Moisturecuring polyurethane hot melt adhesive for lining cloth and preparation method of moisturecuring polyurethane hot melt adhesive

A polyurethane adhesive, moisture curing technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of not fully meeting the development requirements of the interlining industry, and achieves widely adjustable sizing temperature, Good performance and the effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

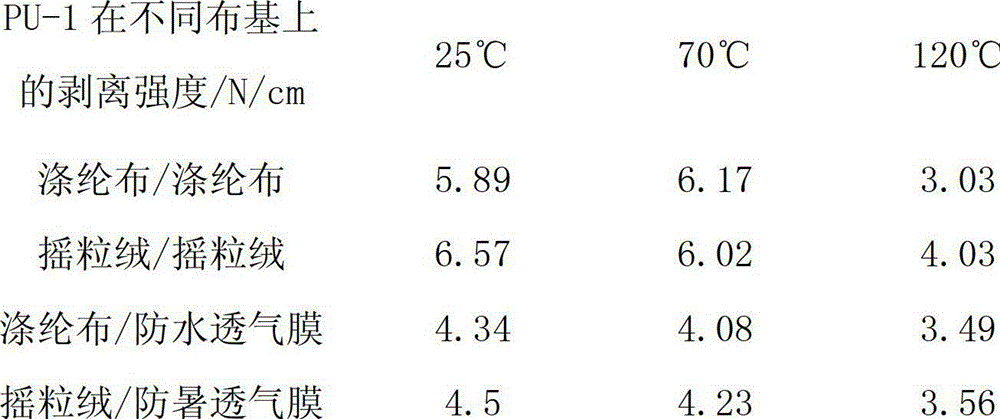

Embodiment 1

[0023] Weigh 5.0 g of polybutylene phthalate diol with a molecular weight of 2000, 300.0 g of polyoxypropylene diol with a molecular weight of 4000, 85.0 g of polyacrylic acid, 1.25 g of antioxidants CHINOX1076 and CHINOX1010, add them to a three-necked flask, and heat Stir and vacuum at 130-145°C for 3.0h. The vacuum degree is lower than 0.1 atmosphere. Cool down to 90°C, add 87.5g of 4,4′-MDI, 0.175g of stannous octoate and 0.075g of bis(2,2-morpholine ethyl) ether under the protection of nitrogen, and react for 45min at 85~95°C. Under the protection of nitrogen, 4.75g of 1,4-butanediol, 10.0g of γ-aminopropyltriethoxysilane KH-550, 5.0g of nano-sized white carbon black were added, and the reaction was stirred at 85-95°C for 1.0h at high speed. The above-mentioned prepolymer was discharged under nitrogen protection, sealed and packaged, and aged in an environment of 85° C. for 6 hours. Promptly obtain interlining fabric composite glue, the sample number is PUR-1.

Embodiment 2

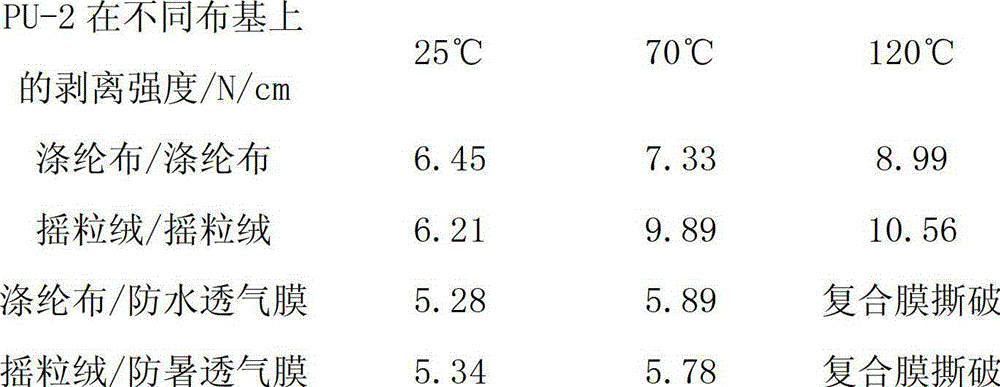

[0025] Weigh 85.0 g of polybutylene adipate diol with a molecular weight of 2000, 210.0 g of polyethylene glycol with a molecular weight of 2000, 94.25 g of polystyrene, 1.25 g of antioxidants CHINOX1076 and CHINOX1010, and add them to a three-necked flask. Heat and stir, and vacuum at 130-145°C for 3.0h. The vacuum degree is lower than 0.1 atmosphere. Cool down to 90°C, add 95.0g of 2,4′-MDI, 0.125g of stannous octoate and 0.125g of bis(2,2-morpholine ethyl) ether under the protection of nitrogen, and react for 45min at 85~95°C. Under the protection of nitrogen, add 2.5g of 1,3-propanediol, 10.0g of γ-glycidyl etheroxypropyl trimethoxysilane KH-560, 0.5g of nano-sized white carbon black, and react with high-speed stirring at 85~95°C for 1.0h. The above-mentioned prepolymer was discharged under the protection of nitrogen, sealed and packaged, and aged at 85° C. for 6 hours. That is to get interlining fabric composite glue, the sample number is PUR-2.

Embodiment 3

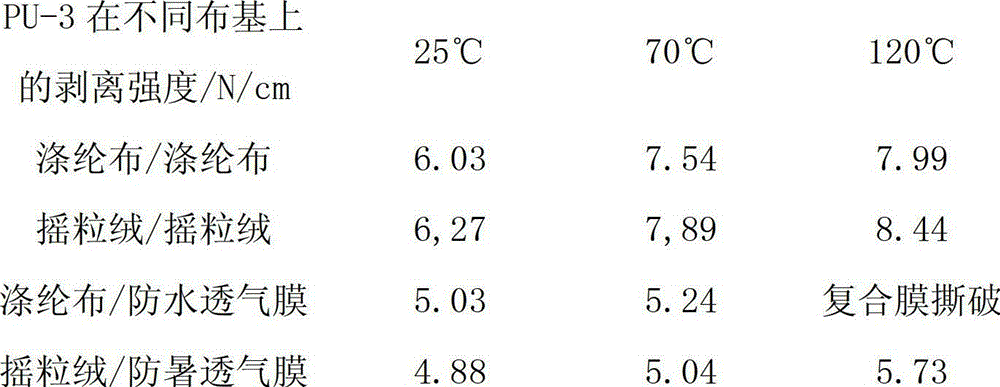

[0027] Weigh 44.75g of polycaprolactone polyol with a molecular weight of 1250, 255.0g of polyoxypropylene glycol with a molecular weight of 4000, 95g of polyethylene-vinyl acetate copolymer, 1.25g of antioxidants CHINOX1076 and CHINOX1010, and add them to a three-necked flask. Heat and stir, and vacuum at 130-145°C for 3.0h. The vacuum degree is lower than 0.1 atmosphere. Cool down to 90°C, add 87.5g of 2,2′-MDI, 0.15g of stannous octoate and 0.1g of bis(2,2-morpholine ethyl) ether under the protection of nitrogen, and react for 45min at 85~95°C. Under the protection of nitrogen, add 5.0g of 1,6-hexanediol, 5.0g of γ-(methacryloyloxy)propyltrimethoxysilane KH-5700, 5.0g of nano-sized white carbon black, stir at 85~95℃ at high speed Reaction 1.0h. The above prepolymer was discharged under the protection of nitrogen, sealed and packaged, and aged at 85°C for 6h. That is to get interlining fabric composite glue, the sample number is PUR-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com