Amorphous iron-nickel phosphonate with efficient photocatalysis oxygen production property and preparation method and application of amorphous iron-nickel phosphonate

A photocatalytic and amorphous technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of low photocatalytic oxygen production efficiency and achieve technological Simple operation, high-efficiency photocatalytic oxygen production performance, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

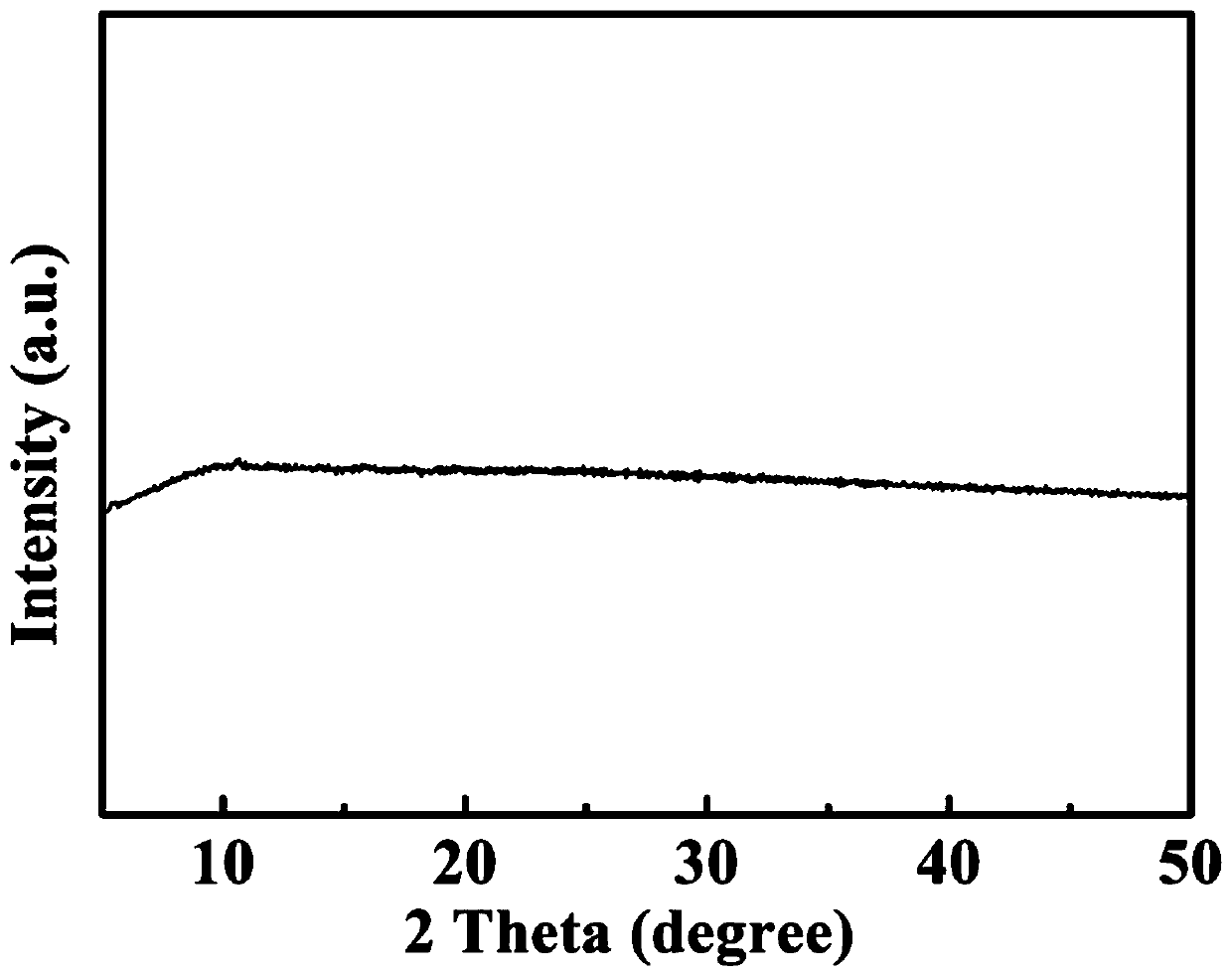

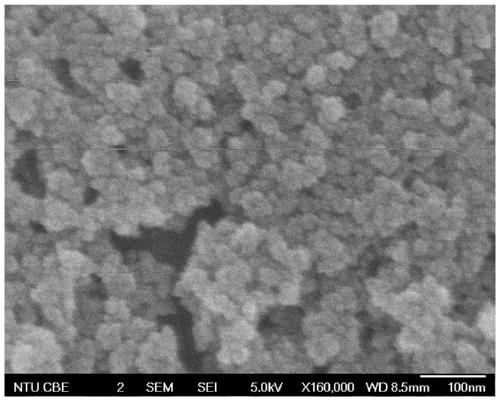

[0022] Dissolve 1 mmol of iron-nickel nitrate in 5 ml of N,N-dimethylformamide (solution A), and dissolve 1 mmol of 2-carboxyethylphosphonic acid in 10 ml of N,N-dimethylformamide (solution B). Add solution A to solution B dropwise under magnetic stirring. After reacting for 12 hours under solvothermal conditions at 140° C., the sample was washed by centrifugation and collected to obtain amorphous iron-nickel phosphonate.

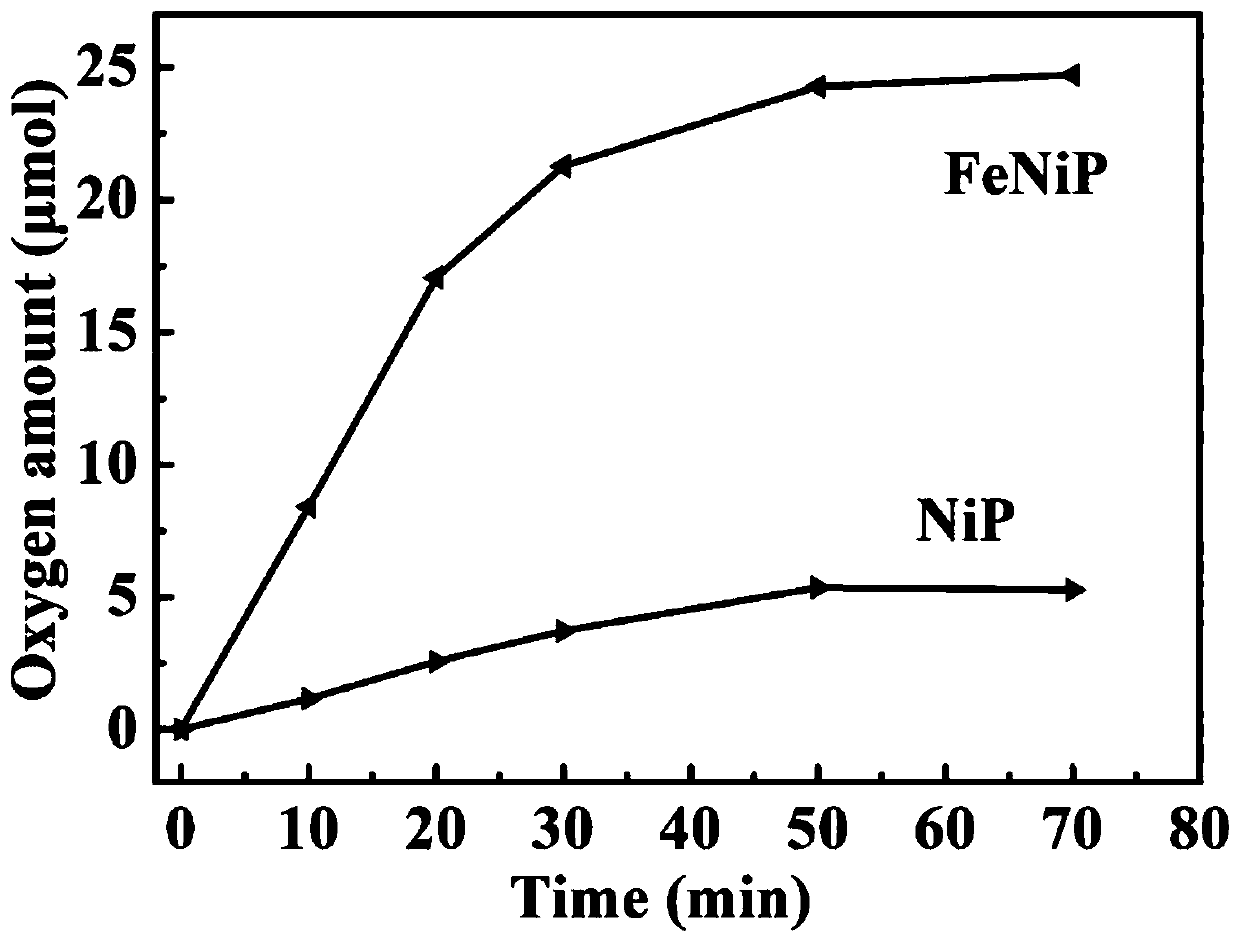

[0023] The photocatalytic performance of the amorphous iron-nickel phosphonate prepared in Example 1 was measured in a closed gas circulation system, and the reaction system was kept at about 20° C. by circulating cooling water. With photocatalyst (the amorphous iron nickel phosphonate that embodiment 1 makes, nickel phosphate), [Ru(bpy) 3 ] Cl 2 ·6H 2 O and Na 2 S 2 o 8 Mix in borate buffer. A 300w xenon lamp was selected as the light source, and the reaction system was backfilled with argon several times to remove air before illumination. Determin...

Embodiment 2

[0026] Dissolve 2mmol of iron-nickel nitrate in 15ml N,N-dimethylformamide (solution A), dissolve 2mmol of 2-carboxyethylphosphonic acid in 15ml N,N-dimethylformamide (solution B), in Add solution A to solution B dropwise under magnetic stirring. After reacting for 24 hours under solvothermal conditions at 160° C., the sample was washed by centrifugation and collected to obtain amorphous iron-nickel phosphonate.

Embodiment 3

[0028] Dissolve 3mmol of iron-nickel nitrate in 25ml of N,N-dimethylformamide (solution A), and dissolve 4mmol of 2-carboxyethylphosphonic acid in 30ml of N,N-dimethylformamide (solution B). Add solution A to solution B dropwise under magnetic stirring. After reacting for 36 hours under solvothermal conditions at 200° C., the samples were washed by centrifugation and collected to obtain amorphous iron-nickel phosphonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com