Defect identification method and system

A defect identification and defect technology, applied in the field of image recognition, can solve the problem that the detection method cannot know the specific location of the defect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

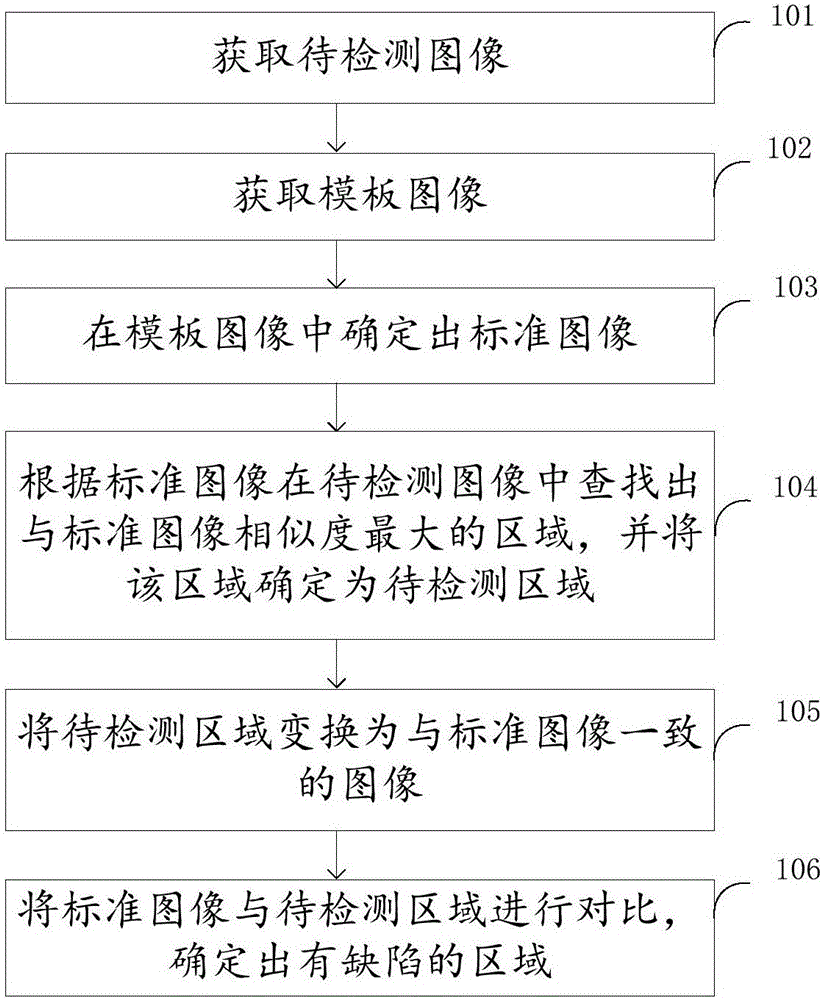

[0036] Please refer to figure 2 , the defect identification method of the defect identification system in this embodiment includes:

[0037] Step 101 , acquiring an image to be inspected. The image to be inspected is an image of a photographed inspection object made on a real object, and the inspection object includes at least one element.

[0038] Specifically, production includes printing, printing, hot pressing, engraving, etching and other processes. Elements can be characters, letters, symbols, words, numbers, strokes, patterns, etc. Each element forms a connected area, and multiple elements can form a A single word, a character string, a sentence or a picture can be used in this way, for example, to represent advertising phrases, logos or trademarks, etc.

[0039] Step 102, acquiring a template image, which is an image including a defect-free detection object.

[0040] The template image can be obtained by taking pictures with a camera or a camera, or can be made by i...

Embodiment 2

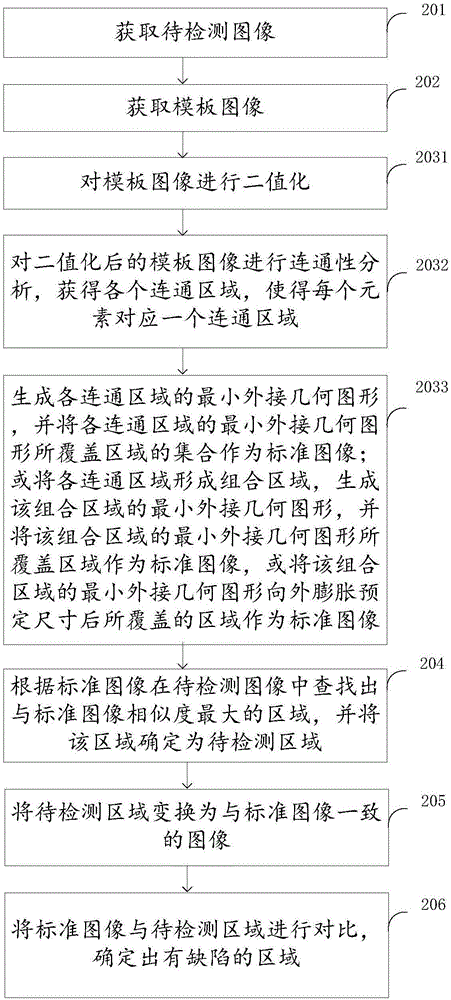

[0119] Please refer to Figure 7 , this embodiment provides a defect identification method, including:

[0120] Step 301 , acquiring an image to be inspected. The image to be inspected is an image of a photographed inspection object made on a real object, and the inspection object includes at least one element.

[0121] Step 302, acquiring a template image, which is an image including a defect-free detection object.

[0122] In step 303, a standard image is determined from the template image. After obtaining the connected regions of each element according to steps 2031 and 2032 in Embodiment 1, obtain the minimum circumscribed geometric figure of each element, such as the minimum circumscribed rectangle, such as Figure 5 The dotted line shown in , and the collection of the area covered by the minimum circumscribed geometry of each element is taken as the standard image. or as Figure 6 As shown, each connected area is formed into a combined area, and the smallest circumsc...

Embodiment 3

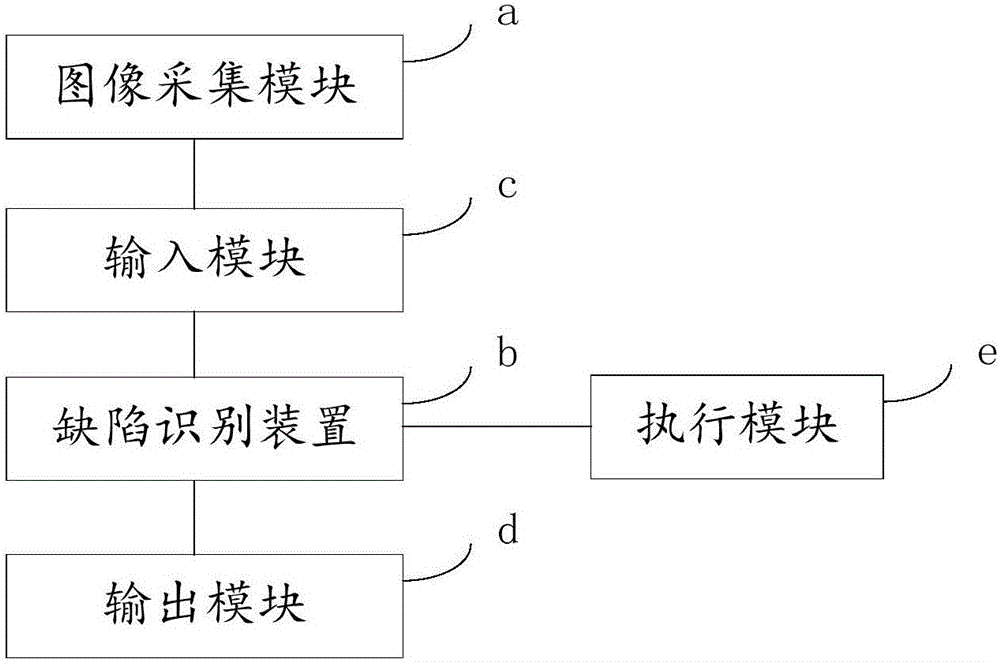

[0132] Please refer to Figure 8 , this embodiment provides a defect identification system, including an image to be inspected acquisition module 401 , a template image acquisition module 402 , a standard image determination module 403 , an area to be inspected determination module 404 , a transformation module 405 and a defect determination module 406 .

[0133] Wherein, the image to be detected acquisition module 401 is configured to obtain an image to be detected. The image to be detected is an image made on a real object of a photographed detection object, and the detection object includes at least one element.

[0134] The template image acquiring module 402 is configured to acquire a template image, where the template image is an image including a defect-free detection object.

[0135] A standard image determination module 403, configured to determine a standard image in the template image, the standard image is the area covered by the minimum circumscribed geometric fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com