Patents

Literature

299results about "Hydrocarbon by dehydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

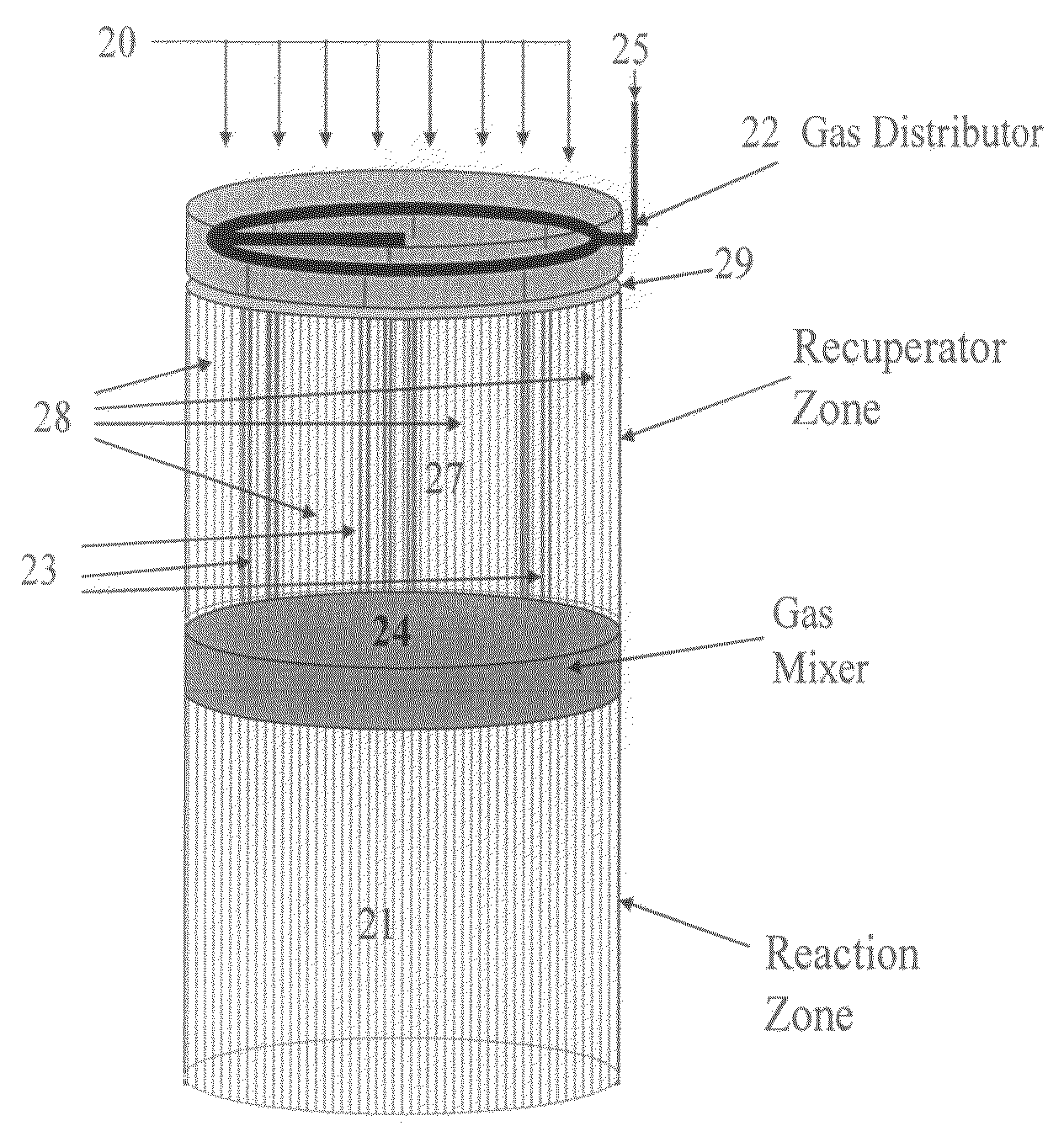

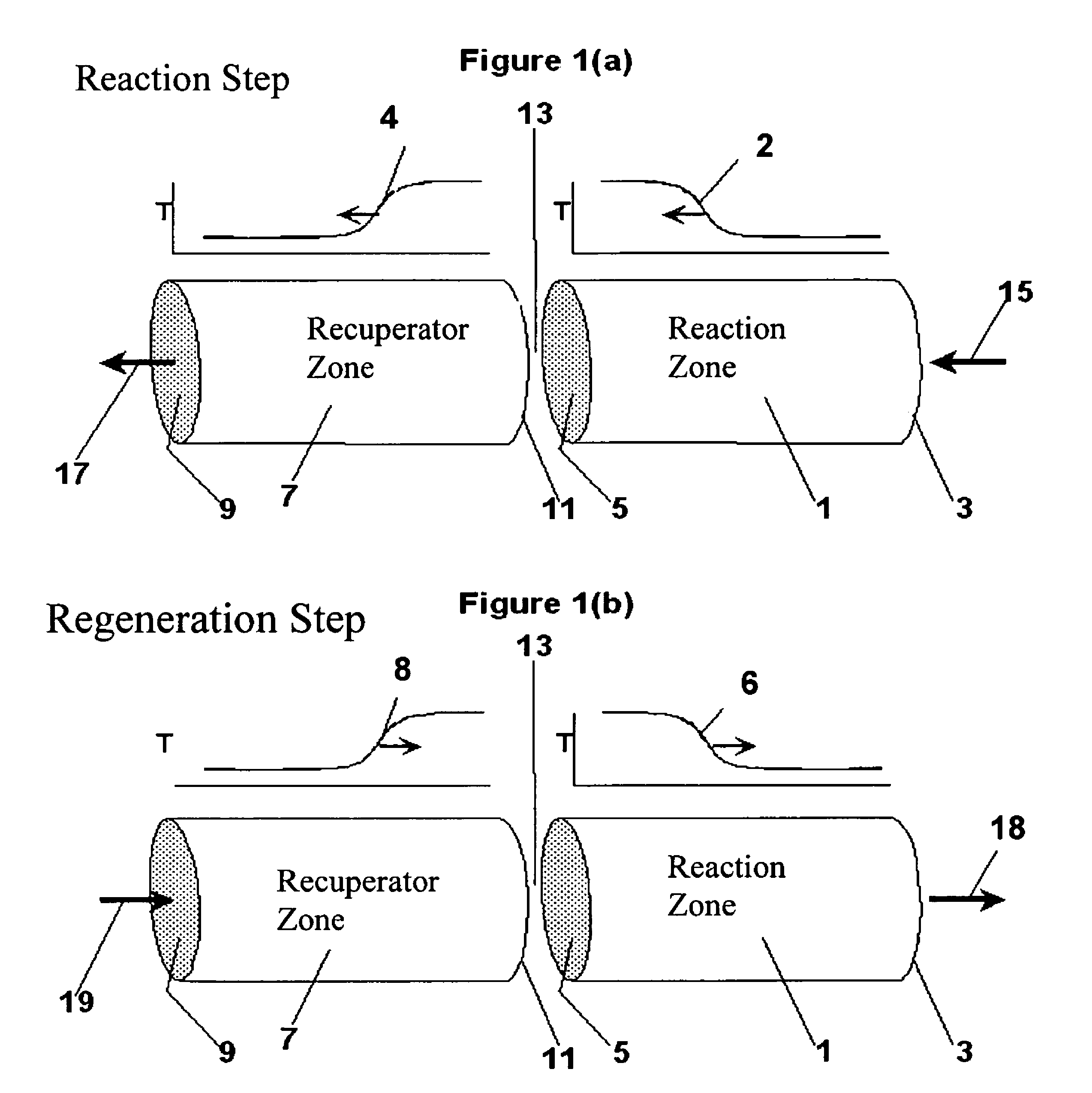

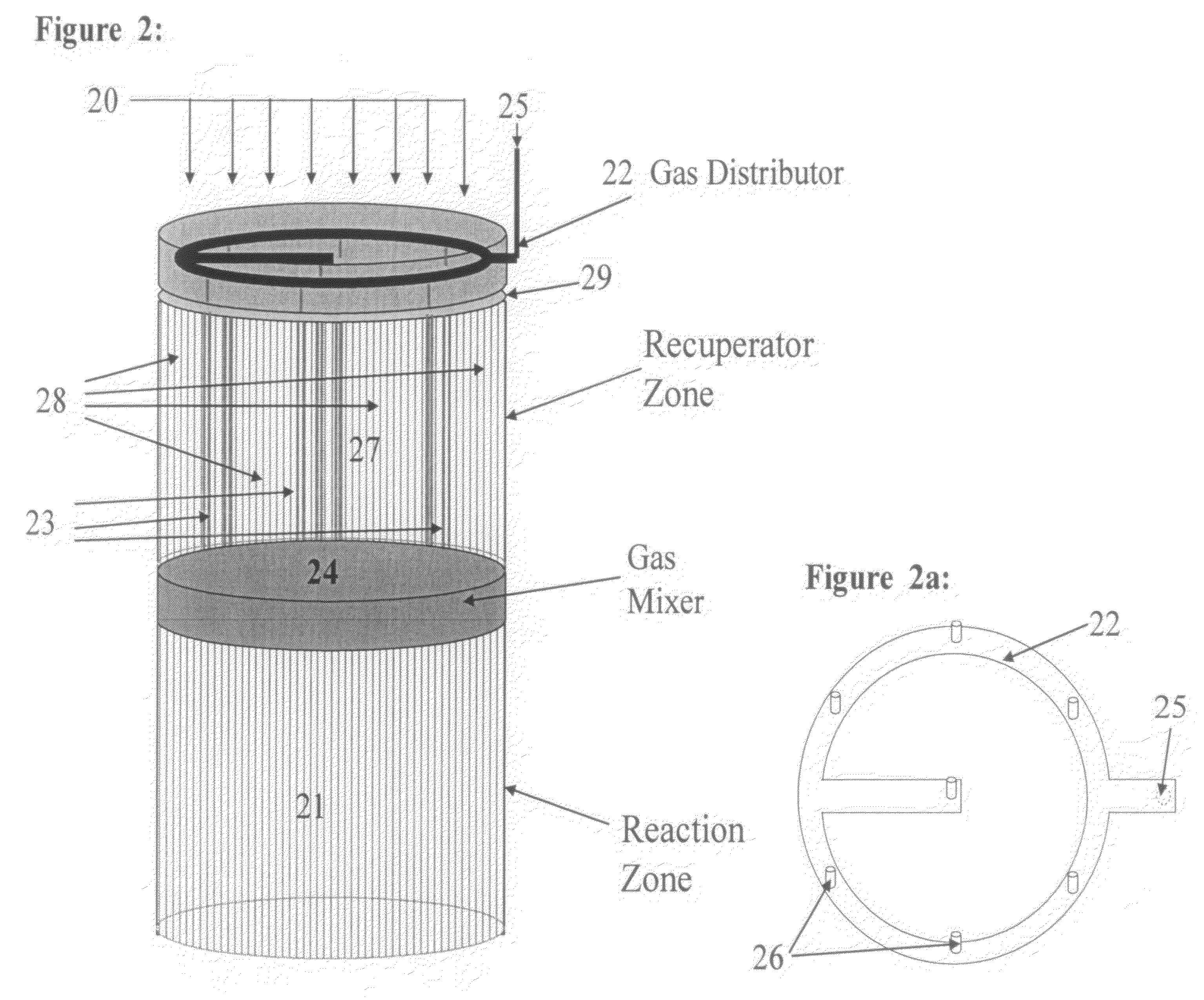

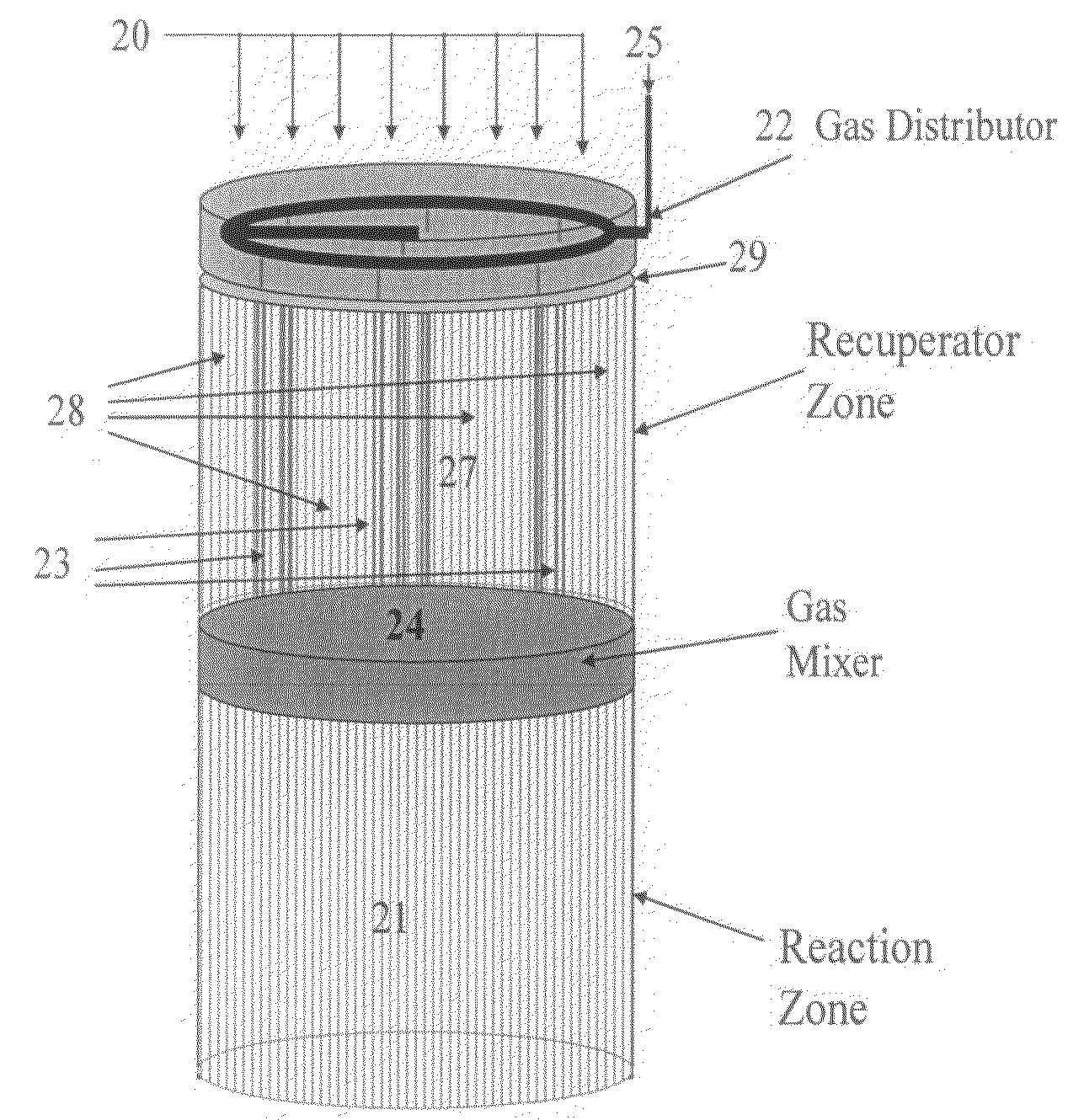

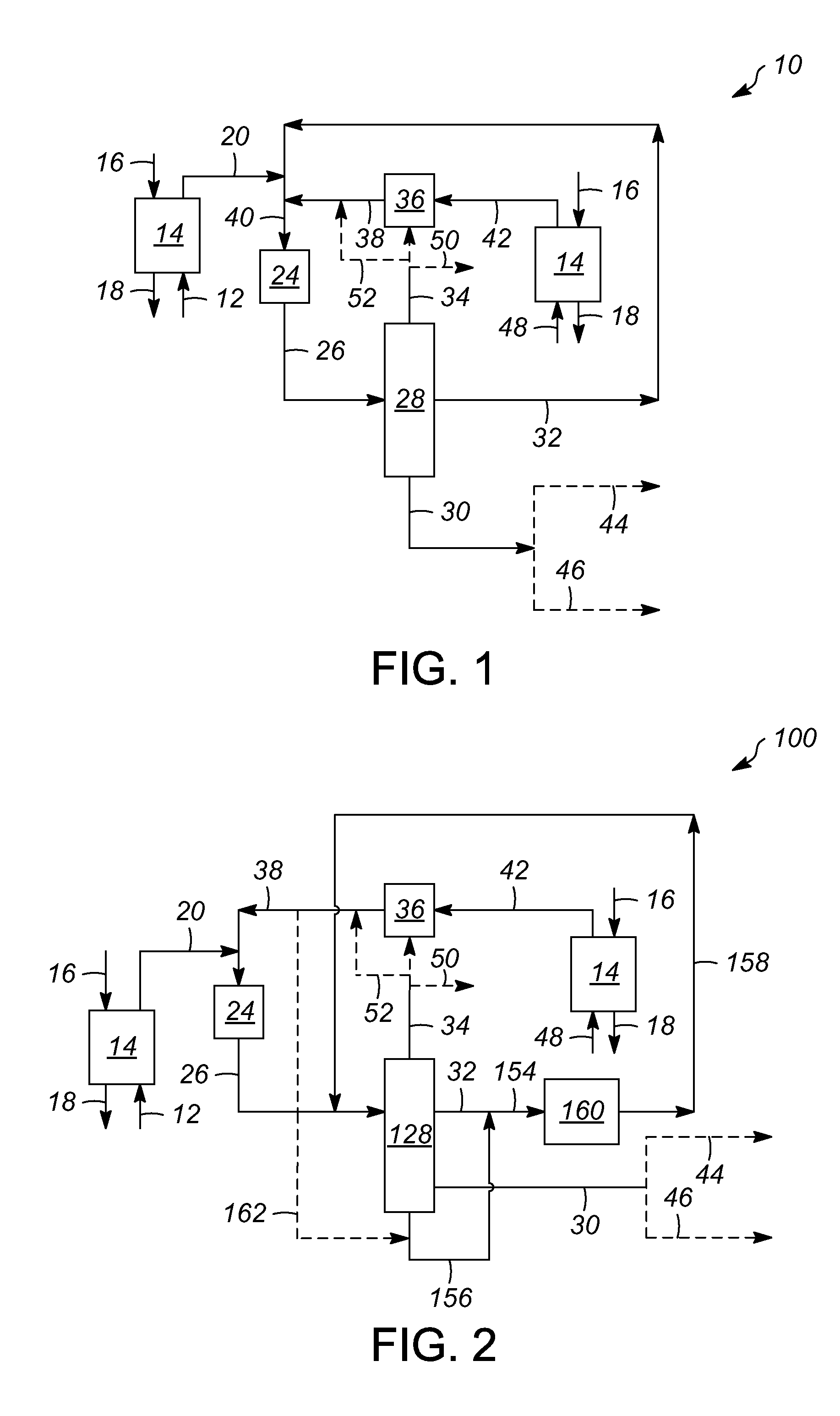

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

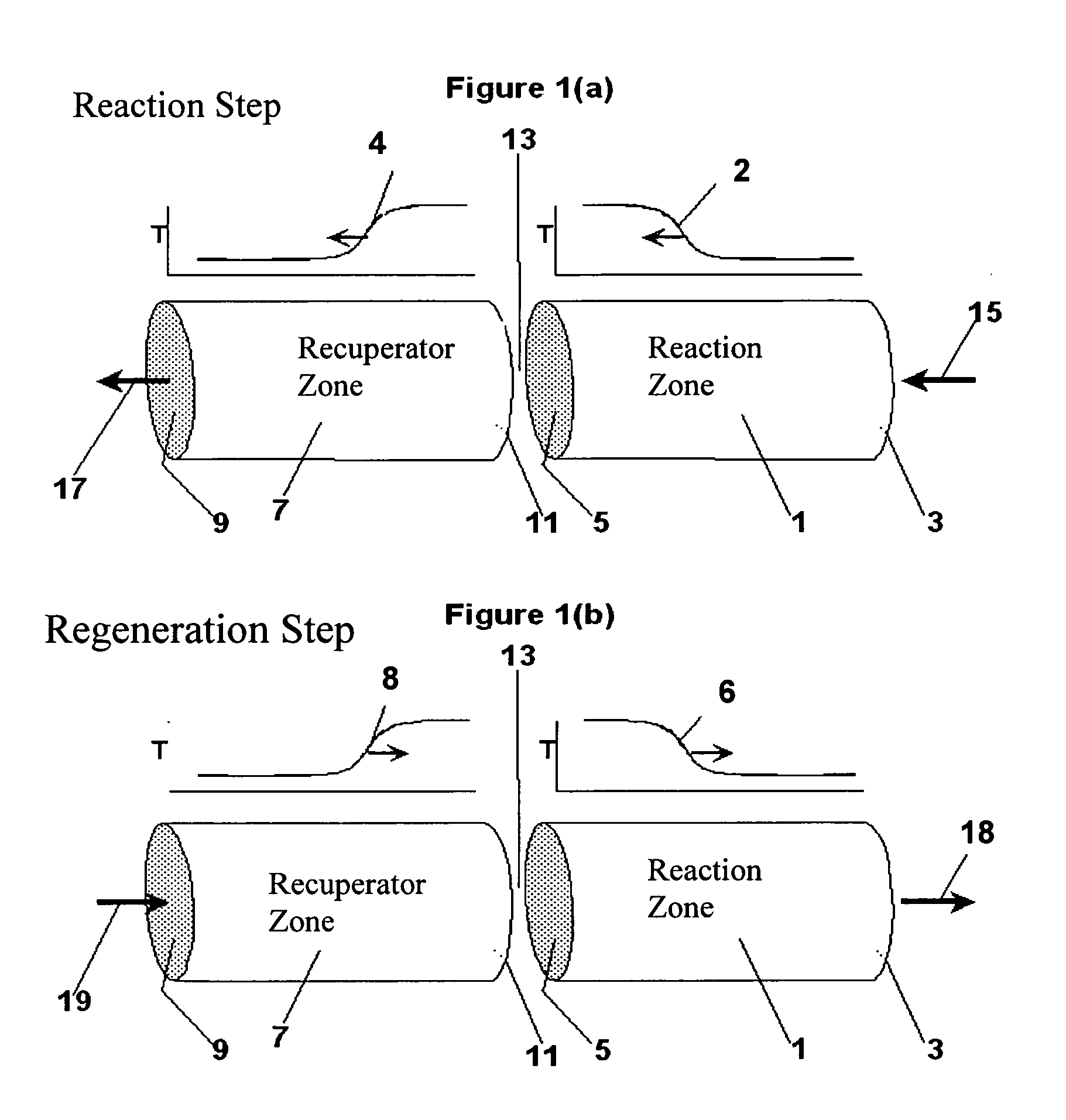

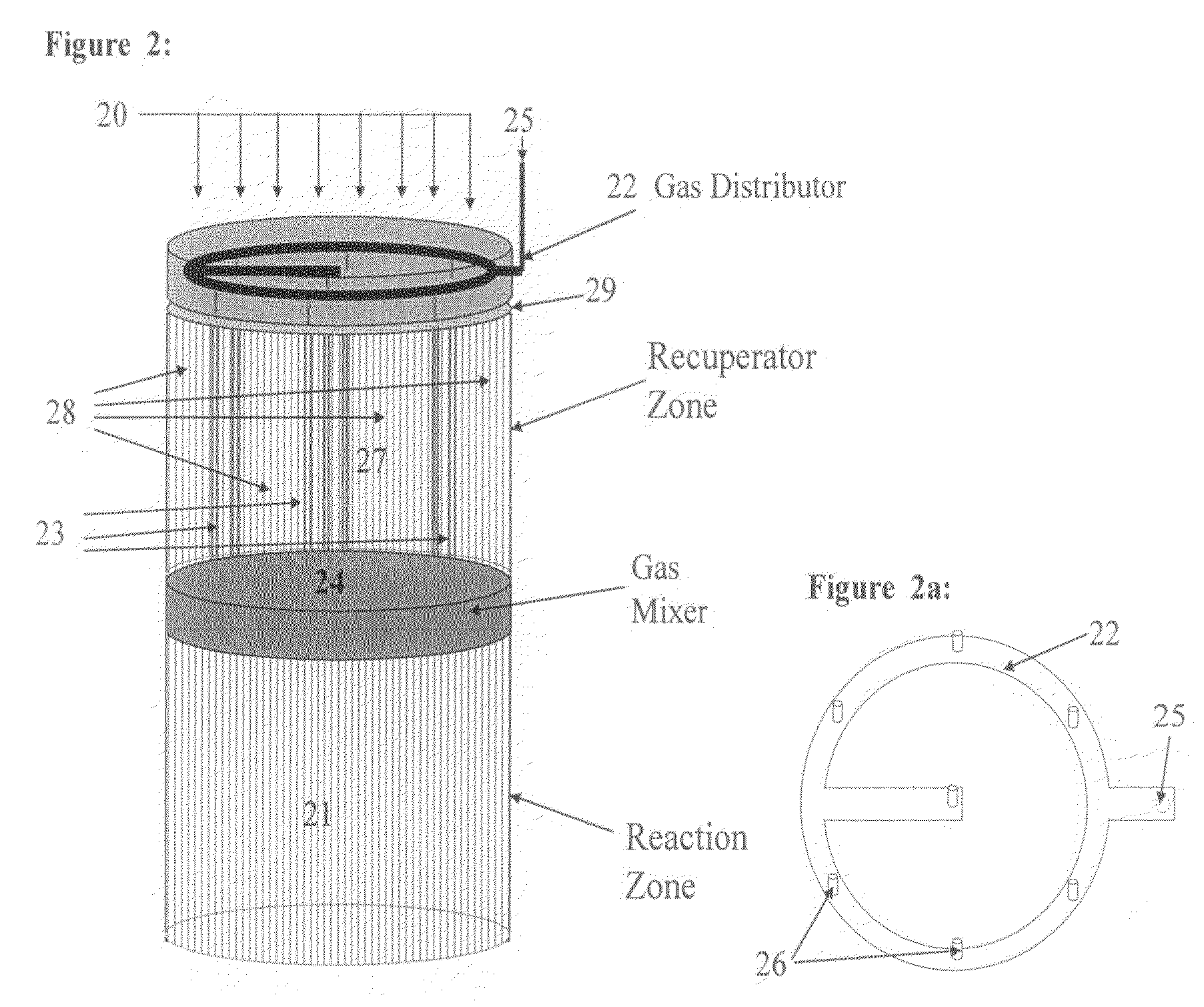

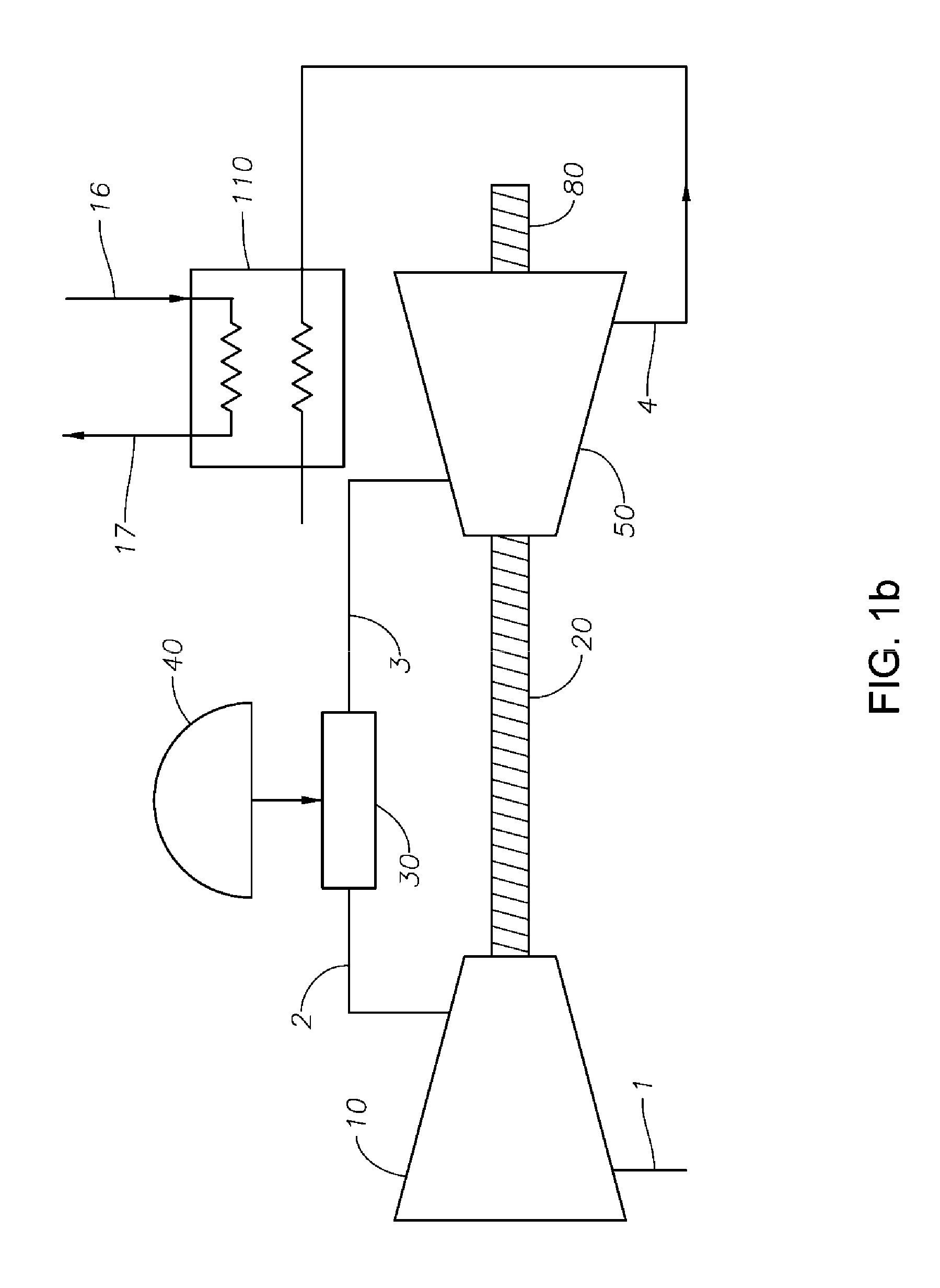

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

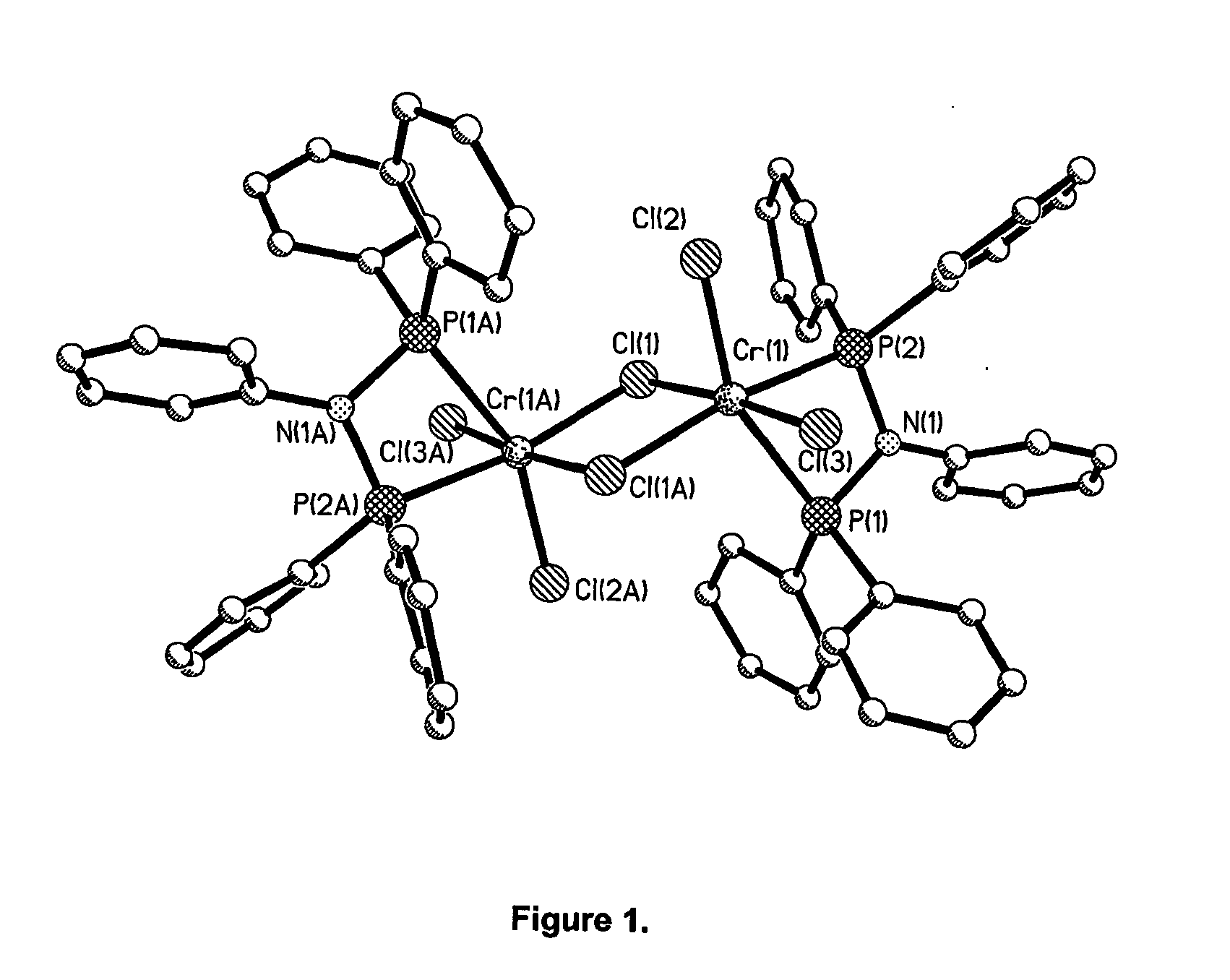

Tetramerization of olefins

ActiveUS20060229480A1Stabilise the catalyst systemImprove catalytic performanceHydrocarbon by dehydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsAlkeneTetramer

The invention describes a process for tetramerisation of olefins wherein the product stream of the process contains more than 30% of the tetramer olefin. The process includes the step of contacting an olefinic feedstream with a catalyst system containing a transition metal compound and a heteroatomic ligand.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

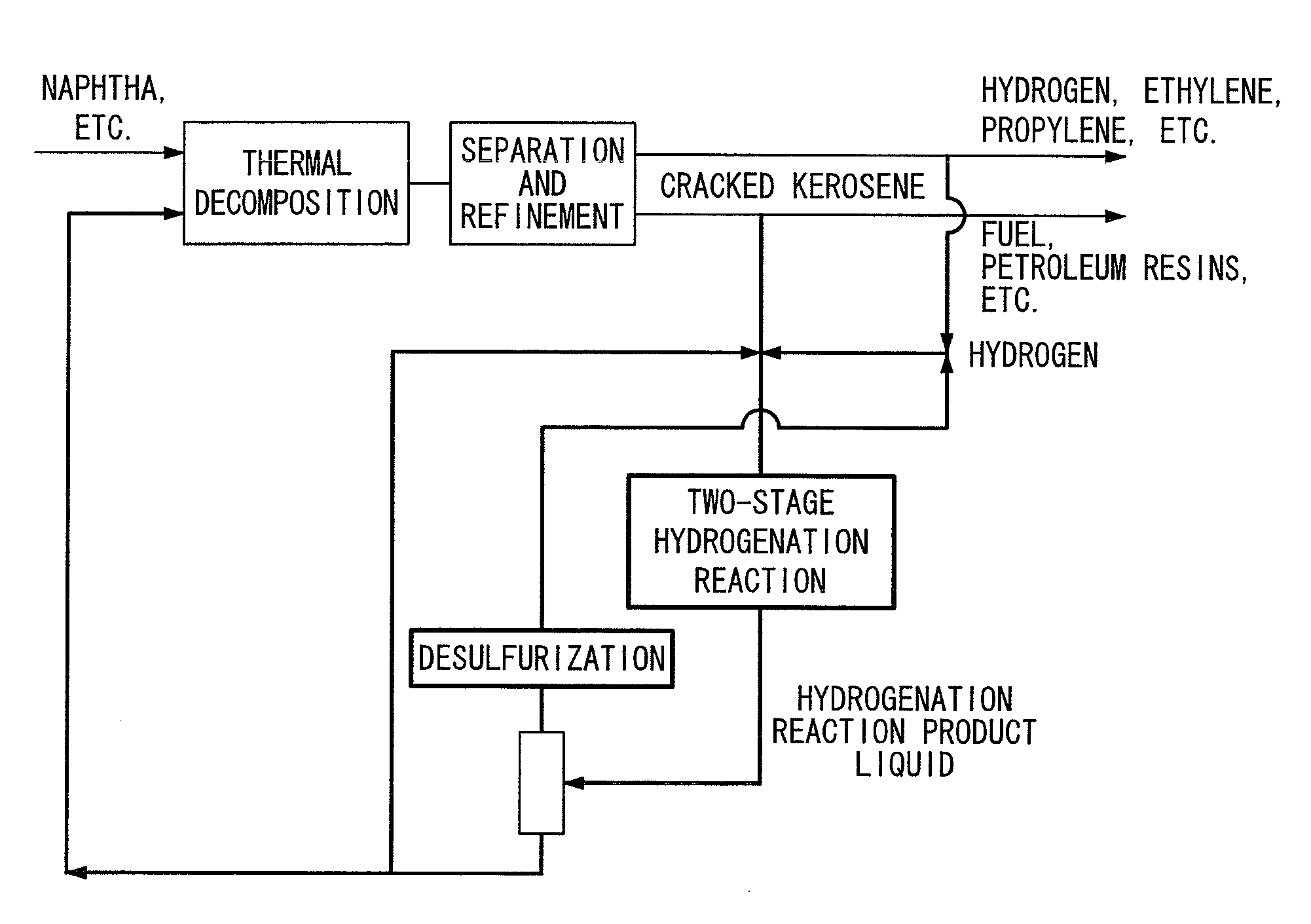

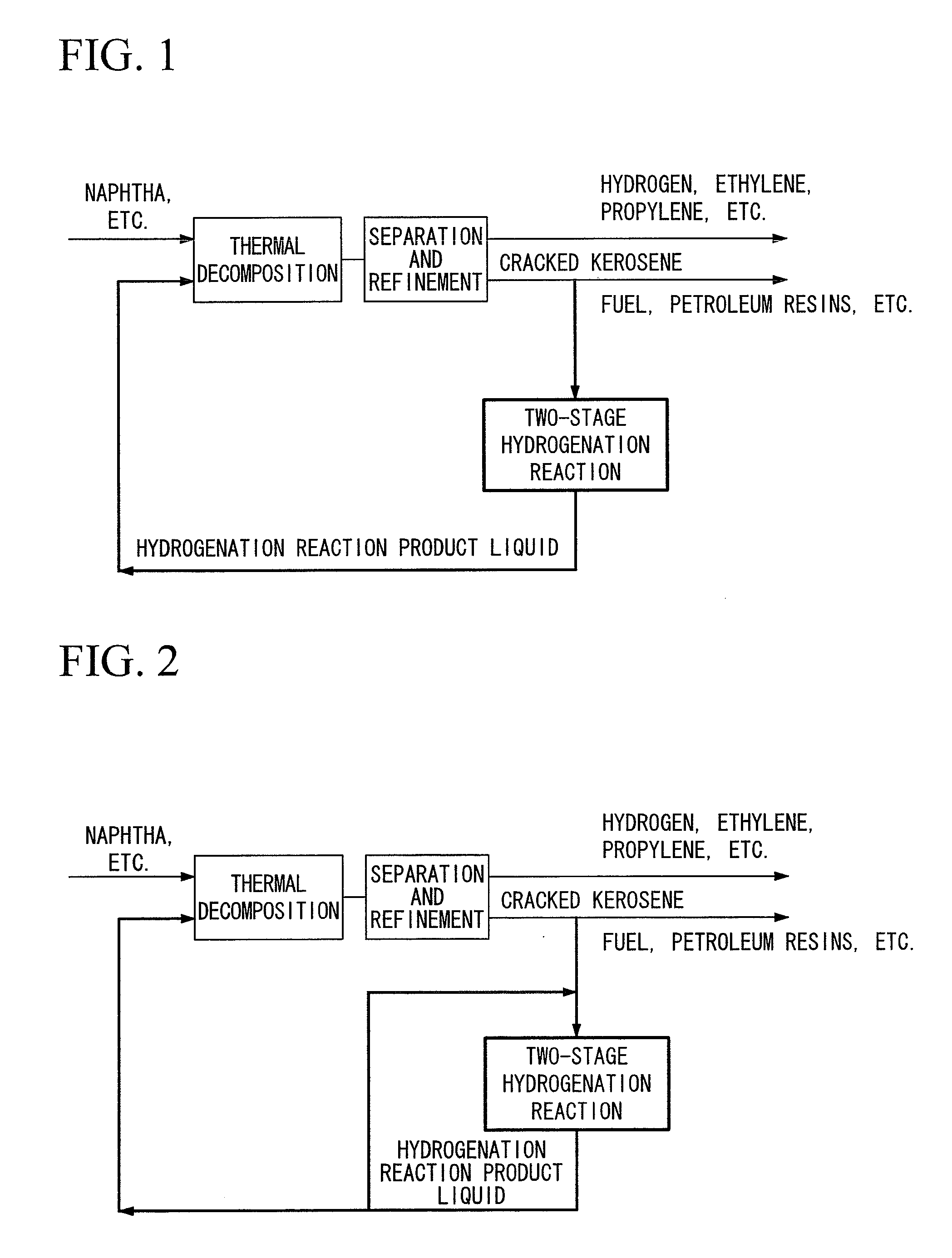

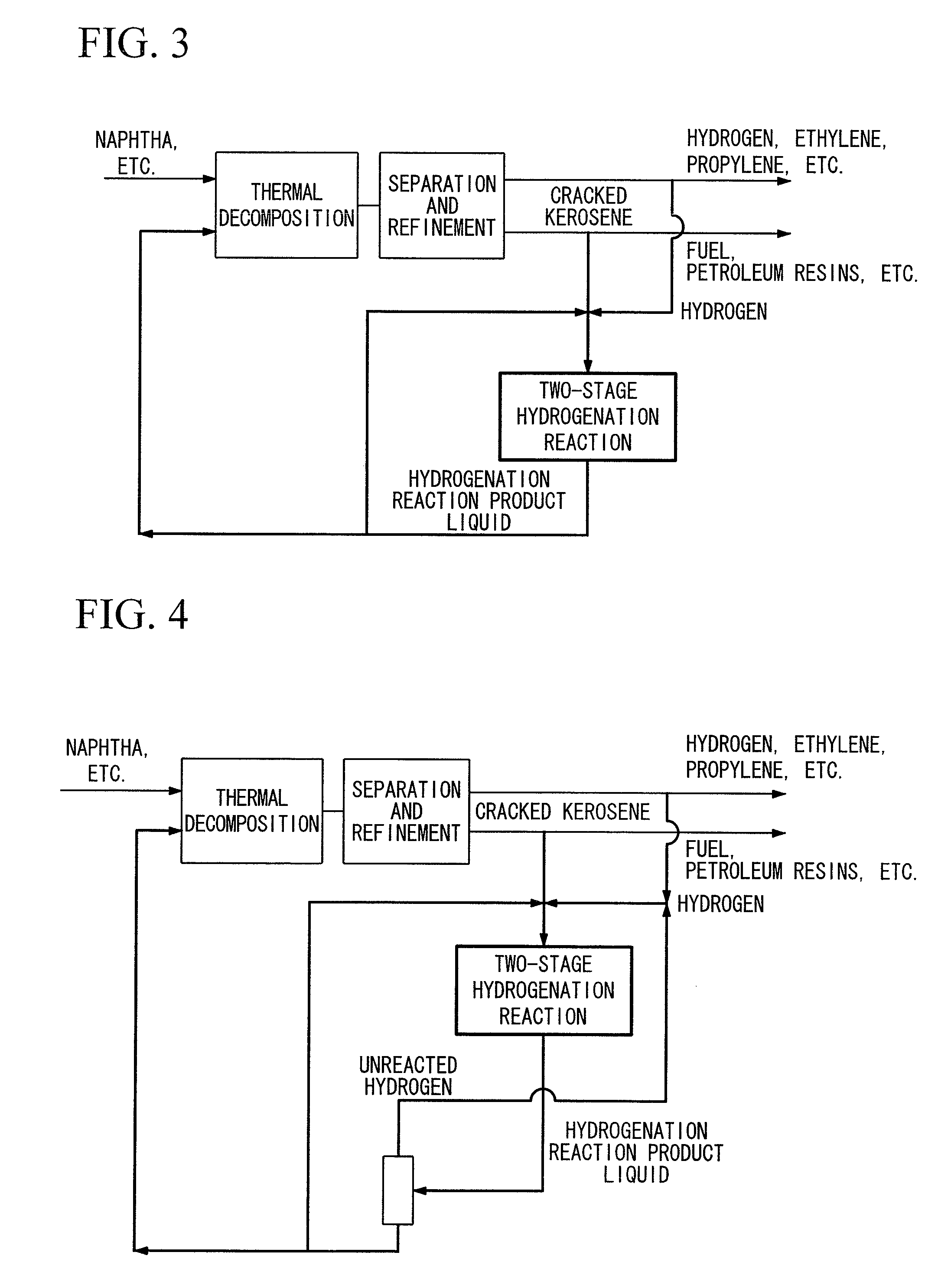

Hydrogenation method and petrochemical process

InactiveUS20100087692A1Long catalyst lifeHigh yieldThermal non-catalytic crackingHydrocarbon by dehydrogenationBenzeneNaphtha

The present invention provides a hydrogenation method capable of converting cracked kerosene into the raw materials for petrochemical cracking having a high thermal decomposition yield by a hydrogenation reaction. The present invention is a petrochemical process for producing at least any of ethylene, propylene, butane, benzene or toluene by carrying out a thermal decomposition reaction at least using naphtha for the main raw material, wherein cracked kerosene produced from a thermal cracking furnace is hydrogenated using a Pd or Pt catalyst in a two-stage method consisting of a first stage (I), in which a hydrogenation reaction is carried out within the range of 50 to 180° C., and a second stage (II), in which a hydrogenation reaction is carried out within the range of 230 to 350° C., followed by re-supplying all or a portion of these hydrogenated hydrocarbons to a thermal cracking furnace.

Owner:SHOWA DENKO KK

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS20080142409A1Efficiently transfer heatEfficient transferHydrocarbon by dehydrogenationFlow mixersExothermic reactionProcess engineering

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

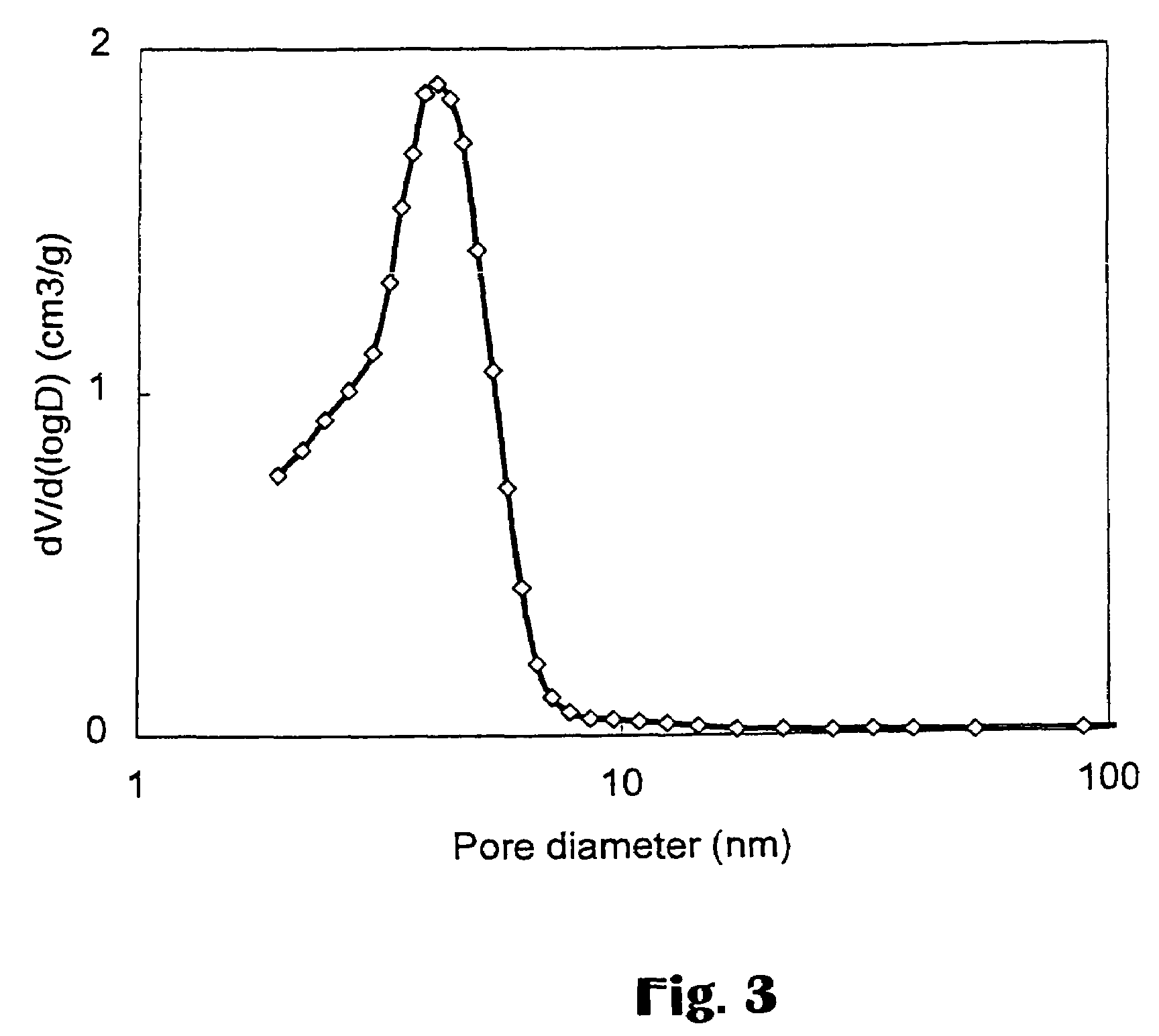

Process for oligomerizing olefins using a silica-alumina based catalyst

ActiveUS20060063955A1Hydrocarbon by dehydrogenationLiquid hydrocarbon mixtures productionChemistryAluminium

An olefin oligomerization process employs a particular silica-alumina catalyst which comprises a non zeolitic support based on silica-alumina containing a quantity of more than 5% by weight and 95% by weight or less of silica (SiO2) and has the following characteristics: a mean pore diameter, measured by mercury porosimetry, in the range 20 to 140 Å; a total pore volume, measured by mercury porosimetry, in the range 0.1 ml / g to 0.6 ml / g; a total pore volume, measured by nitrogen porosimetry, in the range 0.1 ml / g to 0.6 ml / g; a BET specific surface area in the range 100 to 550 m2 / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 140 Å, of less than 0.1 ml / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 160 Å, of less than 0.1 ml / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 200 Å, of less than 0.1 ml / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 500 Å, of less than 0.1 ml / g; and an X ray diffraction diagram containing at least the principal characteristic peaks of at least one of the transition aluminas included in the group composed of alpha, rho, khi, eta, gamma, kappa, theta and delta aluminas.

Owner:INST FR DU PETROLE

Hydrocarbon Conversion

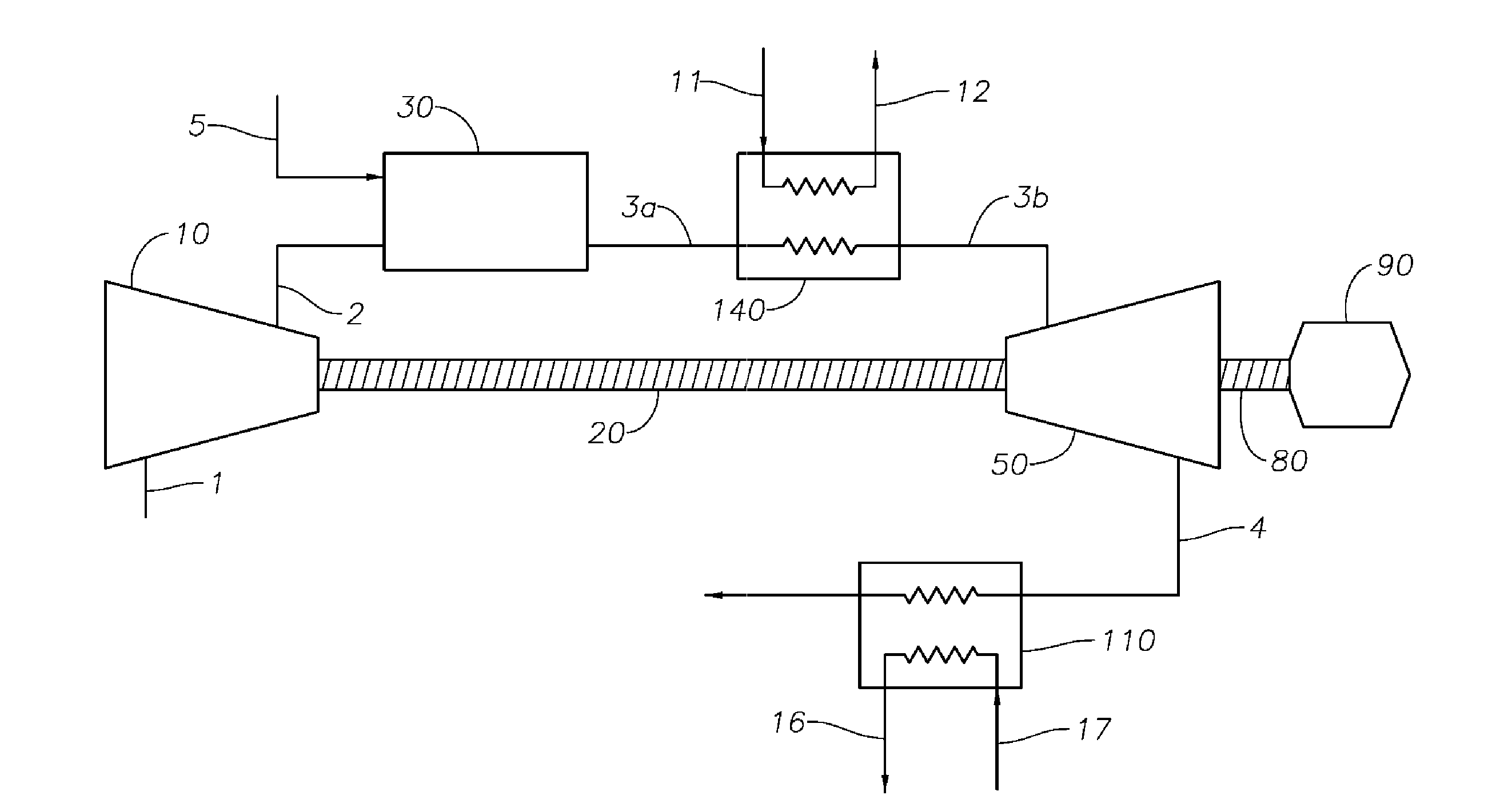

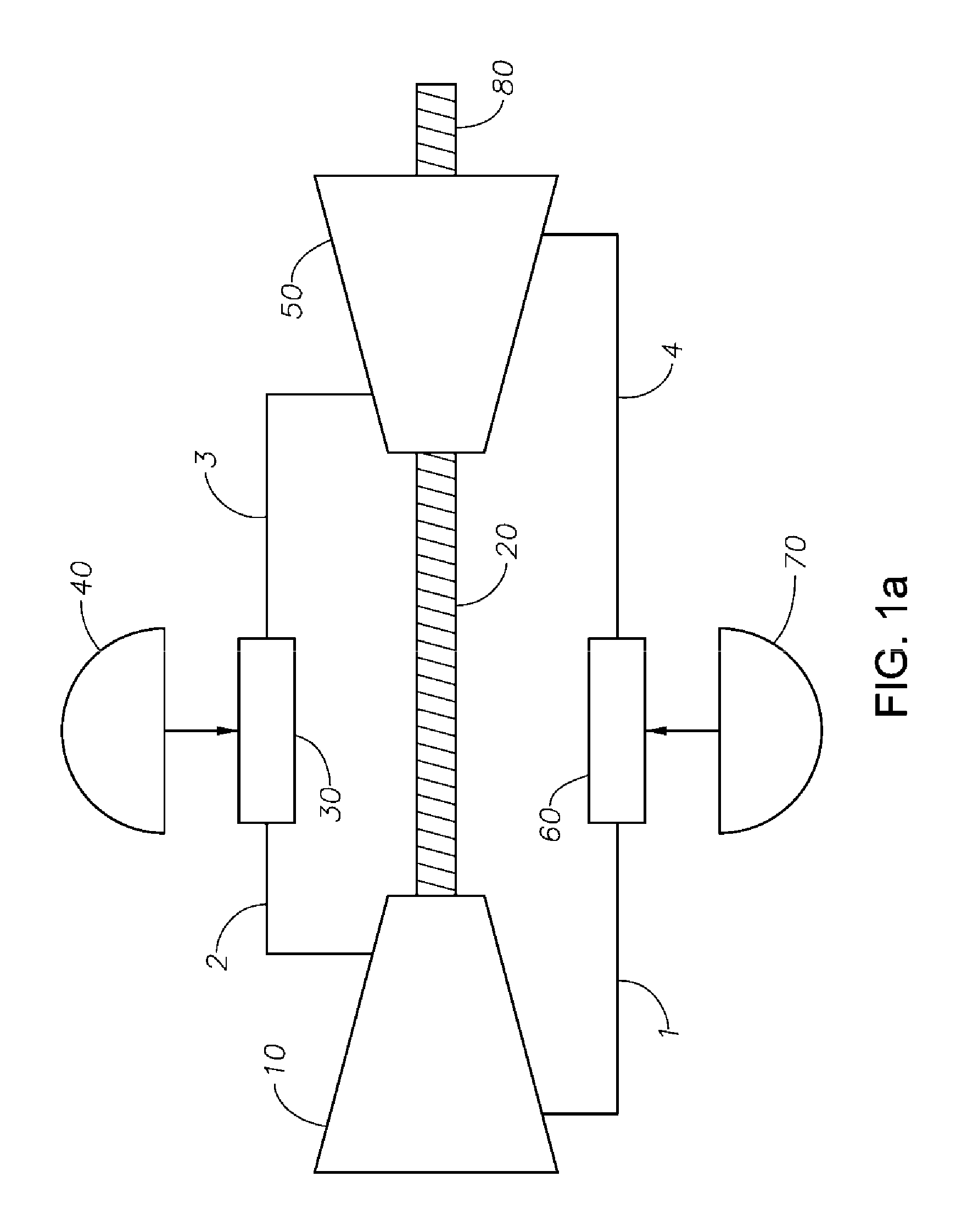

The invention relates to hydrocarbon conversion processes, to equipment useful in such processes, to the products of such hydrocarbon conversion processes and the use thereof, and to the use of energy derived from such processes.

Owner:EXXONMOBIL CHEM PAT INC

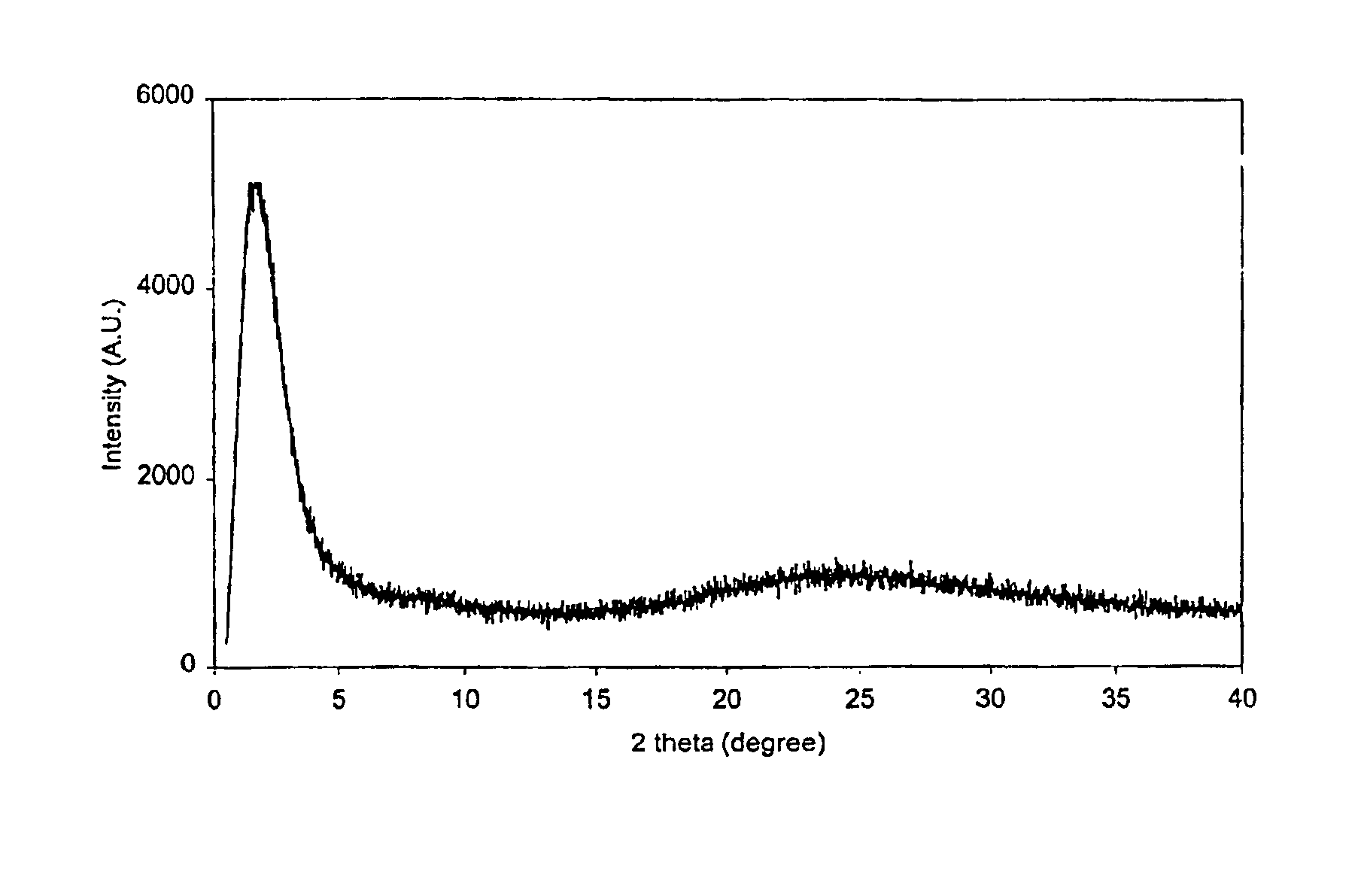

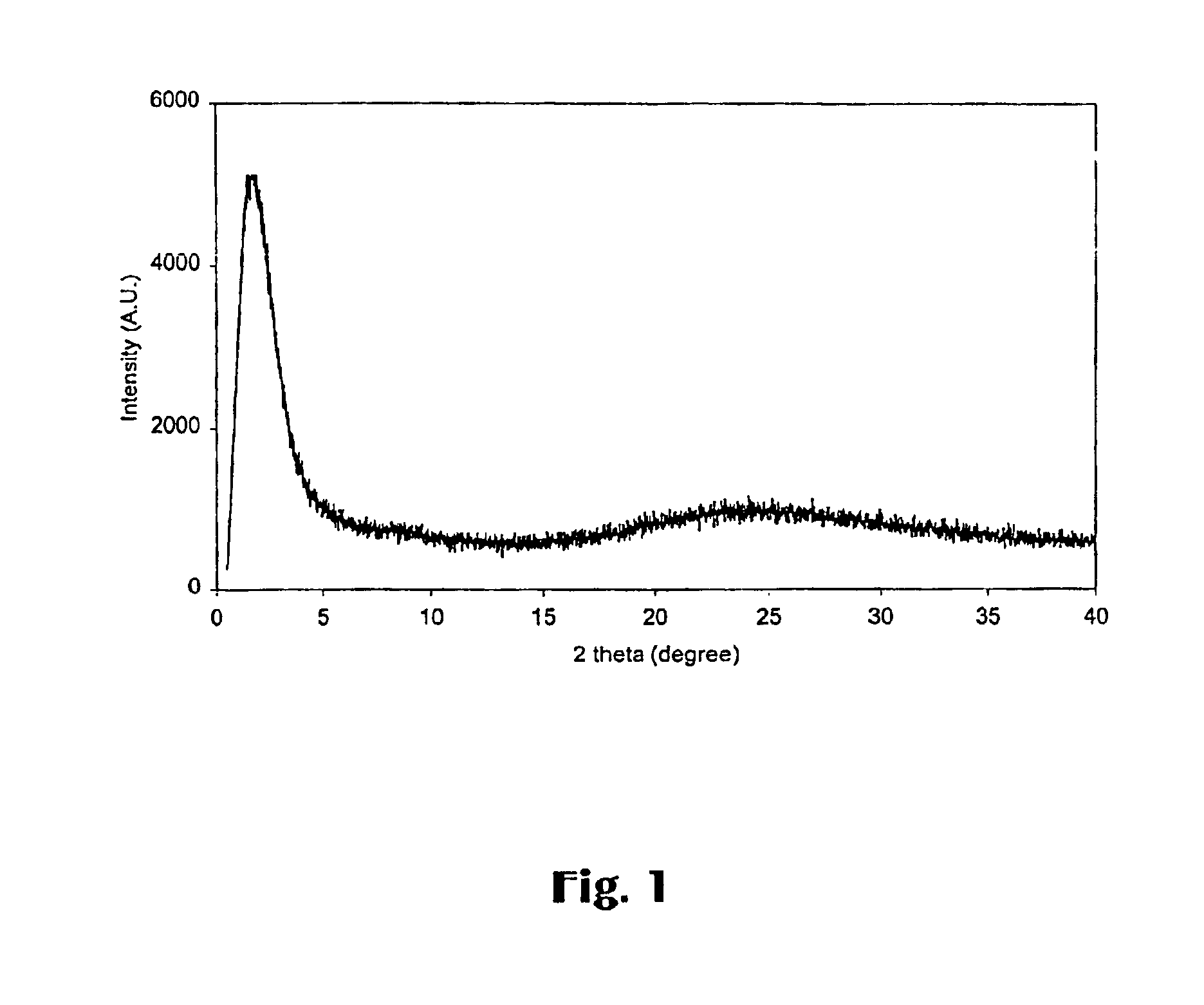

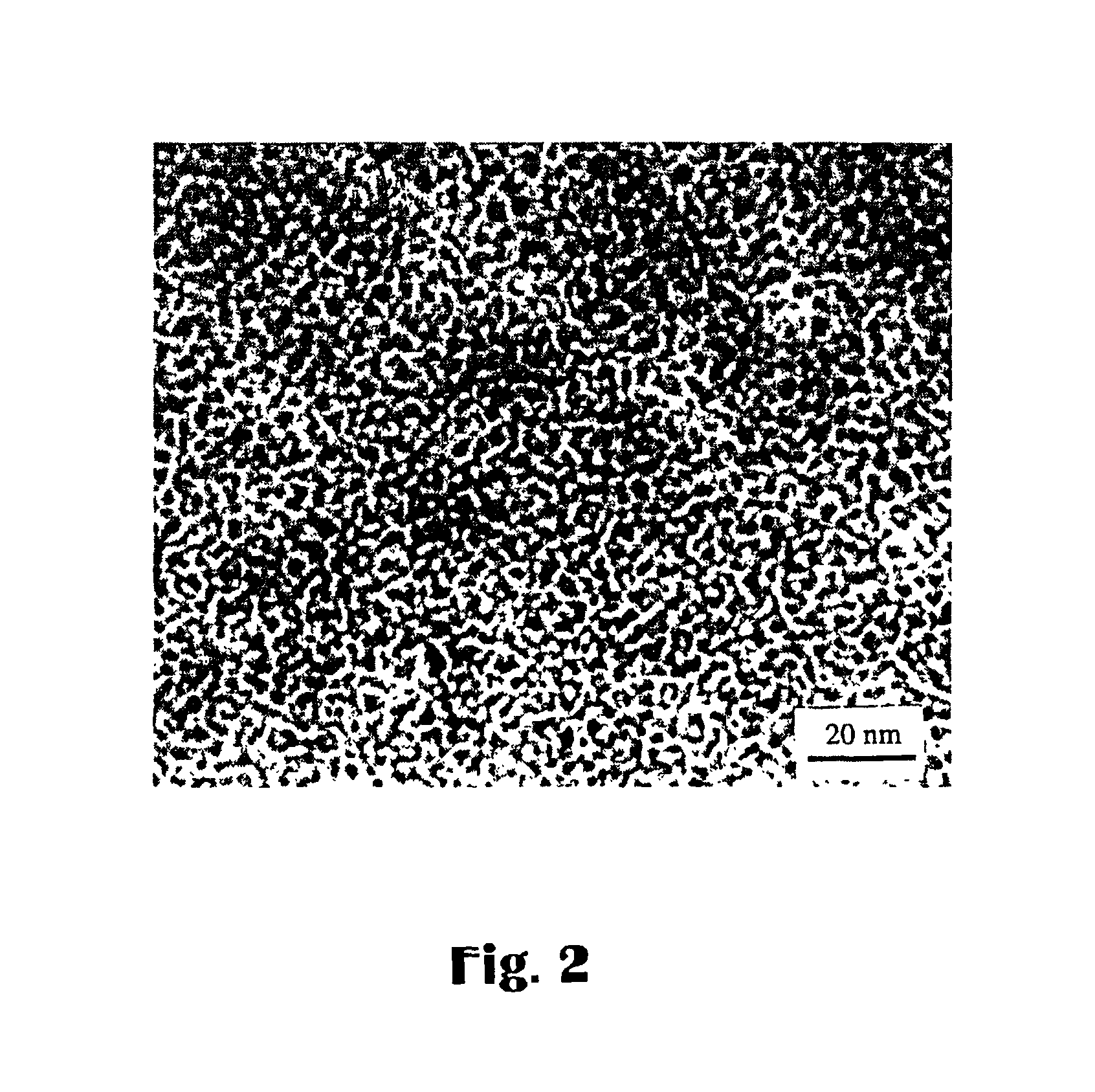

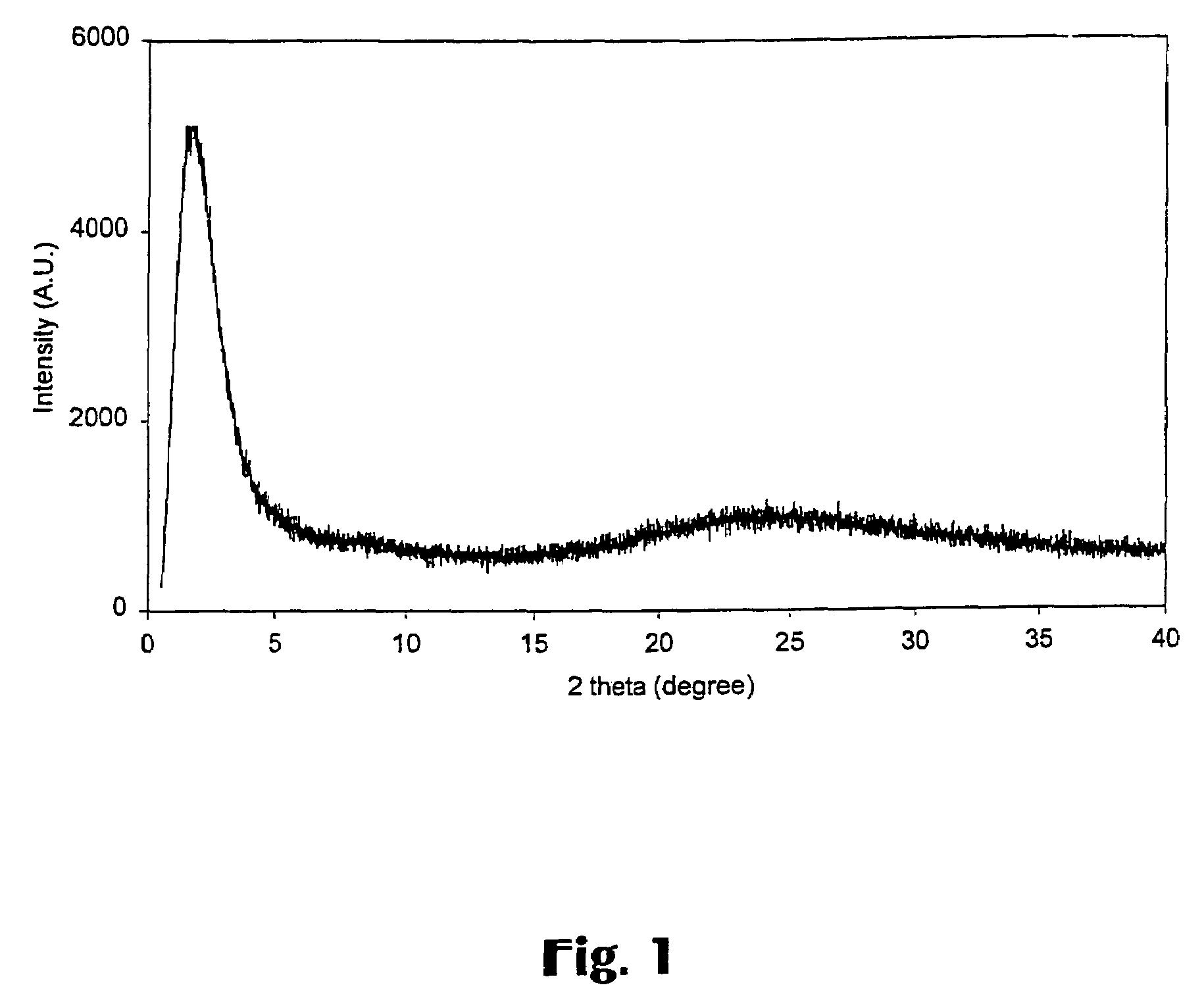

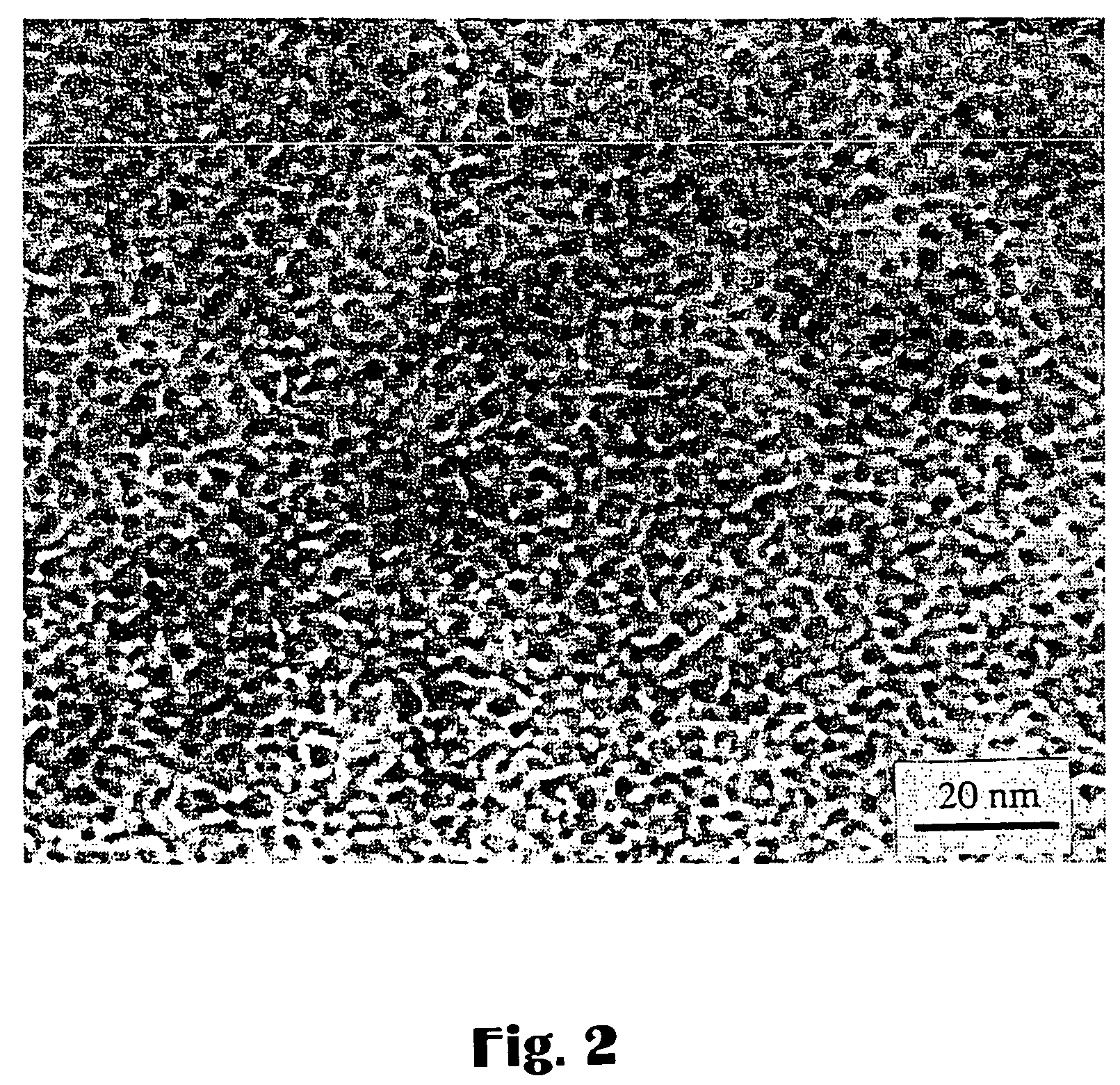

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:ABB LUMMUS GLOBAL INC

Hydrocarbon conversion processes using non-zeolitic molecular sieve catalysts

Hydrocarbon or oxygenate conversion process in which a feedstock is contacted with a non zeolitic molecular sieve which has been treated to remove most, if not all, of the halogen contained in the catalyst. The halogen may be removed by one of several methods. One method includes heating the catalyst in a low moisture environment, followed by contacting the heated catalyst with air and / or steam. Another method includes steam-treating the catalyst at a temperature from 400° C. to 1000° C. The hydrocarbon or oxygenate conversion processes include the conversion of oxygenates to olefins, the conversion of oxygenates and ammonia to alkylamines, the conversion of oxygenates and aromatic compounds to alkylated aromatic compounds, cracking and dewaxing.

Owner:EXXONMOBIL CHEM PAT INC

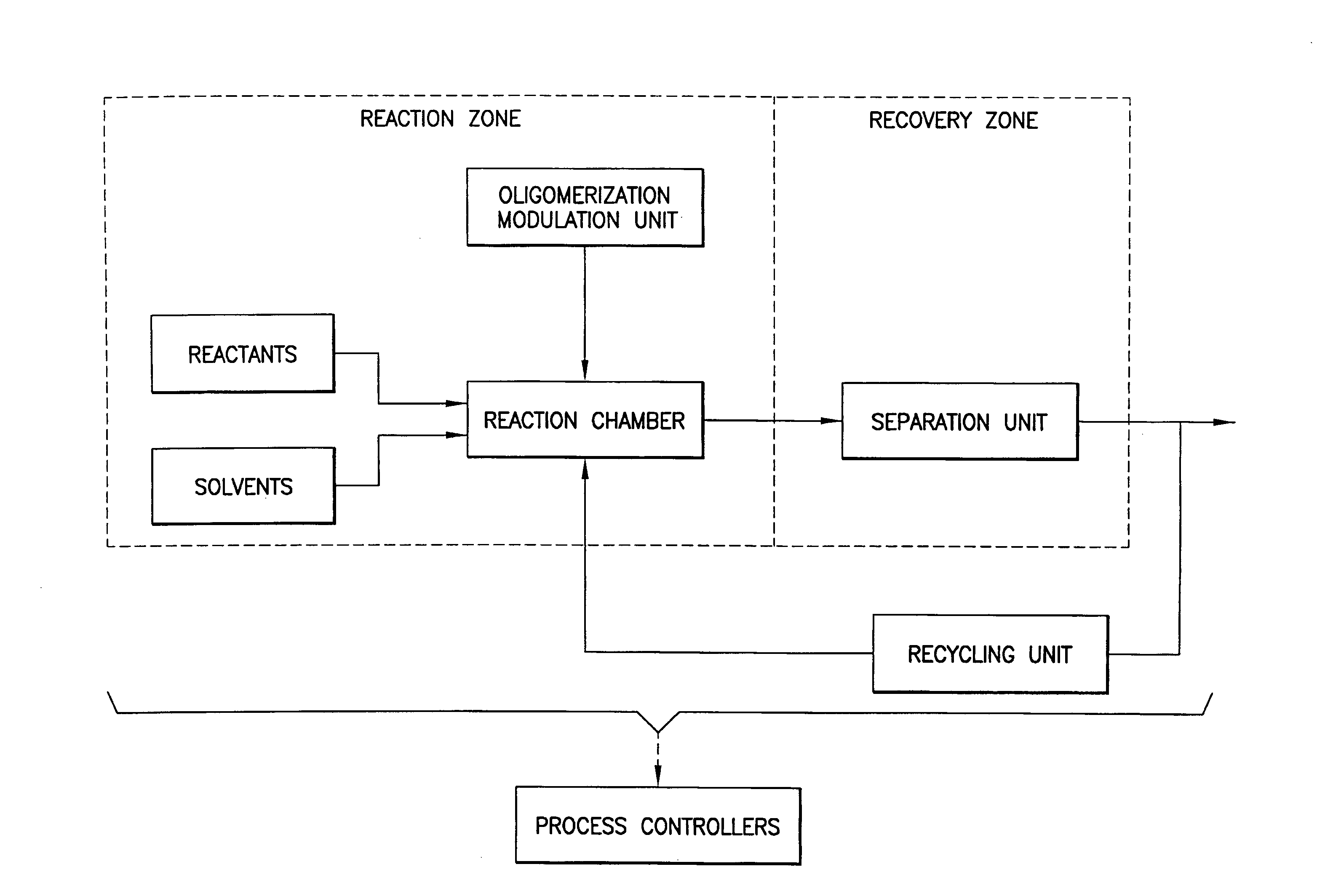

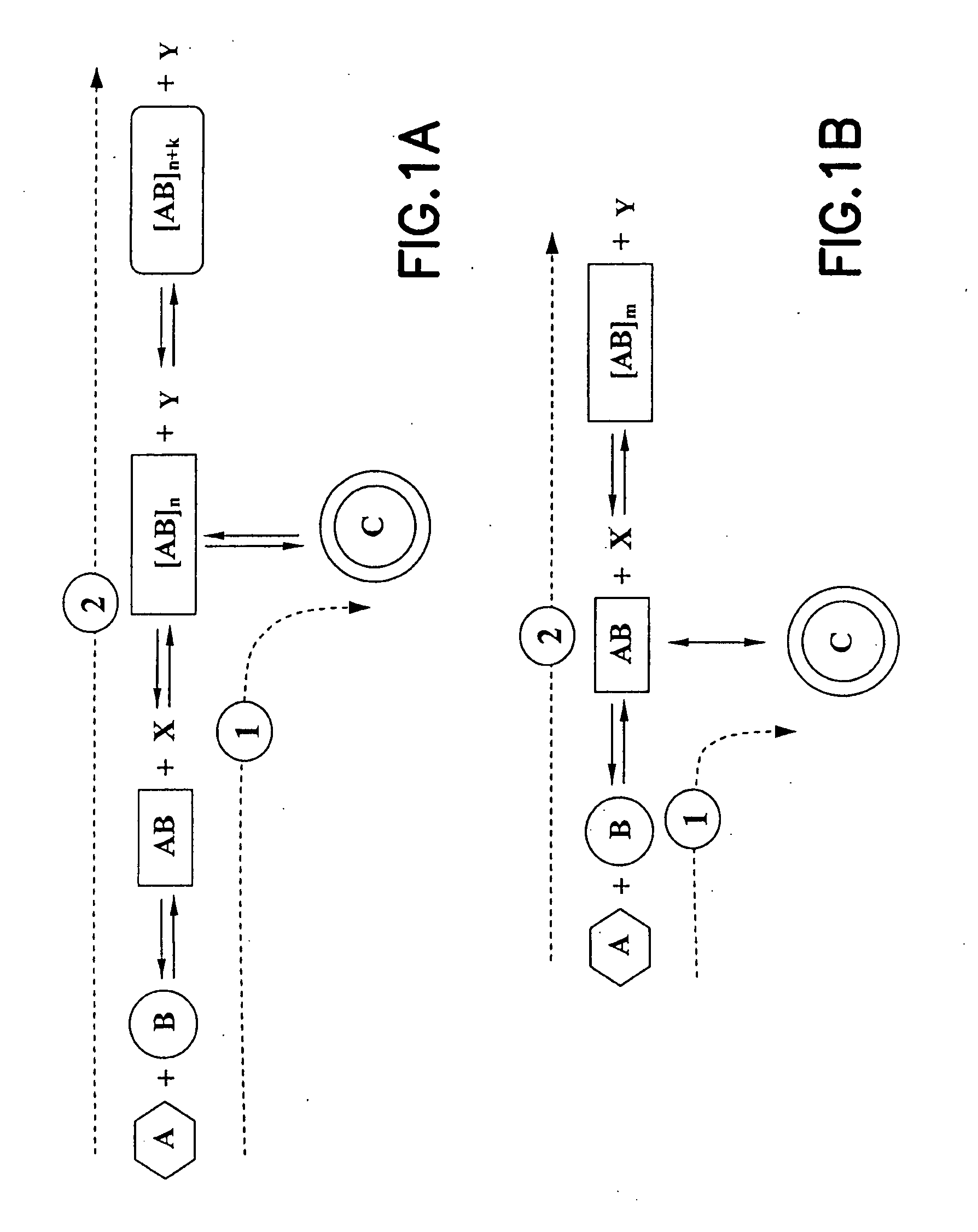

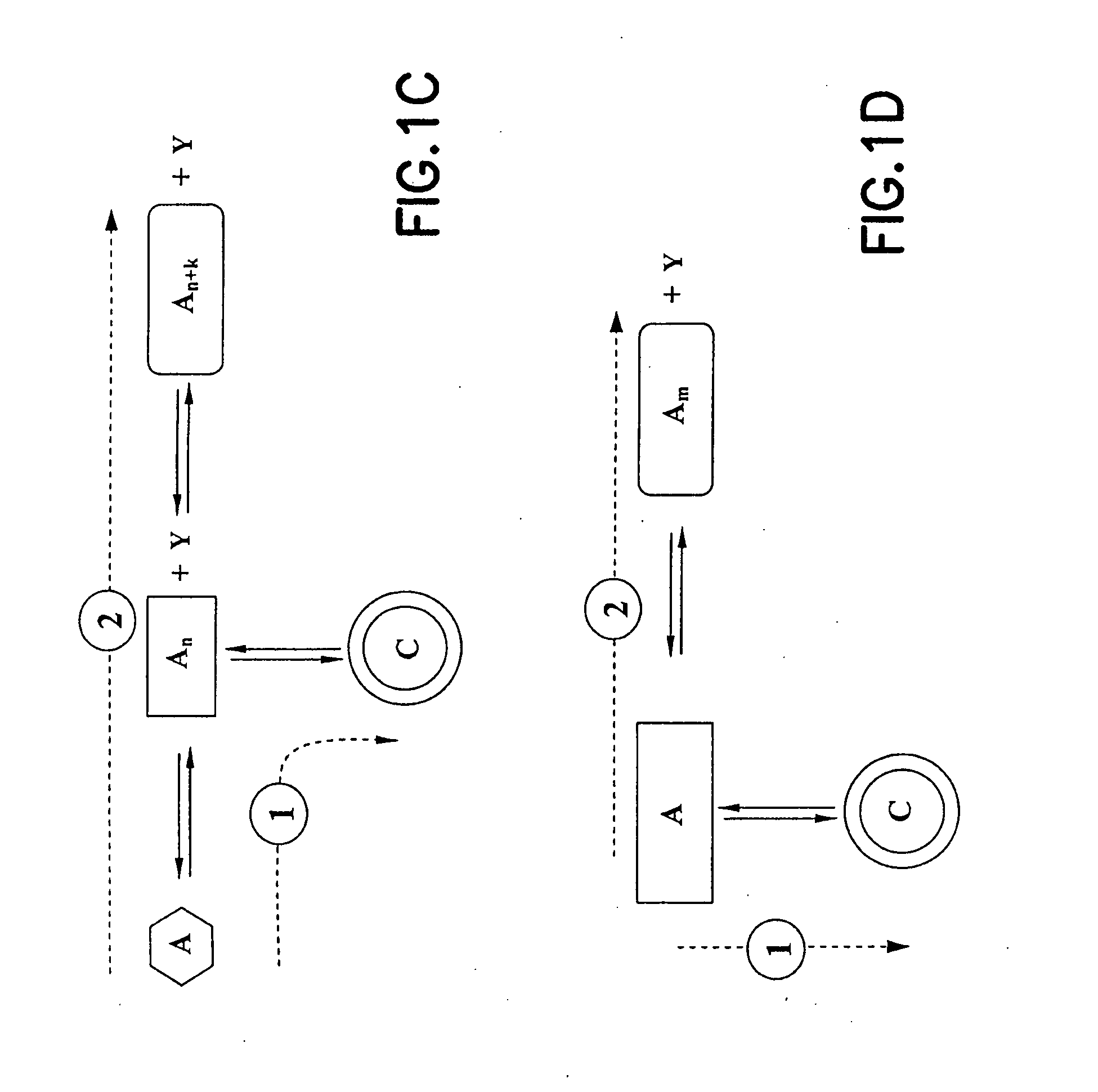

Methods, compositions, and apparatuses for forming macrocyclic compounds

ActiveUS20070217965A1Improve production efficiencyHigh yieldHydrocarbon by dehydrogenationCyclic peptide ingredientsOligomerFiltration

This invention relates to methods, compositions, and apparatuses for producing macrocyclic compounds. First, one or more reactants are provided in a reaction medium, which are capable of forming the macrocyclic compound through a desired reaction pathway that includes at least cyclization, and which are further capable of forming undesired oligomers through a undesired reaction pathway that includes undesirable oligomerization. Oligomerization of such reactions in the reaction medium is modulated to reduce formation of undesired oligomers and / or to reduce separation of the undesired oligomers from the reaction medium, relative to a corresponding unmodulated oligomerization reaction, thereby maximizing yields of the macrocyclic compound. The macrocyclic compound so formed is then recovered from the reaction medium. Preferably, the macrocyclic compound spontaneously separates from the reaction medium via phase separation. More preferably, the macrocyclic compound spontaneous precipitates from the reaction medium and therefore can be easily recovered by simple filtration.

Owner:JOHNSON THOMAS E +1

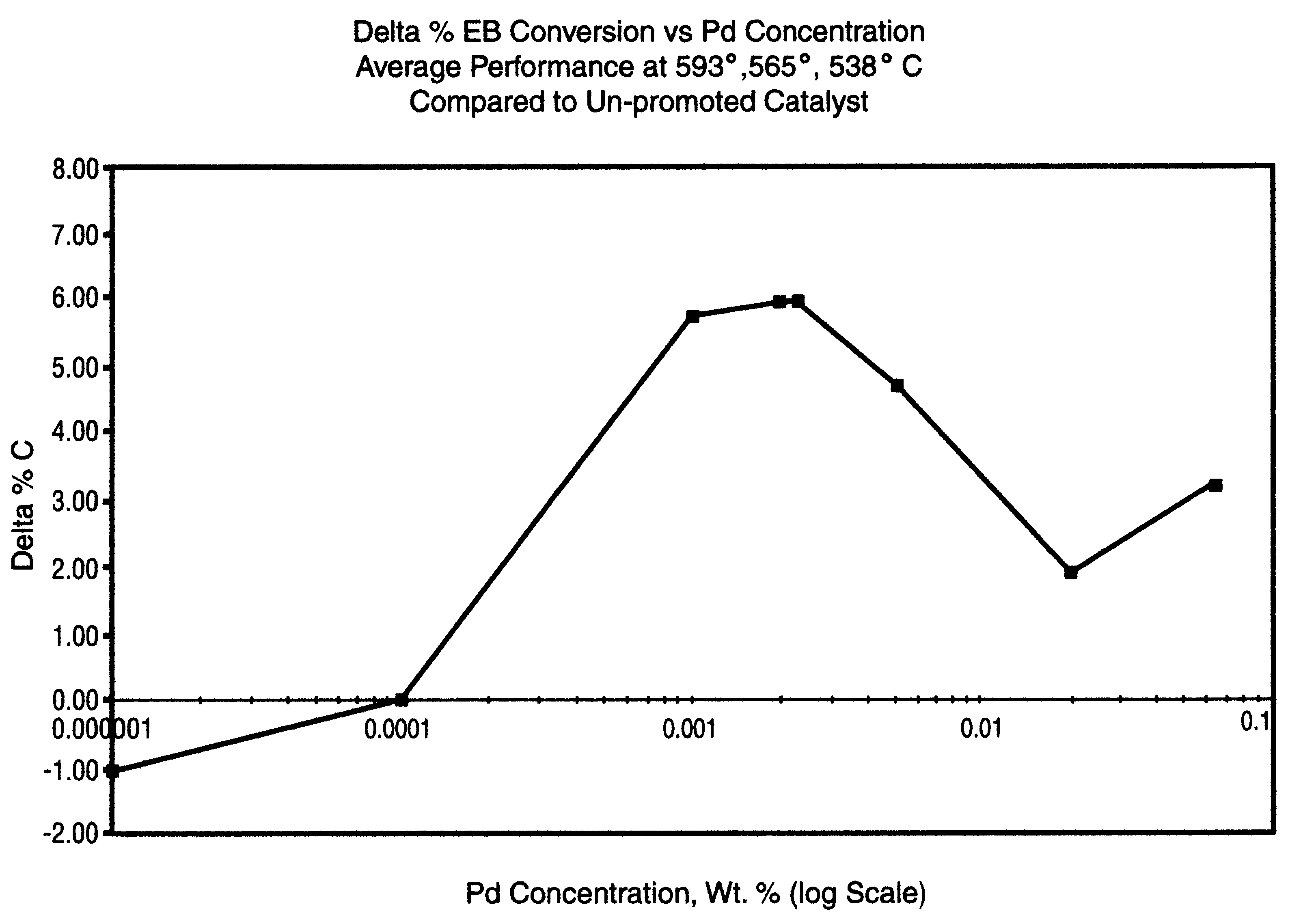

Dehydrogenation catalysts

InactiveUS6191065B1High activityHigh selectivityHydrocarbon by dehydrogenationCatalystsIridiumRhenium

A catalyst for the production of alkenylaromatics from alkylaromatics, wherein the catalyst is predominantly iron oxide, an alkali metal compound and less than about 100 ppm of a source for a noble metal, such as palladium, platinum, ruthenium, rhenium, osmium, rhodium or iridium. Additional components of the catalyst may include compounds based on cerium, molybdenum, tungsten and other such promoters. Also a process for the production of alkenylaromatics from alkylaromatics using this catalyst.

Owner:SUD CHEM INC

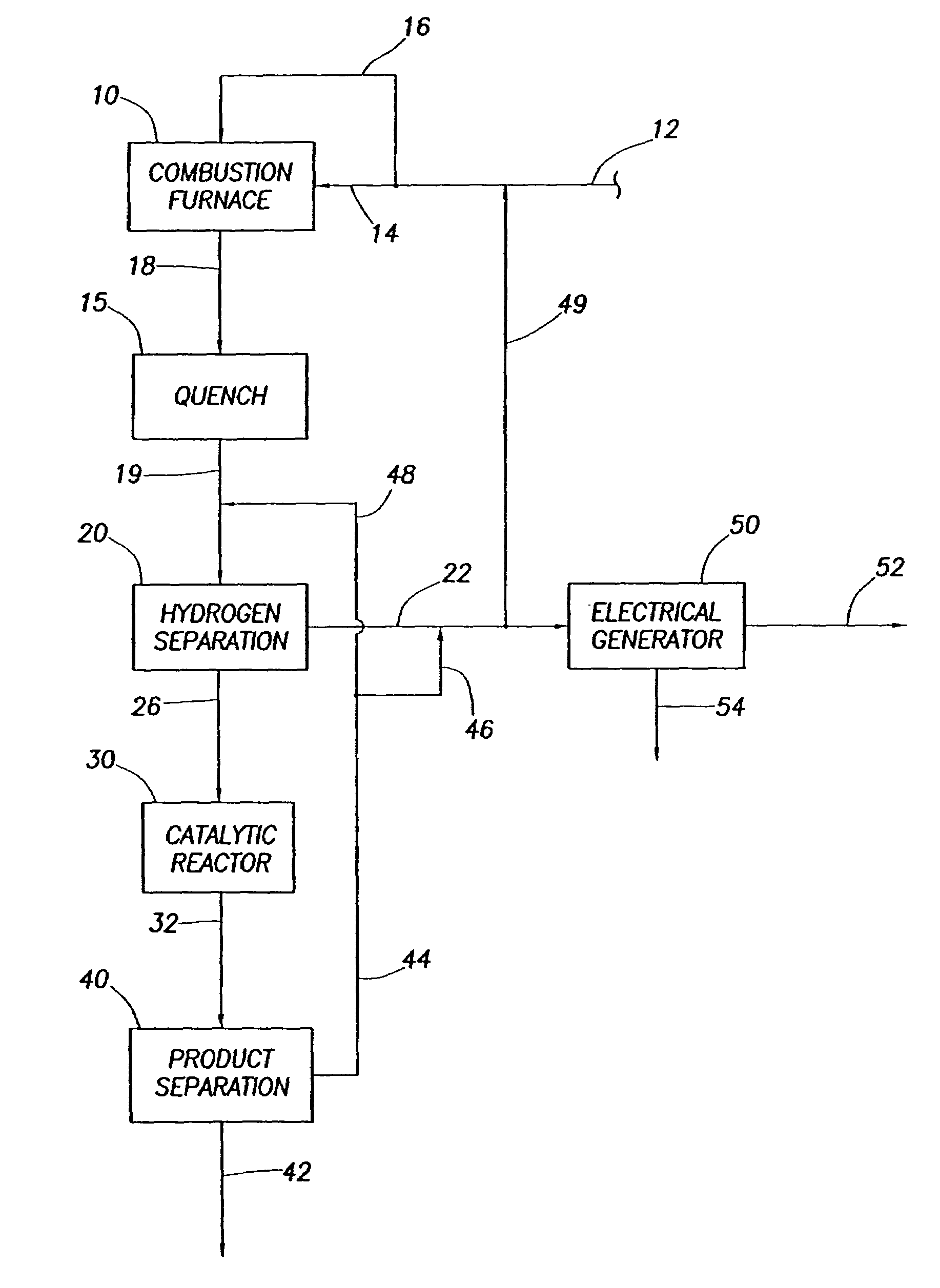

Method for converting natural gas to olefins

InactiveUS7119240B2Hydrocarbon by dehydrogenationOxygen compounds purification/separationFuel cellsPtru catalyst

A process for converting natural gas to an olefin includes heating the gas to a selected range of temperature to convert a fraction of the gas stream to reactive hydrocarbons, primarily ethylene or acetylene, and reacting with hydrogen in the presence of a catalyst to produce the olefin, usually ethylene. A portion of the incoming natural gas may be used to heat the remainder of the natural gas to the selected range of temperature. Hydrogen resulting from the reactions may be used to make electricity in a fuel cell. Alternatively, hydrogen may be burned to heat the natural gas to the selected range of temperature.

Owner:TEXAS A&M UNIVERSITY

Process for dehydrogenating organic compounds in the presence of a supported bimetallic catalyst with a strong interaction between a group VIII metal and tin

InactiveUS6600082B2Synergistic effectHydrocarbon by dehydrogenationHydrocarbon by hydrogenationPlatinumIsomeric shift

Owner:INST FR DU PETROLE

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of refractory oxide containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2 theta (θ). The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:LUMMUS TECH INC

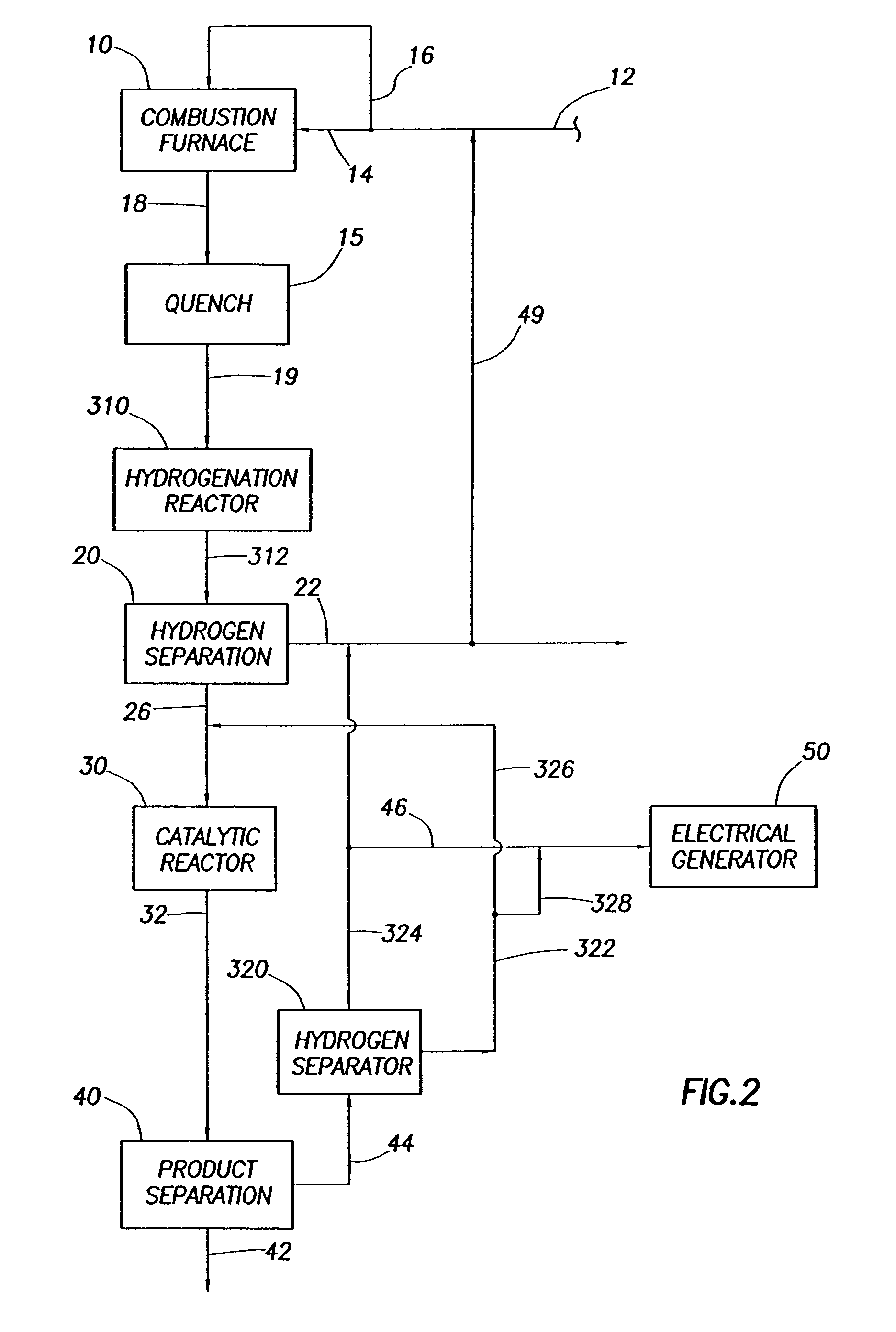

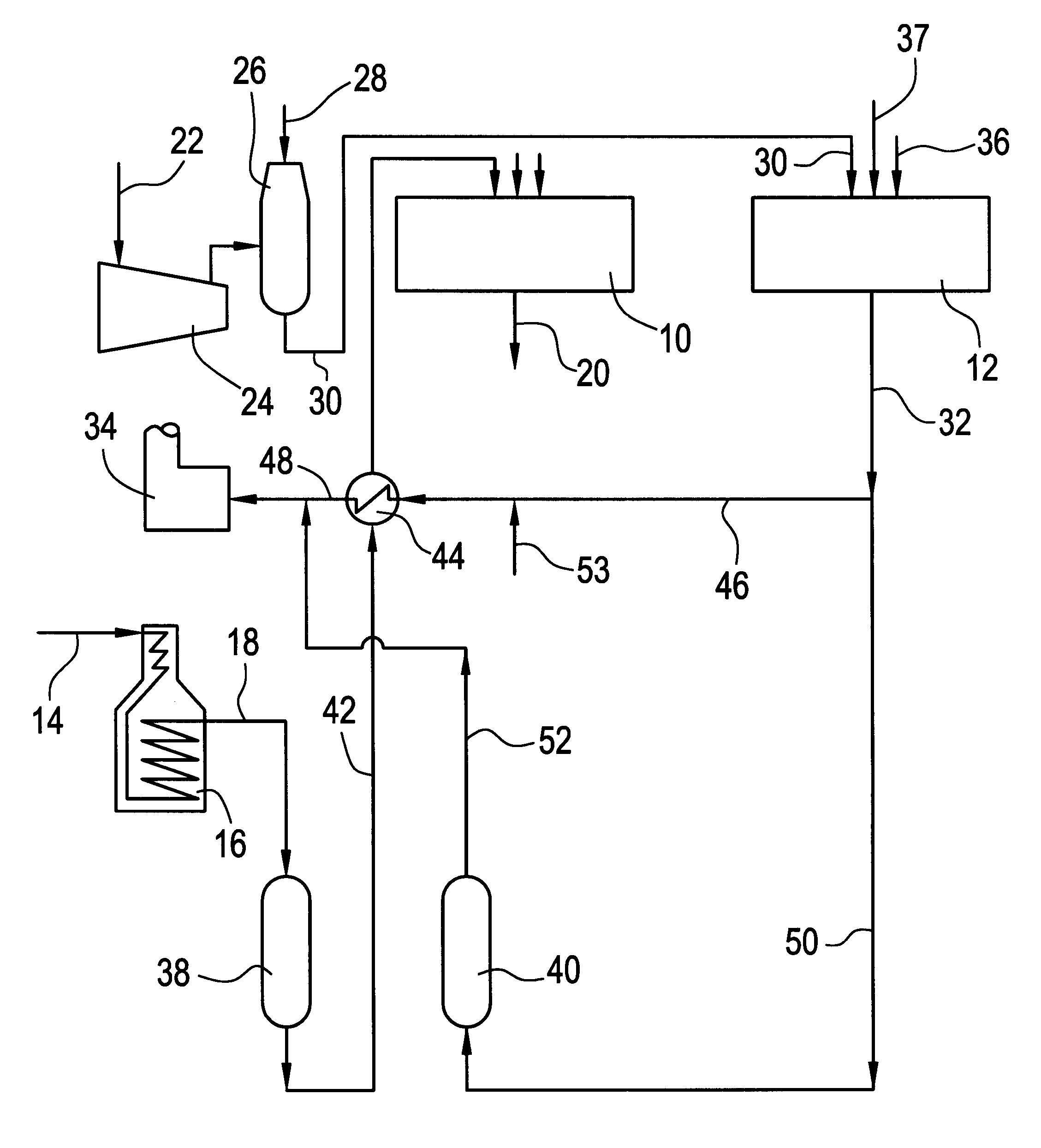

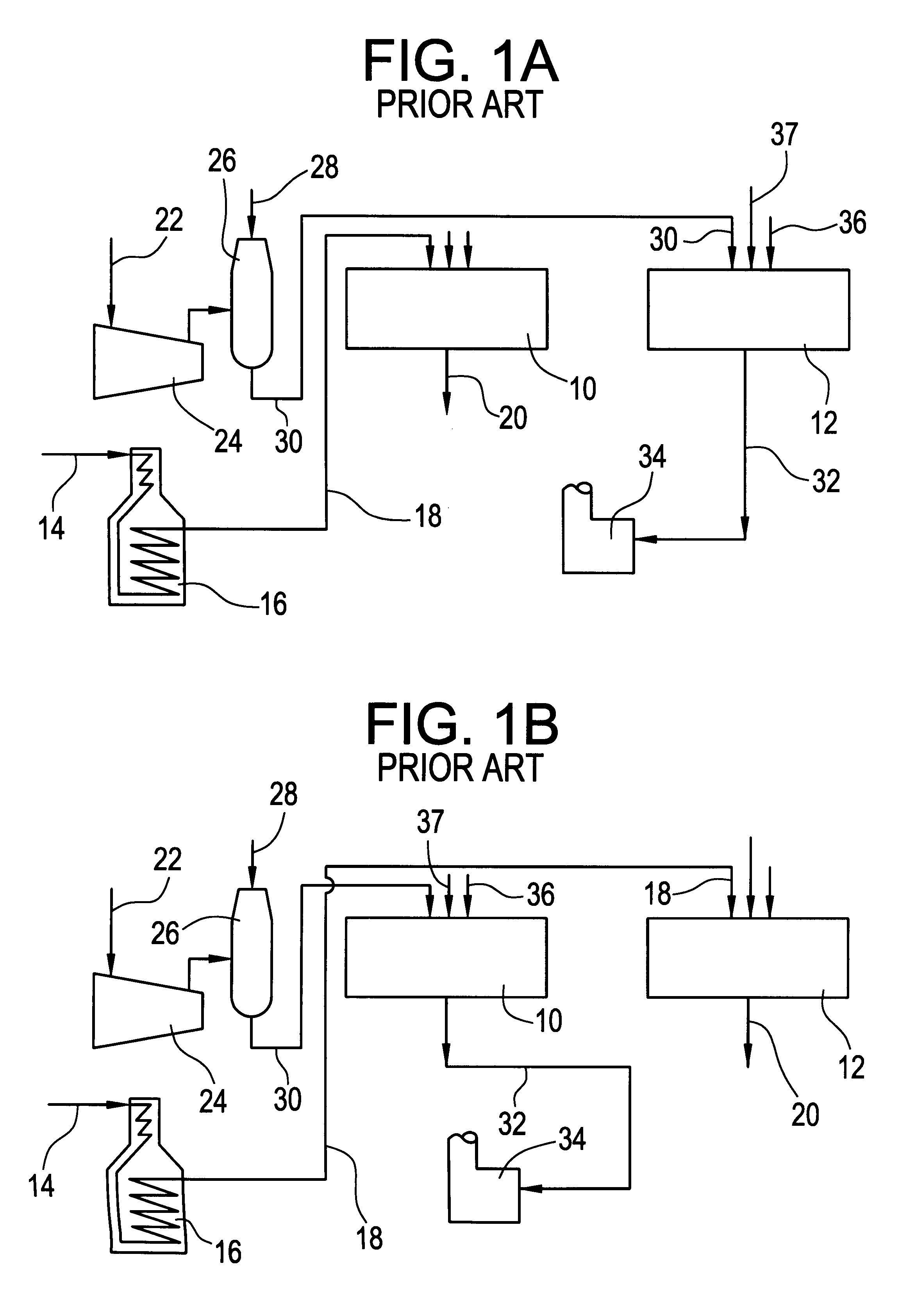

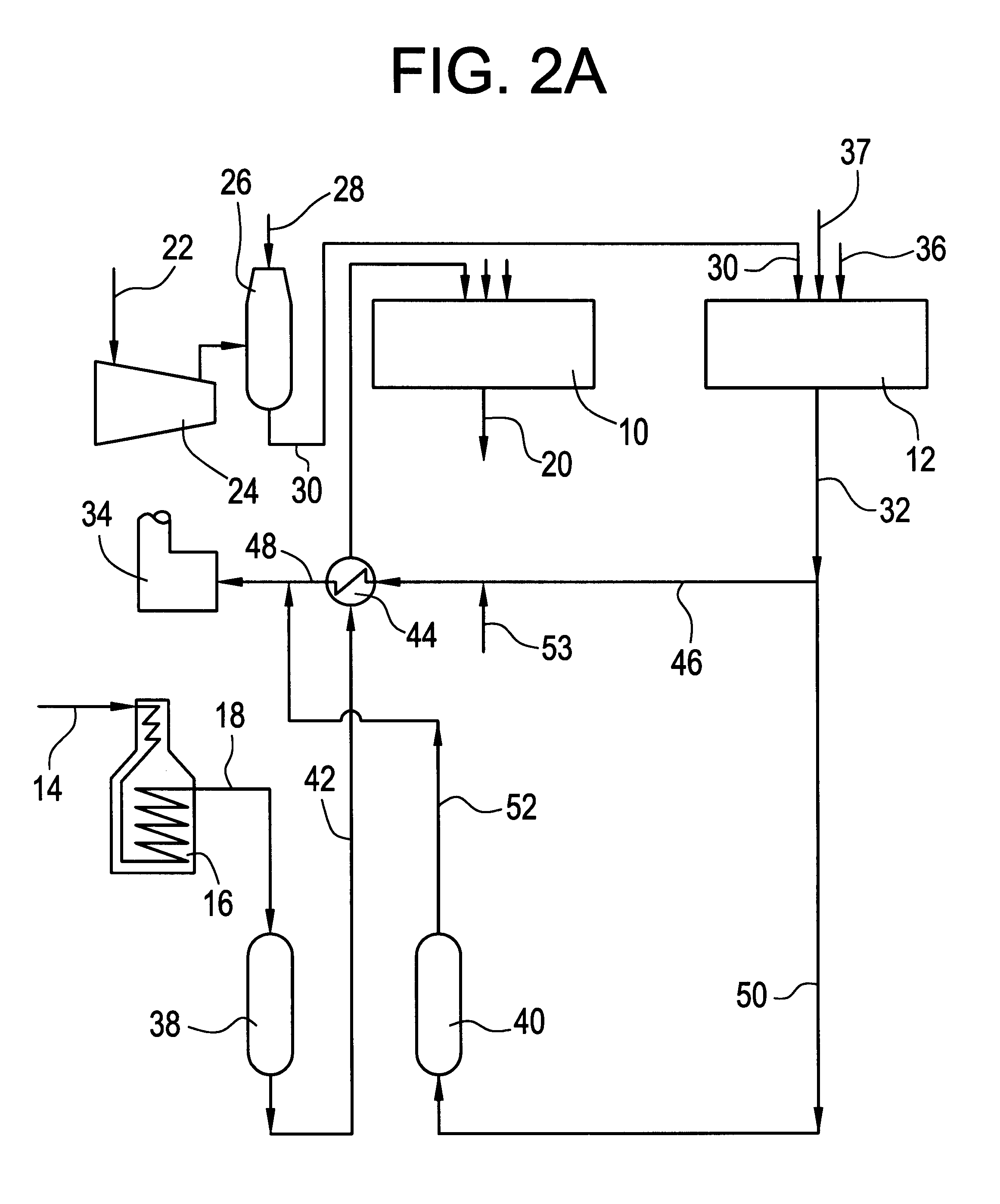

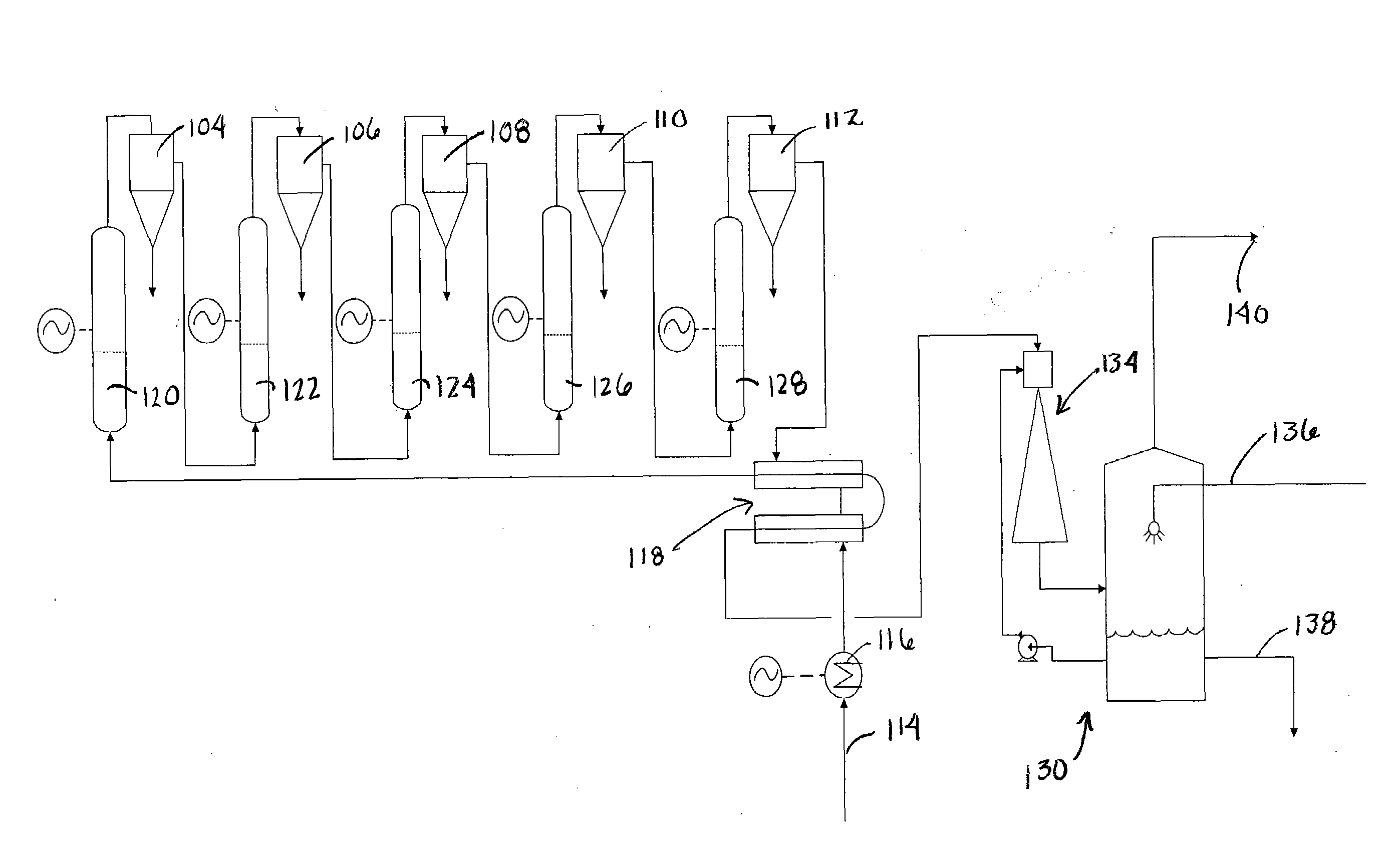

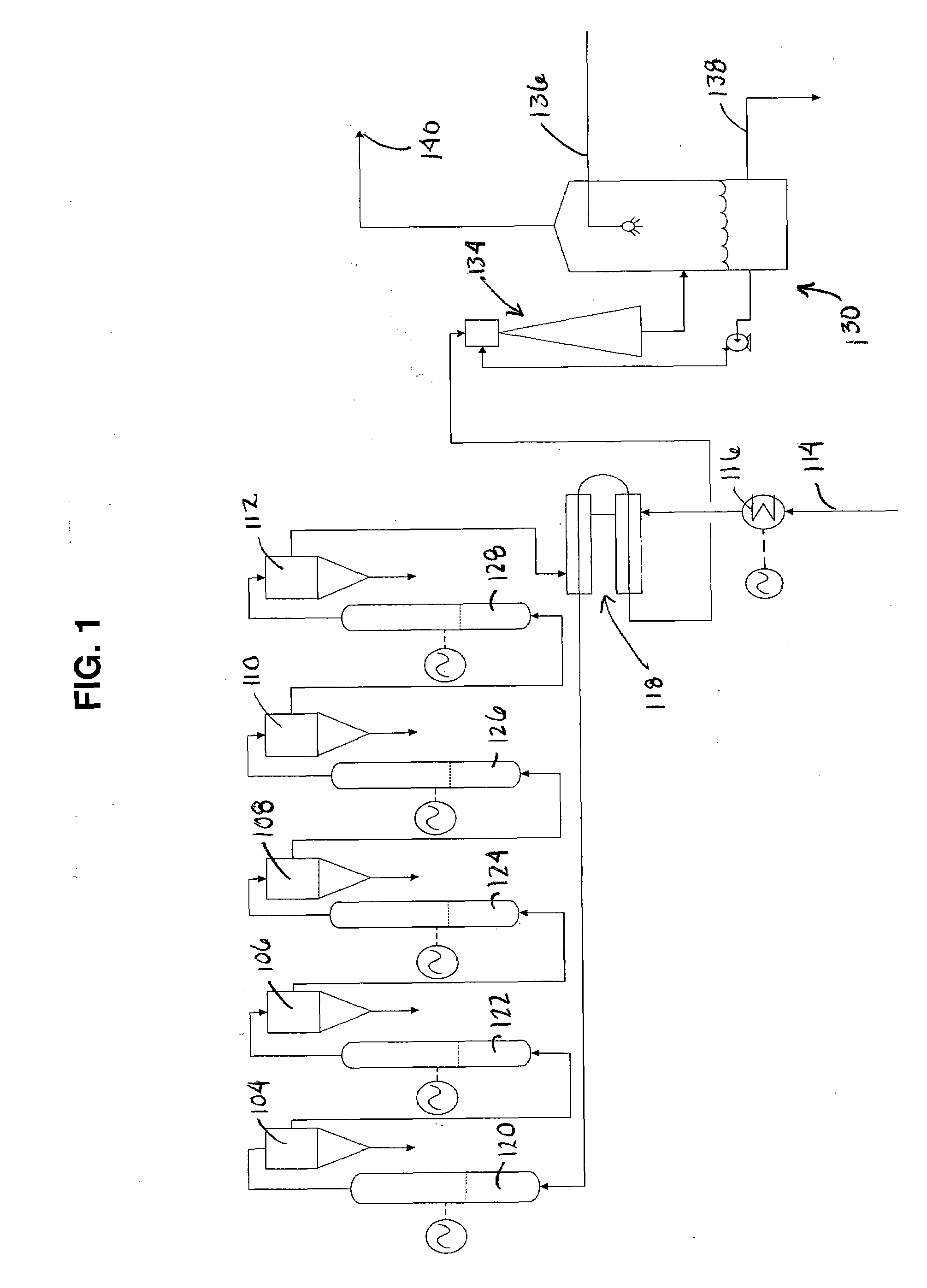

Catalytic hydrocarbon dehydrogenation system with prereaction

InactiveUS6392113B1Improve performanceHydrocarbon by dehydrogenationHydrocarbon by hydrogenationDehydrogenationHydrocarbon

The performance of an endothermic catalytic dehydrogenation process is increased without requiring additional catalyst regeneration and reheat air flow and compression by partially prereacting the preheated hydrocarbon feed and then reheating the partially dehydrogenated effluent from the prereactor to the same hydrocarbon preheat temperature prior to the main catalytic reactor. The preferable source of the heat for reheating is the effluent air from the reheat and regeneration of the catalyst in the main reactor. This same effluent air is used to regenerate the catalyst in the prereactor as needed.

Owner:ABB LUMMUS GLOBAL INC

Catalyst comprising an element from groups 8, 9 or 10 with good accessibility, and its use in a paraffin dehydrogenation process

InactiveUS6498280B1Reduce side effectsHydrocarbon by isomerisationCatalyst carriersAlkaneAlkaline earth metal

A catalyst comprising at least one support, at least one element from groups 8, 9 or 10 of the periodic table, at least one element from group 14 of the periodic table, at least one element from group 13 of the periodic table, at least one alkali or alkaline-earth metal, and, optionally, at least one halogen in an amount in the range from 0 to 0.2% by weight with respect to the total catalyst weight, the catalyst being characterized in that the accessibility of the element from groups 8, 9 or 10 is more than 50%. The invention also concerns a process for preparing a catalyst and the use of the catalyst in a process for dehydrogenating paraffins containing 3 to 22 carbon atoms per molecule.

Owner:INST FR DU PETROLE

Paraffin dehydrogenation catalyst

ActiveUS7012038B2High activityRobust hydrothermal stabilityHydrocarbon by dehydrogenationCatalystsLithium oxideDehydrogenation

One aspect of the invention relates to a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide. The invention also relates to methods of making the dehydrogenation catalyst composite. Another aspect of the invention relates to method of dehydrogenating a dehydrogenatable hydrocarbon involving contacting the dehydrogenatable hydrocarbon with a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide to provide a dehydrogenated hydrocarbon, such as an olefin.

Owner:TEXAS PETROCHEM +1

Dehydrogenation catalyst composition

Owner:UOP LLC

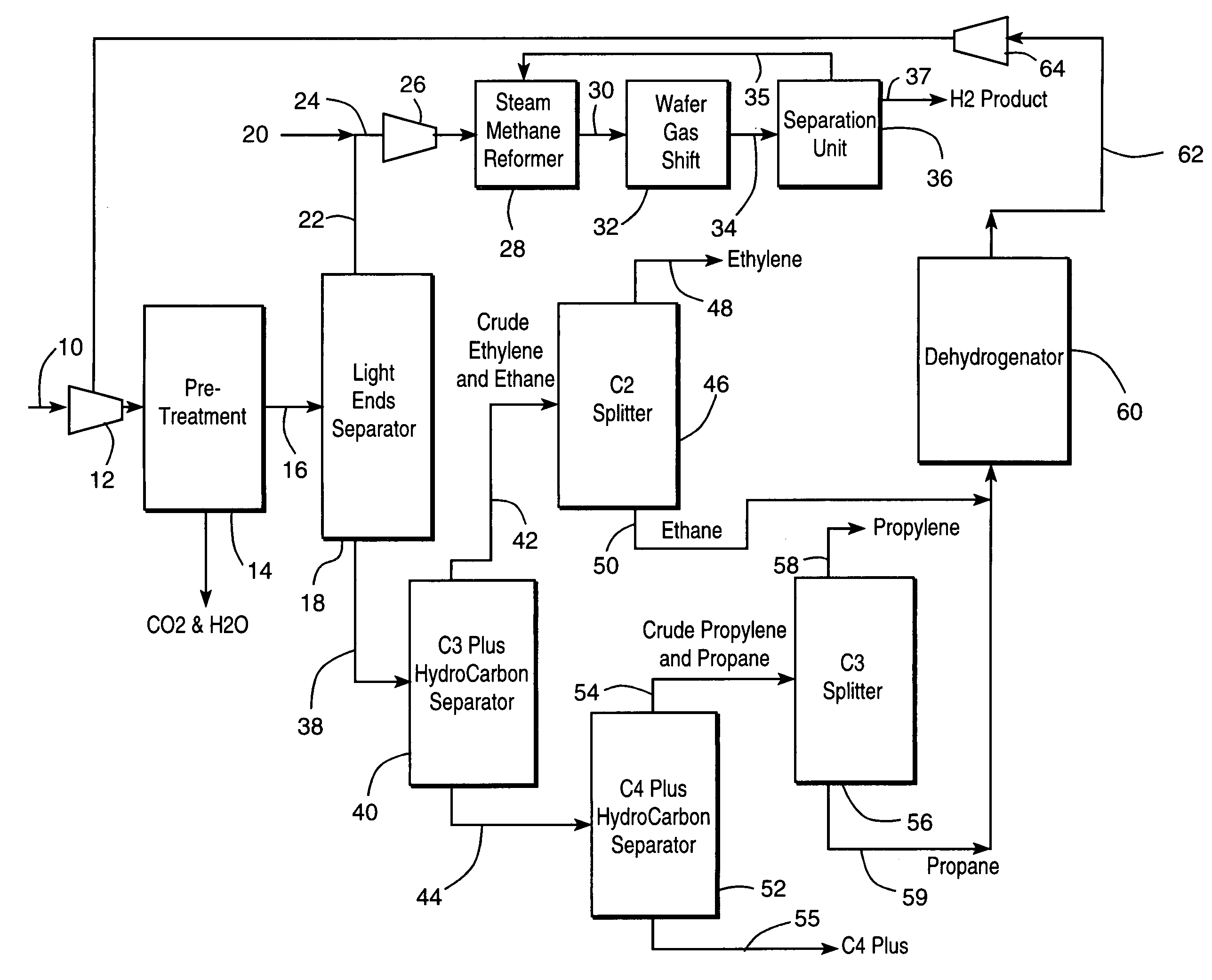

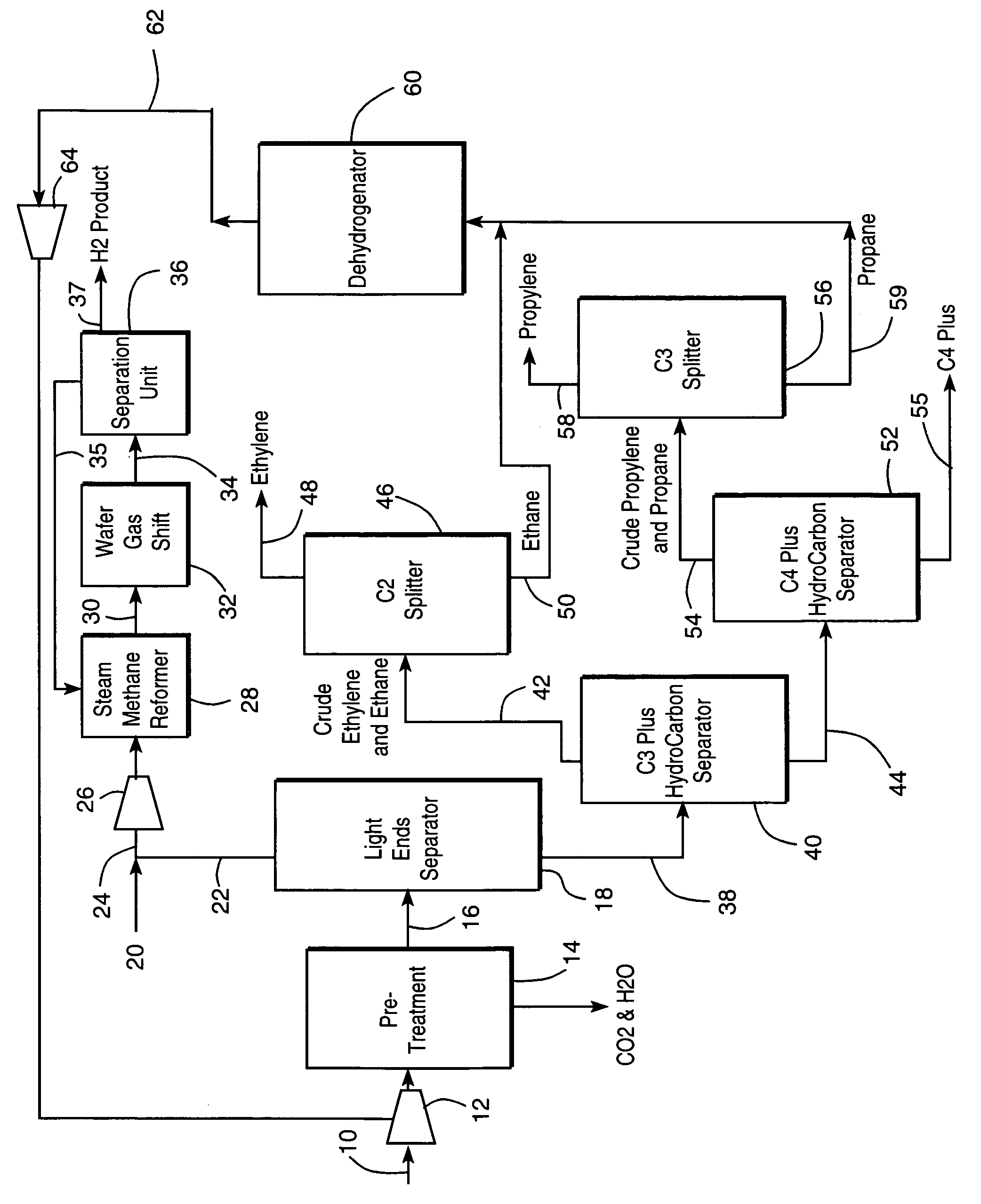

Integrated olefin recovery and hydrogen production from refinery off-gases

A method is disclosed a method for recovering olefins and for producing hydrogen from a refinery off-gas stream in which such stream is conventionally pretreated and separated to obtain a light ends stream that contains nitrogen, hydrogen and carbon monoxide and a heavy ends stream that contains the olefins. The light ends stream is subjected to reforming and a water gas shift reactions after addition of a natural gas stream. The addition of the natural gas increases the hydrogen recovery from the light ends and also stabilizes the hydrocarbon content in the stream to be subjected to the reforming and water gas shift reactions. The heavy ends can be further treated to recover olefins such as ethylene and propylene. The rate of natural gas addition is controlled so that the concentration of the nitrogen in a stream exiting the water gas shift reactor is less than about 5 percent by volume so that hydrogen separation from such stream becomes practical.

Owner:PRAXAIR TECH INC

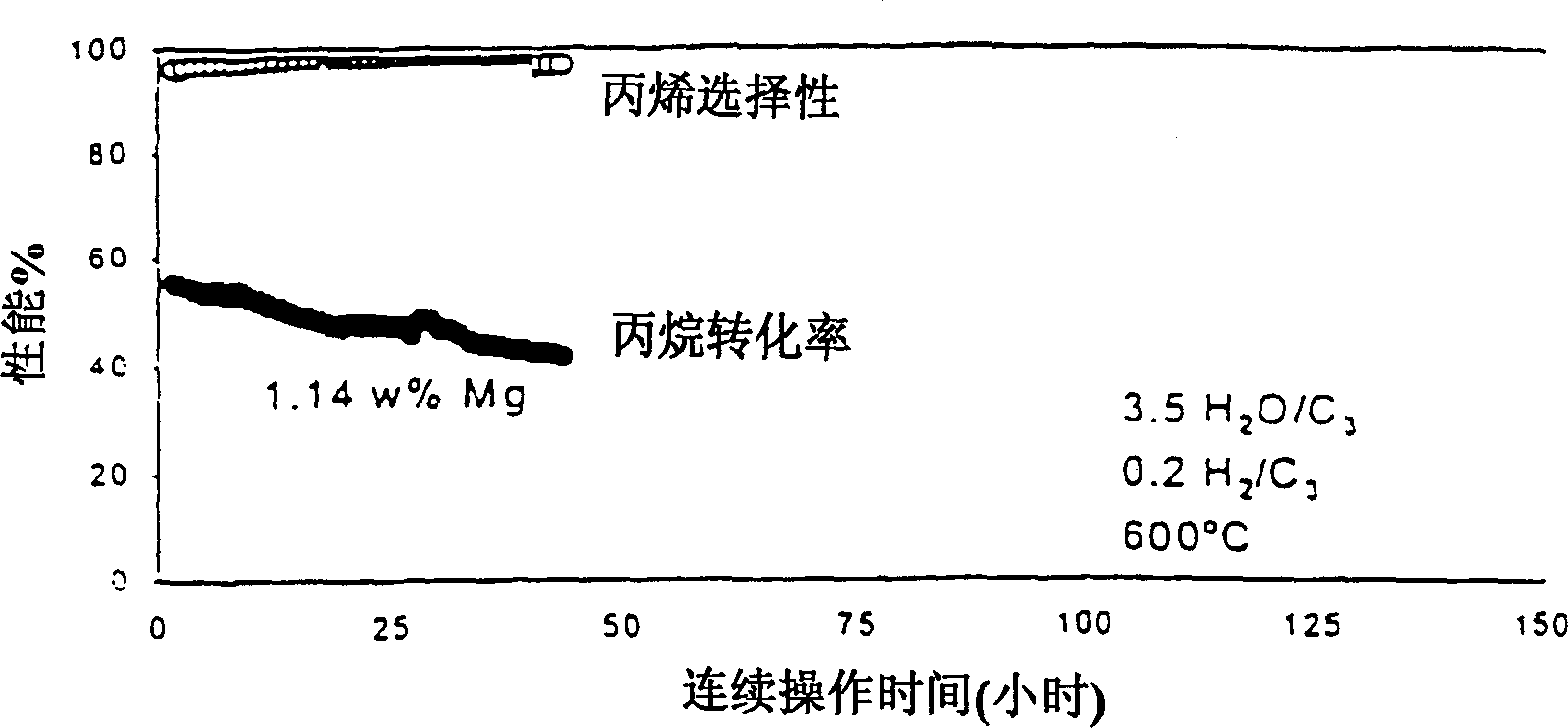

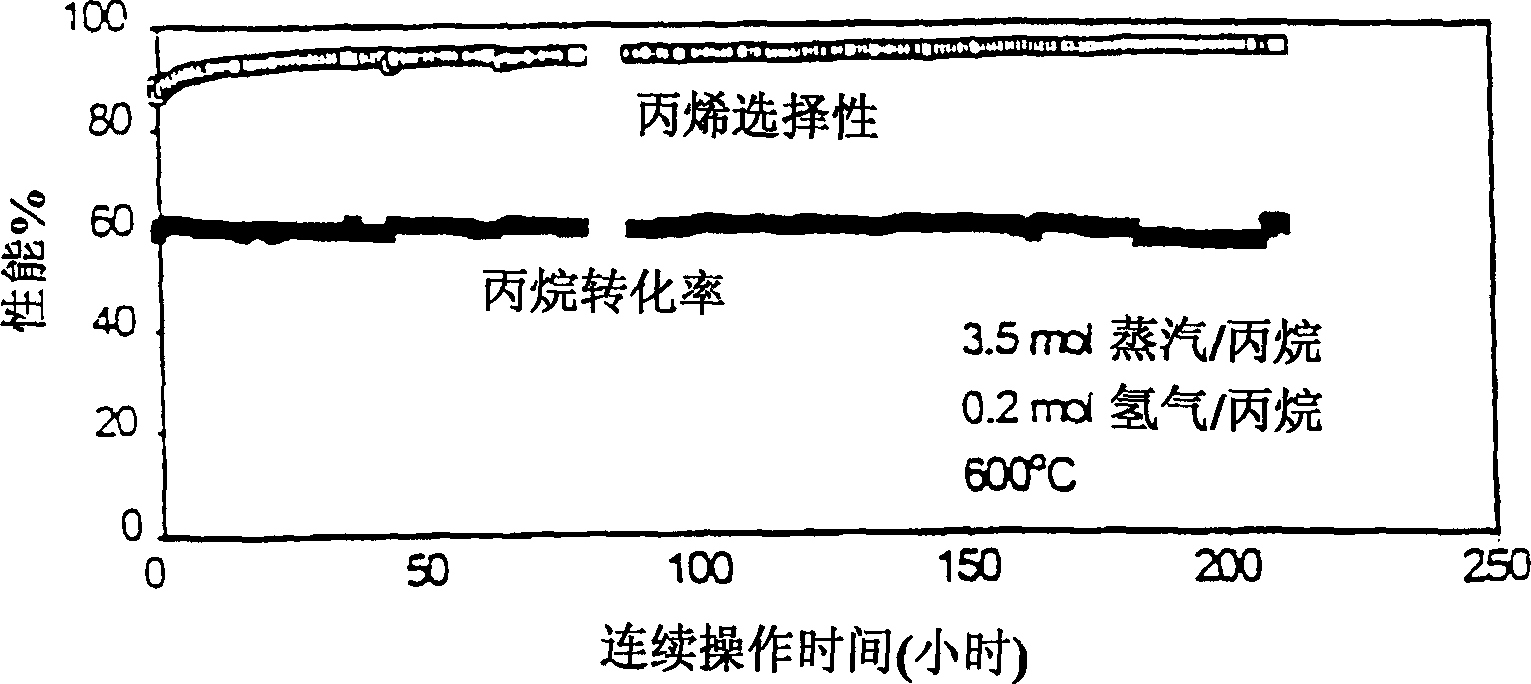

Hydrocarbon dehydrogenation catalyst and process

The present invention discloses a catalyst and a process employing such catalyst for the dehydrogenation of paraffinic hydrocarbons, wherein the catalyst comprises a platinum group metal component, a zinc component and a magnesium component on a support comprising ZSM or borosilicate.

Owner:BP CORP NORTH AMERICA INC

Methods of Regenerating Aromatization Catalysts

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

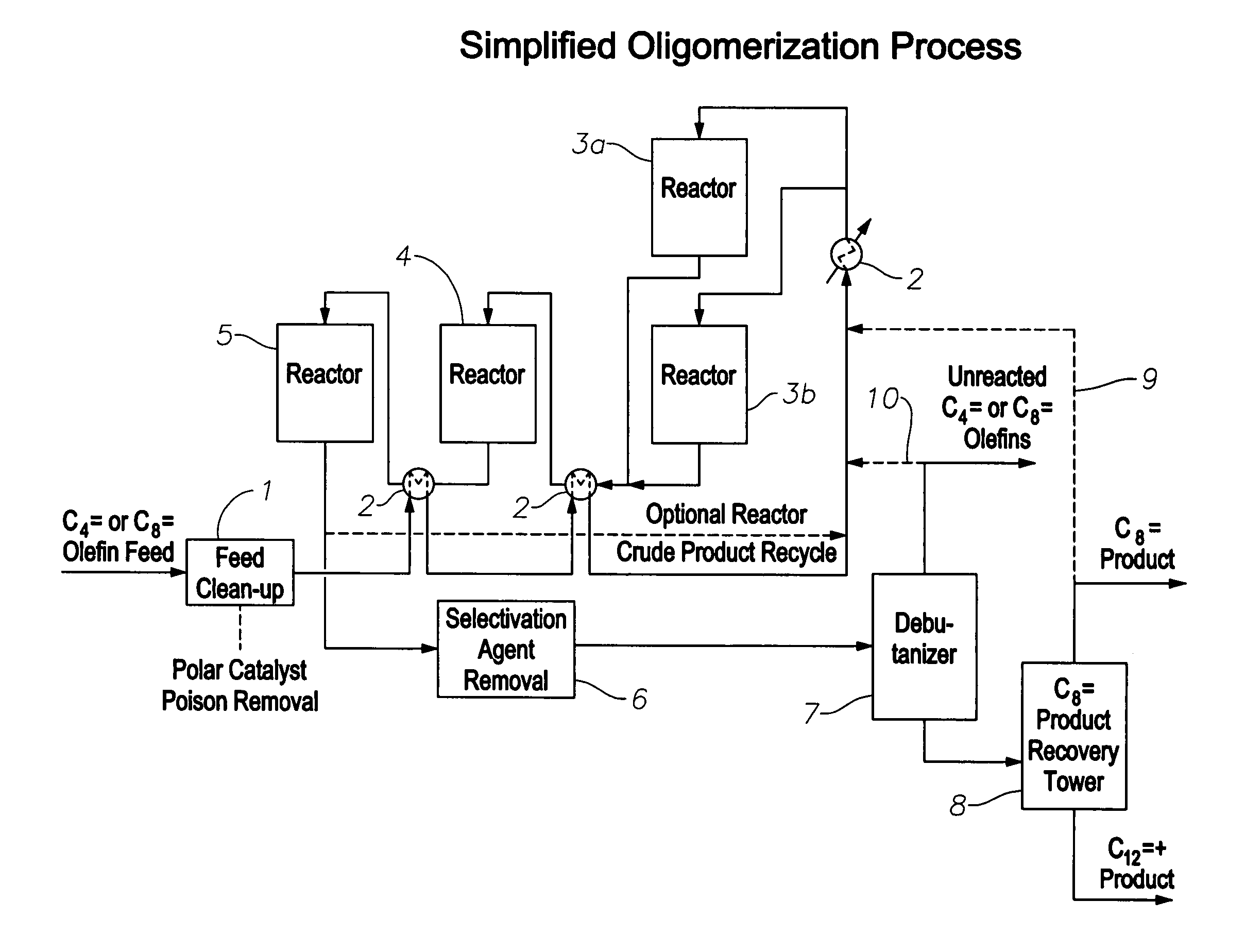

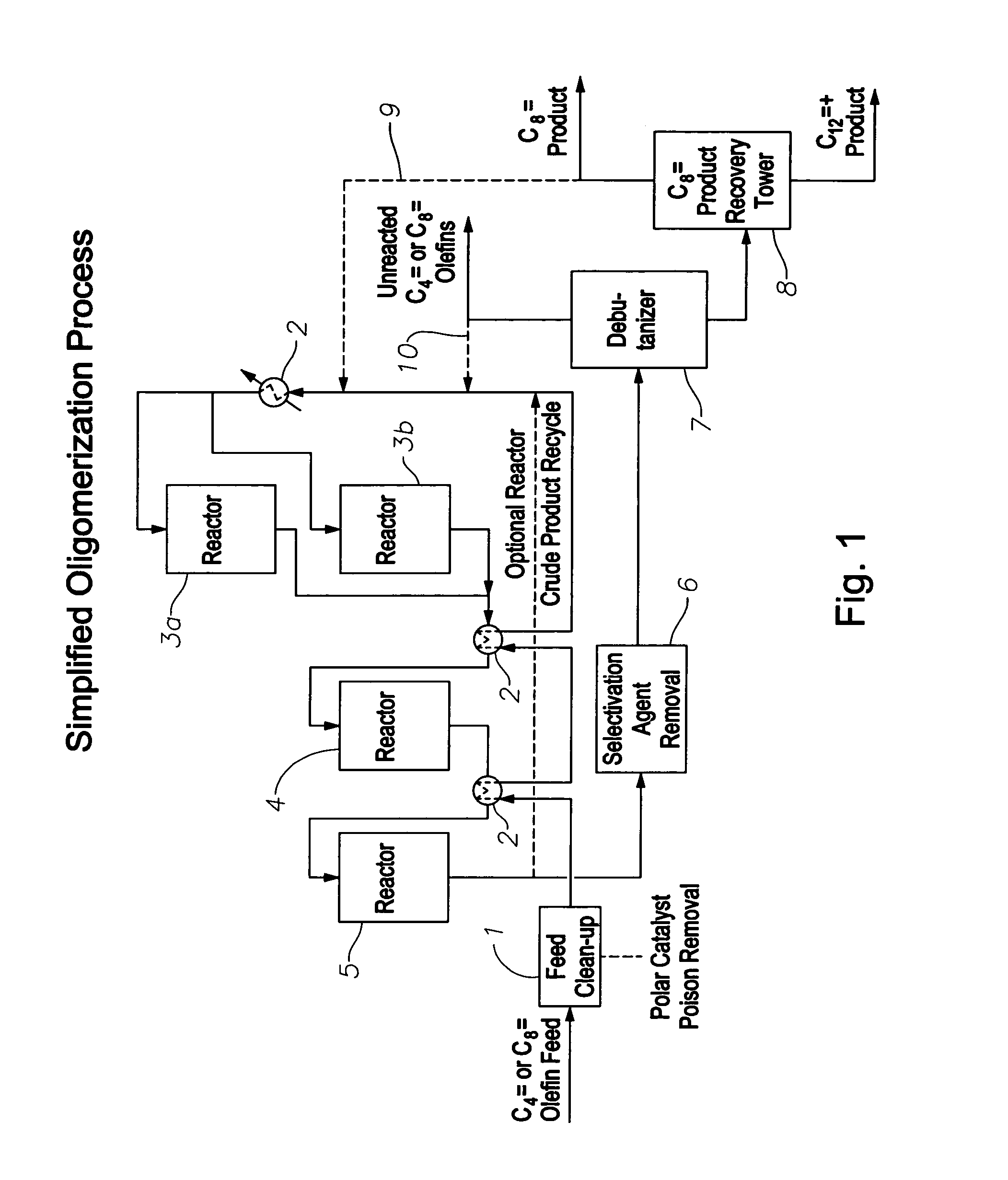

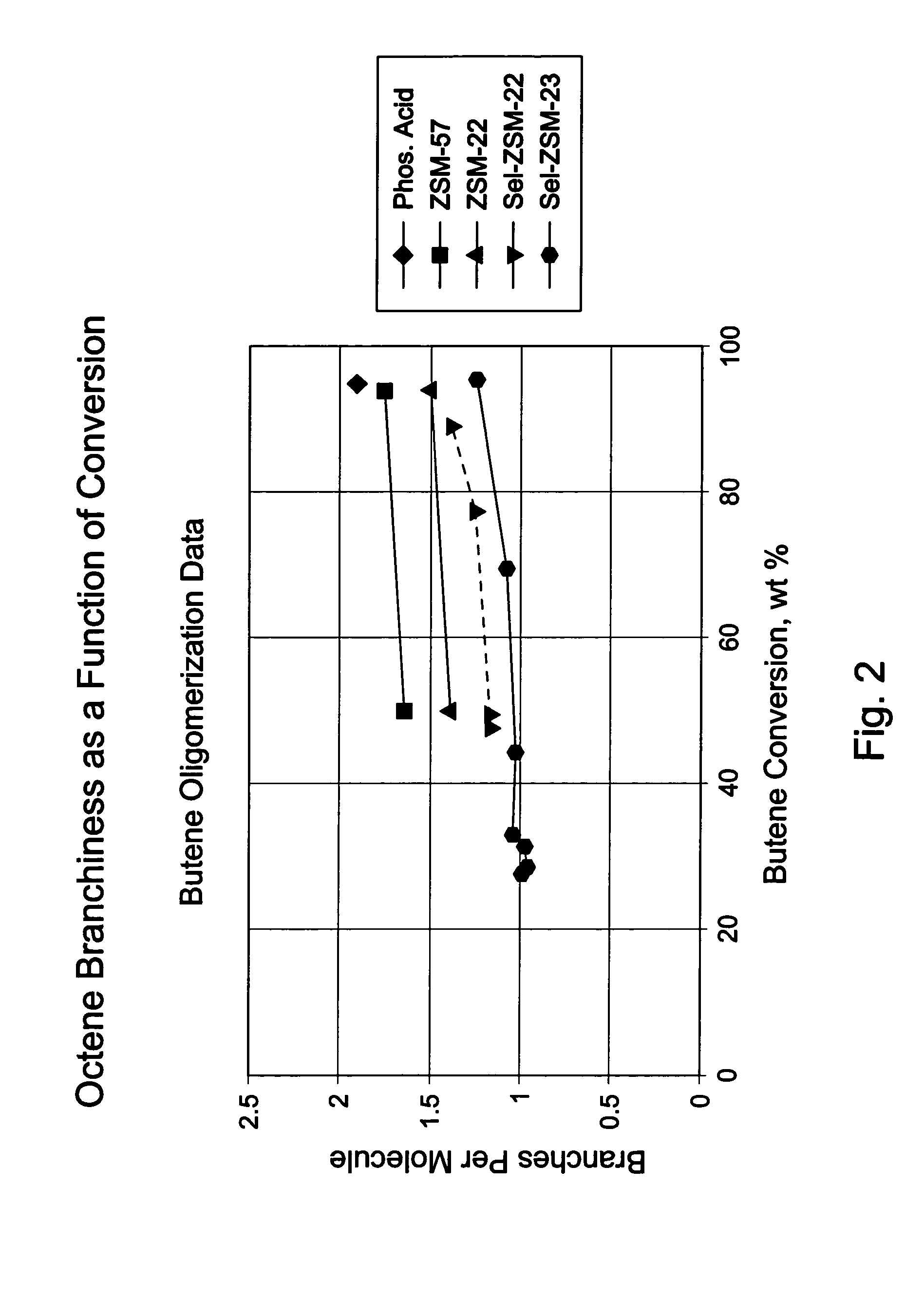

Oligomerization of olefins

ActiveUS7425662B2Increased branchingImprove linearityHydrocarbon by dehydrogenationCarboxylic acid esters preparationButeneMolecular sieve

A selectivated molecular sieve, e.g., ZSM-22 or ZSM-23, is used as olefin oligomerization catalyst to provide product, e.g., octenes and dodecenes from butene, having a low degree of branching and hindered double bonds.

Owner:EXXONMOBIL CHEM PAT INC

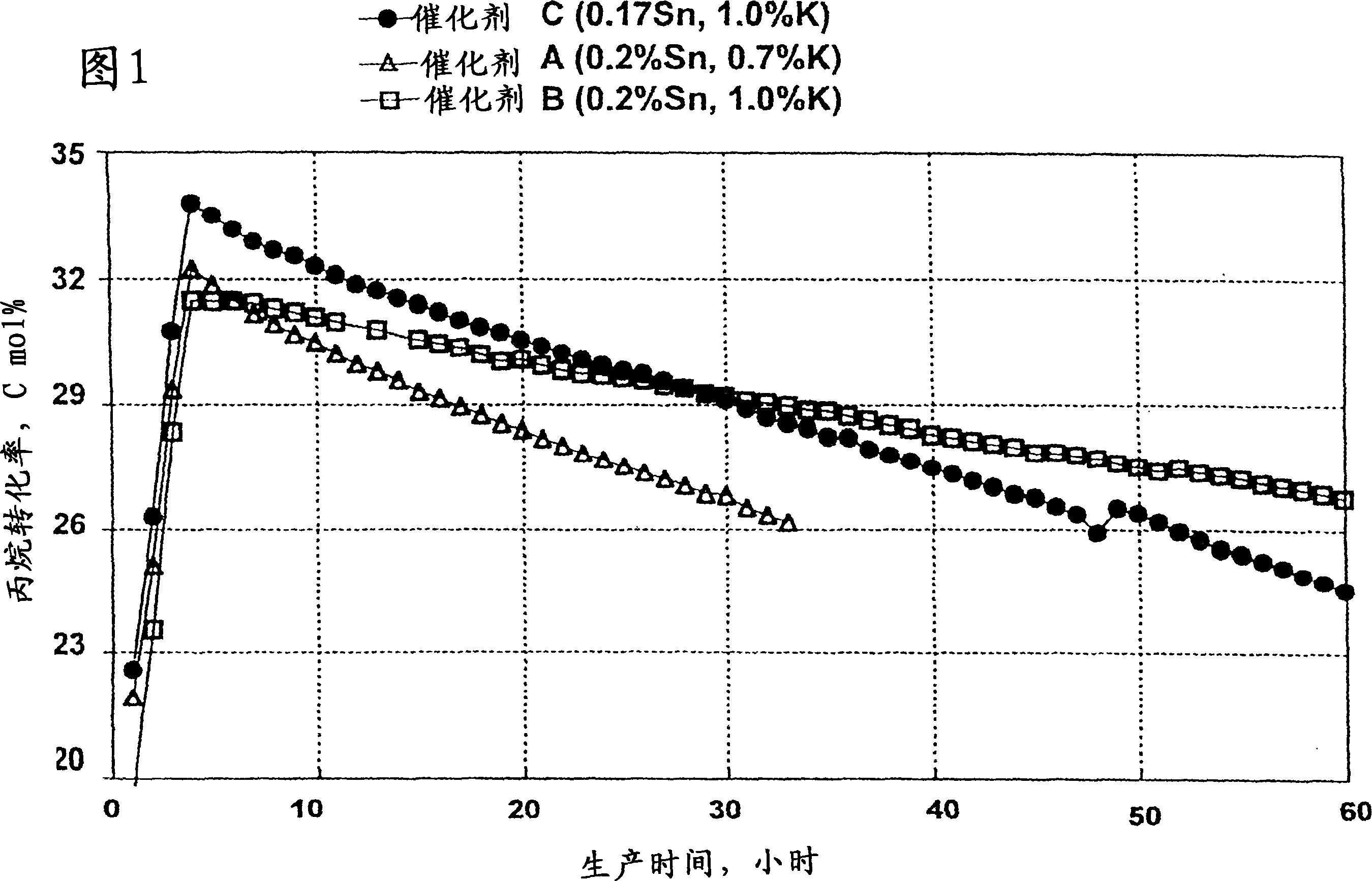

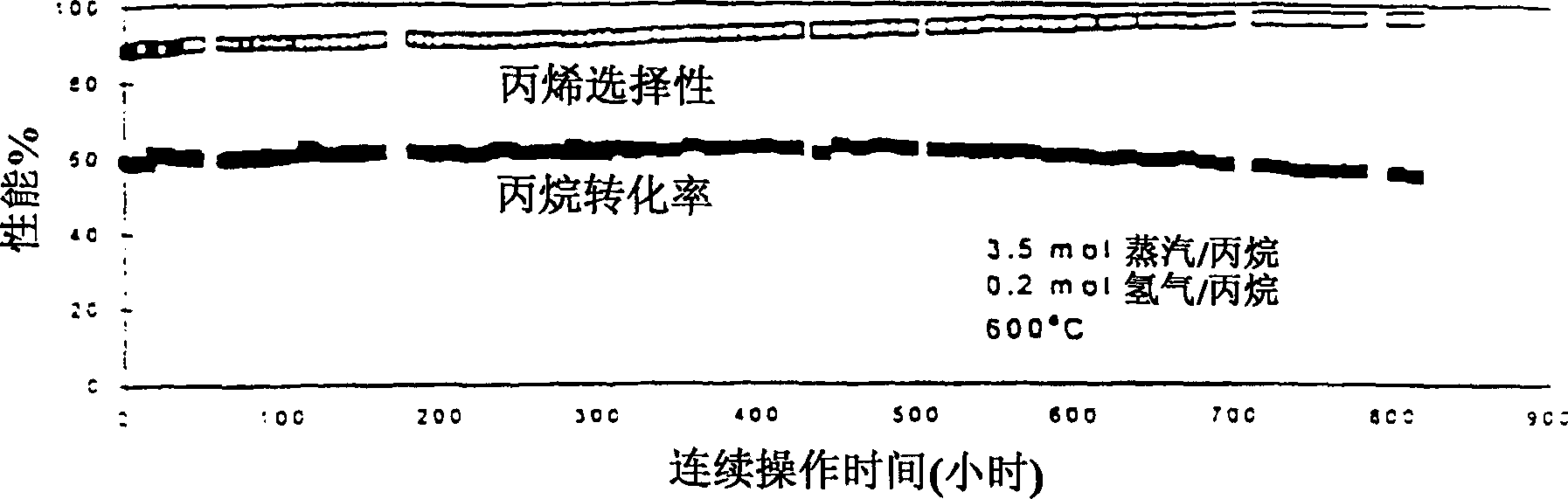

Preparation method of catalyst for producing propylene by propane dehydrogenation under carbon dioxide atmosphere

InactiveCN101785993AEasy to prepareLow costHydrocarbon by dehydrogenationMolecular sieve catalystsDehydrogenationSlow inactivation

The invention belongs to the technical field of catalysts, in particular to a preparation method of a catalyst for producing propylene by propane dehydrogenation under the carbon dioxide atmosphere and an application thereof. The preparation method can overcome the shortcomings of low activity, poor stability, high price and the like of the existing catalyst. An HZSM-5 zeolite with high silicon-aluminum ratio is taken as a carrier, zinc oxide is taken as an active component, the impregnation method in the prior art is adopted for preparing the catalyst, the prepration process is simple convenient, and the cost is low. When the catalyst is used for the reaction for producing the propylene by the propane dehydrogenation under the carbon dioxide atmosphere has the advantages of low price, simple process, high reaction activity, high yield of the propylene, good stability, slow inactivation and the like.

Owner:FUDAN UNIV

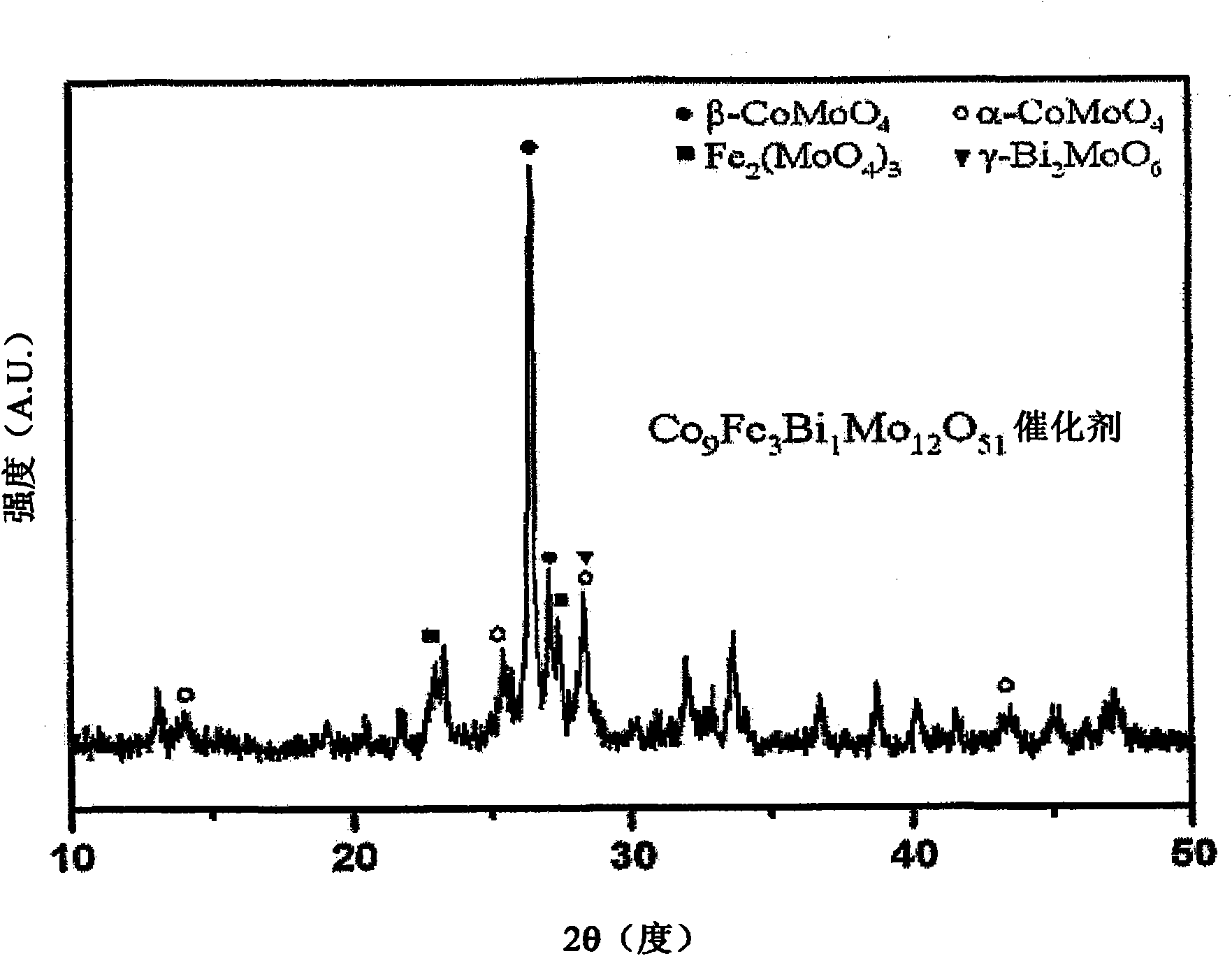

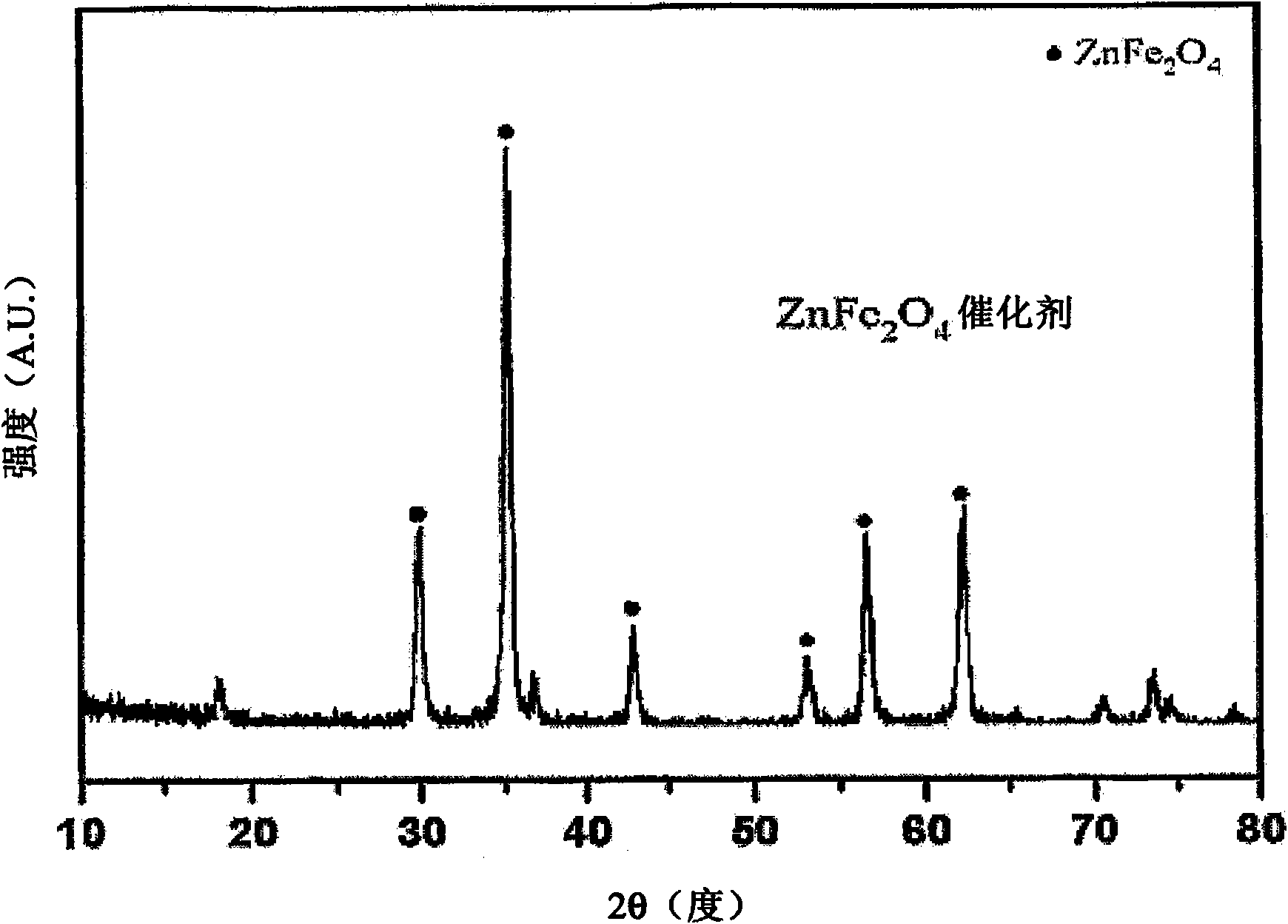

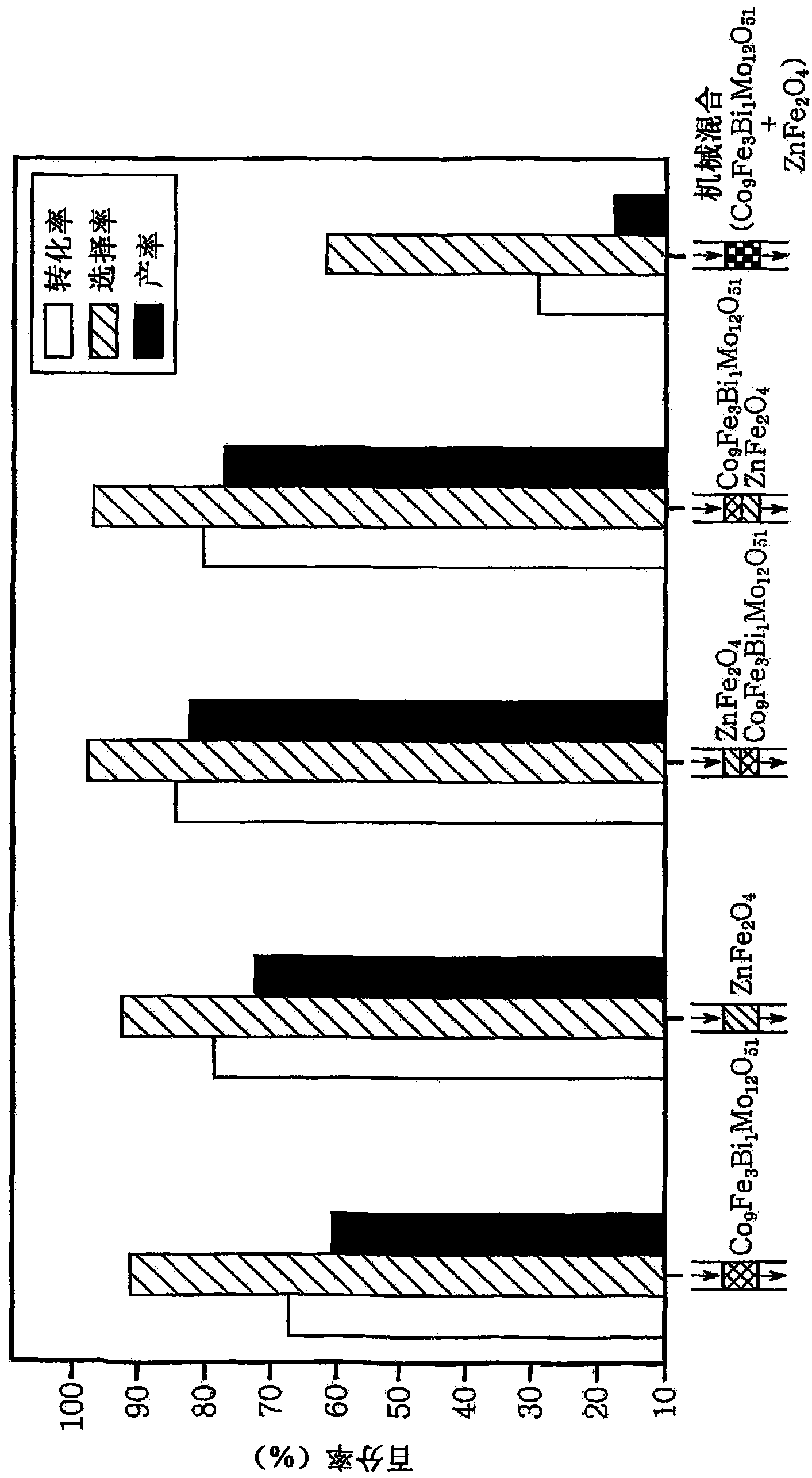

Method for preparing 1,3-butadiene from normal butene by using continuous-flow dual-bed reactor

InactiveCN101980992AHigh activityActivity maximizationHydrocarbon by dehydrogenationCatalystsDehydrogenationFixed bed

The present invention relates to a method for preparing 1,3-butadiene by an oxidative dehydrogenation of normal butene through the use of a continuous-flow dual-bed reactor which is designed in such a manner that a fixed bed reactor thereof is filled with two types of catalysts and two catalyst layers are not physically mixed. More particularly, the present invention relates to a method for preparing 1,3-butadiene through an oxidative dehydrogenation of normal butene using a C4 mixture, as a reactant, containing normal butene and normal butane, by using a continuous-flow dual-bed reactor employing a multi-component bismuth molybdate-based catalyst and a ferrite-based catalyst which have activations different from one another for the oxidative dehydrogenation of the isomers (1-butene, trans-2-butene, cis-2-butene) of normal butene.

Owner:SK INNOVATION CO LTD +1

Processes for making cx-cy olefins from c5 and c6 paraffins

Processes for making CX to CY olefins are provided. The processes include reacting a feedstock comprising C5 and C6 olefins under dimerization or oligomerization conditions to provide a dimerization or oligomerization product. The product is separated into a stream comprising unreacted C5 and C6 paraffins, a stream comprising C10 to CX-1 olefins, and a stream comprising CX to CY olefins, wherein X is at least 14 and Y is greater than X and less than or equal to 36.

Owner:UOP LLC

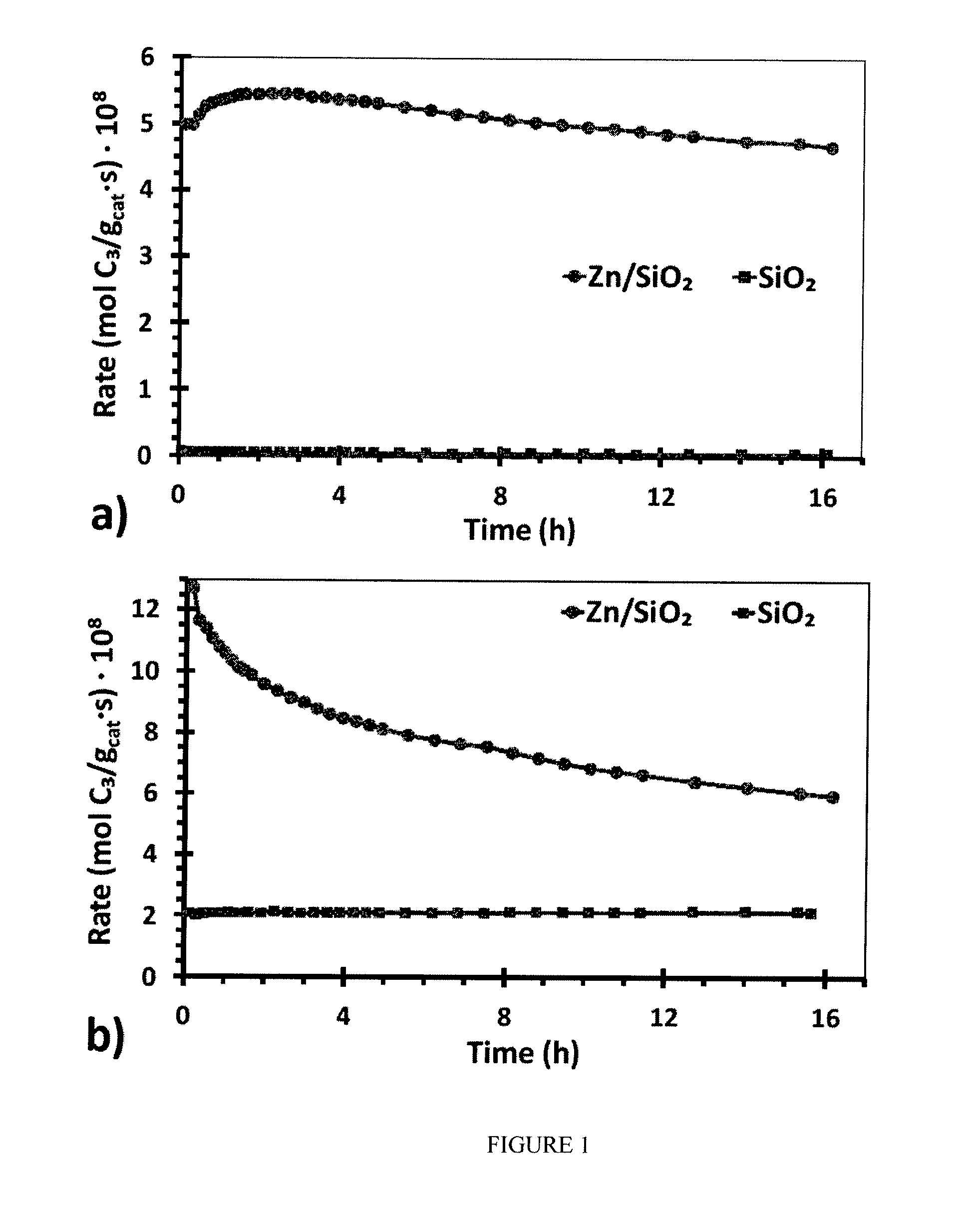

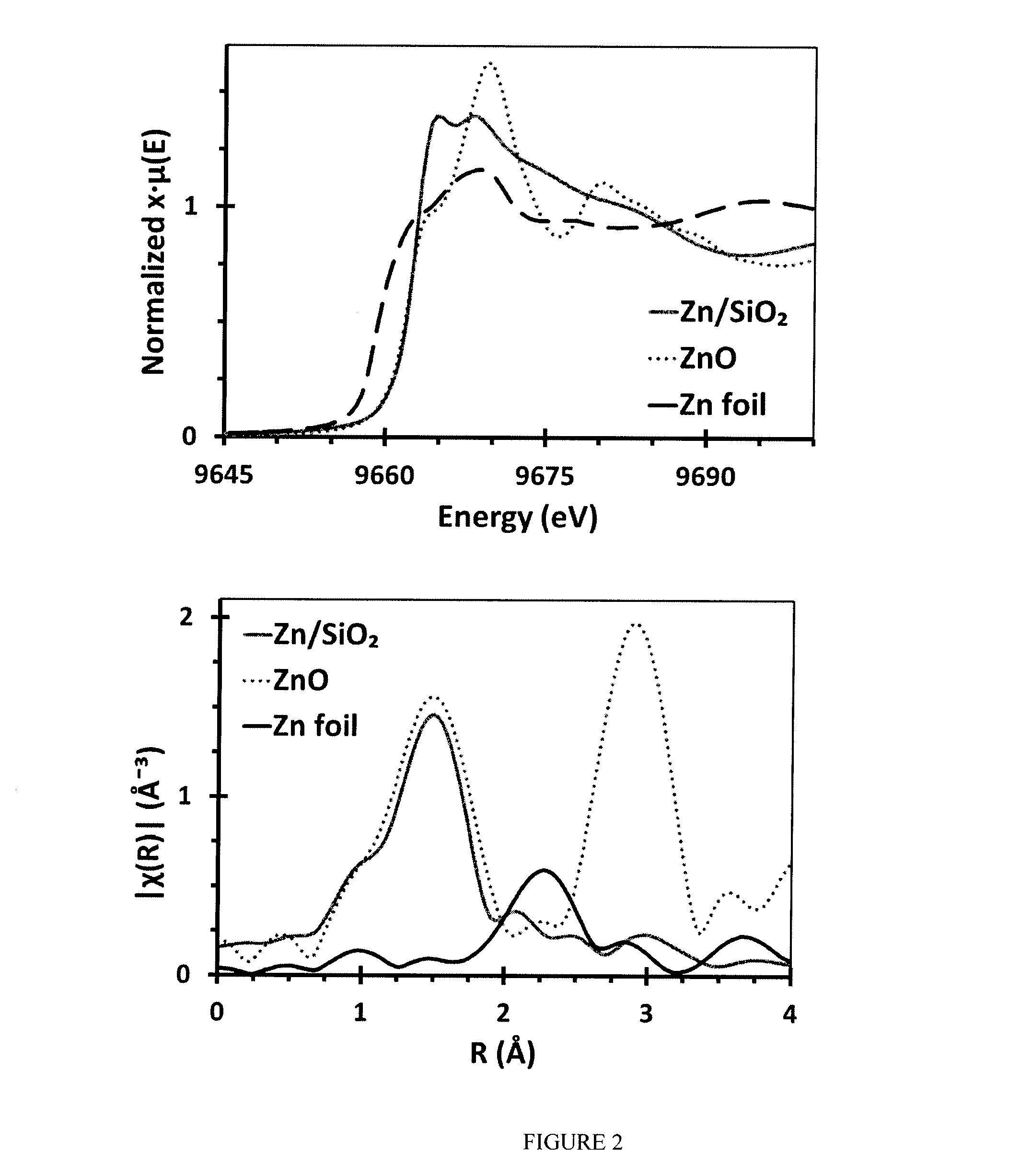

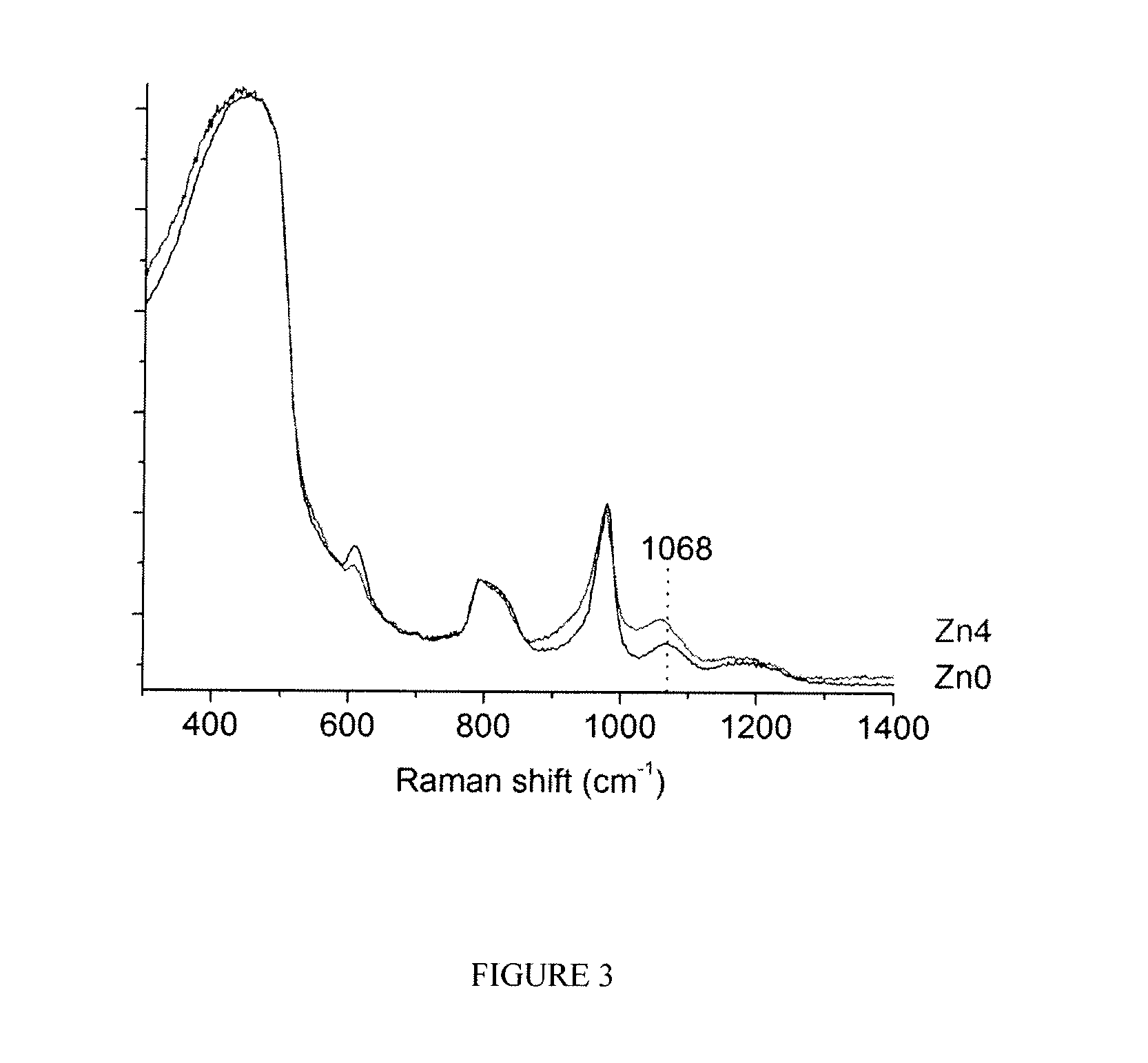

Selective alkane activation with single-site atoms on amorphous support

ActiveUS20140275686A1Retain it catalytic activityHydrocarbon by dehydrogenationCatalystsAlkaneBiological activation

The present invention relates generally to catalysts and methods for use in olefin production. More particularly, the present invention relates to novel amorphously supported single-center, Lewis acid metal ions and use of the same as catalysts.

Owner:UCHICAGO ARGONNE LLC

Method for synthesizing a catalyst based on anisotropic metallic nanoparticles by a micellar means

InactiveUS20080096986A1Easy to monitorMaterial nanotechnologyHydrocarbon by dehydrogenationPtru catalystReduction treatment

The invention relates to a process for preparation of anisotropic metallic nanoparticles comprising at least: a) One stage that is brought into contact with an aqueous solution that comprises at least one source of a metal that is selected from the columns 8, 9 or 10 of the periodic table and at least one soluble surfactant, b) One stage for formation of anisotropic metallic nanoparticles of at least one of said metals, by adding at least one reducing agent to the solution that is obtained in stage a), c) Said particles are: c1) separated from liquid and optionally dried, or c2) deposited on a substrate by impregnation with the suspension obtained in stage b) or after resuspension of the nanoparticles that are obtained at the end of stage c1), whereby the substrate is an oxide of unordered texture, and after separation of the possible residual liquid, the material that is obtained is dried at a temperature that is less than or equal to 120° C., and said solid is subjected to a reduction treatment by hydrogen at a temperature that is less than or equal to 100° C.

Owner:INST FR DU PETROLE

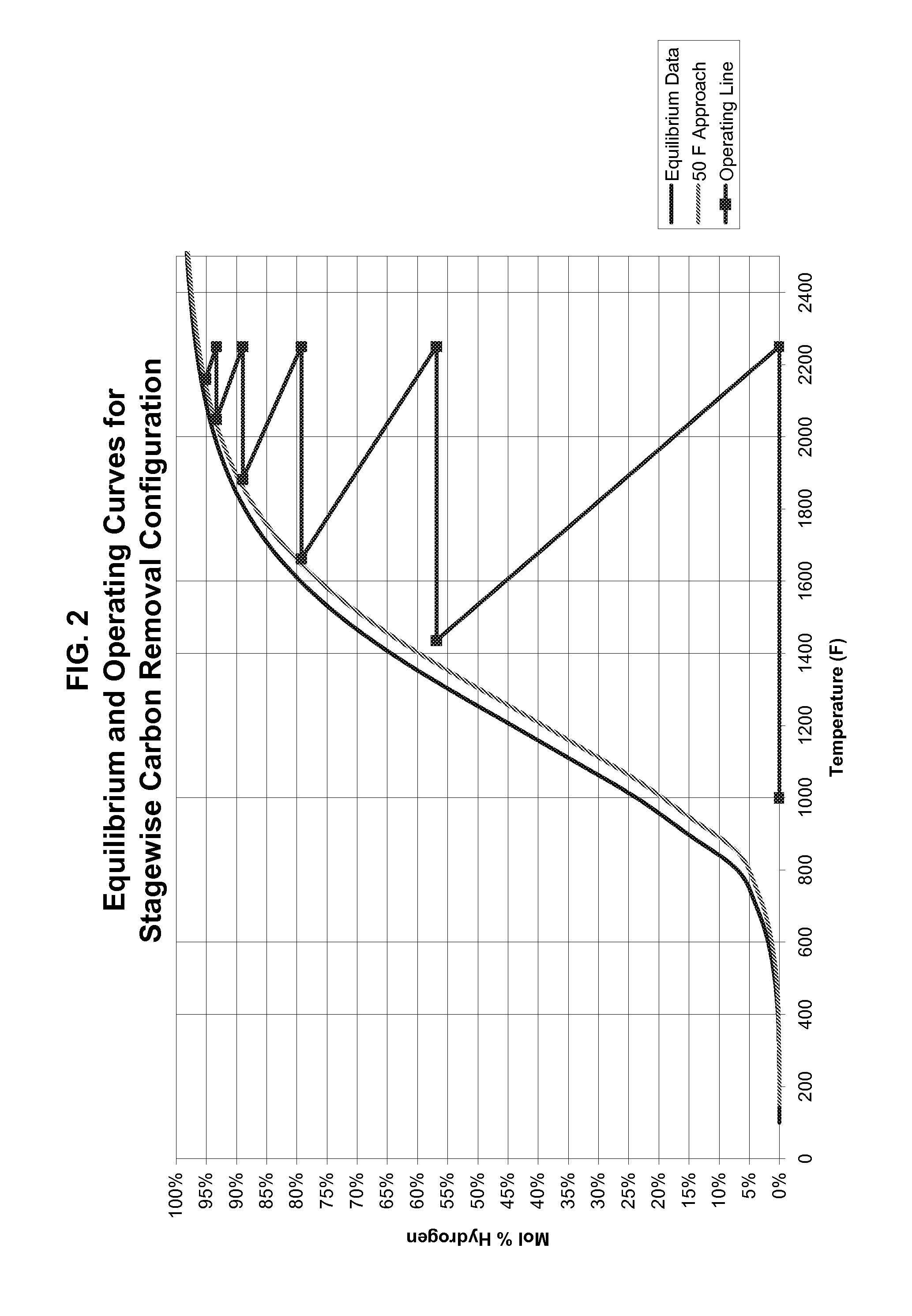

Electric reaction technology for fuels processing

A method and apparatus for producing hydrogen is disclosed wherein a hydrocarbon gas is fed into an electric reaction technology system to decompose the hydrocarbon gas to hydrogen gas and carbon solids. The electric reaction technology system comprises one or more heating zones, wherein each heating zone comprises one or more heating stations and each heating station comprises one or more heating screens followed by a final near-equilibrium attainment zone without additional heat input. After passing the hydrogen gas through the electric reaction technology system the hydrogen gas and any remaining carbon solids and hydrocarbon gas are cooled. The hydrogen gas and any remaining carbon solids and hydrocarbon gas flow through a scrubber, filter, drier or other phase separation system to remove substantially all of the carbon, leaving hydrogen product. The electric reaction technology system can also be used to pyrolyze hydrocarbons.

Owner:EGT ENTERPRISES

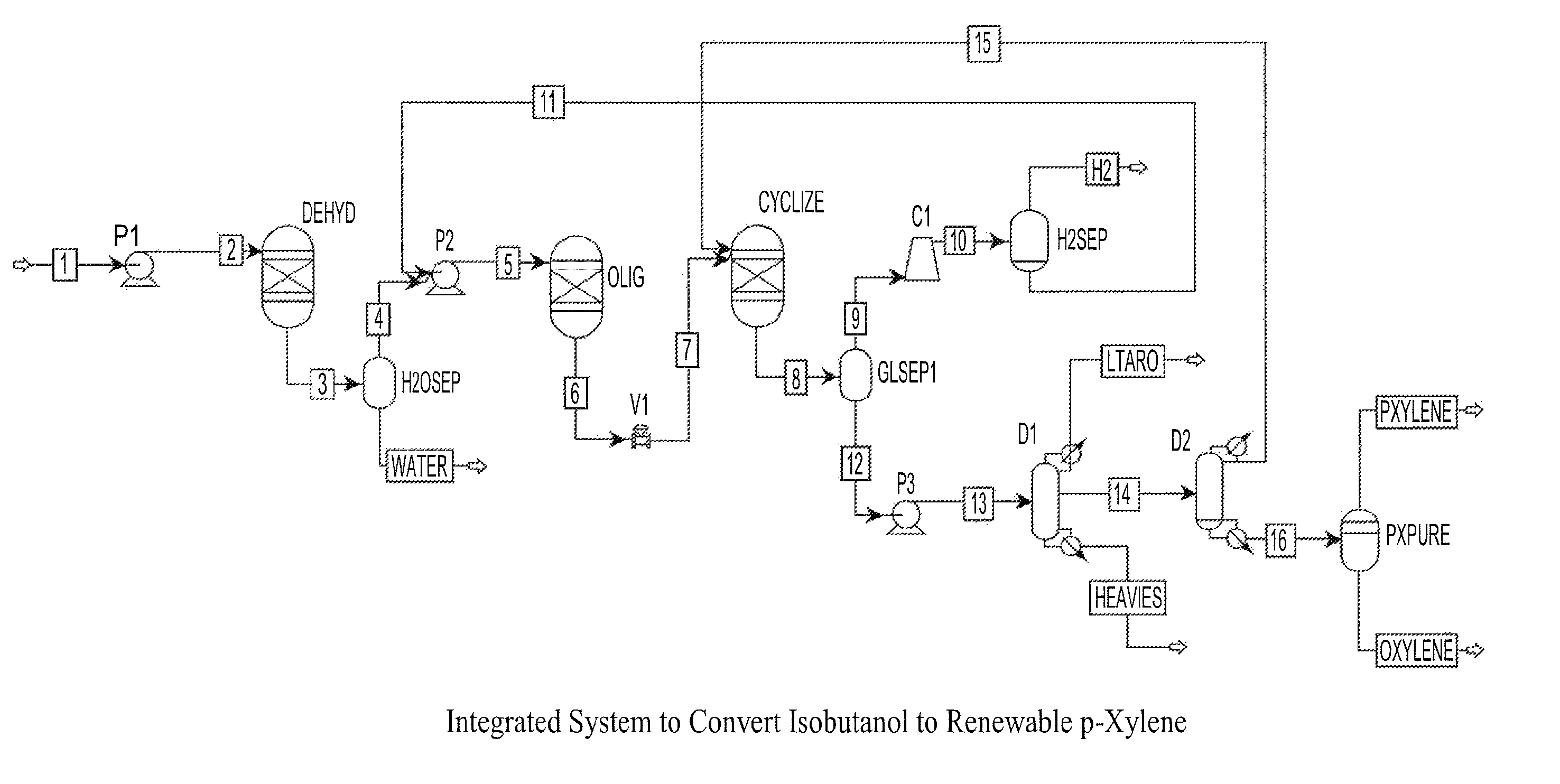

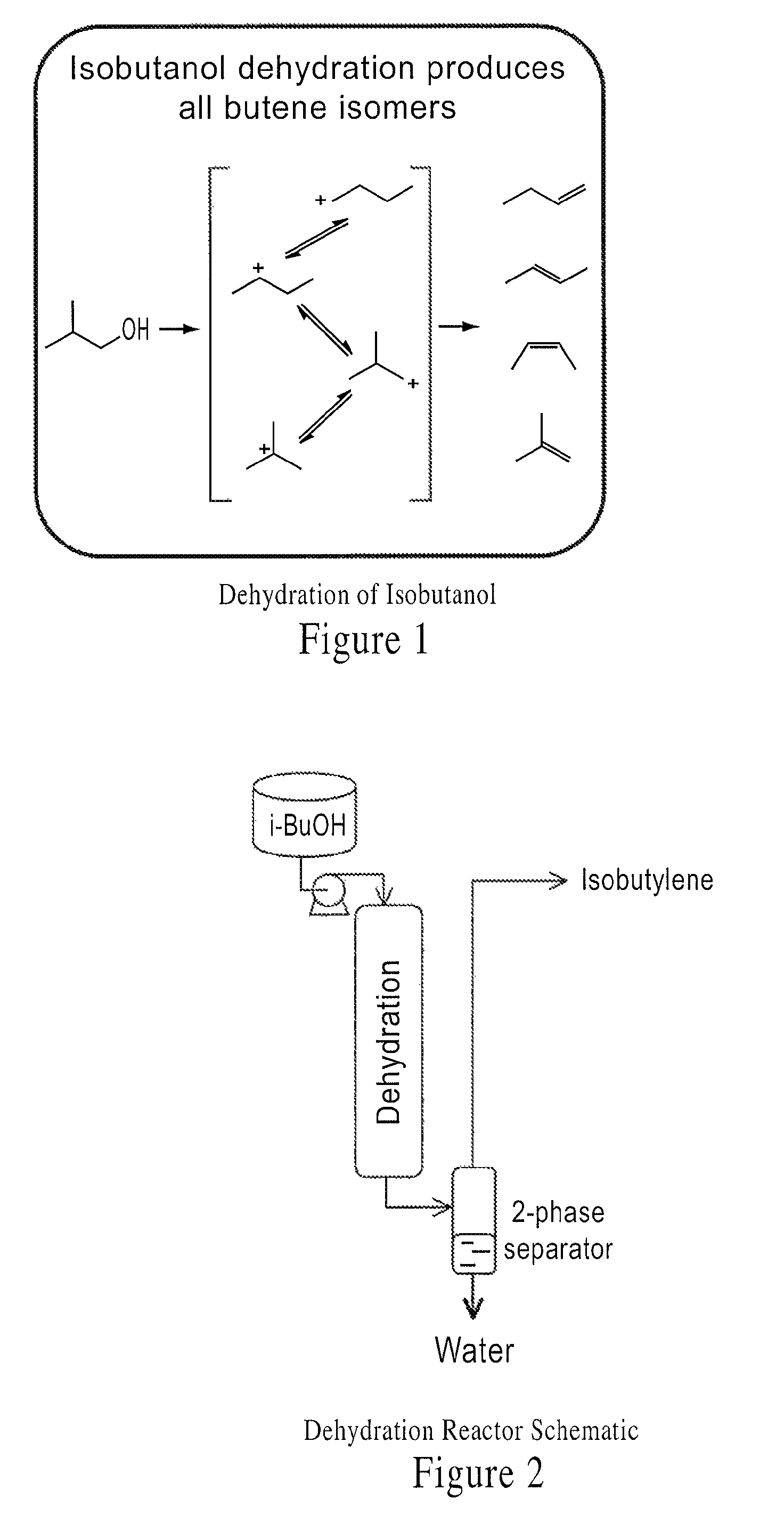

Integrated methods of preparing renewable chemicals

ActiveUS8450543B2Readily and flexibly adaptHydrocarbon by dehydrogenationHydrocarbon by hydrogenationPolyesterPolymer science

Isobutene, isoprene, and butadiene are obtained from mixtures of C4 and / or C5 olefins by dehydrogenation. The C4 and / or C5 olefins can be obtained by dehydration of C4 and C5 alcohols, for example, renewable C4 and C5 alcohols prepared from biomass by thermochemical or fermentation processes. Isoprene or butadiene can be polymerized to form polymers such as polyisoprene, polybutadiene, synthetic rubbers such as butyl rubber, etc. in addition, butadiene can be converted to monomers such as methyl methacrylate, adipic acid, adiponitrile, 1,4-butadiene, etc. which can then be polymerized to form nylons, polyesters, polymethylmethacrylate etc.

Owner:GEVO INC

Paraffin dehydrogenation catalyst

InactiveUS7279611B2High activityRobust hydrothermal stabilityHydrocarbon by dehydrogenationHydrocarbon by hydrogenationParaffin waxLithium oxide

One aspect of the invention relates to a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide. The invention also relates to methods of making the dehydrogenation catalyst composite. Another aspect of the invention relates to method of dehydrogenating a dehydrogenatable hydrocarbon involving contacting the dehydrogenatable hydrocarbon with a dehydrogenation catalyst composite containing alumina, chromium oxide, lithium oxide, and sodium oxide to provide a dehydrogenated hydrocarbon, such as an olefin.

Owner:TEXAS PETROCHEM +1

Sulfur tolerant zeolite catalyst

InactiveUS6063723AHigh yieldHigh selectivityAluminosilicate zeolite type ZSM-12SilicaSulfurDehydrogenation

A process is provided for catalyst dehydrogenation of light paraffinic hydrocarbons using a catalyst comprising a noble metal and an intermediate pore size zeolite having a specified alkali content. The catalyst is sulfur tolerant, so that the dehydrogenation process can be carried out in the presence of sulfur or with periodic exposure to sulfur.

Owner:CHEVROU USA INC

Popular searches

Transportation and packaging Catalytic naphtha reforming Indirect heat exchangers Treatment with hydrotreatment processes Hydrocarbon by hydrocarbon condensation Hydrogen/synthetic gas production Mixing gases with gases/vapours Naphtha treatment Hydrocarbon by hydrocarbon cracking Hydrocarbon from oxygen organic compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com