Patents

Literature

1643 results about "Mortise and tenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mortise (or mortice) and tenon joint connects two pieces of wood or of other material. Woodworkers around the world have used it for thousands of years to join pieces of wood, mainly when the adjoining pieces connect at right angles.

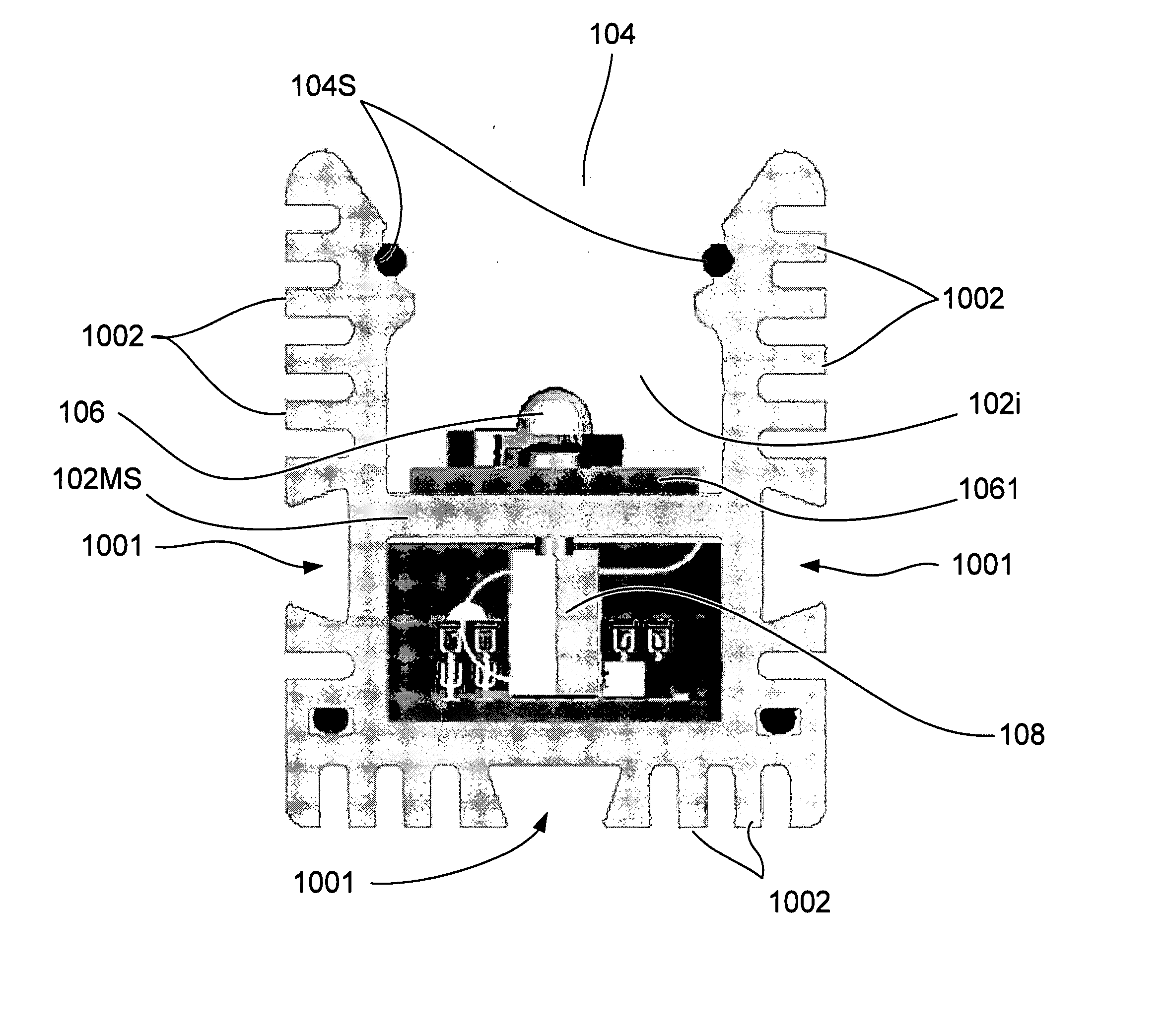

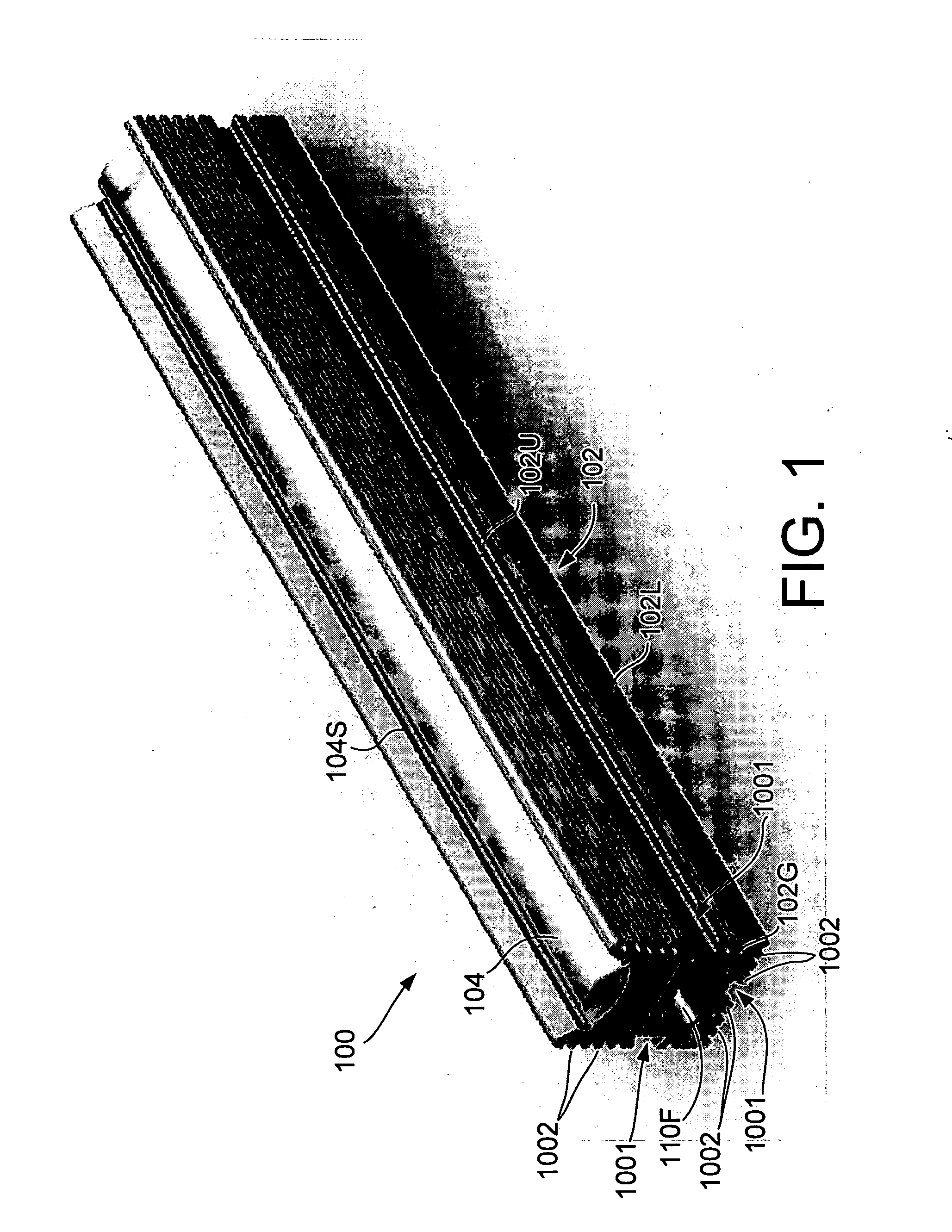

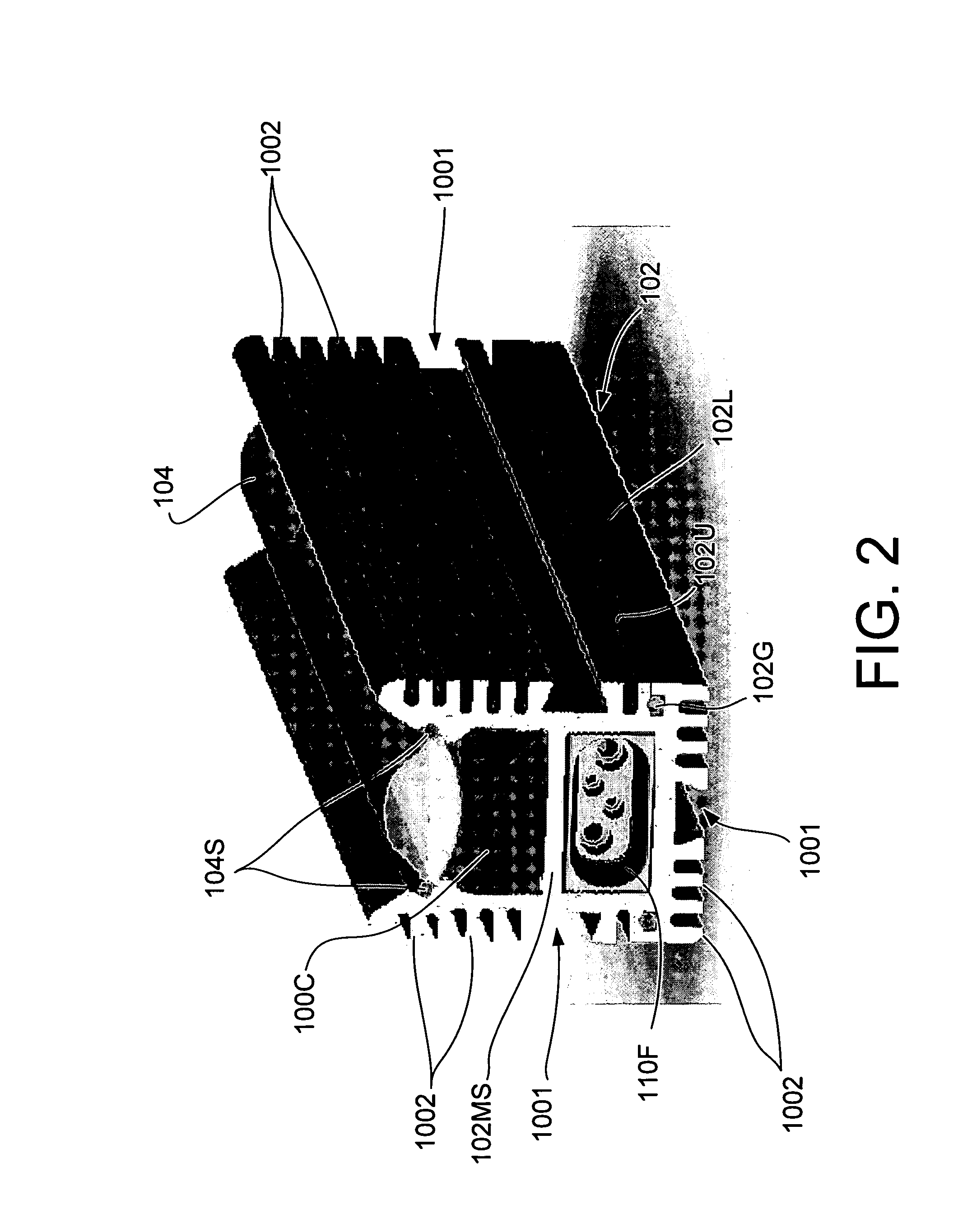

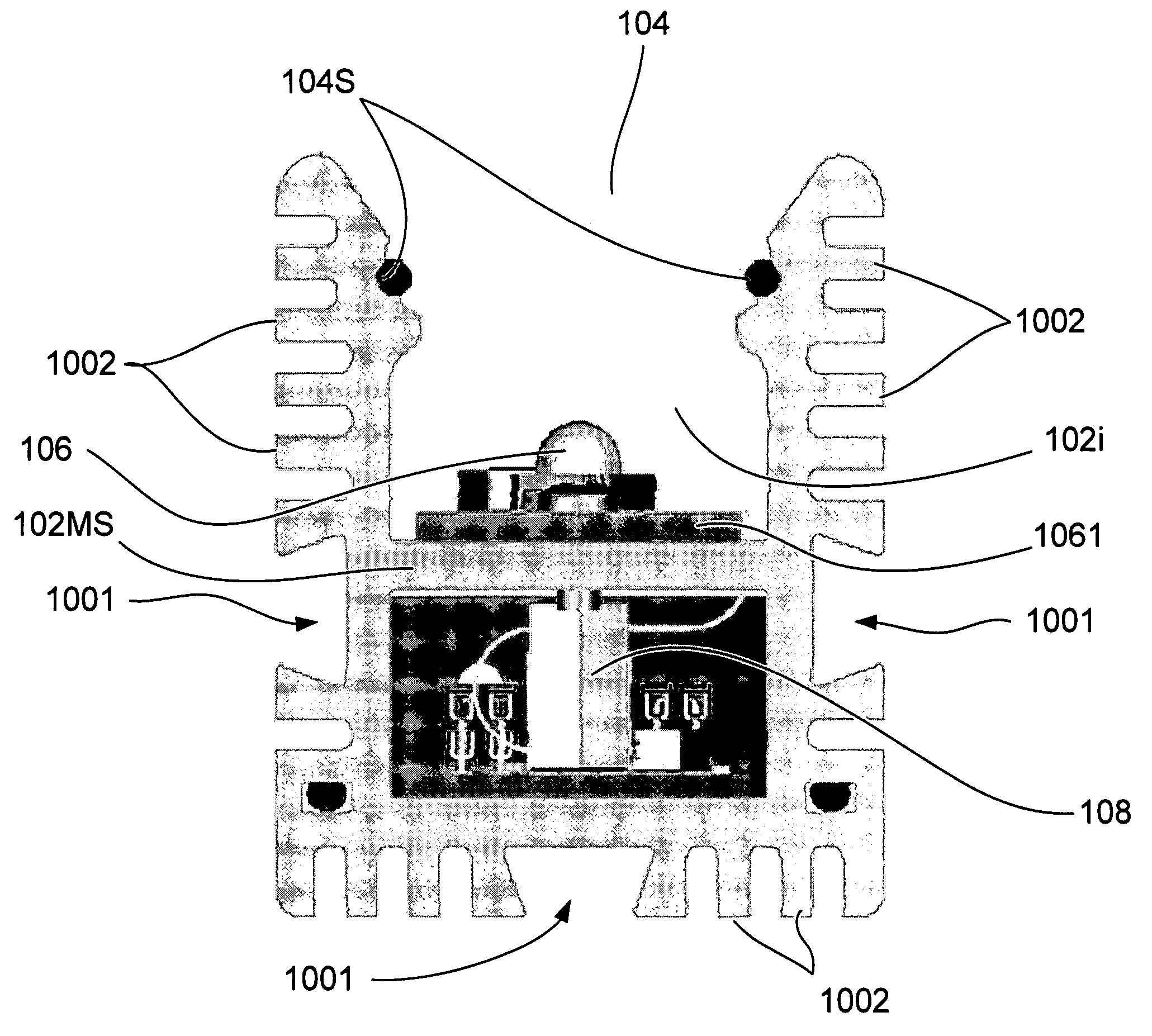

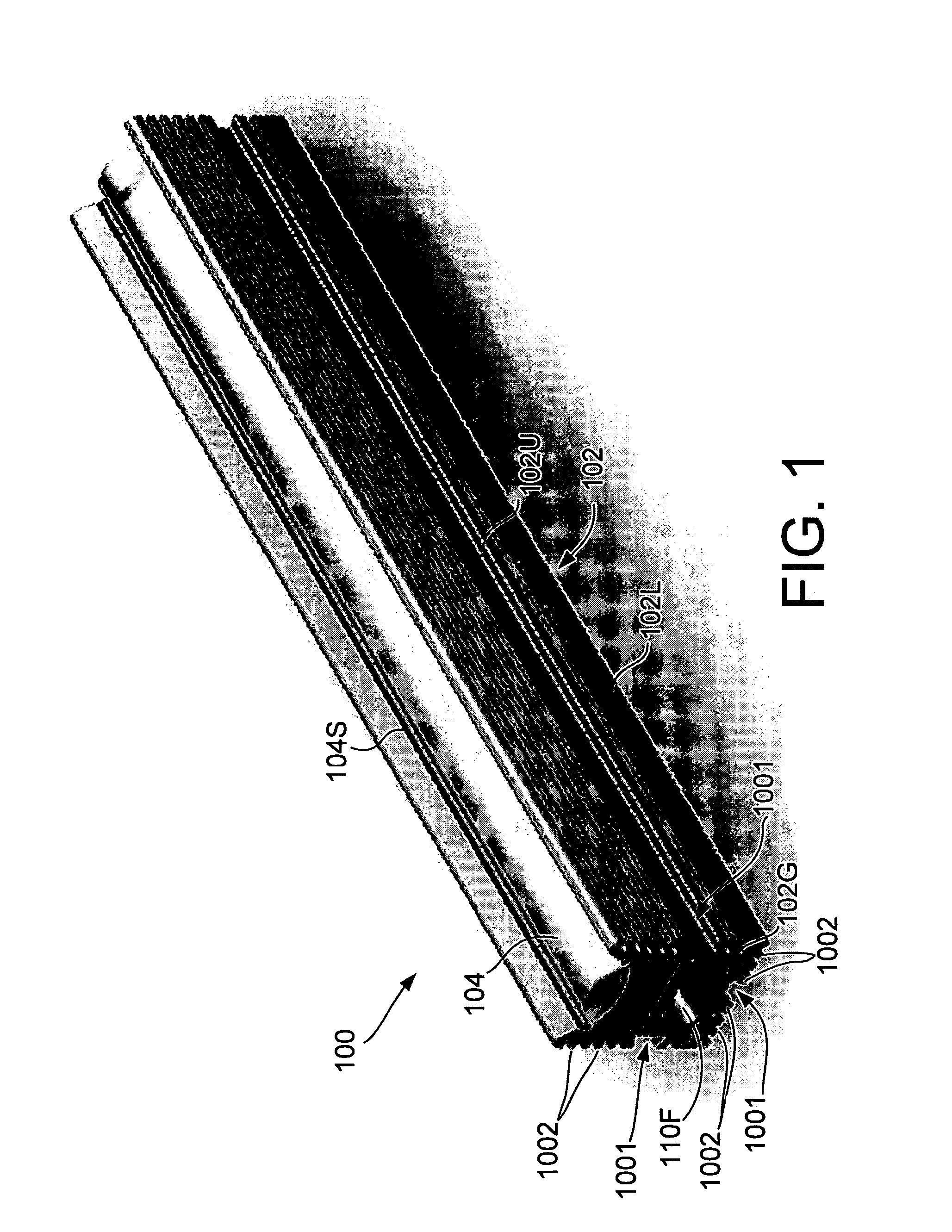

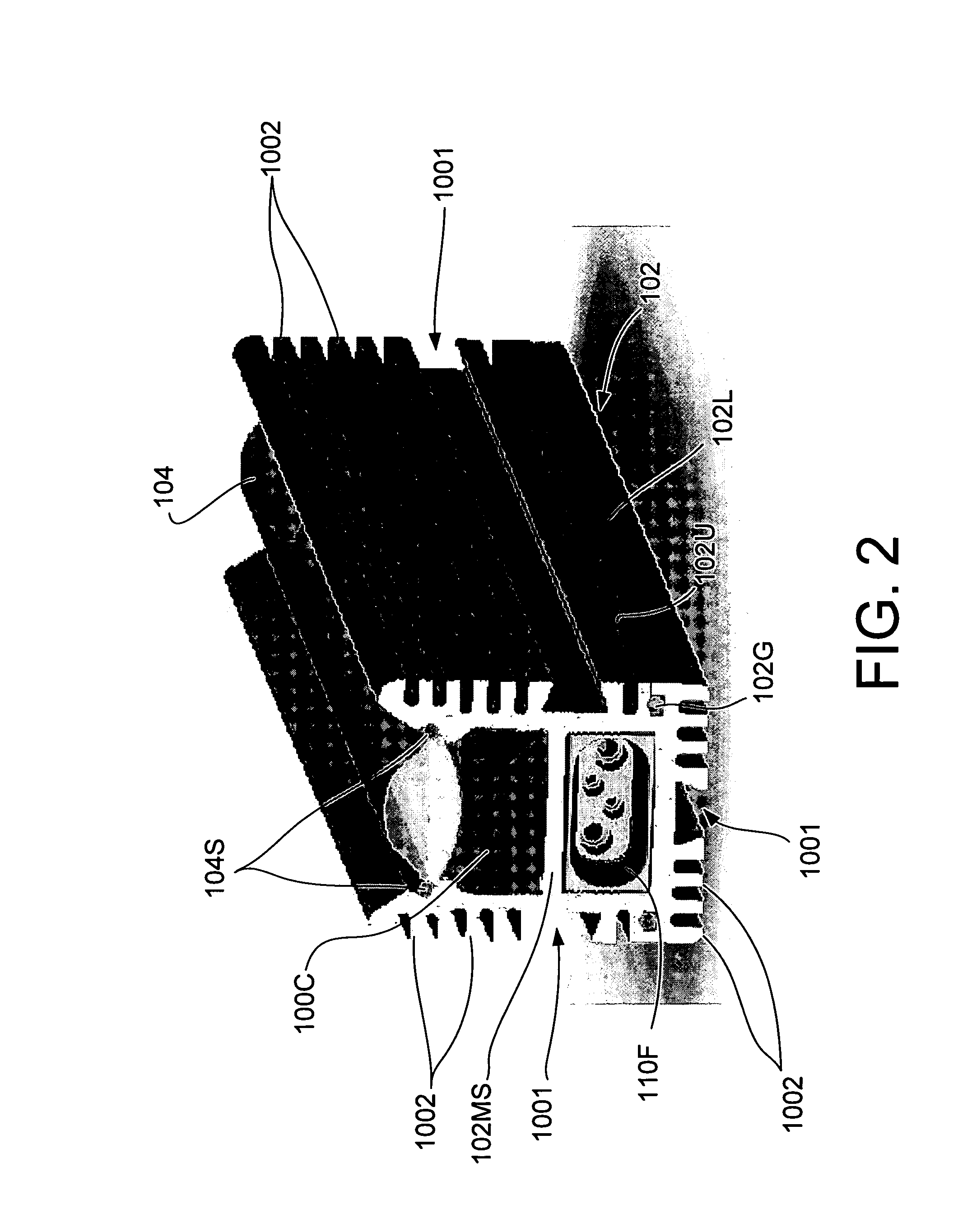

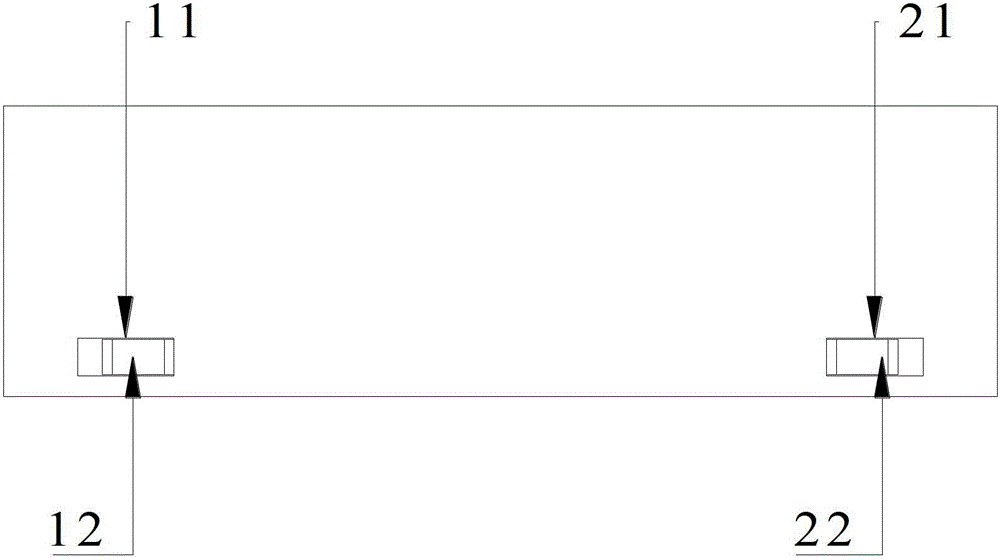

Interconnection arrangement having mortise and tenon connection features

InactiveUS20070058377A1Reduce thermal resistanceEffective reflectionPoint-like light sourceLighting support devicesMortise and tenonInterconnection

An interconnection arrangement features a housing having multiple exterior surfaces. The housing is configured to receive an electrical device therein and has a plurality of the multiple exterior surfaces each having at least one mortise connection feature formed therein which is configured to receive a tenon associated with an accessory and to connect the accessory to the housing.

Owner:INTEGRATED ILLUMINATION SYST

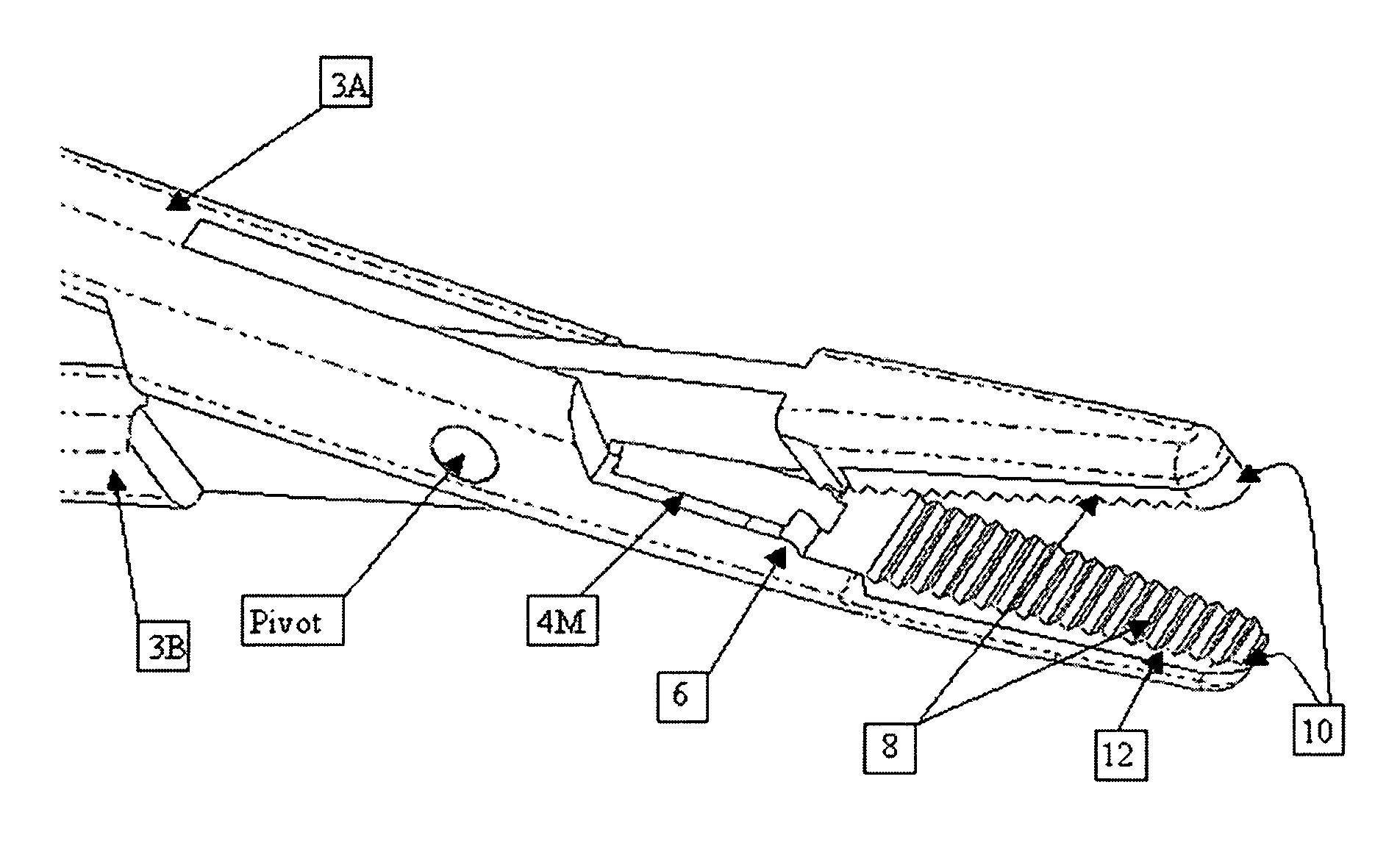

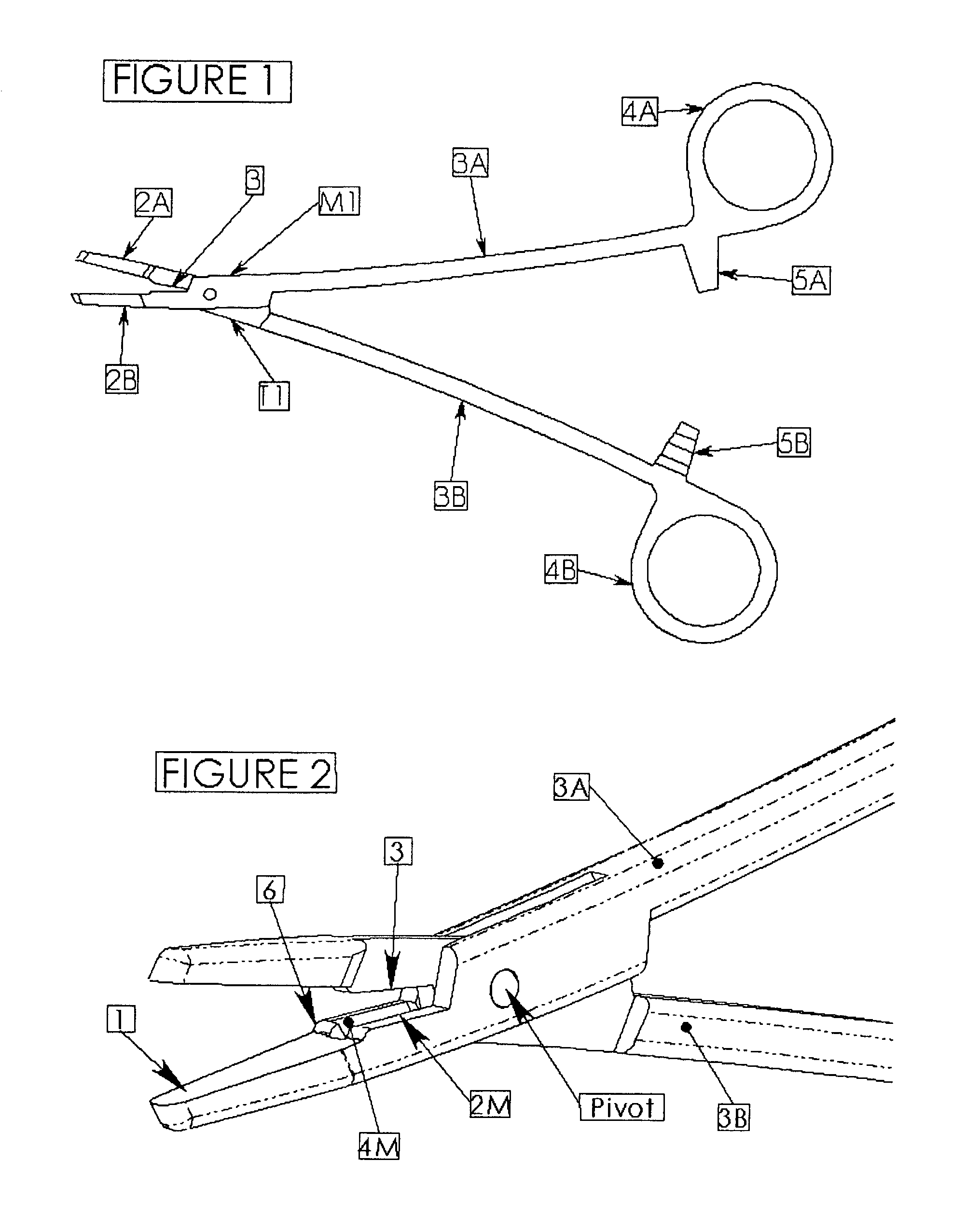

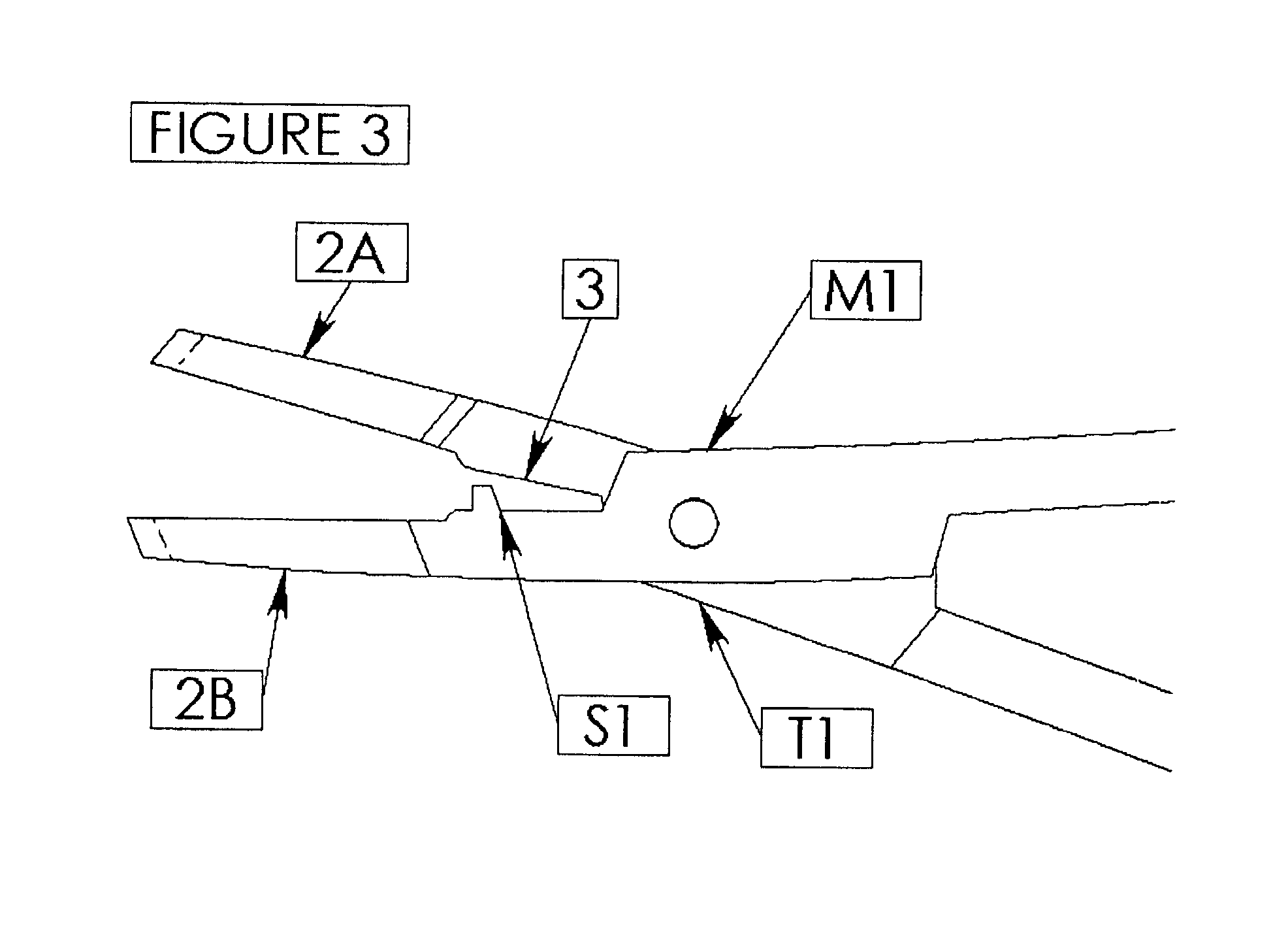

Dual-function medical instrument

A dual-use medical instrument is disclosed. In one embodiment, the instrument has a first handle pivotally attached to a second handle through a mortise and tenon joint to define opposing jaws at the distal end of the surgical instrument, each of the opposing jaws including a distal gripping portion, at least one longitudinally disposed cutting edge situated between the distal gripping portion and said mortise and tenon joint, wherein at least one longitudinal cutting edge is adjacent to said mortise and tenon joint. The instrument can function as a combination needle holder and surgical scissors.

Owner:SUTURECUT

Interconnection arrangement having mortise and tenon connection features

InactiveUS7572027B2Low costImprove cooling effectLighting support devicesPoint-like light sourceMortise and tenonInterconnection

An interconnection arrangement features a housing having multiple exterior surfaces. The housing is configured to receive an electrical device therein and has a plurality of the multiple exterior surfaces each having at least one mortise connection feature formed therein which is configured to receive a tenon associated with an accessory and to connect the accessory to the housing.

Owner:INTEGRATED ILLUMINATION SYST

Modular building materials

Building materials of modules of at least one mortise and tenon and either a curvilinear side face or joinder of the modules at angles other than zero and ninety degrees. Lateral ends of the modules are flush with lateral ends of adjacent modules. Preferably, the modules are: (1) of a low density aggregate cementitious mix; and / or (2) have a hollow space extending from the mortise to the tenon and include a structural support member passing through the hollow space and a compression retainer securing the structural support member to the modules; and / or (3) have grooves circumscribing the modules and which are proximate corresponding grooves on modules placed on top or below. The modules are preferably sealed to one another with sealant placed in the grooves.

Owner:SIMMONS SCOTT +1

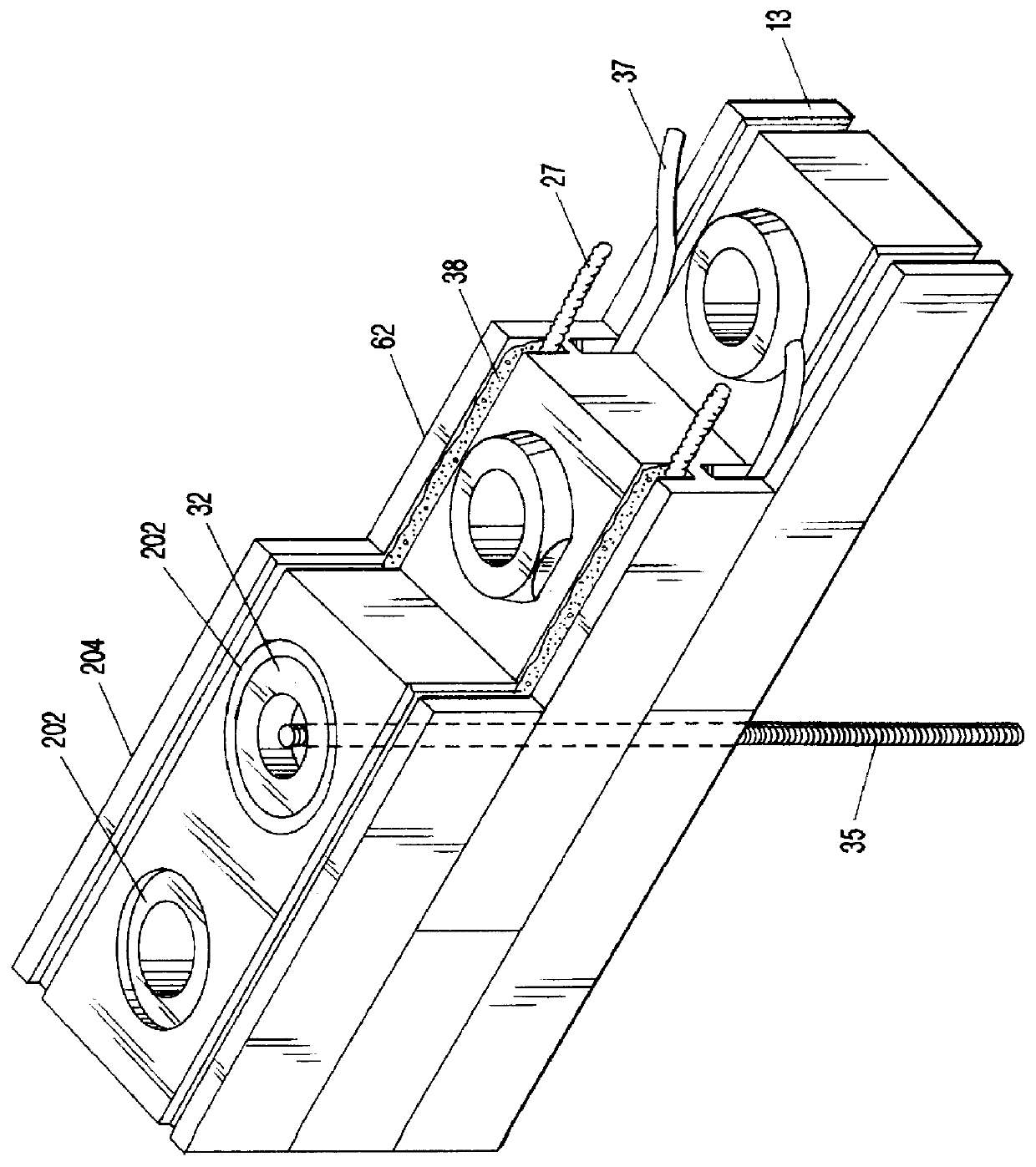

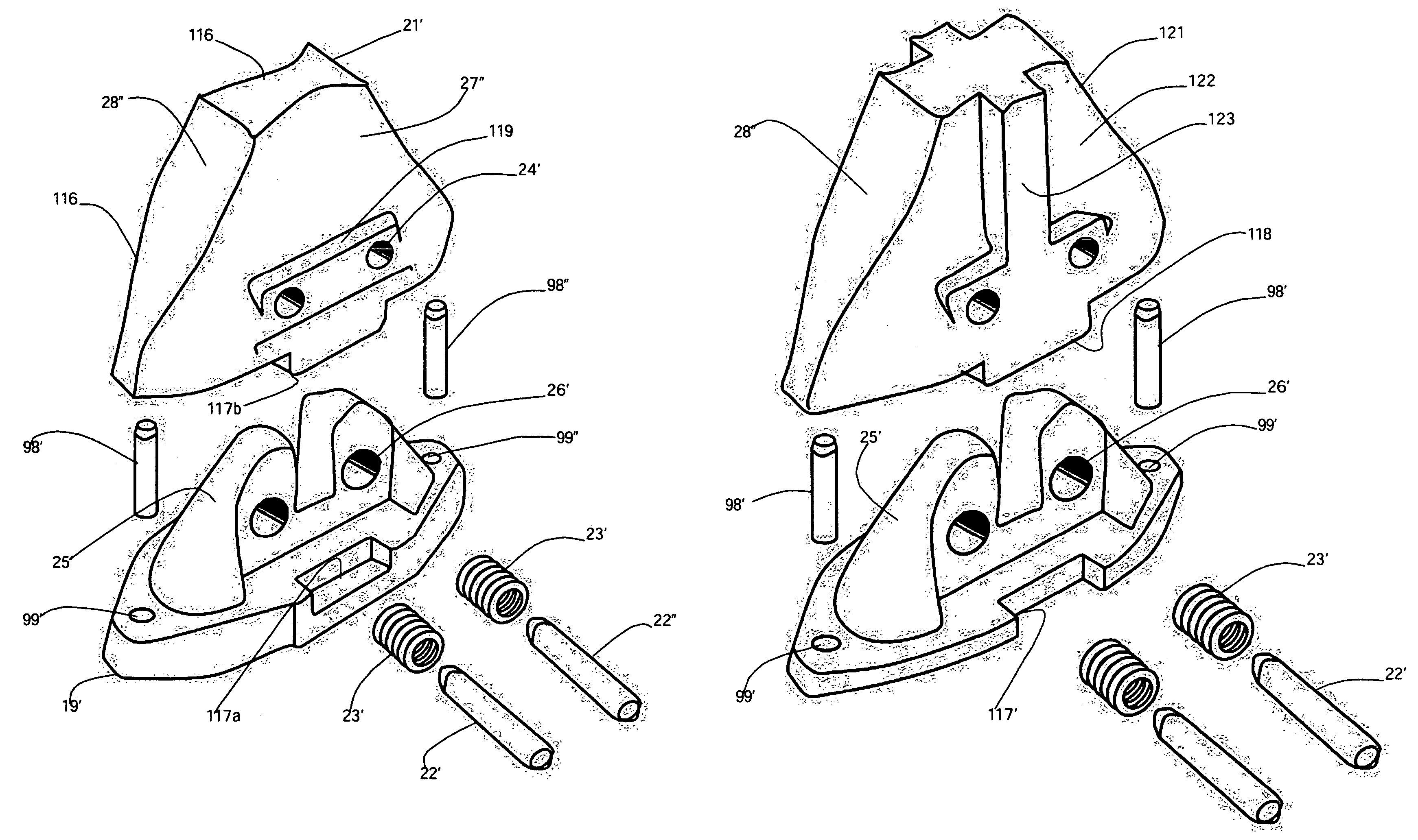

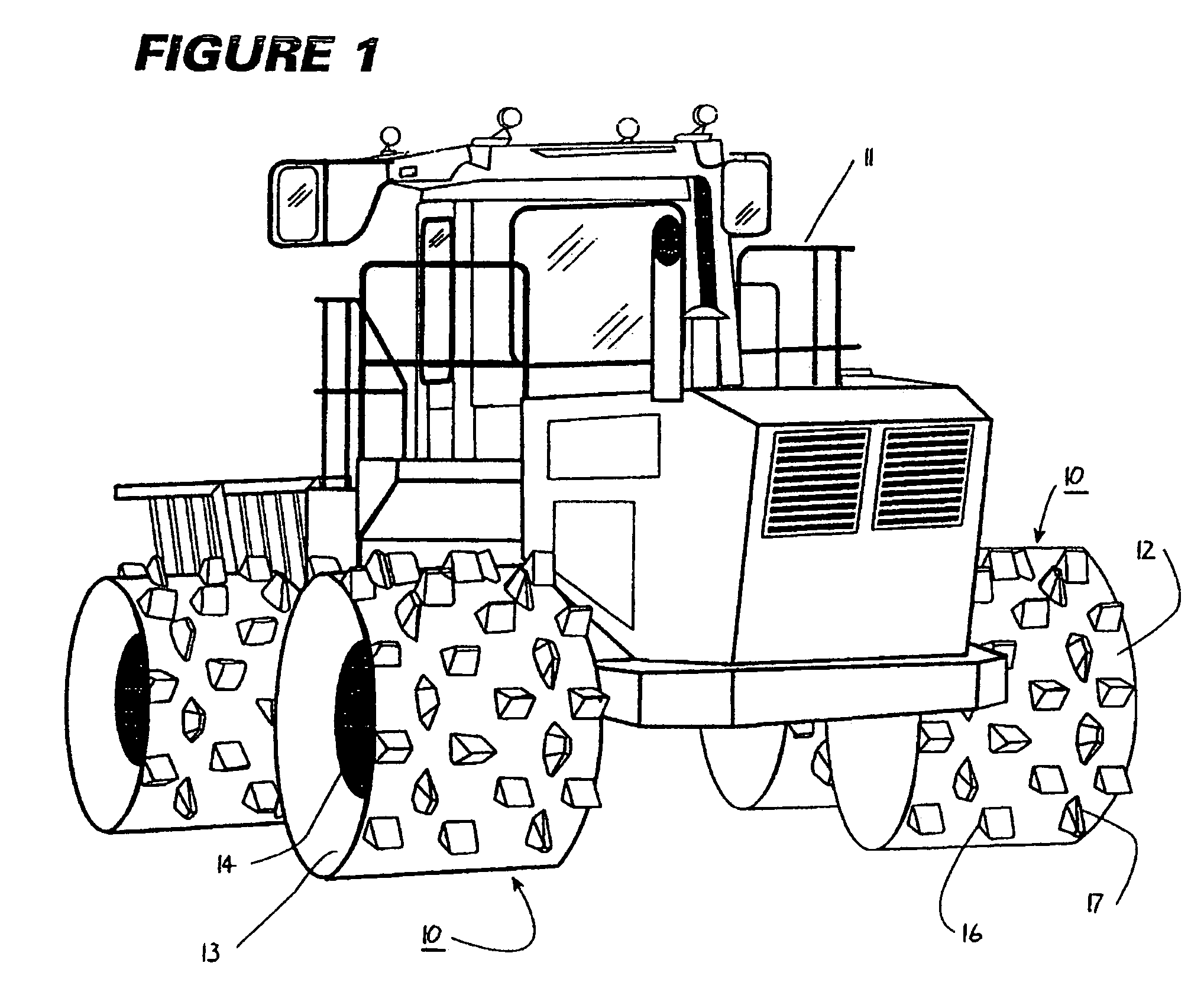

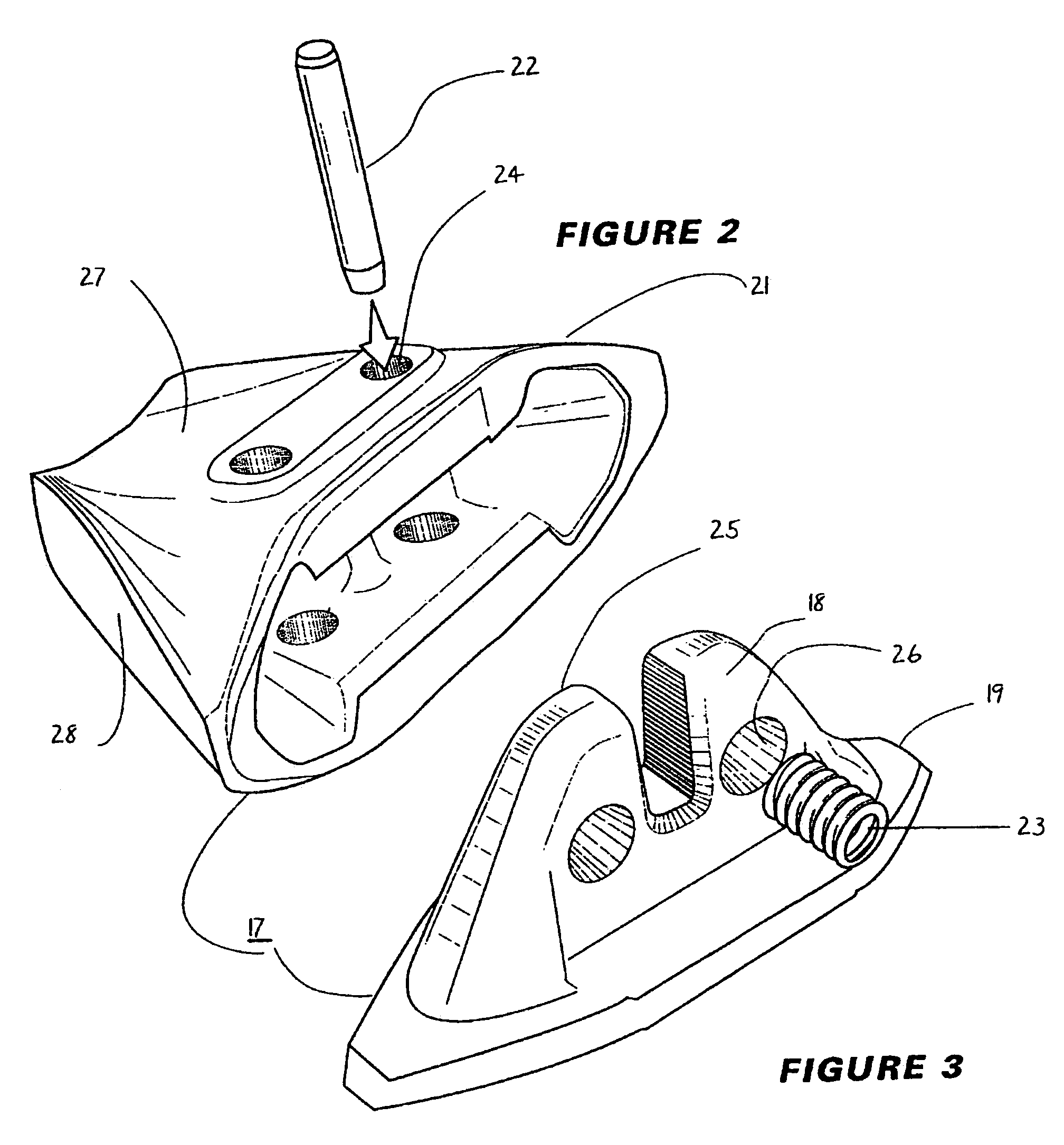

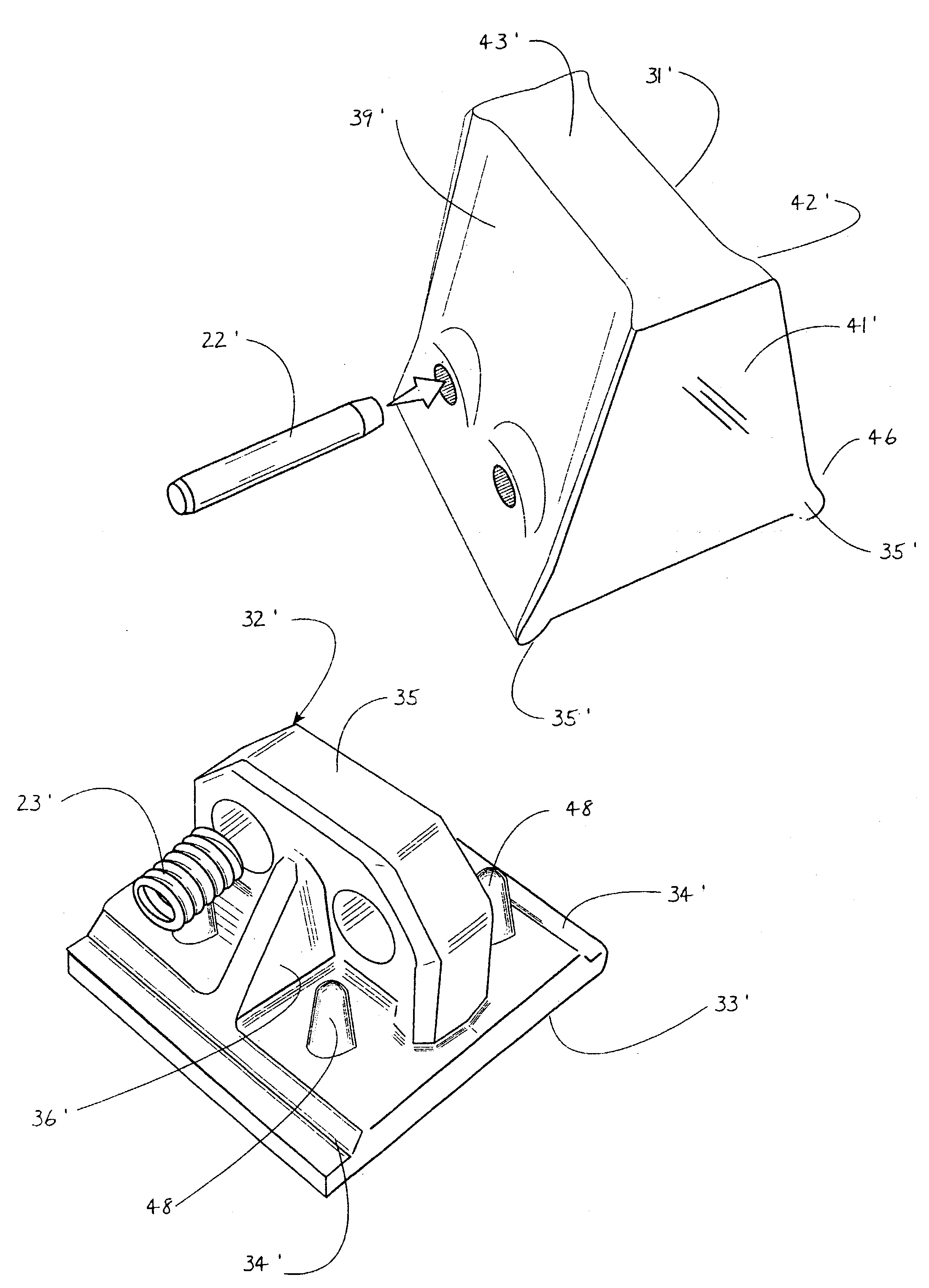

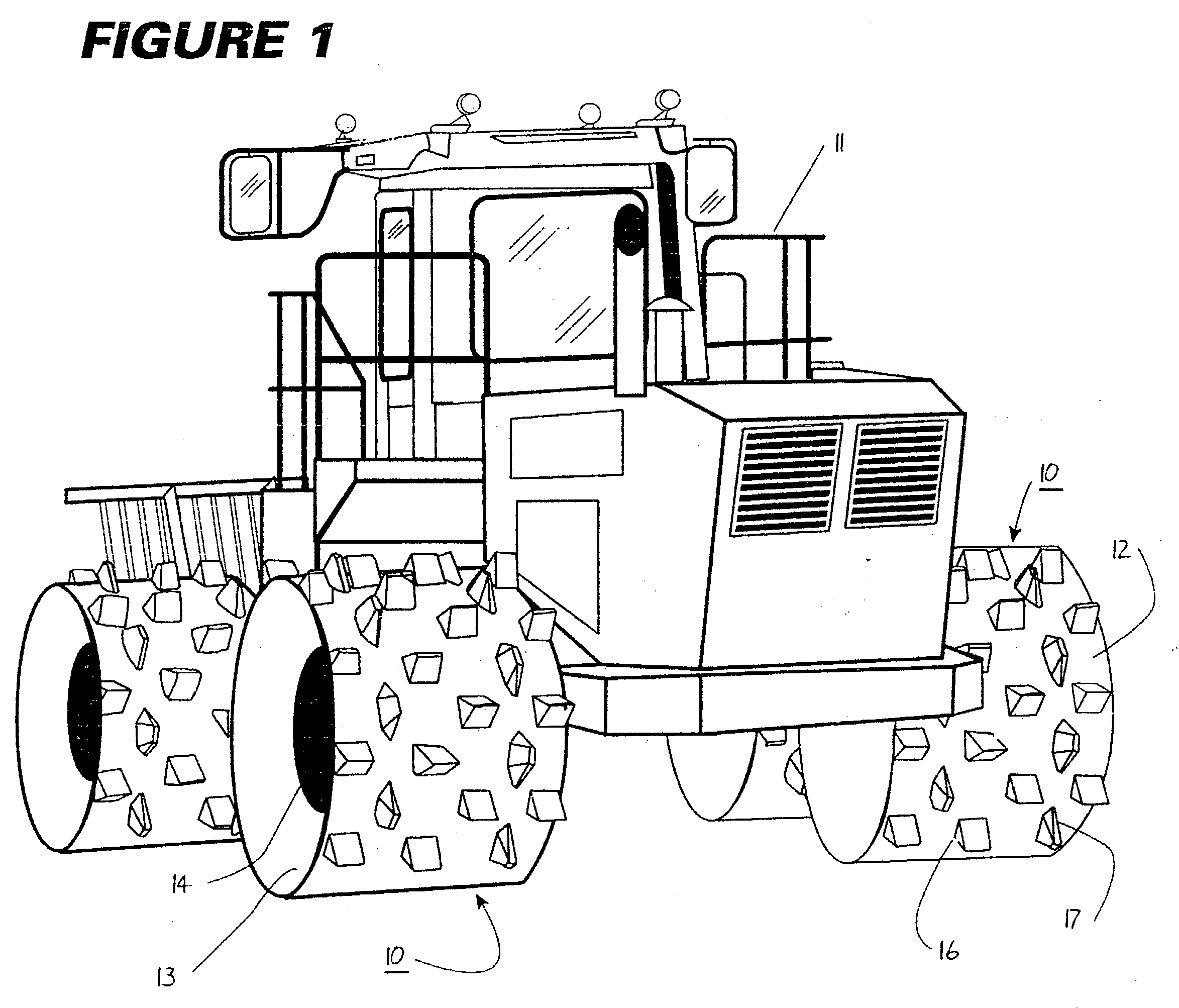

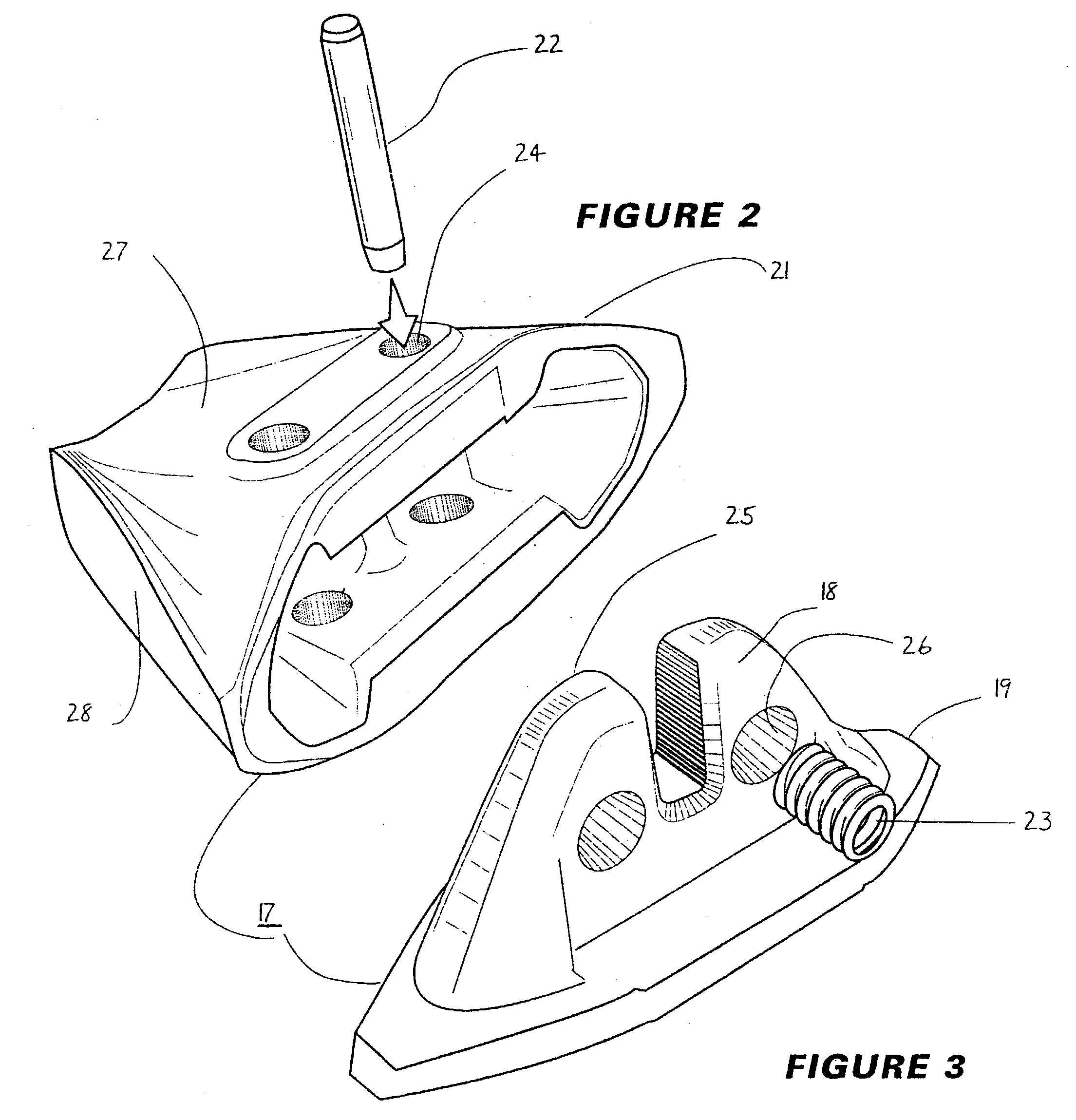

Fill and compaction roller using replaceable cleat assemblies with extended service life

InactiveUS7108452B2Easy to replaceAvoid wear and tearRoads maintainenceSoil preservationMortise and tenonWear resistant

A compaction roller for mounting on a driven compaction vehicle is equipped with both destructive and tractive, highly wear-resistant cleat assemblies. These include readily removable wear caps and supporting bases which have continuous side walls across the parting lines between the parts. Inset in the outer sidewalls are exposed mortise and tenon Jock joints serving to reduce relative movements between the parts under sever working forces. Pins extending radially between the wear caps and supporting bases further enhance the anti-twist resistance between the parts.

Owner:CARON COMPACTOR

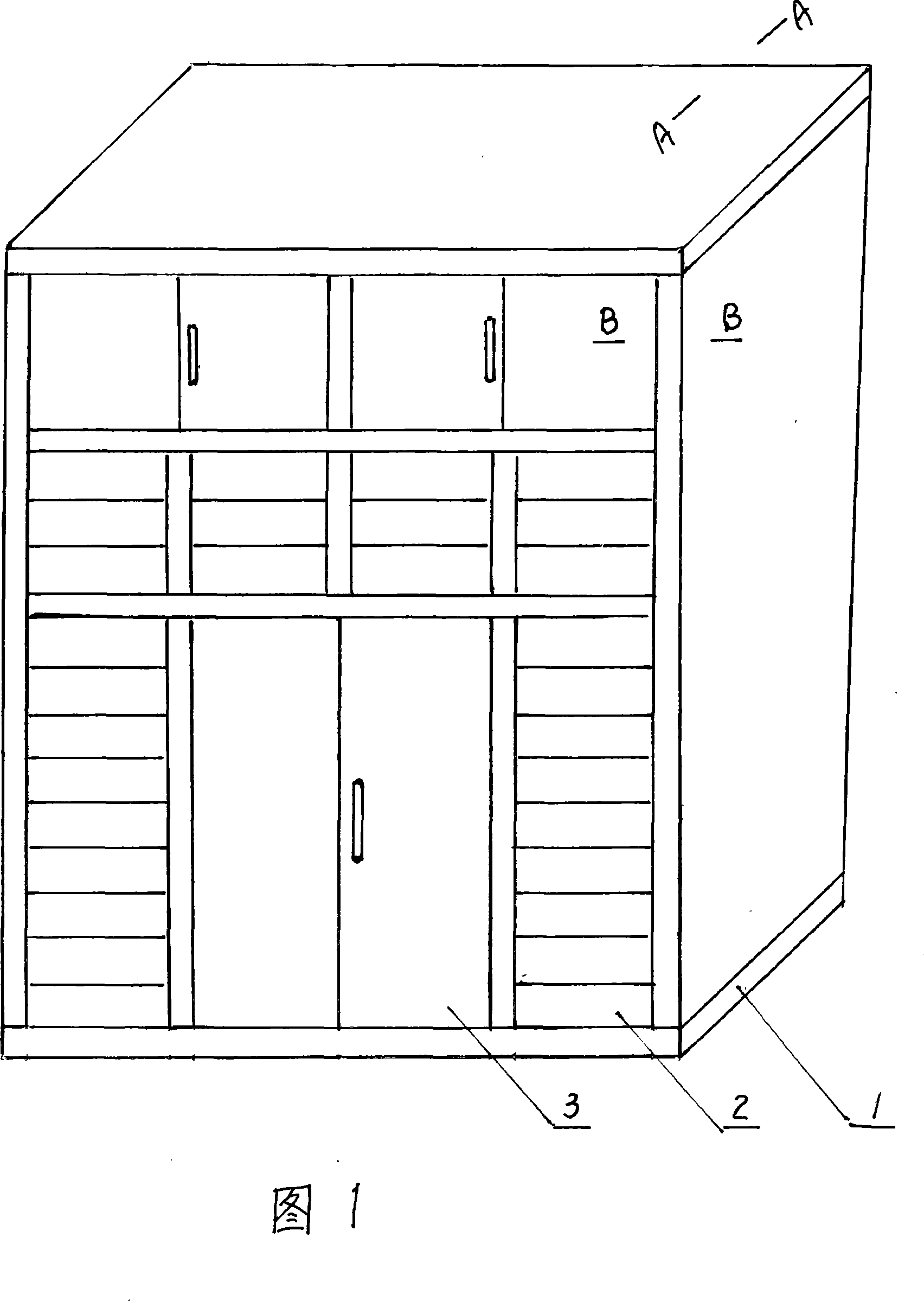

Mortise and tenon type furniture

The present invention relates to a kind of tenon-and-mortise work type furniture. It can be made into various forms according to the different requirements. Said tenon-and-mortise work type furniture is composed of skeleton, drawers and door, the skeleton is formed from vertical plate components and transverse plate components. Said vertical plate components include side wall plates, inner wall plate, vertical partition board and rear wall plate, and the transverse plate components include top cover, base seat and transverse partition board. The connection mode of all the above-mentioned components adopts tenon-and-mortise joint mode, and its door adopts sliding door mode.

Owner:刘瑞东

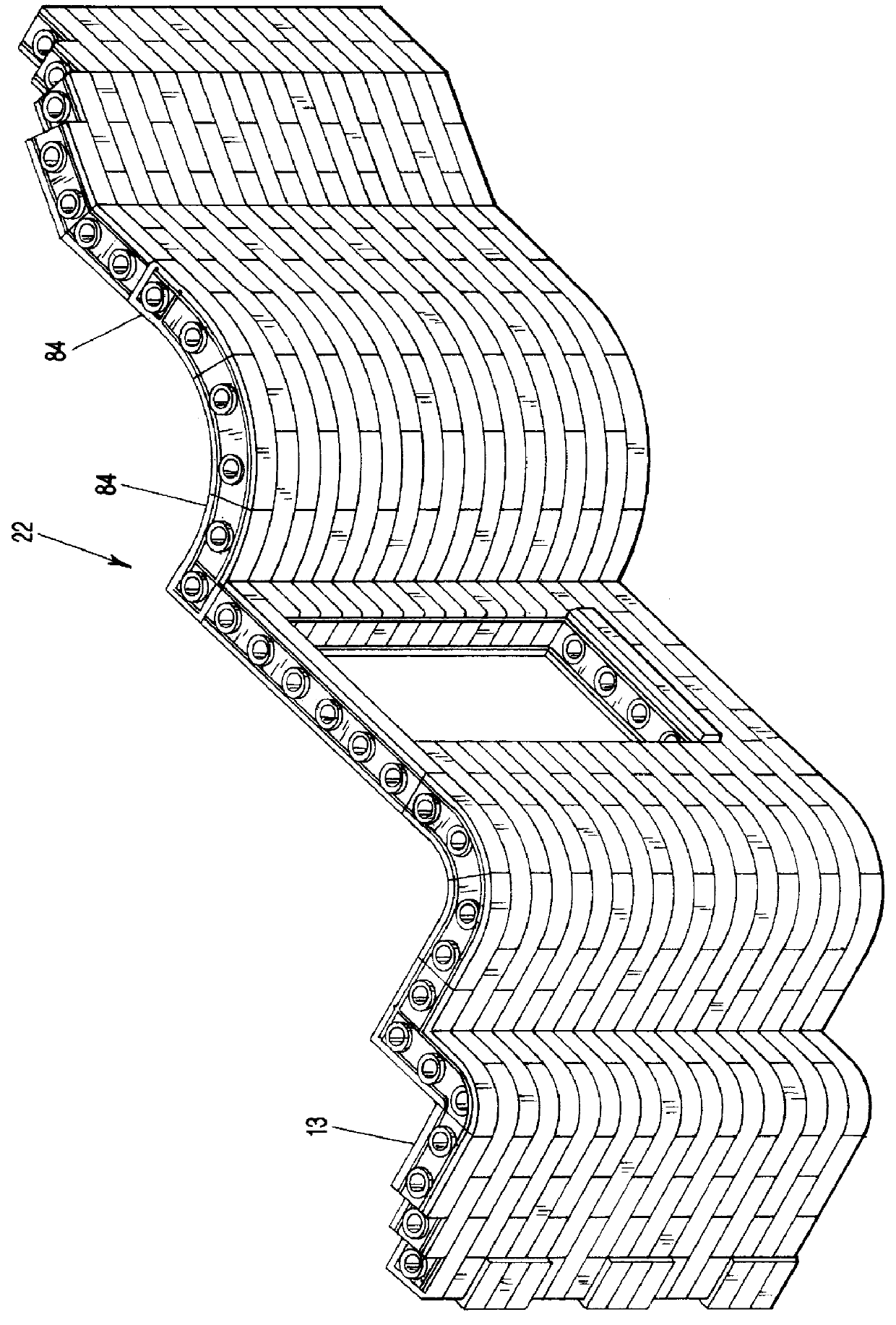

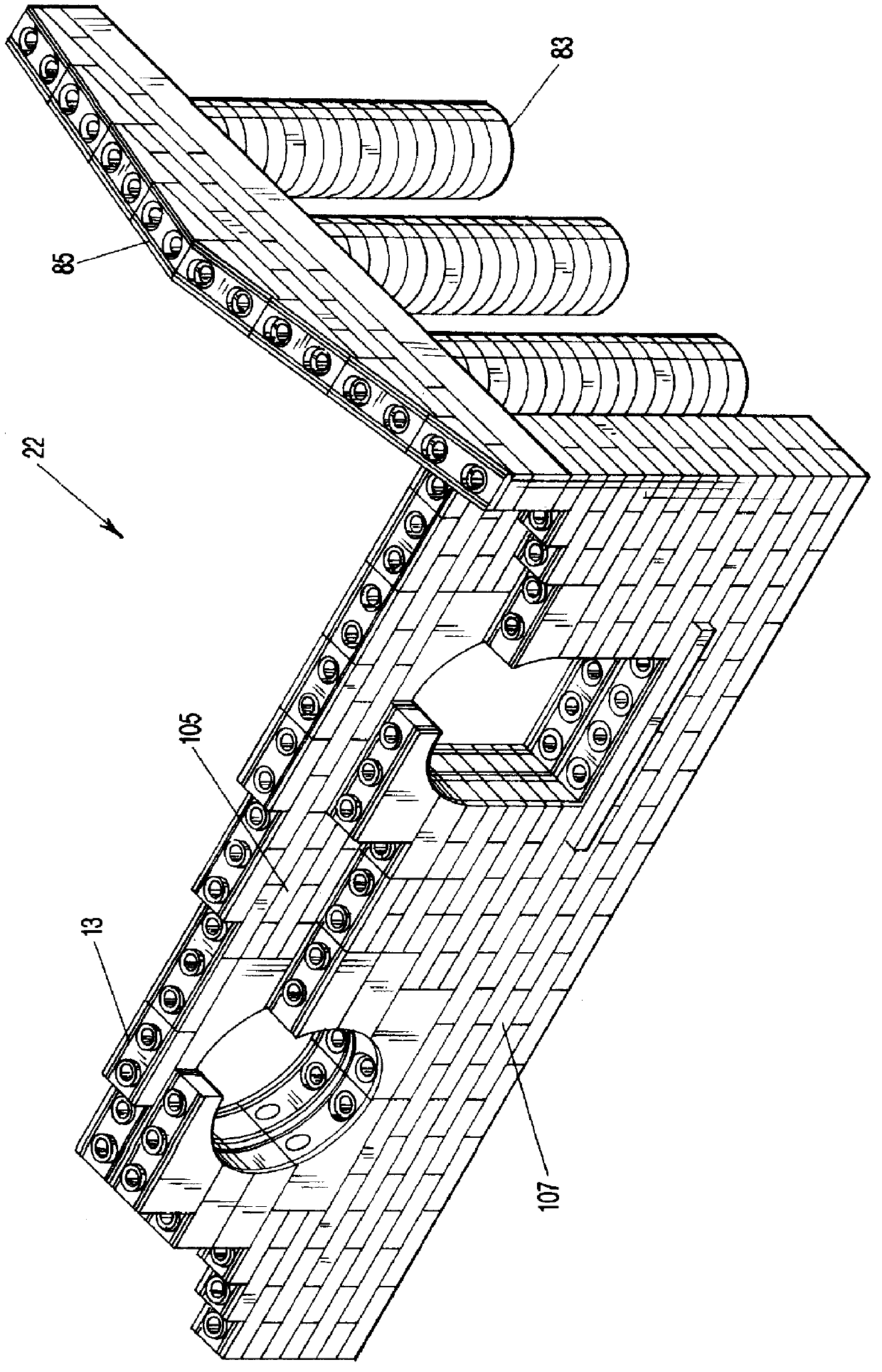

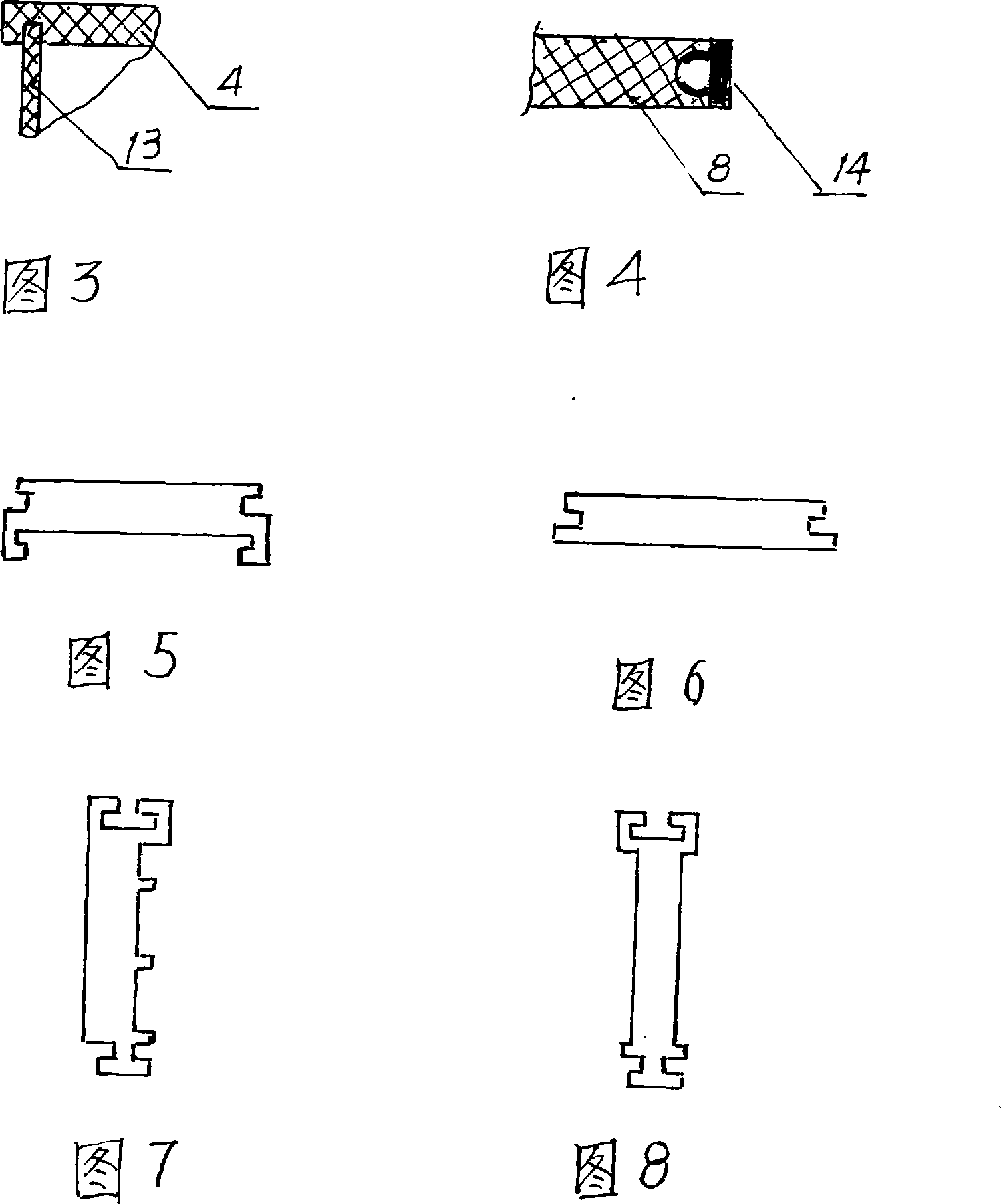

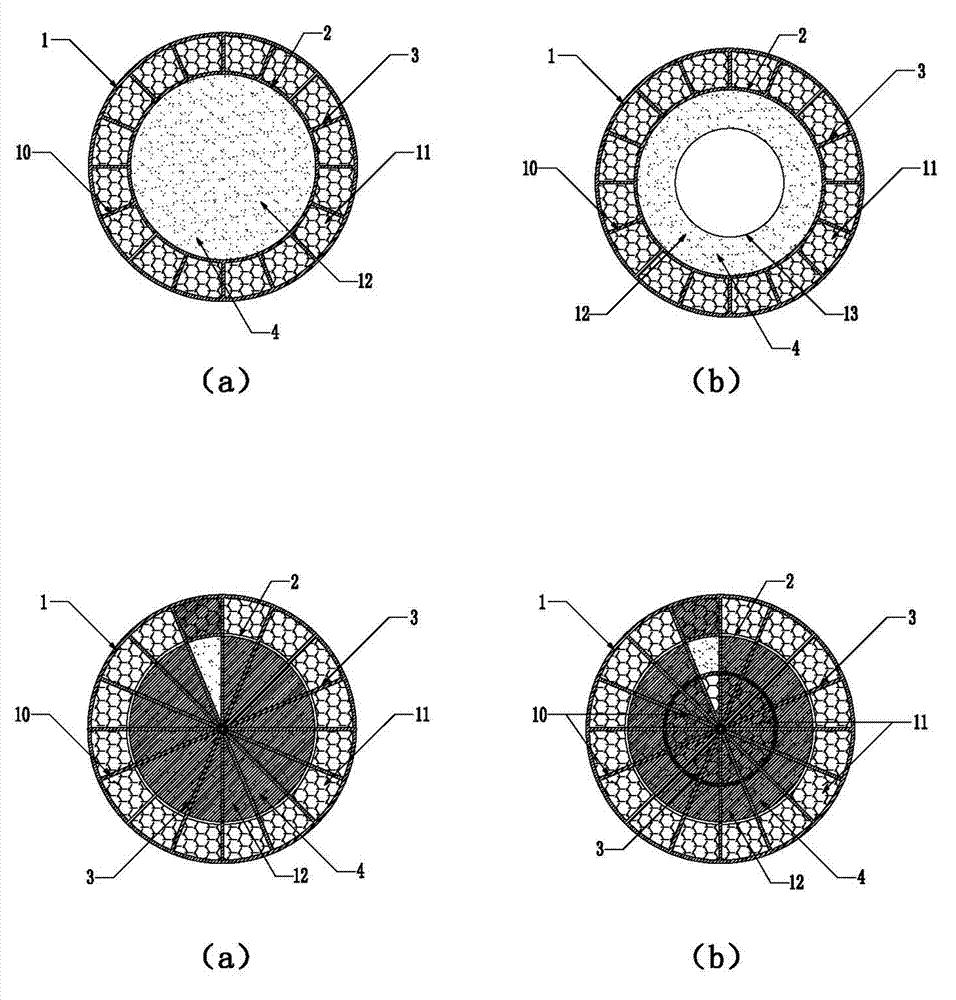

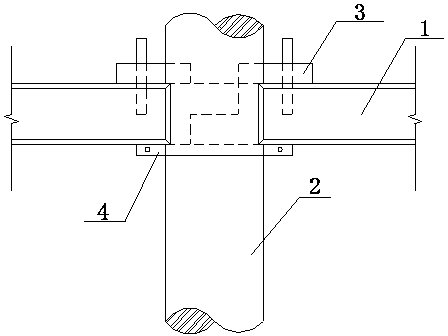

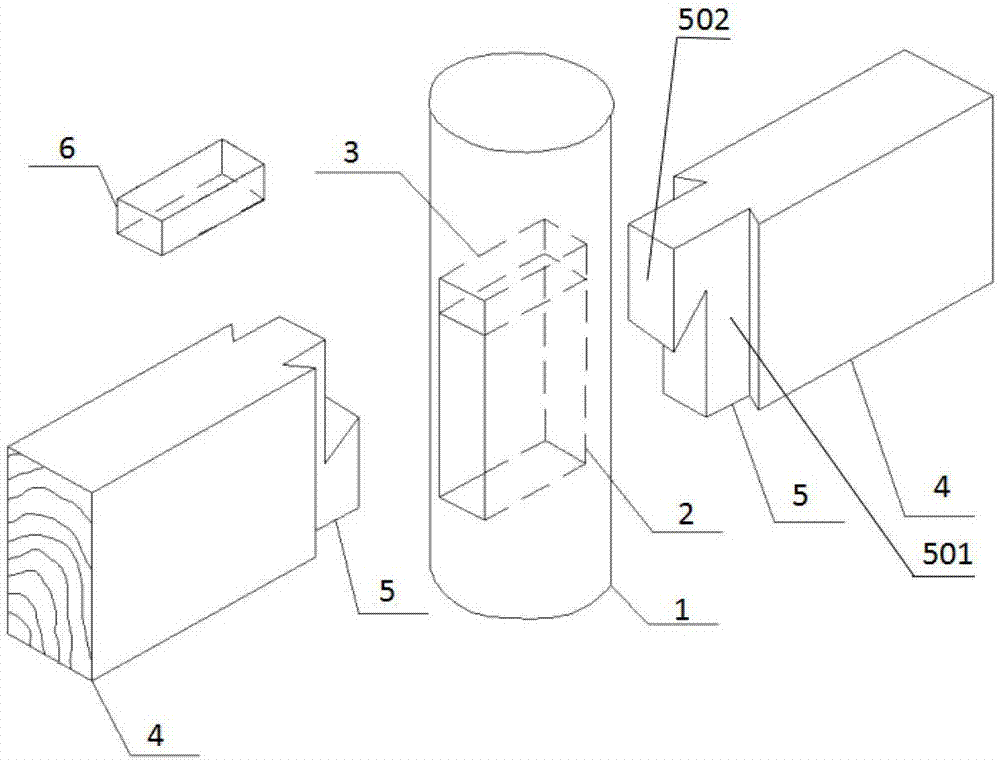

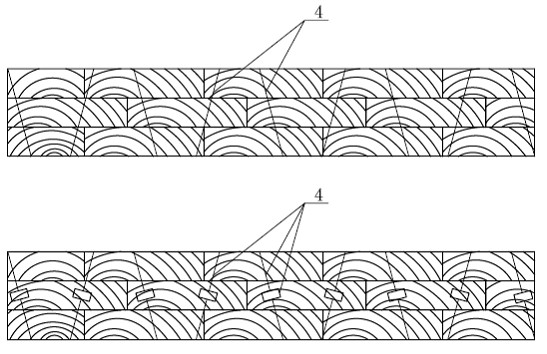

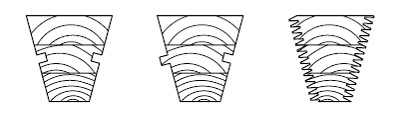

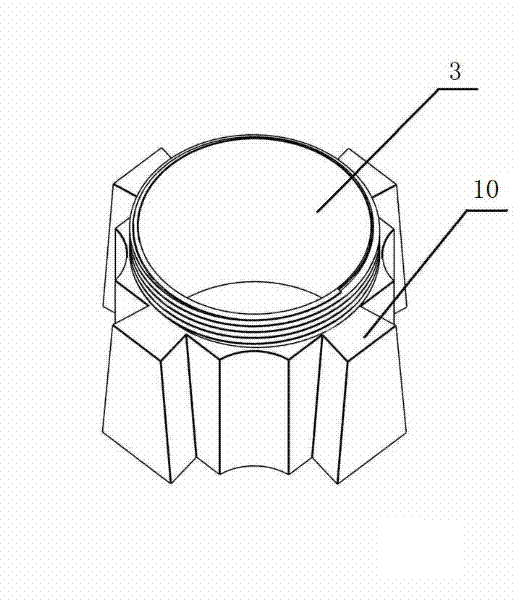

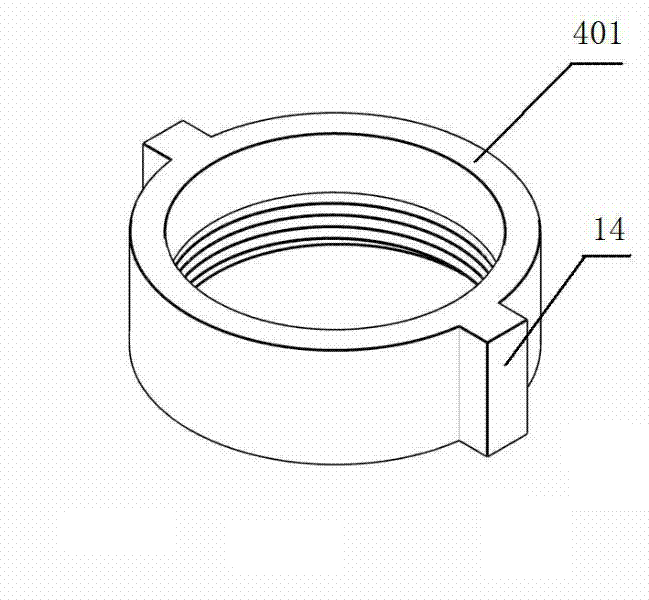

Honeycomb lattice enhanced type composite material double-cylinder structure and anti-collision system using same

InactiveCN103031817AEffectively distributes impact loadsWithstand multiple impactsClimate change adaptationShipping equipmentMortise and tenonFilling materials

The invention discloses a honeycomb lattice enhanced type composite material double-cylinder structure and an anti-collision system using the same. The double-cylinder structure comprises an outer cylinder (1) and an inner cylinder (2), wherein a honeycomb lattice enhanced body (3) is arranged between the outer cylinder (1) and the inner cylinder (2); and a filling material body (4) is filled into the inner cylinder (2). The anti-collision system comprises the honeycomb lattice enhanced type composite material double-cylinder structure, wherein the double-cylinder structure comprises straight cylinder units (5) and bent cylinder units (6); adjacent and mutually connected straight cylinder units (5), the straight cylinder units (5) and the bent cylinder units (6), or the bent cylinder units (6) are connected together through mortise and tenon joints (7) and bolts bars (16) so as to form a strip-shaped or annual anti-collision system; and a moving device (8) is arranged on the inner side of the anti-collision system. The double-cylinder structure is integrally formed in a weaving mode, and the filling material body has higher rigidity, so that the deformation degree can be limited without crack, and the double-cylinder structure is long in service life, low in cost and easy to maintain.

Owner:JIANGSU BOHONG NEW MATERIAL TECH +1

Waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement

ActiveCN103333555AImprove adhesionGood extensibilityRosin coatingsConjugated diene hydrocarbon coatingsMortise and tenonSynthetic rubber

The invention provides a waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement. The waterproof coating is characterized by comprising the following raw materials by weight: 20-50 parts of a synthetic rubber latex, 20-50 parts of emulsified asphalt, 0.5-2 parts of a functional additive and 0.5-2 parts of a dispersant, 20-40 parts of a filler and 10-25 parts of water. The principle is that through coupling effect of the functional additive, part of the molecules in the synthetic rubber and most molecules in the asphalt couple into large molecules with reaction activity; when the large molecules contact with a base plane, the non-reactive molecule segments of the rubber and asphalt and the base plane form physical adsorption, and the molecular segments with reaction activity conduct react with the base plane to form chemical bond effect, so as to generate strong adhesive force; and after bonding, the coating is hardly influenced by environmental factors. Therefore, the waterproof coating provided by the invention has excellent waterproof performance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

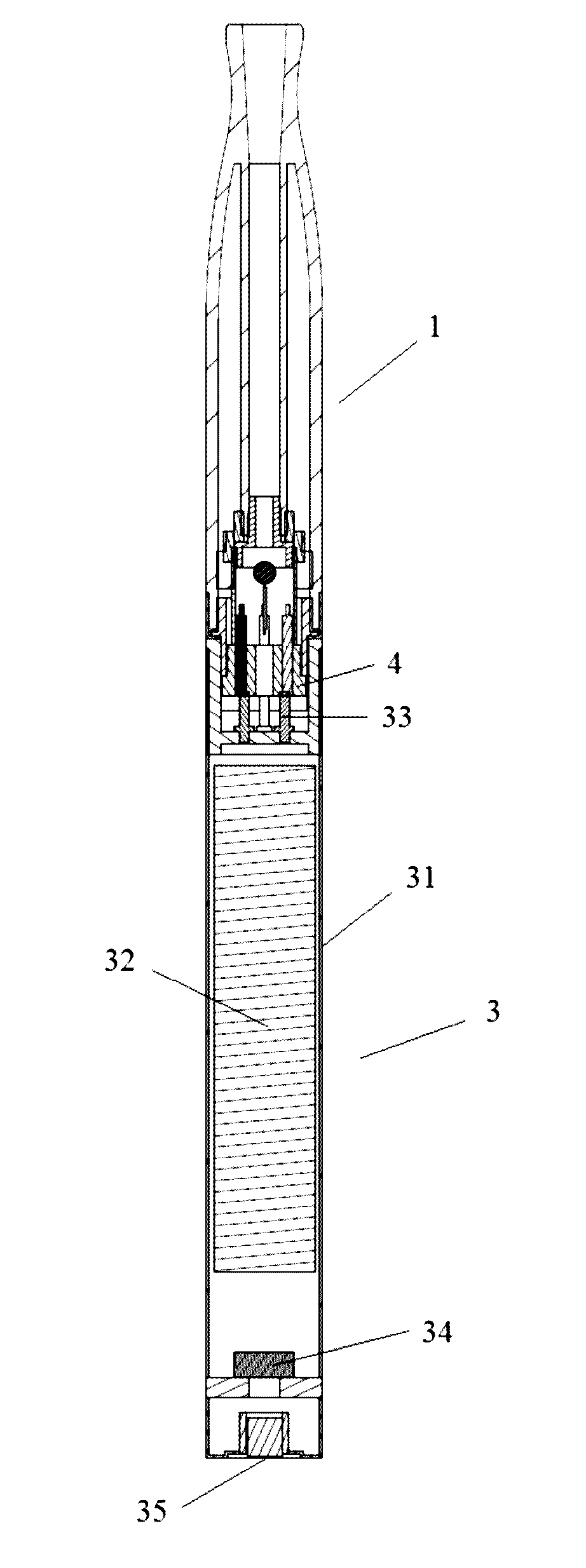

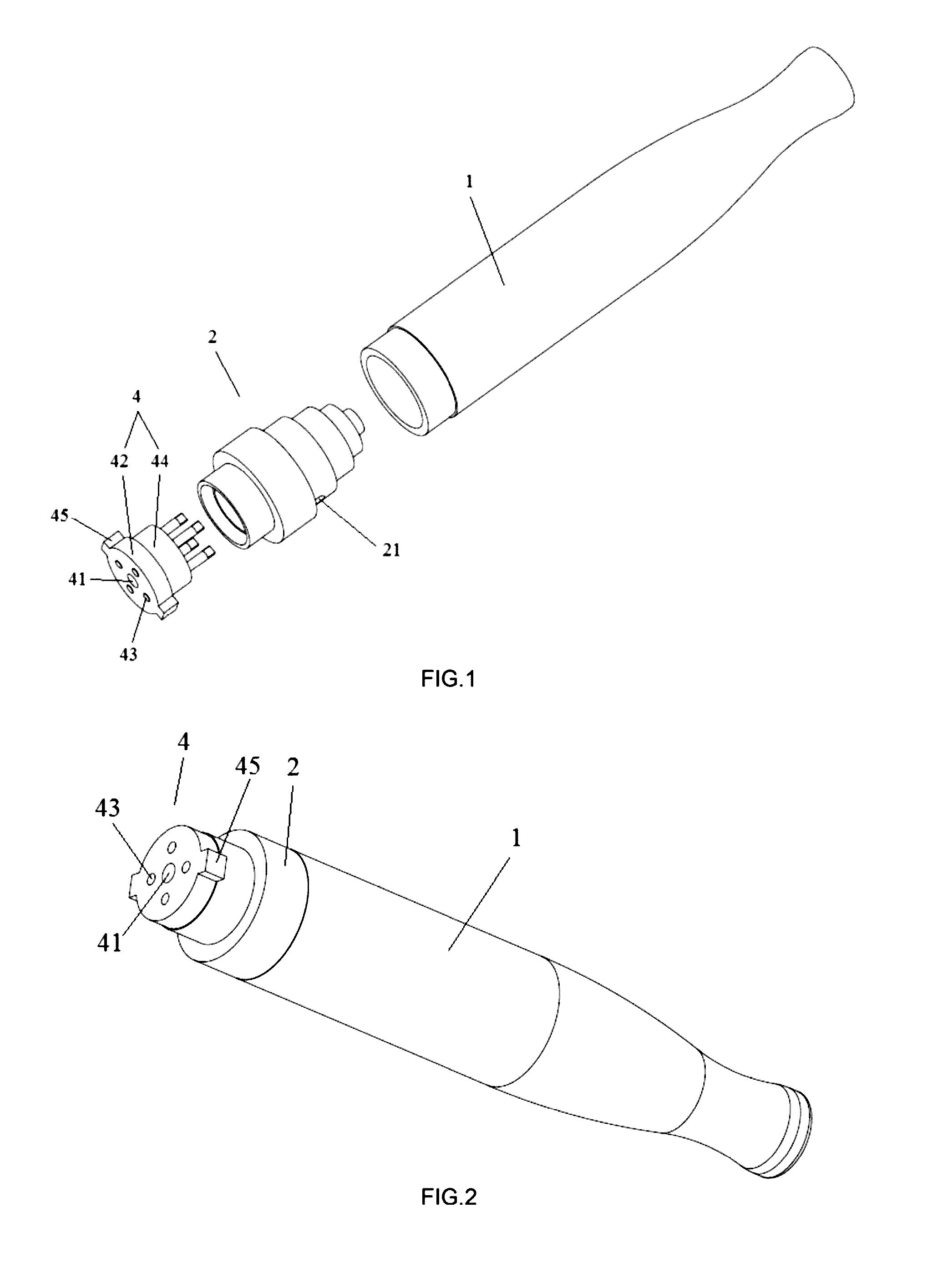

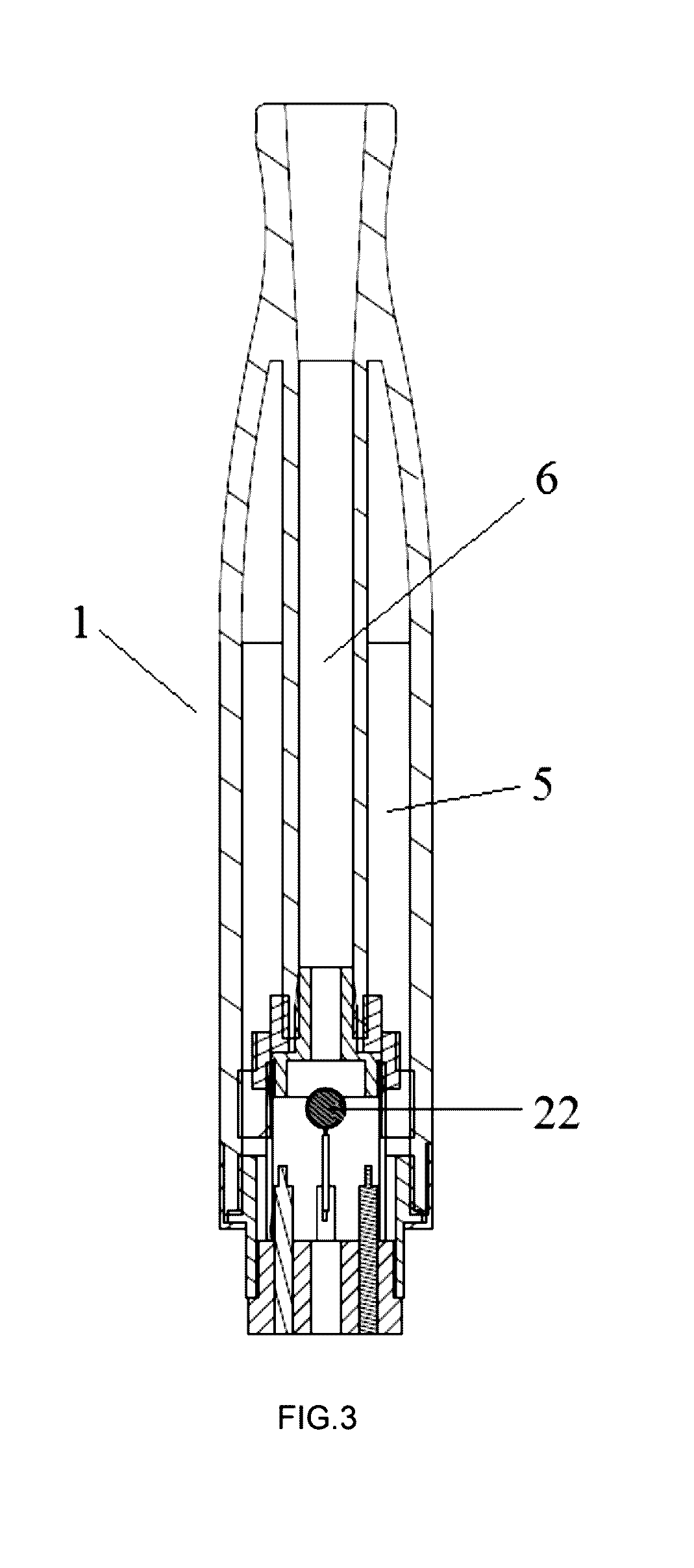

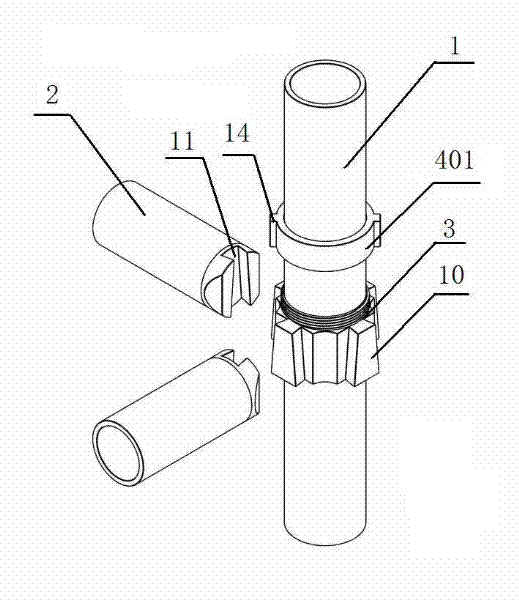

Electronic cigarette and an atomizing device thereof

InactiveUS20160366938A1Prevent replenishmentImprove the safety of useTobacco pipesTobacco devicesMortise and tenonEngineering

An atomizing device of an electronic cigarette comprises an atomizing tube, an atomizing component disposed internal to the atomizing tube, and a connector for connecting a battery component; an e-liquid storage space is provided in an inner portion of the atomizing tube; a bottom part of the e-liquid storage space is sealed by inner walls of the atomizing tube and side walls of the atomizing component; an e-liquid inlet is provided on the atomizing component for inlet of the e-liquid; one end of the connector is fixed at a bottom part of the atomizing component; another end of the connector is fixedly connected to the battery component via mortise and tenon joints. The present invention can prevent unrestricted replenishment of e-liquid and enhance safety of use. Mortise and tenon joints are used to connect the atomizing device and the battery component, thereby facilitating connection and reducing breakdown rate.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

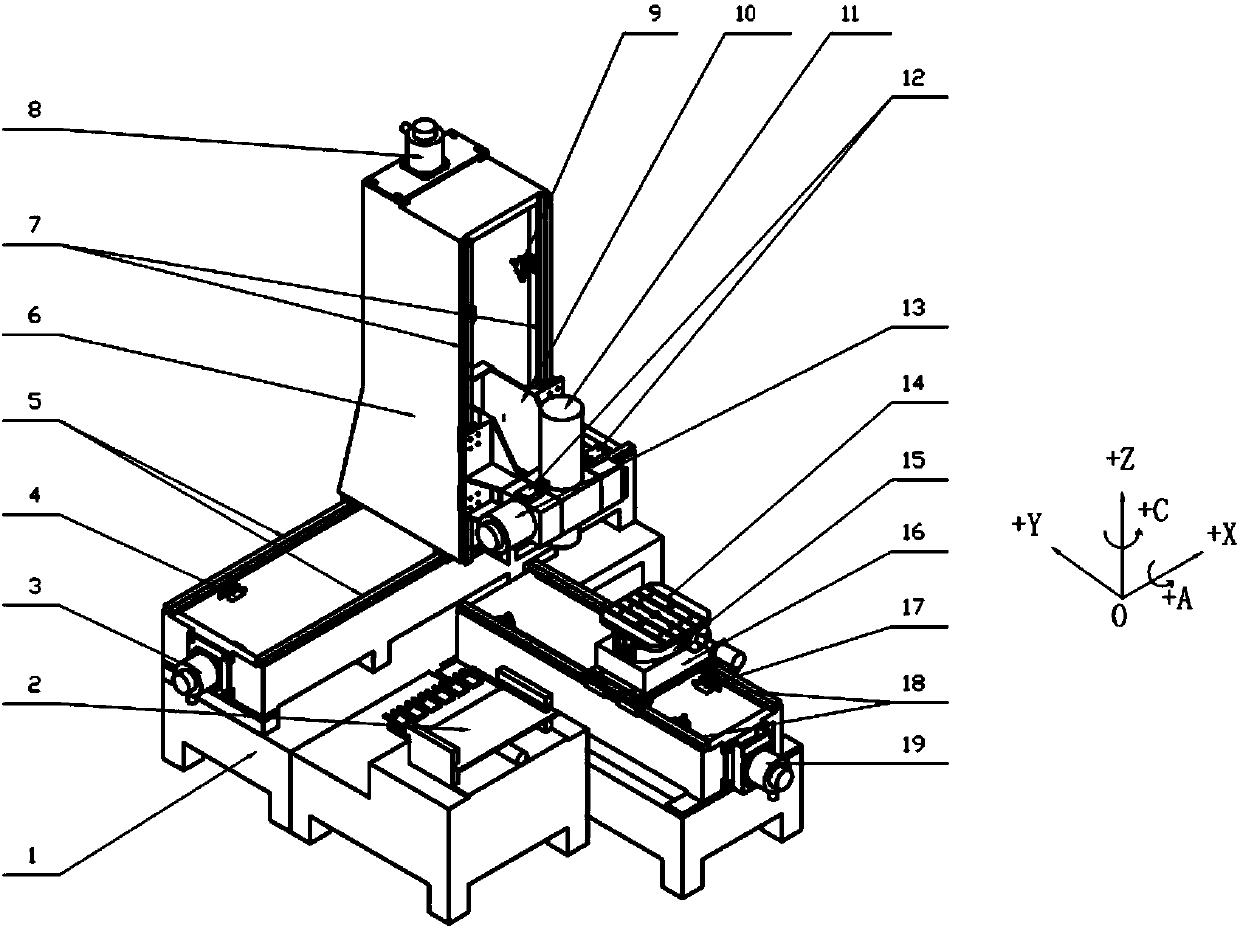

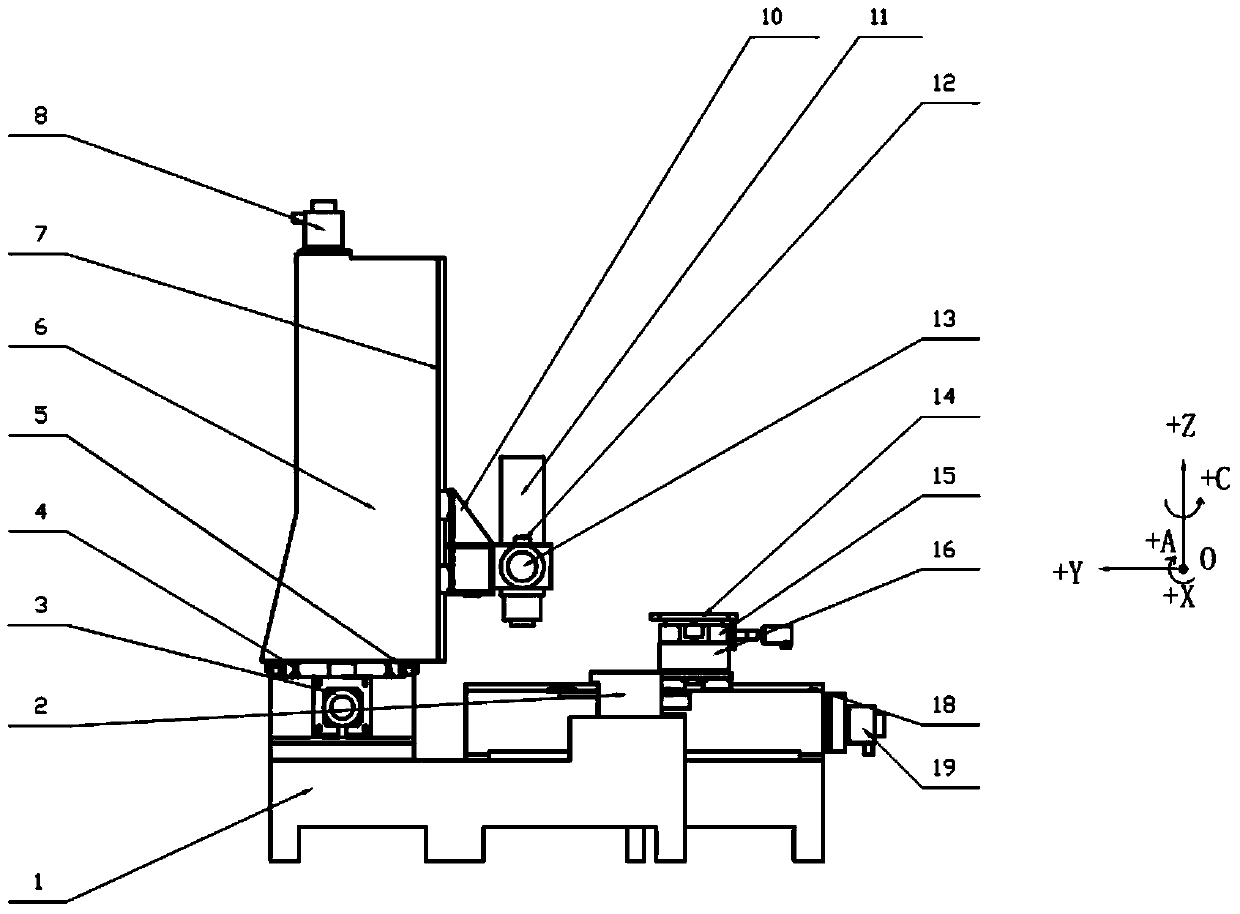

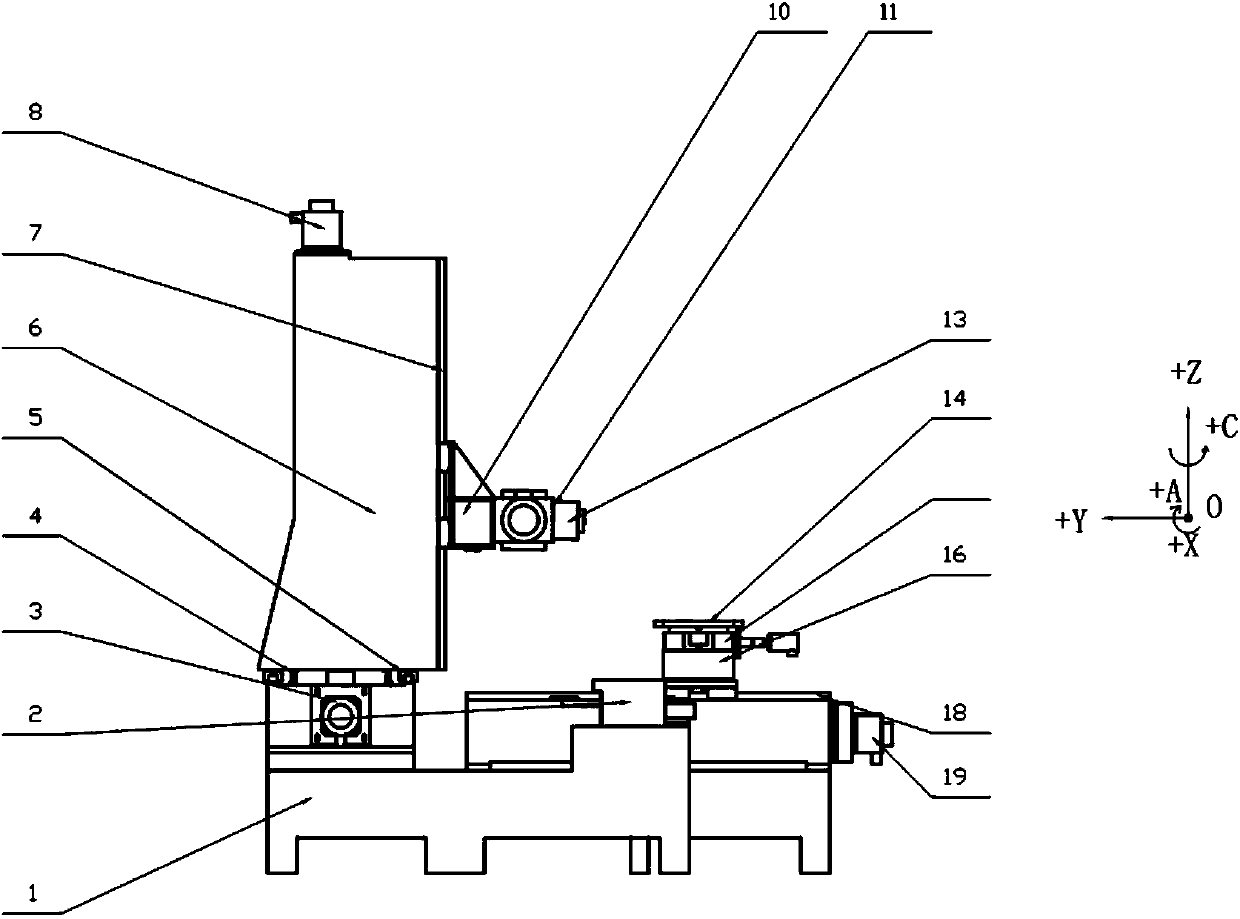

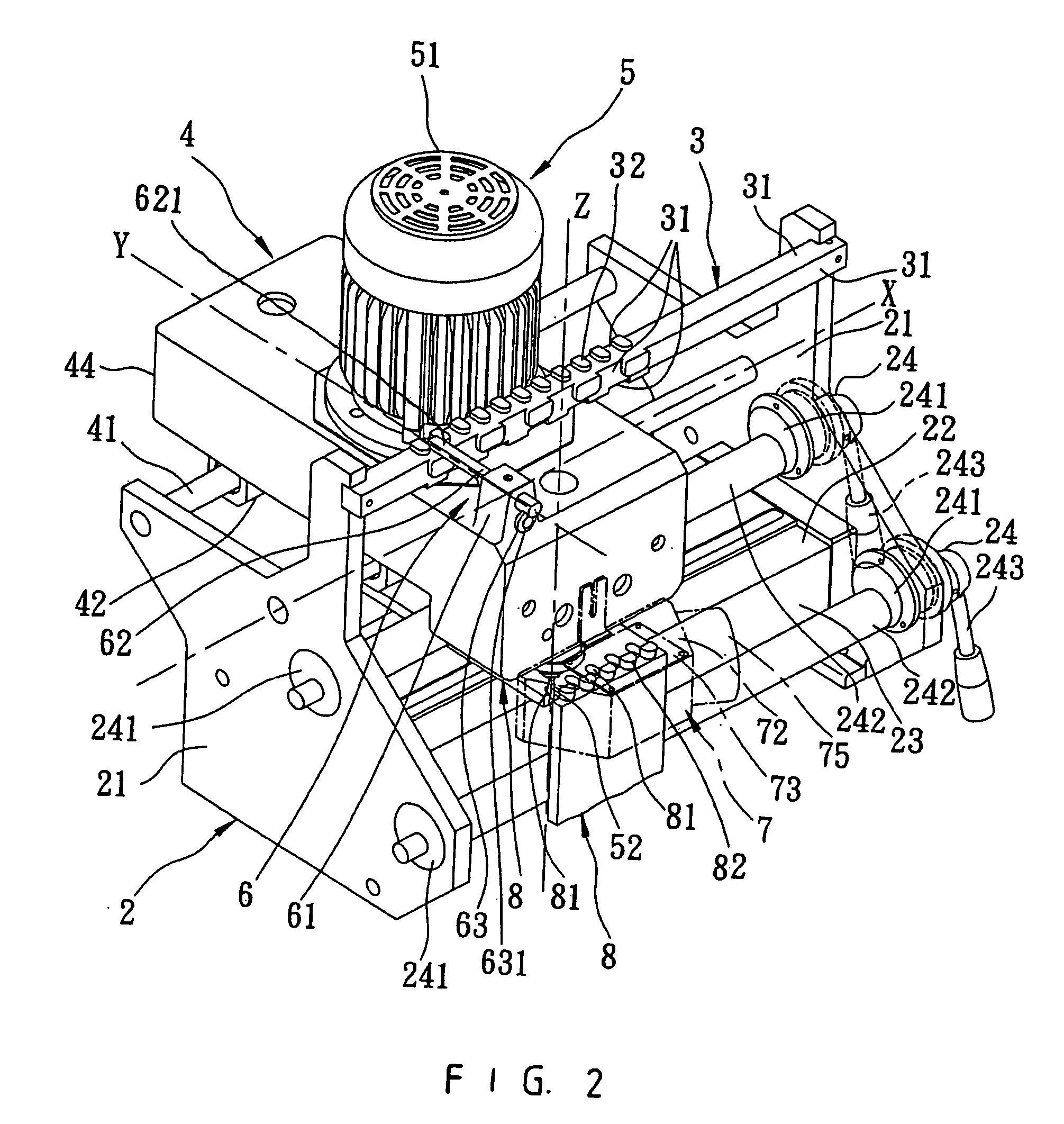

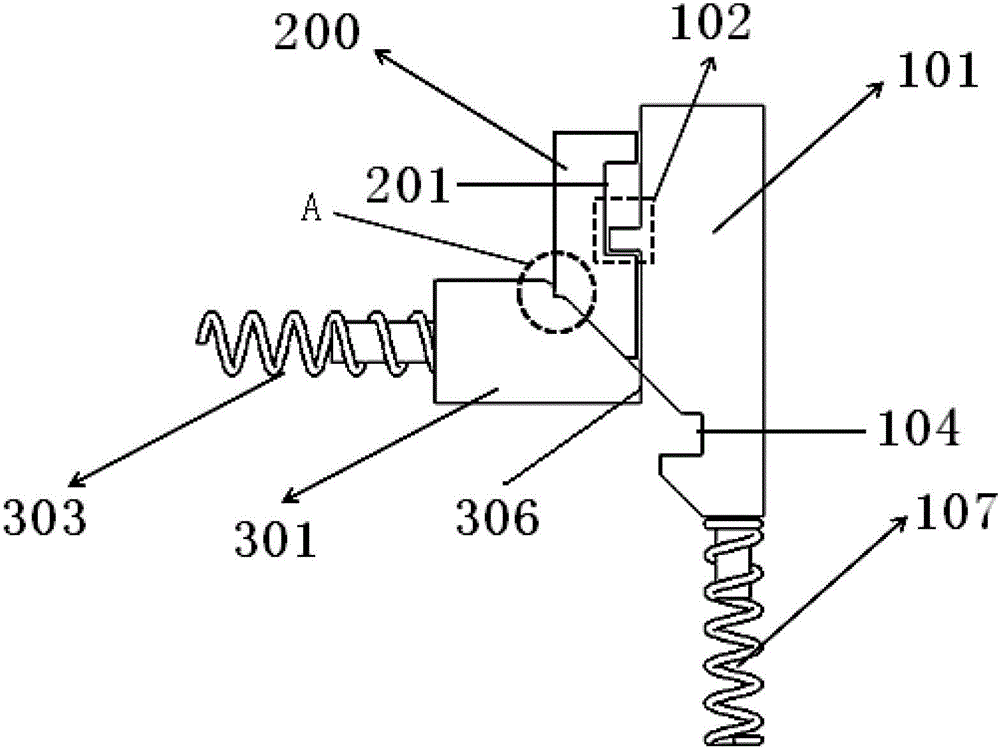

Numerical control five-axis tenon machining machine tool

InactiveCN103802180AImprove machining accuracyPracticalTongue/grooves making apparatusTenon making apparatusNumerical controlMortise and tenon

The invention discloses a numerical control five-axis tenon machining machine tool, and belongs to the technical field of machining machine tools. The numerical control five-axis tenon machining machine tool comprises a machine tool body, upright posts, a rotary positioning turntable, a main shaft component, a tool magazine and a control card used for controlling the machine tool, wherein the upright posts are connected with the machine tool body through X-axial guide rails and move along the X axes under the drive of a drive device; the rotary positioning turntable is connected with the machine tool body through a Y-axial guide rail and moves along the Y axis under the drive of the drive device; the main shaft component is connected with the upright posts through Z-axial guide rails and move along the Z axis under the drive of the drive device; an X-axial guide rail is placed on each of the two cross beams of the machine tool; the upright posts and the cross beams of the machine tool body form guide rail connection; a Y-axial guide rail is placed on each of the two longitudinal beams of the machine tool body; a Y-axial sliding plate and the longitudinal beams of the machine tool body form guide rail connection. The numerical control five-axis tenon machining machine tool can implement the three-dimensional five-axis cutting machining on a complex tenon structure, and the machining level of the machine tool is higher. According to the machine tool, the self gravity of the machine tool is greatly reduced without influencing the use precision of the machine tool.

Owner:刘岩松

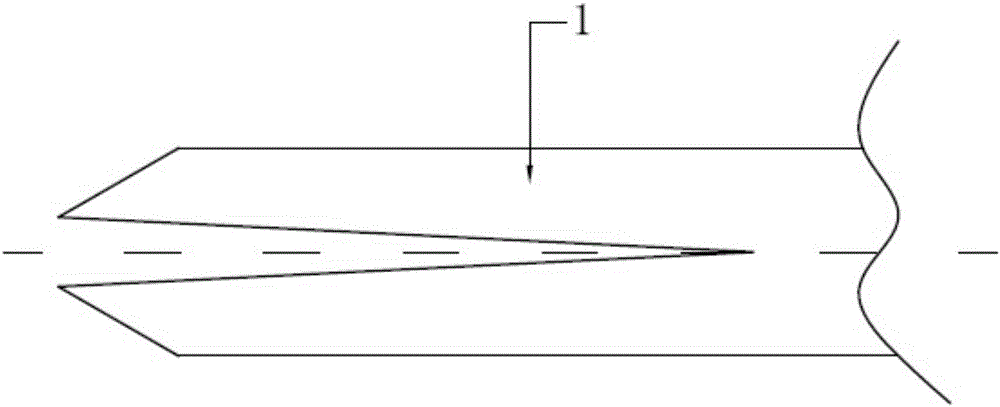

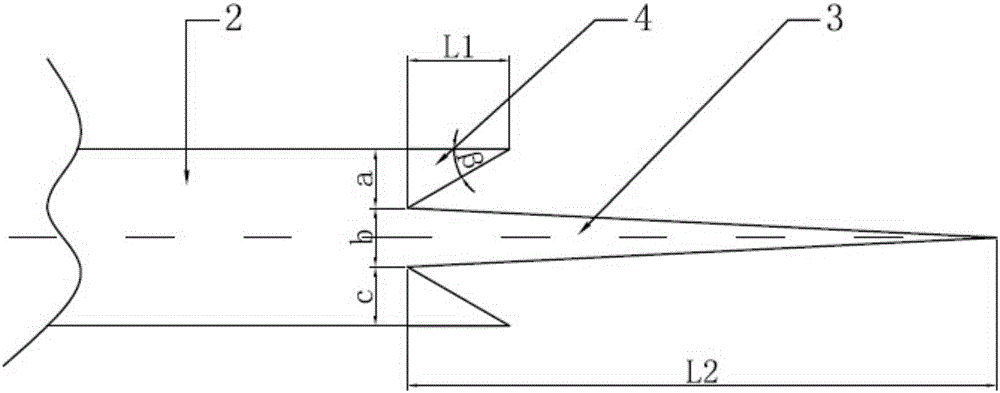

Novel seedling grafting cultivation method

The invention relates to the field of agricultural planting grafting, and provides a novel seedling grafting cultivation method. The sizes of mortise and tenon joints are customized according to the diameter of a rootstock; a fork structure is arranged on the rootstock, and a scion structure complementarily matched with the fork structure is also arranged on the rootstock; the tail end diameter of the scion structure is divided into three equal sections a, b and c; the middle section b is provided with an inserting cone, and the sections a and c at two sides are provided with symmetrical side wings; an angle formed by the side wings and the periphery of a seedling body is beta of 30 degrees; the length of each side wing is L1, and the length of the inserting cone is L2 which is six times the length of L1; the engagement part between the fork structure and the scion structure after engagement is smooth without a gap, is simply tied up by adopting gauze or adhesive tapes, and does not need soil and other nutrient solution. The method provided by the invention is simple in grafting process and large in grafting contact area, changes the conventional methods for cuttage grafting, inarching, adhesive grafting, tooth grafting and the like, and reduces the cultivation cost, the survival rate reaches 100%, and an interface after survival does not have a mark and almost has no difference with the original state by visual measurement.

Owner:JIANGXI ZIYUAN NURSERY

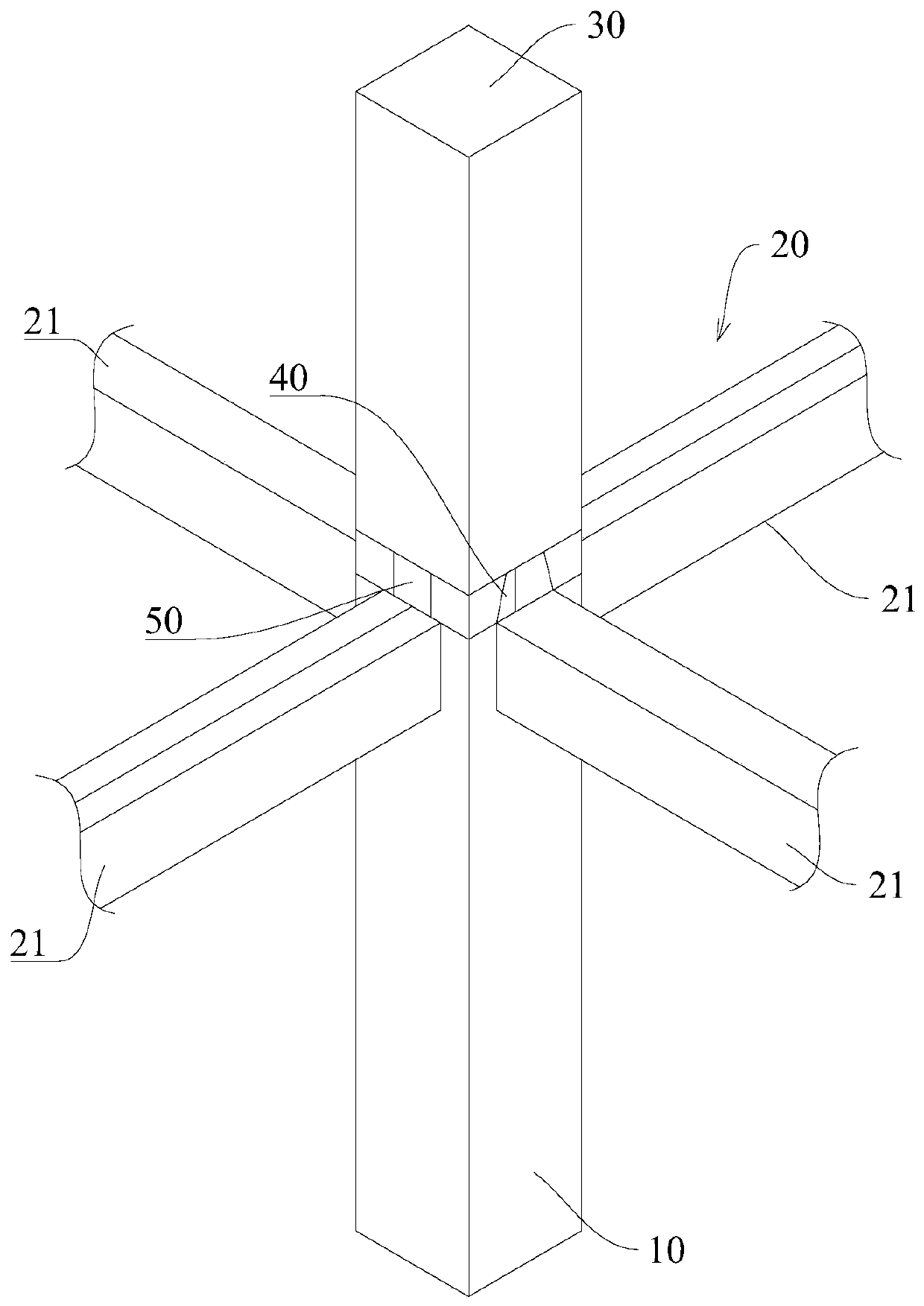

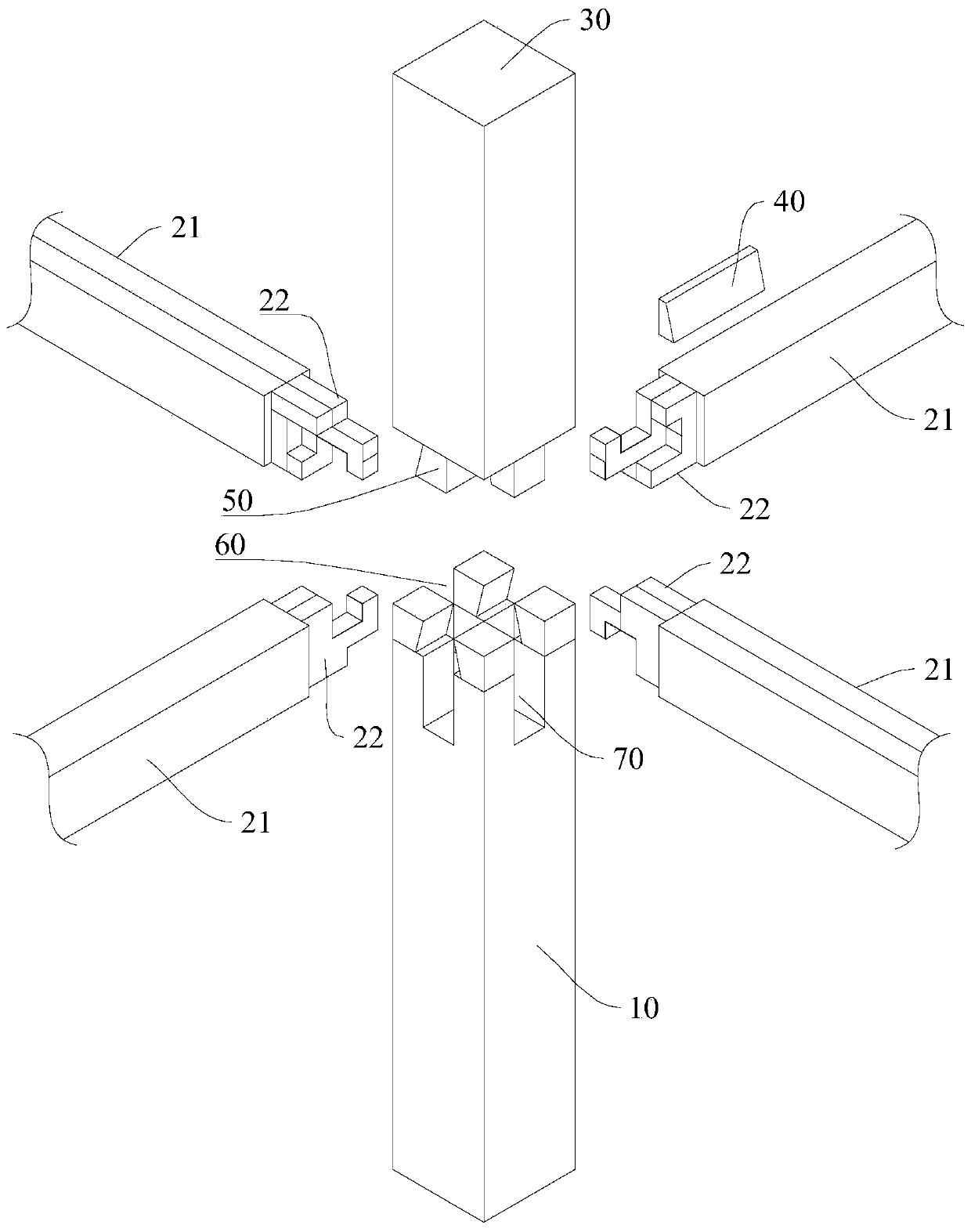

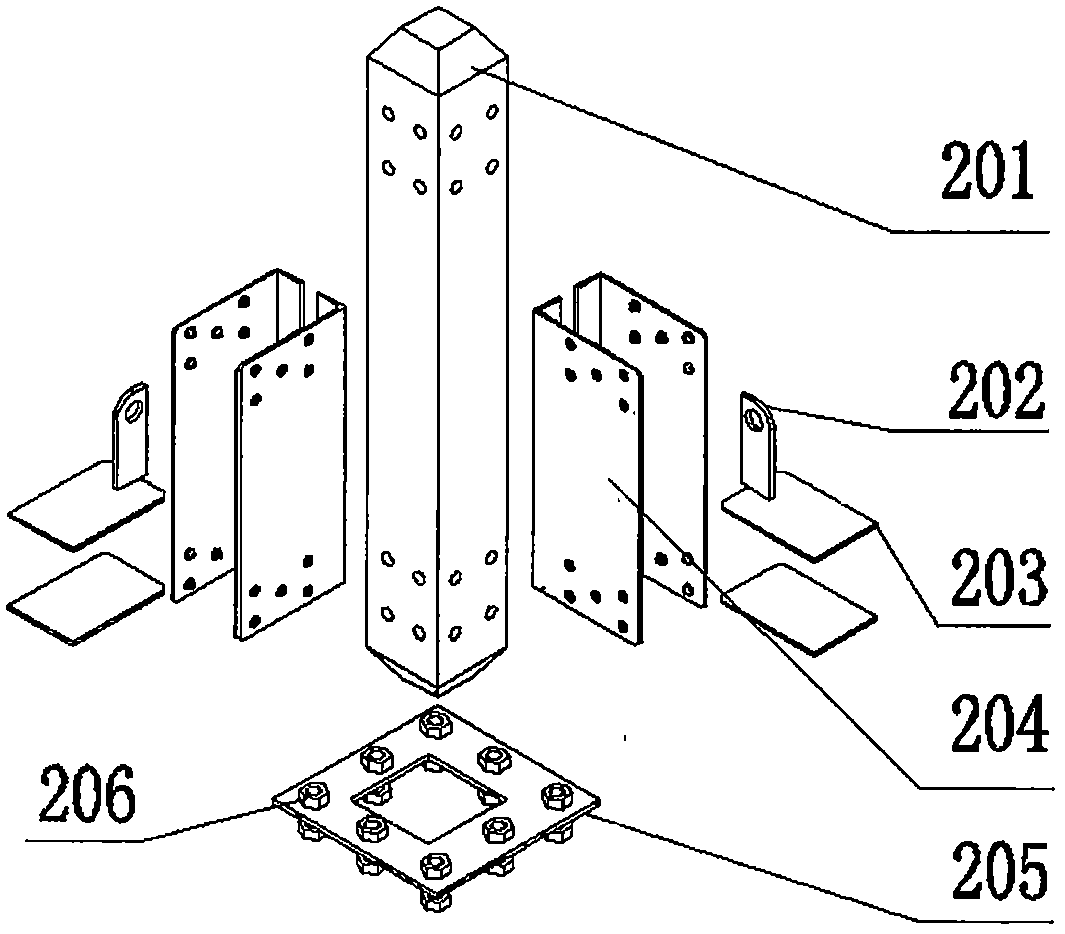

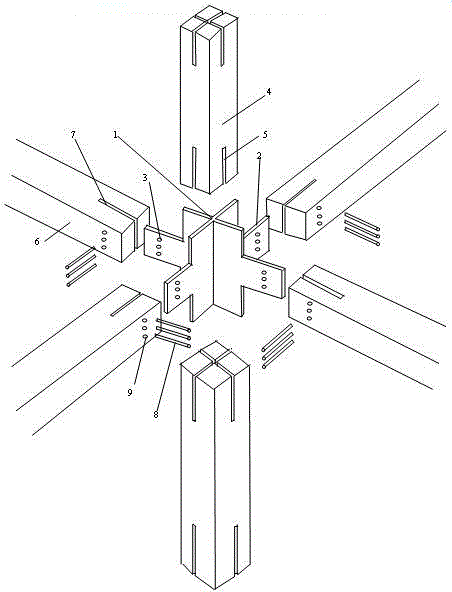

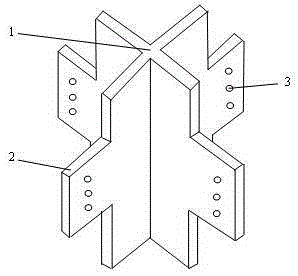

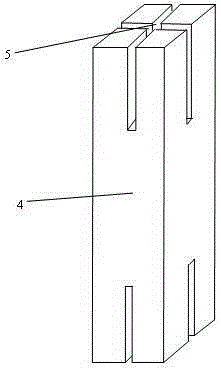

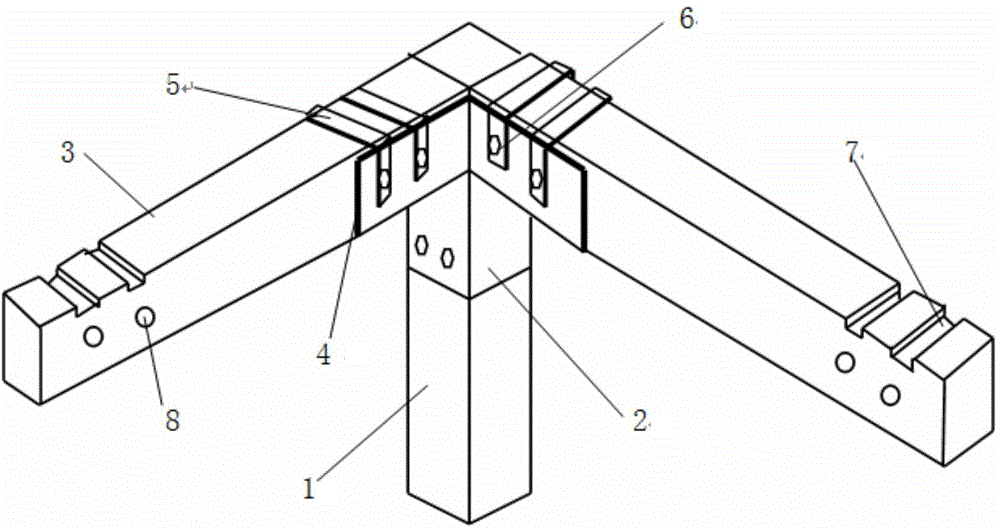

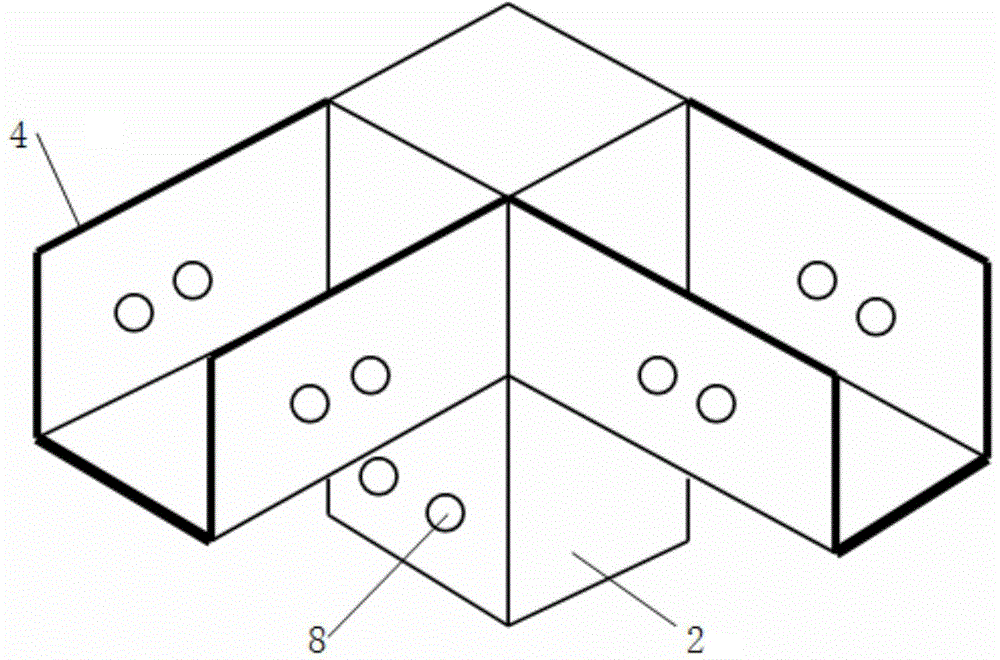

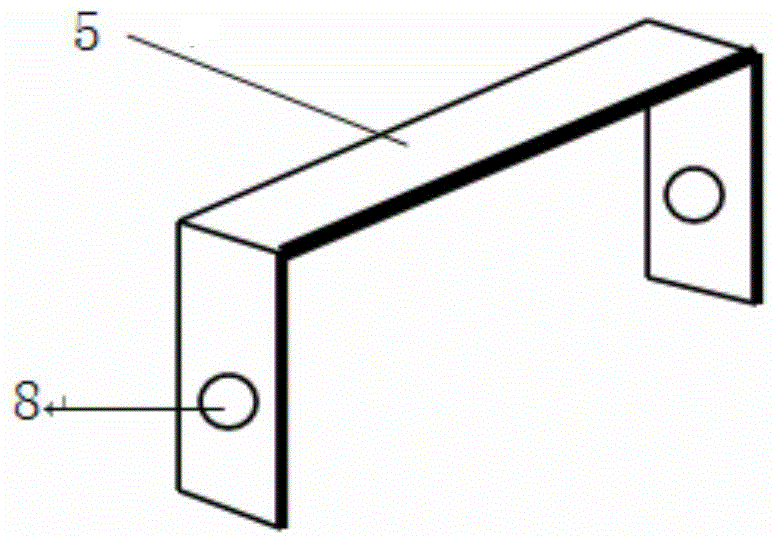

Beam-column mortise and tenon joint type joint structure

ActiveCN110130496AImprove stabilityImprove the safety of useBuilding constructionsMortise and tenonEngineering

The invention provides a beam-column mortise and tenon joint type joint structure, and belongs to the technical field of a beam-column connection structure. The beam-column mortise and tenon joint type joint structure comprises a first supporting column, a combination beam located on the top portion of the first supporting column, a second supporting column and a tenon batten located on the upperpart of the first supporting column, and matched with the first supporting column to clamp the combination beam; the bottom portion of the second supporting column is provided with a second tenon, thetop portion of the first supporting column is provided with a first mortise hole used for containing the second tenon, and a second mortise hole which is located under the first tenon hole used for being matched with the combination beam in an inserting mode, and the second tenon hole communicates with the first tenon hole; the second tenon comprises a longitudinal tenon located on the middle portion of the second supporting column, and a first horizontal tenon and a second horizontal tenon correspondingly arranged on the two sides of the longitudinal tenon, and perpendicular to the longitudinal tenon correspondingly; the tenon batten can be embedded in the second supporting column and a mortise formed through the fact that the tenon batten is connected with the first supporting column inan inserting mode; and the combination beam comprises at least two beam bodies. According to the beam-column mortise and tenon joint type joint structure, the whole structure of the anti-pull effectand safety of use can be effectively improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

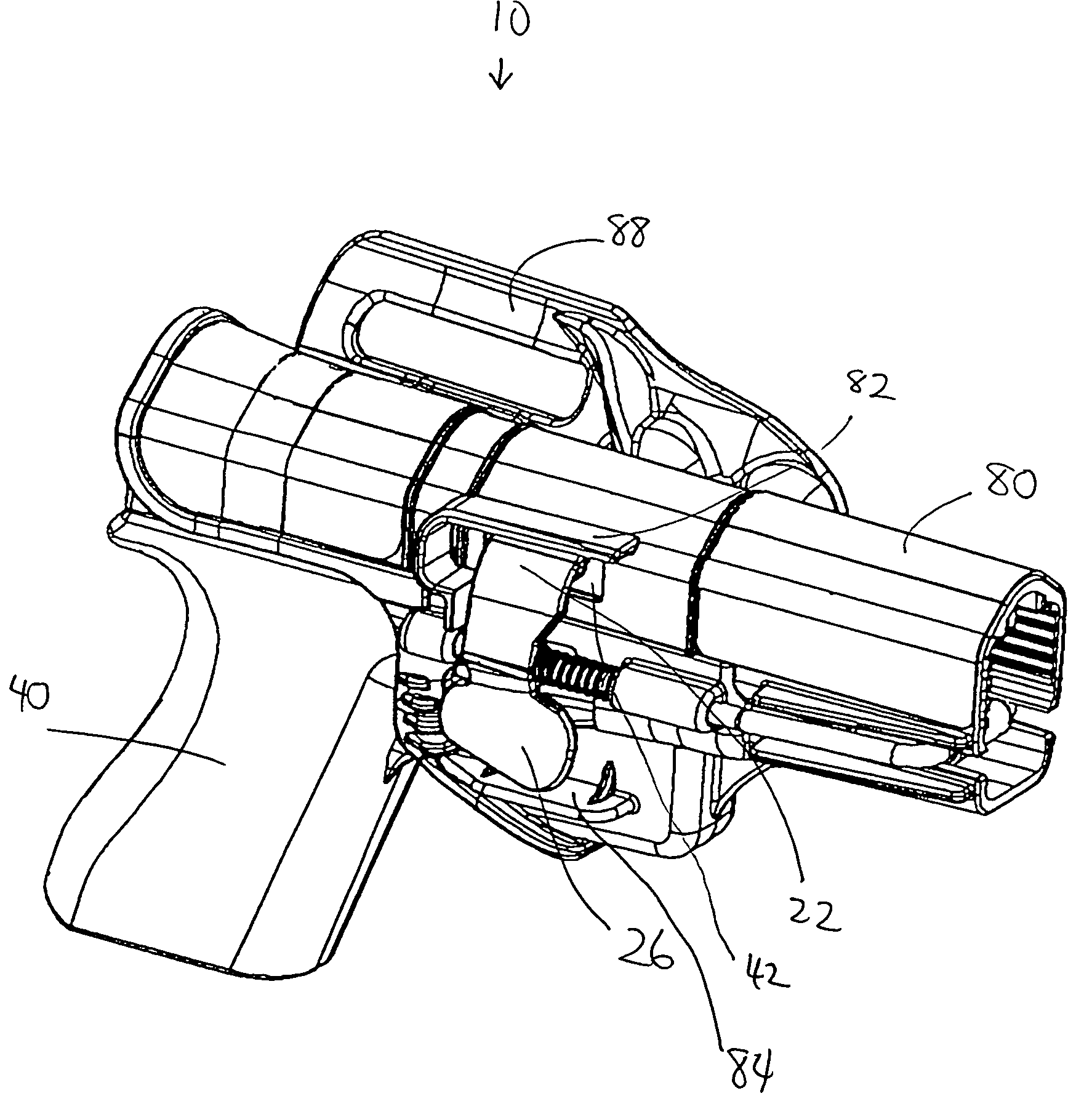

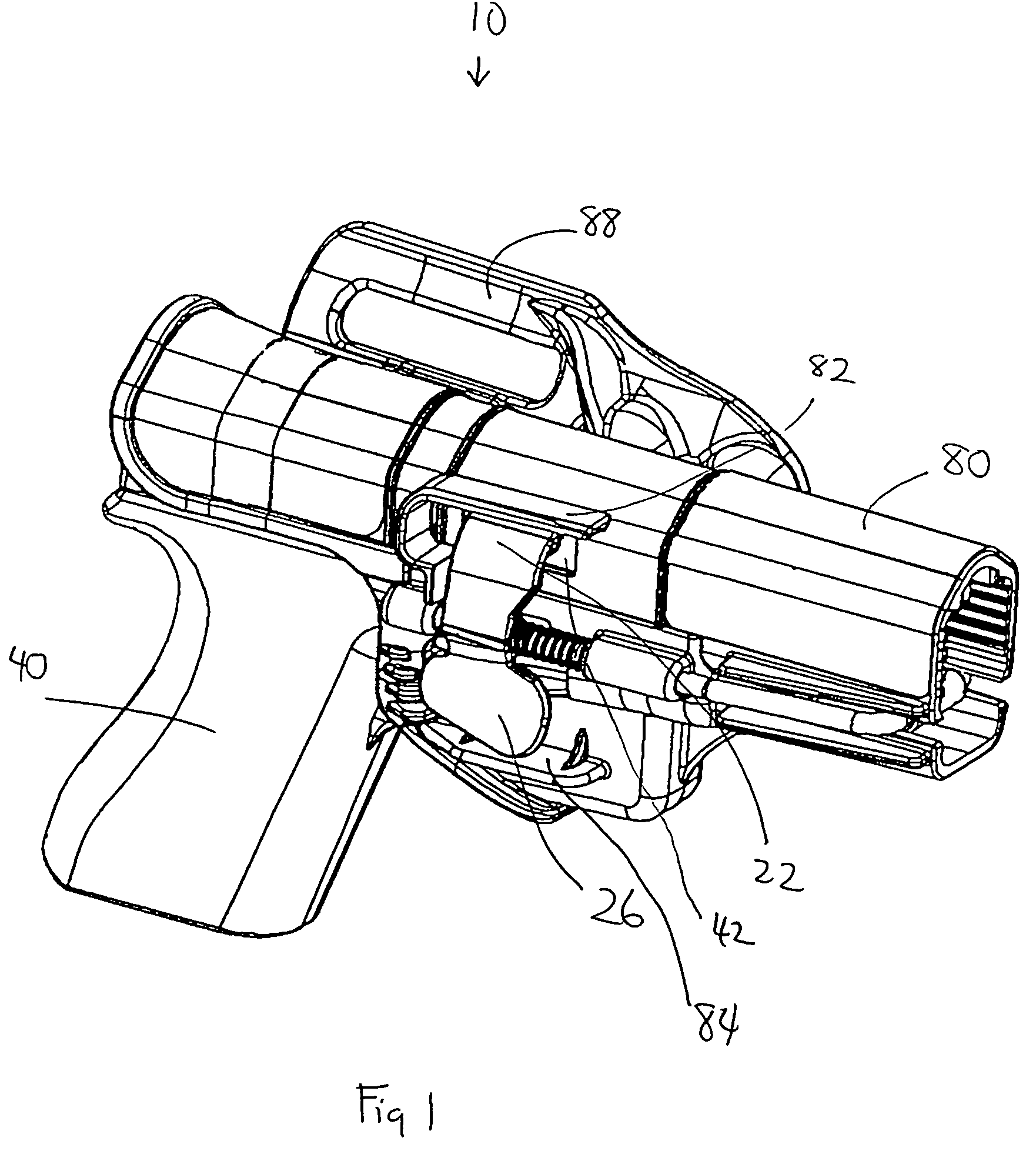

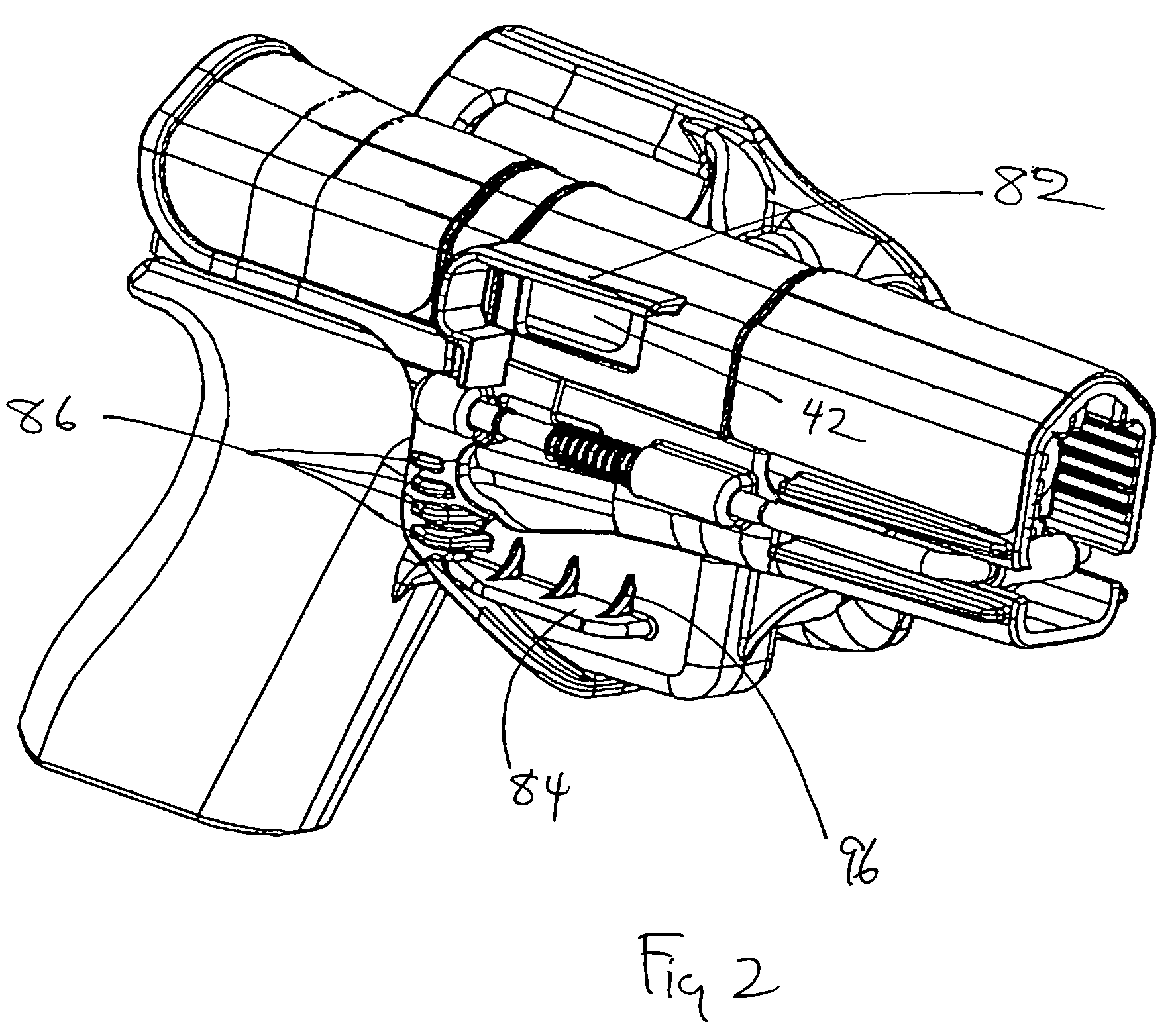

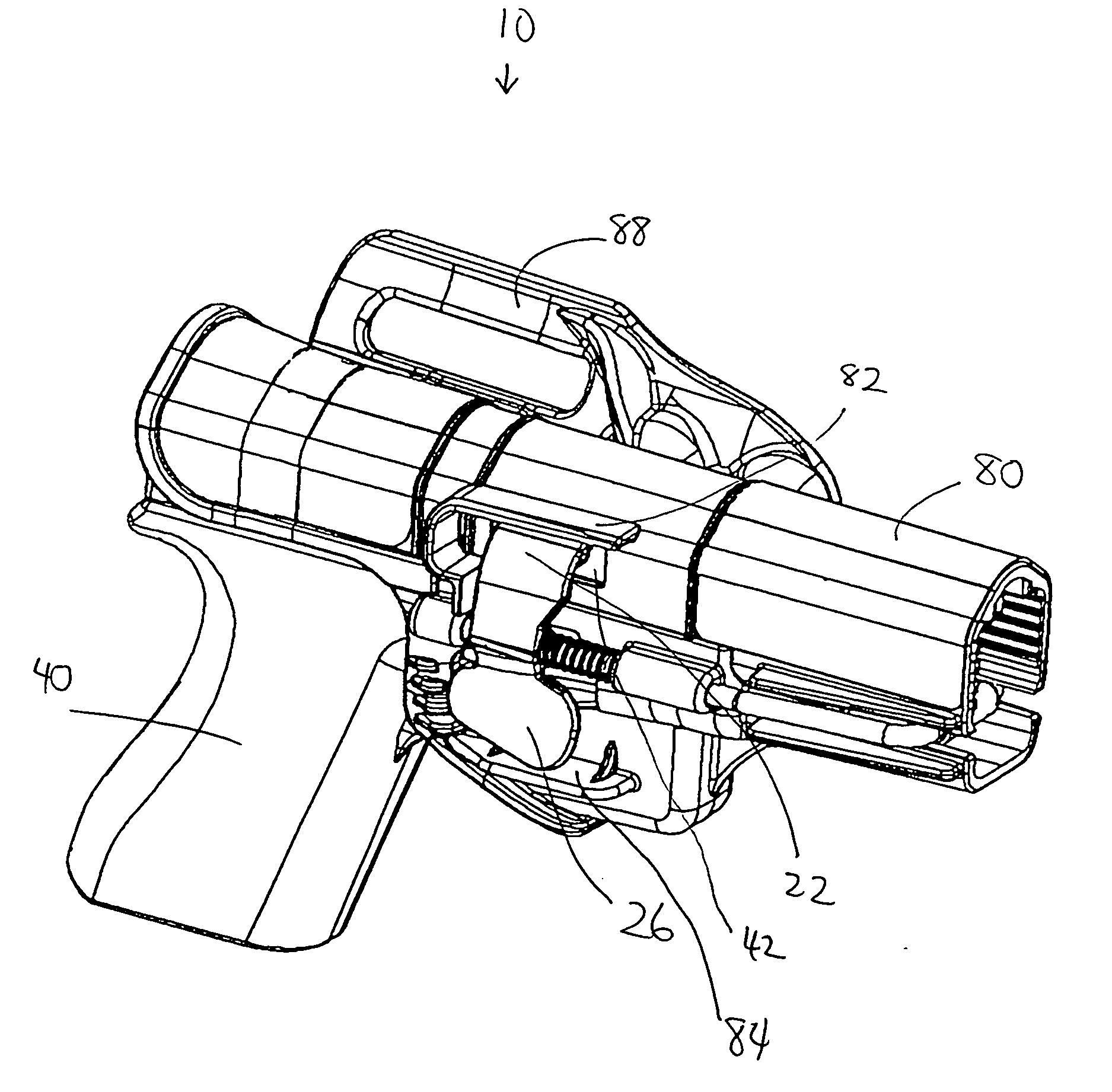

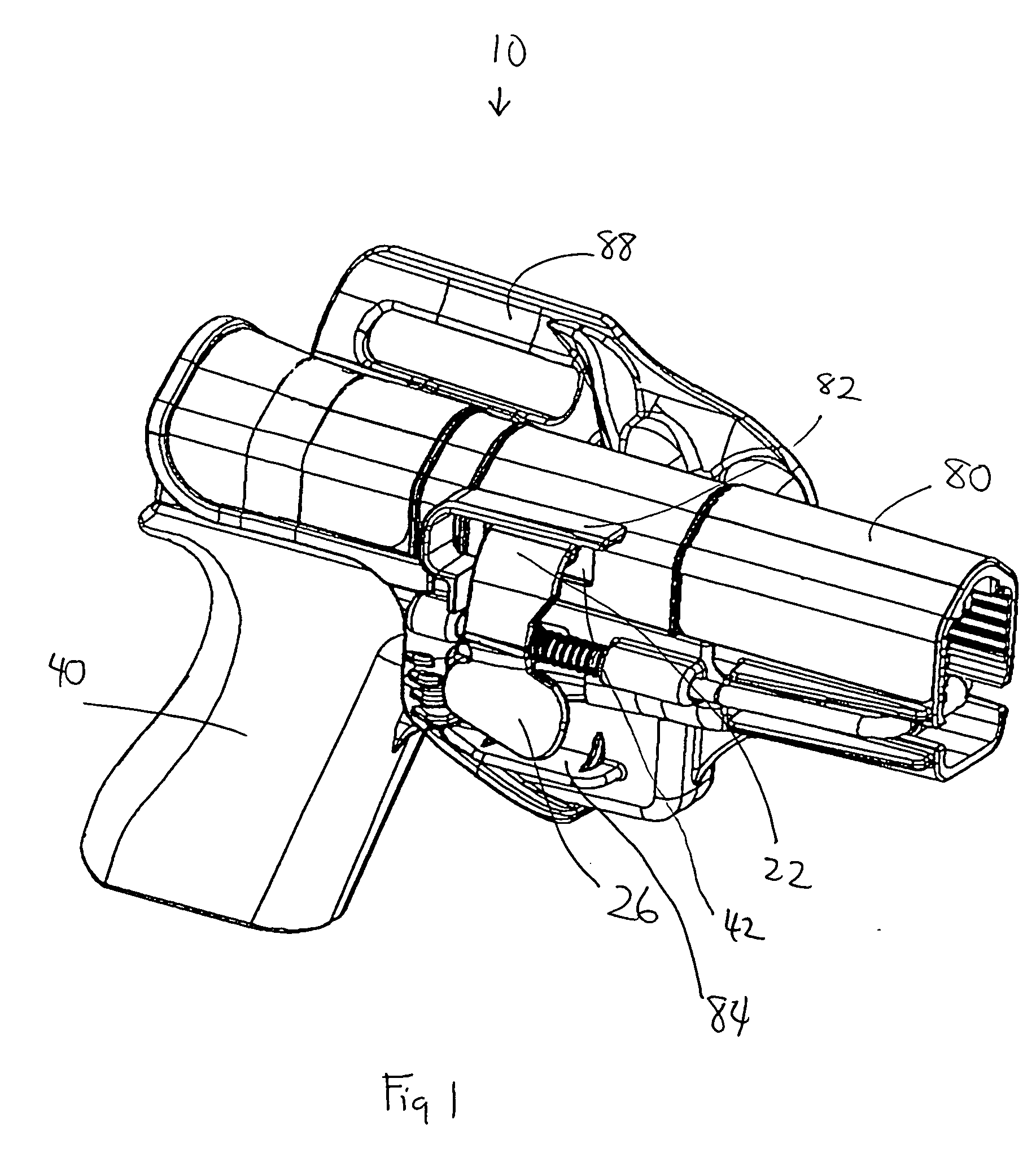

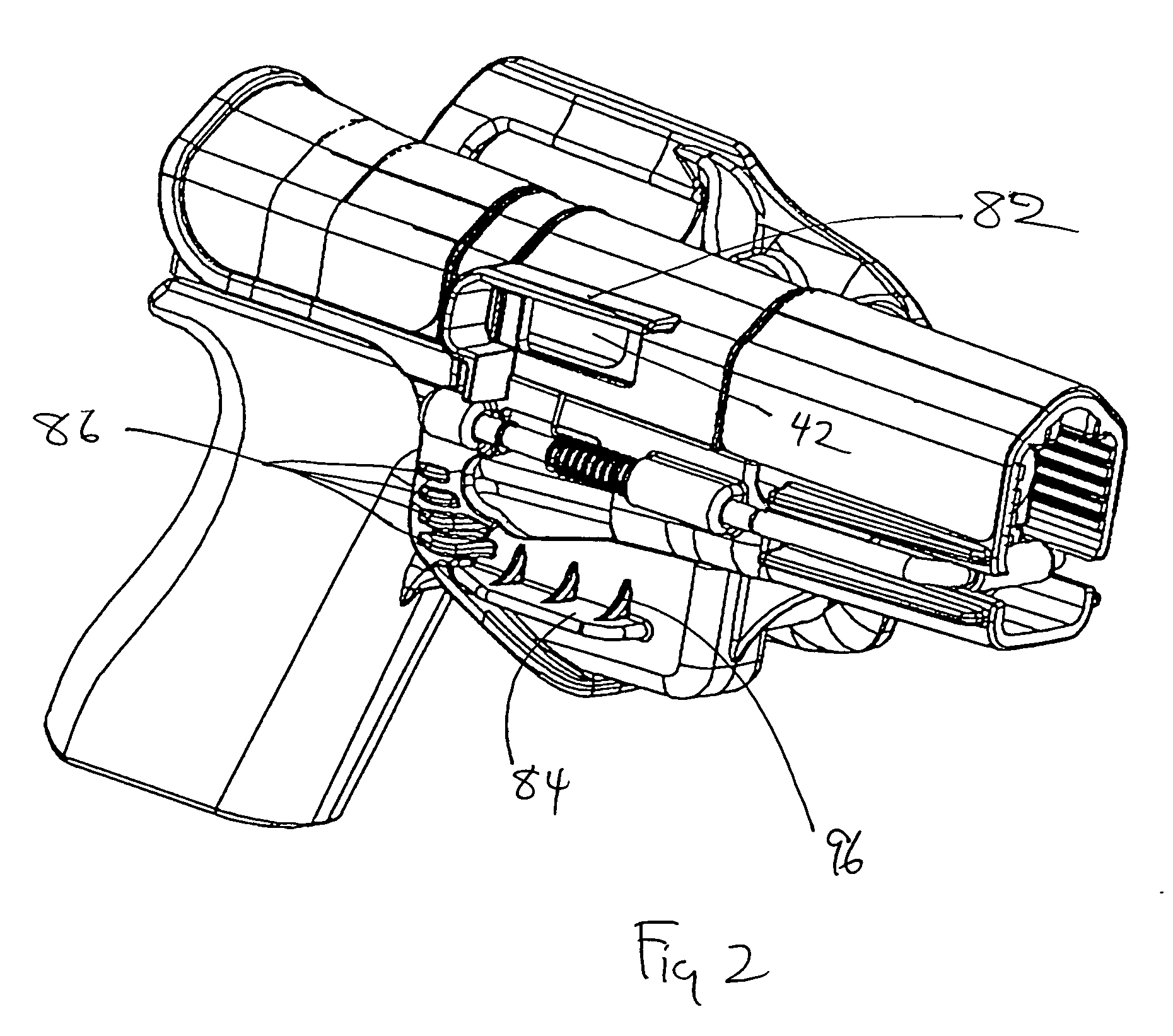

Gun holster

InactiveUS7819294B2Easily be heardProtection wearTravelling carriersArms wearablesMortise and tenonLocking mechanism

The invention includes improvements to a security holster including protective ridges for use around the release mechanism and the locking mechanism. Also included is a mortise and tenon arrangement for securing the holster body to a belt attachment plate.

Owner:POINT BLANK ENTERPRISES

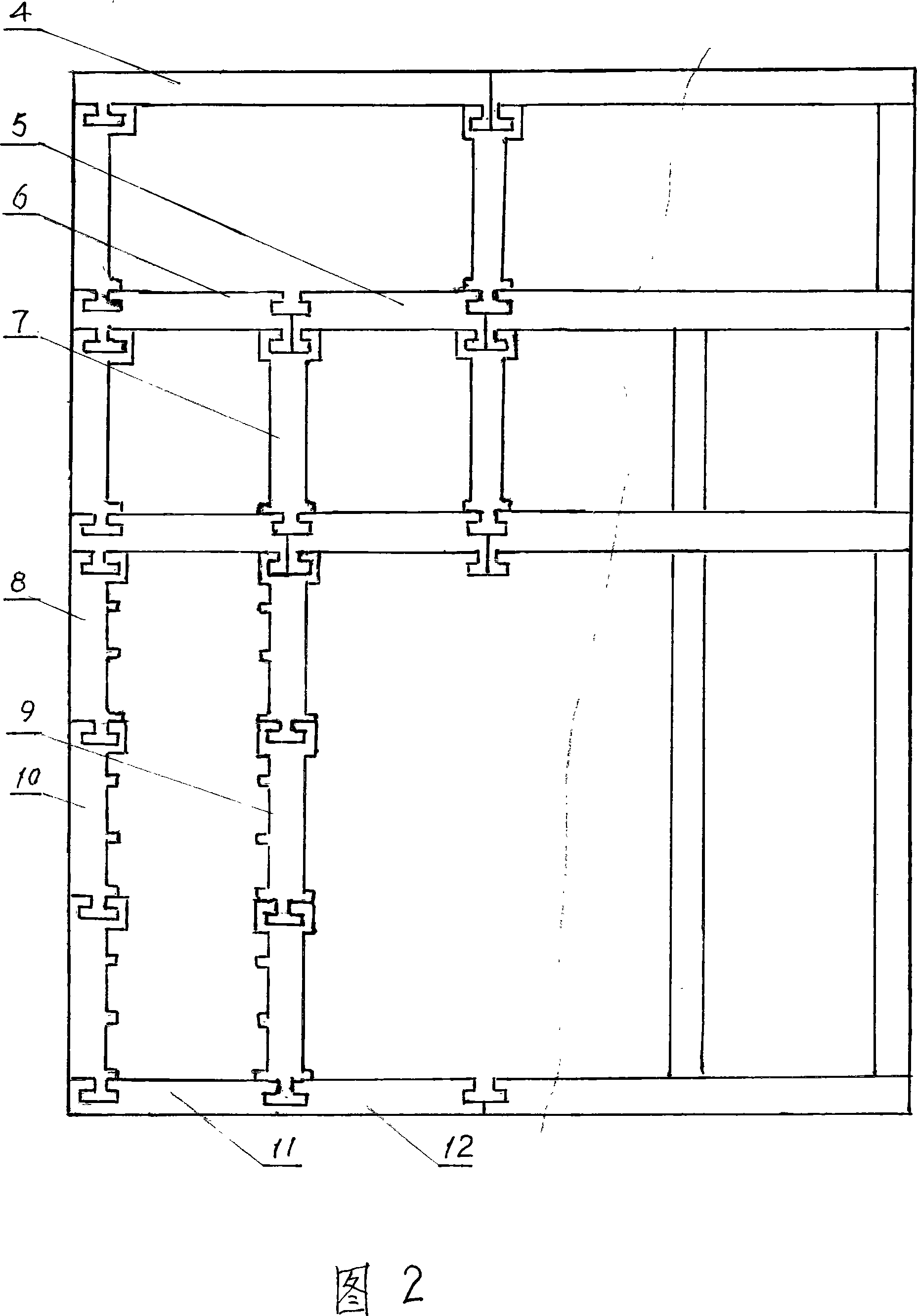

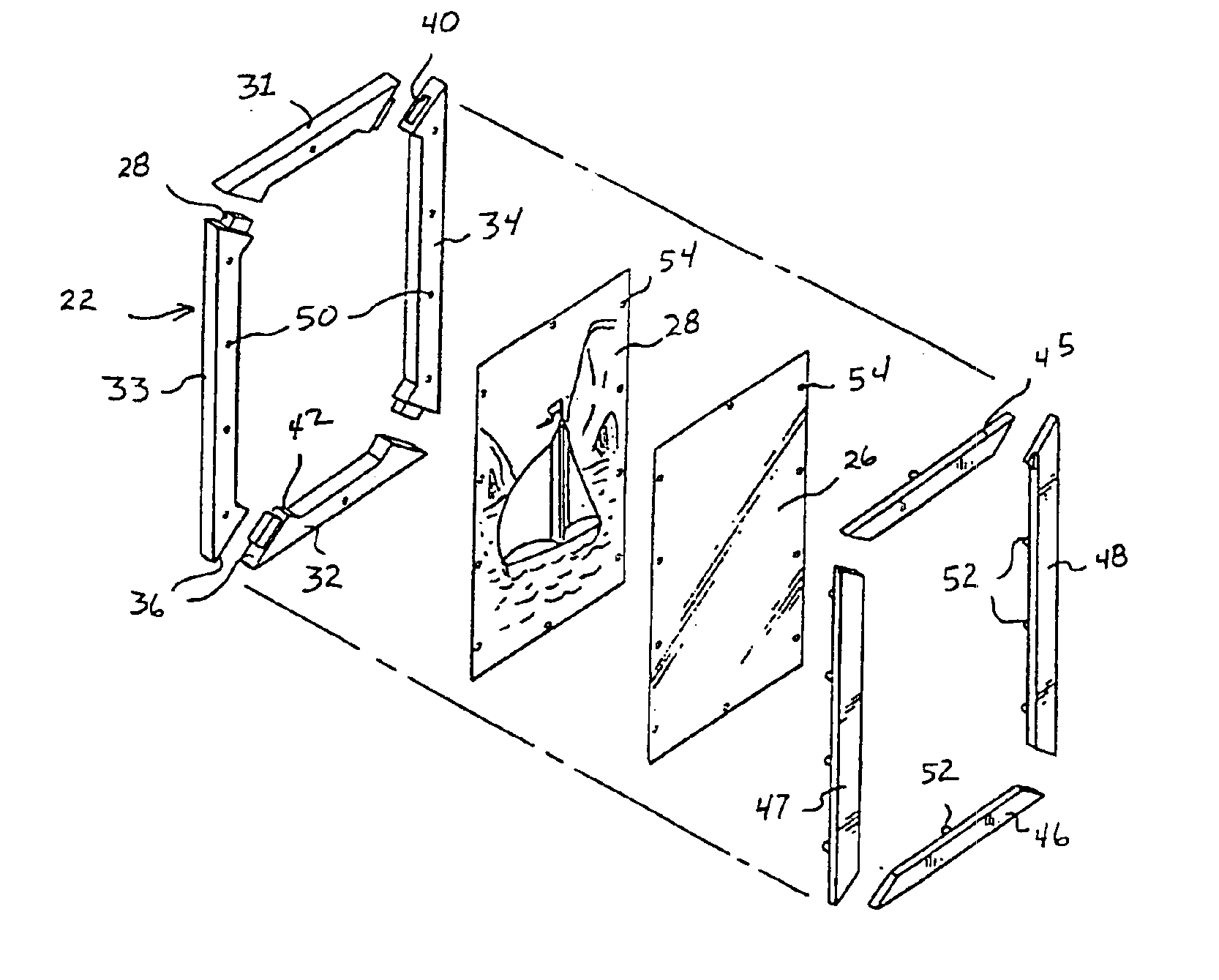

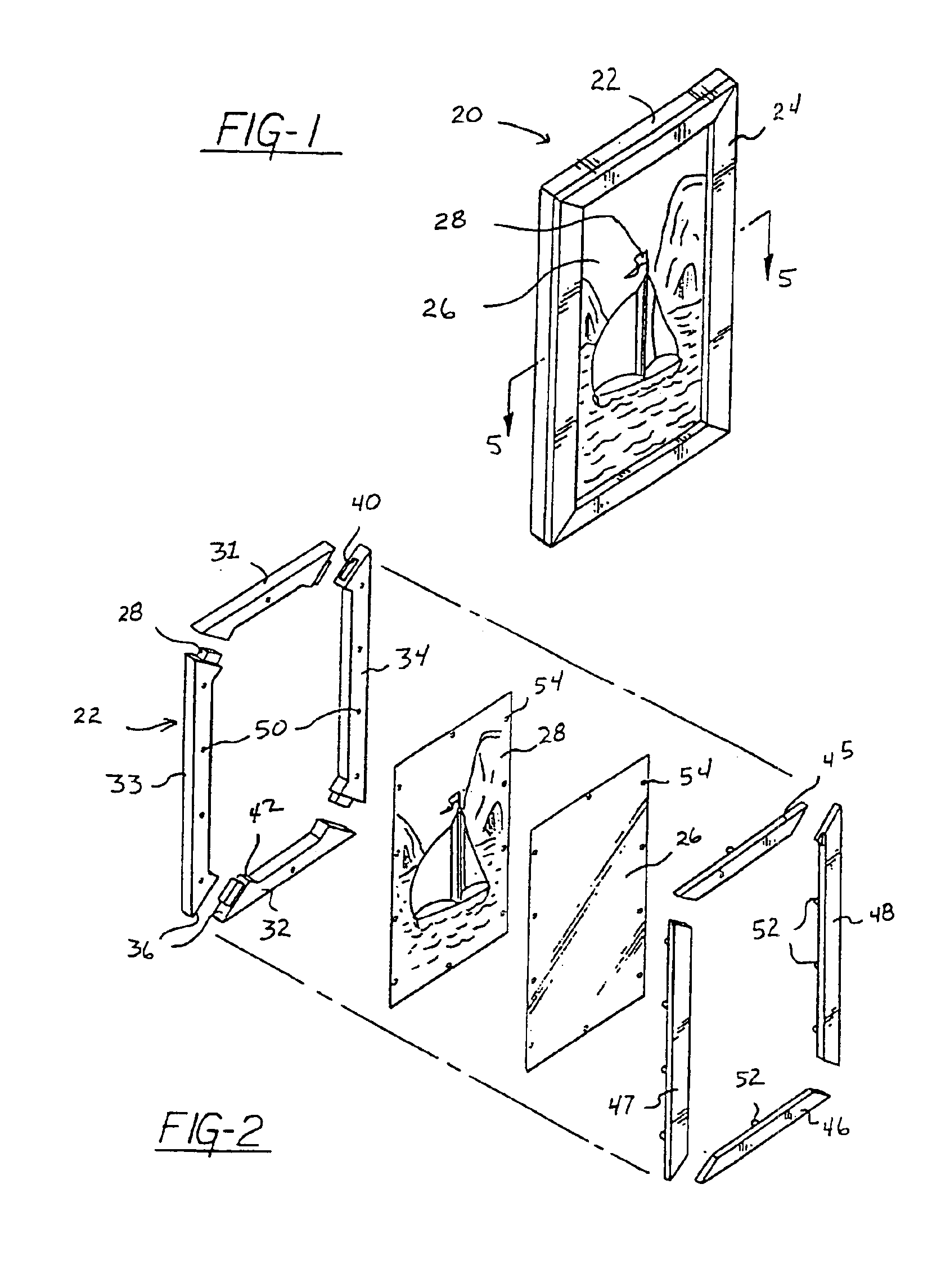

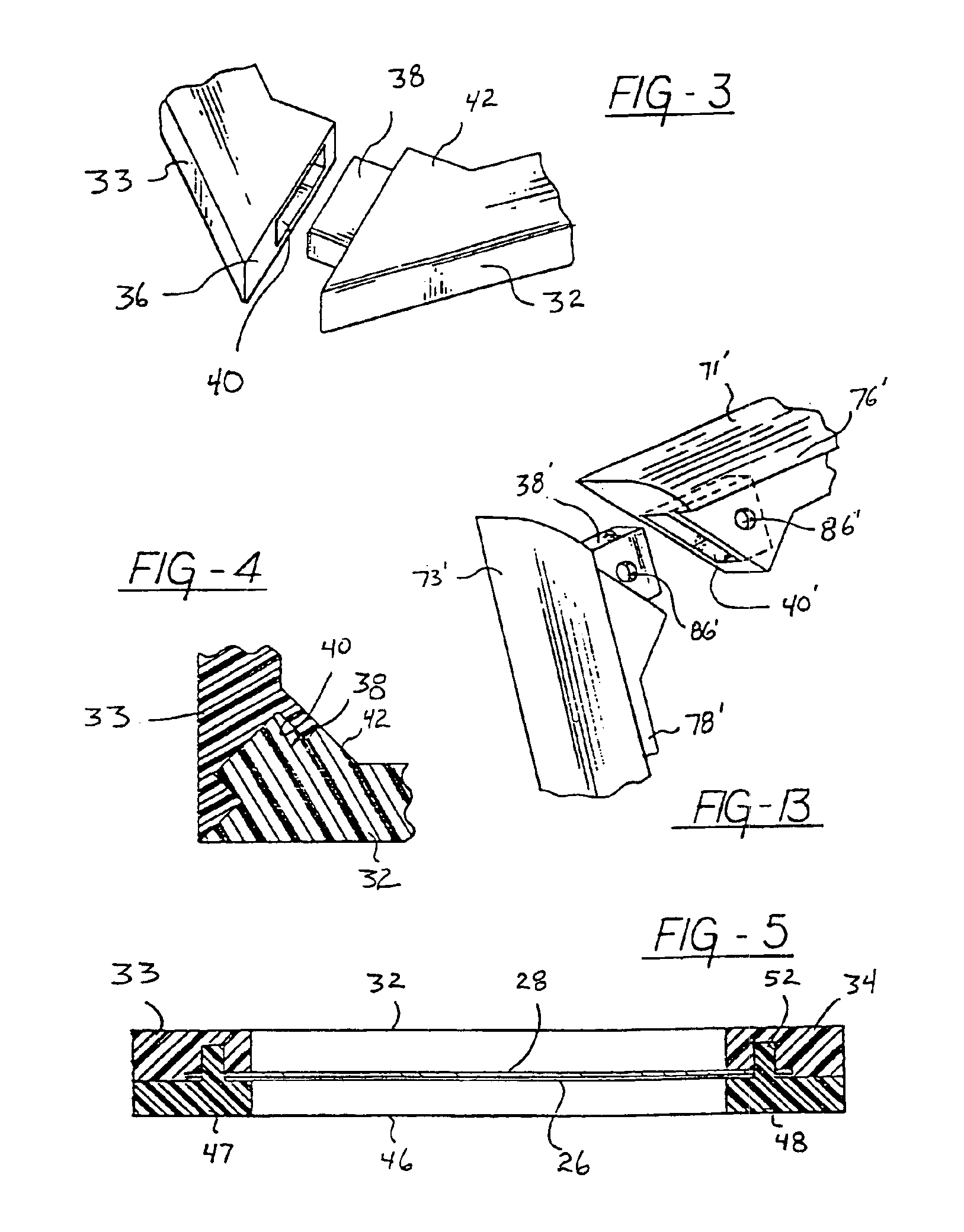

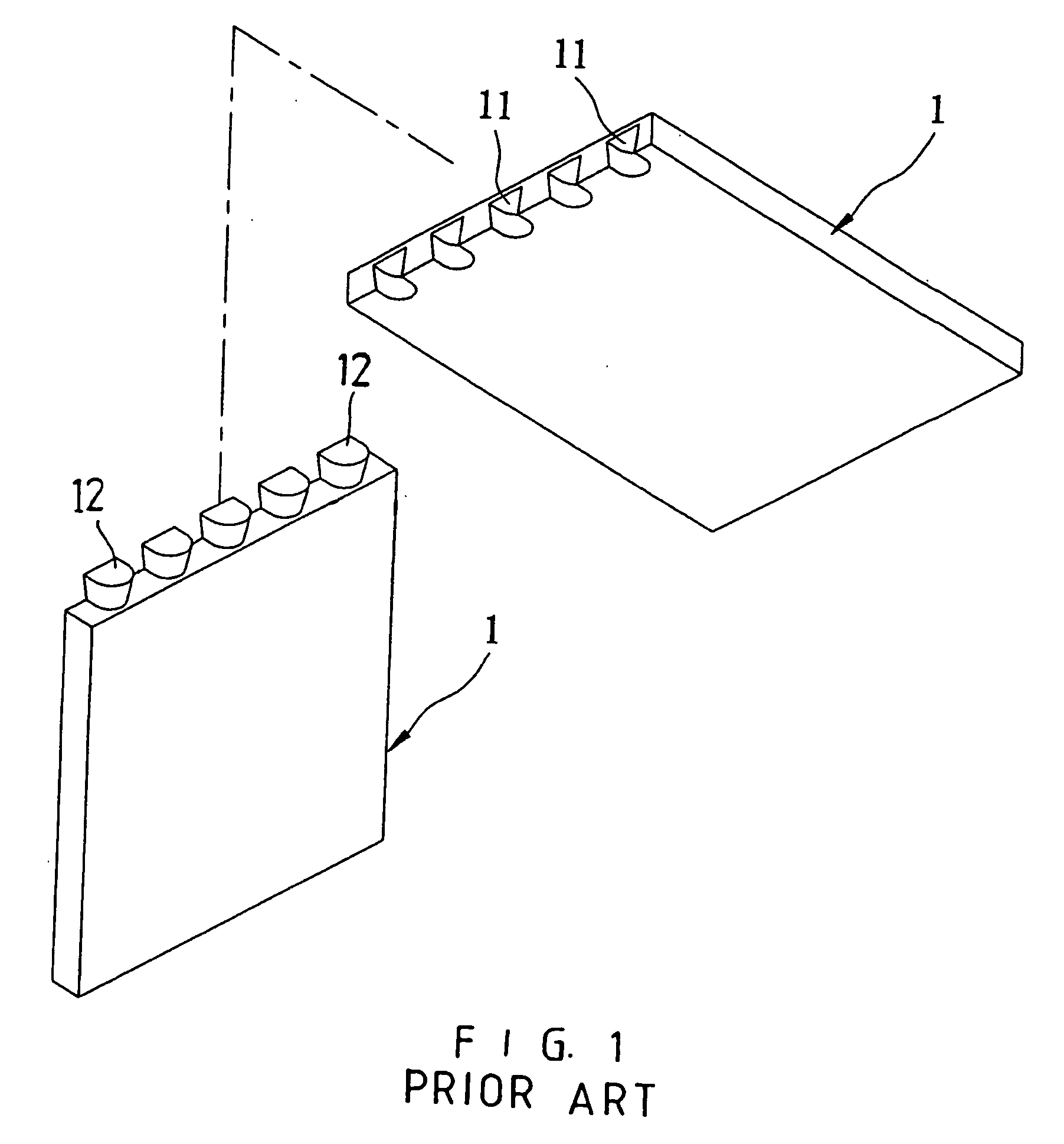

Framing system for securing and displaying flat sheet materials

InactiveUS6962017B1Easy to assembleSpace minimizationPicture framesDomestic mirrorsMortise and tenonEngineering

A peripheral framing system for mounting and displaying a poster or other sheet material. The framing system requires no rigid backing since the framing elements themselves serve to support the poster or other displayed object. The system is comprised of a base structure, a clamping structure and, if desired, a protective translucent covering. The base structure includes several elongated frame members, each of which extends between a pair of angled ends. The ends of adjacent base frame members join together by means of a mortise and tenon to form a rectangular base frame when assembled. The clamping structure comprises several clamping members, one for each of the frame members, with each of the clamping members having a plurality of pegs. The base frame members, translucent cover, and displayed object each have an equal number of holes to receive the pegs. The holes in the base frame members are used to receive and secure the complementary pegs to thereby retain the translucent cover and displayed object in place between the clamping members and base frame members. Thus, during assembly, the displayed object and translucent covering are laid flat on the assembled base frame with their clearance holes aligned with the holes in the frame members. Then, the clamping structure is brought down into place. The clamping structure therefore fastens the displayed object and protective cover securely into place. The result is a frame which displays and protects an object without the need for a rigid backing. Also disclosed is a protective canister capable of transporting and storing the entire framing system. The protective canister comprises a translucent tube with endcaps and is capable of containing the disassembled framing system, the displayed object and the translucent covering. In this manner, the protective canister provides convenient and efficient means in which to store the entire system when it is not being displayed.

Owner:POUNDS STEPHEN T

Semi-automatic mortising machine

InactiveUS20050022899A1Easy constructionReduce the possibility of failureTongue/grooves making apparatusMulti-purpose machinesMortise and tenonMortising machine

A semi-automatic mortising machine includes a support base, a support bar, a guide device, a working device, a distance adjusting device, and a dust collection box. Thus, the displacement direction can be controlled in a manual manner during the working process, and the cutting operation is performed in an automatic manner, so as to cut the mortises and tenons in the workpiece.

Owner:CHANG CHI LO

Steel-wood composited reinforcement device for ancient wood frames

InactiveCN103835525AImprove integrityImprove seismic performanceBuilding repairsMortise and tenonShock resistance

Disclosed is a steel-wood composited reinforcement device for ancient wood frames. The steel-wood composited reinforcement device needs not to be fixed with iron cramps or angle steel, horizontal displacement of mortises and tenons can be prevented through wood components, and bending resistance of beams and columns can be improved through steel fasteners. The steel-wood composited reinforcement devcie is high in flexibility, shock resistance and twisting resistance; with the reinforcement technology, maintenance and replacement can be achieved, and protection and renovation of the wood structure is benefited.

Owner:LUOYANG INST OF SCI & TECH

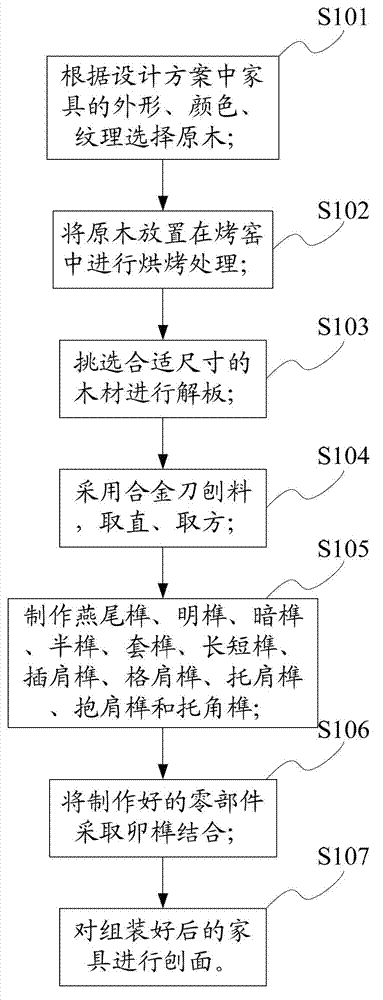

Manufacturing method of mahogany furniture

The embodiment of the invention discloses a manufacturing method of mahogany furniture. The manufacturing method comprises the steps of: (A) selecting raw wood according to the shape, the color and the texture of the furniture in a design scheme; (B) putting the raw wood in a baking kiln for baking treatment; (C) selecting wood with the proper size for board forming; (D) adopting an alloy knife for planing, straightening and squaring; (E) manufacturing dovetail tenons, opening tenons, concealed tenons, half tenons, sleeve tenons, long and short tenons, shoulder inserting tenons, shoulder fixing tenons, shoulder supporting tenons, shoulder holding tenons and angle supporting tenons; (F) carrying out mortise and tenon combination on manufactured parts; and (G) carrying out surface planing on the assembled furniture. Known from the technical scheme, the manufacturing method of the mahogany furniture, disclosed by the invention, has the advantages that before the furniture is assembled, mahogany is firstly baked, and after the baking, the stability of the mahogany is improved, so that the phenomena of shrinkage, cracking and deformation generated due to larger moisture of the wood are prevented.

Owner:田庆记

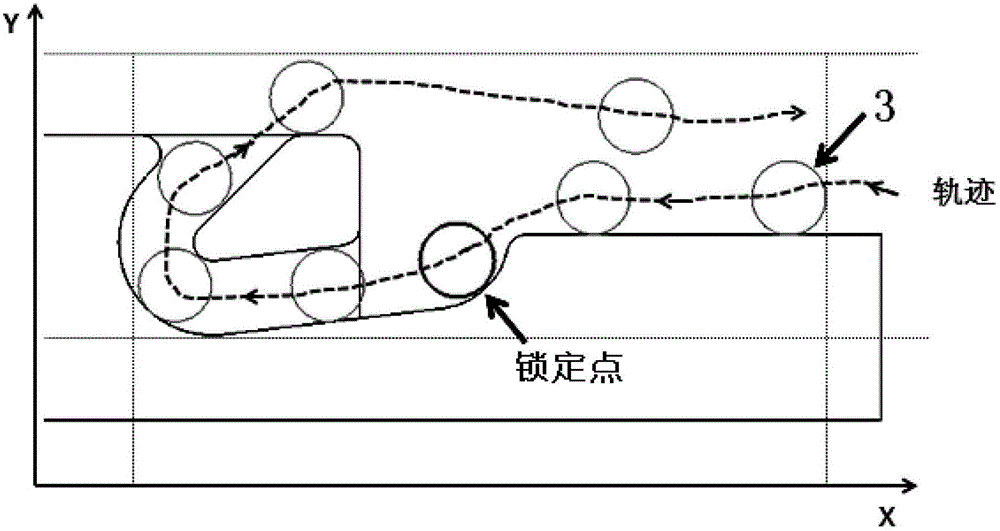

Buckling structure capable of being opened or closed by single hand and operation method thereof

ActiveCN103149981ASave spaceDoes not affect appearanceDigital data processing detailsSecuring devicesRelative displacementMortise and tenon

The invention discloses a buckling structure capable of being opened or closed by a single hand and an operation method thereof. The buckling structure comprises an inserted pin, a floating mortise and tenon and a locking piece, wherein a first clamping part and a second clamping part are arranged on the left side surface of the inserted pin from top to bottom in sequence; a first spring is arranged on the bottom surface of the inserted pin; a third clamping part is arranged on the right side surface of the floating mortise and tenon; a fourth clamping part is arranged at the right side end of the locking piece; a third spring is arranged on the left side surface of the locking piece; the third clamping part and the first clamping part can drive each other to move; during the whole descending or ascending process of the inserted pin, a relative displacement is produced between the third clamping part and the first clamping part, and is greater than the crossed distance between the third clamping part and the fourth clamping part; a clamping and locking part is arranged on the floating mortise and tenon; and a clamping and locking groove matched with the clamping and locking part is formed in the locking piece. The buckling structure can be opened or closed by the single hand, displaces only in the stroke direction, and can meet the requirement of assembling in the Z-axis direction.

Owner:LCFC HEFEI ELECTRONICS TECH

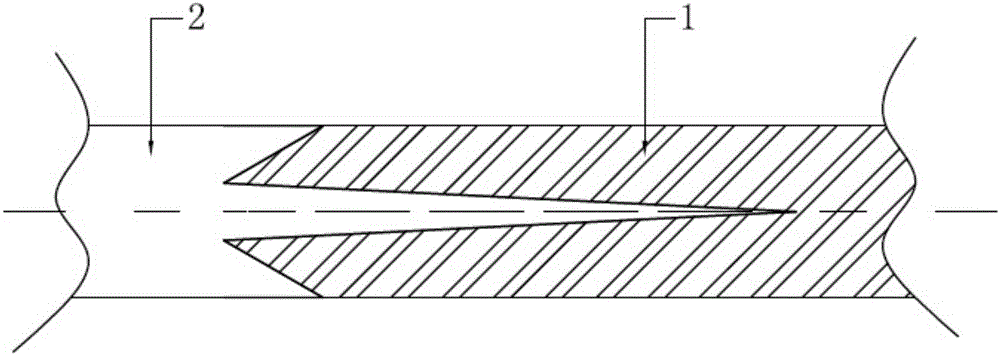

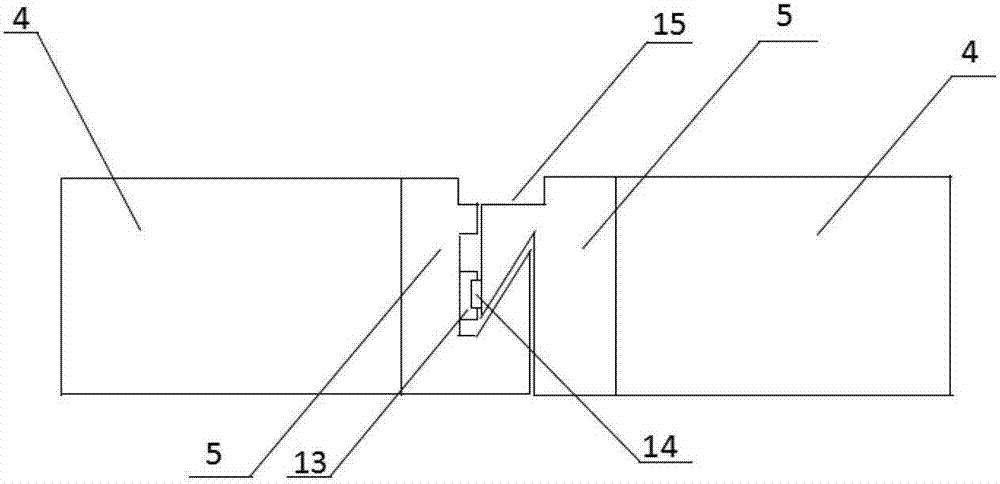

Vertical semi-dovetail tenon node connection structure for wood structure building beam column

InactiveCN106906906AReduce decreaseIncrease stiffnessBuilding constructionsMortise and tenonEngineering

The invention discloses a vertical semi-dovetail tenon node connection structure for a wood structure building beam column. In the wood structure building, the connection between a middle column and a wood beam or a side column and the wood beam adopts the vertical semi-dovetail tenon node connection structure, and knotting to each other is conducted through the tenon vertical semi-dovetail on the wood beam structure, so that the seismic horizontal bearing tensile strength of a frame is improved. Meanwhile, the vertical semi-dovetail tenon node has strong bending resistance ability. The vertical semi-dovetail tenon node is connected and applied to a wood structure farm house or a civil mixed structure, so that the seismic bearing ability of the wood structure farm house or the civil mixed structure is greatly improved; and the vertical semi-dovetail tenon node connection form makes a slight change on the basis of inheriting a traditional mortise and tenon node connection form, a nail and an iron are still not needed, the vertical semi-dovetail tenon node connection form is more suitable for drawing materials and constructing houses locally of remote mountainous areas, and the construction progress and construction quality are improved in a large degree; and meanwhile, cost of vertical semi-dovetail tenon node is low, and the cost of engineering structure can be reduced.

Owner:SOUTHWEAT UNIV OF SCI & TECH

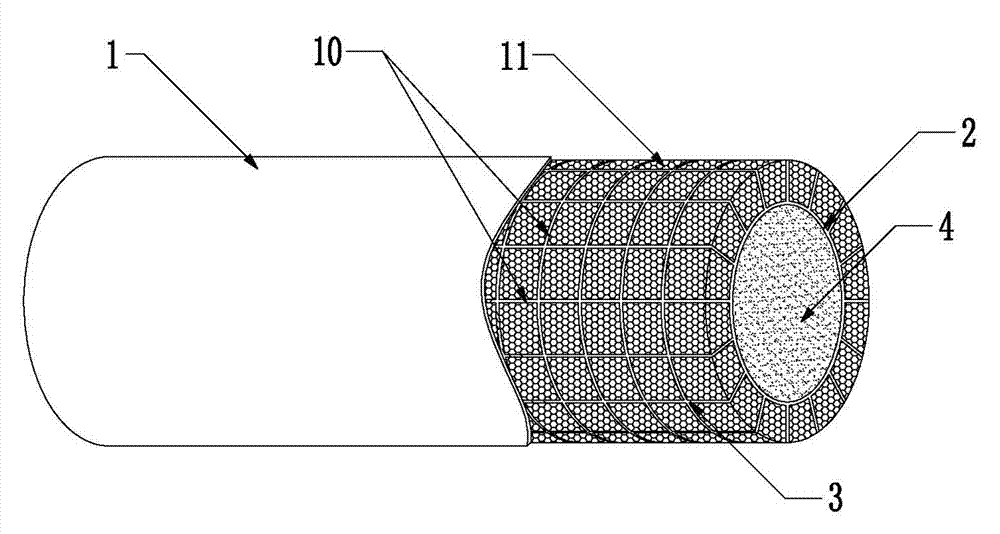

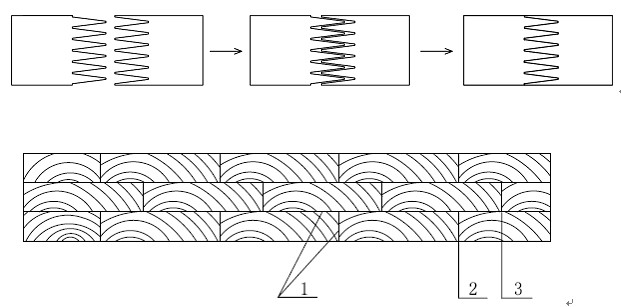

Hollow glued-laminated timber round stake and manufacturing method

InactiveCN102587579AReduce crackingExtended service lifeStrutsWood working apparatusSolid woodAdhesive cement

The invention discloses a hollow glued-laminated timber round stake and a manufacturing method, which belong to the field of timber manufacturing. The round stake is of a hollow structure, the section of the round stake is annular, and the round stake comprises a member unit and an adhesive layer or comprises the member unit, the adhesive layer and a connection unit. The member unit is fixedly connected with the connection unit through the adhesive layer. The manufacturing method comprises adopting small specification solid wood converted timbers to manufacture glued-laminated timbers and assembling, splicing and forming the glued-laminated timbers. The round stake is stable and reliable in product structure performance and free of limit on product size. The wall thickness of the round stake can be adjusted according to using conditions and requirements for structure design. Units which form the products are combined through finger joints, mortise and tenon joints and high strength tree timber serving as wedge blocks to be embedded, so that integral rigidity is improved. The round stake can be used as wood columns for wood structure buildings or applied to gardens, the wood columns are of hollow structures, water pipes, lines, cables and the like can be arranged in the insides in hiding mode, and attractiveness of buildings is enhanced. The hollow glued-laminated timber round stake can replace traditional log stakes.

Owner:NANJING UNIV OF TECH

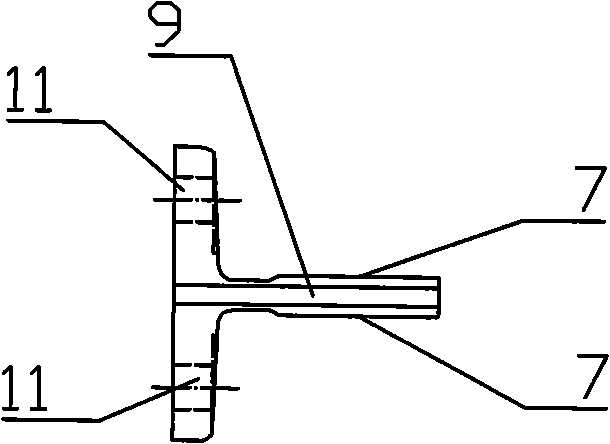

Scaffold

InactiveCN102235085AProlapse will notAvoid safety hazardsScaffold connectionsVertical barMortise and tenon

The invention relates to a scaffold which comprises vertical bars and cross bars. The scaffold is characterized in that the vertical bar is provided with connecting components which are arranged at a certain interval and used for connecting the cross bars, the cross bars are in mortice and tenon joint with the connecting components from up to down, and the upper part of the connecting component is provided with a clamp unit for preventing the cross bar from separating upwards. The scaffold provided by the invention has the advantages that through setting the clamp unit for preventing the cross bar from separating upwards at the upper part of the connecting component, the cross bar connected with the connecting component can not be separated from the connecting component, thereby avoiding the potential safety hazards existing in the utilization of the scaffold.

Owner:周继忠 +2

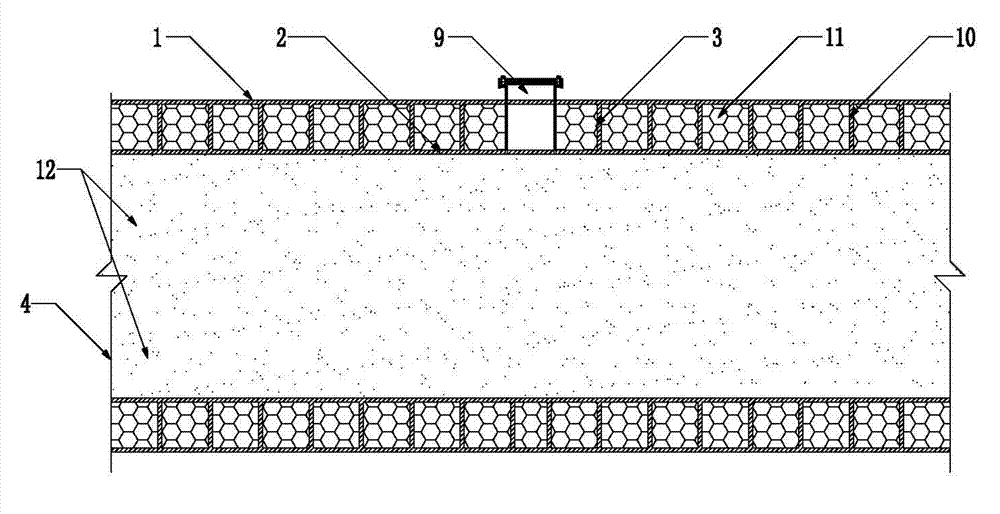

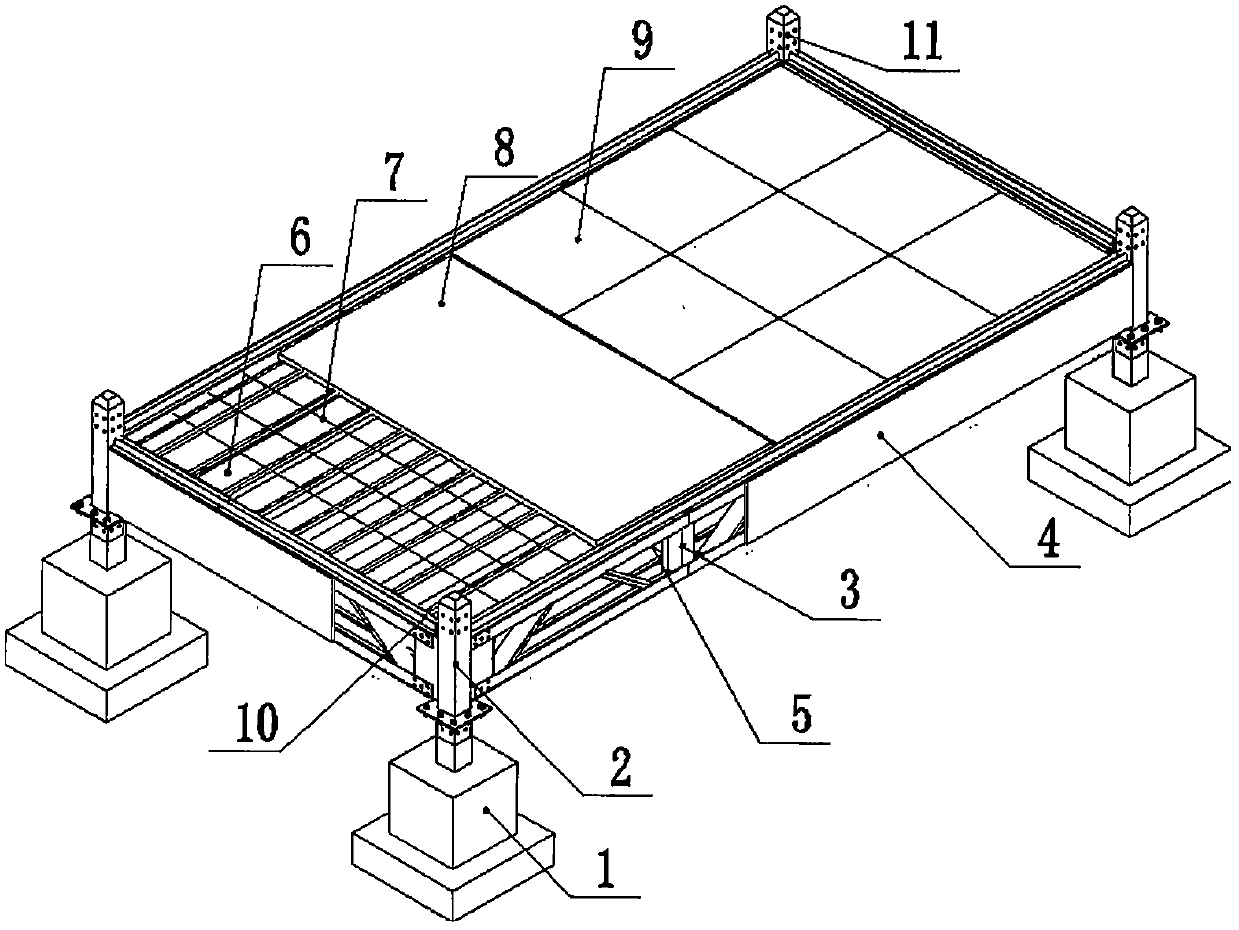

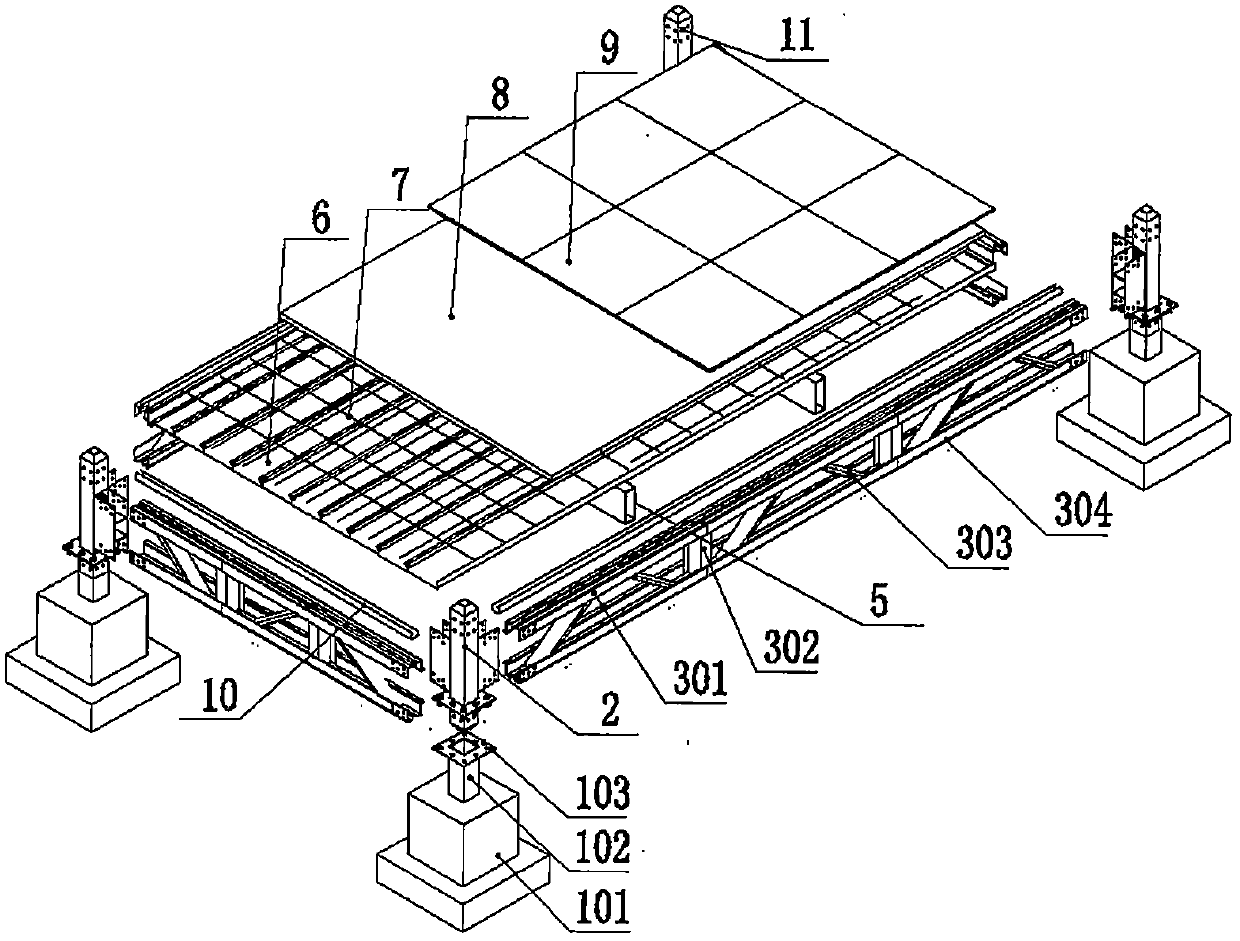

Assembly-type building bottom-layer composite floor and connection mode thereof

PendingCN107780576AImprove prefabrication rateReduce pollutionFloorsGirdersReinforced concreteMortise and tenon

Provided are an assembly-type building bottom-layer composite floor and a connection mode thereof. Factory-fabricated reinforced concrete with embedded parts is used as independent basis, square headshort columns are factory-prefabricated connection components and connected with upper chord members and lower chord members of main beams through pulling rivets to form outer frames of floors; on thebasis of the outer frames, secondary beams, profiled steel sheets and reinforcing meshes are laid horizontally, a surface course is poured, a decorative layer is attached to the surface course, and thus a mortise and tenon joint type connection mode of the floors and basic nodes is formed by combing insertion, pulling rivet connection and flange connection. According to the assembly-type buildingbottom-layer composite floor and the connection mode, the building mode of a traditional bottom-layer floor can be changed, the assembly type can be achieved, and the defects of poor vibration performance and soundproof effect and the like of an assembly-type light steel composite floor can also be overcome; meanwhile, the assembly-type building bottom-layer composite floor also has the advantages that the floor is assembled rapidly and subjected to industrial production easily and is high in strength and high in production speed, and has large actual project significance and market values topromotion and development of assembly-type buildings.

Owner:谢志强 +1

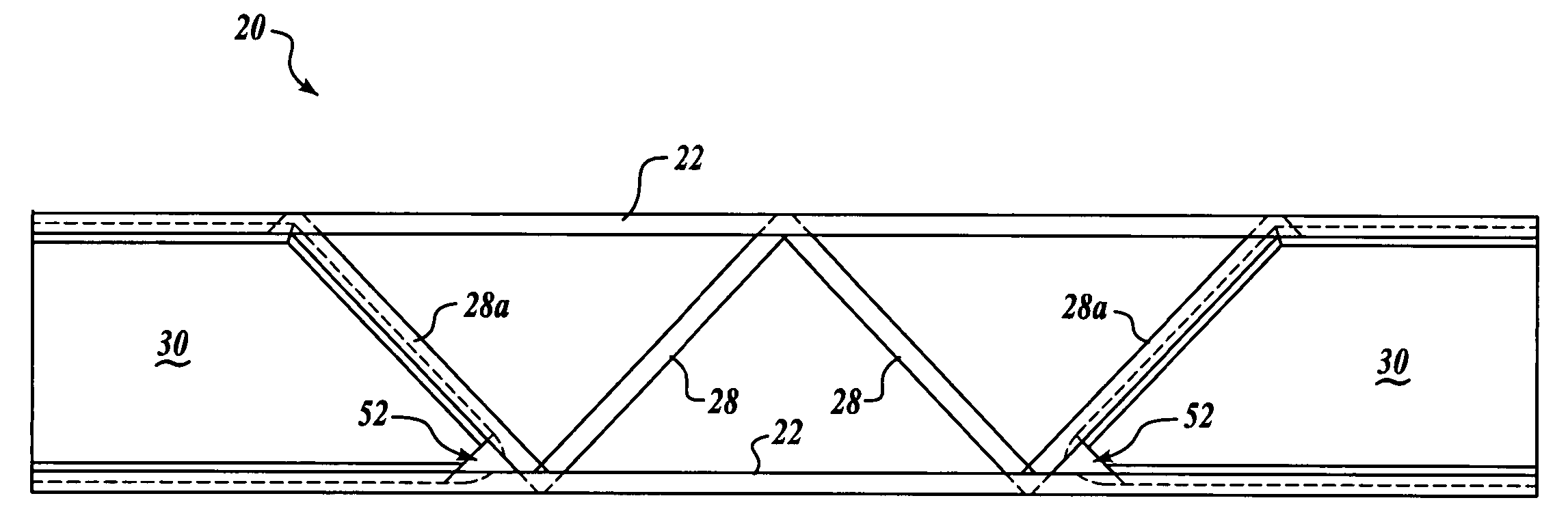

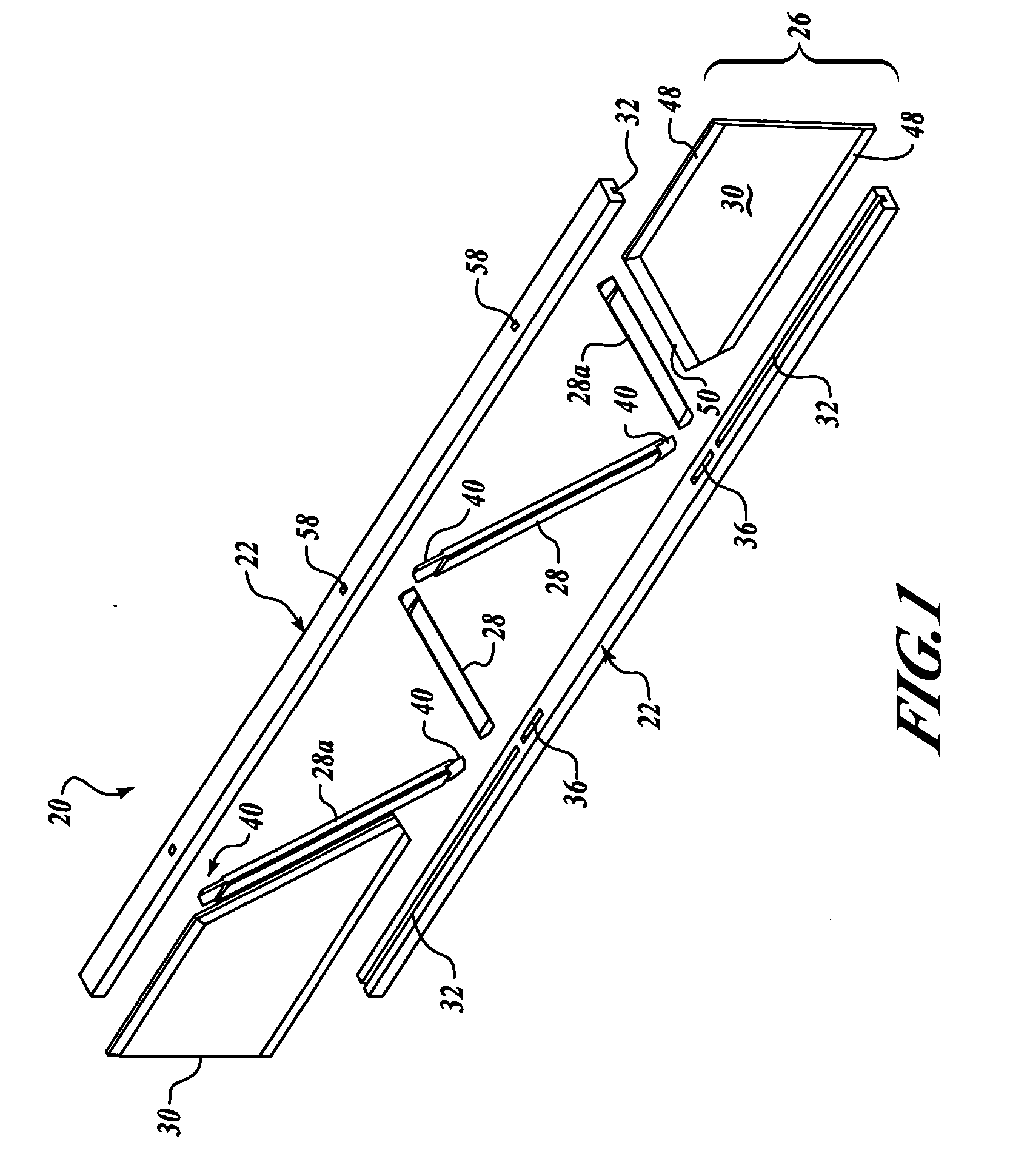

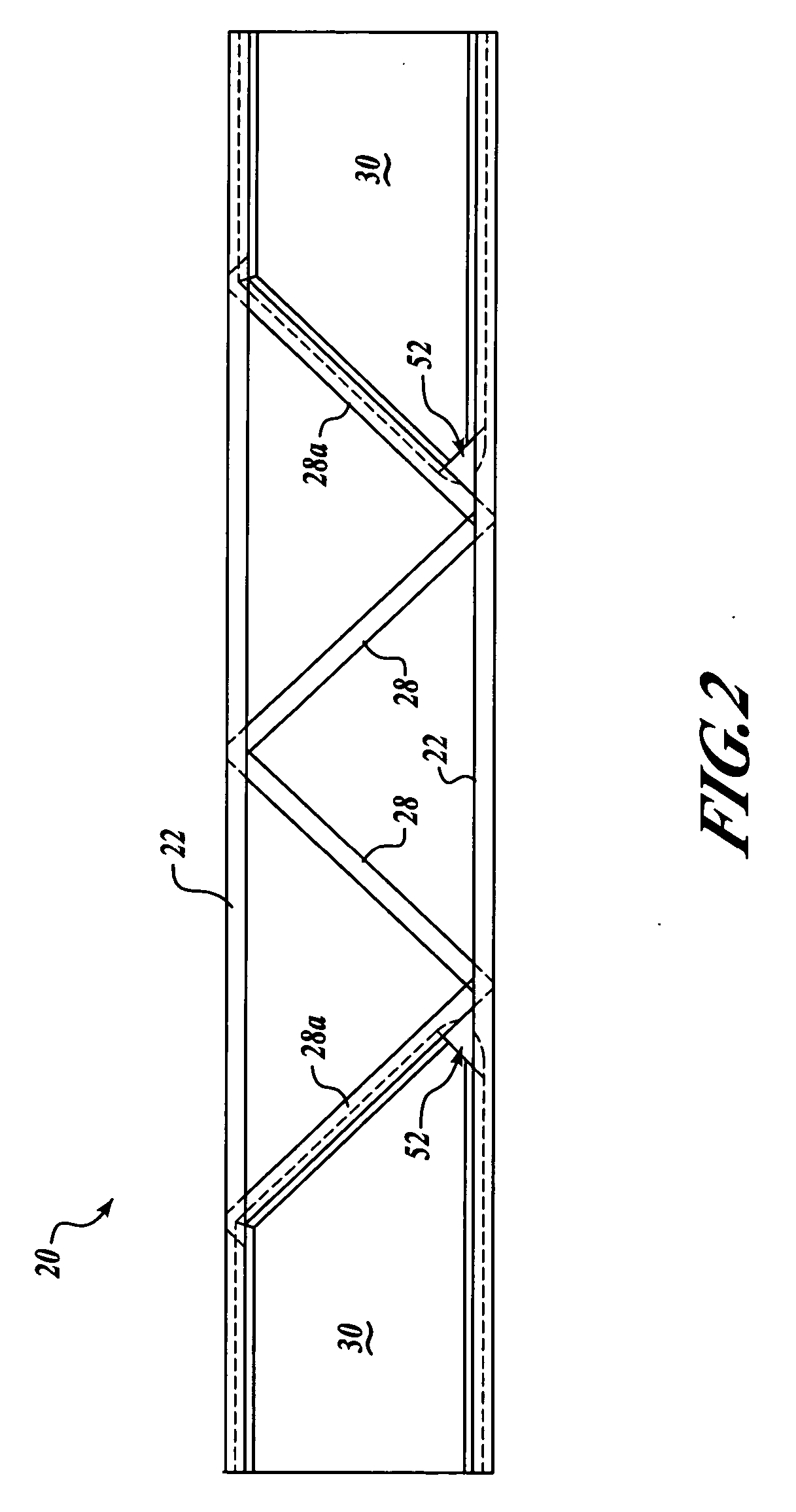

Open web trimmable truss with self locking joint

A wood containing, open web trimmable truss assembly composed of opposed chord members defining an open web central structure that is bounded at each ends by a closed, trimmable end block. The open web central structure is formed by a plurality of web elements attached to the chord members via a mortise and tenon coupling. The trimmable end block is attached to both chord members and the outer most web element.

Owner:WEYERHAEUSER CO

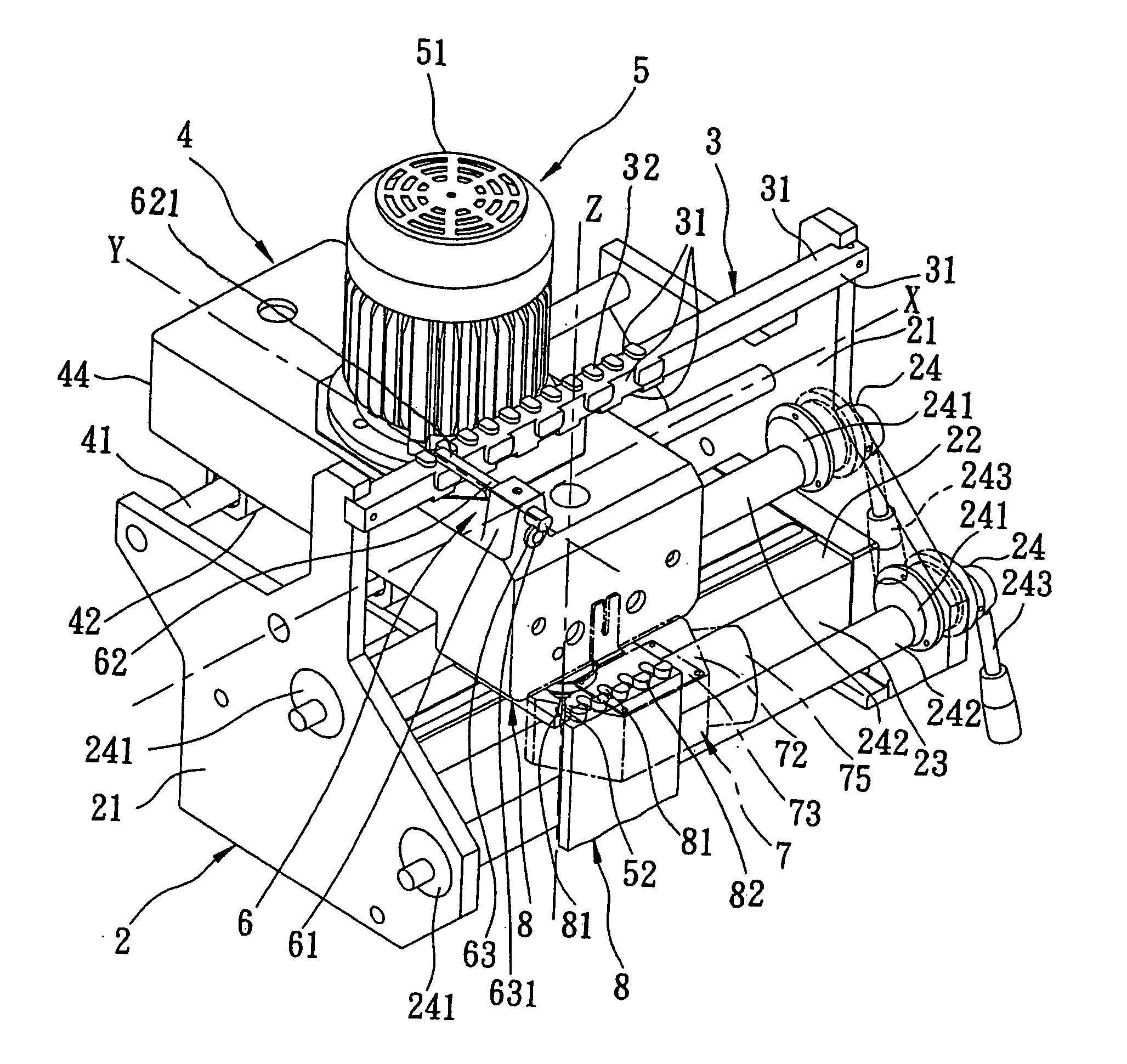

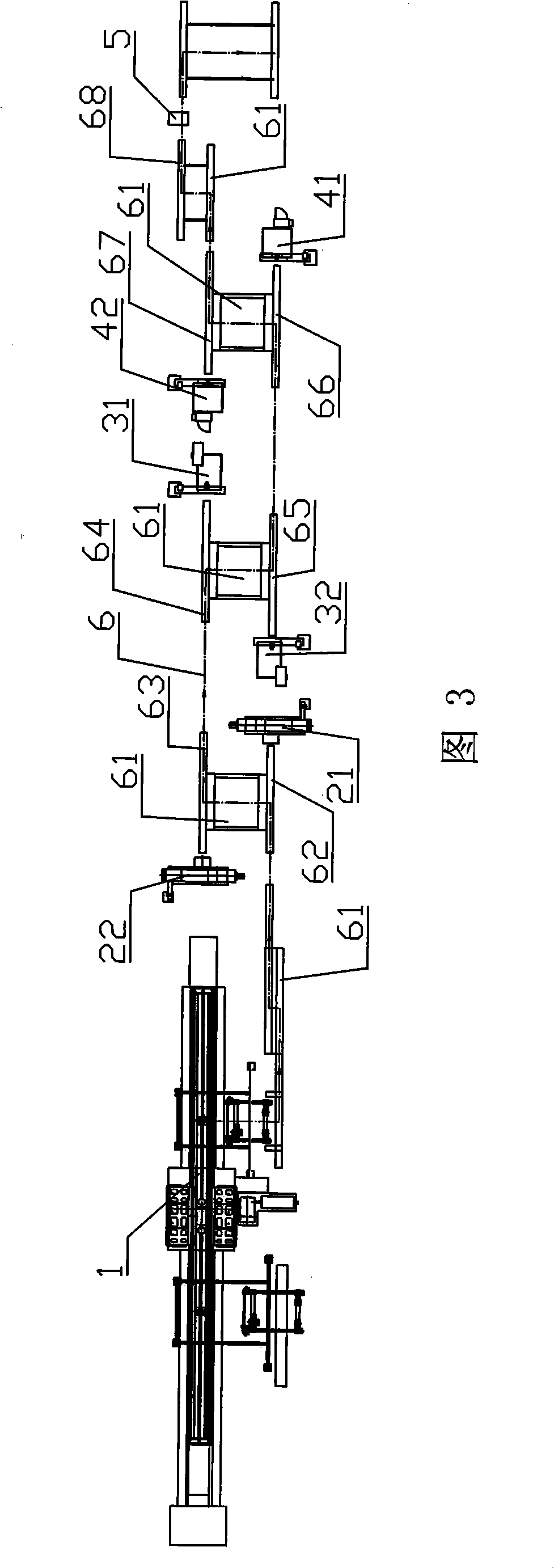

Elevator guide rail automatic production line manufacturing technique and equipment thereof

InactiveCN101323086AImprove working environmentAvoid variance in product qualityOther manufacturing equipments/toolsElevatorsProduction lineMortise and tenon

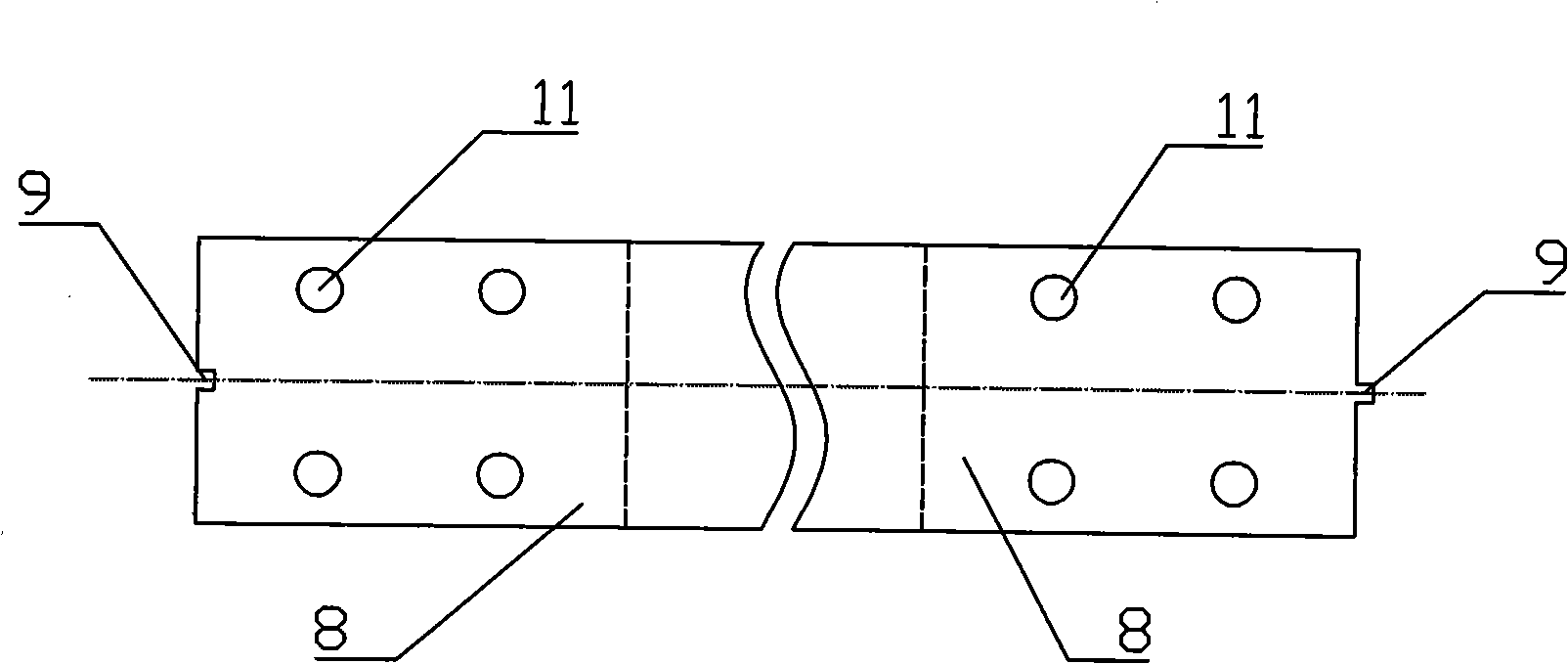

The invention relates to a production technology of automatic production lines, in particular to a production technique of the automation production lines of guiding rails of elevators and equipment thereof, which comprises processing units at two sides of the guiding rail of the elevator, a large back milling unit of the guiding rail of the elevator, a mortise and tenon processing unit of the guiding rail of the elevator, an assembly hole processing unit of the guiding rail of the elevator, a counter-boring processing unit of the guiding rail of the elevator, a transmission feeding system and an electric control system; the electric control system controls the processing units at the two sides of the guiding rail of the elevator, the large back milling unit of the guiding rail of the elevator, the mortise and tenon processing unit of the guiding rail of the elevator, the assembly hole processing unit of the guiding rail of the elevator, the counter-boring processing unit of the guiding rail of the elevator and the transmission feeding system to work cooperatively. All the production processes of the invention are controlled to carry out the production automatically by the electric control system, avoids product differences caused by differences of technology levels of processing workers; the product quality is improved and uniform; defective products can be reduced. Compared with the manual single machine processing, the production technology of automatic production lines improves the production efficiency, reduces the work strength and improves the working environment of workers.

Owner:常州市三利精机有限公司

Gun holster

InactiveUS20050279788A1Protection wearLimited accessTravelling carriersArms wearablesMortise and tenonLocking mechanism

The invention includes improvements to a security holster including protective ridges for use around the release mechanism and the locking mechanism. Also included is a mortise and tenon arrangement for securing the holster body to a belt attachment plate.

Owner:POINT BLANK ENTERPRISES

Fill and compaction roller using replaceable cleat assemblies with extended service life

InactiveUS20040033107A1Easy to replaceEasy to disassembleRoads maintainenceSoil preservationMortise and tenonWear resistant

A compaction roller for mounting on a driven compaction vehicle is equipped with both destructive and tractive, highly wear resistant cleat assemblies. The later includes readily removable wear caps with bulbous full height corner portions and broad wear faces. Anti twist projections and complementary recesses including mortise and tenon type locks at the interface of the wear cap and support bases reduce relative movements between the parts under sever working forces.

Owner:CARON COMPACTOR

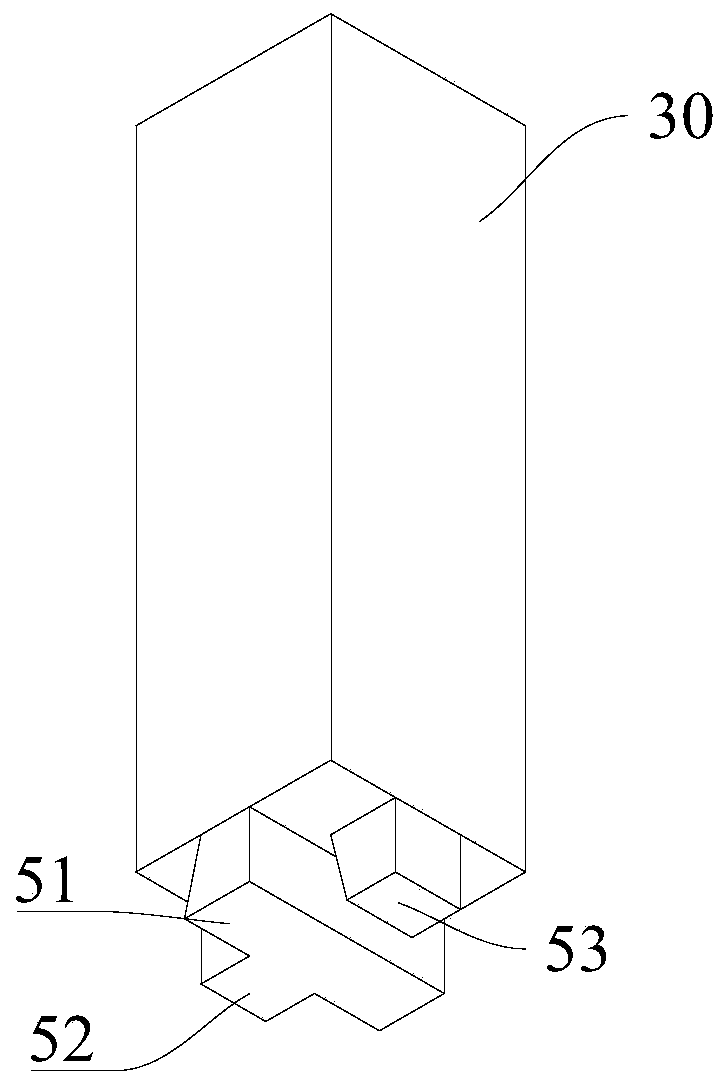

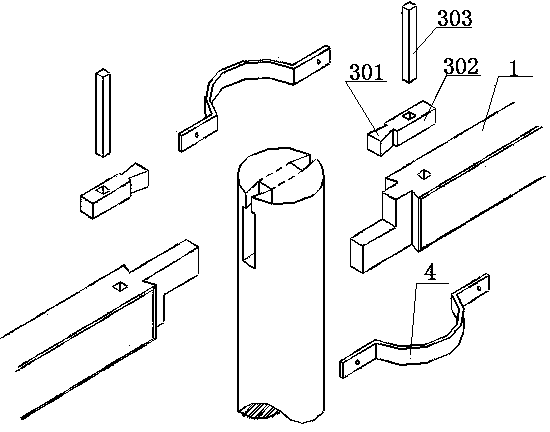

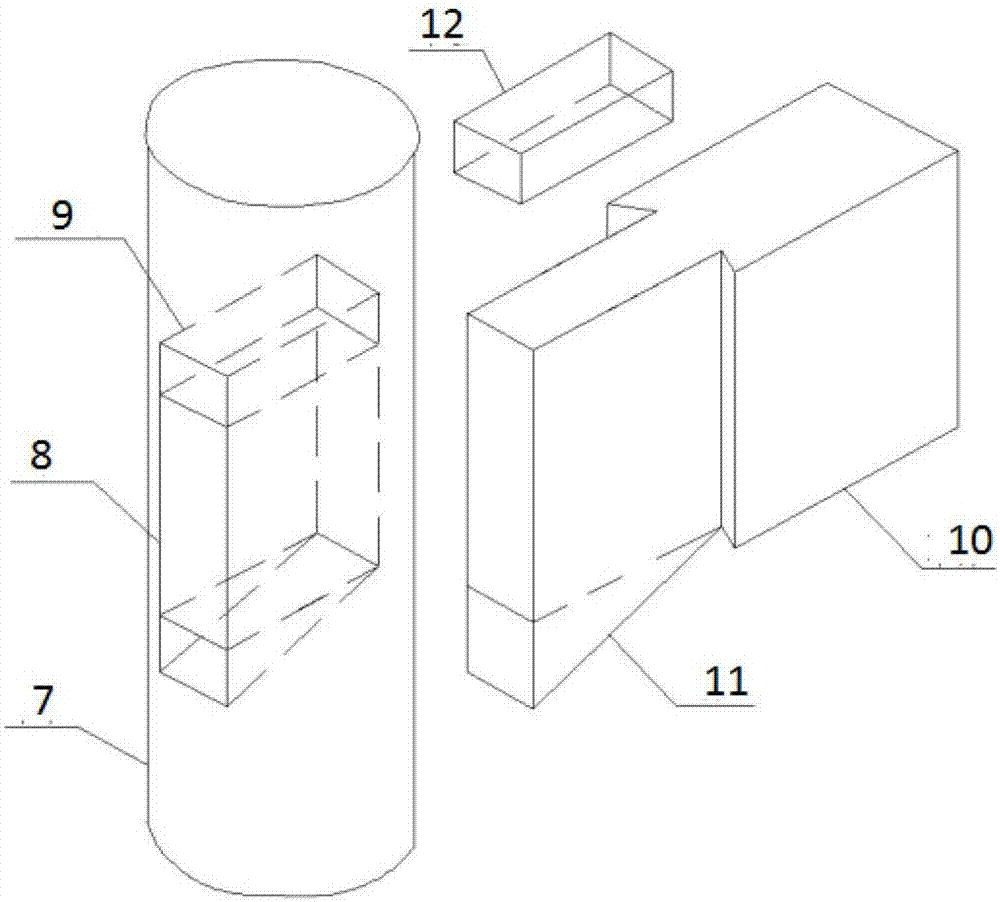

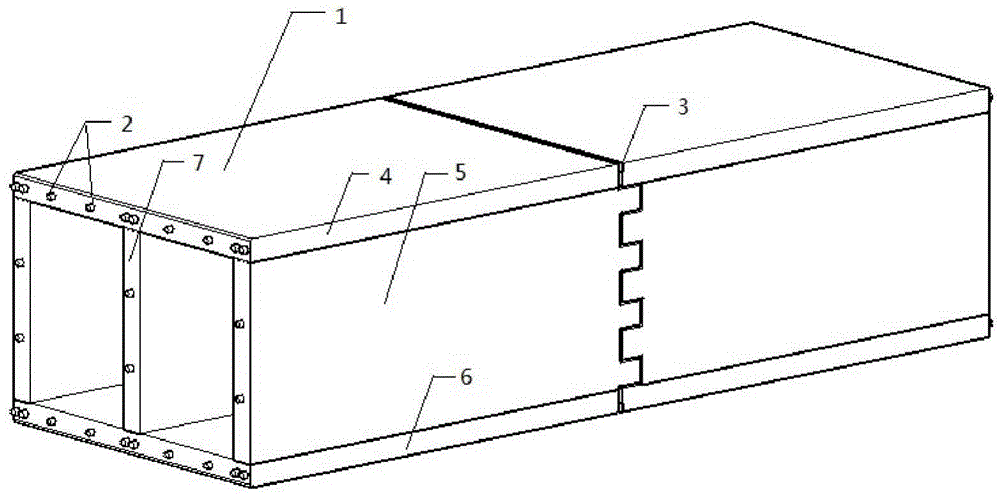

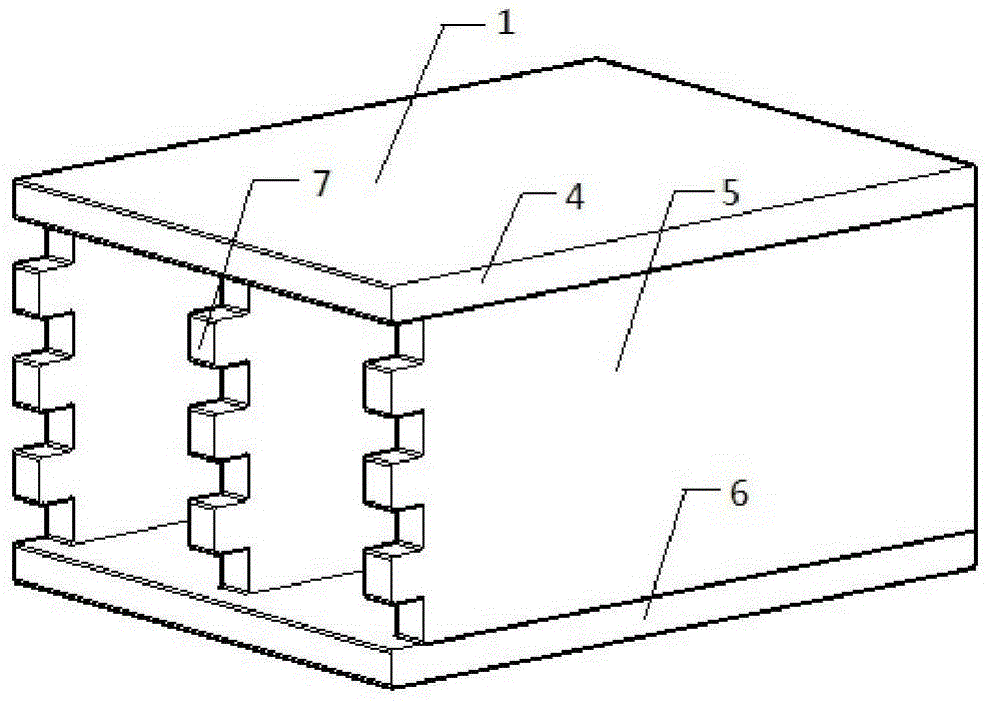

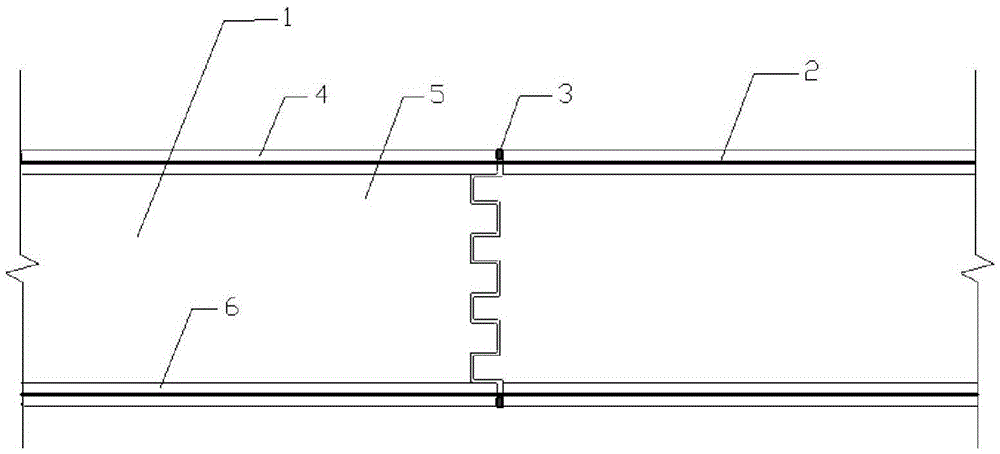

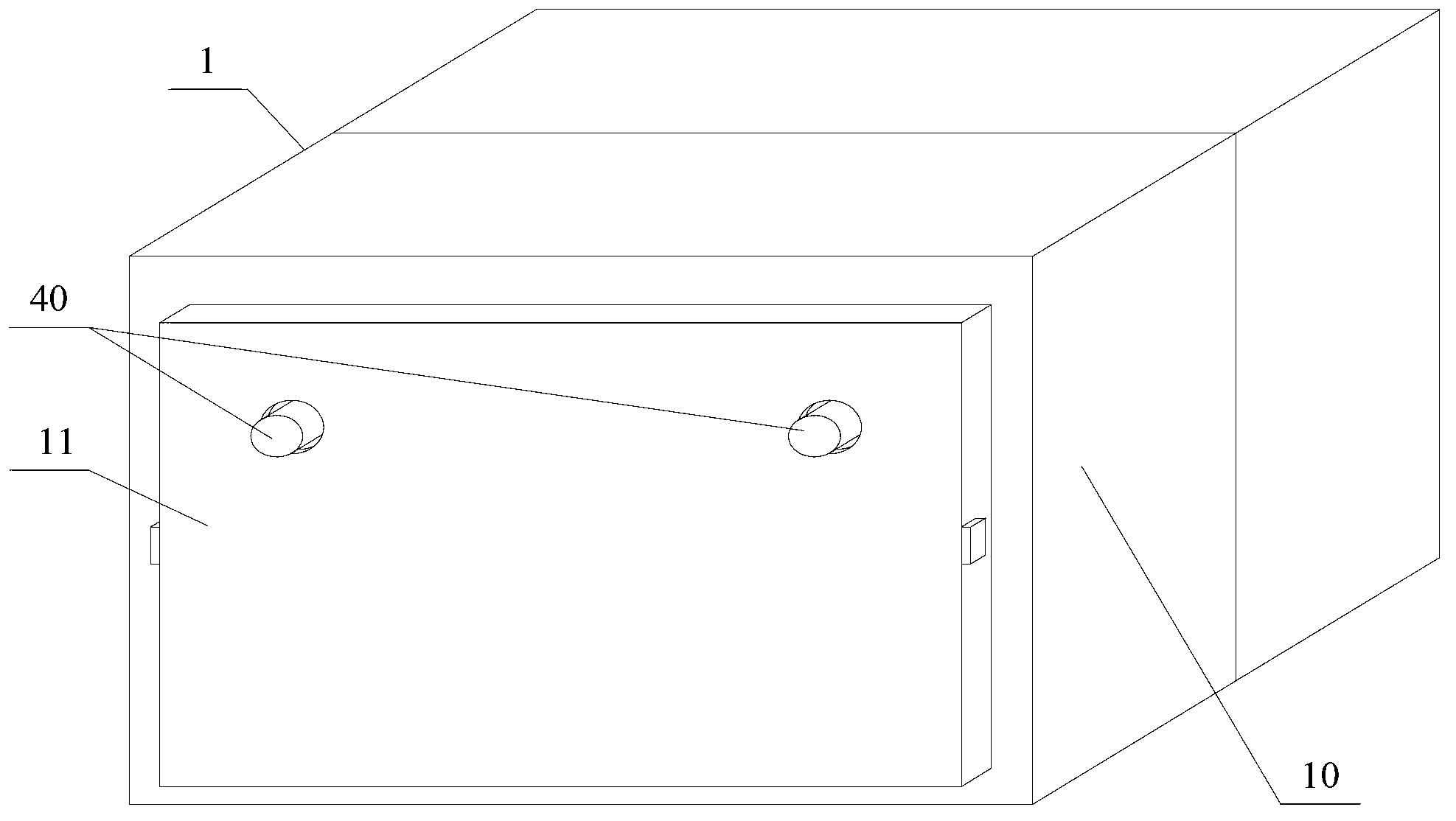

Mortise type prefabricated comprehensive pipe gallery longitudinal connector

InactiveCN105421489AClosely connectedImprove mechanical propertiesArtificial islandsUnderwater structuresMortise and tenonEngineering

The invention discloses a mortise type prefabricated comprehensive pipe gallery longitudinal connector. The mortise type prefabricated comprehensive pipe gallery longitudinal connector comprises prefabricated pipe gallery sections (1), longitudinal prestress ribs (2) and waterstop rubber belts (3), wherein each prefabricated pipe gallery section (1) comprises a top plate (4), side plates (5) and a bottom plate (6). Tenon-and-mortise components which are matched with each other are arranged at the two ends of each pipe gallery section. During on-site construction and splicing, every two adjacent pipe gallery sections are matched with each other according to the tenon-and-mortise relationship, the waterstop rubber belts are reasonably arranged on joints, then prestress is applied through the longitudinal prestress ribs for tensioning, and thus an integral structure is formed by a prefabricated pipe gallery. According to the mortise type prefabricated comprehensive pipe gallery longitudinal connector, the good mechanical property and waterproof performance of the mortise type connector are utilized, the prestress ribs are used for tensioning, the waterstop rubber belts are used for preventing water, and thus the structural integrity of the prefabricated pipe gallery is improved. Abundant structural forms of the prefabricated comprehensive pipe gallery longitudinal connector are provided, and convenience is provided for further development of the structure of the prefabricated comprehensive pipe gallery.

Owner:SOUTHEAST UNIV

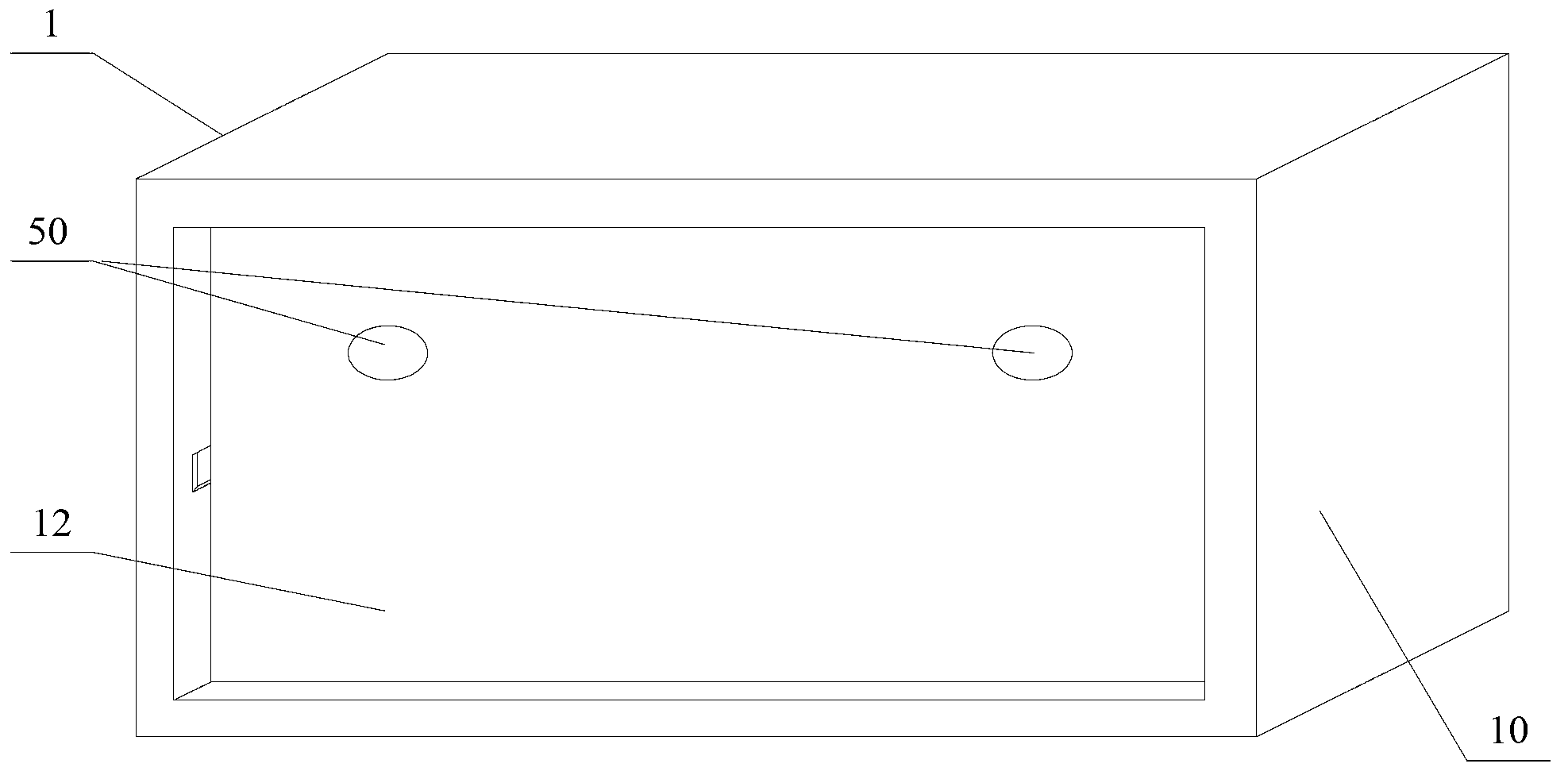

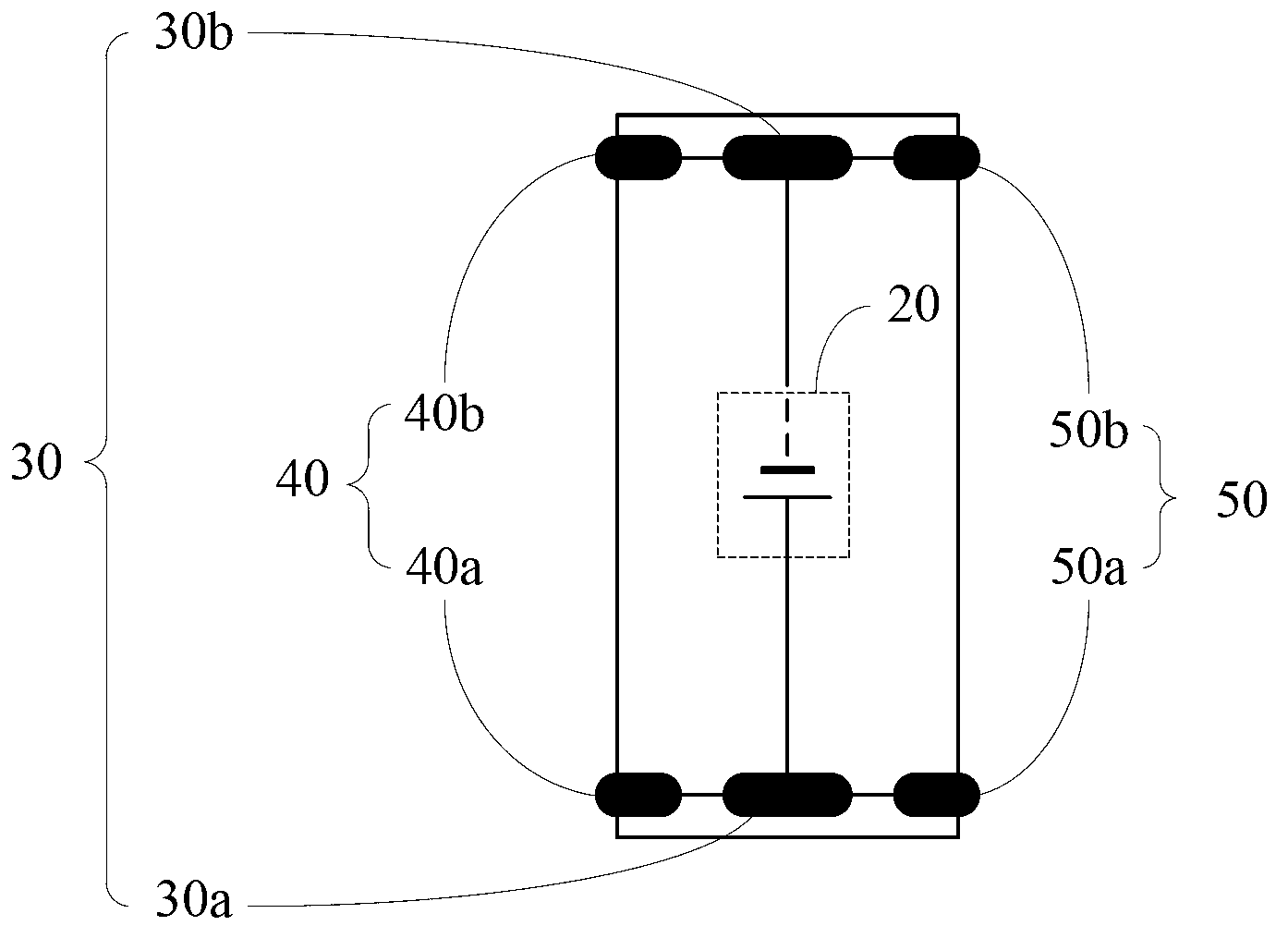

Battery unit and mobile power supply

InactiveCN103219485AChange capacityChange the output voltageBatteries circuit arrangementsElectric powerElectricityMortise and tenon

The invention discloses a battery unit and a mobile power supply provided with the battery unit; the battery unit comprises a first shell, a battery core, electrode contacts, a first group of electric contacts and a second group of electric contacts, wherein the first shell comprises a first outer surface and a second outer surface which are arranged at the positions of the opposite surfaces; the first group of electric contacts are arranged on the first outer surface, and the second group of electric contacts are arranged on the second outer surface; the first group of electric contacts and the second group of electric contacts are respectively and electrically connected with the battery core by the electrode contacts; every two adjacent battery units are combined together in a way of buckling, pinning, mortise and tenon joint or magnetic suction, and the second group of electric contacts of one battery unit have electric conduction relationship with the first group of electric contacts of the other battery unit; and the two battery units are connected in parallel or in series.

Owner:朱金怀

Wooden-structure building beam-column joint structure

ActiveCN105178448AImprove connection strengthImprove bending abilityBuilding constructionsMortise and tenonAdhesive

A wooden-structure building beam-column joint structure is provided. In this structure, a wooden column and a wooden beam are connected through a steel connector; the steel connector is formed by perpendicularly welding two steel sheets special in shape; the steel connector can be divided into two parts according to usable functions, namely a cross steel sheet part and a linear steel sheet part; the wooden column and the steel connector are reinforced with engineering adhesive; the wooden beam and the steel connector are fixed with a steel rod. The wooden-structure building beam and column are connected with the steel connector and the engineering adhesive instead of a mortise and tenon structure, the connective strength, bending resistance and tensile capacity of a joint are substantially higher than those of the mortise and tenon structure, and the wooden-structure building beam-column joint structure is particularly suitable for large wooden connections; the wooden-structure building beam-column joint structure is simple in structure, and members of this structure are easy to mechanically produce; the joint is simple to mount, quick to construct and low in manufacturing cost.

Owner:沈阳促晋科技有限公司

Beam and column joint structure of timber architecture

ActiveCN104790535AImprove connection strengthImprove bending abilityBuilding constructionsMortise and tenonUltimate tensile strength

The invention provides a beam and column joint structure of a timber architecture. According to the beam and column joint structure of the timber architecture, wooden beams and a wooden column are connected through a steel connecting piece; the steel connecting piece is composed of a square sleeve and at least one U-shaped groove, the U-shaped grooves are perpendicularly welded to the side wall of the square sleeve in an integrated mode, the ends of the wooden beams are embedded into the U-shaped grooves, n-shaped clamping hoops are embedded in the upper portions of the U-shaped grooves, and bolts penetrate through the clamping hoops, the walls of the U-shaped grooves and preset bolt installation holes of the wooden beams, so that the wooden beams, the U-shaped grooves and the clamping hoops are fastened into a whole; the end of the wooden column is inserted into the square sleeve, and the wooden beam and the square sleeve are fixedly connected through bolts. According to the beam and column joint structure, the steel connecting piece, the bolts and the clamping hoops are used for replacing mortise and tenon joints to achieve beam-column connection of the timber architecture, the connection strength, the bending resistance and the tension resistance of the node are greatly improved compared with the mortise and tenon joints, and the beam and column joint structure is particularly suitable for connection of large-scale timber structures; the beam and column joint structure is simple, components can be easily and mechanically produced, the construction speed is high, and the manufacturing cost is low.

Owner:河北地下空间建筑工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com