Patents

Literature

407results about How to "Reduce disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

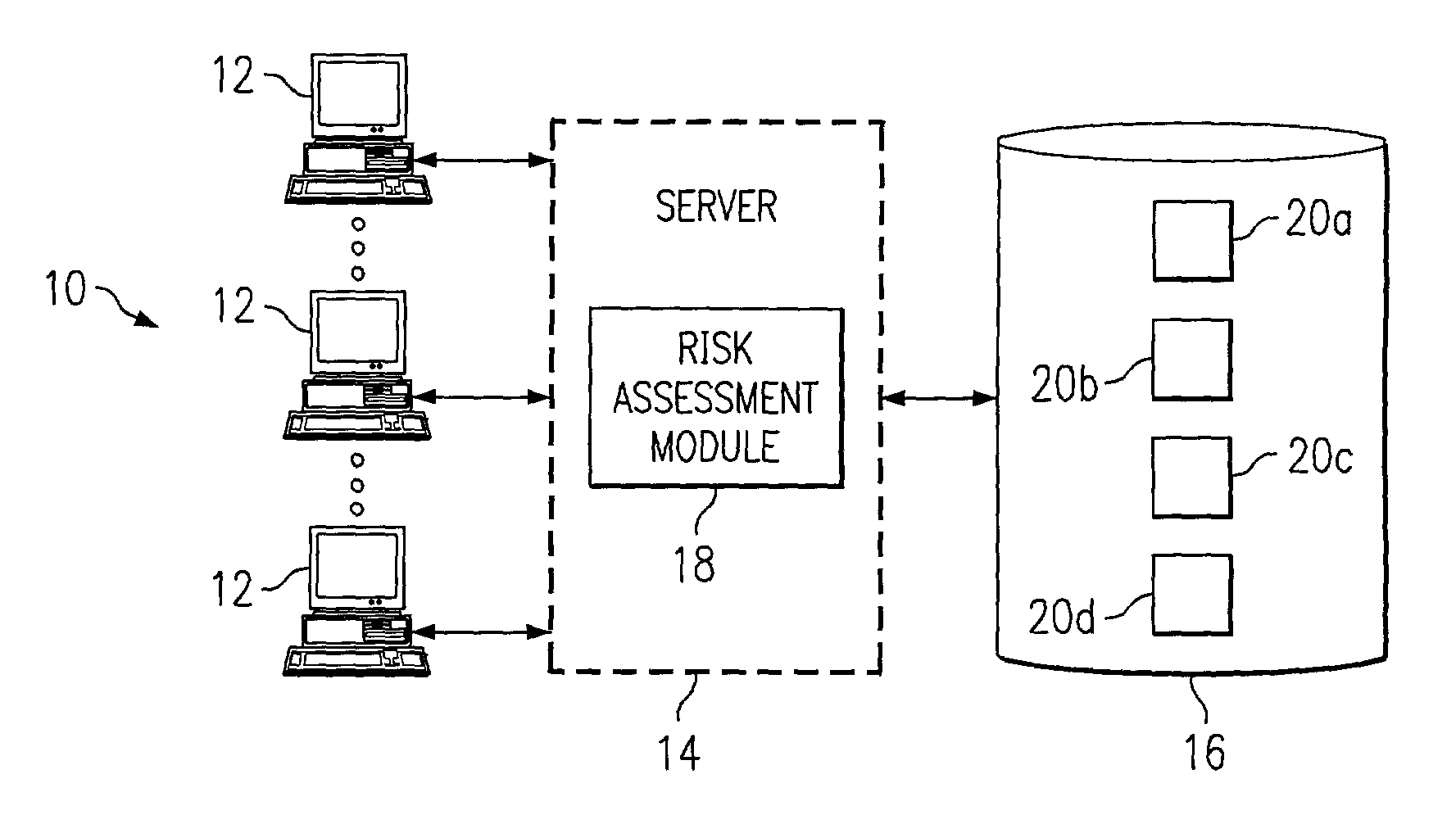

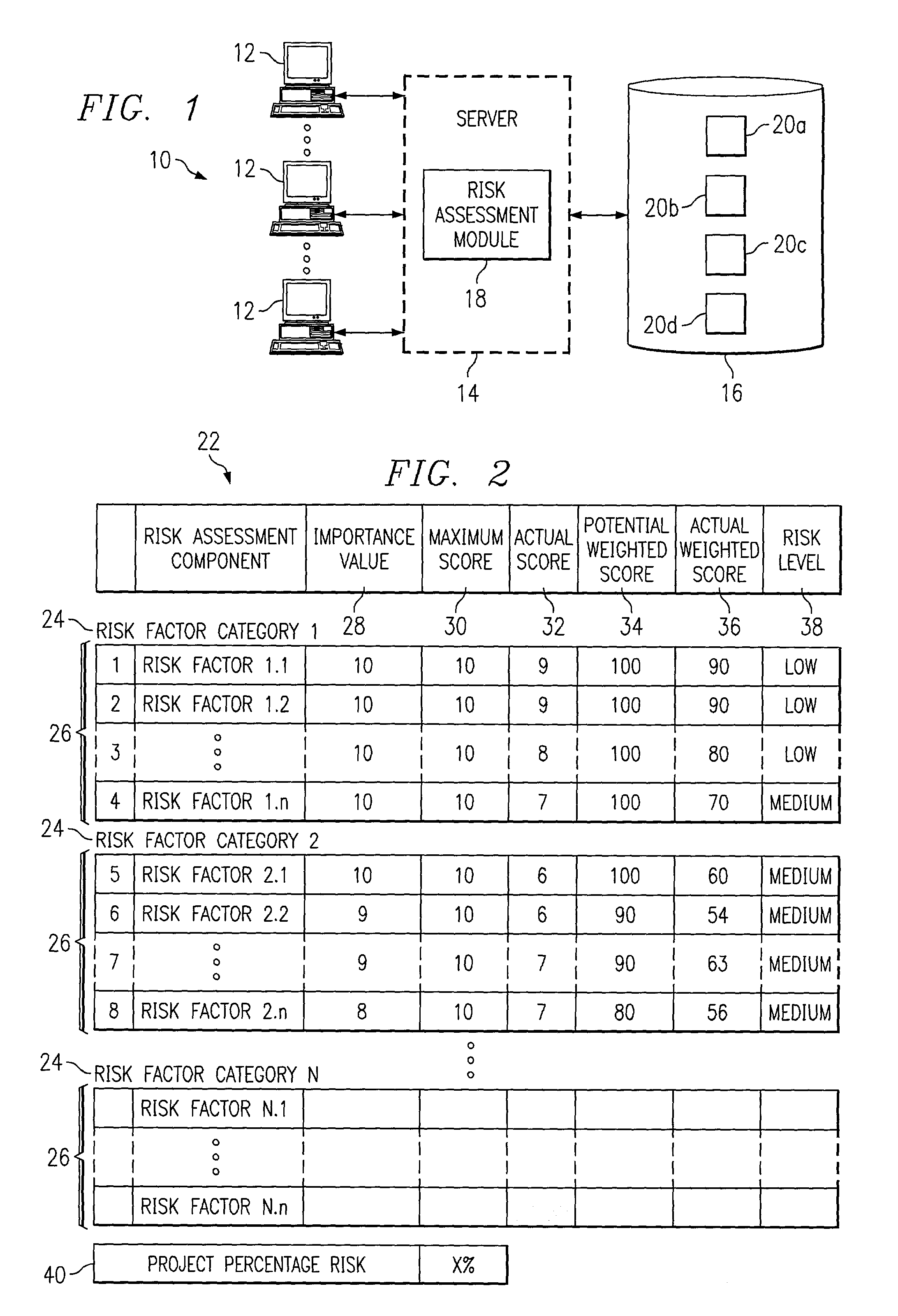

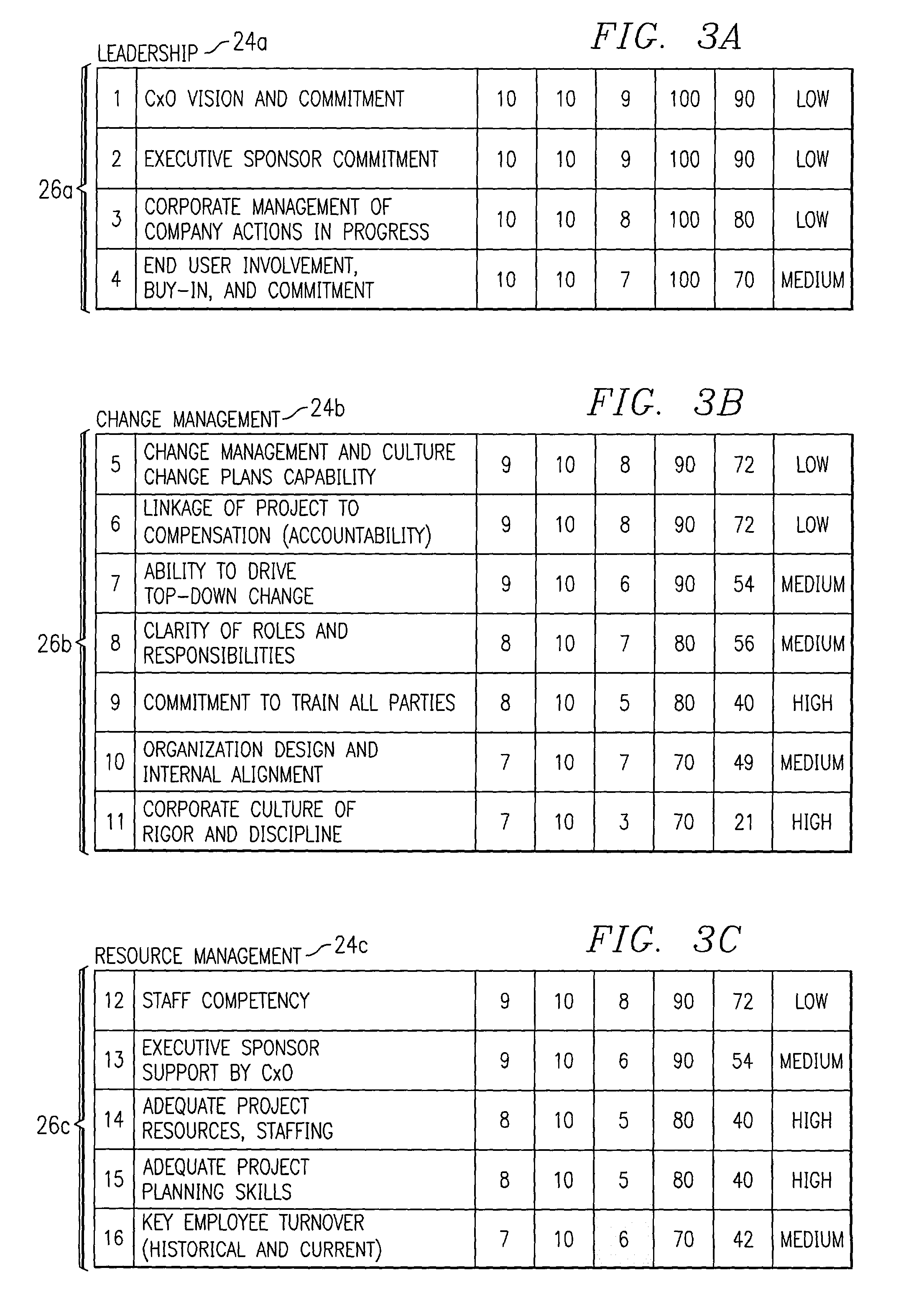

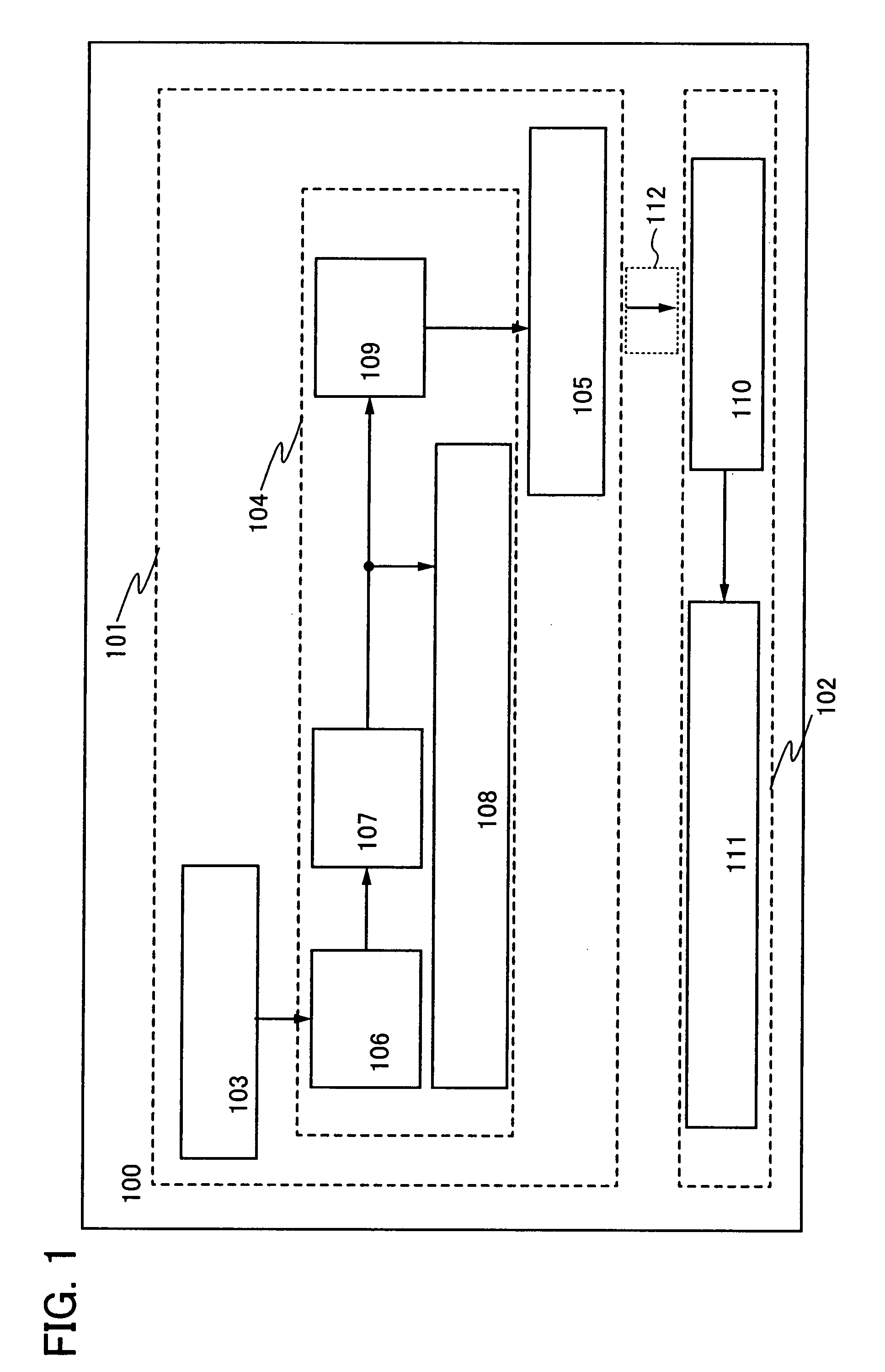

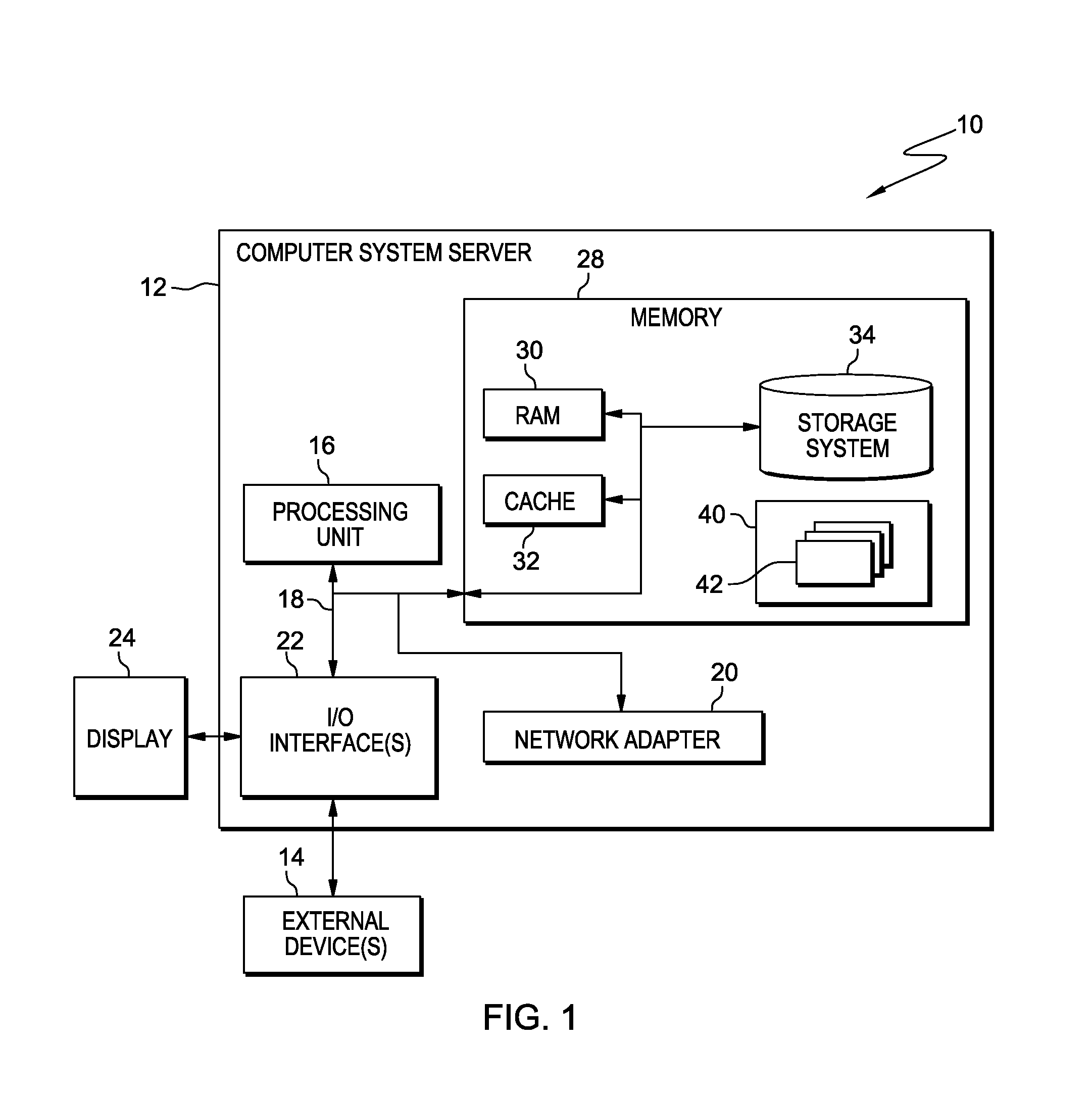

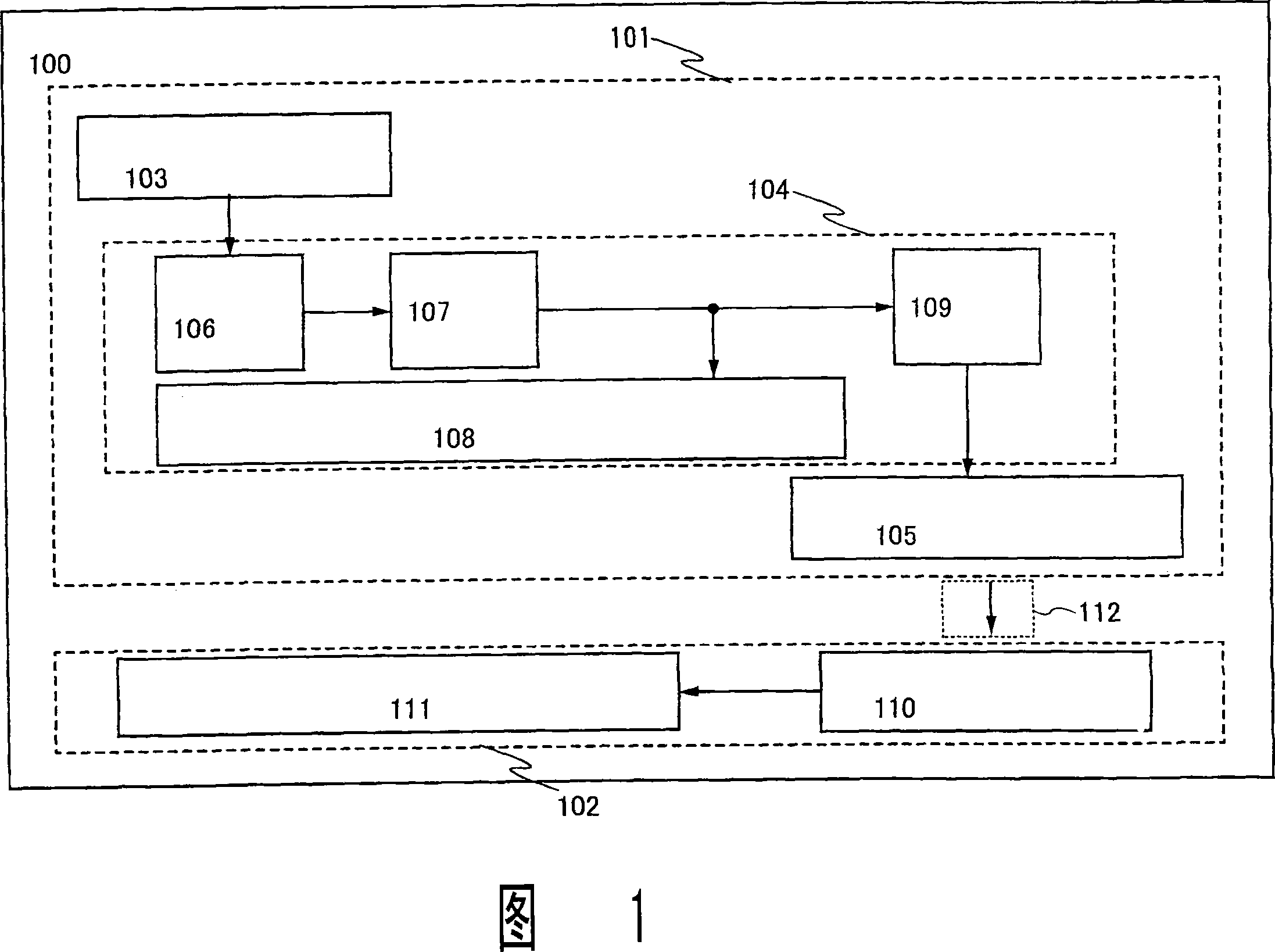

Generating a risk assessment regarding a software implementation project

InactiveUS7359865B1Disadvantages can be reduced eliminatedImplementation be reduced eliminatedFinanceResourcesRisk levelItem generation

A computer-implemented method for generating a risk assessment regarding a software implementation project includes accessing a previously specified importance value and maximum score for each of a multiple of risk factors. The importance value for each risk factor reflects experience of an implementing entity regarding the extent to which the factor may negatively impact a software implementation project if the factor is not adequately addressed, the importance value and maximum score for each factor being multiplied to define a potential weighted score for the factor. An actual score for a particular software implementation project is received for each factor based on an analysis specific to the particular project. An actual weighted score for the particular project is generated for each factor by multiplying the importance value and actual score for the factor, and a relationship between the potential weighted score and actual weighted score for each factor. A risk level for the particular project is assigned to each factor according to the relationship between the potential weighted score and the actual weighted score for the factor. The risk level for each factor represents an assessment regarding the extent to which the factor may negatively impact the particular project if the factor is not adequately addressed. A risk assessment is generated for the particular project including one or more of the assigned risk levels for the particular project for one or more corresponding factors.

Owner:BLUE YONDER GRP INC

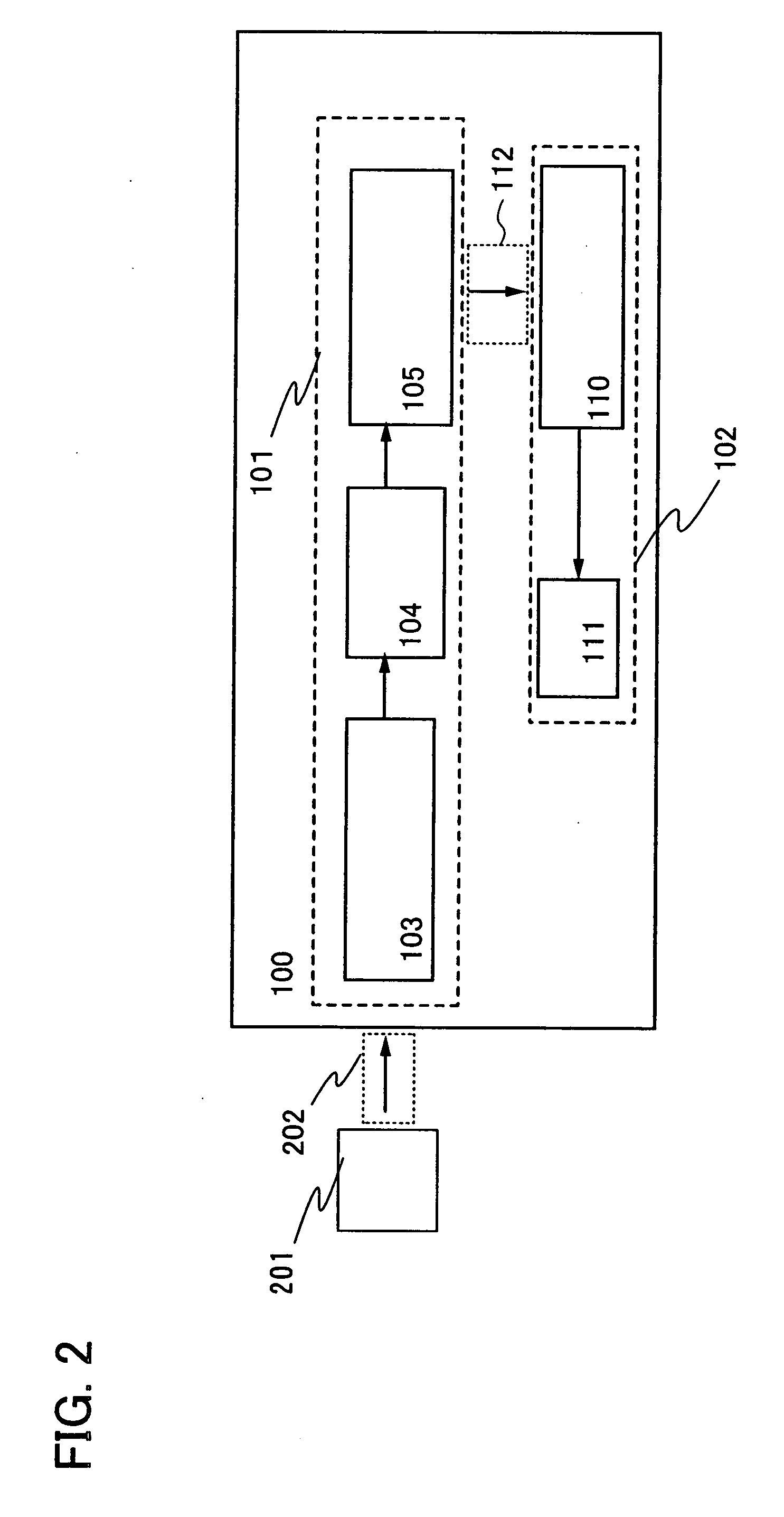

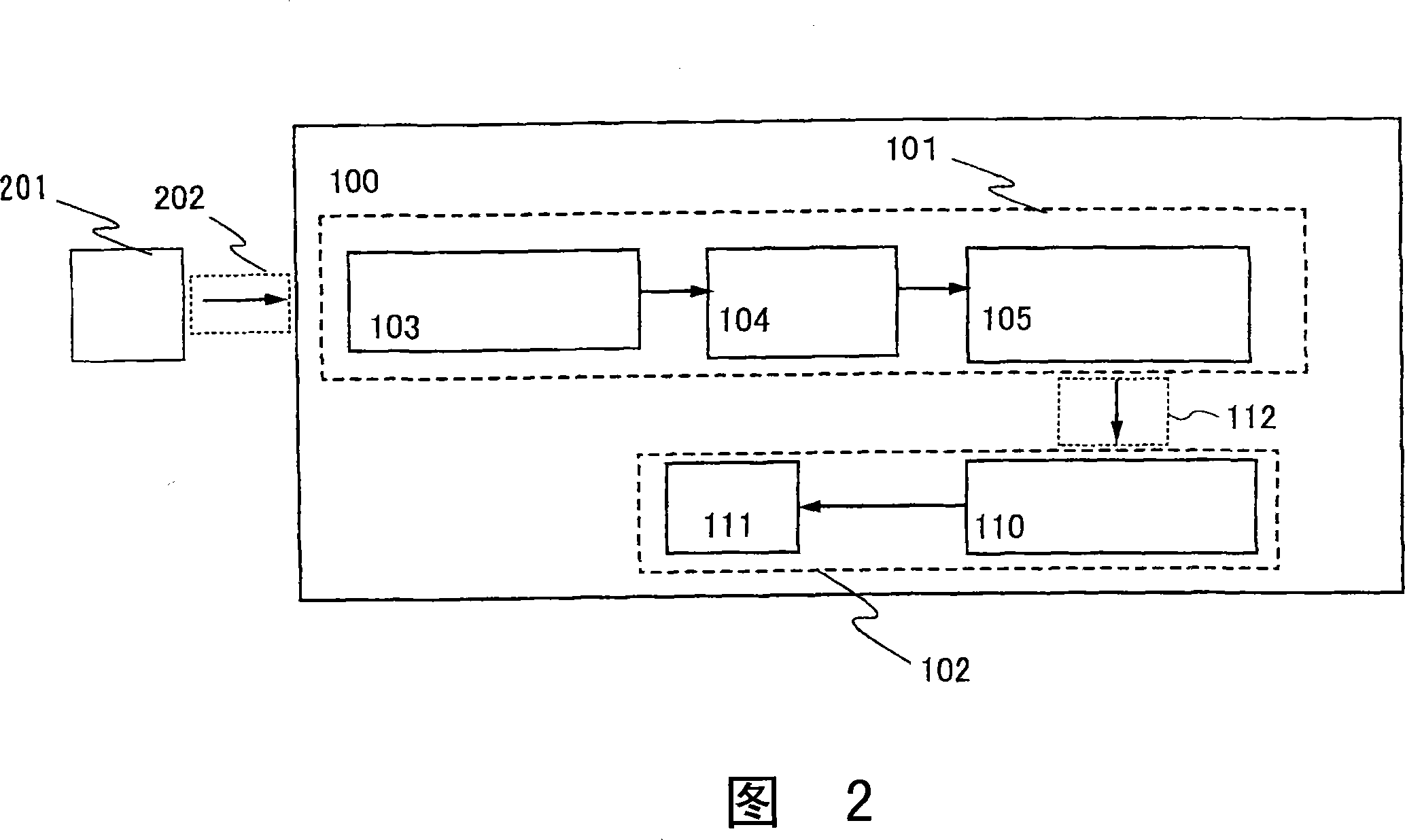

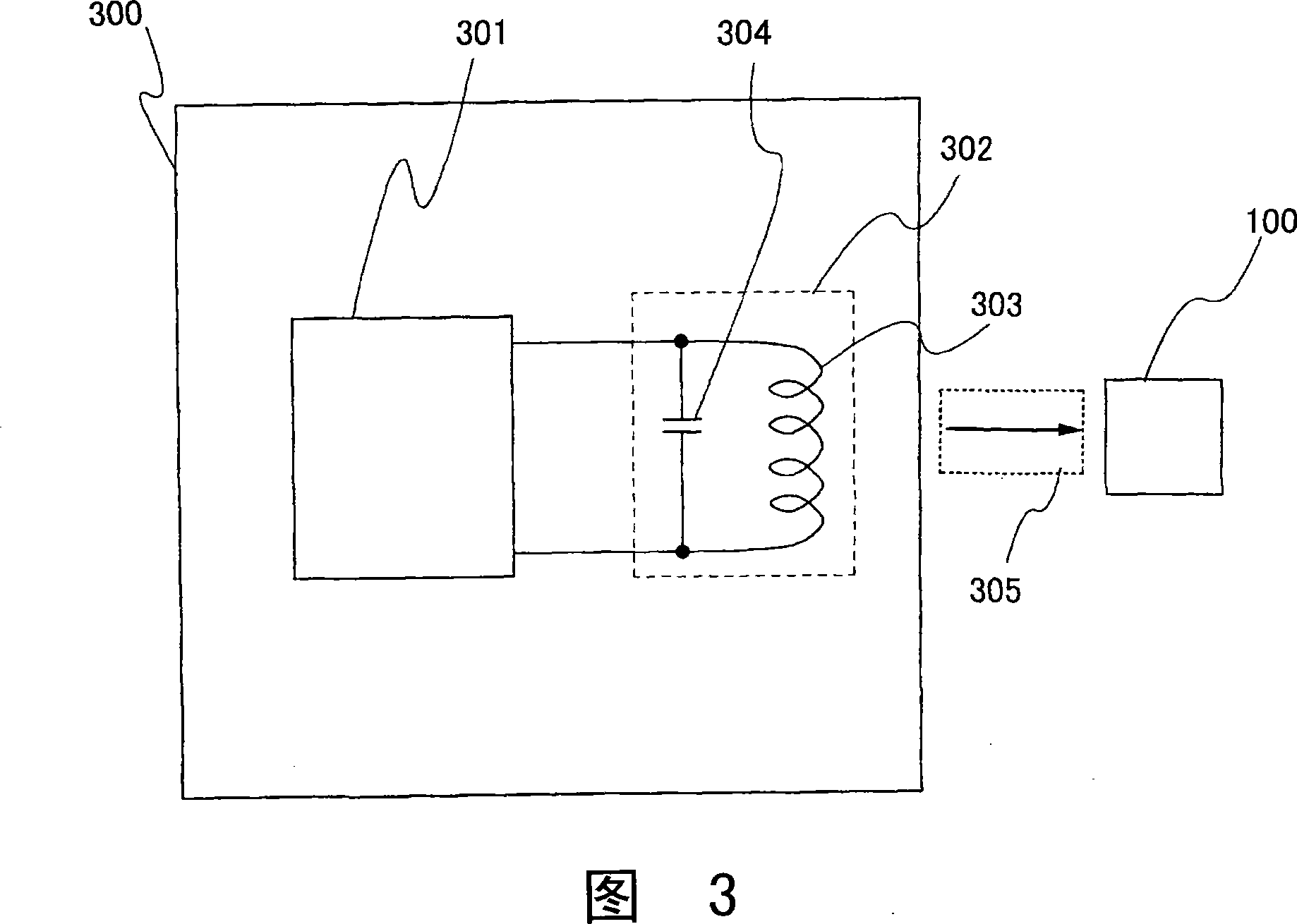

Wireless power receiving device

ActiveUS20090308933A1Low costLow production costBatteries circuit arrangementsAntenna supports/mountingsElectric power transmissionElectricity

To provide a wireless power receiving device and an electronic device having the wireless power receiving device whose production costs do not increase even when frequency of electromagnetic waves received for power supply varies. Further, to provide a wireless power receiving device capable of power transmission without disconnection or poor connection when a load supplied with electricity and a battery connected to an antenna are manufactured in different steps. A power transmitter and receiver portion having first and second antenna circuits and a battery portion and a load portion having a third antenna circuit are provided to charge a battery of the battery portion with a first radio signal received at the first antenna circuit and transmit electricity stored in the battery portion as a second radio signal from the second antenna circuit to the third antenna circuit so that the third antenna circuit supplies electricity to the load.

Owner:SEMICON ENERGY LAB CO LTD

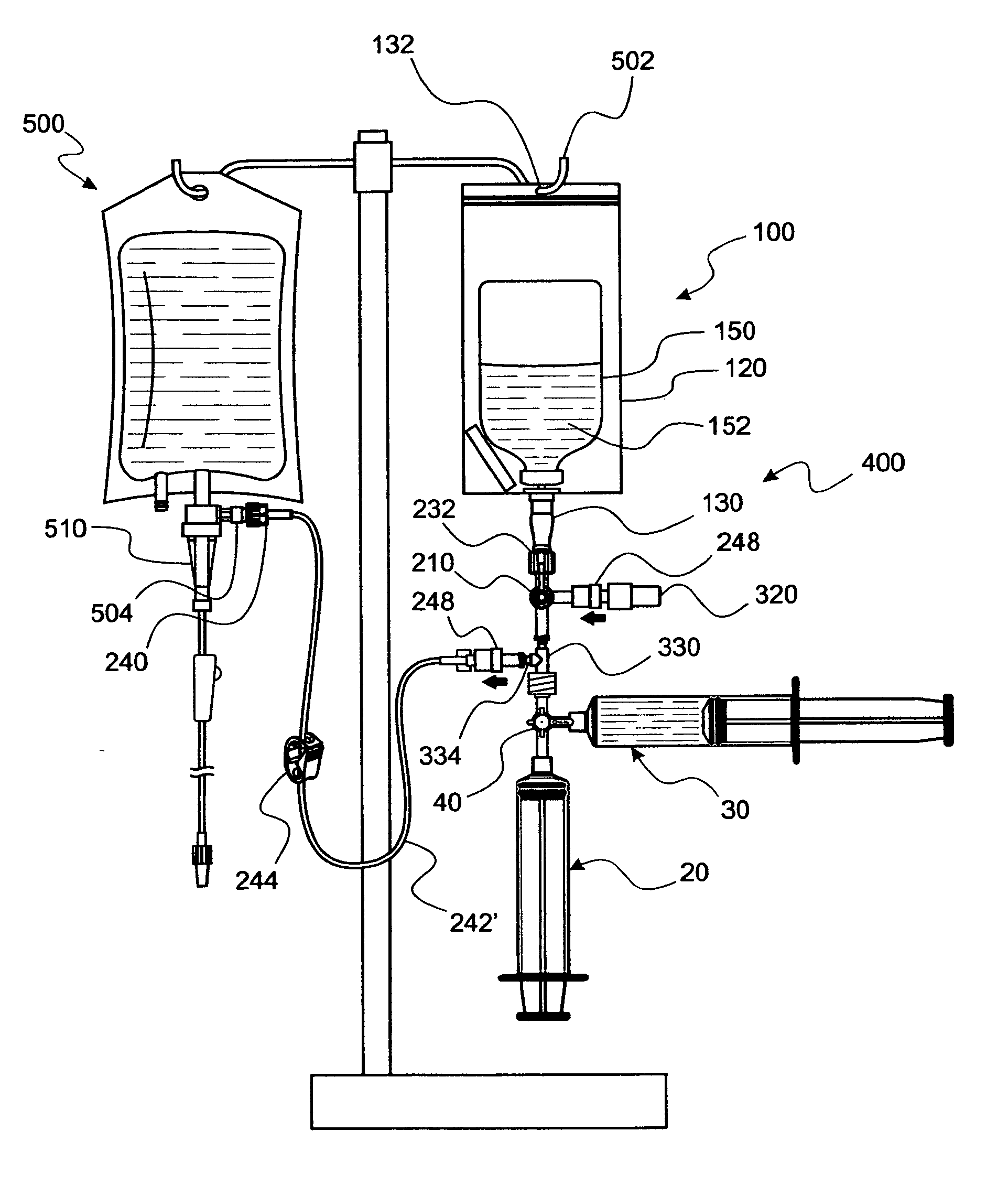

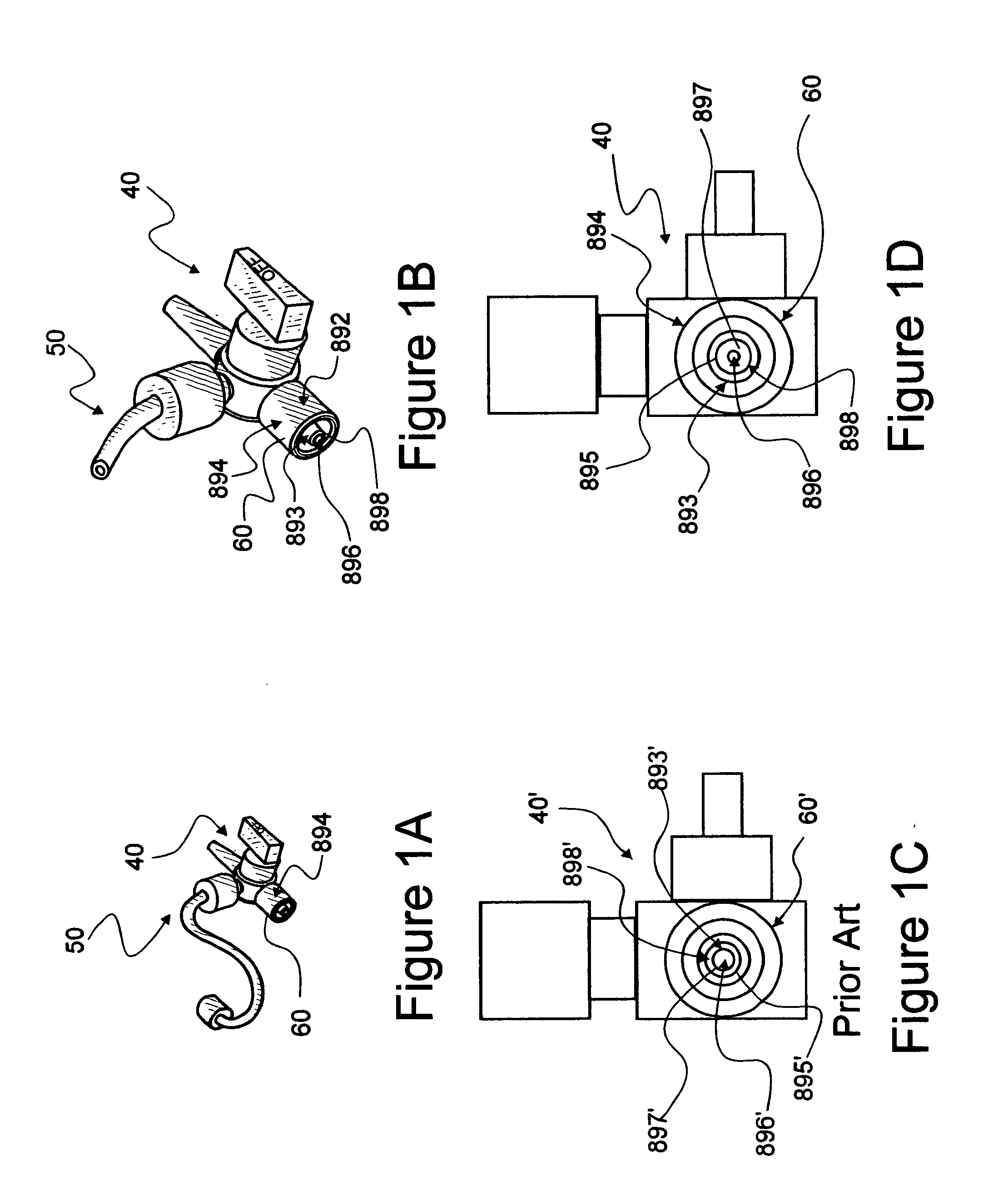

Vial transfer convenience IV kits and methods

InactiveUS20090306621A1Reduce disconnectionImprove securityInfusion devicesPharmaceutical containersEngineeringIntravenous therapy

Convenience kits designed to provide for closed, but selectable liquid transfer from a vial to a variety of IV containers and medical syringes. In particular, a kit for fully enclosing a vial for safety in hazardous drug transfer is disclosed. Generally, the kits contain unitized parts wherever reasonable to limit makes and breaks. Further, pathway determining kits provide selectable pathways for purging connections wish flushing solution where makes and breaks are made between various fluid pathway involved parts such that, when disconnections are made, flush solution is resident at the exposed interface. Also disclosed is a 3-way valve as part of a closed, switchable pathway controlling subsystem by which pathways are selected for reconstituting dry medicine in a vial, displacing a measured dose of liquid from a vial, exchanging gas into the vial for displaced liquid, delivering the measured dose to an IV container.

Owner:INTRAVENA

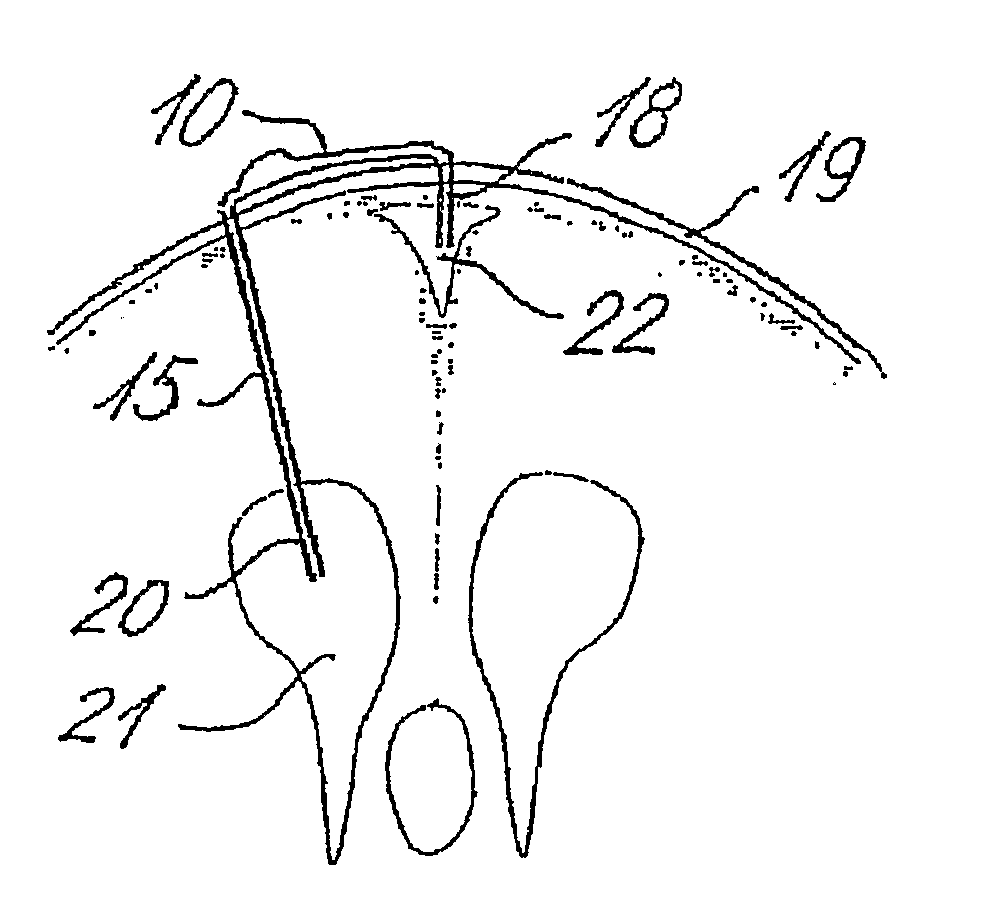

Shunt system with coating and flow restricting component exerting a passive and essentially constant resistance to outflow

InactiveUS20070112291A1Reduce as muchReduce infectionWound drainsFlow monitorsCsf shuntBrain Ventricle

The present invention relates to an improved cerebrospinal fluid shunt system comprising a coating covering at least part of the system and a flow restricting component exerting a passive and essentially constant resistance to flow. The present invention also relates to methods for implanting different catheters of a cerebrospinal fluid shunt system into a brain ventricle and the sinus system, respectively, of an individual. The present invention further relates to methods for shunting cerebrospinal fluid from a brain ventricle to the sinus system of an individual.

Owner:SINU SHUNT

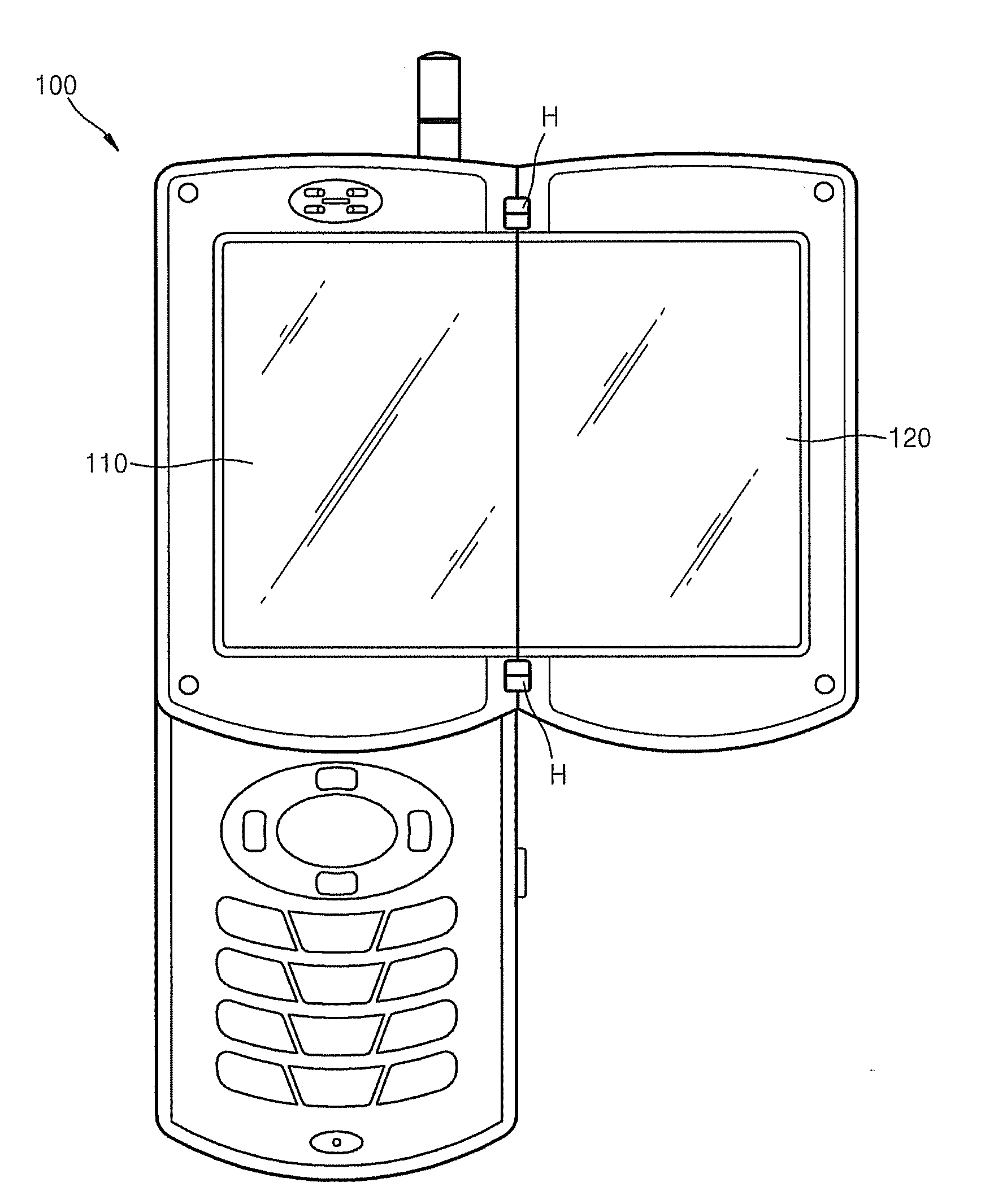

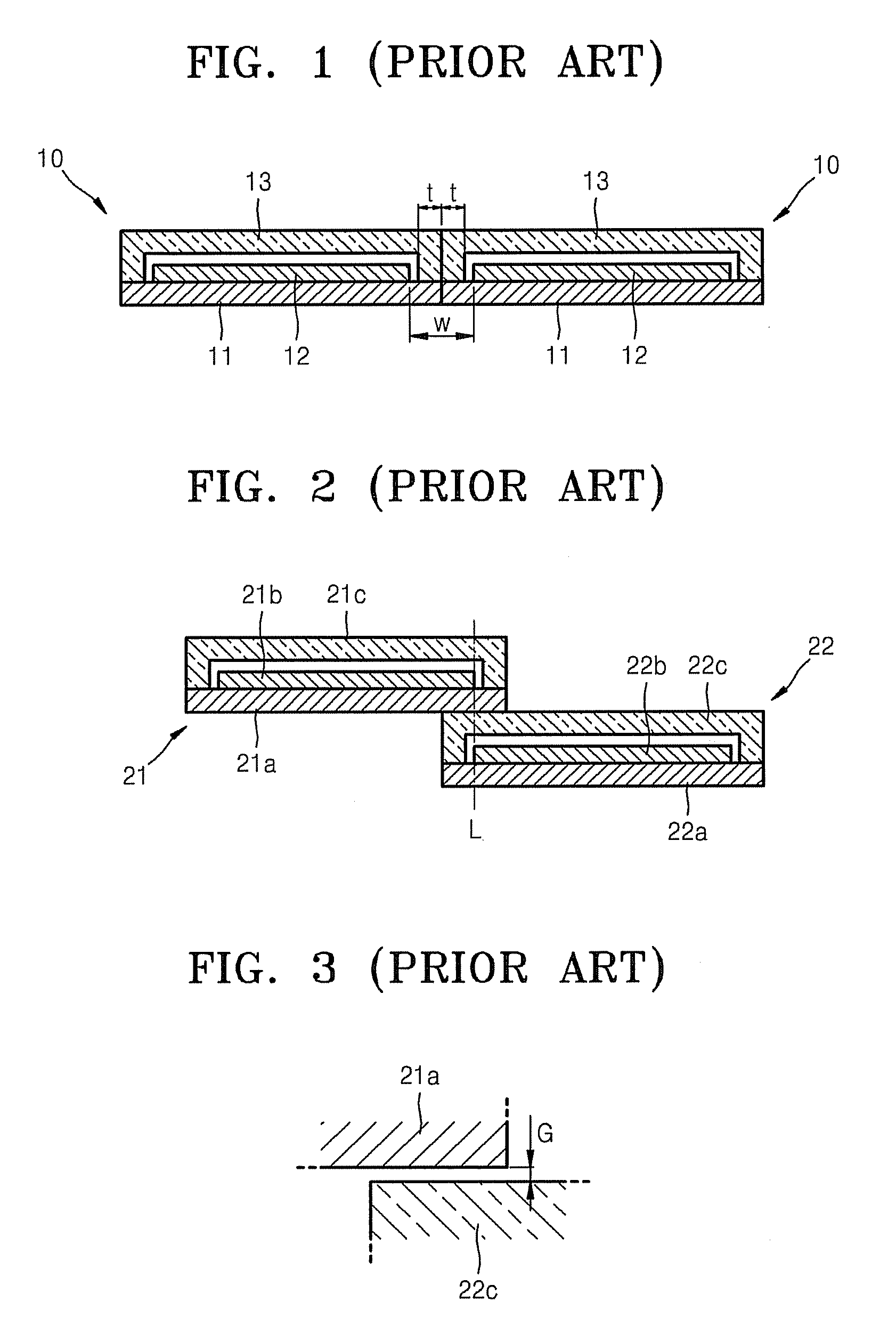

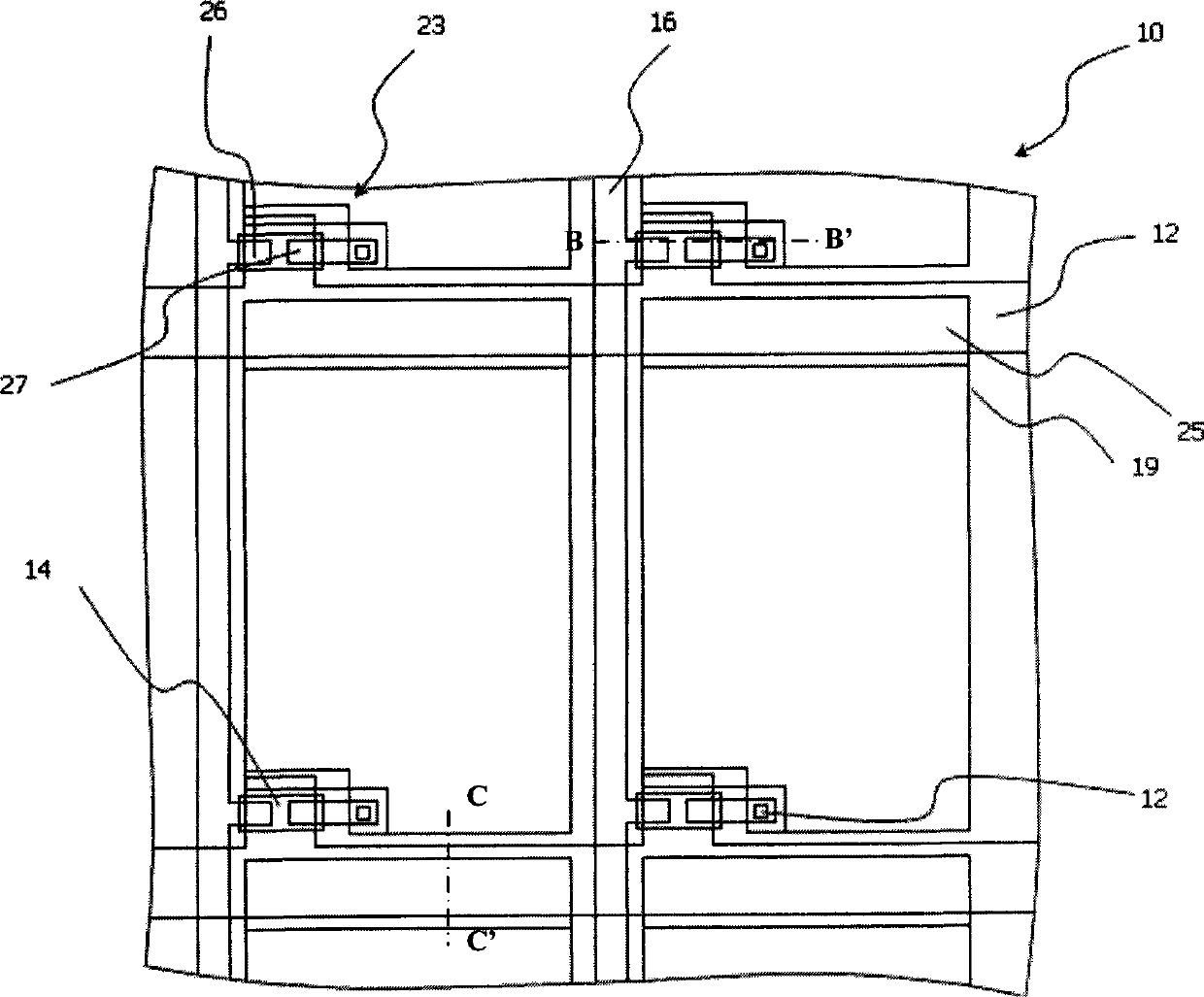

Multi-display apparatus and method thereof

InactiveUS20080224949A1Reduce the differenceReduce disconnectionSolid-state devicesCathode-ray tube indicatorsEngineeringSurface plate

A multi-display apparatus includes two panels disposed with a step difference so that pixel boundaries of display devices formed on substrates overlap, and at least one of the two panels includes a thin film encapsulation layer covering the display device and disposed on an adjacent surface of one of the two panels where there is the step difference to improve a disconnection of an image at a seam between the two panels, and mitigate a perspective difference of the image at the seam due to the step difference between the two panels, thereby realizing a large natural and smooth image.

Owner:SAMSUNG ELECTRONICS CO LTD

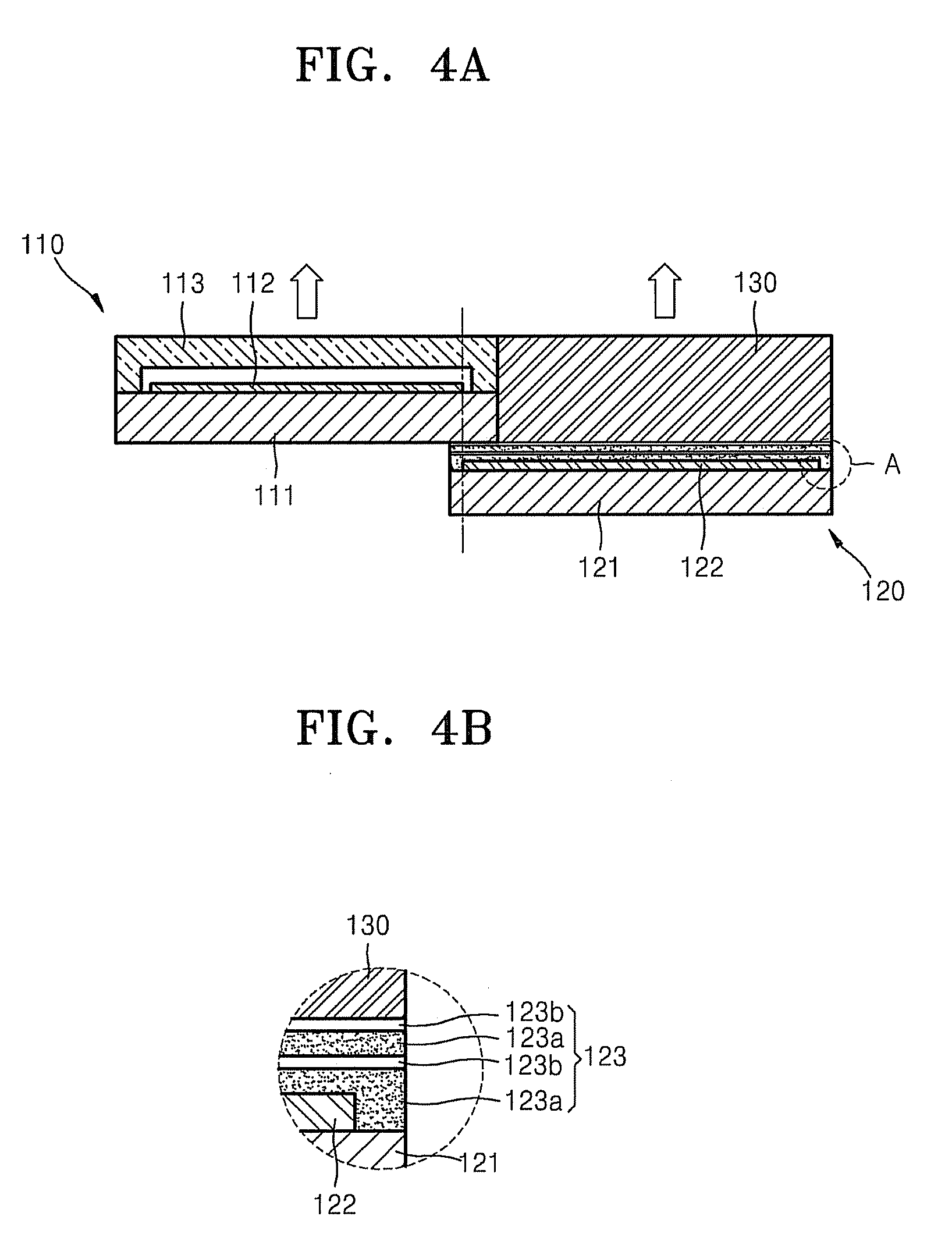

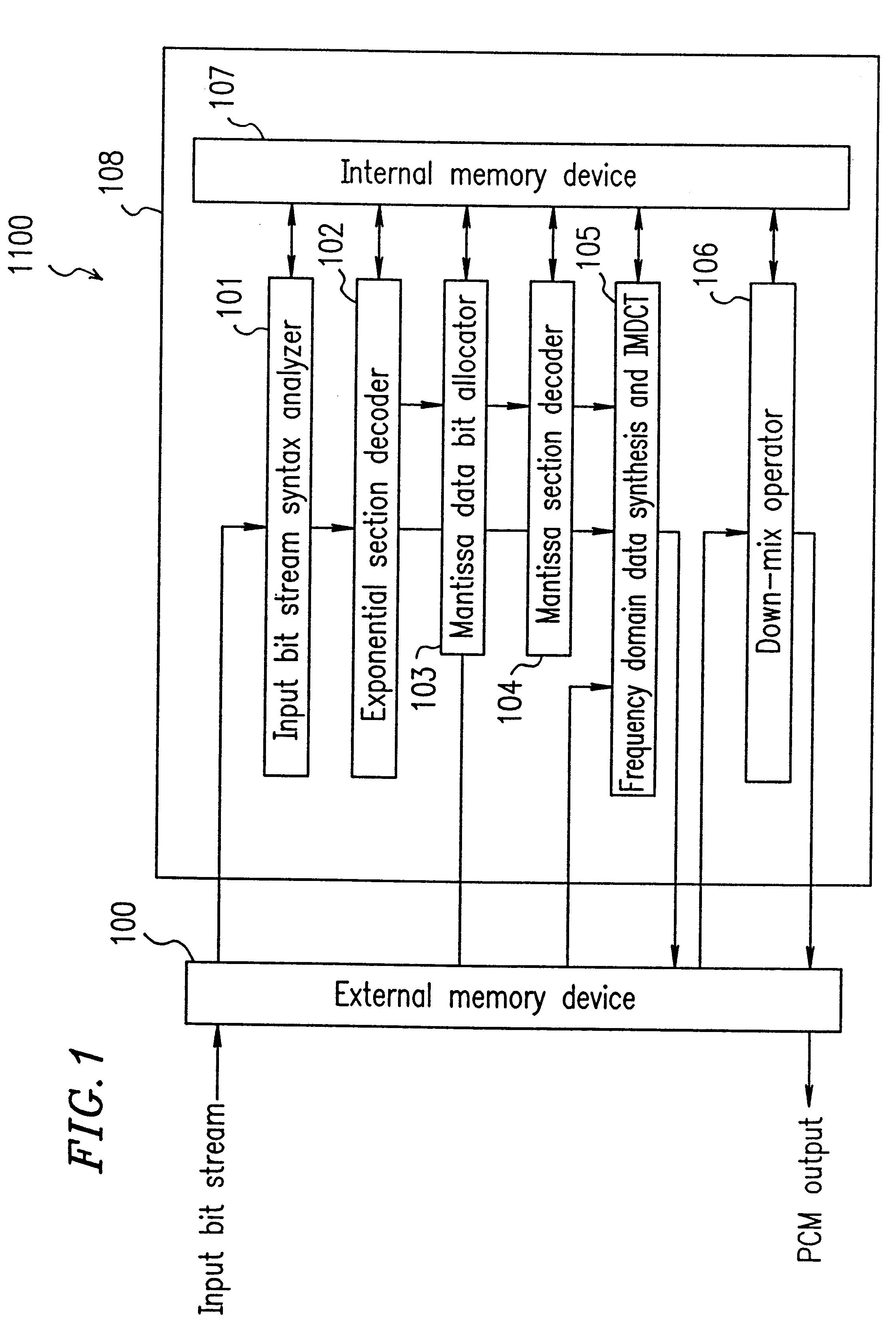

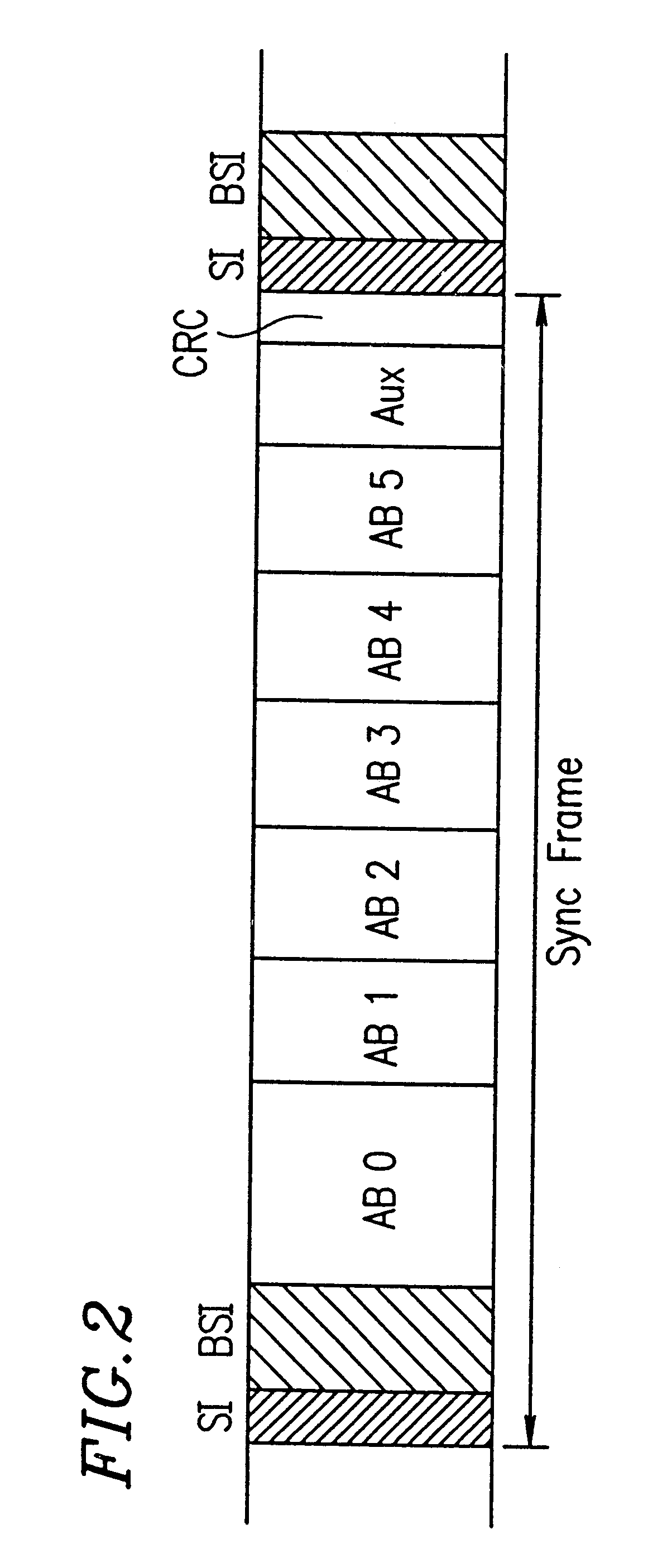

Audio decoding apparatus, signal processing device, sound image localization device, sound image control method, audio signal processing device, and audio signal high-rate reproduction method used for audio visual equipment

InactiveUS6356639B1Easy to useAlleviating decoding processingTelevision system detailsPulse modulation television signal transmissionHigh rateSound image

A sound image localization device which includes a signal source for outputting an audio signal, a signal divider for dividing the audio signal output from the signal source into two digital audio signals respectively for two channels, and a first signal processor for receiving one of the two digital signals and processing the digital signal so as to localize a virtual sound image using a filter having a first frequency characteristic. In addition, the sound image localization device includes a first D / A converter for converting the digital signal output from the first signal processor into an analog signal, a second D / A converter for receiving the other digital signal obtained from the signal divider and converting the signal into an analog signal, a first control speaker for outputting the audio signal obtained by the first D / A converter to a prescribed space area; and a second control speaker for outputting the audio signal obtained by the second D / A converter to a prescribed space area.

Owner:PANASONIC CORP

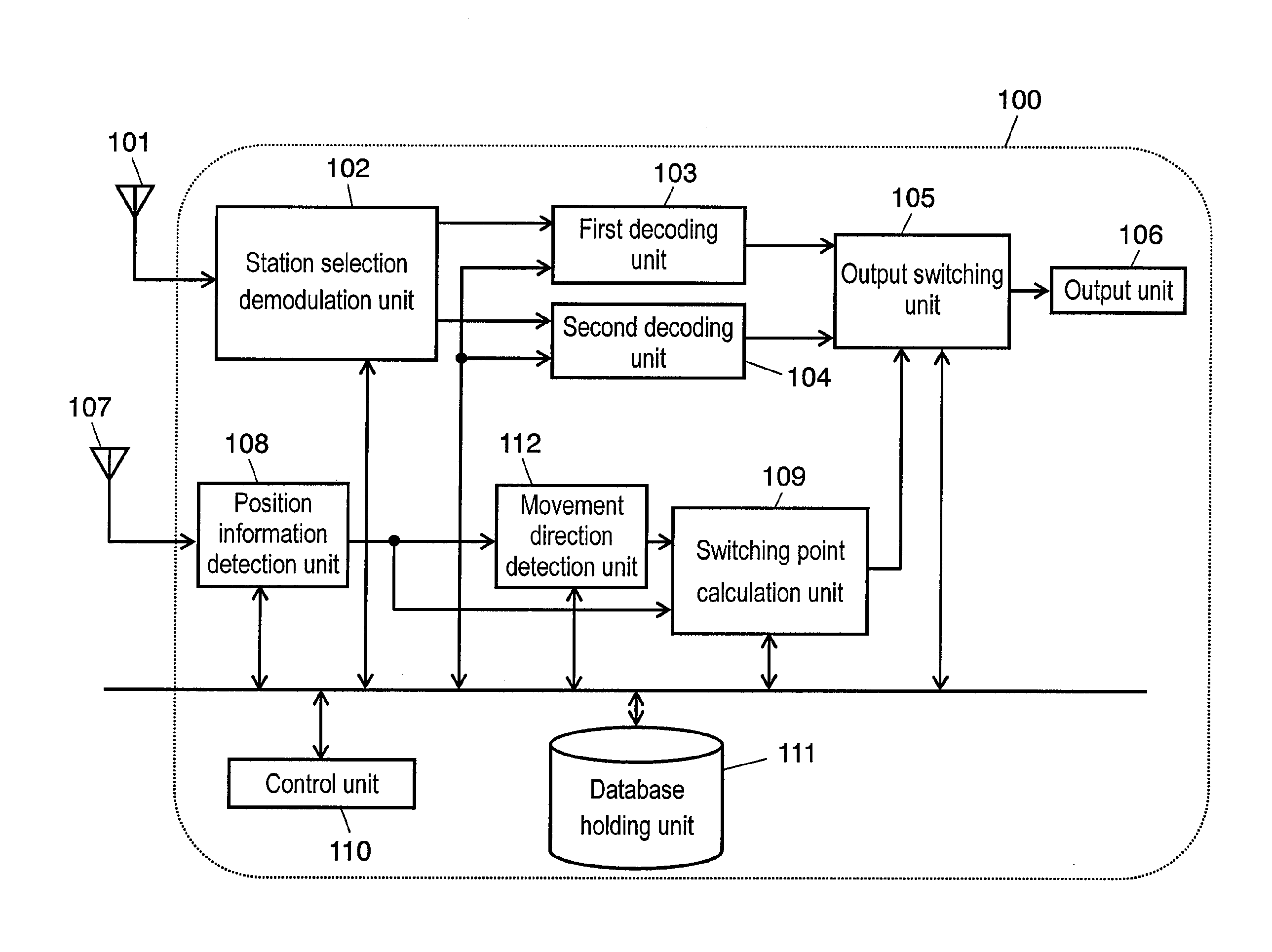

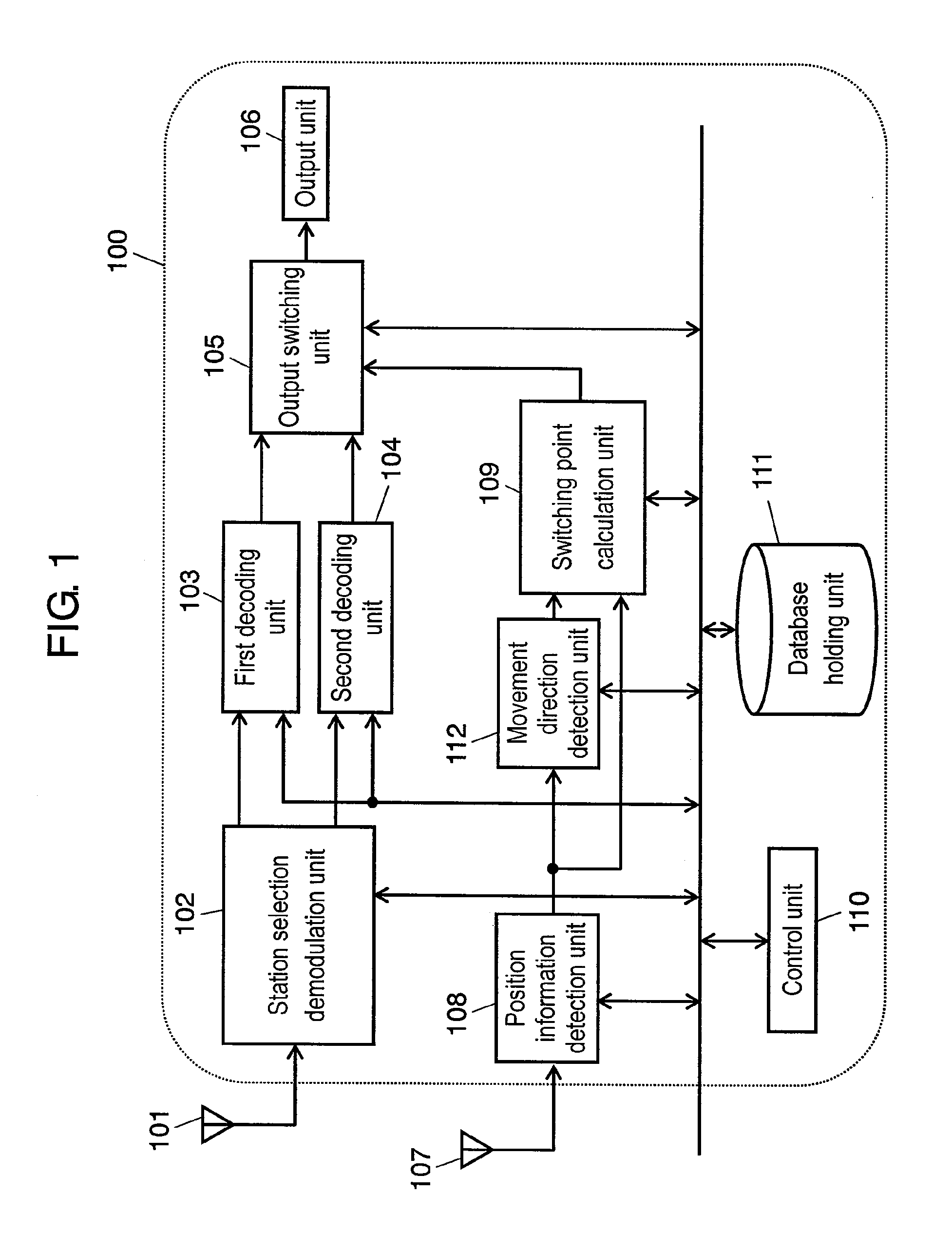

Digital broadcast reception device

InactiveUS20100220818A1Reduce switchingReduce generationTelevision system detailsSpatial transmit diversitySwitching frequencyDigital broadcasting

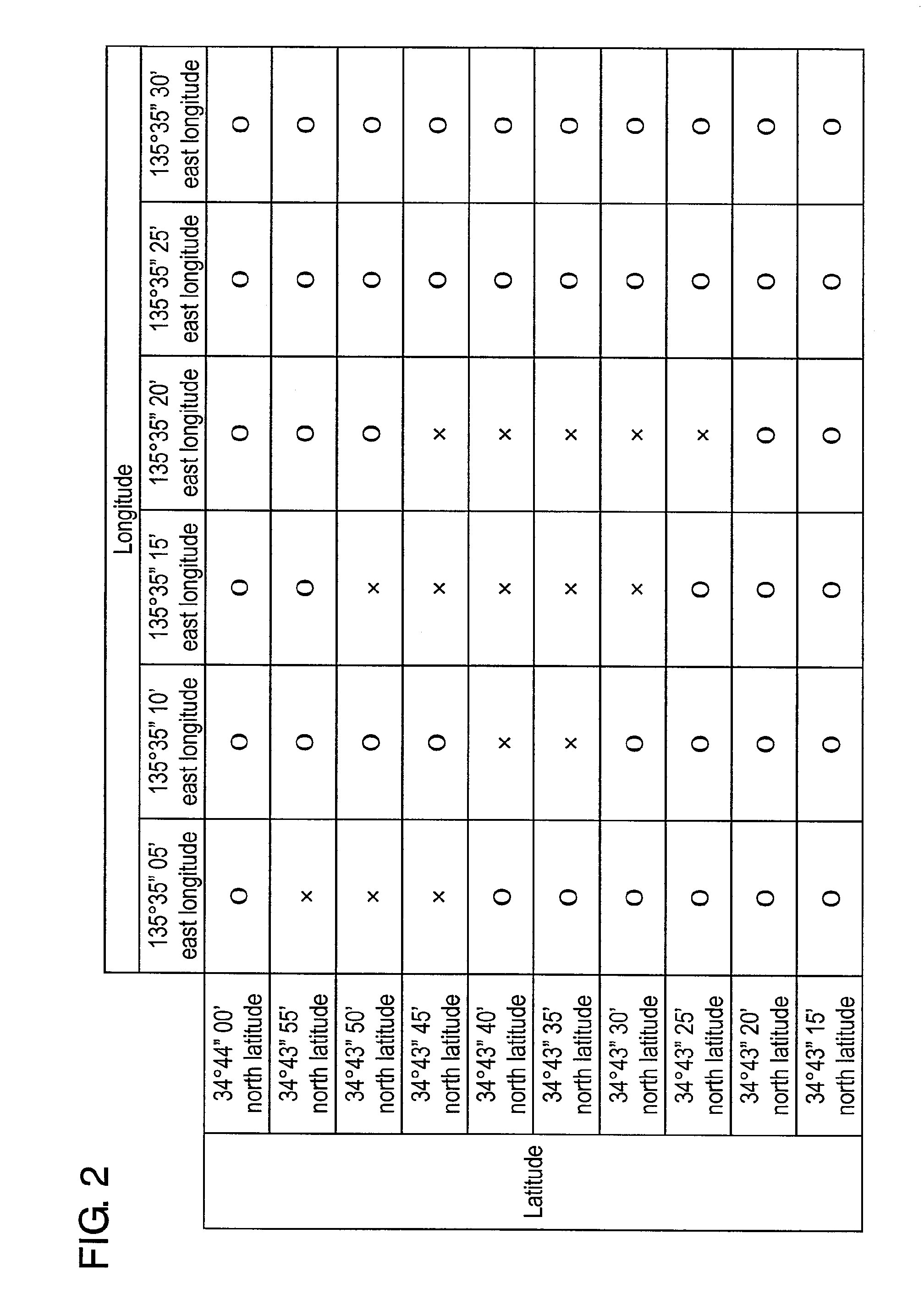

A digital broadcast reception device mounted on a mobile body includes a position information detection unit for detecting the position of the digital broadcast reception device, a database holding unit for storing reception quality of the digital broadcast in advance, a switching point calculation unit for obtaining a hierarchy switching point, and output switching unit for performing a hierarchy switching. The digital broadcast reception device acquires the hierarchy switching frequency generated during movement in advance based on reception quality information previously stored in the database holding unit, and controls the hierarchy switching so as to reduce the switching frequency, thereby reducing disconnections of video and audio.

Owner:PANASONIC CORP

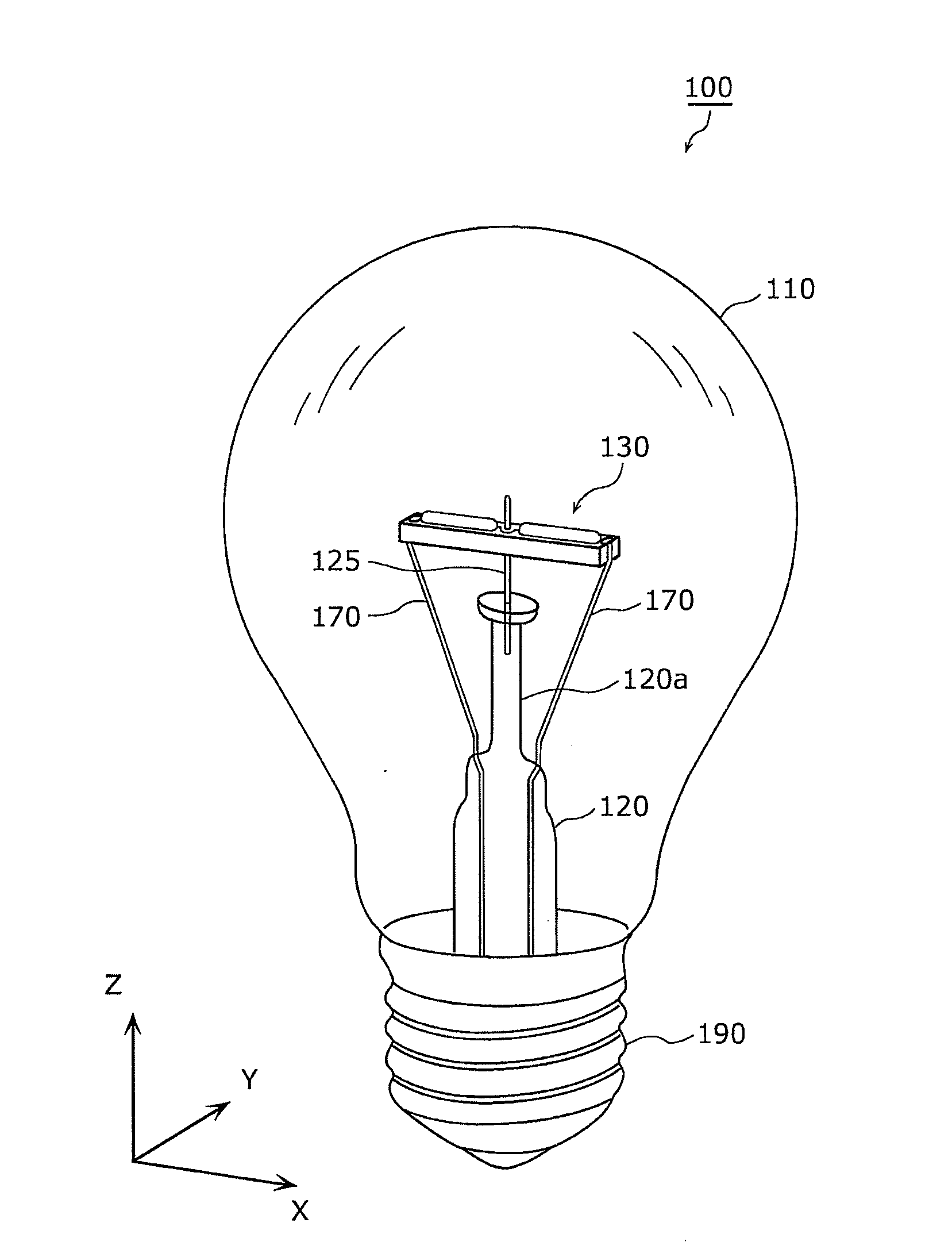

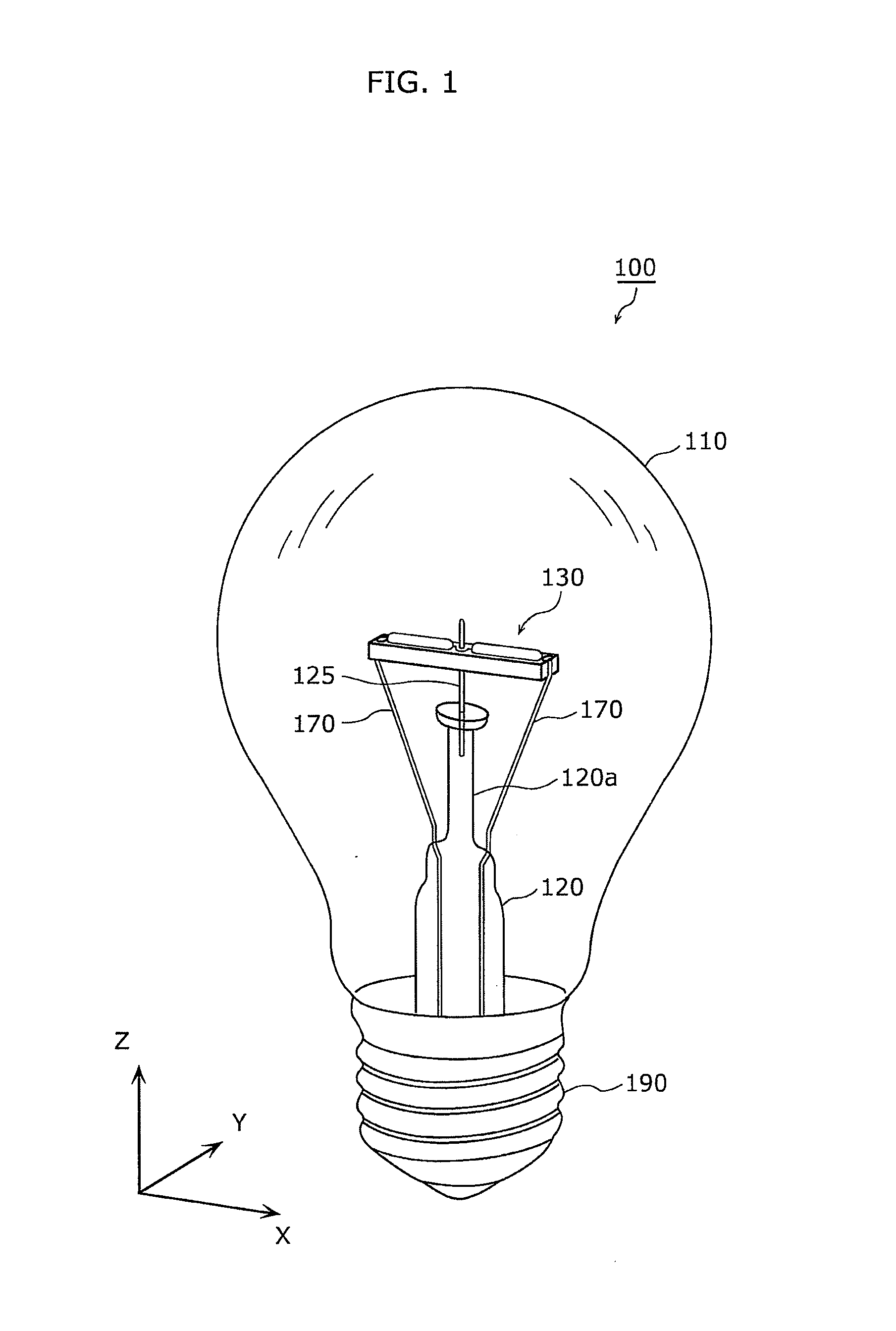

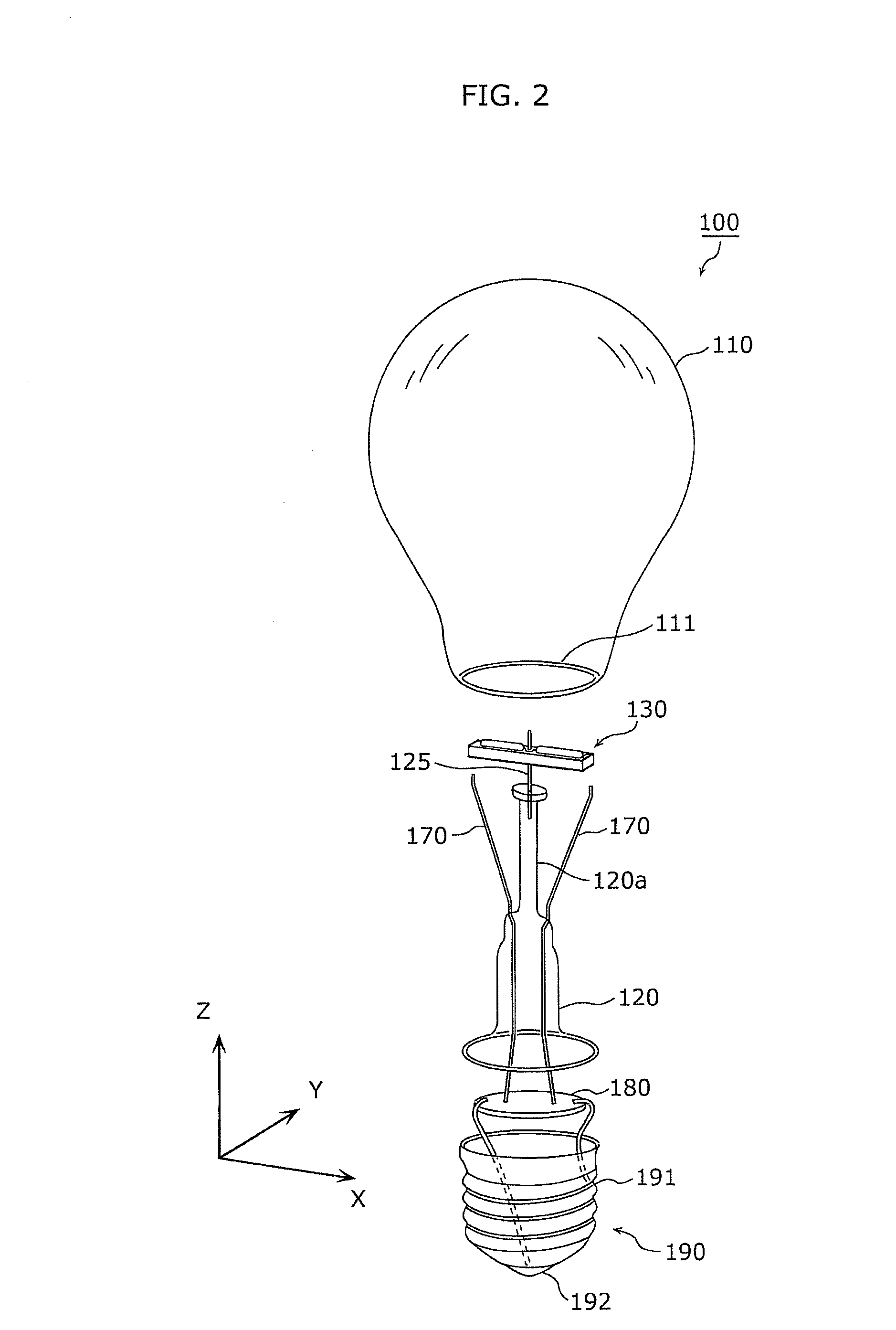

Light bulb shaped lamp and lighting apparatus

InactiveUS20130155683A1Reduce disconnectionPlanar light sourcesNon-electric lightingLight equipmentEffect light

A light bulb shaped lamp includes: a hollow globe having an opening; an LED module having a base platform and an LED chip mounted on the base platform, the LED module being housed in the globe; a stem extending from the opening of the globe to the vicinity of the LED module; and a regulating component which regulates movement of the LED module with respect to the stem.

Owner:PANASONIC CORP

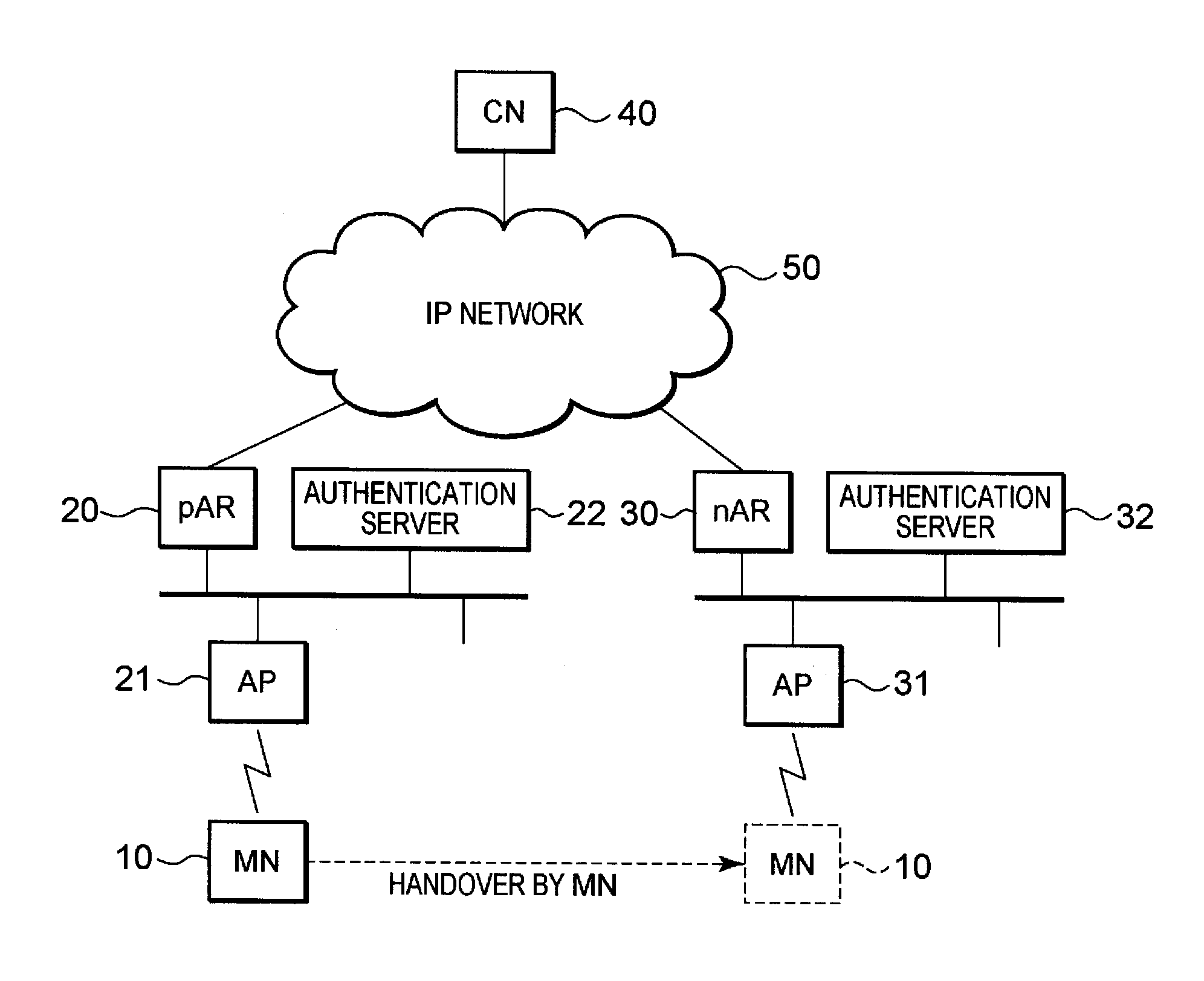

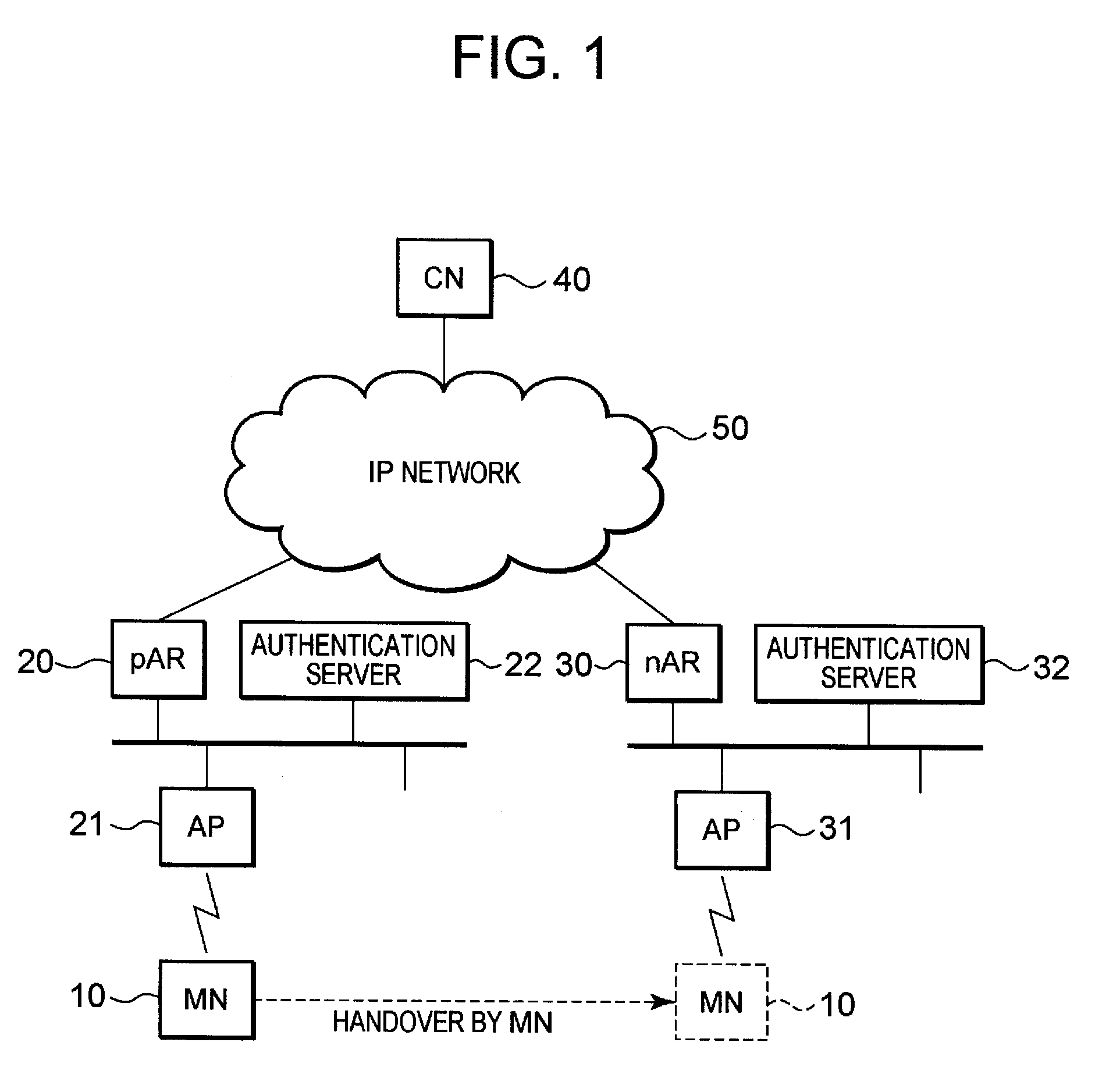

Communication handover method, communication message processing method, and communication control method

InactiveUS20090172391A1Fast securityReduce the possibilityDigital data processing detailsUser identity/authority verificationMessage processingCommunication control

There is disclosed a technique whereby, in a case wherein a mobile node (MN) performs a handover, between access points (APs) present on the links of different access routers (ARs), security is quickly established between the MN and the AP so as to reduce the possibility of a communication delay or disconnection due to the handover. According to this technique, before performing a handover, the MN 10 transmits, to an access router (nAR) 30 that is to be newly connected after the handover, a notification indicating an MAC address for the MN and a communication encryption / decryption key used with the AP 21 before the handover, and the nAR transmits a notification for this information to the AP 31, to which the MN is to be connected after the handover. Therefore, the MN can employ the communication encryption / decryption key used before the handover and communicate with the AP after the handover. Furthermore, by using a process associated with the FMIP, a notification indicating the MAC address of the MN and the communication encryption / decryption key can be transmitted to the nAR.

Owner:PANASONIC CORP

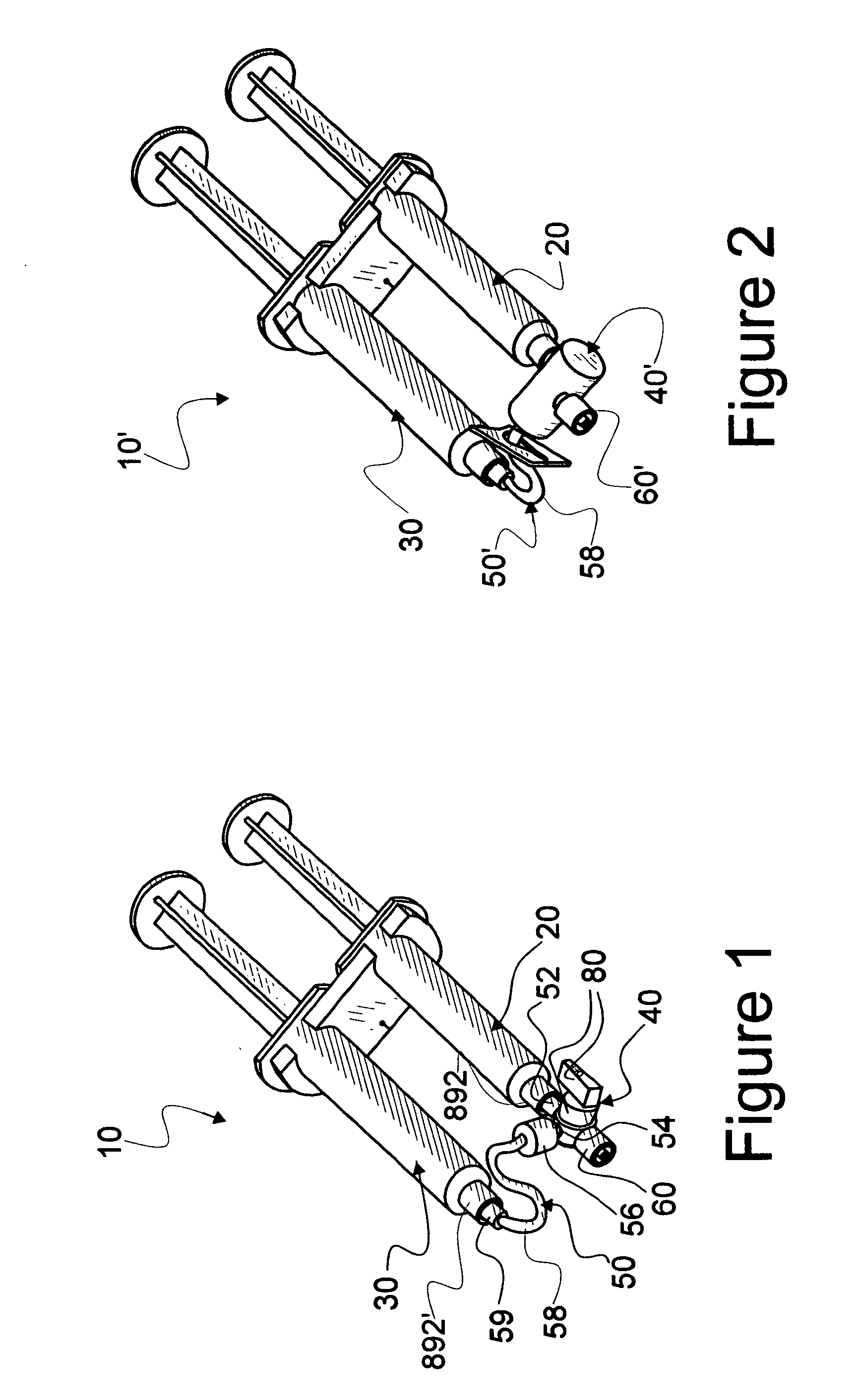

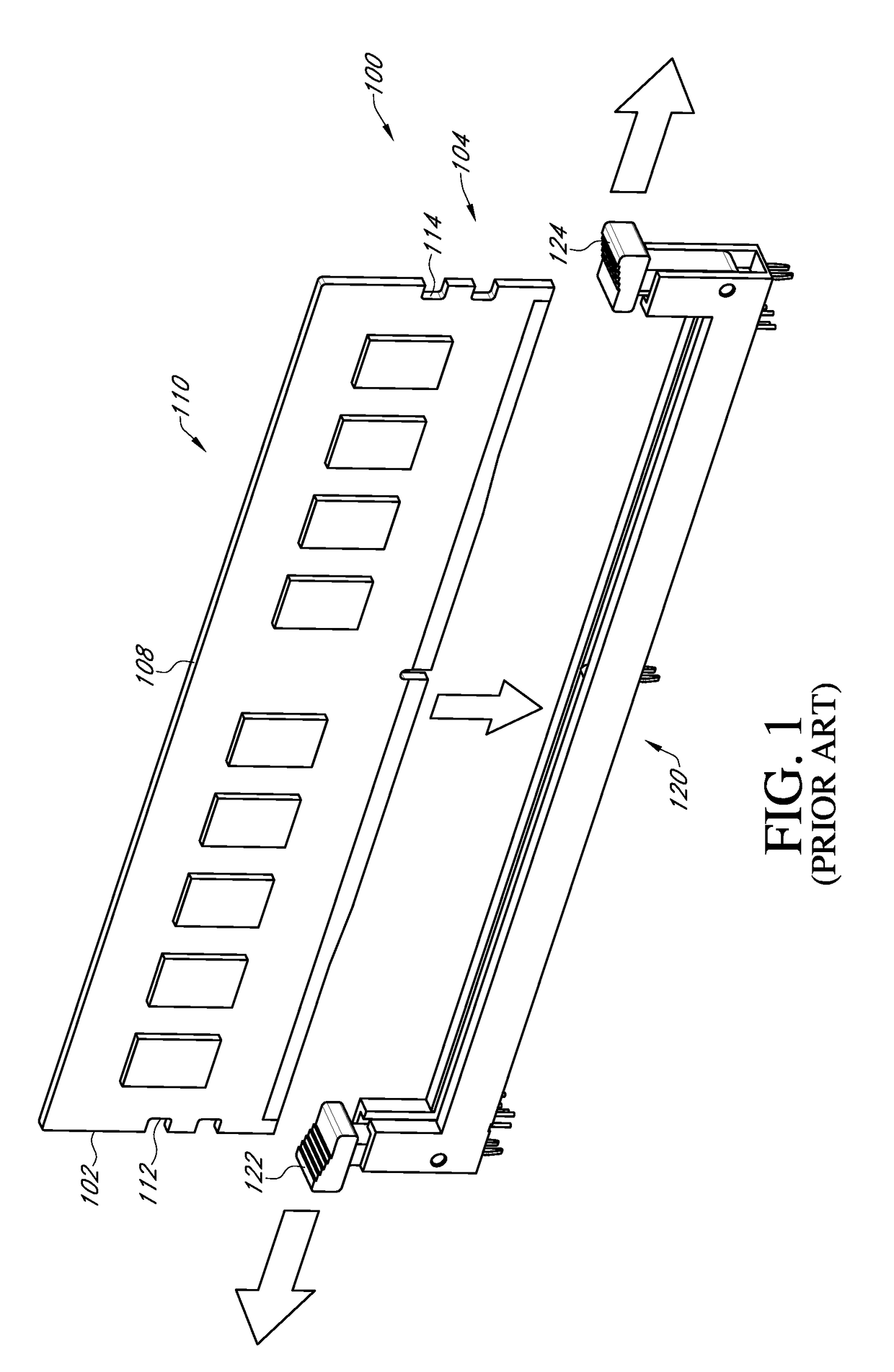

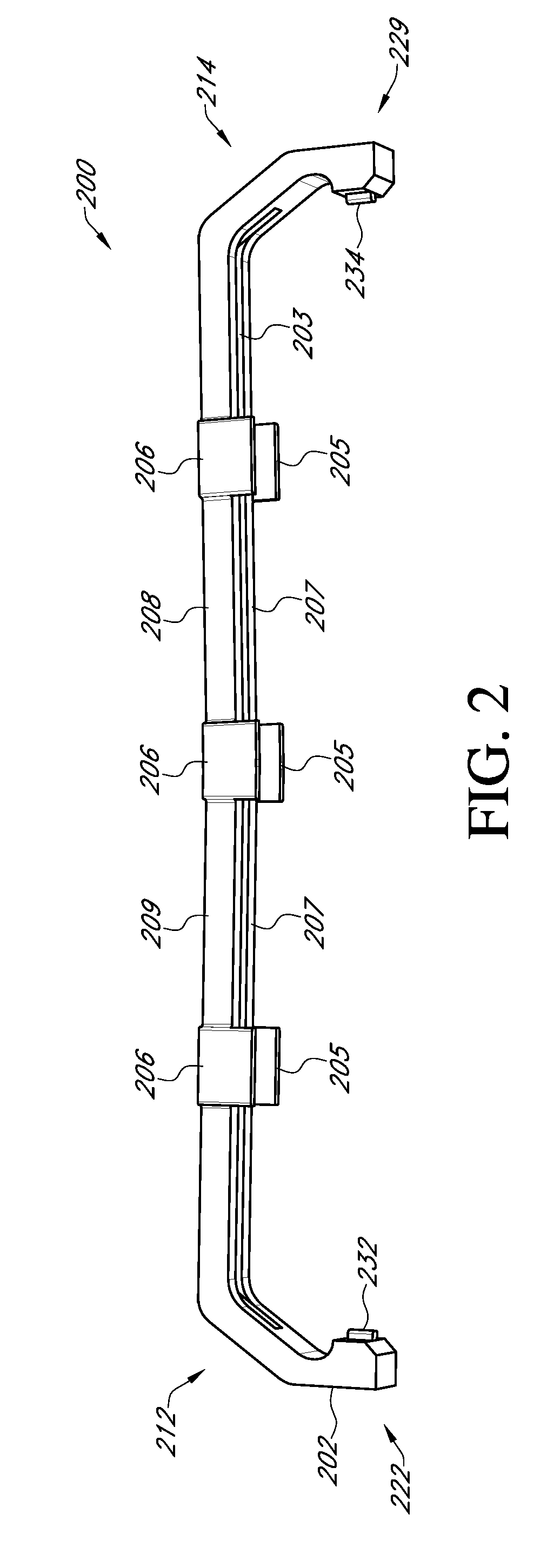

System and method for retaining memory modules

The present invention is an apparatus and method for allowing for the use of commercial dual inline memory module (DIMM) in high shock and vibration environments while preserving serviceability. This system extends the performance of the standard Joint Electron Device Engineering (JEDEC) memory connectors in said environments without sacrificing high speed electrical performance. The system provides a simple clip which locks the module in place using the standard connector latches preventing relative motion of the connector and the DIMM thereby insuring uninterrupted computational performance.

Owner:CRYSTAL GROUP

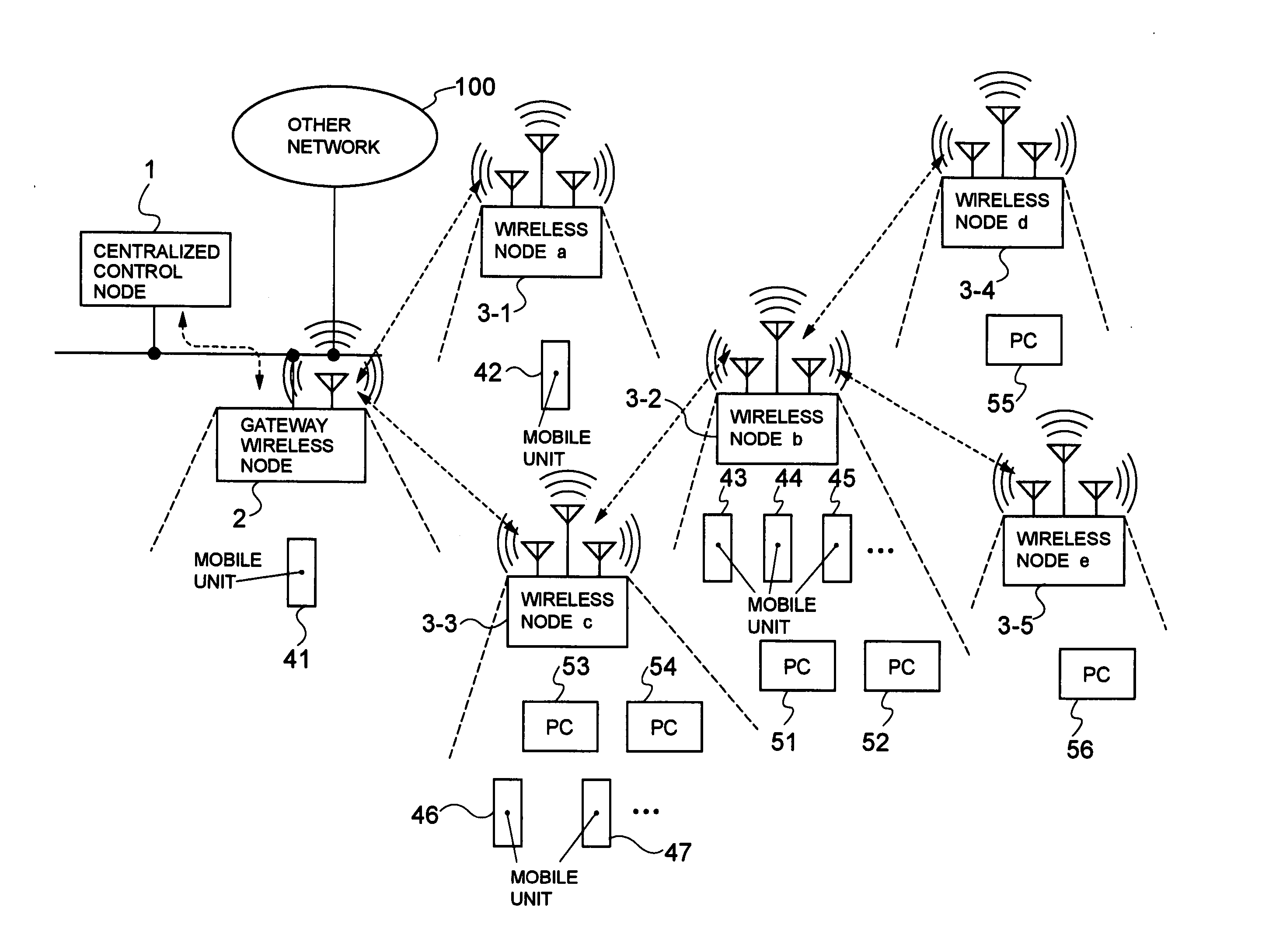

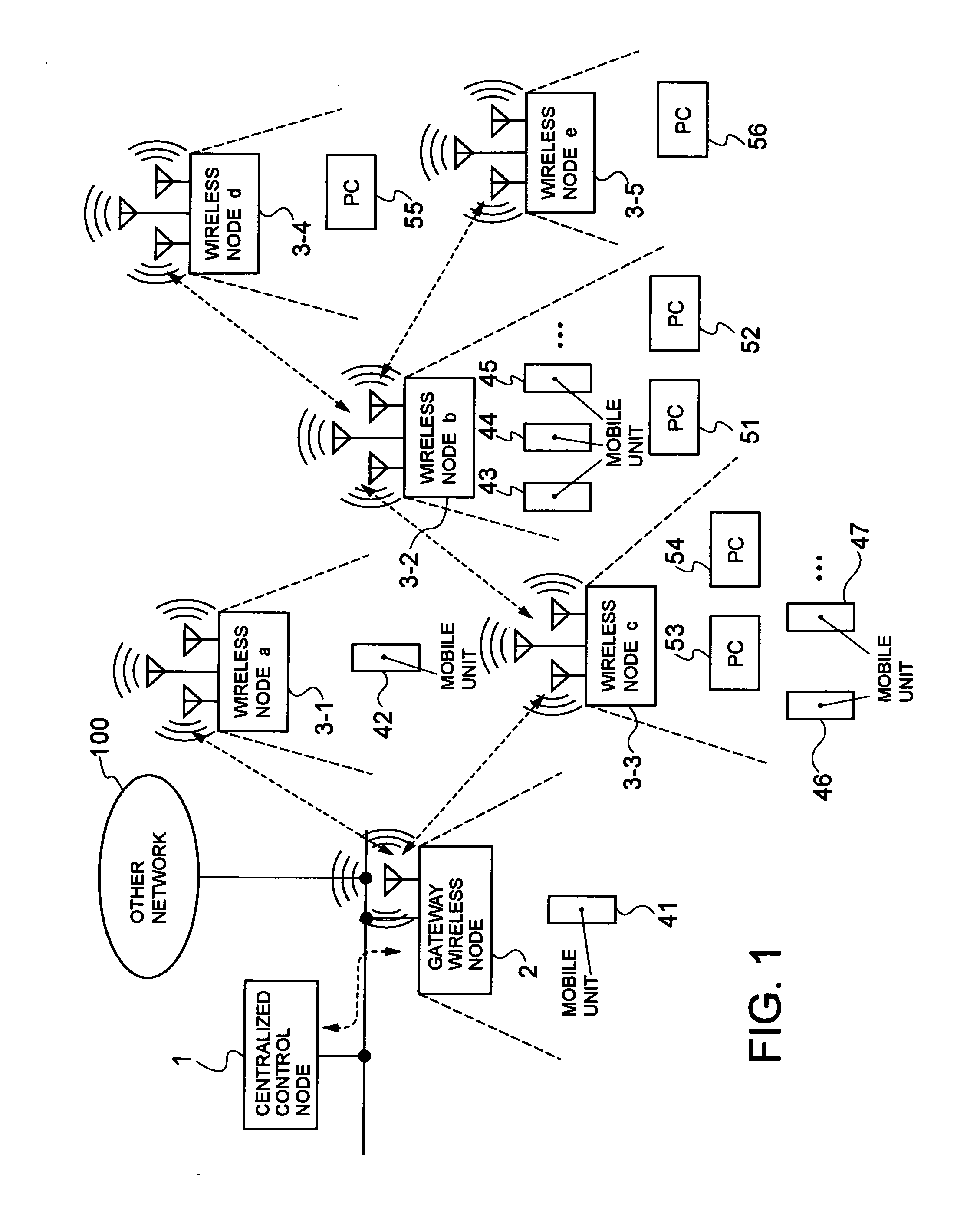

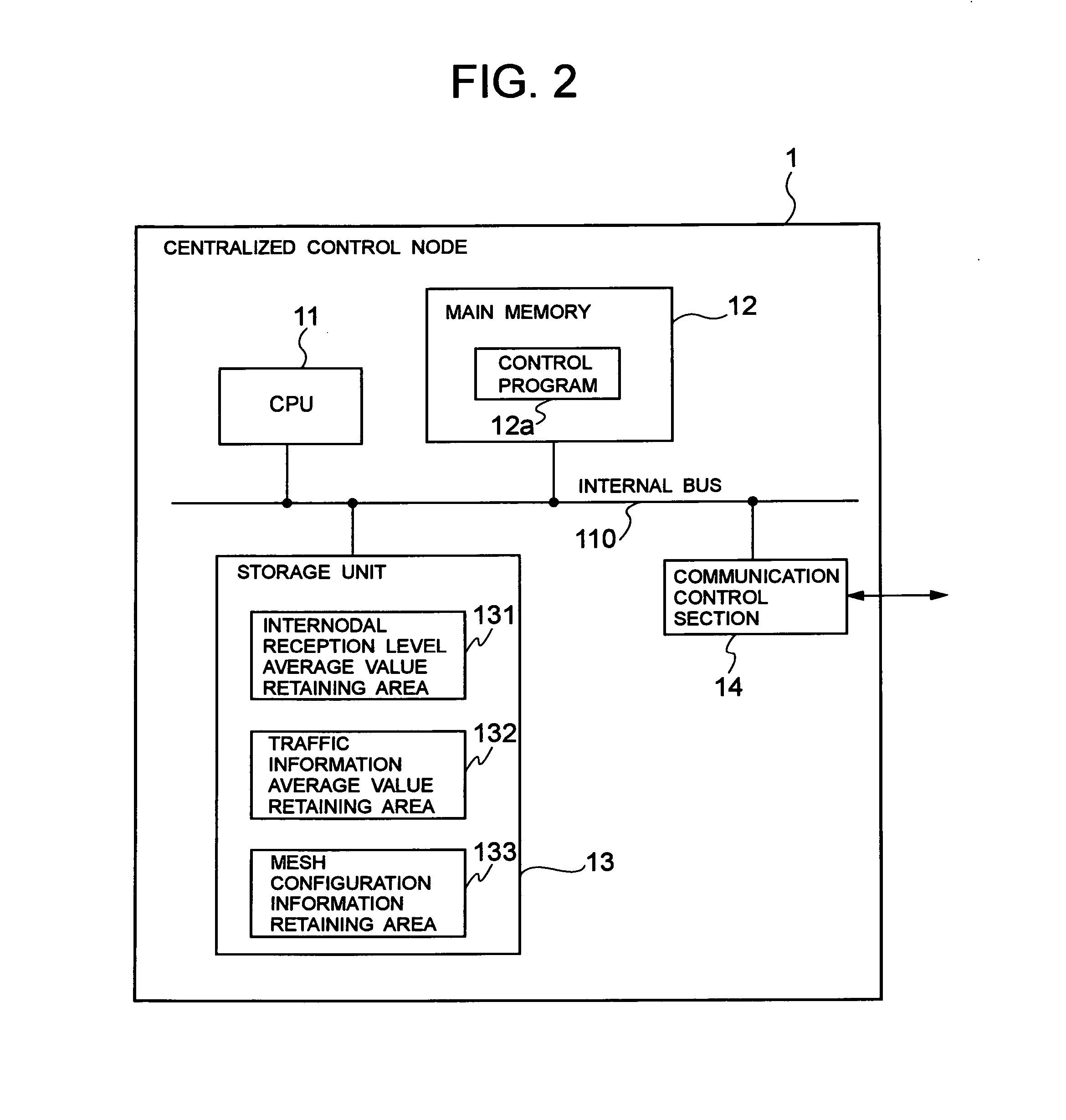

Wireless line control system, centralized control apparatus, wireless line control method used therein and program therefor

InactiveUS20070097906A1Increase loadEasy loadingNetwork traffic/resource managementNetwork topologiesWireless mesh networkControl system

A wireless line control system capable of reducing control signals to wireless nodes with high loads as well as reducing instantaneous interruption or disconnection at user terminals connected to the wireless nodes is provided. In a1 to a3, centralized control node requests reception levels which indicate radio wave propagation states between wireless nodes from each wireless node and acquires the reception levels, and calculates and stores average values thereof. In a4 to a6, the centralized control node requests traffic information from each wireless node and acquires the traffic information, and calculates and stores average values thereof. Based on the averaged historical traffic information and reception levels between wireless nodes, in a7 and a8, the centralized control node determines a configuration of a wireless mesh network which is appropriate from the present to the future, and transmits configuration instructions to each wireless node according to the determined wireless mesh network configuration.

Owner:NEC CORP

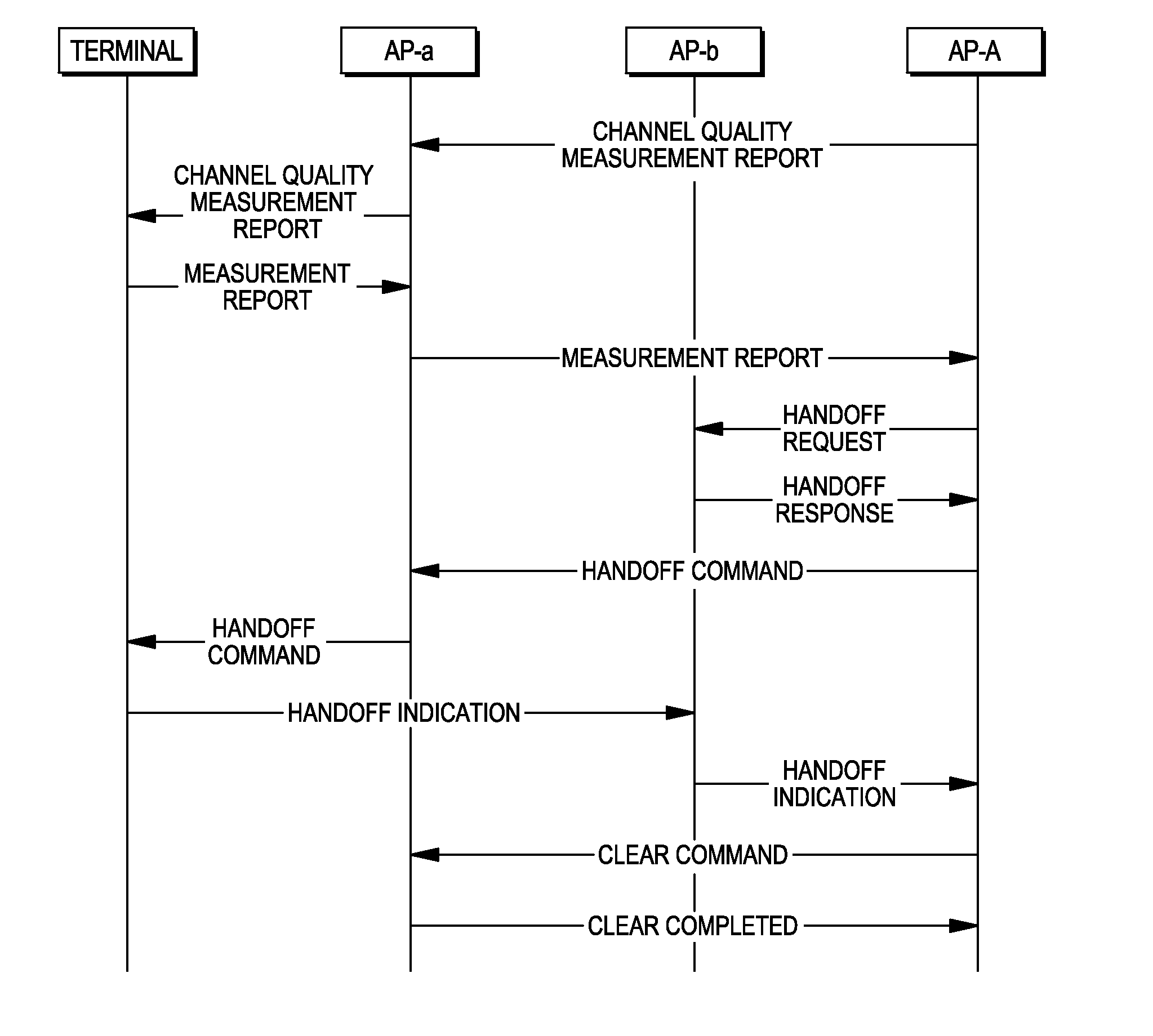

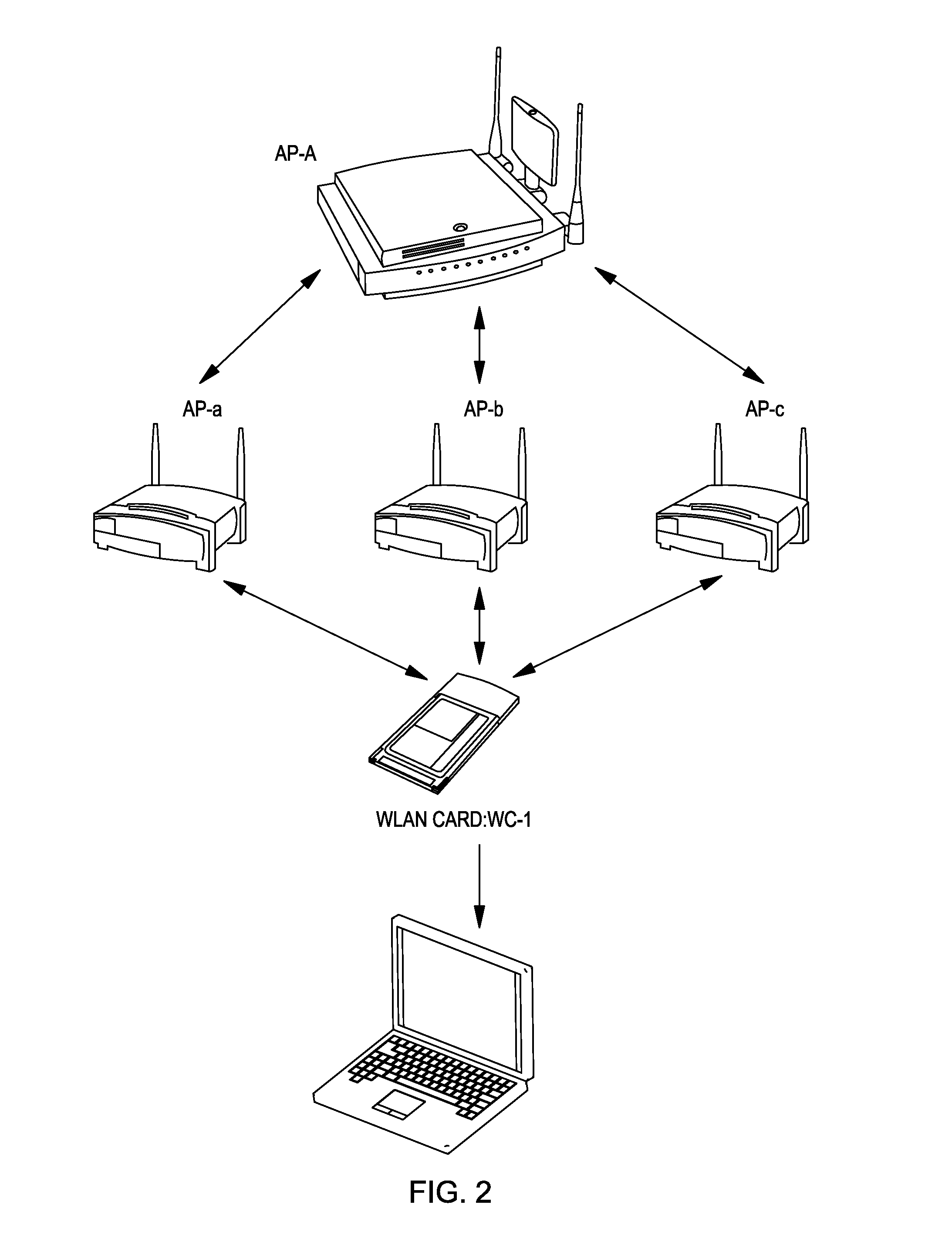

Handing off a terminal among wireless access points

InactiveUS20150117414A1Reduce power consumptionIncrease speedNetwork topologiesWireless commuication servicesNetwork conditionsComputer terminal

A method and system for handing off a terminal among a plurality of wireless access points (APs) connected to a central management AP. The method comprising: receiving network condition information of a terminal communicatively connected to a first wireless AP among the plurality of wireless APs. Determining a second wireless AP the plurality of wireless APs to which the terminal is to be handed off based on the network condition information of the terminal. The second wireless AP is virtually connected to the terminal. Submitting a handoff request to the second wireless AP. Notifying the terminal to hand off to the second wireless AP in response to receiving a handoff response from the second wireless AP.

Owner:IBM CORP

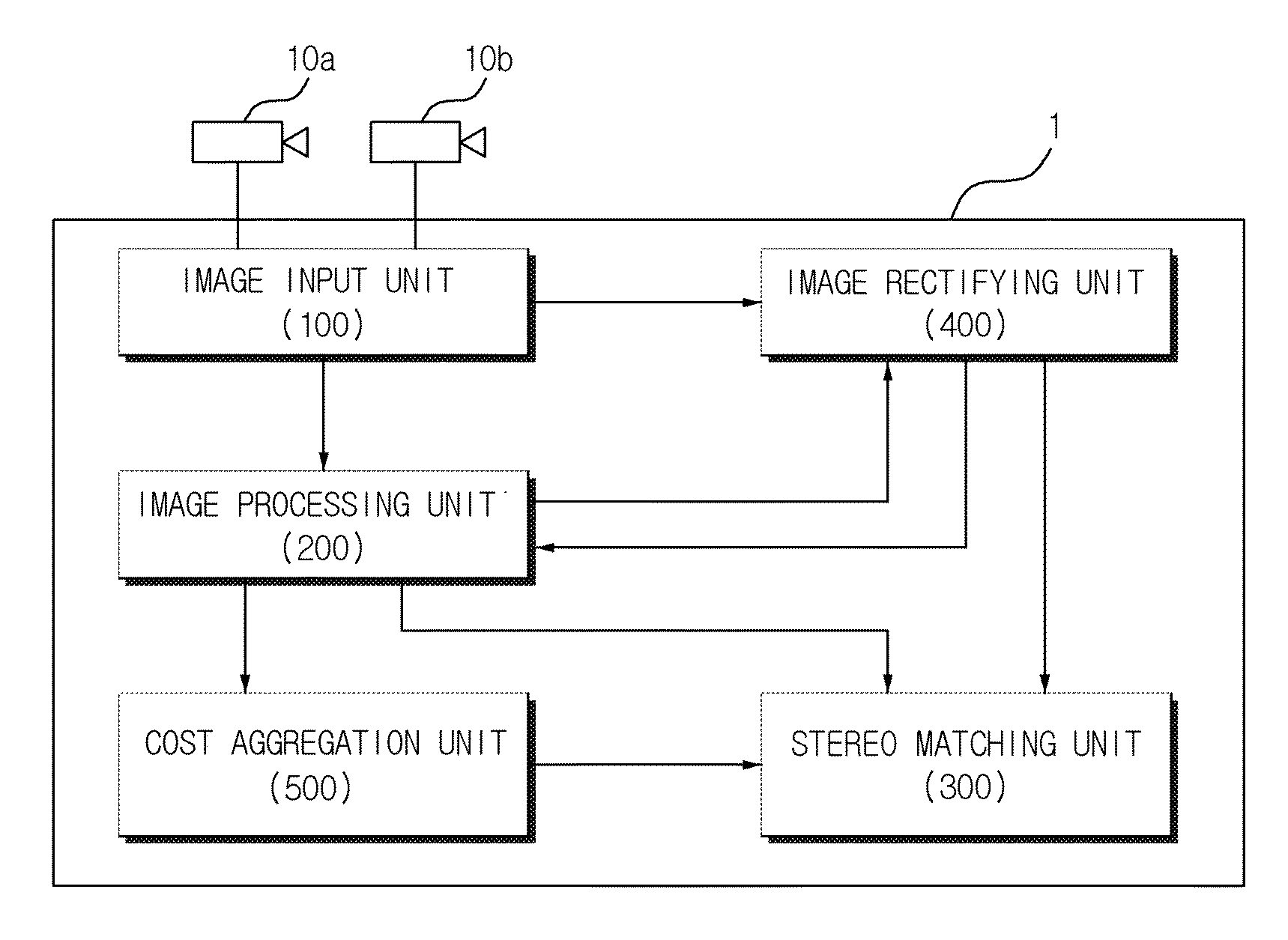

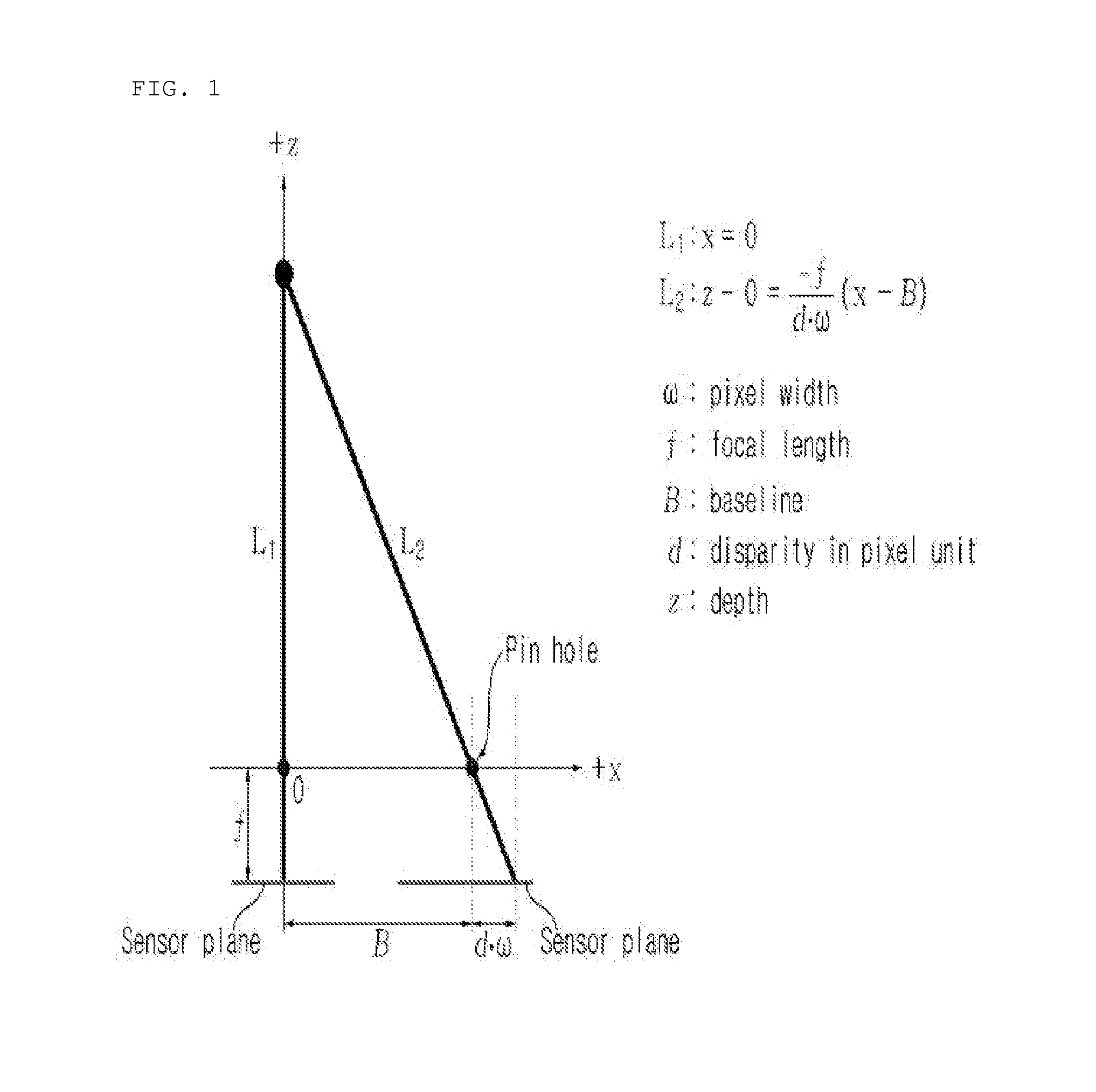

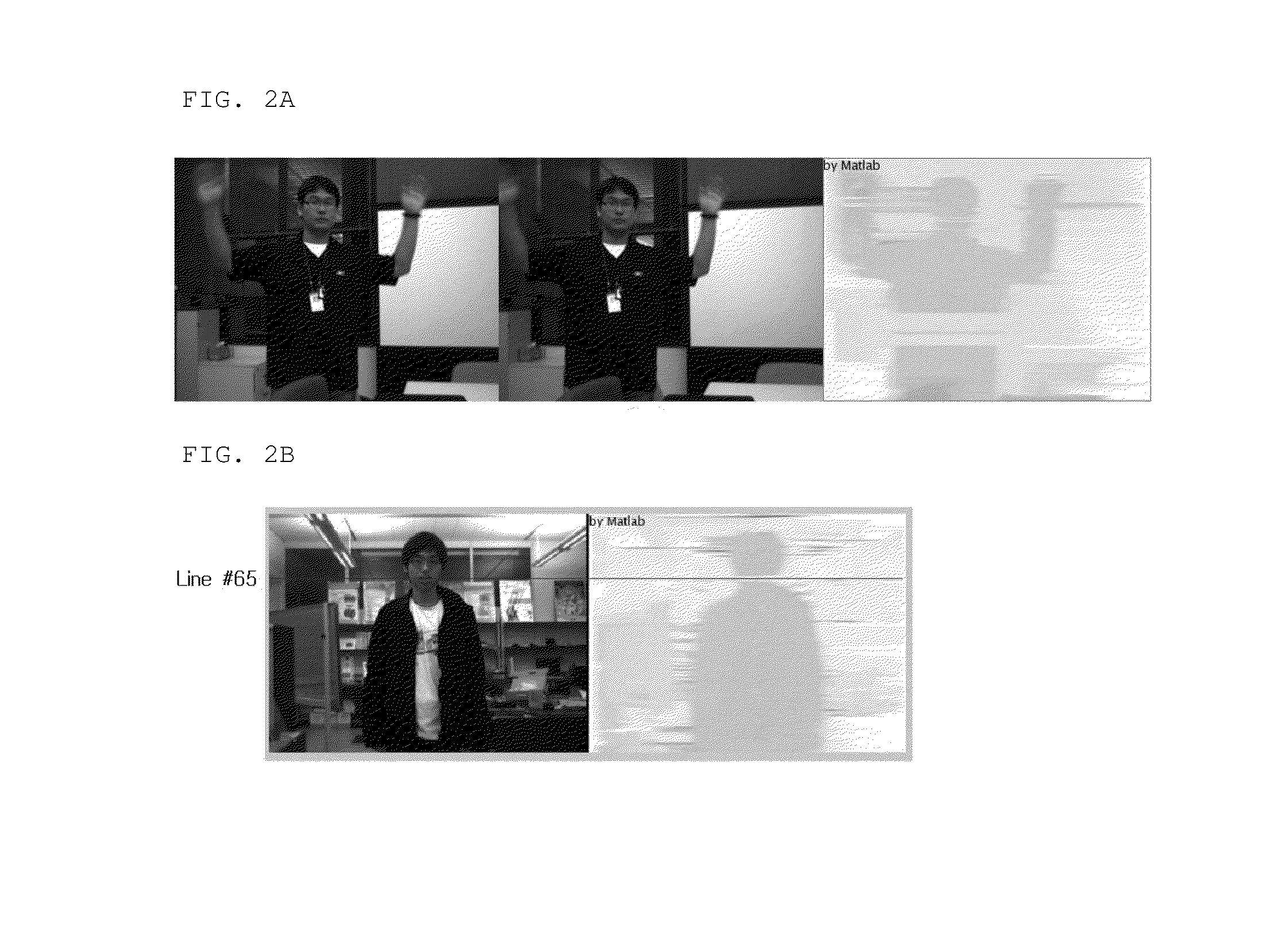

Method and apparatus for stereo matching

Disclosed is a stereo matching method for calculating disparity from binocular images. The stereo matching method extracting distance information of objects included in images by using binocular images, includes receiving the binocular images acquired from a first camera and a second camera for acquiring the binocular images; processing the images so as to increase contrast between objects and background objects included in the received images by using a predetermined first algorithm; and performing, stereo matching using the processed images. An exemplary embodiment of the present invention outputs a disparity map in which objects and background are divided, thereby robustly recognizing a person or obstacles.

Owner:ELECTRONICS & TELECOMM RES INST

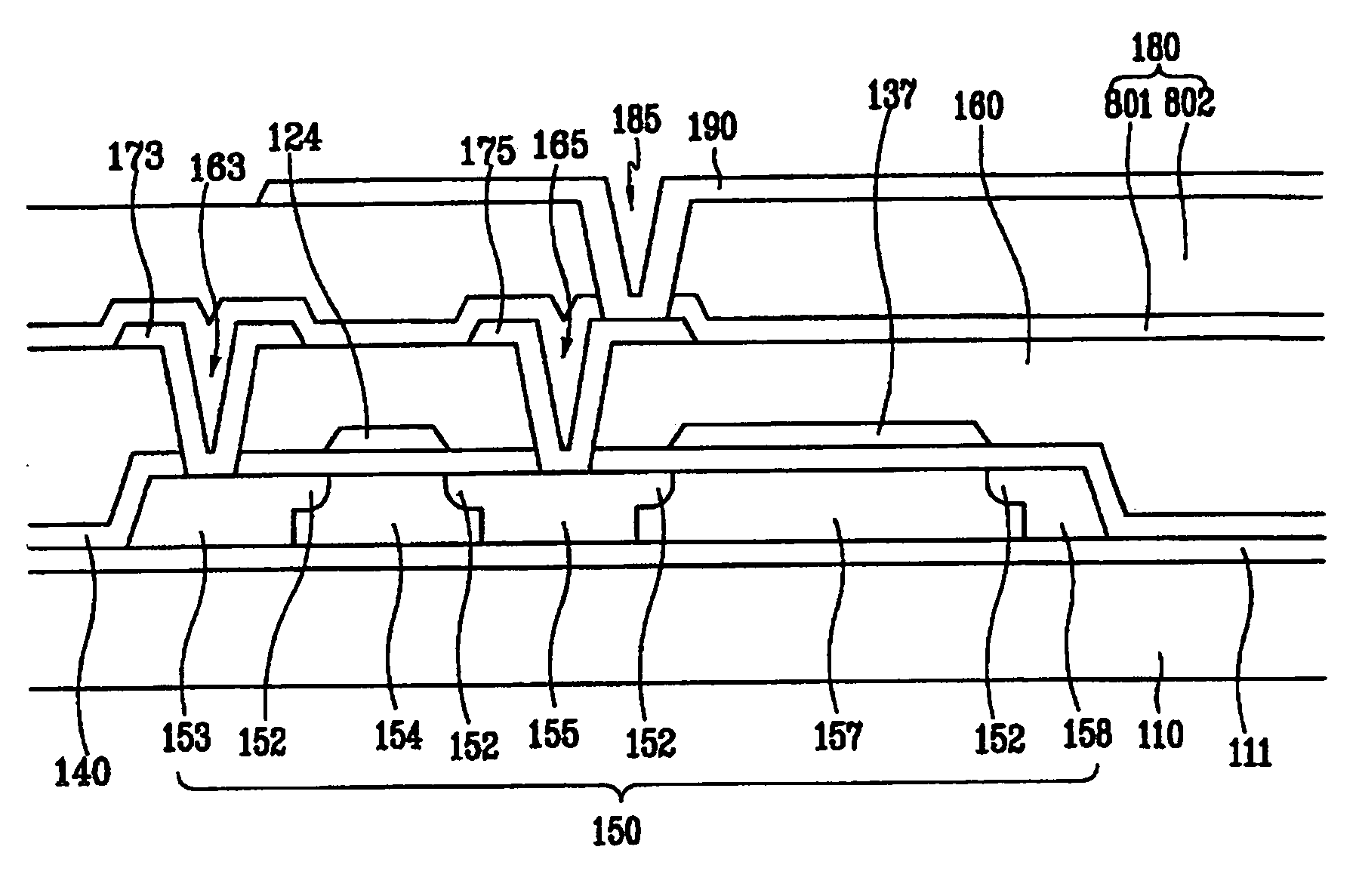

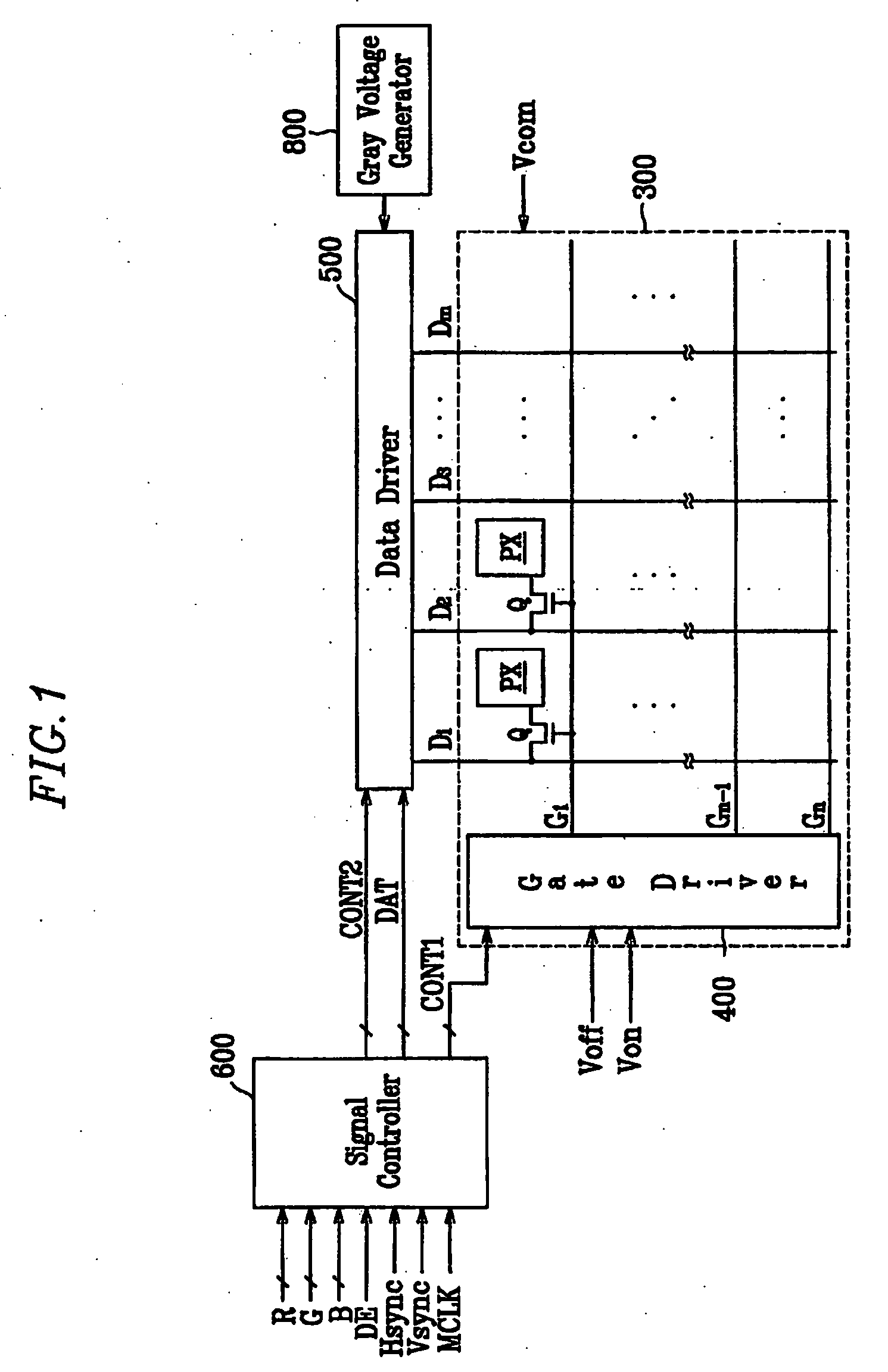

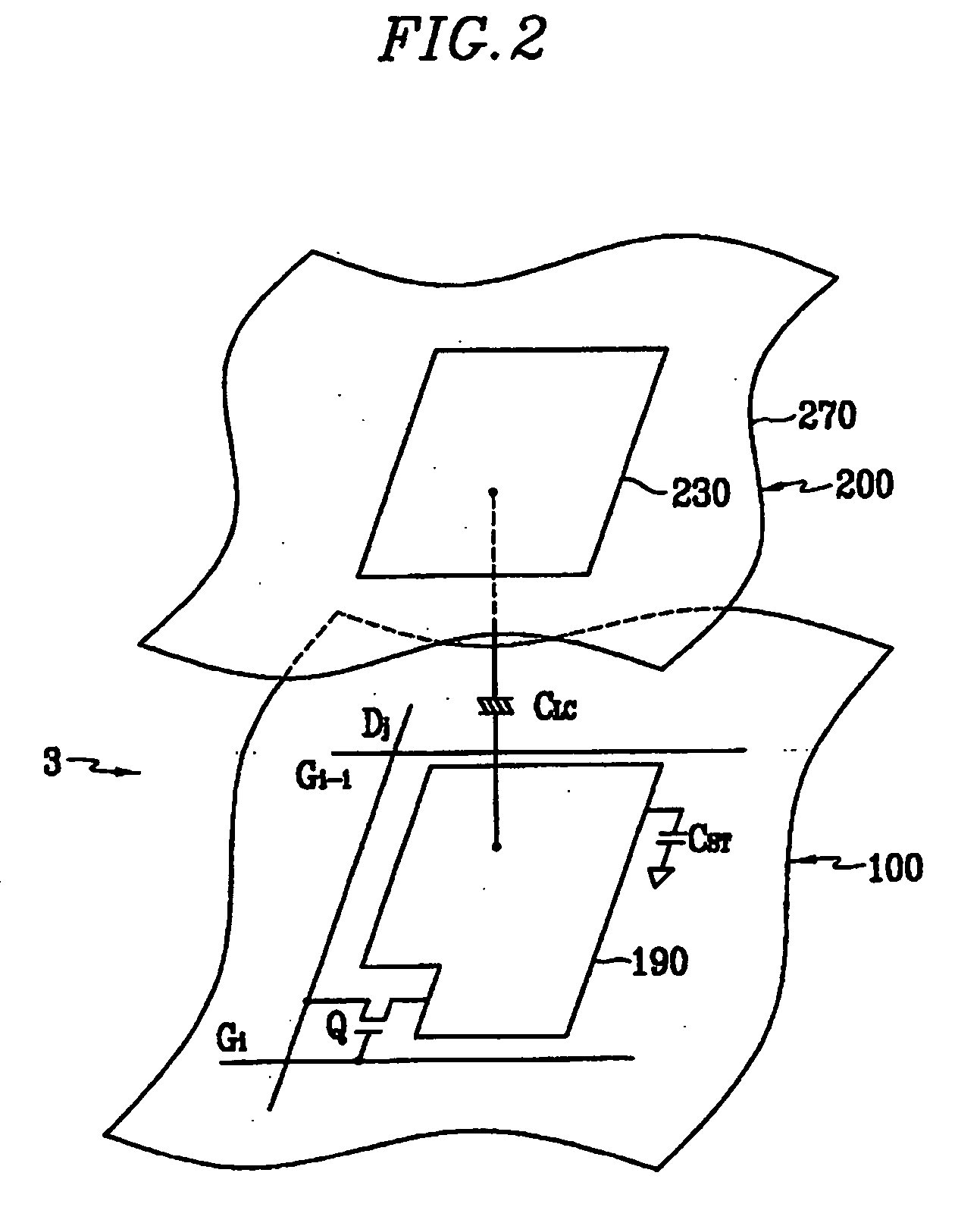

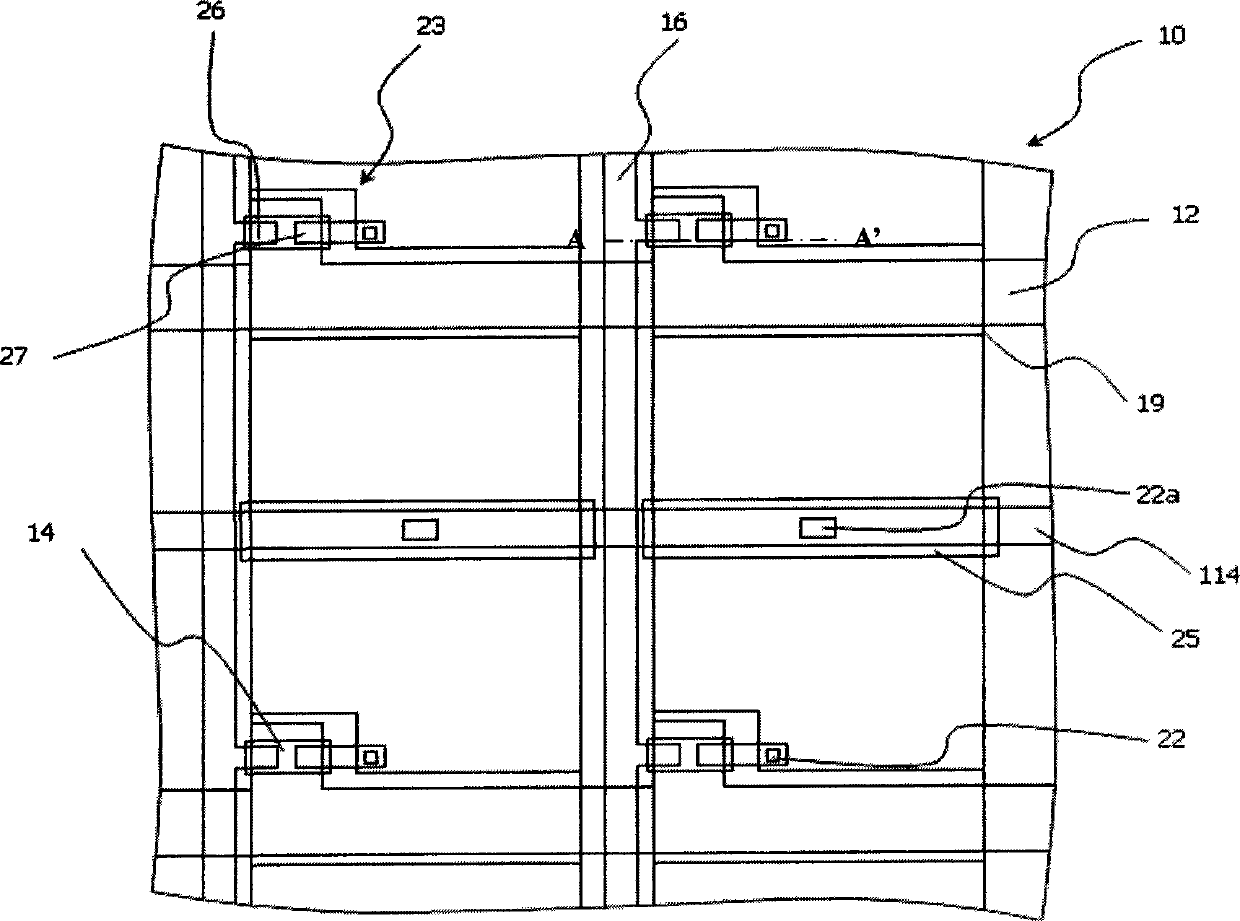

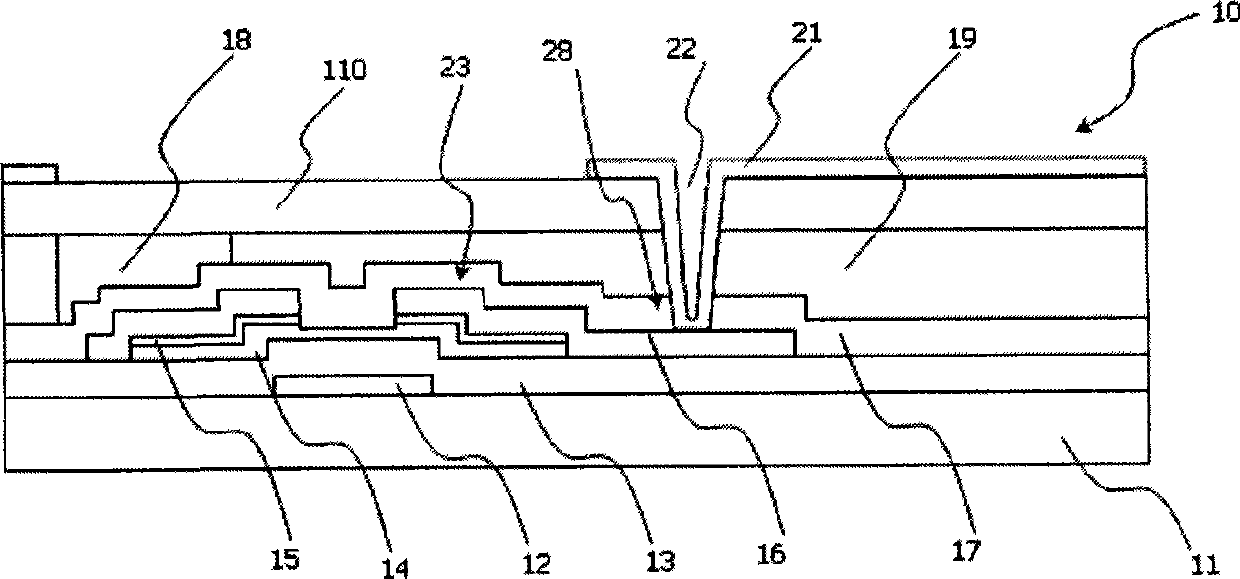

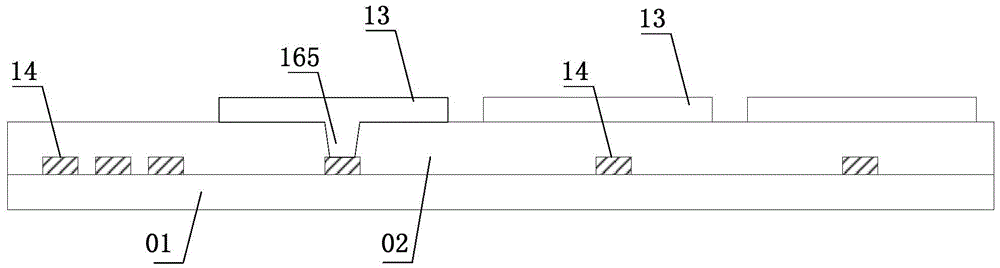

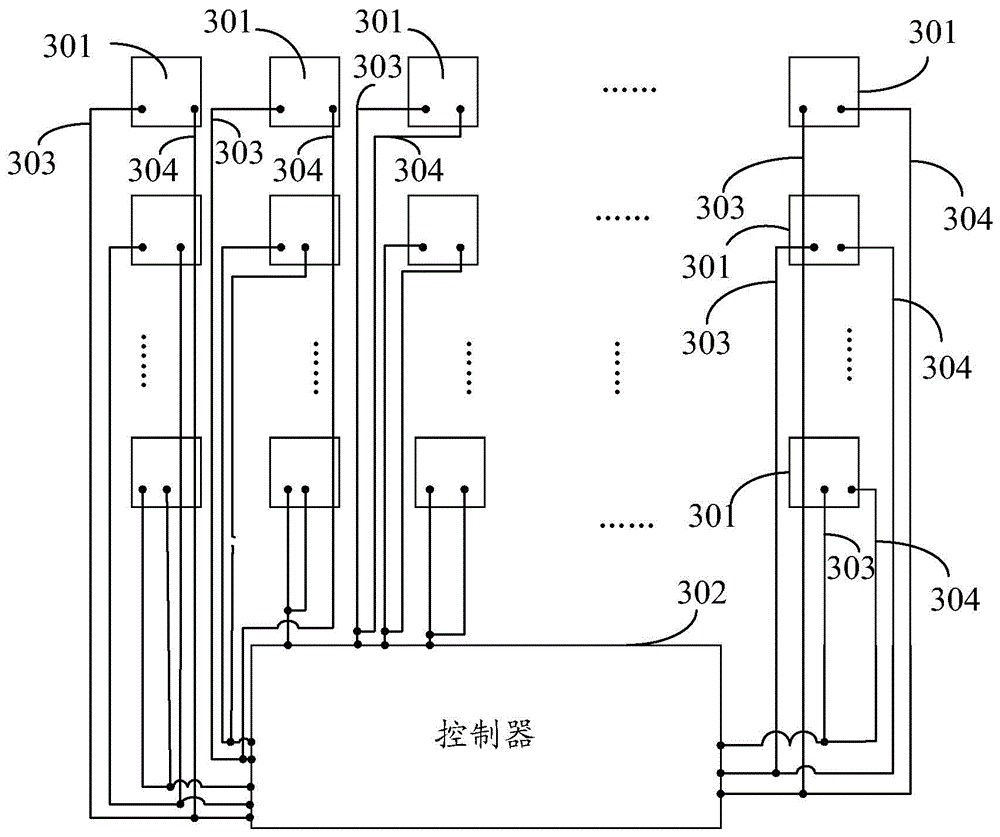

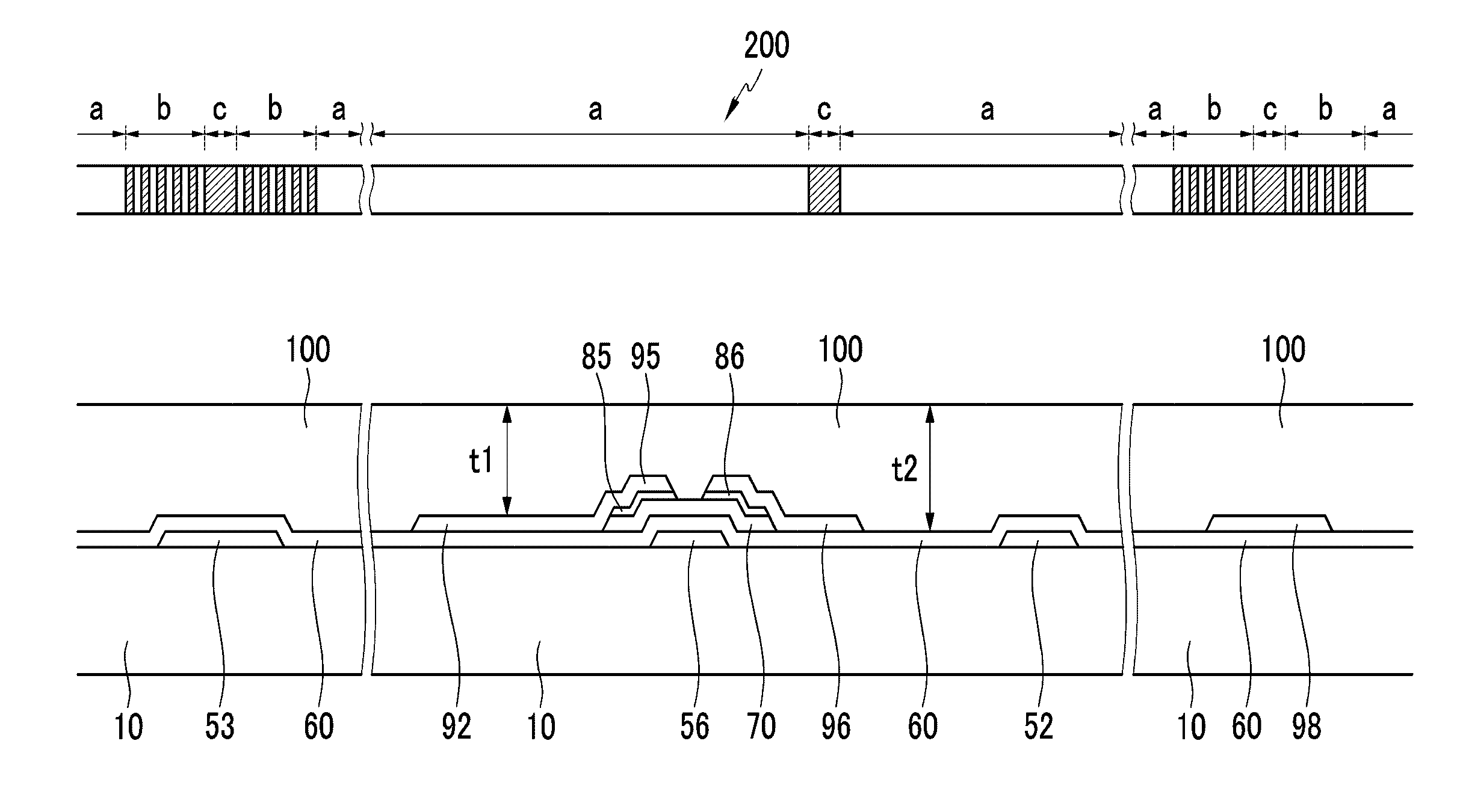

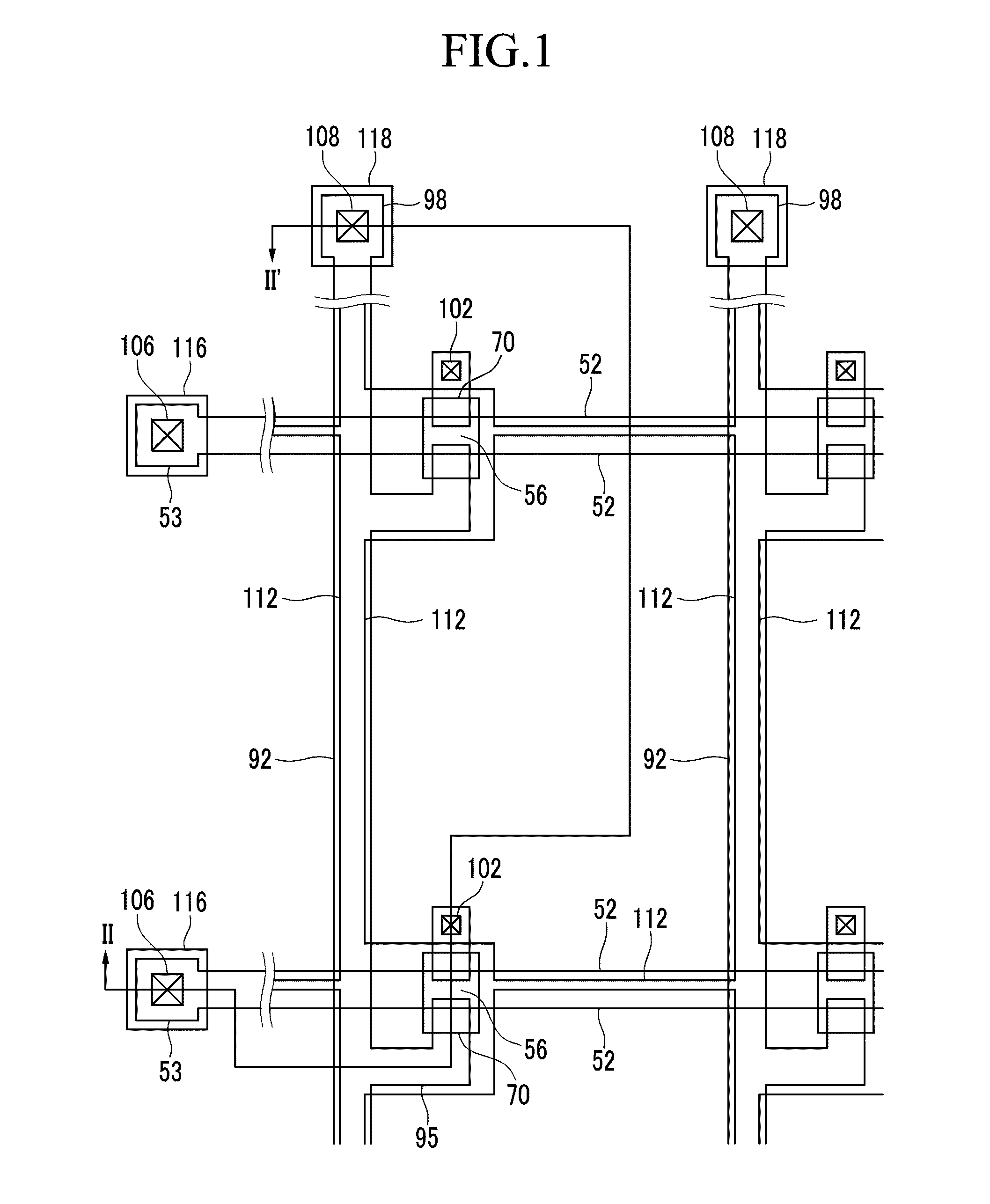

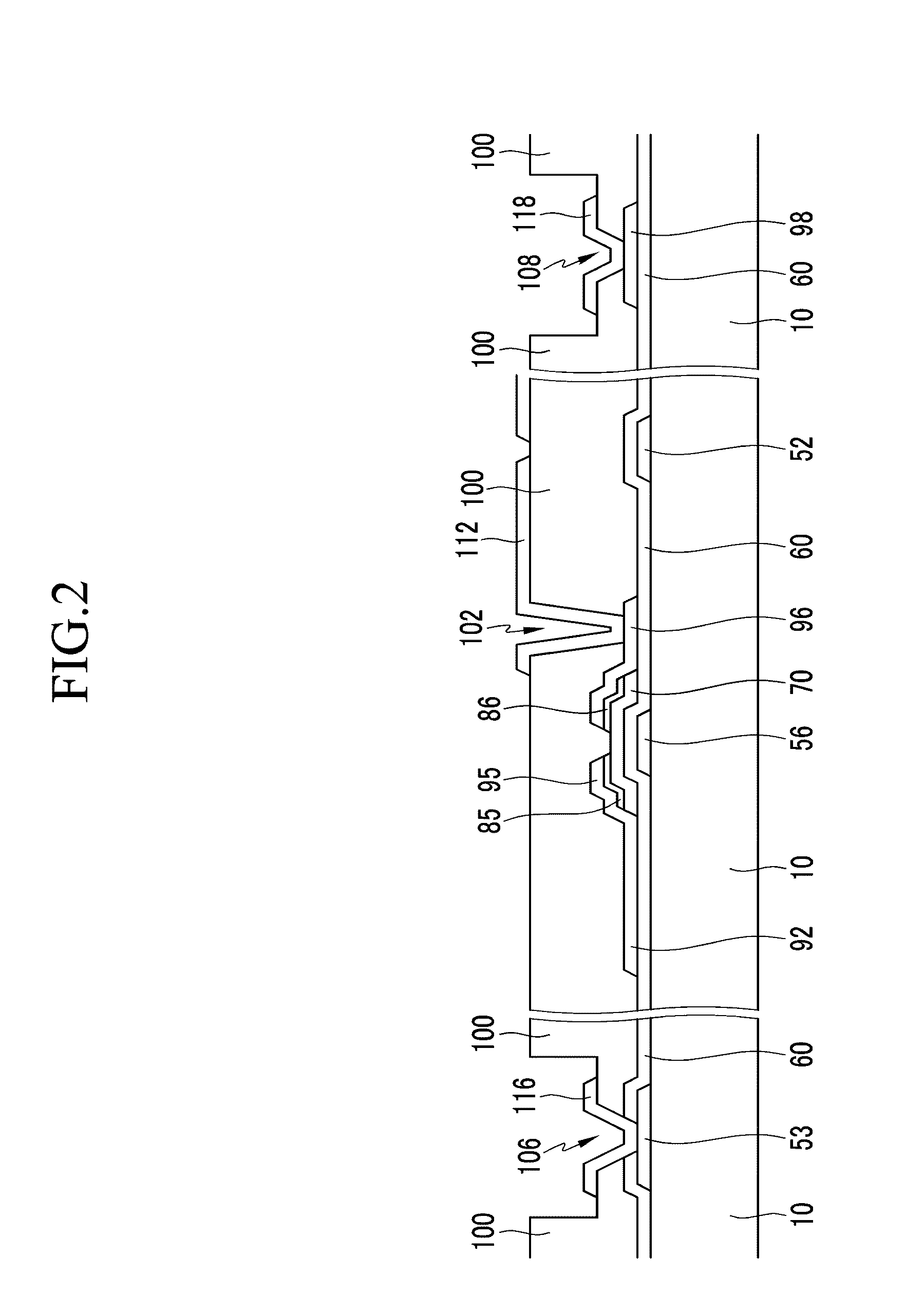

Thin film transistor array panel

ActiveUS20060049407A1Low resistivityAvoid signal delaySolid-state devicesNon-linear opticsTransistorElectrical and Electronics engineering

Improved thin film transistor array panels are provided. In one embodiment, a panel includes a plurality of gate lines, data lines, and a plurality of switching elements connected to the gate lines and the data lines. An interlayer insulating layer is formed between the gate lines and the data lines. A passivation layer covering the gate lines, the data lines, and the switching elements is also provided having a plurality of first contact holes exposing portions of the data lines, wherein the switching elements and the pixel electrodes are connected through the first contact holes. A plurality of contact assistants are formed on the passivation layer and are connected to the data lines through a plurality of second contact holes in the passivation layer. A plurality of auxiliary lines are connected to the data lines through a plurality of third contact holes in the interlayer insulating layer.

Owner:SAMSUNG DISPLAY CO LTD

LCD substrate, LCD and manufacturing method

ActiveCN101387799AReduce disconnectionNo disconnectionSolid-state devicesNon-linear opticsInsulation layerLiquid-crystal display

The invention discloses a liquid crystal display device baseboard, comprising a baseboard, a gate line, a gate electrode, a gate insulation layer, an active layer, a resistance contact layer, a source cathode, a drain electrode and a data line, wherein the data line and the gate line are crossed to define a pixel region, a passive layer is formed above the source and the drain electrodes and the data line, a contact hole is formed above the source cathode of the source and the drain electrodes, a black matrix layer is formed at the region outside the pixel region, a resin layer is formed on the passive layer of the pixel region and exposes the contact hole on the passive layer, an pixel electrode is formed on the resin layer and is connected with the source cathode of the source and the drain electrodes via the contact hole. The invention further discloses a production method of the liquid crystal display device baseboard, a liquid crystal display device and a production method thereof. The invention modifies the CF coating form and coating technique of the prior CF-on-TFT technique, to restrain the bad conduction of liquid crystal display devices, improve processing reliability and improve the display property of TFT baseboards.

Owner:BOE TECH GRP CO LTD +1

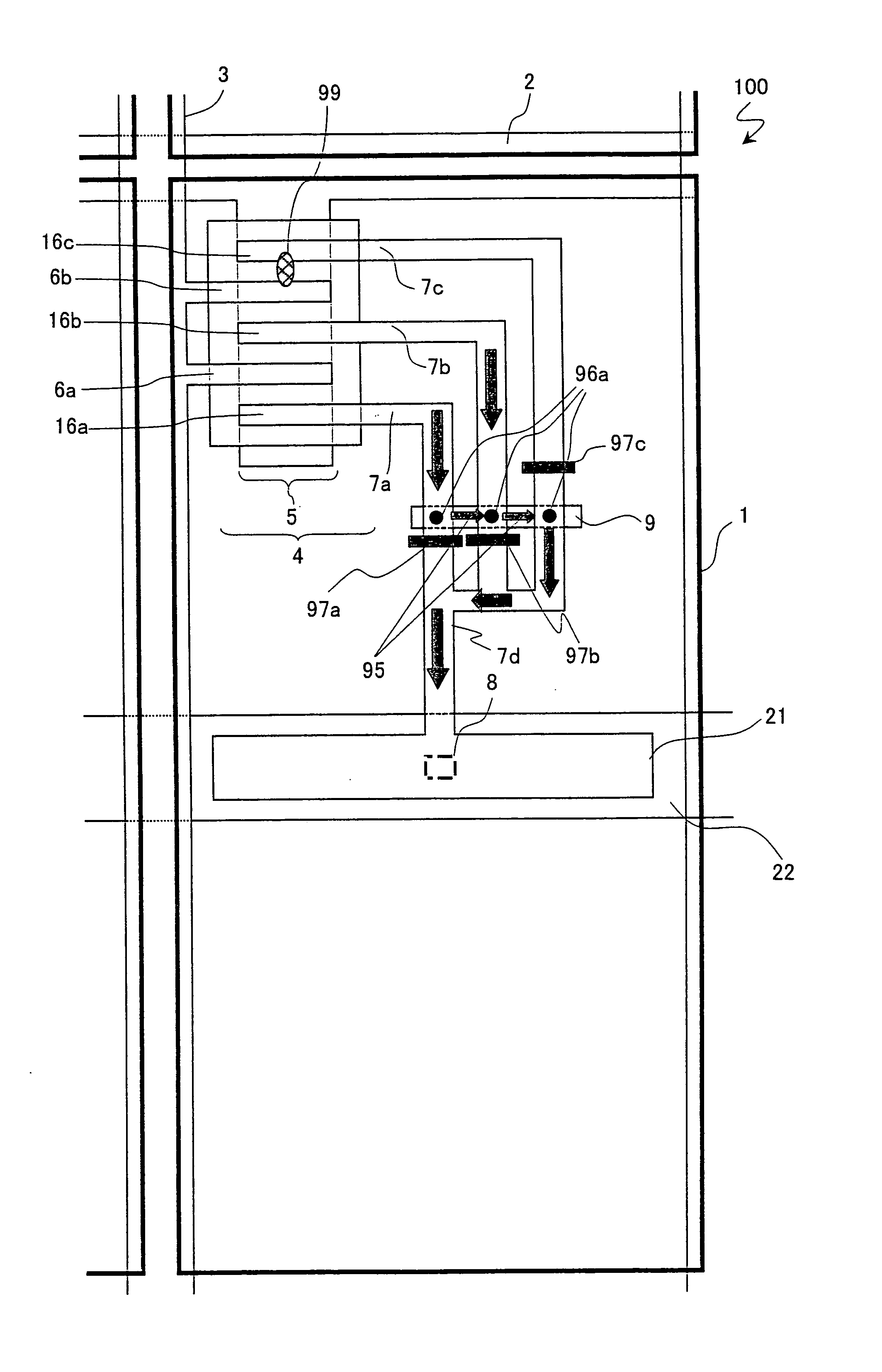

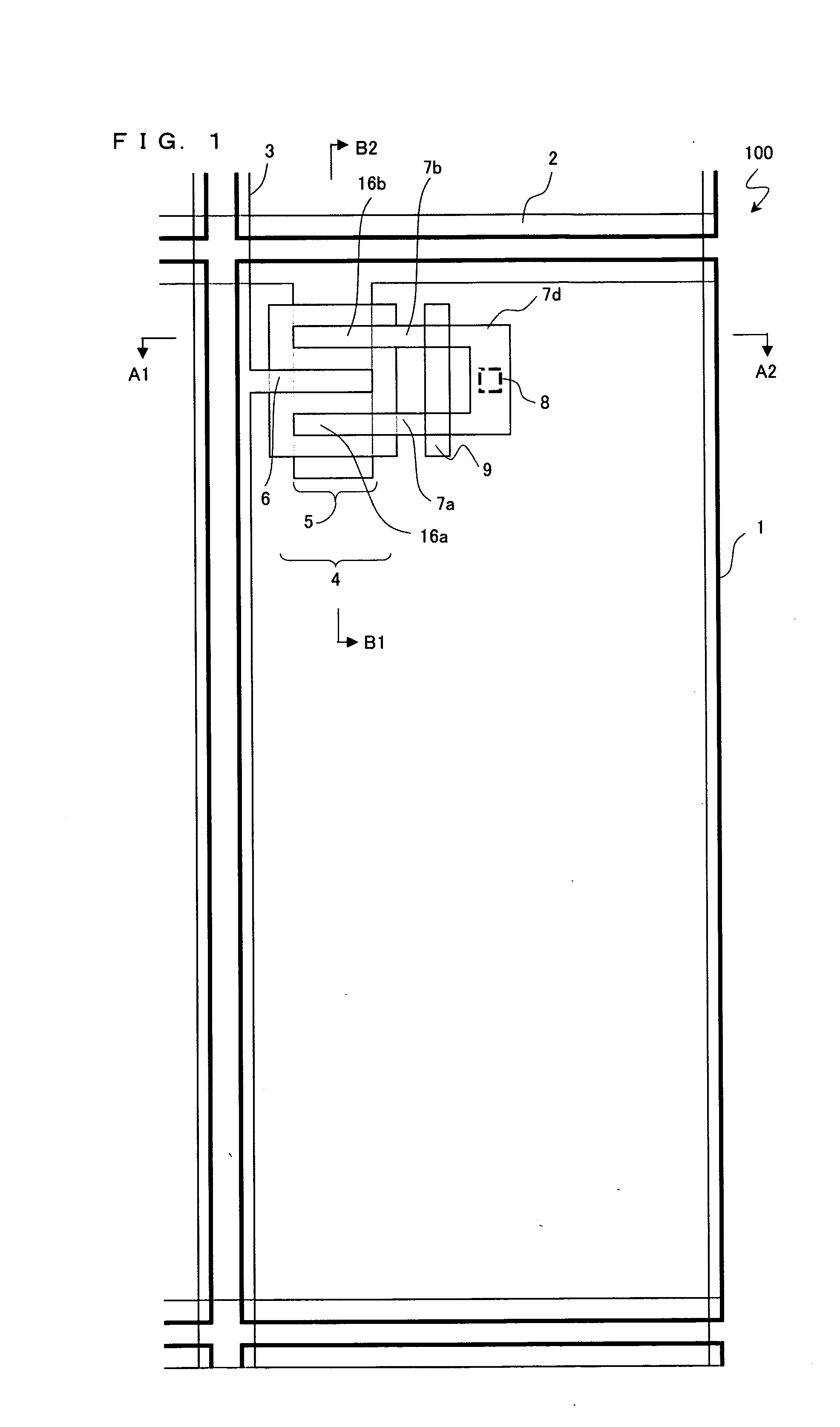

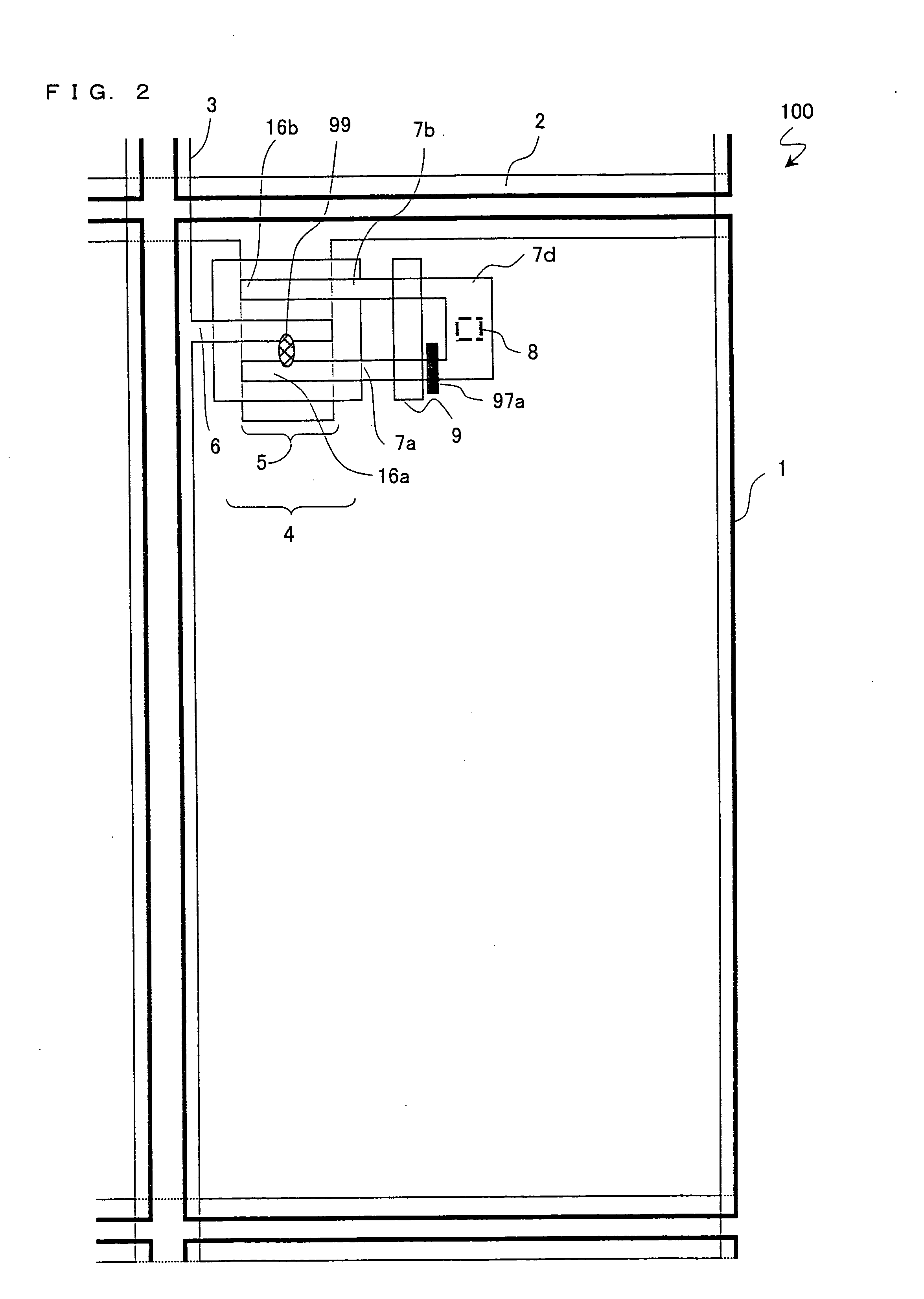

Active Matrix Substrate, Display Apparatus, and Pixel Deffect Correction Method

InactiveUS20080024690A1Improve display qualityHigh yieldStatic indicating devicesSolid-state devicesActive matrixEngineering

An active matrix substrate is constituted of a TFT (4) in which a plurality of drain electrodes (16a and 16b) are provided for a single source electrode (6), and at least one of the drain electrodes is electrically connected to the pixel electrode (1) via the drain outgoing wire. The drain outgoing wire includes a first conductive pattern section having (i) a drain outgoing wire common section (7d) and drain outgoing branch sections (7a and 7b) each of which extends from said drain outgoing common section into each of said drain electrodes, and (ii) a correction connection electrode 9 which is partially overlapped with said branch sections of said first conductive pattern section via an insulating layer. The correction connection electrode 9 is electrically connectable to a plurality of said branch sections by being conducted to said branch sections through said insulating layer. This structure allows pixel defect correction within the pixel.

Owner:SHARP KK

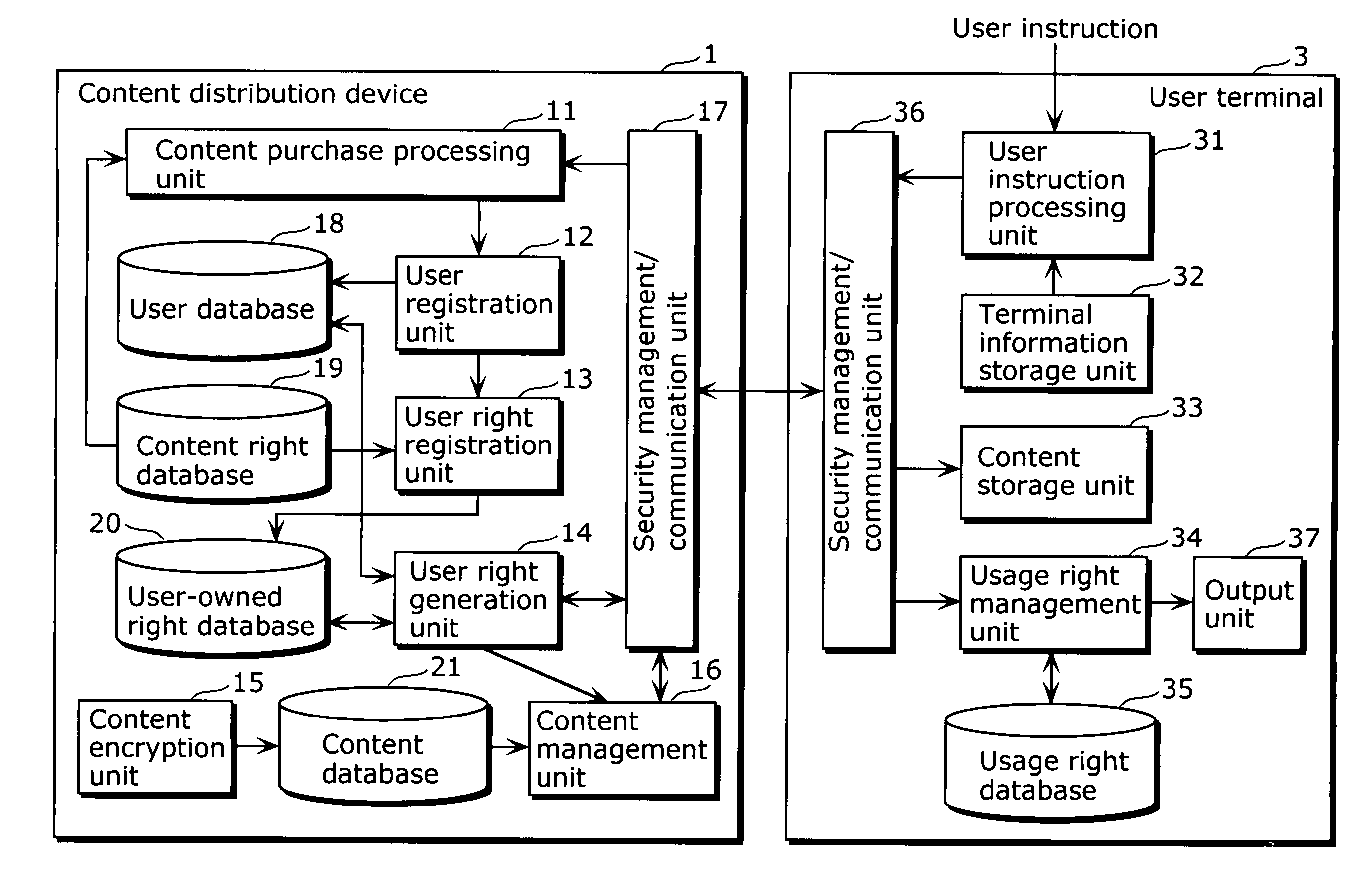

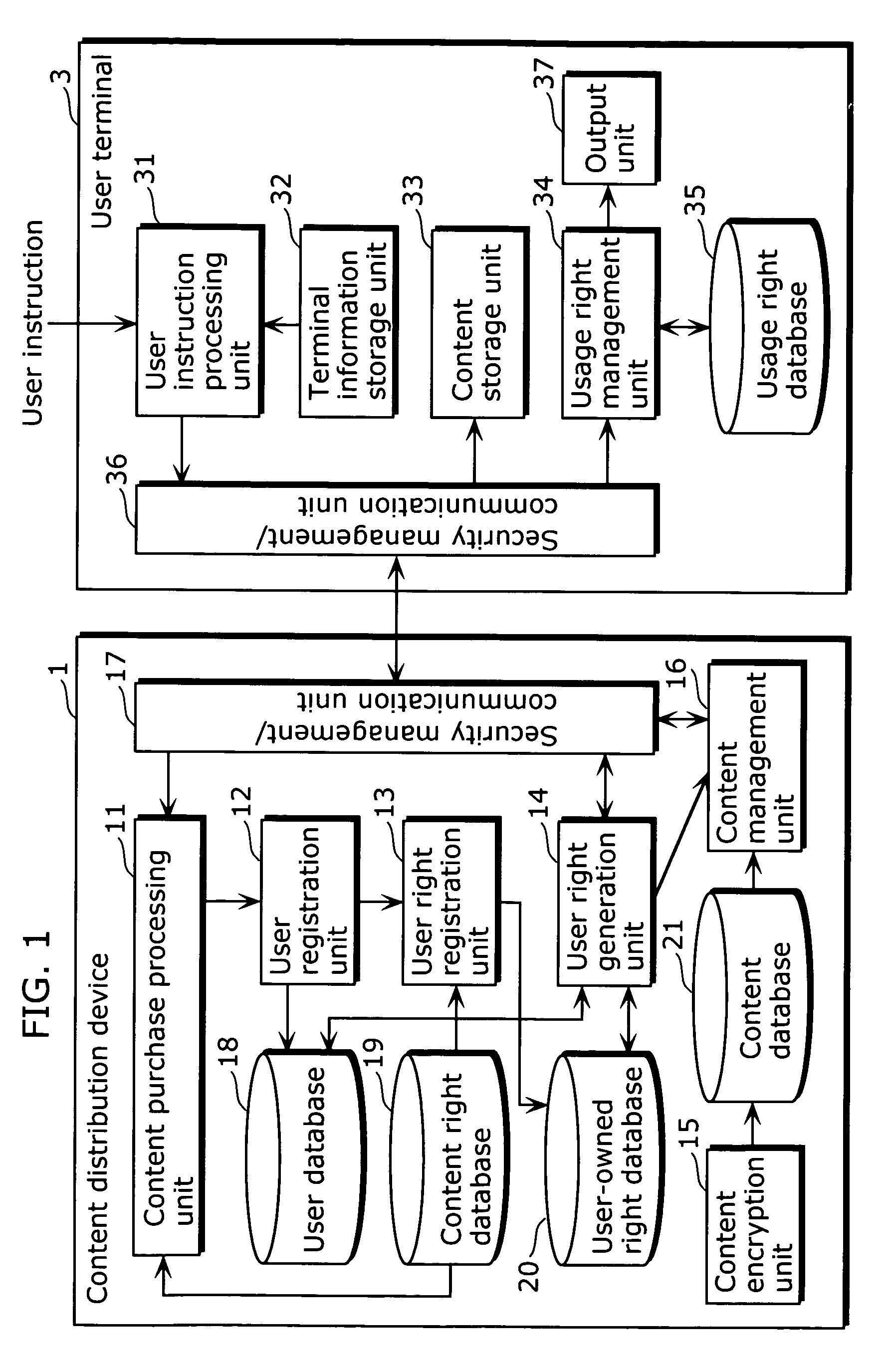

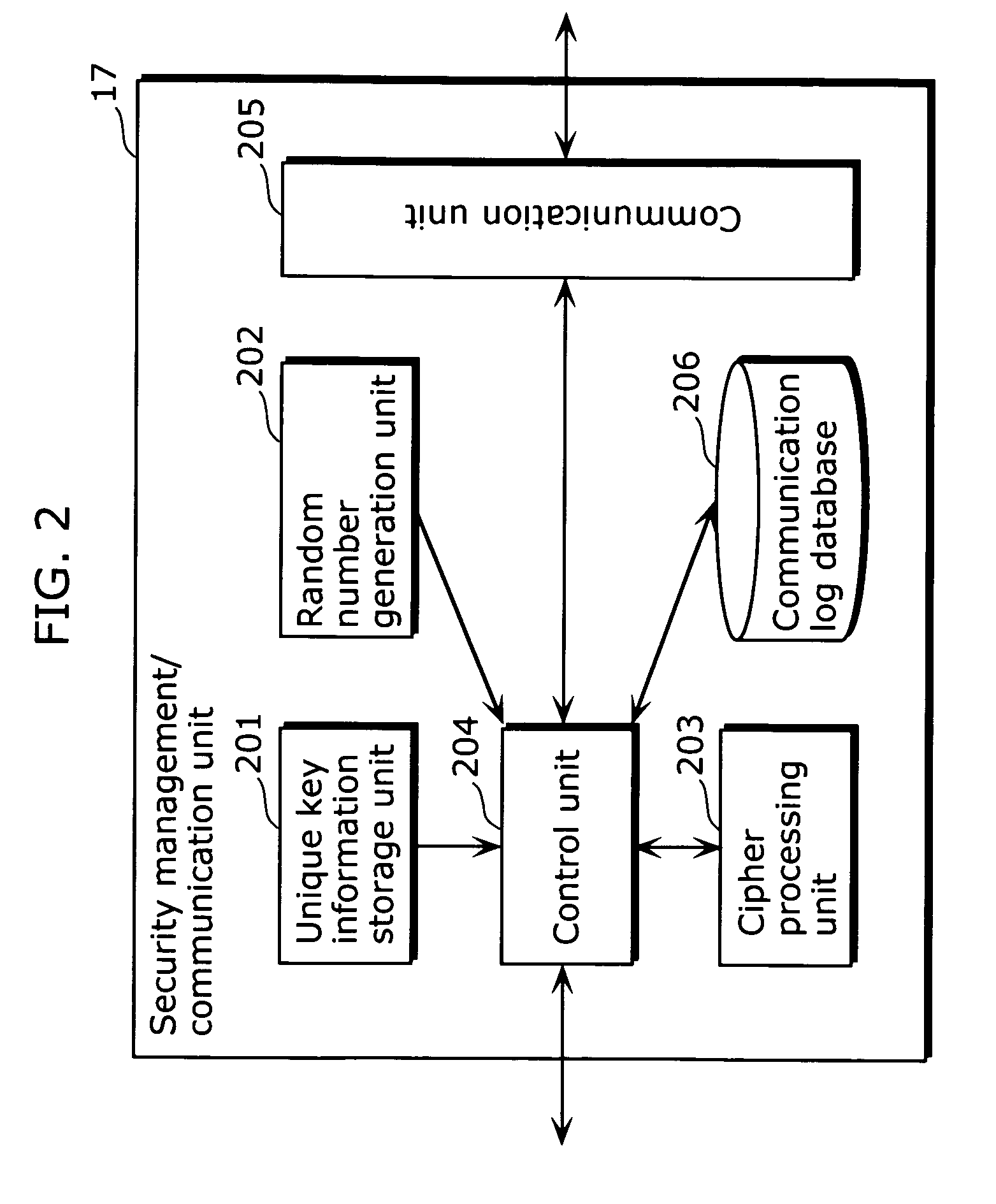

Digital content distribution system

InactiveUS20060195405A1Reduce the number of timesShorten the timePayment architectureSecret communicationContent distributionDigital content

The content distribution system according to the present invention is comprised of: a server device and a terminal device, the server device providing the terminal device with a license for using a content based on transaction processes, each including receiving of a request message, sending of a response message, and receiving of a commit message for finalizing completion of a transaction, and the terminal device controlling use of the content based on the license obtained from the server device, wherein the terminal device includes: a holding unit that holds a 1-bit transaction identification flag indicating whether a current transaction process is in progress or completed; and a sending unit that sends the transaction identification bit instead of an omitted commit message when sending a second or later request message, without sending a commit message in each transaction process except for a last transaction process in successive transaction processes, and the server device includes: a receiving unit that receives the transaction identification flag that is sent together with the second or later request message in the successive transaction processes; and a judgment unit that judges whether or not completion of one transaction should be finalized based on the received transaction identification flag.

Owner:INTERTRUST TECH CORP

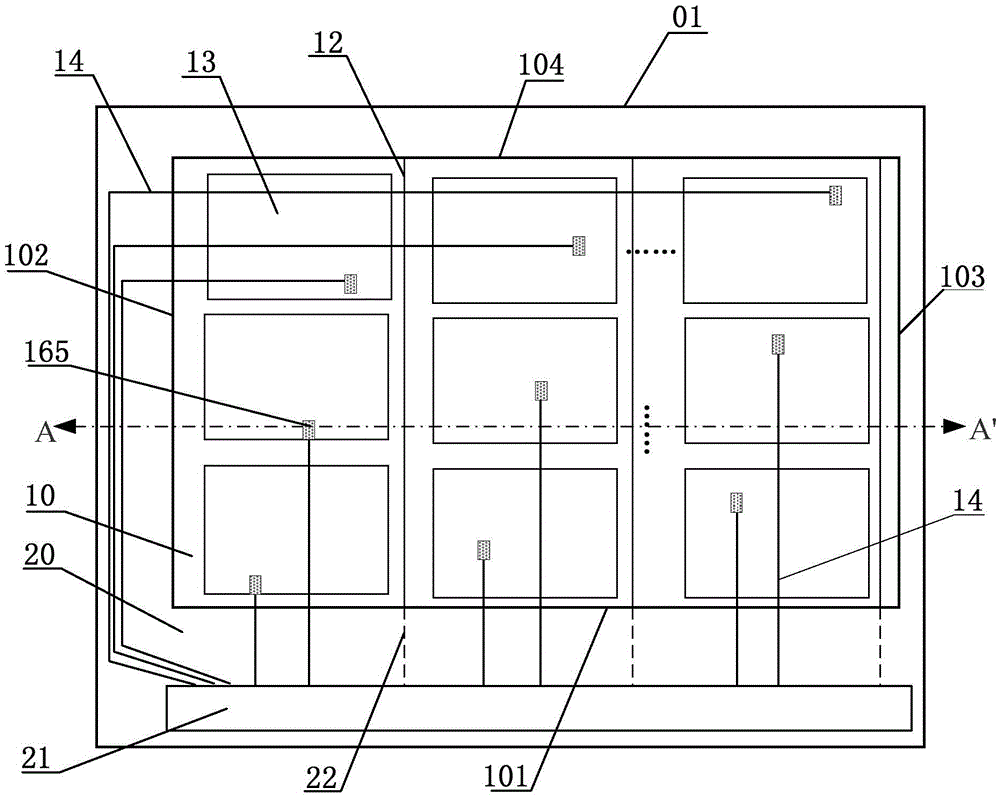

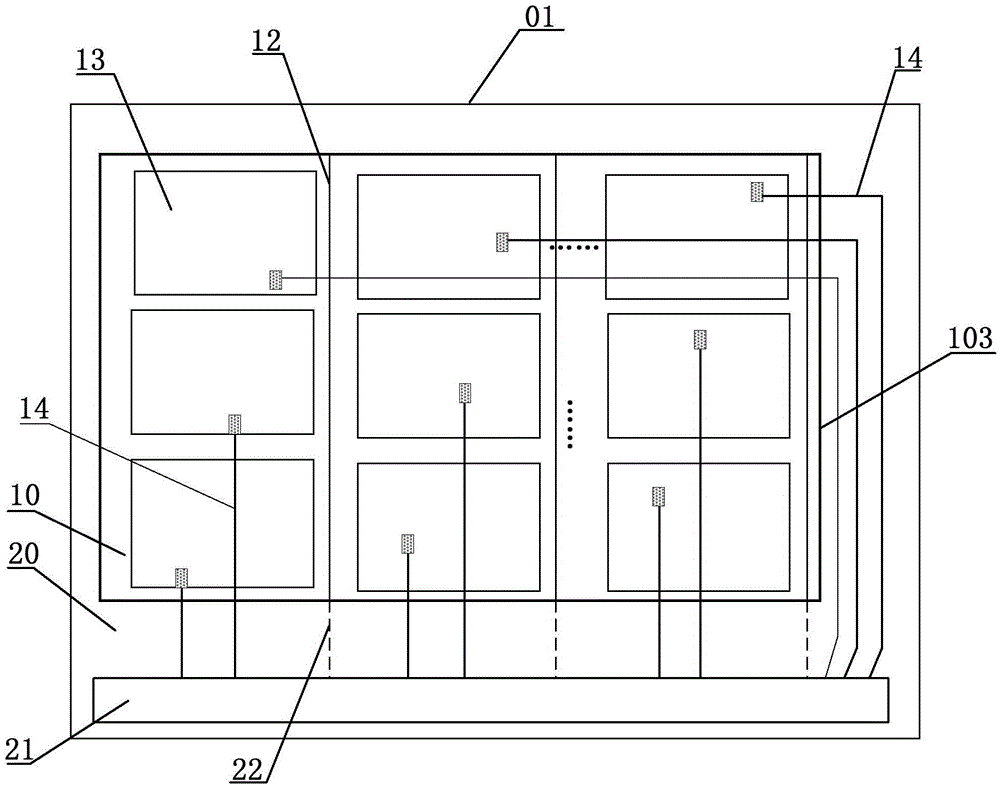

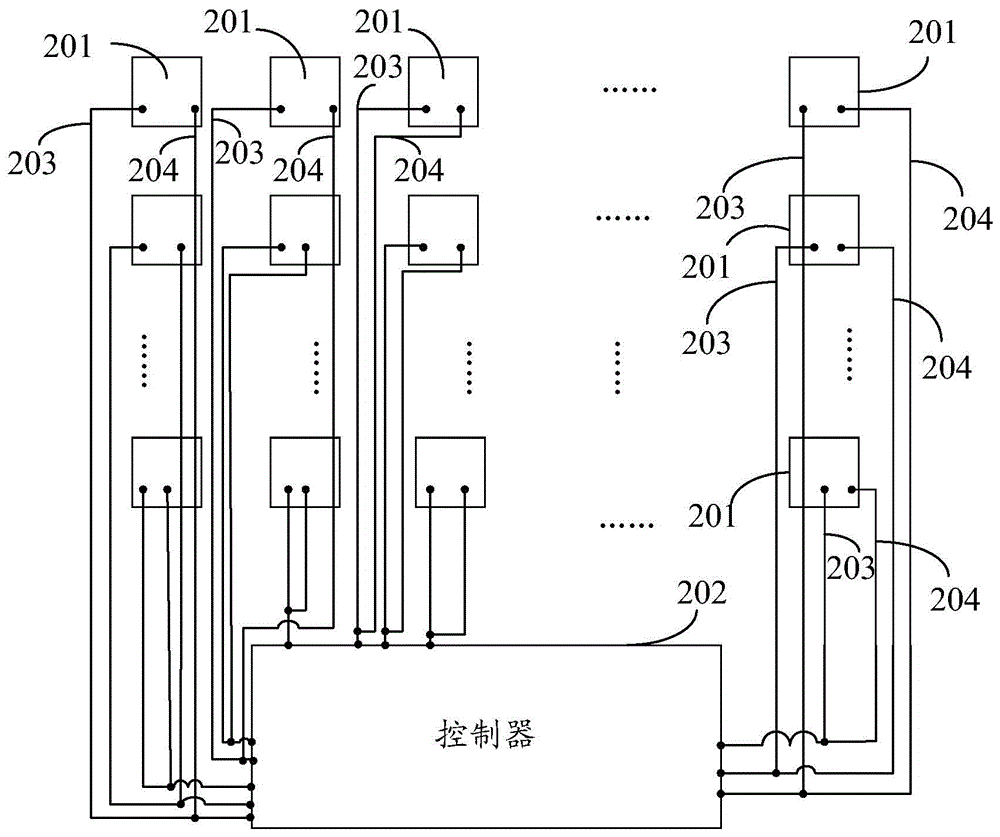

Array substrate, touch control display panel and touch control display device

ActiveCN105609037AReduce capacitanceReduce disconnectionStatic indicating devicesInput/output processes for data processingCapacitanceControl signal

The present invention discloses an array substrate, a touch control display panel and a touch control display device. The array substrate comprises a substrate, a display area and a non-display area around the display area. The non-display area is provided with a driving chip. The display area comprises a plurality of data lines which are electrically connected to the driving chip through multiple first connection lines. The data lines are corresponding to the first connection lines one to one. The array substrate also comprises multiple touch control electrode blocks which are electrically connected to the driving chip through multiple touch control signal lines. In the non-display area, the multiple touch control signal lines and the multiple first connection lines are not overlapped in a direction perpendicular to the substrate. According to the array substrate, the touch control display panel and the touch control display device, the capacitance between the touch control signal lines and the first connection lines is reduced, and thus the possibilities of electrostatic discharge and open or short circuit caused by the electrostatic discharge are reduced.

Owner:SHANGHAI AVIC OPTOELECTRONICS +1

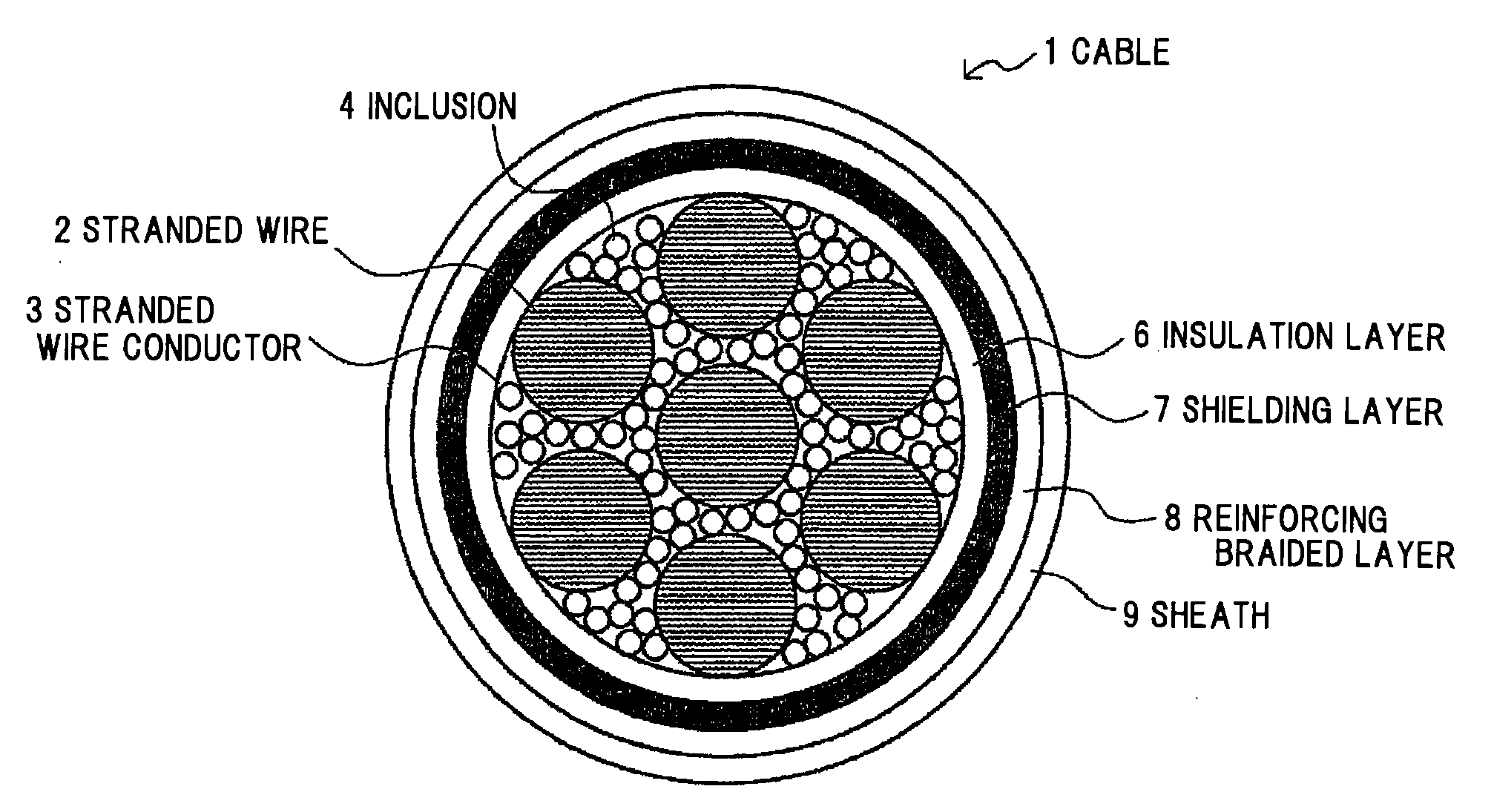

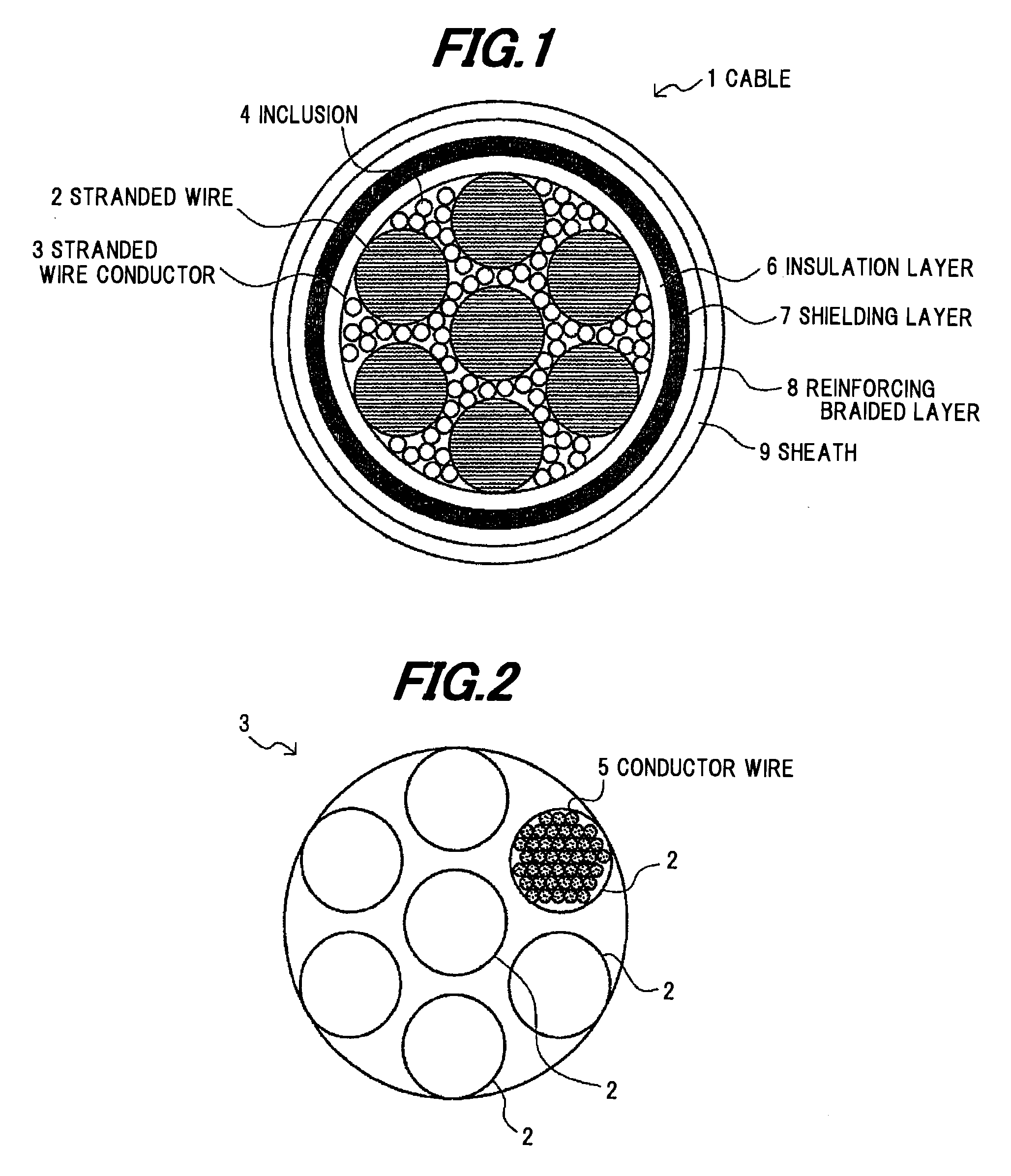

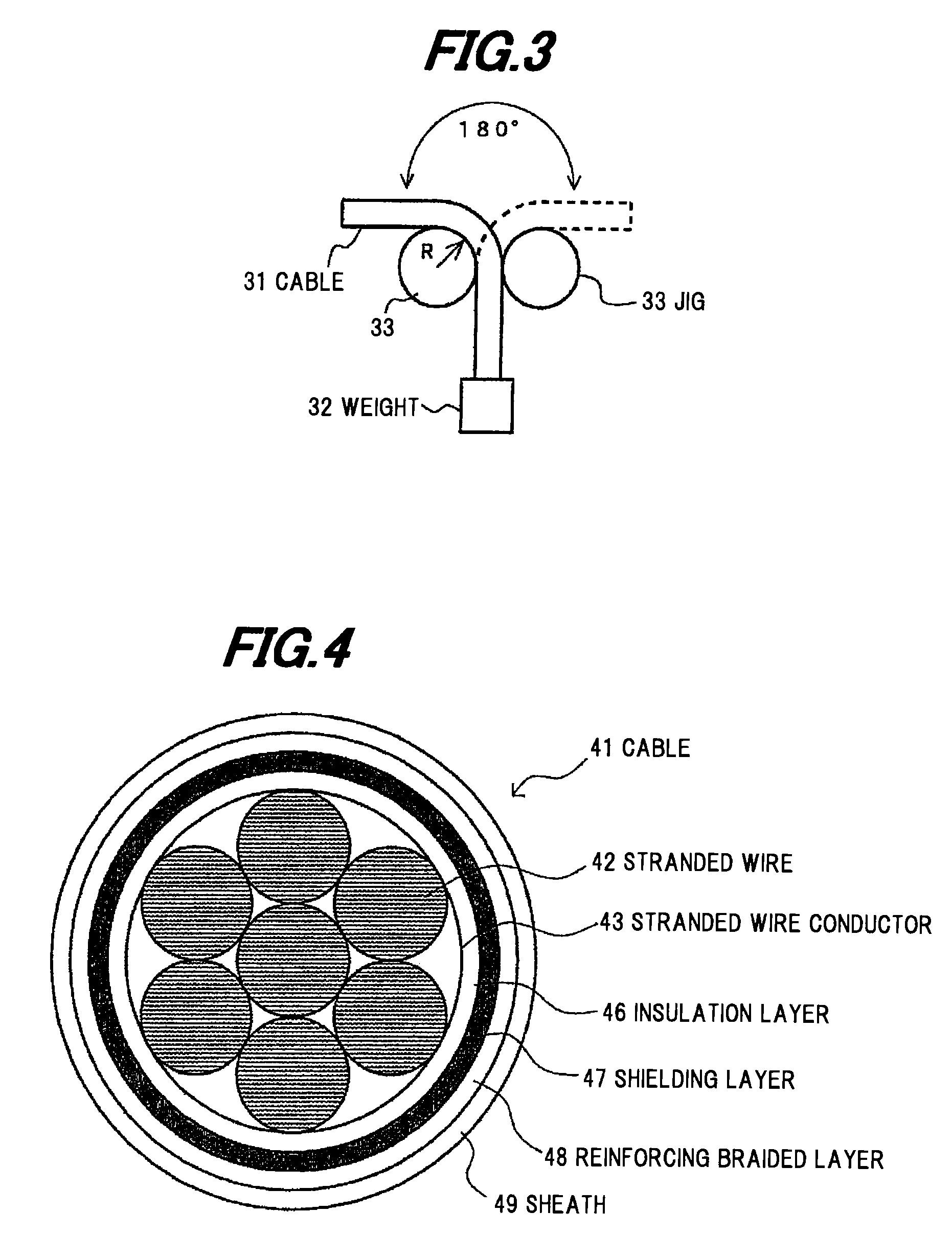

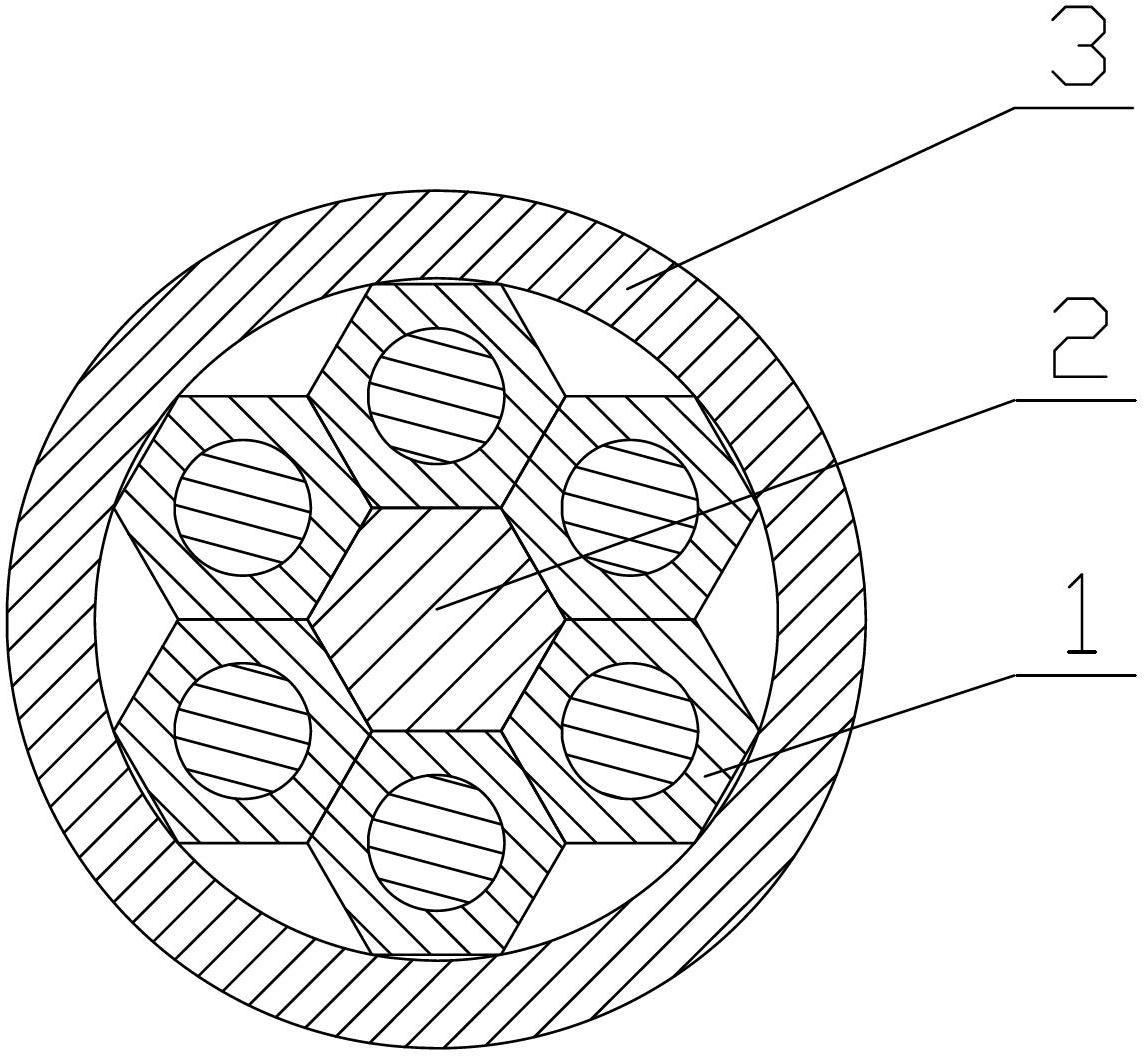

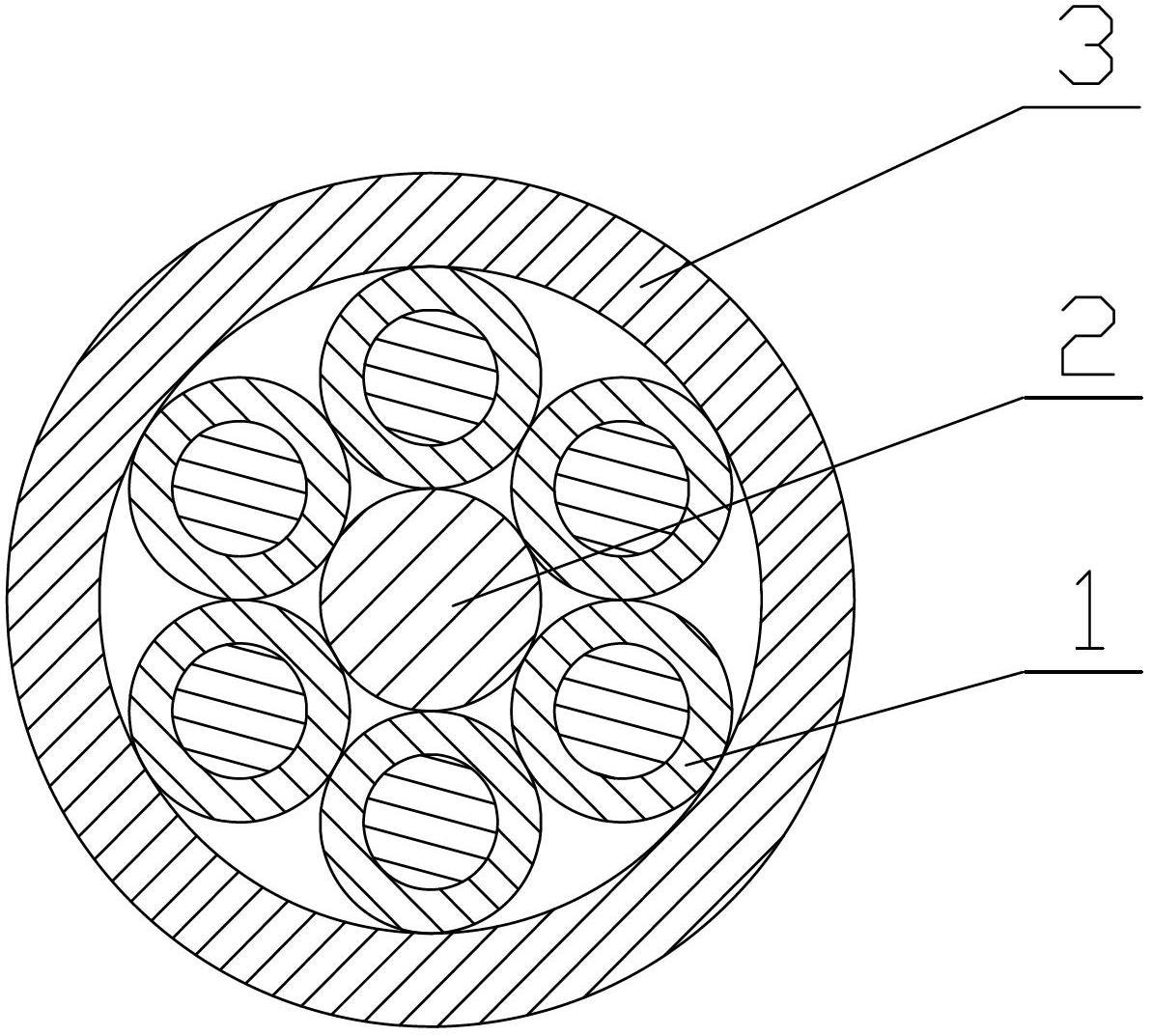

Cable

InactiveUS20110005805A1Reduce mutual contactImprove bending durabilityDetails of conductive coresFlexible cablesElectrical conductorEngineering

A cable includes an inclusion containing stranded wire conductor that includes a plurality of stranded wires formed by twisting a plurality of conductor wires, and a plurality of thin diameter inclusions having an external diameter thinner than that of each of the stranded wires. The inclusion containing stranded wire conductor is formed by together twisting a plurality of the stranded wires and a plurality of the thin diameter inclusions so as to allow one of the thin diameter inclusions to be located between adjacent stranded wires of a plurality of the stranded wires.

Owner:HITACHI CABLE

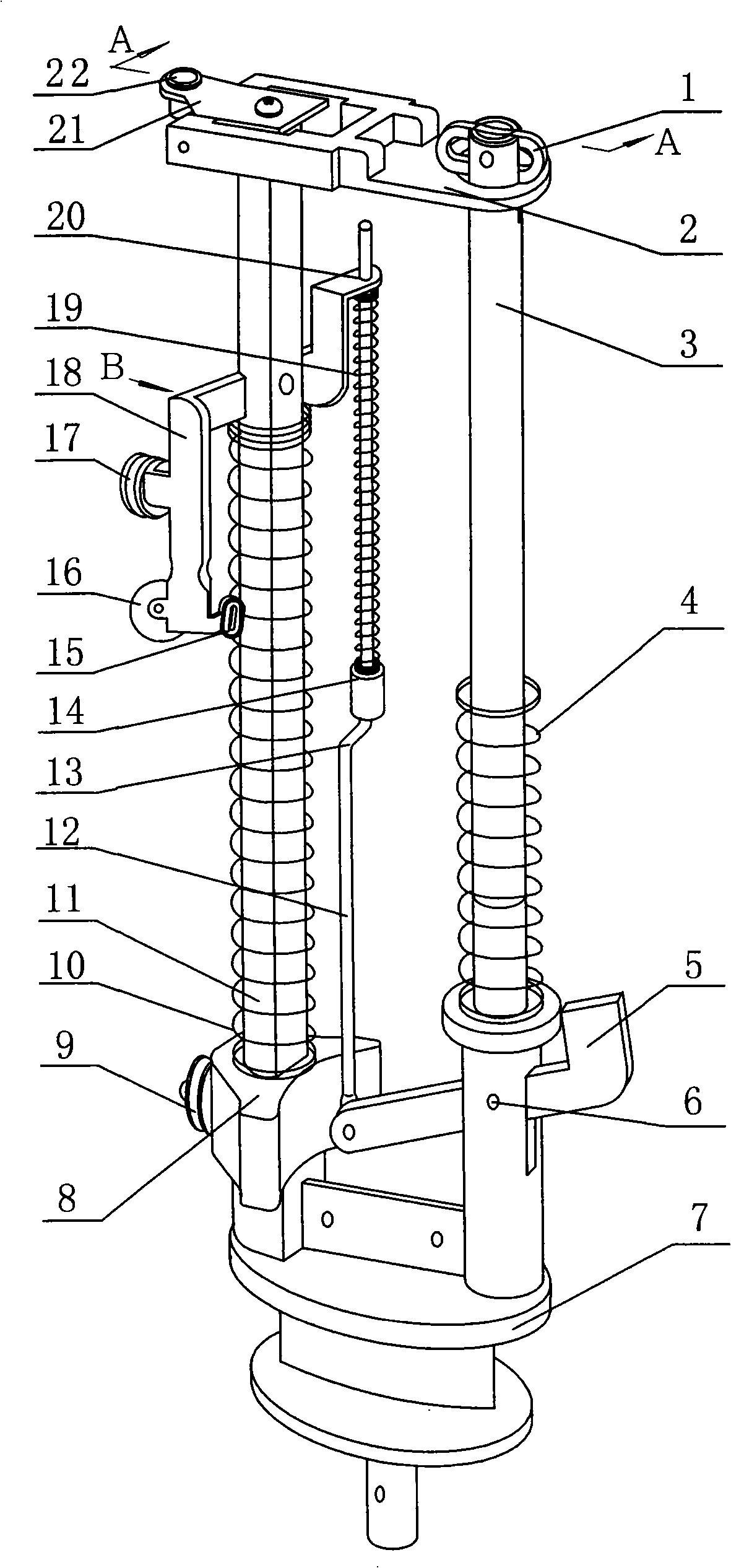

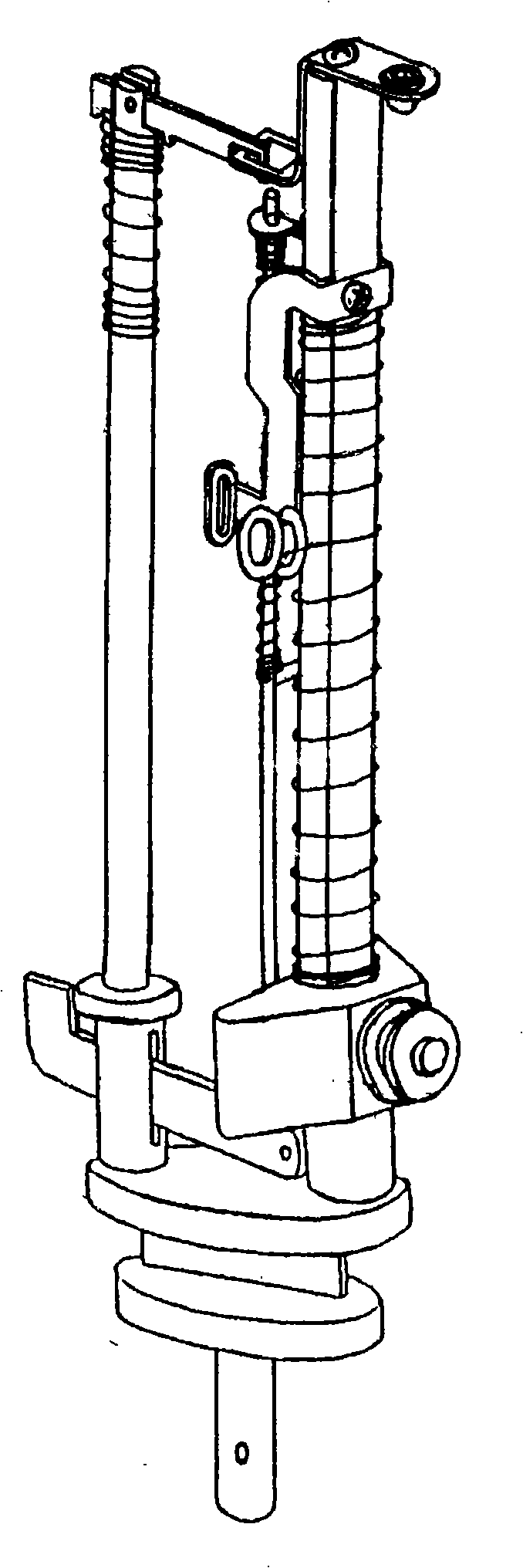

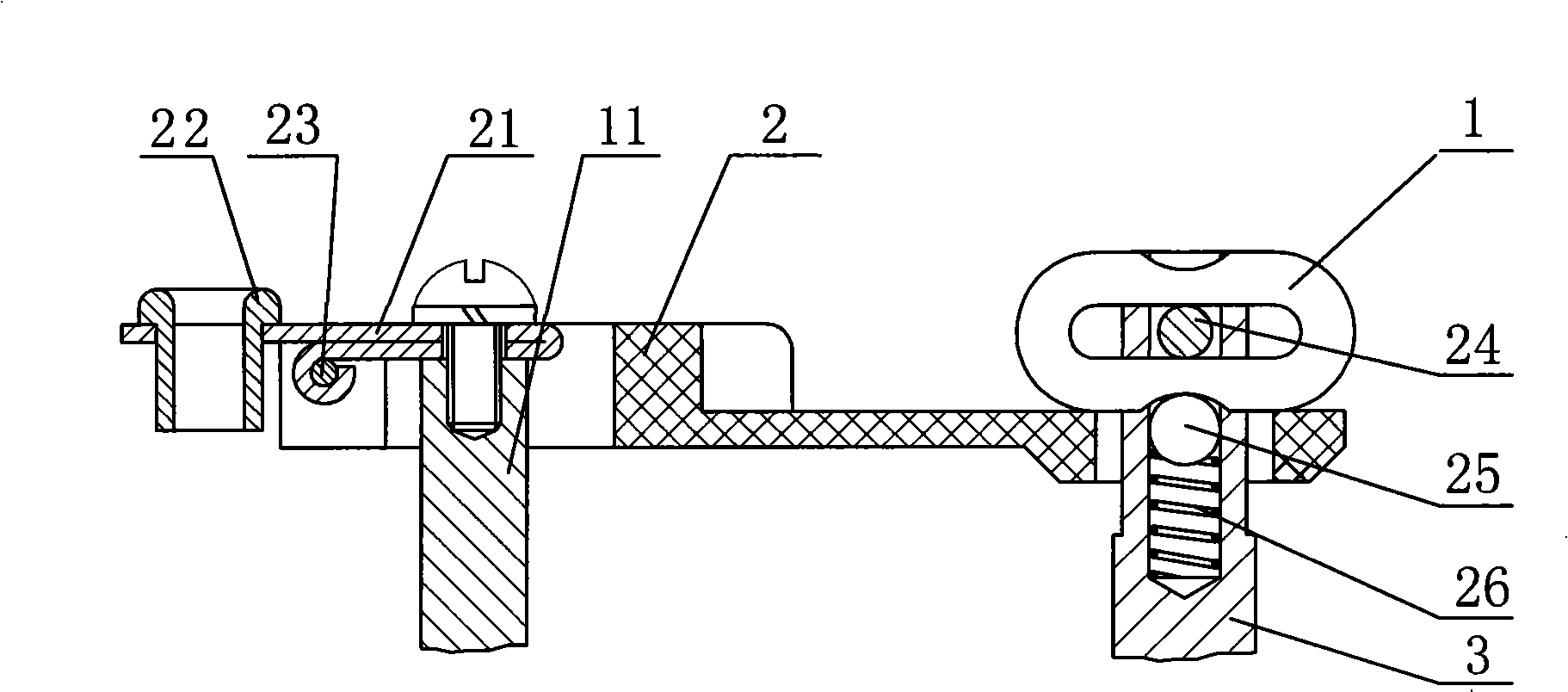

Spring spindle

The invention relates to a spring spindle, wherein, a fixed piece is formed by fixing a right upright post which is fixed with a support and a connecting rod and a left upright post on a track rod, and the spring spindle is formed by connecting a weaving piece and the fixed piece into a whole through a pressure plate and a switch plate; the support is flanged; a pulley is divided into an upper pulley and an intermediate pulley; the upper pulley and the intermediate pulley which are connected to the support are arranged on the right of the right upright post; mounting axial lines of the upper pulley and the intermediate pulley are crossed and angulated at 57 to 63 DEG; a vertical and bended straight section on the middle of the connecting rod is provided with a limit rod; and the pressure plate is matched with a lock catch which is connected to the left upright post. The support is arranged on the right of the right upright post instead of being arranged on the left of the right upright post, thereby the angle between a leading-in porcelain eye and a thread-passing point is reduced to between 27 and 33 DEG; the angle is smaller, the pay-out resistance on bobbin is smaller, and then the pay-out speed is quick and the thread breakage time is greatly reduced; the connecting rod and the support are arranged on both sides of the right upright post so as to maintain routing balance, thereby the speed can be improved by 10 percent and the weaving quality and the production efficiency are greatly improved; and simultaneously the pressure plate has good strength and long service life, is convenient, quick and easy to operate, and is an updated product of the third generation.

Owner:张宝香

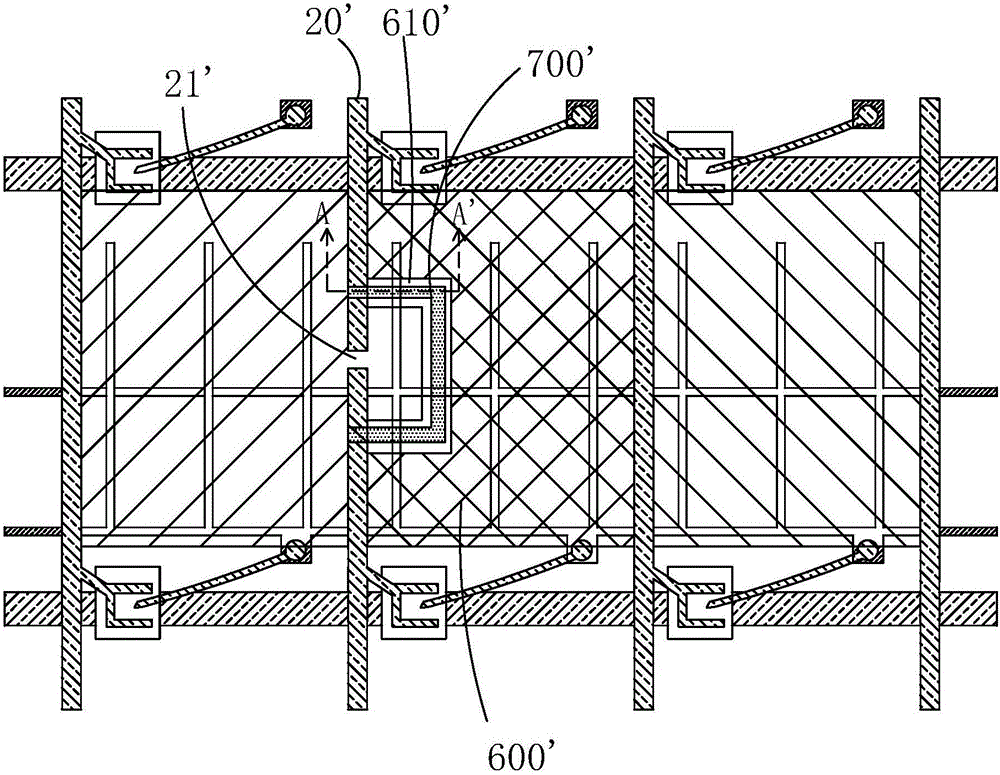

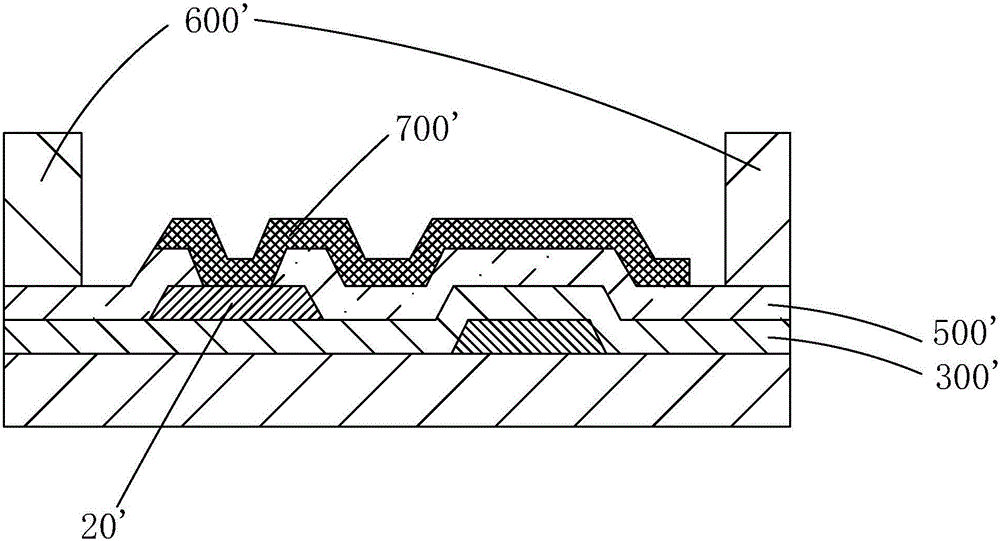

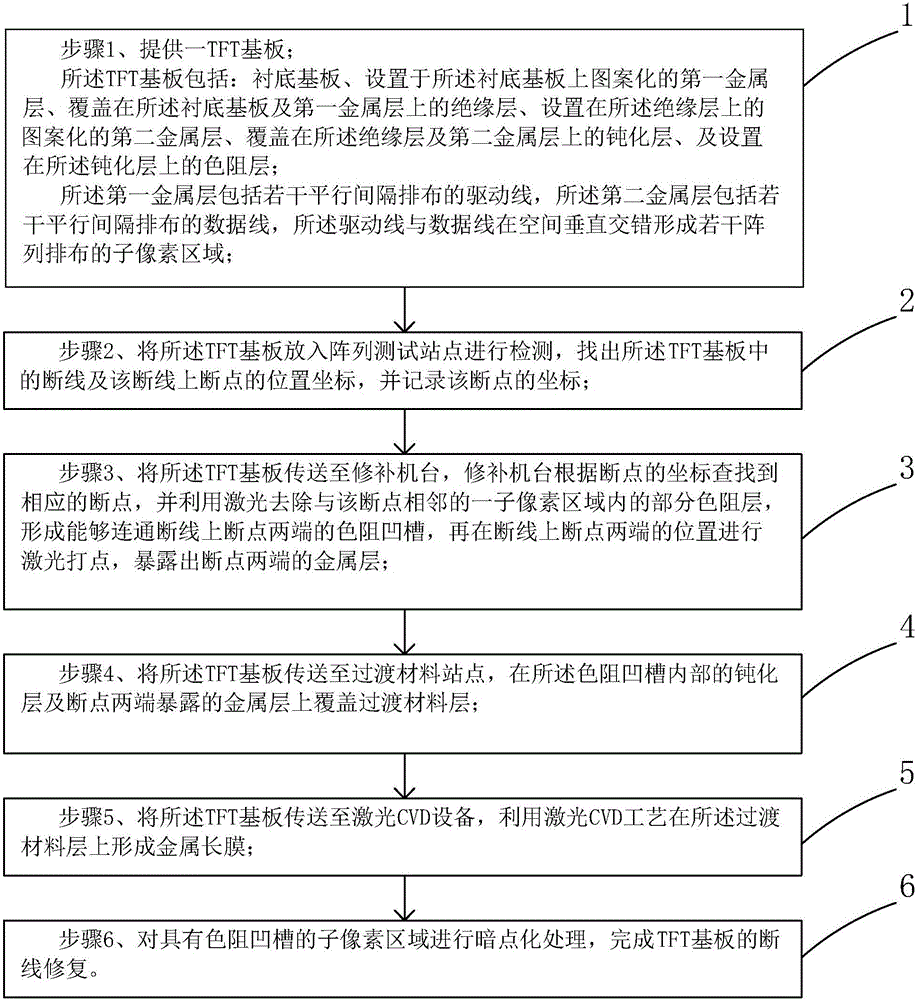

Broken wire restoration method for TFT substrate

ActiveCN105759522AImprove the success rate of disconnection repairGood adhesionSemiconductor/solid-state device testing/measurementSolid-state devicesRestoration methodEngineering

The invention provides a broken wire restoration method for a TFT substrate. The method comprises the steps of firstly, finding a broken wire in the TFT substrate and the position of a break point on the broken wire, then conducting processing on a passivation layer and the intersection positions, located at the two ends of the break point, of the broken wire separately so that a metal layer where the broken wire is located can be exposed, then covering the passivation layer and the exposed parts, at the two ends of the break point, of the metal layer with a transitional material layer, and finally, forming a metal long film on the transitional material layer, so that the parts, at the two ends of the break point, of the broken wire are communicated. Through arrangement of the transitional material layer, the problem that the restoration effect is not good due to residues of a color resistance layer or folds of the passivation layer can be solved, the adhesion effect and uniformity of the metal long film on the passivation layer are improved, wire breaking and peeling risks of the metal long film are lowered, and the success rate for restoring the broken wire of the TFT substrate is raised.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Wireless receiving device

InactiveCN101188365AReduce defectsReduce disconnectionBatteries circuit arrangementsElectromagnetic wave systemElectricityElectrical battery

The invention aims at providing a wireless incoming device and an electronic apparatus with the wireless incoming device. Wherein, the production cost does not increase even when the frequency of the electromagnetic wave receiving for power supply changes. Besides, the invention also aims at providing a wireless incoming device that the power can be transmitted by the manner of no wire break or poor connection when the load of power supply and the batter connected to the aerial are produced by different processes. The wireless incoming device of the invention comprises a power receiving part and a load part. The power receiving part is provided with a first aerial circuit, a second aerial circuit and a batter part. The load part is provided with a third aerial circuit. The battery of the battery part is charged through the first wireless signal receiving from the first aerial circuit and the power in the battery part is transmitted from the second aerial circuit as the second wirelesssignal. The third aerial circuit receives the second wireless signal to supply power to the load.

Owner:SEMICON ENERGY LAB CO LTD

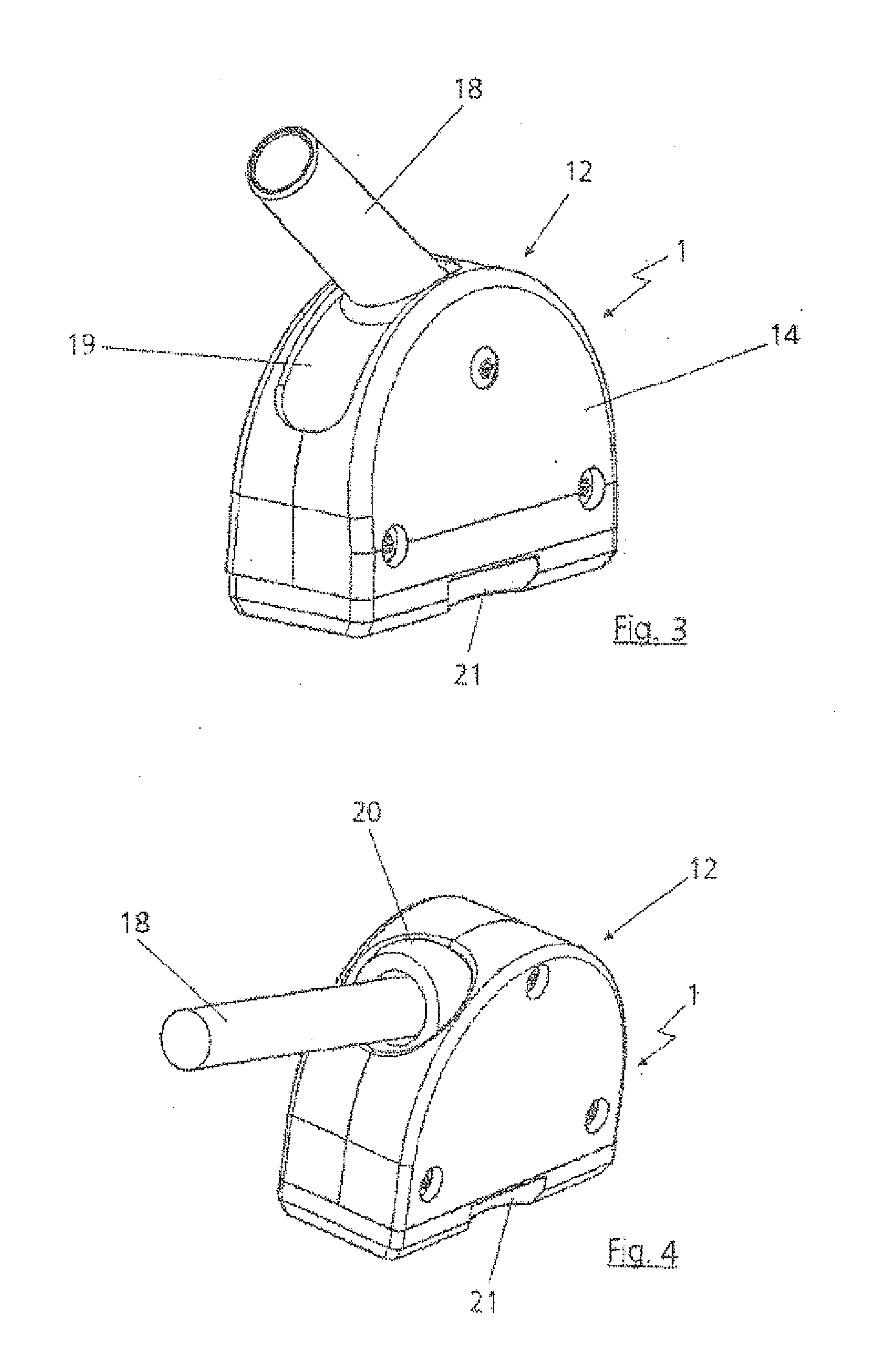

Preparation method for multi-core MgB2/Fe/Cu superconducting wire

ActiveCN102693785AIncrease the critical current densityImprove current carrying capacitySuperconductors/hyperconductorsSuperconductor devicesPower flowNiobium

The invention discloses a preparation method for a multi-core MgB2 / Fe / Cu superconducting wire. The preparation method comprises the following steps of: 1, preparing precursor powder; 2, filling the precursor powder into a pure iron tube, and placing the pure iron tube into a first oxygen-free copper tube to obtain a tubulated composite; 3, performing rotary forging and drawing treatment on the tubulated composite to obtain single-core wires; 4, placing a copper-niobium composite rod and six single-core wires into a second oxygen-free copper tube, performing secondary assembly to obtain a second composite rod, and performing rotary forging and drawing and grooving rolling treatment on the second composite rod to obtain a multi-core MgB2 / Fe / Cu wire; and 5, sealing the two ends of the wire, placing the sealed wire into a vacuum furnace, and performing vacuum sintering to obtain the multi-core MgB2 / Fe / Cu superconducting wire. The multi-core MgB2 / Fe / Cu superconducting wire has critical current density Jc reaching 1.8*10<4>A / cm<2> under 20 K and 1T, and a requirement for the practicability of the multi-core MgB2 / Fe / Cu superconducting wire is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

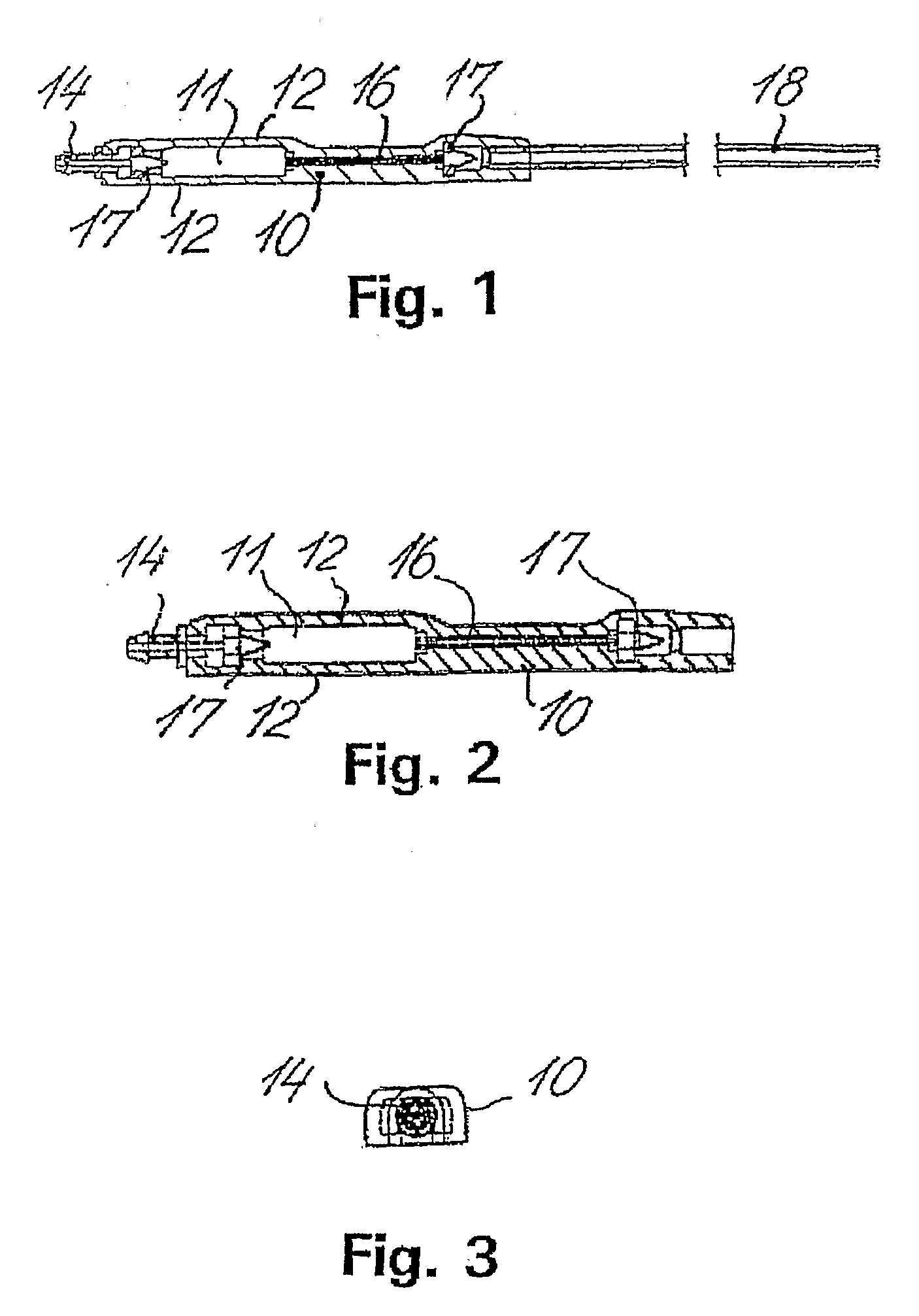

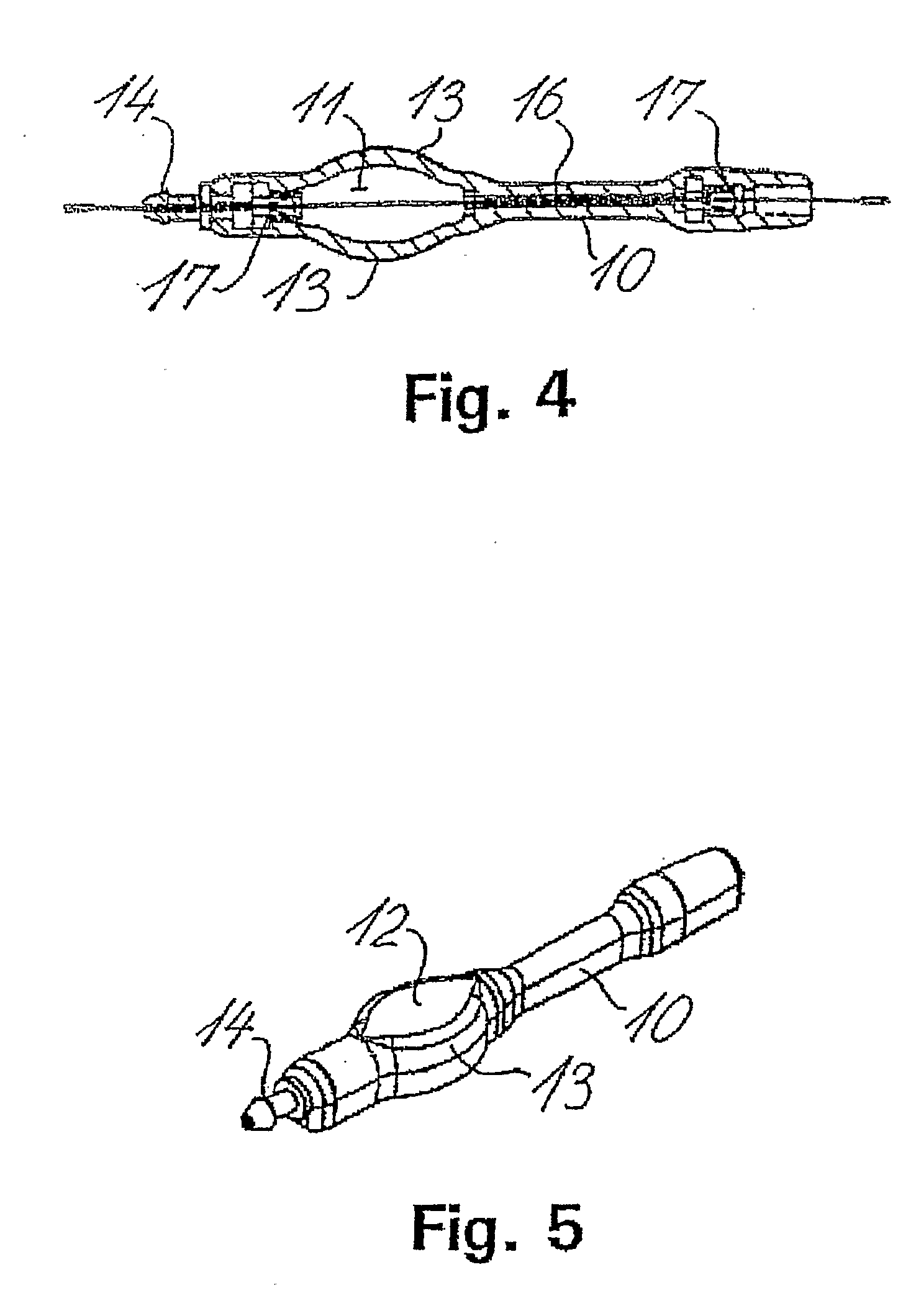

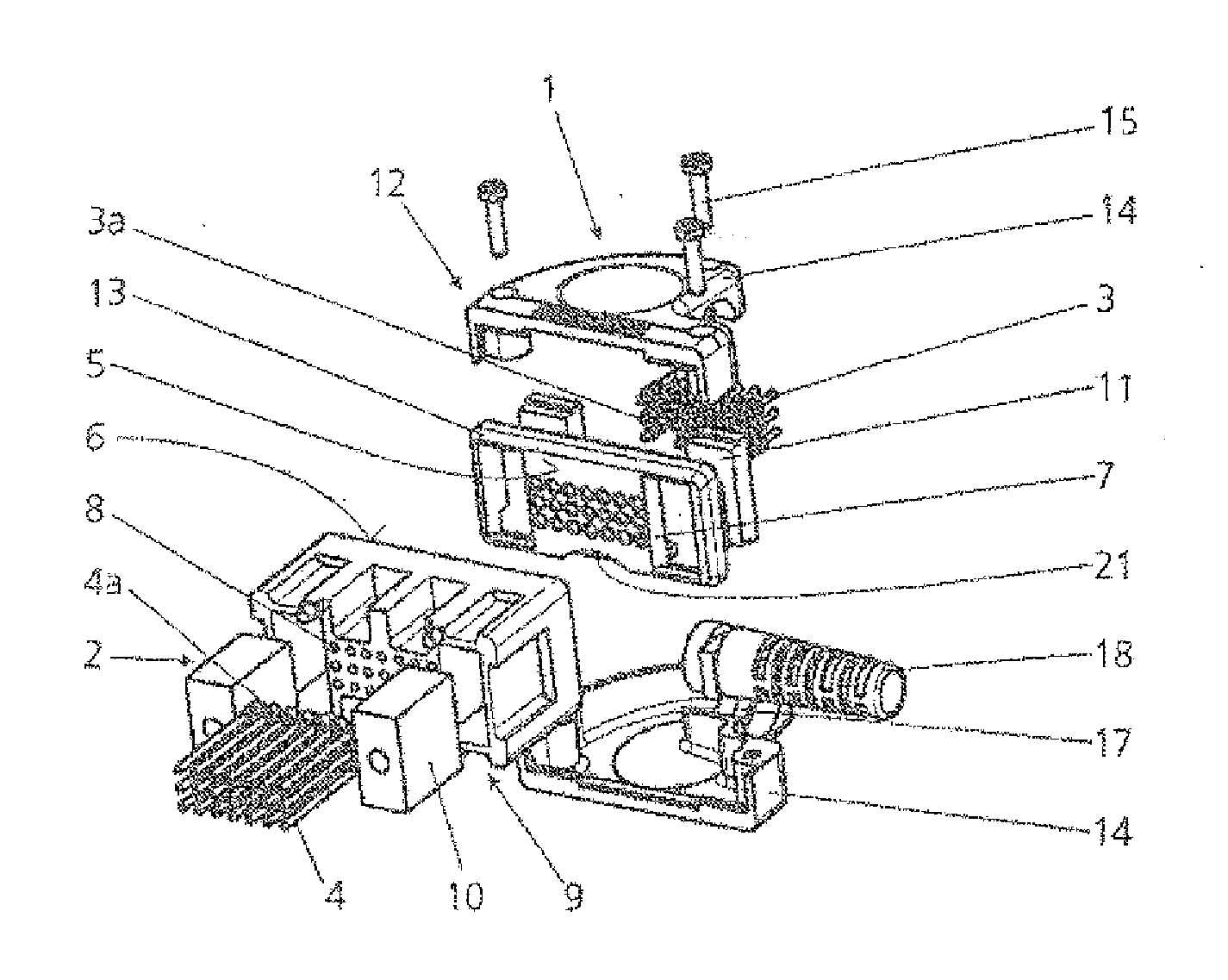

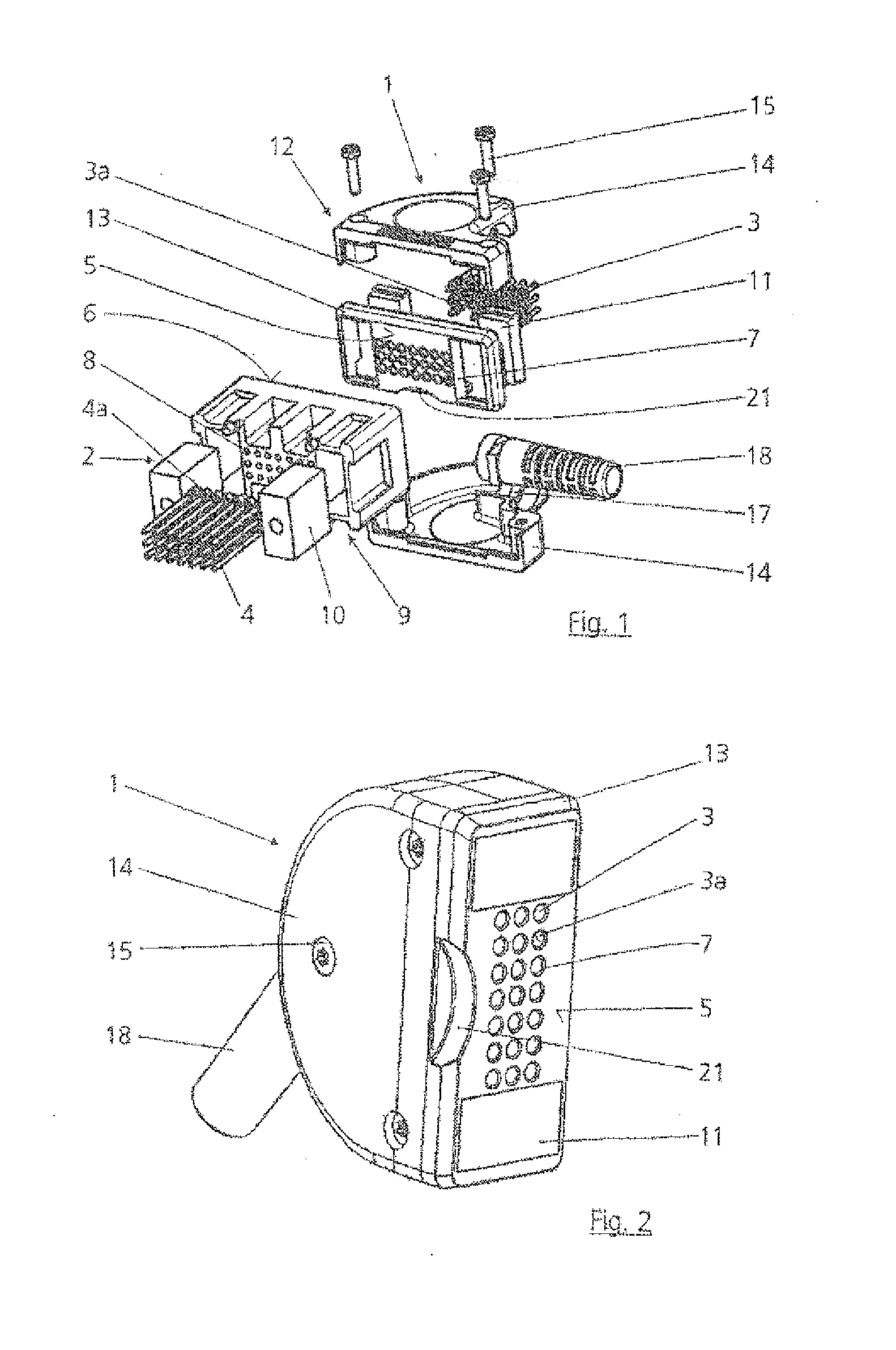

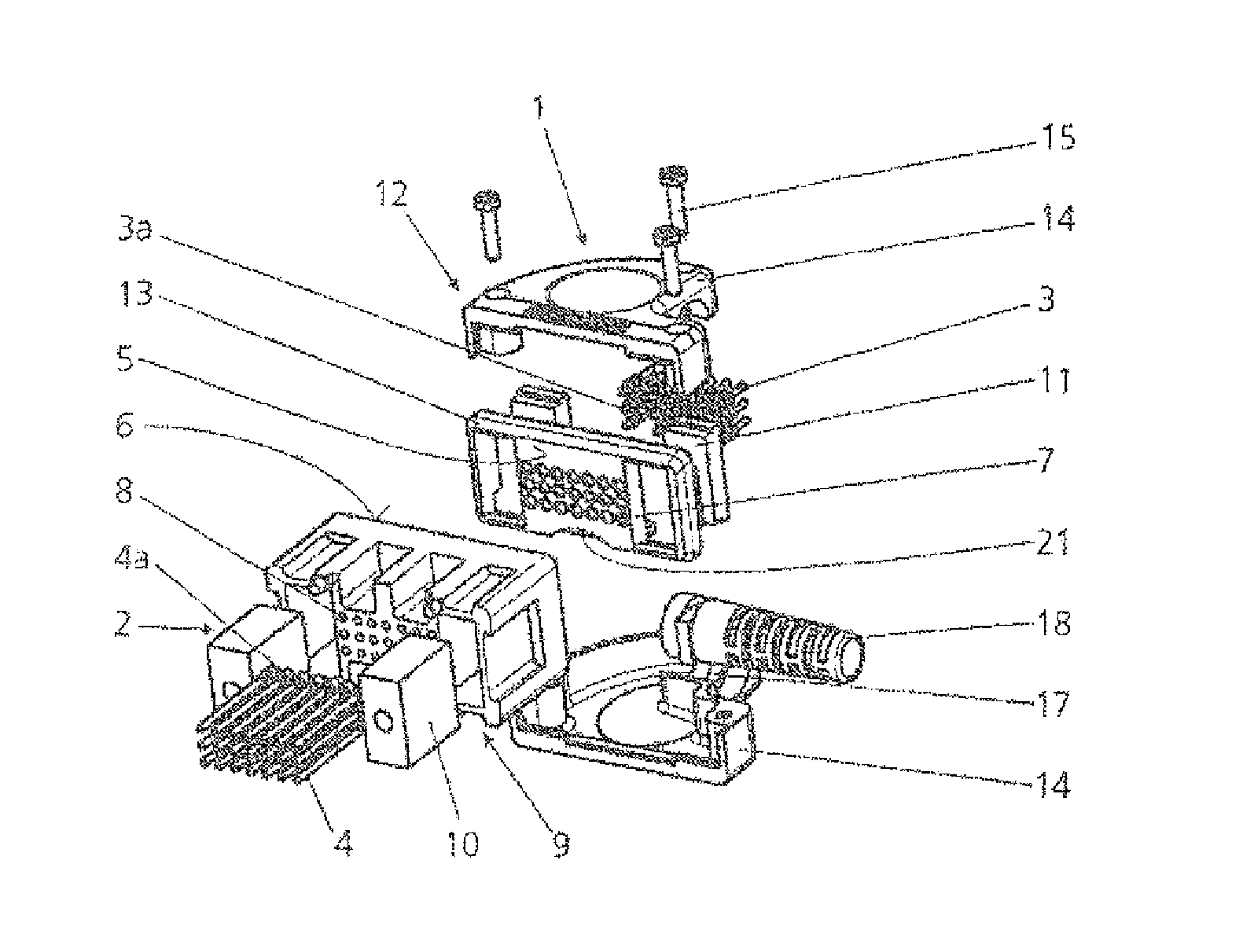

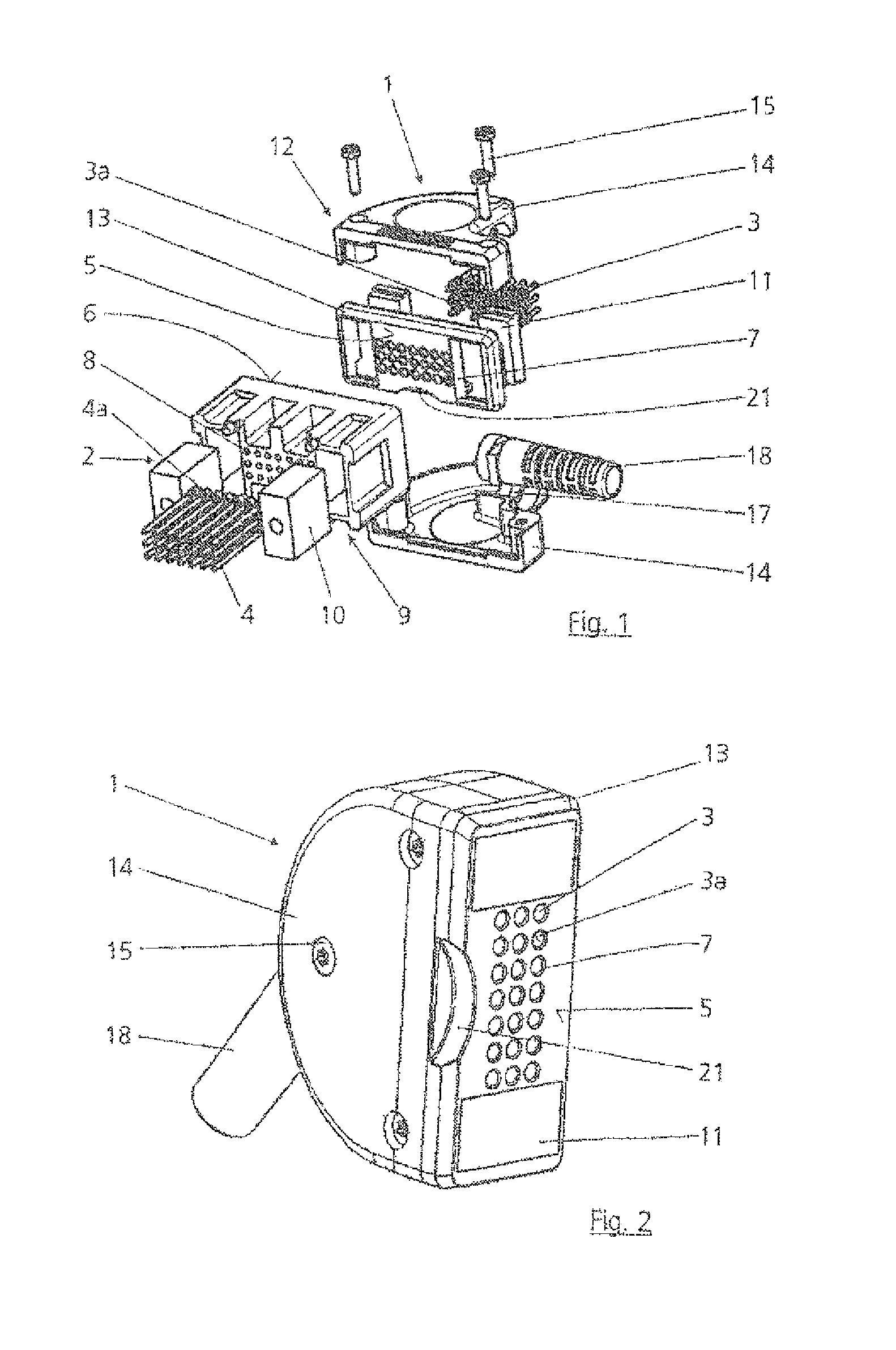

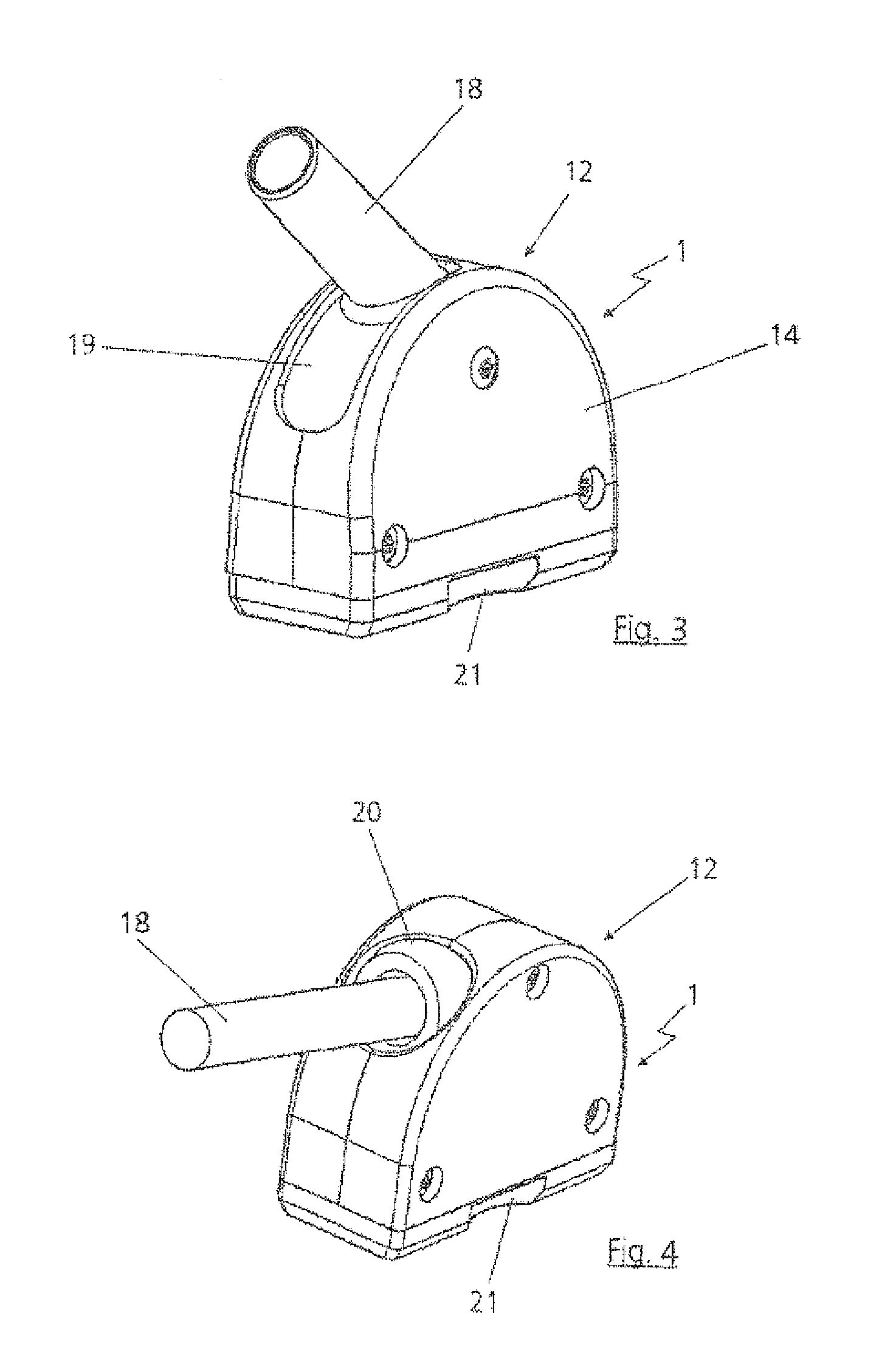

Electrical connection system

ActiveUS20130065407A1Reduce riskReducing risk of inadvertent disconnectionIncorrect coupling preventionCoupling contact membersMagnet deviceElectricity

An electrical connection system includes a plug having contact elements, and a socket having mating contact elements. The plug can be connected magnetically to the socket by means of a magnet device for transmitting signals or current. The magnet device has at least one connection pair, which comprises a magnet and a connecting element, which can be attracted by the magnet, but itself is not in the form of a permanent magnet, wherein respectively the magnet of a connection pair is arranged in the socket, and the connecting element which is not in the form of a permanent magnet is arranged in the plug.

Owner:ROSENBERGER HOCHFREQUENZTECHNIK GMBH & CO KG

Touch panel and touch type display device

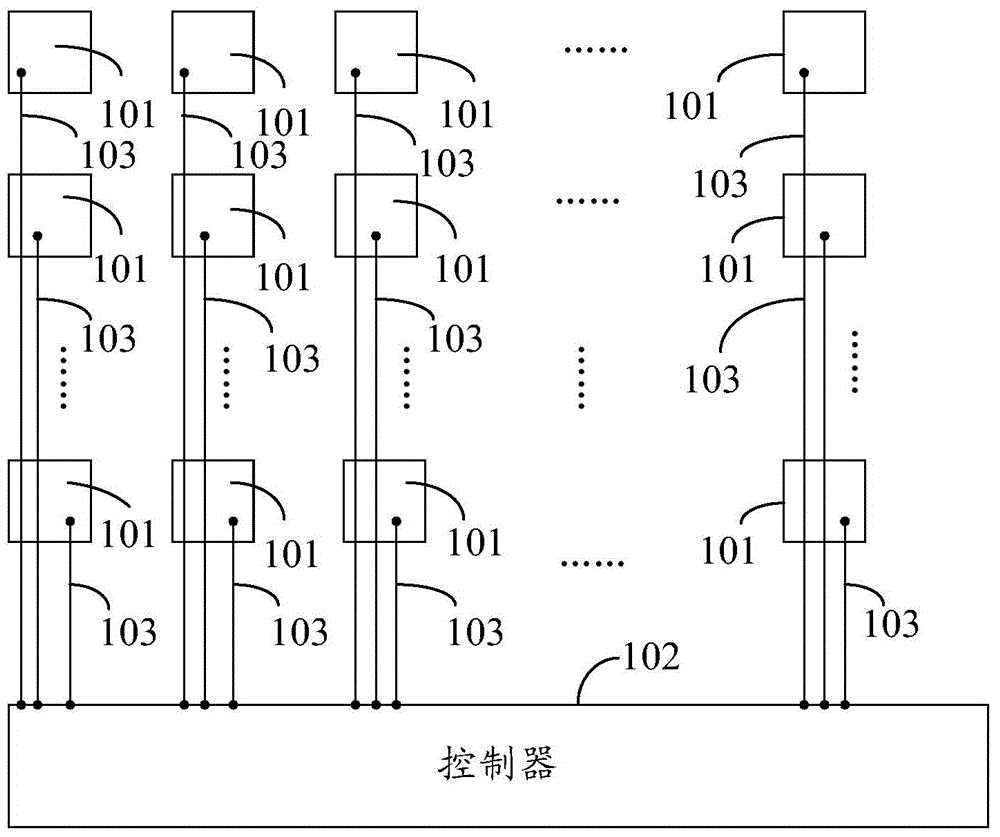

InactiveCN104391601AReduce disconnectionSave pin resourcesNon-linear opticsInput/output processes for data processingDisplay deviceHuman–computer interaction

The invention discloses a touch panel and a touch type display device. The touch panel comprises a controller and a plurality of arrayed touch electrodes, and each touch electrode is electrically connected with the same pin of the controller through at least two leads. By the mode, the problem of disconnection of the leads among the touch electrodes and the controller can be effectively improved, defective rate is decreased, and the service life of the touch panel is prolonged.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

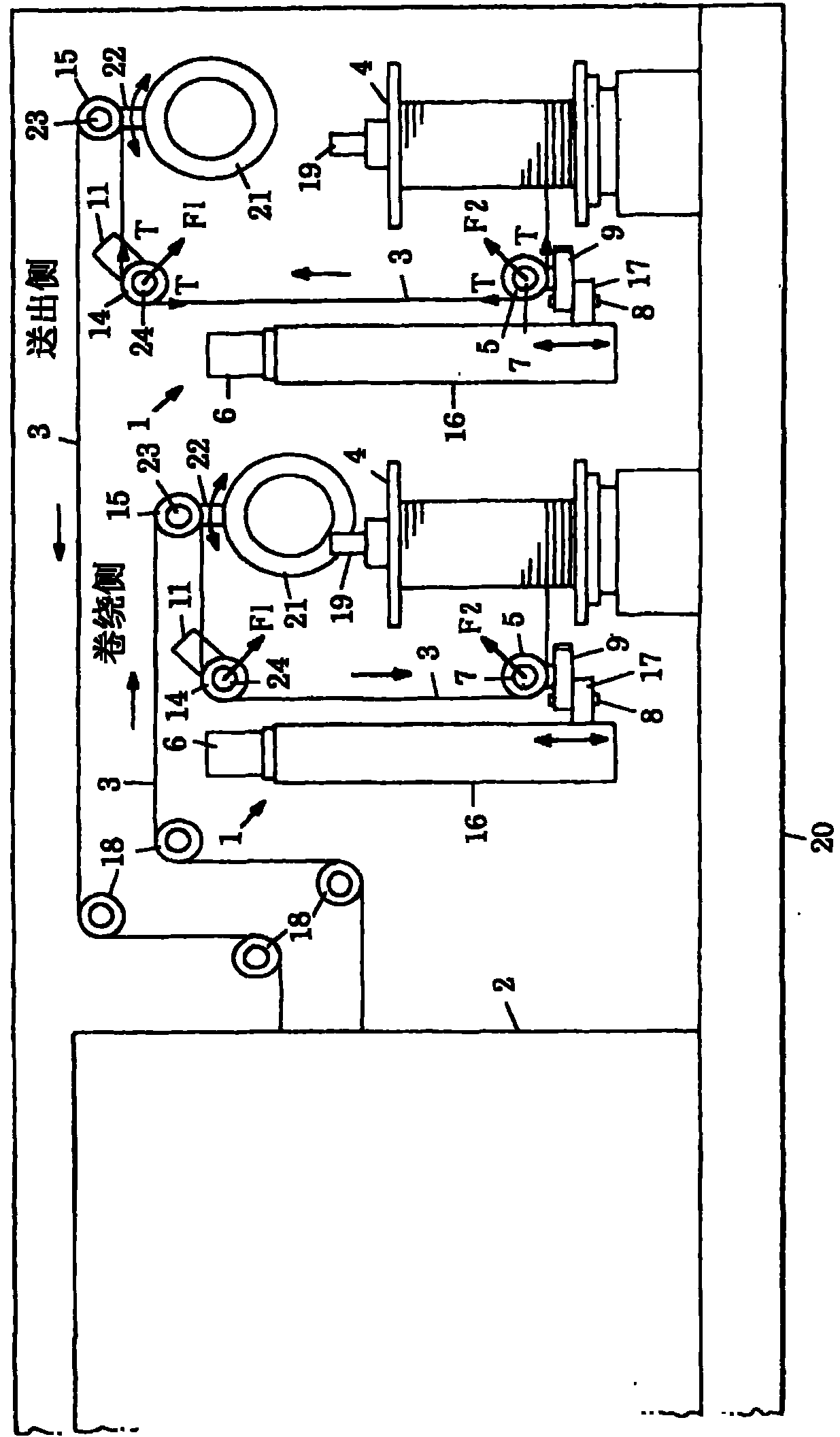

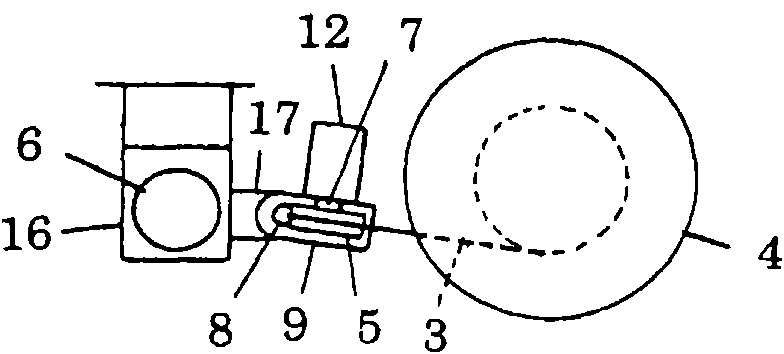

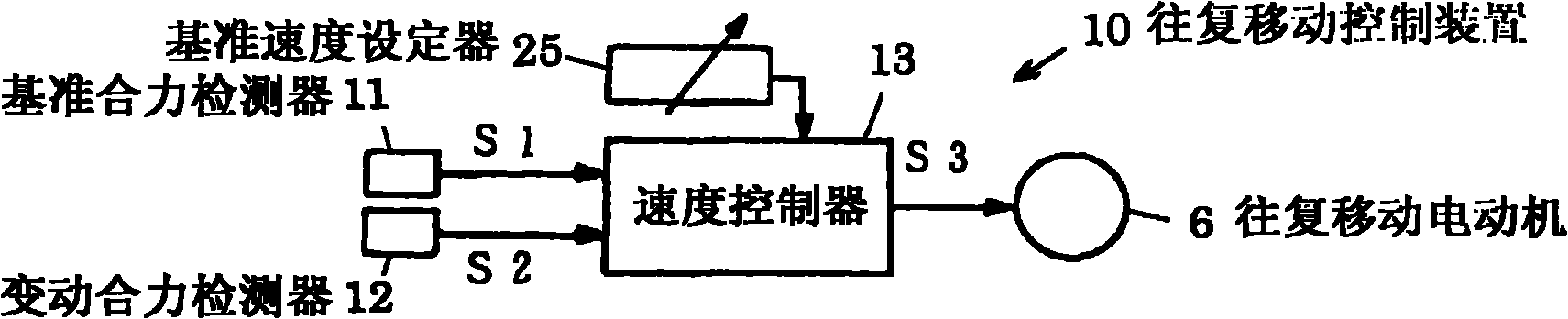

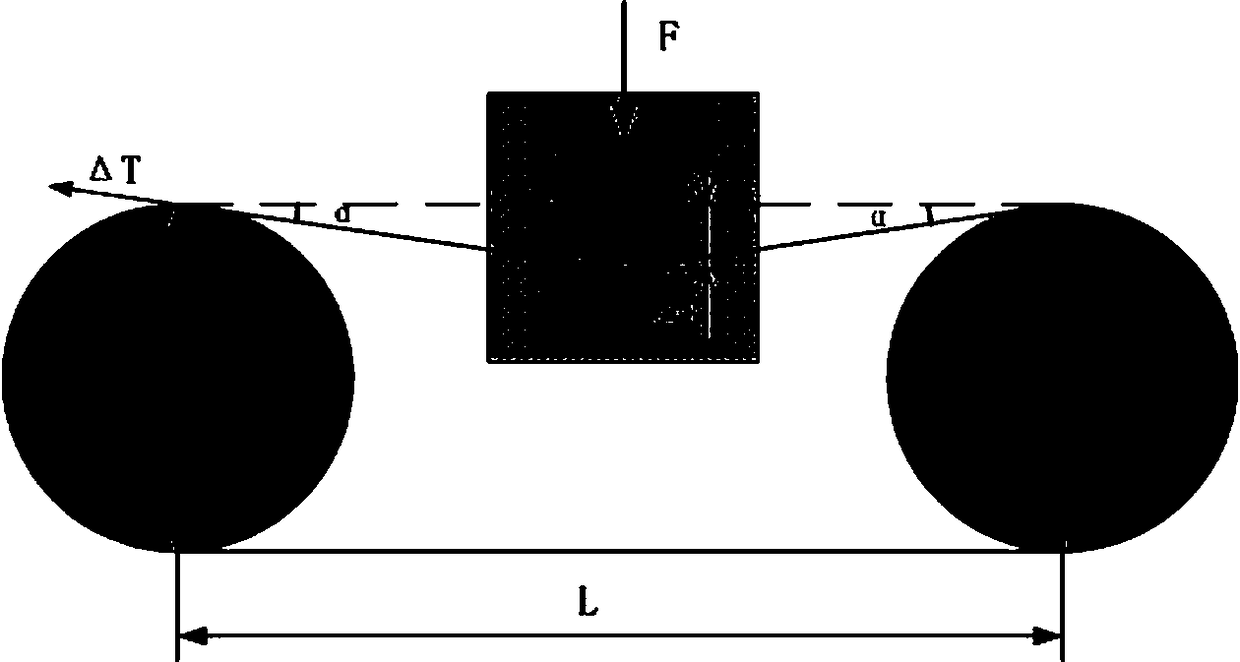

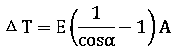

Traverse control method and traverse control device

ActiveCN101804927ADisengagement will not occurUnfavorable situations such as disconnection will not occurFilament handlingMetal working apparatusWire rodReciprocating motion

The invention provides a traverse control technology, capable of preventing the deviation and broken line of a wire rod in advance with the bigger change of the wire rod reeling spacing. A traverse device (1), reels the wire rod (3) of a reel (4) for a linear saw (2) on a traverse roller (5) and a tension roller (14), when the traverse roller (5) is the reciprocating motion along the axial direction of the reel (4), the target position of the wire rod (3) is in the right-angle direction relative to the axial direction of the reel (4) between the reel (4) and the traverse roller (5), the reference force (F1) of the wire rod (3) is detected at the tensioning roller (14), the variation force (F2) based on the displacement of the wire rod (3) deviated from the target position is detected at the traverse roller (5), based on the variation of the difference (delta F) of the reference force (F1) and the variation force (F2), the reciprocating speed (V) of the traverse roller (5) is controlled.

Owner:KOMATSU NTC LTD

Method for manufacturing a thin film transistor array panel

InactiveUS20110177639A1CohesionFurther manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingLine widthImage resolution

A thin film transistor display panel includes gate wiring formed on an insulation substrate and including gate lines, and gate electrodes and gate pads connected to the gate lines; a gate insulation layer covering the gate wiring; a semiconductor pattern formed over the gate insulation layer; data wiring formed over the gate insulation layer or the semiconductor pattern and including source electrodes, drain electrodes, and data pads; a protection layer including a Nega-PR type of organic insulating layer formed all over the semiconductor pattern and the data wiring, wherein the thickness of the Nega-PR type of organic insulating layer in both the gate and data pad regions is smaller than in the other regions; and a pixel electrode connected to the drain electrode. When exposing the Nega-PR type of passivation layer in the pad region during a photolithography process, a photomask having a lattice pattern made of a metal such as Cr that has a line width of less than the resolution of a light exposer is used. Thus, the resulting post-etch height of the passivation layer can be selectively controlled so as to provide reduced effective thickness in the pad regions.

Owner:SAMSUNG DISPLAY CO LTD

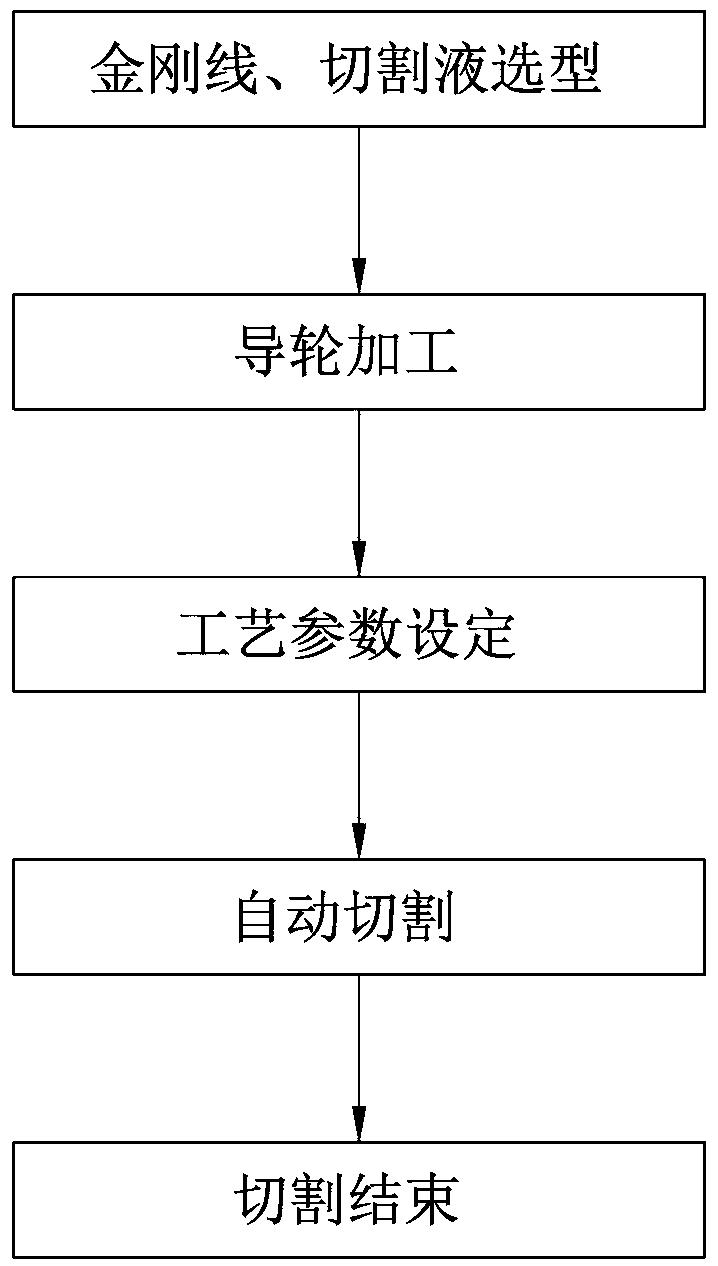

High-efficiency cutting method for crystalline silicon blocks

InactiveCN109304819AThe process takes a short timeIncrease slicing capacityFine working devicesMicrometerCrystalline silicon

The invention discloses a high-efficiency cutting method for crystalline silicon blocks in the field of solar energy application. The high-efficiency cutting method comprises the following steps of 1)diamond wire and cutting liquid selection, wherein a single-polycrystalline mixed sand electroplating diamond wire (the diamond wire diameter ranges from 50 micrometers to 70 micrometers is adopted,the cutting fluid is selected from a low COD coolant and pure water mixture; 2) guide wheel processing; 3) process parameter setting, wherein the diamond wire, the cutting fluid and a guide wheel arematched, after a cutting machine is assembled, the feeding speed of the working table is adjusted to be 800-3000micrometers per minute, the cutting fluid process flow is 110-180 KG / Min, the cutting liquid cooling temperature is 17-23 DEG C; 4) automatic cutting, wherein after the machine is started for warming up by 5-10 minutes, when it is known that the parameters are normal through spot check,automatic cutting starts; and 5) ending of cutting, wherein a rod is lifted to complete silicon block cutting. The high-efficiency cutting method effectively improves the cutting speed and the cuttingefficiency, improves the yield rate, reduces the cost of auxiliary materials like the diamond wire consumption, improves the slice profitability, and can be used for silicon wafer production.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

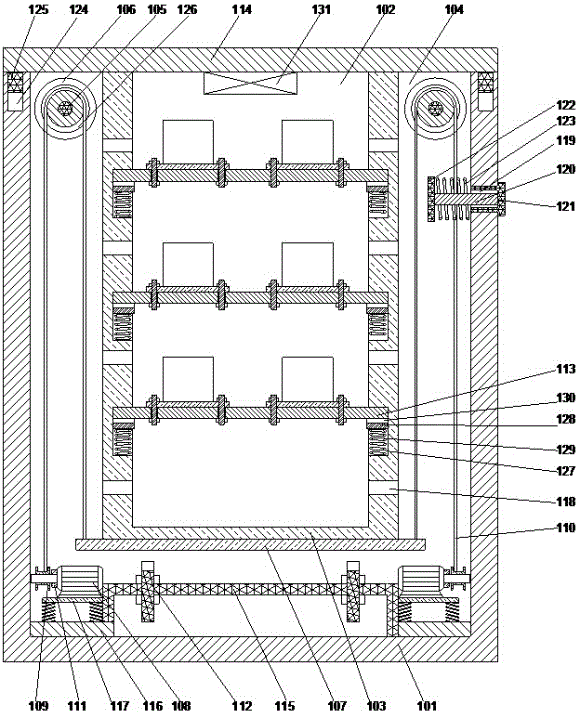

Power distribution cabinet

InactiveCN106129833AReduce disconnectionGuaranteed stabilitySubstation/switching arrangement casingsAnti-seismic devicesEngineeringElectrical and Electronics engineering

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Electrical connection apparatus

ActiveUS8894420B2Reducing risk of inadvertent disconnectionReduce disconnectionEngagement/disengagement of coupling partsRelieving strain on wire connectionElectricityElectrical connection

An electrical connection system includes a plug having contact elements, and a socket having mating contact elements. The plug can be connected magnetically to the socket by means of a magnet device for transmitting signals or current. The magnet device has at least one connection pair, which comprises a magnet and a connecting element, which can be attracted by the magnet, but itself is not in the form of a permanent magnet, wherein respectively the magnet of a connection pair is arranged in the socket, and the connecting element which is not in the form of a permanent magnet is arranged in the plug.

Owner:ROSENBERGER HOCHFREQUENZTECHNIK GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com