Patents

Literature

2058results about "Adhesive articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

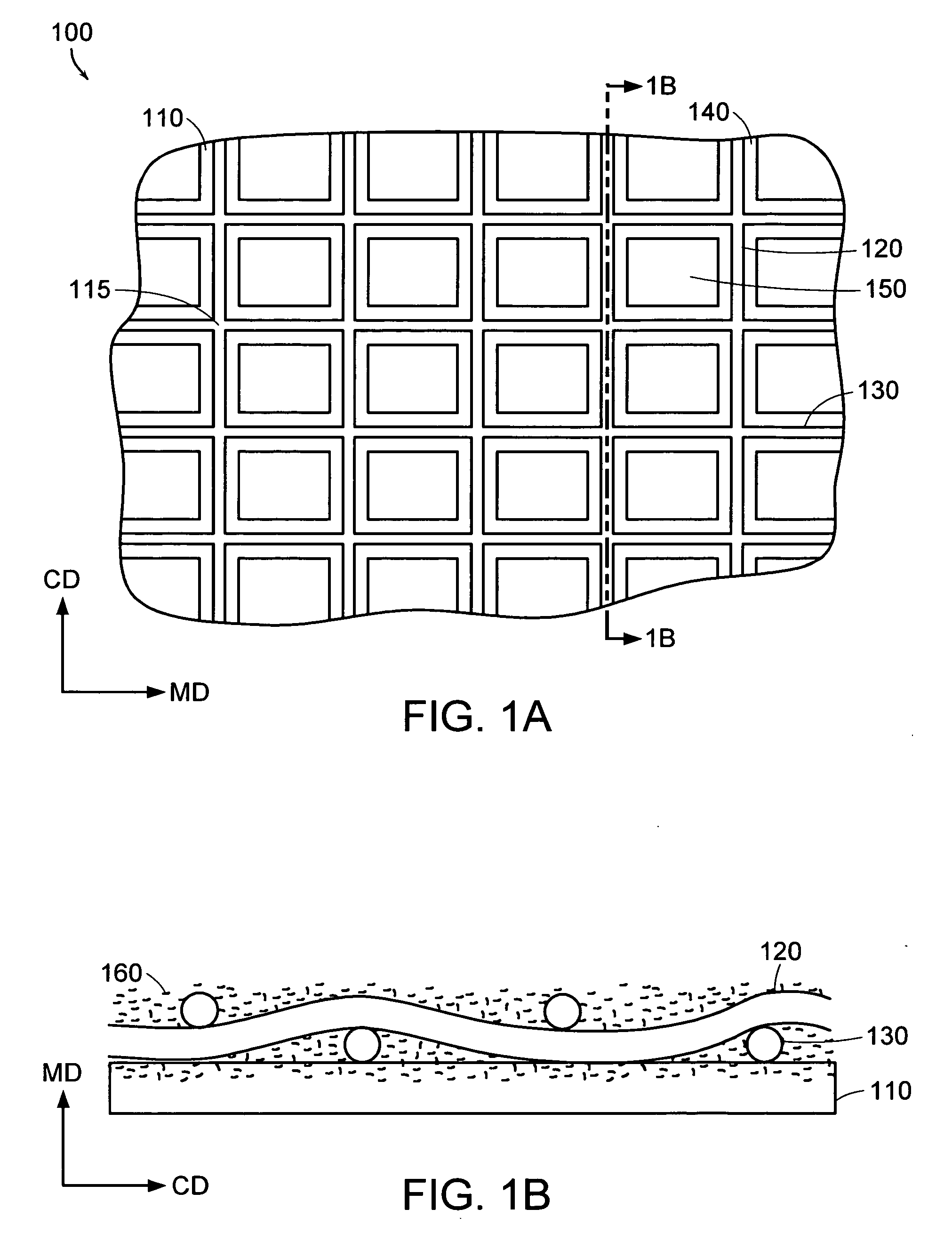

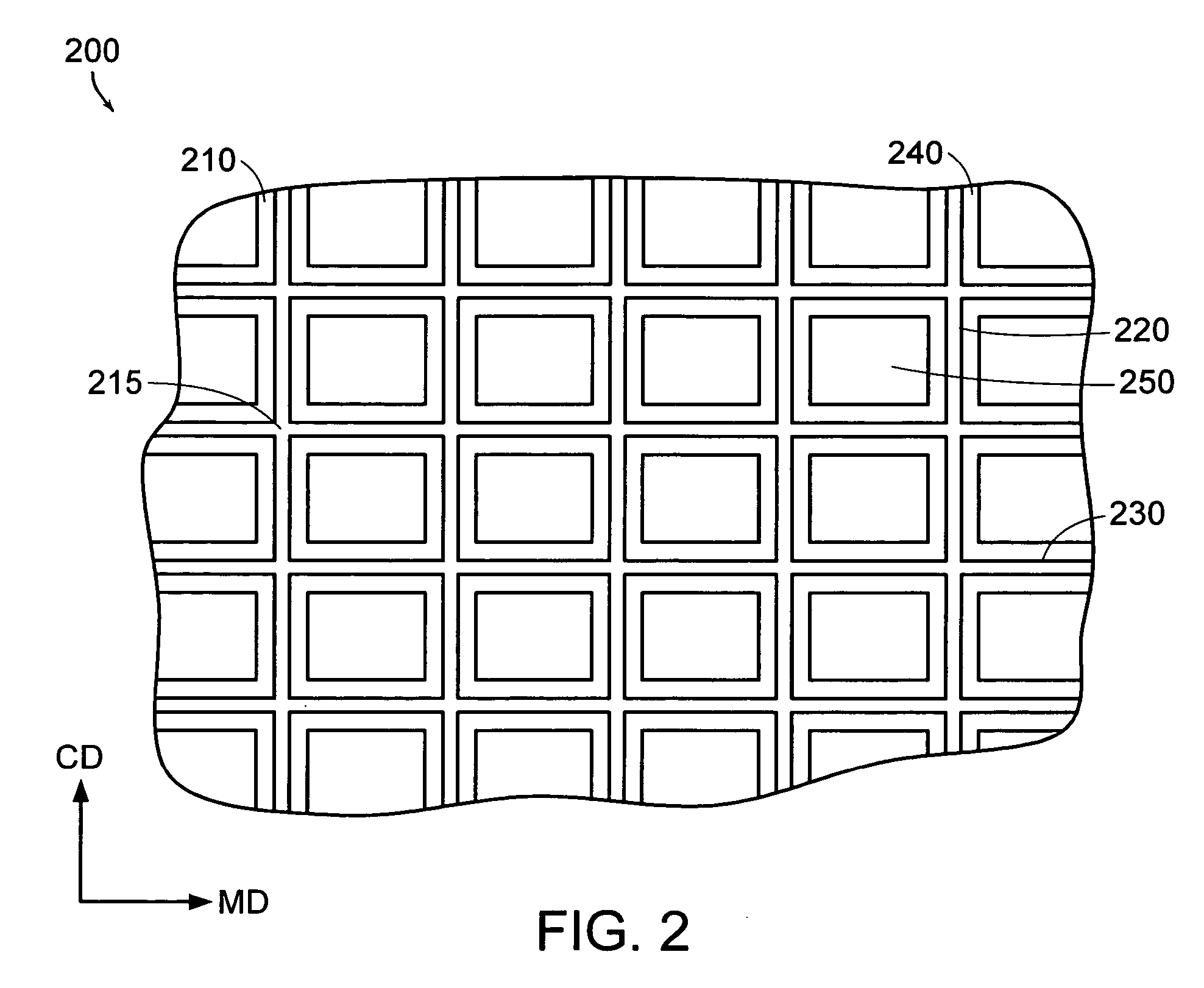

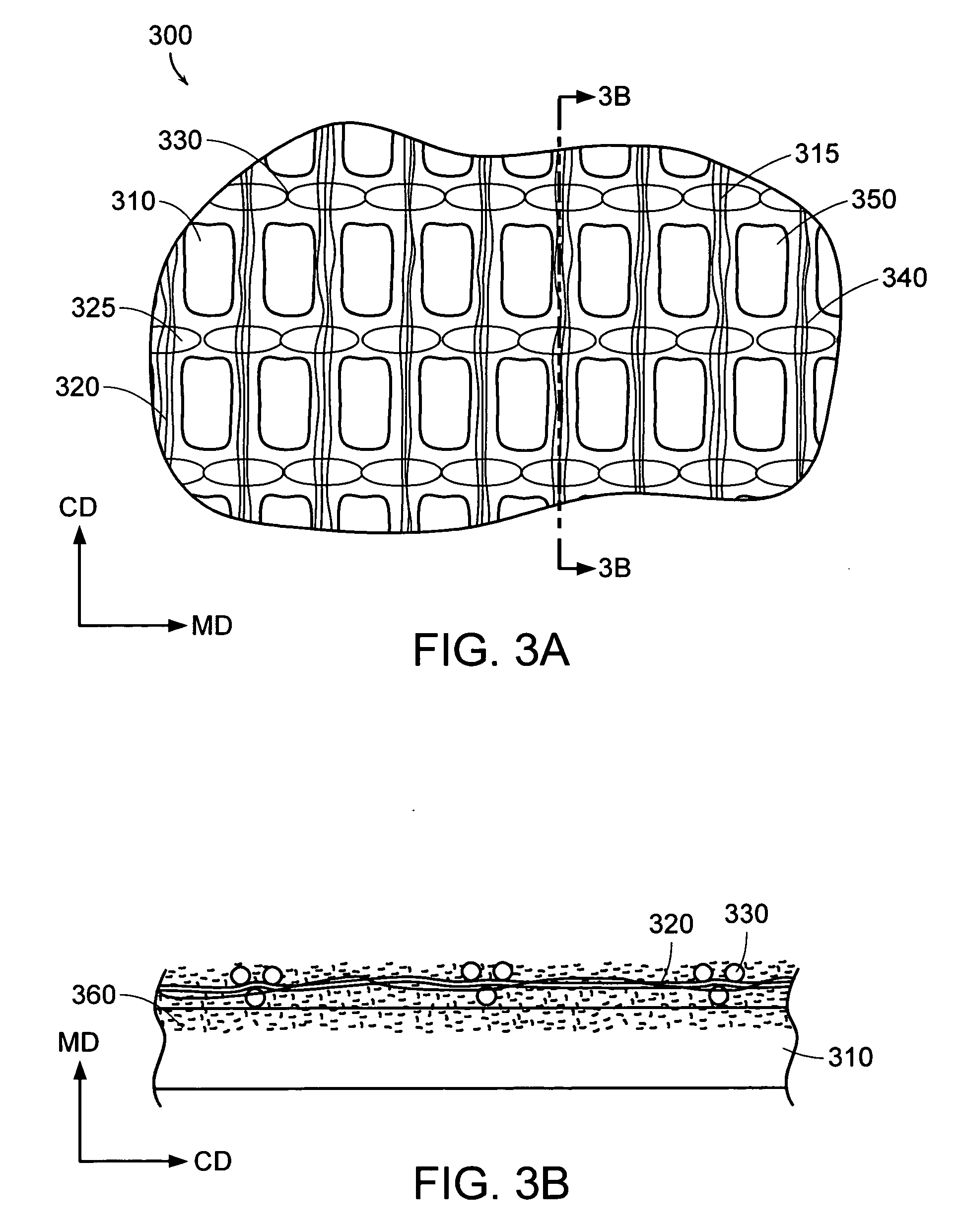

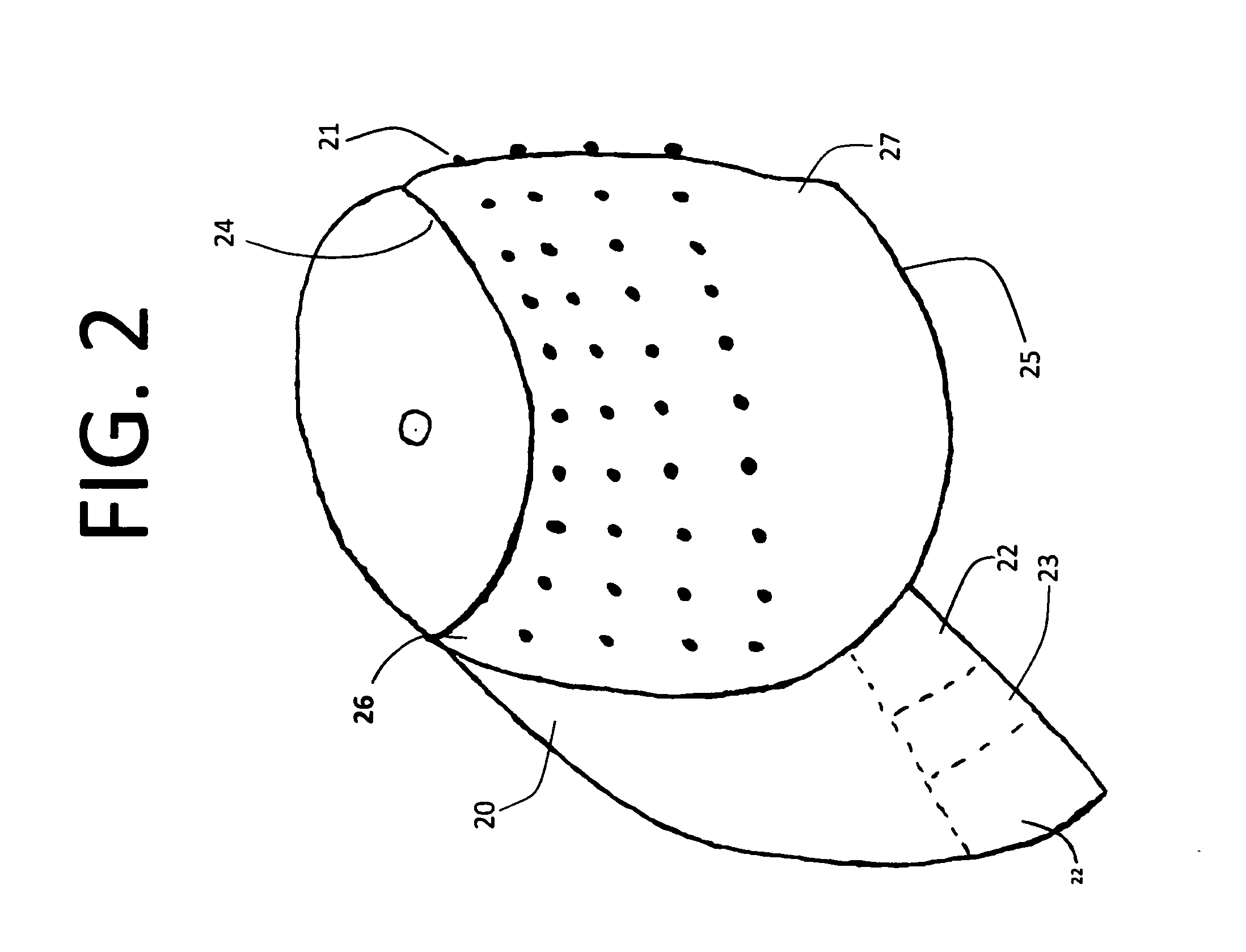

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

Methods and apparatus for applying adhesives in patterns to an advancing substrate

Owner:PROCTER & GAMBLE CO

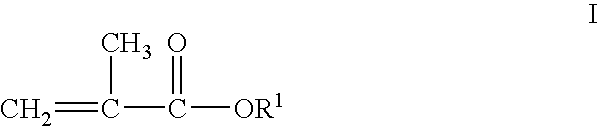

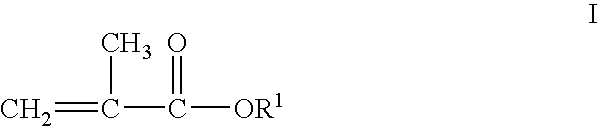

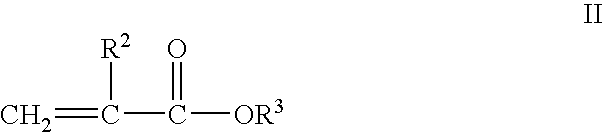

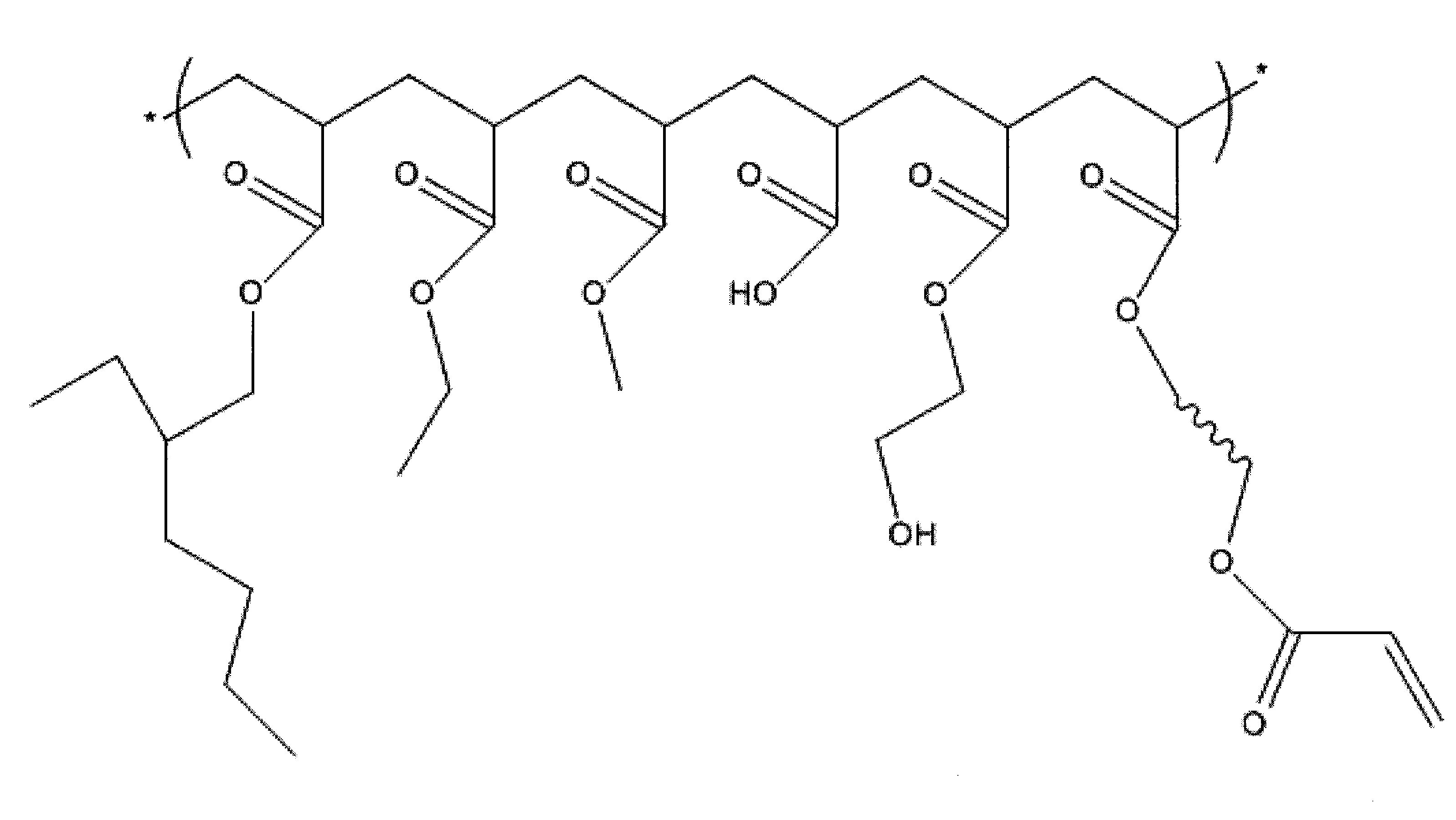

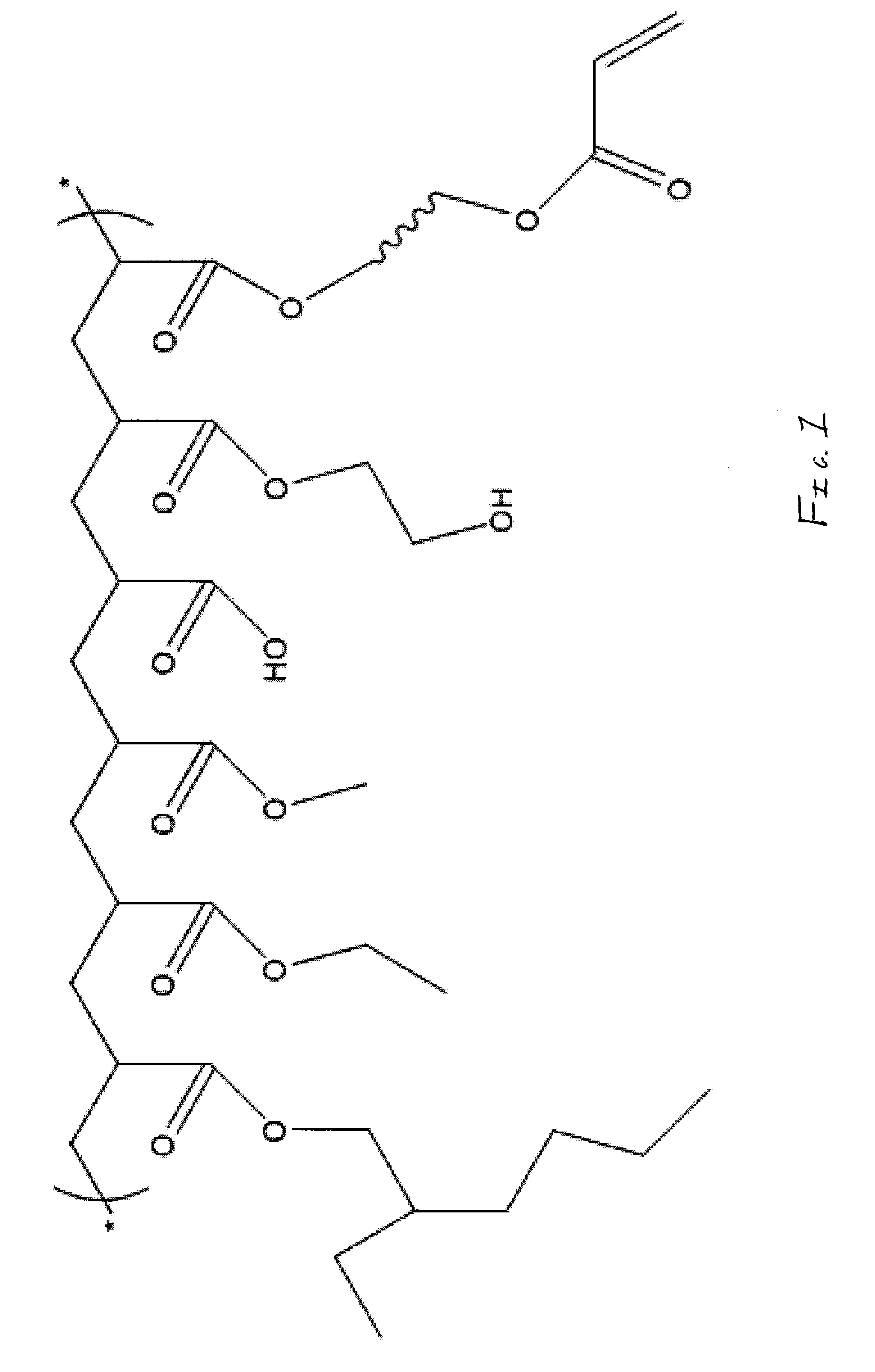

(Meth)acrylate block copolymer pressure sensitive adhesives

Articles are provided that include an optical film and an optically clear pressure sensitive adhesive layer on at least one outer surface of the optical film. Additionally, articles are provided that include a pressure sensitive adhesive layer that resists bubble formation when adhered to an outgassing substrate. The pressure sensitive adhesive layer in the various articles contain a (meth)acrylate block copolymer.

Owner:3M INNOVATIVE PROPERTIES CO

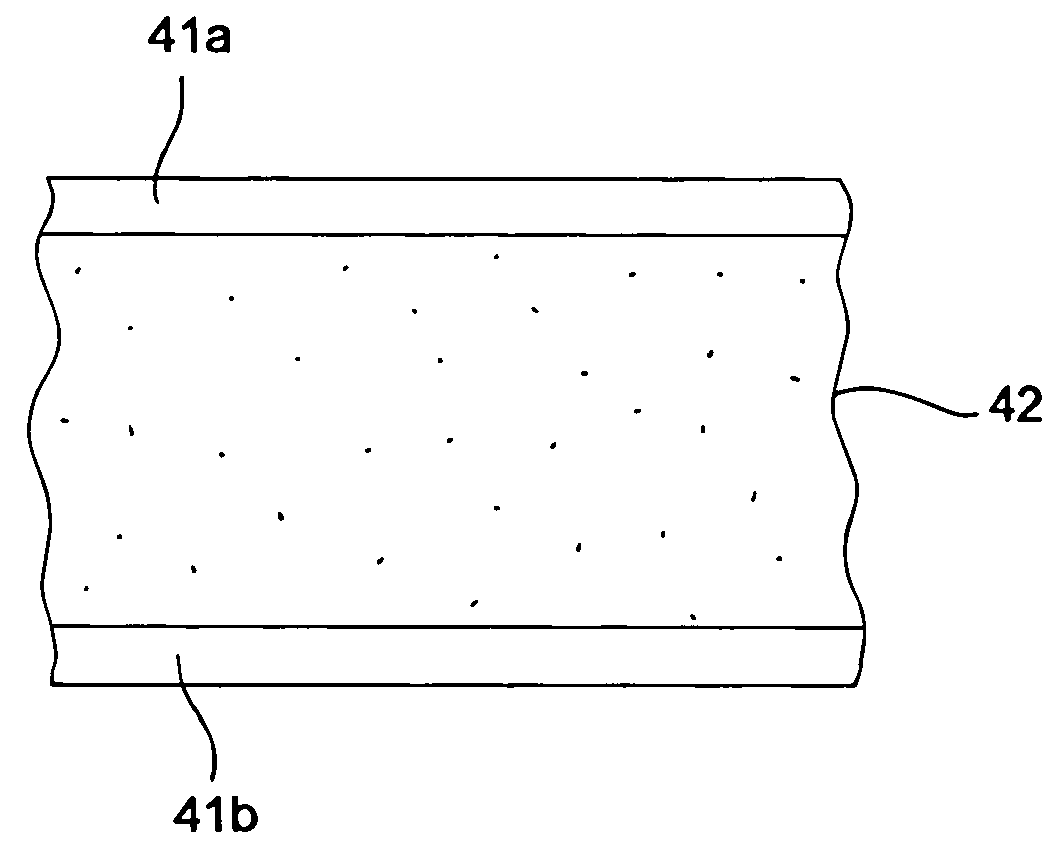

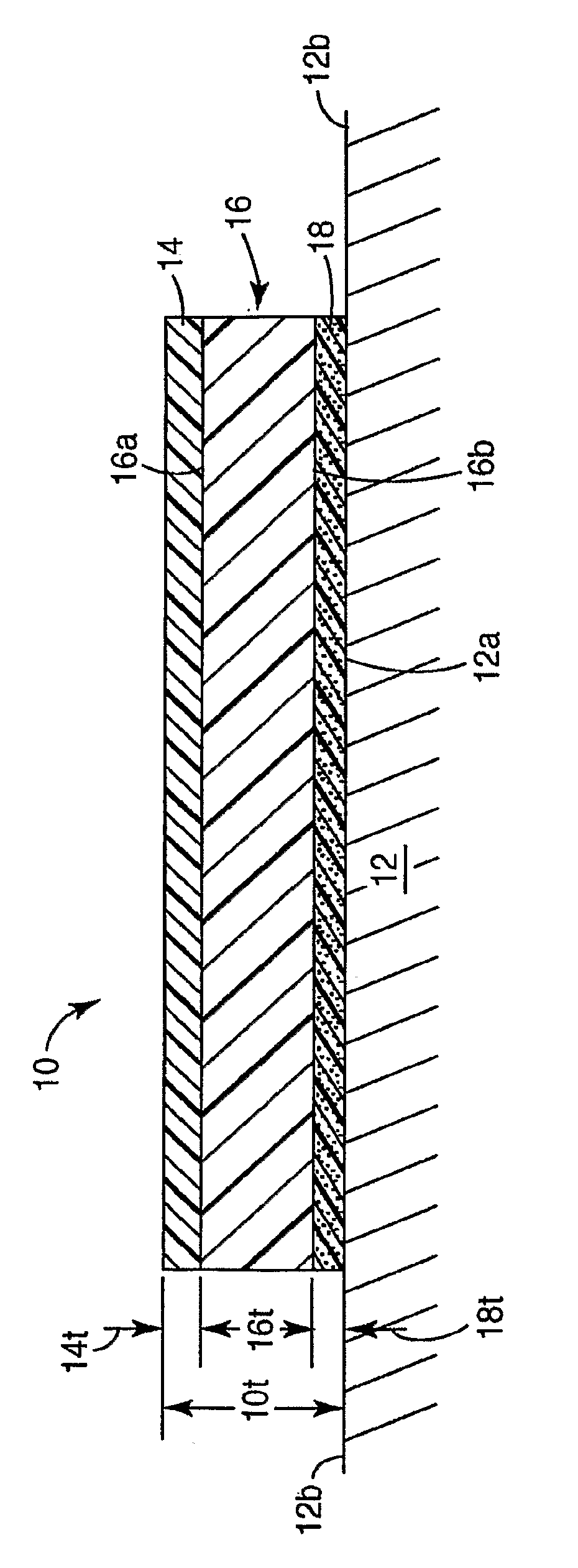

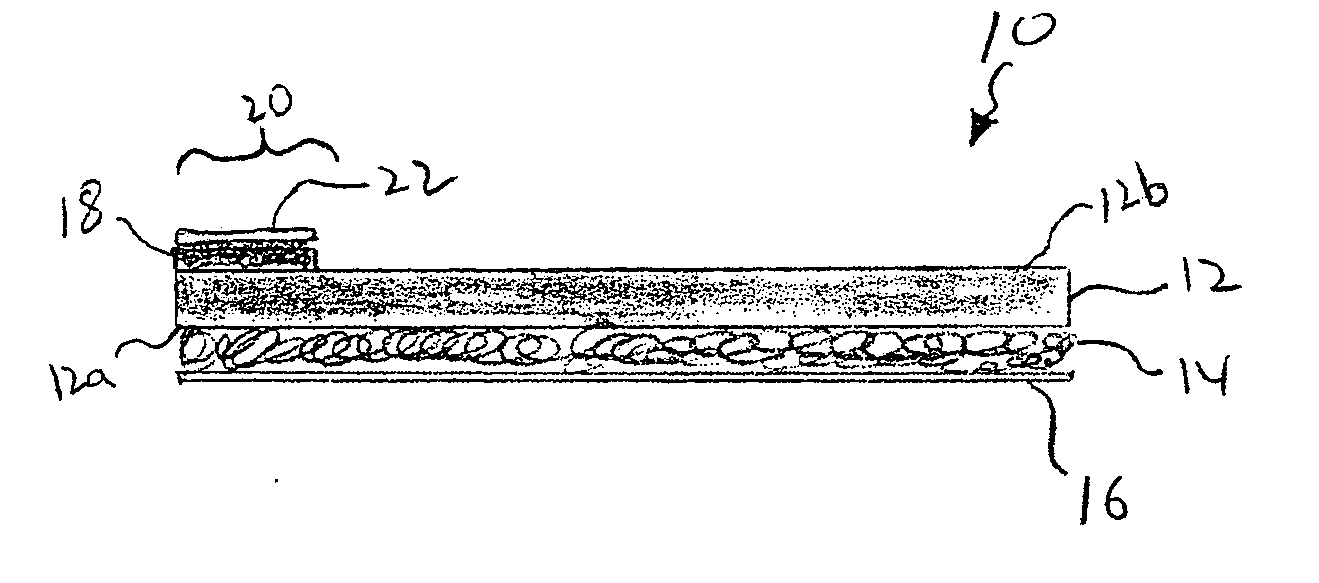

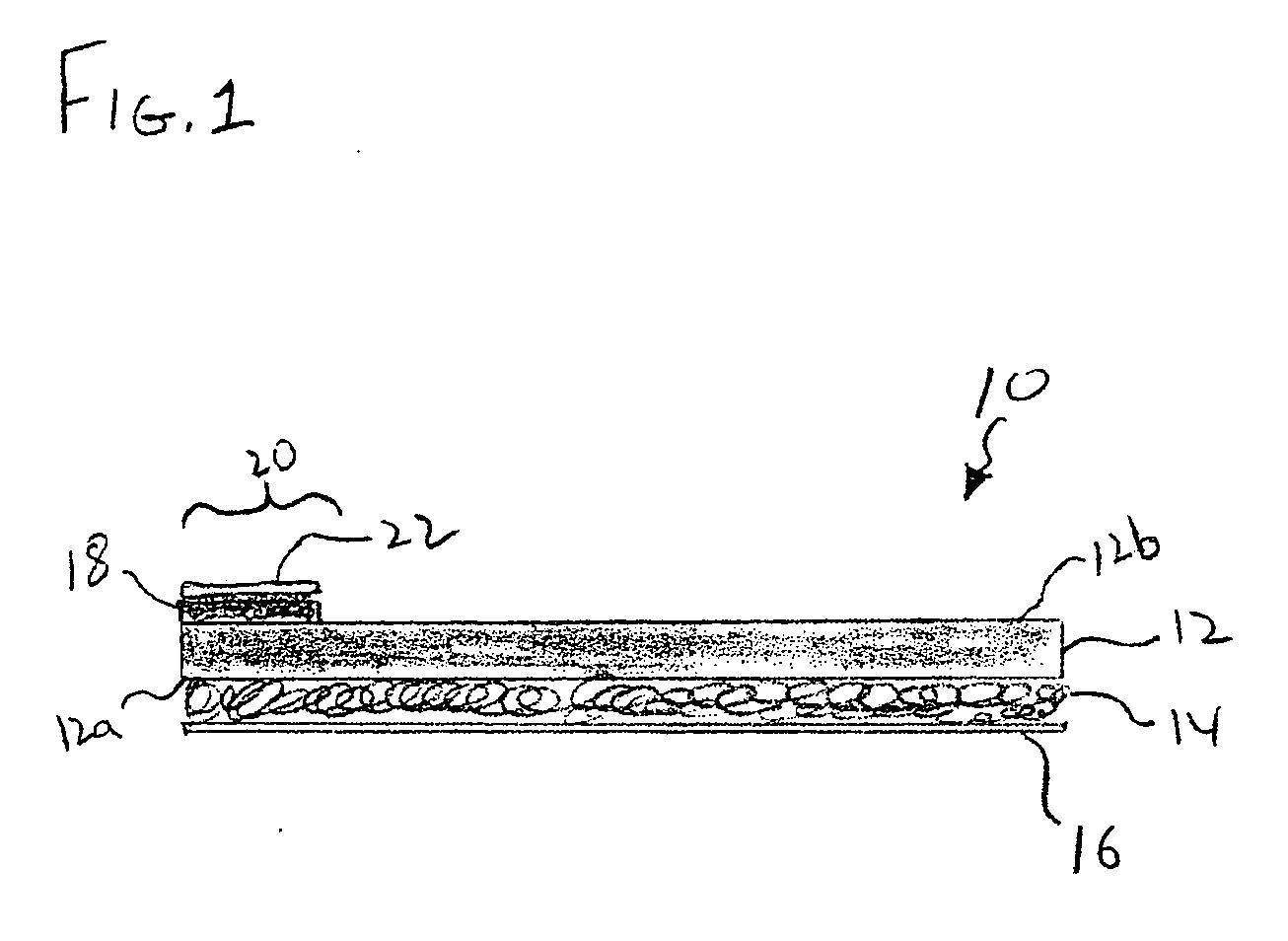

Aerogel/PTFE composite insulating material

ActiveUS20050100728A1Increase flexibilityHigh strengthDigital data processing detailsAdhesive articlesInto-structureMaterials science

A material comprising aerogel particles and a polytetrafluoroethylene (PTFE) binder is formed having a thermal conductivity of less than or equal to 25 mW / m K at atmospheric conditions. The material is moldable or formable, having little or no shedding of filler particles, and may be formed into structures such as tapes or composites, for example, by bonding the material between two outer layers. Advantageously, composites may be flexed, stretched, or bent without significant dusting or loss of insulating properties.

Owner:WL GORE & ASSOC INC

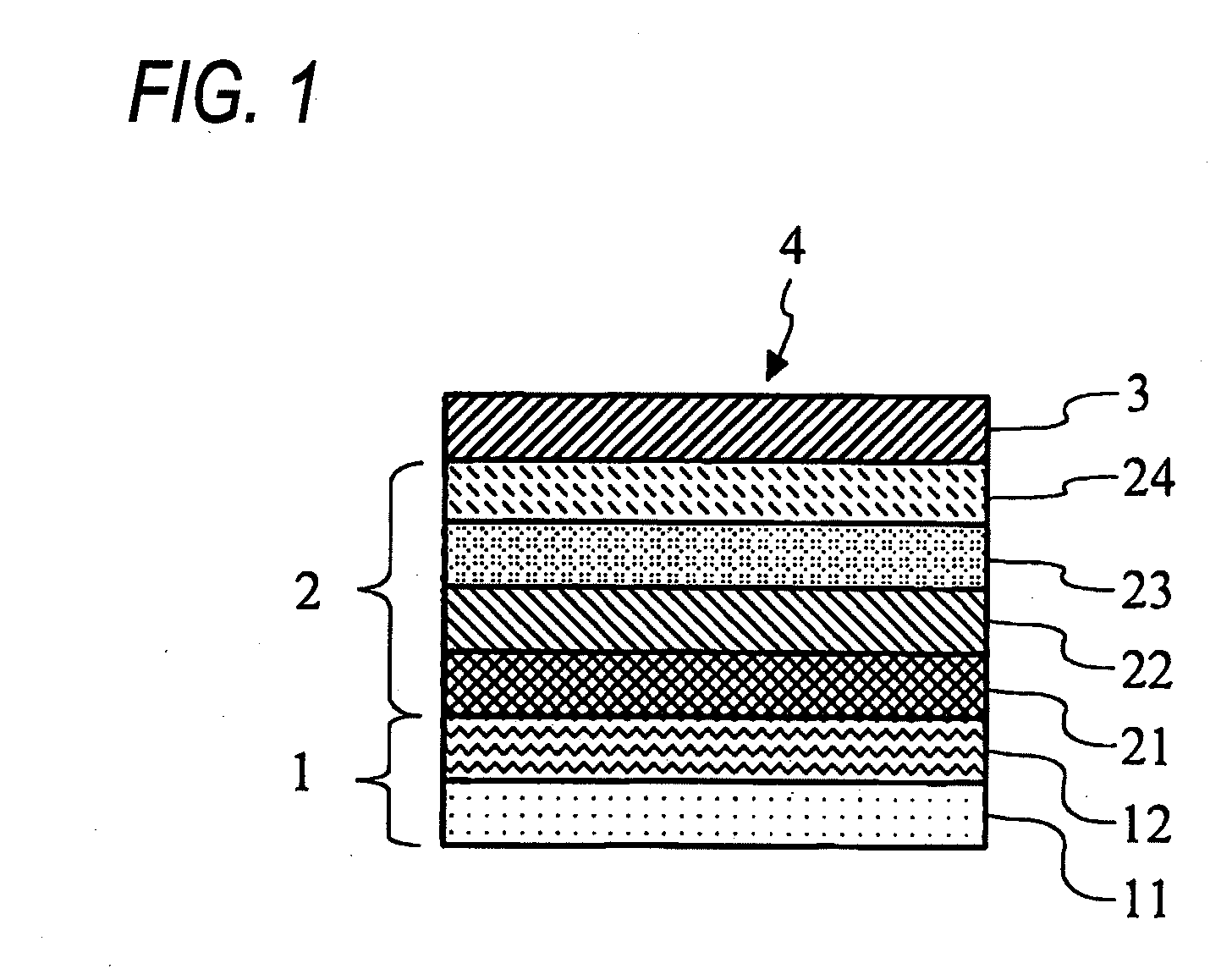

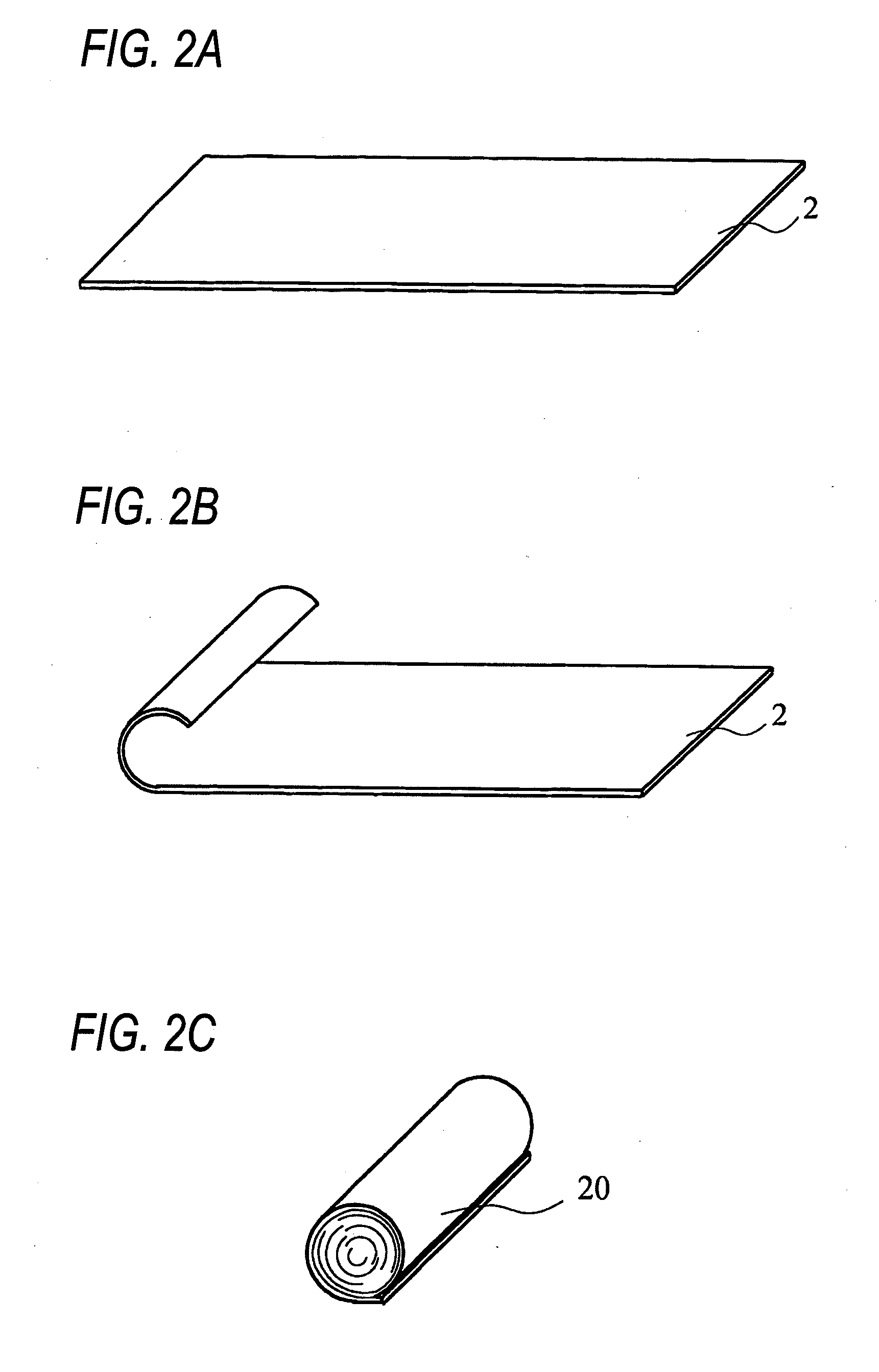

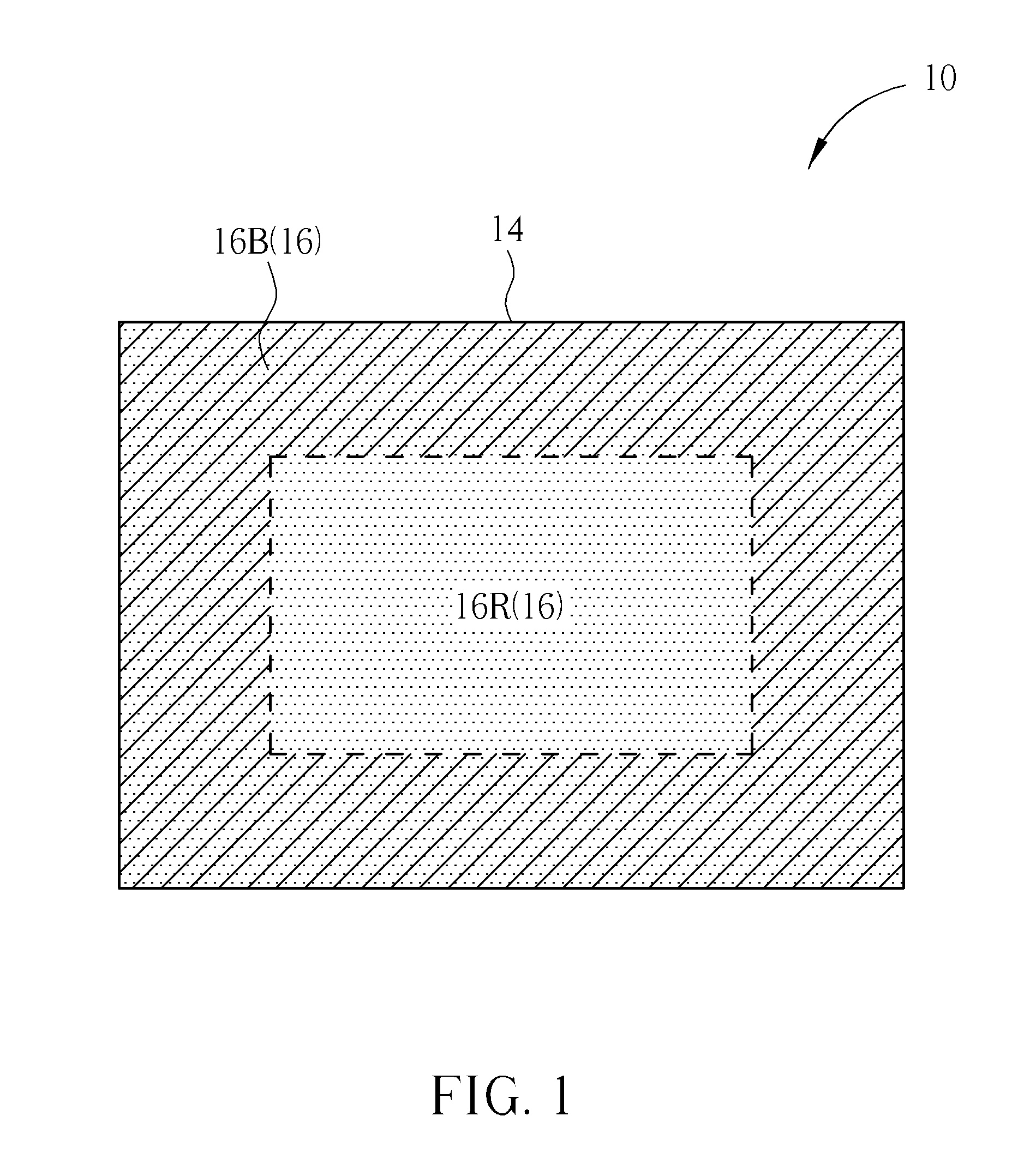

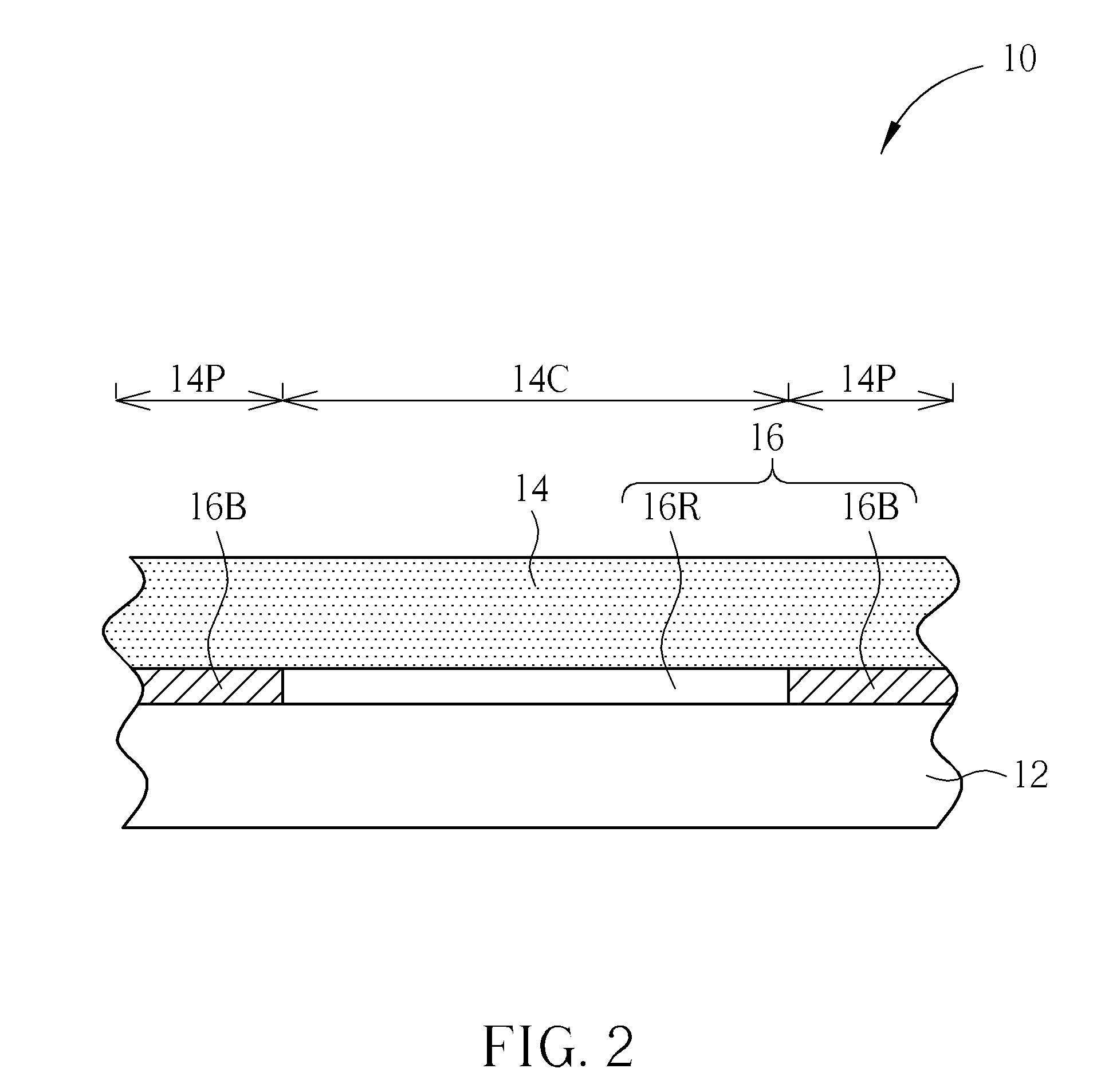

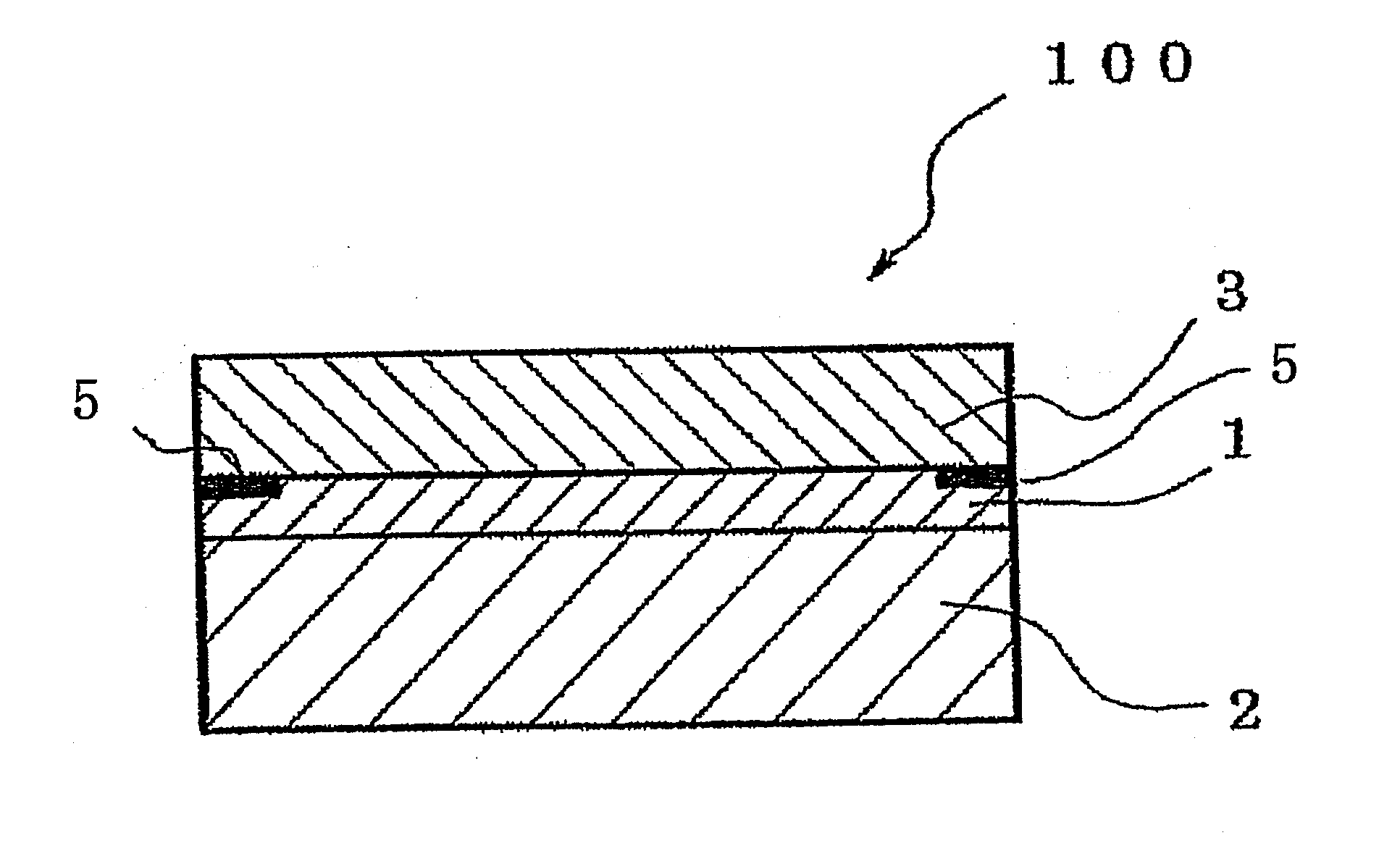

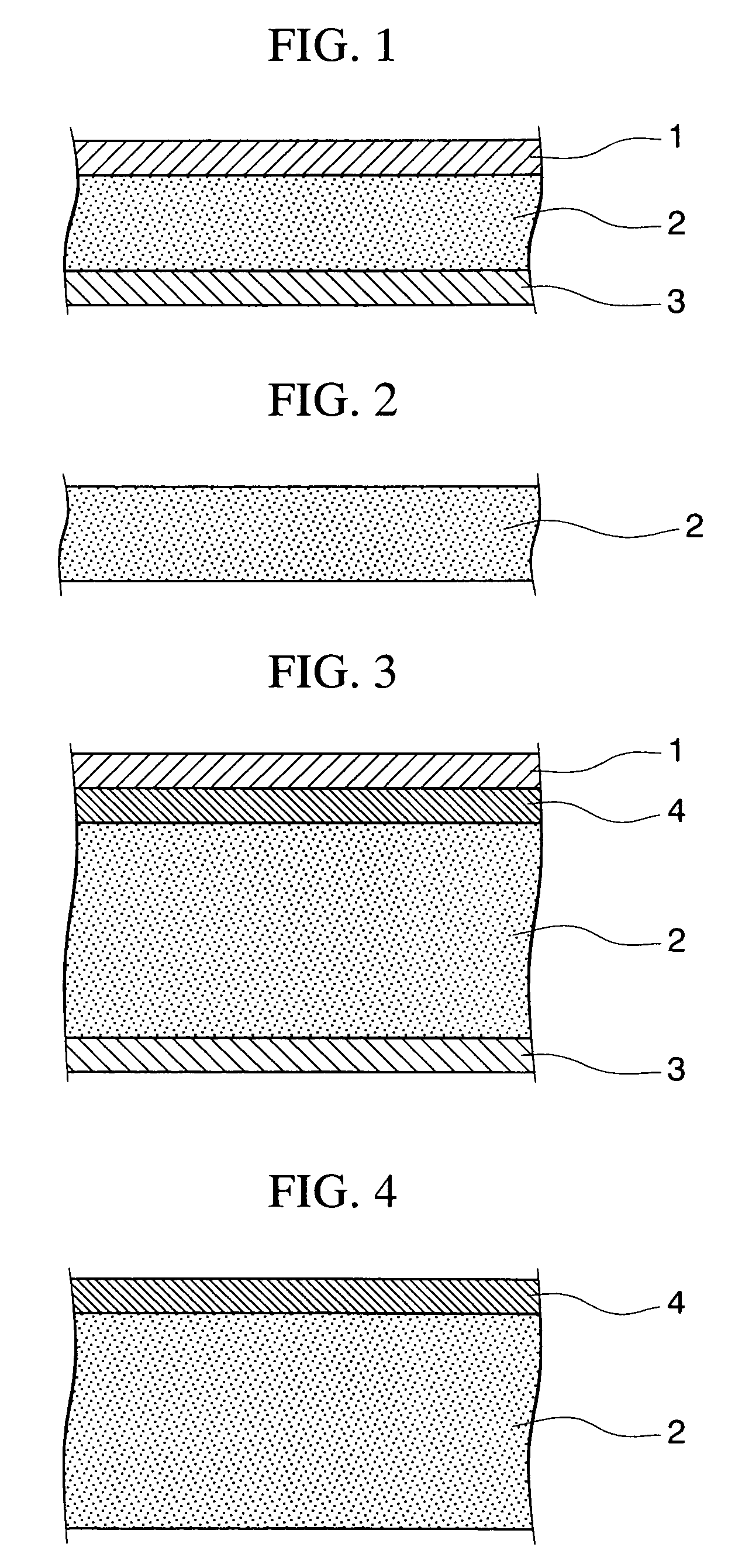

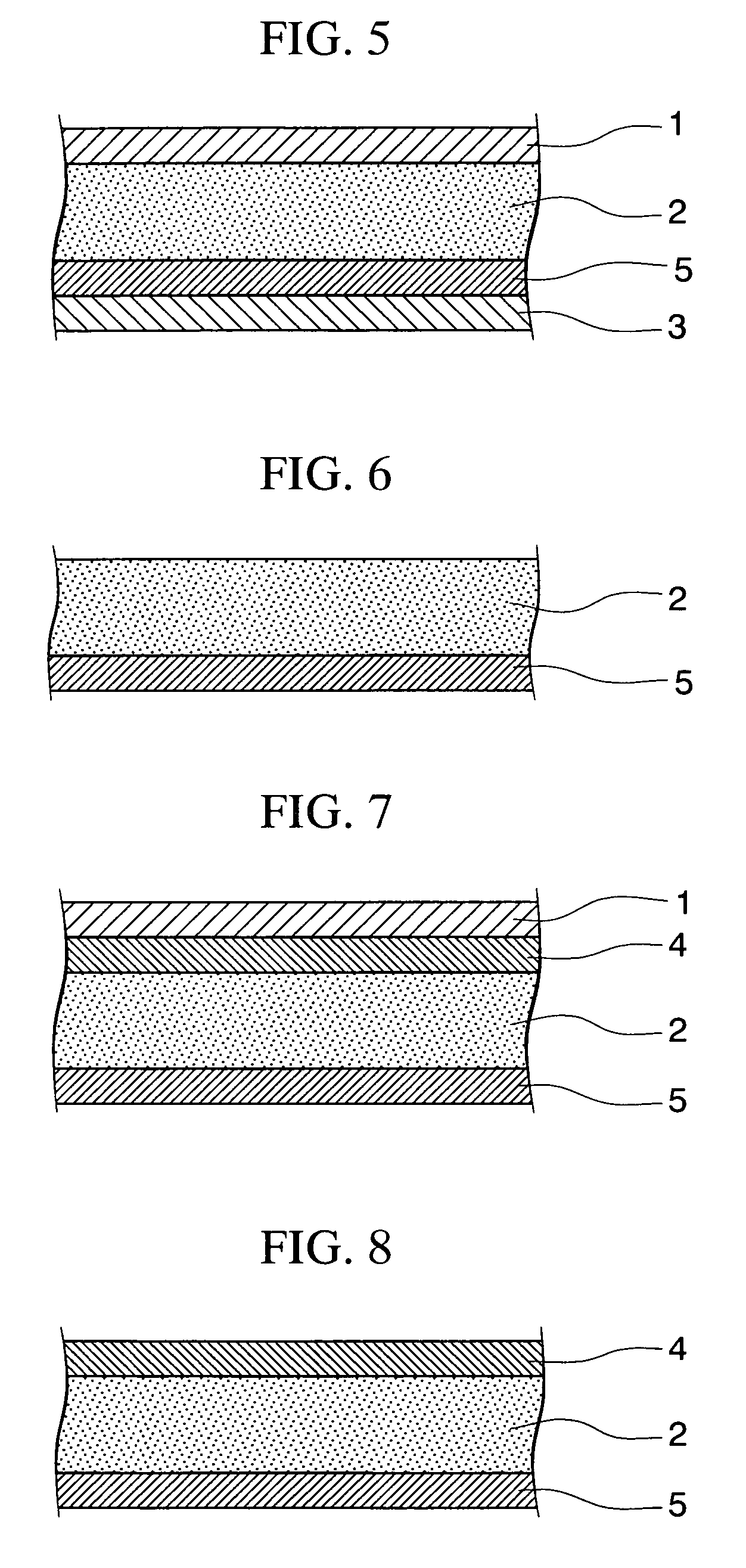

Adhesive optical film, method for manufacturing adhesive optical film and image display

ActiveUS20060108050A1More easilySimply easilyAdhesive articlesSolid-state devicesAdhesiveEngineering

An adhesive layer included in an adhesive-type optical film forms a portion located on the inside of a edge line of an optical film.

Owner:NITTO DENKO CORP

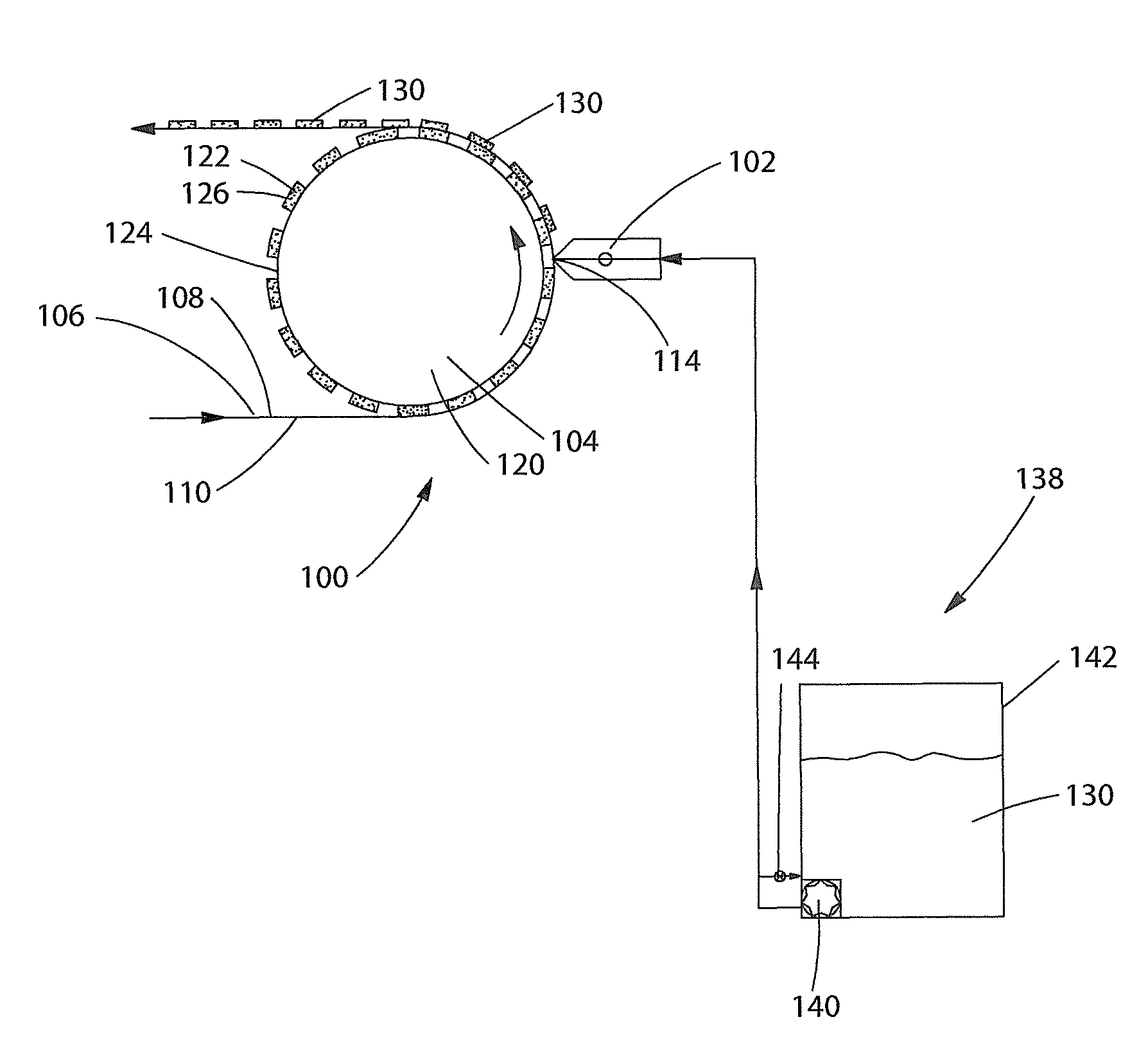

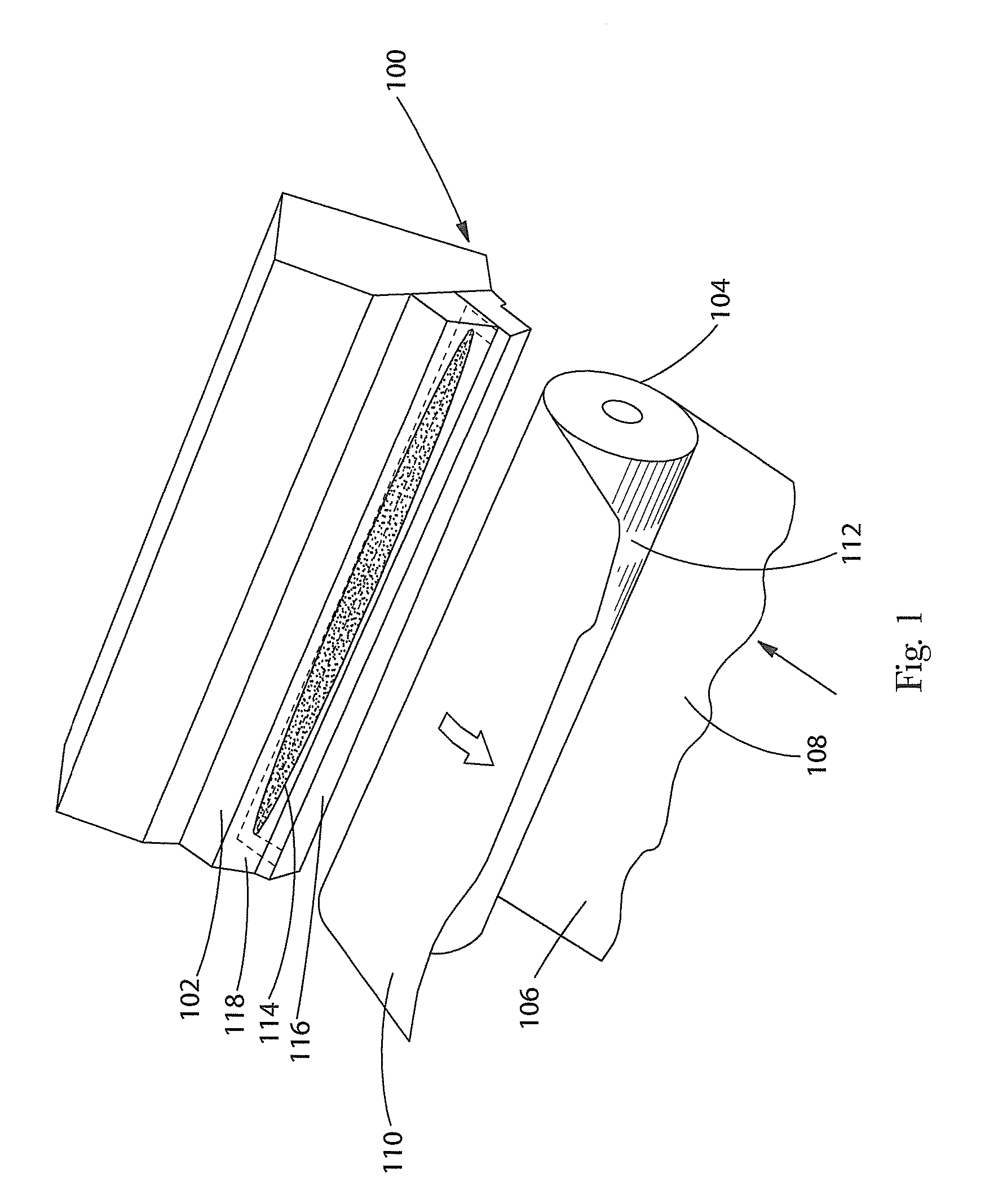

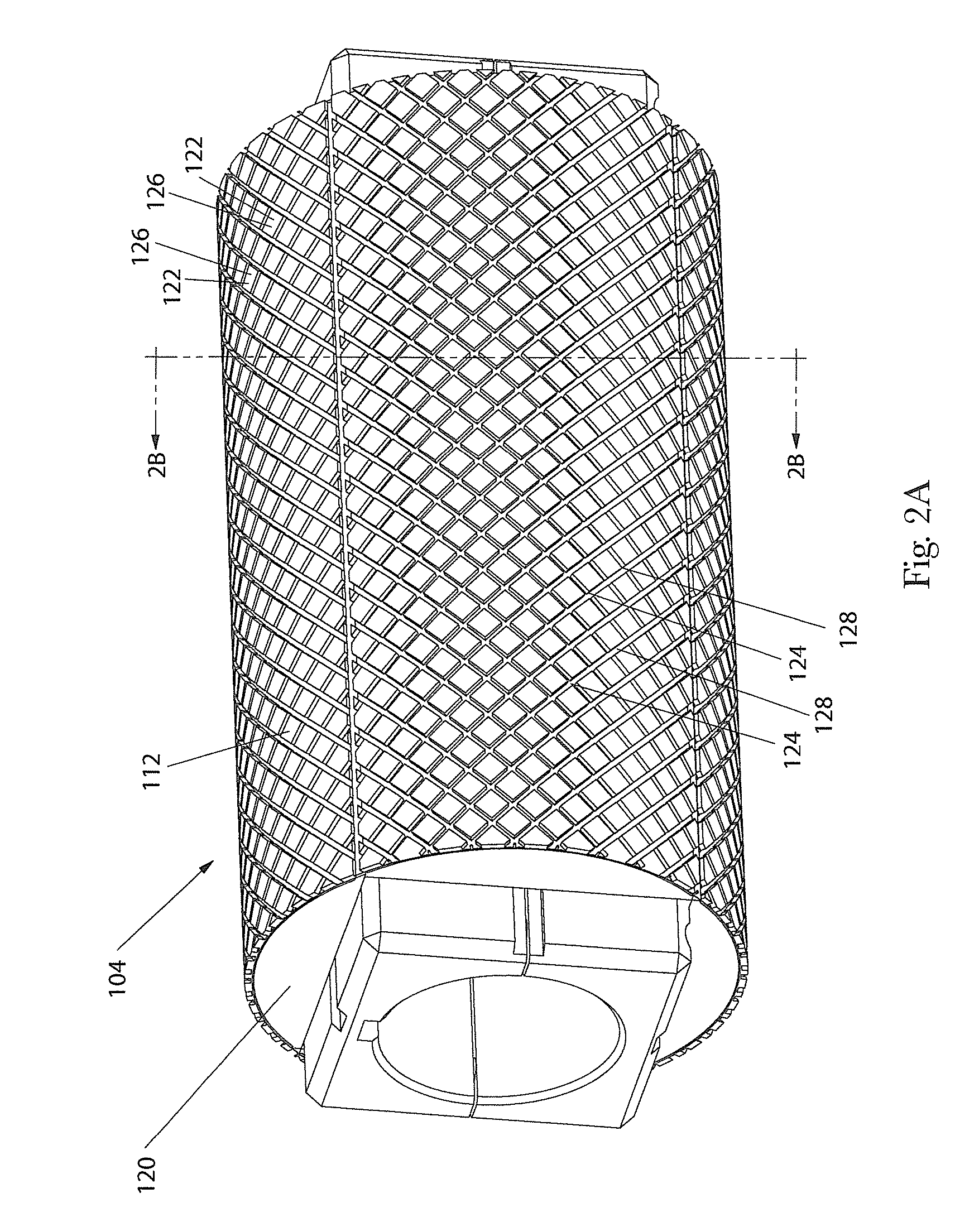

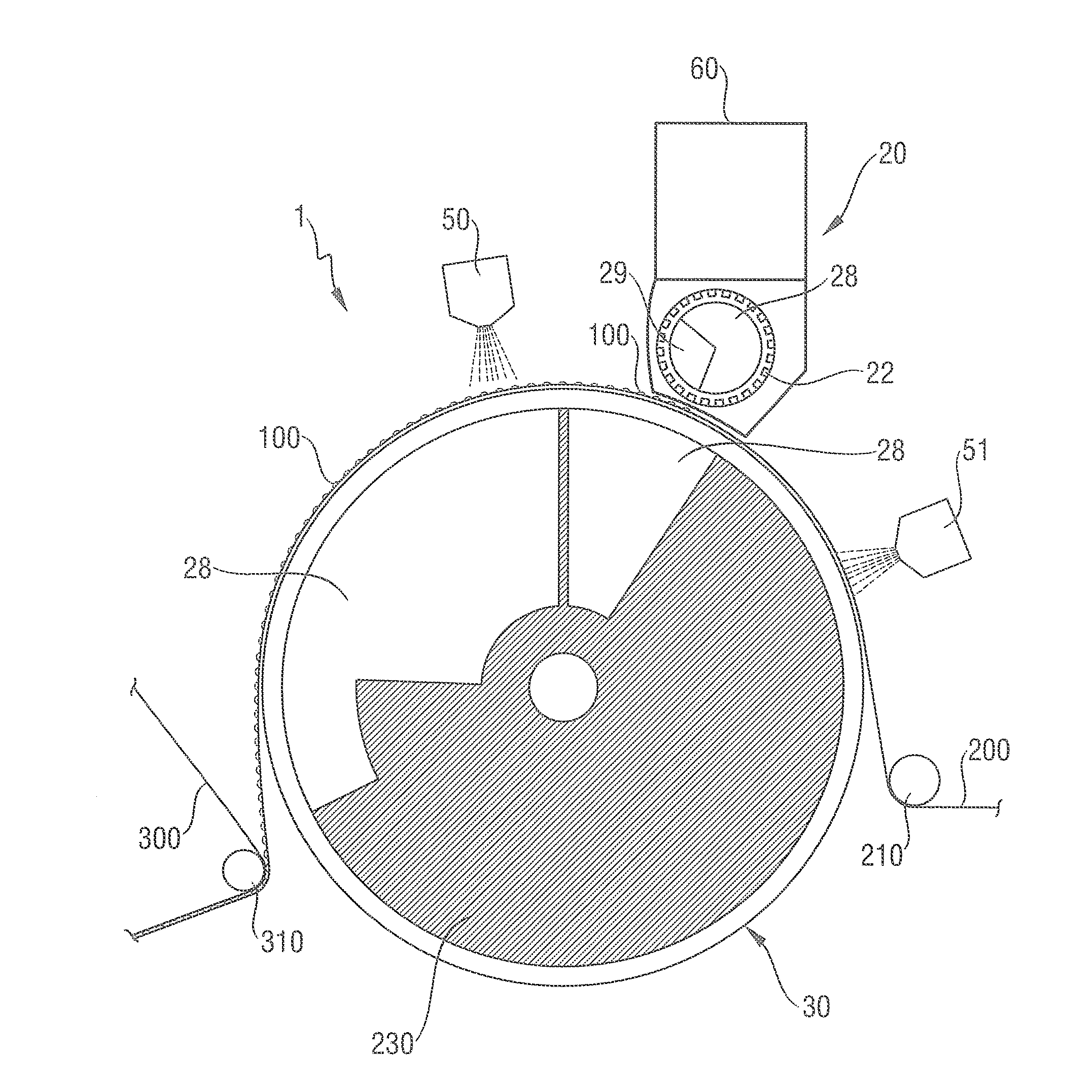

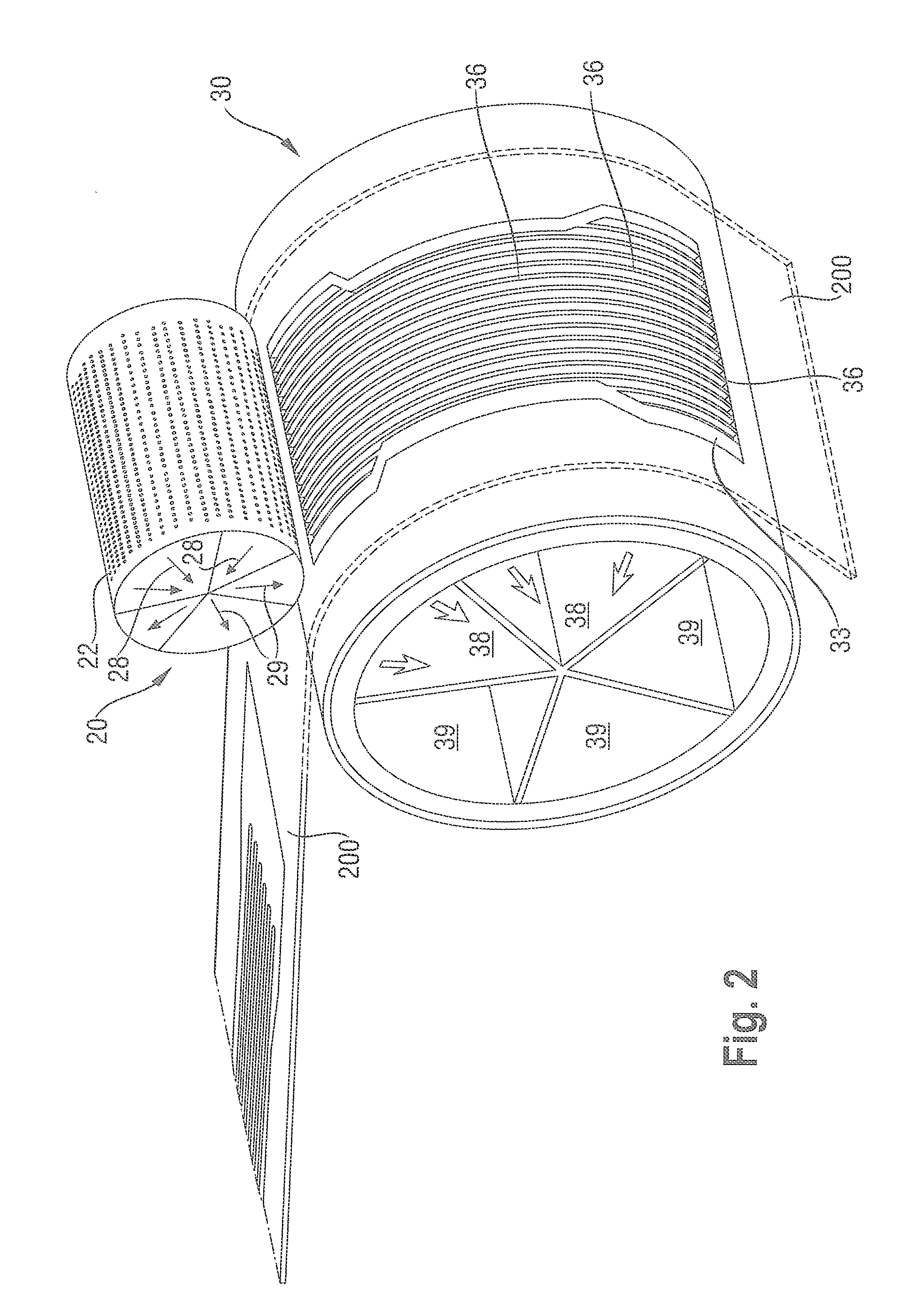

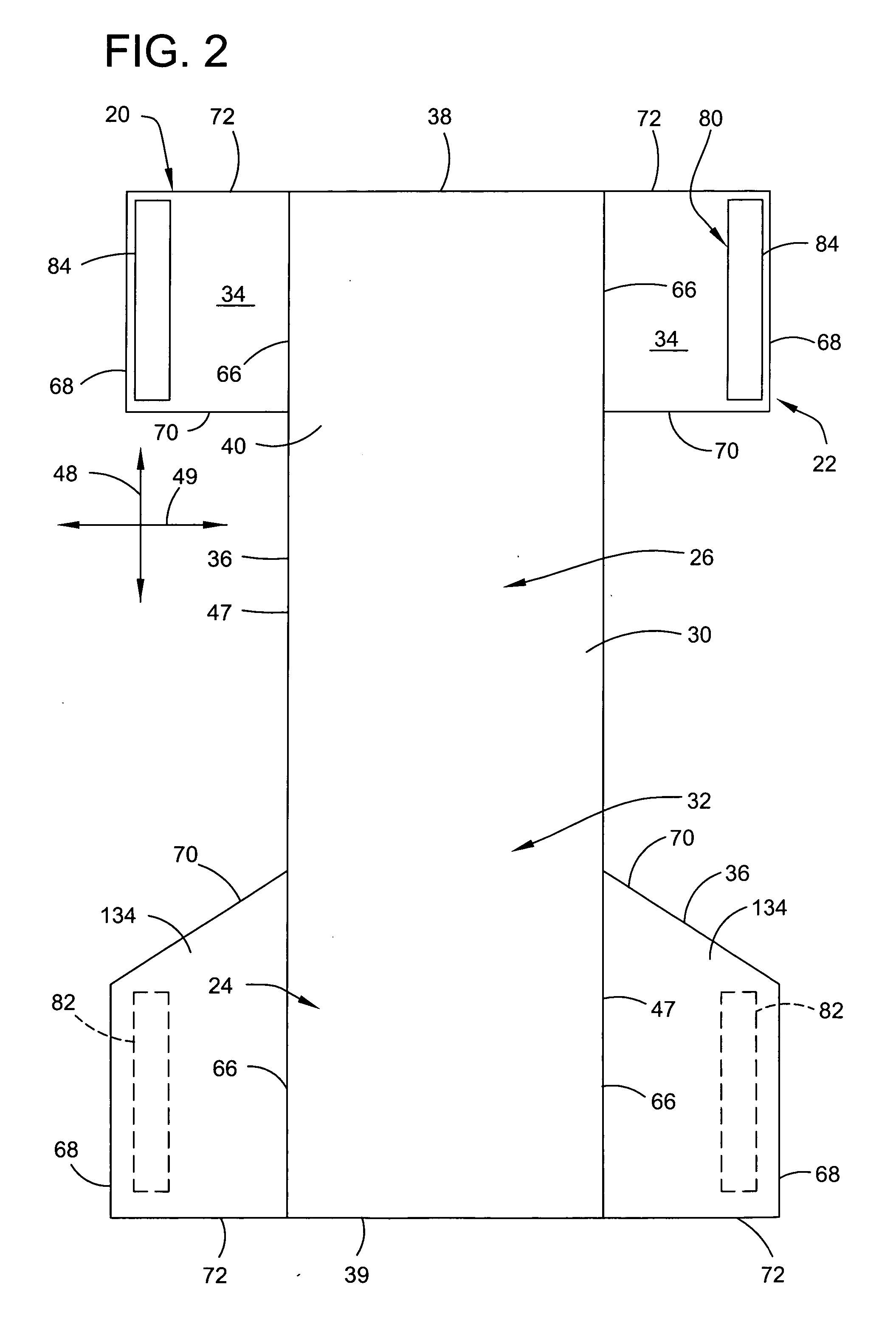

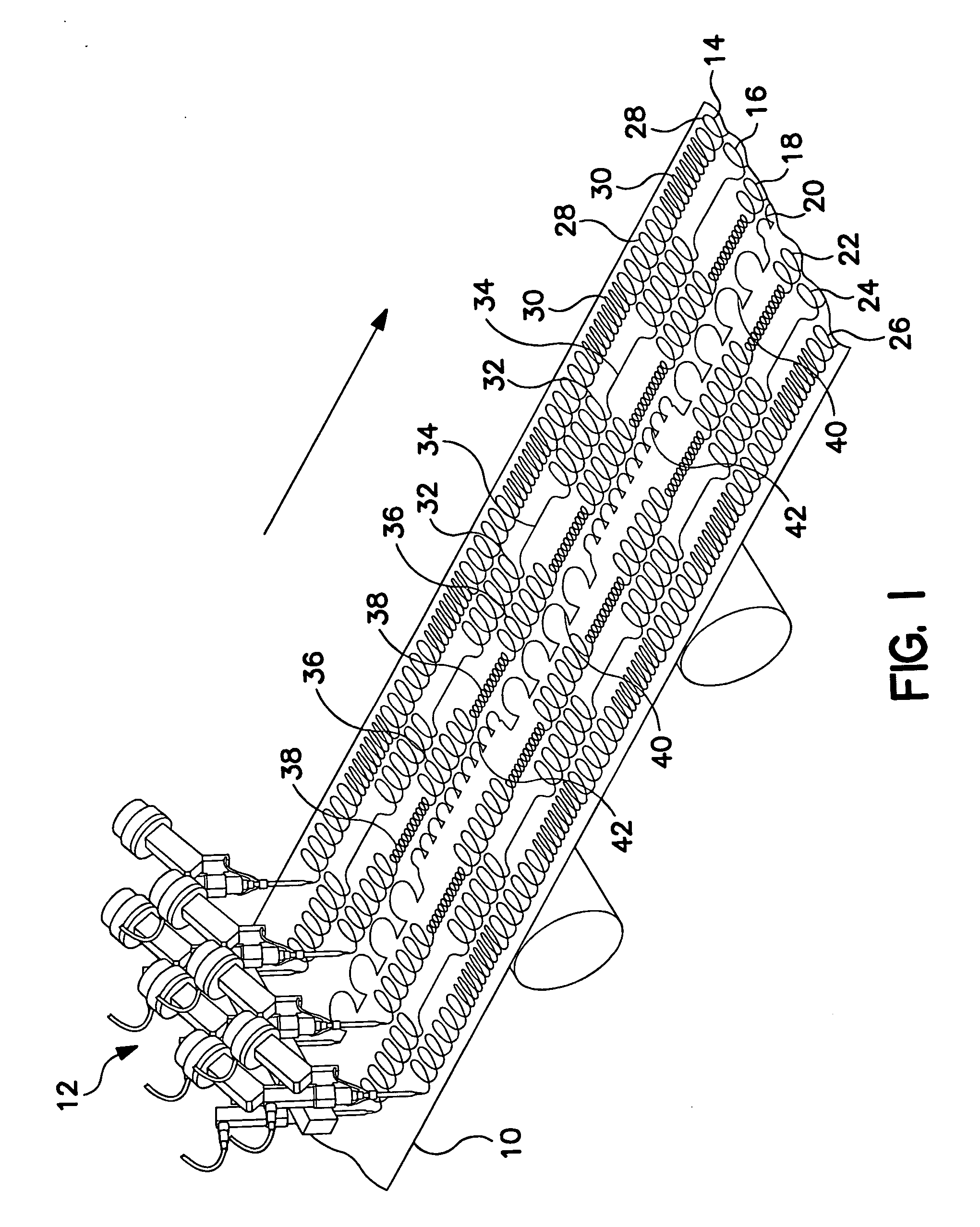

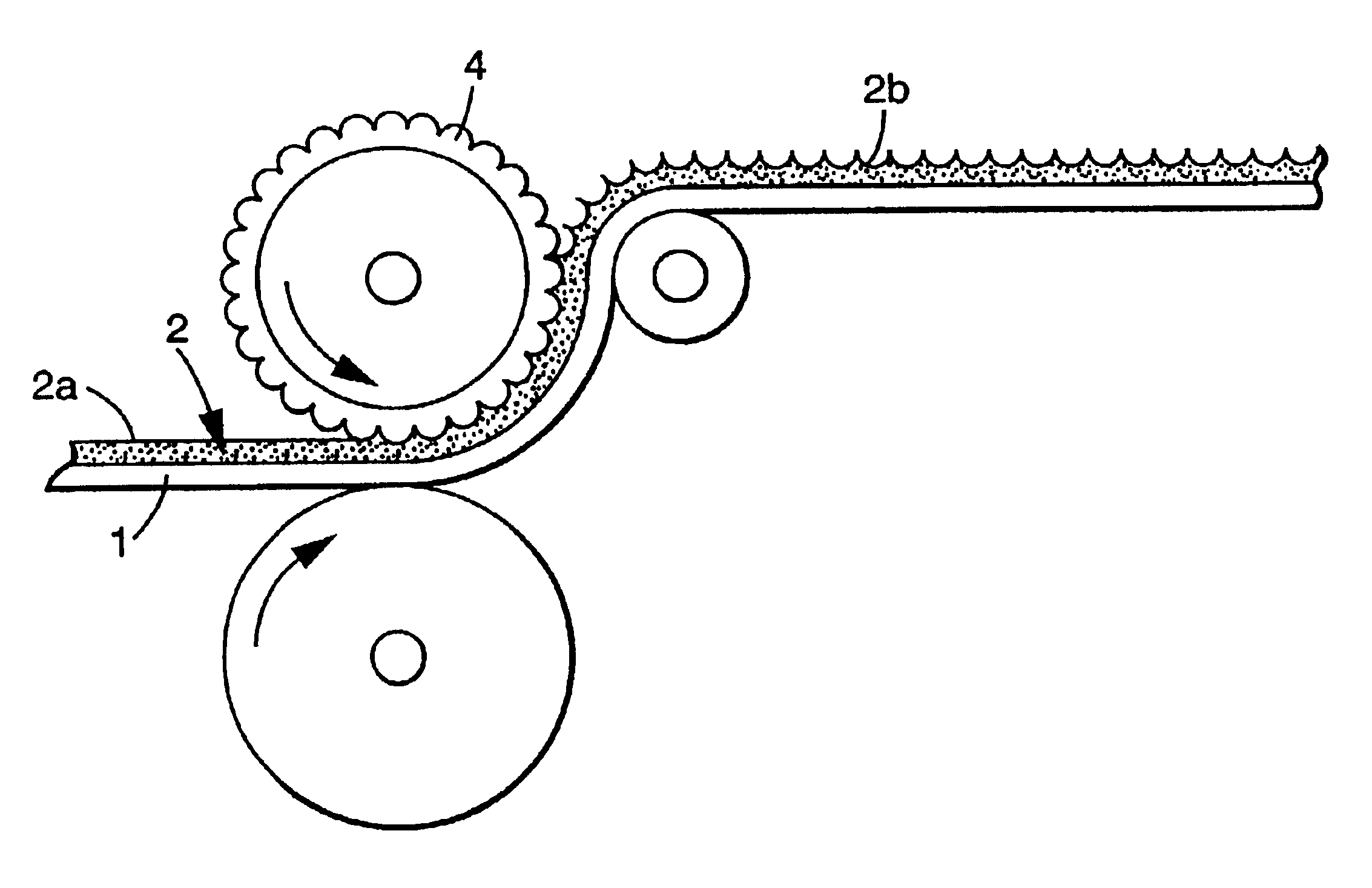

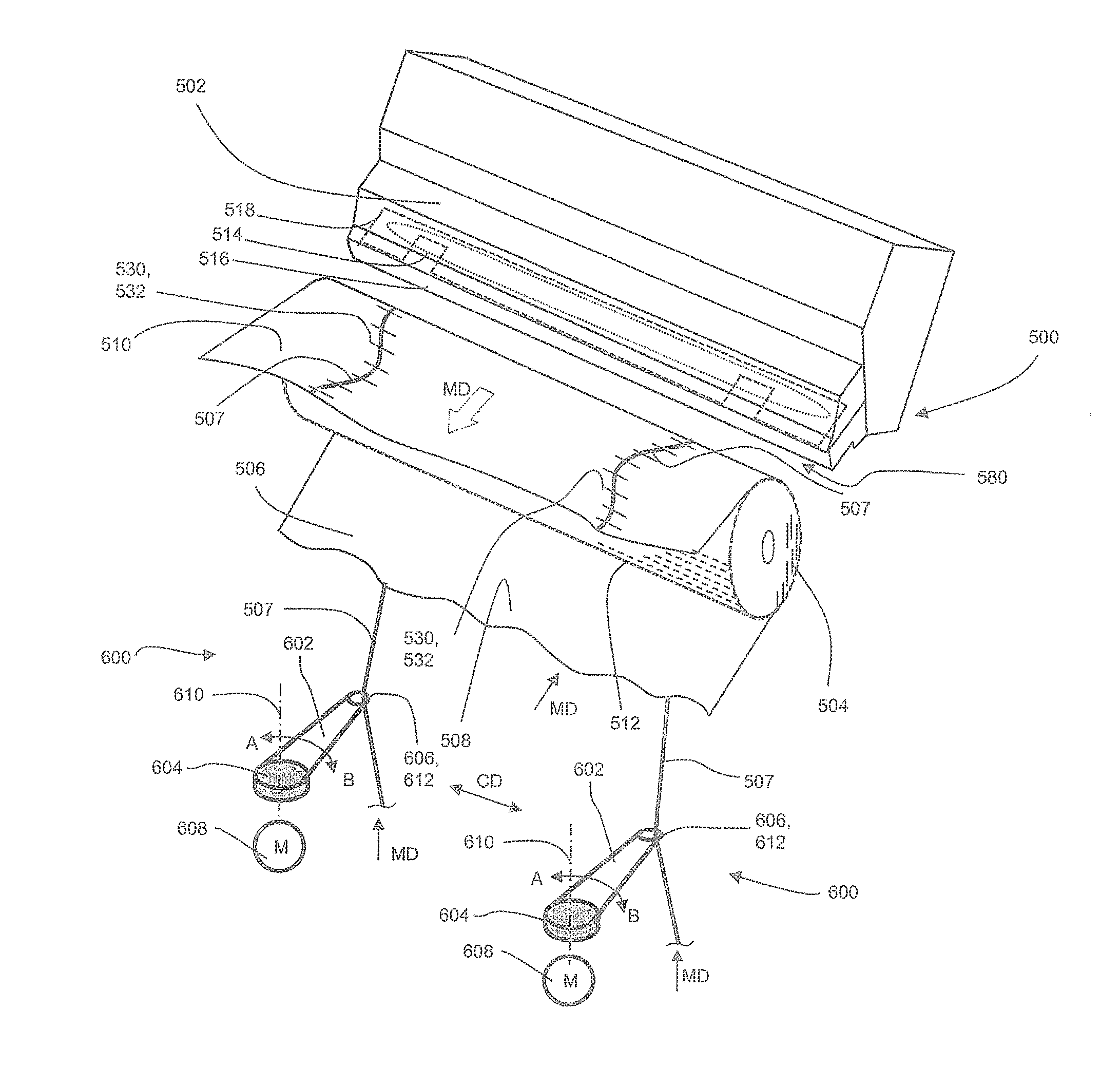

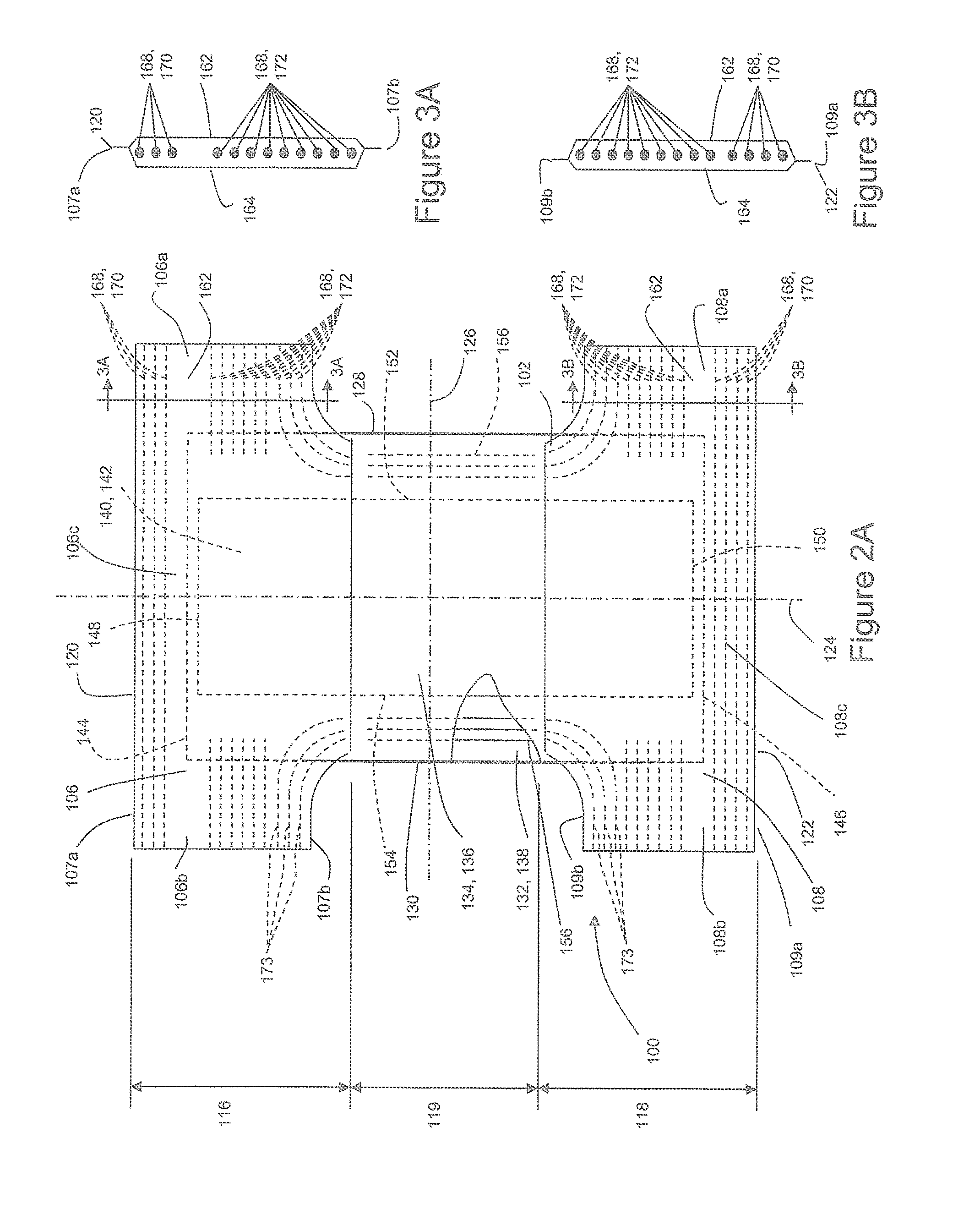

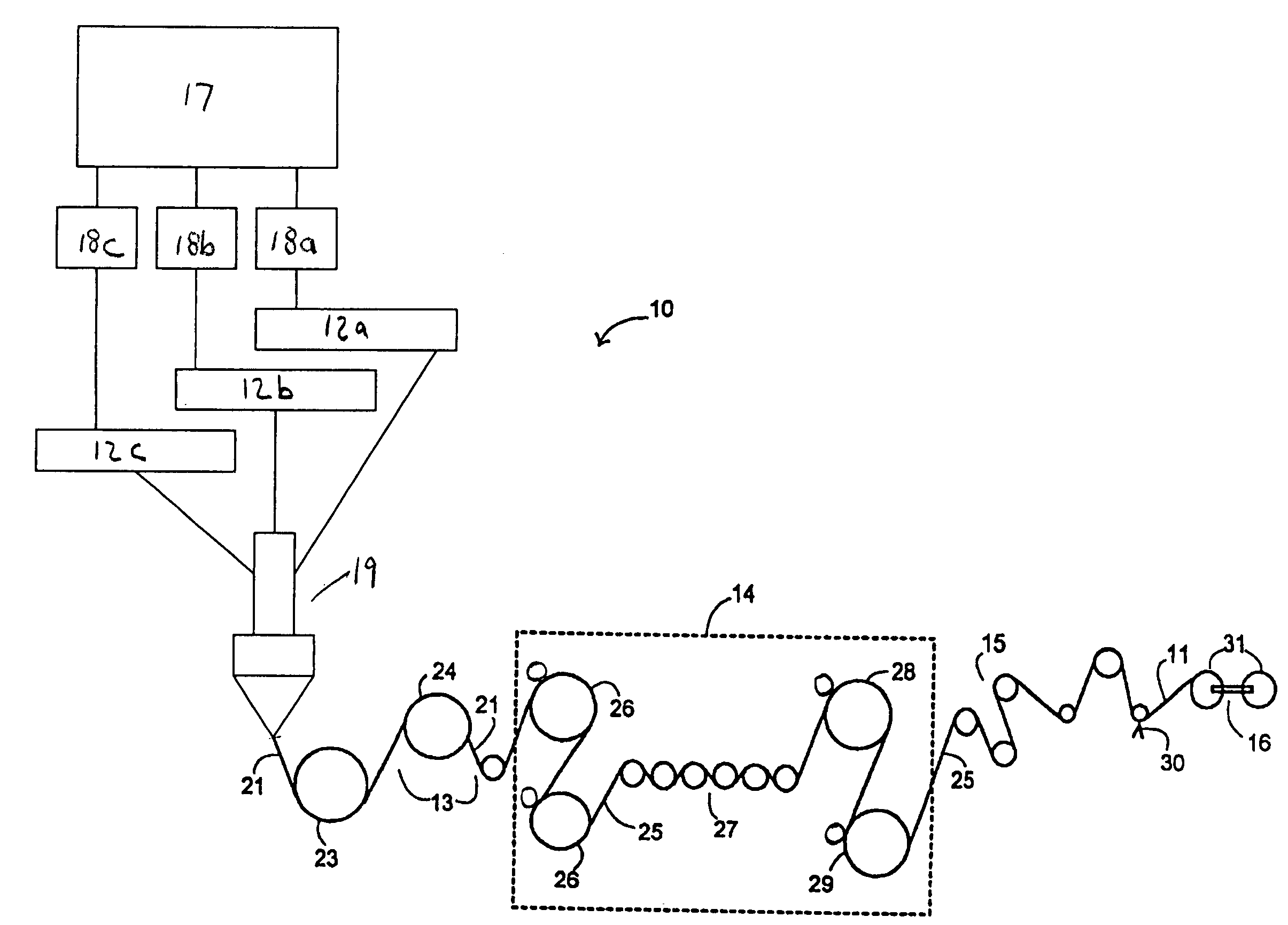

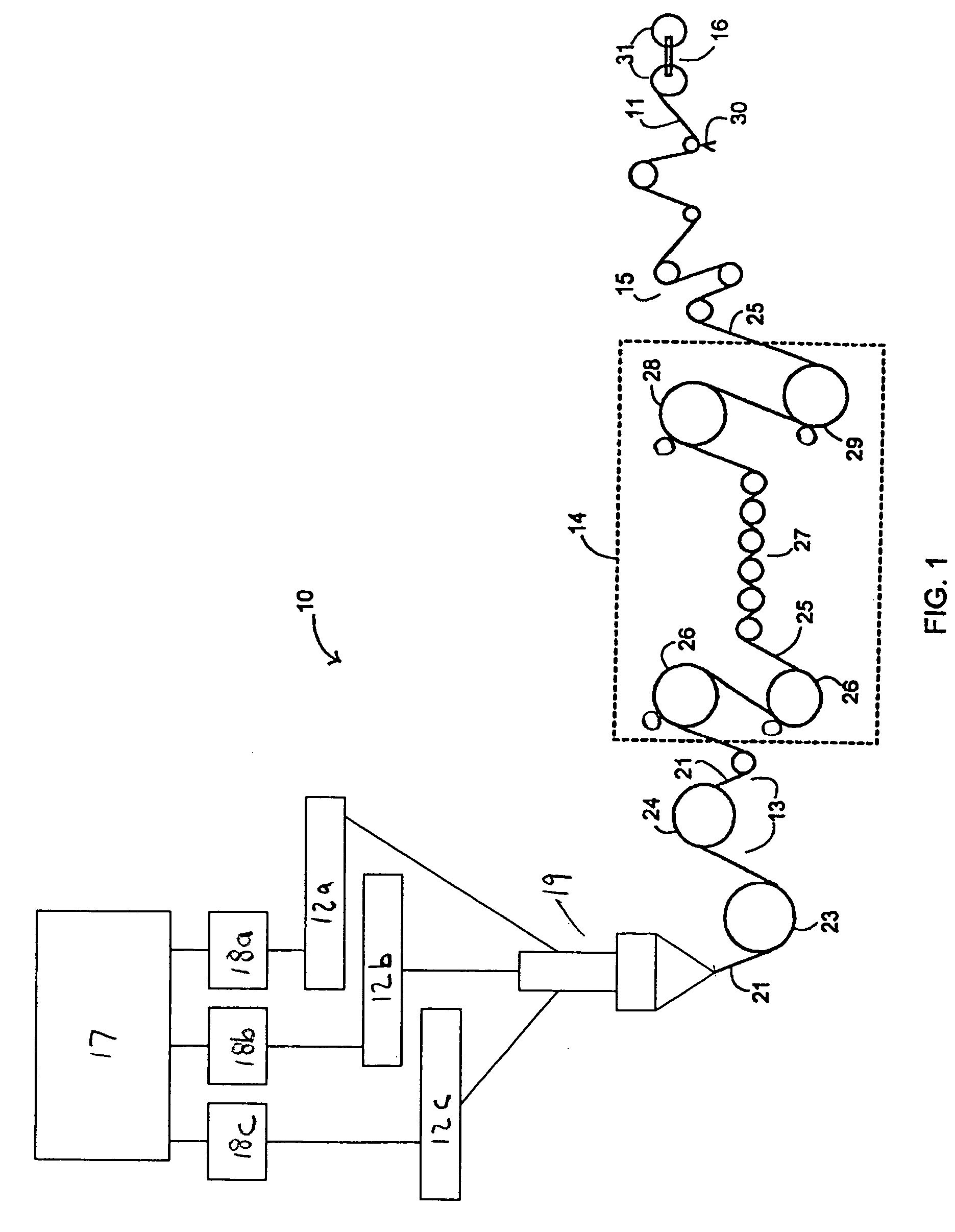

Method and Apparatus for Making Absorbent Structures with Absorbent Material

ActiveUS20120316046A1Boxes/cartons making machineryPaper/cardboard articlesAbsorbent materialMechanical engineering

A method and apparatus for making specific absorbent structures with an absorbent layer with absorbent material with therein substantially longitudinally extending strips that are free of absorbent material, using or having thereto a moving endless surface with receptacle(s) with specific longitudinally extending rods; and specific absorbent structures obtained therewith, suitable for absorbent articles, such as diapers and sanitary napkins.

Owner:THE PROCTER & GAMBLE COMPANY

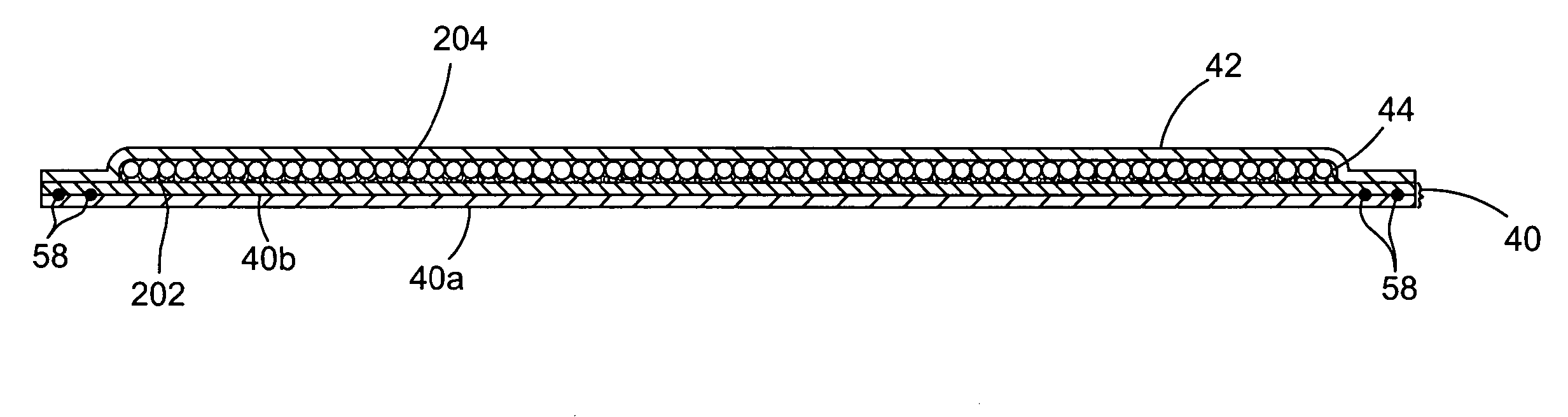

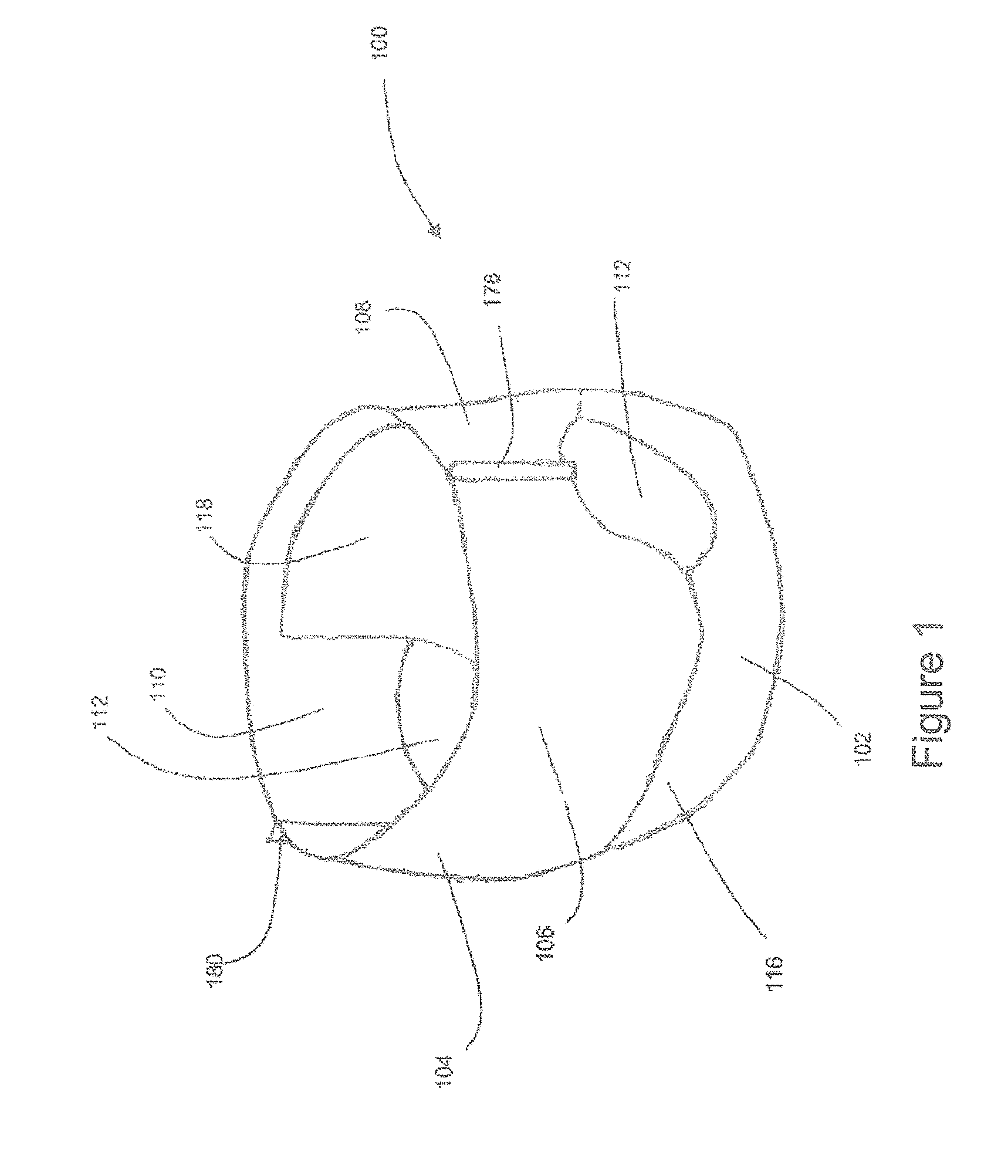

Stretchable absorbent article

An absorbent article having a stretchable substrate and an absorbent composite comprising a layer of adhesive composition in contact with the stretchable substrate. A layer of particulate superabsorbent material is applied to and held by the adhesive composition. The absorbent composite is secured to the substrate by the adhesive composition. The stretchable substrate has a recovery in at least one of the lateral direction and the longitudinal directions of the article as determined by an Elongation and Recovery Test, and the absorbent article has a recovery in the at least one of the lateral direction and the longitudinal direction as determined by the Elongation and Recovery Test that is at least about 60 percent of the recovery of the substrate in the at least one of the lateral direction and the longitudinal direction.

Owner:KIMBERLY-CLARK WORLDWIDE INC

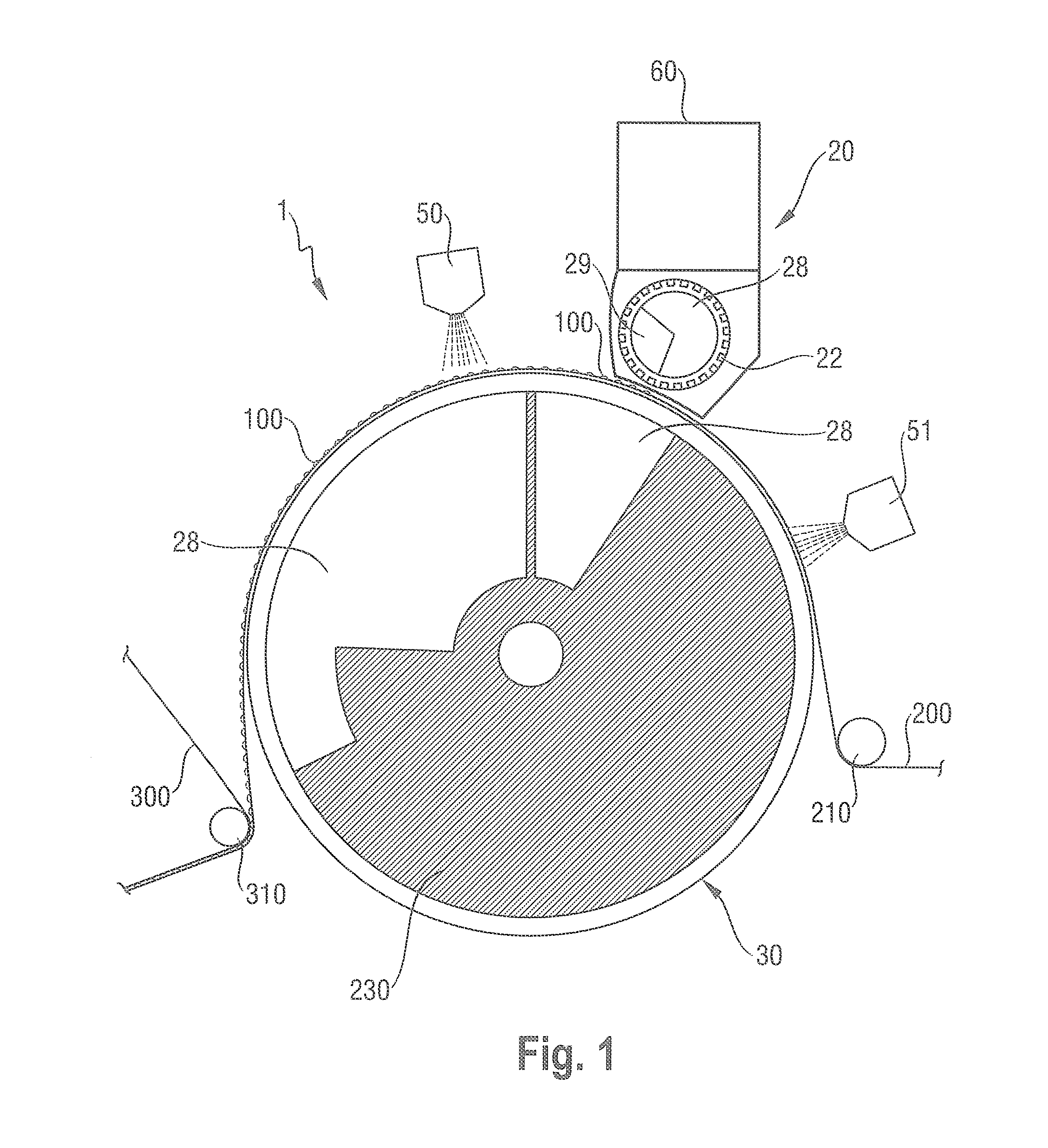

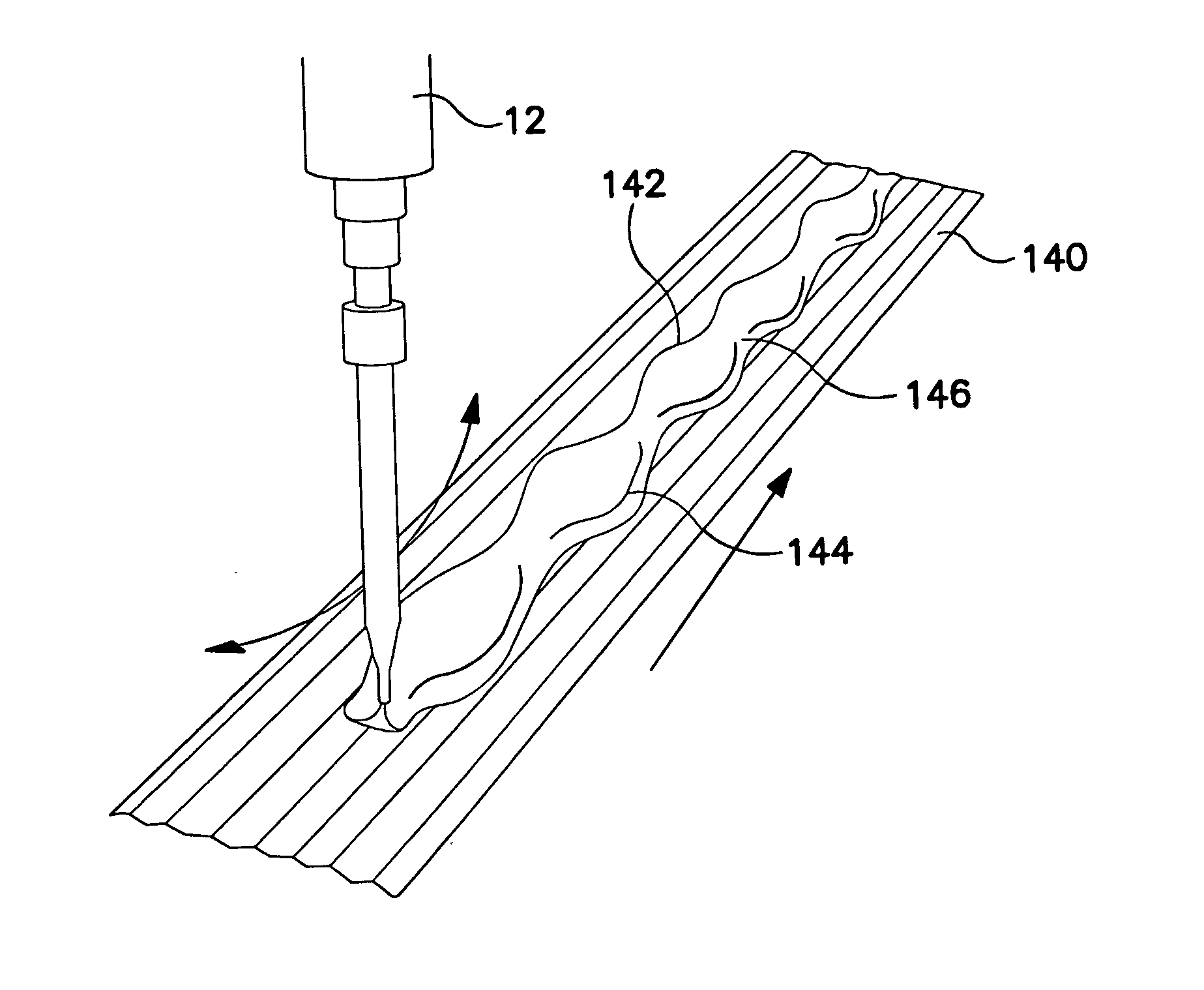

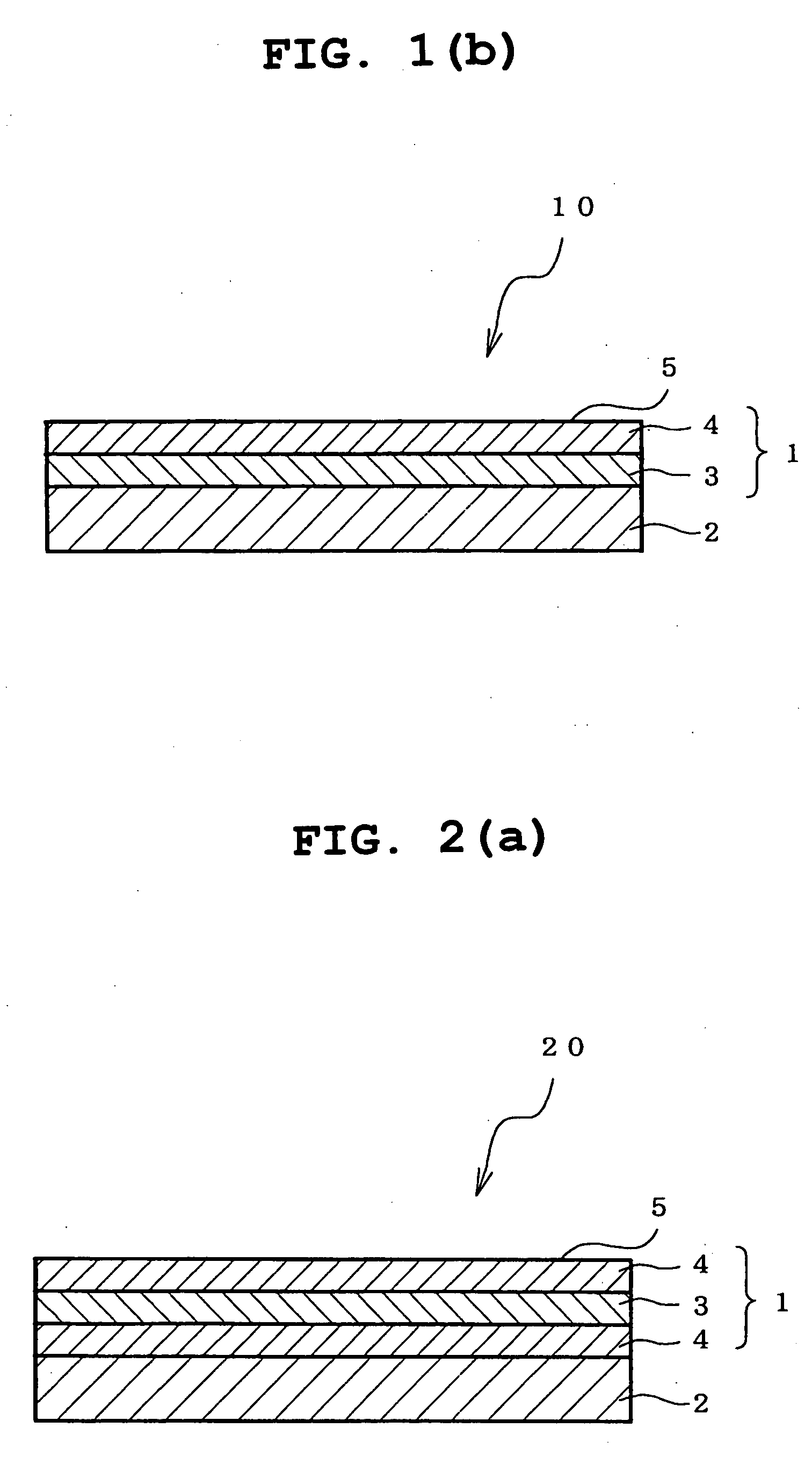

Use of swirl-like adhesive patterns in the formation of absorbent articles

Absorbent products are disclosed comprised of multiple components. At least two of the components are adhered together using an adhesive. In accordance with the present invention, the adhesive is applied in between the components according to a non-uniform pattern that varies as a function of distance. For example, the adhesive pattern may change according to at least one of pattern breadth or adhesive dose in weight per unit area. In one particular embodiment, the pattern contains a swirl-like pattern containing a plurality of loops. Over a particular distance, a change may occur in the size of the loops, in the density of the loops, and / or in alternating between loops and a linear bead. In this manner, placement of the adhesive is carefully controlled in order to counteract mechanical stresses that are placed on the absorbent product during use.

Owner:KIMBERLY-CLARK WORLDWIDE INC

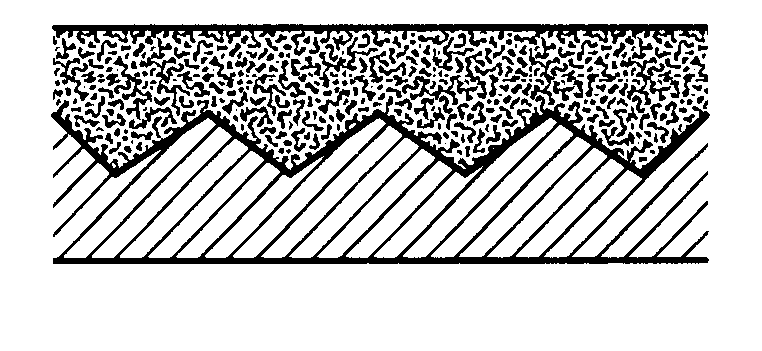

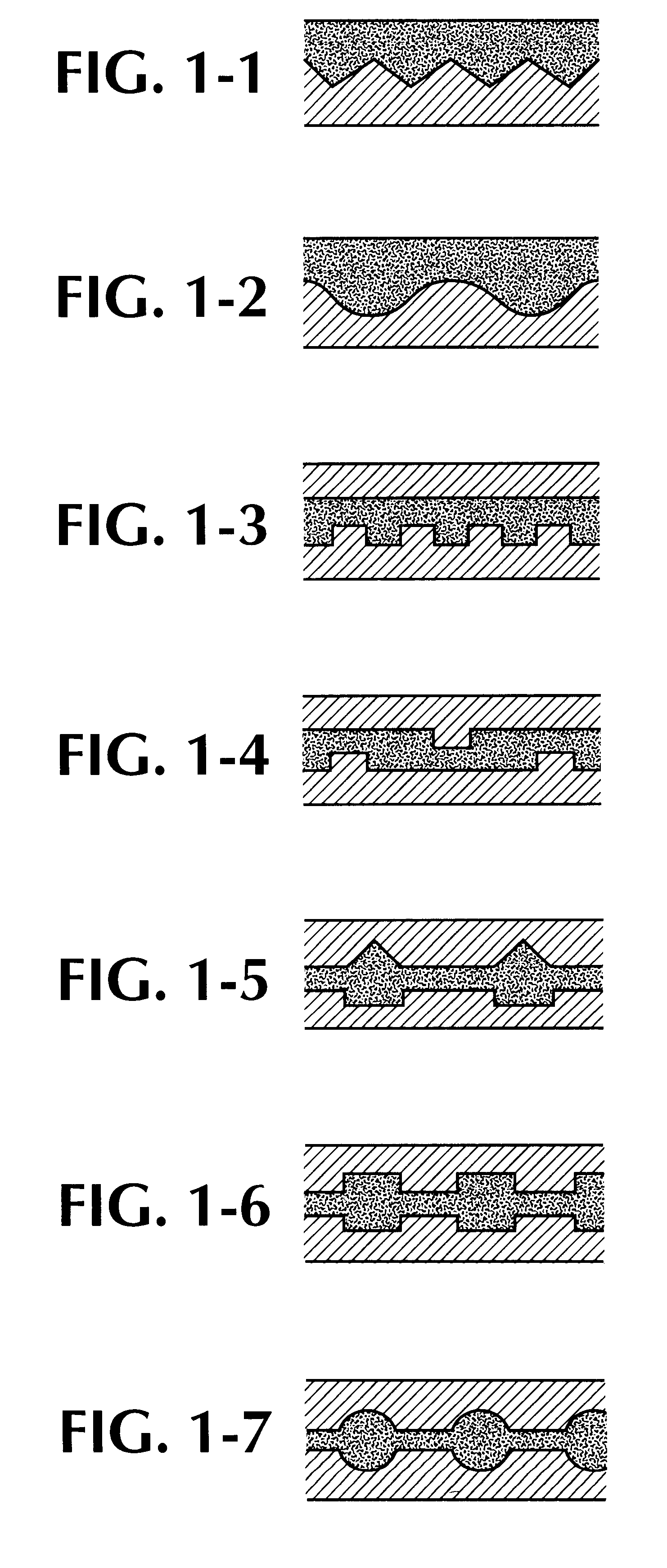

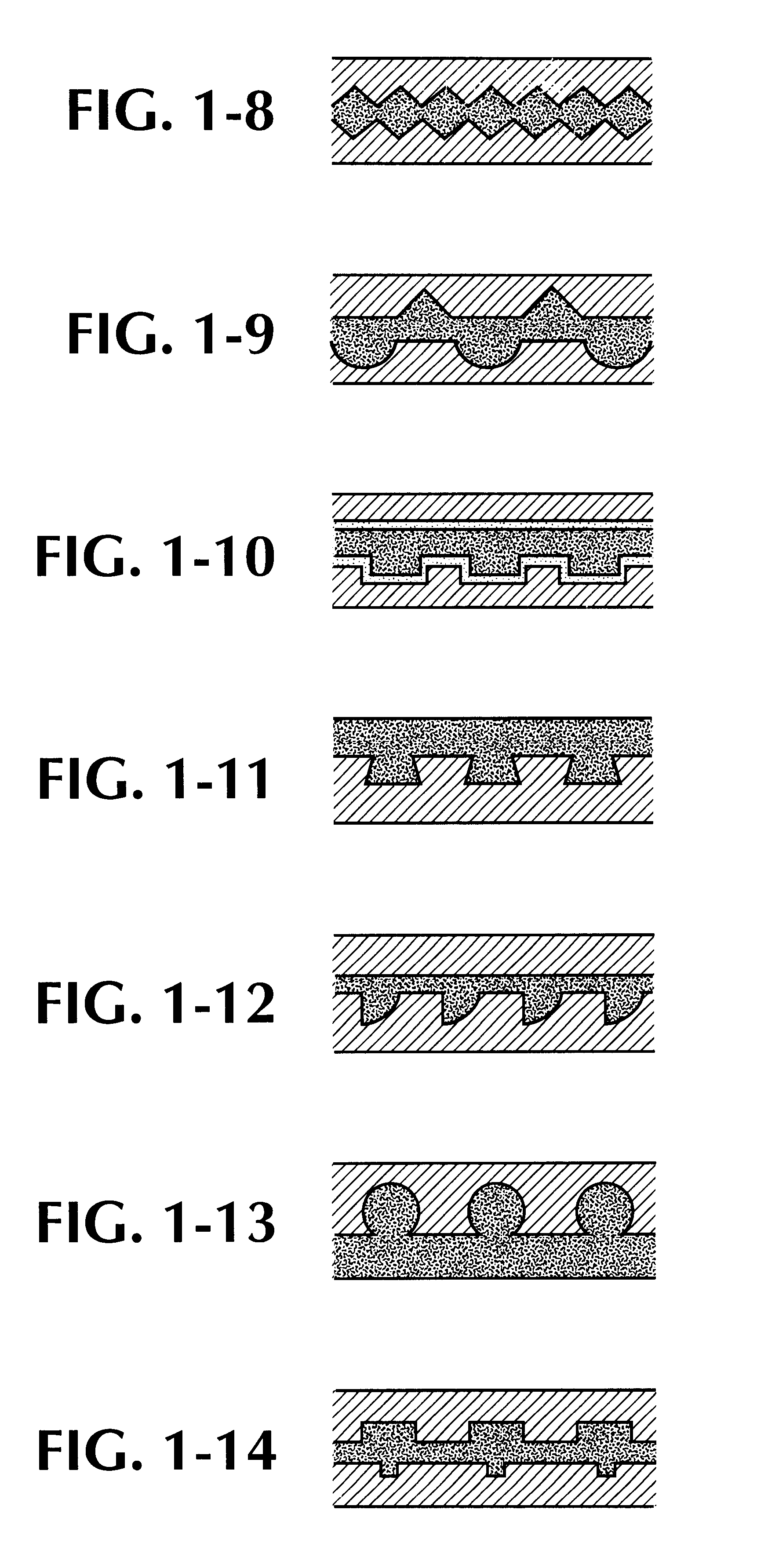

Method for preparing microstructured laminating adhesive articles

ActiveUS20070212535A1Low hazeLow transparencyAdhesive articlesOptical articlesPolymer sciencePressure sensitive

A method of making a microstructured adhesive article that includes (a) providing an article comprising a crosslinked pressure sensitive adhesive layer disposed on a backing; and (b) embossing the surface of the crosslinked pressure sensitive adhesive layer to form a crosslinked pressure sensitive adhesive layer having a microstructured adhesive surface.

Owner:3M INNOVATIVE PROPERTIES CO

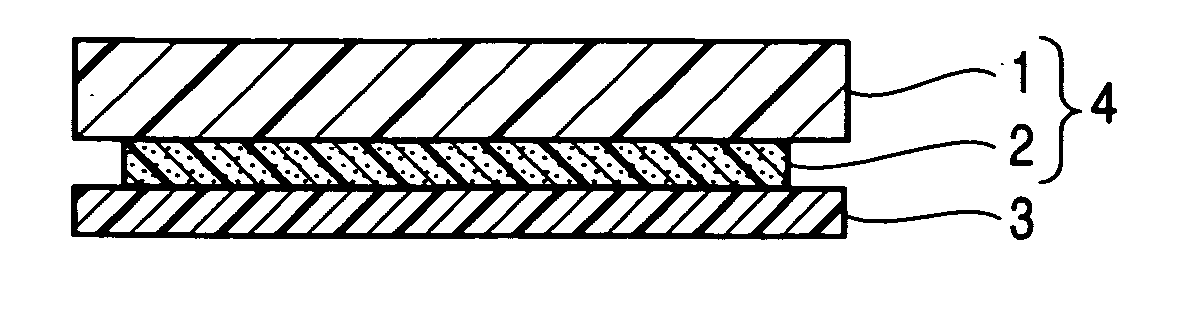

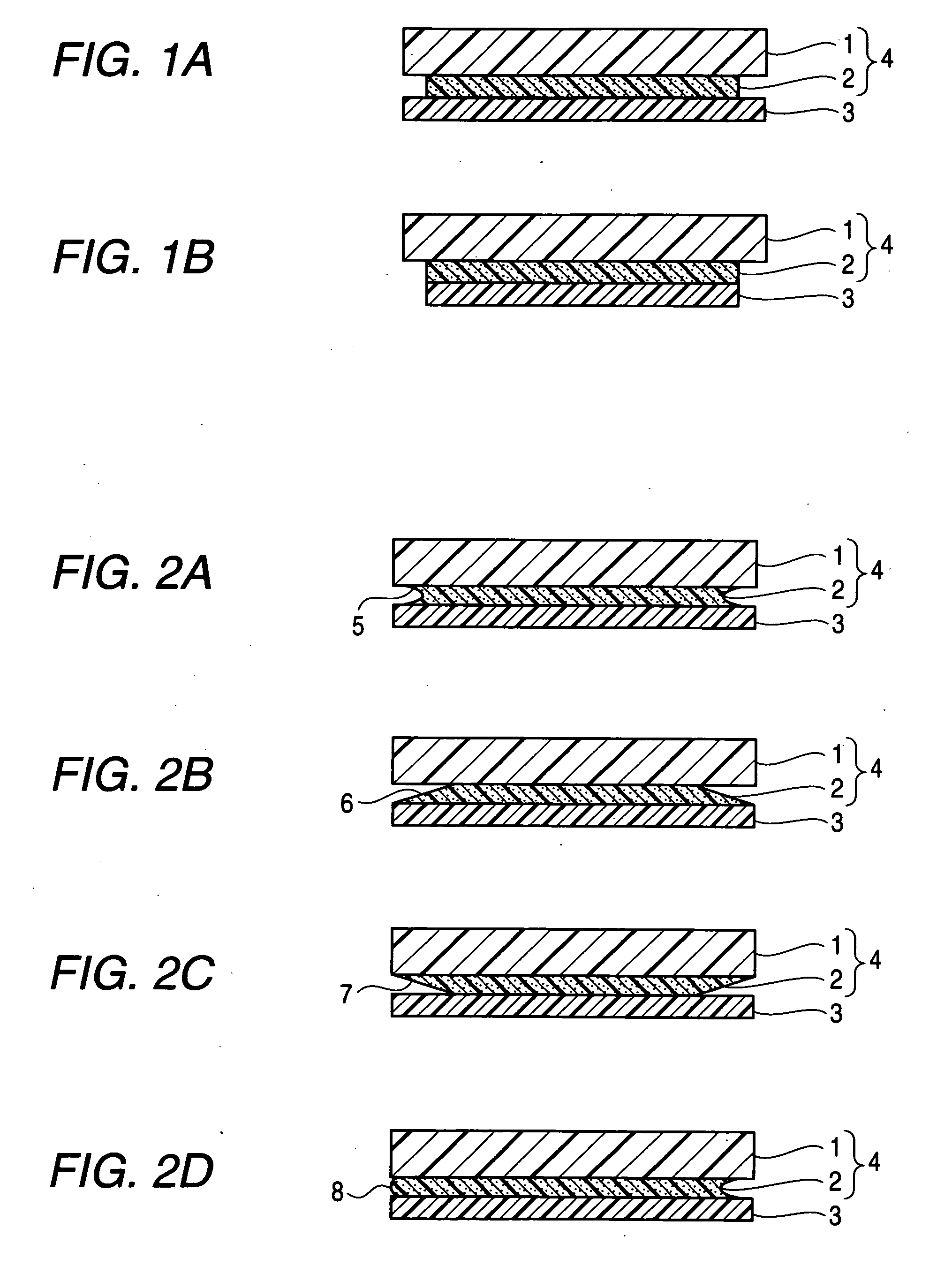

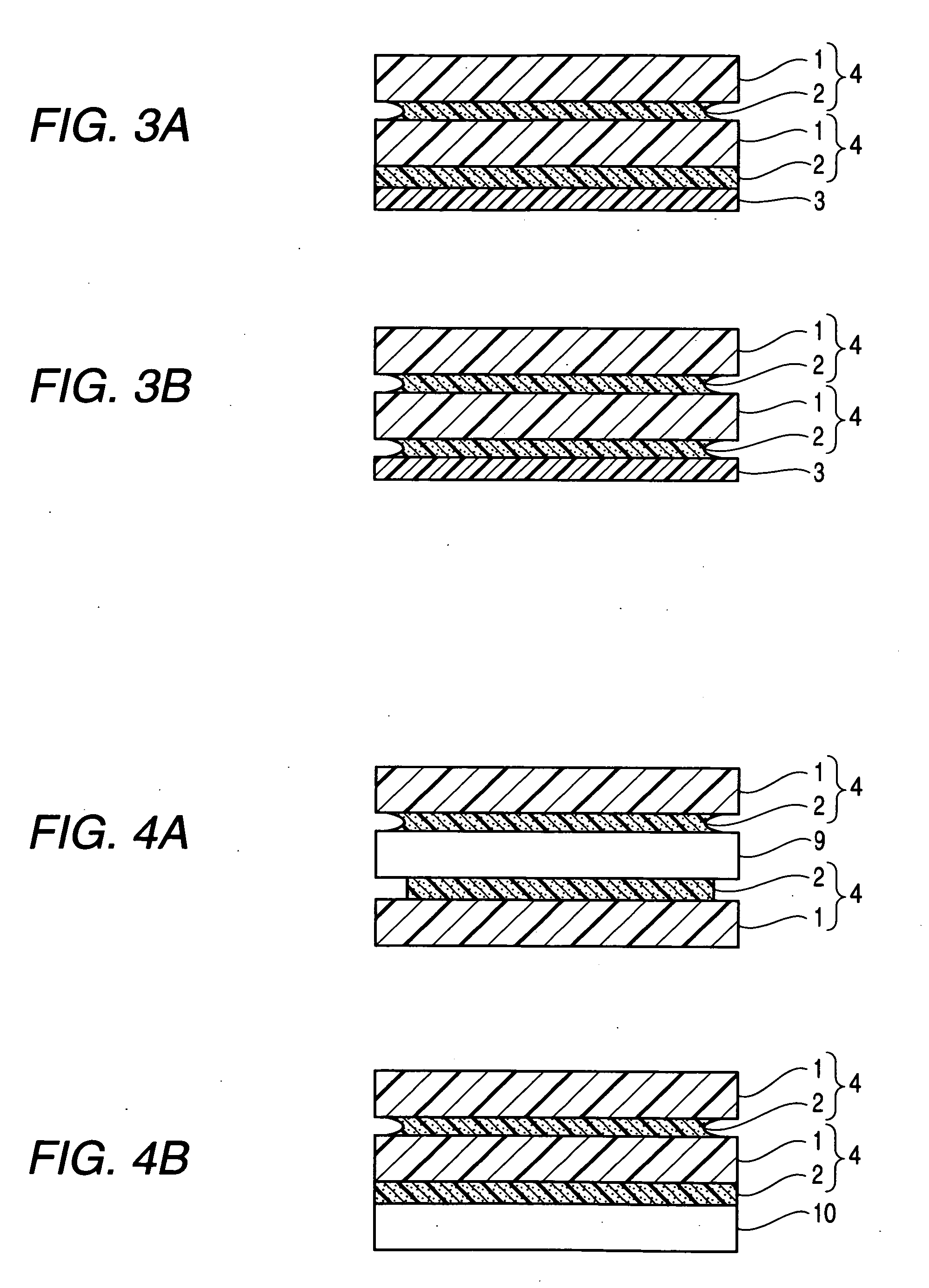

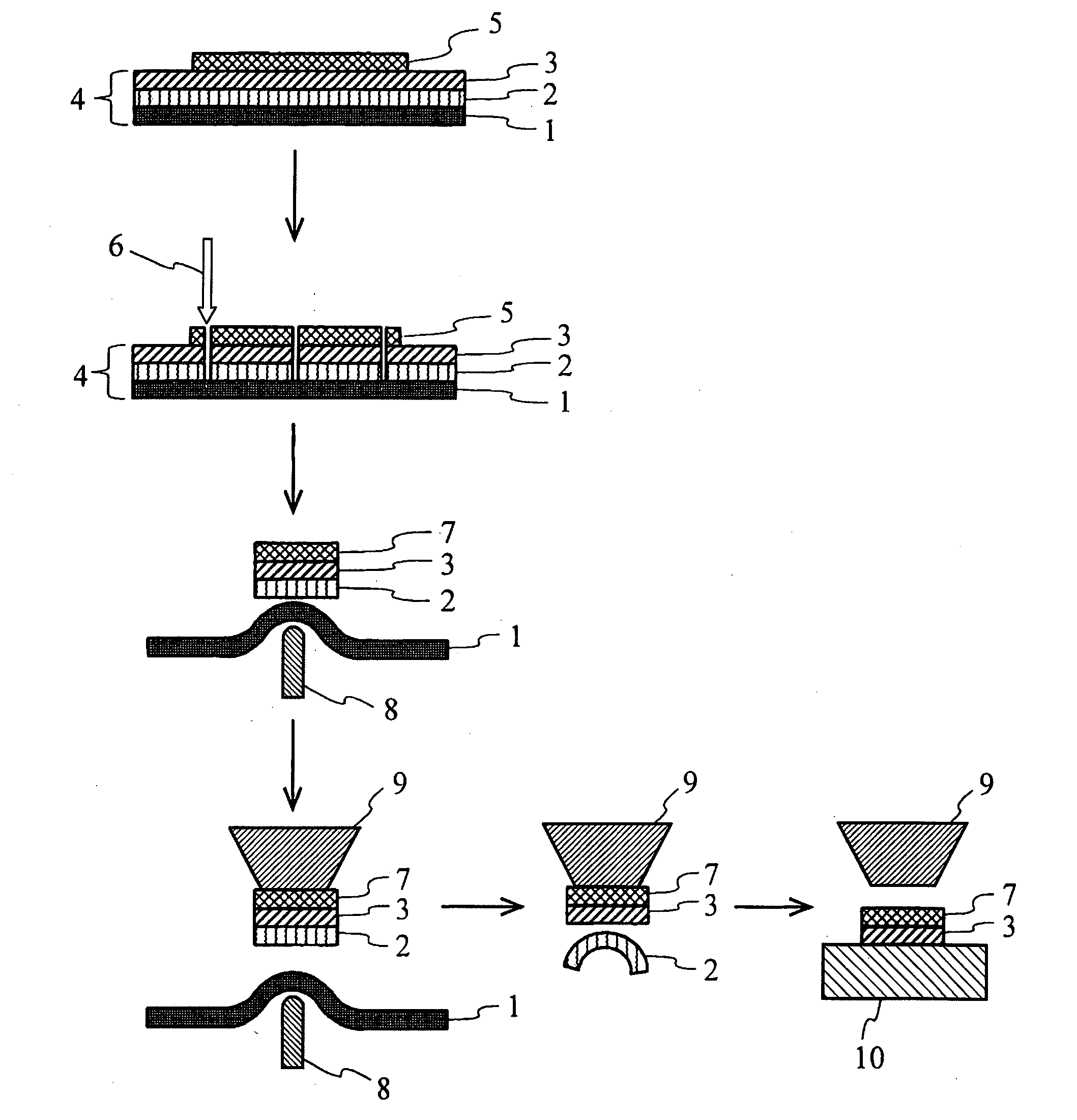

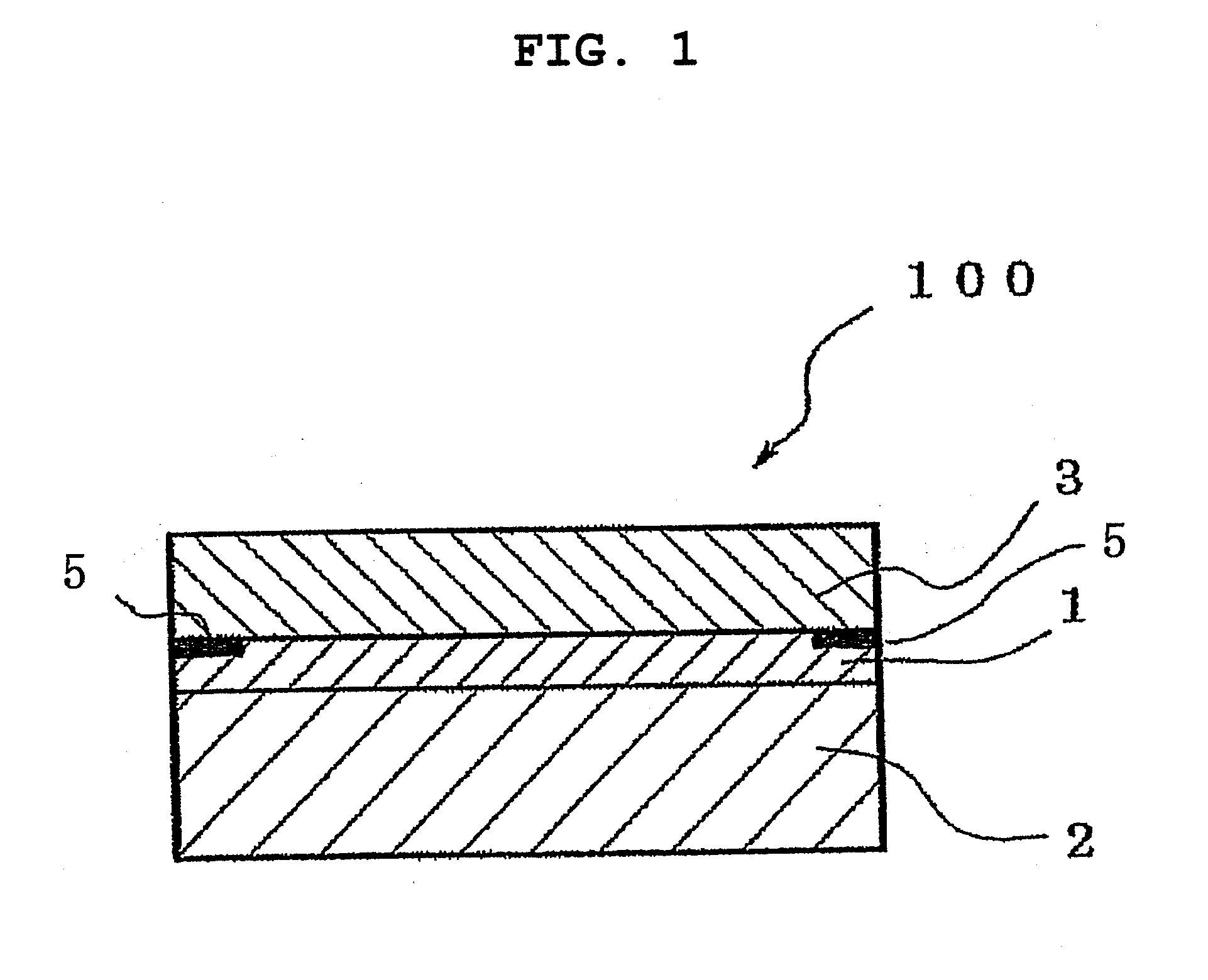

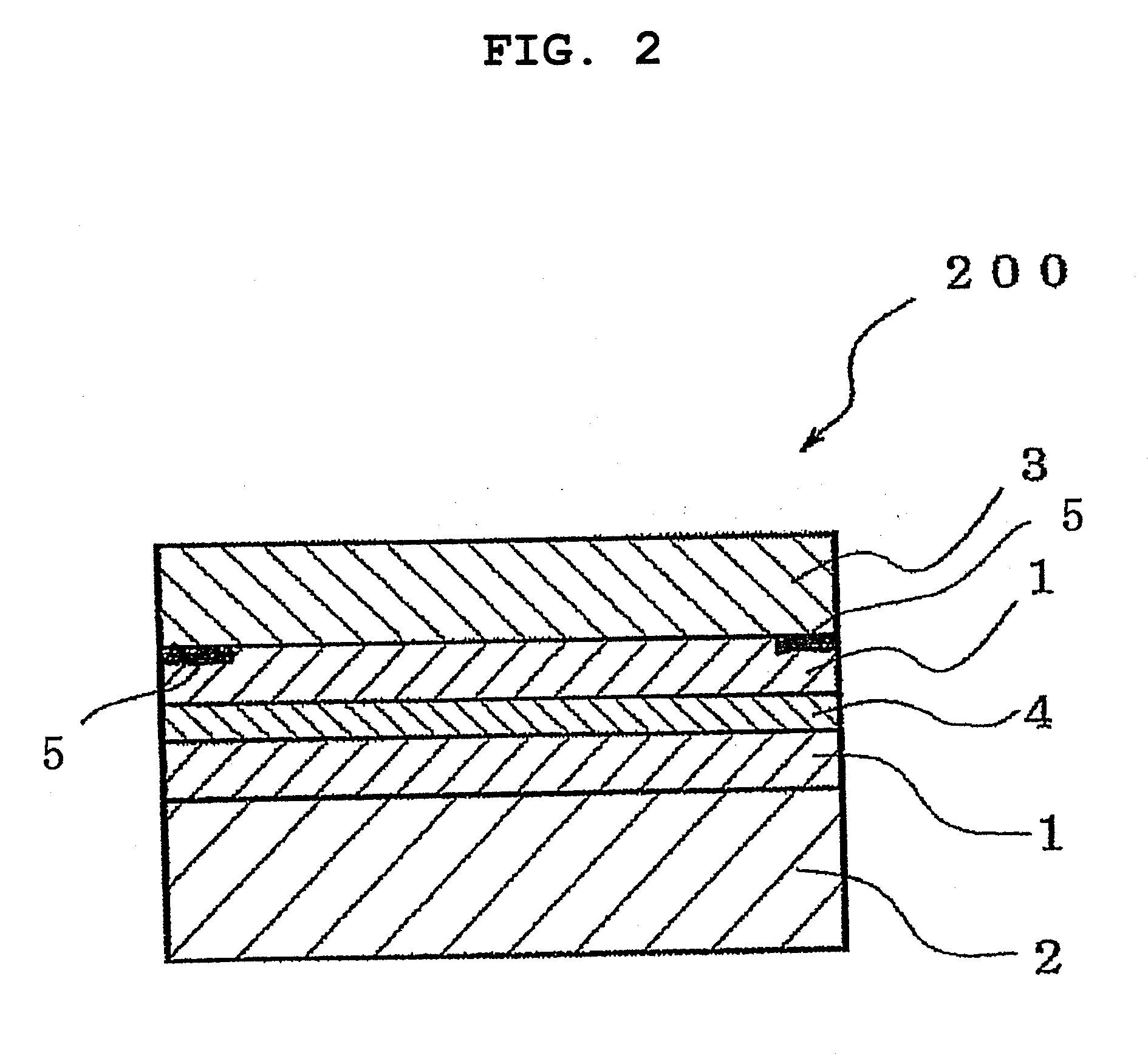

Die attach film-provided dicing tape and production process of semiconductor device

InactiveUS20100279491A1Efficient productionImprove productivityAdhesive articlesSynthetic resin layered productsDicing tapeDevice material

The present invention provides a die attach film-provided dicing tape, which includes a dicing tape, a supporting tape and a die attach film laminated in this order, wherein the supporting tape is a tape having a self-rolling peelability, and a process for producing a semiconductor device by using the die attach film-provided dicing tape.

Owner:NITTO DENKO CORP

(Meth)acrylate block copolymer pressure sensitive adhesives

Articles are provided that include an optical film and an optically clear pressure sensitive adhesive layer on at least one outer surface of the optical film. Additionally, articles are provided that include a pressure sensitive adhesive layer that resists bubble formation when adhered to an outgassing substrate. The pressure sensitive adhesive layer in the various articles contain a (meth)acrylate block copolymer.

Owner:3M INNOVATIVE PROPERTIES CO

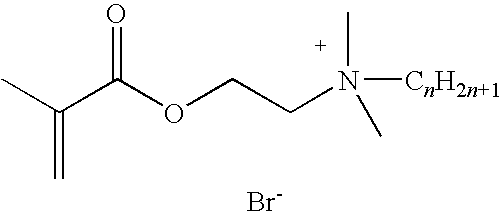

Antimicrobial Adhesive Films

A multi-layer film for reducing microbial contamination on a surface. The multi-layer film can include a core layer having a first surface and a second surface opposite the first surface, an adhesive layer disposed adjacent the first surface of the core layer, and an antimicrobial layer disposed adjacent the second surface. The antimicrobial layer can include a cross-linked matrix and an antimicrobial agent dispersed within the cross-linked matrix, where the cross-linked matrix is derived from a polymerizable precursor comprising a material selected from the group consisting of a polymerizable monomer, a polymerizable polymer having a molecular weight of about 1,000 or less, and combinations thereof.

Owner:3M INNOVATIVE PROPERTIES CO

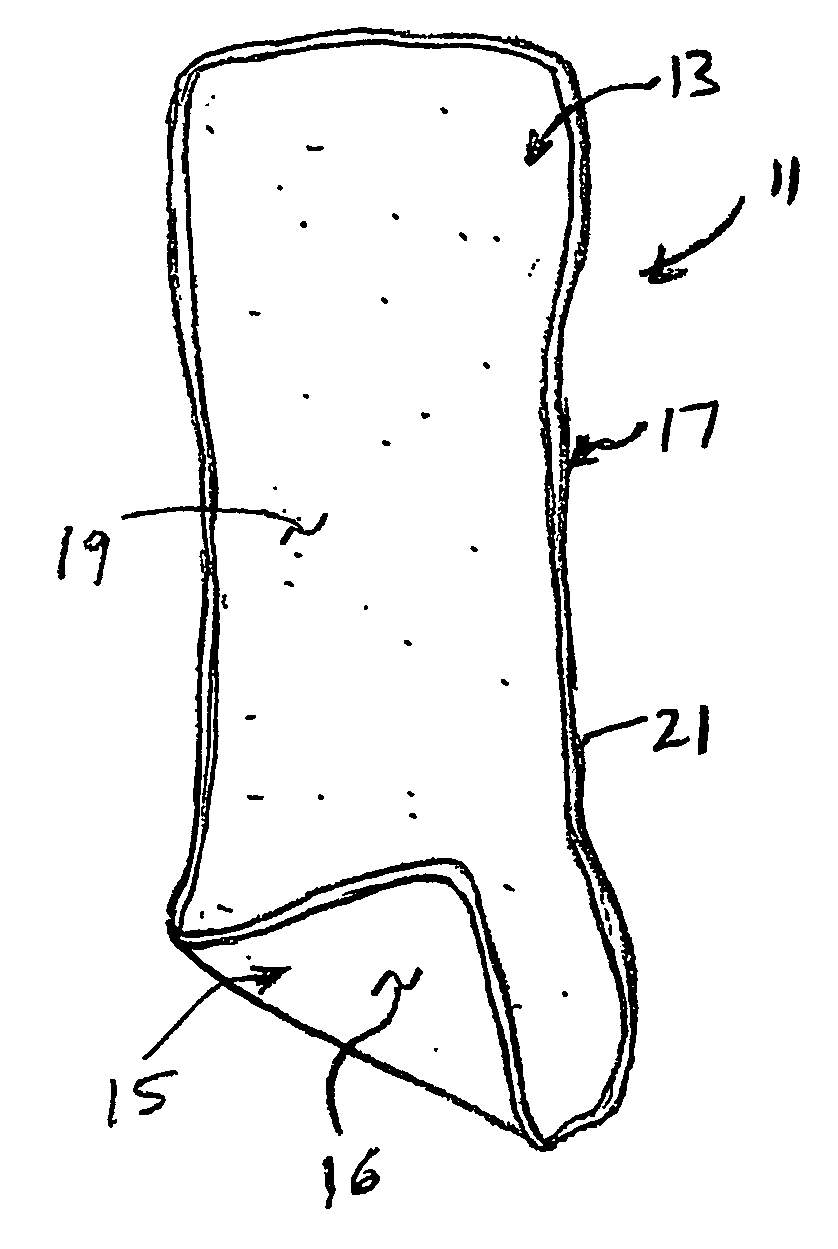

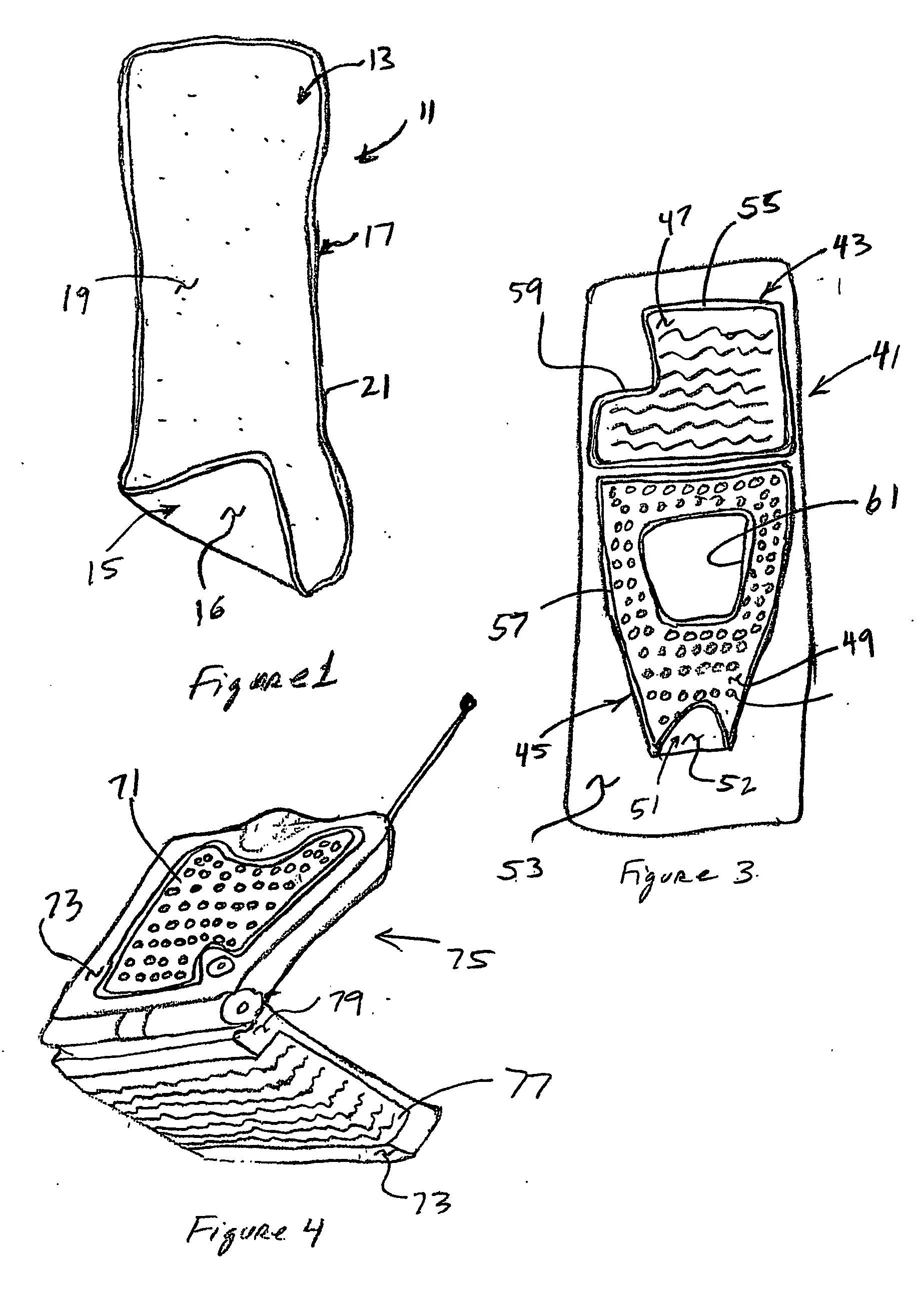

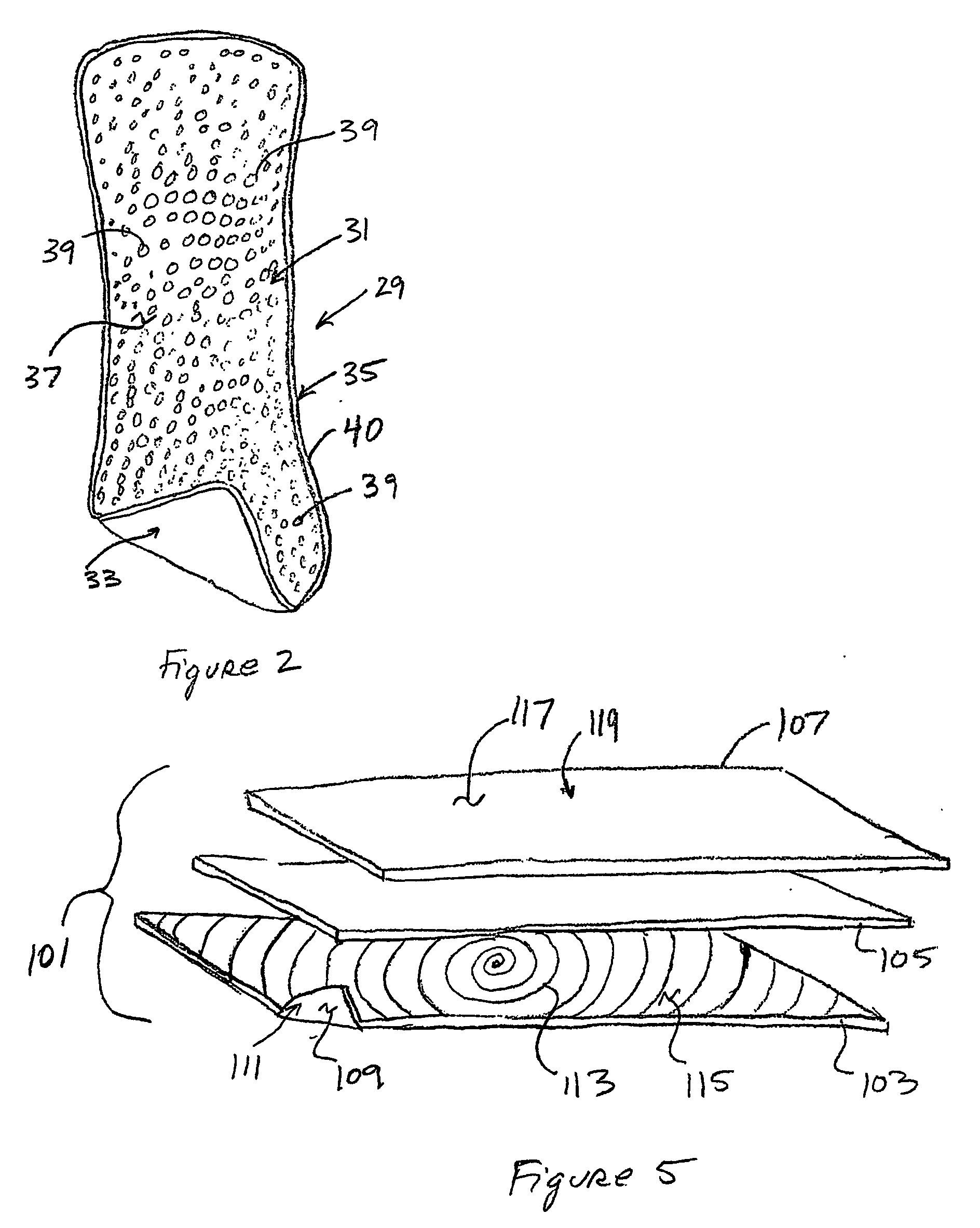

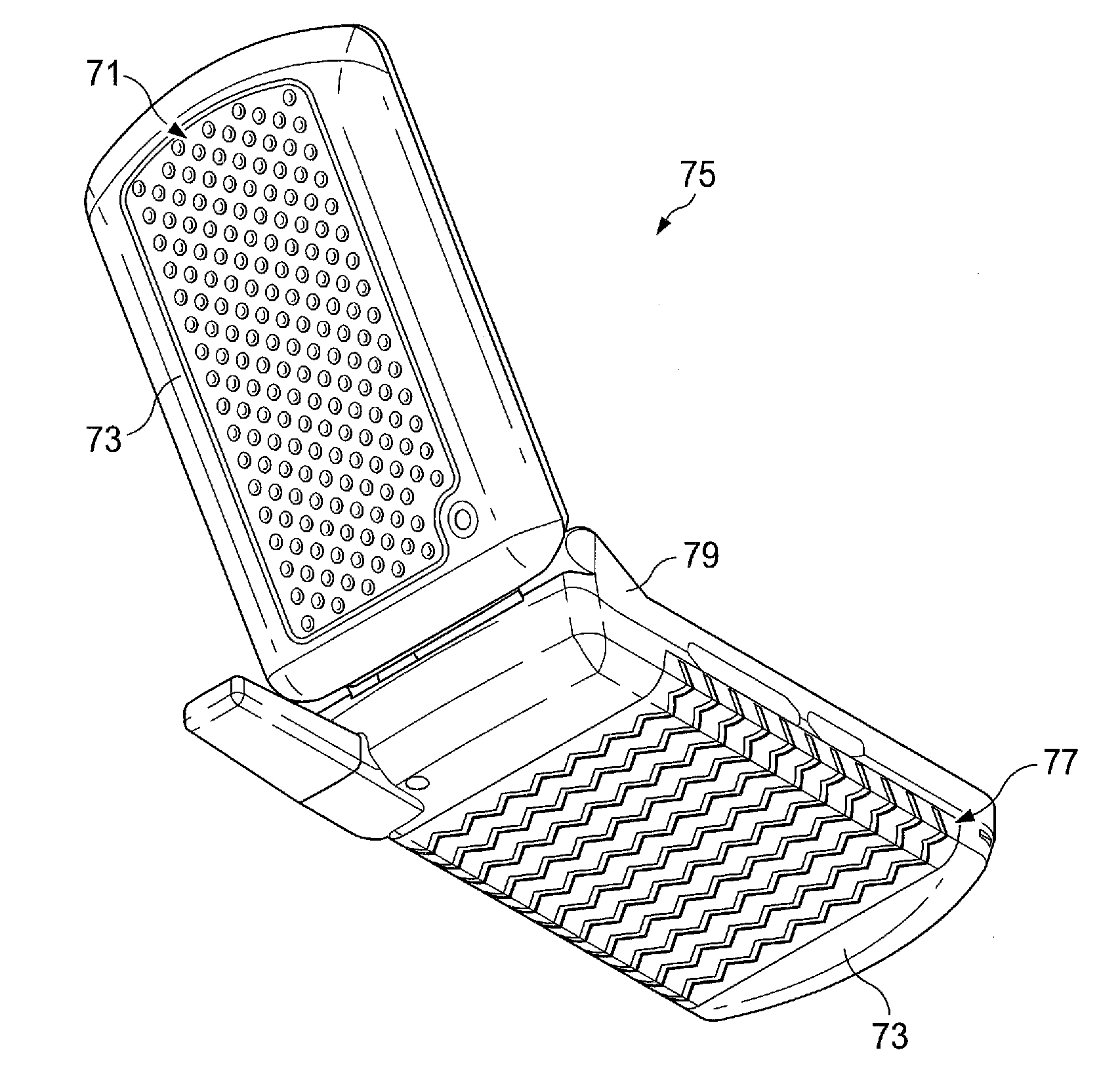

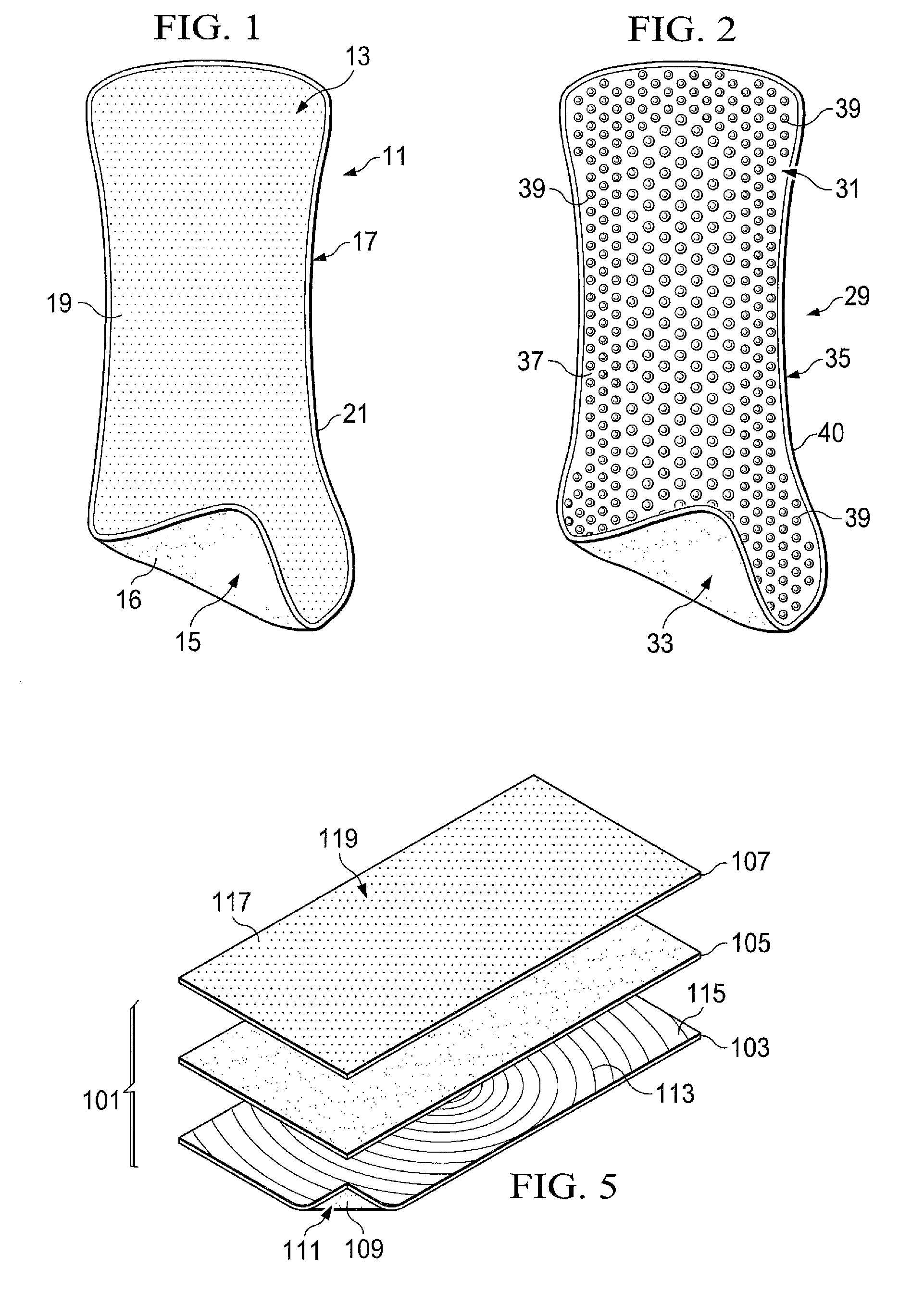

Adhesive backed skins and grips for handheld devices

A skin (11) for use with a handheld electronic device is disclosed. The skin (11) includes a decorative layer, an anti-slip layer adhered over the decorative layer, and an adhesive layer disposed between the decorative layer and the anti-slip layer. The anti-slip layer has a surface finish (19) having a high coefficient of friction. The skin (11) is attached to the handheld electronic device by a layer of adhesive (16) on the back of the decorative layer. The skin (11) is selectively shapped to conform to the contours, shape, and components of the handheld electronic device. The skin (11) provides anti-slip and shock absorption fucntionalities to the handheld electronic device, but does not prevent or impede the handheld electronic device from mating with or connecting to corresponding accessory components.

Owner:ANTONINI FRED A

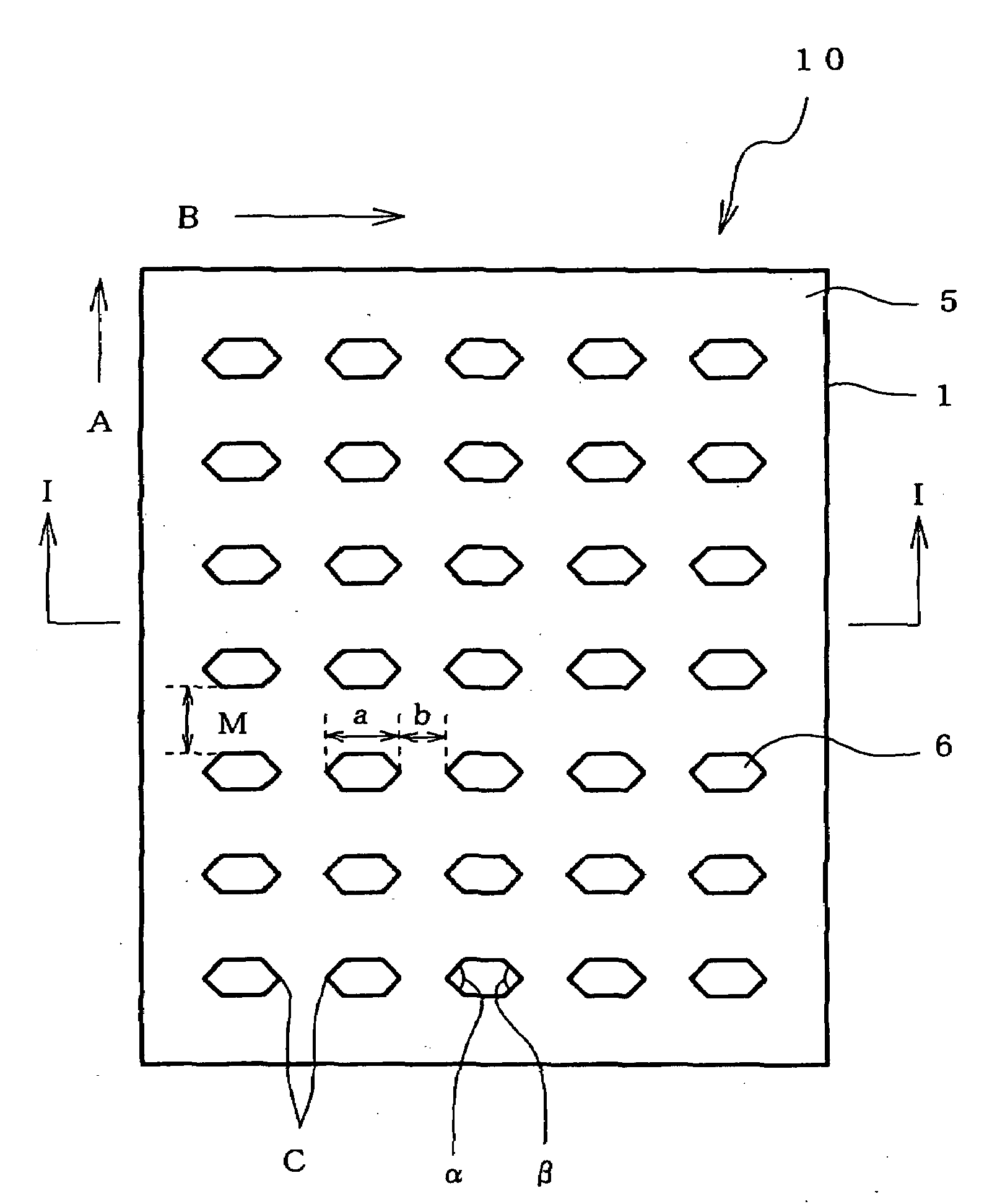

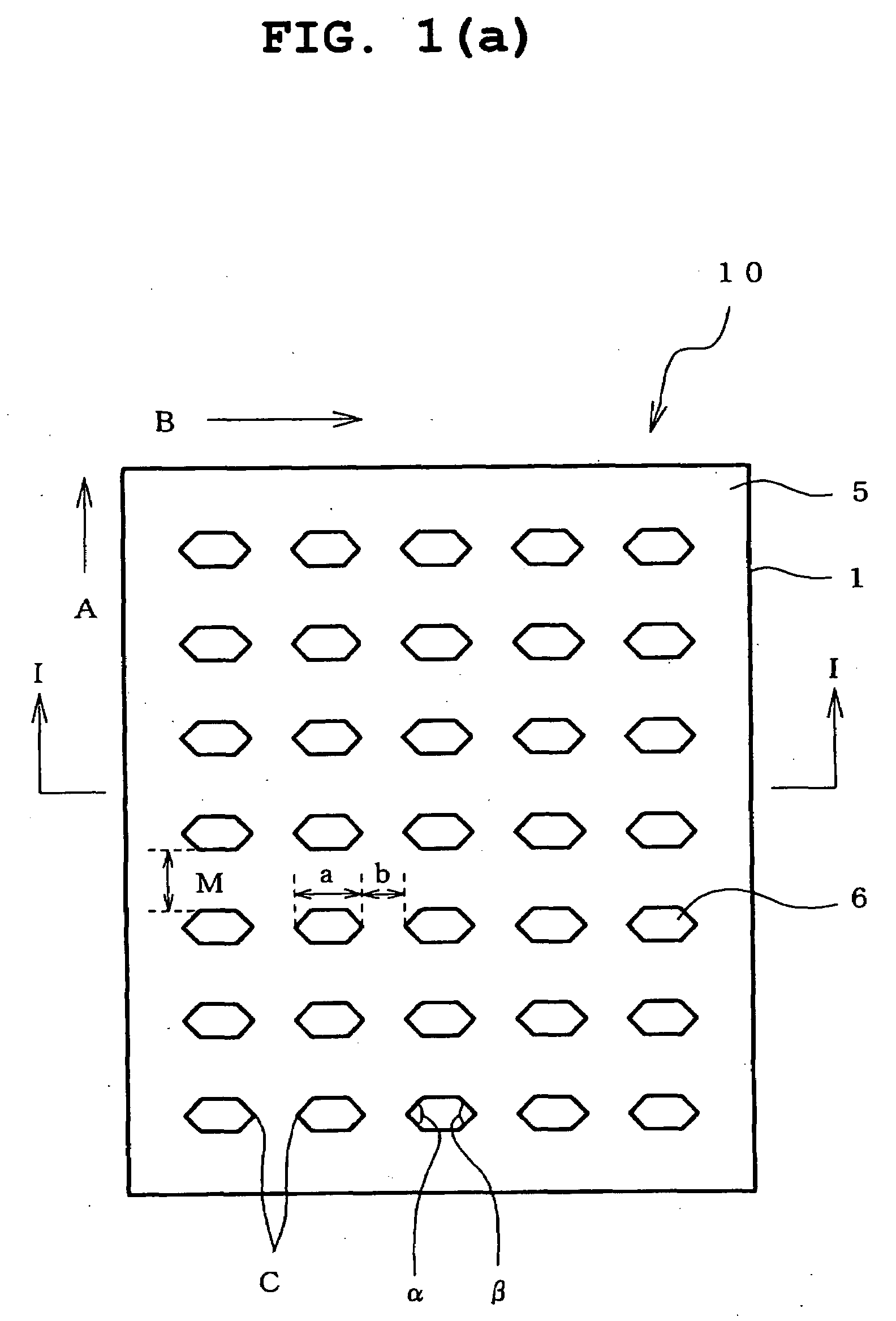

Medical adhesive tape or sheet

InactiveUS20080095979A1Reduce void ratioImprove textureLayered productsAdhesive articlesAdhesive beltFiber diameter

The present invention provides a medical adhesive tape or sheet having a superior texture, which can be easily cut with hands to form a good cross-section. The medical adhesive tape or sheet of the present invention is characterized in that it comprises a support, which is a multi-layer laminate of non-woven fabrics having different fiber diameters and treated with a sealer, and an adhesive layer laminated on one surface of the support, wherein at least the support is perforated, the perforation forms plural pores sequenced at least in one direction, the ratio (b / a) of interval a of the perforated part and interval b of the non-perforated part in one direction is 1-1.5, and the ratio (c / d) of the tensile strength c in the longitudinal direction and the tensile strength d in the width direction is 0.8-1.7. Consequently, a medical adhesive tape or sheet having a superior texture, which can be easily cut with hands to form a good cross-section without using a cutting tool such as scissors and the like is provided.

Owner:NITTO DENKO CORP

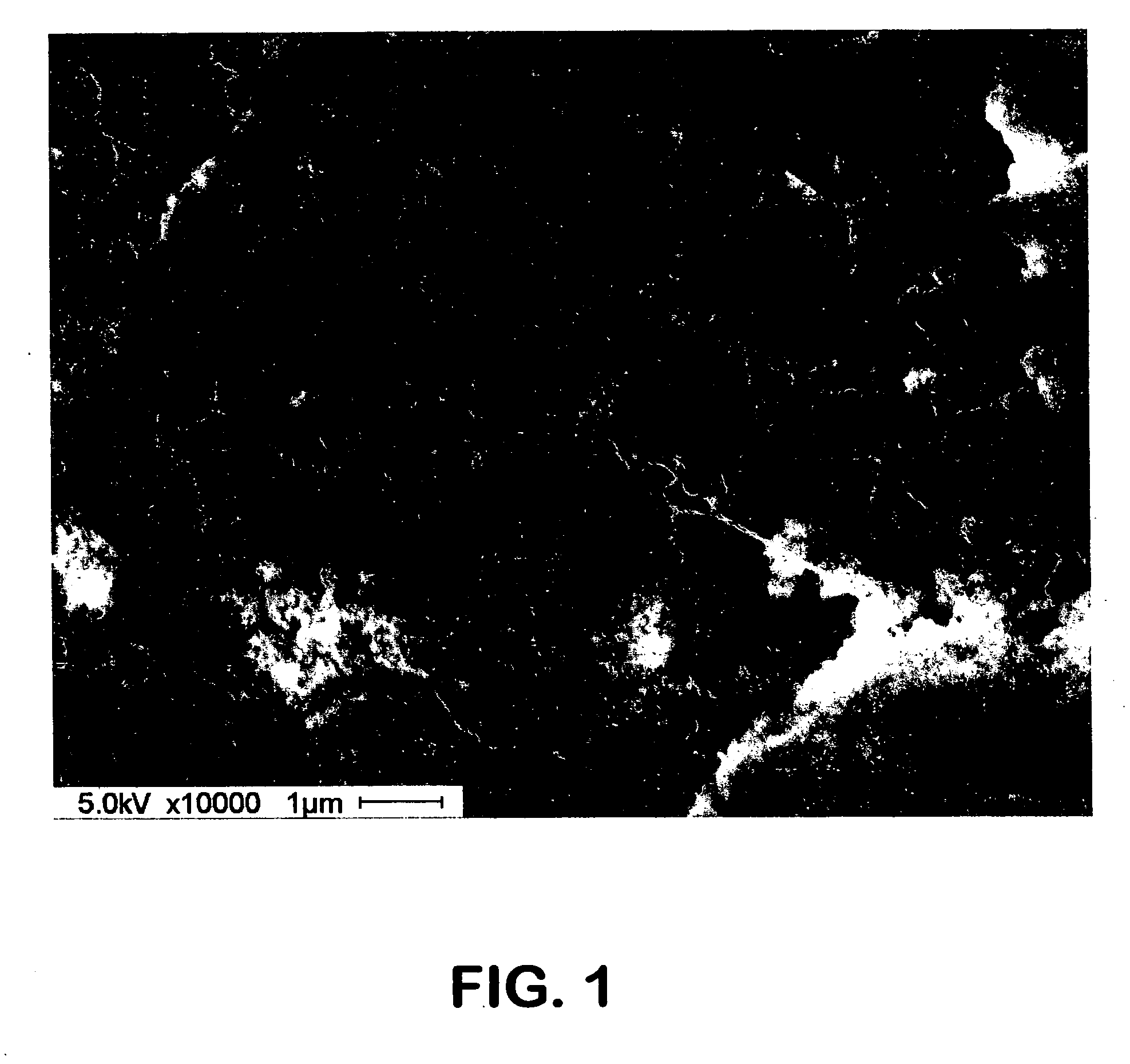

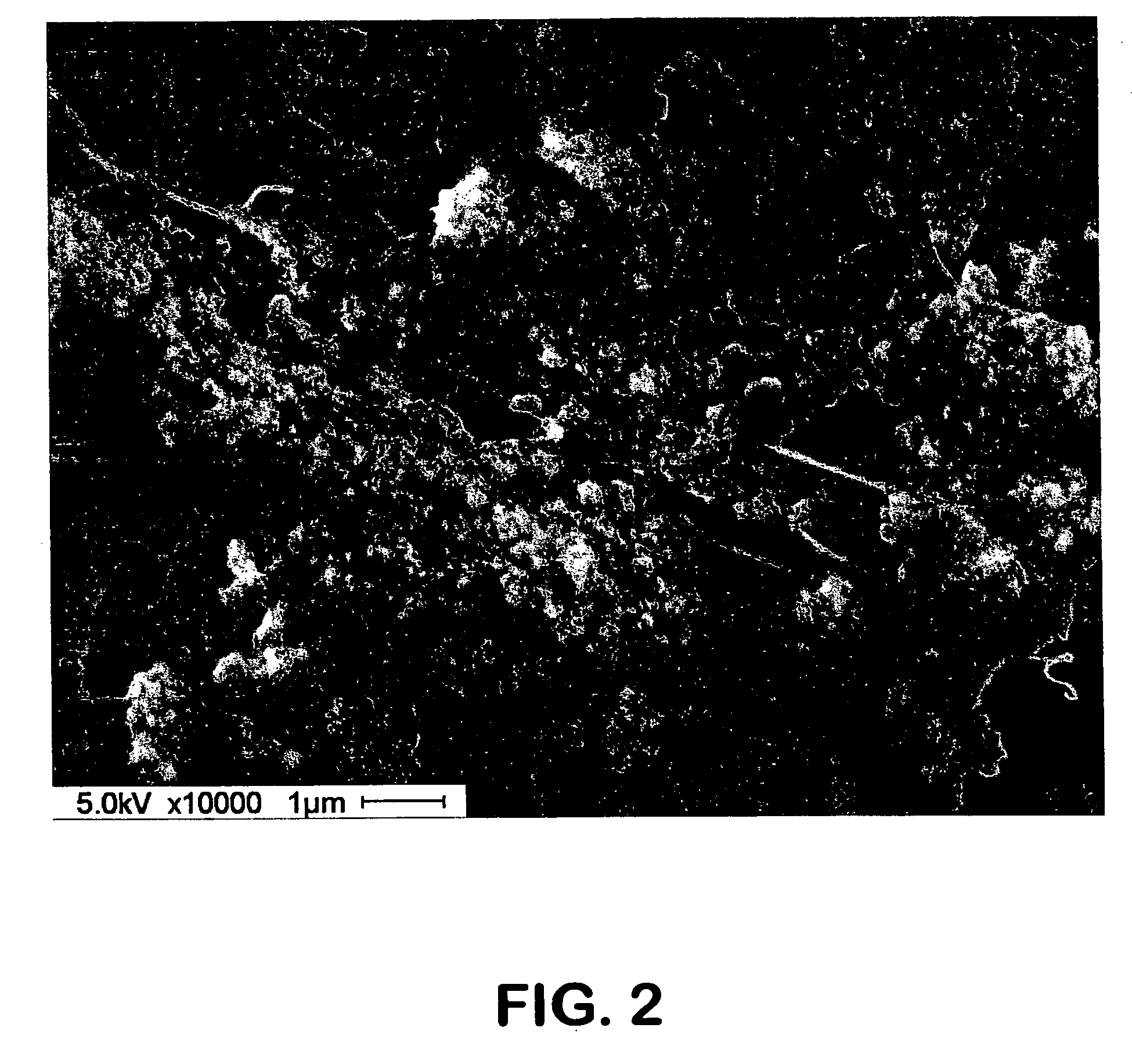

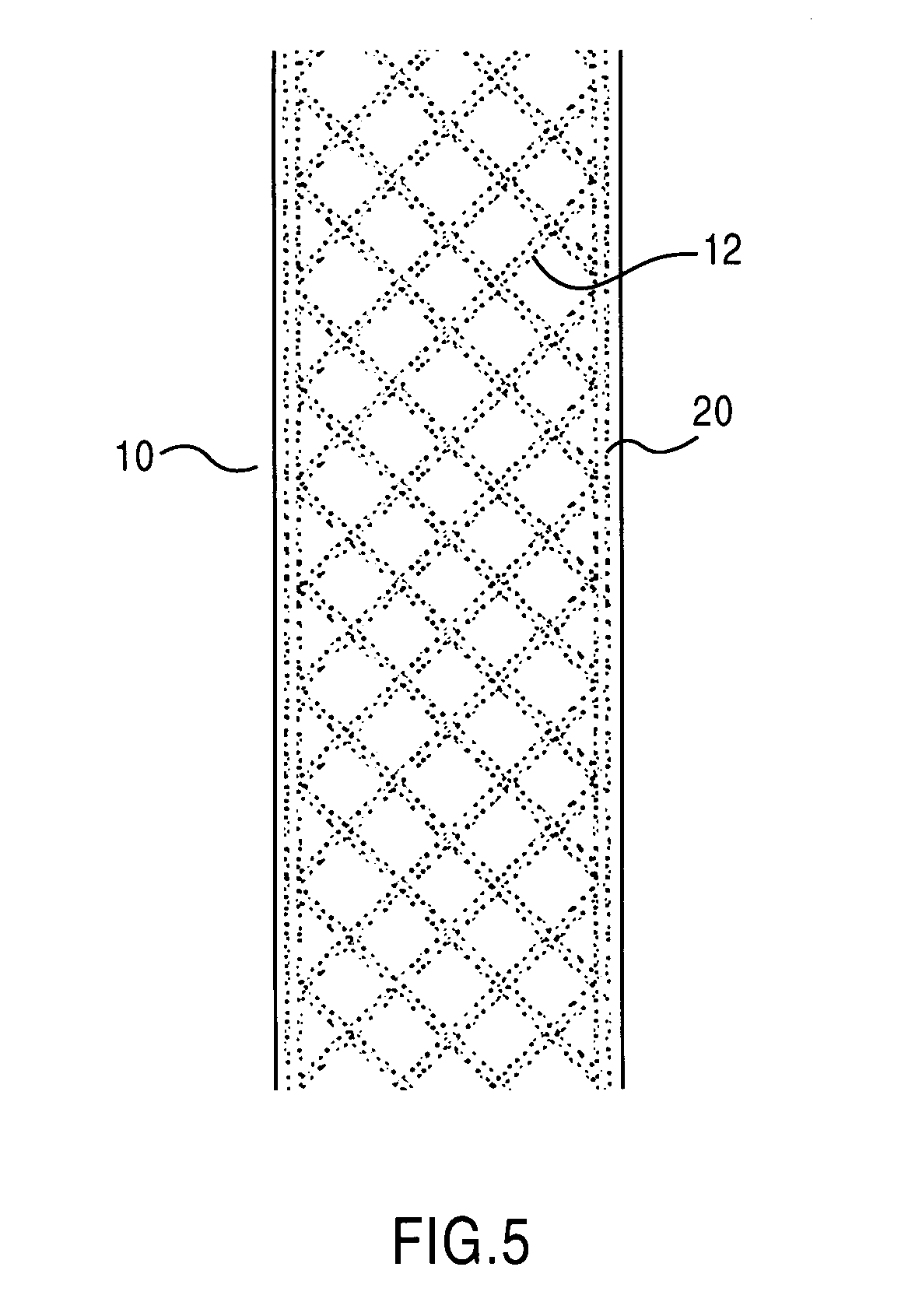

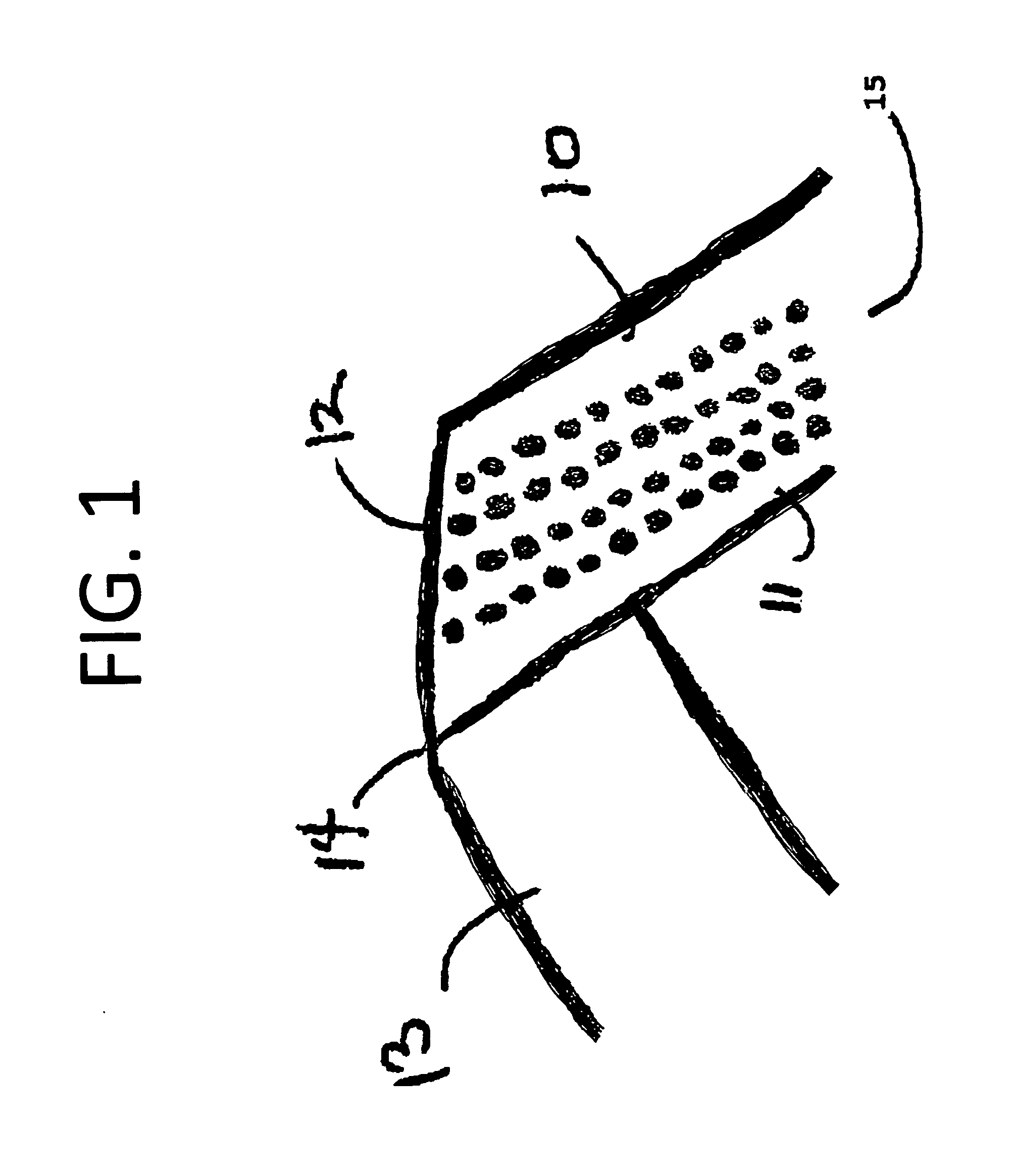

Patterning on surface with high thermal conductivity materials

ActiveUS20060234576A1Improve thermal conductivityHigh resistivityAdhesive articlesPaper/cardboardNanometreThermal transmittance

The present invention provides for high thermal conductivity paper that comprises a host matrix (10), and high thermal conductivity materials (12) added to a surface of the host matrix in a specific pattern (12). The high thermal conductivity materials are comprised of one or more of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers. In particular embodiments the specific pattern comprises one or more of a grid, edging, banding centering and combinations thereof and the high thermal conductivity materials cover 15-55% of the surface of the host matrix. Multiple surfaces, including sub layers my have patterning.

Owner:SIEMENS ENERGY INC

Pressure-sensitive adhesives having microstructured surfaces

InactiveUS6838150B2Reduced constantReduce adhesionAdhesive articlesRecord information storagePressure sensitiveChemistry

The invention provides pressure-sensitive adhesive (PSA) coated articles, including tapes and transfer coatings, having microstructured surfaces and methods of making pressure-sensitive adhesive articles bearing such microstructured surfaces. The performance properties of the pressure-sensitive adhesive articles can be tailored by independently varying the microstructure and the rheological properties of the pressure-sensitive adhesive.

Owner:3M INNOVATIVE PROPERTIES CO

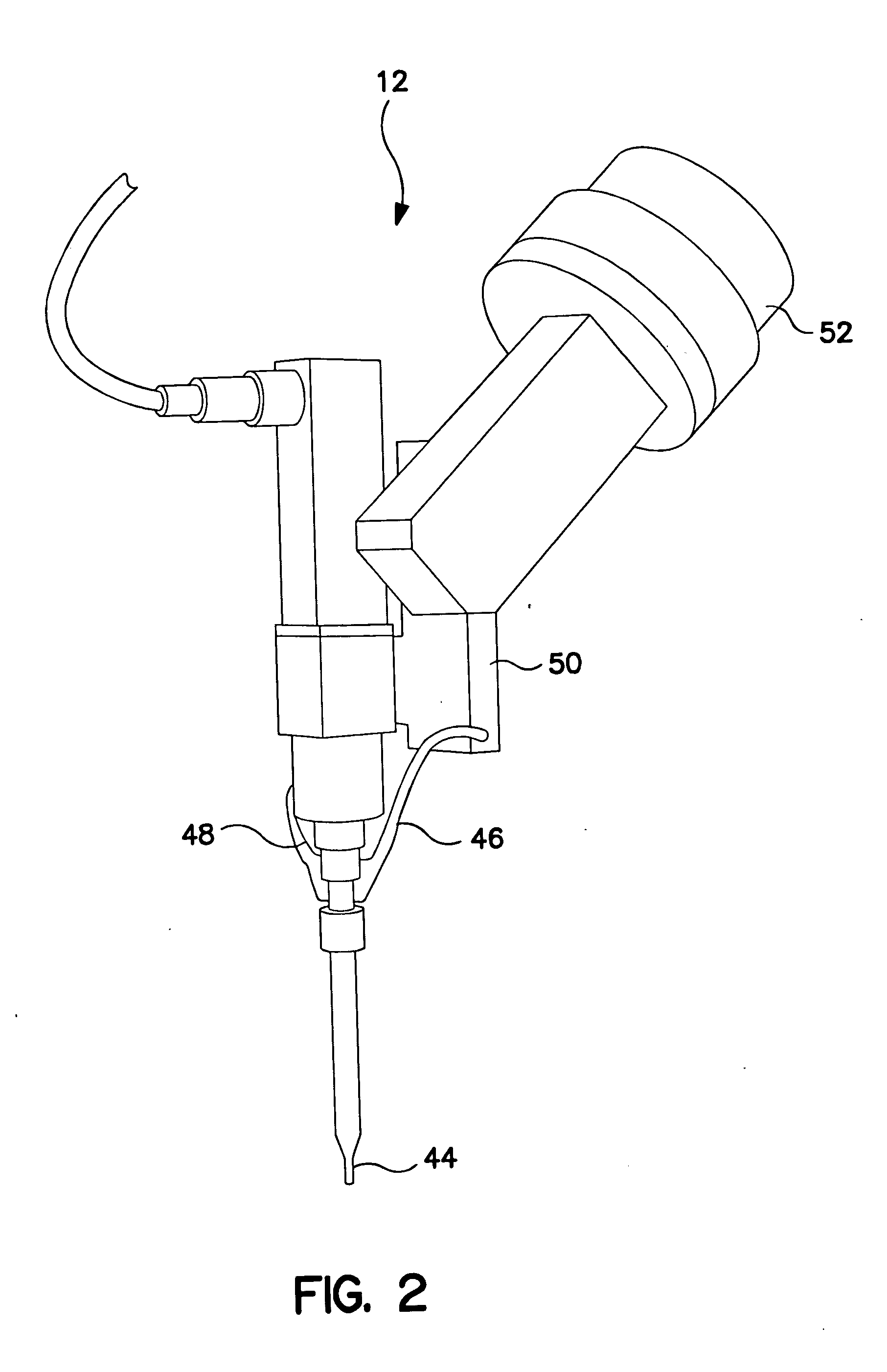

Method and apparatus for applying an elastic material to a moving substrate in a curved path

Owner:PROCTER & GAMBLE CO

Under roof peel and stick tile underlayment

InactiveUS20060243388A1Easy and hassle-free field applicationAdhesive processesAdhesive articlesEngineeringRelease liner

An under roof peel-and-stick tile underlayment, having a core or substrate having an upper and lower surface. On the lower surface of the substrate, an adhesive compound is layered and then covered with a release liner. On the selvage edge of the upper surface of the substrate, an adhesive coating is layered and then covered with a top release liner. After the underlayment is adhered to a roof surface, ceramic tiles, such as Spanish-style tiles are adhered on the upper surface.

Owner:BUILDING MATERIALS INVESTMENT

Adhesive backed skins and grips for handheld devices

A skin (11) for use with a handheld electronic device is disclosed. The skin (11) includes a decorative layer, an anti-slip layer adhered over the decorative layer, and an adhesive layer disposed between the decorative layer and the anti-slip layer. The anti-slip layer has a surface finish (19) having a high coefficient of friction. The skin (11) is attached to the handheld electronic device by a layer of adhesive (16) on the back of the decorative layer. The skin (11) is selectively shaped to conform to the contours, shape, and components of the handheld electronic device. The skin (11) provides anti-slip and shock absorption functionalities to the handheld electronic device, but does not prevent or impede the handheld electronic device from mating with or connecting to corresponding accessory components.

Owner:ANTONINI FRED A

High Thermal Conductivity Mica Paper Tape

InactiveUS20080050580A1Improve thermal conductivityHigh materialDomestic sealsAdhesive articlesPaper tapeOptoelectronics

Owner:SIEMENS ENERGY INC

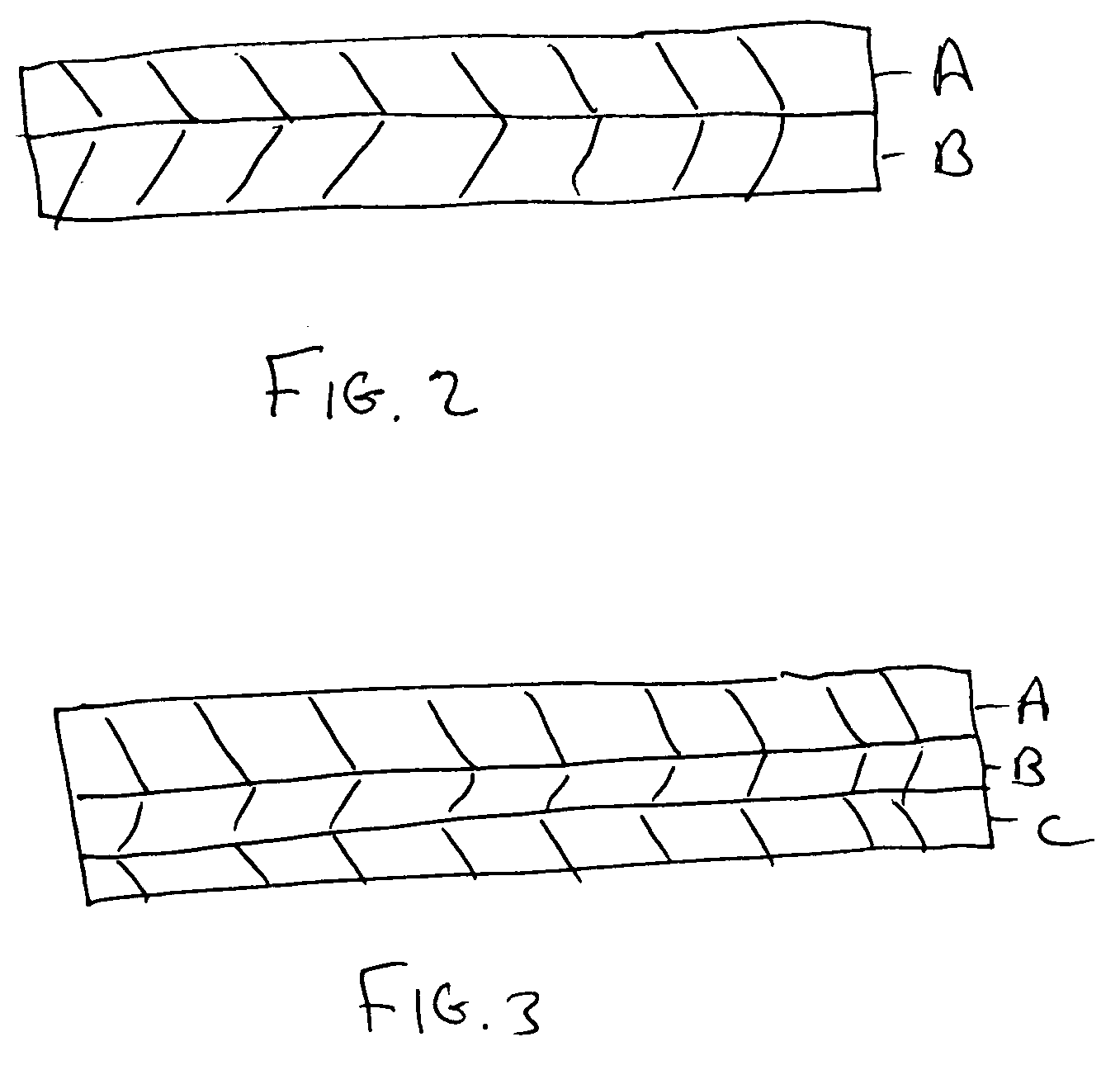

Adhesive tape

An adhesive tape which comprises: (1) a backing film, wherein the backing film has at least two intermeshed coextruded layers of different composition, whose interface has a nonlinear course in cross section, which continues laminarly in the machine direction and has been oriented in the machine direction, and has plane-parallel outer faces; and (2) at least one adhesive layer which is attached to the backing film.

Owner:TESA SE

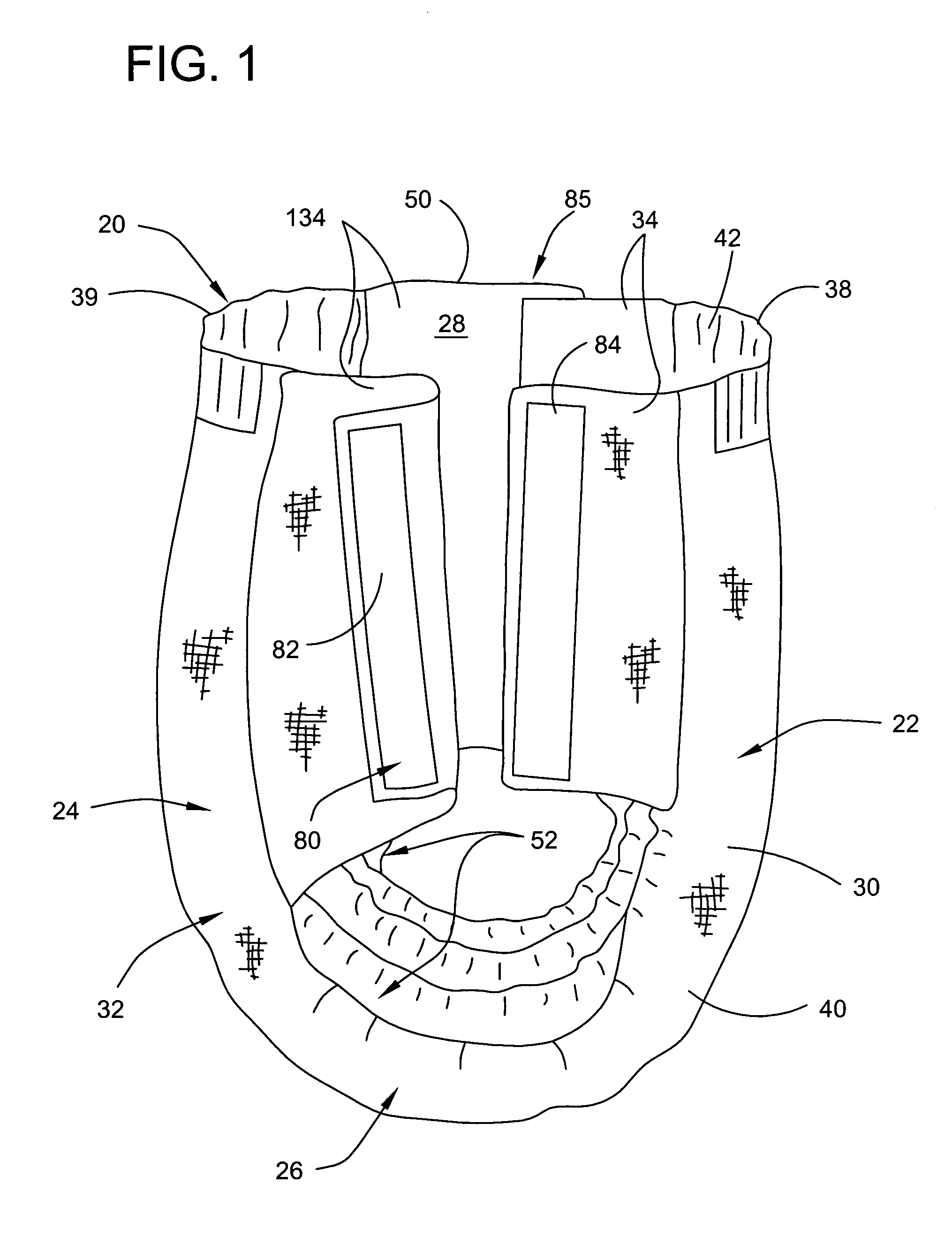

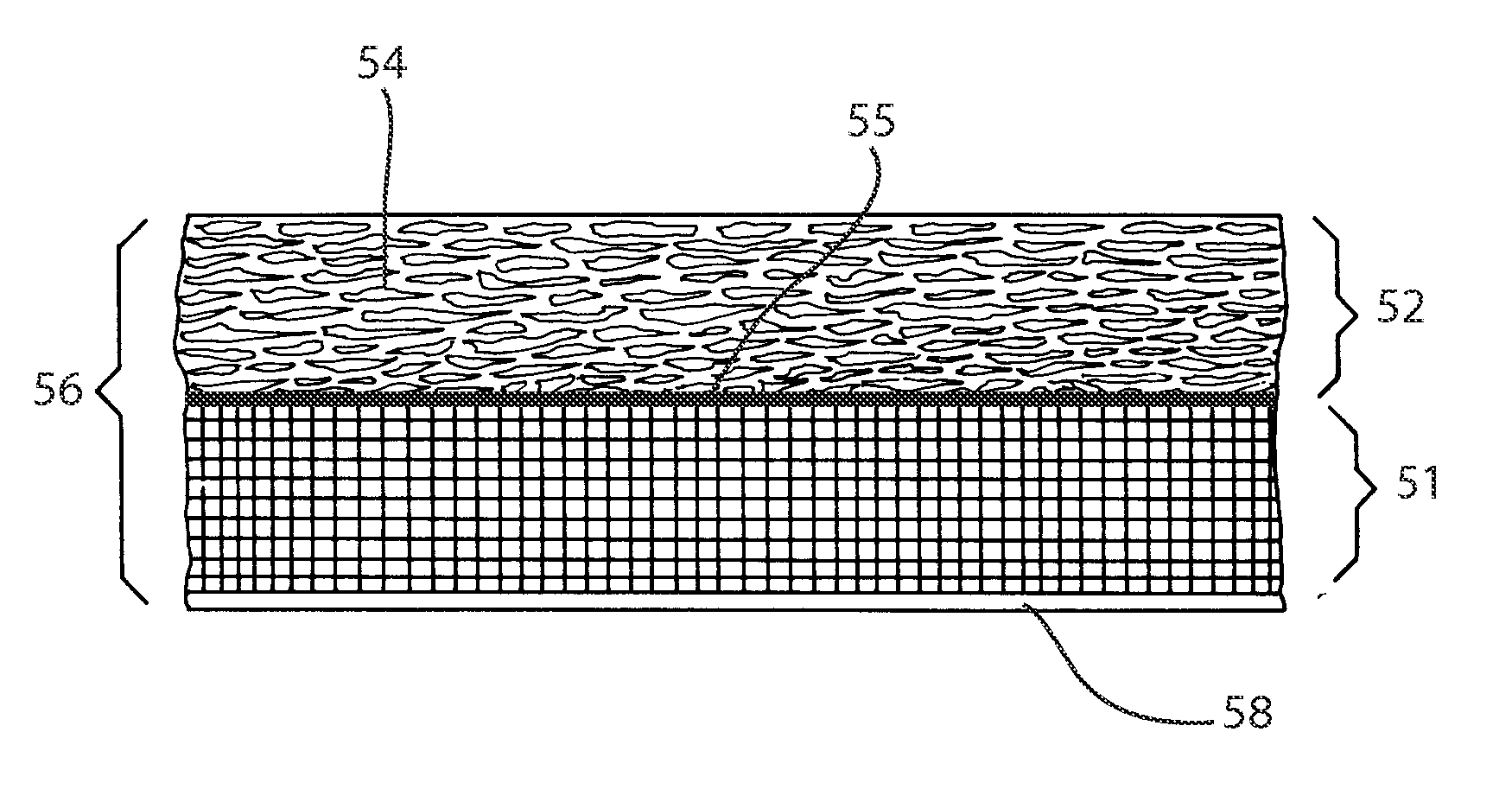

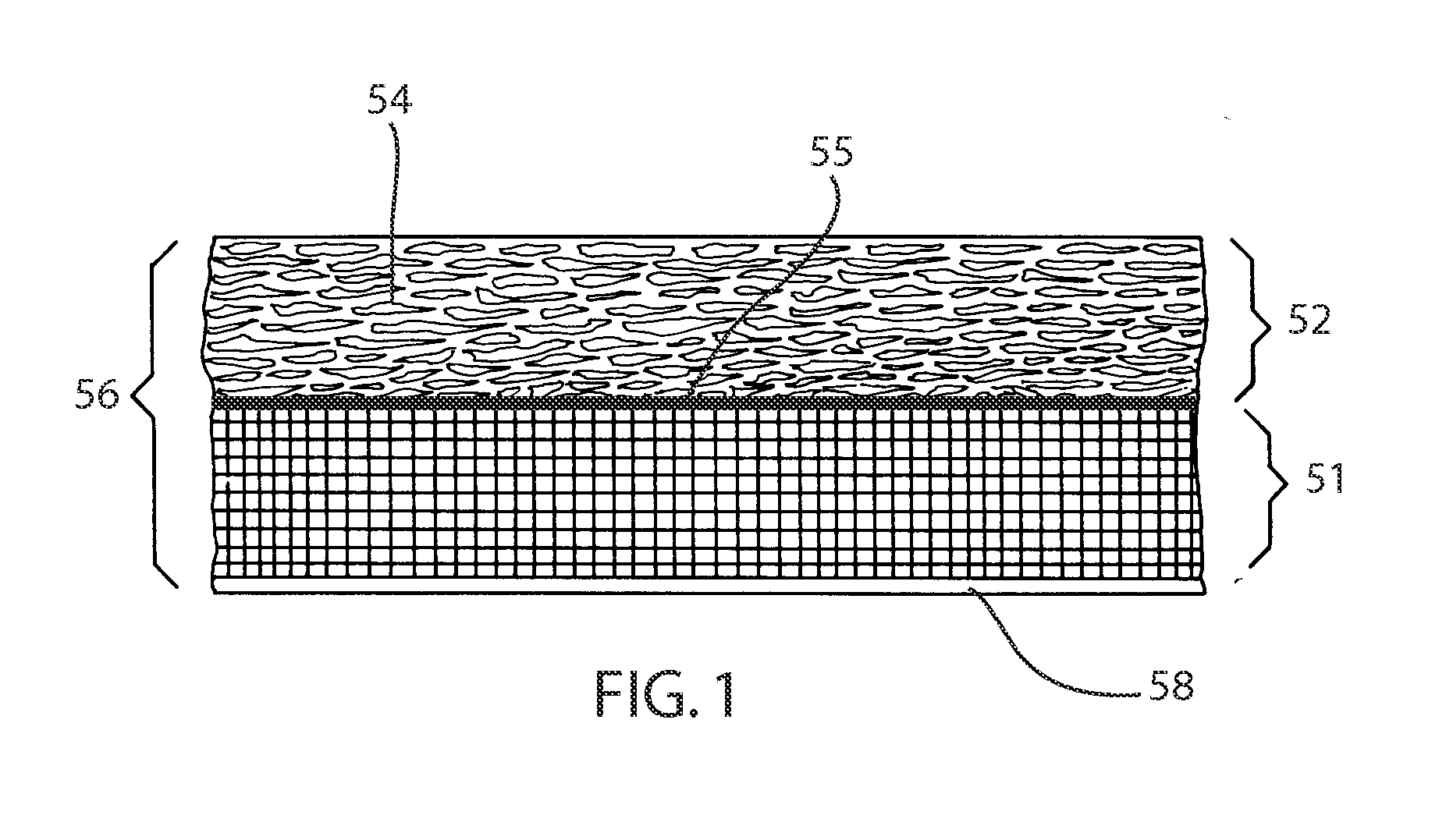

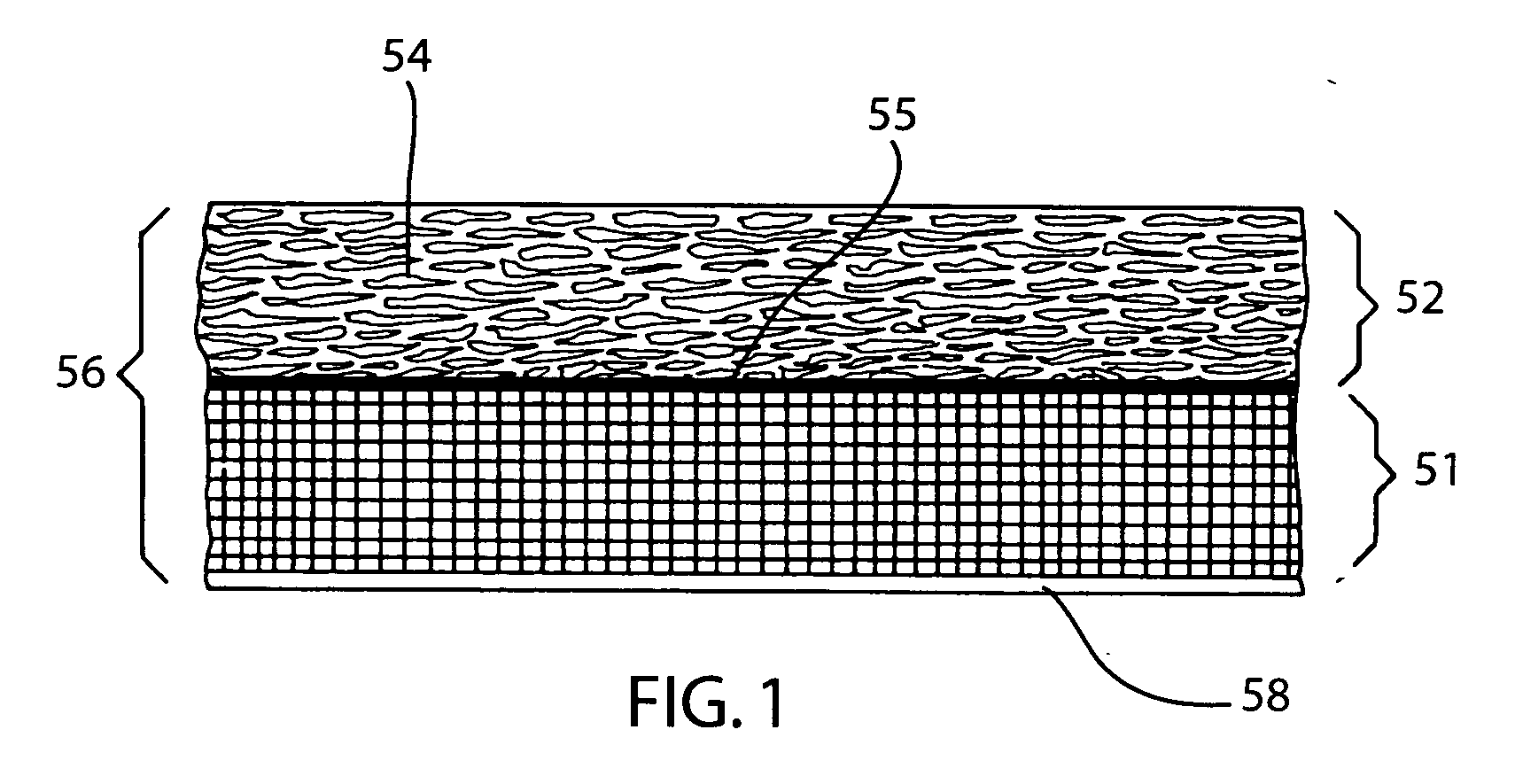

Composite insulation tape with loaded HTC materials

InactiveUS20060231201A1Improve thermal conductivityHigh materialLiquid surface applicatorsDomestic sealsElectrical tapeMaterials science

In one embodiment of the present invention as used for impregnating a composite tape (56) with HTC particles provides for permeating a fabric layer (51) of the composite tape with HTC particles and impregnating an impregnating resin into the composite tape through the fabric layer (51). At least 5% of the HTC particles permeated into the fabric layer are carried out of the fabric layer and into a mica layer (52) bound to the fabric layer by the impregnating resin. In some embodiments the impregnating resin itself contains HTC particles.

Owner:SIEMENS ENERGY INC

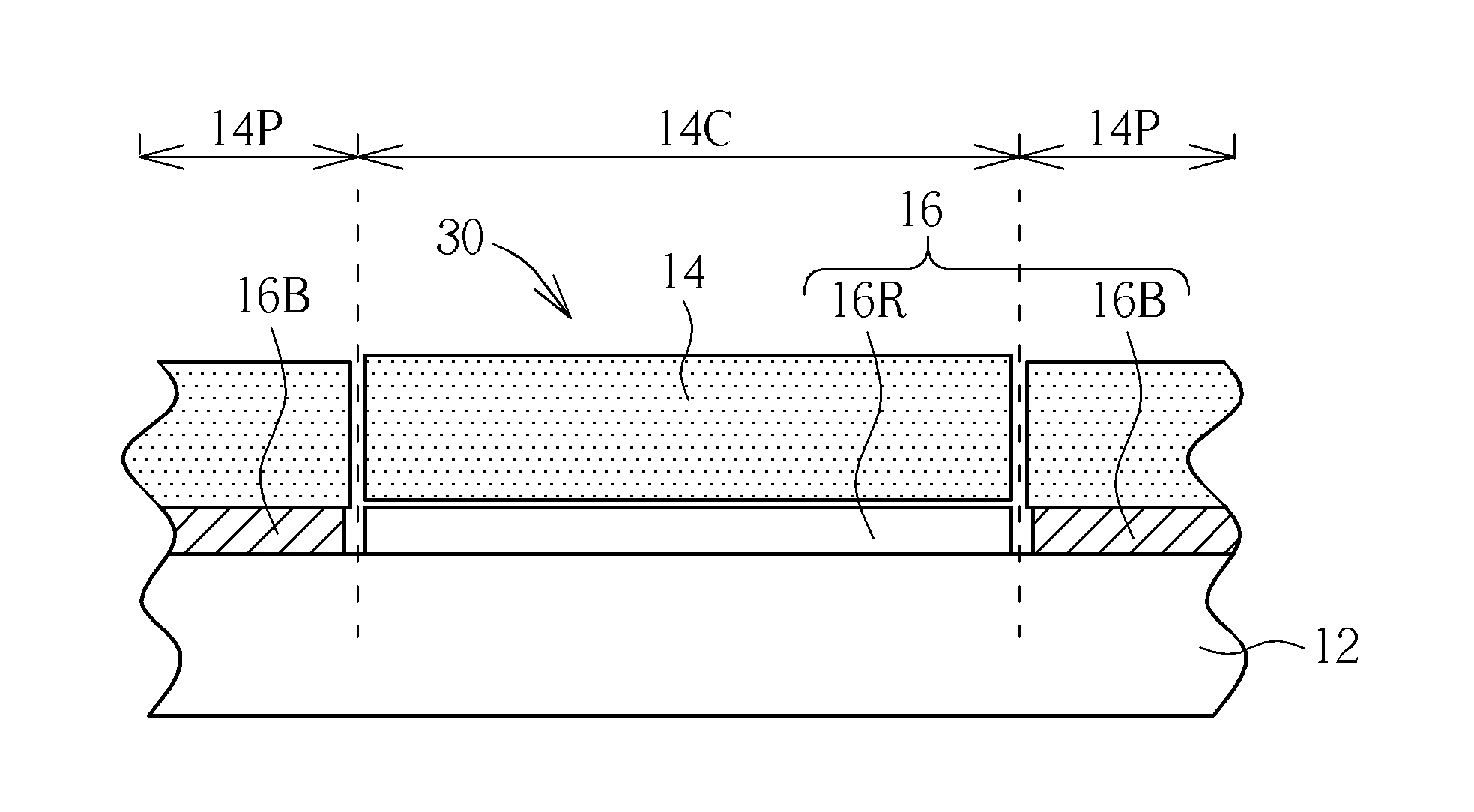

Flexible substrate structure and method of fabricating the same

InactiveUS20120164408A1Quality improvementReduce manufacturing costAdhesive processesLamination ancillary operationsMechanical engineeringStructural engineering

Owner:AU OPTRONICS CORP

Multilayer separable film or sheet

InactiveUS20060088695A1Low production costSaveDomestic sealsProtective equipmentElectrical and Electronics engineeringSheet material

A multilayer film having two or more separable adjacent layers. The multilayer film includes adjacent layers formed of compositions of dissimilar primary materials. Optionally, at least one of the layers contains a slip additive to change the release tension between adjacent layers. The multilayer film may include an adhesive layer between layers, with the adhesive layer more adhesion compatible with one of the layers than the other. The multilayer film may be a relatively inexpensive means to produce labels, films, sheets, containers, etc., requiring protection or isolation of one surface without the additional processes of gluing together individual dissimilar layers. Applications include, but are not limited to, the multilayer film being used as a seal to secure containers, including envelopes, and being imprinted and used as a multilayer labeling system. In one preferred embodiment, at least one layer of the multilayer film undergoes a visibly observable change when the at least one layer is released from at least one other layer; the visibly observable change is useful for many purposes, including, but not limited to, serving as a security mechanism within a container seal which, when the seal is broken, provides evidence that the container was opened.

Owner:COBURN THEODORE

Adhesive compositions derived from highly functionalized ethylene copolymers

ActiveUS20060025527A1Adhesive compositionAdhesive articlesSynthetic resin layered productsEthyl hydrogen maleateHigh pressure

Disclosed are adhesive compositions comprising nonfunctionalized base resins and functionalized ethylene copolymers such as ethylene / maleic anhydride (E / MAH) or ethylene / ethyl hydrogen maleate (E / MAME) copolymer, which are synthesized directly in a high pressure autoclave. These adhesive compositions can be applied as self-supporting films or can be co-extruded or extrusion coated onto a substrate. Also disclosed are multilayer structures, films, pipe coatings and building panels comprising these compositions.

Owner:DOW GLOBAL TECH LLC

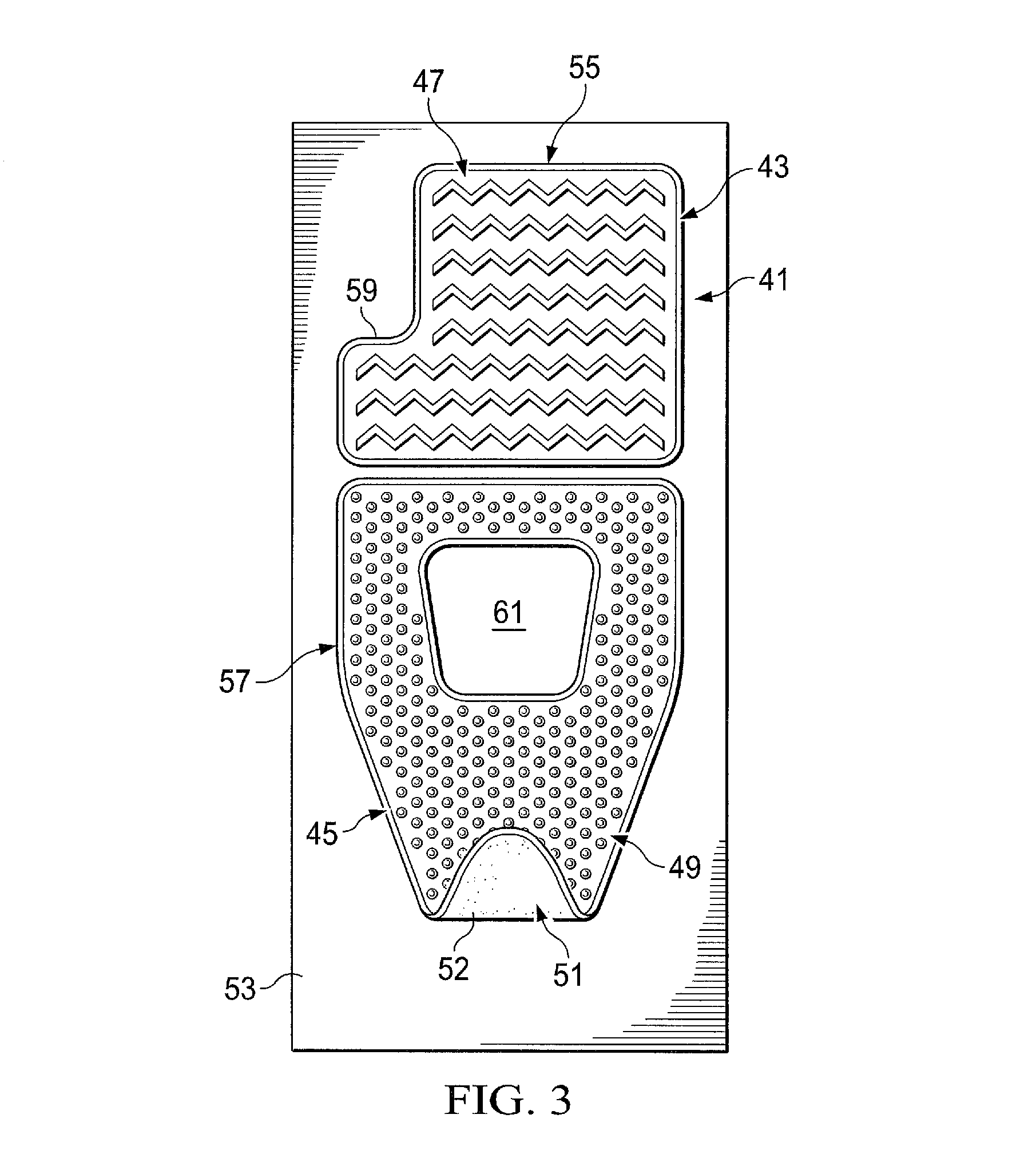

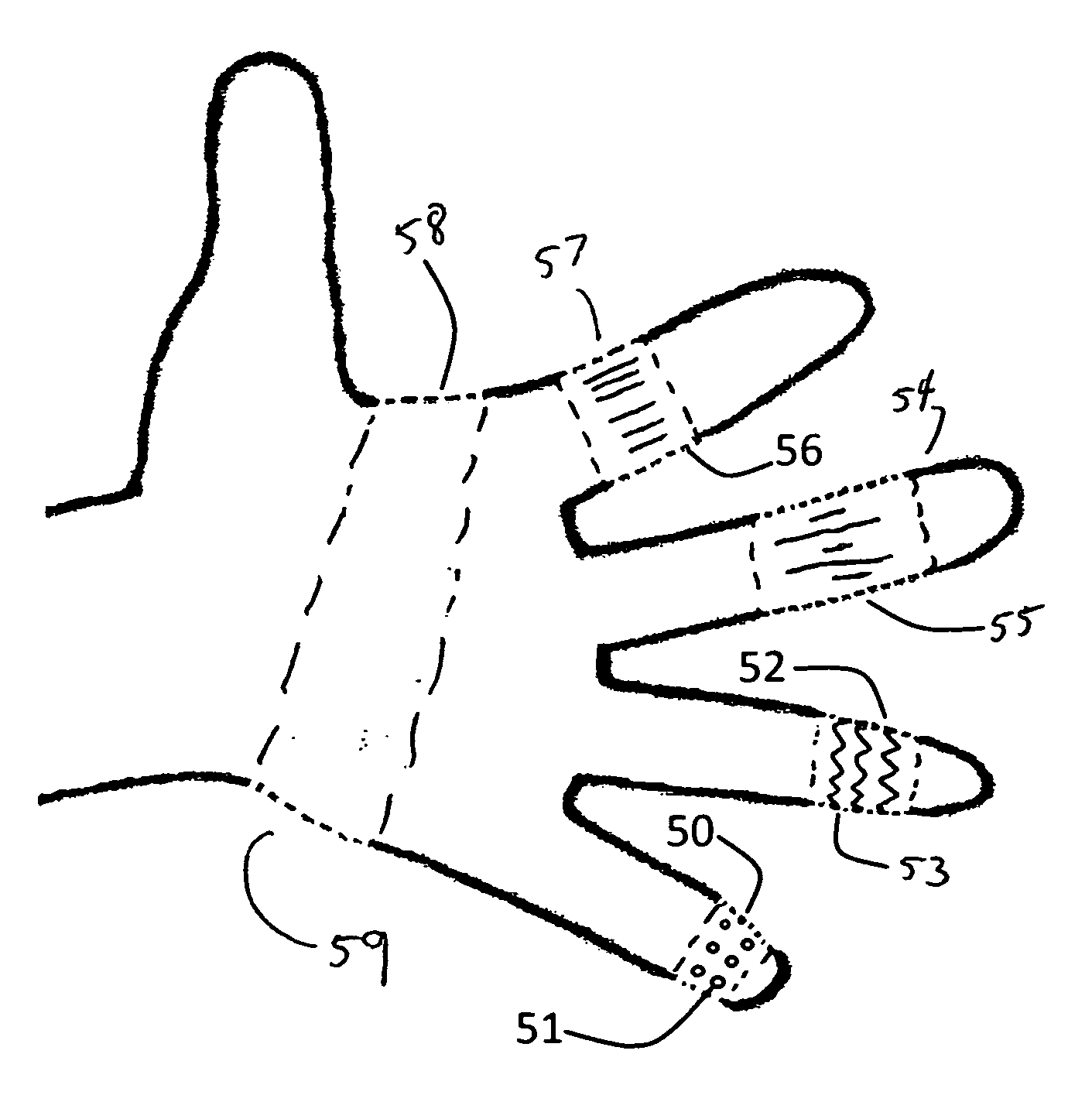

Attachable grip enhancers and sports tapes for the human body

According to the various features, characteristics and embodiments of the present invention which will become apparent as the description thereof proceeds, the present invention provides attachable grip enhancers for general use, as well as in playing the game of various sports, that could be attached to an individual, and uses and methods thereof. The present invention and its embodiments can, among other things, enhance the overall performance in arm tasks conducted by the wrist, forearm and / or bicep areas, as well as hand tasks by, among other things, creating a high coefficient of friction on said areas. Embodiments can additionally benefit users to, among other things, protect an injury, and / or protect from injury, by offering embodiments with a medicated additive and / or shock-absorbing member.

Owner:RAMIREZ JOHN

Ultraviolet radiation curable pressure sensitive acrylic adhesive

ActiveUS20100255239A1Adhesive processesLamination ancillary operationsPolymer scienceUltraviolet radiation

A process for making UV curable pressure sensitive adhesive compositions by derivatizing an acrylic polymer with a derivatizing agent prepared from a hydroxy-functional acrylate monomer and a diisocyanate. The derivatizing agent typically has a ratio of hydroxy-functional acrylate monomer to diisocyanate greater than about 1:1. Also disclosed are UV curable pressure sensitive adhesives made with the derivatizing agent and methods for adhering substrates with pressure sensitive adhesive compositions.

Owner:ARKEMA FRANCE SA

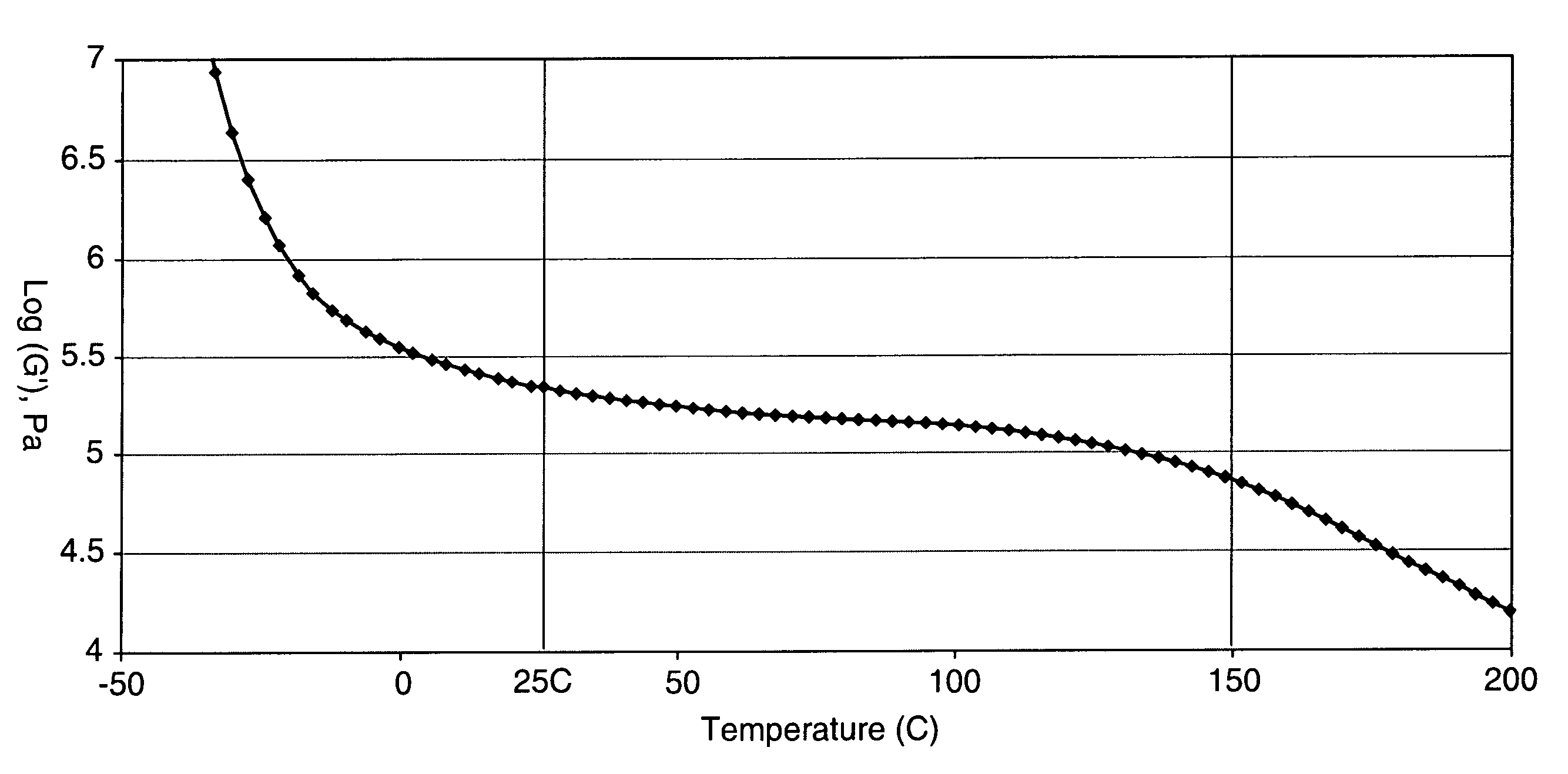

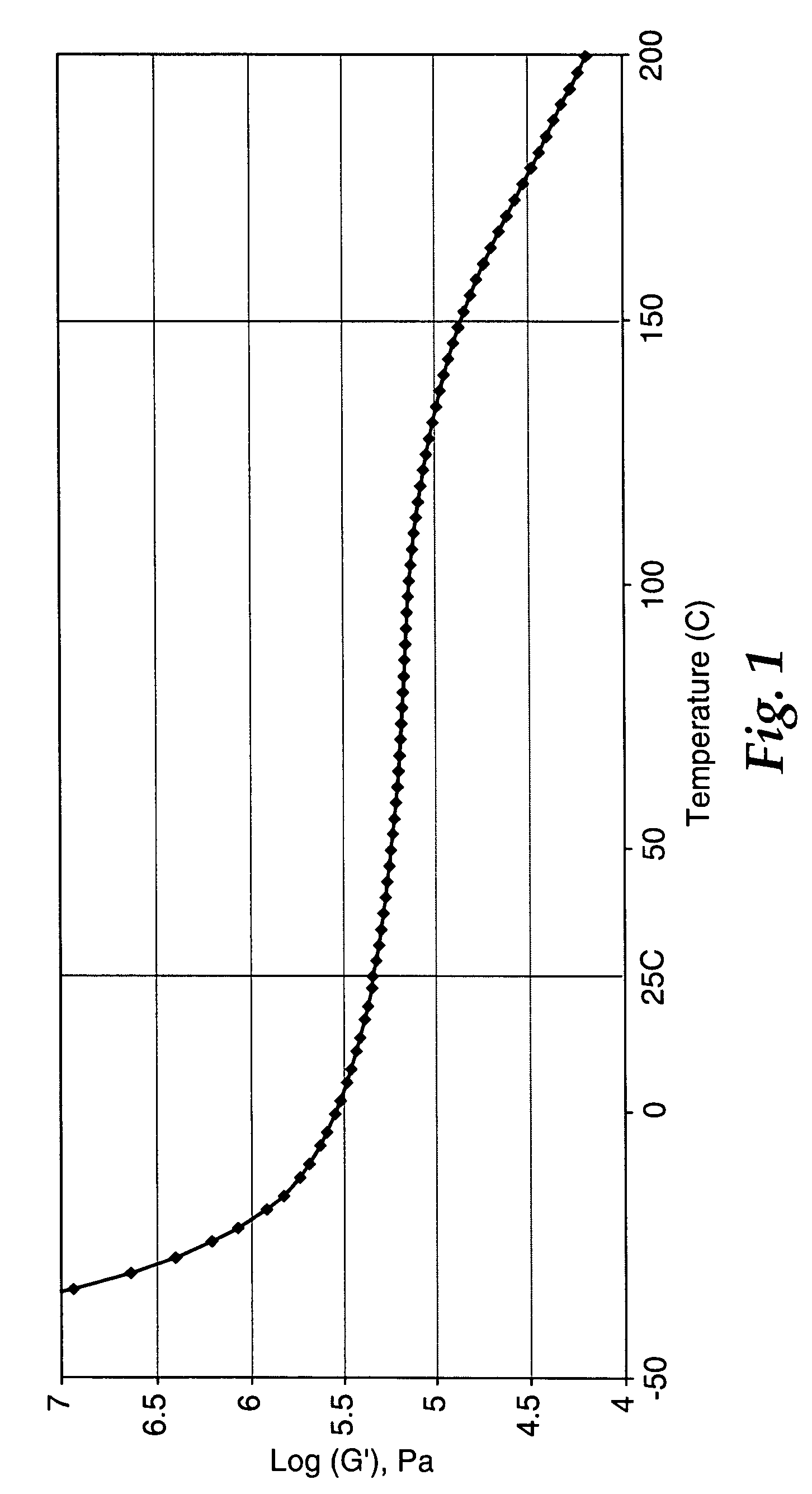

Transparent adhesive sheet for flat panel display and flat panel display

InactiveUS20110254790A1Good flexibilityStatic indicating devicesAdhesive articlesDisplay deviceHydrosilylation

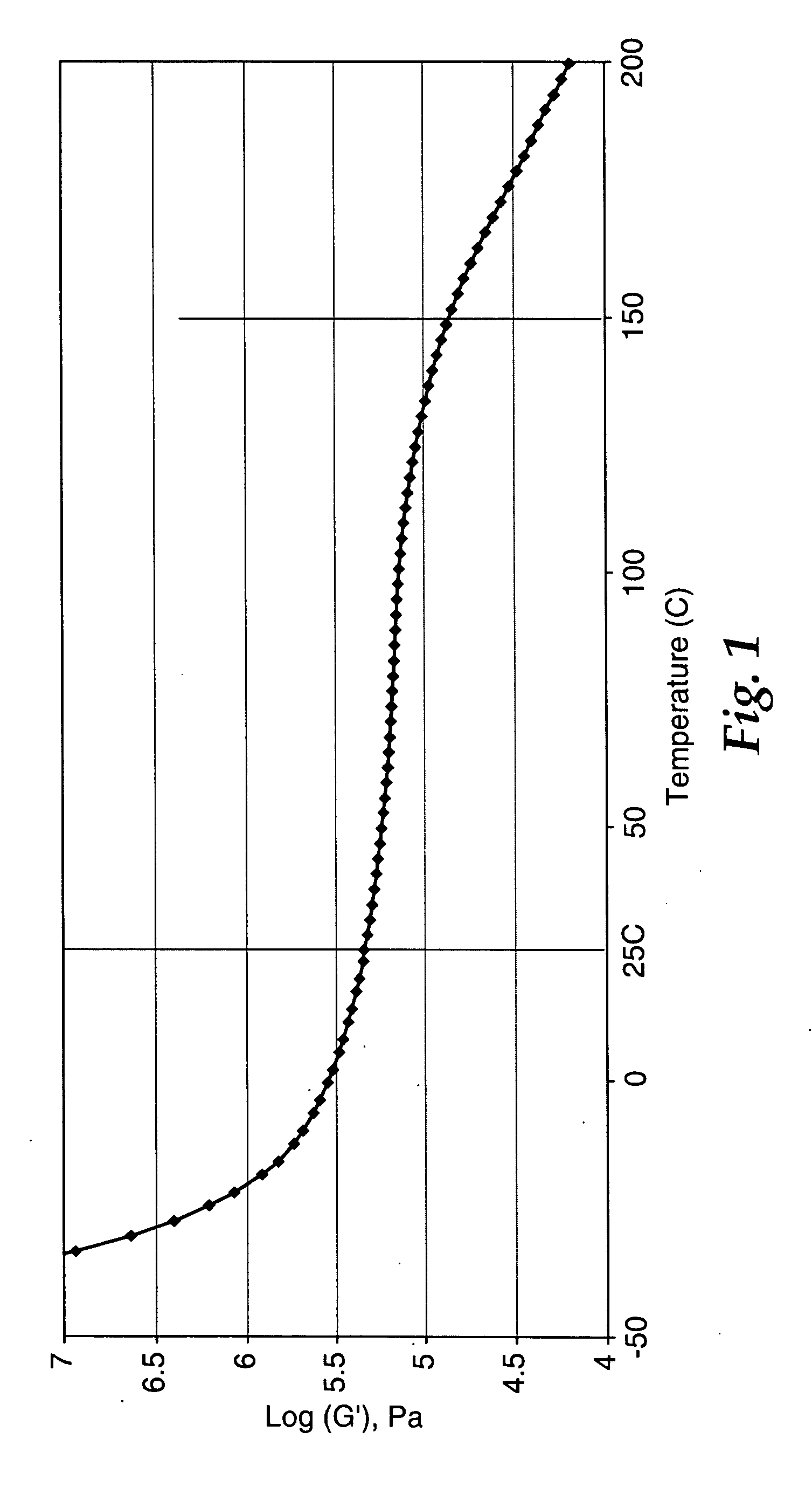

The invention provides a transparent adhesive sheet for flat panel display, which shows superior level difference absorbability and does not develop bubbles in the adhesion surface to a plastic plate. The transparent adhesive sheet for flat panel display is made of a cured product of a composition comprising (A) a polyoxyalkylene based polymer having at least one alkenyl group in one molecule, (B) a compound having an average of not less than 2 and less than 5 hydrosilyl groups in one molecule, and (C) a hydrosilylation catalyst, wherein the transparent adhesive sheet has a shear storage elastic modulus (G′) of not more than 1.0×105 Pa at 25° C. and 1 Hz, and a gel fraction of not less than 40%.

Owner:NITTO DENKO CORP

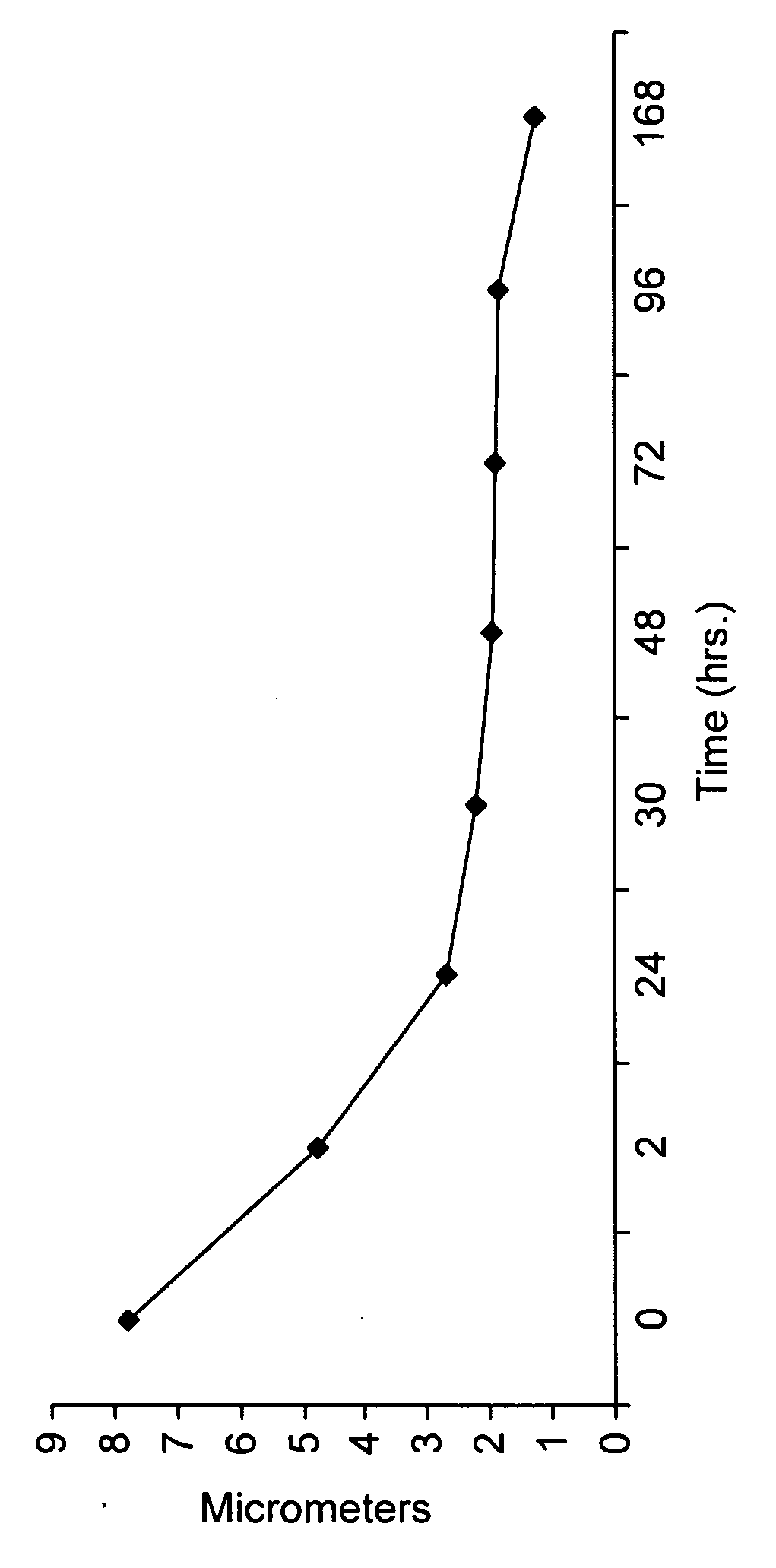

High moisture vapor transmission hot melt moisture cure polyurethane adhesive with excellent hydrolysis resistance

InactiveUS6133400AGood moisture permeabilityImprove washabilityAdhesive articlesSynthetic resin layered productsPolyesterMoisture cure polyurethane

This invention relates to a hot melt moisture cure polyurethane composition which is the reaction product of a polyether polyol formed from a compound selected from the group consisting of ethylene oxide, propylene oxide, 1,2-butylene oxide, 1,4-butylene oxide and mixtures thereof; a low molecular weight polyalkylene glycol having from 3 to 7 carbon atoms; a crystalline polyester polyol having a melting point from about 40 DEG C. to about 120 DEG C.; and at least one polyfinctional isocyanate component wherein said composition has a moisture vapor transmission rate of greater than about 100 g / m2 / day film thickness of from about 450 to about 500 g / m2, and hydrolysis resistance.

Owner:HB FULLER CO

Polyurethane foam sheet and process for layered sheet with the same

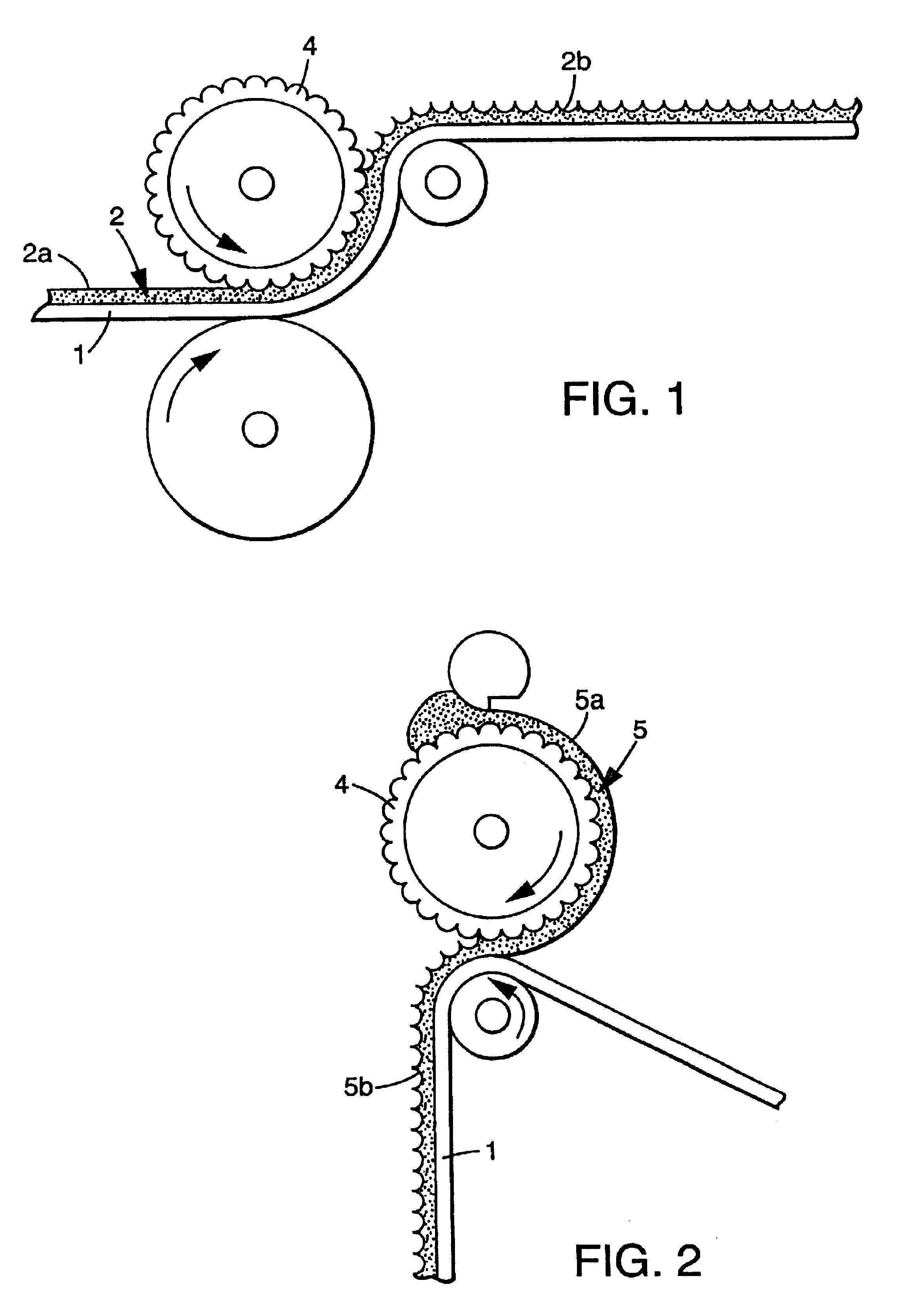

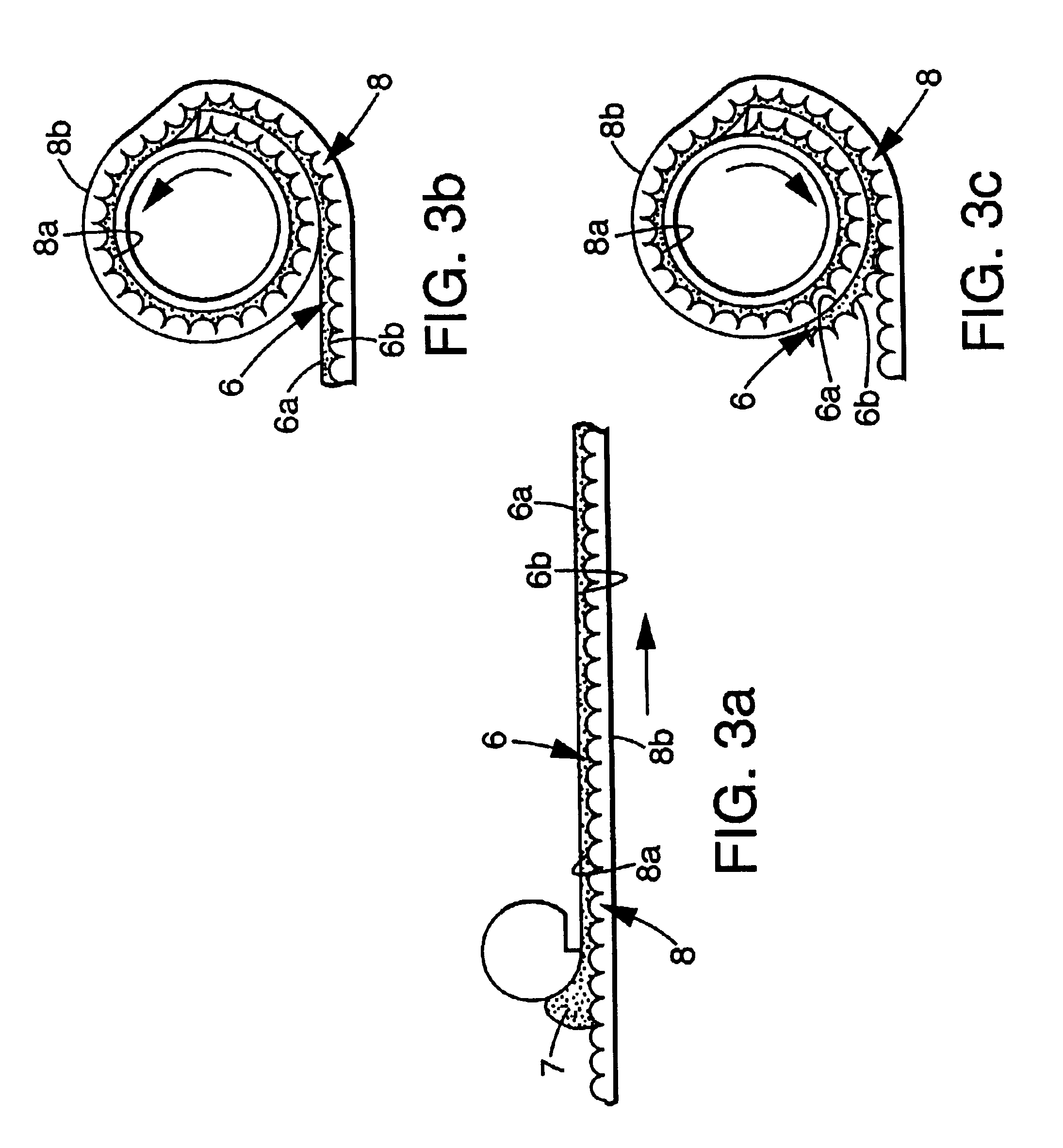

ActiveUS20060079589A1Easy to controlReduce energy consumptionAdhesive articlesSynthetic resin layered productsCushioningPolymer science

A method of producing a polyurethane foam sheet, and a laminated sheet that uses such a foam sheet, that can be applied to artificial leather, synthetic leather, and cushioning materials used in all manner of applications. A polyurethane foam sheet is produced by applying a liquid mixture, obtained by mixing together a heated and melted hot melt urethane prepolymer (A) containing isocyanate groups at molecular terminals, and a compound (B) containing at least 2 active hydrogen atom-containing groups, onto a substrate in a sheet-like manner, and then water foaming the liquid mixture by bringing the sheet-like liquid mixture into contact with water vapor or moisture (water). A laminated sheet is produced by bonding a third substrate to the polyurethane foam sheet.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com