Patents

Literature

561 results about "Geometric figure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

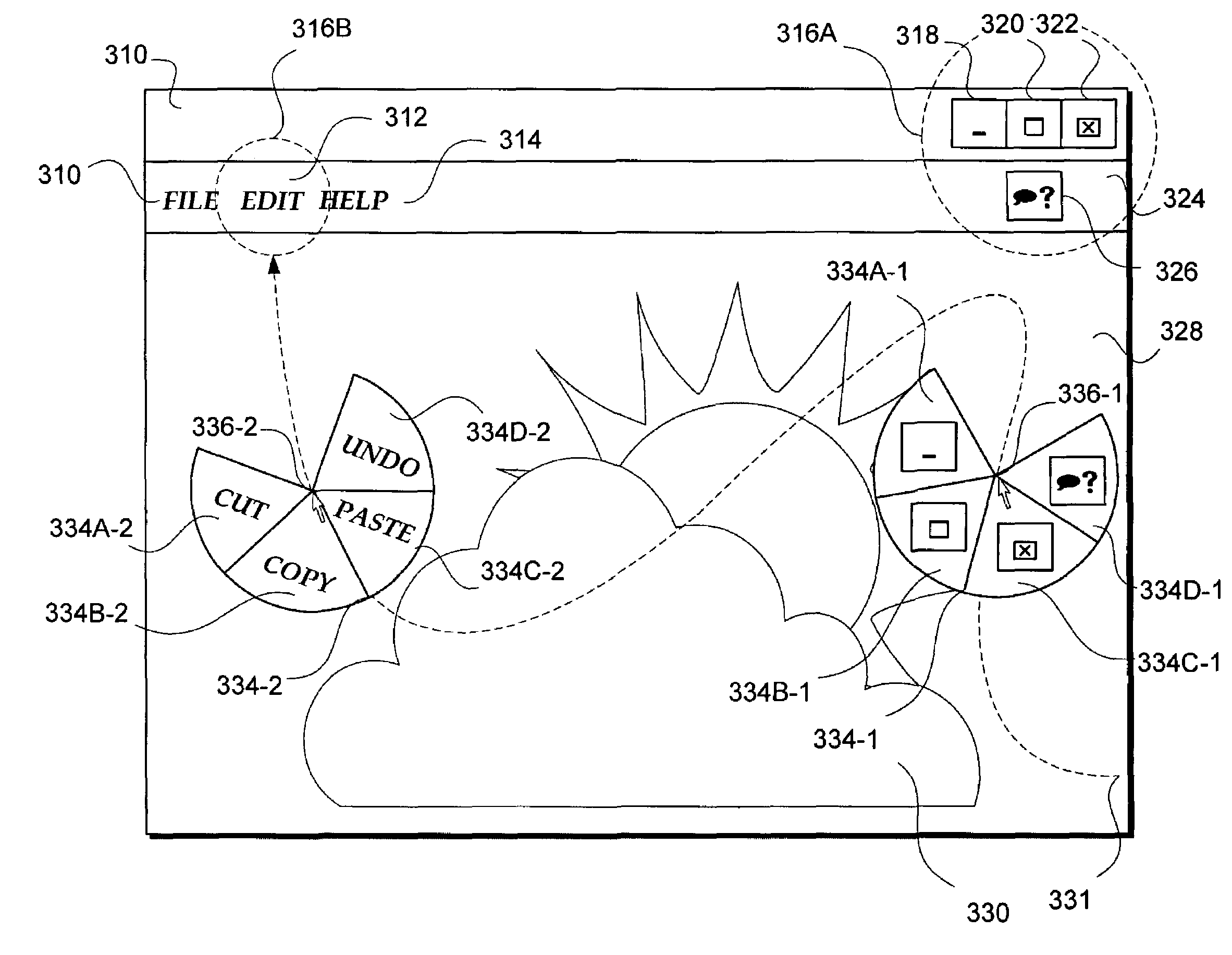

Menus whose geometry is bounded by two radii and an arc

ActiveUS7210107B2Cathode-ray tube indicatorsSpecific program execution arrangementsGraphicsPointing device

Sector menus track a pointer's position as a pointing device is moved. Each sector menu is a geometric figure bounded by two radii and an included arc of a circle. Menu items are housed in segments formed from multiple radii cutting the sector menu. Users select menu items housed in segments by making a direction change from a trajectory course to pass over a desired menu item so as to invoke its operation. The sector menu lacks a segment, defining a devoid segment, which is oriented in a direction toward which the pointer is moving. Segments with different sizes are available to represent the likelihood that a user would choose a given operation in a corresponding menu item housed by a corresponding segment.

Owner:MICROSOFT TECH LICENSING LLC

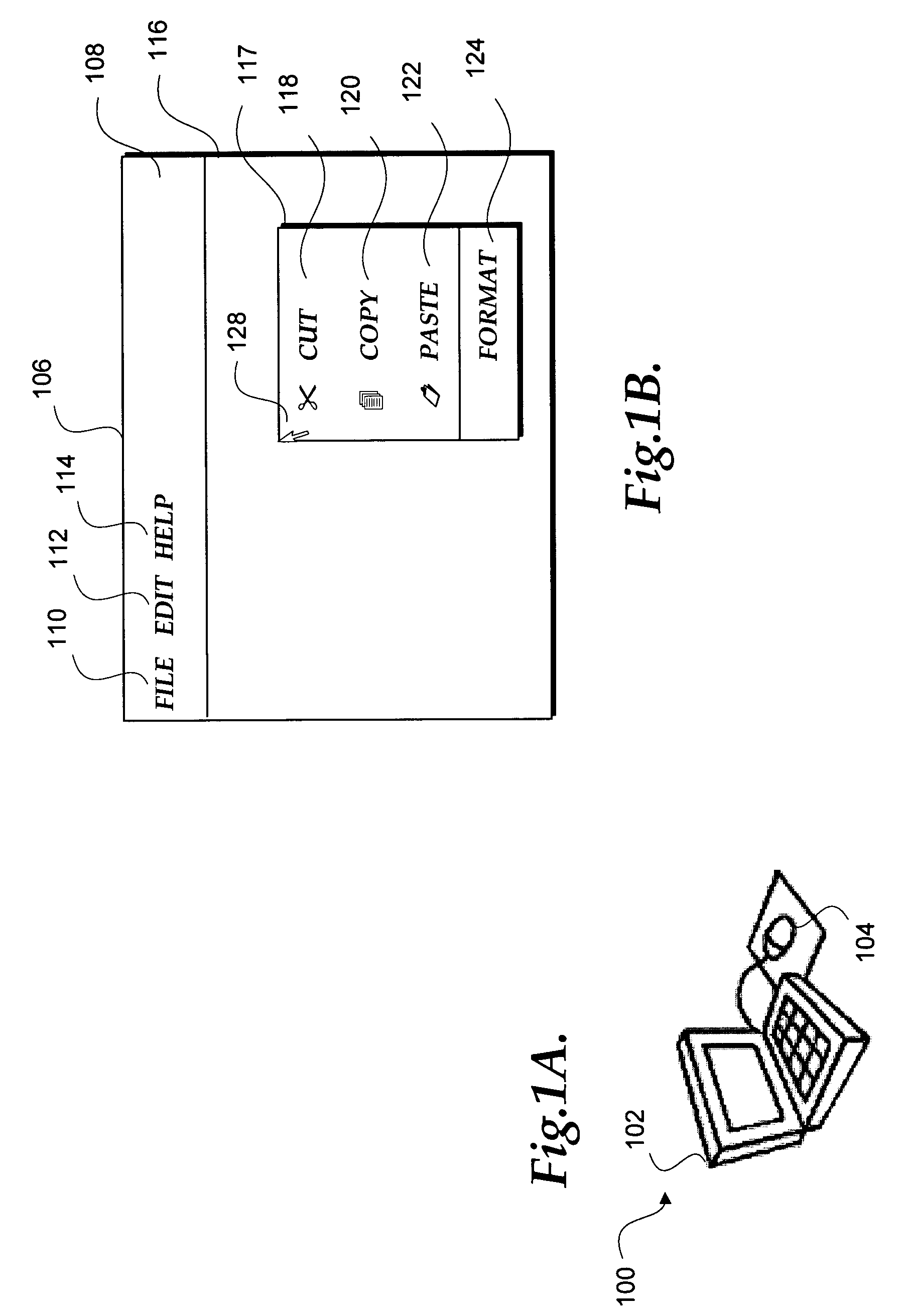

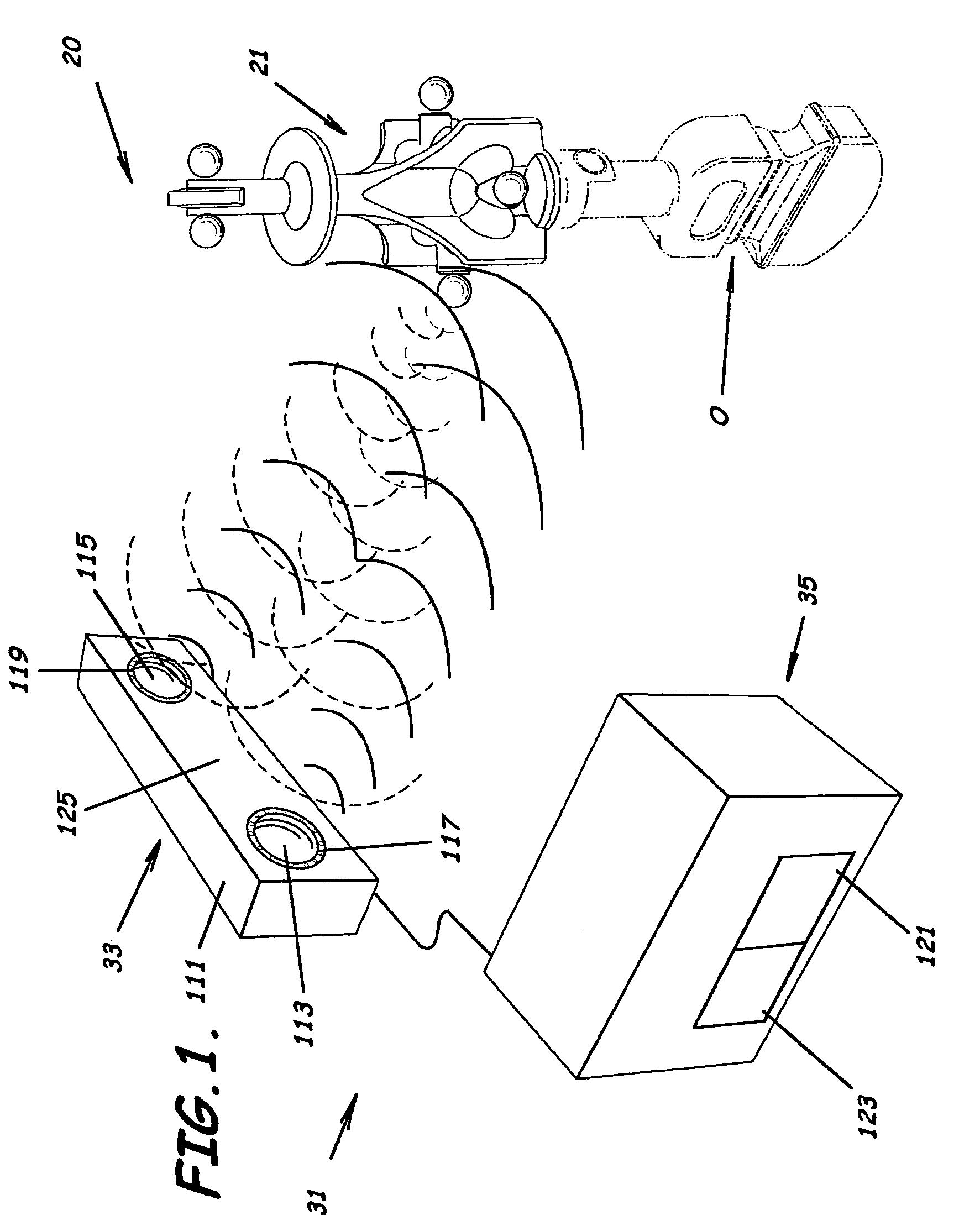

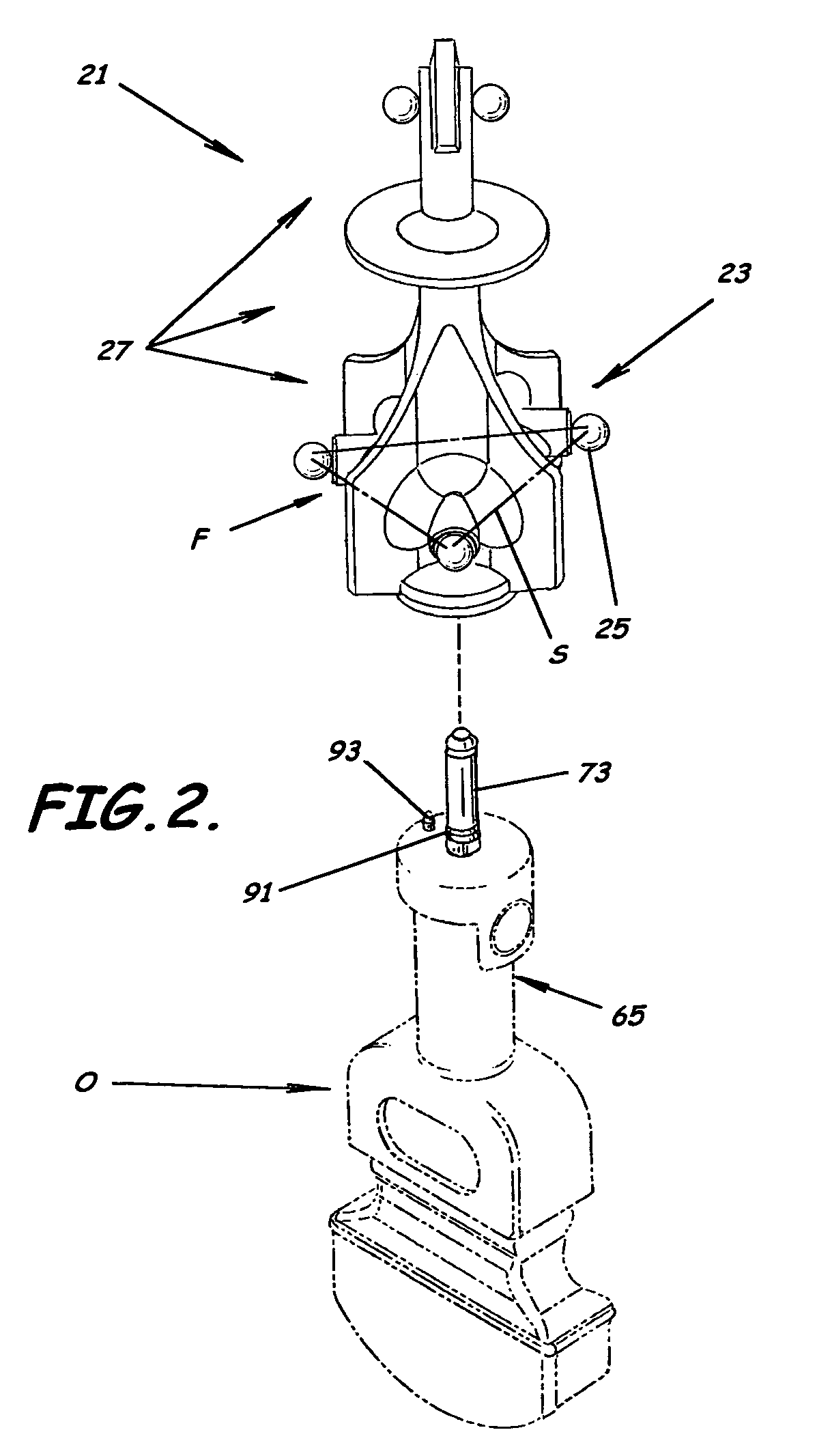

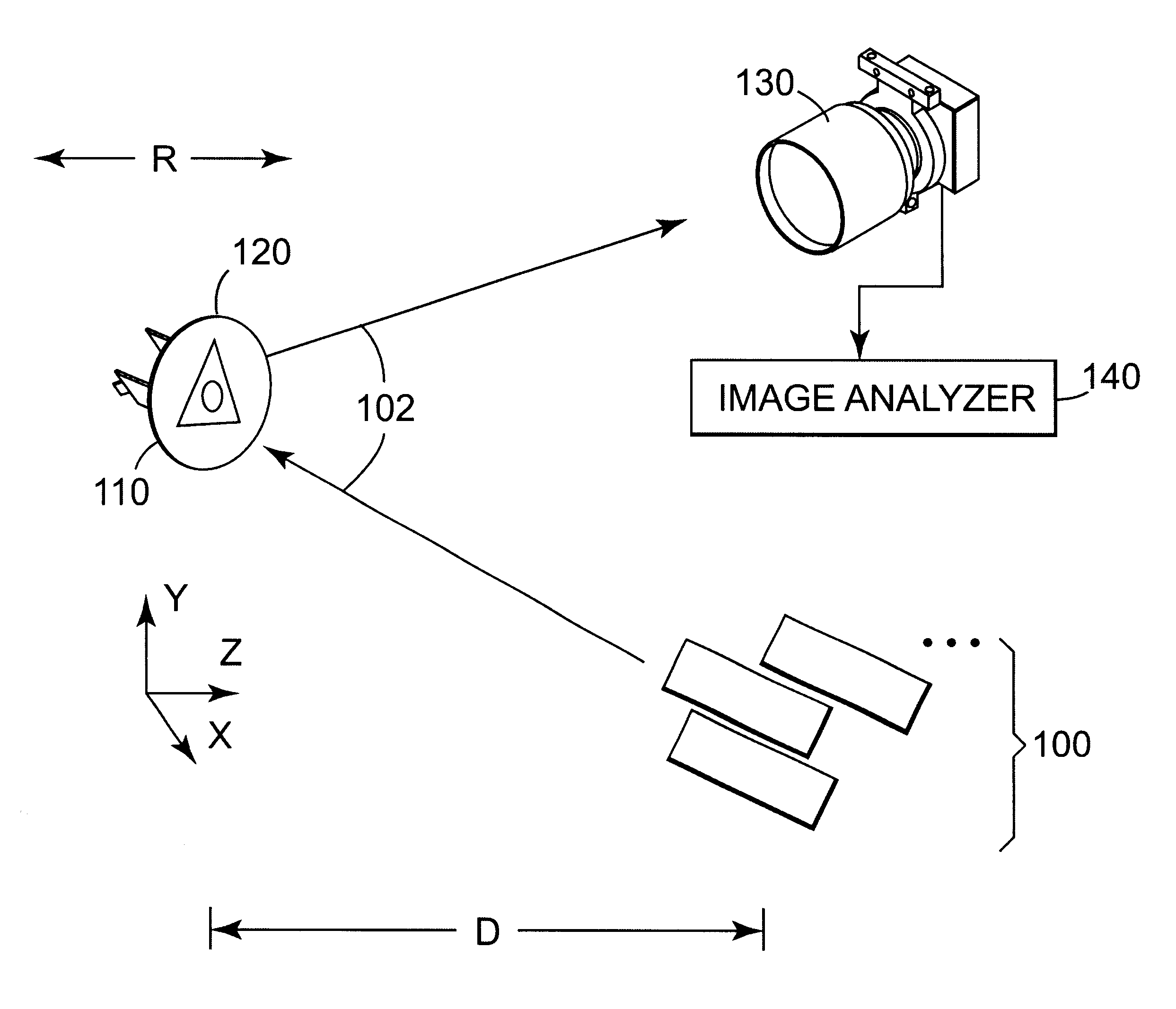

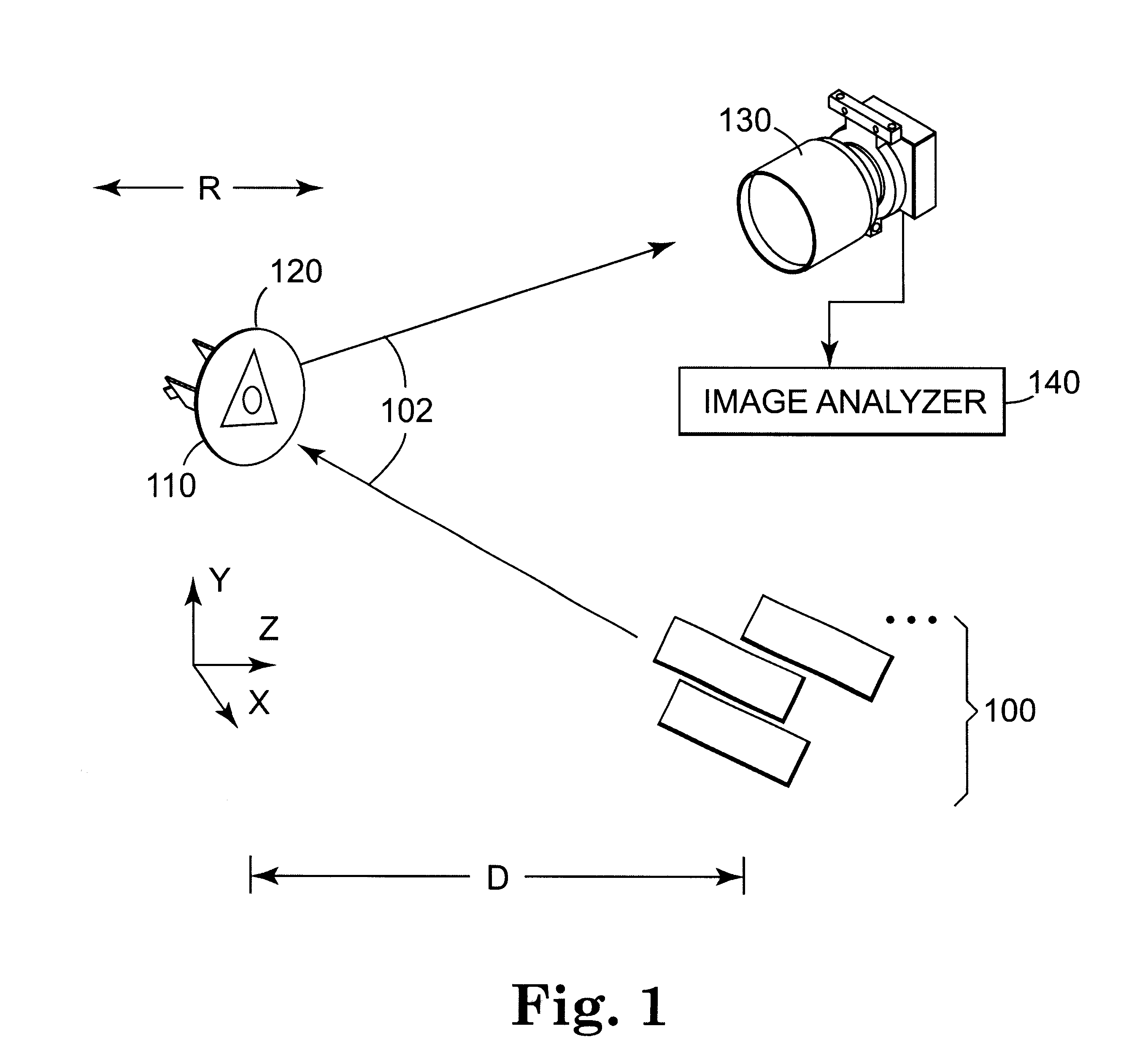

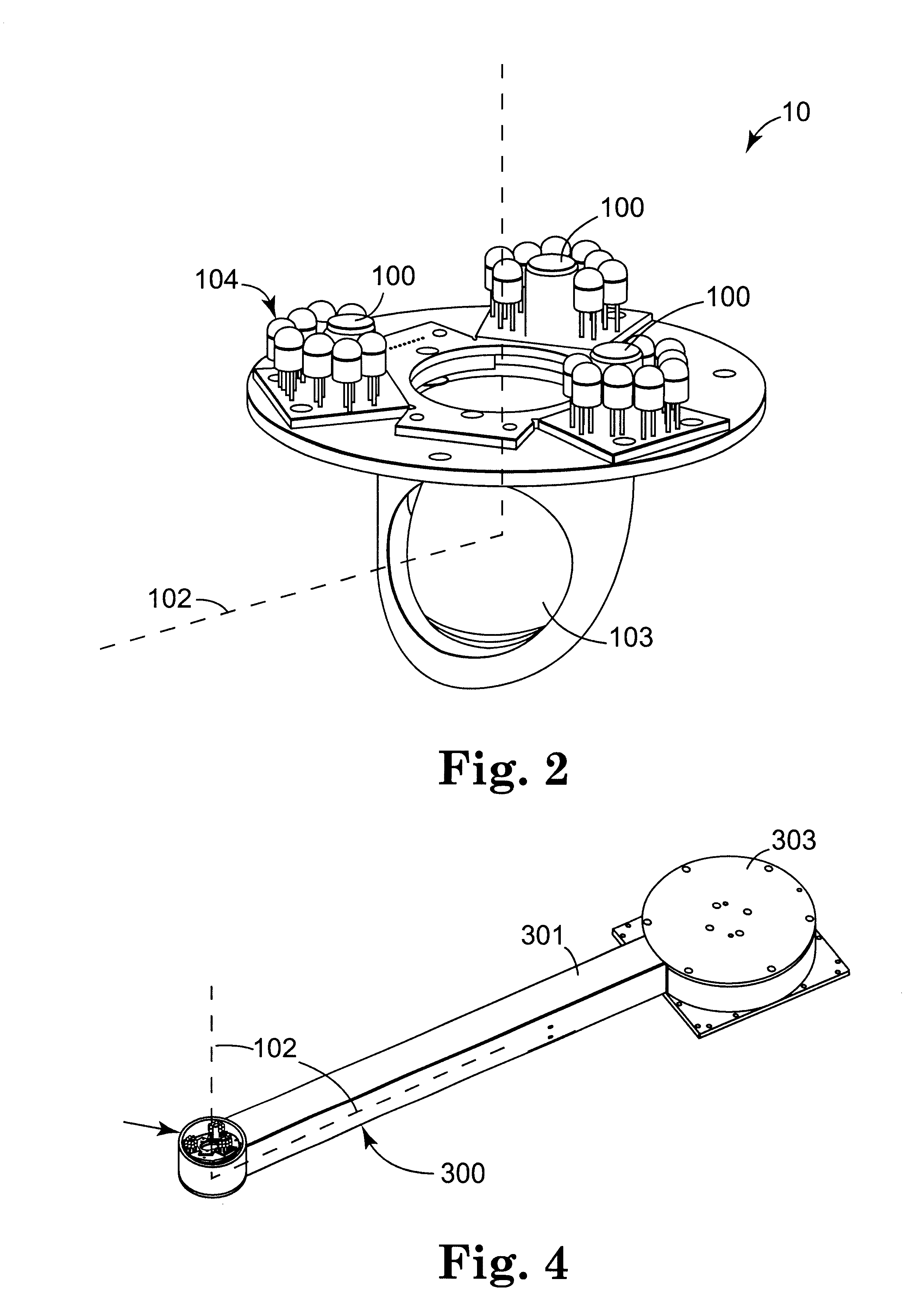

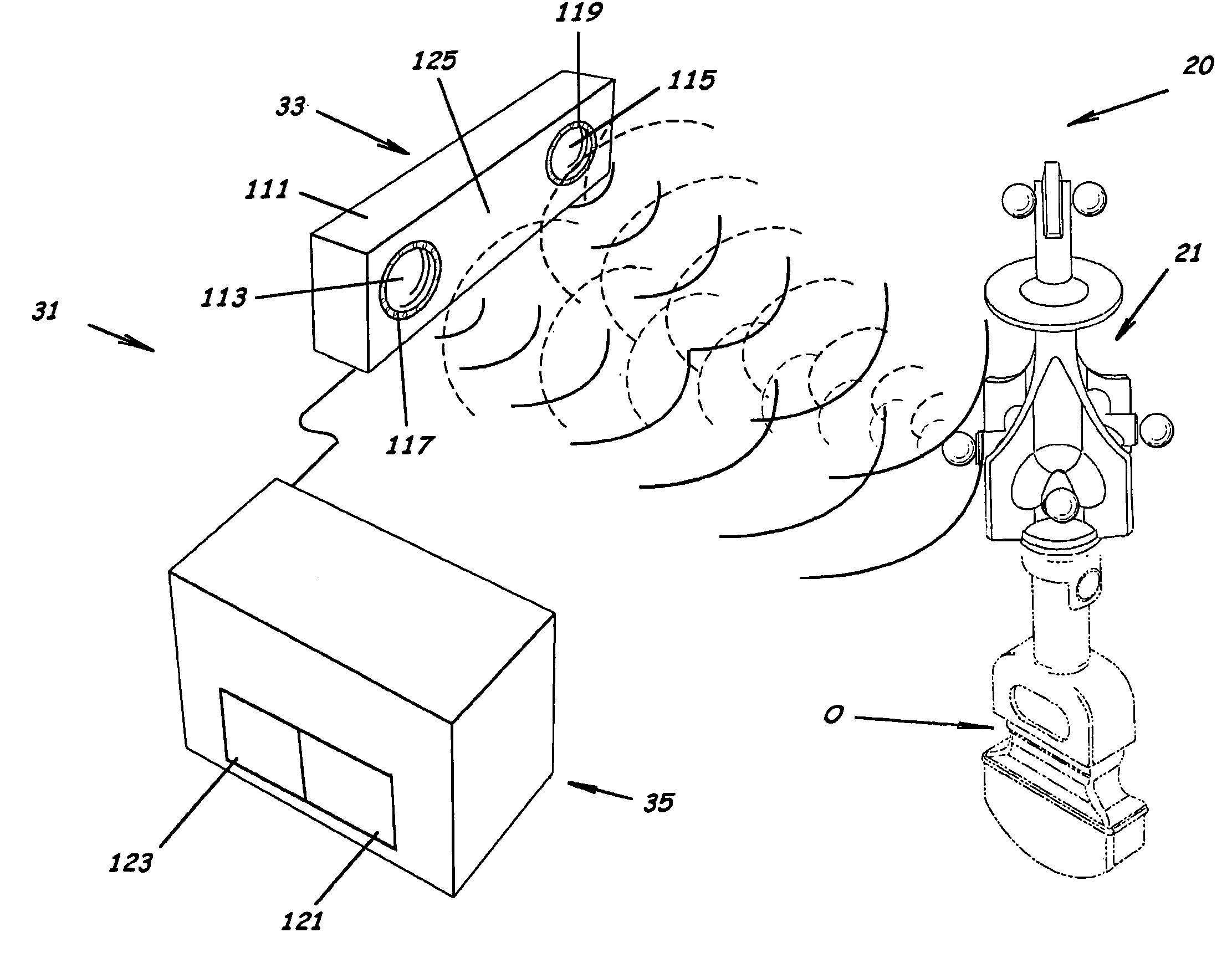

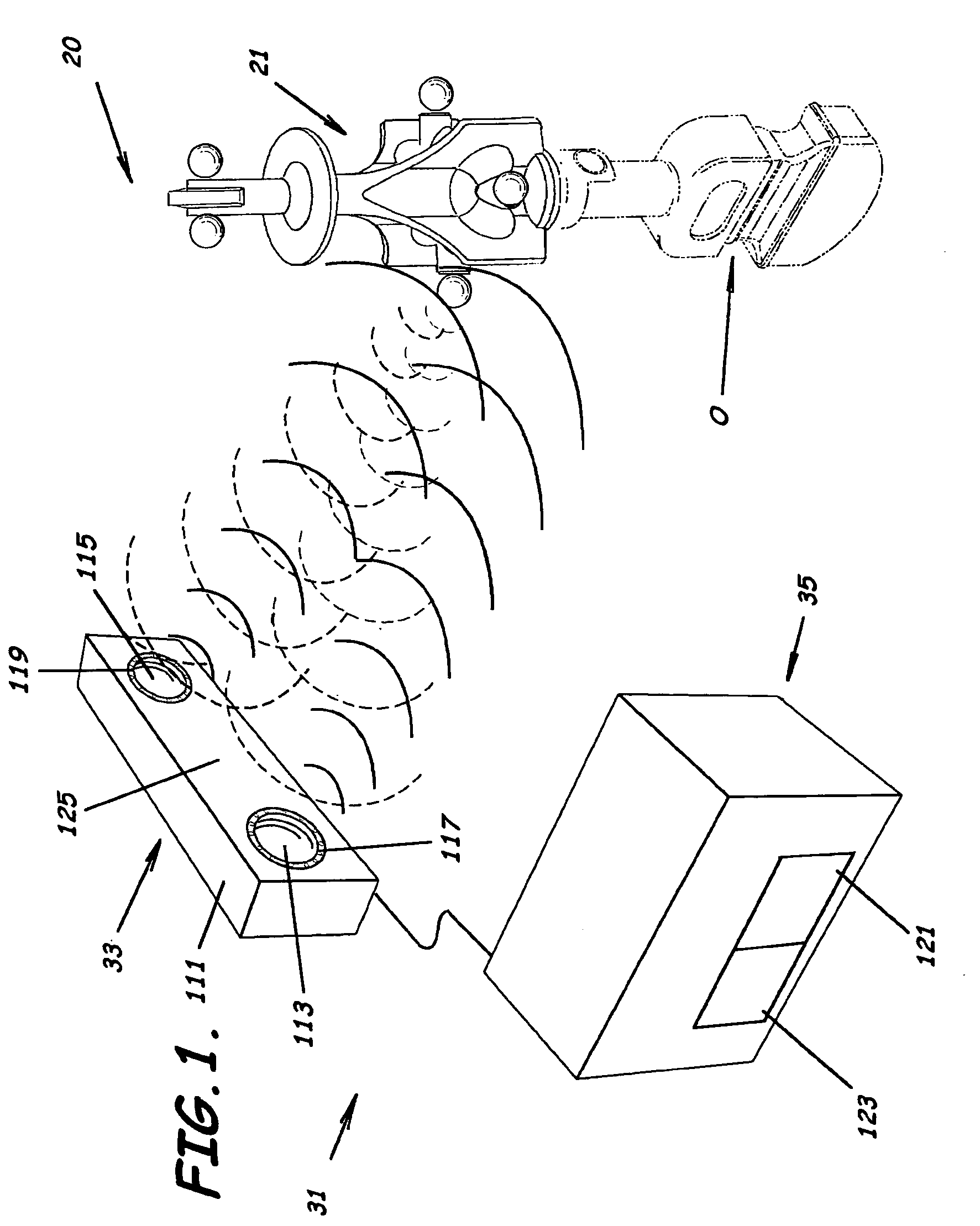

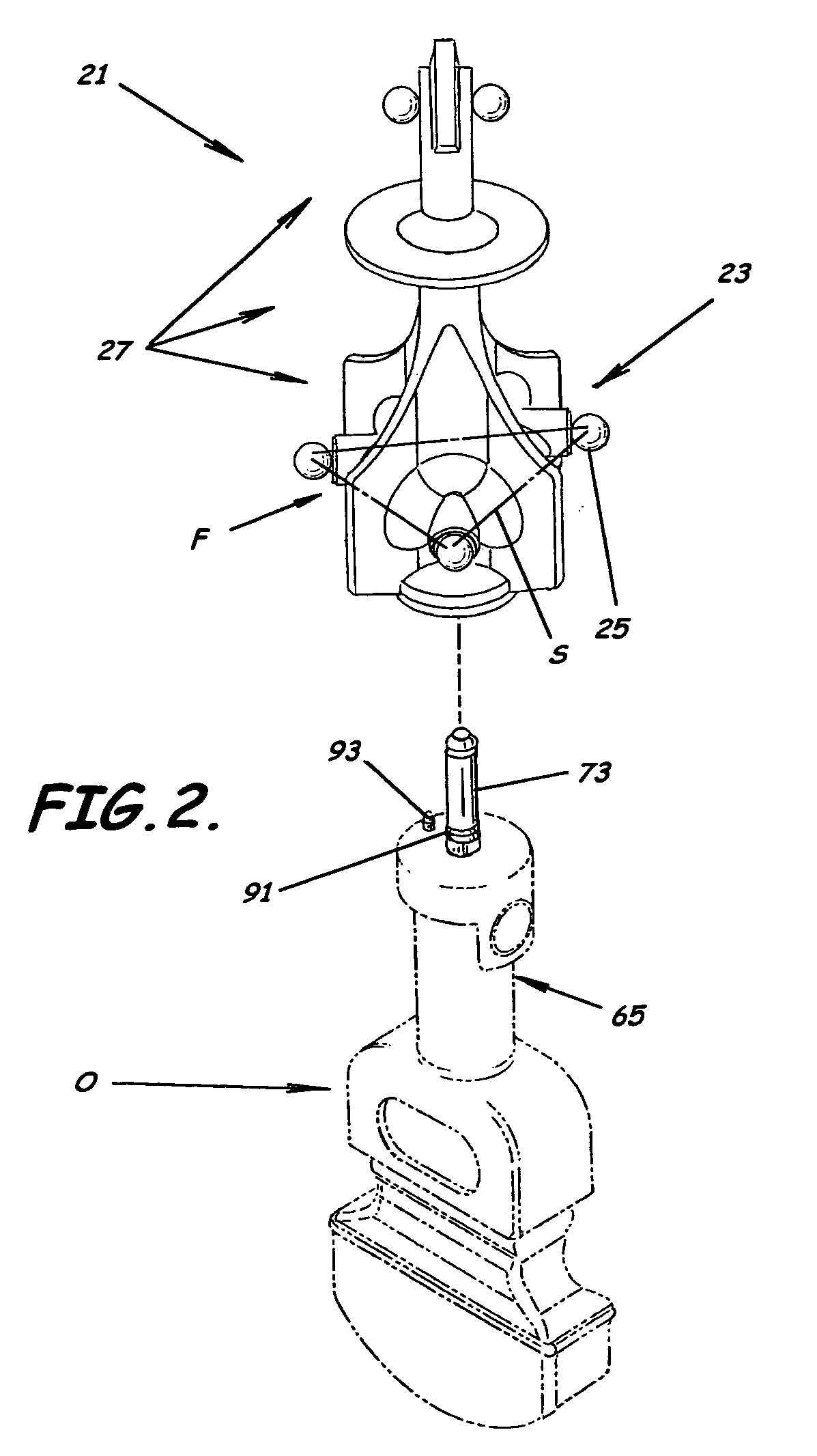

System and tracker for tracking an object, and related methods

ActiveUS7289227B2Convenient and accurateReduce usageUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsEngineeringGeometric figure

A system to track a three-dimensional position and an orientation of a movable object and associated methods are provided. The system includes a tracker having an optically trackable body adapted to connect to the movable object. A plurality of optical indicators are connected or mounted to the optically trackable body to form a plurality of geometric figures. A plurality of obfuscating flanges optically separate the optical indicators from each other to prevent each of the optical indicators from becoming optically coincident with another optical indicator when viewed along a preselected viewing path. The system also includes an apparatus to track the tracker having an optical detector to simultaneously detect the three-dimensional position of at least three of the plurality of optical indicators and a determiner to determine the three-dimensional position and orientation of the optically trackable body from the position of the optical indicators.

Owner:BEST MEDICAL INT

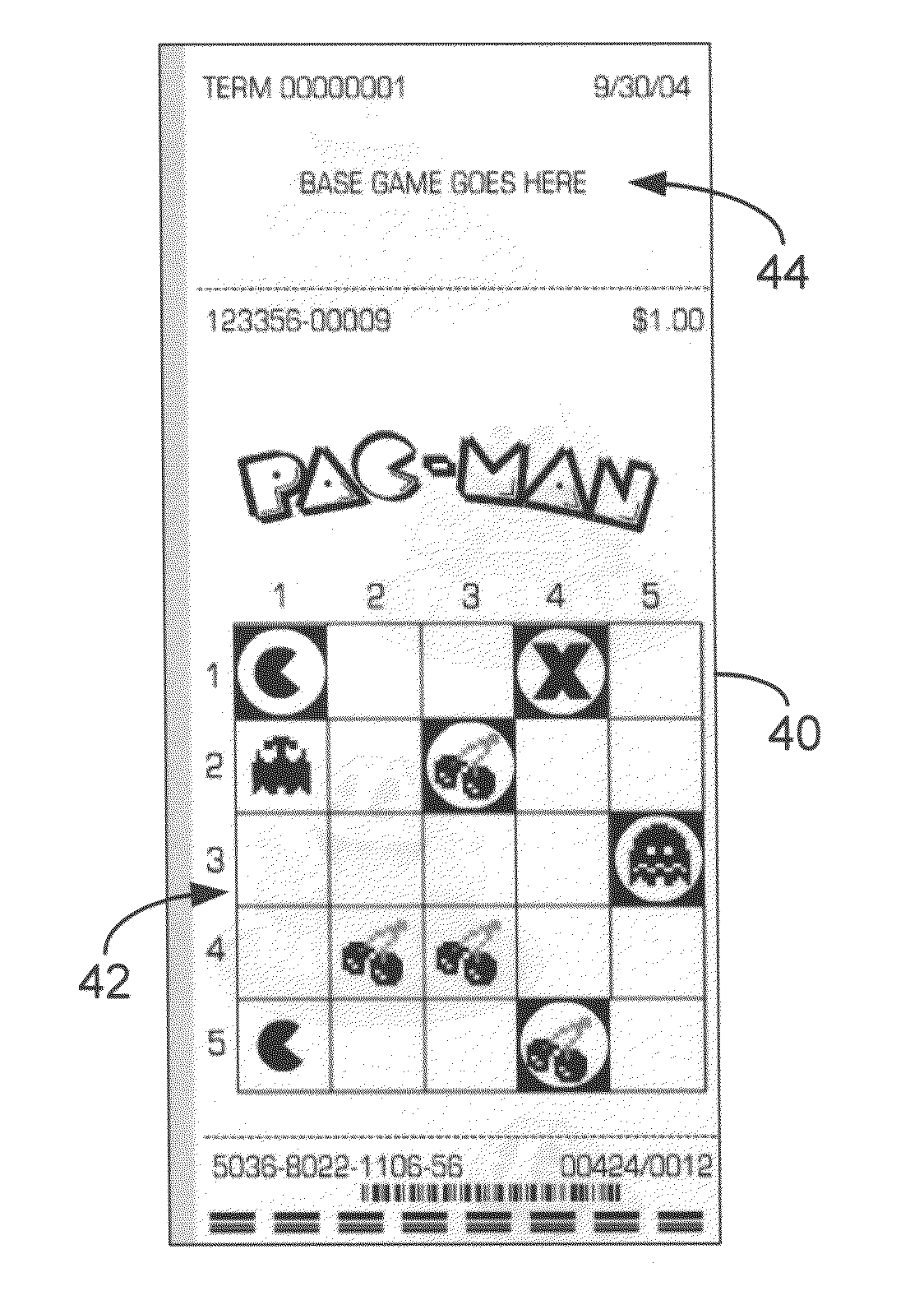

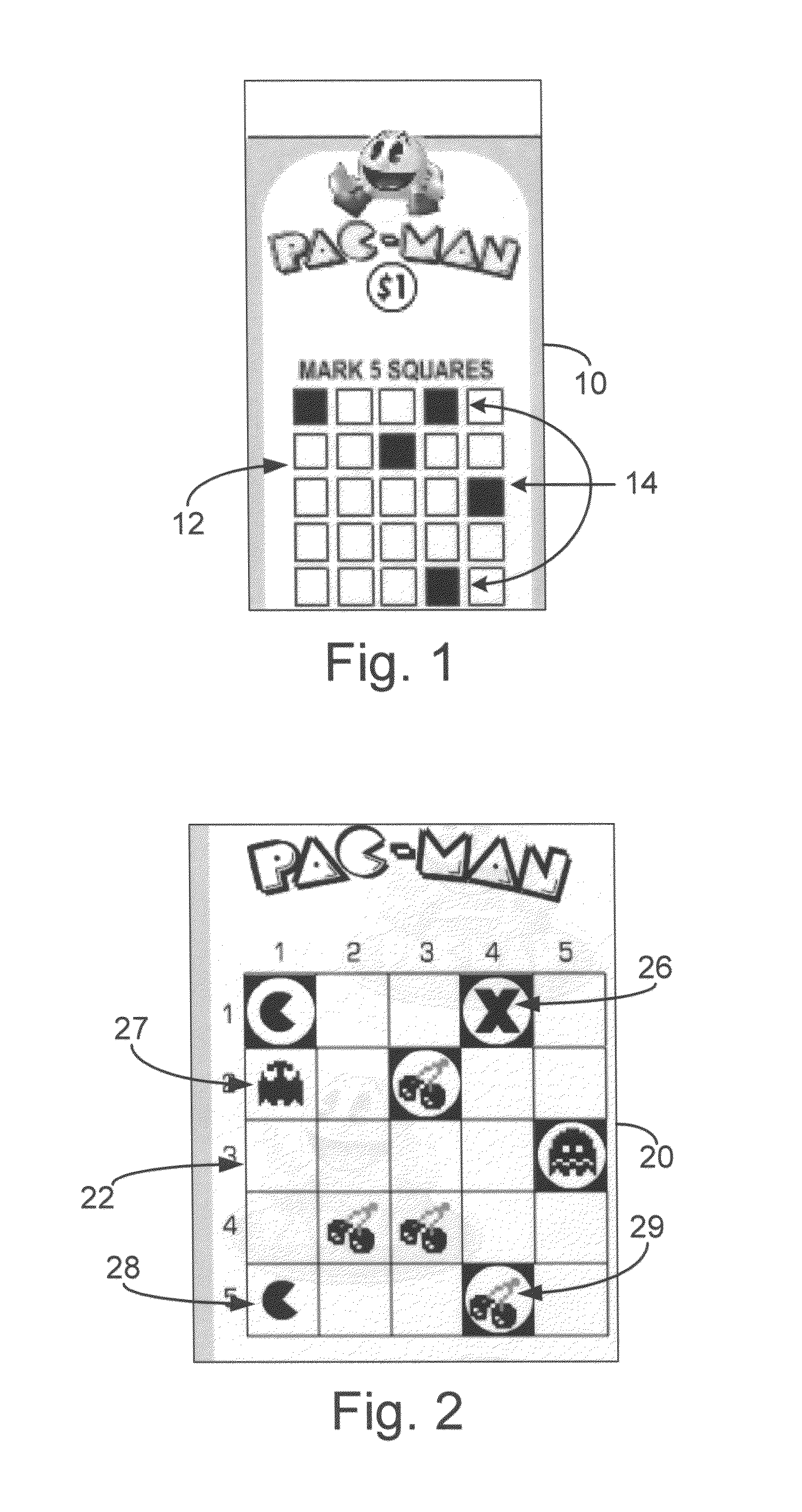

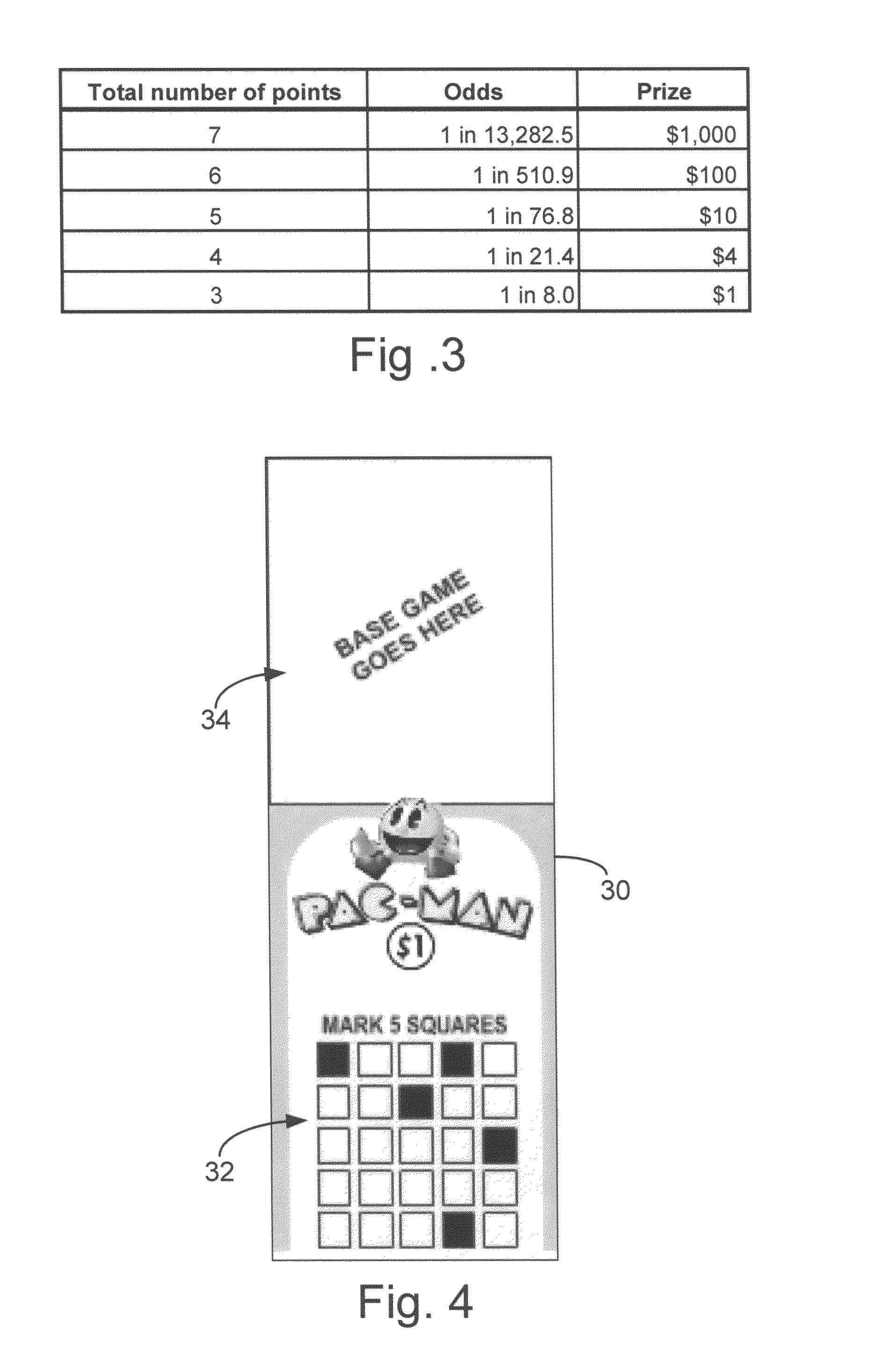

Lottery game played on a geometric figure using indicia with variable point values

A system, method and lottery ticket that implement a lottery game that uses a geometric figure having a plurality of selection spaces from which a player selects at least one selection space. The selection spaces are then populated with one or more game indicia, with each game indicia having a point value, and prizes are awarded based upon the total number of points associated with the game indicia populated into the player-selected selection spaces. Other lottery games can also be played simultaneously therewith on the same ticket or round of play.

Owner:SCI GAMES LLC

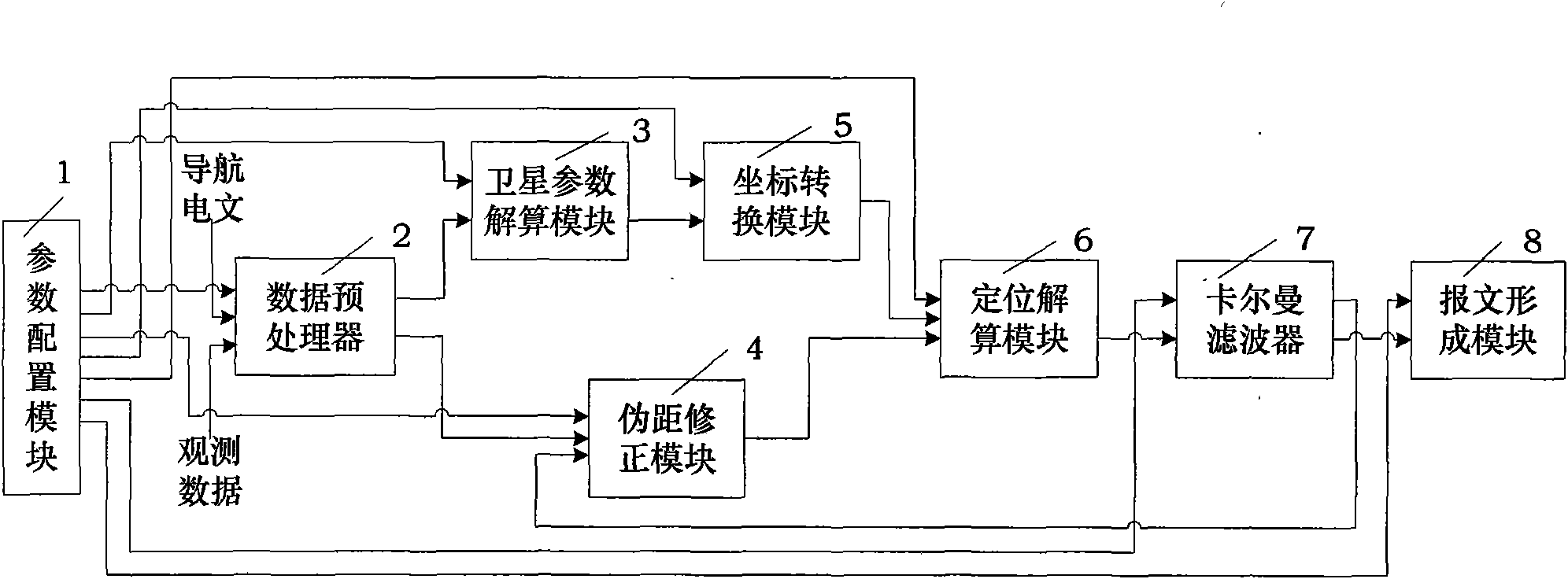

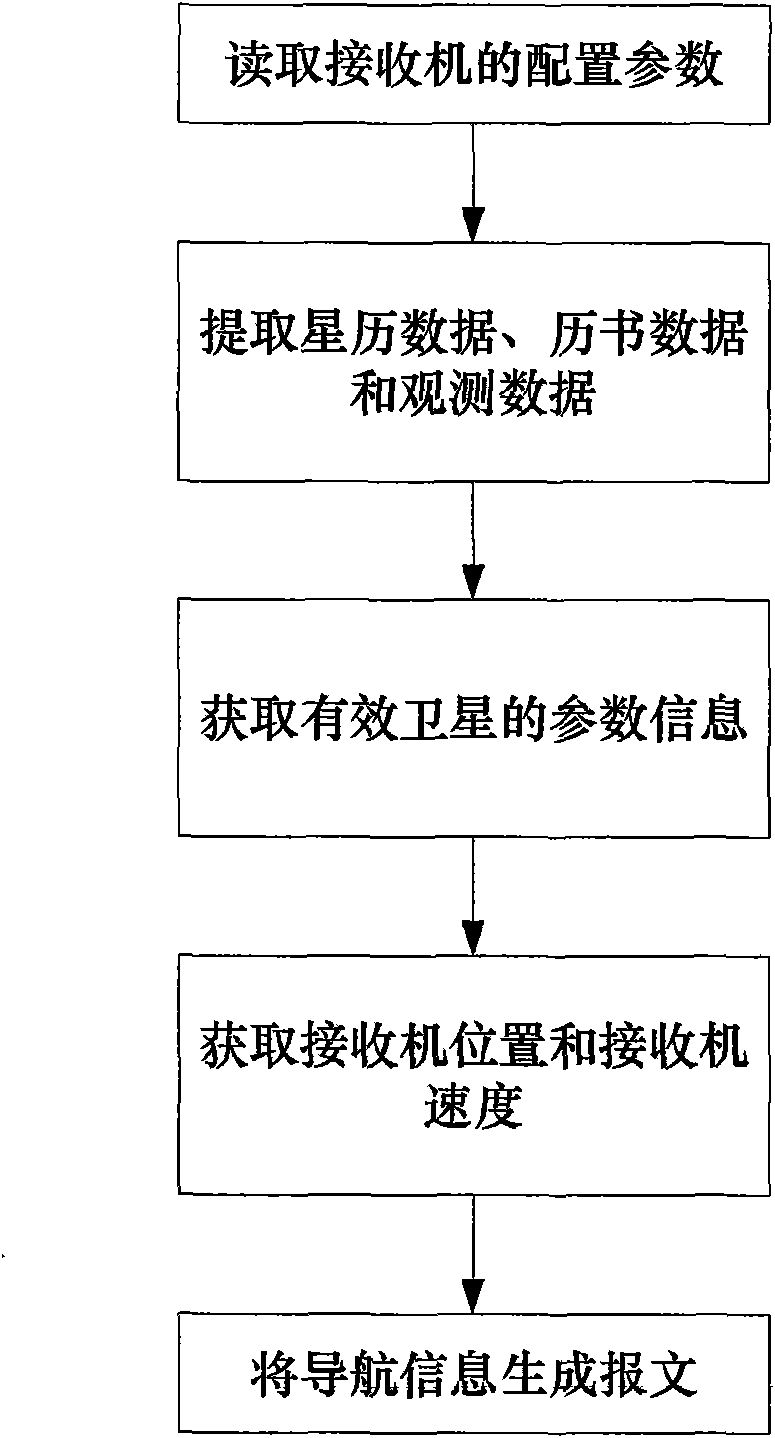

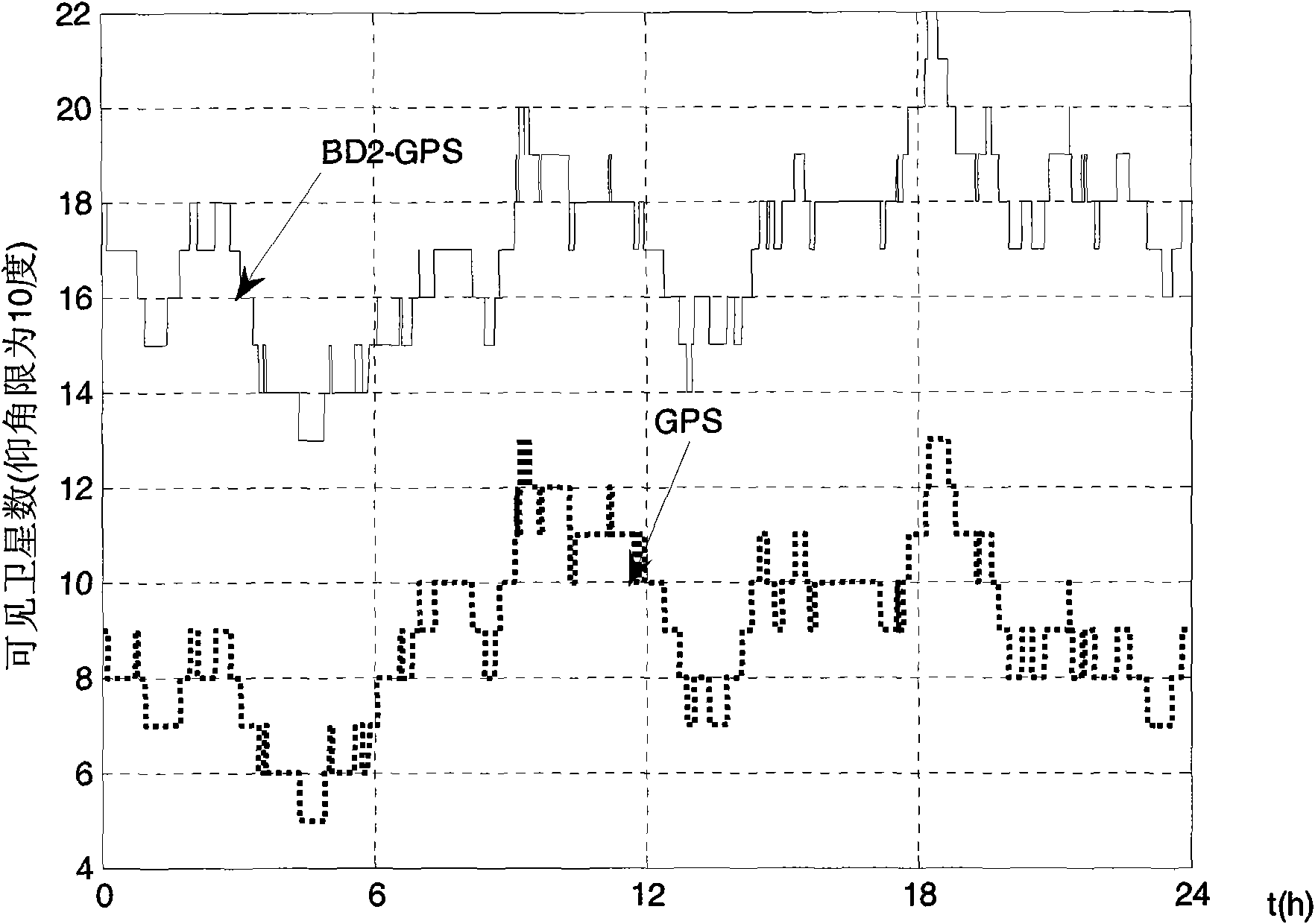

Compatible navigation receiver positioning system and positioning method thereof

InactiveCN101609140AGet rid of dependenceImproving Integrity Monitoring PerformanceNavigational calculation instrumentsBeacon systems using radio wavesUsabilityNavigation system

The invention discloses a compatible navigation receiver positioning system and a positioning method thereof. The system comprises a parameter configuring module, a data preprocessor, a satellite parameter calculating module, a pseudo-distance modifying module, a coordinate conversion module, a positioning calculating module, a kalman filter and a message forming module. The positioning method comprises the steps of: reading a configuration parameter of a receiver; extracting ephemeris data, almanac data and observation data; obtaining parameter information of effective satellites; obtaining the position of the receiver and the speed of the receiver; and generating a message by the navigation information. The invention realizes alternative use of the global positioning system, the independent navigation of the second big dipper navigation system breaks away from the dependency to the other navigation systems at emergency period, and the combination of the many satellite navigation systems increases the quantity of the effective satellites, so as to guarantee the continuity, the usability and the security of satellite positioning service, enhance the geometric figure intensity of the observation satellites, and improve the reliability of the whole global positioning system.

Owner:BEIHANG UNIV

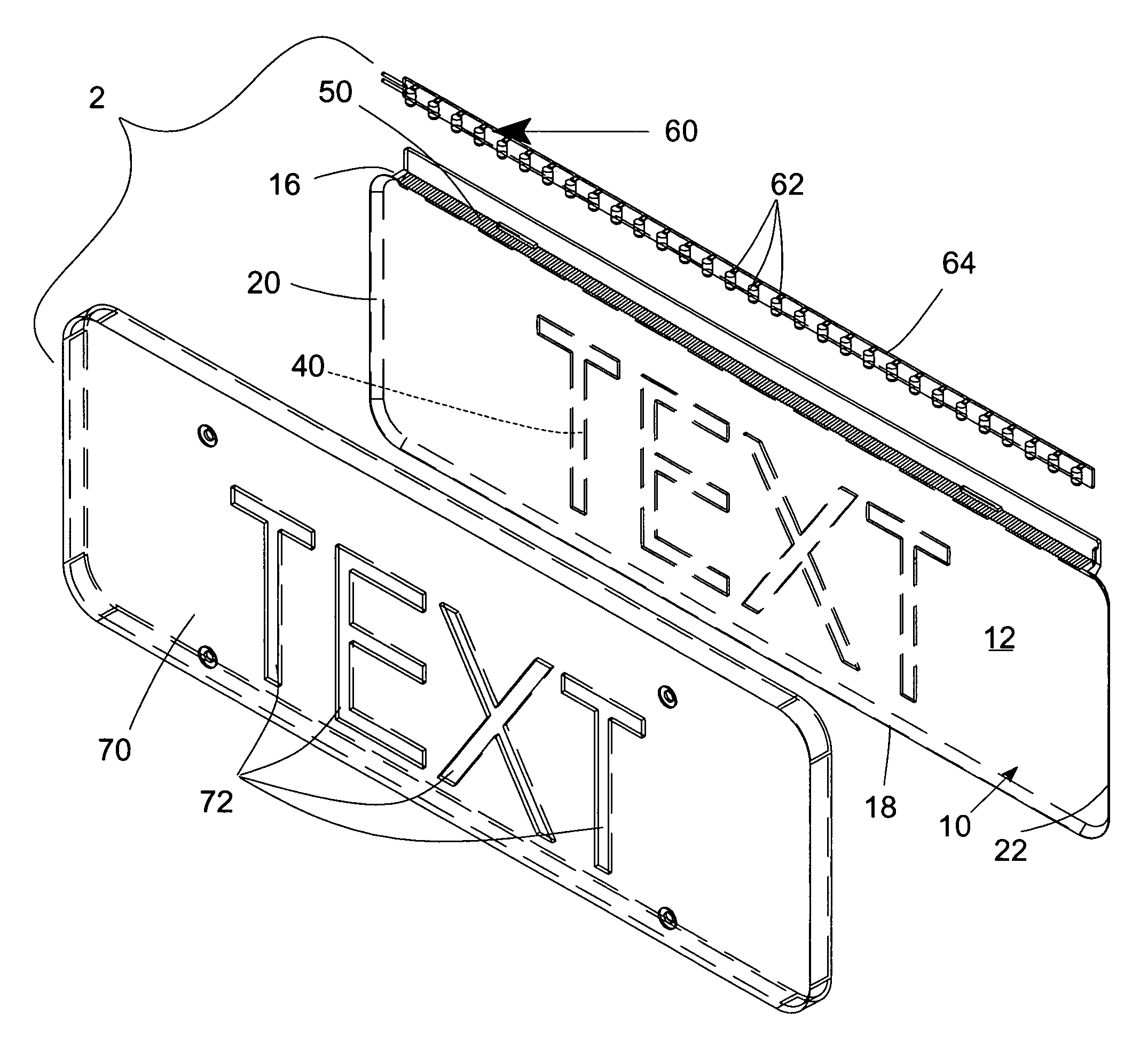

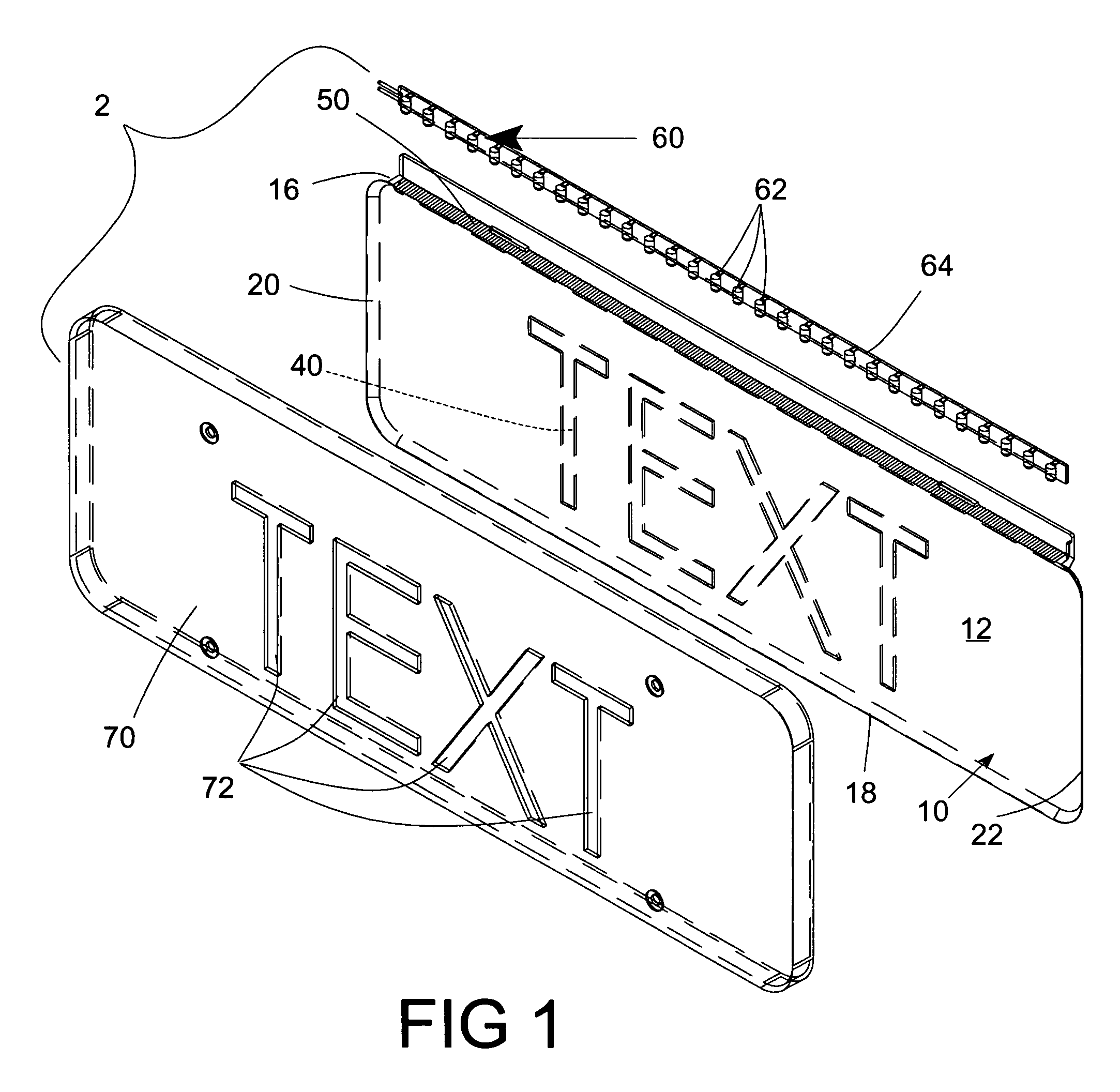

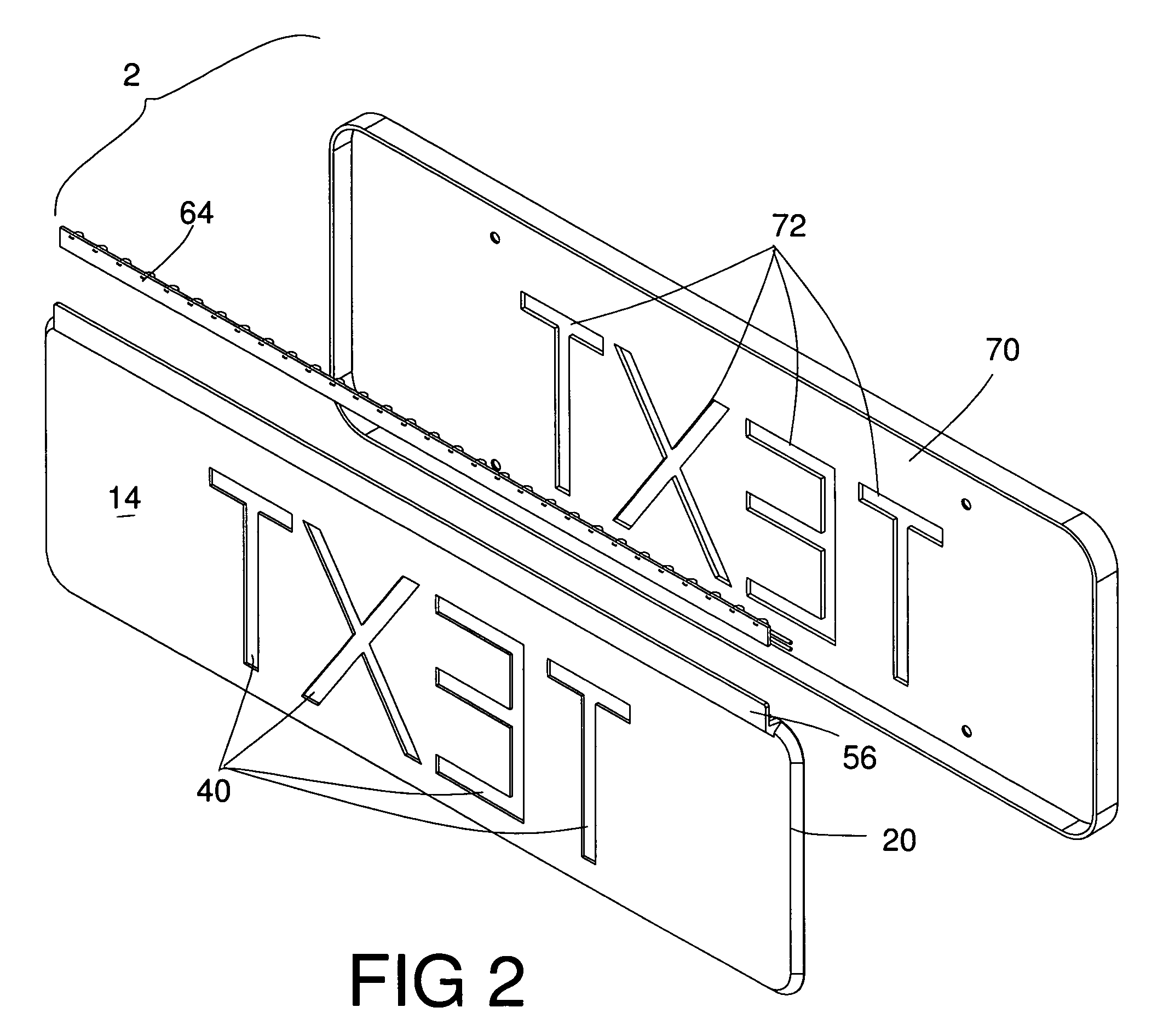

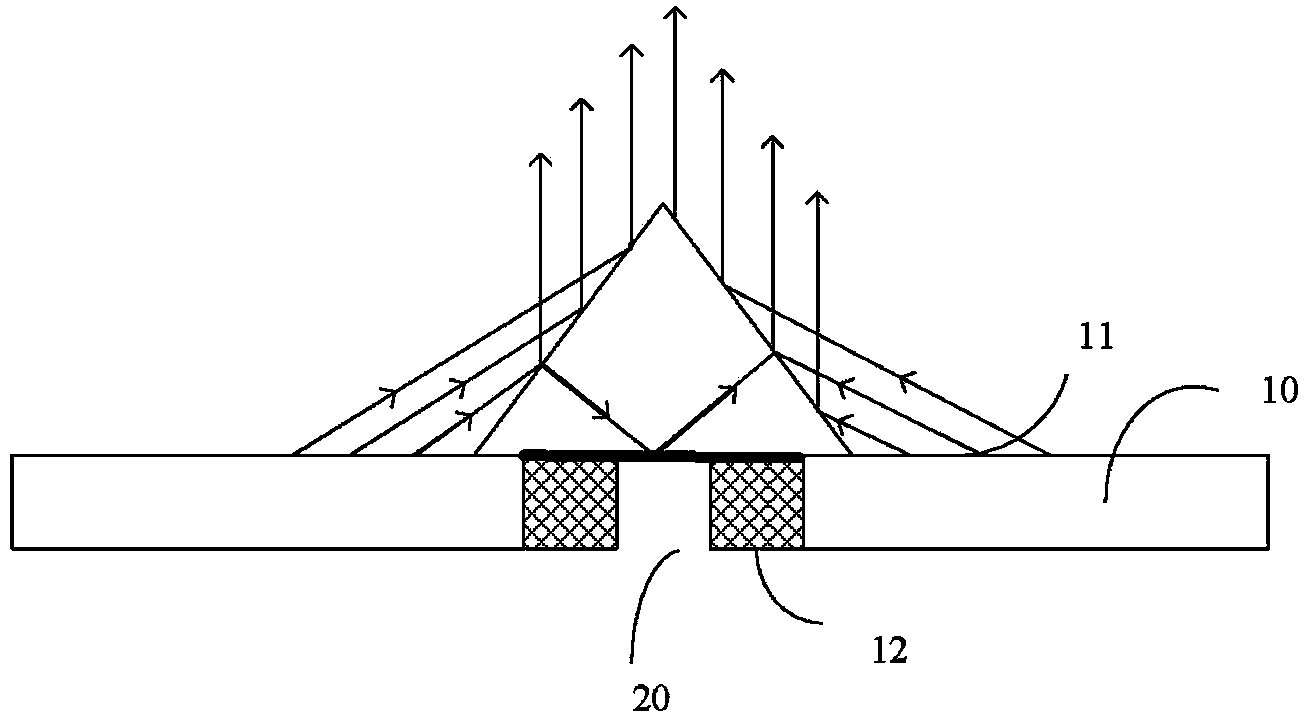

Edge lit sign with illuminated image

InactiveUS7681347B1Uniform lightPlanar/plate-like light guidesIlluminated signsGraphicsGeometric figure

A sign is edge lit and illuminated by an array of light emitting diodes disposed along an edge of a light transmissive panel. A light diffusion surface, which can be formed by a series of serrations on the panel edge, disperses light from the discrete light emitting diodes in the array. A geometric figure, which can be text or graphics or both is formed on one face of the panel by grooves, which redirect diffused light so that an illuminated image, corresponding to the geometric figure, can be seen on the front of the panel. The grooves forming the figure and the light diffusion surface comprise parts of a one-piece panel, and the grooves and the light diffusion surface can be formed when the panel is injection molded.

Owner:IMAGEWORKS DISPLAY & MARKETING GROUP

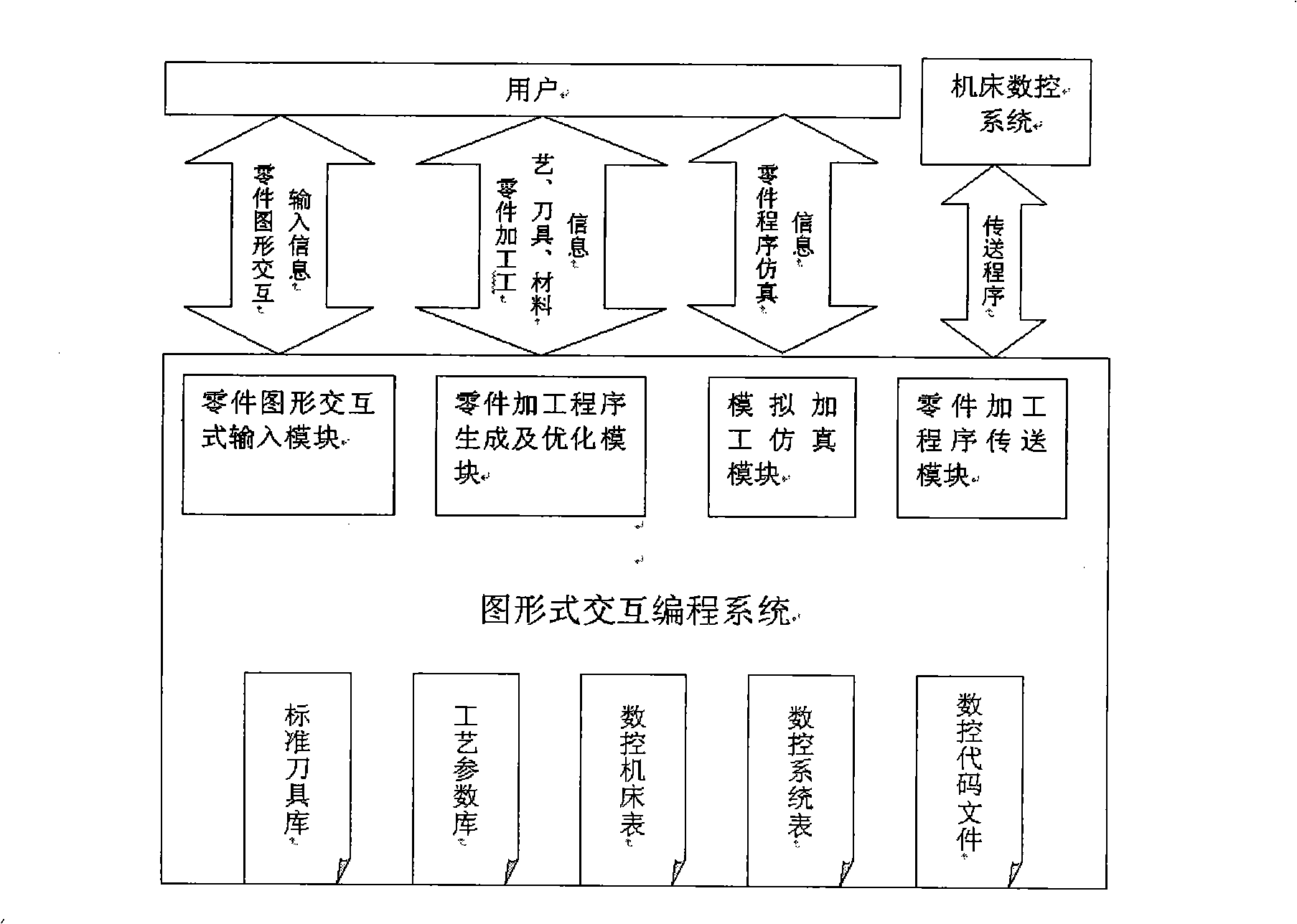

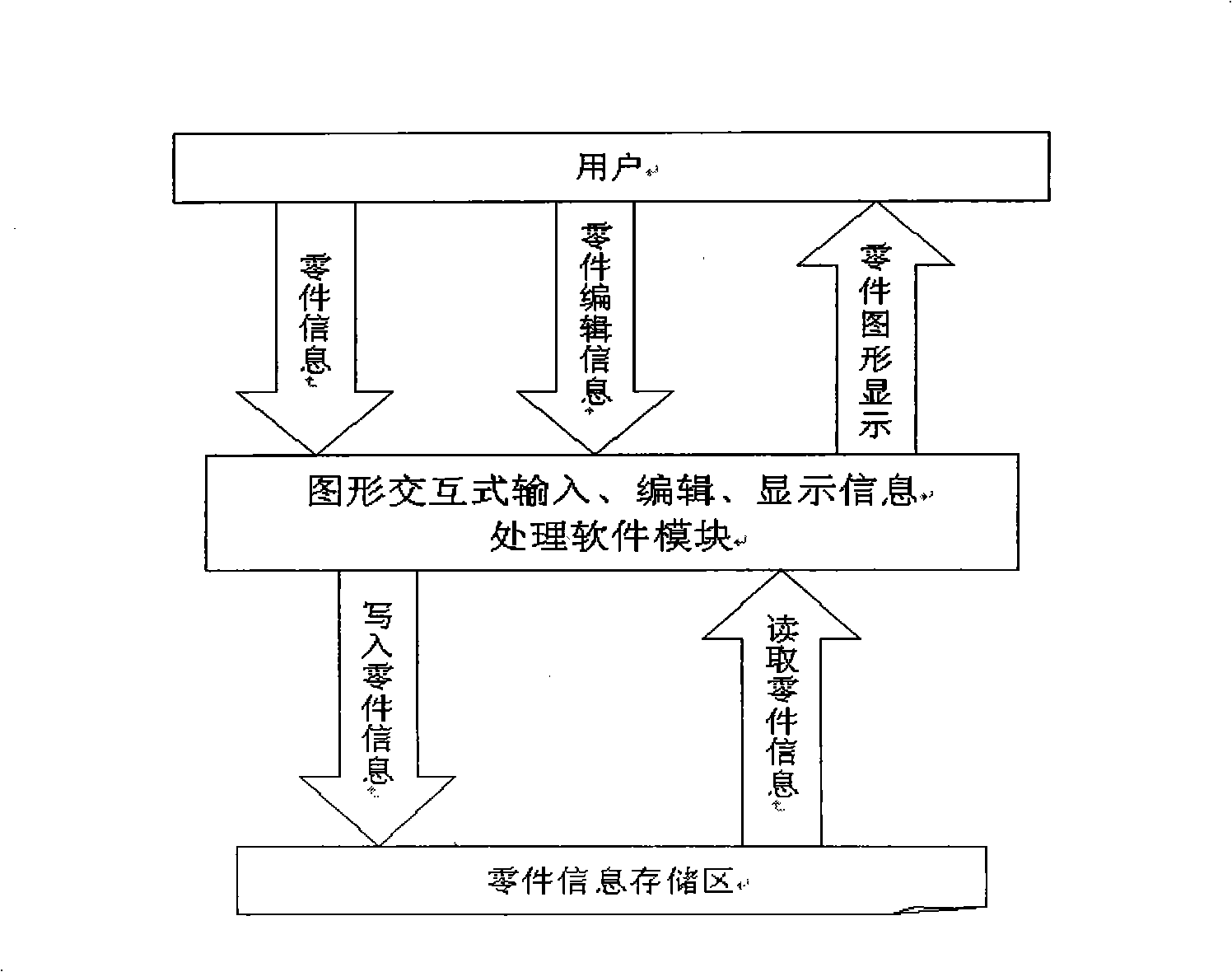

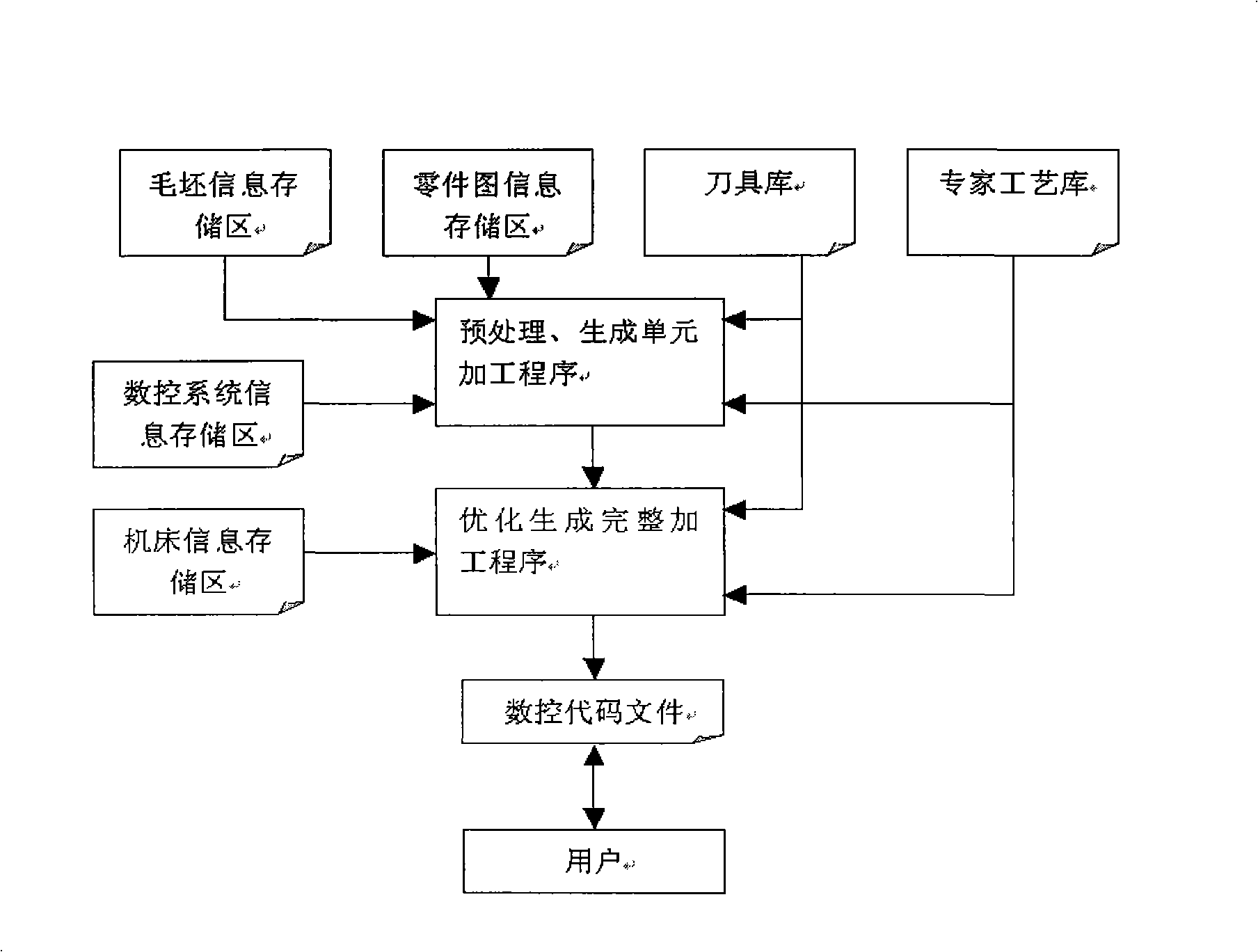

Numerical control longitudinal cutting machine tool machining program simulated realization method and its system

The invention relates to a PC-based numerical control sliver automatic lathe part processing automatic programming and simulation realization method and a system. The method comprises the following steps: A. entering the simulator part graphic interactive input interface, and inputting the geometric figure and the related information of the parts to be processed; B. entering the part processing generation interface, and generating the part processing program and the related processing parameters; C. entering the simulation interface of the part processing program to make simulation inspection to the generated part processing program through the system, and the user can simulate the part processing course on a PC screen; D. transmitting the part processing program to the corresponding numerical control machine, and completing the programming and input of the part processing program. The system comprises processing program interactive generation and simulation, and relates to numerical control machines to realize the generation and simulation of PC-NC machine processing programs. The method and system of the invention can effectively increase the work efficiency of productivity of numerical control sliver automatic lathes.

Owner:四川普什宁江机床有限公司

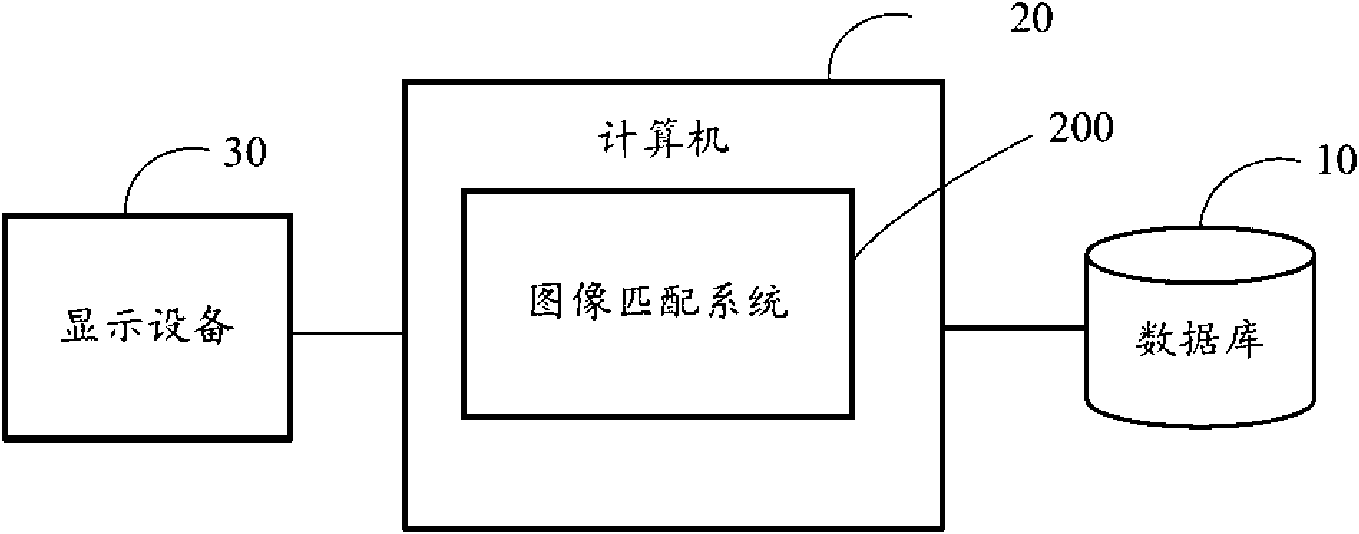

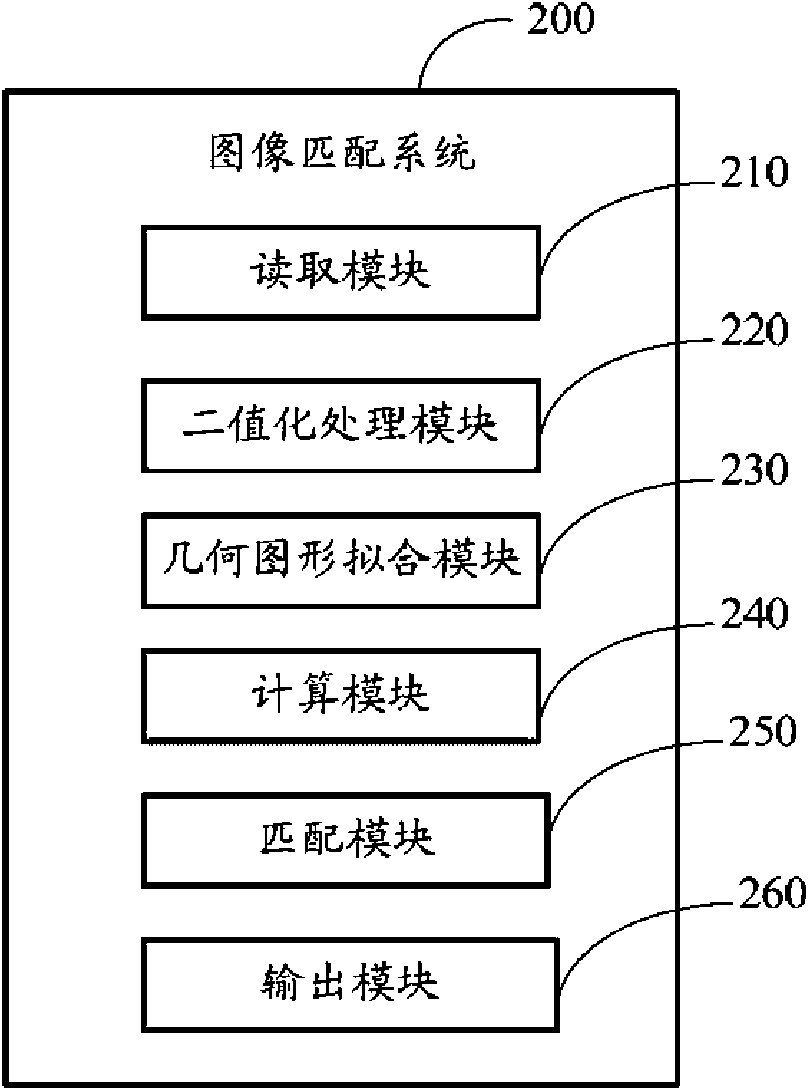

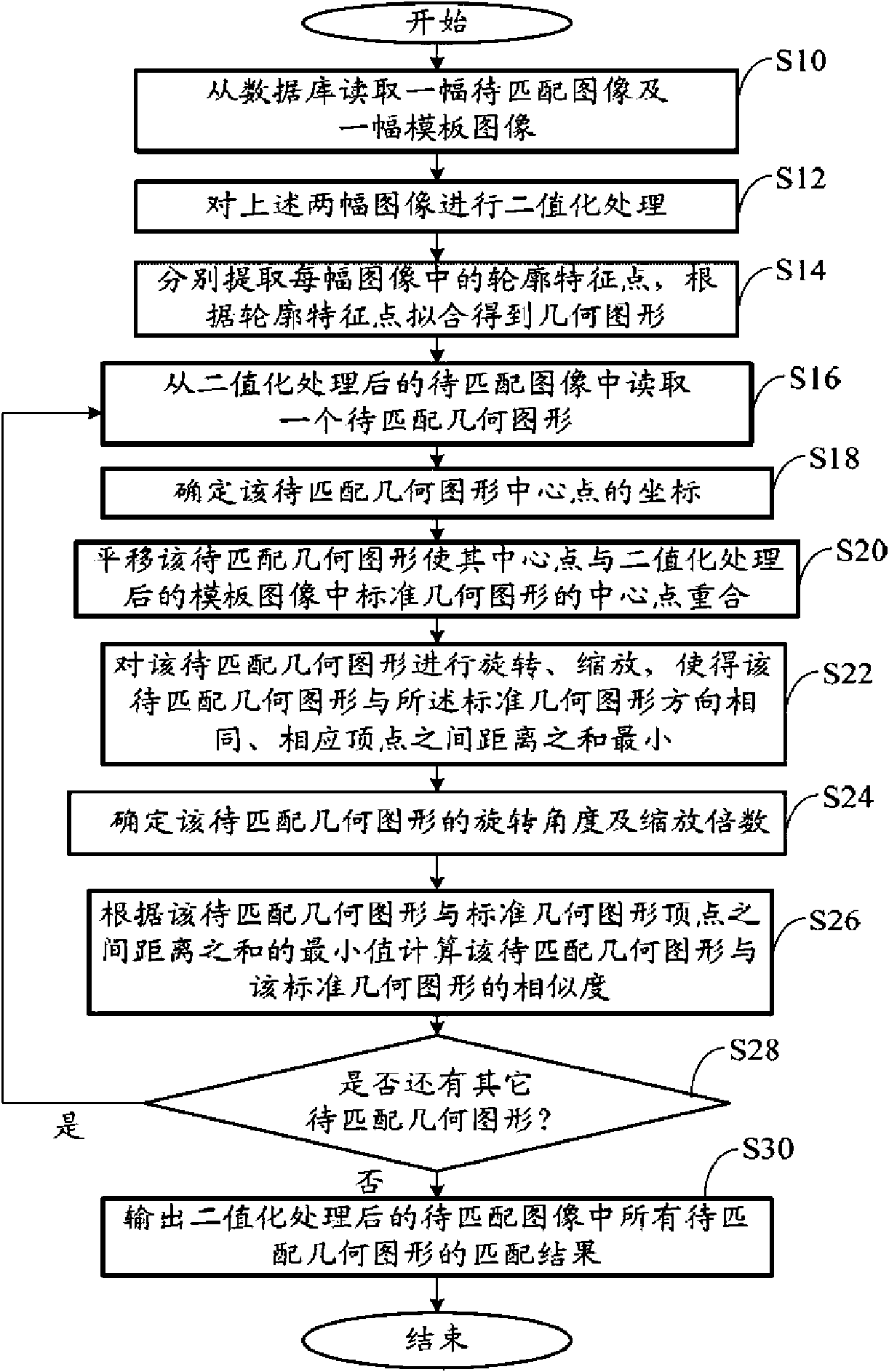

Image matching system and method

ActiveCN101770582ASmall amount of calculationImprove matching speedImage analysisCharacter and pattern recognitionGraphicsImage matching

The invention provides an image matching system applied to a computer. After the computer executes the image matching system to perform binarization processing on an image to be matched and a template image, outline characteristic points are extracted from the image to be matched and the template image, a geometric figure is obtained according to the fit of the outline characteristic points, the image is matched based on the geometric figure, and the coordinate, direction and other information of a target object in the image to be matched are determined. The invention also provides an image matching method. The image matching system and the image matching method can reduce the computed amount in the image matching process and improve the image matching speed.

Owner:量子云码福建科技有限公司

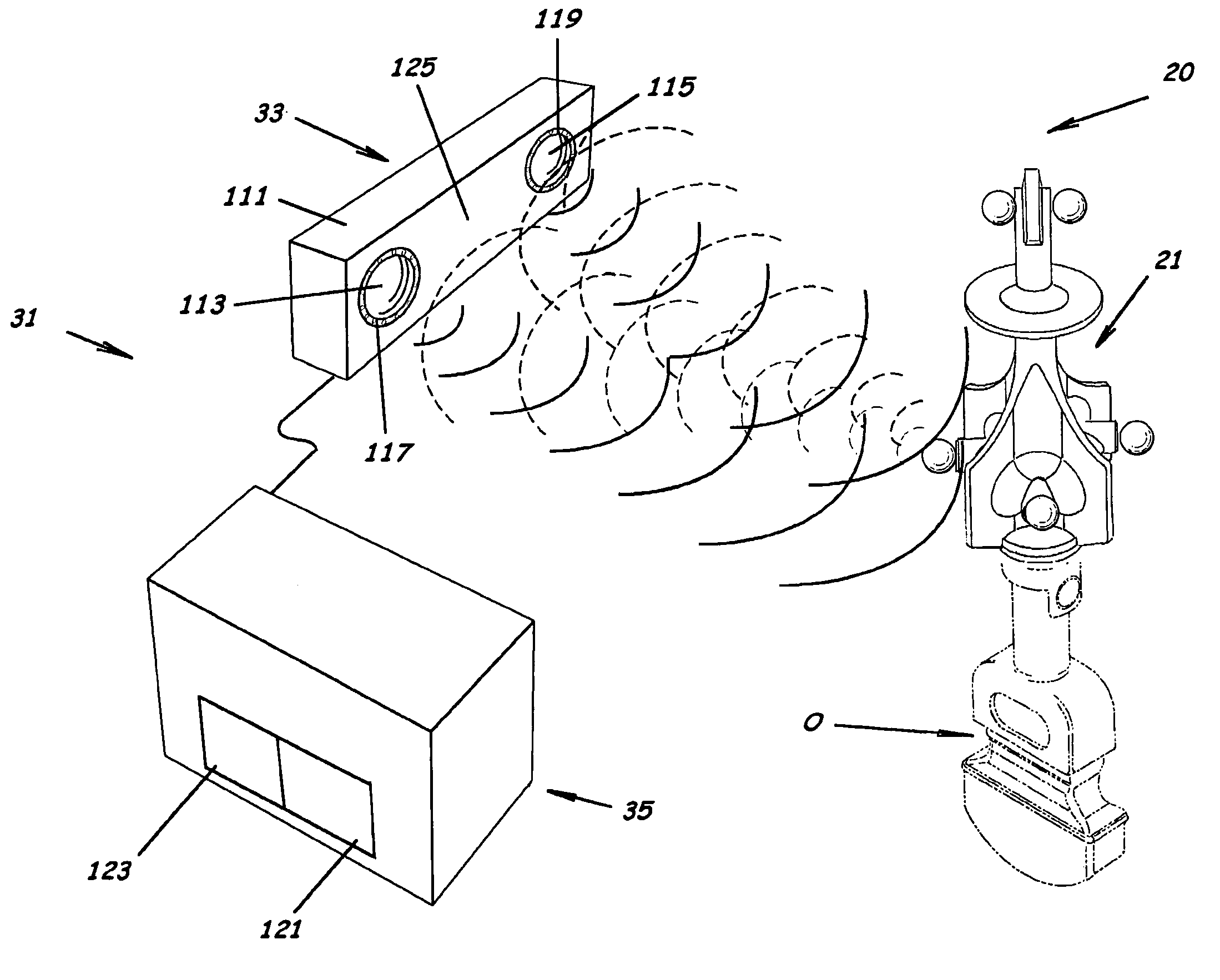

Range measurement system

InactiveUS6392744B1The relationship is accurateReduce the impactOptical rangefindersReflex reflectorsGraphicsObject based

A system and method for accurate measurement of distance and location of an object. The system comprises low-cost optical signal generators, aligned in a known configuration, to project a two-dimensional geometric figure on the object to be measured, or on a target attached to the object. The system captures an image of the projected figure, determines the exact geometry (e.g., area or circumference) of the figure, and calculates the exact distance to the object based on comparison of that geometry to the known configuration of the laser line generators. The invention simultaneously determines relative X and Y position of the object, thereby giving accurate X, Y, and Z coordinates.

Owner:ANALOG TECH

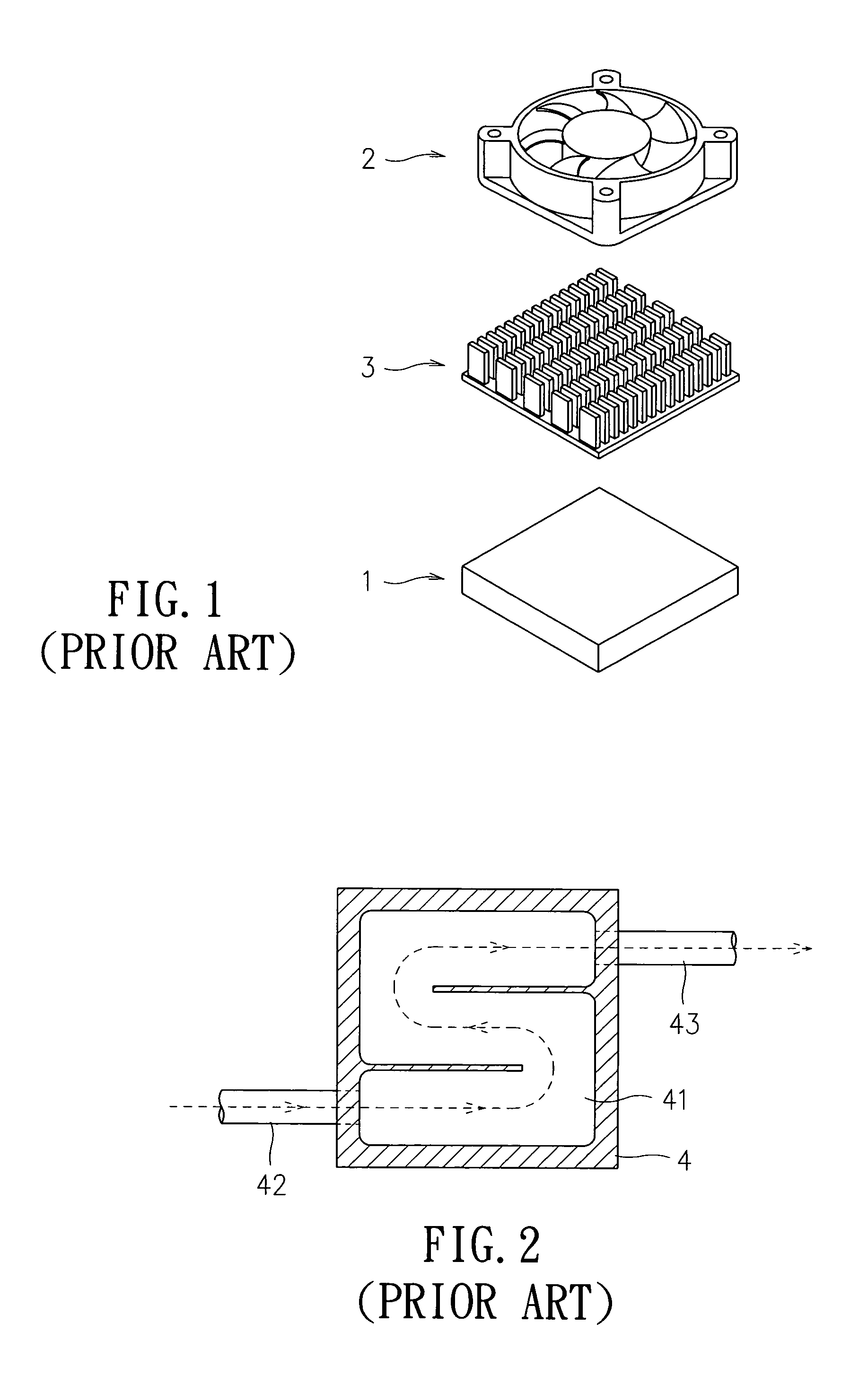

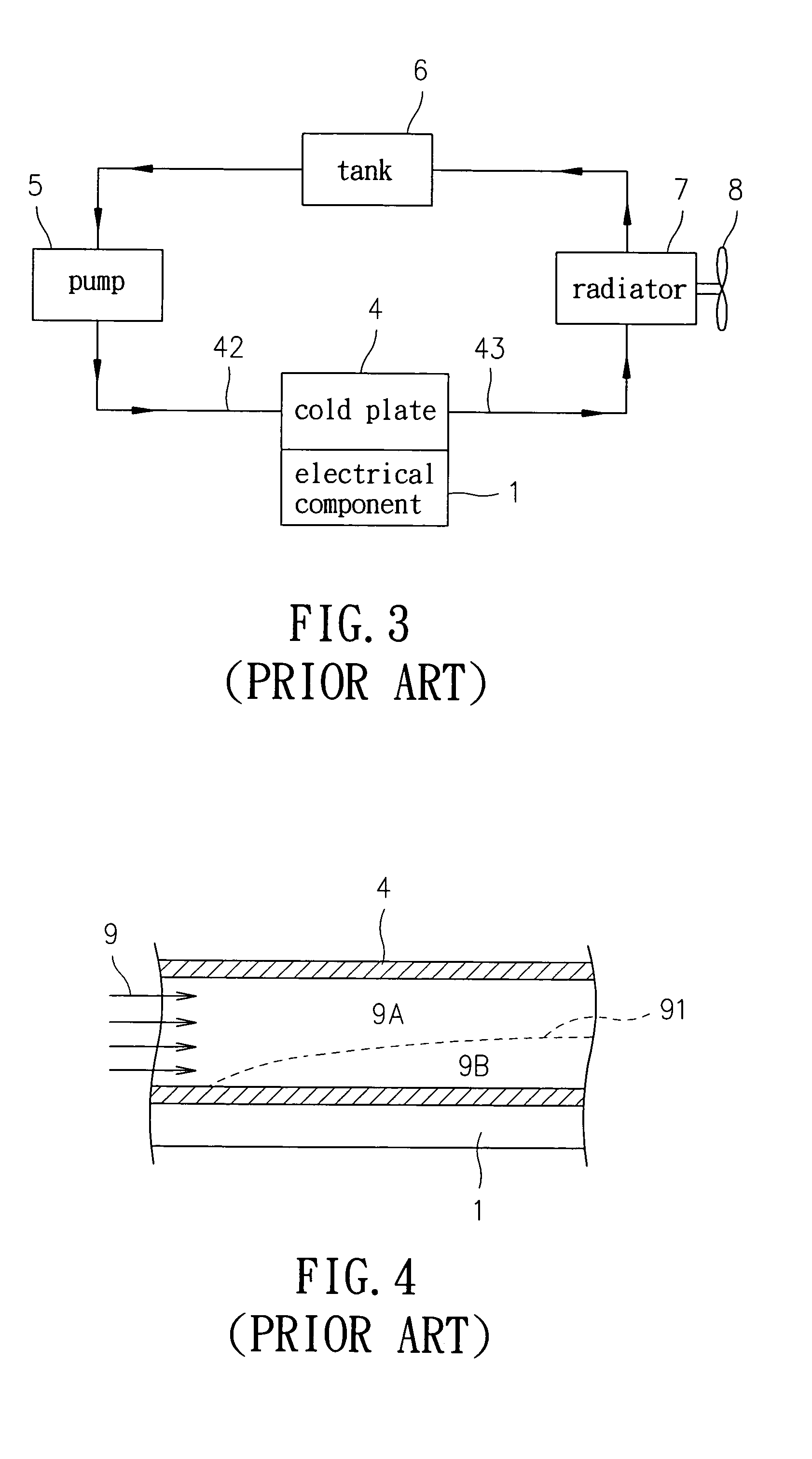

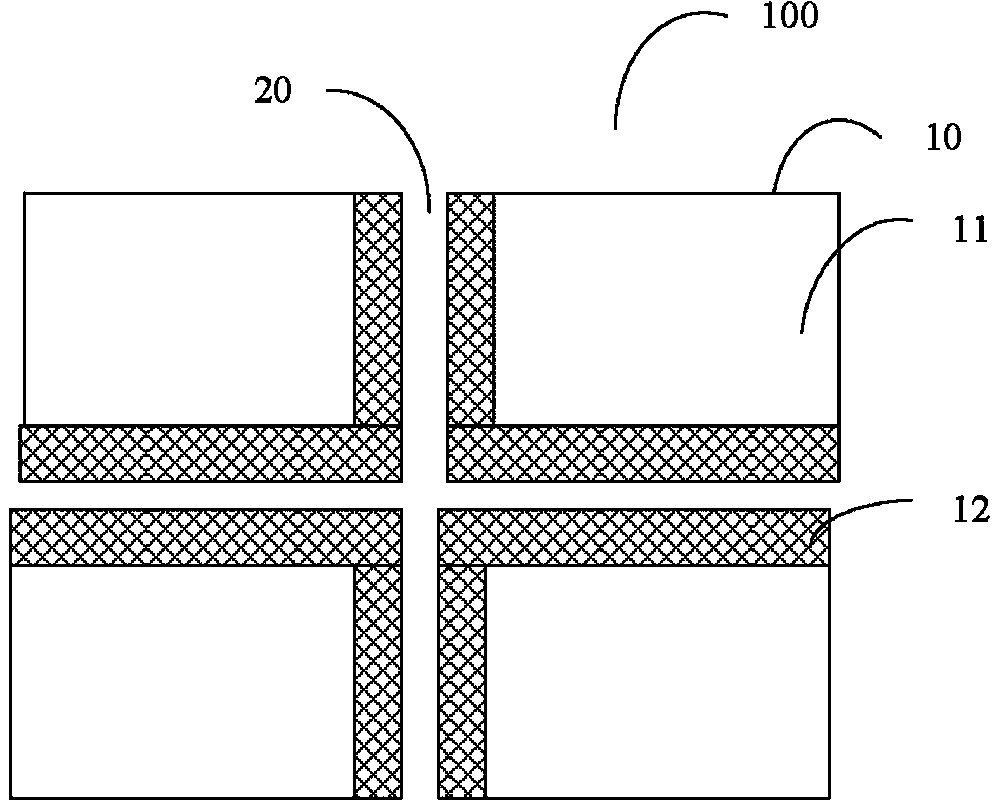

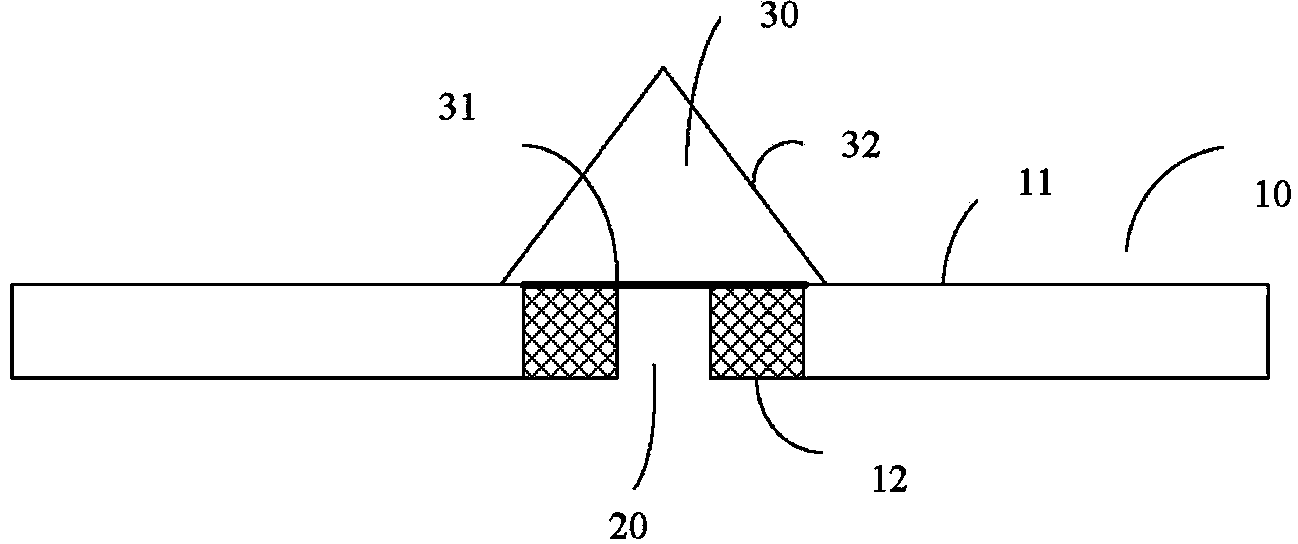

Cold plate with vortex generator

InactiveUS6929058B2Improve heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer efficiency

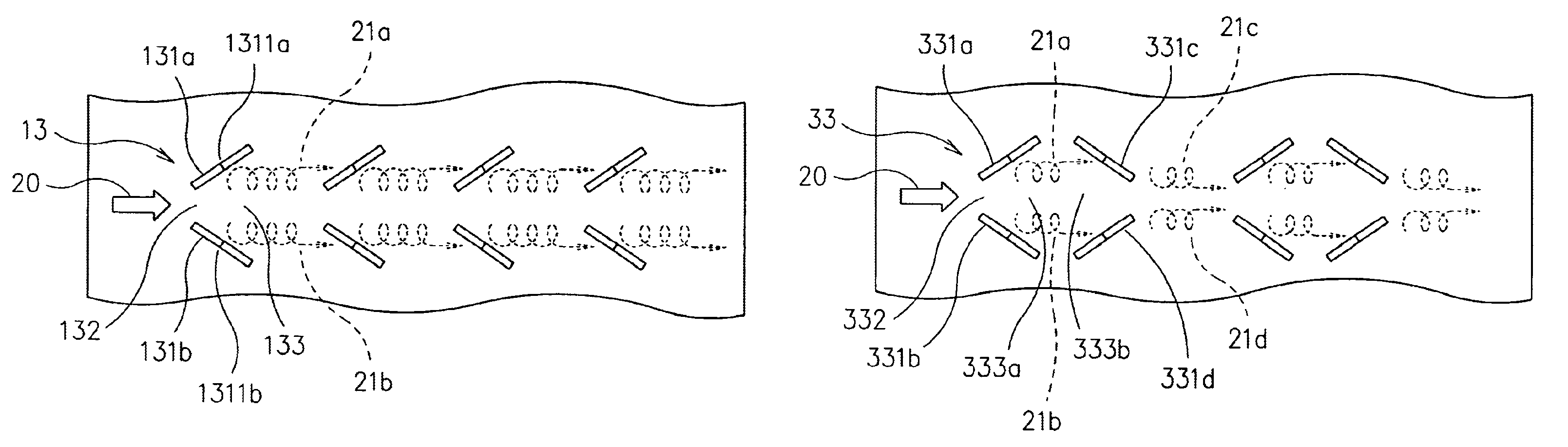

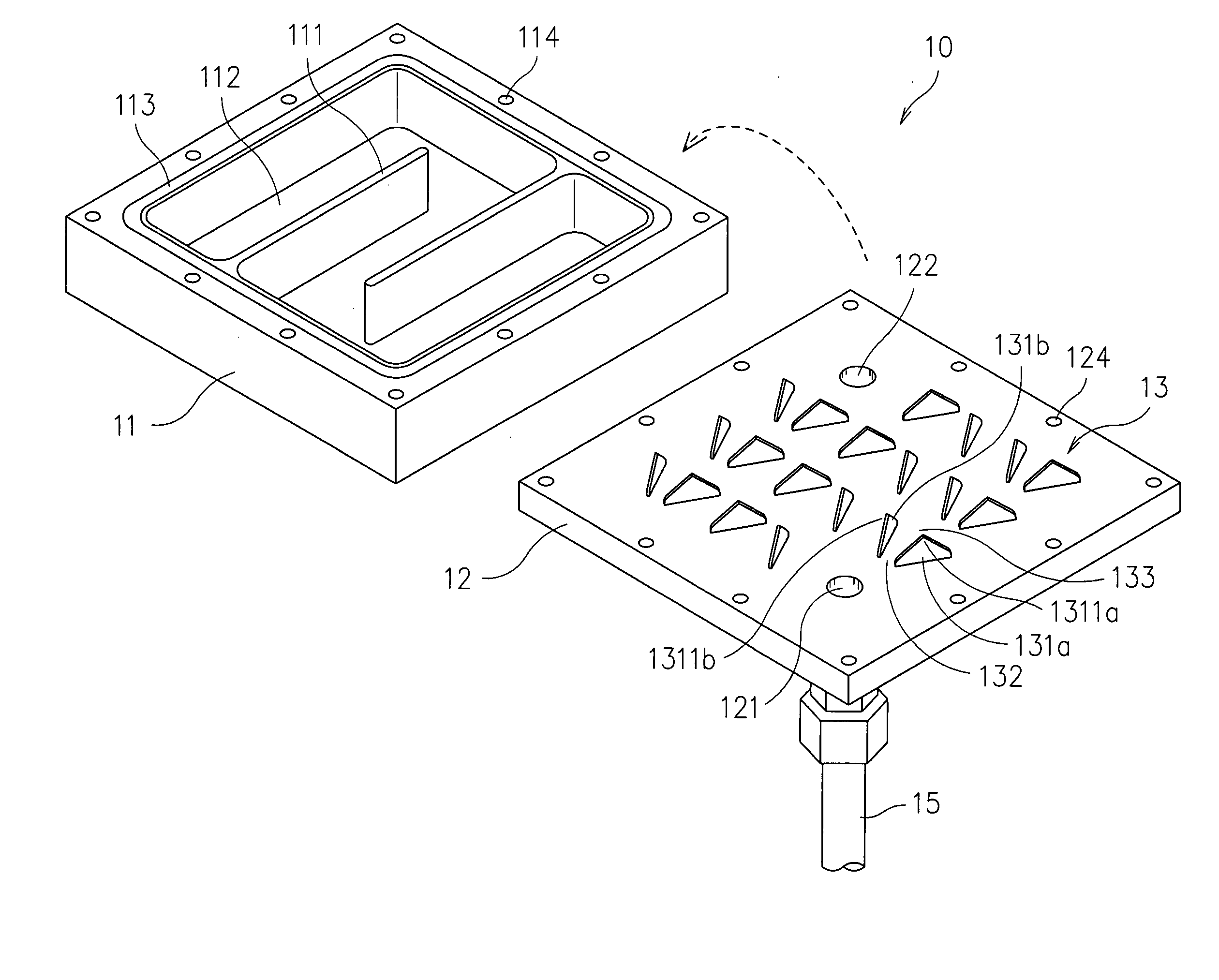

The present invention discloses a cold plate with vortex generator for fluid going through defined an inlet and an outlet according to the flowing directions of the fluid, comprising: a base having a groove, one end of the groove is connected to the inlet and another end is connected to the outlet; a body installed on the base; at least one vortex generator mounted on a surface of the body toward the groove of the base, wherein two unparallel and symmetrical ribs form the vortex generator, one end of the unparallel ribs is a contraction end with a shorter gap, another end is an expansion end with a longer gap, coolant can pass through the gap between the ribs, due to each rib having a sharp portion, an appearance of the rib is a triangle geometric figure. The vortexes increase the liquid mixture and improve the heat transfer on the cold plate, but not cause much pressure drop, therefore the heat transfer of the entire system is more efficient.

Owner:IND TECH RES INST

Cold plate with vortex generator

ActiveUS20050011635A1Improve heat transfer performancePressure drop is notSemiconductor/solid-state device detailsSolid-state devicesEngineeringCold plate

The present invention discloses a cold plate with vortex generator for fluid going through defined an inlet and an outlet according to the flowing directions of the fluid, comprising: a base having a groove, one end of the groove is connected to the inlet and another end is connected to the outlet; a body installed on the base; at least one vortex generator mounted on a surface of the body toward the groove of the base, wherein two unparallel and symmetrical ribs form the vortex generator, one end of the unparallel ribs is a contraction end with a shorter gap, another end is an expansion end with a longer gap, coolant can pass through the gap between the ribs, due to each rib having a sharp portion, an appearance of the rib is a triangle geometric figure. The vortexes increase the liquid mixture and improve the heat transfer on the cold plate, but not cause much pressure drop, therefore the heat transfer of the entire system is more efficient.

Owner:IND TECH RES INST

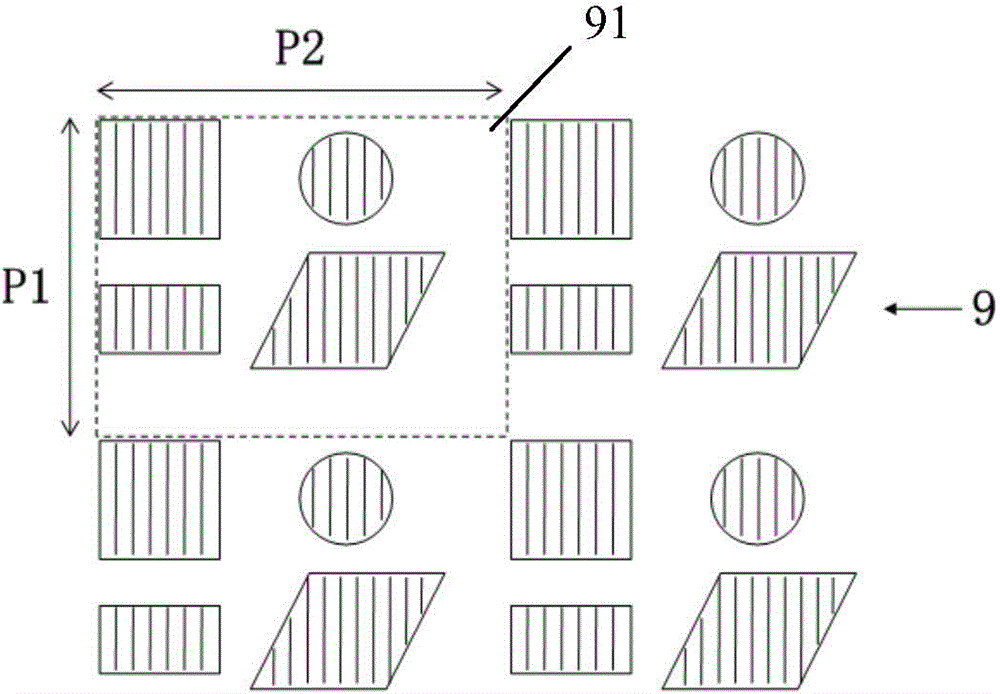

Seamless splice display screen

InactiveCN104299519AFull displayTo achieve the effect of seamless displayIdentification meansComputer graphics (images)Light guide

The invention relates to a seamless splice display screen. The seamless splice display screen comprises at least two adjacent splice display screen bodies. Each display screen body comprises a display region and a frame arranged at the edge of the display region, and gaps are formed in the positions of the spliced frames of the splice display screen bodies. The seamless splice display screen further comprises a gap eliminating device, the gap eliminating device comprises a covering part and a light guide part, the frames and the gaps are covered with the covering part, the light guide part and the covering part form a geometric figure with the closed cross section, and part of light emitted by regions, adjacent to the frames, of the display regions arrives at the gap eliminating device, is refracted and reflected by the gap eliminating device, and enters the eyes of a user.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

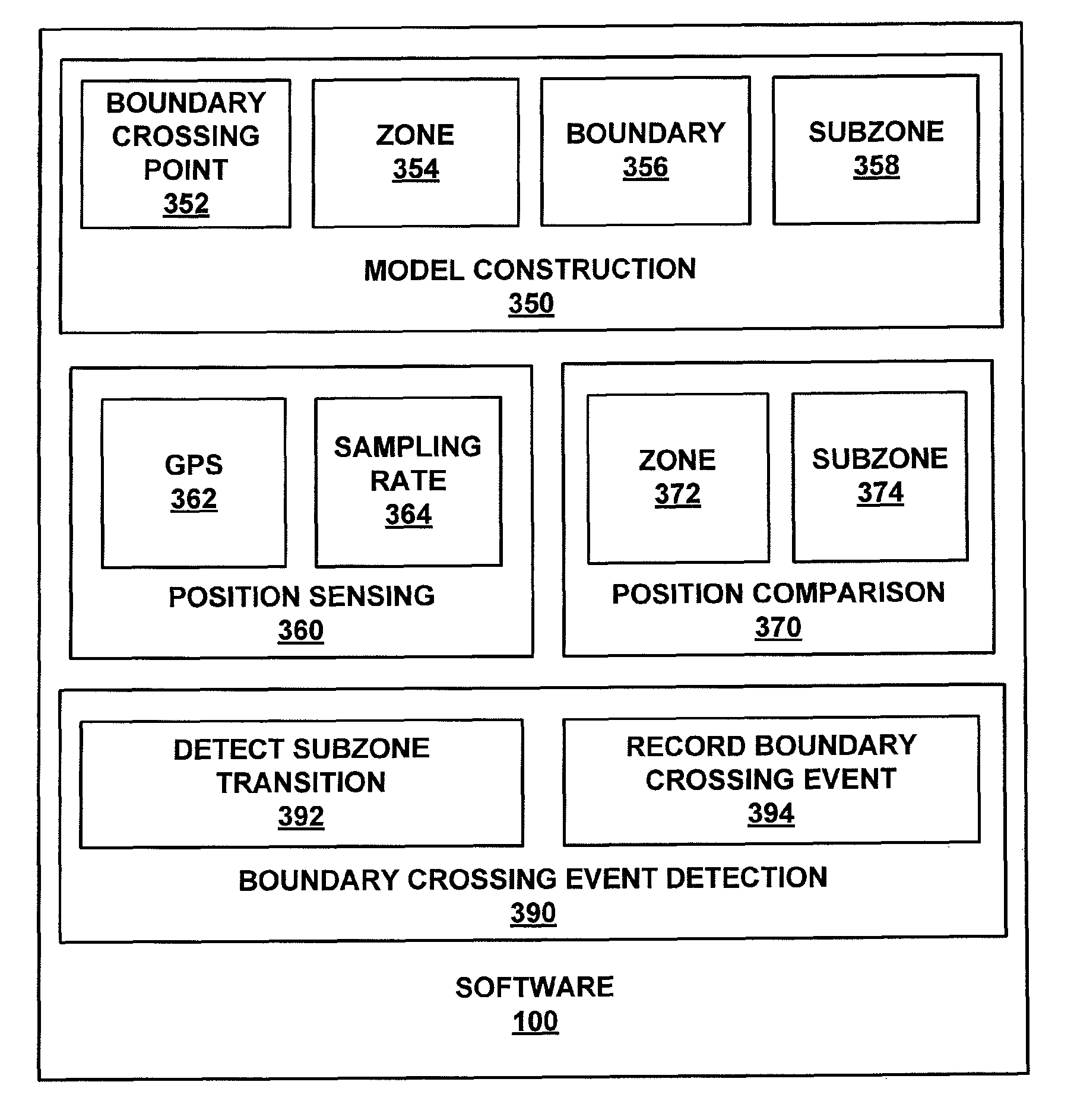

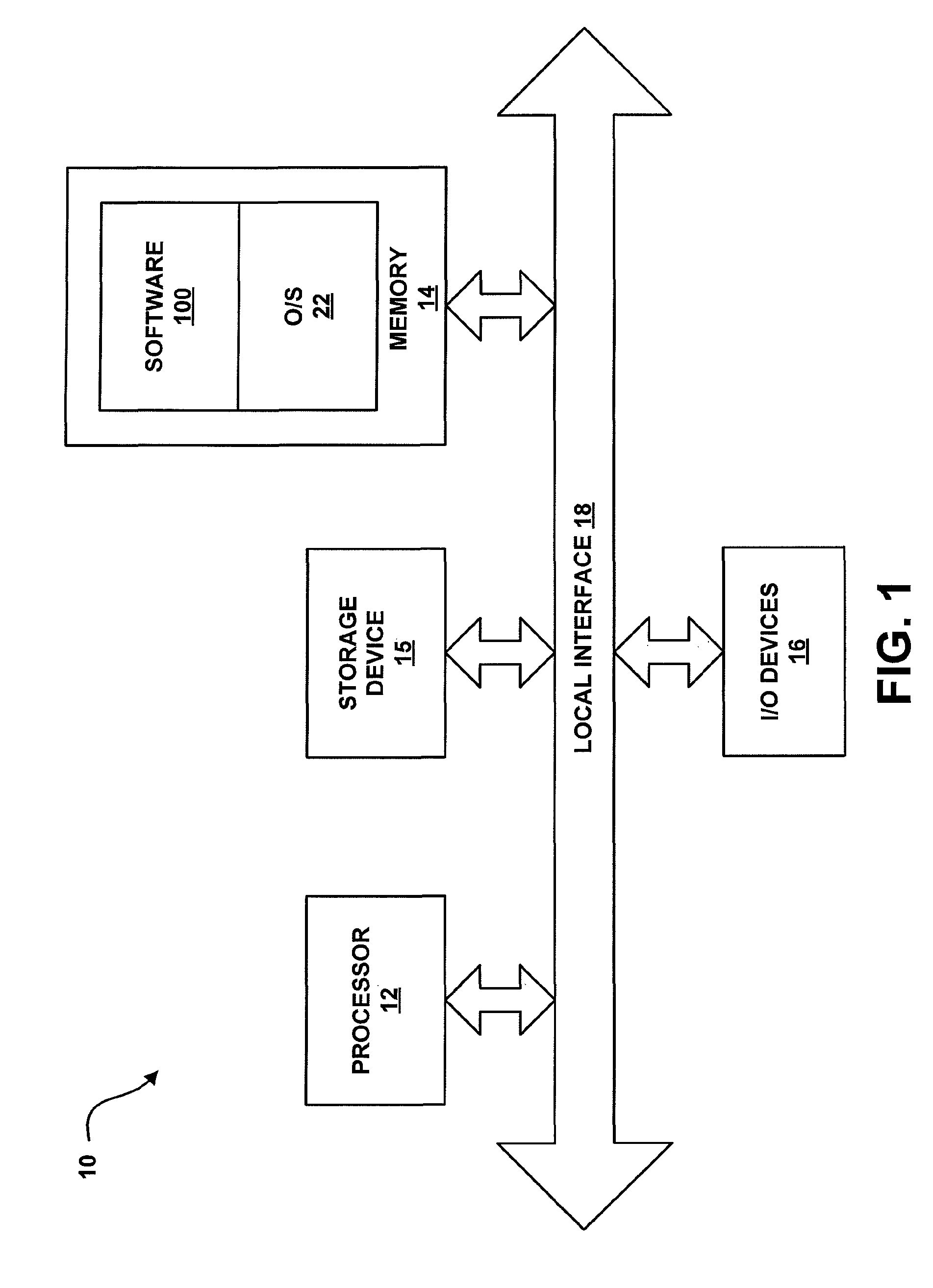

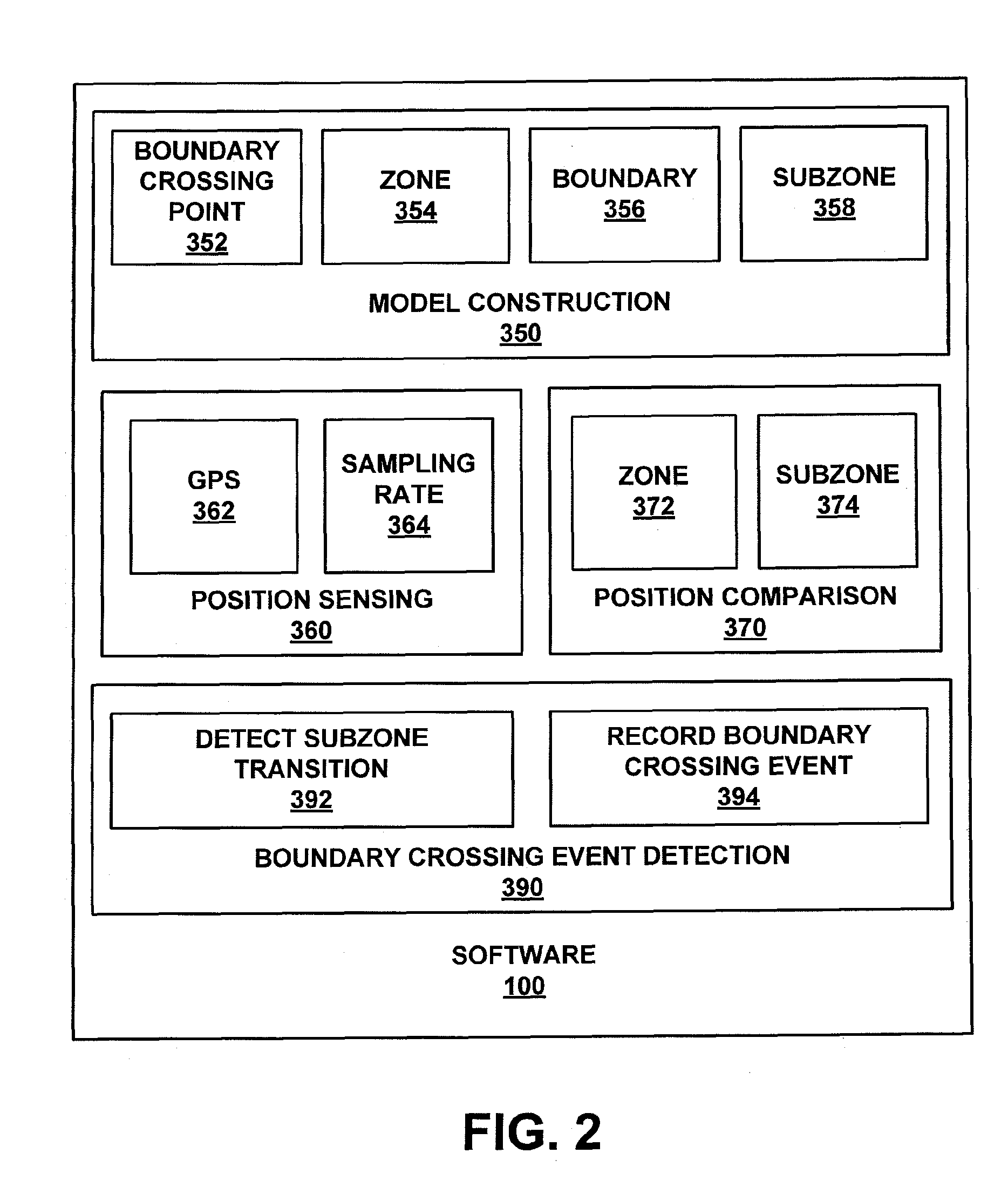

System and method for detecting a boundary crossing event

InactiveUS8284069B2Simple calculationDigital data processing detailsRoad vehicles traffic controlGraphicsEvent model

Owner:ORANGE MANGO SERIES 48 OF ALLIED SECURITY TRUST I

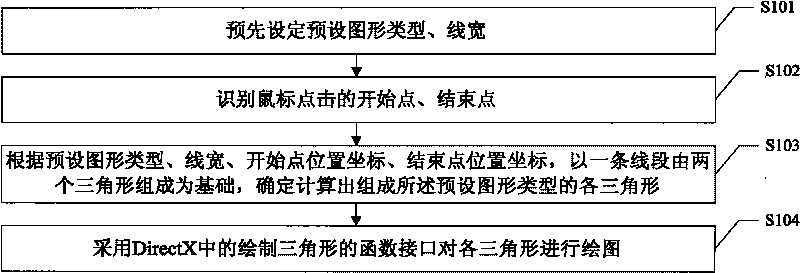

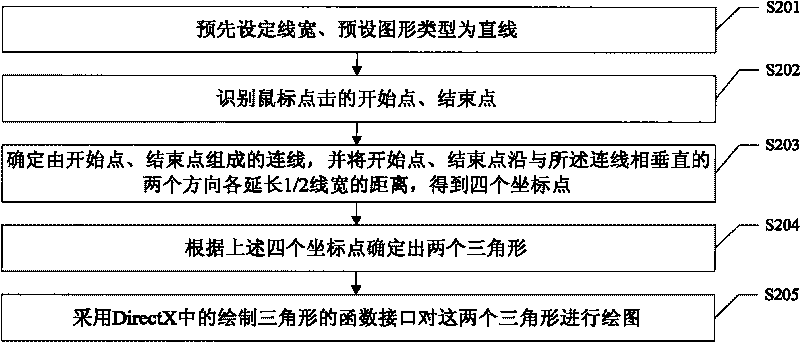

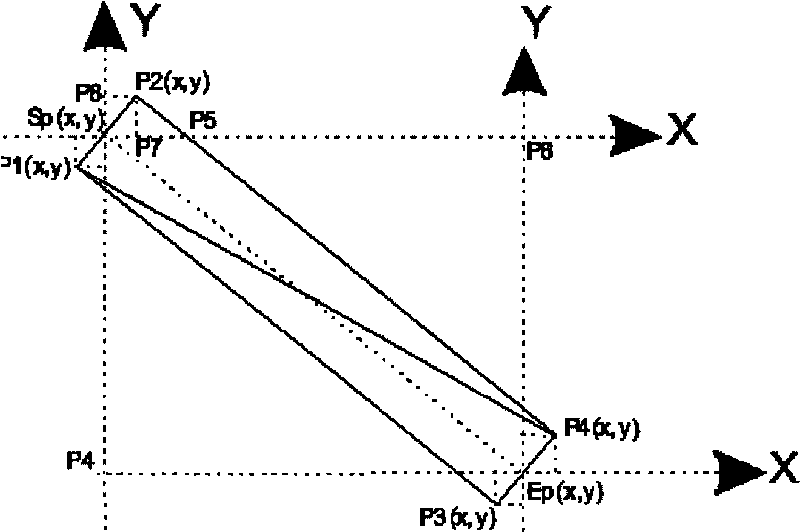

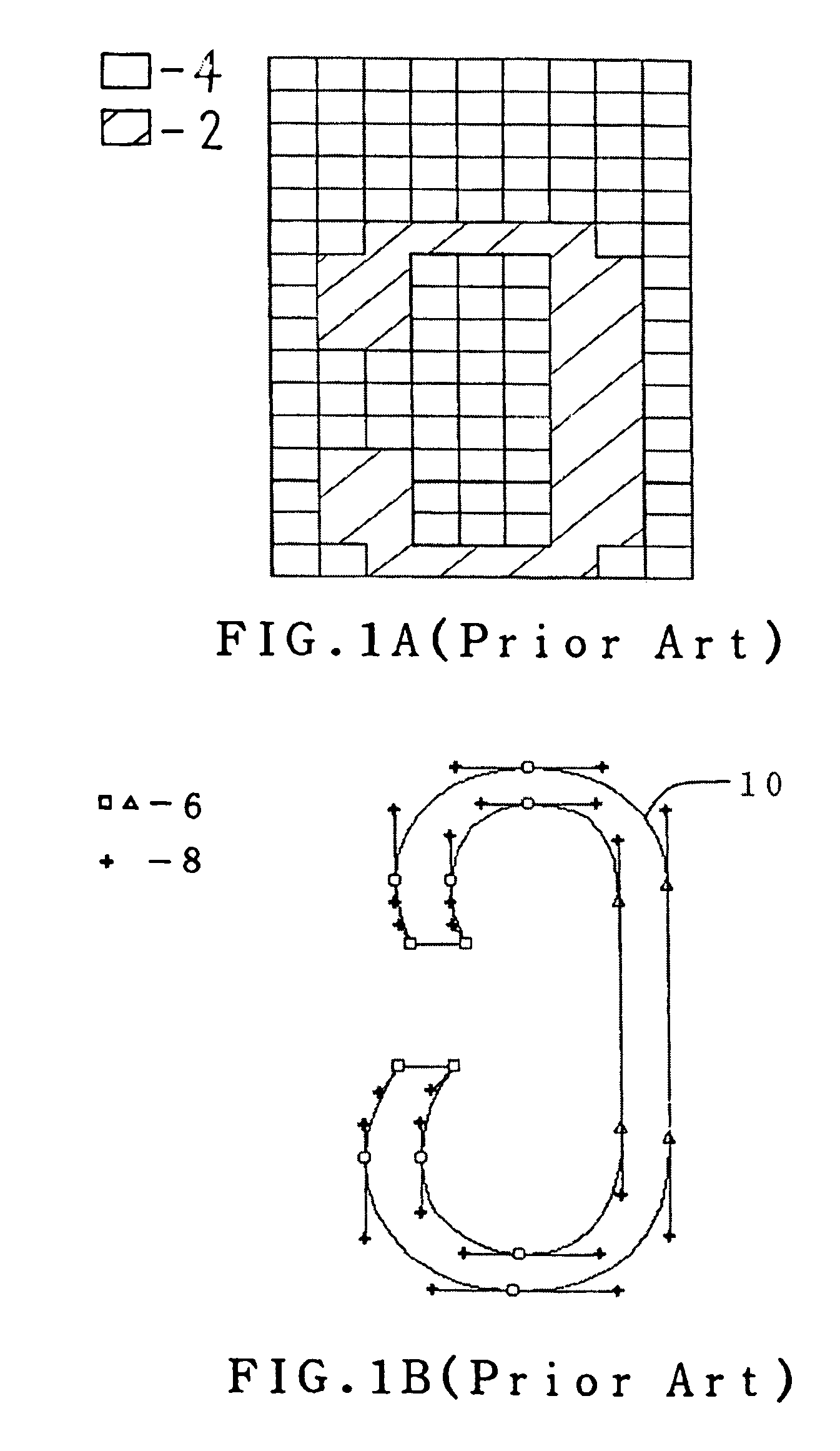

Method and device for drawing geometric figures

InactiveCN101719057AStrong support abilityImprove user experience2D-image generationSpecific program execution arrangementsGraphicsLine width

The invention relates to method and device for drawing geometric figures. The method comprises the following steps of: on the basis of forming a line segment by two triangles, using triangles to represent a preset figure type to be drawn; after recognizing a start point and a finish point clicked by a mouse, calculating to determine each triangle for forming the preset figure type according to the type, line width, start point position coordinates and finish point position coordinates of the preset figure; and drawing each triangle by a triangle drawing function interface in Direct X which has high support for Windows and simple use and supports hardware acceleration. Especially after each geometric figure is represented by triangles by fully making of a display card, a plurality of advantages of the Direct X can be effectively utilized, and therefore the scheme of the invention can effectively enhance the efficiency of drawing two-dimensional figures.

Owner:GUANGDONG VTRON TECH CO LTD

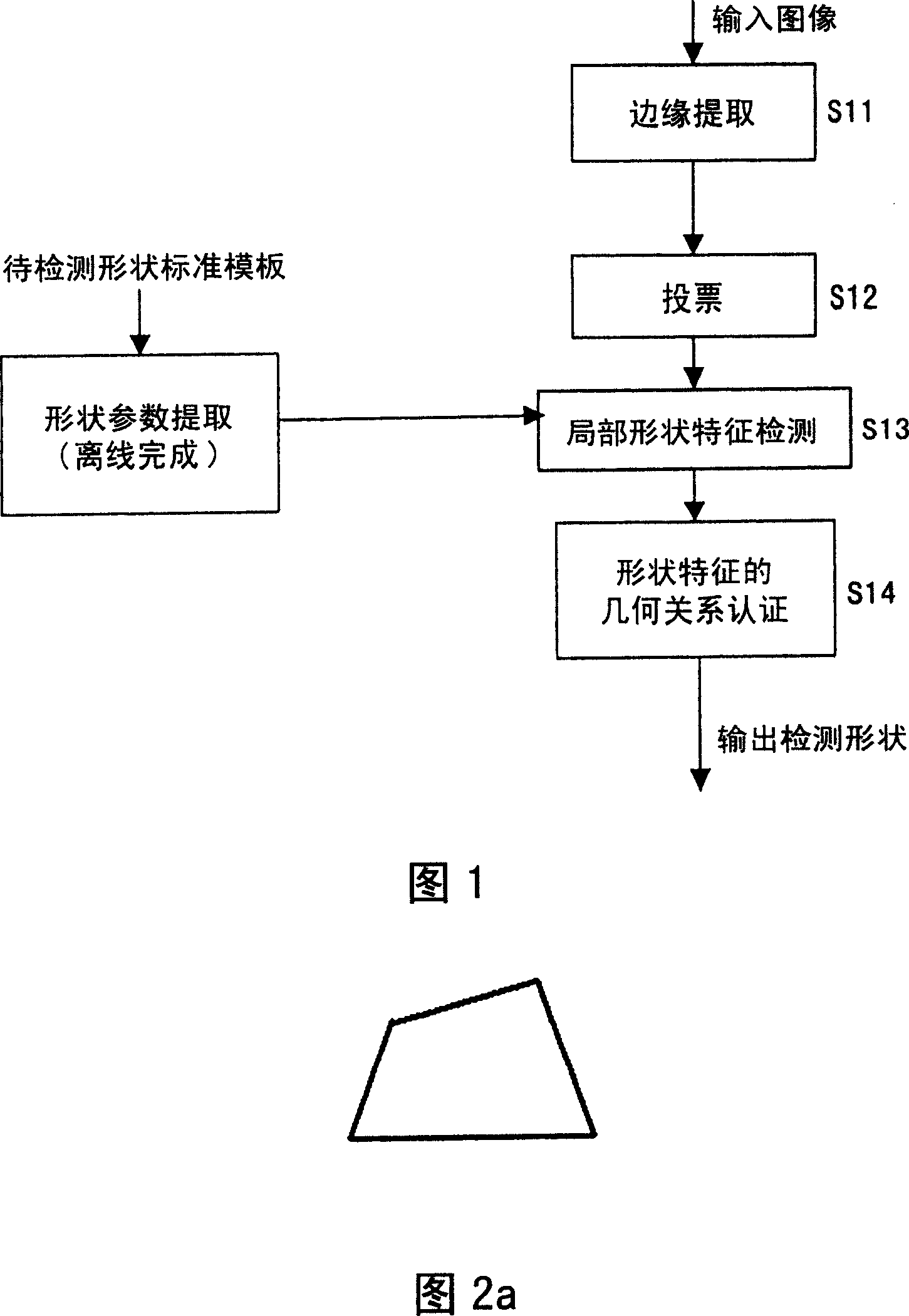

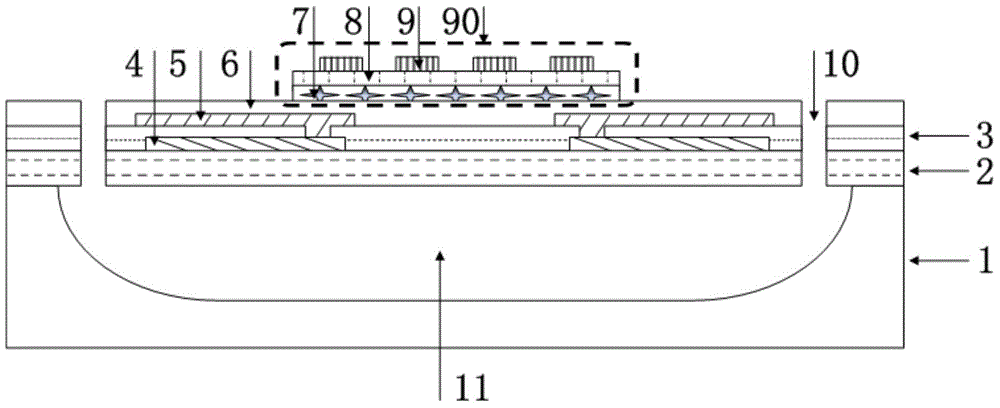

Method and device for detecting geometric figure of image

InactiveCN101110100ACan detect a wide rangeShape detection worksImage enhancementImage analysisPattern recognitionGeometric figure

Owner:PANASONIC CORP

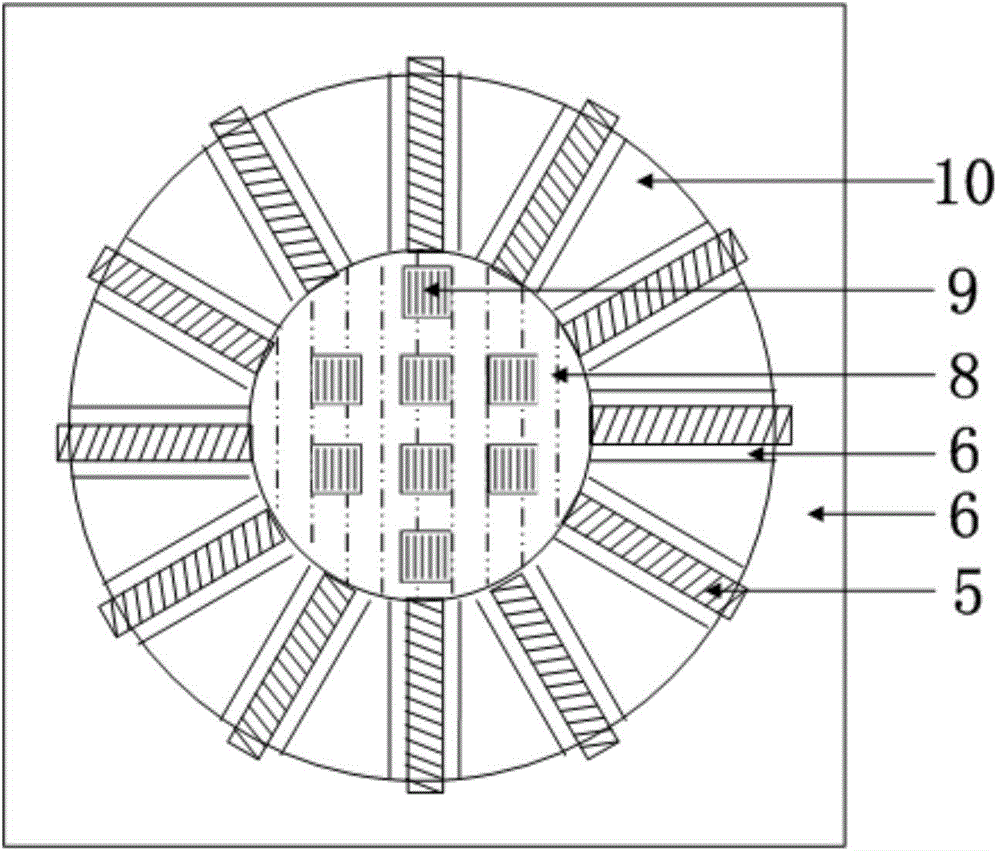

Thermopile infrared detector and manufacturing method thereof

InactiveCN104535197AHigh yieldImprove response ratePyrometry using electric radation detectorsMicro structureCMOS

The invention provides a thermopile infrared detector and a manufacturing method of the thermopile infrared detector. The thermopile infrared detector comprises a substrate, a dielectric supporting film, a thermopile, a metamaterial structure, a middle dielectric layer and a metal micro structure layer, wherein a cavity is formed in the substrate, the dielectric supporting film is located above the cavity and supported by the substrate, the thermopile is located on the dielectric supporting film above the cavity, the metamaterial structure is located above the thermopile and comprises a metal plane reflecting mirror, the middle dielectric layer is located on the metal plane reflecting mirror, the metal micro structure layer is located on the middle dielectric layer and comprises one or more structural period units, and each structural period unit comprises one or more geometric figure units having the light adsorption enhance effect within the infrared spectrum range. Due to the thermopile infrared detector, perform absorption within the infrared band broad spectrum range can be achieved, the infrared adsorption rate and the responding rate of the thermopile infrared detector can be improved, and the manufacturing method is compatible with a conventional CMOS technology.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT

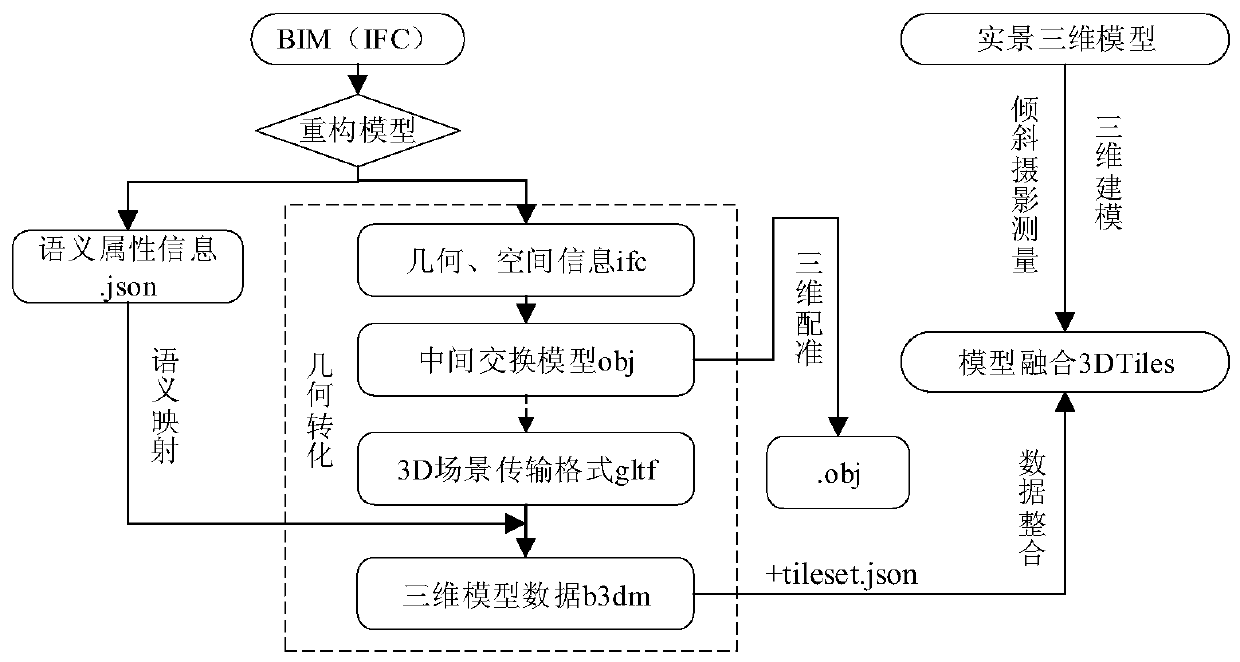

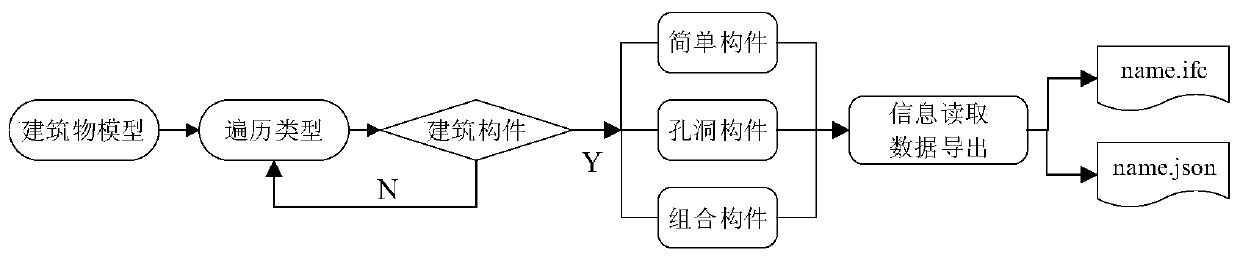

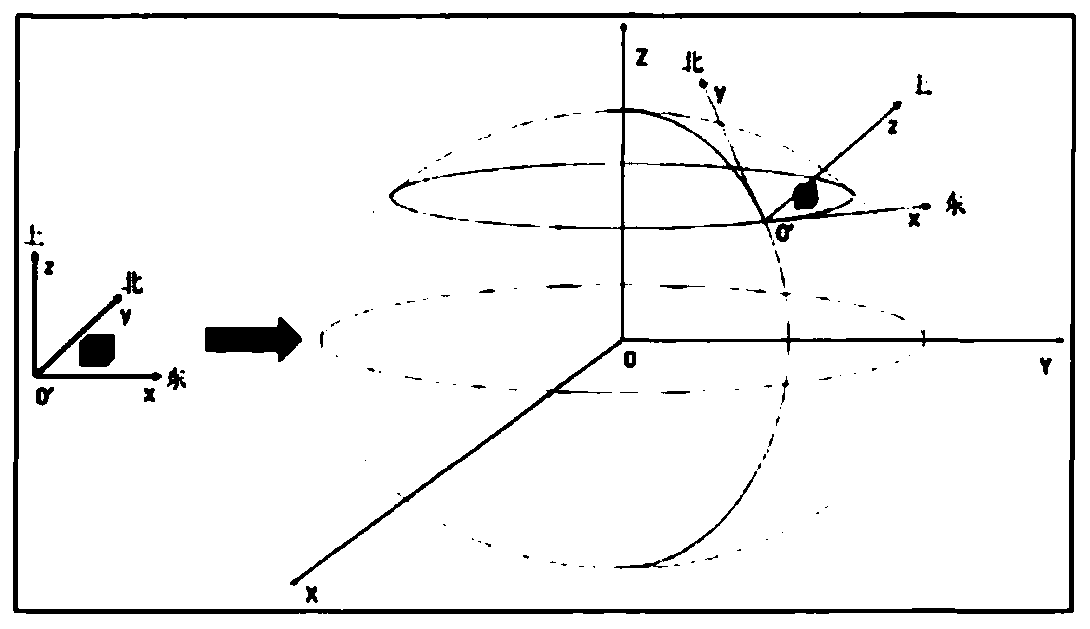

Fusion method of building BIM model and live-action three-dimensional model

ActiveCN110807835ARetain propertiesEfficient acquisitionGeometric CADImage data processingData descriptionModel reconstruction

The invention discloses a fusion method of building BIM model and live-action three-dimensional model. The fusion and conversion process mainly comprises model reconstruction, geometric information conversion, model three-dimensional registration and semantic mapping. The fusion method comprises the steps that firstly, a building BIM model is split, and json attribute files and ifc geometric filesof all components are generated; then, intermediate format exchange is carried out, and ifc is converted into obj; obj is converted into glTF, and three-dimensional geometric figure data transmissionis further achieved; then attributes and geometric data are connected, and glTF and json generate b3dm; and finally, a data description file tileset.json are added, and the data description file tileset.json and b3dm are converted into 3DTiles data. According to the method, the semantic attribute characteristics in the BIM original model are reserved while the geometric figures are completely expressed, and the spatial positions of the two models are unified in the same environment, so that an internal and external integrated display effect is achieved.

Owner:NANJING UNIV OF TECH

System and tracker for tracking an object, and related methods

ActiveUS20060072124A1Easy to detectEasy to installUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsEngineeringGeometric figure

A system to track a three-dimensional position and an orientation of a movable object and associated methods are provided. The system includes a tracker having an optically trackable body adapted to connect to the movable object. A plurality of optical indicators are connected or mounted to the optically trackable body to form a plurality of geometric figures. A plurality of obfuscating flanges optically separate the optical indicators from each other to prevent each of the optical indicators from becoming optically coincident with another optical indicator when viewed along a preselected viewing path. The system also includes an apparatus to track the tracker having an optical detector to simultaneously detect the three-dimensional position of at least three of the plurality of optical indicators and a determiner to determine the three-dimensional position and orientation of the optically trackable body from the position of the optical indicators.

Owner:BEST MEDICAL INT

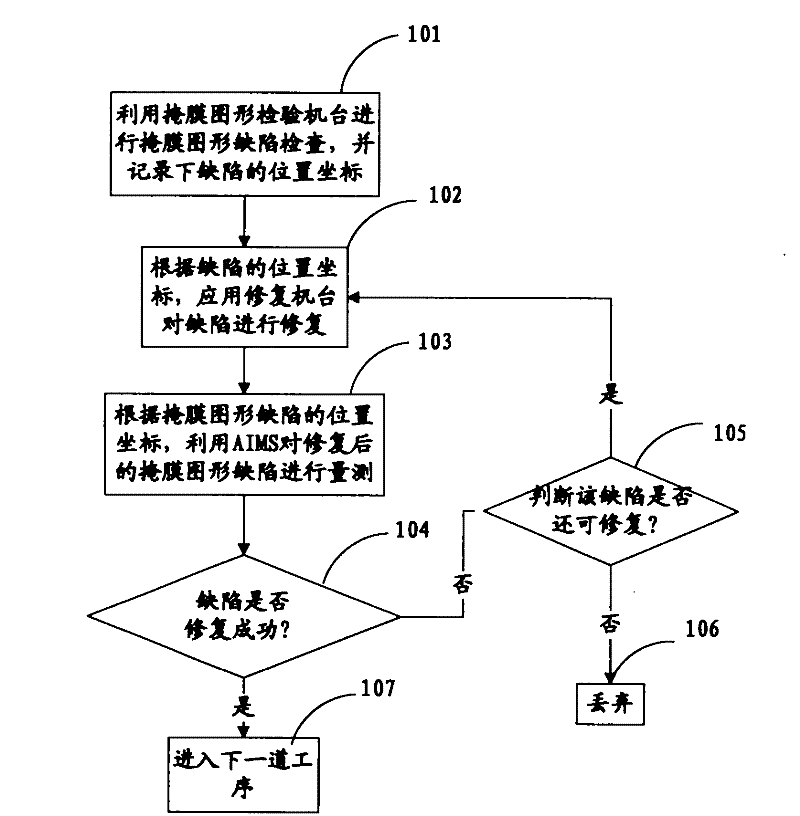

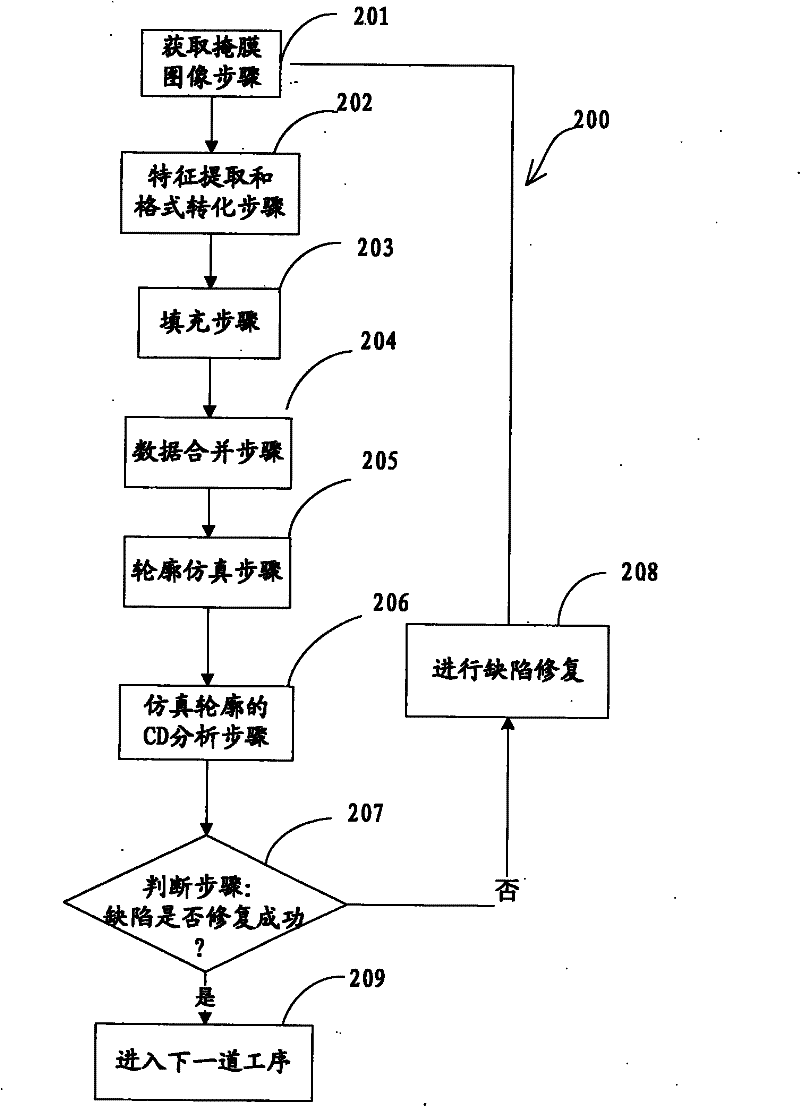

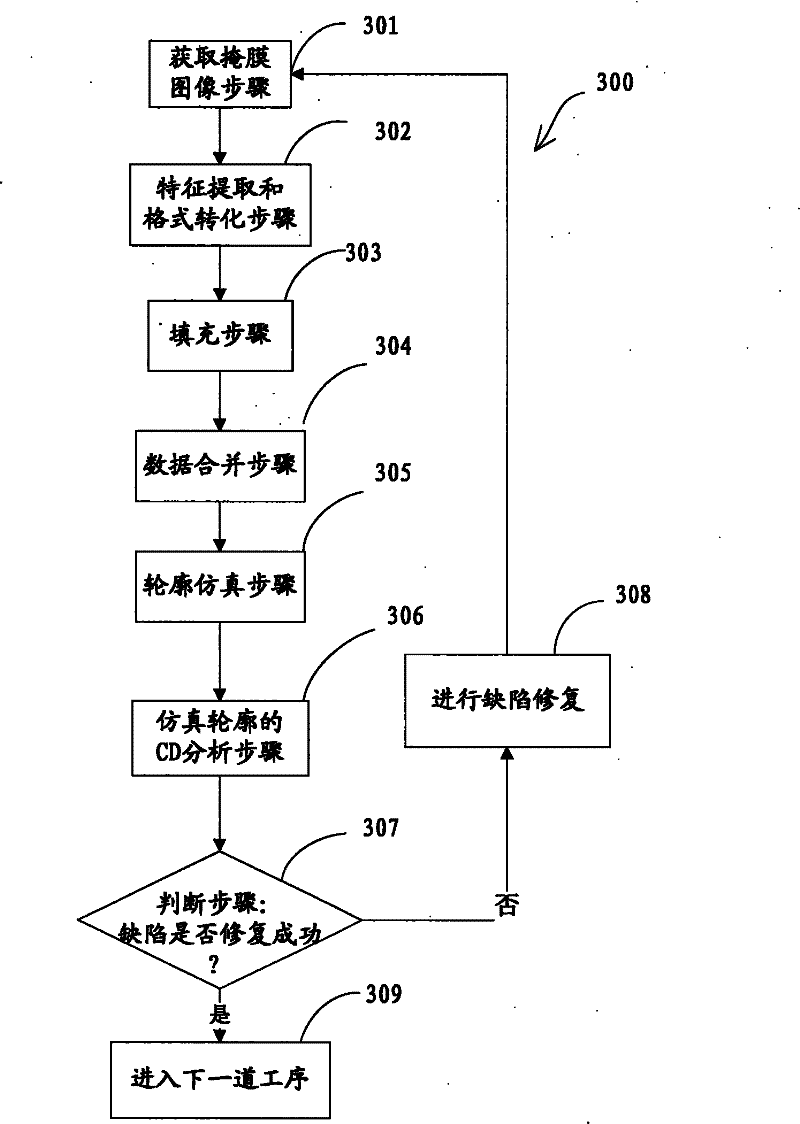

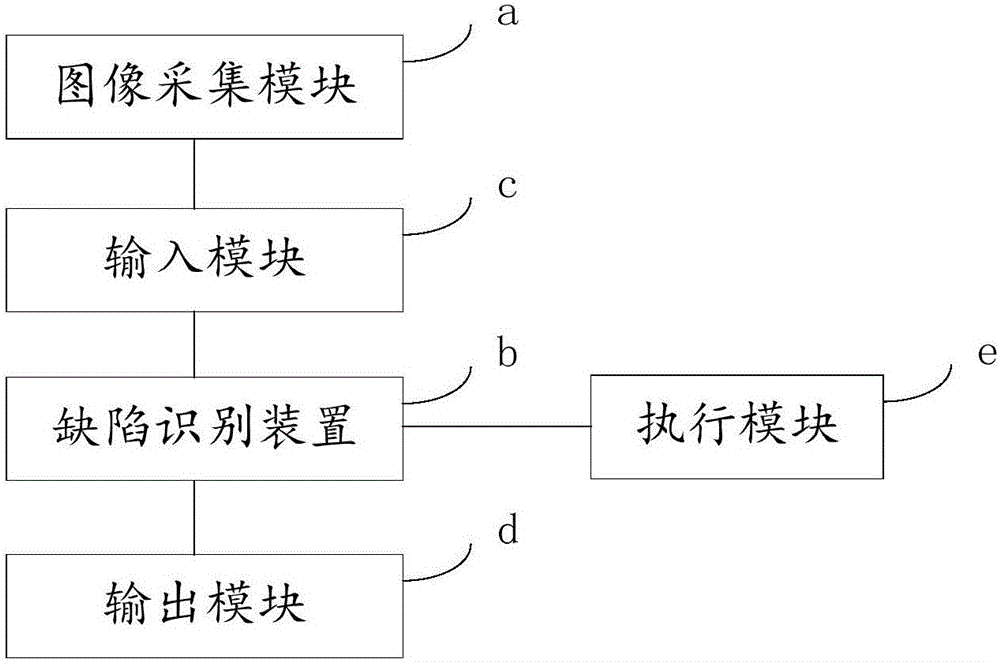

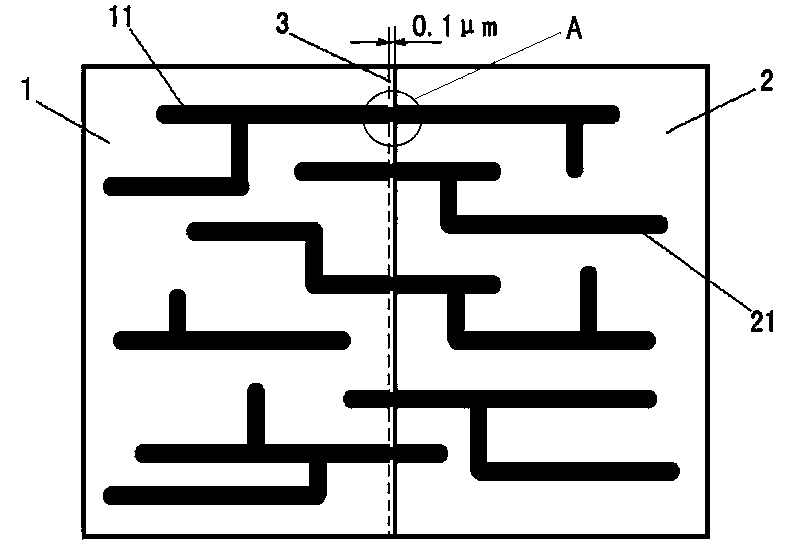

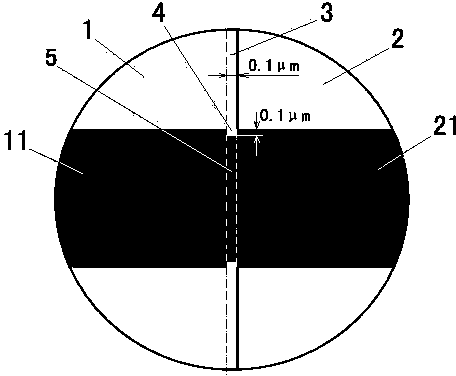

Mask image defection detection method and detection system thereof

InactiveCN102193302AReduce manufacturing costSimple methodOptically investigating flaws/contaminationOriginals for photomechanical treatmentGraphicsFeature extraction

The invention relates to a mask image defection detection method and a detection system thereof. The method comprises the following steps: step of obtaining a mask image-obtaining a mask image to be detected and a normal mask image; step of feature extraction and format conversion-extracting edge characteristic and converted it as geometric figure format to be stored; step of filling-filling the blank area of the rectangular edge contour of the geometric figure; step of data merging-carrying out figure superposition; step of contour simulation-carrying out the contour simulation of wafer; step of critical dimensions analysis of the simulated contour-measuring the critical dimensions and calculating the difference of critical dimensions; and step of judge-judging whether the mask defection restoration is succeed or not through the difference of critical dimensions. The invention further relates to a mask image defection detection system. The method and system in the invention is simple and practicable, and has a substantial effect, thus the lithography mask production cost of 45 nm or higher nanometer level lithography technology is effectively reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

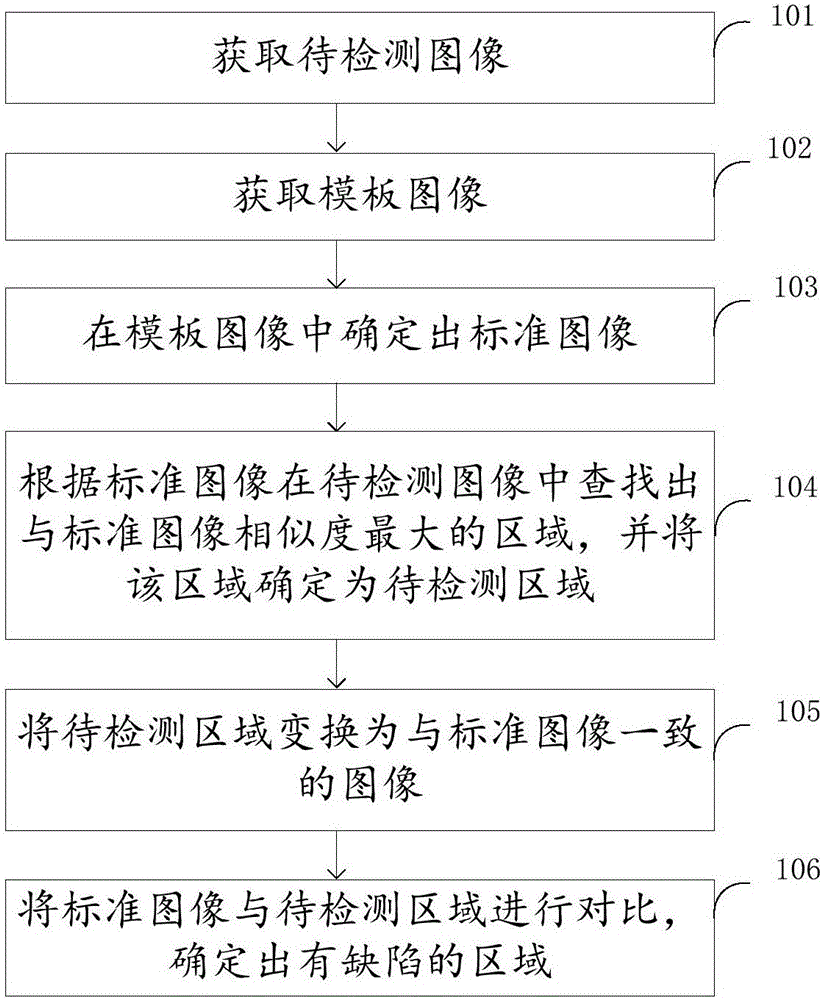

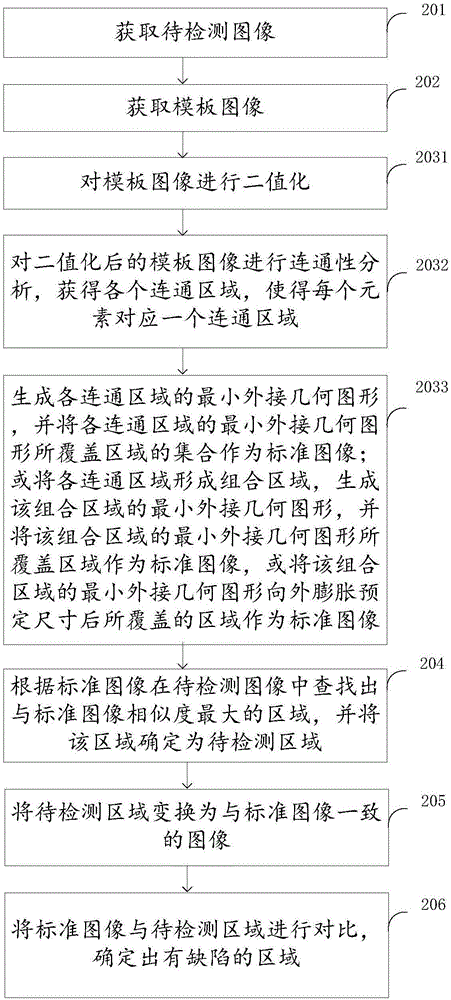

Defect identification method and system

The present invention provides a defect identification method and system. The method comprises: obtaining an image to be detected and a template image; determining a standard image in the template image, wherein the standard image is a set of an area covered by the minimum external geometric figure of a detection object, an area covered after the minimum external geometric figure of the detection object expands outwards with a preset size or an area covered by the minimum external geometric figure of each element; searching out an area having the most similarity to the standard image from the image to be detected according to the standard image, and determining the area as an area to be detected; converting the area to be detected as an image consistent to the standard image; and comparing the standard image with the area to be detected, determining the area having defects. The defect identification method can identify whether there are defects in the area to be detected and can obtain the concrete positions of the defects.

Owner:SHENZHEN HUAHAN WEIYE TECH

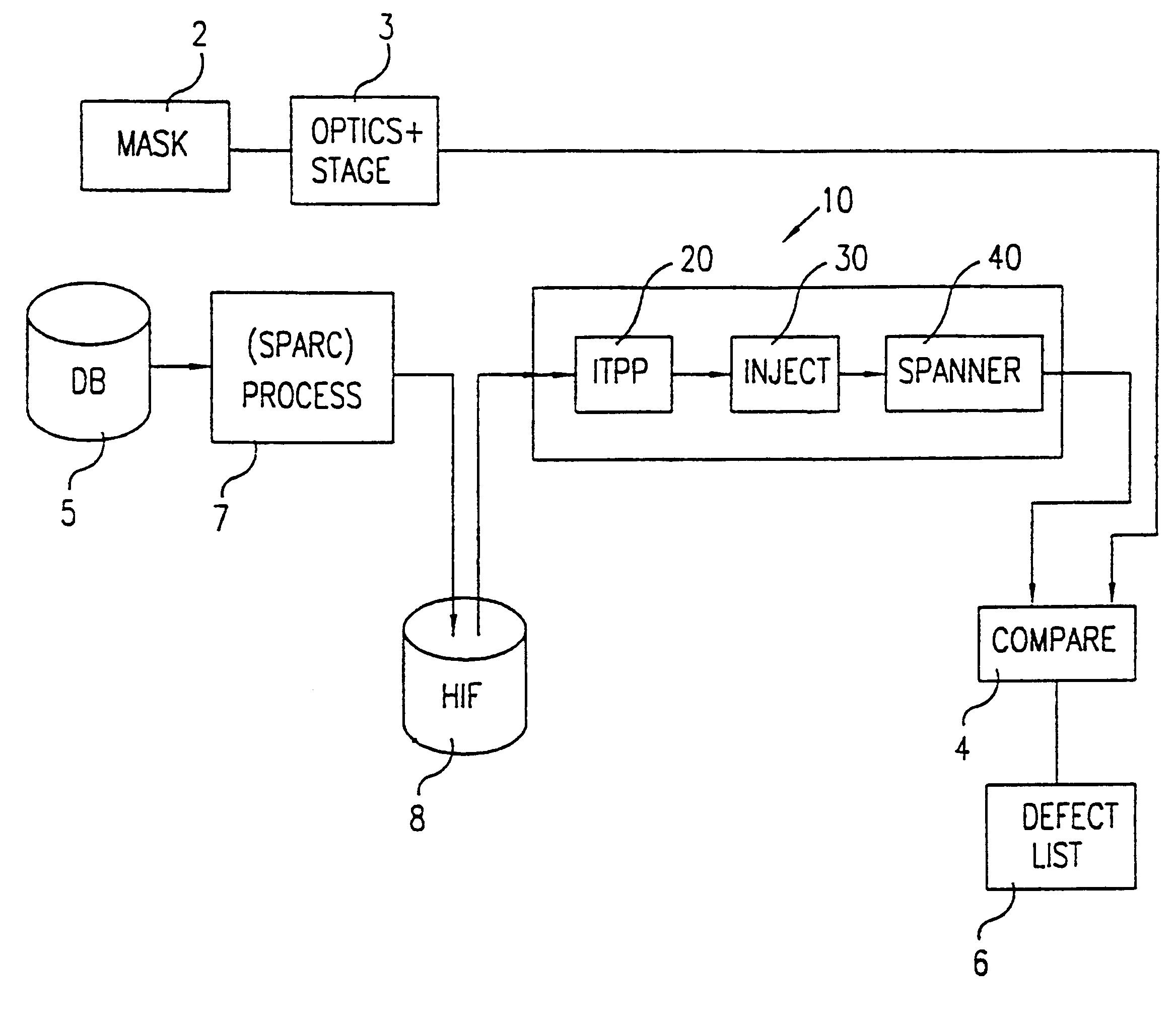

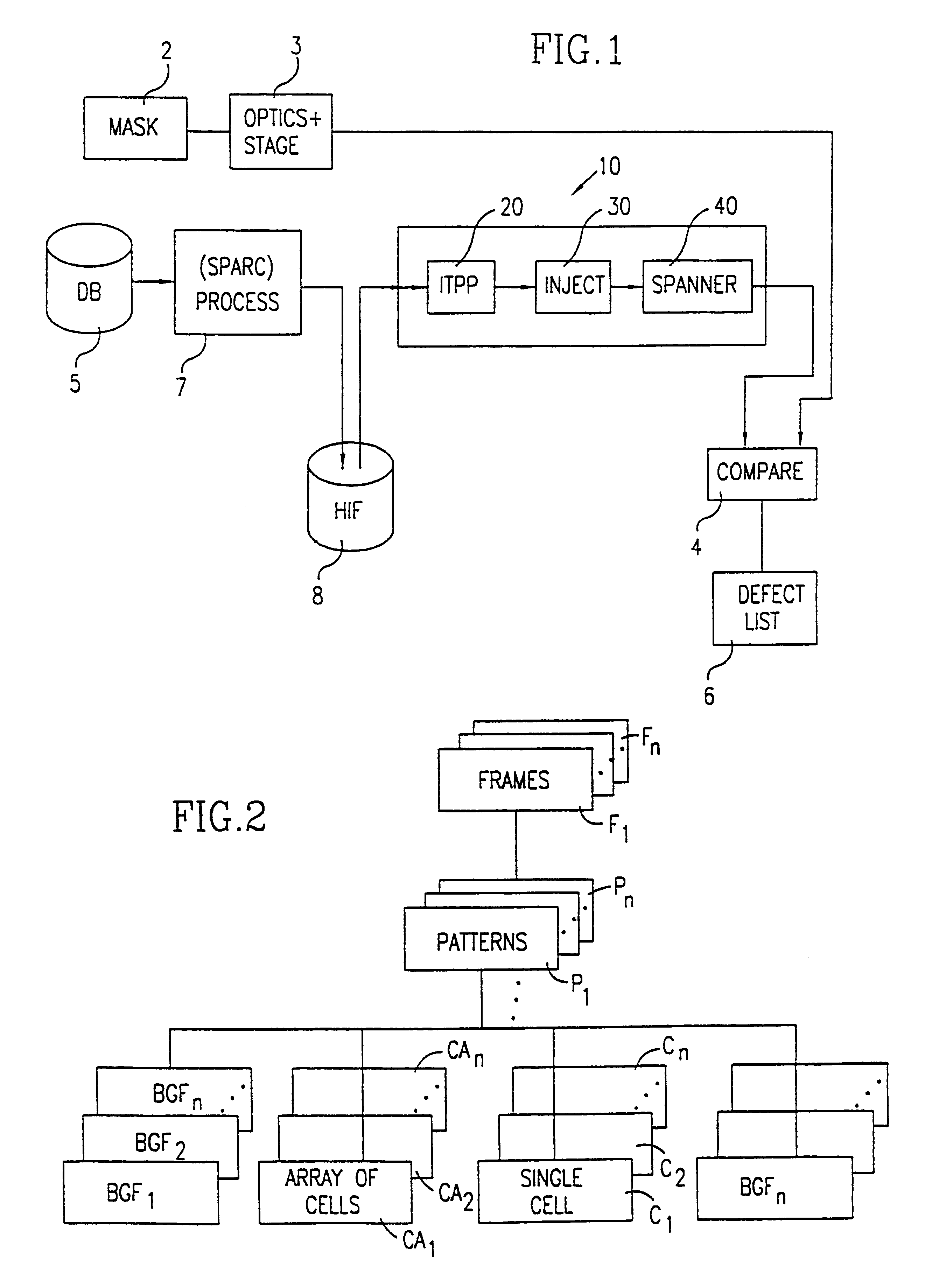

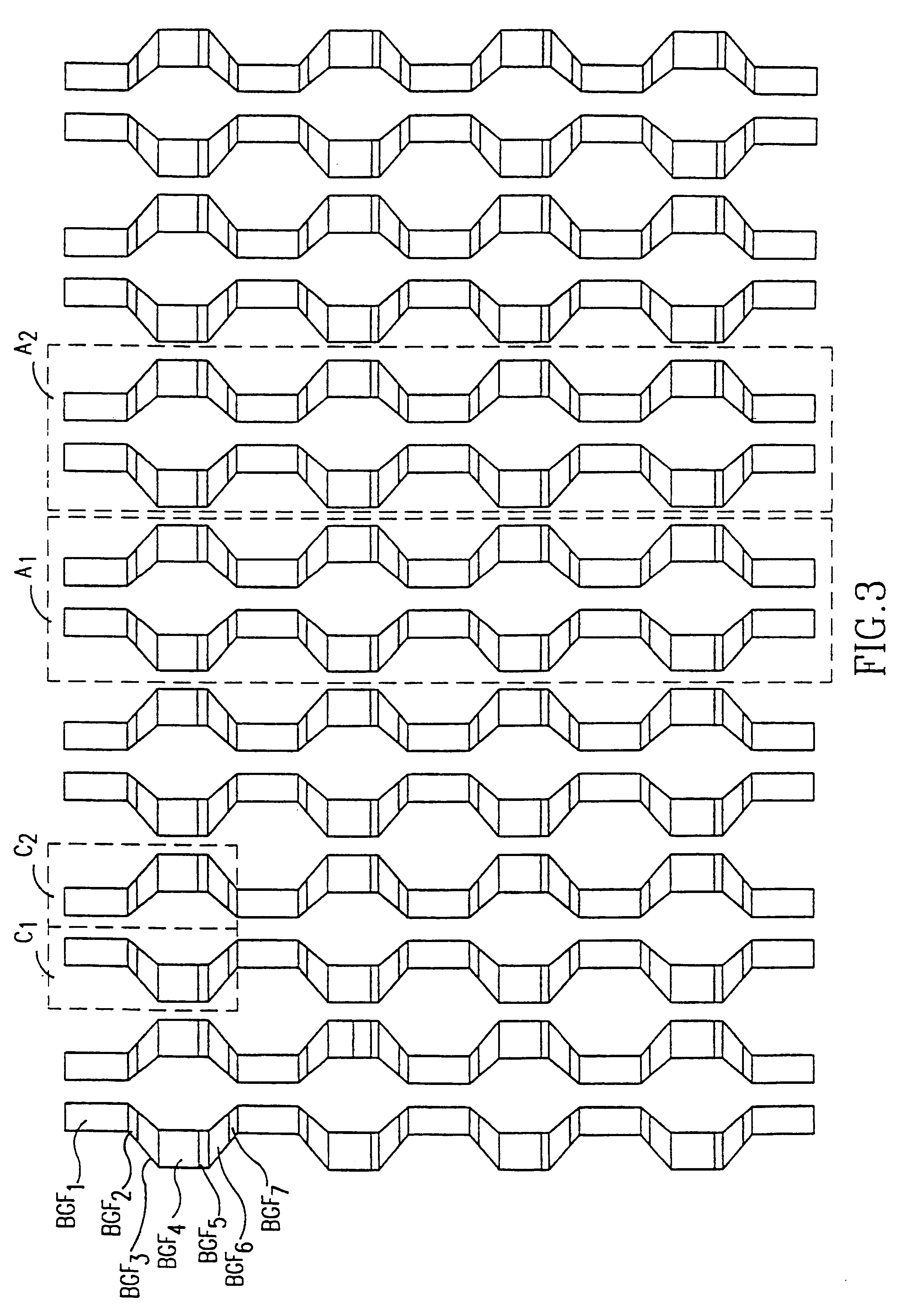

Data converter apparatus and method particularly useful for a database-to-object inspection system

Data converter apparatus for converting in real time data stored in an input compact format into an output expanded real time format. The data including a plurality of groups and repetition of the groups. The groups including, each, many basic geometric figures (BGF). The data converter includes a processor adapted to selecting data relating to a predetermined division, dividing and processing the data into consecutive bins according to scan order, which bins have structural correspondence to the input format. The data converter is further capable of sub-dividing the division into sub-divisions which have structural correspondence to the output format. The data processor is further capable of processing and allocating the BGFs in the bins to sub-divisions to thereby produce a division data stream in the output expanded real time format.

Owner:APPLIED MATERIALS INC

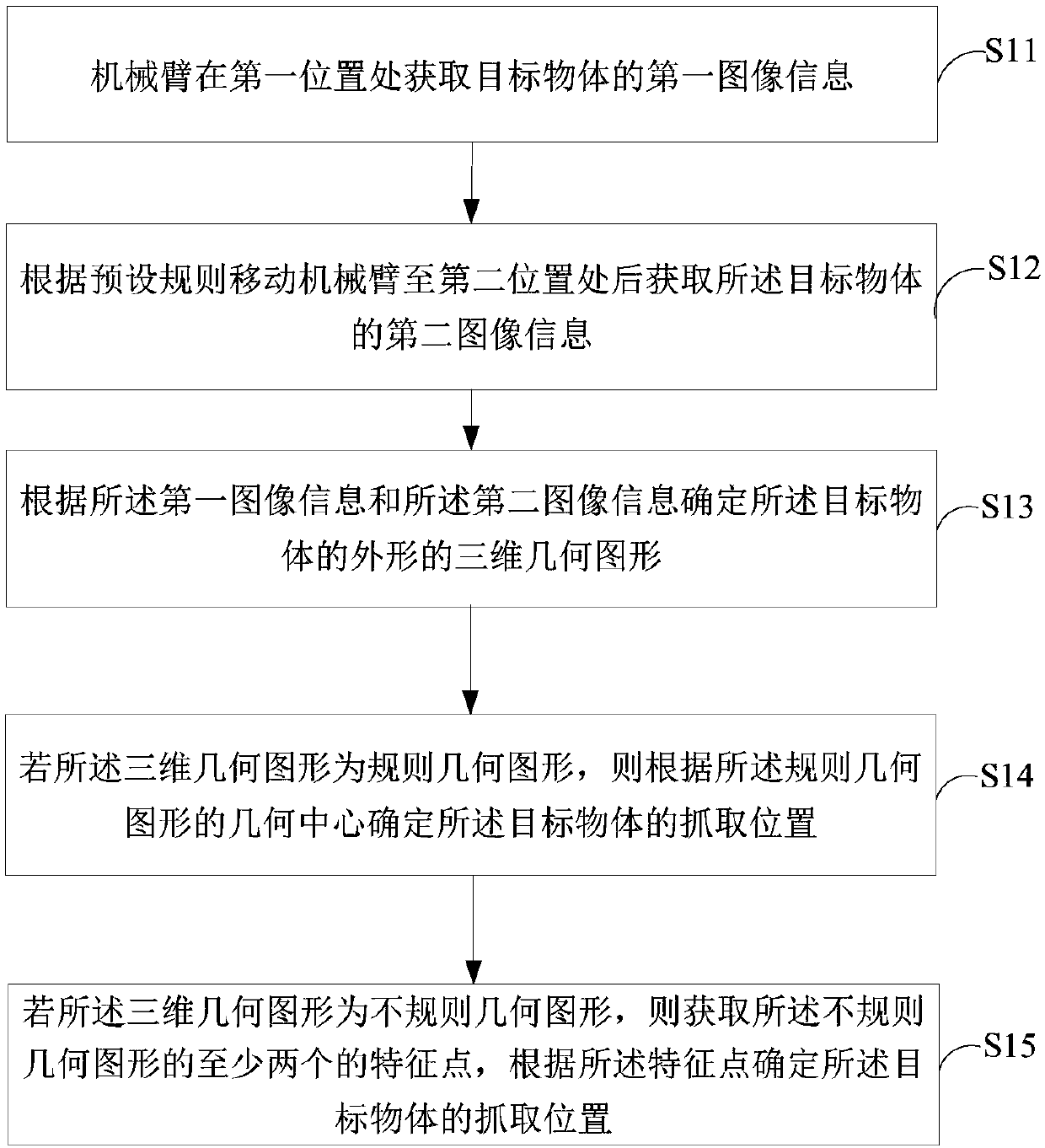

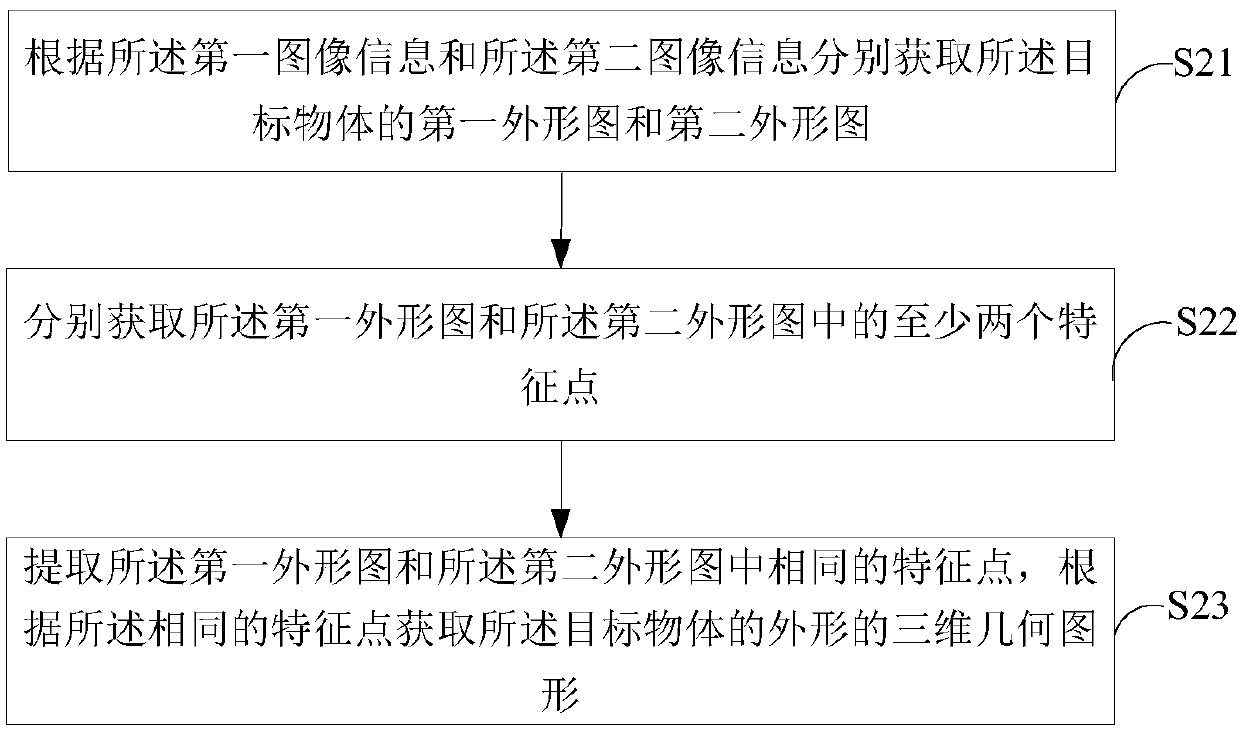

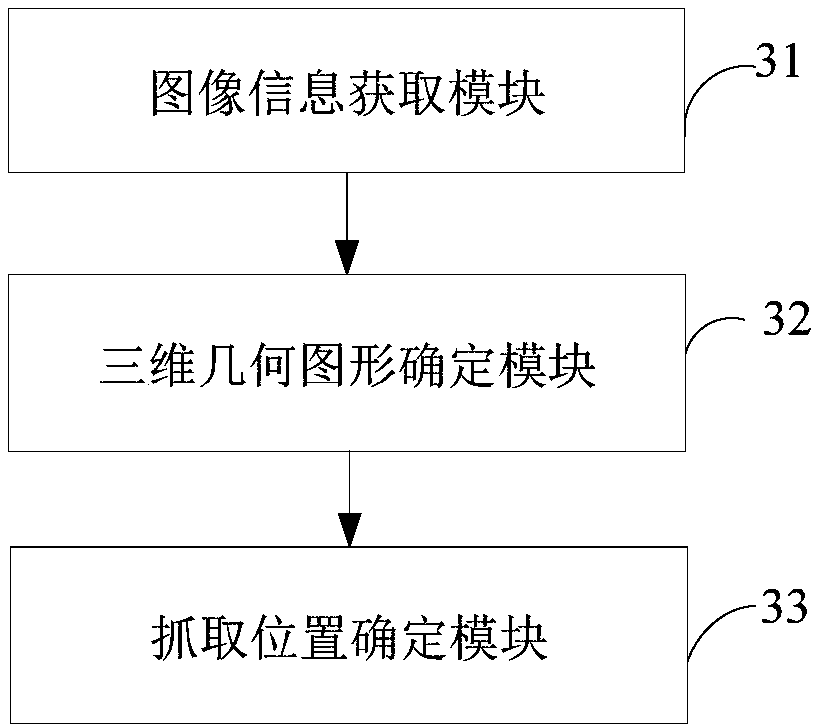

Grabbing position detecting method and device and mechanical arm

ActiveCN108044627AIncrease the chances of a successful crawlImprove accuracyProgramme-controlled manipulatorImage analysisGraphicsComputer vision

The invention is suitable for the technical field of intelligent detection, and provides a grabbing position detecting method and device and a mechanical arm. The method includes the steps that the mechanical arm obtains first image information and second image information of a target object at the first position and the second position correspondingly, and a three-dimensional geometric figure ofthe appearance of the target object is determined; if the three-dimensional geometric figure is a regular geometric figure, the grabbing position of the target object is determined according to the geometric center of the geometric figure; or at least two feature points of an irregular geometric figure are obtained, and the grabbing position of the target object is determined according to the feature points. In the process, according to the image information, obtained at different positions, of the target object, three-dimensional geometric figure of the appearance of the target object is determined, and the accuracy of the detected appearance of the target object is improved; and different methods are adopted for target objects with different appearances for determining the grabbing position, the appropriate grabbing positions are found quickly and accurately according to self features of the target objects, and the successful grabbing rate of the mechanical arm is improved.

Owner:SHENZHEN YUEJIANG TECH CO LTD

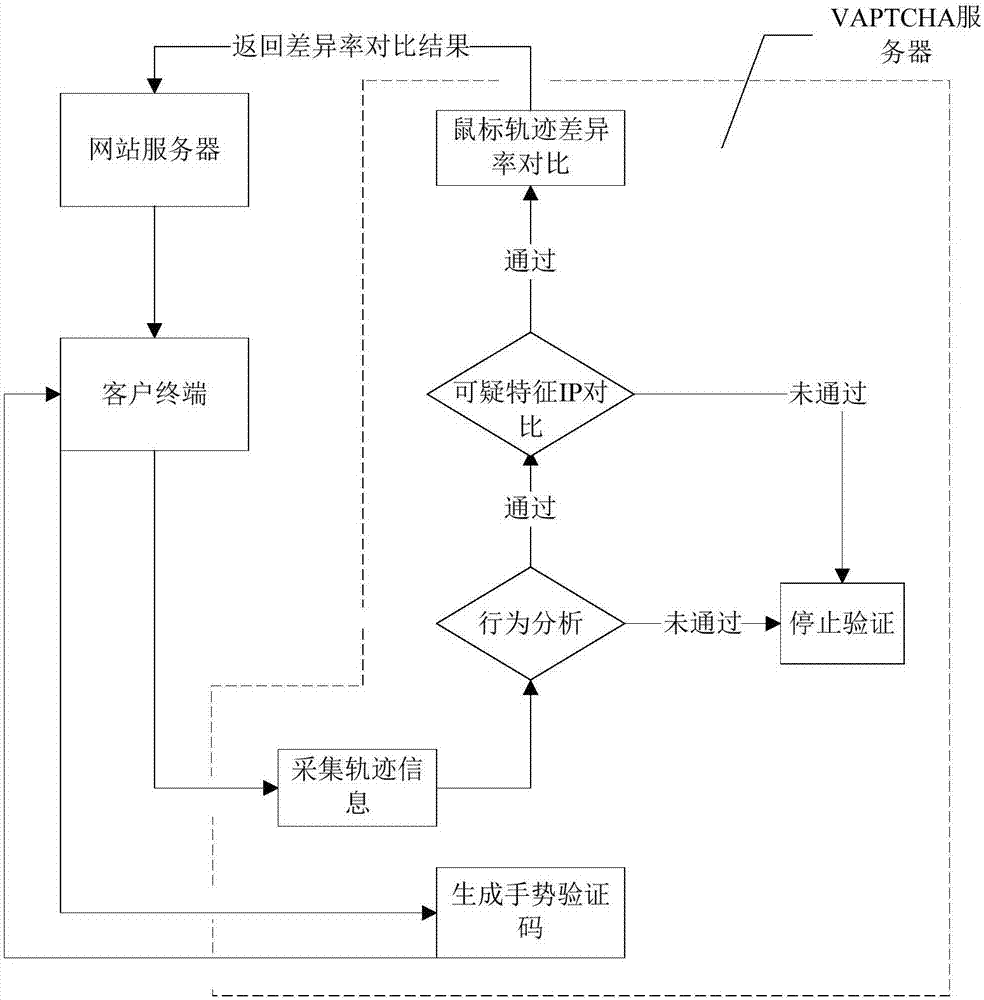

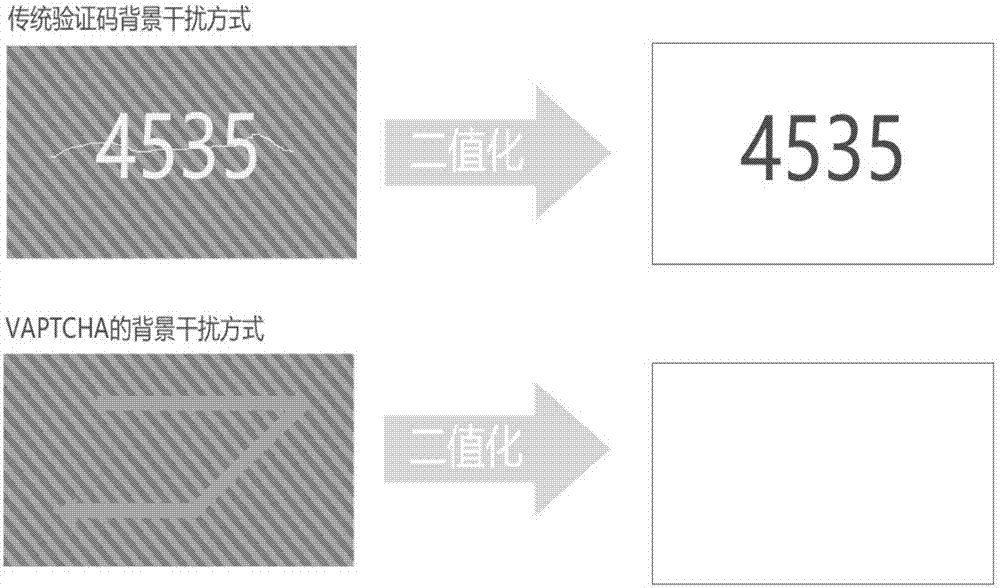

A verification method and system for VAPTCHA (Variation Analysis based Public Turing Test to Tell Computers and Humans Apart)

InactiveCN106991315AEasy to identifyImprove experienceDigital data authenticationTransmissionGraphicsValidation methods

Owner:袁精侠

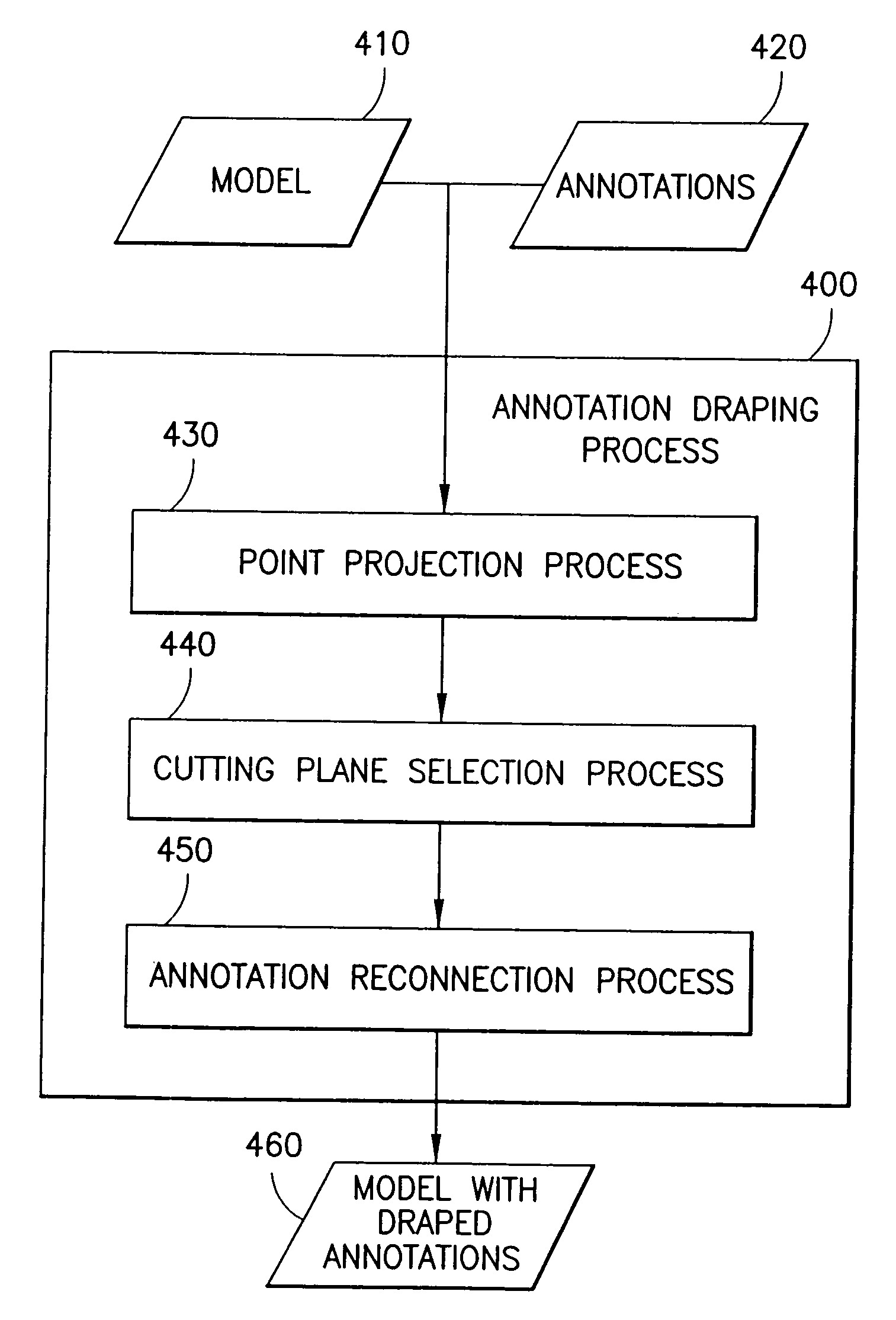

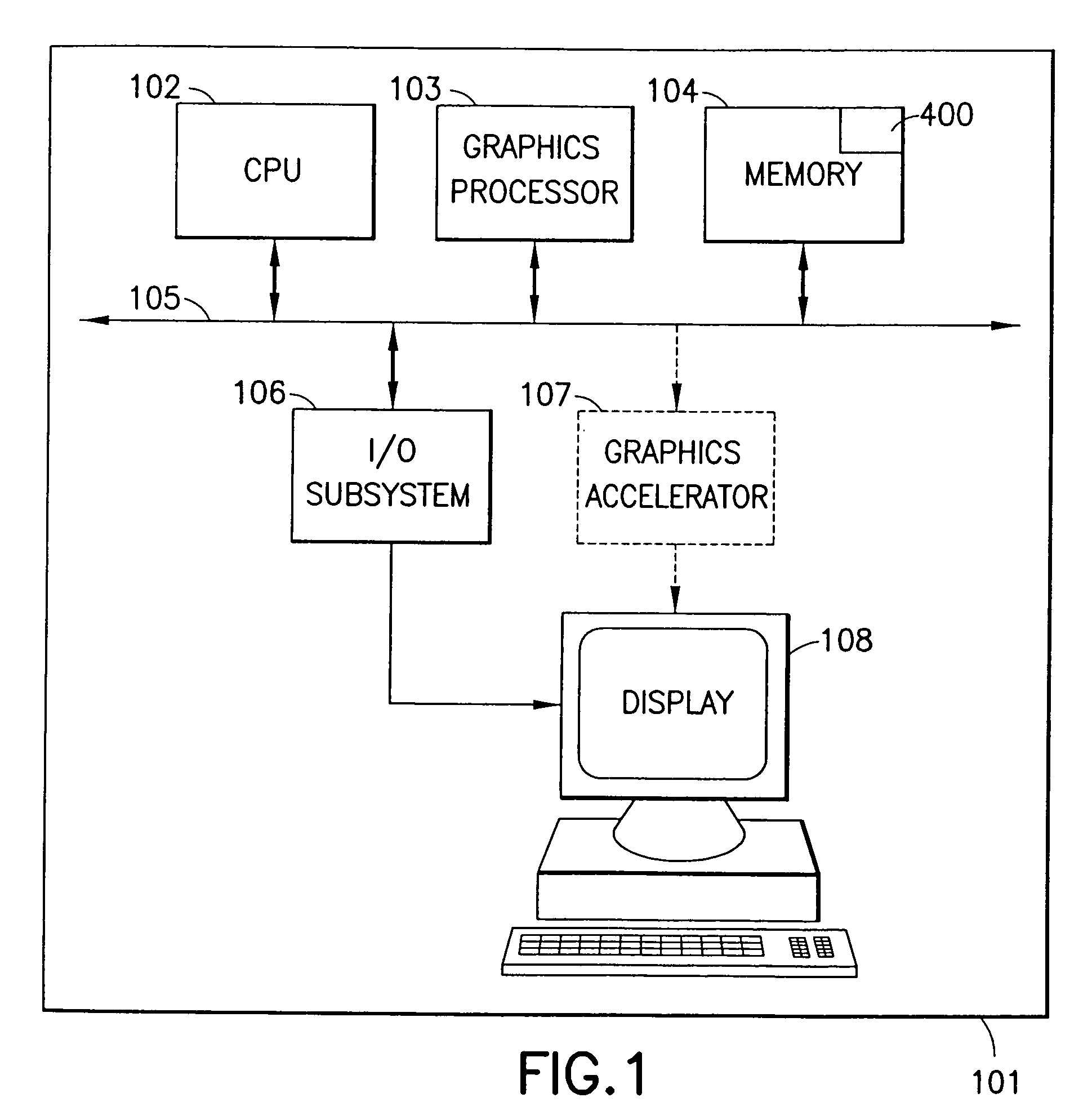

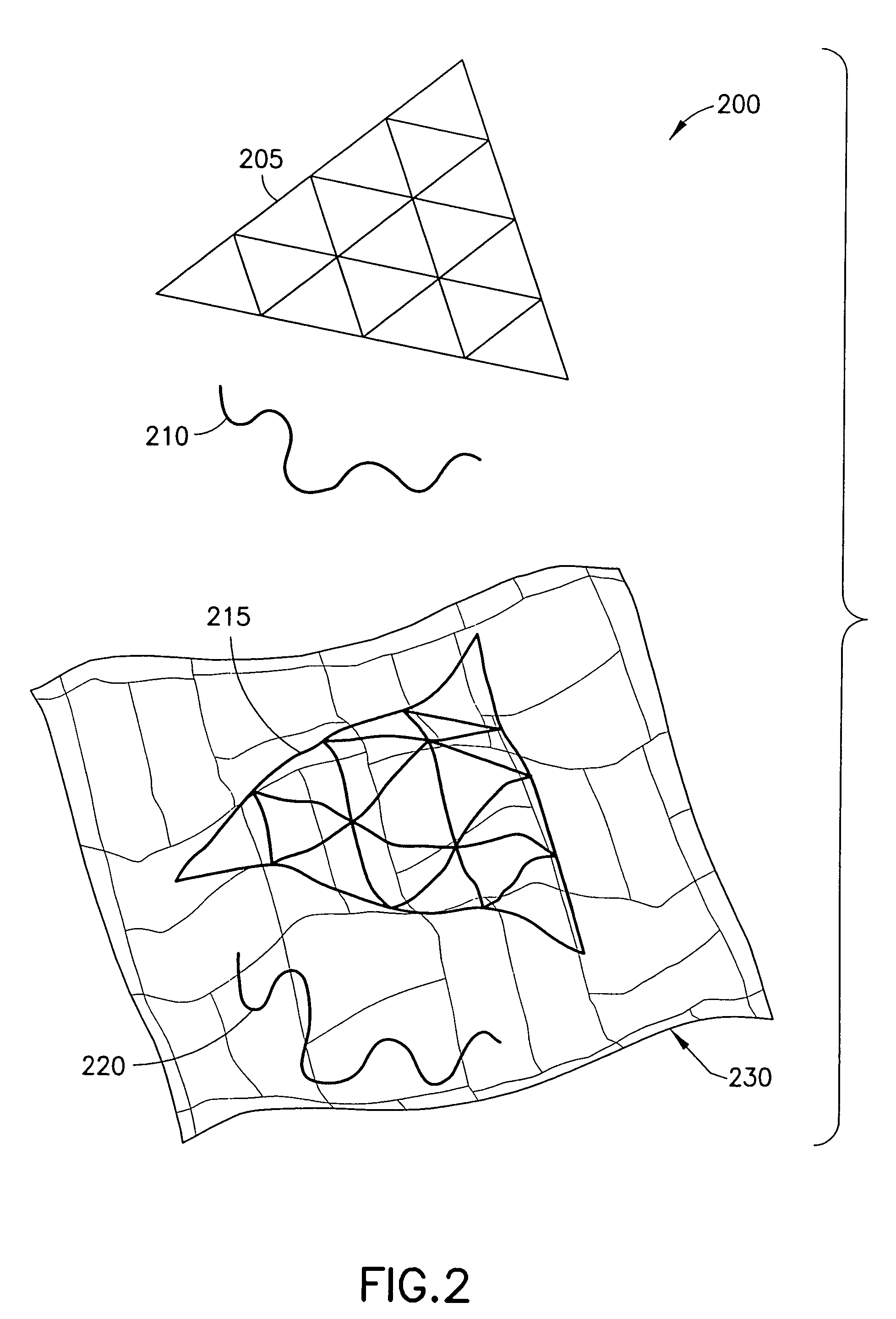

Apparatus, system, and method for draping annotations on to a geometric surface

InactiveUS6978230B1Adequate amount of fidelityIncrease speedCathode-ray tube indicatorsSoftware simulation/interpretation/emulationComputer scienceLine segment

Vertices of an annotation are projected onto a surface of a (2D or 3D) model and reconnected to preserve the original appearance of the annotation. The result of our method is a new set of geometry for the annotation that geometrically conforms to the surface of the model. A plane is defined by the midpoint of the original line segment and the two projected vertices. This plane is used to create the new line segments that conform to the surface, e.g. by doing a “surface walk” between the projected points along the line defined by the intersection of the plane and the surface.

Owner:IBM CORP +1

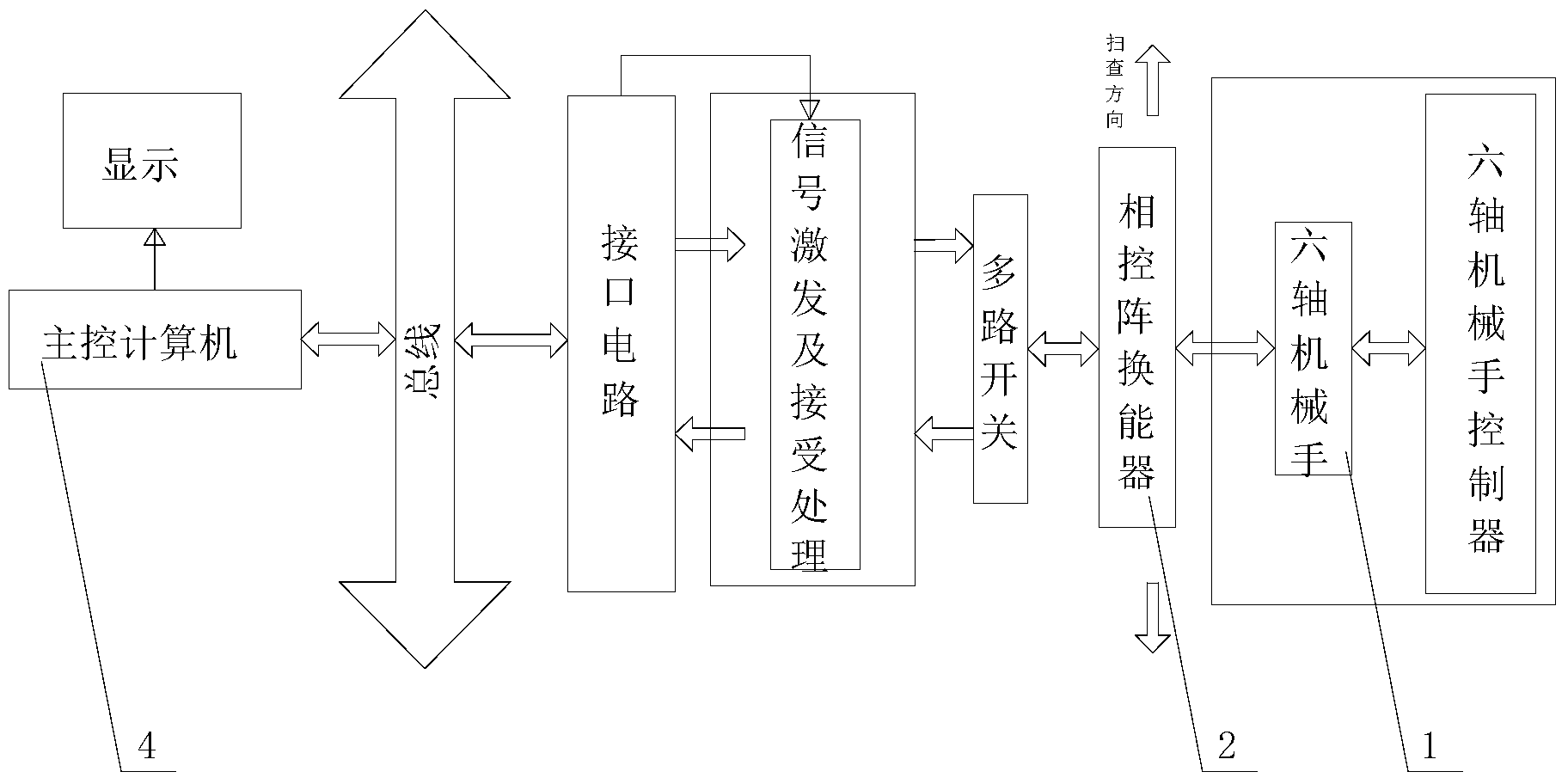

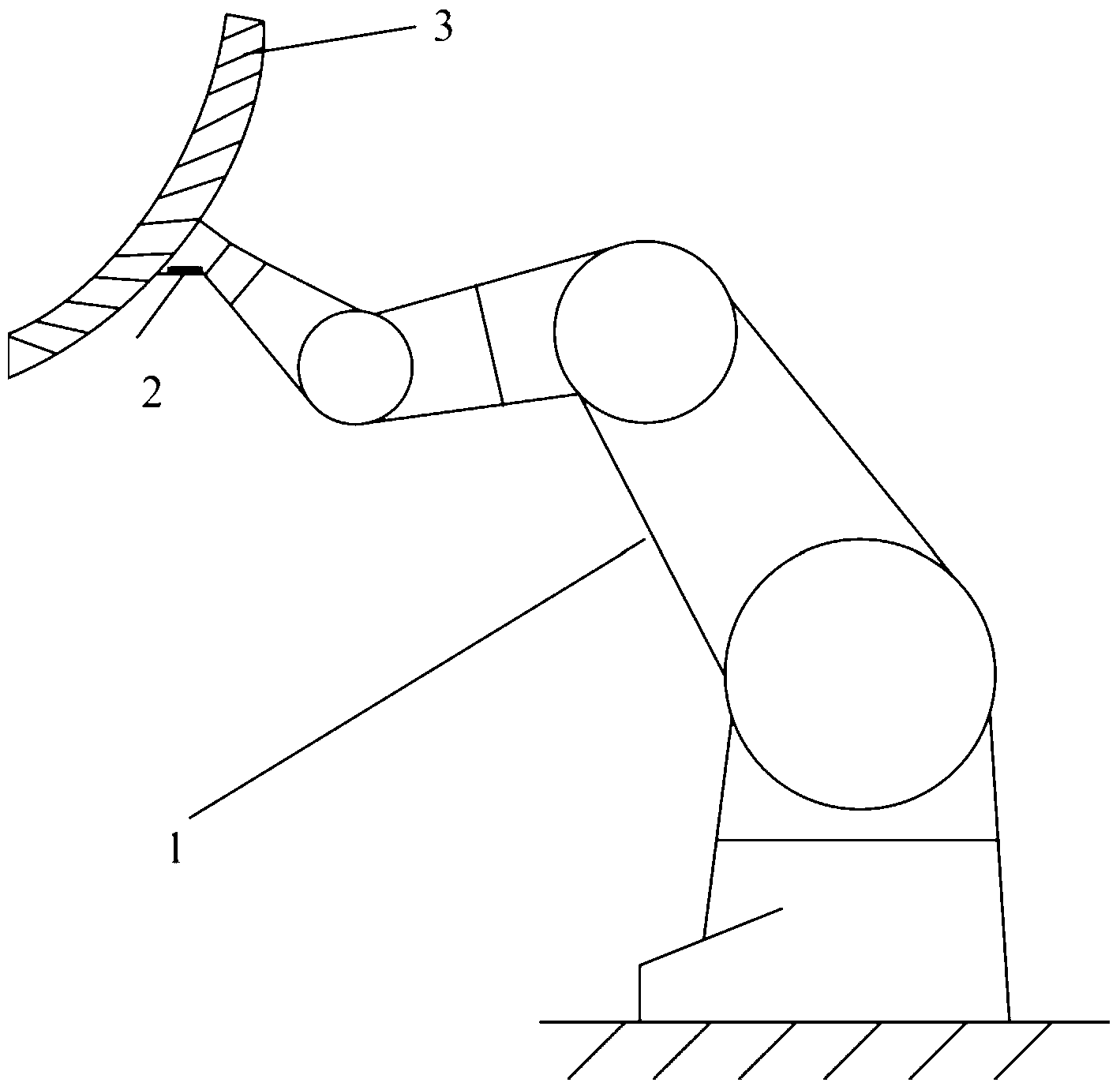

Automatic detecting and imaging method of hyper-acoustic phased array of weld joint in complex space

ActiveCN103969336AEfficient automatic detectionIncrease flexibilityAnalysing solids using sonic/ultrasonic/infrasonic wavesGraphicsEngineering

The invention relates to an automatic detecting and imaging method of a hyper-acoustic phased array of a weld joint in a complex space. The automatic detecting and imaging method comprises the following steps: 11) determining a scanning trace according to a three-dimensional CAD model of the complex space; 12) clamping a hyper-acoustic phased array transducer with a six-shaft manipulator to track and scan the weld joint along the determined scanning trace, so as to obtain detected data and a detected result of the weld joint, and displaying the detecting result of the weld joint in a three-dimensional weld joint figure. As the manipulator is used in the weld joint detection, high-efficient automatic detection is realized; the detected result is displayed visually into the three-dimensional geometric figure of a workpiece by applying the computer three-dimensional visualization technology, so that detectors can position and quantify defects conveniently.

Owner:CRRC QINGDAO SIFANG CO LTD

Method and apparatus for measuring a intracorporal passage image

InactiveUS6857196B2Choose accuratelyProvide compensationSurgeryPerson identificationMagnificationGeometric figure

A medical measuring apparatus for measuring a lumen of an intracorporeal passage as it appears in an image wherein the apparatus preferably includes a measuring adjunct and an object to image retainer. The measuring adjunct preferably includes at least one geometric figure outline having a border formed by a portion of the measuring adjunct such that an aperture having a geometric shape is defined for measuring the lumen of the intracorporeal passage. The at least one geometric figure outline preferably includes a corresponding measurement specification (for example, in the metric system). In at least one embodiment, the at least one geometric figure outline is preferably utilized to measure an occlusion associated with the intracorporeal passage (for example, a renal tumor). The object to image retainer is for housing the measuring adjunct and compensates for a magnification ratio relating to the intracorporeal passage and the intracorporeal passage as it appears in the image.

Owner:DALRYMPLE ROBERT

Splicing exposing method for photo-etched large-size CCD (Charge Coupled Device) chip

ActiveCN103412468AImprove performanceQuality improvementPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsMicrometer

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

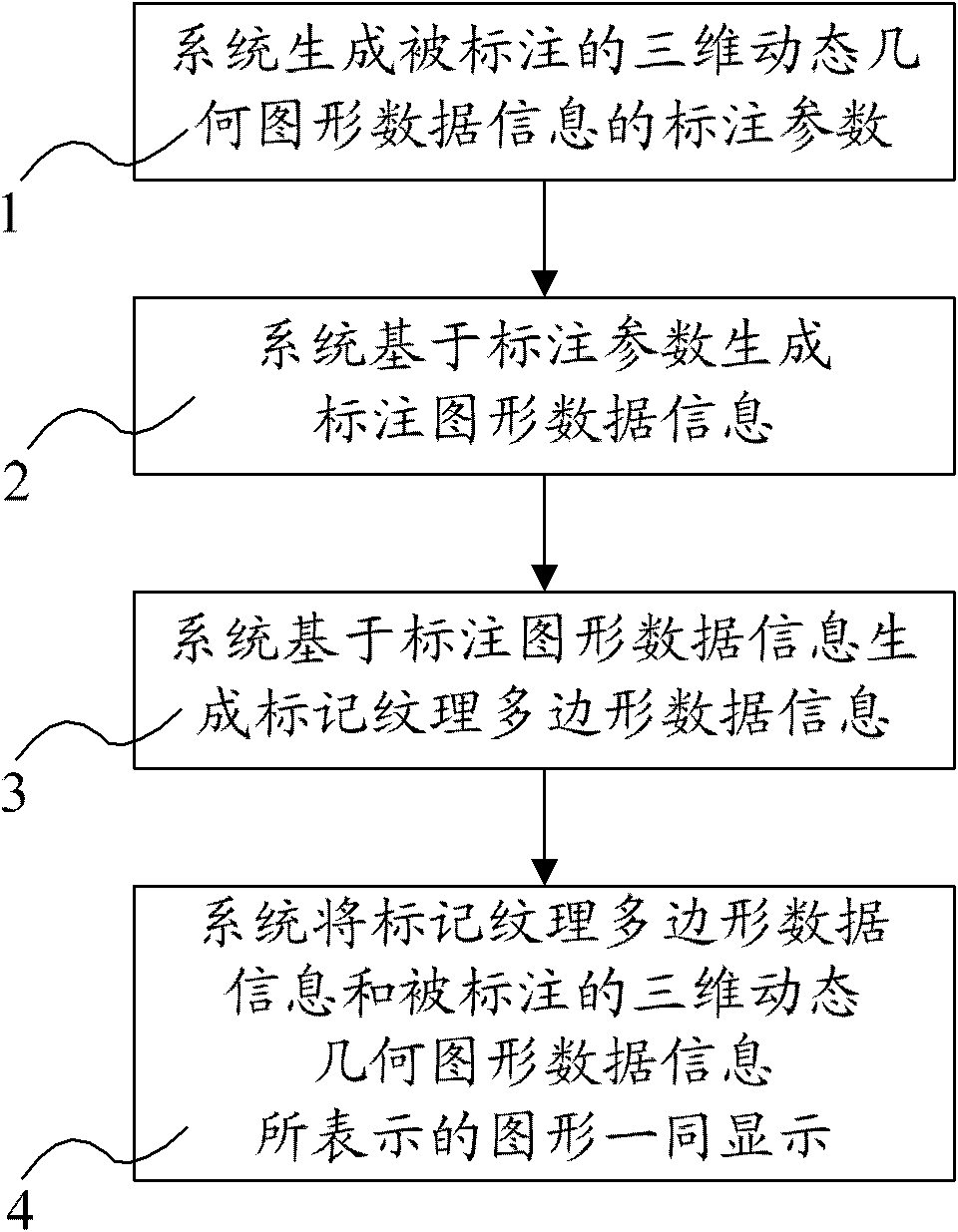

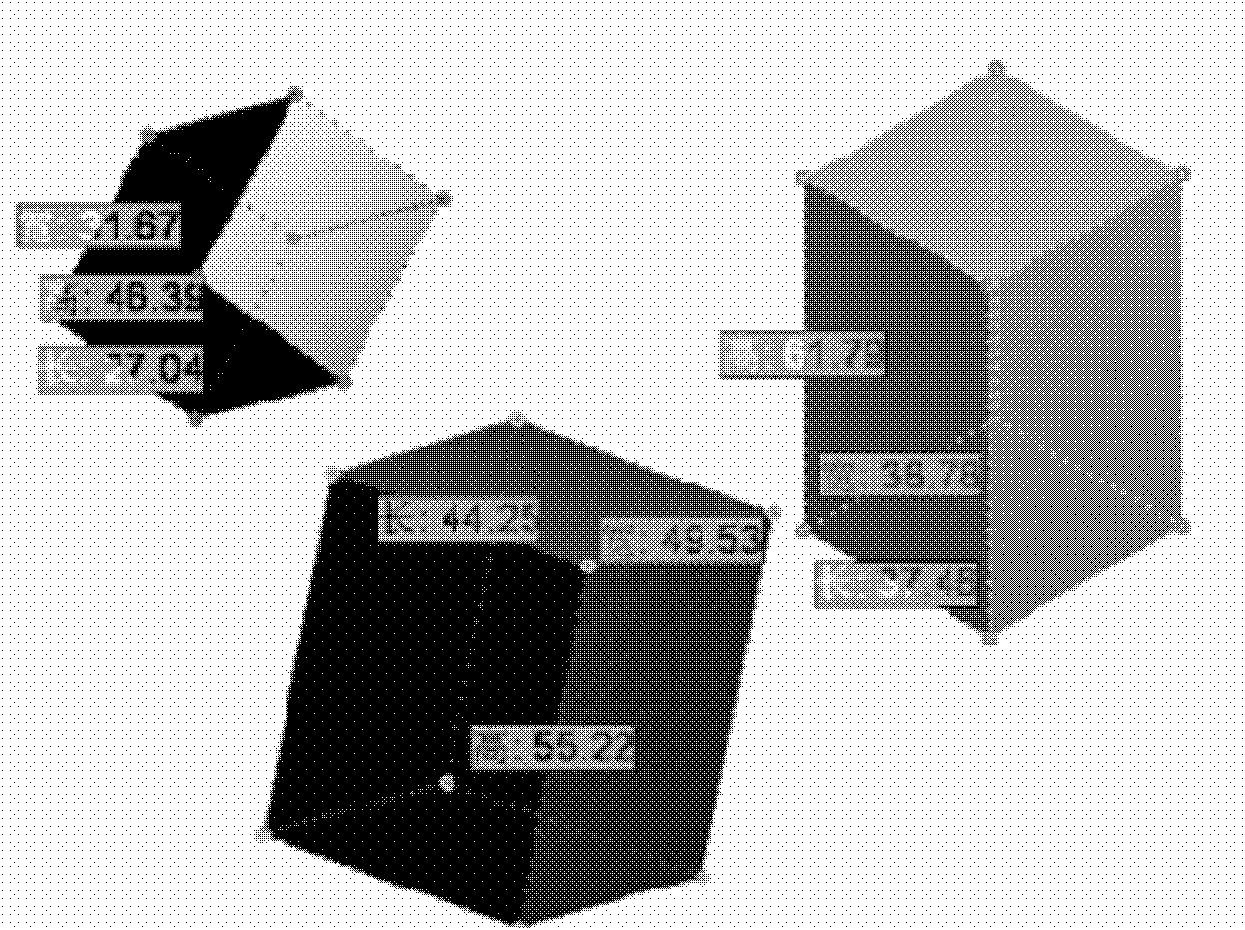

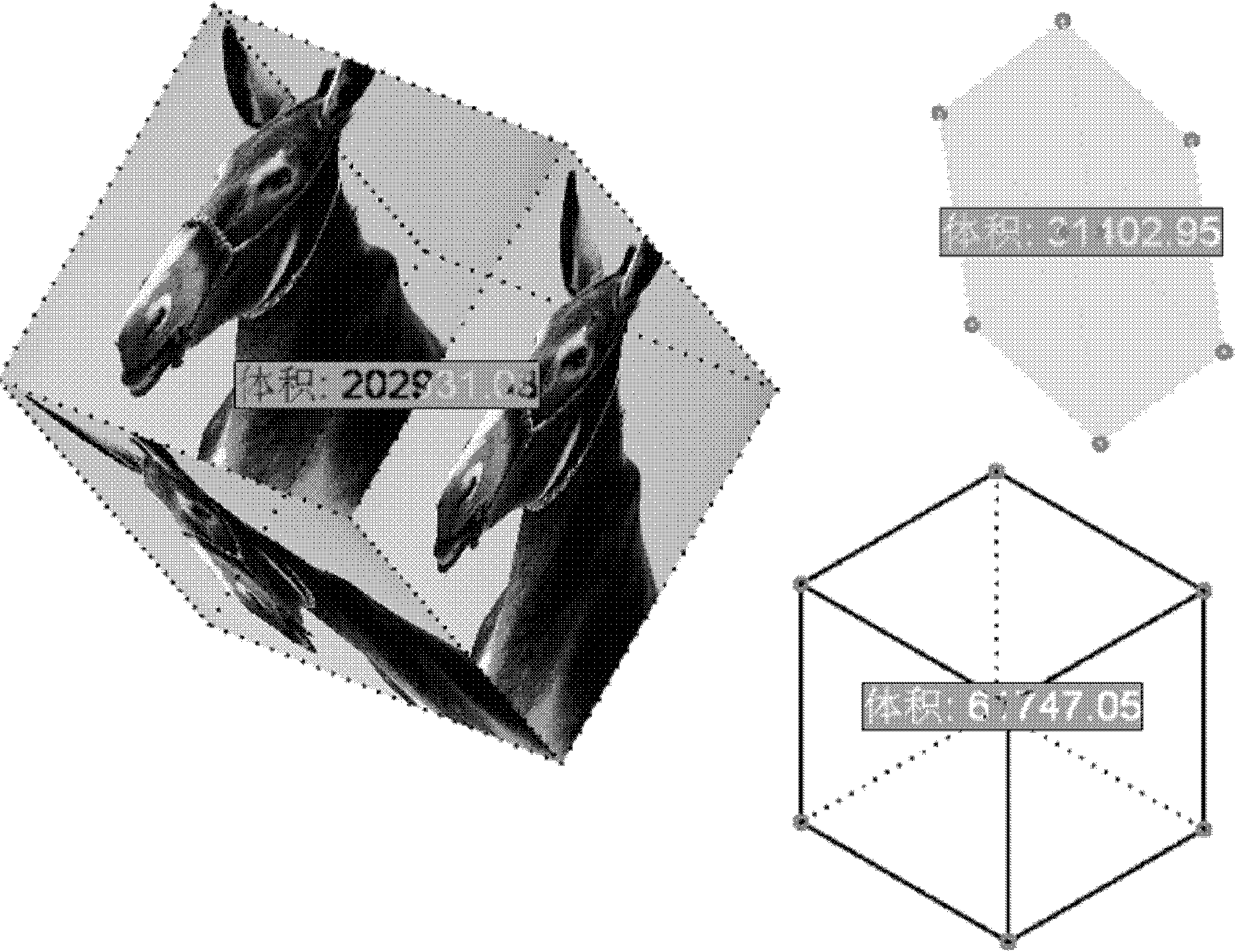

Method for labeling three-dimensional (3D) dynamic geometric figure data information in computer system

The invention relates to a method for controlling three-dimensional (3D) dynamic geometric figure data information label display in a computer system, and the method provided by the invention comprises the following steps: firstly generating a label parameter of labeled 3D dynamic geometric figure data information; then generating label figure data information based on the label parameter; generating the label texture polygon data information based on the label figure data information; and finally displaying figures which are represented by the label texture polygon data information and the labeled 3D dynamic geometric figure data information simultaneously so as to realize the control on the 3D dynamic geometric figure data information label display. By using the method for labeling the 3D dynamic geometric figure data information in the computer system, the label can form an organic integer with the geometric figure to flexibly and dynamically label a 3D scene with high generality and the render effect in match with the scene; and better user experience can be provided since a user can distinguish the 3D scene conveniently. The method is simple and convenient in application mode, low in realization cost and wide in application range.

Owner:宁波万里电子科技有限公司

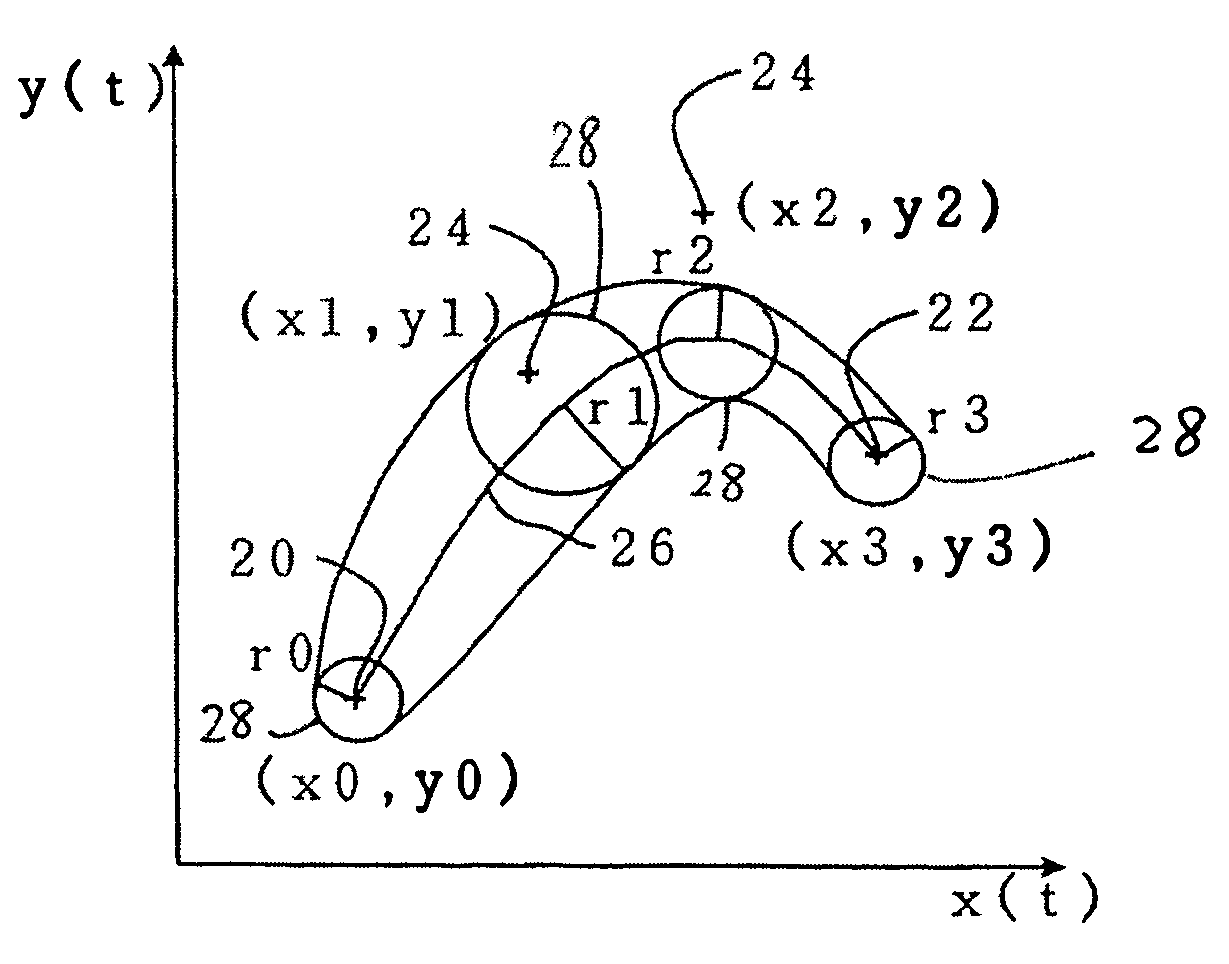

Method of font generation for displaying the thickness of strokes of characters

InactiveUS7499055B2Reduce data volumeDisplay readily and refinedDrawing from basic elementsCharacter and pattern recognitionGraphicsAlgorithm

The present invention employs the notion of a Chinese writing brush in moving a geometric figure to produce a style of calligraphy, where the area of the geometric figure is large or small, then the strokes of a character are thick or thin. Hence the purpose is that the variance of the strokes of a character can be achieved using the present invention. The present invention only decides a moving path for the strokes of a character and the size of a geometric figure at starting points and end points, and then moves the geometric figure along the moving path, where the area the geometric figure passes is the style of calligraphy.

Owner:IND TECH RES INST

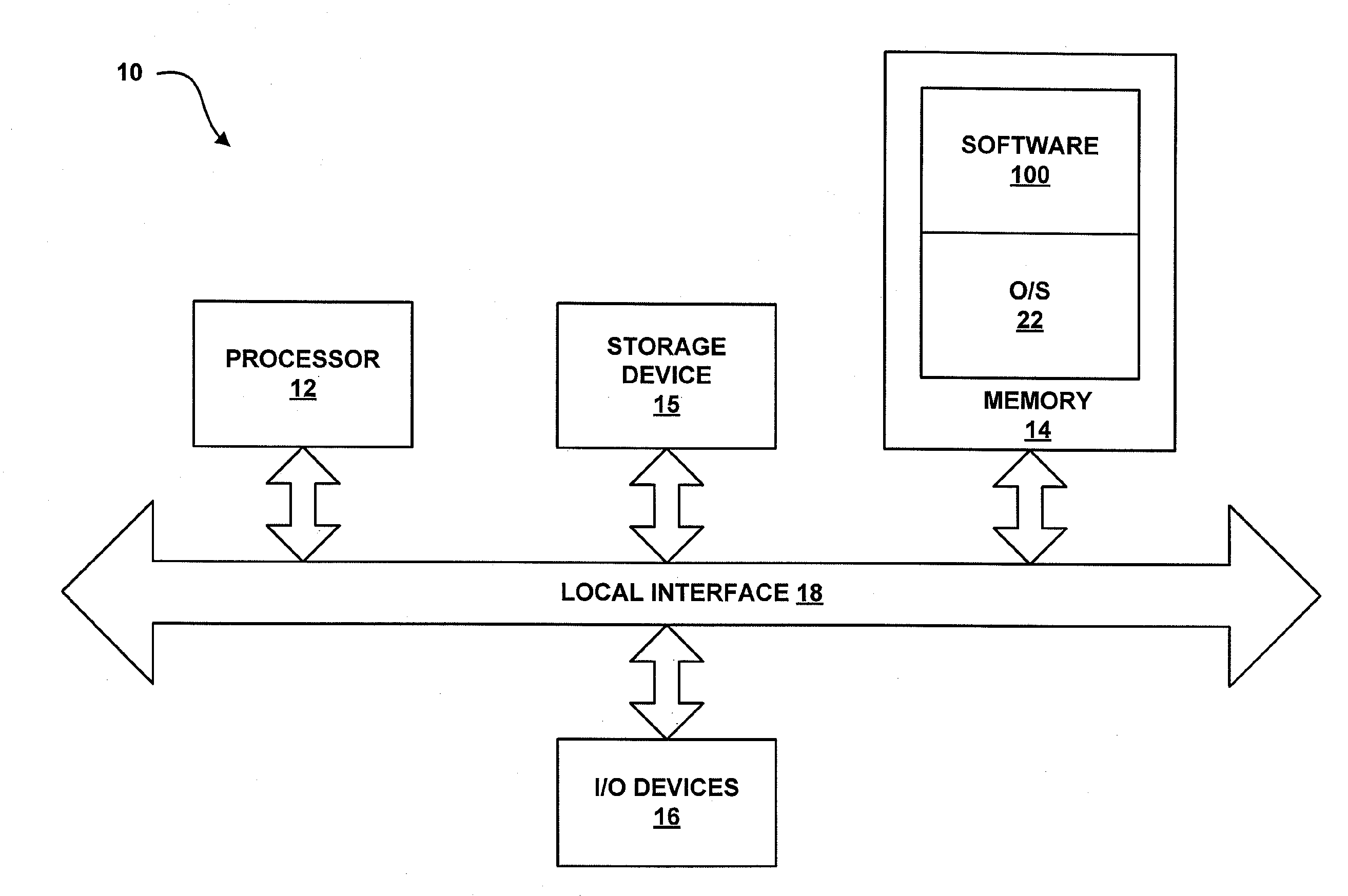

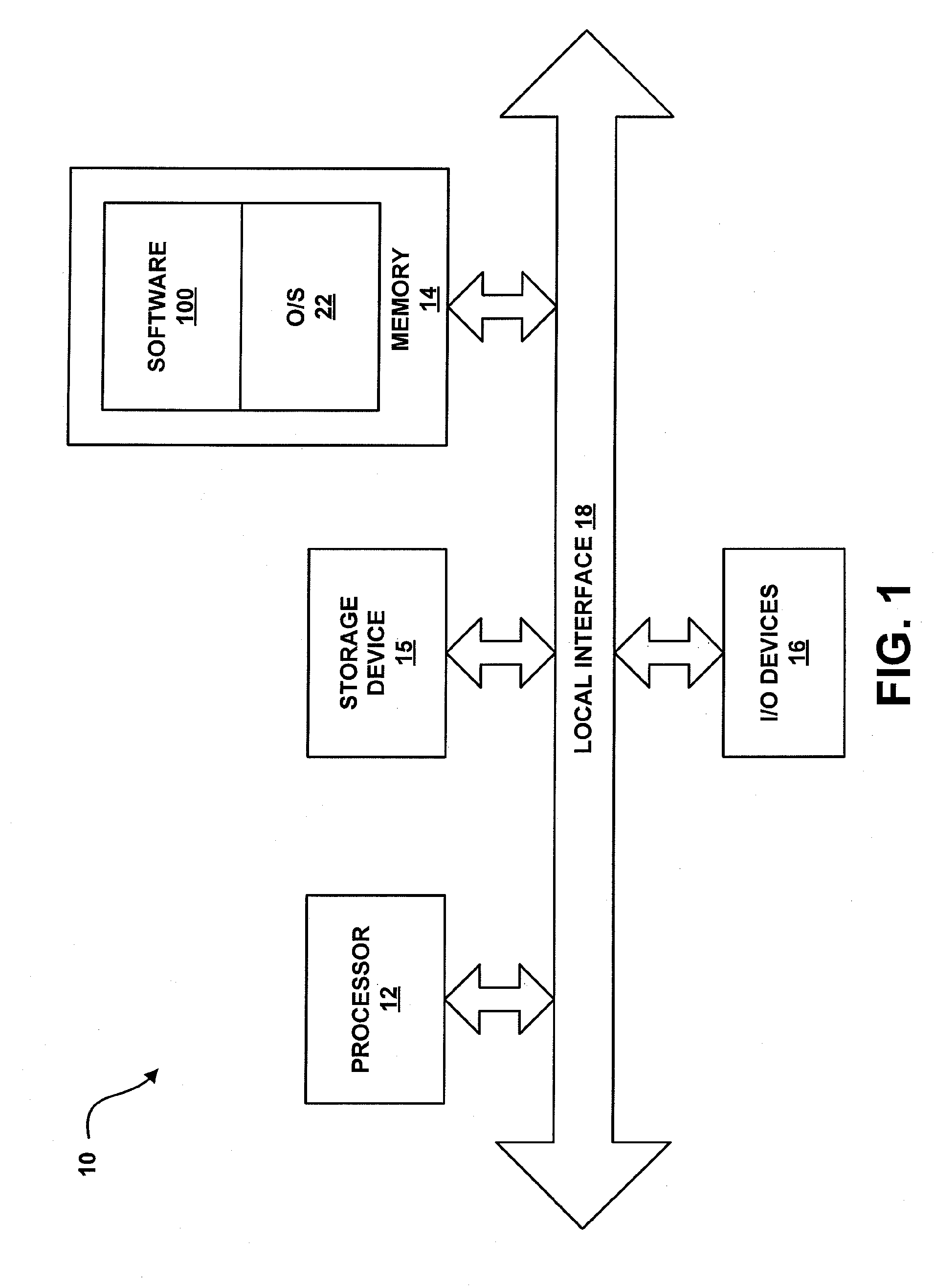

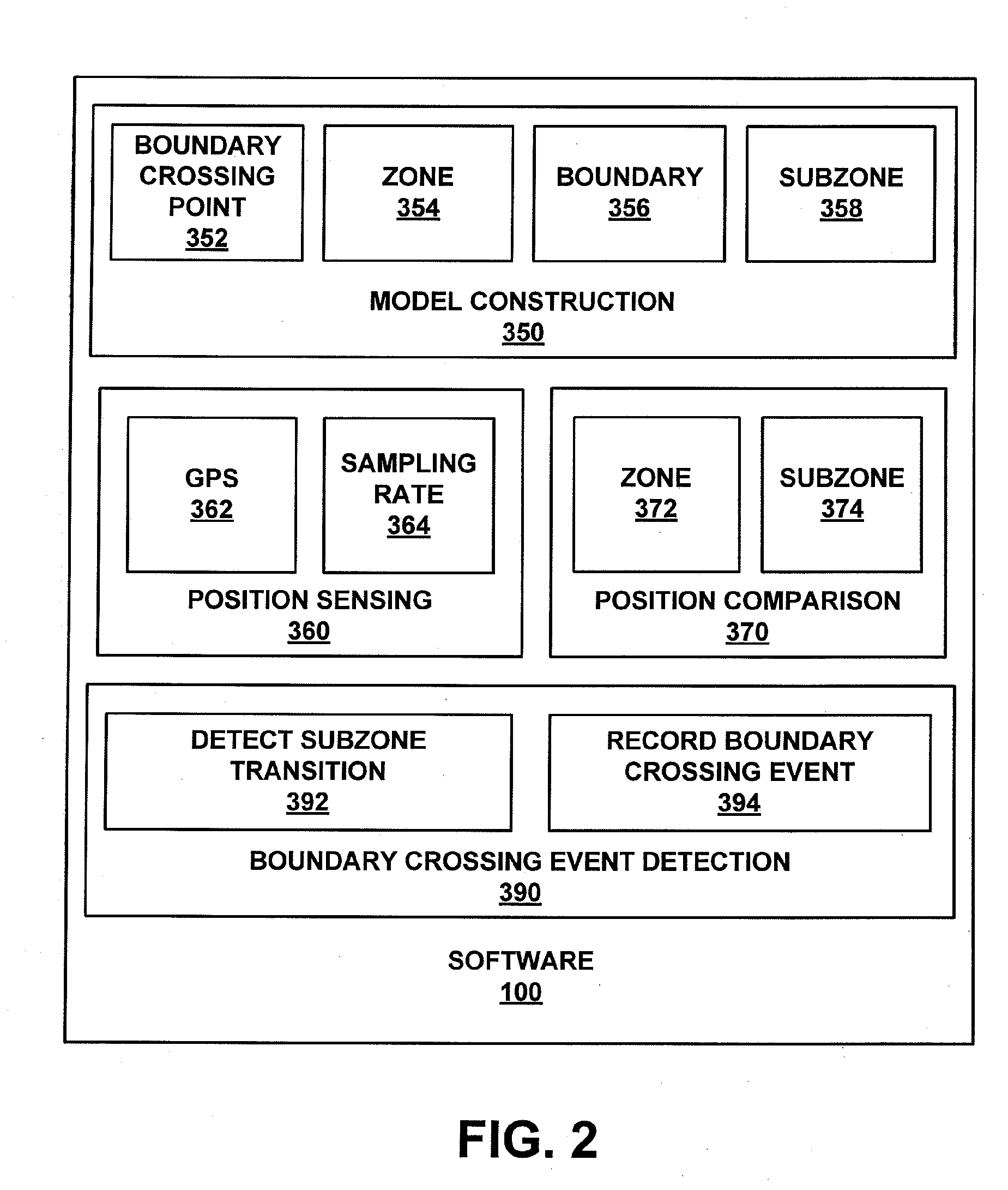

System and method for detecting a boundary crossing event

InactiveUS20100033338A1Simple calculationDigital data processing detailsRoad vehicles traffic controlGraphicsEvent model

Model zone data and model subzone data is employed to simplify calculations for determining where and / or when a boundary crossing event has occurred. A system for detecting a boundary crossing event employs a memory and a processor. The processor in one embodiment is configured by the memory to perform the steps of sensing current position; comparing the sensed current position to model zone data to determine presence within a geometric figure constructed around a boundary crossing point; comparing the sensed current position to model subzone data to determine presence within a first portion of the geometric figure; comparing the sensed current position to model subzone data to determine presence within a second portion of the geometric figure; and detecting a boundary crossing event as a result of movement from the first portion of the geometric figure to the second portion of the geometric figure.

Owner:ORANGE MANGO SERIES 48 OF ALLIED SECURITY TRUST I

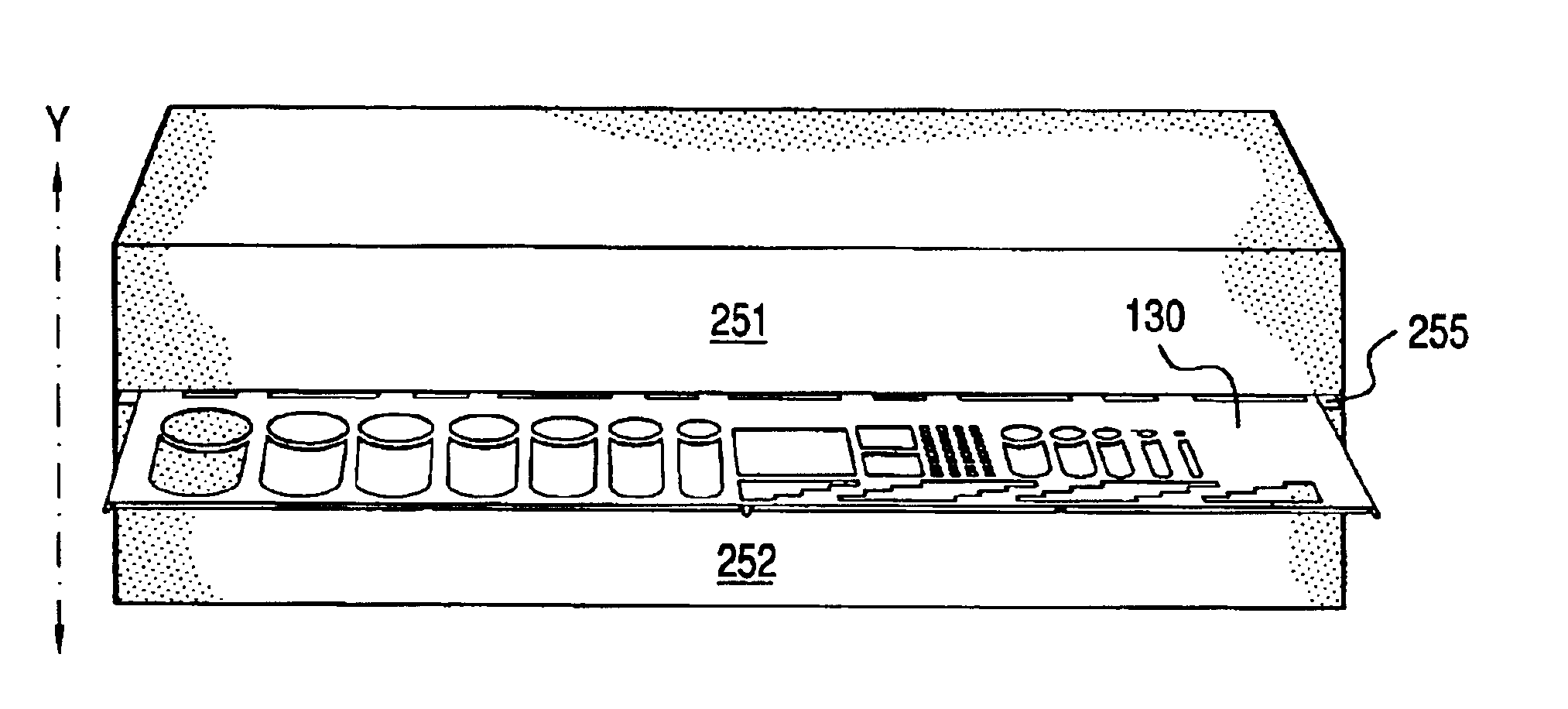

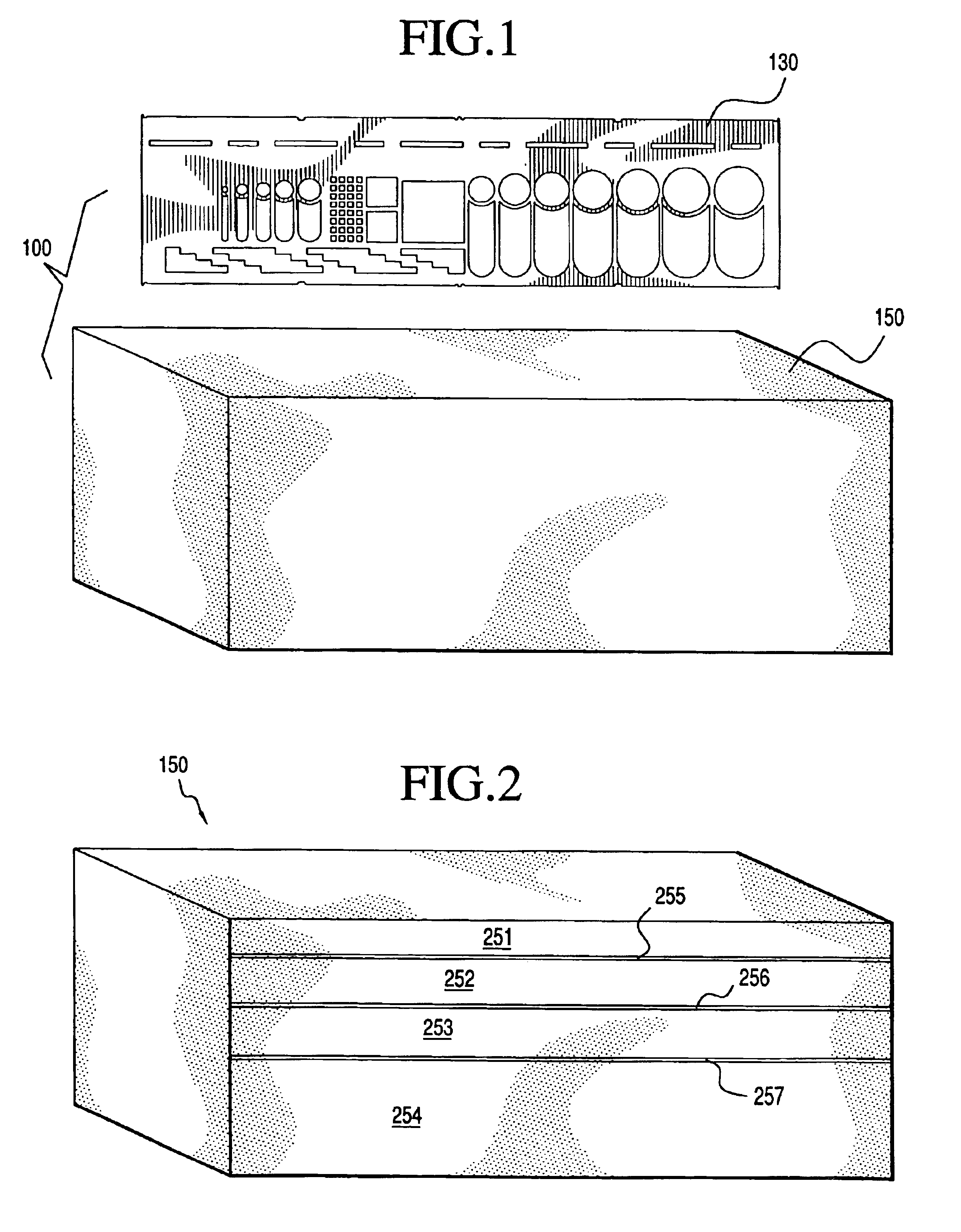

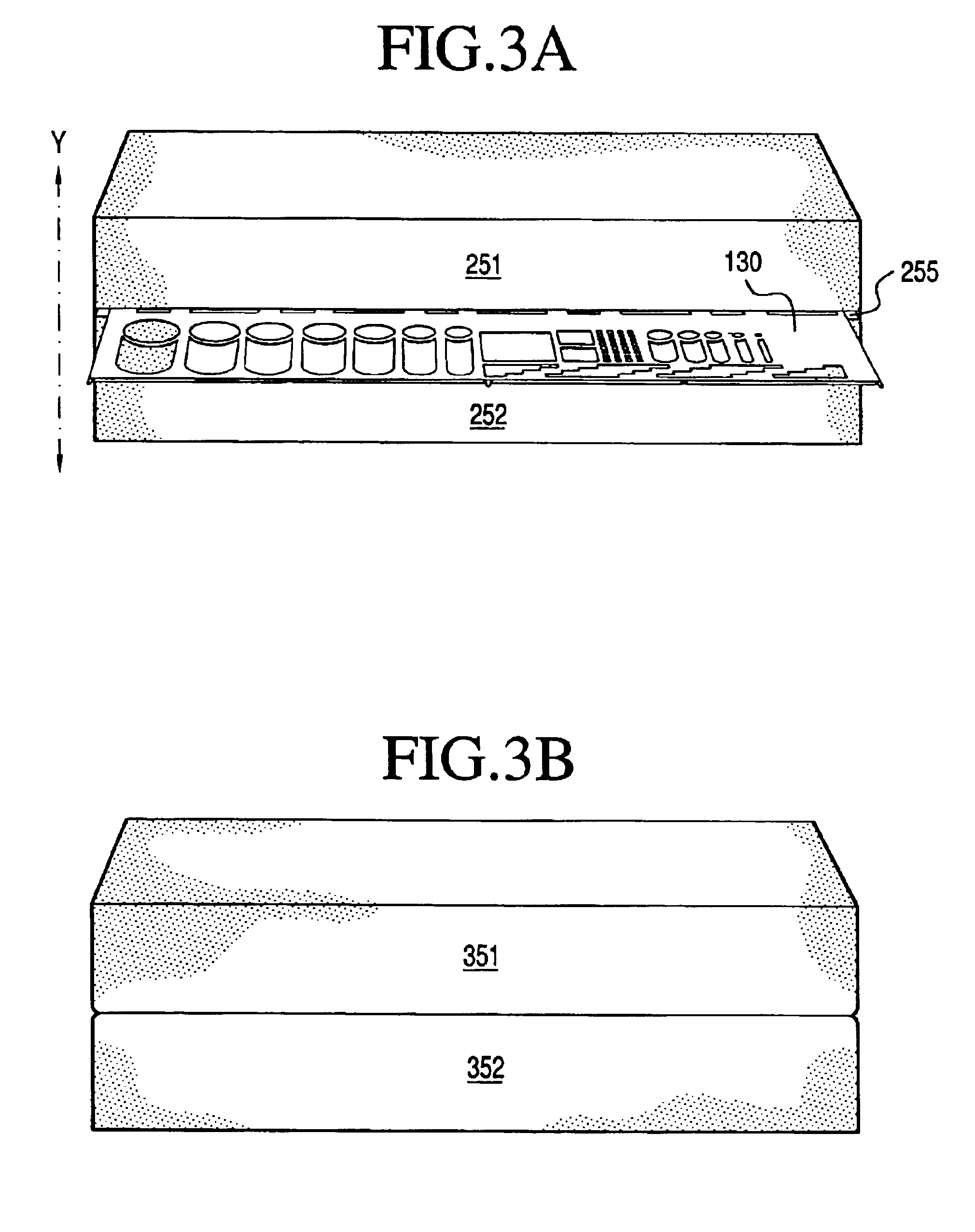

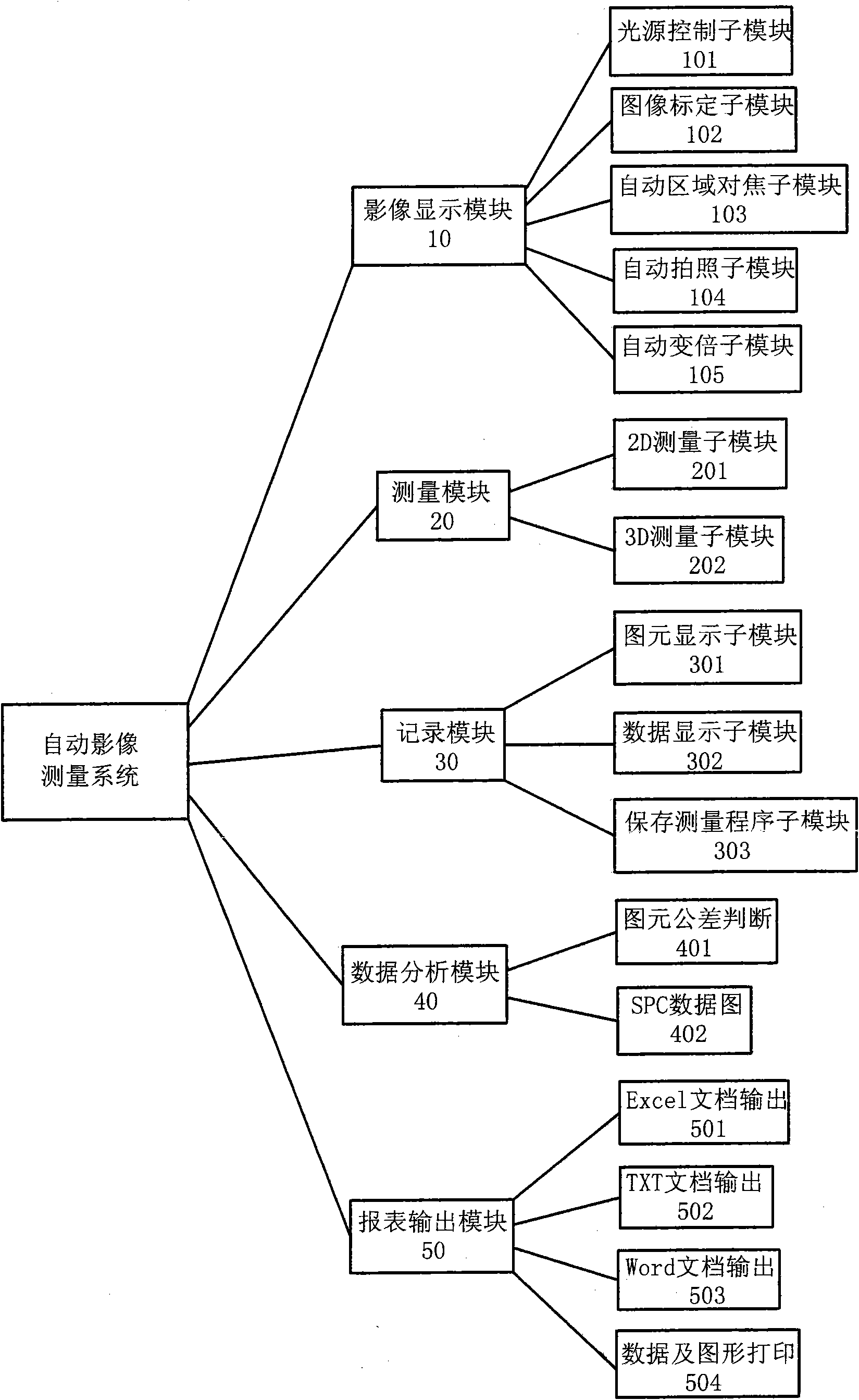

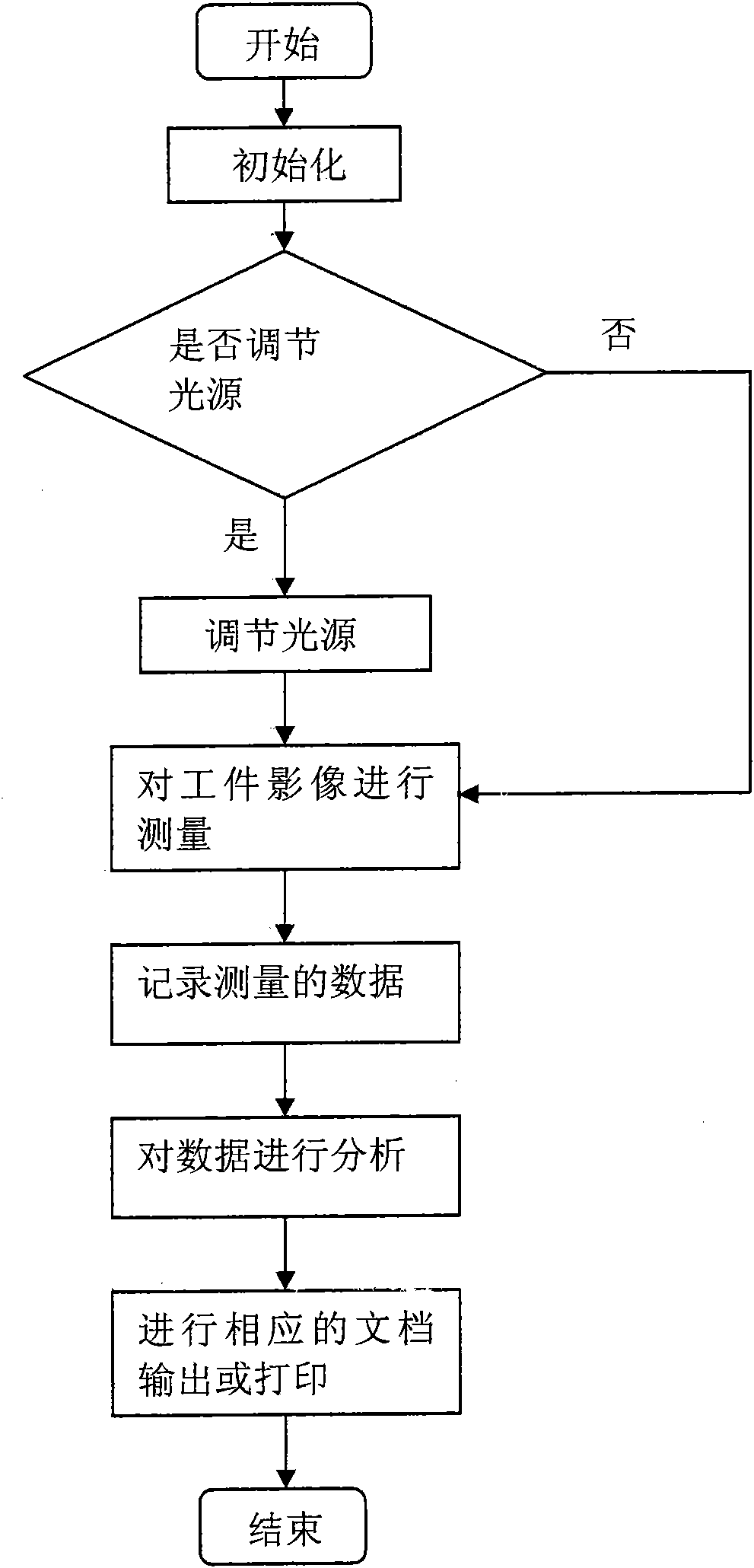

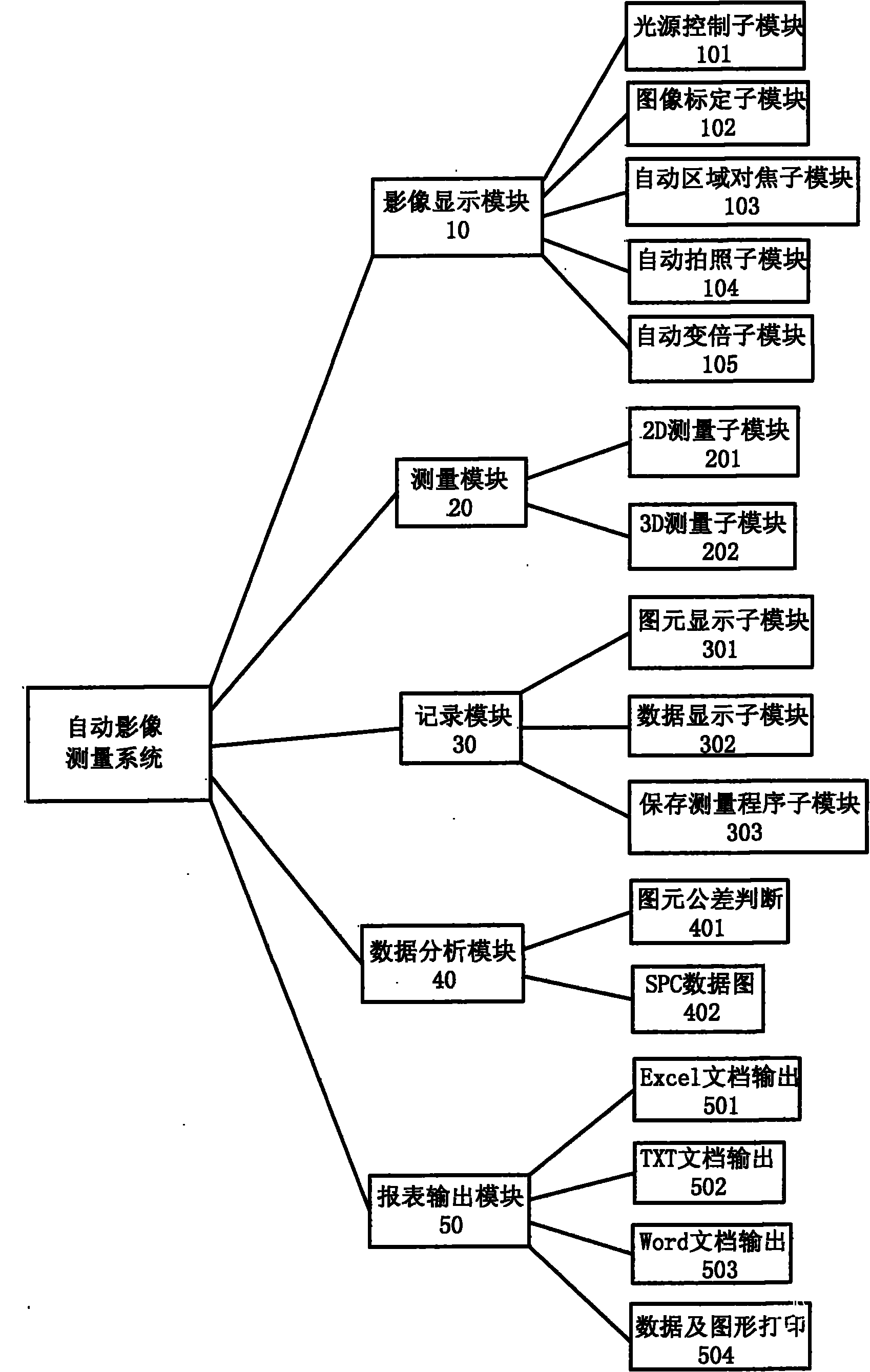

Automatic image measuring system

ActiveCN101839693AHigh transplantabilityImprove update efficiencyUsing optical meansGraphicsAnalysis data

The invention relates to an automatic image measuring system, belongs to a computer system for automatically measuring a workpiece by adopting a mode of measuring a workpiece image, and is mainly used for observing, measuring and analyzing a workpiece product. The automatic image measuring system comprises an image display module, a measuring module, a recording module, a data analysis module and a report output module, wherein the image display module is used for capturing the workpiece image and displaying a structure of each part of the workpiece; the measuring module is used for carrying out shape and position measurement on the workpiece image displayed in the image display module by a geometric figure measuring tool; the recording module records a measuring result, displays the measuring result in a figure and data mode and records a measuring process in a DXF file format; the data analysis module analyzes measuring data and comprises graphics primitive tolerance judgment and an SPC data graph; and the report output module is used for exporting the measuring data and an analysis result. The system adopts a modular design, has high portability and updating efficiency, has functions of automatic shooting, automatic focusing, automatic light source control, SPC data analysis and the like, greatly improves measuring efficiency and acquires more comprehensive analysis data.

Owner:东莞市嘉腾仪器仪表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com