Patents

Literature

13041 results about "Sizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sizing or size is any one of numerous substances that is applied to, or incorporated into, other materials—especially papers and textiles—to act as a protective filler or glaze. Sizing is used in papermaking and textile manufacturing to change the absorption and wear characteristics of those materials.

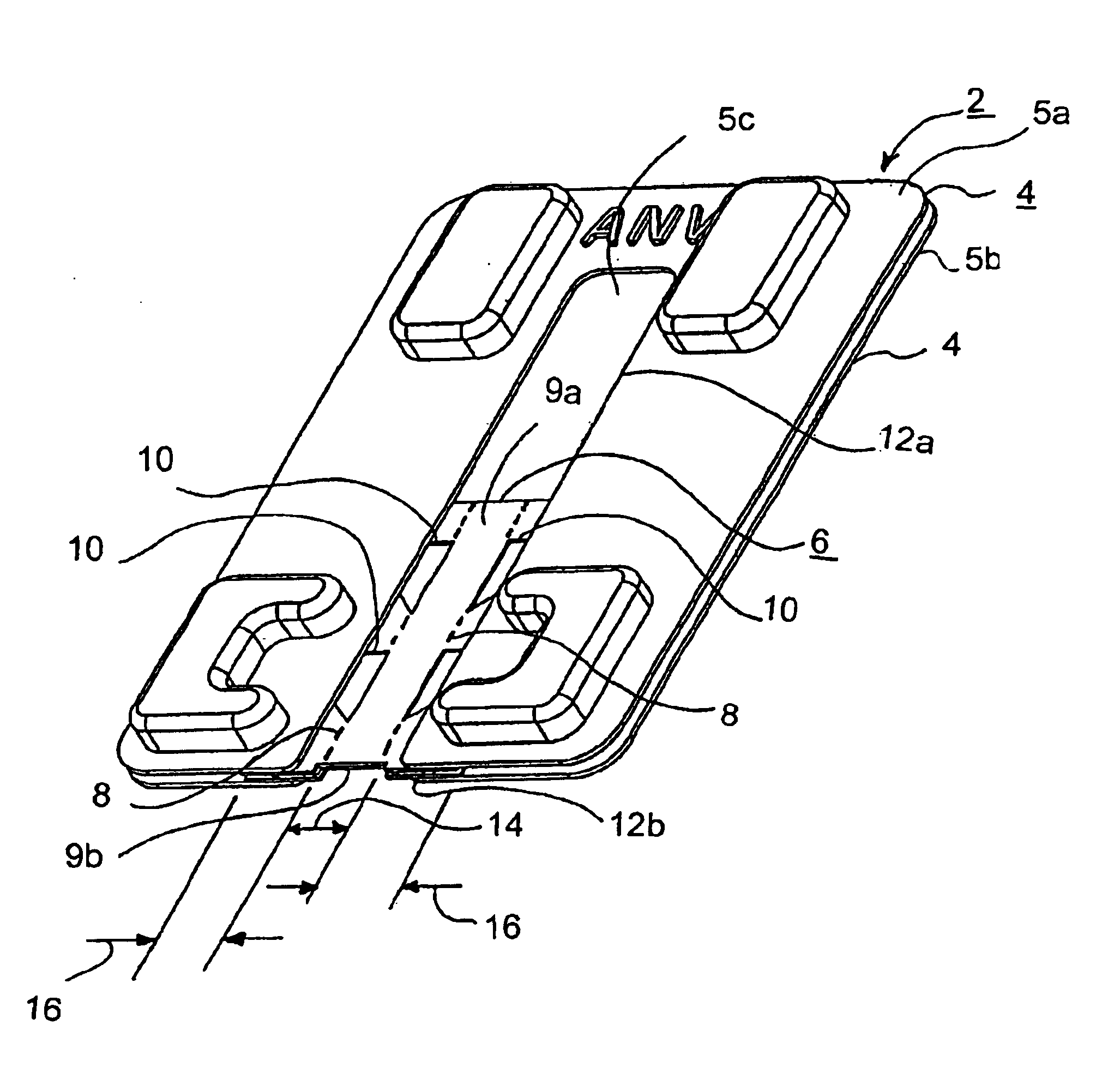

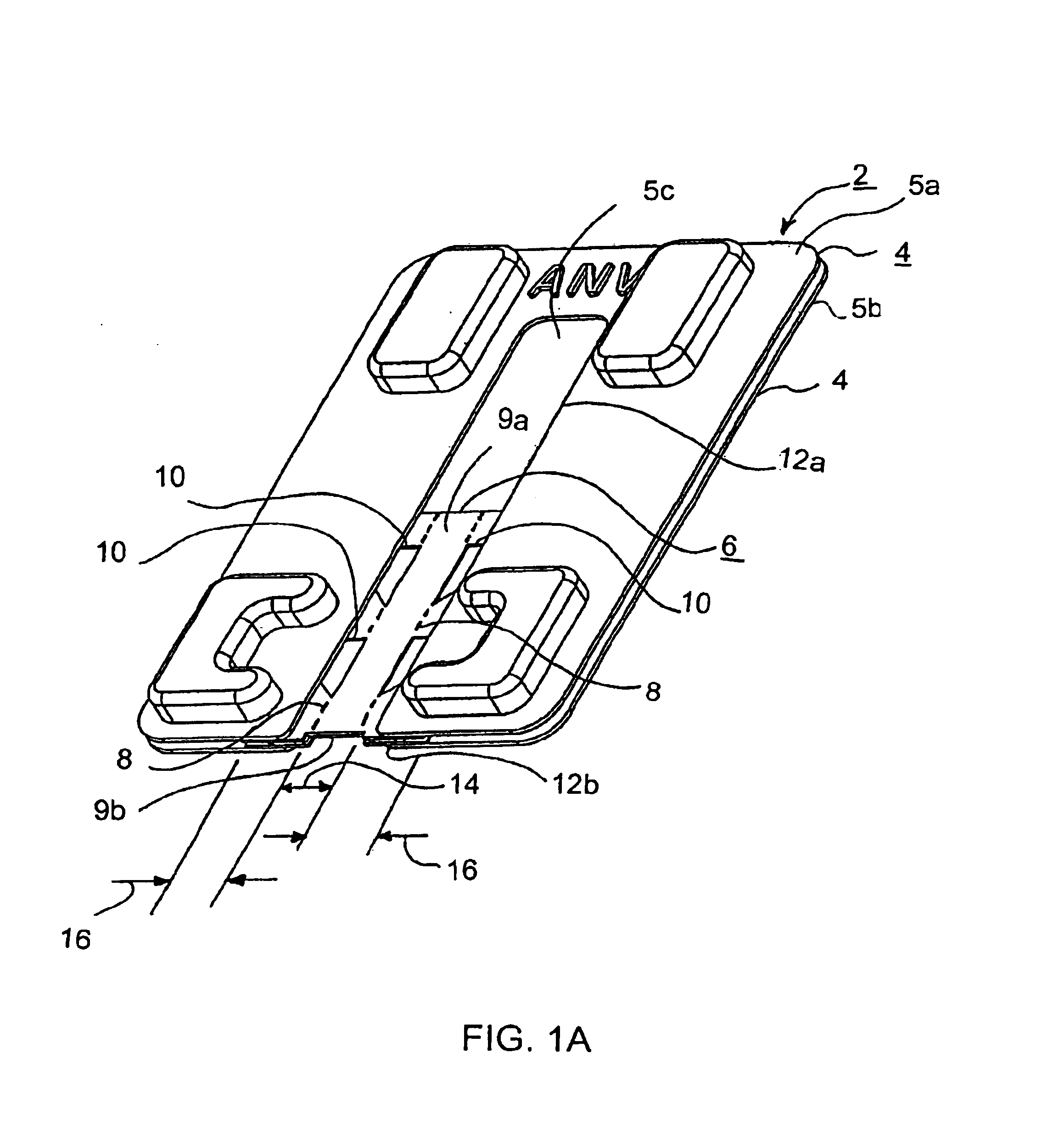

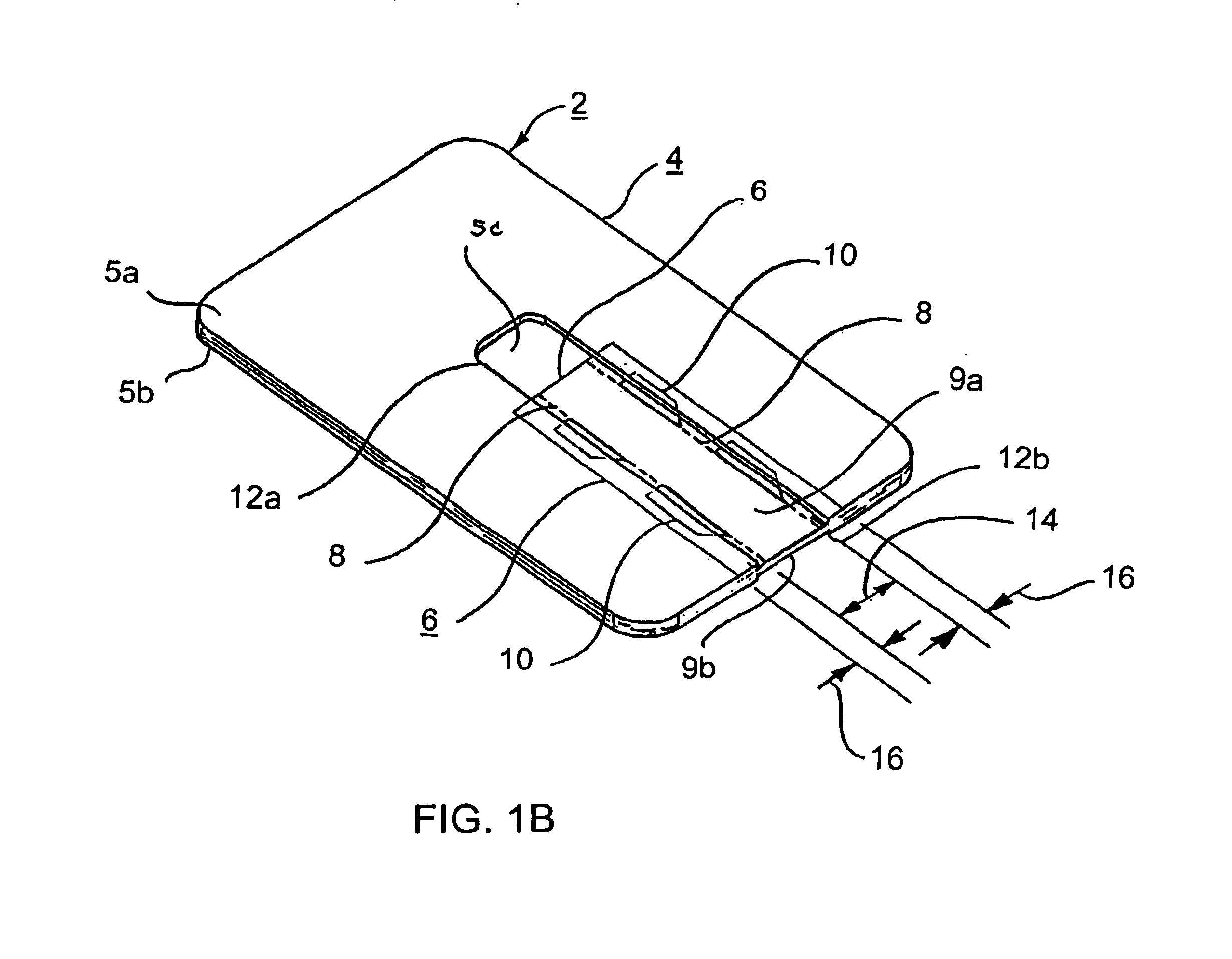

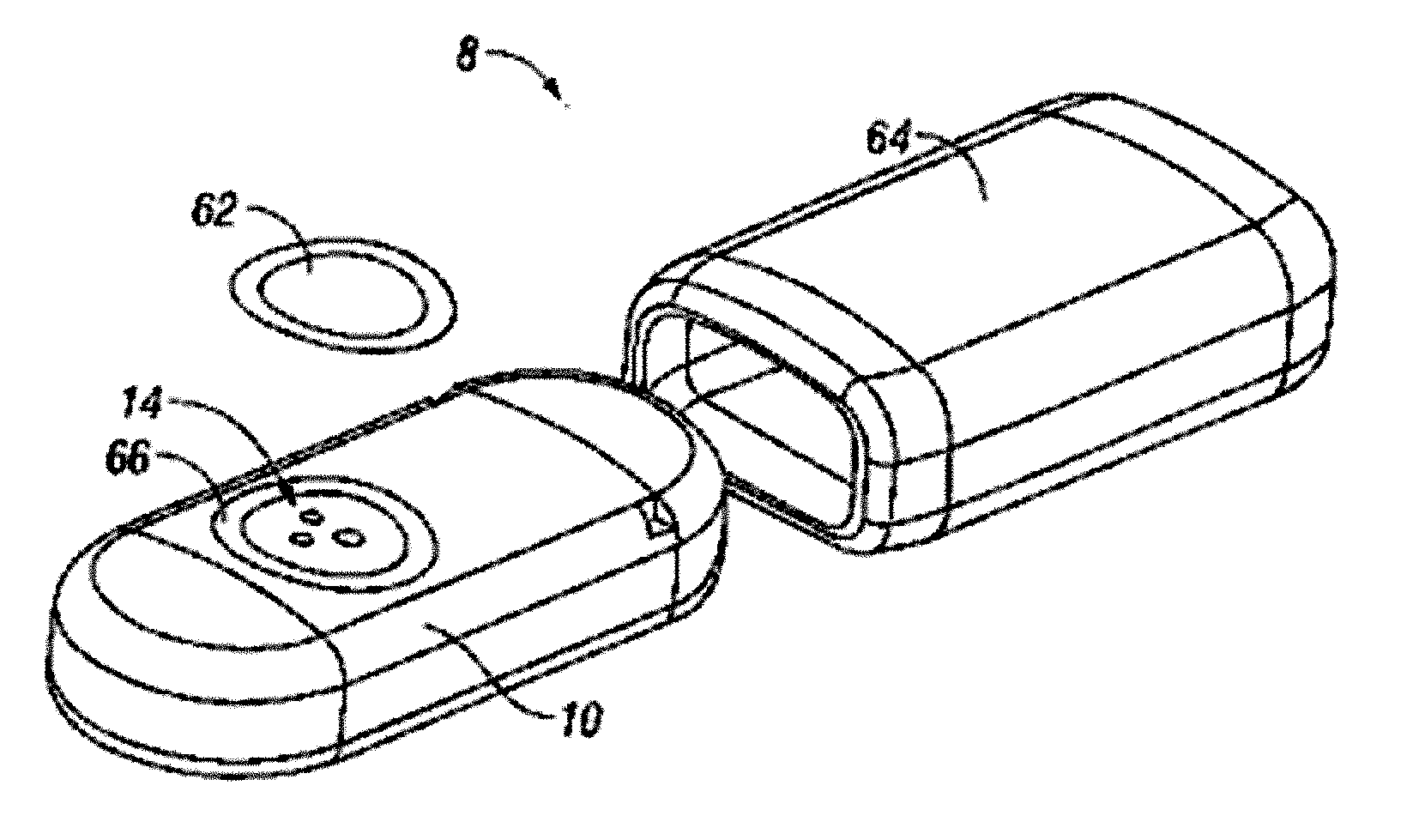

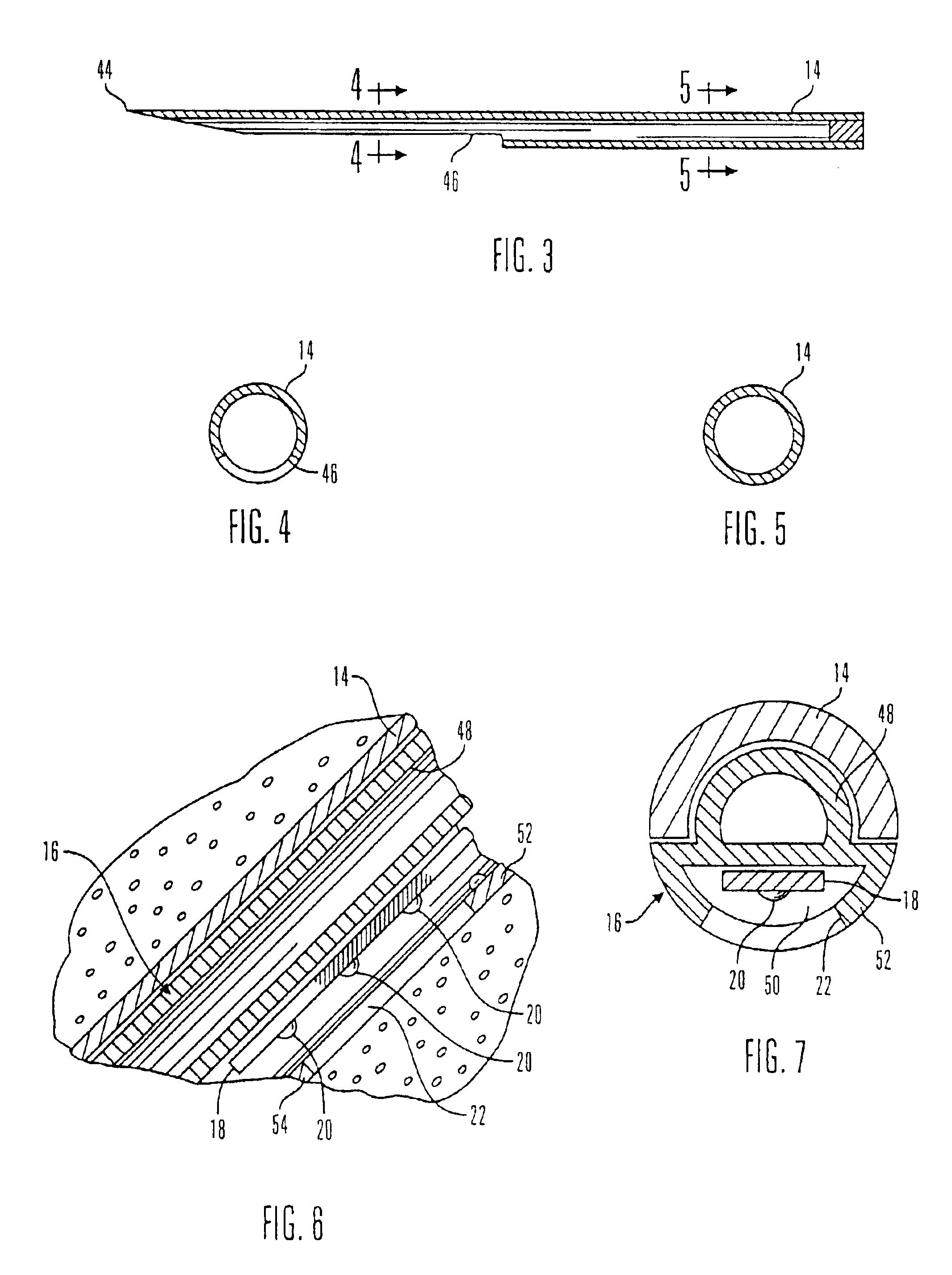

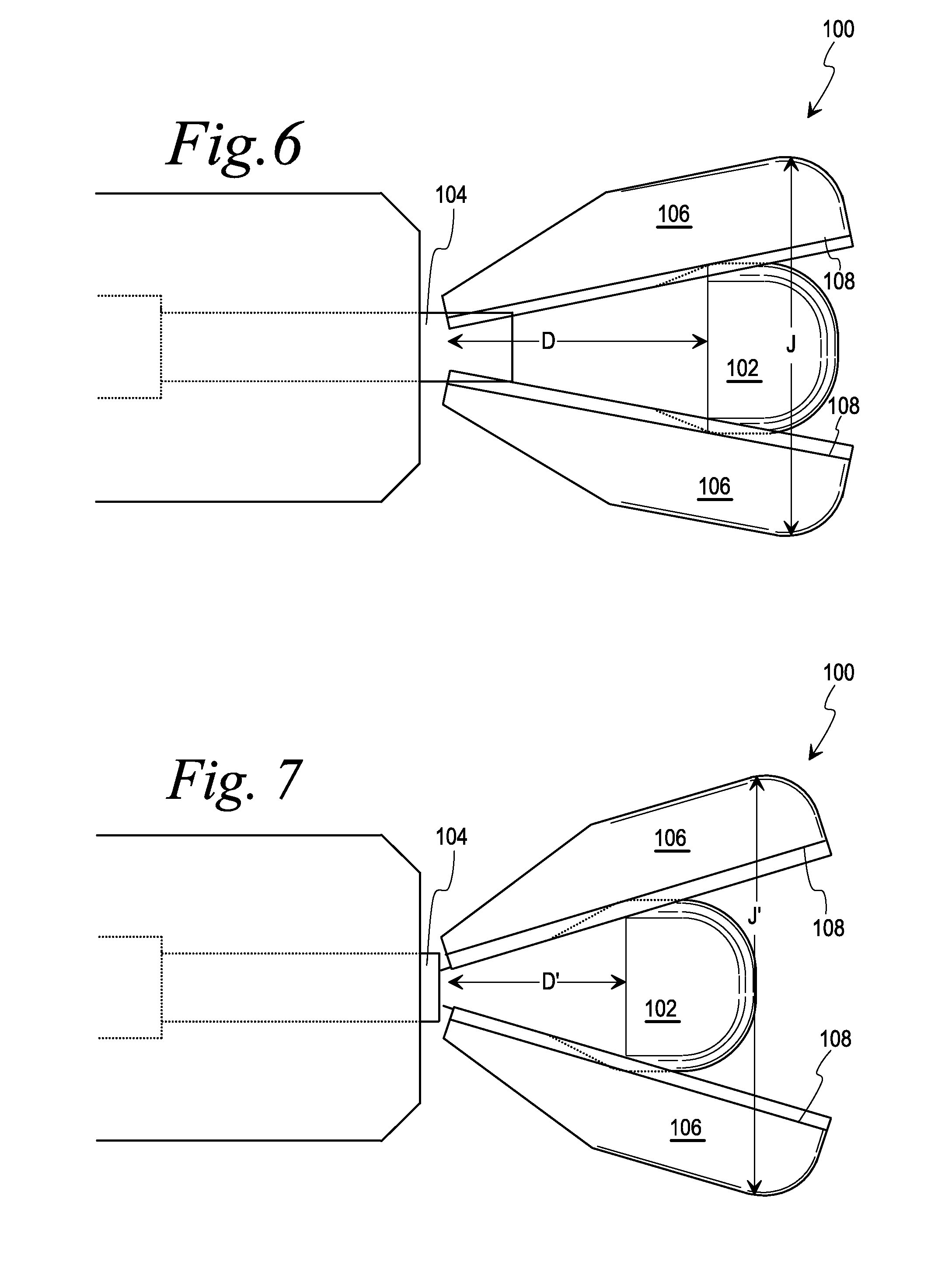

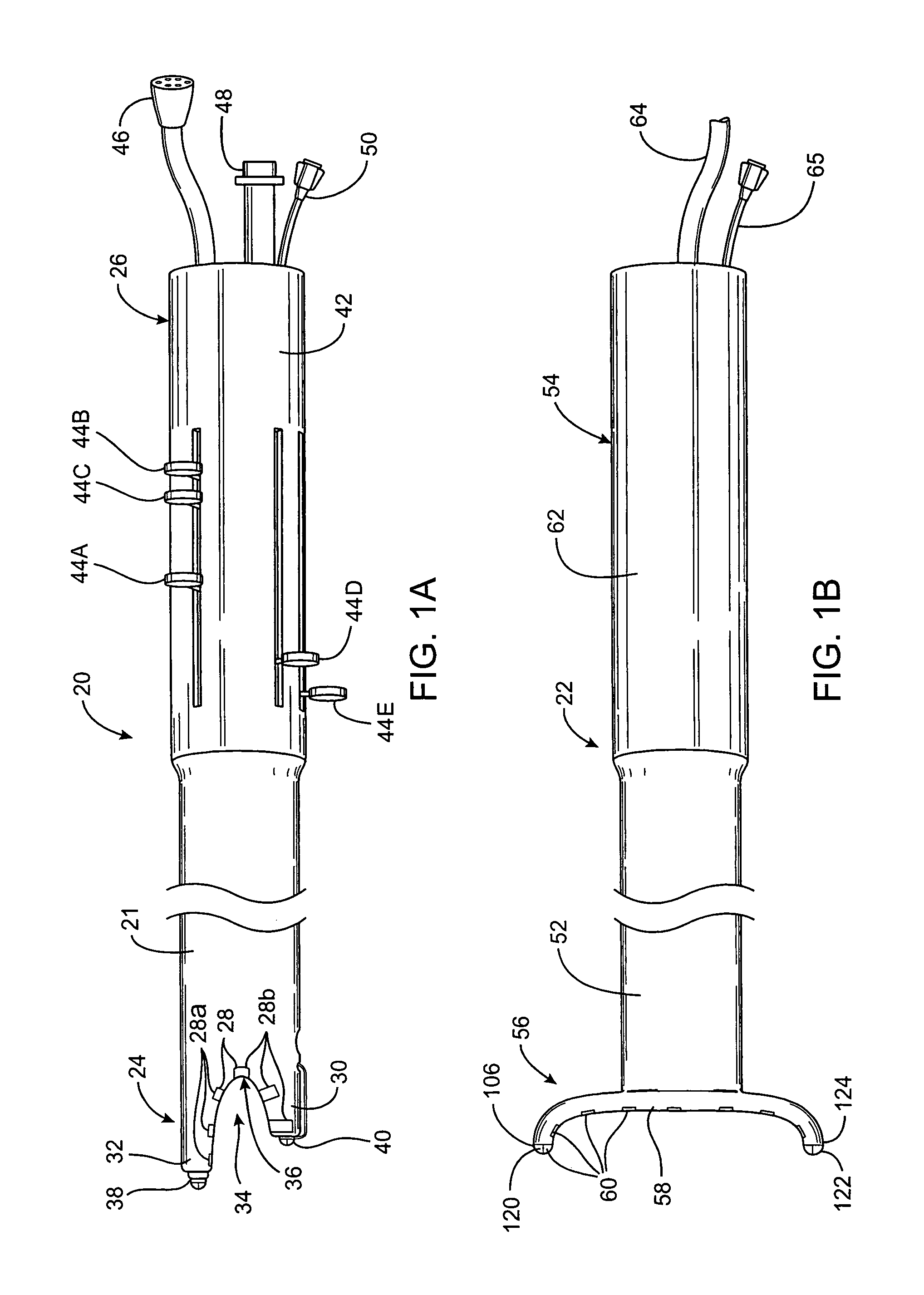

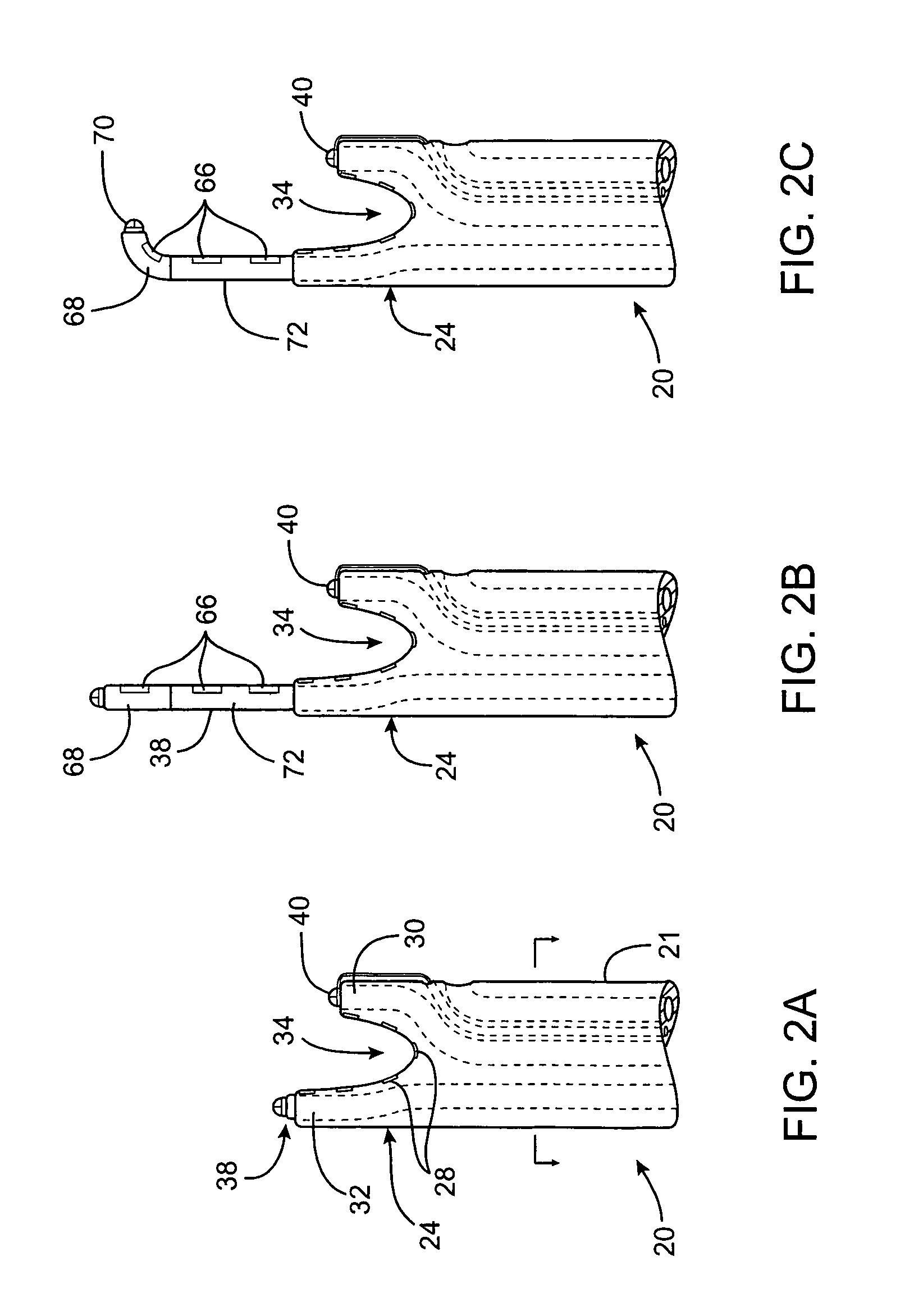

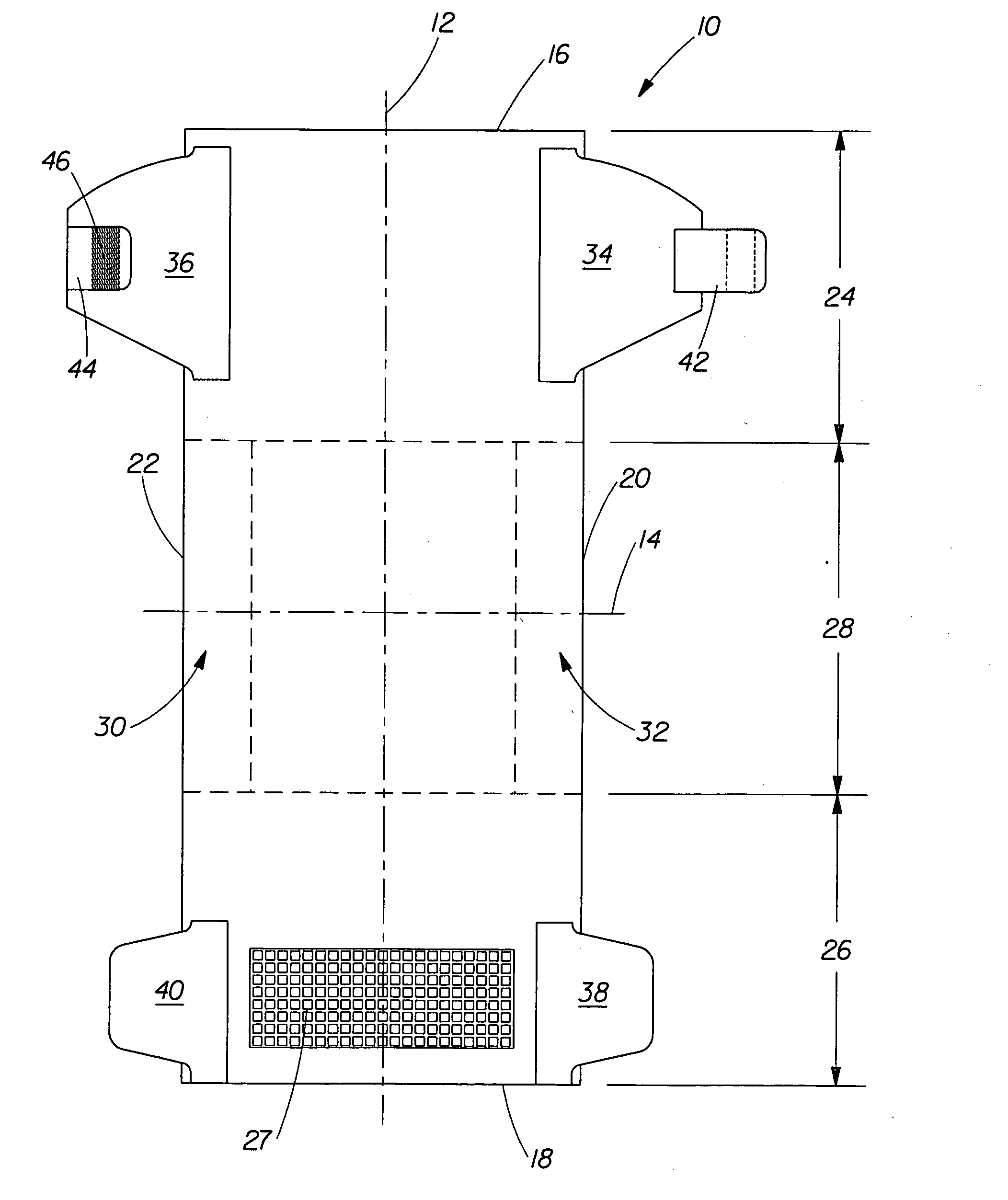

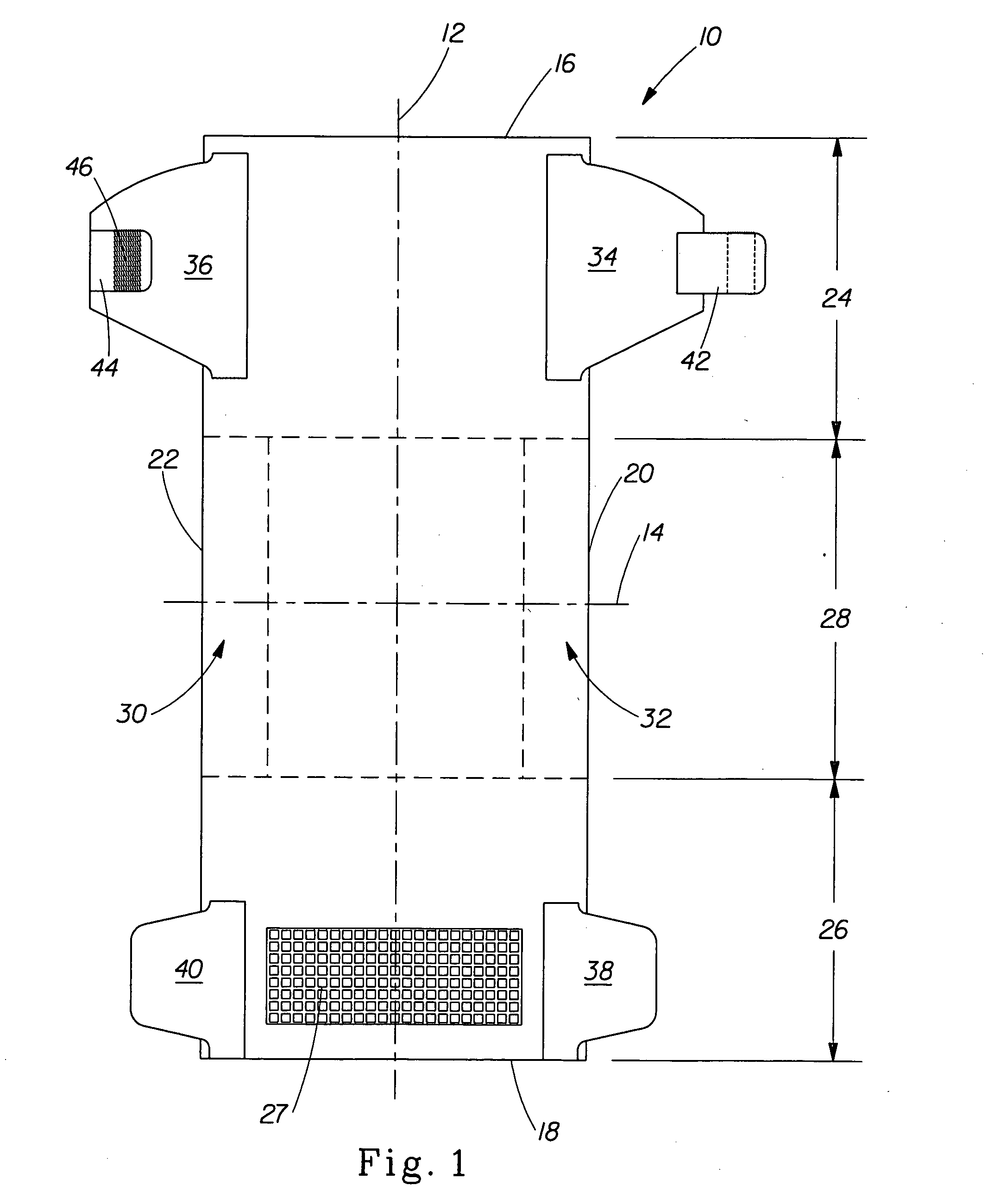

Apparatus and method for applying reinforcement material to a surgical stapler

InactiveUS6939358B2Small sizeEasy to manufactureSurgical furnitureDiagnosticsEngineeringSurgical department

An apparatus and method used to apply a self-adherent strip of bio-compatible, staple line reinforcement material onto a working surface of a surgical stapler. The apparatus effectively contains and supports reinforcement material during sterilization and shipment. At the point of use, the apparatus provides a simple method for applying the reinforcement material to a variety of staplers. Once the reinforcement material is applied, no excess material remains attached to the stapler thus post-attachment removal of excess material is avoided. The apparatus is simple to manufacture, accommodates a wide variety of reinforcement material shapes and configurations, allows for accurate sizing of the reinforcement material to a variety of stapler jaws, and provides a very low profile package to reduce packaging, shipping, and storage costs.

Owner:WL GORE & ASSOC INC

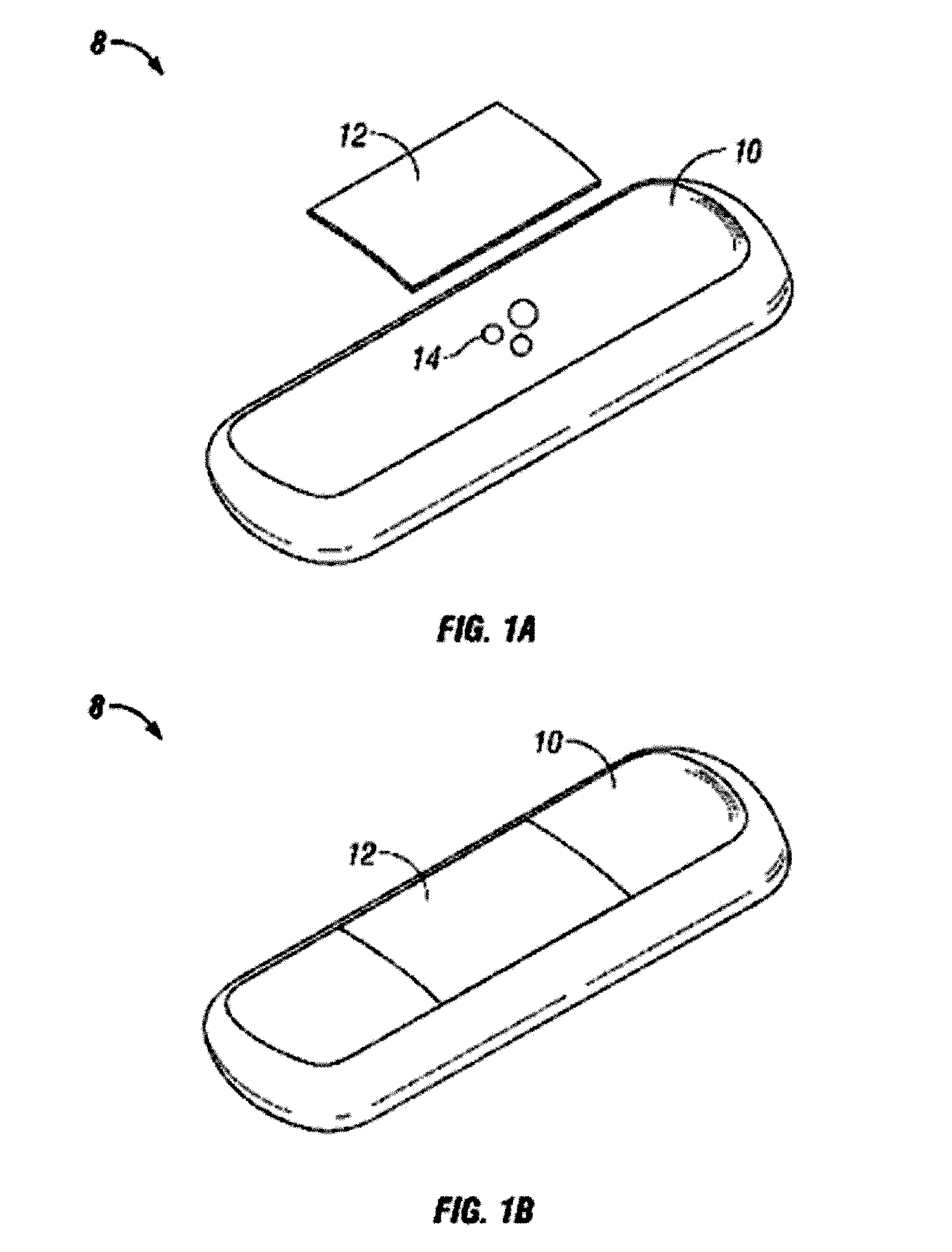

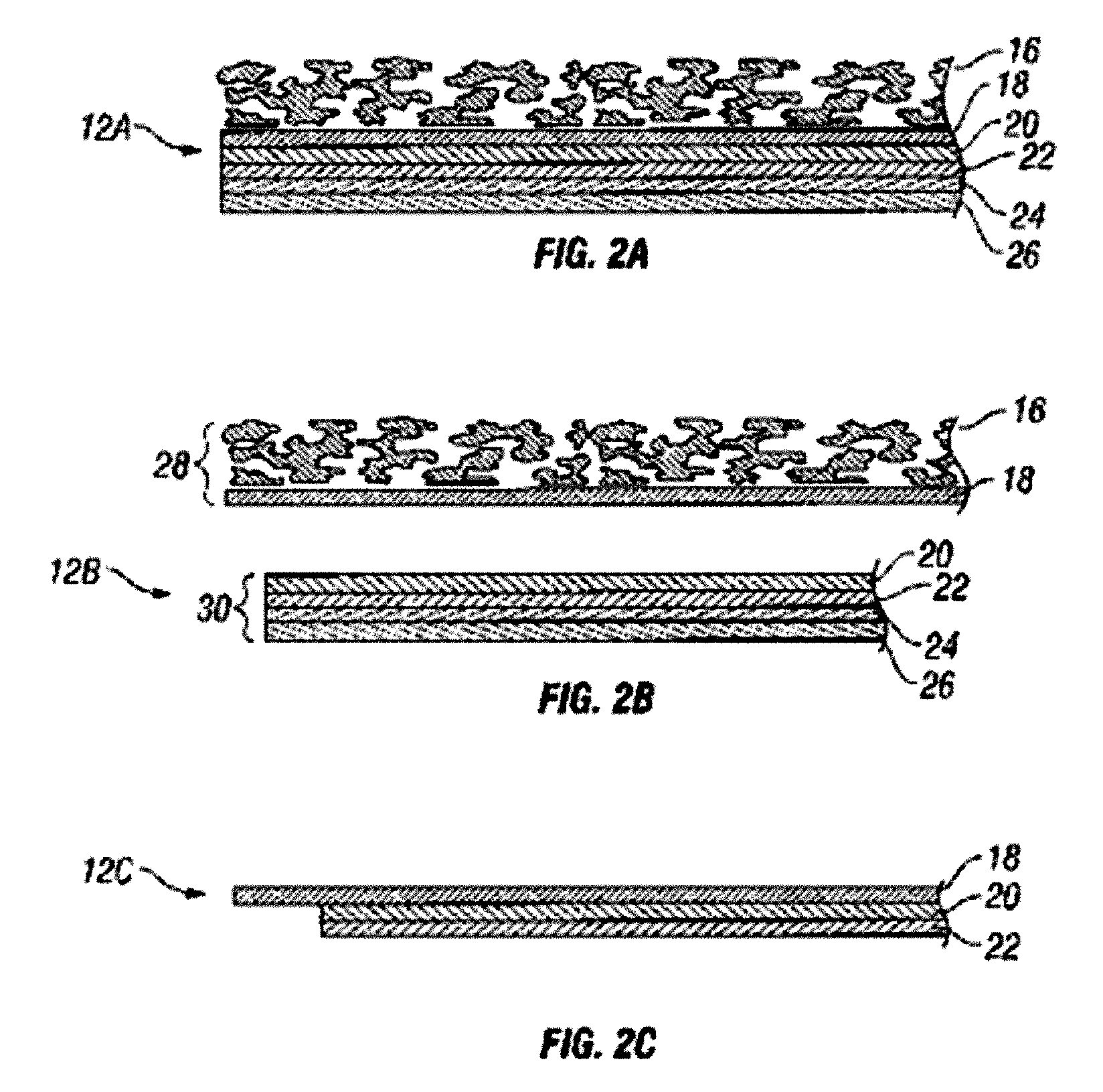

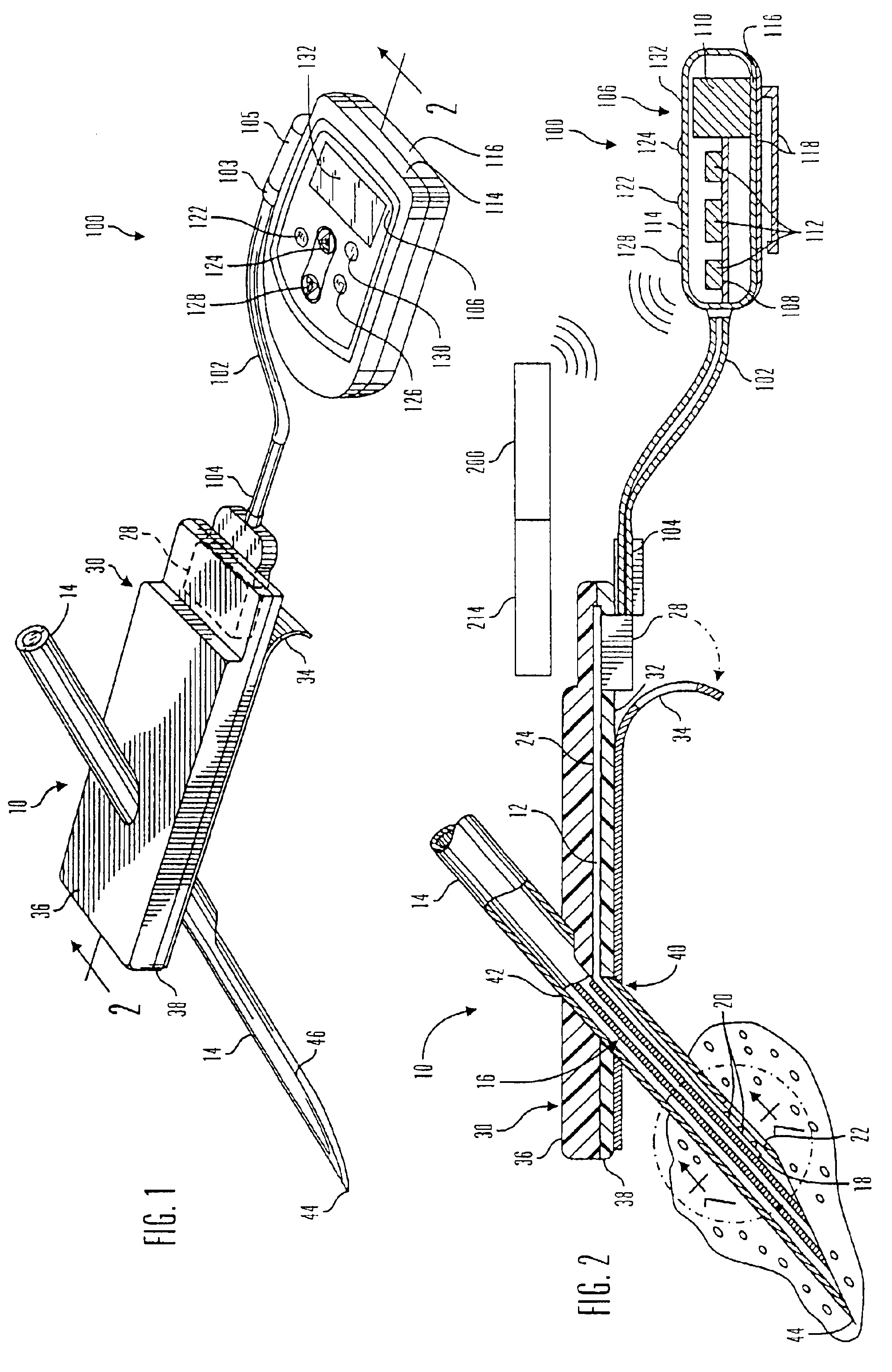

Systems and methods for manufacture of an analyte-measuring device including a membrane system

InactiveUS20060015020A1Minimized in sizeMaximize adhesionLaminationLamination apparatusAnalyteBiomedical engineering

Abstract of the DisclosureSystems and methods for manufacture of an analyte-measuring device, including adhering a membrane system that allows the passage of the analyte therethrough to a sensing mechanism. The implantable analyte-measuring device includes a body formed from a material that is substantially similar to the membrane system so as to enable sufficiently strong adhesion therebetween, which enables a sufficiently strong adhesive joint capable of withstanding in vivo cellular forces. In some embodiments, the device body includes an insert to which the membrane system is adhered, wherein the insert is formed from a material substantially similar to the membrane system to enable strong adhesion therebetween. The analyte-measuring device is designed with optimized device sizing and maximum membrane adhesion and longevity to enable controlled transport of analytes through the membrane system in vivo with improved device performance.

Owner:DEXCOM

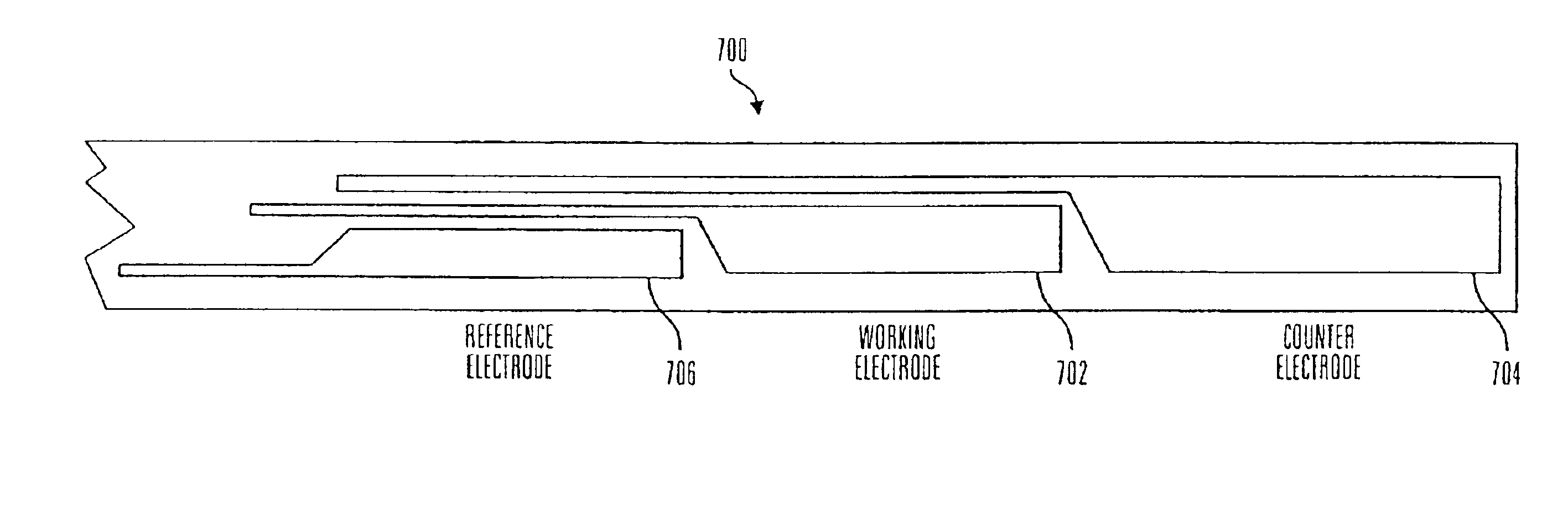

Glucose sensor package system

A glucose sensor package system that includes a glucose sensor and a protective package that indicates exposure to temperature changes to indicate proper temperature control. Also covered are methods of transporting and sterilizing the package. In addition, glucose sensors directed to various sizing and positioning of the electrodes on the glucose sensor are covered.

Owner:MEDTRONIC MIMIMED INC

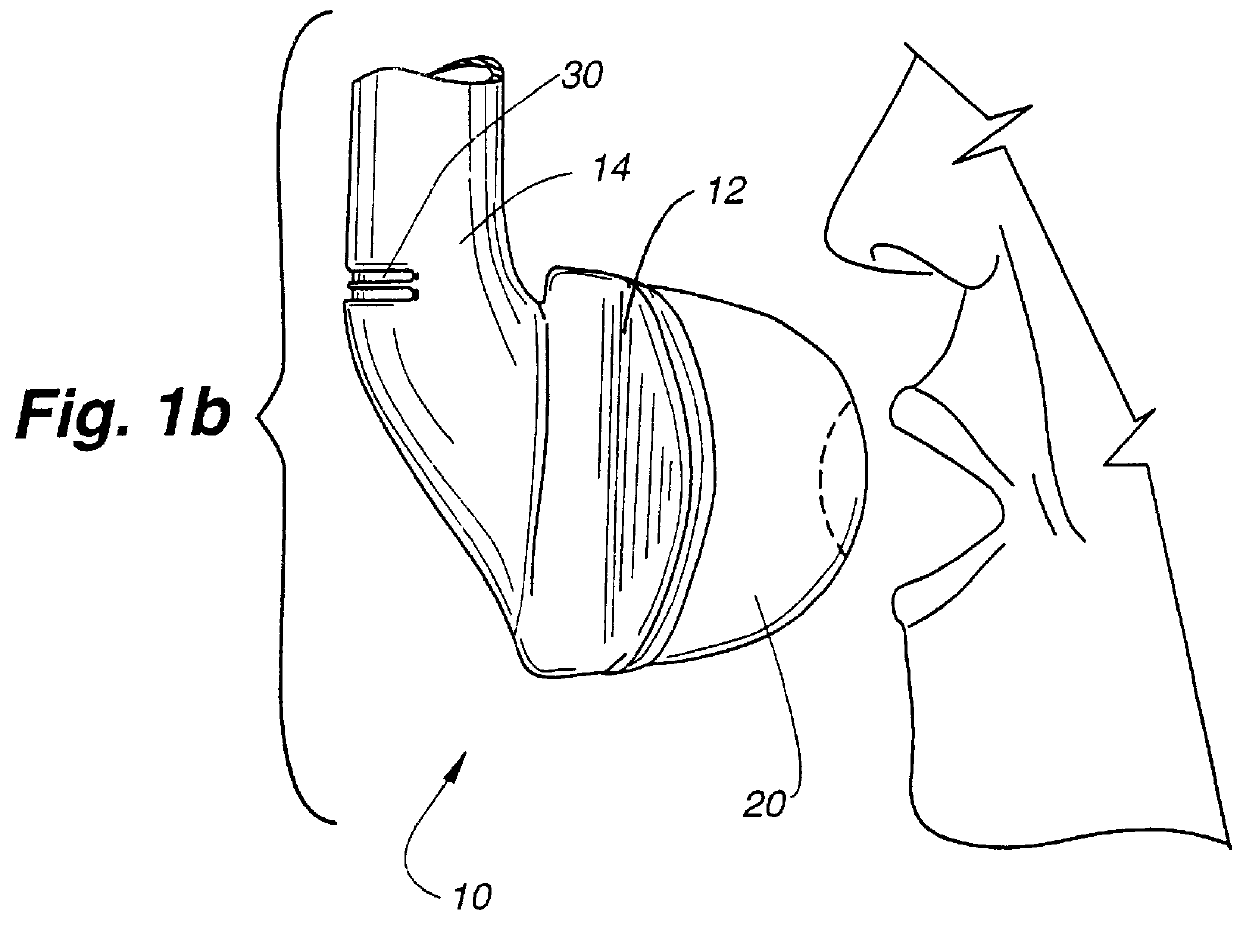

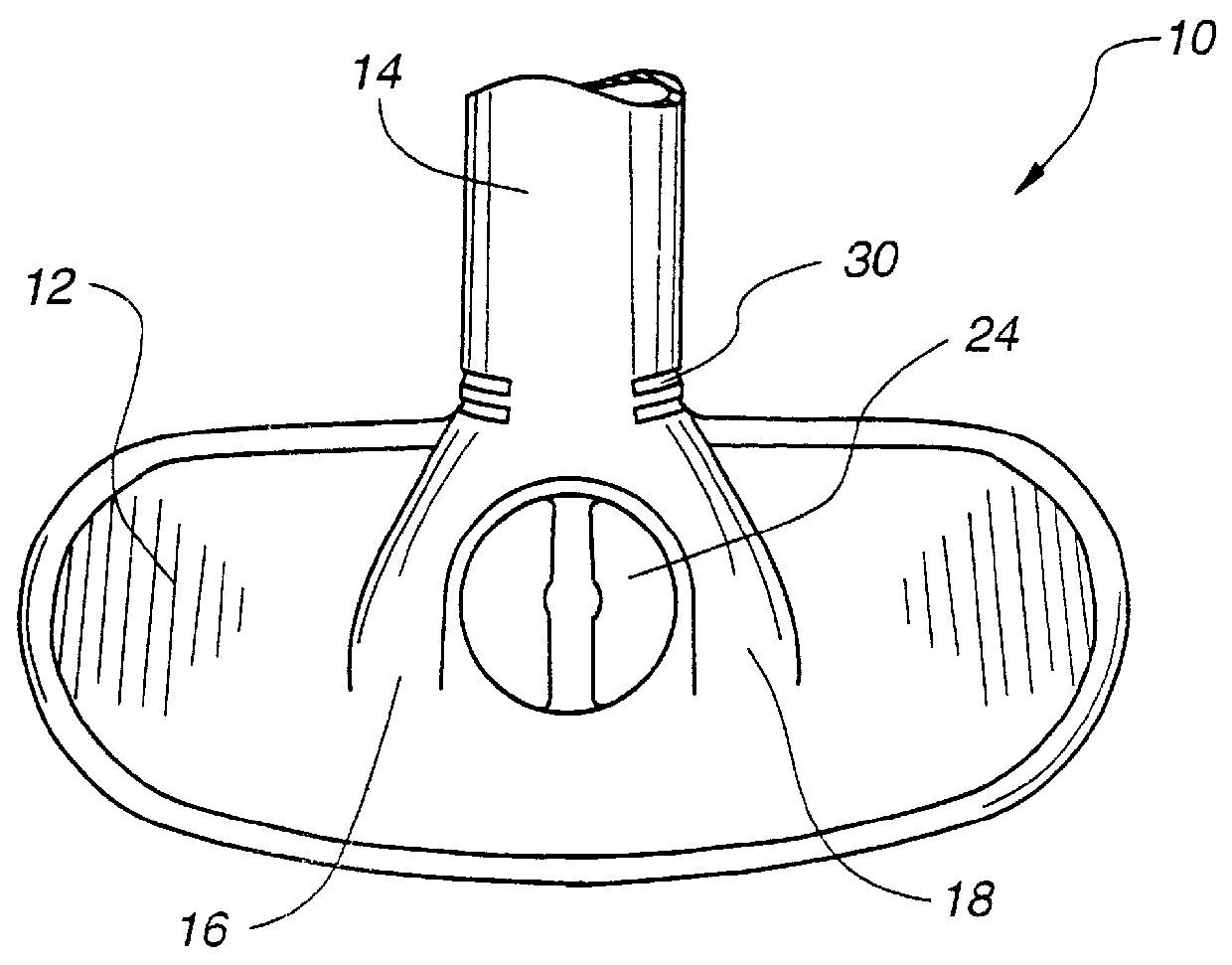

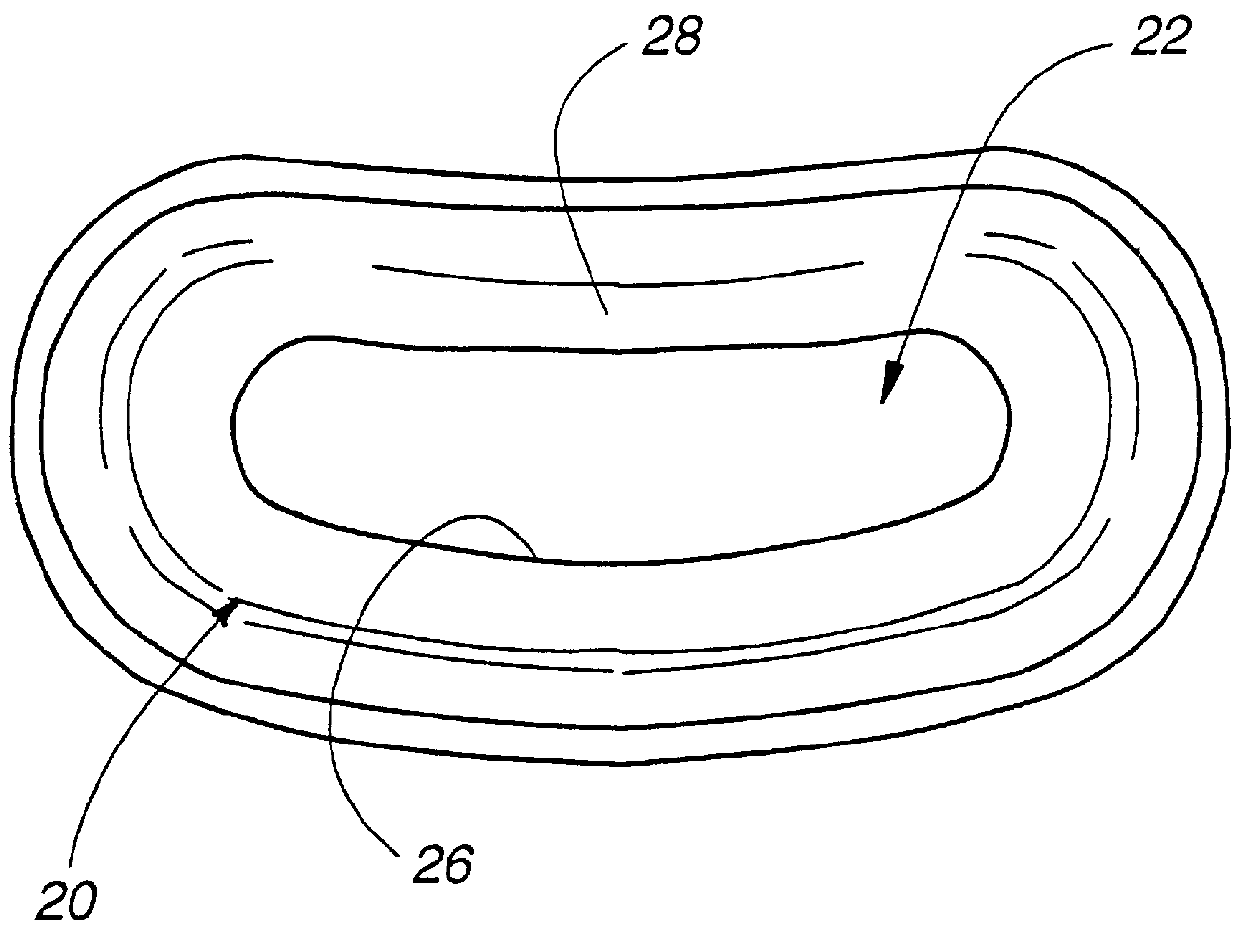

Facial masks for assisted respiration or CPAP

A combination mouth and nasal mask (40) for assisted respiration or CPAP is disclosed. The combination mask (40) has a frame (42) to the rear side of which is mounted a separate nasal cushion (44) and mouth cushion (46). Both the nasal cushion (44) and the mouth cushion (46) separately form a rolled edge seal around the patient's face in the vicinity of the nose and in the vicinity of the lips. Inlet air is communicated from within the housing (48) to the mouth chamber, circumscribed by the mouth cushion (46) by means of one or more interconnecting tubes (62). The proportion of air communicated to the mouth chamber (48) is controlled by the sizing and number of the tube(s), thus providing for free flow of air, restricted flow of air and pressure equalization, or zero flow of air. A mouth mask (10) for assisted respiration or CPAP also is disclosed.

Owner:RESMED LTD

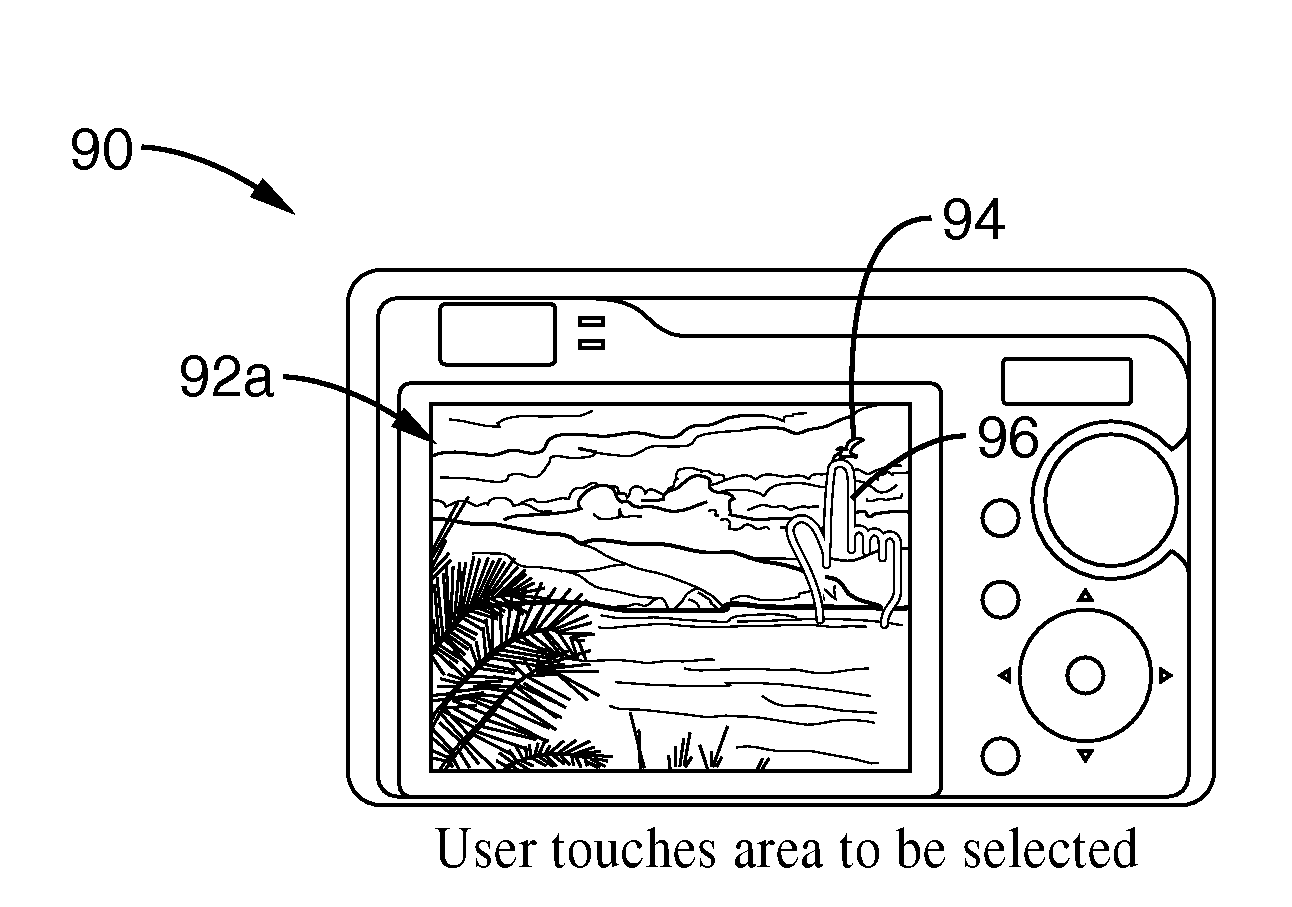

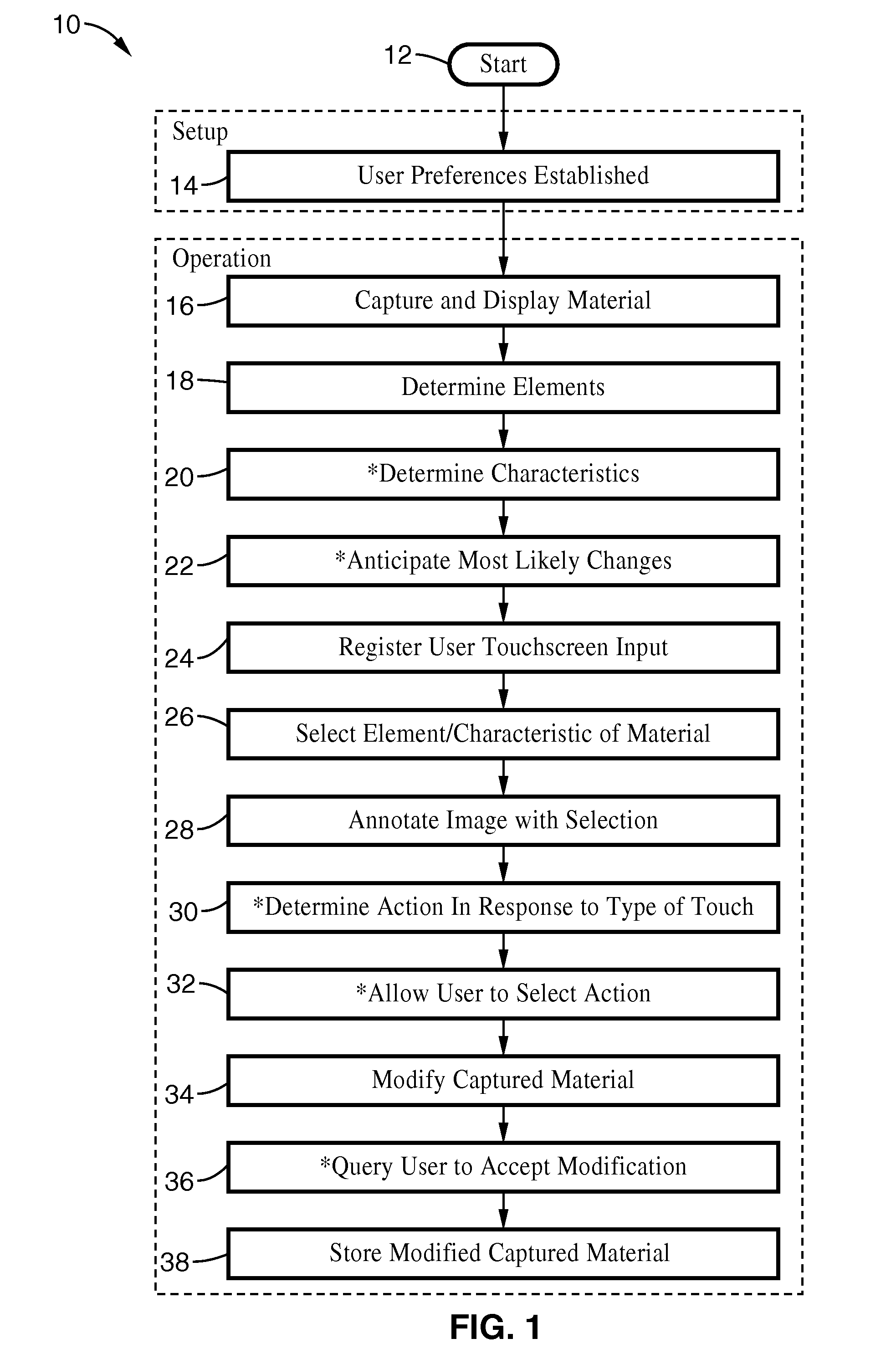

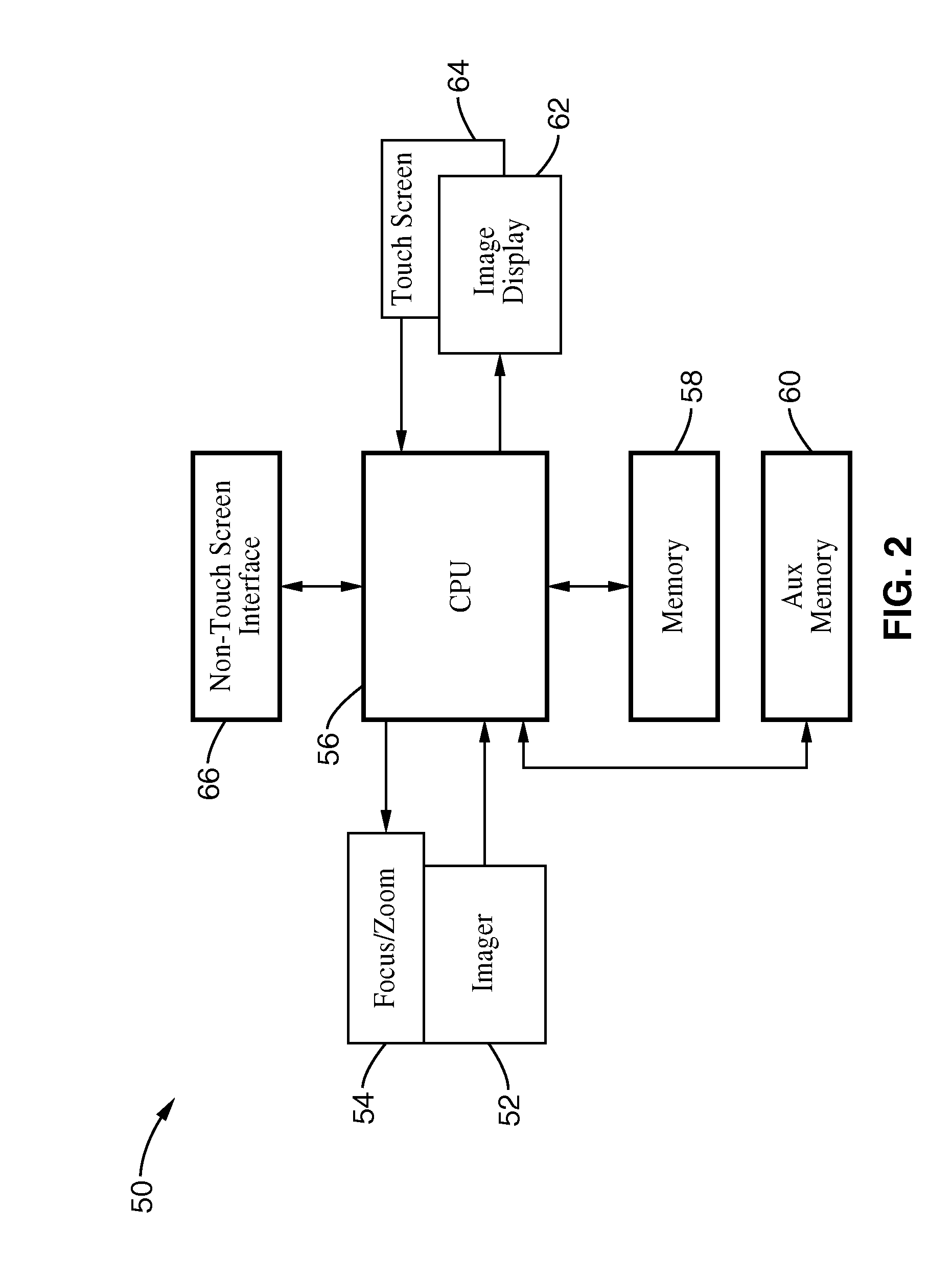

Method and apparatus for performing touch-based adjustments within imaging devices

ActiveUS20090256947A1Reduce the amount of processingReduce the amount requiredTelevision system detailsCharacter and pattern recognitionUser inputDisplay device

A camera and method which selectively applies image content adjustments to elements contained in the image material. By way of example, the method involves registration of user touch screen input and determination of the arbitrary extent of a specific element in the captured image material at the location at which touch input was registered. Once selected, the element can be highlighted on the display, and additional user input may be optionally input to control what type of adjustment is to be applied. Then the element within the captured image material is processed to apply automatic, or user-selected, adjustments to the content of said element in relation to the remainder of the captured image. The adjustments to the image element may comprise any conventional forms of image editing, such as saturation, white balance, exposure, sizing, noise reduction, sharpening, blurring, deleting and so forth.

Owner:SONY CORP +1

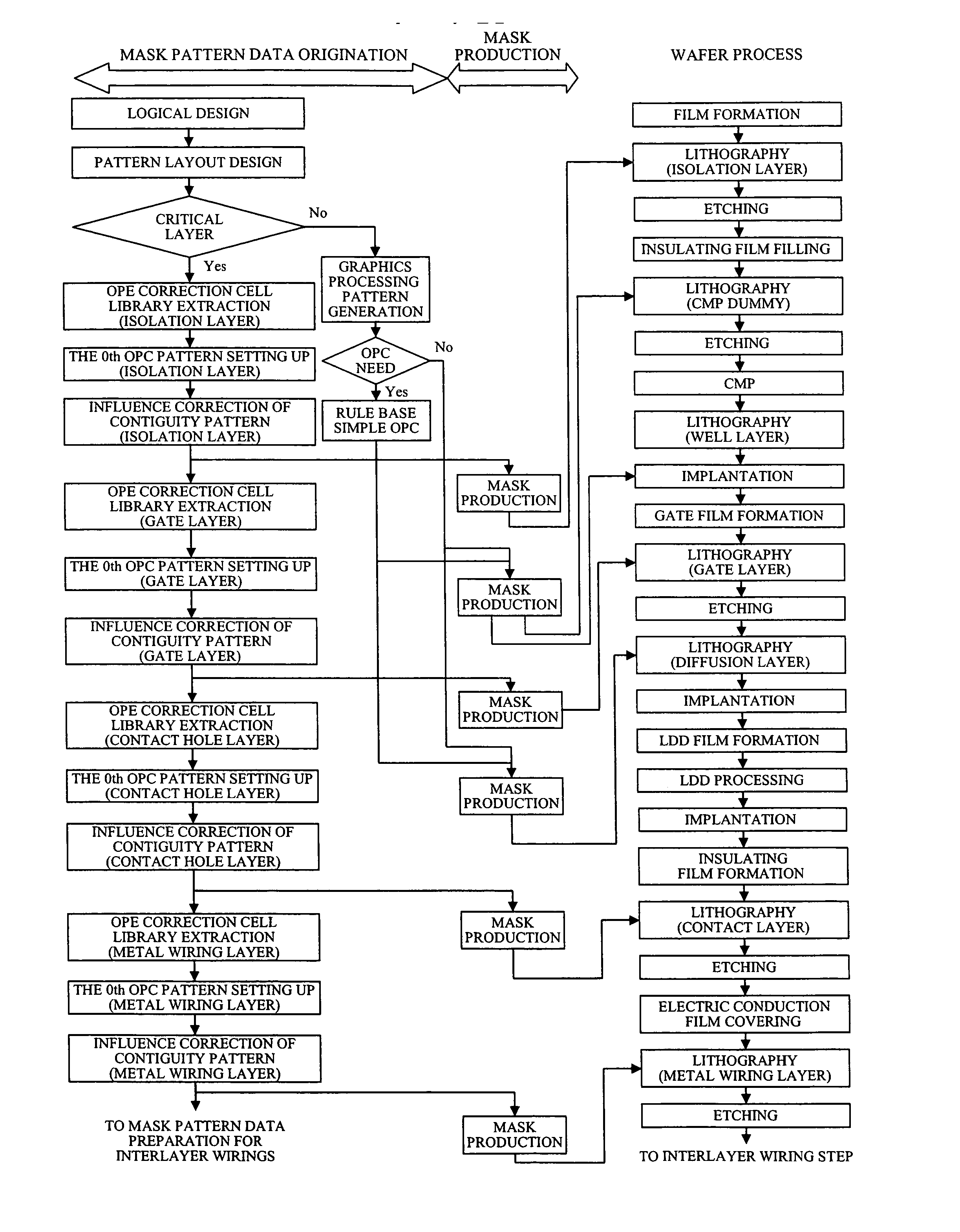

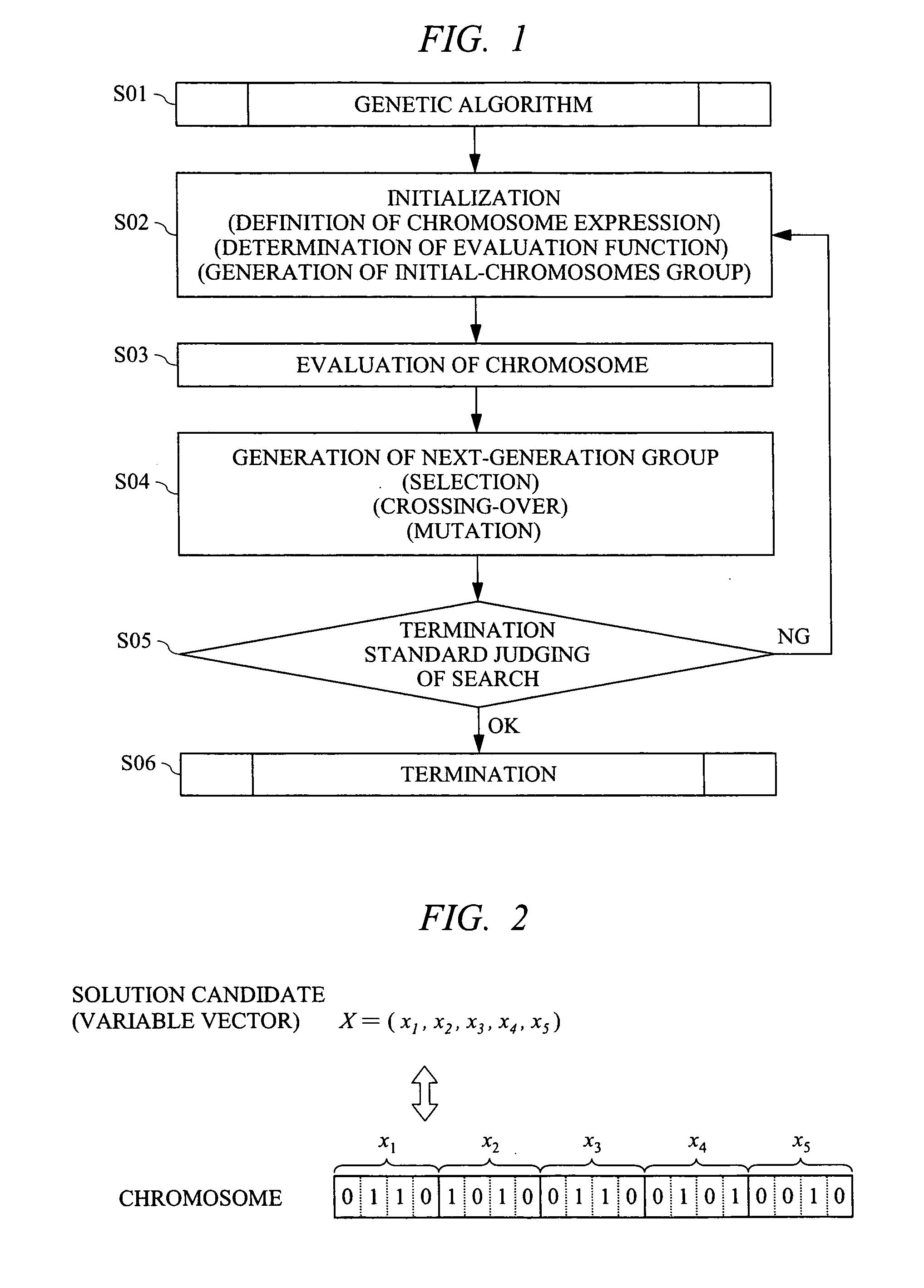

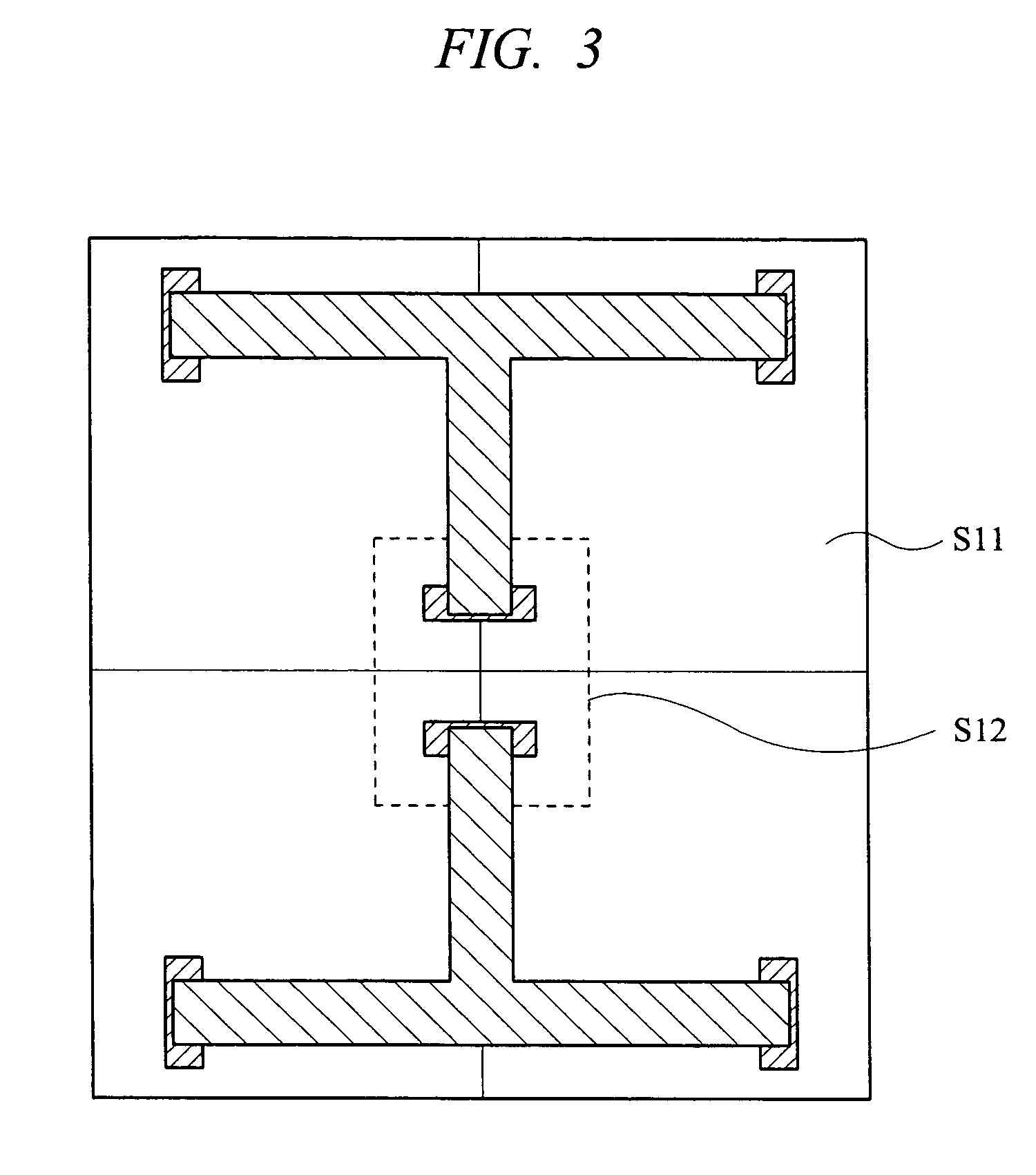

Mask pattern design method and manufacturing method of semiconductor device

InactiveUS20070074145A1Extended processing timeLower manufacturing requirementsOriginals for photomechanical treatmentSpecial data processing applicationsDevice materialSemiconductor chip

To a cell library pattern which makes the basic constitution of a semiconductor circuit pattern, OPC processing is performed beforehand, and a semiconductor chip is produced using this cell library pattern. Since it is influenced by the pattern of the cell arranged to the circumference and the pattern arranged around other cells at this time, correction processing (optimization processing) is performed. The part of this correction processing is a portion in which a pattern faces between cell boundaries in the inside of the region specified from the cell boundary, and proximity effect correction is performed by making the width, the length, and the position of this portion into variables. Or proximity effect correction is performed by making a polygon into a variable. Or sizing is done and proximity effect correction is performed.

Owner:RENESAS TECH CORP

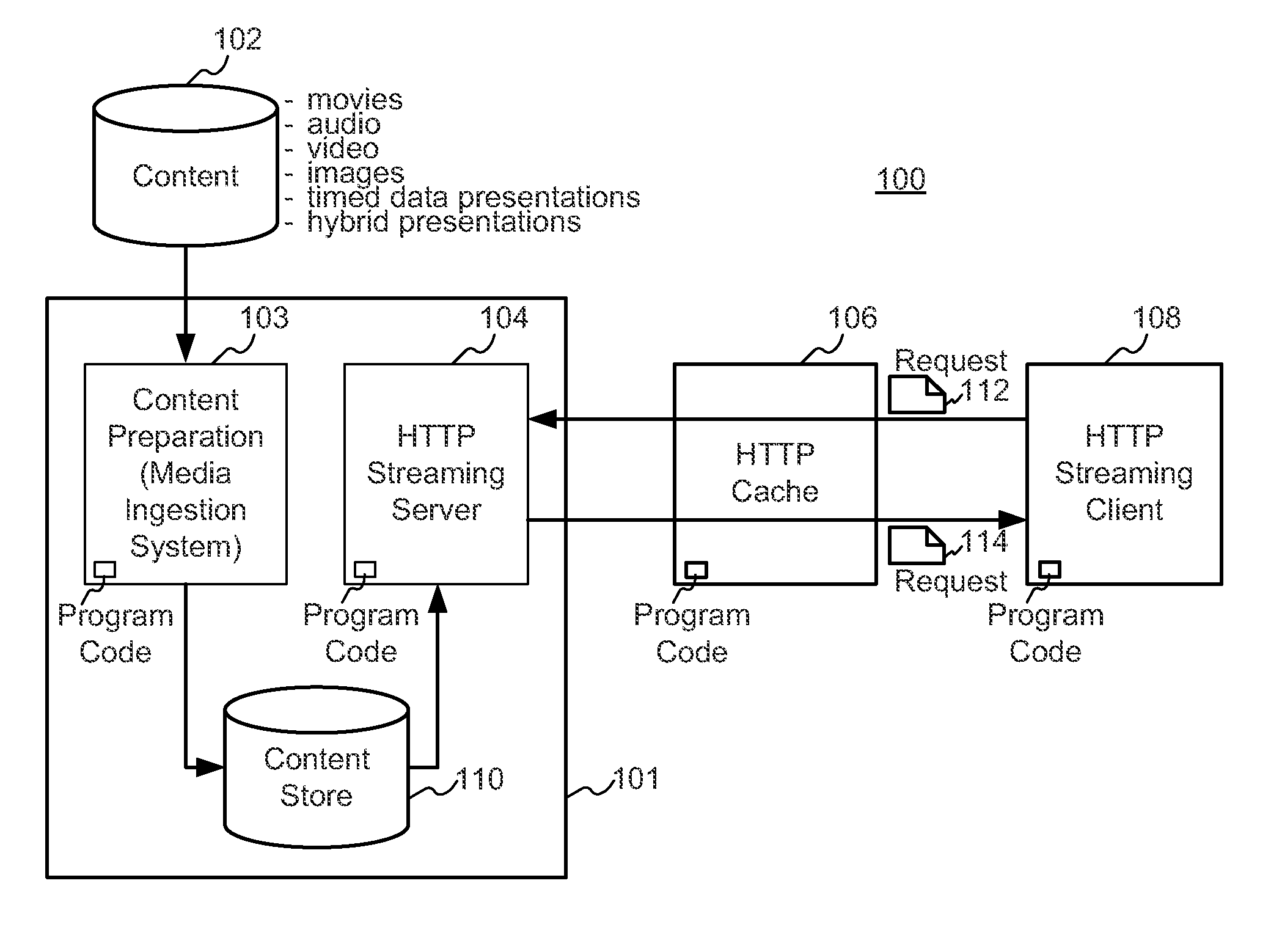

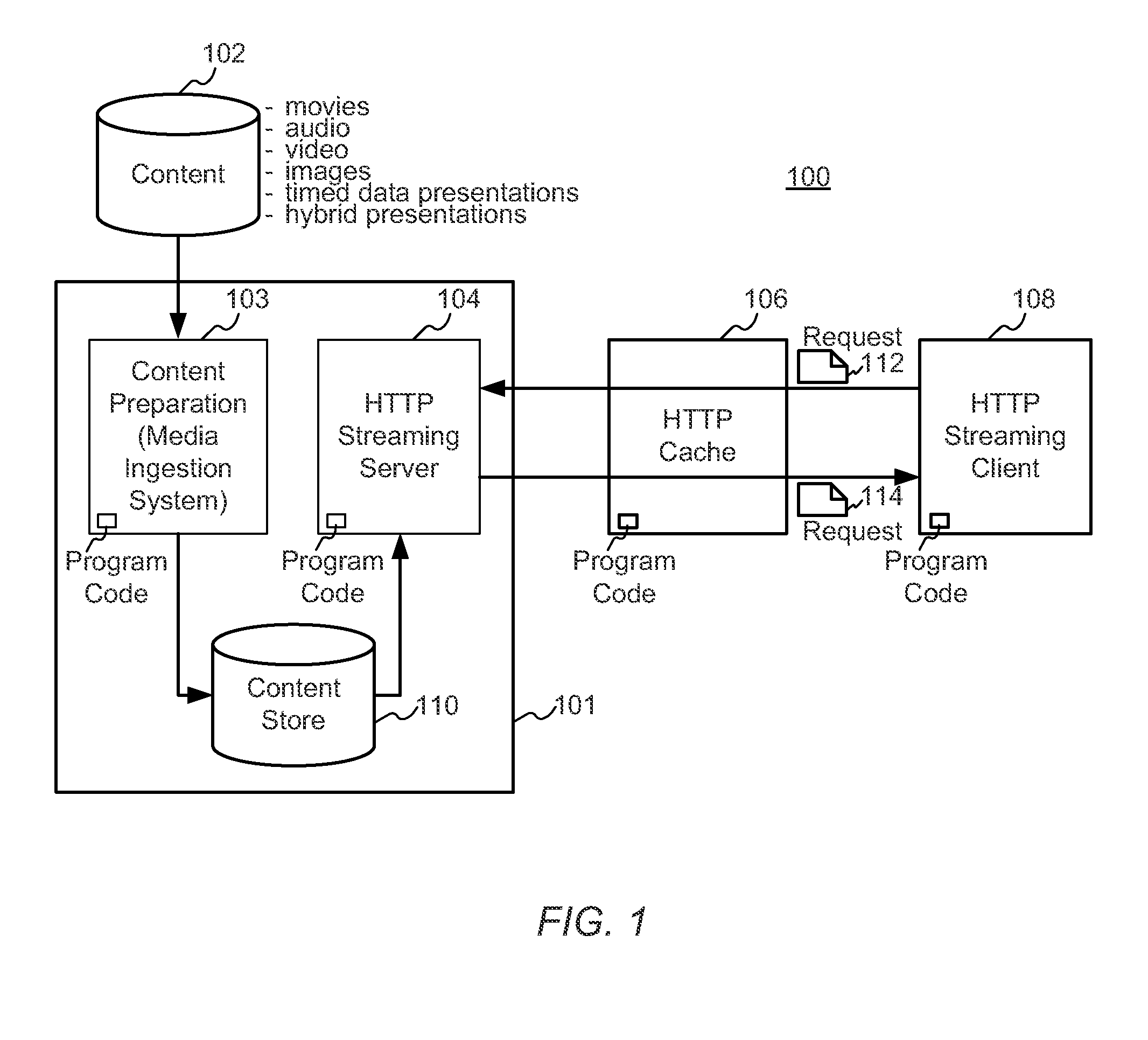

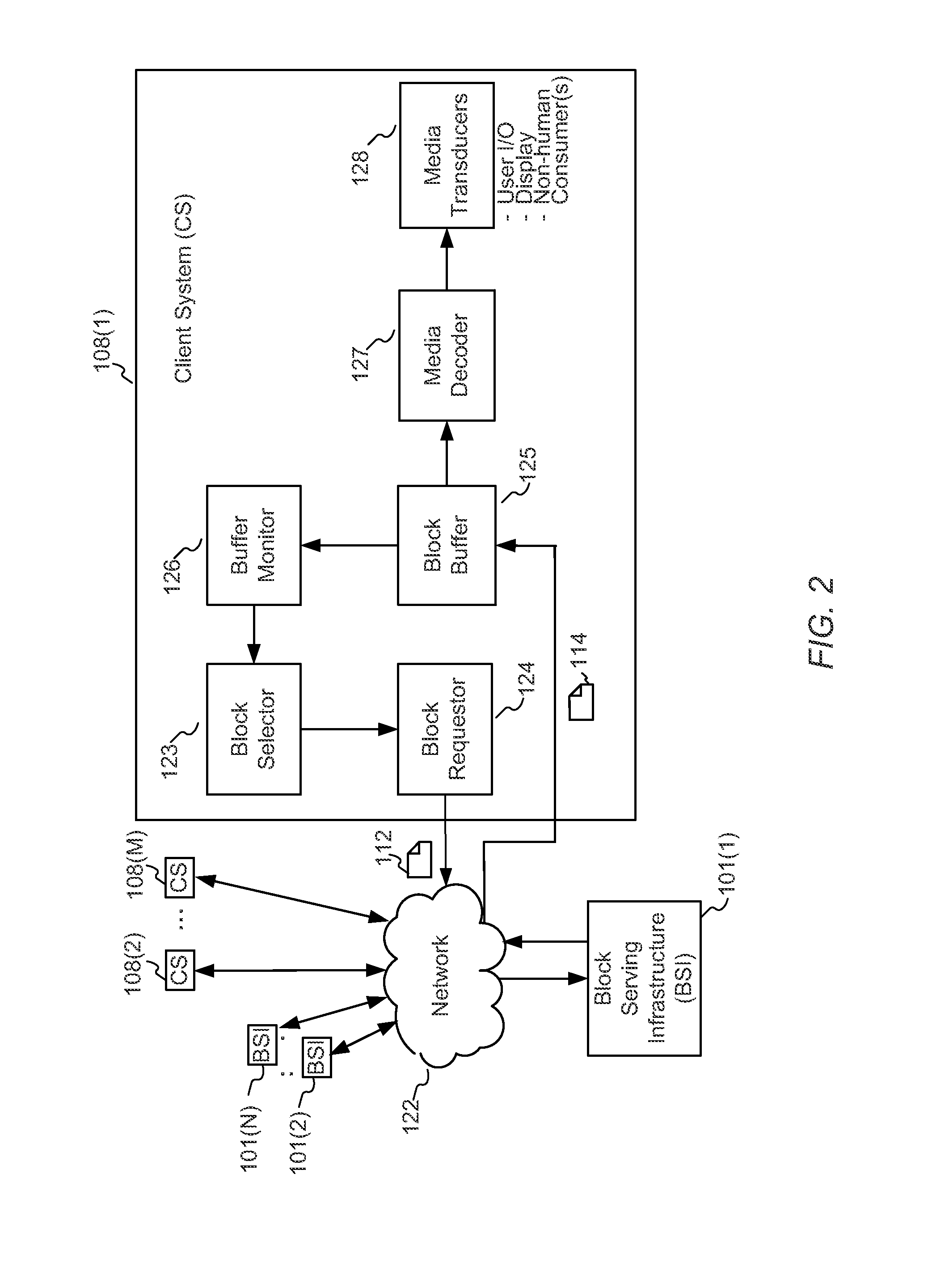

Enhanced block-request streaming system using signaling or block creation

ActiveUS20110238789A1Improve bandwidth efficiencyImprove user experiencePulse modulation television signal transmissionMultiple digital computer combinationsTransport systemPoint placement

A block-request streaming system provides for improvements in the user experience and bandwidth efficiency of such systems, typically using an ingestion system that generates data in a form to be served by a conventional file server (HTTP, FTP, or the like), wherein the ingestion system intakes content and prepares it as files or data elements to be served by the file server. The system might include controlling the sequence, timing and construction of block requests, time based indexing, variable block sizing, optimal block partitioning, control of random access point placement, including across multiple presentation versions, dynamically updating presentation data, and / or efficiently presenting live content and time shifting.

Owner:QUALCOMM INC

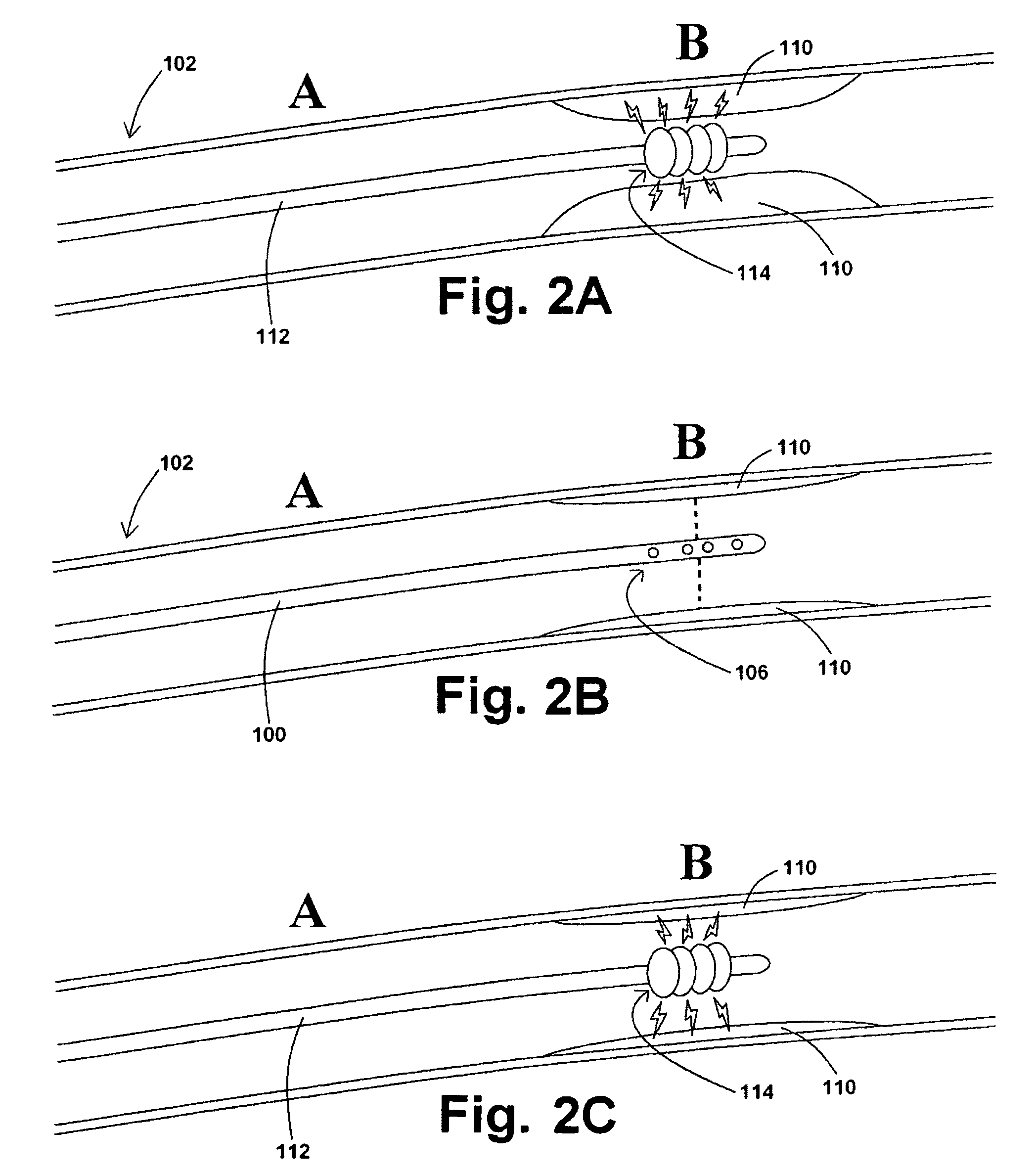

Methods and devices for rotating an active element and an energy emitter on a catheter

InactiveUS20070276419A1Reduce coupling energyUltrasonic/sonic/infrasonic diagnosticsCannulasSizingBiomedical engineering

Owner:TYCO HEALTHCARE GRP LP

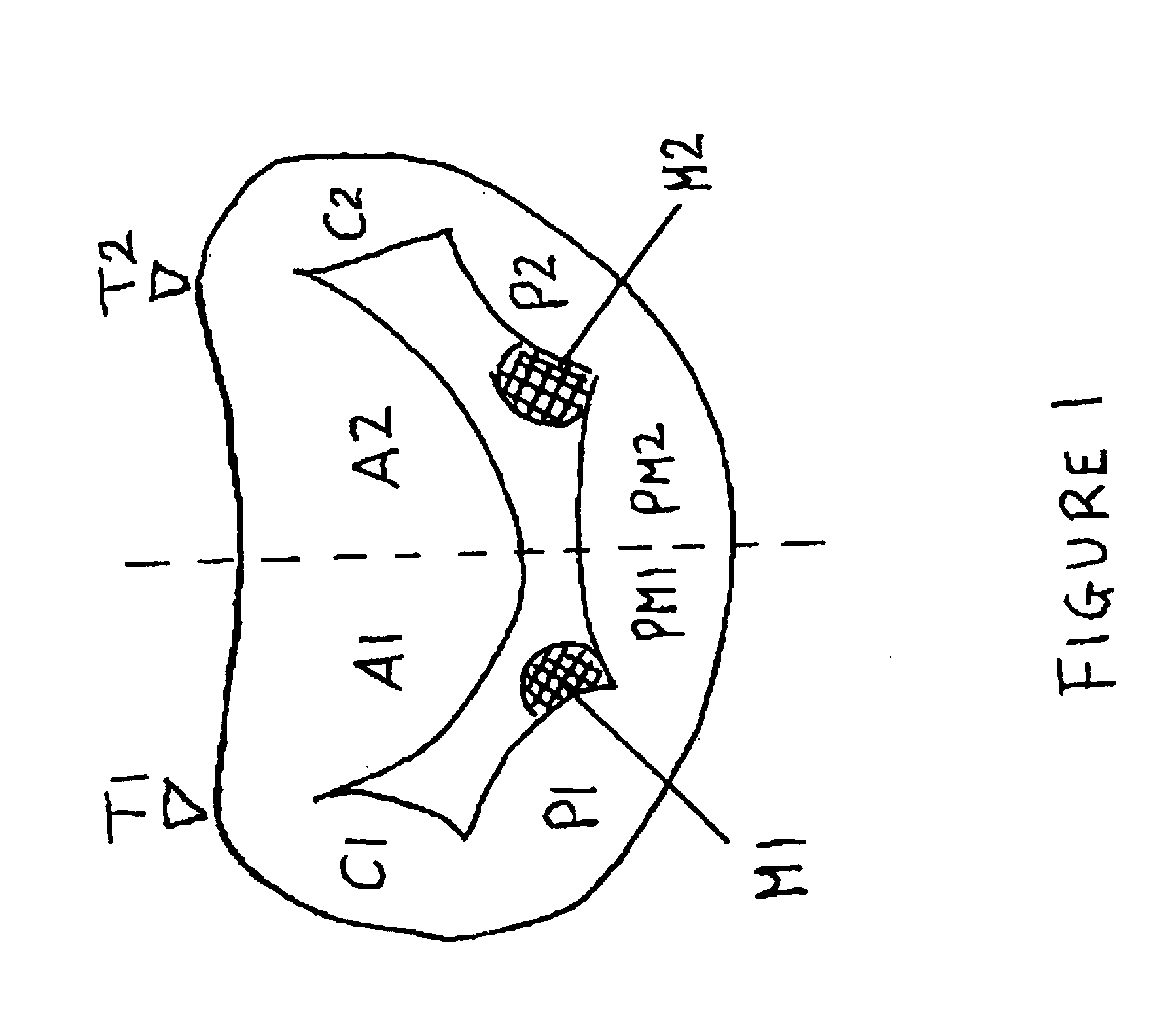

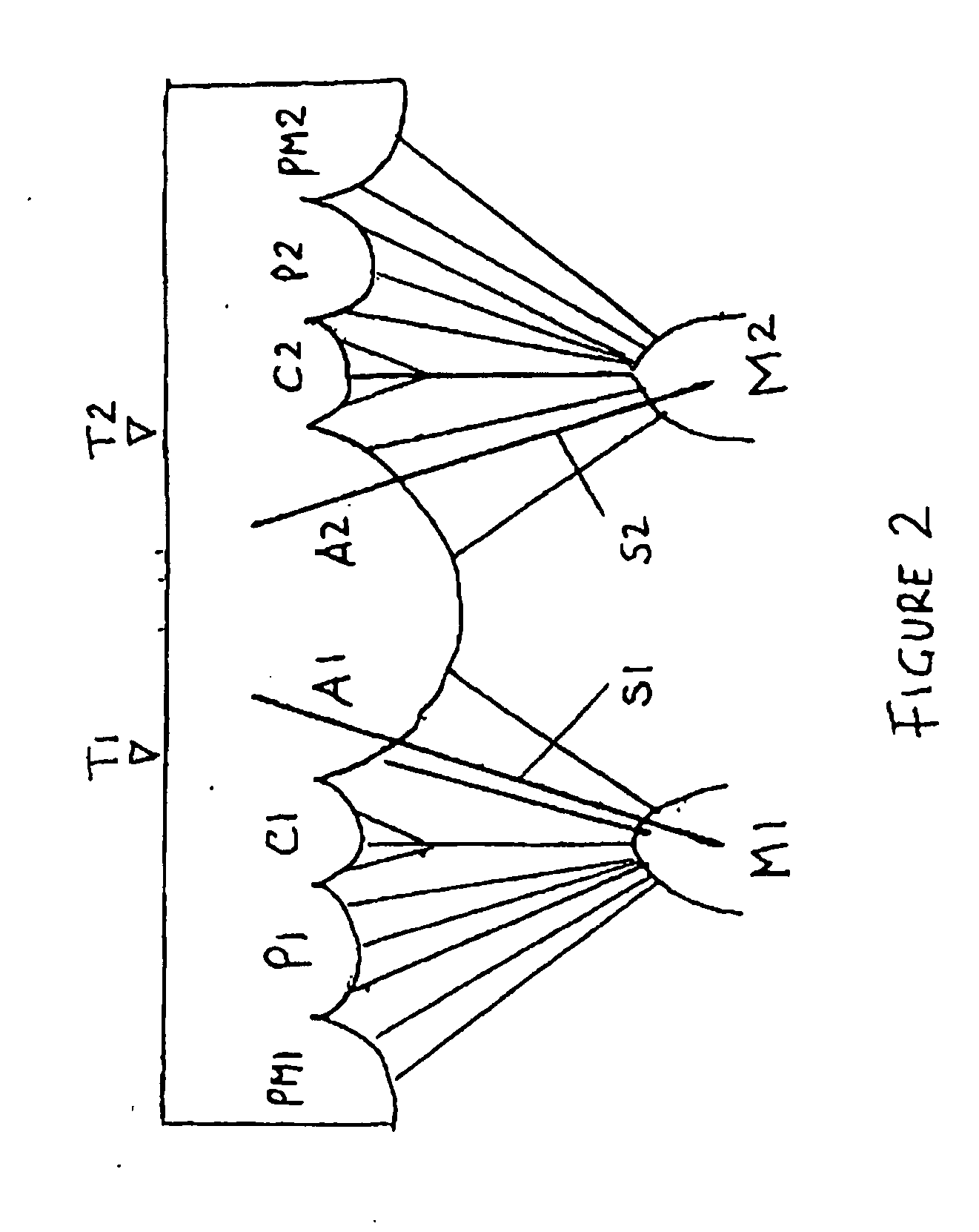

Papilloplasty band and sizing device

Unique semi-circular papillary muscle and annulus bands are described that are useful for modifying the alignment of papillary muscles, a mitral valve annulus and / or a tricuspid valve annulus. Methods to effect the alignment are also described and an unique sizing device that can be used for such alignment is described.

Owner:THE INT HEART INST OF MONTANA FOUND

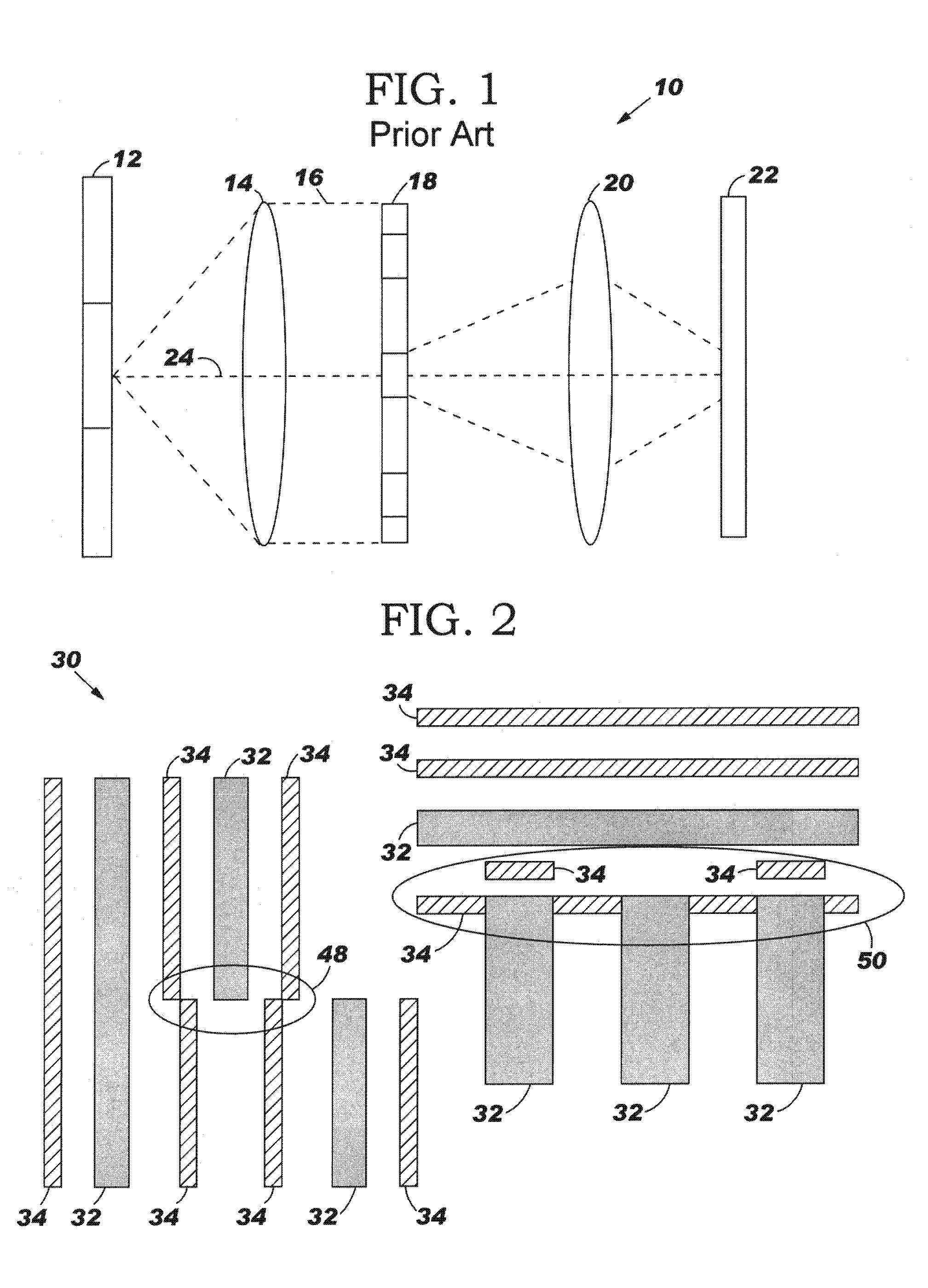

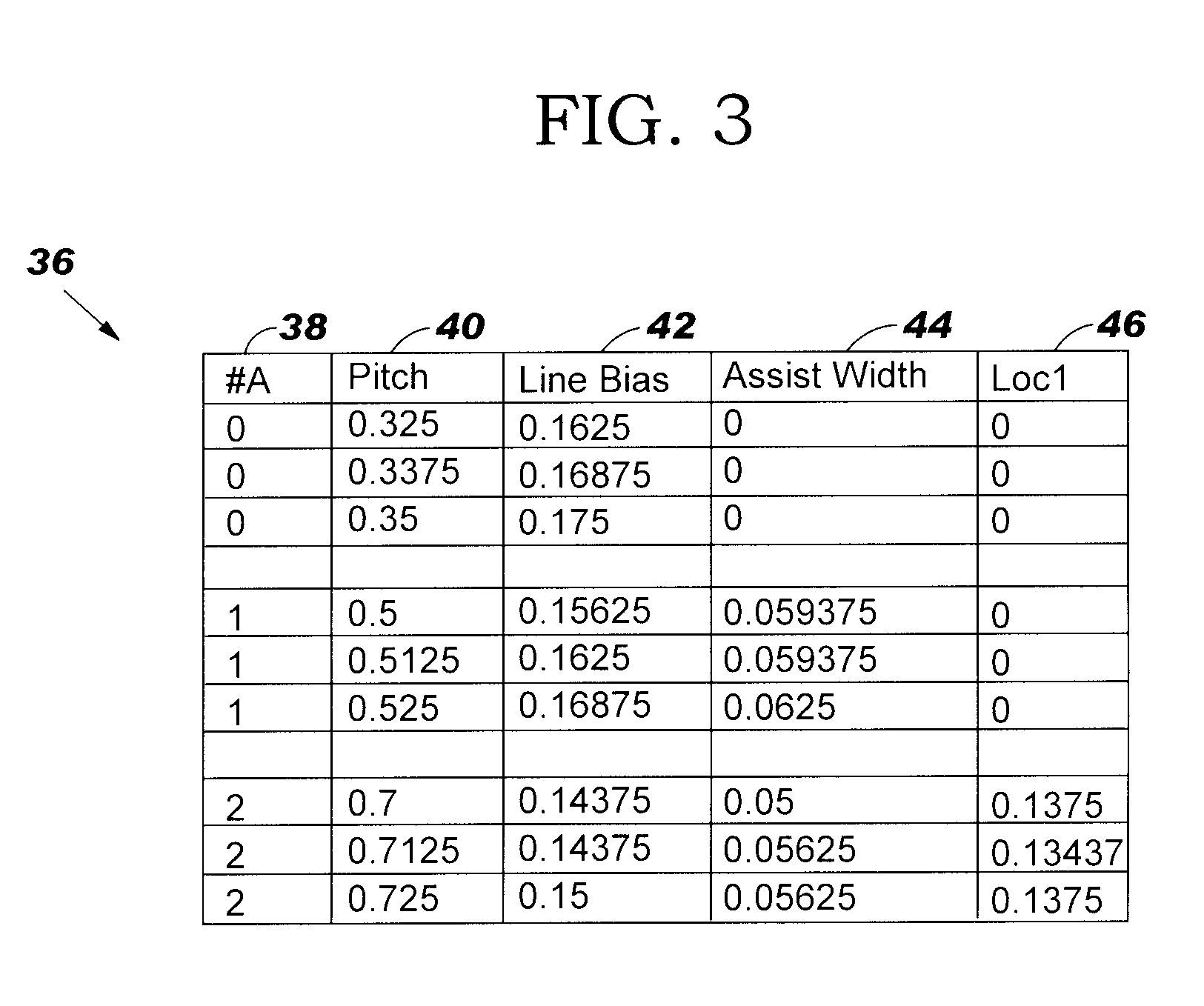

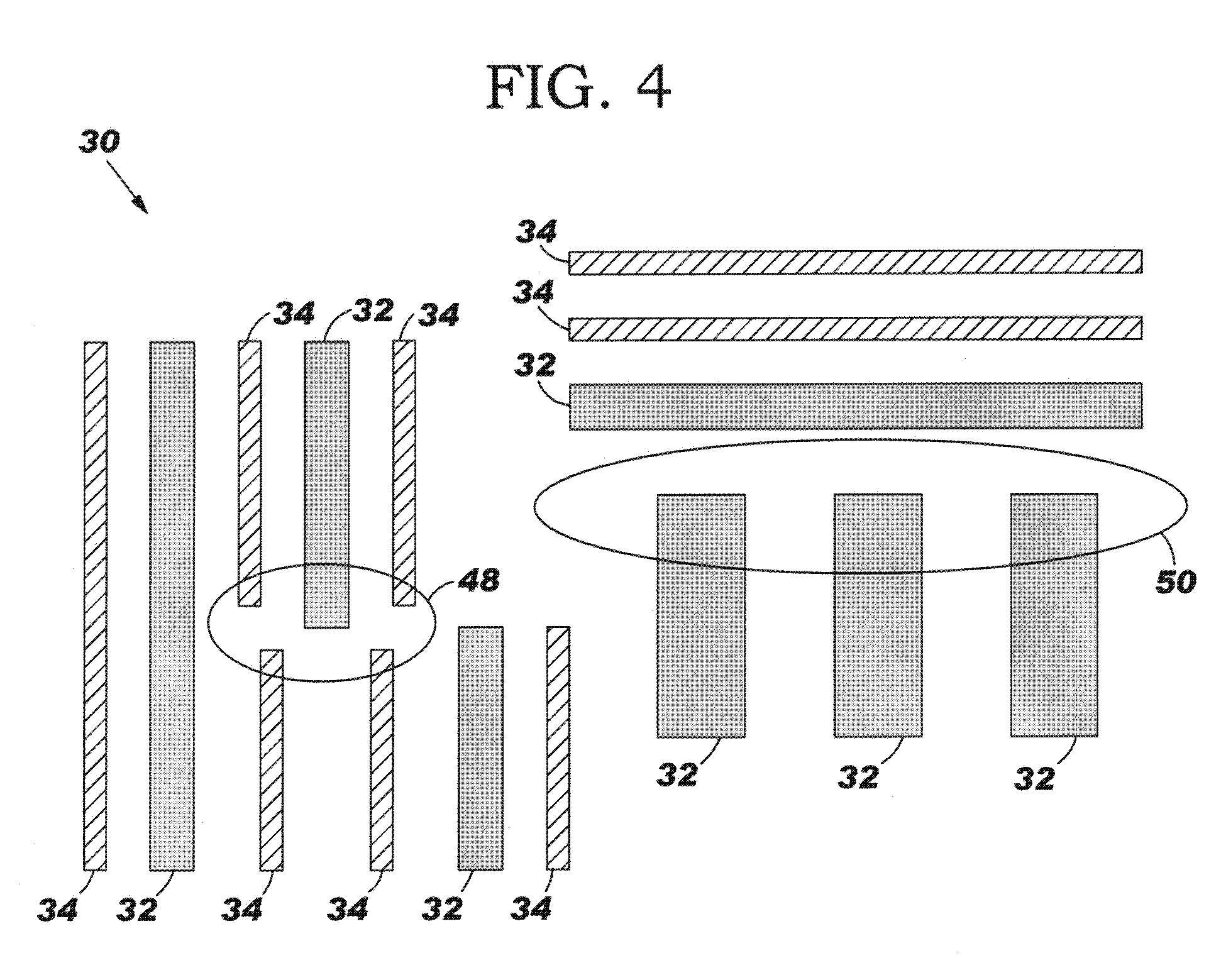

Pliant SRAF for improved performance and manufacturability

InactiveUS7115343B2Expand coverageImprove photolithographic effectPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringFigure of merit

A method for increasing coverage of subresolution assist features (SRAFs) in a layout. A set of possible SRAF placement and sizing rules for a given pitch is provided, ranked according to some figure of merit. During SRAF placement, the fit of a plurality of different SRAF solutions is successively evaluated to find the SRAF solution, or combinations thereof, which most improves lithographic performance while avoiding manufacturability problems. In general, the method comprises: obtaining a plurality of SRAF configurations for the layout; ranking the SRAF configurations based on a figure of merit; applying a highest ranked SRAF configuration to the layout; applying a predetermined number of lower ranked SRAF configurations to the layout; and selecting SRAF features from at least one of the applied SRAF configurations to provide the optimal SRAF configuration for the layout.

Owner:GLOBALFOUNDRIES INC

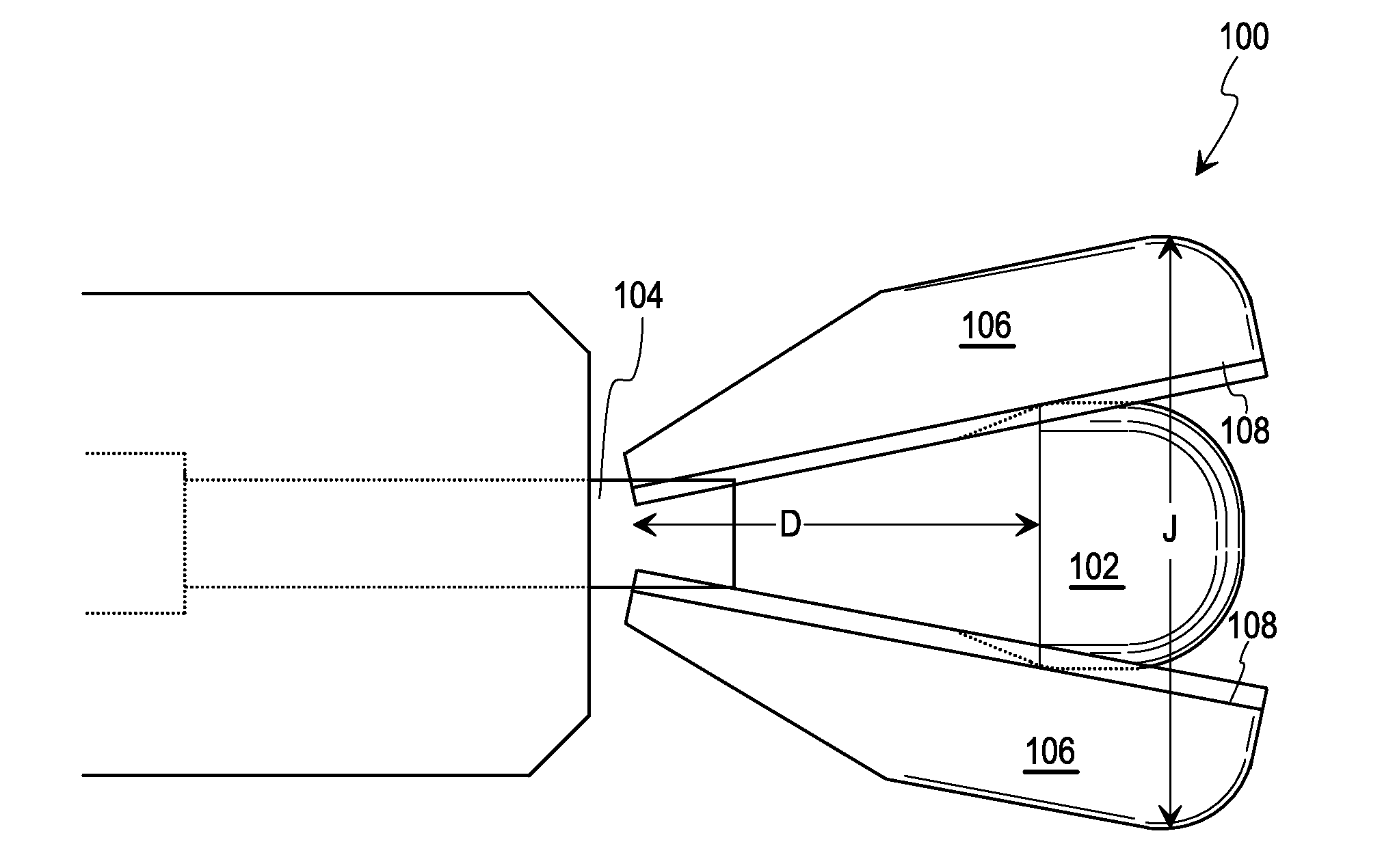

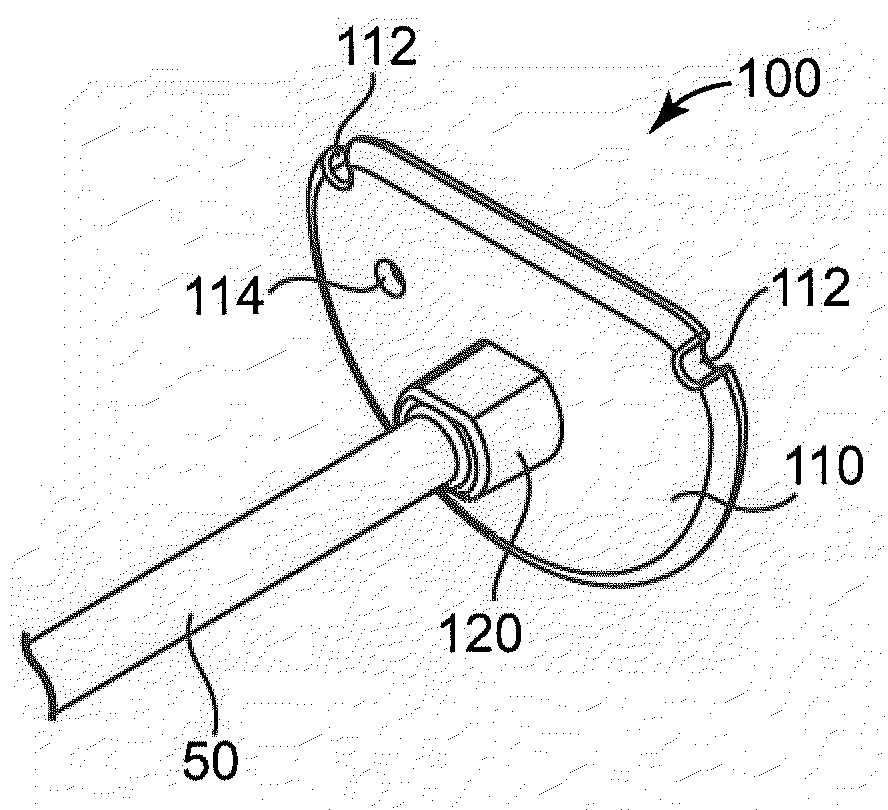

Disc Space Sizing Devices And Methods Of Using The Same

A spacing device is provided for adjusting the spacing between adjacent vertebral bodies. The spacing device has a distal end with at least one distraction member adapted for insertion into an intervertebral disc space and movable between a low profile first configuration and a higher profile second configuration. Also provided is an actuator for moving the distraction member between the first configuration (for delivery of the distal end of the spacing device to a target disc space) and the second configuration (for manipulation of the space between adjacent vertebral bodies).

Owner:SPINAL ELEMENTS INC

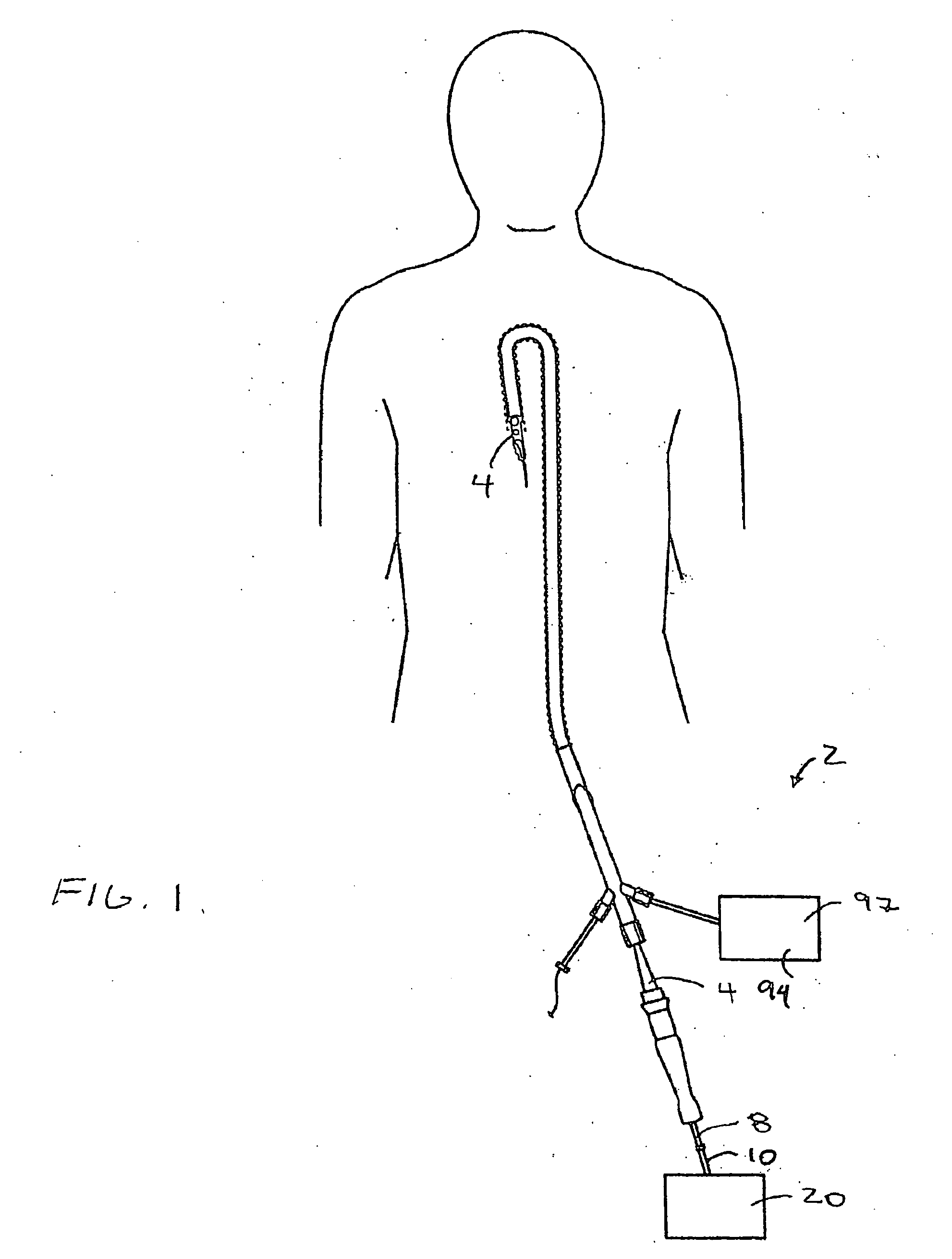

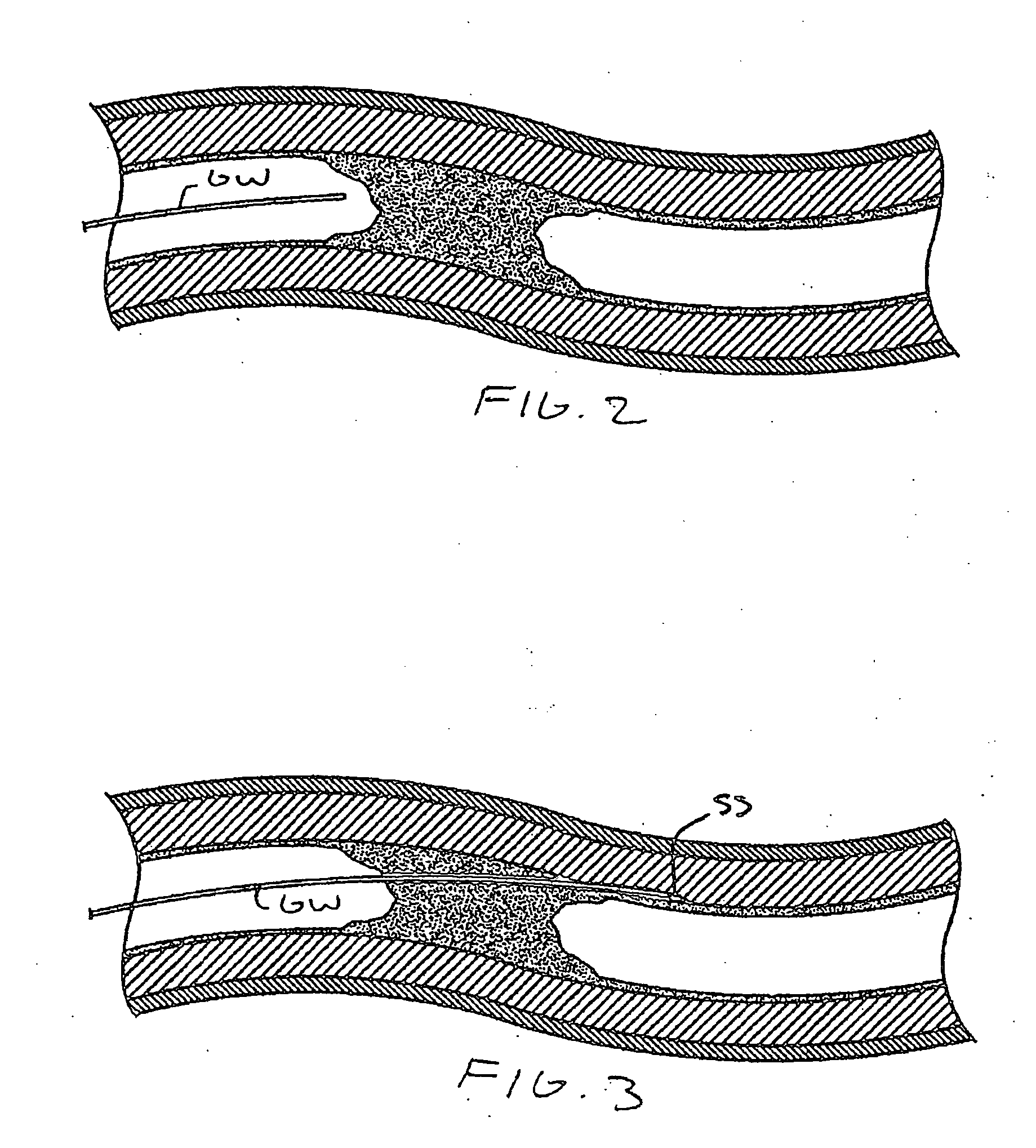

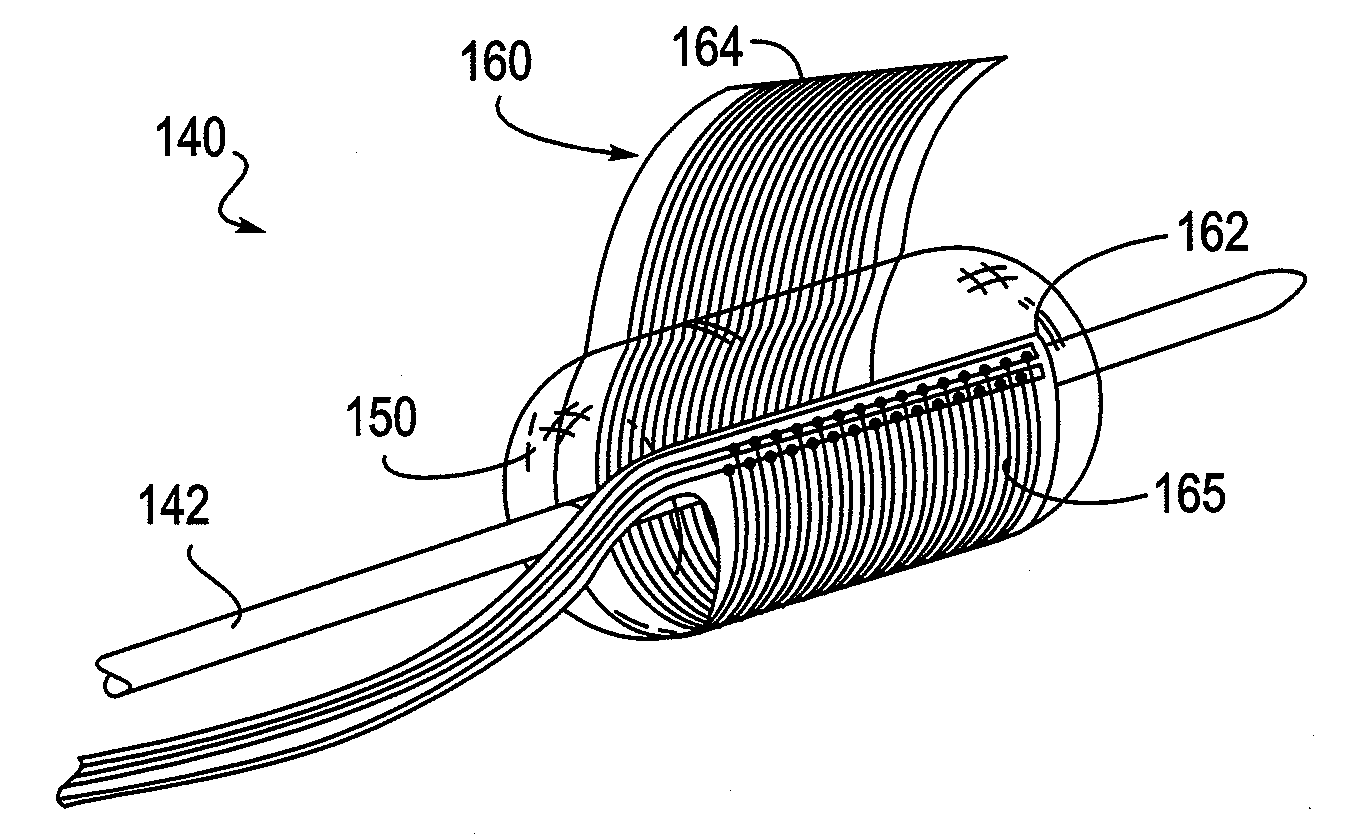

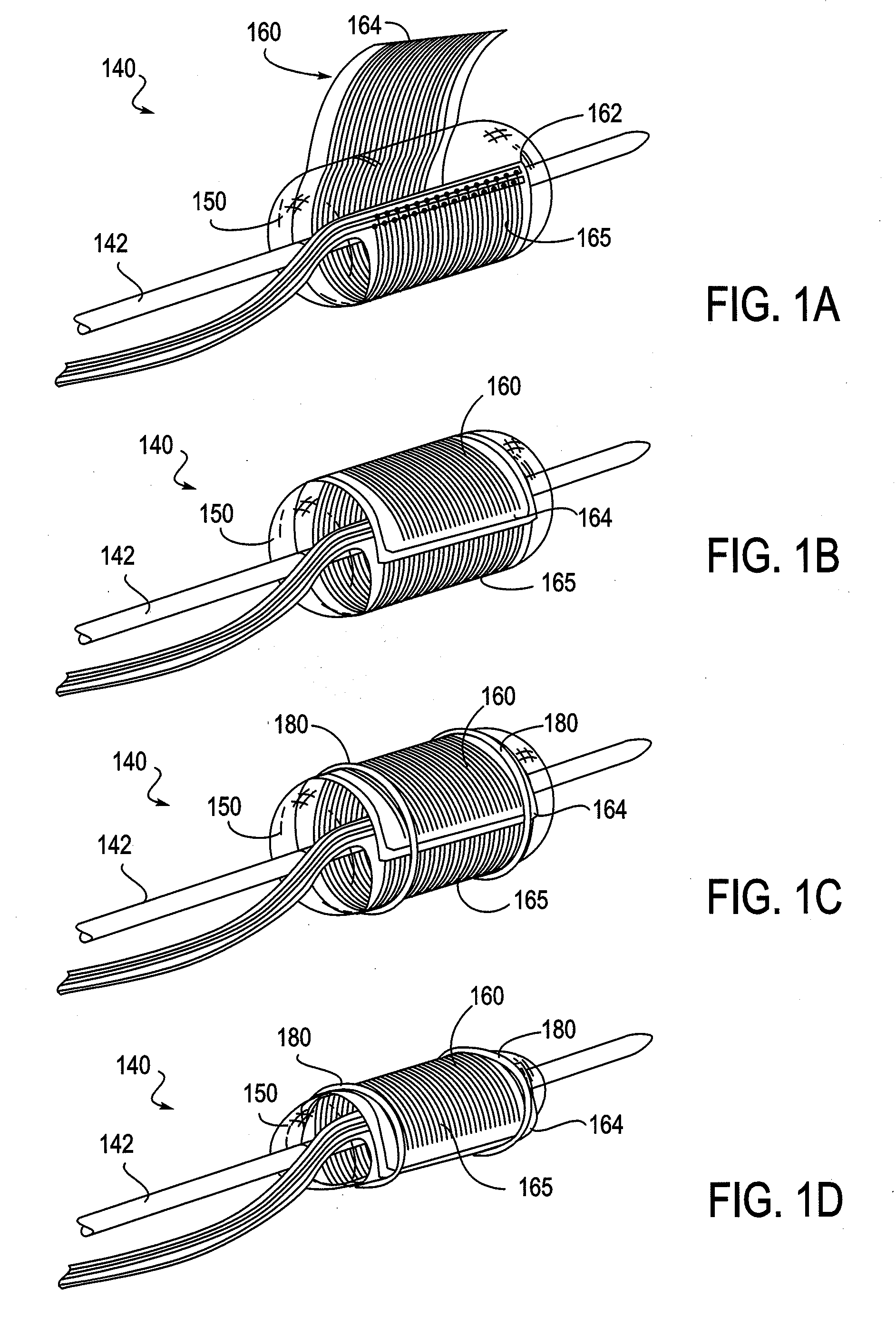

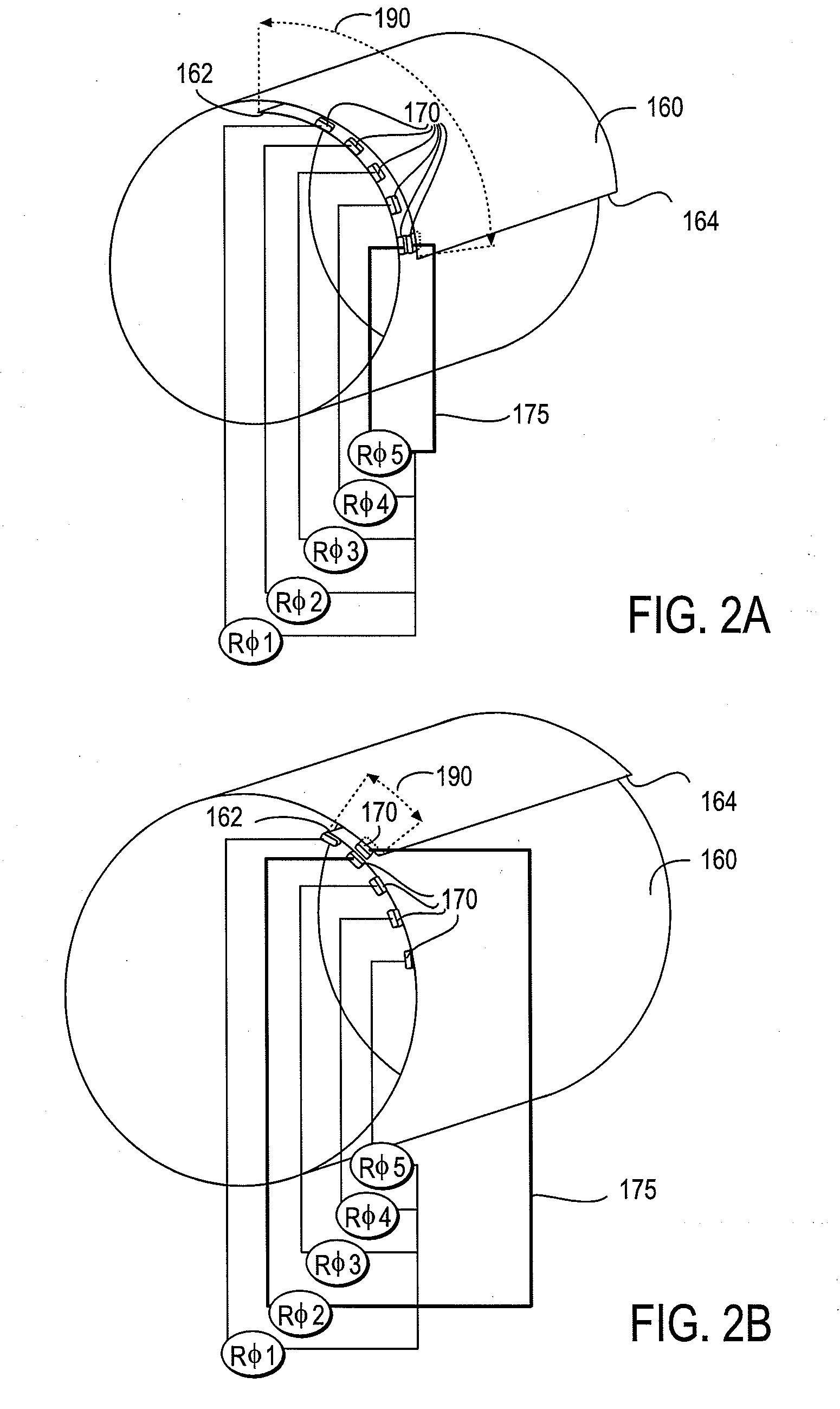

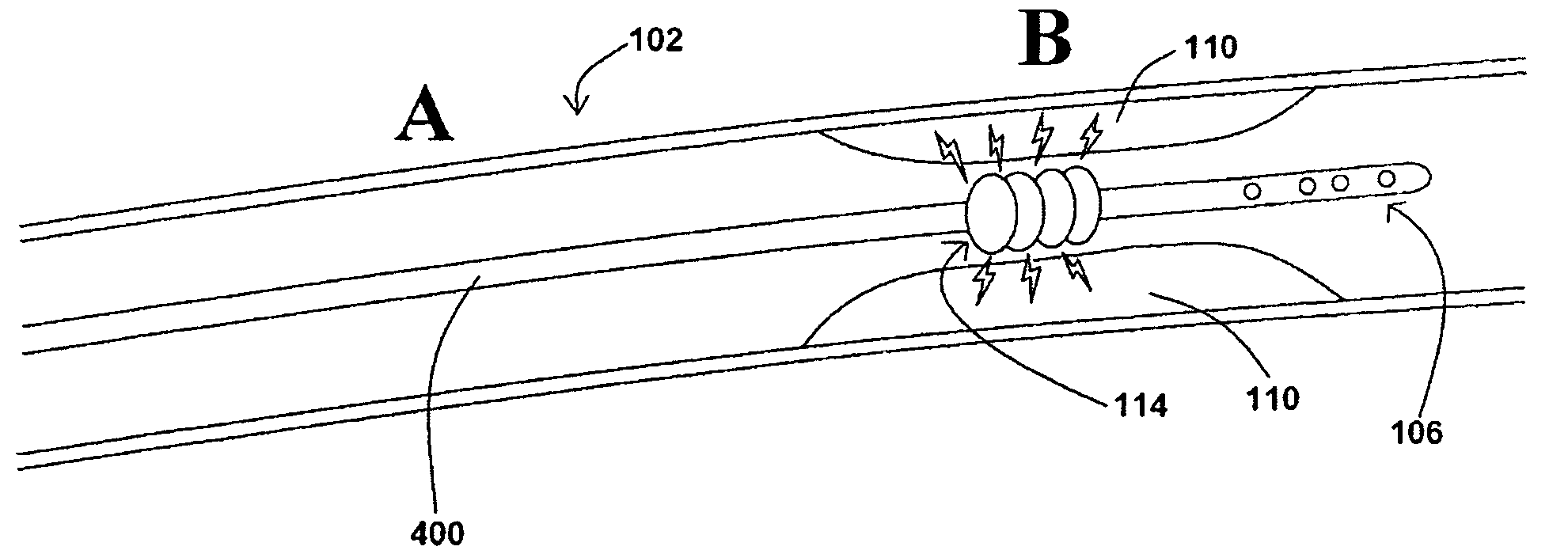

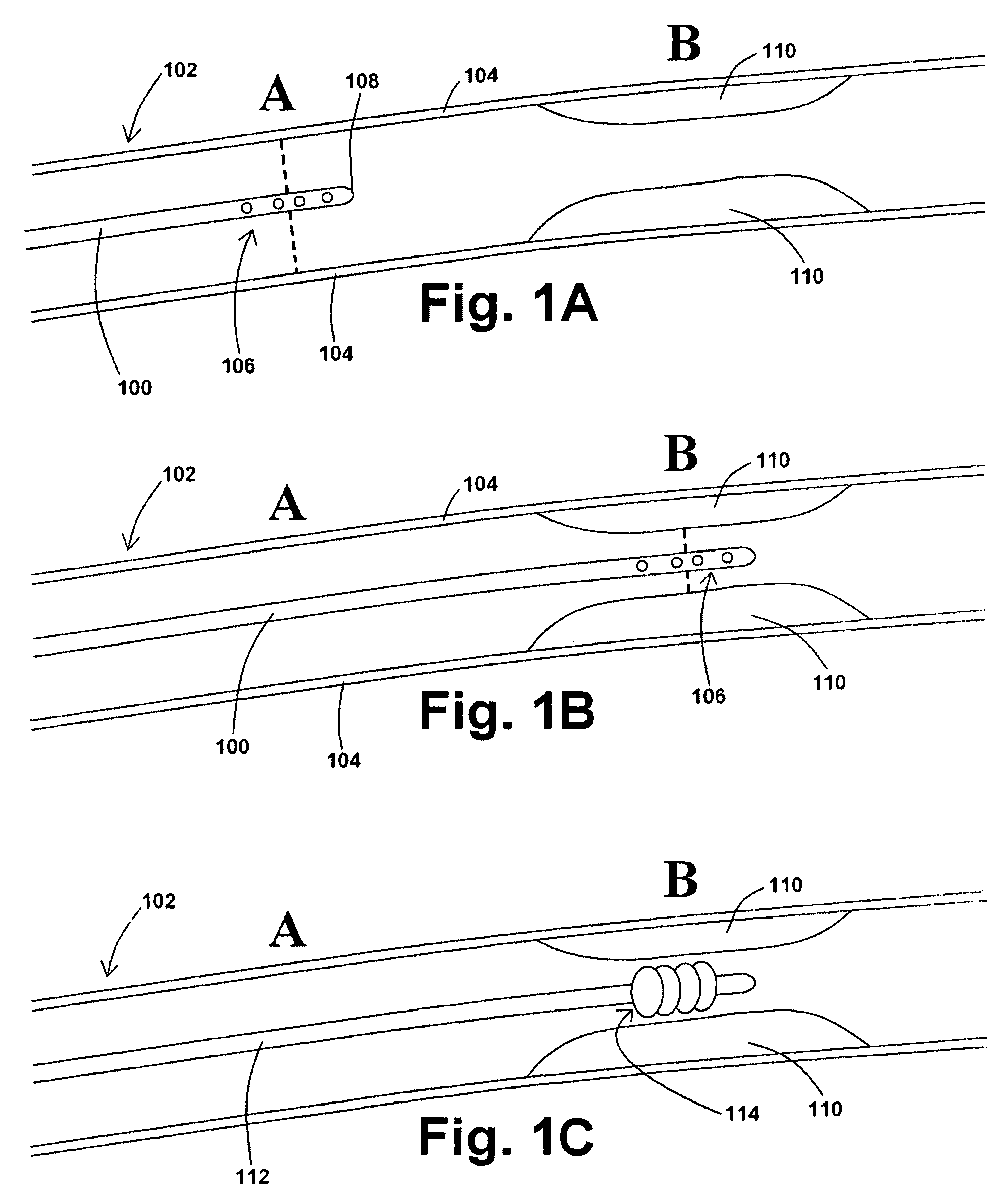

Electrical means to normalize ablational energy transmission to a luminal tissue surface of varying size

Methods and devices for measuring the size of a body lumen and a method for ablating tissue that uses the measurement to normalize delivery of ablational energy from an expandable operative element to a luminal target of varying circumference are provided. The method includes inserting into the lumen an expandable operative element having circuitry with resistivity or inductance that varies according to the circumference of the operative element, varying the expansion of the operative element with an expansion medium, measuring the resistivity of the circuitry, and relating the resistivity or inductance to a value for the circumference of the operative element. In some embodiments the sizing circuit includes a conductive elastomer wrapped around the operative element. Other embodiments of the method apply to operative elements that include an overlapping energy delivery element support in which the overlap varies inversely with respect to the state of expansion, and which is configured with sizing electrodes that sense the amount of the overlap.

Owner:TYCO HEALTHCARE GRP LP

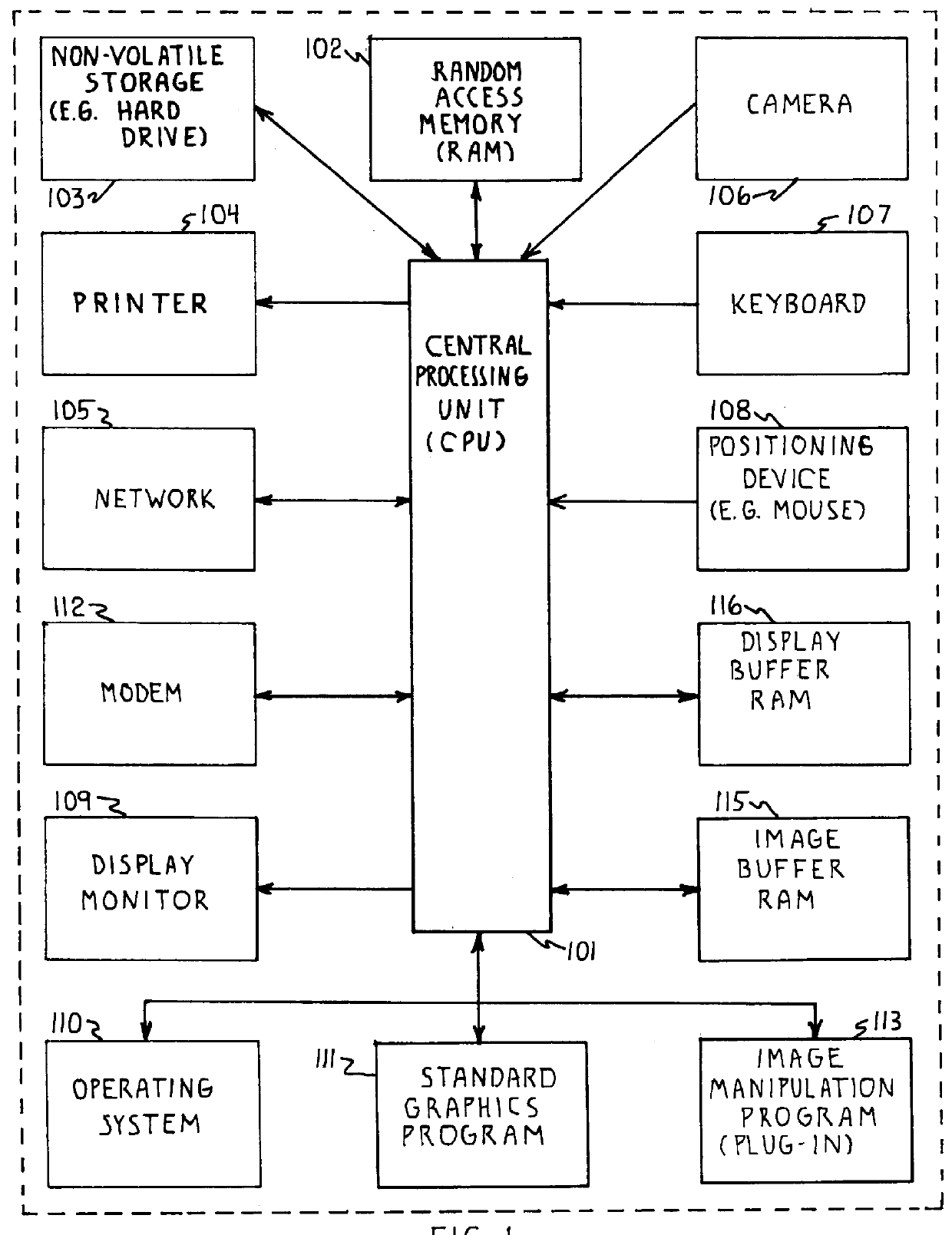

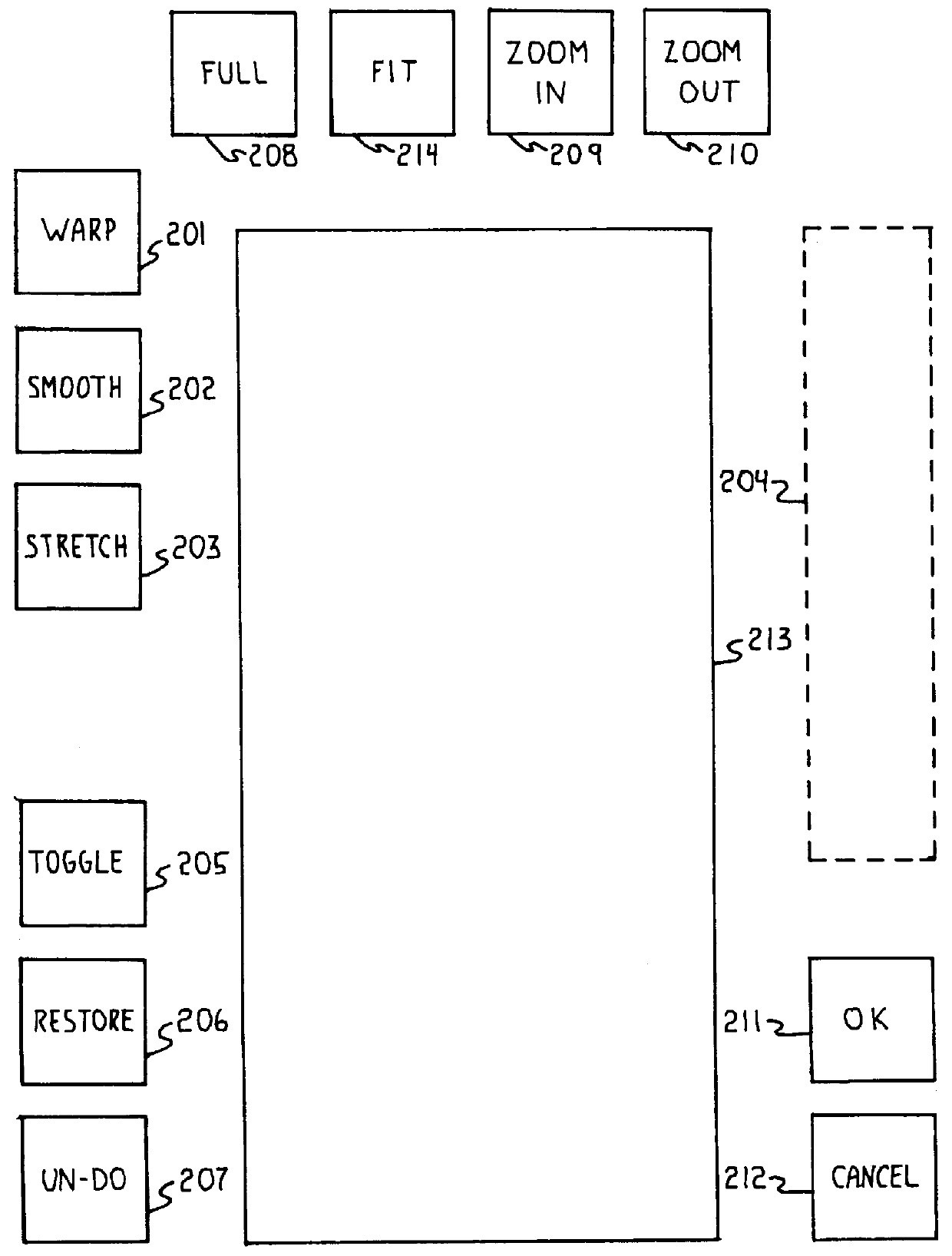

Apparatus for modifying graphic images

InactiveUS6084598AIncrease speedConsistent qualityDrawing from basic elementsGeometric image transformationChange managementShape change

A computer system modifies digital images of the human form as well as other objects. The computer system provides intuitive means for accessing warp, smooth, stretch, copy, and paste tools for image modification; undo, toggle and restore tools for change management; and zoom, fit, and full tools for image display sizing. The computer system is controlled by a program that uses a combination of novel approaches to make image manipulation fast and easy. Buttons are displayed only when they are actually available for use, based on the current system operating mode. The image sizing tools enable an image size change to accomodate the tool size without a required change to the cursor state or to the edit mode state. When regions are defined by the user, the cursor shape changes to indicate whether the cursor is located inside a region, outside the region, and on the region bounding box; allowing a user to perform different operations depending upon cursor location rather than depending upon, and requiring, user executed button pushing as a specific operation. The computer system uses display contexts and bitmap masks that enhance operation speed. Operations are always performed on the full image resolution rather than a displayed image resolution.

Owner:CHEKERYLLA JAMES

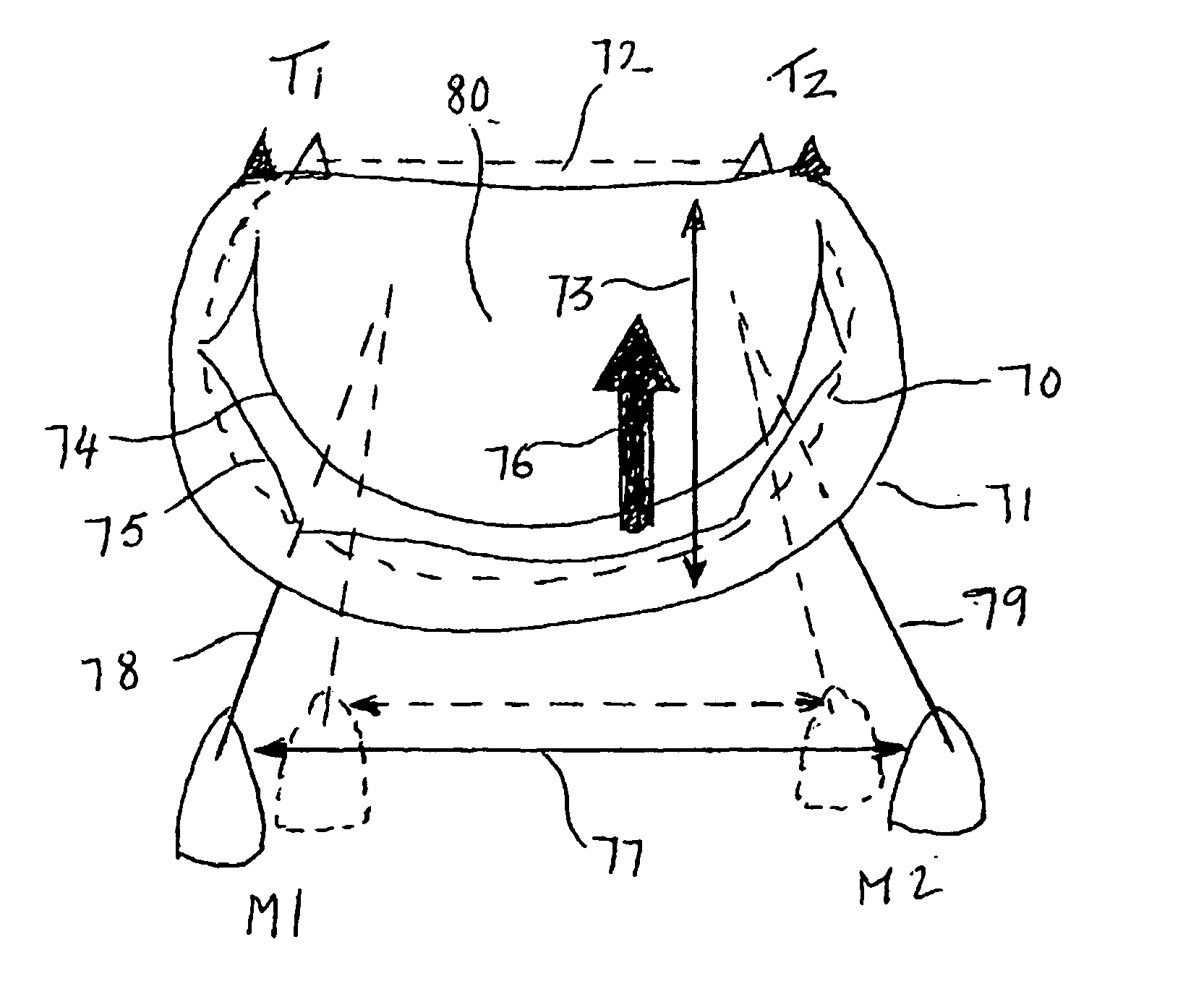

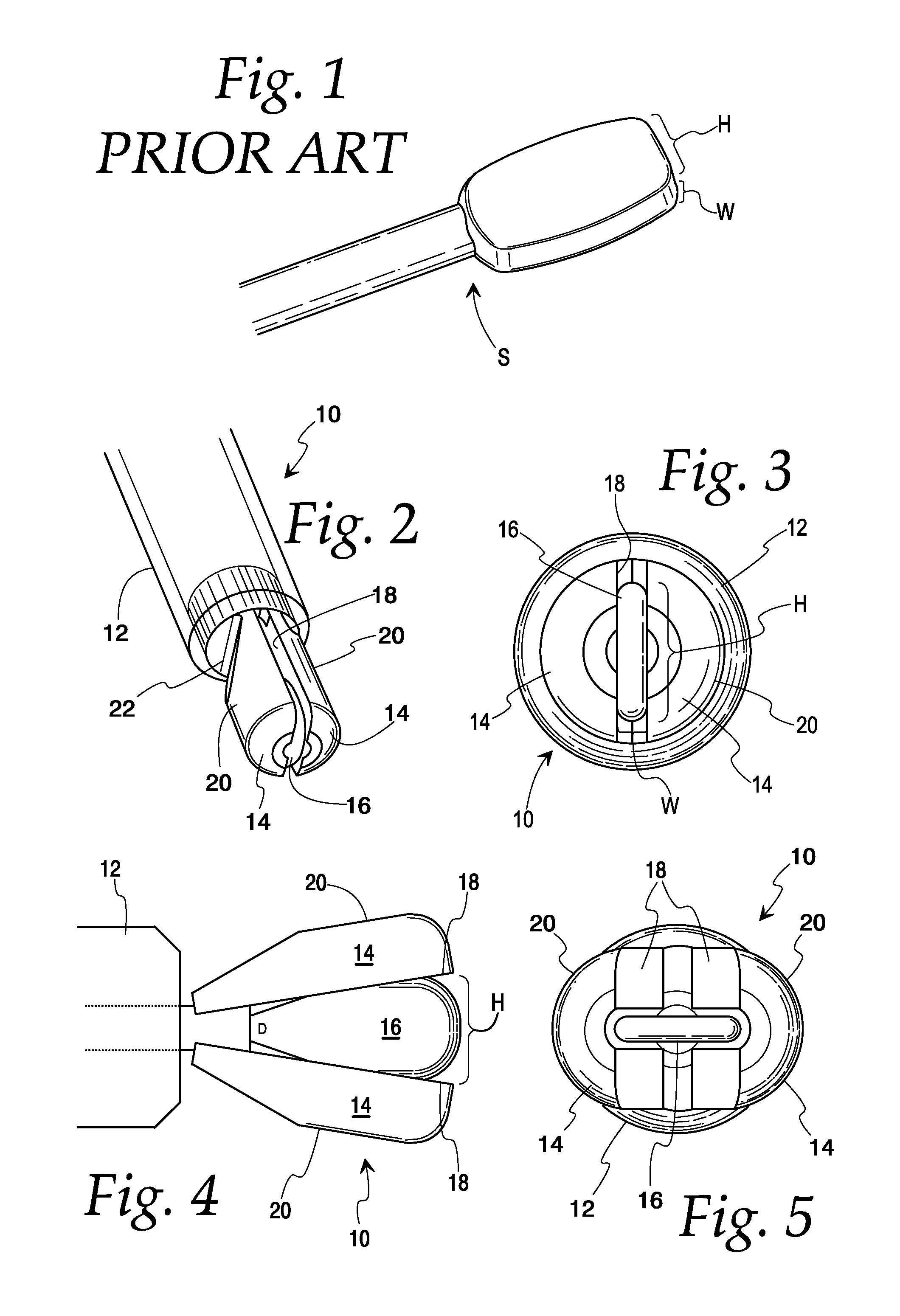

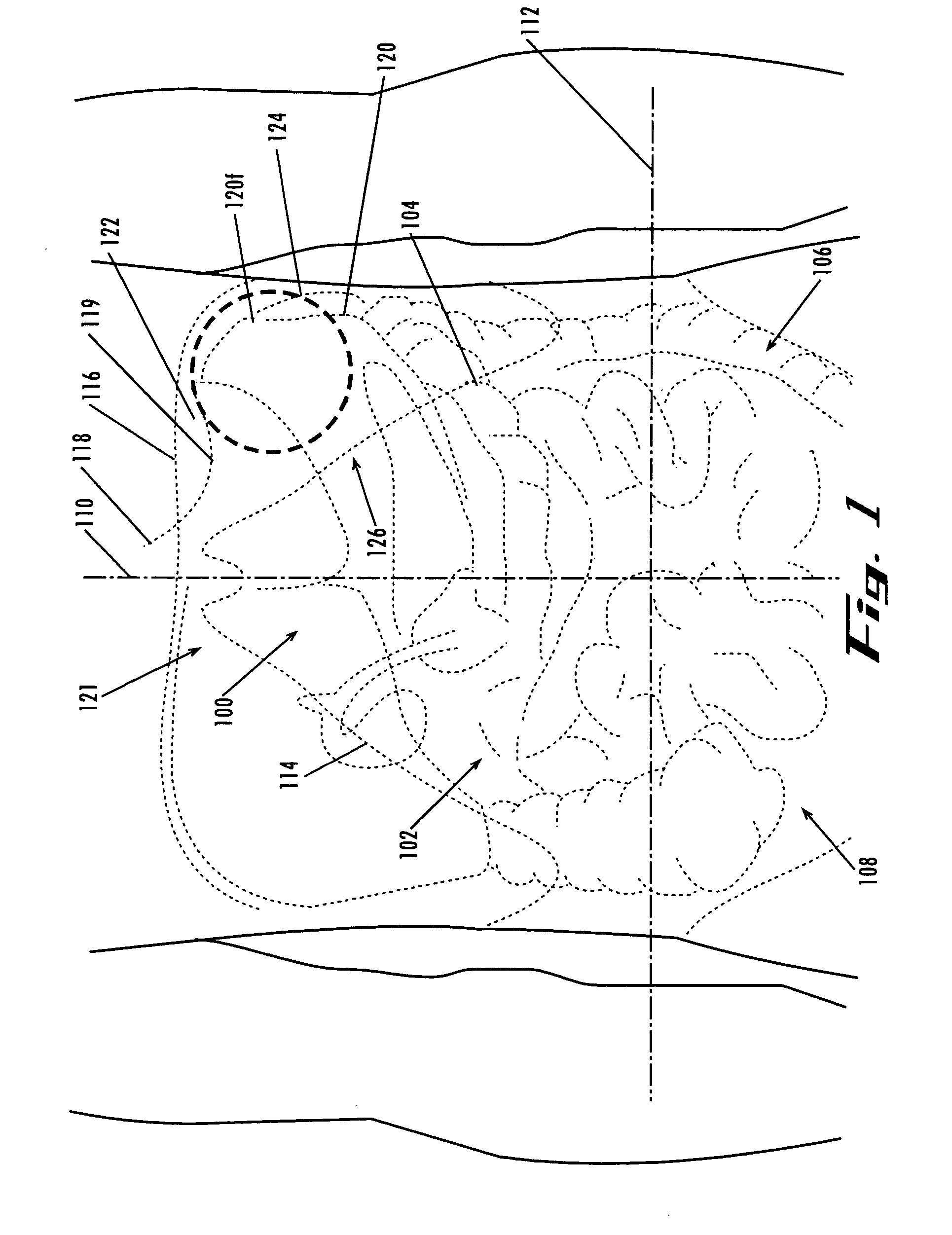

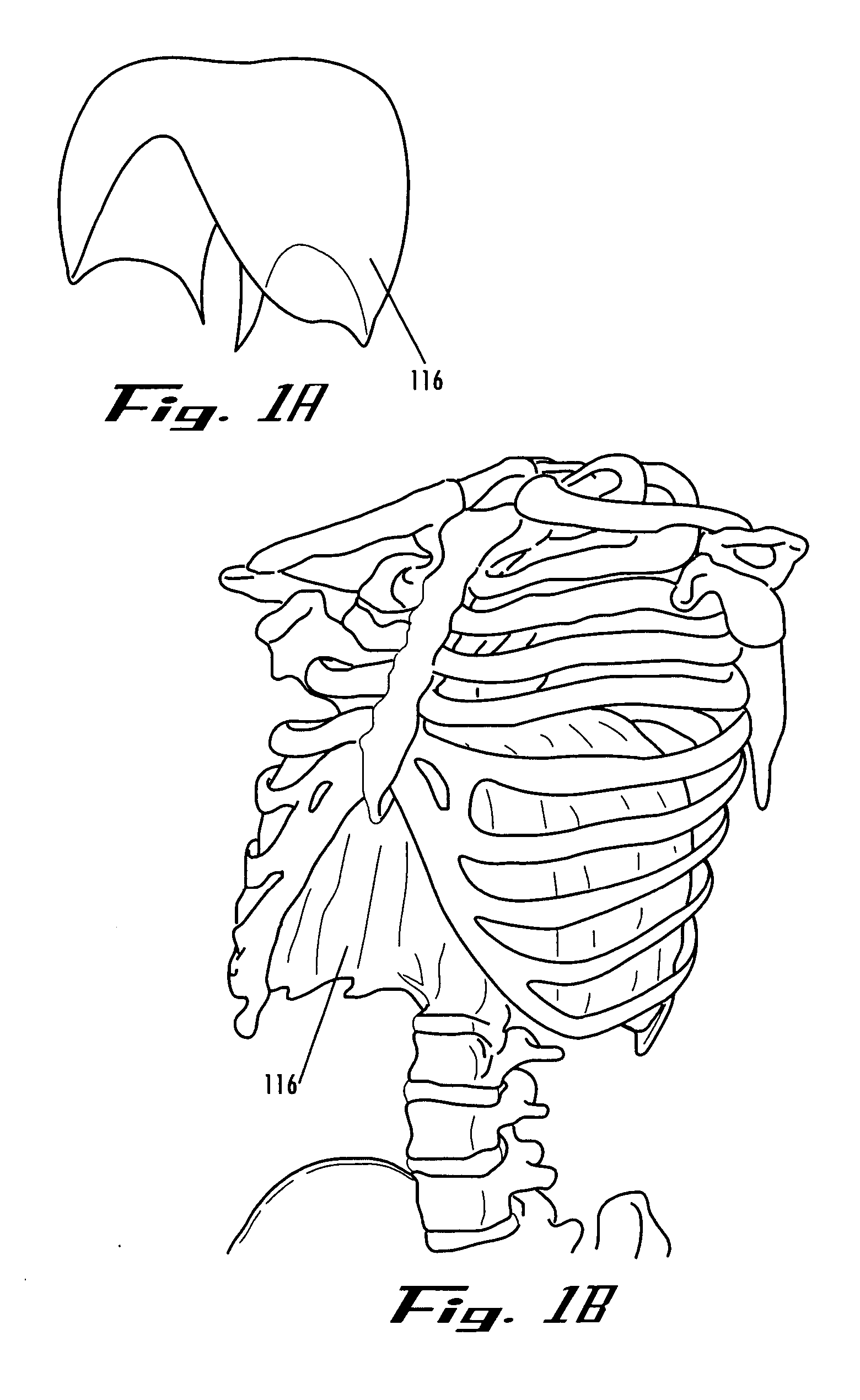

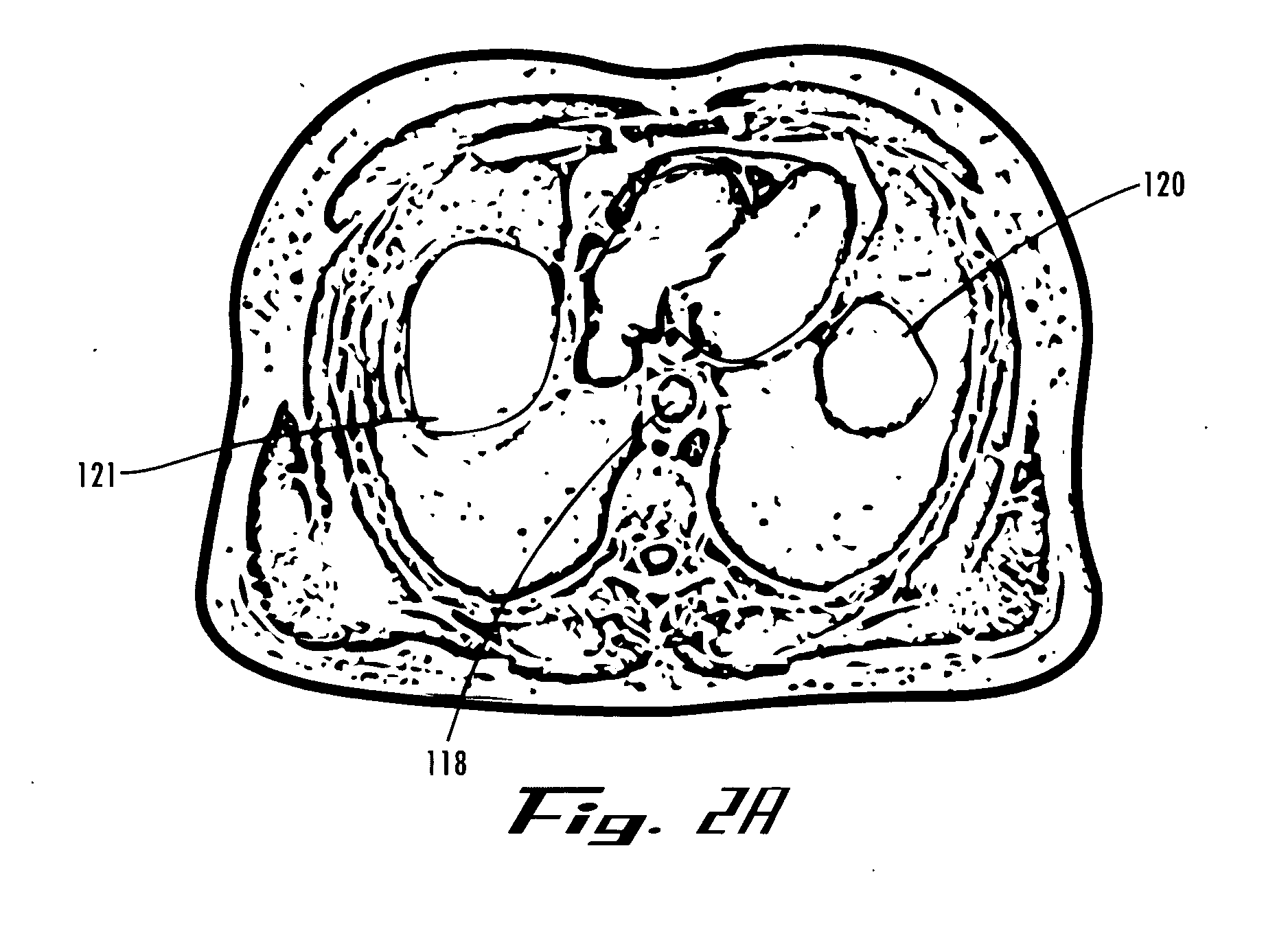

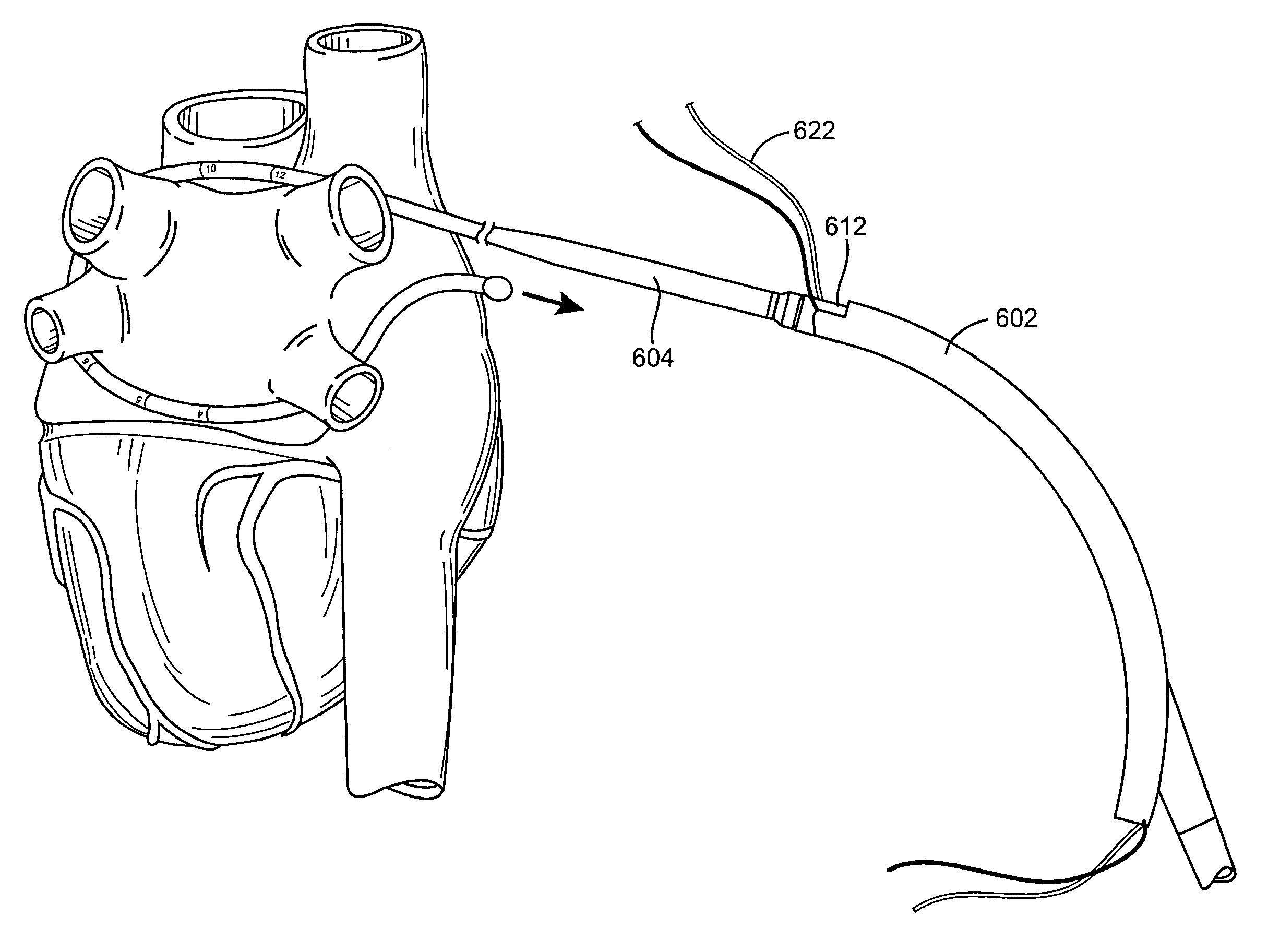

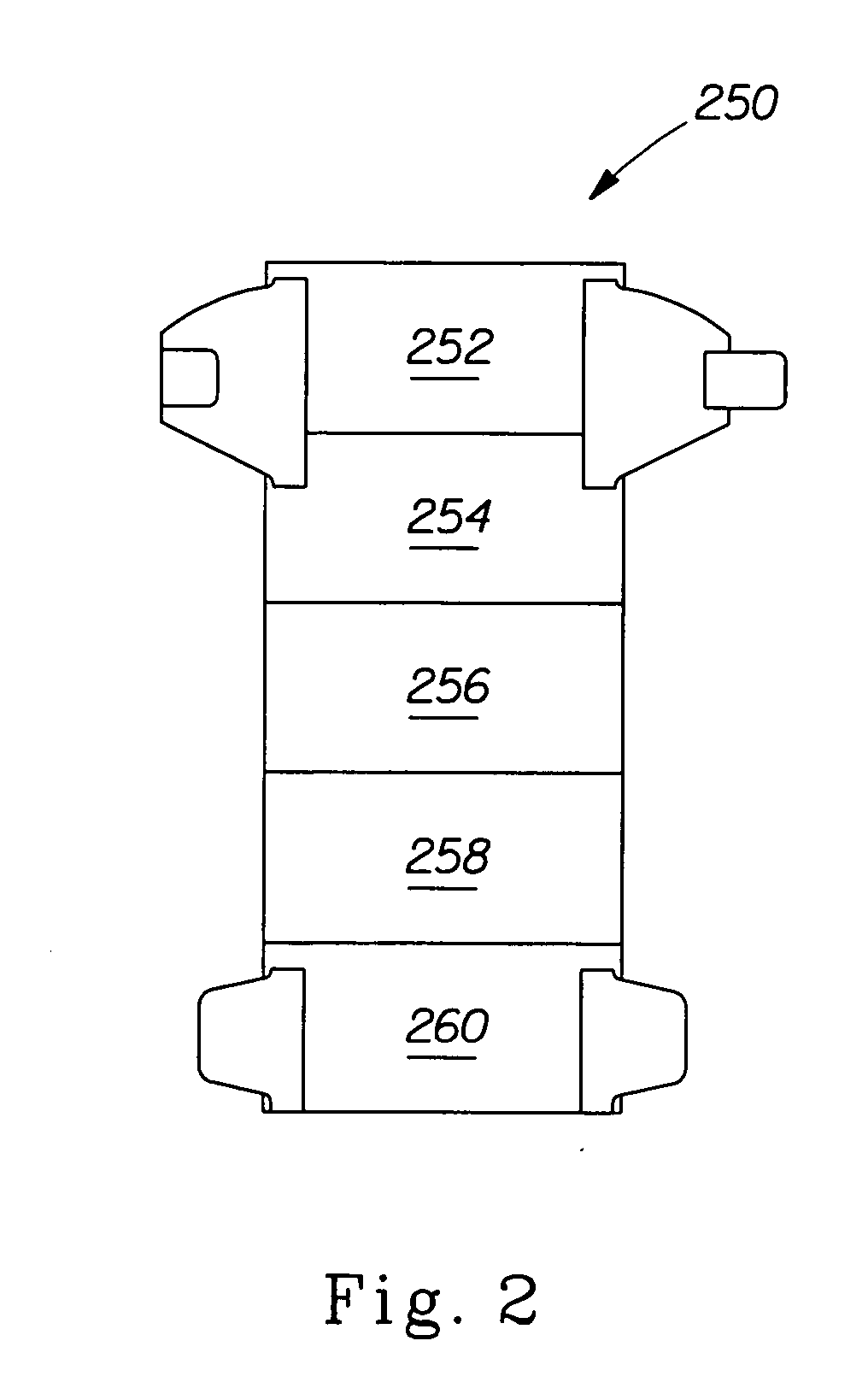

Deformable Sizer and Holder Devices for Minimally Invasive Cardiac Surgery

InactiveUS20090192602A1Reduce pointsReduce stepsHeart valvesMinimally invasive cardiac surgeryEngineering

Described is a device for sizing a heart valve annulus by a minimally invasive route, the device comprising: a sizing plate having first and second major surfaces, wherein the sizing plate comprises a deformable material such that the sizing plate can deform and fit through the minimally invasive route; and an elongate handle to which the sizing plate is attached. Also described is a similarly deformable device for holding an annuloplasty device. Additionally, methods of using the deformable sizing and holding devices are disclosed.

Owner:MEDTRONIC INC

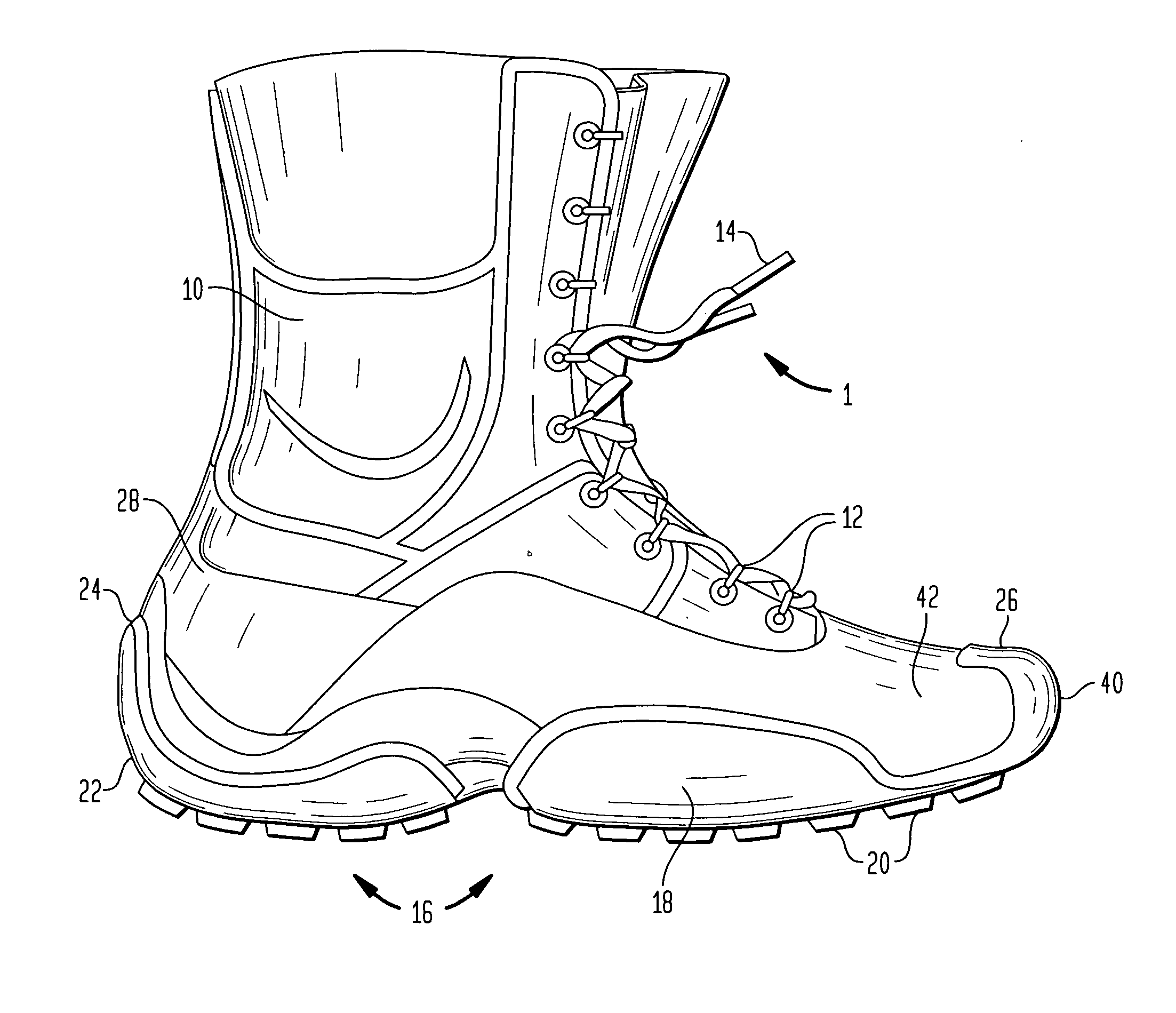

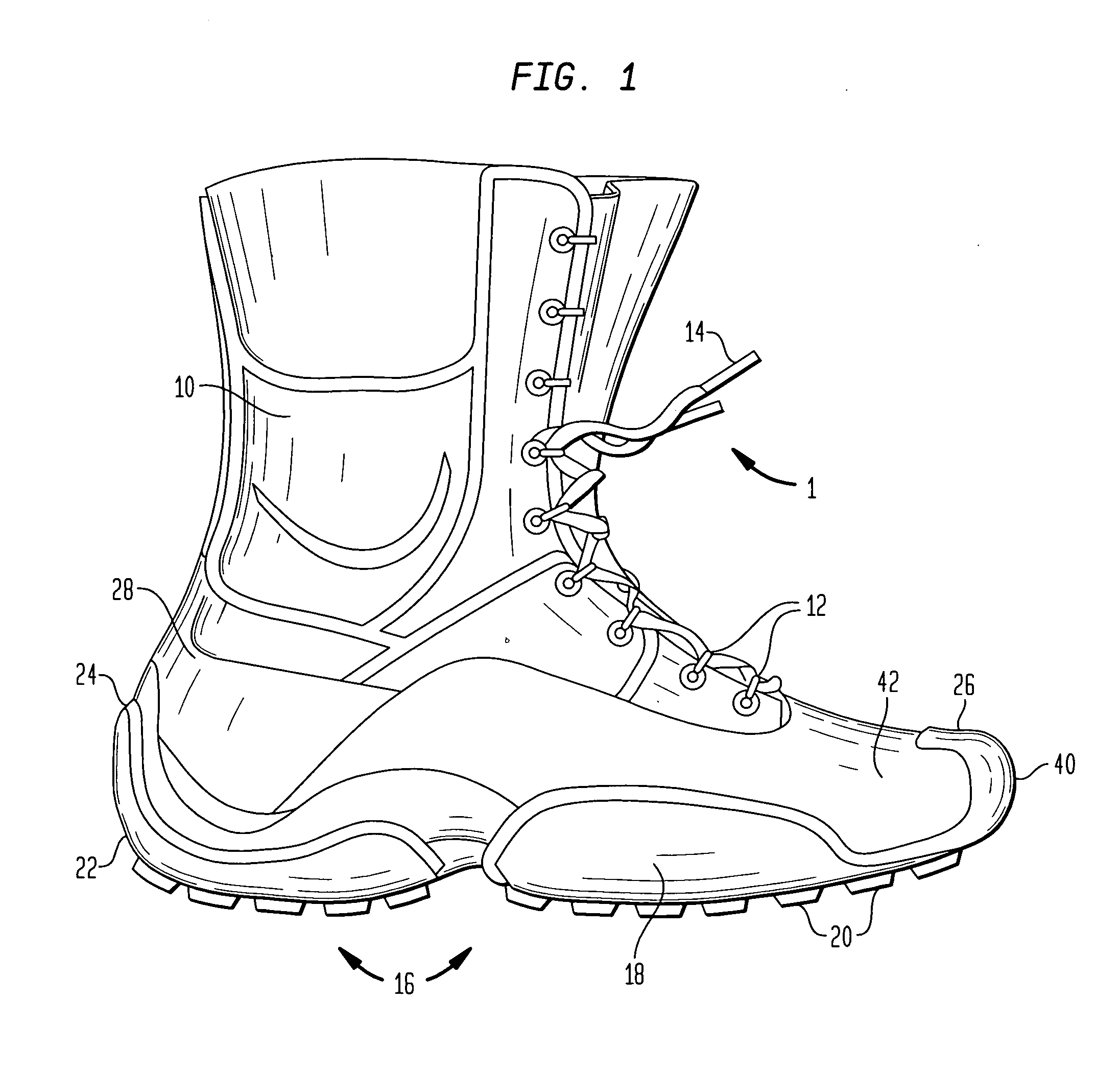

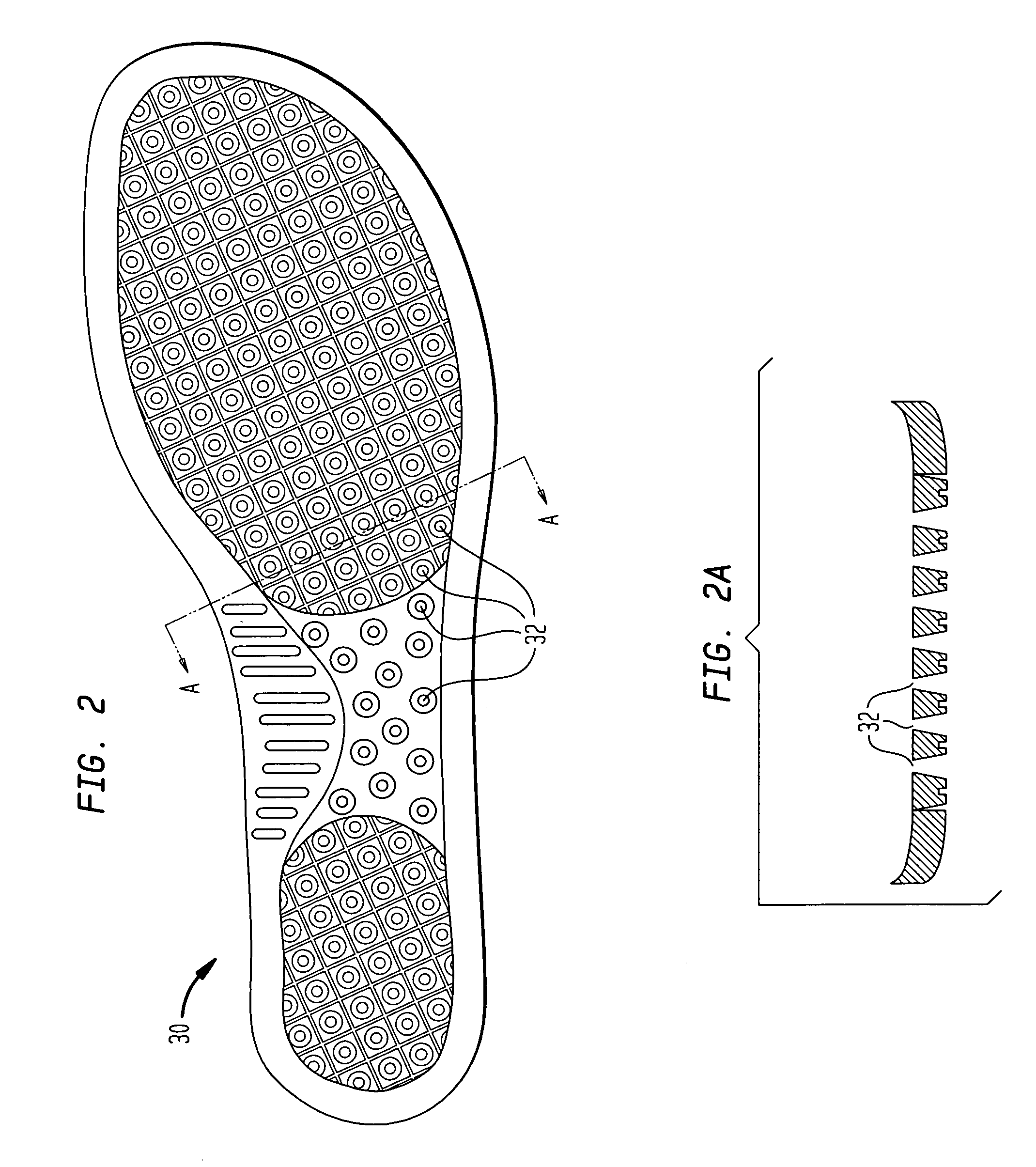

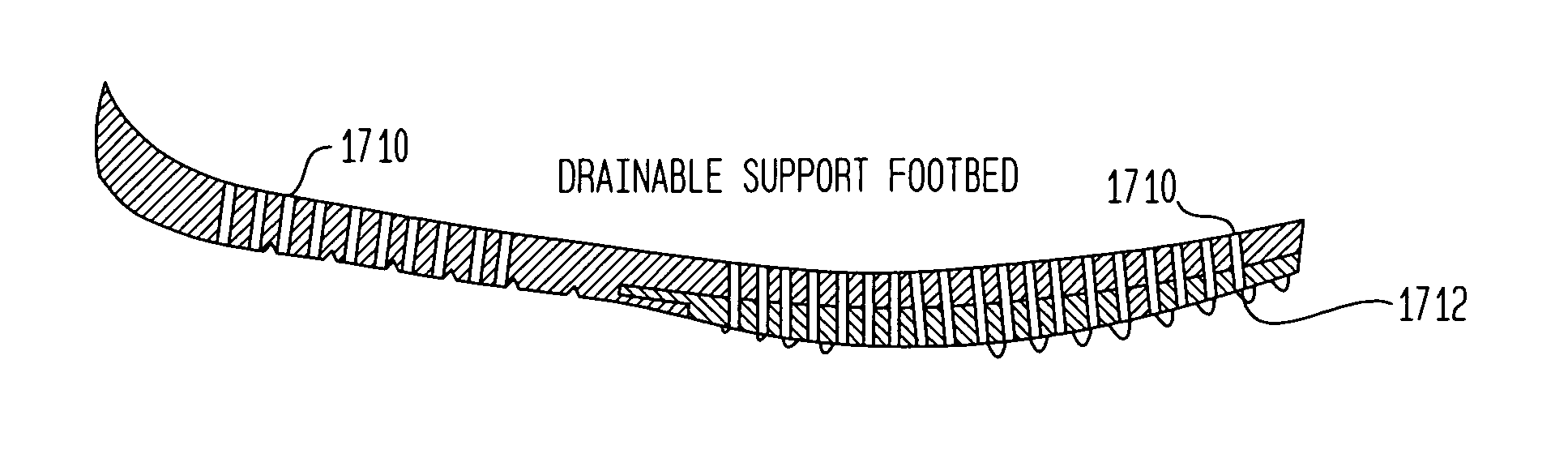

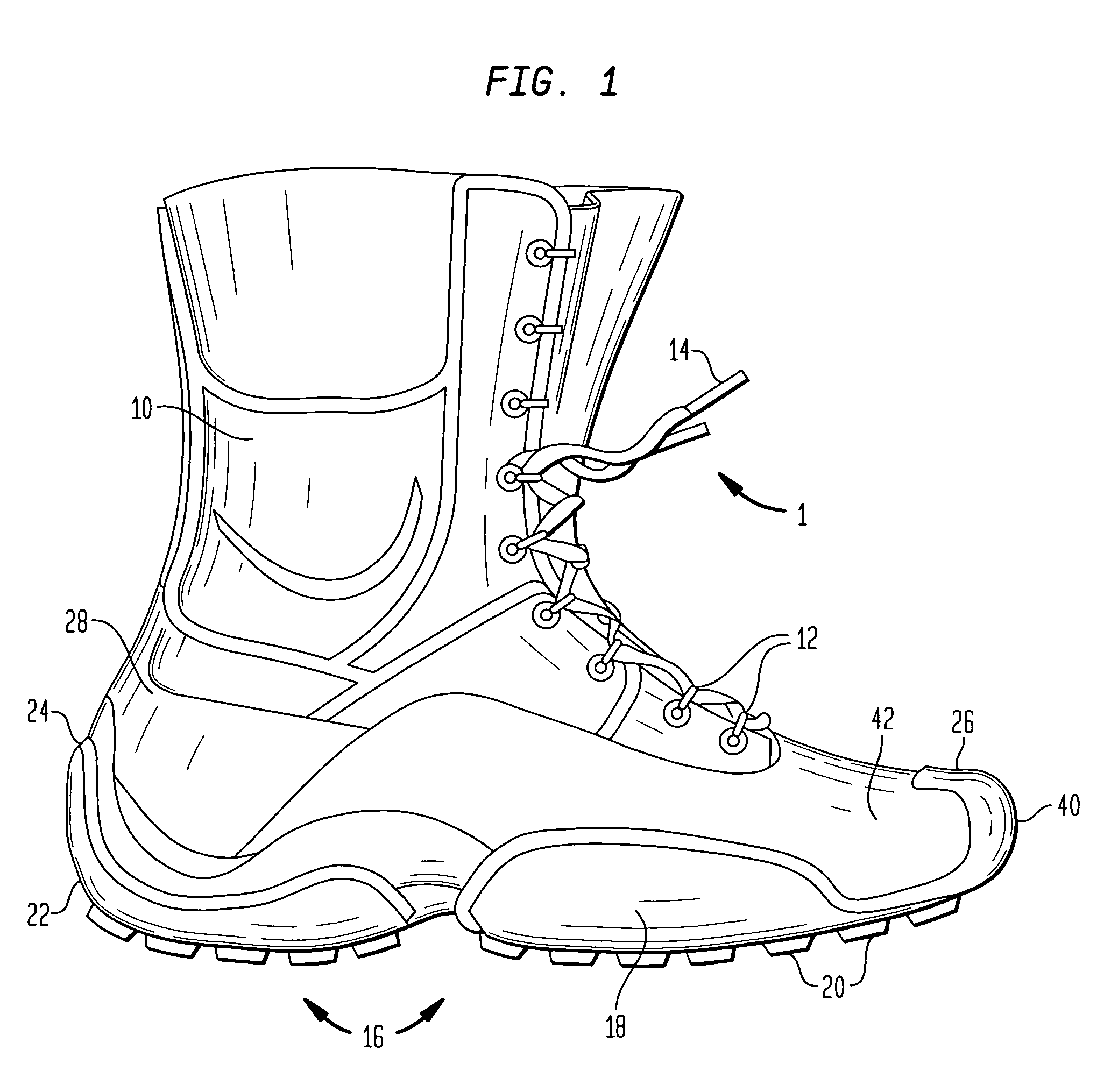

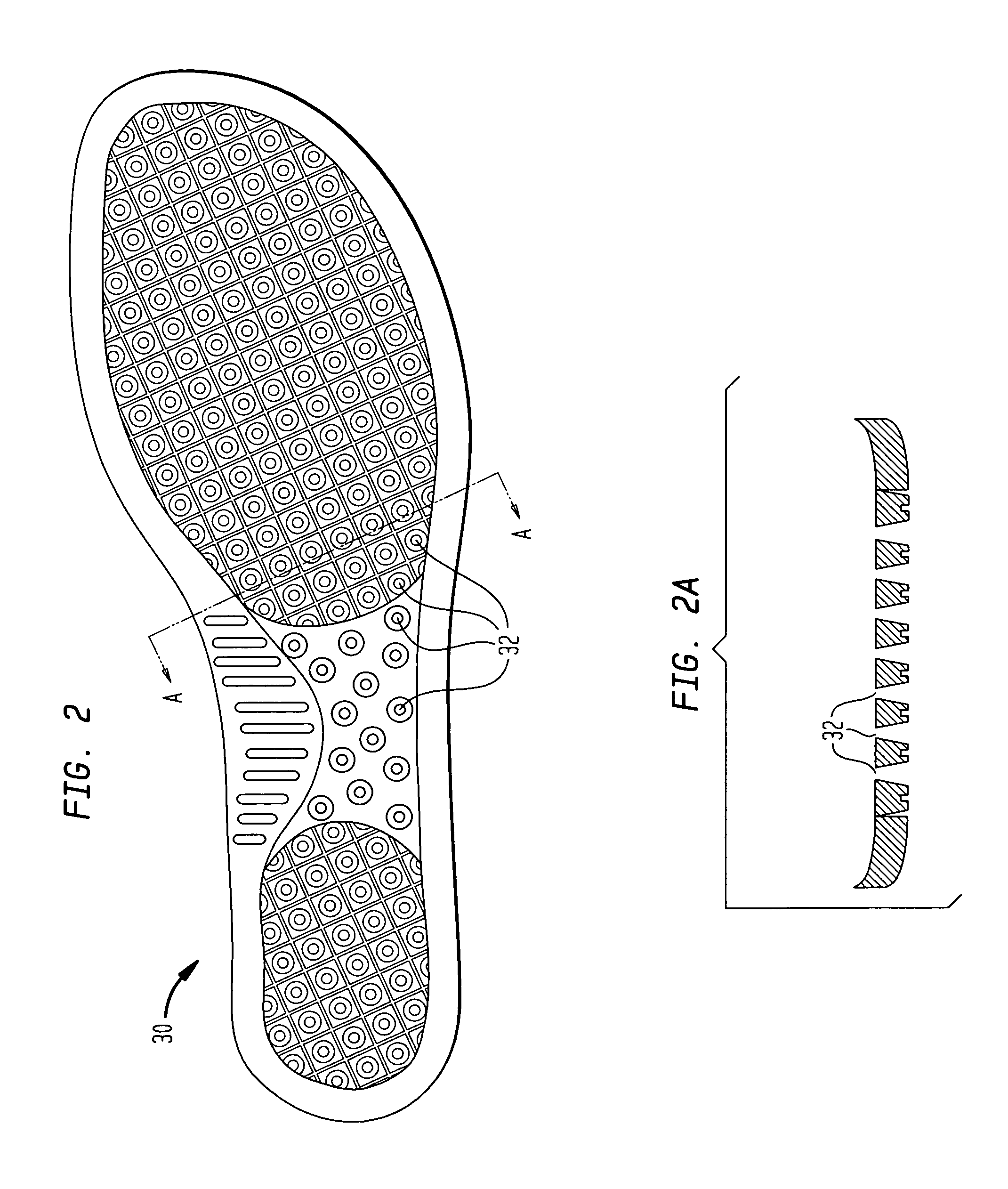

Extreme service footwear

The present invention provides articles of footwear adapted for use in extreme and hazardous environments by members of the military, law enforcement personnel and others who require durable and functional footwear. The footwear include protective coverings that may be proof, puncture proof, fire retardant or water repelling. Drainage holes can be positioned in the toe region and along the outsole to enable a wearer to quickly drain water from the article of footwear. Single use or replaceable drainage plugs may cover the holes to prevent entry of water into the boot or other article of footwear. Removable and / or replaceable footbeds may be employed, and such footbeds may provide adjustable sizing of the article of footwear using interchangeable cartridges. A support saddle may be employed with the footbed to enhance foot support under heavy loads. These and other features herein are suited for use in a wide variety of footwear.

Owner:THE TIMBERLAND COMPANY

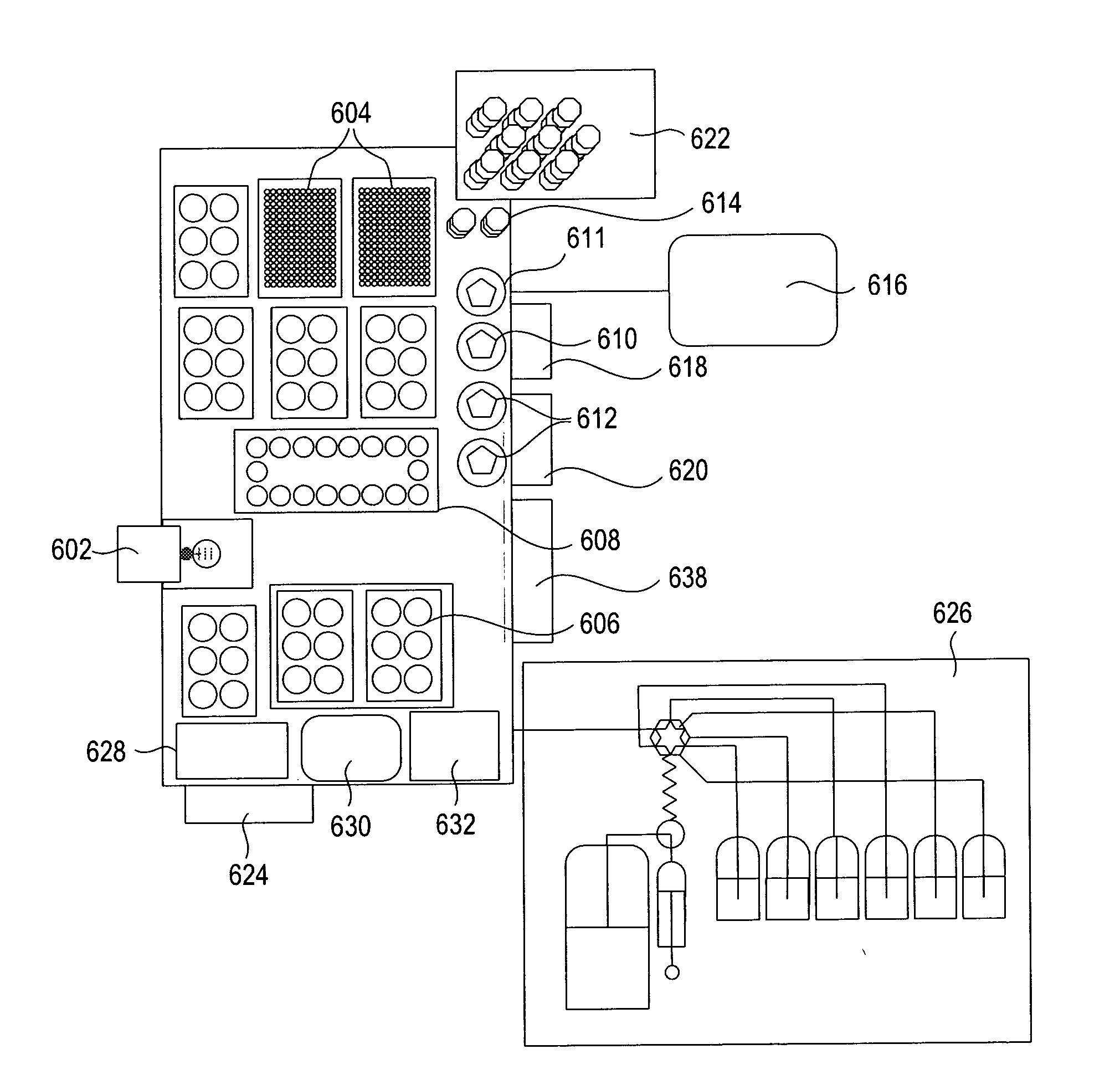

Preparation and characterization of formulations in a high throughput mode

ActiveUS20050058574A1Improve throughputFormula flexibleLibrary tagsFlow propertiesAnalysis dataAdditive ingredient

The invention is an automated robotic system for the production and testing of formulations at a very high throughput. It is an integrated system of hardware and software capable of preparing and evaluating hundreds of emulsions per day. The system can formulate aqueous solutions (SL), oil in water emulsions (EW), suspo-emulsions (SE), micro capsule suspensions (CS), micro-emulsions (ME), and suspension concentrates (SC) at the 1 ml to 25 ml scale. The system can process emulsions rapidly in an automated way and enable very flexible formulation recipes to be introduced. The system allows chemists to generate experimental samples of varying recipe and method to be conducted in parallel with projected throughput of up to 1200 formulations processed and characterized per day. Materials and consumables can be distributed from storage storage systems to the work stations where dispensing of ingredients in various states can be performed, including solids, liquids, gels, pastes, suspensions and waxes. The emulsions formed can be characterized using methods including phase diagnosis, turbidity analysis, viscosity and particle sizing using automated test equipment. An integrated module can also perform Tank Mix Compatibility testing in high throughput mode. The modular system allows future processes and tests to be added, either to a station, or as a new station. The software capability includes tracking of processes from start to finish and the integration of analytical data with the as-designed and as-formulated experimental results.

Owner:SYNGENTA LTD

Devices and methods for treatment of obesity

ActiveUS20070250020A1Avoid expansionAvoid insufficient lengthSuture equipmentsDilatorsDevice implantPERITONEOSCOPE

Implantable devices, instruments, kits and methods for treatment of obesity. One or more devices can be implanted adjacent to or in contact with the stomach to occupy a space to prevent the stomach from expanding into that space as food is taken into the stomach. Alternatively, one or more devices may be implanted and expanded to displace at least a portion of the wall of the stomach to decrease the internal volume of the stomach that is available to receive food. Devices may be anchored to one or more internal structures at one or more locations without piercing through the wall of the stomach. Devices can be implanted using minimally invasive methods, such as percutaneous or laparoscopic methods. Delivery instruments are also provided. An intra-gastric sizing device is provided to facilitate implantation of an extra-gastric device in some method embodiments.

Owner:VIBRYNT

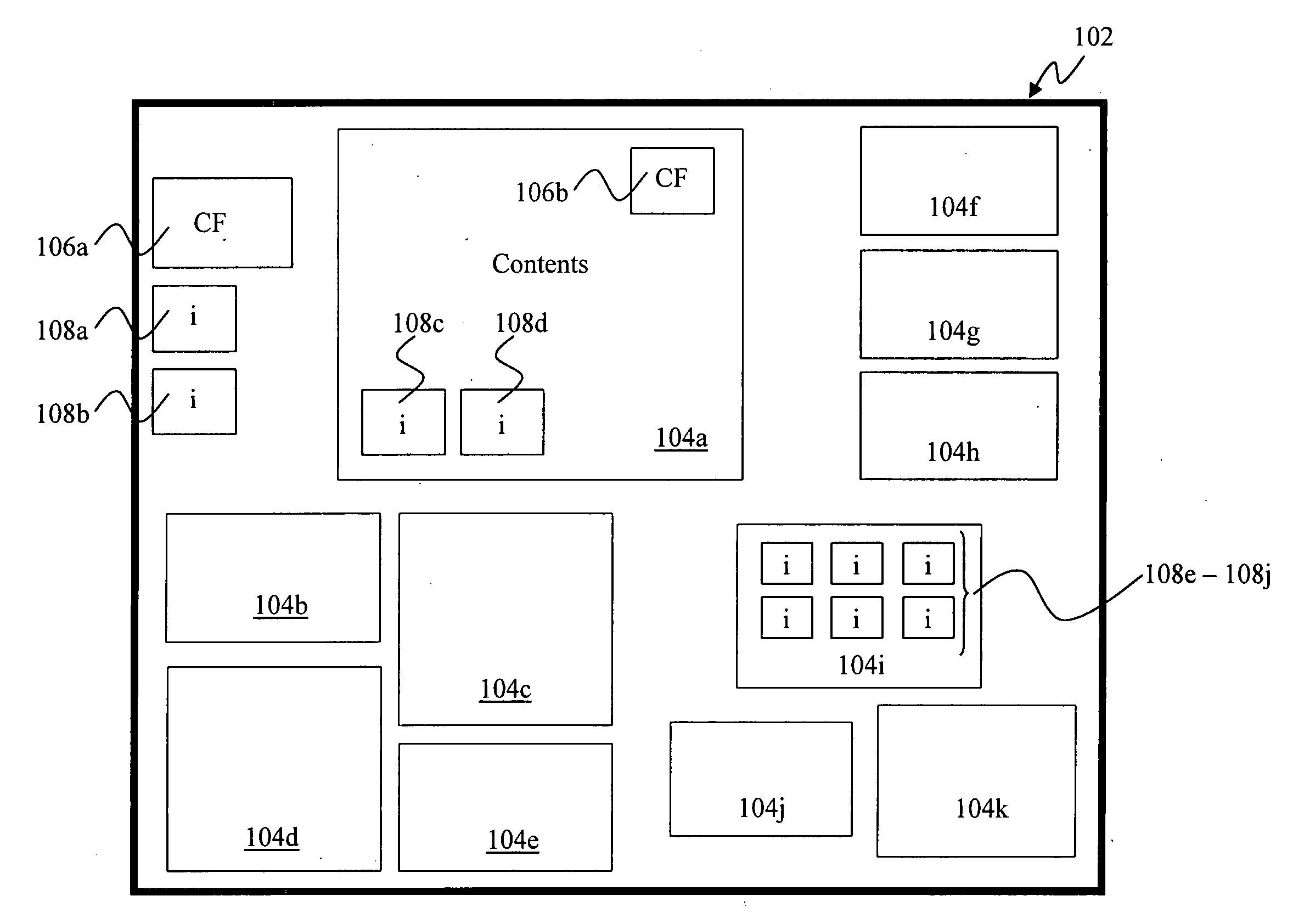

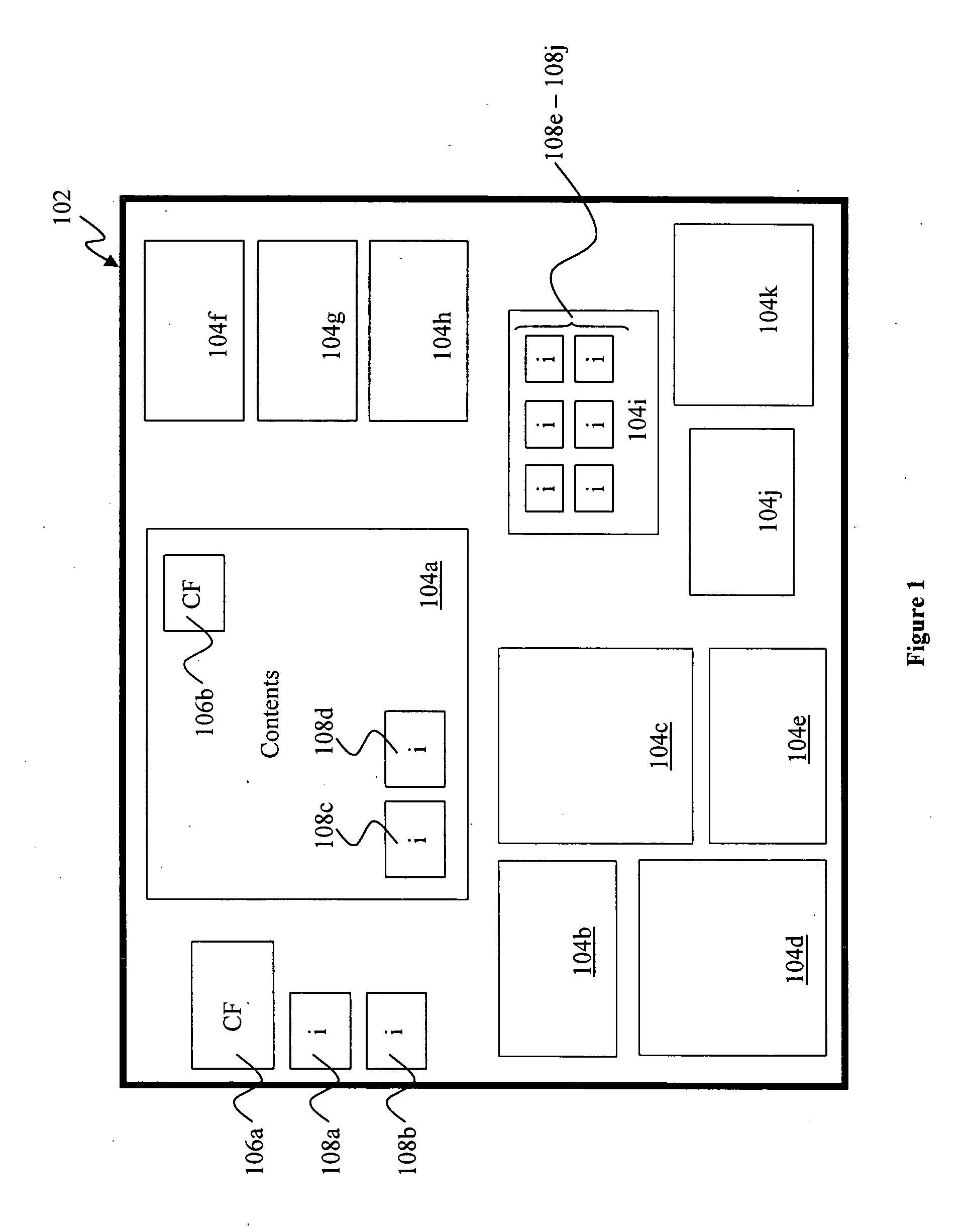

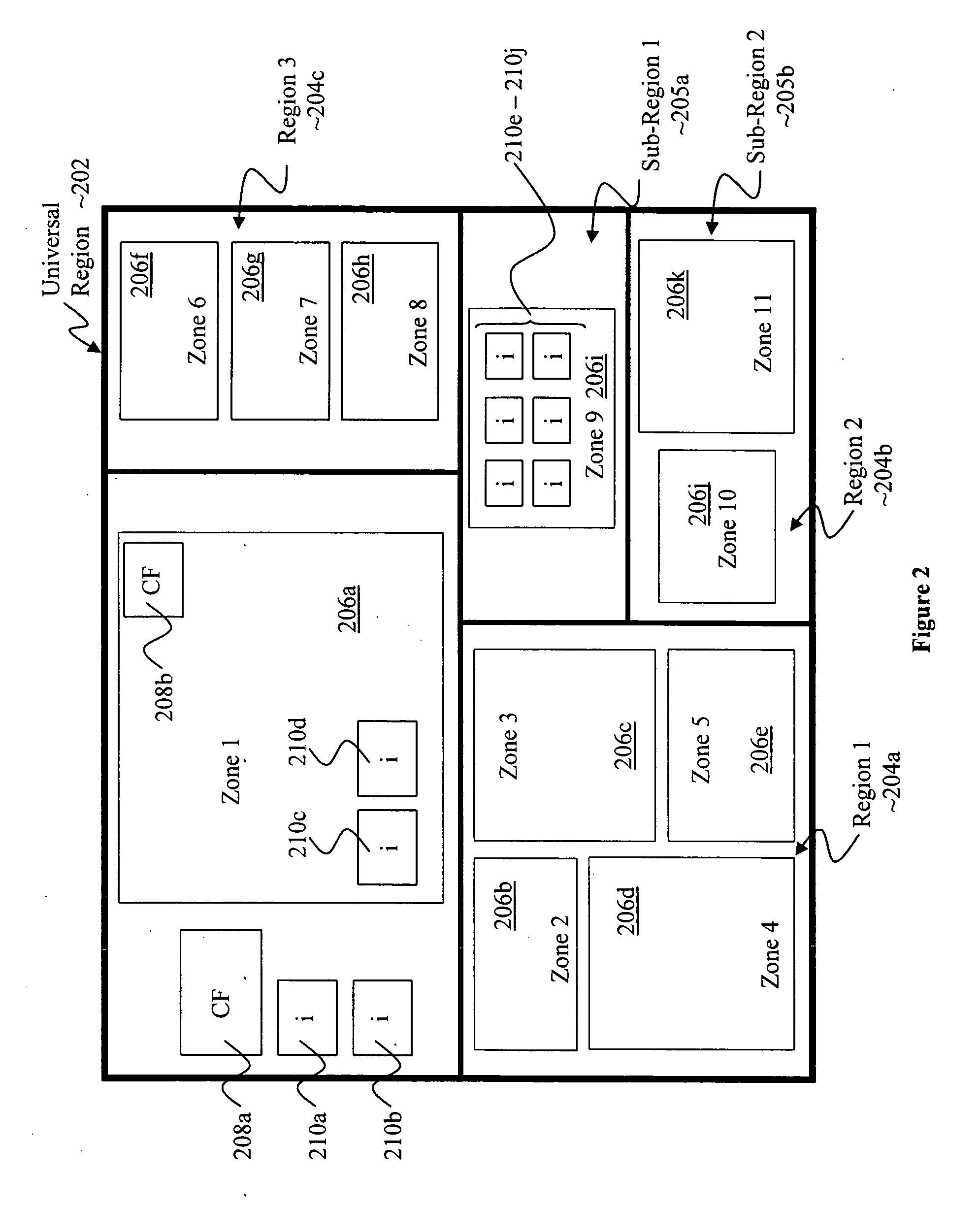

Display container cell modification in a cell based EUI

InactiveUS20080189653A1Cathode-ray tube indicatorsInput/output processes for data processingDisplay deviceTheoretical computer science

In a cell based EUI, existing display container cells nested within a “host” display container cell are automatically shifted and / or downsized, if necessary, to increase available space to facilitate the creation of another display container cell nested within the “host” display container cell, in response to a request to perform the creation. Similar shifting and / or downsizing are performed to facilitate expansion of one of the nested display container cells; and shifting and upsizing are performed to facilitate contraction of one of the nested display container cells. In one embodiment, shifting and / or downsizing / upsizing are performed in view re-sizing priorities of the display container cells and attributes of a host display container cell governing placement and / or alignment of immediately nested display container cells. In one embodiment, an efficient extended boundary method is employed.

Owner:BROADBAND GRAPHICS LLC - A WASHINGTON LIMITED LIABILITY

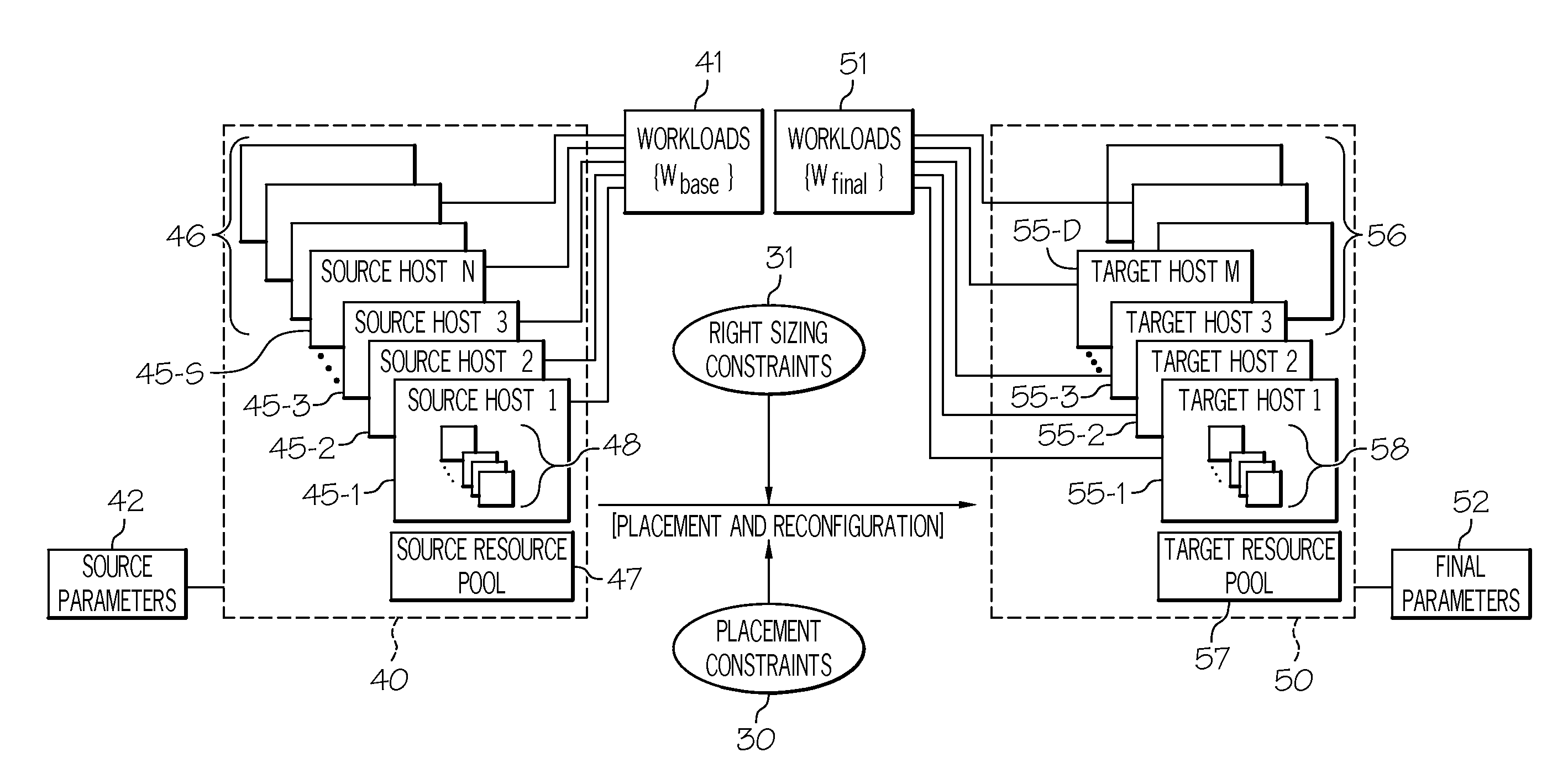

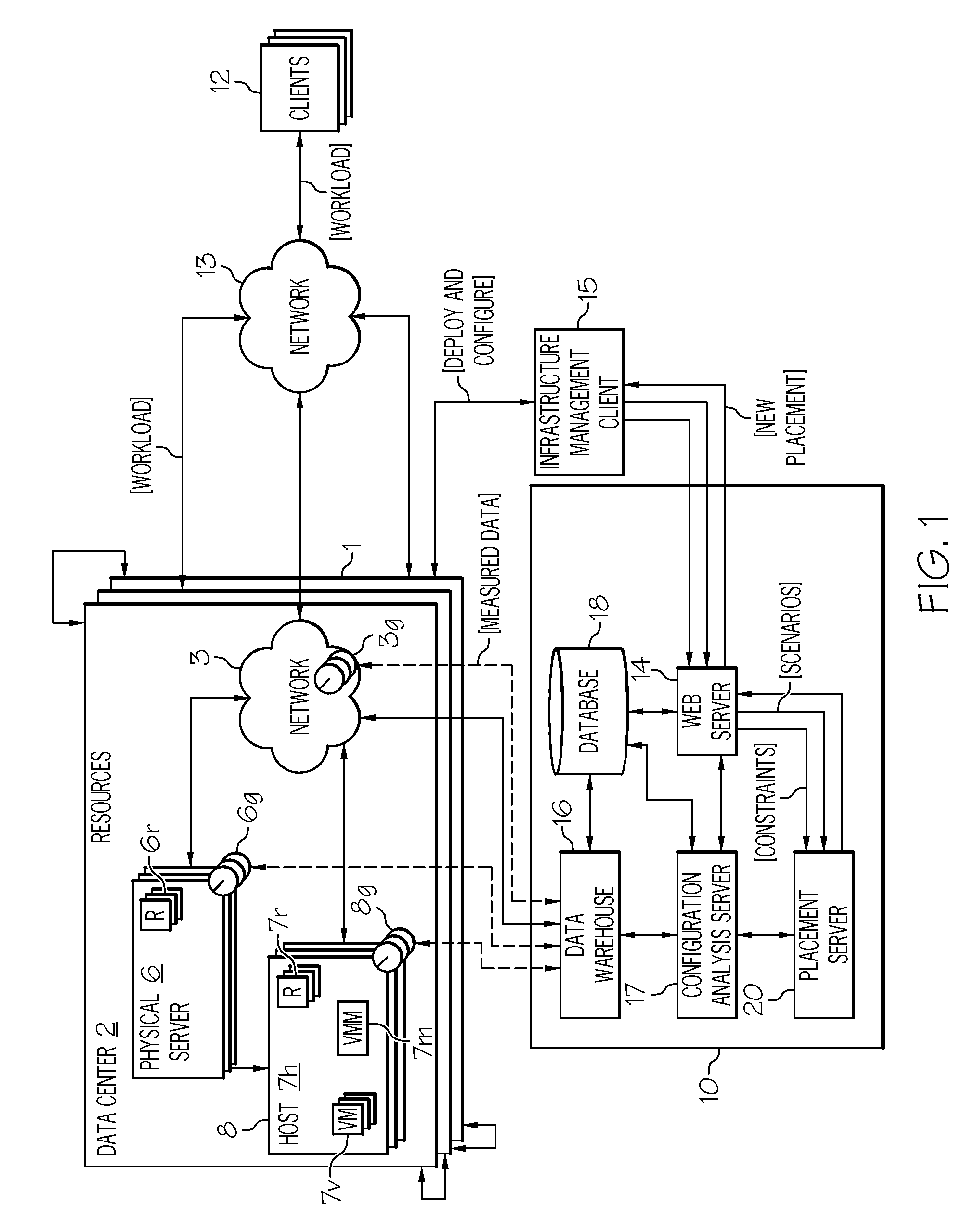

System and method for automated assignment of virtual machines and physical machines to hosts with right-sizing

ActiveUS20140019965A1Software simulation/interpretation/emulationMemory systemsSizingVirtual machine

A system and method for reconfiguring a computing environment comprising a consumption analysis server, a placement server and a data warehouse in communication with a set of data collection agents and a database. The consumption analysis server operates on measured resource utilization data to yield a set of resource consumptions in regularized time blocks, collects host and virtual machine configurations from the computing environment and determines available capacity for a set of target hosts. The placement server assigns a set of target virtual machines to the target set of hosts in a new placement that is right-sized according to a set of right-sizing constraints and rules. In one mode of operation the new placement is nearly optimal. In another mode of operation, the new placement is “good enough” to achieve a threshold score based on an objective function of capacity headroom. The new placement is implemented in the computing environment.

Owner:CA TECH INC

Methods and devices for ablation

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

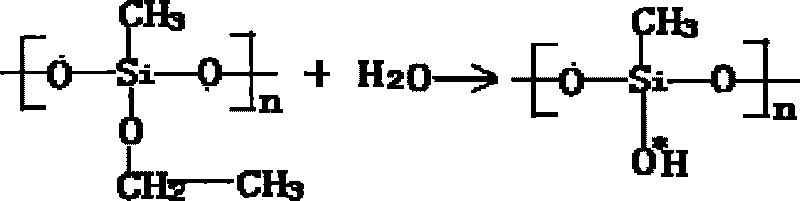

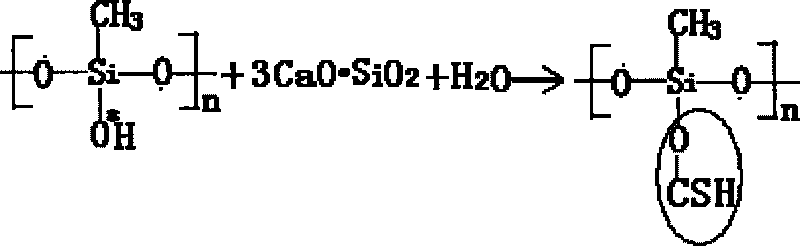

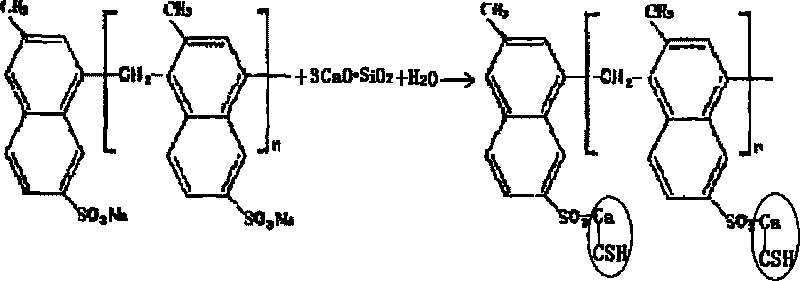

Waterproof roll capable of carrying out chemical bonding and physical crosslinking synergism with concrete

ActiveCN101694114AImprove stabilityIncreased durabilityRoof covering using flexible materialsTextiles and paperAntioxidantPlasticizer

The invention discloses a wet-laying and pre-laying waterproof roll which is made by the following processes: dipping and coating a modified asphalt compound on a blank body, controlling the thickness and sizing, coating a membrane, rolling, and the like, wherein the modified asphalt compound contains modified asphalt, a plasticizer, an antioxidant, a functional auxiliary agent and a filling gent. A preparation method of the waterproof roll comprises the following steps: putting substrate asphalt in a reaction pot, adding a thickening agent, irregular polyethylene and styrene-polybutadiene-styrene segmented copolymer, evenly mixing, heating and stirring for 1.5-2 hours, then reducing the temperature to about 180 DEG C, adding padding, the plasticizer, the antioxidant and the functional auxiliary agent into the reaction pot and stirring for 0.5-1h, evenly mixing and modifying, then conveying into a colloid mill for repeatedly milling to the material, then dipping and coating the modified asphalt on the blank body, controlling the thickness, sizing, coating the membrane and rolling, and finally preparing the waterproof roll which has excellent performance and can carry out chemical bonding and physical crosslinking synergism with the concrete, namely, a CPS waterproof roll for short.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

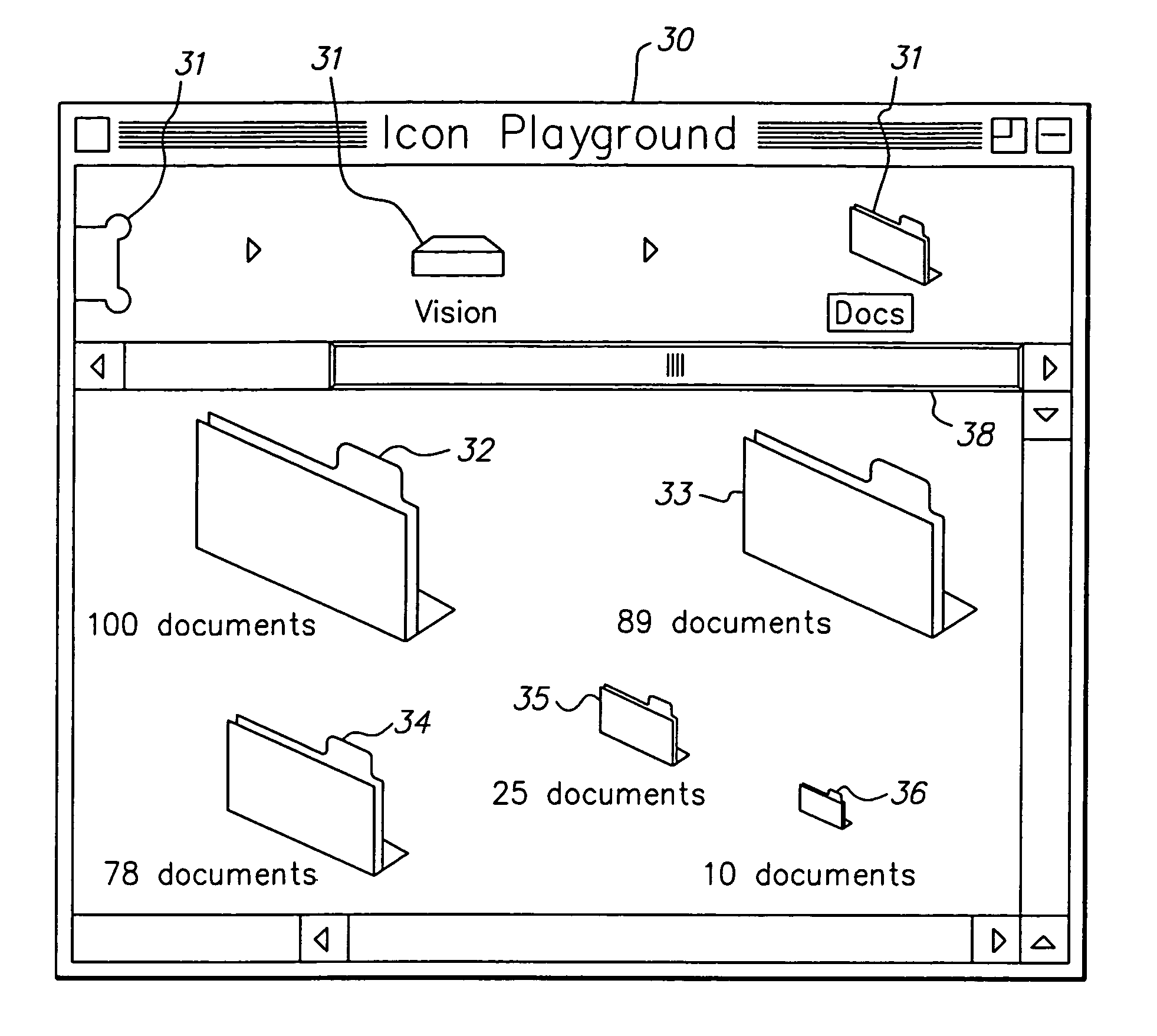

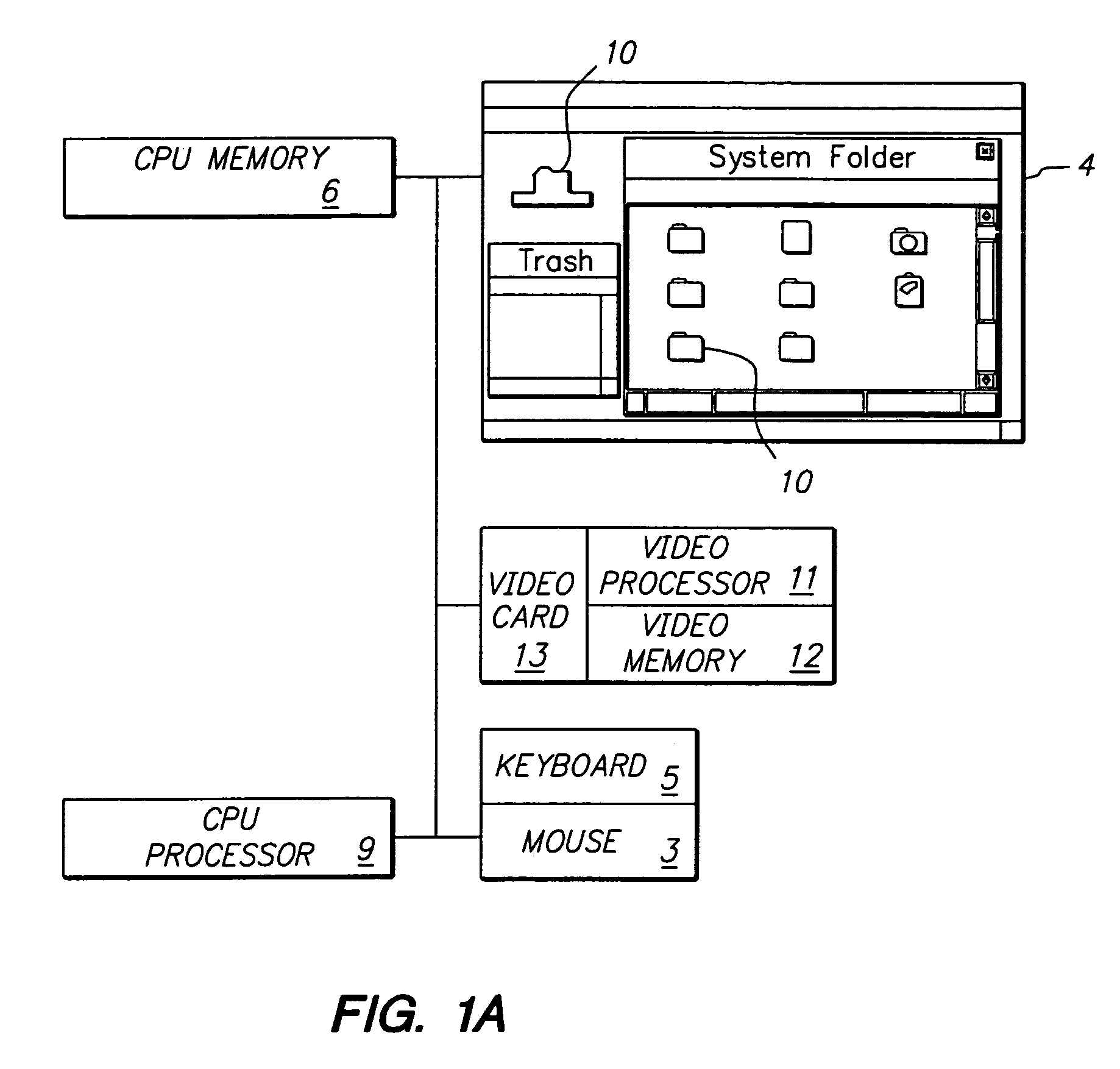

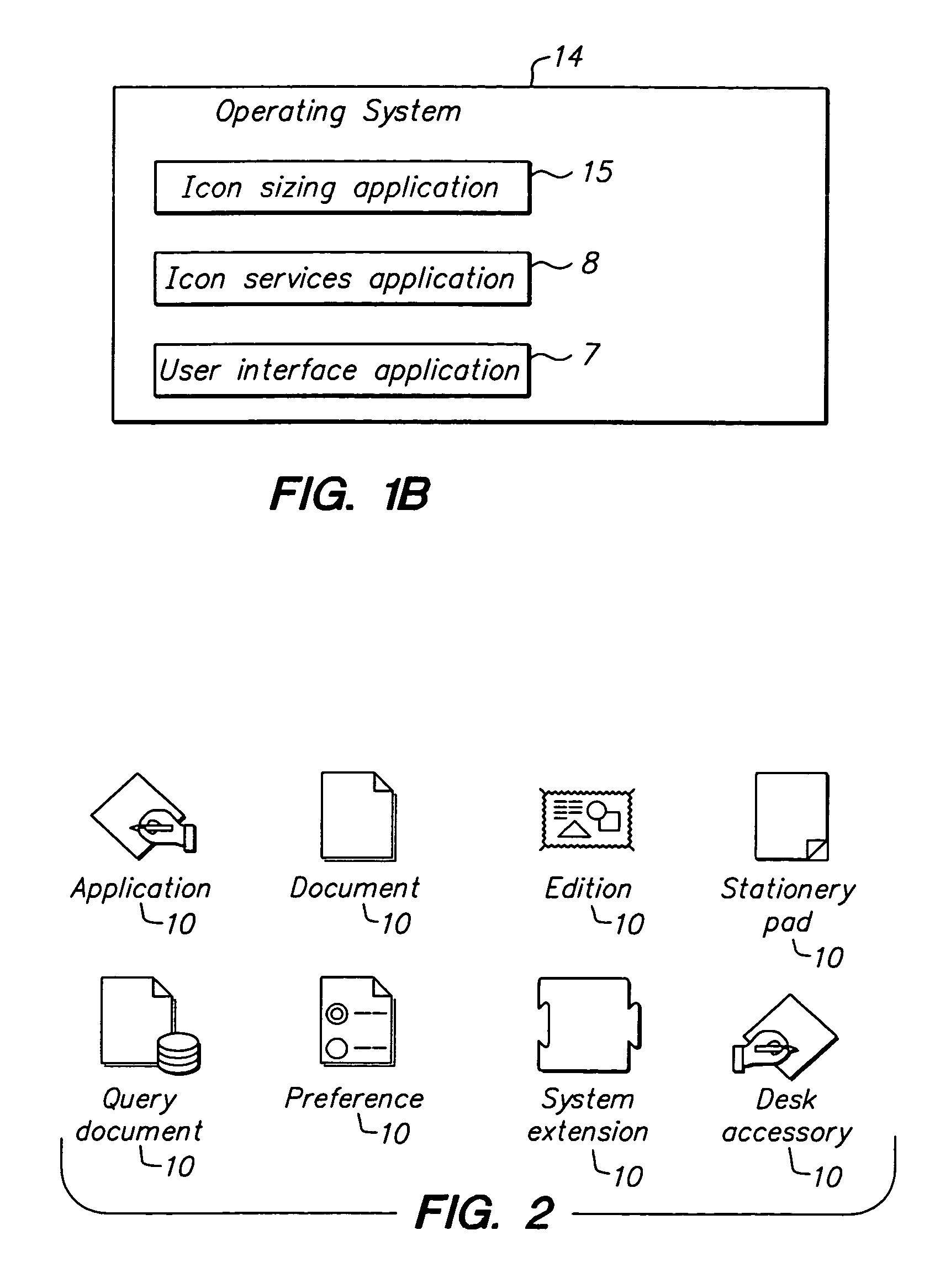

Graphical user interface for computers having variable size icons

InactiveUS7216304B1Efficiently employedExecution for user interfacesInput/output processes for data processingGraphicsGraphical user interface

Owner:APPLE INC

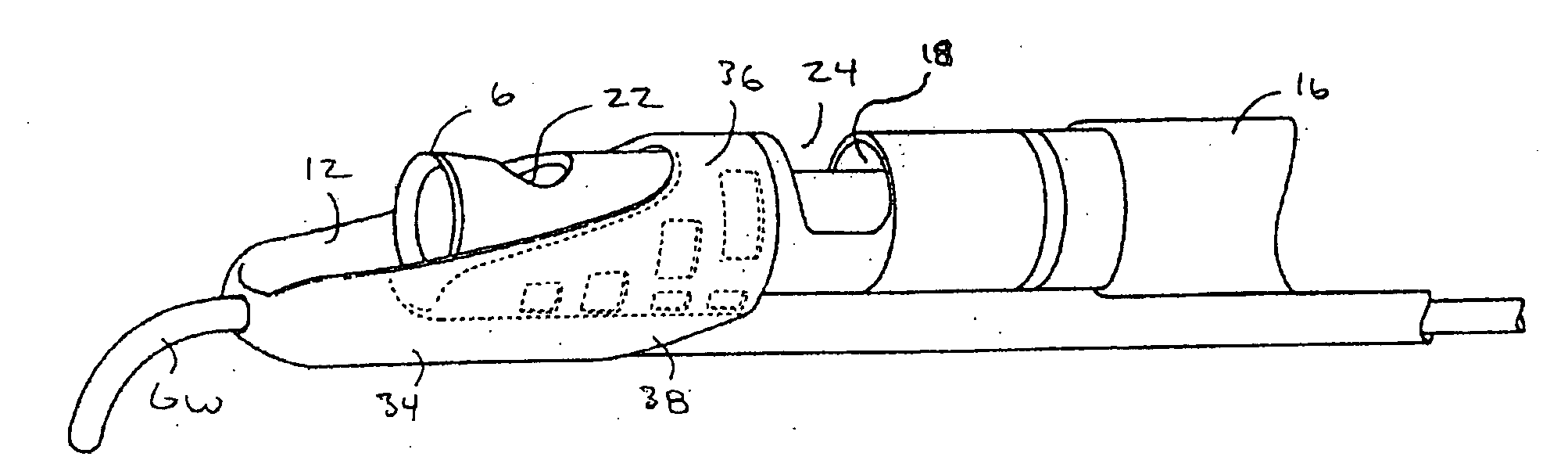

Devices, systems, and methods for removing stenotic lesions from vessels

The present application provides various devices, systems, and methods for removing stenotic lesions from vessels. In at least one embodiment of an exemplary device, the device comprises at least one sizing portion and at least one treatment portion. Such a device may be useful to, for example, remove a stenotic lesion from a vessel by positioning the device within a vessel lumen, operating the sizing portion to obtain luminal size parameter data, operating the treatment portion at a location within the vessel lumen at or near a stenotic lesion, and ceasing operation of the treatment portion when the luminal size parameter data indicates a preferred luminal size parameter.

Owner:3DT HLDG

Disposable absorbent articles with zones comprising elastomeric components

Absorbent articles having a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core disposed between said topsheet and said backsheet are disclosed. The absorbent articles include a thermoplastic elastomer joined to or disposed in a stretch zone on at least one component or region of the absorbent article to impart an elastic resistance that provides sizing or shaping capabilities to the article. The absorbent article can be in the form of diapers, pull-on diapers, training pants, sanitary napkins, wipes, bibs, incontinence briefs or inserts.

Owner:THE PROCTER & GAMBLE COMPANY

Method and composition for the sizing of paper with a mixture of a polyacid and a polybase

InactiveUS6171444B1Easy to produceHigh color fastnessNatural cellulose pulp/paperSpecial paperHueWater resistant

Compositions and methods are provided for the sizing of paper, to enhance the quality of images printed thereon. The novel sizing compositions contain as a sizing agent a mixture of a polyacid and a polybase. When applied to a paper substrate, such as in an internal or external sizing process, the sizing compositions result in a sized paper substrate that provides high quality printed images when printed with an ink containing a reactive dye having ionizable and / or nucleophilic groups capable of reacting with the sizing agent. Images printed on a paper substrate coated with the sizing compositions of the invention are bleed-resistant, water-resistant (e.g., water-fast), and / or are characterized by an enhanced chroma and hue.

Owner:SRI INTERNATIONAL

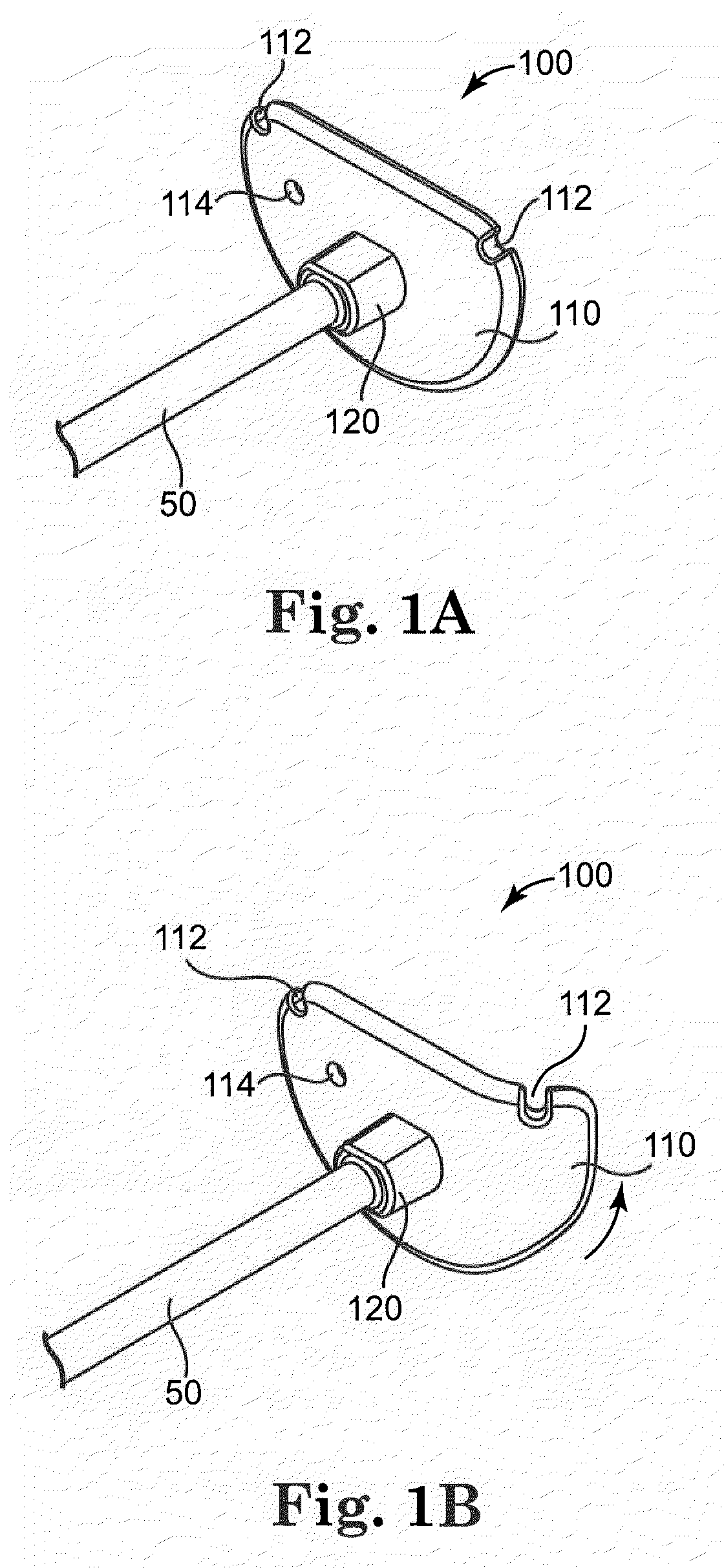

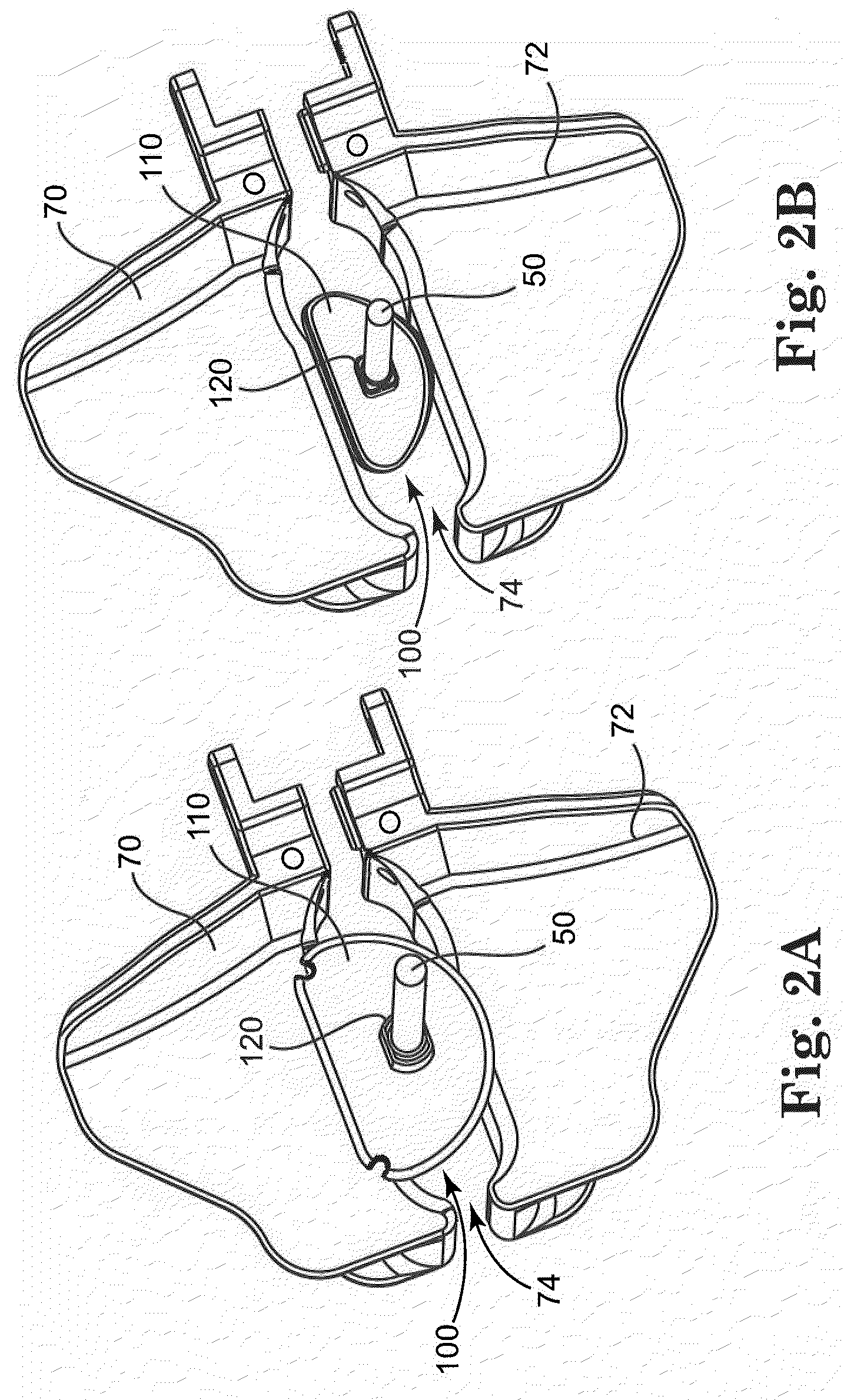

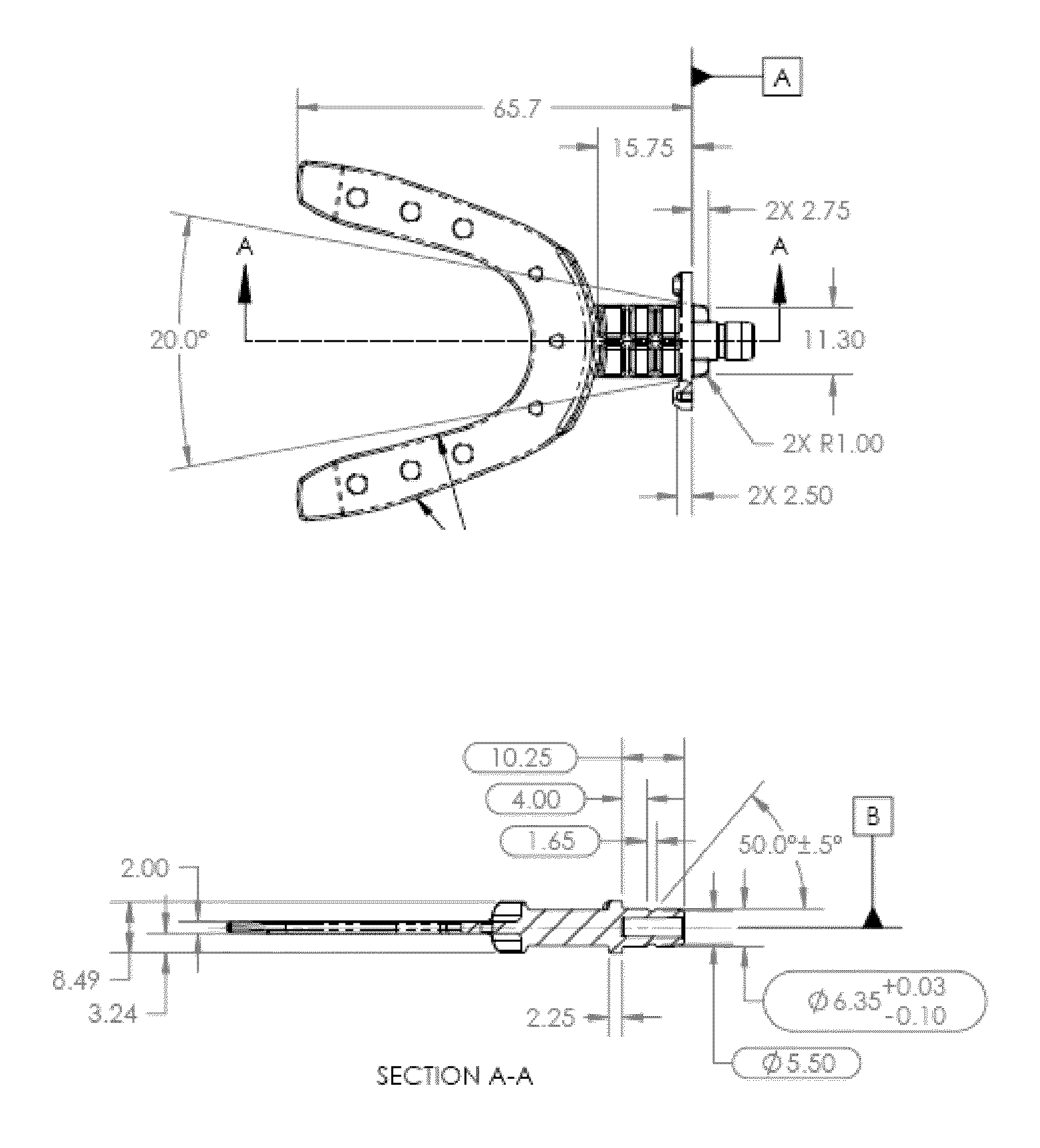

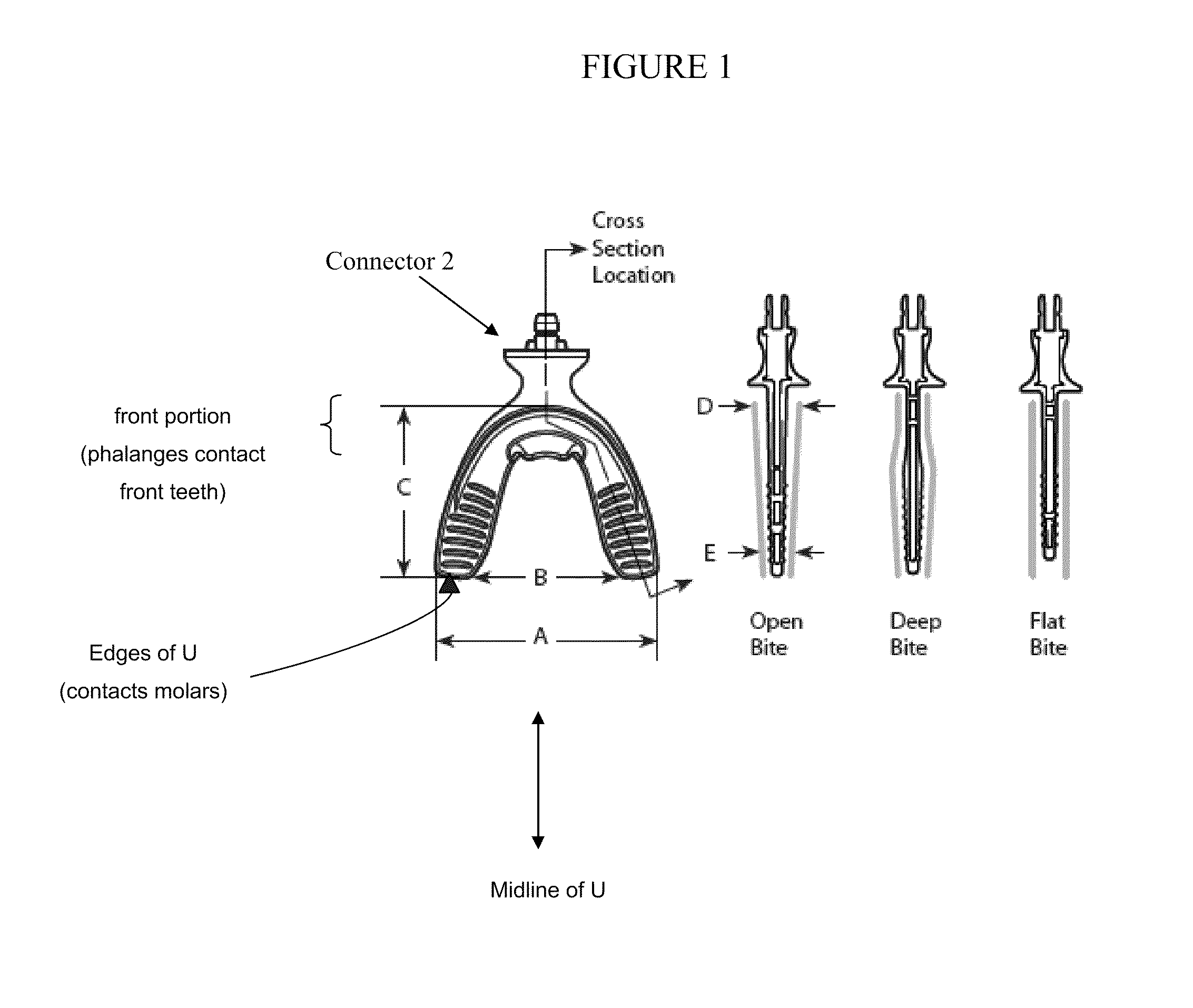

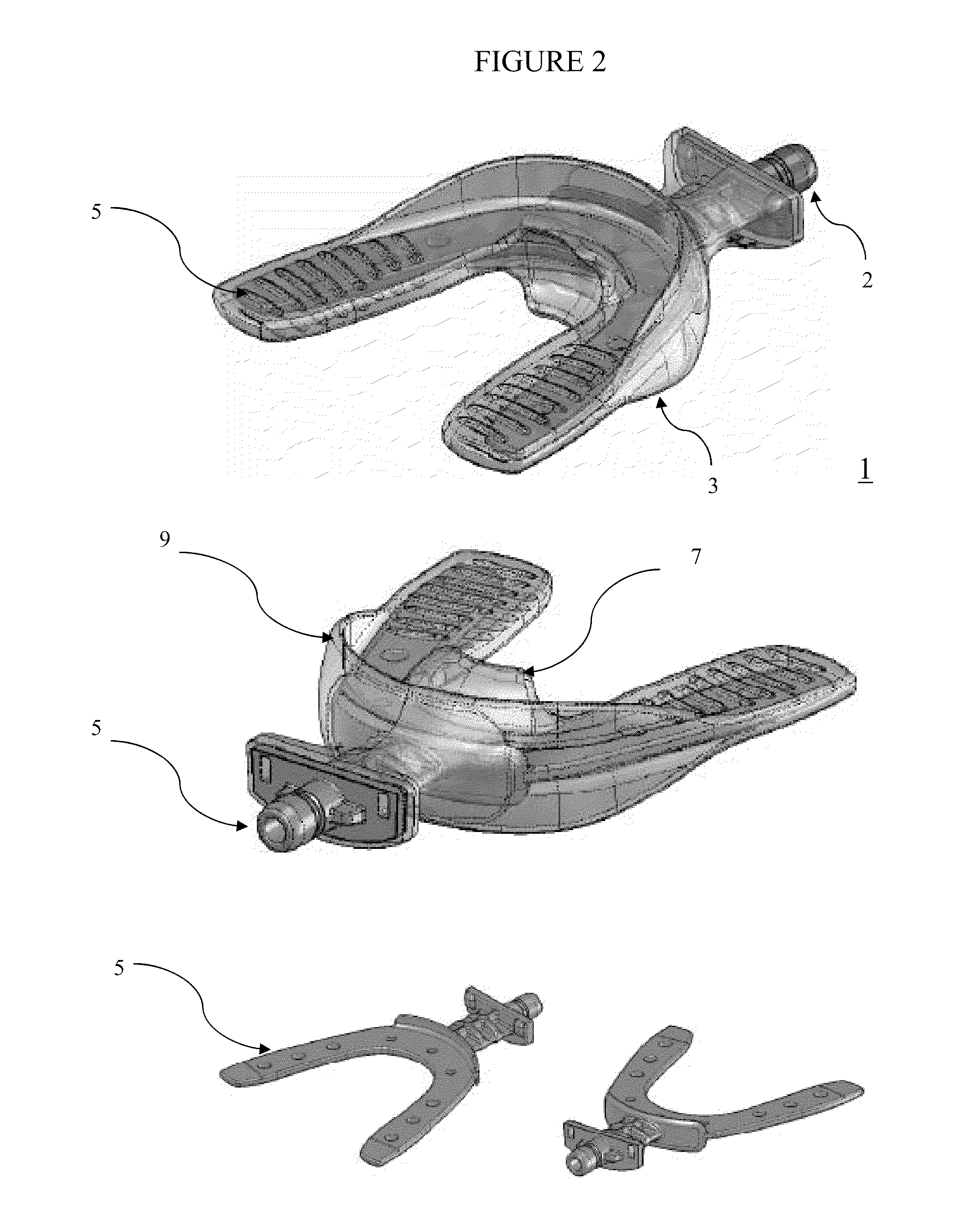

Vibrating dental devices

InactiveUS20100055634A1Speed boney remodelingEnhance boney remodelingBracketsDental toolsDental EquipmentBite plates

A variety of improvements to the vibrating devices for dental remodeling are provided, including improved bite plate designs that accommodate common patient bite structure, a connector for a bite plate, a sizing tray for same, as well as better motors providing improved performance characteristics for an extraoral vibrator, and a completely intraoral vibrating dental plate with very thin cross section.

Owner:ADVANCED ORTHODONTICS & EDUCATION ASSOC LLC

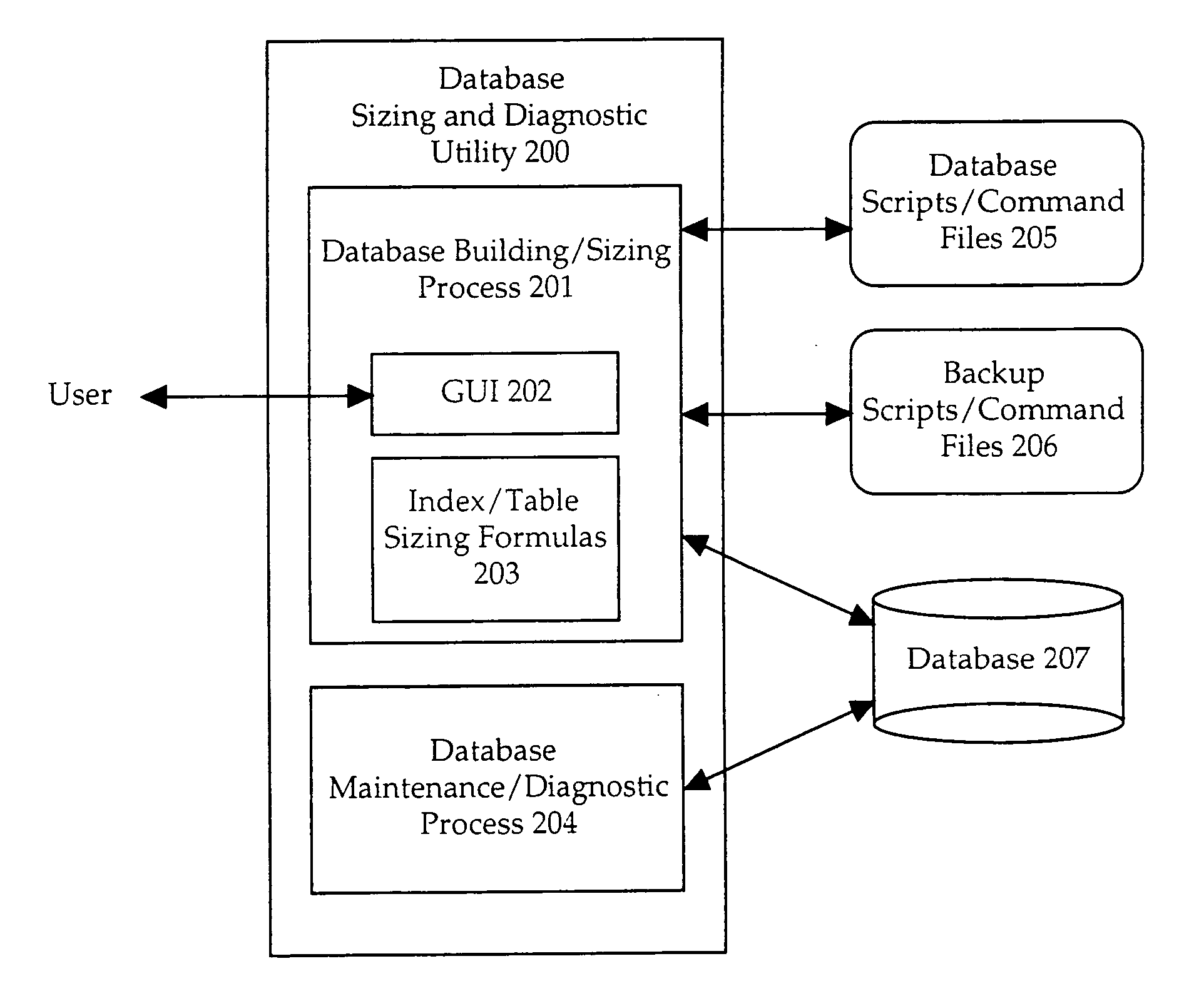

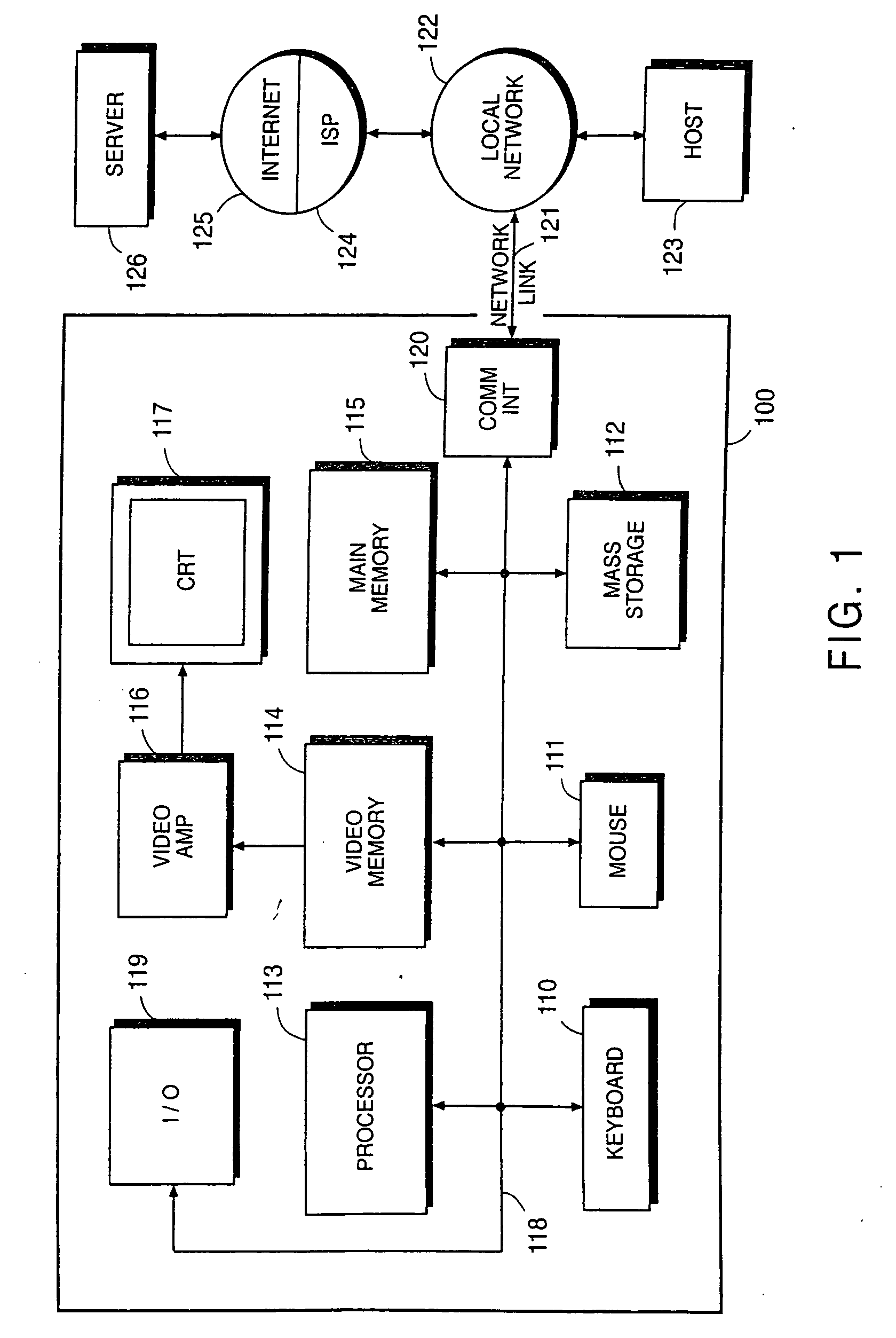

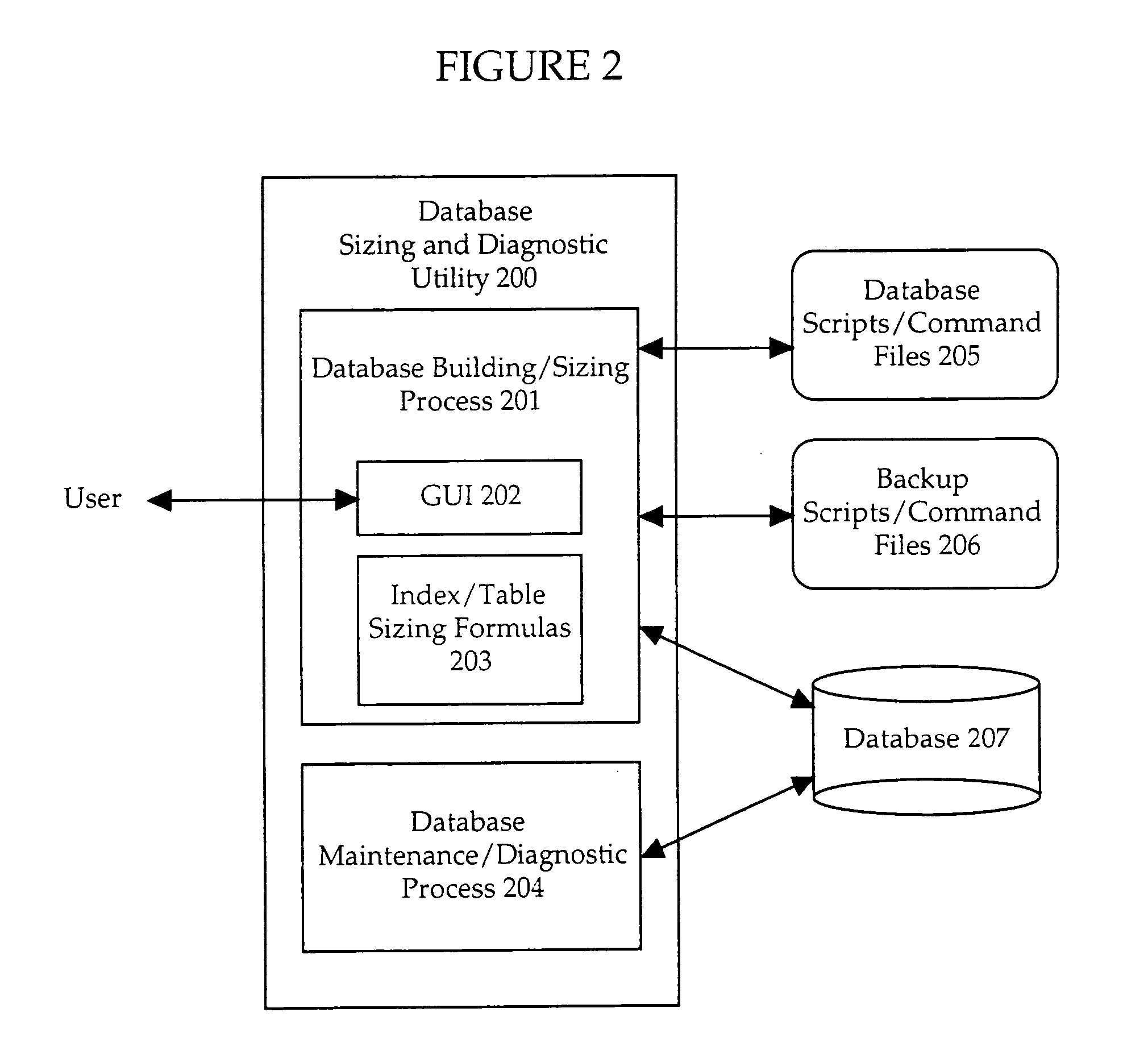

Database sizing and diagnostic utility

InactiveUS20070162514A1Valid matchSpecial data processing applicationsDatabase indexingTime scheduleDatabase backup

A system for automated installation and maintenance of databases. One or more embodiments provide a user interface (or wizard) that obtains information from a user regarding aspects of the network environment and application data requirements. Using the information obtained from the user, a sizing process builds a database, or resizes an existing database, to efficiently match the needs of the user. An automated maintenance process self monitors, diagnoses, and fixes database problems, such as by rebuilding table keys and indexes. When the diagnostic cannot fix a problem, appropriate notification takes place. In one embodiment, the user information is processed using sizing formulas to obtain values for building the database. Database scripts and command files are generated which, when executed, build the appropriately configured database. Also, in accordance with the user information, scripts and command files may be generated that will implement a database backup process upon a user-specified schedule.

Owner:CIVETTA VINCENT +3

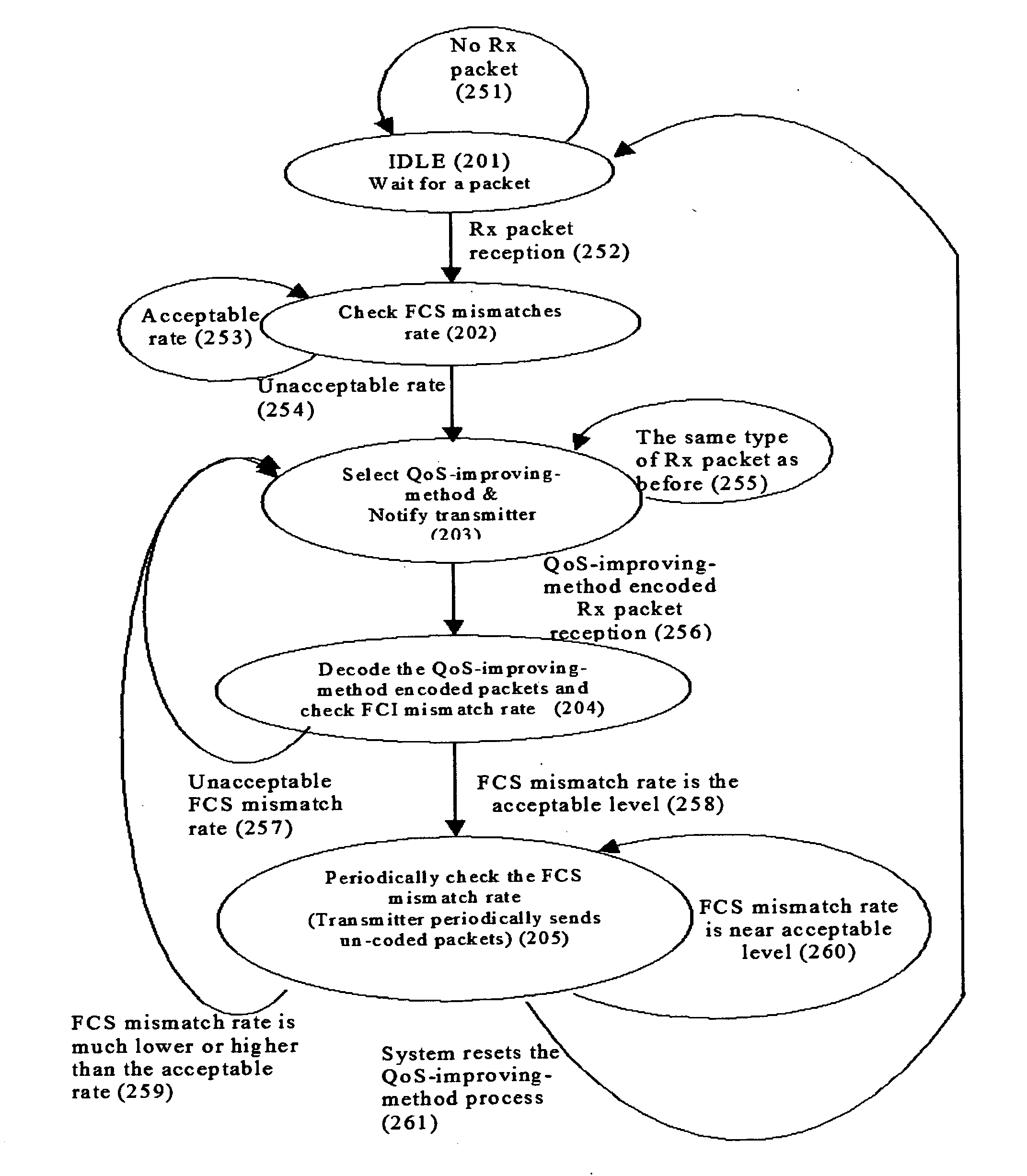

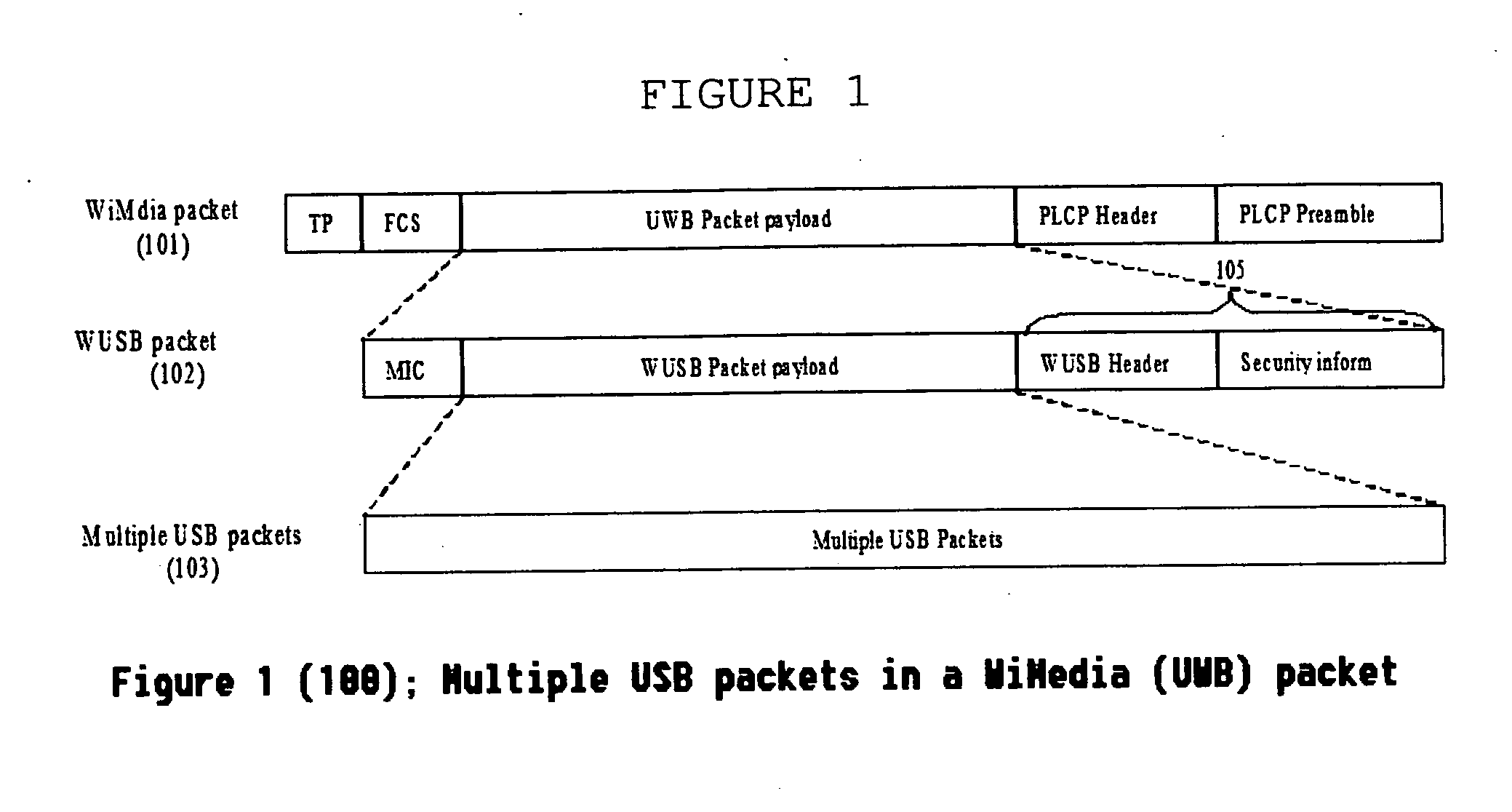

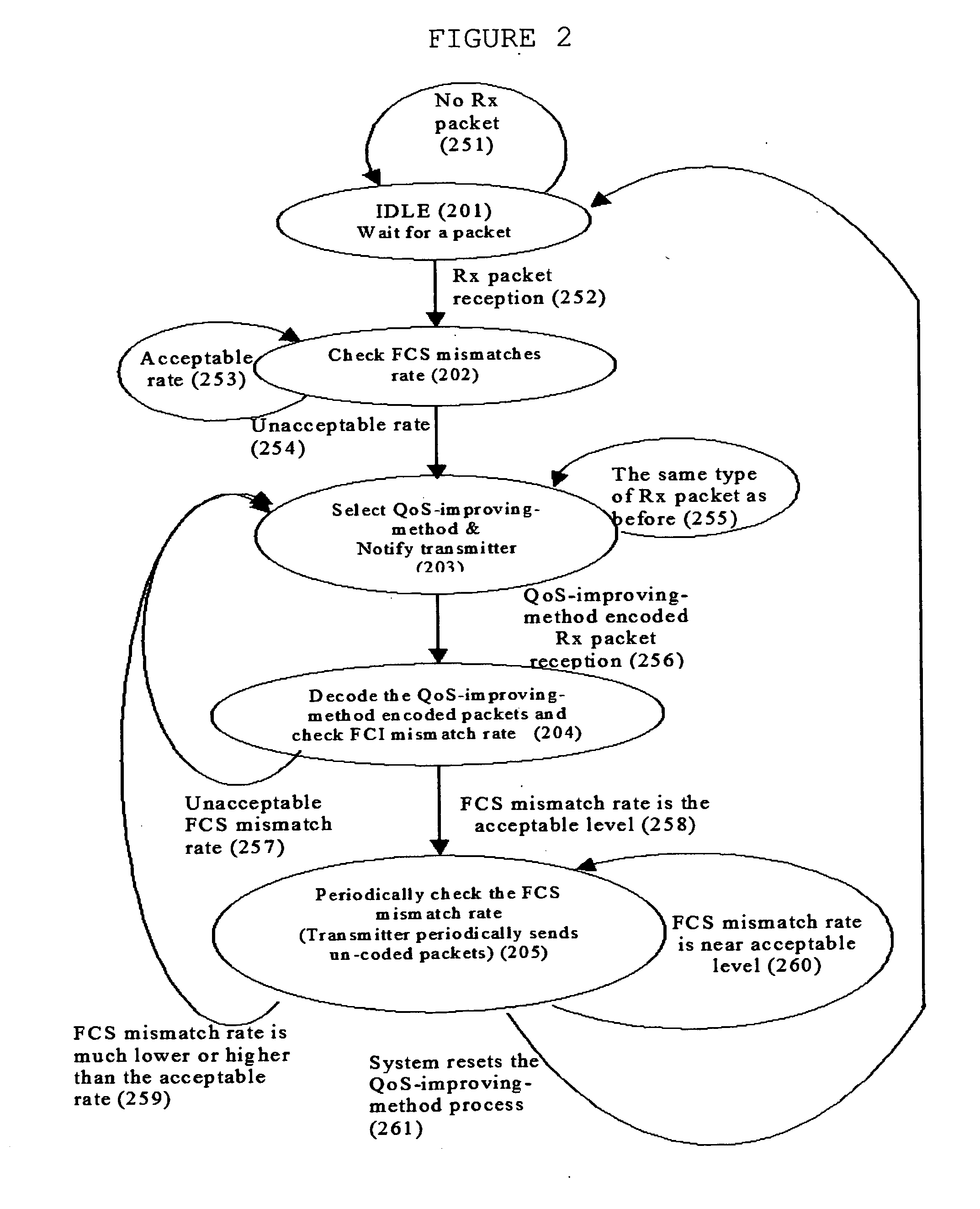

Method of improving wireless communication QoS by means of automatic packet sizing and forward error correcting based on the dynamic error rate forecast

InactiveUS20070097985A1Network traffic/resource managementData switching by path configurationForward error correctionError correcting

A method to meet the adequate QoS of wireless network by automatically sizing the packet length and / or by adding appropriate FEC (Forward Error Correction) based on the error rate forecast that is derived from the past behavior of the wireless communication channel.

Owner:LEE HYUN

Extreme service footwear

The present invention provides articles of footwear adapted for use in extreme and hazardous environments by members of the military, law enforcement personnel and others who require durable and functional footwear. The footwear include protective coverings that may be proof, puncture proof, fire retardant or water repelling. Drainage holes can be positioned in the toe region and along the outsole to enable a wearer to quickly drain water from the article of footwear. Single use or replaceable drainage plugs may cover the holes to prevent entry of water into the boot or other article of footwear. Removable and / or replaceable footbeds may be employed, and such footbeds may provide adjustable sizing of the article of footwear using interchangeable cartridges. A support saddle may be employed with the footbed to enhance foot support under heavy loads. These and other features herein are suited for use in a wide variety of footwear.

Owner:THE TIMBERLAND COMPANY

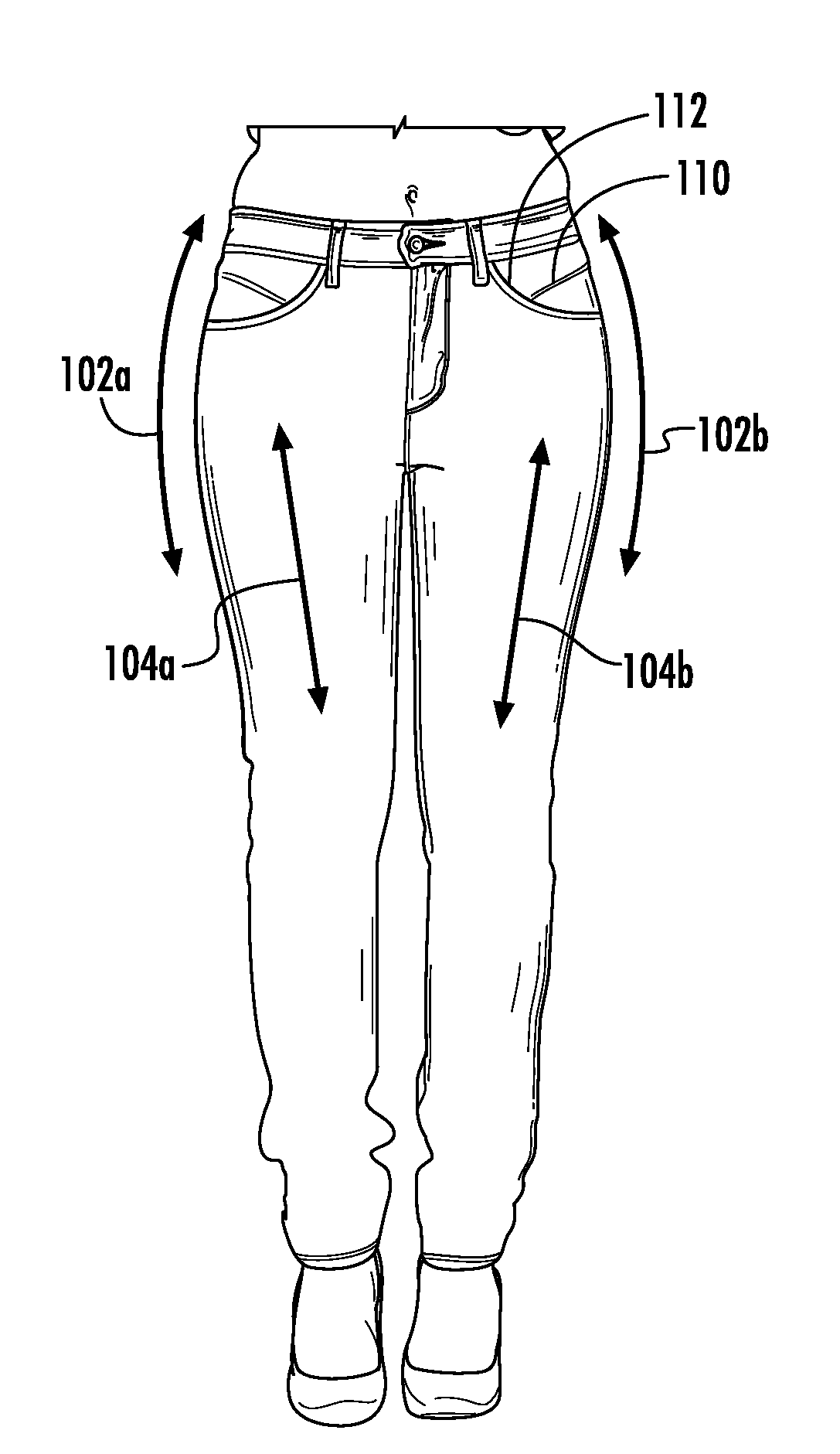

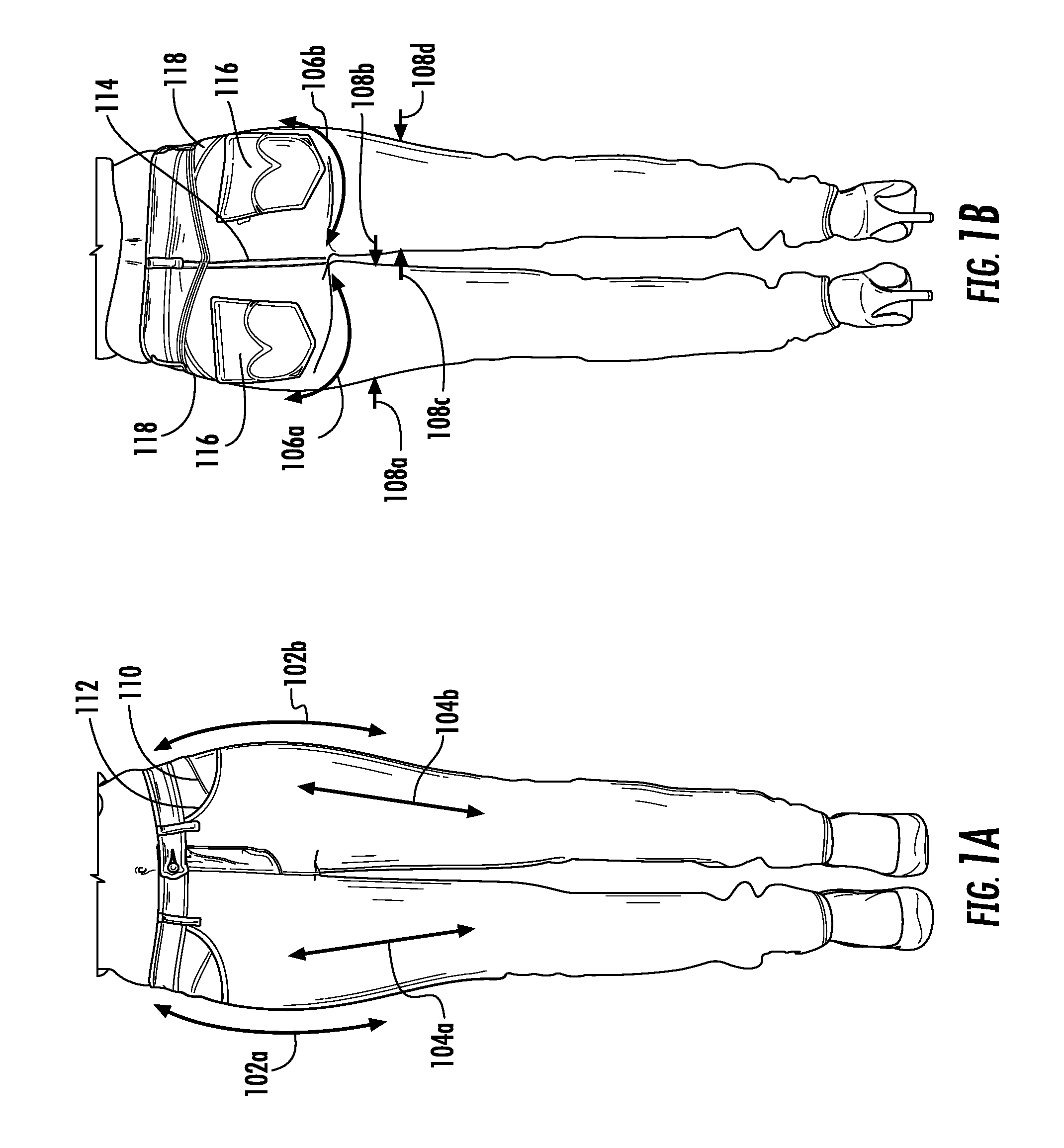

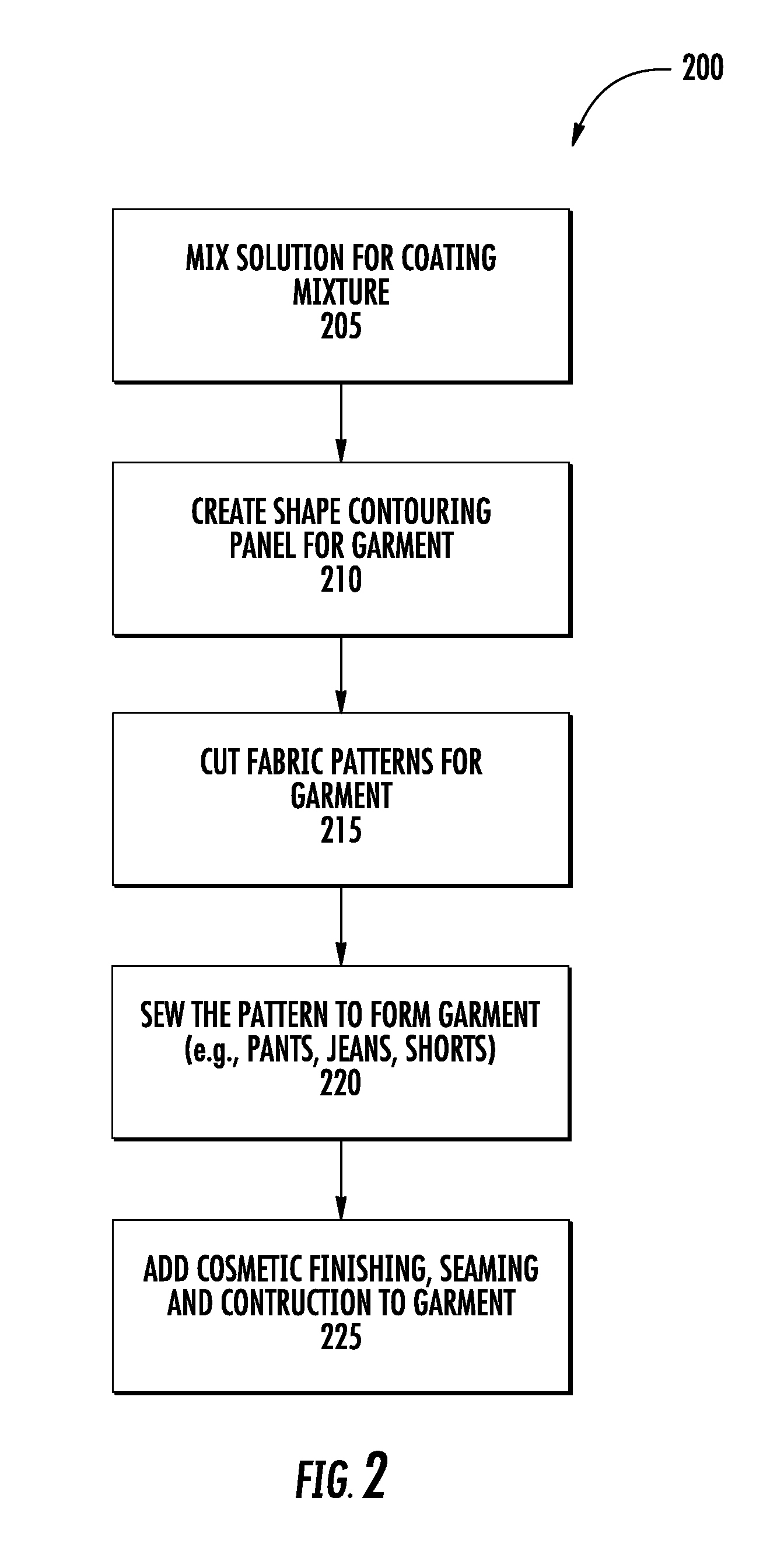

Shaped Fit Sizing System with Body Shaping

InactiveUS20140165265A1Reduce stretchIncrease elasticityGarment special featuresTrousersBody shapeEngineering

Jeans are fitted based on the concept of shape, not size. There are at least three shape categories for different levels of curviness. With shape category information, the consumer can more easily find and fit a pair of form-fitting jeans. These jeans can also include a body shaping panel on an inside surface of a material of the pants to help actively shape the body. The body shaping panel enhances the body's natural curves while de-emphasizing the body's flaws, so the consumer can feel confident and attractive in their jeans.

Owner:LEVI STRAUSS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com