Flexible tool for precision machining of blade body of thin-walled blade part

A precision machining and flexible tooling technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of strong variability of system dynamic characteristics, vibration and deformation, difficult clamping, etc., to improve processing quality and efficiency, and facilitate clamping with the effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

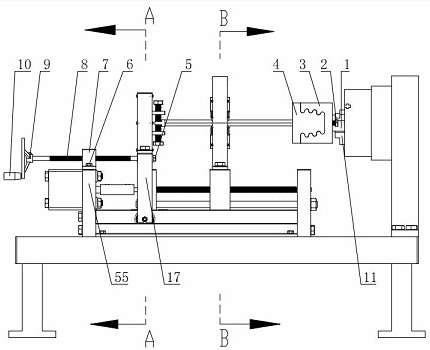

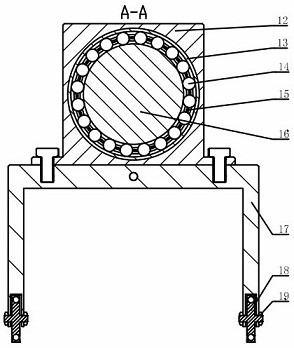

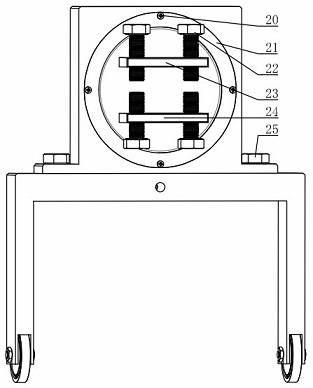

[0025]A thin-walled blade parts of the present invention is precision processing flexible tooling, mainly including a tank mechanism, auxiliary support rotating mechanism, a multi-bolt clamping mechanism, and a lead rail rail mechanism. Here the examples referenceFigure 1 ~ 10 .

[0026]Such asfigure 1 As shown, a main view of the device of the present invention. Among them, the groove mechanism is composed of a cylindrical boss 1, a bolt 2, and a gauze 3. There is a cylindrical boss 1 at the bottom of the groove 3, and the cylindrical boss 1 is sandwiched with a triangular chuck 11, and the grooved groove 3 is made according to the shape of the hoe 4, and the trench 3 cooperates with the hoe 4, and the bolt 2 passes through the groove. 3 The bottom threaded hole will top the hoe 4, so that the groove 3 is more secure with the hoe 4. For multi-bolt clamping mechanisms, the auxiliary support rotating mechanism and the lead rail rail mechanism willFigure 2 ~ 9description.

[0027]Such asfig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com