Patents

Literature

265 results about "Moisture cure polyurethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moisture-cure polyurethanes or polyurethane prepolymer are isocyanate-terminated prepolymers that are formulated to cure with ambient water. Cured PURs are segmented copolymer polyurethane-ureas exhibiting microphase-separated morphologies. One phase is derived from a typically flexible (subambient glass transition temperature, Tg) polyol that is generally referred to as the “soft phase”. Likewise the corresponding “hard phase” is born from the di- or polyisocyanates that through water reaction produce a highly crosslinked material with softening temperature well above room temperature.

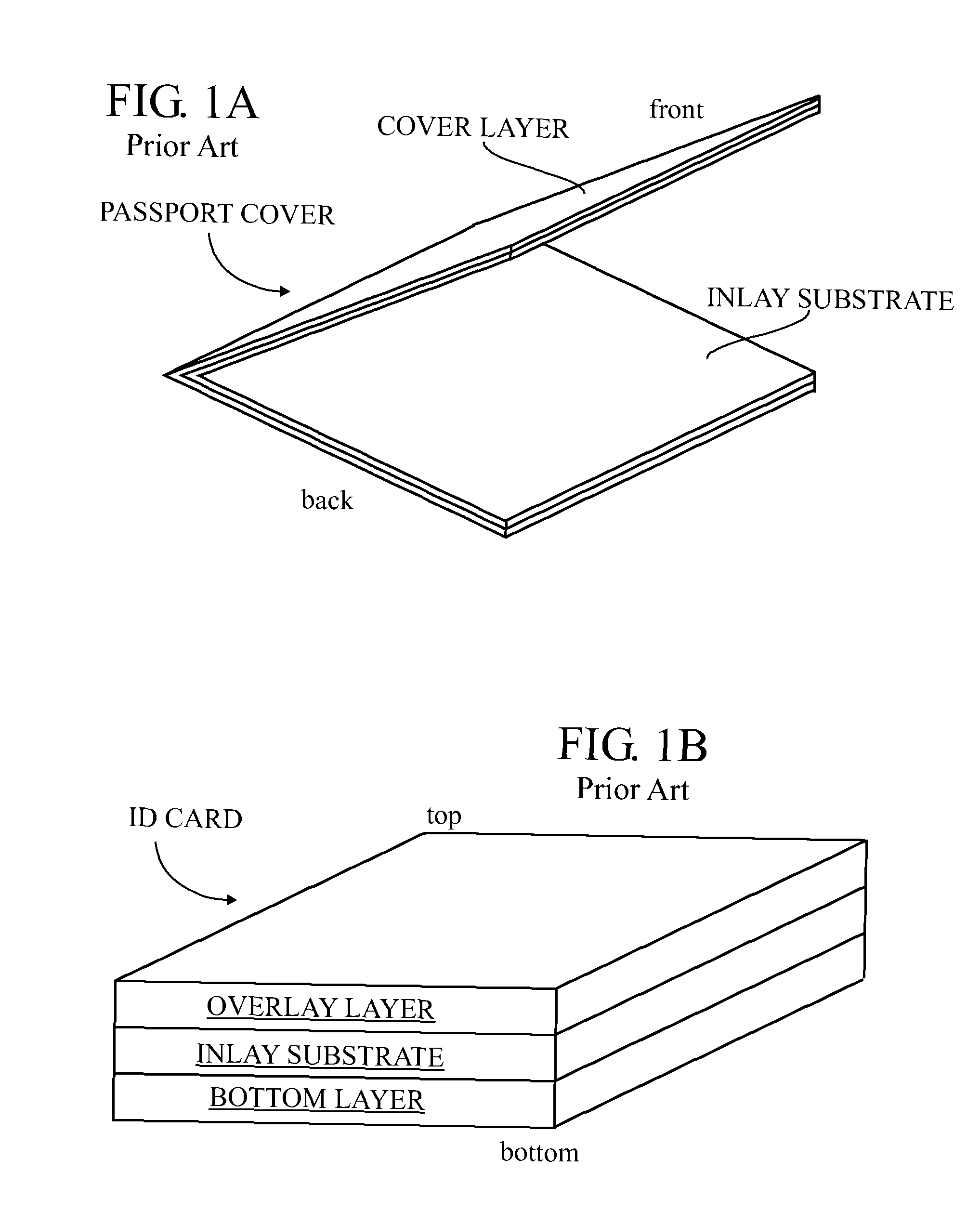

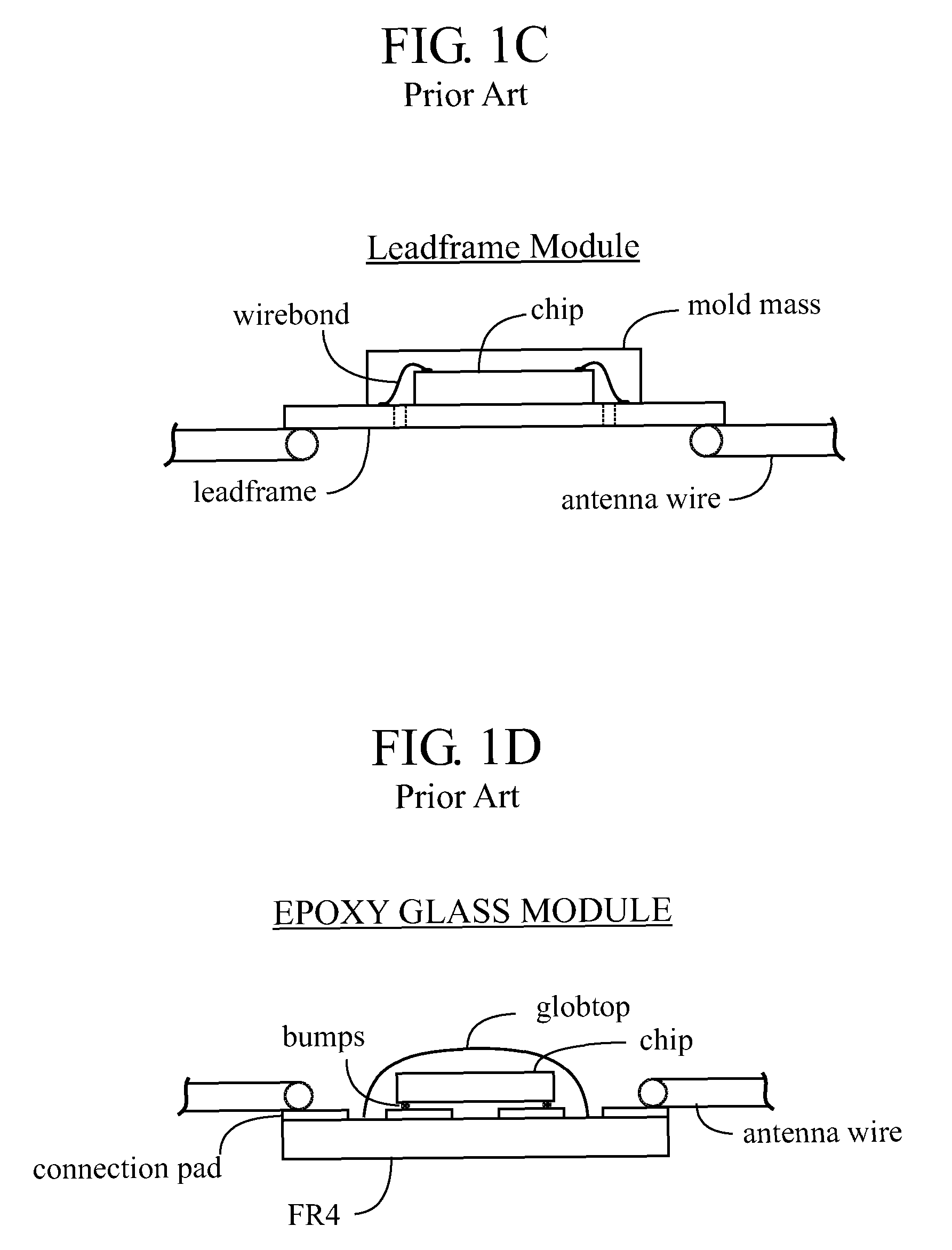

Inlays for security documents

InactiveUS20090315320A1Prevent skimmingReduce warpage and breakageSolid-state devicesRadiating elements structural formsMoisture cure polyurethaneElectromagnetic shielding

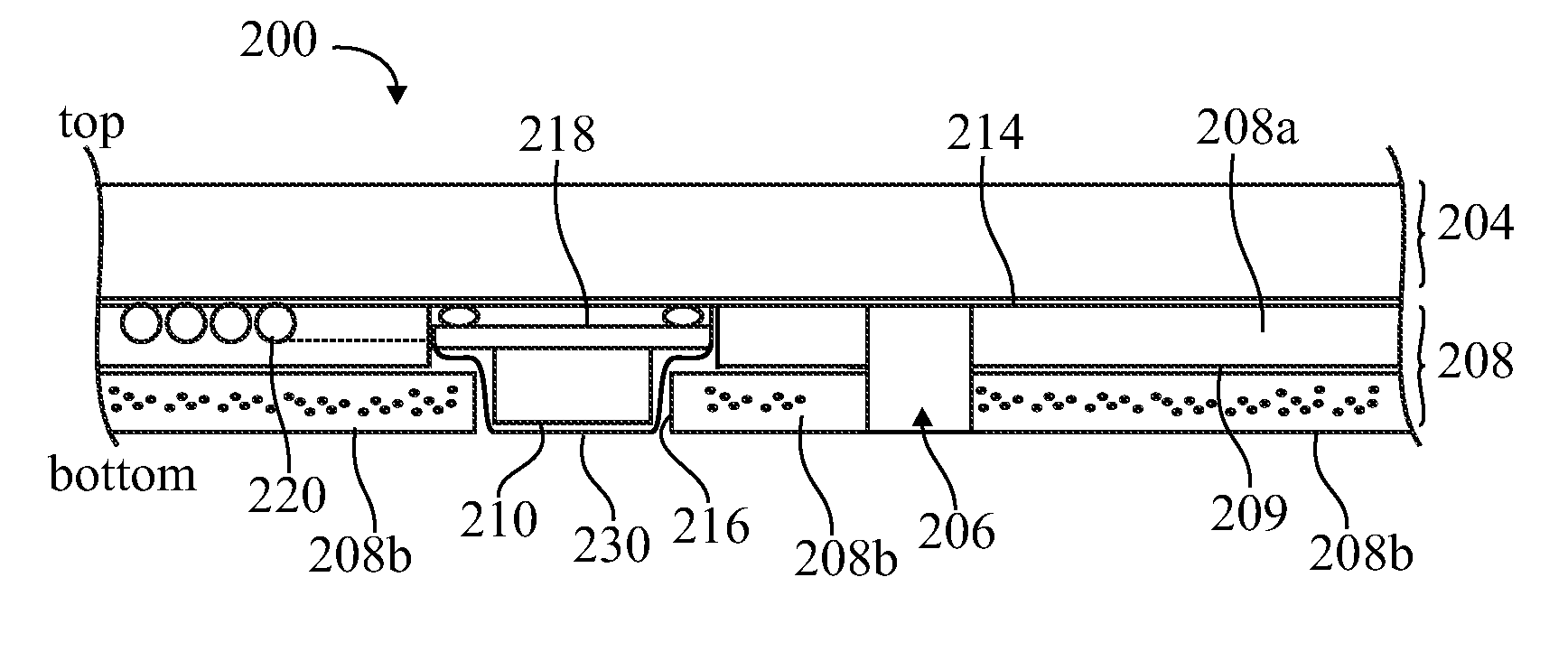

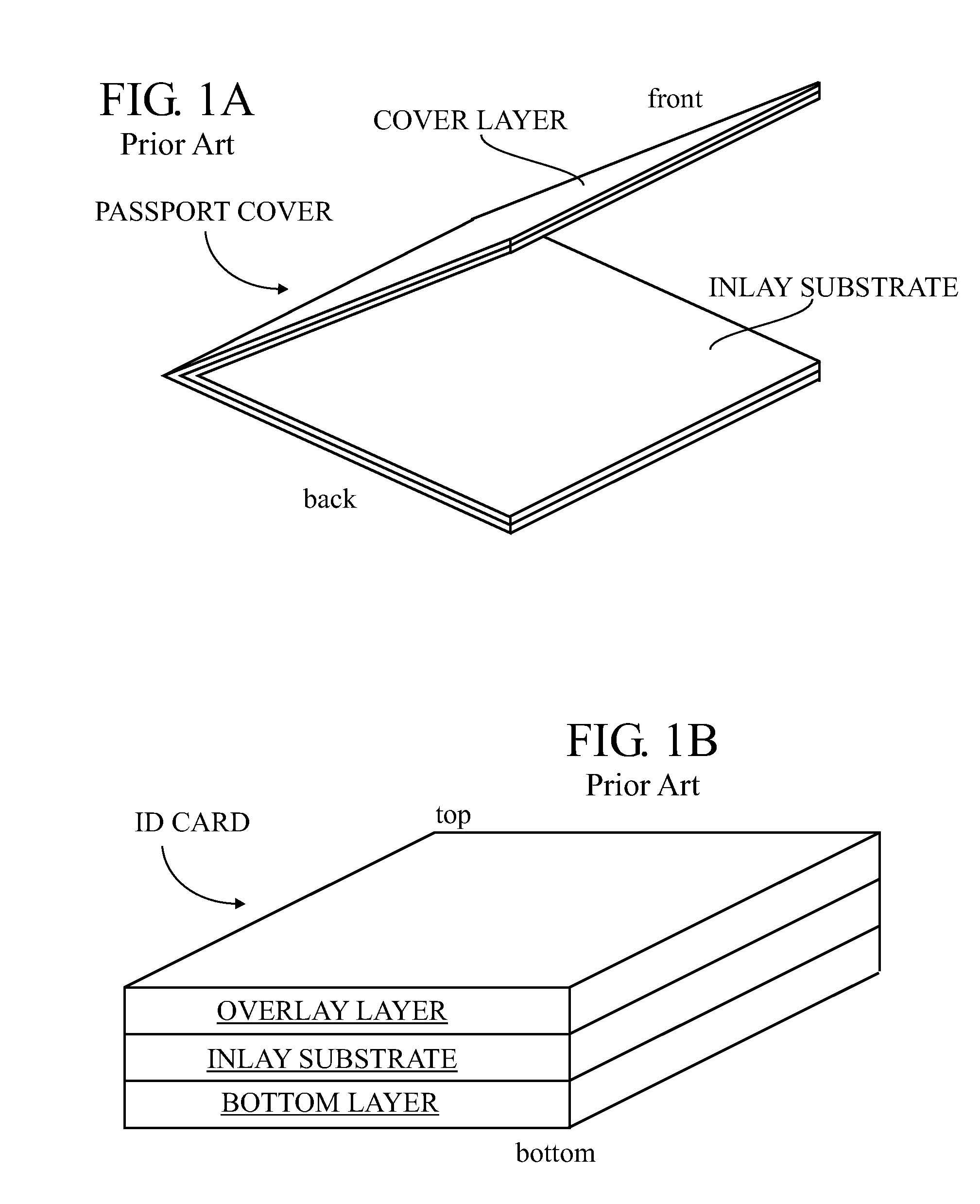

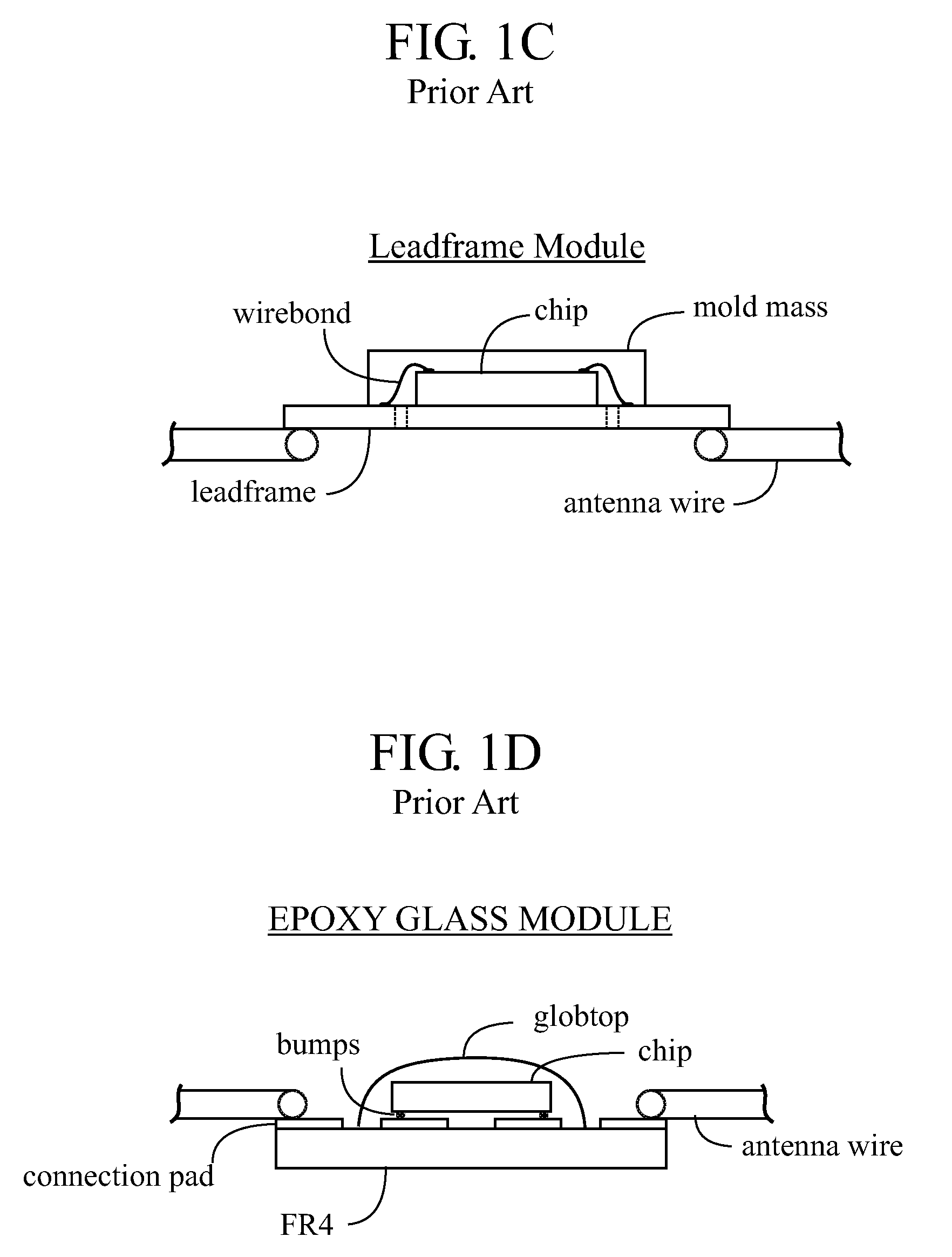

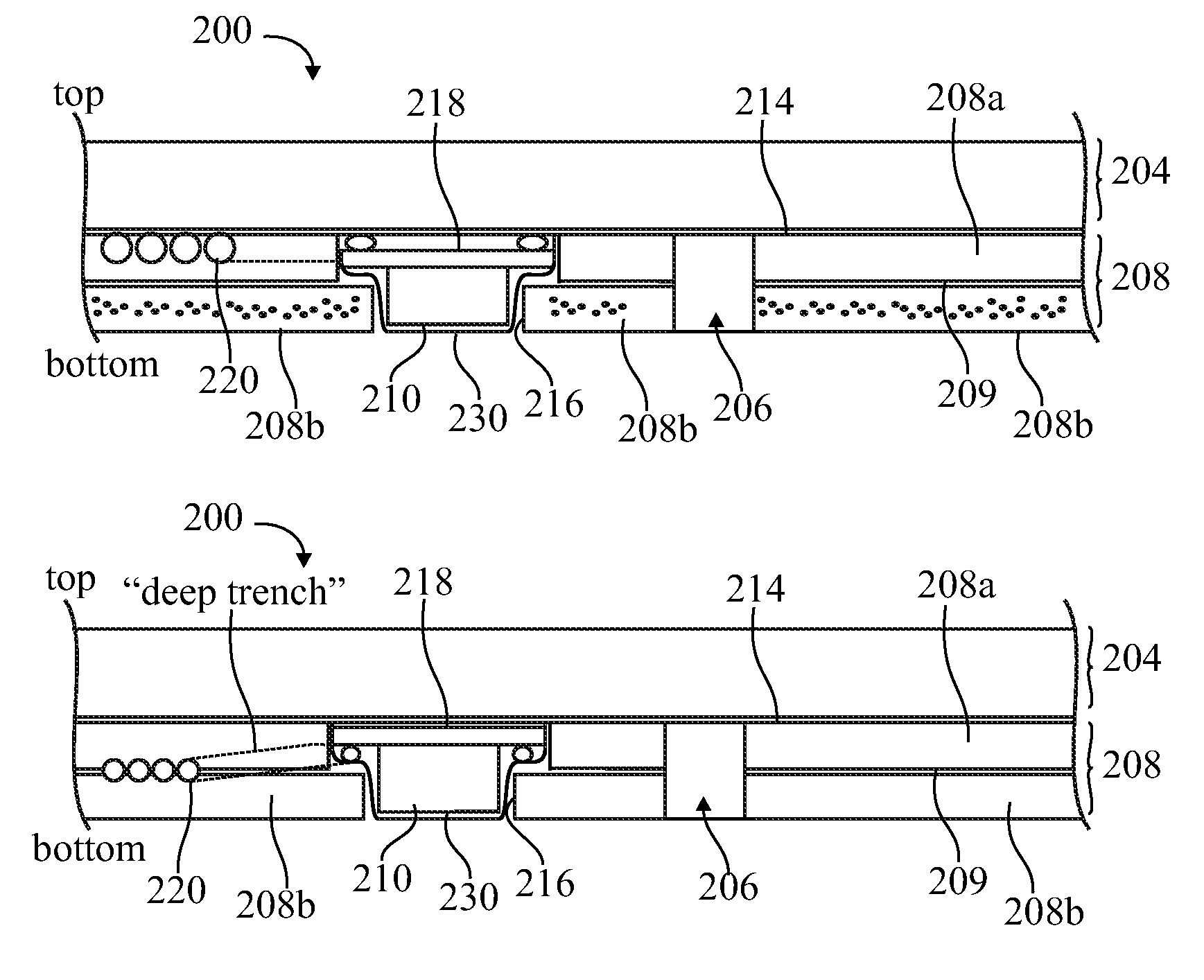

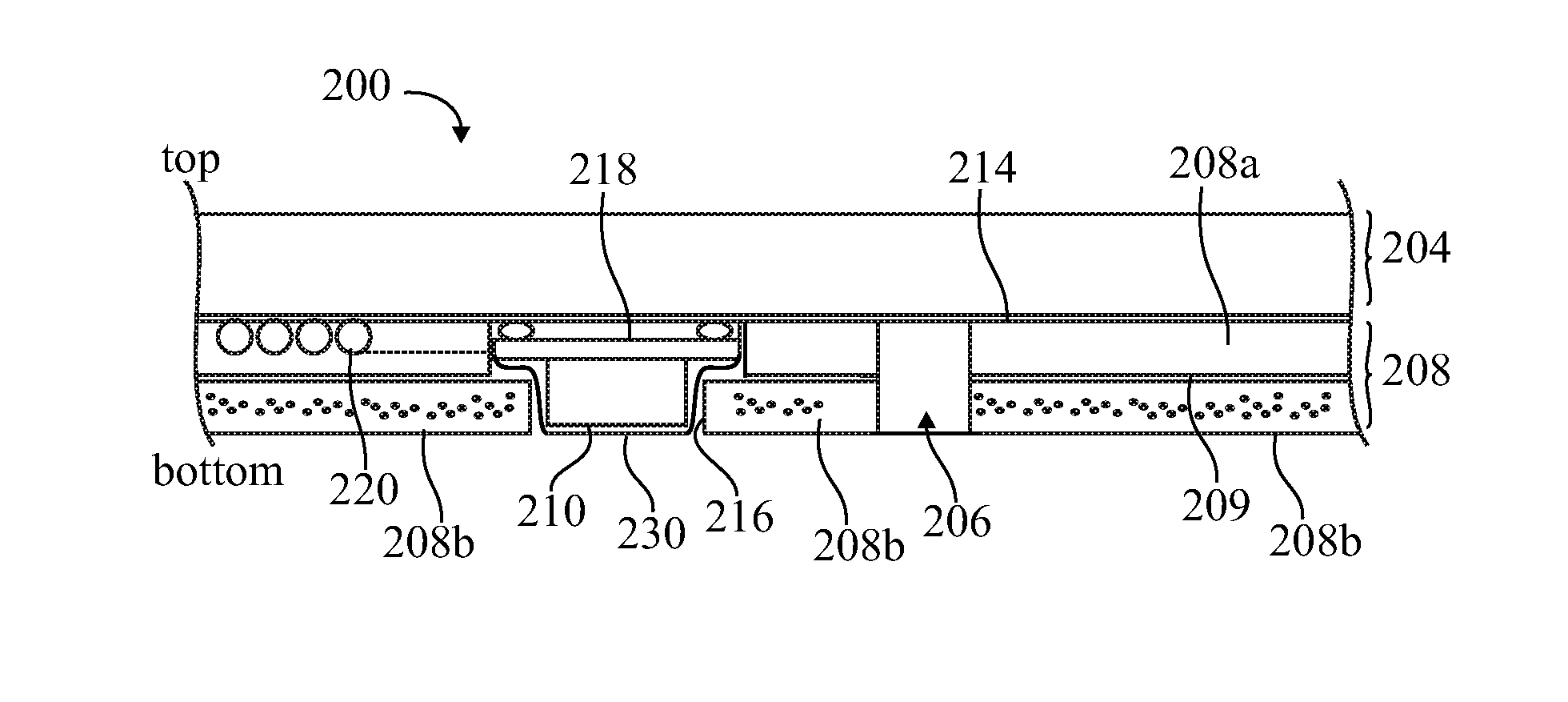

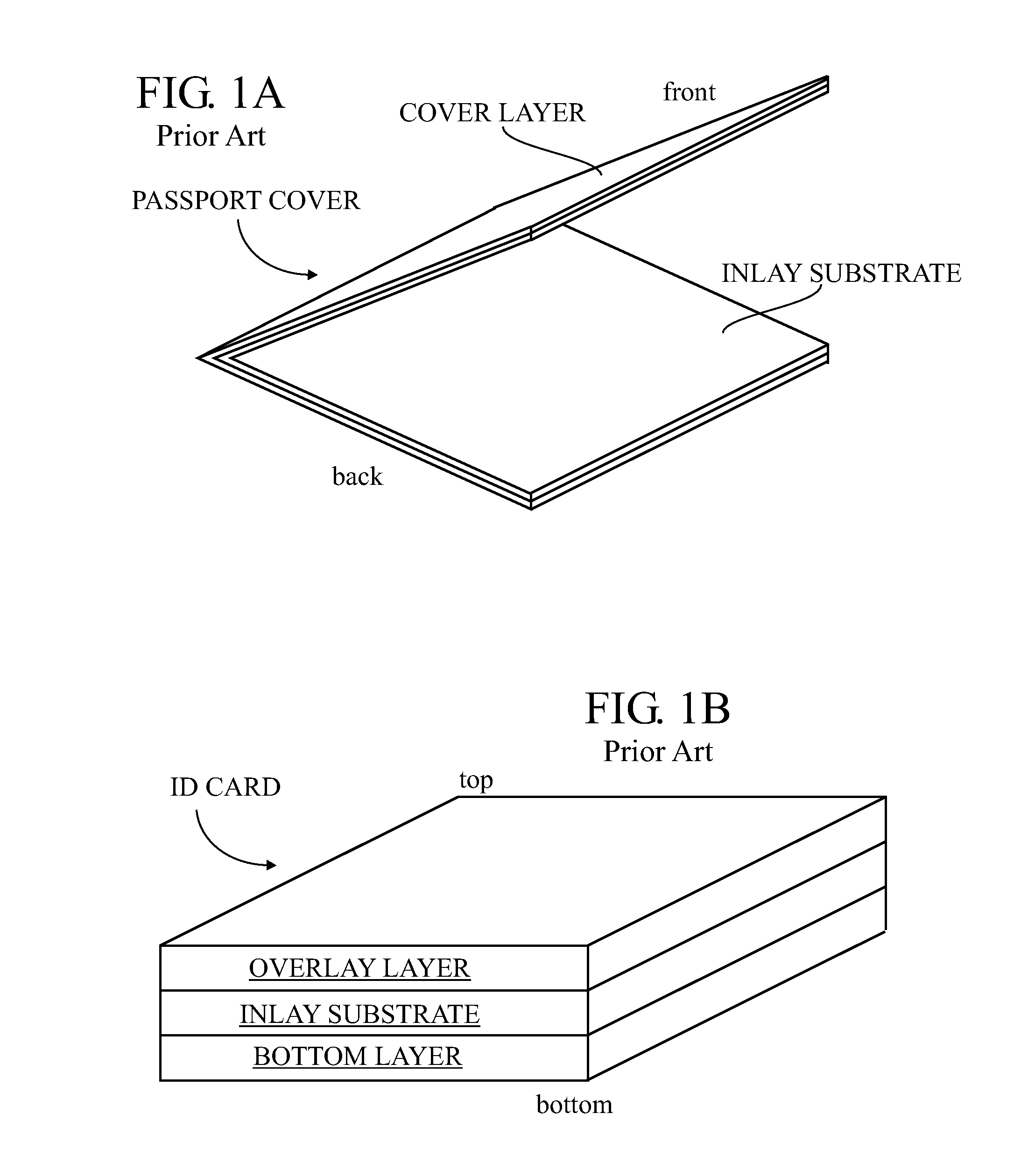

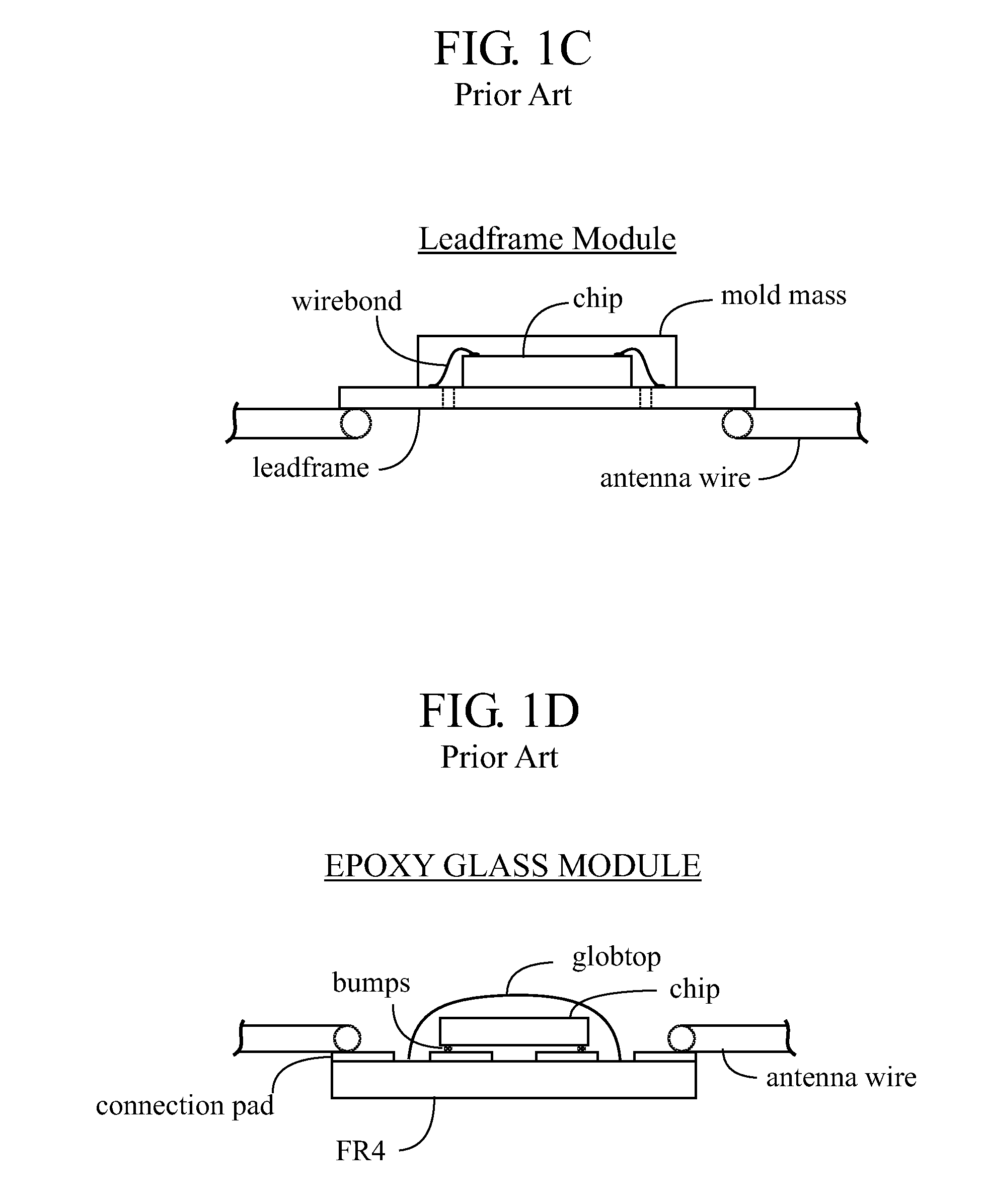

Secure inlays for secure documents such as a passport comprising an inlay substrate may have laser ablated recesses within which a chip module is installed. Channels for an antenna wire may be formed in a surface of the substrate. Instead of using wire, the channels may be filled with a flowable, conductive material. Patches homogenous with the substrate layer may be used to protect and seal the chip and interconnection area. The inlay substrate may include two layers, and the antenna wire may be between the two layers. A moisture-curing polyurethane hot melt adhesive may be used to laminate a cover layer and the additional inlay substrate layers. The adhesive layer may include metal nanoscale powder and ink for electromagnetic shielding. Additional security elements may include material that is optically changeable by an electromagnetic field. Ferrite-containing layers may be incorporated in the inlay substrate.

Owner:ASSA ABLOY AB +2

Inlays for security documents

InactiveUS8608080B2Reduce warpage and breakageProduction impossibleSolid-state devicesRadiating elements structural formsElectromagnetic shieldingConductive materials

Owner:ASSA ABLOY AB +2

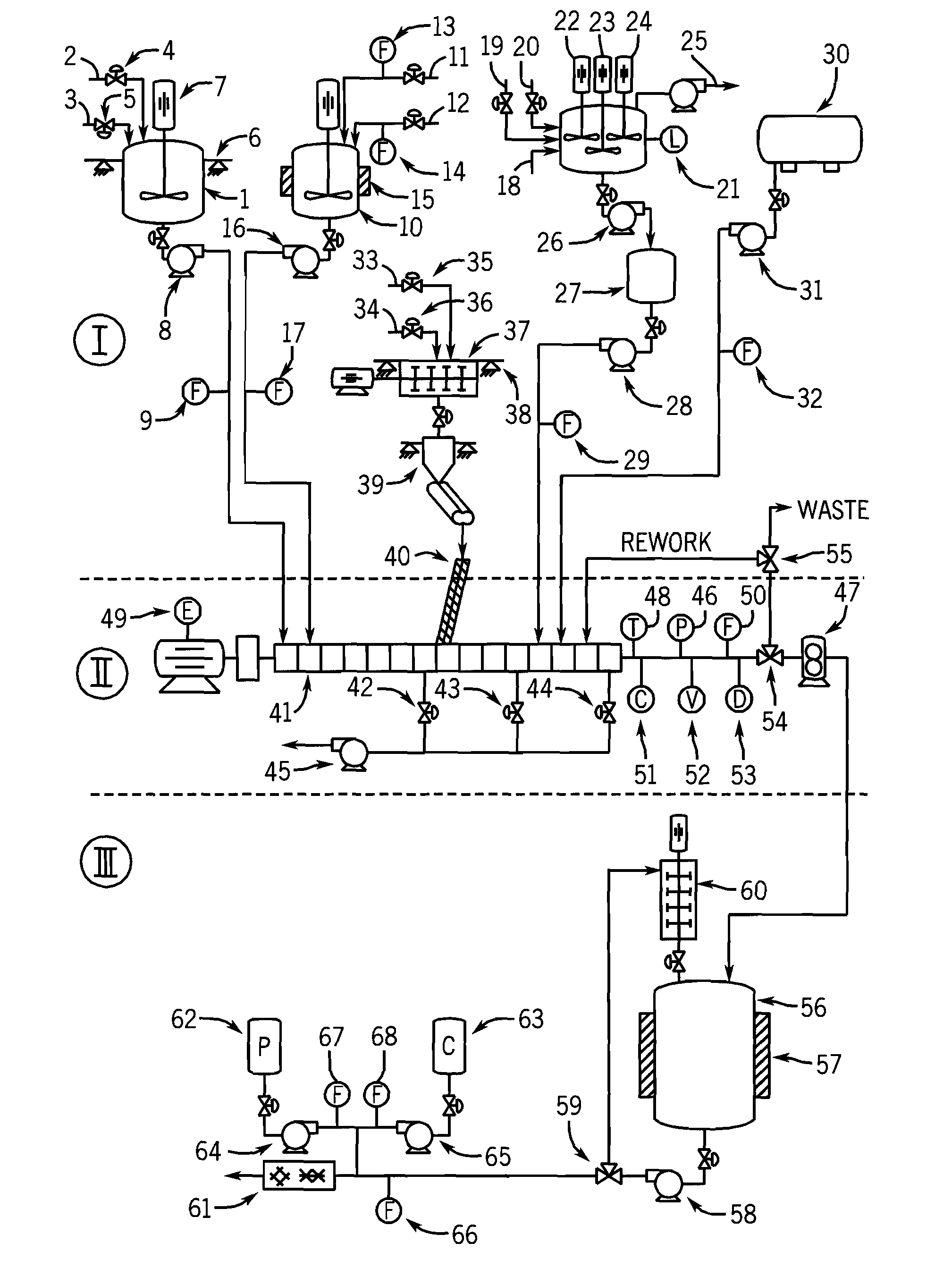

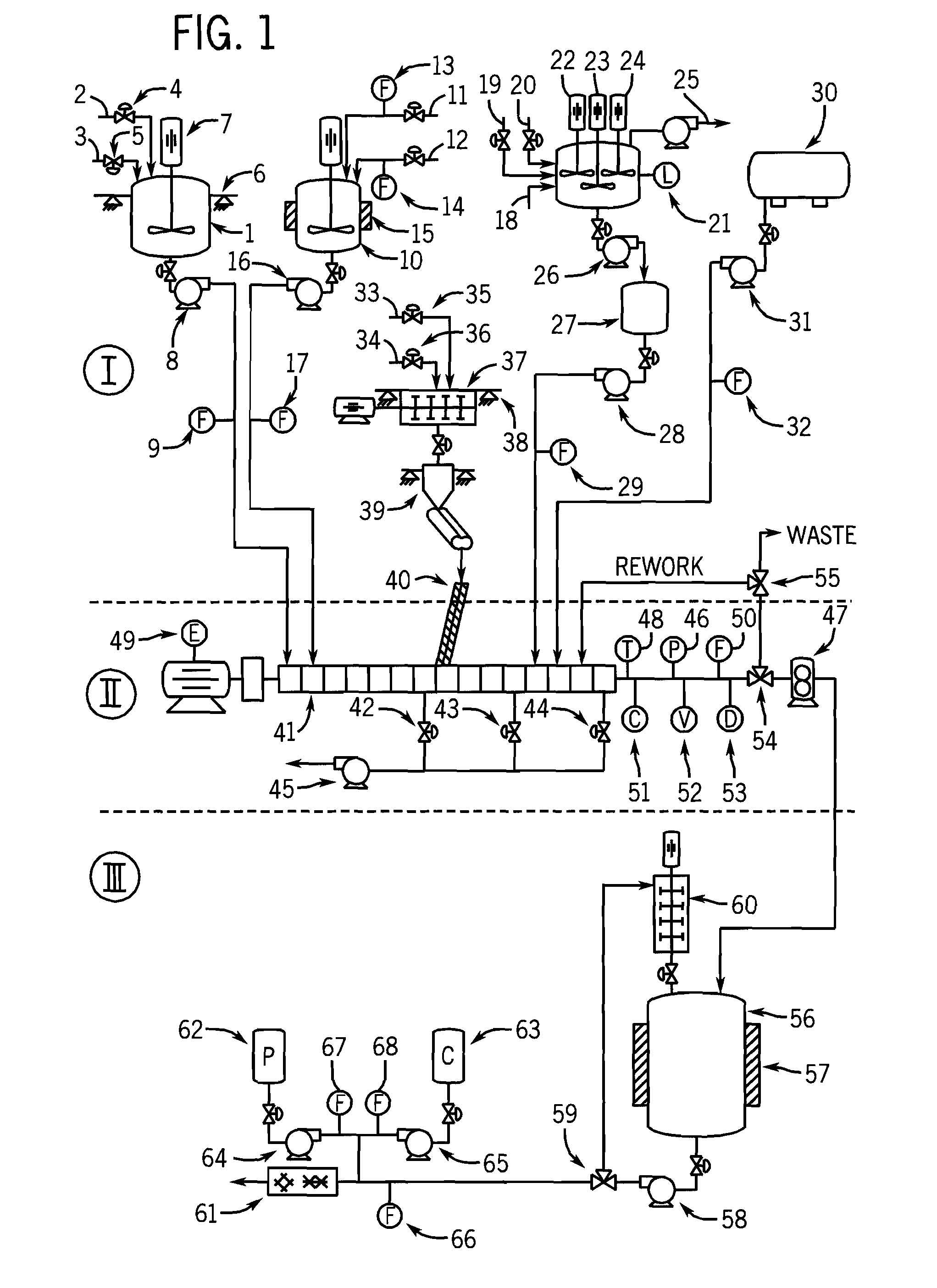

Continuous Process for the Production of Moisture-Cure, Polyurethane Sealants and Adhesives

ActiveUS20090198036A1High surface area-to-volume ratioMinimization requirementsArtifical filament manufactureChemical reactionAdhesive

A process for continuous manufacturing of moisture-curable polyurethane formulations used as sealants and adhesives. The process is characterized by the fact that the reactive components are introduced independently, and without the need for a prepolymer, to a mixer. Solid or liquid raw materials can be either pre-blended or fed directly to the mixer, a twin-screw extruder, which provides the requisite energy to homogenously mix the raw materials and drive the chemical reaction. The process is designed so that the extruder barrel and screw allow variable feed addition and heat exchange down the length of the machine. This allows various operations to be performed at different points in the extruder, including reaction, dispersive mixing, distributive mixing and devolitization.

Owner:BOSTIK INC

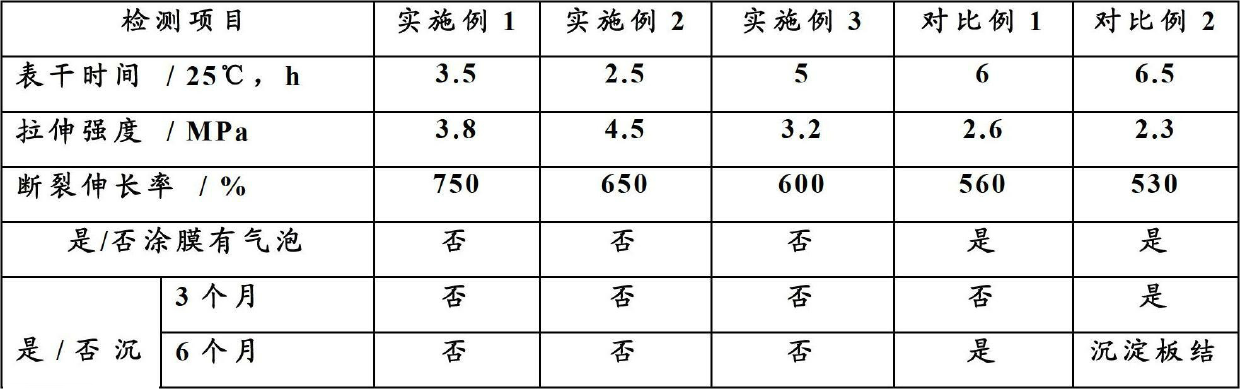

Latent curing single-component polyurethane water-proof coating and preparation method thereof

ActiveCN102807812AFast curingSolve the speed problemPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a latent curing single-component polyurethane water-proof coating and a preparation method thereof. The latent curing single-component polyurethane water-proof coating consists of the following components in parts by weight: 30-50 parts of diisocyanate, 150-190 parts of polyether polyol, 140-170 parts of chlorinated paraffin, 400-500 parts of a filler, 0.3-0.5 parts of a silane coupling agent, 8-15 parts of a latent curing agent, 0.8-1.1 parts of a catalyst and 120-165 parts of a diluting agent. The latent curing single-component polyurethane water-proof coating plays a role solving the problems of easiness in foaming in a crosslinking process and swelling and bubbling in a storing process existing in the conventional single-component moisture curing polyurethane water-proof coating, can be used for reducing the specific weight of polyurethane in the waterproof coating for reducing the cost, and has high mechanical property and low-temperature flexibility.

Owner:大岩(上海)建筑材料有限公司

High moisture vapor transmission hot melt moisture cure polyurethane adhesive with excellent hydrolysis resistance

InactiveUS6133400AGood moisture permeabilityImprove washabilityAdhesive articlesSynthetic resin layered productsPolyesterMoisture cure polyurethane

This invention relates to a hot melt moisture cure polyurethane composition which is the reaction product of a polyether polyol formed from a compound selected from the group consisting of ethylene oxide, propylene oxide, 1,2-butylene oxide, 1,4-butylene oxide and mixtures thereof; a low molecular weight polyalkylene glycol having from 3 to 7 carbon atoms; a crystalline polyester polyol having a melting point from about 40 DEG C. to about 120 DEG C.; and at least one polyfinctional isocyanate component wherein said composition has a moisture vapor transmission rate of greater than about 100 g / m2 / day film thickness of from about 450 to about 500 g / m2, and hydrolysis resistance.

Owner:HB FULLER CO

Method of making water repellent laminates

ActiveUS20060269758A1Soft handKeep clean and dryGarment special featuresSynthetic resin layered productsPolyesterMoisture cure polyurethane

The invention relates to a method of making a water repellent laminate including applying a hot melt moisture cure adhesive to a primary substrate and bonding the primary substrate with a secondary substrate that has been treated with a water repellent material prior to the lamination. The adhesive composition includes a hot melt moisture cure polyurethane prepolymer formed from a polyol component and a polyisocyanate component. The polyol component includes a first polyether polyol having a number average molecular weight of from about 500 to about 8,000, a first polyester polyol having a melting point of less than about 40° C. or a second polyether polyol having a molecular weight of from about 200 to about 1,000, and a crystalline polyester polyol having a melting point of from about 40° C. to about 120° C.

Owner:HB FULLER CO

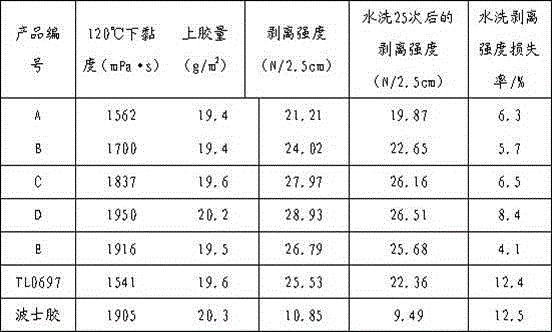

Moisturecuring polyurethane hot melt adhesive for lining cloth and preparation method of moisturecuring polyurethane hot melt adhesive

ActiveCN102977838AHigh bonding strengthWidely adjustable sizing temperaturePolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention discloses a moisturecuring polyurethane hot melt adhesive for lining cloth and a preparation method of the moisturecuring polyurethane hot melt adhesive. The preparation method comprises the following steps of: 1, heating and melting polyester polyol, polyether polyol, antioxidant and tackifying resin, stirring and mixing uniformly, and vacuum-degassing for 3.0h; 2, under the protection of nitrogen, adding MDI (diphenyl-methane-diisocyanate) and a catalyst in the reaction system, reacting for 45min at a temperature of 85-95 DEG C; 3, under the protection of nitrogen, adding a chain extender, a silane coupling agent and nanoscale white carbon black, reacting for 1.0h at a temperature of 85-95 DEG C to obtain a prepolymer; and 4, under the protection of nitrogen, transferring the reaction mixture to an aluminum foil bag, sealing and then curing for 6h at a temperature of 85 DEG C to obtain the moisturecuring polyurethane hot melt adhesive with wide and adjustable coating temperature and little residual CO2. The moisturecuring polyurethane hot melt adhesive is especially suitable for the industry of the lining cloth, and has the characteristics of high stripping strength and wide and adjustable sizing temperature.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

Aqueous two-component or multicomponent aqueous epoxy resin primer composition

InactiveUS20110027591A1Improve adhesionAdhesive processesSynthetic resin layered productsEpoxyAminosilochrome

The invention relates to two-component or multicomponent aqueous epoxy resin primer compositions comprising a first component, a second component, and an optional other component. The first component contains at least water and an epoxy resin while the second component contains at least one polyamine. The composition also comprises carbon black and / or epoxy silane and / or epoxy siloxane and / or an amino silane and / or an amino siloxane and / or mercaptosilane. The aqueous epoxy resin primer compositions improve adhesion of moisture-curing polyurethane adhesives or sealants on various bases.

Owner:SIKA TECH AG

Matte-finish polyurethane coating composition

InactiveUS20040063844A1Highly controlled glossHighly controlled sheen propertyConductive materialSpecial tyresUltraviolet lightsMoisture cure polyurethane

The invention relates to a color pigmented moisture-curing polyurethane coating that cures to form a film having a matte finish, as well as methods of producing the coating. The coating is suitable for use as a protective and / or decorative coating. The coating comprises one or more specified color pigments, polyisocyanates, polyols, tertiary amines, and a matting agent or agents. The combination of constituents provide a finished form coating with highly controlled gloss and sheen characteristics. Additional optional ingredients may be added to the coating composition, including catalysts, ultraviolet light stabilizers, wetting agents, solvents, and agents to increase slip and flow.

Owner:URS BHASKAR R

Adhesive for solid wood floor and preparation method thereof

ActiveCN103013425AIncrease elasticityGood adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolid woodLow noise

The invention discloses an adhesive for a solid wood floor and a preparation method of the adhesive. The adhesive is a one-component moisturecuring polyurethane elastic adhesive which consists of polyether polyol, polyisocyanates, a plasticizer, padding, a catalyst, a water removing agent, a coupler and an antioxygen. The adhesive used to pave the solid floor overcomes the deficiencies that at present, in solid wood floor pavement, the solid wood floor is large in noise, free from elasticity, poor in stability, has sound like an empty drum, and cannot be used in a ground heating system and the like due to rough grounds which have to be used. The adhesive has the advantages of one-component moisturecuring, convenience in operation, strong adhesive strength, safety, environment friendliness and the like, and can be adjusted in different colors according to colors of the solid wood floors. The solid wood floors paved have the advantages of elasticity, comfort, low noise, and can be used in the ground heating system and the like, and the risk of deformation and crack of the solid wood floor can be reduced. The adhesive is suitable for paving various solid wood floors and elastically adhering skirting lines, thresholds and stairs and the like, and meanwhile the adhesive is further used for paving ceramic tiles.

Owner:NANTONG GAOMENG NEW MATERIAL

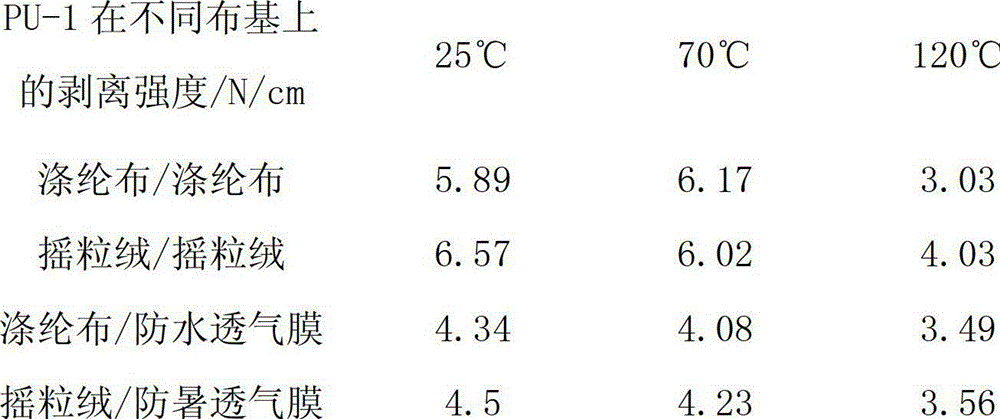

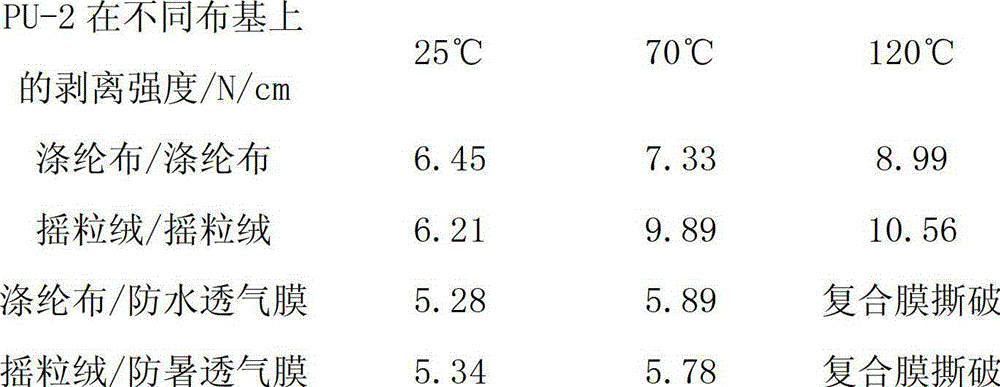

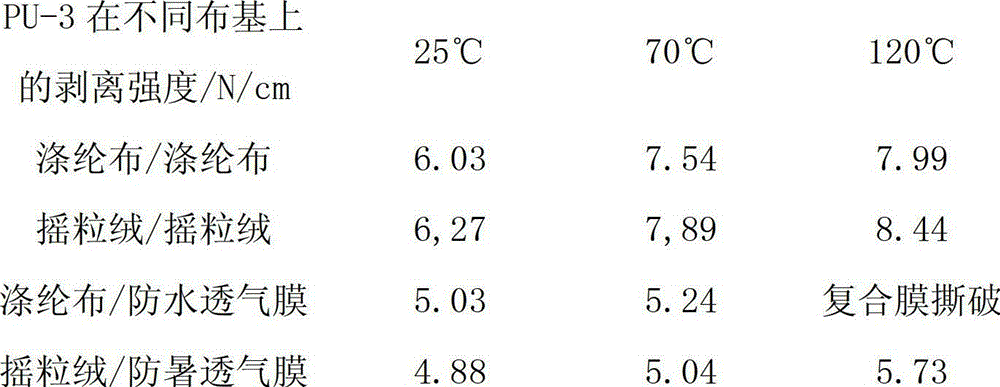

High-permeability single-component polyurethane hot-melt adhesive for fabric combination and preparation method thereof

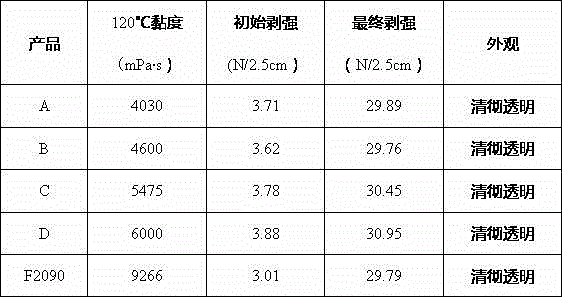

The invention belongs to the technical field of polyurethane, and particularly relates to a high-permeability single-component polyurethane hot-melt adhesive for fabric combination and a preparation method thereof. Crystalline polyester polyol, amorphous polyester polyol, polyether polyol and chain extender react with isocyanate, and thereby the hot-melt adhesive is prepared. The moisture-curable single-component polyurethane hot-melt adhesive has high initial bonding strength and final bonding strength, good moisture permeability and excellent temperature resistance, and is suitable for flow line production, and moreover, the high-permeability single-component polyurethane hot-melt adhesive has excellent environment-friendliness, and is applicable to the combination of various polyurethane films and various base fabrics.

Owner:南通恒华粘合材料科技有限公司

Moisturecured one-component polyurethane paint and preparation method thereof

ActiveCN102676039ASolving Storage Stability IssuesImprove physical and mechanical propertiesPolyurea/polyurethane coatingsPlasticizerMoisture cure polyurethane

The invention relates to moisturecured one-component polyurethane paint and a preparation method thereof. The polyurethane paint comprises the following raw materials in percentage by weight: 10%-20% of polyisocyanate monomer, 20%-40% of polyether polylol, 5%-15% of plasticizer, 30%-50% of modified mineral powder, 1%-5% of latent curing agent, 0.1%-2% of environment-friendly catalyst covered with cyclodextrin, 0.1%-1% of defoamer and 0.1%-1% of mono-isocyanate compound, wherein the modified mineral powder is mineral powder of which the surface is covered with a covered agent by a chemical covering method; and the environment-friendly catalyst covered with the cyclodextrin is in a nanometer cavity of the cyclodextrin, and the cyclodextrin is unmodified cyclodextrin or modified cyclodextrin or the composition of the unmodified cyclodextrin and the modified cyclodextrin. The moisturecured polyurethane paint disclosed by the invention solves the problem in storage stability of a one-component polyurethane product, and the storage life of the moisturecured polyurethane paint can exceed one year.

Owner:苏州中材非金属矿工业设计研究院有限公司 +1

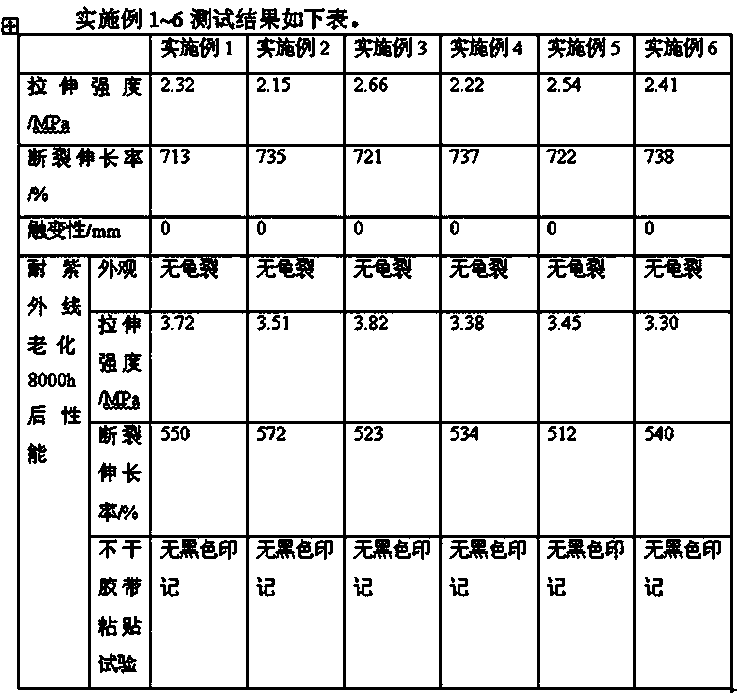

One-component moisture-cured polyurethane sealant with excellent ultraviolet resistance

ActiveCN103834345AImproves UV resistanceIncrease elasticityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantUltraviolet

A one-component moisture-cured polyurethane sealant with excellent ultraviolet resistance belongs to the technical field of one-component moisture-cured polyurethane sealants, mainly solves the problems of photooxidation aging phenomenon, mechanical properties decreasing, sealant surface cracking, yellowing of white sealants and black water flowing of black sealants for the reason of rain erosion of one-component moisture-cured polyurethane sealants in the prior art under the effects of long-term irradiation of ultraviolet ray in natural light, and is mainly characterized by including 8 to 20 parts of a polyurethane prepolymer (I), 20 to 30 parts of a polyurethane prepolymer (II), 0.5 to 2 parts of a water absorption stabilizer, 0.1 to 0.7 part of a silane coupling agent, 0.1 to 1 part of a light stabilizer, 0.1 to 1 part of an antioxidant, 28 to 50 parts of a polyurethane-use filler, 1 to 4 parts of carbon black, 1 to 35 parts of a thixotropic agent and 0.4-2 parts of a catalyst. The one-component moisture-cured polyurethane sealant has the advantages of no cracking after placing in an ultraviolet aging box for 8000h, no black mark after pasting with a non-setting adhesive tape, good elasticity maintainence and less than 30% of decrease of the elongation at break, and is suitable for auto-body exterior caulking.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Single-component moisture-curing polyurethane adhesive and preparation method thereof

ActiveCN104263310AMeet the actual requirementsHigh activityPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a single-component moisture-curing polyurethane adhesive and a preparation method thereof. The preparation method of the adhesive is characterized by comprising the following step: by adopting an organic solvent as a solvent, performing reaction on polyether glycol and / or polyester glycol, diphenyl methane diisocyanate, polymethylene polyphenyl isocyanate and triatomic primary alcohol of which the molecular weight is less than 200 to prepare the adhesive. The average degree of functionality of an obtained high-functionality NCO-terminated prepolymer is more than or equal to 3, and the single-component moisture-curing polyurethane adhesive disclosed by the invention is suitable for splicing and tenoning (or assembling) of woods and bonding and compounding of stone materials, fireproof plates, plastic aluminum plates, bakelite plates, oak boards, some metals such as aluminum and iron, zinc-plating plates, PVC membranes and the like, is especially suitable for adhesion of rosewoods and red woods, and can meet the special requirements of some products.

Owner:周建明

Moisture-Curable Polyurethane Hot-Melt Adhesive

ActiveUS20070232764A1Excellent final adhesive strengthImprove adhesionPolyureas/polyurethane adhesivesChemical recyclingPolyesterMoisture cure polyurethane

A moisture-curable polyurethane hot-melt adhesive, which includes a urethane prepolymer obtained by a reaction between polyisocyanate and polyols, wherein the polyols contain: long-chain aliphatic polyester polyol (A) represented by a general formula (I); aliphatic polyether polyol (B) having a number average molecular weight of 3,000 to 15,000; and aromatic polyester polyol (CI) which has a number average molecular weight of 1,000 to 5,000 and has a glass-transition temperature of 40° C. or more; (in the general formula (I), R1 and R2 each independently represent a straight chain alkylene group wherein the number of carbon atoms in the group is an even number, the sum of the number of carbon atoms in R1 and R2 is 12 or more, and n represents a number of 3 to 40).

Owner:DAINIPPON INK & CHEM INC

Plastic sizing agent for silane-modified single component wet cured polyurethane playing court and preparation method thereof

The invention relates to plastic sizing agent for a silane-modified single component wet cured polyurethane playing court; the plastic sizing agent comprises 7 to 11% of isocyanate, 25 to 40% of polyether polyol A, 1 to 3% of polyether polyol B, 10 to 20% of dissolvant, 20 to 40% of solid filler, 5 to 25% of plasticizer, 0.1 to 5% of silane coupling agent, 0.4 to 2% of pigment, 0.1 to 2% of anti-aging agent, 0.1 to 2% of ultraviolet absorbent, 0.1 to 1% of water, 0.001 to 0.1% of catalyst and 0.001 to 0.1% of polymerization inhibitor. The plastic sizing agent for a silane-modified single component wet cured polyurethane playing court is suitable for basketball courts and indoor venues, is convenient to use, does not need to be blended, and has stronger cohesive force with bottom foundations and low requirements on environment moisture; and after the plastic sizing agent is modified by the silane coupling agent, all indexes of the plastic sizing agent are superior to national standard.

Owner:SHANDONG INOV POLYURETHANE

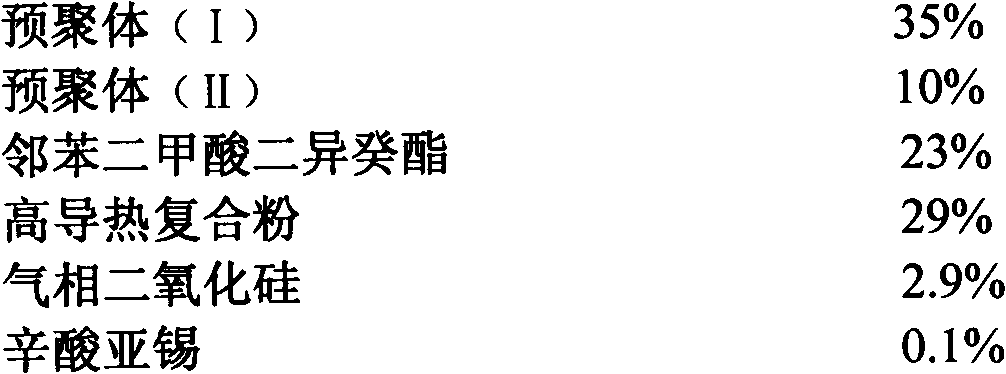

High-elasticity heat-conducting environment-friendly polyurethane sealant

ActiveCN102504749AGood adhesionImprove thermal conductivityNon-macromolecular adhesive additivesOther chemical processesHeat resistanceHeat conducting

The invention provides high-elasticity heat-conducting environment-friendly polyurethane sealant, belongs to the technical field of one-component moisture-curing polyurethane sealant, and aims to provide a high-elasticity heat-resisting waterproof heat-conducting adhesive one-component polyurethane sealant capable of excellently adhering various substrates such as various types of wood, concrete and the like, and a preparation method of the sealant. The invention is characterized in that the sealant is prepared in such a way that 25 to 60 percent of prepolymer prepared with high-activity high-molecular-weight polyether polyol and isocyanate is mixed with 15 to 30 percent of plasticizing agent, 15 to 35 percent of heat-conducting filling material, 2 to 10 percent of thixotropic agent and 0.01 to 1 percent of amine / tin compound. The sealant provided by the invention is used for paving and adhering all sorts of wood floor, particularly for paving emerging wood floor of a ground heating mechanism, so as to replace the traditional wood joist paving way.

Owner:WOLAN TECH

Method of making water repellent laminates

ActiveUS7344619B2Soft handKeep clean and dryGarment special featuresSynthetic resin layered productsPolyesterMoisture cure polyurethane

The invention relates to a method of making a water repellent laminate including applying a hot melt moisture cure adhesive to a primary substrate and bonding the primary substrate with a secondary substrate that has been treated with a water repellent material prior to the lamination. The adhesive composition includes a hot melt moisture cure polyurethane prepolymer formed from a polyol component and a polyisocyanate component. The polyol component includes a first polyether polyol having a number average molecular weight of from about 500 to about 8,000, a first polyester polyol having a melting point of less than about 40° C. or a second polyether polyol having a molecular weight of from about 200 to about 1,000, and a crystalline polyester polyol having a melting point of from about 40° C. to about 120° C.

Owner:HB FULLER CO

Wet cured polyurethane hot melt adhesive and preparation method thereof

ActiveCN104974707AImprove performanceEasy to apply gluePolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a wet cured polyurethane hot melt adhesive and a preparation method thereof; a modifier acrylic ester monomer containing hydroxyl and a polyurethane adhesive are selected for graft copolymerization, and a wet cured polyurethane hot melt adhesive is modified; the obtained wet cured polyurethane hot melt adhesive is good in comprehensive performance, has a moderate viscosity for facilitating adhesive applying operation, besides, has a relatively high initial viscous force, and improves performance requirements of special fields.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Laminates for security documents

InactiveUS20150227829A1Prevent skimmingReduce warpage and breakageSemiconductor/solid-state device detailsSolid-state devicesMoisture cure polyurethaneEngineering

Secure inlays for secure documents such as a passport comprising an inlay substrate may have laser-ablated recesses within which a chip module is installed. The inlay substrate may include two layers, and the antenna wire may be between the two layers. A moisture-curing polyurethane hot melt adhesive may be used to laminate a cover layer and the additional inlay substrate layers. The adhesive layer may be used (i) as a sealant, to protect the interconnections, (ii) as a fixing mechanism for the chip module, and (iii) as an adhesive for joining the two substrates (inlay and leadframe substrates) together. Method and apparatus are disclosed.

Owner:ASSA ABLOY AB

Preparation method for silane-modified moisture-curable polyurethane hot melt adhesive

ActiveCN104449535AEnhanced van der Waals forceImprove wetting effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWhitening Agents

The invention discloses a preparation method for a silane-modified moisture-curable polyurethane hot melt adhesive. The method comprises the following steps: (1) heating and mixing polyester polyol, polyether polyol, tackifying resin, an antioxidant and a fluorescent whitening agent at a certain temperature, performing reduced pressure degassing for 2 hours, and cooling to 90 DEG C; (2) adding isocyanate and a catalyst into a reaction system under the nitrogen protection, and reacting at 85-95 DEG C for 45 minutes; (3) adding a chain extender and a silane coupler under the nitrogen protection, and reacting at 85-95 DEG C for 1 hour to obtain a prepolymer; (4) transferring a reaction mixture into an aluminum foil bag under the nitrogen protection, sealing, and curing at 85 DEG C for 6 hours to obtain the silane-modified moisture-curable polyurethane hot melt adhesive with excellent performance.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

High-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and preparation method thereof

InactiveCN111849408AExtended opening hoursHigh initial bond strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a high-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials inparts by weight: 20-50 parts of polyether polyol, 10-40 parts of crystalline polyester polyol, 5-30 parts of liquid polyester polyol, 10-20 parts of polyisocyanate, 10-35 parts of thermoplastic acrylic resin, 2-15 parts of tackifying resin, 0.1-0.5 parts of a catalyst and 0.1-1 part of an antioxidant. The moisture-curable polyurethane hot melt adhesive provided by the invention has the advantagesof long opening time, high initial adhesion strength, high curing speed, higher final adhesion strength, favorable damp-heat resistance and favorable high / low-temperature impact resistance, and can achieve the goals of no pressure maintaining and high-efficiency production of electronic products.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD +3

Bottom agent-free type single component moisture-curing polyurethane adhesive

ActiveCN1995256AGood adhesionPolyureas/polyurethane adhesivesPolyurethane adhesiveMoisture cure polyurethane

The invention discloses a base agent-free single-component wet solidifying polyurethane binder, which is reacted by the following parts: polyurethane prepolymer, binding accelerant, 2,2-dimorphia diethyl ester and tin dibutyl dilaurate catalyst, elasticizer, fill, ultraviolet absorbent and stabilizer, wherein the single-component polyurethane binder possesses excellent binding property for binding and assembling automobile and other vehicle.

Owner:TONSAN ADHESIVES INC

Moisture-Curing Polyurethane Composition with Good Low-Temperature Performance

InactiveUS20090202837A1Stable storageIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsMoisture cure polyurethaneSealant

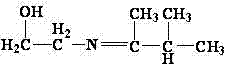

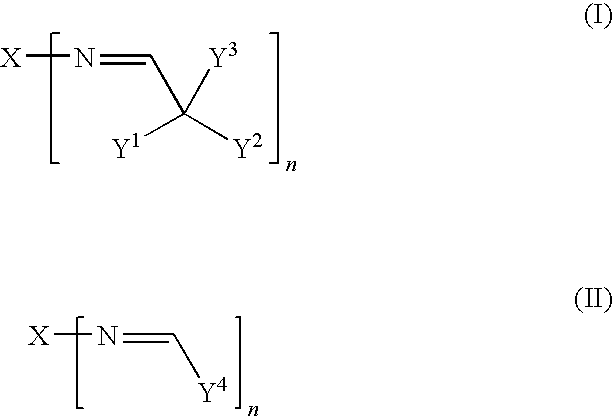

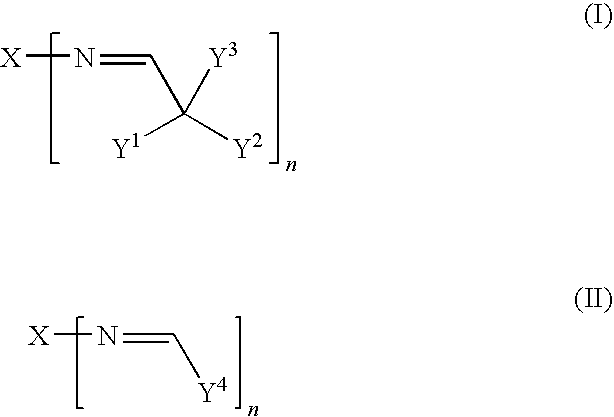

The present invention relates to one-component moisture-curing compositions comprising at least one isocyanate-containing polyurethane polymer P which has a mean molecular weight of at least 4000 g / mol, and at least one polyaldimine ALD of the formula (I) or (II), where the content of isocyanate groups is at most 3.5% by weight, based on the sum of the isocyanate-containing constituents present in the composition. The compositions are suitable especially as sealants and are notable for good low-temperature performance.

Owner:SIKA TECH AG

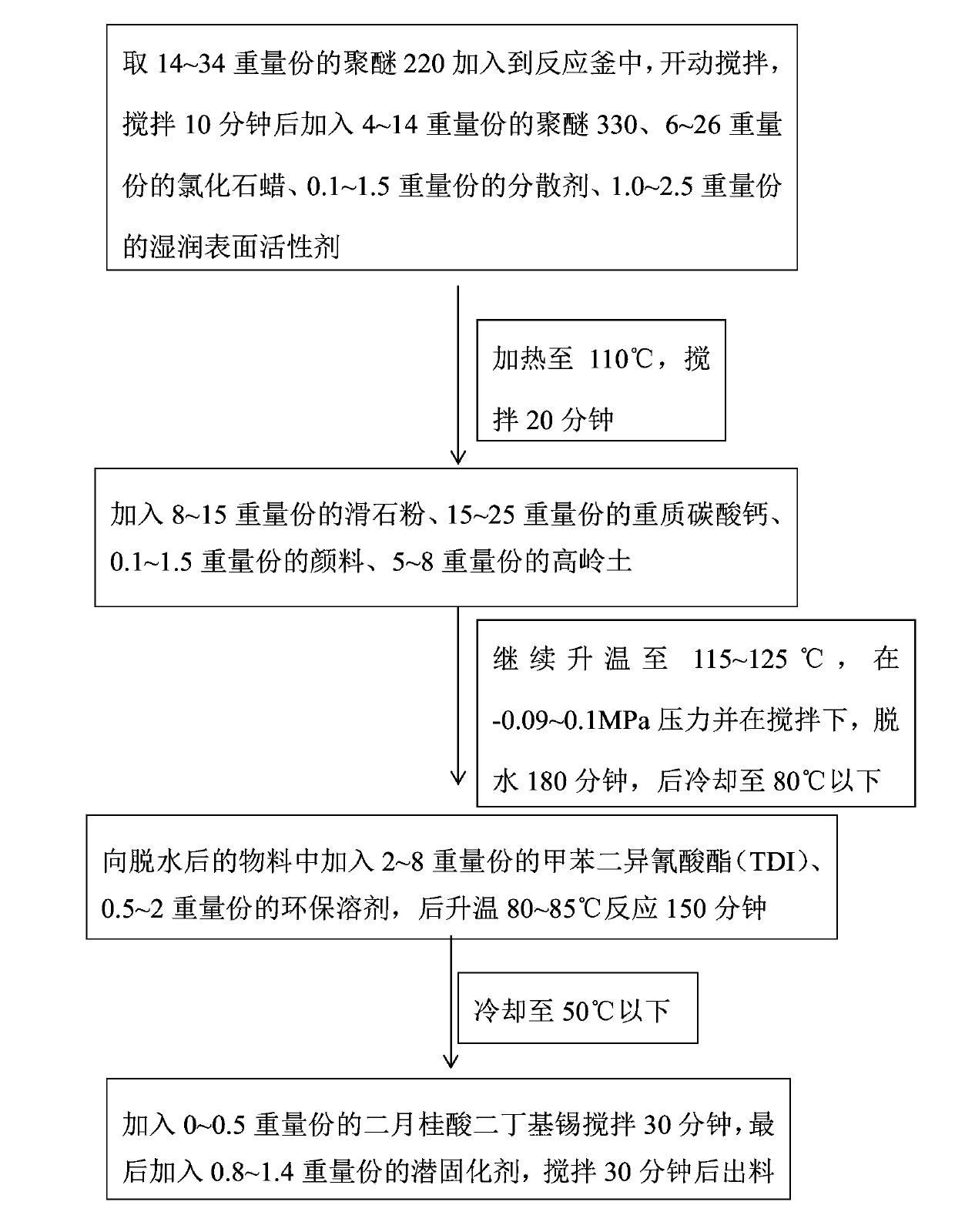

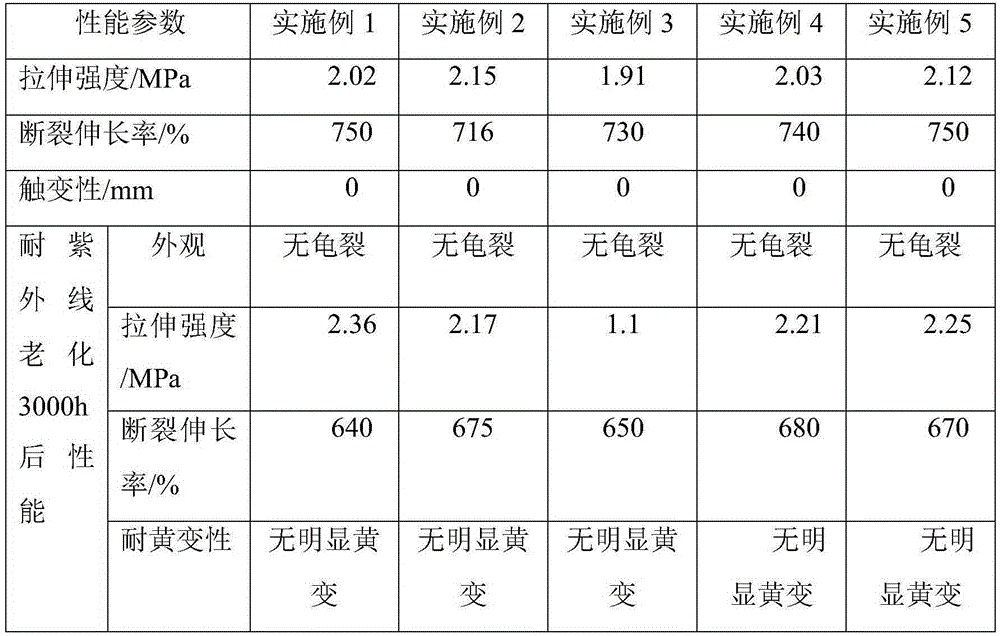

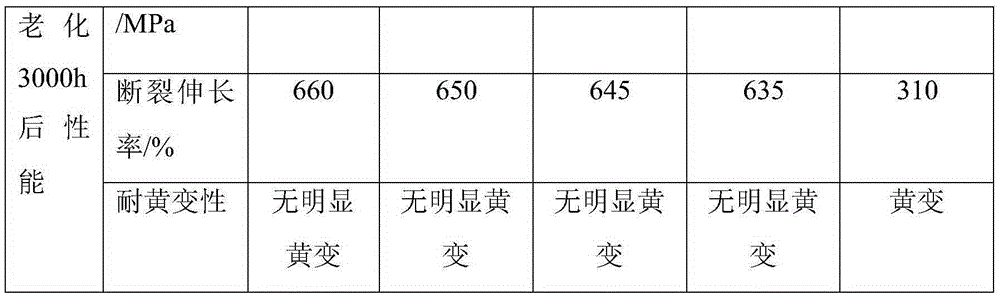

Single-component moisture curable polyurethane waterproof coating and preparation method thereof

InactiveCN103965765ASolve the problem that the construction quality is difficult to guaranteeGood storage stabilityPolyurea/polyurethane coatingsToluene diisocyanateChlorinated paraffins

The invention provides a single-component moisture curable polyurethane waterproof coating and a preparation method thereof. The single-component moisture curable polyurethane waterproof coating comprises the following raw materials by weight: 14-34 part of polyether 220, 4-14 parts of polyether 330, 6-26 parts of chlorinated paraffin, 0.1-1.5 parts of a dispersing agent, 1.0-2.5 parts of a wetting surfactant, 8-15 parts of talcum powder, 15-25 parts of heavy calcium carbonate, 0.1-1.5 parts of a pigment, 5-8 parts of kaolin, 2-8 parts of toluene diisocyanate (TDI), 0.5-2 parts of environment-friendly solvent, 0-0.5 part of dibutyltin dilaurate, and 0.8-1.4 parts of a latent curing agent. In the preparation process of the polyurethane coating, the wetting surfactant and the latent curing agent are added, so that even if a fundamental plane with a lot of dust is encountered in a construction process of the coating, sand holes and other problems cannot arise. Adding of the latent curing agent can prevent the coating from undergoing micro-foaming during construction.

Owner:YANTAI DONGJU WATERPROOF THERMAL INSULATION ENG CO LTD

High moisture vapor transmission hot mele moisture cure polyurethane adhesive with exellent hydrolysis resistance

InactiveCN1341133AAdhesive articlesSynthetic resin layered productsPolyesterMoisture cure polyurethane

Owner:HB FULLER CO

Solvent-free single-component wet-curing polyurethane court elastic material sizing agent and preparation method

The invention relates to a solvent-free single-component wet-curing polyurethane court elastic material sizing agent and preparation method. The sizing agent is prepared by adopting the following raw material formula: 25 to 40 parts of polyurethane pre-polymer with an end sealed by NCO, 20 to 45 parts of inorganic packing, 10 to 15 parts of plasticizer, 8 to 12 parts of viscosity reducer and 10 to 25 parts of functional additive; the polyurethane pre-polymer with the end sealed by the NCO is a reaction product of polyether glycol and excessive diisocyanate. According to the sizing agent prepared by adopting the formula and a process provided by the invention, the weakness that an existing material needs to be diluted by adding an organic solvent so as to be used can be solved; the sizing agent contains no organic solvent, thereby being small in viscosity, good in self leveling performance and convenient for construction; meanwhile, the solvent pollution during the material production, field construction and field application processes can be avoided, and the environmental friendliness can be realized; moreover, no organic solvent is contained, thus fewer material is used for per unit construction area of the same thickness, and the cost is saved.

Owner:王亚松

One-component moisture cured polyurethane sealant excellent in weather resistance and preparation method thereof

InactiveCN105255433AGood yellowing resistanceGood weather resistanceNon-macromolecular adhesive additivesOther chemical processesAntioxidantUltraviolet

The invention discloses one-component moisture cured polyurethane sealant excellent in weather resistance and a preparation method thereof and relates to the field of moisture cured polyurethane sealant. The polyurethane sealant is prepared from, by mass, 20-50 parts of polyurethane prepolymers, 0.5-2 parts of water absorbing and stabilizing agents, 0.1-0.7 part of silane coupling agents, 0.1-1 part of light stabilizing agents, 0.1-1 part of antioxidant, 2-10 parts of titanium dioxide, 28-50 parts of polyurethane-used filling materials, 1-35 parts of thixotropic agents and 0.4-2 parts of first catalysts. According to the polyurethane sealant, the light stabilizing agents and the antioxidant are added, in the process of preparing the polyurethane prepolymers, alicyclic or cycloaliphatic isocyanate is used for replacing 4, 4'-diphenylmethane diisocyanate in the existing polyurethane prepolymers, and the polyurethane sealant is not prone to yellowing under ultraviolet irradiation for a long time, slow in mechanical performance degradation and suitable for being used for a long time.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

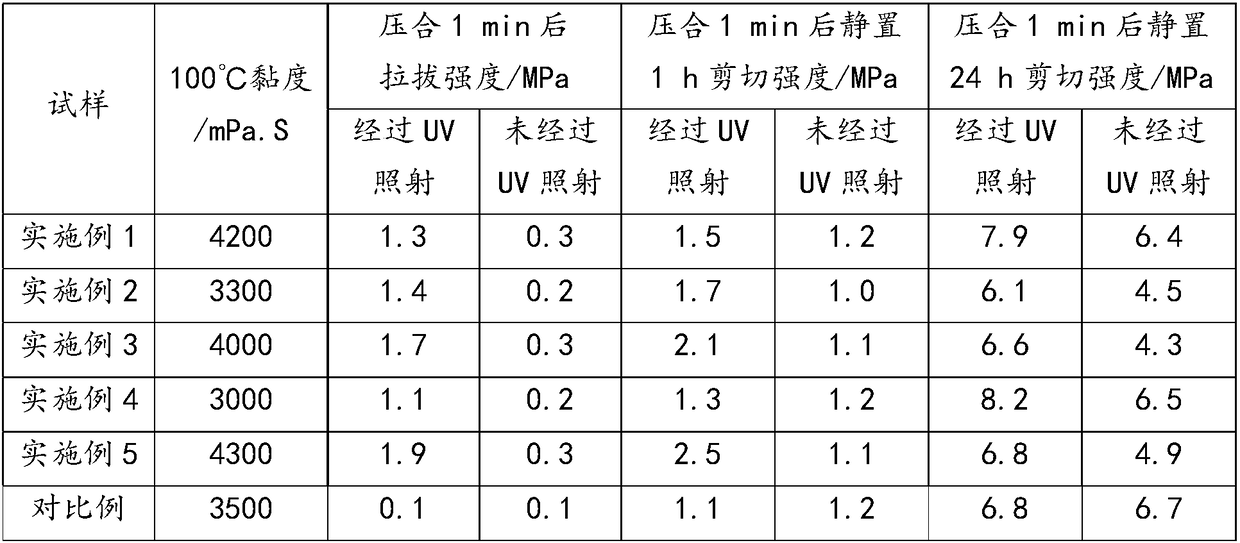

Preparation method of UV pressure-sensitive/moisture double-curing polyurethane hot melt adhesive

ActiveCN108084952APressure sensitivity hasImprove initial tackNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerPolymer science

The invention belongs to the technical field of adhesive and particularly relates to a preparation method of UV pressure-sensitive / moisture double-curing polyurethane hot melt adhesive. Hydroxy acrylamide in the hot melt adhesive generates pressure sensitivity after being subjected to UV / PUR illumination to achieve a key effect; UV irradiation is conducted after hot melt adhesive application and before adhesion, pressure is applied to an adhesion piece after adhesion, a certain time is maintained, and adhesive liquid can be crosslinked into an elastomer polymer in a viscoelastic state and haspressure sensitivity and high initial adhesion; pressing is conducted for 1 minute after assembling and adhesion, and the pull strength can reach to 1 to 2 MPa, so that rapid adhesion and positioningeffects are achieved; after pressing, moisture curing polyurethane reaction is continuously conducted and the pull strength after 24-hour curing can reach to 7 to 9 MPa, so that high adhesion strengthis guaranteed.

Owner:信泰永合(烟台)新材料有限公司

PTMG (polyoxytetramethylene glycol) modifying moisture curing polyurethane melt adhesive and preparation method thereof

ActiveCN104449537AImprove hydrolysis resistanceReduced flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesAntioxidant

The invention discloses a PTMG (polyoxytetramethylene glycol) modifying moisture curing polyurethane melt adhesive and a preparation method thereof. The melt adhesive product comprises the following raw materials in parts by weight: 18-35 parts of polypropylene glycol, 15-30 parts of polytetrahydrofuran glycol, 8 parts of poly adipic acid-1, 6 hexanediol esterdiol, 0.5 part of an antioxidant, 15-20 parts of tackifying resin, 24-25 parts of 4, 4'- ditan diisocyanate, 0.01 part of a catalyst, 0-0.5 part of a chain extender, 0-2 parts of a silane coupler, and 0-0.5 part of white carbon black. The PTMG modifying moisture curing polyurethane melt adhesive prepared by the preparation method disclosed by the invention has the advantages of high stripping strength, good washing resistant performance, good flexibility, environmental protection and the like.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com