Patents

Literature

36results about How to "Improve bending durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

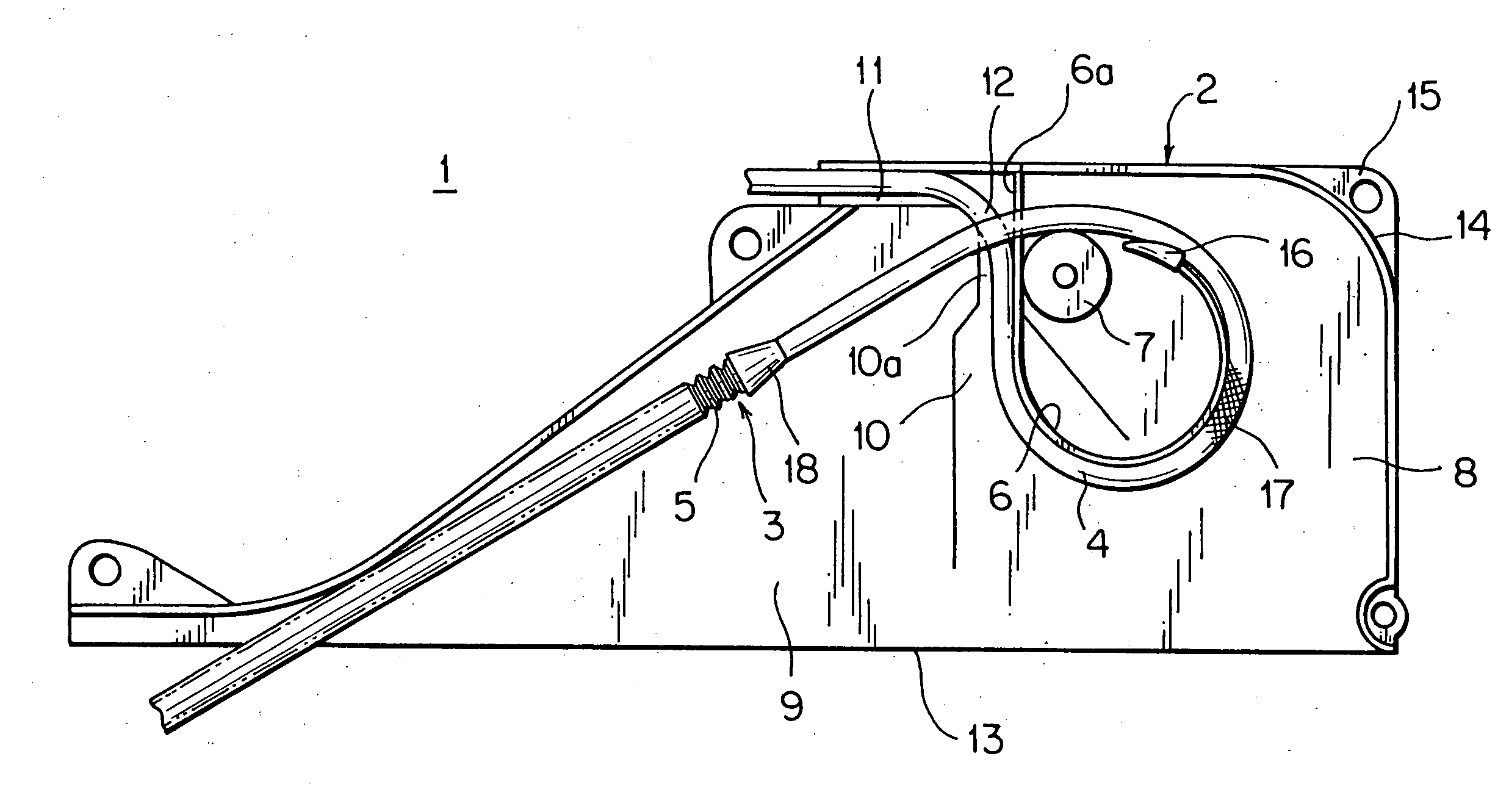

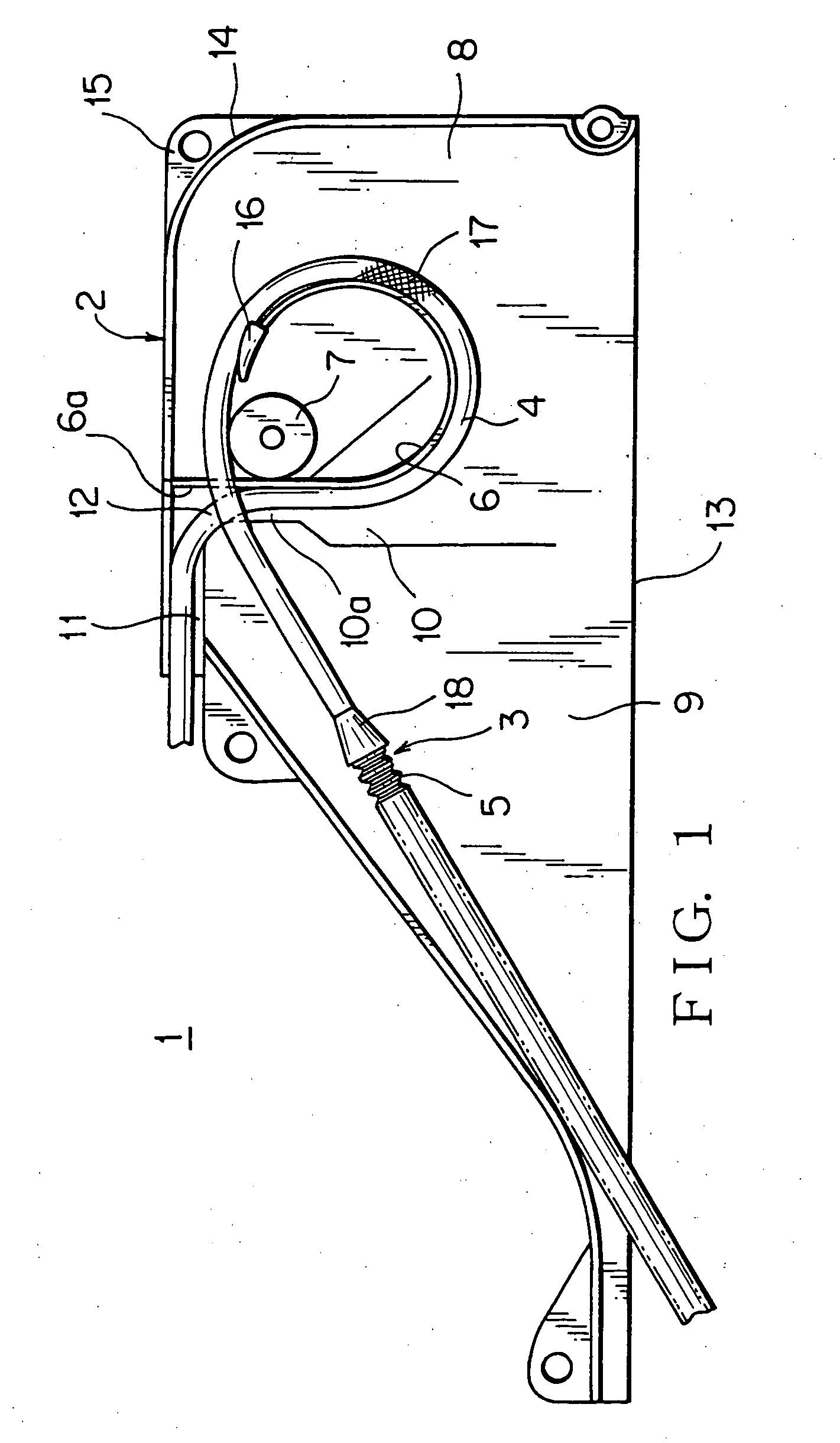

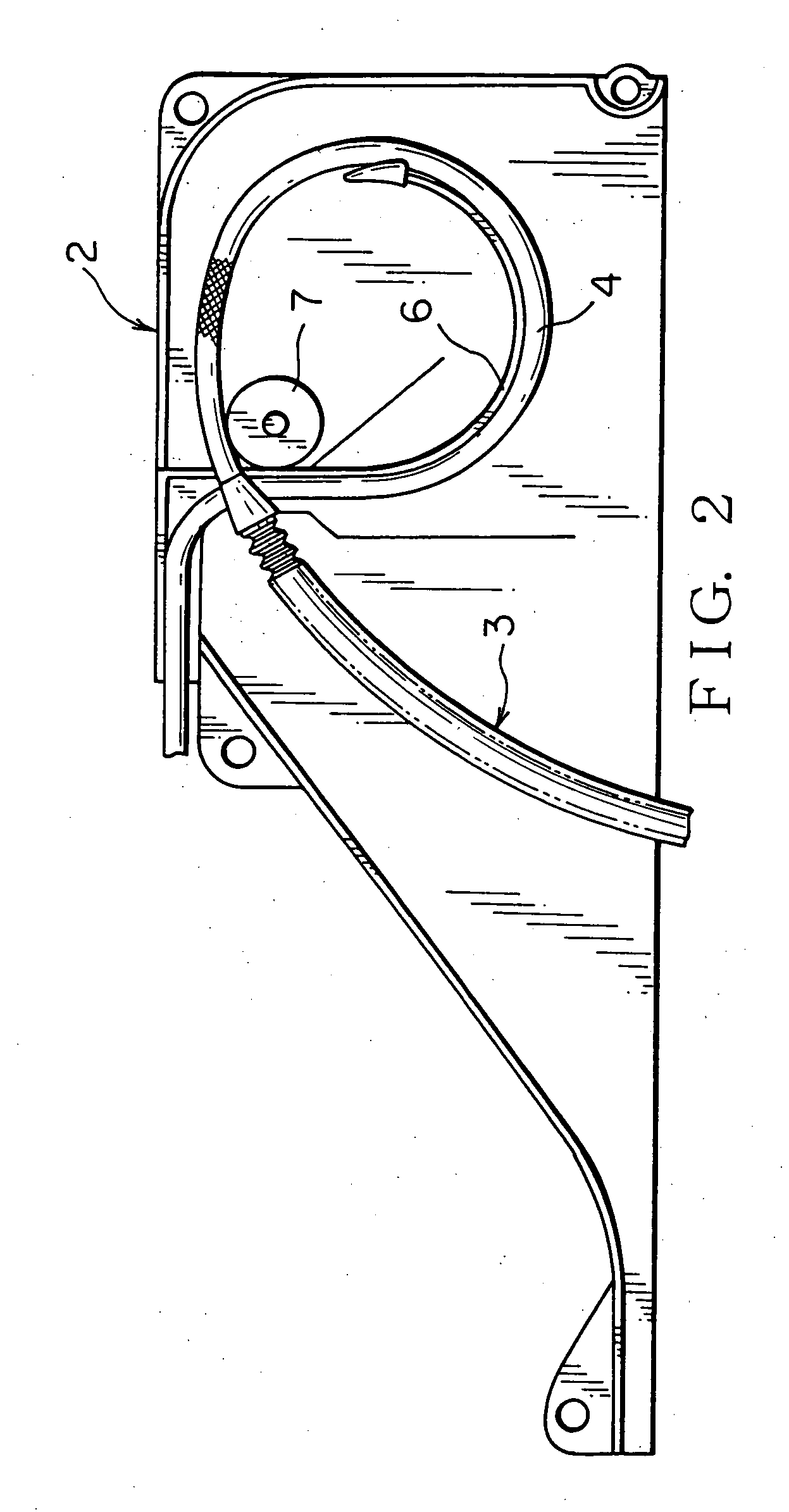

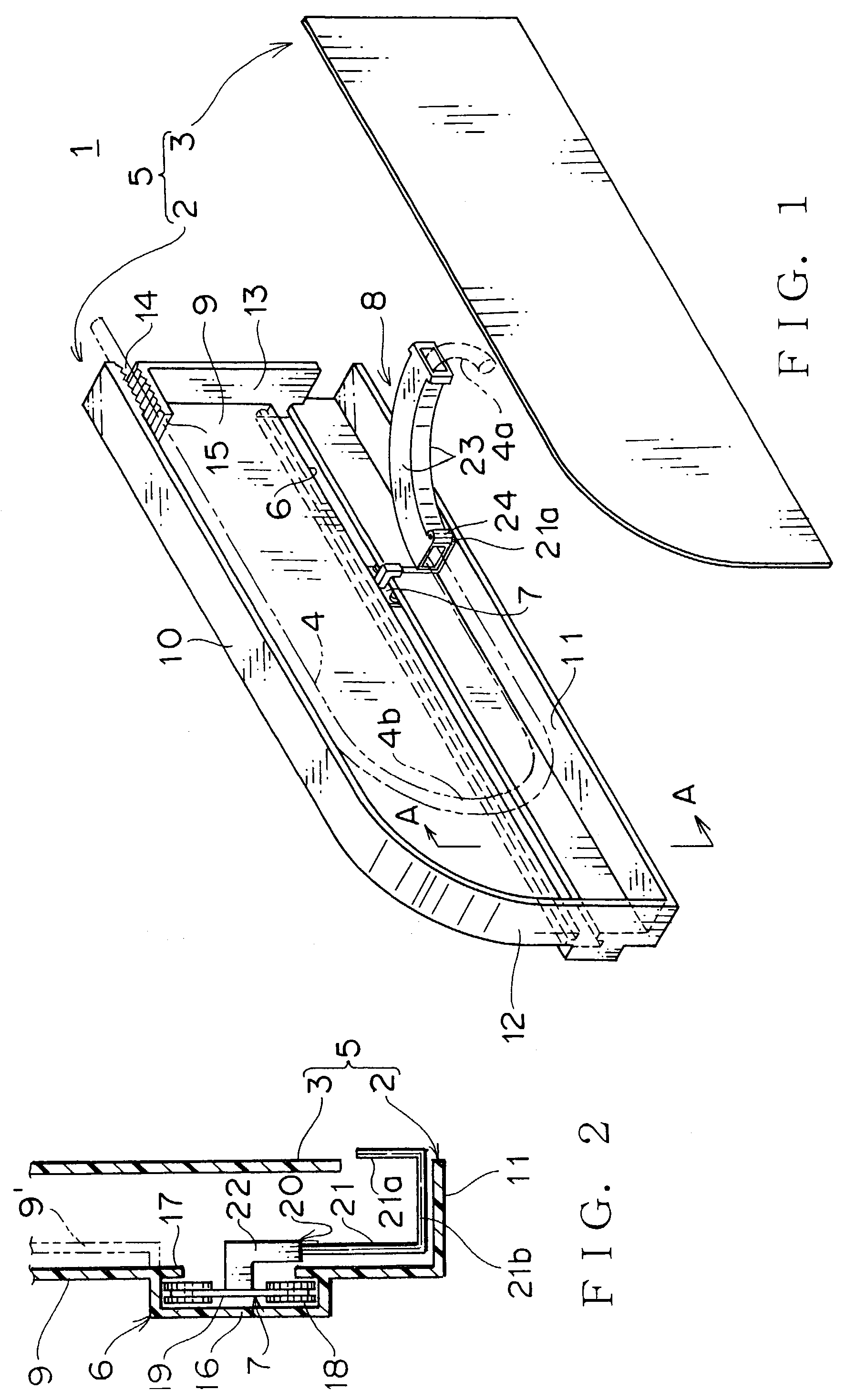

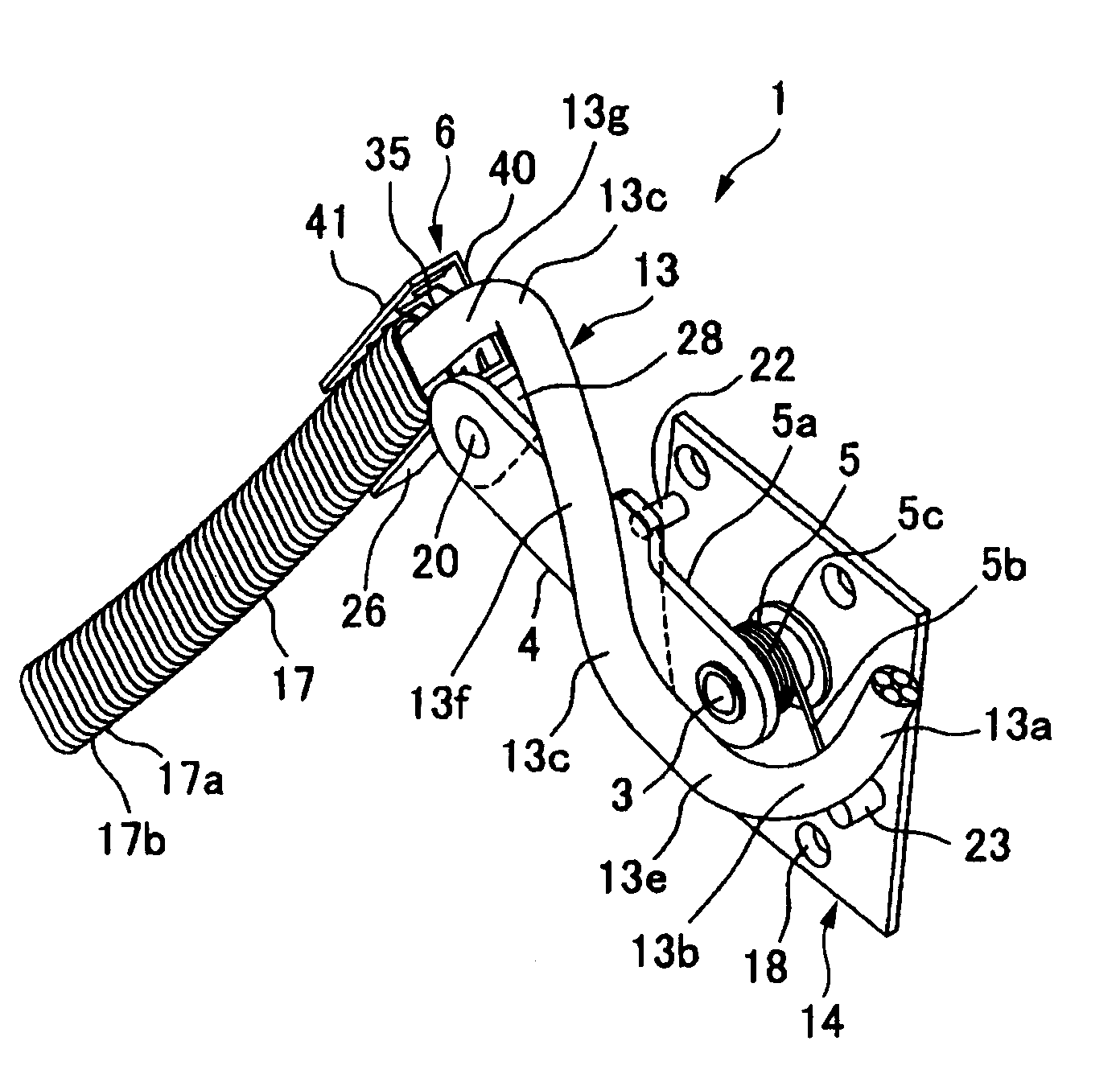

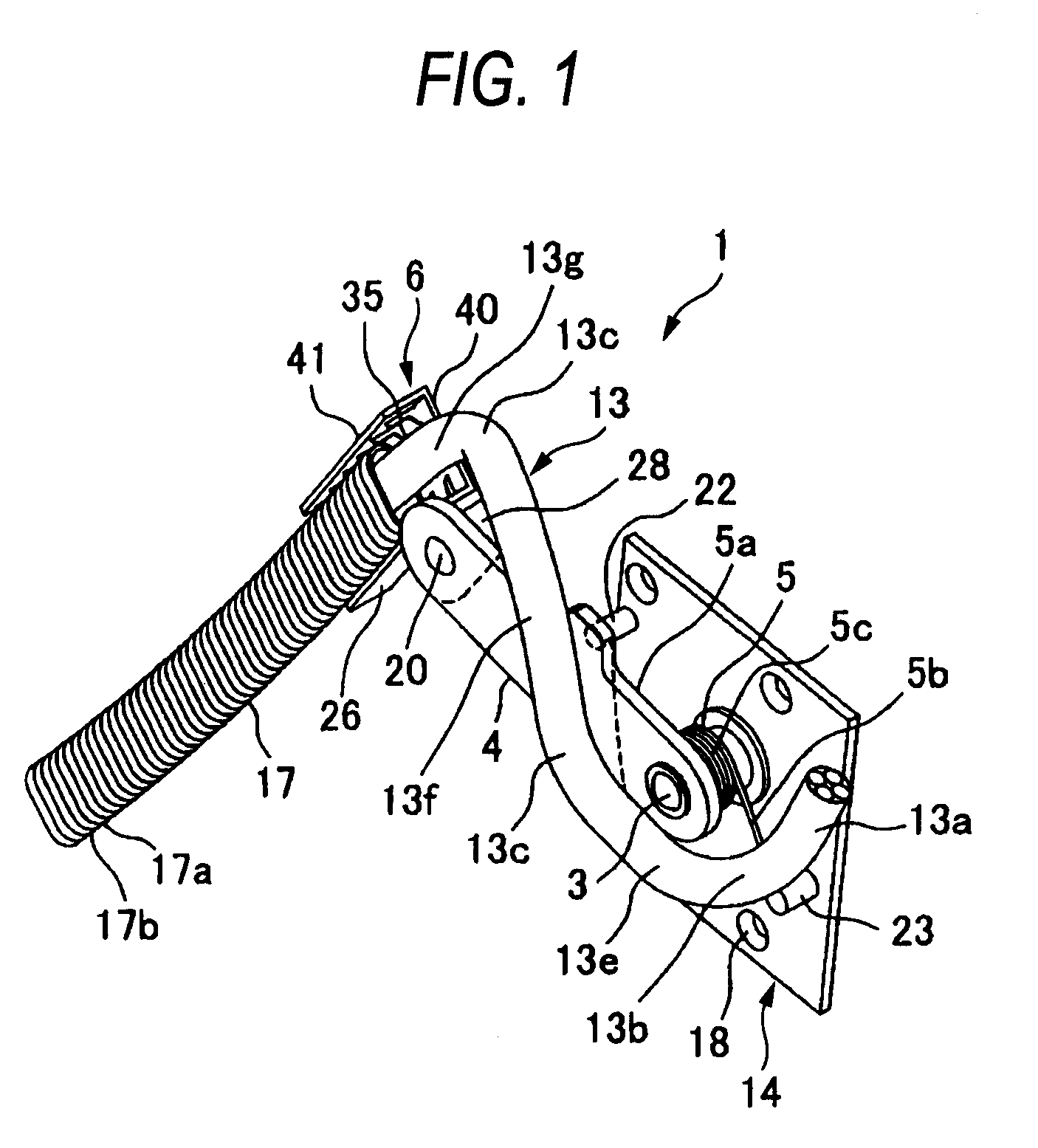

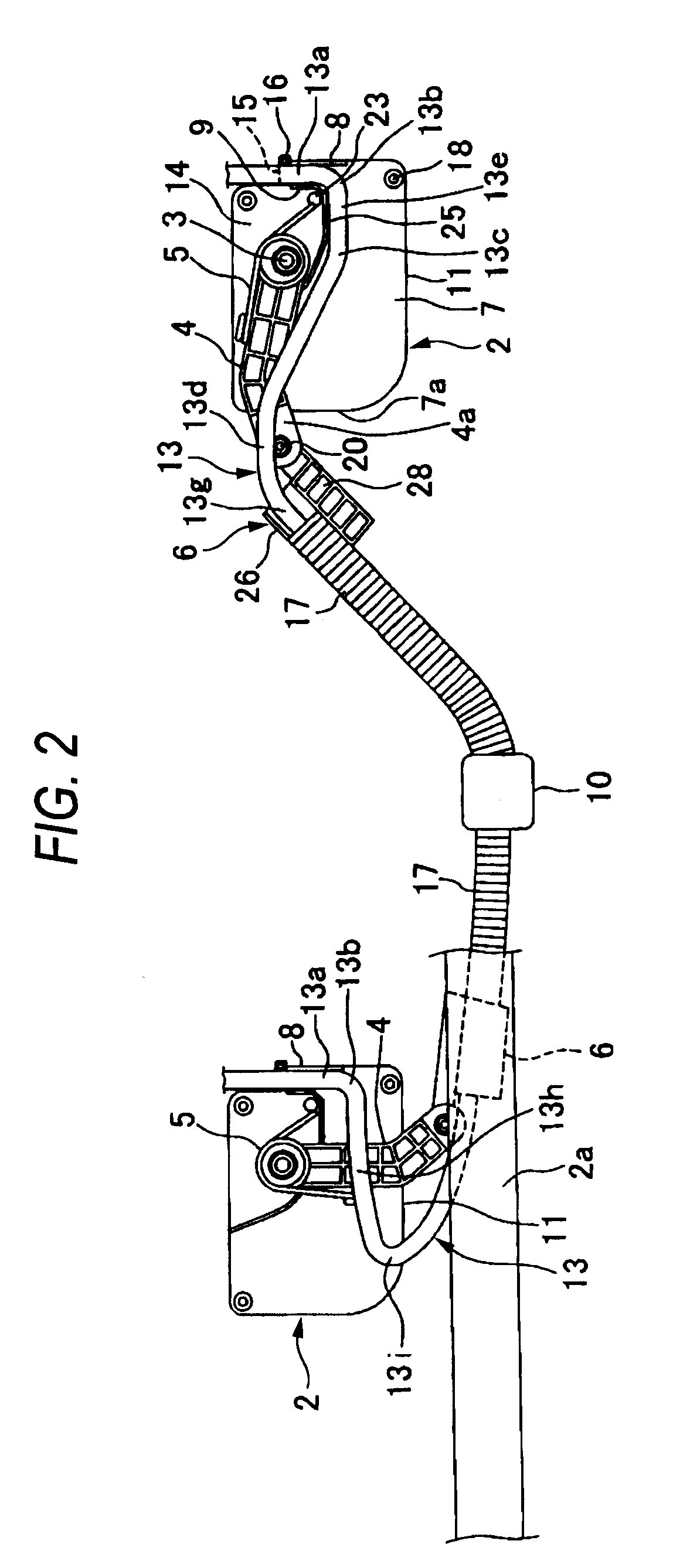

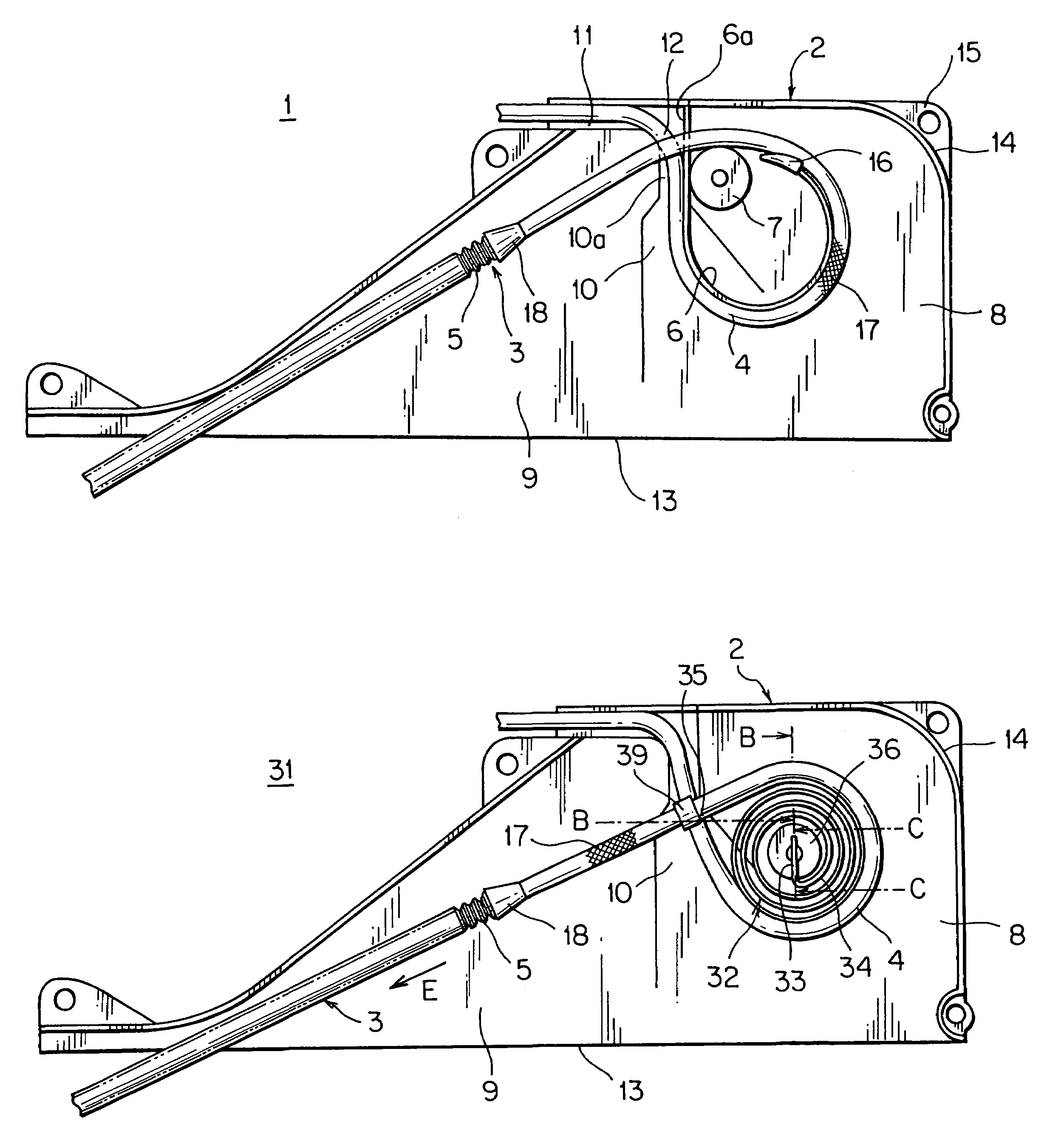

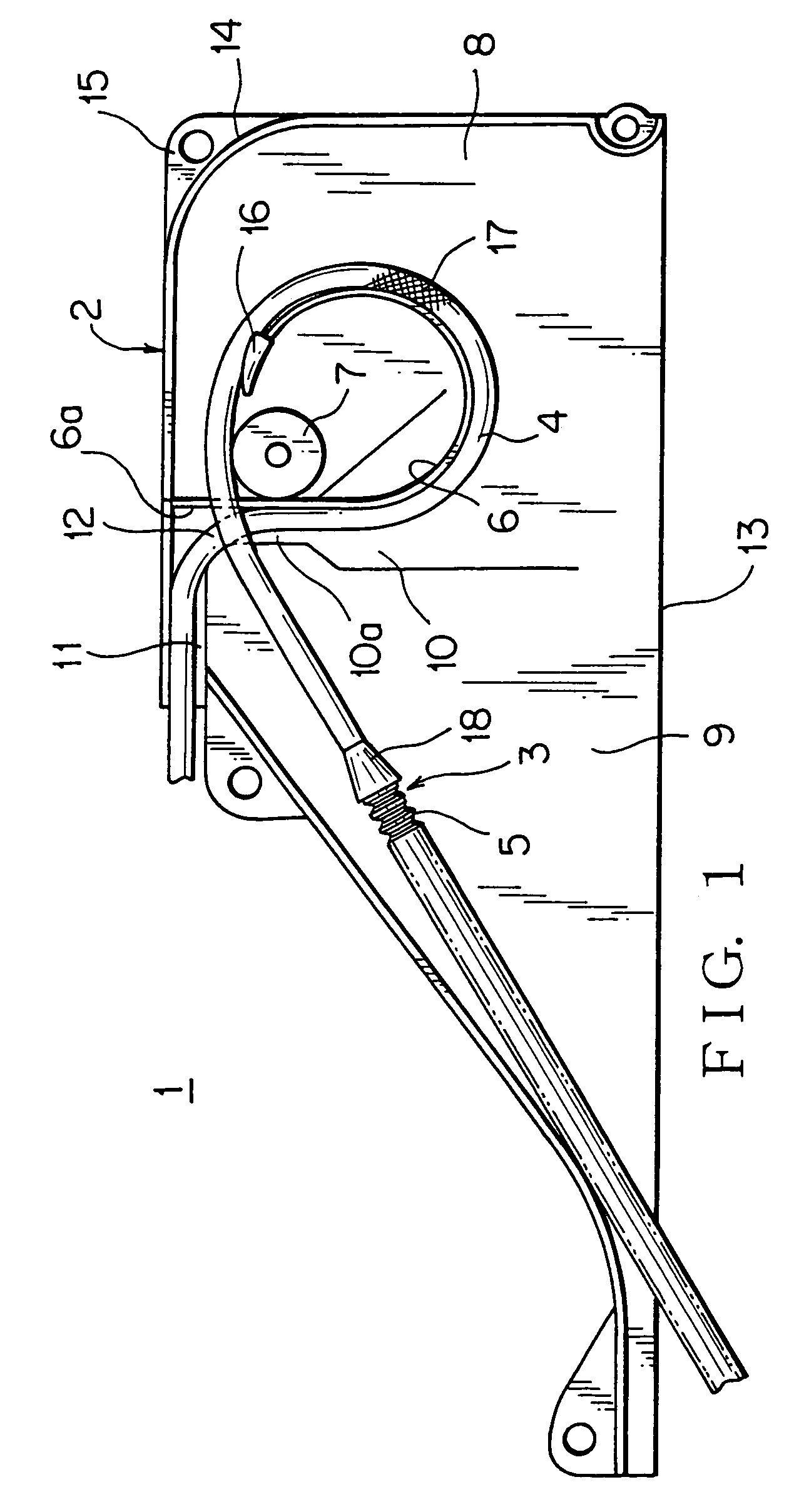

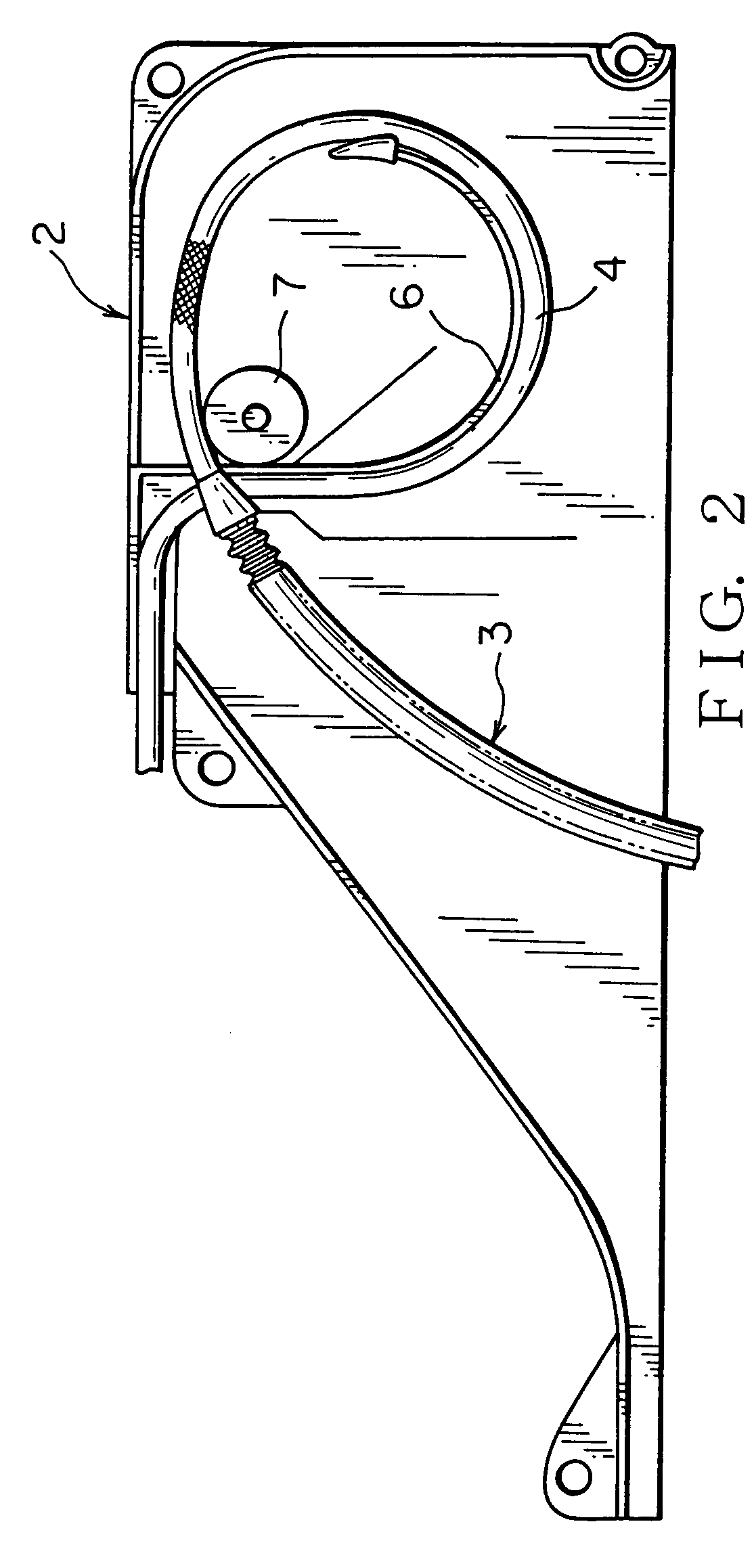

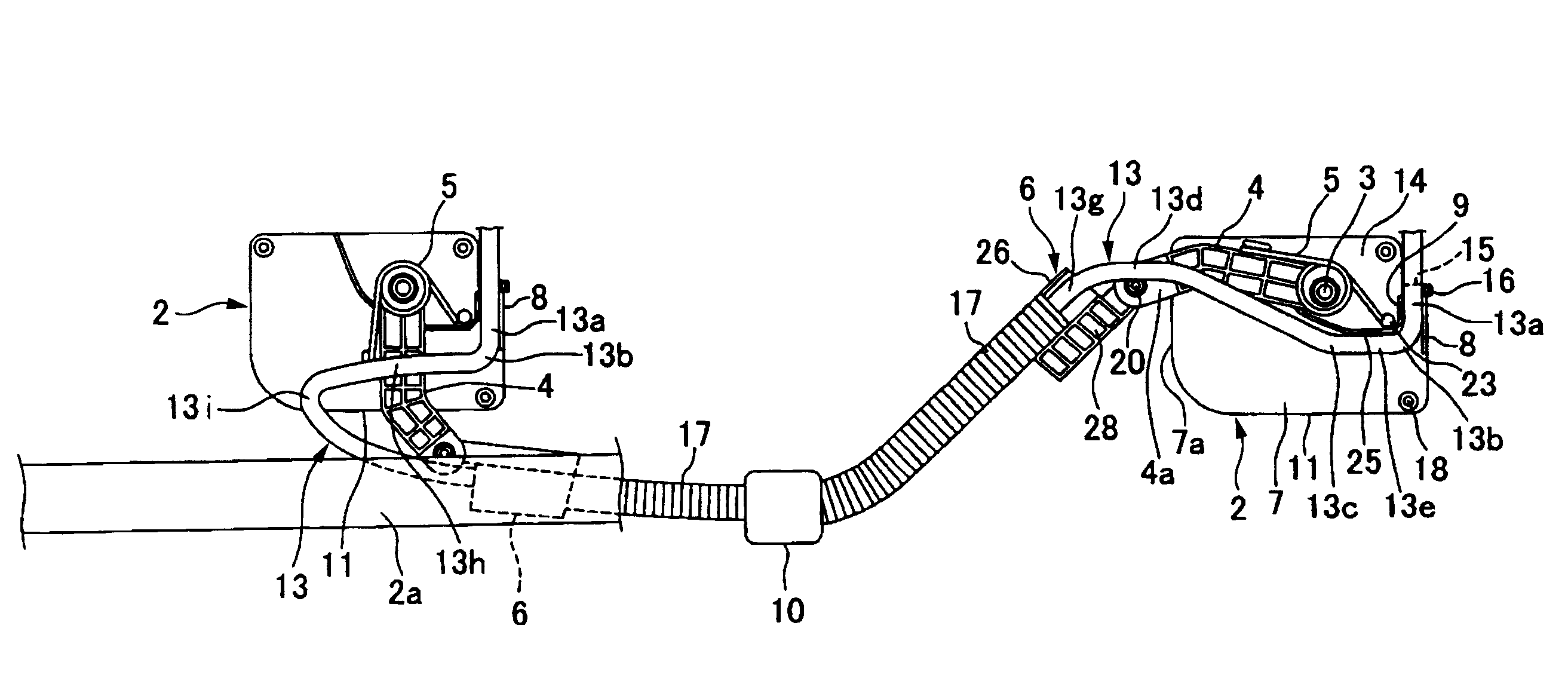

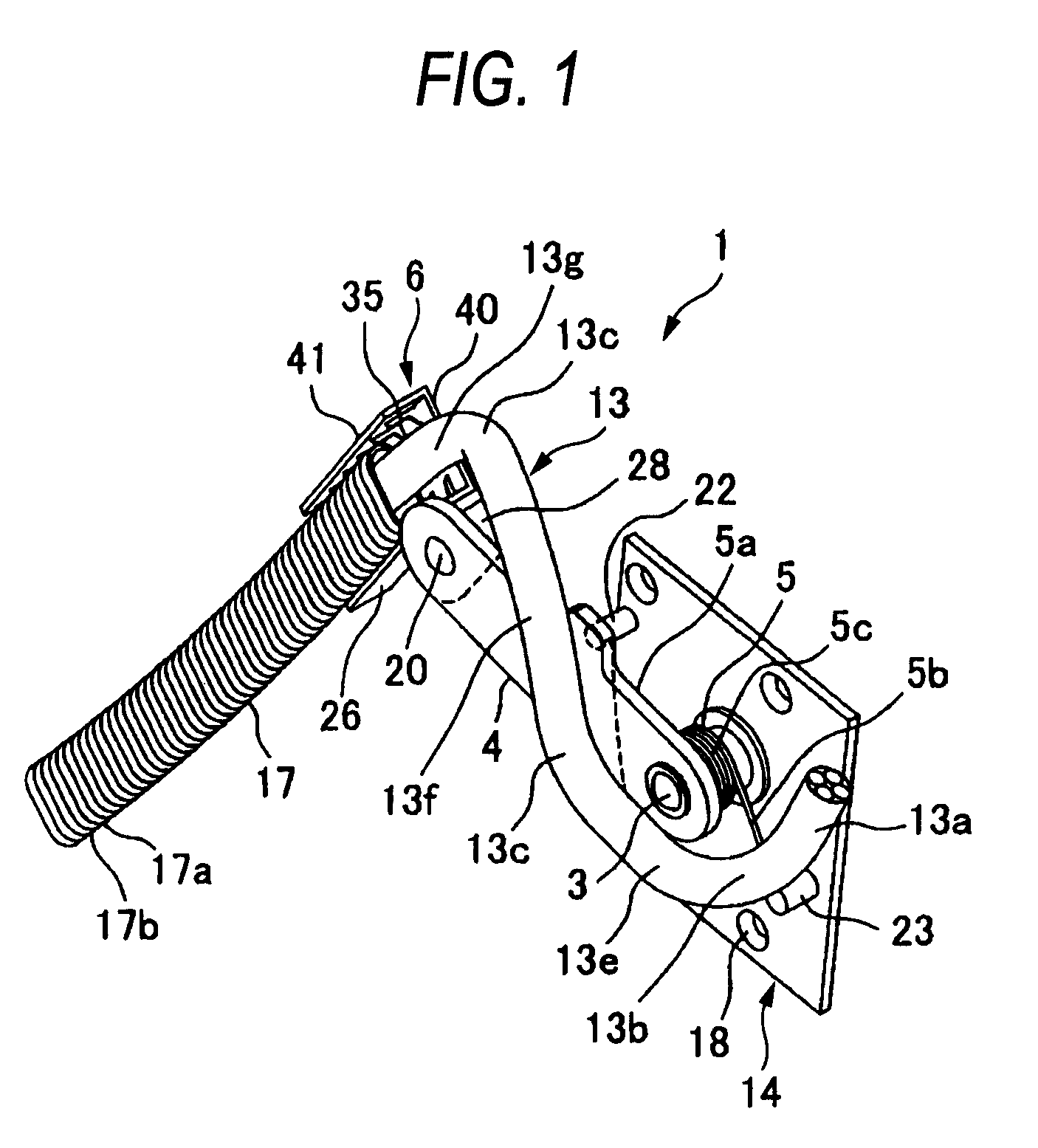

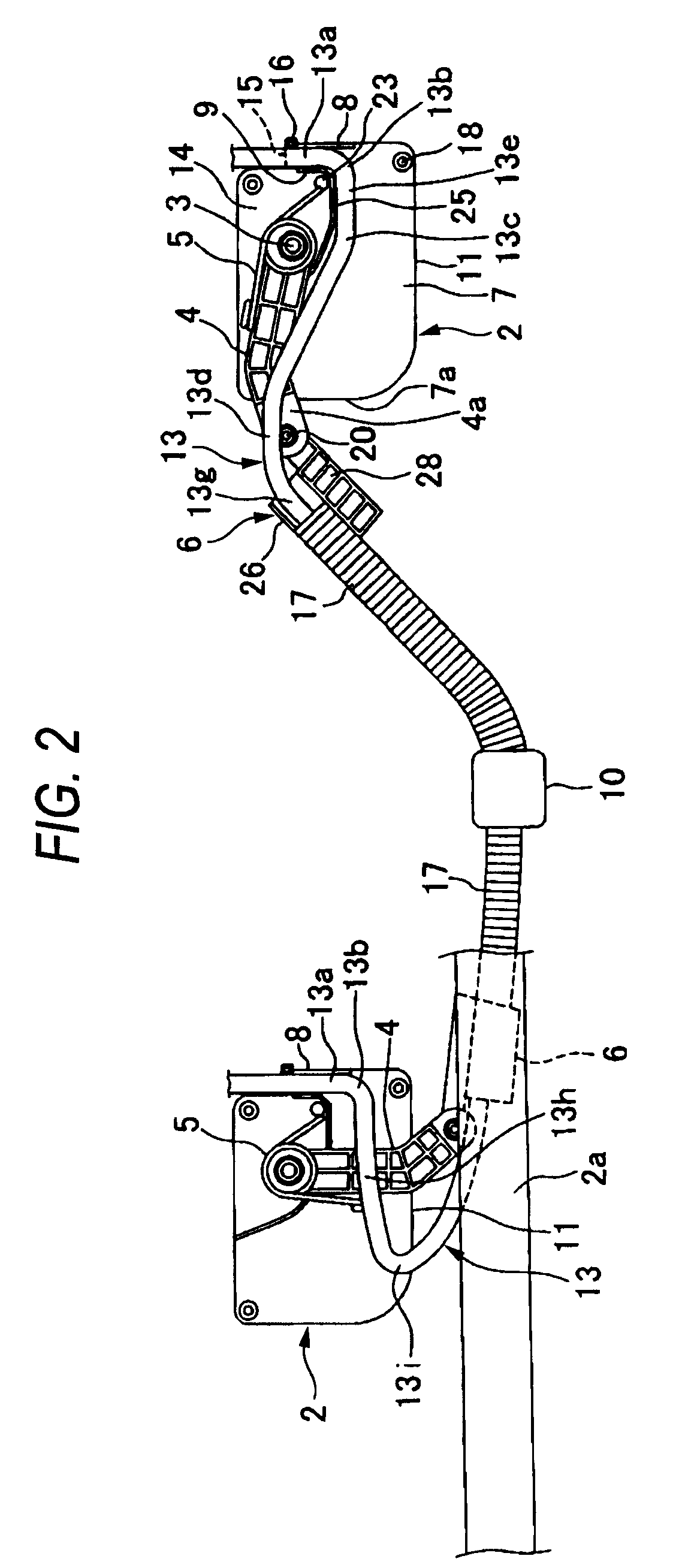

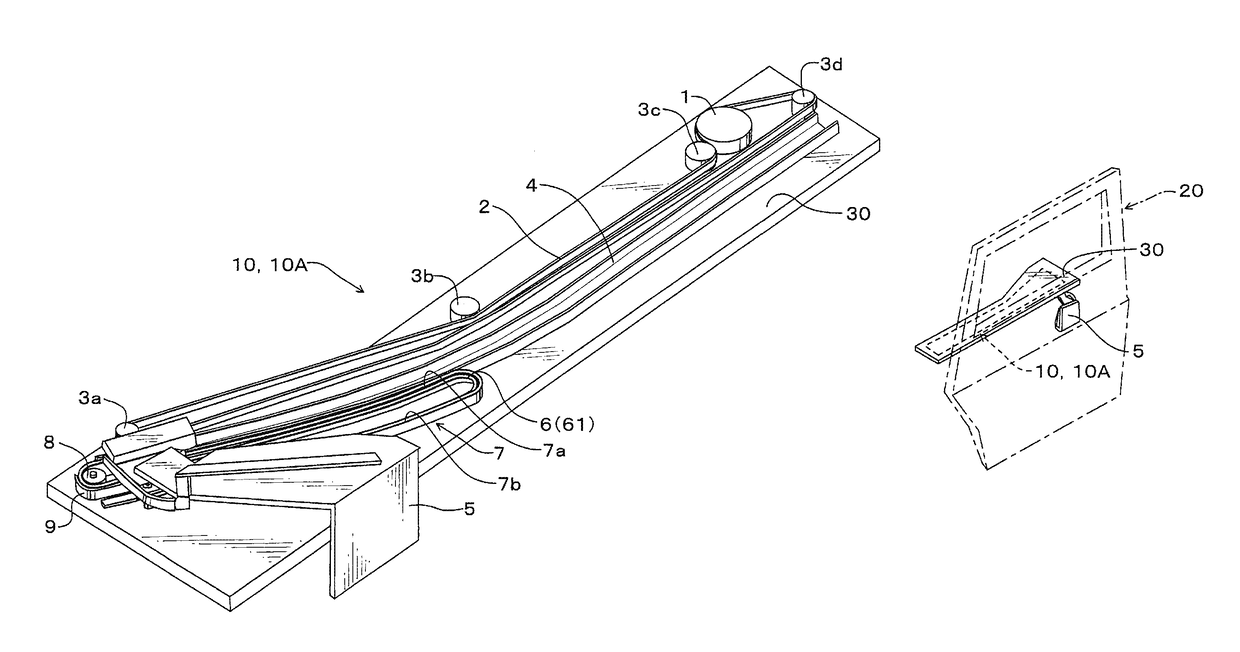

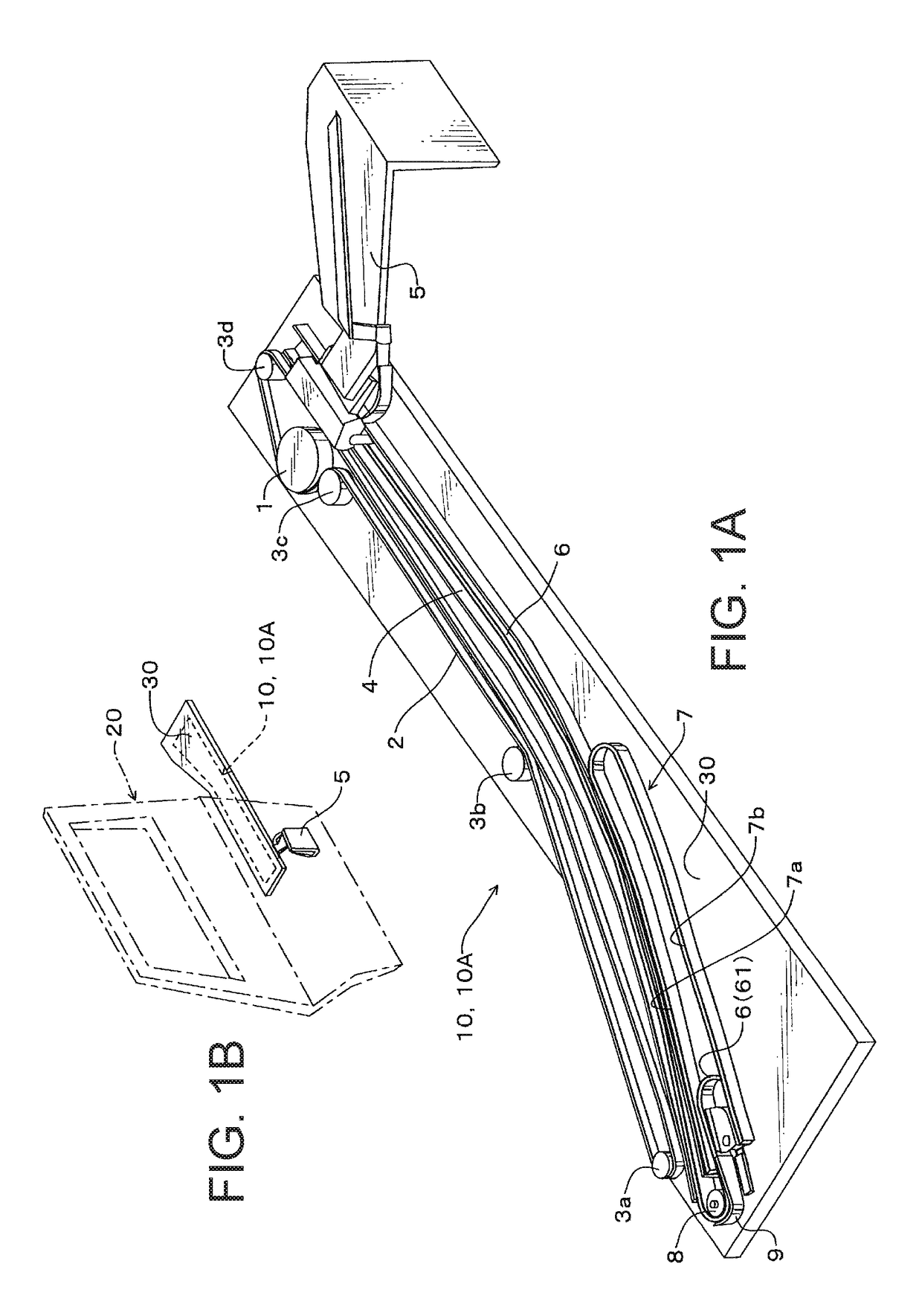

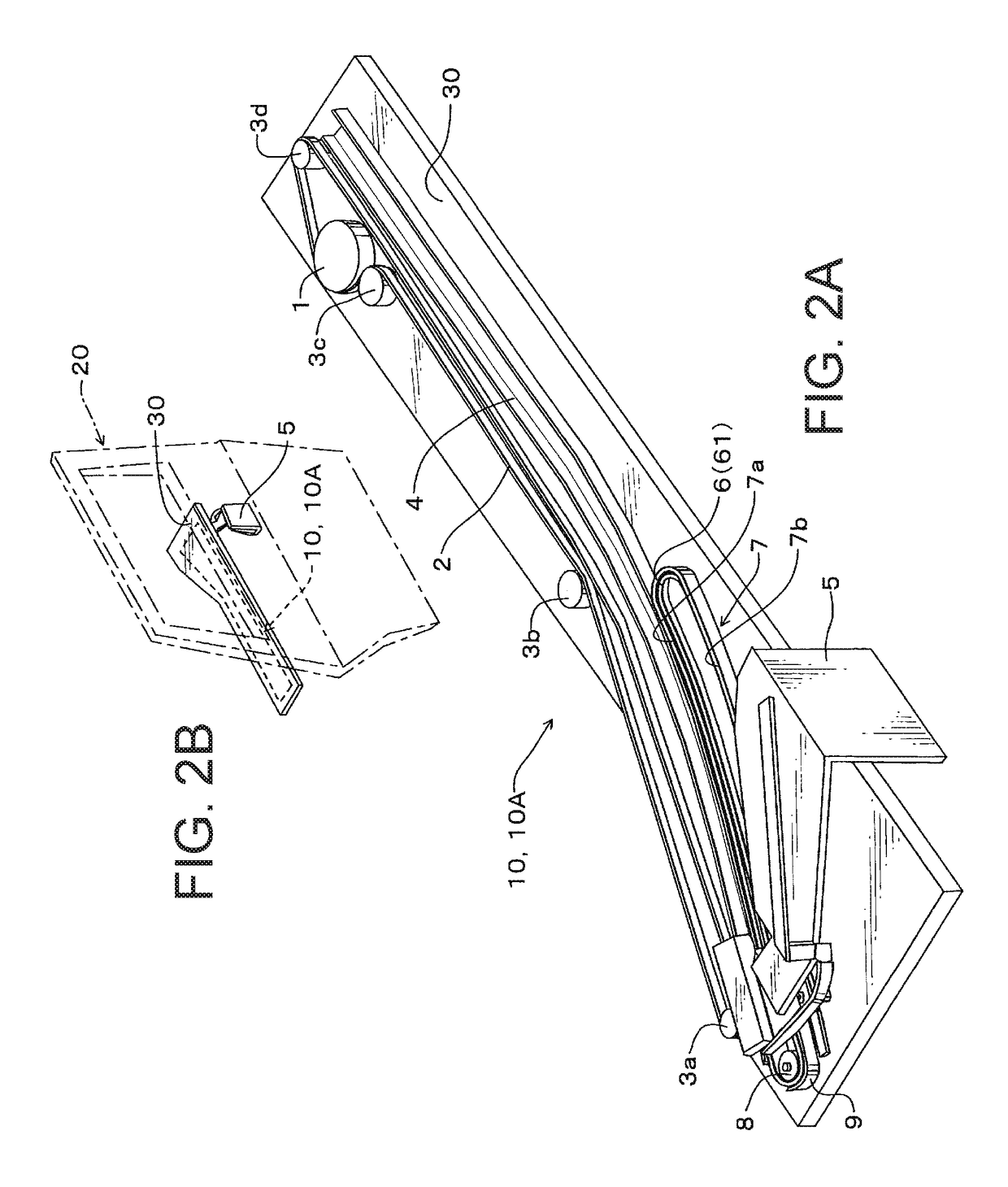

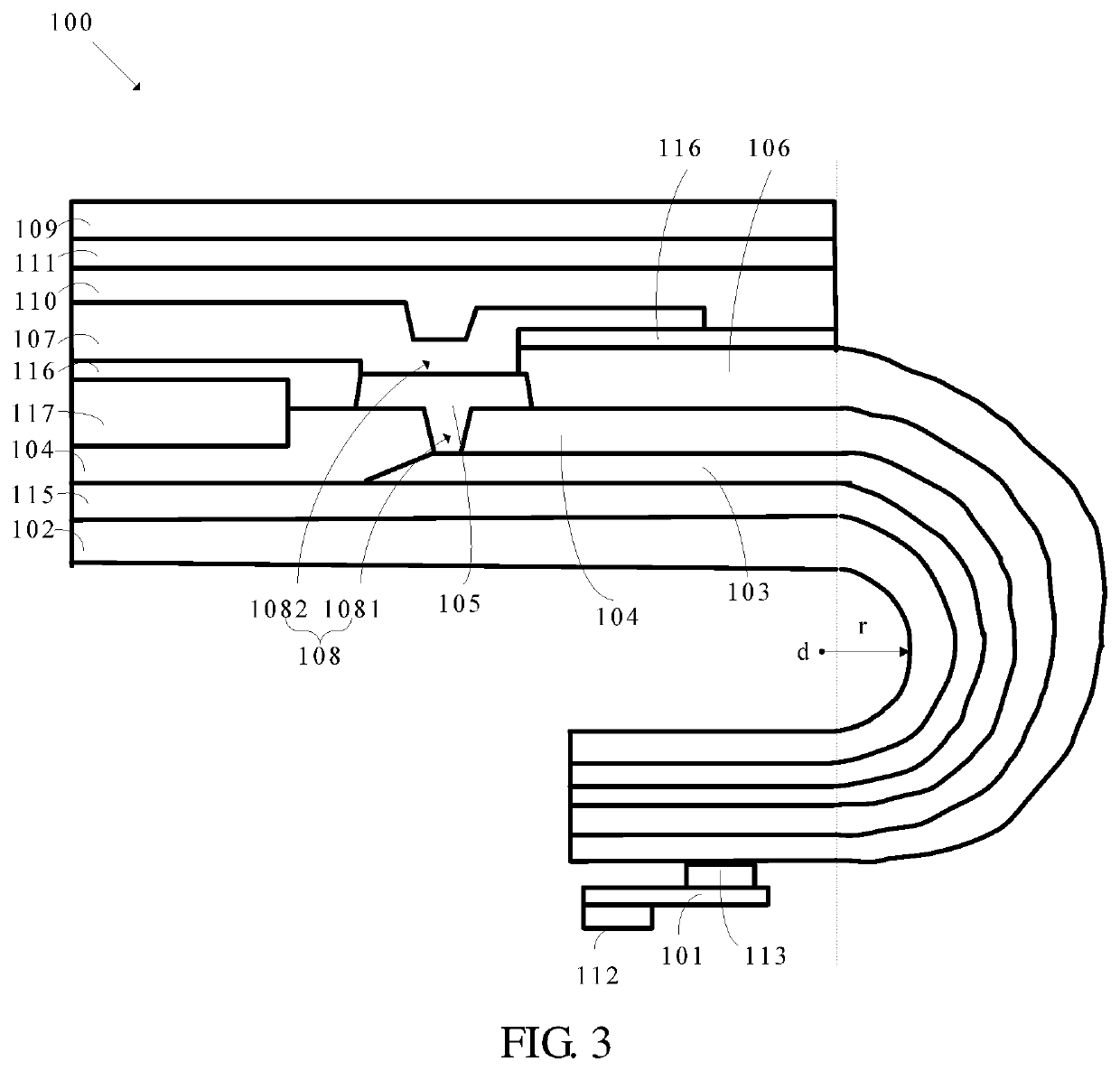

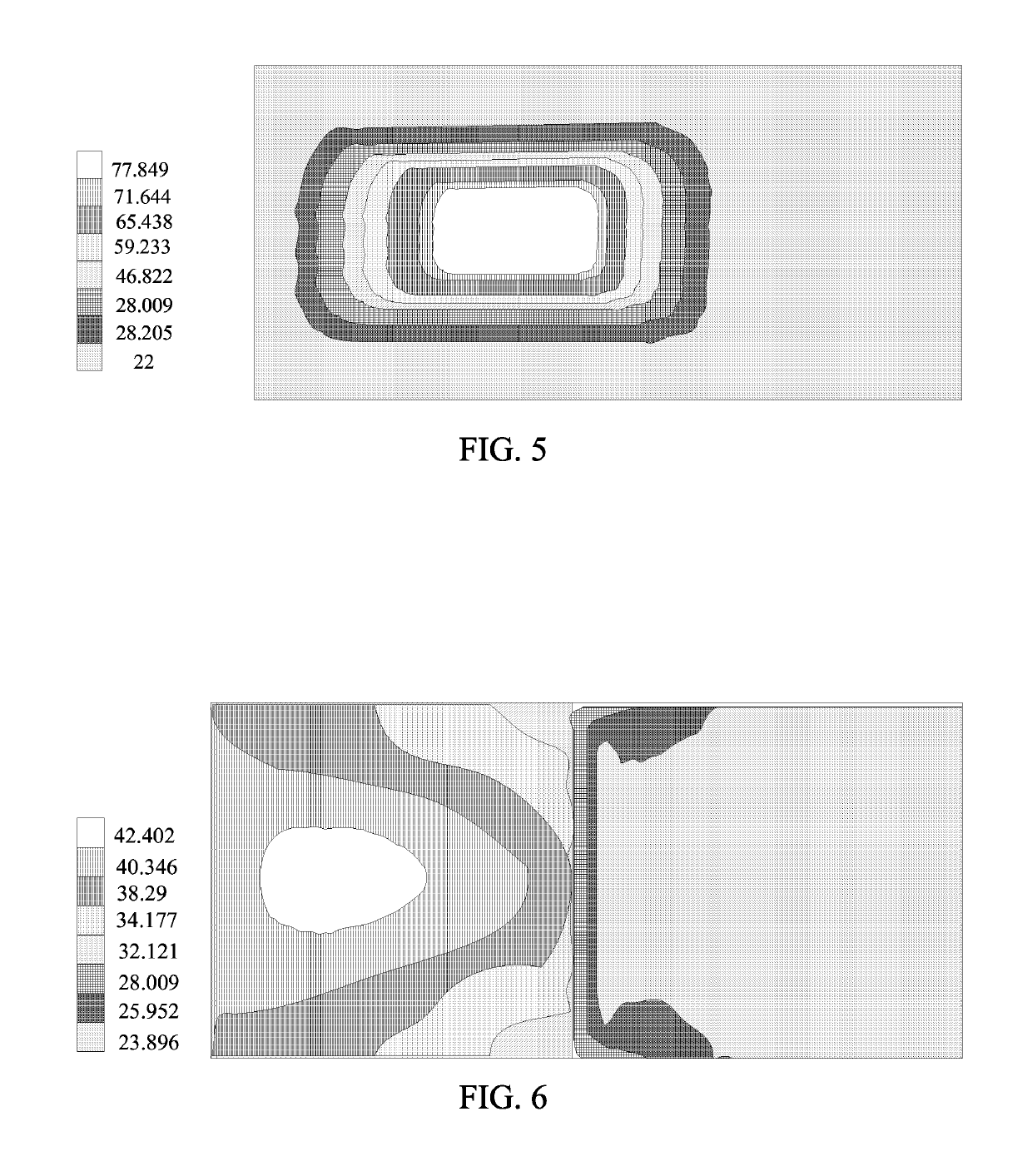

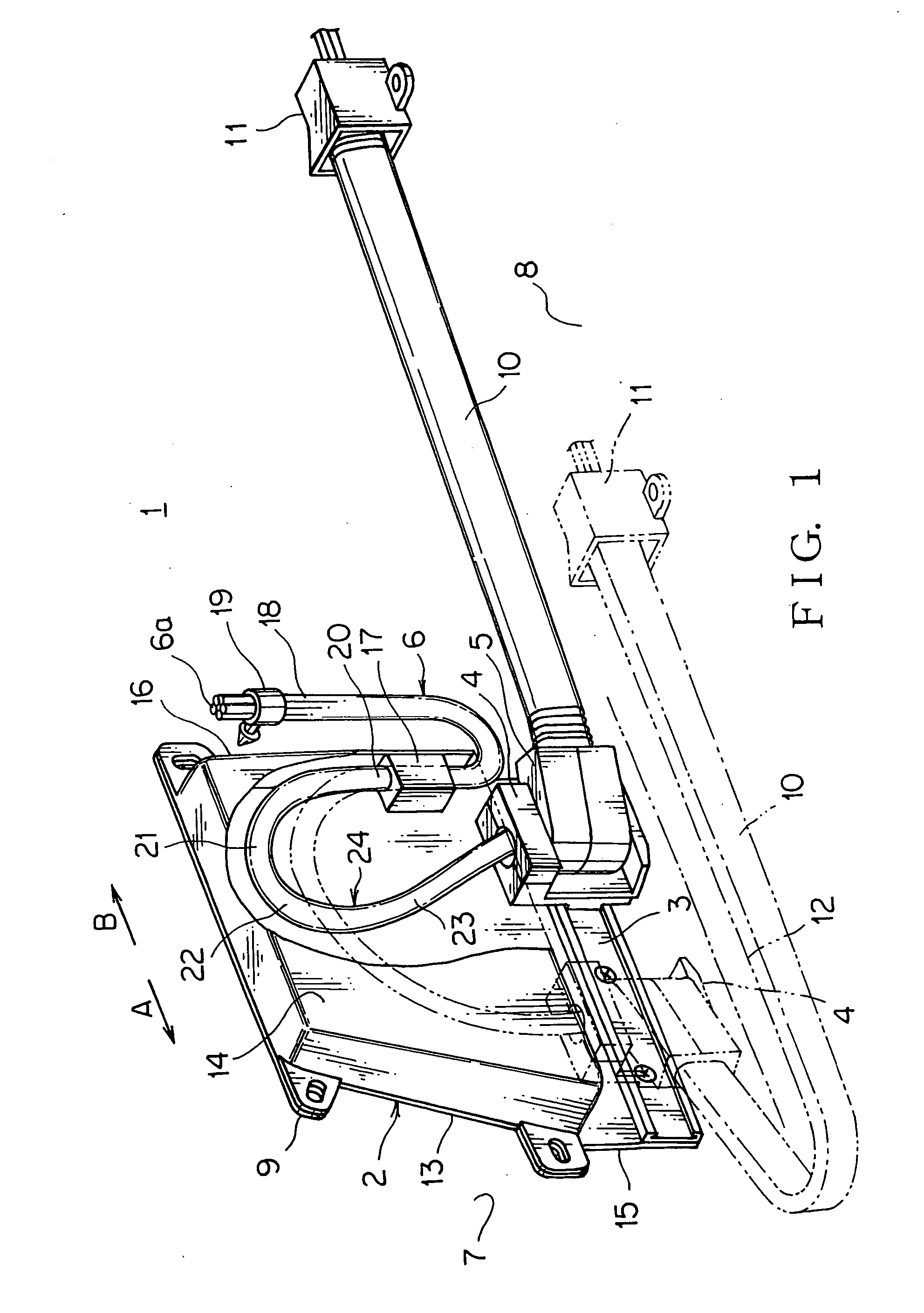

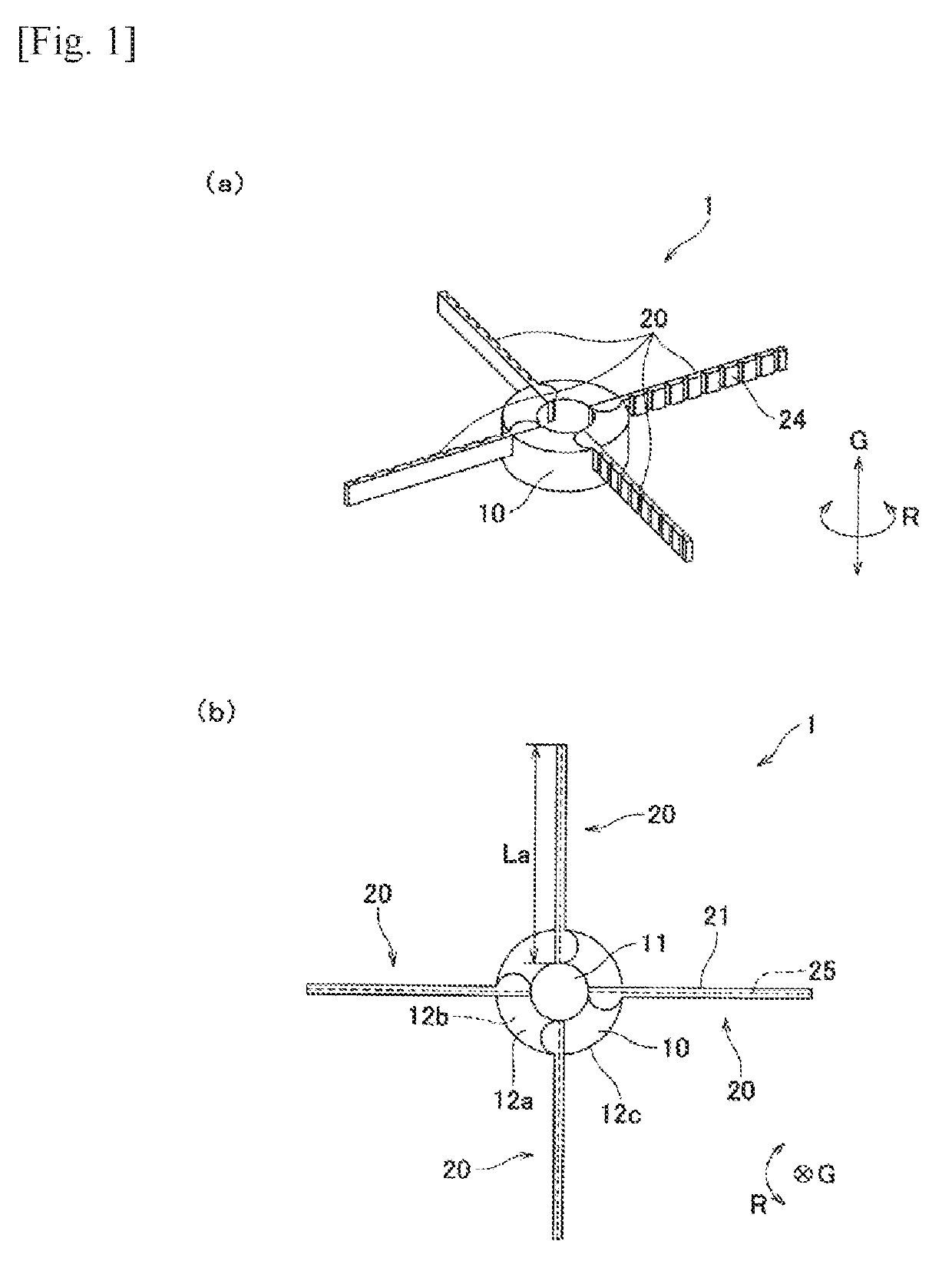

Continuous electric power supply device

InactiveUS20050092512A1Improve bending durabilityAbsorb slack of a wire harness smoothlyConductive materialCable arrangements between relatively-moving partsMechanical engineeringCable harness

For miniaturizing a power supply structure to absorb slack of a wire harness and improving bending durability, a continuous electric power supply device 1 includes a wire harness 3 formed to have a loop portion 4, an elastic member 6 along the loop portion 4, the elastic member energizing the loop portion to expand in a radial direction. The loop portion 4 and the elastic member 6 are disposed in a protector 2. The protector has a opening 13 for leading the harness and a guide portion 7 for supporting the loop portion 4 at a position opposite to the opening 13. The elastic member, flat spring 6 can have a length forming a loop shape to intersect itself.

Owner:YAZAKI CORP

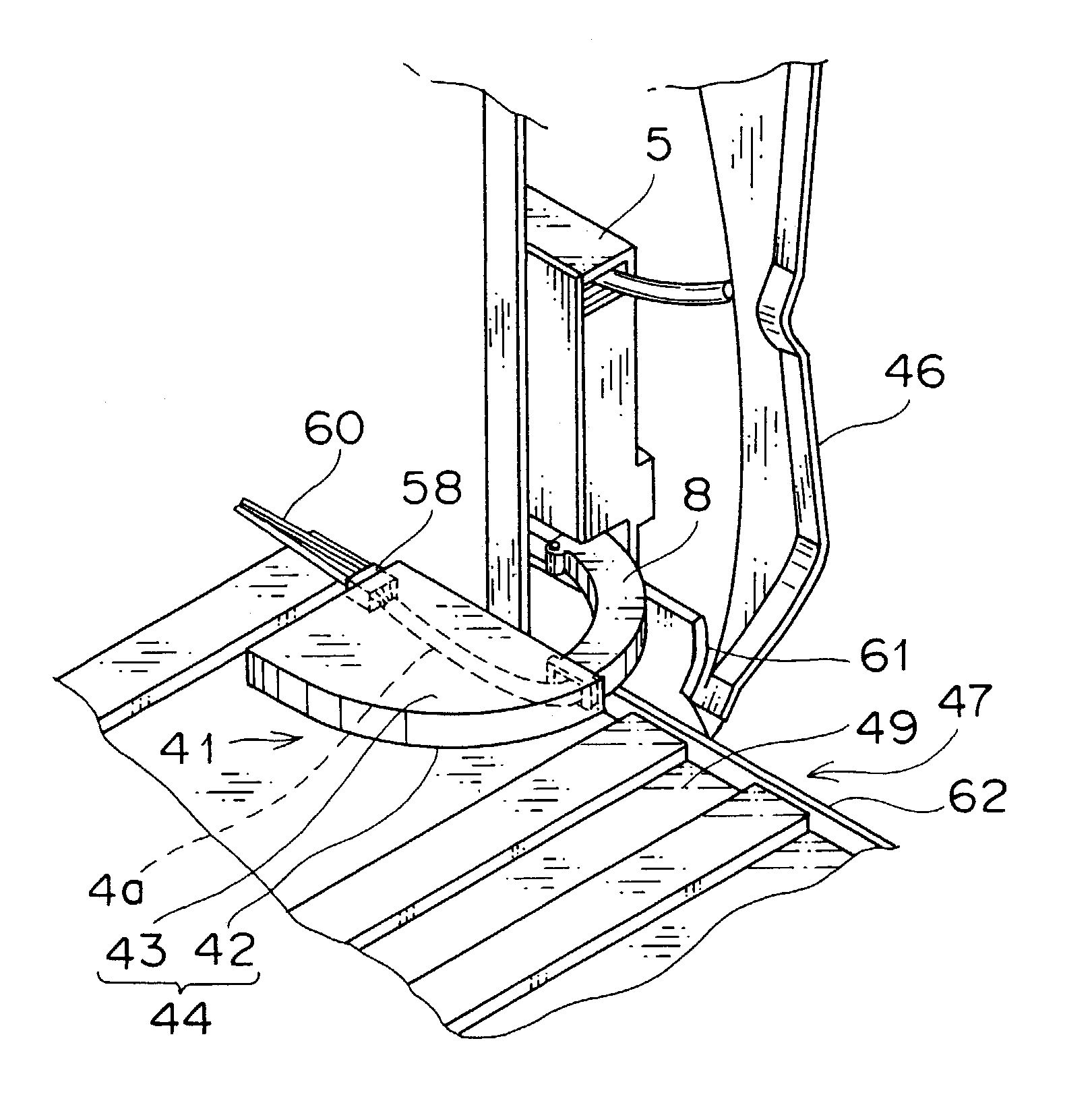

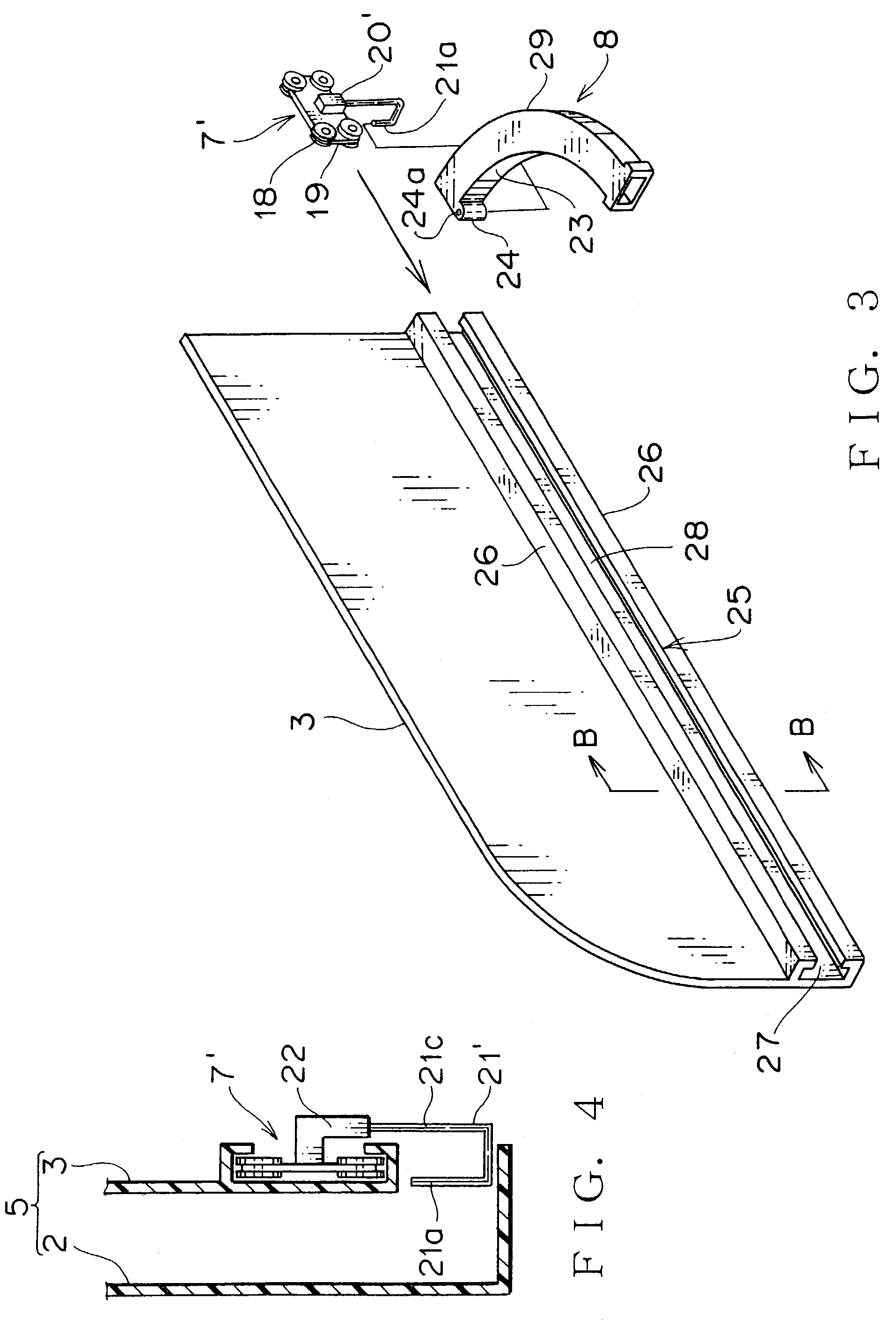

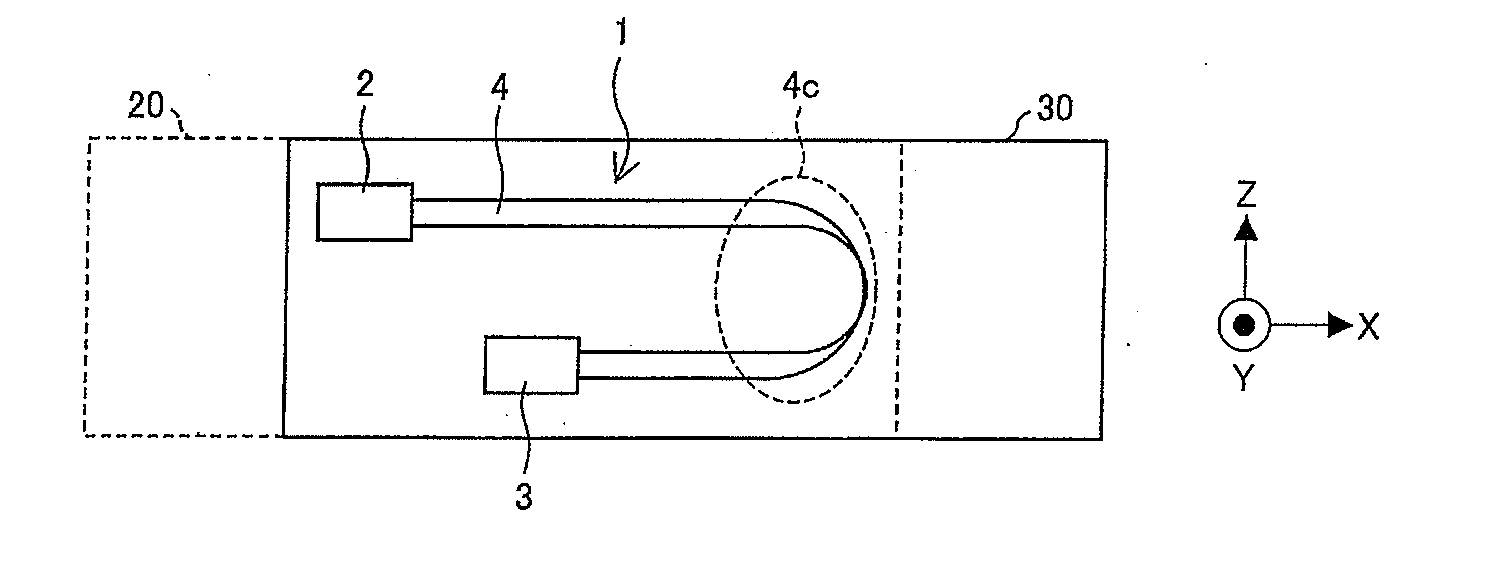

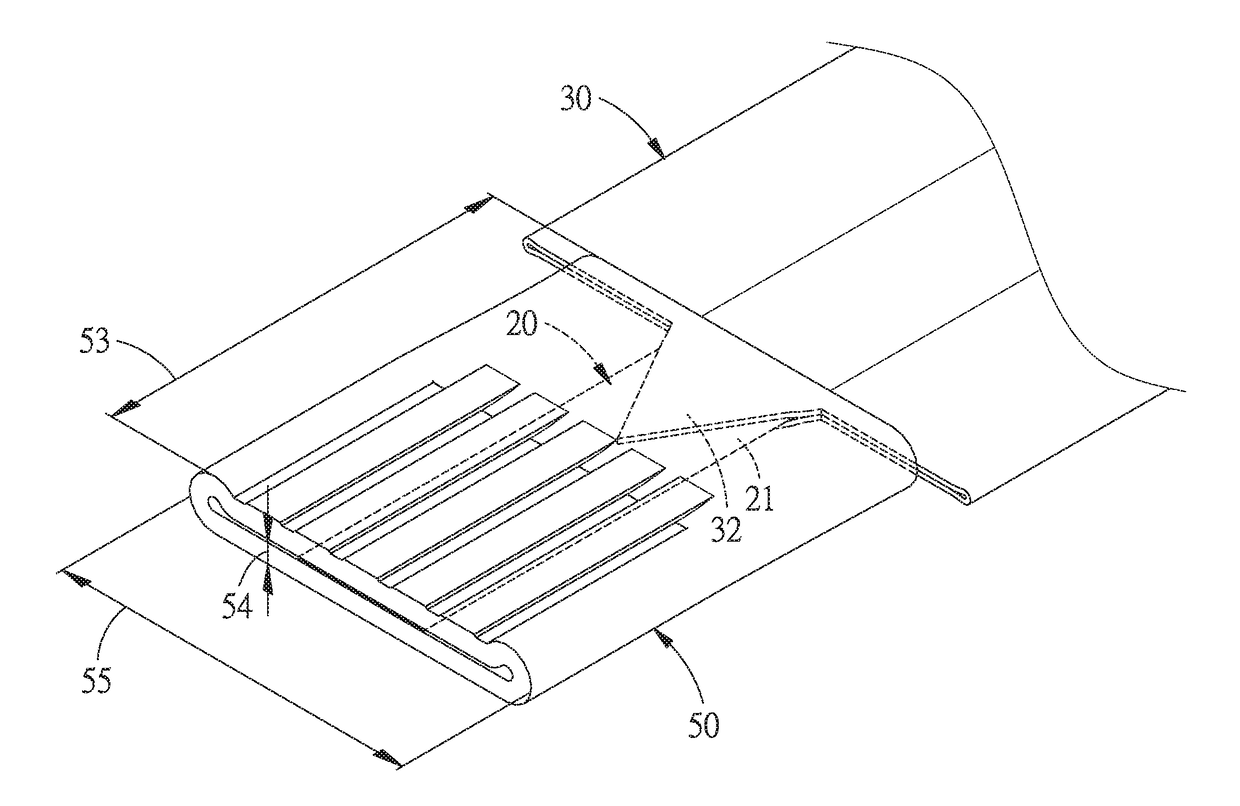

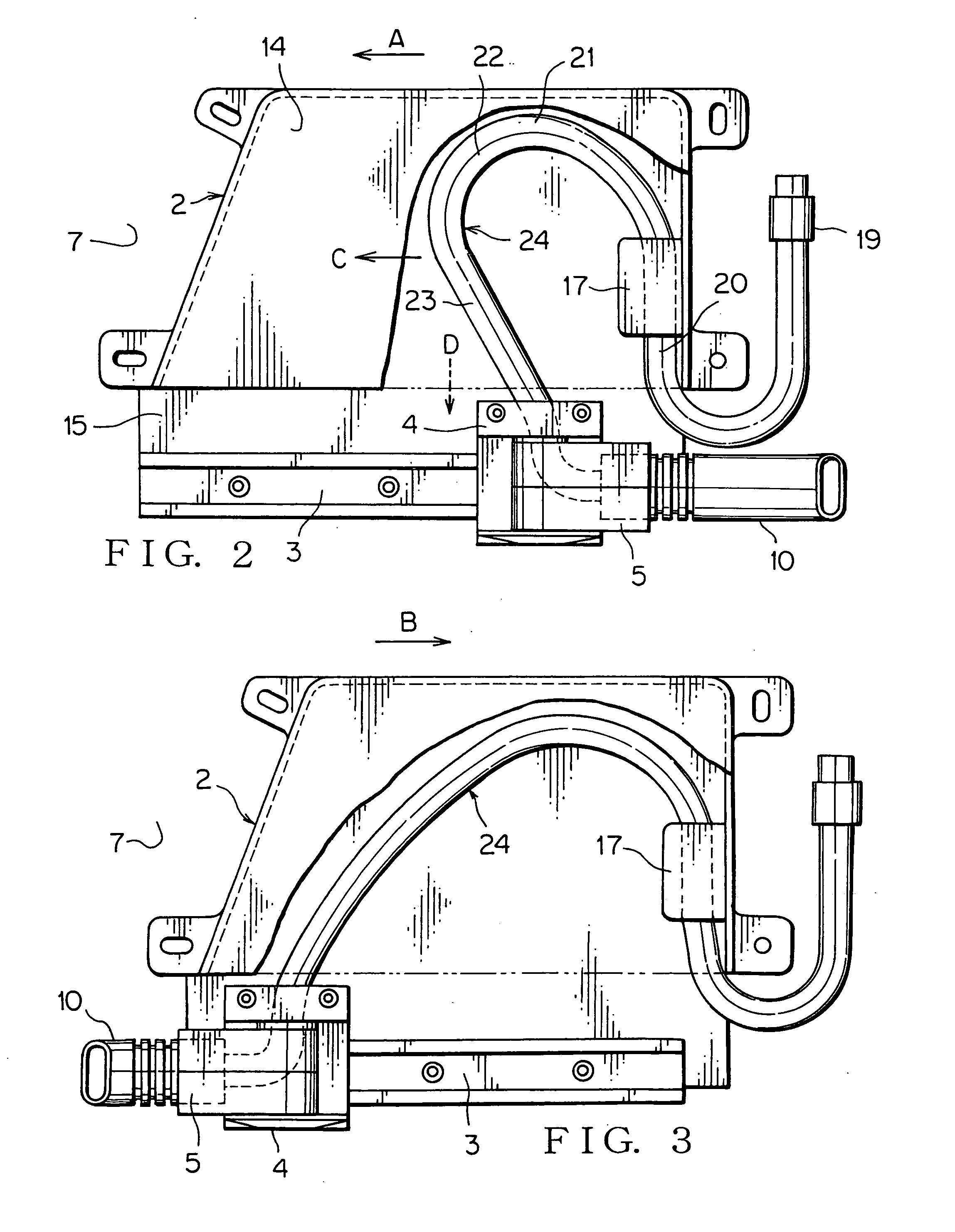

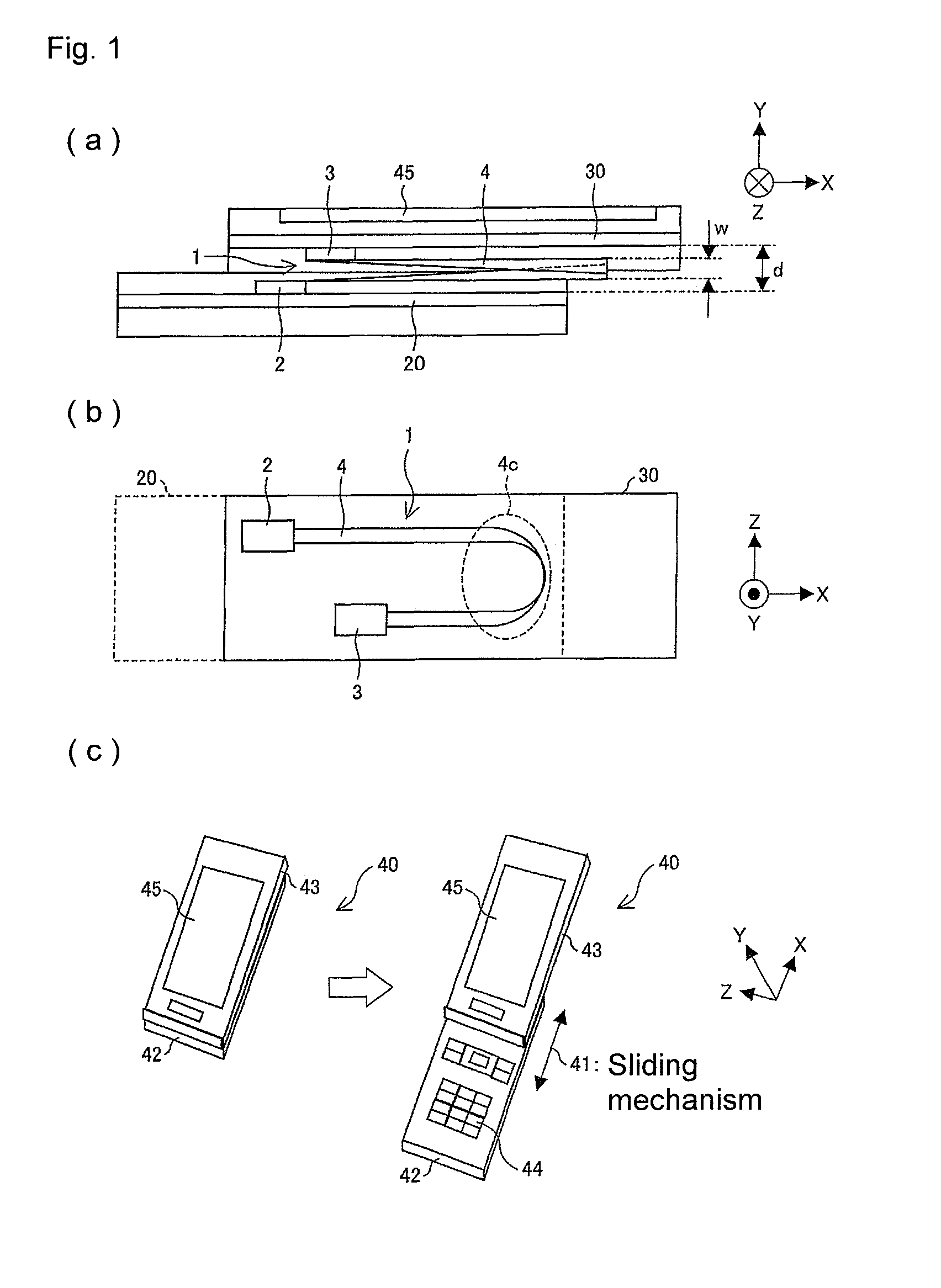

Power-supply wiring device and harness layout structure by the power-supply wiring device

InactiveUS7042738B2Avoid interferenceImprove bending durabilityBus-bar/wiring layoutsInsulated cablesElectric wireCable harness

A power-supply wiring device, which protects electric wires between a sliding and fixed structures, and absorbs wire length change by sliding motion of the sliding structure, and a harness layout structure with the power-supply wiring device are provided. The power-supply wiring device includes a first case 5 for receiving a wire harness 4 folded into a U-shape, a moving portion 7, a harness holding member 8 disposed rotatably at the moving portion 7, a second case 44 receiving the harness holding member 8 freely to be swung. In the harness layout structure, the first case 5 and the second case 44 are mounted respectively on the sliding structure and the fixed structure, and the harness holding member 8 connects between the fixed and sliding structures.

Owner:YAZAKI CORP

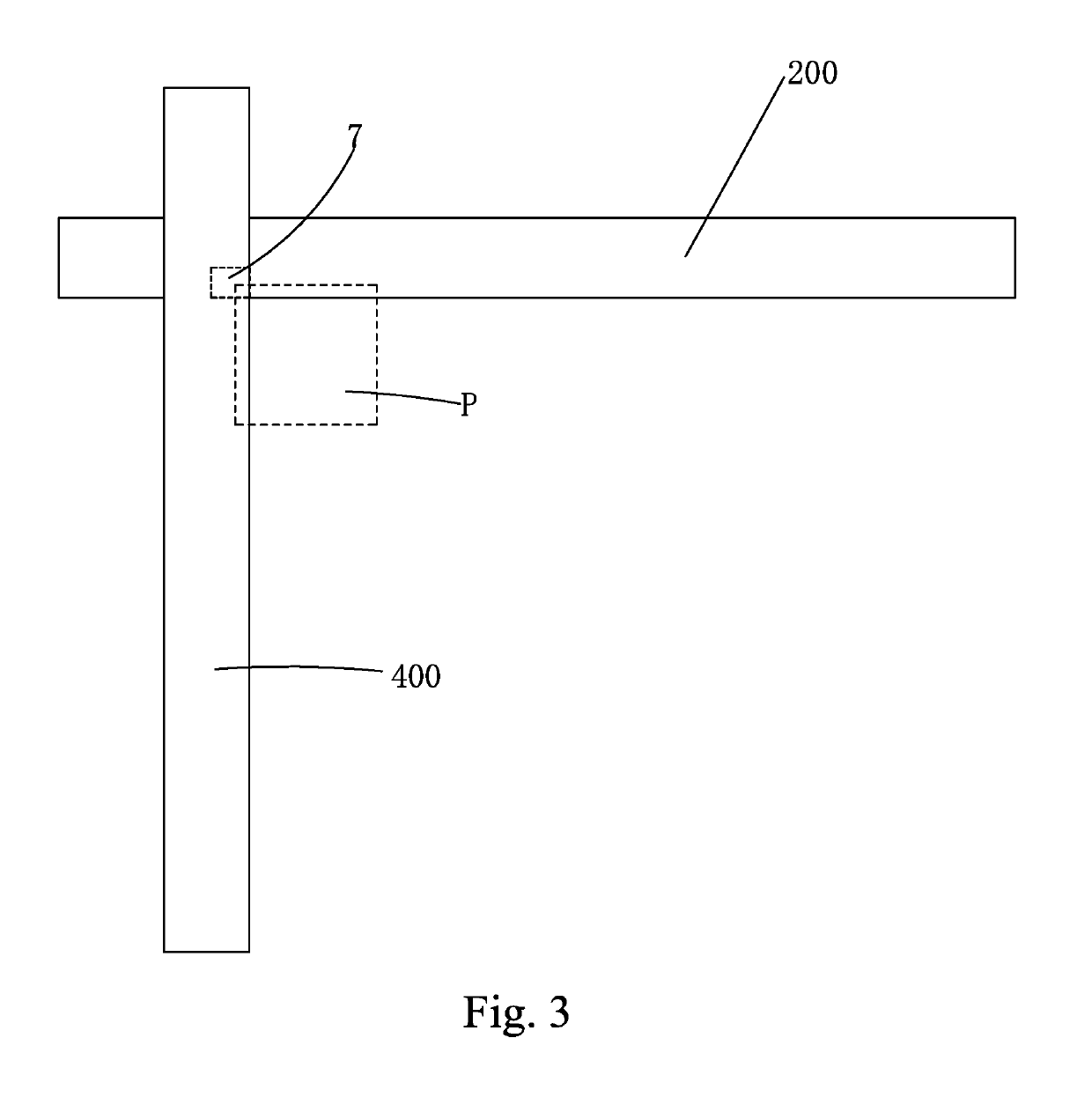

Feeding structure for sliding structural body

ActiveUS20090095858A1Reduce extra spaceMade thinnerSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Owner:YAZAKI CORP +1

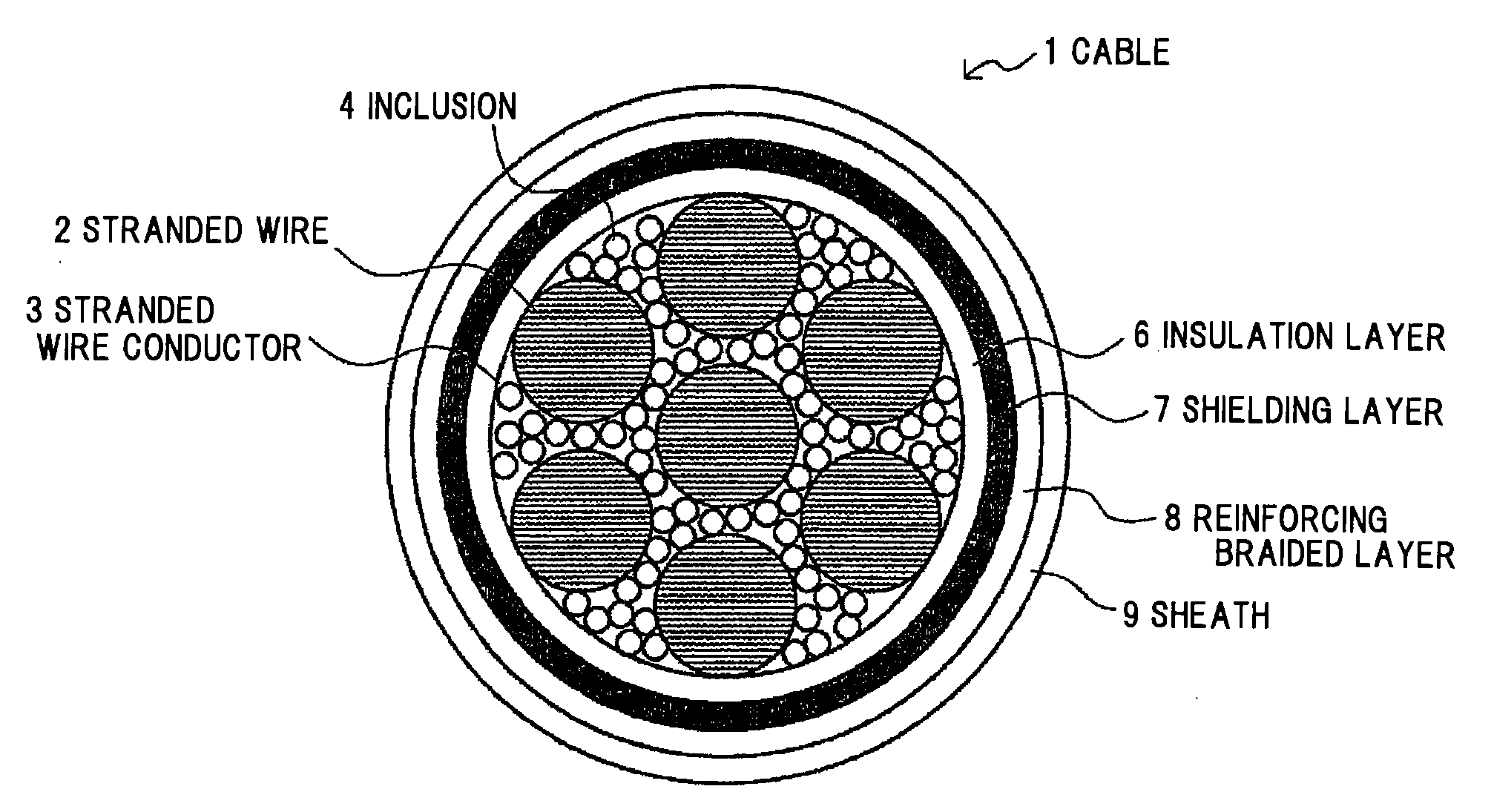

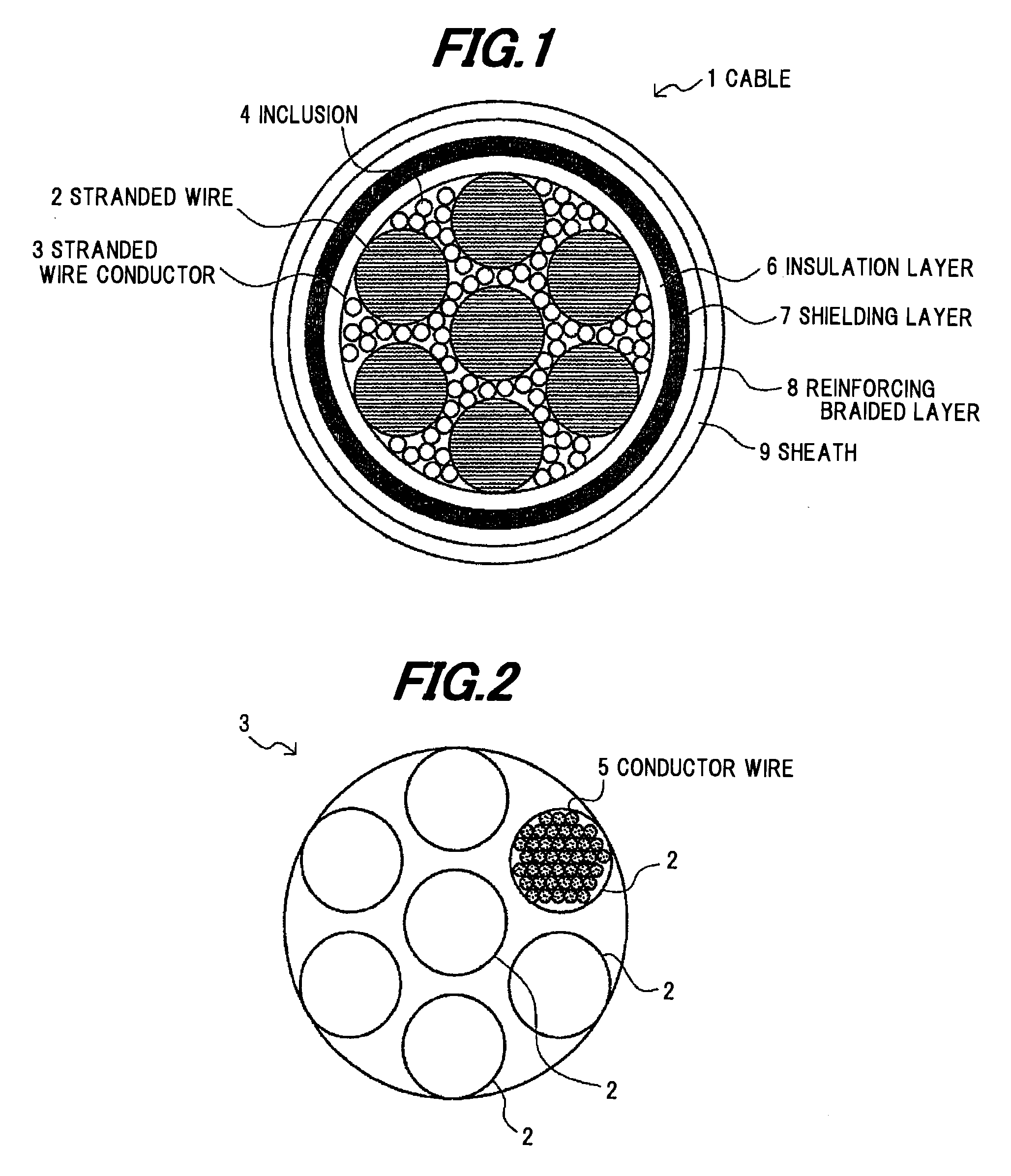

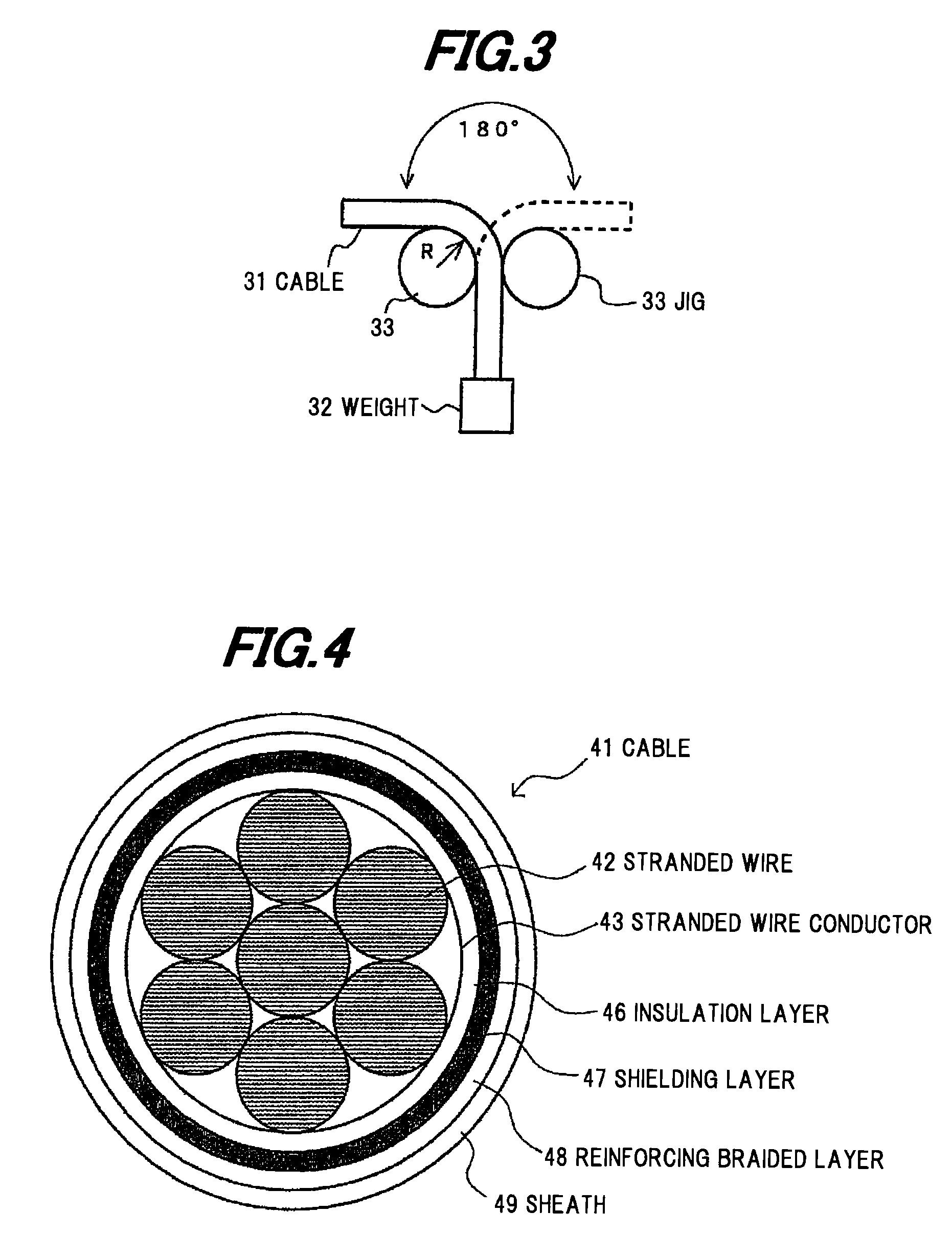

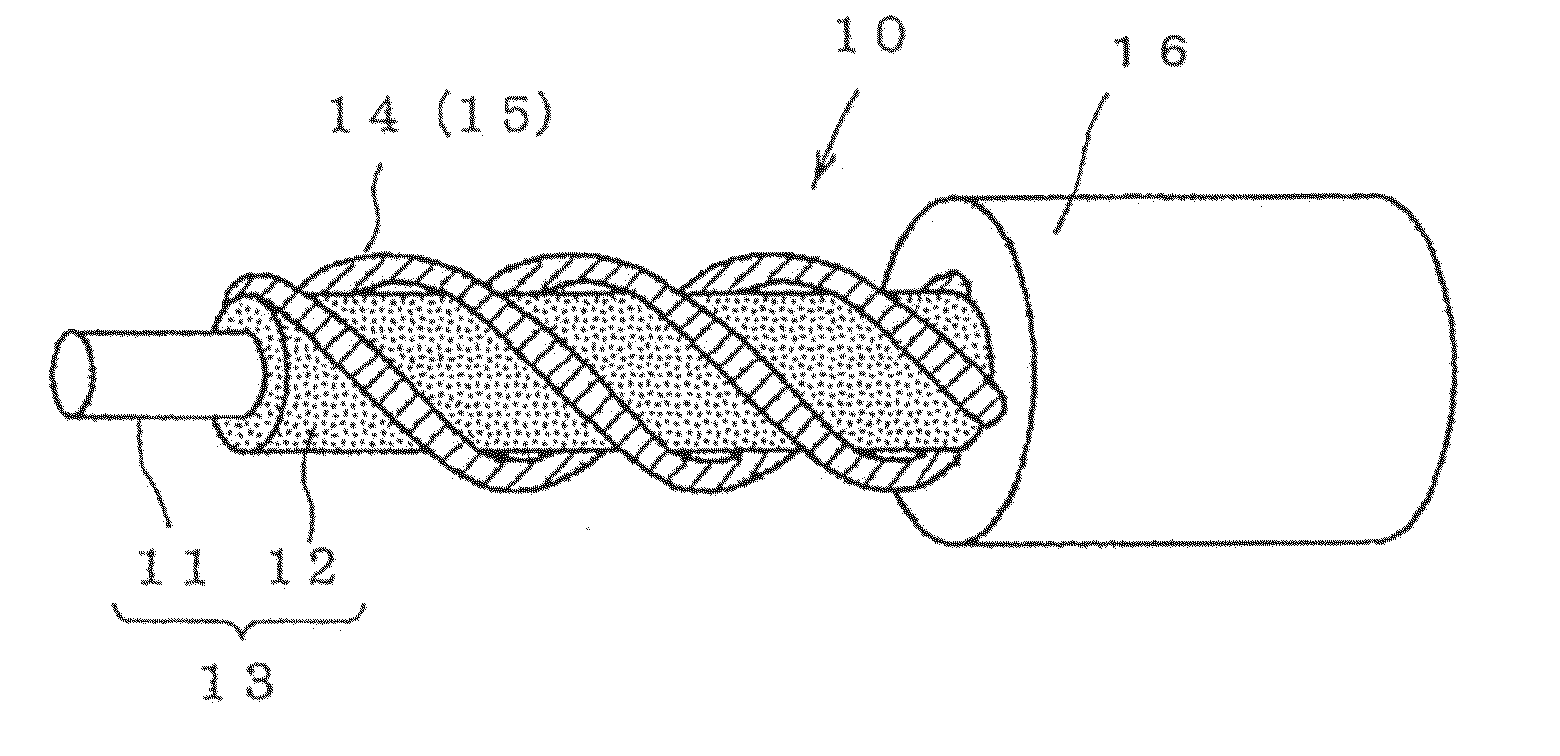

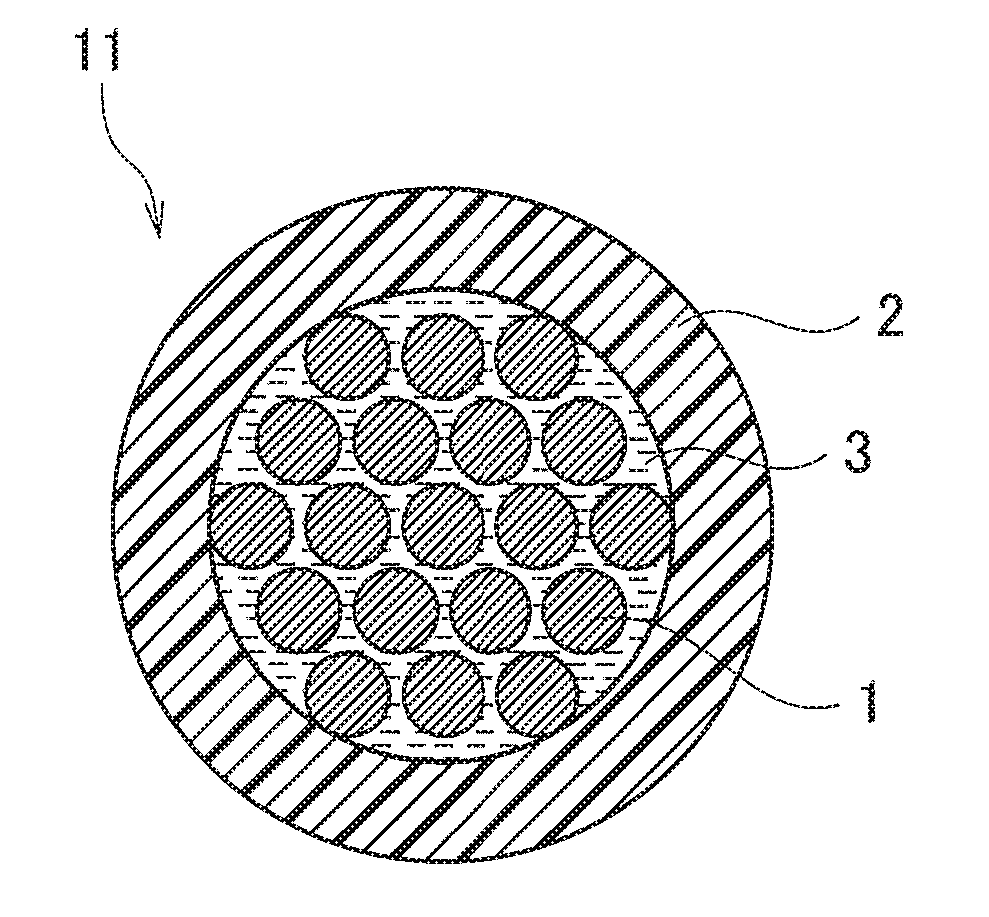

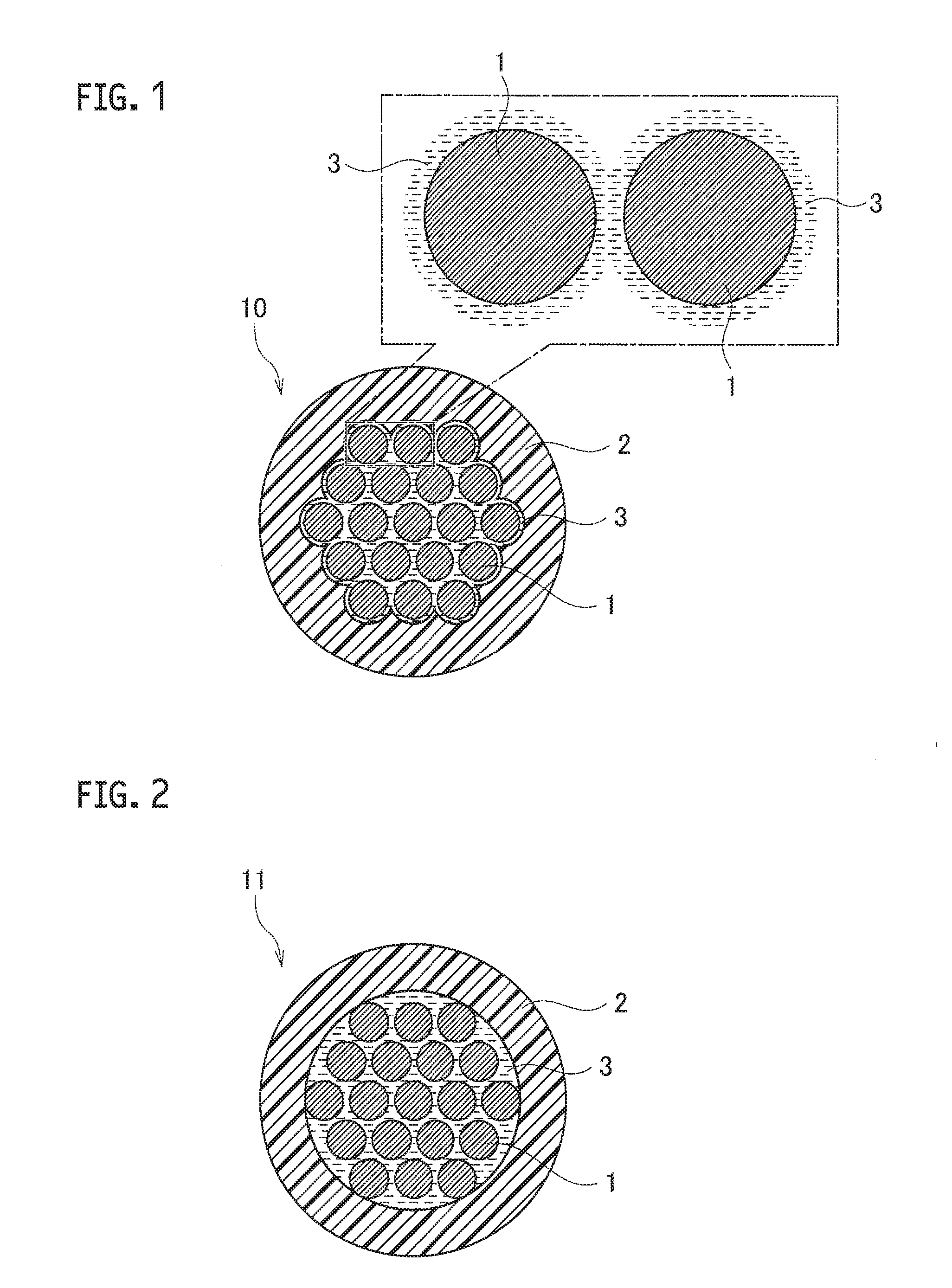

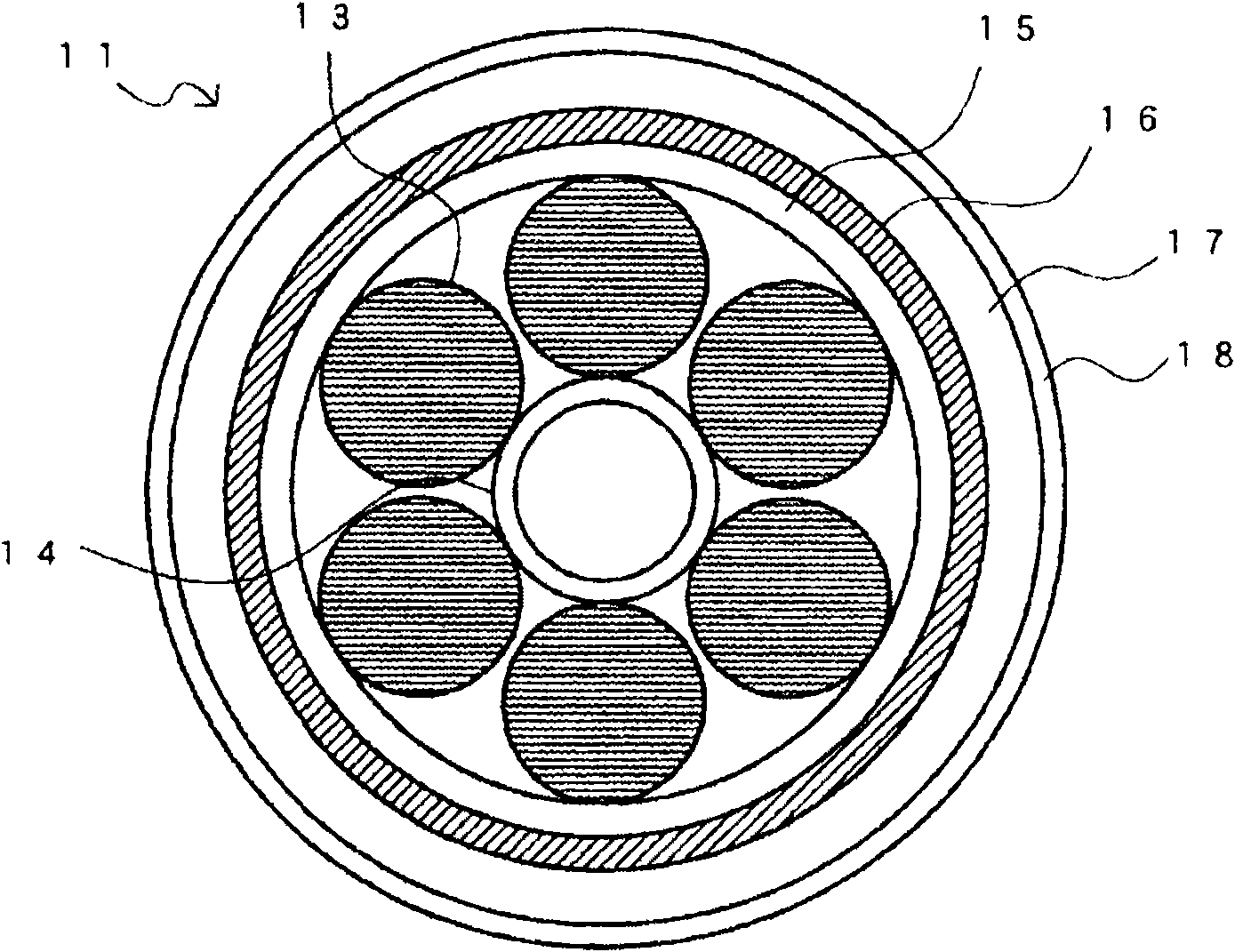

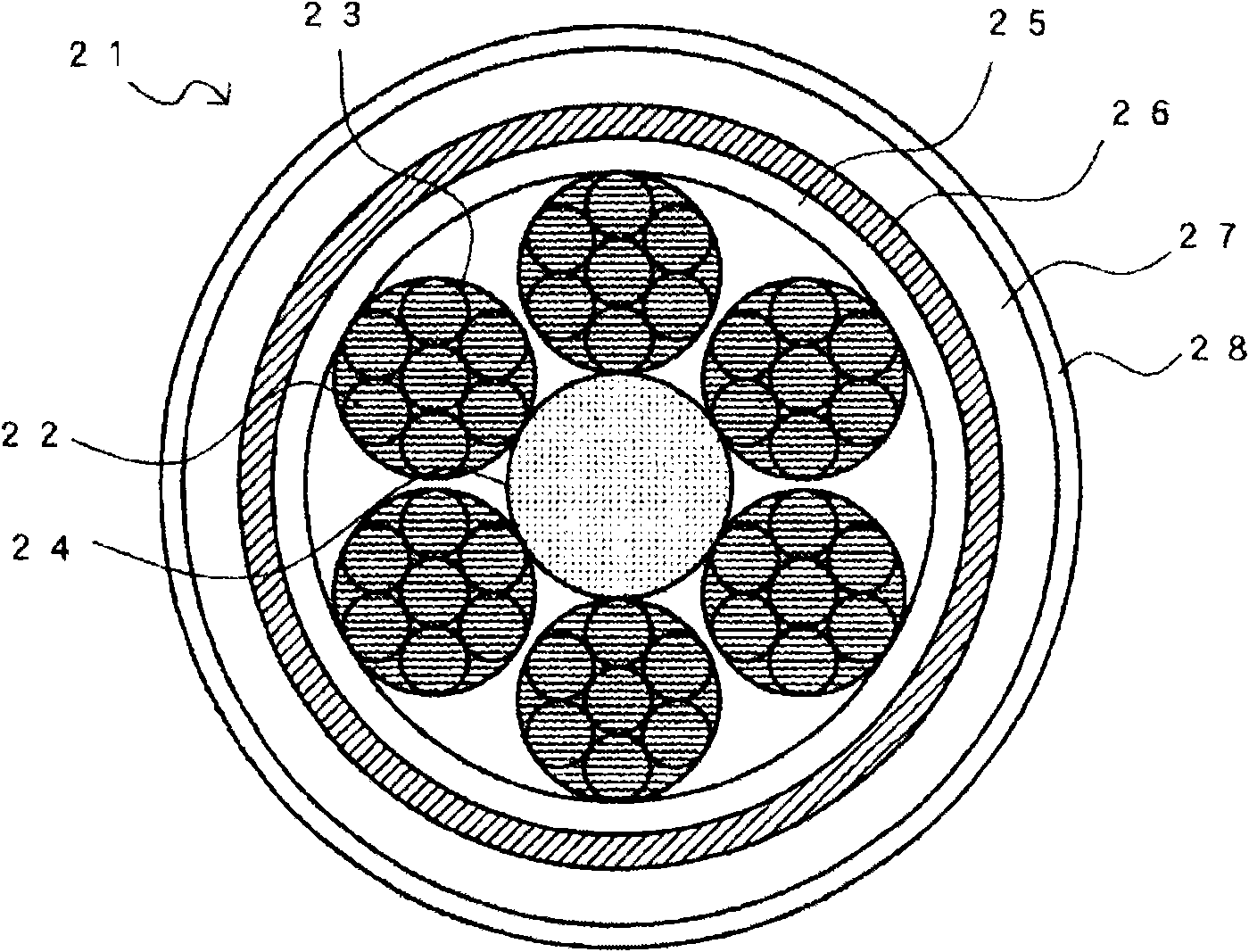

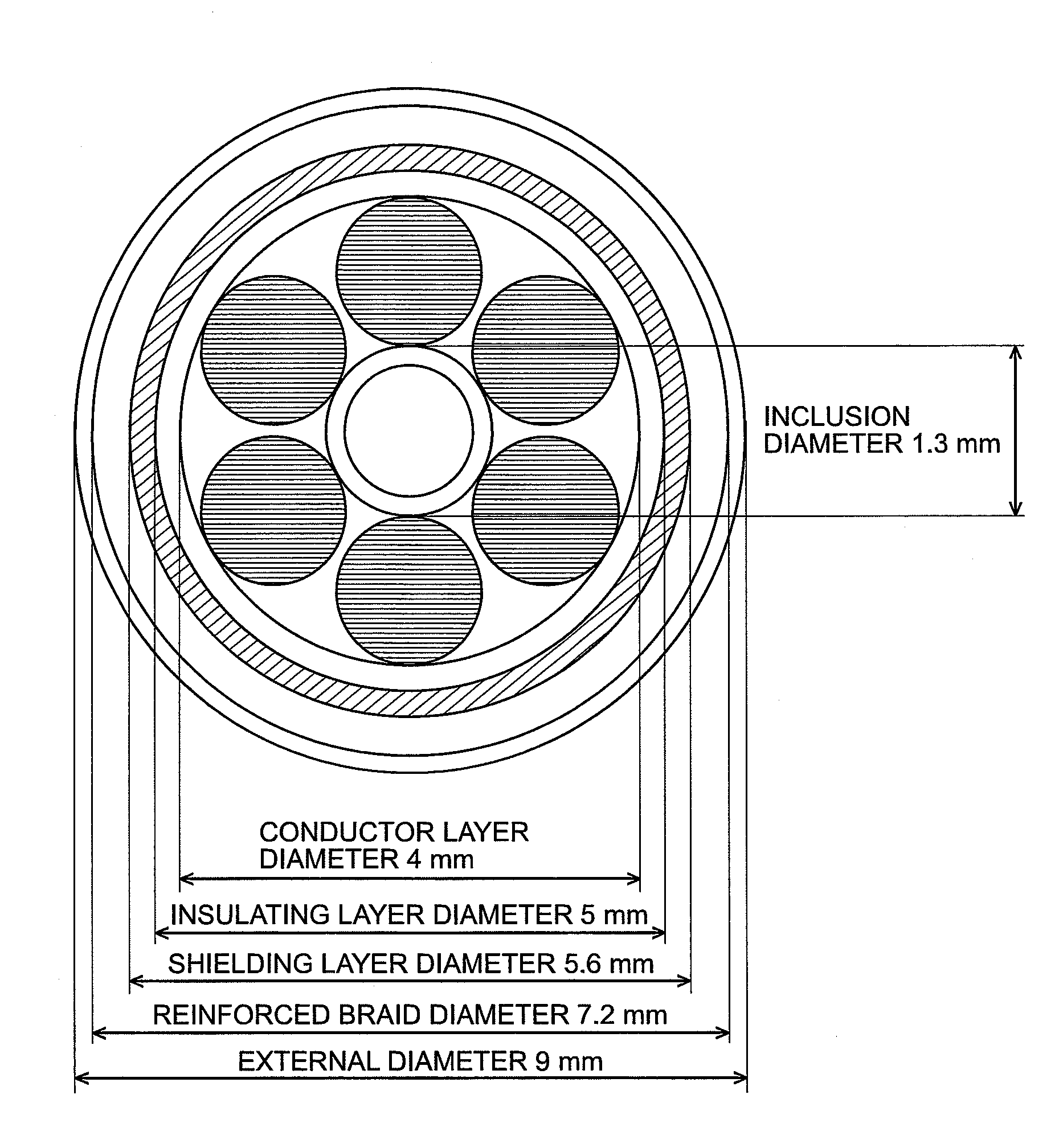

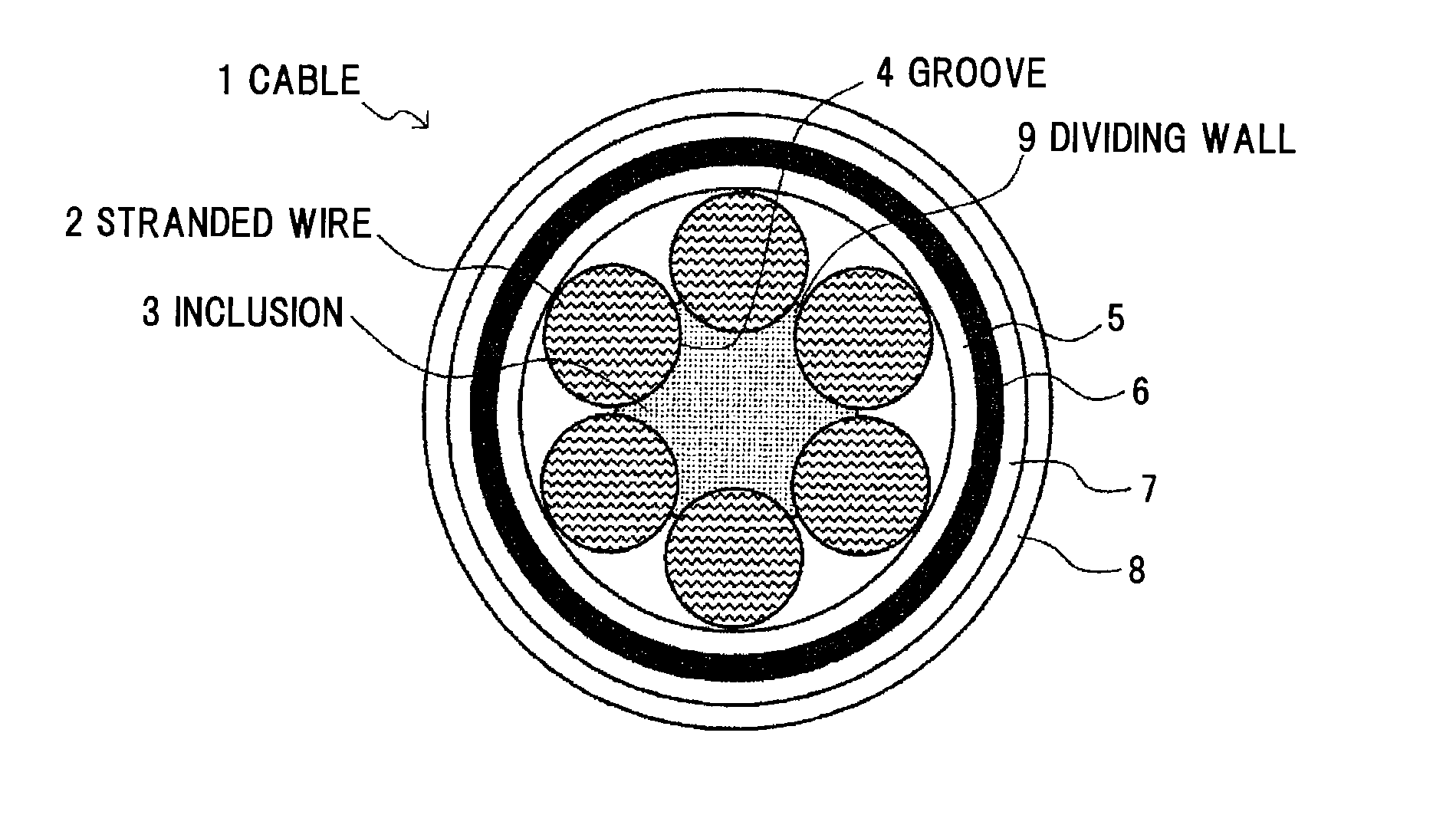

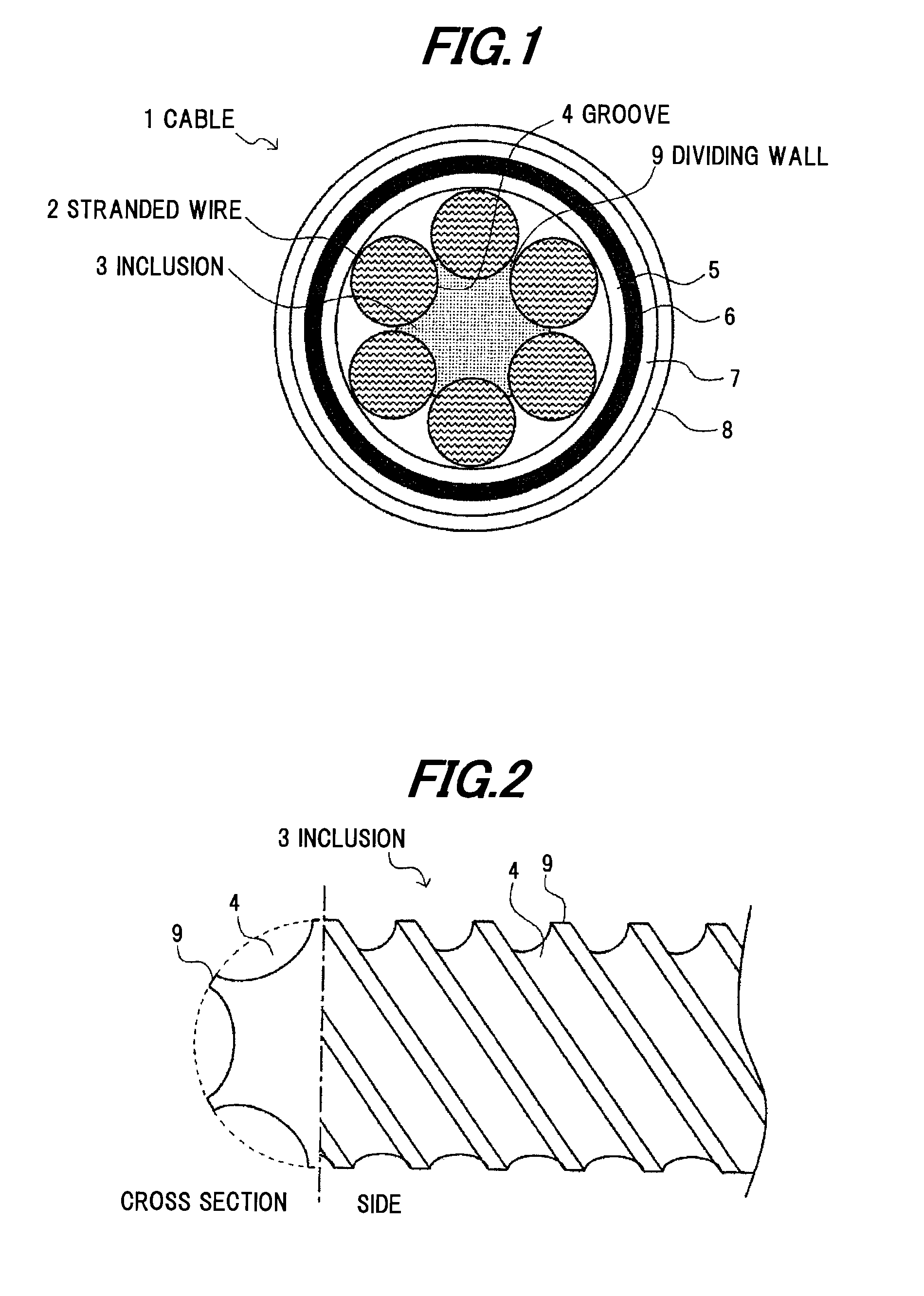

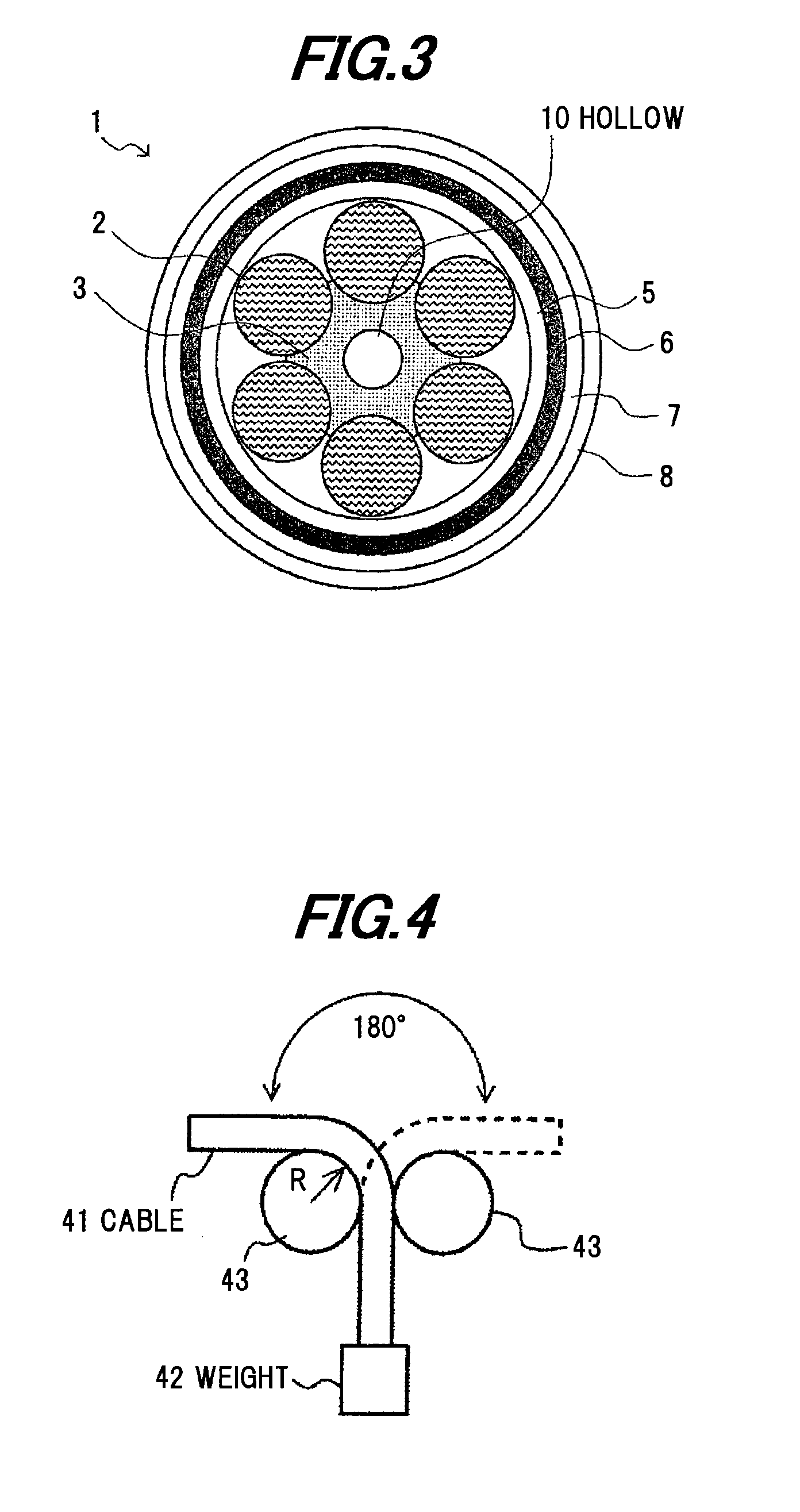

Cable

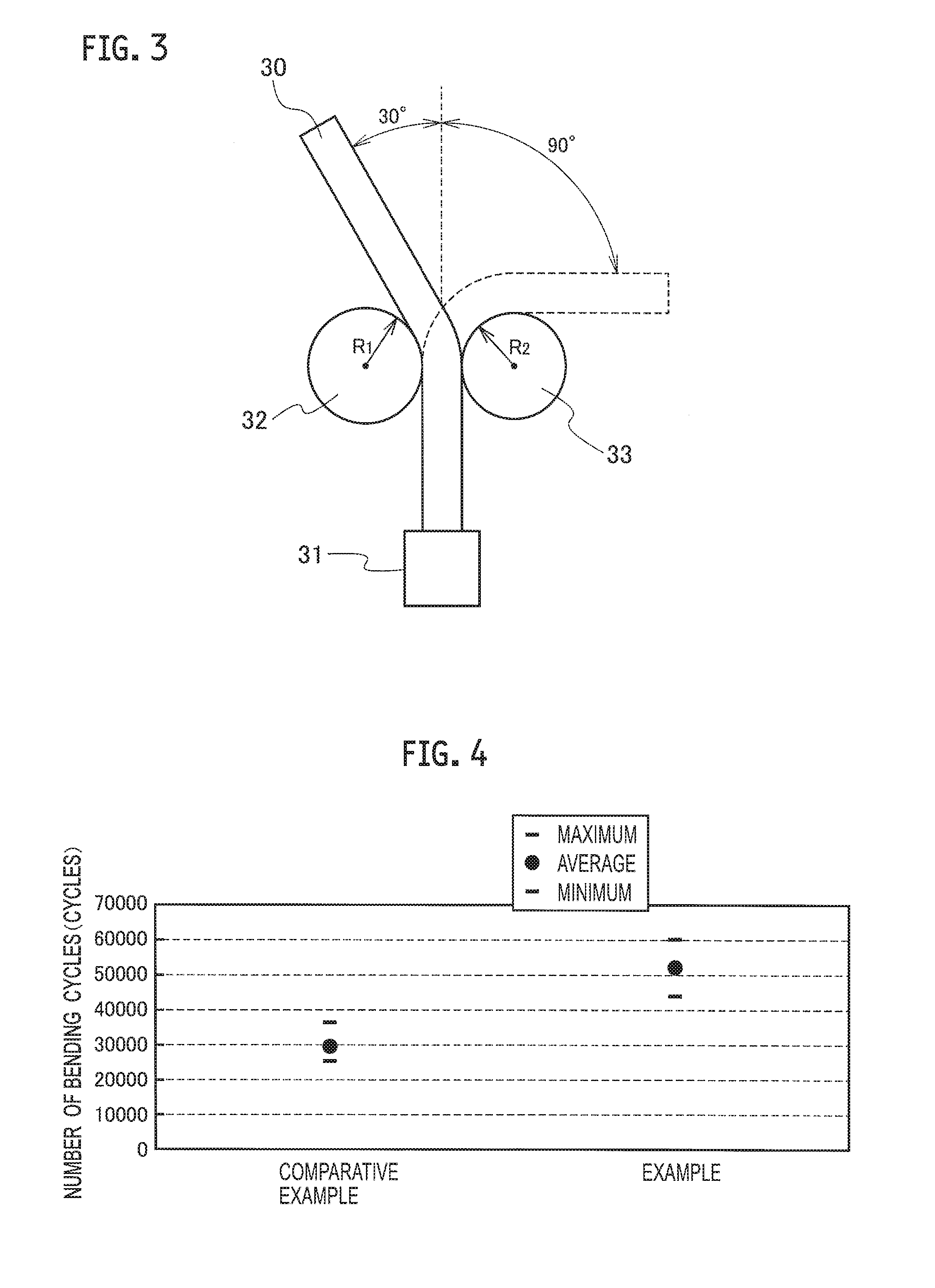

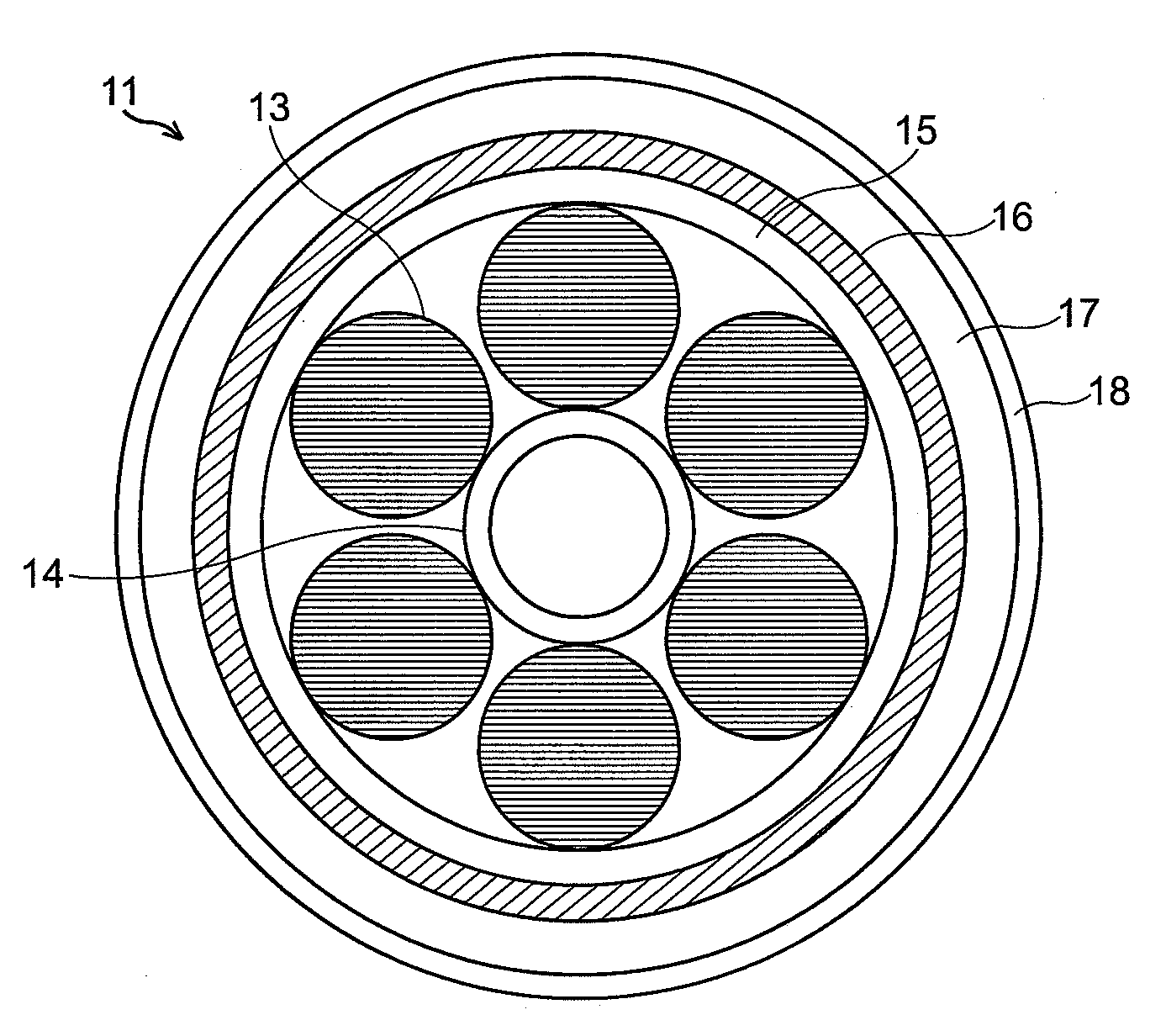

InactiveUS20110005805A1Reduce mutual contactImprove bending durabilityDetails of conductive coresFlexible cablesElectrical conductorEngineering

A cable includes an inclusion containing stranded wire conductor that includes a plurality of stranded wires formed by twisting a plurality of conductor wires, and a plurality of thin diameter inclusions having an external diameter thinner than that of each of the stranded wires. The inclusion containing stranded wire conductor is formed by together twisting a plurality of the stranded wires and a plurality of the thin diameter inclusions so as to allow one of the thin diameter inclusions to be located between adjacent stranded wires of a plurality of the stranded wires.

Owner:HITACHI CABLE

Continuous electric power supply device

InactiveUS7265295B2Improve bending durabilityAbsorb slack of a wire harness smoothlyConductive materialCable arrangements between relatively-moving partsEngineeringMechanical engineering

For miniaturizing a power supply structure to absorb slack of a wire harness and improving bending durability, a continuous electric power supply device 1 includes a wire harness 3 formed to have a loop portion 4, an elastic member 6 along the loop portion 4, the elastic member energizing the loop portion to expand in a radial direction. The loop portion 4 and the elastic member 6 are disposed in a protector 2. The protector has a opening 13 for leading the harness and a guide portion 7 for supporting the loop portion 4 at a position opposite to the opening 13. The elastic member, flat spring 6 can have a length forming a loop shape to intersect itself.

Owner:YAZAKI CORP

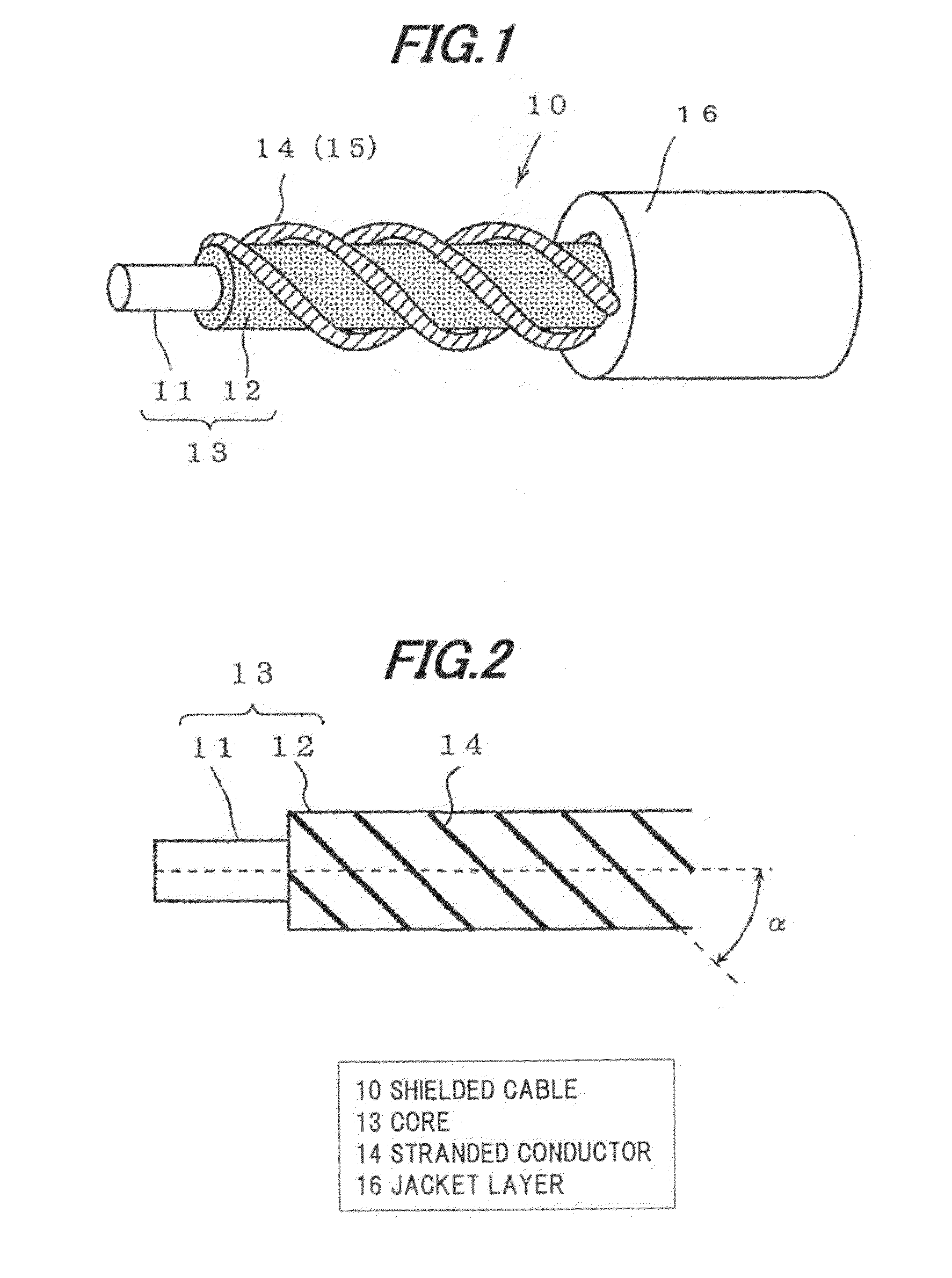

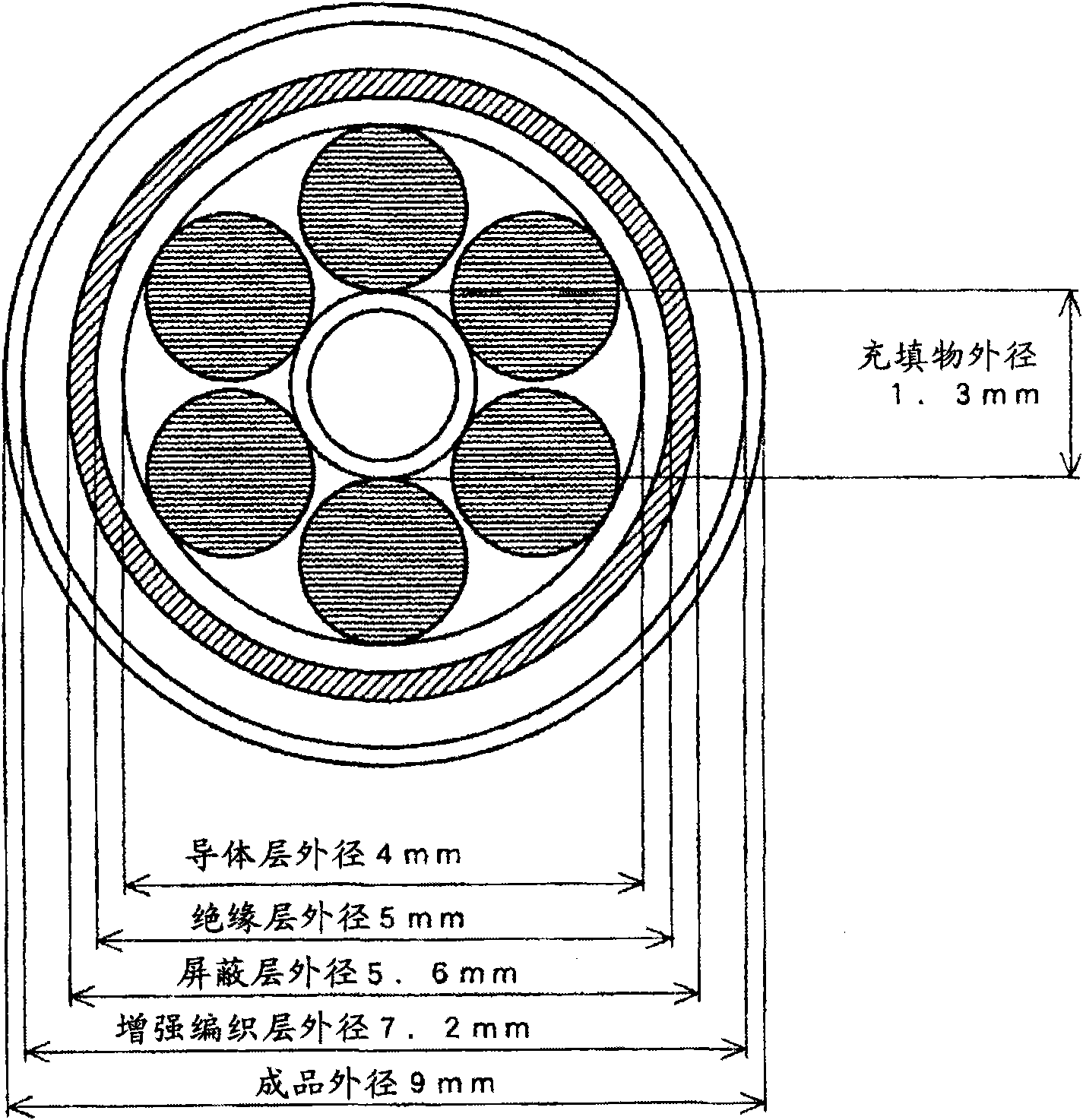

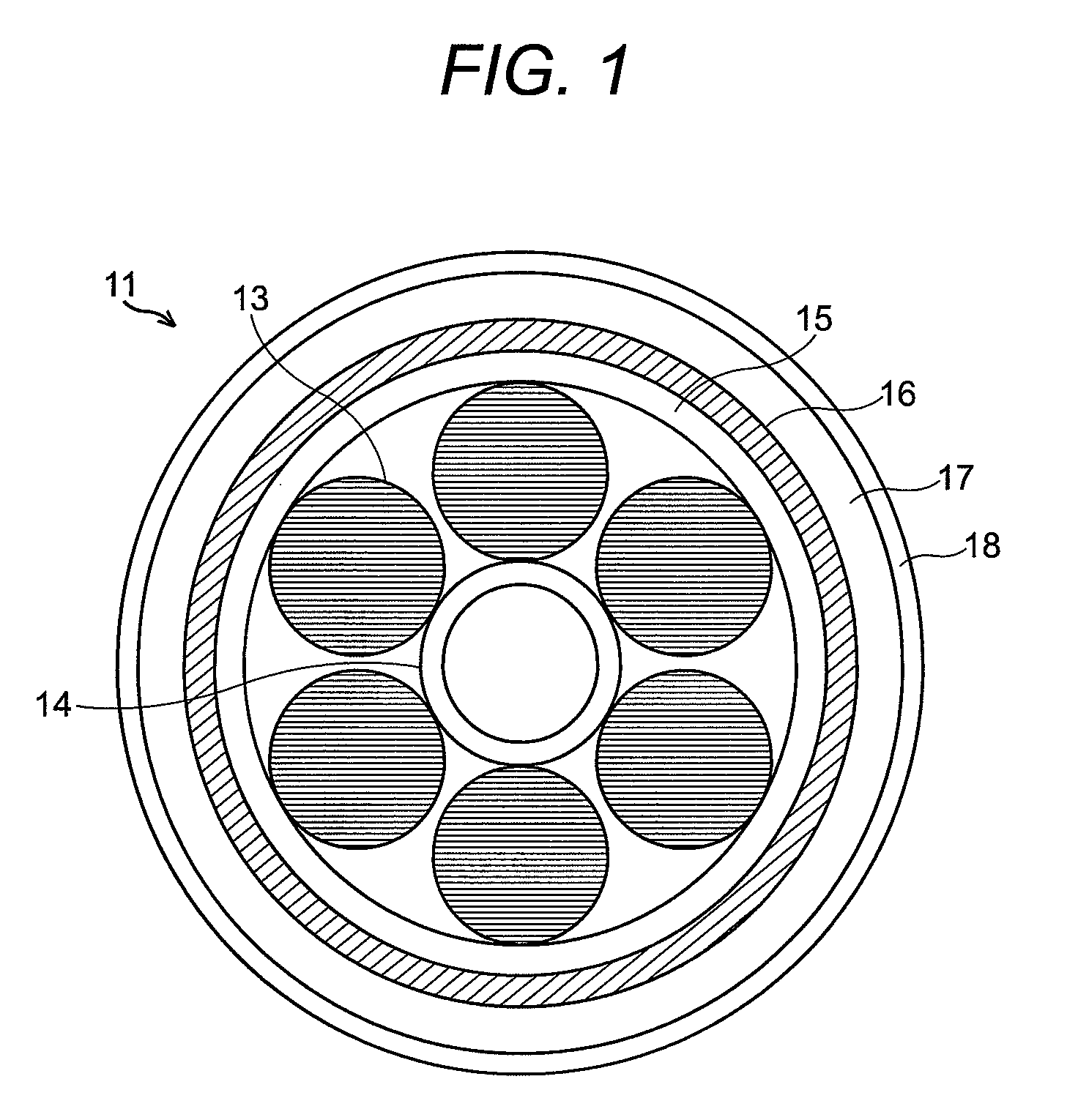

Shielded cable

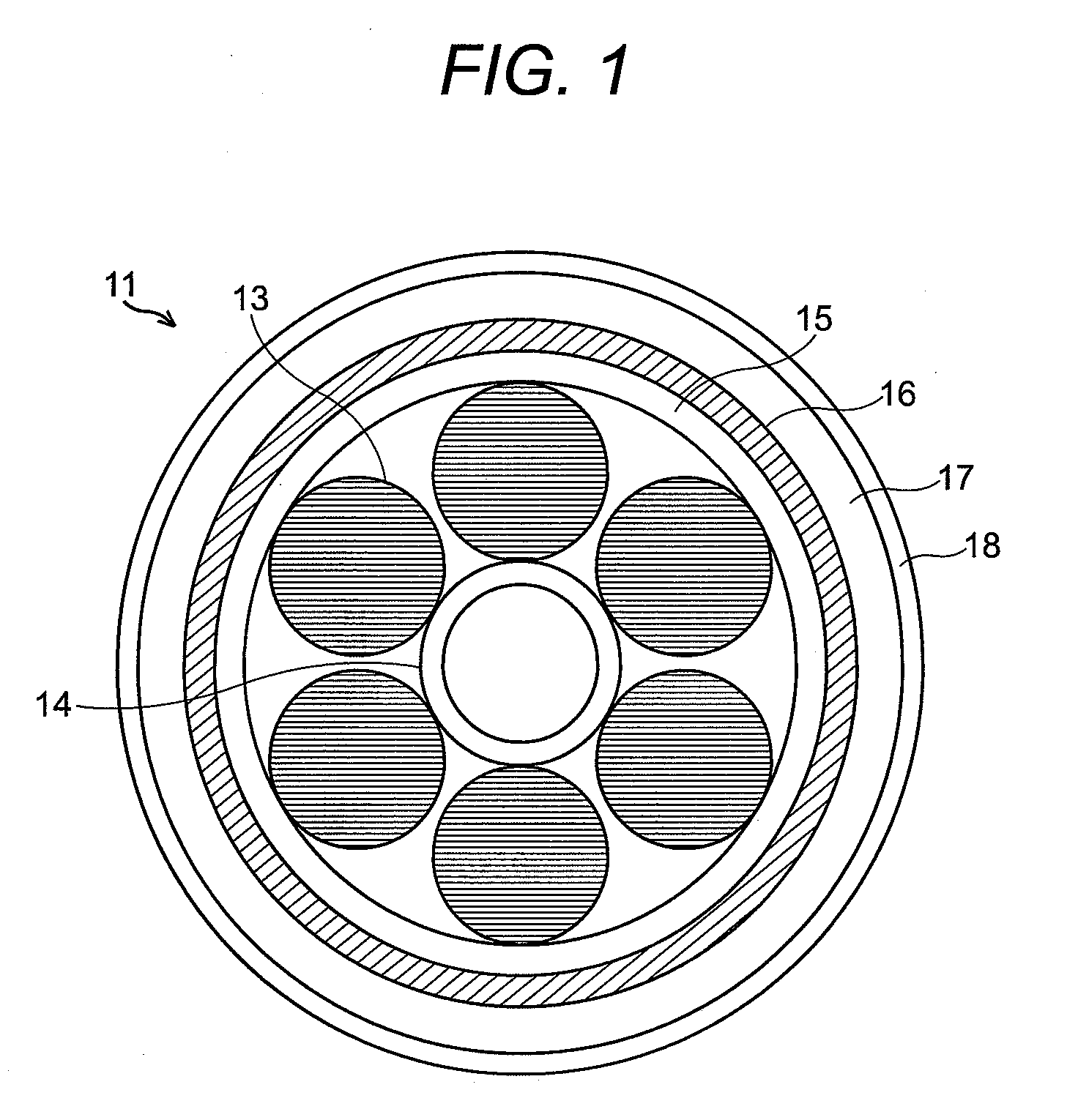

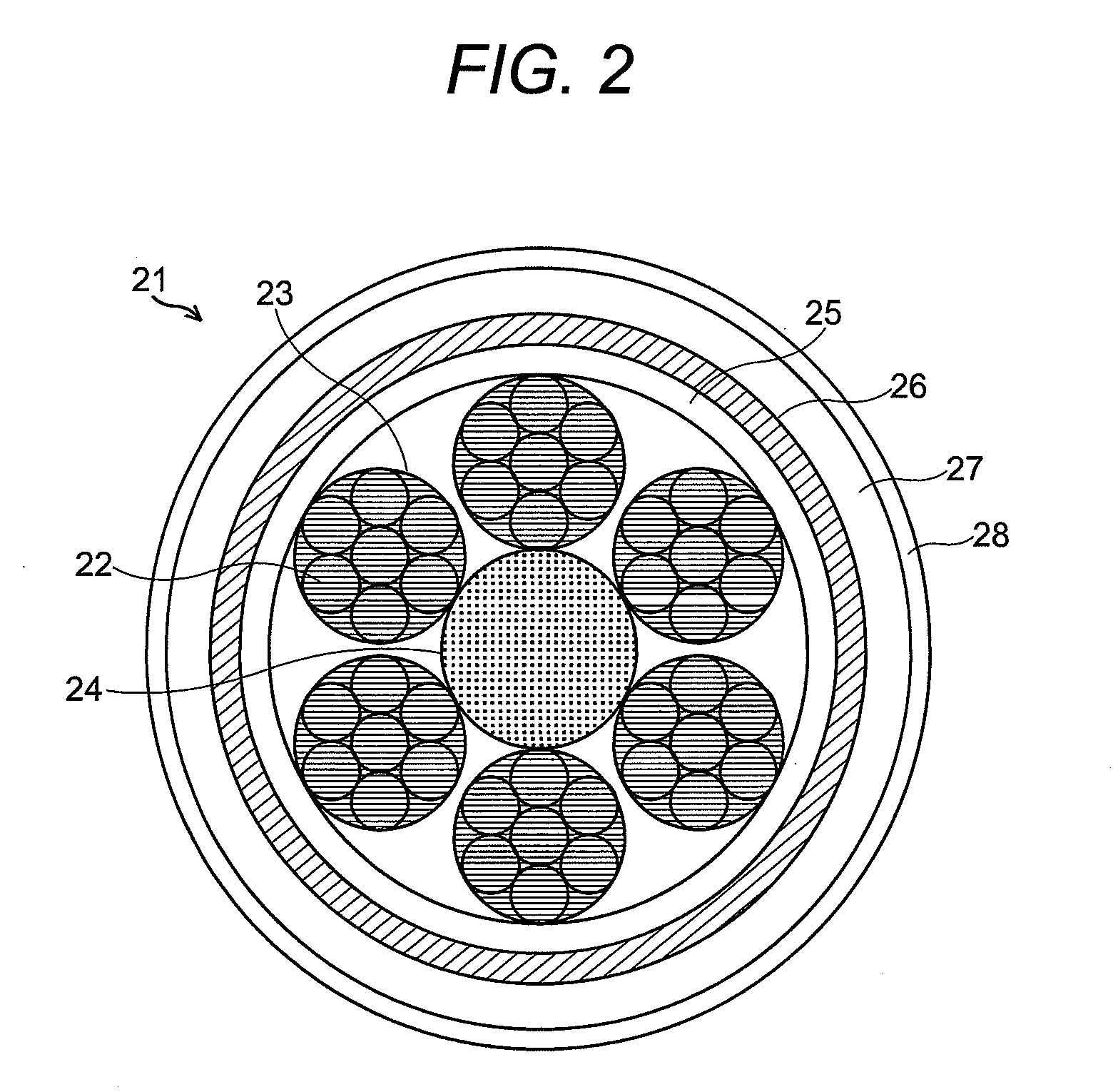

ActiveUS20110079410A1Improve bending durabilityIncreased durabilityCable conductor constructionPower cables with screens/conductive layersShielded cableInsulation layer

A shielded cable includes a core comprising an insulated wire including an inner conductor and an insulation layer formed on an outer periphery of the inner conductor, a shield layer formed on an outer periphery of the core, and a jacket layer formed on an outer periphery of the shield layer. The shield layer includes a stranded conductor shield layer including a stranded conductor spirally wound around the core, and the stranded conductor includes a plurality of conductor strands stranded together. The shield layer may further include a tinsel copper braided shield layer or a metal plated strand braided shield layer that is formed between the core and the stranded conductor shield layer.

Owner:HITACHI METALS LTD

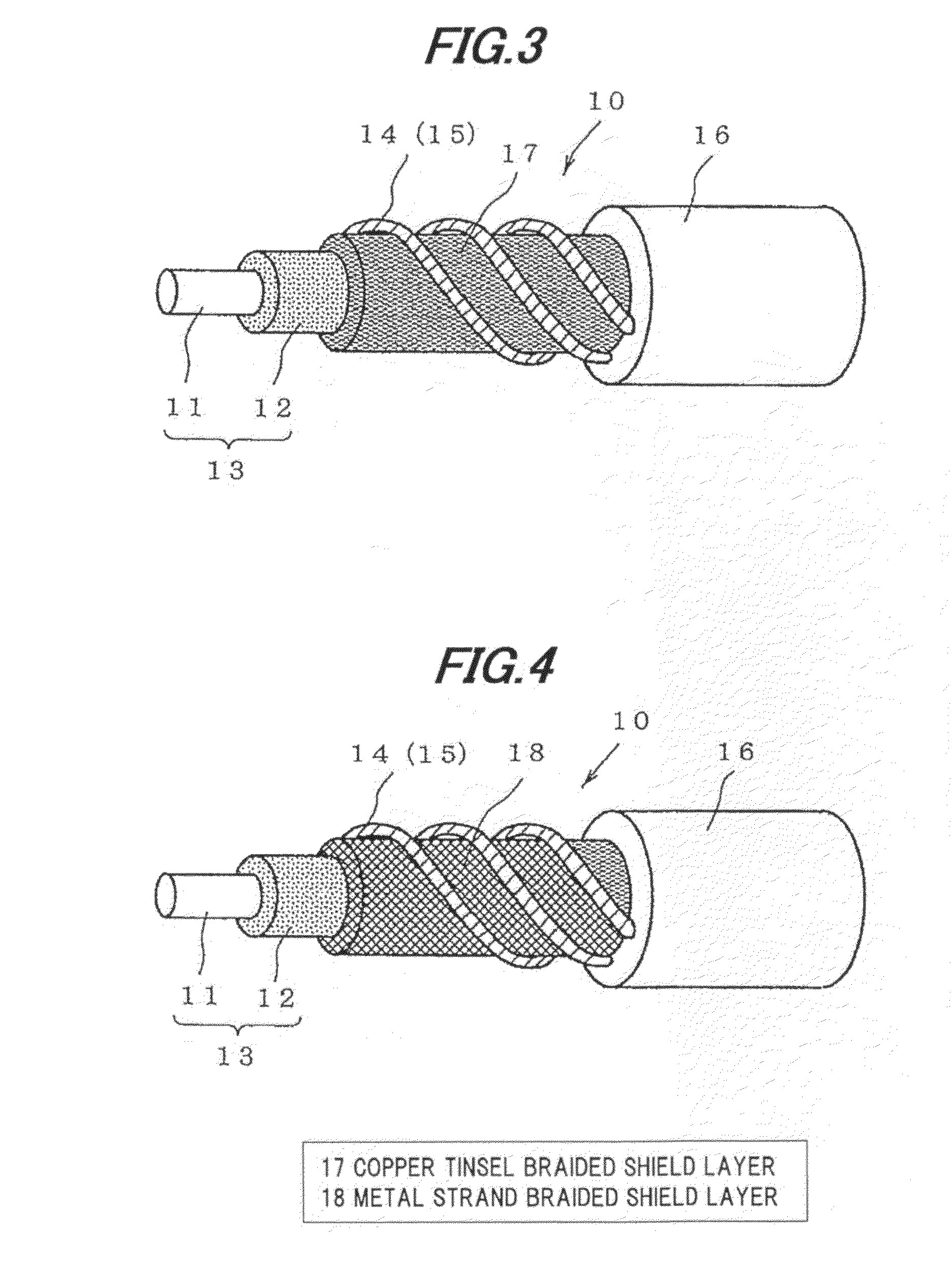

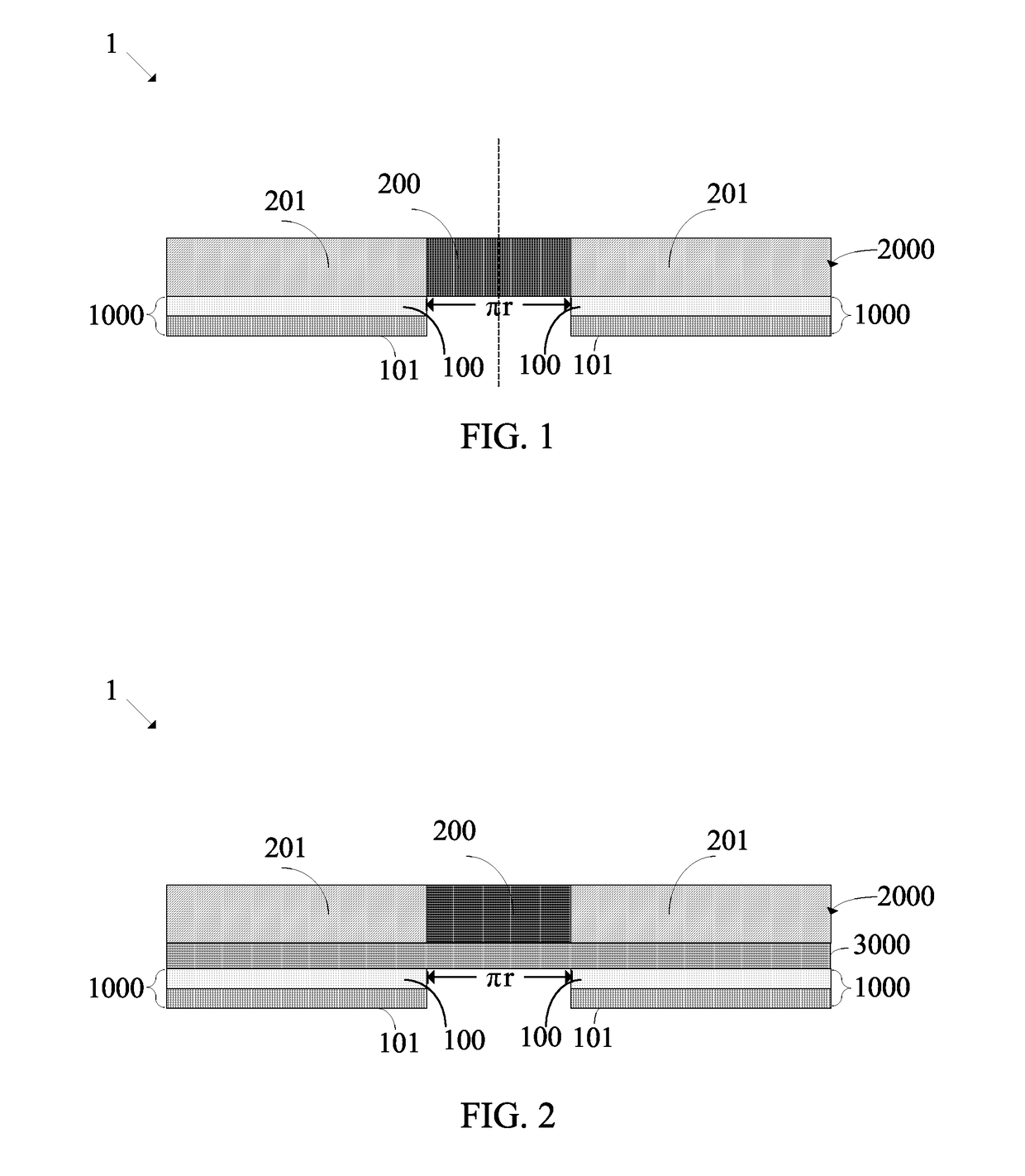

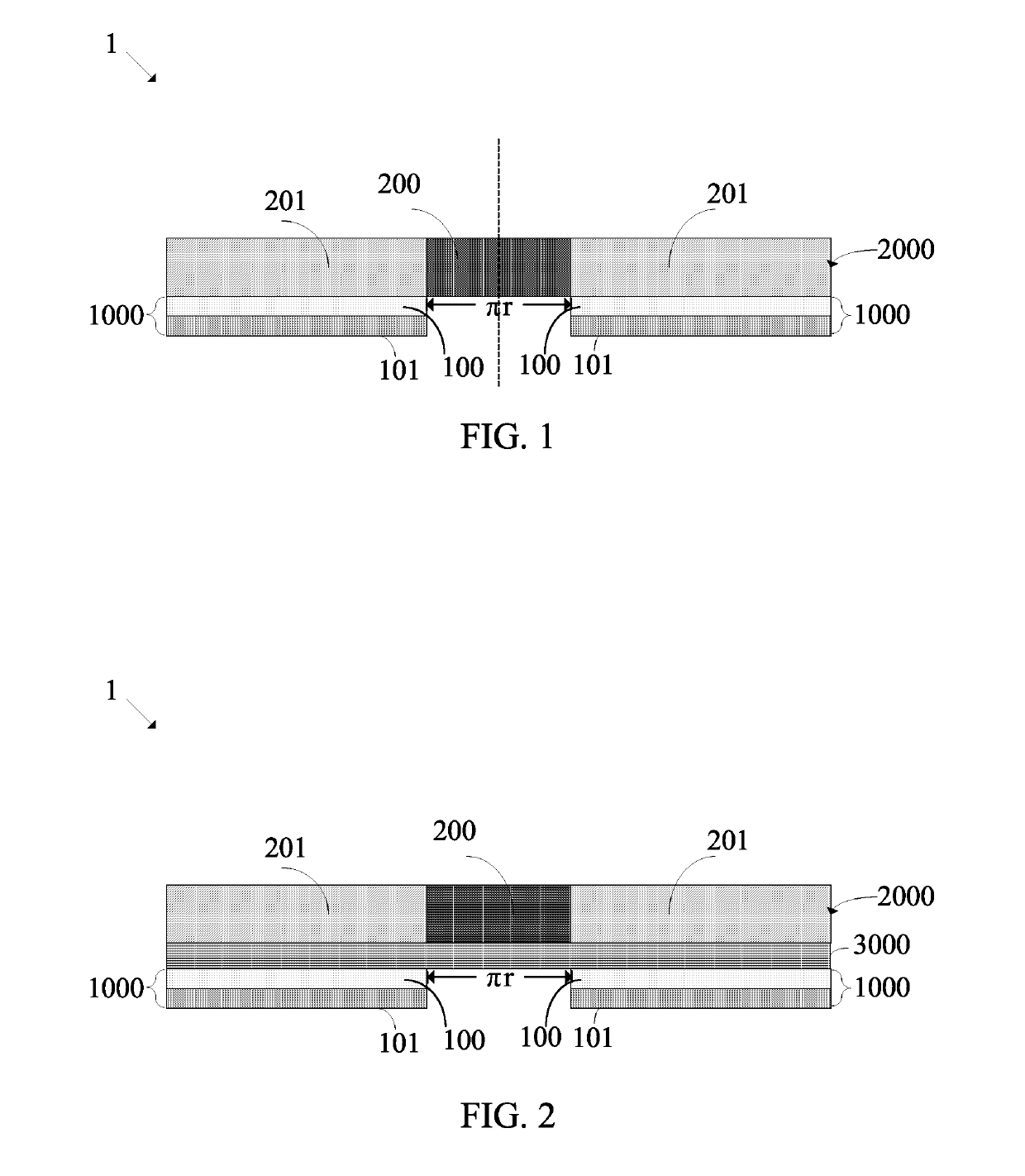

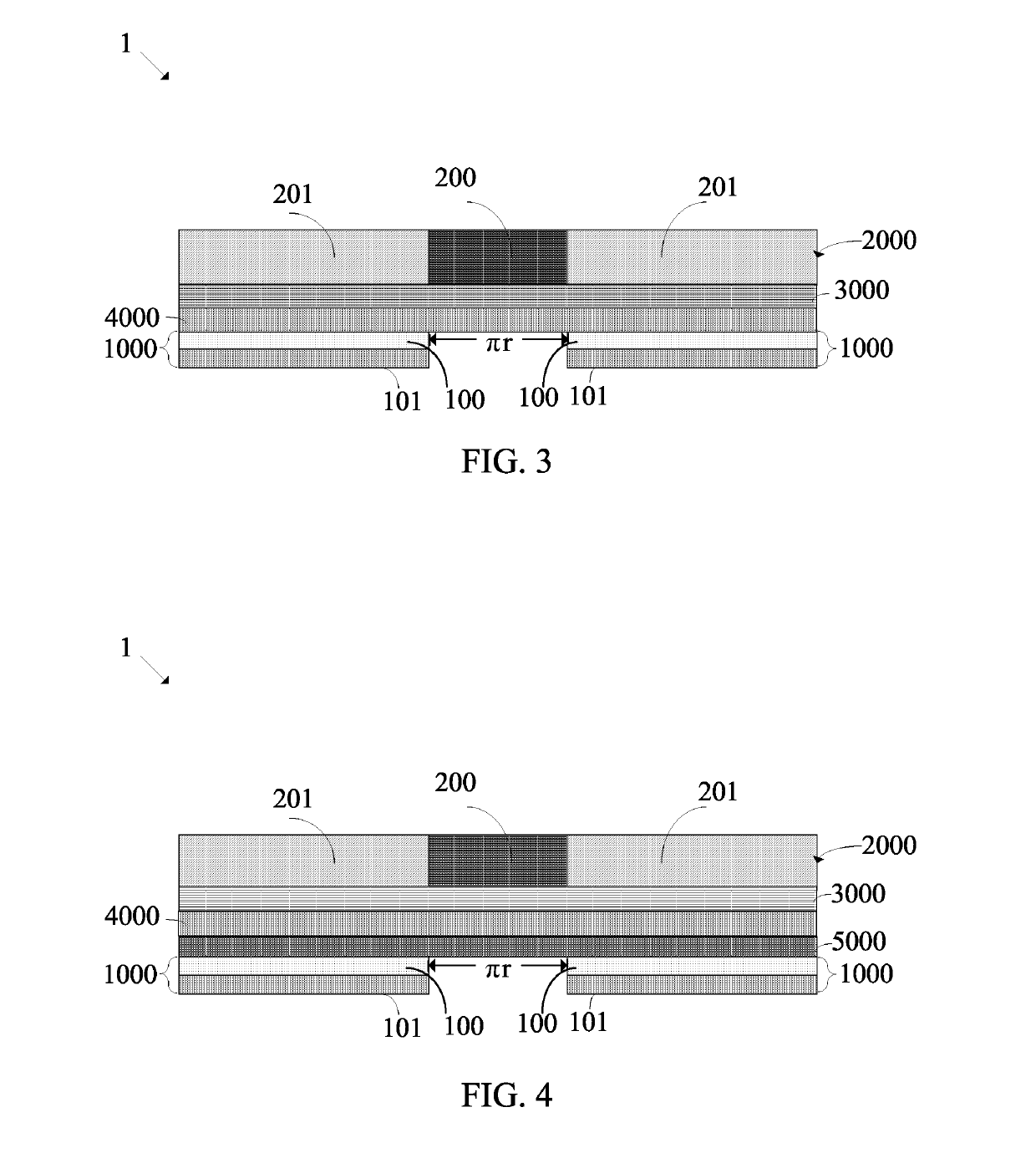

Flexible display device

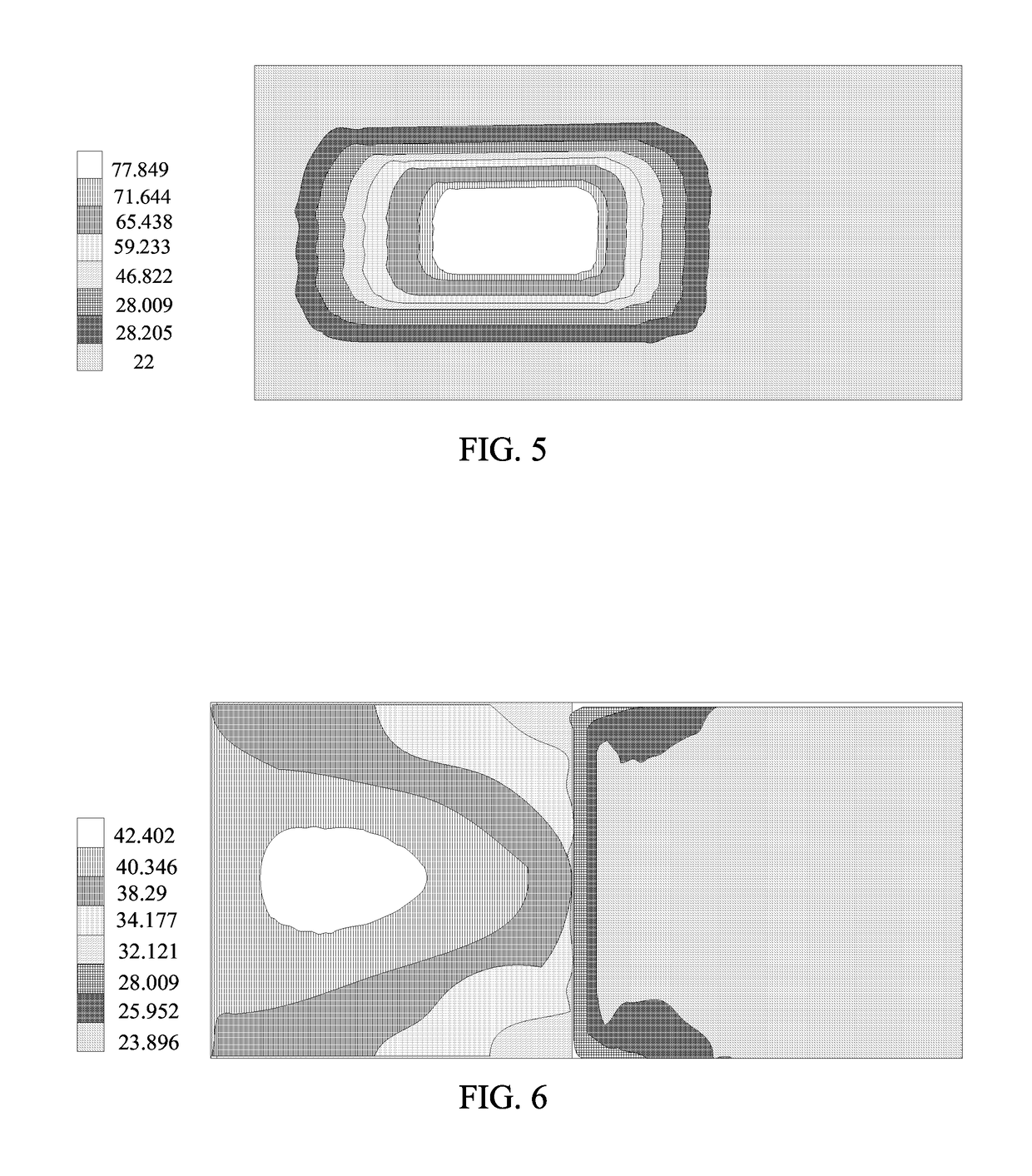

ActiveUS20190075688A1Improve cooling effectLower performance requirementsSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayElectrical and Electronics engineering

A flexible display device includes a flexible display panel and a heat dissipating layer. The flexible display panel includes a bending region and a non-bending region. The heat dissipating layer includes a first heat dissipating sublayer and a second heat dissipating sublayer. The first heat dissipating sublayer is disposed on the non-bending region and the second heat dissipating sublayer is disposed on the first heat dissipating sublayer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

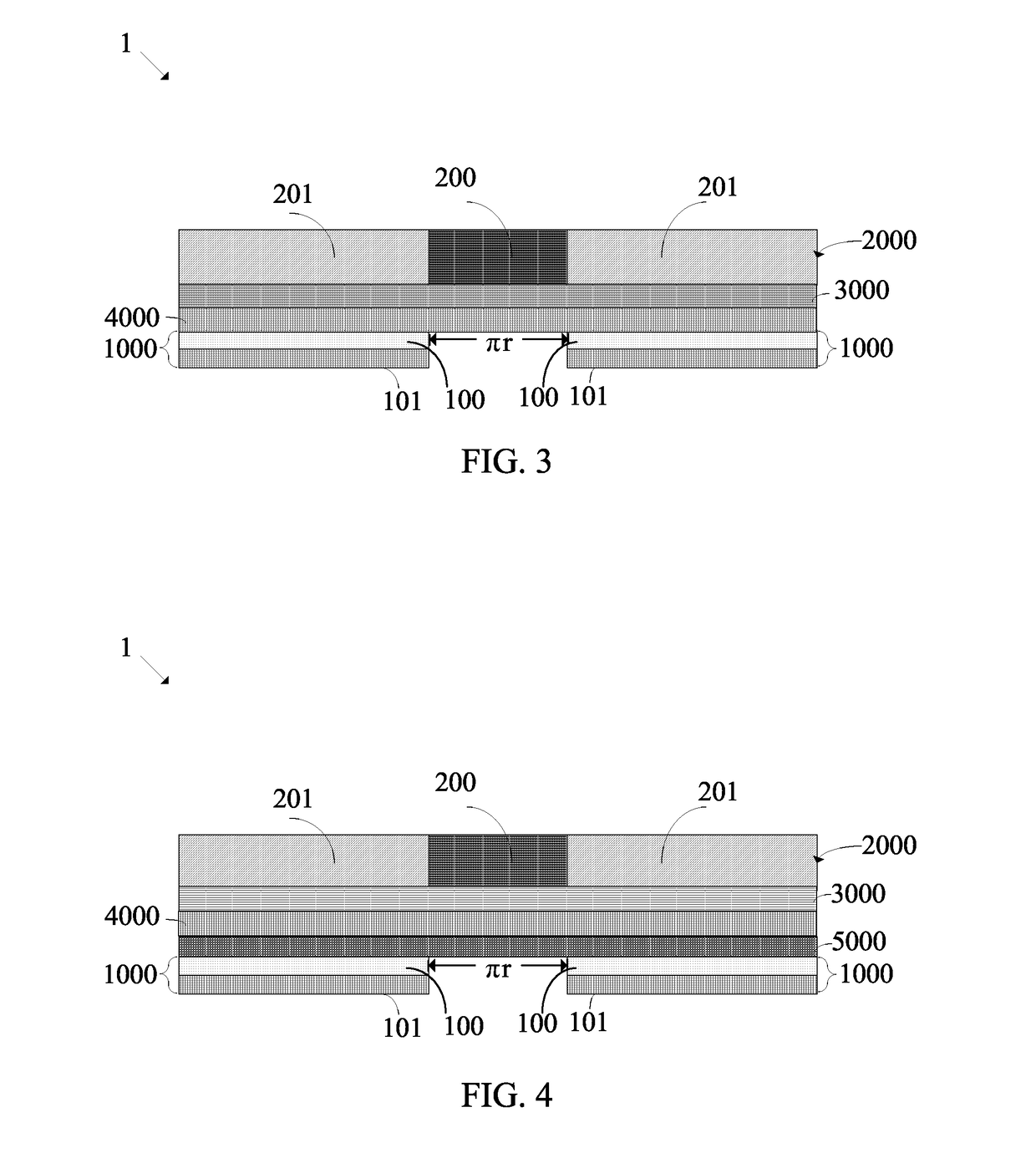

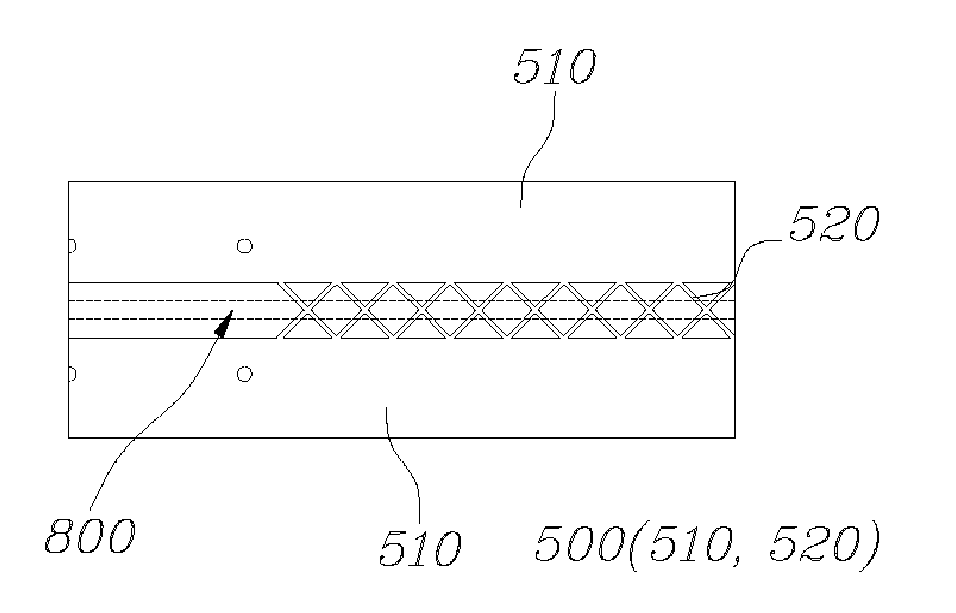

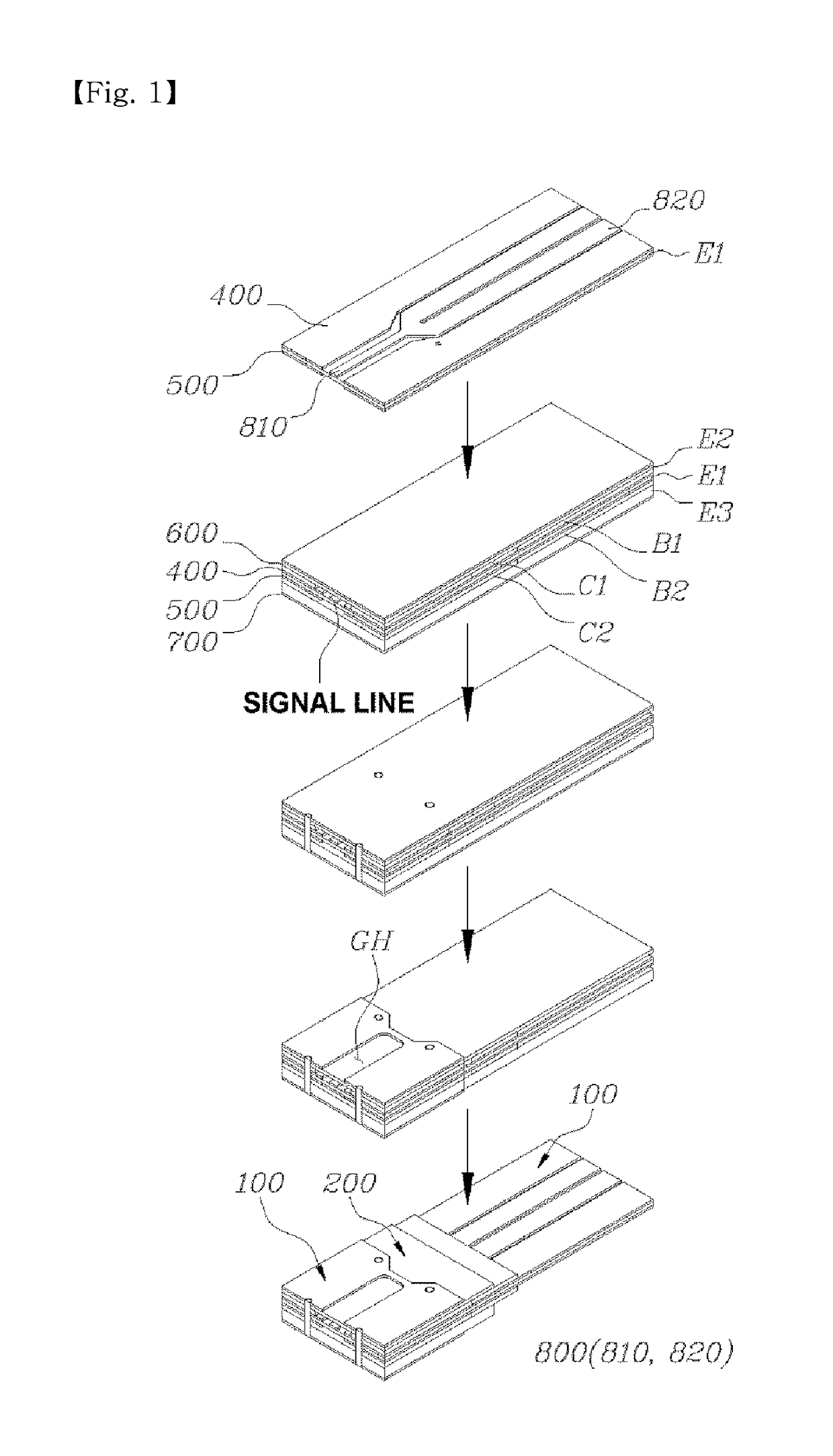

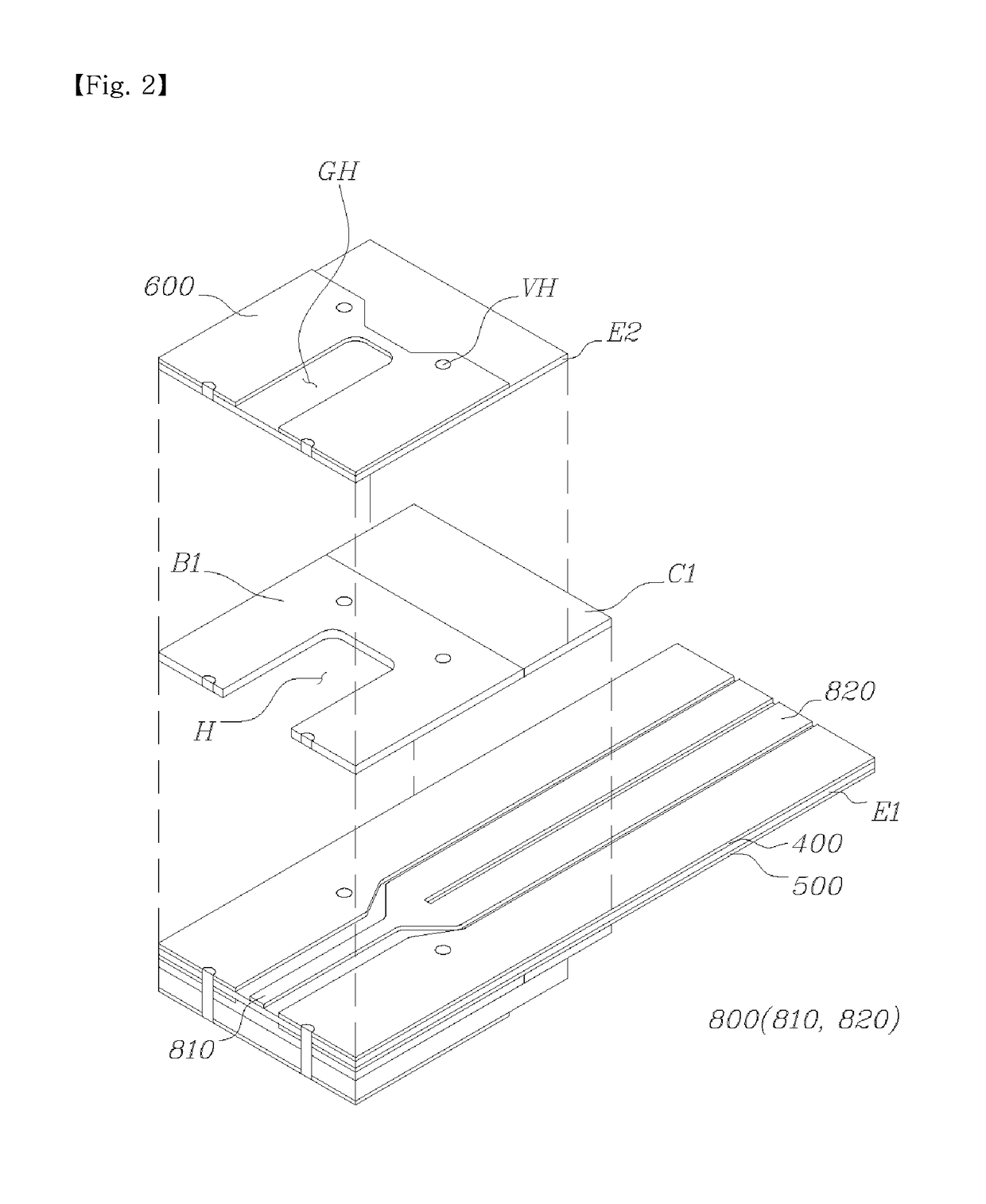

Flexible circuit board having enhanced bending durability and method for preparing same

ActiveUS20180206335A1Avoid damageMore bending durableCircuit bendability/stretchabilityCross-talk/noise/interference reductionFlexible circuitsEngineering

Provided are a flexible circuit board having enhanced bending durability and a method for preparing same. A method for preparing a flexible circuit board having enhanced bending durability, according to the present invention, comprises the steps of: (a) forming a signal line and a first ground layer on a first dielectric body and forming a second ground layer on the bottom side of the first dielectric body; (b) preparing a second dielectric body; (c) preparing a first bonding sheet and a first protective sheet which is connected to one end of the first boding sheet or of which one or more parts are overlapped on one end of the first bonding sheet; (d) bonding the second dielectric body onto the first dielectric body by means of the first bonding sheet; (e) forming a via hole such that the first ground layer and second ground layer can be conducted; and (f) cutting in the width direction the second dielectric body placed on the first protective sheet.

Owner:GIGALANE CO LTD

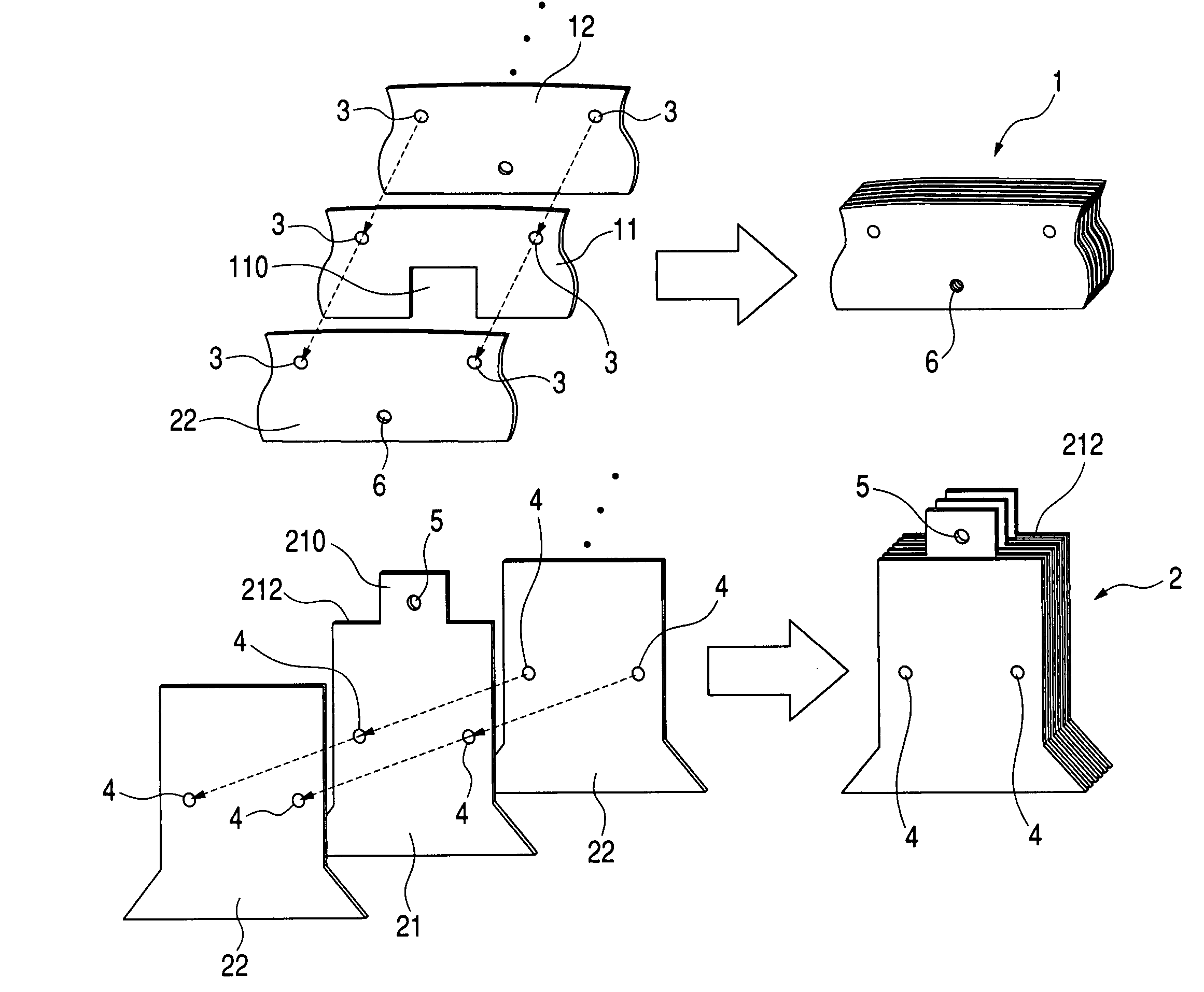

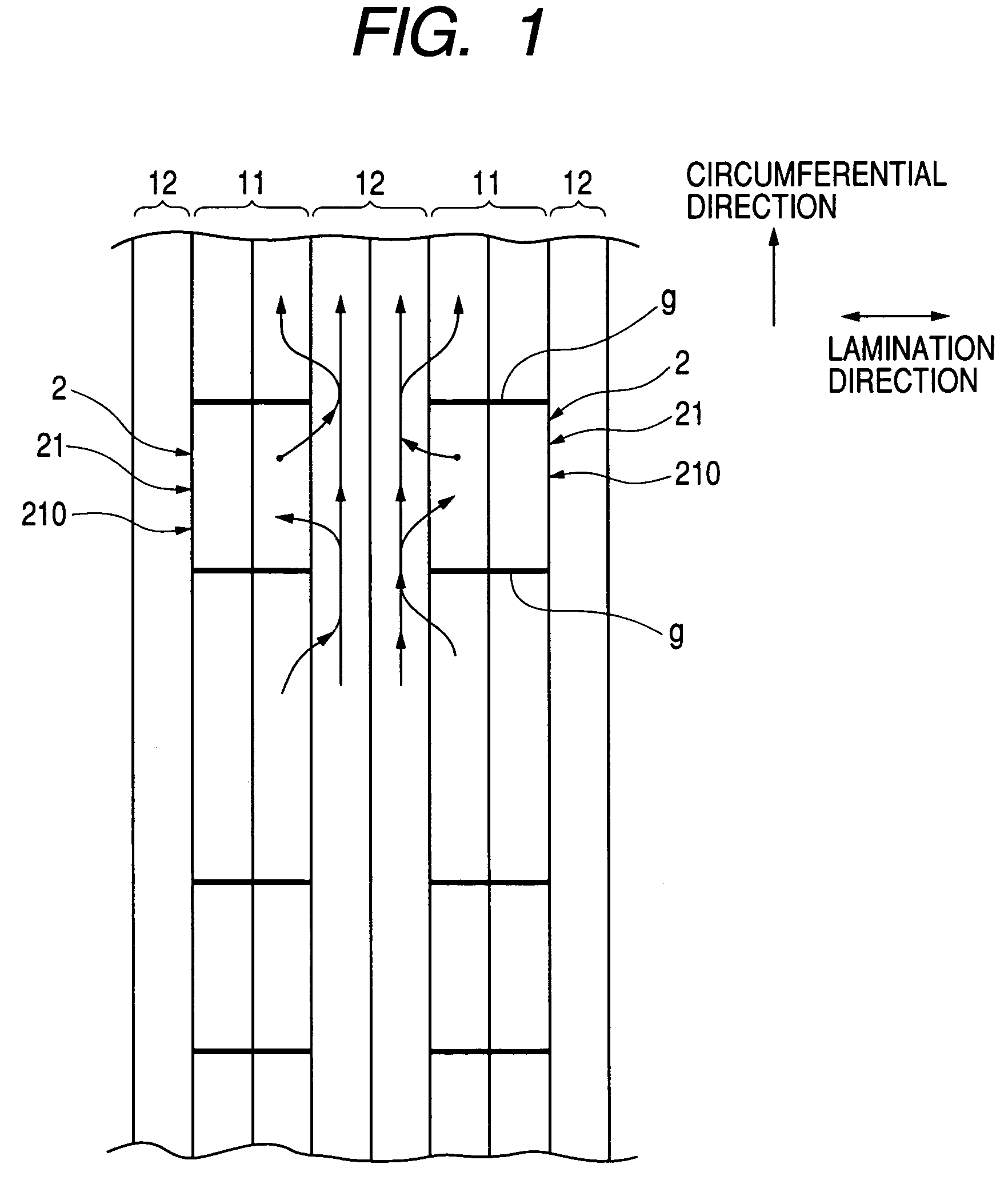

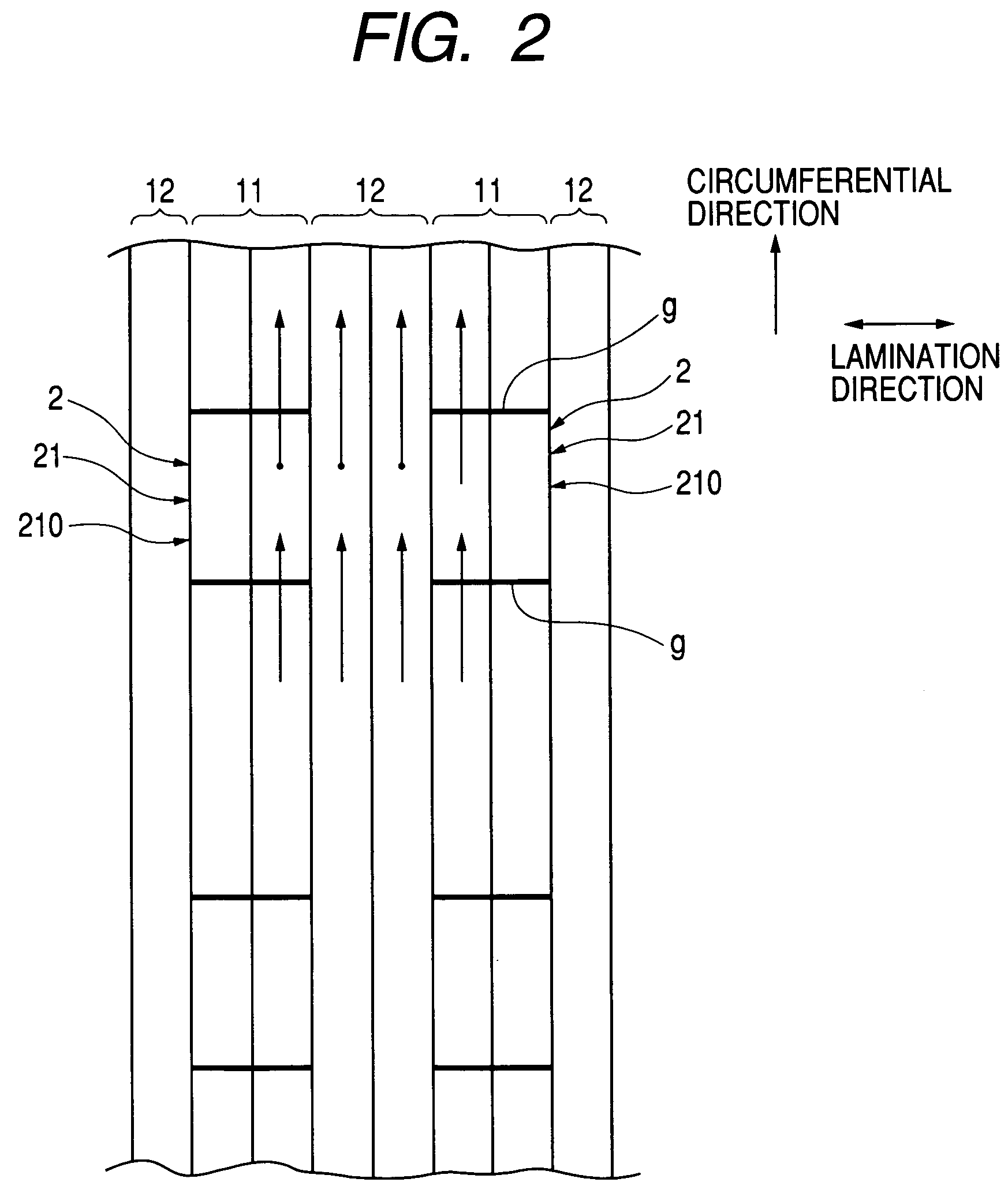

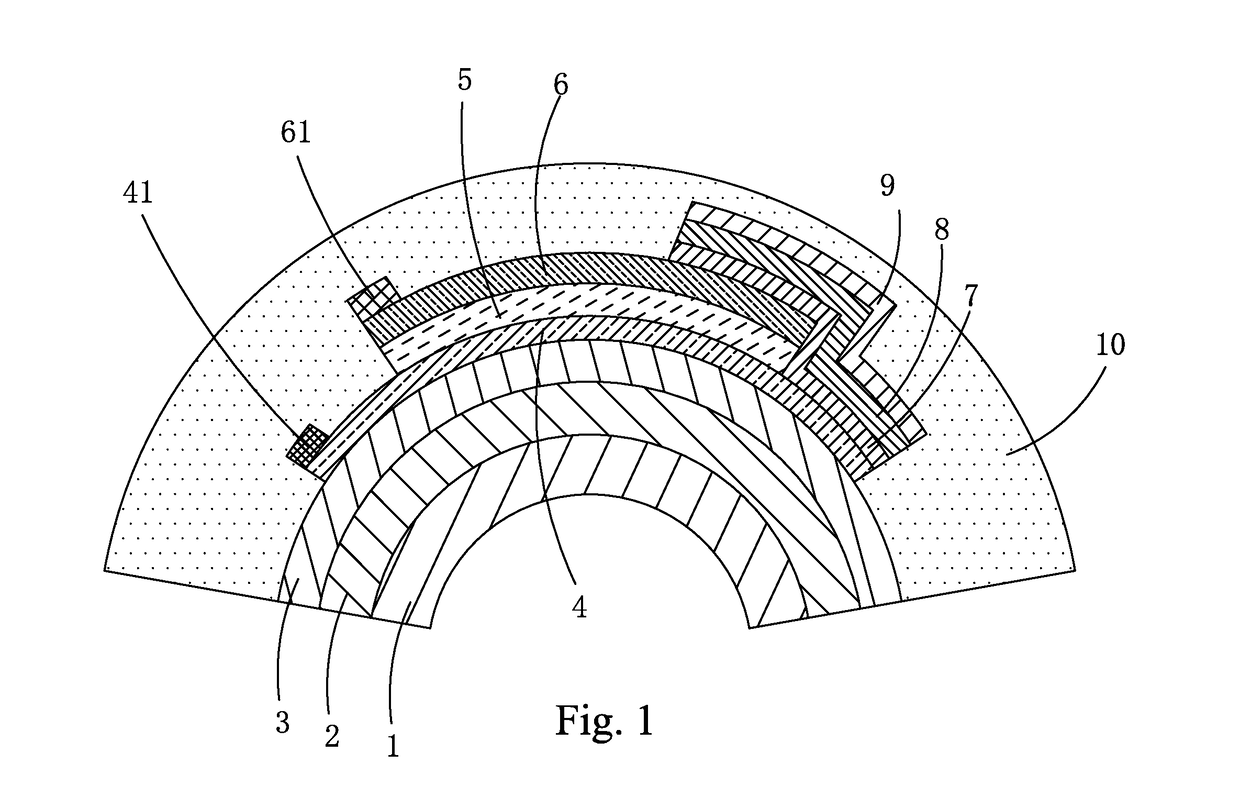

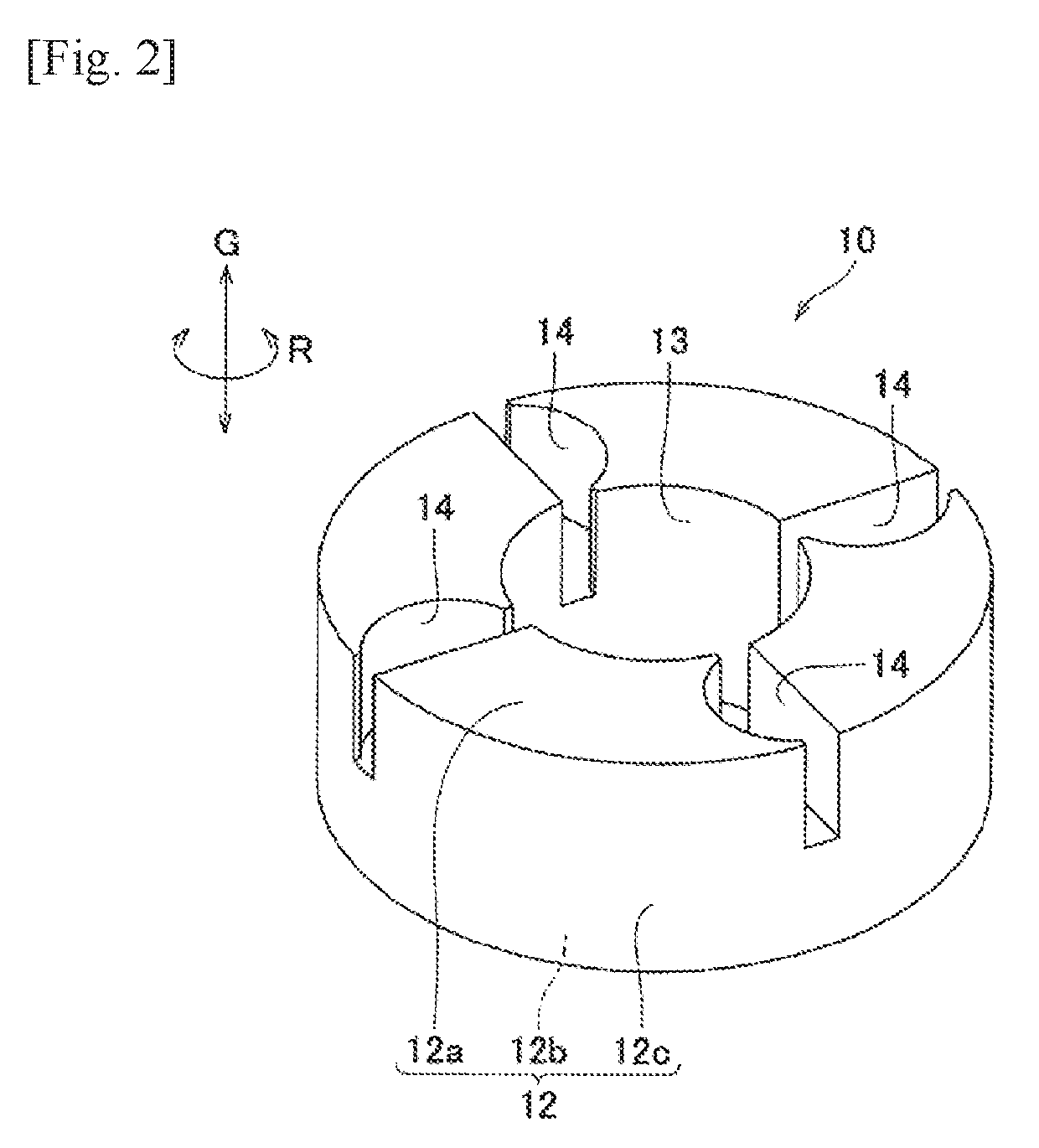

Combined stator core for an electric rotary machine

InactiveUS6960861B2Simplify workReduce in quantityMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringMechanical engineering

Owner:DENSO CORP

Feeding structure for sliding structural body

ActiveUS7980518B2Reduce bending stressIncreased durabilityPipe supportsSemiconductor/solid-state device detailsMechanical engineeringEngineering

Owner:YAZAKI CORP +1

Highly-flexible electric wire

InactiveUS20160104557A1Increasing in costIncreasing in thicknessSynthetic resin layered productsFlexible cablesElectrical conductorPolypropylene glycol

A highly-flexible electric wire includes: a conductor; and an insulator layer covering the conductor and further includes a liquid lubricant interposed between the conductor and insulator layer. The lubricant contains at least one selected from the group consisting of polyethylene glycol, polypropylene glycol, and fluorine lubricants. Such a configuration enables the conductor and insulator layer to slide smoothly on each other, therefore increasing the flexibility.

Owner:YAZAKI CORP

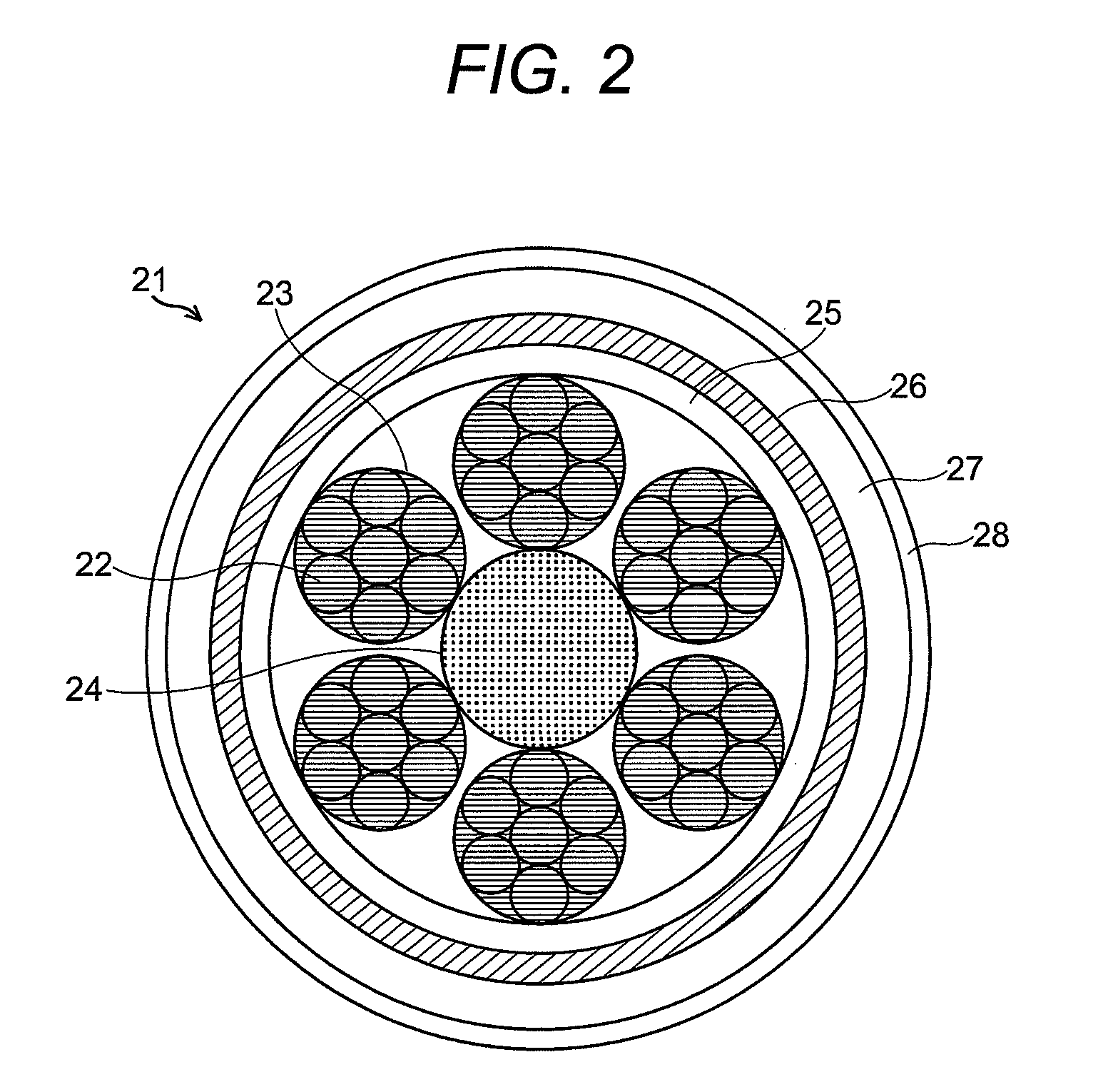

Cable

InactiveUS20100270054A1Good effectImprove bending durabilityNon-insulated conductorsPower cables with screens/conductive layersElectrical conductorEngineering

Owner:TOYOTA JIDOSHA KK +1

Cable

InactiveCN101872657AImprove bending durabilityImprove flexibilityNon-insulated conductorsFlexible cablesElectrical conductor

Owner:PROTERIAL LTD +1

Wire harness routing structure

ActiveUS9670708B2Avoid breakingImprove bending durabilityCable arrangements between relatively-moving partsPower-operated mechanismCable harnessClosed state

Owner:YAZAKI CORP

Cable

InactiveUS9040826B2Improve bending durabilityIncrease flexibilityNon-insulated conductorsPower cables with screens/conductive layersElectrical conductorEngineering

Owner:TOYOTA JIDOSHA KK +1

Cable

InactiveUS20110024151A1Physical contactAvoid contactCable arrangements between relatively-moving partsInsulated cablesEngineeringMechanical engineering

Owner:HITACHI CABLE +1

Security laminates with a security feature detectable by touch

InactiveUS20100330304A1Minimized brittlenessGood physical propertiesDomestic sealsOther printing matterPolyesterInternet privacy

A security laminate precursor comprising a plurality of lamellae and layers, wherein at least one of the outermost lamellae is an axially stretched linear polyester film and the security laminate precursor comprises a touch-detectable relief structure on a side of the security laminate precursor having as outermost lamella the axially stretched linear polyester film, the relief structure being associated with a viewable non-surface image which is a pattern made up of micro-perforations. A security laminate and a process for preparing a security laminate are also disclosed.

Owner:AGFA NV

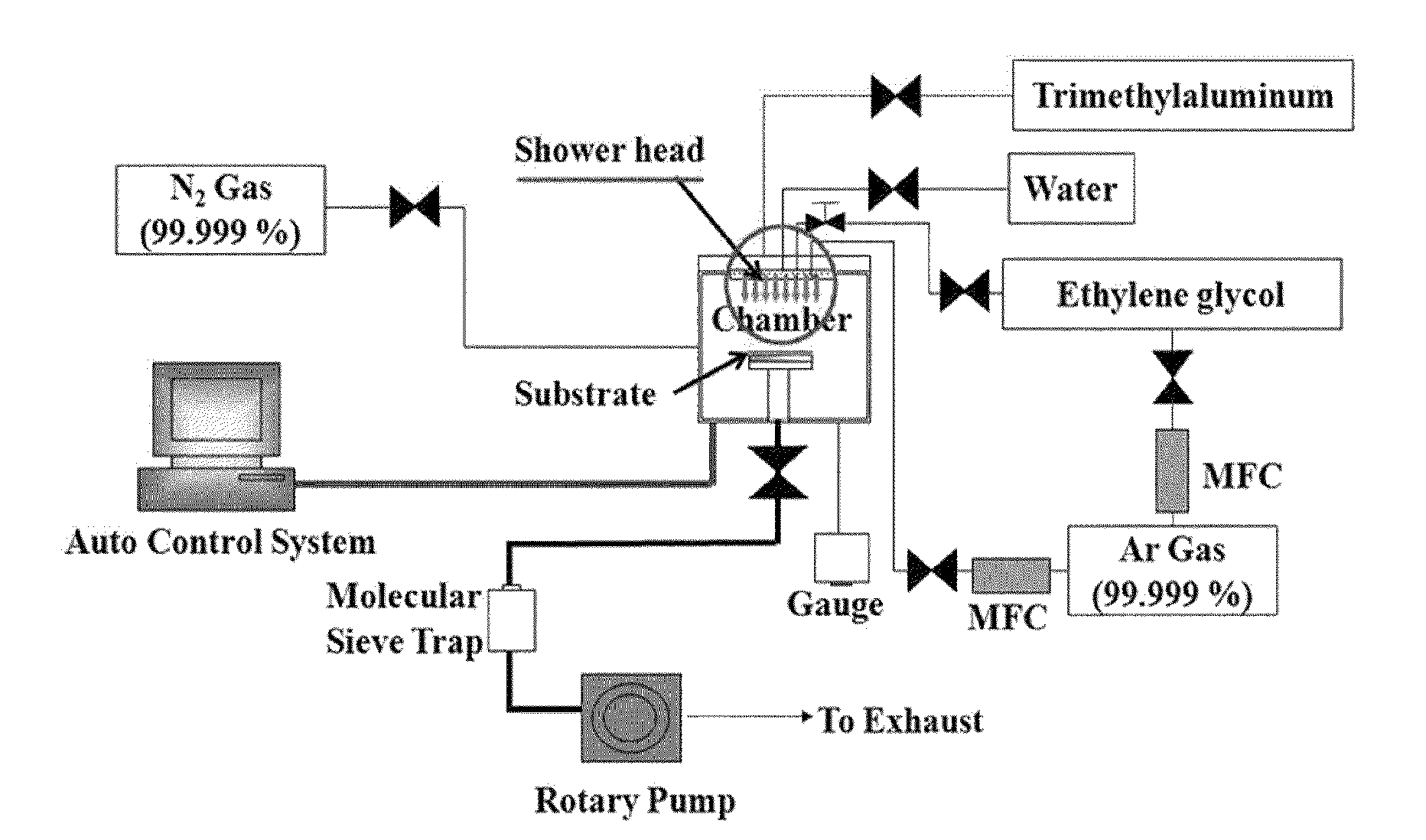

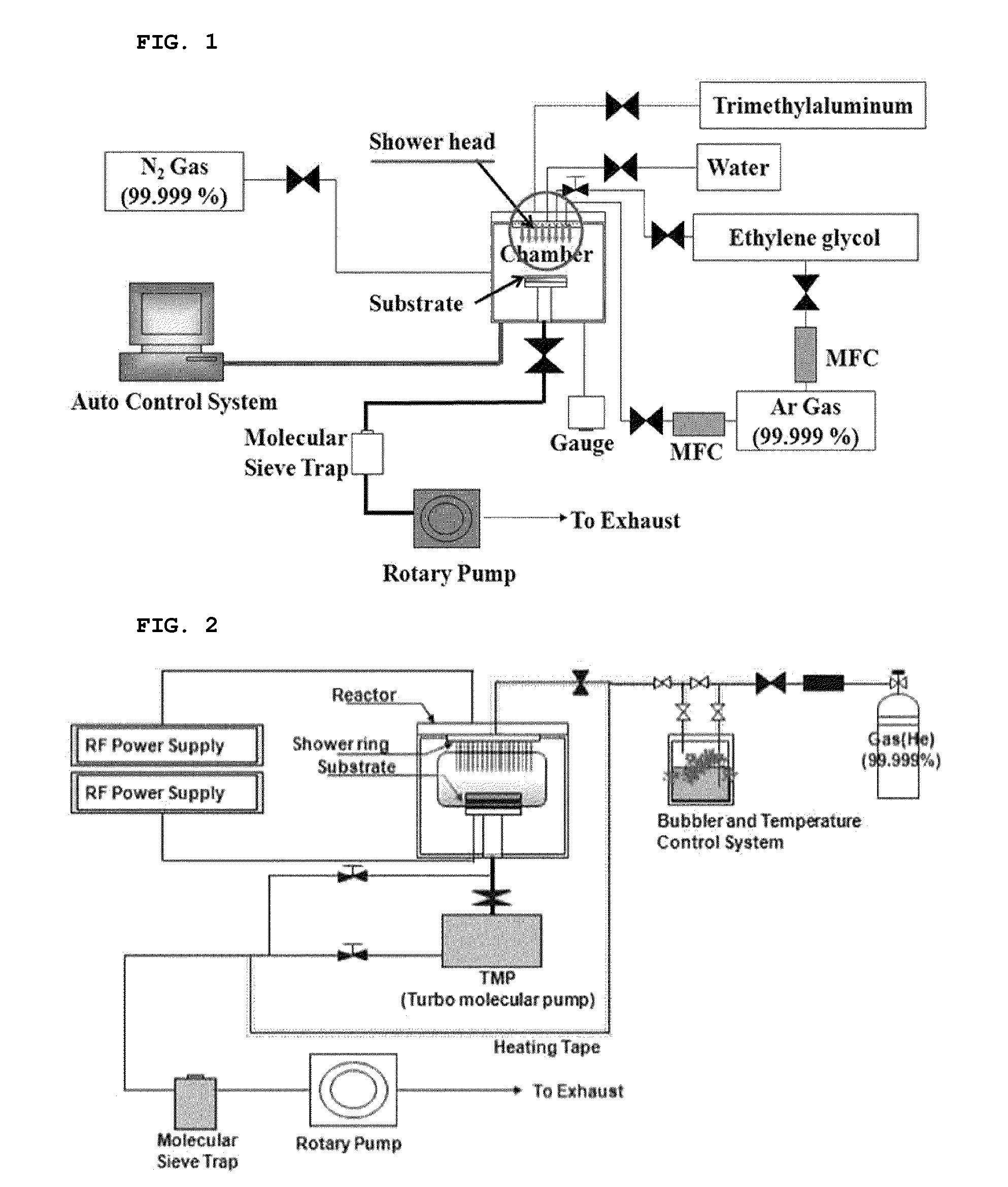

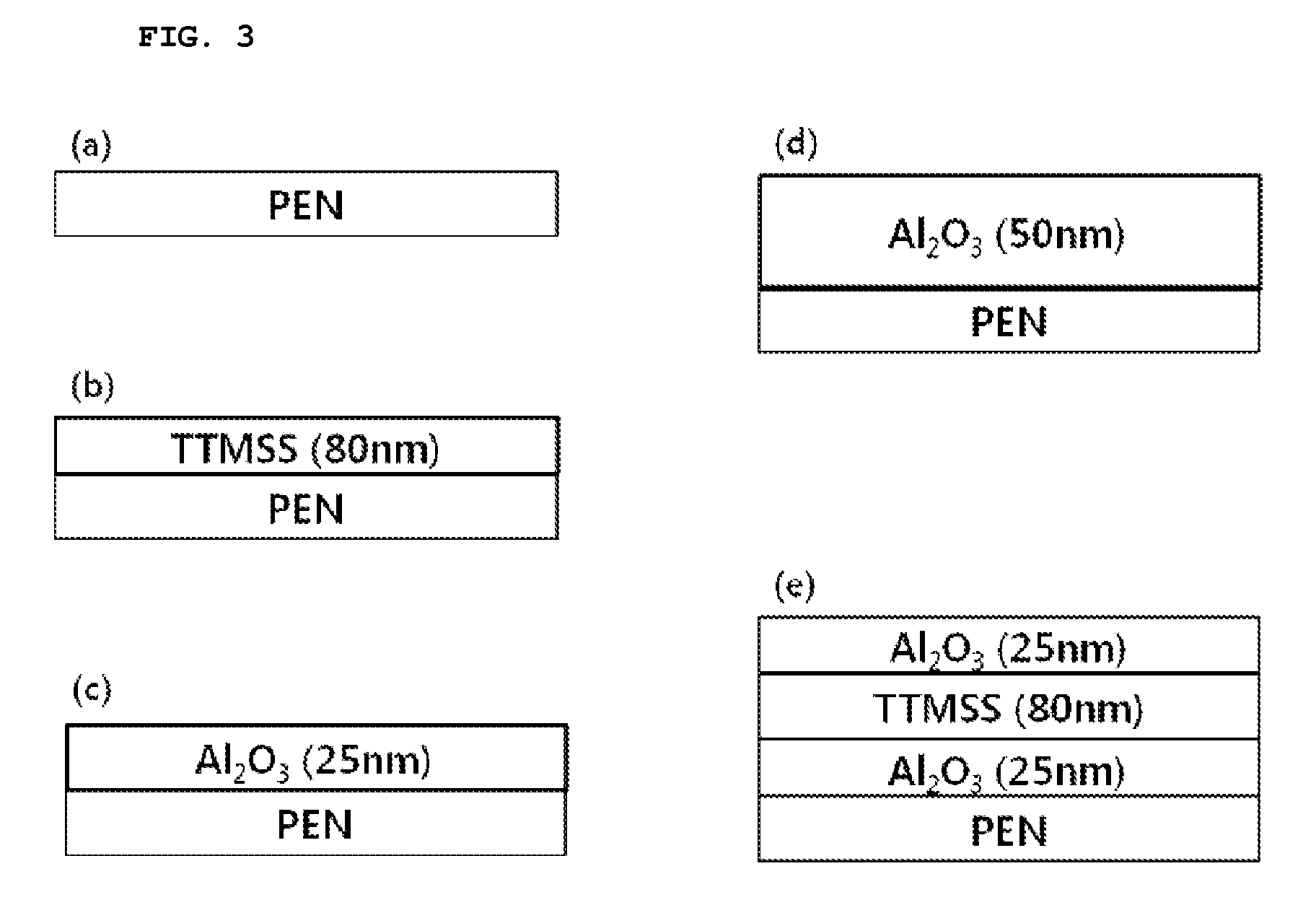

Polymer/inorganic multi-layer encapsulation film

ActiveUS9196849B2Suppressing permeation of oxygen and moisturePrevent degradationSolid-state devicesSemiconductor/solid-state device manufacturingPolymer thin filmsOptoelectronics

This invention relates to a polymer / inorganic multi-layer encapsulation film, and more particularly, to a multi-layer encapsulation film, which includes a plasma polymer thin film layer formed using a cross-shaped precursor having Si—O bonding and an inorganic thin film layer, and ensures flexibility and has improved encapsulation.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

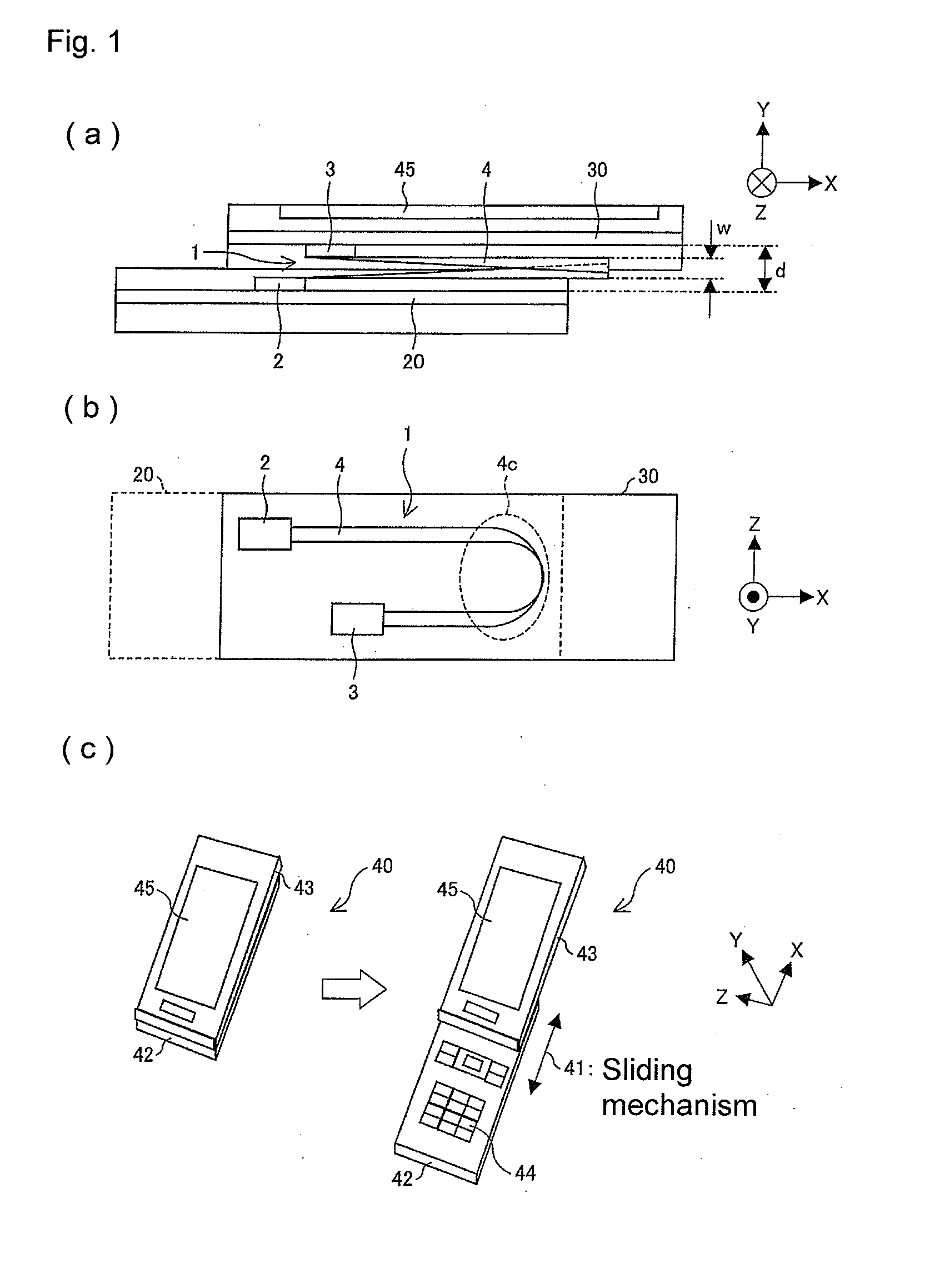

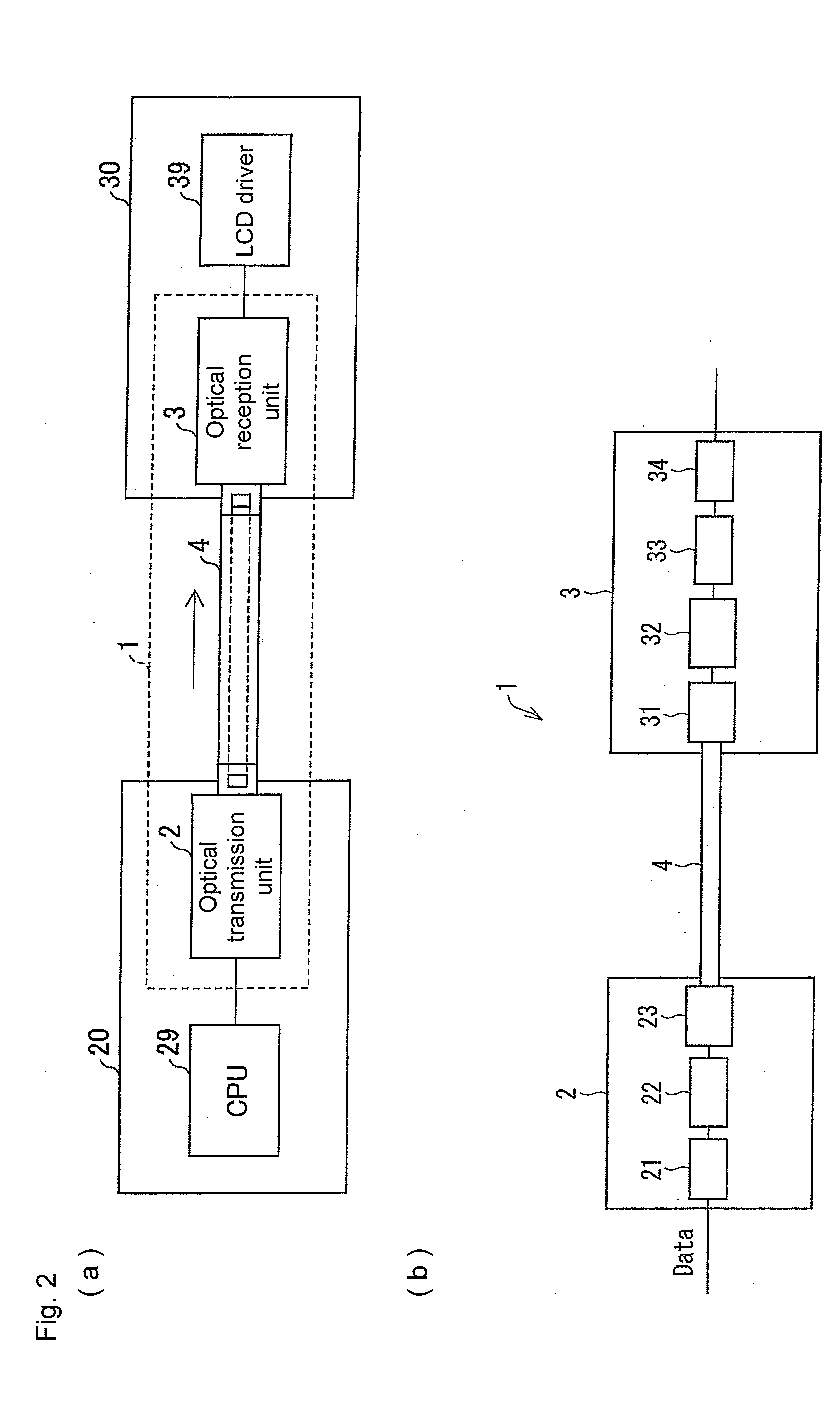

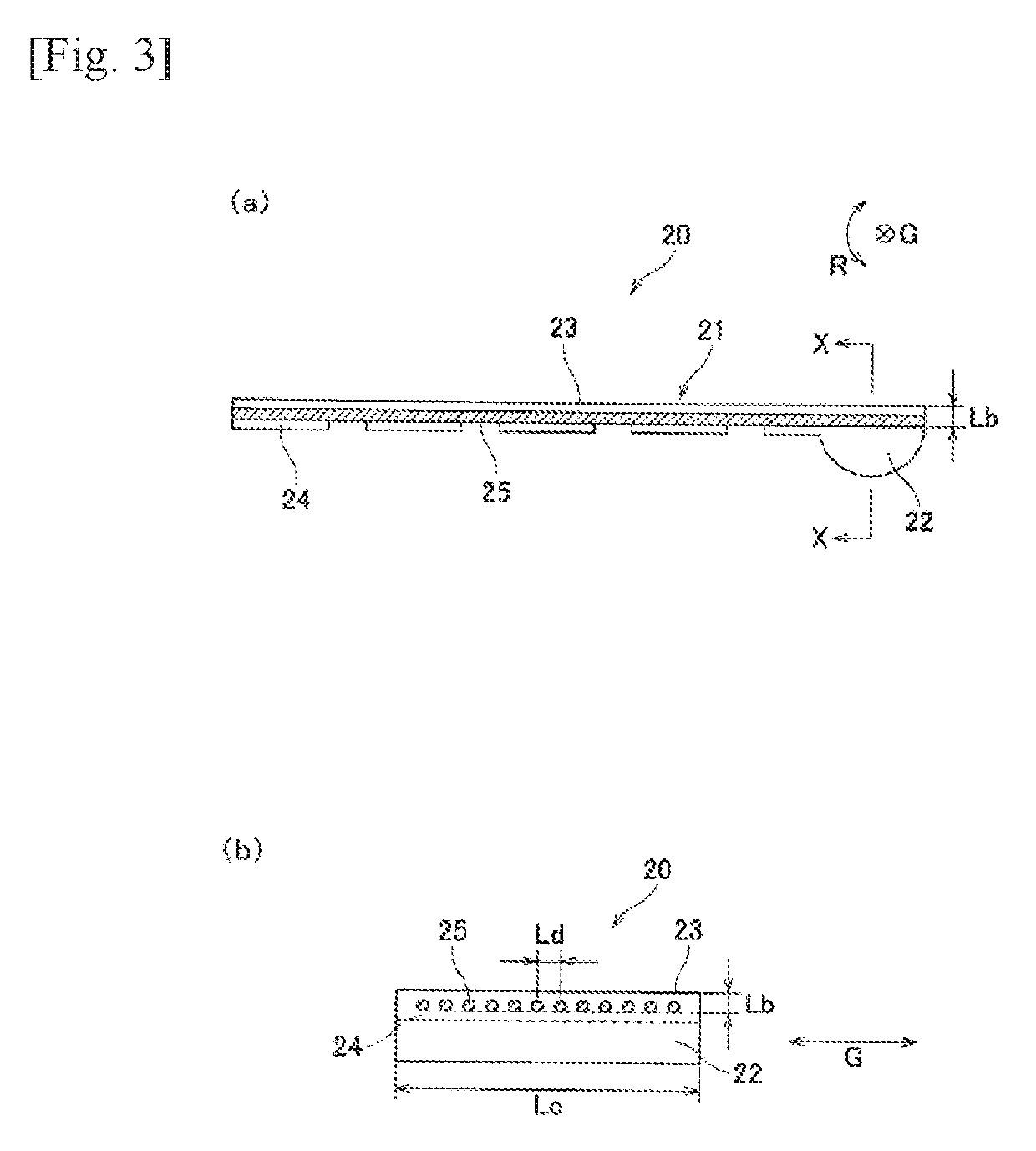

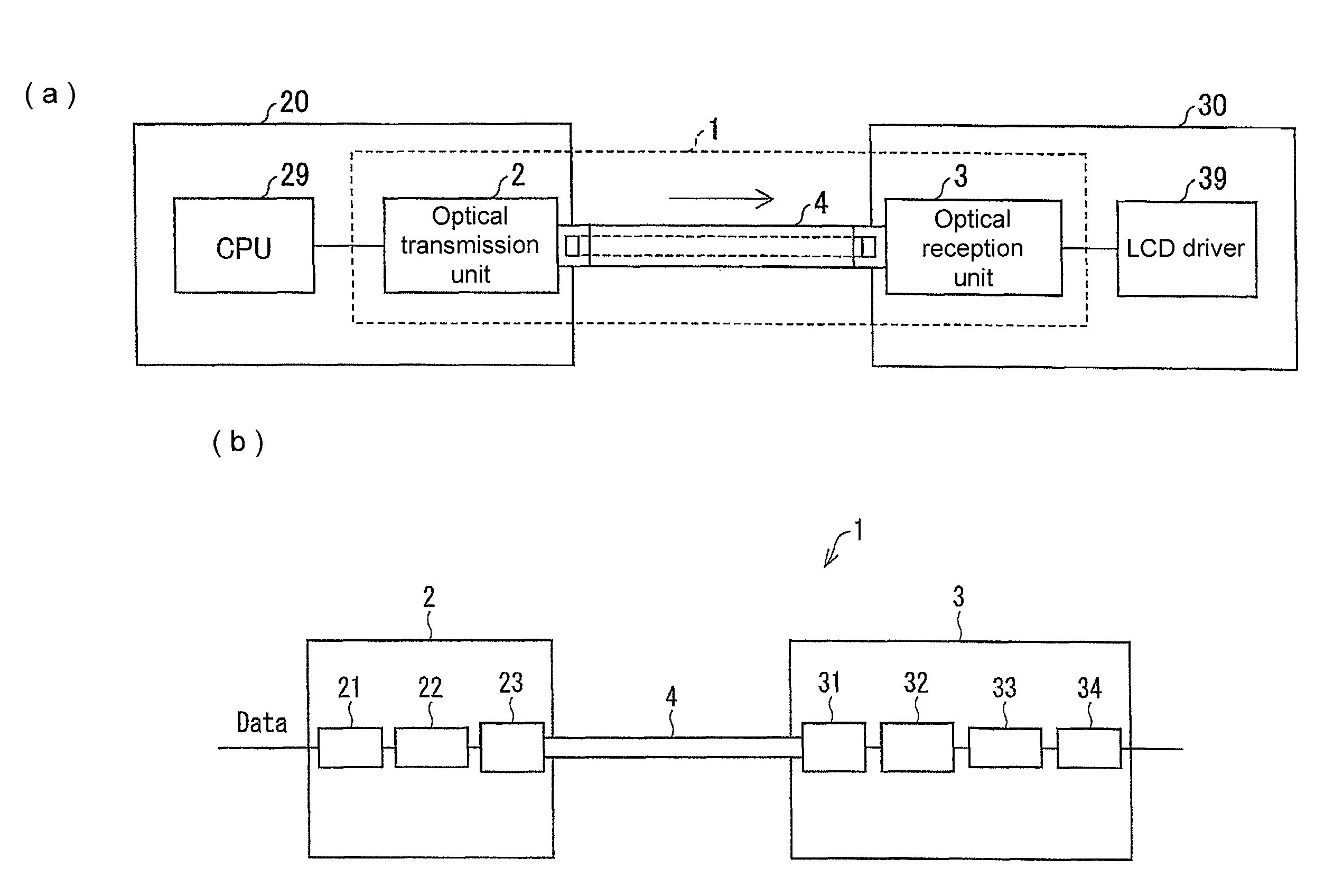

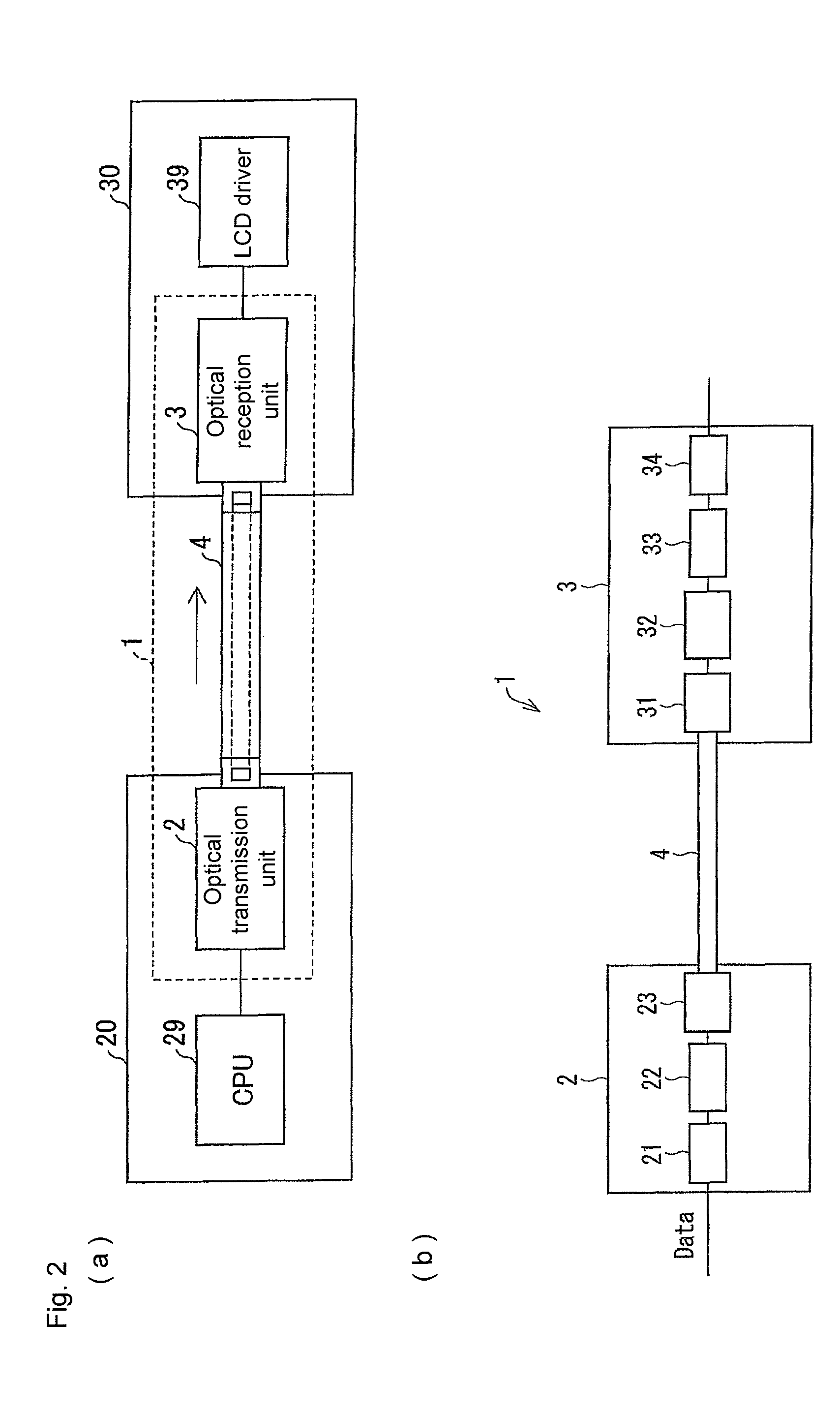

Optical transmission module, electronic instrument, method for assembling optical transmission module, and optical transmission method

InactiveUS20110135249A1Low profileImprove bending durabilityCircuit optical detailsOptical articlesElectronic instrumentComputer module

An optical transmission module has an optical transmission path in which optical transmission is performed between a first circuit board and a second circuit board disposed opposite the first circuit board. The optical transmission path has a folded structure having a bending radius. A circumferential portion drawn by the bending radius is provided substantially perpendicular to board surfaces of the first circuit board and the second circuit board.

Owner:ORMON CORP

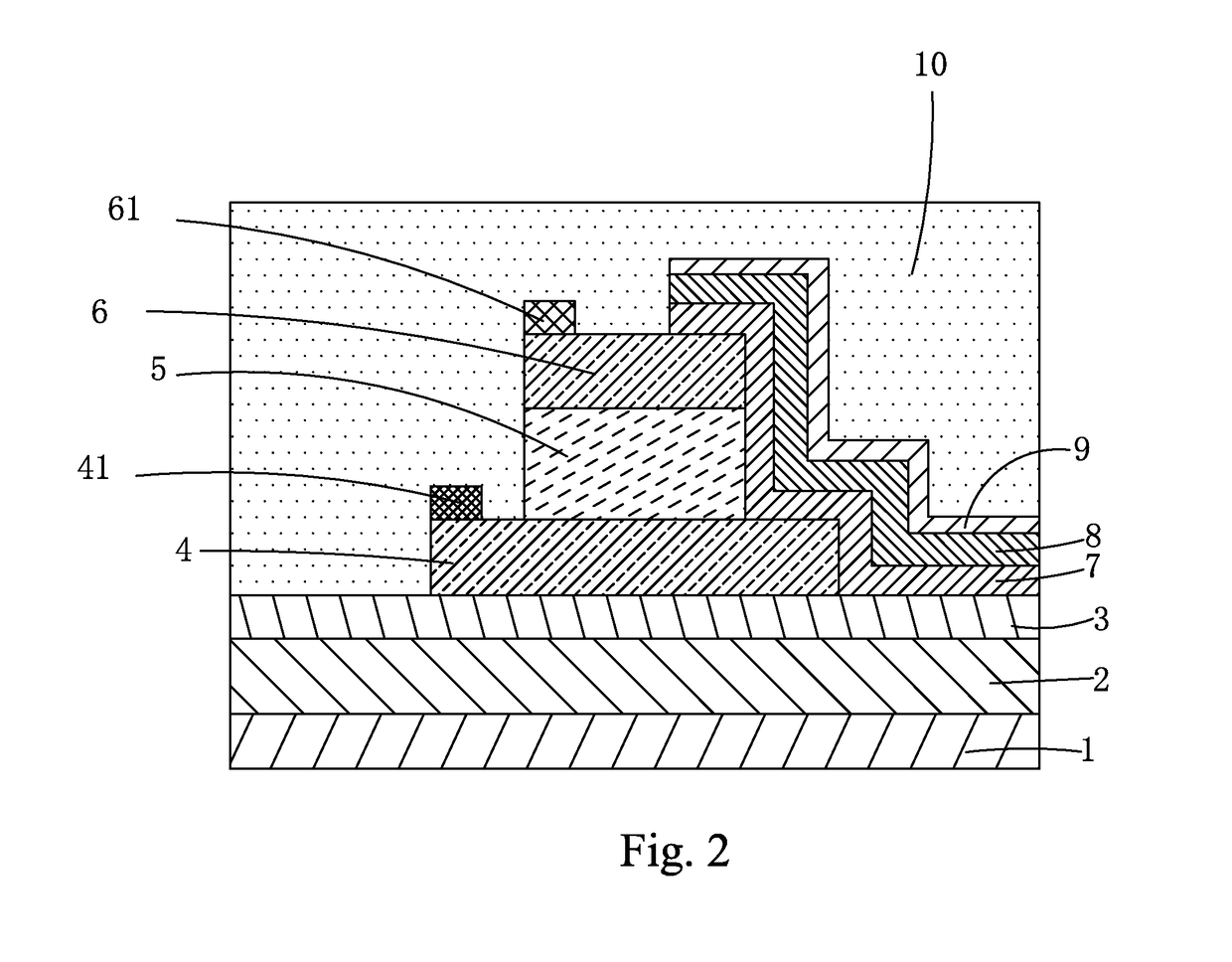

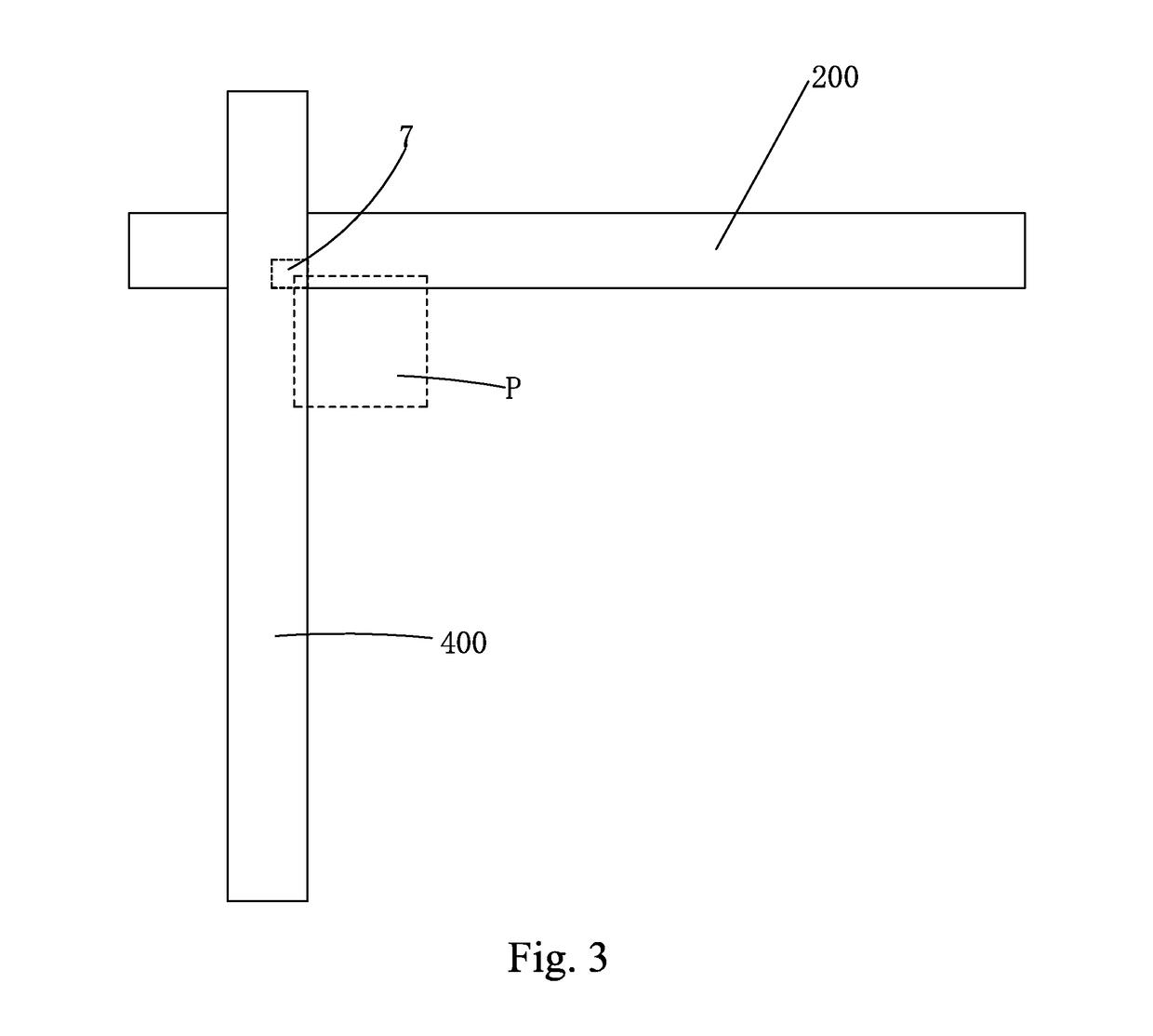

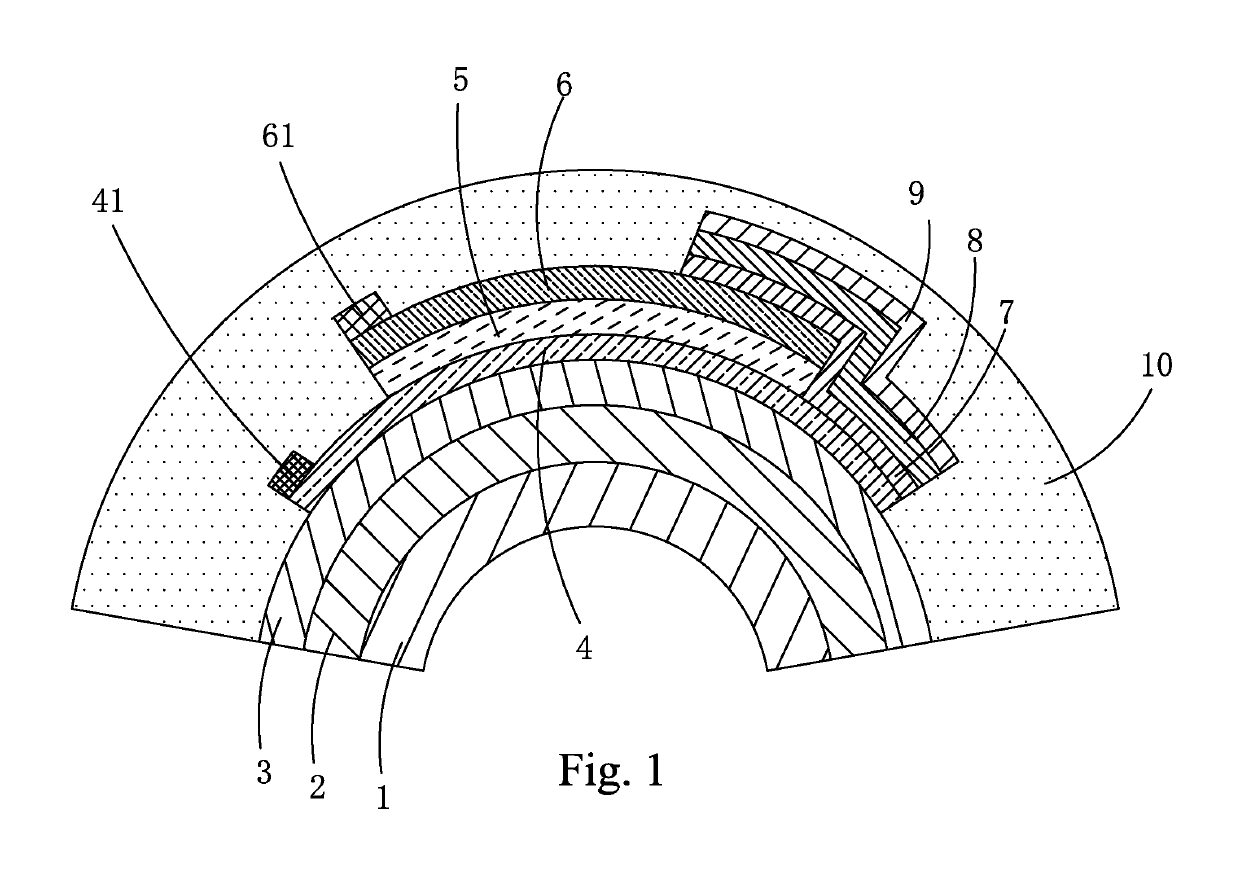

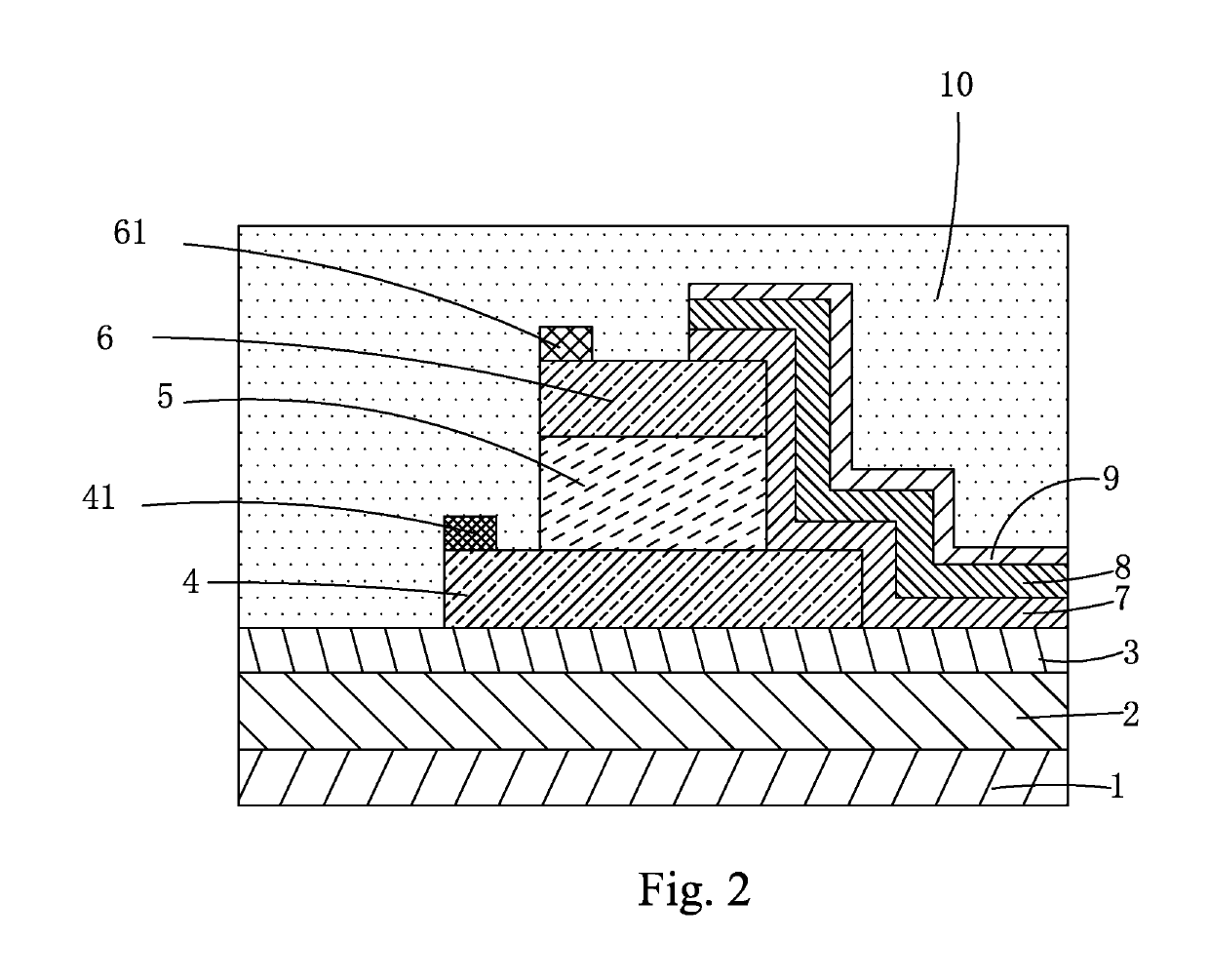

Thin-film transistor and fabrication method thereof and array substrate

ActiveUS20190088791A1Improve electrical performanceReduce pixel areaTransistorSolid-state devicesHexagonal boron nitrideEngineering

The present invention provides a thin-film transistor and a fabrication method thereof, and an array substrate. The thin-film transistor includes a separation layer (5) arranged between the source electrode (4) and the drain electrode (6). An oxide semiconductor channel layer (7) is arranged on one side of the separation layer (5) and the drain electrode (6) to contact a portion of an upper surface of the drain electrode (6), a side surface of the drain electrode (6) and the organic separation layer (5), and a portion of an upper surface of the source electrode (4) to serve as a vertical channel, of which a channel length corresponds to a thickness of the separation layer (5). Varying the thickness of the separation layer to reduce the length of the vertical channel to a sub-micrometer order would greatly reduce the size of the thin-film transistor and reduce the area of a pixel. The vertical channel does not cause a short channel effect so as to improve electrical performance of the thin-film transistor. Using a multiple-layered hexagonal boron nitride film to make a moisture / oxygen barrier layer (2) and using a double-layered graphene film to make the source electrode (4) and the drain electrode (6) help significantly improve bending durability of the thin-film transistor.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Touch screen and display device

InactiveUS20210357052A1Improve bending durabilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTouchscreen

A touch screen and a display device are provided. The touch screen includes a substrate, source and drain layers, a planarization layer, an anode layer, a pixel defining layer, and a touch electrode layer stacked in sequence. The touch screen further includes via holes, and the via hole includes a first via hole and a second via hole. The first via hole is defined on the planarization layer, the anode layer is electrically connected to the source and drain layer through the first via hole. The second via hole is defined on the pixel defining layer, and the touch electrode layer is connected to the anode layer through the second via hole.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

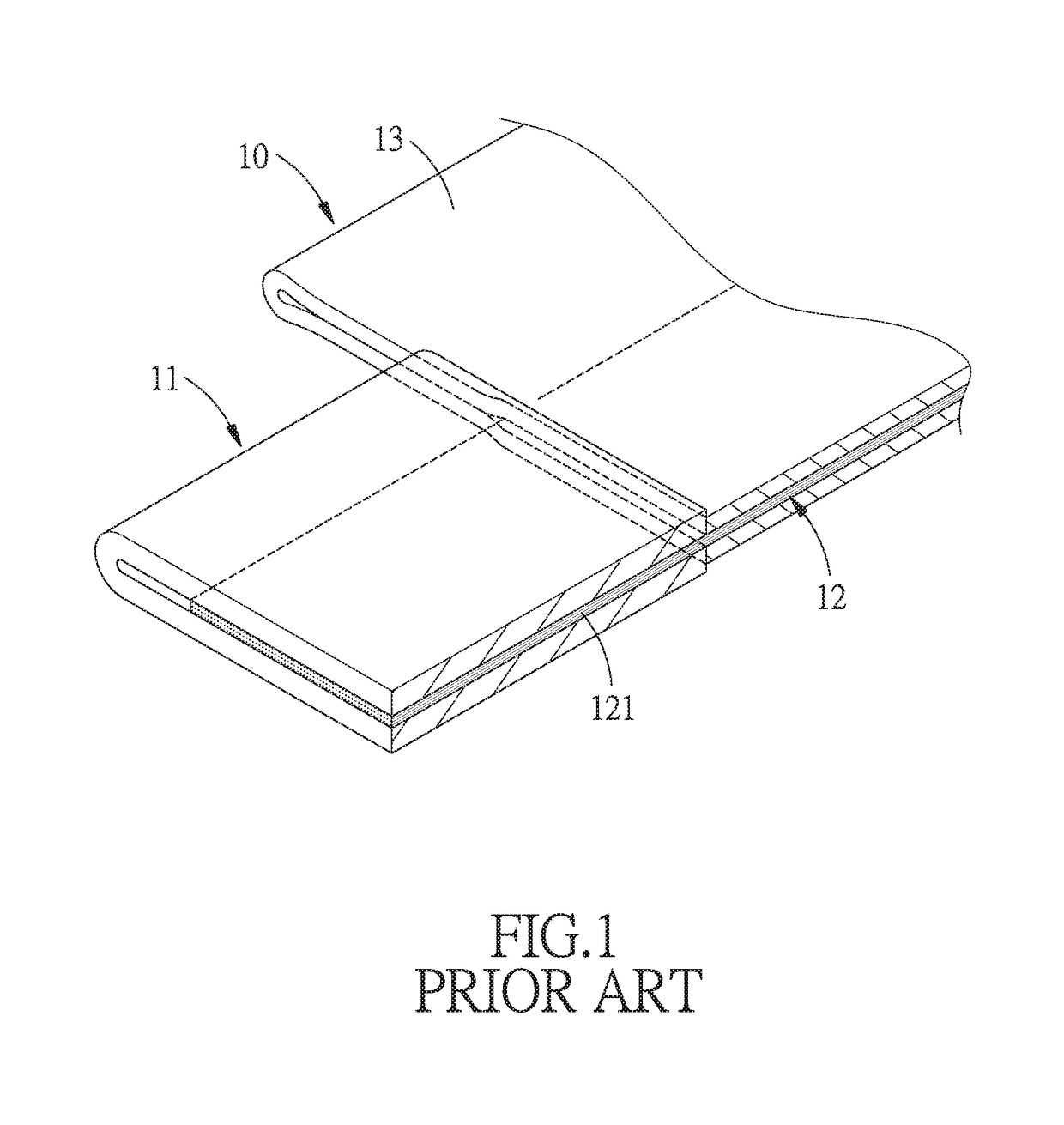

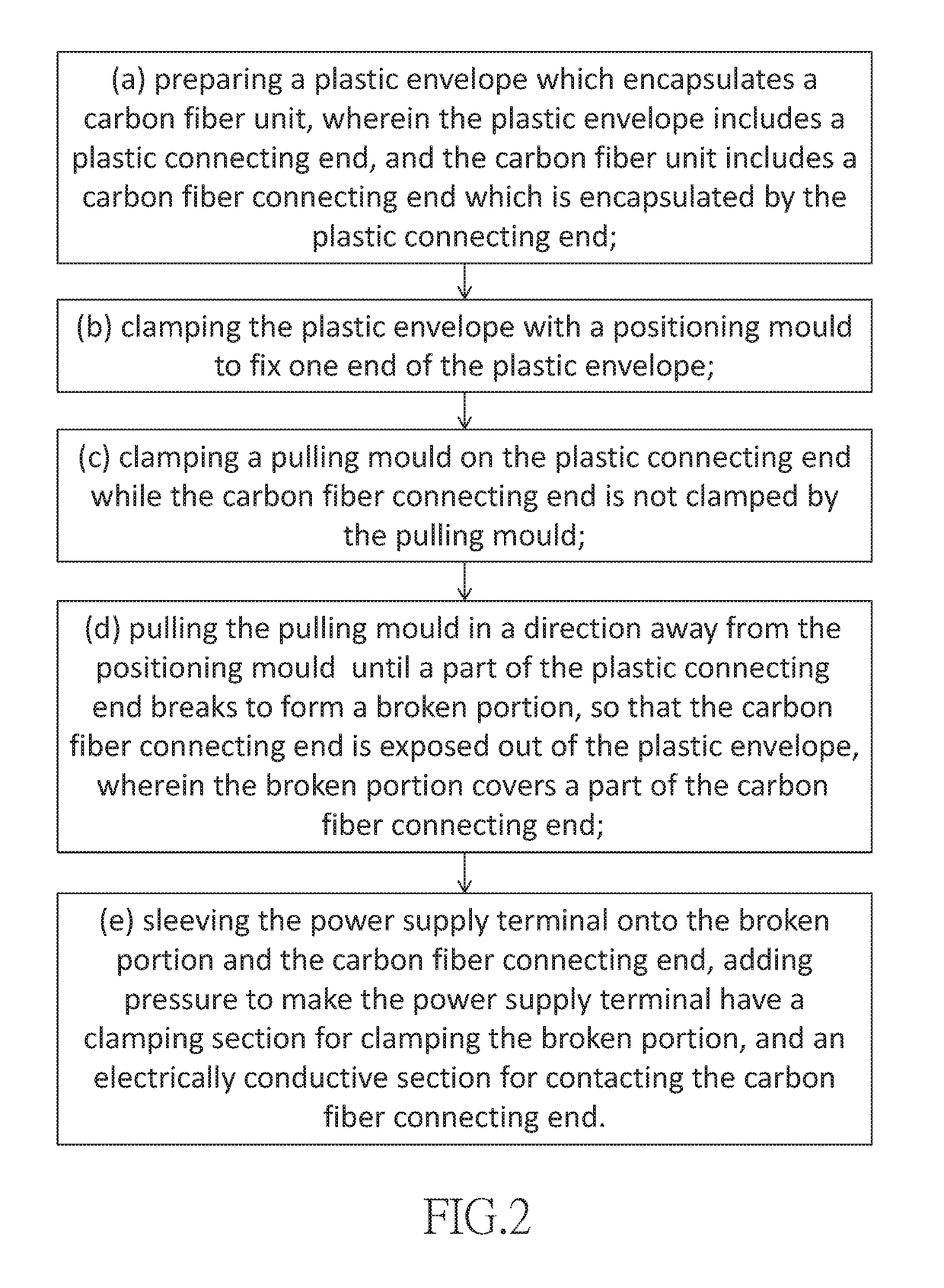

Method and package for packaging a thermal conductive strip with power supply terminals

ActiveUS20180014356A1Improve yield rateImprove bending durabilityLine/current collector detailsLamination ancillary operationsFiberCarbon fibers

A thermal conductive strip with a power supply terminal includes: a carbon fiber unit including a carbon fiber connecting end; a plastic envelope which encapsulates the carbon fiber unit and has a length smaller than a length of the carbon fiber connecting end, and further includes a broken portion which covers a part of the carbon fiber connecting end; and the power supply terminal sleeved onto the broken portion and the carbon fiber connecting end, and including a clamping section for clamping the broken portion, and an electrically conductive section for contacting the carbon fiber connecting end. The power supply terminal is partially clamped on the plastic envelope and partially eclectically connected to the carbon fiber, which improves the yield rate and the bending durability of the thermal conductive strip of the present invention.

Owner:TAIWAN TECH

Flexible display device

ActiveUS10517196B2Lower performance requirementsHeat dissipation performance of the flexible display deviceSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayElectrical and Electronics engineering

A flexible display device includes a flexible display panel and a heat dissipating layer. The flexible display panel includes a bending region and a non-bending region. The heat dissipating layer includes a first heat dissipating sublayer and a second heat dissipating sublayer. The first heat dissipating sublayer is disposed on the non-bending region and the second heat dissipating sublayer is disposed on the first heat dissipating sublayer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Electric supply device for slide structure

InactiveUS20070111551A1Smoothly securely carry-outImprove bending durabilityCoupling device connectionsElectric devicesEngineeringMechanical engineering

Owner:YAZAKI CORP

Thin-film transistor having oxide semiconductor channel layer vertically exending along lateral sides of source electrode, separation layer, and drain electrode and array substrate including same

ActiveUS10483401B2Small sizeReduce areaTransistorSolid-state devicesHexagonal boron nitrideEngineering

The present invention provides a thin-film transistor and a fabrication method thereof, and an array substrate. The thin-film transistor includes a separation layer (5) arranged between the source electrode (4) and the drain electrode (6). An oxide semiconductor channel layer (7) is arranged on one side of the separation layer (5) and the drain electrode (6) to contact a portion of an upper surface of the drain electrode (6), a side surface of the drain electrode (6) and the organic separation layer (5), and a portion of an upper surface of the source electrode (4) to serve as a vertical channel, of which a channel length corresponds to a thickness of the separation layer (5). Varying the thickness of the separation layer to reduce the length of the vertical channel to a sub-micrometer order would greatly reduce the size of the thin-film transistor and reduce the area of a pixel. The vertical channel does not cause a short channel effect so as to improve electrical performance of the thin-film transistor. Using a multiple-layered hexagonal boron nitride film to make a moisture / oxygen barrier layer (2) and using a double-layered graphene film to make the source electrode (4) and the drain electrode (6) help significantly improve bending durability of the thin-film transistor.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

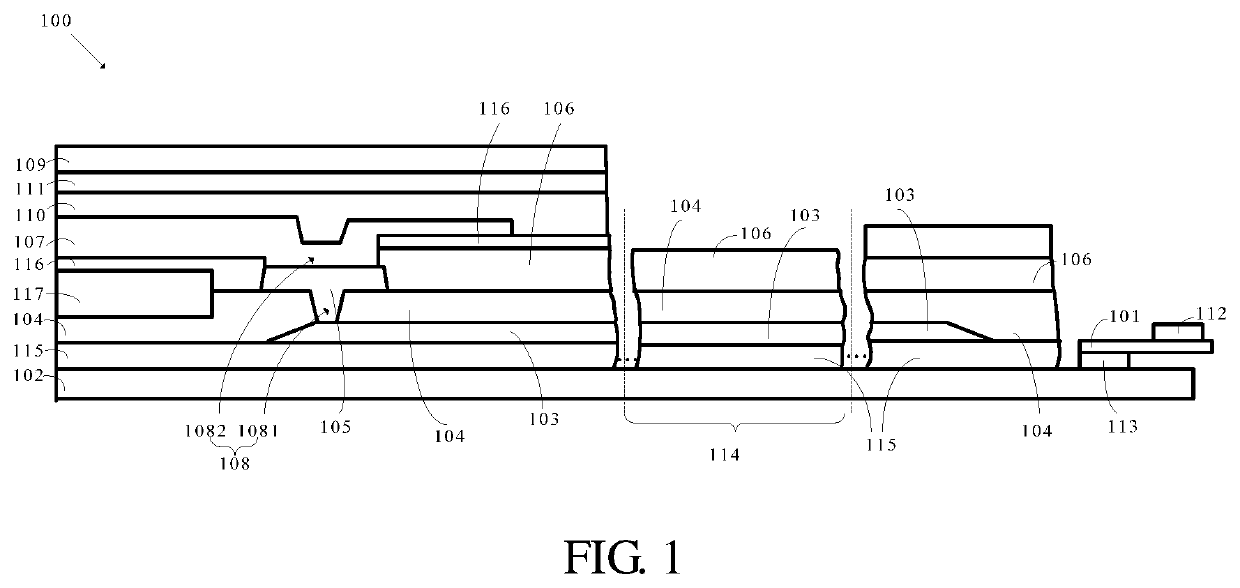

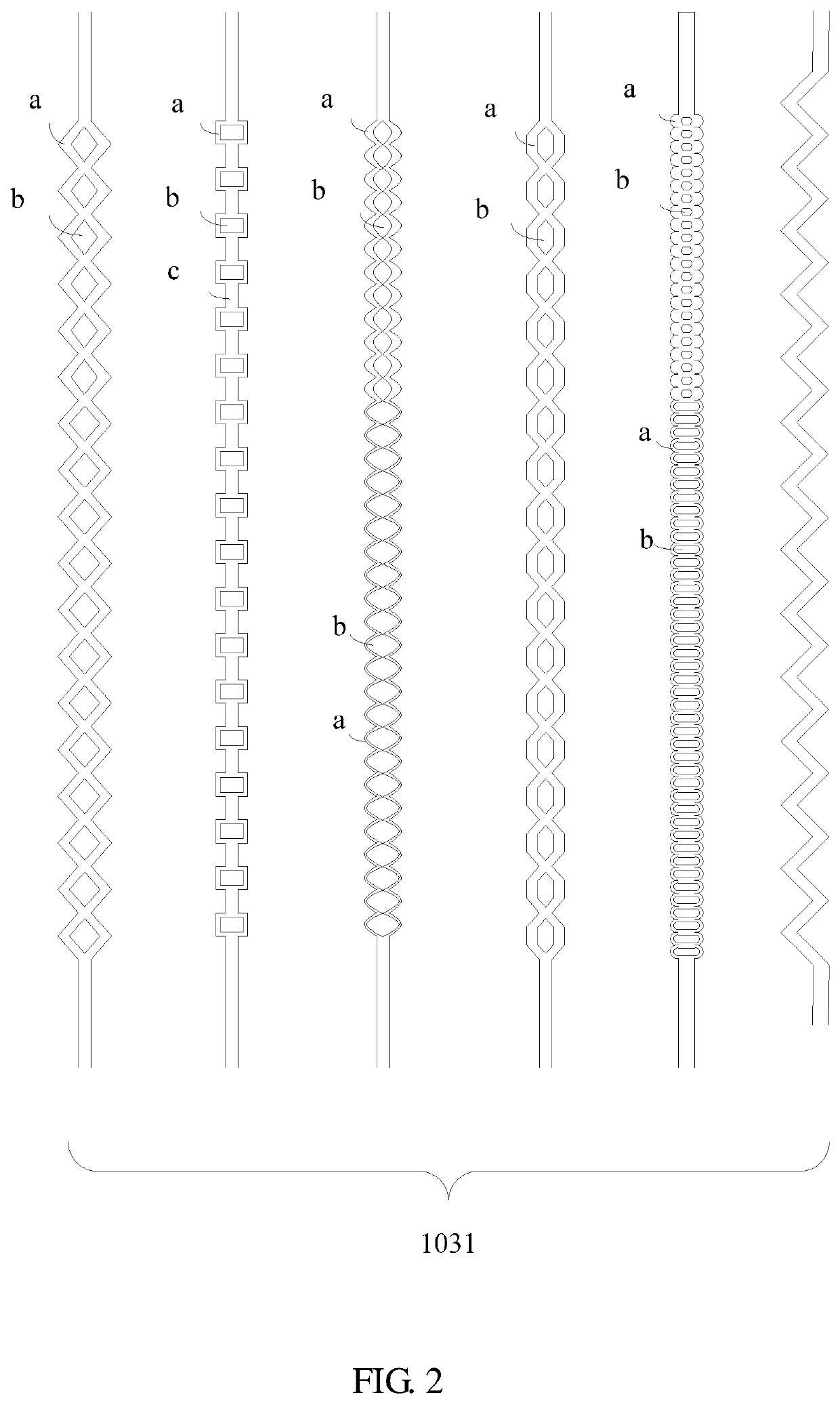

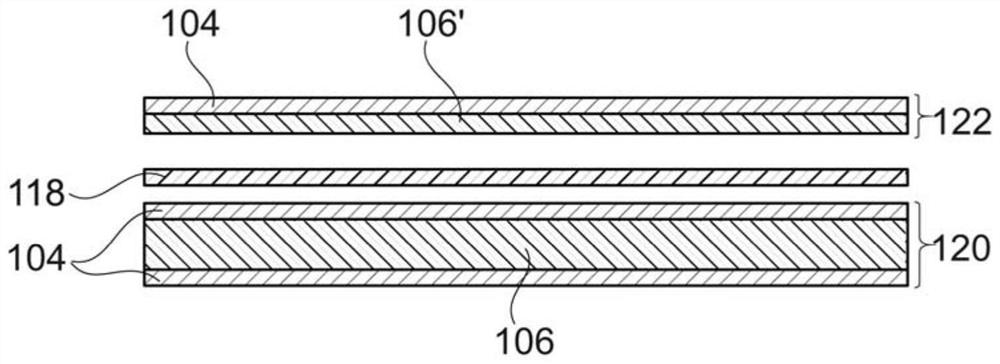

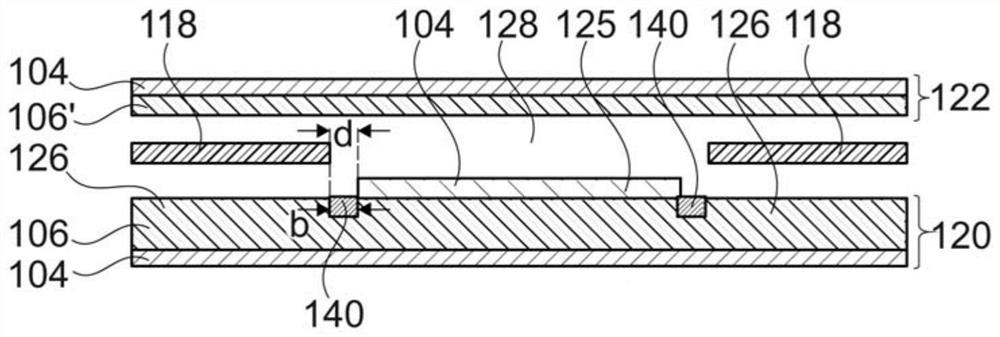

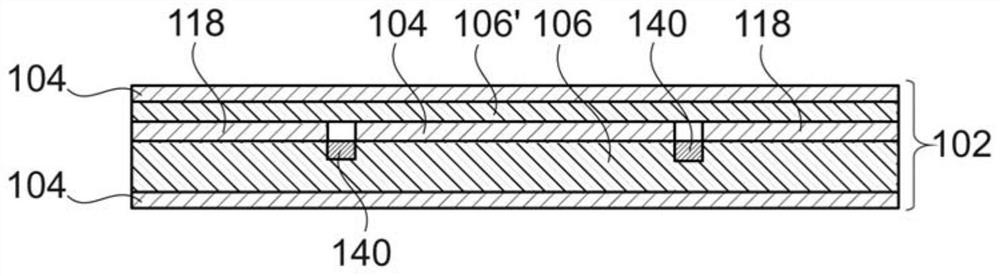

Semi-flexible component carrier and manufacturing method thereof

ActiveCN112349676AAvoid restrictionsOvercoming significant deficienciesCircuit bendability/stretchabilitySemiconductor/solid-state device detailsYoung's modulusMechanical engineering

The invention discloses a semi-flexible component carrier (100). The semi-flexible component carrier comprises stack (102) comprising at least one electrically insulating layer structure (106) and / orat least one electrically conductive layer structure (104), wherein the stack (102) defines at least one rigid portion (108) and at least one semi-flexible portion (110); at least one electrically insulating layer structure (106') of the at least one electrically insulating layer structure (106) forming at least a portion of the semi-flexible portion (110) comprises a material having an elongationgreater than 3% and a Young's modulus less than 5 GPa. The invention also relates to a manufacturing method of the semi-flexible component carrier.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Vane Member for Paper Sheet Conveyance Impeller

ActiveUS20190291999A1Suppresses plastic deformationEnhances bending durability and restorabilityCoin countersCoin/currency accepting devicesPaper sheetPolyester

The present invention relates to a vane member for a paper sheet conveyance impeller in which at least one vane member is disposed so as to protrude from the external peripheral surface of a rotatable cylindrical member, the vane member being provided with: a vane member body comprising a thermosetting polyurethane elastomer; and a plurality of core wires which comprise polyester fibers and are arranged along the axial direction of a rotary shaft of the cylindrical member. At least a portion of the core wires being embedded within the vane member body.

Owner:MITSUBOSHI BELTING LTD

Adhesive layer, adhesive composition, solvent-free adhesive composition, adhesive agent, and adhesive sheet

PendingUS20210238458A1Improve bending durabilityIncreased durabilityAdhesive articlesSynthetic resin layered productsPolymer scienceAcrylic resin

An adhesive layer is formed by curing an adhesive composition [I] containing an acrylic resin (X), and has an adhesive strength (α) of not less than 25 N / 25 mm, a bending durability (β) of not less than 100,000 times, and a moist heat haze resistance (γ) of not greater than 1.0% as measured under predetermined conditions. The adhesive layer has excellent adhesive strength to adherends, excellent bending durability, and excellent moist heat haze resistance.

Owner:MITSUBISHI CHEM CORP

Optical transmission module, electronic instrument, method for assembling optical transmission module, and optical transmission method

InactiveUS8639068B2Improve bending durabilityLow production costCircuit optical detailsOptical articlesComputer moduleElectronic instrument

An optical transmission module has an optical transmission path in which optical transmission is performed between a first circuit board and a second circuit board disposed opposite the first circuit board. The optical transmission path has a folded structure having a bending radius. A circumferential portion drawn by the bending radius is provided substantially perpendicular to board surfaces of the first circuit board and the second circuit board.

Owner:ORMON CORP

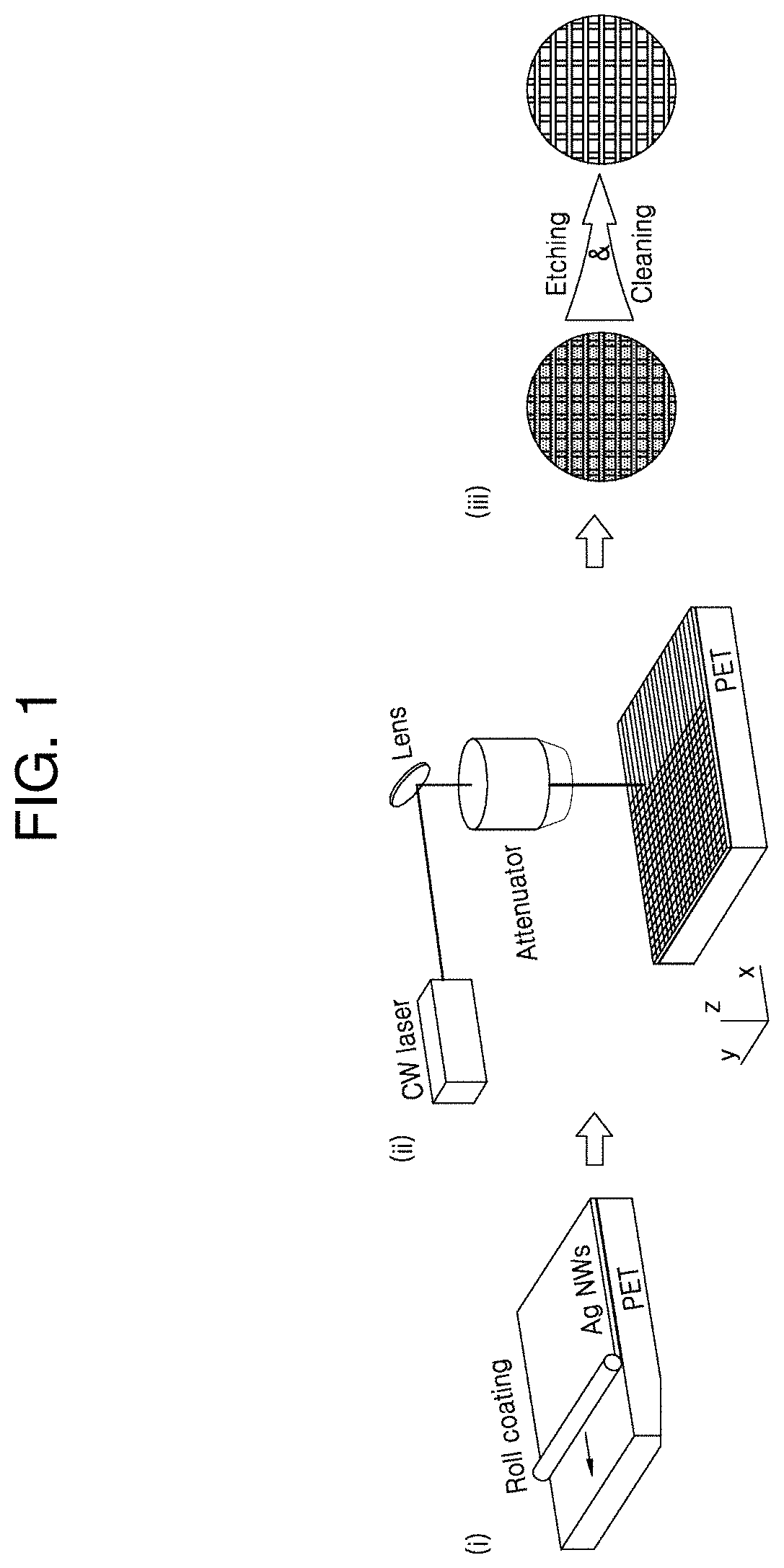

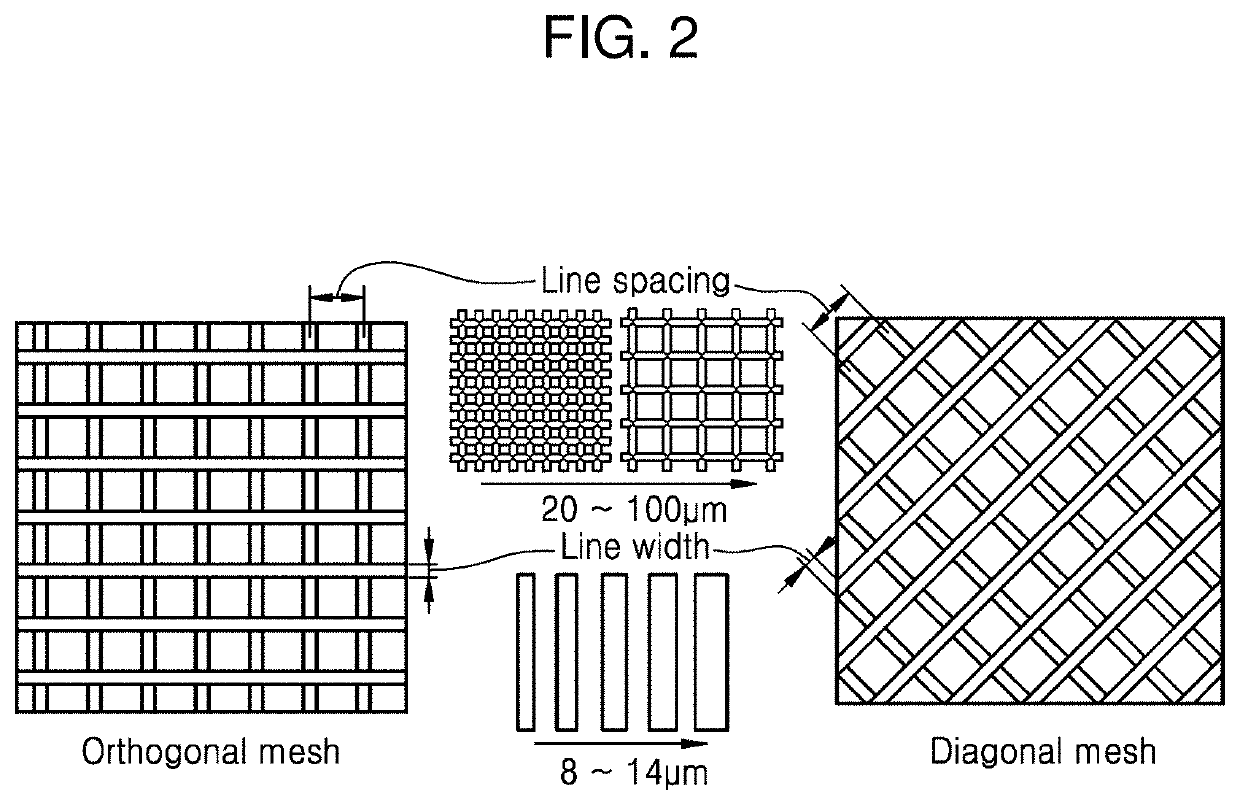

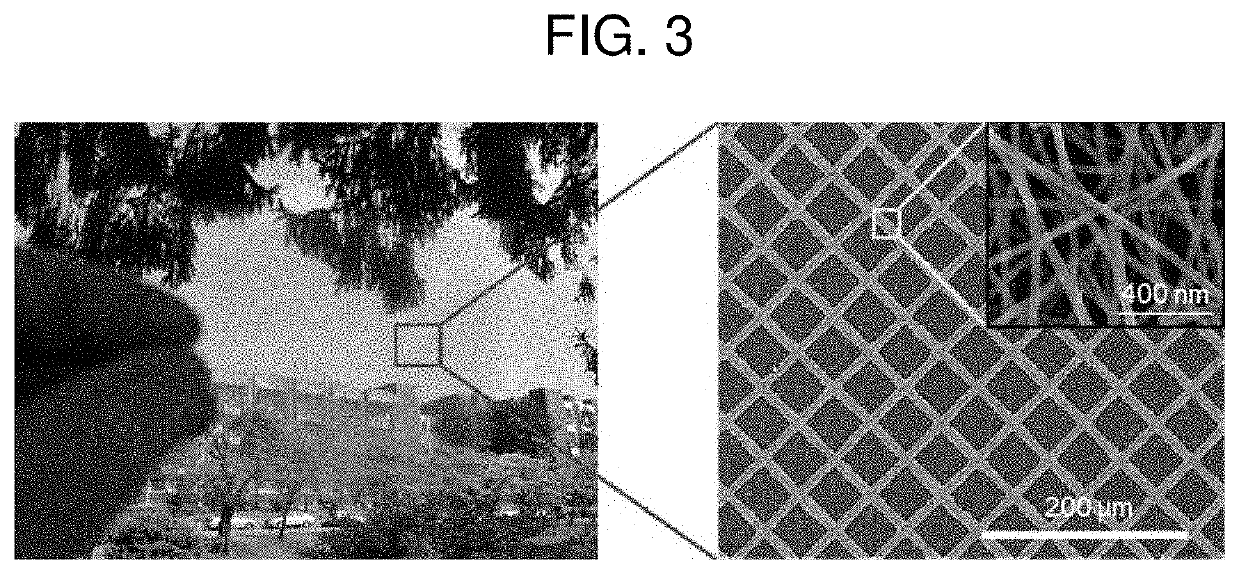

Silver nanowire-mesh (ag nw-mesh) electrode and manufacturing method thereof

ActiveUS20220051829A1Improve bending durabilityConductive layers on insulating-supportsMagnetic/electric field screeningSilver nanowiresMesh grid

According to one aspect of the present invention, a silver nanowire mesh (Ag NW-mesh) electrode and a fabricating method thereof. The Ag NW-mesh electrode includes a flexible substrate; and a mesh pattern layer which is disposed on the flexible substrate and in which a plurality of first meal lines and a plurality of second metal lines are composed of Ag NWs and intersect each other in an orthogonal or diagonal direction to form a grid pattern, wherein the first metal lines and the second metal lines of the mesh pattern layer form an angle of 35 degrees to 55 degrees with respect to a bending direction.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com