Zeolite molecular sieve synthesis method

A technology of zeolite molecular sieve and synthesis method, which is applied in the direction of molecular sieve and alkali exchange compound, chemical equipment and method, crystalline aluminosilicate zeolite, etc., which can solve the problems of harsh synthesis conditions, many safety hazards, and increase synthesis cost, and achieve production High cost, avoiding the danger of high-pressure explosion, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of synthetic method of zeolite, and described synthetic method comprises the following contents:

[0036] (1) Mix inorganic alkali, silicon source, aluminum source, and water, and get a gel after mixing evenly;

[0037] (2) Dry the gel obtained in step (1) at 80-160°C until the water evaporates completely;

[0038] (3) Put the mixture obtained in step (2) into the reactor, and pass water vapor into the reactor to carry out the crystallization reaction, the reaction temperature is 100-240°C, and the reaction time is 10-150h;

[0039] (4) Washing and drying the solid product obtained in step (3) to obtain zeolite.

[0040] In the method of the present invention, the inorganic base described in step (1) can be one or more of NaOH, KOH, LiOH; the silicon source can be one or more of white carbon black, silica gel, silica sol or water glass species; the aluminum source can be one or more of sodium aluminate, aluminum sulfate, aluminum chloride...

Embodiment 1

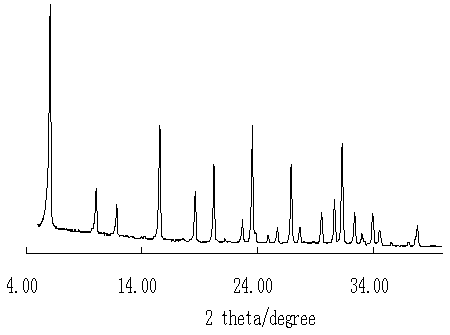

[0112] First, take 4 g of sodium hydroxide and 3.7 g of sodium aluminate in 50 mL of distilled water, and stir until they are completely dissolved. Add 3.5 g of white carbon black slowly and stir for 30 min. Put it into the reactor for crystallization at 110°C for 3h. Then dry at 100°C until the water evaporates completely. Then the resulting mixture is placed in the reactor (the inlet line of the reactor is connected to the water vapor source, and the outlet line is connected to the outside atmosphere). Under the conditions of crystallization for 20h. Finally, the solid product was washed to neutrality, and dried at 120°C for 12 hours. The obtained sample number was CL1, and the XRD spectrum of the obtained sample was as follows: figure 1 As shown, it is X zeolite with high crystallinity.

Embodiment 2

[0114] First, take 2 g of sodium hydroxide and 3 g of sodium aluminate in 30 mL of distilled water and stir until they are completely dissolved. Slowly add 2g of white carbon black and stir for 30 min. Put it into the reactor for crystallization at 80°C for 3.5h. Then dry at 100°C until the water evaporates completely. Then the resulting mixture is placed in the reactor (the inlet line of the reactor is connected to the water vapor source, and the outlet line is connected to the outside atmosphere). Under the conditions of crystallization for 10h. Finally, the solid product was washed to neutrality and dried at 120° C. for 12 hours. The obtained sample number was CL2, and the obtained sample was X zeolite with high crystallinity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com