Waterproof roll capable of carrying out chemical bonding and physical crosslinking synergism with concrete

A waterproofing membrane and composite technology, which is used in building structures, building insulation materials, textiles and papermaking, etc., can solve the problems of inability to peel off by artificial methods, difficult to master the operation, and insufficient adhesion, and achieve reliable adhesion. knot effect, excellent tensile strength, the effect of large surface friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

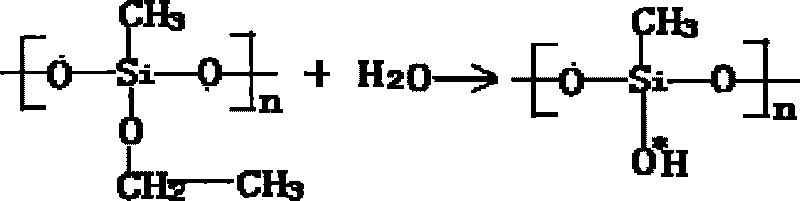

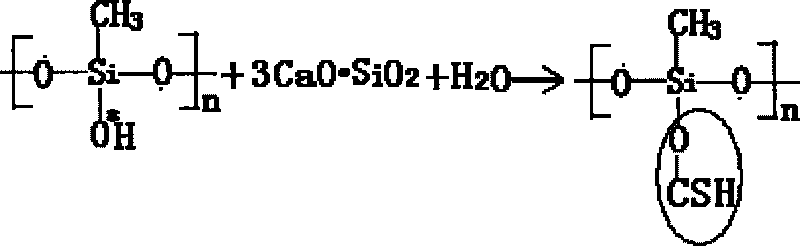

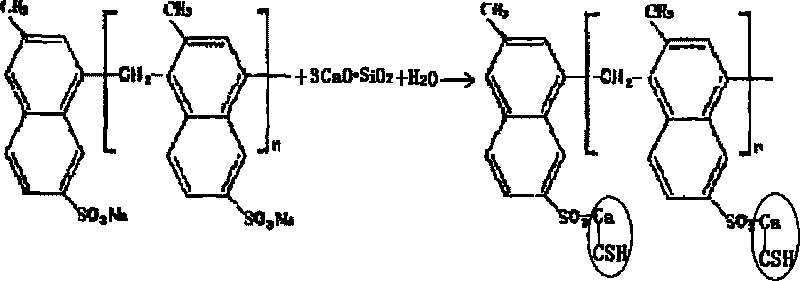

Method used

Image

Examples

Embodiment 1

[0048] 3000 kilograms of matrix asphalt is placed in the reaction tank, and 200 kilograms of tackifier ordinary rubber powder, 200 kilograms of random polypropylene (APP) and 300 kilograms of styrene-butadiene-styrene block copolymer (SBS) are added, Mix evenly, then increase the temperature to 200-210°C, stir for 1.5-2h, then lower the temperature to about 180°C, then add 3000 kg filler bicarbonate powder, 100 kg plasticizer butyl naphthenate, 50 kg Antioxidant tris(2,4-di-tert-butylphenyl)phosphite and 60 kg of functional additive polymethylethoxysilane were added to the reaction tank, stirred for 0.5-1h, fully mixed and modified, and then transported to Colloid mill, the material is repeatedly ground, and then the modified asphalt compound is dip-coated on the polyester carcass, thickness control and setting, laminating, winding and other processes are prepared to prepare CPS wet paving / pre-paving with excellent performance waterproof materials.

Embodiment 2

[0050] Put 5000 kg of base asphalt in the reaction tank, add 150 kg of tackifier styrene-butadiene rubber and ordinary rubber powder, 300 kg of random polypropylene (APP) and 500 kg of styrene-butadiene-styrene block Copolymer (SBS), mix evenly, then raise the temperature to 200-210°C, stir for 1.5-2h, then lower the temperature to about 180°C, then add 2000 kg filler heavy calcium carbonate powder, 2000 kg talcum powder, 300 kg Plasticizer butyl naphthenate, 80 kilograms of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, 80 kilograms of functional auxiliary agent polynaphthaldehyde sulfonic acid sodium salt are added to reaction tank, stir 0.5- 1h, fully mixed and modified, and then transported to the colloid mill, the material was repeatedly ground, and then the modified asphalt compound was dip-coated on the glass fiber matrix, thickness control and shaping, coating, winding and other processes were carried out. Prepare CPS wet-laid / pre-laid waterproof membrane with ex...

Embodiment 3

[0052] 2000 kilograms of matrix asphalt is placed in the reaction tank, and 100 kilograms of tackifier common rubber powder, 150 kilograms of random polypropylene (APP) and 200 kilograms of styrene-butadiene-styrene block copolymer (SBS) are added, Mix evenly, then increase the temperature to 200-210°C, stir for 1.5-2h, then lower the temperature to about 180°C, then add 1000 kg of filler bicarbonate powder, 1000 kg of asbestos powder, and 200 kg of plasticizer naphthenic acid Add butyl ester, 50 kg of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, and 70 kg of functional additive polynaphthaldehyde sulfonic acid sodium salt into the reaction tank, stir for 0.5-1h, and fully mix and modify Then it is transported to the colloid mill, the material is repeatedly ground, and then the modified asphalt compound is dip-coated on the composite fiber matrix, the thickness is controlled and shaped, the film is coated, and the winding process is prepared into a CPS with excellent pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com