Patents

Literature

4396results about How to "Increase production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

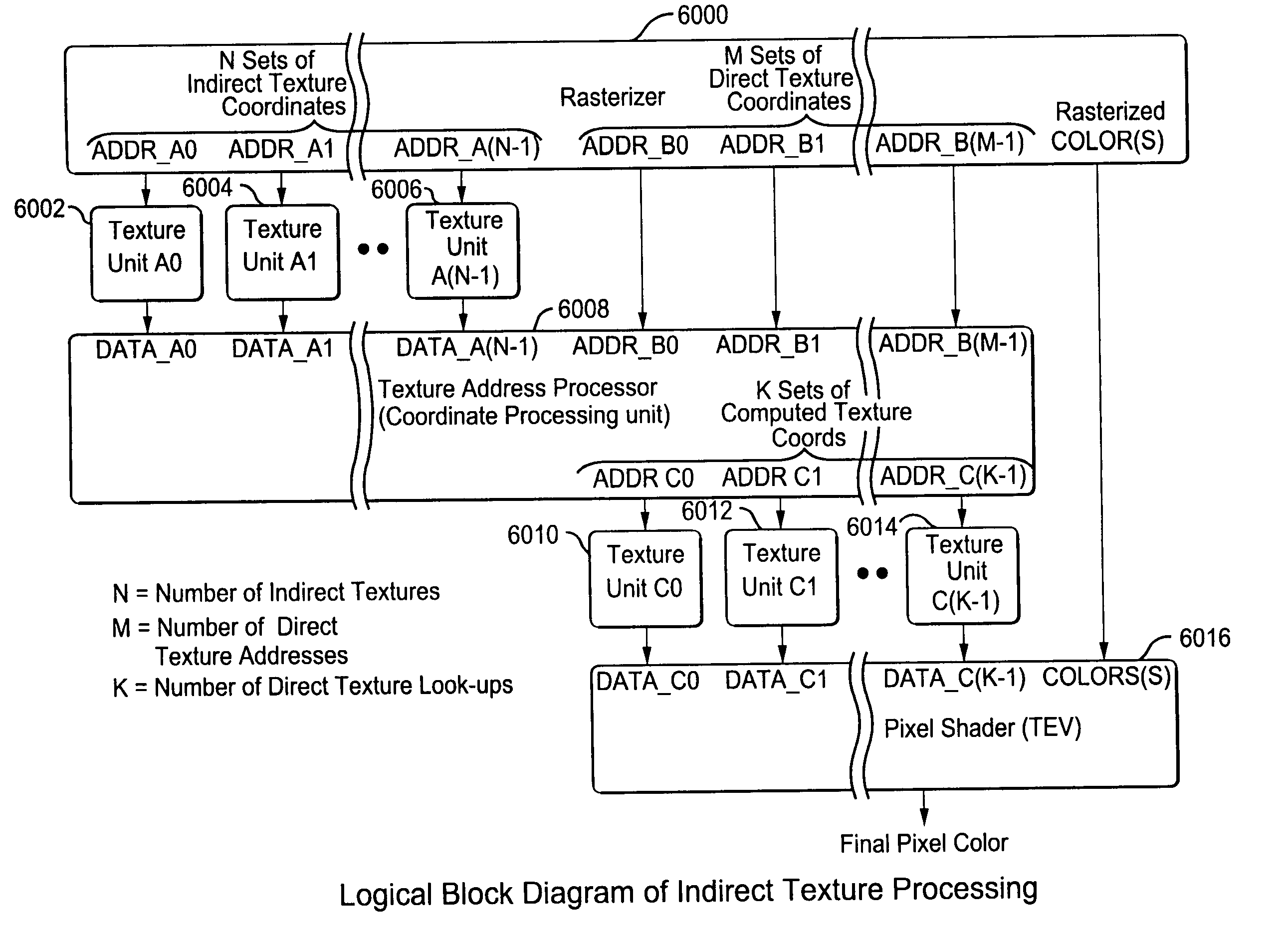

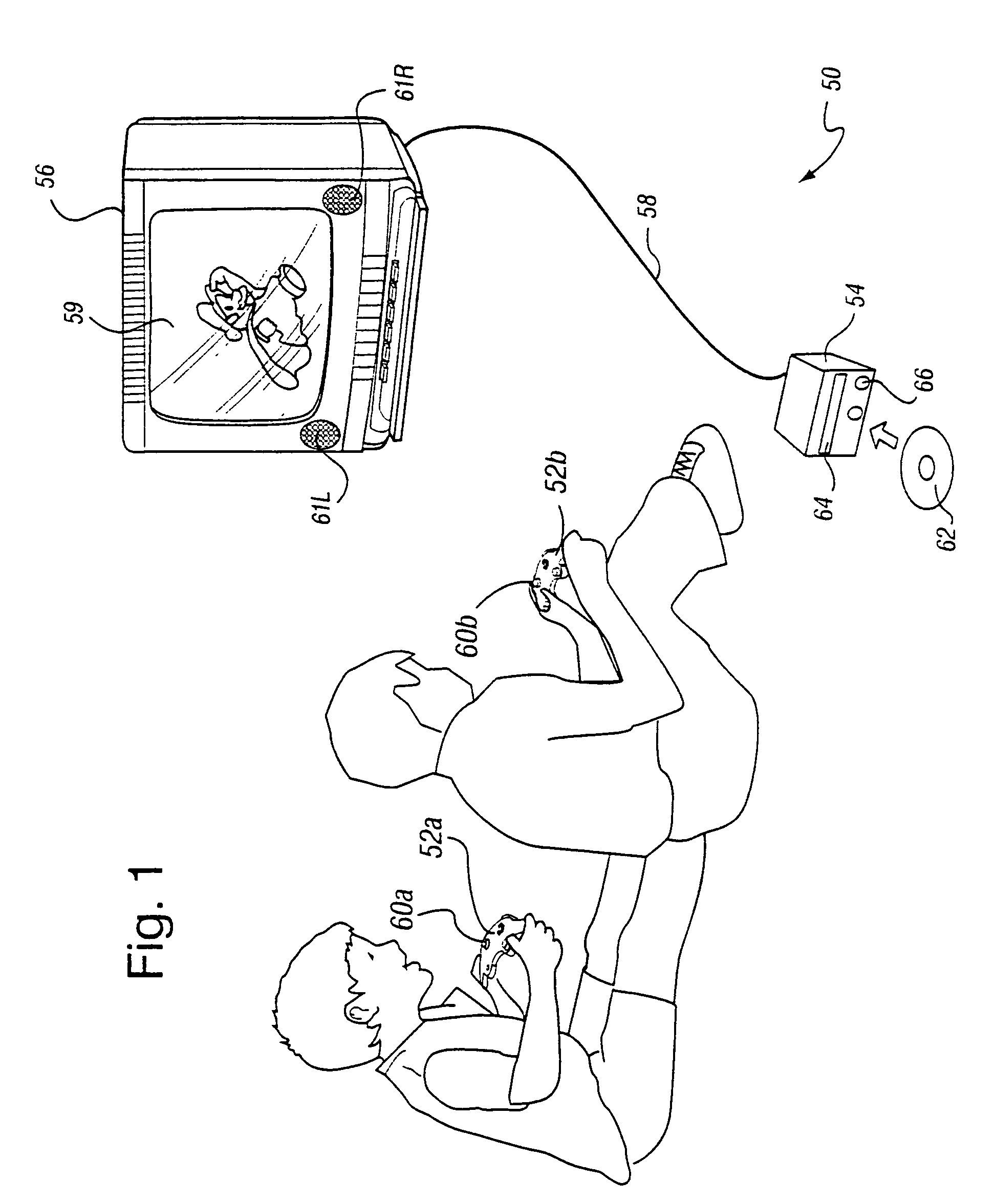

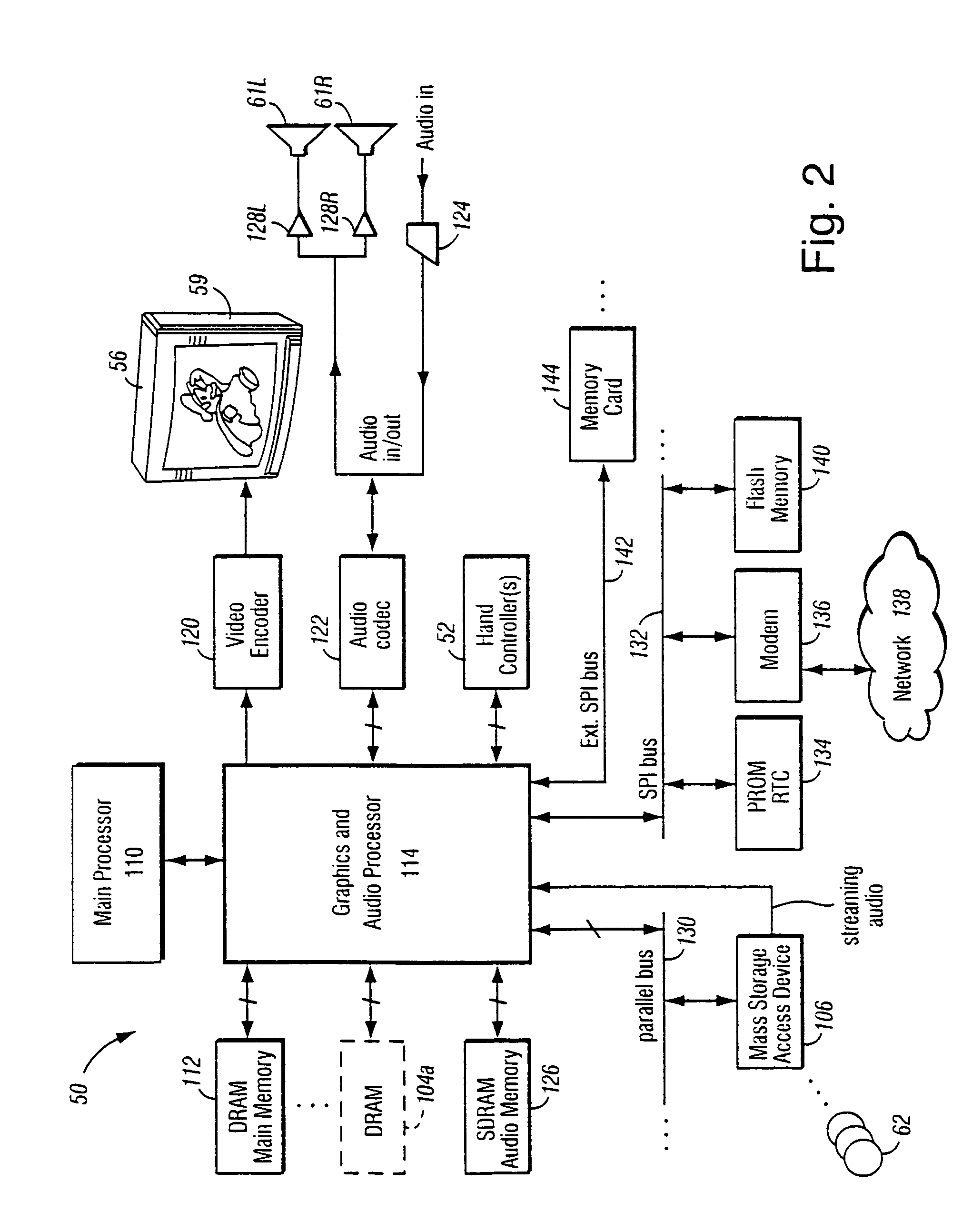

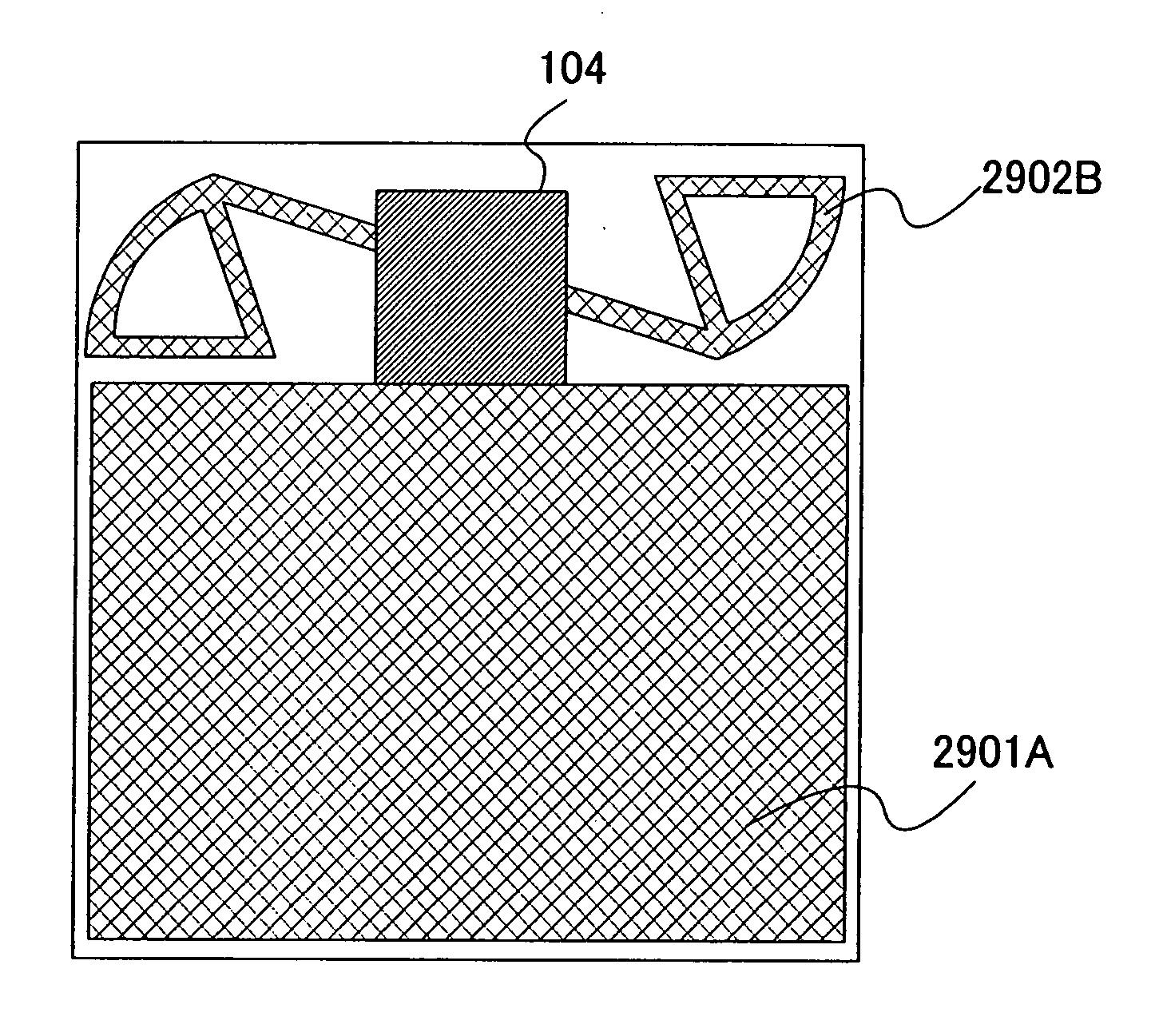

Method and apparatus for interleaved processing of direct and indirect texture coordinates in a graphics system

InactiveUS7002591B1Efficient implementationIncrease in texture mapping hardware complexityCathode-ray tube indicators3D-image renderingPattern recognitionProcessing

A graphics system including a custom graphics and audio processor produces exciting 2D and 3D graphics and surround sound. The system includes a graphics and audio processor including a 3D graphics pipeline and an audio digital signal processor. The graphics pipeline renders and prepares images for display at least in part in response to polygon vertex attribute data and texel color data stored as a texture images in an associated memory. An efficient texturing pipeline arrangement achieves a relatively low chip-footprint by utilizing a single texture coordinate / data processing unit that interleaves the processing of logical direct and indirect texture coordinate data and a texture lookup data feedback path for “recirculating” indirect texture lookup data retrieved from a single texture retrieval unit back to the texture coordinate / data processing unit. Versatile indirect texture referencing is achieved by using the same texture coordinate / data processing unit to transform the recirculated texture lookup data into offsets that may be added to the texture coordinates of a direct texture lookup. A generalized indirect texture API function is provided that supports defining at least four indirect texture referencing operations and allows for selectively associating one of at least eight different texture images with each indirect texture defined. Retrieved indirect texture lookup data is processed as multi-bit binary data triplets of three, four, five, or eight bits. The data triplets are multiplied by a 3×2 texture coordinate offset matrix before being optionally combined with regular non-indirect coordinate data or coordinate data from a previous cycle / stage of processing. Values of the offset matrix elements are variable and may be dynamically defined for each cycle / stage using selected constants. Two additional variable matrix configurations are also defined containing element values obtained from current direct texture coordinates. Circuitry for optionally biasing and scaling retrieved texture data is also provided.

Owner:NINTENDO CO LTD

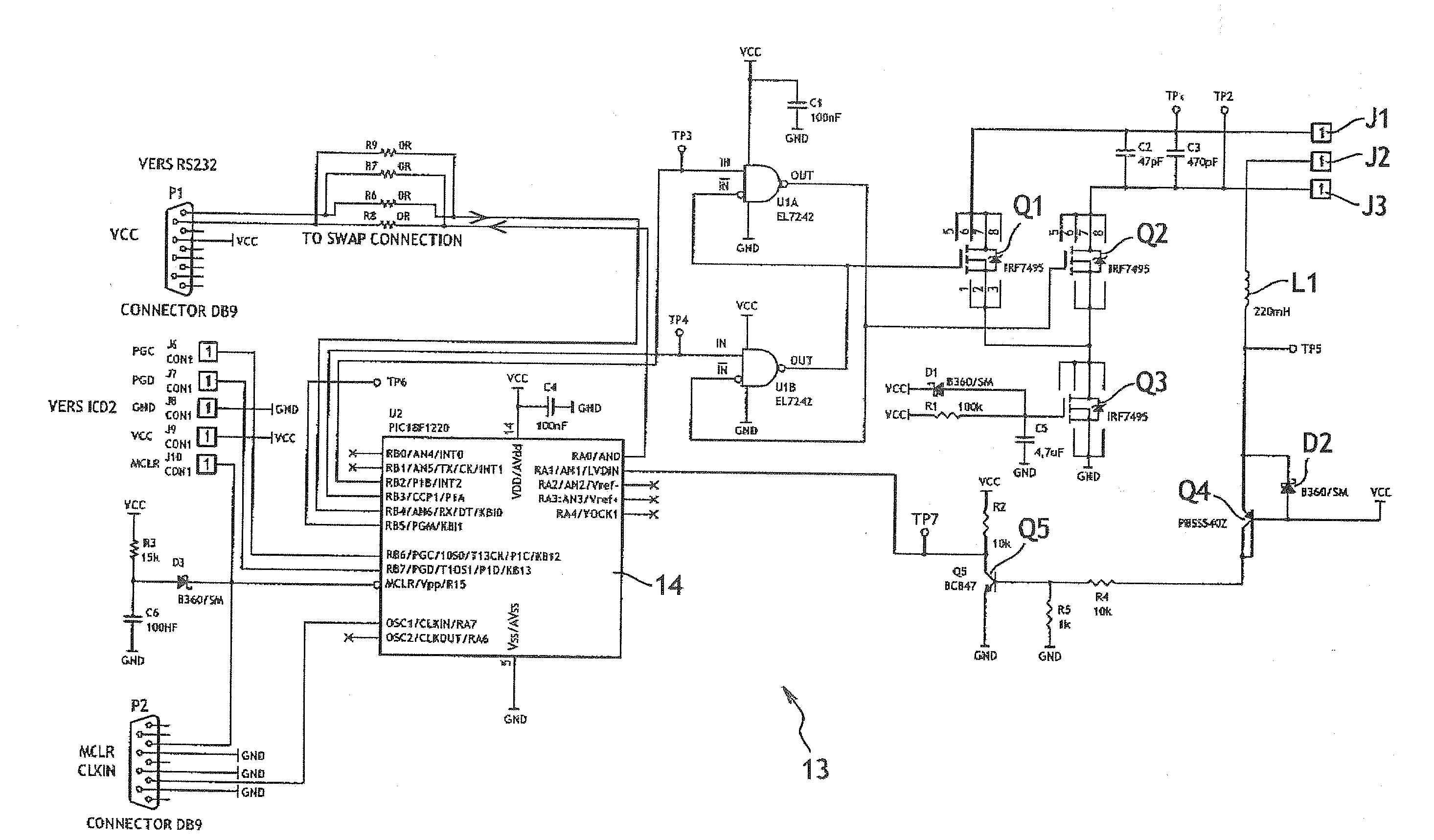

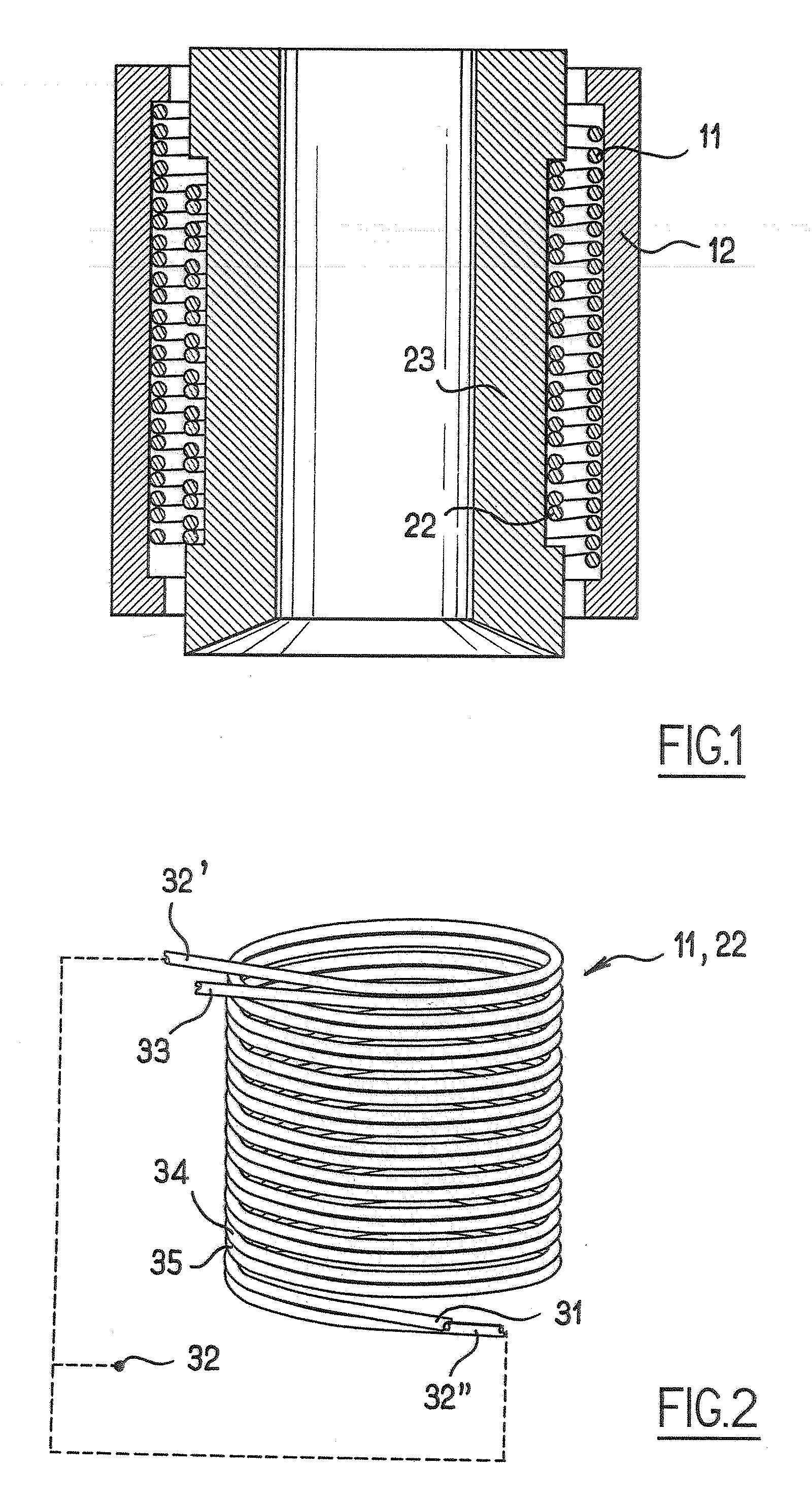

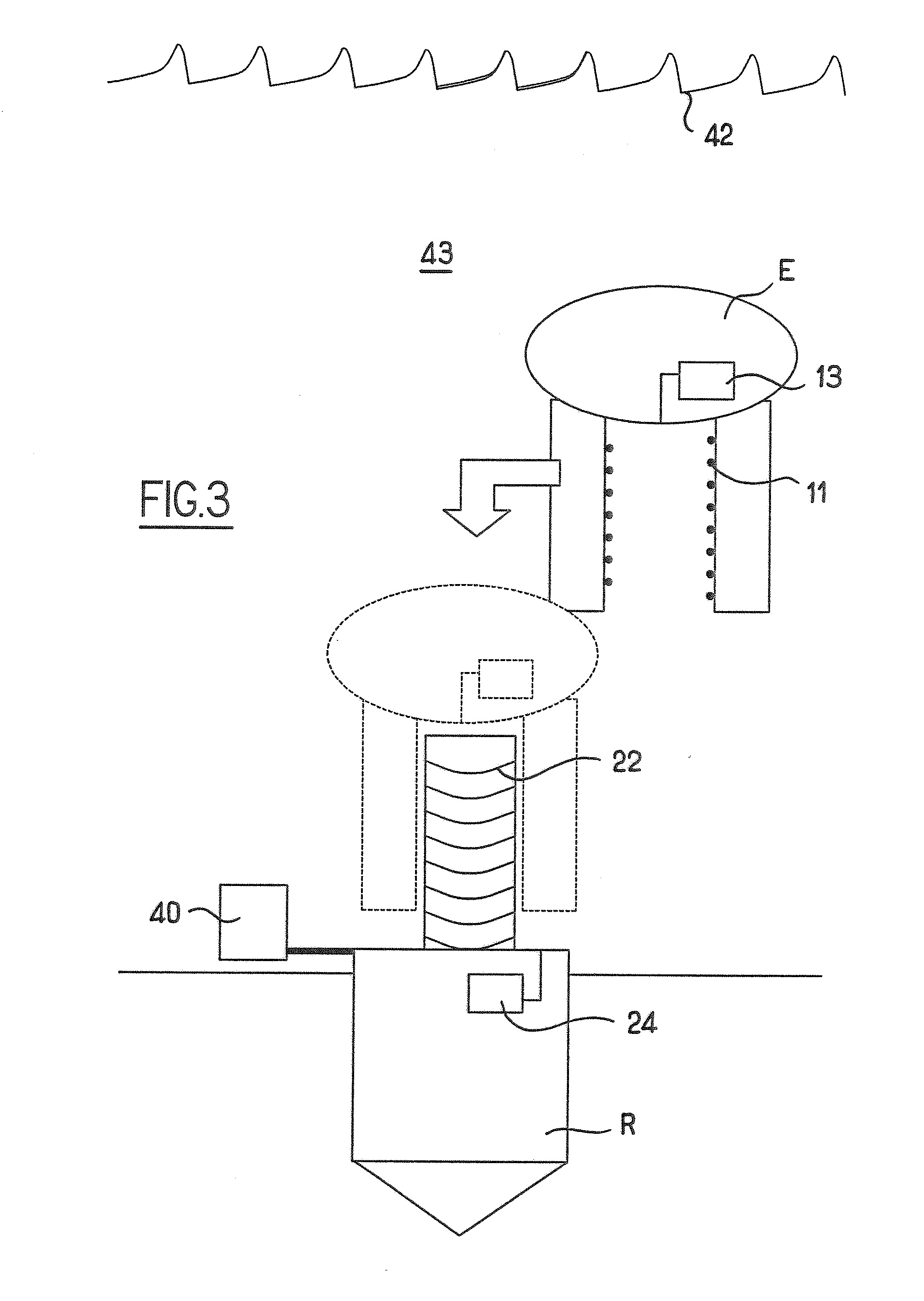

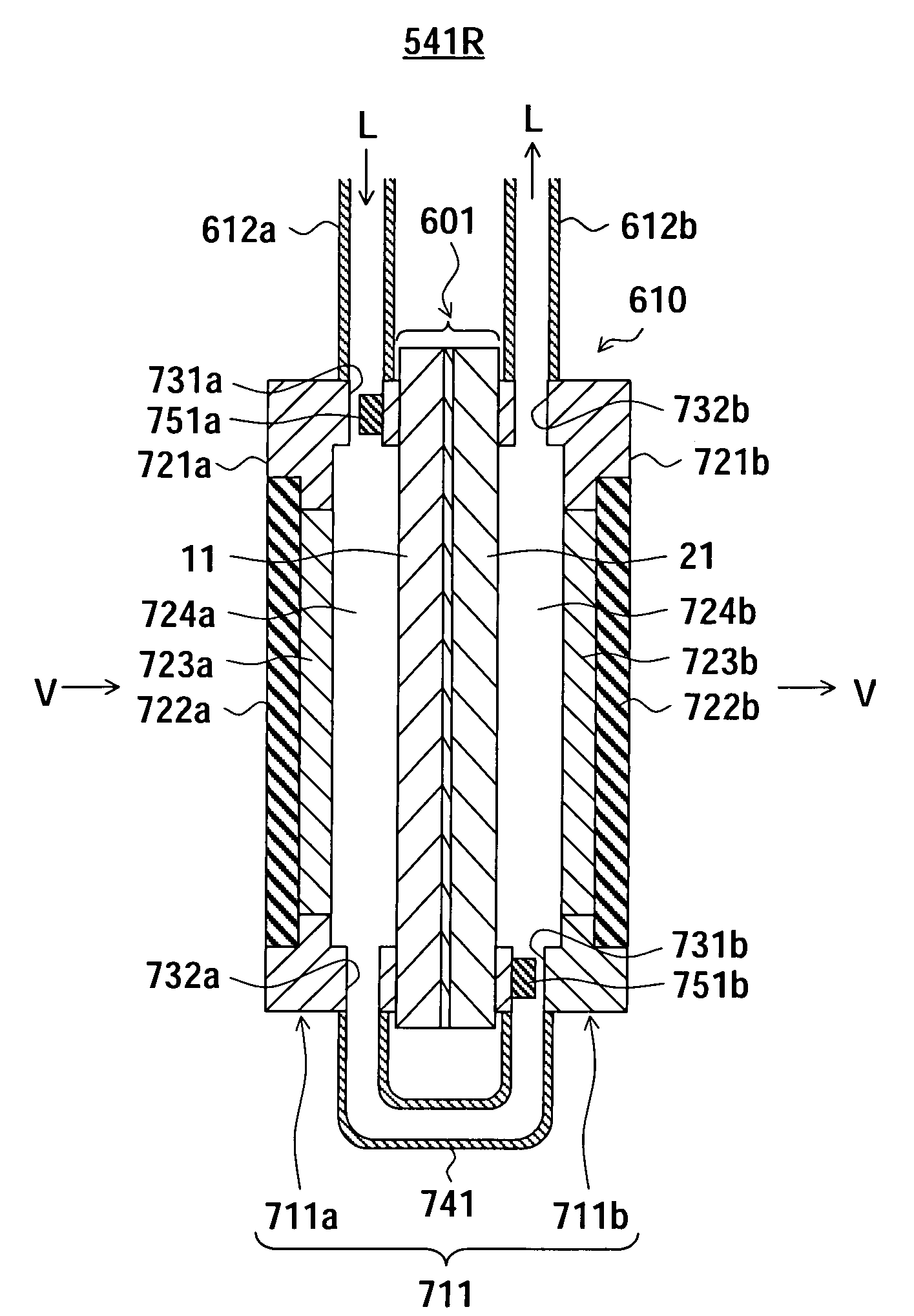

System for electrical power supply and for transmitting data without electrical contact

InactiveUS20100104031A1Simple and robustSimple and reliable synchronizationNear-field transmissionPower distribution line transmissionElectricityEngineering

The invention relates to an assembly comprising a power transmitter (E) and a power receiver (R) respectively comprising a primary coil (11) and a secondary coil (22), in which the transmitter and the receiver are of the electromagnetic induction type and allow on the one hand the powering without electrical contact of the receiver by the transmitter, and on the other hand a bidirectional communication without electrical contact between the transmitter and the receiver.

Owner:DELACHAUX

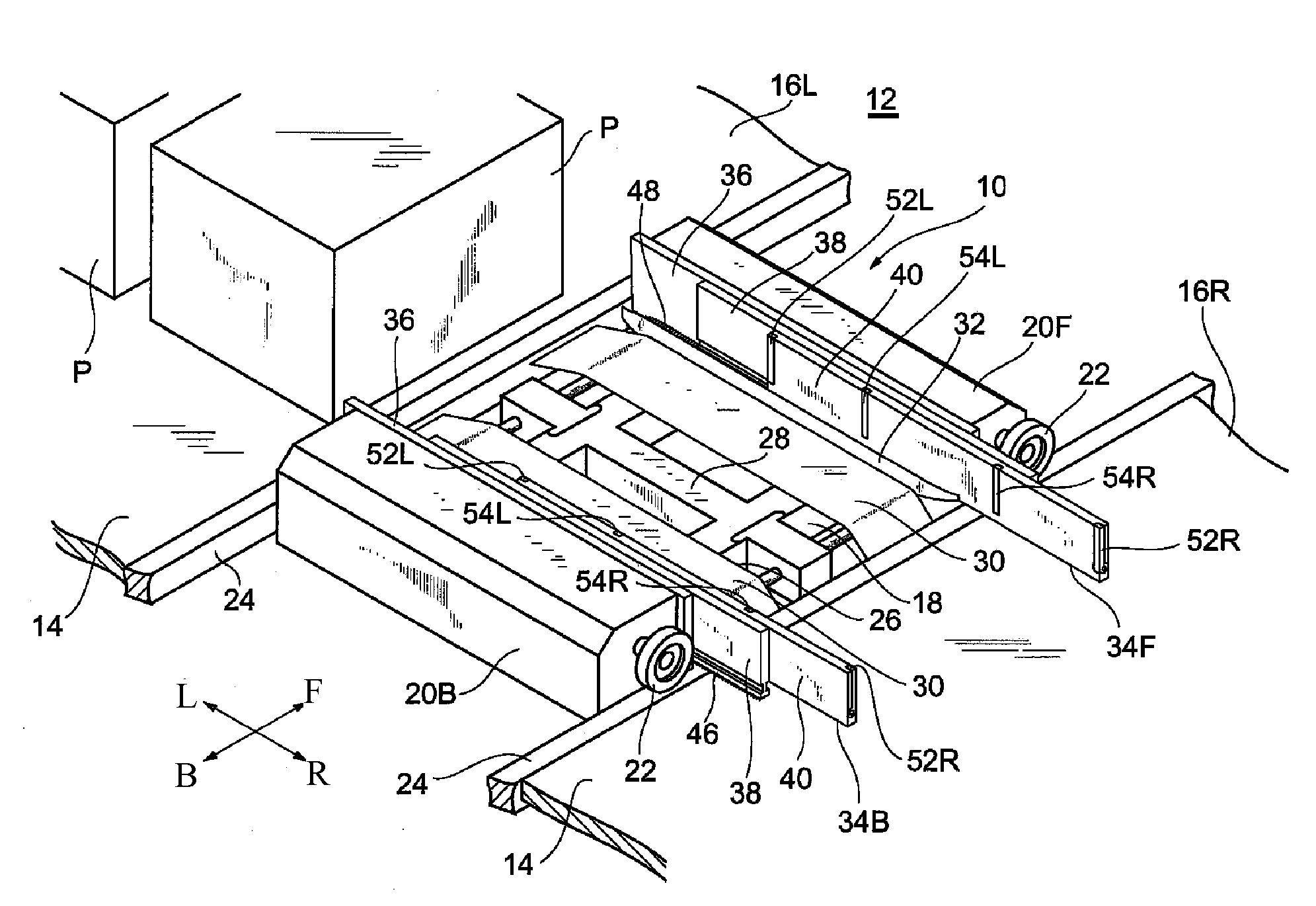

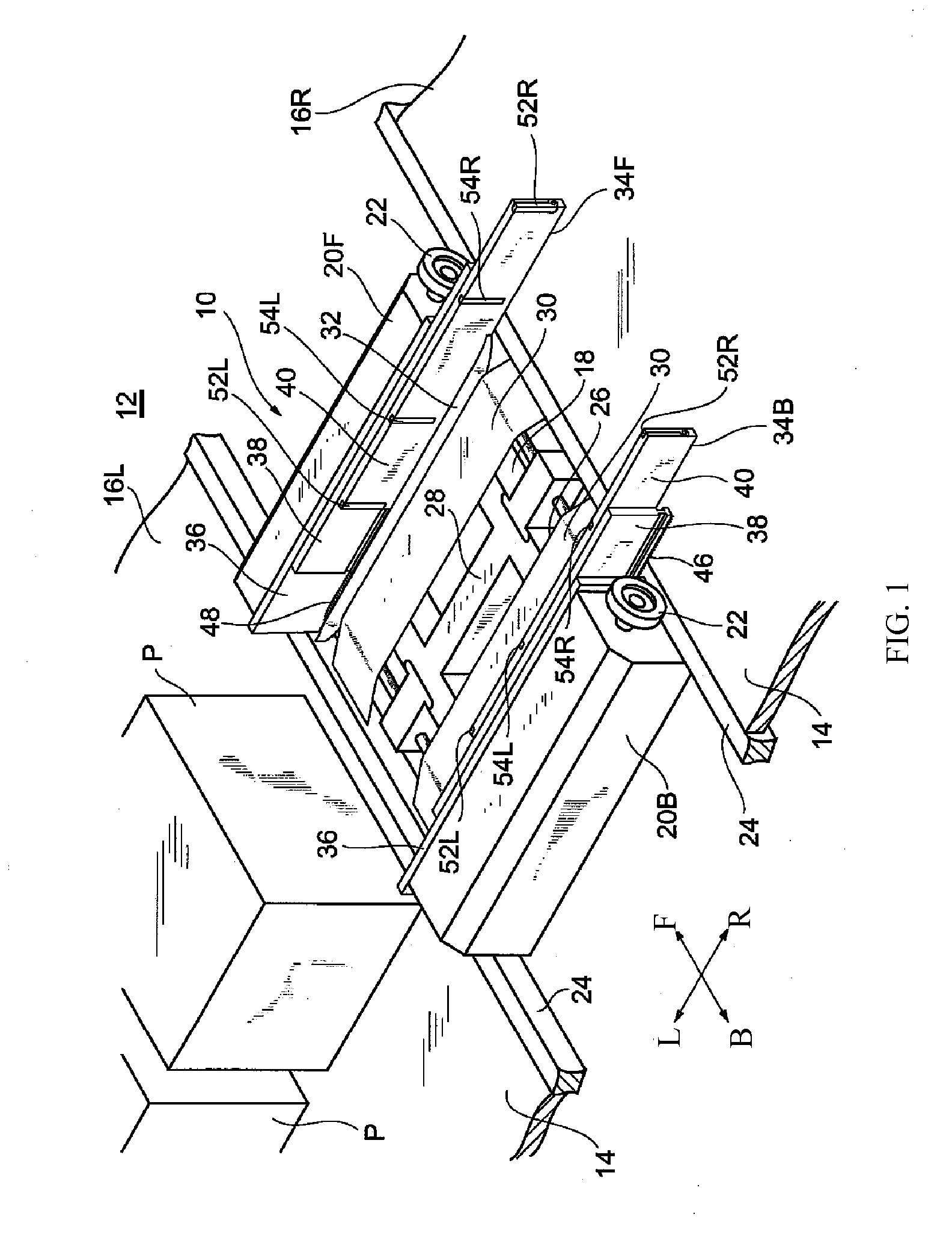

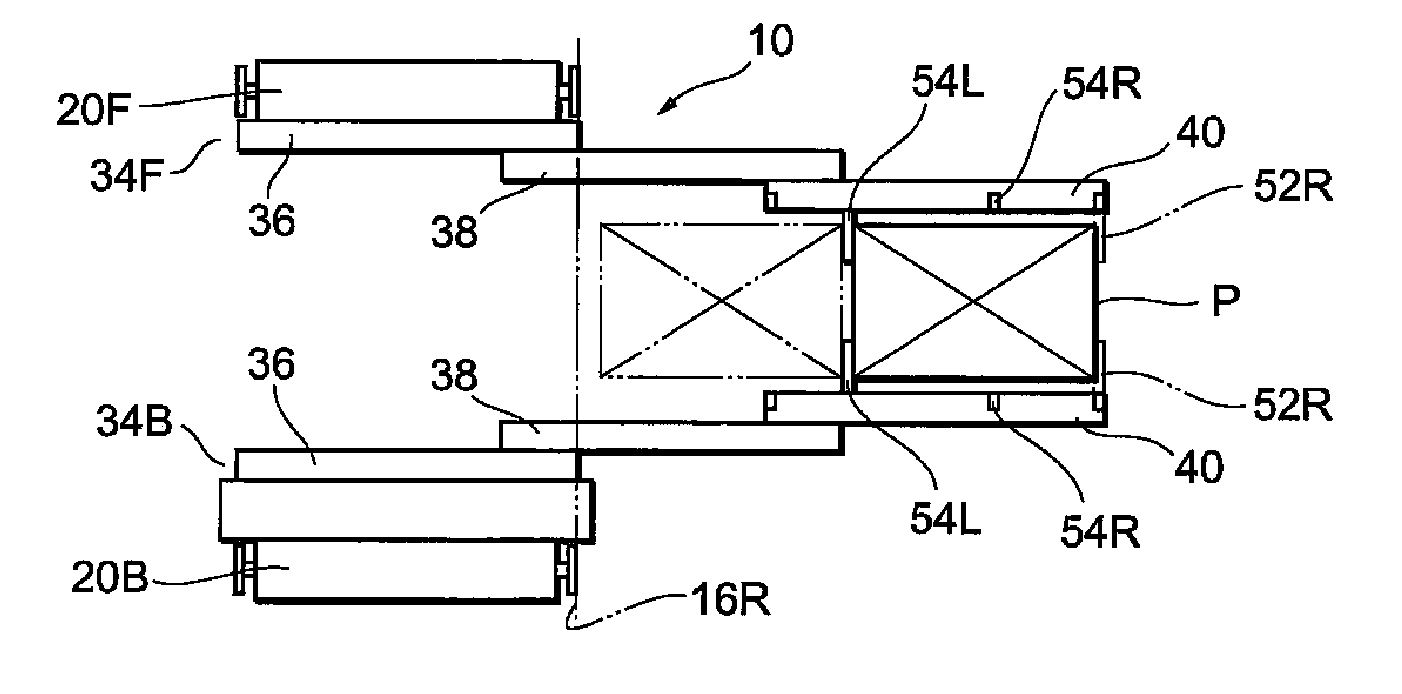

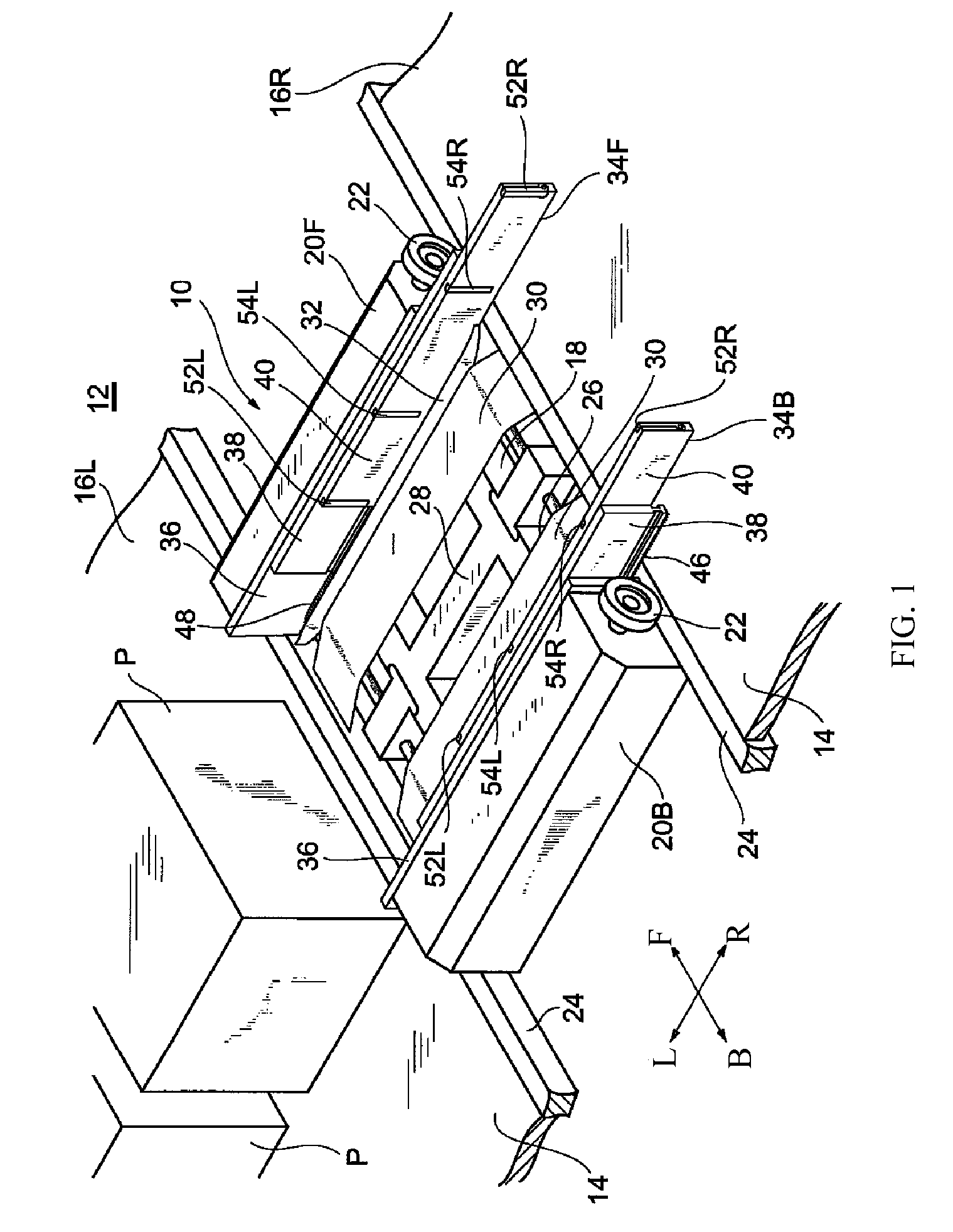

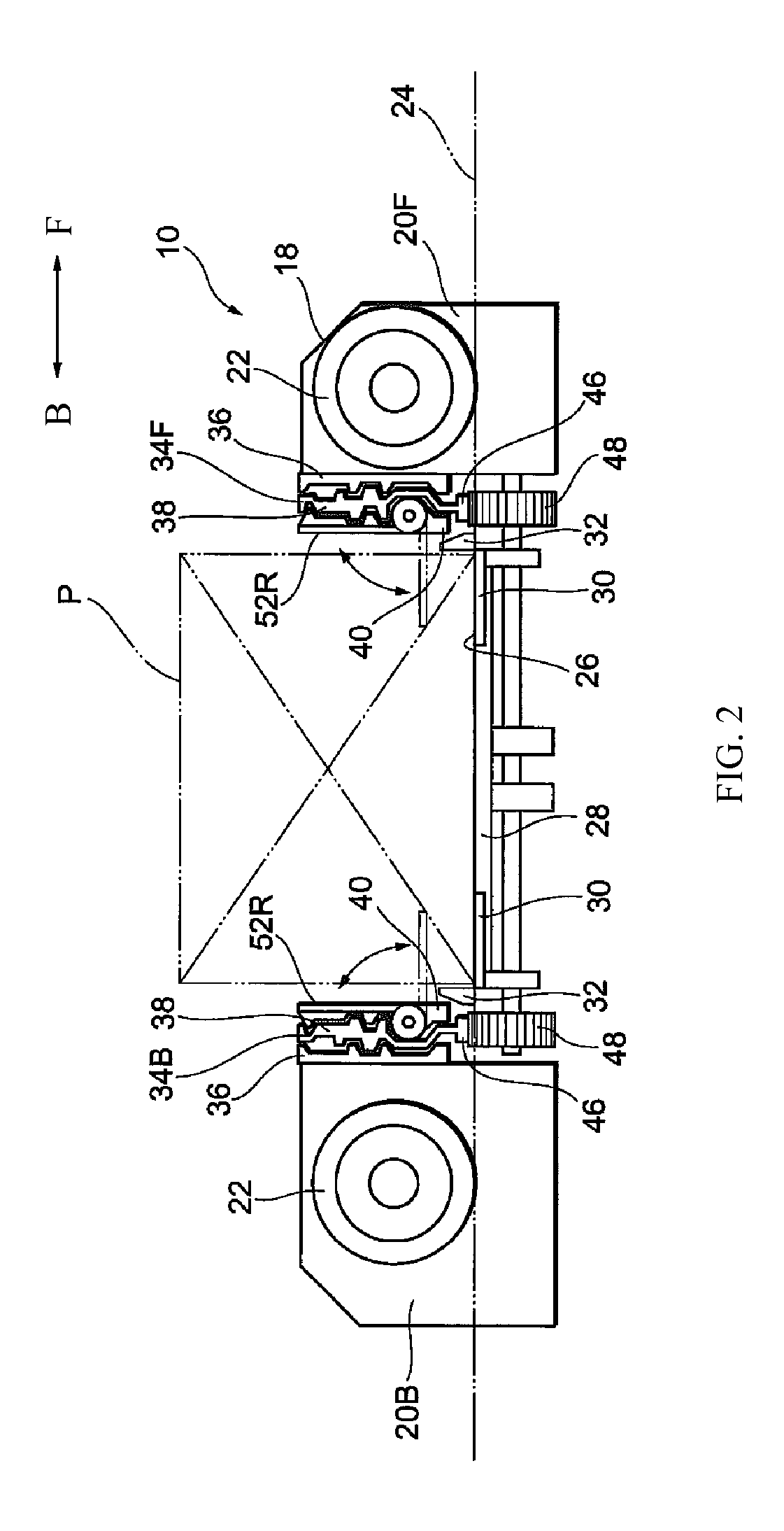

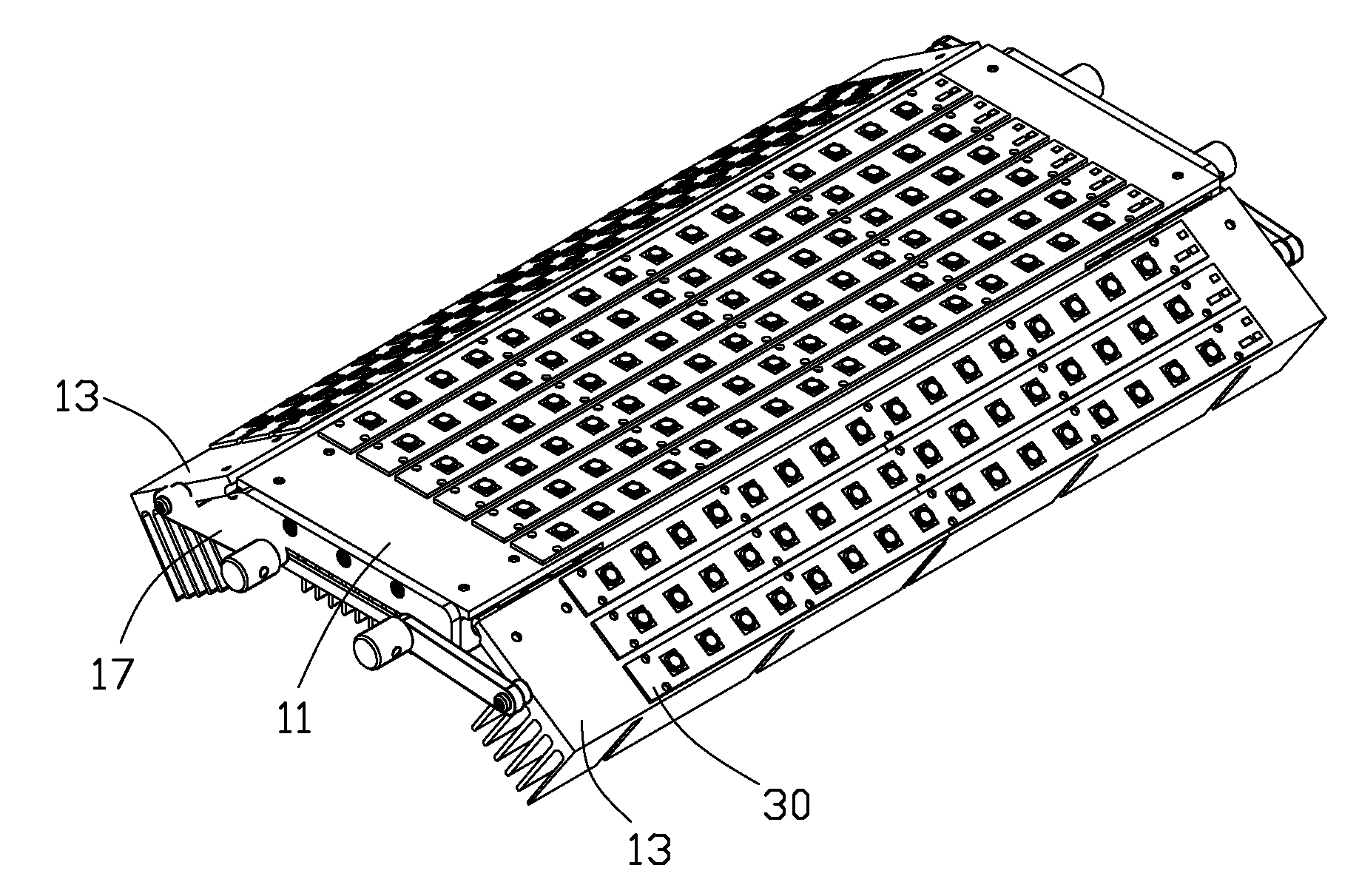

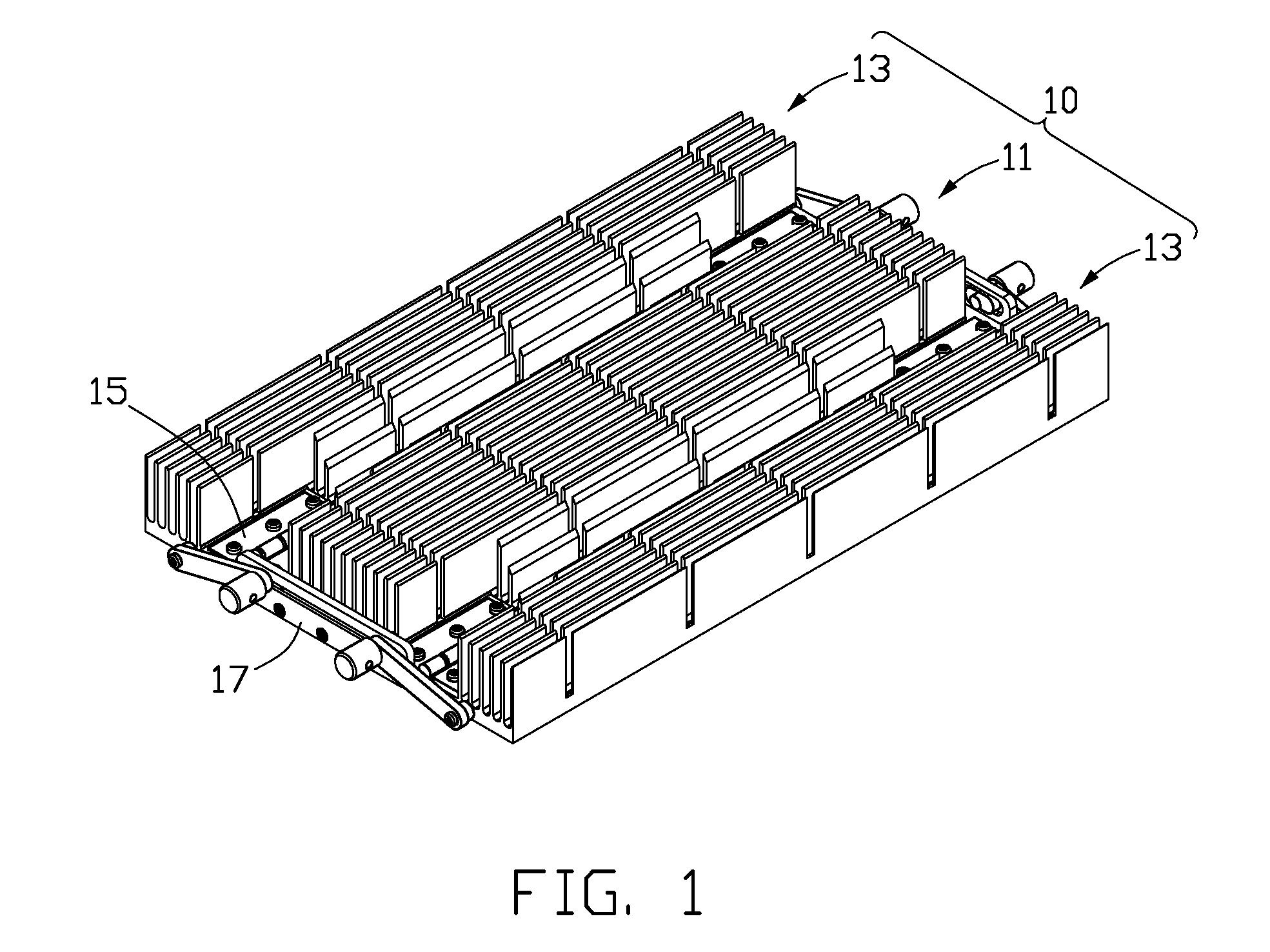

Transferring shuttle for three dimensional automated warehouse

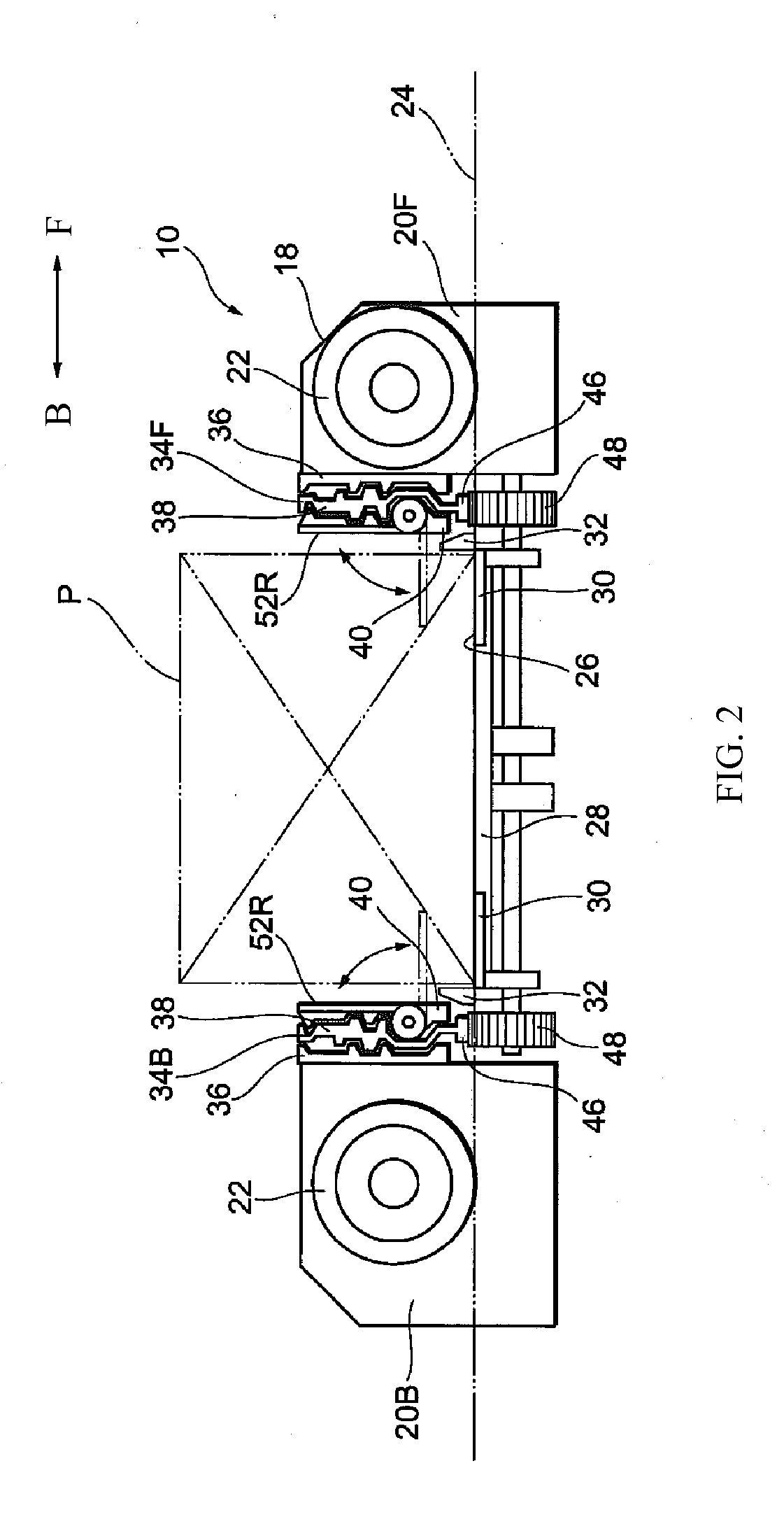

ActiveUS20110008138A1Reduce overlapIncrease production costLoading/unloadingStorage devicesEngineeringMechanical engineering

Owner:DEMATIC

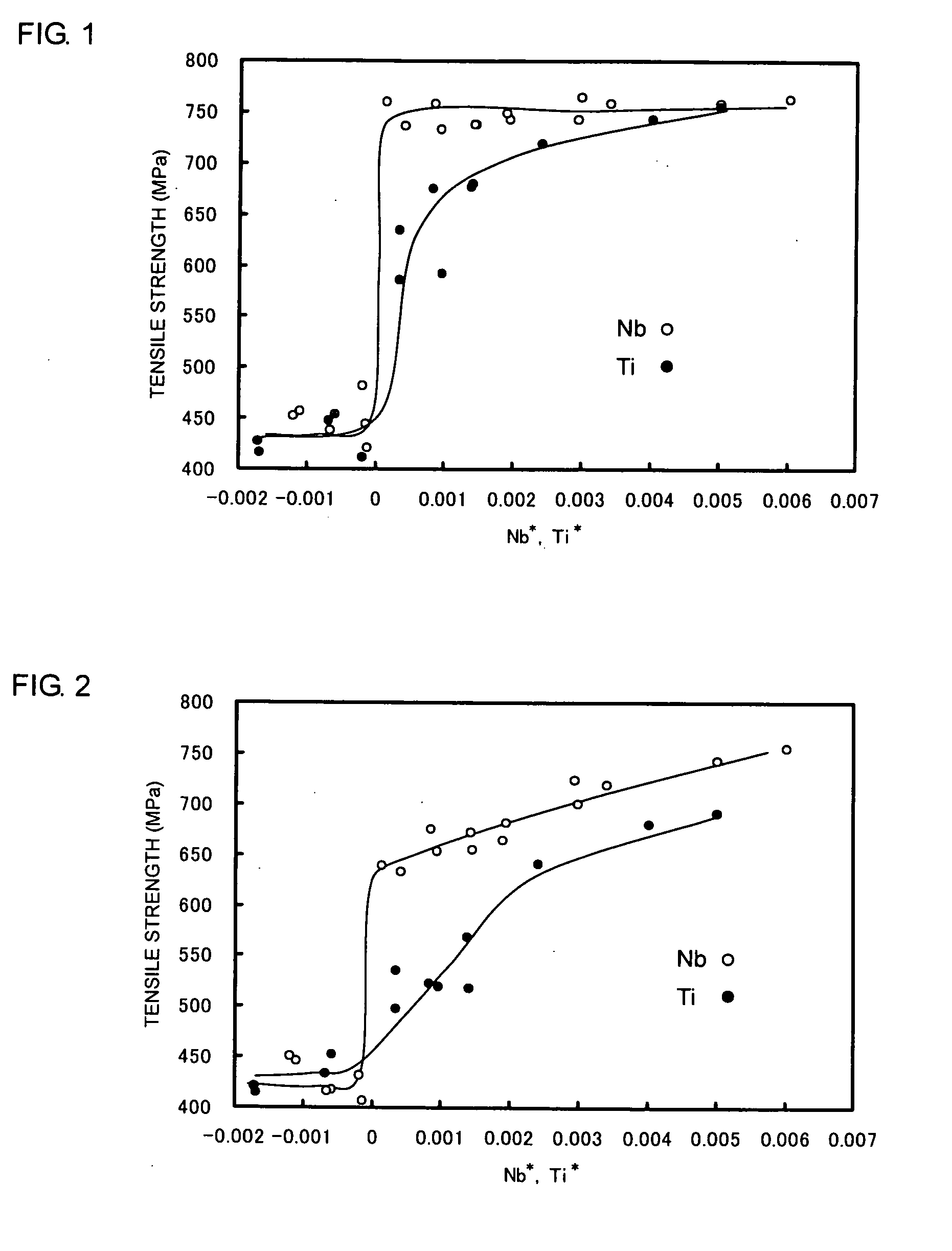

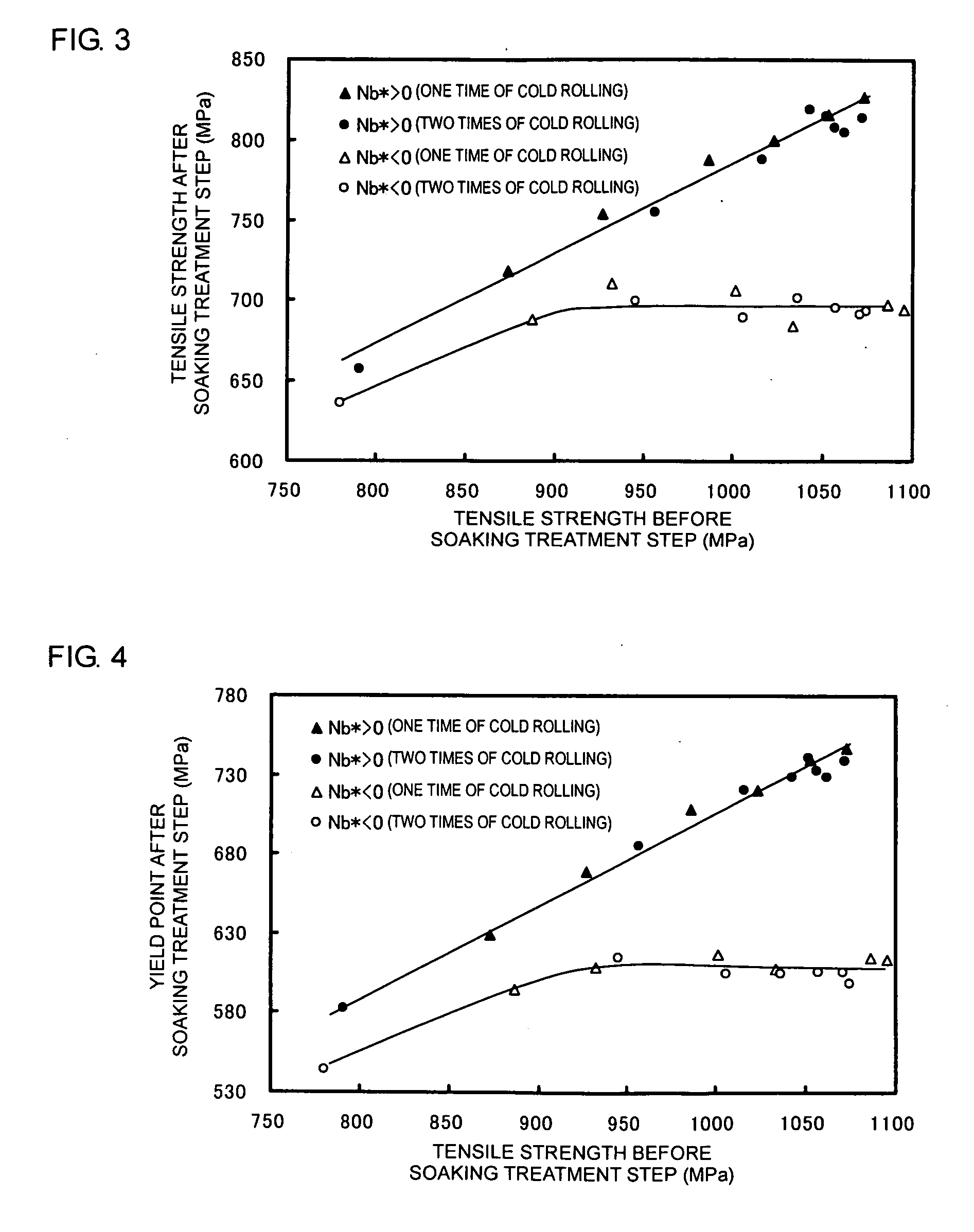

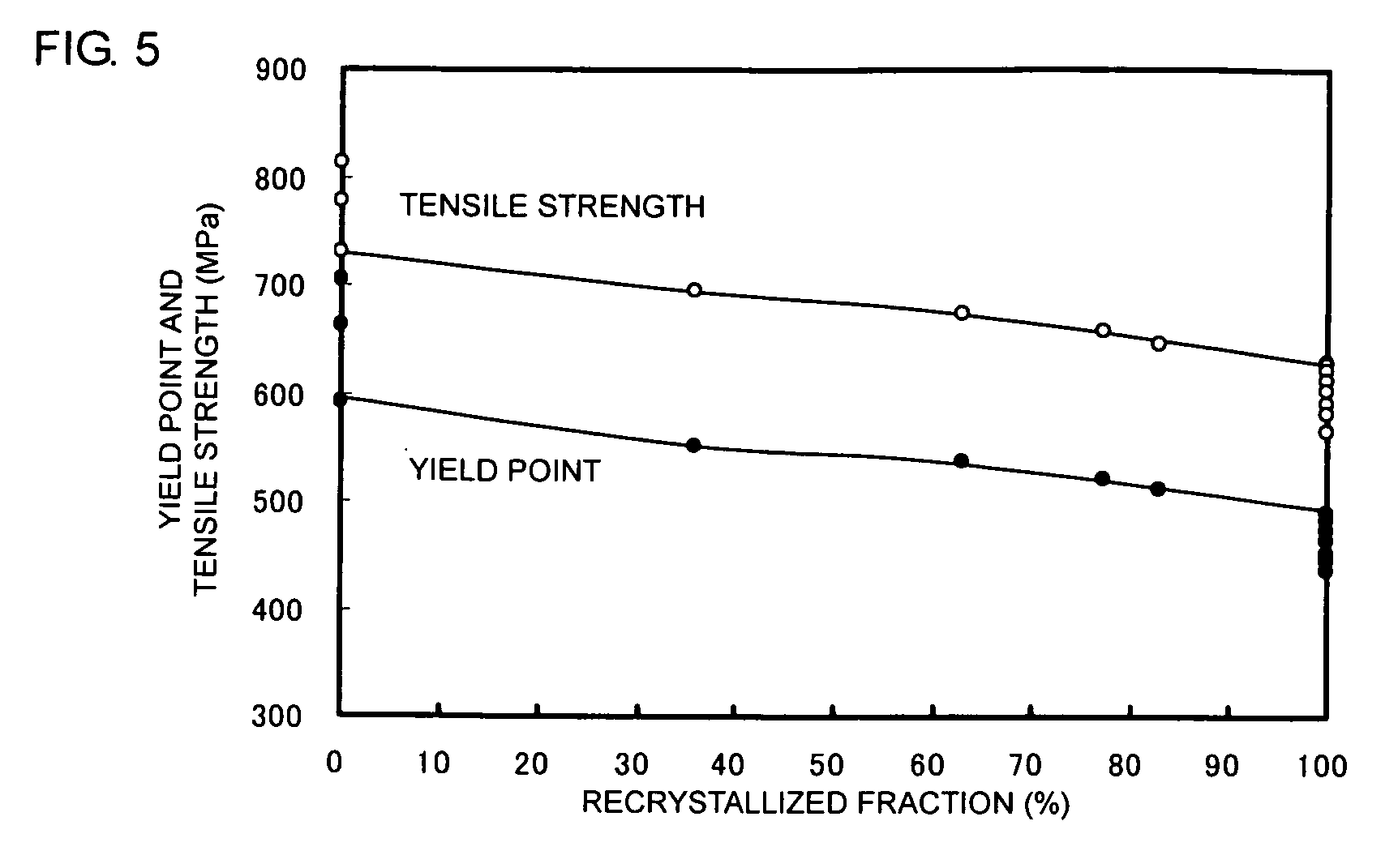

Non-Oriented Electrical Steel Sheet and Production Process Thereof

ActiveUS20090202383A1Excellent mechanical characteristicImprove surface propertiesInorganic material magnetismTransformers/inductances detailsElectrical steelMagnetic characteristic

A main object thereof is to provide a non-oriented electrical steel sheet being excellent in surface characteristics and having both excellent mechanical characteristics and magnetic characteristics necessary for a rotor of rotating machines such as motors and generators which rotate at a high speed, and a method for producing the same. To achieve the object, the present invention provides a non-oriented electrical steel sheet comprising in % by mass: 0.06% or less of C; 3.5% or less of Si; from 0.05% or more to 3.0% or less of Mn; 2.5% or less of Al; 0.30% or less of P; 0.04% or less of S; 0.02% or less of N; at least one element selected from the group consisting of Nb, Ti, Zr and Vin the predetermined range; and a balance consisting of Fe and impurities; and having a recrystallized fraction being less than 90%.

Owner:NIPPON STEEL CORP

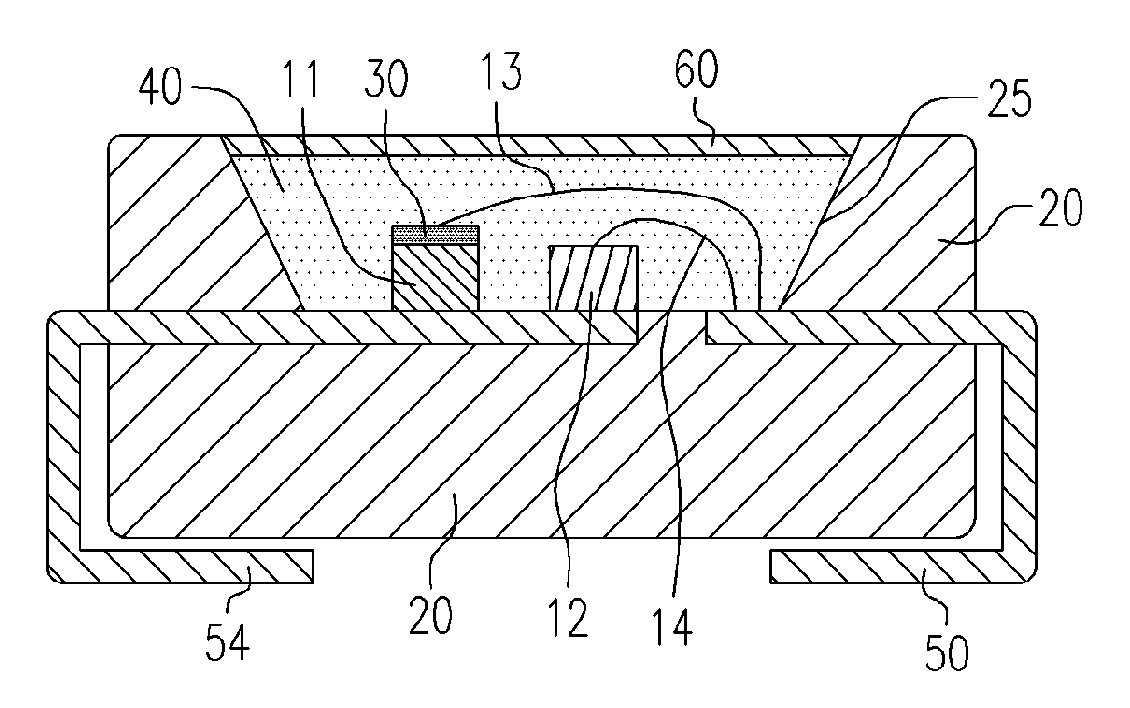

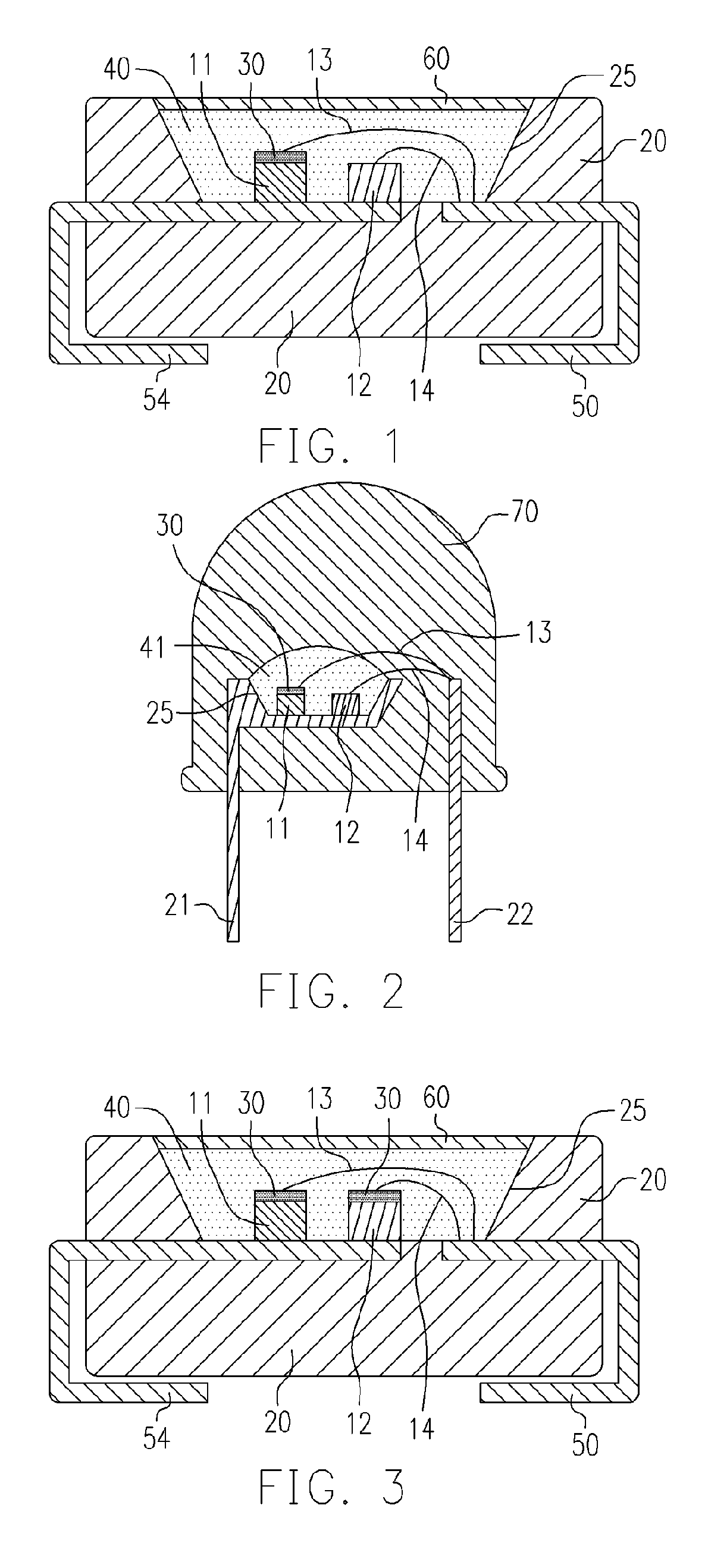

White LED device

InactiveUS20060067073A1Increase production costUniform white lightNon-electric lightingPoint-like light sourcePhosphorFluorescence

A white LED device is described, including two LED dies capable of emitting a first color light and a second color light, respectively, and a phosphor layer coated on at least one of the two LED dies. The phosphor layer is capable of emitting a third color light when stimulated by the first or second color light, and a light mixing structure is also disposed to mix the first to third color lights into uniform white light without chromatic deviation.

Owner:CHUNGHWA PICTURE TUBES LTD

Wireless power receiving device

ActiveUS20090308933A1Low costLow production costBatteries circuit arrangementsAntenna supports/mountingsElectric power transmissionElectricity

To provide a wireless power receiving device and an electronic device having the wireless power receiving device whose production costs do not increase even when frequency of electromagnetic waves received for power supply varies. Further, to provide a wireless power receiving device capable of power transmission without disconnection or poor connection when a load supplied with electricity and a battery connected to an antenna are manufactured in different steps. A power transmitter and receiver portion having first and second antenna circuits and a battery portion and a load portion having a third antenna circuit are provided to charge a battery of the battery portion with a first radio signal received at the first antenna circuit and transmit electricity stored in the battery portion as a second radio signal from the second antenna circuit to the third antenna circuit so that the third antenna circuit supplies electricity to the load.

Owner:SEMICON ENERGY LAB CO LTD

Acicular calcite and aragonite calcium carbonate

InactiveUS6071336AIncrease costIncrease production costCalcium/strontium/barium carbonatesPigmenting treatmentToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

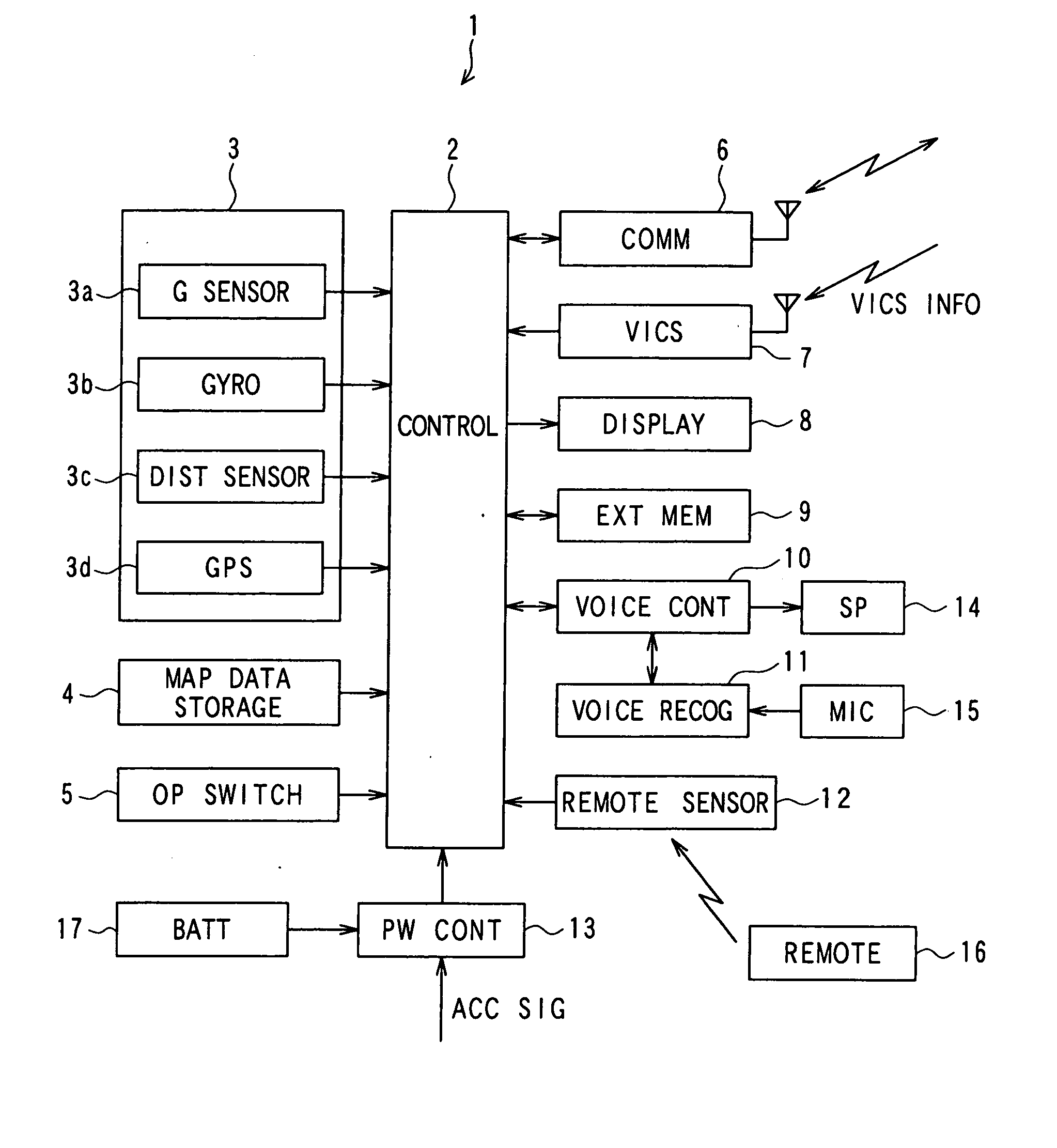

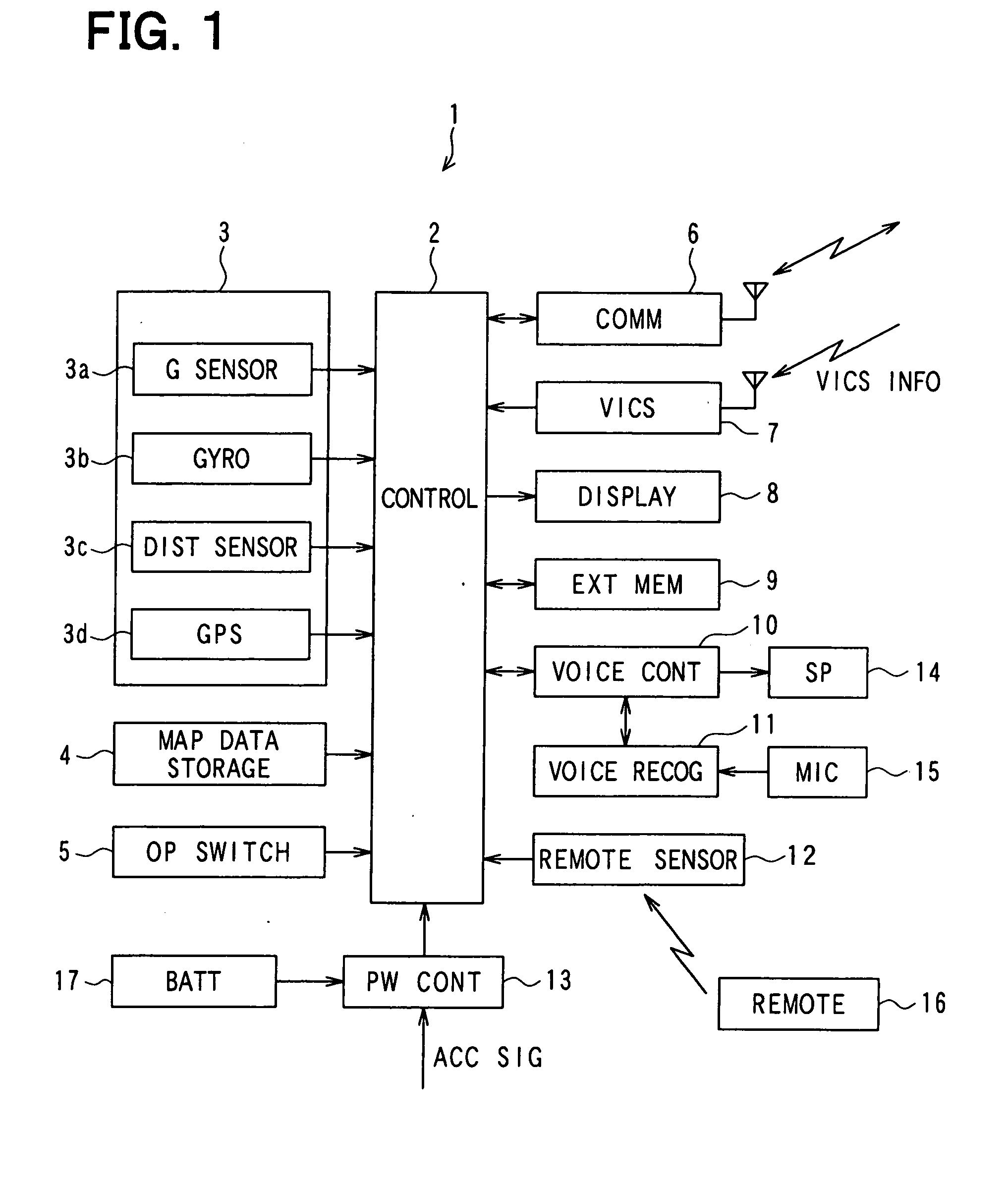

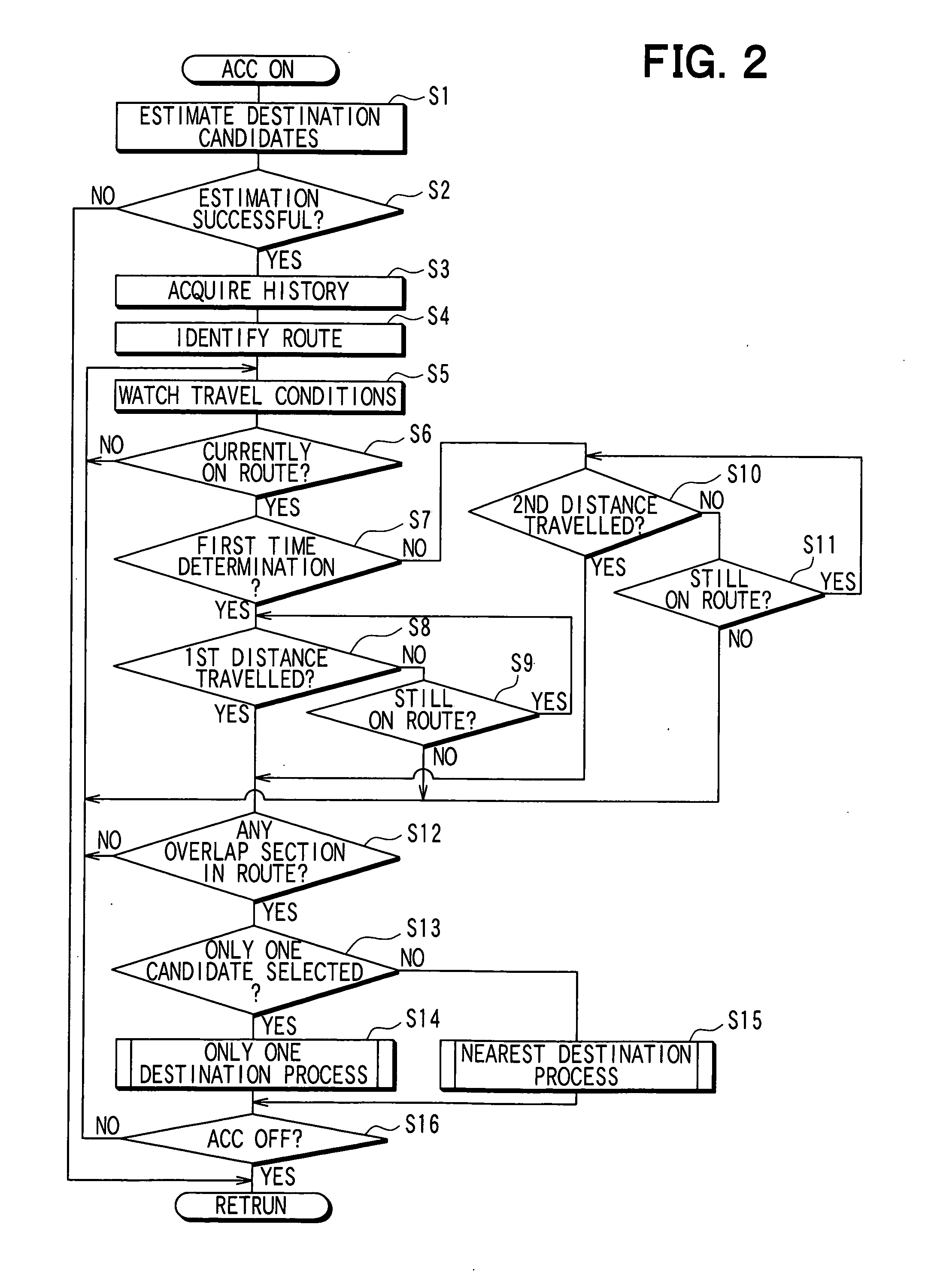

Vehicle navigation apparatus

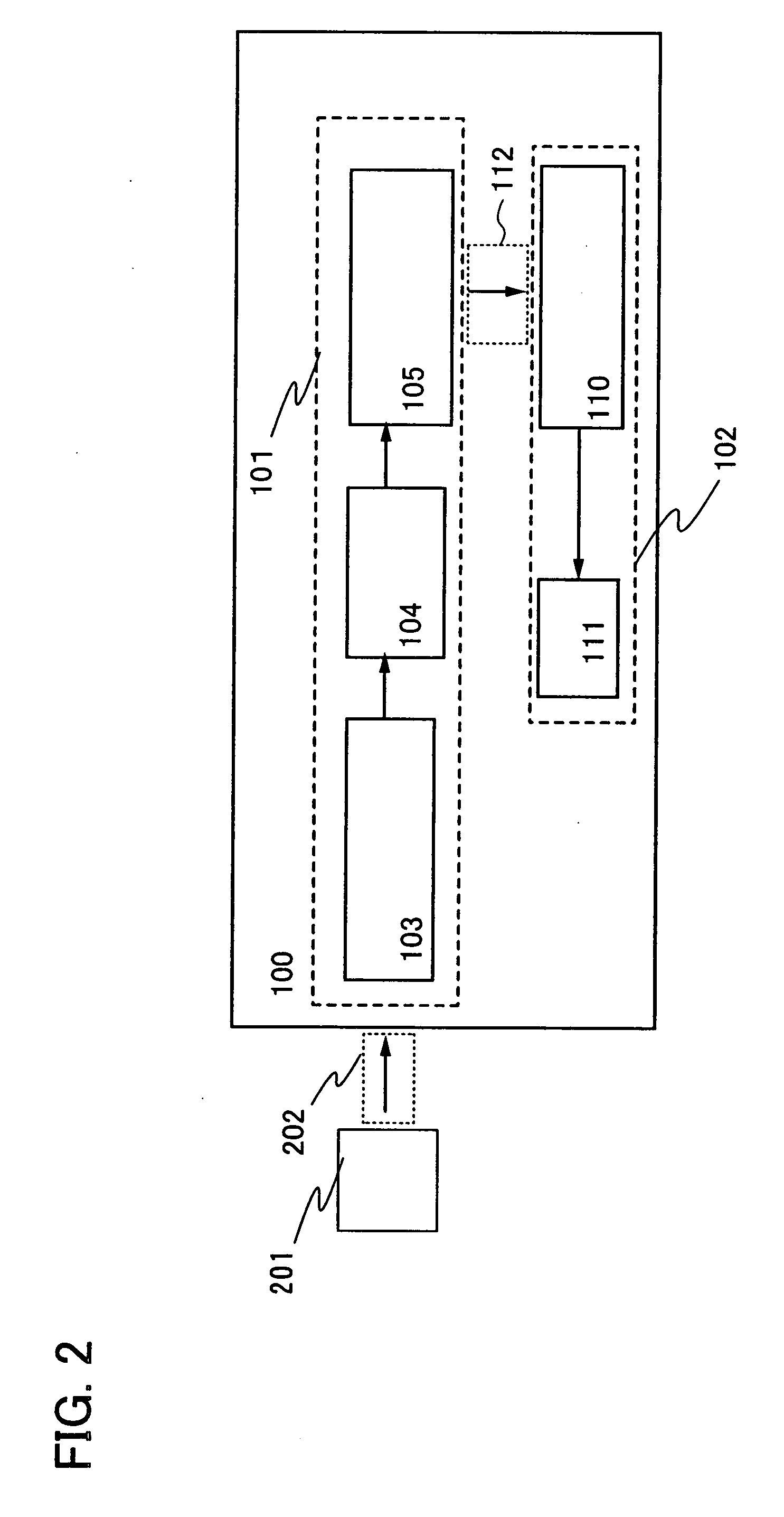

InactiveUS20100332130A1Improve usabilityIncrease production costInstruments for road network navigationRoad vehicles traffic controlMarine navigationReal-time computing

A vehicle navigation apparatus determines whether or not the currently traveled route having a current vehicle position matches with estimated routes after determining, on the basis of the traveled route history, the estimated routes which correspond to destination candidates. Then, the navigation apparatus further determines whether or not the subsequent portion of the estimated route overlaps with other estimated route, for selecting one of the destination candidates. The vehicle navigation apparatus thus selects the destination candidate, in a highly accurate manner in terms of user preference, based on the traveled route history.

Owner:DENSO CORP +2

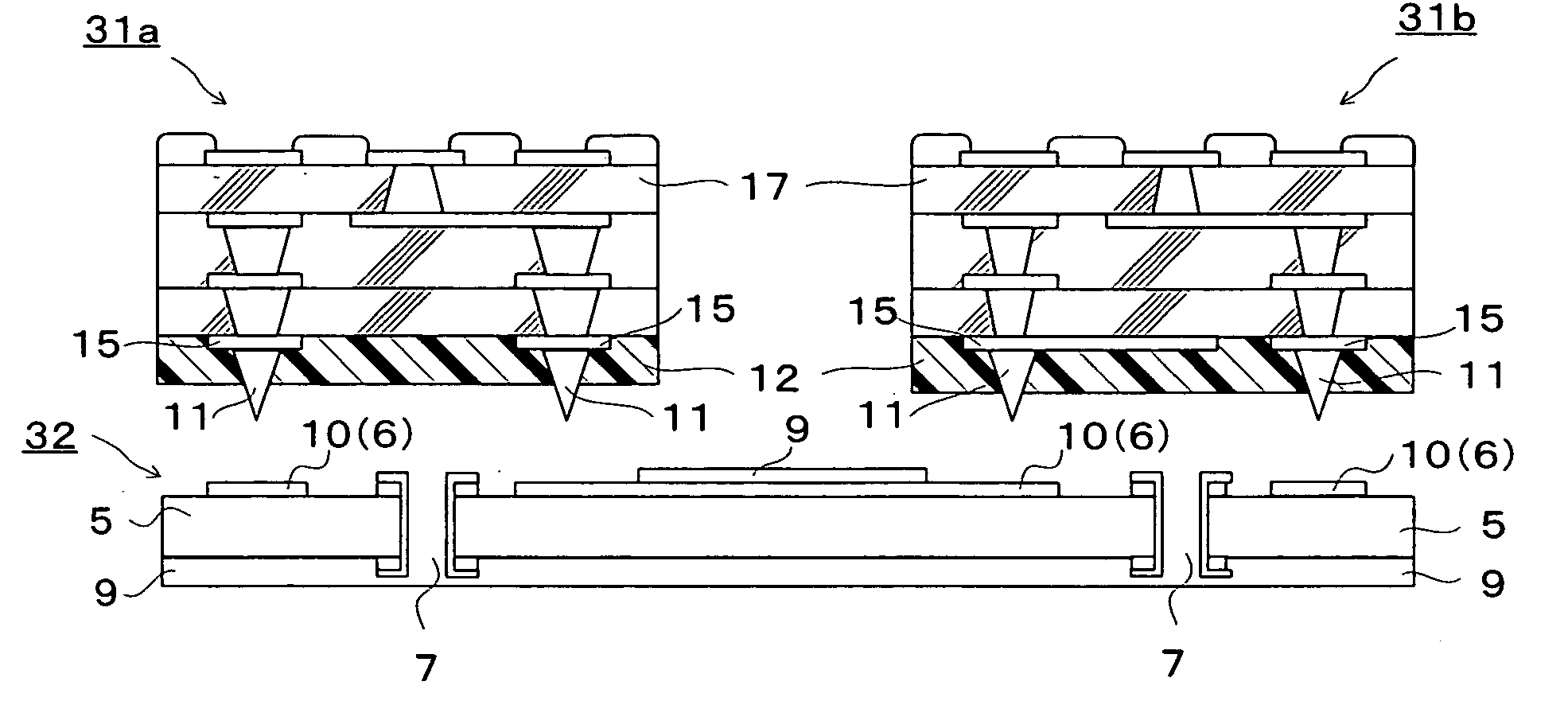

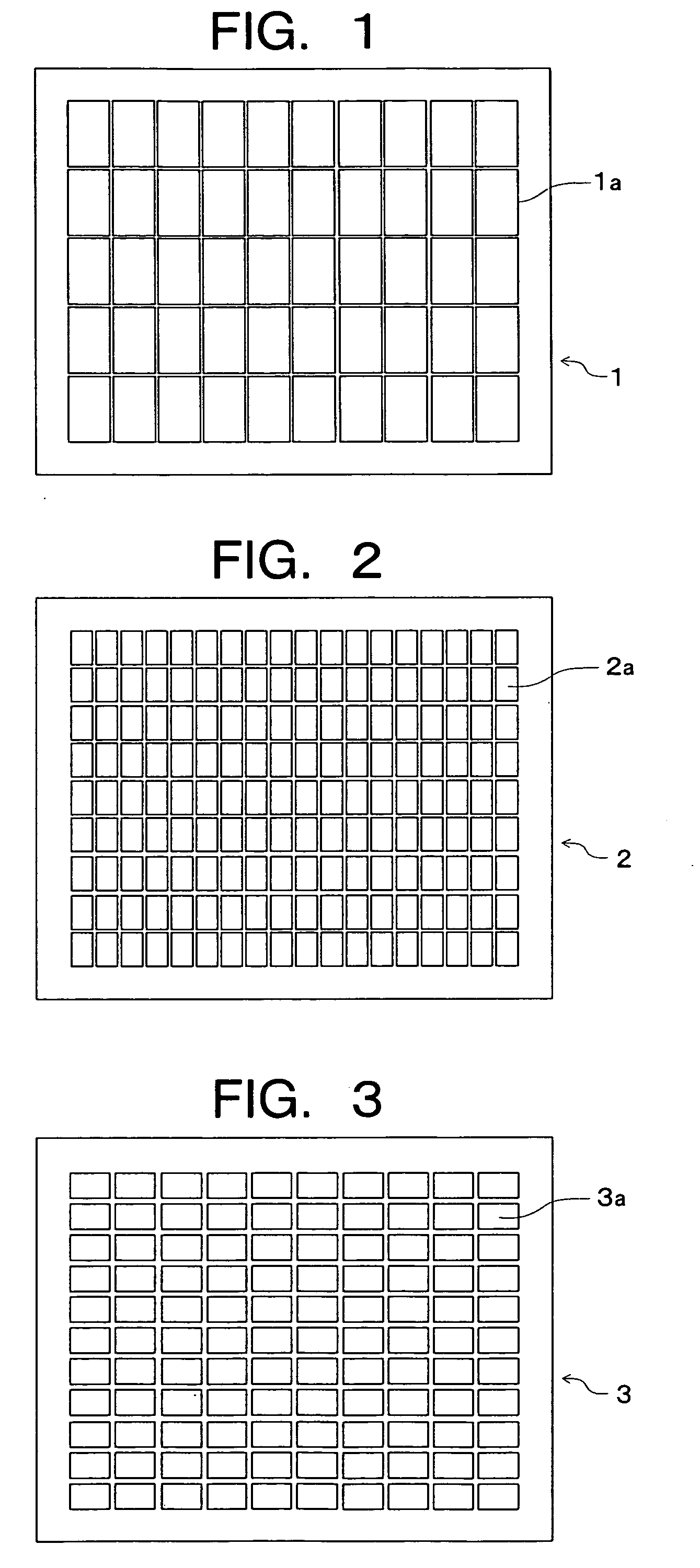

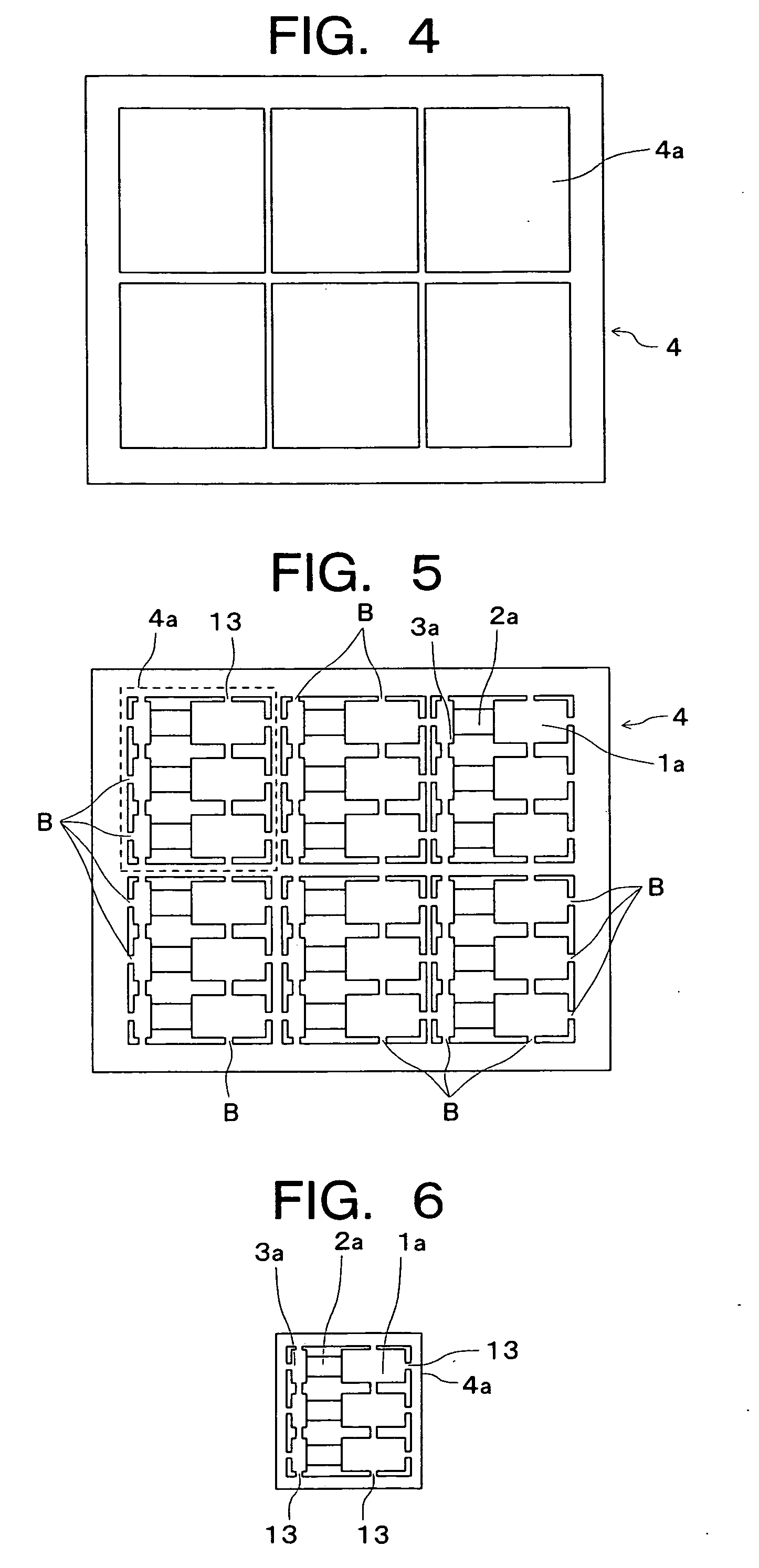

Printed circuit board assembled panel, unit sheet for packaging a printed circuit board, rigid-flexible board and method for manufacturing the same

InactiveUS20090014205A1Enhance production yieldMaterial loss be lowerPrinted circuit assemblingPrinted circuit aspectsPrinted circuit boardEngineering

Owner:DAI NIPPON PRINTING CO LTD

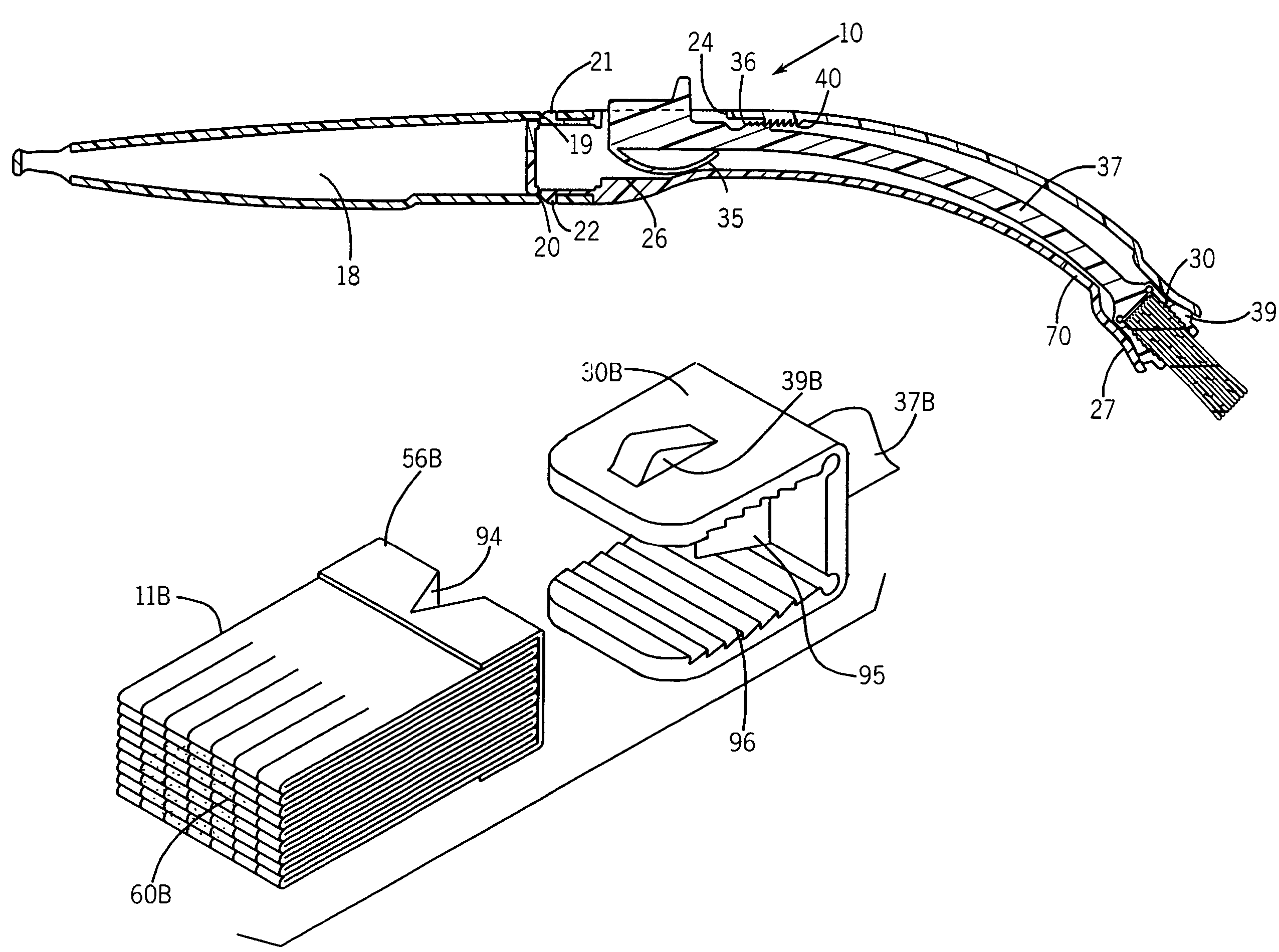

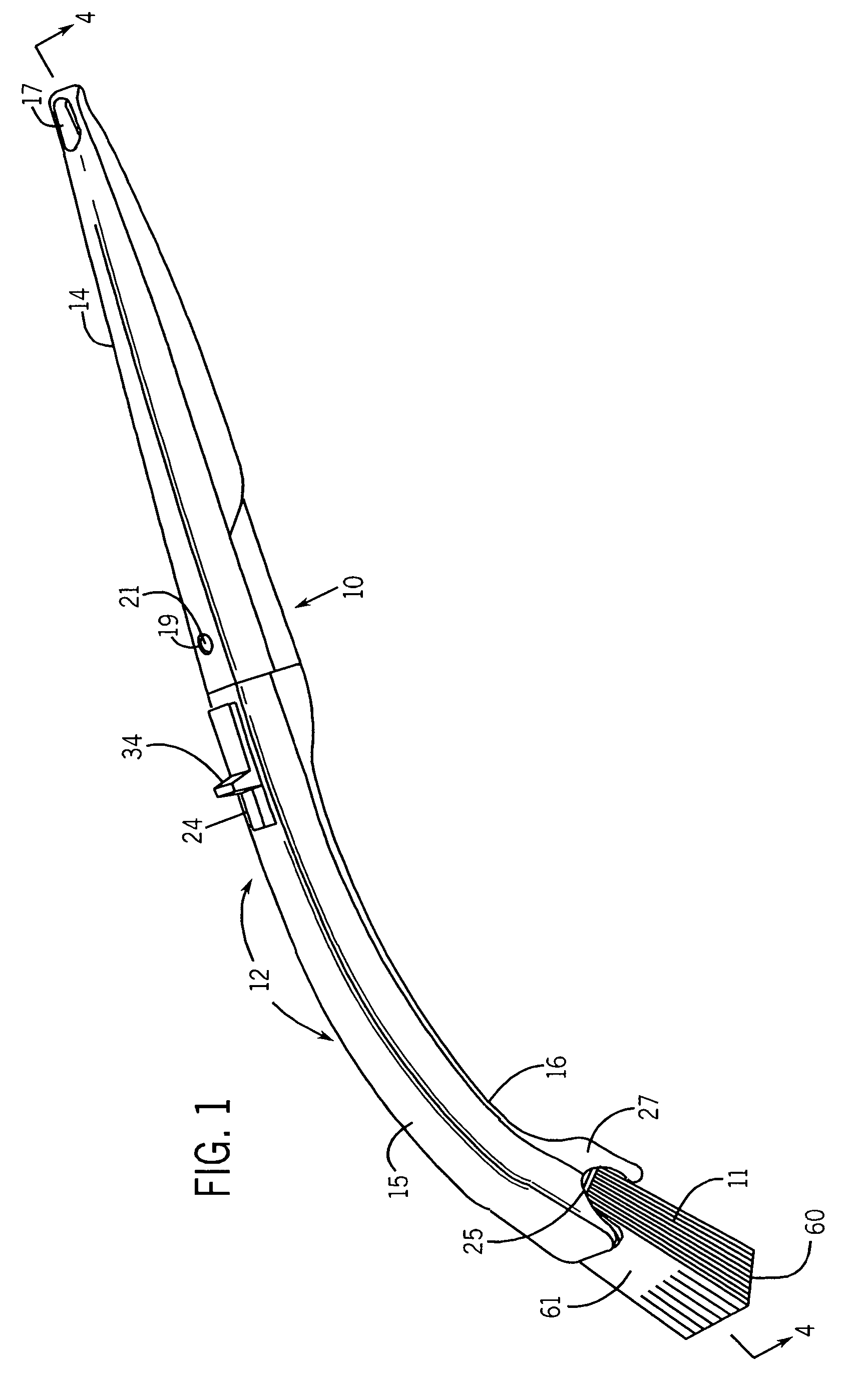

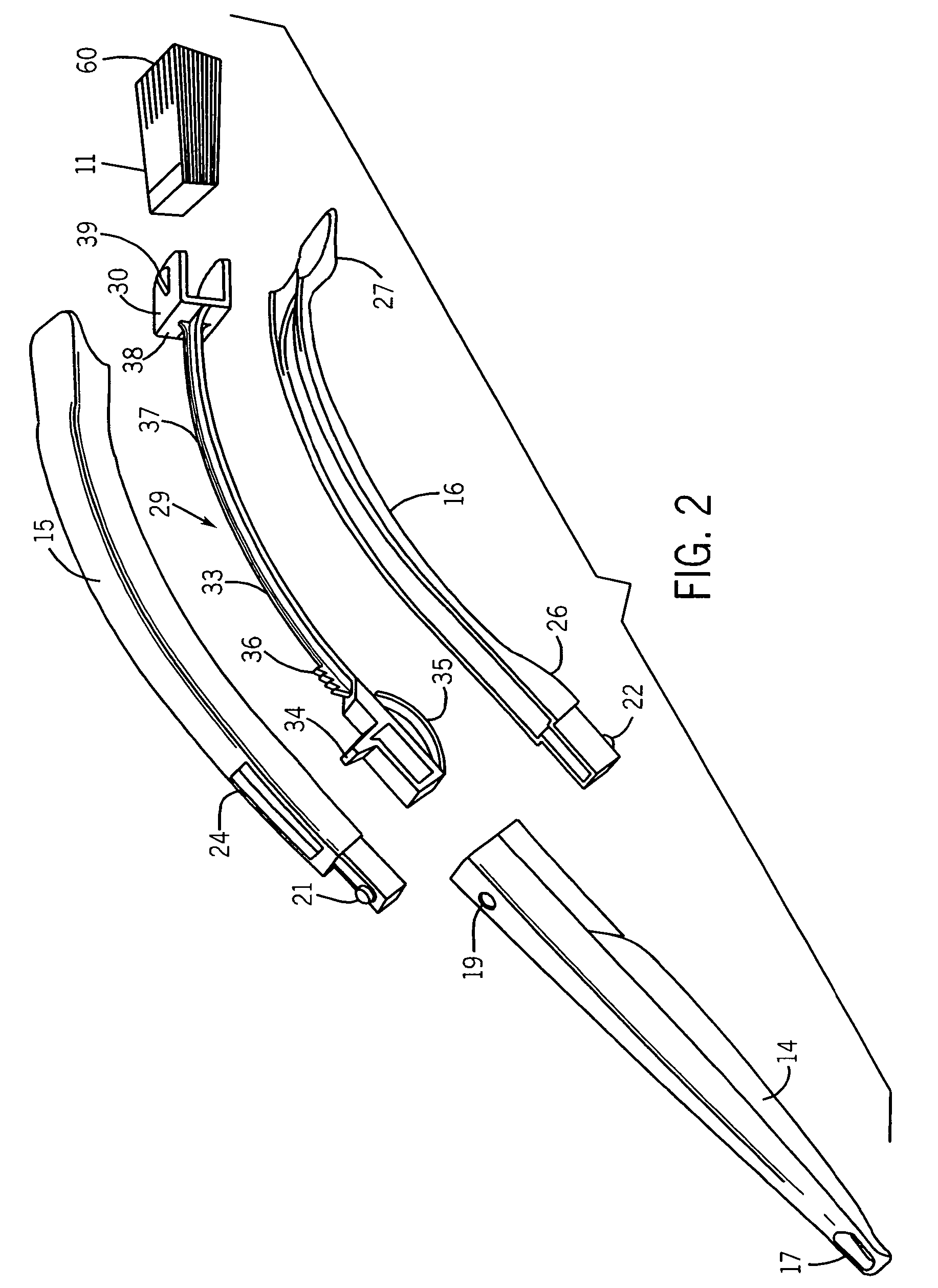

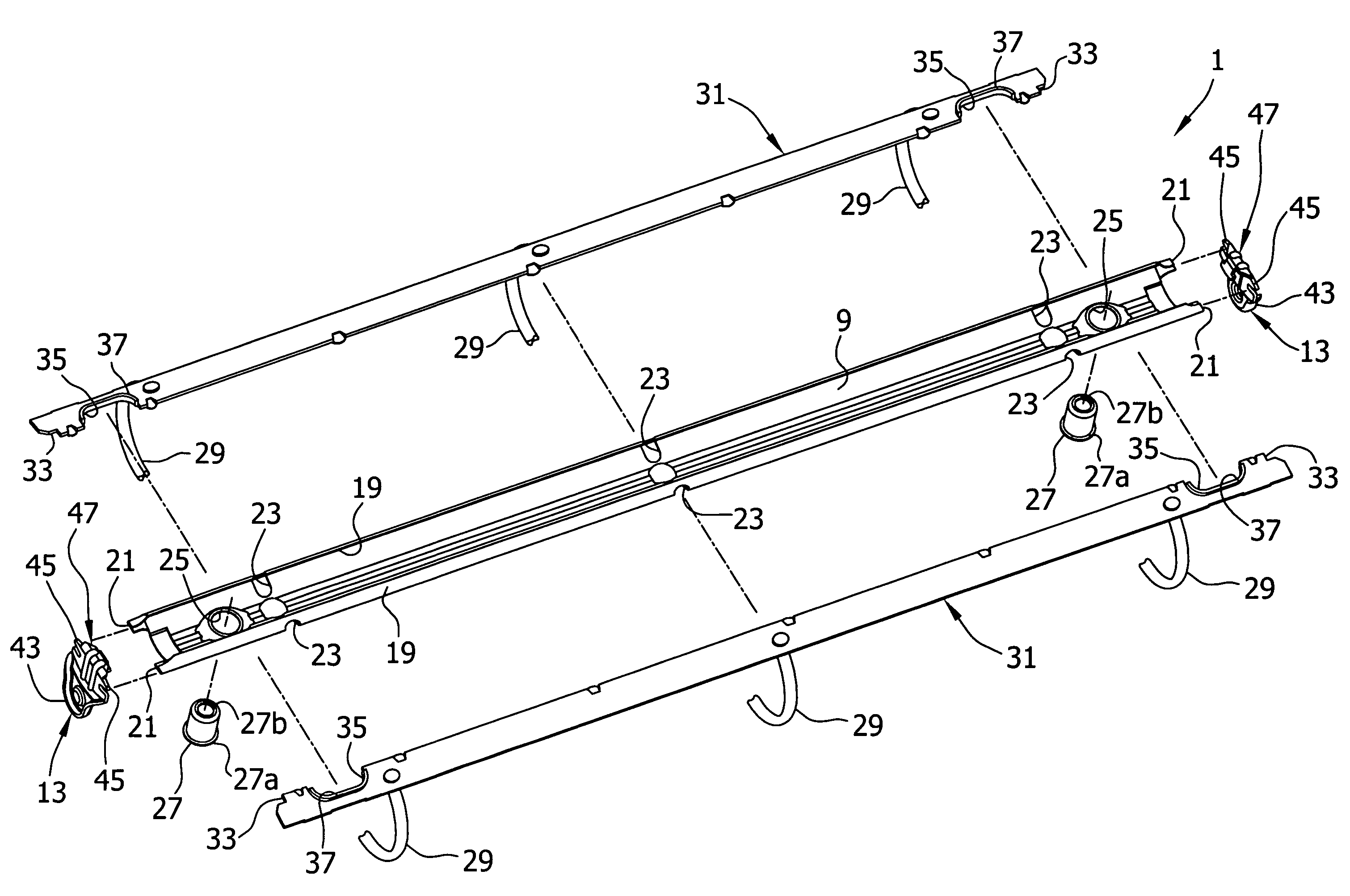

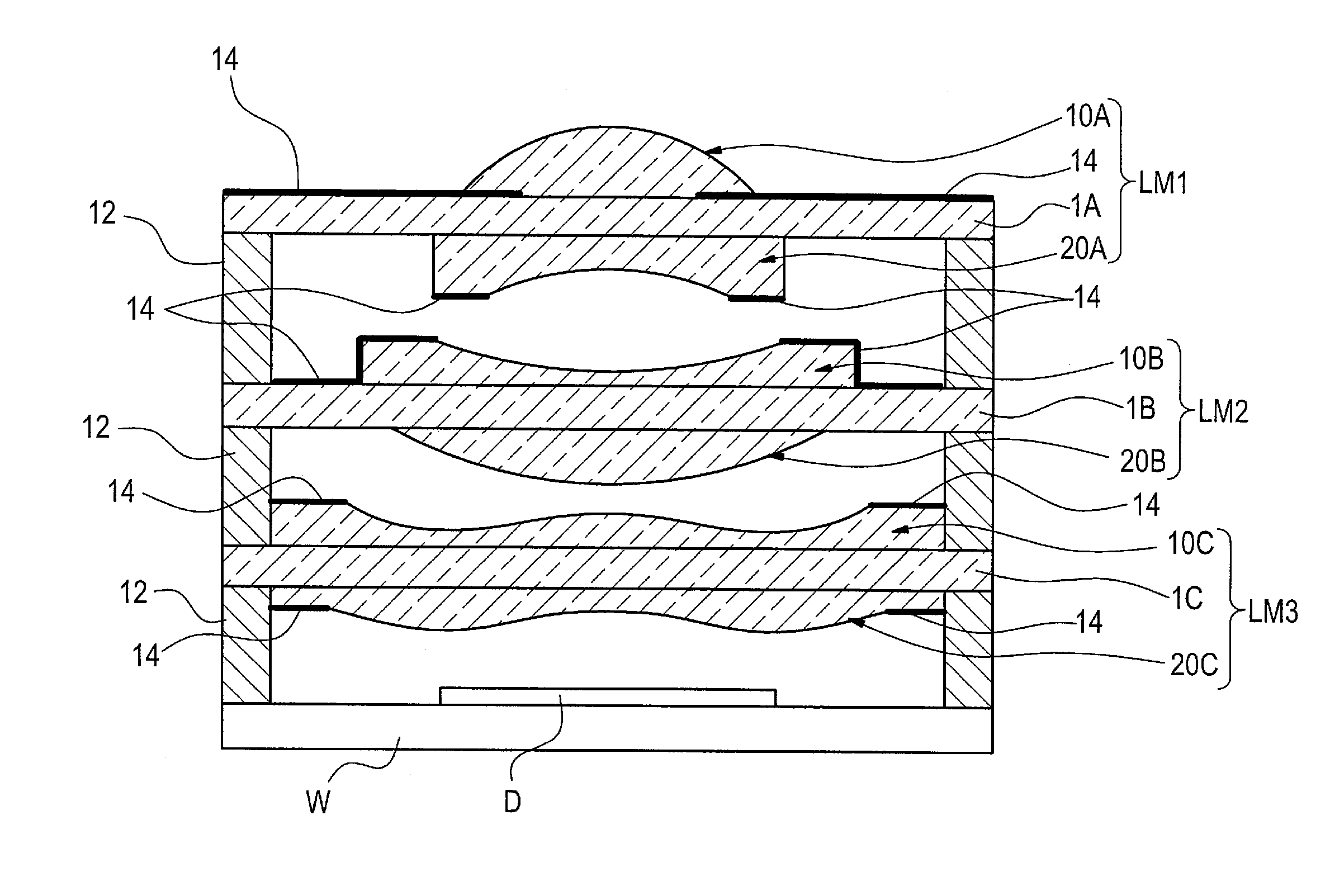

Transferring shuttle for three dimensional automated warehouse

ActiveUS8790061B2Reduce overlapIncrease production costStorage devicesLoading/unloadingEngineeringMechanical engineering

A transferring shuttle, which transfers package(s) between a pair of layered stacked racks in a three dimensional automated warehouse, includes a mobile platform which runs between the stacked racks; elastic mechanisms, which include telescoping rails that extend into the stacked racks and surround a package; and terminal fingers placed at the ends of the rails, which can move between an extended position, which allows the package to be engaged and a contracted position. The rails also contain inner fingers between the terminal fingers. The inner fingers can push the package further into the stacked rack than previously possible.

Owner:DEMATIC

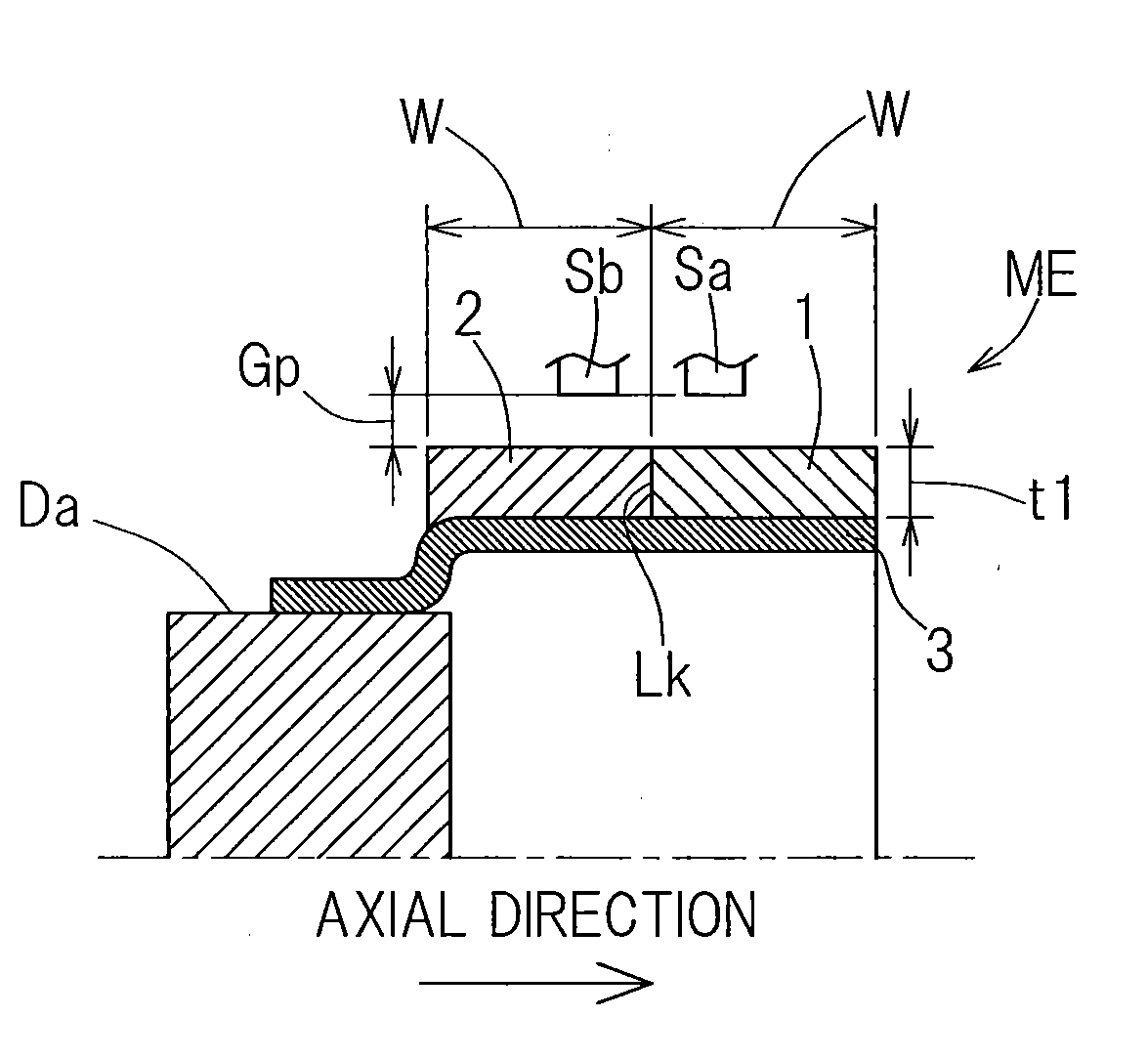

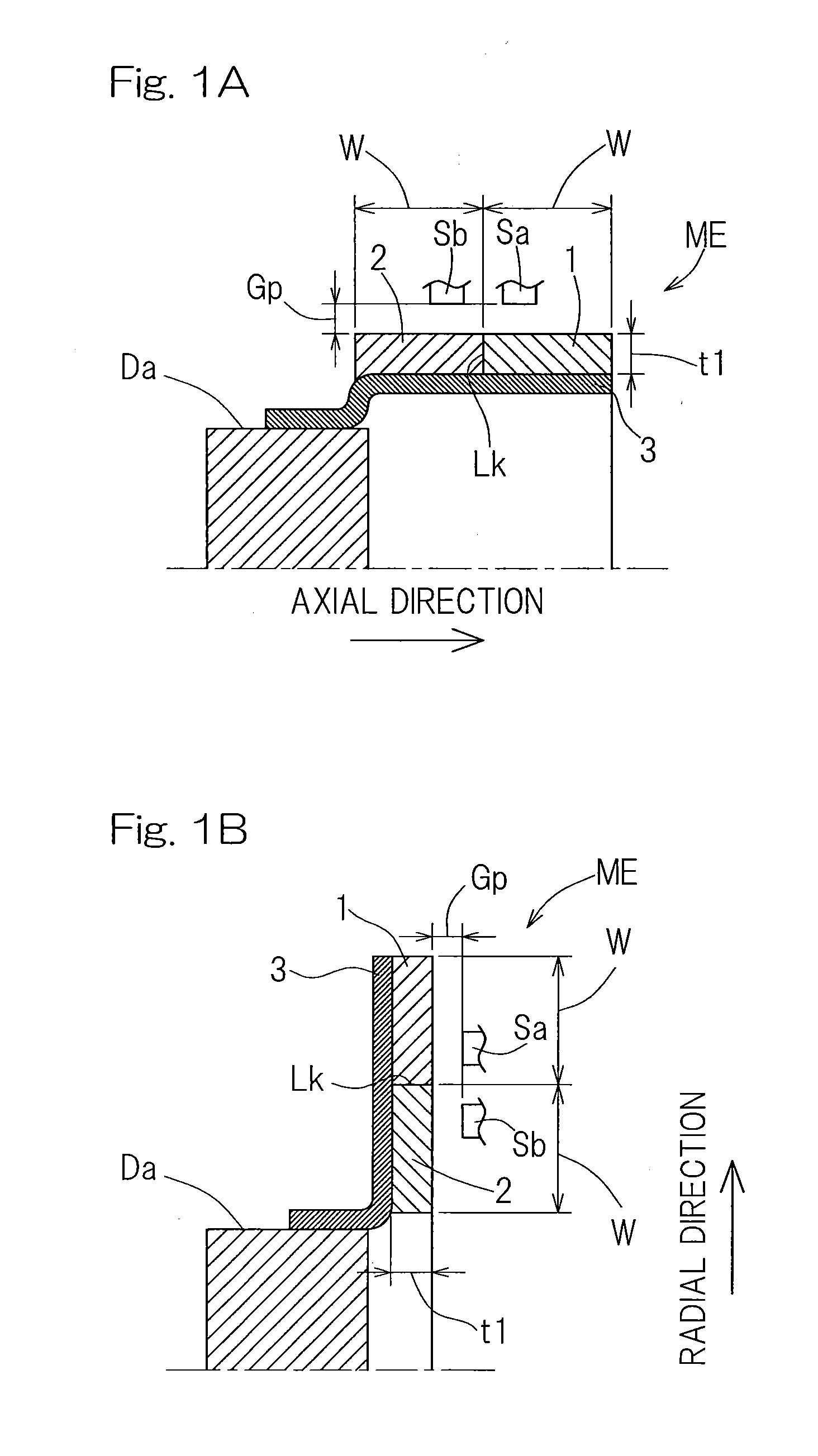

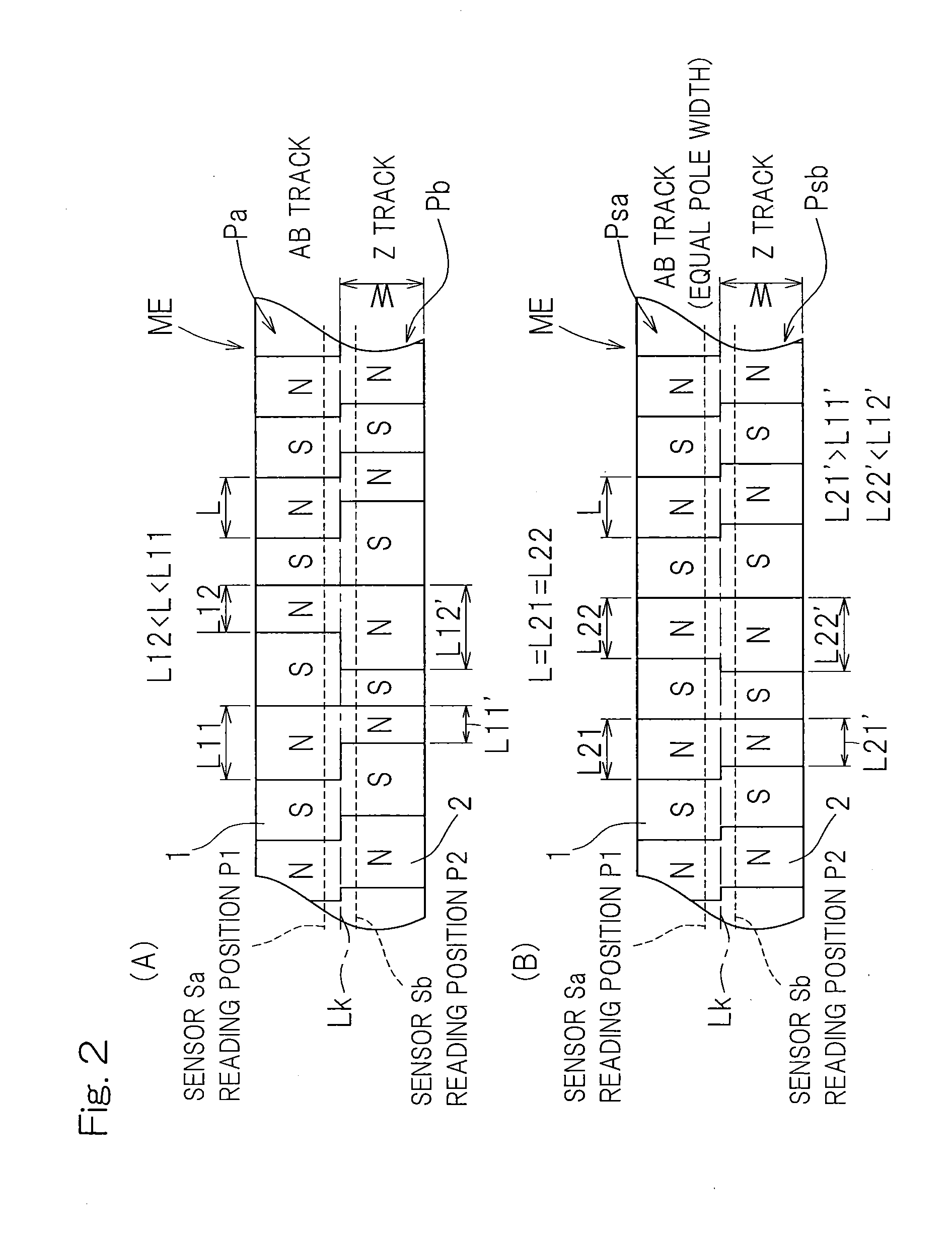

Magnetic encoder

ActiveUS20130063138A1Improve interferenceLow detection sensitivityUsing electrical meansConverting sensor outputEncoderMagnetic signal

Provided is a magnetic encoder which includes plural rows of magnetic encoder tracks. One magnetic encoder track of the magnetic encoder tracks includes magnetic pattern magnetized thereto to generate signals of equal pitch for detection of rotation. The magnetized magnetic pattern includes N poles and S poles arranged in alternate fashion. The magnetic encoder is configured to be employed spaced through an air gap from sensors that read magnetic signals of the respective magnetic encoder tracks. The magnetic encoder track is configured such that the magnetic pattern thereof acting on position of the corresponding sensor is, under the interference of magnetism of the plural rows of magnetic encoder tracks, detected by the corresponding sensor as an equal pitch magnetic pattern.

Owner:NTN CORP

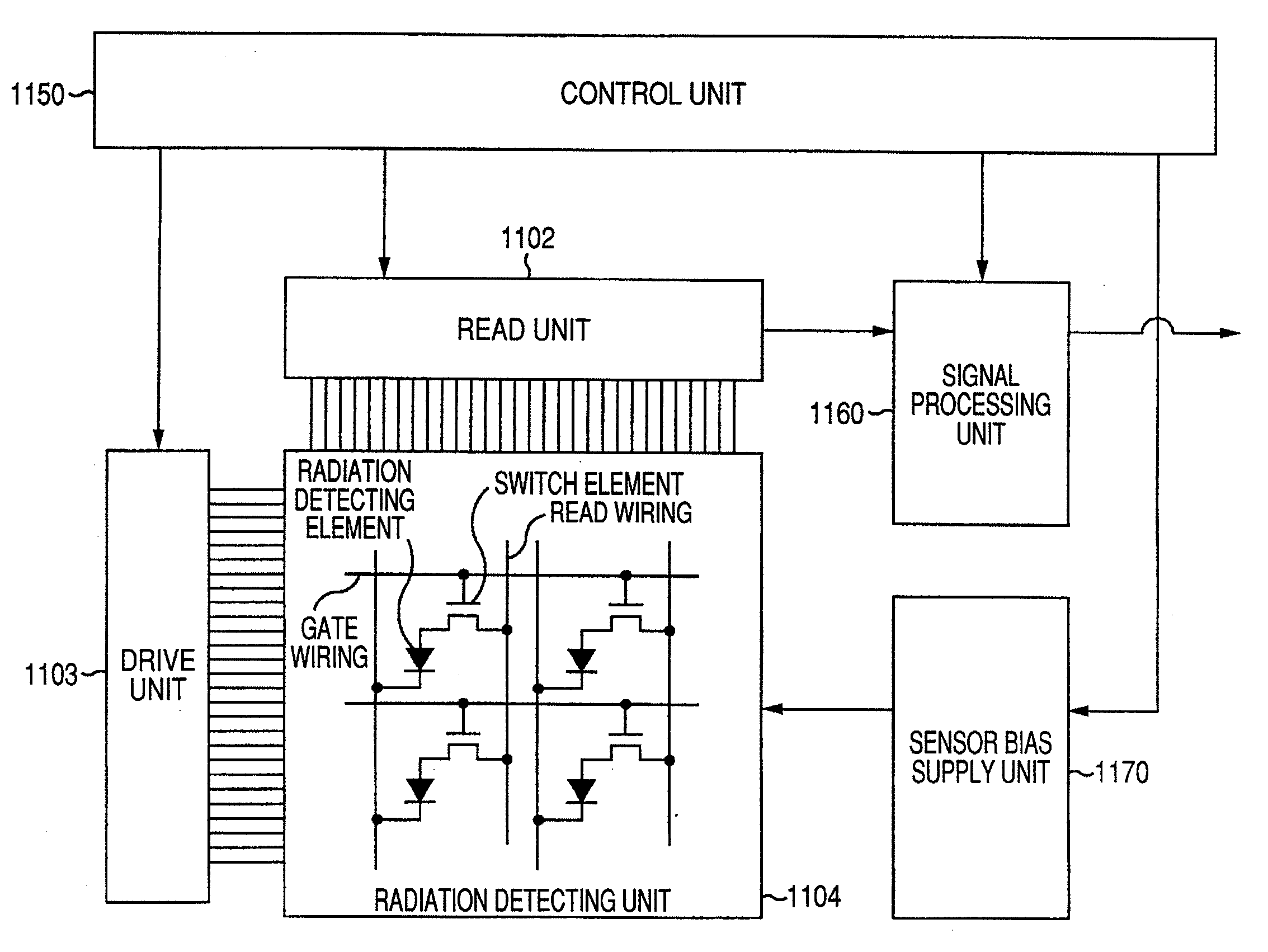

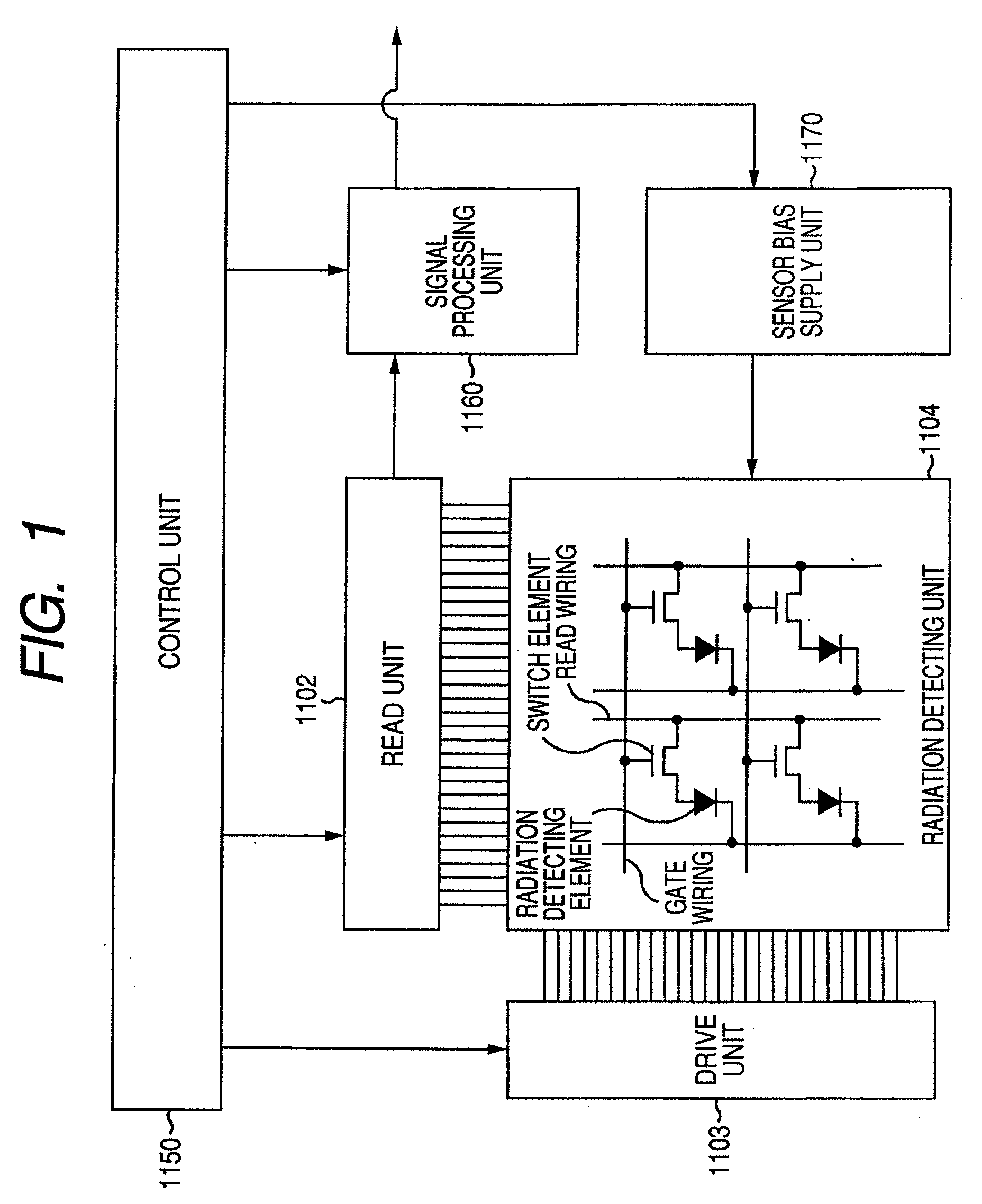

Radiation imaging apparatus and radiation imaging system

InactiveUS20070210258A1More time consumingReduce yieldTelevision system detailsSolid-state devicesRadiation imagingElectric signal

A radiation imaging apparatus comprises a read unit reading the electric signal in the radiation detecting elements in a radiation detecting unit comprises the radiation detecting elements converting incident radiation into electric signals arranged two-dimensionally, a control unit controlling the radiation detecting unit with such that a first radiation detecting element group is made senseless state and a second radiation detecting element group is made sensible state, and a signal processing unit performing a subtraction processing such that the electric signal in the radiation detecting elements made senseless state read by the read unit is subtracted from the electric signal in the radiation detecting elements made sensible state read by the read unit according to the state control by the control unit, to reduce conspicuous line noise in an image by a relatively simple configuration.

Owner:CANON KK

Display device and method for production thereof

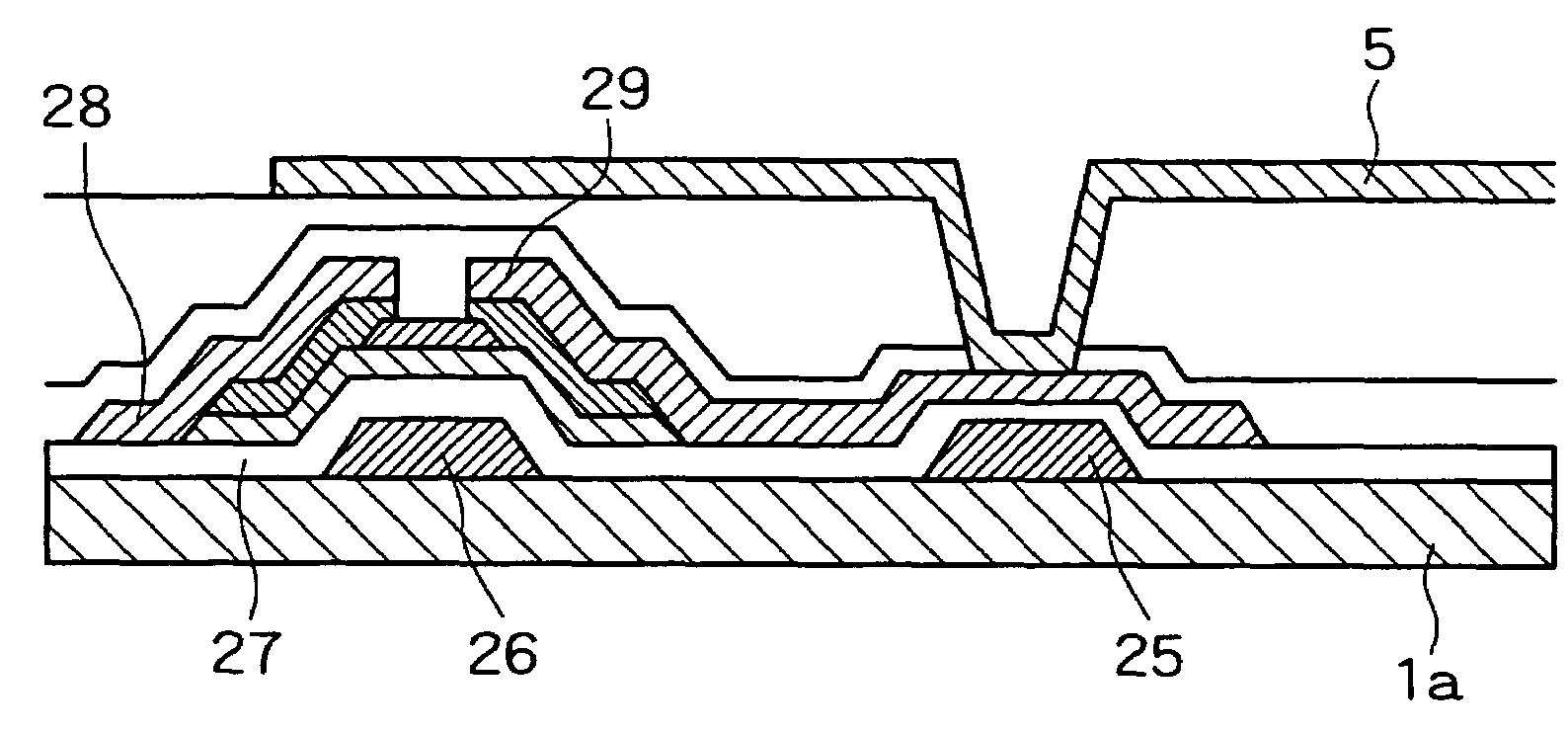

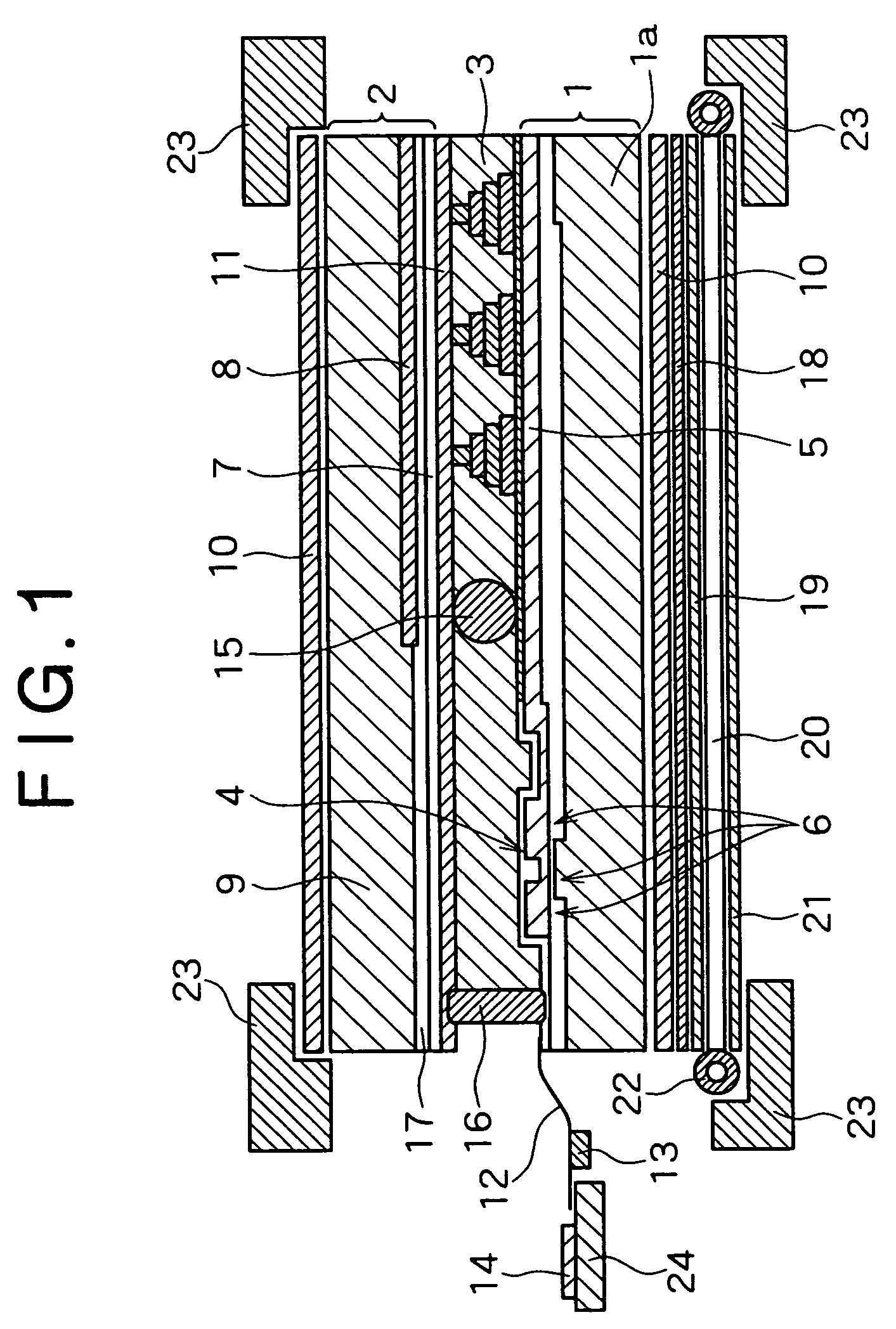

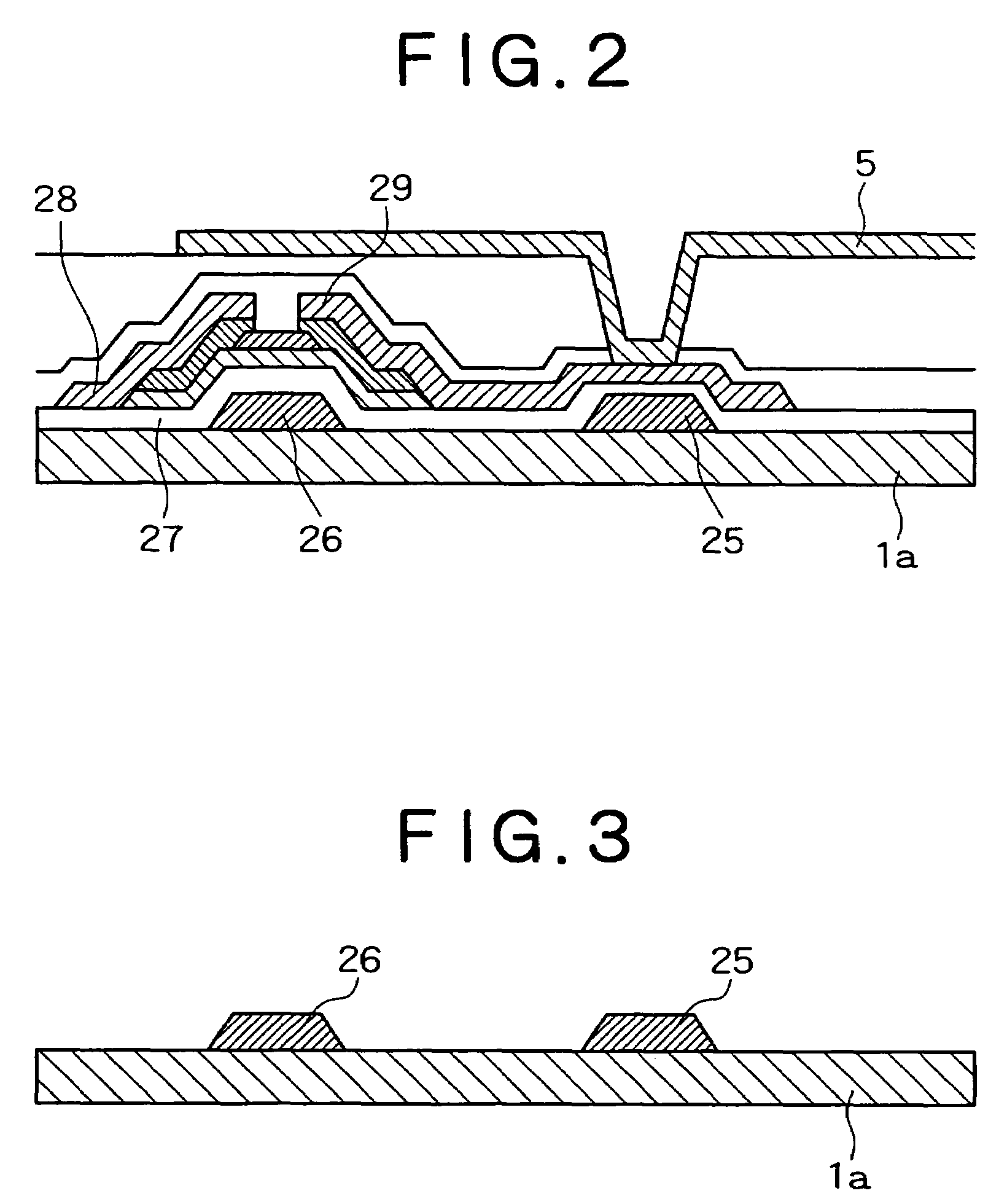

ActiveUS7365810B2Increase resistanceQuality improvementStatic indicating devicesNon-linear opticsDisplay deviceTransparent conducting film

A display device and a method for production thereof. The display device comprises a substrate, thin film transistors and a transparent conductive film which are formed on the substrate, and an aluminum alloy film which electrically connects the thin film transistors to the transparent conductive film, such that there exists an oxide film of said aluminum alloy at the interface between said aluminum alloy film and said transparent conductive film, said oxide film having a thickness of 1 to 10 nm and containing oxygen in an amount no more than 44 atom %. The display device has the aluminum alloy film and the transparent conducive film in direct contact with each other, obviating the necessity of barrier metal between them.

Owner:KOBE STEEL LTD

Base material for artificial leather and process for producing the same

ActiveUS20110039055A1Improve compactnessFlat surfaceSynthetic resin layered productsFilament/thread formingFiber bundleEngineering

Owner:KURARAY CO LTD

Exhaust gas purifying catalyst and method of producing same

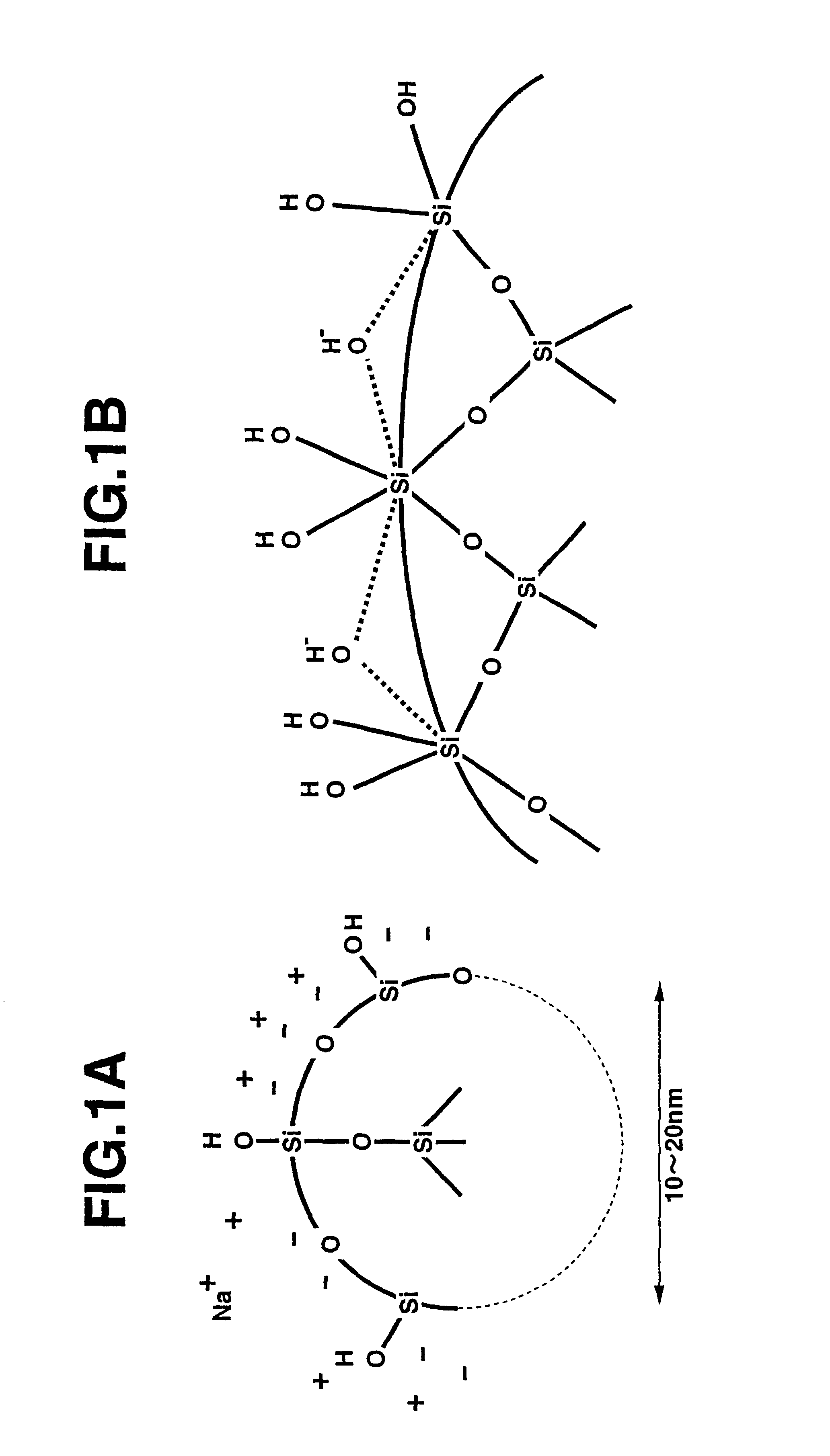

InactiveUS6589901B2Improve heat resistanceReduce stickingInternal combustion piston enginesMolecular sieve catalystsColloidal silicaColloid

An exhaust gas purifying catalyst for exhaust gas discharged from an automotive internal combustion engine. The catalyst comprises a substrate over which a hydrocarbons adsorbing material layer is formed as a lower layer to absorb hydrocarbons contained in exhaust gas. The hydrocarbons adsorbing material layer contains zeolite and colloidal silica which has undergone firing. The colloidal silica is in a chain-like form and / or a spherical form before and after the firing. Additionally, a catalyst component layer is formed as an upper layer over the hydrocarbons adsorbing material layer. The catalyst component layer contains a catalyst metal.

Owner:NISSAN MOTOR CO LTD

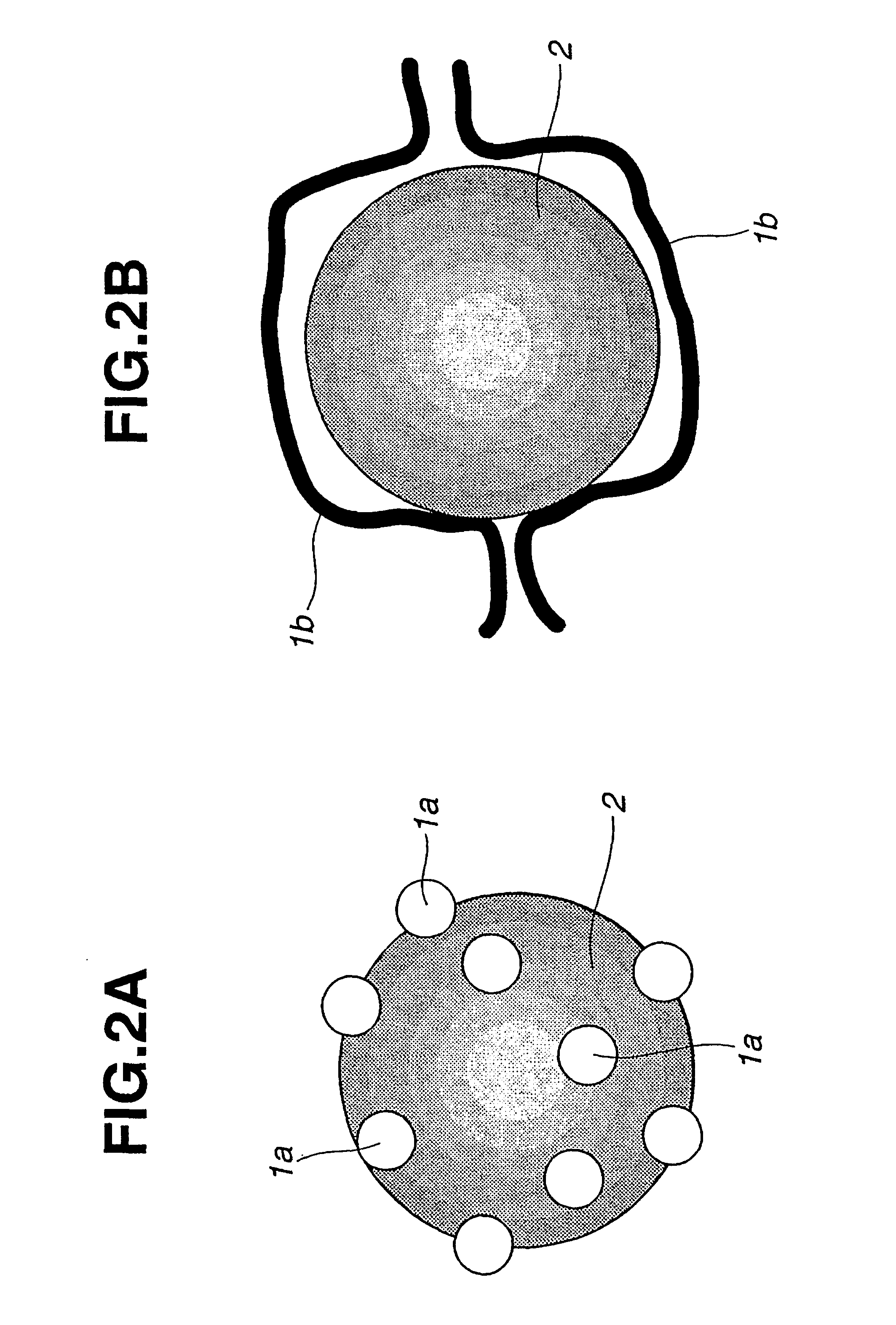

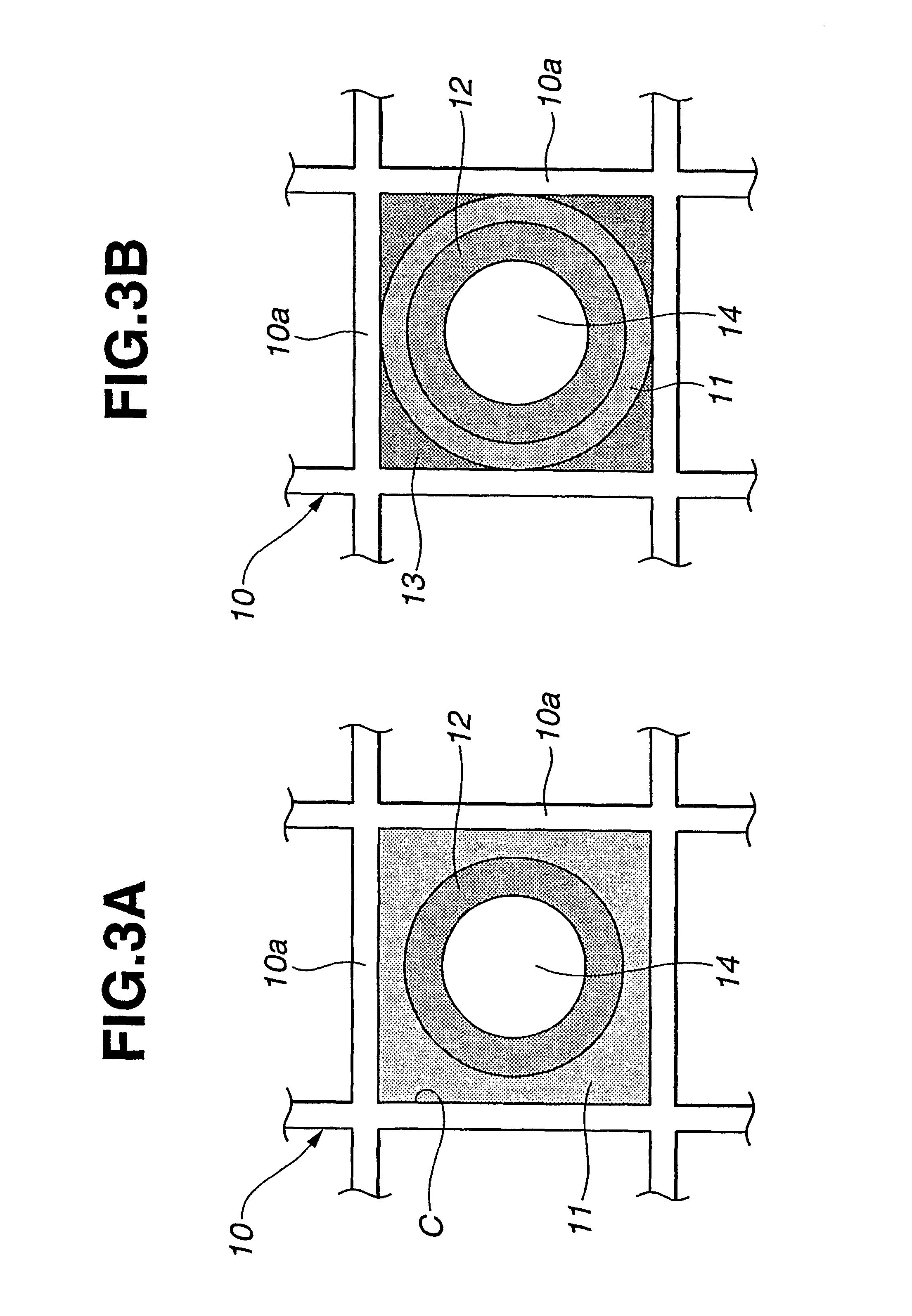

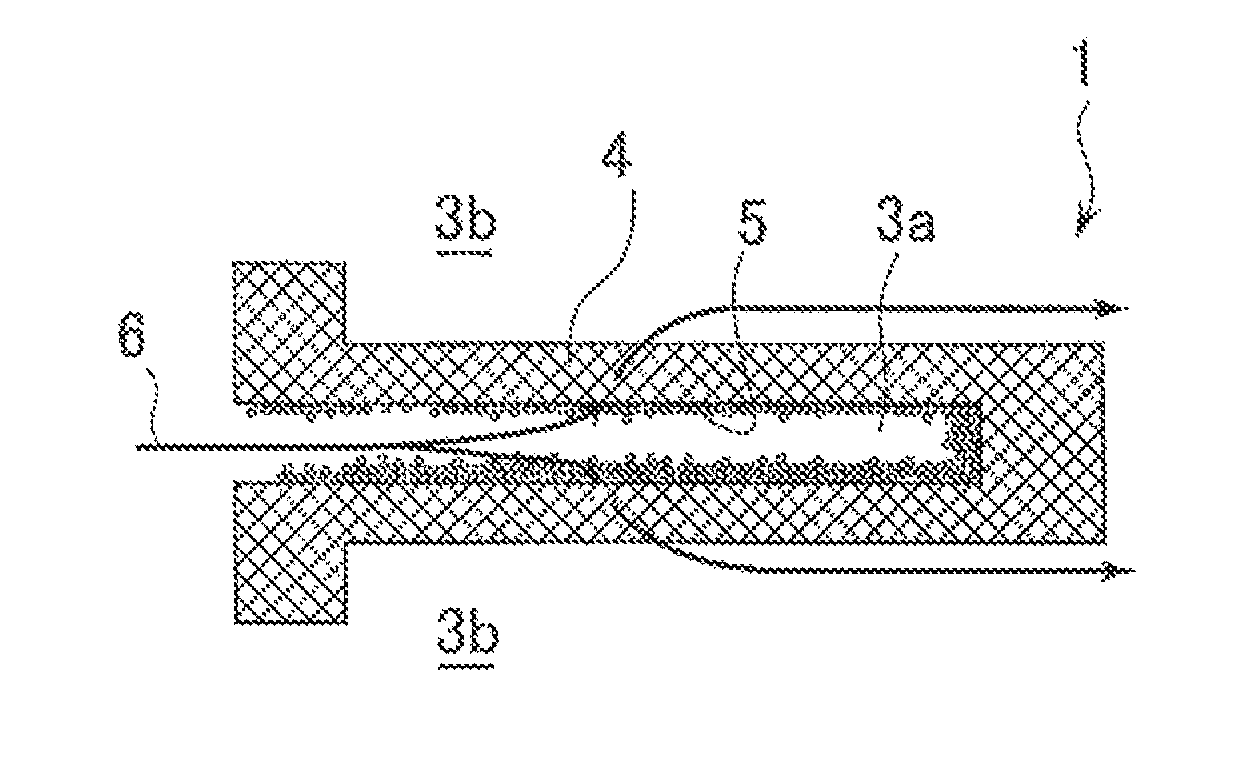

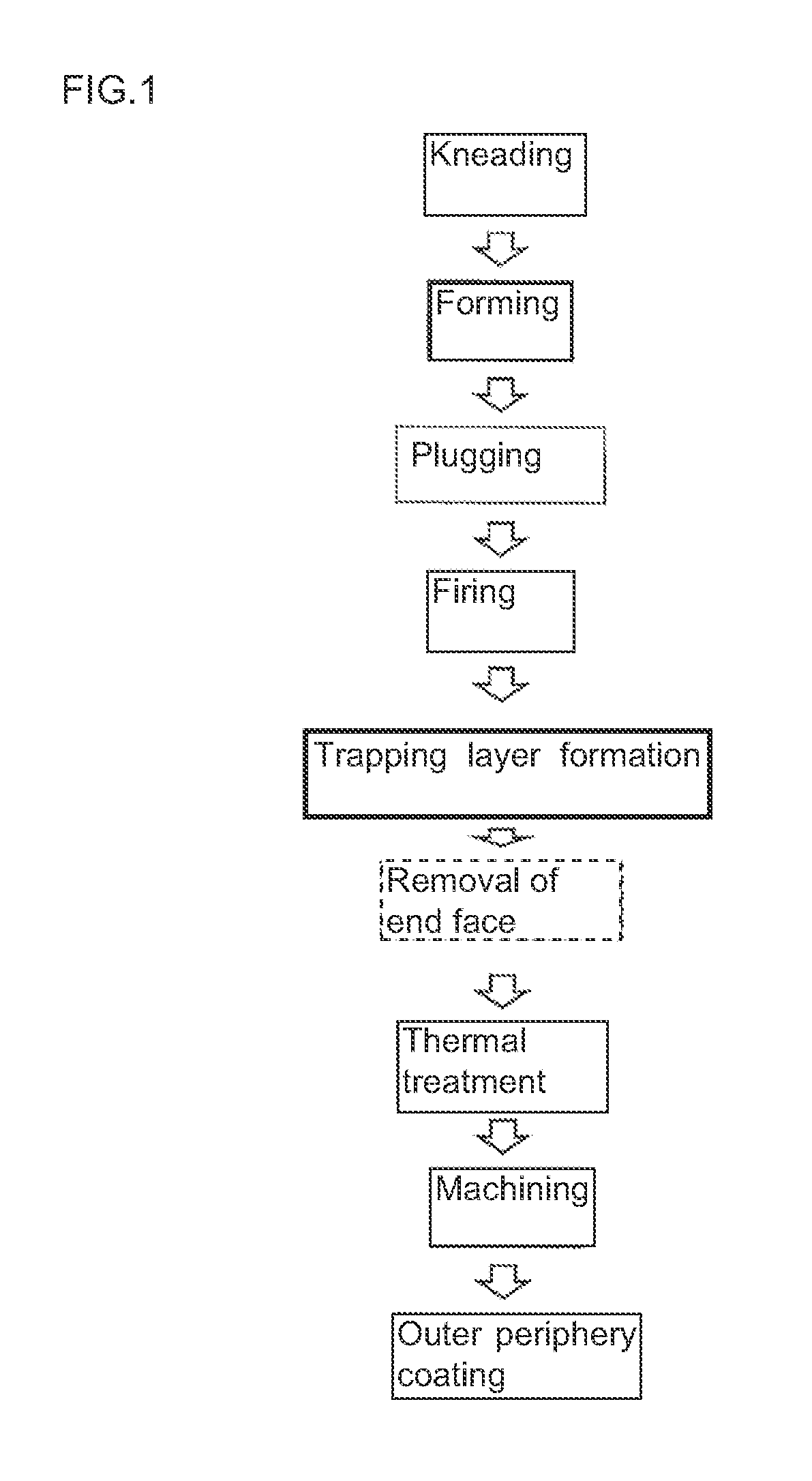

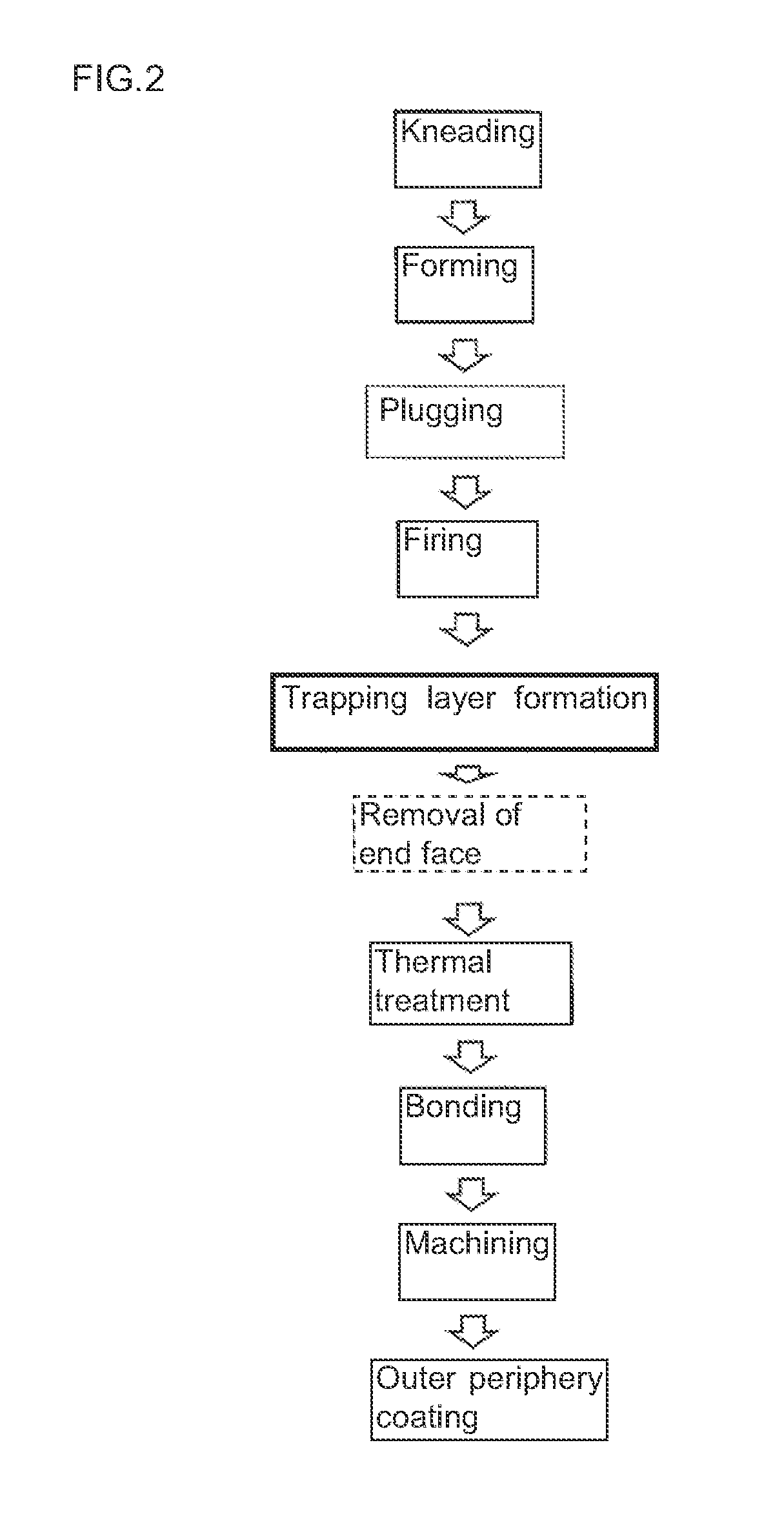

Method for manufacturing plugged honeycomb structure

ActiveUS8277880B2Suppress scatterIncrease production costCatalyst carriersPretreated surfacesHoneycomb structureMaterials science

A method for manufacturing a plugged honeycomb structure including a step of mixing ceramic particles with a gas on one end face side of the plugged honeycomb structure, and a step of sucking the gas containing the ceramic particles from the other end face side of the plugged honeycomb structure to send the ceramic particles mixed in the gas into cells of the plugged honeycomb structure to allow the ceramic particles to adhere to surfaces in the cells of the plugged honeycomb structure.

Owner:NGK INSULATORS LTD

Cleaning brush with disposable/replaceable brush head

InactiveUS7159265B2Long to cleanIncrease production costBoard cleaning devicesCarpet cleanersBristleRemote system

Owner:SC JOHNSON & SON INC

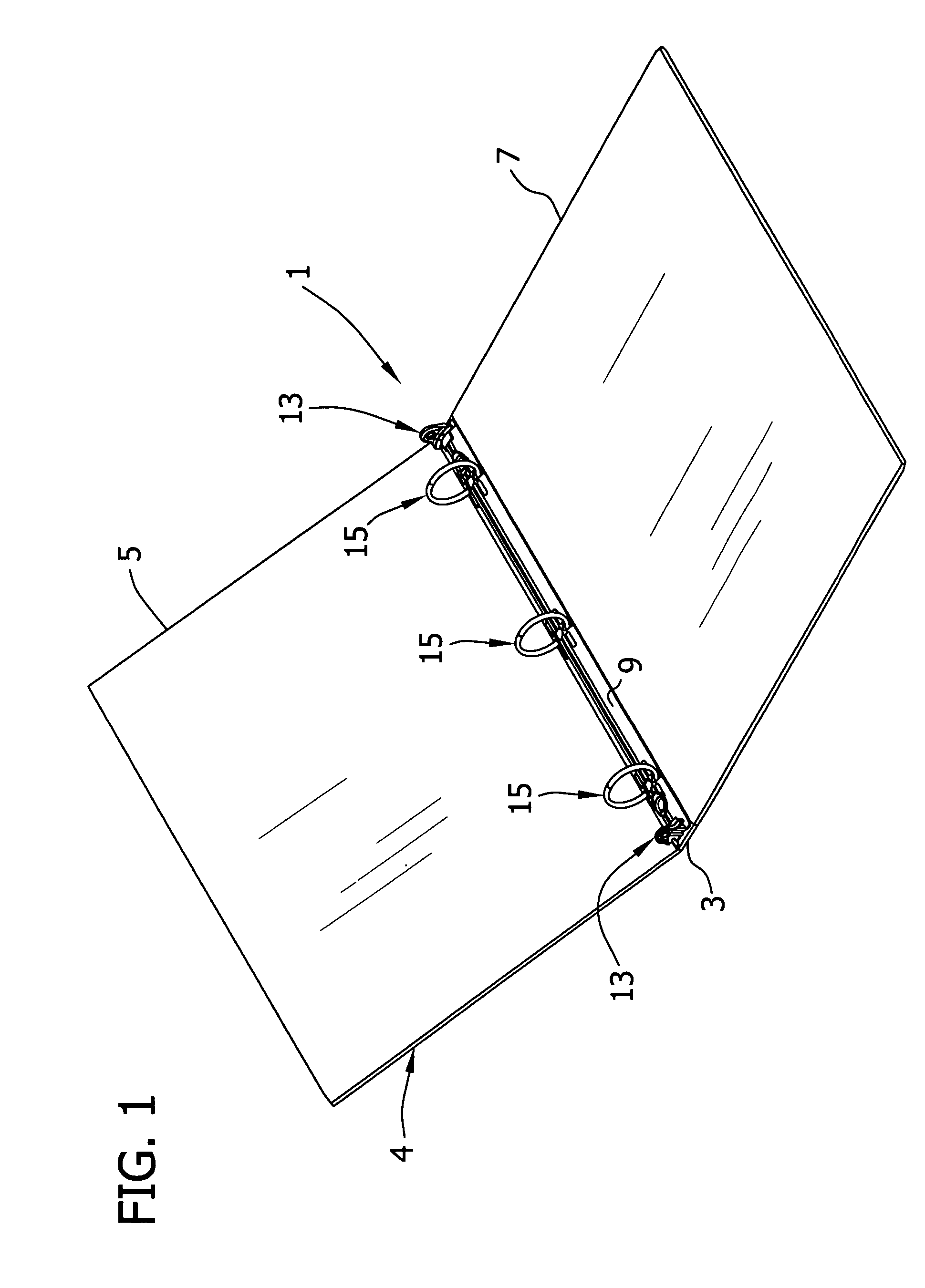

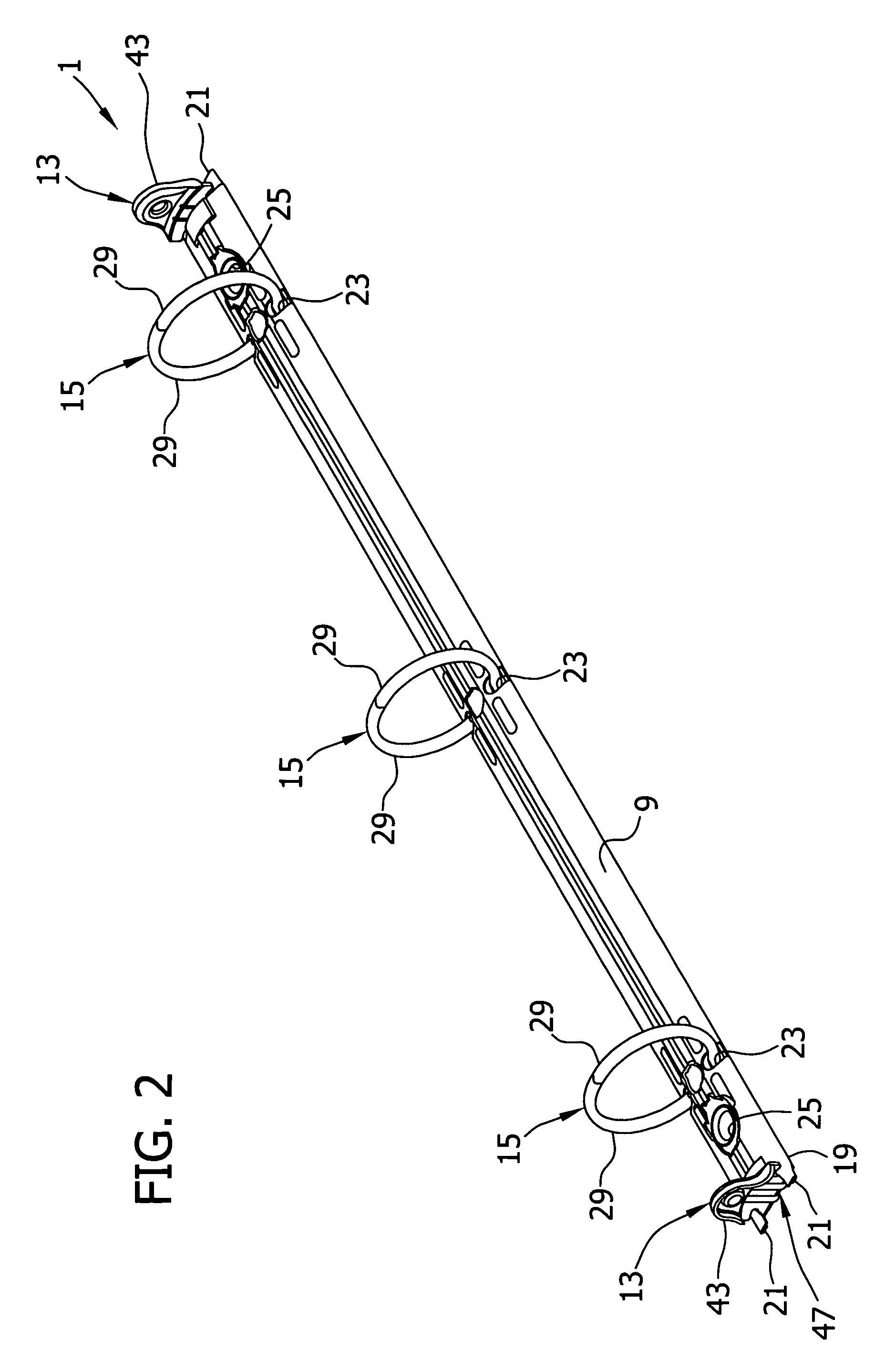

Ring binder mechanism with reinforced hinge plates

InactiveUS20060008318A1Keep the openings relatively smallDifficult to fabricateFiling appliancesSheet bindingFastenerHinge angle

A ring binder mechanism for retaining loose-leaf pages comprises an elongate housing that supports two hinge plates for loose pivoting motion. Ring members attach to the hinge plates and move with the pivoting motion of the hinge plates between a closed position and an open position. Levers are pivotally attached to longitudinal ends of the housing for pivoting the hinge plates to move the ring members. The hinge plates define an opening therein, generally adjacent to one of the levers, for receiving a fastener through the hinge plates to attach the mechanism to a cover. Reinforcing structure is provided around the opening for rigidifying the hinge plates in that area and for preventing the hinge plates from bending or deforming near the opening during operation.

Owner:WORLD WIDE STATIONARY MFG CO LTD

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

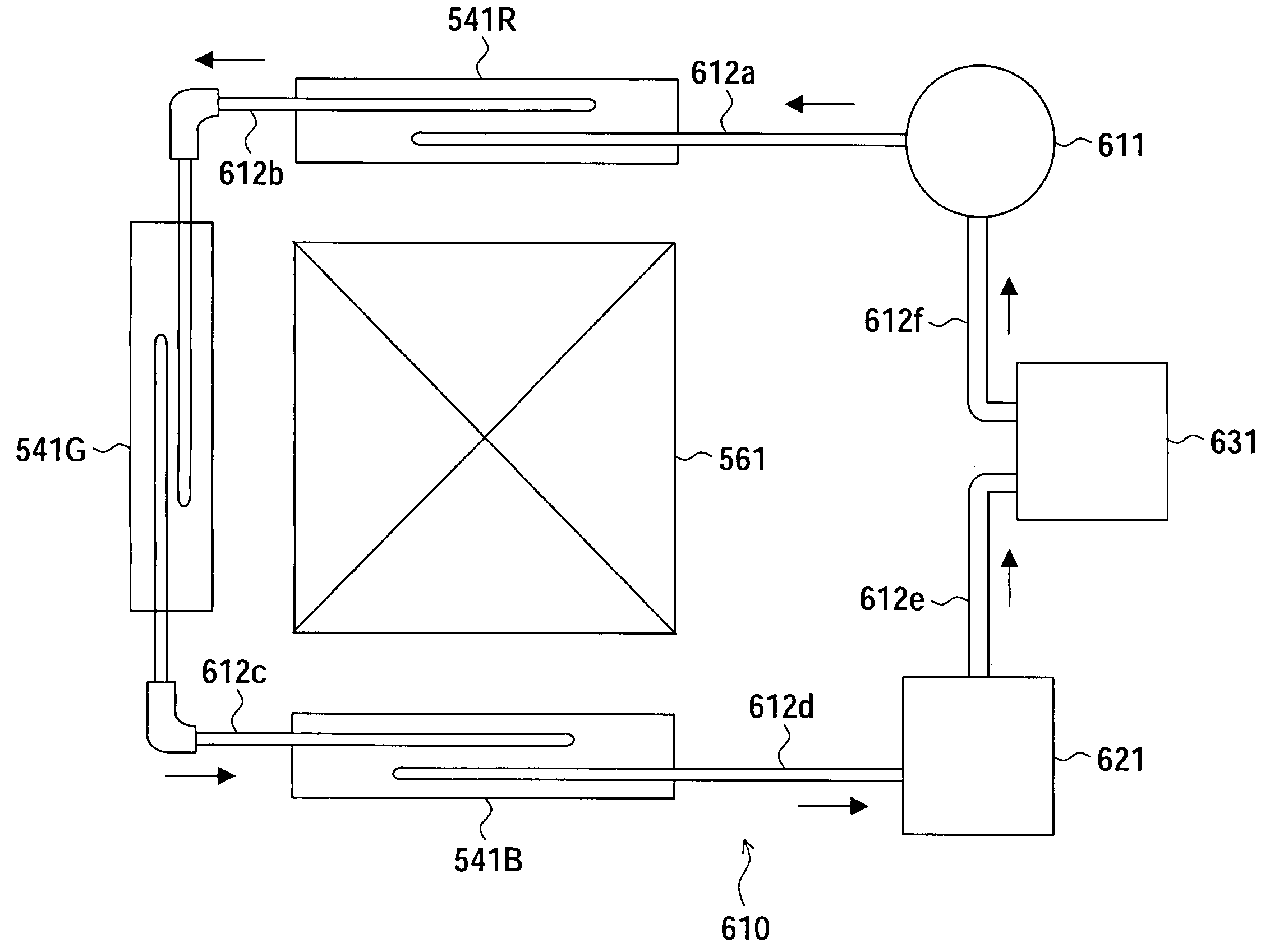

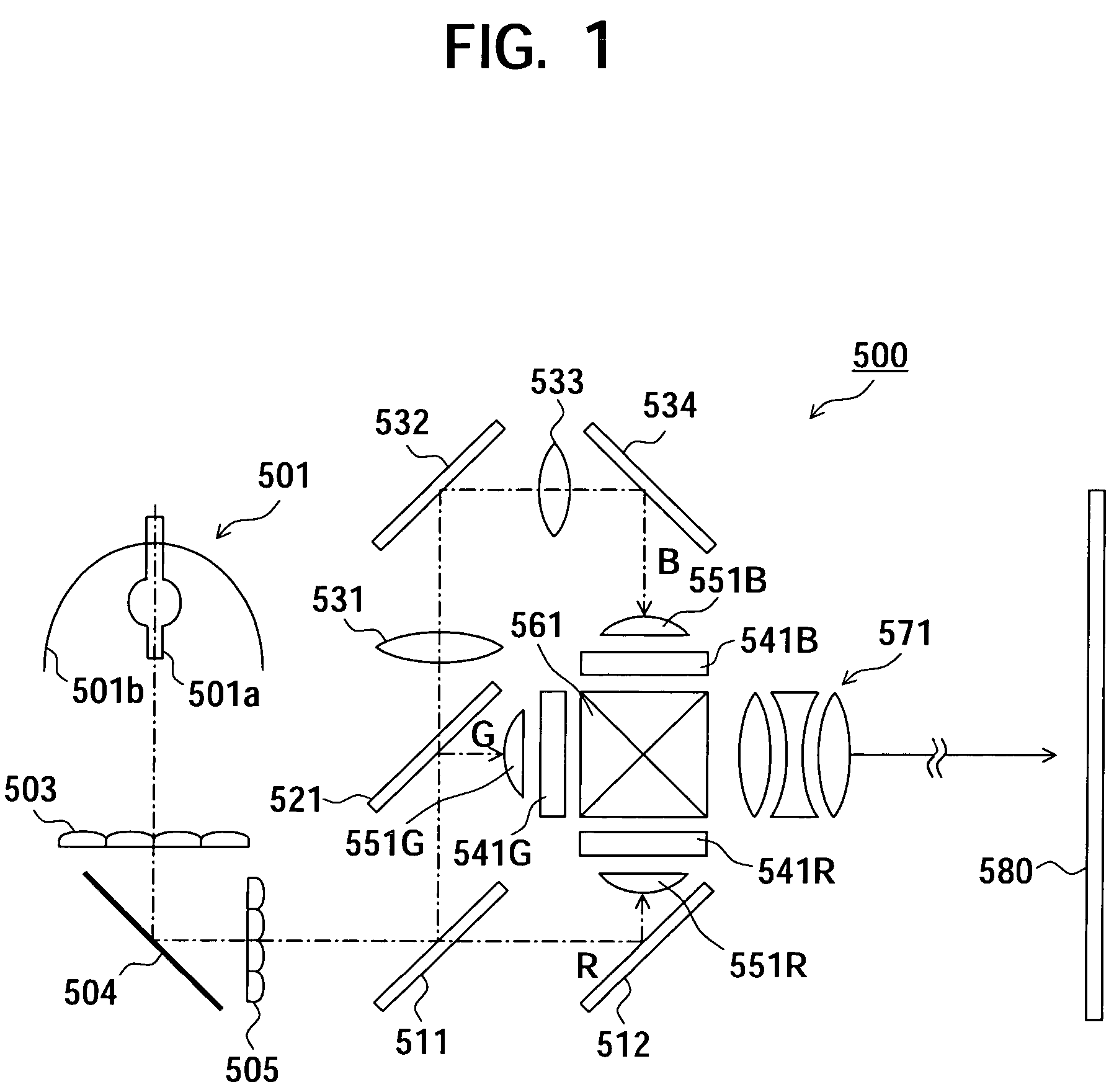

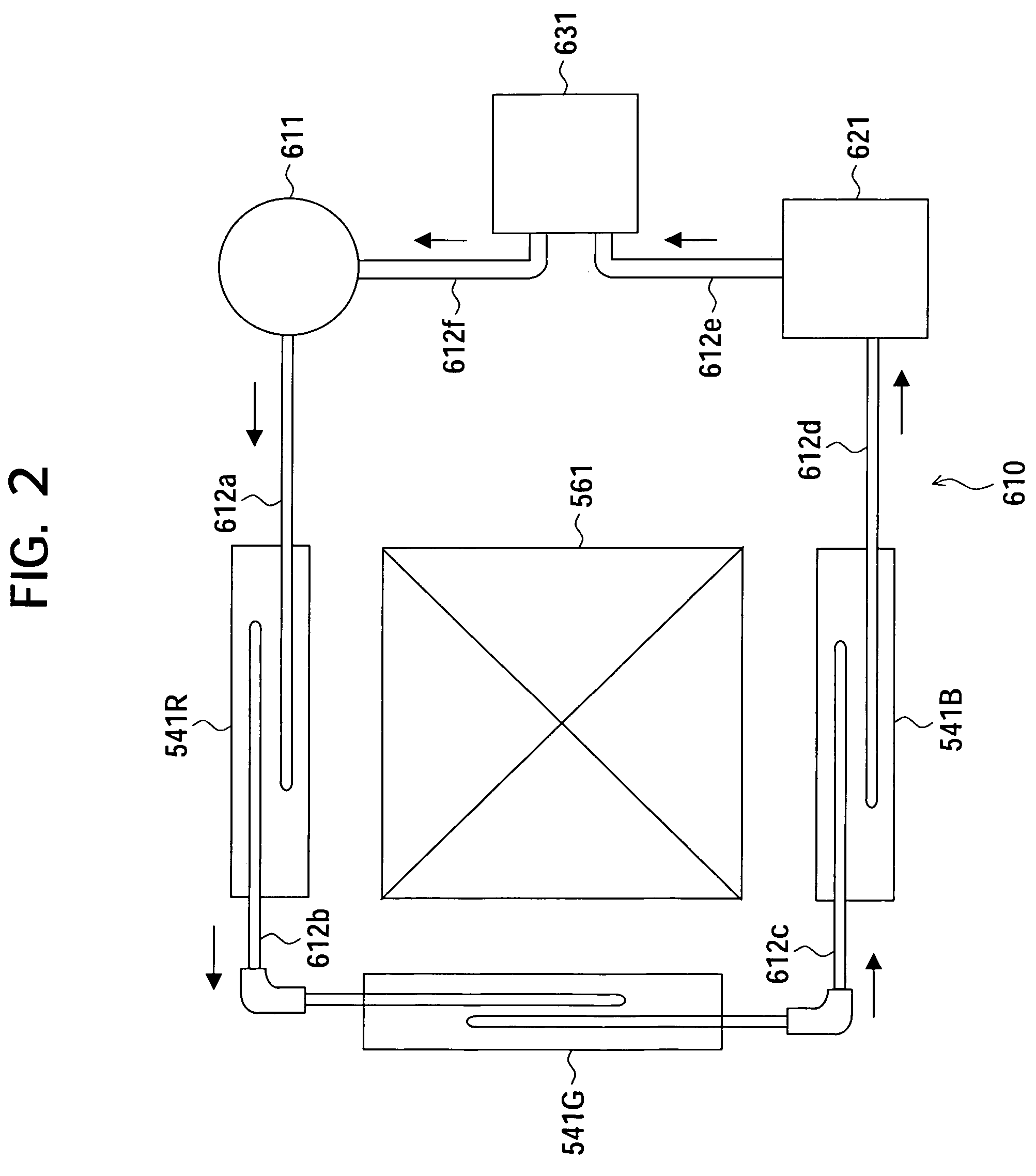

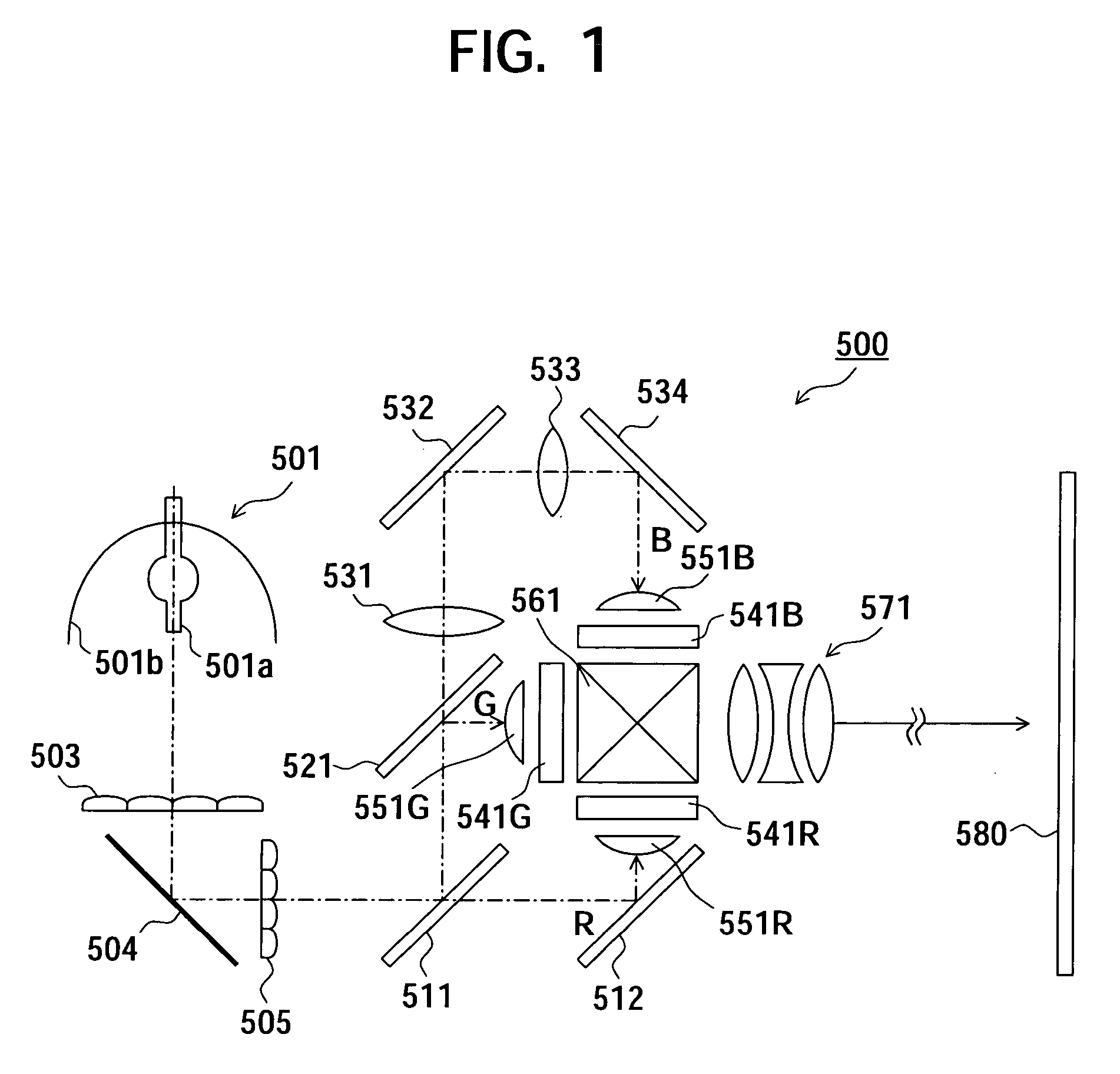

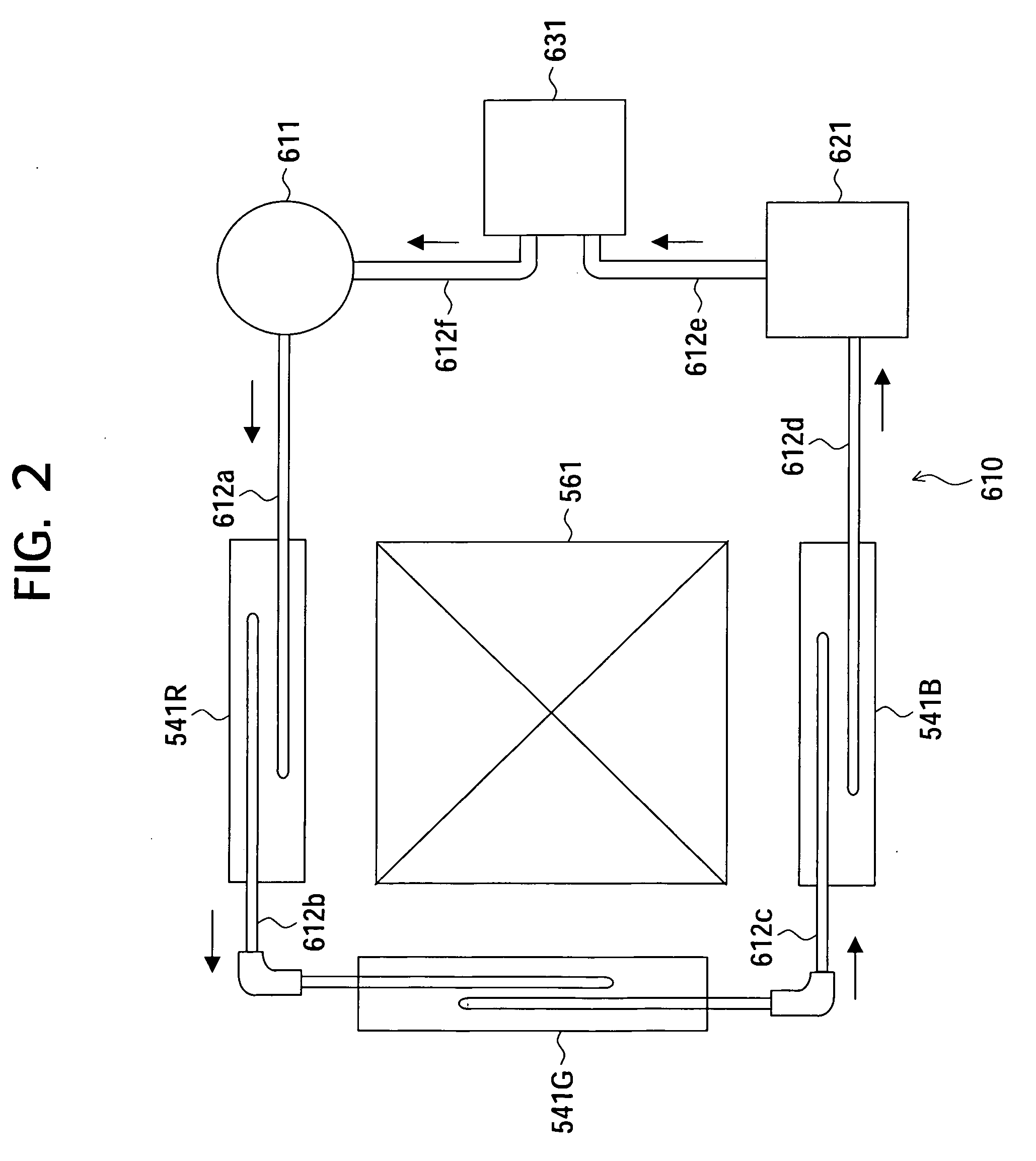

Liquid crystal display apparatus and cooling device

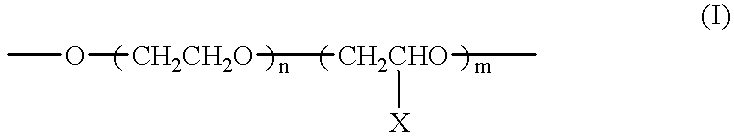

InactiveUS7535543B2Improve thermal conductivityIncrease the areaProjectorsColor television detailsLiquid-crystal displayDisplay device

A liquid crystal display device constrains the injection of air bubbles in a cooling fluid into a display panel. In the display device, the cooling fluid is supplied to a receiving space of a receiving unit placed and opposed to a surface of a liquid crystal panel to which the light is emitted from a light source to thereby cool the liquid crystal panel. Namely, by a cooling fluid pump, the cooling fluid received in the receiving unit is drained from a drain port and the cooling fluid is supplied from a feed port to the receiving unit and received in the receiving space. In the above case, a part of a flow path of the cooling fluid supplied from the feed port is blocked by a flow path block unit placed and opposed to the feed port to thereby disperse the flow thereof around the flow path block unit.

Owner:SONY CORP

Resin composition and jig for use in transportation

InactiveUS6344513B1Excellent static charge dissipating performanceLittle changeSemiconductor/solid-state device manufacturingSpecial tyresFiberCarbon fibers

Owner:TEIJIN LTD

Acicular calcite and aragonite calcium carbonate

InactiveUS6022517AReduce conductivityIncrease production costCalcium/strontium/barium carbonatesAmmonium nitratesToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

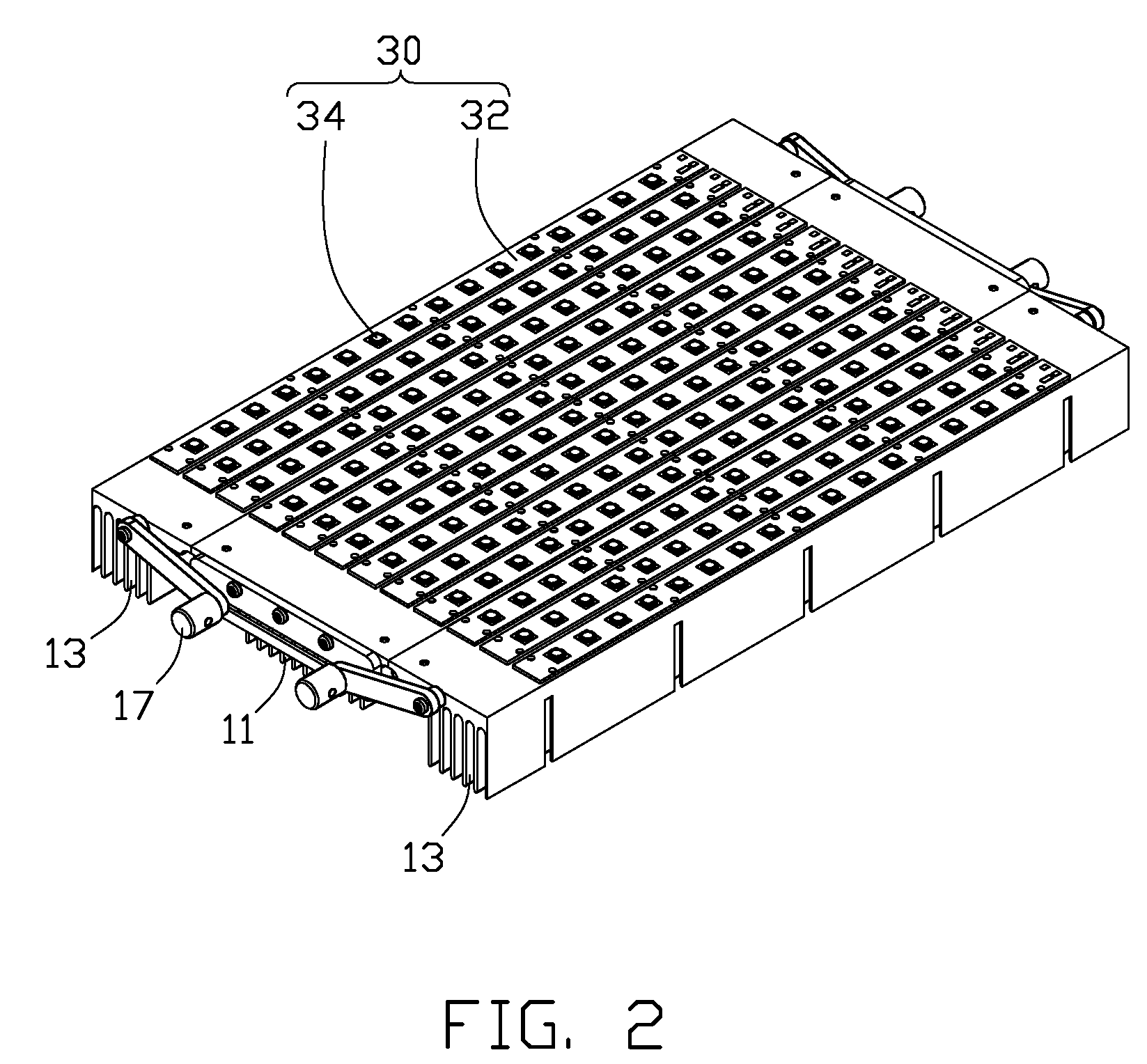

LED lamp

InactiveUS20090141494A1Dissipate heat generatedIncrease production costPlanar light sourcesLighting support devicesEngineeringDeuteron radiation

An LED lamp includes a first heat sink, a second heat sink and a plurality of LED modules. The second heat sink is located at a lateral side of the first heat sink and pivotally connects with the first heat sink. The LED modules are evenly attached on bottoms of the first and second heat sinks. The second heat sink can be rotated relative to the first heat sink to be fixed at a required position, whereby an illumination angle of the LED lamp can be adjusted. Heat generated by the LED modules is dissipated by the first and second heat sinks.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

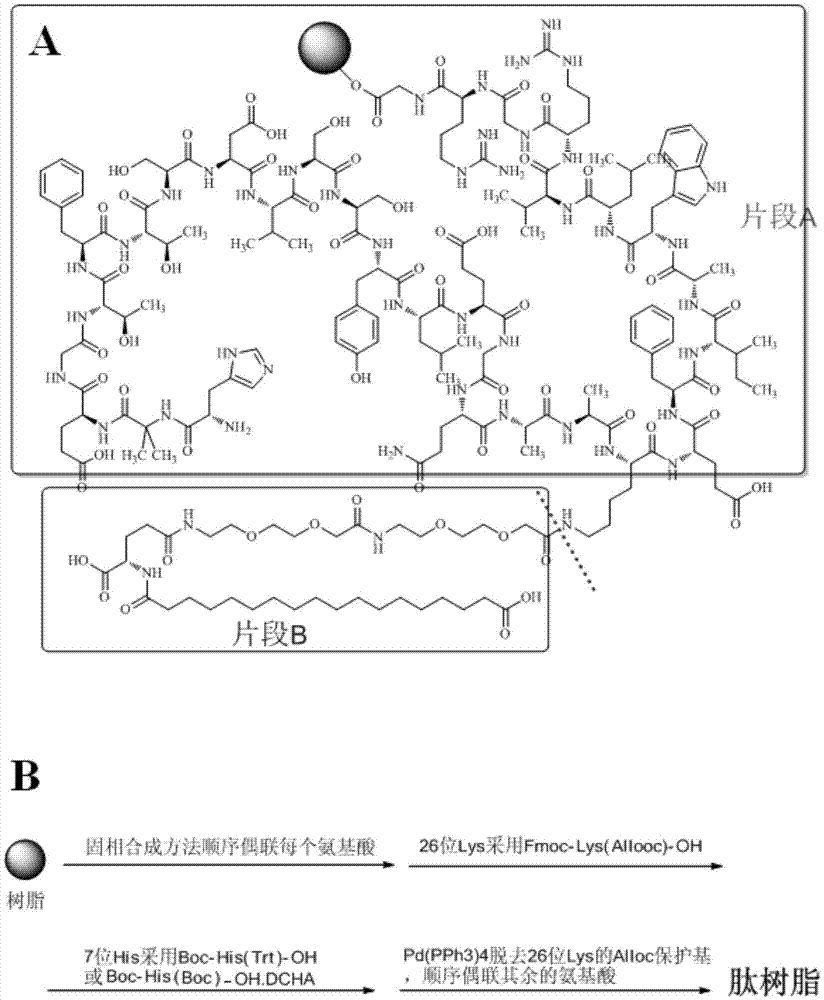

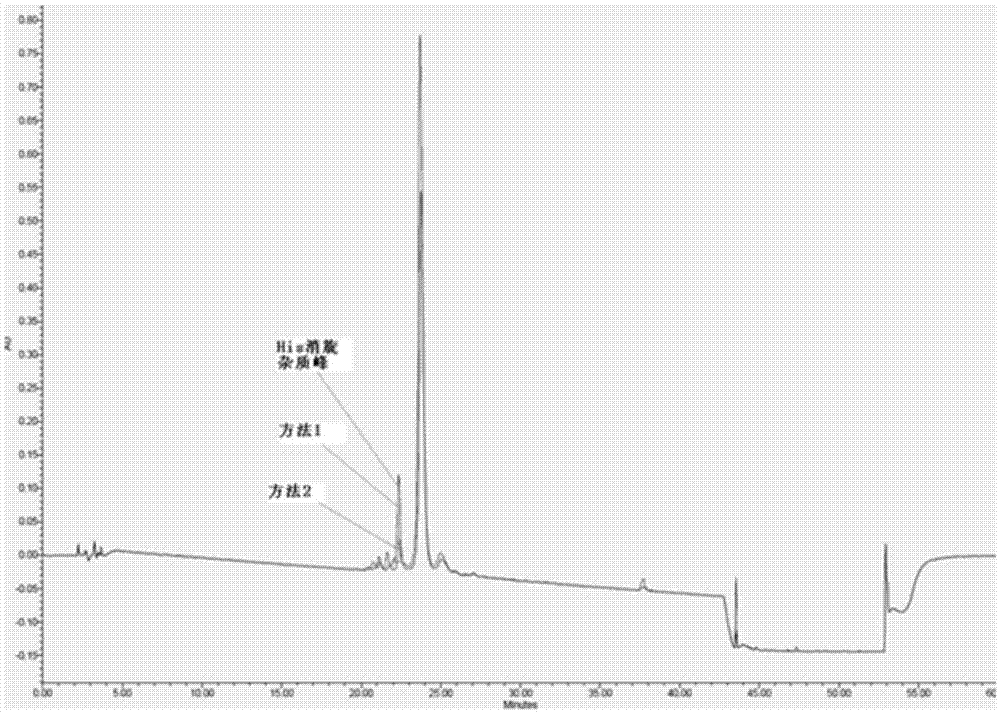

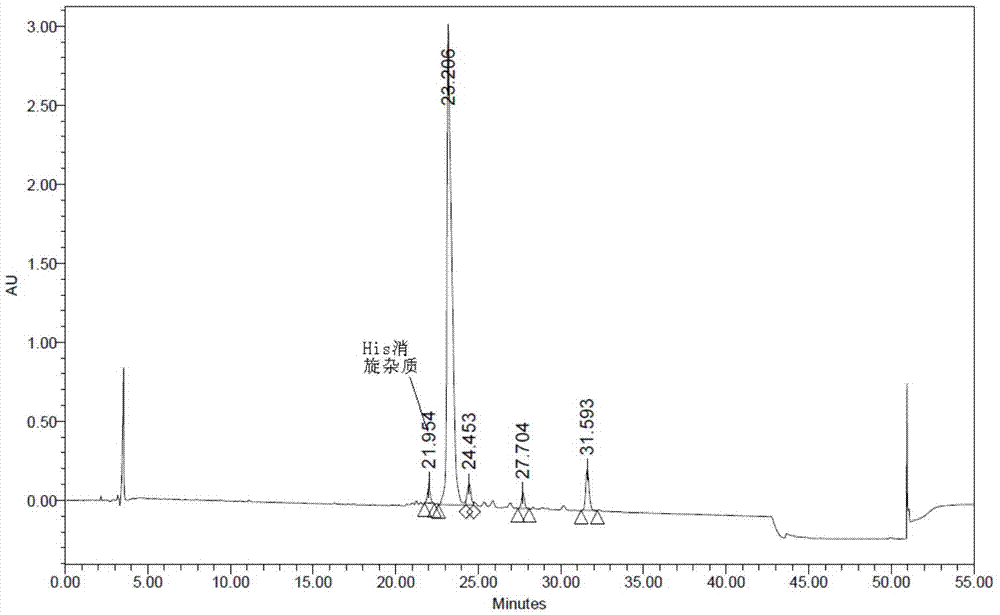

Method for preparing semaglutide

InactiveCN106928343AEasy to operateNo side effectsPeptide-nucleic acidsPeptide preparation methodsSide reactionSemaglutide

The invention relates to the field of polypeptides, in particular to a method for preparing semaglutide. The method has the advantages that Fmoc-Lys (Alloc)-OH protection amino acid is used as a raw material, de-protection is carried out by the aid of selected Pd (PPh3) 4, accordingly, operation procedures are simple, only 1-2 times of simple elimination reaction operation are required, each elimination reaction operation is carried out for 10-30 min, side reaction is prevented, the operation procedures are safe, and enlarged production can be facilitated; Boc-His (Boc)-OH. DCHA and Boc-His (Trt)-OH are used as raw materials in the procedures, and accordingly His racemization risks can be reduced to the greatest extent; special fragments are coupled, and accordingly the synthesis efficiency can be improved.

Owner:HYBIO PHARMA

Liquid crystal display apparatus and cooling device

InactiveUS20060125998A1Improve cooling efficiencySuppress noiseProjectorsColor television detailsLiquid-crystal displayDisplay device

A liquid crystal display device constrains the injection of air bubbles in a cooling fluid into a display panel. In the display device, the cooling fluid is supplied to a receiving space of a receiving unit placed and opposed to a surface of a liquid crystal panel to which the light is emitted from a light source to thereby cool the liquid crystal panel. Namely, by a cooling fluid pump, the cooling fluid received in the receiving unit is drained from a drain port and the cooling fluid is supplied from a feed port to the receiving unit and received in the receiving space. In the above case, a part of a flow path of the cooling fluid supplied from the feed port is blocked by a flow path block unit placed and opposed to the feed port to thereby disperse the flow thereof around the flow path block unit.

Owner:SONY CORP

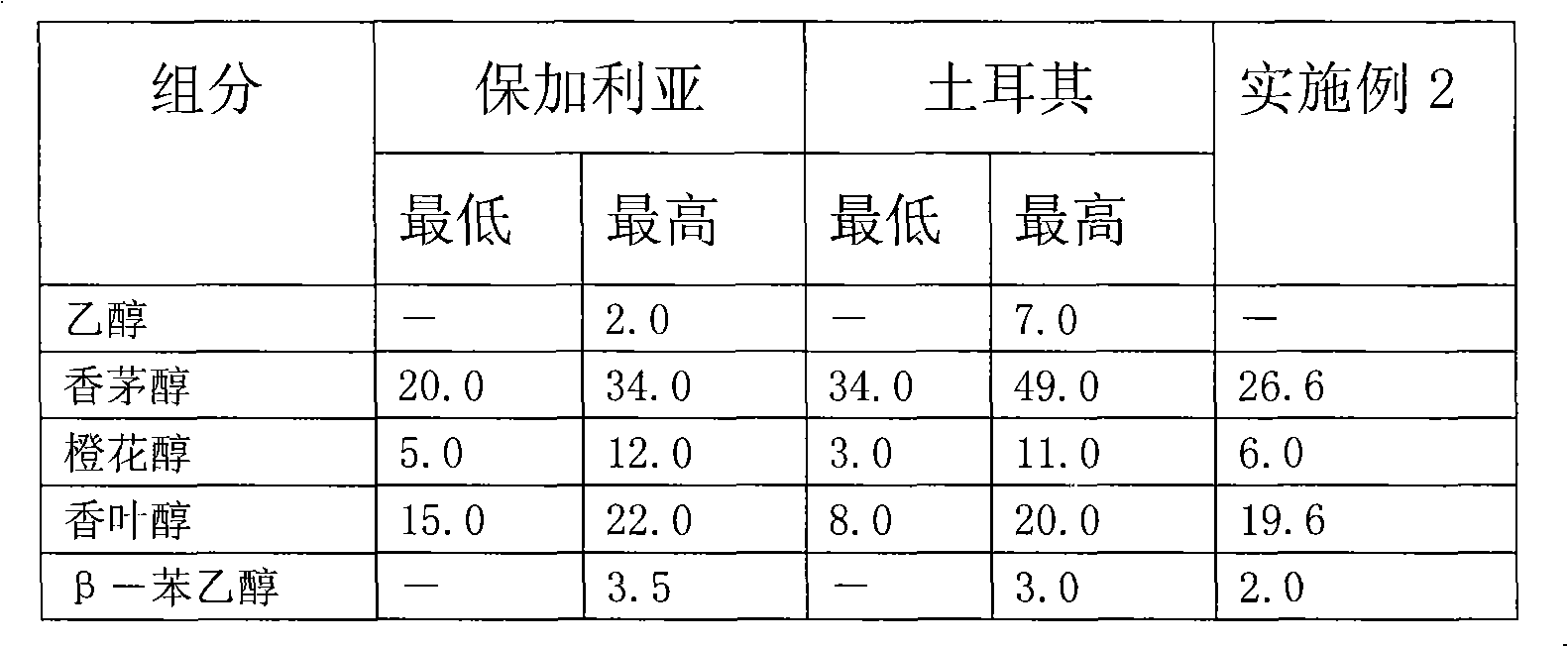

Method for extracting rose essence oil and rose absolute by water vapor water distillation technology

InactiveCN101280243AImprove stabilityImprove the yield of active ingredientsEssential-oils/perfumesFatty-oils/fats productionSlagWater vapor

The invention discloses a method of extracting rose essential oil and rose pure dew, using the distillation technique in the water vapor. The method includes the steps: (1) the roses are fed into a distillation kettle; (2) deionized water is added to the distillation kettle; (3) non-iodine salt is added to the distillation kettle; (4) the coiled pipe is opened to supply steam and heat the distillation kettle; (5) the condenser is opened to supply cooled water; the cooled oil water is mixed with steam; (6) the oil water mixture cooled by the condenser is guided into an oil water separator for the oil water separation; (7) the water layer separated by the oil water separator flows back to the distillation kettle to have repeated distillation; when the repeated distillation is finished, the repeated flow valve is closed and the collector valve is opened to collect the water layer so that the rose pure dew is obtained; (8) when the oil and water are divided into layers, the oil water separator is opened to collect the water layer so that the rose essential oil is obtained; (9) water is released and the waste slag is discharged. The method of extracting the rose essential oil and the rose pure dew has the advantages of high stability of the products, high content of the active composition, simple operation, easy mastery and low production cost.

Owner:浙江景和旅游产业发展有限公司

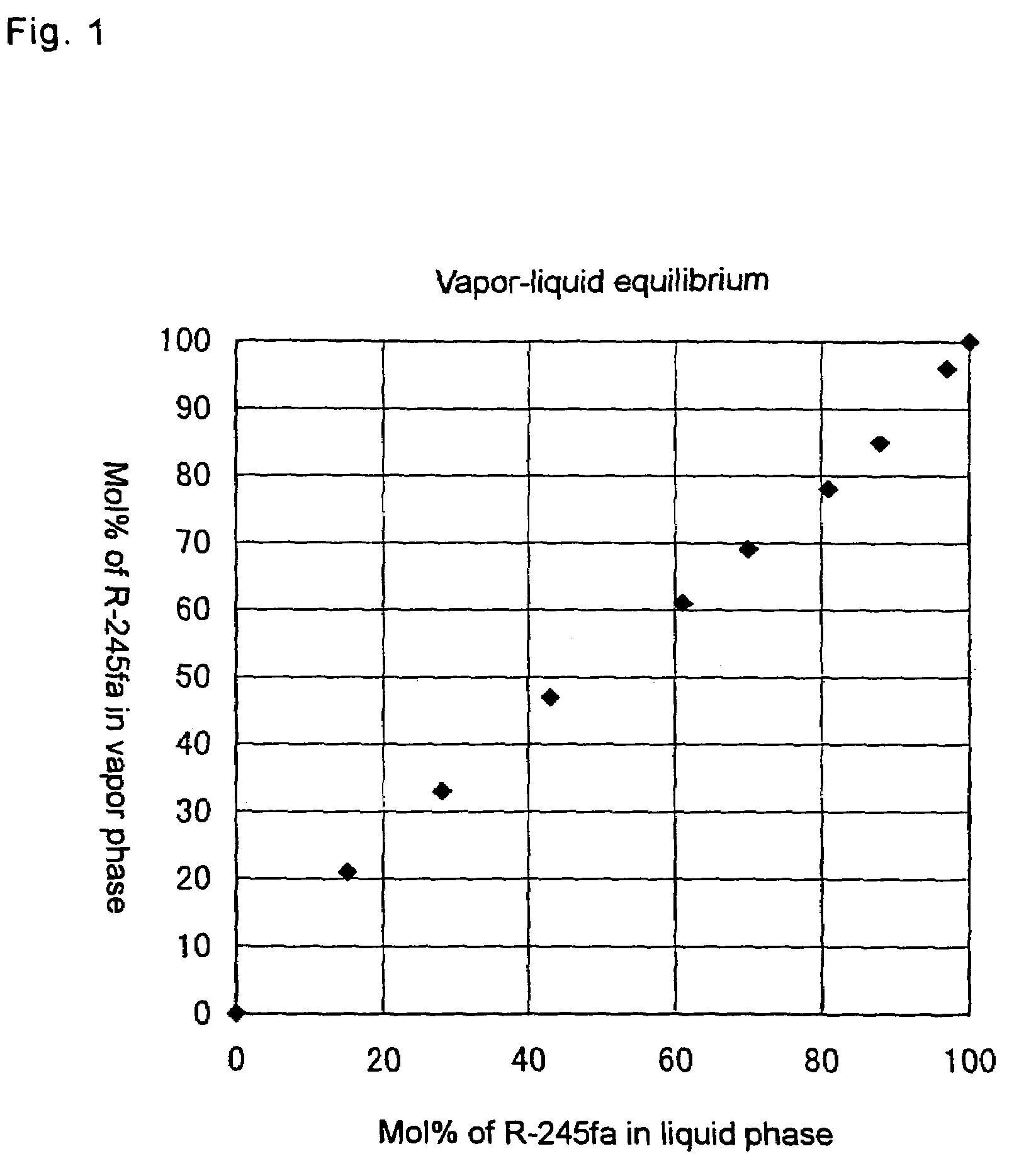

Azeotropic composition, comprising 1, 1, 1, 3,3-pentafluoropropane and 1, 1, 1-trifluoro-3-chloro-2-propene, method of separation and purification of the same, and process for producing 1, 1, 1,3,3-pentafloropropane and 1, 1, 1-trifluoro-3-chloro-2-propene

InactiveUS7183448B2Delayed recoveryIncrease production costPreparation by hydrogen halide split-offOther chemical processesDistillationPentafluoropropane

A mixture comprising at least 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is subjected to a distillation operation, and thereby, a distillate comprising an azeotropic composition consisting substantially of 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is obtained and a bottom product comprising 1,1,1,3,3-pentafluoropropane or 1,1,1-trifluoro-3-chloro-2-propene which each is separated and purified.

Owner:DAIKIN IND LTD

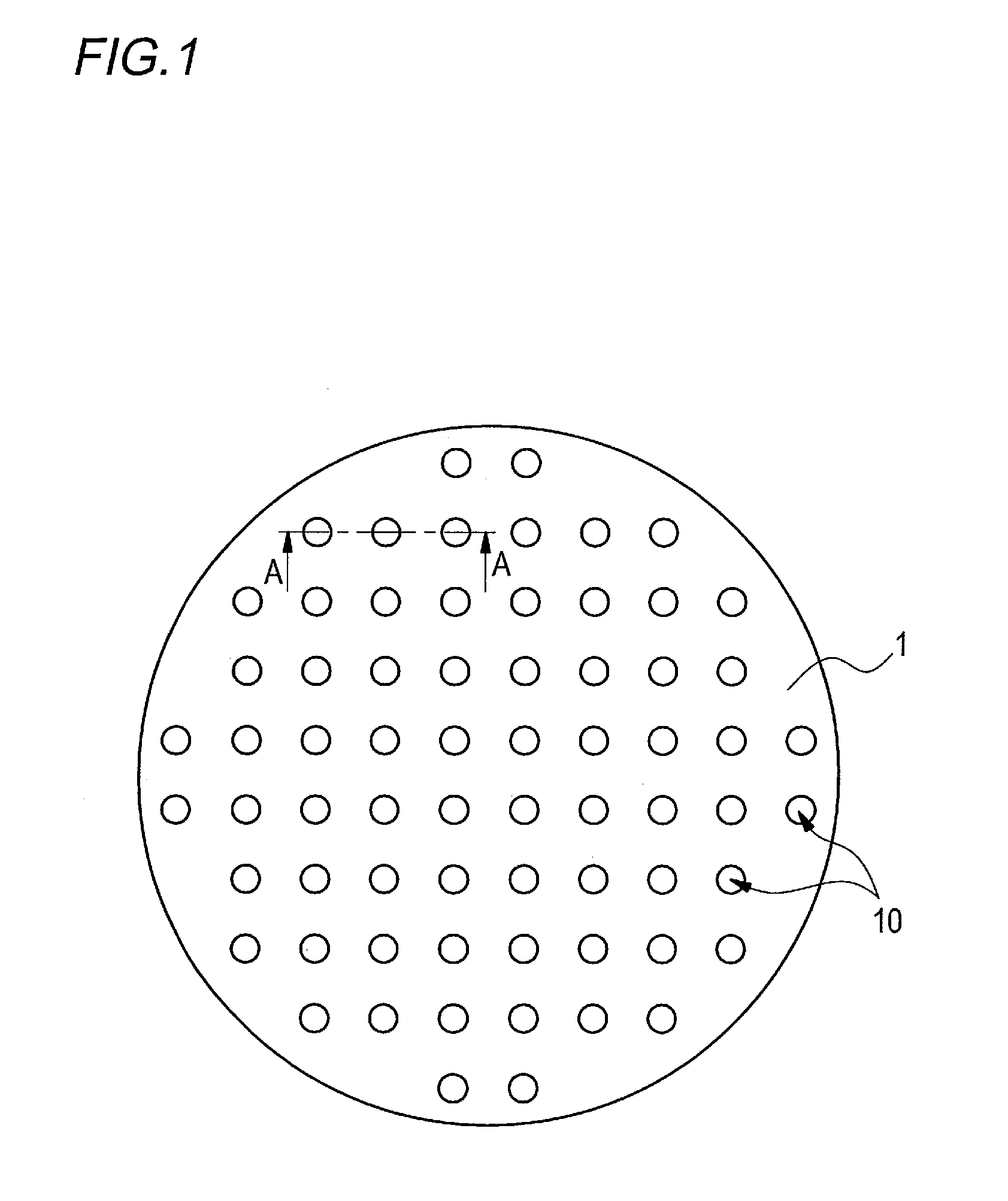

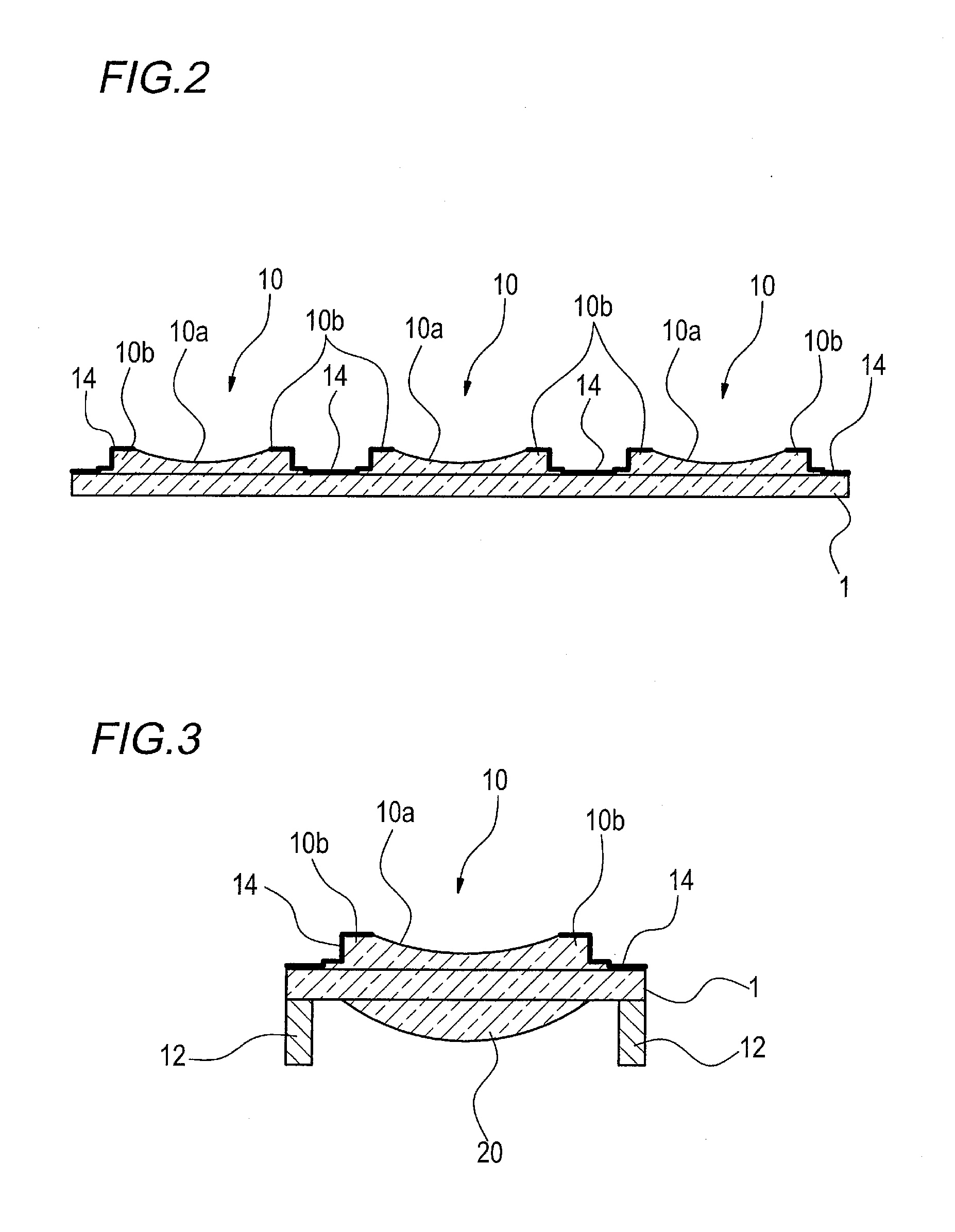

Wafer level lens, production method of wafer level lens, and imaging unit

InactiveUS20120134028A1Avoid light transmissionPrevent penetrationSolid-state devicesOptical articlesResistOptical axis

A sufficient light-shielding property is obtained by a wafer level lens having at least one lens module having a substrate and a plurality of lenses formed on the substrate in which the wafer level lens has a black resist layer formed on the surface of the lens module or on the surface of the substrate and the black resist layer is formed with a pattern having an opening at a part intersecting the optical axis of the lens, and generation of defects such as ghosts, flares and the like due to a reflected light can be prevented and an increase in the production cost can be suppressed.

Owner:FUJIFILM CORP

Method for smelting ultra-low carbon steel

ActiveCN102719593AHigh carbon contentReduce carbon contentManufacturing convertersProcess efficiency improvementHigh carbonSlag

The invention provides a method for melting ultra-low carbon steel. The method adopts a desulfuration of molten iron-converter-RH-continuous casting process, wherein a sulfur content in the molten iron is 0.002%-0.006% after desulphurization; converter smelting controls oxygen blowing time, an oxygen gun flow, a bottom-blowing intensity and a smelting period, adopts slag-stopping tapping, steel tapping with a content of C being 0.06%-0.08% and with a temperature of 1650-1680 DEG C, and an oxygen content in the molten iron is 0.03%-0.05%; an RH adopts forced decarburization with a highest vacuum degree of 67-100 MPa and decarburization time of 15-27 min, and a carbon content in the molten iron is 0.0010%-0.0020% and a dissolved oxygen content in the molten iron is 0.025%-0.040% after the decarburization; the molten iron is recycled for 3-5 min after deoxidation by adding aluminium and recycled for another 3-5 min after adding other alloys; a nitrogen content in the molten iron is 0.0015%-0.0035%, and the temperature is 1590-1640 DEG C; and killed steel treatment is carried out for 10-30 min. The method adopts converter tapping with a high carbon and low oxygen content, can use less or not use slag modified agents during the tapping process, accelerates the production rhythm, makes the molten steel cleaner, and reduces the production cost.

Owner:ANGANG STEEL CO LTD

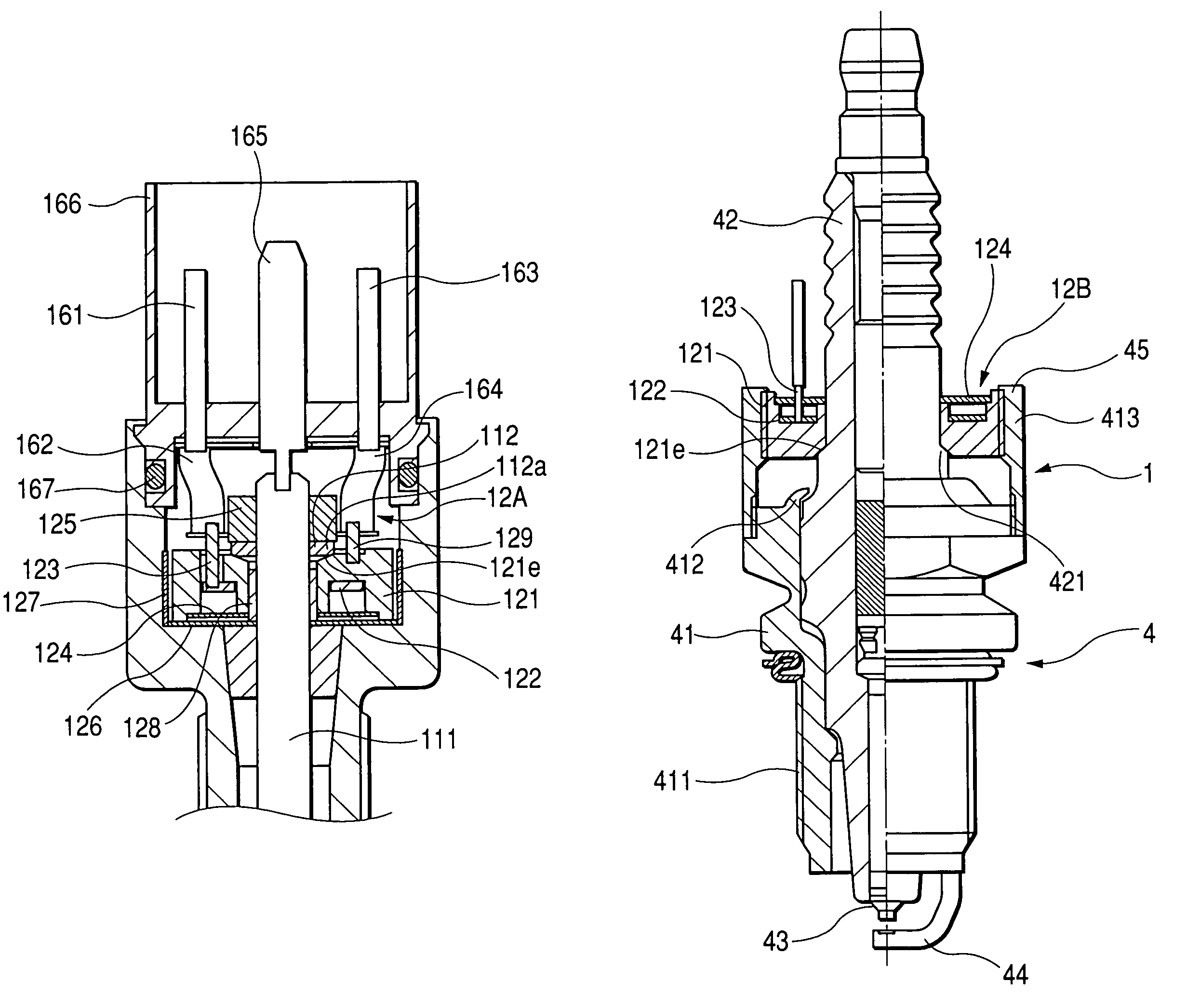

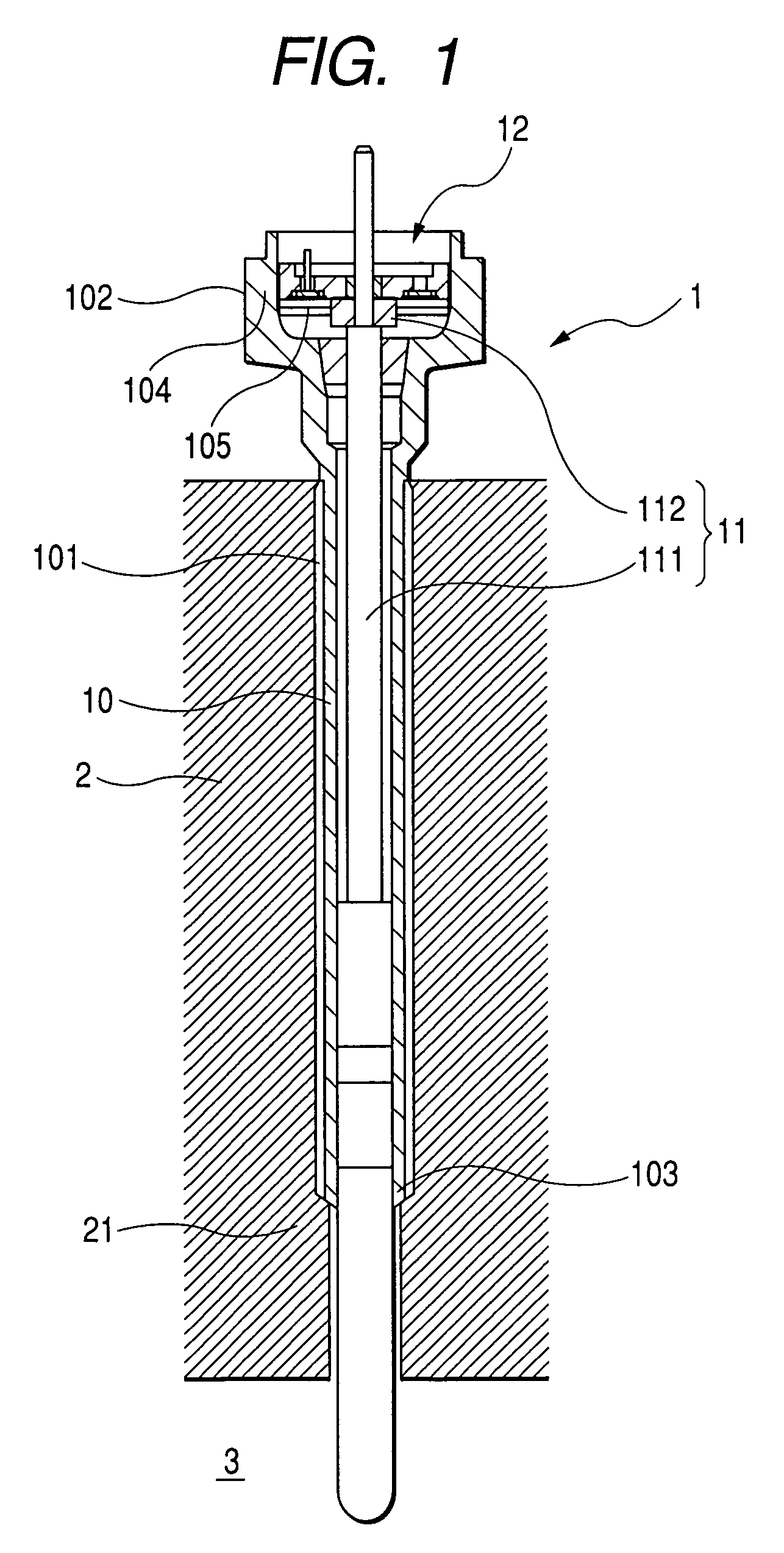

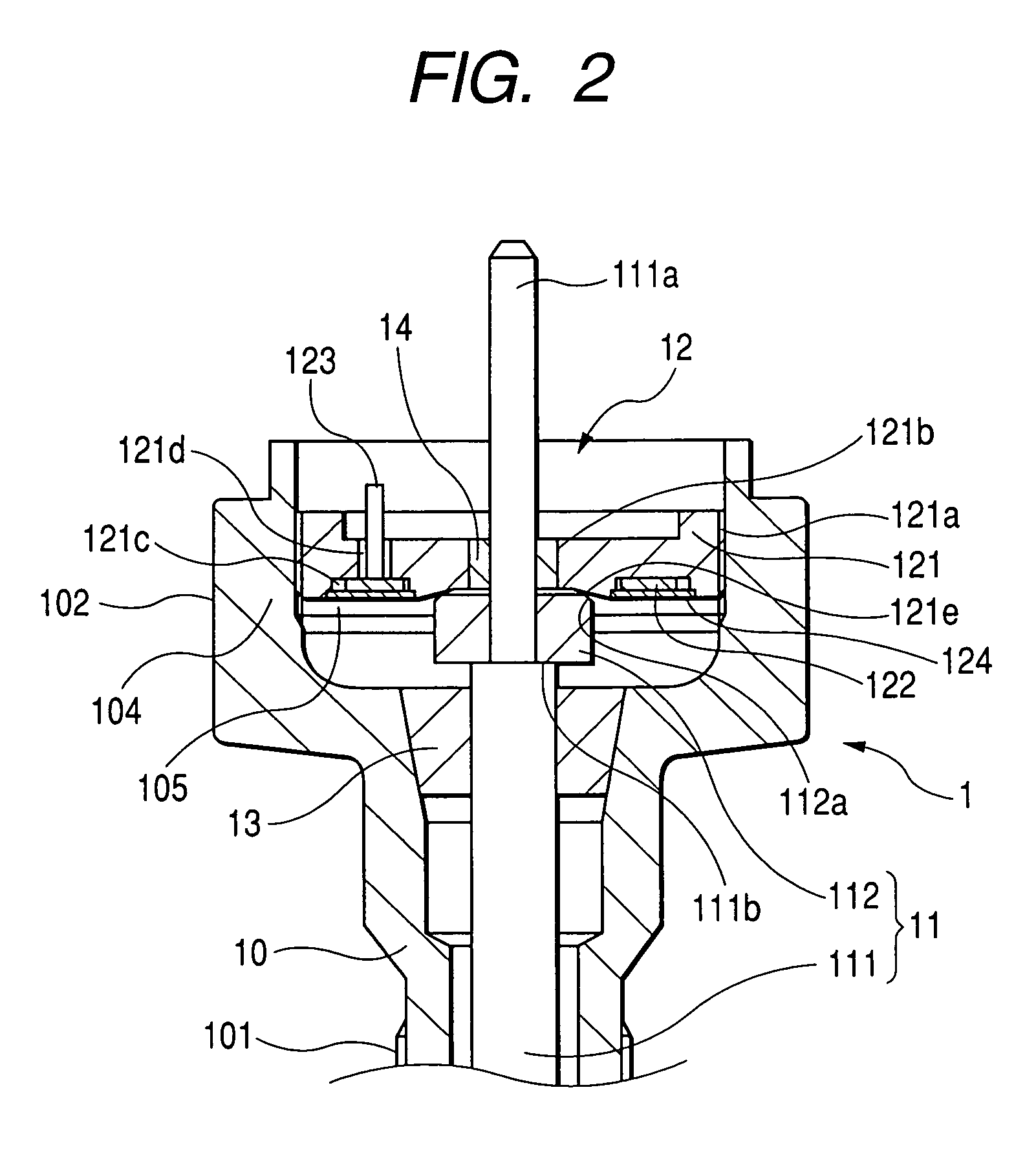

Combustion pressure sensor designed to ensure stability of output characteristic and sensitivity

ActiveUS6973820B2Minimize unit-to-unit variation in sensitivityEnsure output stabilityIncandescent ignitionFluid pressure measurementElectricityCombustion

A combustion pressure sensor for an internal combustion engine is provided. The sensor includes a sensing element such as a piezoelectric device sensitive to a physical load applied thereto to produce an electric signal indicative thereof and a bendable member. The bendable member is bent upon application of the combustion pressure in the engine to apply the physical load to the sensing element. Specifically, the physical load is applied to the sensing element which arises from the bend deformation of the bendable member, thus eliminating the need for a complete surface-to-surface contact between the sensing element and the bendable member. This results in a decreased unit-to-unit variation in sensitivity of combustion pressure sensors and ensures the stability of output characteristics of the combustion pressure sensor.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com