Patents

Literature

6842results about How to "Improve quality and efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

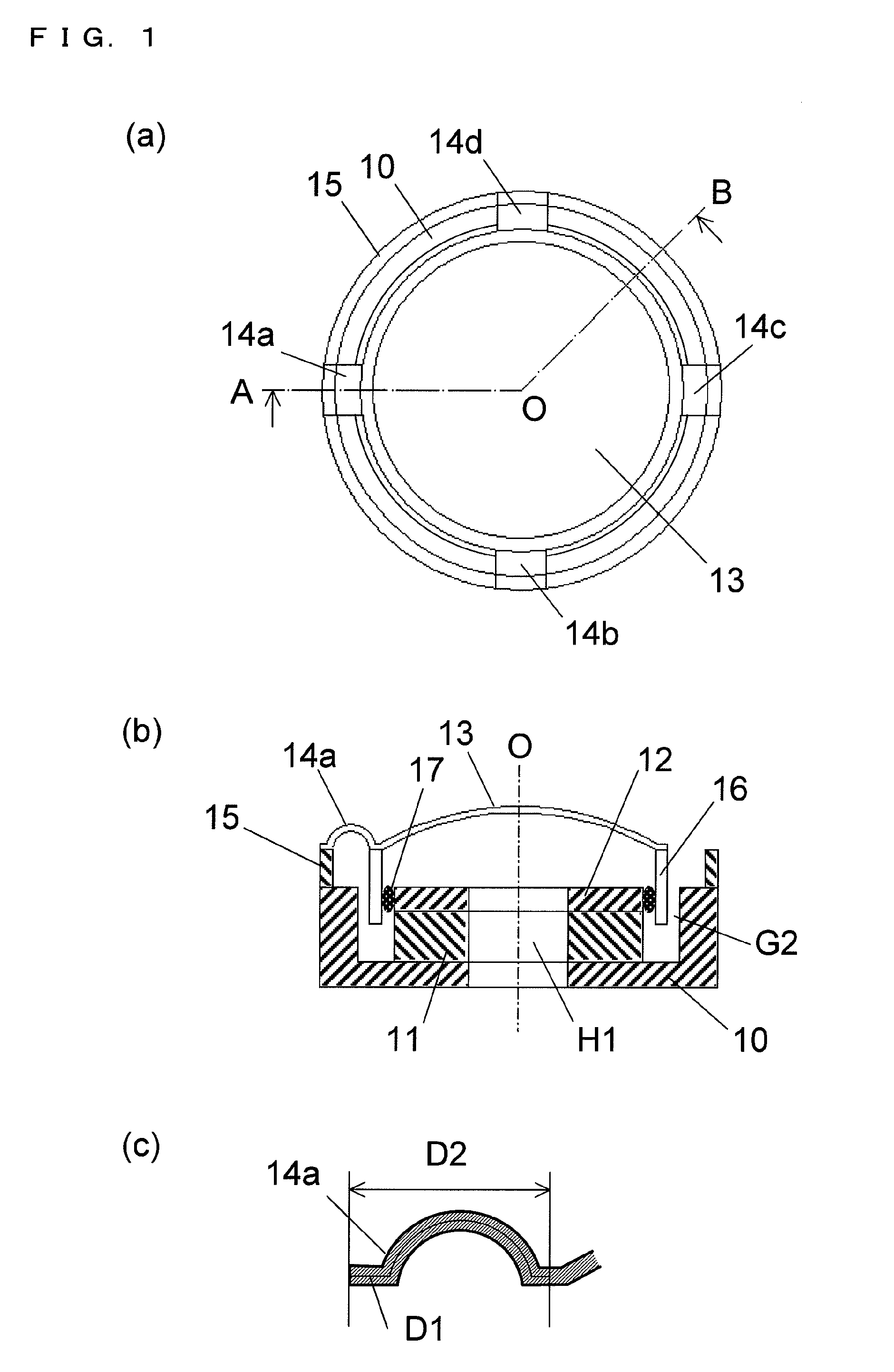

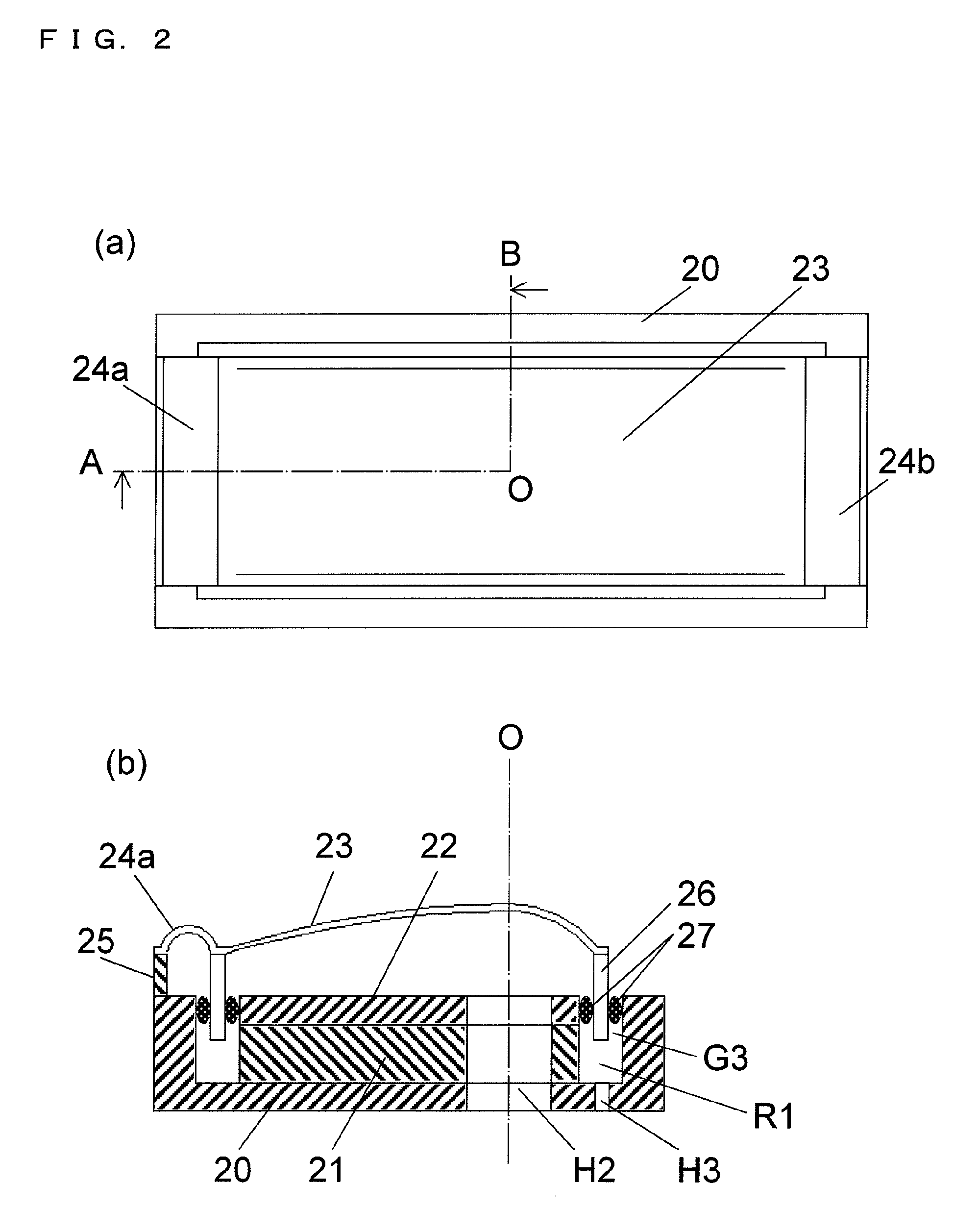

Loudspeaker, video device, and portable information processing apparatus

ActiveUS20110044489A1Reduce non-linear distortionImprove quality and efficiencyLoudspeaker diaphragm shapeSound producing devicesLoudspeakerEngineering

A loudspeaker according to the present invention includes: a diaphragm that vibrates back and forth to emit a sound; a magnetic circuit that is provided on a rear side of the diaphragm and has a magnetic gap on a diaphragm side; a voice coil that is directly or indirectly joined to the diaphragm and disposed within the magnetic gap; a magnetic fluid that is loaded within the magnetic gap; and a plurality of first edge pieces that are provided at different positions in an outer circumferential portion of the diaphragm for vibratably supporting the diaphragm, each of the first edge pieces having a non-linear cross-sectional shape.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

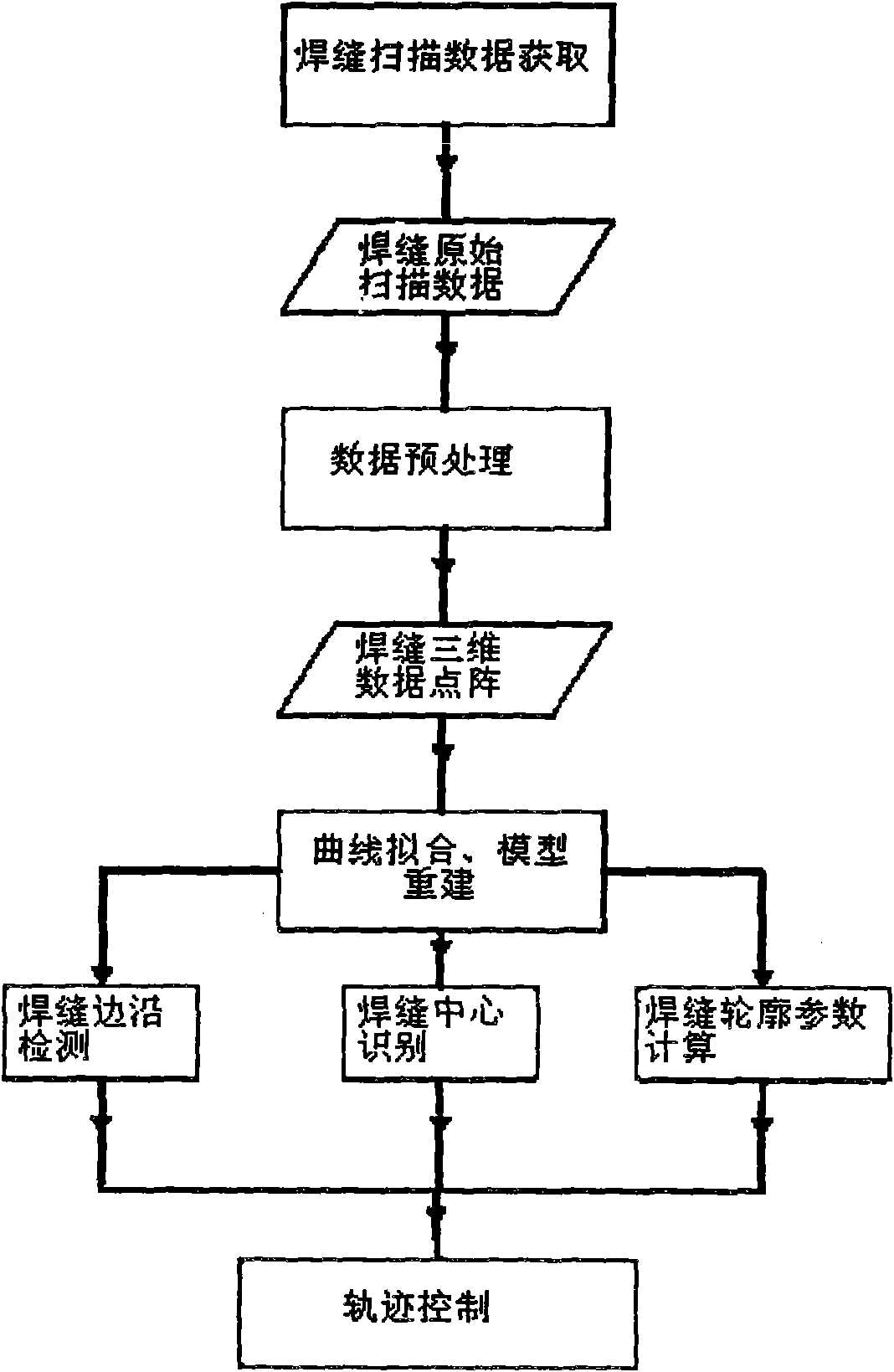

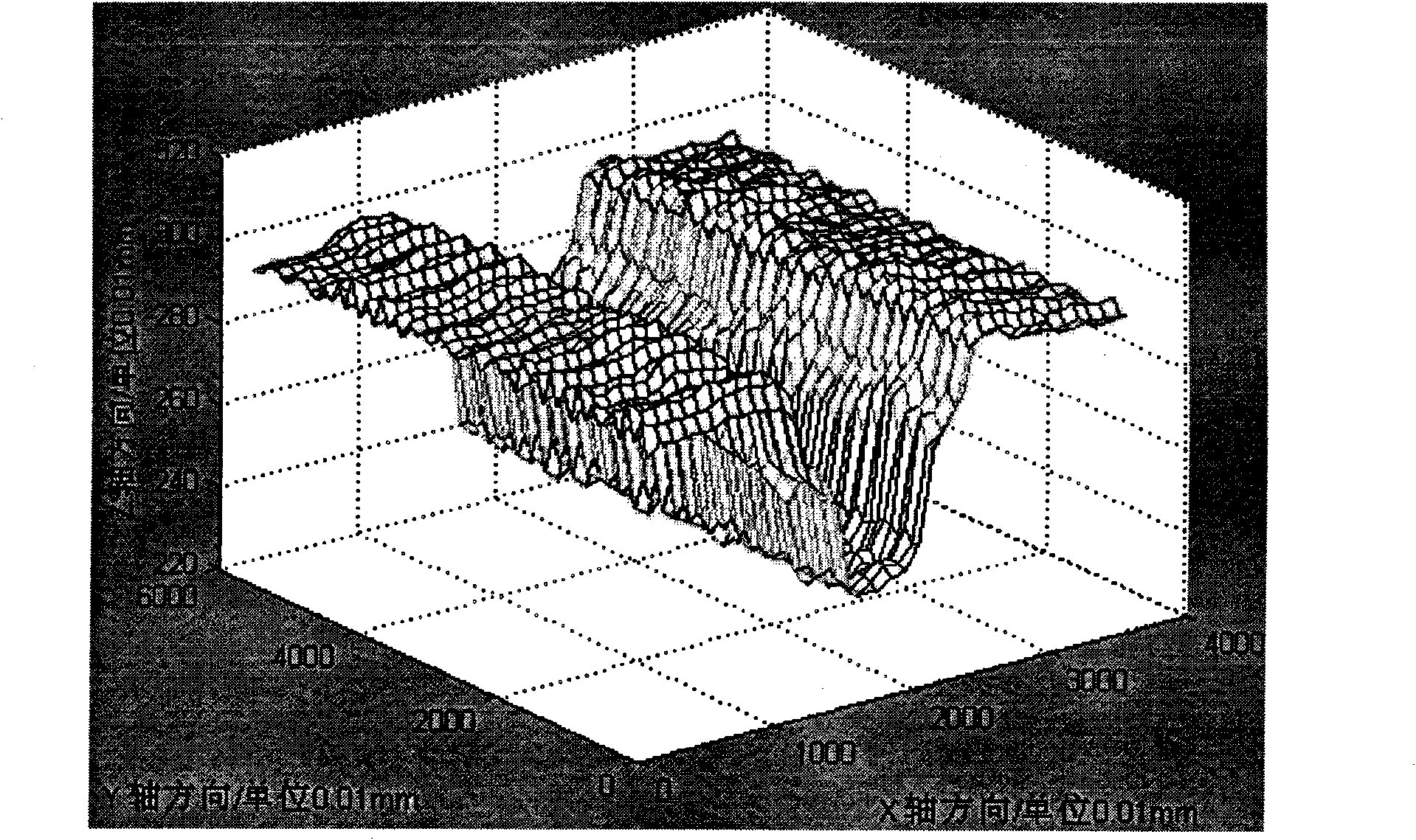

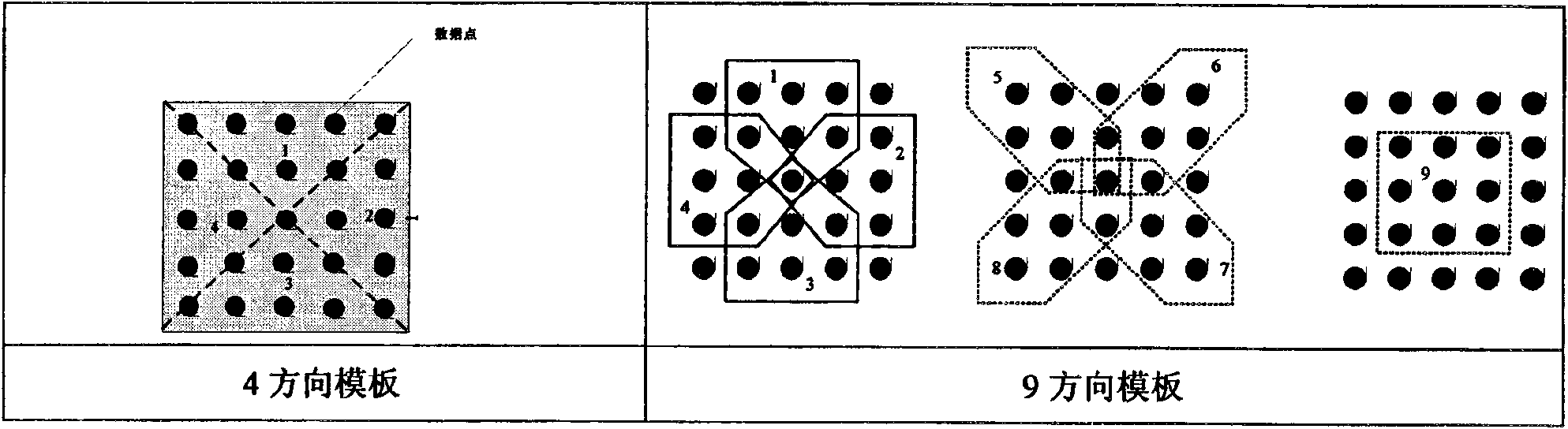

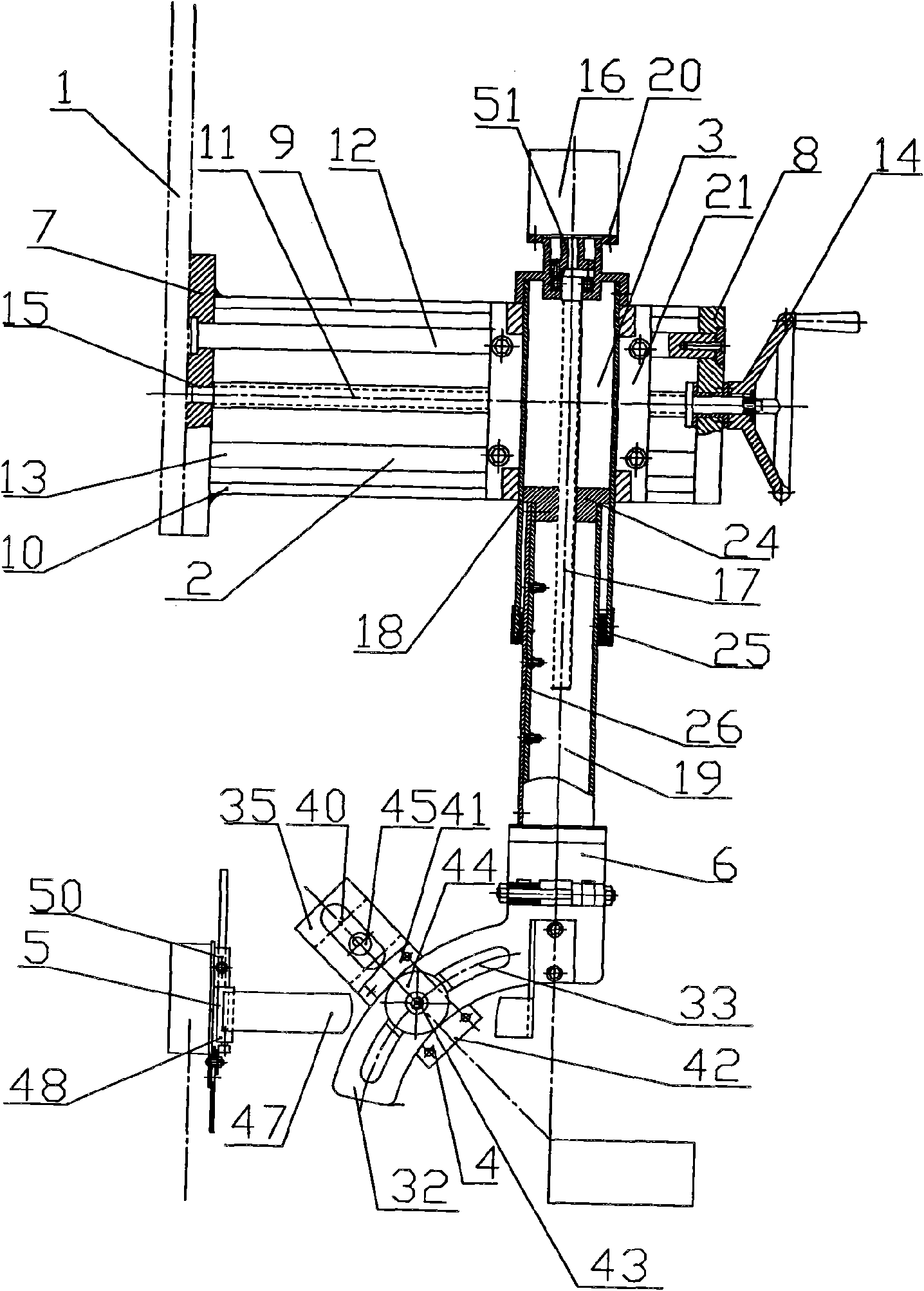

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

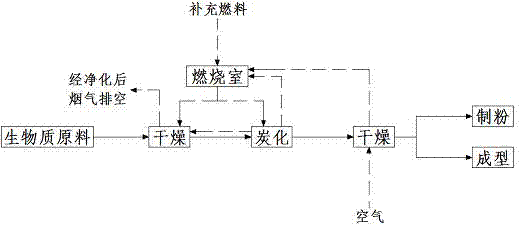

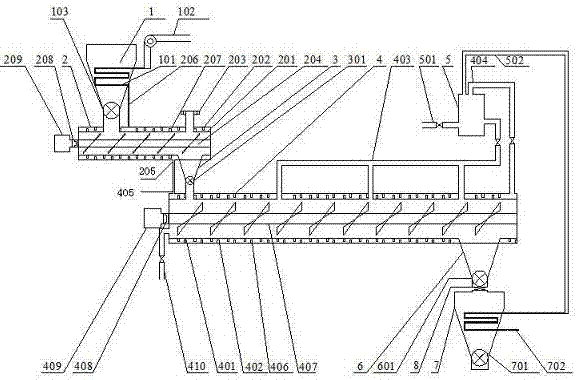

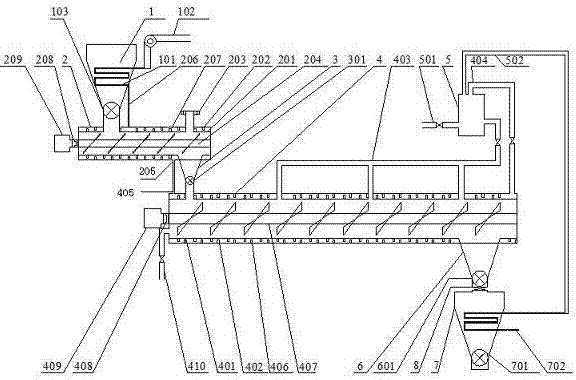

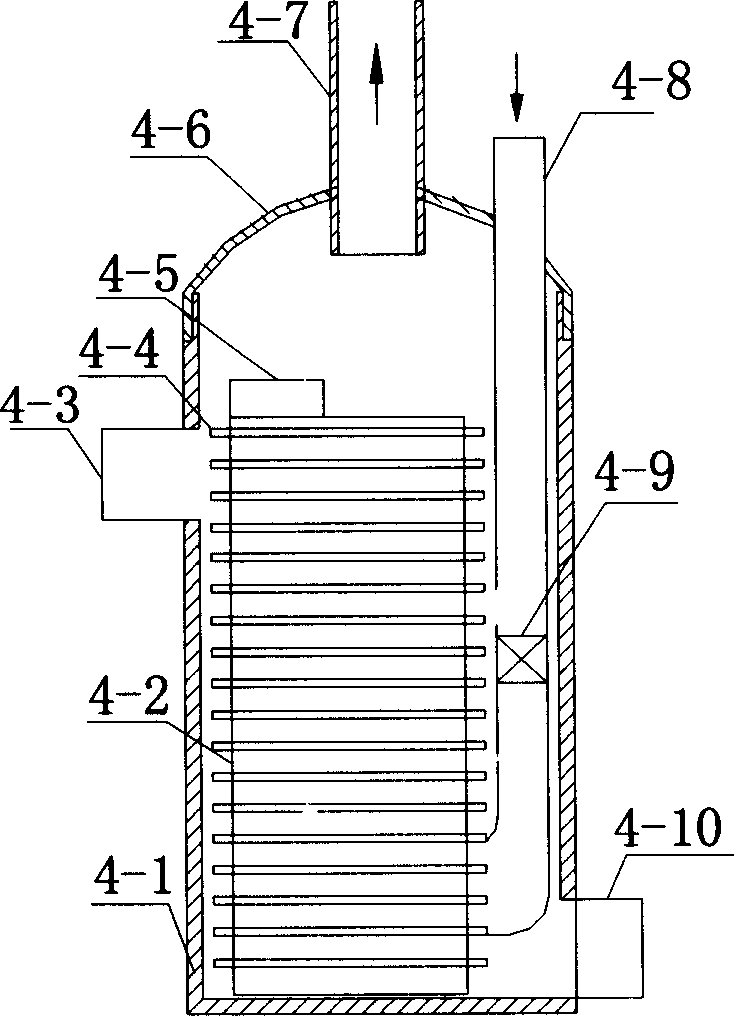

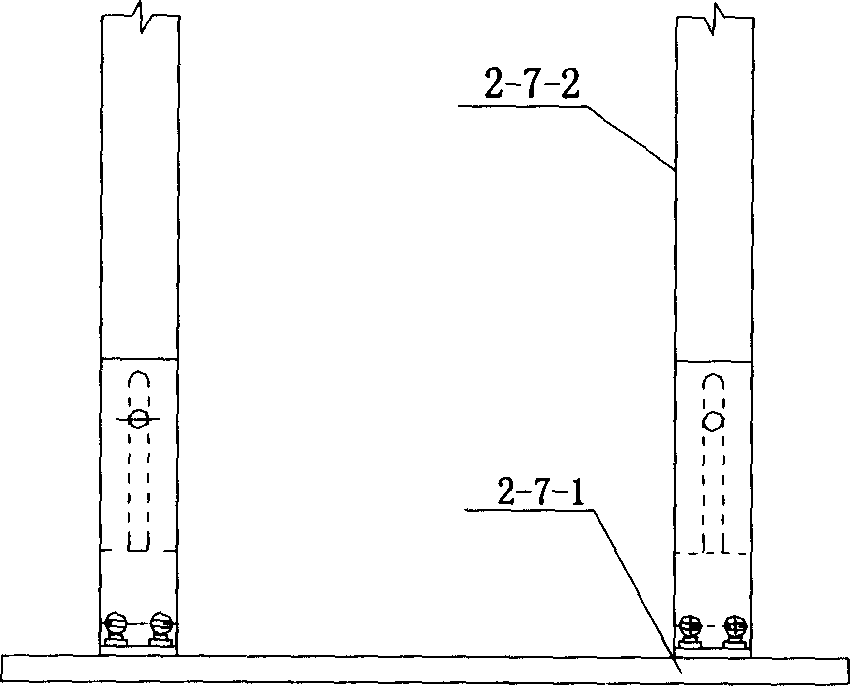

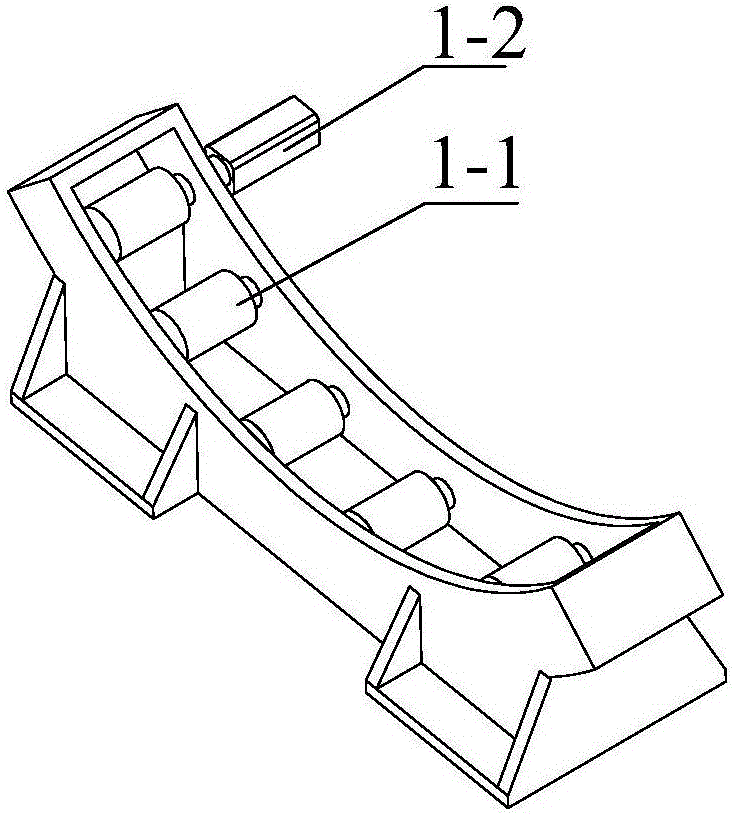

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

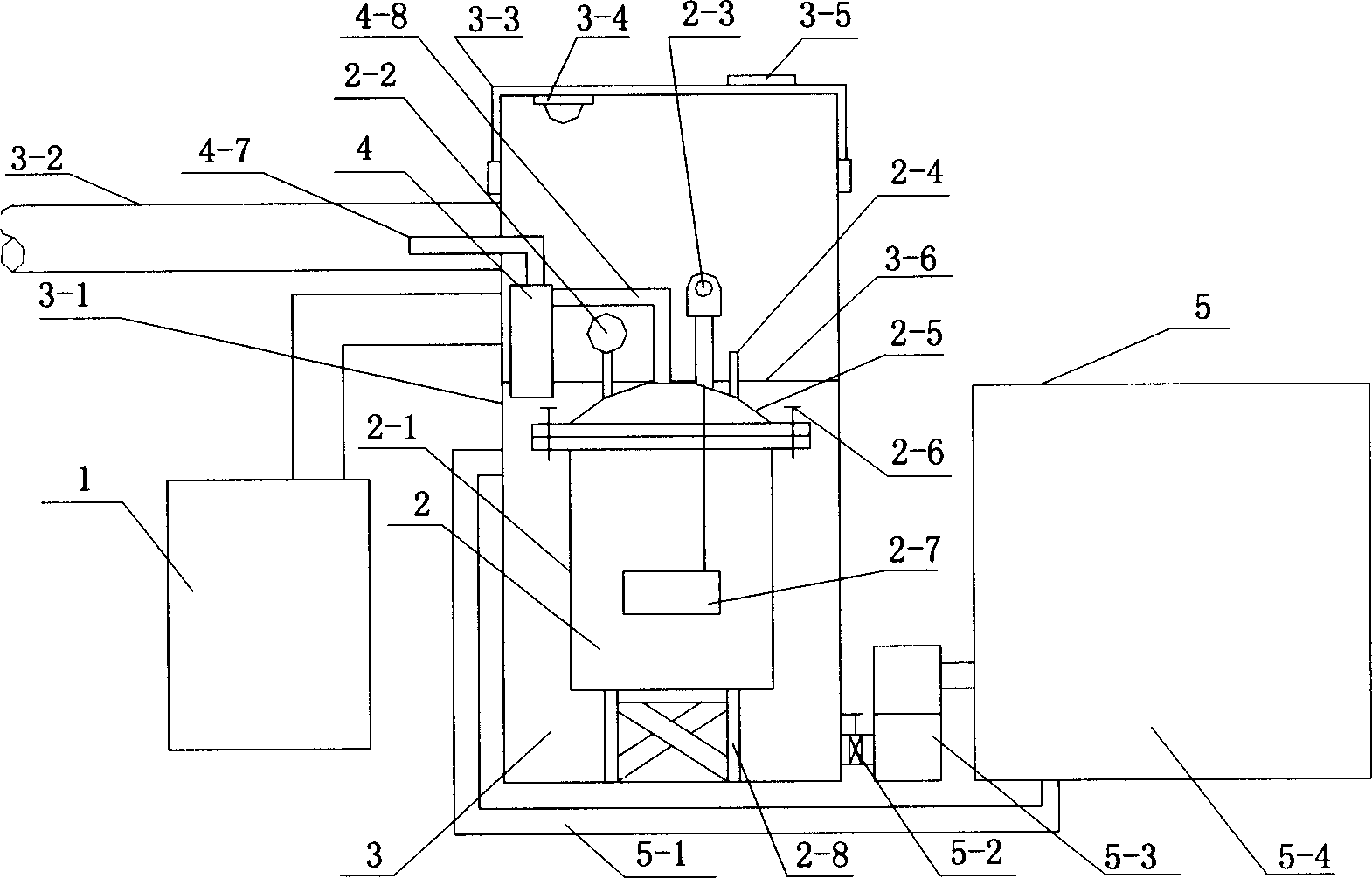

Apparatus and process for preparing carbon fiber reinforced silicon carbide composite material

The invention relates to equipment of producing carbon fiber enhanced carborundum composite material. The equipment is made up with controlling system, protection kettle system, working kettle system, security isolation system, and protection liquid circulating system. Controlling system connects to every part through leads. Security isolation and working kettle system are installed into protection kettle system. Security isolation connects to working kettle system through air intake duct. Protection liquid circulating system connects to protection kettle through pressure adjusting set. Technics of precast product are as follows: spraying protective layer material on precast product of carbon fiber, spraying strengthening layer material and getting production of precast product. Install the production into working kettle shell to produce carbon fiber enhanced carborundum composite material. The invention reduce producing period to several hours, which improves quality and efficiency and reduce production cost. It can operate in normal pressure and resist burning and exploding. Construction of the equipment is simple, technics reasonable and operation convenient.

Owner:UNIV OF JINAN

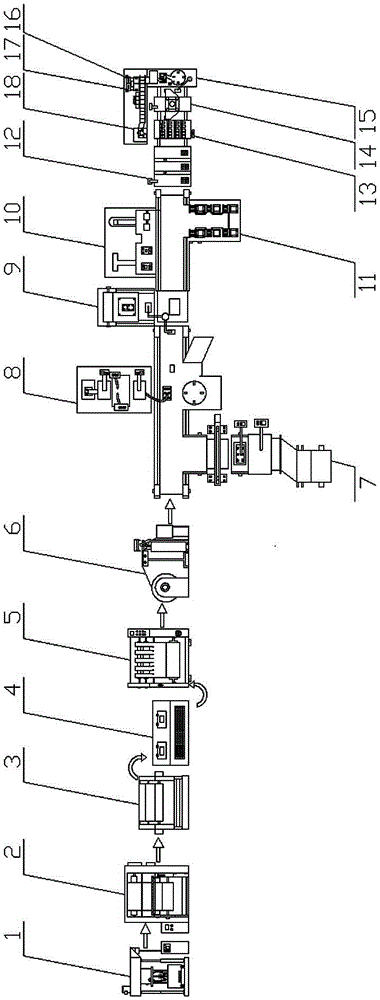

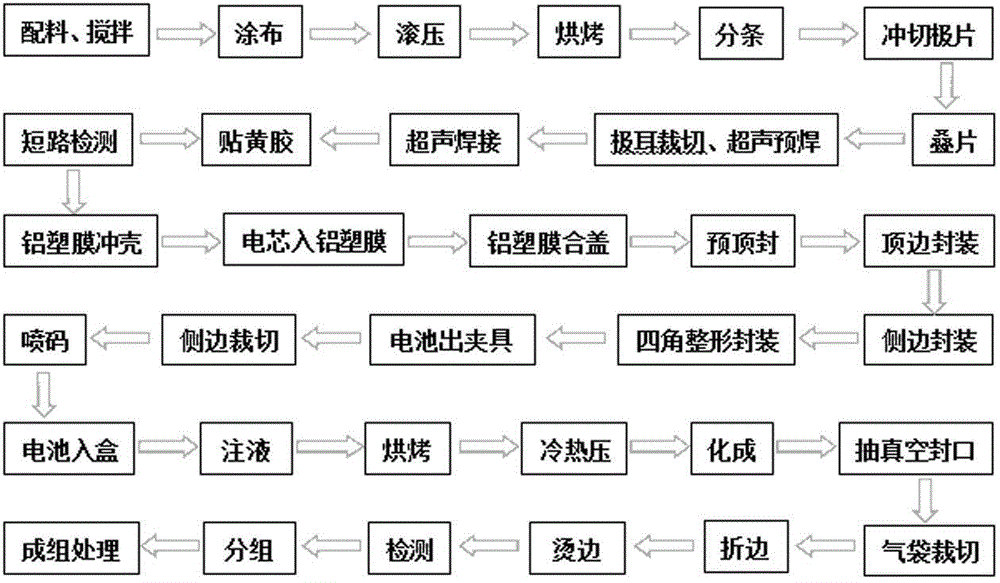

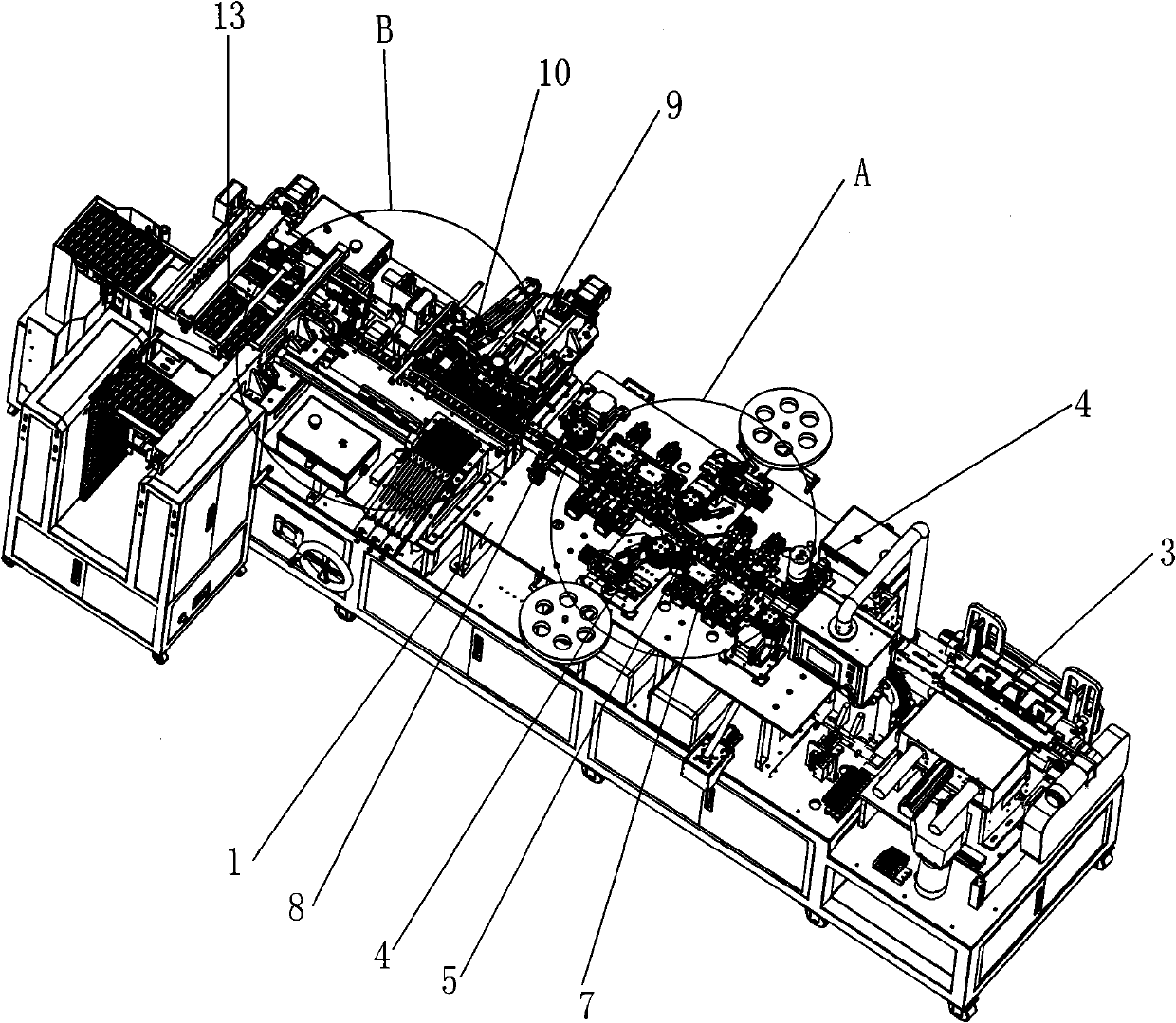

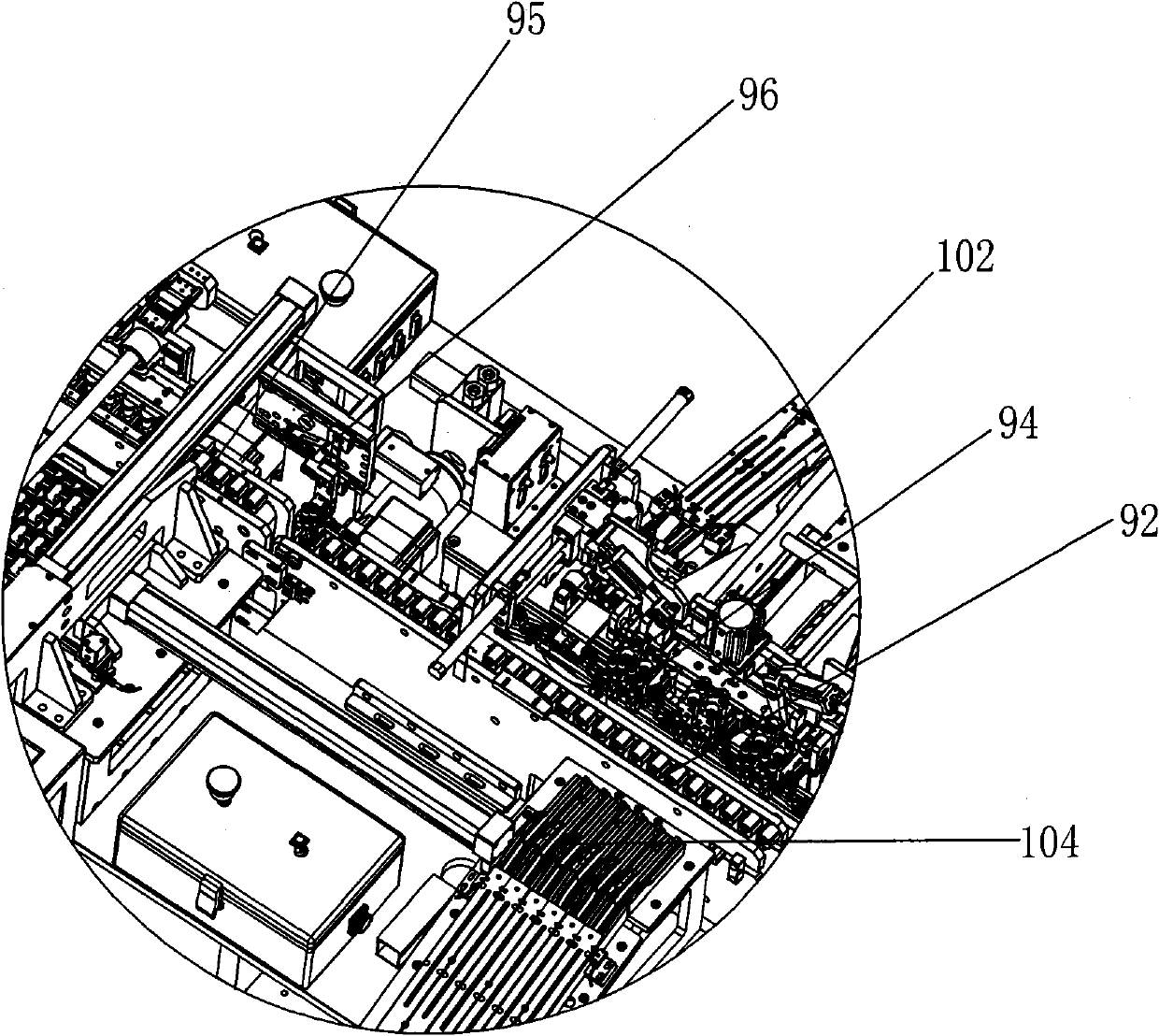

Power type lithium battery full-automatic production line and production technology thereof

ActiveCN105280957AStorableAchieve readFinal product manufactureElectrolyte accumulators manufactureProduction lineControl system

The invention relates to a power type lithium battery full-automatic production line and a production technology thereof. The power type lithium battery full-automatic production line mainly consists of a pole piece manufacturing unit, a battery assembling unit, a battery liquid injecting unit and a factory processing unit; each unit key equipment electrical control system is composed of a PLC, an industrial personal computer, a hydraulic and pneumatic component; the PLC controls each mechanism of the equipment to act in a coordinated manner; and the industrial personal computer collects data to realize the function that the data of the whole line can be stored, read and the like. The main effects lie in that mutual matching of production efficiency of each unit is realized through key debugging for production parameters, a conveyor is adopted in an intermediate link, and full automation of production process is finally realized; the production line is compatible with multi-standard battery production requirements, the production when the product is remodeled can be realized just by adjusting the equipment parameters and replacing partial work fixtures, and order form-based production requirement of the product is met; key equipment and technology on the line are independently researched and developed, the operation is reliable and stable, and the production line has higher cost performance.

Owner:东营黄蓝知识产权运营管理有限公司

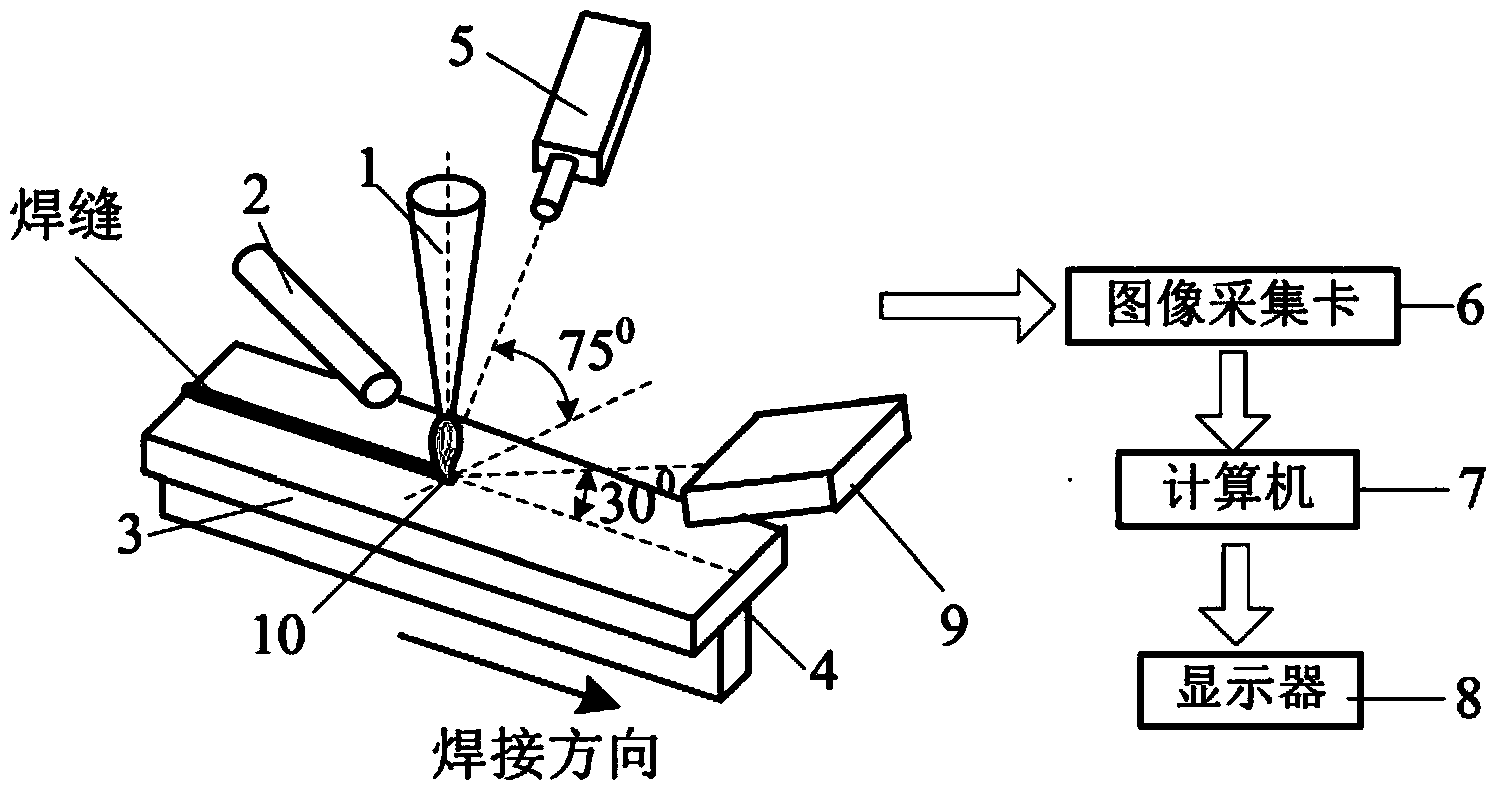

Laser lap welding gap detecting system and laser lap welding gap detecting method based on molten pool image visual sensing

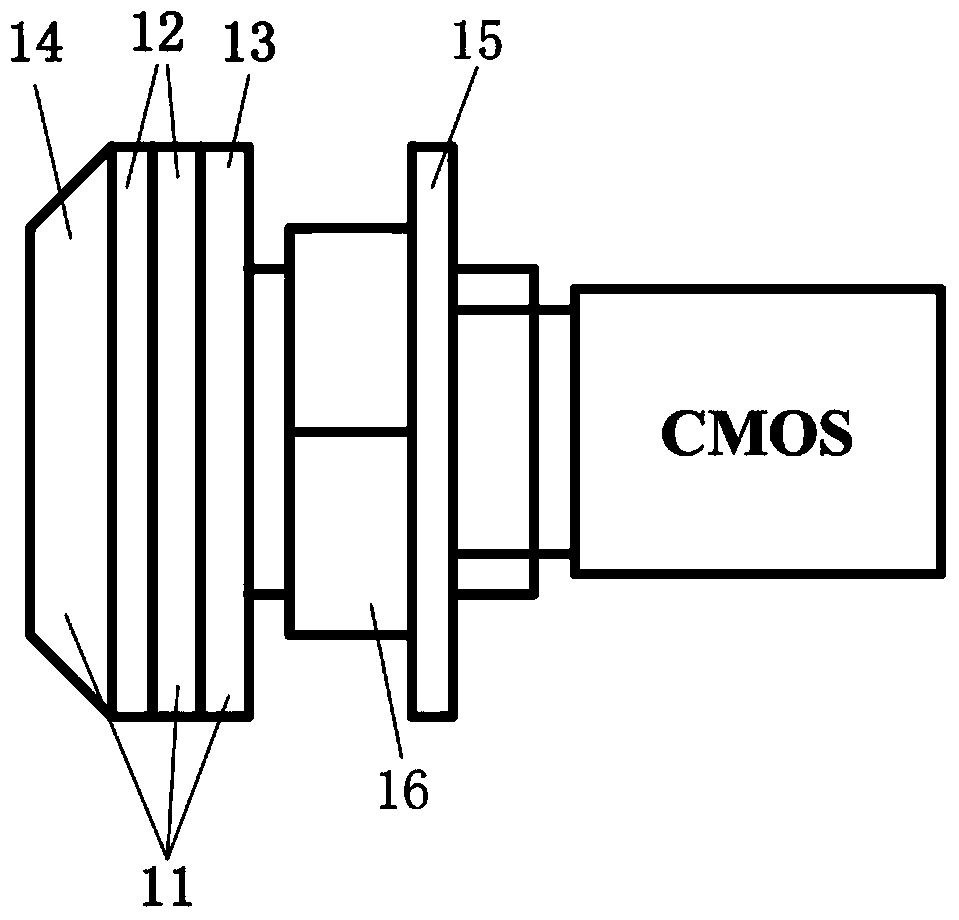

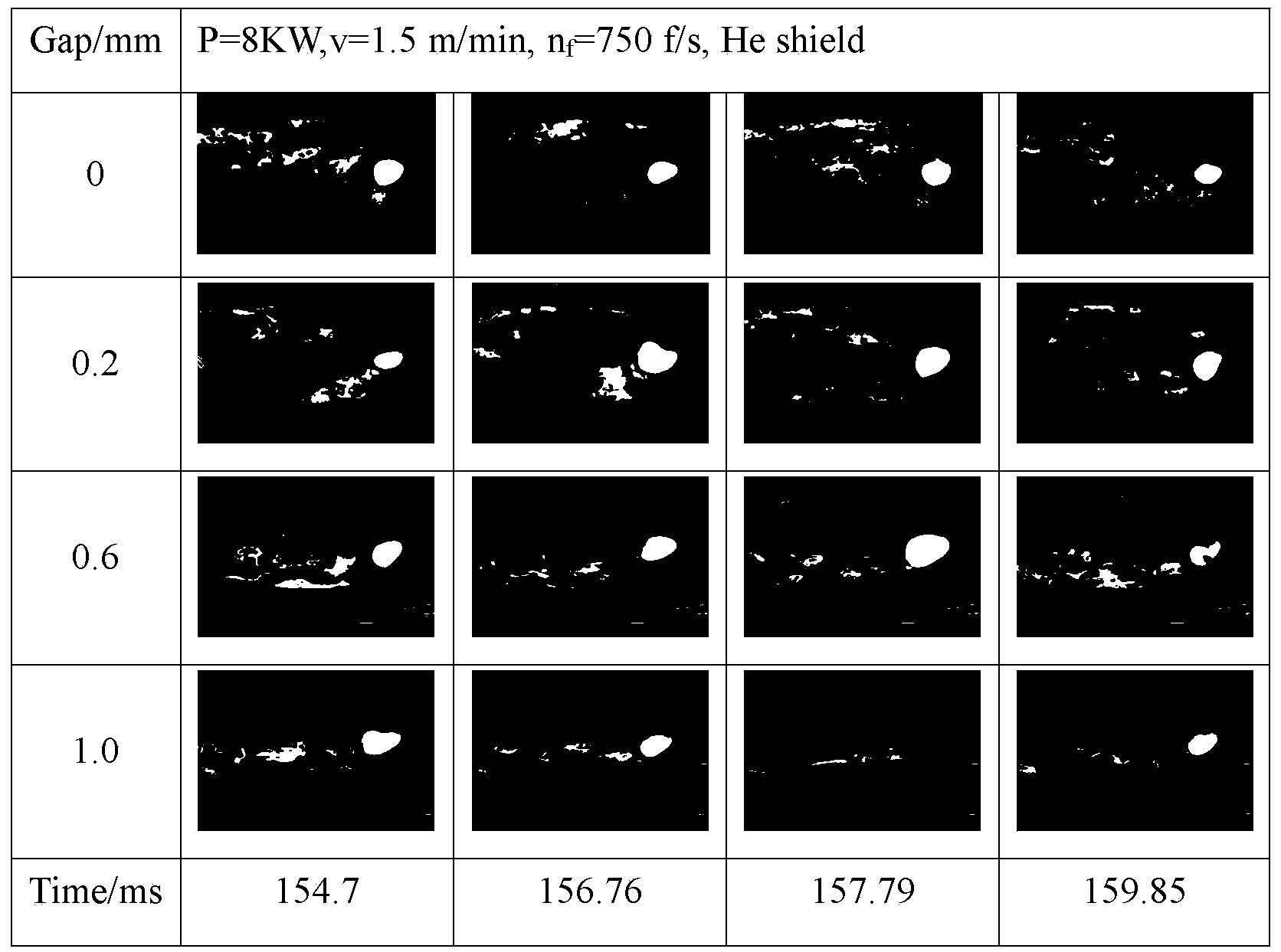

ActiveCN103506756AMeet the requirements of seam trackingImprove quality and efficiencyLaser beam welding apparatusAnti jammingDisplay device

The invention discloses a laser lap welding gap detecting system and a laser lap welding gap detecting method based on molten pool image visual sensing. The detecting system is a visual sensing system and comprises a CMOS camera, a light filtering system, a secondary light source, an image capture card, a computer, a display and the like, wherein the CMOS camera has a LinLog photosensory technology. According to the detecting method, the secondary light source and emitted light of molten pools are used as light sources; plasma is filtered out by utilizing the light filtering system, and light intensity is adjusted; the computer is used for collecting and displaying molten pool images in real time, wherein the molten pool images are obtained by the CMOS camera; molten pool image edges and areas and orifice image edges and areas are extracted and calculated by utilizing a Labview image processing platform, and the quantitative relations between molten pool sizes and orifice areas and between the molten pool sizes and orifice gaps are obtained. The detecting system is simple in structure, clear in monitoring image, high in light signal detecting accuracy, strong in anti-jamming capacity, good in engineering practicability and capable of monitoring laser welding of T-type overlap joint gaps in real time.

Owner:SHANGHAI JIAO TONG UNIV

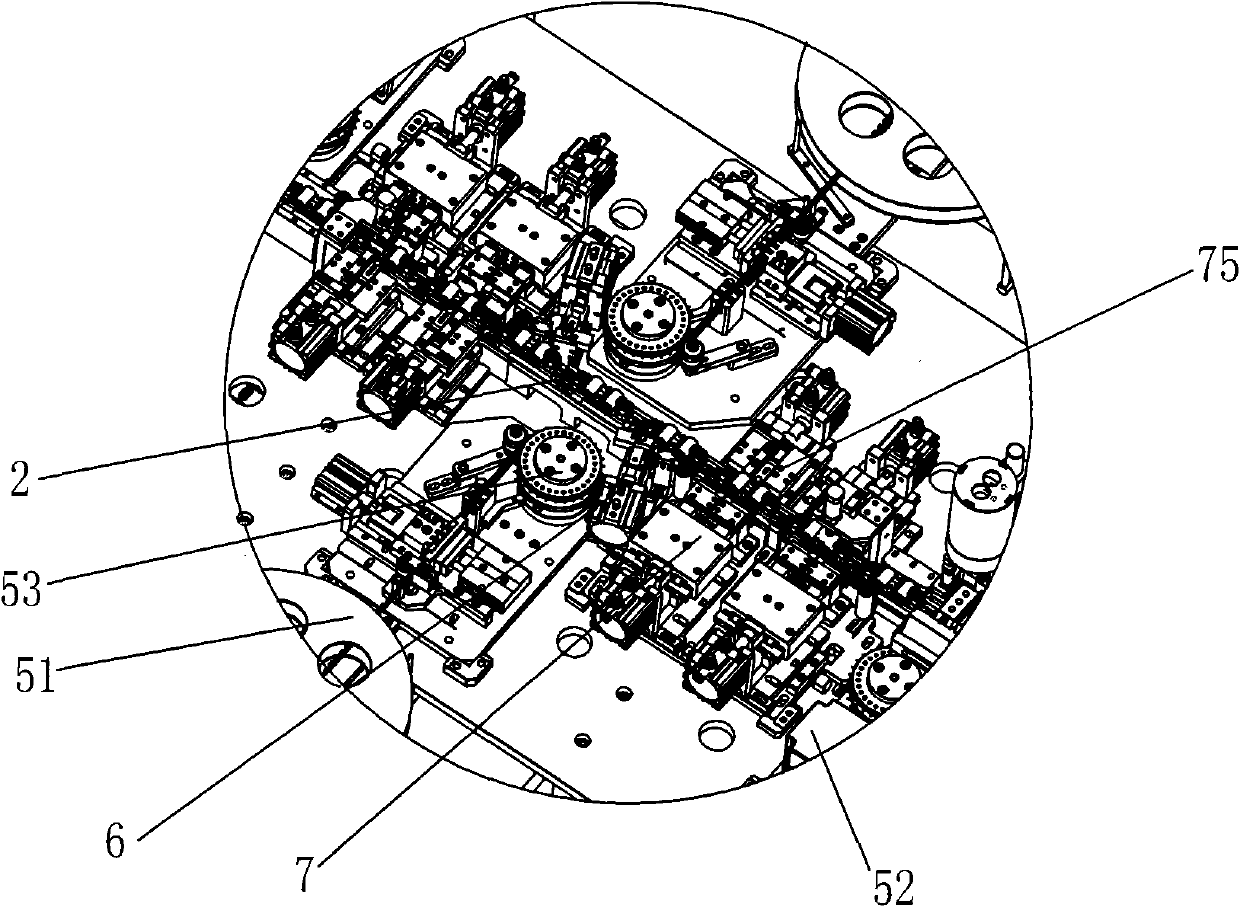

Automatic spot welding equipment

ActiveCN101992341AQuality improvementImprove quality and efficiencyResistance welding apparatusHigh volume manufacturingElectrical control

The invention relates to automatic spot welding equipment which comprises a stand and a workbench arranged on the stand, wherein the workbench is provided with a battery feed mechanism, a steel band feed mechanism, a transfer mechanism, a welding tab cut-off mechanism, a welding mechanism and a good product blanking mechanism, wherein the battery feed mechanism and the steel band feed mechanism are respectively used for feeding a battery and a steel band connected with a welding tab into a welding station; the transfer mechanism is used for bearing and transferring the battery; the welding tab cut-off mechanism is used for cutting off the welding tab on the steel band; the welding mechanism is used for welding the welding tab to the anode end and the cathode end of the battery; the transfer mechanism is provided with a battery clamping seat used for clamping the battery, and an elastic piece inwards pressing the battery is arranged on the battery clamping seat; and the mechanisms are connected with a master control circuit. In the invention, the structural design of the equipment is reasonable, and the automatic feeding, the welding and the property detecting of the battery and the steel band are realized by adopting electrical control, thus the equipment has the advantages of high feed speed, high welding precision and good welded product quality, improves the quality and the production efficiency of the welded product, reduces the labor intensity of workers, saves the production cost and is particularly suitable for producing batteries welded with welding tabs in batches, thereby improving market competitive force of enterprises.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

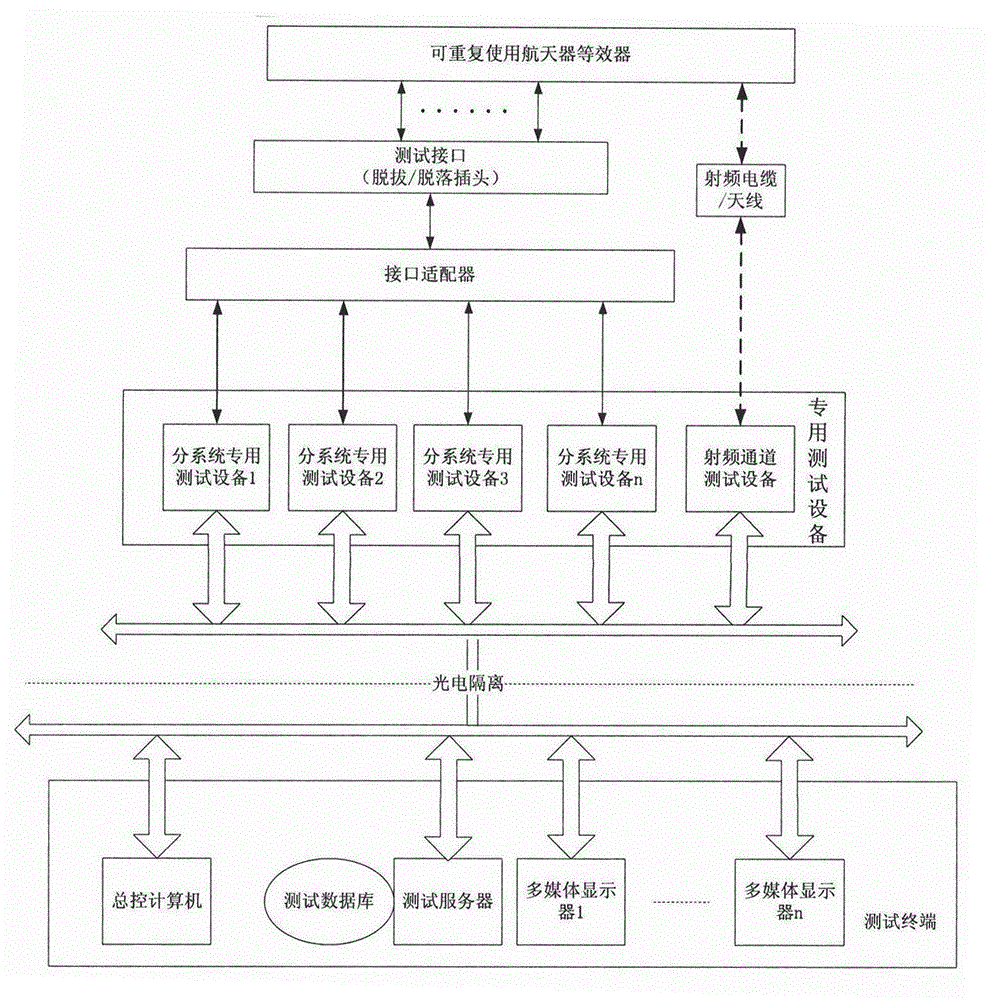

Avionics system automatic test platform based on reusable spacecraft

InactiveCN102915029AReduce typesReduce workloadElectric testing/monitoringAutomatic controlTest quality

The invention discloses an avionics system automatic test platform based on a reusable spacecraft, which comprises an interface adapter, special test equipment, a photoelectric isolation network and a test terminal. According to the characteristics that the spacecraft has many subsystems and the subsystems are distributed dispersedly, the avionics system automatic test platform based on the reusable spacecraft unifies the adapter of the comprehensive test platform, reduces the types of ground equipment, realizes functional modularization of each system and integration of the system structure, and can automatically generate and change input signals or excitation sources, automatically control the on and off of input and output of a tested object, automatically measure and record output signals, automatically process test data, automatically interpret the work state of test equipment, automatically execute test program and automatically judge the test data so as to shorten the construction time of a test system and solve the problem about distributed remote test. The test system has high generality, flexibility and test efficiency, reduces the workload of testers and improves the test quality and the test efficiency.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

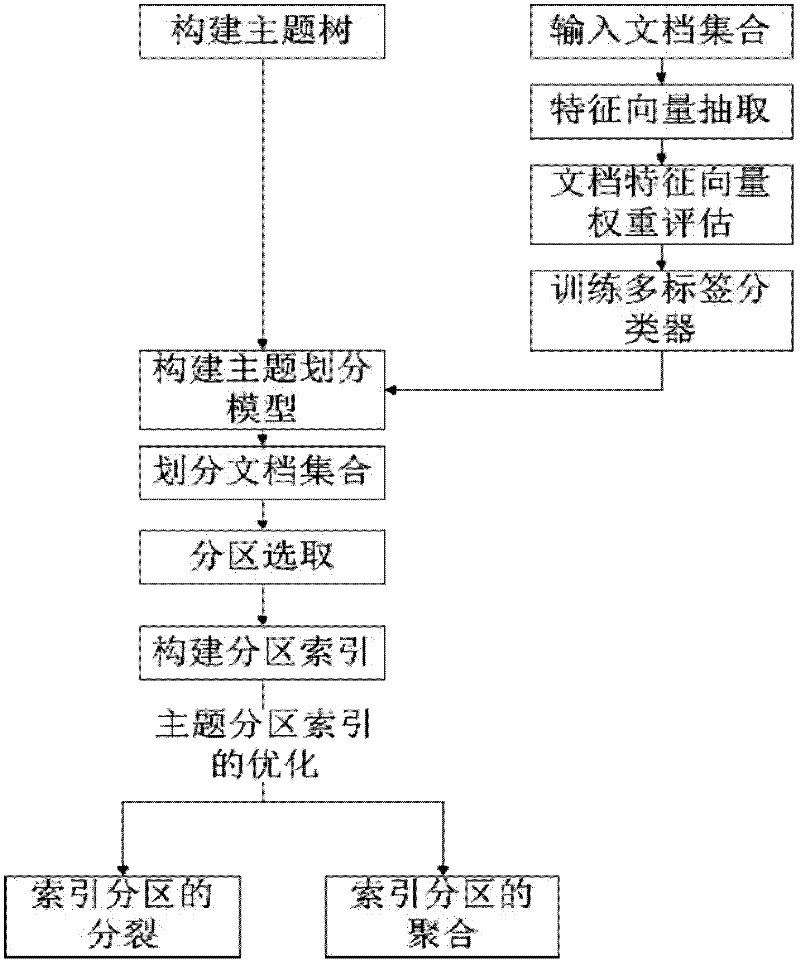

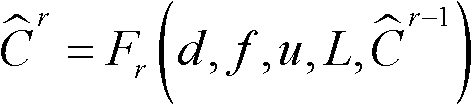

Theme map expansion based knowledge resource organizing method

InactiveCN102567464ASimple structureQuality assuranceSpecial data processing applicationsResource utilizationThermal expansion

The invention discloses a theme map expansion based knowledge resource organizing method, which is characterized by including: organizing resources to build resource indexes, and providing a search architecture based on themes on the basis of a map architecture formed by knowledge resources and theme incidence relations therein. In the search architecture, themes of documents are organized to be index entry, document collection is divided by combining internal relations of succession, correlation, polysemy of the document themes and multi-label classifying technology, proper partition is selected by a partition selecting method based on threshold value so as to guide building and inquiring of the indexes. During inquiring, inquiry results are acquired from a route to the relevant index partition and are gathered and organized according to the theme relations, and resource utilization rate and inquiring efficiency are improved sufficiently on the premise of guaranteeing quality of the inquiry quality. Further, by the index partition gathering and breaking technology, the index structure is further optimized and quality of the inquiry results and inquiring efficiency are improved.

Owner:XI AN JIAOTONG UNIV

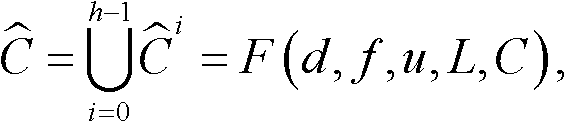

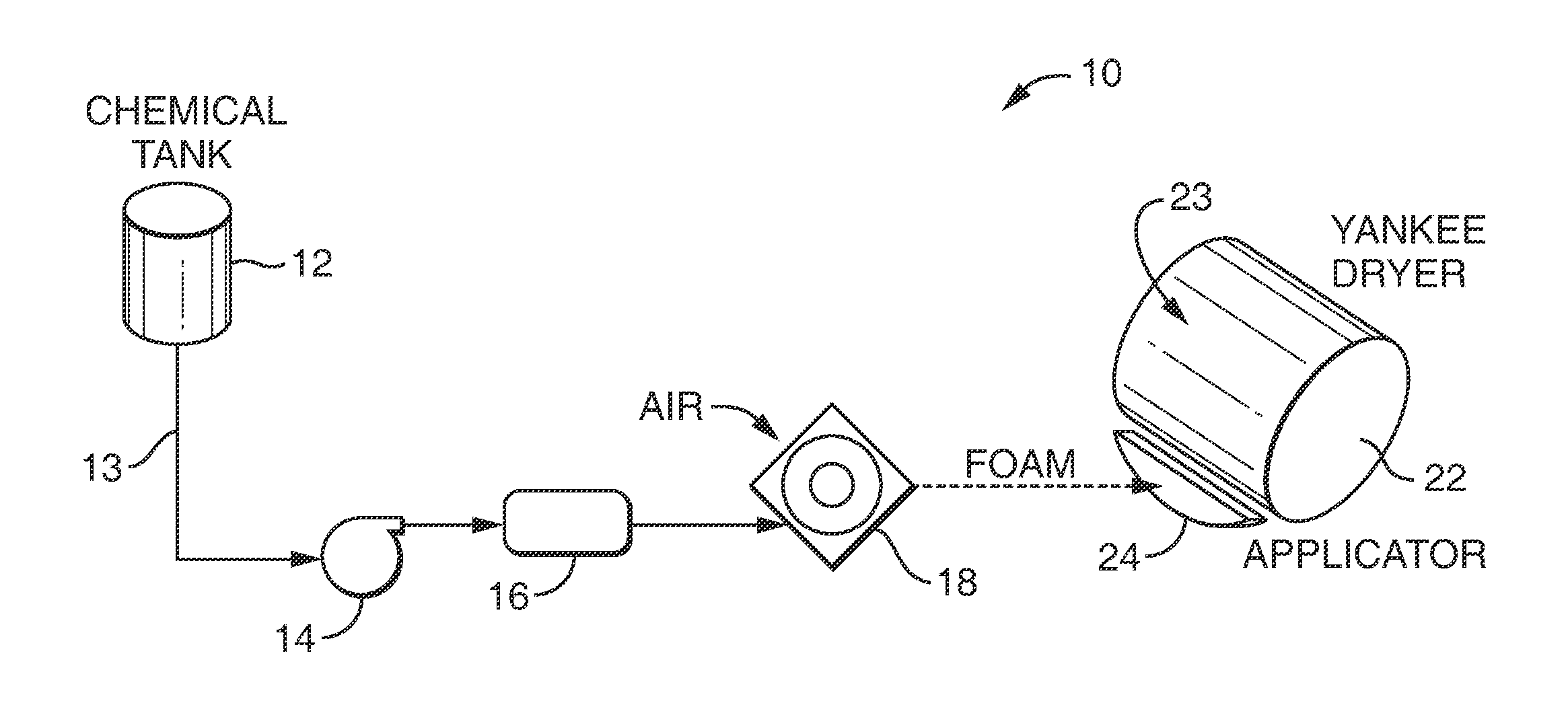

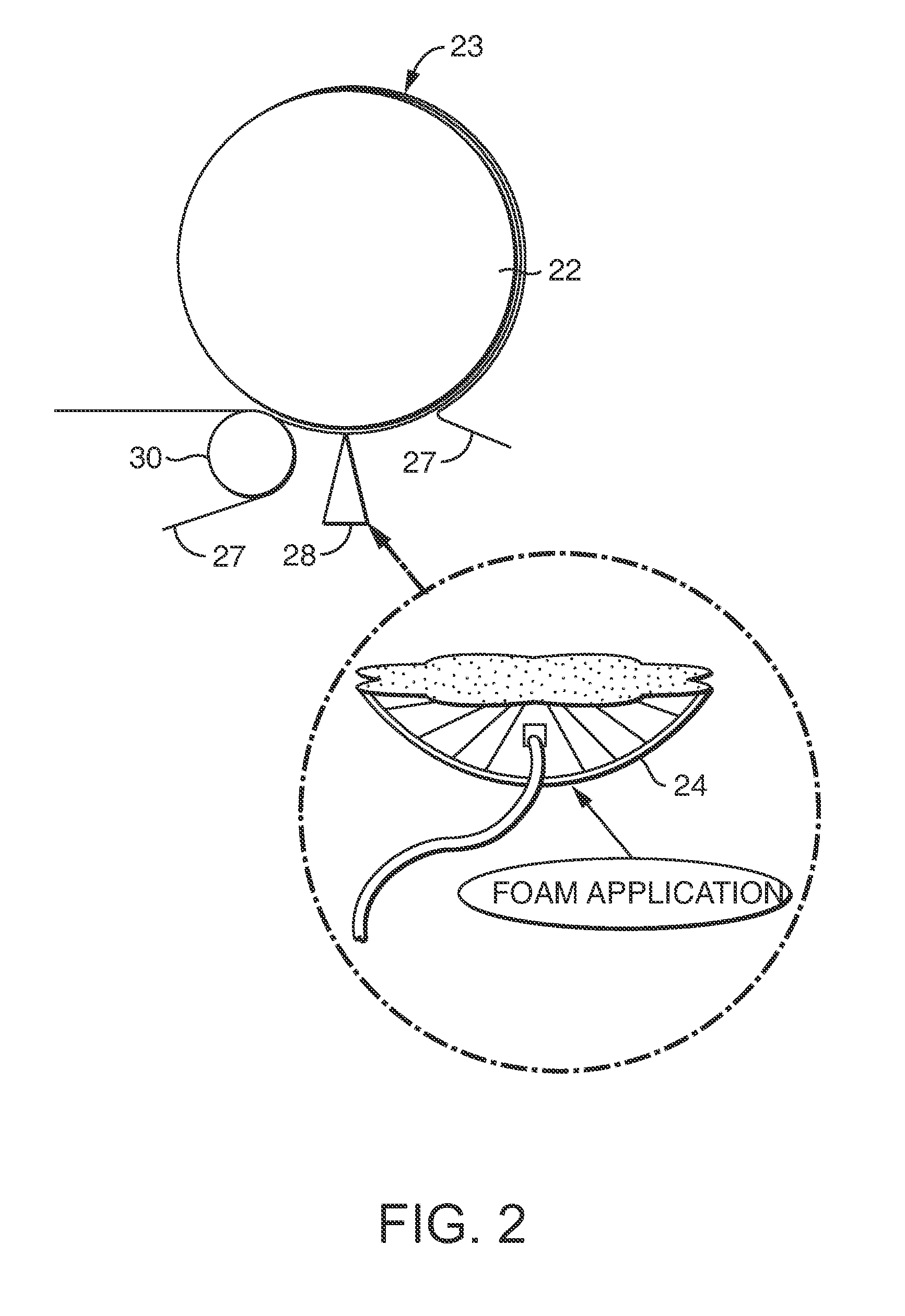

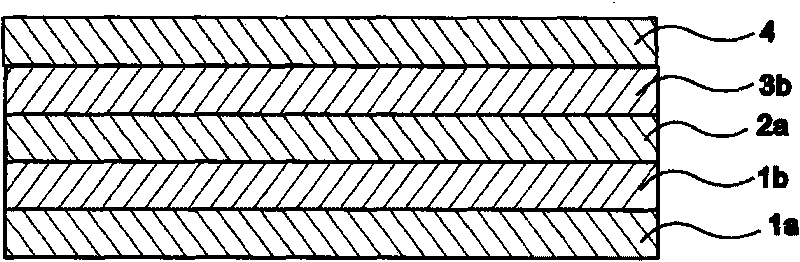

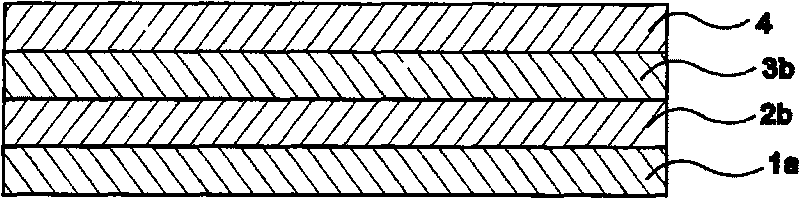

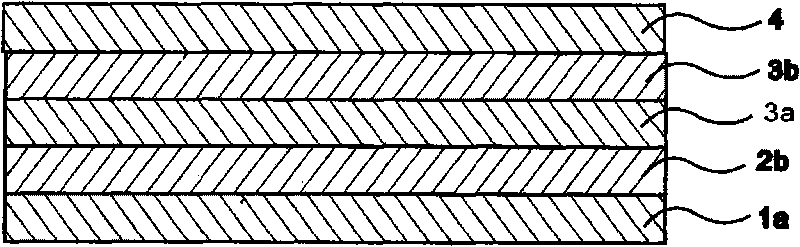

Substrates comprising frothed benefit agents and the method of making the same

ActiveUS20120164200A1Less energyImprove quality and efficiencyCosmetic preparationsNon-fibrous pulp additionFiberChemistry

The present invention provides a nonwoven substrate comprising a fibrous web defining a surface; and a layer of a benefit agent wherein said benefit agent is selected from an additive composition, an enhancement component and combinations thereof; wherein said benefit agent is frothed and bonded to the fibrous web surface through a creping process. Additionally, the present invention provides for a method of creping a nonwoven substrate and also provides for a nonwoven substrate comprising an adhesive film of an aqueous, frothed, benefit agent.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method and device for printing pictures and texts on surface of irregular object

InactiveCN101734030ASimple color printingEfficient Color PrintingDecorative surface effectsDuplicating/marking methodsPlastic moldingElectrical and Electronics engineering

The invention relates to a method and a device for printing pictures and texts, particularly to a method and a device for printing fine pictures and texts on the surface of an irregular object, which comprises the following steps of: a. manufacturing a compound transfer printing film; b. pre-deforming the compound transfer printing film; c. placing the deformed compound transfer printing film in a plastic hollow blow molding mould, realizing transfer printing in the plastic molding process, or clinging the deformed compound transfer printing film to a printing undertaking object, and sharing through one or more modes of heating, infrared illumination, ultraviolet illumination and pressurization to realize transfer printing; and d. removing a substrate layer and a stripping layer. The invention has the advantages that the printing of fine pictures and texts can be carried out on the surfaces of a regular object and the irregular object, pictures and texts are continuous, whether the local surface or the entire surface can be printed once through the invention, and the invention has a good solution particularly for an object with a complicated surface.

Owner:赵东林

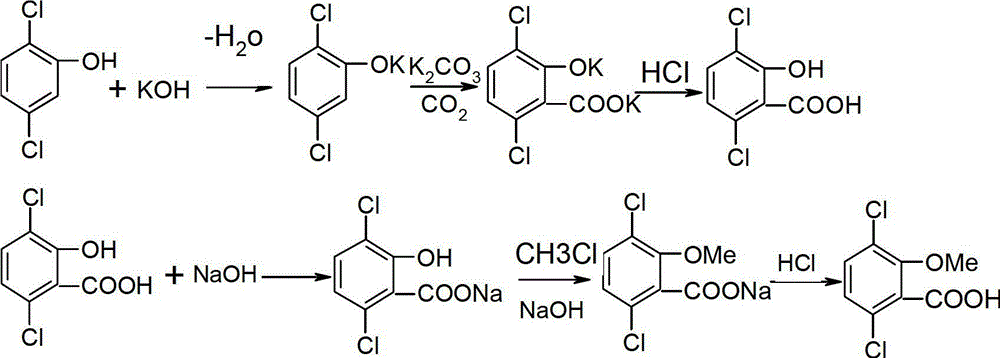

Synthetic process of herbicide dicamba

ActiveCN102942474AImprove one-way yieldImprove quality and efficiencyOrganic compound preparationCarboxylic compound preparationMethoxylaricinolic acidFixed bed

The invention relates to a preparation method of herbicide dicamba. The preparation method includes: (1) liquid potassium hydroxide and 2, 5-dichlorophenol are reacted according to molar ratio of 0.95:1-1:1 to obtain 2, 5-dichlorophenol potassium; (2) at the presence of anhydrous potassium carbonate and catalyst, the 2, 5-dichlorophenol potassium obtained in the step (1) is reacted with CO2 to generate 3, 6-dichlorosalicylic acid, pressure of CO2 is controlled to be 4-6MPa, reaction temperature ranges from 100 DEG C to 160 DEG C, and molar ratio of anhydrous potassium carbonate and 2, 5-dichlorophenol potassium is 1-2:1; and (3) in alkaline condition, at the temperature of 70-100 DEG C, the 3, 6-dichlorosalicylic acid obtained in the step (2) and chloromethane are reacted under the action of the catalyst through a tube fixed-bed reactor according to molar ratio 1:1-3.5, saponification and acidification are performed to obtain 3, 6-dichloro-2-methoxysalicylic acid, namely the dicamba. The process is high in reaction yield, simple in reaction condition, good in product quality, small in three wastes and low in energy consumption.

Owner:JIANGSU YOUJIA CHEM +2

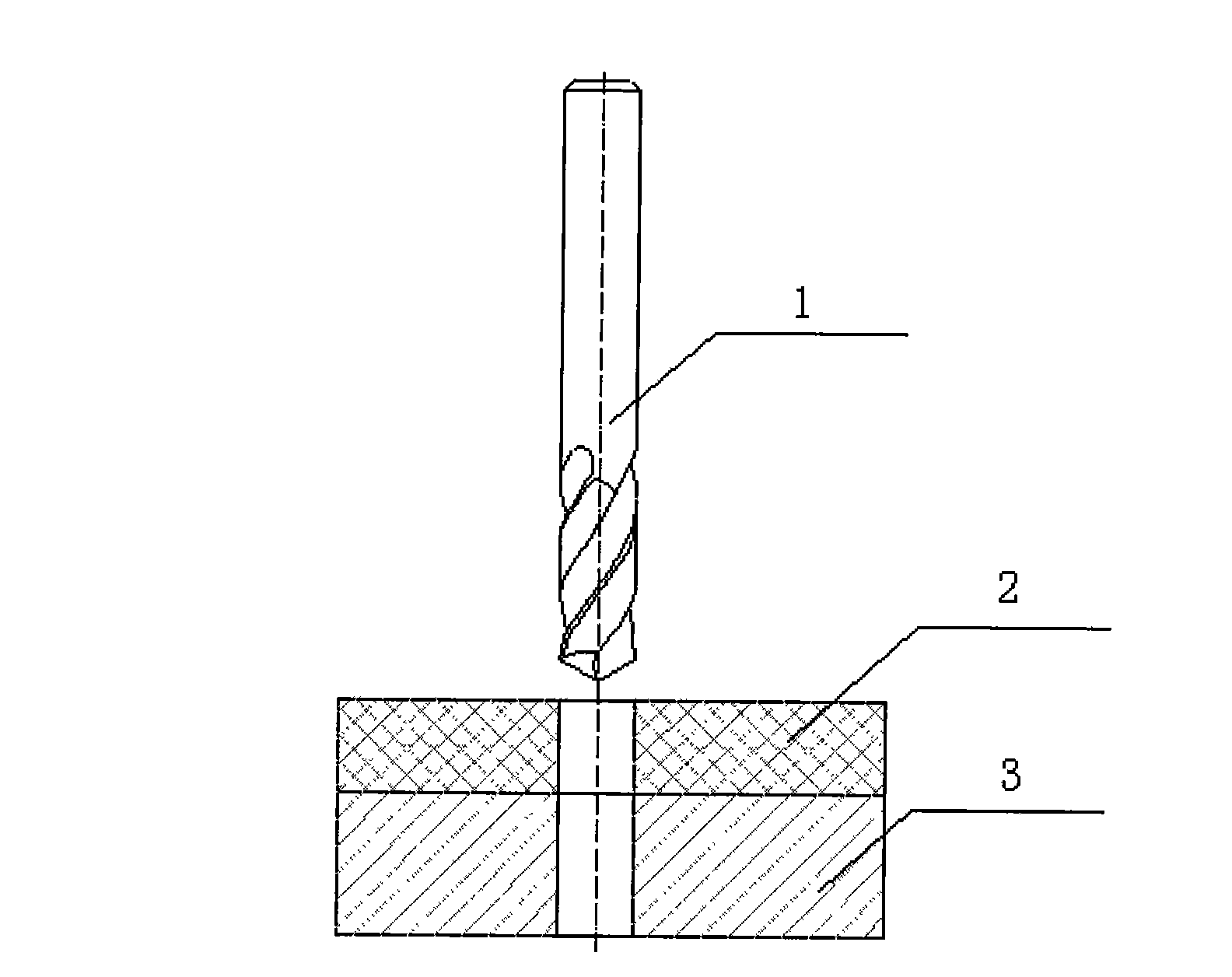

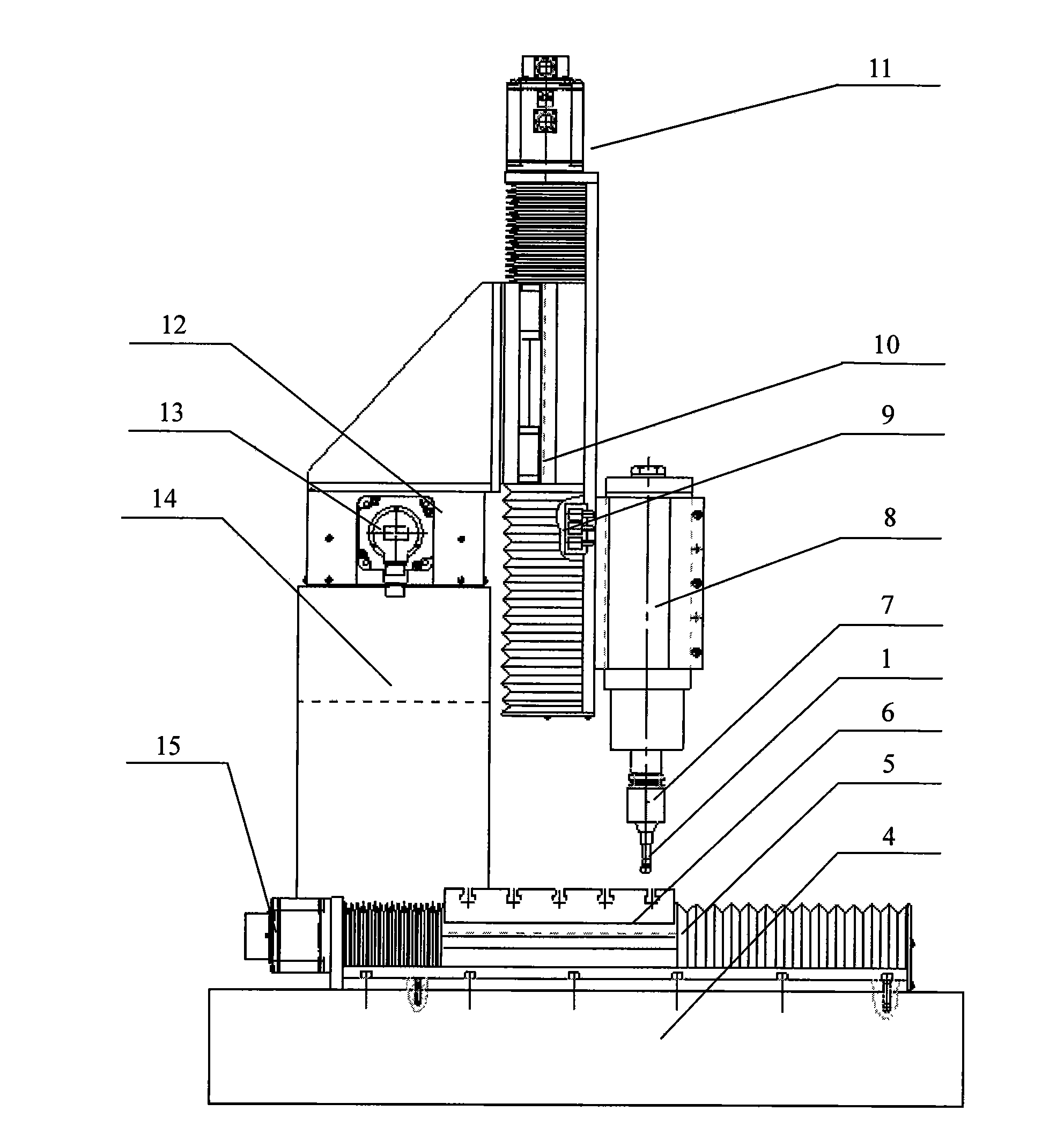

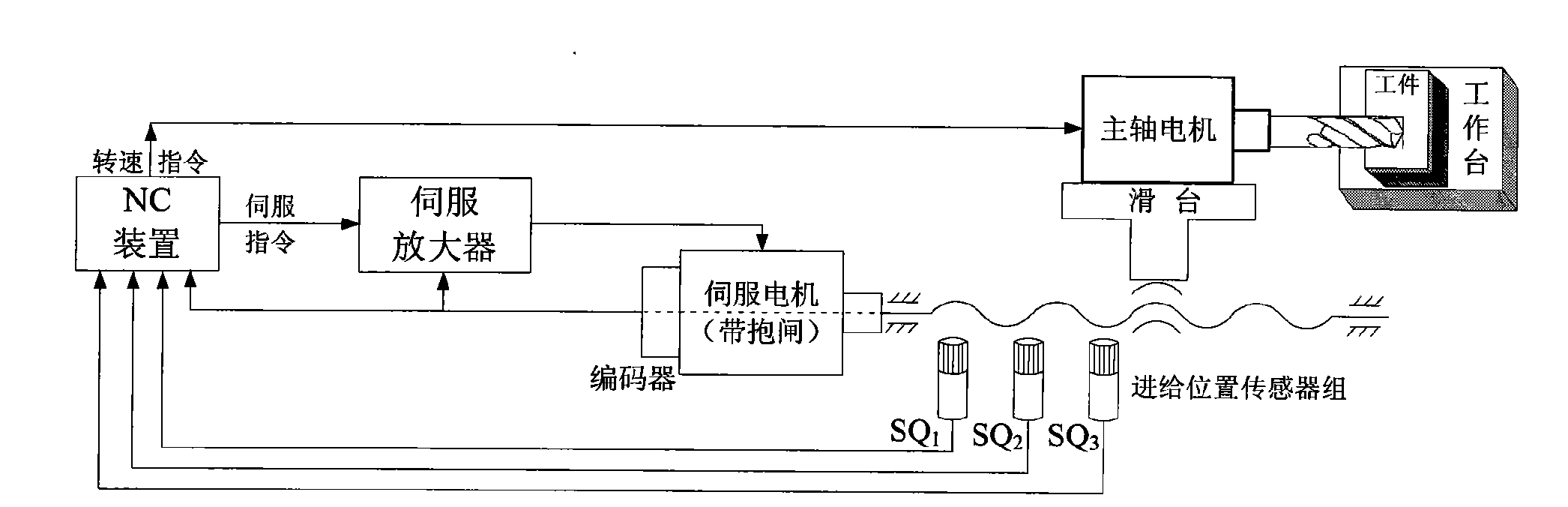

Method and device of disposing holes on carbon fiber composite material and meal material which are overlapped

InactiveCN101670448AHigh degree of automationGuaranteed stabilityAutomatic control devicesTransportation and packagingManufacturing technologyControl manner

The invention relates to a method and device of disposing high-quality holes on carbon fiber composite material and meal material which are overlapped, belonging to the field of the mechanical processing and manufacturing technology. The method of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized in that in the process of disposing holes on the carbon fiber composite material and the meal material which are overlapped by a device of disposing holes, such as a polycrystalline diamond (PCD), a coating, a cemented carbide bit and a diamond grinding rod, the rotating speed and the feeding speed of a cutter are automatically changed according to the materials on which holes are to be disposed by the hardware triggering or software numerical-control programming control mode of a feeding position sensor set so that the cutter can be in the optical process parameter state. The device of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized by comprising a body, the cutter the handle of the cutter, an electric main shaft, the feeding position sensor set, a vertical feeding sliding-platform, a main shaft variable-frequency speed-regulating system and a hole disposing device numerical control system. The invention realizes the adaptive continuous processing, obviously improves the quality and the processing efficiency of holes disposed integrally on different overlapped materials and lowers the production cost.

Owner:DALIAN UNIV OF TECH

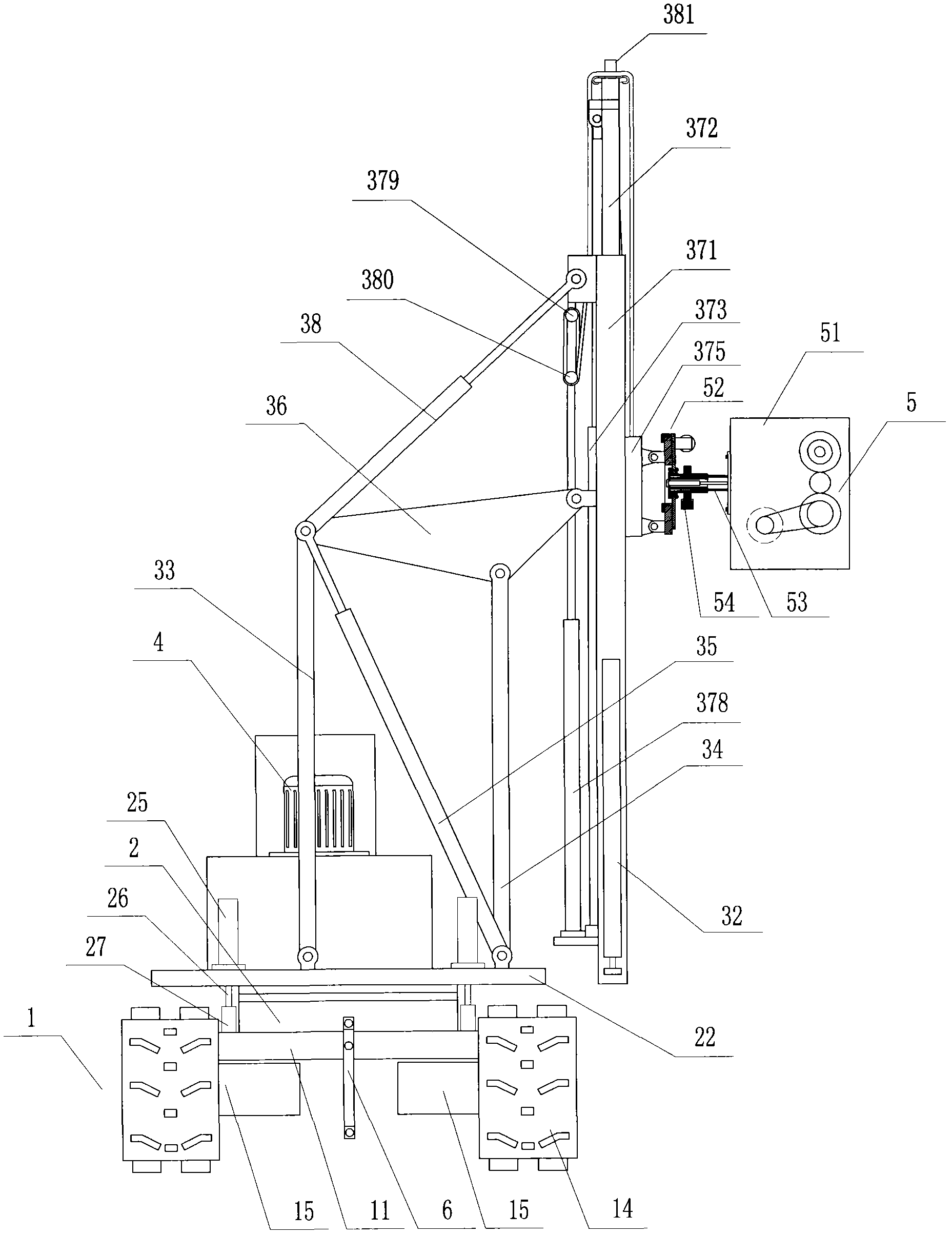

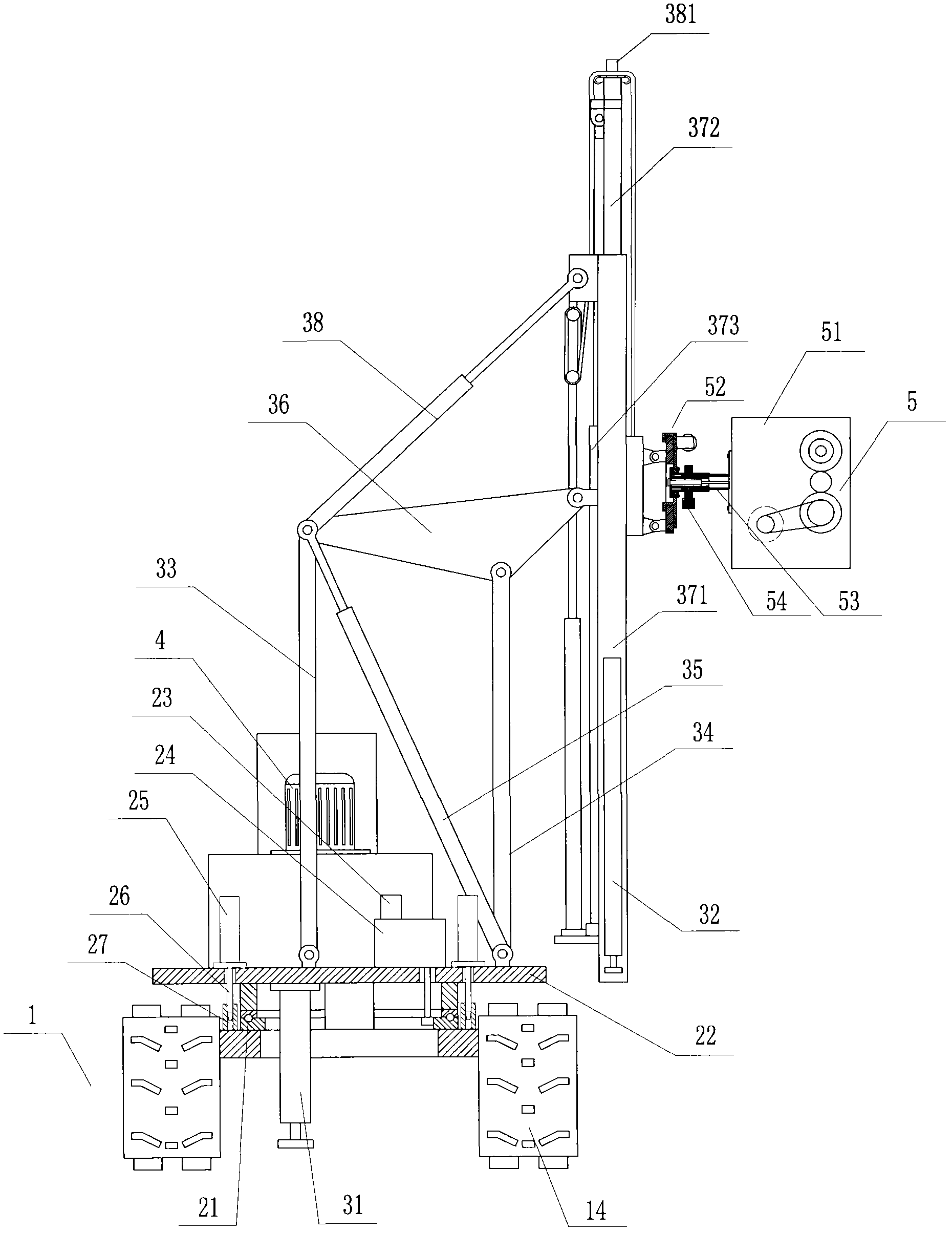

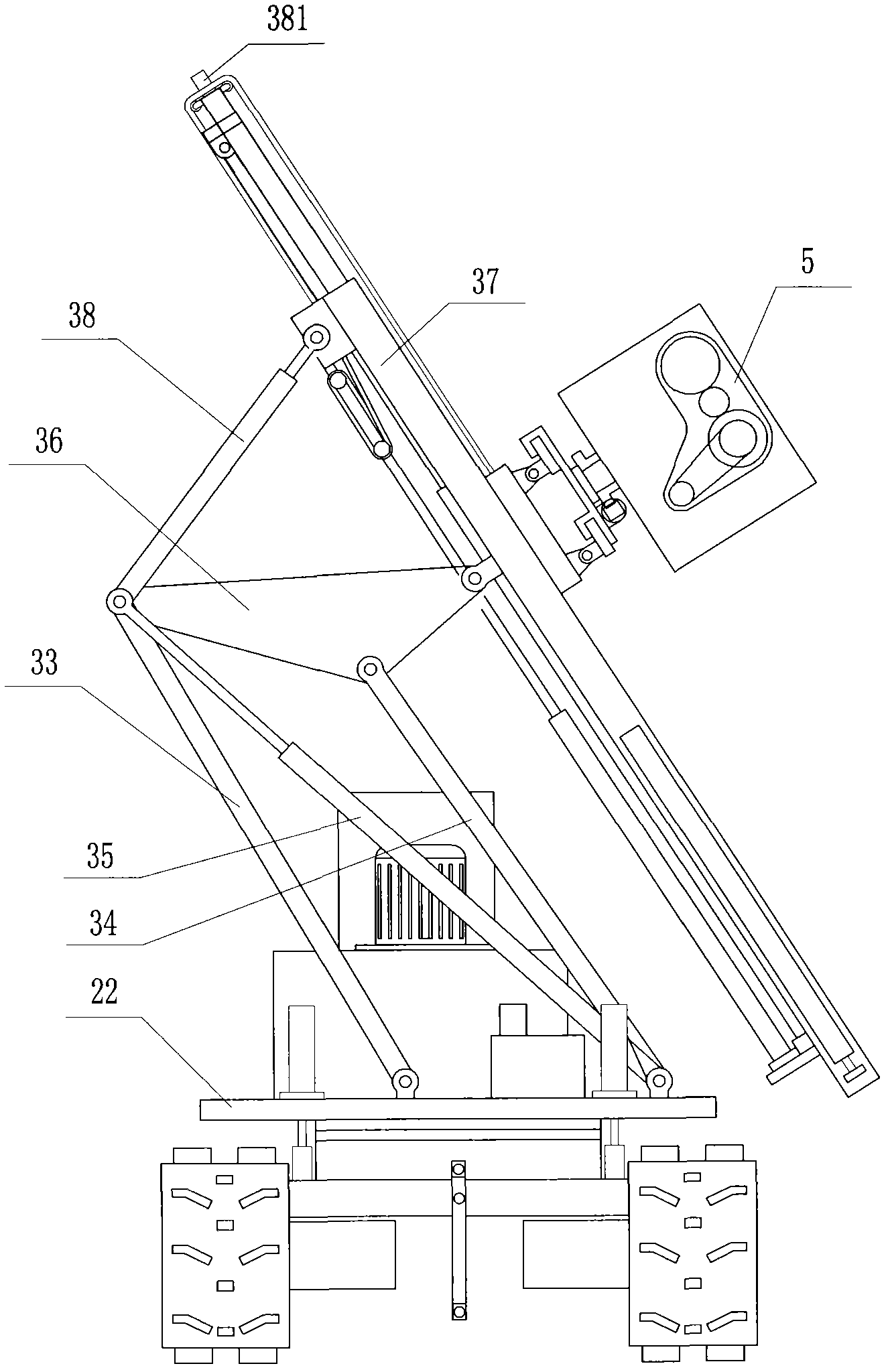

Building wall construction robot

ActiveCN102383585AWalking smoothlyImprove efficiencyBuilding constructionsEngineeringArchitectural engineering

The invention discloses a building wall construction robot, which comprises a crawler unit, a rotary turntable device, a retraction regulating mechanical arm, a construction tool lifting device, a plaster hopper device, a construction position locking device, a trackless guide device and a power device. The building wall construction robot is compact in structure, stable in walking, flexible in movement, and accurate in direction change; the construction tool has large lift; the construction tool lifting device is full automatic; and the construction process completely simulates a manual plastering mode, trackless guide is adopted, the trouble of laying a guide rail is avoided, and the construction quality and construction efficiency are greatly improved.

Owner:蒋京德

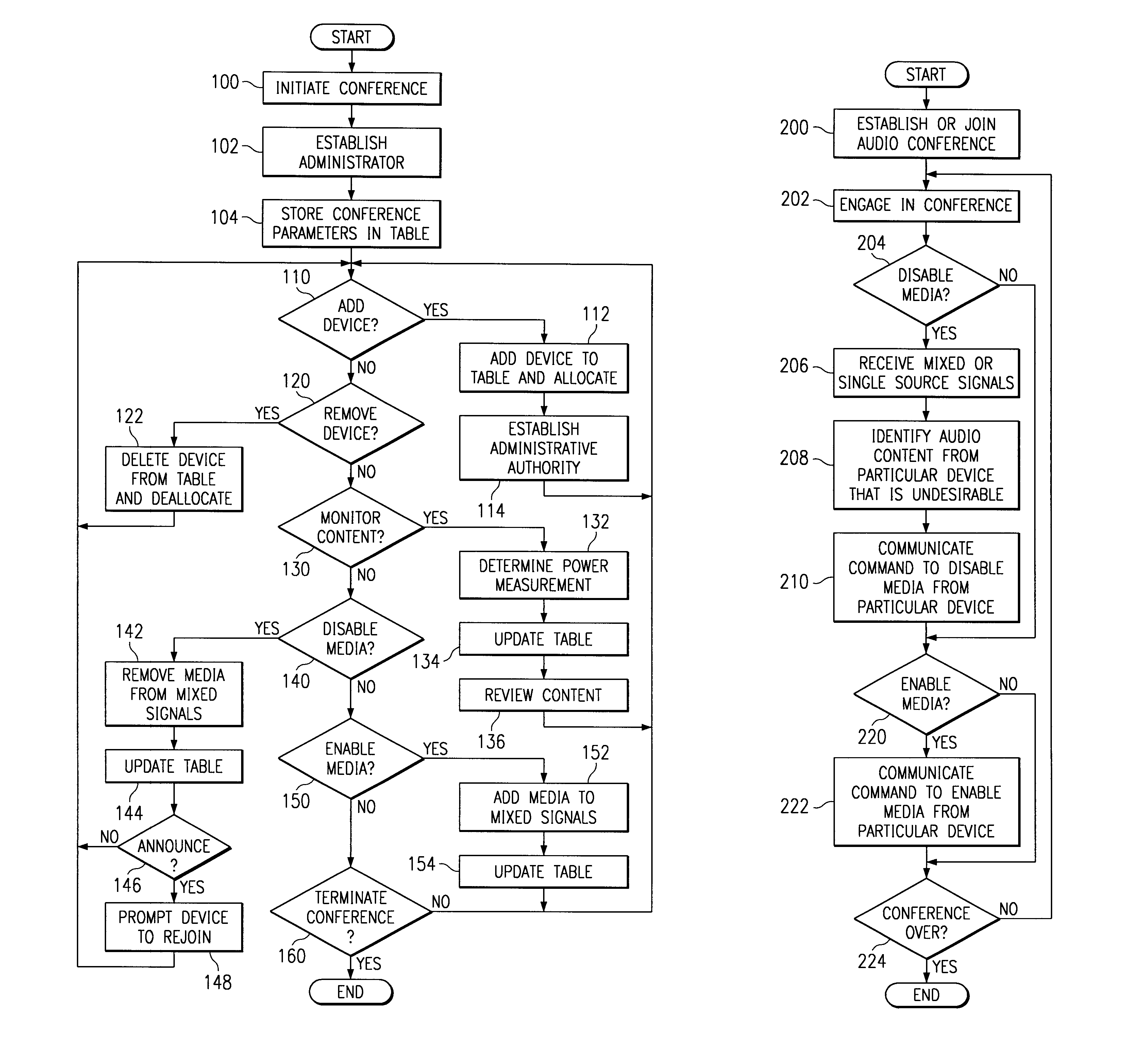

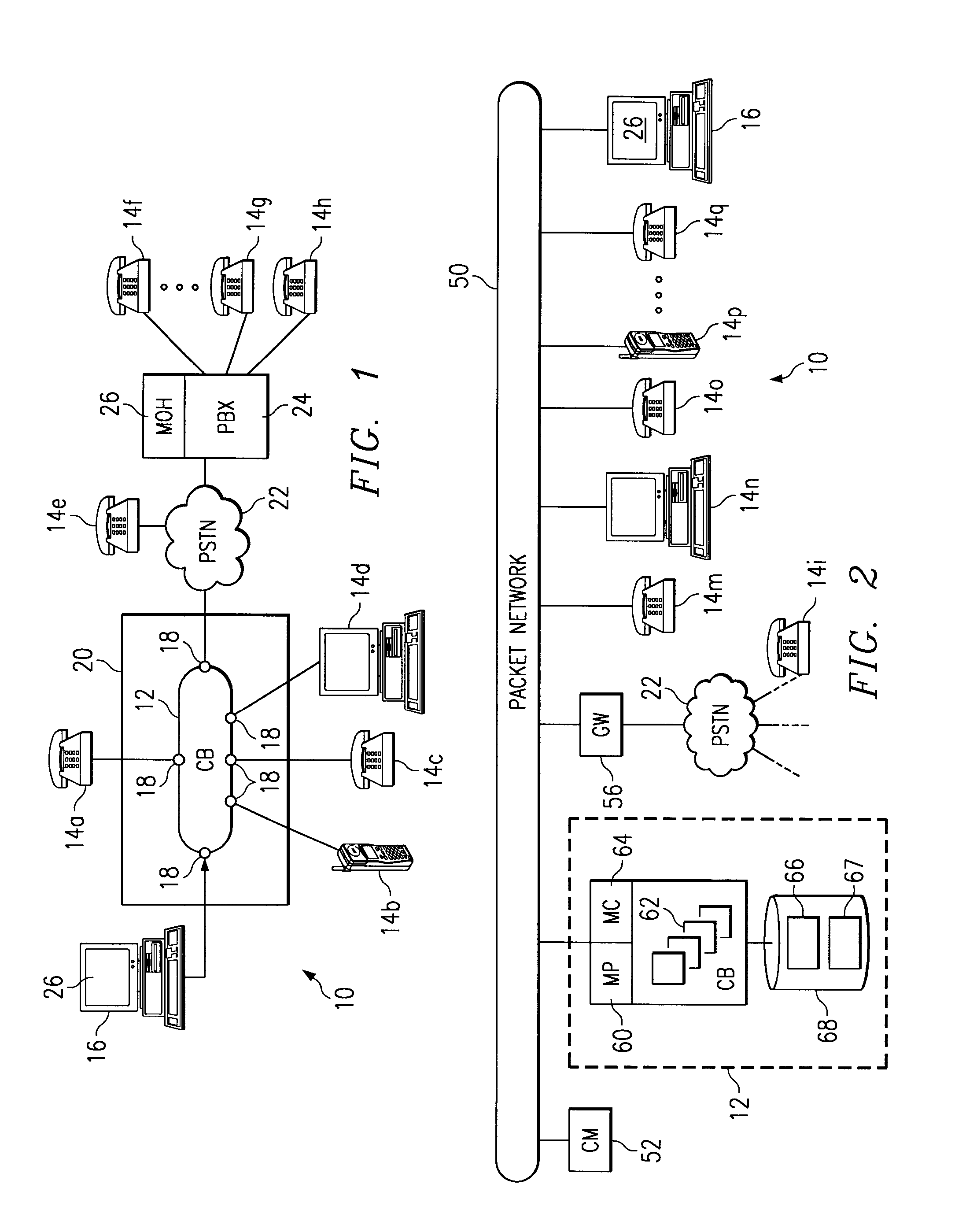

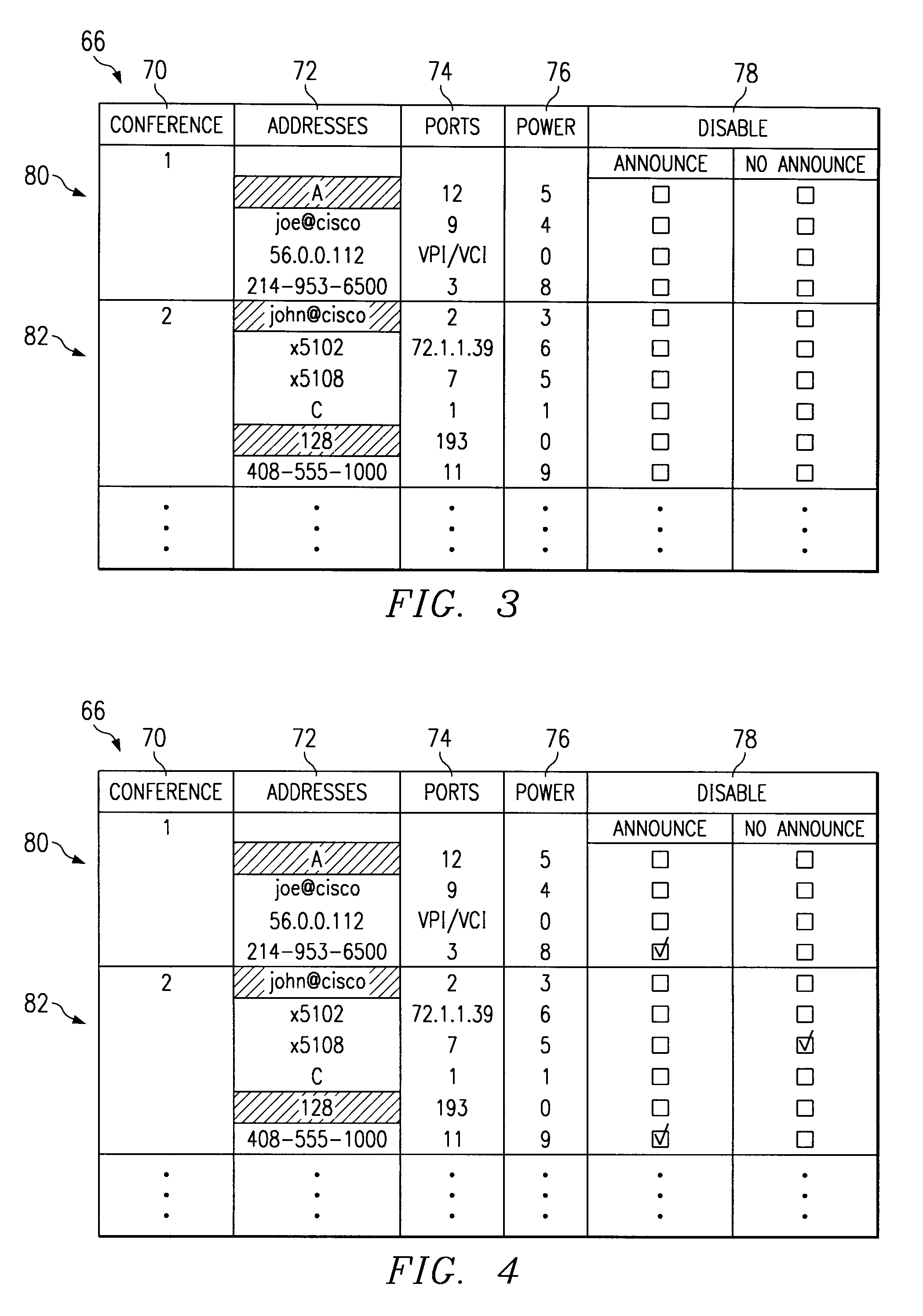

Apparatus and method for controlling an audio conference

InactiveUS6839416B1Improve quality and efficiencySpecial service for subscribersExisting connections interruptionConference managementHuman–computer interaction

A conferencing system includes a number of devices that can participate in an audio conference using a conference bridge. Responding to a human or automated conference administrator, the bridge determines that audio content of media from a particular device is undesirable, and disables media from the particular device. If appropriate, the device receives prompts to rejoin the conference at a later time.

Owner:CISCO TECH INC

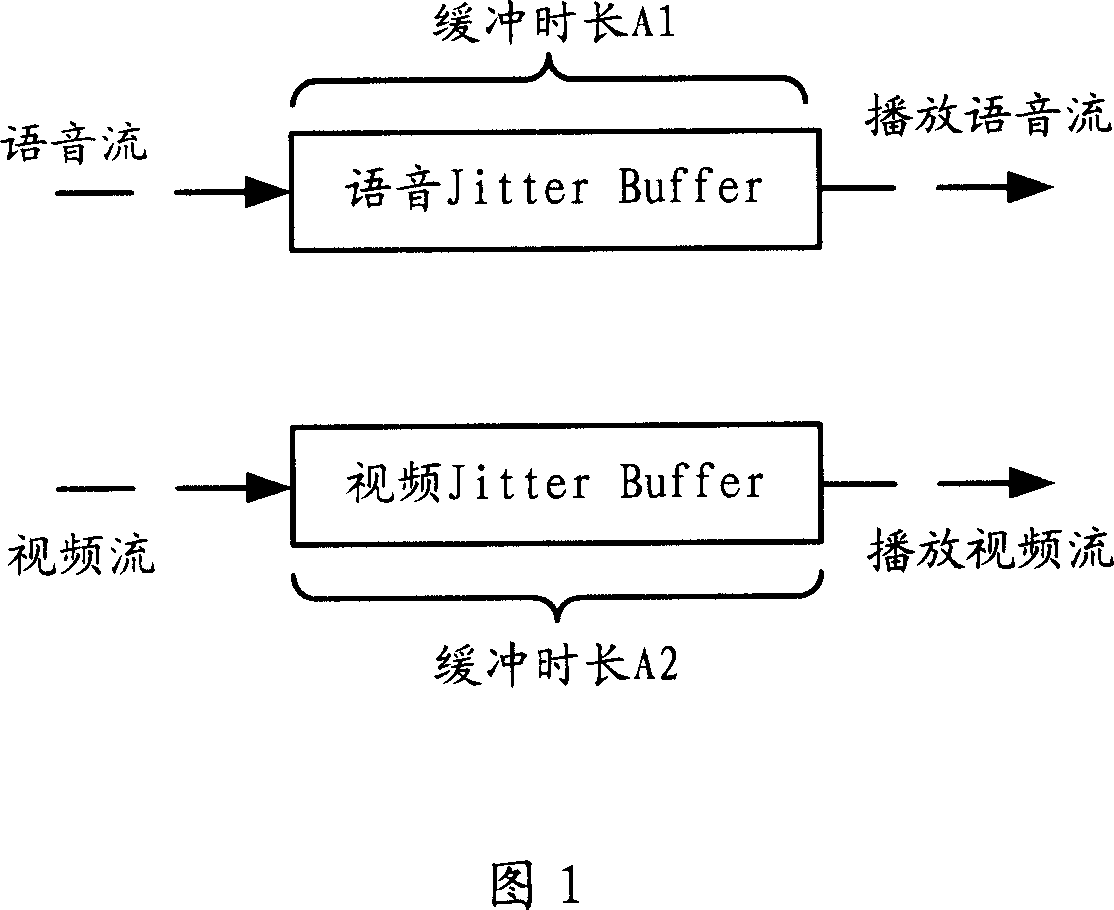

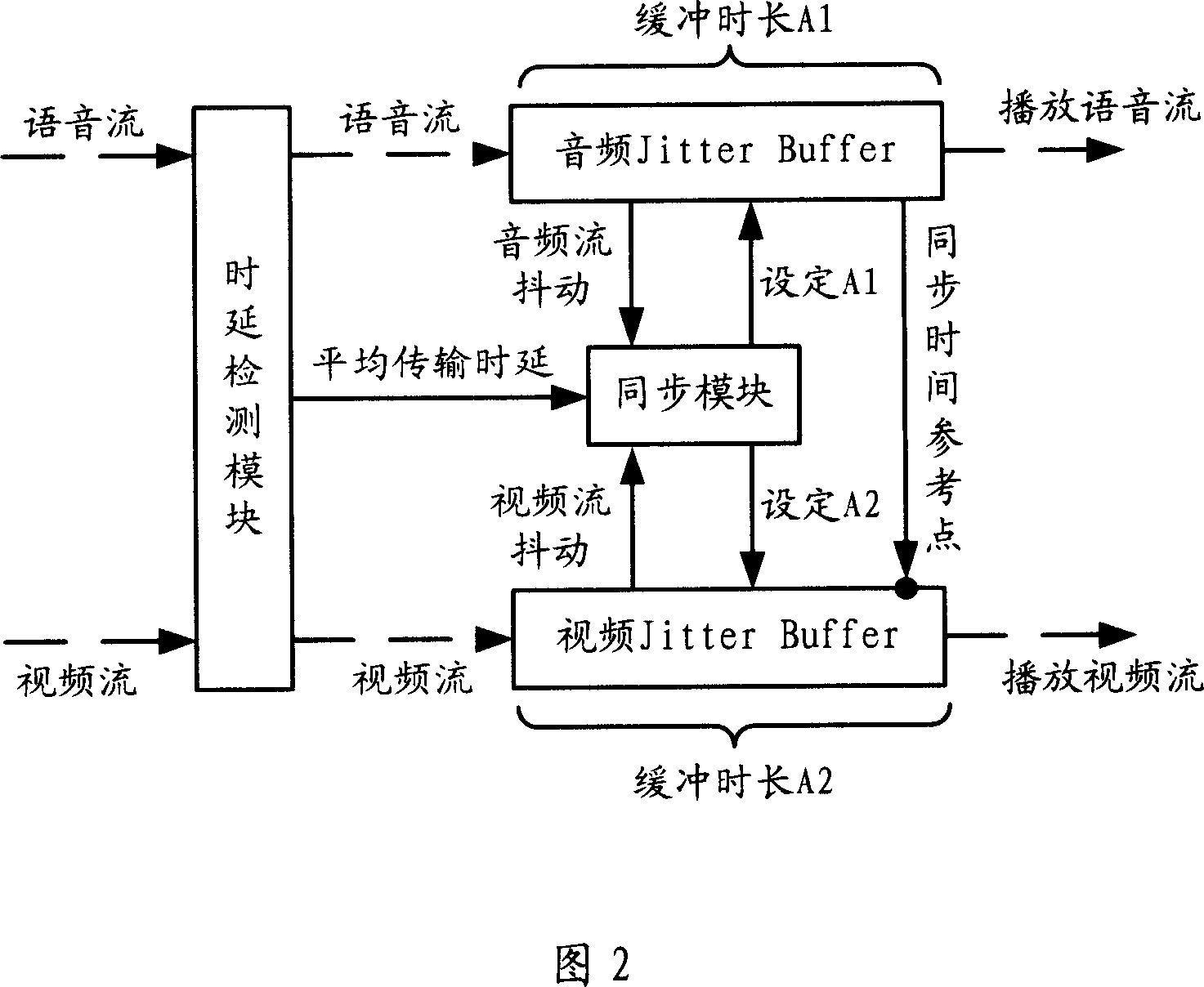

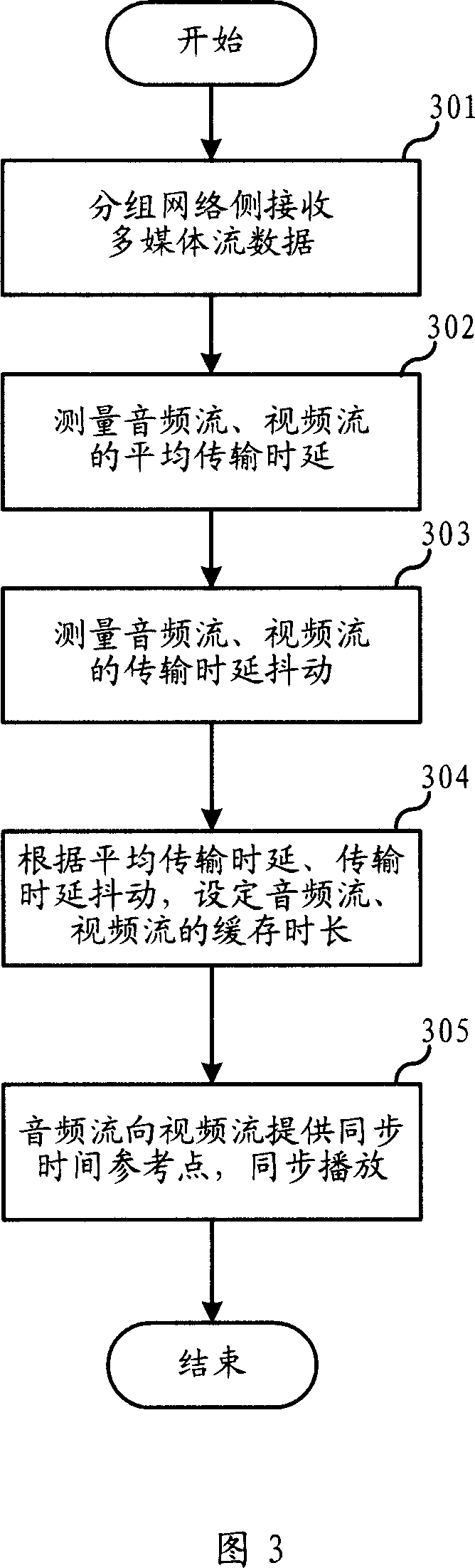

Lip synchronous method for multimedia real-time transmission in packet network and apparatus thereof

InactiveCN1949879AAnti-jitterHigh synchronization accuracyPulse modulation television signal transmissionTransmissionPacket generatorTransmission time delay

The invention relates to multimedia real-time transmission in packet network, disclosing a lip synchronizing method and device for multimedia real-time transmission in packet network, able to simply and effectively regulate to overcome network dithering and variation and implementing lip synchronization of audio and video streams. And it sets buffers which can flexibly regulate buffering time length according to network time delay information and implement synchronization of audio and video streams by regulating their buffering time lengths; it sets a time delay detection module to detect transmission time delays of audio and video data in packet network and then uses synchronizing module to refer to their average transmission time delay and transmission time delay so as to synchronize audio and video modules; it uses the synchronizing module to calculate buffer-storing time lengths of audio and video buffers and flexibly sets them to resist network transmission dithering; it makes one of the audio and video parties regularly transmit synchronous time reference point to the other one so as to coordinate their synchronization.

Owner:HUAWEI TECH CO LTD

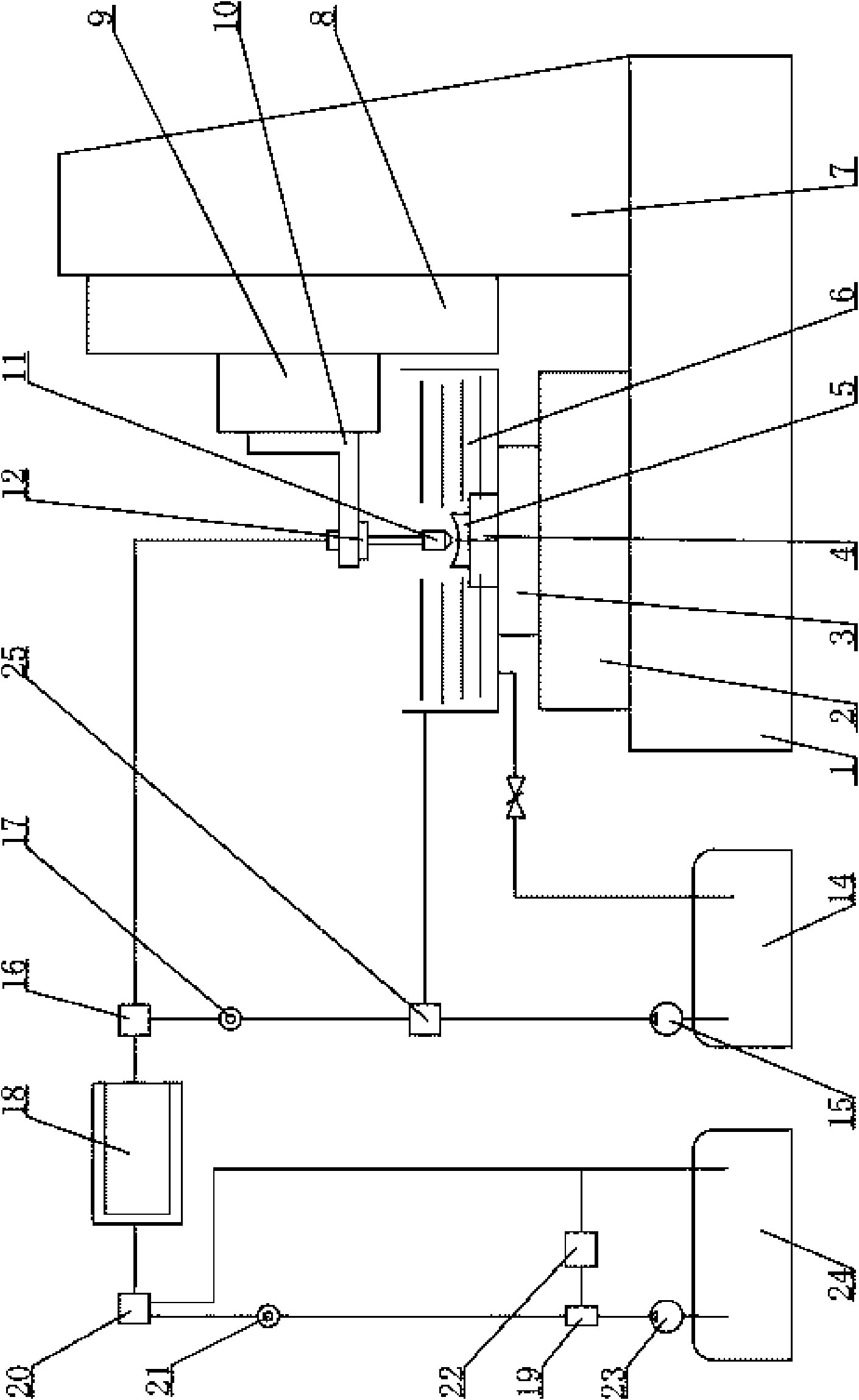

Dynamic pressure cavitation jet polishing device of colloidal flow and method

InactiveCN101670556AImprove quality and efficiencyImprove processing efficiencyBlast gunsAbrasive feedersCavitationSemiconductor materials

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmoothsurface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Owner:HARBIN INST OF TECH

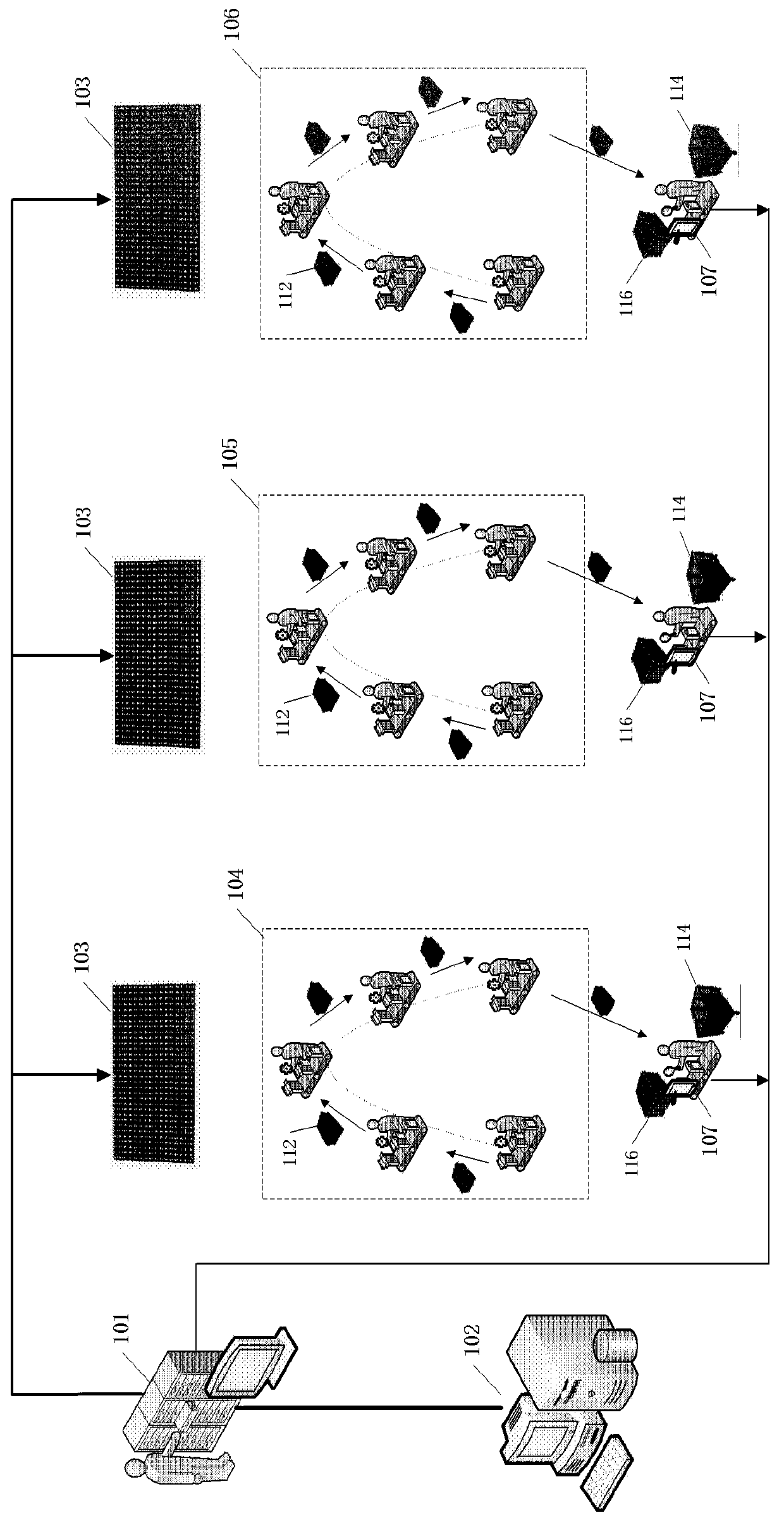

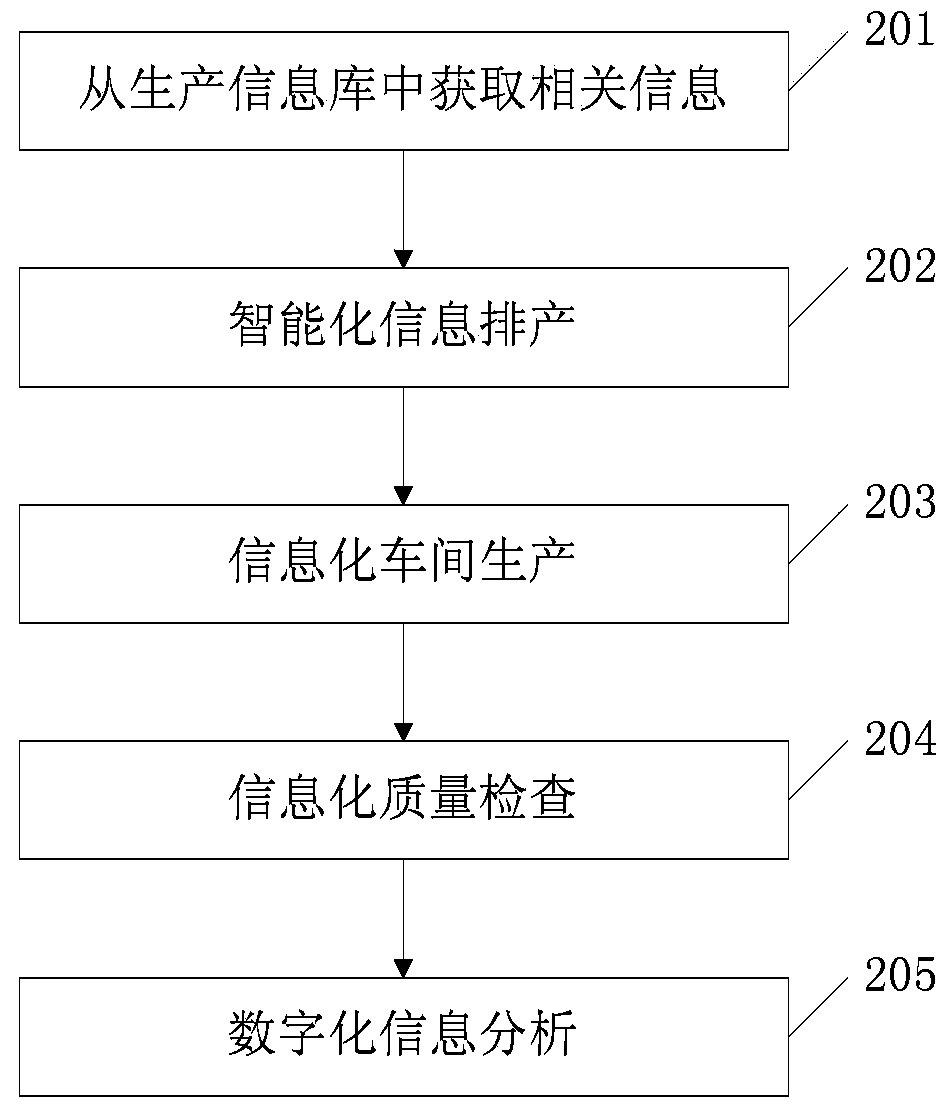

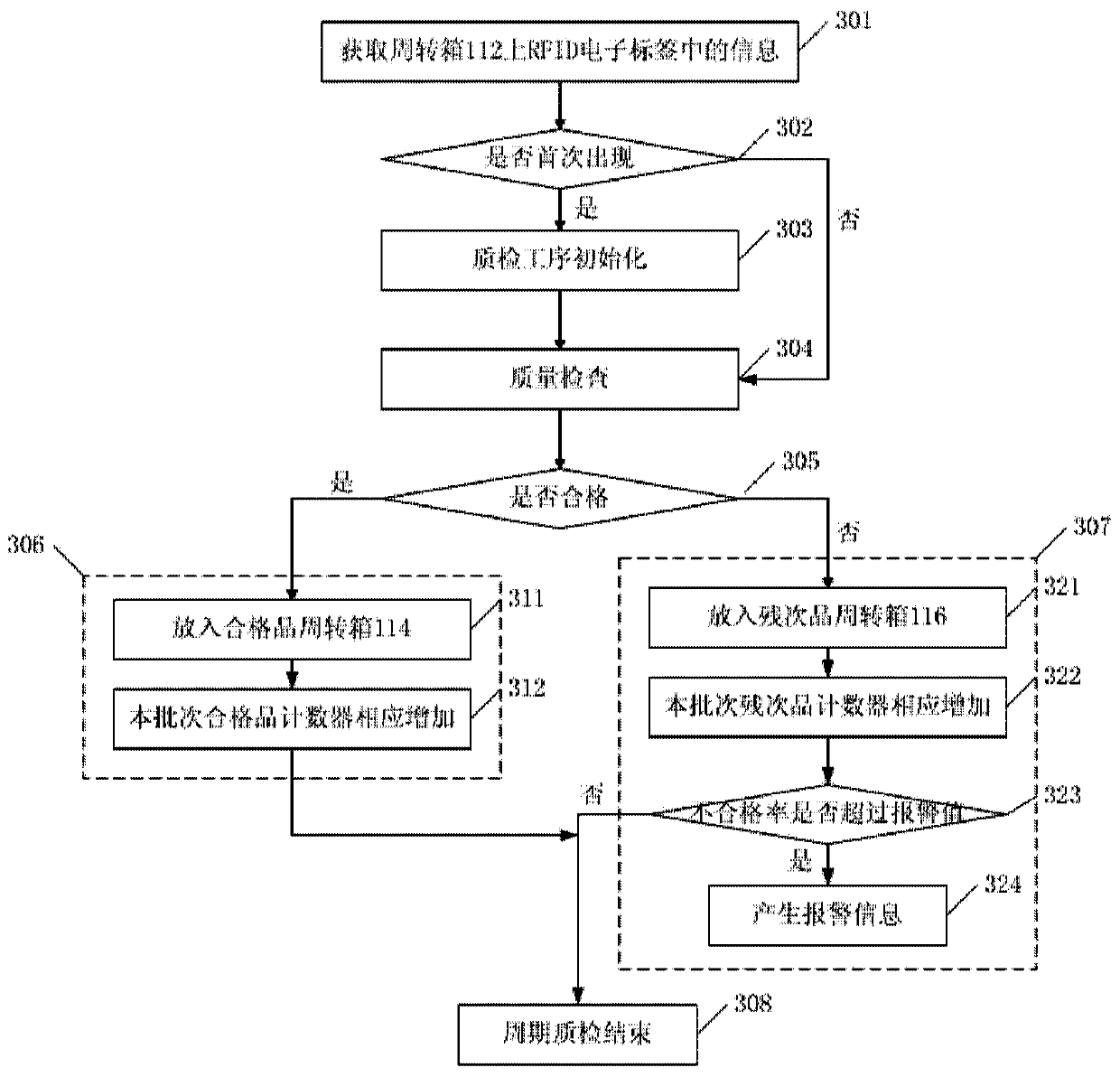

Motor producing quality monitoring and managing system and corresponding method

InactiveCN103440554ABest production statusTo achieve the purpose of trackingResourcesManufacturing computing systemsProduction lineDisplay board

The invention discloses a motor producing quality monitoring and managing system and a corresponding method. The system comprises a quality monitoring subsystem and a material circulating subsystem. The quality monitoring subsystem comprises a workshop control center, a master control center, a workshop electronic display board, producing lines and unit quality detecting points. The material circulating subsystem comprises turnover boxes of products in process on the producing lines, turnover boxes of qualified products of the detecting points and defective product turnover box. Batch processing of turnover boxes with pasted RFID electronic labels is used during the producing process, and products with the same model number in the same batch use the same turnover box. The RFID electronic labels on the turnover boxes at the working positions are read and written, so that production information of each procedure is recorded, and when product reject ratio exceeds an alarming value, alarming information is timely generated. After production, the producing record of a product of each model number of each worker during the producing process is analyzed, so that next production arrangement is helped to be optimized, productivity is arranged reasonably, and the fact that producing quality is improved stably is guaranteed.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

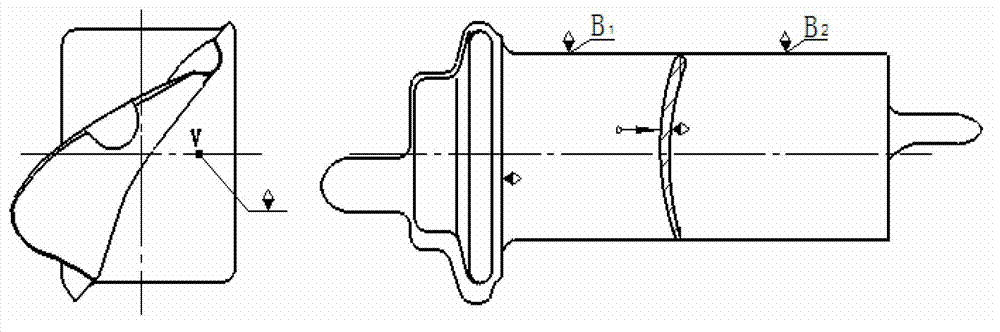

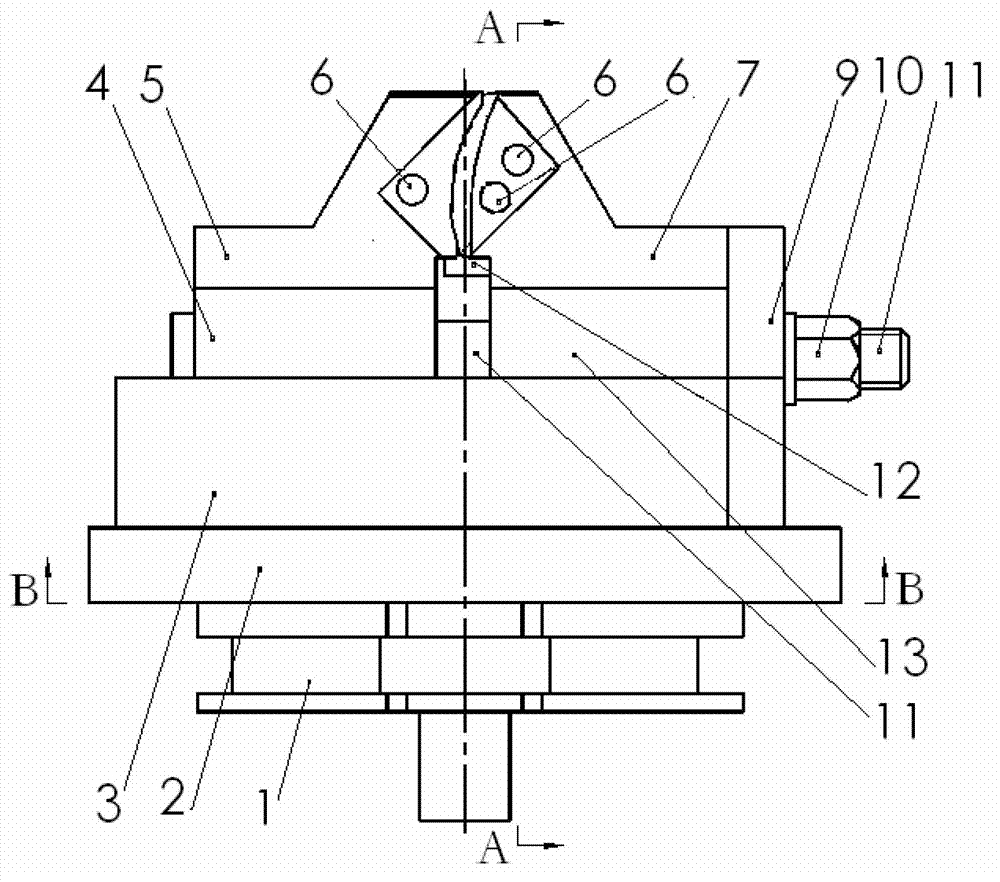

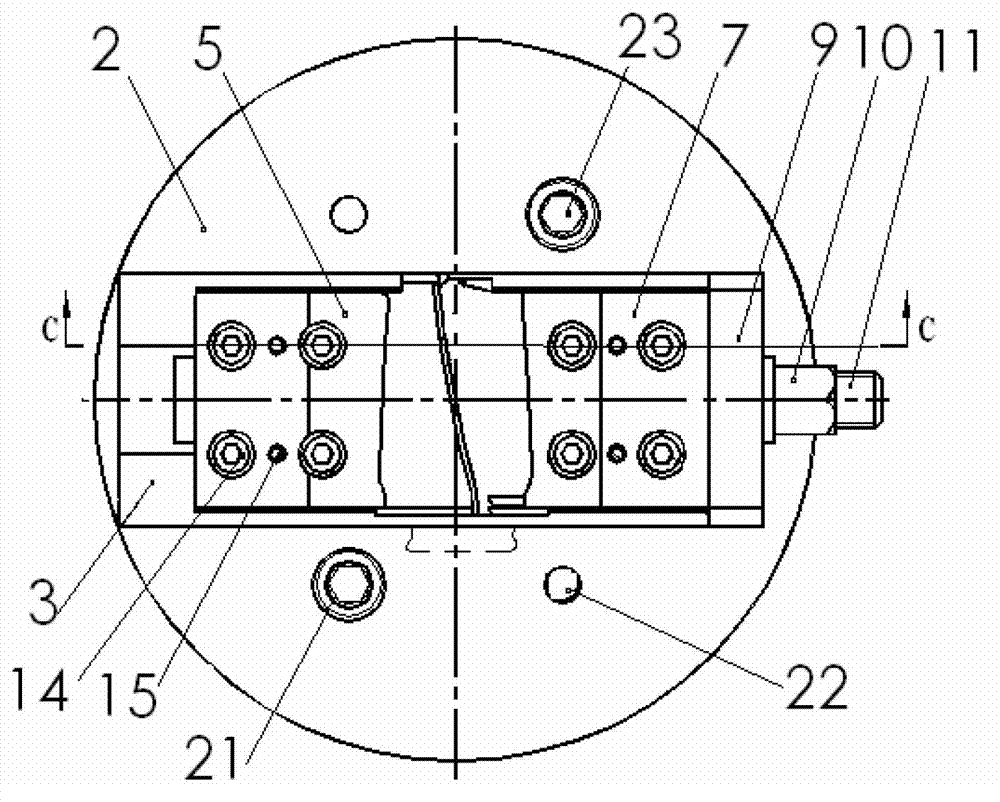

Method and clamp for moulding surface positioning clamping of finish forge blade

ActiveCN102773733AImprove rigidityImprove quality and efficiencyPositioning apparatusMetal-working holdersAdhesiveEngineering

The invention relates to a method and a clamp for moulding surface positioning clamping of a finish forge blade. According to the method, a vane is subjected to positioning clamping through a basin mounding surface of the blade, an inner side moulding surface of a blade root marginal plate, and a V point on the inner side mounting surface of the blade root marginal plate, by the positioning of an air inlet edge, and the clamping of a back mounding surface of the blade, as well as by using a high-accuracy positioning adhesive, and an adhesive coating method, and through a positioning block of the basin moulding surface of the blade and a clamping block of the back moulding surface of the blade. According to the method and the clamp, a satisfying contact area can be obtained by adoption of the high-accuracy adhesive, and the positioning rigidity of the blade is enhanced by adoption of the basin moulding surface of the blade, the inner side moulding surface of the blade root marginal plate and the V point on the inner side moulding surface of the blade root marginal plate for the positioning. According to the method and the device, the problems that the accurate positioning is difficult to realize and the moulding surface of the blade deforms or is damaged because the blade is thin, the blade body is small and the moulding surface is complex are solved. By the method and the device, the positioning accuracy of the mechanical processing of the blade is improved, and the technological process is optimized, so that the processing quality and the production efficiency of the blade are improved, the process is simple, the number of fixtures is reduced, the processing cycle is shortened, and the production cost is reduced.

Owner:AECC AVIATION POWER CO LTD

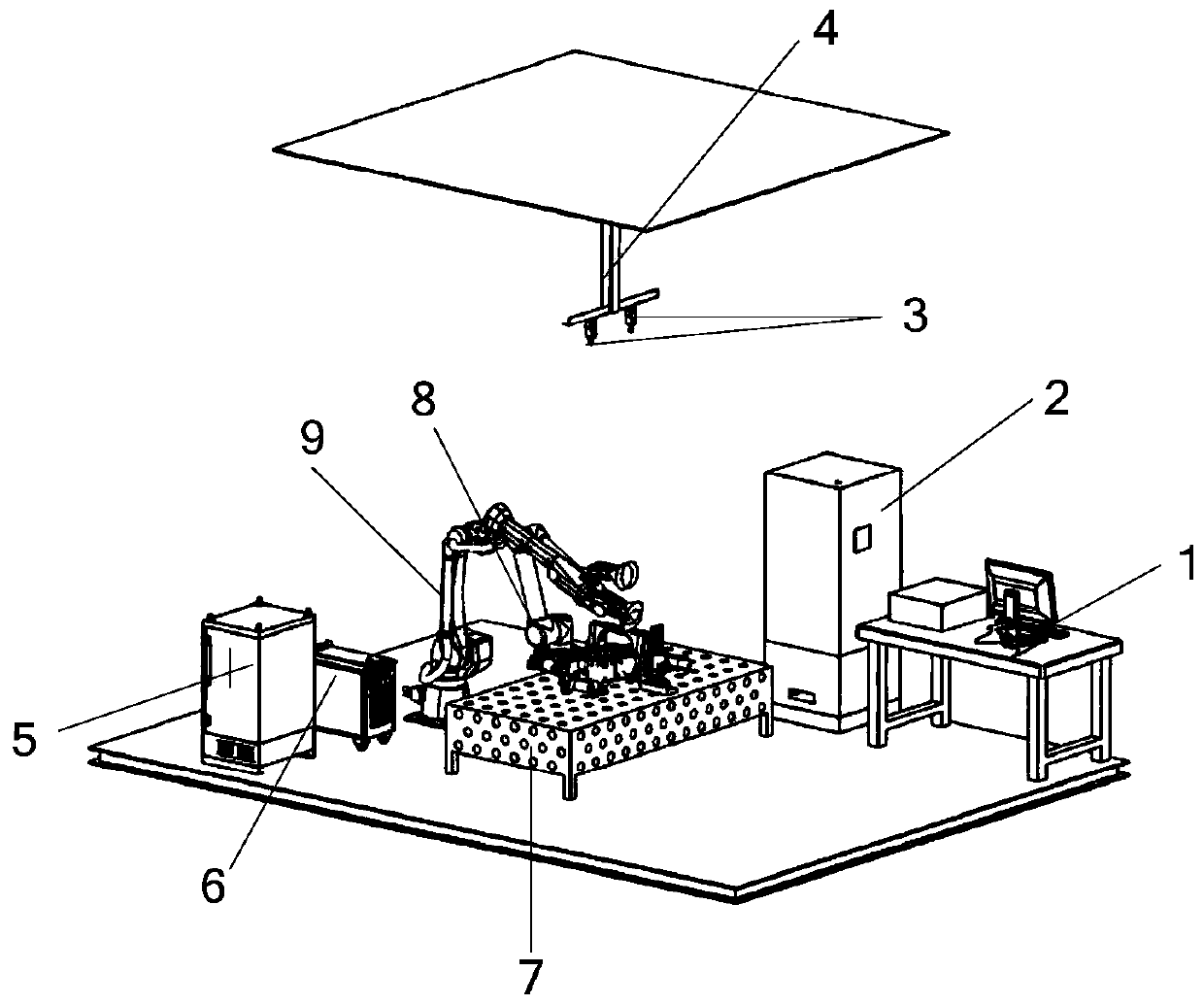

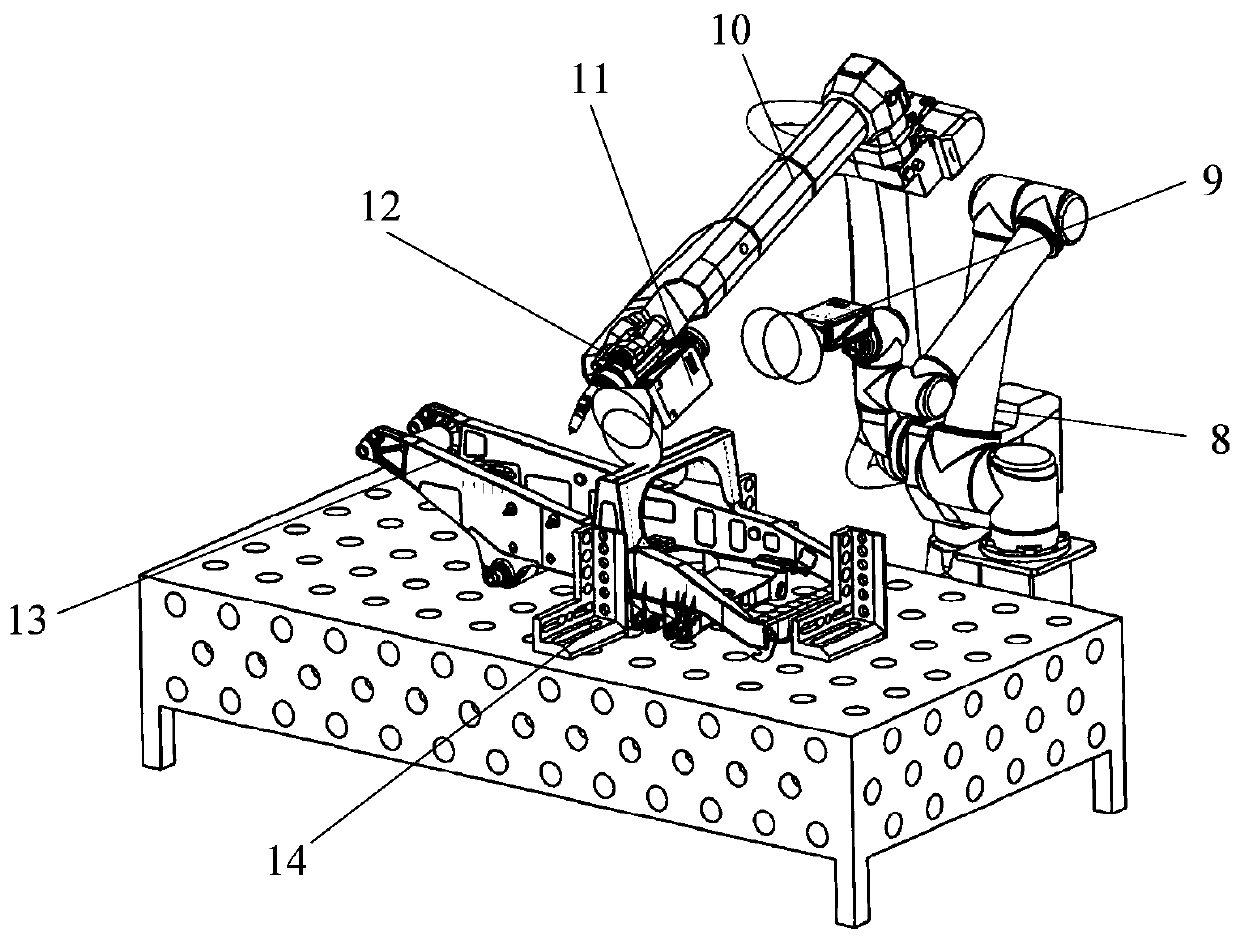

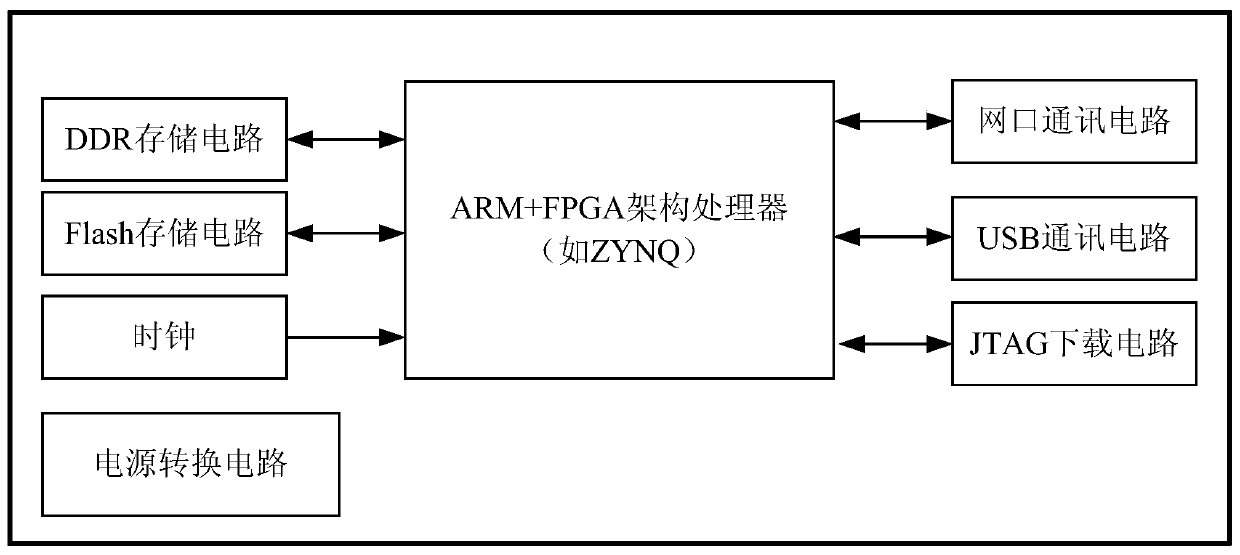

Flexible welding robot system and welding method thereof

ActiveCN110524581AAvoid harmAchieve high flexibilityProgramme-controlled manipulatorTotal factory controlImaging processingSimulation

The invention discloses a flexible welding robot system and a welding method thereof. The welding method comprises the following steps: a global vision unit recognizes image information of a to-be-welded workpiece and locates the position of the to-be-welded workpiece; a flexible welding robot unit precisely recognizes the position of a to-be-welded workpiece through a precise positioning visual assembly, an image processing control machine solves a welding path, and the flexible welding robot conducts welding operation. A flexible detection robot unit recognizes the geometric dimension and quality of the appearance of a welded workpiece through a stereoscopic vision detection assembly, generates a welding quality report according to parameter information set by a user, and transmits a position with the welding deviation exceeding a threshold value and deviation value information to the flexible welding robot for repair welding. A master control unit executes image processing, data communication and motion control of the welding robot and the detection robot; and a workbench unit is used for quickly clamping different types of welding workpieces. The harm of welding operation to the body of a worker is avoided, and high flexibility and intelligence of the flexible welding robot system are achieved.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

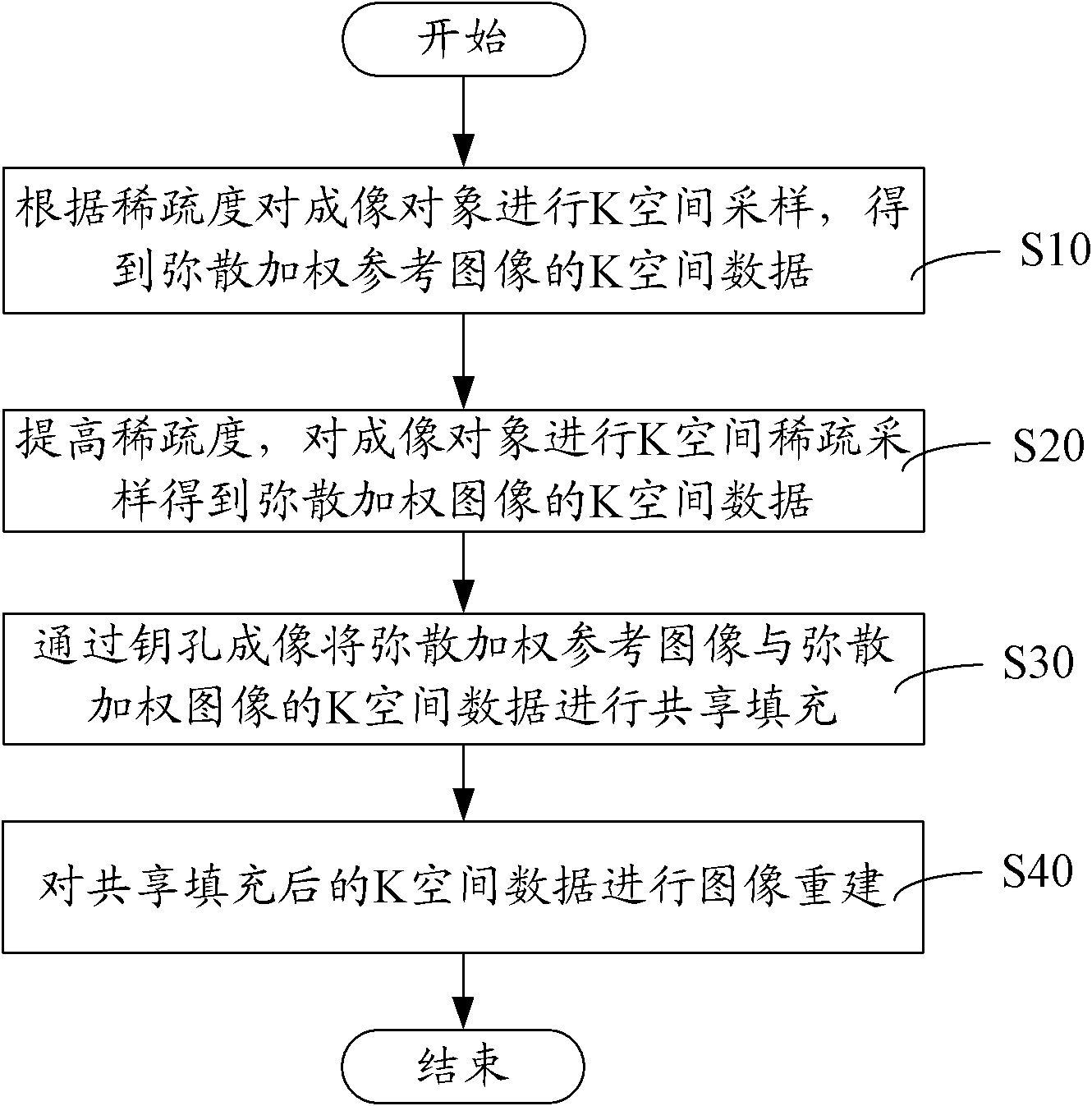

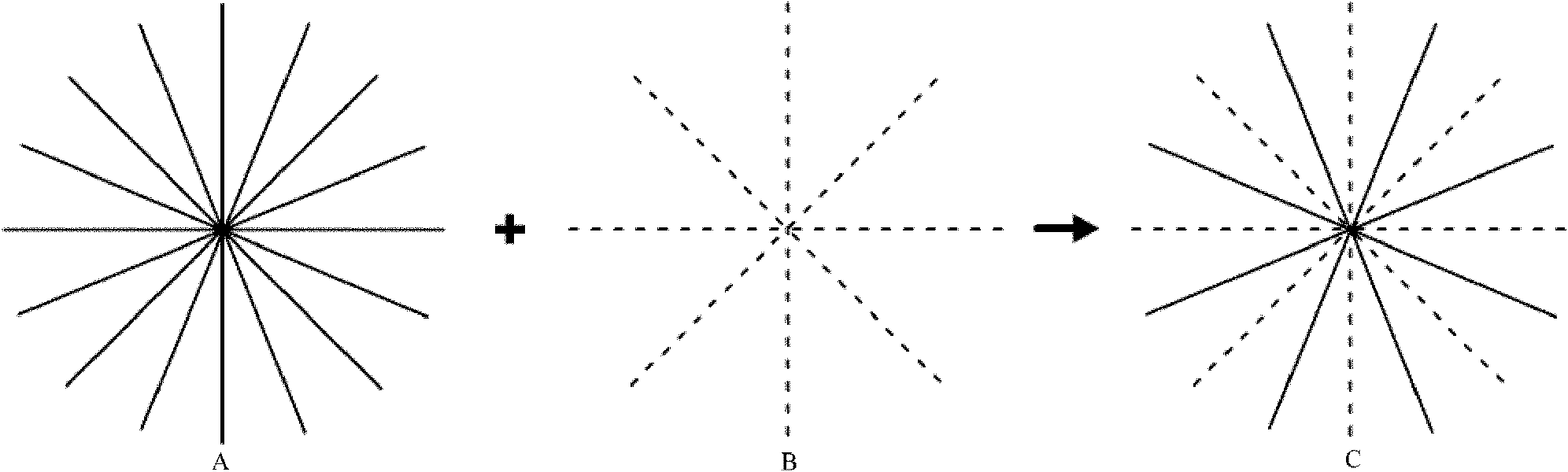

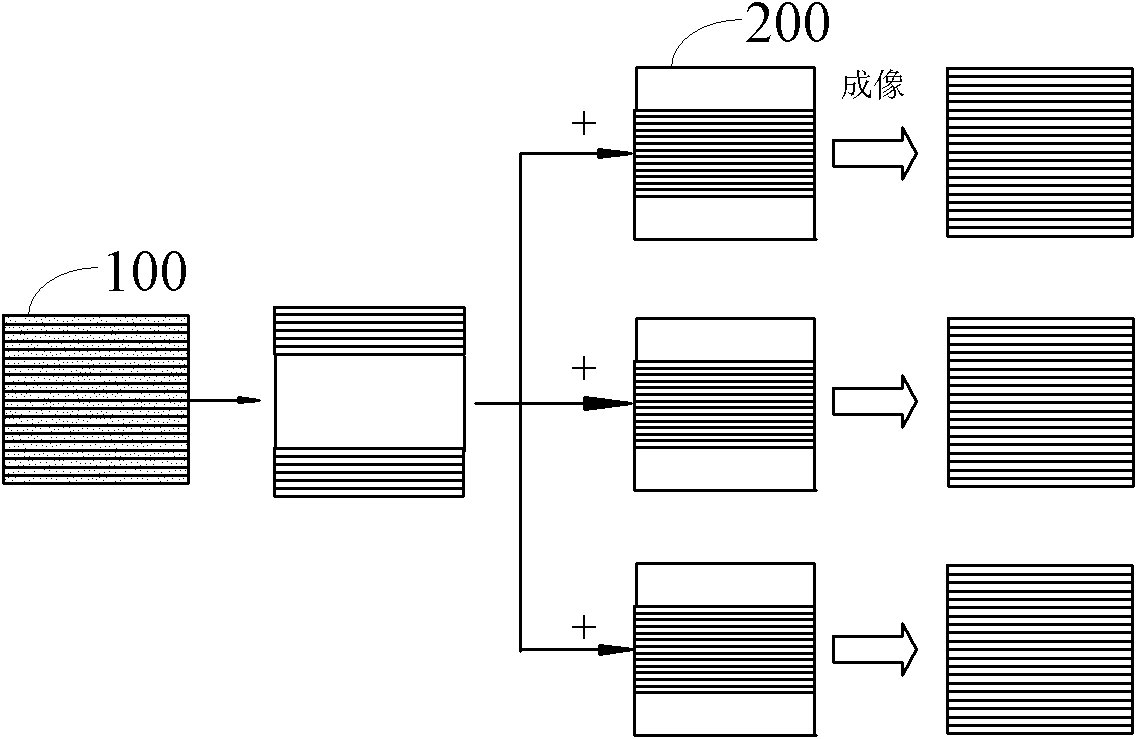

Magnetic resonance diffusion tensor imaging method and system

ActiveCN102018514AAcquisition speed is fastFast imagingDiagnostic recording/measuringSensorsComplete dataRapid imaging

The invention relates to a magnetic resonance diffusion tensor imaging method which comprises the following steps: performing K space sparse sampling on an imaging object to obtain K space data of a diffusion weighted reference image; performing K space sparse sampling on the imaging object to obtain the K space data of a diffusion weighted image; performing share filling on the K space data of the diffusion weighted reference image and the diffusion weighted image by keyhole imaging; and performing image reconstruction on the K space data after share filling. The magnetic resonance diffusion tensor imaging method and system provided by the invention have the advantages of reconstructing complete data, shortening the scanning time, improving the data acquiring speed and achieving rapid imaging by adopting sparse sampling rapidly and continuously to acquire K space data and performing share filling under the action of the keyhole imaging technology.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

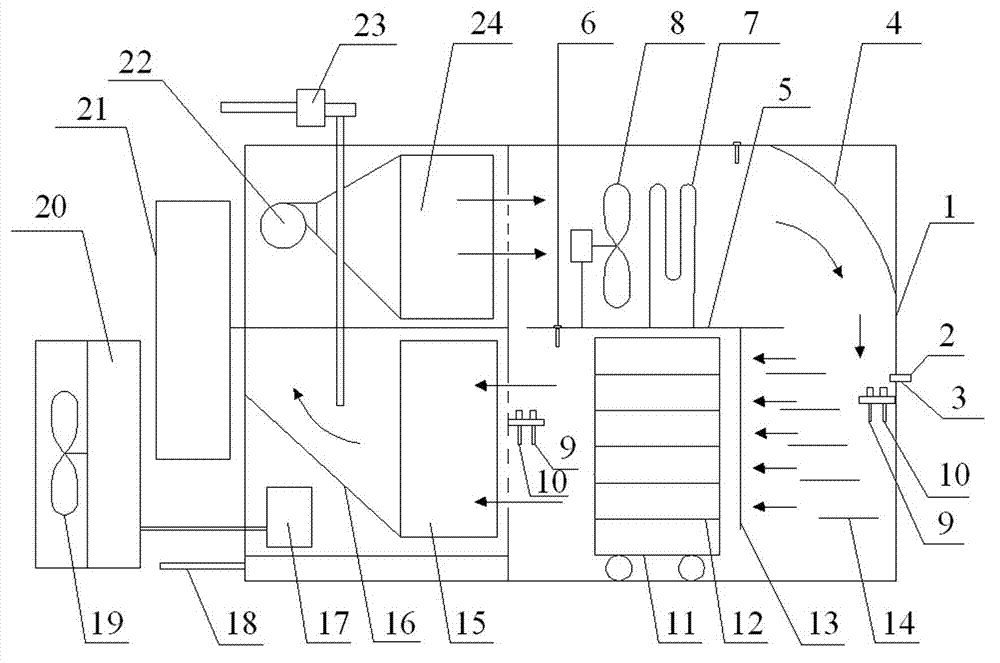

Drying unit of nitrogen-source heat pump

InactiveCN102818434ALow energy consumptionPrevent oxidationDrying gas arrangementsDrying machines with local agitationProcess engineeringDry gas

The invention discloses a drying unit of a nitrogen-source heat pump, comprising a drying box, a control system and an outdoor condenser, wherein the drying box comprises a box body, a heat pump chamber and a drying chamber; and the heat pump chamber and the drying chamber are arranged in the box body. The drying unit forms drying gas adjusting equipment with a nitrogen source, heat-pump equipment and a nitrogen device form a nitrogen heat-pump combining device so as to construct a closed circulation loop which adopts nitrogen as a medium to dry materials and effectively control the content of nitrogen in the drying chamber; and high-viscosity glass cement is used for sealing internal and external gaps of a drying room, a ventilating channel is modified, and a baffle, an arc-shaped air guide plate and an air uniformizing plate are added to enable the gas drying medium to be uniformly distributed in the drying chamber under certain air speed. The drying unit disclosed by the invention has the beneficial effects that the heat pump and a nitrogen combining device are used, the advantages of no pollution and low energy consumption of the heat pump can be fully utilized, the materials are dried under the condition of adopting nitrogen as a drying medium, the oxidation of the materials is prevented, the nutritional ingredients of the materials are retained, and the quality of dried products is improved.

Owner:HENAN UNIV OF SCI & TECH

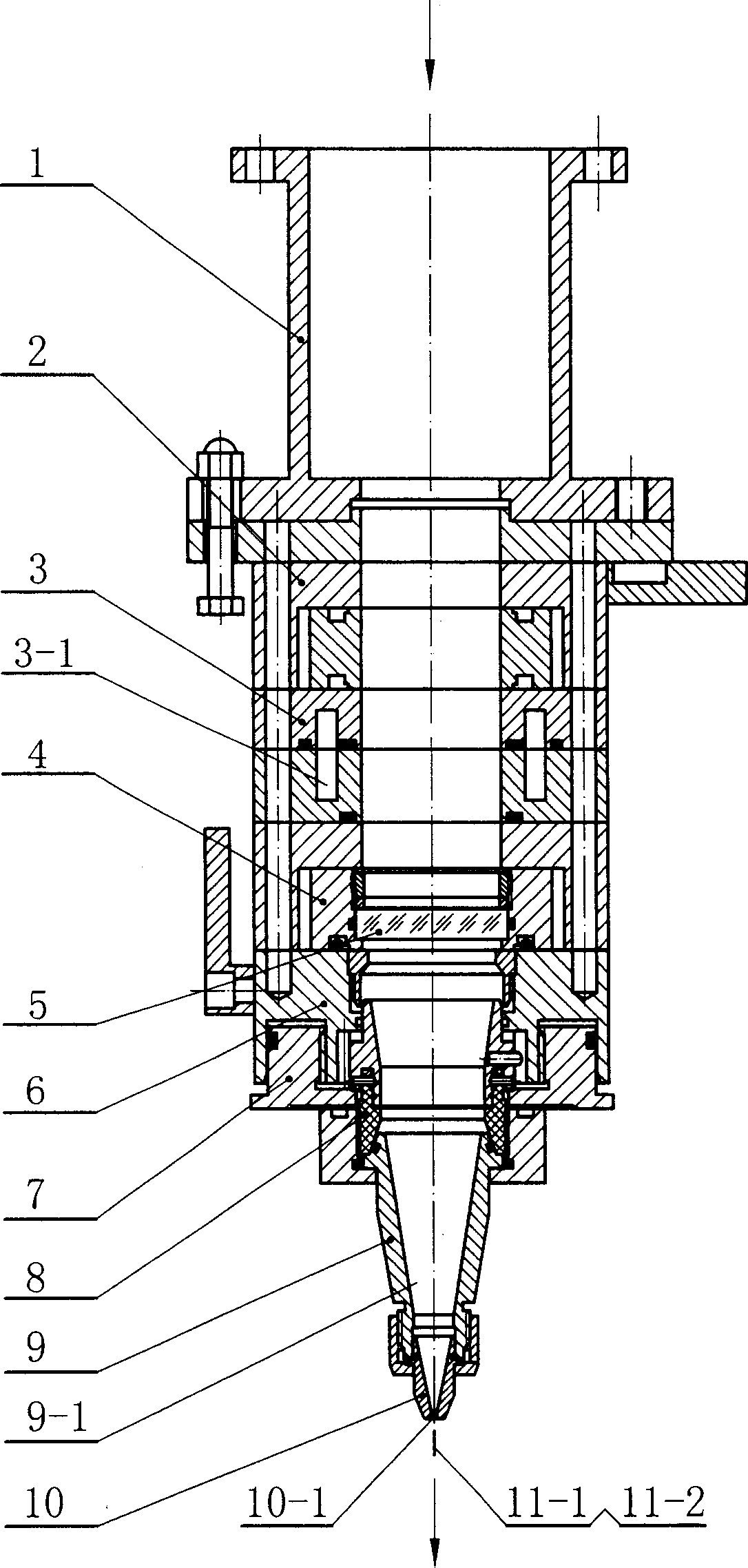

Digital-control laser cutting head and method for making same

InactiveCN1827282AIncreasing the thicknessIncrease profitLaser beam welding apparatusLight energyLaser cutting

The invention discloses a digital control laser cutter head used in CO2 digital control laser cutter and relative producing method. Wherein, the digital control layer cutter head comprises a connecting tube 1, a glass base box 2, a water cooling element 3, a focusing glass base element 4, a focusing glass 5, an aeration element 6, an adjusting nut 7, a high-strength insulated separating sheath 8, a transition nozzle 9, and a cutting nozzle 10. The inner hole 9-1 of said transition nozzle is in reverse taper shape; the upper and lower parts of water cooling element are integrated annular cooling water channels, while the annular cooling water channel 3-1 is one-time mechanically processed; the main elements as glass base box 2, water cooling element 3, focusing glass base element 4, aeration element 6 and adjusting nut 7 are made from ultrahigh strength rigid duralium LC4. With said invention, the consumed pressure and light energy of digital control laser cutter head is lower and the focusing effect is better. And said invention has better sealing property, thicker cut plate, high plate utilization, high strength, high pressure resistance and high heat conductivity.

Owner:LONGYAN LISHANG PRECISION MACHINERY

Super fine crystal microalloyed medium carbon steel coil and its producing method

InactiveCN1858284AImprove appearance qualityImprove quality and efficiencyFurnace typesMetal rolling arrangementsMetallic materialsHeating furnace

The present invention relates to metal material, and especially cold forging steel coil for fastener and its production process. The superfine crystal microalloyed medium carbon steel coil has the alloy elements including: C 0.10-0.25 wt%, Si not more than 0.08 wt%, Mn 0.80-1.70 wt%, P not more than 0.035 wt%, S not more than 0.035 wt%, V, Nb, Ti and Al trace quantity, and Fe for the rest. Its production process includes the following steps: smelting in a converter, external refining, casting blank; heating to 1100 deg.c in a heating furnace; rolling at 750-830 deg.c, finish rolling in a TMCP process and rolling in a two phase region and great deformation quantity; controlled cooling and spinning; cooling and bundling at temperature lower than 500 deg.c. The cold forging steel coil is used in producing fastener directly in a cold header, has simple technological process, low cost, less pollution and raised production efficiency.

Owner:MAANSHAN IRON & STEEL CO LTD

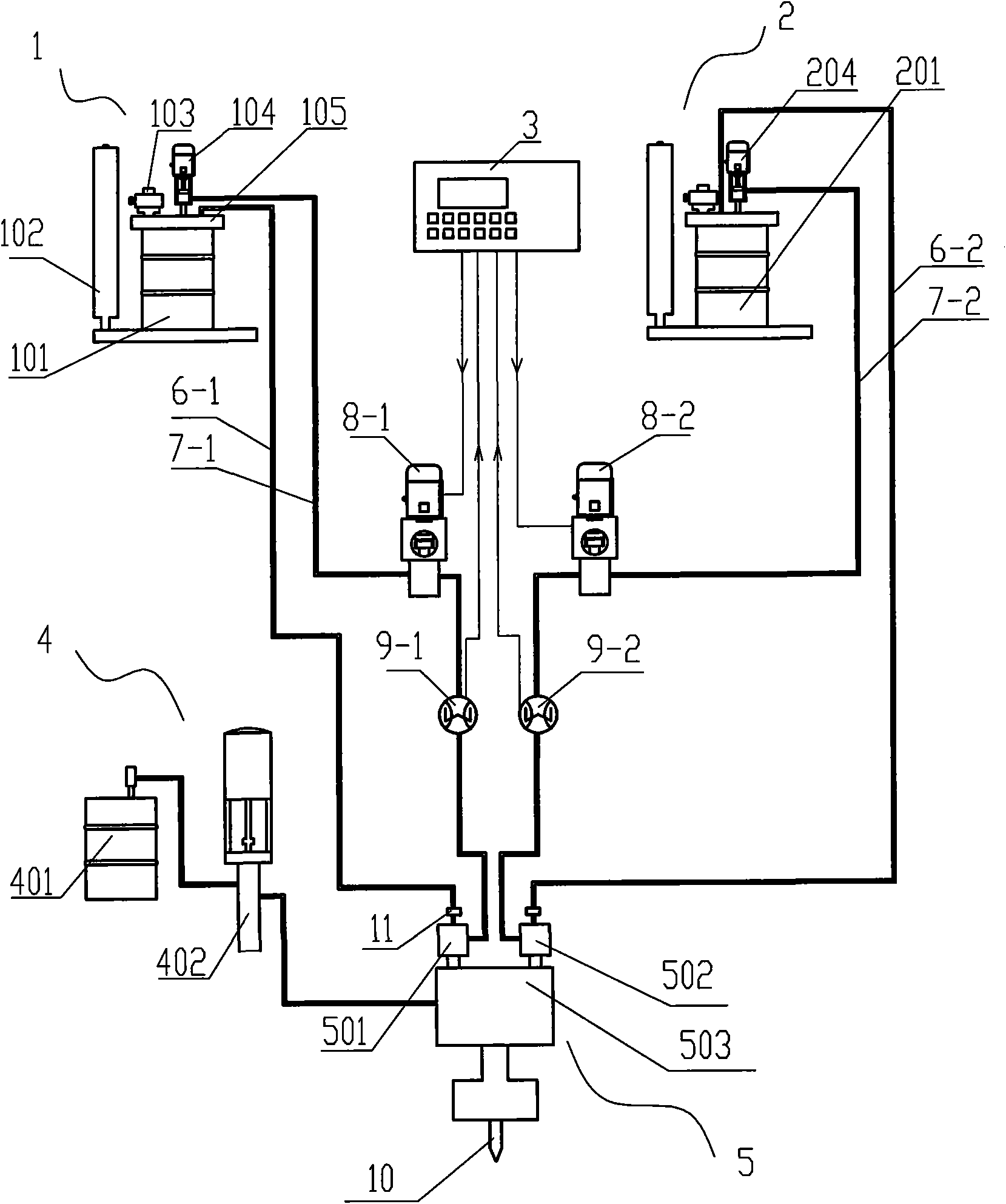

Two-component spraying system

InactiveCN101850312AHigh trafficWide range of proportional adjustmentLiquid spraying apparatusProgrammable logic controllerEngineering

The invention discloses a two-component spraying system which comprises a first material conveying system, a second material conveying system and a spray gun, wherein the structure of the first material conveying system is identical to that of the second material conveying system; a discharge port of a first material conveying pump of the first material conveying system is communicated with a mixing device through a first material conveying pipe; a first gear pump and a first flow meter are sequentially arranged on the first material conveying pipe; the output end of the mixing device is connected with the spray gun; the output end of a programmable logic controller (PLC) is respectively connected with the control ends of the first gear pump and a second gear pump; and the output ends of the first flow meter and a second flow meter are respectively connected with the input end of the PLC. In the invention, the PLC and the flow meters are used for accurately controlling the flow and the ratio of two-component coatings, and the flow and the ratio are automatically regulated by utilizing programs; and the ratio regulation range of two components is wider.

Owner:河北新兴铸管有限公司

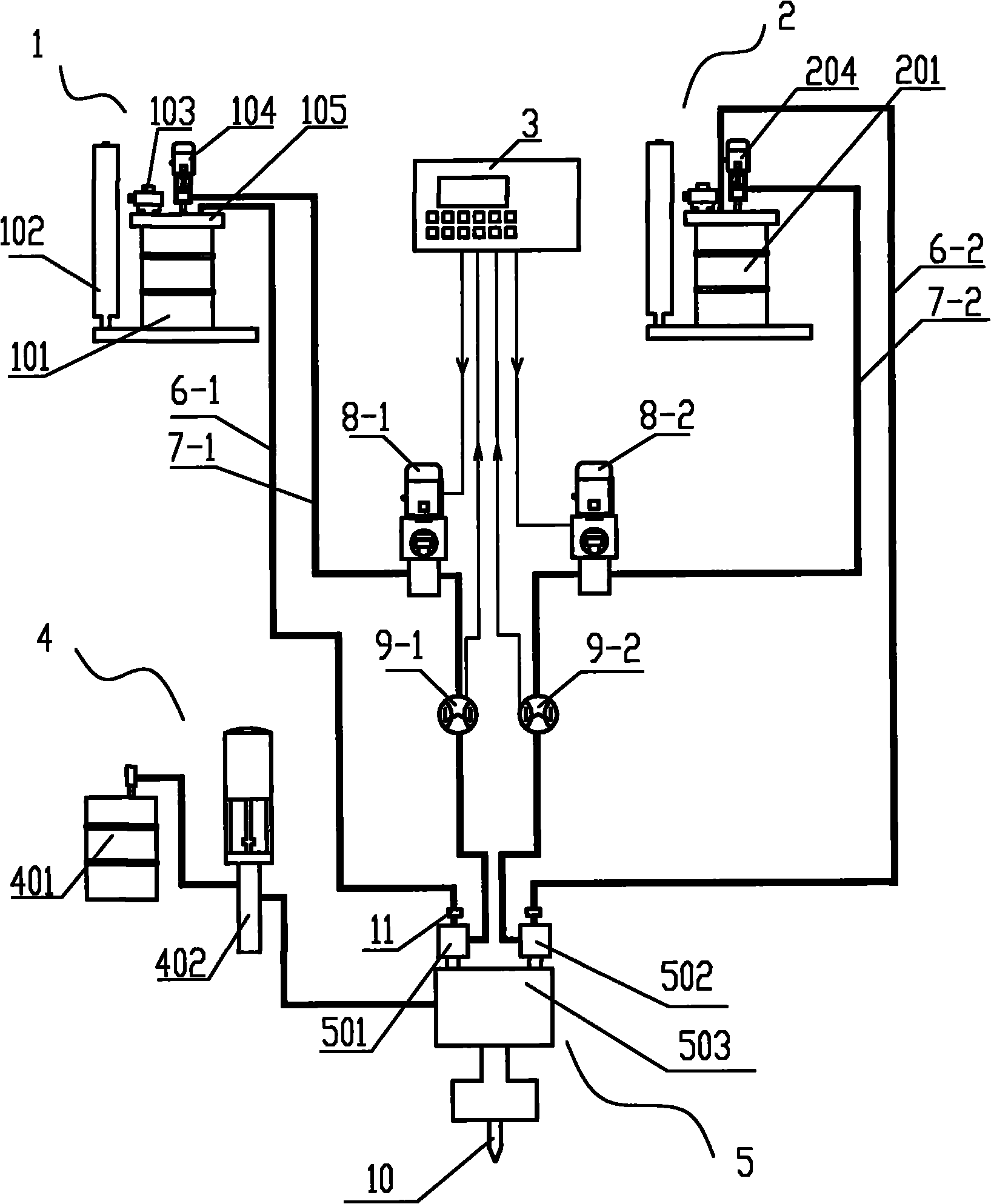

Construction process of cast-in-situ bored pile

The invention relates to a construction process for the pile foundation in the civil engineering, in particular to a construction process of a bored pouring pile. During the process, a steel casing is sunk on the upper surface of the dense soil layer at the soft soil layer section; the wall of the pile is protected by the steel casing; subsequently, a rotary excavation drilling machine with a friction-typed drilling rod is used for forming hole; at the dense soil layer section, the rotary excavation drilling machine with a lock-typed drilling rod is used for forming hole. Therefore, the boring deviation and diameter enlarging of the pile can be effectively avoided; the pile quality and the operation efficiency are improved; if the dense soil layer section contains the substance with plenty of underground water, the slurry is used for protecting the wall of the pile during the hole-forming process; after the hole is completed, the hole is arranged statically for certain a time; the sunk slag at the bottom of the pile is removed by a cylindrical drilling bucket; and if the dense soil layer contains the substance which has no underground water basically or has little underground, the dry hole-forming method is used. The construction process can avoid collapsing of the hole, reduces the displacement of the slurry and reduces the pollution to the environment.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

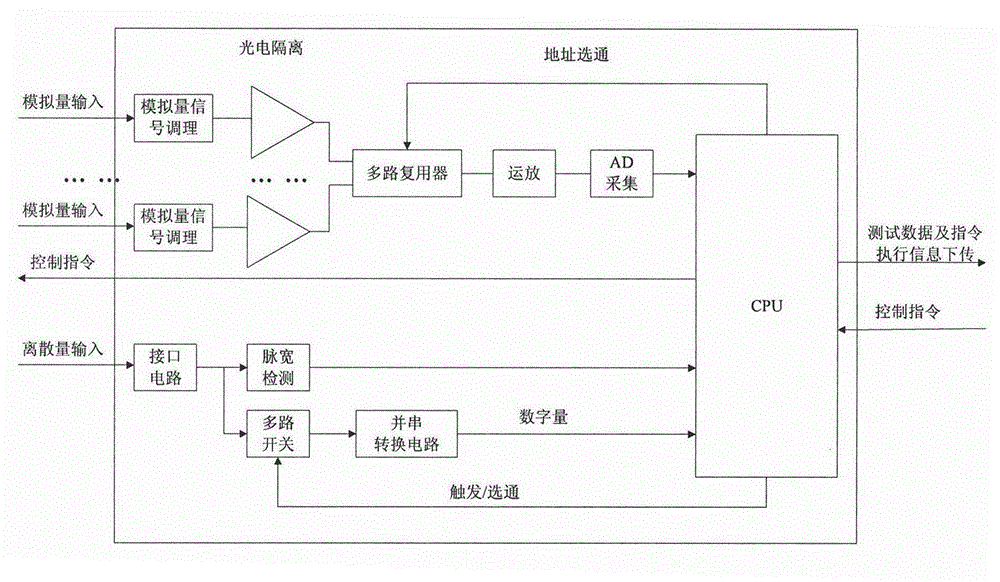

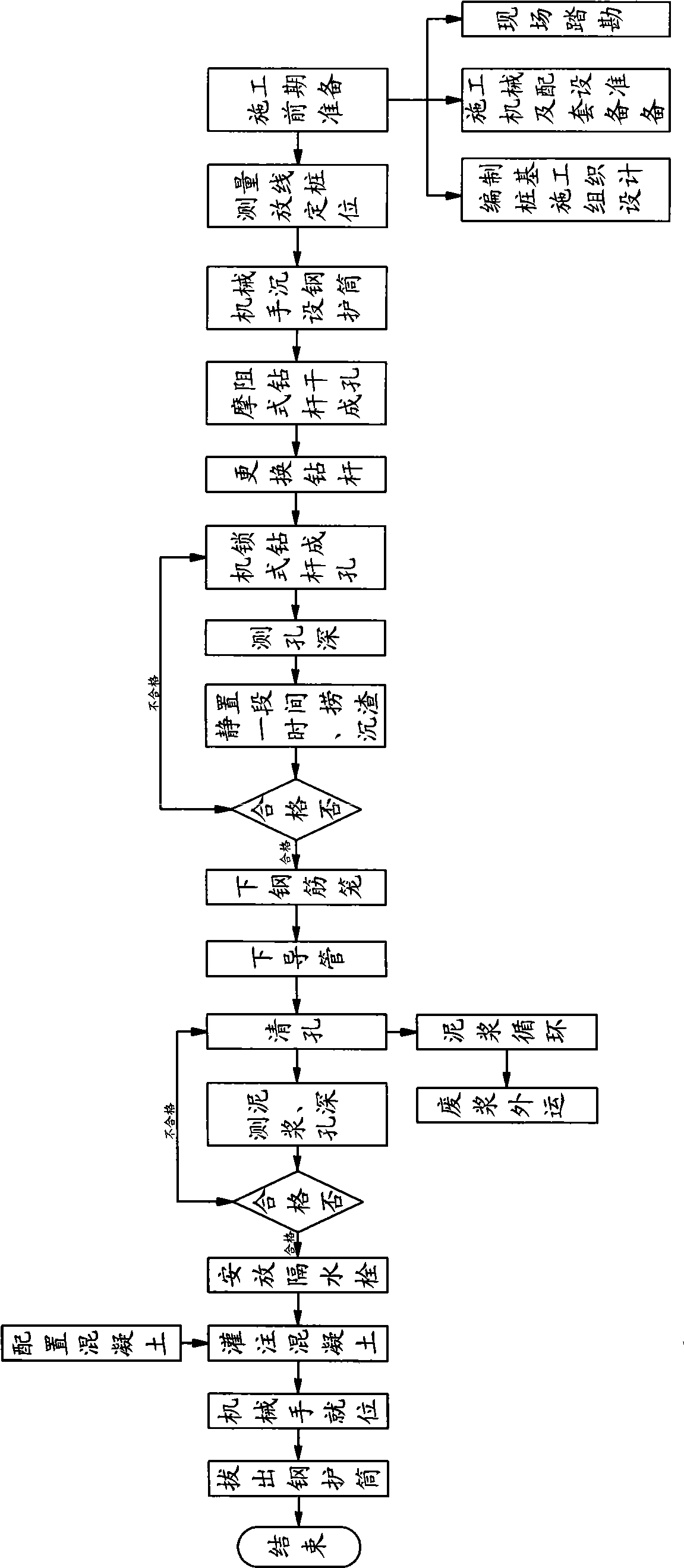

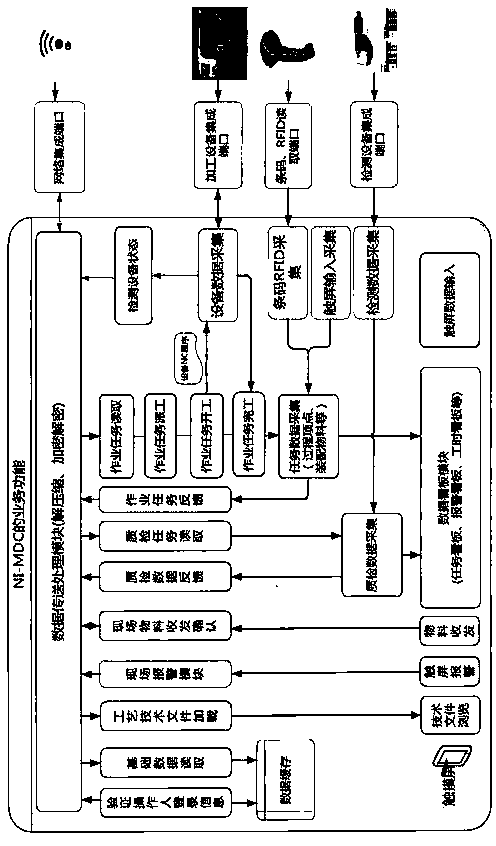

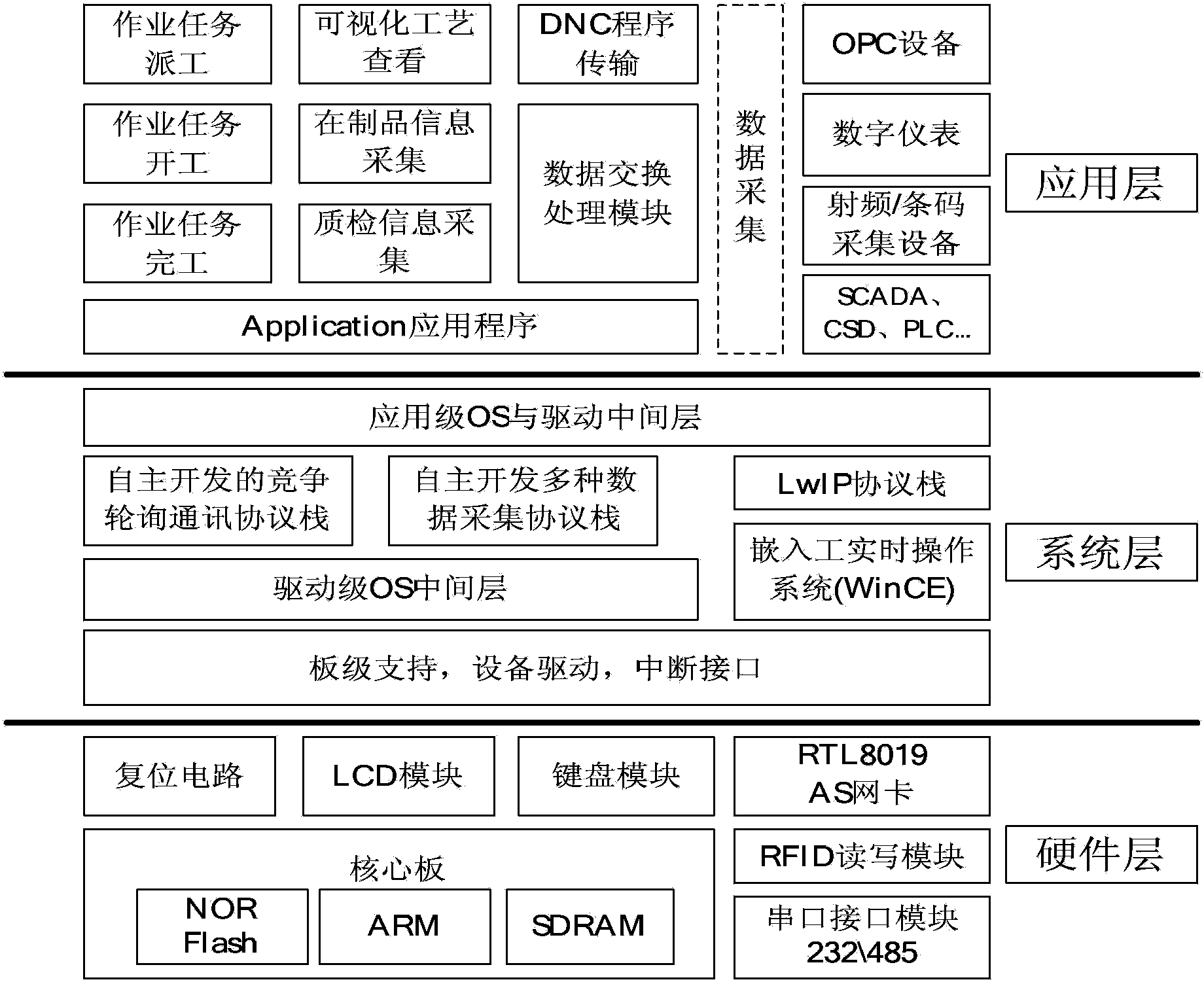

Embedded type integratedly-manufactured data collecting terminal based on network

The invention discloses an embedded type integratedly-manufactured data collecting terminal (NI-MDC) based on a network. The NI-MDC comprises an NI-MDC system platform and an NI-MDC drive software system, wherein the NI-MDC system platform comprises a core board, a reset circuit, an LCD module, touch screen equipment, a keyboard module, a DM9000 network card, an RFID read-write module and a serial interface read-write module. By means of an on-site data collecting end, the NI-MDC can finish real-time collecting of work data, material data, quality data, equipment state data and the like, provides accurate original data timely for production operation management of enterprises after the data are filtered and gathered by a data processing module and transmitted to a management system such as an MES, can carry out practical and effective production monitoring on a production site, and is safe, reliable, simple and practical.

Owner:信华信技术股份有限公司

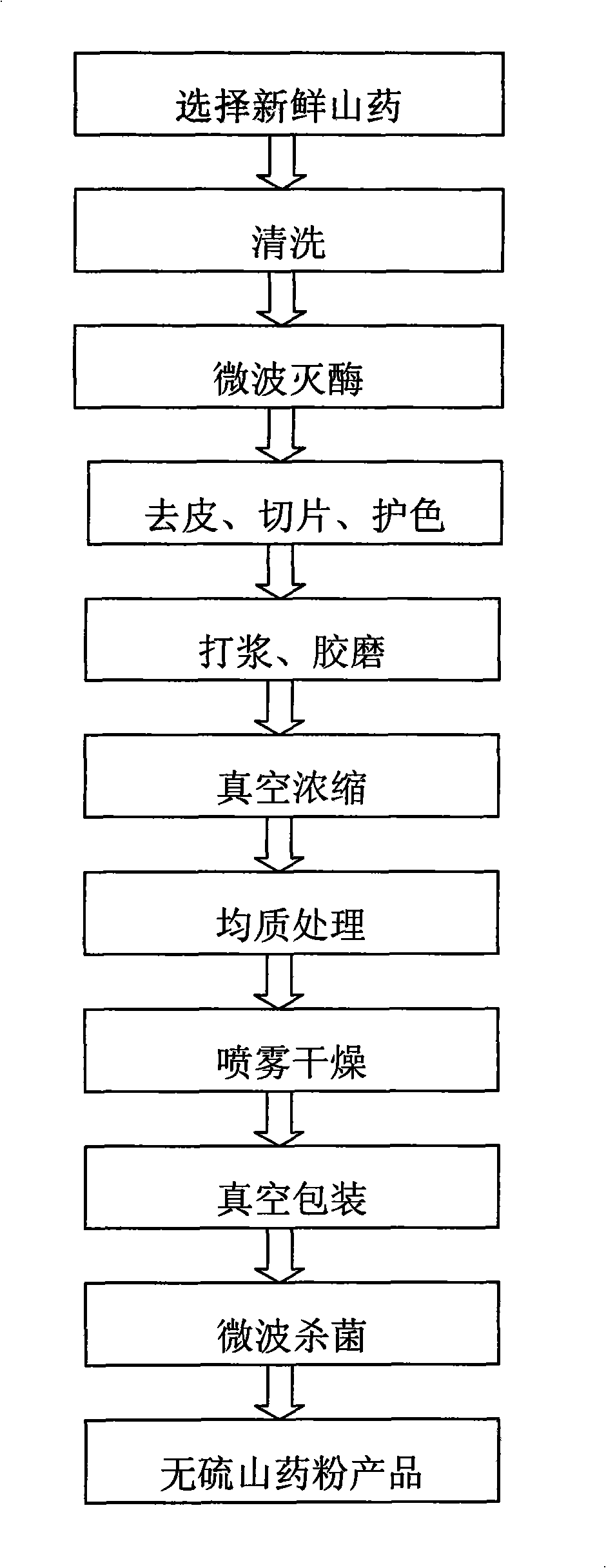

Production method for spray-drying Chinese yam powder without using sulfur to protecting color

InactiveCN101513241AImprove quality and efficiencyIncrease productivityHair cosmeticsDead plant preservationVitamin CAdditive ingredient

The invention relates to a production method for spray-drying Chinese yam powder without using sulfur to protecting color. The Chinese yam is prepared from fresh Chinese yam and is obtained by the steps of microwave enzyme deactivation, shelling, slicing, color protection, pulping, grinding, vacuum condensation, homogenization, spray-drying, vacuum packaging and microwave sterilization. The Chinese yam raw material is deactivated by microwave at temperature of 60 DEG C, cut to slice, and is soaked in sulfur-free color protection liquid containing phytic acid, Ethylenediaminetetraacetic acid disodium, vitamin C and citric acid, the color protection liquid and the Chinese yam slice is pulped together and is milled by a colloid mill, the Chinese yam slurry is concentrated by a vacuum condensation equipment until the content of solid is 15-25% and is homogeneously processed, homogenized liquid material is sprayed and dried by a centrifugal spray-drying machine, the obtained Chinese yam powder is packaged by vacuum and is sterilized by a microwave sterilization equipment to prepare the sulfur-free Chinese yam powder product. The invention has high production efficiency and low cost, the produced Chinese yam product has good color, high safety and complete nutrient composition, and can applied for field such as foodstuff, medicine and cosmetic product.

Owner:袁书林

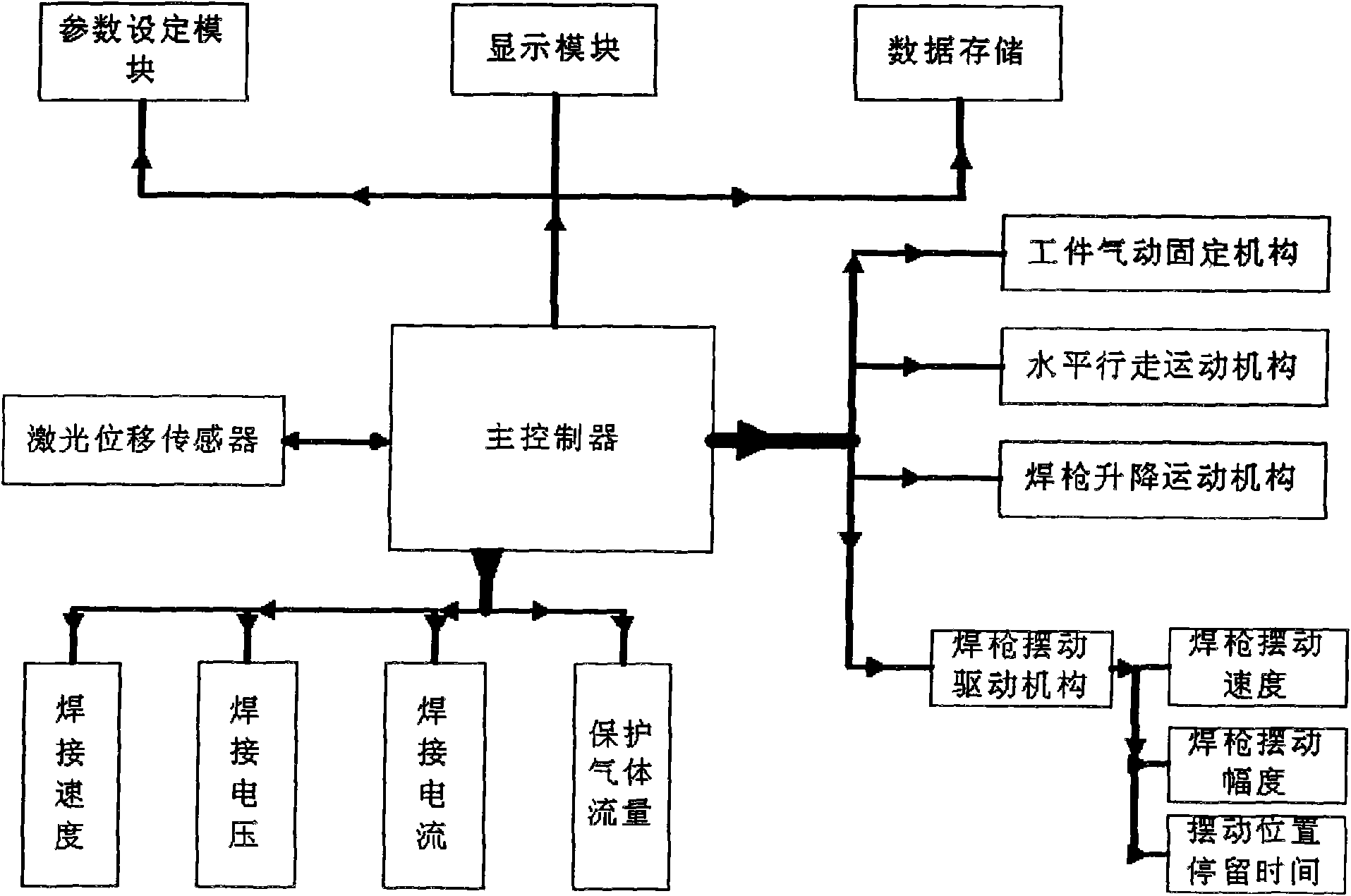

Detection and control system for container corrugated plate welding track based on laser ranging

InactiveCN101554672ARealize detectionImprove quality and efficiencyComputer controlArc welding apparatusLaser rangingAutomatic control

The invention relates to a detection and control system for a container corrugated plate welding track based on laser ranging, comprising a laser displacement sensor, a welding torch pose adjusting device and a circuit control device. The laser displacement sensor and the welding torch pose adjusting device are connected with the circuit control device through a circuit; one end of a welding torch space position and pose adjusting mechanism is fixed on a stand; and the laser displacement sensor is arranged at the lower end of the welding torch space position and pose adjusting mechanism. Through the diction of the corrugated plate welding line, the control of the welding torch pose and the automatic control of the welding process, the invention achieves the effect that the thickness of welding lines of a downslope welding section from a wave crest to a wave trough, a upslope welding section from a wave trough to a wave crest, a wave crest tangential path and a wave trough are consistent, remarkably improves the uniformity of welding lines of each welding section, greatly reduces the labor intensity of workers, reduces the manual expense of production and is fast and convenient to adjust parameters. The welding speed is more than three times of general manual welding or profile modeling welding, and automatic control is available in the whole process.

Owner:SHANDONG UNIV

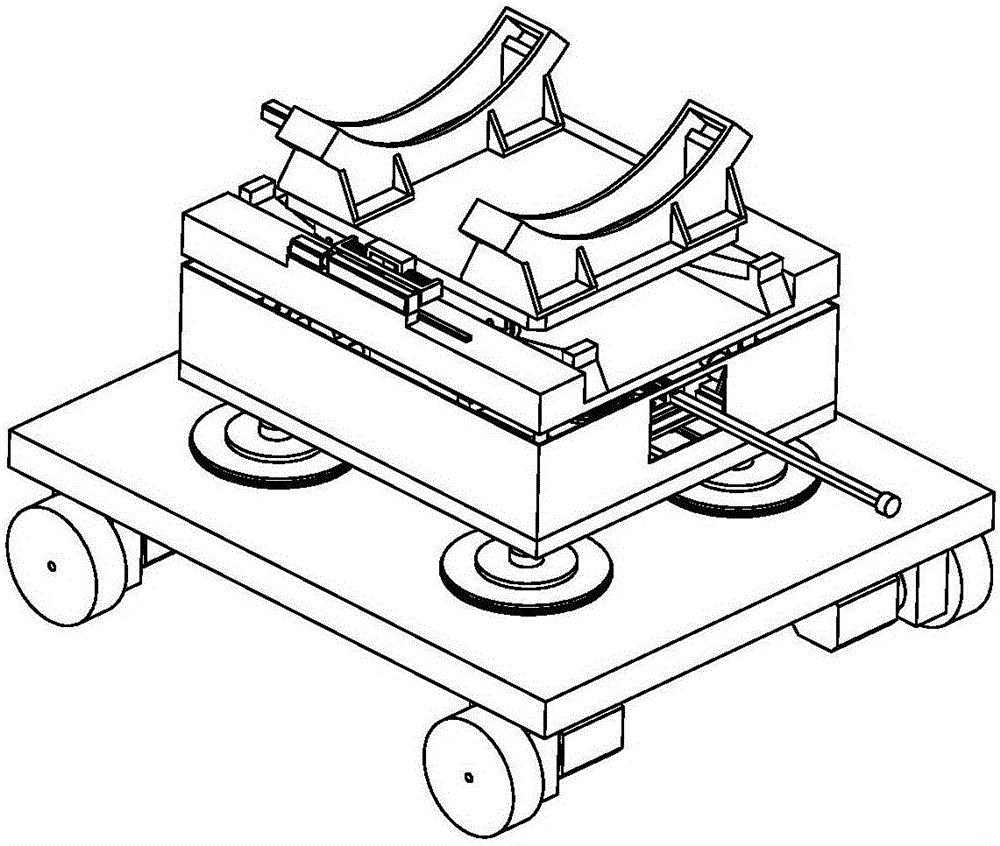

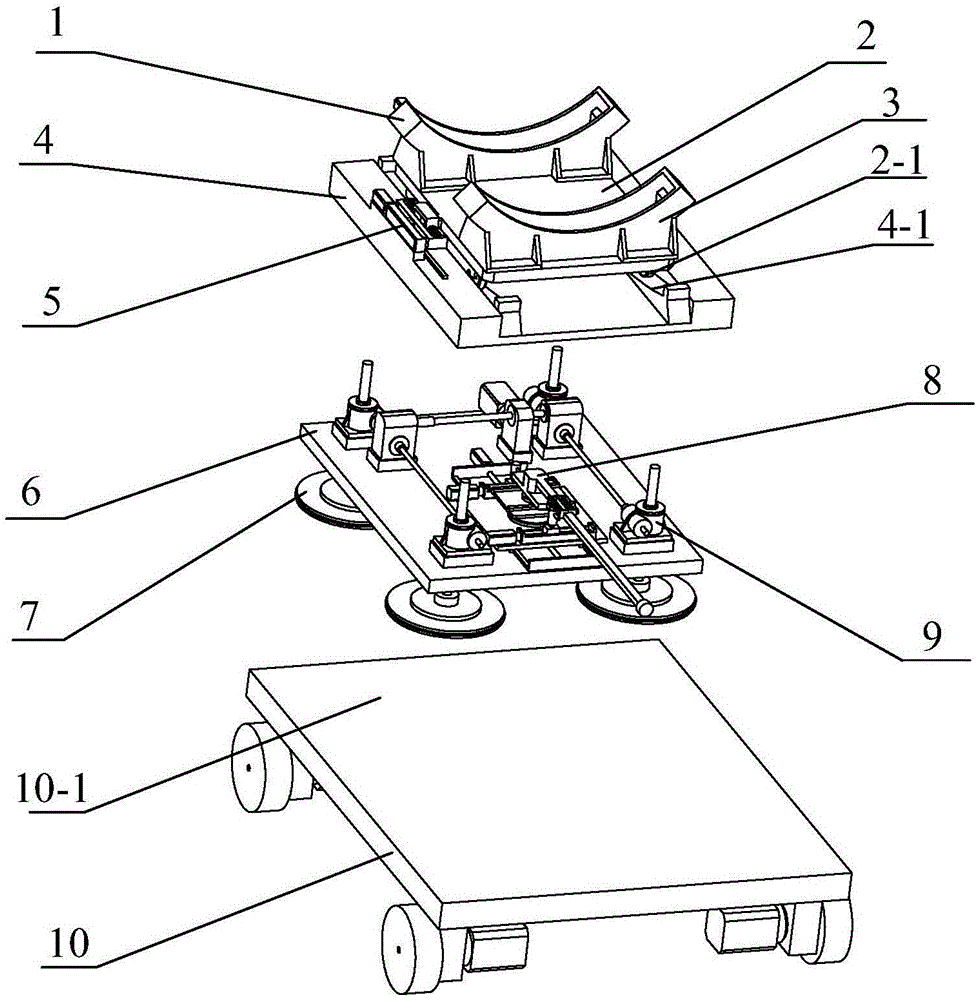

Modular automatic pick-up fitting device based on air flotation technology

ActiveCN106378620AImprove flexibilityHigh control precisionMetal working apparatusFloating platformMechanical engineering

The invention relates to a modular automatic pick-up fitting device based on an air flotation technology. A floating platform is arranged above an air flotation supporting AGV, an air flotation mechanism under the floating platform is connected to an air flotation plane on the air flotation supporting AGV, a plane pose operating mechanism is arranged in the middle position on the floating platform, two circular guide rails which are parallel to each other are arranged on a lifting platform, a pitching platform is arranged on the two circular guide rails, an automatic cabin section bracket and a driven cabin section bracket are arranged on the pitching platform, the automatic cabin section bracket and the driven cabin section bracket are parallel to each other, bracket rollers are arranged in the automatic cabin section bracket, a roller driving motor is arranged on the outer side of the automatic cabin section bracket, the output end of the roller driving motor is rotatably connected to one of the bracket rollers in the automatic cabin section bracket, bracket rollers are arranged in the driven cabin section bracket, rollers are arranged under the pitching platform, the rollers are rotatably connected to the circular guide rails, and a pitch attitude operating mechanism is arranged on one side of the pitching platform.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com