Cable

A technology for cables and fillers, applied in cables, insulated cables, bendable cables, etc., can solve the problems of high bending durability and flexibility, and achieve the effect of high bending durability and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

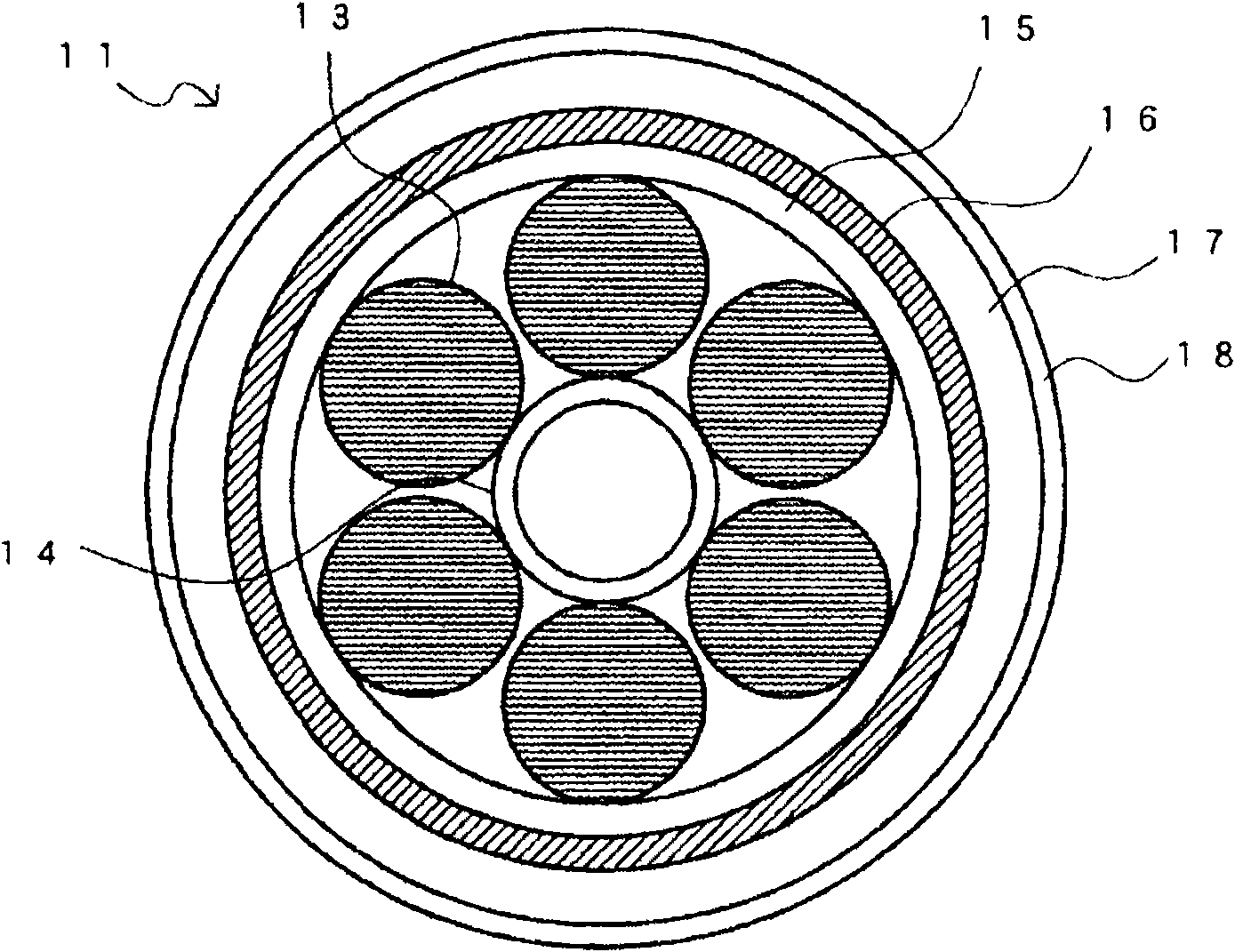

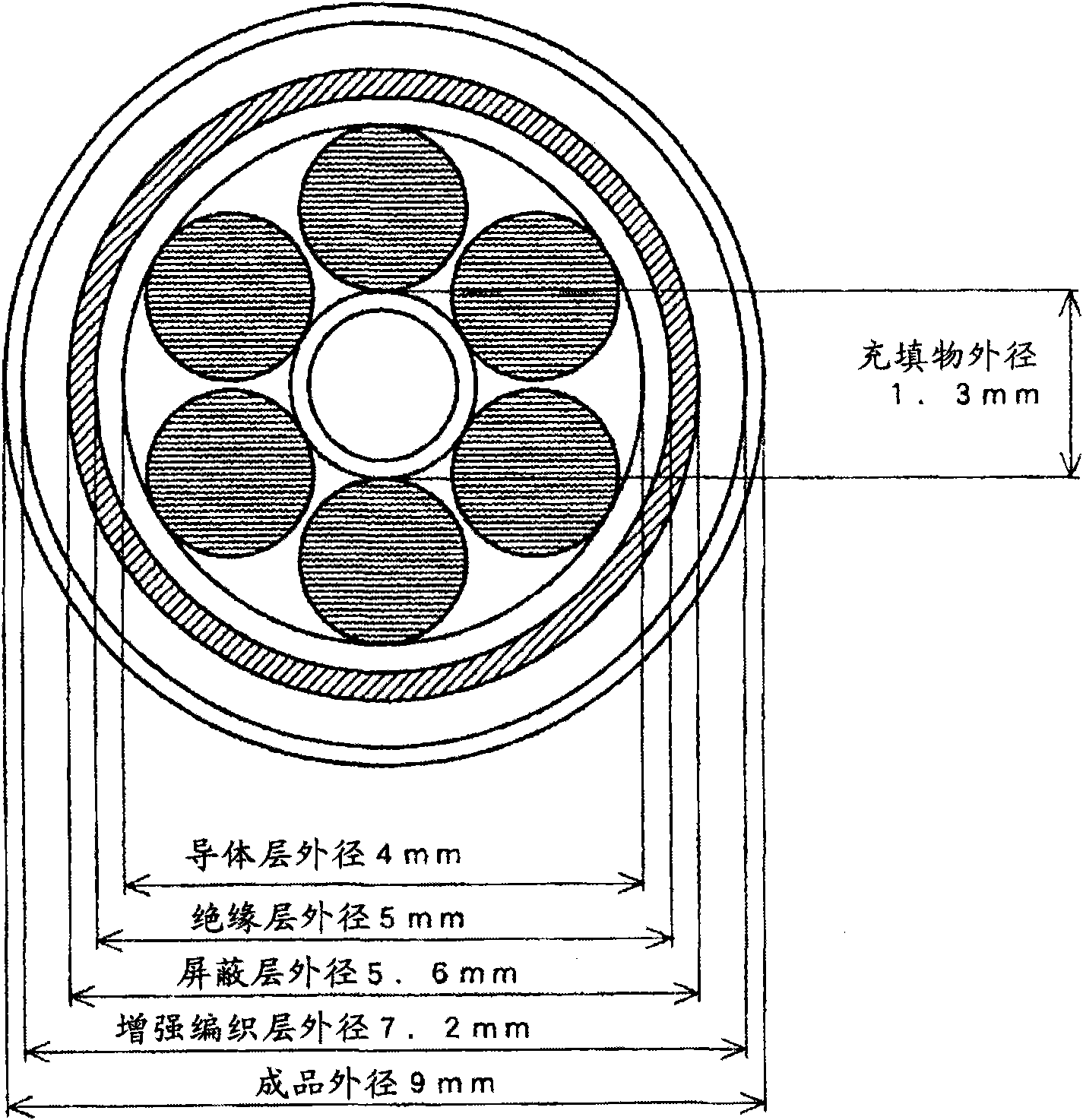

[0051] Example 1 is figure 1 In the cable 11, six twisted wire conductors 13 formed by twisting a plurality of bare conductor wires (soft copper wires (TPC, tough copper)) are arranged around the center. The insulating layer 15 uses cross-linked polyethylene. The shielding layer 16 is braided with tinned copper. The reinforced braided layer 17 uses polyvinyl alcohol fiber material. In addition, the reinforced braided layer 17 may also use a polyethylene terephthalate fiber material or a polyethylene 2,6-naphthalate fiber material. The filler 14 uses a silicon tube made of a silicone resin with a Shore (A) hardness of 45±5 degrees. The dimensions of each component are as image 3 Shown. In addition, the conductor layer is a layer composed of the twisted wire conductor 13.

Embodiment 2

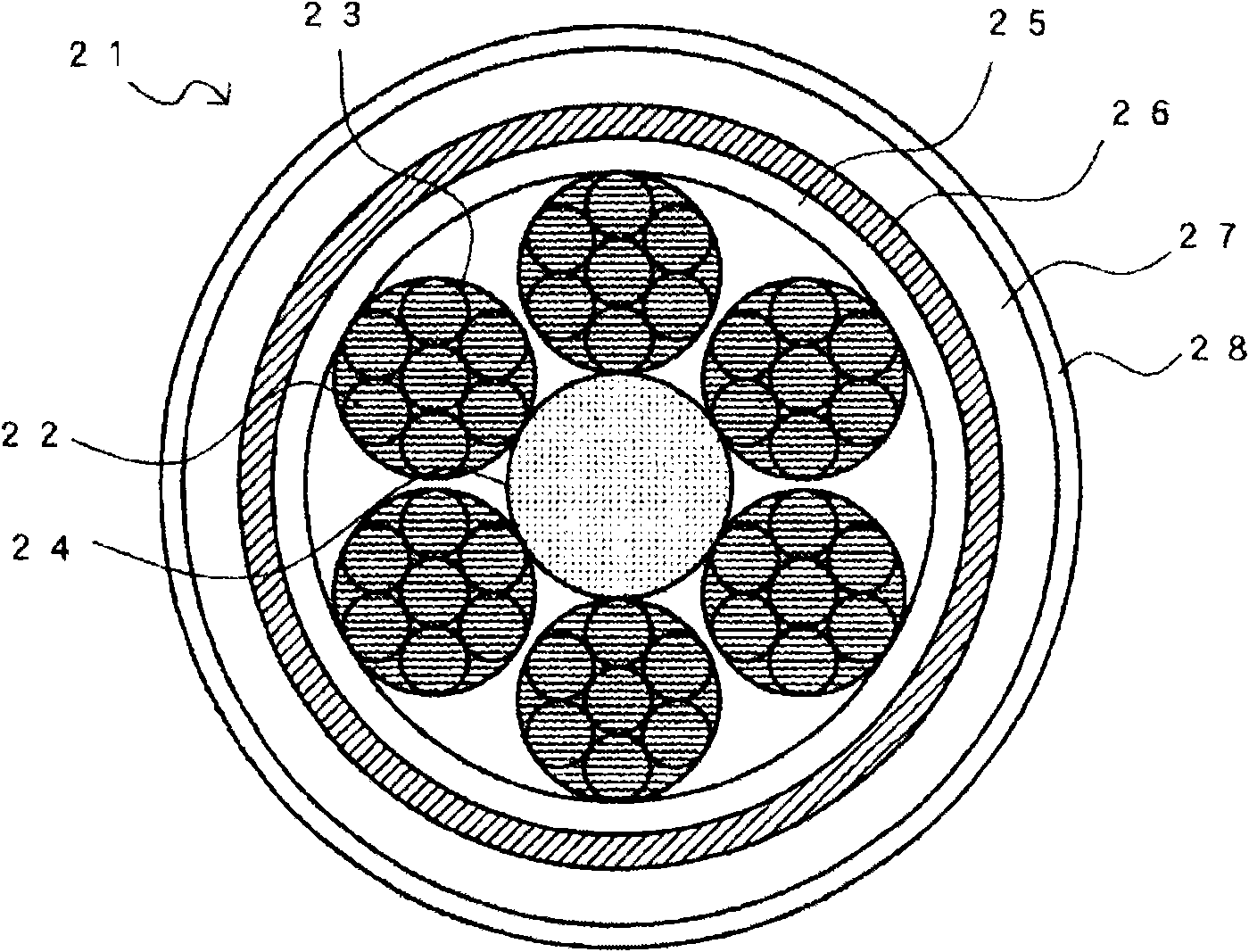

[0052] Example 2 is figure 2 In the cable 21, a plurality of bare conductor wires (same as above) are twisted as a twisted wire conductor 22, and six twisted strands 23 formed by twisting a plurality of twisted wire conductors 22 are arranged around the center. In addition, staple fiber yarn is used for the filler 24. The other layers are the same as in Example 1.

[0053] The cable of the comparative example is Figure 4 As shown, it does not contain fillers and has a figure 1 The filler 14 of the cable 11 becomes a structure of a twisted wire conductor. That is, the cable 41 of the comparative example is twisted with 7 twisted wire conductors 42 formed by twisting a plurality of bare conductor wires (tin-copper alloy) with each other around it figure 1 The cable 11 is similarly provided with an insulating layer 45, a shielding layer 46, a reinforced braided layer 47 and a sheath 48 in order.

[0054] The three cables of Example 1, Example 2 and Comparative Example 3 were subjec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com