Patents

Literature

55results about "Aluminosilicate zeolite type ZSM-12" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrothermally stable metal promoted zeolite beta for NOx reduction

InactiveUS7332148B2Good hydrothermal stabilityImprove stabilityAluminosilicate zeolite type ZSM-12Aluminium compoundsNitrogen oxidesIr absorption

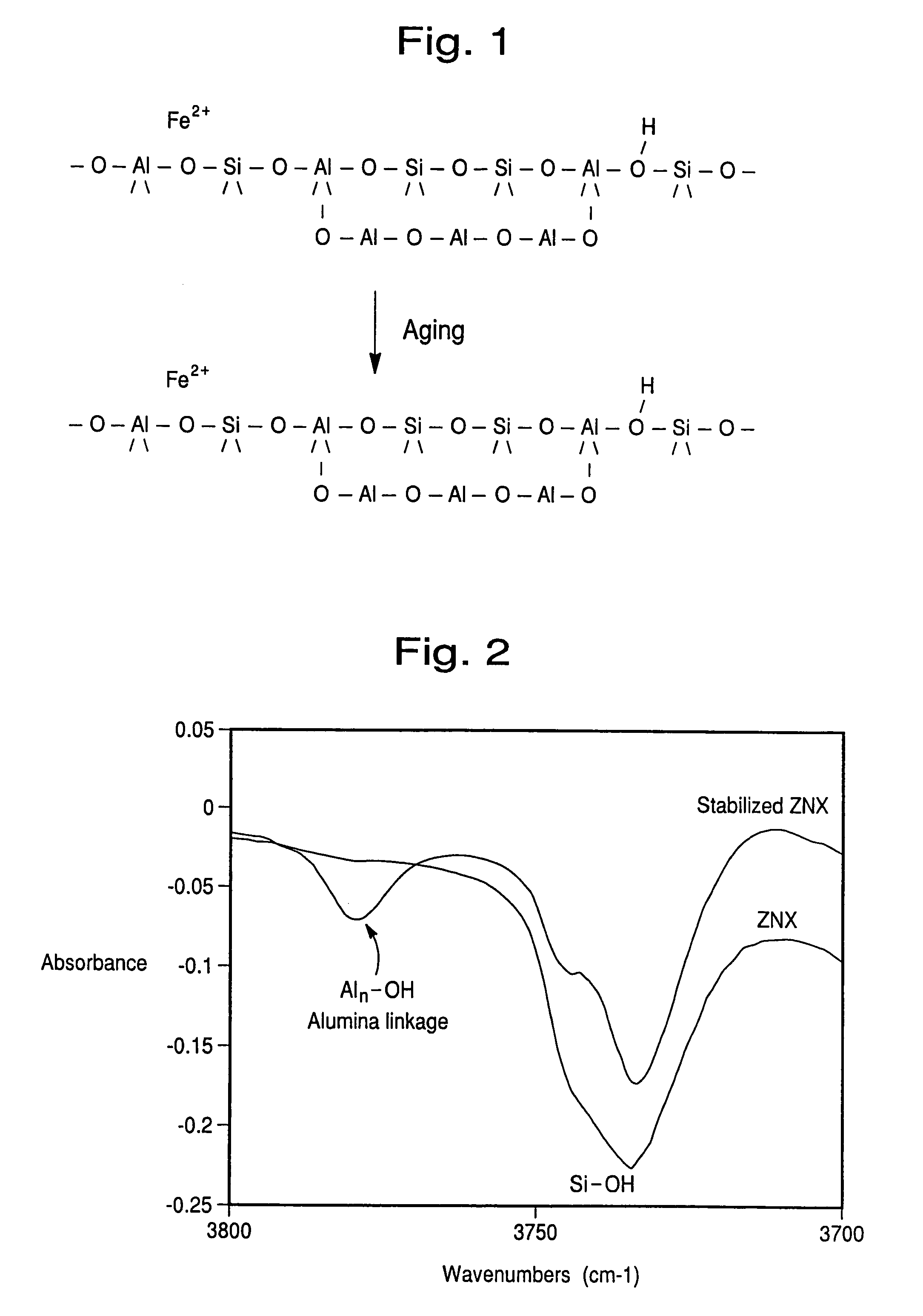

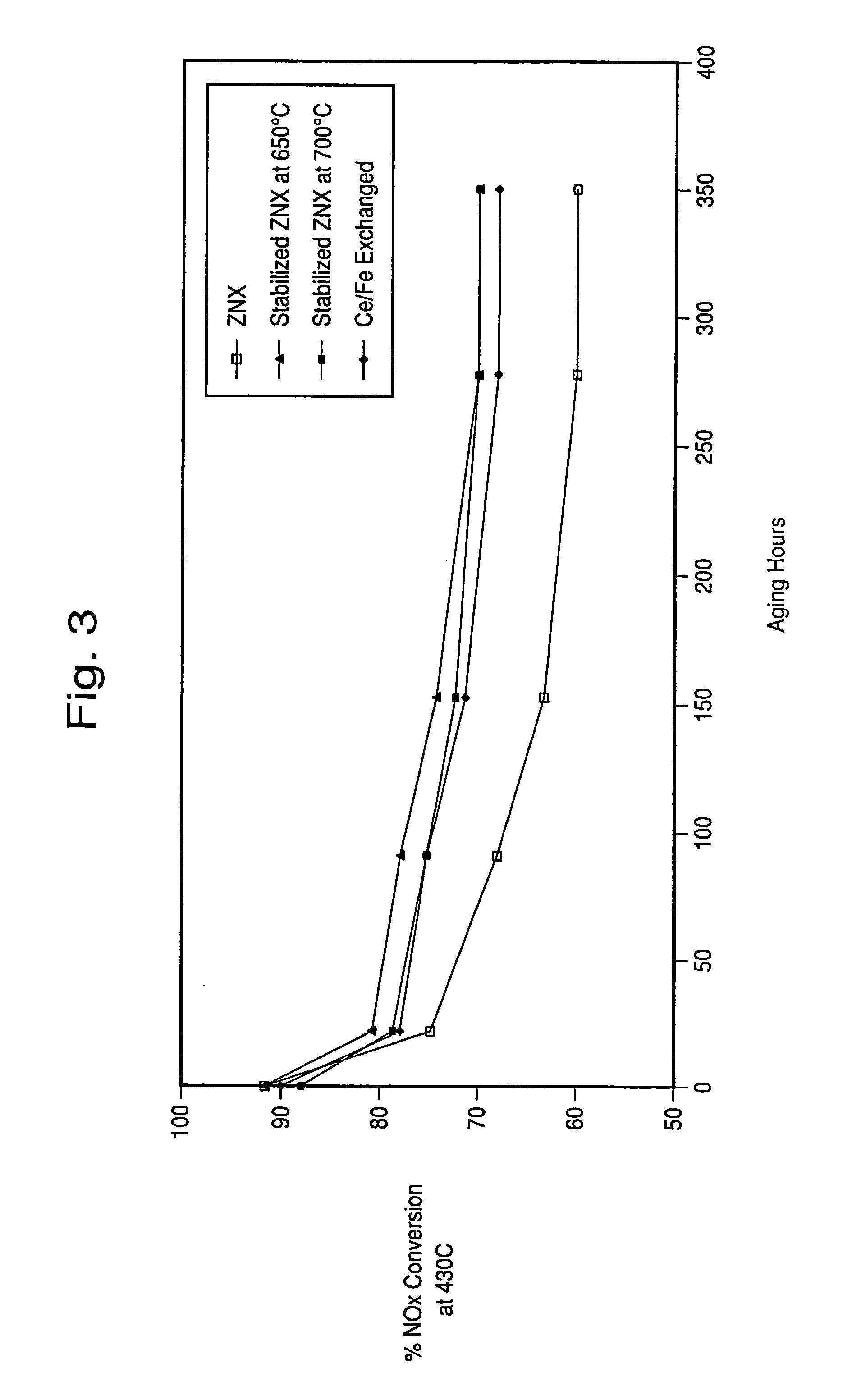

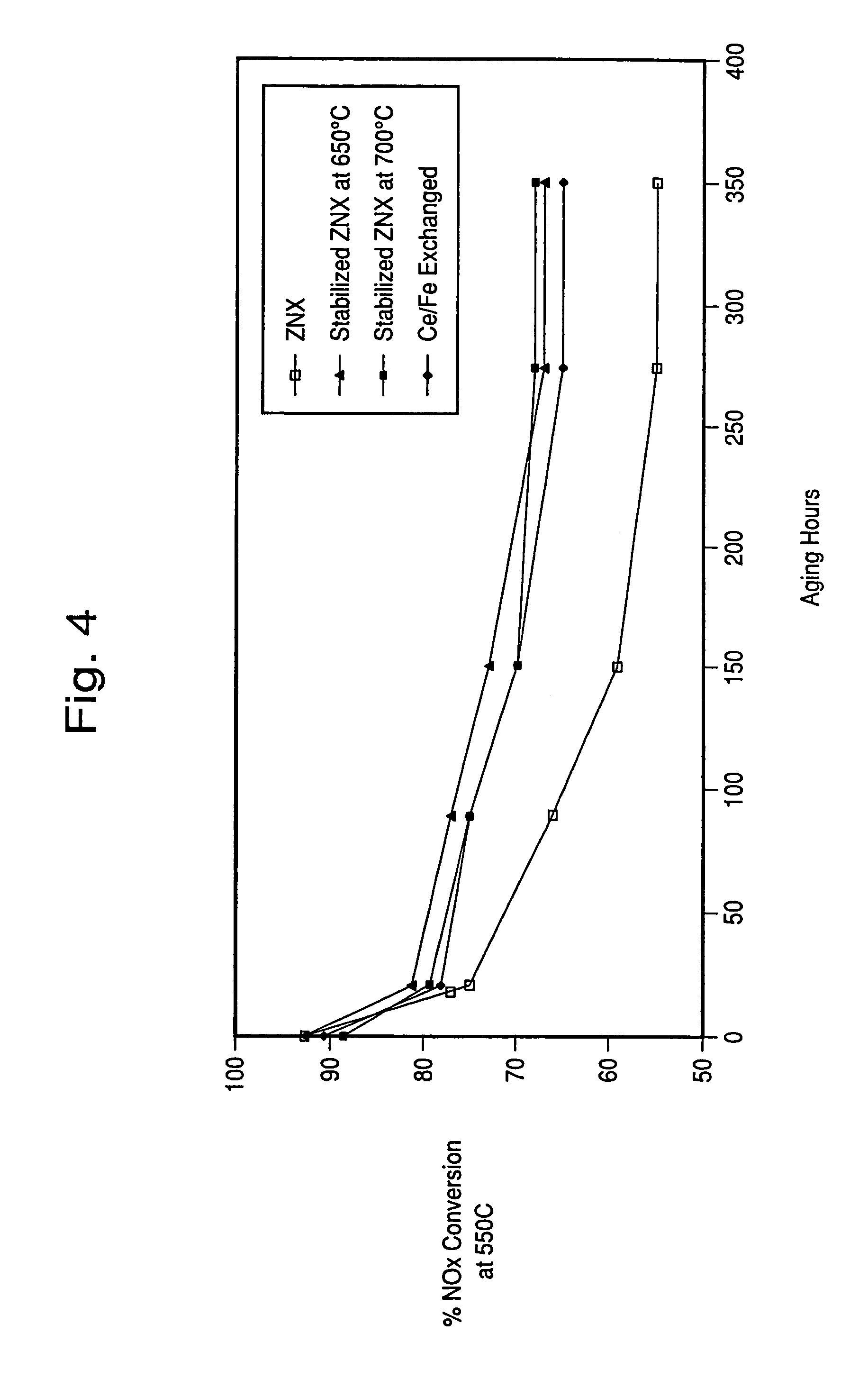

A stabilized metal promoted aluminosilicate zeolite, useful in the selective catalytic reduction of nitrogen oxides with ammonia, having a silica to alumina mole ratio of at least 8 and less than 30 and an FT-IR absorption peak at 3781 plus or minus 2 cm−1 which stabilizes the zeolite against further dealumination such as under oxidizing and harsh hydrothermal conditions.

Owner:ENGELHARD CORP

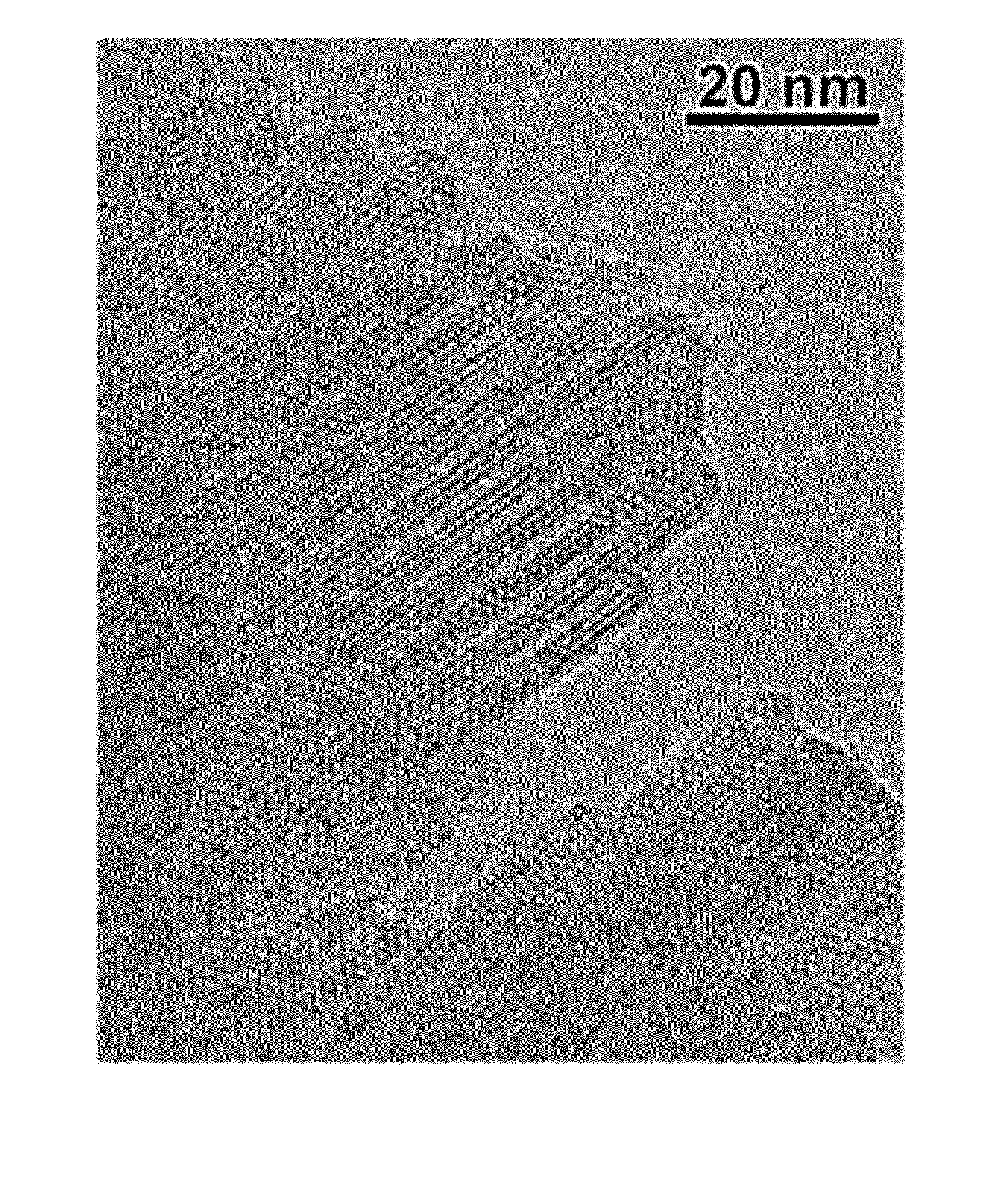

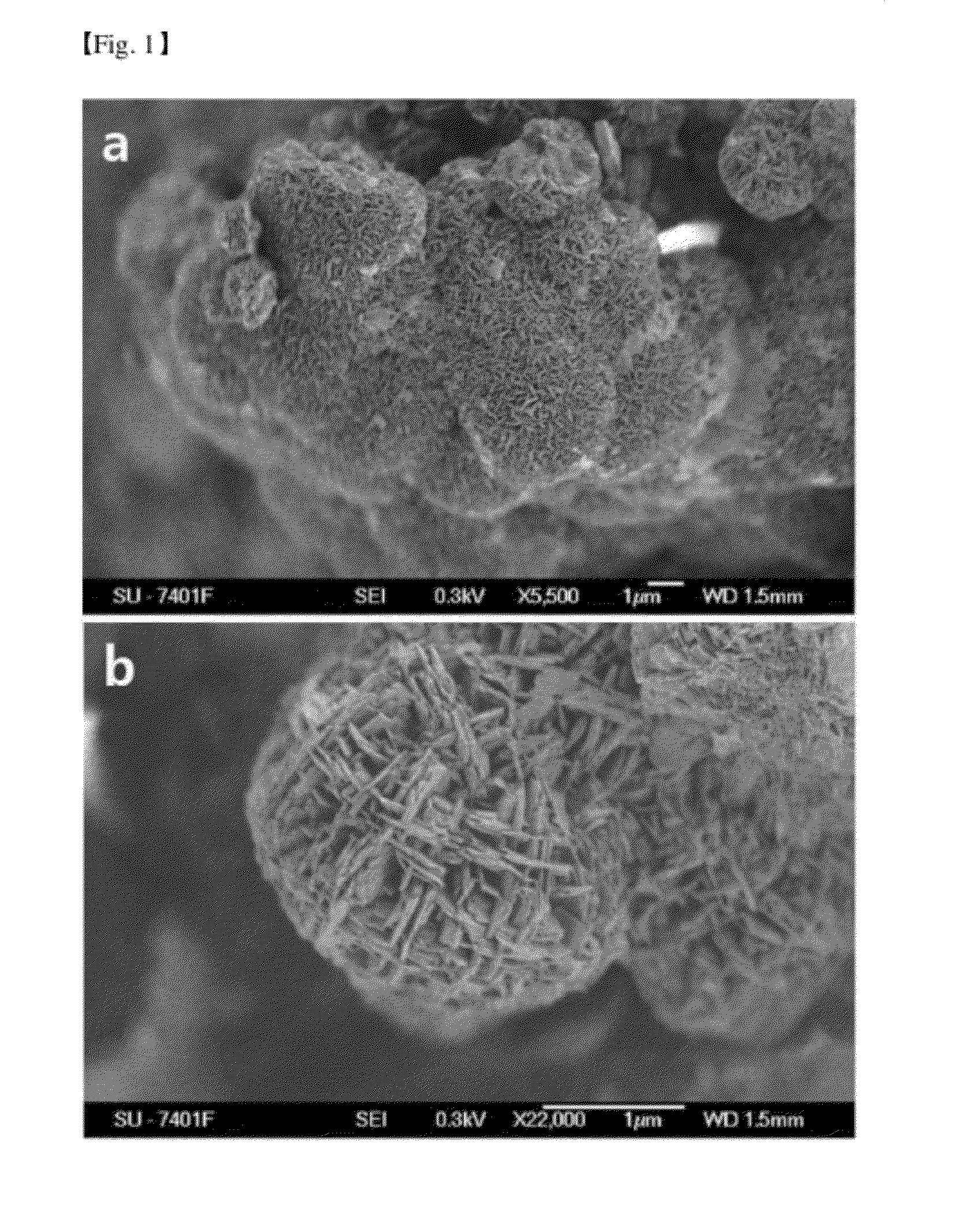

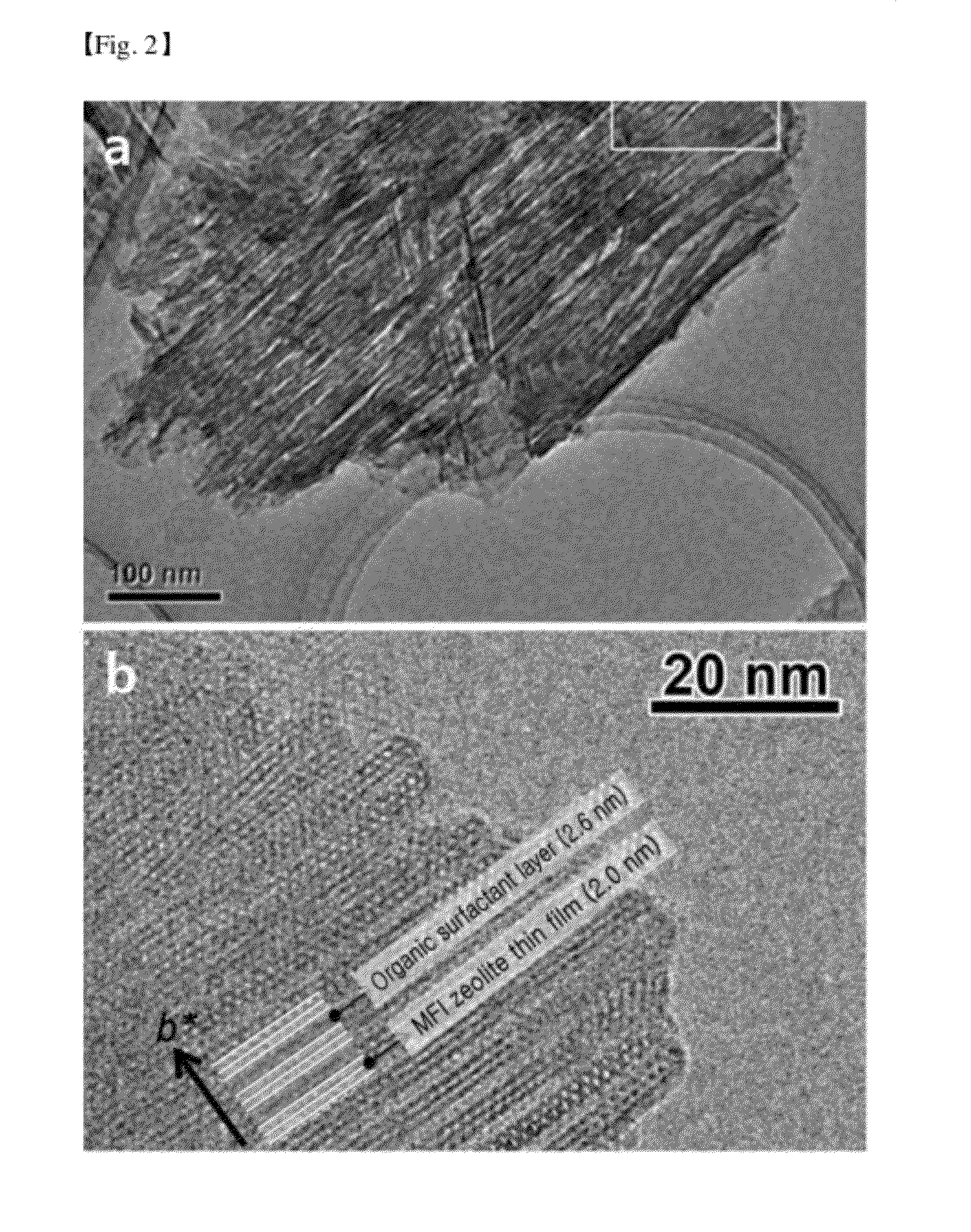

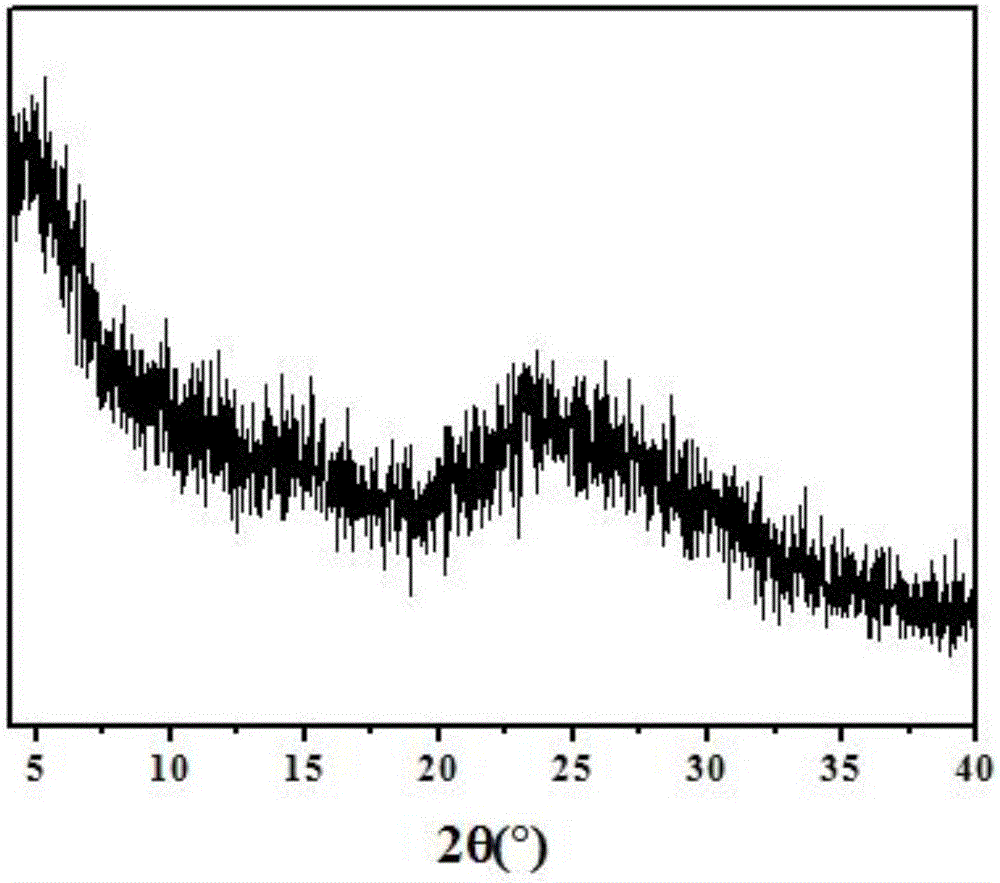

Regularly stacked multilamellar and randomly aligned unilamellar zeolite nanosheets, and their analogue materials whose framework thickness were corresponding to one unit cell size or less than 10 unit cell size

InactiveUS20120165558A1Increase surface areaHigh catalytic activityHydrogenAluminium compoundsIon exchangeOrganic reaction

The present invention relates to microporous molecular sieve materials and their analogue molecular sieve materials having a crystalline unilamellar or multilamellar framework with a single unit cell thickness in which layers are aligned regularly or randomly, the molecular sieve materials being synthesized by adding an organic surfactant to the synthesis composition of zeolite. In addition, the present invention relates to micro-mesoporous molecular sieve materials activated or functionalized by dealumination, ion exchange or other post treatments, and the use thereof as catalyst. These novel materials have dramatically increased external surface area by virtue of their framework with nano-scale thickness, and thus exhibit improved molecular diffusion, and thus have much higher activities as catalyst and ion exchange resin than conventional zeolites. In particular, the materials of the present invention exhibit high reactivity and dramatically increased catalyst life in various organic reactions such as carbon-carbon coupling, alkylation, acylation, etc. of organic molecules.

Owner:KOREA ADVANCED INST OF SCI & TECH

Sulfur tolerant zeolite catalyst

InactiveUS6063723AHigh yieldHigh selectivityAluminosilicate zeolite type ZSM-12SilicaSulfurDehydrogenation

A process is provided for catalyst dehydrogenation of light paraffinic hydrocarbons using a catalyst comprising a noble metal and an intermediate pore size zeolite having a specified alkali content. The catalyst is sulfur tolerant, so that the dehydrogenation process can be carried out in the presence of sulfur or with periodic exposure to sulfur.

Owner:CHEVROU USA INC

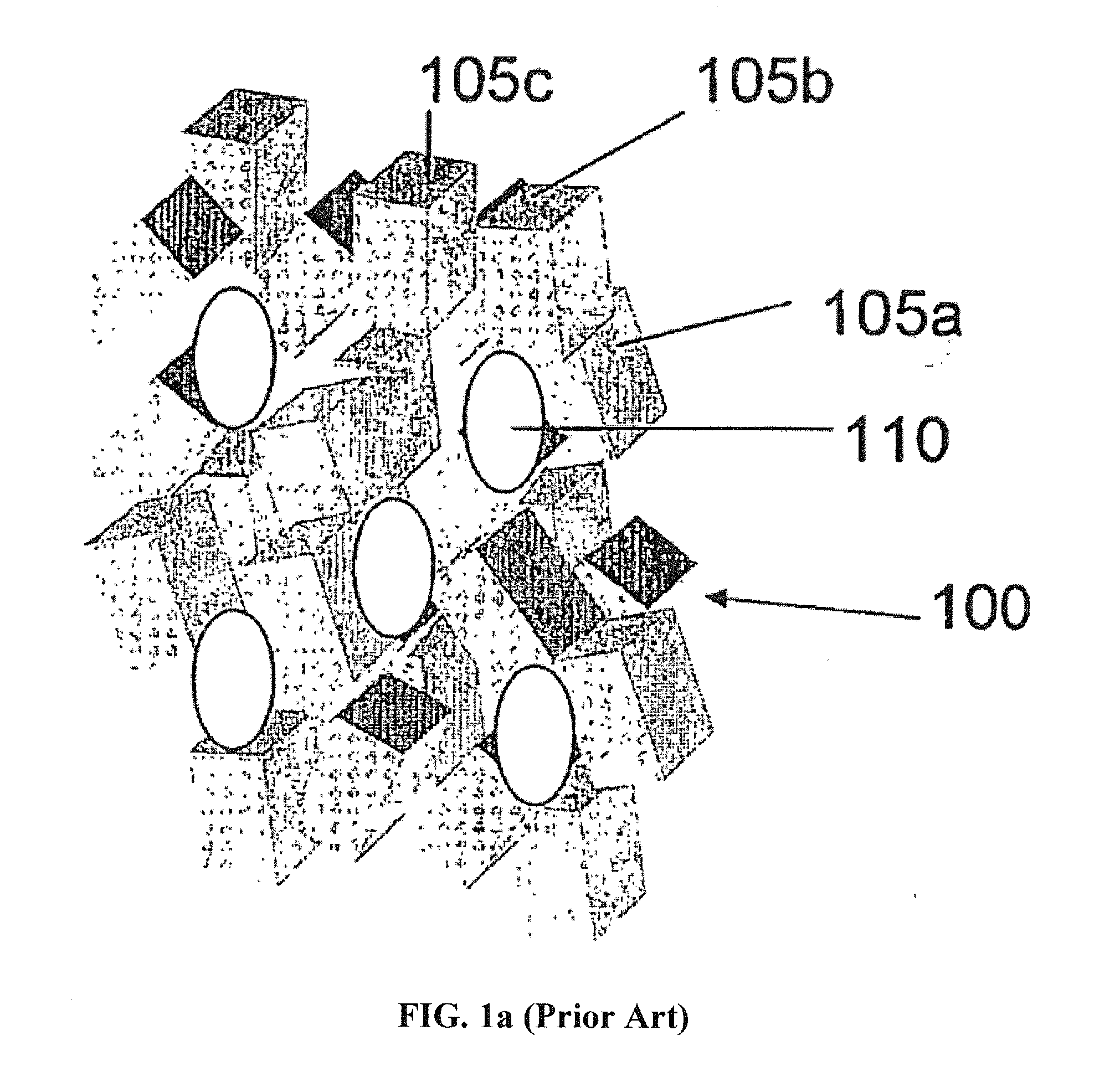

Dehydroxylation pretreatment of inorganic materials in mesopore introduction process

Mesoporous compositions and methods for preparing mesoporous and / or mesostructured materials from inorganic materials are provided. Various embodiments described herein relate to the preparation of mesoporous and / or mesostructured zeolites via a dehydroxylation pretreatment followed by a mesopore introduction step.

Owner:RIVE TECH

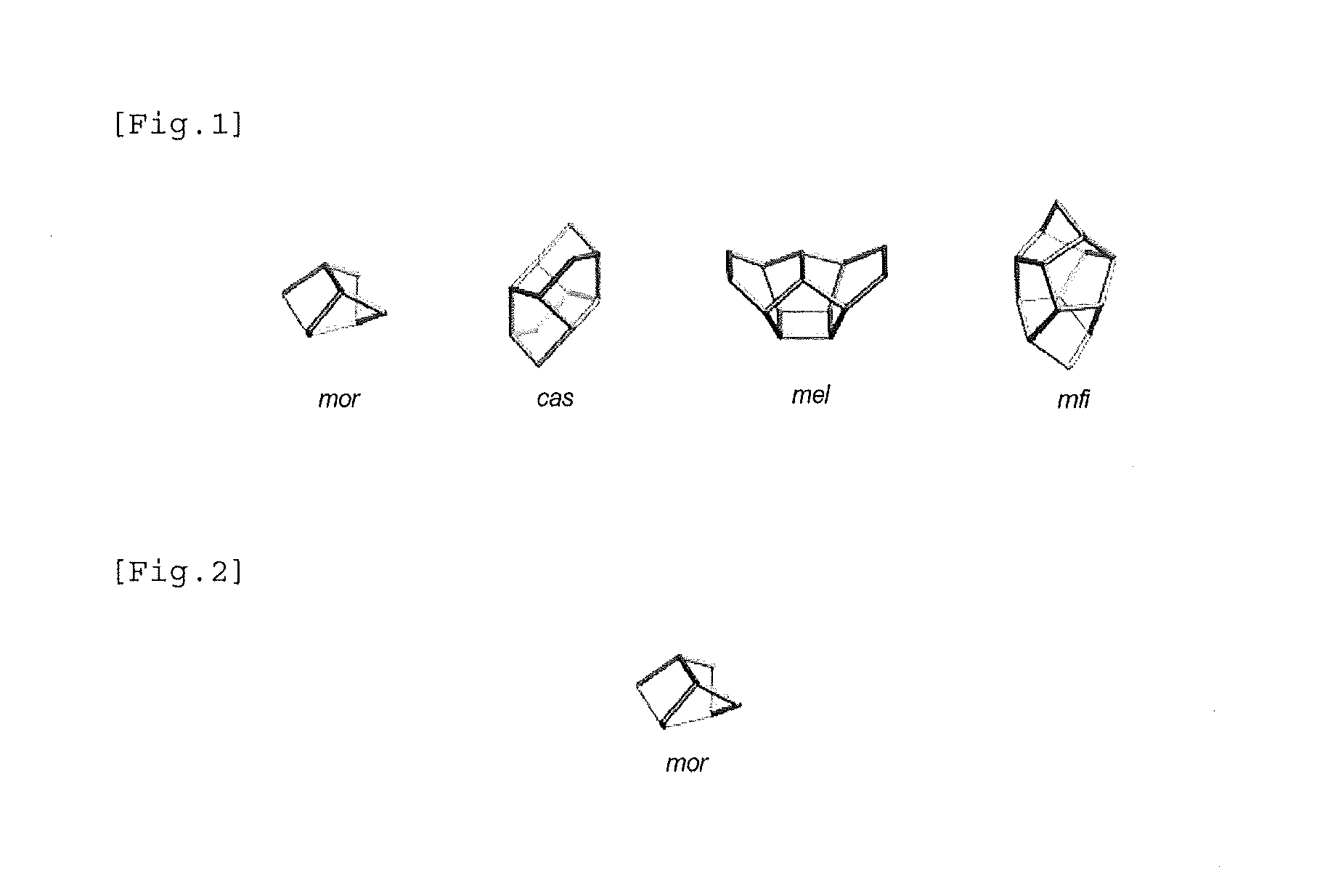

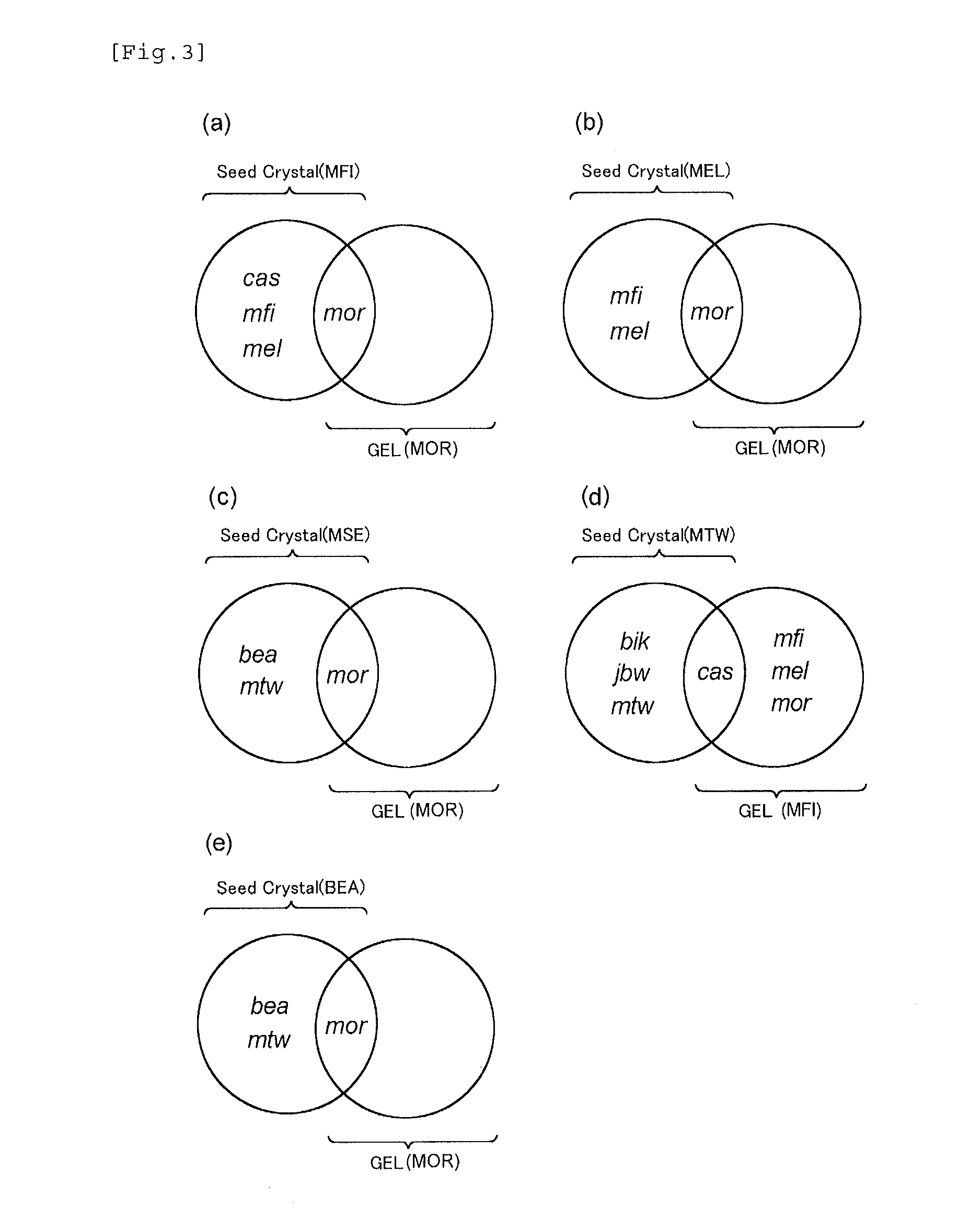

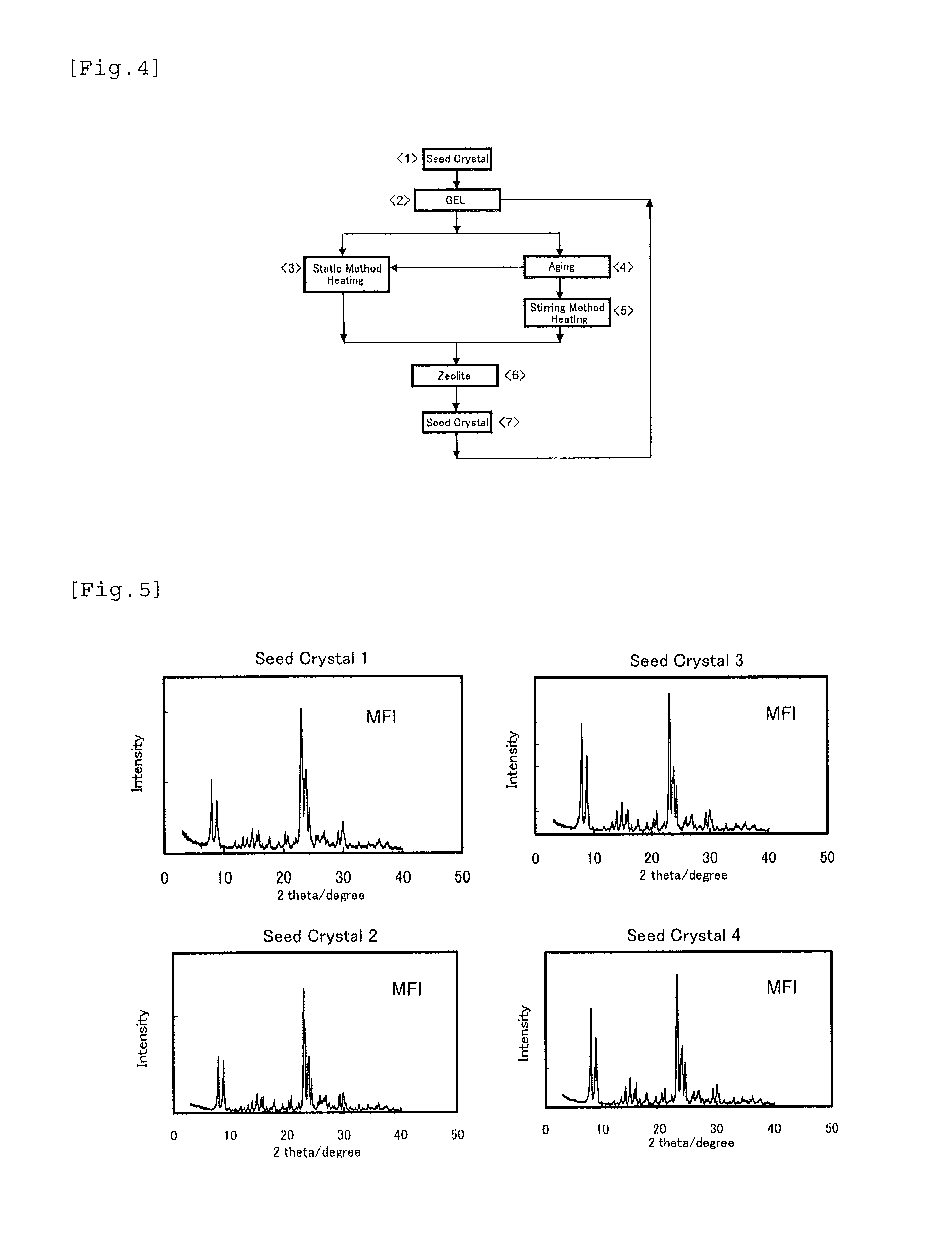

Zeolite production method

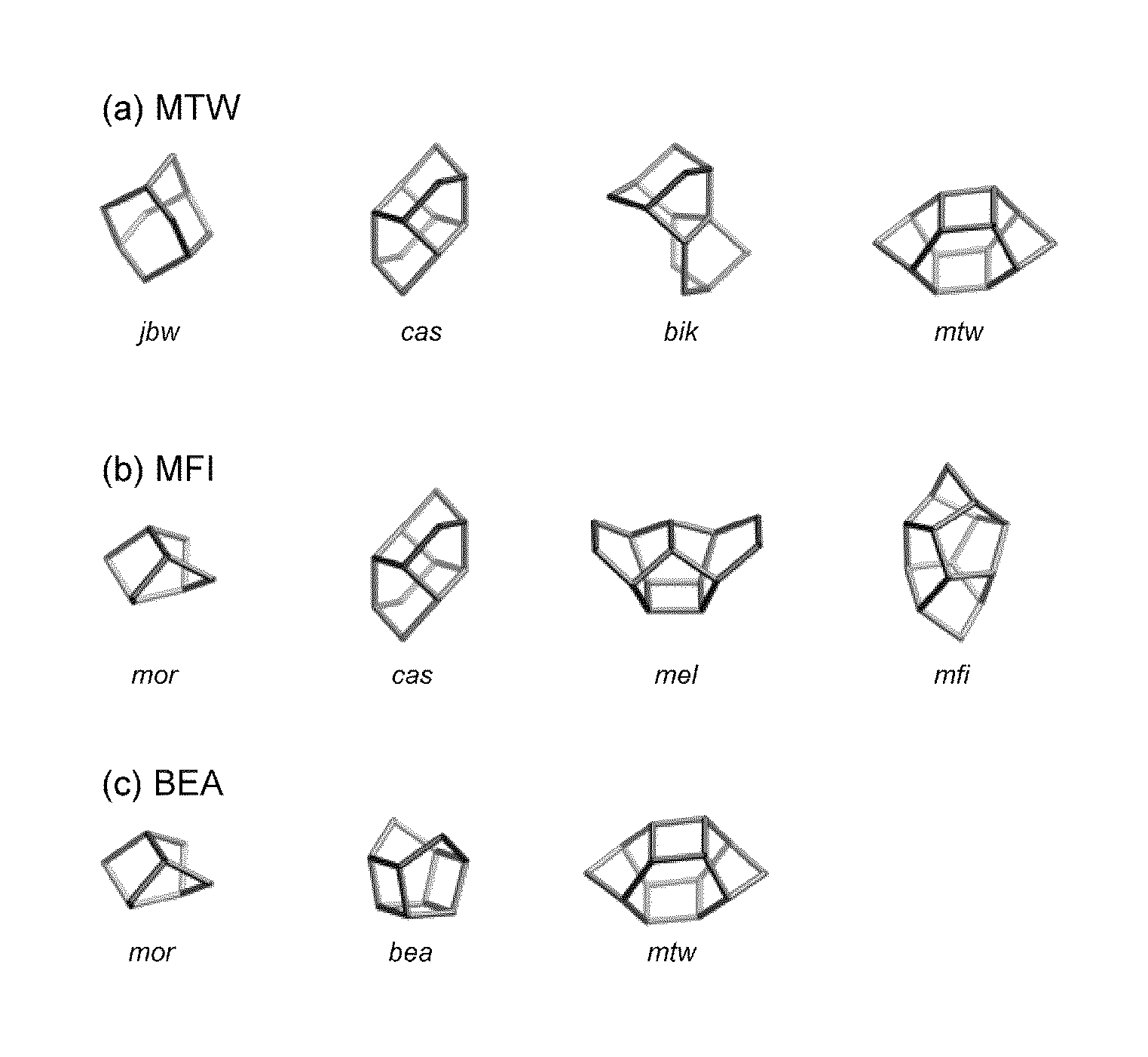

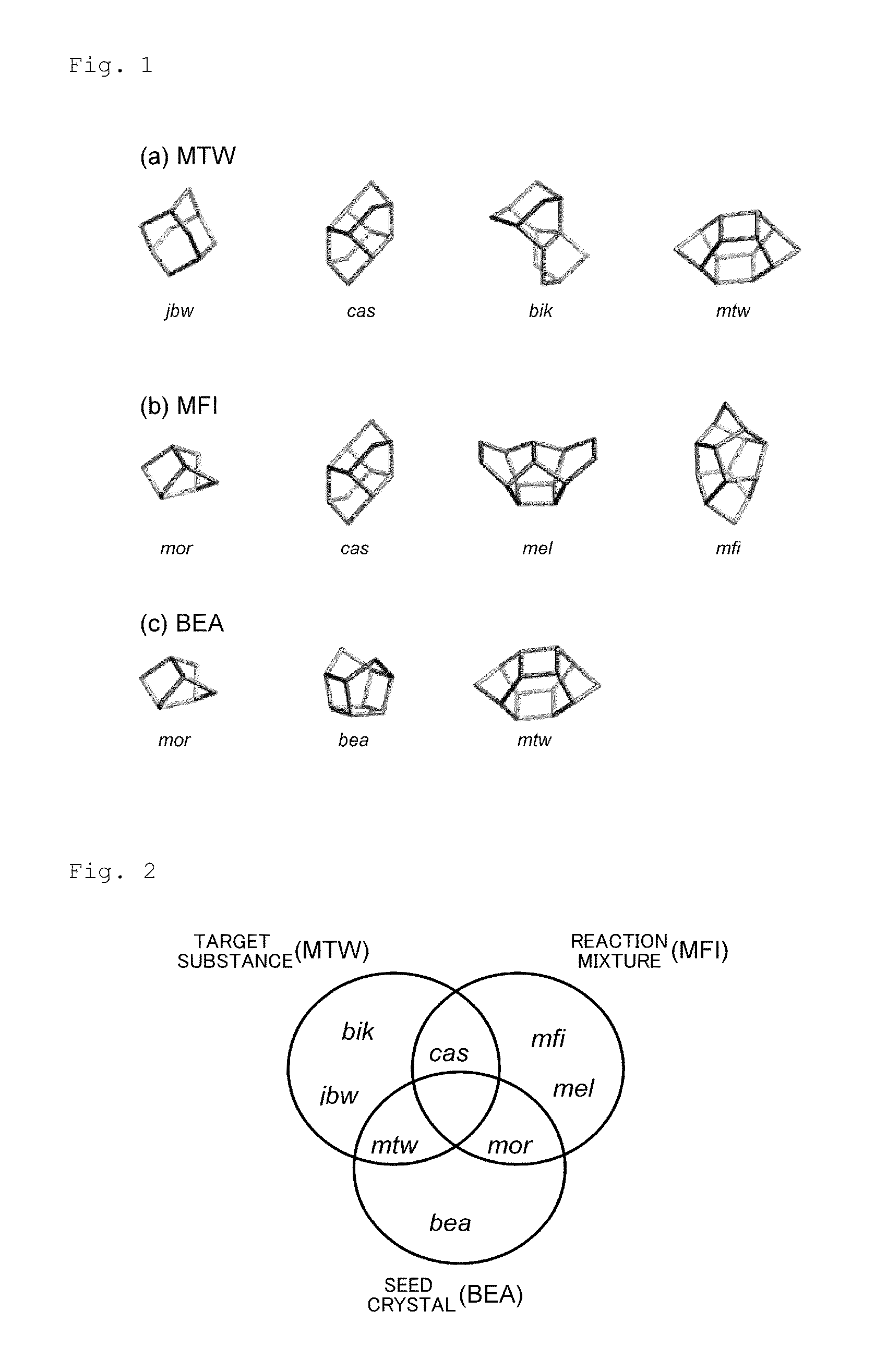

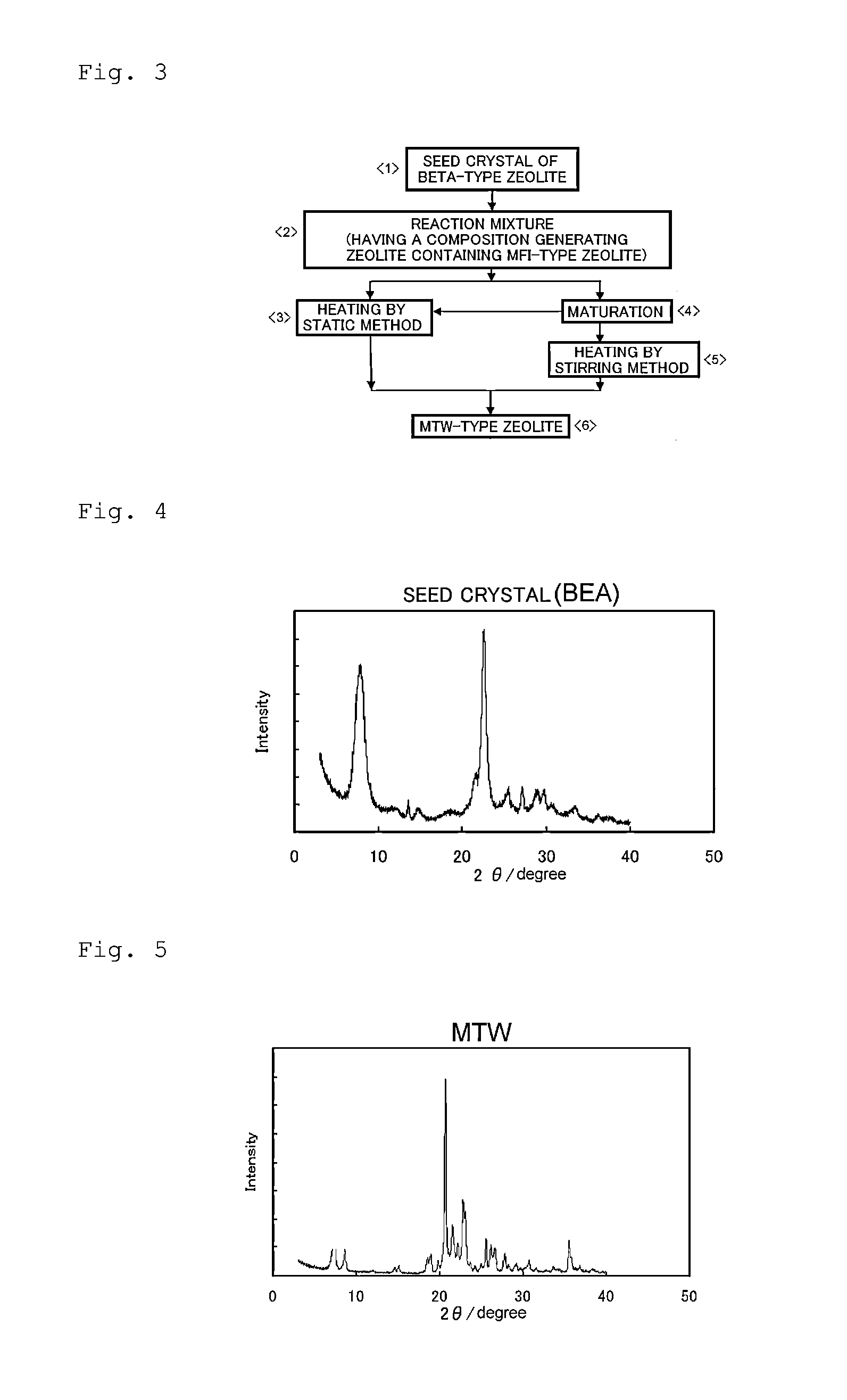

ActiveUS20130156690A1Readily and inexpensively produceEfficient productionFrom gel statePolycrystalline material growthOrganic structureBuilding unit

Disclosed is a method for readily and inexpensively producing zeolite without using an organic structure-directing agent (organic SDA). Specifically disclosed is a method whereby a gel containing a silica source, an alumina source, an alkaline source and water is reacted with zeolite seed crystals, to produce a zeolite with the same kind of skeletal structure as the zeolite. The gel used is a gel of a composition whereby, when a zeolite is synthesized from this gel only, the synthesized zeolite comprises at least one of the kinds of composite building units of the target zeolite.

Owner:MITSUI MINING & SMELTING CO LTD +1

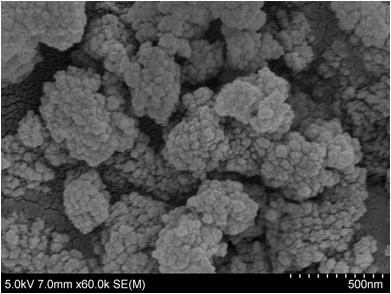

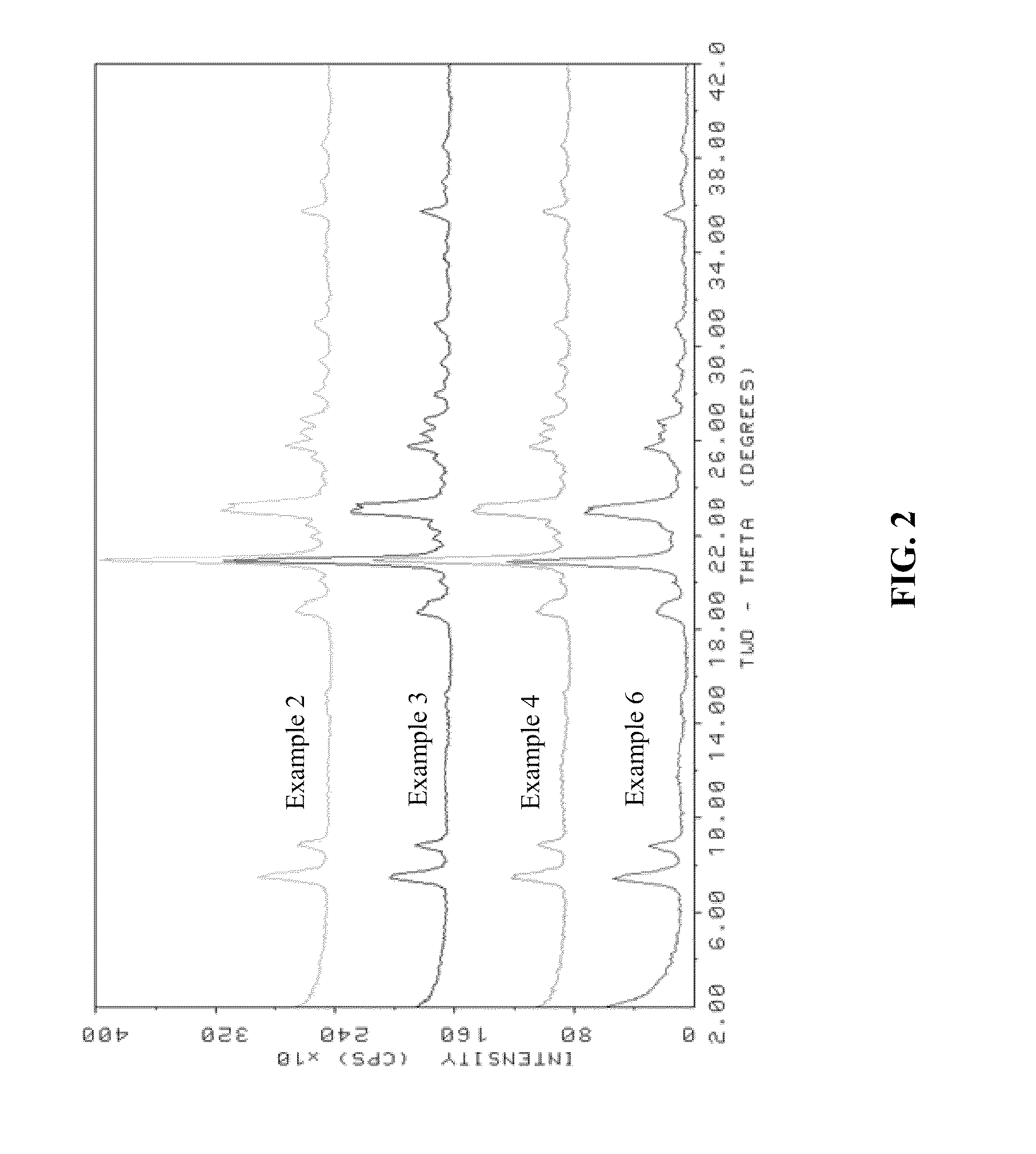

ZSM-5/ZSM-12 composite molecular sieve and synthetic method thereof

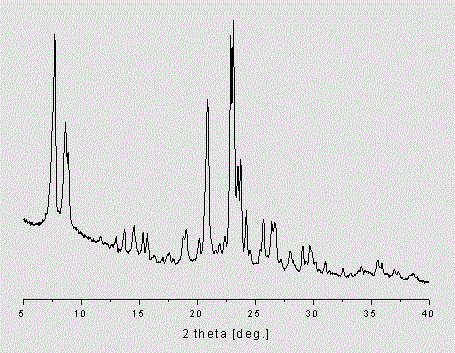

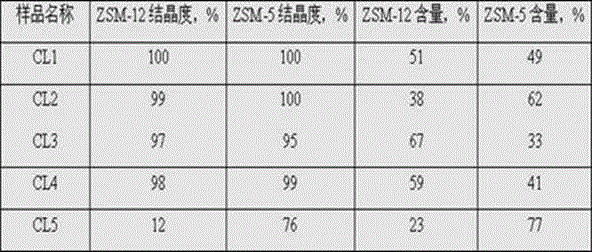

ActiveCN104591216AIntegrity guaranteedAvoid crystallinity lossAluminosilicate zeolite type ZSM-12Molecular sieve catalystsCrystal structureColloid

The invention provides a ZSM-5 / ZSM-12 composite molecular sieve. The ZSM-5 / ZSM-12 composite molecular sieve has the following two crystal forms at the same time: a ZSM-12 molecular sieve and a ZSM-5 molecular sieve. The synthetic method for the ZSM-5 / ZSM-12 composite molecular sieve provided by the invention comprises the following steps: adding the ZSM-12 molecular sieve into a glucose solution for ultrasonic treatment and carrying out filtering, drying and roasting so as to obtain a treated ZSM-12 molecular sieve; then mixing water, an alkali source, a template agent, an aluminum source and a silicon source and carrying out crystallization so as to prepare pre-crystallized colloid; then mixing the pre-crystallized colloid with the treated ZSM-12 molecular sieve and carrying out crystallization at a temperature of 160 to 220 DEG C for 5 to 25 h so as to obtain the ZSM-5 / ZSM-12 composite molecular sieve. According to the invention, glucose is introduced into the pores of the ZSM-12 molecular sieve and becomes carbon after roasting; the carbon occupies the pore channels of the ZSM-12 molecular sieve to prevent alkali from entering the interior of ZSM-12 molecular sieve crystals, so the ZSM-12 molecular sieve is not destroyed in the process of crystallization and the integrity of crystal structure is maintained, which are beneficial for improvement of the physical and chemical properties and the catalytic activity of the ZSM-5 / ZSM-12 composite molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis of porous crystalline materials in fluoride media

In a process for synthesizing a porous crystalline material, a mixture capable of forming said material is prepared wherein the mixture comprises sources of water, an oxide of a tetravalent element Y, preferably silicon, an oxide of a trivalent element X, wherein X is selected from the group consisting of aluminum, boron, gallium, iron, and indium, fluoride ions, and an organonitrogen cation RN<m+> capable of directing the synthesis of said material, wherein the molar ratio of fluoride ions to organonitrogen cations RN<m+> in said mixture is greater than 1.15 m but less than 2.5 m. The mixture is maintained under crystallization conditions until crystals of said material are formed and the resultant crystalline material is recovered.

Owner:EXXON RES & ENG CO

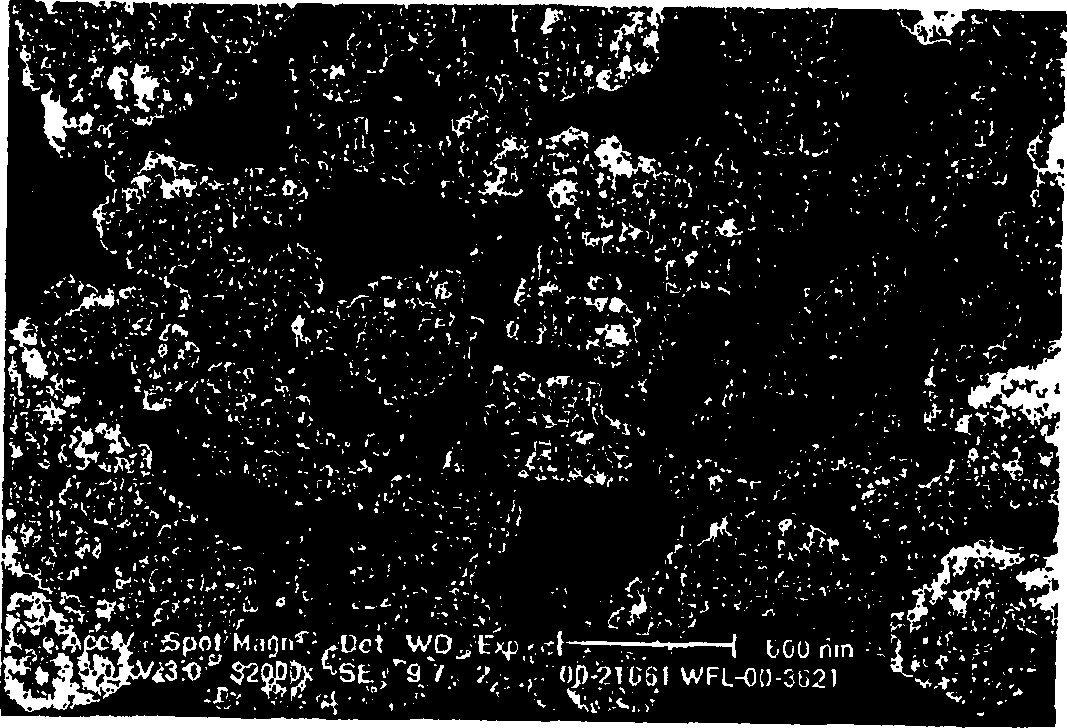

High activity small crystal zsm-12

InactiveCN1774398AAluminosilicate zeolite type ZSM-12Molecular sieve catalystsCrystalline materialsHigh activity

A porous crystalline material having a ZSM-12 skeleton structure and a composition conforming to the following molar relationship: X2O3: (n)YO2, wherein X is a trivalent element, Y is a tetravalent element, n is less than 60, and the average crystal of the material The size is less than 0.1 microns, and the material has a diffusion parameter for mesitylene of at least 1000 x 10-6 sec-1 when measured at a temperature of 100°C and a mesitylene pressure of 2 Torr.

Owner:EXXONMOBIL CHEM PAT INC

Perturbed synthesis of materials

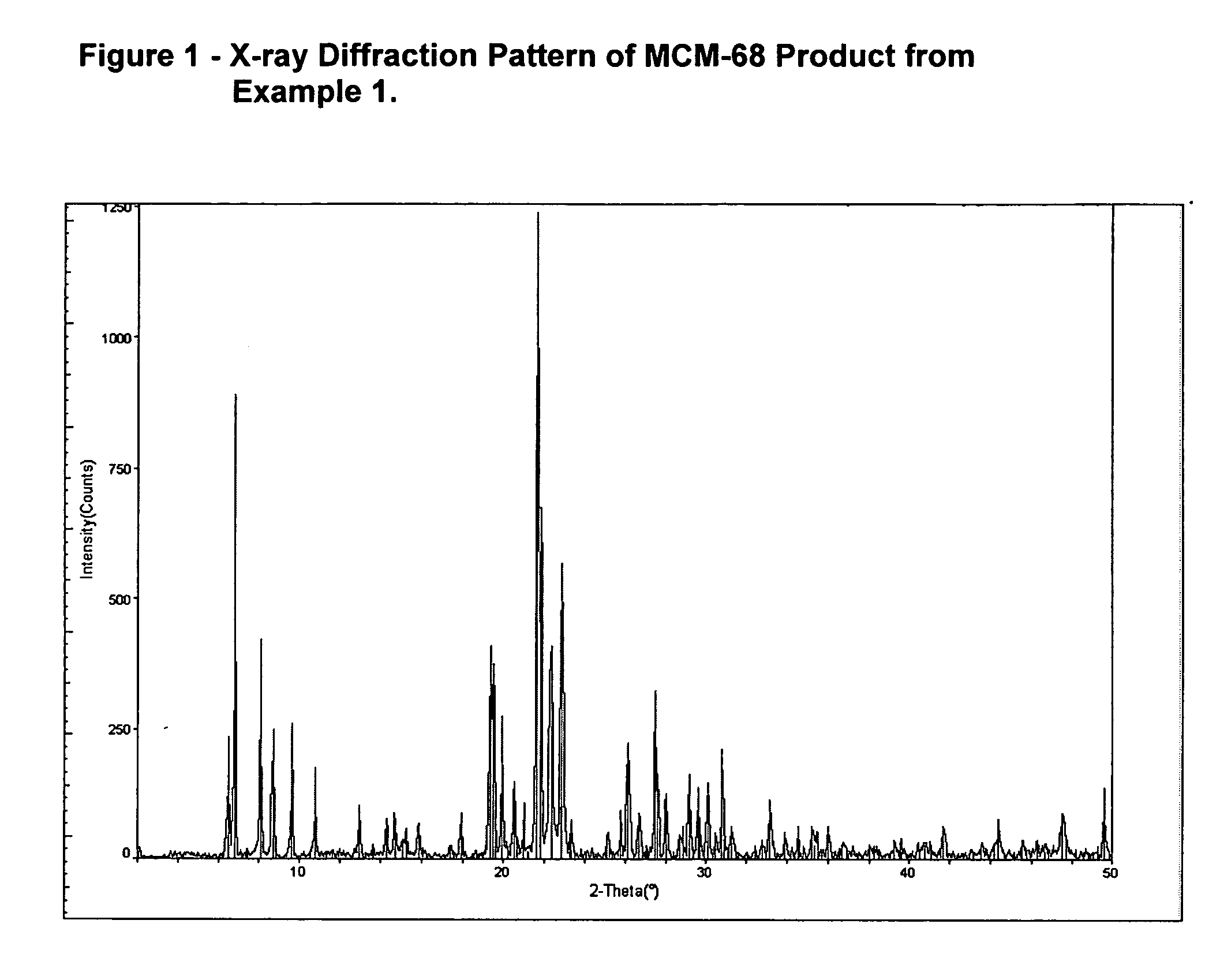

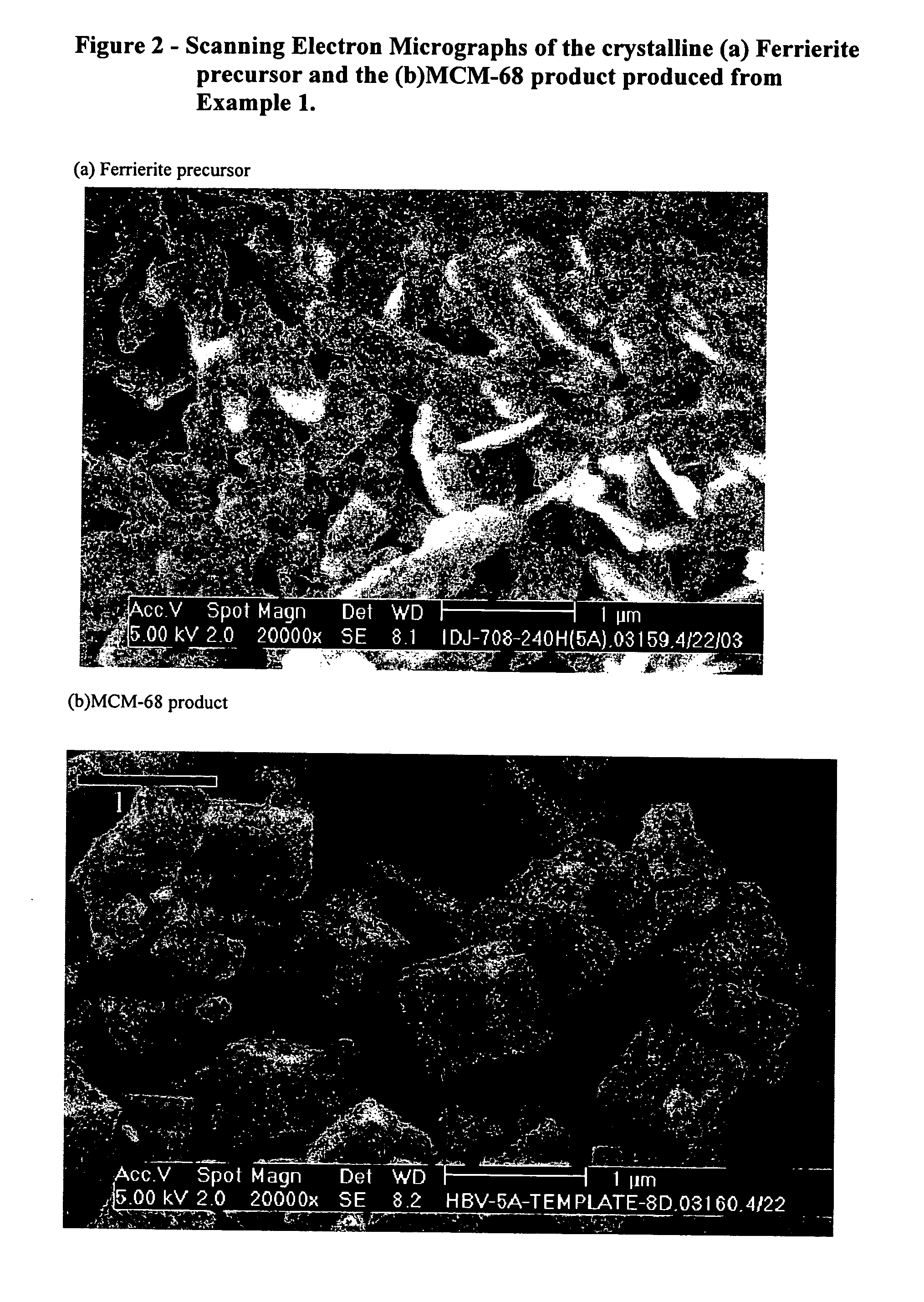

InactiveUS20070154387A1Ferrierite aluminosilicate zeoliteAluminium compoundsCrystallographySynthetic materials

The present invention is a method that perturbs the initial crystallization of a material from a less desired phase into a more desired phase. More specifically, the present invention is a method to form a different crystallization of a zeolite, mesoporous material, SAPO4, AlPO4 or porous inorganic oxide after the hydrothermal synthesis has started and a precursor crystalline phase has formed.

Owner:EXXON RES & ENG CO

Method for synthesis of high silicon zeolite molecular sieve with universal gel

InactiveCN106542537AHigh crystallinityHigh purityFerrierite aluminosilicate zeoliteAluminosilicate zeolite type ZSM-12FiltrationBasic research

Relating to molecular sieve preparation methods, the invention aims to provide a method for synthesis of a high silicon zeolite molecular sieve with universal gel. The method includes the steps of: mixing deionized water with an aluminum source evenly, then adding NaOH, adding a silicon source under stirring, performing stirring continuously until the solution forms a silica-alumina gel; adding a zeolite molecular sieve seed crystal into the silica-alumina gel, performing stirring, then placing the mixture into a reaction kettle, and carrying out pumping filtration and drying on a crystallization product, thus obtaining raw powder of the high silicon zeolite molecular sieve. The product obtained by the invention not only maintains good crystallinity and purity, but also has good catalytic reaction activity. The whole production process does not use organic template agent, also greatly shortens the crystallization time through seed crystal synthesis, thus reducing unnecessary loss in the production process. The adopted inorganic raw materials are environment-friendly and low in price. Therefore, the method provided by the invention is of important significance for the basic research of zeolite molecular sieve and application in the field of actual chemical production.

Owner:ZHEJIANG UNIV

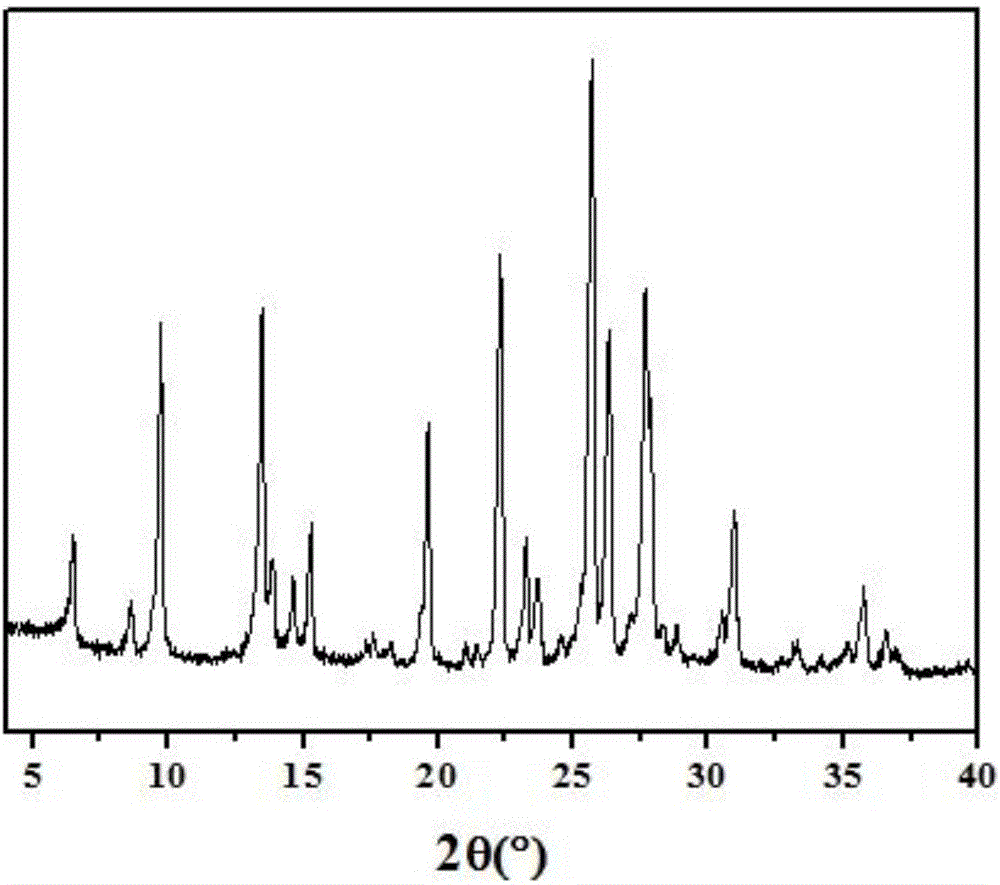

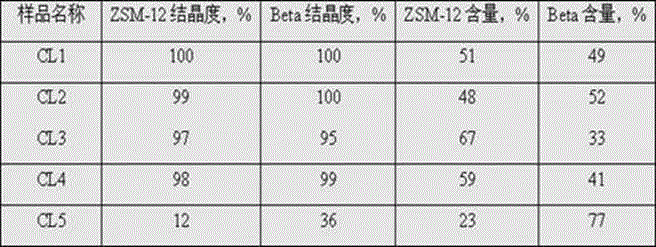

Beta/ZSM-12 composite molecular sieve and its synthesis method

ActiveCN104591217AGood hydrocarbon molecular crackingGood isomerizationCatalyst carriersAluminosilicate zeolite type ZSM-12Molecular sieveSynthesis methods

The invention provides a Beta / ZSM-12 composite molecular sieve. The Beta / ZSM-12 composite molecular sieve has the following two crystal forms at the same time: a ZSM-12 molecular sieve and a Beta molecular sieve. The synthesis method for the Beta / ZSM-12 composite molecular sieve provided by the invention comprises the following steps: adding the ZSM-12 molecular sieve into a glucose solution for pretreatment so as to obtain a treated ZSM-12 molecular sieve; then mixing water, an alkali source, a template agent, an aluminum source and a silicon source and carrying out high-temperature crystallization so as to prepare pre-crystallized colloid; then mixing the pre-crystallized colloid with the treated ZSM-12 molecular sieve and carrying out crystallization at a temperature of 100 to 180 DEG C for 5 to 25 h so as to obtain the Beta / ZSM-12 composite molecular sieve. According to the invention, glucose is introduced into the pores of the ZSM-12 molecular sieve and becomes carbon after roasting; the carbon occupies the pore channels of the ZSM-12 molecular sieve to prevent alkali from entering the interior of ZSM-12 molecular sieve crystals, so the ZSM-12 molecular sieve is not destroyed in the process of crystallization and the integrity of crystal structure is maintained, which are beneficial for improving the physical and chemical properties and the catalytic activity of the Beta / ZSM-12 composite molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

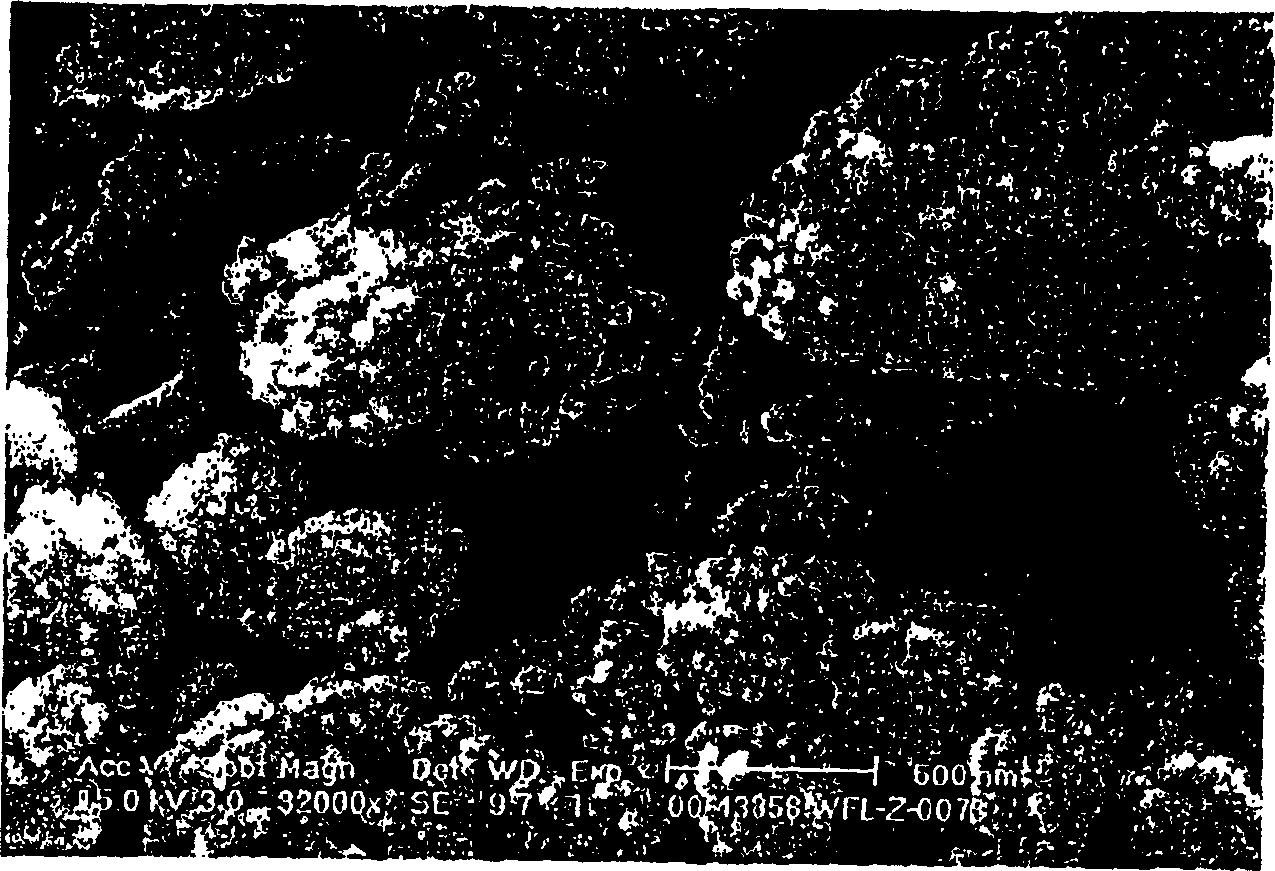

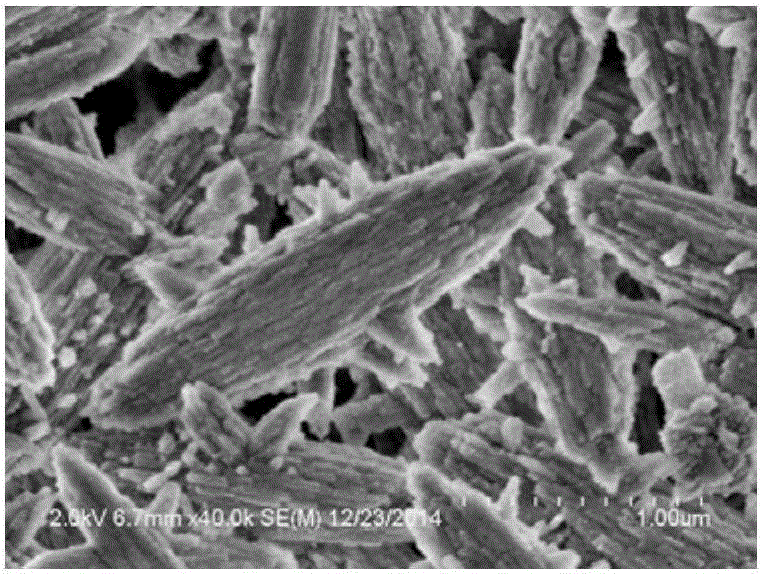

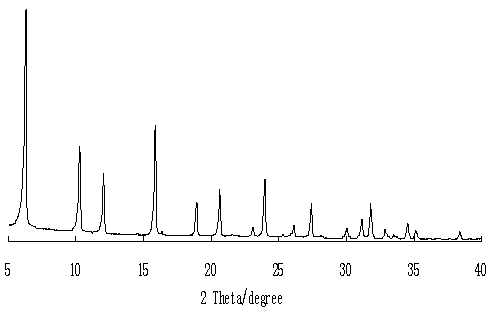

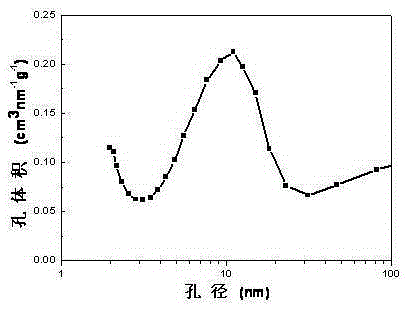

Synthesizing method of gallosilicate molecule sieve Ga-ZSM-12

InactiveCN101792153AReduce carbon deposition rateImprove diffusivityAluminosilicate zeolite type ZSM-12Molecular sieveRoom temperature

The invention relates to a synthesizing method of a gallosilicate molecule sieve Ga-ZSM-12, belonging to the field of preparation of zeolite molecule sieve catalysts and solving the problems of high cost and low catalytic activity of a Ga-ZSM-12 molecule sieve synthesized by adopting a methyltriethylammonium bromide (MTEABr) template agent at present. The synthesizing method of the gallosilicate molecule sieve Ga-ZSM-12 comprises the following steps of: preparing an alkali source, a gallium source, a silicon source, a template agent and deionized water into a uniform mixture; crystallizing at 160-200 DEG C for 4-6 days; cooling to room temperature; and filtering, washing, drying and roasting a product to prepare a pure-phase Ga-ZSM-12 molecule sieve. The synthesizing method has low synthesizing cost of the Ga-ZSM-12 molecule sieve; and in addition, the Ga-ZSM-12 molecule sieve can be outstandingly enhanced in catalytic property because a molecule sieve crystal has a secondary mesoporous structure and can be used in the fields of a petrochemical industry, an organic chemical industry, a fine chemical industry, and the like as a catalyst.

Owner:HEILONGJIANG UNIV

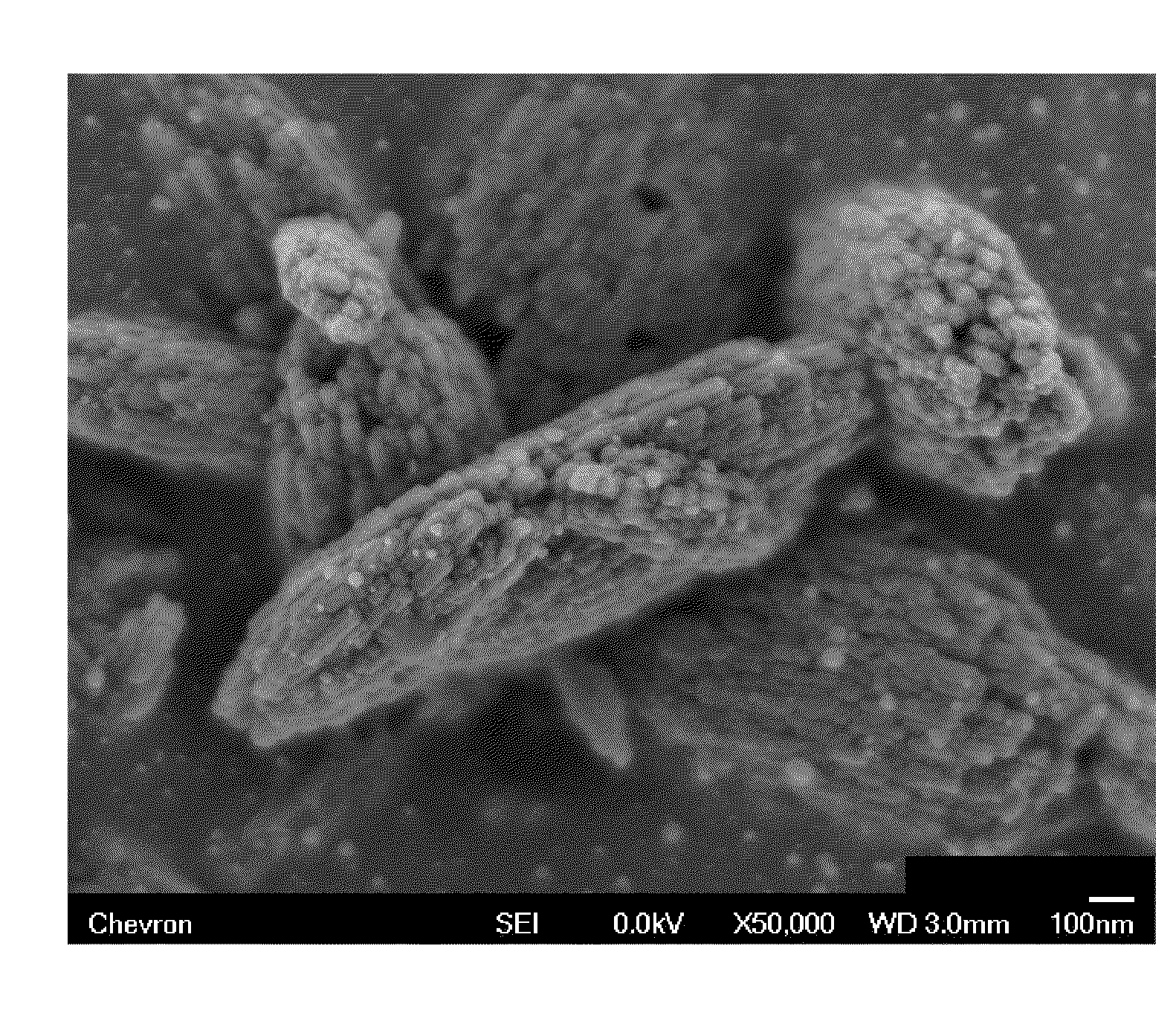

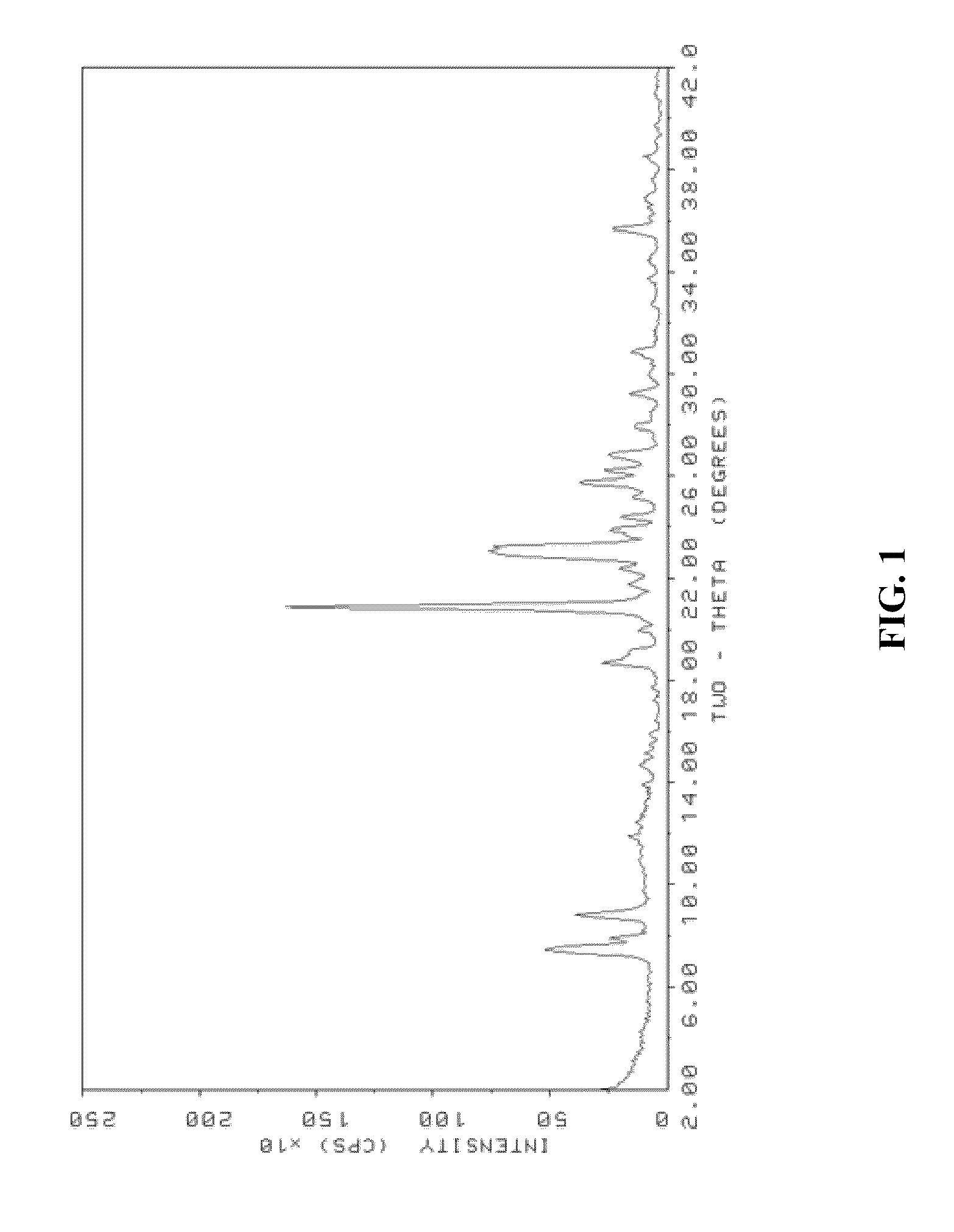

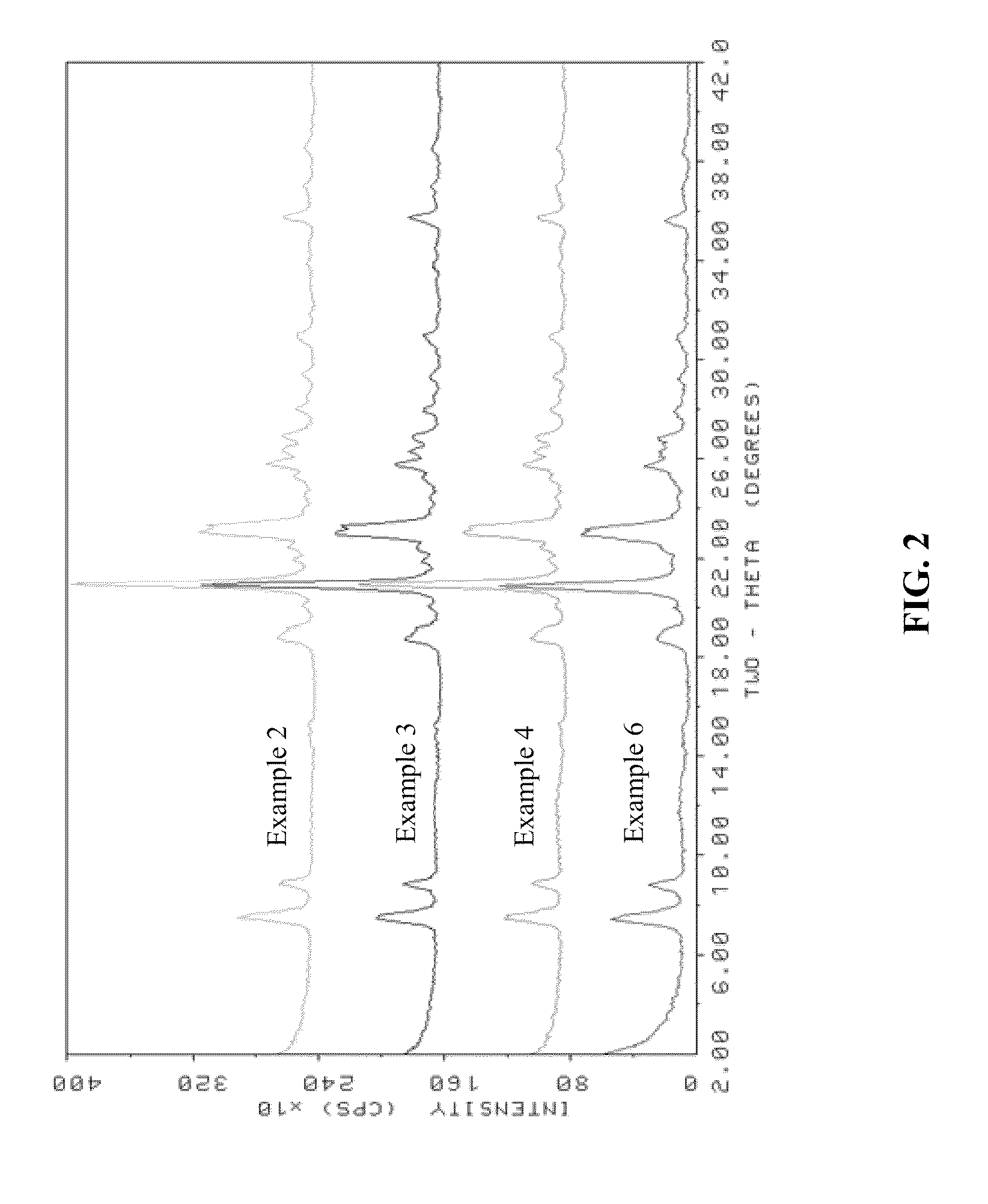

Synthetic method of ZSM-12 type zeolite molecular sieve

ActiveCN106587102ASmall sizeHigh feasibilityAluminosilicate zeolite type ZSM-12Molecular sieveImpurity

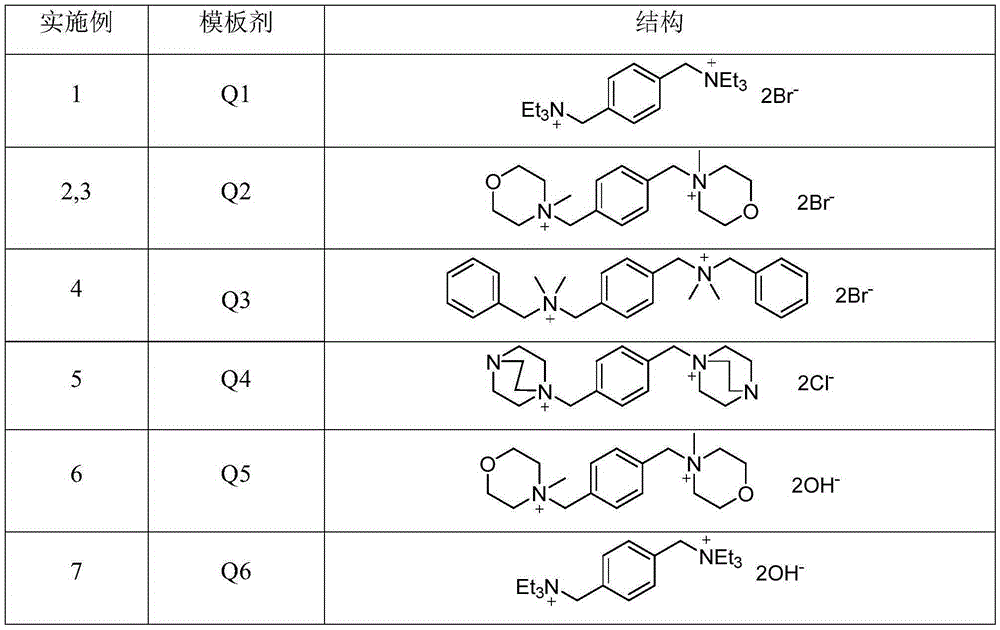

The invention relates to a synthetic method of ZSM-12 type zeolite molecular sieve. The method mainly solves the problems that a template for synthesis of the ZSM-12 type zeolite molecular sieve has low feasibility and the amount of impurities in the obtained ZSM-12 type zeolite molecular sieve is more in the prior art. The initial mole ratio of SiO2:Al2O3:alkaline substance A:template Q is 10:(0.5-4.5):(0.2-4.0):(0.5-5.0):(80-400), the silicon source, the aluminium source, the template Q and water are uniformly mixed in order to obtain a mixture, hydrothermal crystallization is carried out for the mixture at 95-180 DEG C for 20-200 hours, the products are washed and dried, and the ZSM-12 type zeolite molecular sieve is obtained. The technical scheme better solves the technical problem, and can be applied to industrial catalytic application.

Owner:CHINA PETROLEUM & CHEM CORP +1

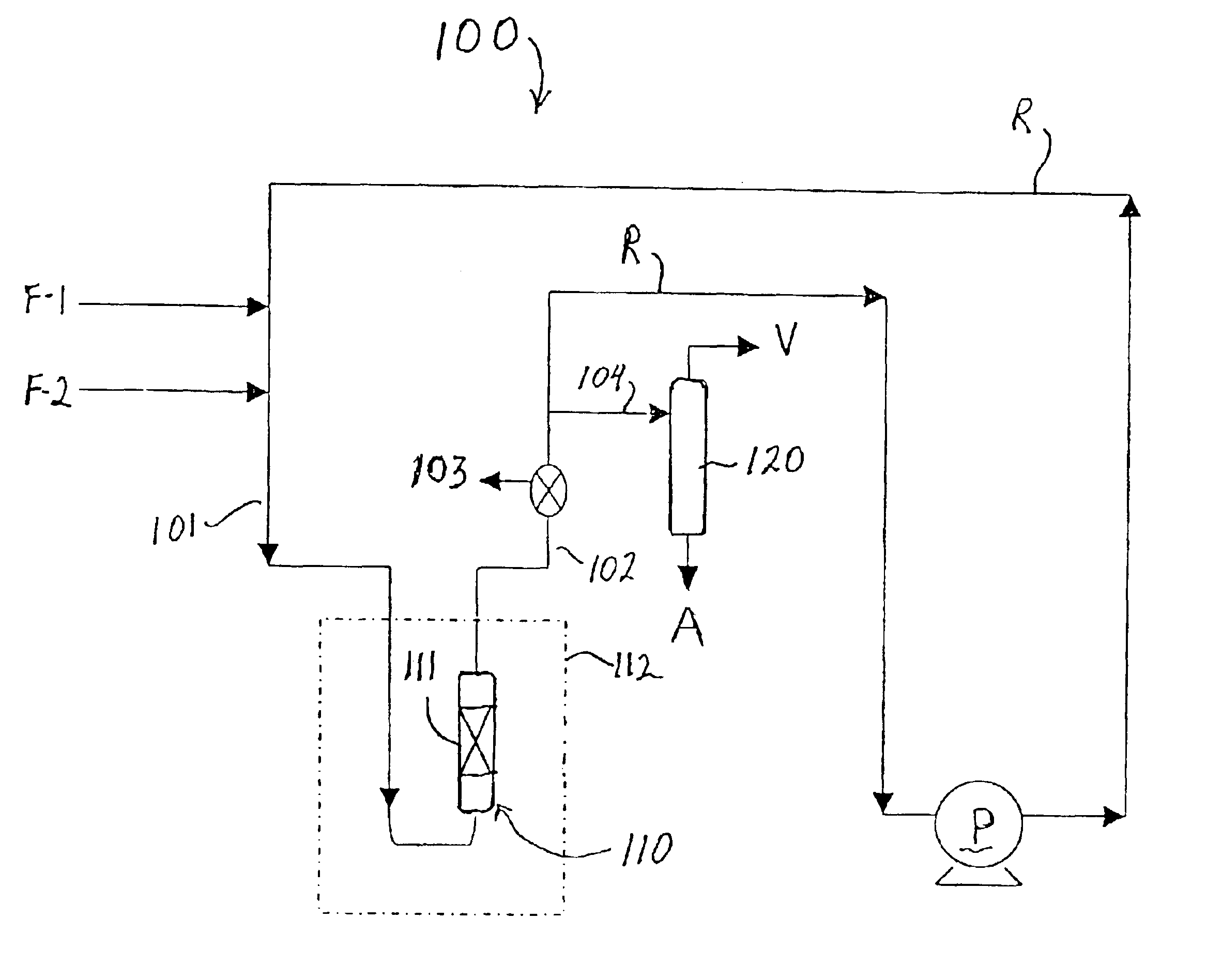

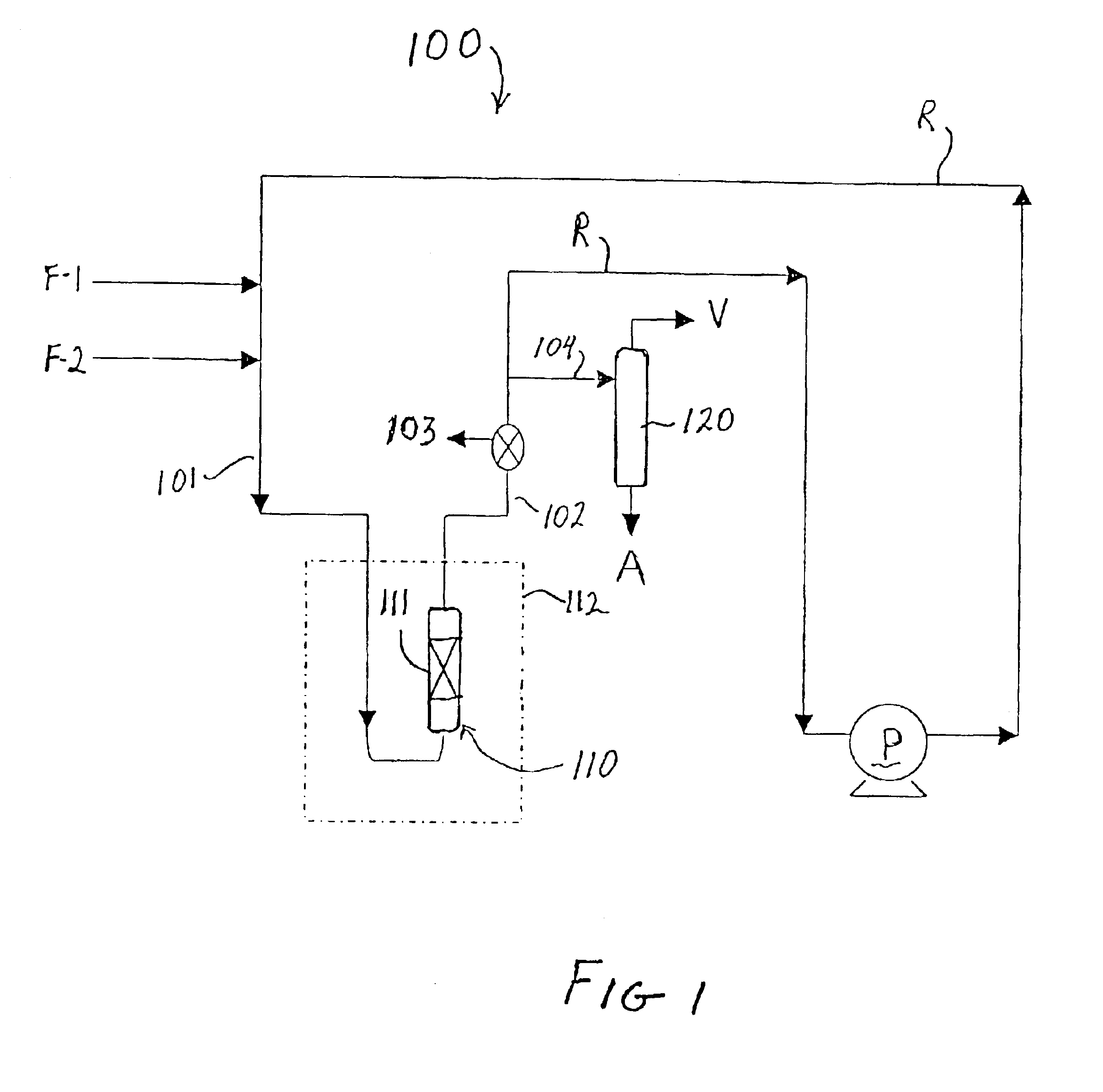

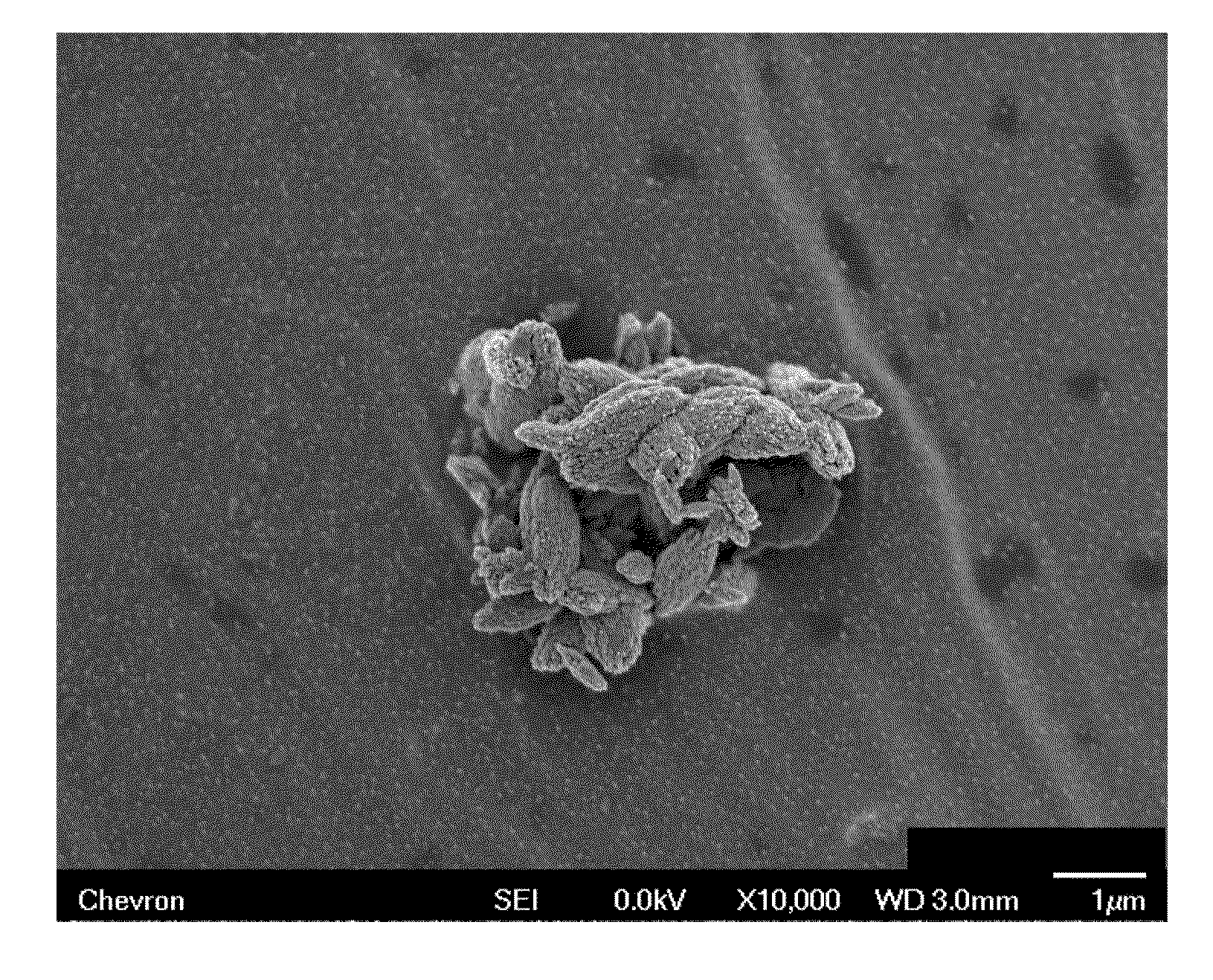

Process for isosomerizing a hydrocarbonaceos feestock using aluminosilicate zsm-12

ActiveUS20110124940A1Hydrocarbon by isomerisationAluminosilicate zeolite type ZSM-12IsomerizationBoron

An aluminosilicate ZSM-12 may be prepared de novo in a small crystalline form from a reaction mixture containing a source of silica and a source of alumina A small crystalline form of aluminosilicate ZSM-12 may also be prepared from a small crystalline form of borosilicate ZSM-12 by replacement of boron in the borosilicate ZSM-12 framework with aluminum. The aluminosilicate ZSM-12 is useful as an isomerization selective catalyst in processes such as isomerization dewaxing hydrocarbon feedstocks.

Owner:CHEVROU USA INC

Alkylation process

Owner:ABB LUMMUS GLOBAL INC

Method for making aluminosilicate ZSM-12

An aluminosilicate ZSM-12 may be prepared de novo in a small crystalline form from a reaction mixture containing a source of silica and a source of alumina. A small crystalline form of aluminosilicate ZSM-12 may also be prepared from a small crystalline form of borosilicate ZSM-12 by replacement of boron in the borosilicate ZSM-12 framework with aluminum. The aluminosilicate ZSM-12 is useful as an isomerization selective catalyst in processes such as isomerization dewaxing hydrocarbon feedstocks.

Owner:CHEVROU USA INC

Zeolite molecular sieve synthesis method

InactiveCN109928404AIncrease production costHigh Pressure Explosion Hazard AvoidanceAluminosilicate zeolite type ZSM-12Faujasite aluminosilicate zeoliteMolecular sieveSynthesis methods

The invention discloses a zeolite molecular sieve synthesis method, and belongs to the field of molecular sieve synthesis. The synthesis method comprises: uniformly mixing an inorganic alkali, an aluminum source, a silicon source and water to obtain a gel, drying the gel until the water is completely evaporated, crystallizing, washing, and drying to obtain zeolite. According to the present invention, the synthesis method belongs to atmospheric pressure synthesis, and has low production cost, and the properties of the prepared zeolite molecular sieve can meet the needs of catalytic industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

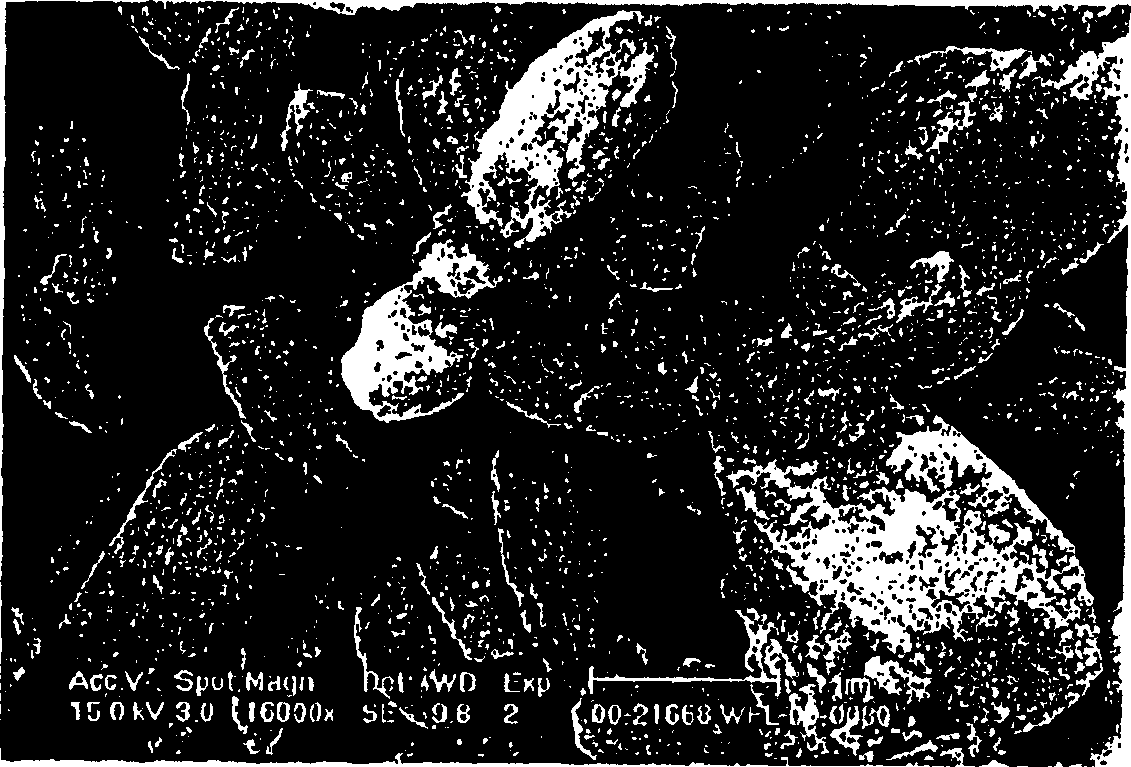

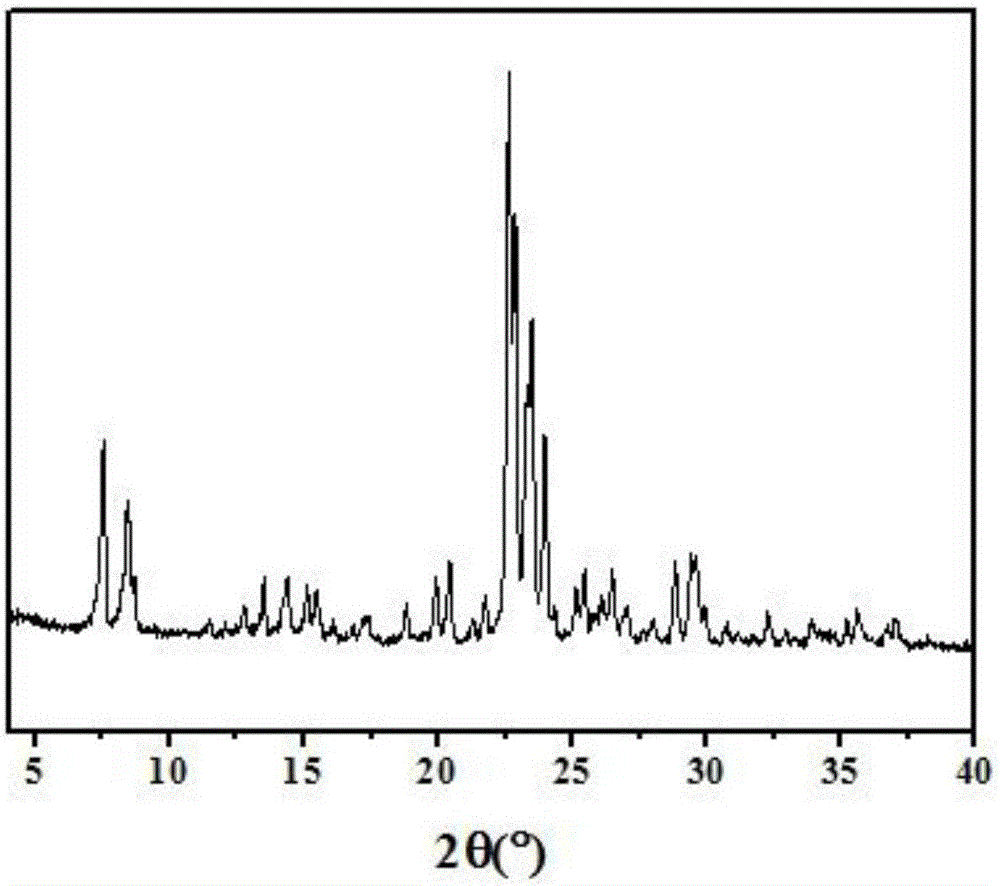

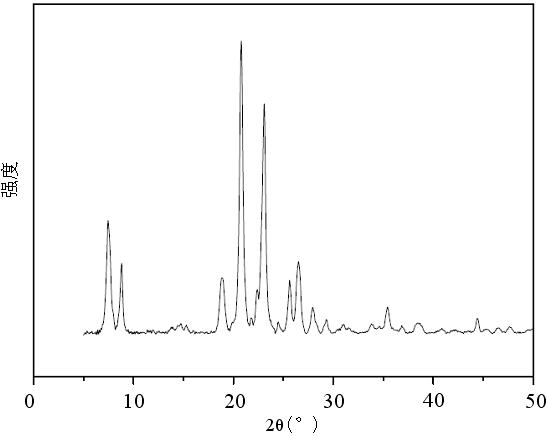

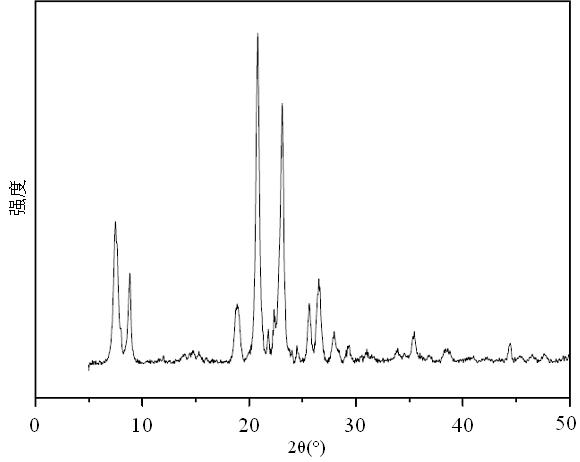

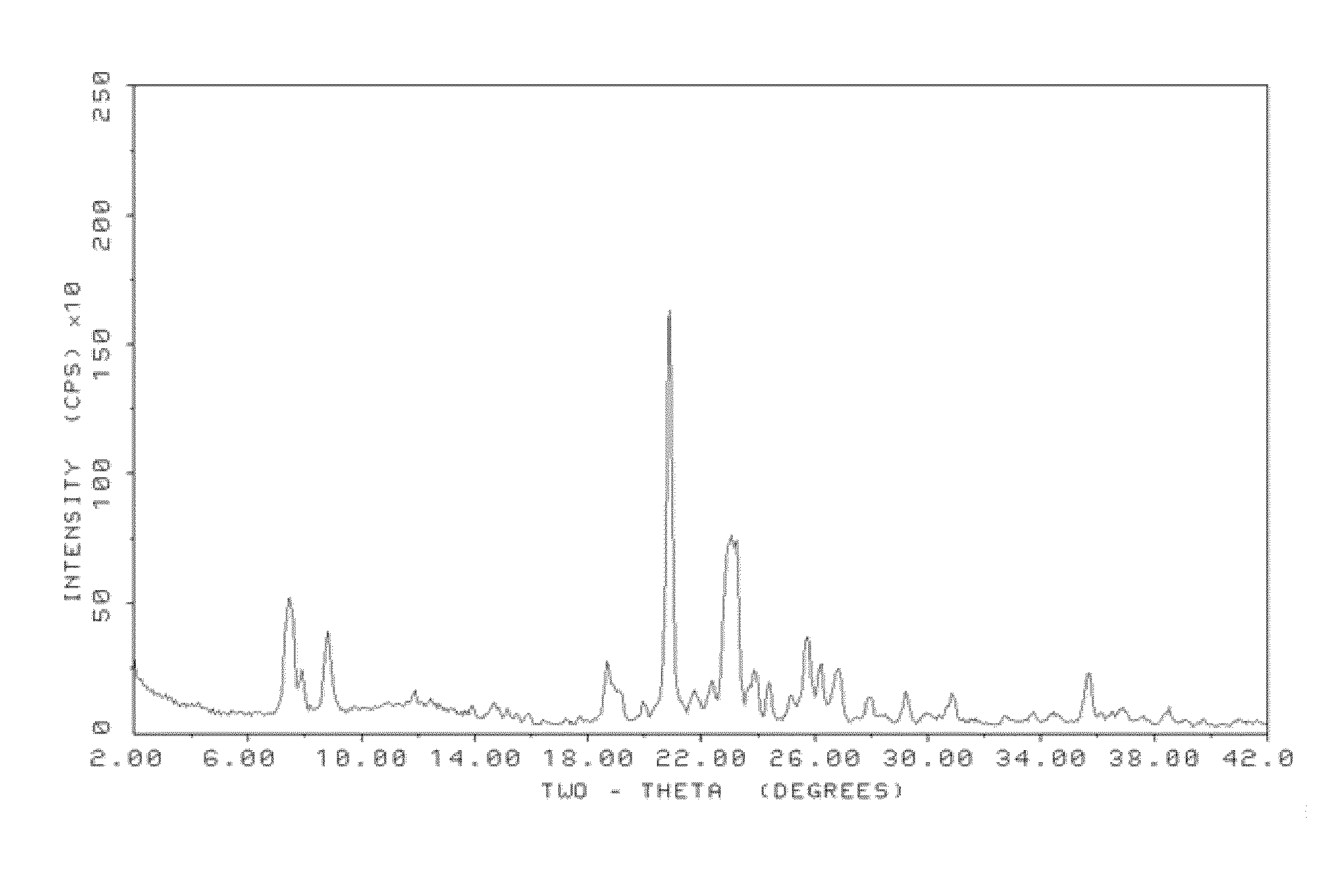

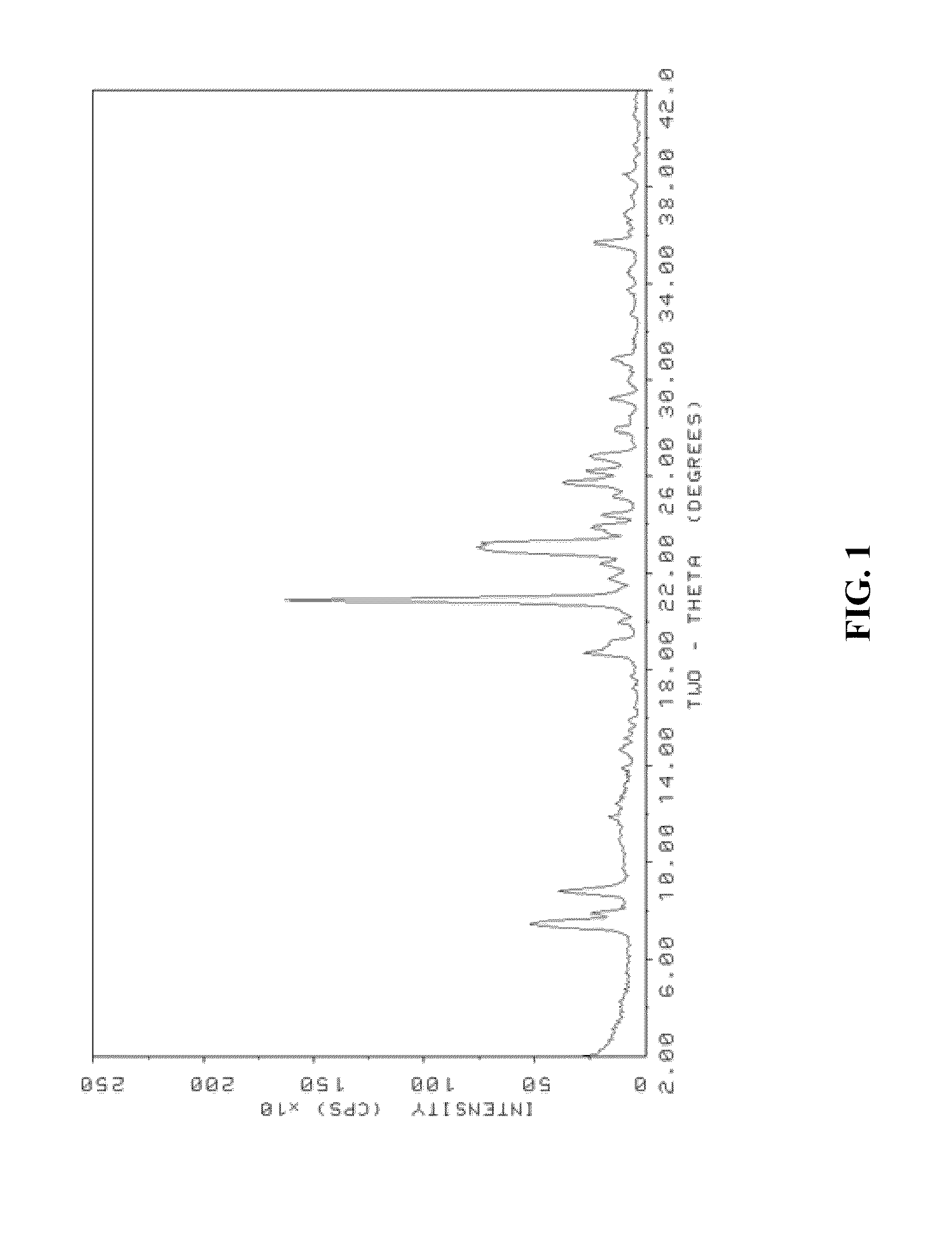

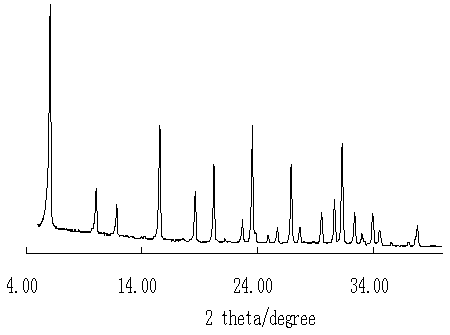

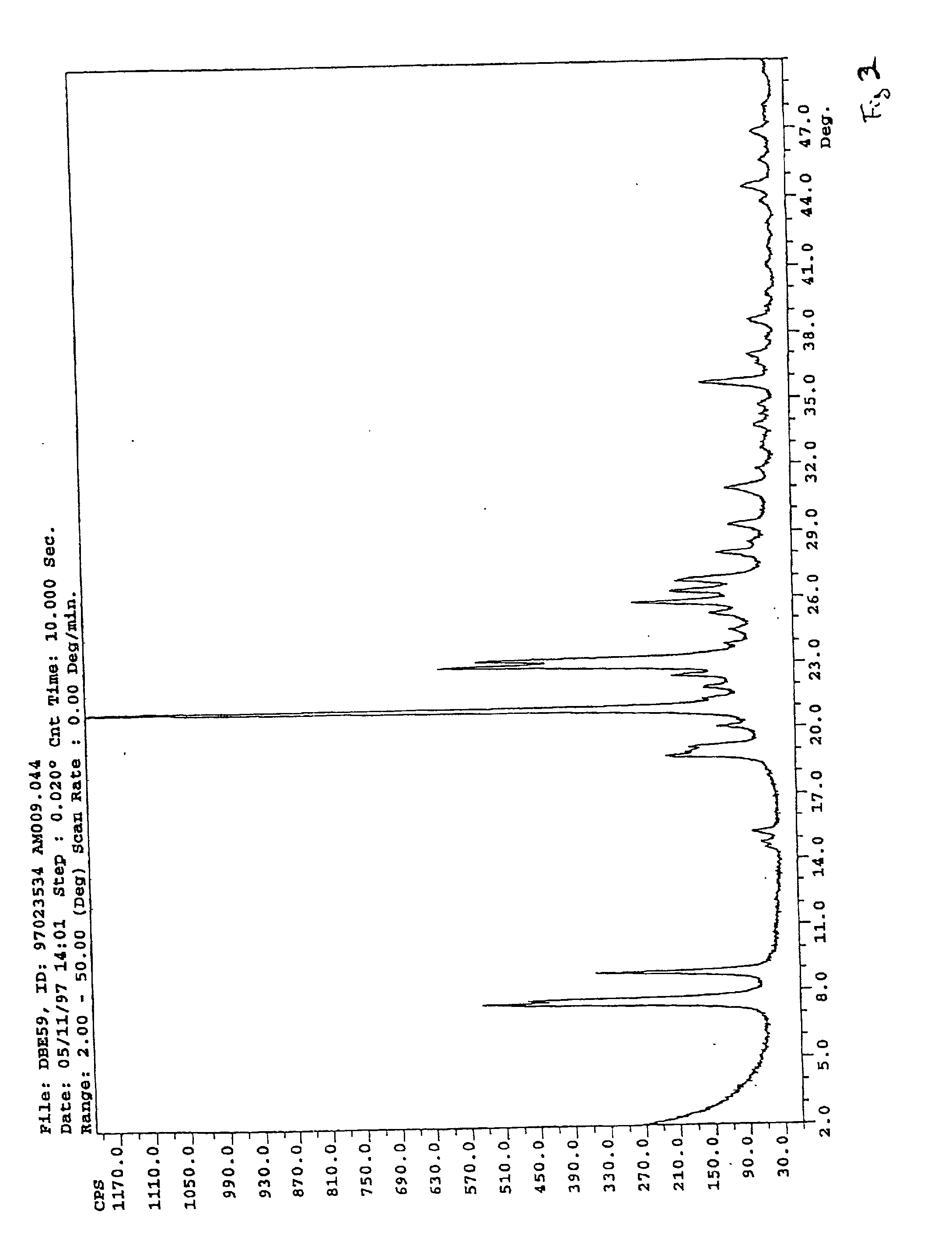

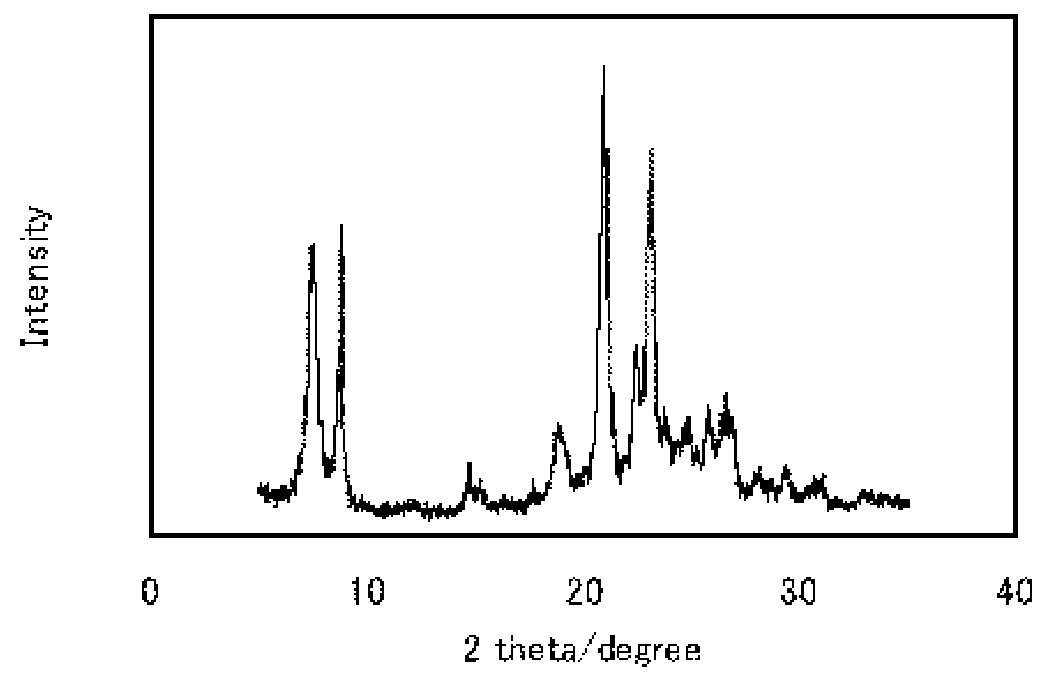

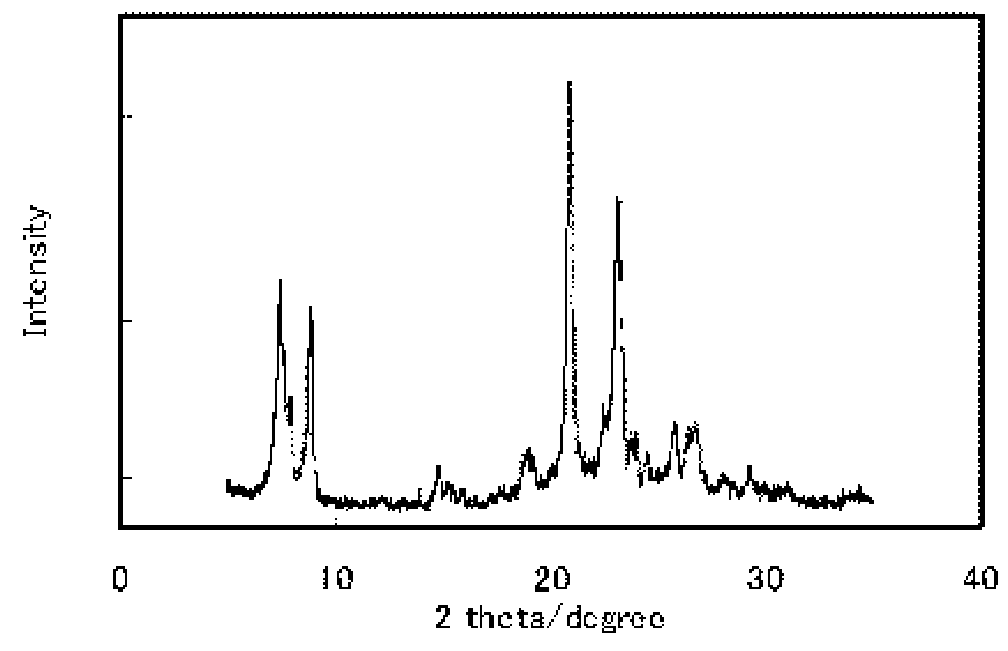

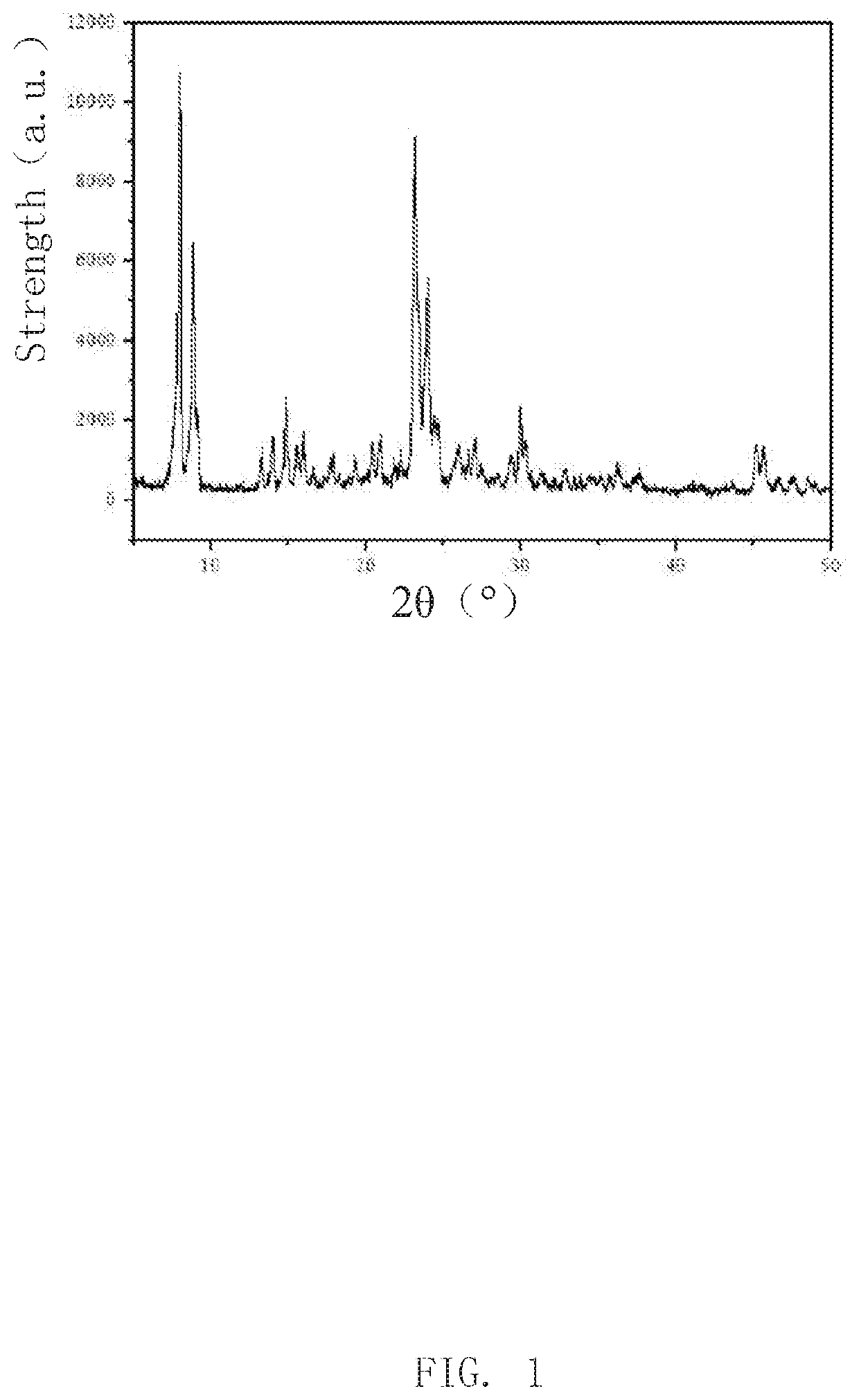

ZSM-12 molecular sieve with special crystal orientation as well as preparation method thereof

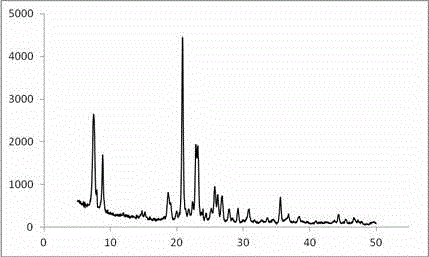

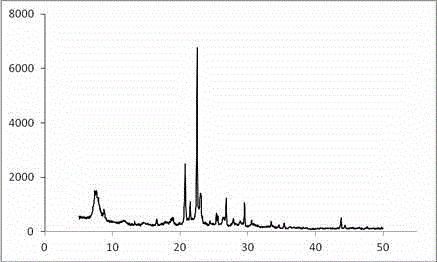

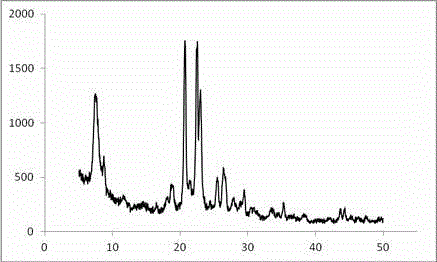

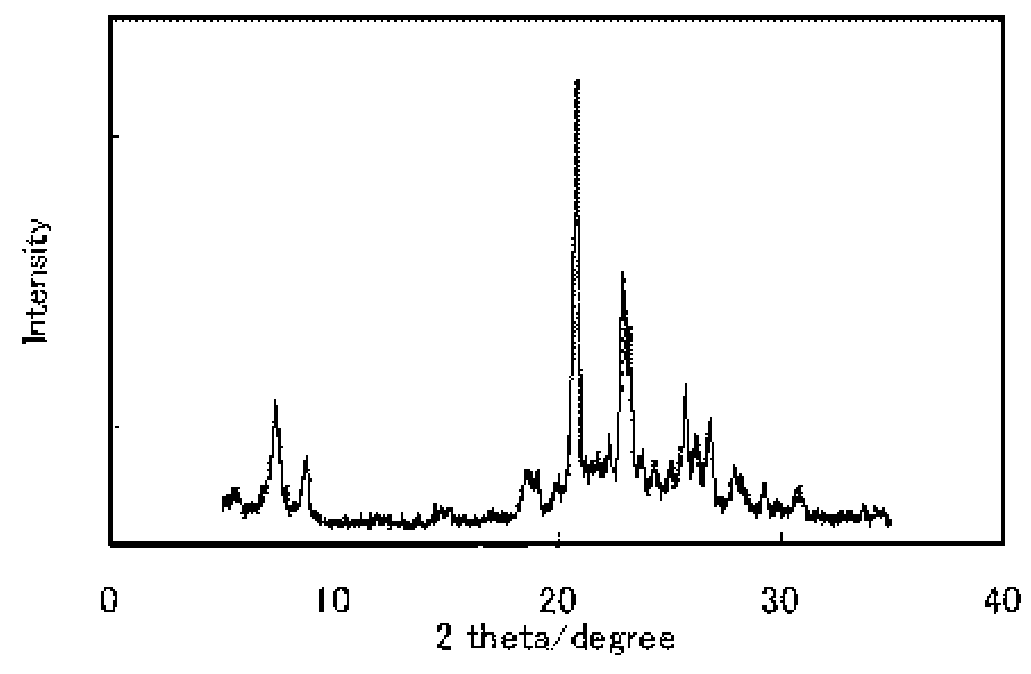

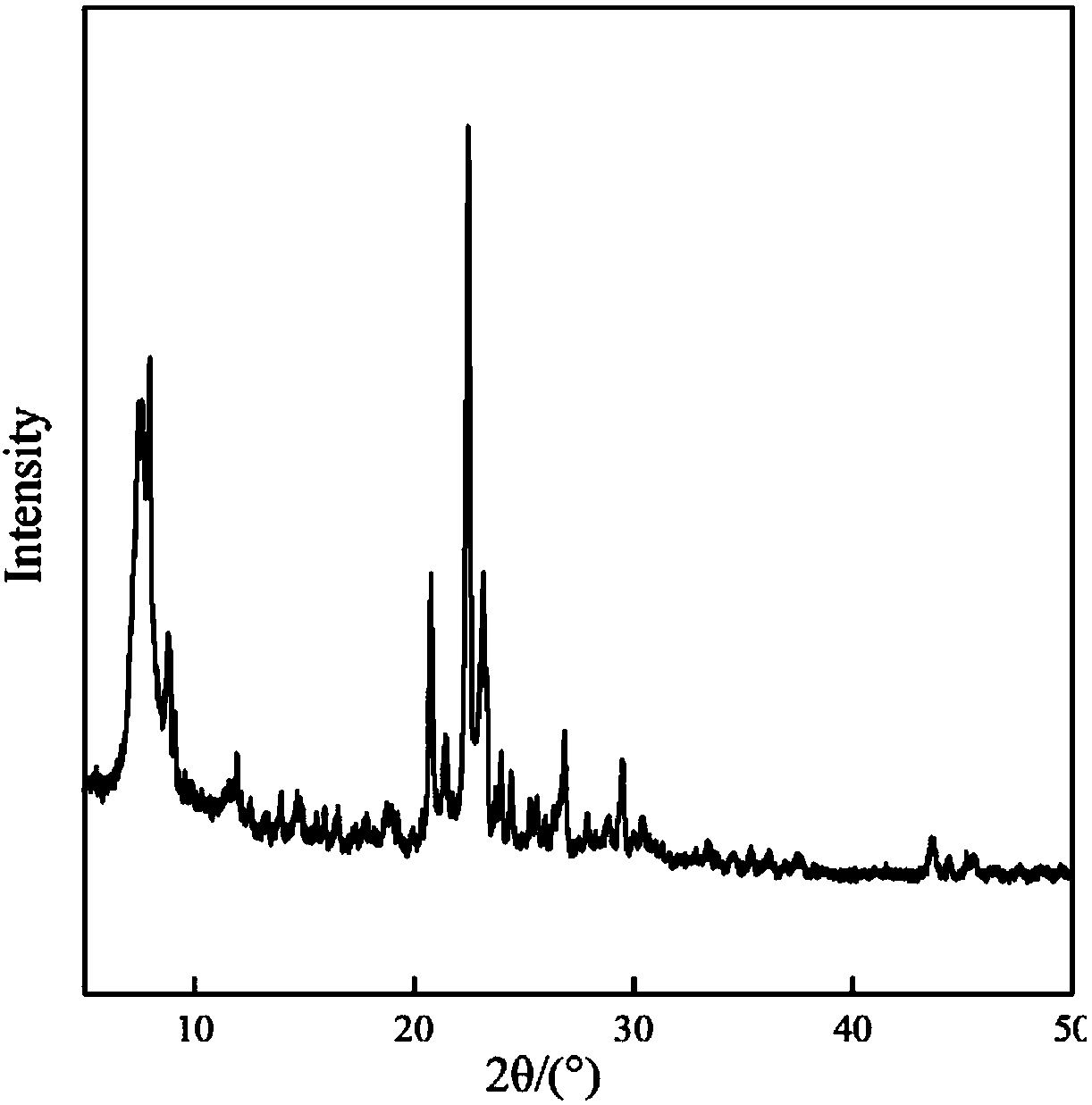

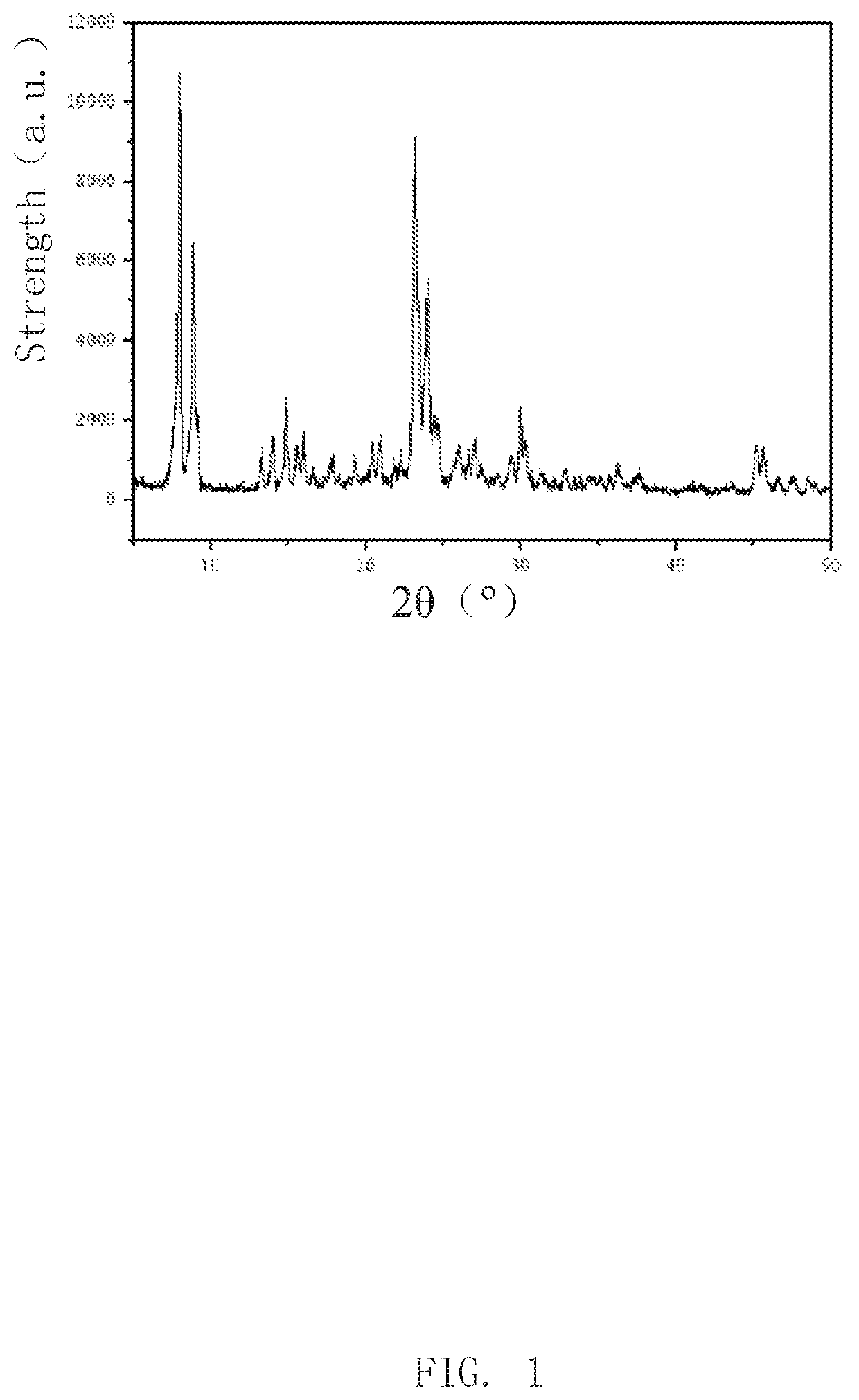

InactiveCN104445262AImprove conversion rateAluminosilicate zeolite type ZSM-12Organic chemistryMolecular sieveCrystal orientation

The invention relates to a ZSM-12 molecular sieve with special crystal orientation as well as a preparation method thereof, and mainly solves the problem in the prior art that crystal orientation of the ZSM-12 molecular sieve cannot be controlled. According to the technical scheme, the ZSM-12 molecular sieve with special crystal orientation comprises SiO2 / Al2O3 which is smaller than 360, three characteristic diffraction peaks appear at 2theta: A=7.6+ / -0.2, B=20.9+ / -0.2 and C=22.6+ / -0.2 on an XRD (X-Ray Diffraction) spectrum of the ZSM-12 molecular sieve; the corresponding crystal faces are respectively (0, 0, 2), (3, 0, 0) and (0, 0, 6), the molecular sieve is preferably oriented in at least one of the three crystal face directions, and the relative intensity range is B / A=0.2-10 and C / A=0.1-10. The technical scheme well solves the technical problem, and the prepared molecular sieve can be used for various catalytic processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

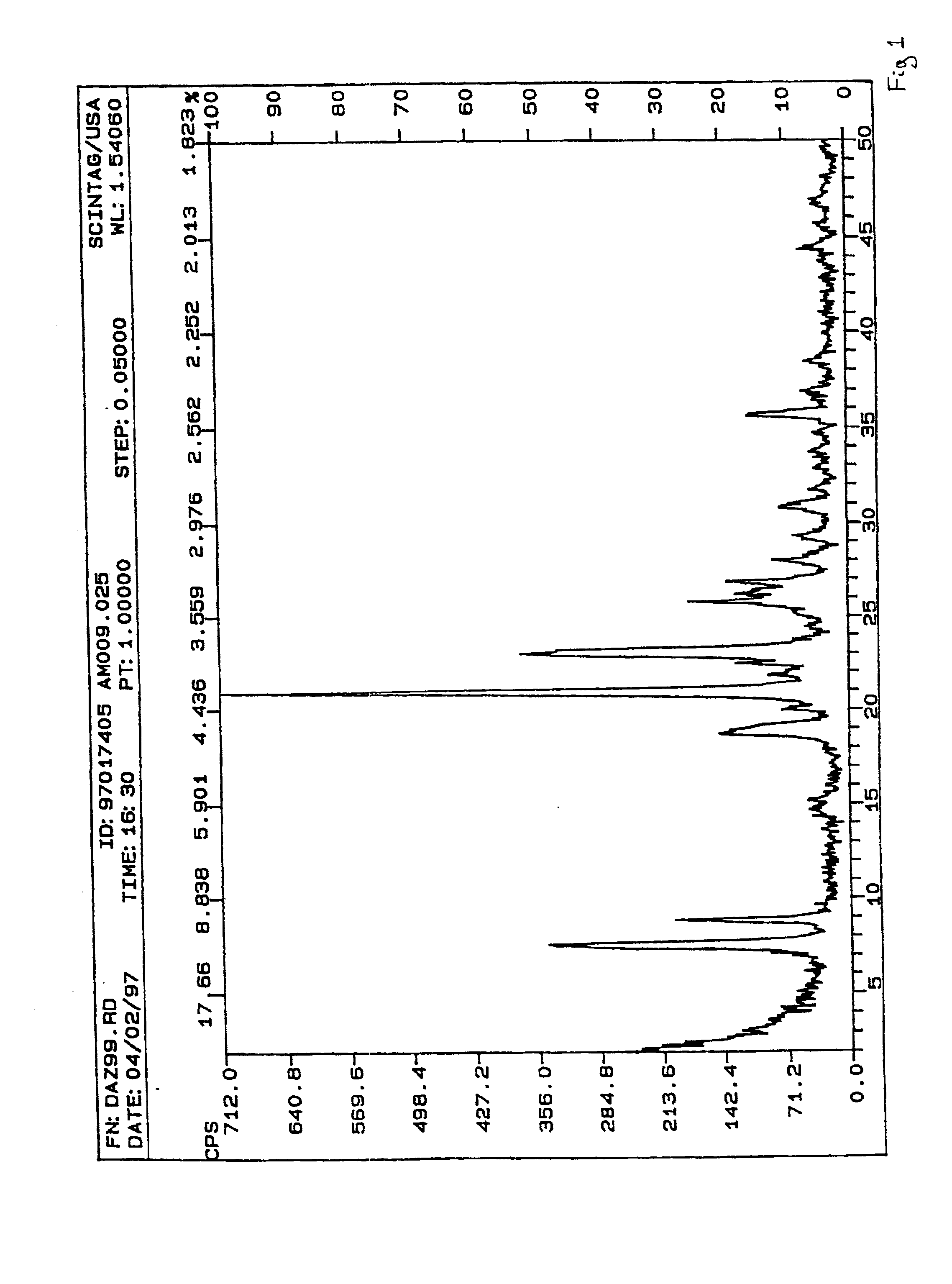

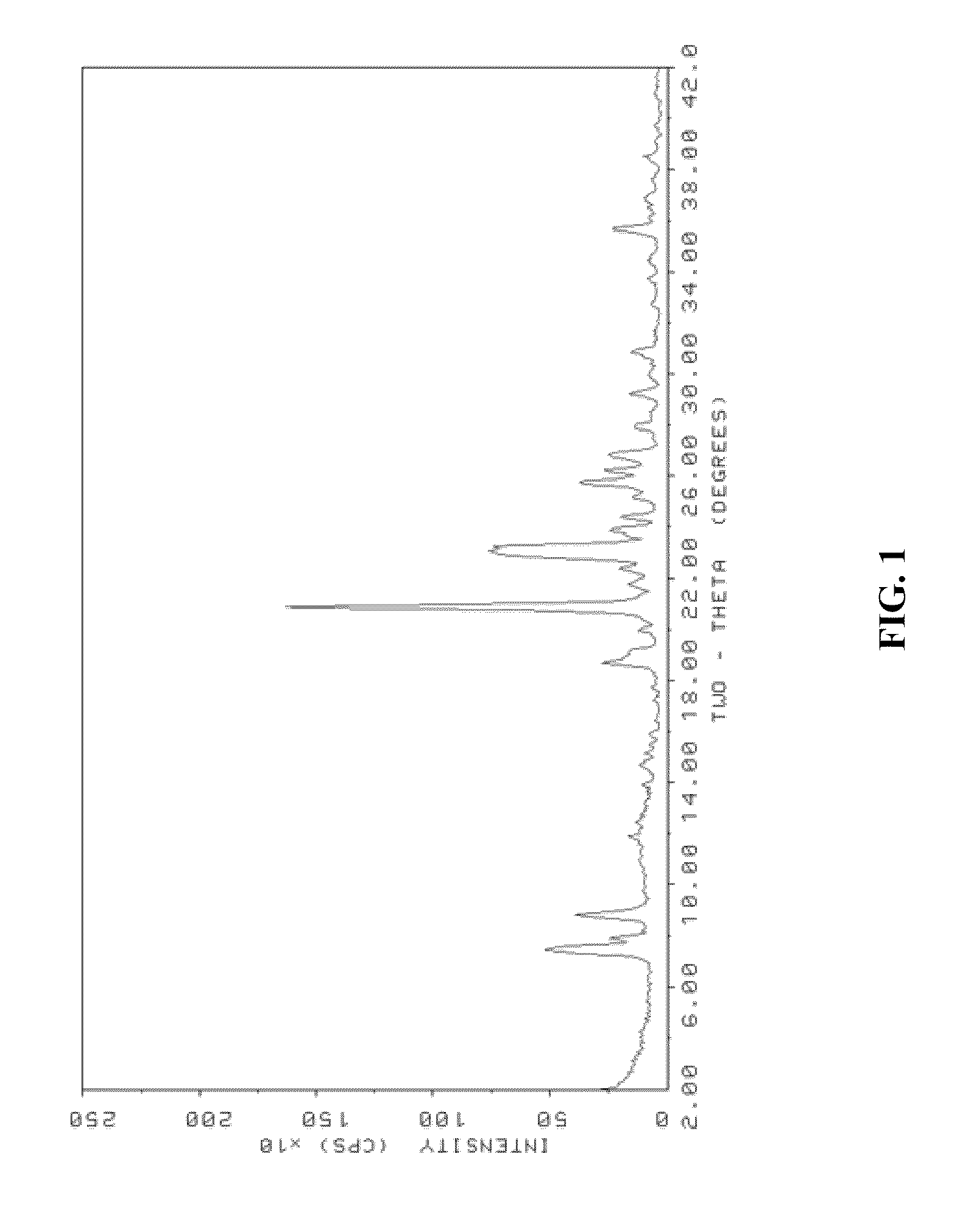

Synthesis of ZSM-12

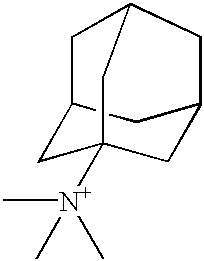

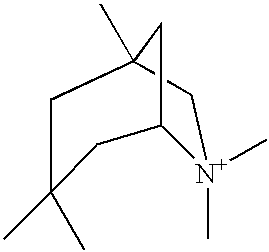

InactiveUS20020150533A1Aluminosilicate zeolite type ZSM-12Aluminium compoundsPhysical chemistryMethyl group

This invention provides a process for the synthesis of ZSM-12 using the N,N-dimethylhexamethyleneimine cation as a directing agent. The process enables ZSM-12 to be produced at silica / alumina molar ratios below 50 with little or no co-production of impurity phases. Small crystal forms of ZSM-12 can also be produced using the process of the invention.

Owner:EXXONMOBIL CORP (US)

Multi-level pore channel molecular sieve preparation method

InactiveCN105236444ARetain relative crystallinityEconomic aftertreatment methodAluminosilicate zeolite type ZSM-12Pentasil aluminosilicate zeoliteMolecular sieveOrganic base

The invention relates to a new multi-level pore channel molecular sieve preparation method, and belongs to the technical field of inorganic porous materials. According to the method, the urea solution is used to replace the NaOH solution or organic alkali solution as the desilication reagent, the amount of NH3 generated in an in-situ manner is controlled by using the urea solution concentration, the reaction temperature and the reaction time, the pH value of the reaction slurry during the process is constant, and the method is the economic, environmental protection and convenient post-treatment method. According to the present invention, the prepared multi-level pore channel molecular sieve can well maintain the relative crystallinity, the micro-pore pore volume and most of the acid characteristics of the original molecular sieve; and the obtained sample can be directly used for the acid-catalyzed reaction without NH4<+> ion exchange and subsequent water washing, drying and calcination process, such that the process is substantially simplified.

Owner:DALIAN UNIV OF TECH

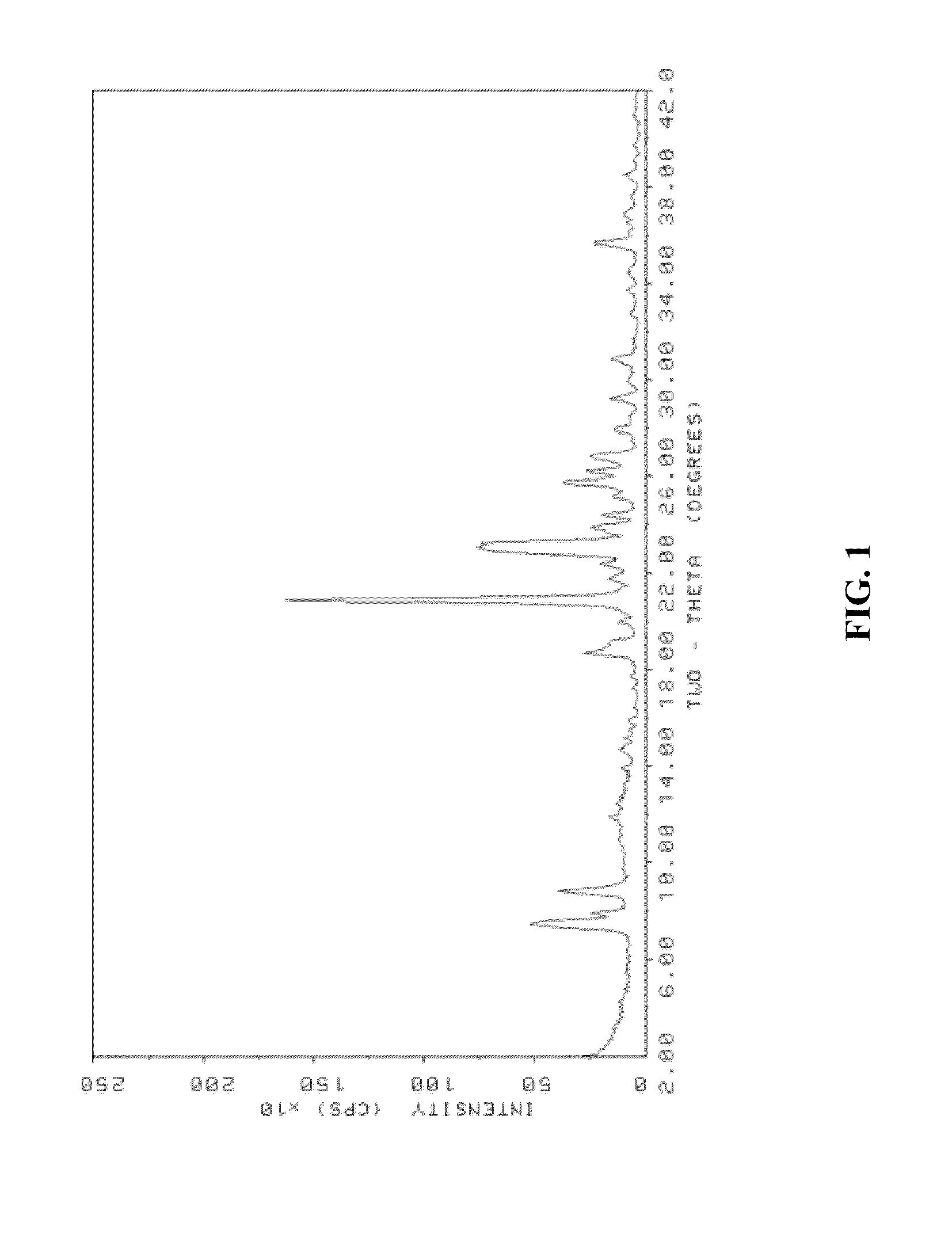

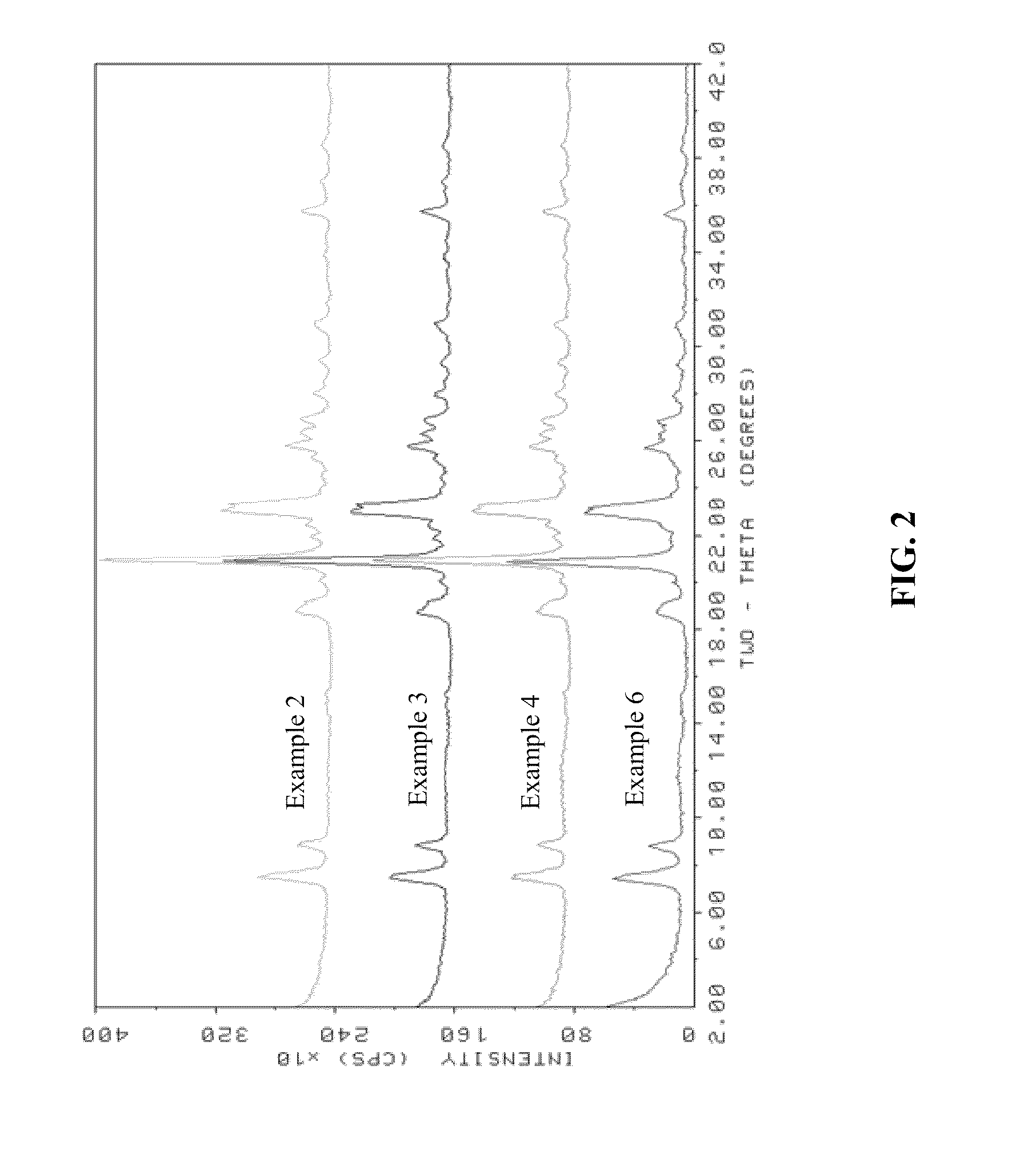

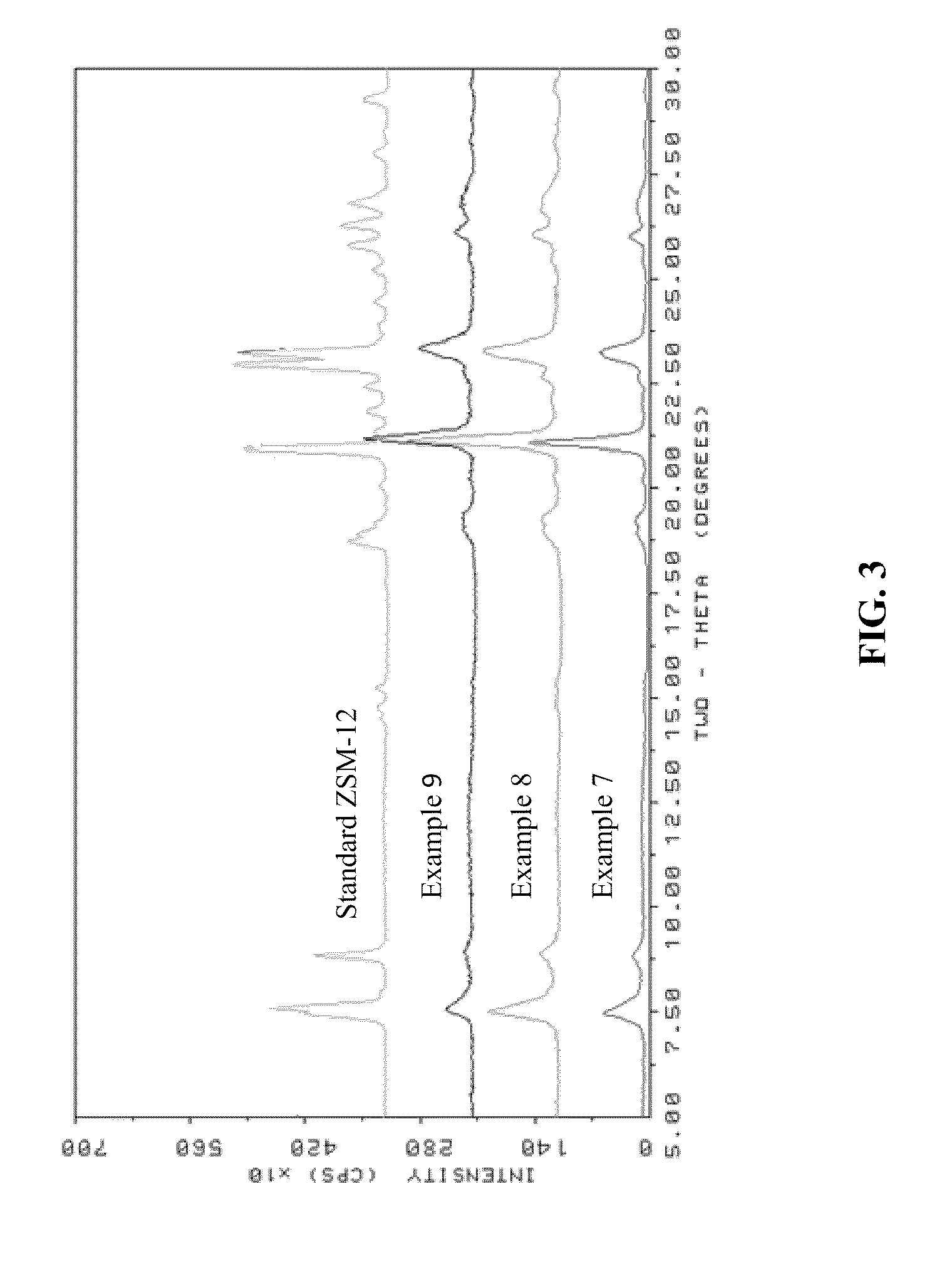

Method for producing MTW-type zeolite

ActiveUS8834836B2Low costLow cost productionAluminosilicate zeolite type ZSM-12Aluminium compoundsSilicon dioxideOrganic chemistry

Provided is a method for producing an MTW-type zeolite. The reaction mixture contains a silica source, an alumina source, an alkali source, and water is reacted with a seed crystal of a zeolite to produce an MTW-type zeolite. The reaction mixture has a composition, which makes a synthesized zeolite contain an MFI-type zeolite when the zeolite is synthesized solely from the reaction mixture, is used. As the seed crystal, a beta-type zeolite which has a ratio of SiO2 / Al2O3 of 8 to 50 and does not contain a structure direction agent is used. The seed crystal is added to the reaction mixture, in a proportion of 0.1% by mass to 20% by mass based on a silica component in the reaction mixture. The reaction mixture to which the seed crystal has been added is heated at 100° C. to 200° C. in a sealed state.

Owner:THE UNIV OF TOKYO +1

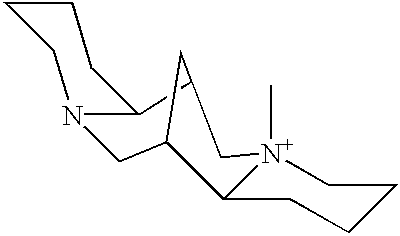

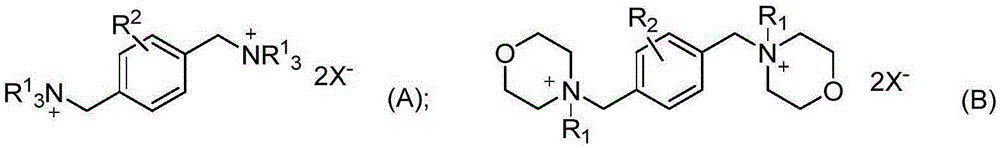

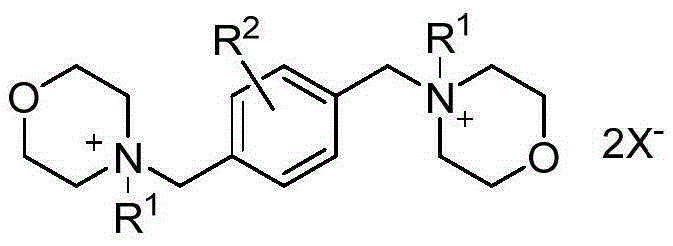

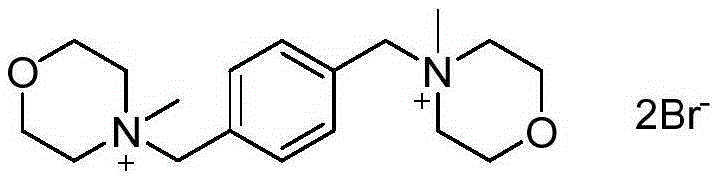

Gemini quaternary ammonium salt or quaternary ammonium salt compound and preparation method

ActiveCN106588816ASpecial structureHigh purityAluminosilicate zeolite type ZSM-12Organic chemistryMolecular sieveQuaternary ammonium cation

The invention relates to gemini quaternary ammonium salt or a quaternary ammonium salt compound and a preparation method. The technical problems that a template existing in the prior art is poor in framework rigidity and poor in guidance quality are mainly solved. According to the technical scheme, gemini quaternary ammonium salt or the quaternary ammonium salt compound is adopted, and the structure is shown as the following structure general formula, wherein R1 is alkyl of C1-C10, R2 is at least one of H, halogen and alkyl of C1-C6, and X is any one of chlorine, bromine, iodine and hydroxyl, and the problem is solved well. Gemini quaternary ammonium salt or the quaternary ammonium salt compound is high in structural rigidity and can serve as a template to be used for synthesis of a zeolite molecular sieve. The general formula is shown in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing MTW-type zeolite

ActiveUS9333495B2Small loadLow production costAluminosilicate zeolite type ZSM-12Molecular sieve catalystsLithiumOrganic compound

A method for producing an MTW-type zeolite, comprising (1) mixing an alumina source, an alkali source, a lithium source, and water so as to obtain a reaction mixture (2) Adding a seed crystal of an MTW-type zeolite before or while a silica source is added to the reaction mixture in a proportion of 0.1 to 20% by weight relative to the silica component in the reaction mixture. Mixing and stirring the reaction mixture. Wherein the MTW-type zeolite of the seed crystal has a SiO2 / Al2O3 ratio of 10 to 500 and does not contain an organic compound. The reaction mixture has a composition represented by the following molar ratios: SiO2 / Al2O3=12 to 200, Na2O / SiO2=0.1 to 0.3, Li2O / (Na2O+Li2O)=0.05 to 0.5 and H2O / SiO2=10 to 50. (3) Air tightly heating the reaction mixture, to which the seed crystal of the MTW type zeolite has been added, at 100 to 200° C.

Owner:THE UNIV OF TOKYO +1

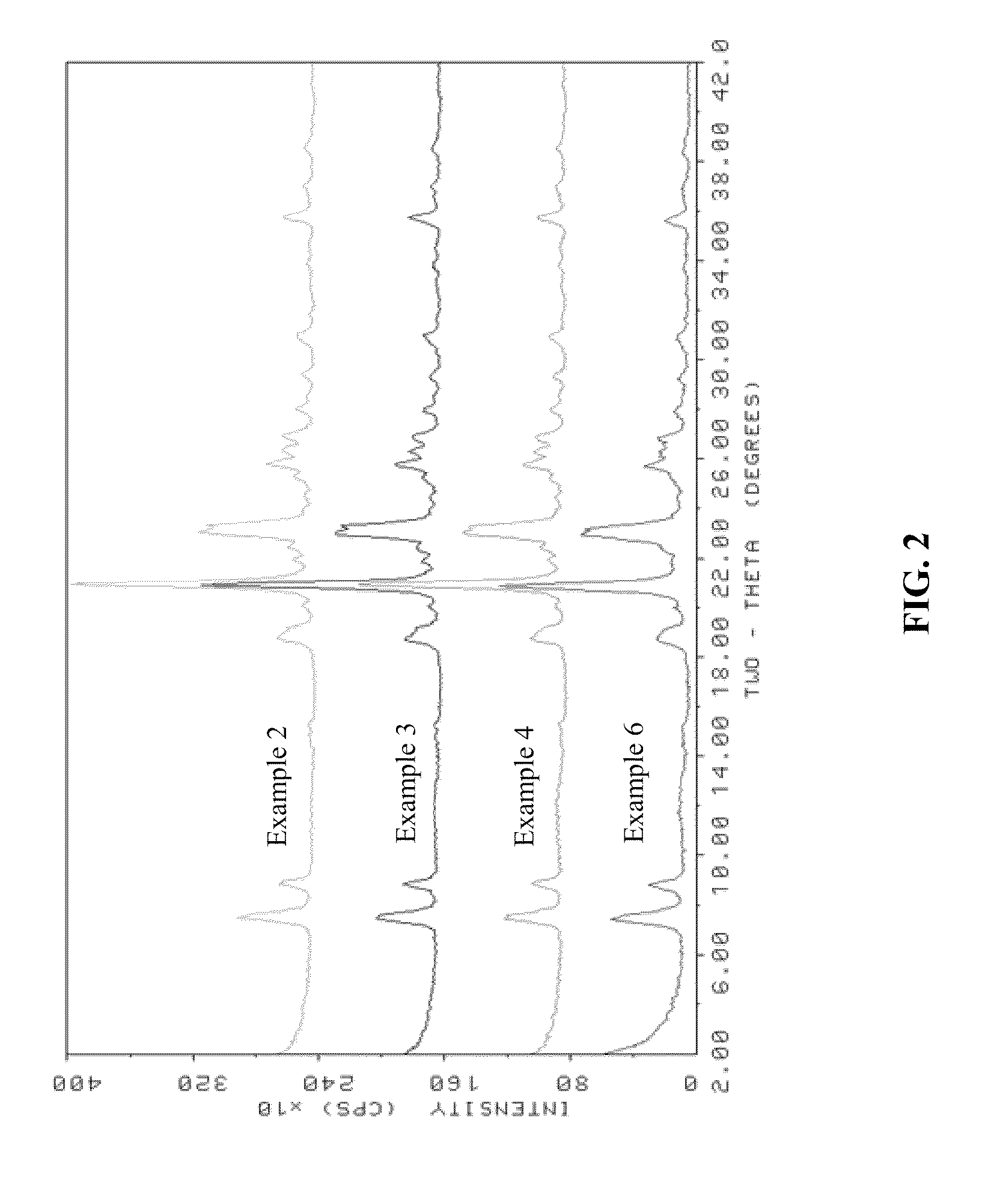

Method for making aluminosilicate zsm-12

ActiveUS20110123433A1Sufficient formAluminosilicate zeolite type ZSM-12Aluminium compoundsIsomerizationSilicon dioxide

An aluminosilicate ZSM-12 may be prepared de novo in a small crystalline form from a reaction mixture containing a source of silica and a source of alumina. A small crystalline form of aluminosilicate ZSM-12 may also be prepared from a small crystalline form of borosilicate ZSM-12 by replacement of boron in the borosilicate ZSM-12 framework with aluminum. The aluminosilicate ZSM-12 is useful as an isomerization selective catalyst in processes such as isomerization dewaxing hydrocarbon feedstocks.

Owner:CHEVROU USA INC

Process for isomerizing a hydrocarbonaceous feedstock using aluminosilicate ZSM-12

Owner:CHEVROU USA INC

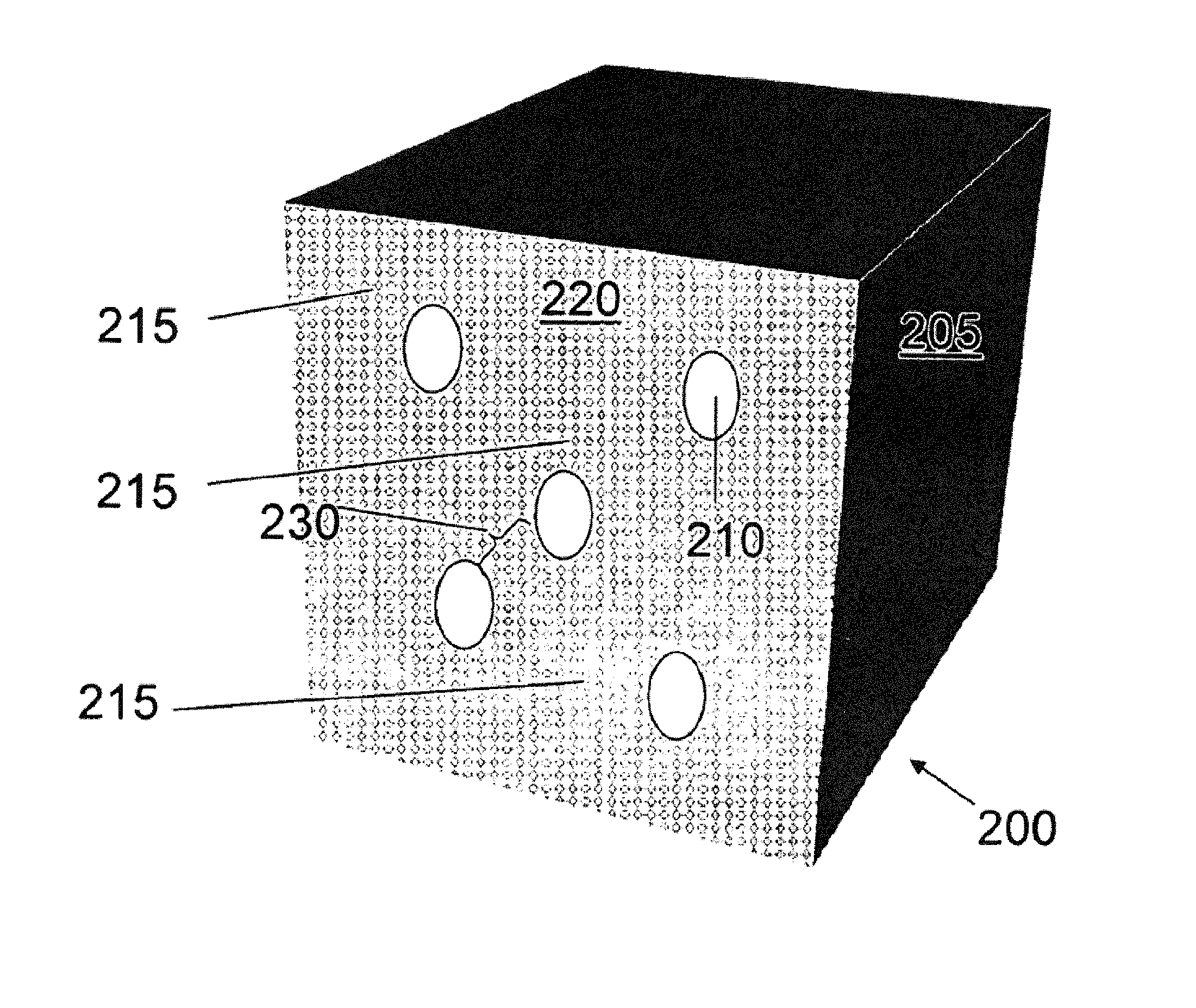

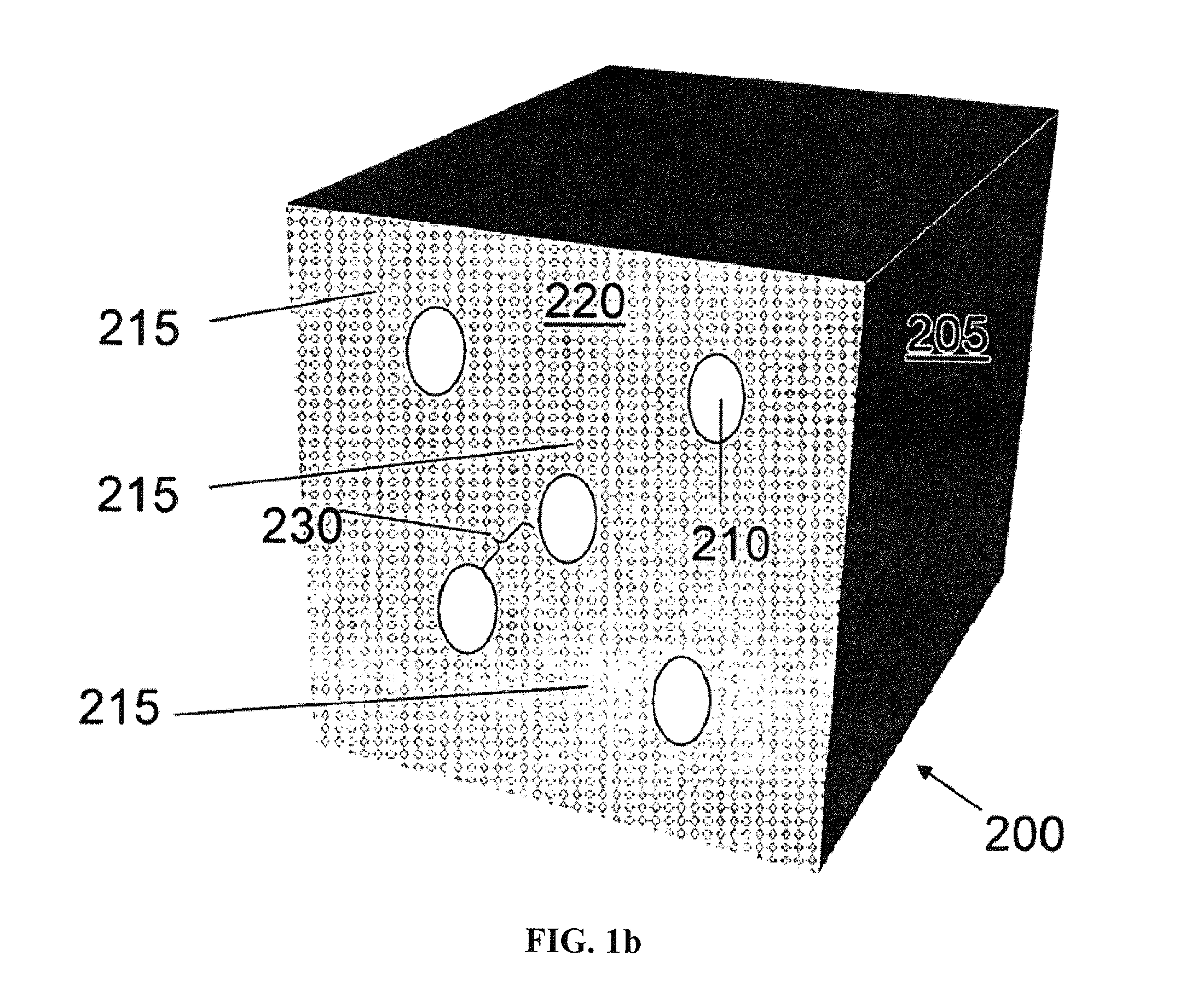

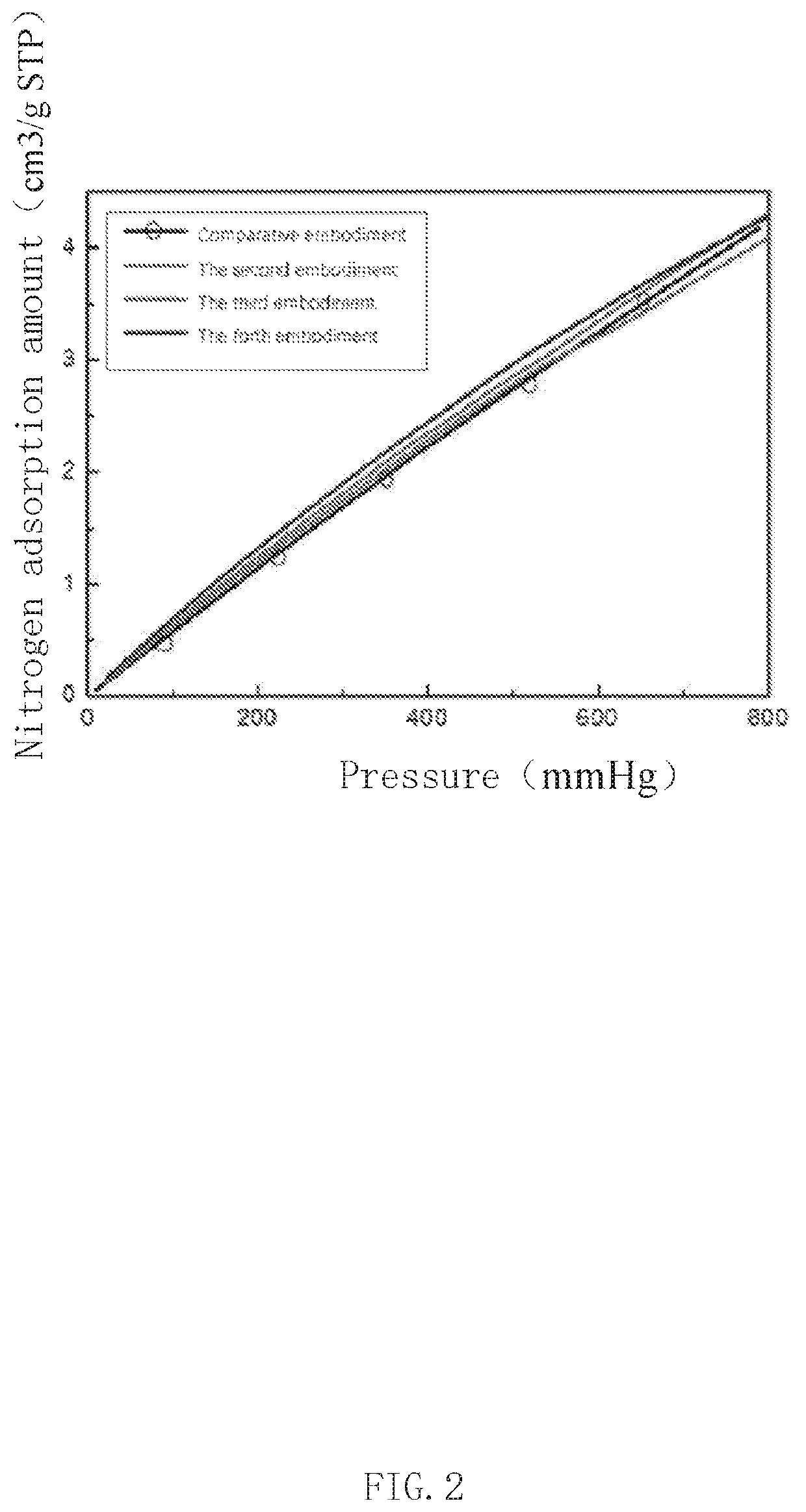

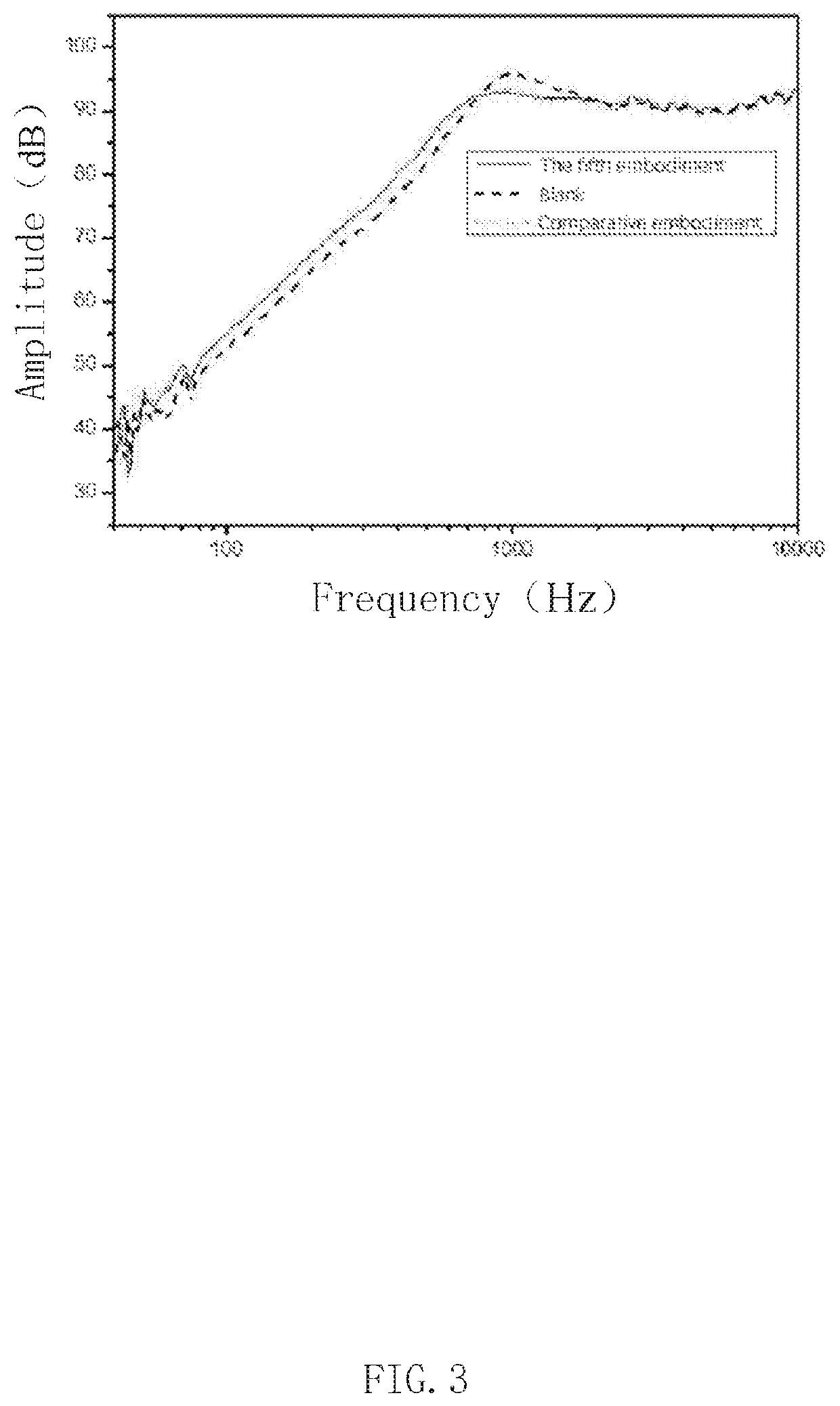

Sound absorbing material and speaker box using same

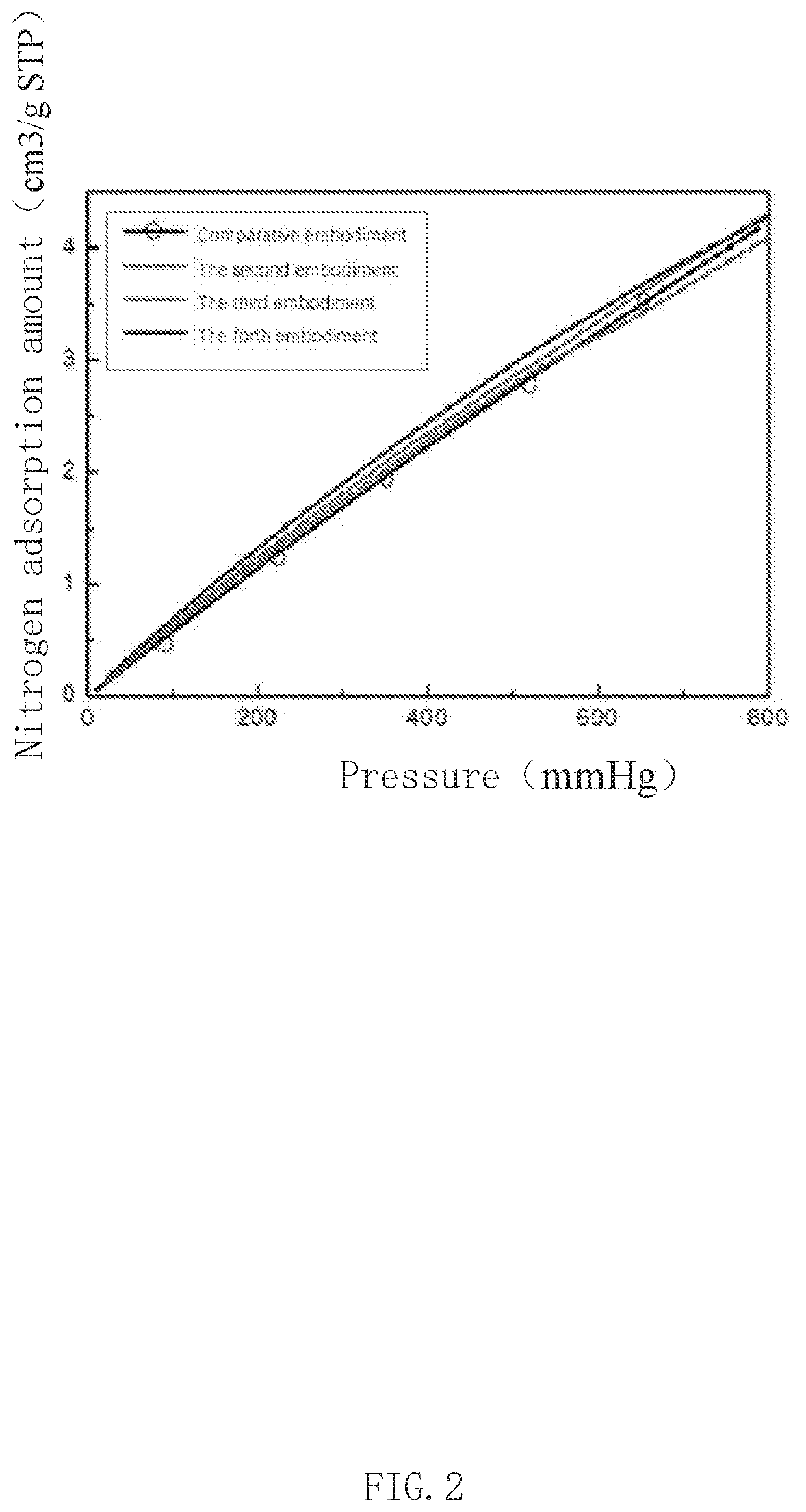

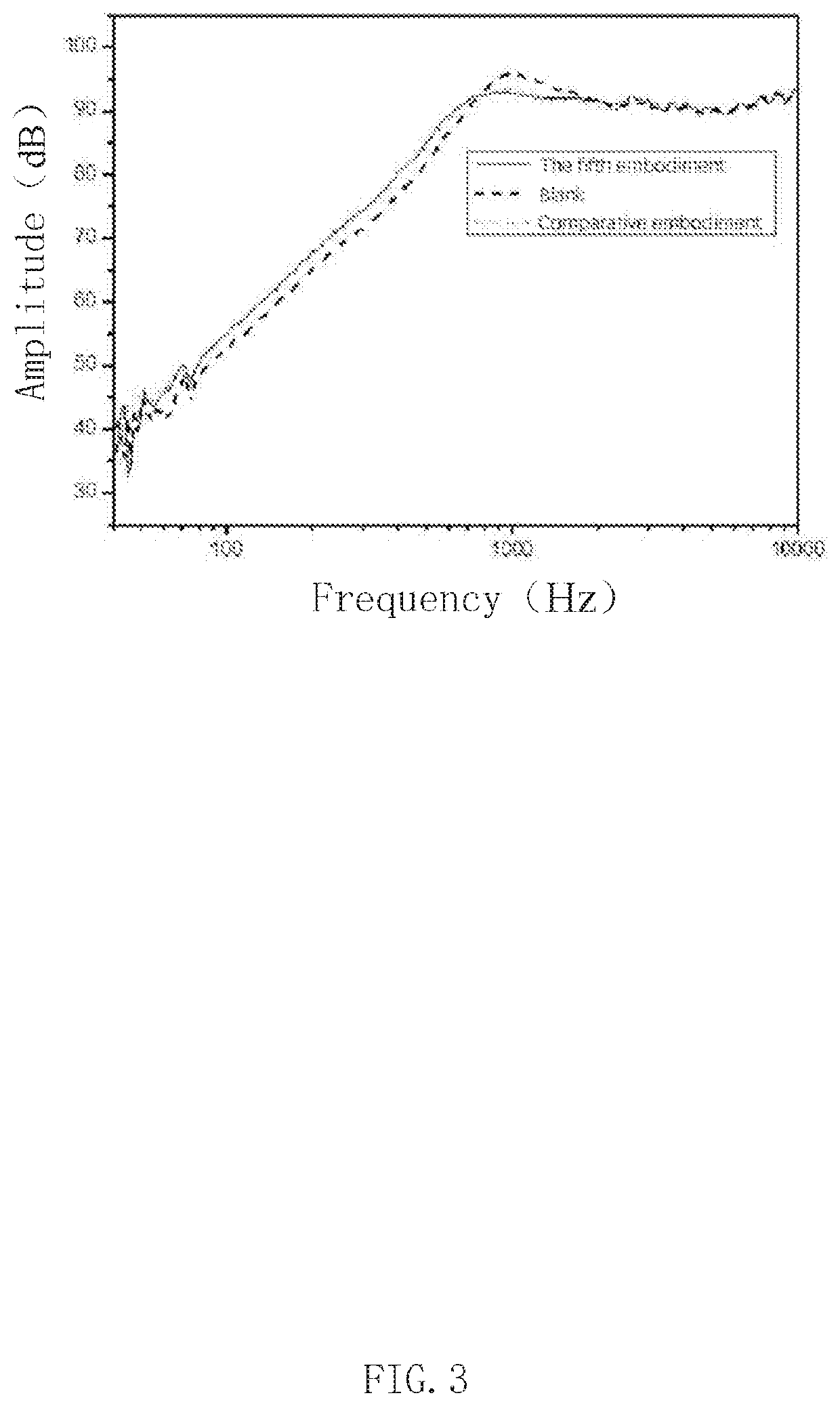

ActiveUS20200037063A1Improve the stability of actionImprove stabilityAluminosilicate zeolite type ZSM-12Molecular-sieve borosilicatesEngineeringAcoustics

The present disclosure provides a sound absorbing material. The sound absorbing material comprises MFI-structural-type zeolite. The MFI-structural-type zeolite comprises a framework, and the framework comprises SiO2 and AlO3, and the mass ratio of Si to Al in the framework is less than 200 and not less than 50. The present disclosure also provides a speaker box applying the sound absorbing material. The sound absorbing material provided by the present disclosure and the speaker box using the sound absorbing material can further improve the performance of the speaker box, reduce the failure of zeolite and improve the performance stability of the speaker box.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

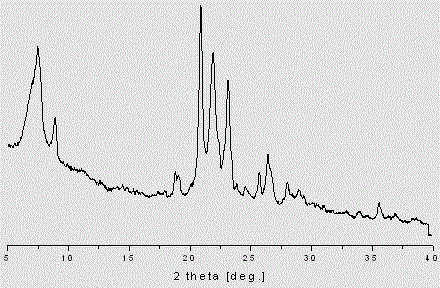

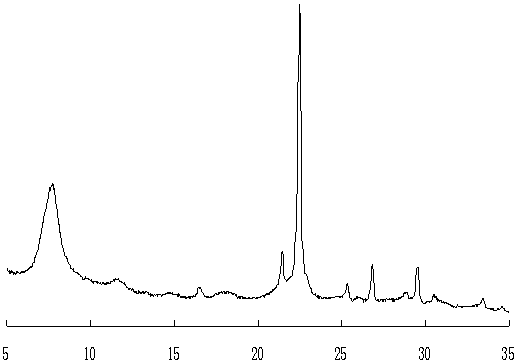

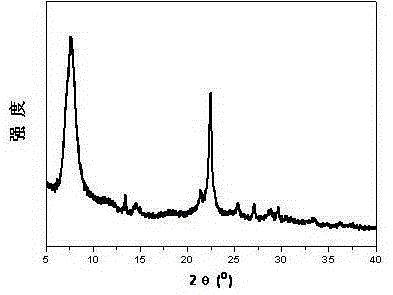

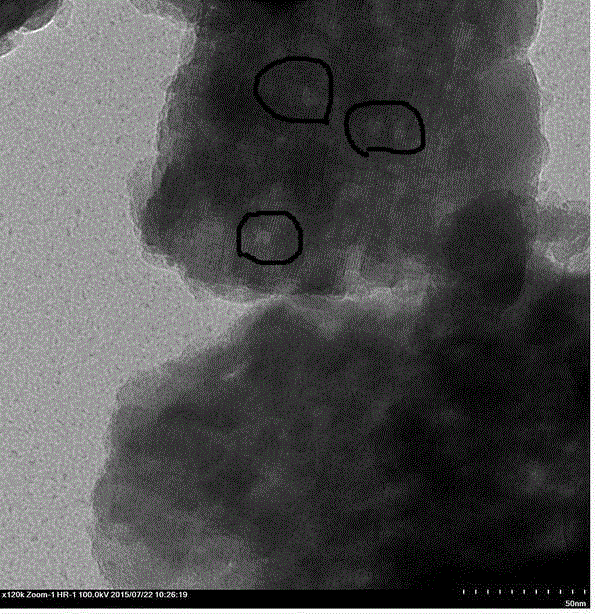

Beta/ZSM-12 intergrowth zeolite molecular sieve and preparation method thereof

ActiveCN108275698AEmission reductionSimple methodCatalyst carriersAluminosilicate zeolite type ZSM-12Molecular sieveChemical physics

The invention relates to a Beta / ZSM-12 intergrowth zeolite molecular sieve and a preparation method thereof. The intergrowth zeolite molecular sieve has a topological structure with MTW and a topological structure with BEA, wherein the particle size of the topological structure with the BEA is about 300nm; the particle size of the topological structure with the MTW is 3 to 4mu m; the silica-alumina ratio of the intergrowth zeolite molecular sieve is 10 to 80. The problems of single morphology dimension, complex preparation and higher cost of the intergrowth zeolite molecular sieve synthesizedin the prior art are mainly solved. The composite molecular sieve material can be used for the fields of catalysis, adsorptive separation and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Sound absorbing material and speaker box using same

ActiveUS11109149B2Improve the stability of actionImprove stabilityAluminosilicate zeolite type ZSM-12Molecular-sieve borosilicatesEngineeringMechanical engineering

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

Rapid ion exchange method of molecular sieve

InactiveCN104276582AImprove controllabilityAvoid inhomogeneityAluminosilicate zeolite type ZSM-12Faujasite aluminosilicate zeoliteMolecular sieveMicrowave

The invention relates to a rapid ion exchange method of a molecular sieve so as to mainly solve technical problems of long exchange time and low utilization rate of an exchange fluid existing in ion exchange of a molecular sieve. The rapid ion exchange method of a molecular sieve contains the following steps: a) a sodium molecular sieve and an ion exchange solution are mixed, the molecular sieve is dispersed in the solution to form a mixture, the liquid-solid weight ratio of the molecular sieve to the solution is 0.1-50, and weight concentration of the solution is 0.01-50%; b) the above mixture is put into a microwave environment, microwave heating is adopted for exchange, heating-up time of microwave heating is 0.01-10h, the temperature rises to 180 DEG C from the temperature of the mixture, and constant temperature time is 0-20h; and c) after microwave ion exchange, the above mixture is filtered to obtain the required molecular sieve after ion exchange. By the technical scheme, the above problems are solved well. The rapid ion exchange method can be applied in industrial production for preparation of a molecular sieve based catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Perturbed synthesis of materials

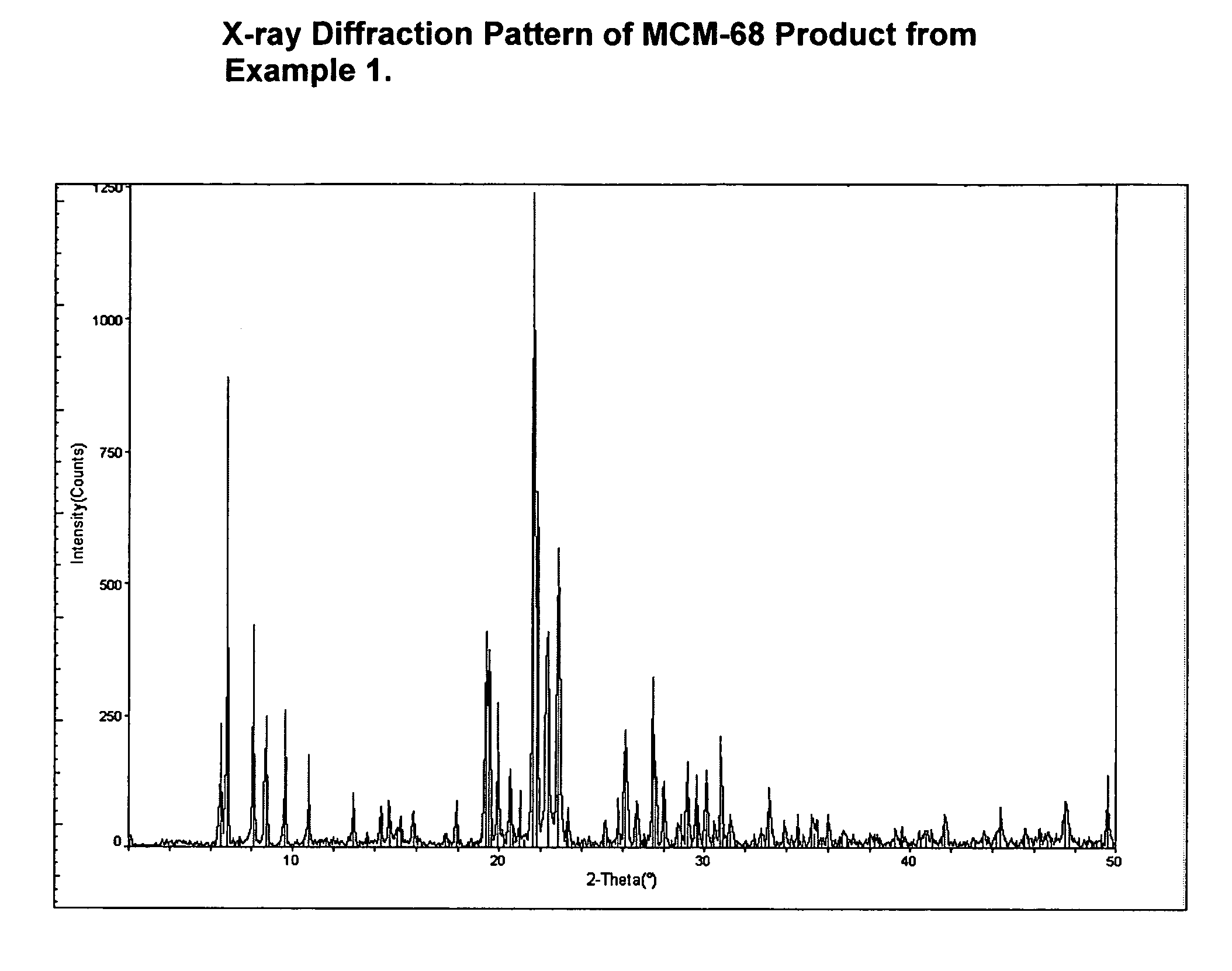

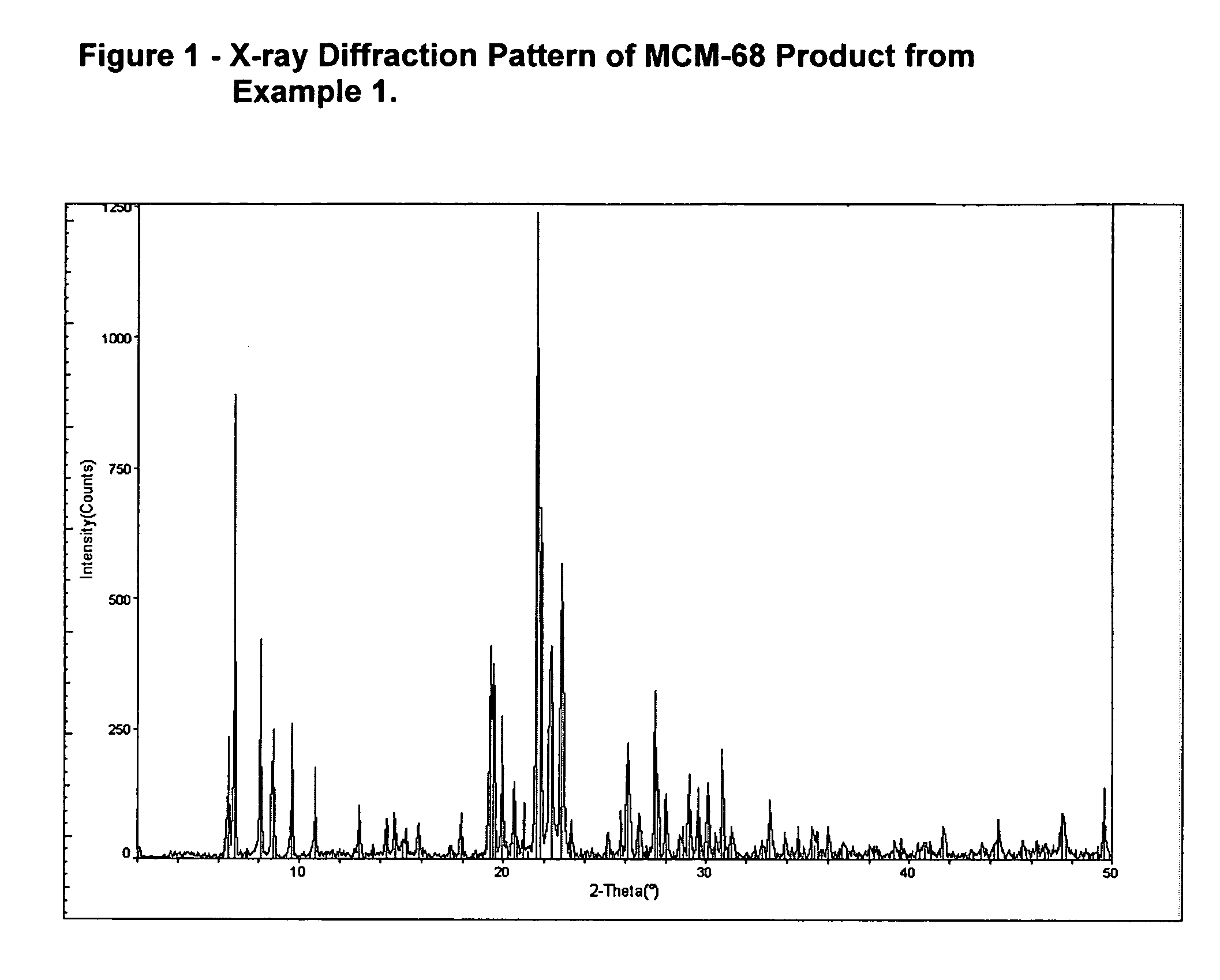

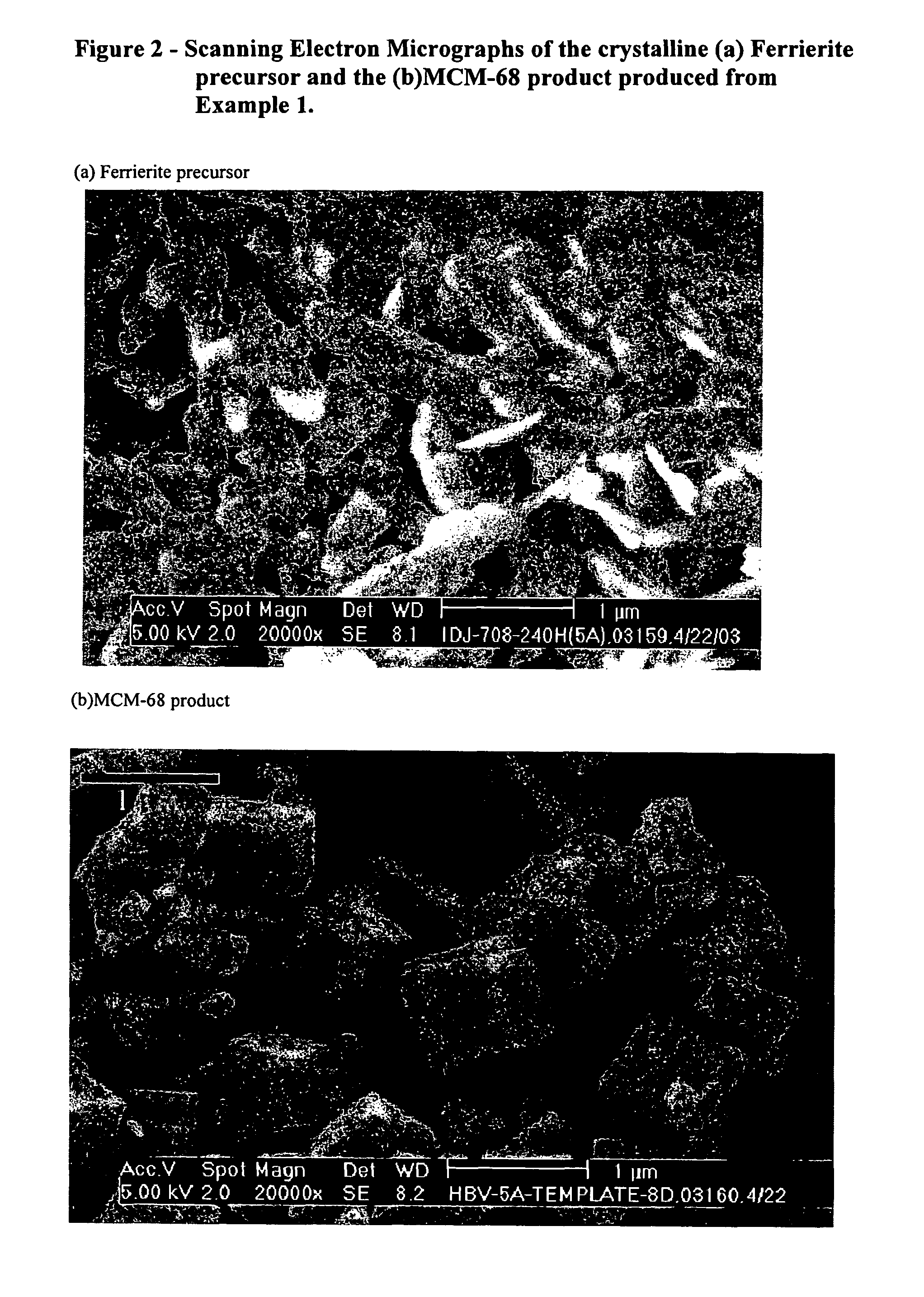

InactiveUS8562941B2Ferrierite aluminosilicate zeoliteAluminosilicate zeolite type ZSM-12CrystallographyHydrothermal synthesis

The present invention is a method that perturbs the initial crystallization of a material from a less desired phase into a more desired phase. More specifically, the present invention is a method to form a different crystallization of a zeolite, mesoporous material, SAPO4, AlPO4 or porous inorganic oxide after the hydrothermal synthesis has started and a precursor crystalline phase has formed.

Owner:EXXON RES & ENG CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com