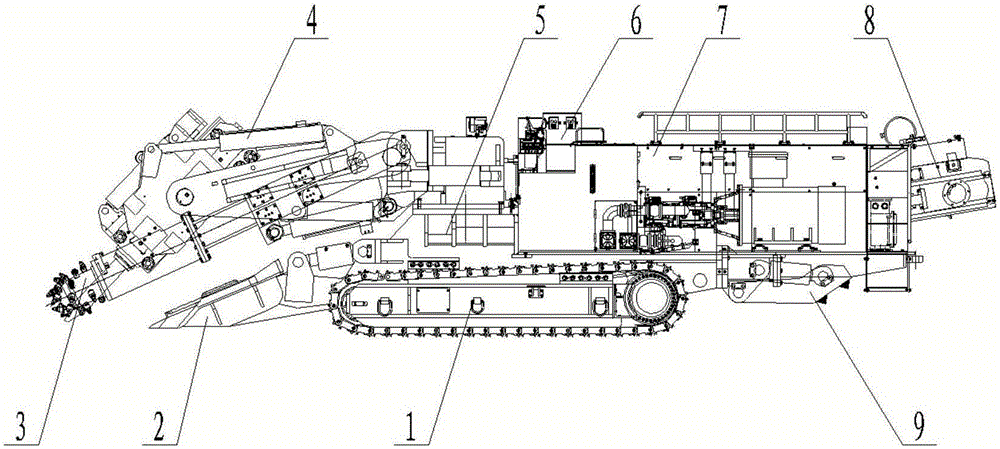

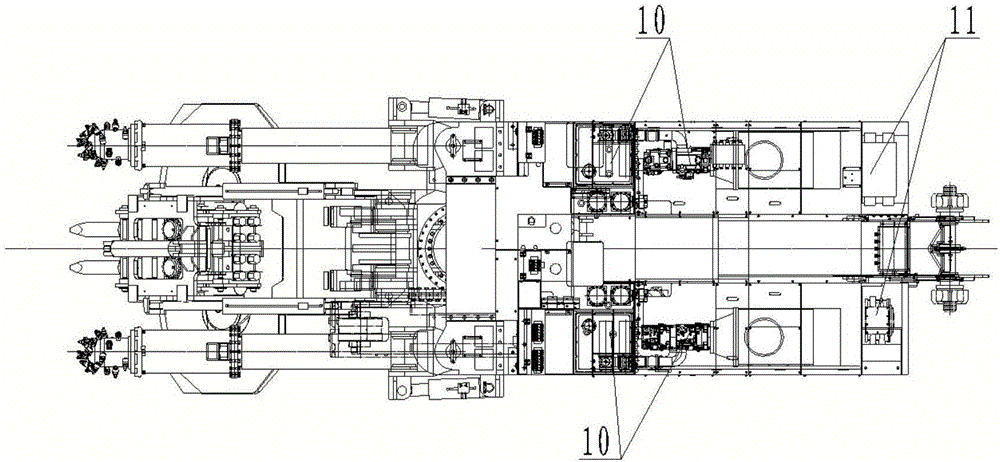

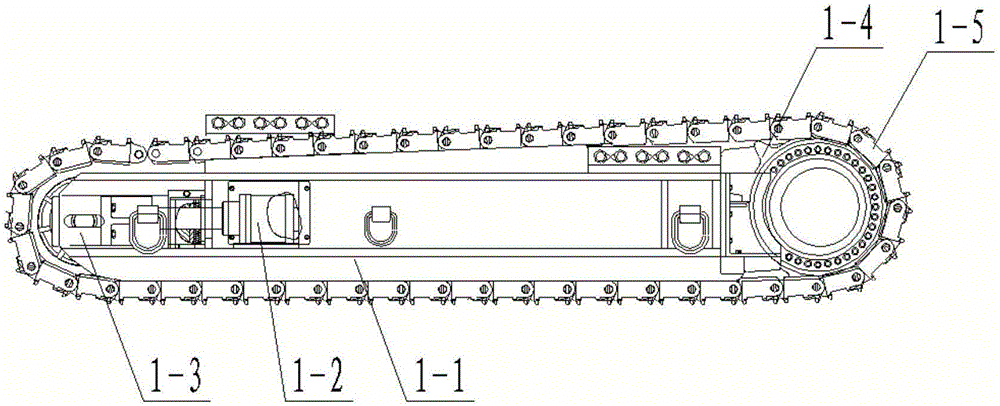

Efficient rapid rock drift tunneller

The invention belongs to the technical field of underground coal mine developing equipment, particular relates to an efficient rapid rock drift tunneller, and aims at solving the problems that rock drift tunnelling efficiency is low, rock drift forming is poor, the worker labor intensity is large, and many potential safety hazards exist. The efficient rapid rock drift tunneller comprises a walking part, an insertion board part, two cutting arms, a telescopic part, an engine body part, a control part, a guard board part, a conveying part, a rear support part, two hydraulic systems and electric systems; the walking part is arranged below the engine body part, the insertion board part is hinged to the front end of the engine body part, the telescopic part is arranged in the middle of the upper front portion of the engine body part, the cutting arms are symmetrically arranged on the left side and the right side of the upper front portion of the engine body, the conveying part is arranged in the middle of the engine body part, the rear support part is installed on the rear portion of the engine body, the hydraulic systems are symmetrically arranged on the left side and the right side of the middle of the engine body part, an operating part is installed above the engine body part, the guard board part is fixed on the two sides of the engine body part, and the electric systems are arranged on the two sides of the tail part of the engine body part.

Owner:SHANXI TIAN JU HEAVY IND

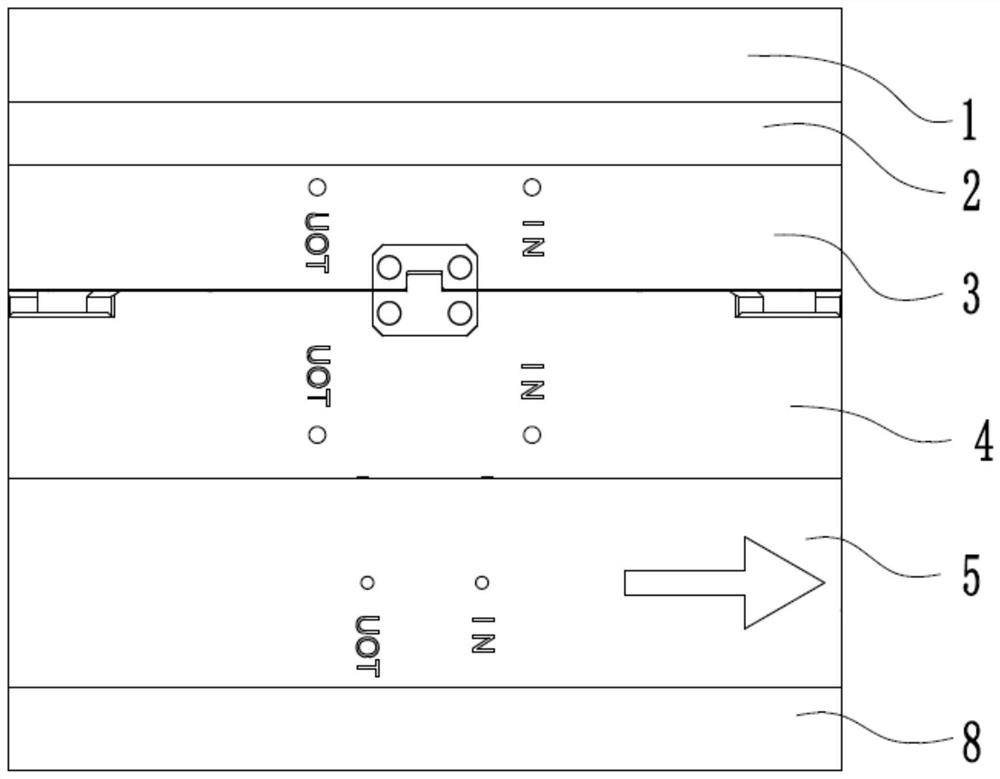

Assembled monolithic concrete frame structure system and frame shear structure system formed by assembled monolithic concrete frame structure system

The invention discloses an assembled monolithic concrete frame structure system and a frame shear structure system formed by the assembled monolithic concrete frame structure system. The assembled monolithic concrete frame structure system comprises precast columns, precast beams and precast floors, wherein the precast beams and the precast columns are connected to form a frame structure; the precast floors are arranged on the frame structure in an overlapping manner and are connected with the precast beams. The assembled monolithic concrete frame shear structure system comprises the assembled monolithic concrete frame structure system and precast sheer walls. According to the assembled monolithic concrete frame structure system and the frame shear structure system formed by the assembled monolithic concrete frame structure system, building materials can be saved, the structure self-weight is reduced, the construction speed is increased, the production efficiency is improved, the precast sheer wall bodies and seam construction are improved, the appearance and development of inclined cracks of the precast sheer wall bodies are reduced, and the anti-seismic working performance of the precast concrete frame structure system and the frame shear structure system formed by the precast concrete frame structure system is effectively enhanced.

Owner:ZHENGZHOU UNIV

Automatic slitting equipment for pipes

InactiveCN112077912AAvoid concentrated stressReduce chippingMetal working apparatusControl systemControl engineering

The invention discloses automatic slitting equipment for pipes, and relates to the technical field of pipe processing. The automatic slitting equipment comprises a control system and a rack and further comprises a feeding mechanism, a bearing roller mechanism, a clamping roller mechanism, a conveying mechanism, a cutting mechanism and a discharging mechanism which are arranged on the rack; the bearing roller mechanism is used for bearing and driving pipes to synchronously rotate; the bearing roller mechanism is sequentially provided with a feeding station and a cutting station in the length direction of the bearing roller mechanism; the feeding mechanism is used for conveying the pipes to the feeding station; the conveying mechanism is used for conveying the pipes from the feeding stationto the cutting station; the clamping roller mechanism is used for being matched with the bearing roller mechanism to jointly clamp the pipes; the cutting mechanism is used for cutting off the pipes; the discharging mechanism is used for moving the cut-off pipes out of the cutting station; and a control system is used for controlling operation of all the mechanisms. The pipes are synchronously rotated during tool feeding of a tool, so that the pipes are stressed uniformly, the edge breakage probability is greatly reduced, the rejection rate is decreased, the processing efficiency is improved, and the automation degree is high.

Owner:GUANGZHOU ZHI JIAN GENERAL EQUIP MFG CO LTD

Processing method of 'XianHu series' dried Dendrobium Candidum

The invention discloses a processing method of 'XianHu series' dried Dendrobium Candidum. The processing method comprises the following steps: collecting fresh branches of 'XianHu series' Dendrobium Candidum, removing impurities, spreading on a bamboo sieve, baking for 5-10min over a 130-135 DEG C brazier so that the fresh branches are softened; cutting with scissors so that the length of each stem segment is 6-8cm; twisting and curling the cut dendrobium officinale stem segments into Dendrobium Candidum spiral bodies with 4-6 threads; bundling the spiral bodies tightly with kraft paper, and baking for 18-30h over a 65-70 DEG C brazier, thus finishing preliminary shaping; after preliminary shaping, releasing the Dendrobium Candidum spiral bodies; tightly bundling the Dendrobium Candidumspiral bodies with new kraft paper again, and baking for 18-30h over a 35-40 DEG C brazier, thus finishing secondary shaping; and finally polishing to obtain the 'XianHu series' dired Dendrobium Candidum. The processing method provided by the invention is simple to operate, easy to control, high in standardization and high in efficiency.

Owner:武义寿仙谷中药饮片有限公司

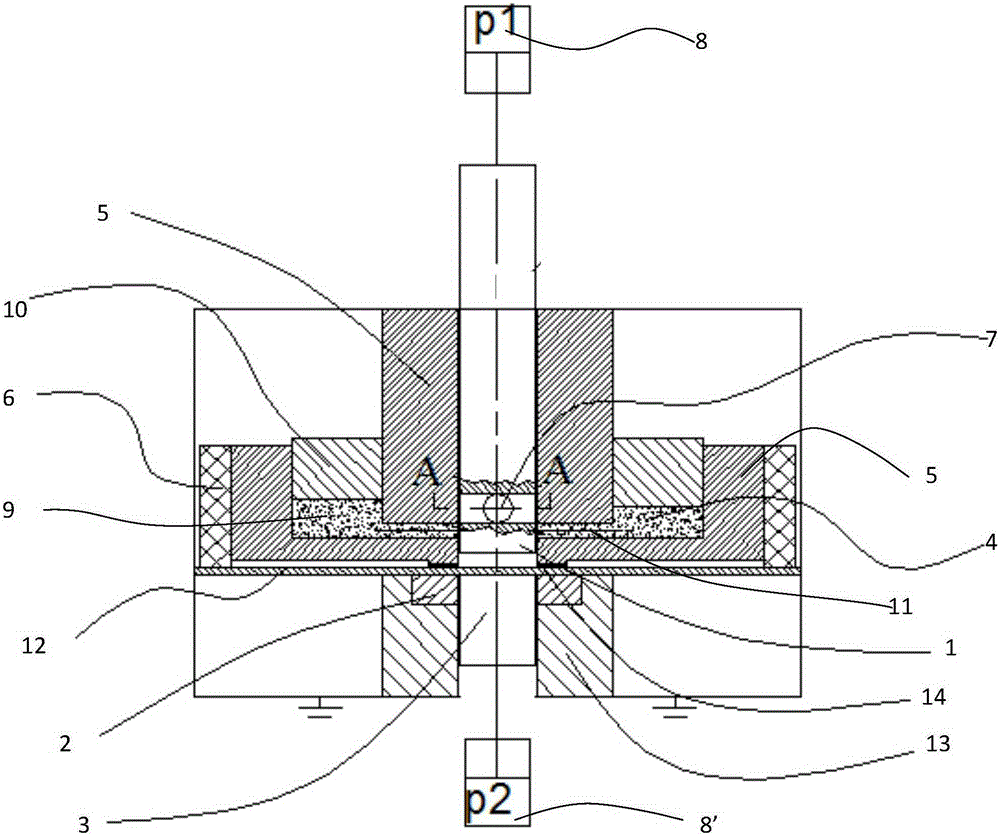

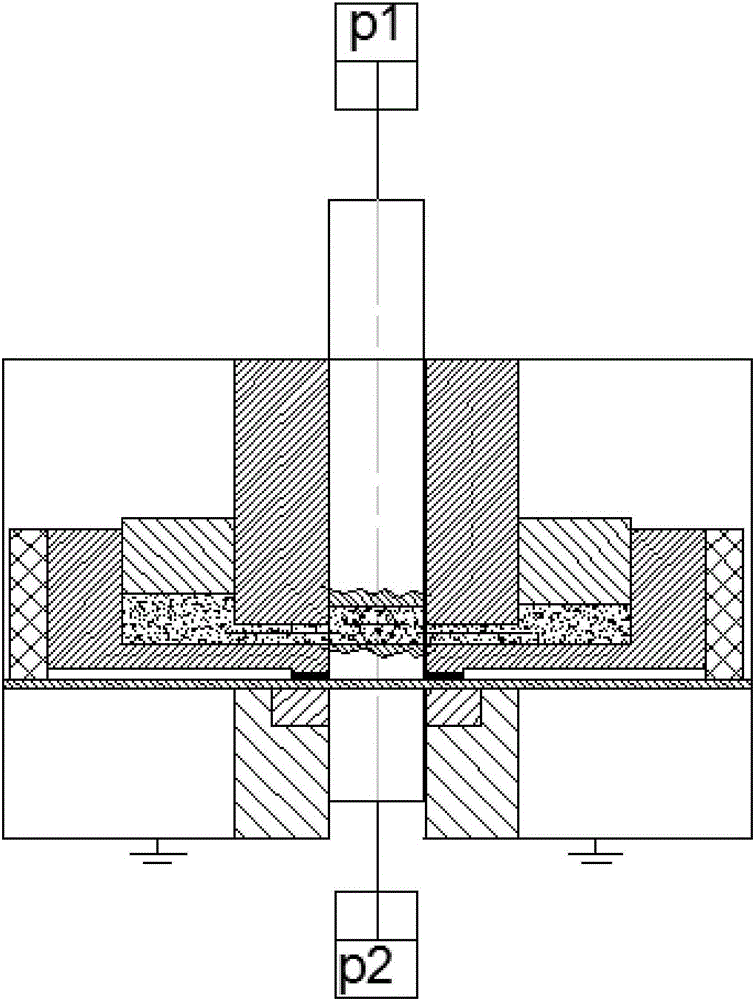

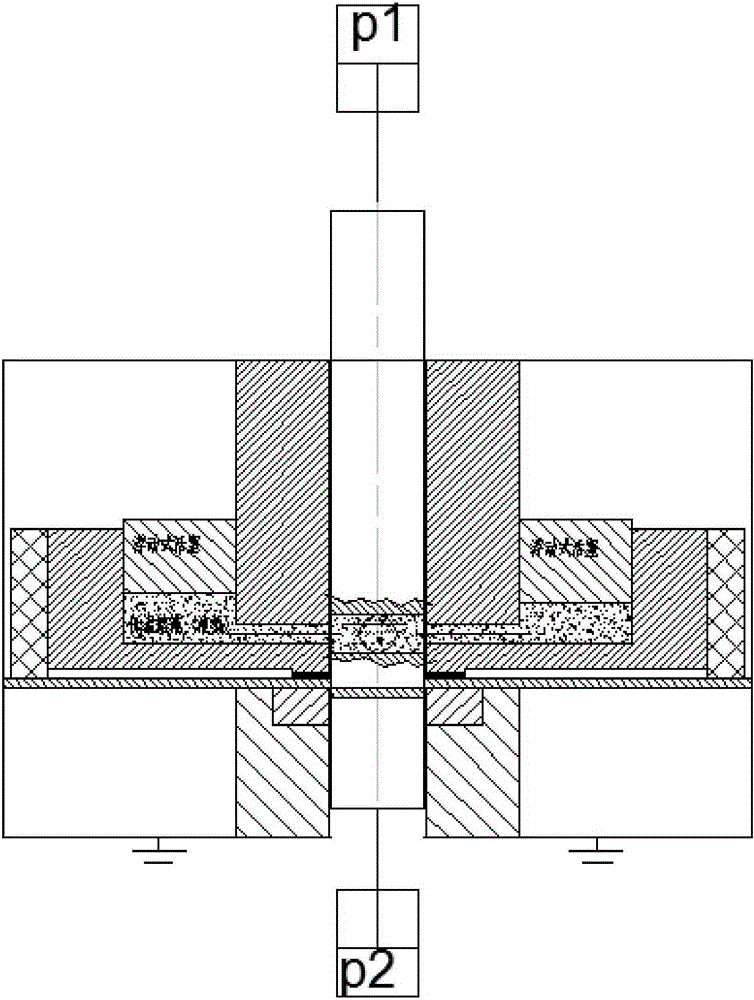

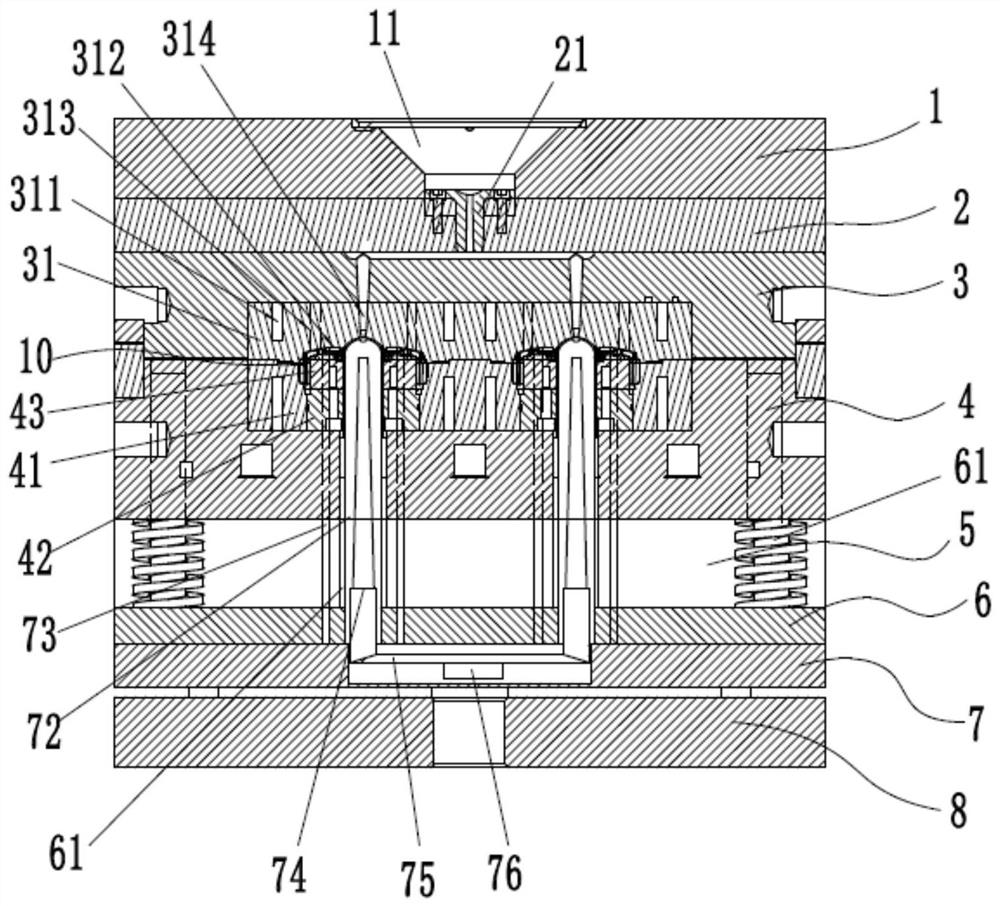

Cryogenic stamping, shearing and forming device with terrace die for micro workpieces and forming method using cryogenic stamping, shearing and forming device

InactiveCN105328003APrevent downward flowAchieve precision machiningShaping toolsHydraulic cylinderPiston

The invention relates to a cryogenic stamping, shearing and forming device with a terrace die for micro workpieces and a forming method using the cryogenic stamping, shearing and forming device, and belongs to the field of mechanical engineering. The cryogenic stamping, shearing and forming device comprises the terrace die, a hollowing block, an ejector rod, a low-temperature solution, a blank holder, a heat insulating material and a terrace die supporting base, wherein the side wall of the terrace die is locally provided with a through hole; a hydraulic cylinder drives the terrace die to move in the blank holder; the hollowing block is fixed in a hollowing block supporting base; the hydraulic cylinder drives the ejector rod to move in the hollowing block; a storage slot capable of accommodating the low-temperature solution is formed in the blank holder; the top of the storage slot is provided with a floating type piston; and the inner side wall of the blank holder is provided with a side wall hole capable of allowing the low-temperature solution to flow. The forming method based on the device comprises the five steps of clamping plates, cooling, stamping and shearing, drawing the plates out of the die and carrying out shape inspection. According to the cryogenic stamping, shearing and forming device with the terrace die for micro workpieces and the forming method using the cryogenic stamping, shearing and forming device, the advantages are that precision processing for micro workpieces is realized, deckle edges and burrs are reduced in a facilitated mode, section is flattened, section forming precision and forming precision for forming the workpieces are improved, and batched production is realized.

Owner:JILIN UNIV

Removal device for metal expansion bolt

The invention provides a removal device for a metal expansion bolt. The removal device for the metal expansion bolt comprises an operating handle. The lower surface of the operating handle is connected with a threaded ejection rod provided with external threads. The outer side of the middle portion of the threaded ejection rod is connected with an internal threaded sleeve in a threaded mode. Two removal mechanisms are symmetrically hinged to the two sides of the outer circumferential surface of the internal threaded sleeve correspondingly, wherein the outer side edge of the lower portion of the threaded ejection rod is wrapped with the middle portions of the removal mechanisms, the lower portions of the removal mechanisms can be inserted into the space between a bolt part and a sleeve part of the metal expansion bolt mounted in a fixing structure, and the removal mechanisms are used for removing the sleeve part from the fixing structure. The removal device for the metal expansion bolt is simple in structure and convenient to manufacture and use, the expansion bolt can be removed from a mounting position easily and completely, no residue is left, a fracture surface is flush with the structure, and subsequent construction is facilitated.

Owner:姜军鹏

Aromatic additive for citron natural tobaccos and preparation method thereof

InactiveCN101878953APromote secretionRelieve symptomsTobacco treatmentEssential-oils/perfumesSolventCITRUS MEDICA FRUIT

The invention relates to an aromatic additive for tobaccos, in particular to an aromatic additive for citron natural tobaccos and a preparation method thereof, and the spicy additive can increase the quality of aroma, soften the smoke and improve the residual smell and the throat comfort. 70 to 95 percent of alcohol solvent is used for respectively extracting citrons, rose hips and heterophylly falsestarwort root by reflux, extracts are respectively collected, and after being mixed, the three types of extracts are added into the mixed solvent of ethanol and propylene glycol, so that the aromatic additive is obtained. The aromatic additive, the natural aromatic plants of which are reasonably prepared, extracted, concentrated and then added into sampled cut tobacco, can remarkably increase the quality of aroma, soften the smoke and improve the residual smell and the throat comfort, and can promote the salivary secretion of the cavity to alleviate the ailment of the throat and achieve the effect of reducing the harm of smoking.

Owner:HUBEI CHINA TOBACCO IND +1

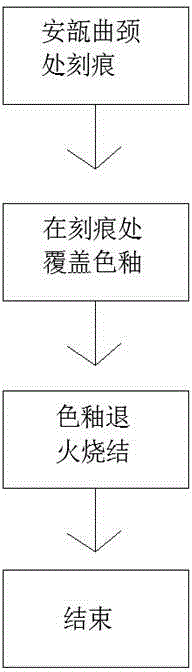

Method for machining crooked neck nicking color ring easy-to-break ampoule

The invention discloses a method for machining a crooked neck nicking color ring easy-to-break ampoule. The method specifically includes that (1) annular nicking is performed at a position of crooked neck of the ampoule, and the nicking length is at least 30% of perimeter of the crooked neck of the ampoule; (2) colored glaze covers a nicking position; (3) the colored glaze is subjected to annealing and sintering. According to the method for machining the crooked neck nicking color ring easy-to-break ampoule, traditional point nicking of the crooked neck ampoule is changed to continuous nicking, controlling is convenient and accurate, the process is quite simple, meanwhile, the colored glaze covers long nicking position for connection into a whole during breaking, then the problem that chips of glass are generated due to long nicking and together breaking during breaking is solved, a breaking surface is quite smooth, usage is quite safe, the colored glaze does not have breaking stress function, factors that are hard to control and directly affect breaking force, such as coefficient of linear thermal expansion and temperature of the colored glaze, are not required to be considered as long as the appearance is bright and attractive, the process is quite simple, meanwhile, dirt accumulation and residuals of chips of glass in cuts of the nicking position can be perfectly avoided, and the method is quite sanitary and safe.

Owner:重庆长古科技有限公司

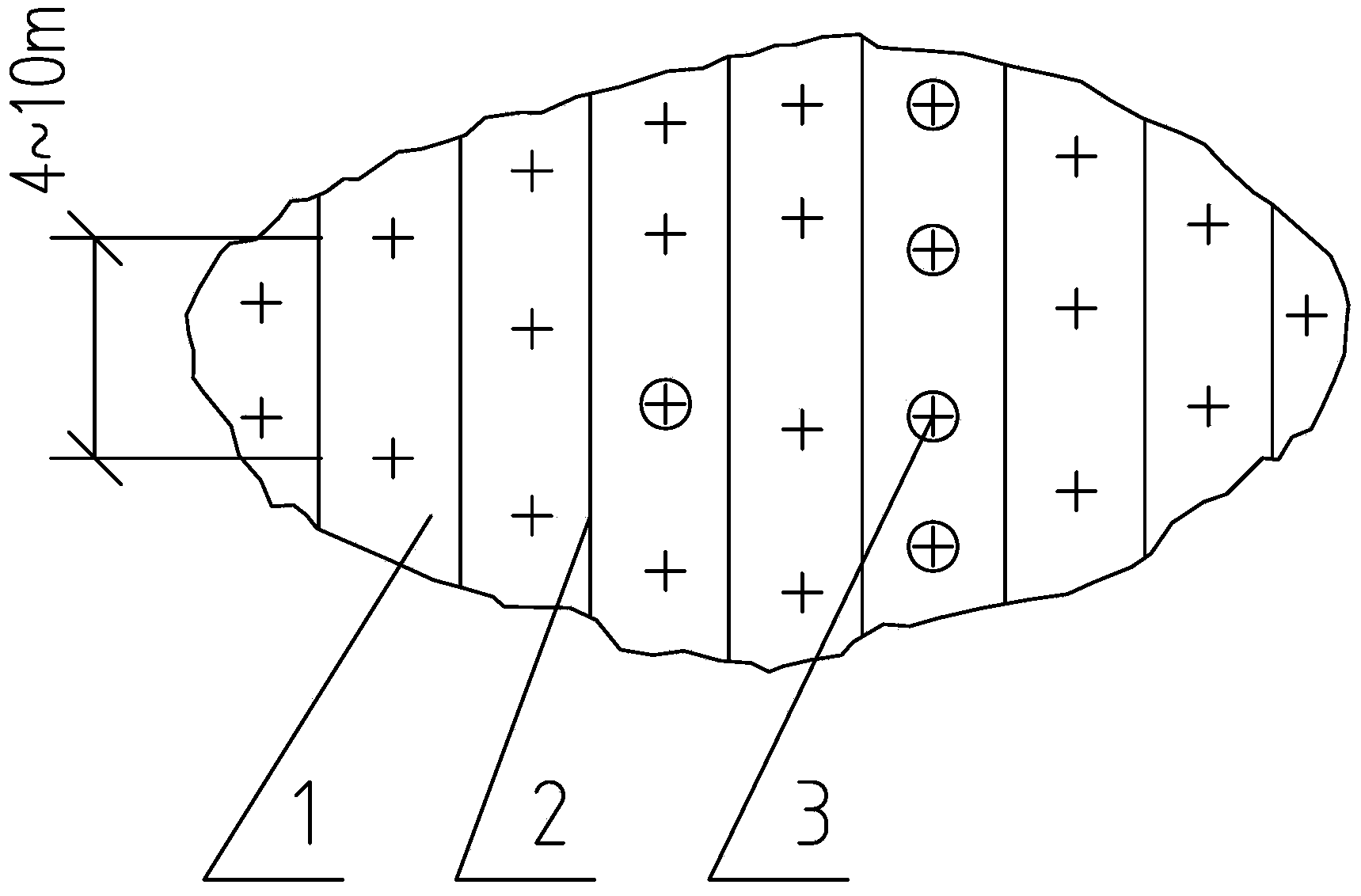

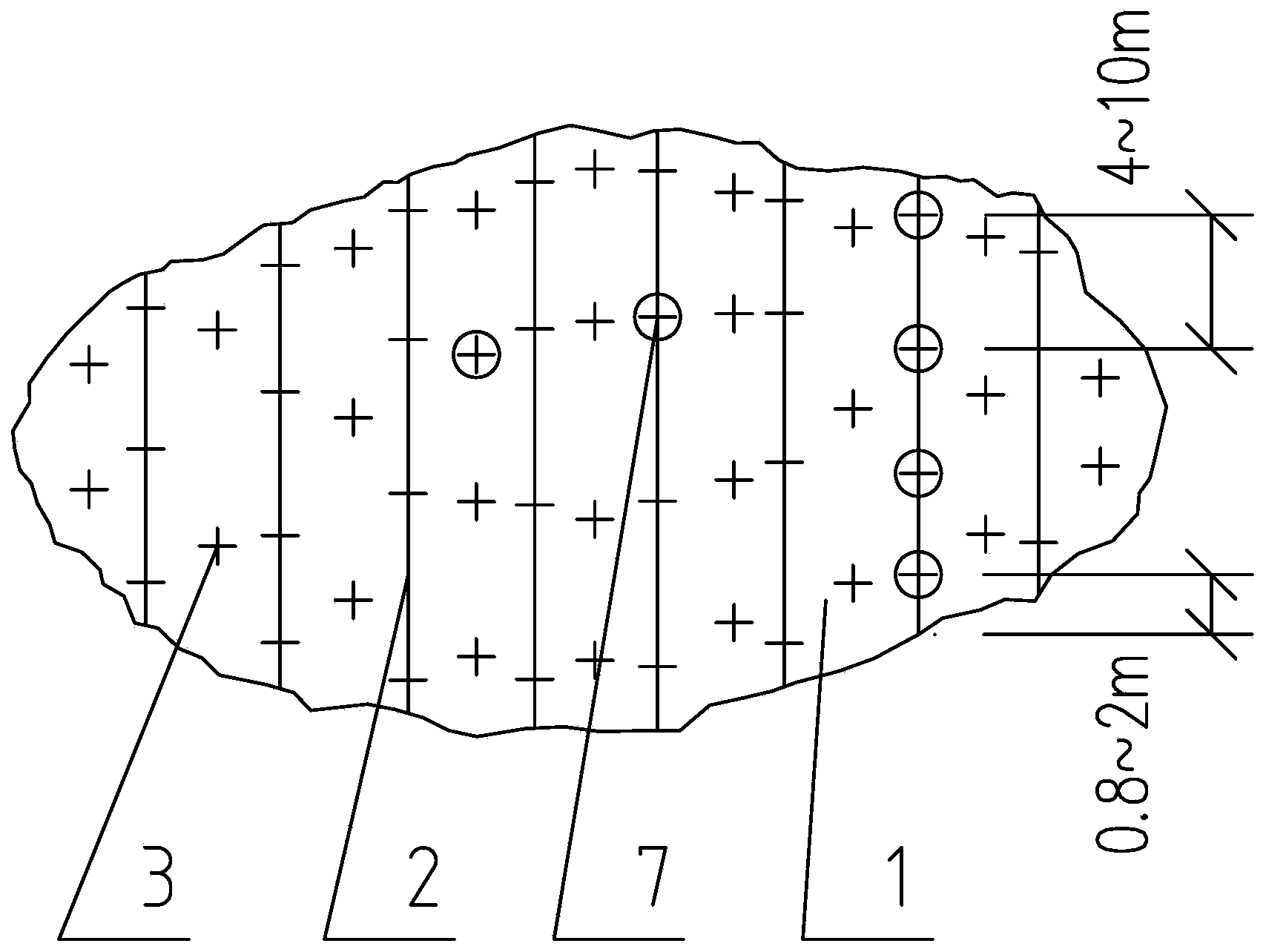

Method for cutting flat stone through long crack propagation

ActiveCN103817805ALow costFlat sectionStone-like material working toolsStress effectsE infrastructure

The invention discloses a method for cutting a flat stone through long crack propagation. The method includes the steps that according to the thickness requirement of the cut flat stone, through long crack grooves are cut in the preset vertical section of the surface of the flat stone, a series of alternating holes are drilled between the two crack grooves through a rock drill, pipes connected with a hydraulic system for outputting alternating pressure are inserted into hole openings, and then the hole openings are sealed; the hydraulic system for outputting alternating pressure is started, the output pressure of the hydraulic system is gradually increased, water in the holes is continuously pressed into the gap between the flat stone and a rock mass, upward force alternates along with the output alternating pressure of the system, through the alternating tensile stress effect, the long crack grooves in the surface of the flat stone are cracked and propagated in the opening type propagation stress state, cracks are continuously propagated, and then the flat and through vertical section is formed. The method for cutting the flat stone into long stone strips with rectangular sections is low in cost, has a great cost advantage in stone machining and can be applied to infrastructure engineering.

Owner:李衍远

PVC pipe cutting process

ActiveCN111958685AHigh precisionFlat sectionMetal working apparatusPipe fittingStructural engineering

The invention discloses a PVC pipe cutting process. The PVC pipe cutting process comprises the following steps: step 1, controlling a transposition assembly to send a cutting pipe to a feeding position opposite to a feeding assembly; step 2, placing one end of a whole pipe fitting into the feeding assembly, and feeding the pipe fitting into the cutting pipe by the feeding assembly; step 3, controlling a clamp assembly to fix the pipe fitting extending into the cutting pipe, and dragging the pipe fitting into the cutting pipe according to the required cutting length; step 4, controlling the distance between a plurality of spray heads in a high-pressure spray head assembly; step 5, supplying high-pressure water to the multiple spray heads through a high-pressure hose, controlling the pipe fitting to rotate, and finishing multi-section cutting of the pipe fitting; step 6, controlling the feeding assembly to reversely rotate to withdraw the remaining pipe fitting from the cutting pipe, controlling the transposition assembly to convey the cutting pipe to a discharging position, and controlling the clamp assembly to push the cut pipe fitting out of the cutting pipe; and step 7, repeatingthe steps from step 1 to step 6 until the pipe fitting is cut. The PVC pipe cutting process can simultaneously cut multiple sections of PVC pipes each time.

Owner:湖北晨升汽车零部件科技有限公司

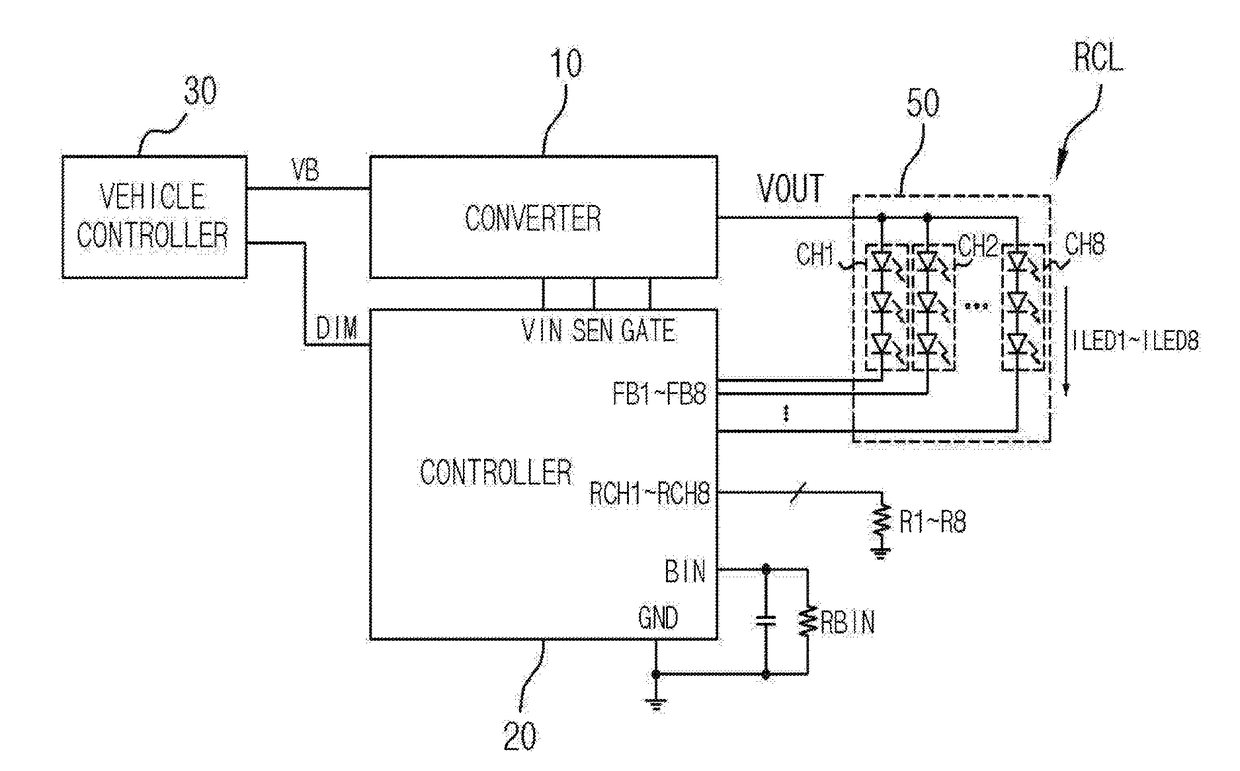

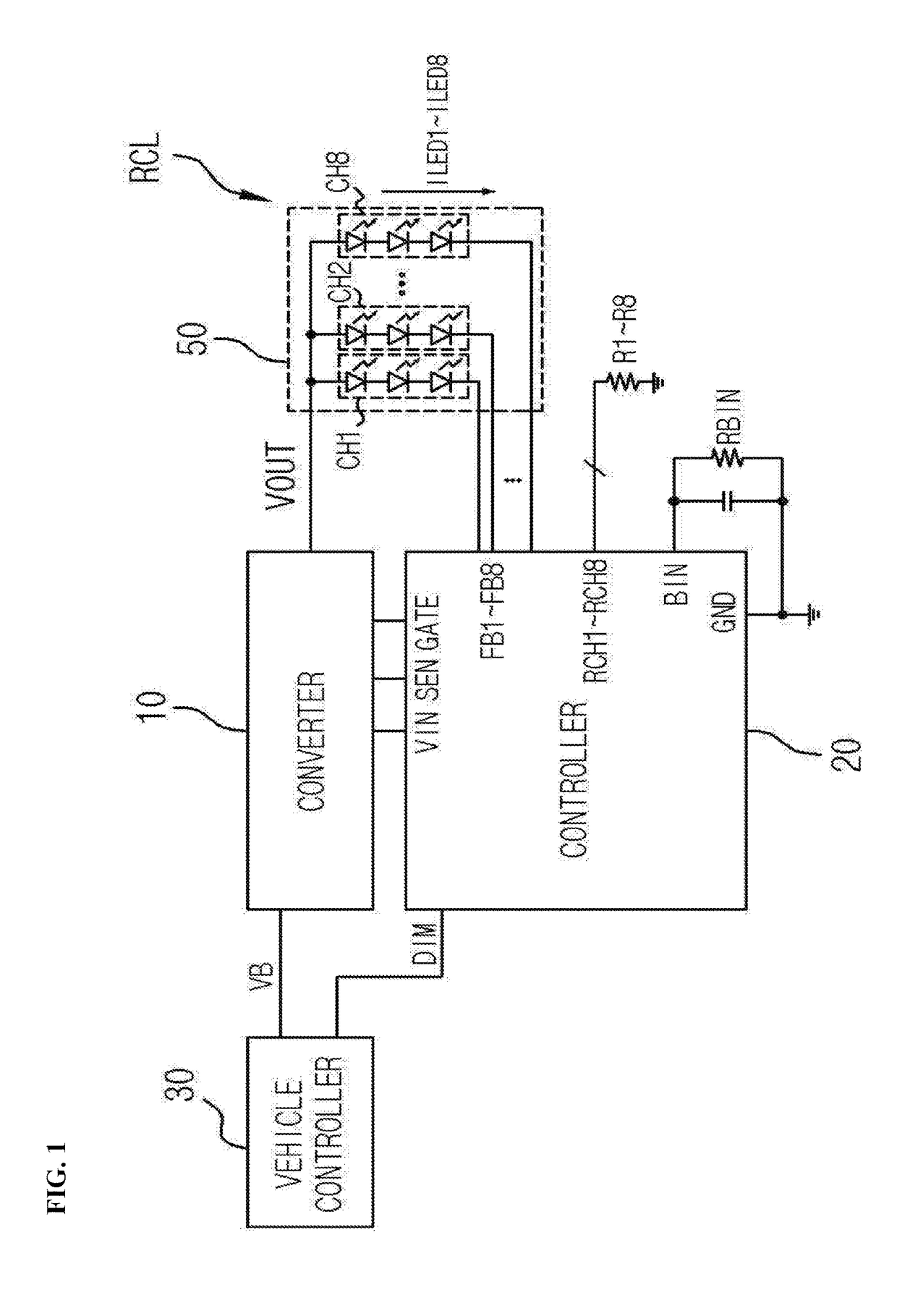

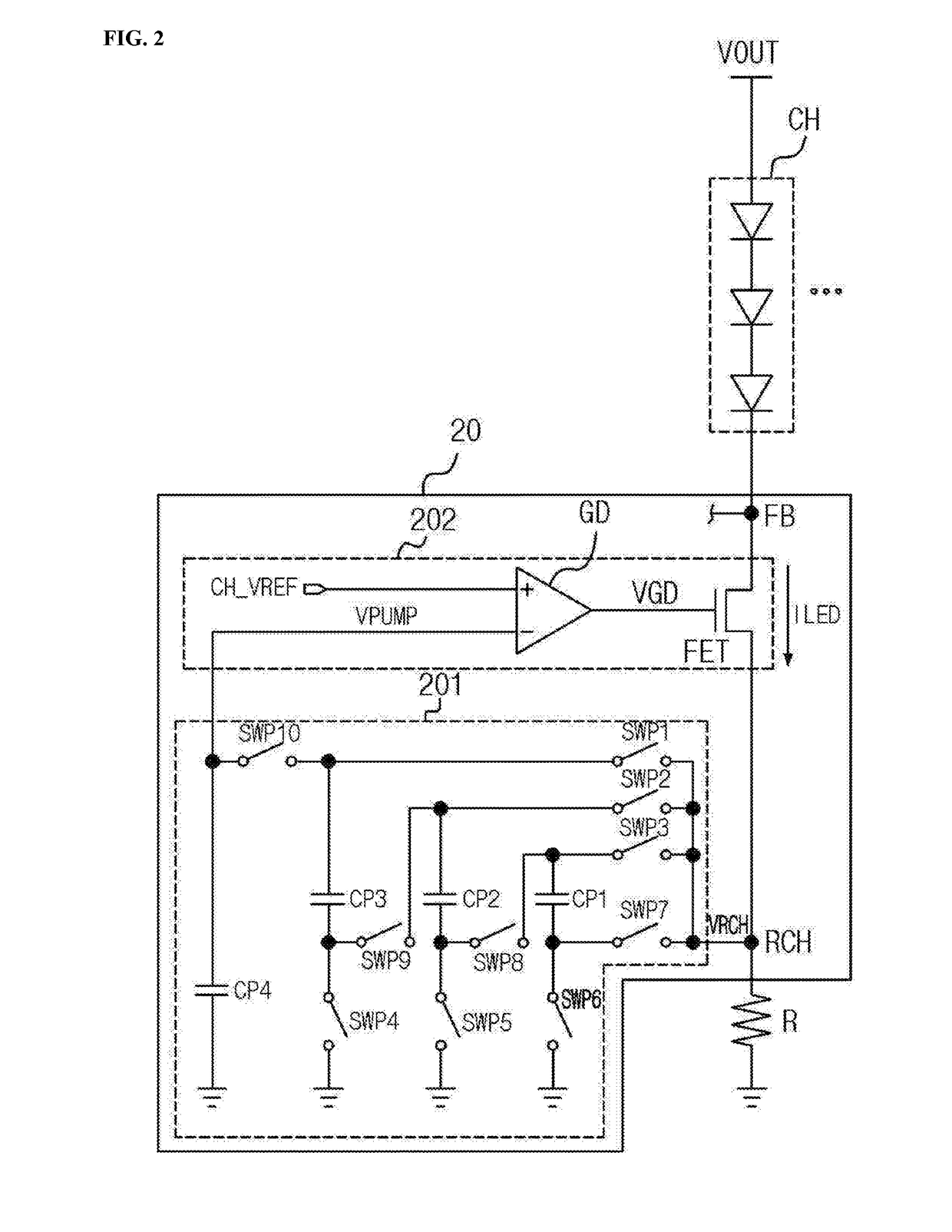

Lamp control device

ActiveUS20170374712A1Reduce power lossSmall sizeElectrical apparatusElectric circuit arrangementsElectrical currentResistor

Disclosed is a lamp control device. The lamp control device may include: a lamp having an LED channel; a channel resistor corresponding to the LED channel; and a controller configured to boost a channel resistor voltage applied to the channel resistor, and retain a channel current of the LED channel as a target current, using the boosted channel resistor voltage.

Owner:SILICON WORKS CO LTD

Novel daub for graphite bonding

The invention discloses a novel daub for graphite bonding, and belongs to the field of graphite equipment bonding materials. The daub comprises the following components, by mass, 60-80% of water glass, 10-20% of a curing agent, and 10-20% of graphite powder. According to the daub for graphite bonding in the present invention, volatile components are less, and the water glass has low viscosity so as to gradually eliminate produced volatile component bubbles, such that no bubble exists inside the daub after curing, and the cured section is smooth; and the daub can resist a temperature of 400 DEG C while a heat temperature requires only 130 DEG C.

Owner:NANTONG SANXIN CARBON GRAPHITE EQUIP

Lacerable non-woven fabric adhesive elastic bandage

The invention relates to a lacerable non-woven fabric adhesive elastic bandage. The bandage is made of an elastic lacerable non-woven fabric and an adhesive, wherein the elastic lacerable non-woven fabric is selected from elastic chemical fiber lacerable non-woven fabrics; and the adhesive comprises the following components in part by weight: 1-100 parts of sanitary synthetic adhesive, 0-100 parts of sanitary hot -melt pressure sensitive adhesive, 0-100 parts of solvent oil, 0.01-3 parts of environment-friendly additive, 1-2 parts of coloring agent, 0.001-2 parts of anti-aging agent and 0-50 parts of filling agent. Because the cross lapping technology is adopted during the manufacturing process of the used non-woven fabric, the non-woven fabric is lacerable. After the non-woven fabric is made into the bandage, the bandage can be easily lacerated crosswise, the fracture surface is flat, and a great use convenience is brought for medical care personnel and related personnel.

Owner:SHANDONG CHAORUISHI BIOMAGNETISM ENG TECH RES CENT

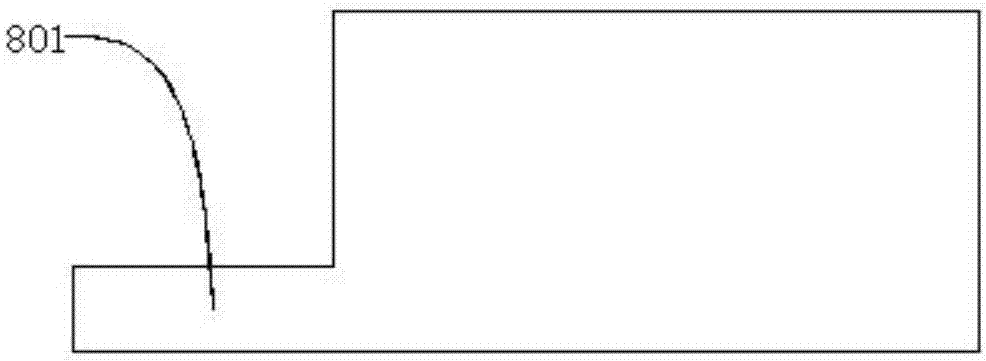

Automatic disconnection device of a fin

ActiveCN102398071AFlat sectionImprove work efficiencyNibbling shearing machinesShearing machine accessoriesEngineeringStructural engineering

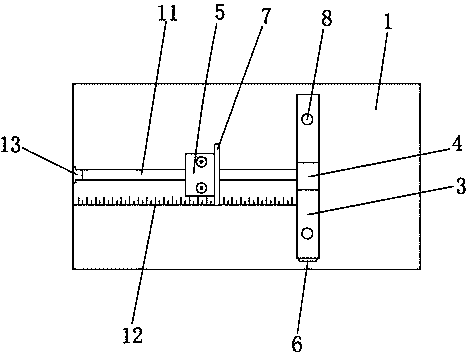

The invention discloses an automatic disconnection device of a fin, comprising a machine frame and a cutting pier (8) fixed on the machine frame. It also includes a cutter component slidably cooperating on the machine frame, the cutter component being connected with the driving mechanism, the vertical face of the cutting pier (8) being clearance fitting with the cutting edge of the cutter (11) in the cutting component. The automatic disconnection device of a fin has high production efficiency, smooth fin section, and uniform length of cut fin.

Owner:宁波路润冷却器制造有限公司

Paper cutting device

The invention discloses a paper cutting device which comprises a working table, a cutting cutter, a cutter rest, a cutting cutter driving device, a distance fixed sliding block and a control panel with a control button. A blade of the cutting cutter is vertically downward and is installed on the working table through the cutter rest, the cutting cutter driving device drives the cutting cutter to downwards move, a blade groove matched with the blade of the cutting cutter in size and a sliding groove of the distance fixed sliding block are formed in the top of the working table, a distance fixed plate is further arranged on the distance fixed sliding block, and a scale dent is further arranged on the lateral side of the sliding groove. The paper cutting device is easy and convenient to operate, a distance can be rapidly adjusted through the distance fixed sliding block, and the cutting cutter driving device then drives the cutting cutter to downwards move to rapidly cut paper; the fracture surface of the cut paper is flush, high in using rate and not prone to being torn and damaged; the blade groove in the top of the working table can well prevent direct contact between the blade of the cutting cutter and the top of the working table, and the service life is prolonged.

Owner:蔡利君

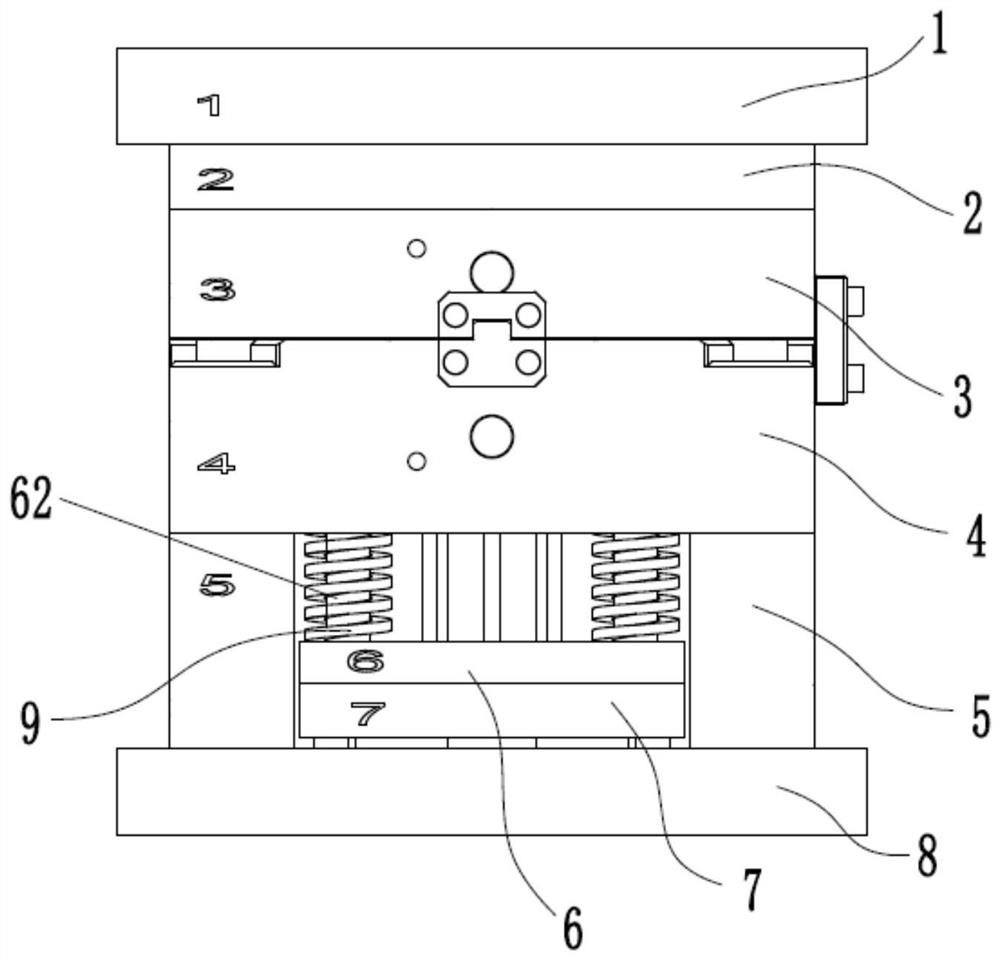

Injection molding device for inner gears with pouring gates cut in mold, and injection molding method

The invention provides an injection molding device for inner gears with pouring gates cut in a mold, and an injection molding method. The injection molding device comprises an upper jacking plate, a lower jacking plate, a first mold plate and a second mold plate, an upper mold cover is embedded in the first mold plate, a lower mold cover is embedded in the second mold plate, two lower mold cavities of the lower mold cover are both internally provided with upper central reverse mold gears, injection molding cavities are formed among the corresponding upper mold surface located on the upper moldcover, the upper central reverse mold gears and the inner walls of the lower mold cavities, the tops of two central rods arranged on the lower jacking plate penetrate through the upper jacking plateand the second mold plate to be attached to the semi-spherical concave surface of the upper mold surface, semi-spherical grooves located at the tops of the central rods communicate with the corresponding pouring gates, arc-shaped chutes distributed at the tops of the central rods enable the semi-spherical grooves to communicate with the injection molding cavities, two cutter sleeves of the upper jacking plate sleeve the corresponding central rods respectively, and annular cutting edges located at the tops of the cutter sleeves abut against the opened lower edges of the injection molding cavities. According to the injection molding device for the inner gears with the pouring gates cut in the mold, and the injection molding method, all pouring heads can be cut off at a time while multi-pointpouring is realized, and using is convenient.

Owner:九江华旭塑胶制品有限公司

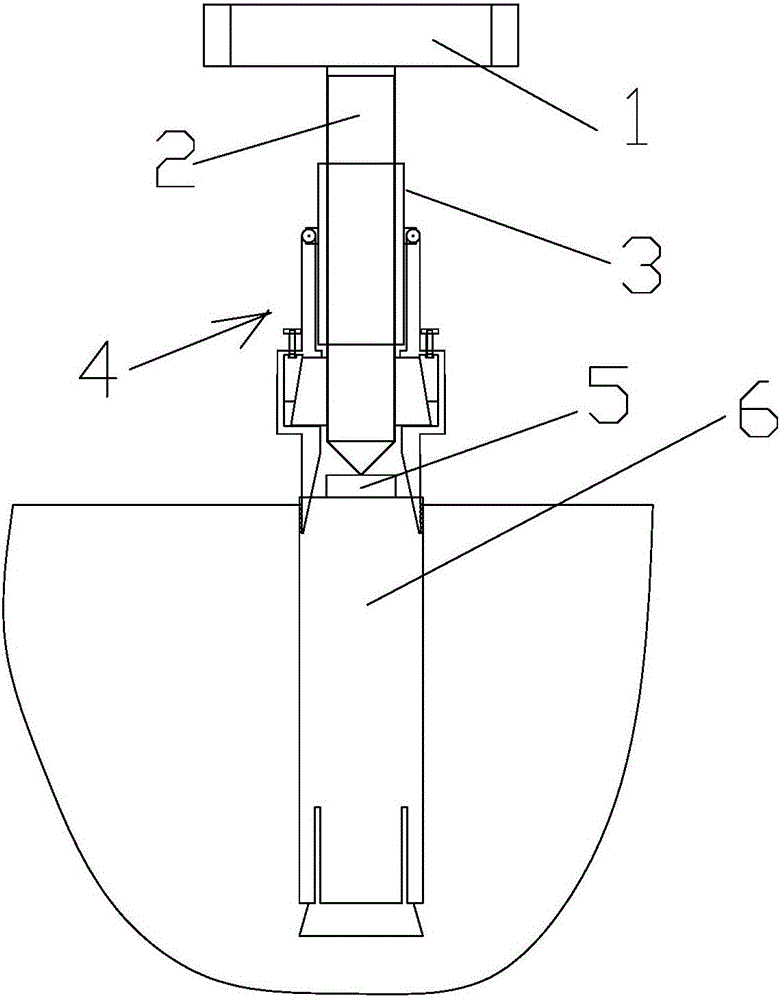

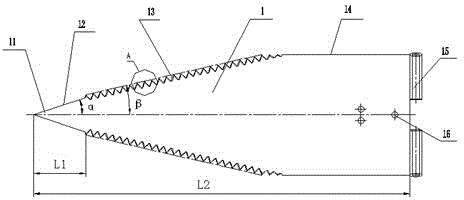

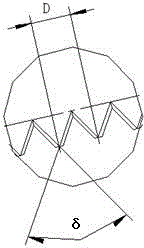

Digging head for handheld seedling digger

The invention discloses a digging head for a handheld seedling digger. The digging head comprises a digging head body. The digging head body comprises inner molded surfaces, outer molded surfaces and side end molded surfaces, the side ends of the inner molded surfaces and the side ends of the outer molded surfaces are connected with one another by the side end molded surfaces, and pedals are mounted at opposite ends of a working head of the digging head body; molded lines, which are close to the working head, of the side end molded surfaces are oblique straight lines, molded lines, which are close to the opposite ends of the working head, of the digging head body are flat molded lines, and the flat molded lines are connected with the oblique straight lines by sawtooth molded lines which are obliquely arranged; angles of teeth of the sawtooth molded lines range from 60 degrees to 70 degrees; the distances among the teeth range from 5mm to 15mm. The digging head for the handheld seedling digger has the advantages that when seedlings are about to be transplanted, the digging head can be inserted into the ground while roots which are adjacent to sawtooth portions of the digging head in the advancing direction of the digging head can be cut off, and accordingly requirements of ball transplanting methods for the large seedlings can be met.

Owner:SUZHOU LU LU SHUN ELECTRICAL EQUIP

Cutting and falling device for chip packing pipe

The invention discloses a cutting and falling device for a chip packing pipe. The cutting and falling device comprises a base, a right side working table, a sending-in air cylinder, a guiding seat, a guiding rod, a supporting plate, a limiting seat, an aluminum mould, a heating pipe, a copper sleeve, a cutting mechanism, a left side working table, a material box, an adjusting seat, a material pushing mechanism, a photoelectric sensor, a blocking strip and a material guiding plate, wherein the guiding seat, the guiding rod, the supporting plate, the limiting seat, the aluminum mould, the heating pipe, the copper sleeve, the cutting mechanism, the left side working table, the material box, the adjusting seat, the material pushing mechanism, the photoelectric sensor, the blocking strip and the material guiding plate are distributed symmetrically along the right side working table. The heating pipe works to heat chip packing pipes, so that stress is relieved; when the chip packing pipes trigger the photoelectric sensor, the cutting mechanism works to cut the chip packing pipes; because the chip packing pipes are sent to a machine continuously, the follow-up chip packing pipes are prevented from moving left by the cutting mechanism, so that deformation of the follow-up chip packing pipes is caused; the sending-in air cylinder pushes the supporting plate to move left, so that the cutting mechanism is driven to move left; and the sending-in air cylinder resets after the cutting mechanism resets, so that deformation of the follow-up chip packing pipes can be removed, opening cracking is prevented, then the material pushing mechanism pushes the cut chip packing pipes to falling into the material box, so that cutting and falling are completed.

Owner:池州华宇电子科技股份有限公司

Automobile sealing strip cutting device

ActiveCN103085100AFlat sectionKeep healthyCleaning using gasesMetal working apparatusWaste materialPhysical health

The invention discloses an automobile sealing strip cutting device which comprises a machine frame, a guide assembly, a locking device, an incising assembly and a guard cover. The guide assembly and the locking assembly are placed on the upper surface of the machine frame and arranged on a straight line, the incising assembly is arranged on the locking assembly, and the guard cover is covered on the exterior of the locking assembly. The length of an obtained material strip through incision can be guaranteed and conform to demands by applying of the locking assembly to lock the material strip and combination of a measuring assembly. At the same time, the material strip is automatically cut off by the incising assembly after the material strip is locked by the locking assembly, and the purposes that the cross section of the material strip is smooth and does not incline can be guaranteed. Waste materials and dust produced in the process of cutting the material strip are collected by a material receiving box and a cleaner respectively, so that the waste materials and the dust cannot scatter on the ground and pollute the air, and physical health of workers is guaranteed. The guard cover is placed on the incising assembly and the locking assembly, safety when the workers work is guaranteed. The automobile sealing strip cutting device belongs to the technical field of machinery.

Owner:建新赵氏科技股份有限公司

Lead delay element rotary cutter

ActiveCN102935527AFlat sectionFast revolutionShearing machinesShearing machine accessoriesScrapPersonal computer

The invention provides a lead delay element rotary cutter which comprises a rotary cutting assembly, a feeding detection mechanism, a horizontal and vertical straightening mechanism, a tensioning device, a linear (or disc type) wire inlet platform and an industrial personal computer which are all arranged on a worktable. A lead delay cord is driven by the feeding detection mechanism which is driven by a stepping motor and straightened by the straightening mechanism, passes a hollow lead delay cord fixing shaft of the rotary cutting assembly and then butts against the rotary cutting position, a high-accuracy coder detects required cutting length information and then sends instructions to rotary cutting blades, a rotary cutting cylinder arranged on the rotary cutting assembly pushes the rotary cutting blades to radially move towards the axis of the lead delay cord fixing shaft to cut off the lead delay cord, and rotary cutting is completed. The radially symmetrically arranged rotary cutting blades and rotary cutting riding wheels simultaneously apply force in the axis direction on the circumference of the lead delay cord, radial thrust in all directions is offset, the section of a cut lead delay element is level and does not deform, U-shaped section cannot be formed, and product scraps are few.

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

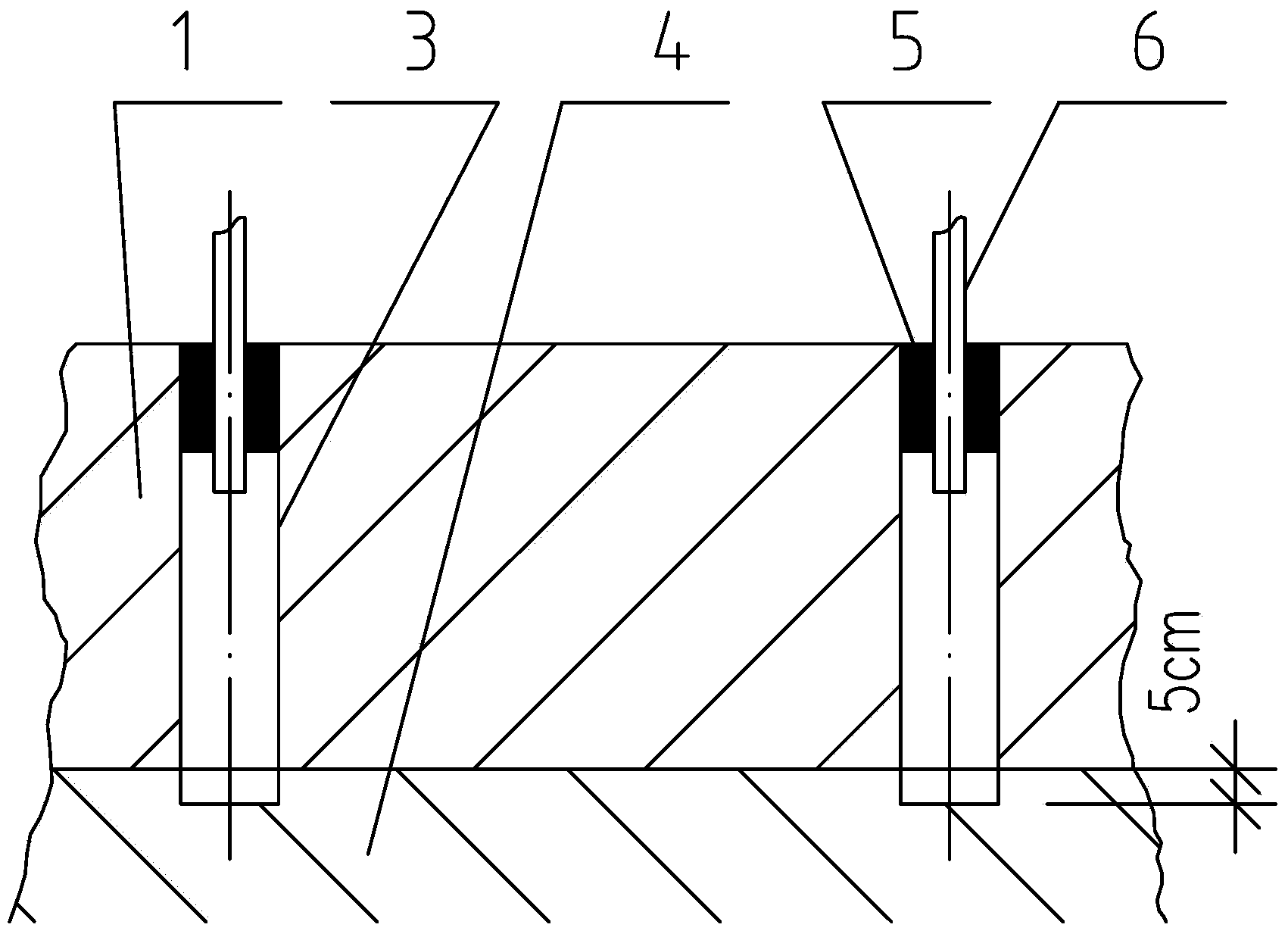

Post-cast strip inflatable arc angle rectangular flexible pipe side mold support construction method

ActiveCN109025294AReduce the number of supportsReduce the number of units usedBuilding material handlingBuilding insulationsEngineeringRebar

The invention relates to a post-cast strip side mold support construction method; an inflatable arc angle rectangular flexible pipe is arranged in a gap between an upper layer steel bar and a lower layer steel bar in the post-cast strip position; in inflation, the arc angle rectangular flexible pipe is extruded by the upper and lower layer steel bars so as to fill the gap caused by the steel bars;the soft pipe is inflated to form an air column so as to space the concrete; the cross section outer contour of the arc angle rectangular flexible pipe is an arc-shaped rectangular shape; the arc angle rectangular is a rectangular with four arc-shaped corners, and is an axially symmetrical and centrosymmetric geometric figure; the arc angle rectangular flexible pipe comprises a soft pipe outer wall and a soft pipe inner wall; the soft pipe outer wall cross section is the cross section contour of the arc angle rectangular flexible pipe, i.e., an arc angle rectangular; the soft pipe inner wallcomprises an upper pipe inner wall, a lower pipe inner wall and a common inner wall; the area enclosed by the upper pipe inner wall and the lower pipe inner wall is an air pump pressurization area; anarea enclosed by the soft pipe outer wall, the lower portion of the upper pipe inner wall and the upper portion of the lower pipe inner wall is an air connection area; the common inner wall has a constant pressure hole. The method employs the inflatable arc angle rectangular flexible pipe support, is good in moulding effect, high in construction quality, and high in efficiency.

Owner:FUJIAN JIANGXIA UNIV

Preparing method of bamboo powder reinforced high density polyethylene material

The invention discloses a preparing method of a bamboo powder reinforced high density polyethylene material. The preparing method comprises a bamboo powder coupling step and a composite material preparing step. The interaction between bamboo powder obtained after treatment of an aluminate coupling agent and HDPE is enhanced, bamboo powder is evenly dispersed, and impact performance and tensile performance are obviously improved. The section of the composite material is more flat, fine and smooth, and the flowing rate of polymeric material melt is reduced.

Owner:林建君

Bar material automatic lifting continuous feeding saw material heating equipment

ActiveCN103447825BReduce labor intensitySame lengthOther manufacturing equipments/toolsMetal working apparatusProduction linePunch press

The invention relates to equipment for automatically lifting, continuously feeding, sawing and heating bars. The equipment comprises a loading device, a lifting device, a feeding device, a blanking device and a heating hot punching device, wherein the loading device comprises a loading frame, a loading platform, an ejector rod, a linkage rod, a driving wheel and an ejector cylinder; the lifting device comprises a lifting chain, a chain wheel, a driving chain wheel and a lifting motor; the feeding device comprises a feeding frame, a V-shaped wheel, a compression cylinder, a compression guide wheel and a feeding limit switch; the blanking device comprises a guide mechanism, a saw-cutting mechanism and a material rotating mechanism; and the heating hot punching device comprises a heating groove, a heating furnace, a blanking guide groove and a punch press. A fully-automatic production line of lifting, feeding, blanking and heating hot punching is manufactured and formed on a valve shell, so full-automatic control is realized, production efficiency is improved, energy consumption is saved, workers are protected from directly operating beside the heating furnace, scalding and sunstroke accidents are avoided, labor intensity is reduced, and the automatic level is increased and product quality is improved.

Owner:NINGBO JIEKELONG PRECISION MFG +1

Road micro-expanding and slow-setting cement

InactiveCN101955327AExtended service lifeSmall expansion coefficientCement productionPortland cementCement manufacturing

The invention discloses road micro-expanding and slow-setting cement, which relates to the technical field of cement manufacturing and aims to solve the technical problems of uneven section of water stable layer, loose internal structure, easy cracking, easy expansion and the like of a road using common portland cement. The road micro-expanding and slow-setting cement of the invention comprises the following components in percentage by weight: 35 percent of rotary kiln clinker, 10 percent of dihydrate gypsum and 55 percent of yellow phosphorus slag. The road micro-expanding and slow-setting cement is suitable for severe cold areas.

Owner:GANZIZHOU LUDINGQIAO CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com