Patents

Literature

59 results about "Mortising machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

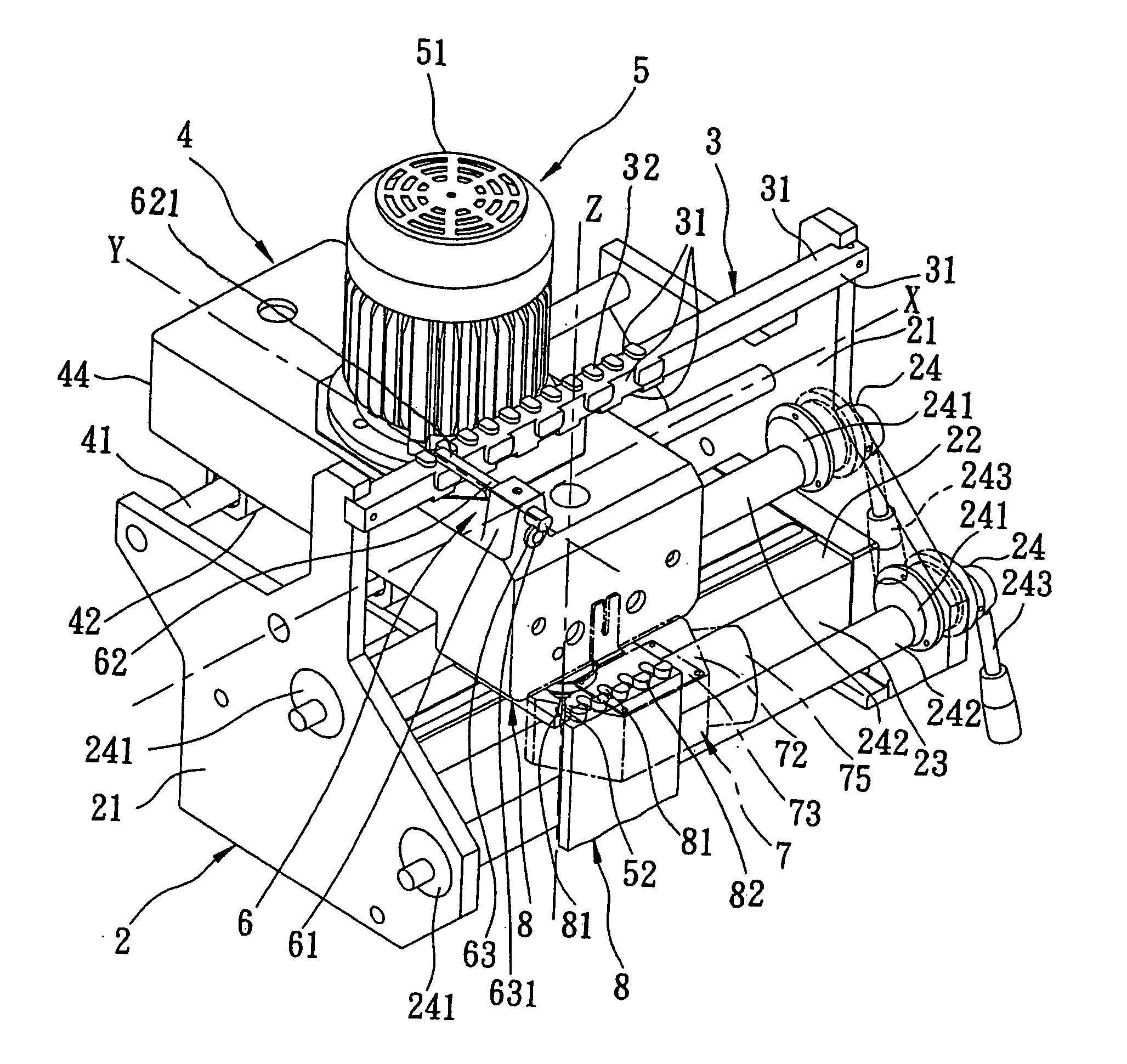

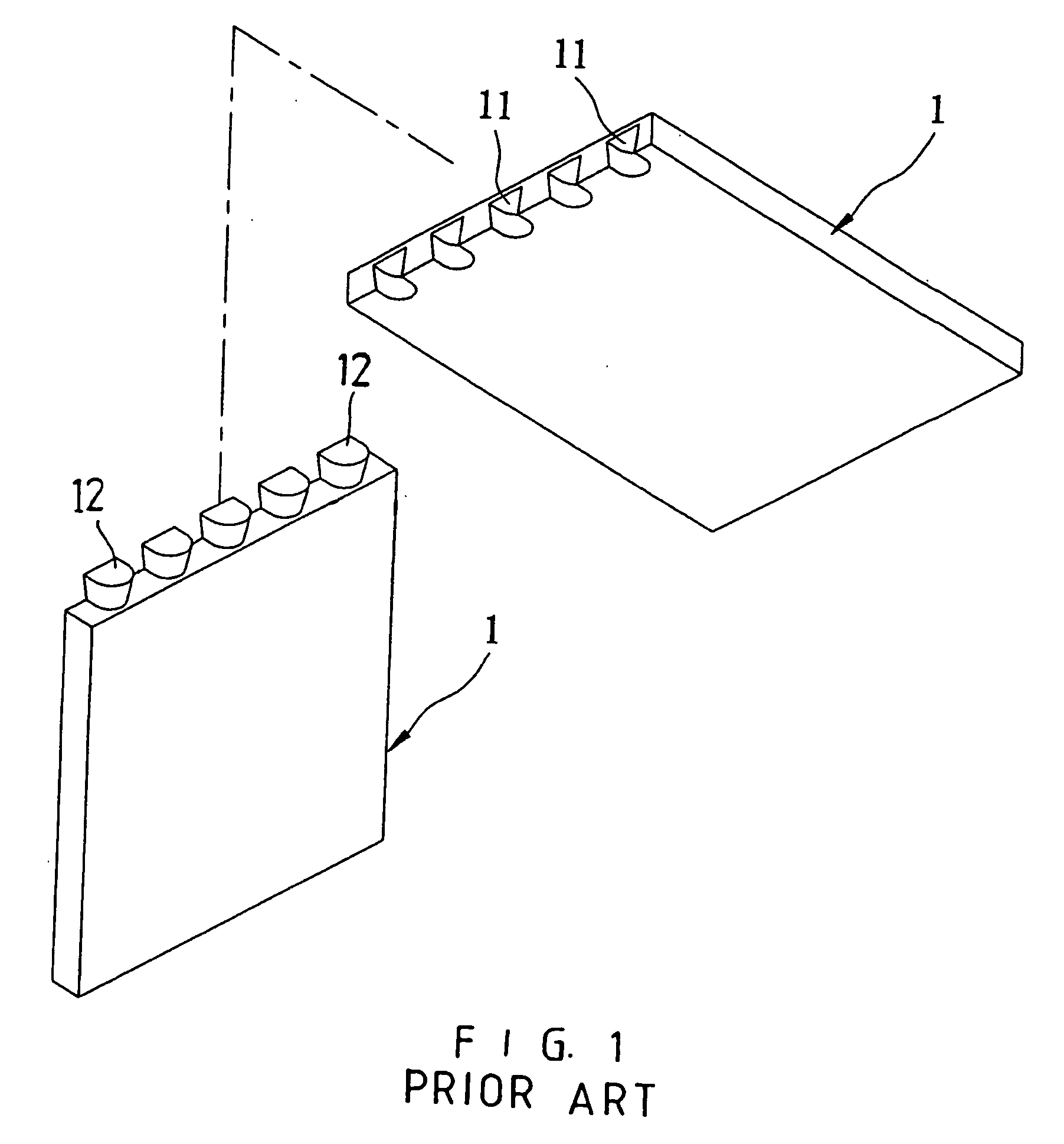

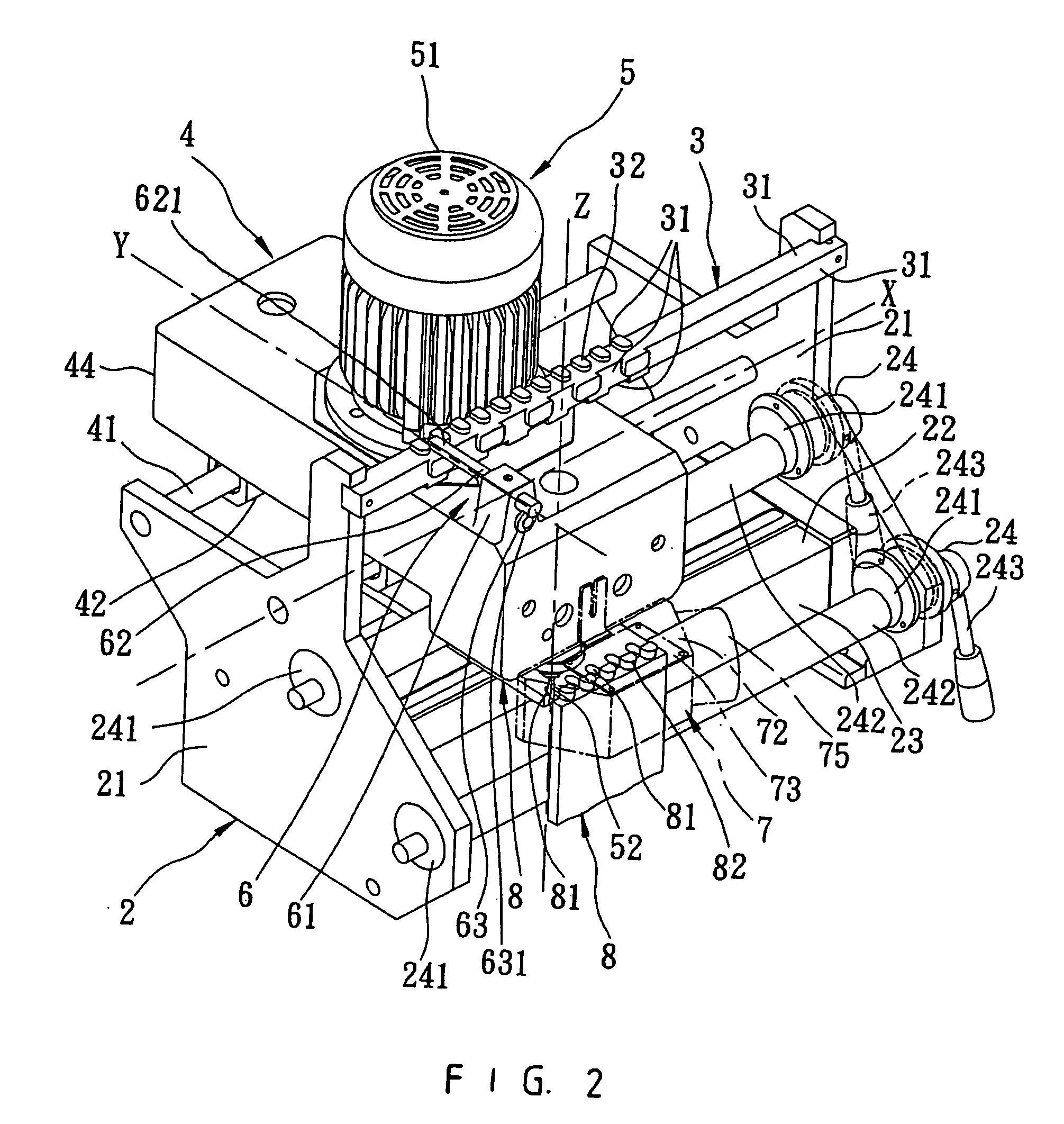

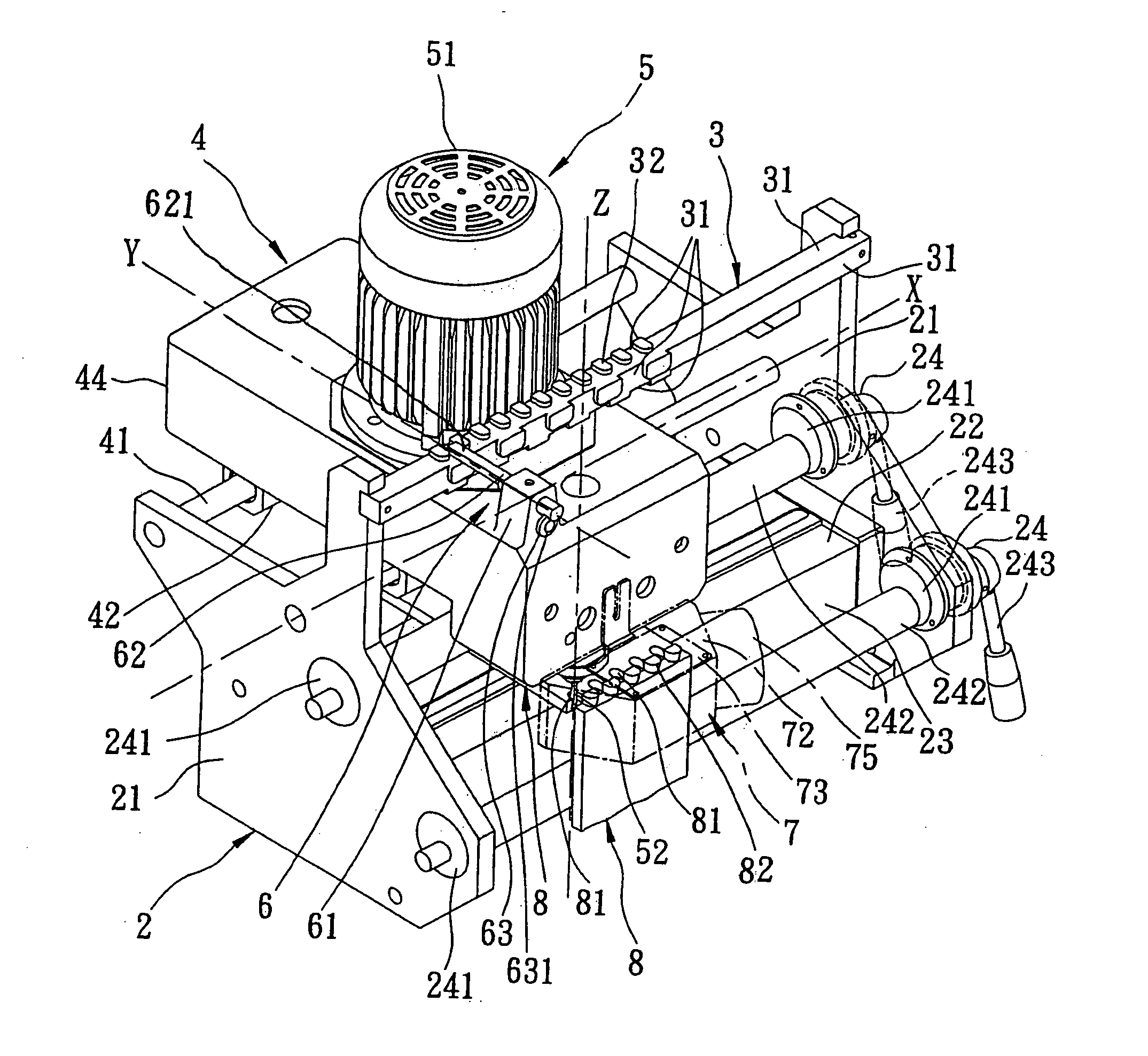

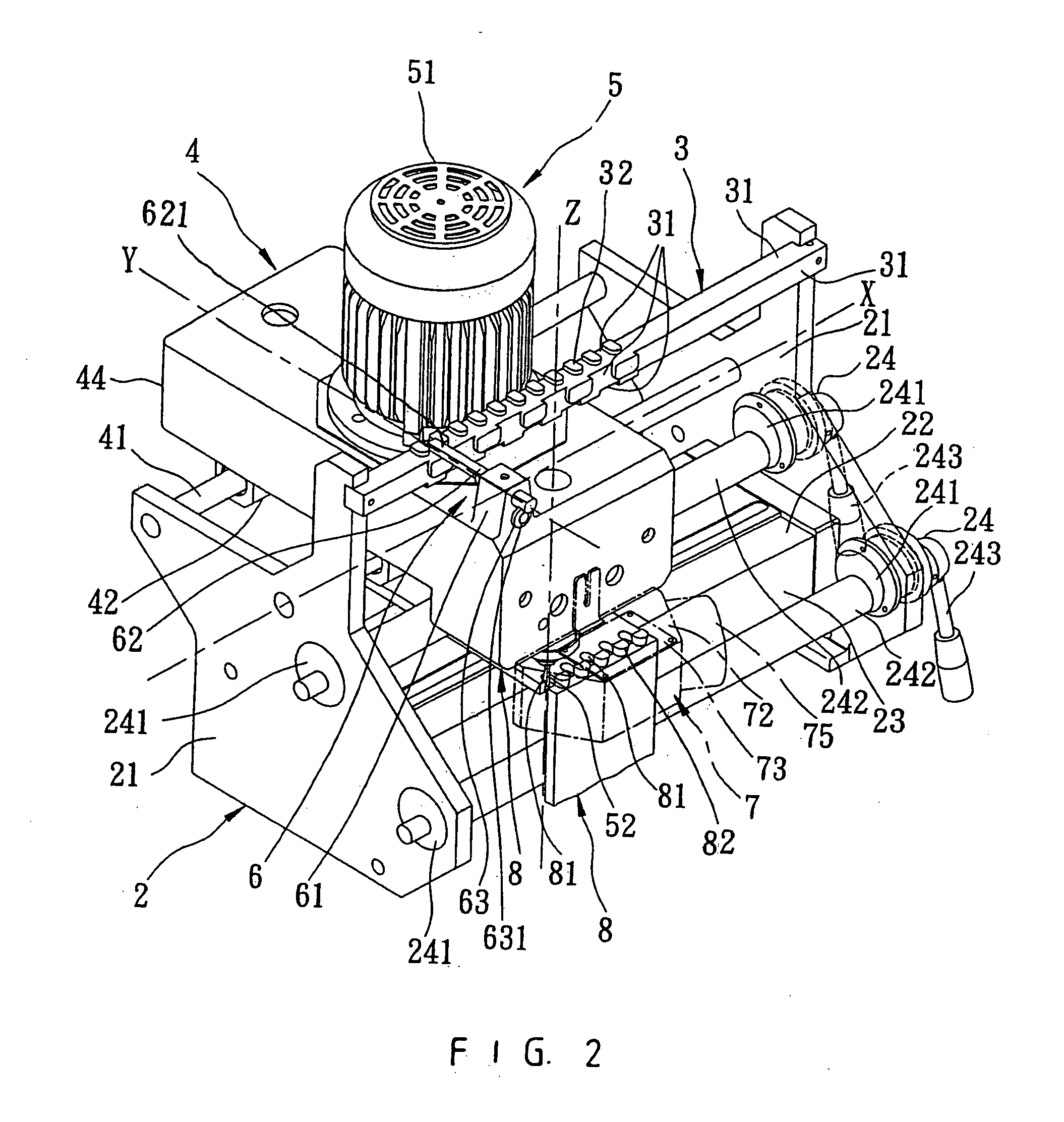

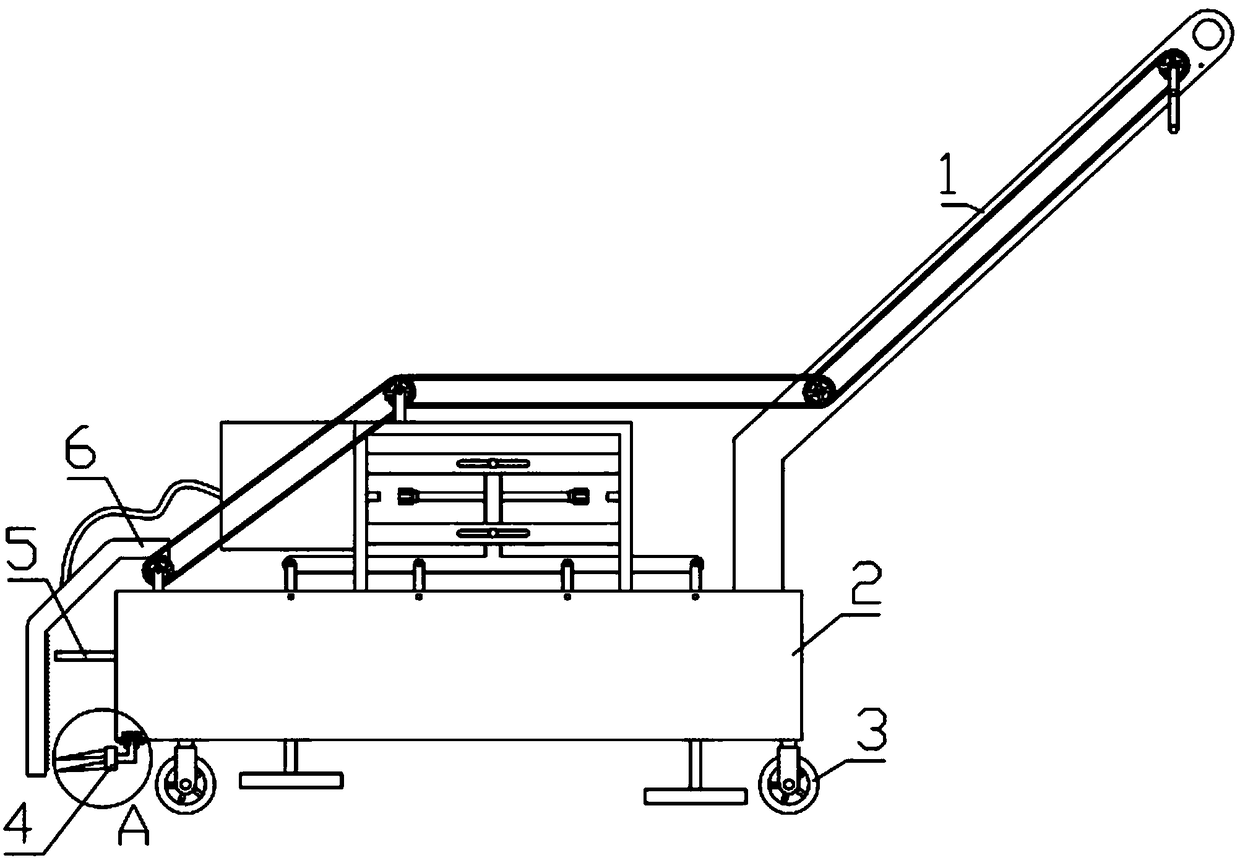

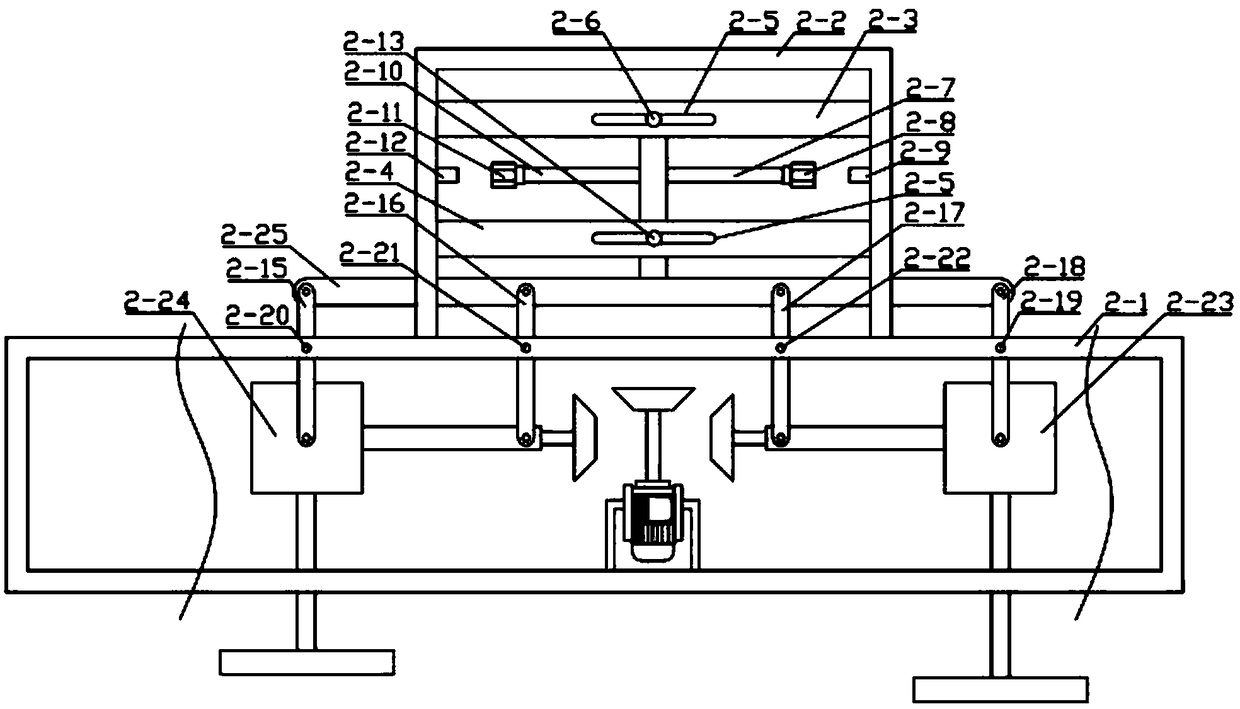

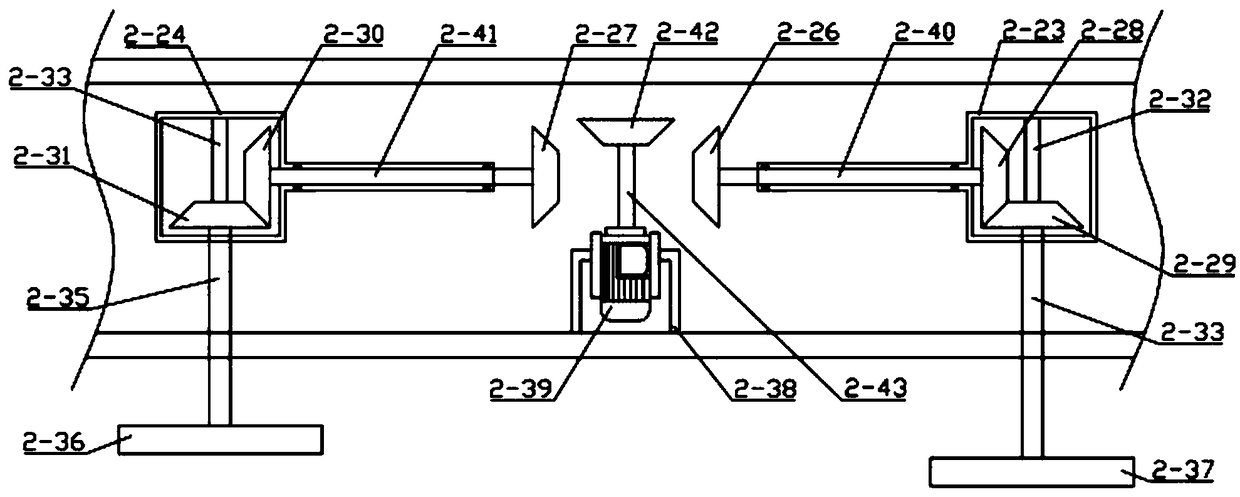

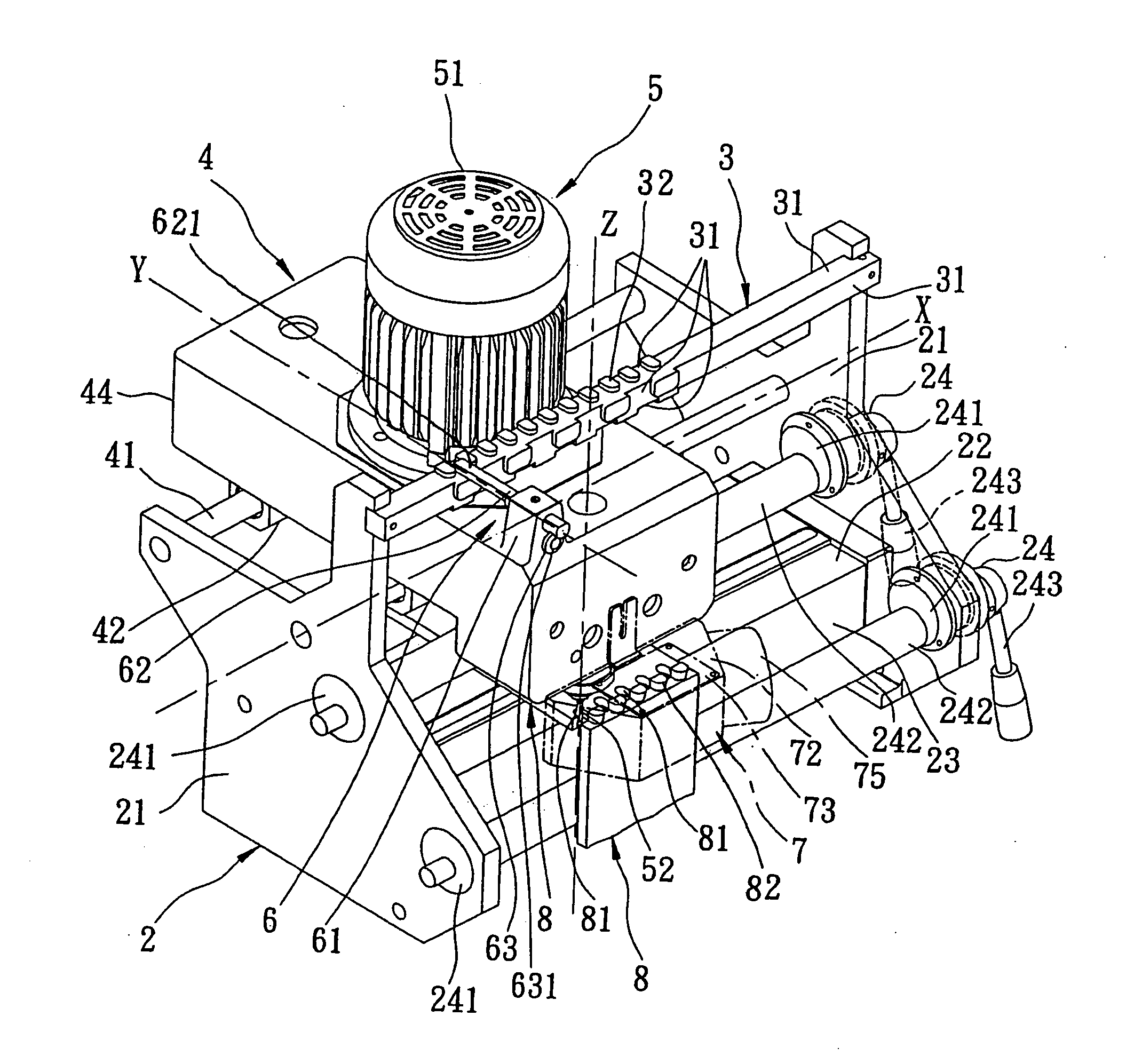

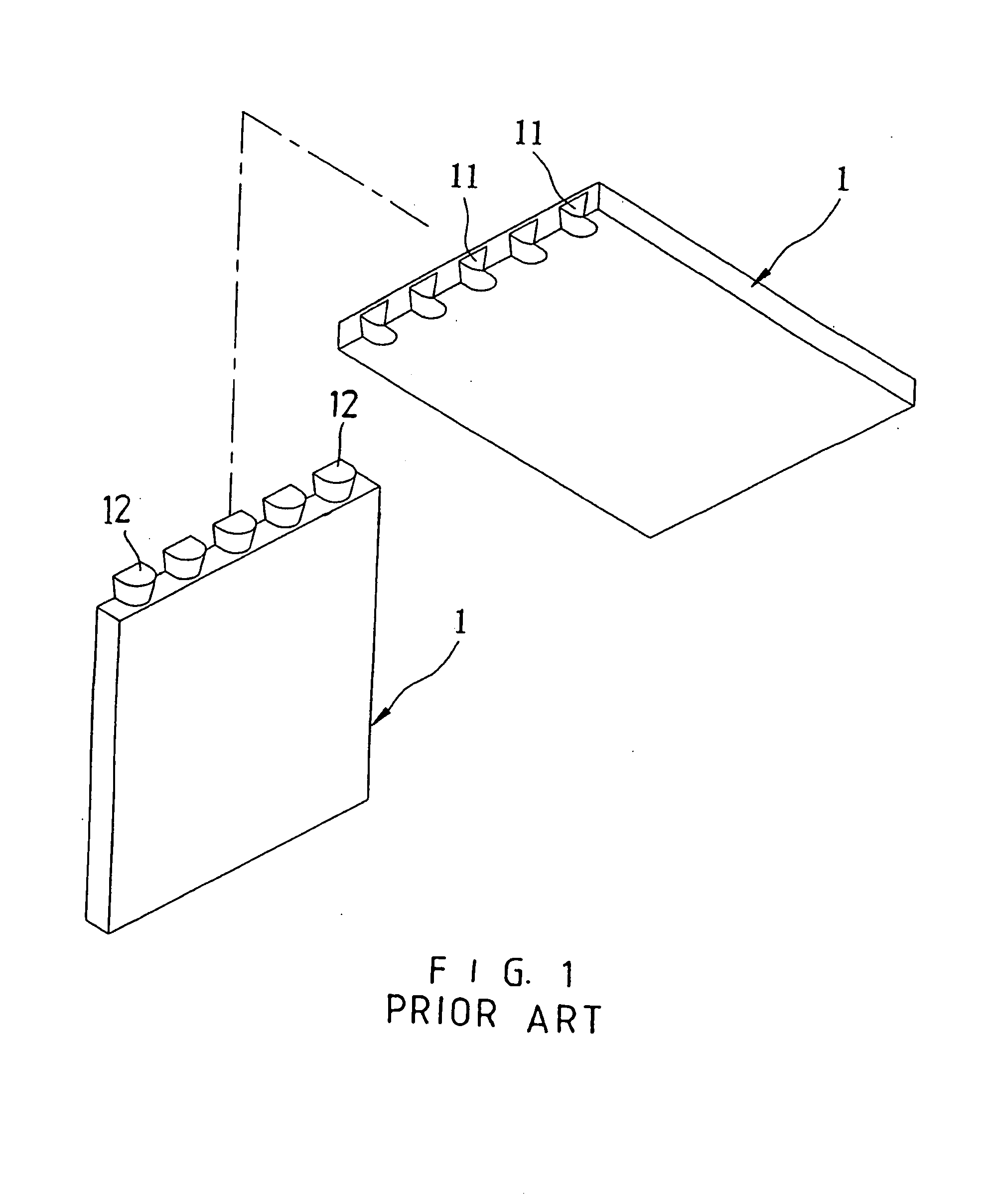

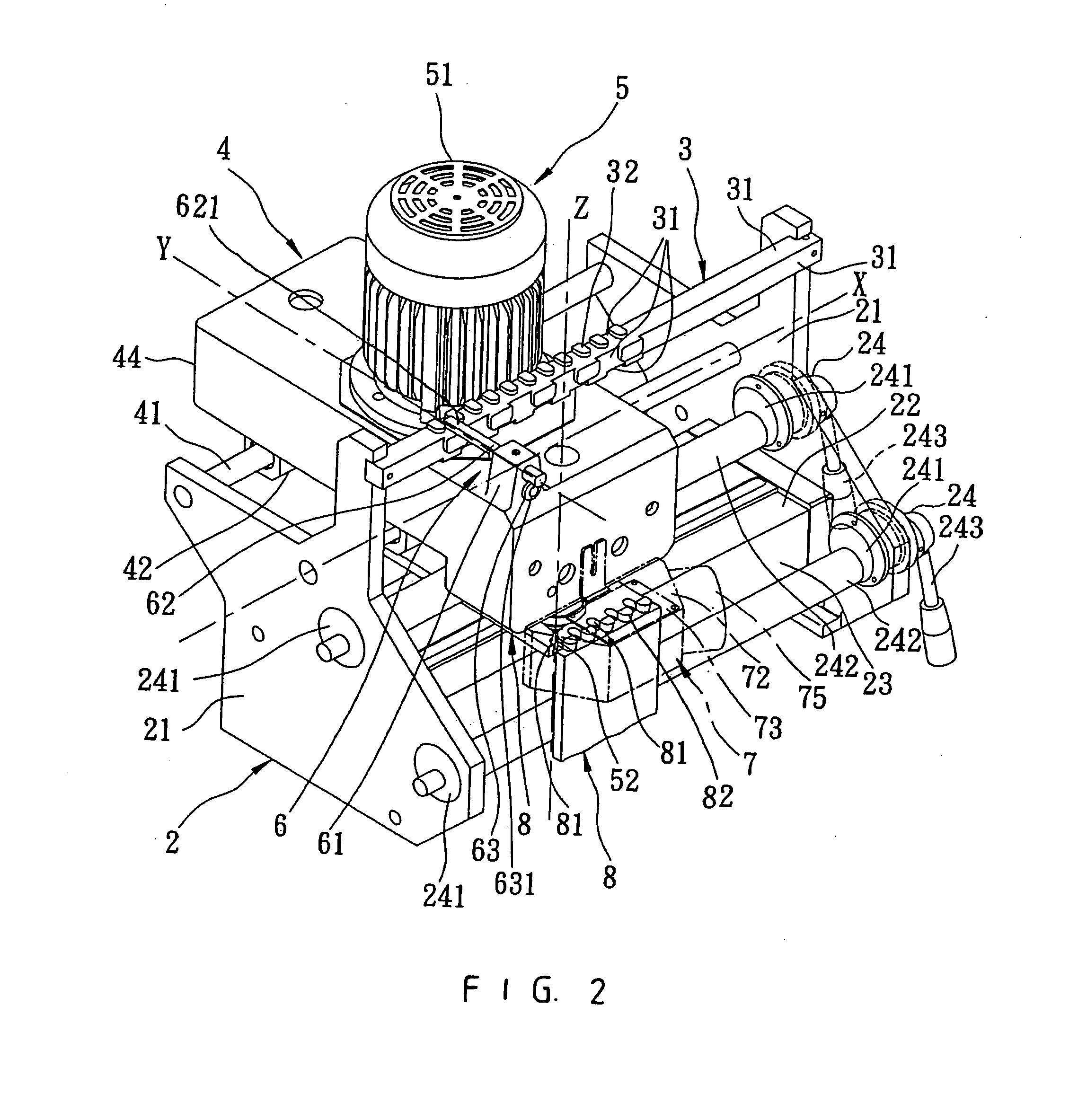

Semi-automatic mortising machine

InactiveUS20050022899A1Easy constructionReduce the possibility of failureTongue/grooves making apparatusMulti-purpose machinesMortise and tenonMortising machine

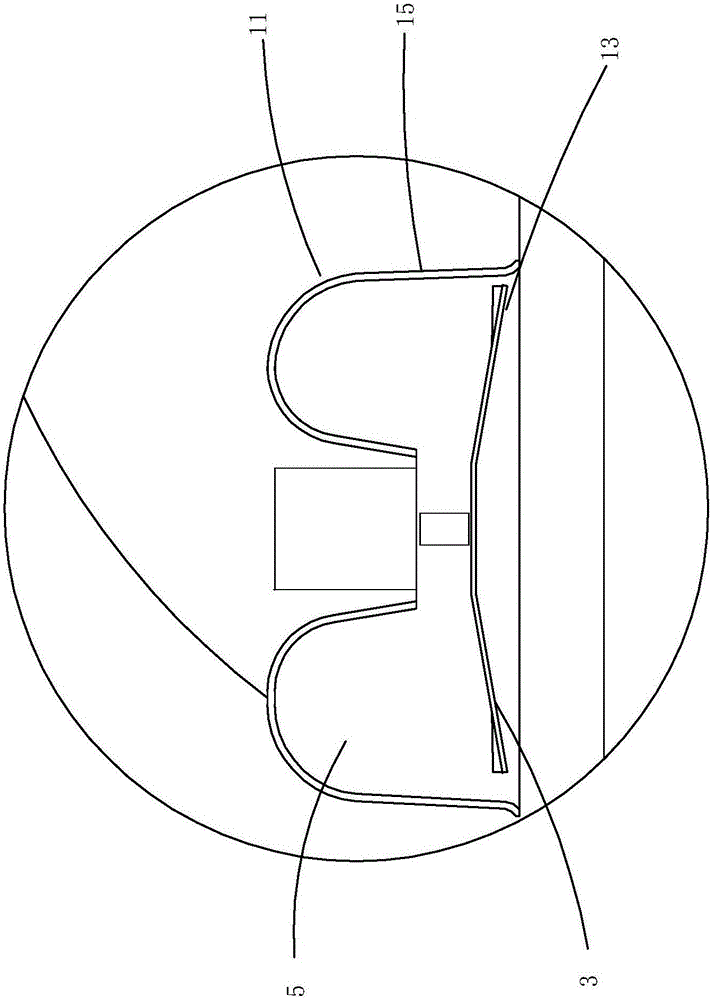

A semi-automatic mortising machine includes a support base, a support bar, a guide device, a working device, a distance adjusting device, and a dust collection box. Thus, the displacement direction can be controlled in a manual manner during the working process, and the cutting operation is performed in an automatic manner, so as to cut the mortises and tenons in the workpiece.

Owner:CHANG CHI LO

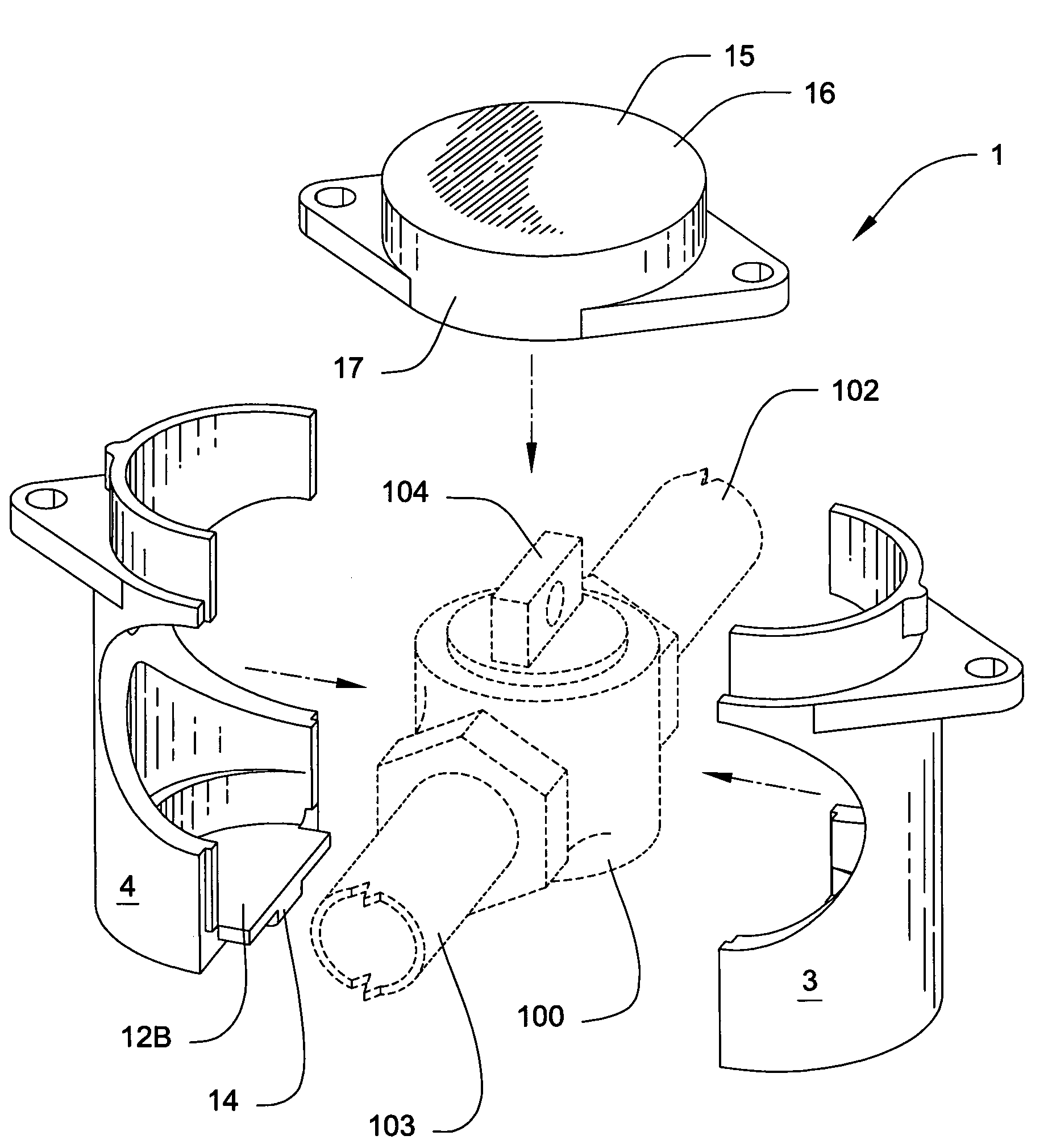

Valve cover

InactiveUS20060070662A1Easy to participateFit tightlyVessel mounting detailsCombustion enginesEngineeringVALVE PORT

Owner:LINELOX

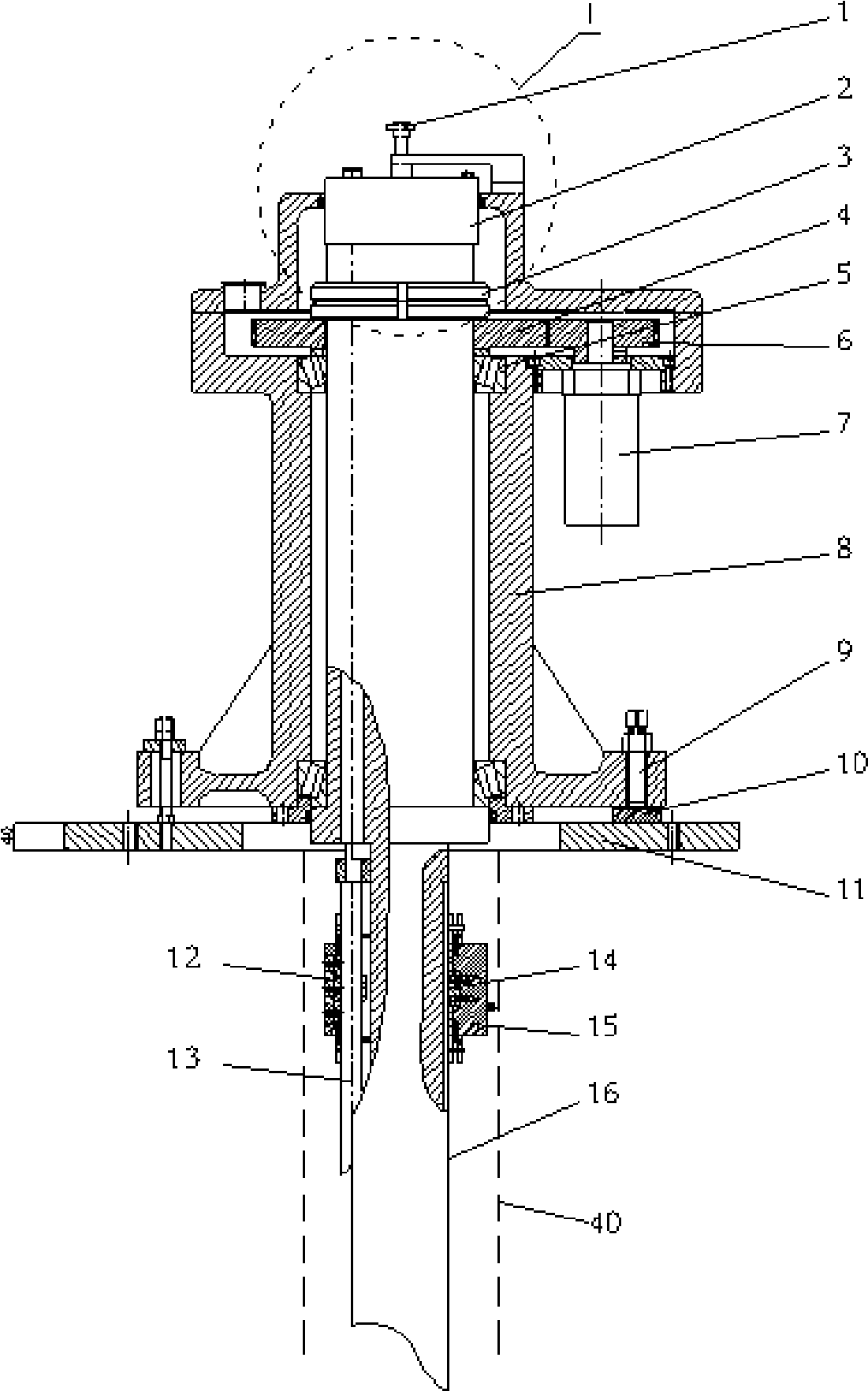

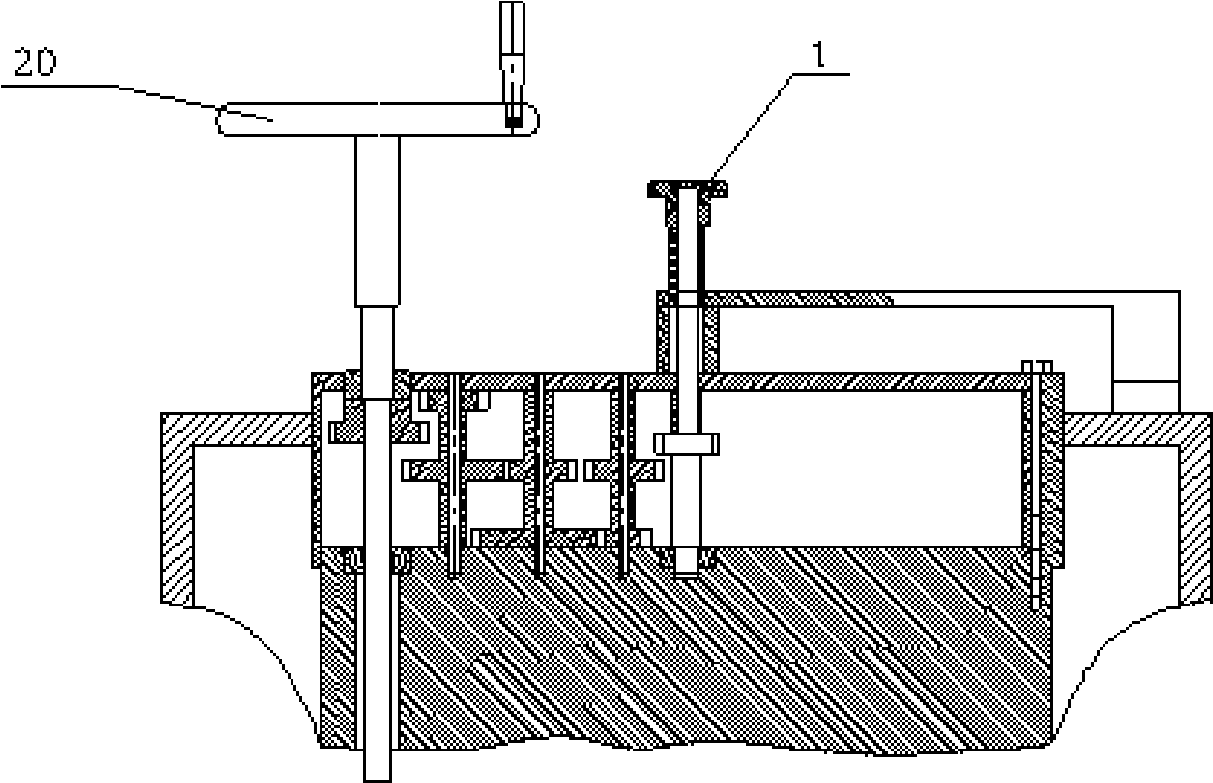

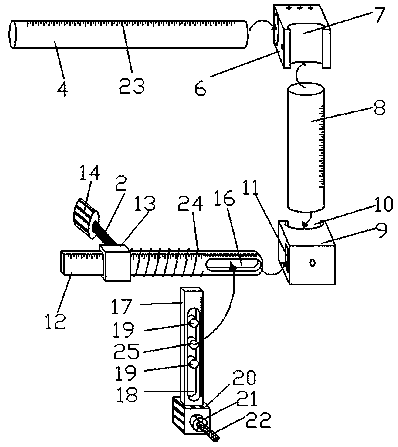

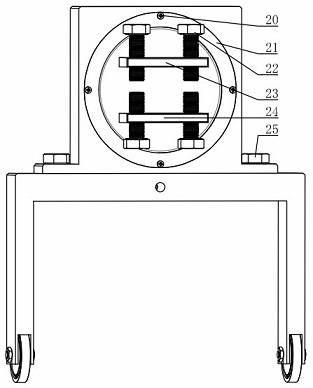

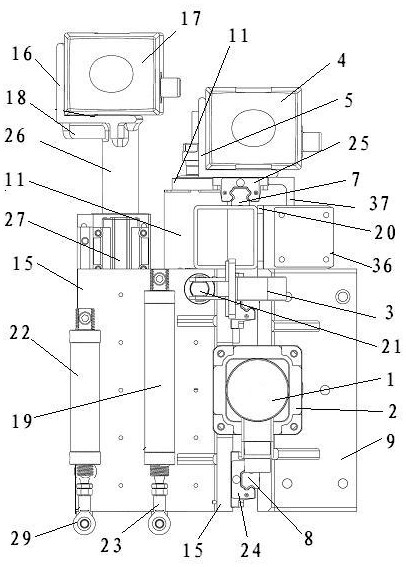

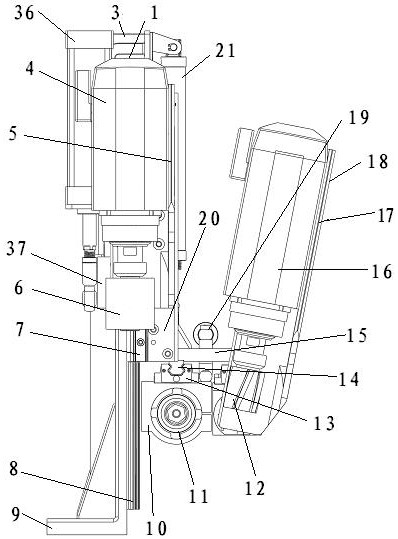

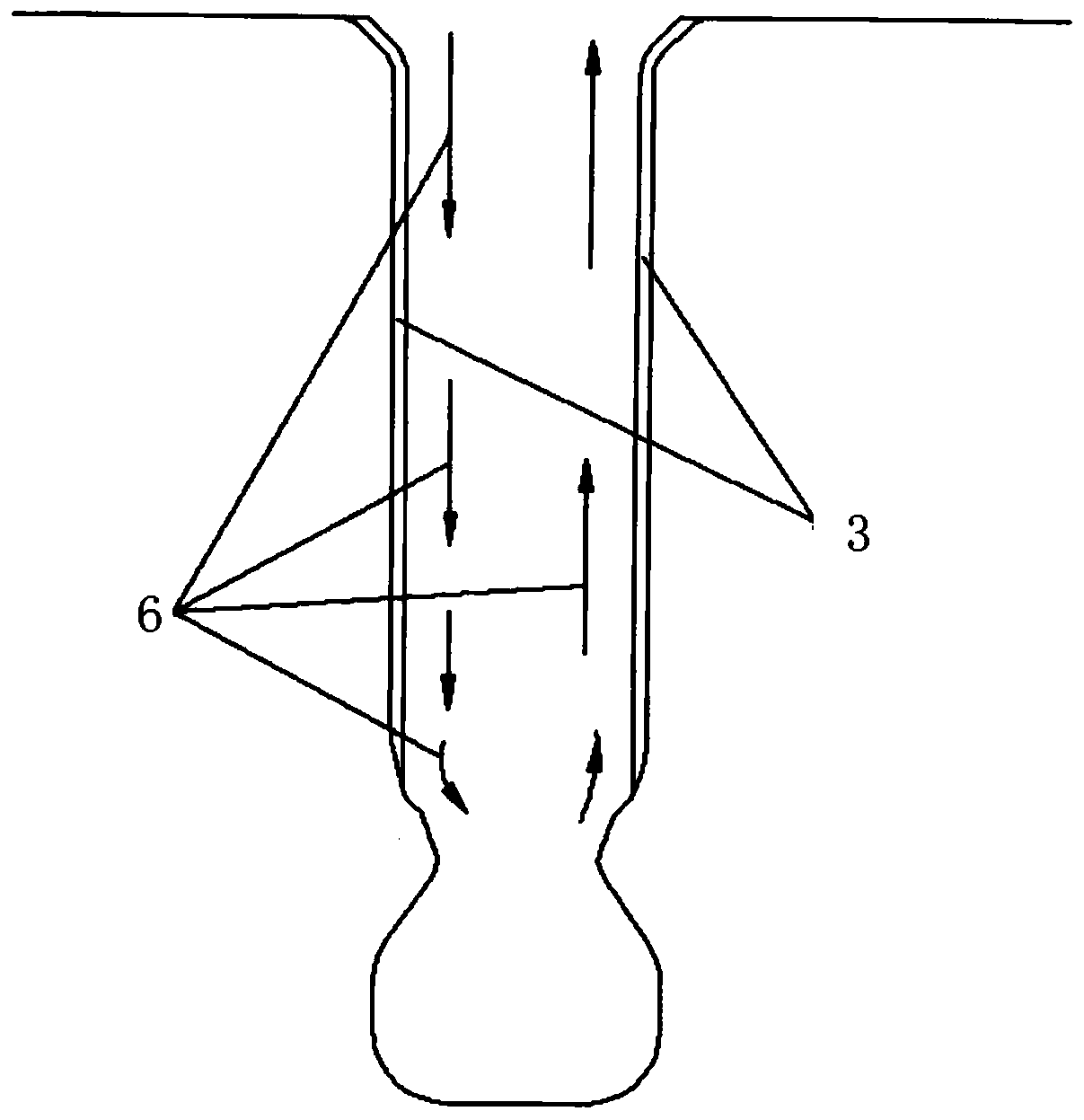

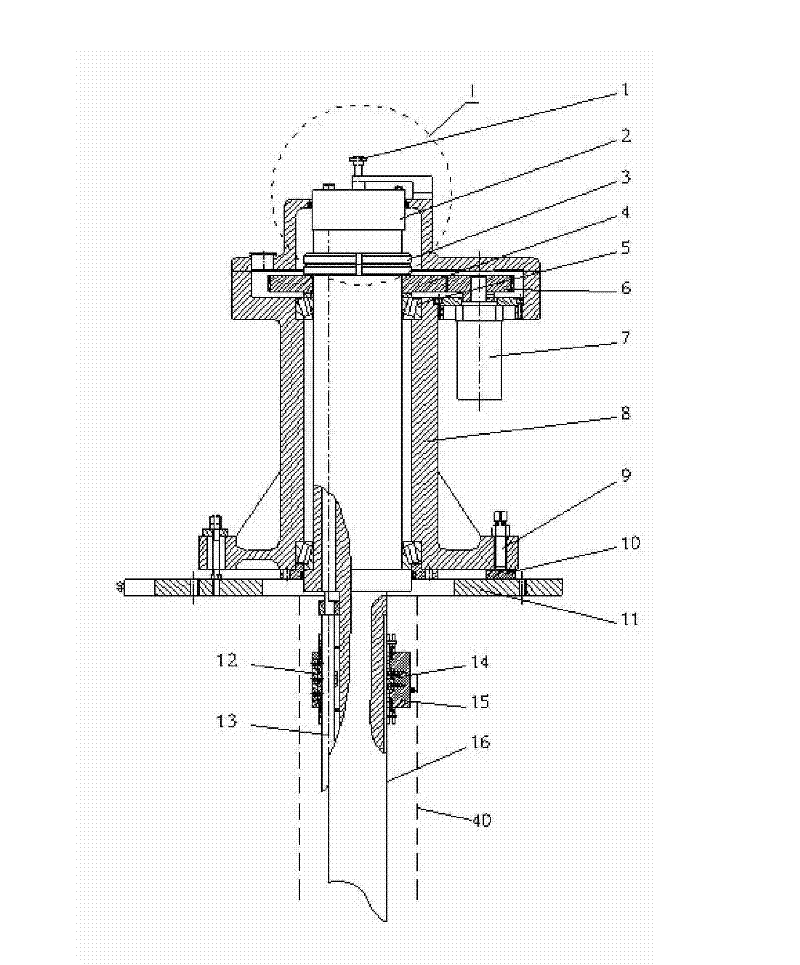

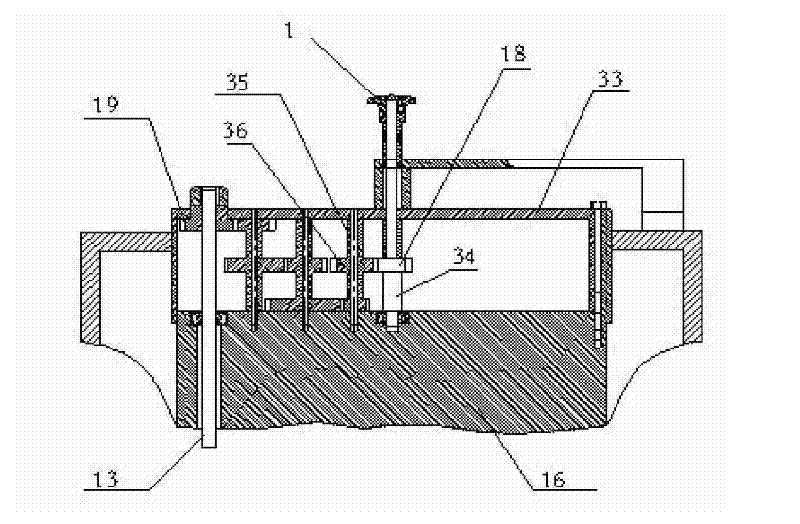

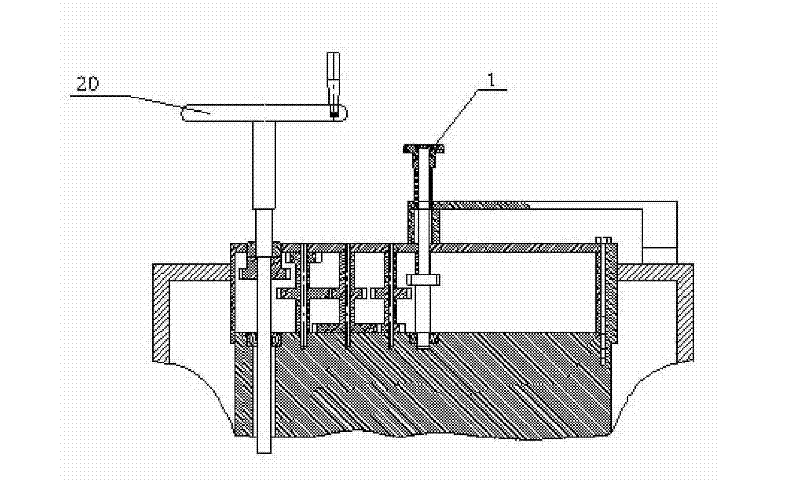

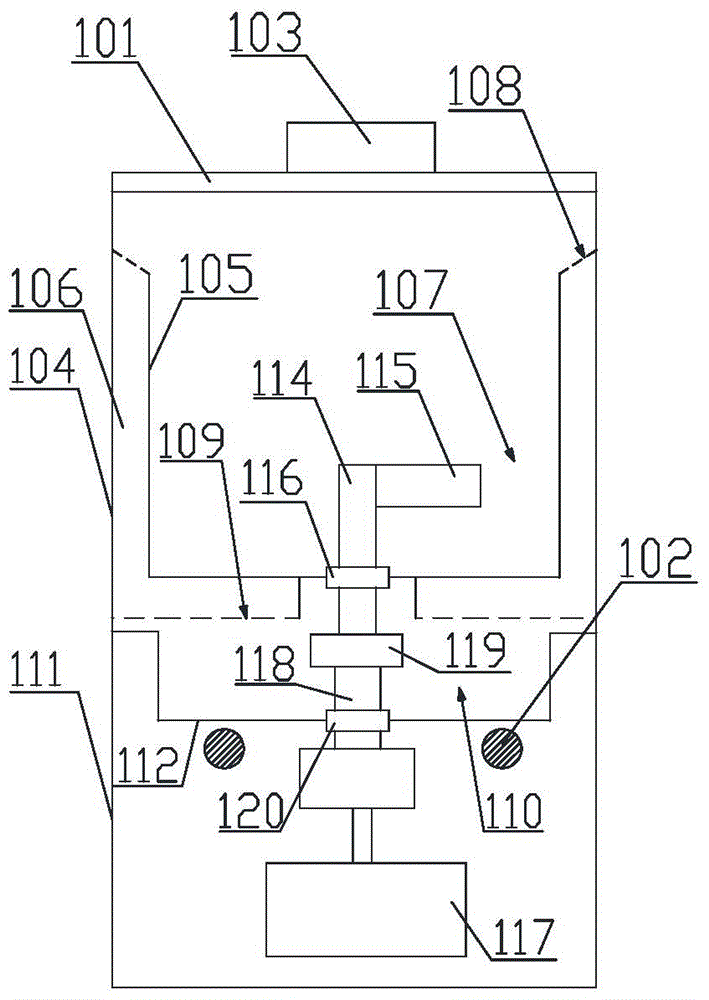

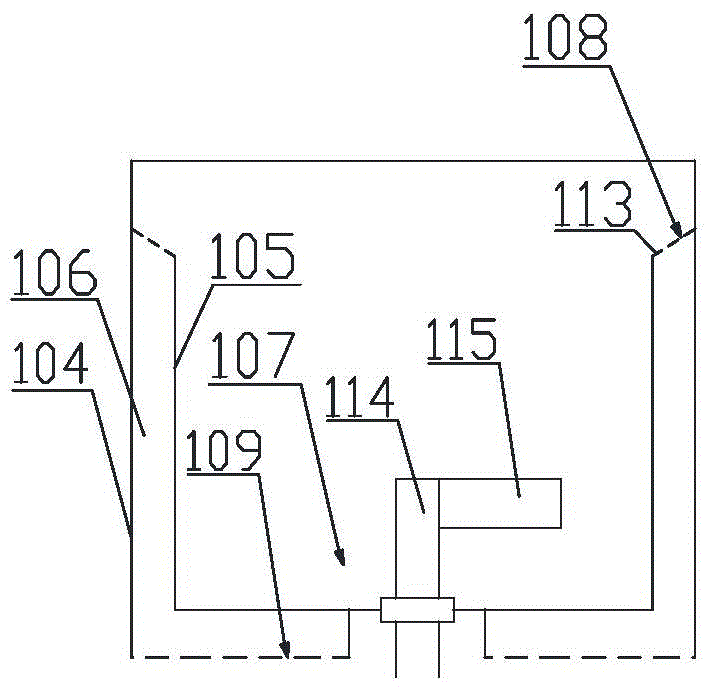

A boring machine

ActiveCN101530929AReduce labor intensityGood boring controllabilityFeeding apparatusOther manufacturing equipments/toolsEngineeringDeep hole

The invention relates to a field processing boring machine, which includes a hydraulic station, a variable speed machine, a boring bar, a feed screw, a boring knife rack, and a blade, which is characterized in that the top surface of the boring bar is mounted with a gear shifting box, the feed screw is axially mounted in the boring bar adjacent to the boring bar external diameter, the upper end of the feed screw is connected to the gear shifting box; the boring knife rack is mounted on the boring bar through a first Huff cramping apparatus, the lower end of the feed screw is connected to feed screw nuts, the feed screw nuts are connected to the first Huff cramping apparatus, the boring bar is provided with knife rack guides, the knife rack guides are mounted with navigation keys, the navigation keys are connected to the boring knife rack. The present invention solves the field quickly boring big, deep hole problem in industry field, and has good boring controllable performance and high accuracy; also simultaneously integrates the milling function to the flange end-face and has electric and manual switch operation schema, has good operating performance, reduces labor intensity and improves its operating efficiency.

Owner:WUCHANG SHIPBUILDING IND

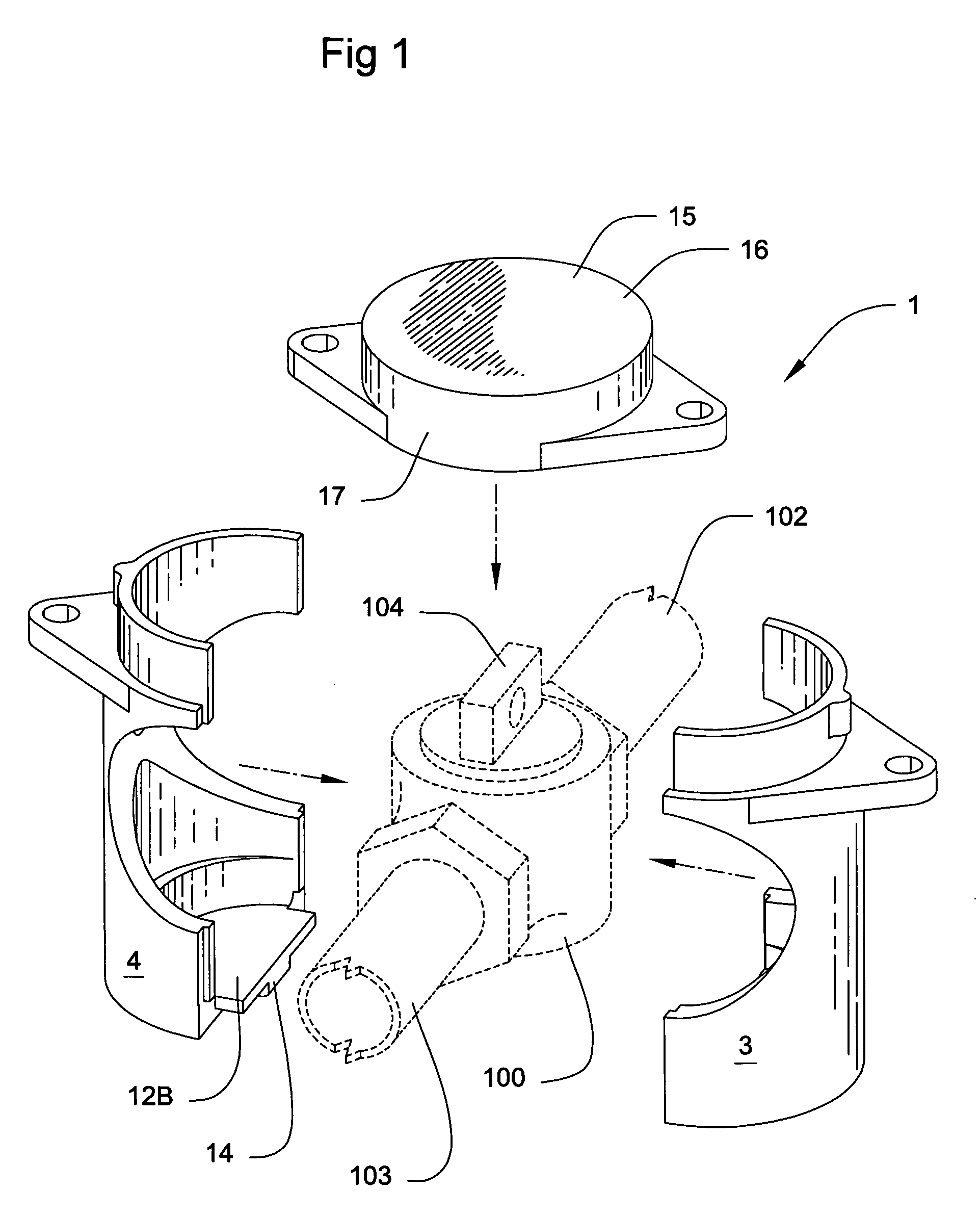

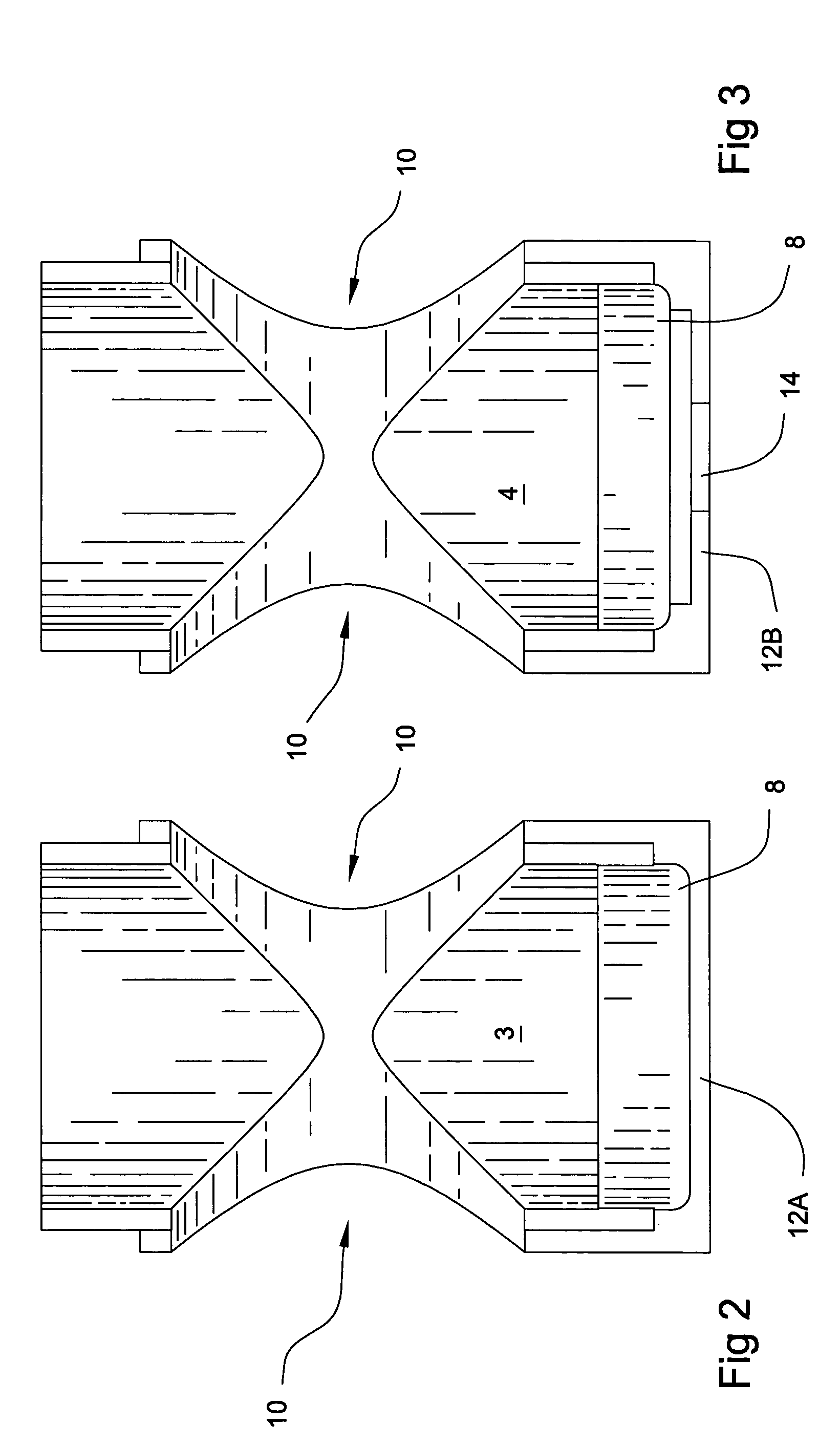

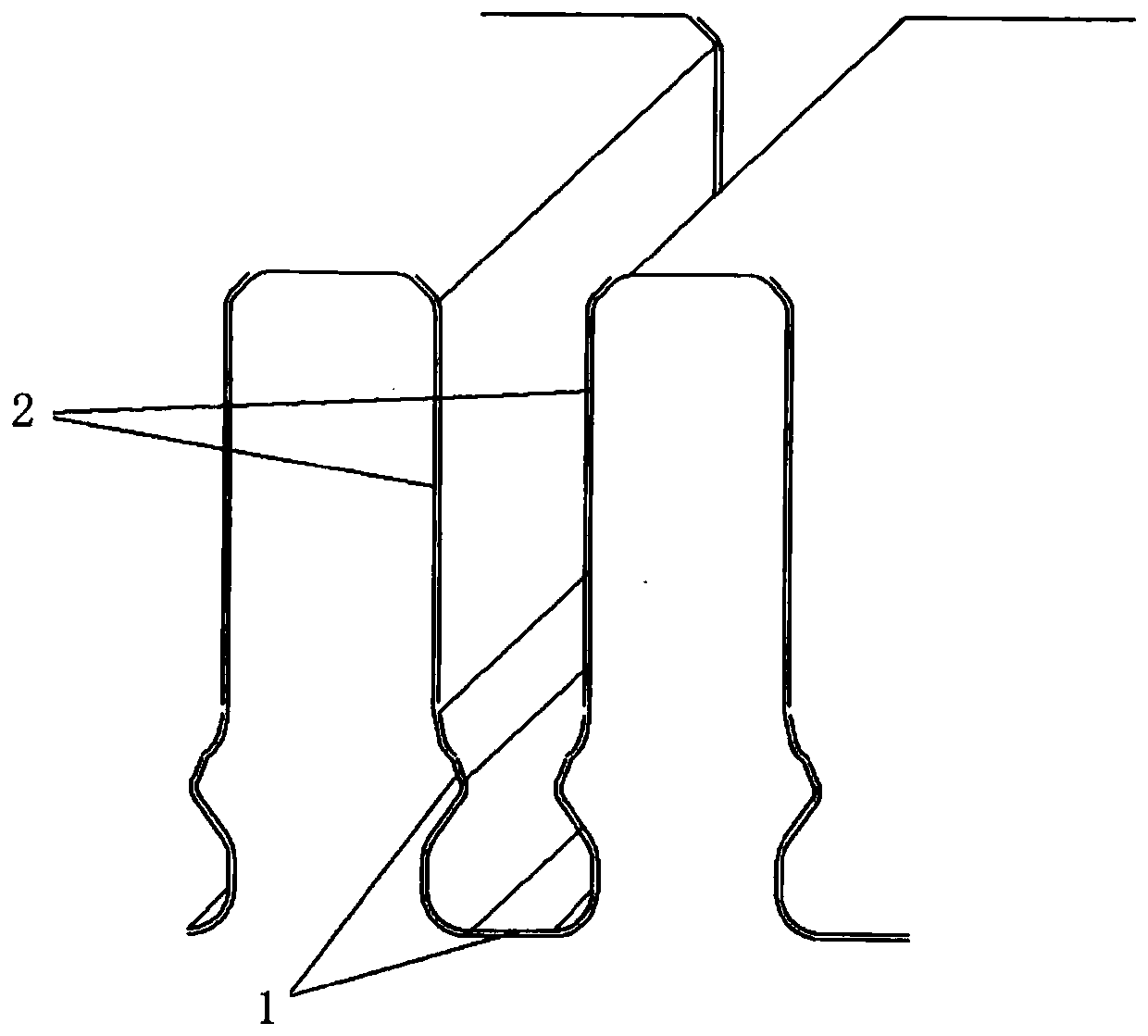

Semi-automatic mortising machine

InactiveUS20050145297A1Reduce the possibility of failureEasy maintenanceTongue/grooves making apparatusMulti-purpose machinesMortise and tenonSemi automatic

A semi-automatic mortising machine includes a support base, a support bar, a guide device, a working device, a distance adjusting device, and a dust collection box. Thus, the displacement direction can be controlled in a manual manner during the working process, and the cutting operation is performed in an automatic manner so as to cut the mortises and tenons in the workpiece.

Owner:CHANG CHI LO

Method for producing hard wood composite floor

InactiveCN1565818AReduce moisture contentUniform strength and densityWood working apparatusWood layered productsParquetinaHeat press

The invention discloses a method for producing wood composite floor which includes the following steps: prepressing the base material for not less than 20 seconds at pressure above 8MPa and temperature above 100 degree Centigrade; cooling the base material, sanding the base material according to the required thickness with grinding belt whose mesh is above 100m, then choosing one side of the base material as decorative surface, and sanding the decorative surface with grinding belt whose mesh is above 200m to obtain a base material with a thickness tolerance of + / -0.3mm and an angularity of less than 2%; combining the base material, the faced layer, the balance layer into a blank, heat pressing for not less than 20 seconds at the temperature above 150 degree Centigrade and pressure above 5Mpa; then cooling the treated base material for 8 hours or longer, cutting and machining into the finished product in the mortising machine.

Owner:段素英

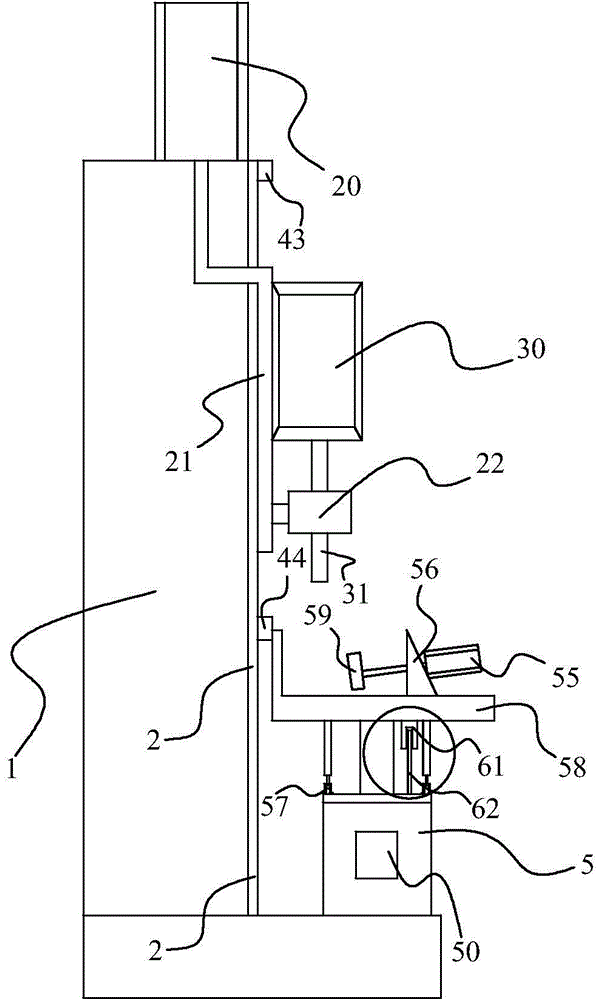

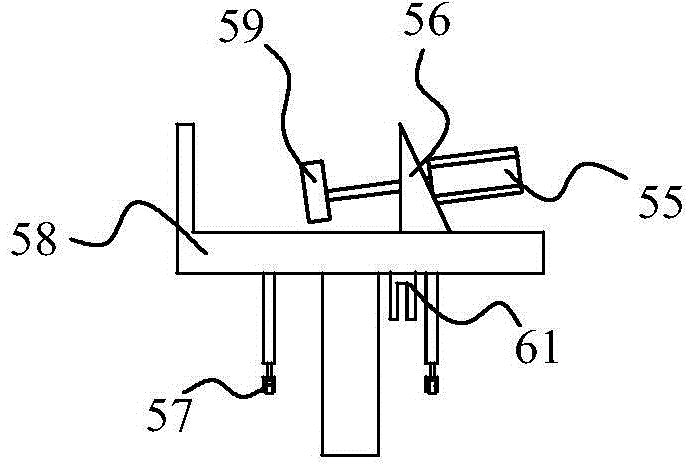

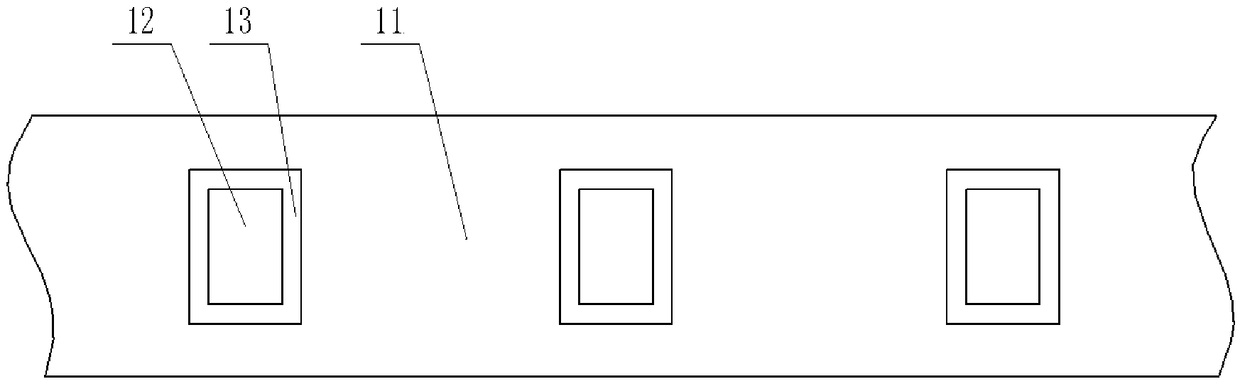

Woodmaking mortising machine and notching method

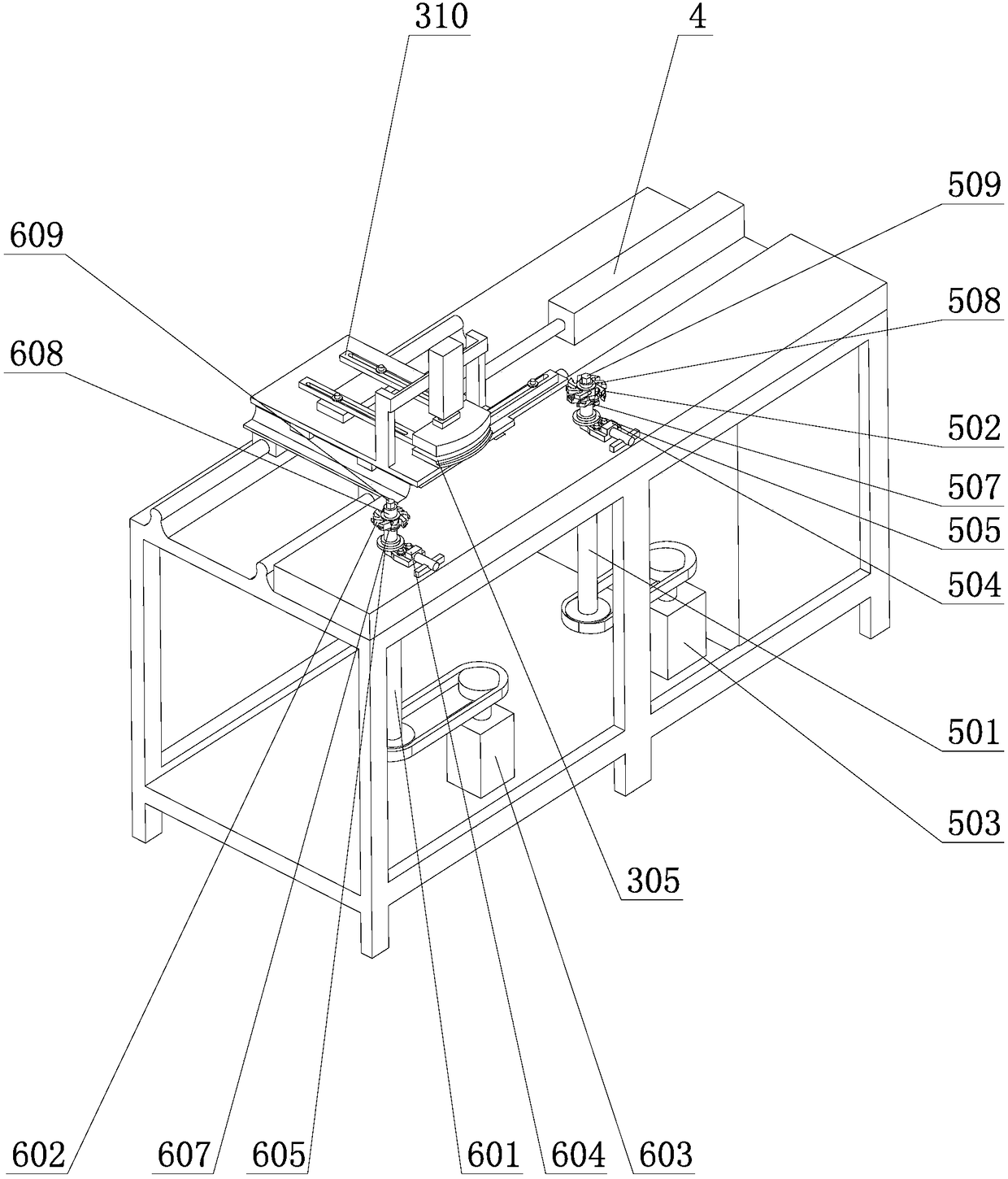

The invention discloses a woodmaking mortising machine, which comprises a rack (1), wherein transverse and longitudinal devices, a workbench (58) and a punching machine (30) are separately arranged on the transverse and longitudinal devices; a transverse movement sensing device is arranged on the transverse device; the transverse movement sensing device comprises a limiting switch and a slit switch; a longitudinal movement sensing device is arranged on the longitudinal device; the longitudinal movement sensing device is an approaching switch.

Owner:ZHEJIANG SCI-TECH UNIV

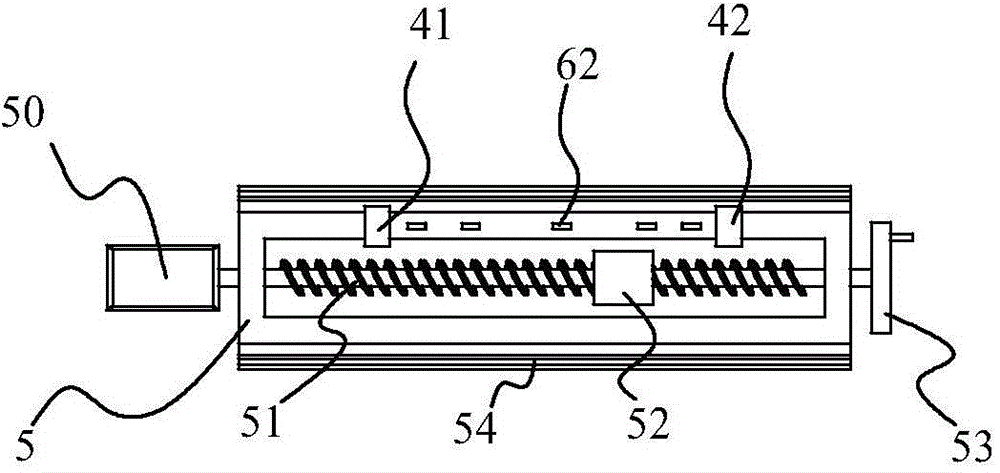

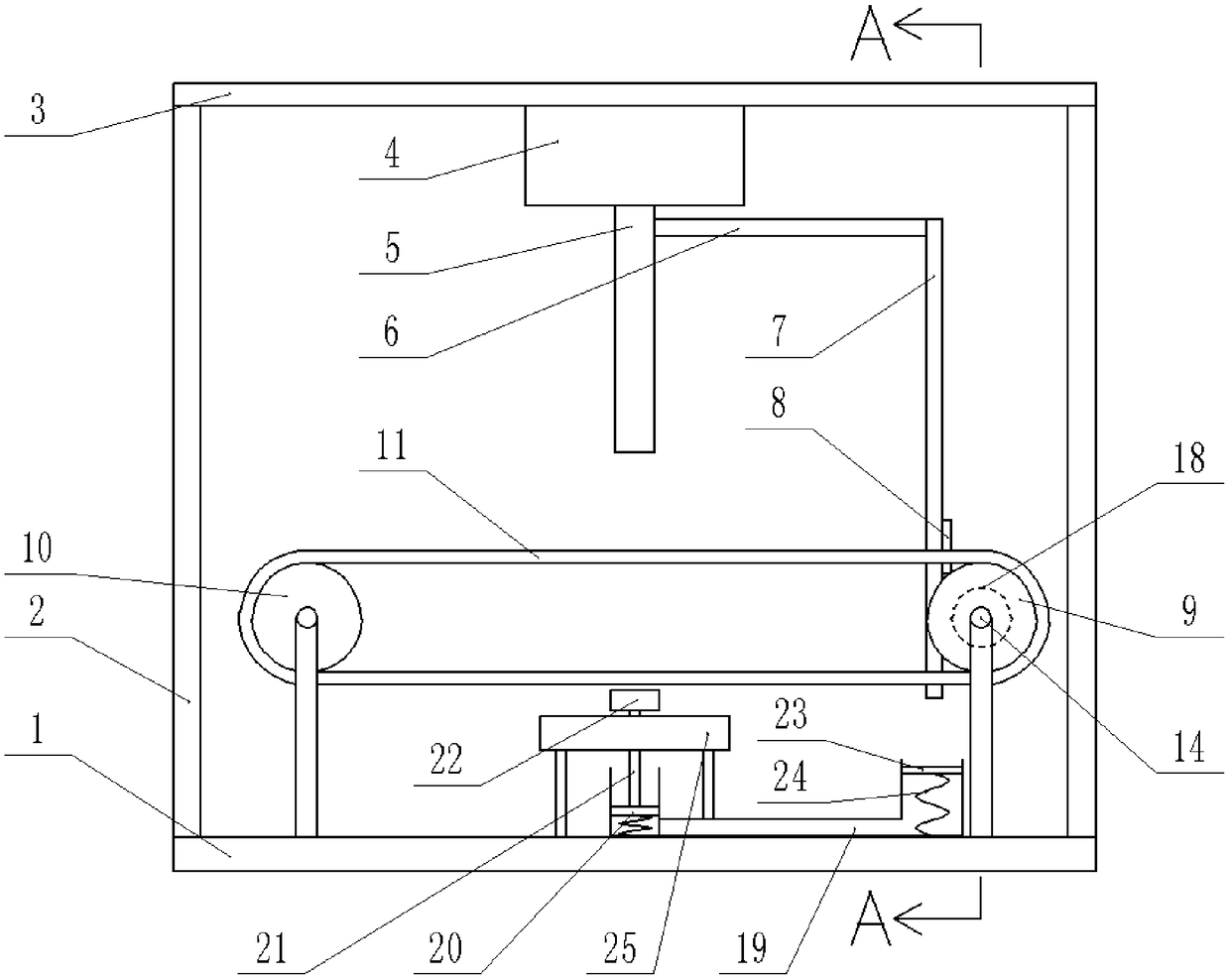

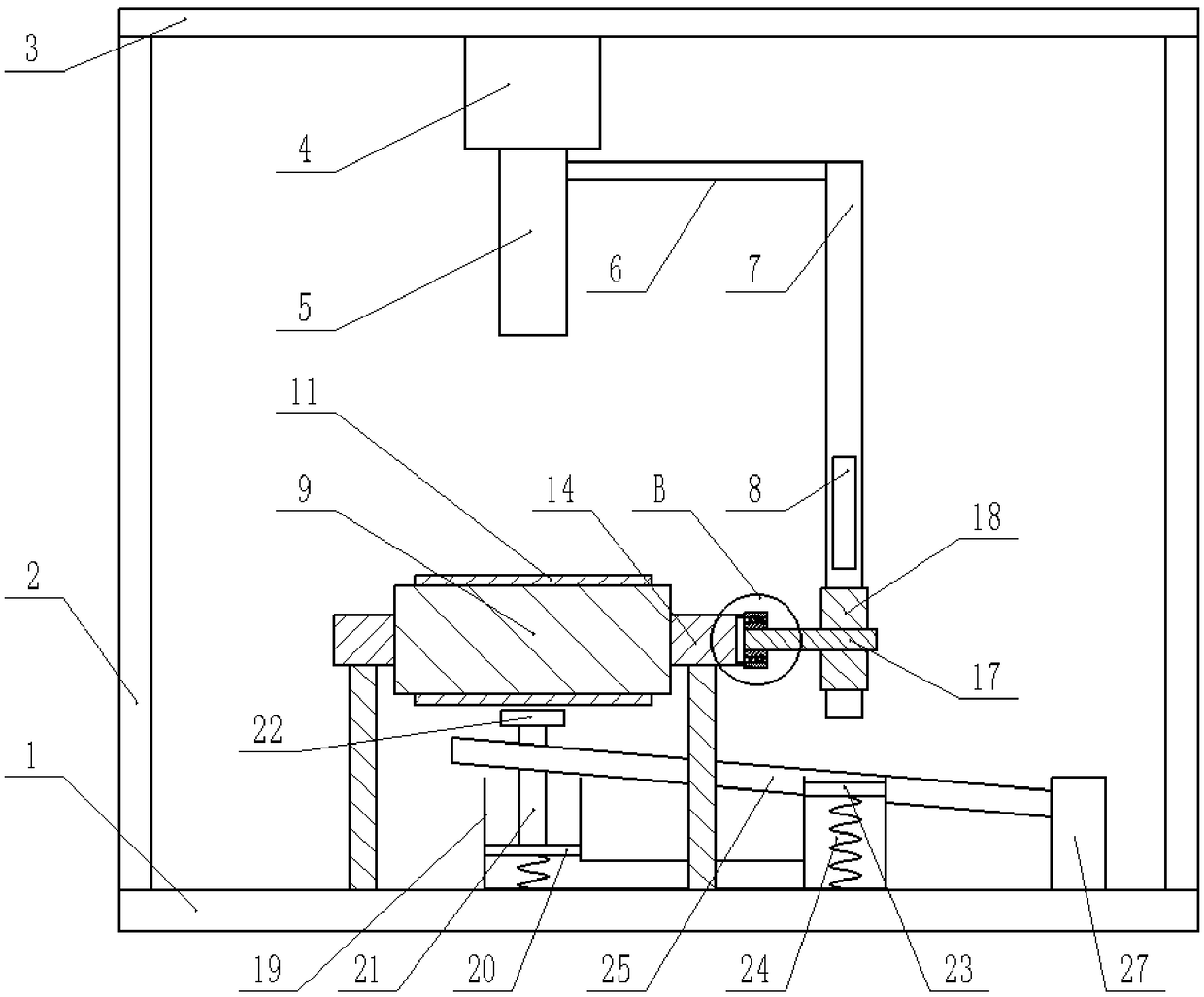

Rapid feeding device of mortising machine

ActiveCN108908552AEasy to take outEasy to transportWood mortising machinesWood slotting machinesDrive shaftEngineering

The invention belongs to the technical field of wood product processing, and particularly discloses a rapid feeding device of a mortising machine. The rapid feeding device comprises a base and a stamping unit, the stamping unit is arranged on the base, the stamping unit comprises a stamping head, and the stamping head is vertically arranged downwards; the rapid feeding device further comprises a conveying unit and a linkage unit, the conveying unit comprises a conveying belt, a driving wheel and a driven wheel, the conveying belt is wound between the driving wheel and the driven wheel, the conveying belt is located below the stamping head, a through groove is formed in the conveying belt, and a flange which is made of a flexible material is arranged at the bottom of the through groove in the circumferential direction; a driving shaft is arranged on the driving wheel, a driven shaft is arranged on the driven wheel, and the driving shaft and the driven shaft are rotationally connected tothe base; and the linkage unit comprises a one-way bearing, a rotating shaft and a parallel rod, the driving shaft is fixedly connected with the outer ring of the one-way bearing, the rotating shaftis fixedly connected with the inner ring of the one-way bearing, a gear is arranged on the rotating shaft, a rack is vertically arranged on the parallel rod, and the rack is meshed with the gear. According to the scheme, the problem that most existing mortising machines adopt manual feeding is solved.

Owner:贵州鑫大福门业有限公司

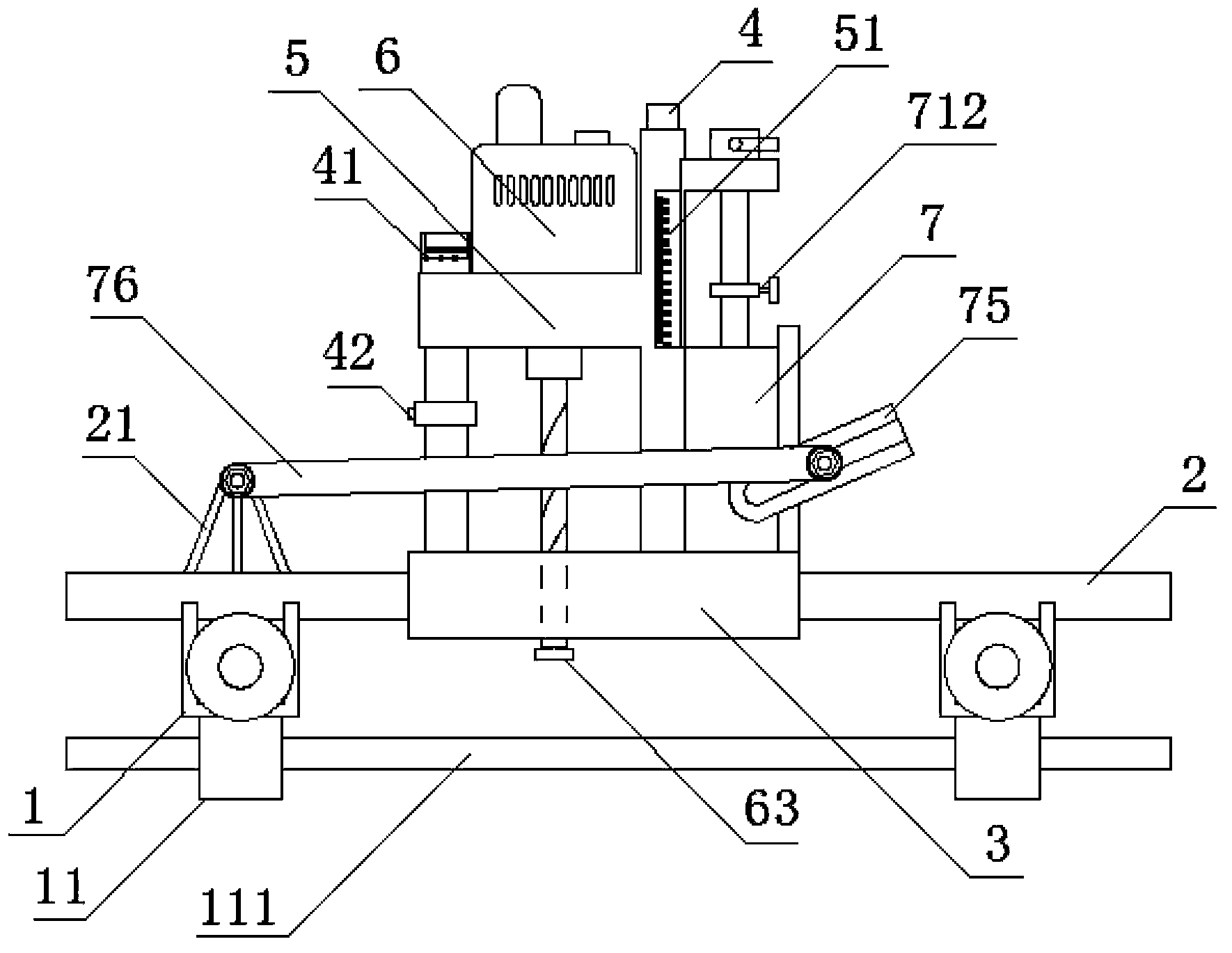

Door lock mortising machine

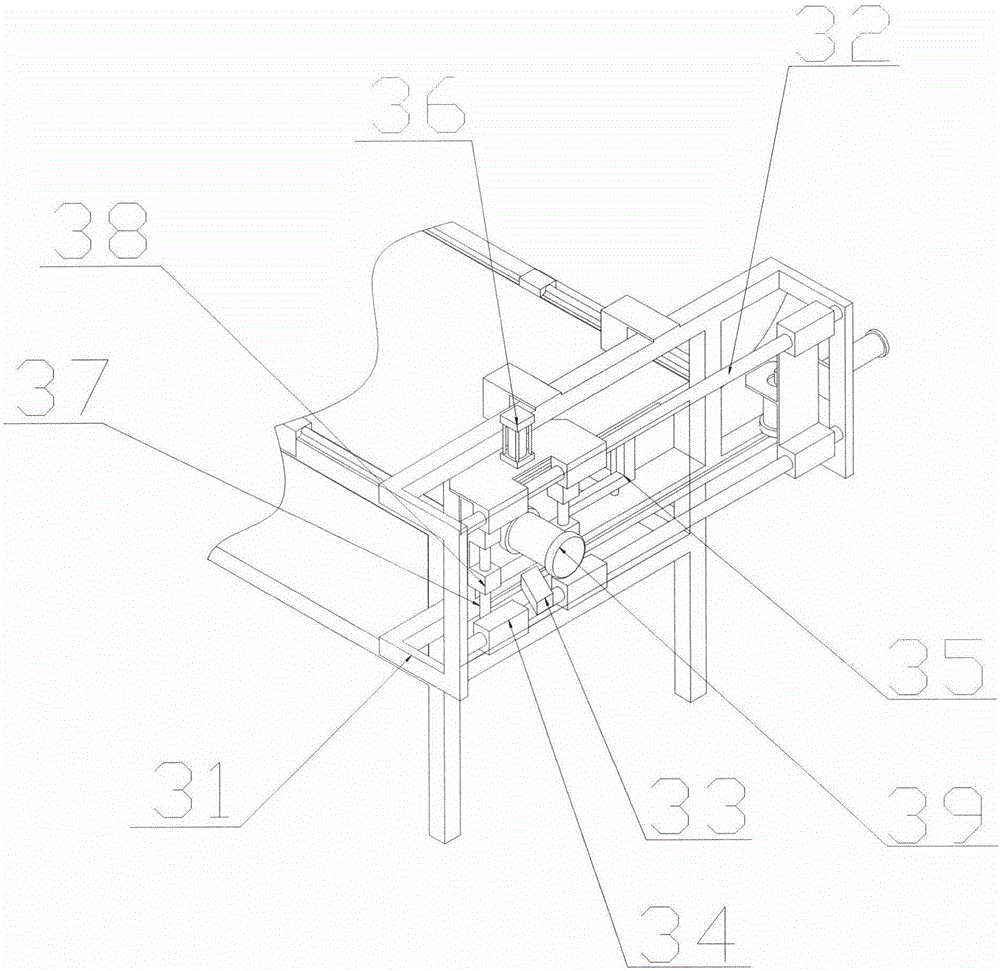

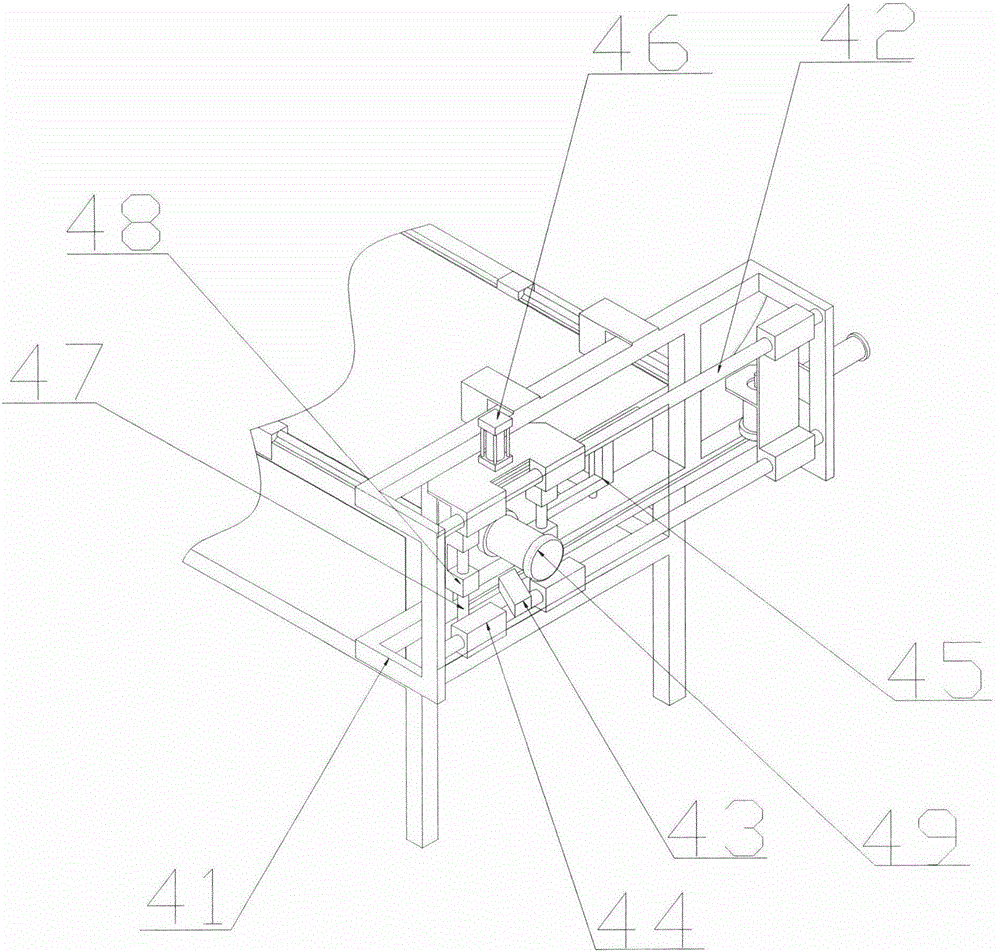

InactiveCN103350438APrecise positioningRapid positioningWood mortising machinesWood slotting machinesDetentOperation safety

The invention relates to a door lock mortising machine which comprises a transverse beam, a transverse guide rail, a chassis, a vertical guide rail, a fixed bracket, a motor, a rocker arm end support, a cavity, a lifting poker, a transmission shaft, a crank, a rocking bar, an oscillating arm, a rocker arm, a reducing sleeve, a tool bar, a tool bit, clamping boards, a bidirectional lead screw and a hand wheel. Compared with the prior art, the door lock mortising machine has the advantages that the door lock mortising machine can locate on a wood door accurately and move precisely, a side hole positioner is used for machining a lock hole of the wood door, the lock hole can be machined through one-step installation, positioning and puncturing instead of through a plurality steps and a plurality of machines, work efficiency is improved, the labor intensity of workers is reduced, and the door lock mortising machine is simple and convenient to use, accurate and fast in positioning, safe and reliable in operation, small in seize, convenient to carry and suitable for machining lock holes in various wood doors.

Owner:XUZHOU FENG ZHAN MACHINERY

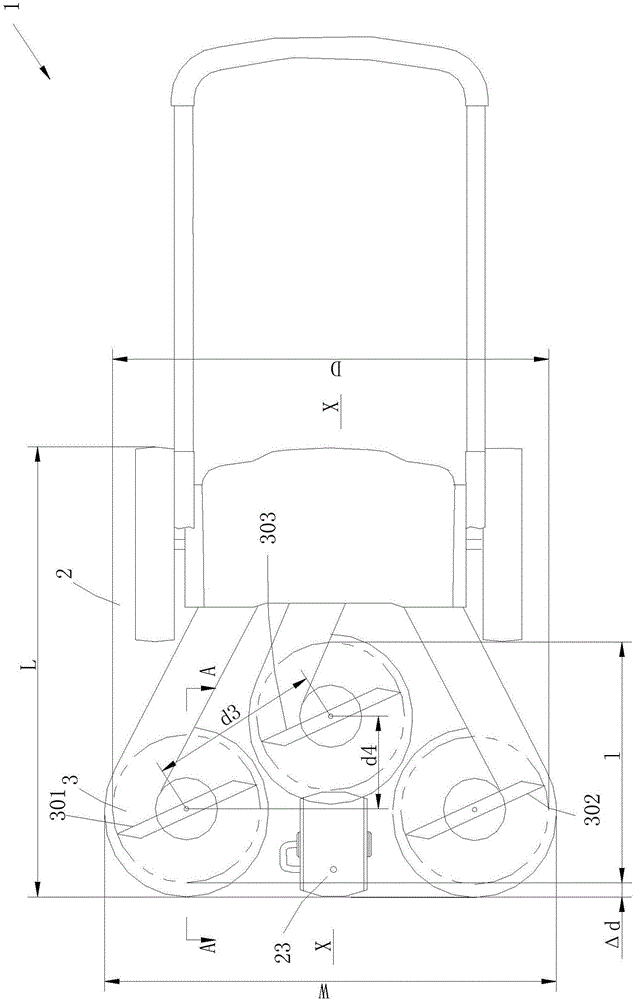

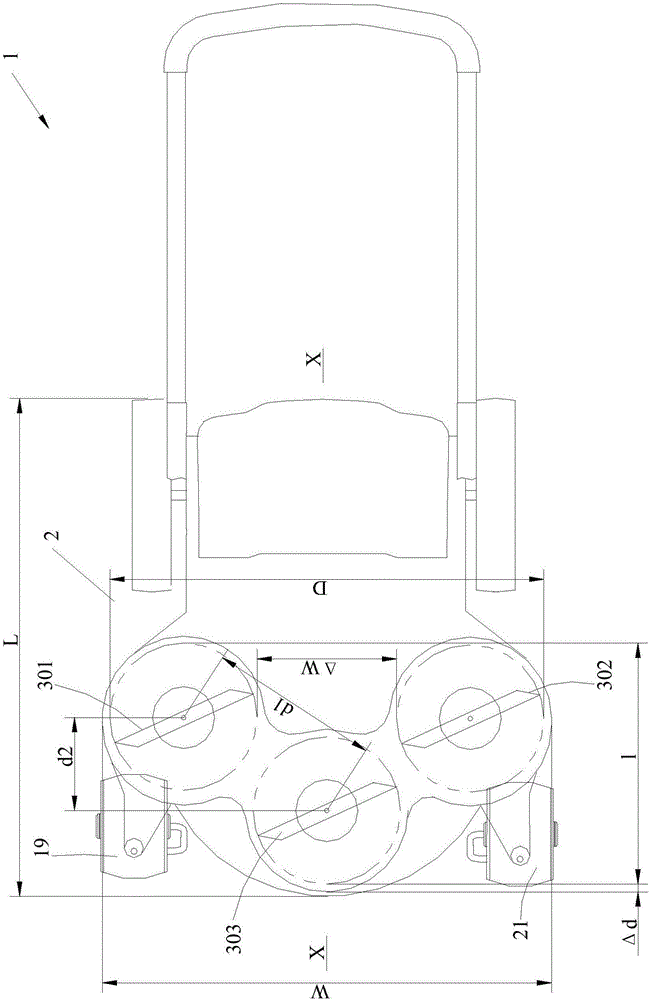

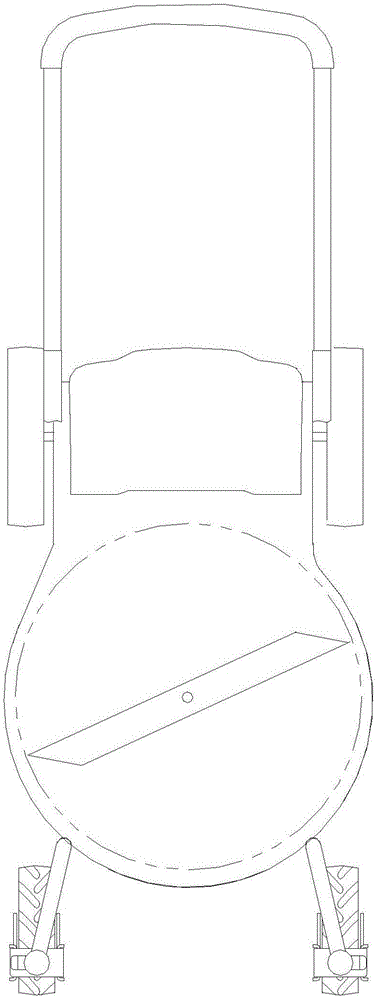

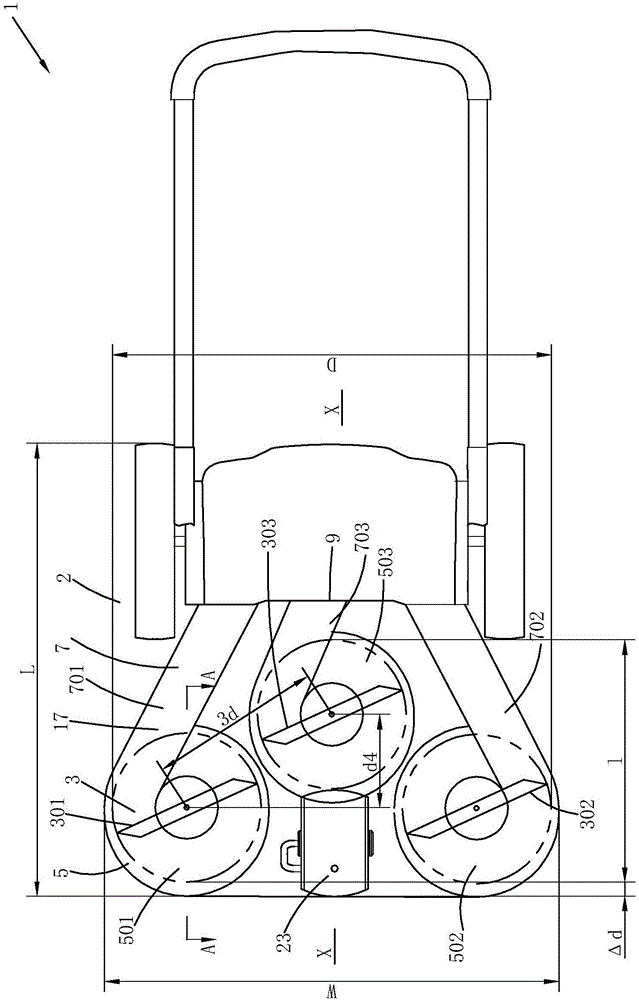

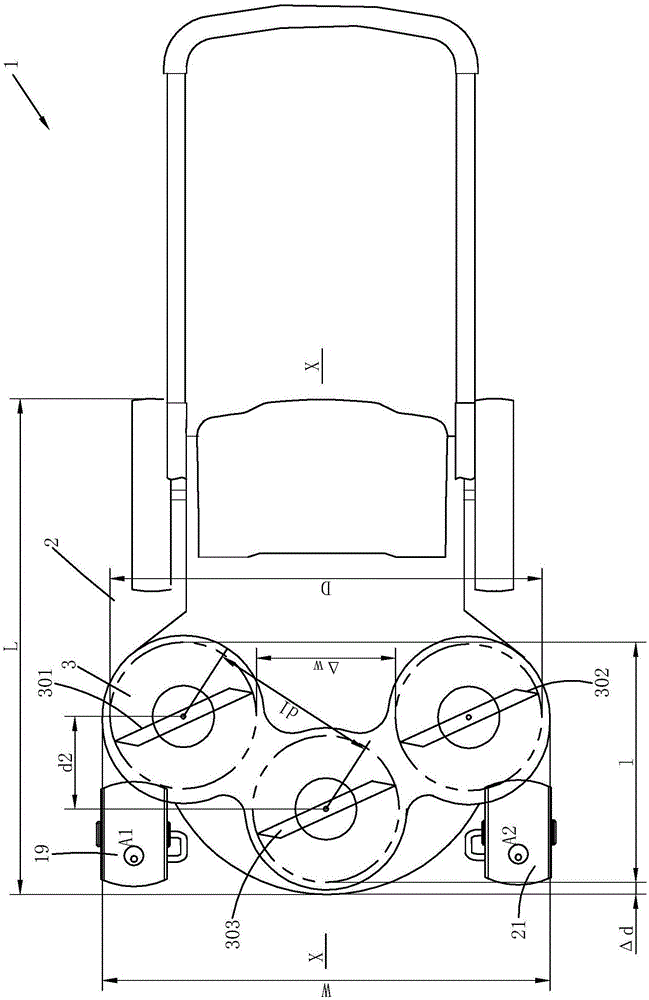

Multifunctional mowing machine

The invention relates to a mowing machine, in particular to a multifunctional mowing machine. The mowing machine comprises a cart handle, a mowing mechanism for mowing grass of different heights, universal wheels, a grass teasing mechanism, an auxiliary mowing mechanism and a protection cover mechanism with a water spraying function. By means of the mowing machine, lawns of different heights can be mowed, the using requirement is met, styling of the lawns is facilitated, the lawns are better beautified, disordered lawns can be teased, and mowing is facilitated; the mowing machine has an auxiliary mowing function, grass which grows highly is conveniently mowed, abrasion on the main mowing machine can be reduced, and mowing is more thorough; the mowing machine is provided with a protection cover with the water spraying function, blades can be prevented from hurting people, the situation that dust influences the health of the human body during mowing can also be prevented, the dustproof effect is achieved, and the functions are diversified. The bottom of the cart handle is fixedly connected with the right end of the mowing mechanism for mowing the grass of different heights, and the protection cover mechanism with the water spraying function is connected with the mowing mechanism for mowing the grass of different heights, and connected with the cart handle.

Owner:NINGBO LANGHUI TOOLS CO LTD

Multifunctional numerical control tenon and mortise machine and achieving method thereof

InactiveCN108582298AEasy to processSimple structureDovetailed workMulti-purpose machinesNumerical controlEngineering

The invention discloses a multifunctional numerical control tenon and mortise machine. A rack is included, and is provided with a Y axis motor guide rail which is provided with a Y axis motor base; aY axis motor used for providing power for moving in the Y axis direction and a fixed support are arranged in the Y axis motor base, and the fixed support is provided with an X axis support; an X axisguide rail is arranged on the side edge of the X axis support, and is connected with a tool bit device, and an X axis moving device is arranged at the upper end of the X axis support; and the two sides of the Y axis motor guide rail are each provided with a fixed guide rail, and the fixed guide rails are provided with a plurality of fixtures. The invention further discloses an achieving method ofthe multifunctional numerical control tenon and mortise machine. The multifunctional numerical control tenon and mortise machine has the characteristics of being simple in structure, low in manufacturing cost, convenient to use, high in speed, suitable for drilling various different holes, good in safety and the like.

Owner:DONGYANG XINHE ELECTRONICS MACHINERY

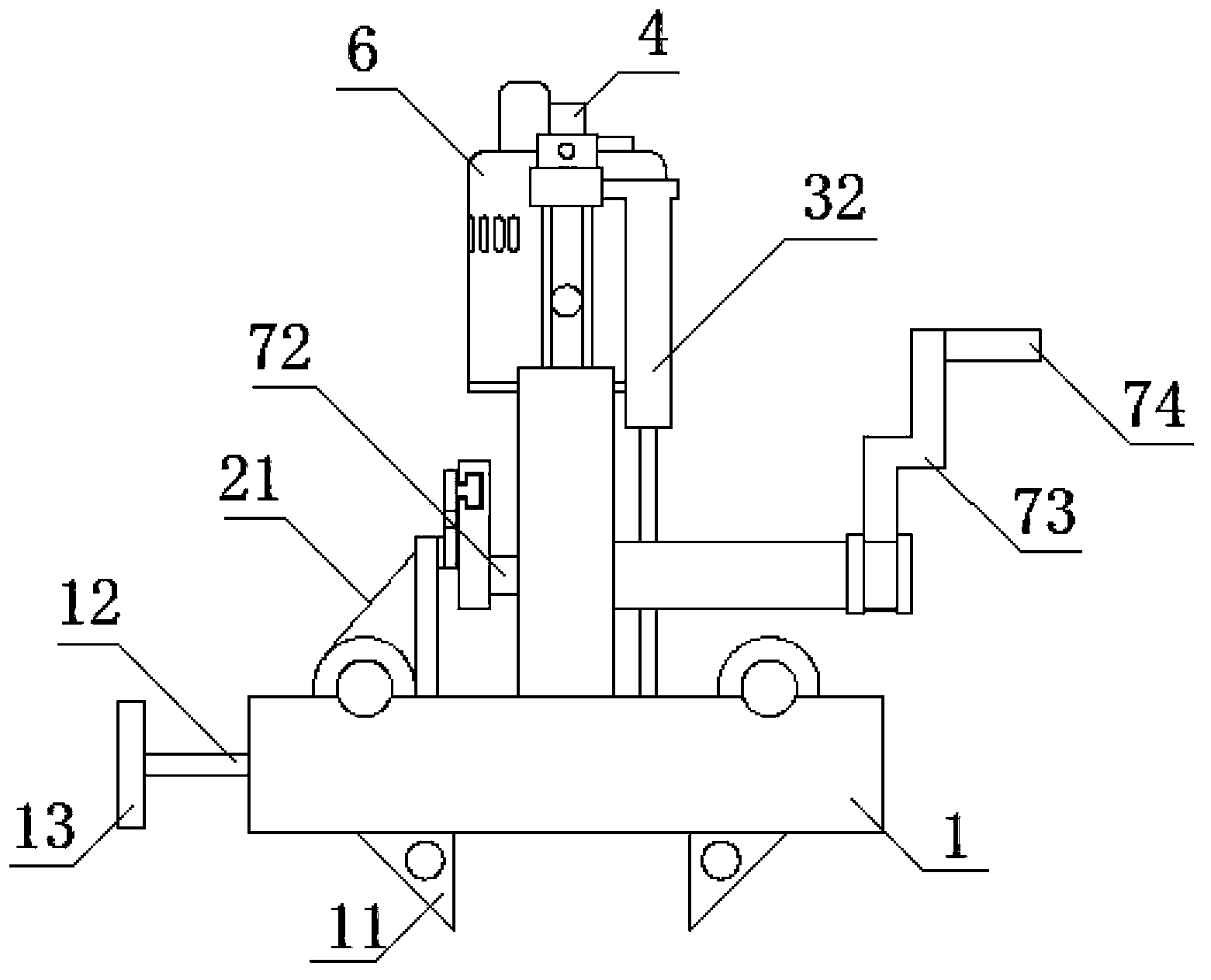

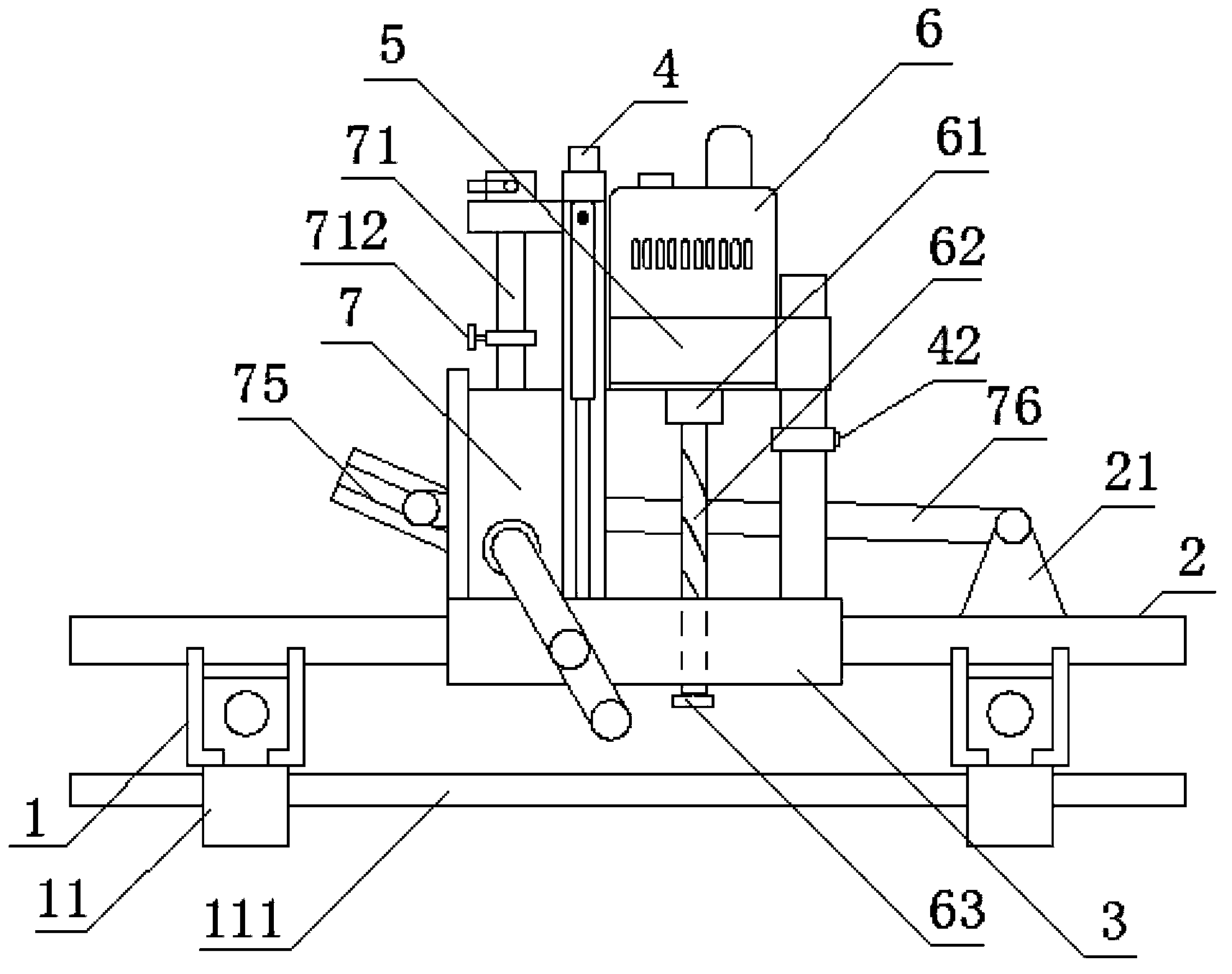

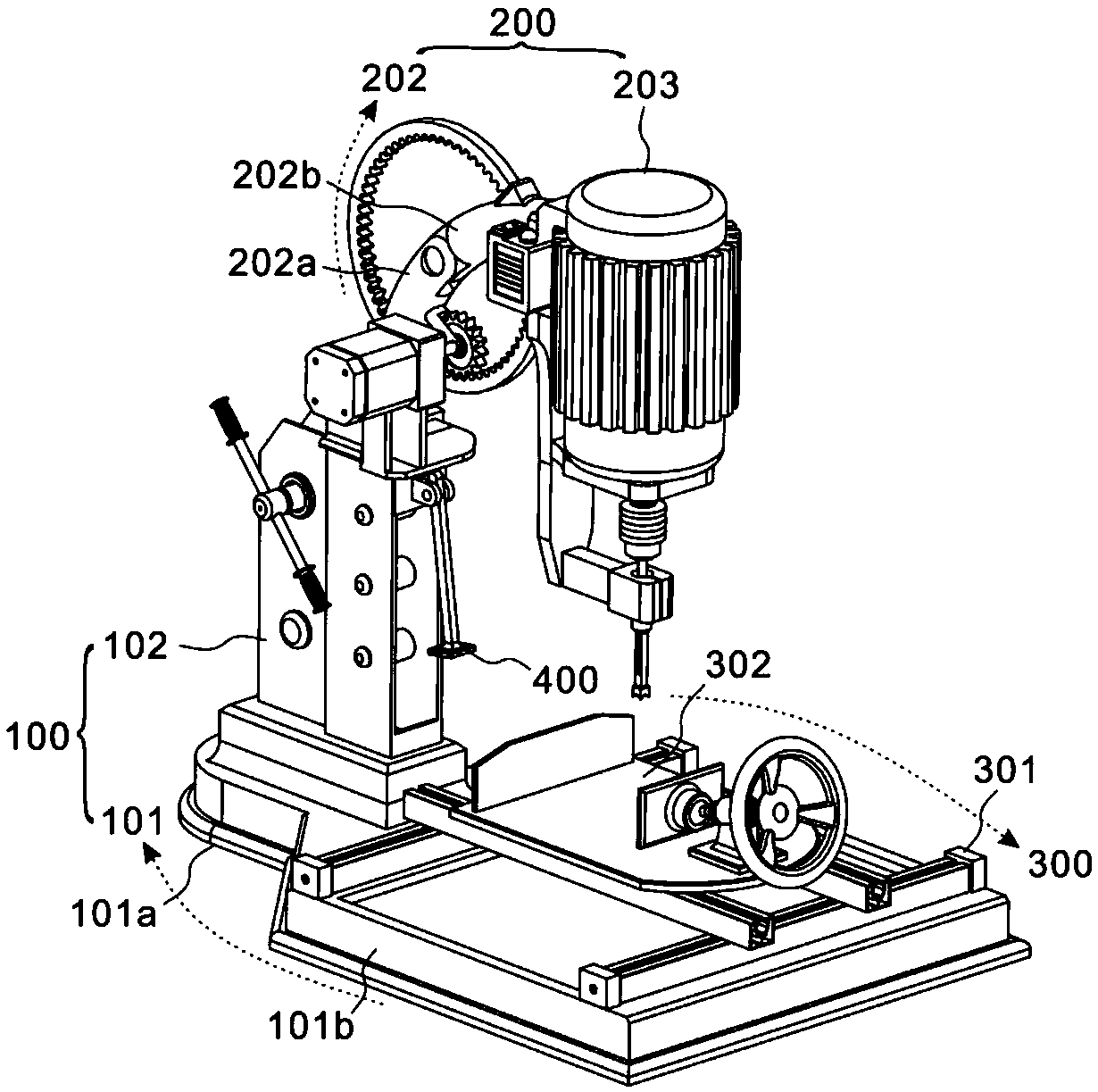

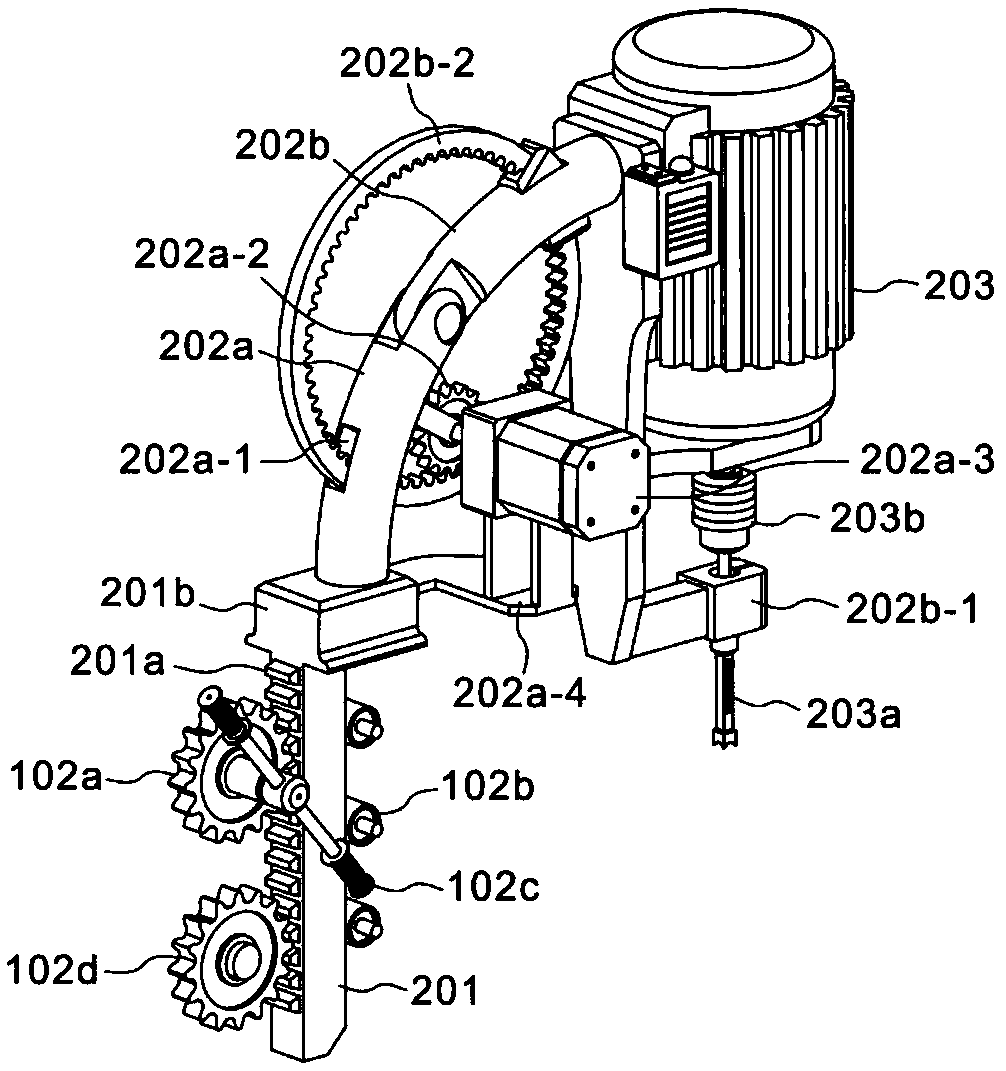

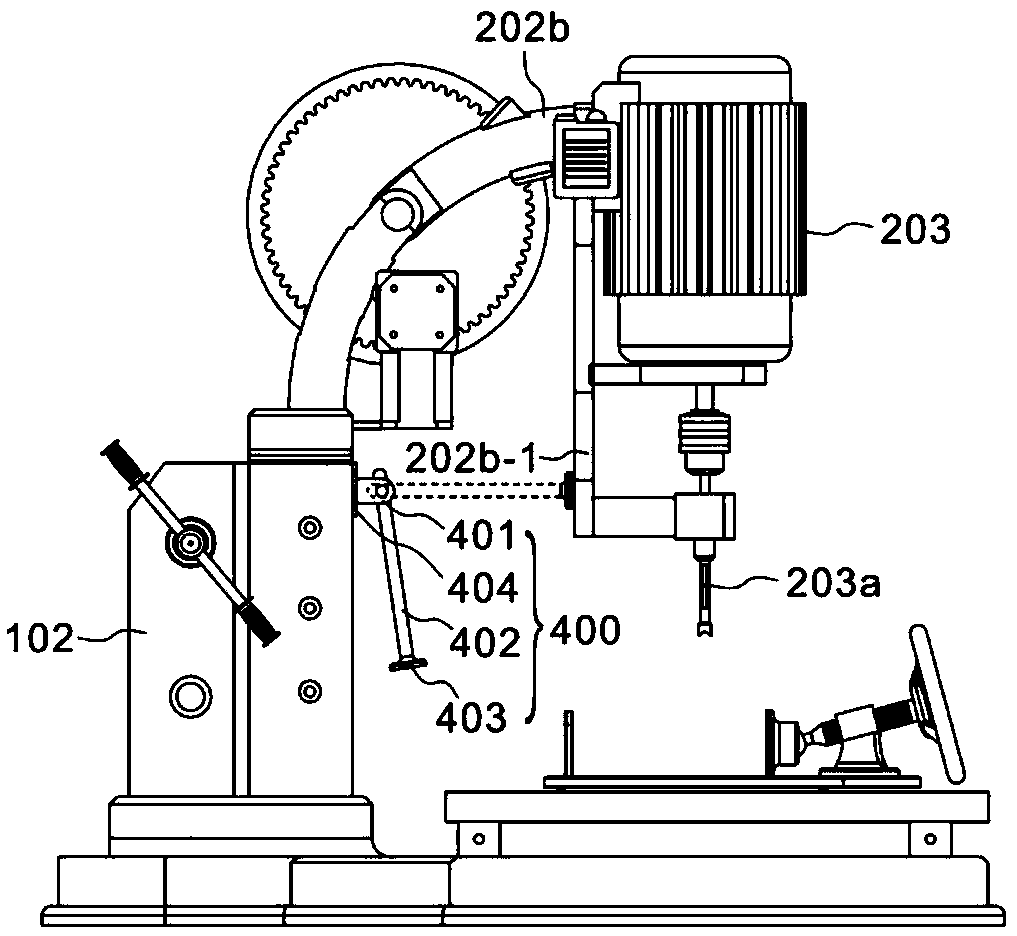

Multidirectional adjustable mortising machine

ActiveCN108638233AIncrease productivityEasy to operateStationary drilling machinesTongue/grooves making apparatusDrive wheelTongue and groove

The invention discloses a multidirectional adjustable mortising machine. The multidirectional adjustable mortising machine comprises a pedestal assembly, a lifting assembly and a supporting assembly.The pedestal assembly comprises a base and a guide stand column, wherein the guide stand column is fixed to the upper surface of the base. The lifting assembly comprises a guide part, a cantilever anda first power part. The lower end of the guide part is inserted into the guide stand column in a penetrating mode, and a driving wheel and guide rollers are arranged inside the guide stand column andmatched with the guide part. One end of the cantilever is connected with the top of the guide part, and the other end of the cantilever is connected with the first power part. The supporting assemblyis arranged on the base. According to the multidirectional adjustable mortising machine, due to the fact that a first cantilever and a second cantilever are arranged in a subsection hinge joint mode,the angle and the position of a drill bit can be timely adjusted by the first power part which is used for machining mortises, and the mortises with slopes can be machined. Due to the fact that a horizontal adjusting part comprises a longitudinal track and a transverse track, the mortises in random shapes and at random positions can be carved, and a plurality of mortises can be machined in sequence.

Owner:吴小江

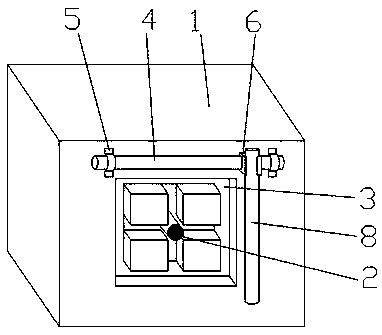

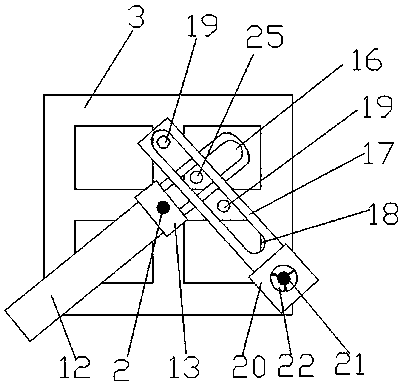

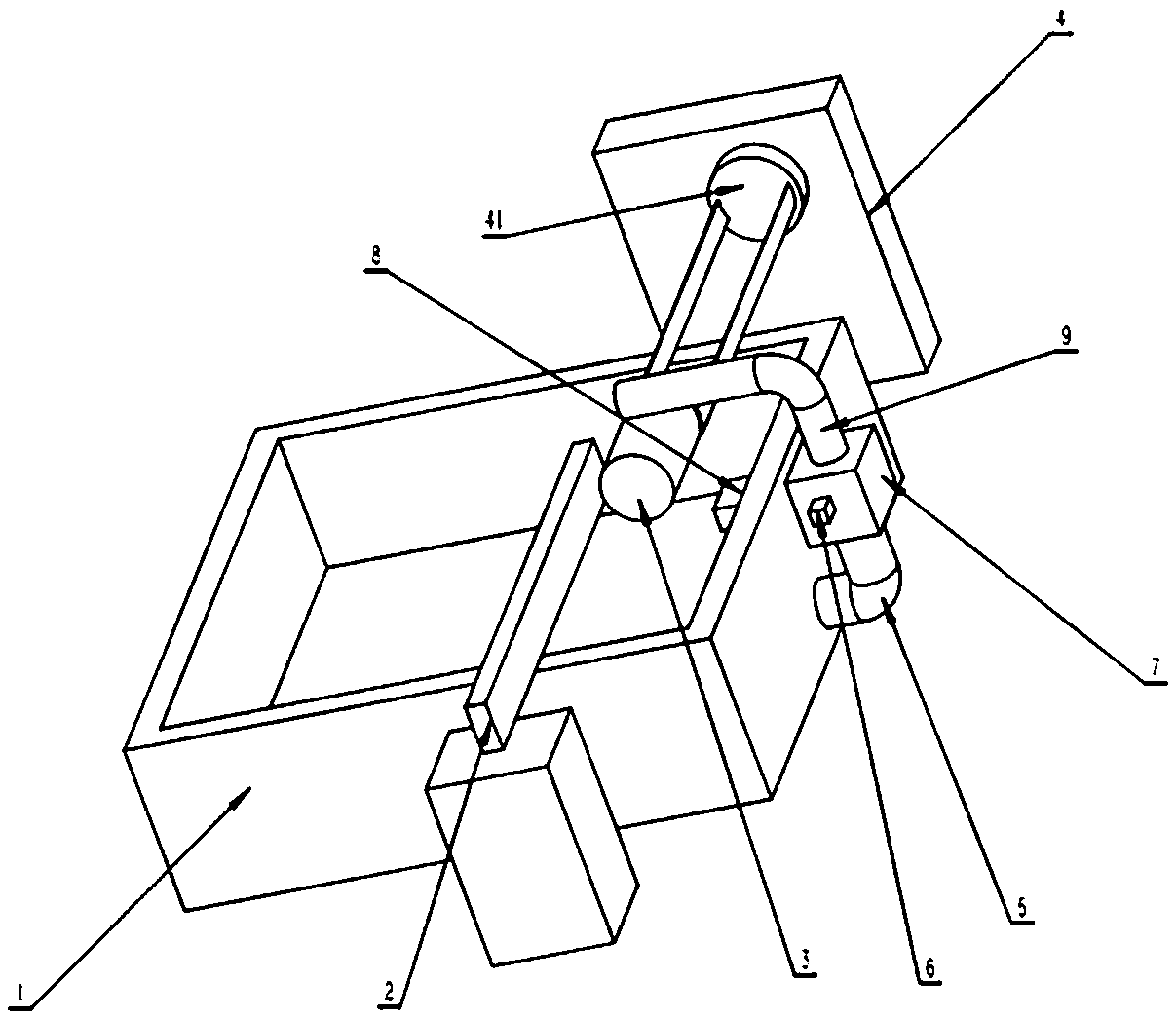

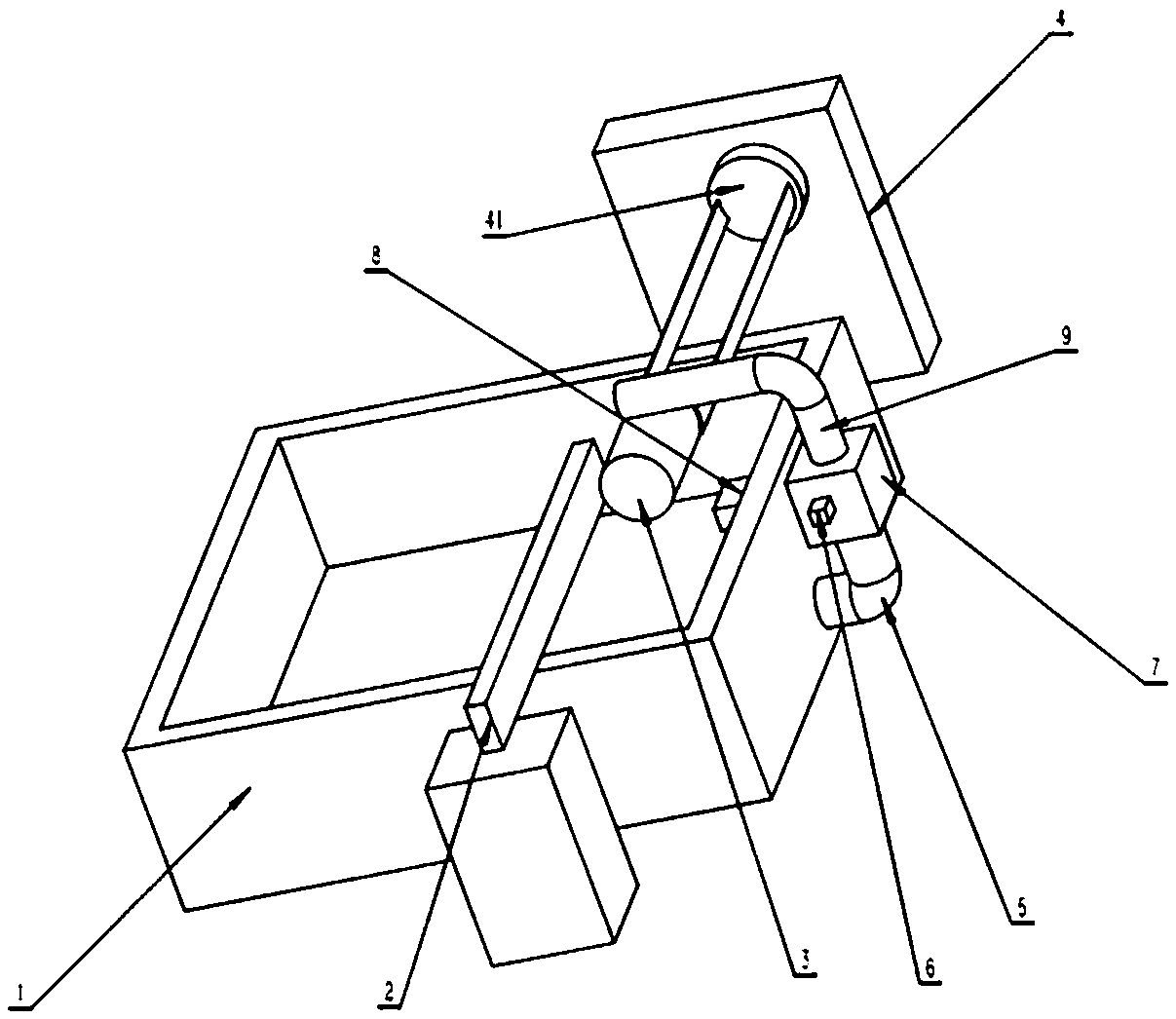

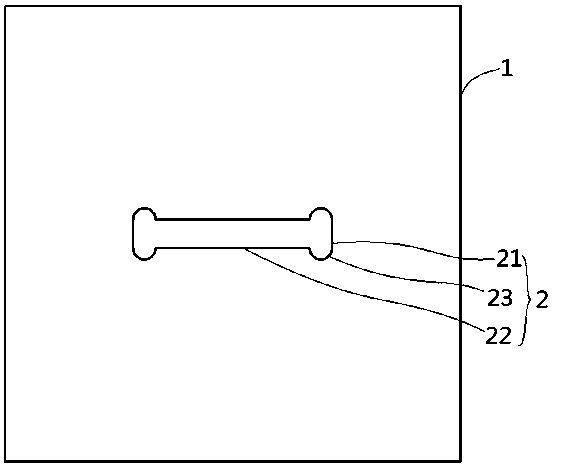

Combined tenon-groove mechanism adapted to various shapes of slotted holes and tenon-groove method

InactiveCN110978167APrecise tongue and groove structureImproving the way humans experience tongue and grooveDovetailed workTool bitMilling cutter

The invention discloses a combined tenon-groove mechanism adapted to various shapes of slotted holes. The combined tenon-groove mechanism includes a rectangular frame body, a horizontal sliding bar isfixed to the surface of the rectangular frame body through supporting hanging lugs, the horizontal sliding bar is connected with a vertical sliding bar through a first rectangular sliding block,the vertical sliding bar is connected with a rotary bar through a second rectangular sliding block, and the rotary bar is fixedly connected with a moving drive shaft through a third rectangular sliding block; the rotary bar is provided with a first straight sliding slot, the first straight sliding slot is connected with a second straight sliding slot of a milling supporting rod through rotary plungers,the second straight sliding slot is provided with cylindrical sliding blocks, and the moving drive shaft and the cylindrical sliding blocksare arranged in a groove bodyshaped like a Chinese character'tian'; and the milling supporting rod is fixedly connected with a milling motor, a three-jaw fixture and a milling cutter head.The invention further provides a corresponding tongue-groove method. The combined tenon-groove mechanism enables the milling cutter head to run according to a rectangular, circular or elliptical trajectory of a specific size through motion conversion so that various precise tongue-groove structures can be milled, and an existing tenon-groove method of relying on artificial experience is greatly improved.

Owner:利辛县爱侣家俱加工有限公司

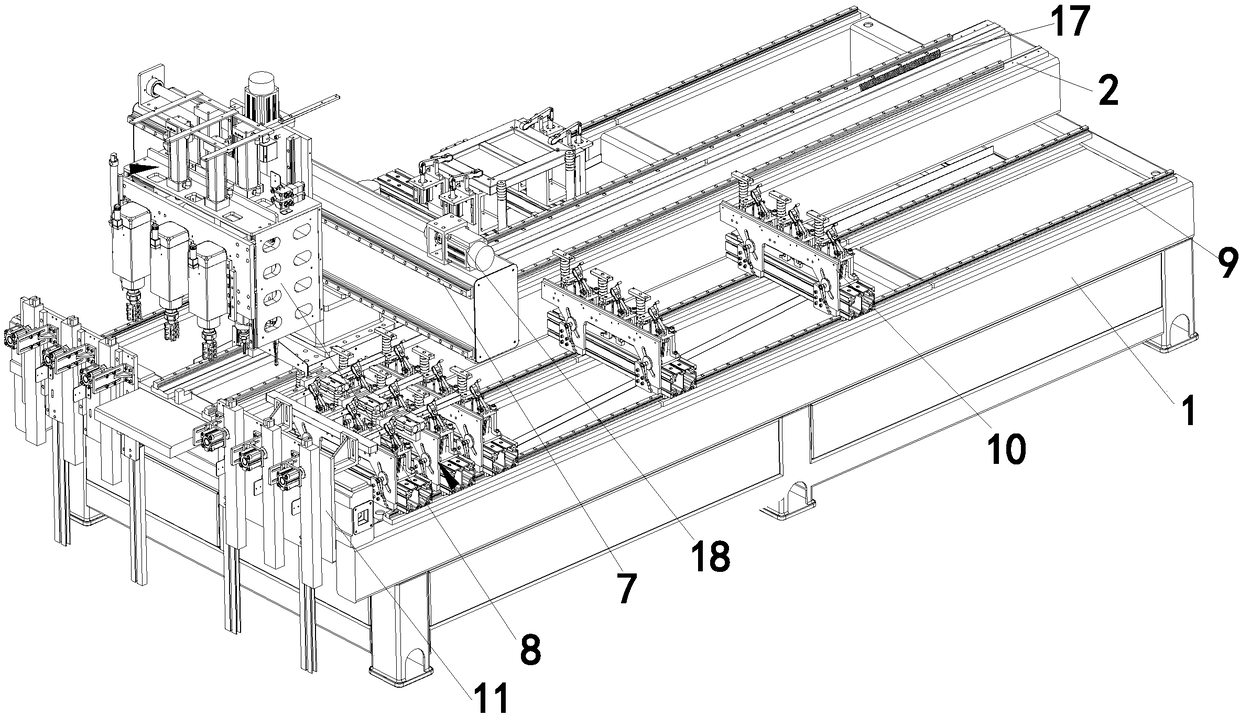

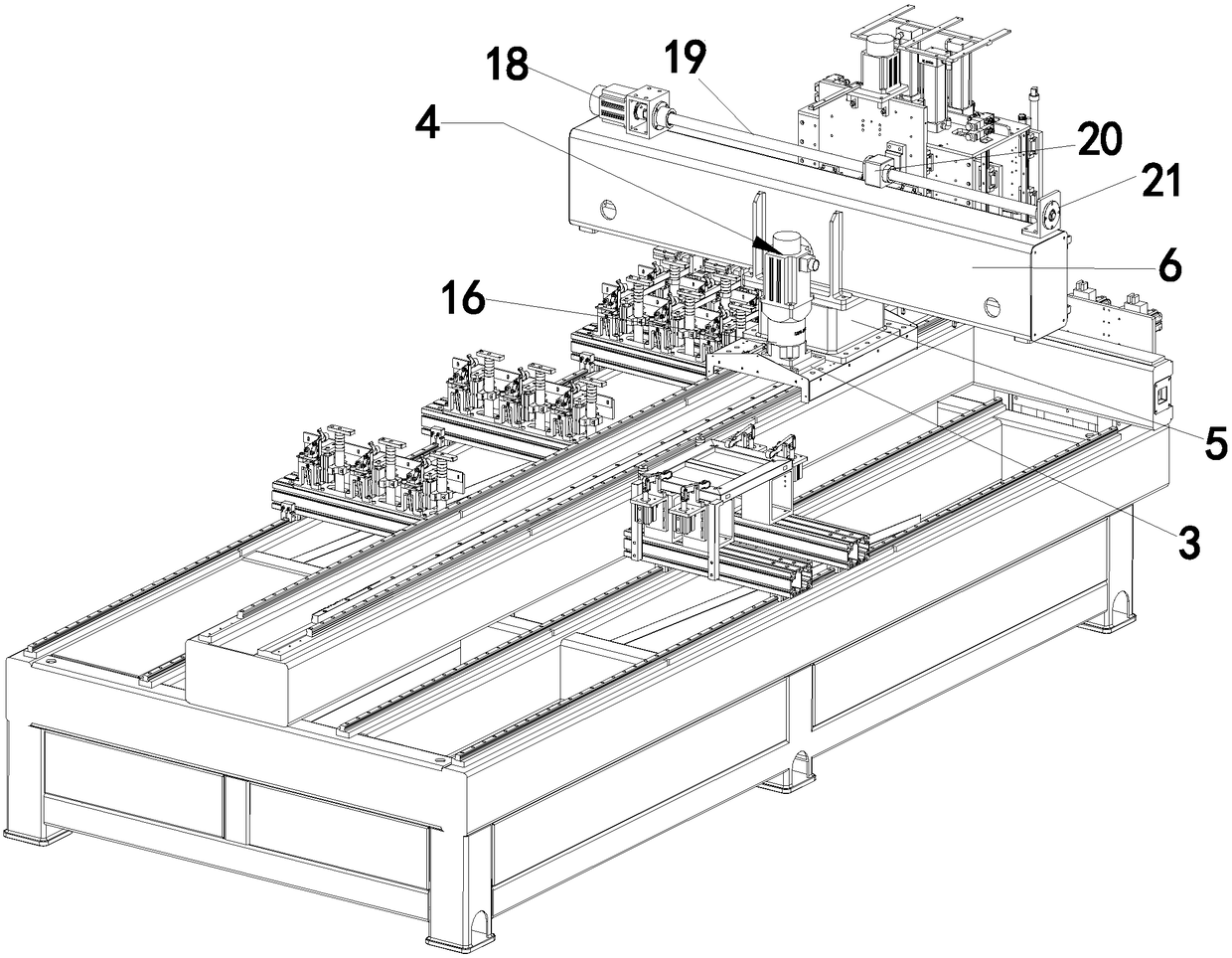

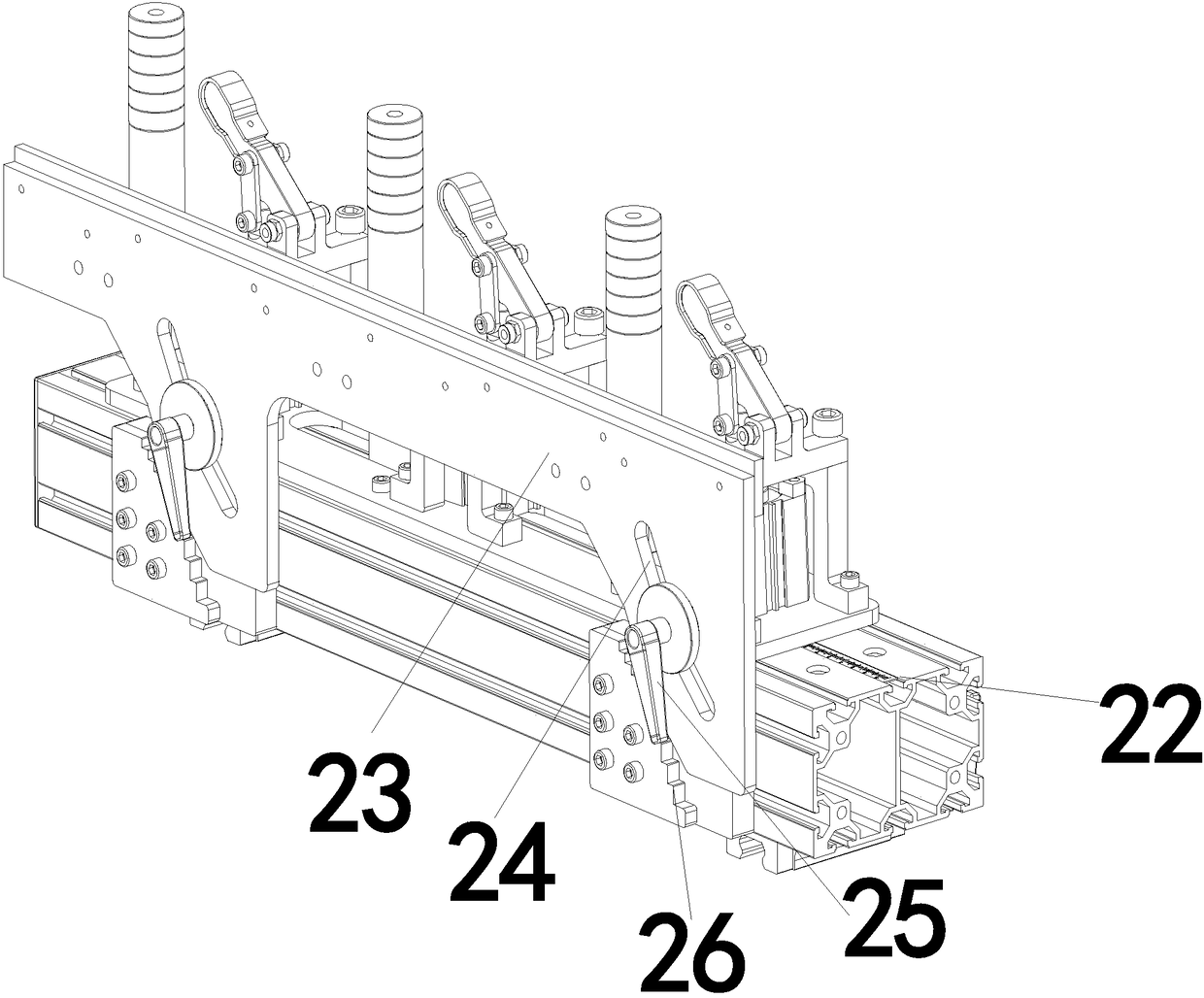

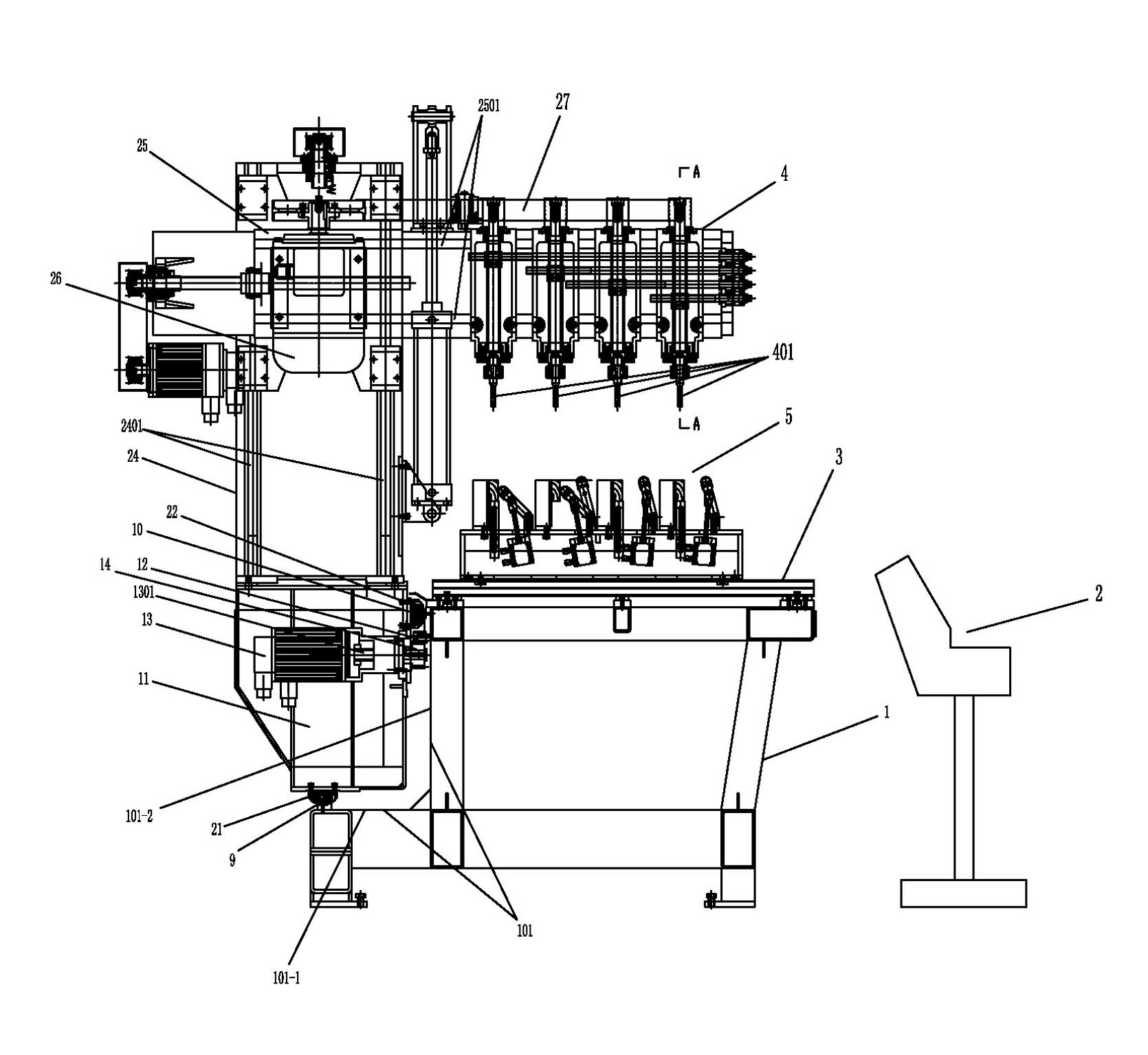

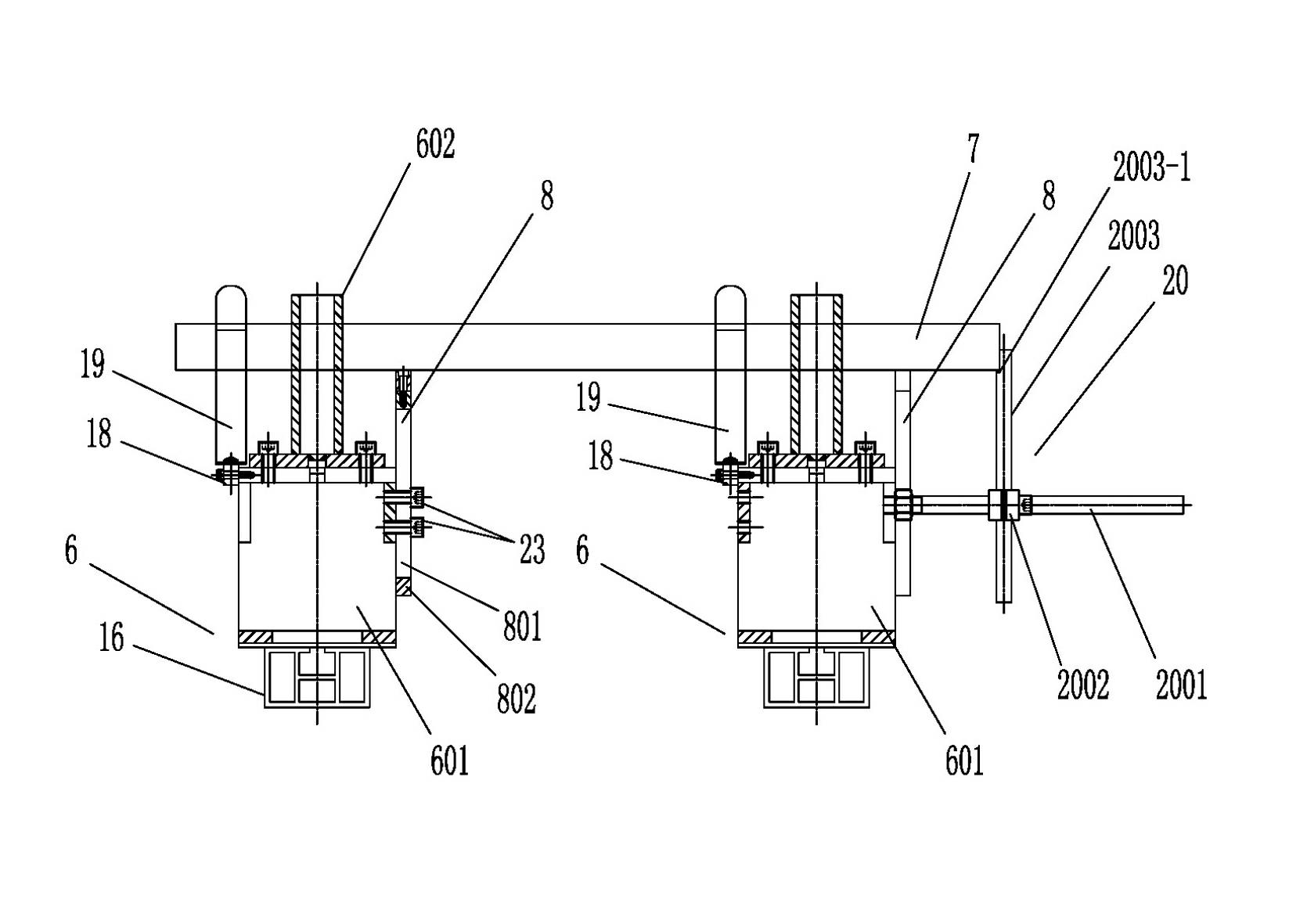

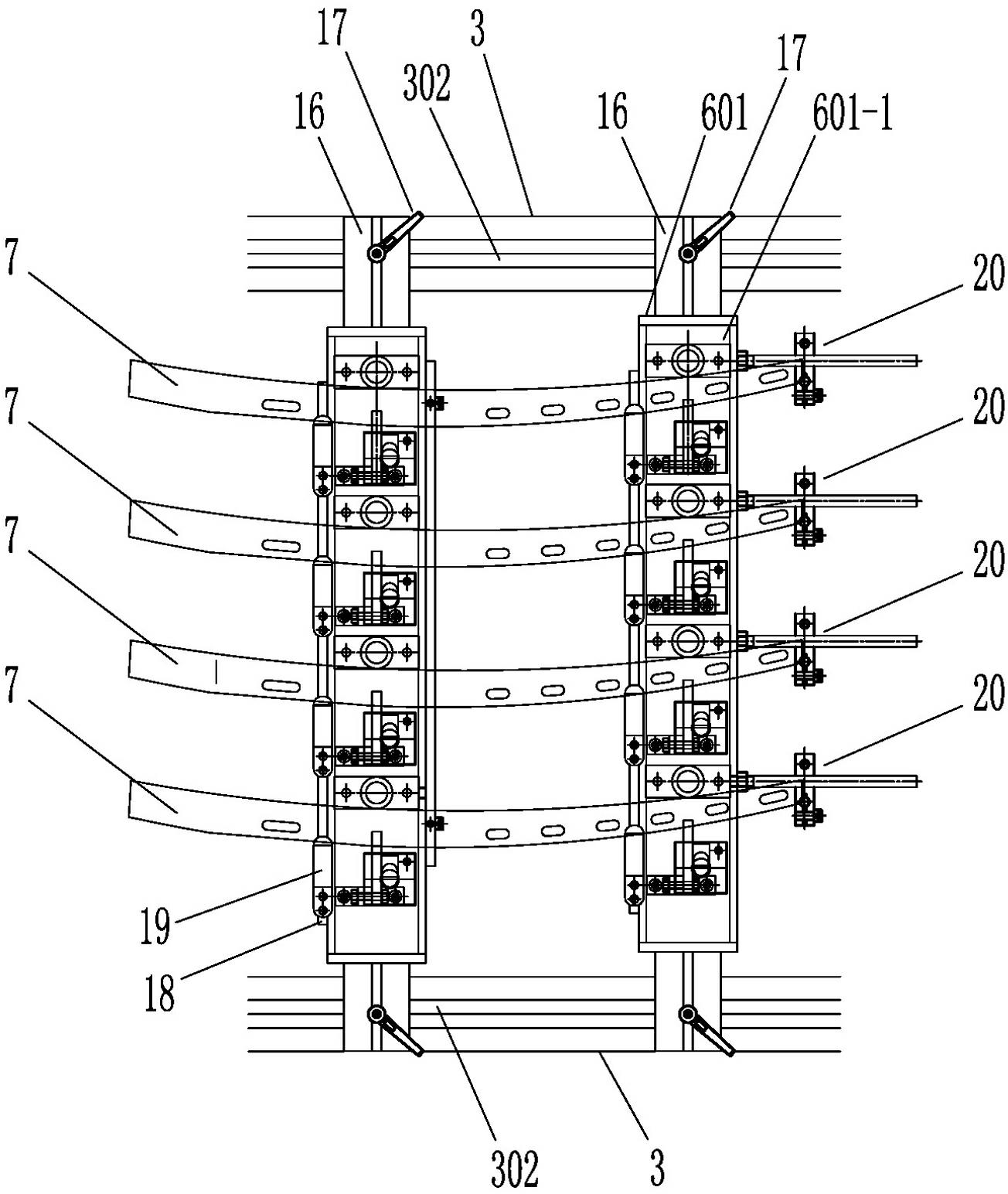

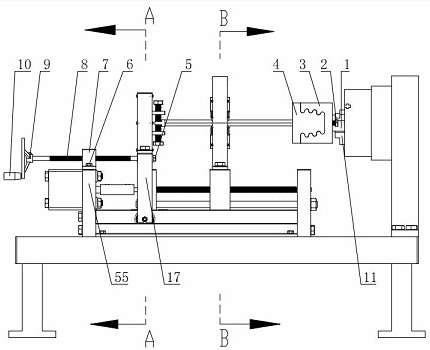

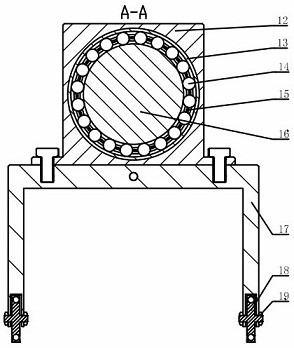

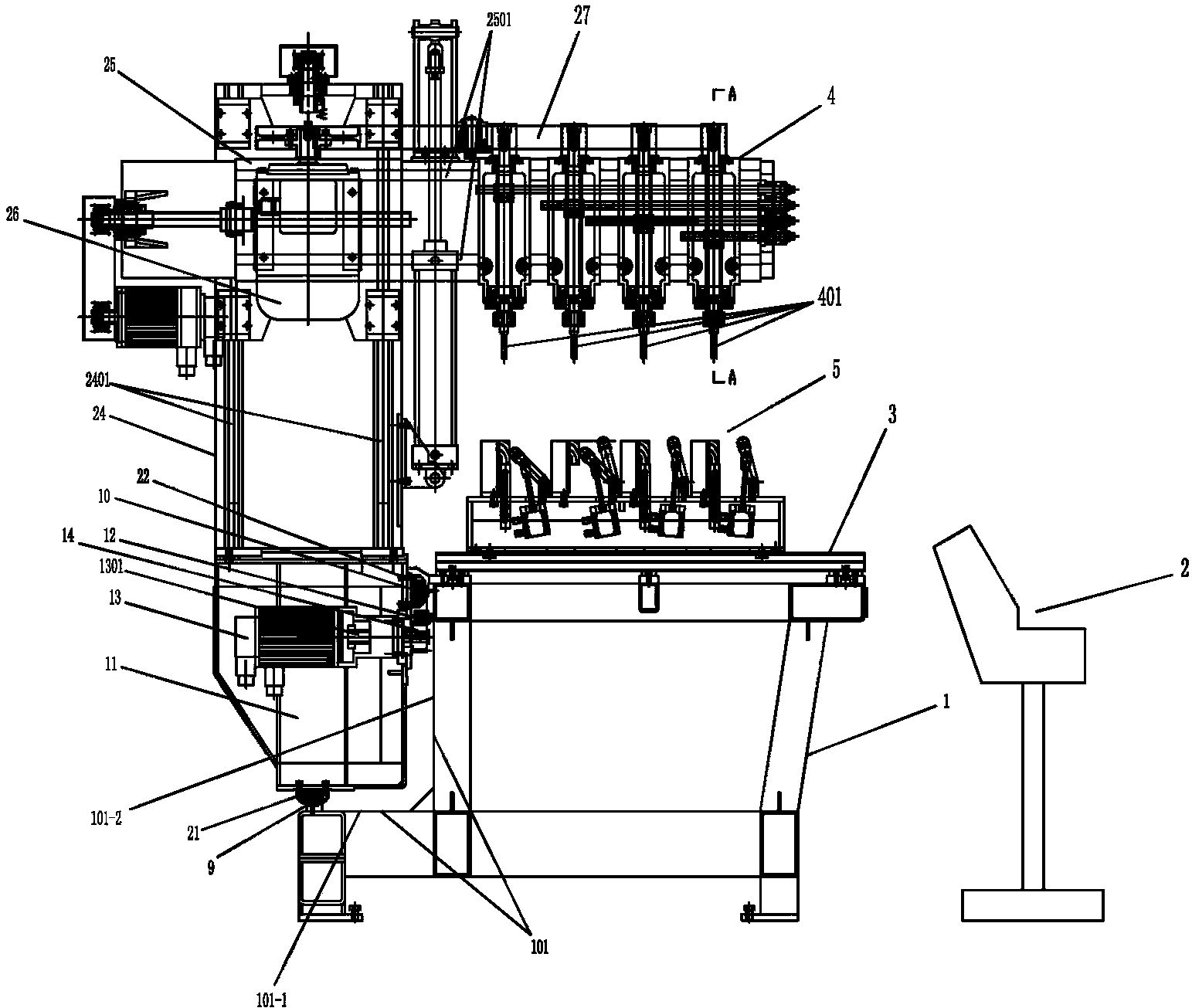

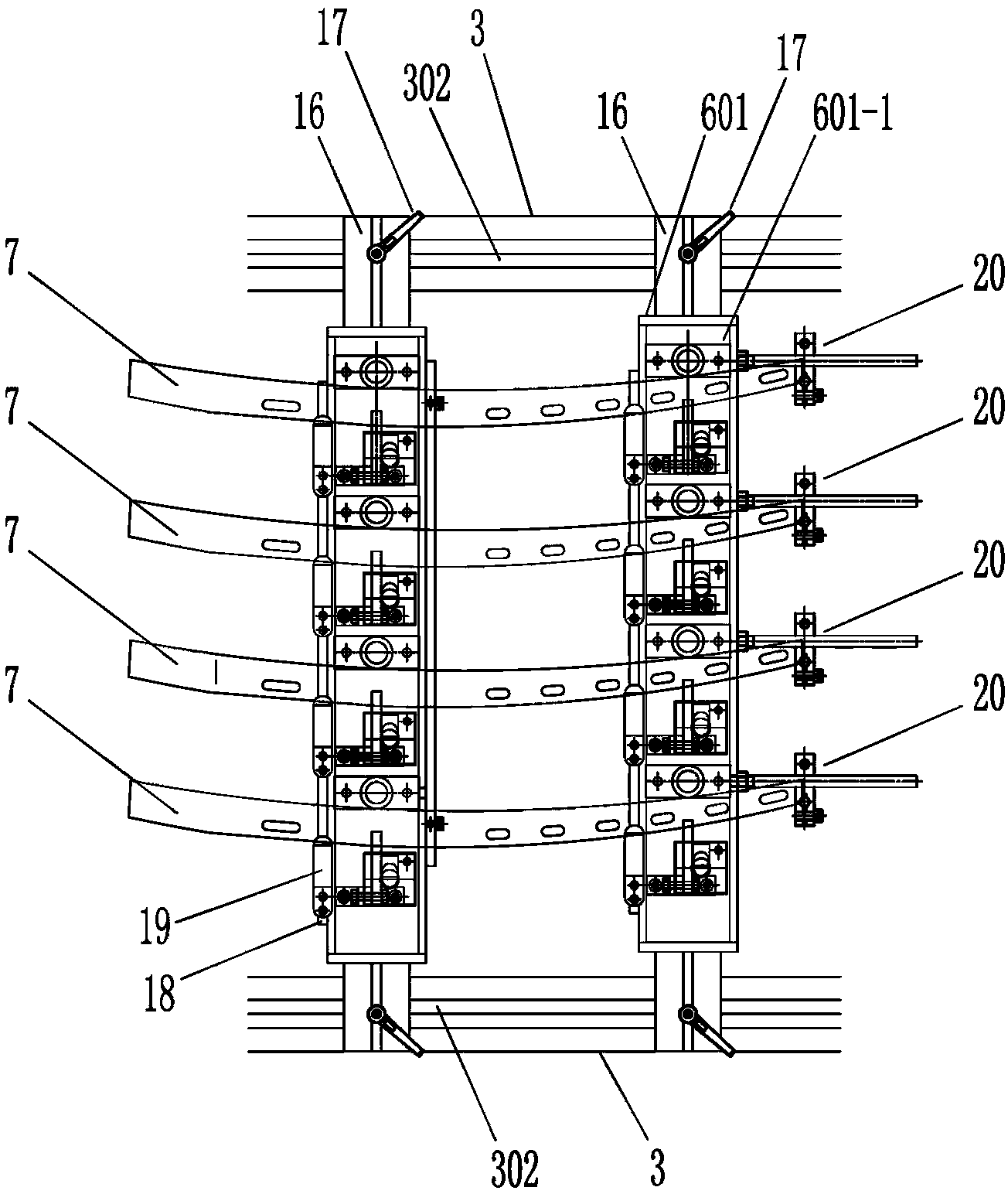

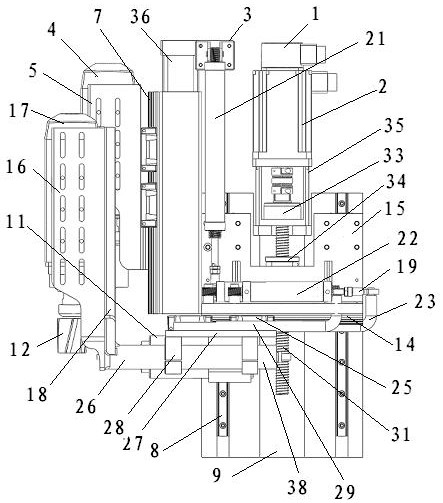

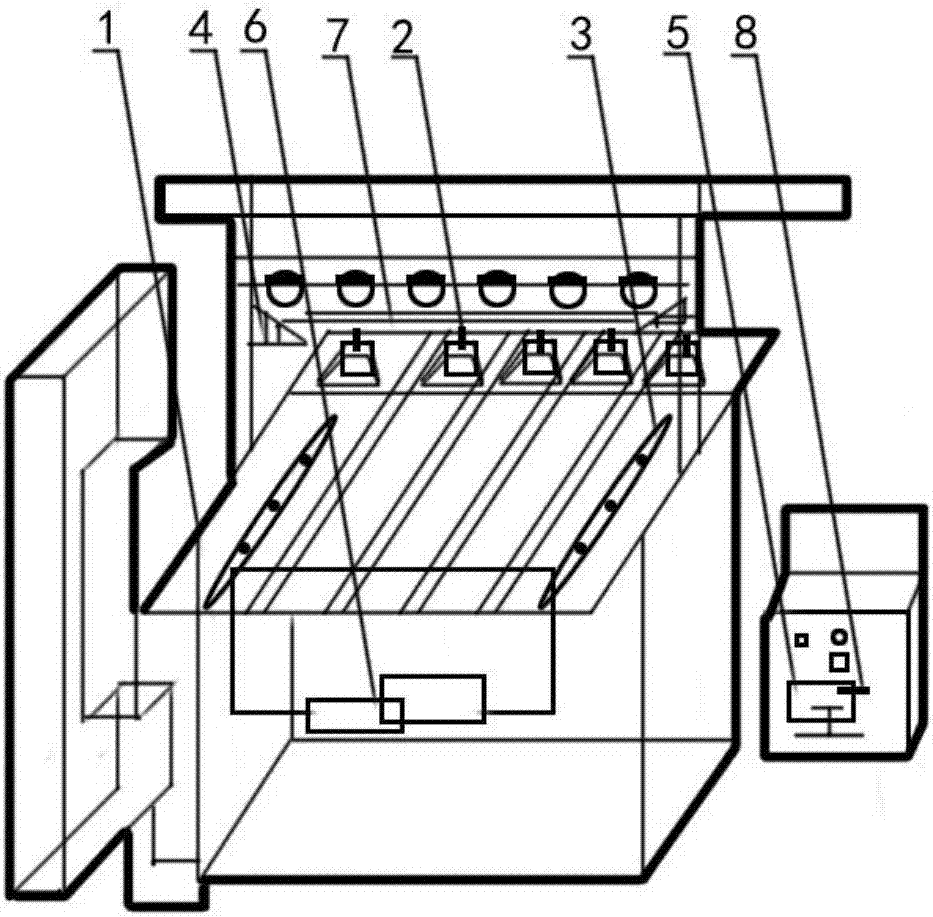

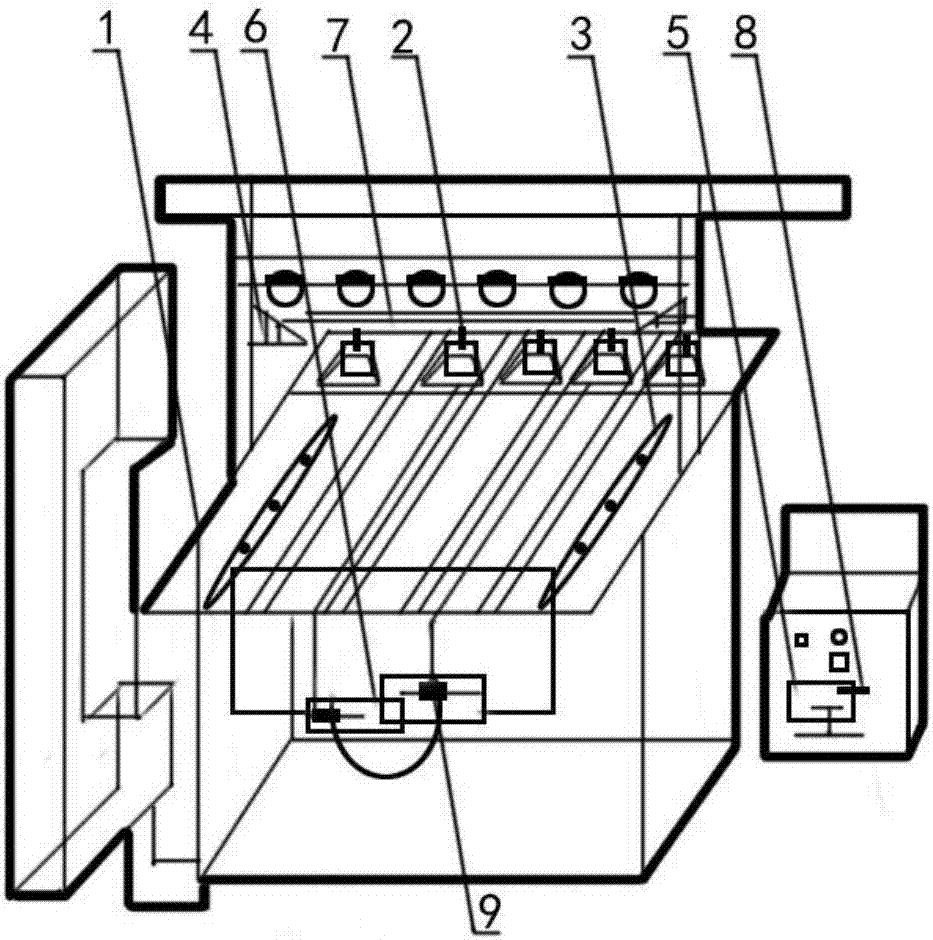

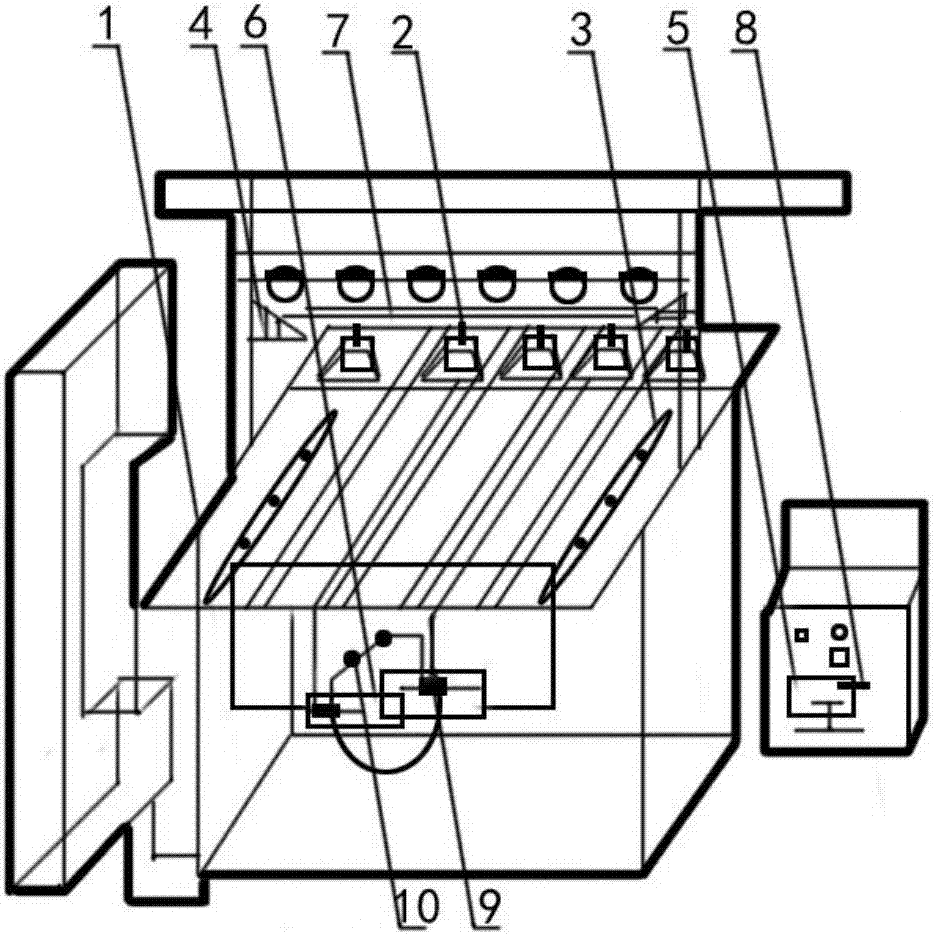

Numerical-control multi-shaft seat mortising machine

InactiveCN102528864APrecise and firm pressingSatisfy processingDovetailed workNumerical controlMilling cutter

The invention relates to a numerical-control multi-shaft seat mortising machine which comprises a base and a numerical control device, wherein a workbench is arranged at the top end of the base, a cantilever type spindle seat is arranged above the workbench, and a plurality of spindle milling cutters are arranged on the cantilever type spindle seat. The numerical-control multi-shaft seat mortising machine is characterized in that at least one group of workpiece clamp structure is arranged on the workbench, each group of clamp structure is formed by two multi-station clamps, and each multi-station clamp is formed by a clamping seat, a cylindrical clamping column, a pressing cylinder and a pressing plate; an L-shaped end surface is arranged at the rear side of the base, a horizontal linear guide rail and a vertical linear guide rail are fixed on the L-shaped end surface respectively along the length extension direction of the base; and a tool-measure device is fixed on the cantilever type spindle seat on one side of one of the spindle milling cutters. For the numerical-control multi-shaft seat mortising machine with the structure, material pressing is firmer, the overall structure is more compact and stable, and the service life and the precision of the linear guide rails are ensured; as the tool-measure device is additionally arranged on one side of one of the spindle milling cutter, tool measure for another time is not needed when the mortise of a same workpiece is machined or after the tool is replaced.

Owner:NEW MAS WOODWORKING MACHINERY & EQUIP

Dovetail mortising machine for panel-type furniture

ActiveCN104999527AReasonable structural designHigh precisionDovetailed workPulp and paper industryToolbox

The invention discloses a dovetail mortising machine for panel-type furniture. The dovetail mortising machine comprises a machine body, wherein a toolbox is arranged at the bottom of the machine body; a half-mortising assembly is arranged at one end of the machine body; a full-mortising assembly is arranged at the other end of the machine body; an adsorption platform is arranged on the upper surface of the machine body; the adsorption platform is connected with a vacuum adsorption pump arranged on the machine body; a gantry assembly is arranged on the machine body. The dovetail mortising machine has the following advantages: the structural design is reasonable, the machined products are high in accuracy, the process is simple, and the production efficiency can be greatly increased.

Owner:苏中奕

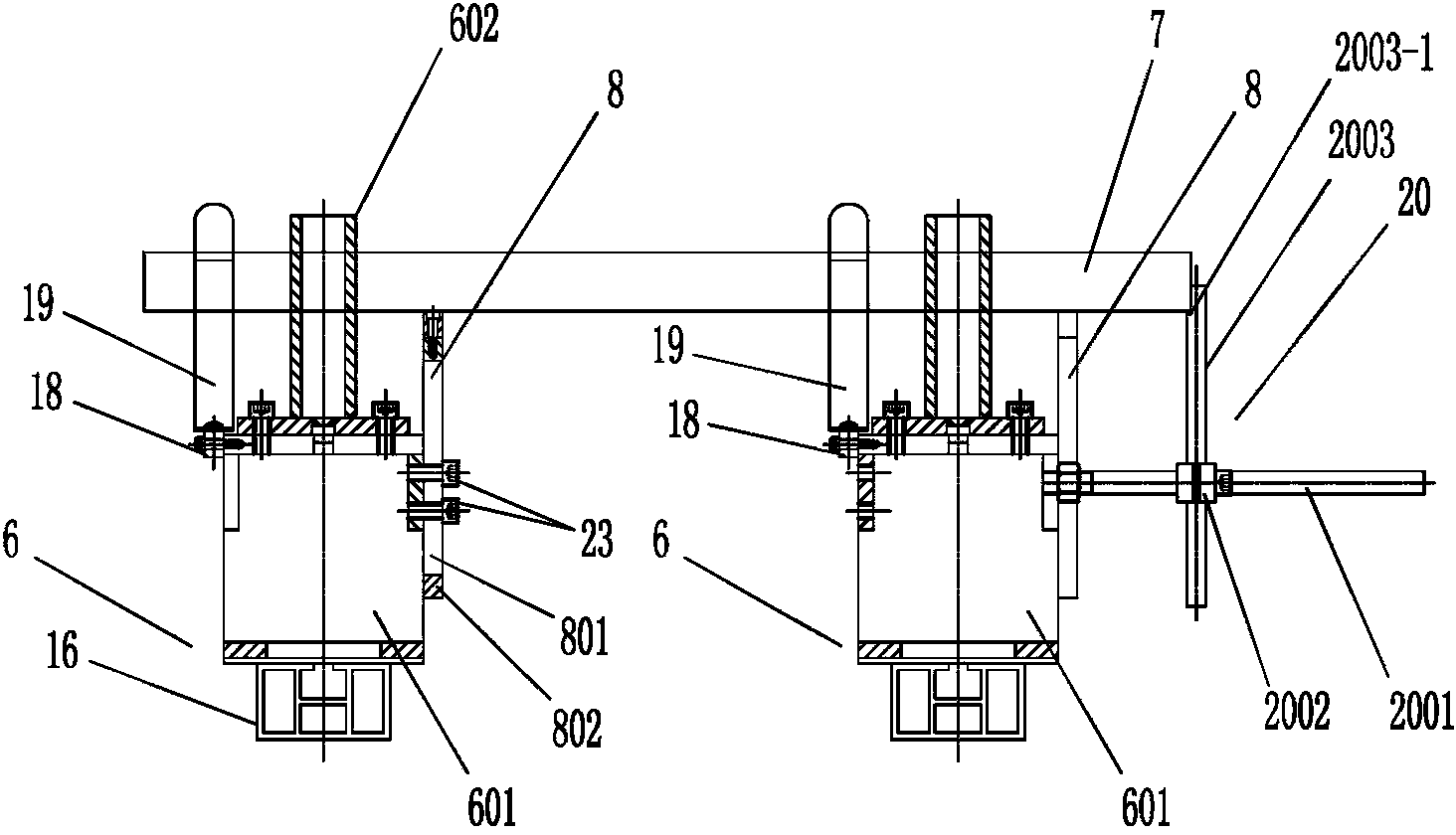

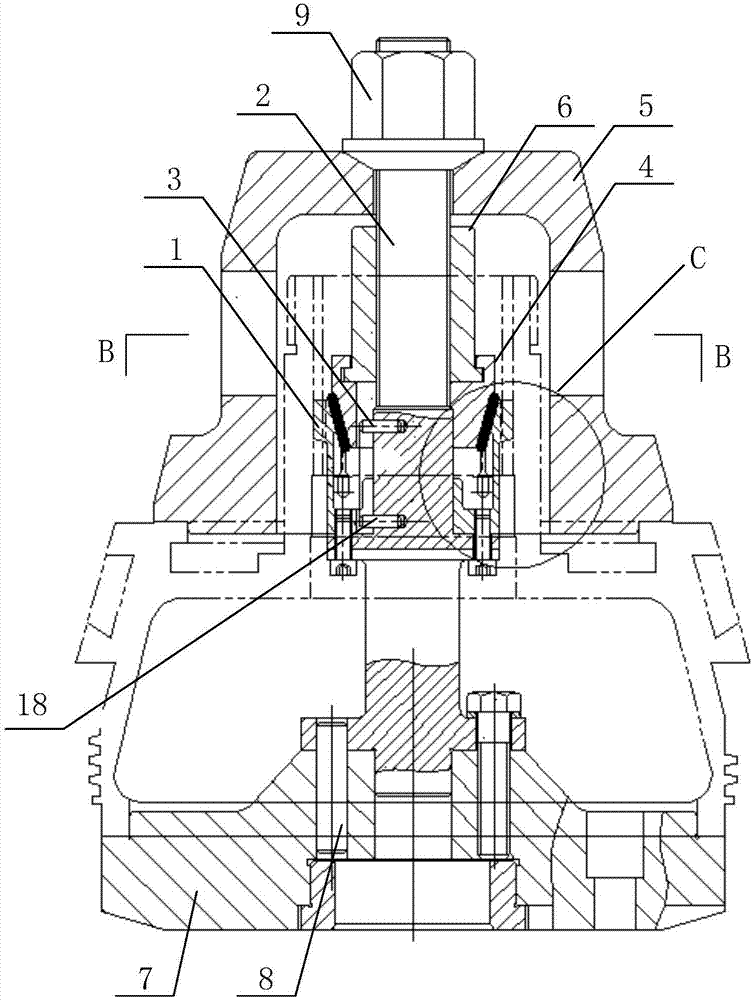

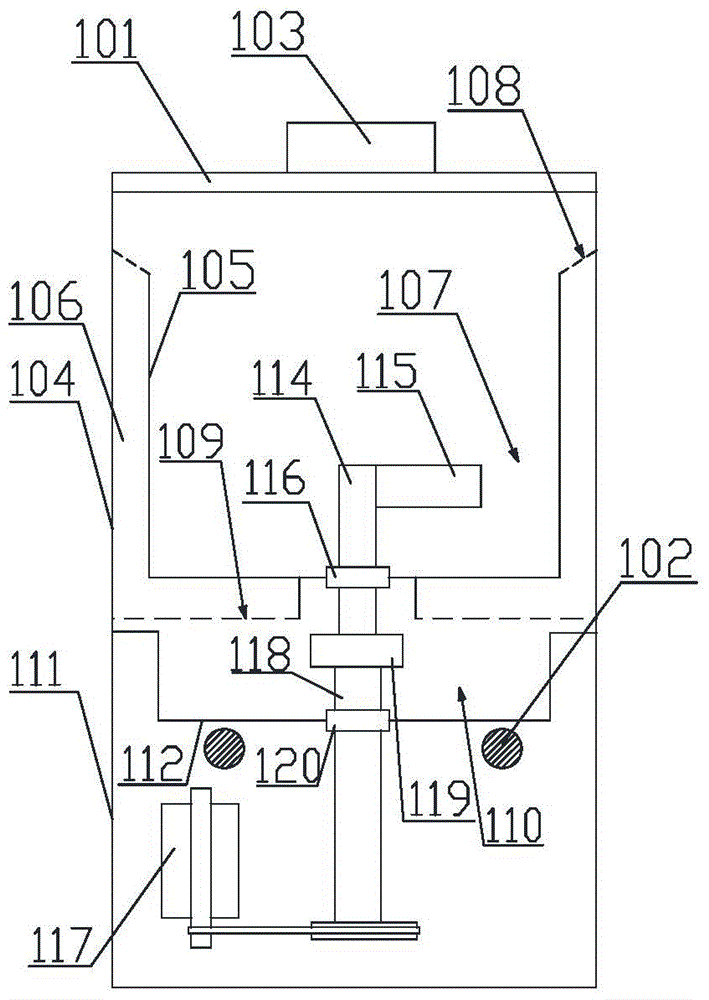

Flexible tool for precision machining of blade body of thin-walled blade part

PendingCN112873145ANo distortionImprove quality and efficiencyWork benchesMachining vibrationsPressure sensing

The invention discloses a flexible tool for precision machining of a blade body of a thin-walled blade part. The flexible tool comprises a mortise mechanism, a multi-bolt clamping mechanism, an auxiliary support rotating mechanism and a lead screw guide rail mechanism, wherein a plurality of flexible telescopic rods are arranged in the auxiliary support rotating mechanism, and the flexible telescopic rods have a pressure sensing function. The multi-bolt clamping mechanism is adopted for clamping a blade crown, and the auxiliary support rotating mechanism is adopted for auxiliary support of the blade body, and the lead screw guide rail mechanism is used as a base of the auxiliary support rotating mechanism so that the auxiliary support rotating mechanism is moved in the required direction. When a certain part of the blade body needs to be supported, the auxiliary support rotating mechanism can be moved to the designated part of the blade body through control over the lead screw guide rail mechanism for auxiliary support of the blade body. According to the flexible tool, on one hand, it can be guaranteed that machining vibration and distortion are avoided during machining of the thin-walled blade part, on the other hand, clamping and dismounting of workpieces are facilitated, and the machining quality and machining efficiency of the thin-walled blade part are improved.

Owner:HENAN POLYTECHNIC UNIV

Mowing machine

The invention relates to a mowing machine. The mowing machine comprises a shell body, a plurality of cutting members and a cutting motor. The cutting motor is mounted in the shell so as to provide a driving force. The cutting members are driven by the cutting motor so as to rotatably execute a mowing operation. Cutting ranges of at least two of the cutting members have overlapped portions along the longitudinal direction of the shell body, so that the ratio of total output power of the mowing machine to a size of the mowing machine is greater than or equal to 6kW / m<3>. Compared with the traditional mowing machines, the mowing machine has the advantage that the size is remarkably reduced in case of the same power. Therefore, the size / power ratio of the mowing machine can be effectively lowered, and the size can be smaller in case of given required output power.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Semi-automatic mortising machine

InactiveUS20050145299A1Reduce the possibility of failureEasy maintenanceTongue/grooves making apparatusMulti-purpose machinesMortise and tenonSemi automatic

Owner:CHANG CHI LO

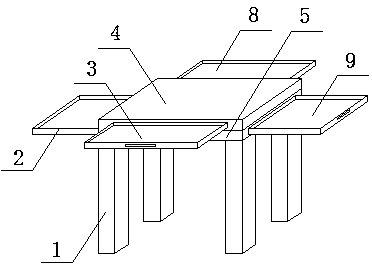

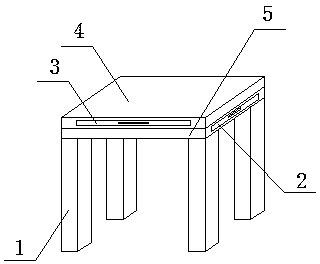

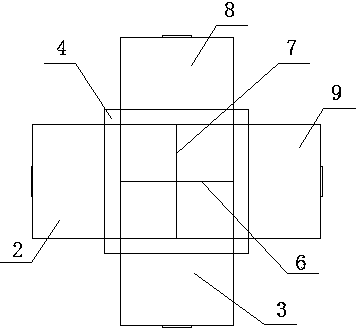

Method for manufacturing multipurpose table

InactiveCN104188346AEasy to prepareSimple structureExtensible tablesFeetEngineeringMortising machine

The invention discloses a method for manufacturing a multipurpose table. The method comprises the following steps that A, two wood plates with the length of 60 cm, the width of 60 cm and the thickness of 4 cm are selected and manufactured into an upper table top and a lower table top, a groove with the length of 40 cm, the width of 30 cm and the height of 2 cm is dug in the middle of one side face of the upper table top through a mortising machine, a groove with the length of 40 cm, the width of 30 cm and the height of 2 cm is dug in the middle of the other side face of the upper table top, the grooves in the two sides of the upper table top are communicated in the upper table top, an upper separation plate is fixedly arranged between the communicated grooves, a groove with the length of 40 cm, the width of 30 cm and the height of 2 cm is dug in the middle of the other side face of the lower table top, the grooves in the two sides of the lower table top are communicated in the lower table top, and a lower separation plate is fixedly arranged between the communicated grooves. The method has the advantages that the manufacturing method is simple, the manufactured product is simple in structure, the strength is high, and the purposes are wide.

Owner:路亚相

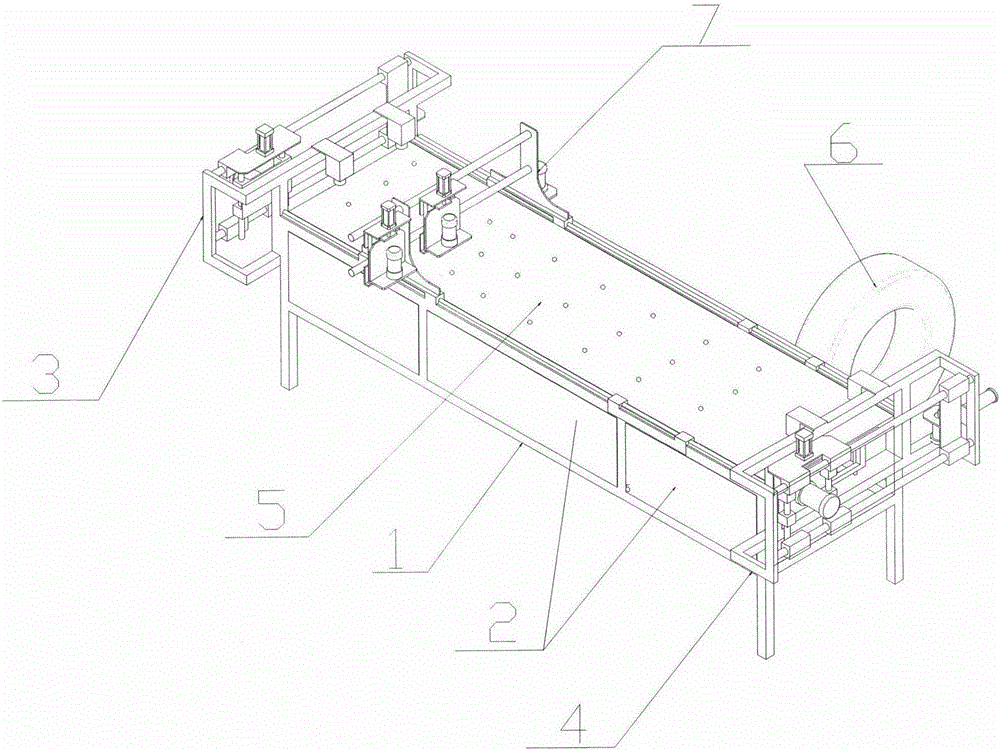

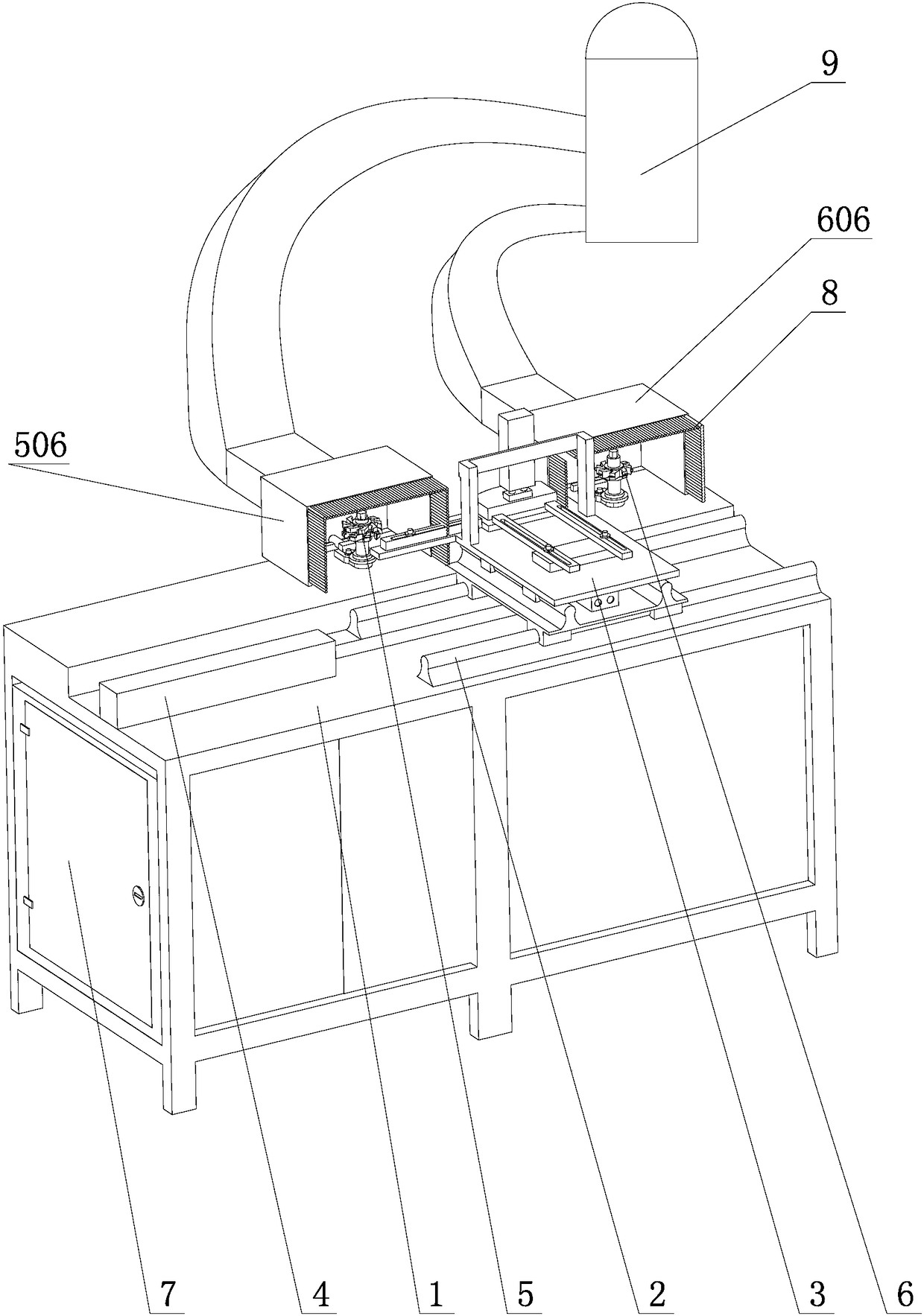

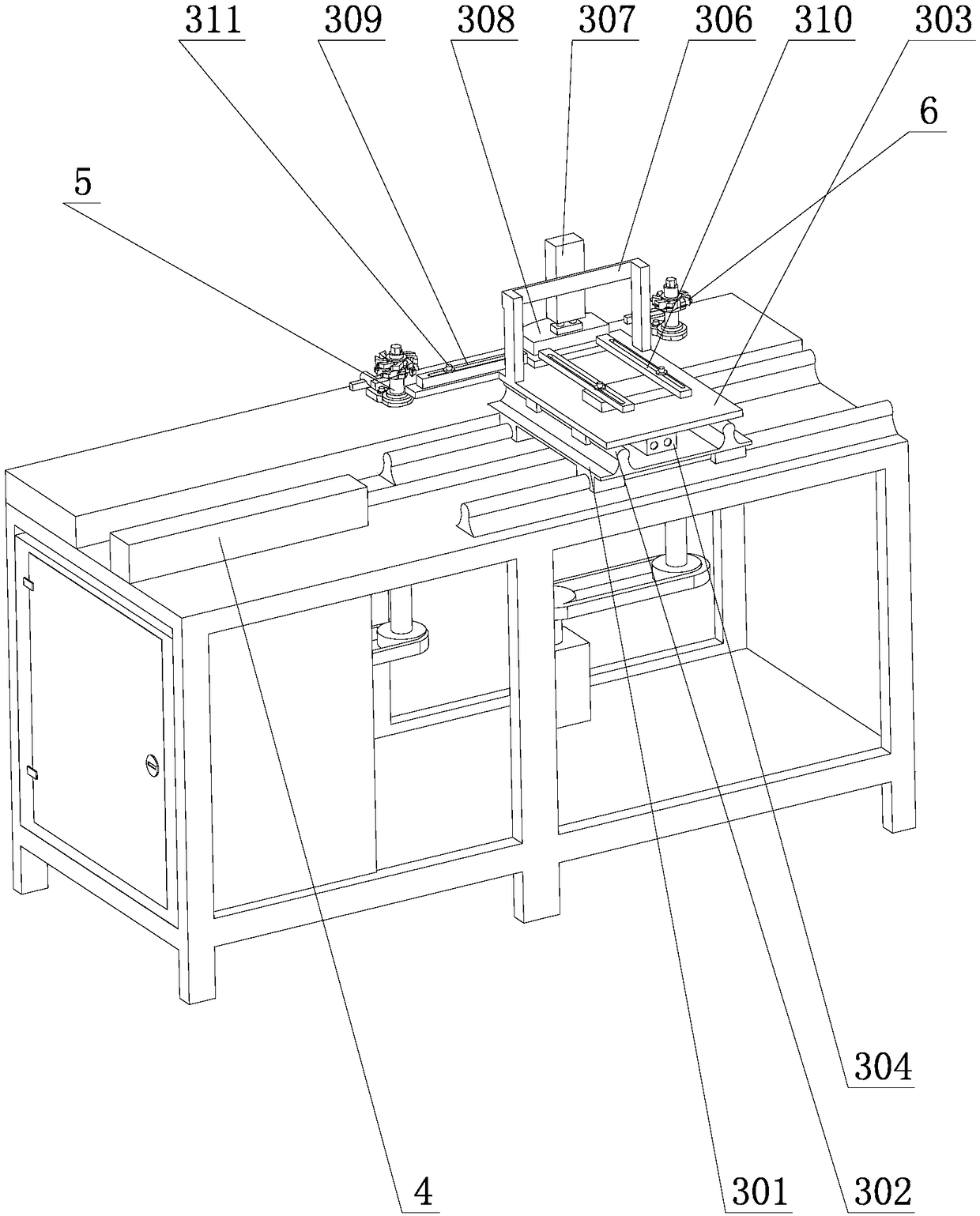

Comb back mortise and comb tooth tenon integrated machining profiling machine for combs

ActiveCN108356930AStable processingRealize clamping positioningTongue/grooves making apparatusEngineeringTongue and groove

A comb back mortise and comb tooth tenon integrated machining profiling machine for combs comprises a workbench; the workbench is provided with a transverse guide rail in the length direction of the workbench; a positioning and clamping mechanism is arranged on the transverse guide rail; one end of the workbench is provided with a transverse driving cylinder; a piston rod of the transverse drivingcylinder is connected with the positioning and clamping mechanism; the portion, on one side of the positioning and clamping mechanism, of the workbench is provided with a comb tooth tenon machining mechanism and a comb back mortise machining mechanism in a spaced manner in the length direction; a controller is arranged on the workbench; and the controller is connected with the transverse drivingcylinder, the positioning and clamping mechanism, the comb tooth tenon machining mechanism and the comb back mortise machining mechanism through guide wires. The comb back mortise and comb tooth tenonintegrated machining profiling machine for the combs has the beneficial effects of being reasonable in structural design, capable of machining comb backs and comb teeth, high in mechanical degree, good in machining quality and the like.

Owner:山东周广胜木雕有限公司

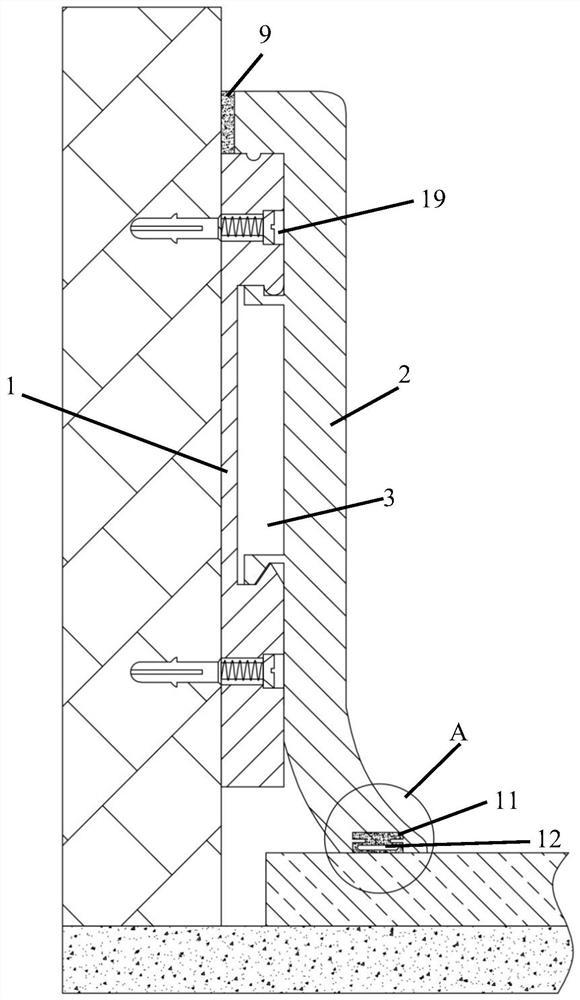

Split type easy-to-disassemble skirting line

InactiveCN111809834AReasonable structural designImprove deformation resistanceBuilding constructionsStructural engineeringAluminum foil

The invention discloses a split type easy-to-disassemble skirting line. The split type easy-to-disassemble skirting line comprises a fixed bottom plate and a decorative panel. The fixed bottom plate and the decorative panel are connected through a mortise mechanism. According to the skirting line, a single structure of a traditional skirting line is abandoned, and a split type combined structure is adopted. A wiring cavity is formed in the fixed bottom plate. The technical problems that in the prior art, an exposed wiring duct laid on a skirting line is not attractive and occupies space are solved. A noise-reduction sealing layer is arranged at the attaching position of the decoration panel and a wall body, therefore the skirting line has a silencing effect. In addition, a combination of arock wool layer and an aluminum foil layer serves as a fireproof layer, aluminum-foil paper is pasted to the outer side of the rock wool layer, the rock wool layer is prevented from absorbing water and being damped, and durability is enhanced. The split type easy-to-disassemble skirting line is compact in structure, reasonable in design, rapid and convenient to disassemble and assemble, firm andstable in structure after being installed, not prone to disengagement, good in fire resistance, high in safety and suitable for market application and popularization.

Owner:河北德林新型装饰材料有限公司

Automatic milling and boring machine

InactiveCN109834312AConvenience for subsequent useMaintainance and safety accessoriesBoring/drilling machinesEngineeringCooling water temperature

The invention relates to mechanical processing equipment, in particular to a milling and boring machine. The automatic horizontal type milling and boring machine comprise a lathe bed, a lower slidingseat, an upper sliding seat, a workbench, a main shaft box, a stand column, a boring shaft, a feeding servo system, a guide rail and an electrical system; a material cutting system is arranged on theright side of the lathe bed, the material cutting system comprises a cavity, a cutting knife, a support, a water pump and a PLC control device, wherein the PLC control device is arranged on the waterpump, the water pump is a water pump with adjustable water outlet amount, an inlet and an outlet are formed in the water pump, a temperature sensor and a liquid level meter are arranged in the cavity,wherein the temperature sensor is used for detecting the temperature of the cooling water, the liquid level meter is used for measuring the liquid level; the liquid level meter and the temperature sensor are connected with the PLC control device, and are used for providing an input signal for the PLC control device, a positioning tool which is rotated relative to the support and used for fixing aworkpiece are arranged on the support, and the inlet is connected with the water outlet of the cavity. According to the milling and boring machine, the workpiece is subjected to material cutting processing, so that the subsequent use is facilitated.

Owner:宁波市创搏精密机械有限公司

Numerical-control multi-shaft seat mortising machine

Owner:NEW MAS WOODWORKING MACHINERY & EQUIP

Turning-milling combined machining center of woodworking lathe

InactiveCN112265077ARealize special-shaped holeRealize the processing effectMulti-purpose machinesGrinding machinesNumerical controlSlide plate

The invention discloses a turning-milling combined machining center of a woodworking lathe and relates to a woodworking lathe component. A milling head group frame is structurally improved, a group ofrotary knife rests are additionally arranged, and turning of special shapes with different angles and shapes can be conveniently realized. The turning-milling combined machining center of the woodworking lathe comprises an assembly seat, a shaft grinding mechanism, a shaft drilling mechanism, a shaft milling mechanism and a shaft sliding plate, and is characterized in that the shaft sliding plateand the assembly seat are L-shaped; two vertical surfaces of the shaft sliding plate and the assembly seat are in relative movement connection with shaft sliding plate guide rails through shaft sliding blocks in the opposite direction; the shaft grinding mechanism and the shaft drilling mechanism are installed on the shaft sliding plate, and the shaft grinding mechanism is installed on one side of the vertical face of the shaft sliding plate and moves up and down relative to the shaft sliding plate; and the shaft drilling mechanism is installed on the lower side of the shaft sliding plate, and the shaft milling mechanism and the shaft drilling mechanism are installed on the lower side of the plane of the shaft sliding plate in parallel. The turning-milling combined machining center is a numerical control four-axis four-linkage machine tool part combining the functions of a lathe, a drilling machine, a milling machine and a mortising machine.

Owner:赣州科匠机电设备有限公司

Method for broaching deformation and eliminating cutter receiving edges of large axial mortise notch

The invention discloses a method for broaching deformation and eliminating cutter receiving edges of a large axial mortise notch. The method comprises the steps that a broaching tool is used for roughly broaching a square groove, expanding the groove, forming and finely broaching the mortise groove to the final size required by the design layer by layer on a numerical control broaching machine ina gradual cutting type broaching mode, and final broaching machining is completed; and a mortise flash structure is roughly broached, the machining allowance of 0.2mm-0.3mm is reserved, after fine broaching machining of a mortise and rough broaching machining of a flash are completed, fine milling machining is carried out on the axial cutter receiving edges, caused by cutter relieving of the broaching tool, of the flash allowance part, an end milling cutter is adopted for fine milling, and fine milling machining of the flash allowance of the single mortise is completed. According to the technical scheme, the good mortise machining quality and the relatively stable and controllable machining period are obtained, so that the requirements of most production units in large axial mortise machining are met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Mowing machine

The invention relates to a mowing machine. The mowing machine comprises a shell body and a cutting motor, wherein the shell body has a longitudinal direction parallel to an advancing direction of the mowing machine and a transverse direction which is parallel to a working plane and is vertical to the advancing direction of the mowing machine; and the cutting motor is mounted in the shell so as to provide a driving force. The mowing machine comprises at least 2 cutting members, wherein the cutting members are driven by the cutting motor so as to rotatably execute a mowing operation, cutting ranges of at least two of the cutting members have overlapped portions along the longitudinal direction of the shell body, and the ratio of a longitudinal size to a transverse size of the shell body is smaller than 1.5. The mowing machine has the beneficial effects that the cutting ranges of a plurality of cutting members are partially overlapped along the length direction of the shell body, so that the size of the shell body in the length direction is reduced, thus, the size and weight of the mowing machine are reduced, and the user operation can be laborsaving.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

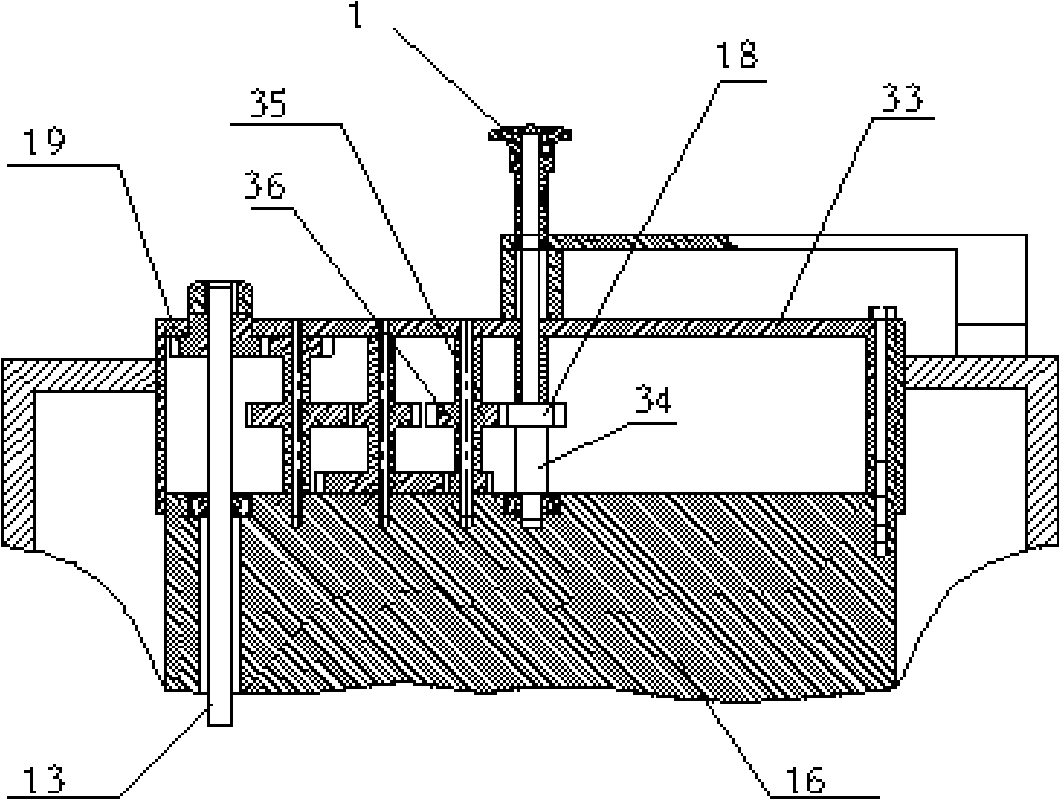

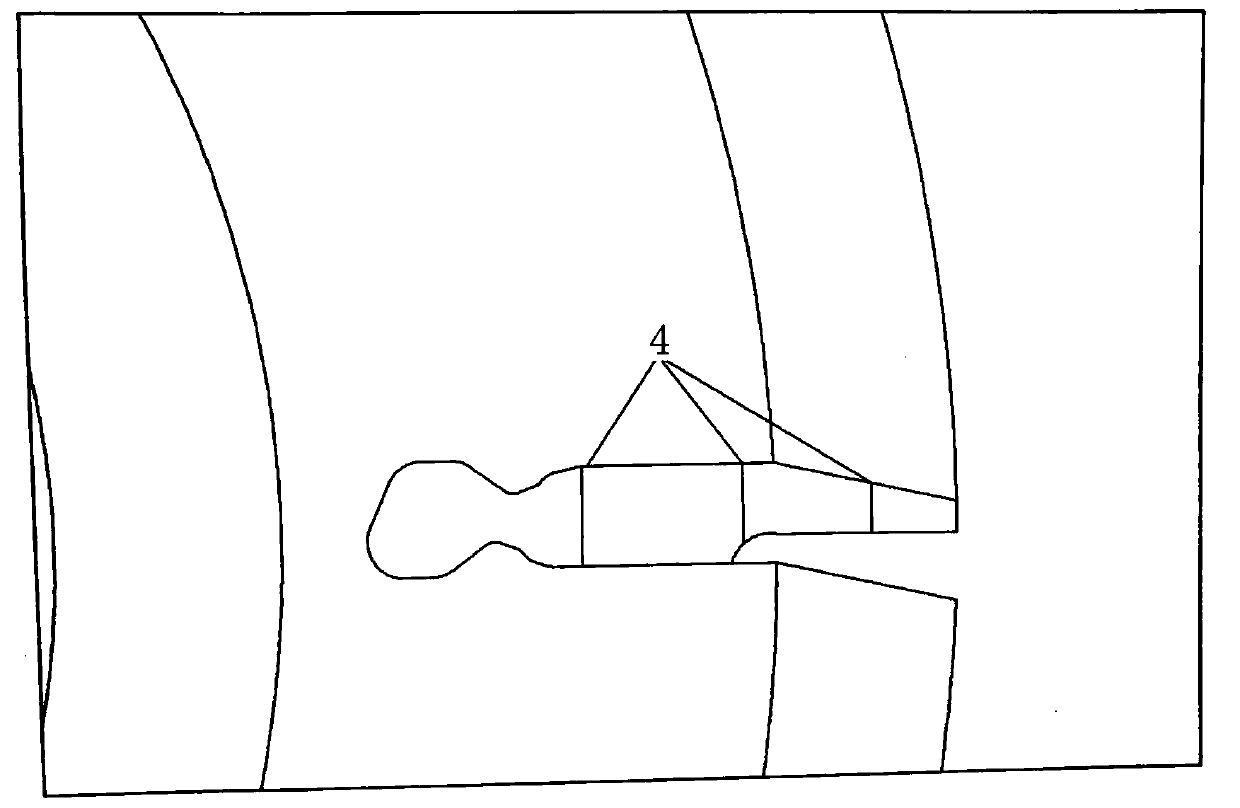

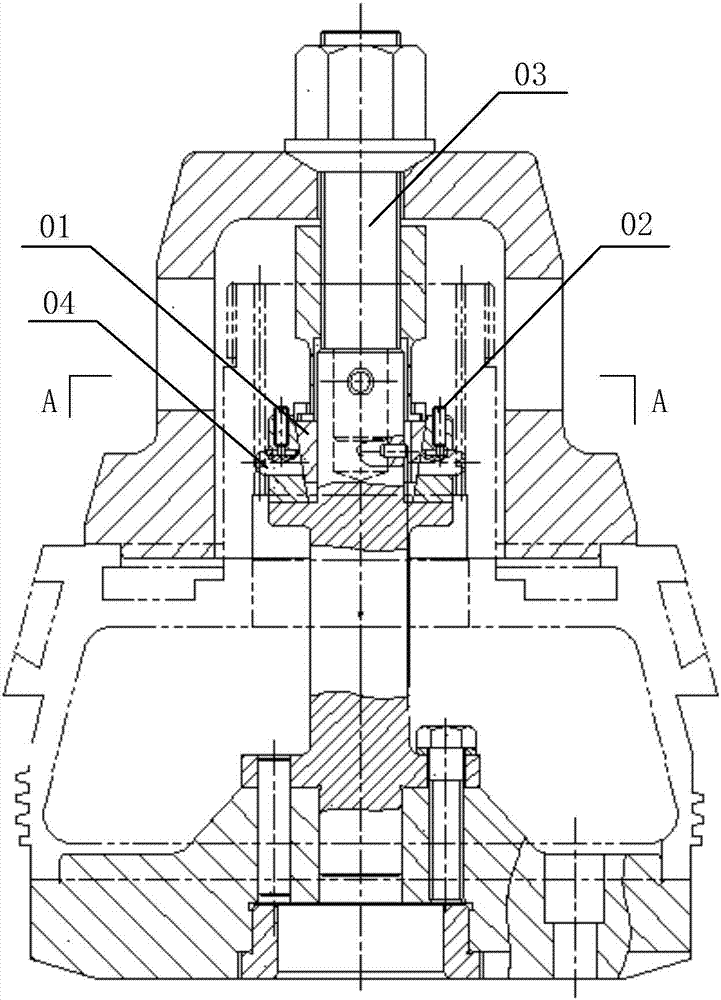

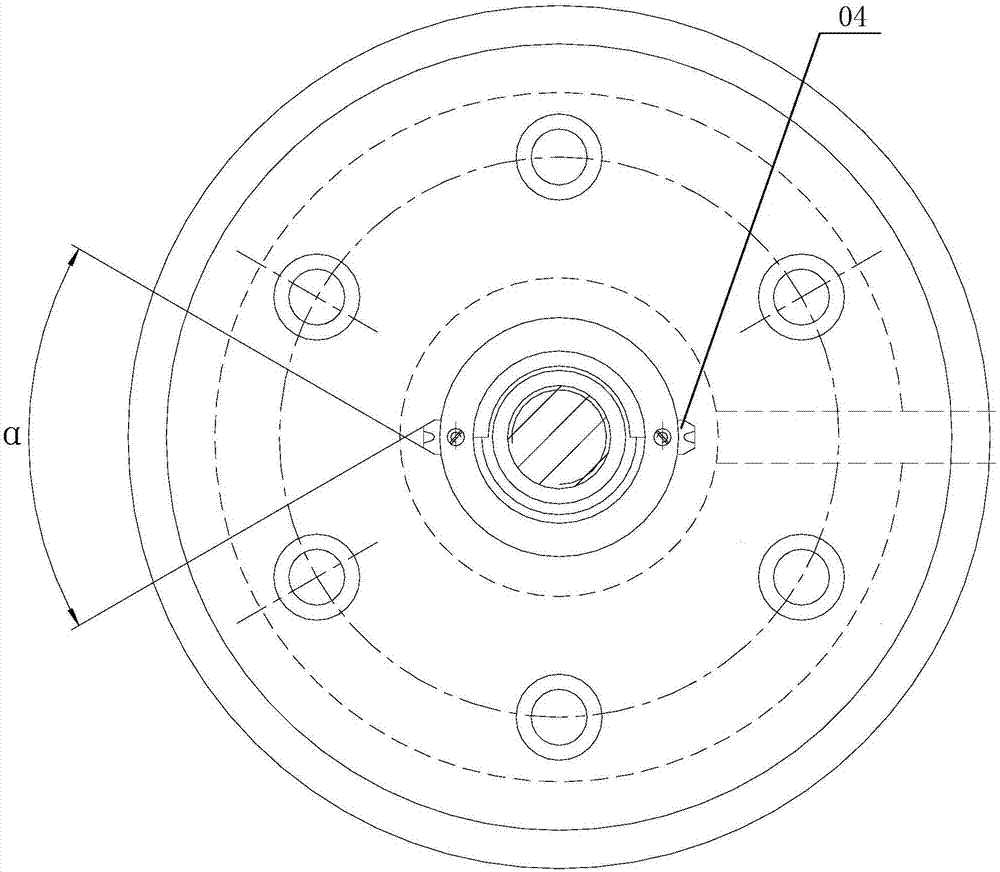

Mortise machining device for disks of air compressors

ActiveCN107378019AReduce the situation of circumferential playImprove processing qualityExpansion mandrelsGas compressorEngineering

The invention discloses a mortise machining device for disks of air compressors. The mortise machining device comprises a cone, an elastic bushing and a mandrel driving the cone to clamp the elastic bushing. The side surface of the cone is a first bevel; the bushing comprises a cone fixing part and a groove fixing part fixedly connected with the cone; the cone fixing part is provided with a second bevel fitting with the first bevel; the groove fixing part is provided with a groove matching surface matched with an internal spline groove. According to the mortise machining device for disks of air compressors, the cone moves along the direction close to the elastic bushing so as to drive the elastic bushing to expand to be matched with the internal spline groove, and thus, the mortise machining device is in close fit with the internal spline; in other words, the elastic bushing compresses the internal spline through the elastic bushing, which is favorable for realizing more-fixed angular positioning, eliminating clearance, reducing circumference moving of the disks and effectively improving machining quality of mortises.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

Seat mortising machine propulsion operation saw blade direction speed harmonization component

InactiveCN106903754AAvoid affecting the operation effectGuaranteed uptimeDovetailed workCircular sawsHarmonizationEngineering

The invention provides a seat mortising machine propulsion operation saw blade direction speed harmonization component. The seat mortising machine propulsion operation saw blade direction speed harmonization component comprises a machine body (1), wherein information sensing modules (2), horizontal sensing modules (3), direction sensing modules (4) and a management module (5), wherein the information sensing modules (2) are respectively arranged at the two sides of a saw blade during operation; the horizontal sensing modules (3) are used for sensing the horizontal direction of the saw blades; the direction sensing modules (4) are used for sensing the positions of the saw blades; the management module (5) is used for processing integrated information; parallel counting modules (6) are arranged on the horizontal sensing modules (3) and are used for recording the condition of parallel positions between the saw blades; height sensing modules (7) are arranged on the direction sensing modules (4); and a reminding module (8) is arranged on the management module (5). The seat mortising machine propulsion operation saw blade direction speed harmonization component has the beneficial effects that the speed of the saw blades is adjusted by sensing the parallel positions and specific height conditions of different saw blades, so that each saw blade is pulled to an appropriate position, thereby preventing an operation effect from being affected and enabling the operation of the machine body to be smooth.

Owner:NINGXIA BAICHEN IND PROD DESIGN CO LTD

A boring machine

ActiveCN101530929BReduce labor intensityGood boring controllabilityFeeding apparatusOther manufacturing equipments/toolsEngineeringDeep hole

The invention relates to a field processing boring machine, which includes a hydraulic station, a variable speed machine, a boring bar, a feed screw, a boring knife rack, and a blade, which is characterized in that the top surface of the boring bar is mounted with a gear shifting box, the feed screw is axially mounted in the boring bar adjacent to the boring bar external diameter, the upper end of the feed screw is connected to the gear shifting box; the boring knife rack is mounted on the boring bar through a first Huff cramping apparatus, the lower end of the feed screw is connected to feedscrew nuts, the feed screw nuts are connected to the first Huff cramping apparatus, the boring bar is provided with knife rack guides, the knife rack guides are mounted with navigation keys, the navigation keys are connected to the boring knife rack. The present invention solves the field quickly boring big, deep hole problem in industry field, and has good boring controllable performance and high accuracy; also simultaneously integrates the milling function to the flange end-face and has electric and manual switch operation schema, has good operating performance, reduces labor intensity and improves its operating efficiency.

Owner:WUCHANG SHIPBUILDING IND

A steamed bun machine

The invention discloses a steamed bread machine, comprising a steamed bread barrel, a barrel cover, a heating device, a stirring device and a stirring driving device. The barrel cover is arranged on the steamed bread barrel; An interlayer is provided between the outer barrel wall and the inner barrel wall, a raw material placement area is arranged on the inner side of the inner barrel wall, and the stirring device extends into the interior of the raw material placement area; an upper ventilation hole is provided at the upper connection between the outer barrel wall and the inner barrel wall, and the outer The bottom wall of the barrel wall is provided with a lower ventilation hole, and a water storage area is arranged below the outer barrel wall, and a steam channel is formed along the direction of the water storage area, the lower ventilation hole, the interlayer, the upper ventilation hole and the raw material placement area. In the present invention, the steamed bread barrel adopts a double-layered barrel wall structure, which makes the heat conduction more gentle, the steamed steamed bread surface is white, tender and smooth, the steamed bread inner flesh is soft and strong, and the taste is excellent.

Owner:QINGDAO AUCMA DOMESTIC ELECTRICAL APPLIANCE

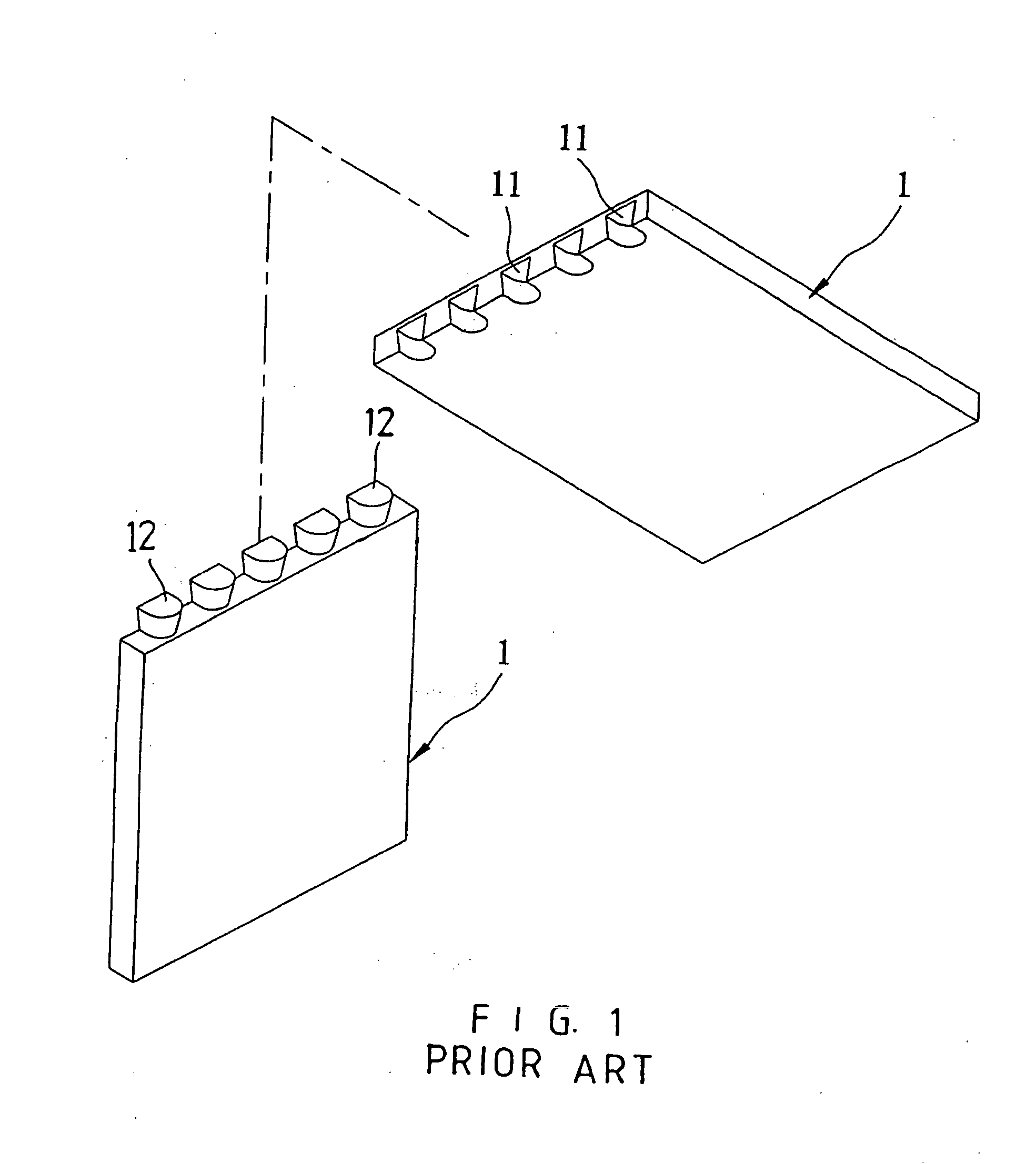

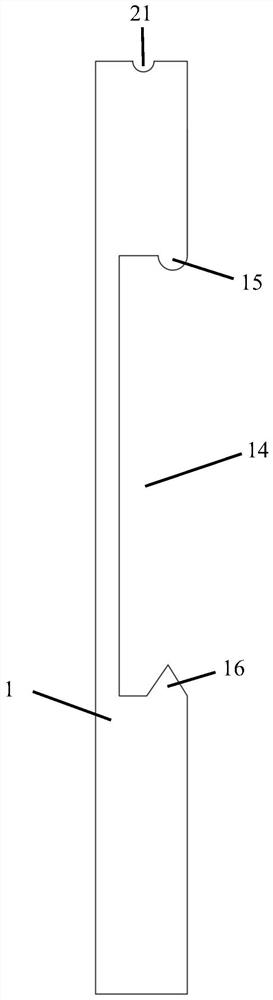

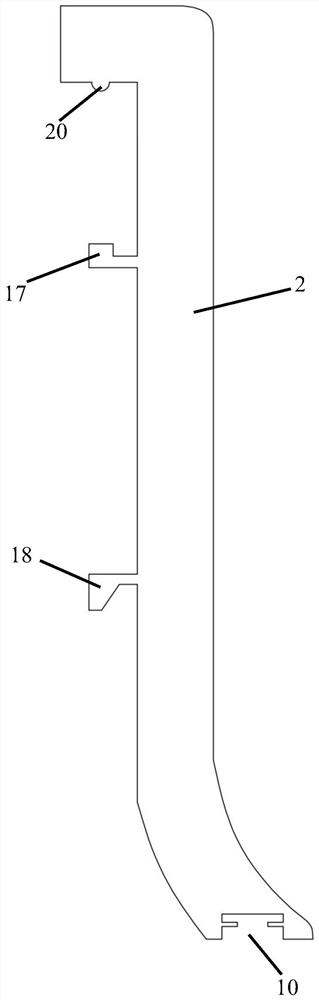

Carbon fiber section material and mortise and tenon structural assembly of carbon fiber section material

InactiveCN110030237AImprove mechanical performanceSimple structureSheet joiningFiberMortise and tenon

The embodiment of the invention provides plates and a mortise and tenon structural assembly comprising the plates. The mortise and tenon structural assembly comprises a first plate and a second plate,wherein a mortise is formed in the first plate, first accommodating areas protruding outwards are arranged at the joint of adjacent side walls of the mortise, a tenon is arranged on the second plate,and second accommodating areas recessed inwards are arranged at the joint of the tenon and the second plate. By arranging the containing areas on the plate, the tenon and the mortise machined in a milling mode can be tightly combined without gaps; and in addition, the plates and the mortise and tenon structural assembly comprising the plates are simple in structure, do not need screws for auxiliary fixation, and improve the stress capacity of the plates under the condition of not affecting the strength of material.

Owner:杨炯 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com