Patents

Literature

9902results about "Hydrogen/synthetic gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

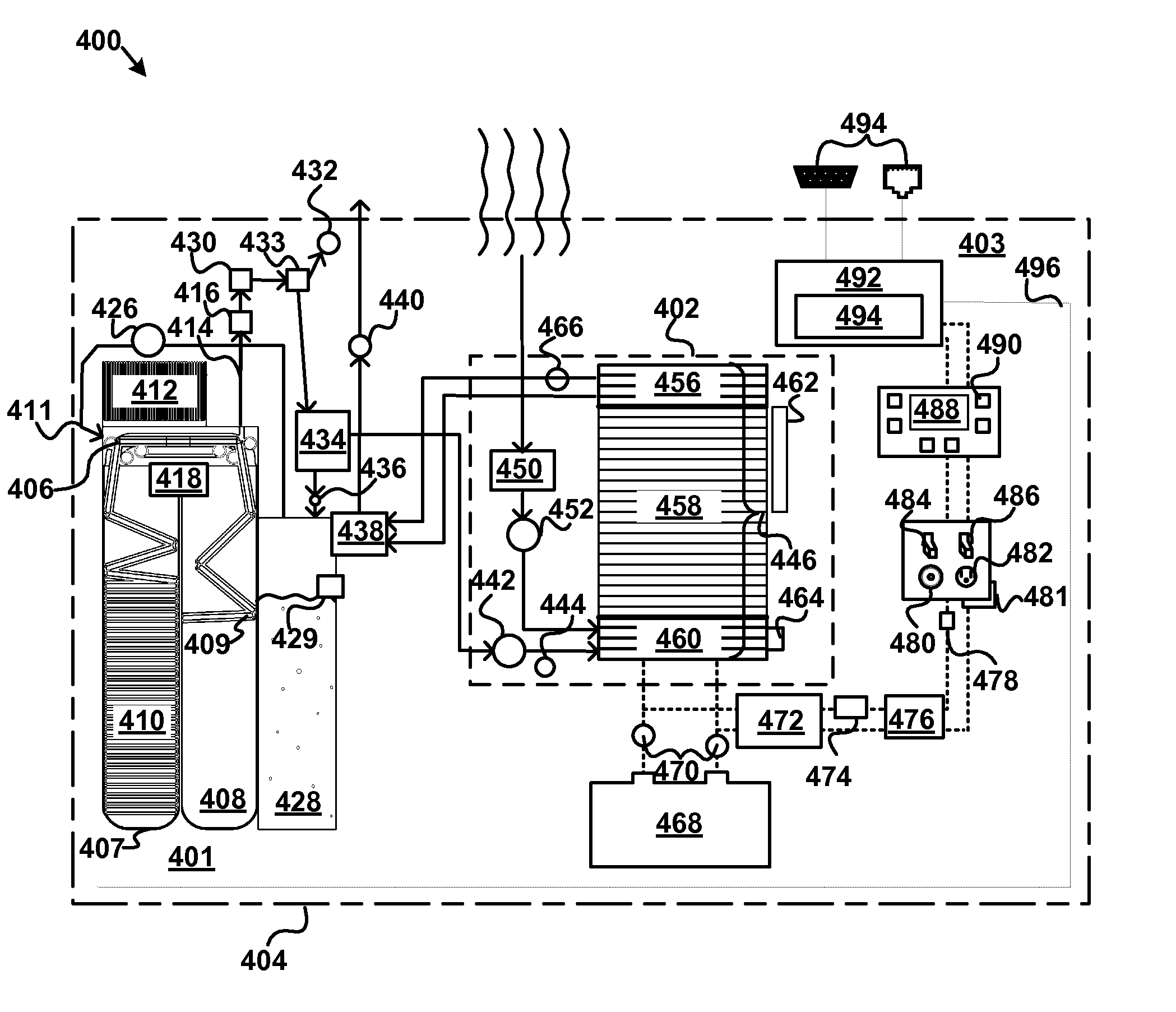

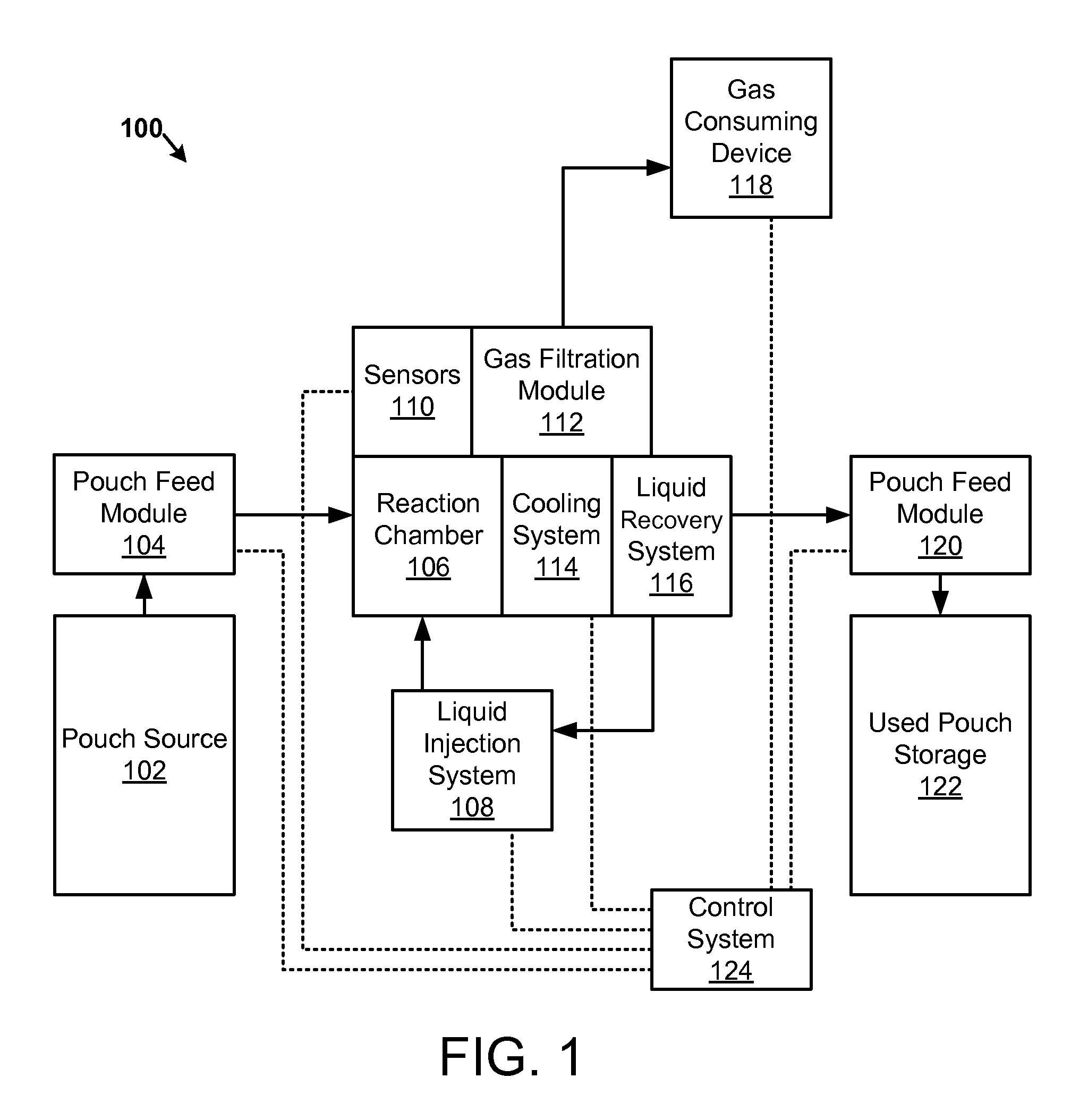

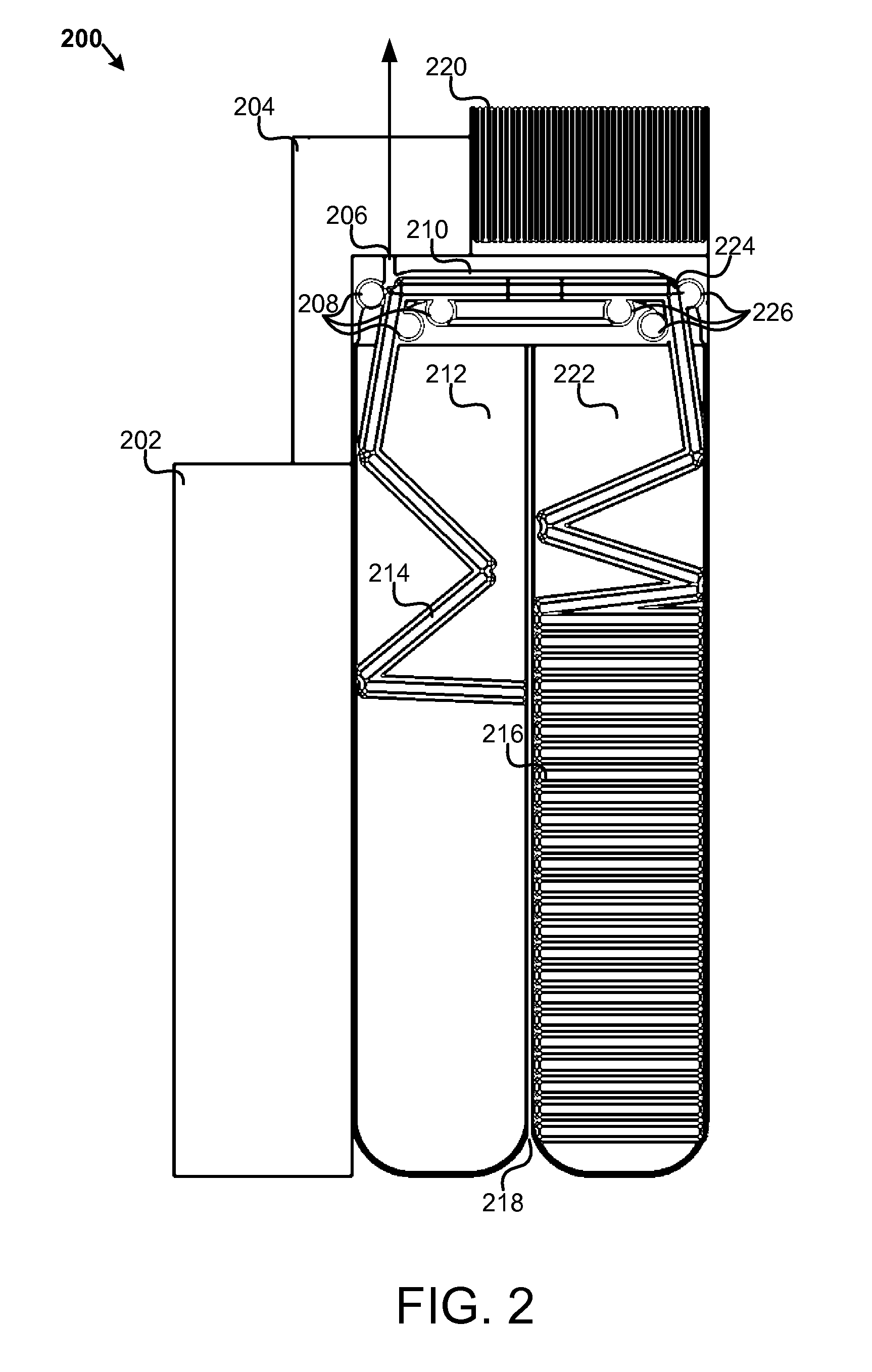

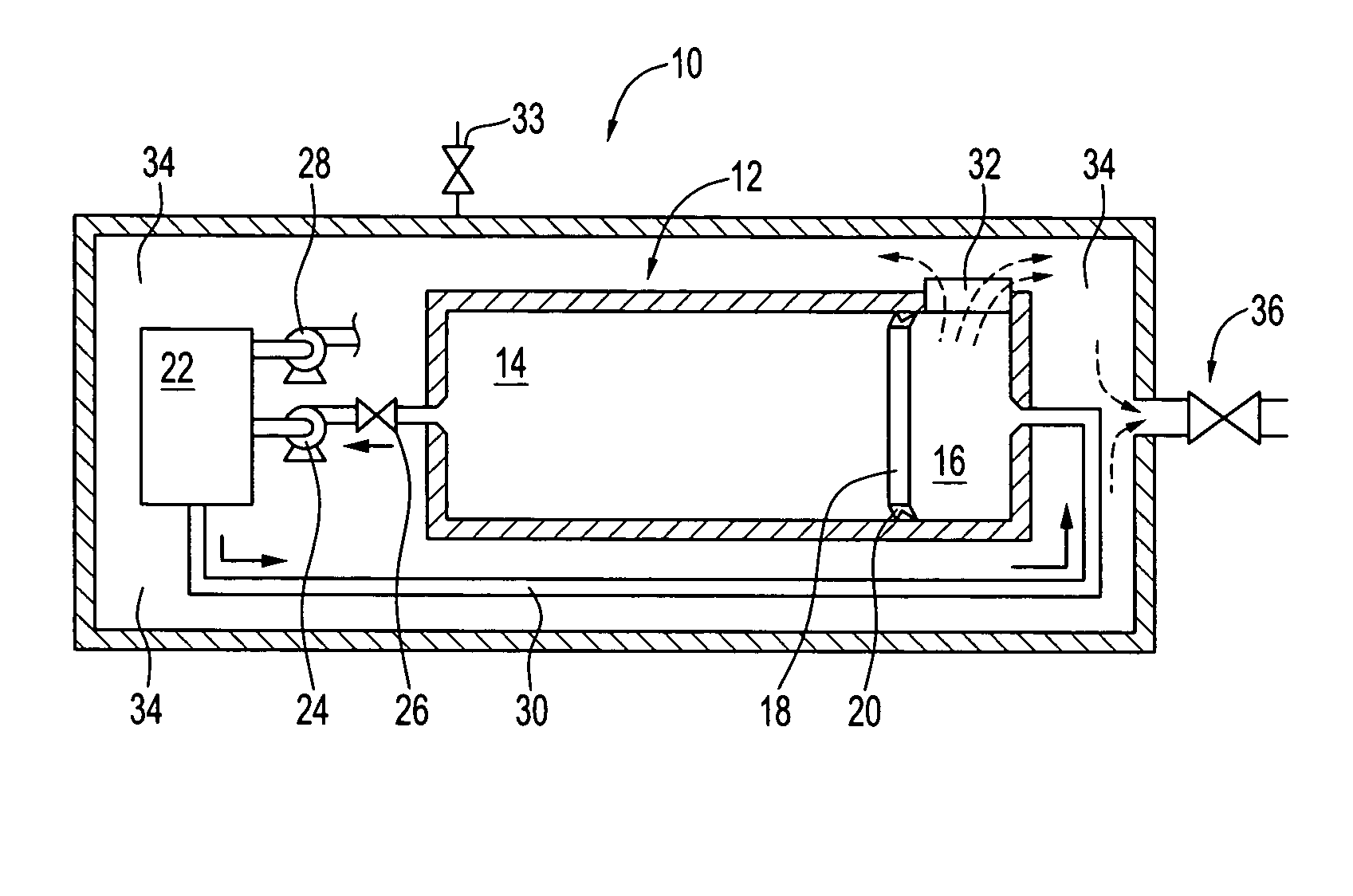

Apparatus, system, and method for generating a gas from solid reactant pouches

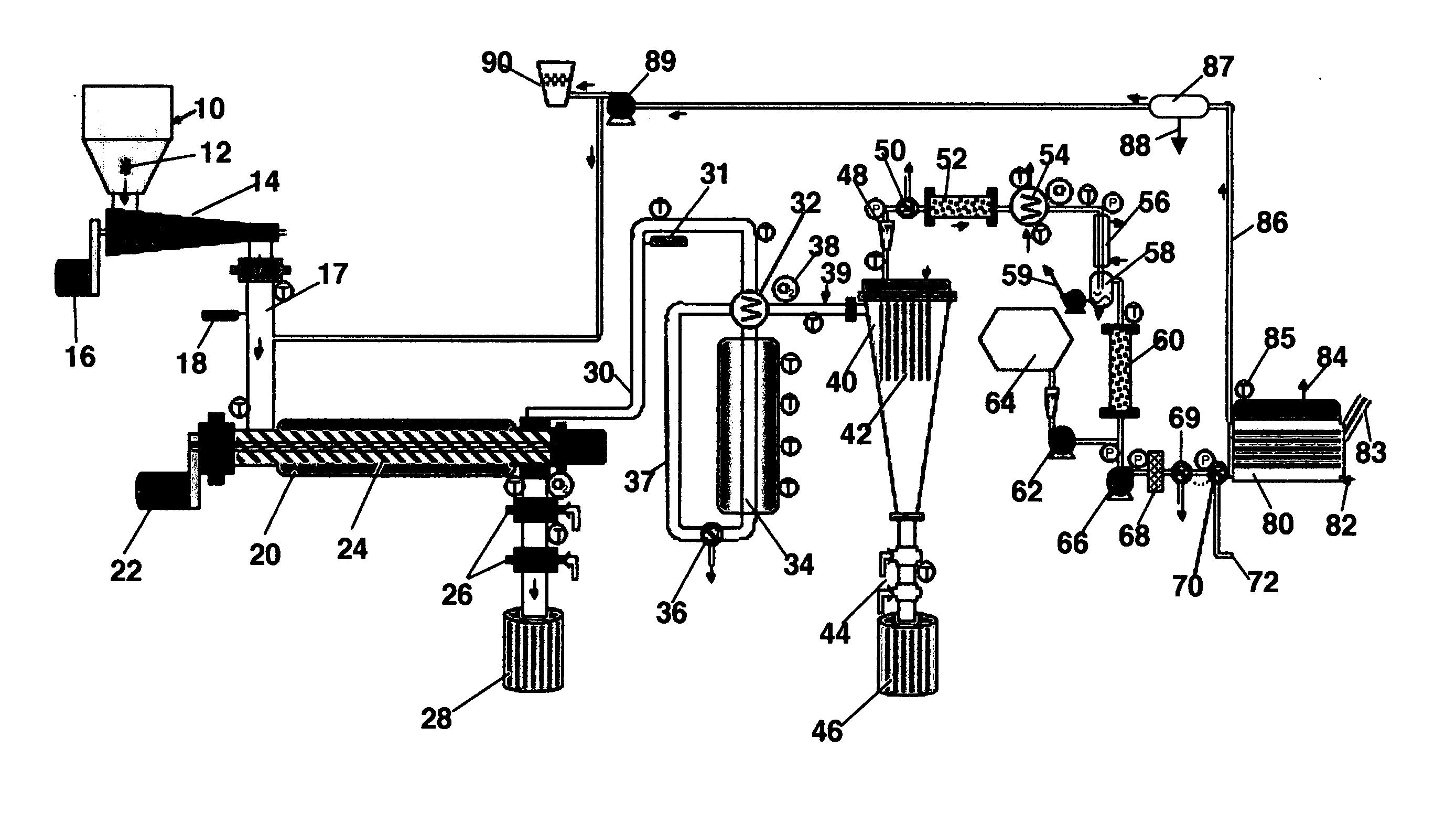

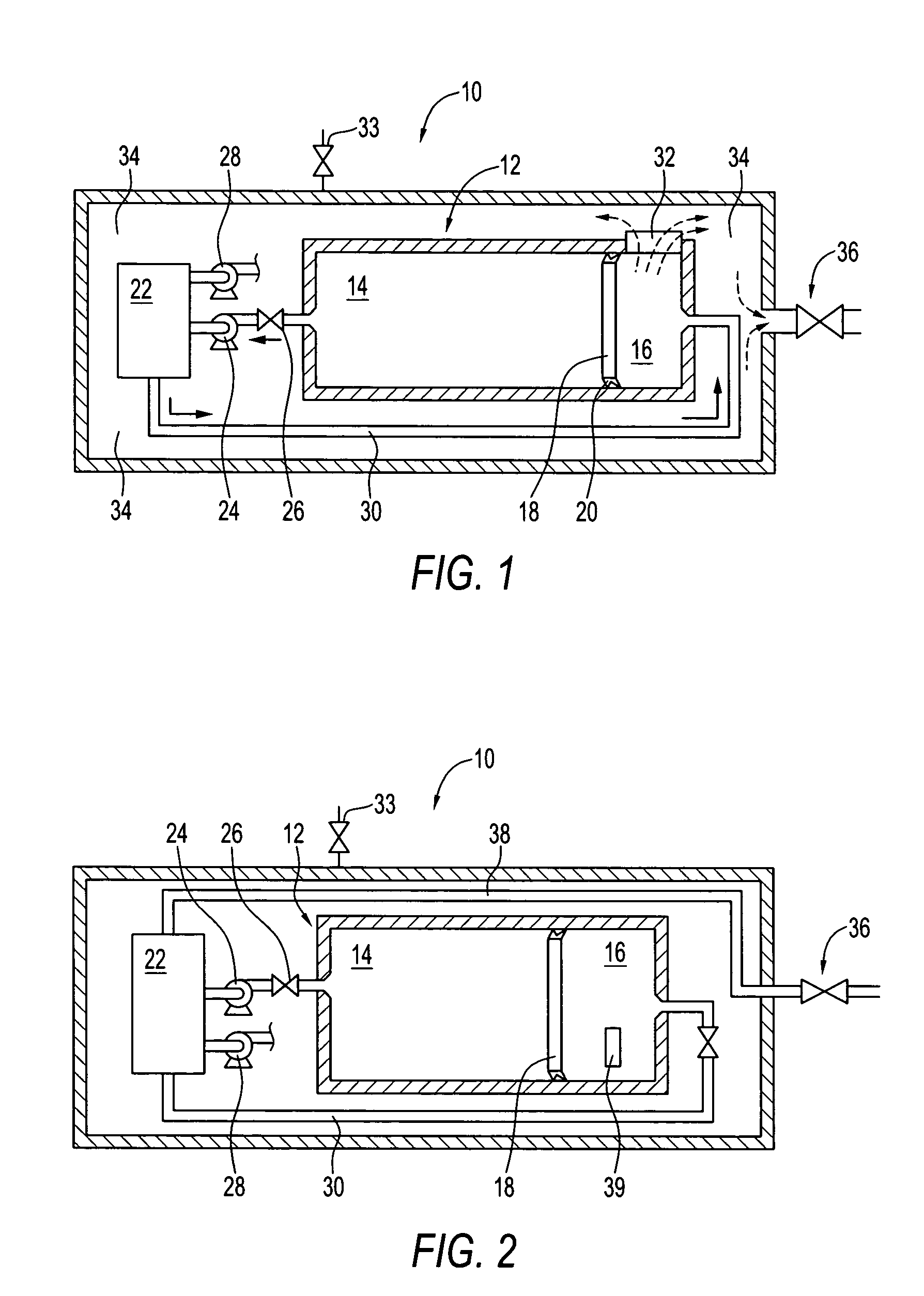

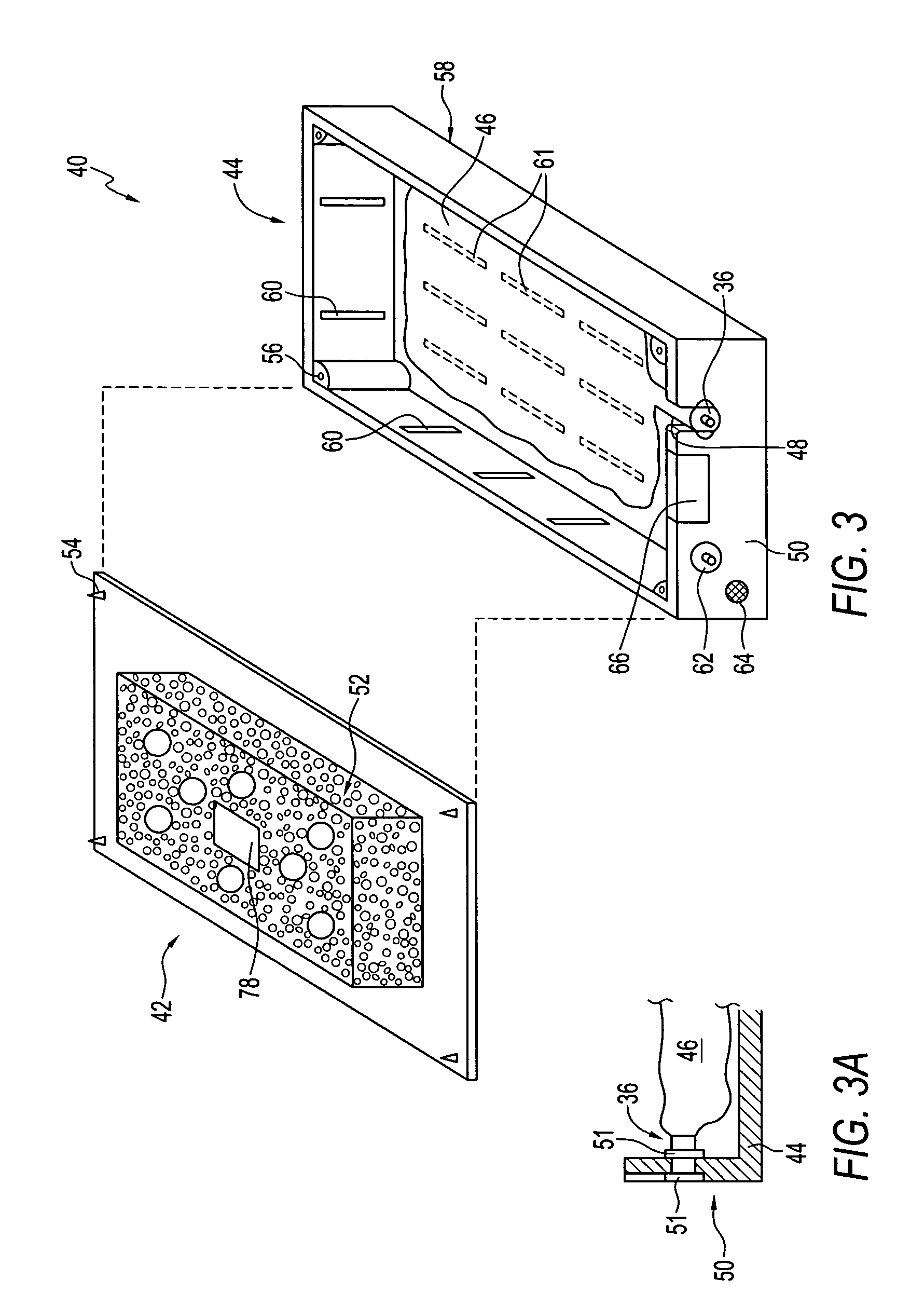

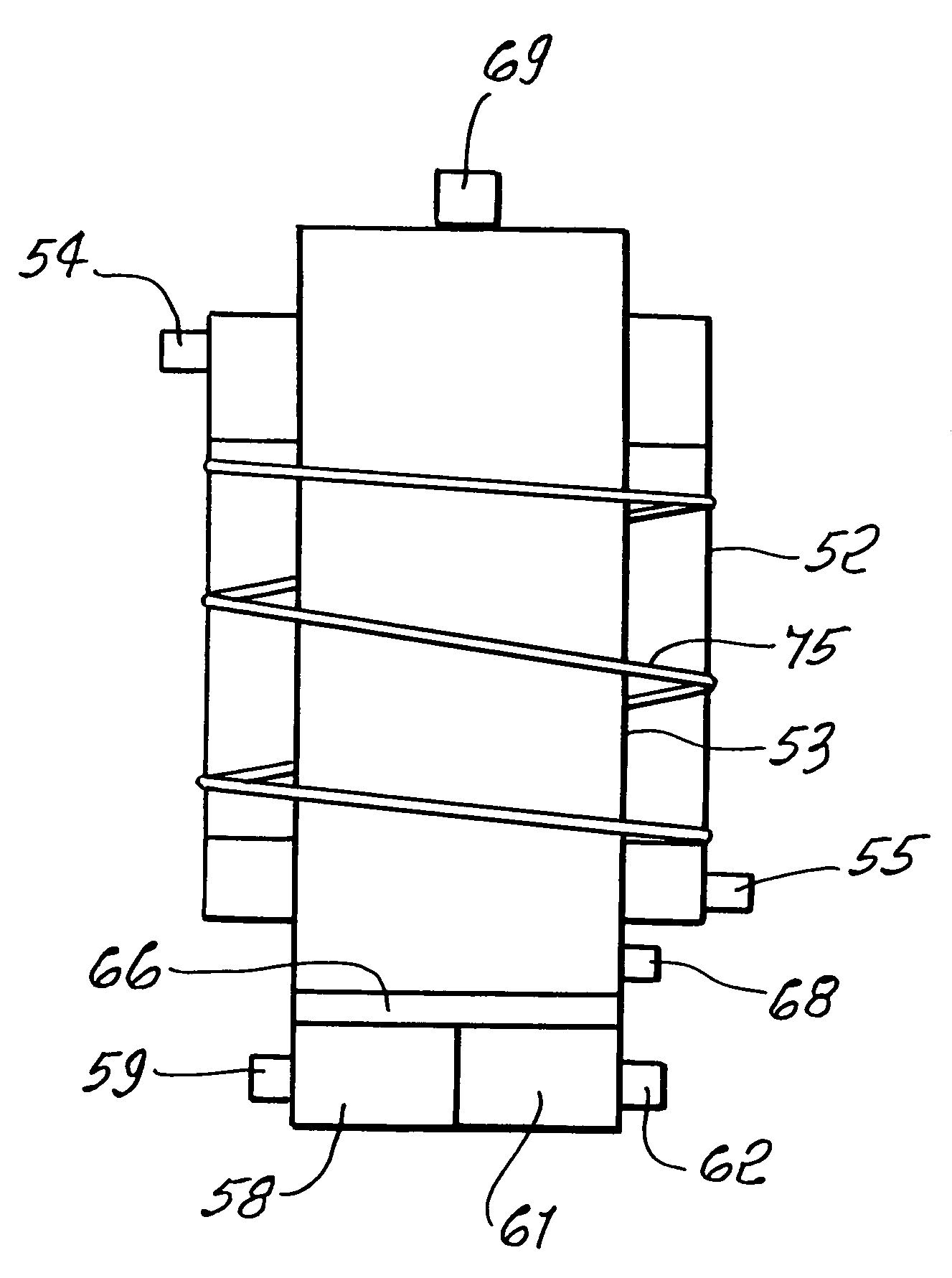

An apparatus, system, and method are disclosed for generating a gas. One or more liquid permeable pouches each define a cavity that contains a solid anhydrous reactant, such as a chemical hydride. A reaction chamber made of a heat, chemical and / or pressure resistant material receives the one or more pouches from a pouch feeder that transfers the one or more pouches into the reaction chamber successively at a feed rate. One or more liquid sources inject a liquid reactant into the reaction chamber so that the liquid reactant contacts a portion of the one or more pouches. The one or more liquid sources inject the liquid reactant at an injection rate that corresponds to the feed rate. A gas outlet releases a gas, such as hydrogen, oxygen, ammonia, borazine, nitrogen, or a hydrocarbon, that is produced by a reaction between the solid reactant and the liquid reactant.

Owner:TRULITE INC

Electromagnetic susceptors with coatings for artificial dielectric systems and devices

InactiveUS20030226840A1Enhanced radiationLow dielectric constantGas treatmentMethane captureChemical treatmentSusceptor

A coated susceptor of electromagnetic energy for chemical processing made of a matrix material that surrounds a non-matrix material that is made from a material that is different from the matrix material, in which the matrix material is constructed of material having lower dielectric losses compared to the non-matrix material, the non-matrix material initially absorbs electromagnetic energy applied to the electromagnetic susceptor to a greater extent than the matrix material, the non-matrix material produces subsequent heat in the matrix material, and the surface of the susceptor is coated with a material that interacts with applied electromagnetic energy of at least one frequency and initially absorbs electromagnetic energy and produces heat.

Owner:DALTON ROBERT C

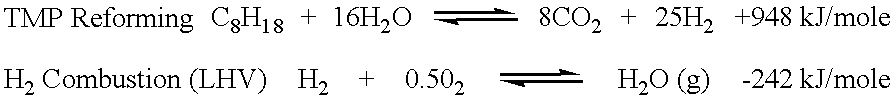

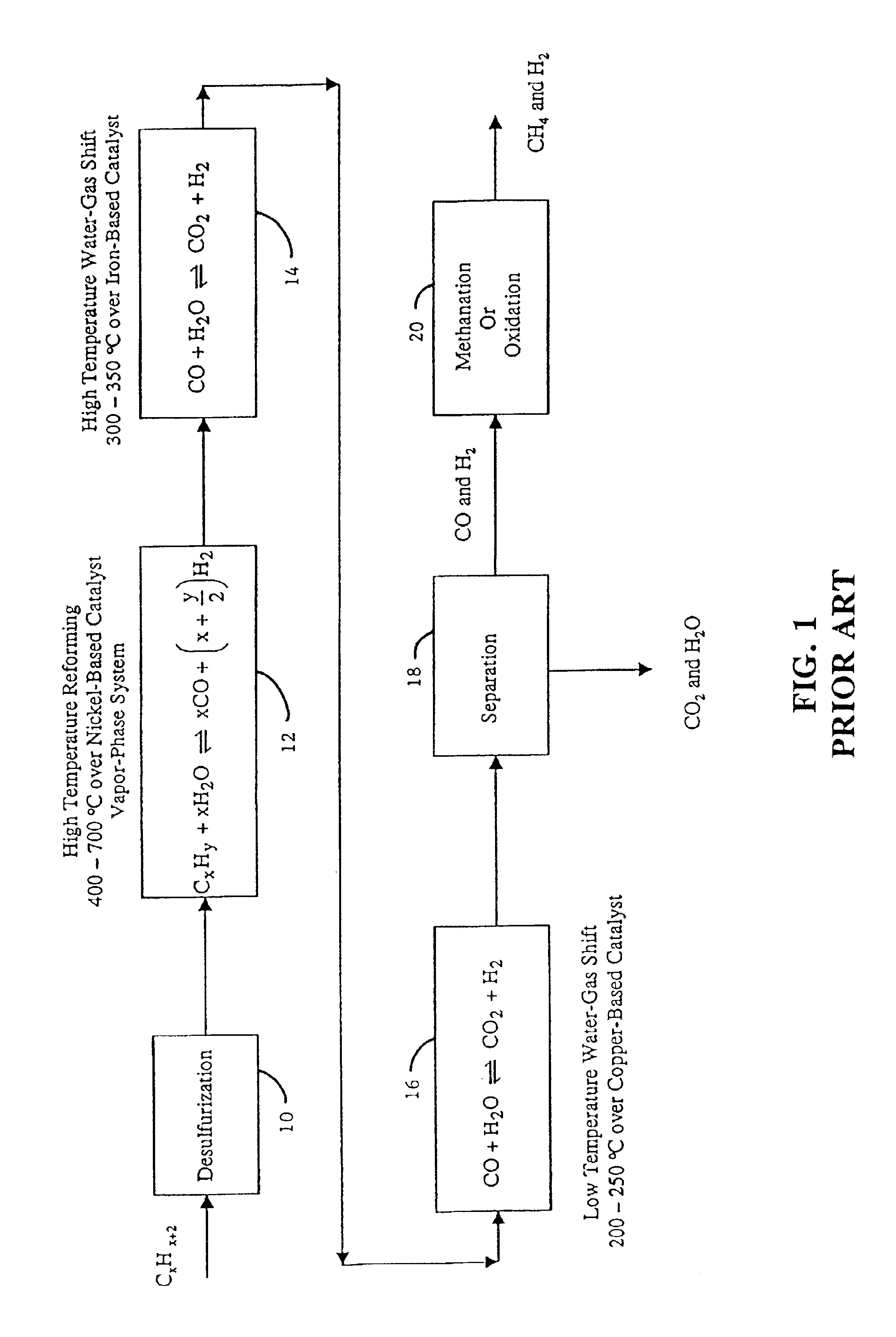

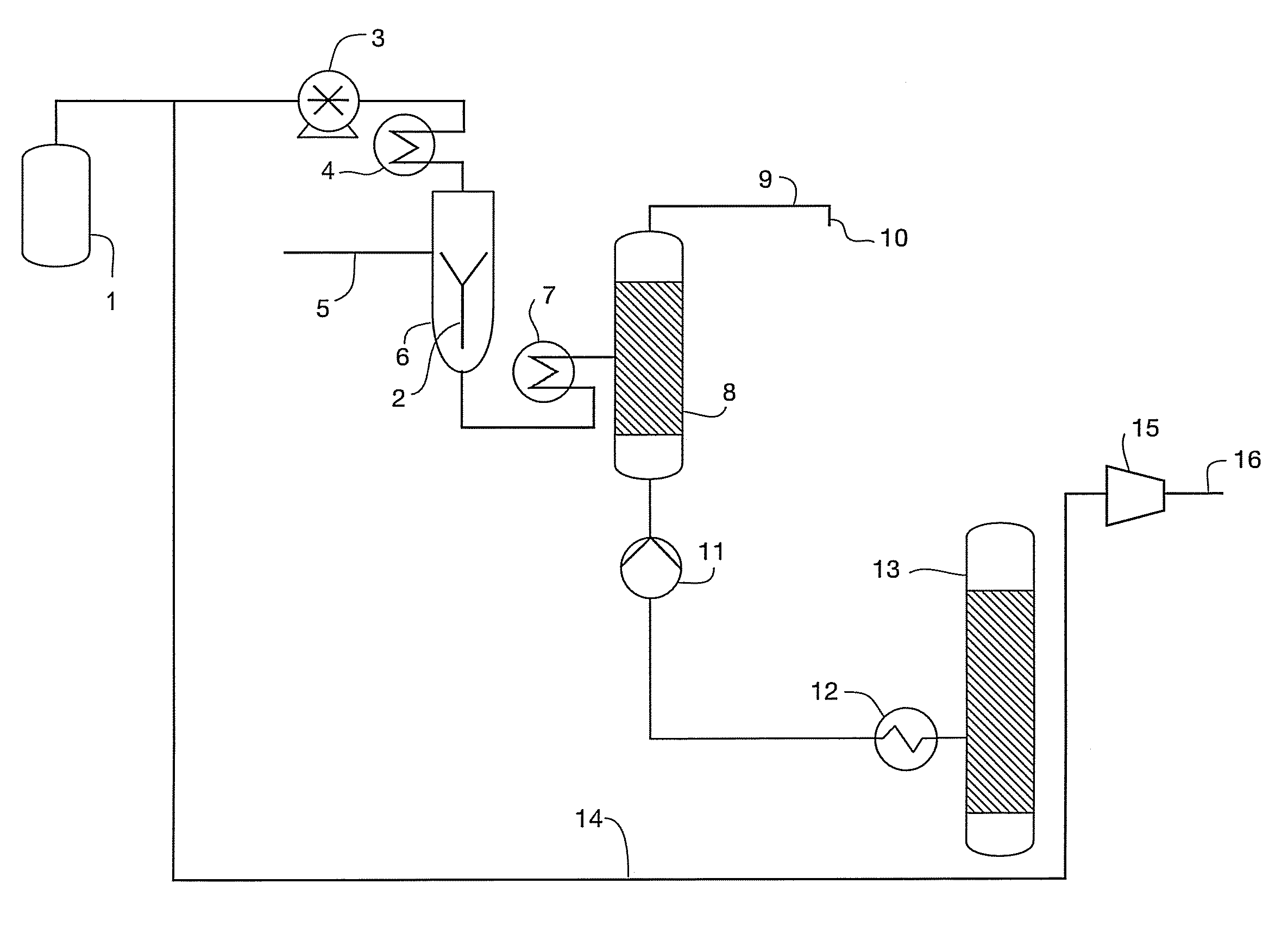

Method and system for supplying hydrogen for use in fuel cells

InactiveUS6348278B1Reduce hydrogen concentrationImprove concentrationElectricity cogenerationRegenerative fuel cellsHydrogenCombustor

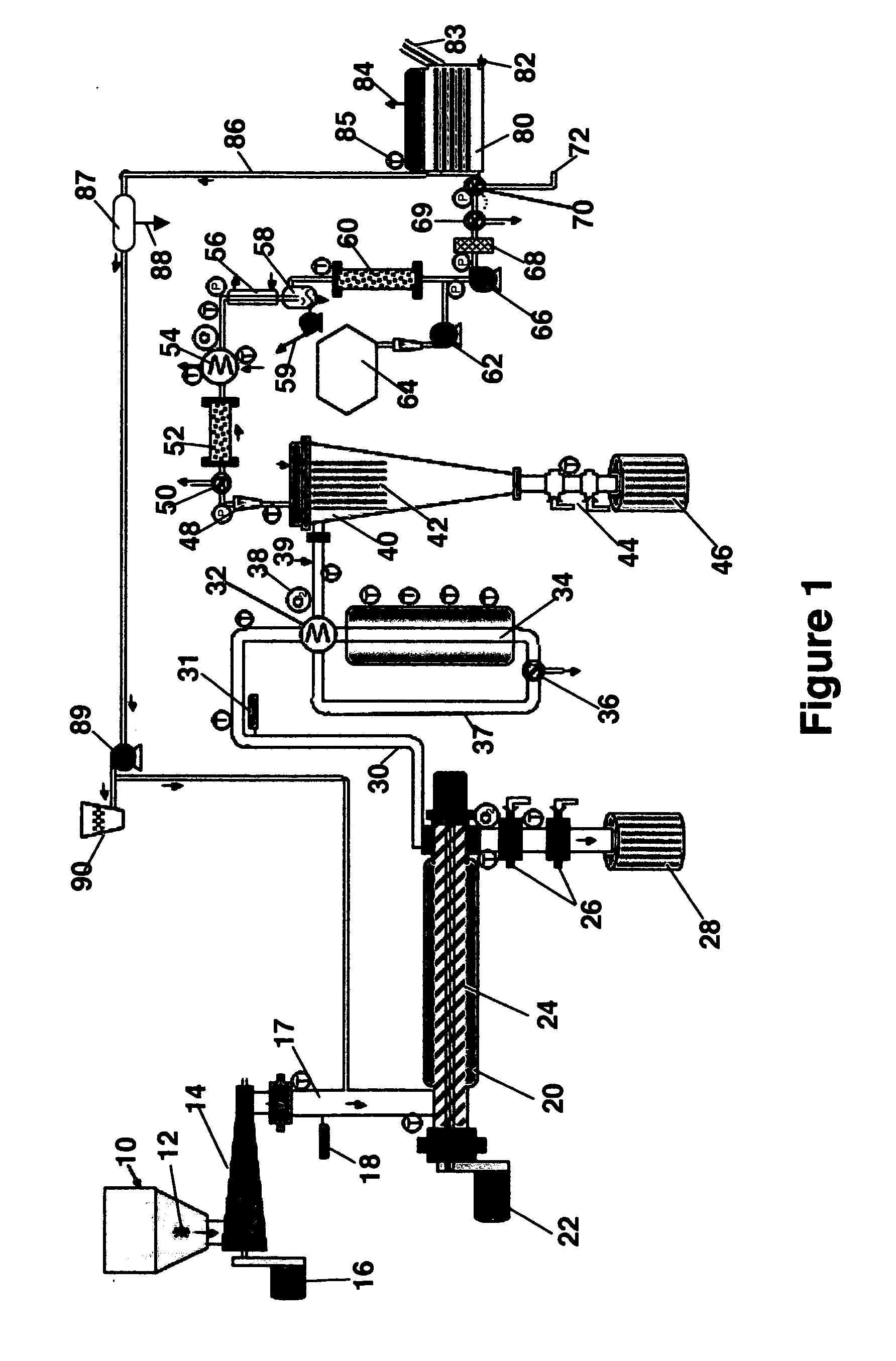

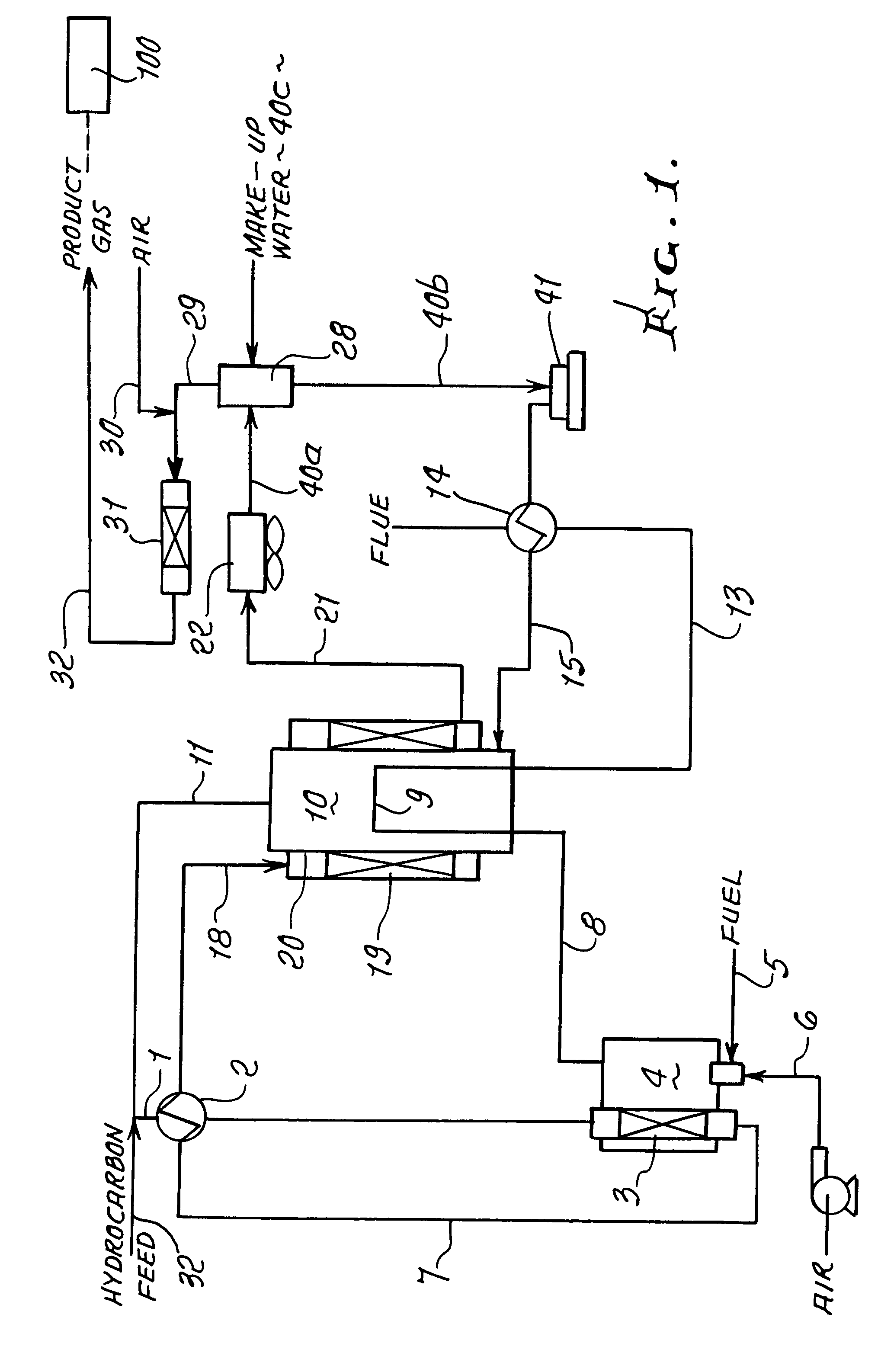

The present invention provides a method and system for efficiently producing hydrogen that can be supplied to a fuel cell. The method and system of the present invention produces hydrogen in a reforming reactor using a hydrocarbon stream and water vapor stream as reactants. The hydrogen produced is purified in a hydrogen separating membrane to form a retentate stream and purified hydrogen stream. The purified hydrogen can then be fed to a fuel cell where electrical energy is produced and a fuel cell exhaust stream containing water vapor and oxygen depleted air is emitted. In one embodiment of the present invention, a means and method is provided for recycling a portion of the retentate stream to the reforming reactor for increased hydrogen yields. In another embodiment, a combustor is provided for combusting a second portion of the retentate stream to provide heat to the reforming reaction or other reactants. In a preferred embodiment, the combustion is carried out in the presence of at least a portion of the oxygen depleted air stream from the fuel cell. Thus, the system and method of the present invention advantageously uses products generated from the system to enhance the overall efficiency of the system.

Owner:MOBIL OIL CORP

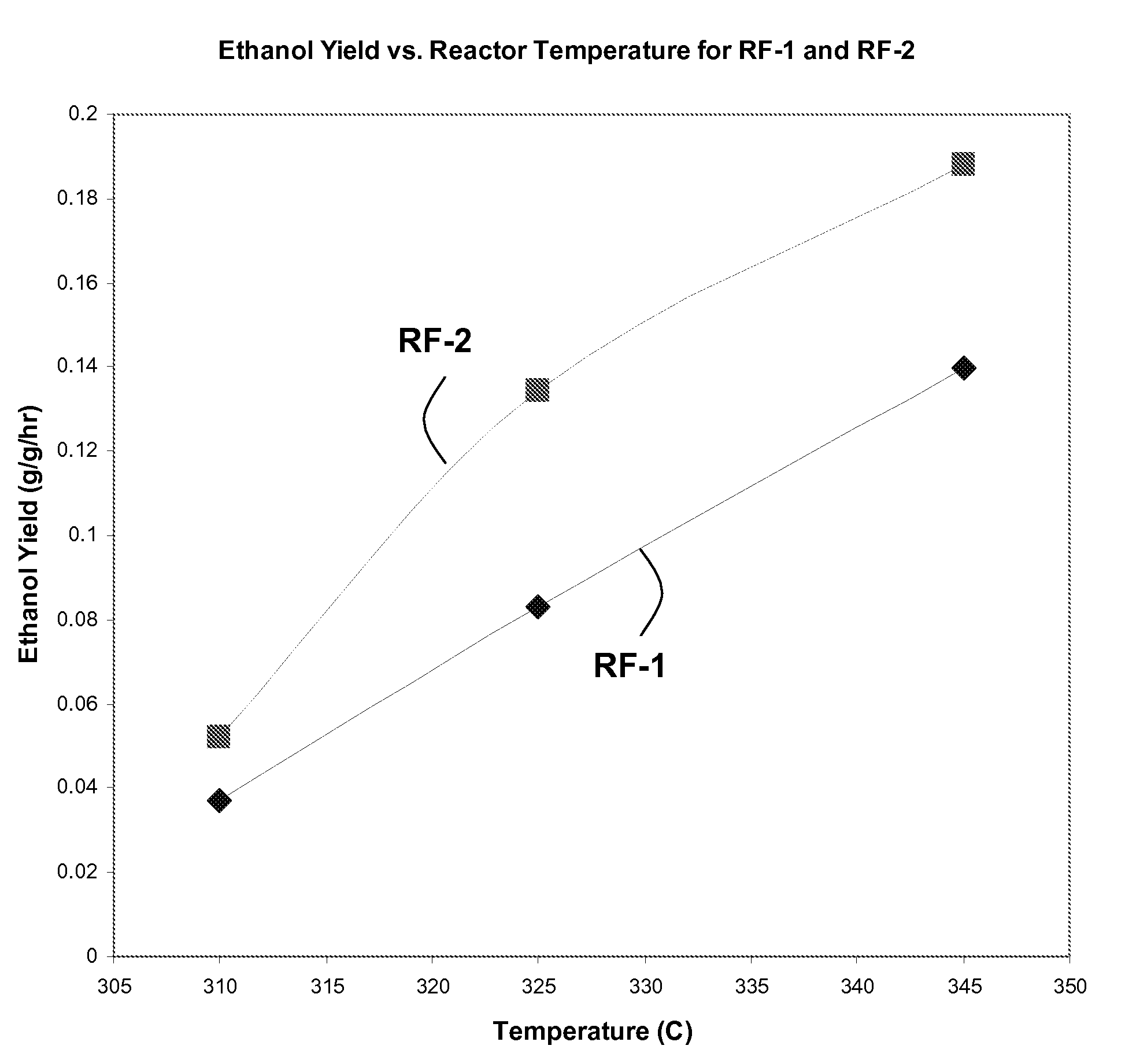

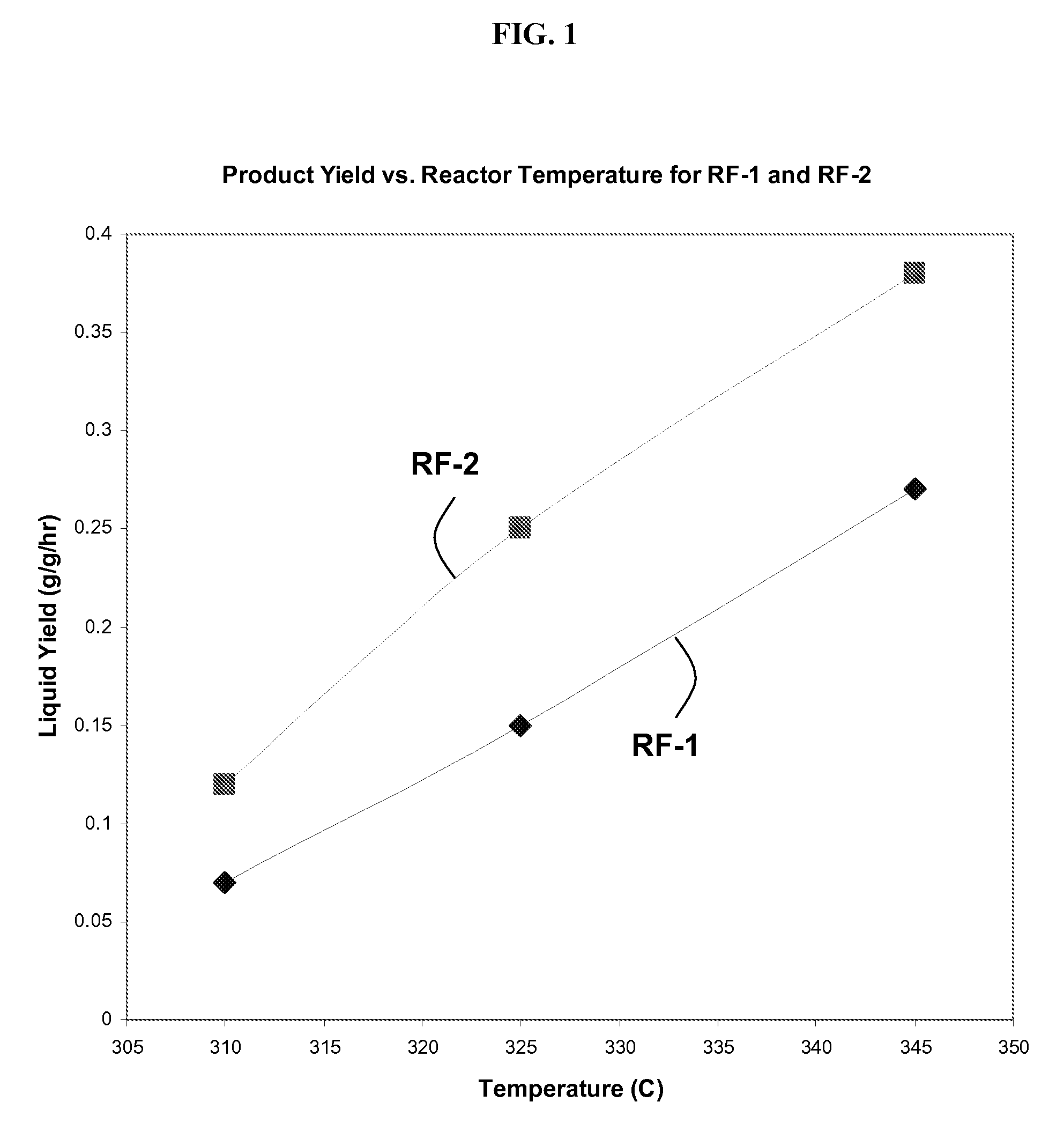

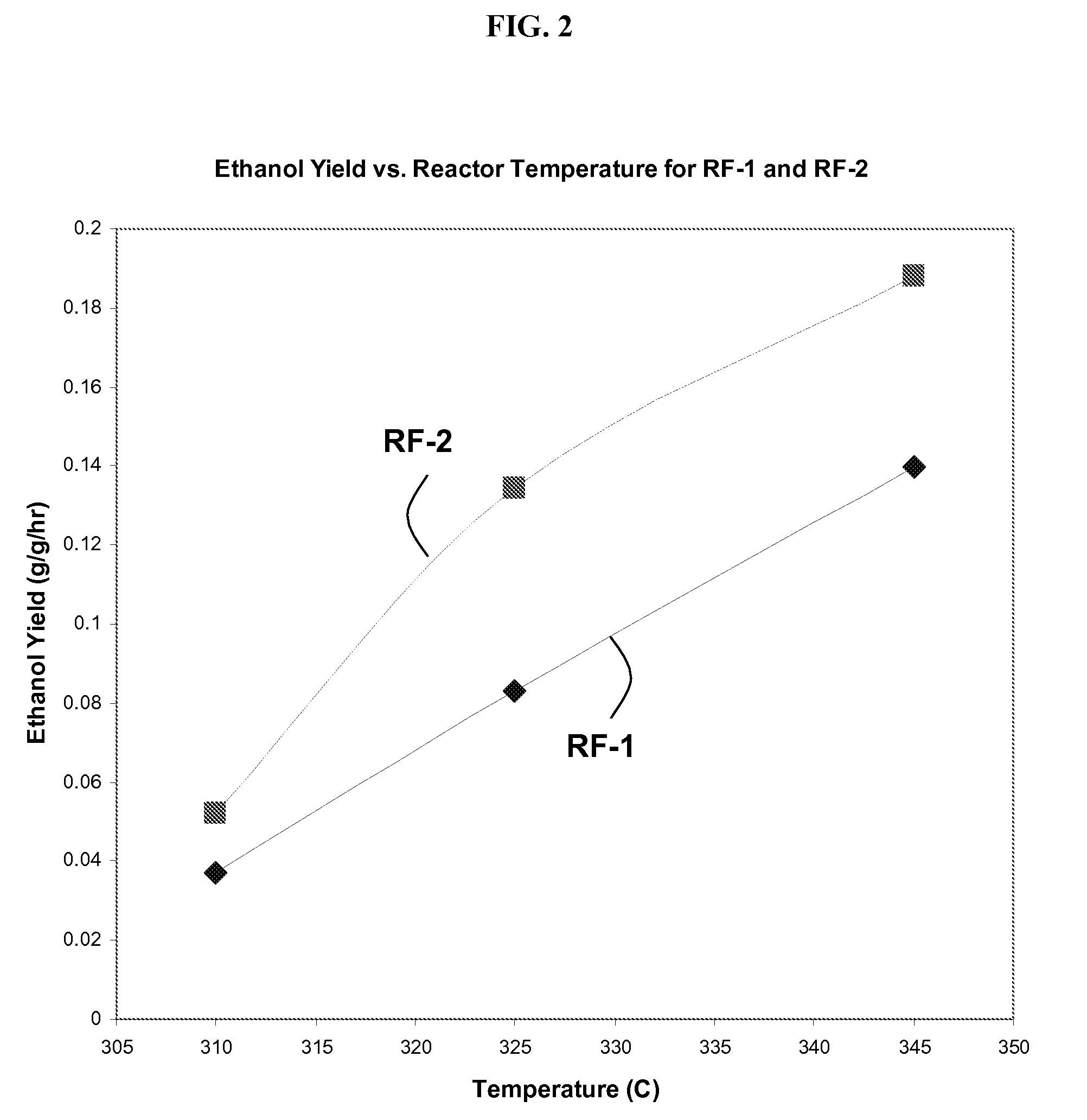

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

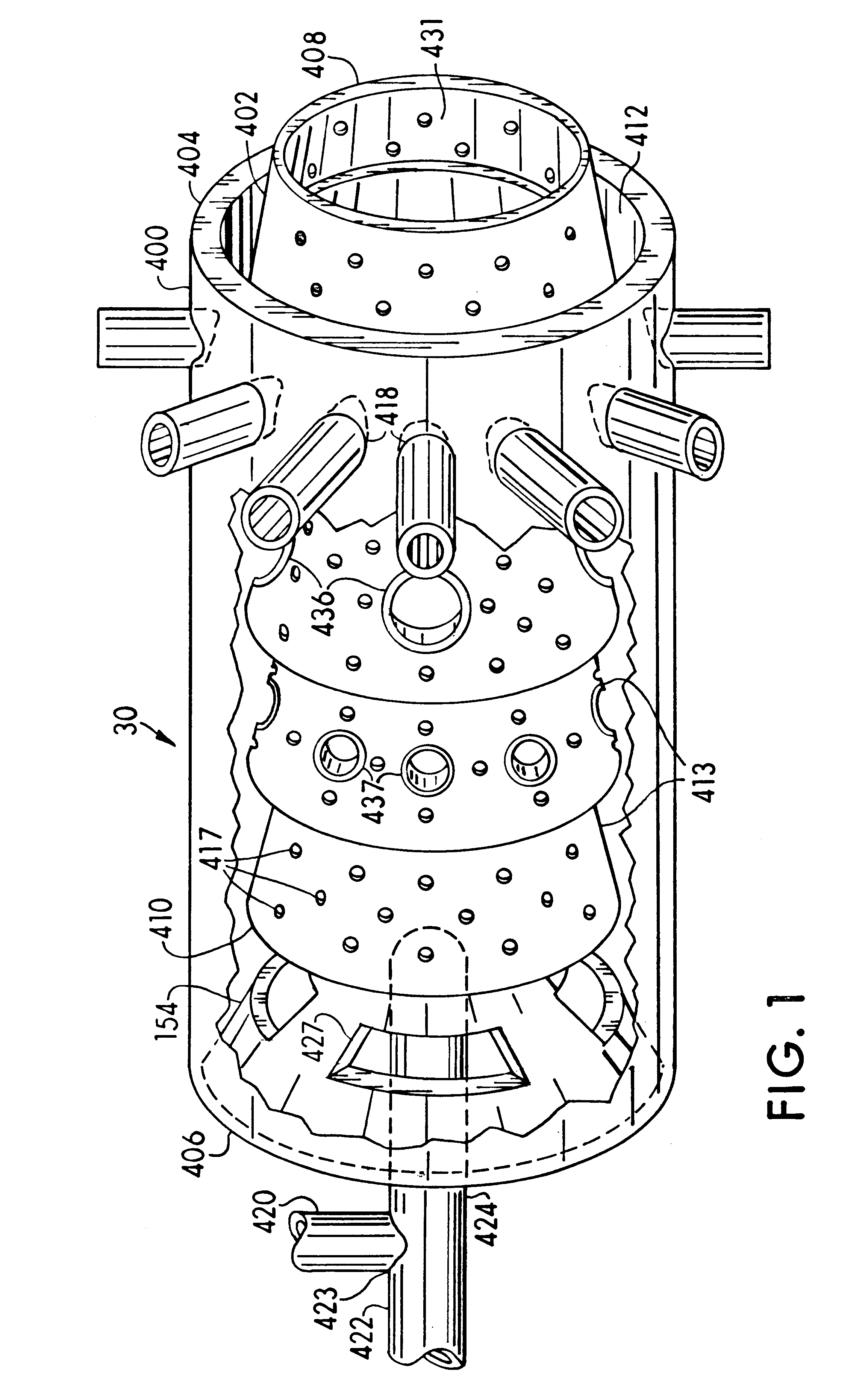

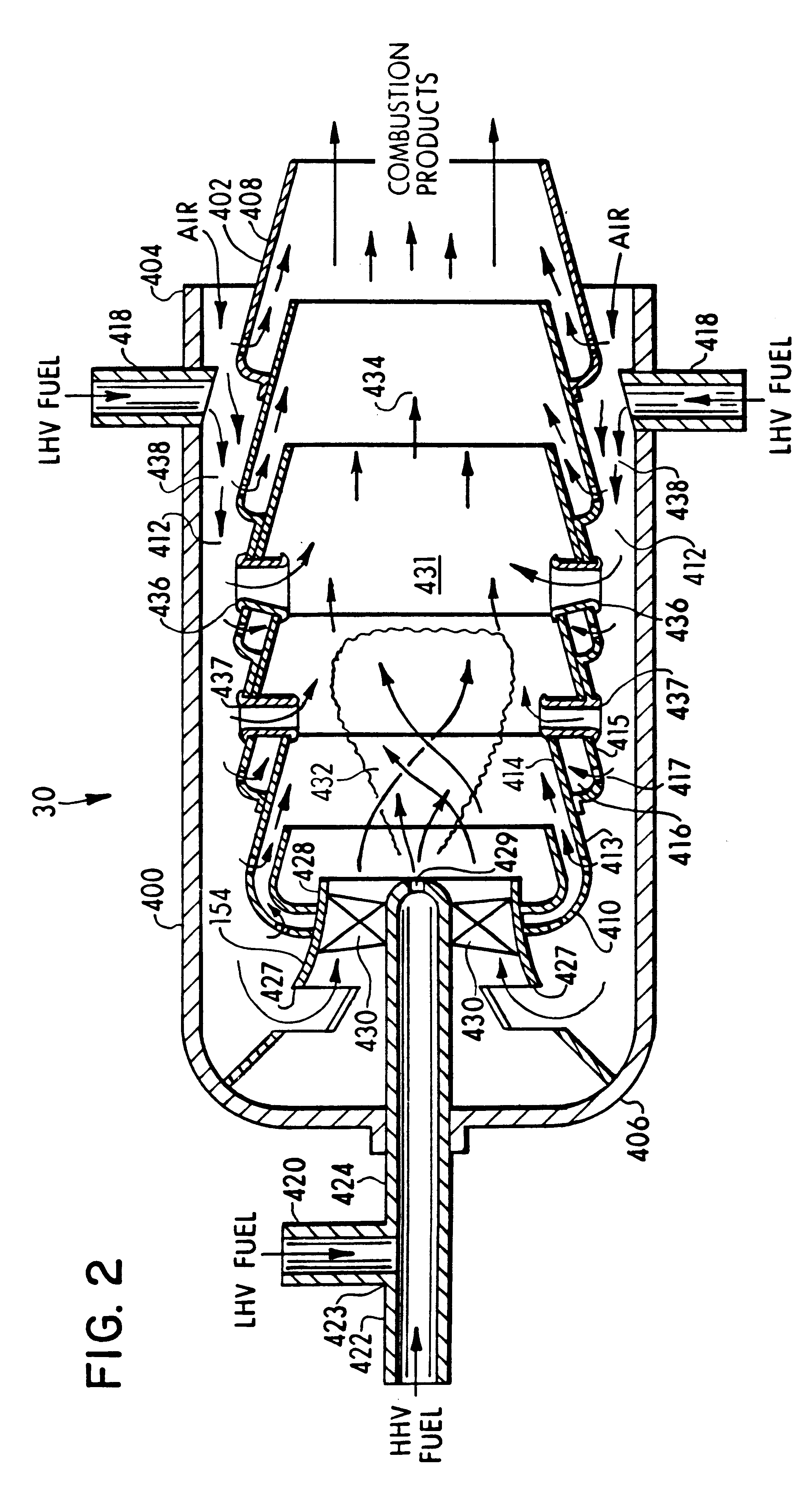

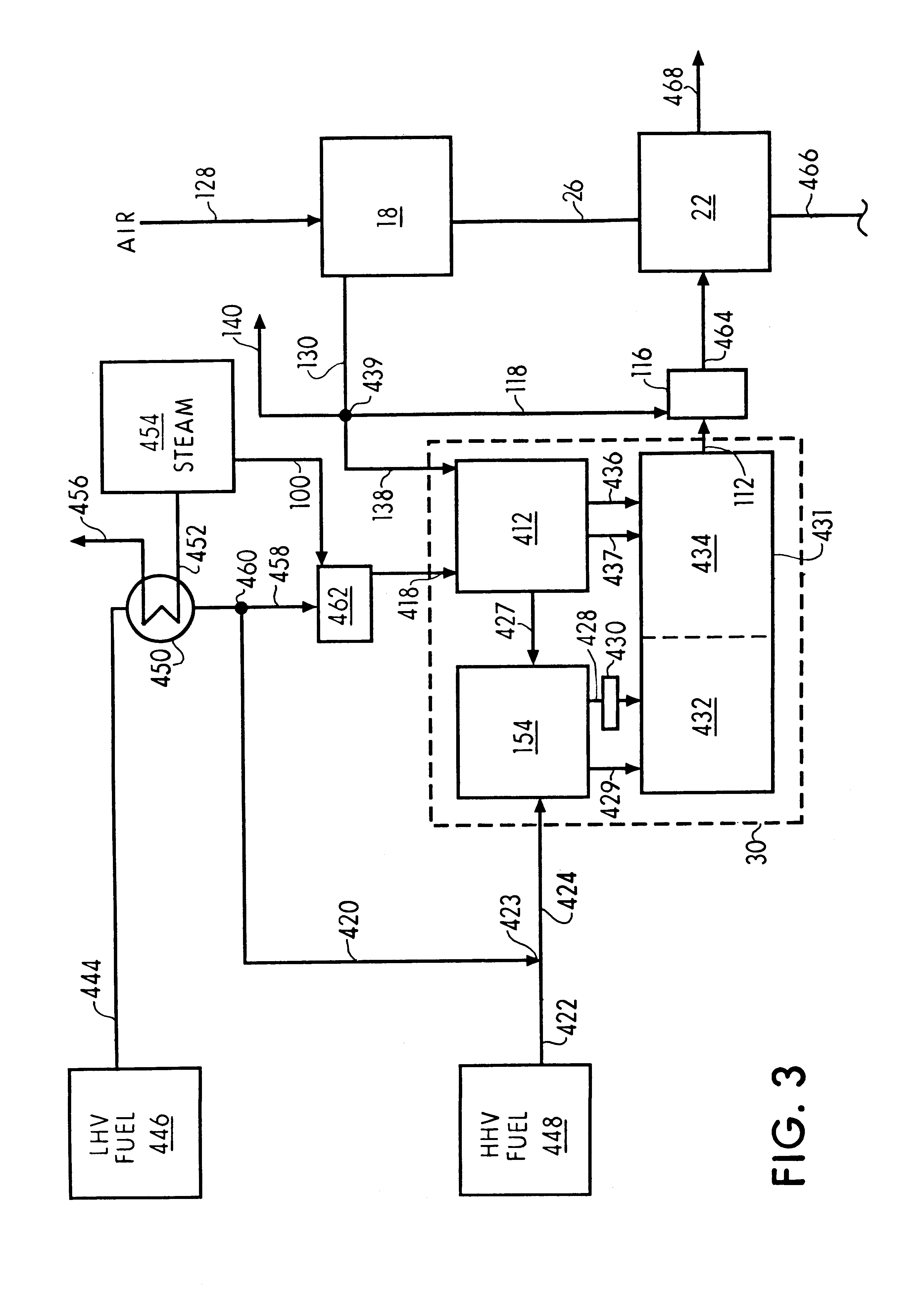

Staged combustion of a low heating value fuel gas for driving a gas turbine

A process is provided for combusting a low heating value fuel gas in a combustor to drive an associated gas turbine. A low heating value fuel gas feed is divided into a burner portion and a combustion chamber portion. The combustion chamber portion and a combustion air are conveyed into a mixing zone of the combustor to form an air / fuel mixture. The burner portion is conveyed into a flame zone of the combustor through a burner nozzle while a first portion of the air / fuel mixture is conveyed into the flame zone through a burner port adjacent to the burner nozzle. The burner portion and first portion of the air / fuel mixture are contacted in the flame zone to combust the portions and produce flame zone products. The flame zone products are conveyed into an oxidation zone of the combustor downstream of the flame zone while a second portion of the air / fuel mixture is also conveyed into the oxidation zone. The second portion is combusted in the oxidation zone in the presence of the flame zone products to produce combustion products. The combustion products are conveyed into the associated gas turbine and drive the gas turbine.

Owner:MARATHON OIL CO +1

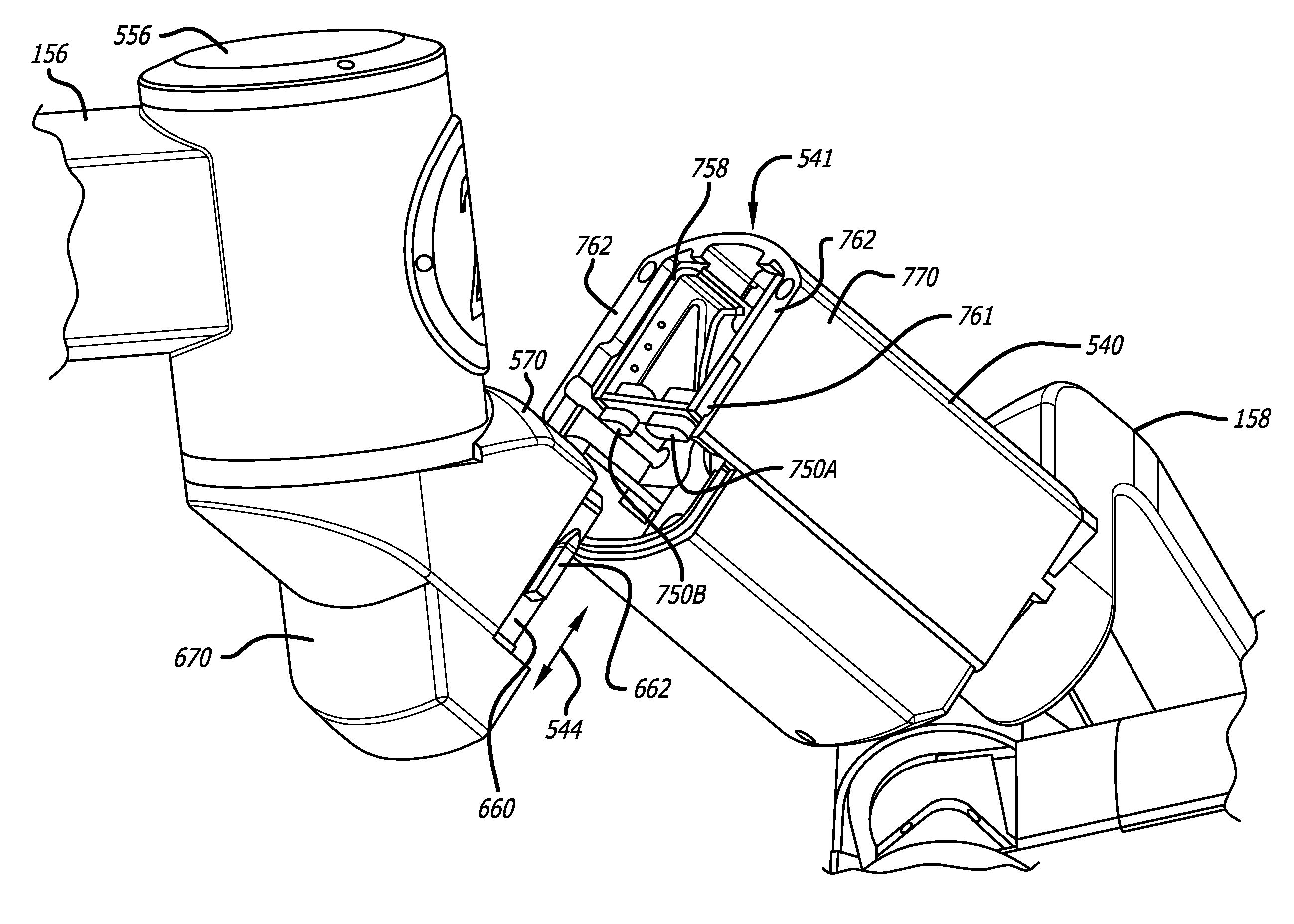

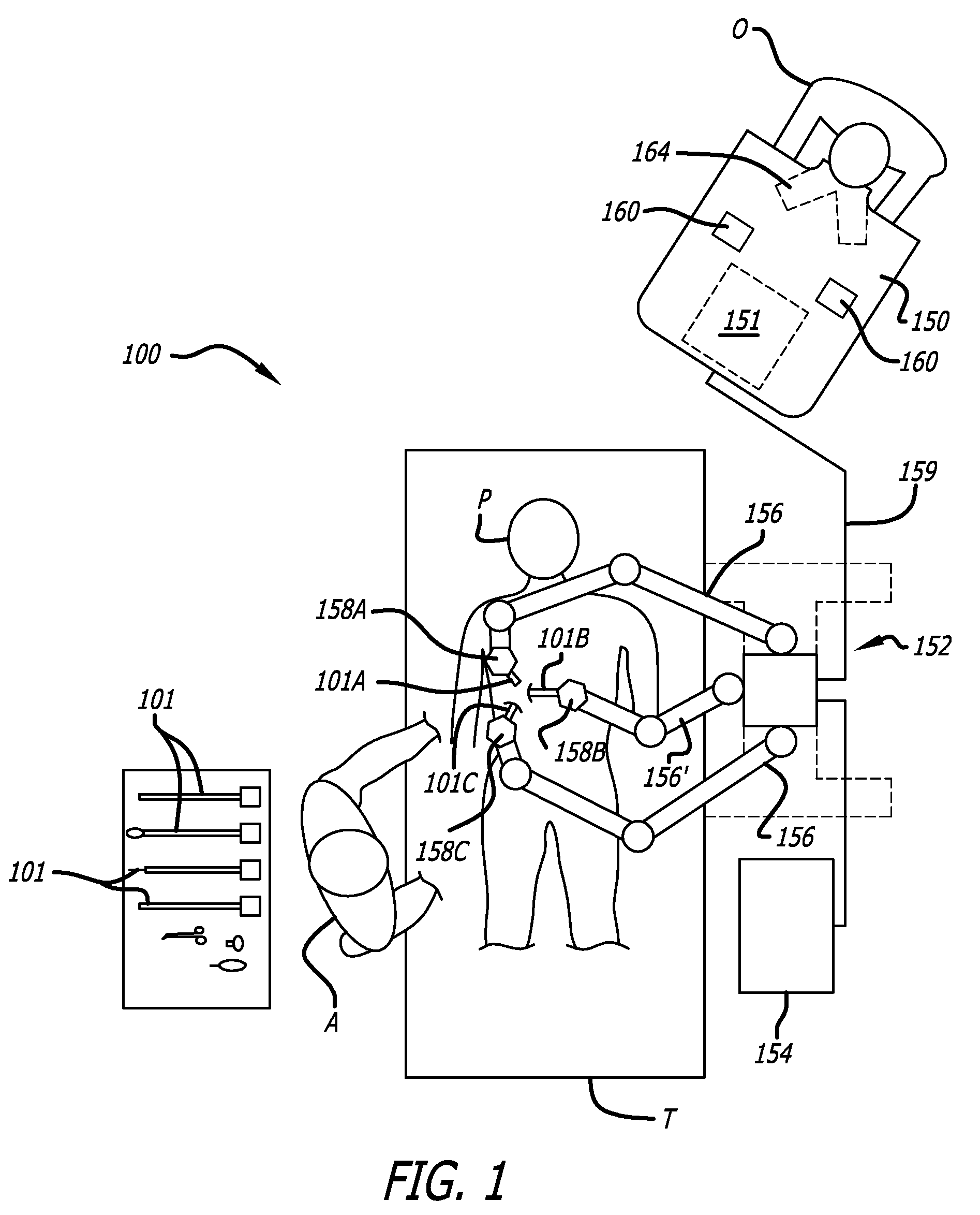

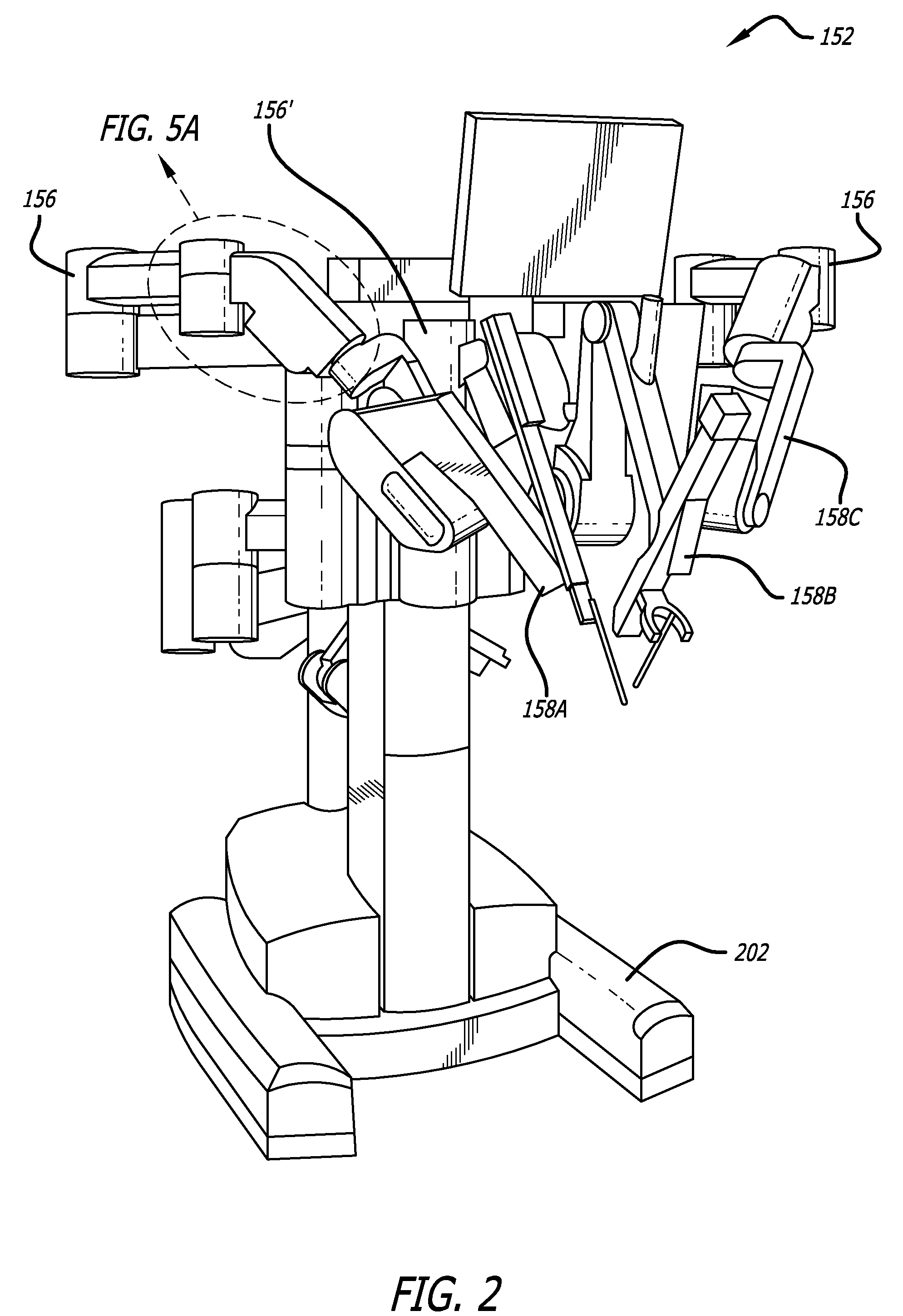

Electro-mechanical interfaces to mount robotic surgical arms

In one embodiment of the invention, a method of mounting a surgical robotic arm to a set-up arm of a robotic surgical system is provided that includes sliding a pair of guide slots of the surgical robotic arm over a pair of guide tabs in the set-up arm; aligning electrical connectors in the set-up arm to electrical connectors of the surgical robotic arm; and coincidentally mating male electrical connectors to female electrical connectors while finally mating the guide tabs in the set-up arm to flanges of a housing of the surgical robotic arm.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

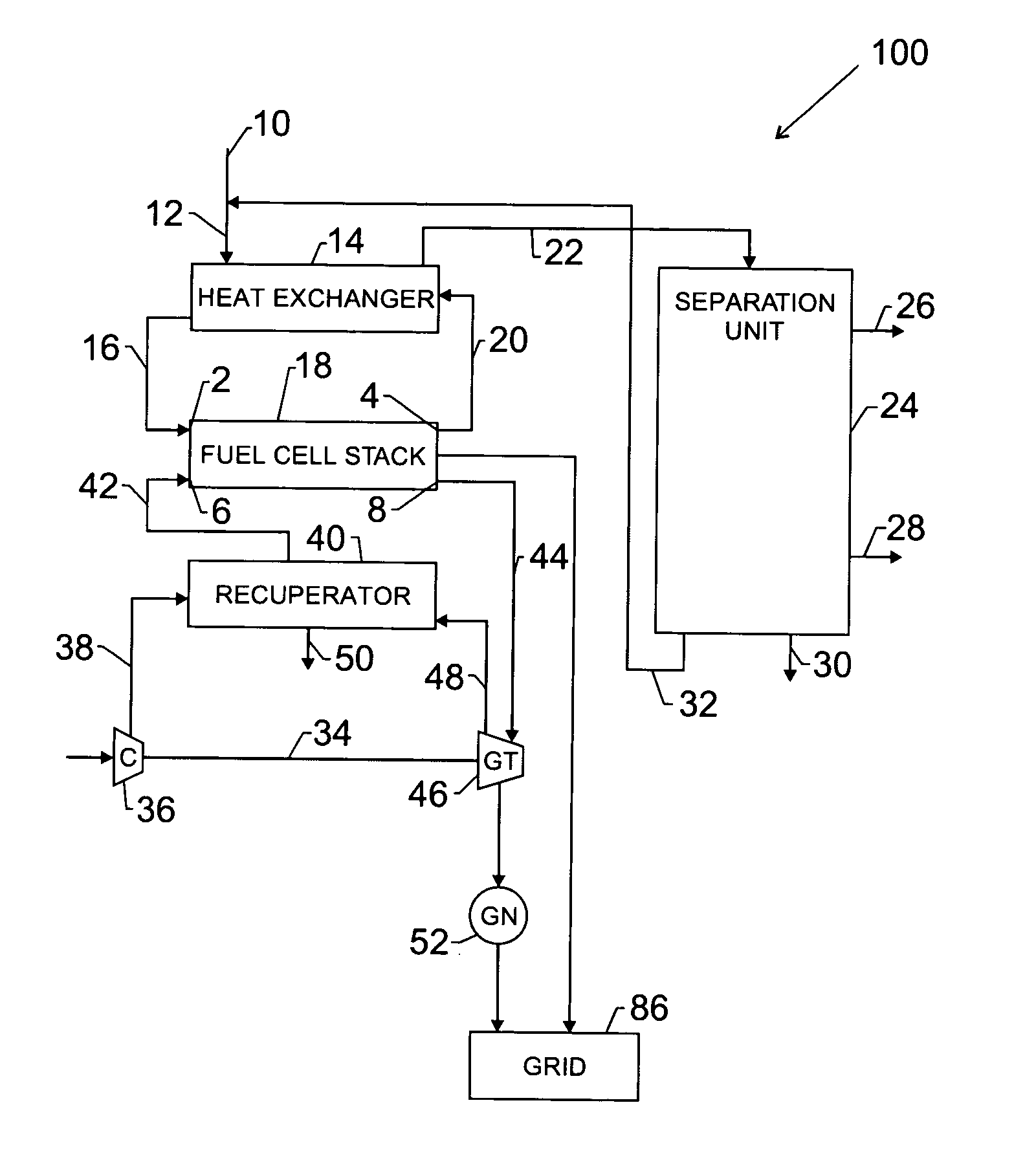

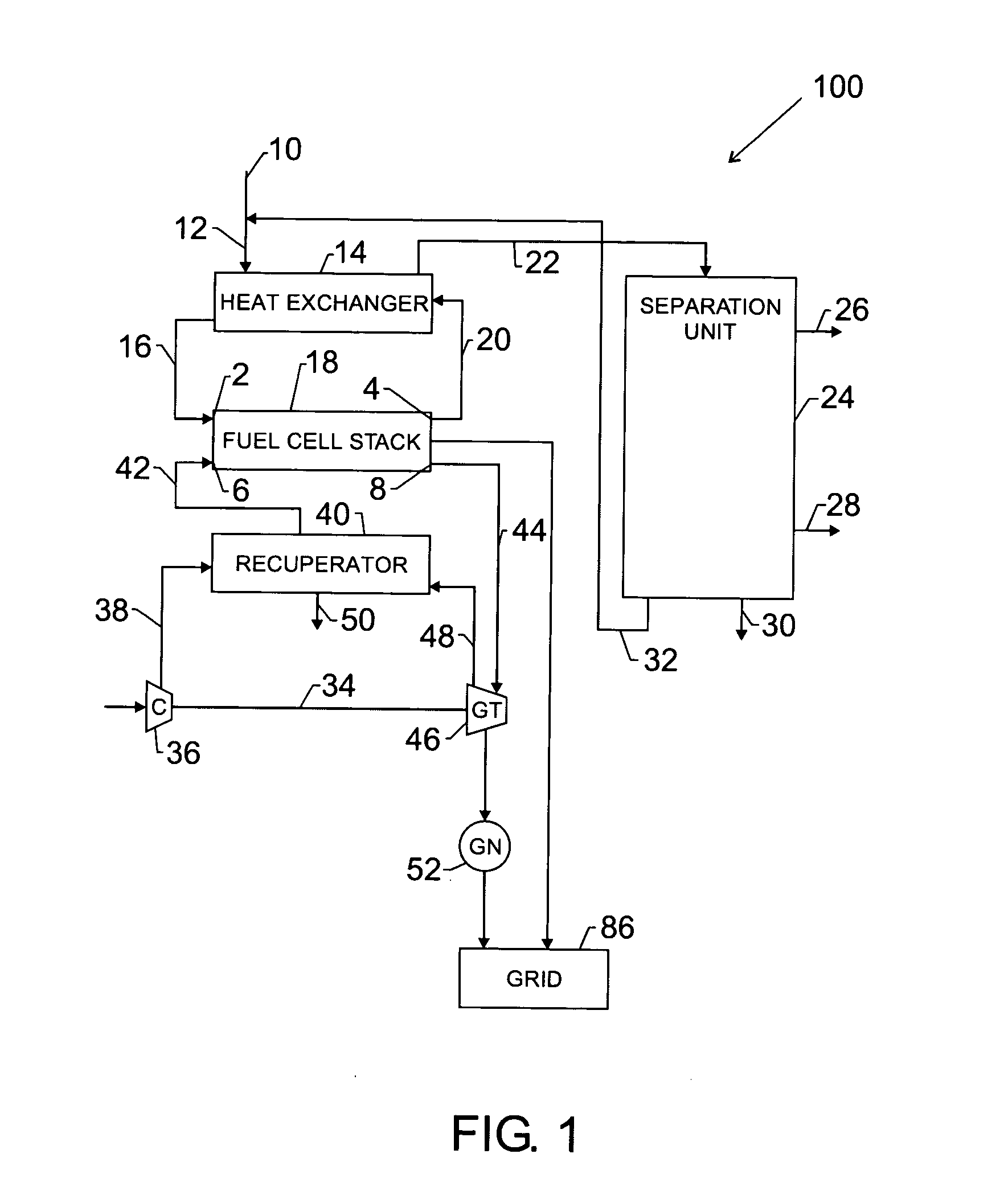

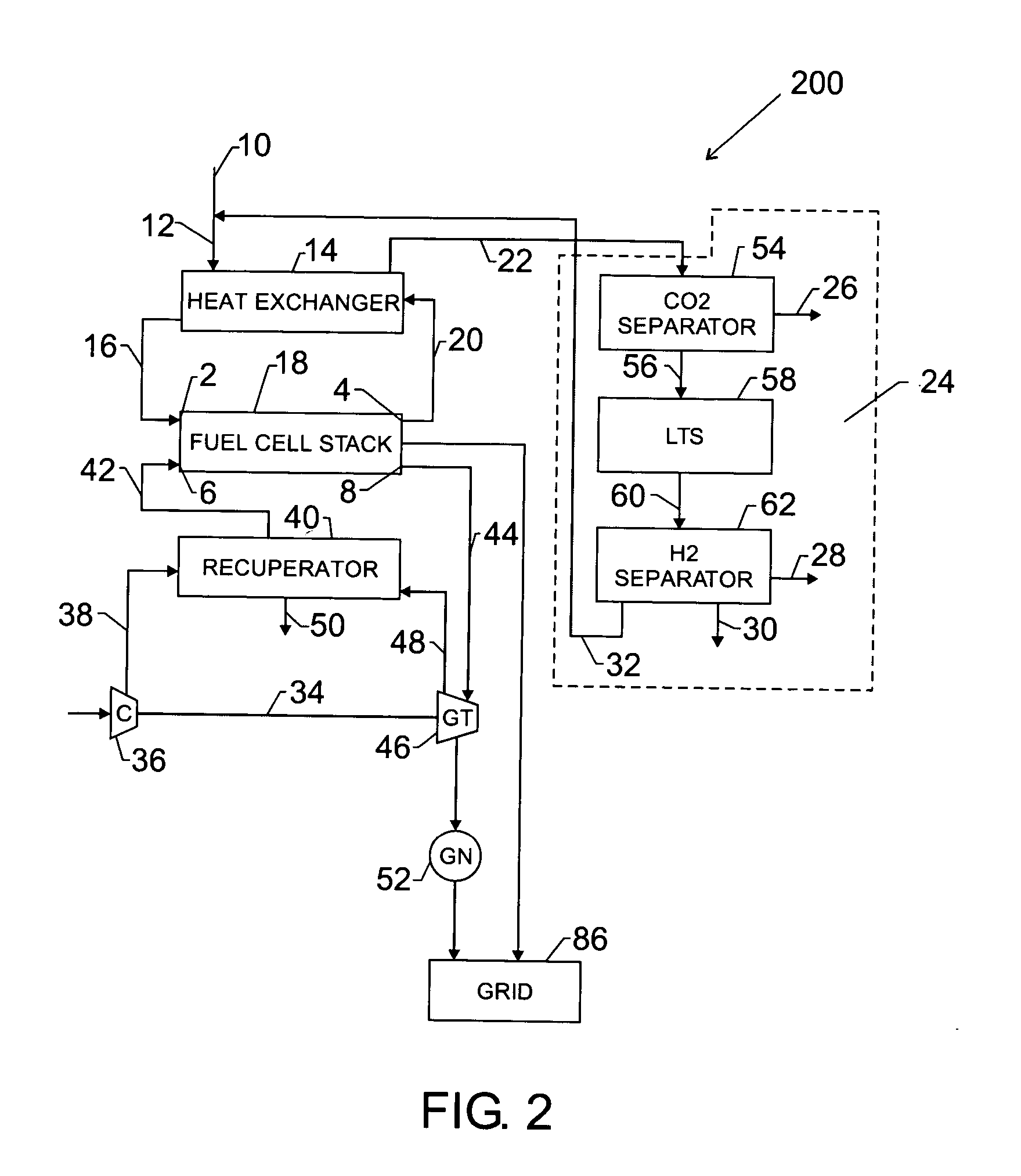

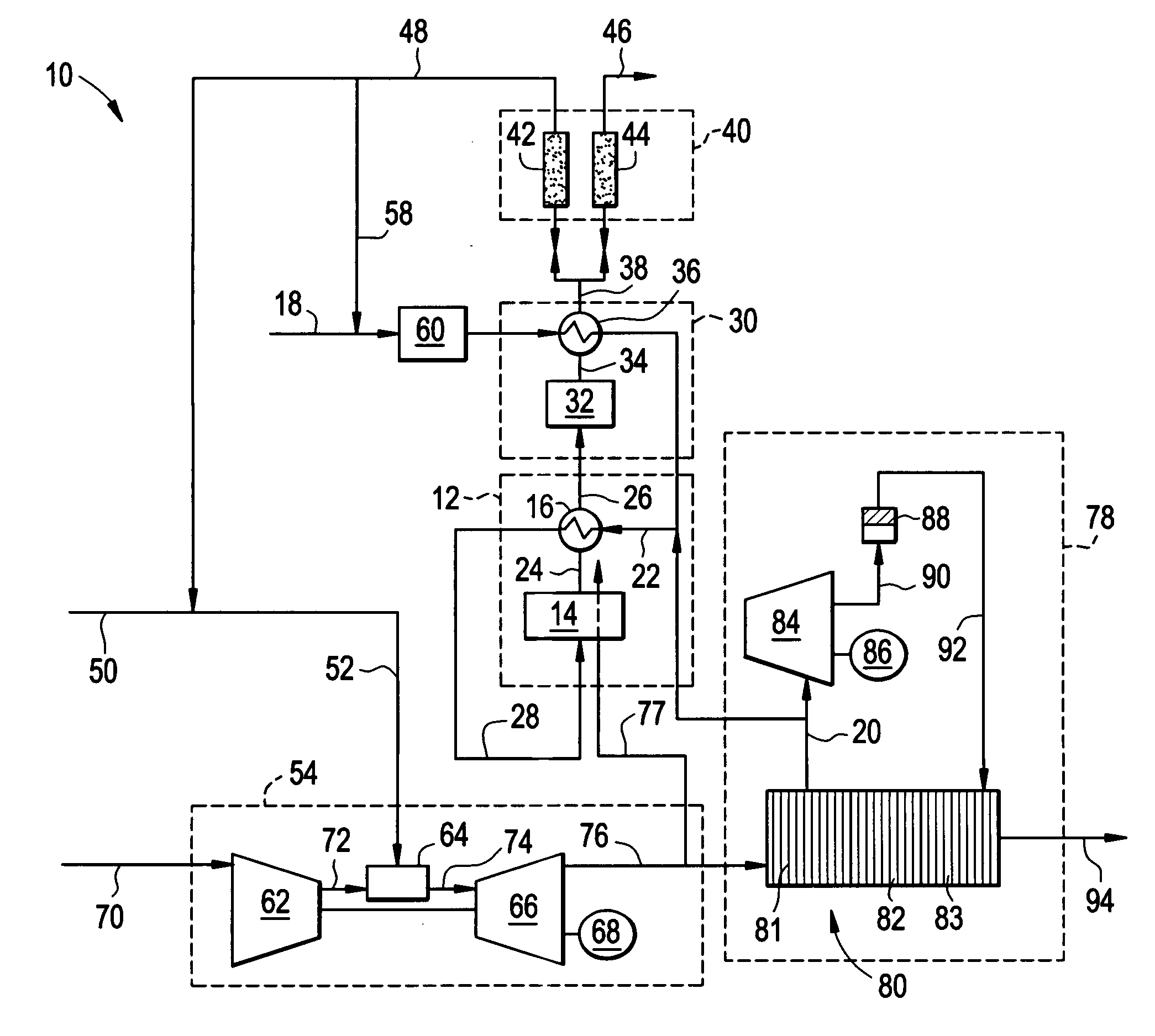

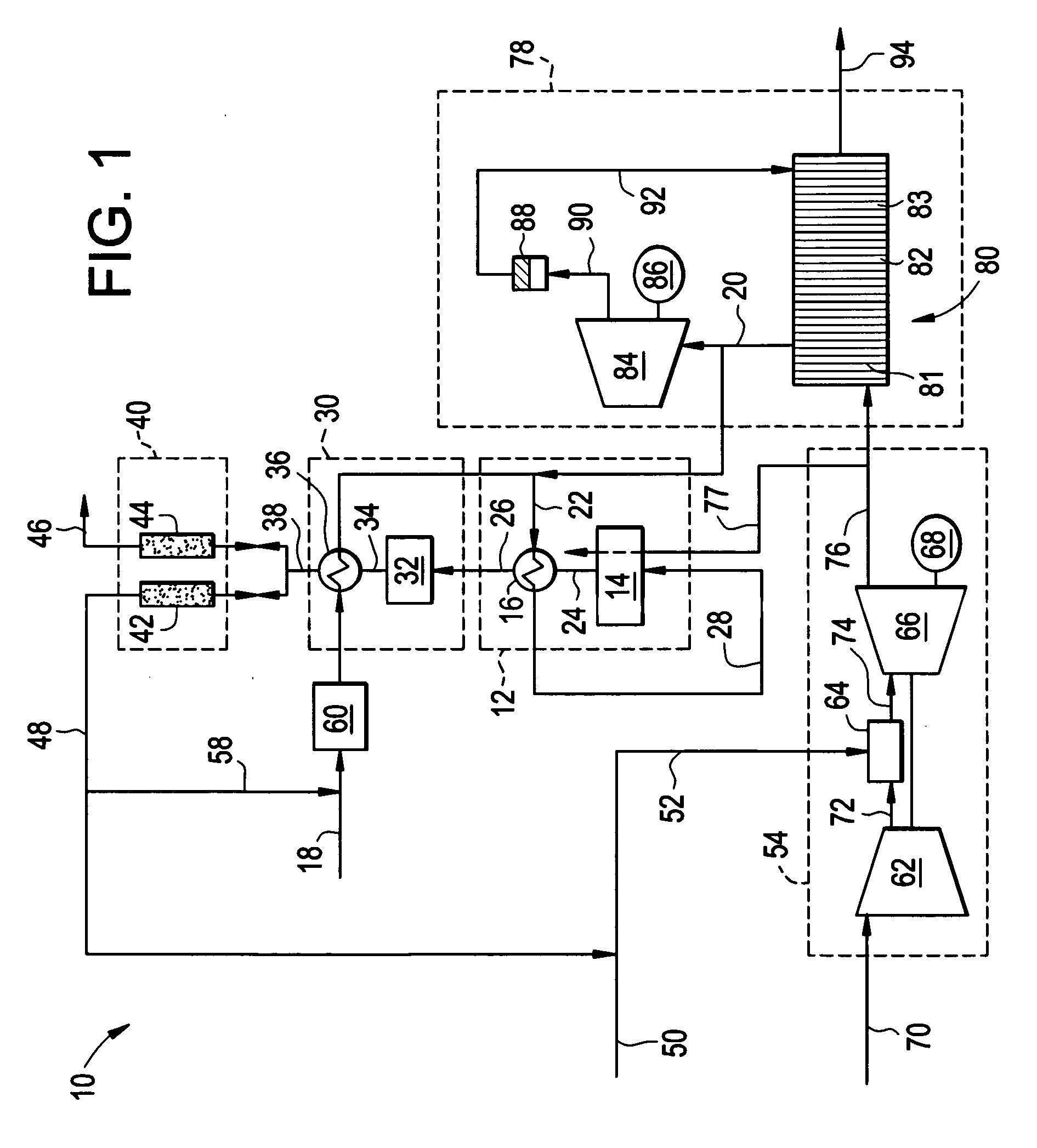

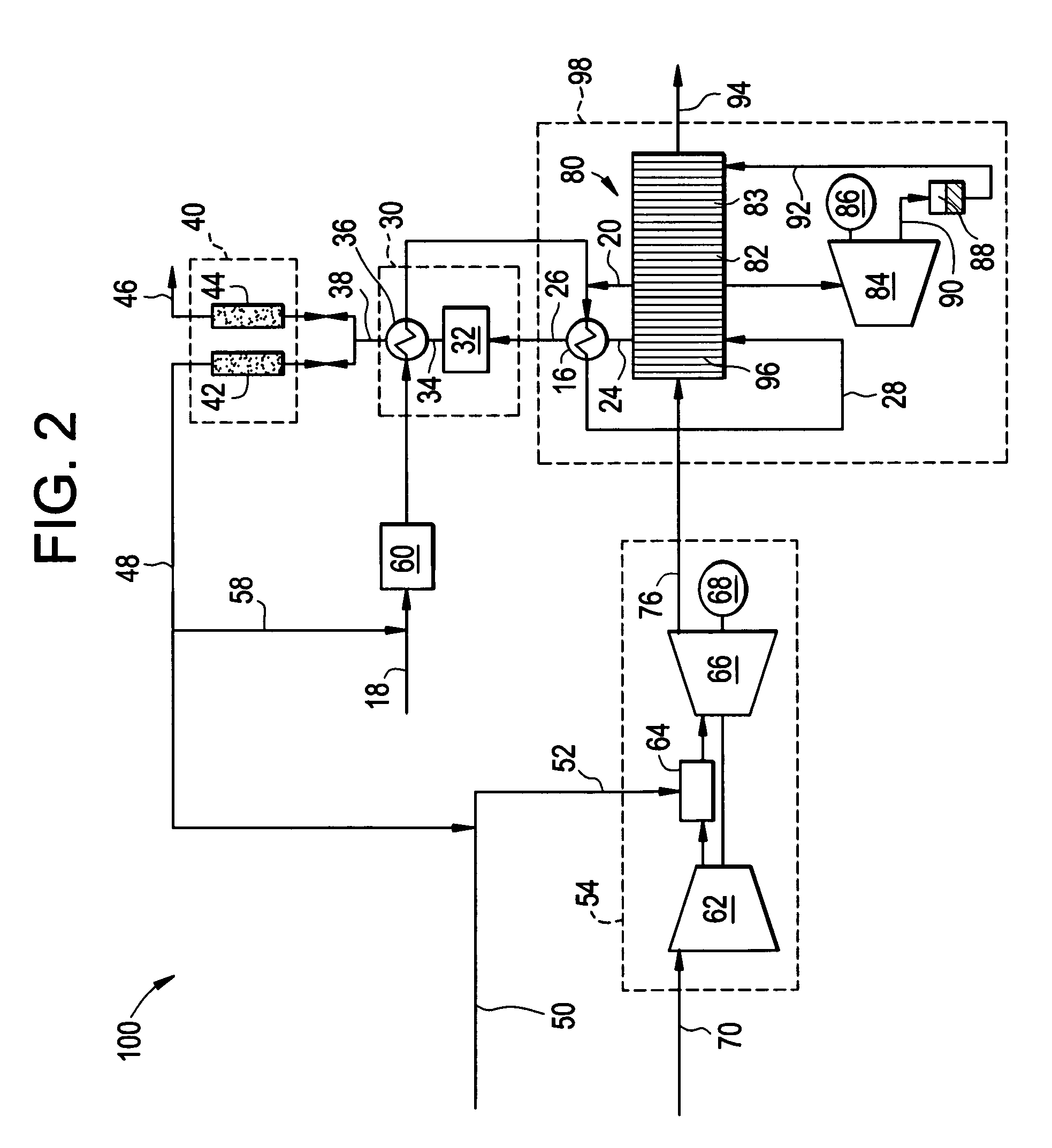

System and method for co-production of hydrogen and electrical energy

InactiveUS20050123810A1Fuel cell combinationsHydrogen separation at low temperatureHydrogenFuel cells

A system and method for co-production of hydrogen and electrical energy. The system comprises a fuel cell assembly comprising a plurality of fuel cells. The fuel cells further comprise a cathode inlet for receiving a compressed oxidant, an anode inlet for receiving a fuel feed stream, an anode outlet in fluid communication with an anode exhaust stream and a cathode outlet in fluid communication with a cathode exhaust stream. At least a portion of the fuel feed stream reacts with the oxidant to produce electrical power. The anode exhaust stream comprises hydrogen. The co-production system further comprises a separation unit in fluid communication with the fuel cell assembly. The separation unit is configured to receive the anode exhaust stream from the fuel cell assembly to separate hydrogen from the anode exhaust stream.

Owner:GENERAL ELECTRIC CO

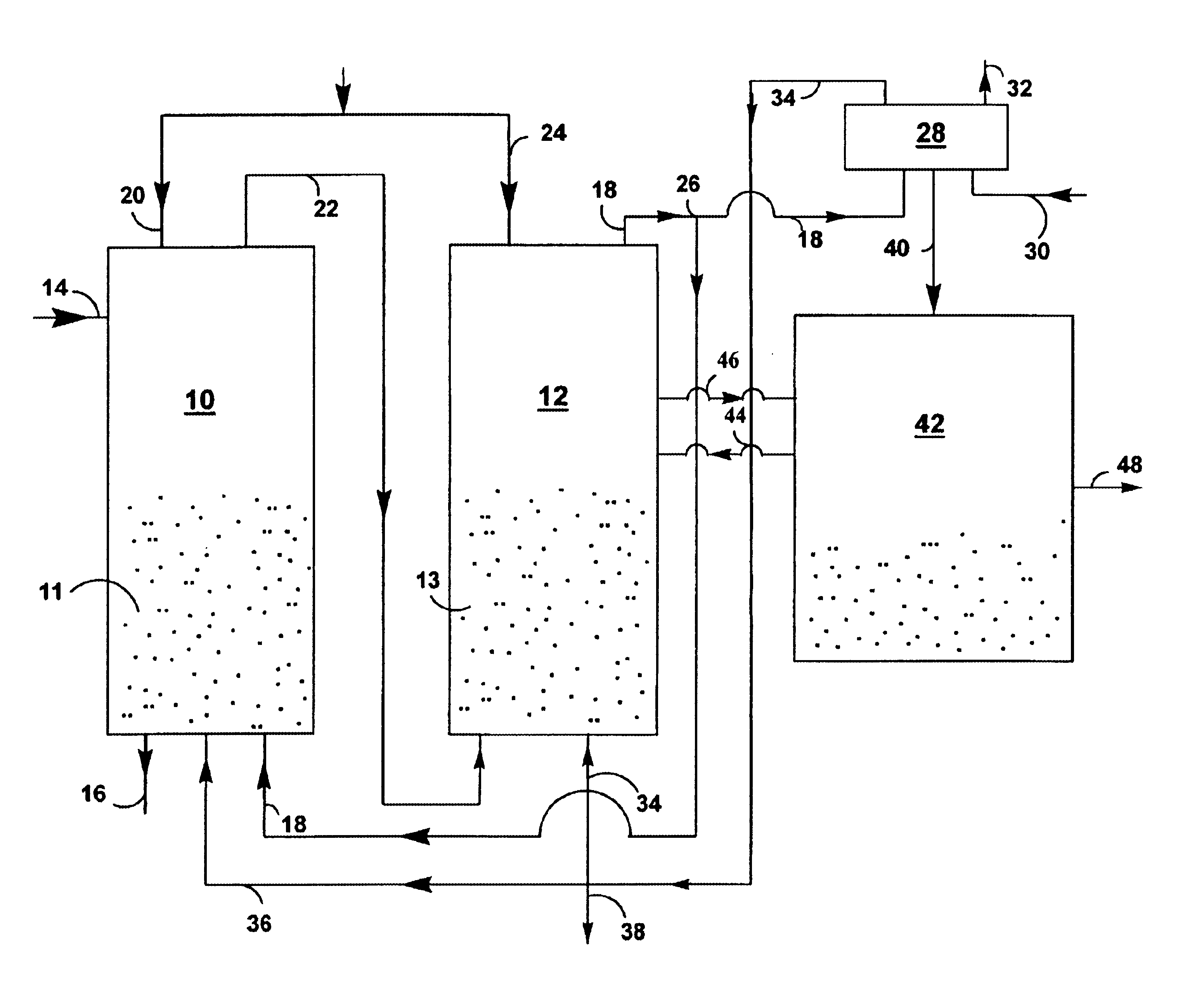

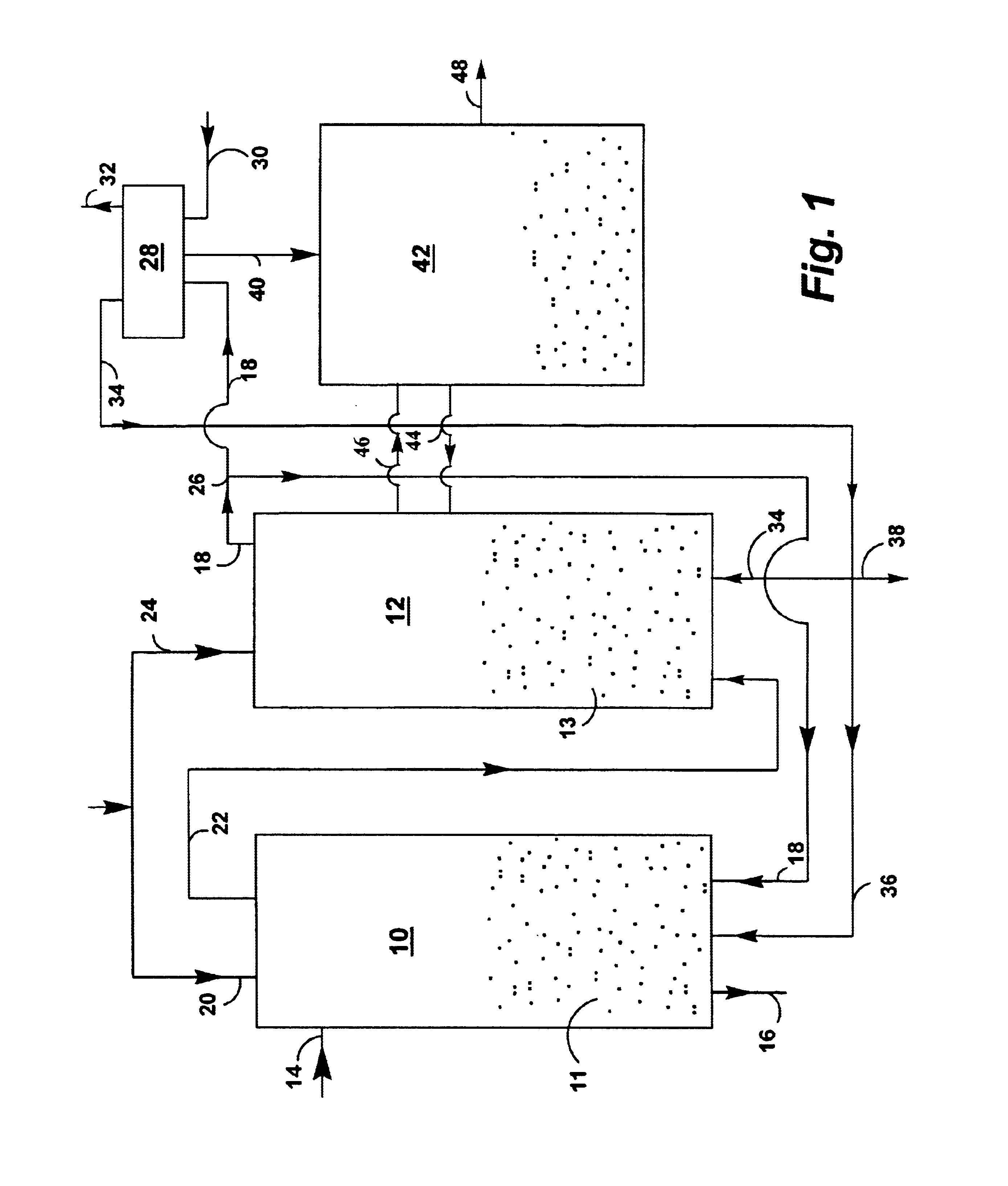

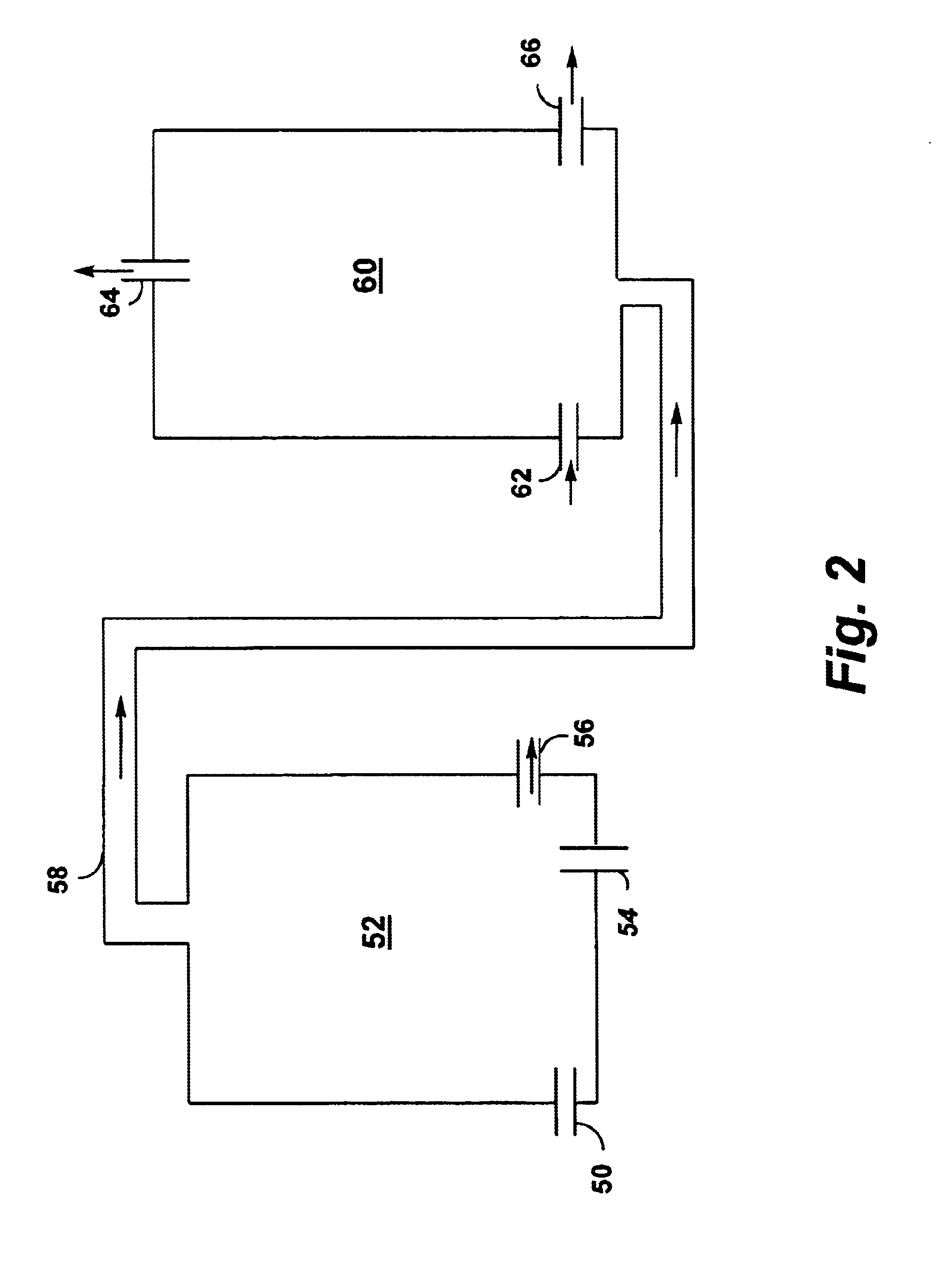

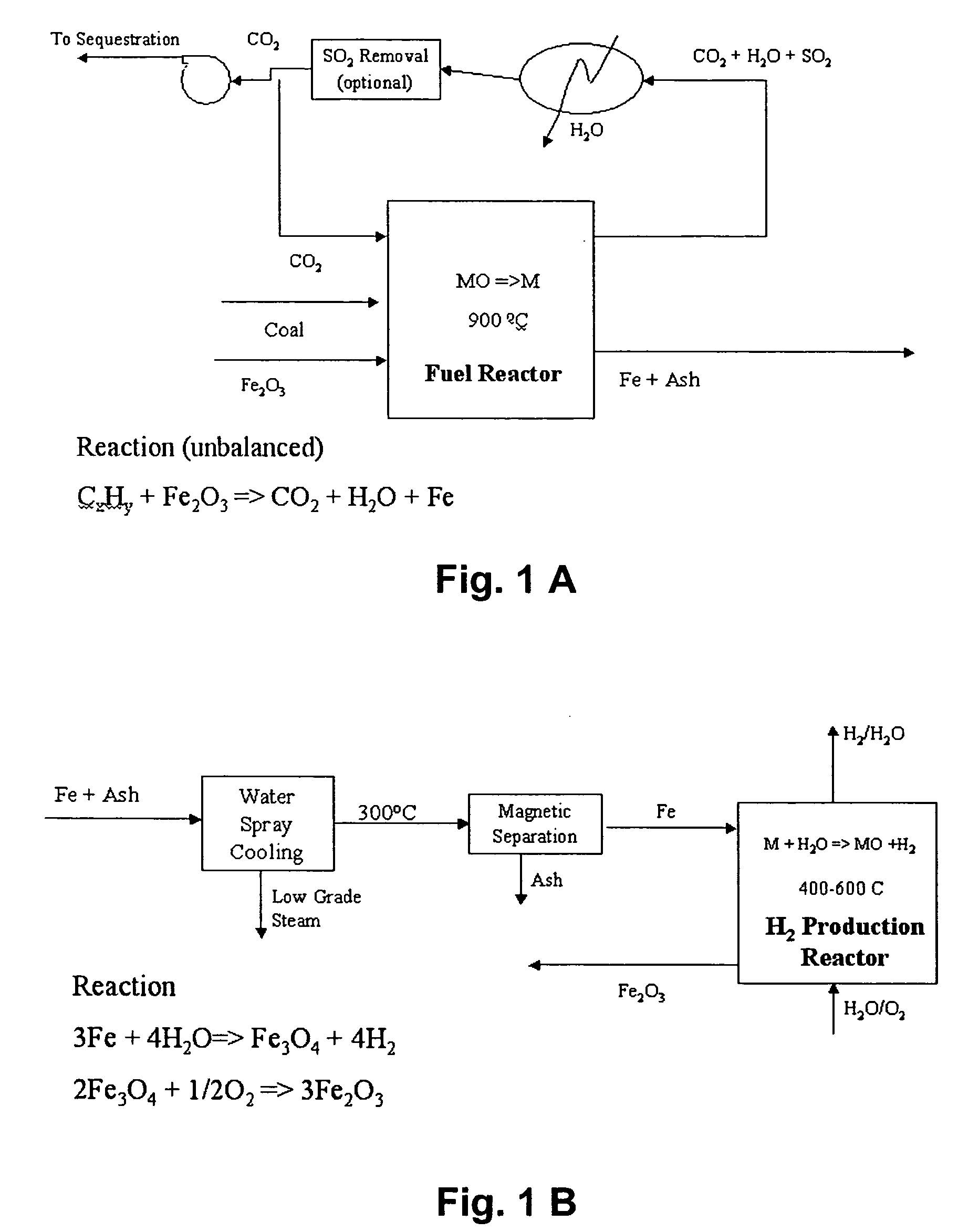

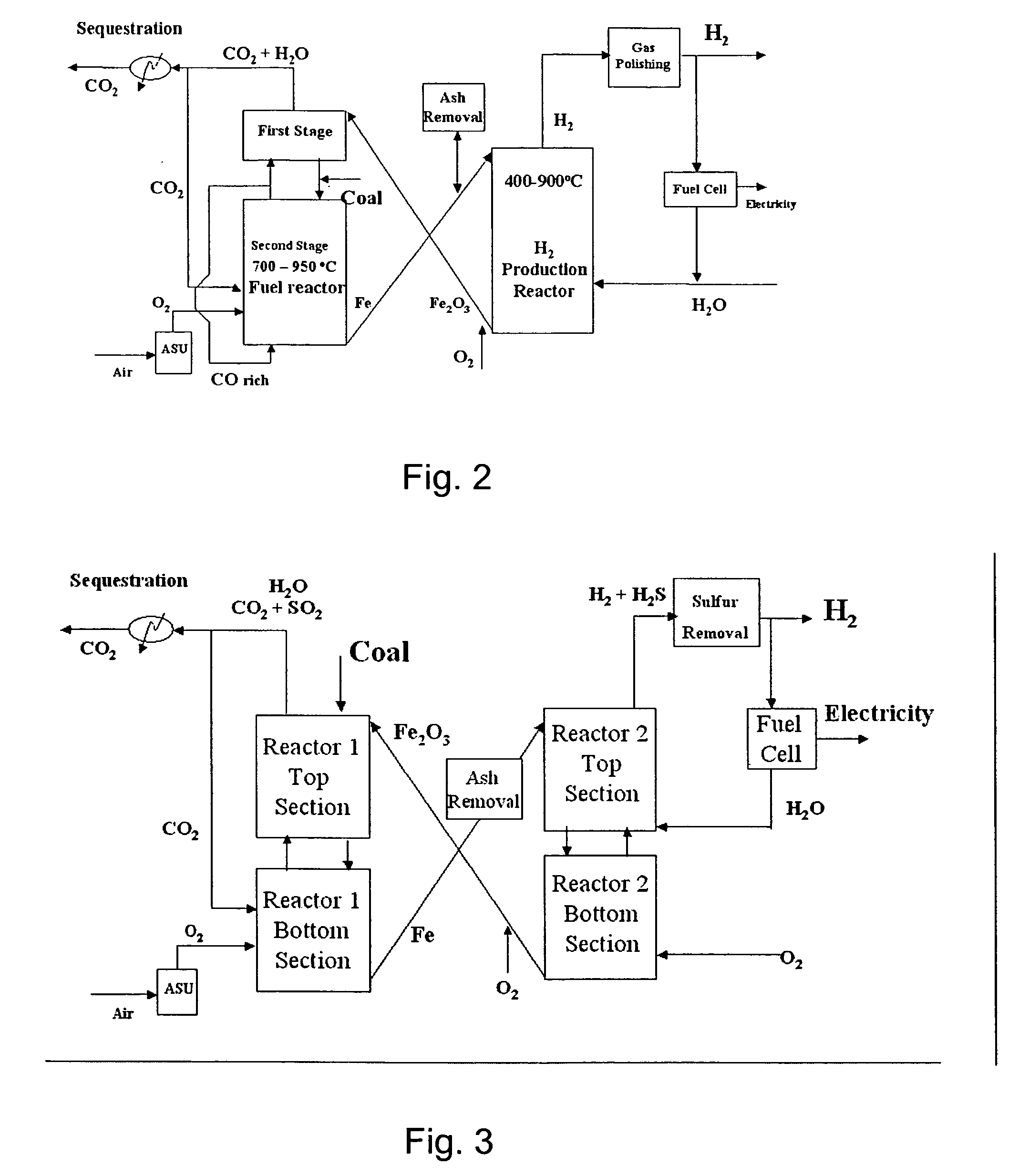

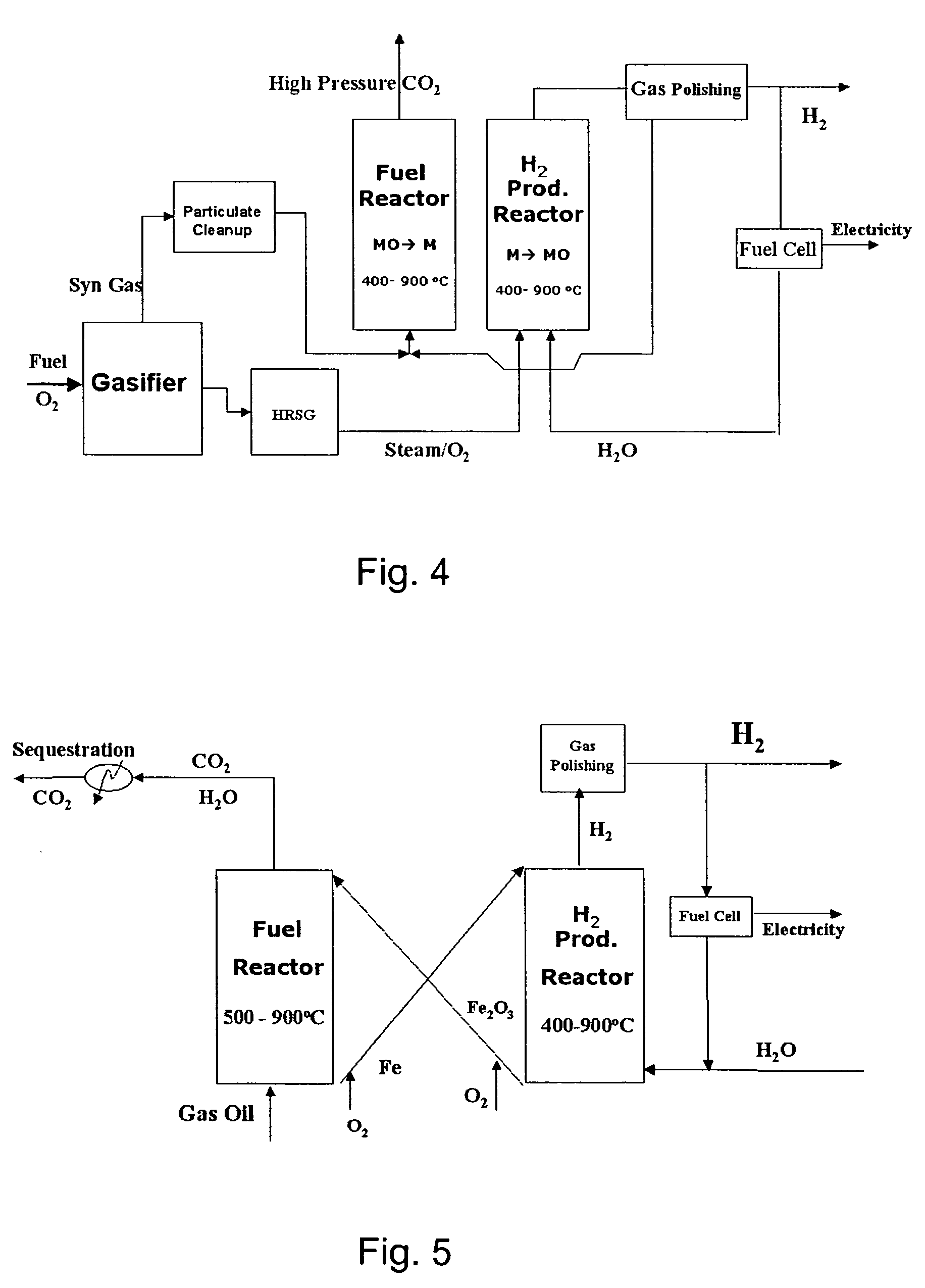

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

Selective Removal and Recovery of Acid Gases from Gasification Products

Processes and apparatuses are described for the selective removal and recovery of acid gases from a gas source comprising at least hydrogen sulfide and carbon dioxide. A step-wise approach is illustrated wherein hydrogen sulfide may be selectively removed from a gas source by treatment with methanol under conditions where substantially all the hydrogen sulfide may be removed. The partially purified gas source may then be provided with a second treatment with methanol under conditions which selectively remove carbon dioxide from the gas stream. Such methods are generally applicable to any gas source comprising at least hydrogen sulfide and carbon dioxide, for example, a gas source produced from the catalytic gasification of a carbonaceous material, the combustion of a carbonaceous material, or the oxy-blown gasification of a carbonaceous material.

Owner:SURE CHAMPION INVESTMENT LTD

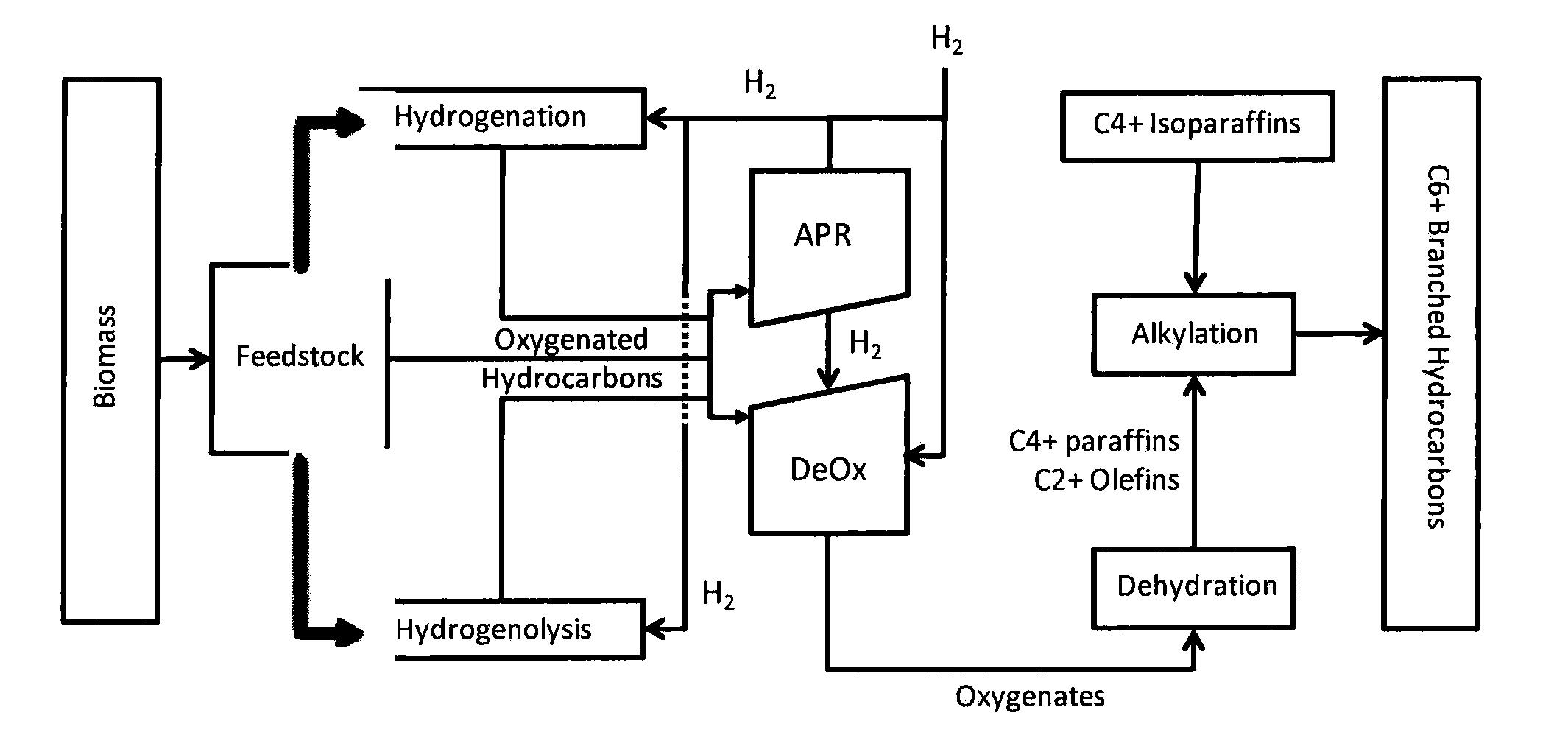

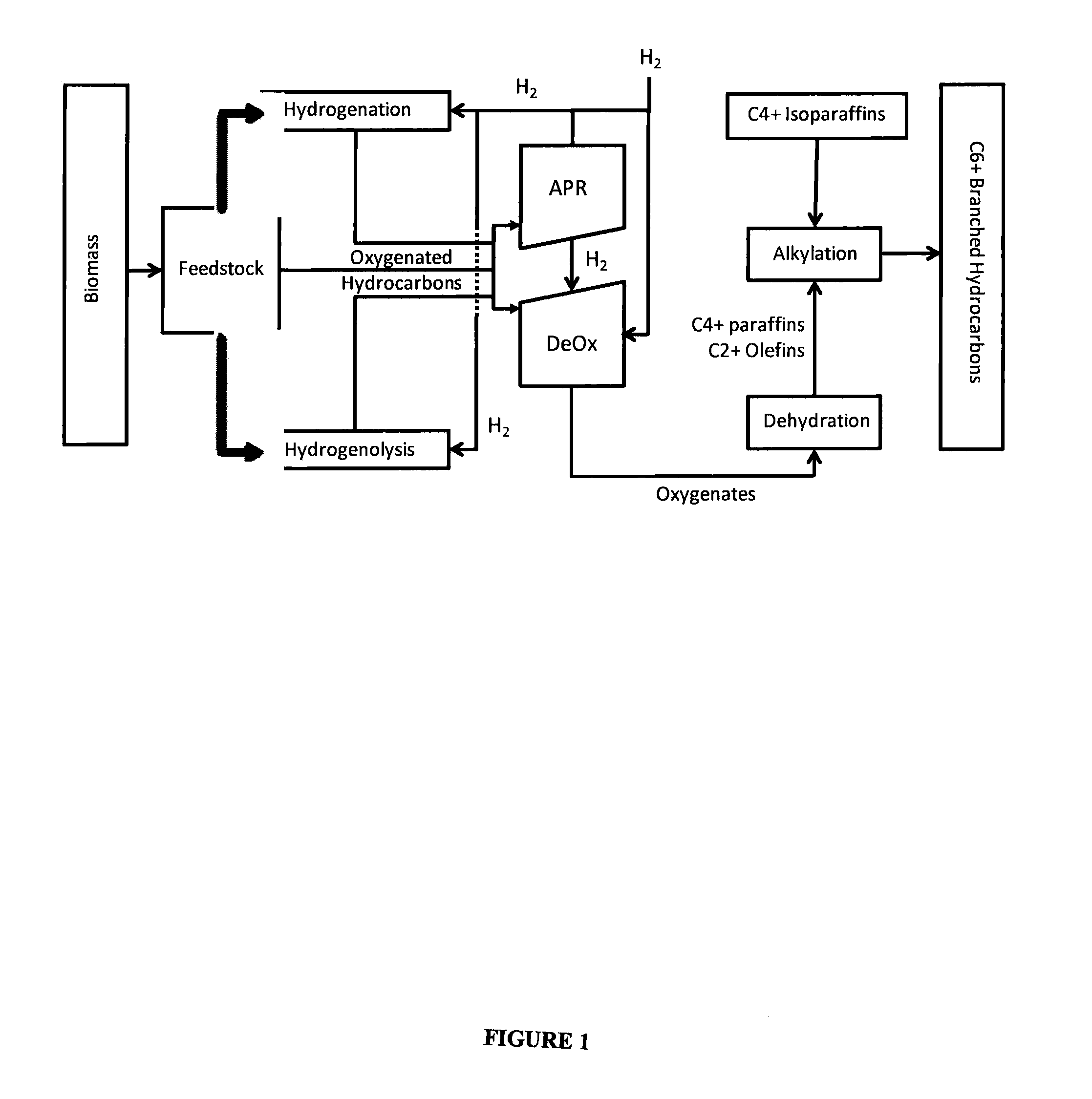

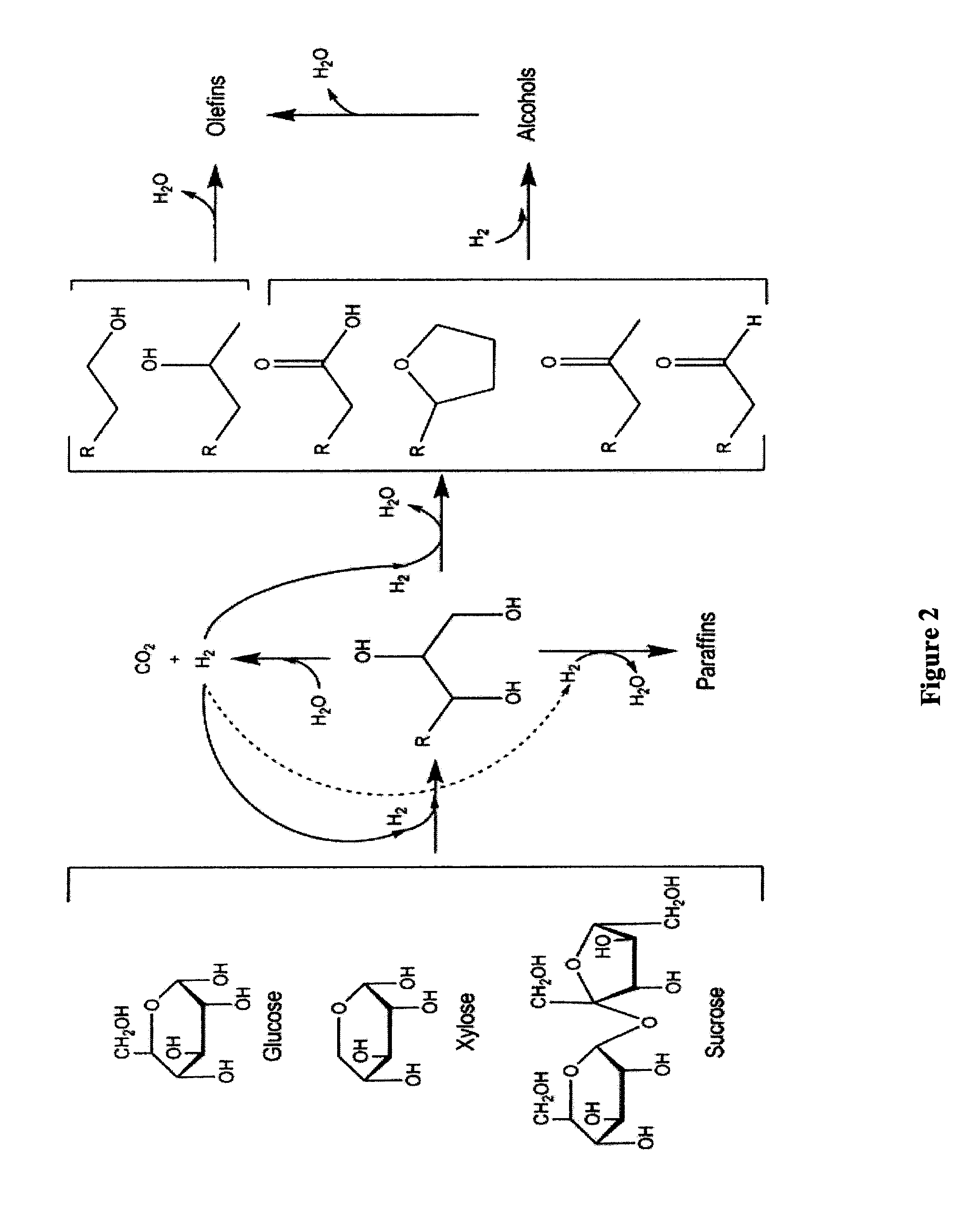

Synthesis of liquid fuels from biomass

ActiveUS20100076233A1Hydrocarbon by metathesis reactionLiquid hydrocarbon mixture productionFuranAlkane

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to paraffins useful as liquid fuels. The process involves the conversion of water soluble oxygenated hydrocarbons to oxygenates, such as alcohols, furans, ketones, aldehydes, carboxylic acids, diols, triols, and / or other polyols, followed by the subsequent conversion of the oxygenates to paraffins by dehydration and alkylation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

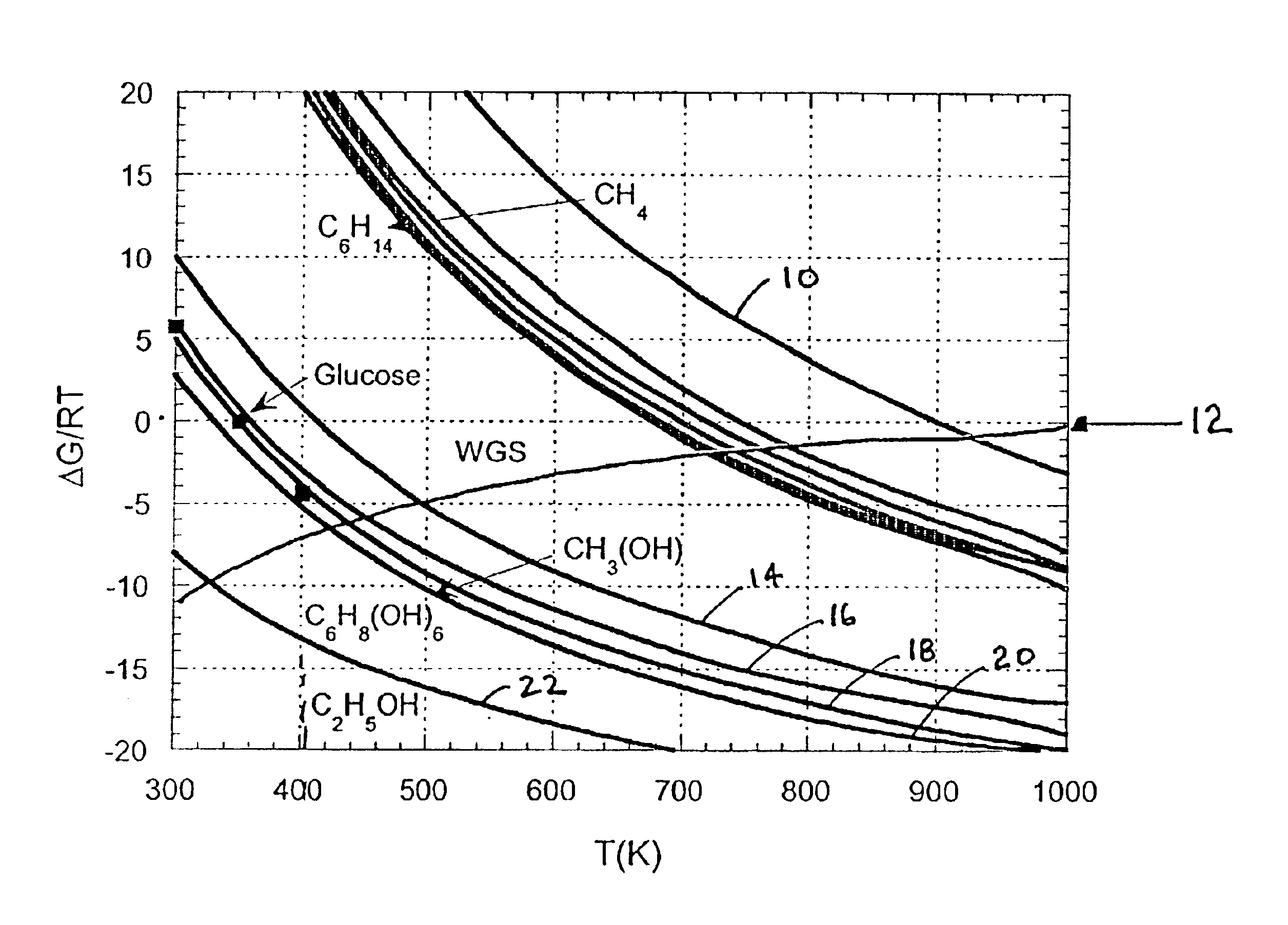

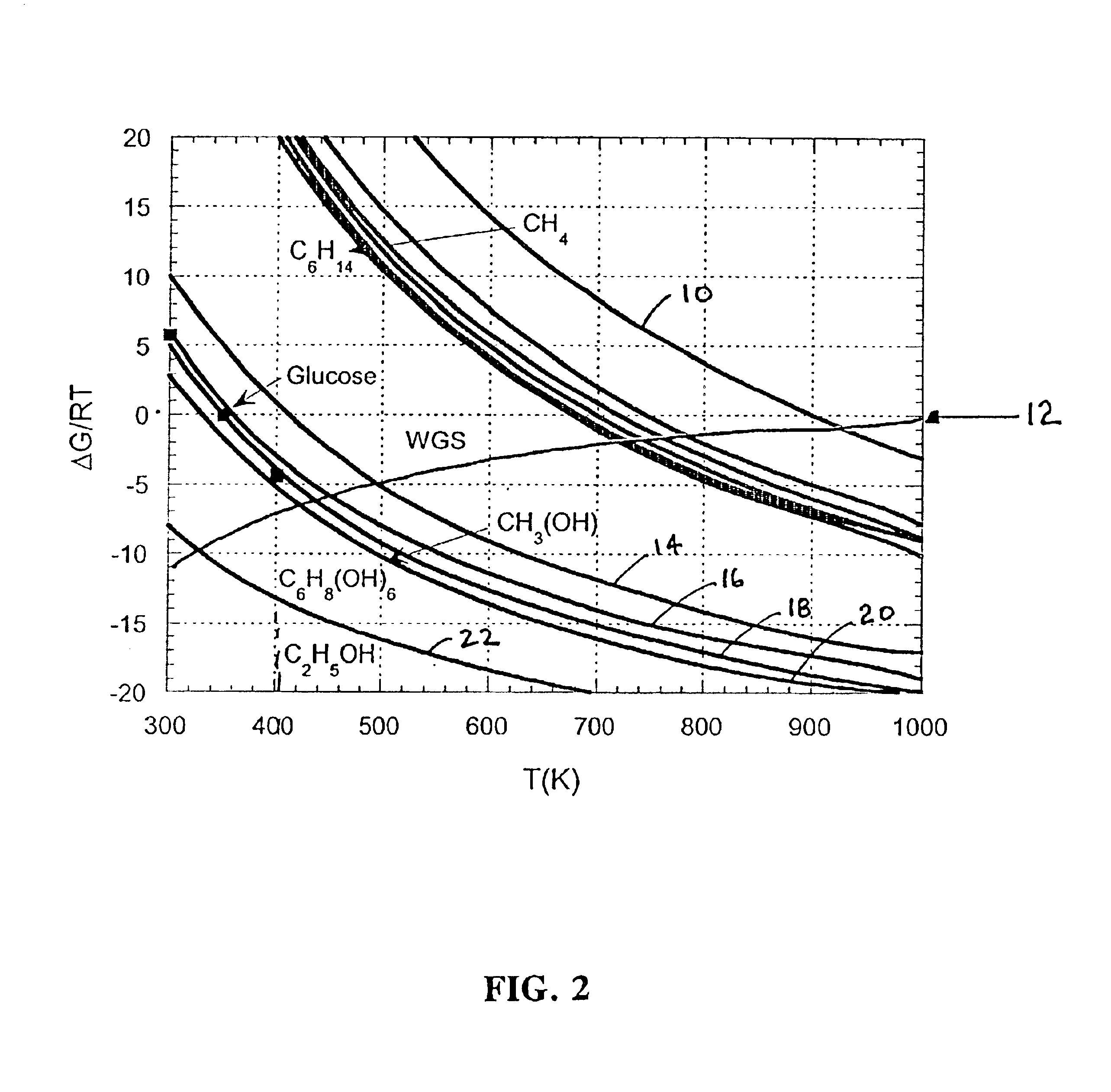

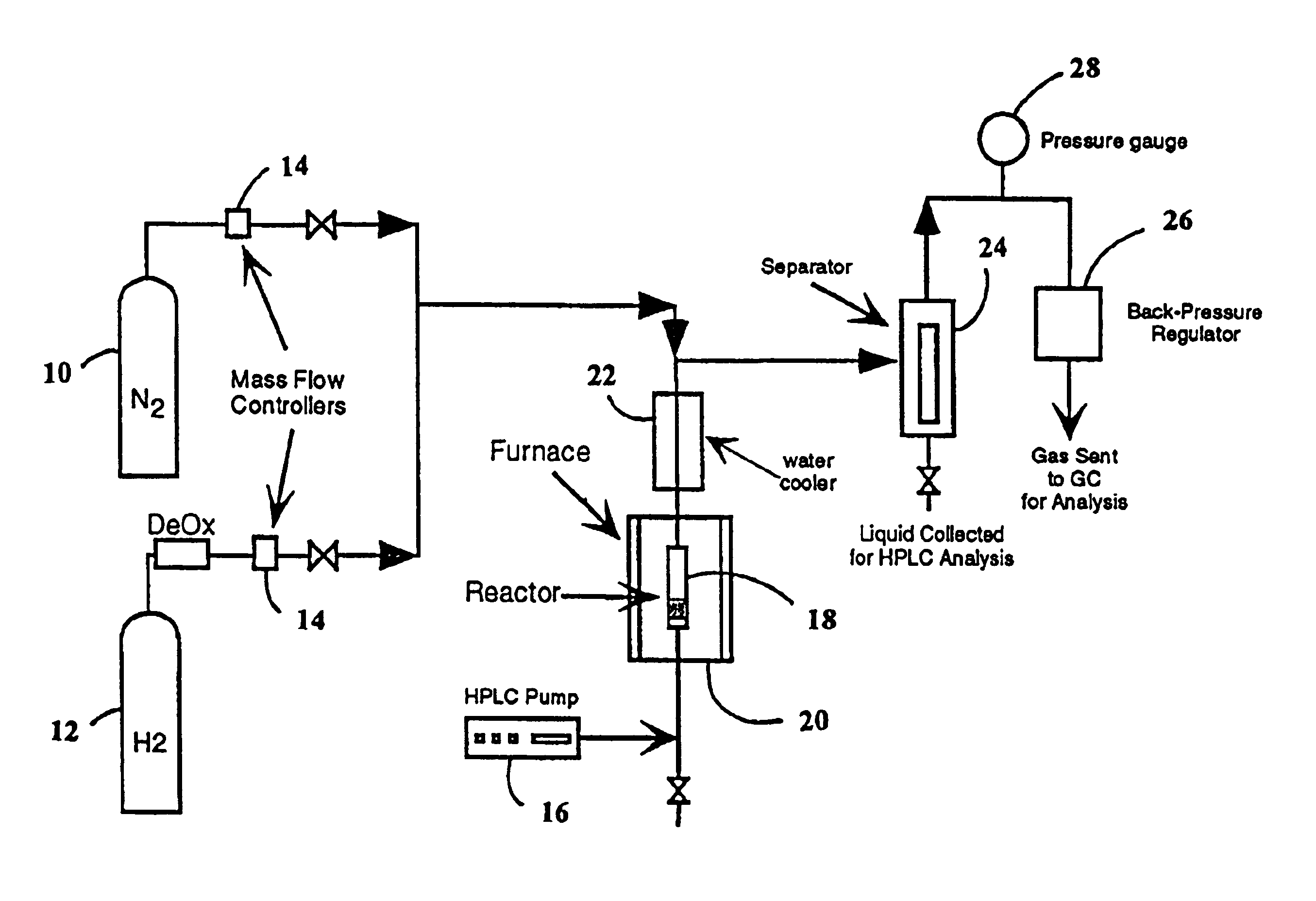

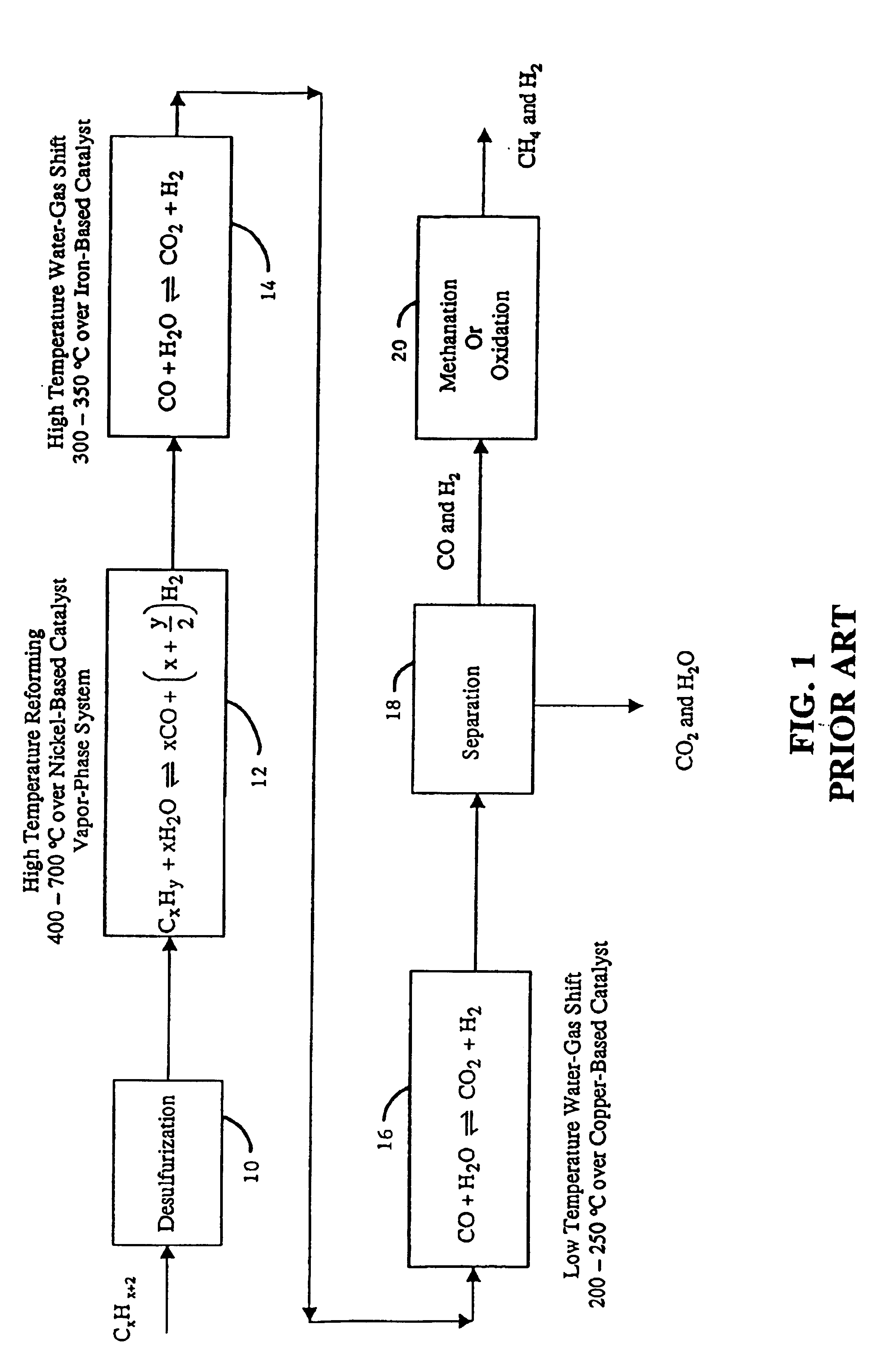

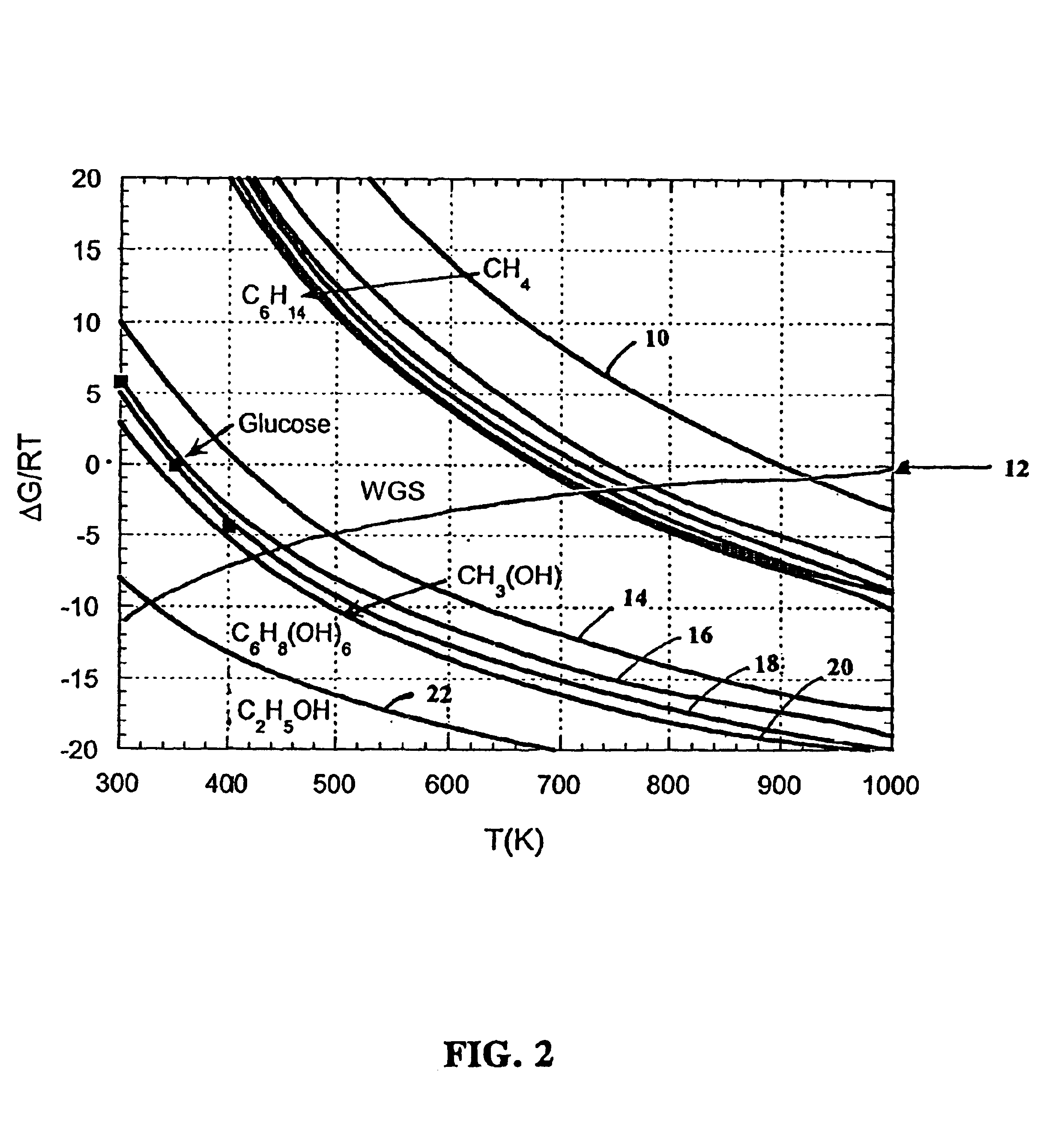

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964757B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

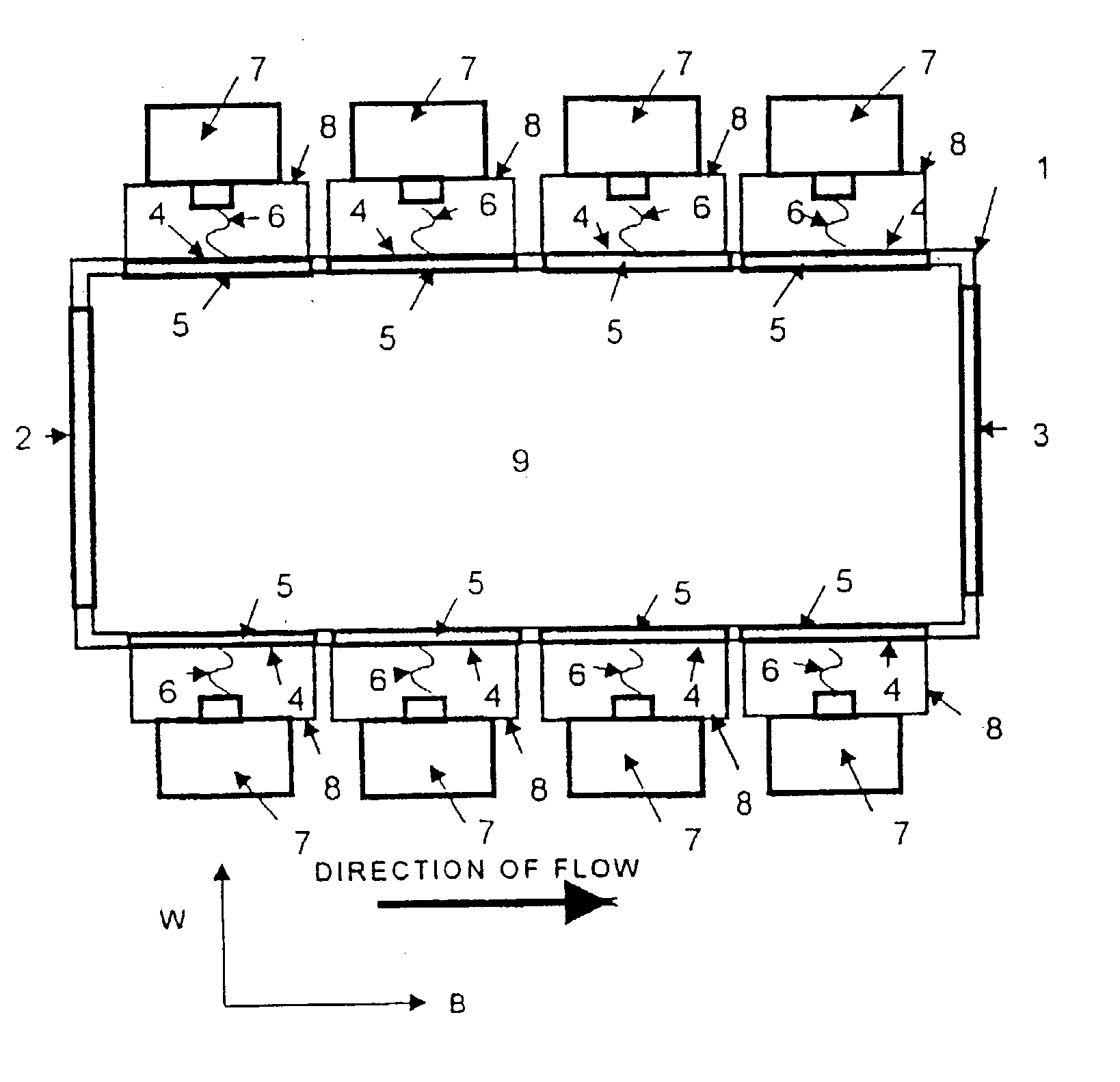

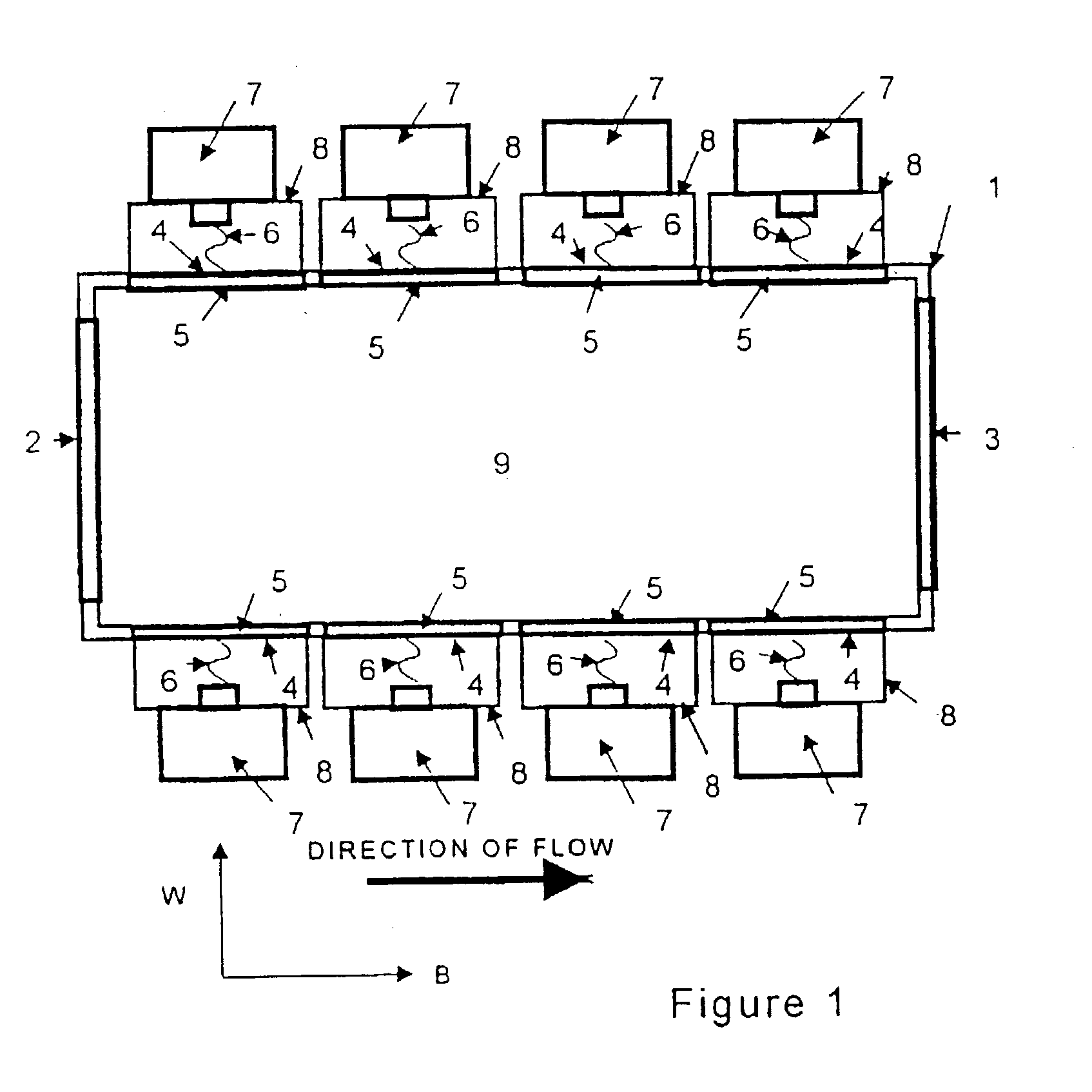

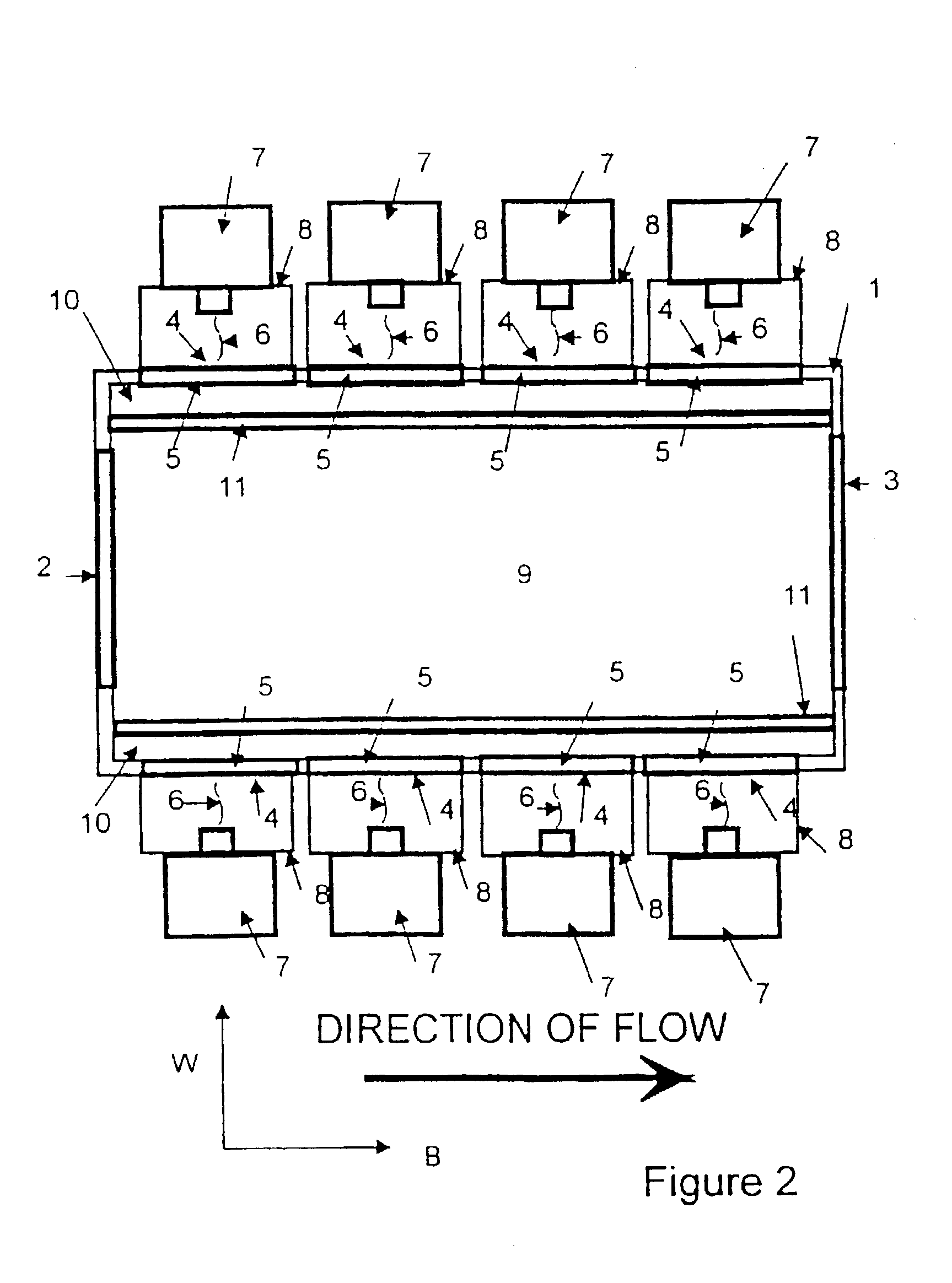

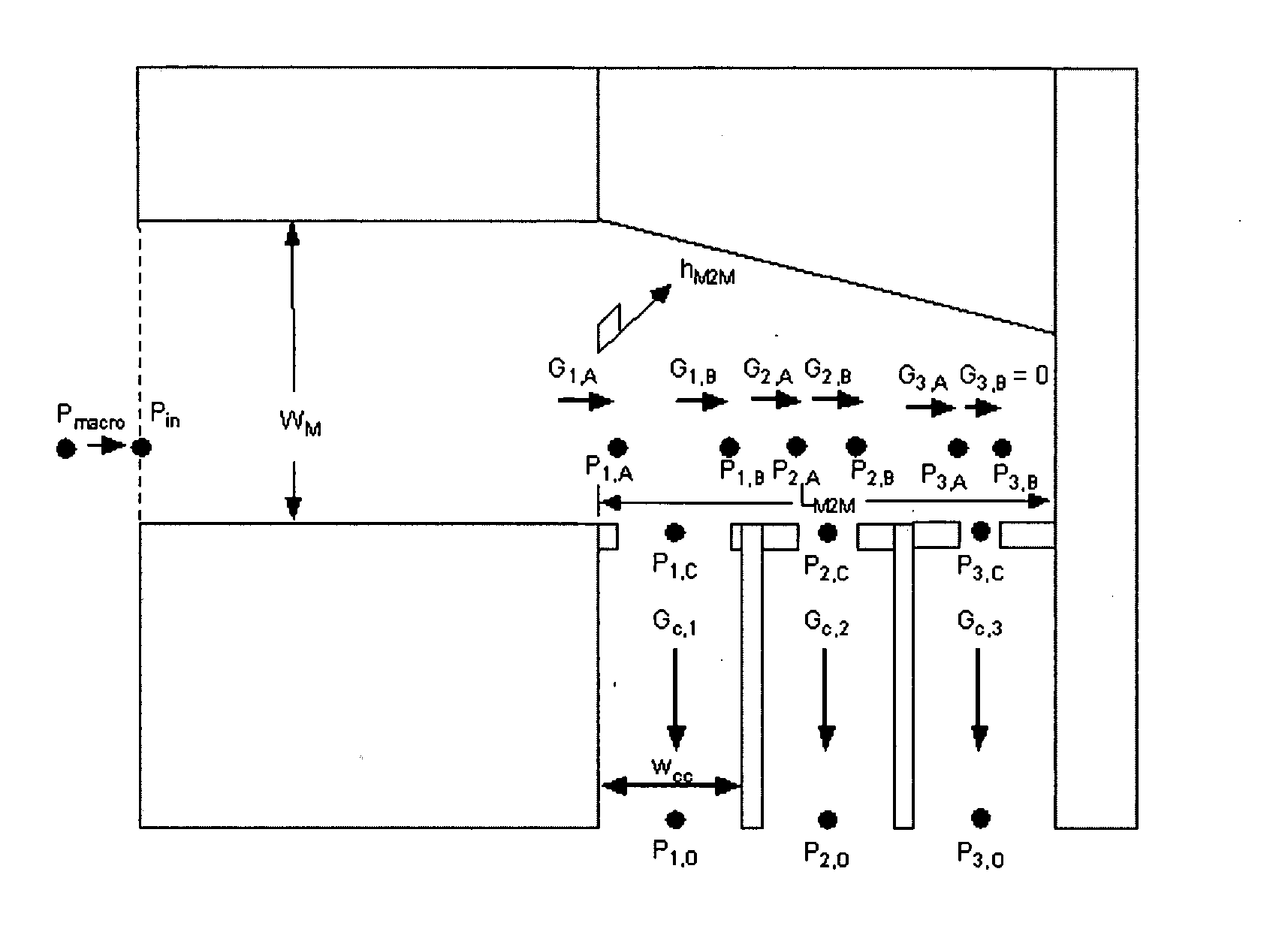

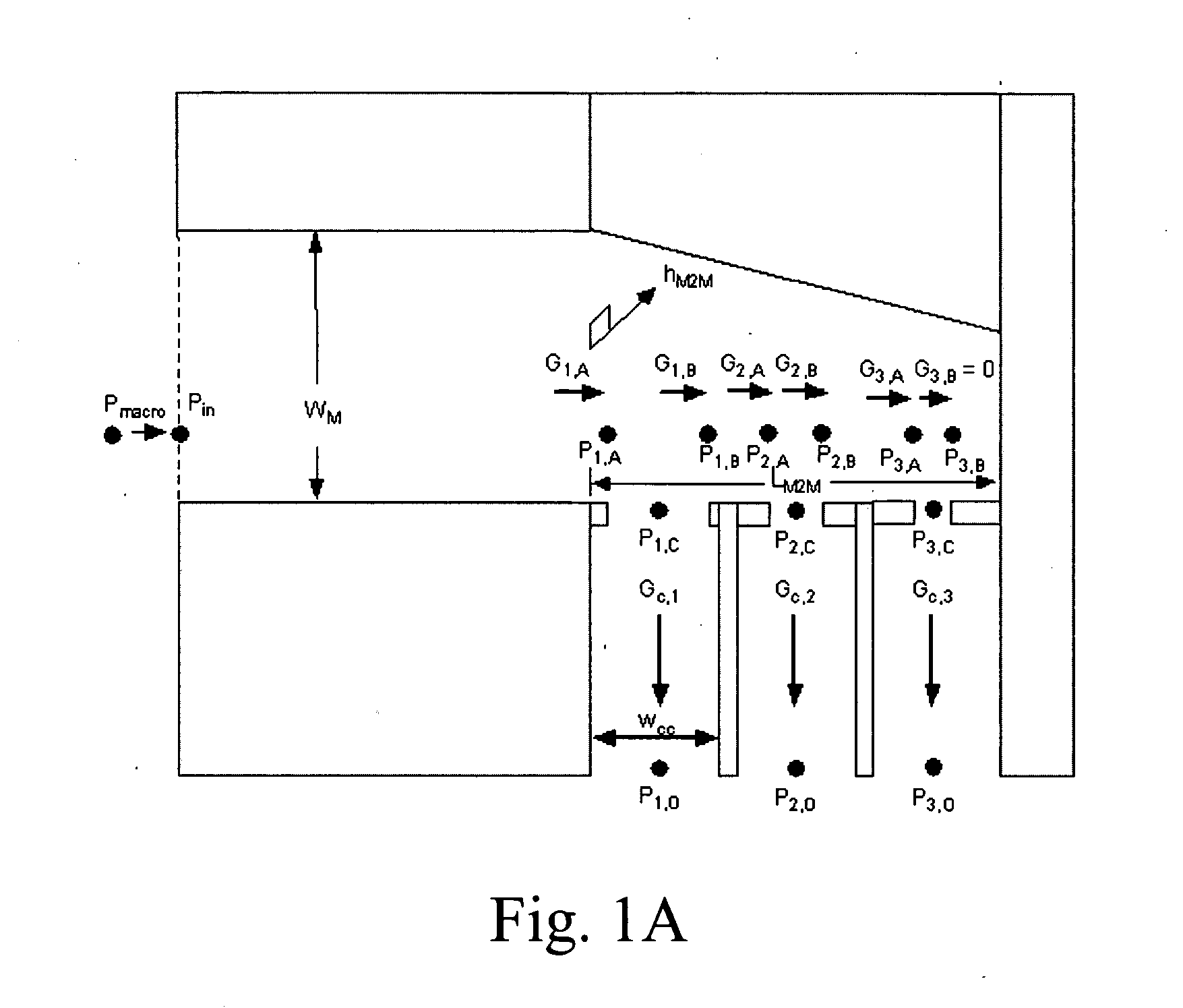

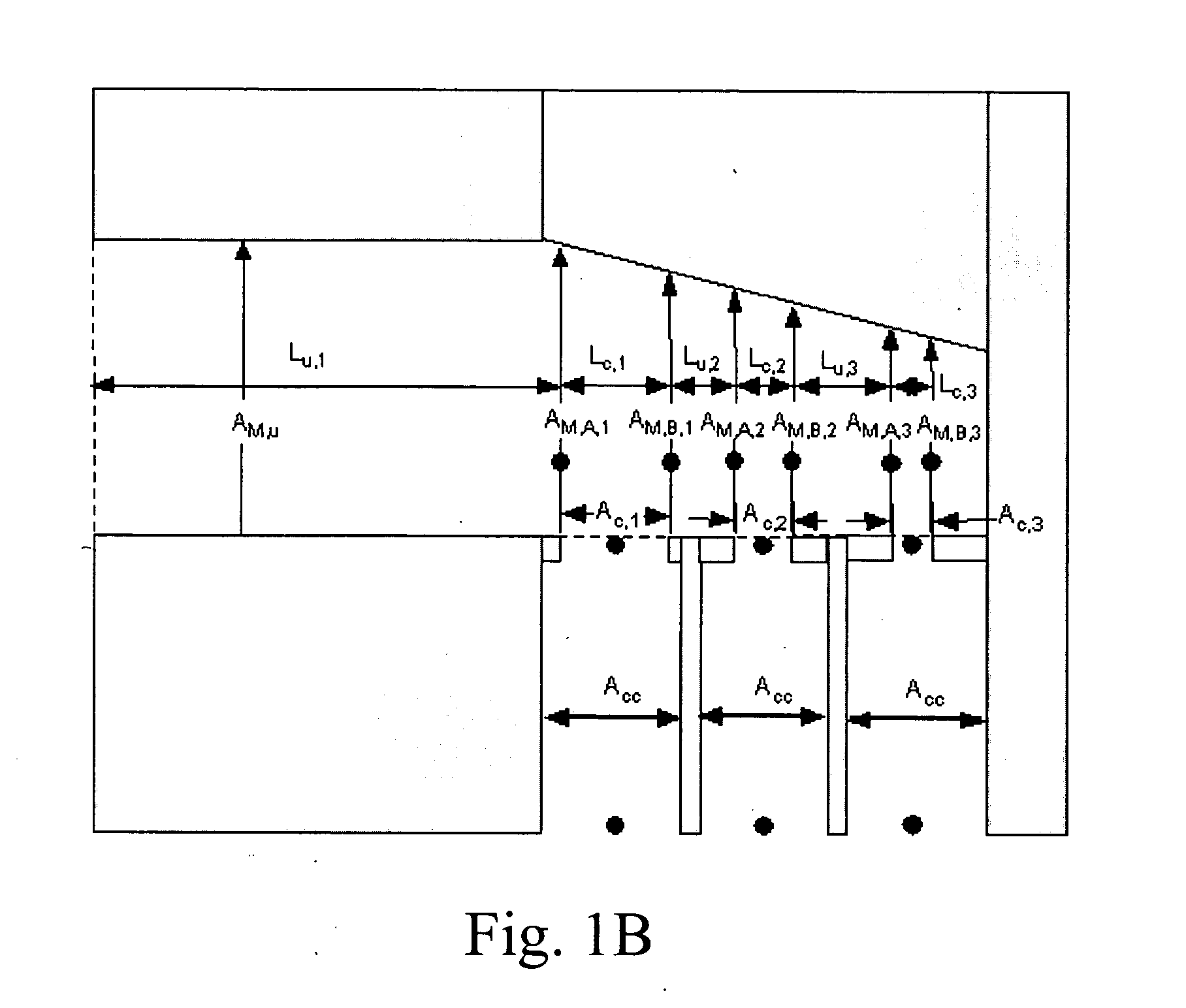

Manifold designs, and flow control in multichannel microchannel devices

InactiveUS20050087767A1Equally distributedLow costChemical/physical/physico-chemical microreactorsSemiconductor/solid-state device manufacturingEngineering

Owner:VELOCYS CORPORATION

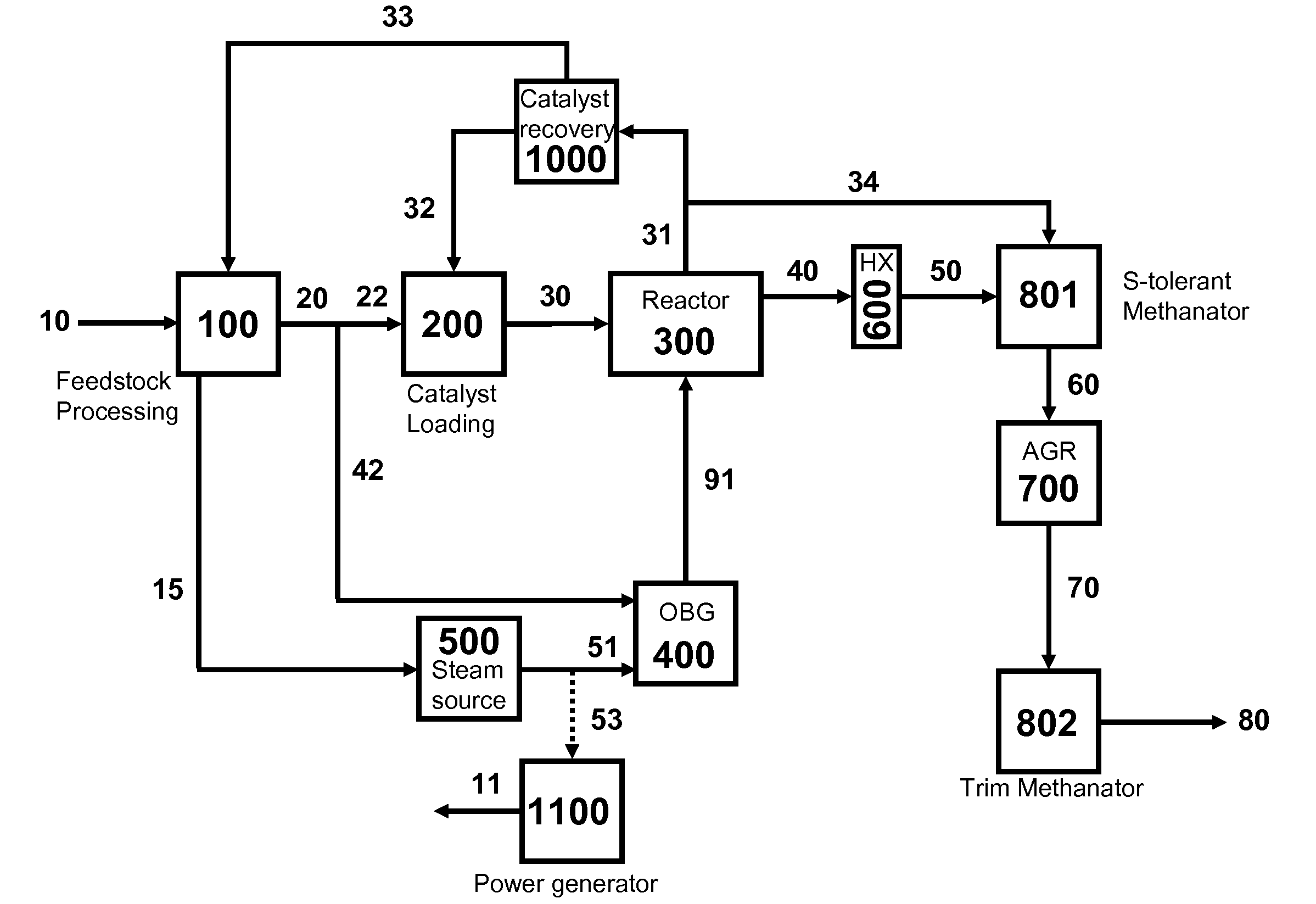

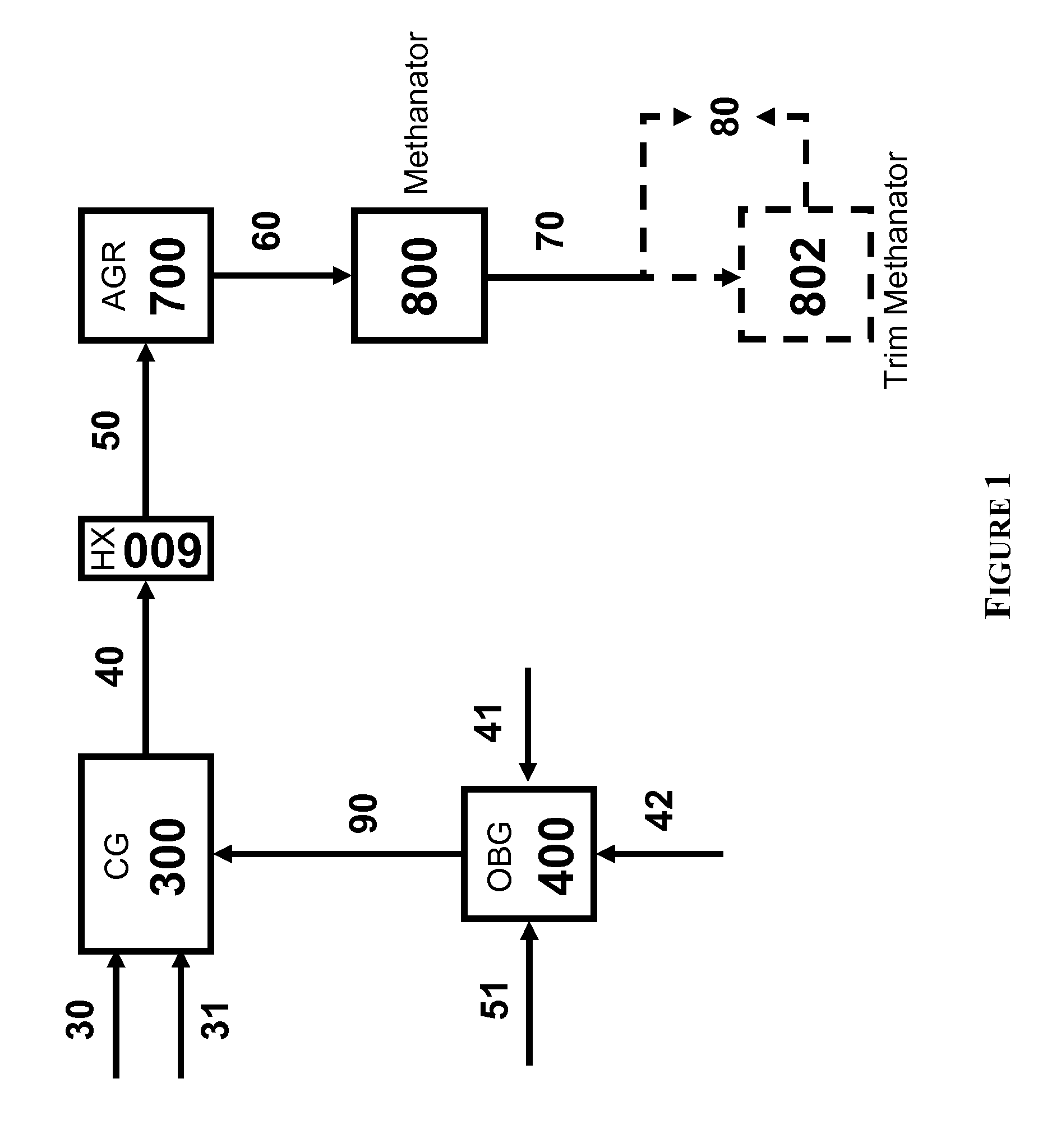

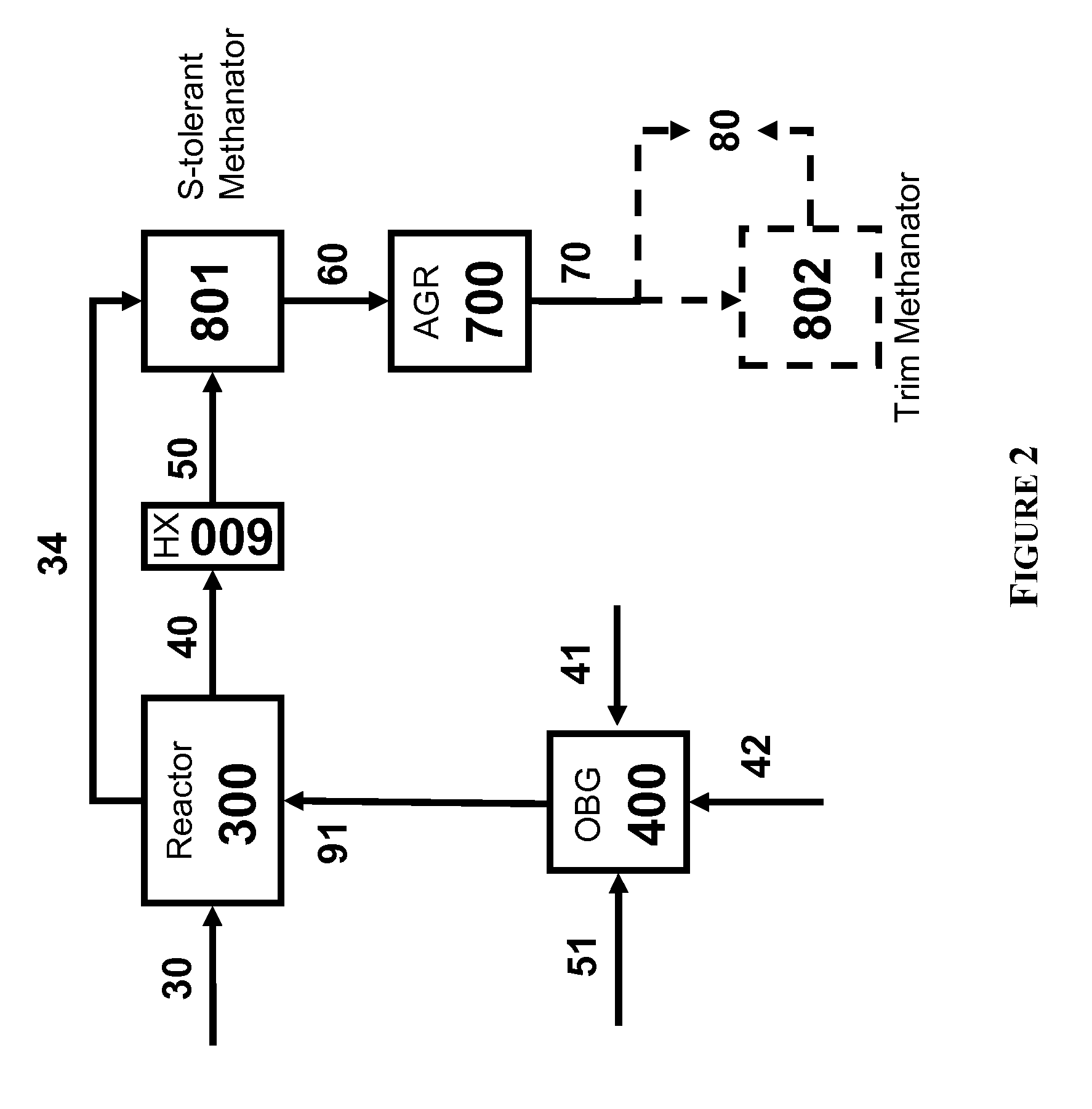

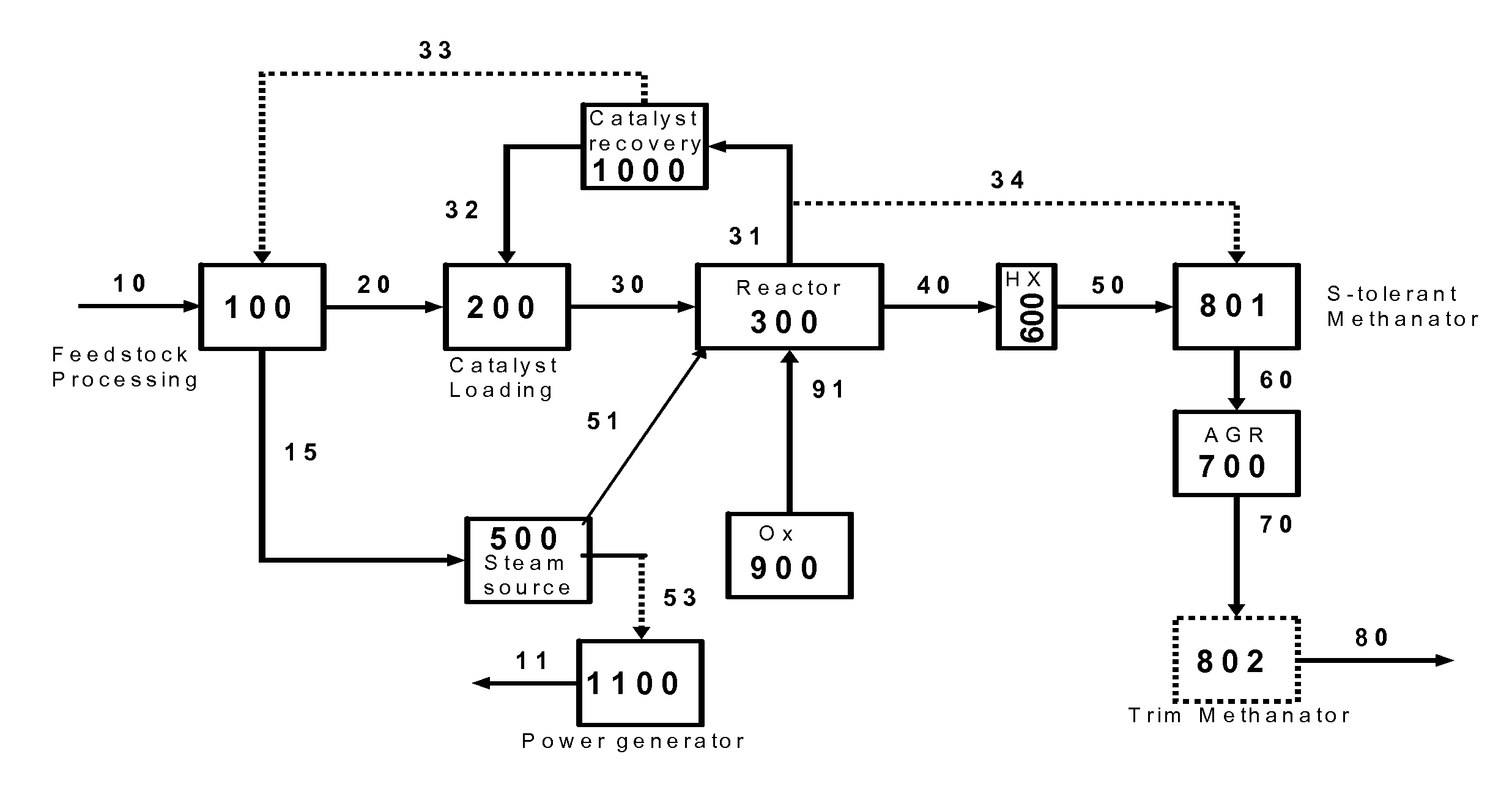

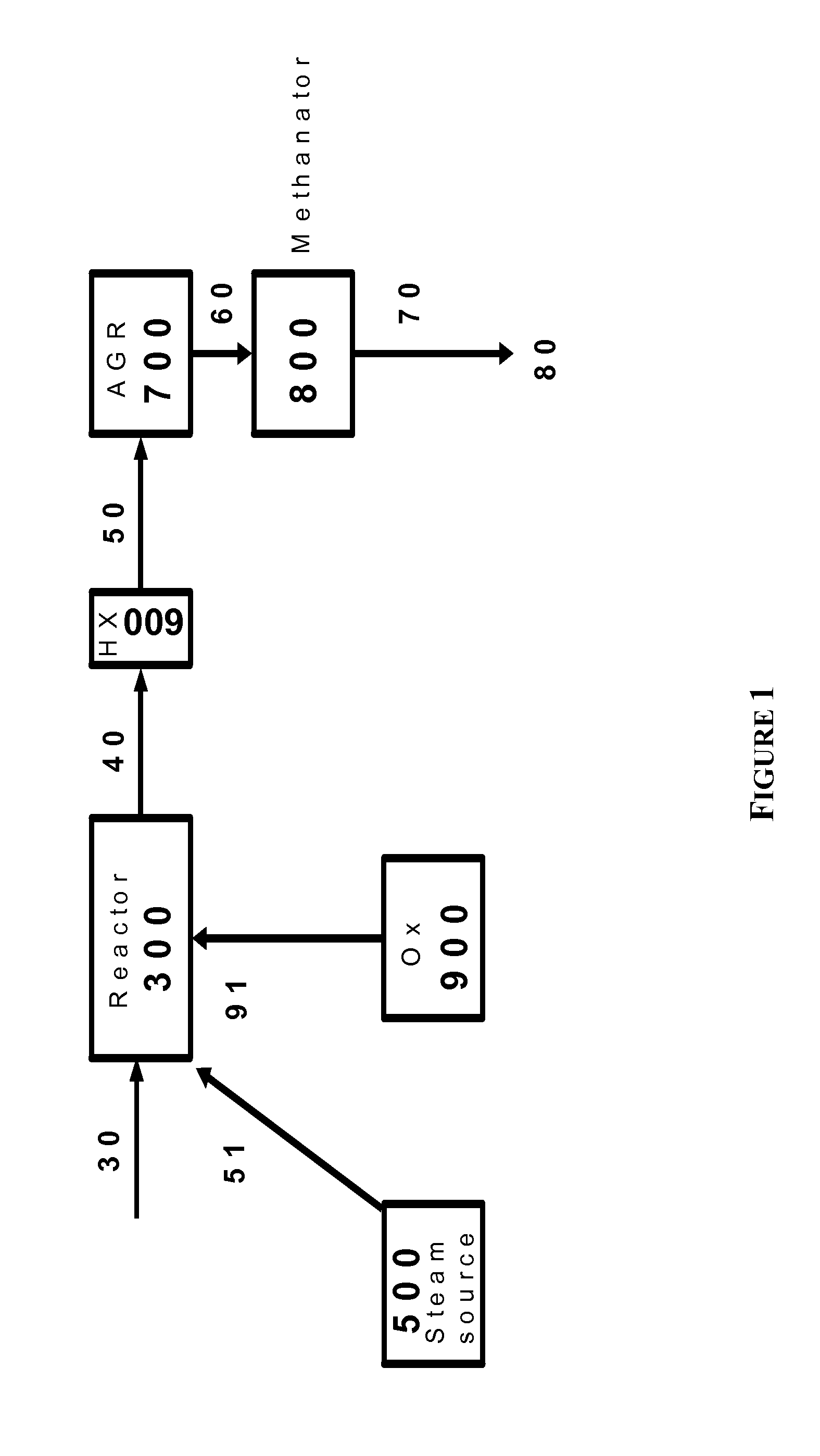

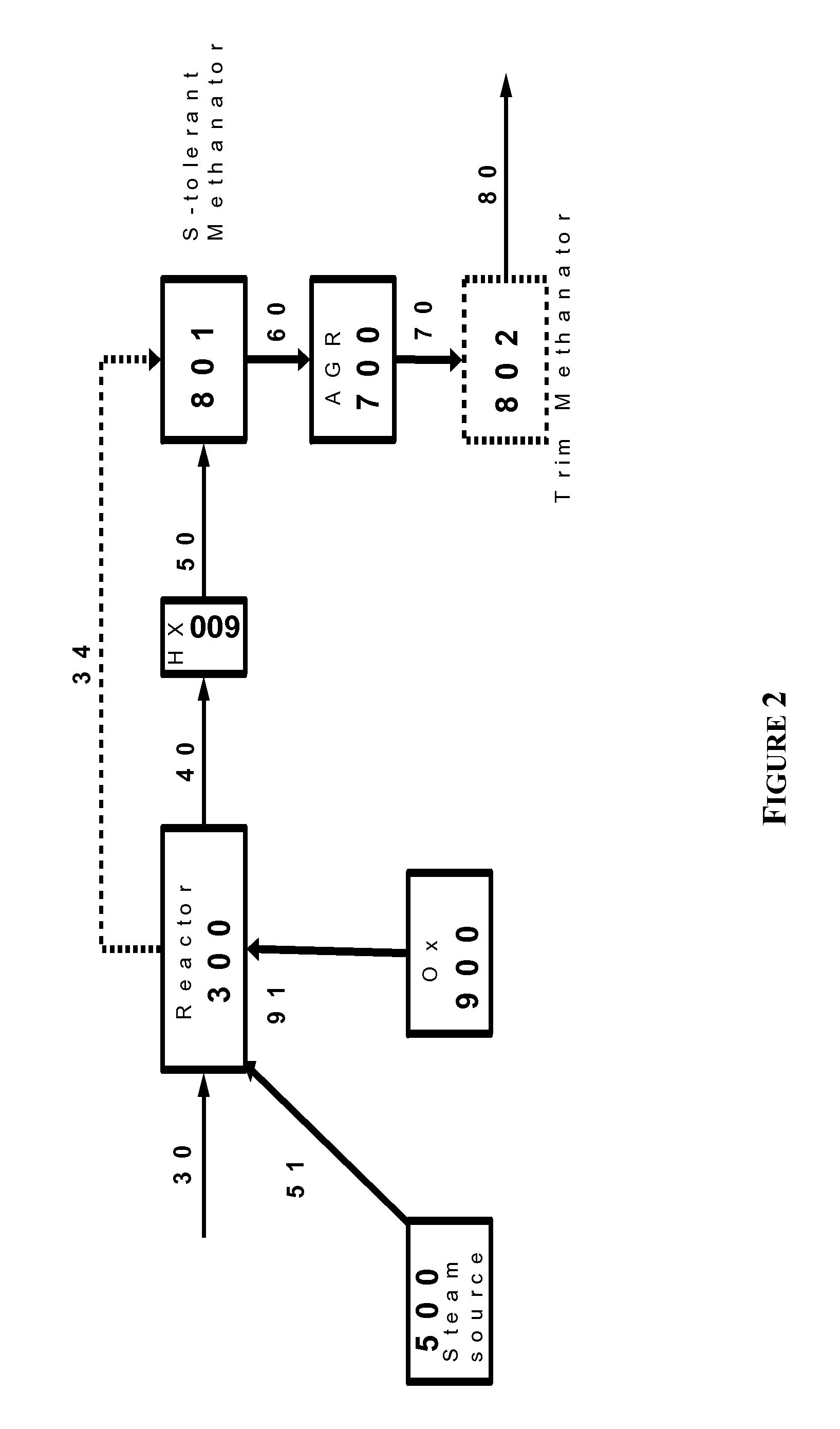

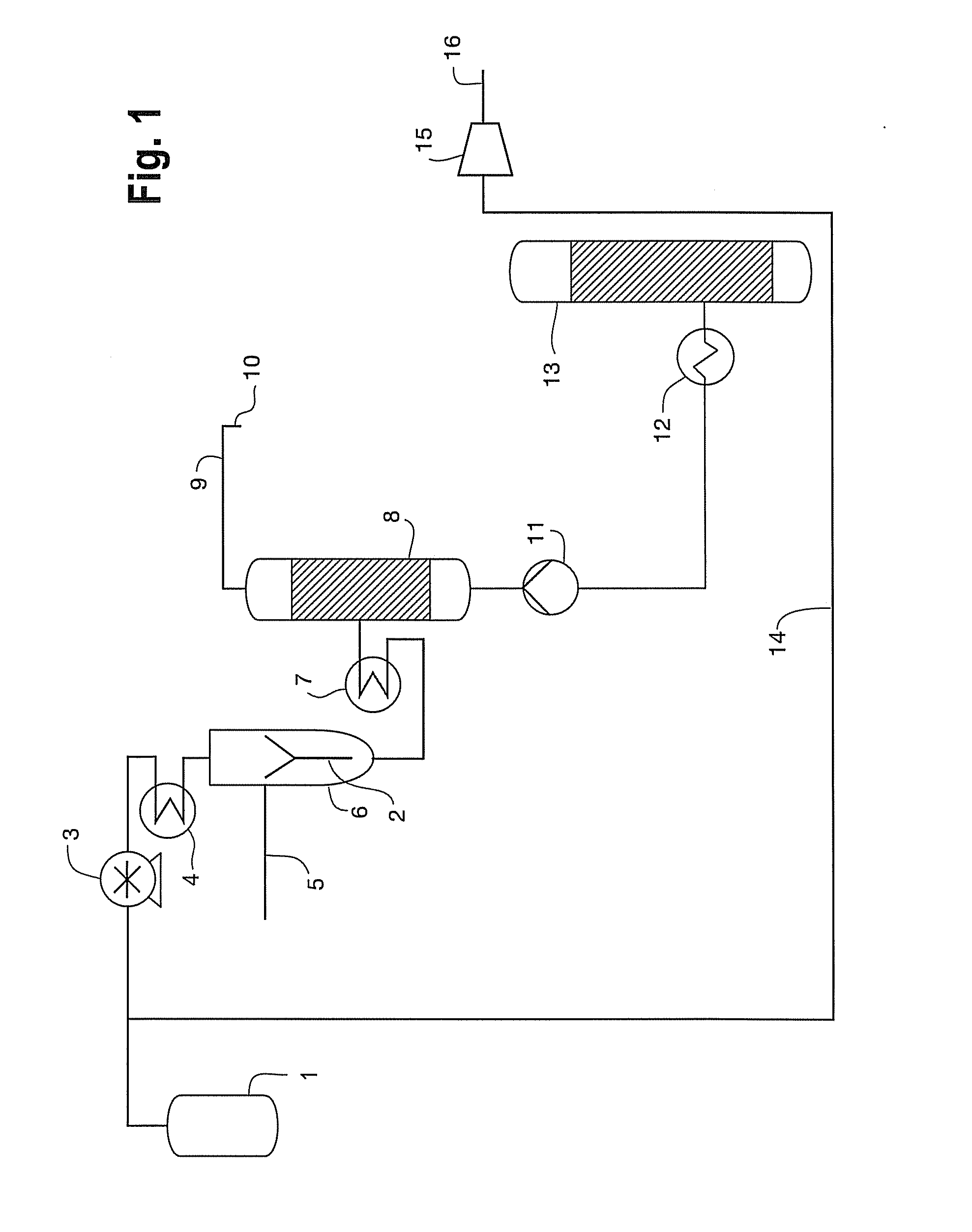

Processes for Gasification of a Carbonaceous Feedstock

The present invention relates to processes and continuous processes for preparing gaseous products, and in particular, methane via the catalytic gasification of carbonaceous feedstocks in the presence of steam. In one aspect of the invention, the processes comprise at least partially combusting a first carbonaceous feedstock with an oxygen-rich gas stream in an oxygen-blown gasifier, under suitable temperature and pressure, to generate a first gas stream comprising hydrogen, carbon monoxide and superheated steam; and reacting a second carbonaceous feedstock and the first gas stream in a catalytic gasifier in the presence of a gasification catalyst under suitable temperature and pressure to form a second gas stream comprising a plurality of gaseous products comprising methane, carbon dioxide, hydrogen, carbon monoxide and hydrogen sulfide. The processes can comprise using at least one catalytic methanator to convert carbon monoxide and hydrogen in the gaseous products to methane and in certain embodiments do not recycle carbon monoxide or hydrogen to the gasifier.

Owner:SURE CHAMPION INVESTMENT LTD

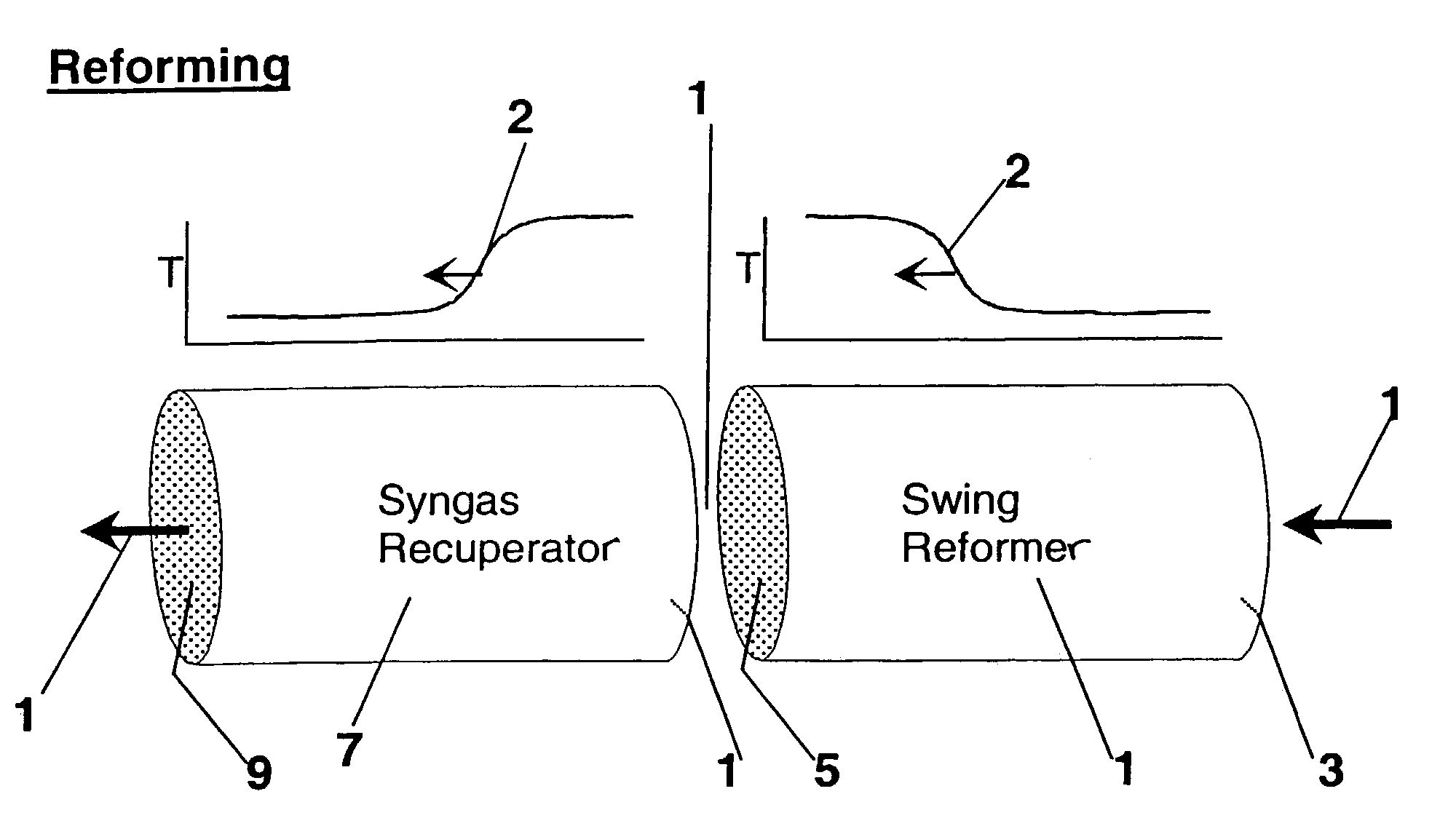

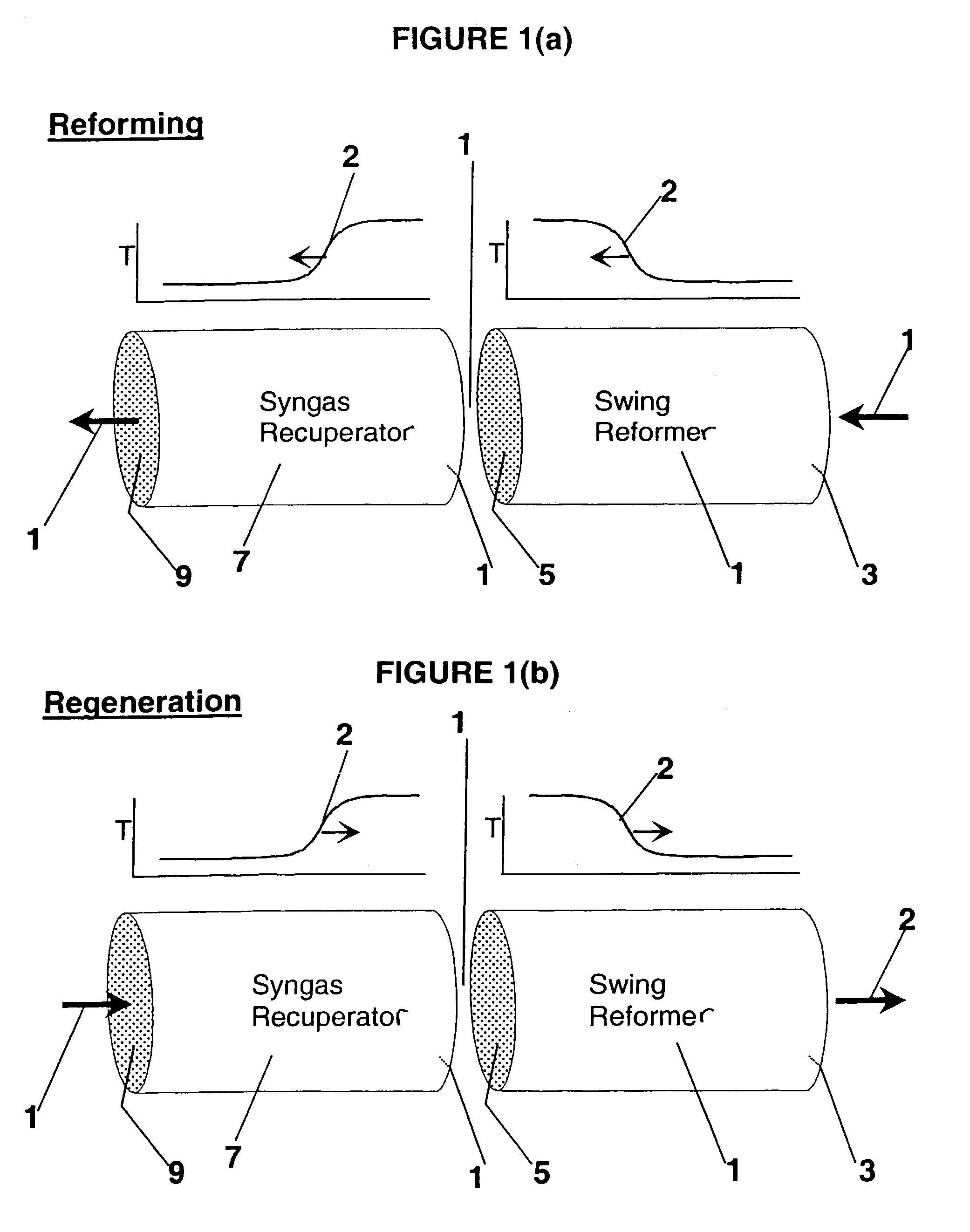

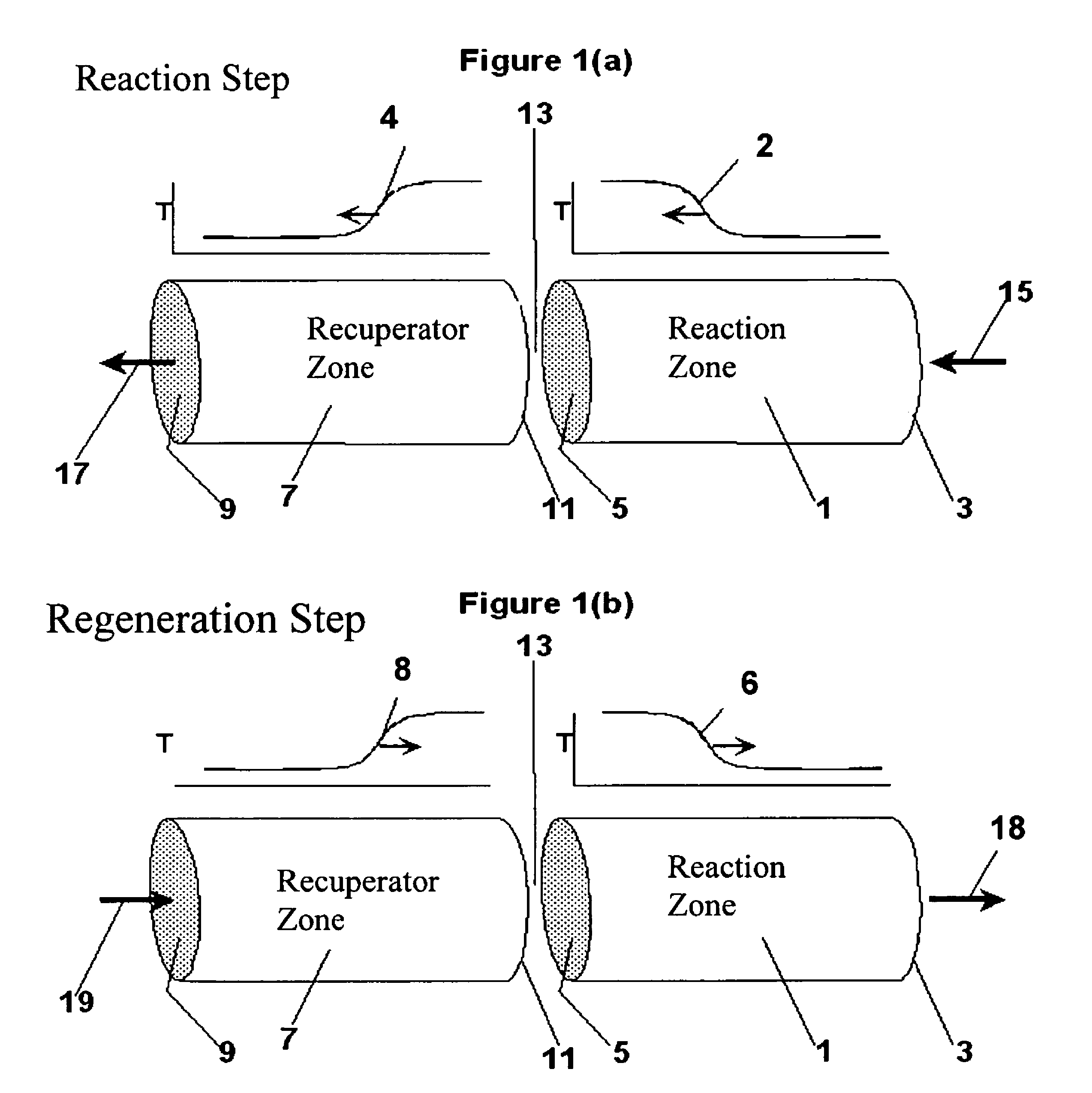

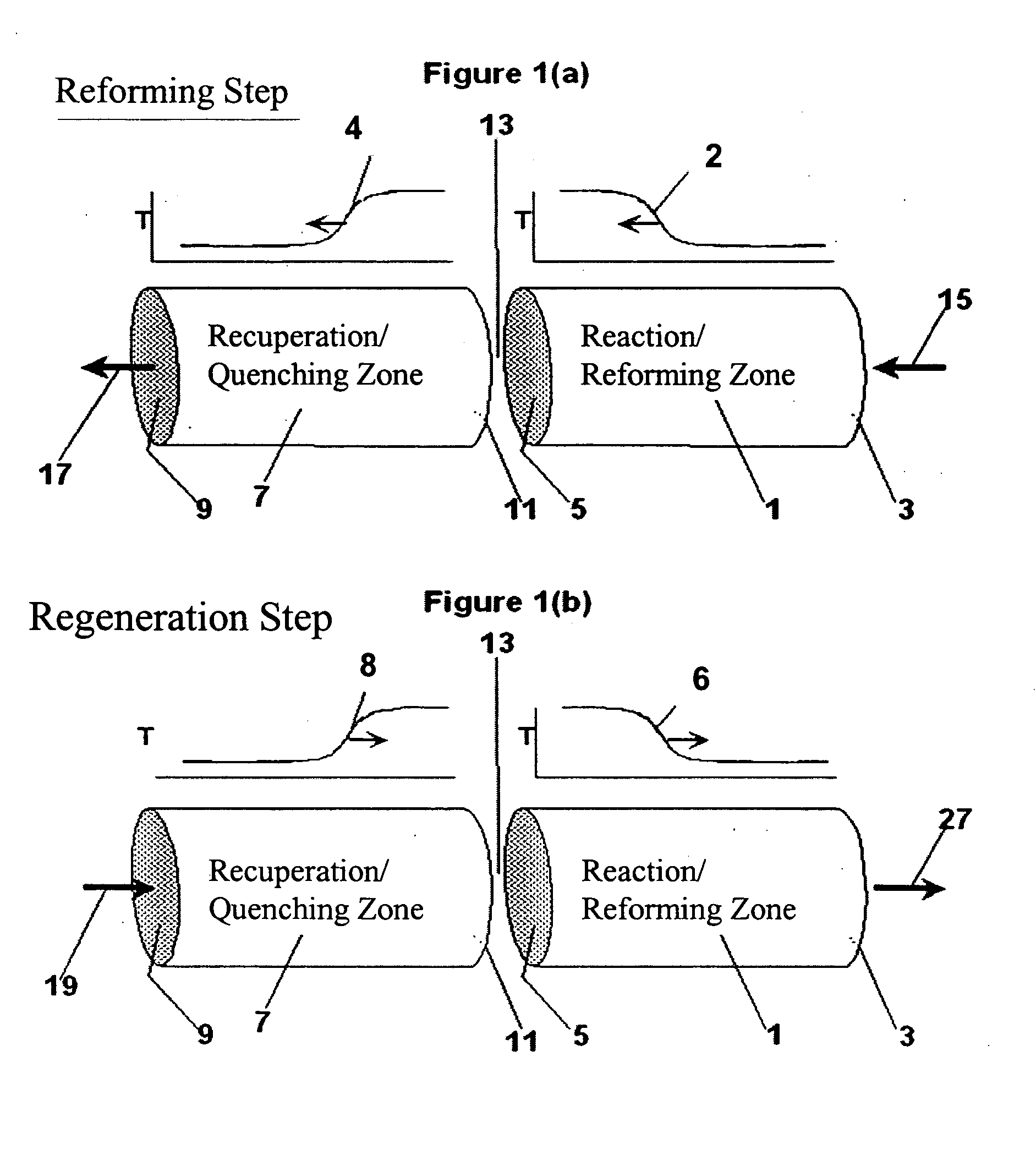

Pressure swing reforming

Synthesis gas is produced though a cyclic method where the first step of the cycle includes reforming a hydrocarbon feed over a catalyst to synthesis gas in a first zone of a bed and the second step reheats this first zone. A hydrocarbon feed is introduced to a bed along with CO2 and optionally steam where it is reformed into synthesis gas. The synthesis gas is collected at a second zone of the bed and an oxygen-containing gas is then introduced to this second zone of the bed and combusted with a fuel, thereby reheating the first zone to sufficient reforming temperatures. Additionally, a non-combusting gas can also be introduced to the second zone to move heat from the second zone to the first zone.

Owner:EXXON RES & ENG CO

Processes for Gasification of a Carbonaceous Feedstock

The present invention relates to processes for preparing gaseous products, and in particular, methane via the catalytic gasification of carbonaceous feedstocks in the presence of steam and an oxygen-rich gas stream. The processes comprise using at least one catalytic methanator to convert carbon monoxide and hydrogen in the gaseous products to methane and do not recycle carbon monoxide or hydrogen to the catalytic gasifier.

Owner:SURE CHAMPION INVESTMENT LTD

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964758B2High energy costWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIII transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

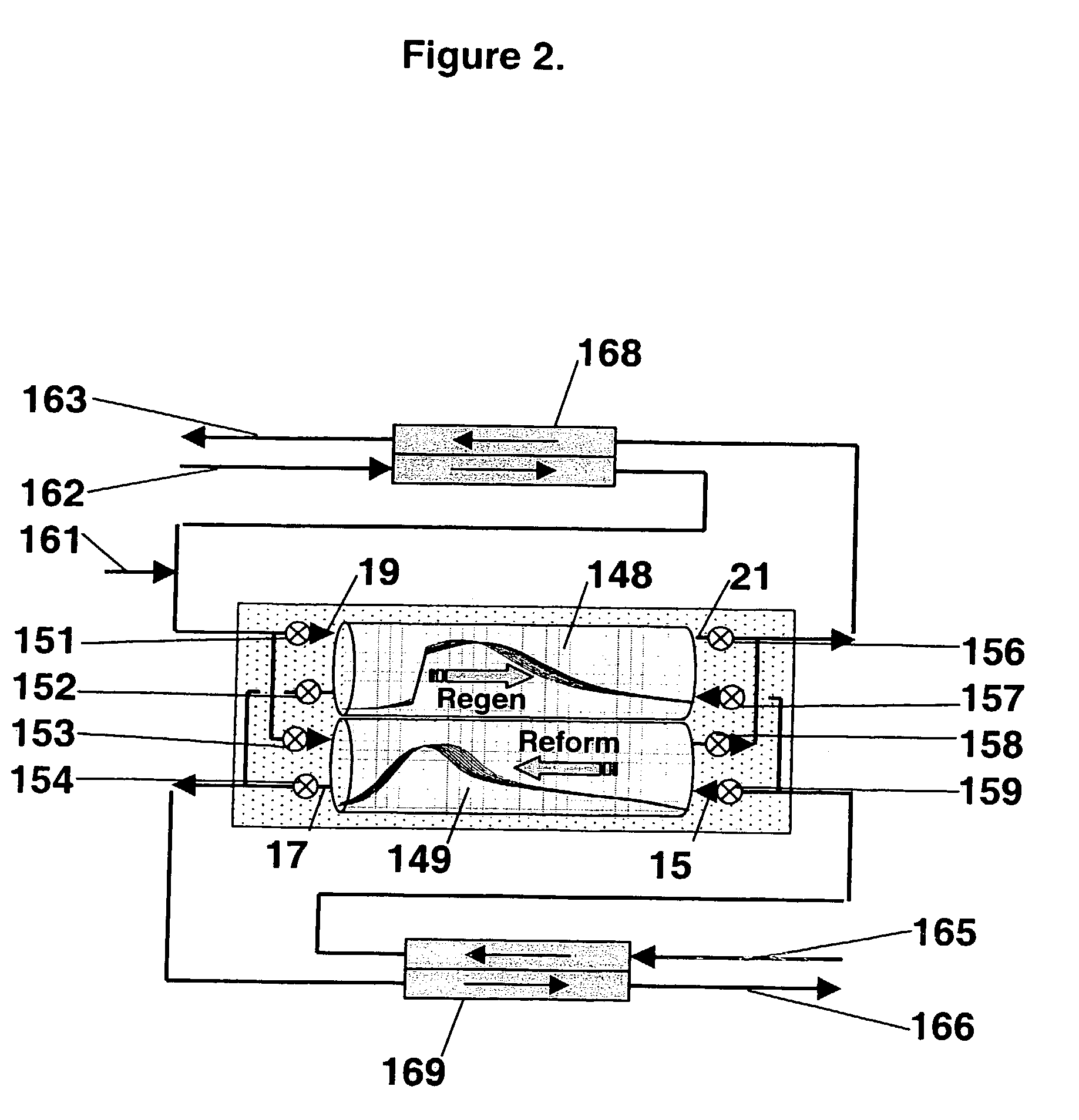

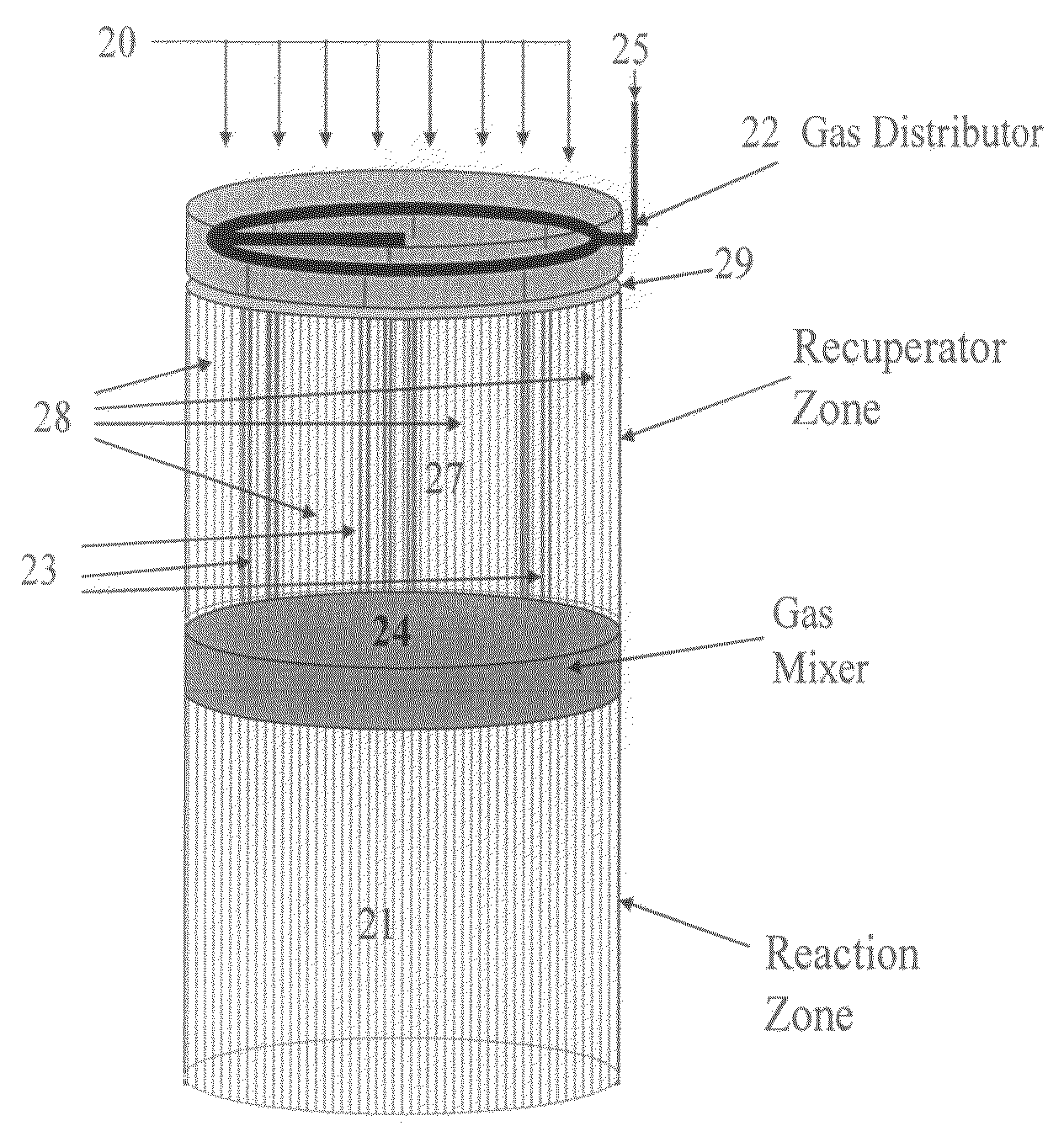

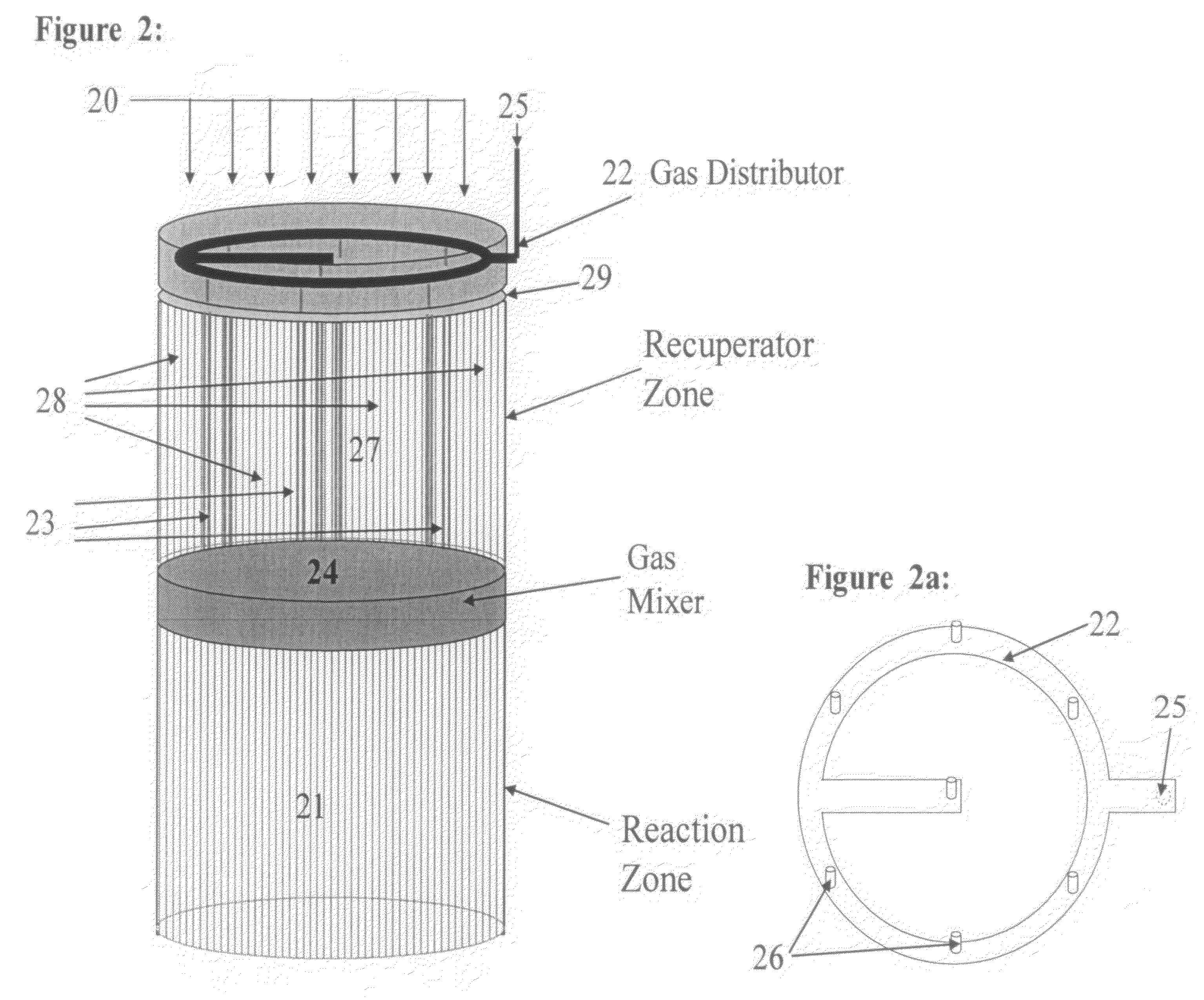

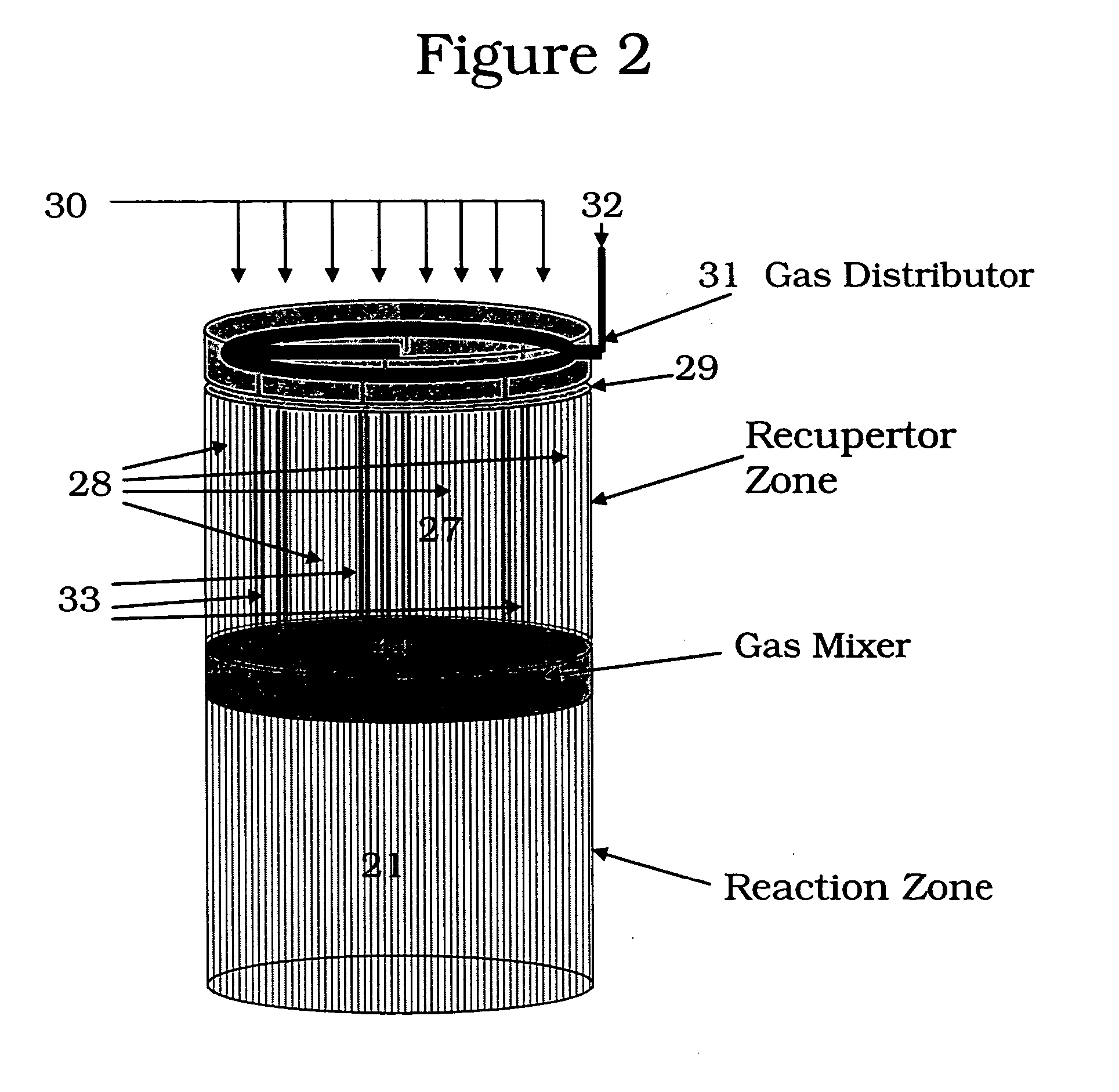

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

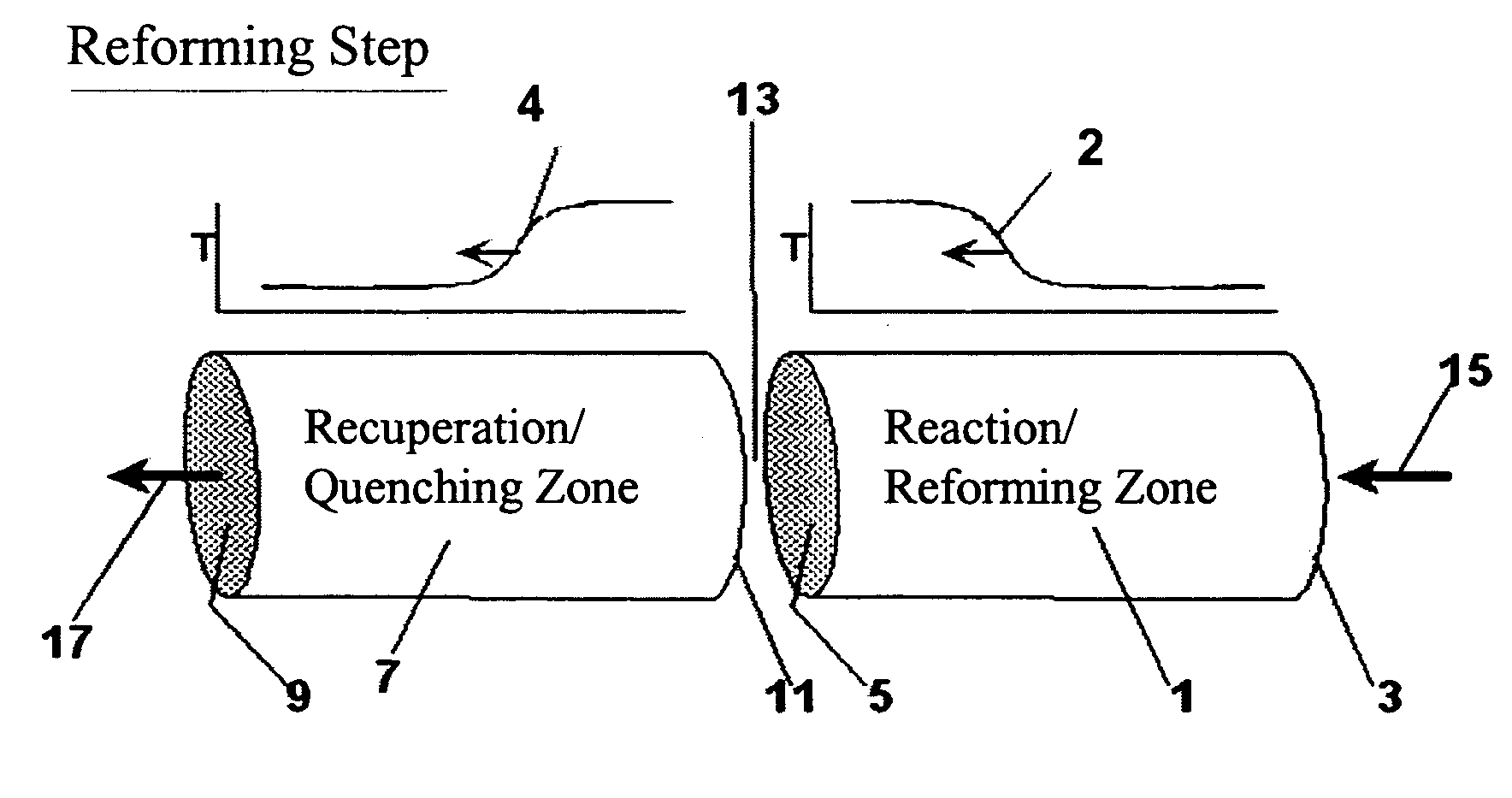

Methane conversion to higher hydrocarbons

ActiveUS20070191664A1Efficient preparationValid conversionGenerators with non-automatic water feedFlow mixersReactor systemReagent

The present invention provides a process for the manufacture of acetylene and other higher hydrocarbons from methane feed using a reverse-flow reactor system, wherein the reactor system includes (i) a first reactor and (ii) a second reactor, the first and second reactors oriented in a series relationship with respect to each other, the process comprising supplying each of first and second reactant through separate channels in the first reactor bed of a reverse-flow reactor such that both of the first and second reactants serve to quench the first reactor bed, without the first and second reactants substantially reacting with each other until reaching the core of the reactor system.

Owner:EXXONMOBIL CHEM PAT INC

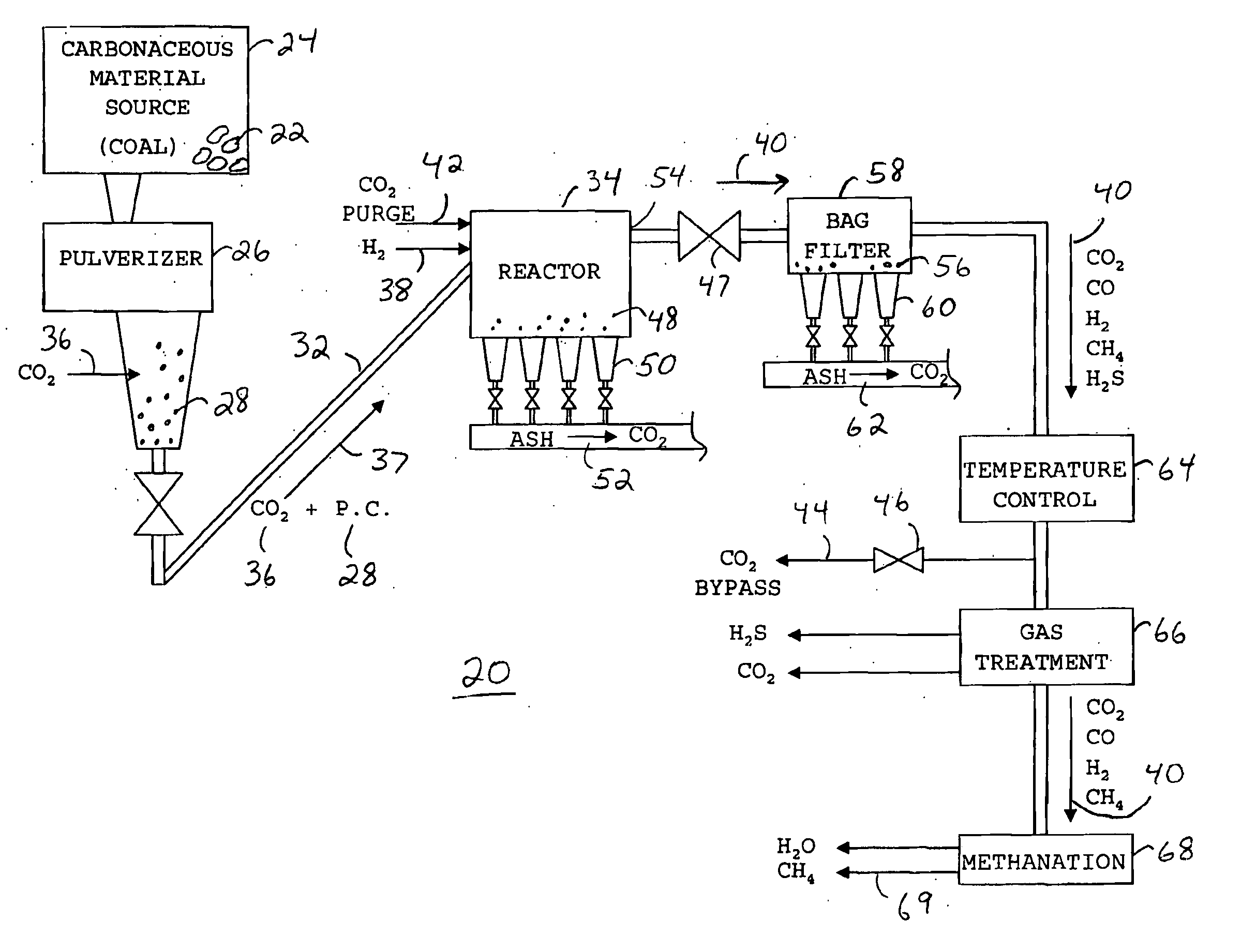

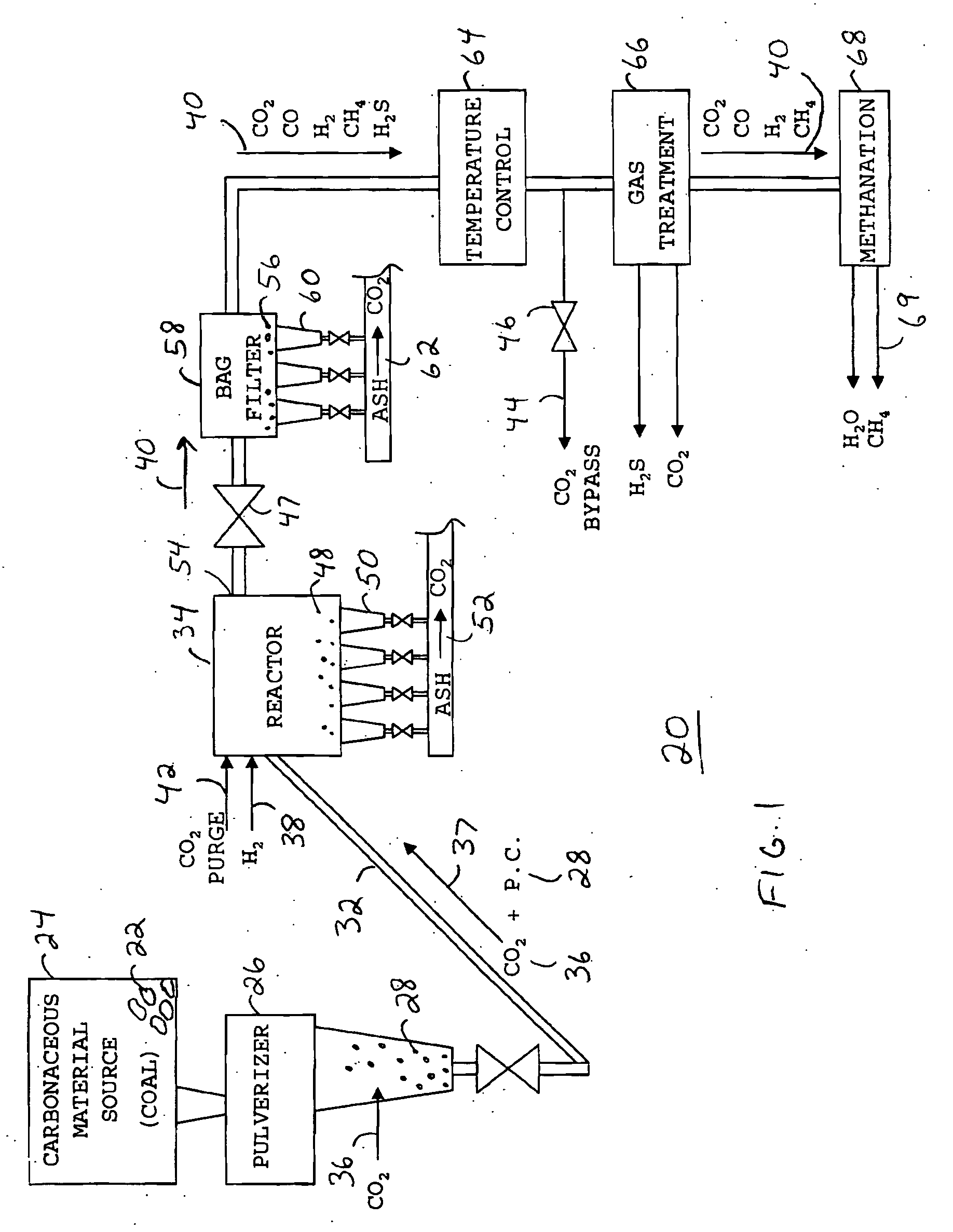

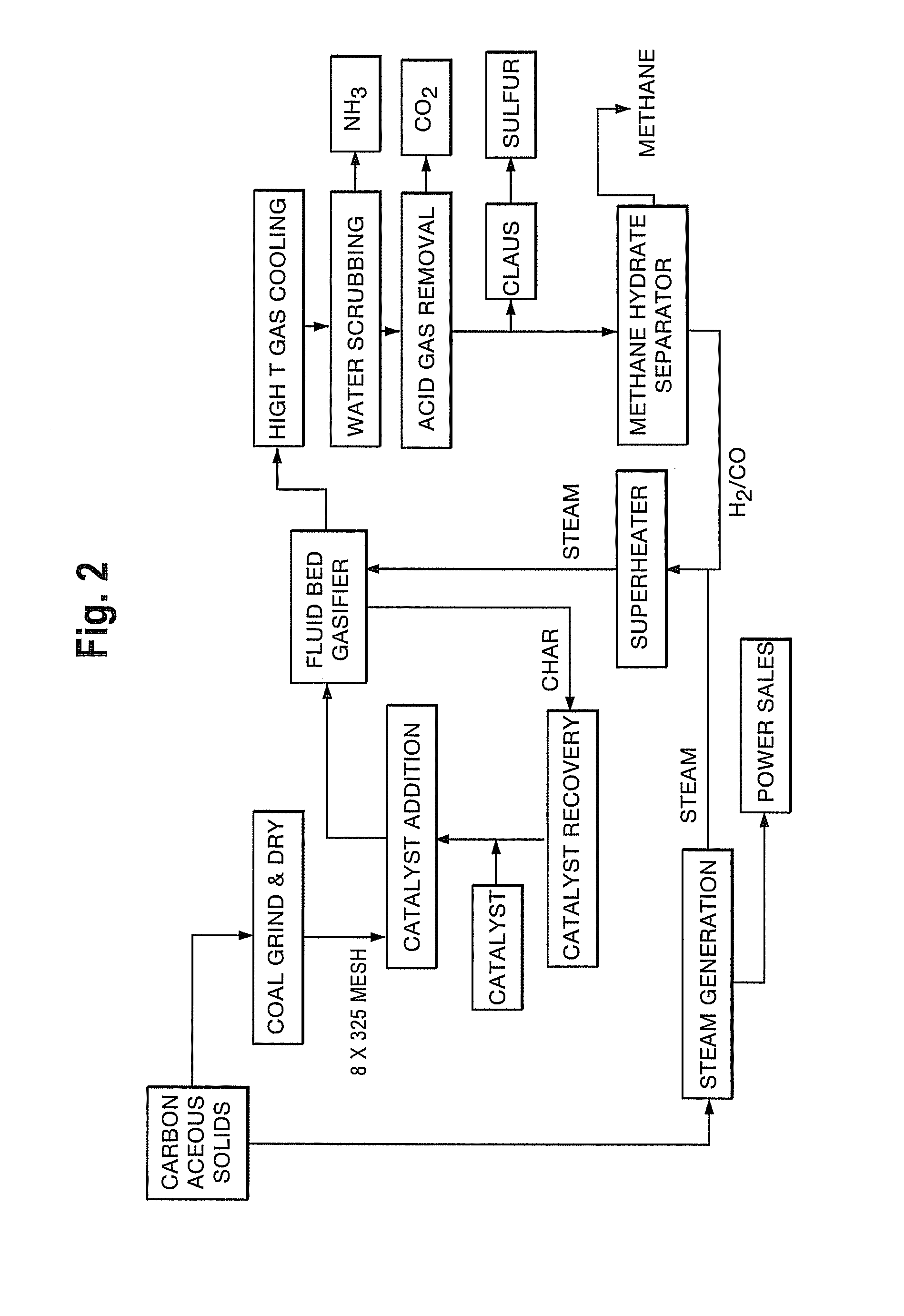

Method and apparatus for producing methane from carbonaceous material

InactiveUS20060265953A1Efficient productionEfficient deliveryHydrogen separationGaseous fuelsHydrogenReaction zone

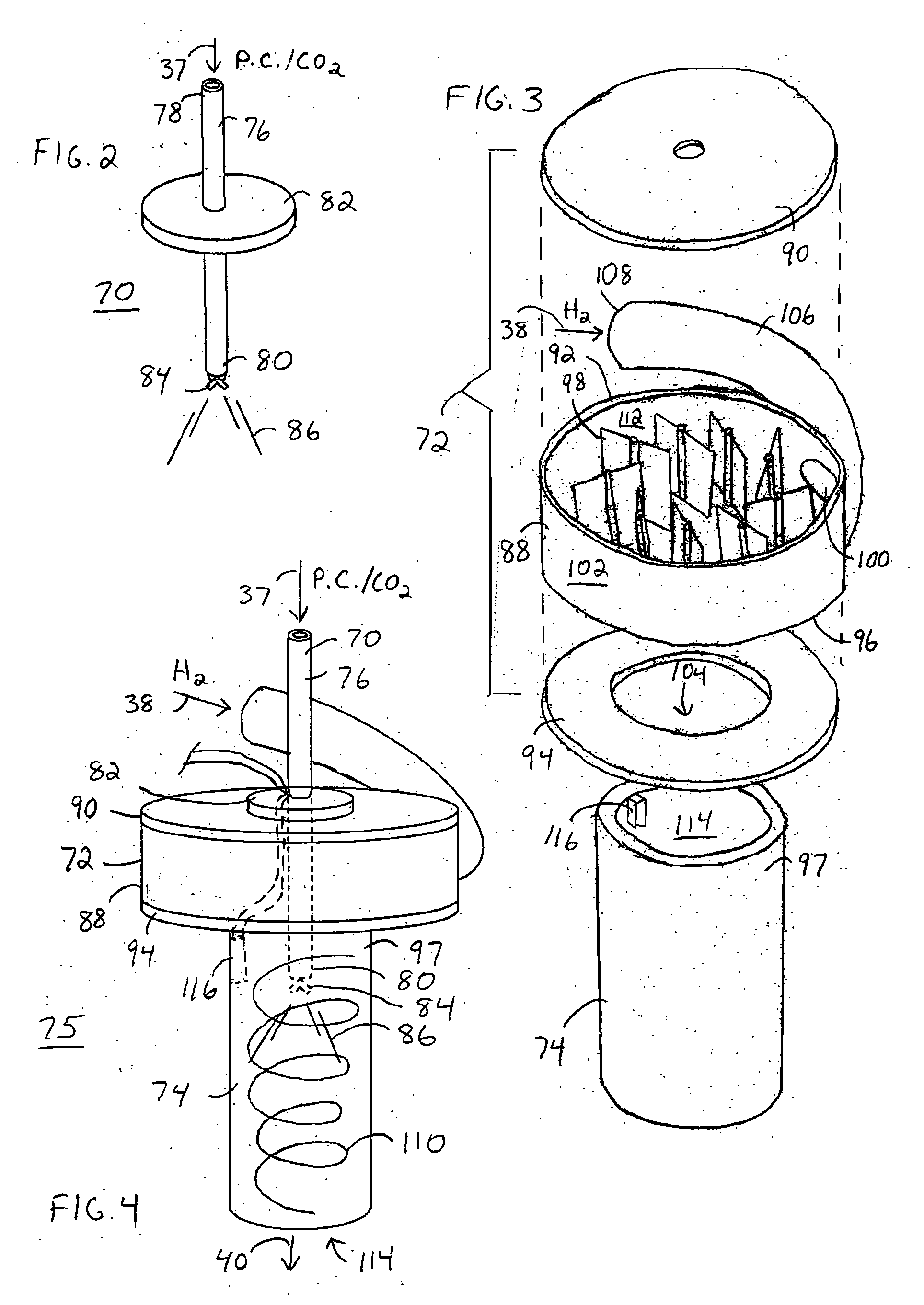

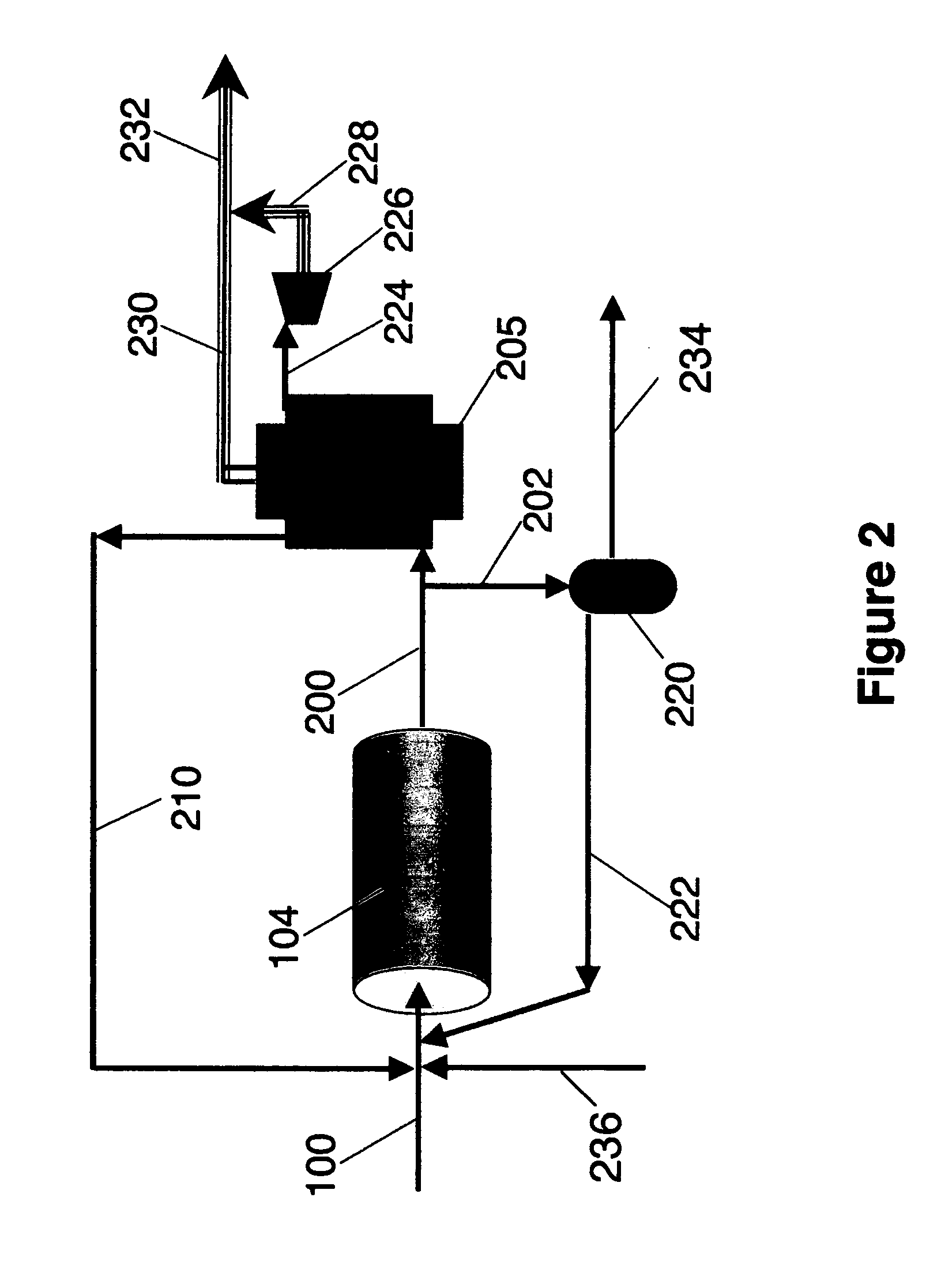

A method for producing methane (69) from a carbonaceous (22) material includes conveying pulverized carbonaceous material (28) entrained in an inert carrier fluid, such as carbon dioxide (36), into a reactor (34). The reactor (34) includes a vortex region (72) for receiving hydrogen gas (38) and imparting a swirling motion to the hydrogen gas (38). The pulverized carbonaceous material (28) is exposed to the swirling stream of hydrogen gas (38) in a first reaction zone (114) within the reactor (34) to form an exit gas (40) that includes methane (69). Remaining unreacted carbonaceous material (28) is further exposed to the hydrogen gas (38) in a second, low velocity, reaction zone (120). The methane rich exit gas (40) is subsequently extracted from the reactor (34) for further processing.

Owner:ARIZONA PUBLIC SERVICE

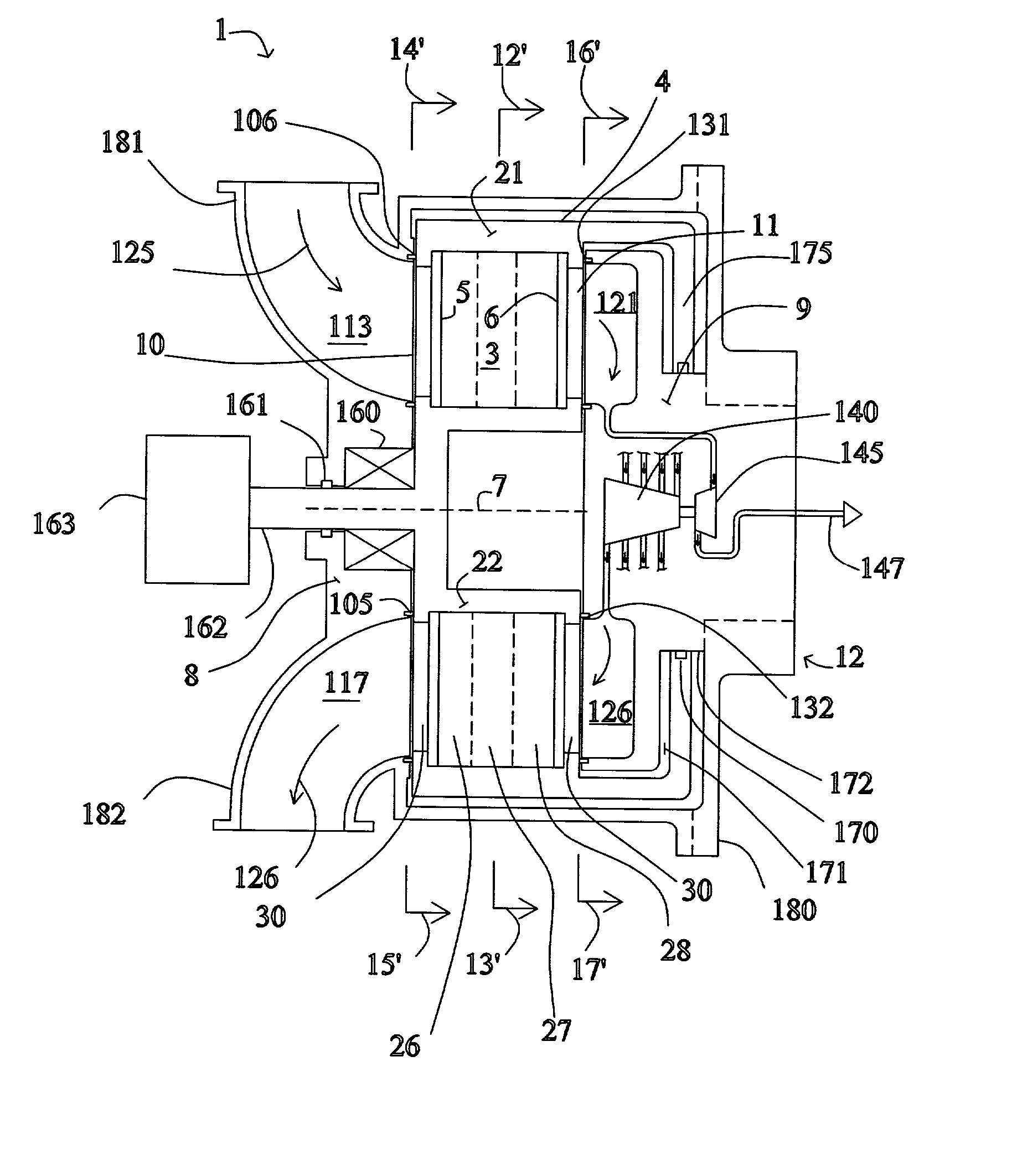

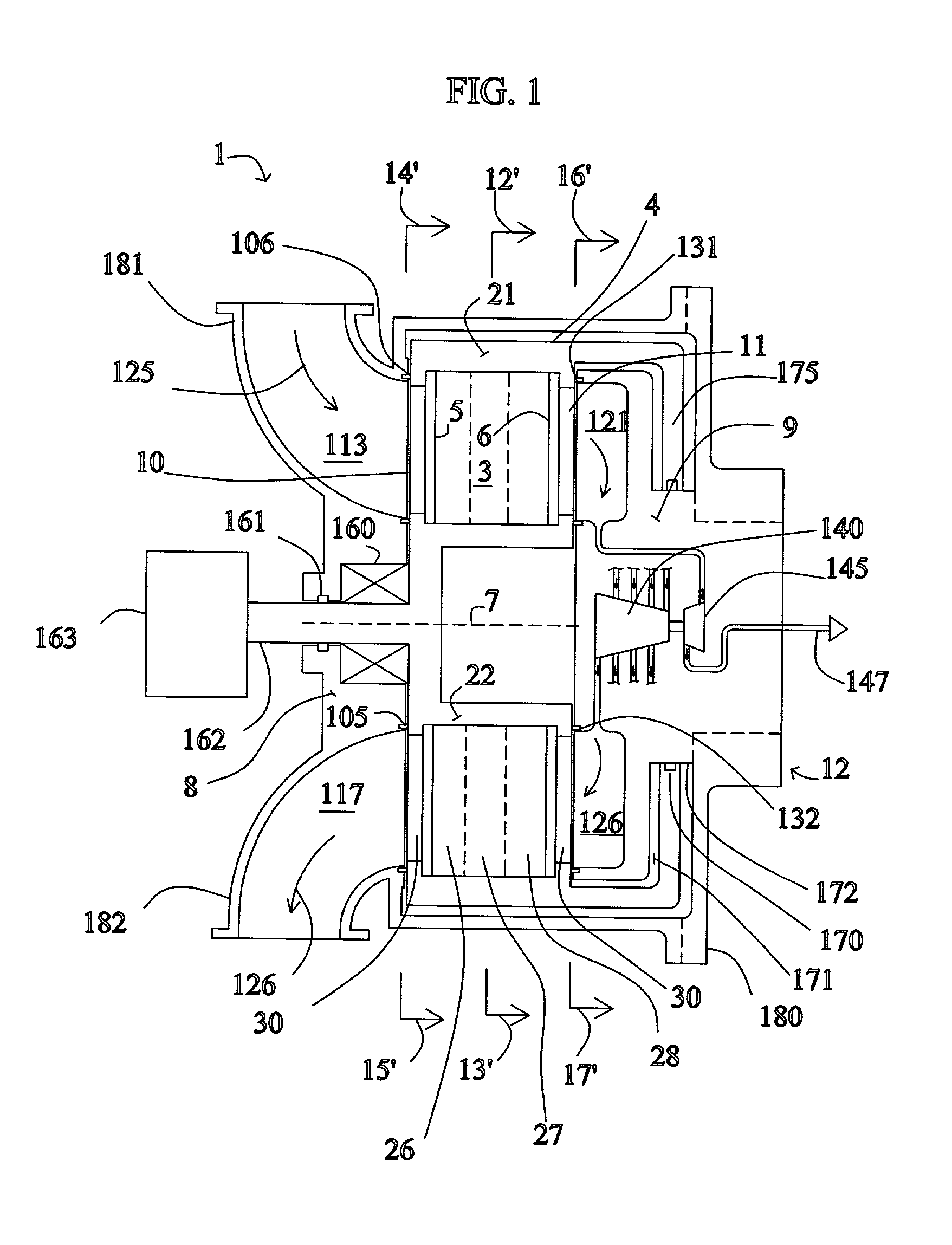

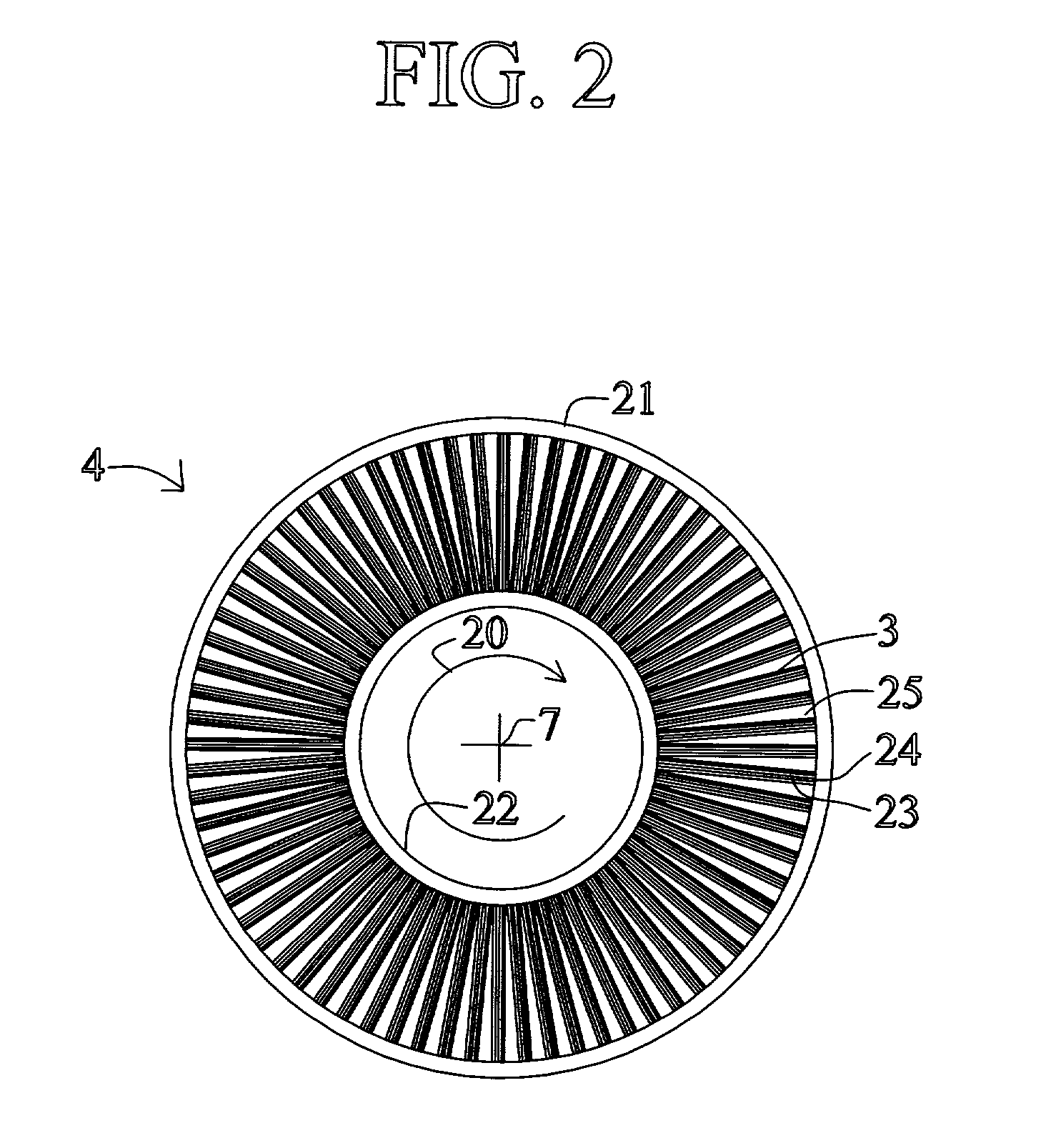

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

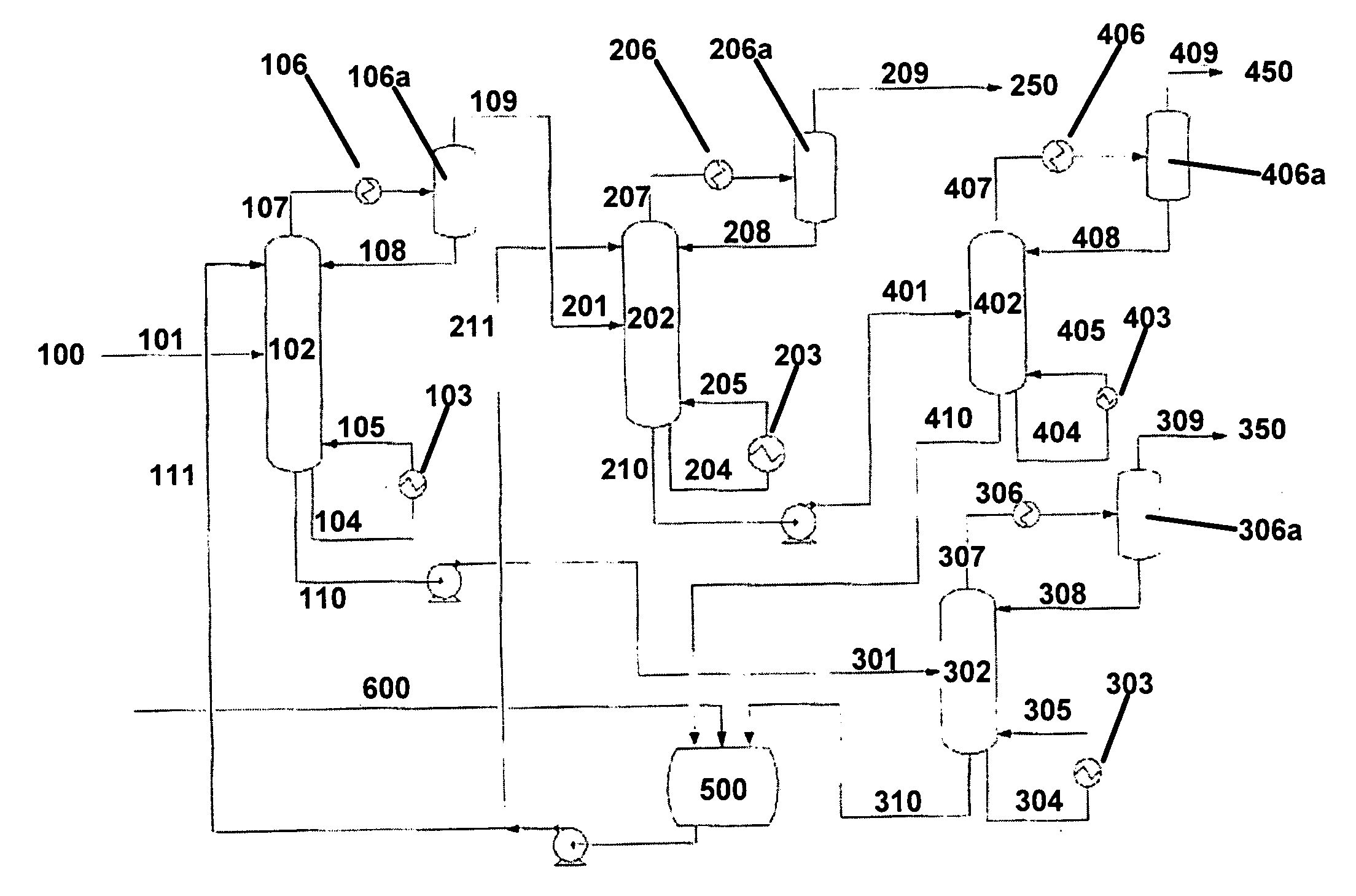

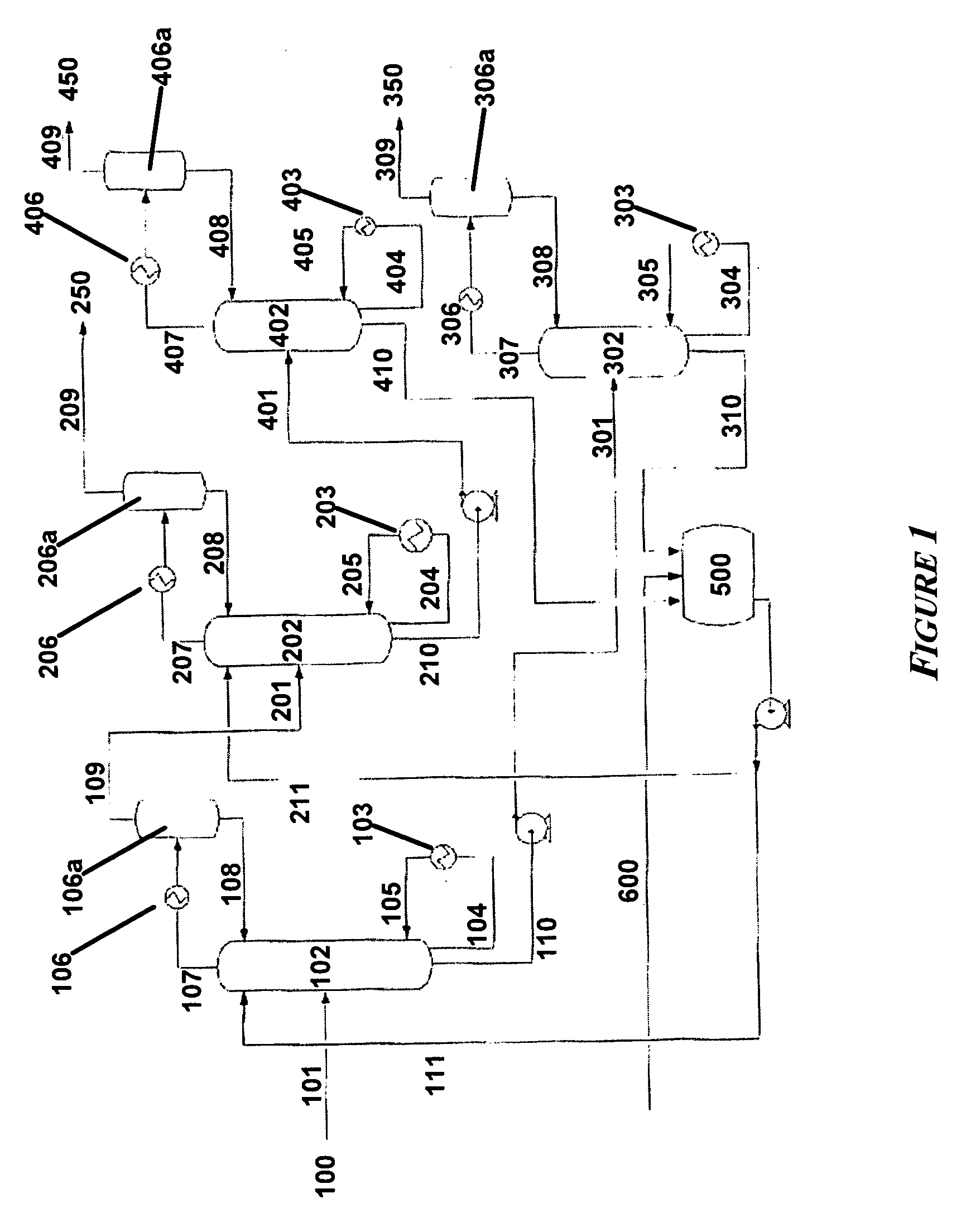

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

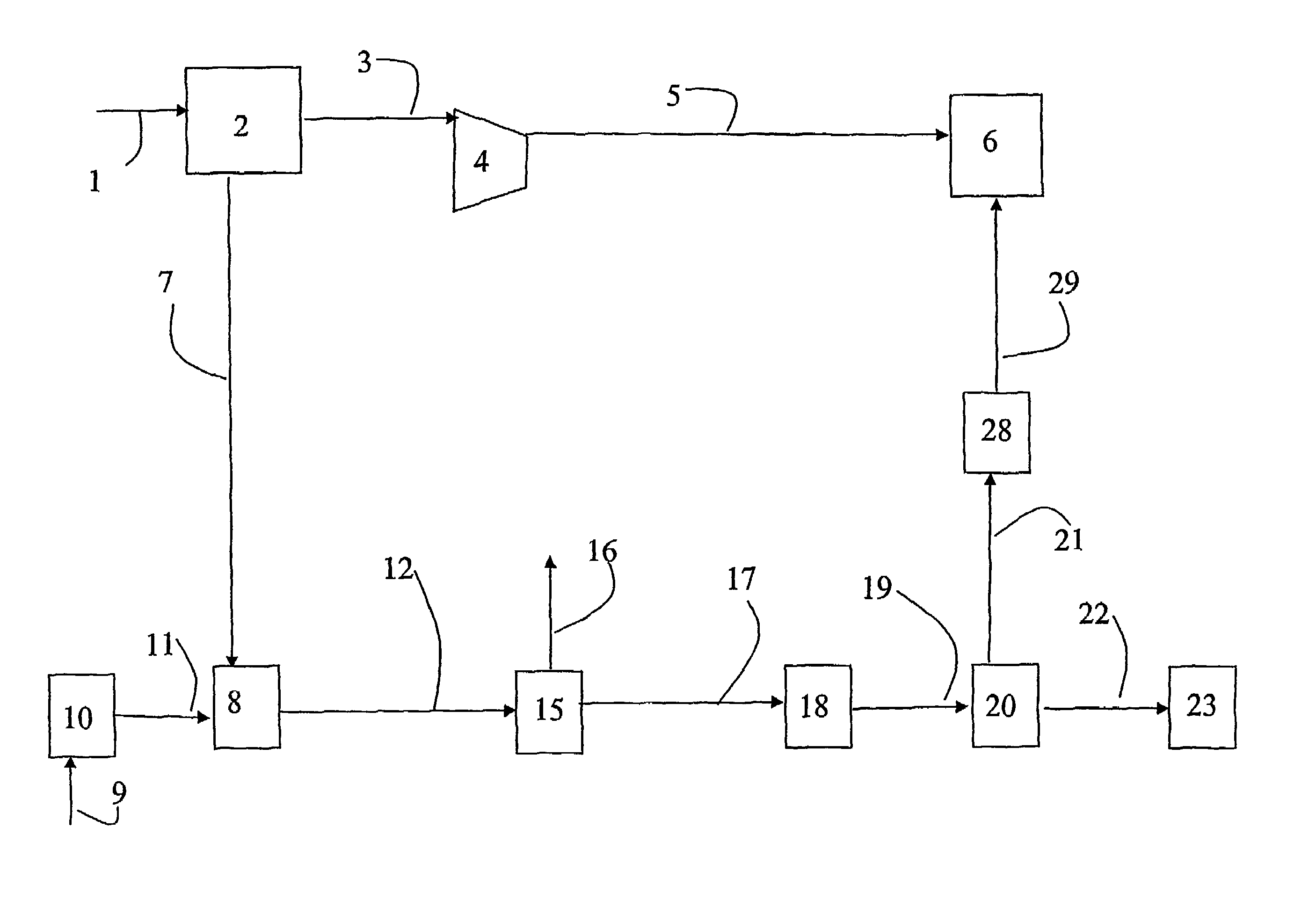

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

Plant and a method for increased oil recovery

Owner:DEN NORSKE STATS OLJESELSKAP AS

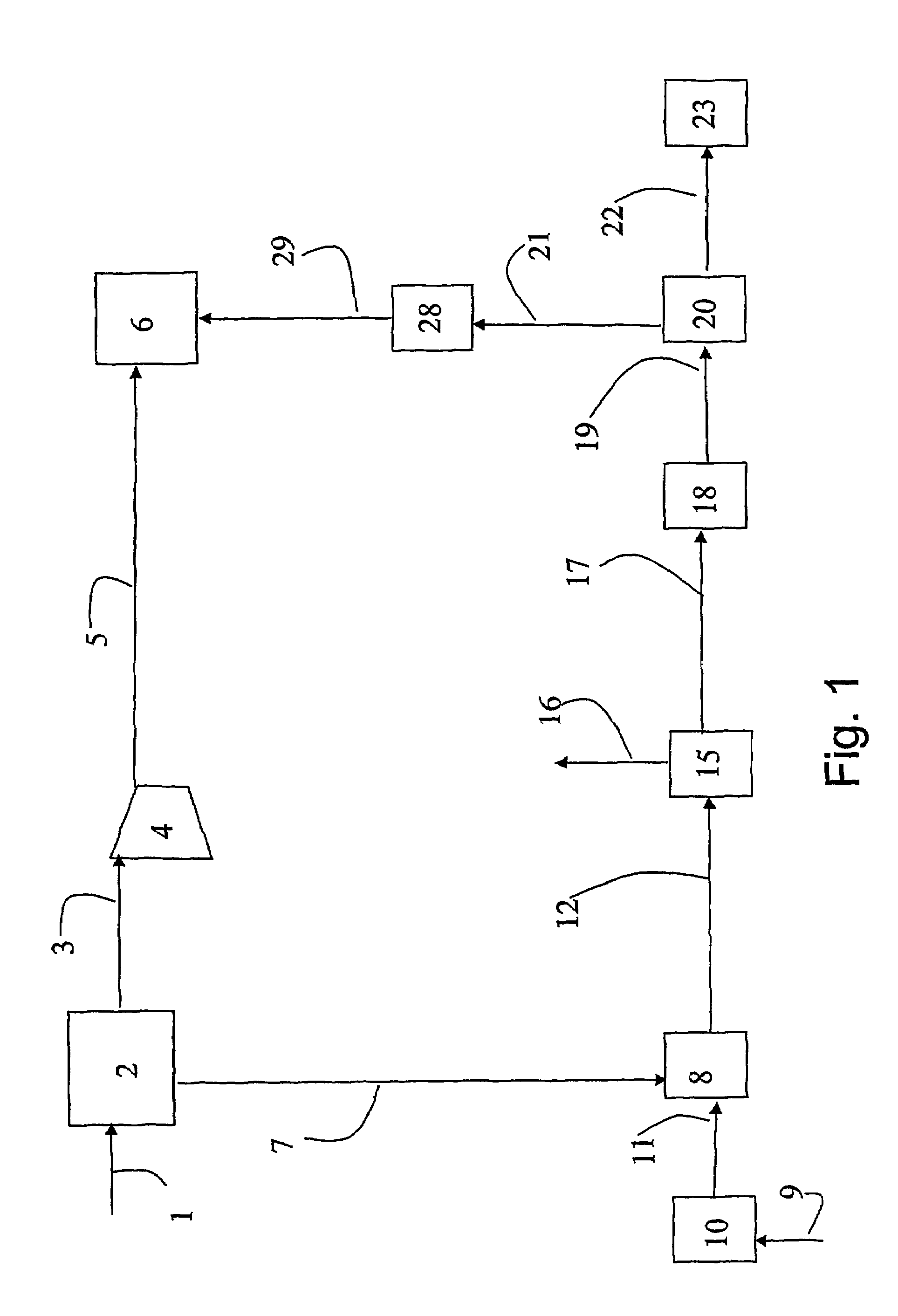

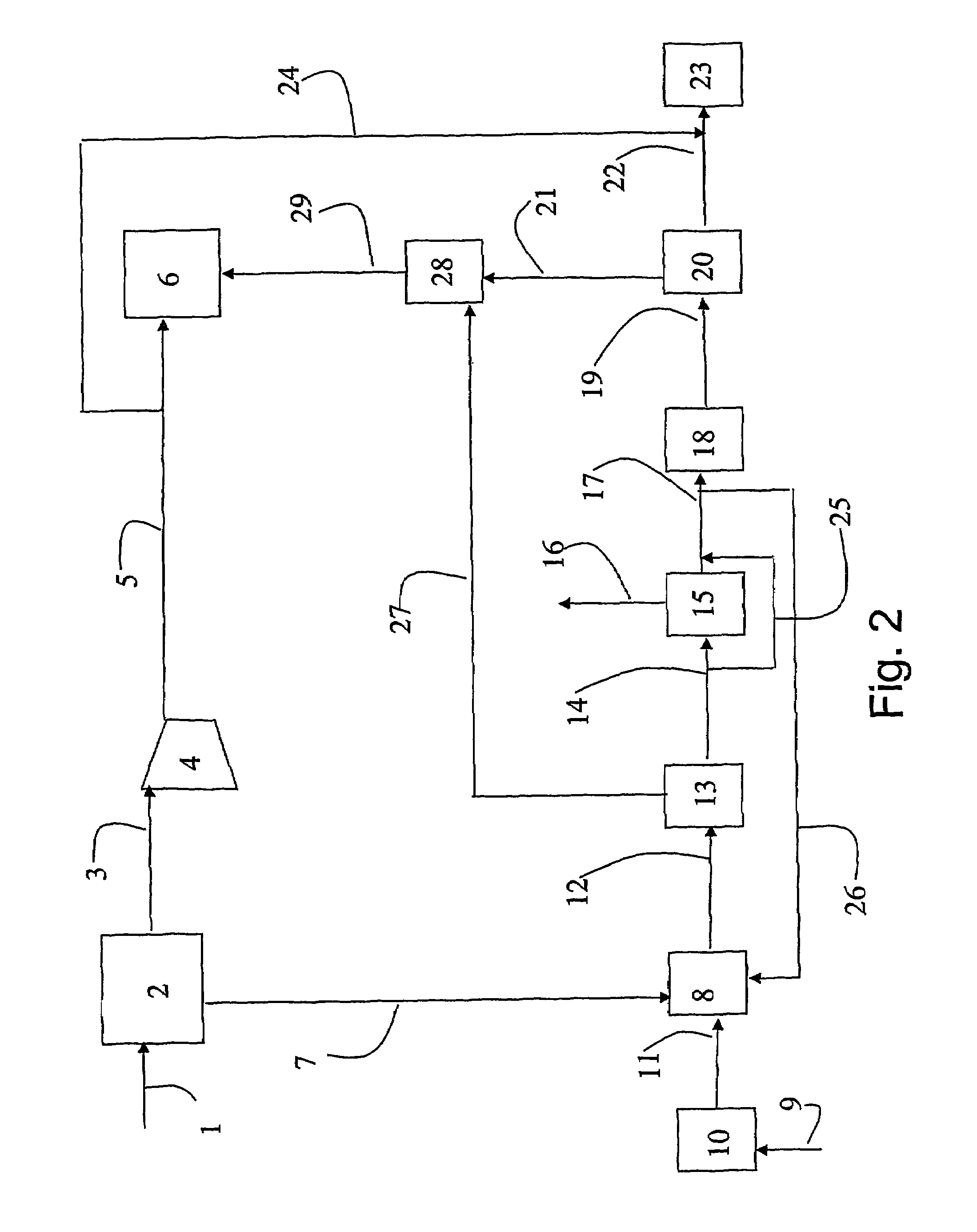

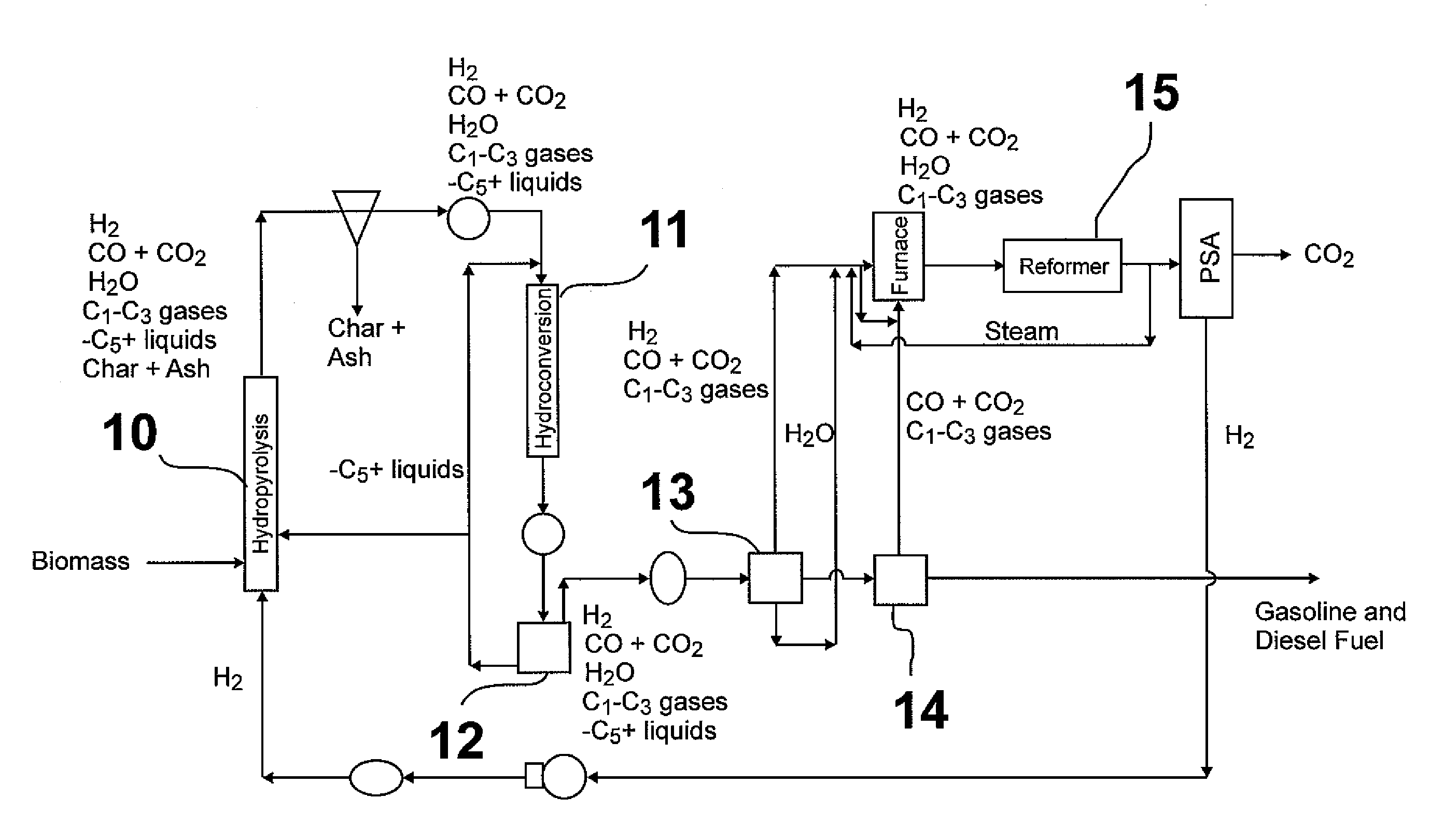

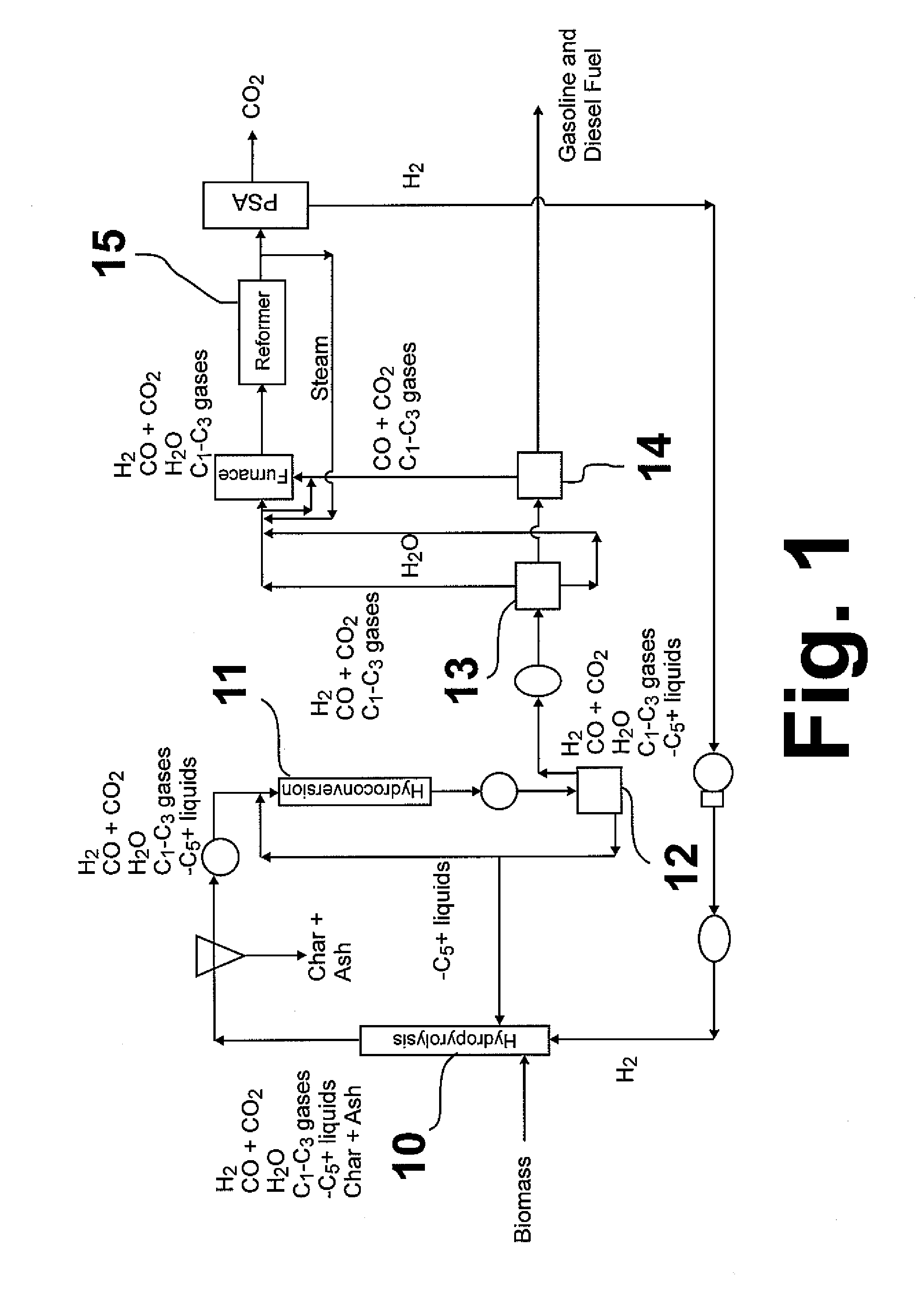

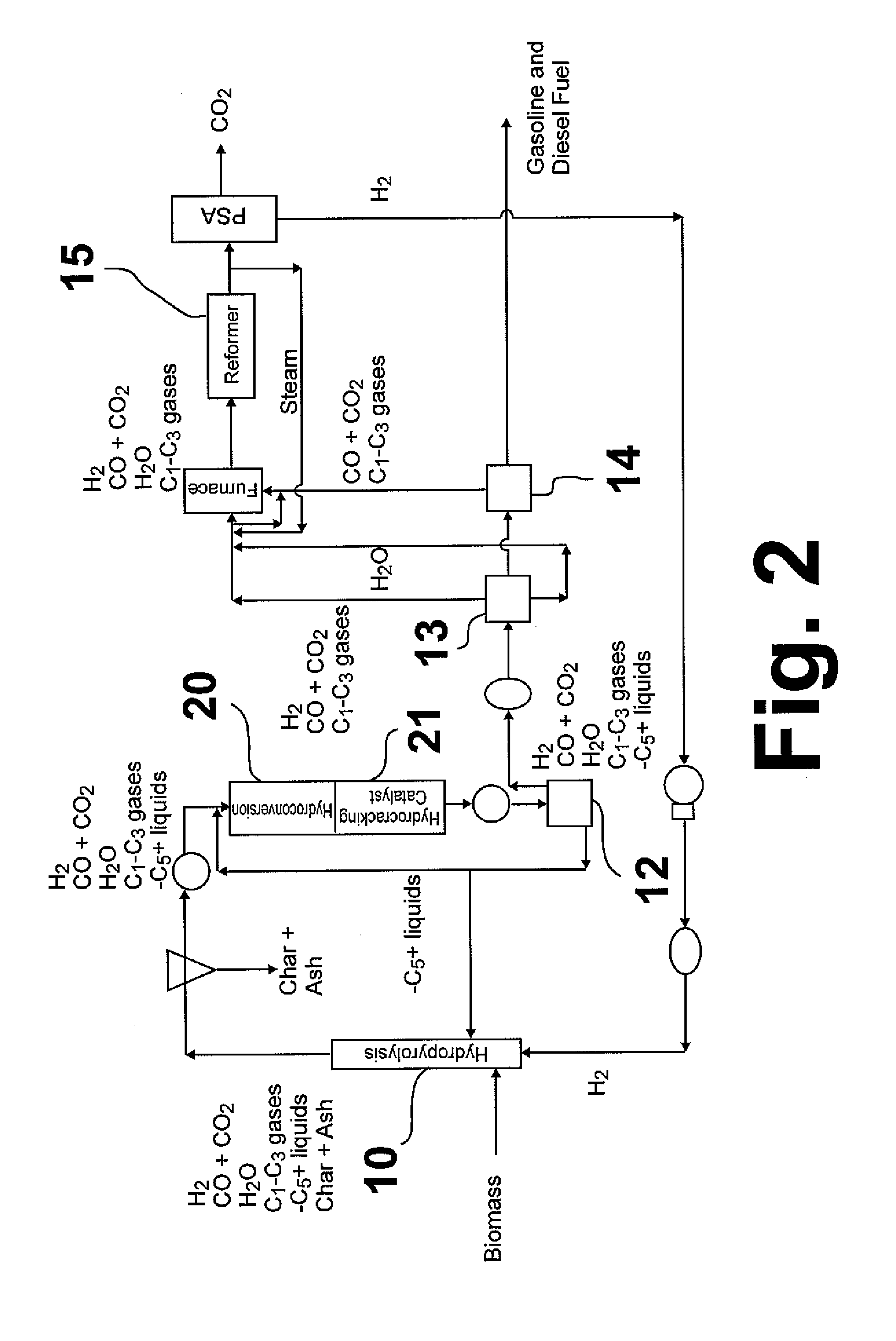

Hydropyrolysis of biomass for producing high quality liquid fuels

A self-sustaining process for producing high quality liquid fuels from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, producing a partially deoxygenated hydropyrolysis liquid, which is hydrogenated using a hydroconversion catalyst, producing a substantially fully deoxygenated hydrocarbon liquid and a gaseous mixture comprising CO and light hydrocarbon gases (C1-C3). The gaseous mixture is reformed in a steam reformer, producing reformed molecular hydrogen, which is then introduced into the reactor vessel for hydropyrolizing the biomass. The deoxygenated hydrocarbon liquid product is further separated to produce diesel fuel, gasoline, or blending components for gasoline and diesel fuel.

Owner:GAS TECH INST

Reforming system for combined cycle plant with partial CO2 capture

A combined cycle system includes, a pre-steam-methane-reformer operating at a temperature of less than about 800 degrees Celsius to reform a mixed fuel stream to generate a first reformate stream, a water-gas-shift reactor to convert carbon monoxide in the first reformate stream to carbon dioxide and form a second reformate stream, a carbon dioxide removal unit for removing carbon dioxide from the second reformate stream and form a carbon dioxide stream and a third reformate stream; wherein less than about 50 percent of the carbon contained in the mixed fuel stream is recovered as carbon dioxide by the removal unit, a gas turbine unit for generating power and an exhaust stream, and a steam generator unit configured to receive the exhaust stream, wherein the heat of the exhaust stream is transferred to a water stream to generate the steam for the mixed fuel stream and for a steam turbine.

Owner:GENERAL ELECTRIC CO

Process and Apparatus for the Separation of Methane from a Gas Stream

InactiveUS20090260287A1Combustible gas chemical modificationHydrogen separation using liquid contactHydrogenWater vapor

Processes for conversion of a carbonaceous composition into a gas stream comprising methane are provided, where an energy-efficient process and / or apparatus is used to separate methane out of a gas stream comprising methane, carbon monoxide, and hydrogen. Particularly, methane can be separated from hydrogen and carbon monoxide using novel processes and / or apparatuses that generate methane hydrates. Because hydrogen and carbon monoxide do not readily form hydrates, the methane is separated from a gas stream. The methane can be captured as a substantially pure stream of methane gas by dissociating the methane from the hydrate and separating out any residual water vapor.

Owner:SURE CHAMPION INVESTMENT LTD

Fuel cartridges for fuel cells and methods for making same

Fuel supplies for fuel cells are disclosed. The fuel supplies can be a pressurized or non-pressurized cartridge that can be used with any fuel cells, including but not limited to, direct methanol fuel cell or reformer fuel cell. In one aspect, a fuel supply may contain a reaction chamber to convert fuel to hydrogen. The fuel supplies may also contain a pump. The fuel supply may have a valve connecting the fuel to the fuel cell, and a vent to vent gas from the fuel supply. Methods for forming various fuel supplies are also disclosed.

Owner:INTELLIGENT ENERGY LTD

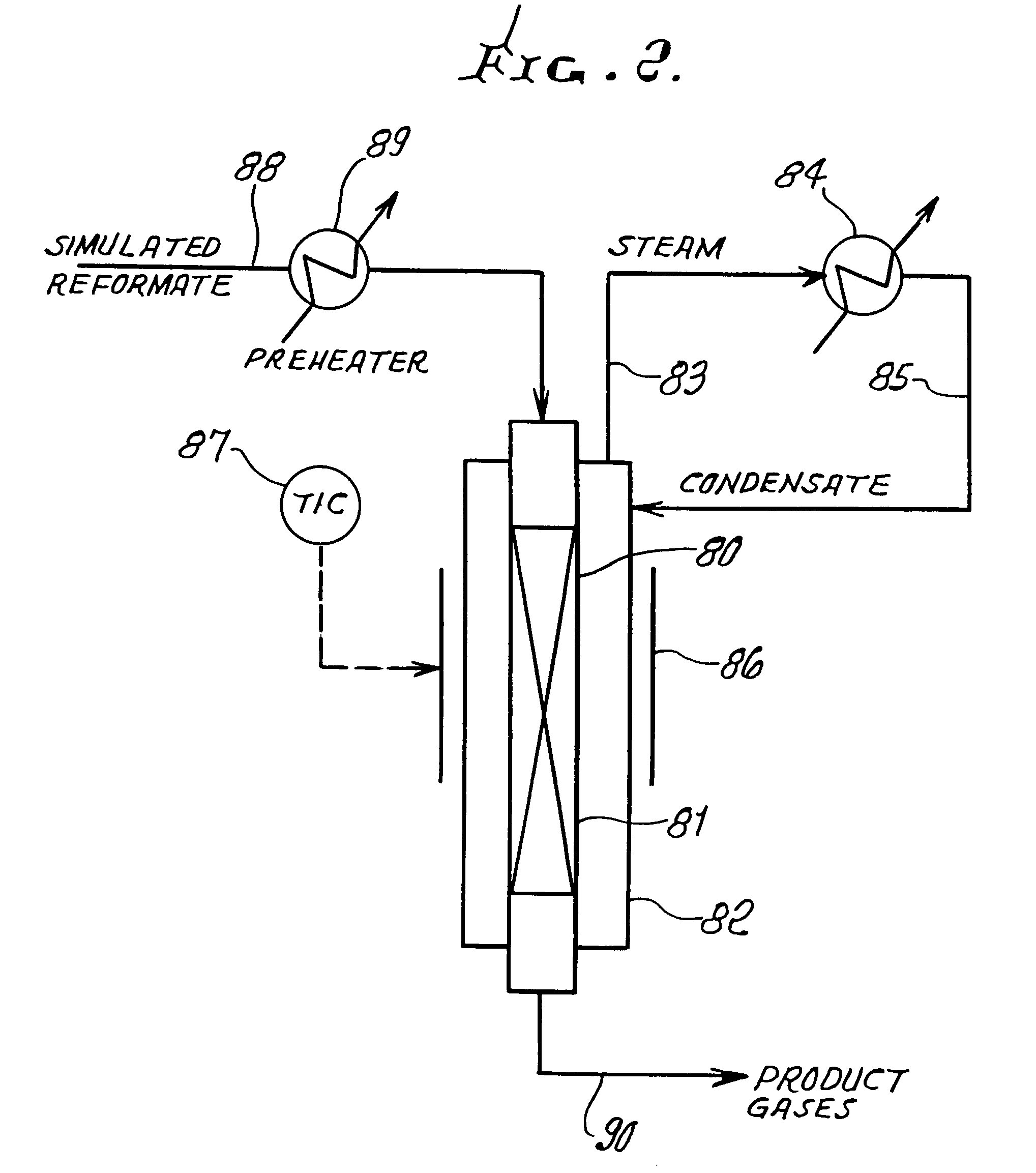

Thermally-integrated low temperature water-gas shift reactor apparatus and process

InactiveUS7074373B1Reduced toleranceExtended temperature rangeHydrogenPhysical/chemical process catalystsWater-gas shift reactionProduct gas

A thermally-integrated lower temperature water-gas shift reactor apparatus for converting carbon monoxide in the presence steam comprises a catalyst bed that is disposed within an outer region surrounding a waste heat recovery steam generator operating at a selected pressure corresponding to the optimum temperature for conducting the catalytic water-gas shift reaction and a process for useful recovery of the exothermic heat of reaction to generate steam that is used in a process for the conversion of hydrocarbon feedstock into useful gases such as hydrogen.

Owner:HARVEST ENERGY TECH

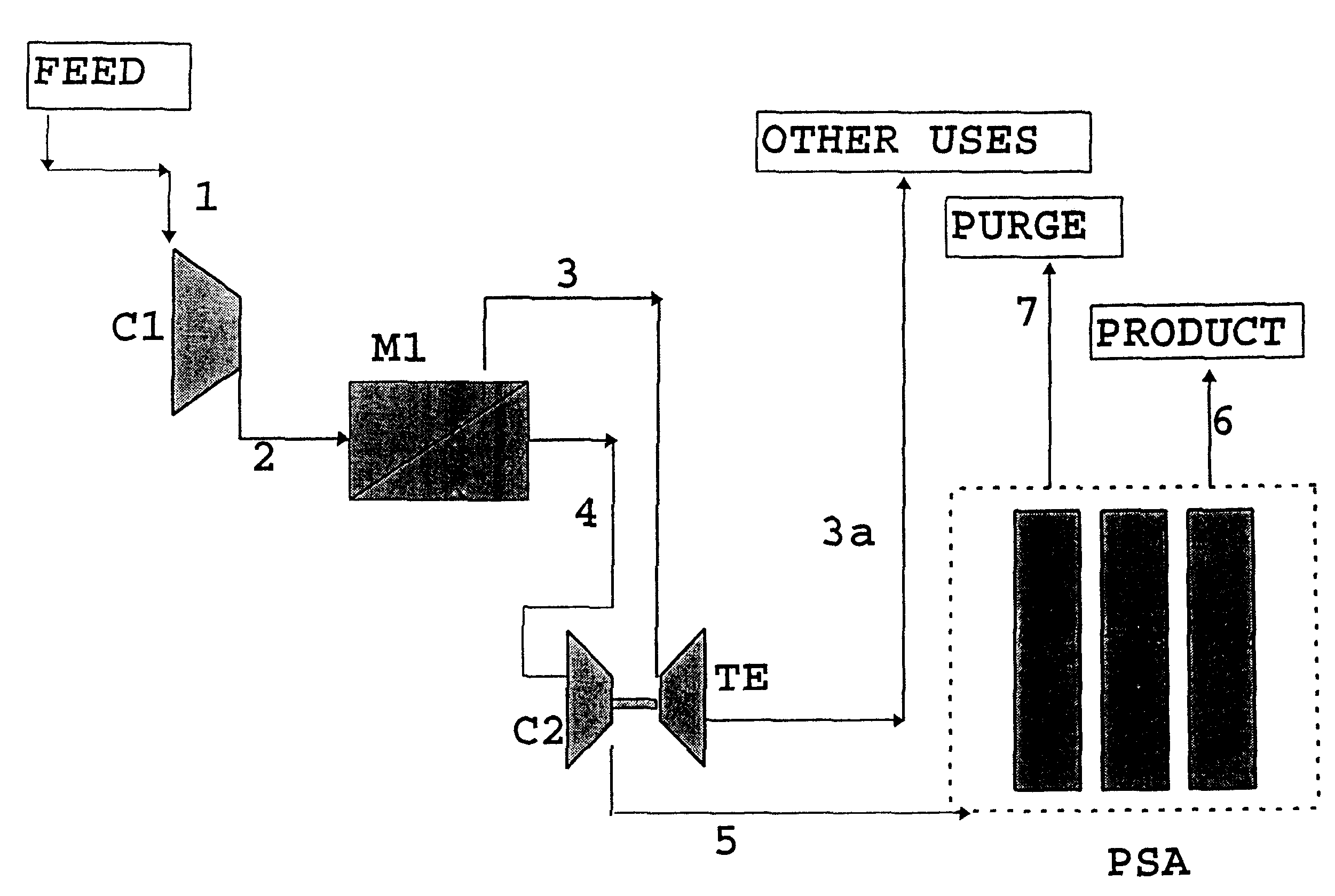

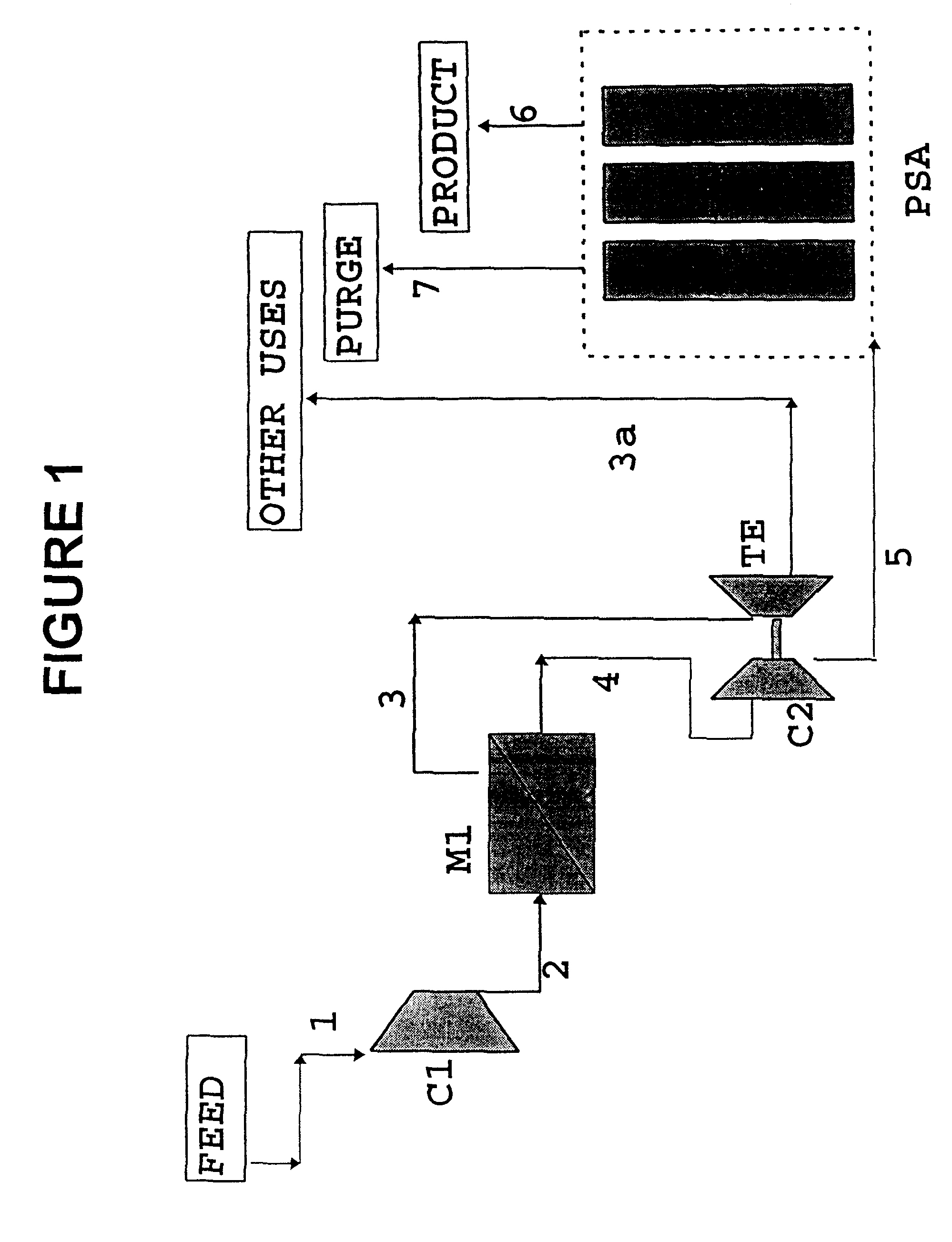

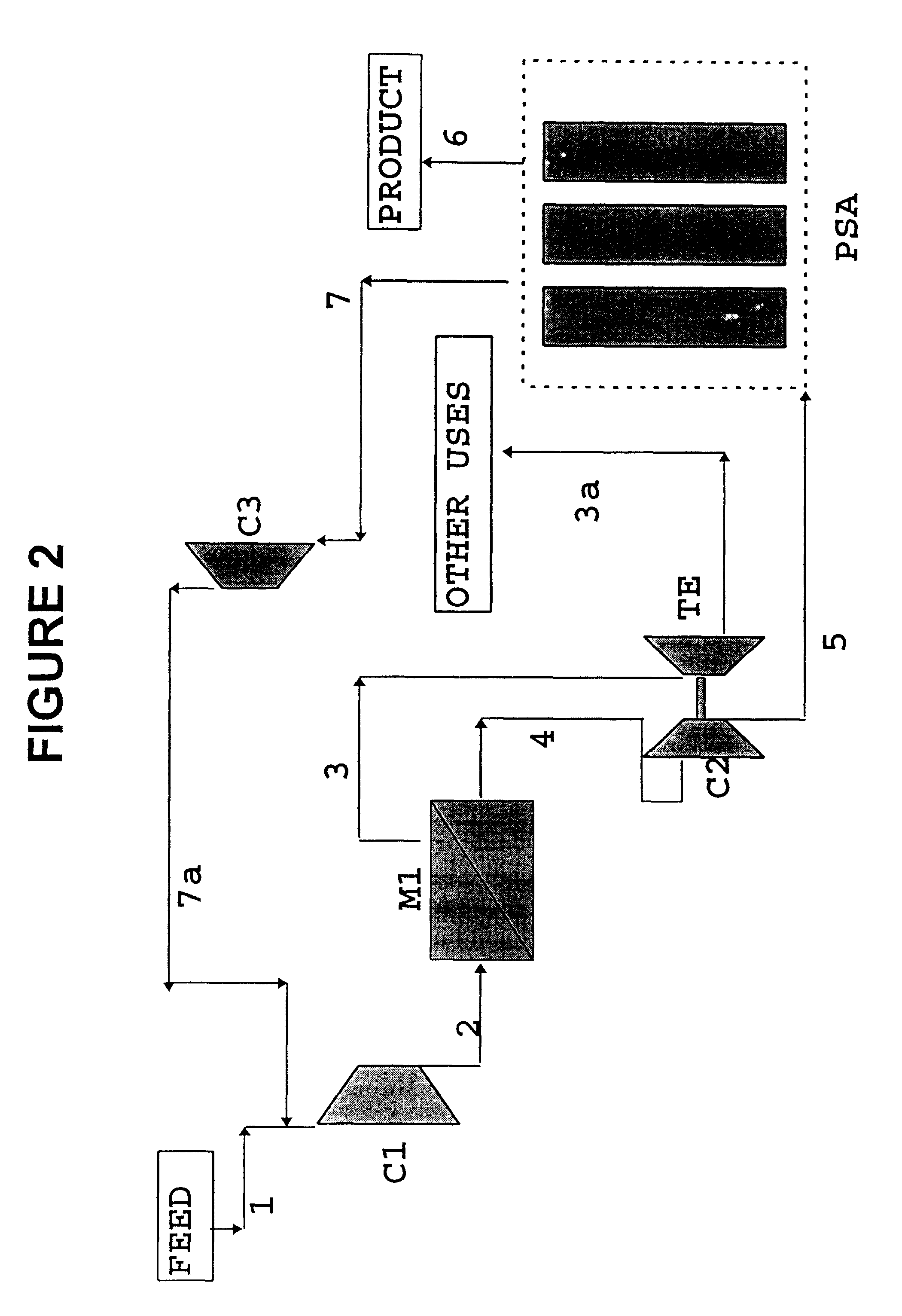

Process for the separation/recovery of gases

InactiveUS6179900B1Low costHigh purityNitrogen purification/separationGas treatmentHydrogenHigh pressure

A process for the separation / recovery of gases is described where the desired component to be separated from the gaseous mixture is present in low / very low molar amount and / or low / moderate pressure, the process comprising contacting the gaseous mixture with a separation membrane unit containing high permeability / medium selectivity membranes which separate the feed stream into a permeate stream, enriched in the desired component and at a lower pressure and a retentate stream lean in the desired component and at a higher pressure. The retentate stream is made to convey its pressure to the permeate stream which then is directed to an adsorption PSA unit for further purification of the permeate stream so that the effluent stream from the PSA unit which contains the purified component has a purity of up to 99.90%. The process is useful for separating hydrogen from refinery off gases such as FCC gases and can also be applied to other gases such as helium and any other valuable gases present in gaseous streams in low to very low molar contents and low to moderate pressures.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH +1

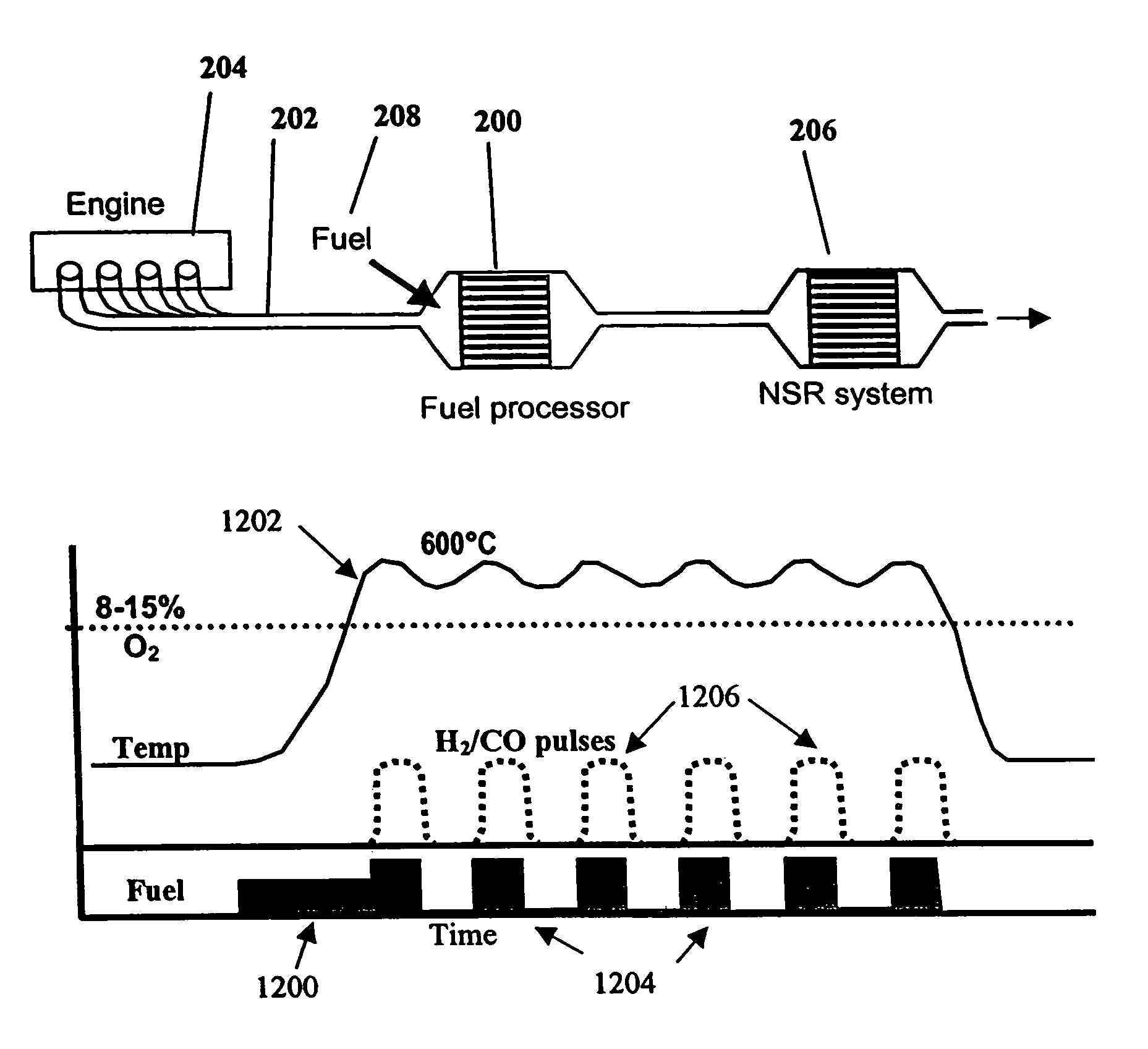

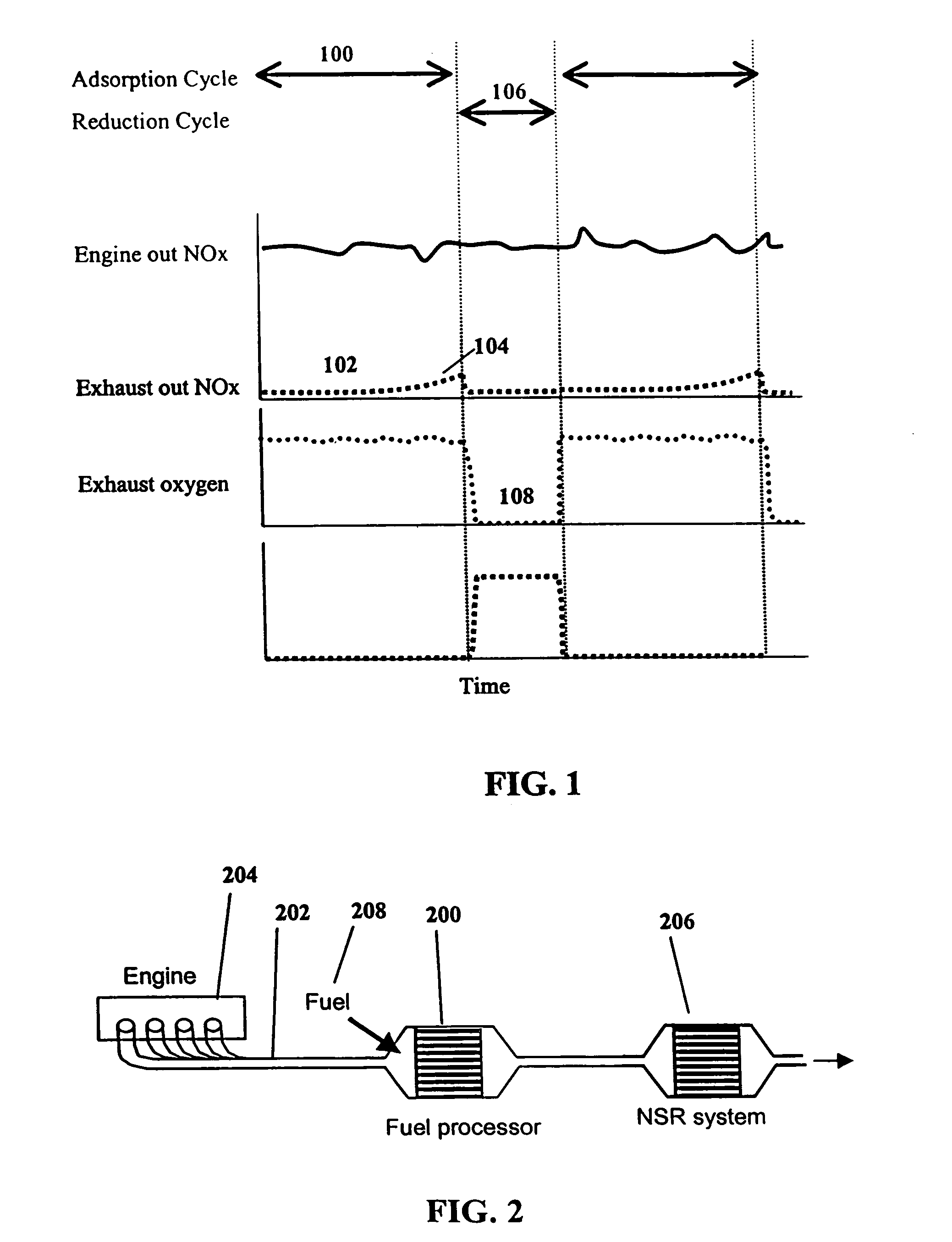

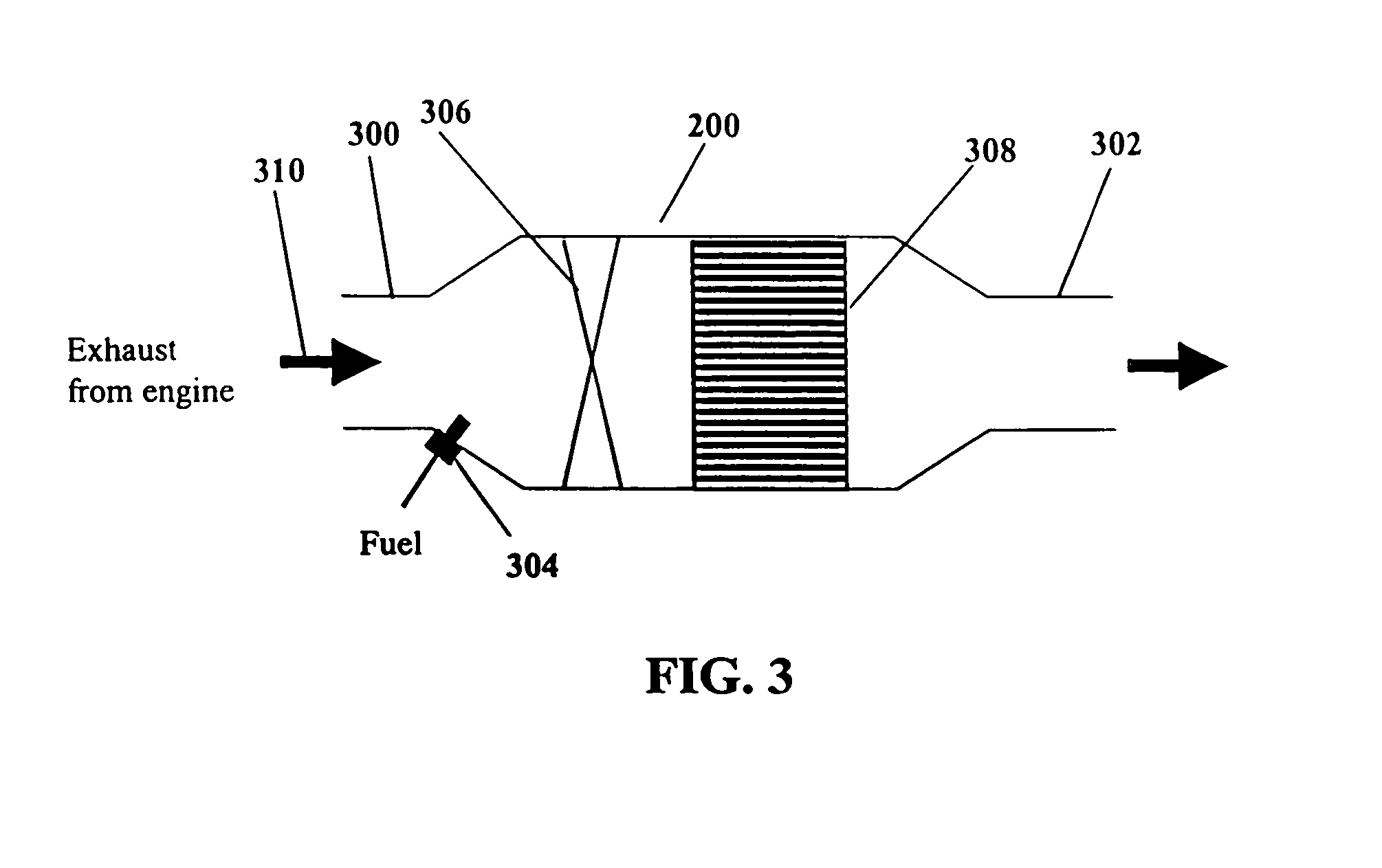

System and methods for improved emission control of internal combustion engines using pulsed fuel flow

InactiveUS7082753B2Save oilReducing greenhouse gas emissionExhaust apparatusCombustion enginesPartial oxidationExternal combustion engine

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction (“NSR”) emission control systems. The system generally includes a NSR catalyst, a fuel processor located upstream of the NSR catalyst, and at least one fuel injection port. The fuel processor converts a fuel into a reducing gas mixture comprising CO and H2. The reducing gas mixture is then fed into the NSR catalyst, where it regenerates the NSR adsorbent, reduces the NOx to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor generally includes one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration using pulsed fuel flow. Control strategies are also provided.

Owner:INT ENGINE INTPROP CO LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com