Patents

Literature

202results about How to "Improve carbonization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

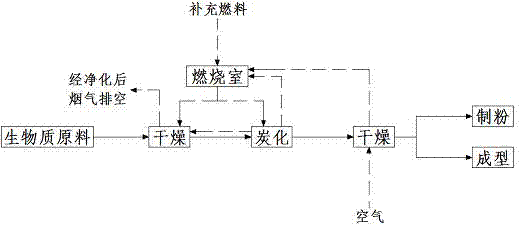

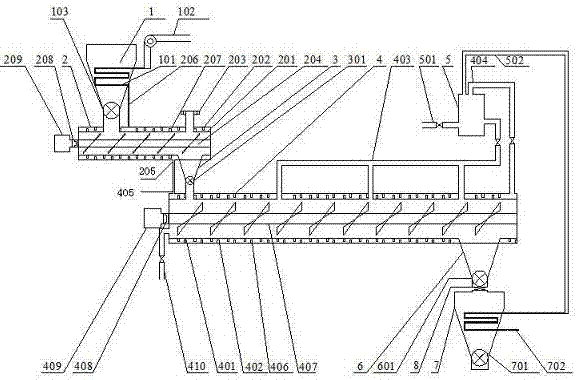

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

In-situ carbonization curing treatment method for shallow soft ground

ActiveCN104912055AEasy to adjust the depth of mixingImprove uniformityOrganic fertilisersSoil preservationResource utilizationCarbonization

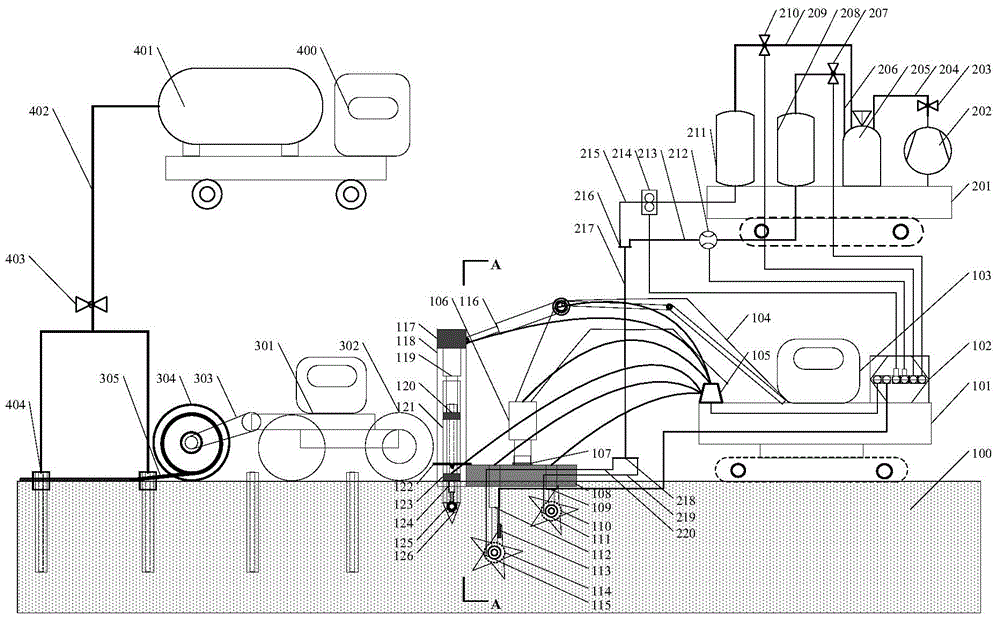

The invention discloses an in-situ carbonization curing treatment method for a shallow soft ground, and belongs to the field of civil engineering ground stabilization. The method includes the steps that pretreated ground soil is broken and stirred through a crawler-type stirrer; a first curing agent and a second curing agent are mixed, the mixed curing agents are sprayed into the ground soil, and the mixed curing agents and the ground soil are evenly stirred; U-type drain boards are inserted at intervals through a board inserting device; a compacting device and a film laying device are started, and films are laid while the treated ground soil is rolled; carbon dioxide gas is injected to carry out ventilating carbonization on the compacted ground soil; the steps are repeated, and the steps of mixing the curing agents for the pretreated ground soil, inserting the drain boards, and compacting, sealing and stabilizing the treated ground soil in a carbonization mode are completed continuously. The treatment system and method are simple and reliable and capable of adapting to a complex environment, construction is safe and efficient, and quantification of the curing agents in ground treatment and resource utilization of carbon dioxide are achieved.

Owner:SOUTHEAST UNIV

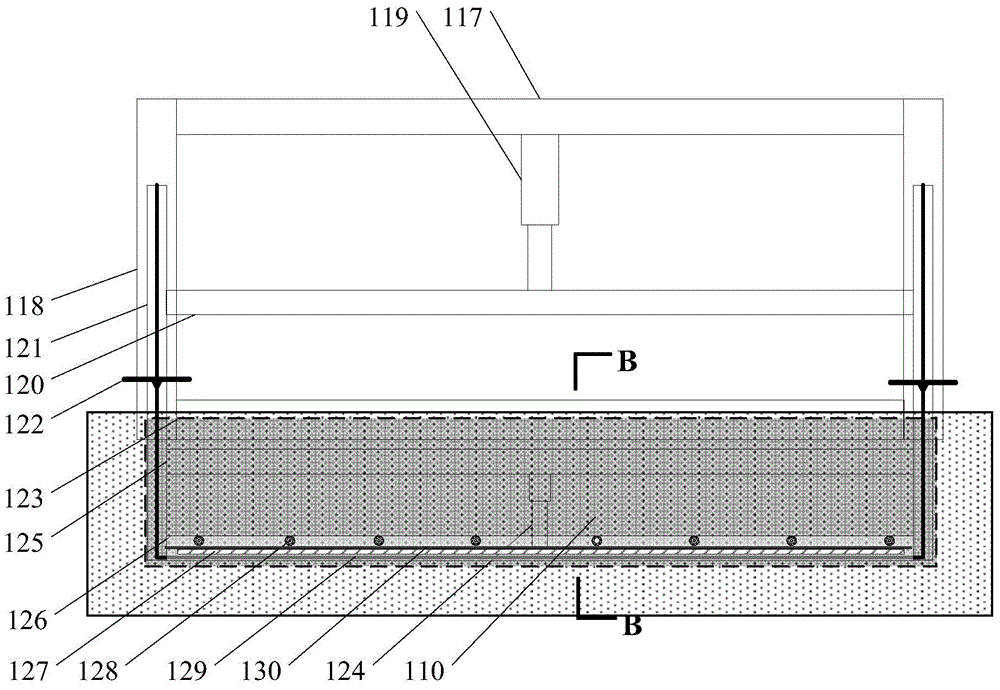

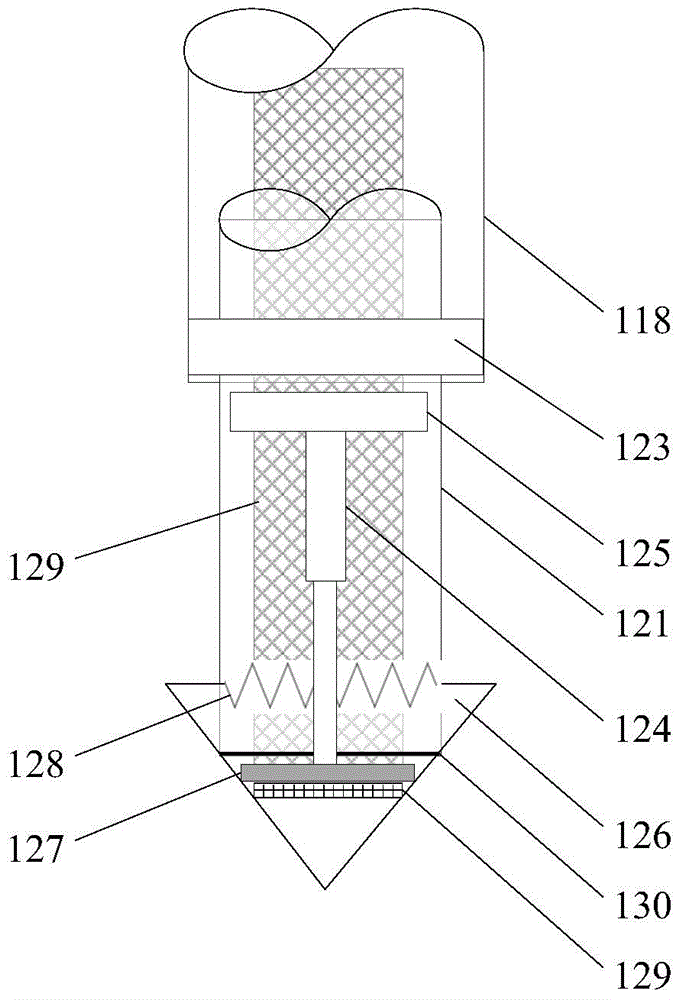

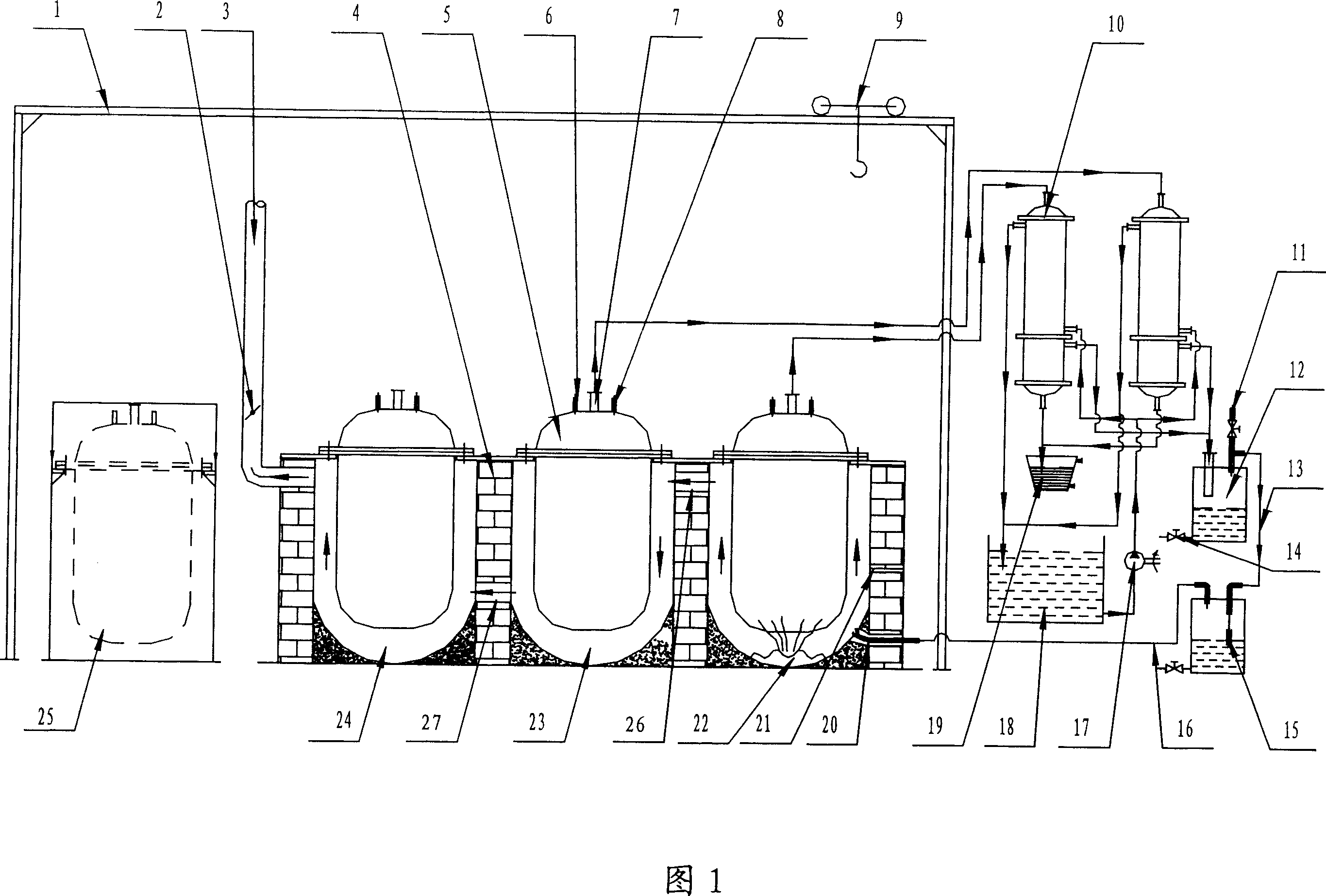

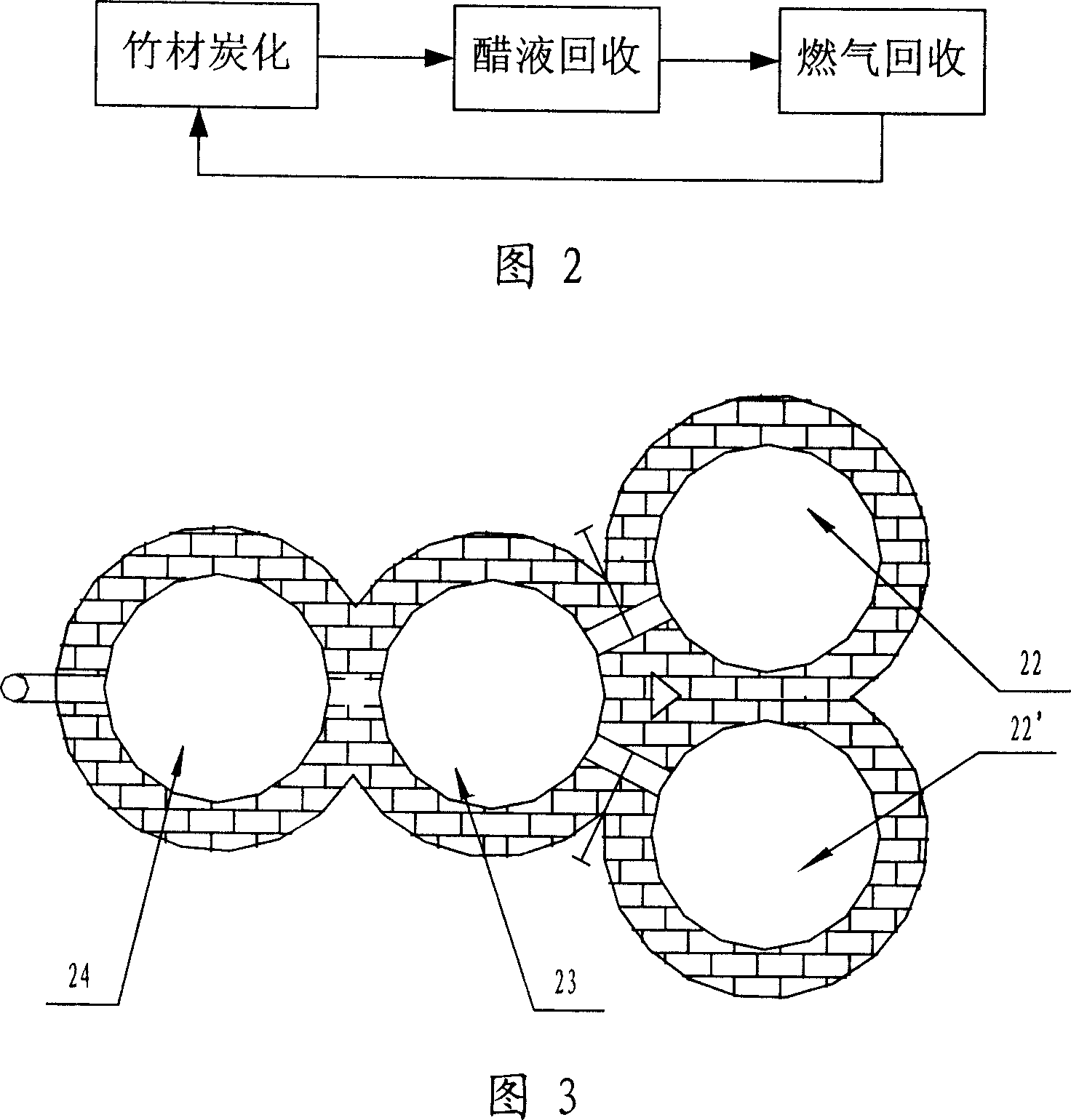

Bamboo charing heating furnace, kettle, system and process

InactiveCN101020827AHigh activityAvoid heatingBiofuelsPyroligneous acid productionHigh energyProcess engineering

The present invention discloses bamboo charing heating furnace, kettle, system and process. The heating furnace one furnace body, and one heating cavity, one pre-charing cavity and one pre-heating cavity successively connected inside the furnace body. The charing system includes one bamboo charing unit, one vinegar liquid recovering unit and one fuel gas recovering unit. The charing process includes the steps of bamboo charing, vinegar liquid recovering and fuel gas recovering. The present invention is used for bamboo charing, and has short charing period, high production efficiency and high energy utilizing rate.

Owner:NANJING FORESTRY UNIV

Preparation method of novel biochar

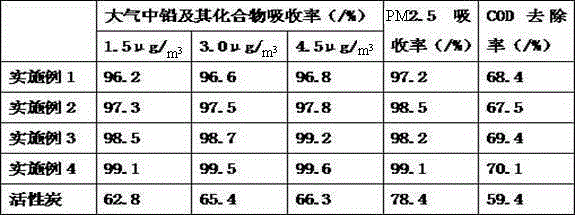

The invention relates to a preparation method of novel biochar, which comprises following steps: (1) crushing plant straws into powder, soaking the plant straws and soaking the plant straws in an ammonium acetate water solution at normal temperature, and cooking the plant straws in a mixed liquid prepared from oxalic acid, sodium nitrate, tannin acid and water; (2) washing filter residue in clear water to remove acid on surface of the plant straw powder; (3) cooking the filtrate; (4) mixing a solid substance obtained in the step (3) with carbon powder according to the weight ratio of 100:2.5 uniformly and performing high-temperature treatment; (5) mixing the treated raw materials with activated charcoal according to the weight ratio of 60:2 uniformly, and performing carbonization treatment with nitrogen gas filled into a quartz tube continuously so that the nitrogen gas is circulated in the quartz tube to prepare the biochar. The method for producing the biochar can reach more than 64.5% in carbonization rate of the plant straws, and is reduced by about 10% in energy consumption during the process.

Owner:QUANJIAO SHENGYUAN BIOMASS ENERGY CO LTD

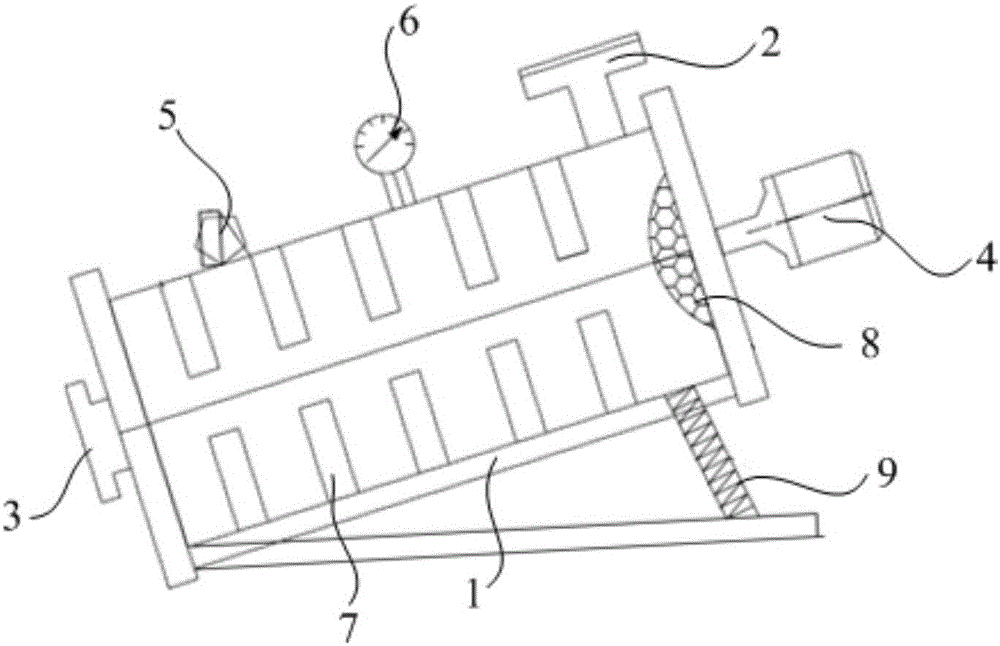

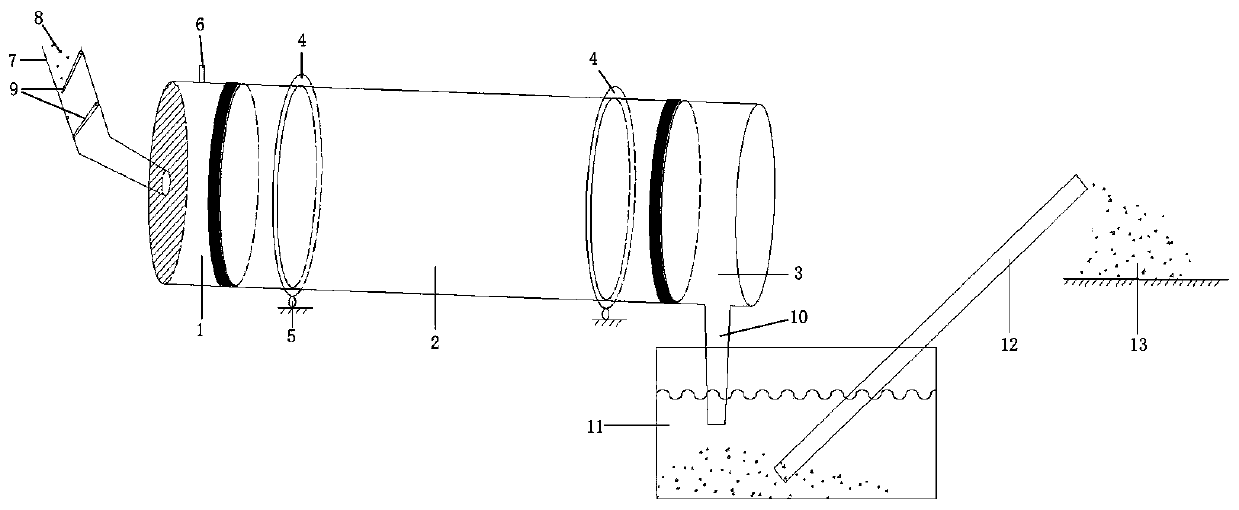

Microwave-assisted vacuum horizontal-type biochar carbonizing device

ActiveCN105131985ASpeed up carbonationSolve the problem of single heat sourceBiofuelsSpecial form destructive distillationVacuum pressureEngineering

The invention discloses a microwave-assisted vacuum horizontal-type biochar carbonizing device. The device includes a carbonizing rotary kiln, on which a material inlet and a material outlet are formed. A plurality of electric-heating apparatuses and microwave generating apparatuses are uniformly disposed in the carbonizing rotary kiln. A vacuum pump, a vacuum valve and a vacuum pressure meter for vacuumizing the carbonizing rotary kiln are disposed on the carbonizing rotary kiln. In the microwave-assisted vacuum horizontal-type biochar carbonizing device, the electric-heating apparatuses and microwave generating apparatuses are uniformly disposed in the carbonizing rotary kiln, wherein the microwave generating apparatuses are used for assisting the electric-heating apparatuses to pyrolyze biomass, so that the carbonizing efficiency of biomass is greatly increased. Through the vacuum pump, a vacuum situation inside the carbonizing rotary kiln during pyrolysis on the biomass is achieved, wherein the vacuum situation can increase effective yield of the biochar.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

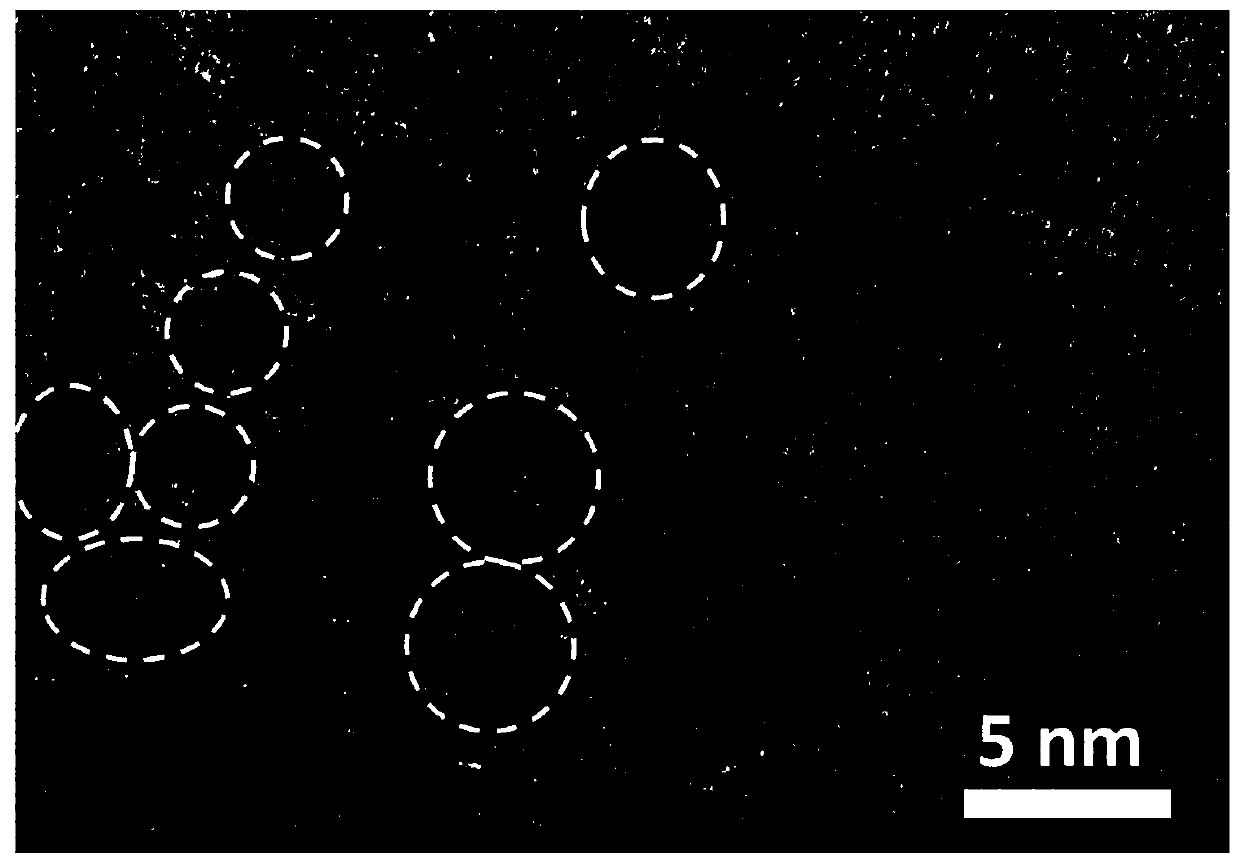

Method for preparing crystal nucleus prefabricated nano calcium carbonate and special equipment

InactiveCN1648051ALarge particle sizeSmall particle sizeCalcium/strontium/barium carbonatesPolycrystalline material growthSlurryCalcium carbonate crystals

The present invention discloses process and apparatus for preparing pre-nucleated nano calcium carbonate. The process includes the following steps: calcining limestone to generate CaO, and slaking to form Ca(OH)2 solution; pumping Ca(OH)2 slurry into pre-nucleating reactor to generate great amount of crystal nuclei; leading the crystal nuclei into sealed carbonizing reactor and introducing CO2 to produce nano calcium carbonate slurry; filtering, and drying to for pre-nucleated nano calcium carbonate. The special apparatus is the pre-nucleating reactor, which is cylindrical and has partition board to separate into upper and lower layers and spherical porous stuffing in the upper layer. The pre-nucleating technology results in greatly raised carbonizing efficiency and makes it possible to obtain nanometer calcium carbonate crystal with small particle size and narrow size distribution.

Owner:上海耀华纳米科技有限公司

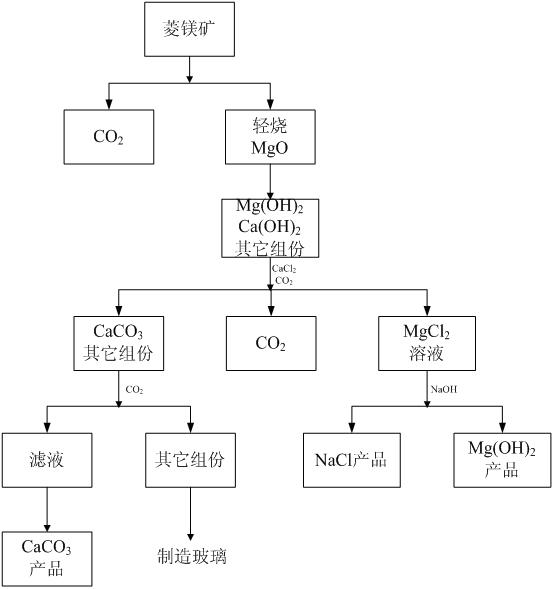

Magnesite carbonization method for producing magnesium hydroxide and calcium carbonate product

InactiveCN101987734AImprove carbonization efficiencyTake advantage ofCalcium/strontium/barium carbonatesMagnesium hydroxideCalcium carbonateEngineering

The invention discloses a magnesite carbonization method for producing magnesium hydroxide and a calcium carbonate product, and belongs to the technical field of inorganic chemical industry. The method comprises the following steps of: calcining and grinding magnesite, mixing with water, adding CaCl2 into pulp, introducing CO2 gas, and stirring and filtering to obtain a primary filter cake and primary filtrate; adding alkali into the filtrate, and stirring and filtering to obtain a secondary filter cake and secondary filtrate; performing spray drying on the secondary filter cake to obtain Mg(OH)2; drying the secondary filtrate to obtain NaCl; adding water into the primary filter cake, introducing CO2 gas, and stirring and filtering to obtain a third filter cake and third filtrate; performing spray drying on the third filtrate to obtain CaCO3; and filtering and drying the third filter cake to obtain a product serving as a raw material for producing glass for subsequent treatment. The CaCl2 is added in the carbonization reaction process, the carbonization efficiency is improved, high-purity magnesium hydroxide and calcium carbonate products are prepared, other useful components serve as raw materials for producing glass and is subsequently treated and utilized, the production process flow is simple, the equipment requirement is low, and after the treatment, other pollution is not generated.

Owner:LIAONING TECHNICAL UNIVERSITY

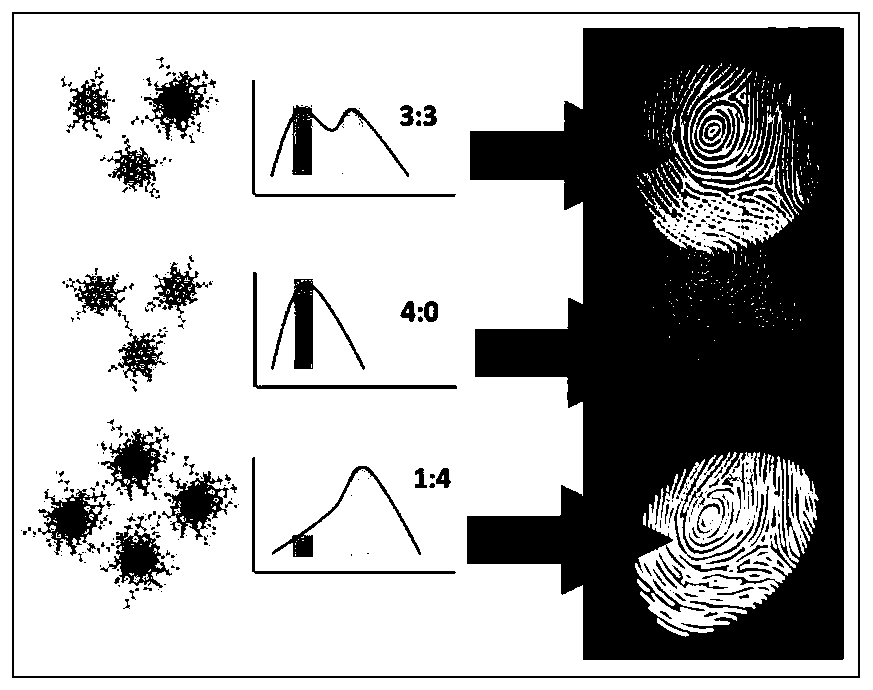

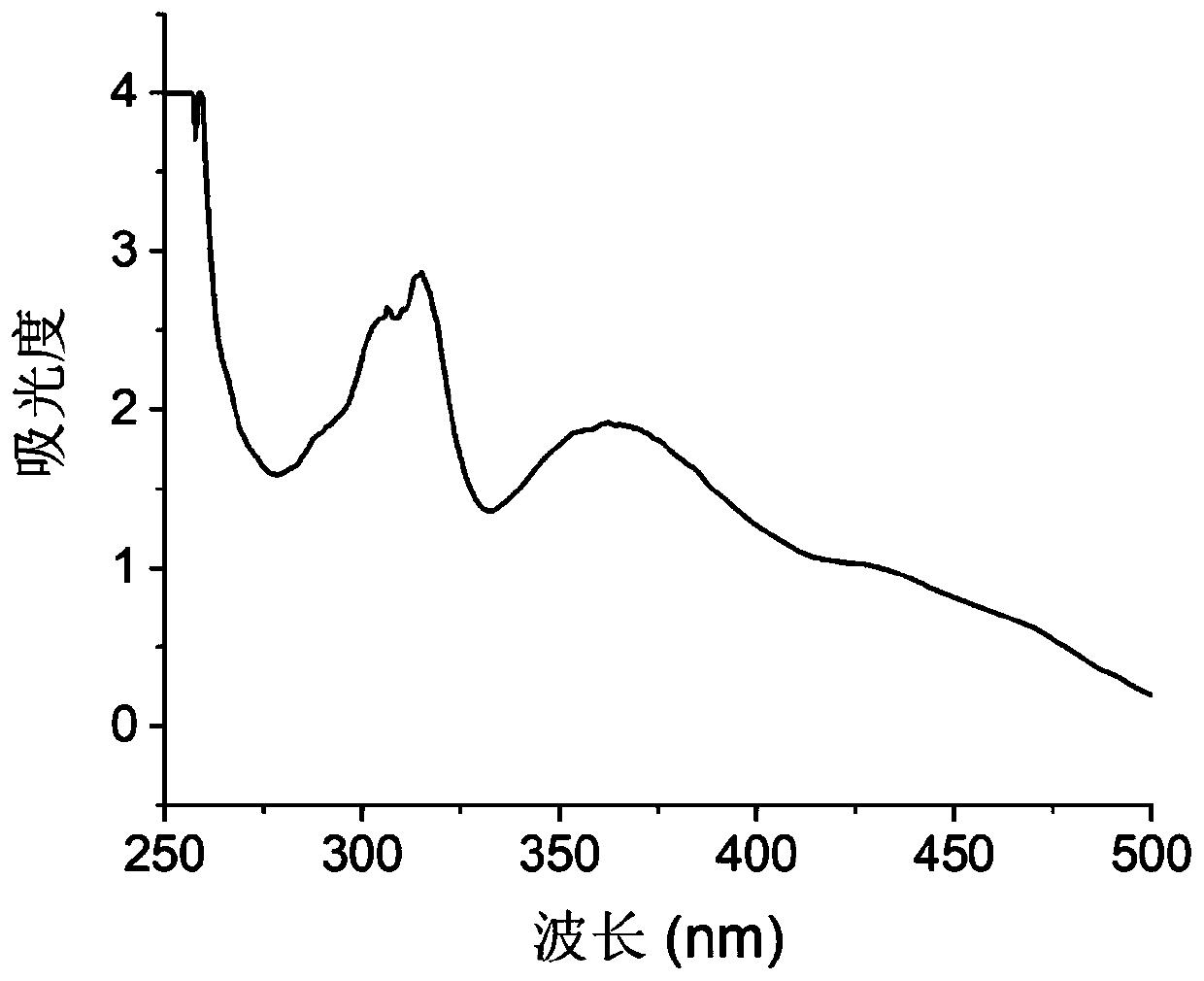

Amphiphilic graphene quantum dot material, preparation method thereof, fluorescent coding anti-counterfeiting ink based on the material and preparation method of the ink

ActiveCN110615428AInhibit side effectsSimple separation and purification processMaterial nanotechnologyGrapheneQuantum yieldCarbonization

The invention discloses an amphiphilic graphene quantum dot material, a preparation method thereof, fluorescent coding anti-counterfeiting ink based on the amphiphilic graphene quantum dot material and a preparation method of the fluorescent coding anti-counterfeiting ink. Hydrophobic citrate is used as a carbon source, hydrophilic amino alcohol is used as a nitrogen doping agent, and the amphiphilic graphene quantum dot material with hydrophobic ester groups and hydrophilic alcoholic hydroxyl edge groups is prepared through carbonization treatment. The prepared amphiphilic graphene quantum dot material has a high fluorescence quantum yield and good light, heat and chemical stability, and can be dispersed in various polar and non-polar solvents. Under certain conditions, the amphiphilic graphene quantum dot material can form an aggregate on the surfaces of a solution and a solid, and fluorescence emission of the amphiphilic graphene quantum dot material is changed from a single peak tomultiple peaks. The aggregation degree and aggregation state of the amphiphilic graphene quantum dot material are regulated and controlled, so that the fluorescence emission intensities of the amphiphilic graphene quantum dot material at different wavelengths are correspondingly changed, and the fluorescence coding marking based on the fluorescence intensity ratio is realized.

Owner:XI AN JIAOTONG UNIV

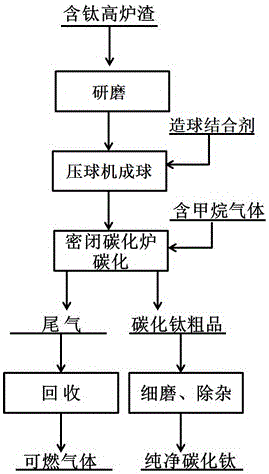

Titanium carbide preparation method based on carbonization titanium extraction treatment of titanium-bearing blast furnace slag

The invention provides a titanium carbide preparation method based on carbonization titanium extraction treatment of titanium-bearing blast furnace slag. The method comprises the steps that the titanium-bearing blast furnace slag serves as the raw material, grinding and balling are conducted, heating is conducted to 1,100 DEG C to 1,300 DEG C, methane is decomposed into hydrogen and carbon black, and a titanium carbide crude product is obtained after reduction and carbonization are conducted; the titanium carbide crude product is subjected to levigating treatment and purifying, and a more pure titanium carbide product can be obtained; the processes of the method are simple and easy to operate, due to the fact that methane is decomposed to obtain hydrogen and carbon black with high activity, hydrogen and the titanium-bearing blast furnace slag are subjected to a gas-solid reaction, and the reduction efficiency is high; meanwhile, by means of the carbon black with the high activity, the carbonization efficiency is greatly improved, the overall reaction efficiency is improved, the carbonization temperature is decreased, tail gas obtained from the reaction is used as gas fuel supply for heating of a closed-type carbide furnace, therefore, energy consumption is effectively reduced, an existing titanium-bearing blast furnace slag resource is better utilized, the added value of the titanium-bearing blast furnace slag is increased, and good industrial application value is achieved.

Owner:CHONGQING UNIV

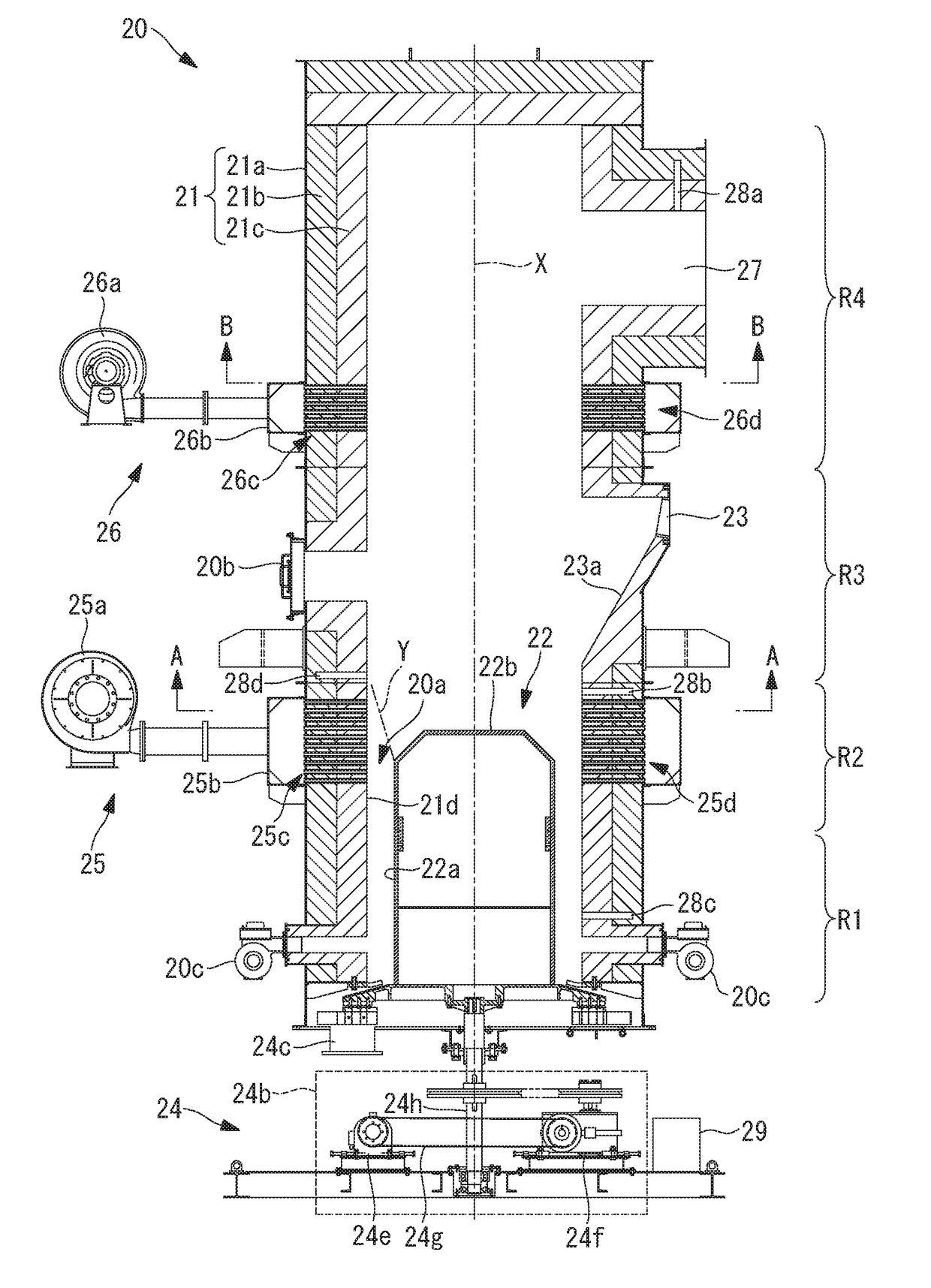

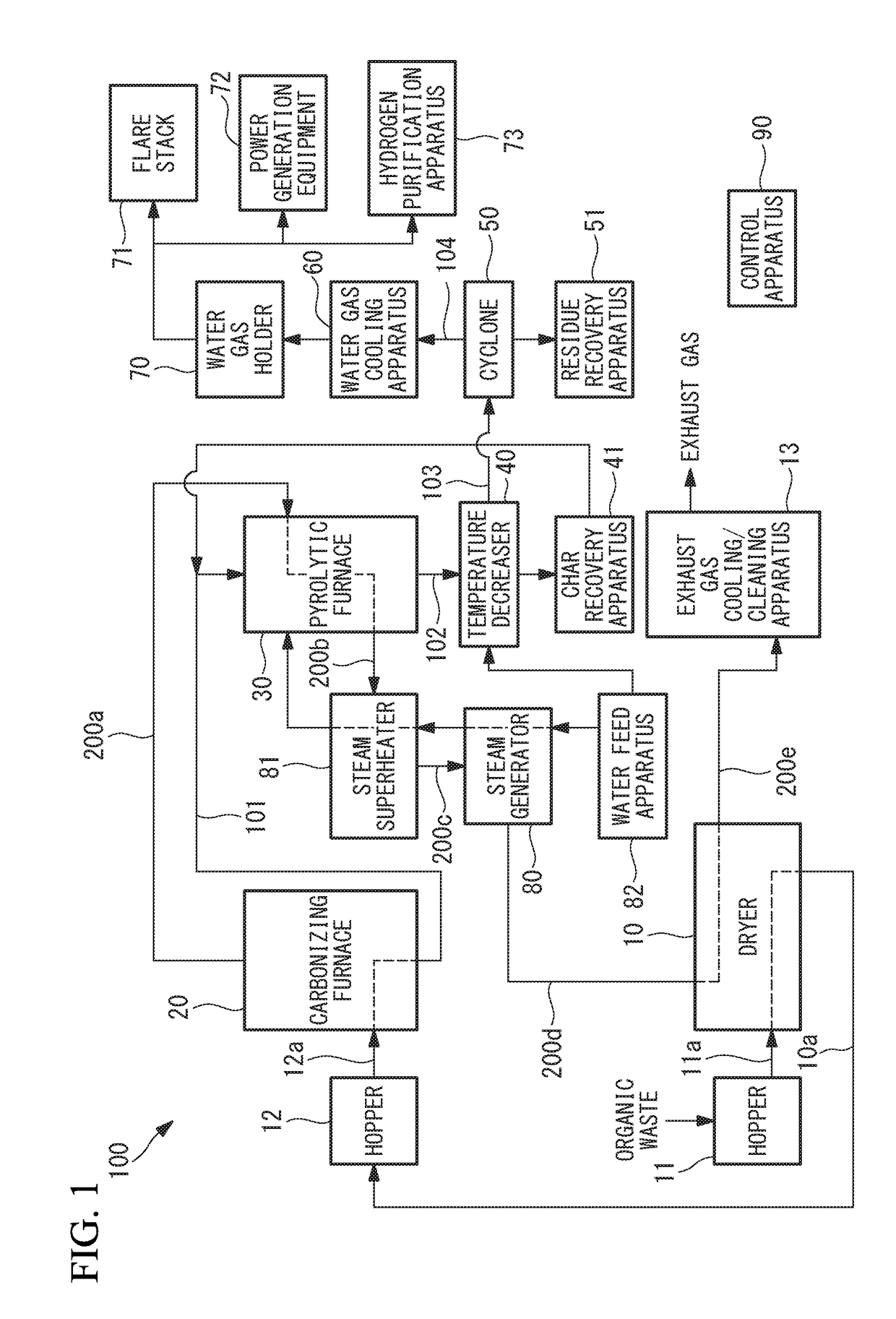

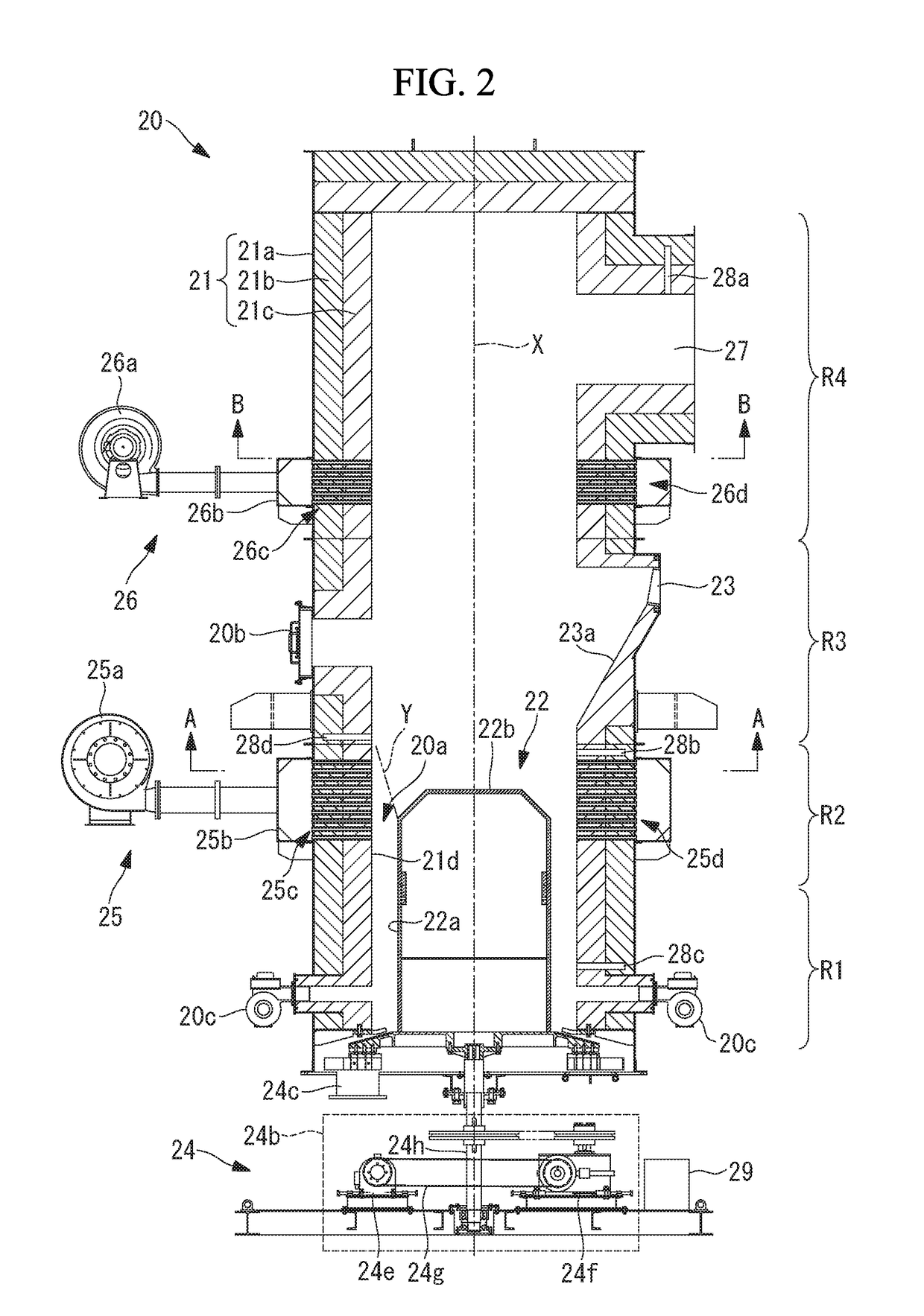

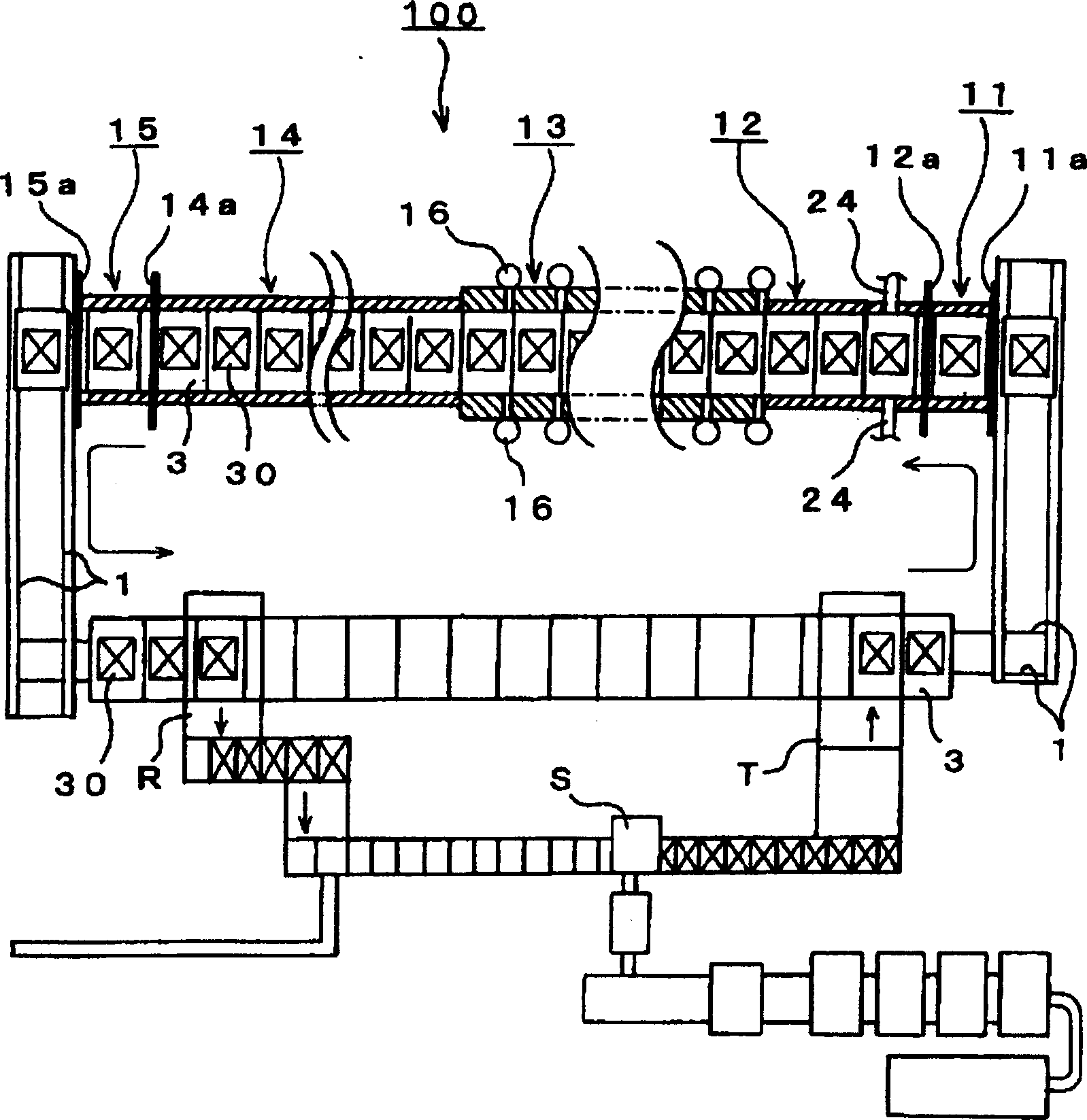

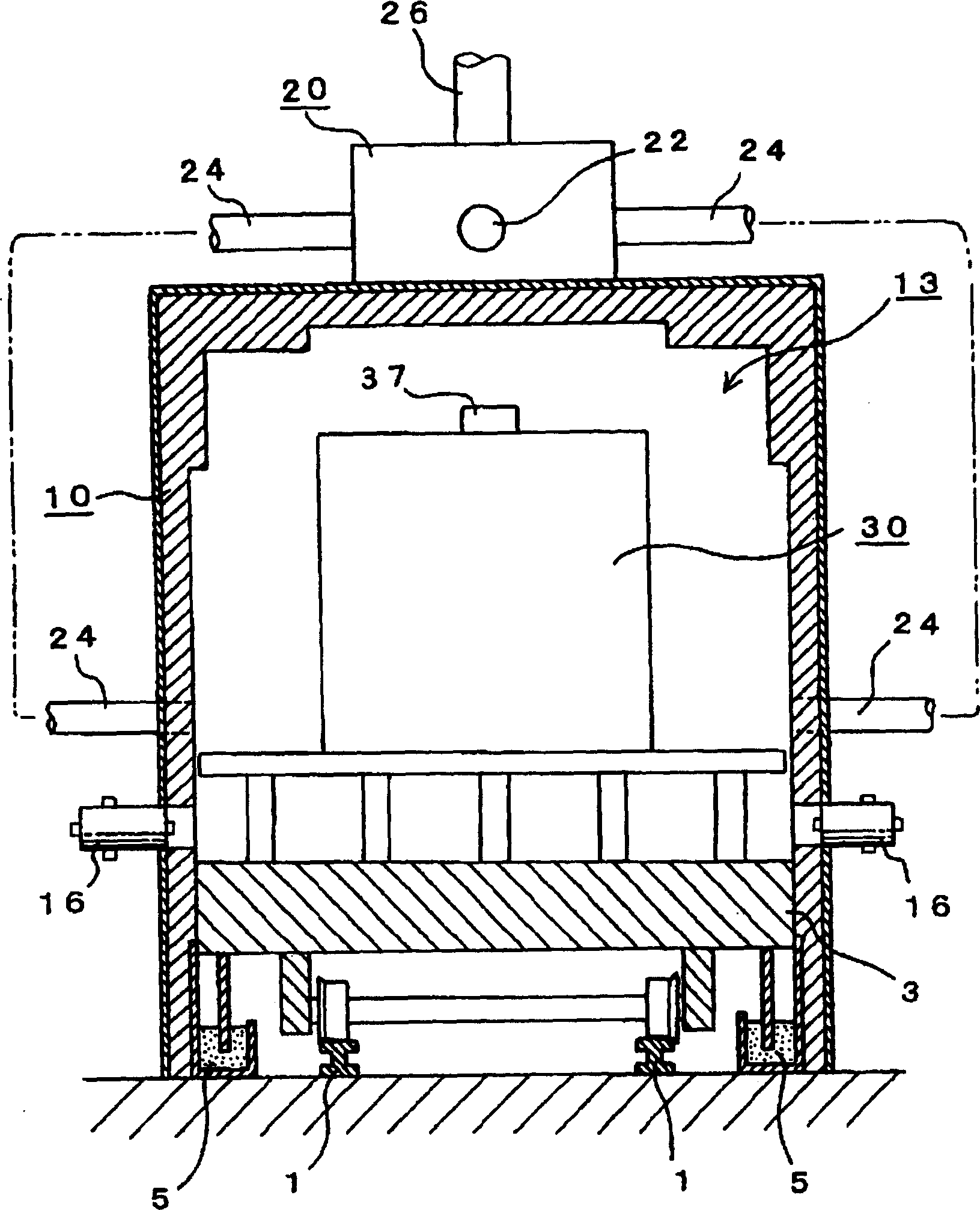

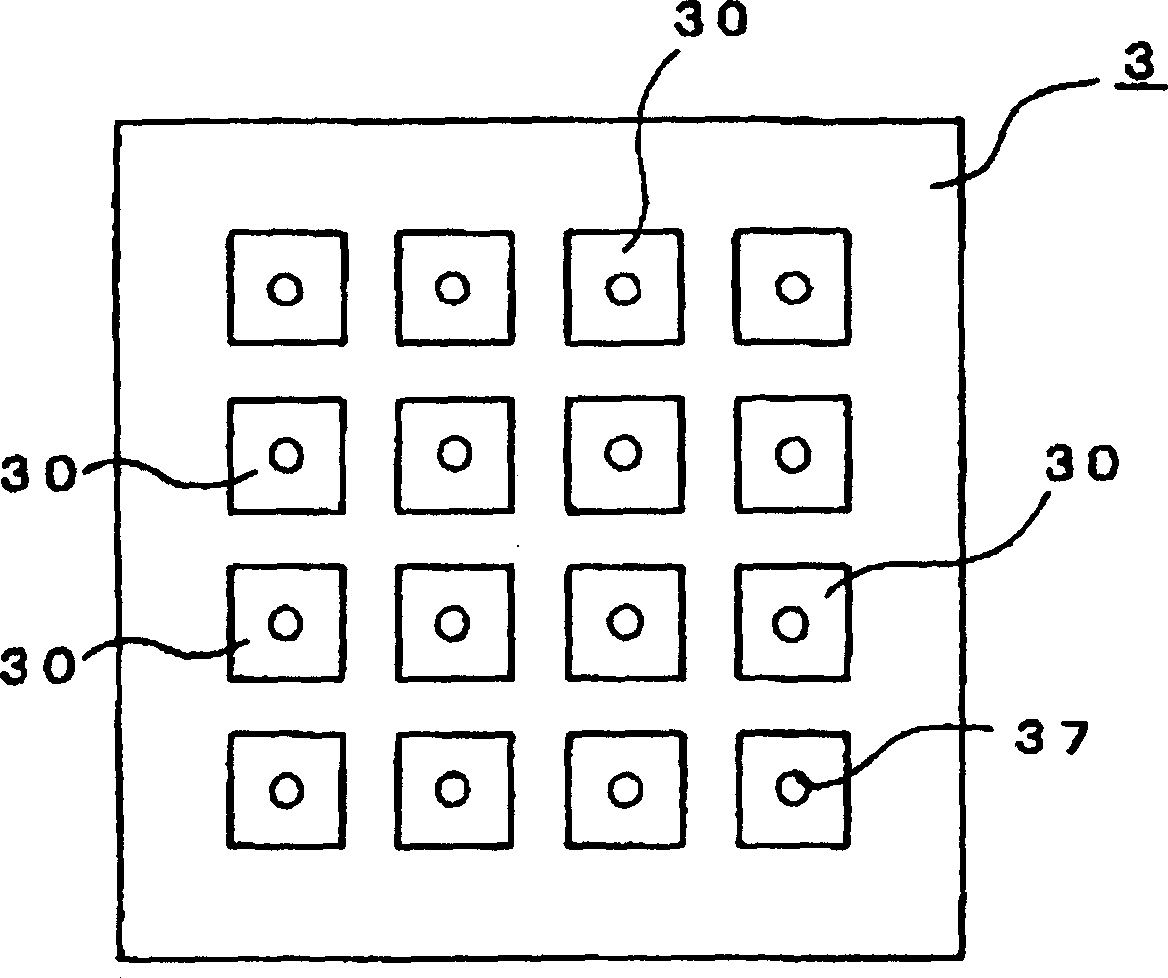

Carbonizing furnace, pyrolytic furnace, water gas generation system, hydrogen gas generation system, and power generation system

ActiveUS20170348741A1Improve combustion efficiencyInhibition defectHydrogen separationTransportation and packagingCarbonizationReaction temperature

Provided is a carbonizing furnace capable of improving combustion efficiency of combustible gas generated by combustion of organic waste and of improving carbonization efficiency of organic waste by appropriately controlling the temperature of carbide. Provided is a pyrolytic furnace in which heating gas can be suppressed from outflowing to the outside from a gap between the upper surface of the body part of the pyrolytic furnace and the outer circumferential surface of a reaction tube where a pyrolysis reaction between carbide and a gasification agent is caused, and in which the temperature of a region where the pyrolysis reaction is caused can be suppressed from being reduced. Provided is a water gas generation system which improves thermal efficiency without using a dedicated heat source for generating water steam to be used as a gasification agent for carbide, promotes a pyrolysis reaction, and thereby, achieves the excellent heat efficiency. Provided are a hydrogen gas generation system and a power generation system which use water gas generated by a water gas generation system including a carbonizing furnace and a pyrolytic furnace and which have excellent productivity. Provided is a carbonizing furnace which improves combustion efficiency by controlling the supply amount of air being supplied to the carbonizing furnace according to the temperature of combustion gas in the carbonizing furnace, and which improves carbonization efficiency by controlling the discharge amount of carbide to be discharged to the outside according to the temperature of carbide or the deposit amount of organic waste in the carbonizing furnace, to make the temperature of carbide appropriate, and by controlling the temperature of air being supplied to the carbonizing furnace. In addition, provided is a pyrolytic furnace which blocks outflow of heating gas or water gas by providing seal portions at the attachment positions of a body part, a reaction tube, and a water gas outlet part, etc. of the pyrolytic furnace, and which maintains a pyrolysis reaction temperature by providing a pyrolysis promoting mechanism to the reaction tube. Provided is a water gas generation system which has excellent thermal efficiency and in which a combustion gas flow path is formed so as to allow combustion gas generated by a carbonizing furnace to flow through a carbonizing furnace, a pyrolytic furnace, a steam superheater, a steam generator, a dryer, and the like. Provided is a hydrogen gas generation system or a power generation system formed by combining the water gas generation system with a hydrogen purifying apparatus or a power generation equipment.

Owner:TAKAHASHI SEISAKUSHO

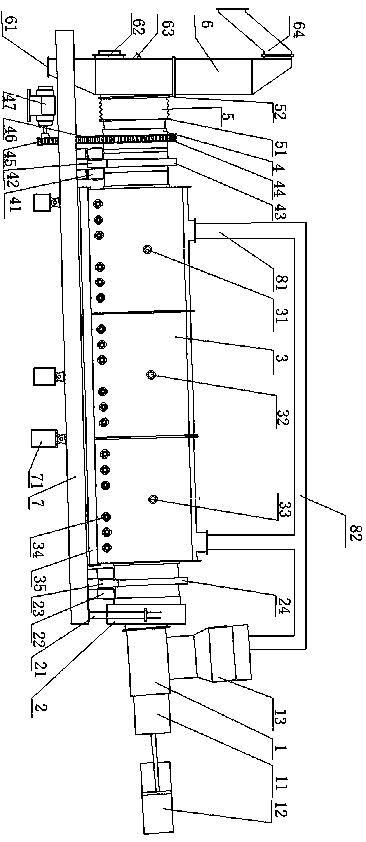

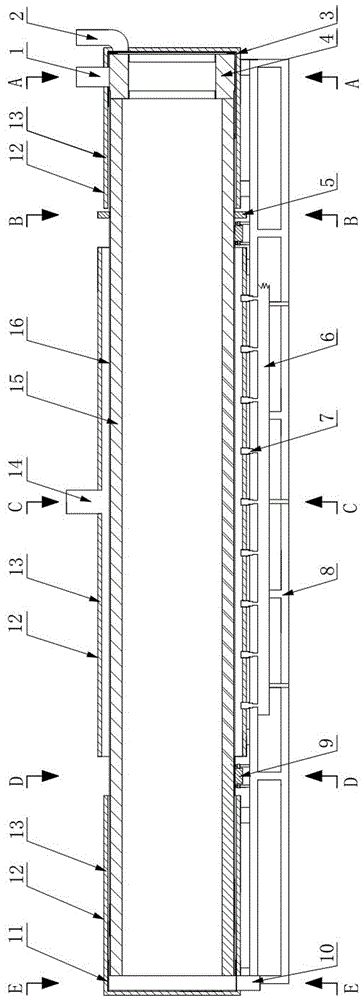

Zoned-temperature-control rotary continuous pyrolyzing and carbonizing device for biomass

ActiveCN105505416AEasy to moveSave gas consumptionBiofuelsIndirect heating destructive distillationTemperature controlEngineering

The invention discloses a zoned-temperature-control rotary continuous pyrolyzing and carbonizing device for biomass. The device comprises a kiln and a rotary furnace arranged in the kiln. The rotary furnace slowly rotates; a furnace head is installed at the head end of the rotary furnace, a furnace tail is installed at the tail end of the rotary furnace, and the furnace head is connected with a feeding device; the rotary furnace is sequentially divided into a plurality of zones in the length direction of a furnace body, independent temperature measuring devices are arranged in the portions, in all the zones, of the kiln, and a plurality of ignition devices, a plurality of gas pipes and a plurality of oxidant gas pipes are further arranged in the portions, in all the zones, of the kiln; flow deflectors are arranged in the rotary furnace. As the rotary furnace is divided into the zones, and the gas inflow and the air inflow in the portions, in all the zones, of the kiln are controlled to carry out zoned temperature control, the different temperatures at all the zones of the rotary furnace can be independently controlled, energy can be fully saved, and carbonizing efficiency can be improved; due to rotation of the rotary furnace and guide of the flow deflectors, straw slowly rotates forwards in the rotary furnace, and therefore the drying process, the pre-carbonizing process and the carbonizing process of the straw are achieved in the rotary furnace.

Owner:江苏联兴成套设备制造有限公司

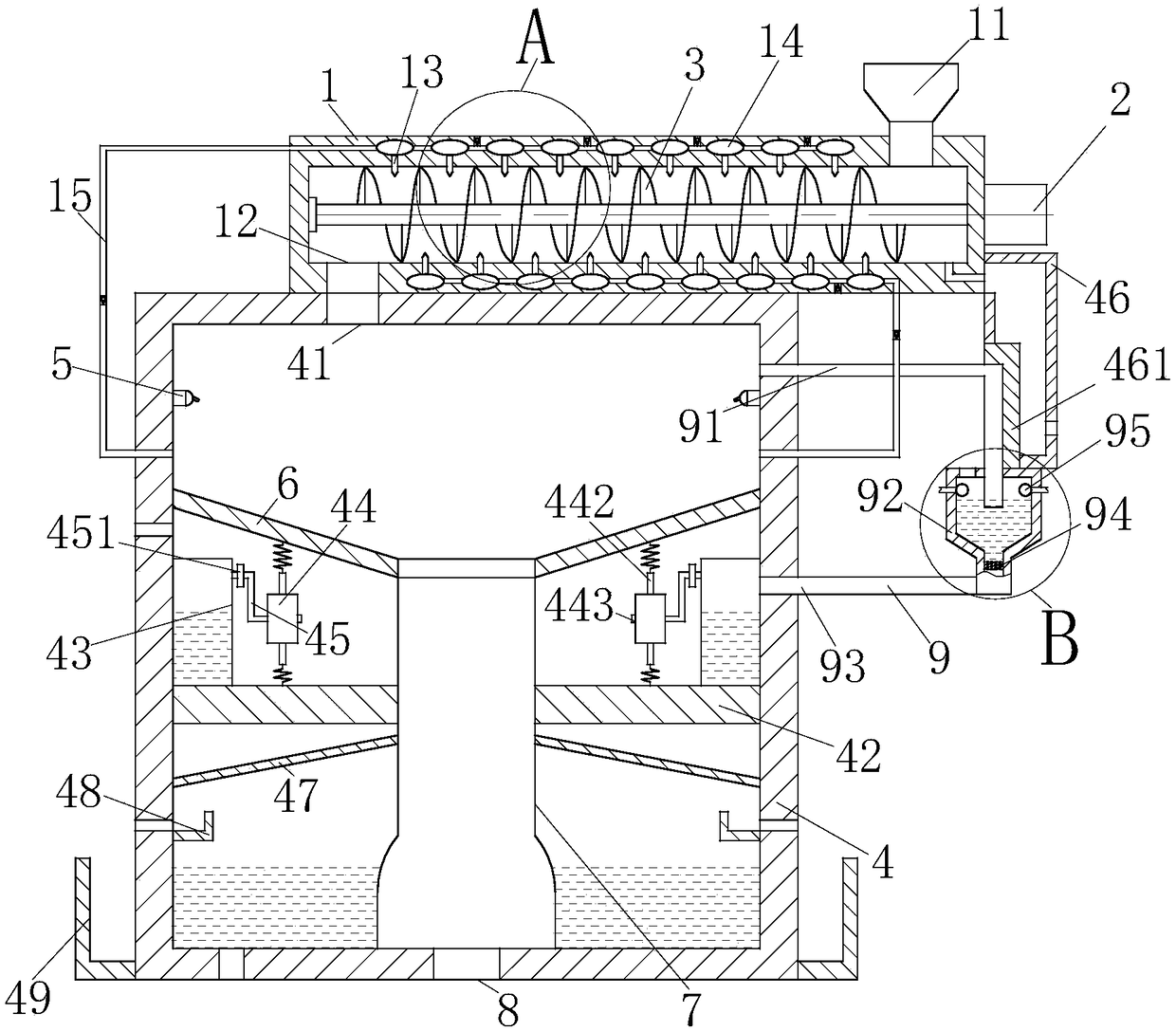

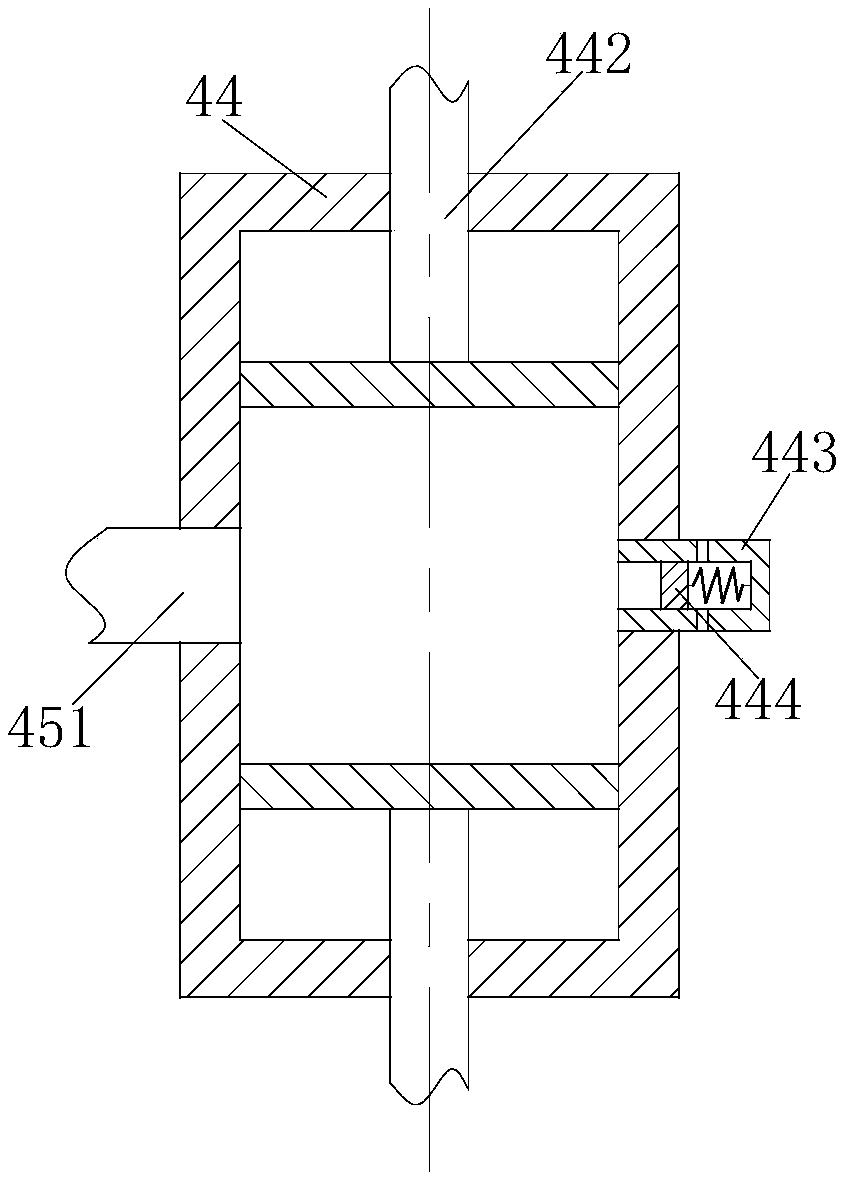

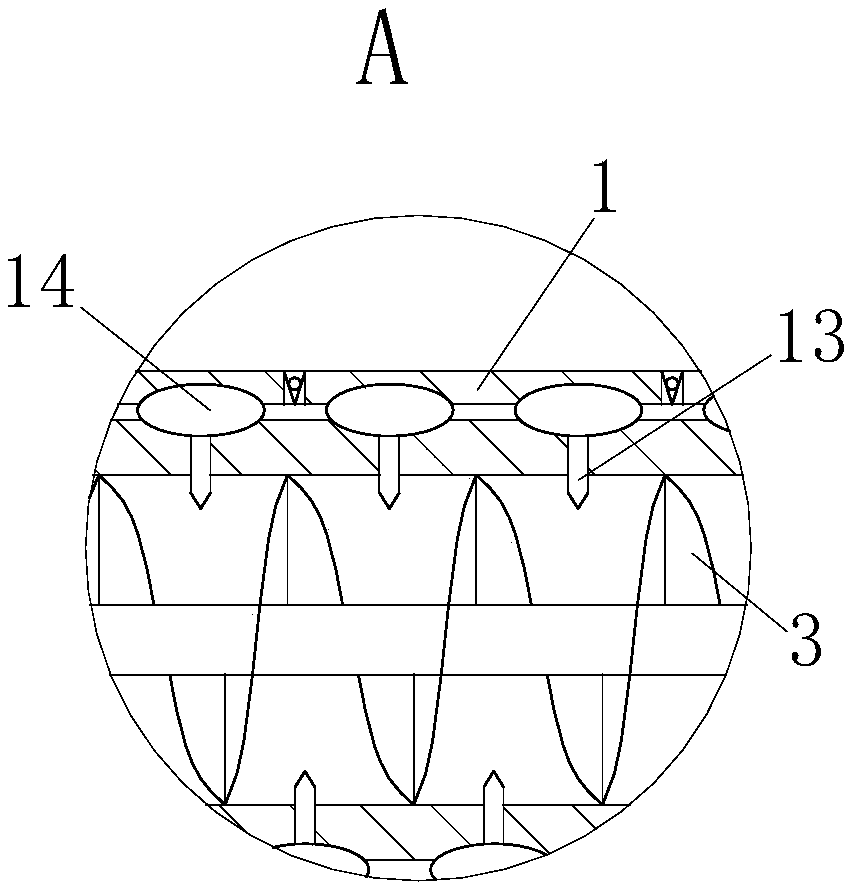

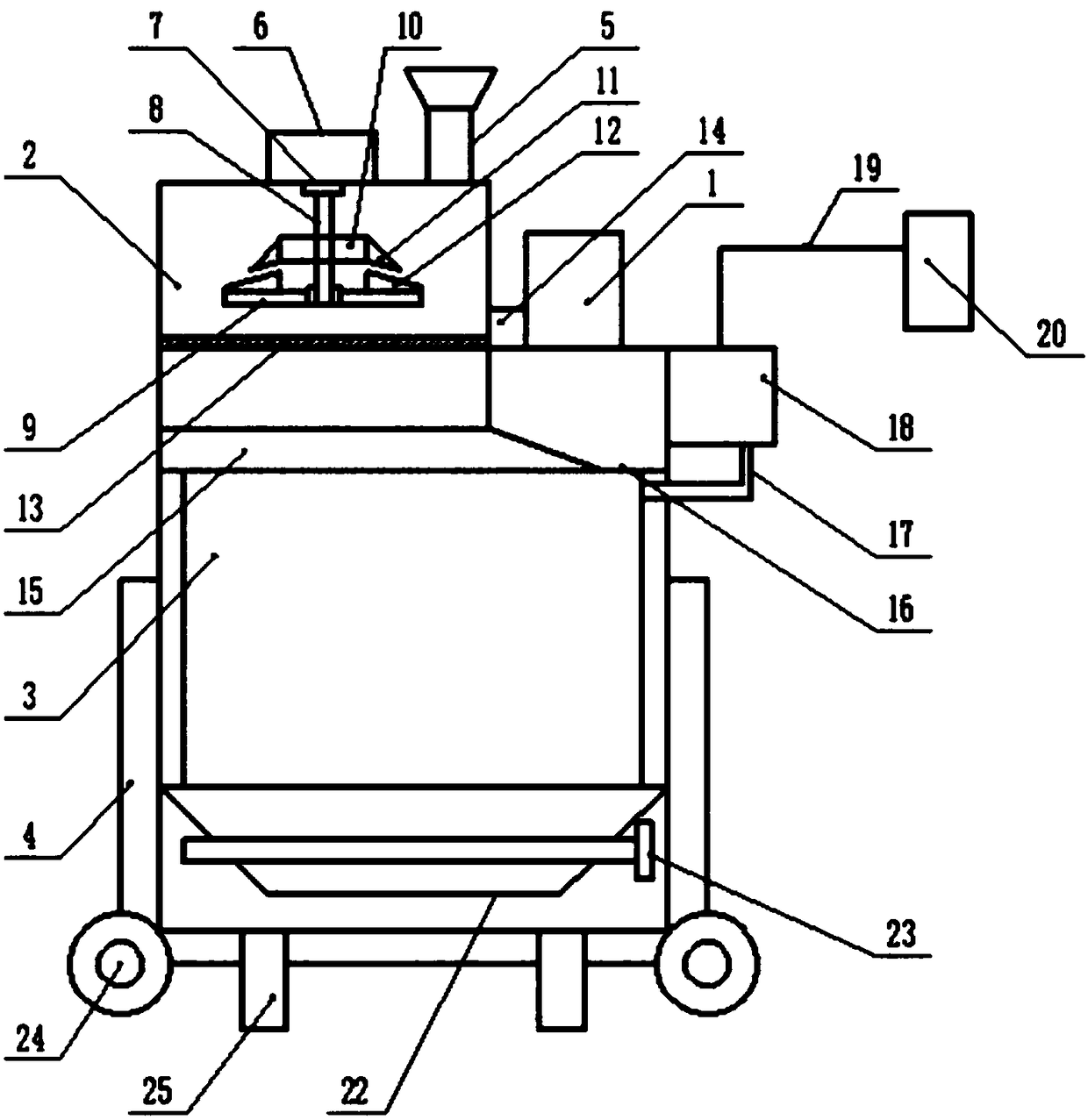

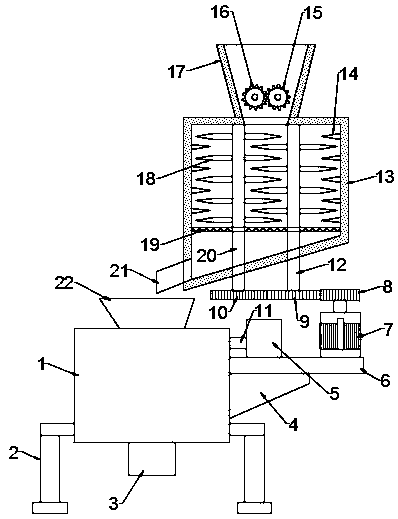

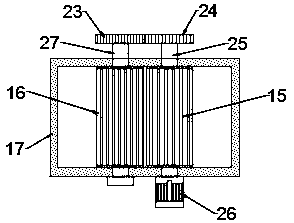

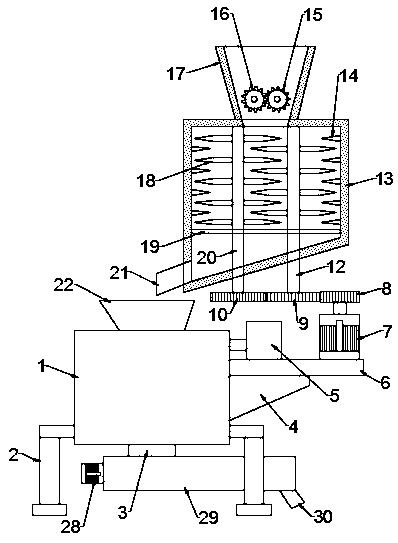

Preheating type straw carbonizing apparatus for recovering waste heat

InactiveCN107099306AImprove carbonization efficiencyScientific and reasonable designBiofuelsEnergy inputExhaust fumesCarbonization

The invention discloses a preheating type straw carbonizing apparatus for recovering waste heat. The preheating type straw carbonizing apparatus comprises a carbonizing apparatus main body, wherein a spiral pushing device is mounted at the top of the carbonizing apparatus main body; a feeding hopper is mounted at the top of the spiral pushing device; a drying bin is arranged inside the carbonizing apparatus main body; a stirring rod is mounted inside the drying bin; a servo motor is mounted at a position, corresponding to the stirring rod, on the carbonizing apparatus main body; and a first electromagnetic valve is mounted below the drying bin. According to the invention, a pollution-free straw carbonizing apparatus capable of achieving complete carbonization is designed, a high-temperature carbonizing cavity is communicated with the drying bin through a waste heat return pipe, high-temperature waste gas generated during carbonization enters the drying bin through the waste heat return pipe to dry straws, and meanwhile, the stirring rod is used for stirring materials uniformly, thereby preventing damp straws from being burnt insufficiently, improving the carbonization efficiency of the straws, and reducing heat energy consumption.

Owner:王利华

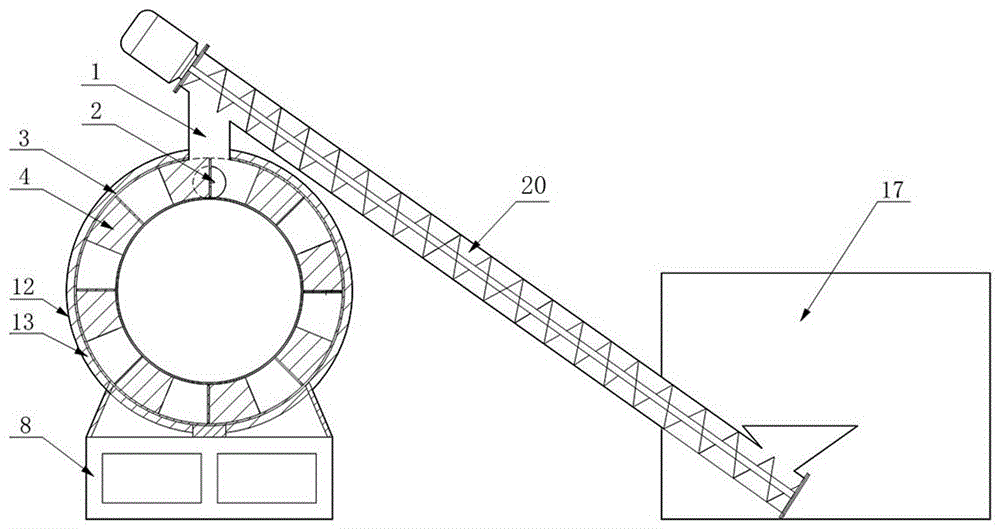

Carbonizing device for solid waste recycled aggregates for concrete

ActiveCN107814502ASolve the unsustainable carbonizationSolve efficiency problemsProductsCarbon compoundsConstruction aggregateVALVE PORT

The invention discloses a carbonizing device for solid waste recycled aggregates for concrete. The device comprises a loading bin, a drum type carbonizing bin and a storage bin, wherein the loading bin and the storage bin are arranged on two ends of the drum type carbonizing bin in a sealing way; a circumferential rack is arranged on an outer surface of the drum type carbonizing bin, and is meshedwith a fixed motor transmission gear. A double-spiral turnover plate is arranged on an inner cylinder wall of the drum type carbonizing bin. The loading bin is provided with a carbon dioxide air inlet, and a feed hopper is arranged on the end part; a discharging leakage pipe is arranged on the bottom part of the storage bin. The feed hopper is sealed by a valve closed by automatic rebound, and adischarge hole is sealed by a water tank. The carbonizing device not only realizes continuous production of recycled aggregates carbonizing, but also realizes full seal of a carbonizing space, guarantees that no CO2 gas is lost during a carbonizing process, and provides a way for industrial production of solid waste recycled aggregates carbonizing. Meanwhile, according to the carbonizing device, the recycled aggregates can fully absorb the CO2 gas, and the mechanical strength of the recycled aggregates is greatly improved.

Owner:CHINA UNIV OF MINING & TECH

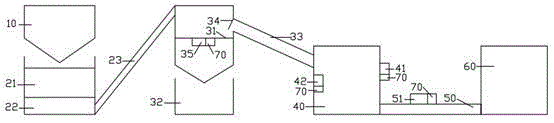

Crop straw carbonization system

ActiveCN108929709ACut evenlyImprove carbonization efficiencyBiofuelsIndirect heating destructive distillationCarbonizationEngineering

The invention belongs to the technical field of straw carbonization equipment, and in particular relates to a crop straw carbonization system. The crop straw carbonization system includes a push box,a motor, an auger, a carbonization box, a fire spraying module, a partition, a collection cover and a carbon outlet, wherein a feed hopper is arranged on the push box, and the feed hopper is located at the right upper side of the push box; the motor is installed on the right side of the push box; the auger is located in the push box, one end of the auger is rotatably connected onto the right sidewall of the push box, and the other end of the auger is connected with the output shaft of the motor; the push box is also provided with a discharge port, and the discharge port is located at the leftlower side of the push box; the carbonization box is located under the push box; the fire spraying module is located on the side wall of the carbonization box; the partition is installed in the carbonization box, the partition is located below the fire spraying module, and the middle of the partition is provided with a through hole; the collecting cover is located in the carbonization box, the upper end of the collecting cover is connected with the bottom of the partition, the collecting cover communicates with the through hole in the partition, and the lower end of the collecting cover is installed at the bottom surface of the carbonization box; and the carbon outlet is located at the bottom of the carbonization box, and the carbon outlet communicates with the collecting cover.

Owner:苏州理合文科技有限公司

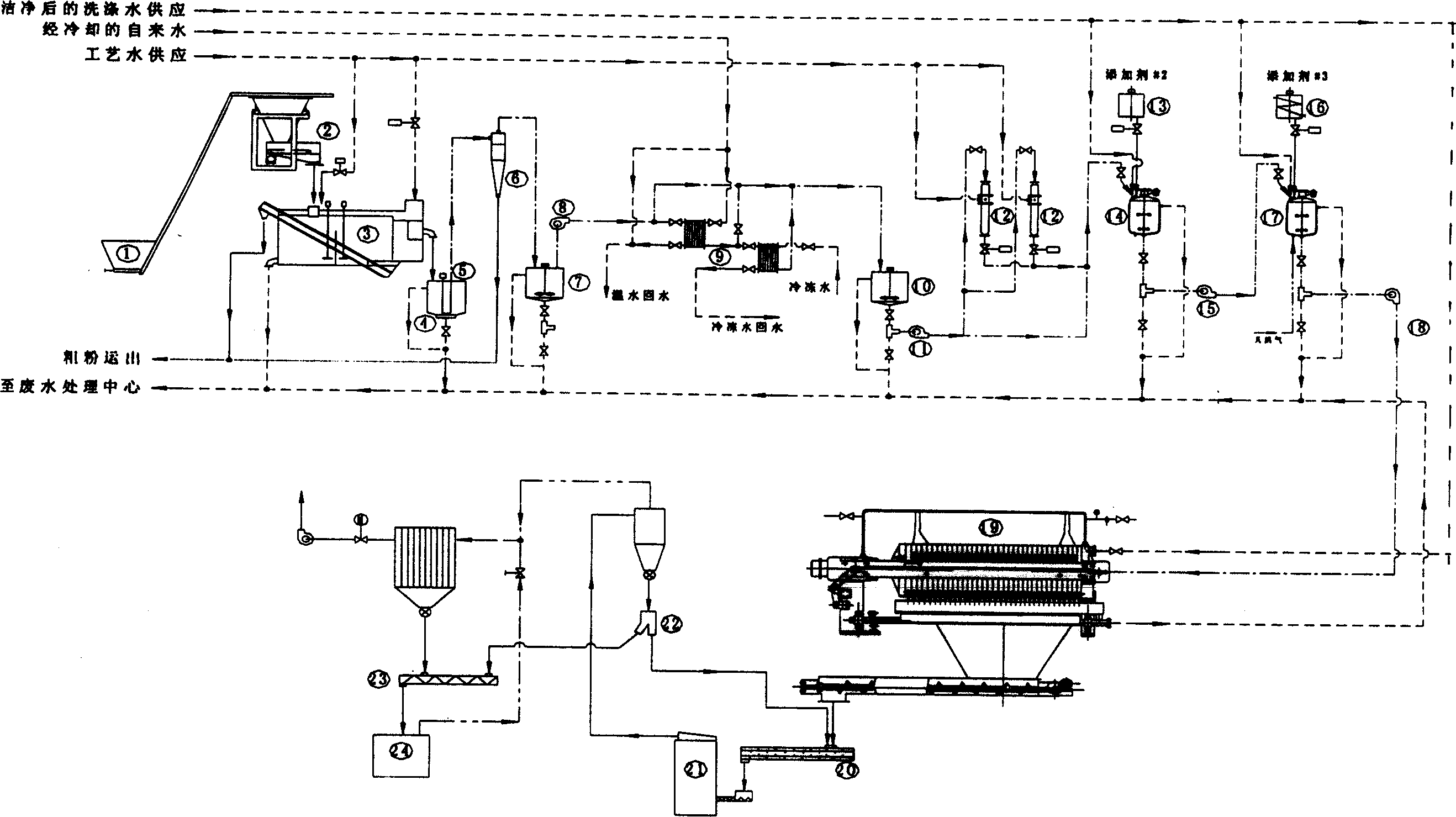

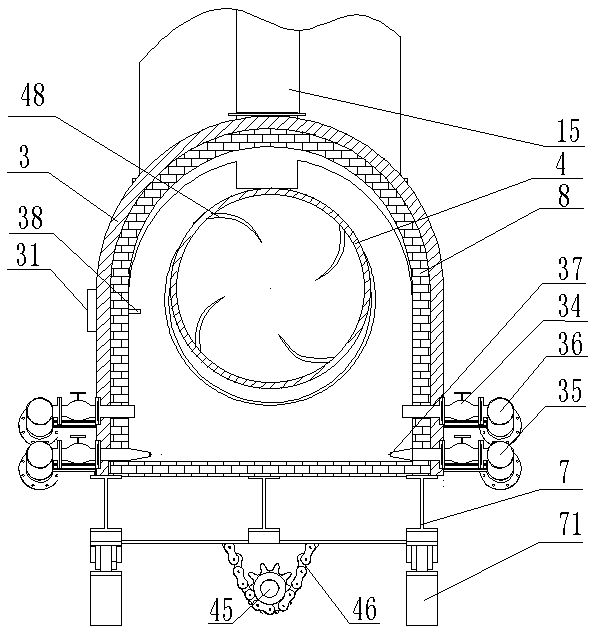

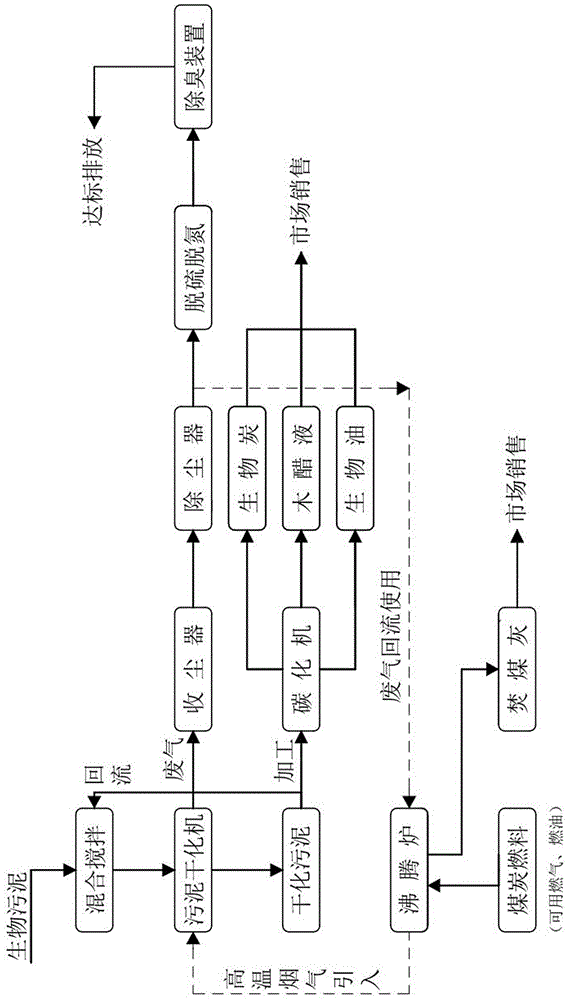

Commercial treatment method and system for biological sludge and rotary sludge carbonizing machine

ActiveCN105753281AImprove environmental safetyReduce processing costsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention relates to resourceful treatment on biological sludge.A commercial treatment method for biological sludge includes the steps that the biological sludge is dried, the dried sludge with the water content being 7-10% is carbonized and generates biochar, pyroligneous liquor and biological tar through high-temperature pyrolysis, and biochar, pyroligneous liquor and biological tar are packaged for sale; methane gas generated in the treatment process is recovered and used for carbonization treatment on the dried sludge.According to a rotary sludge carbonizing machine, a handpiece component and a tail component are fixed to the two ends of a rack, the two ends of a rotary cylinder are inserted into the handpiece component and the tail component and matched with the handpiece component and the tail component in a sealed mode, and a supporting and driving mechanism matched with the rotary cylinder is arranged on the rack; a guiding plate is arranged on the front portion of the rotary cylinder, a lifting plate is arranged on the inner wall of the rotary cylinder, and a combustor is arranged in a heat preservation outer cover below the rotary cylinder.A commercial treatment system for the biological sludge comprises biological sludge drying treatment complete equipment and dried sludge carbonizing treatment complete equipment.The harmful biological sludge is turned into wealth, and the commercial treatment method and system for the biological sludge have high socioeconomic performance and can create huge wealth for enterprises and the society.

Owner:四川泰翱农业科技有限公司

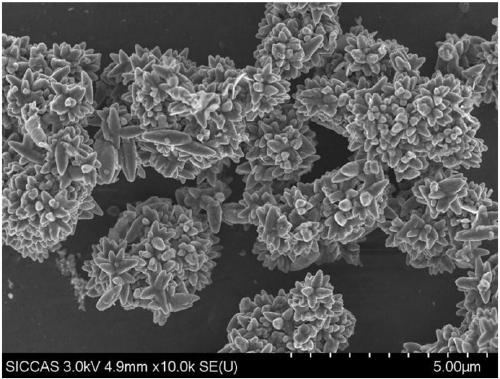

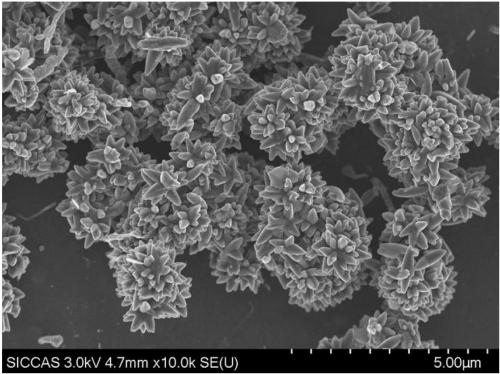

Method for preparing flower-sphere-shaped light calcium carbonate by using ultra-fine ground heavy calcium carbonate as seed crystal

ActiveCN109956490ASimple process equipmentMild reaction conditionsCalcium/strontium/barium carbonatesCalcium hydroxidePrill

The invention discloses a method for preparing flower-sphere-shaped light calcium carbonate by using ultra-fine ground heavy calcium carbonate as a seed crystal. The method comprises the following steps: adding the ultra-fine ground heavy calcium carbonate used as the seed crystal into calcium hydroxide concentrate slurry, performing mixing, introducing carbon dioxide, and performing a carbonization reaction to obtain the flower-sphere-shaped light calcium carbonate, wherein an addition amount of the ultra-fine ground heavy calcium carbonate is 0.5-2% of a mass of the flower-sphere-shaped light calcium carbonate. According to the method provided by the invention, the flower-sphere-shaped light calcium carbonate prepared by the method is grown and arranged in a radioactive spherical shape by using the ultra-fine ground heavy calcium carbonate seed crystal as a core, the structure makes the flower-sphere-shaped light calcium carbonate have high light scattering ability, and paper whiteness and opacity can be significantly improved; and in addition, due to the induction action of the seed crystal, the efficiency of carbonization is improved, covering of un-reacted calcium hydroxide isreduced, so that the flower-sphere-shaped light calcium carbonate has extremely-narrow particle size distribution, and the spherical particles give good rheological properties to the slurry.

Owner:DSSUN NEW MATERIAL SHANDONG

Preparation method for nano calcium carbonate special for low modulus silicone adhesive

ActiveCN107118590AGood compatibilityReduce reunionNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsCarbonizationSlurry

The invention discloses a preparation method for nano calcium carbonate special for low modulus silicone adhesive. The preparation method is implemented according to the following steps: 1) preparing Ca(OH)2 slurry; 2) carrying out carbonization; 3) adding a crystal form conditioning agent; 4) carrying out surface treatment; 5) adding a modulus conditioning agent; 6) carrying out filter pressing, drying and smashing on calcium carbonate boiled size in after the modulus conditioning agent is added to prepare the nano calcium carbonate special for the low modulus silicone adhesive, wherein the moisture of the nano calcium carbonate is less than or equal to 0.3%. The nano calcium carbonate prepared by the preparation method has good compatibility with polydimethylsiloxane, and cohesive energy is reduced after the nano calcium carbonate and the polydimethylsiloxane are mixed so as to achieve an effect of lowering silicone adhesive product modulus.

Owner:FUJIAN HONGFENG NANO TECH

Method for preparing cubic calcium carbonate from lime dust

InactiveCN108017079ASimple production processImprove carbonization efficiencyCalcium/strontium/barium carbonatesDispersityCalcium hydroxide

The invention discloses a method for preparing cubic calcium carbonate from lime dust. Calcium hydroxide emulsion is prepared from the lime dust and water in a certain ratio through a digestion reaction, multi-stage deslagging and aging are performed, refined calcium hydroxide emulsion is obtained, a crystal form controller is added, carbon dioxide is introduced simultaneously for a carbonizationreaction, calcium carbonate emulsion with certain concentration can be obtained, then dehydration, drying, crushing and packaging are performed on the calcium carbonate emulsion, and a cubic industrial precipitated calcium carbonate product is obtained finally. The problems that the process is complex, particle size of the product is non-uniform and the dispersity is poor when carbide slag and limestone are taken as raw materials for preparing calcium carbonate at present are solved.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

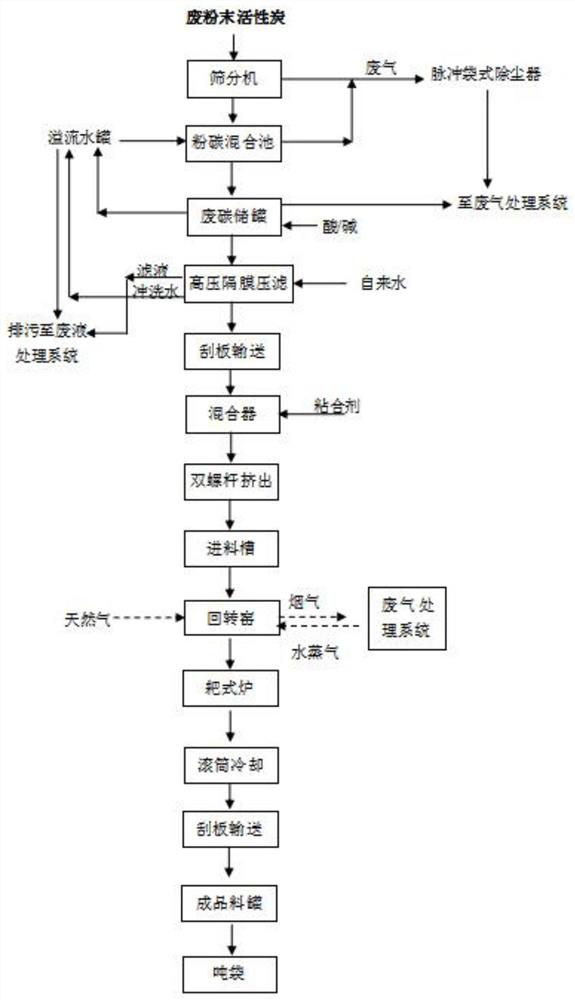

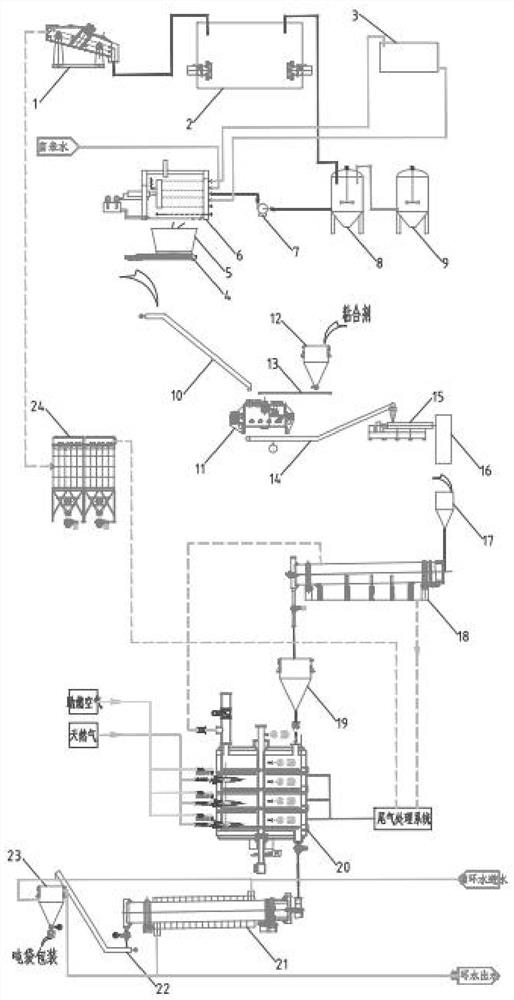

Regeneration system and regeneration method for waste activated carbon

PendingCN111889089AReduce lossLarge particle sizeCombustible gas purificationFilter regenerationEngineeringProcess engineering

The invention belongs to the technical field of activated carbon manufacturing and relates to a regeneration system and preparation method for waste activated carbon, especially to a regeneration system and regeneration method for waste activated carbon. The regeneration system for waste activated carbon comprises a waste activated carbon treatment unit, a mixing and granulating unit, a drying andcarbonizing unit and a finished product cooling unit which are mounted in sequence, wherein the waste activated carbon treatment unit is used for introducing waste activated carbon and screening, mixing, neutralizing and washing the waste activated carbon; an adhesive is added into a washed secondary raw material through the mixing and granulating unit, and extrusion is conducted to form semi-finished particles, and if a fed material is granular activated carbon, treatment via the mixing and granulating unit is not needed; the particles are subjected to drying, carbonizing and activating through the drying and carbonizing unit so as to form a high-temperature finished product; and the high-temperature finished product is cooled by the finished product cooling unit to form a finished product.

Owner:TIANJIN TISUN ITASCA TECH

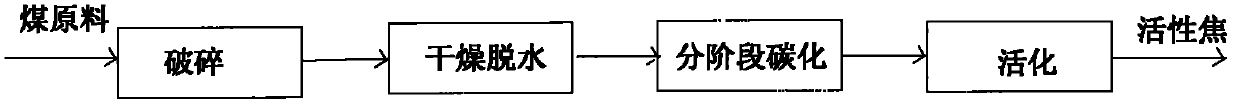

Preparation method of activated coke for water treatment

InactiveCN102001653AImprove adsorption capacityRelease fullyCarbon compoundsOther chemical processesBrown coalResidence time

The invention relates to a preparation method of an activated coke for water treatment, which comprises the following steps of: firstly, crushing coal materials until reaching proper particle diameters; then drying and dehydrating the crushed coal materials; then carrying out carbonizing treatment on a dried and dehydrated product in stages to obtain a carbonizing product, wherein the temperature in the first stage is 400-450 DEG C and the residence time is for 60-120min, the temperature in the second stage is 600-650 DEG C and the residence time is for 60-120min; and finally, carrying out activating treatment on the carbonizing product through an activating agent, and then reducing temperature to obtain the activated coke. The invention solves the technical problems that the volatilization of substances in the carbonizing product is not adequate and the large and medium pores can not be formed because the one-off carbonizing mode is utilized for the activated coke produced in the prior art, and the activated coke is not suitable for water treatment, reduces the production cost, and is a preparation method of the activated coke with excellent water treatment property for water treatment by using brown coal as the raw materials.

Owner:北京国能普华环保工程技术有限公司 +1

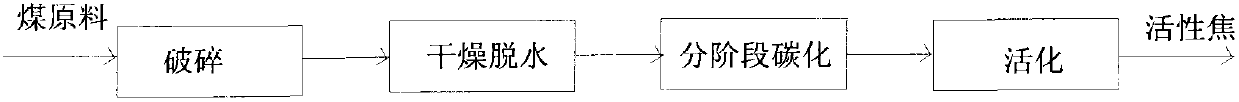

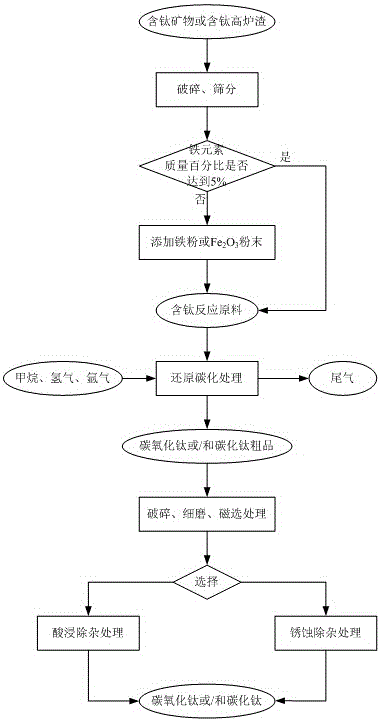

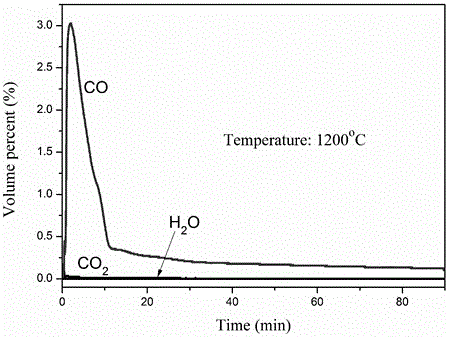

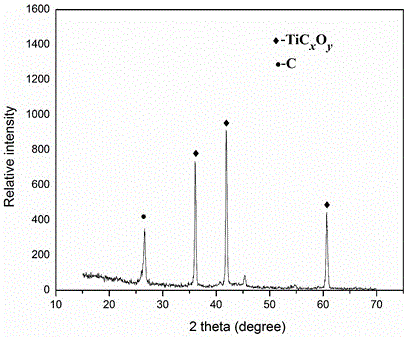

Method for preparing carbon-doped titanium oxide or/and titanium carbide from titanium-containing mineral or slag

InactiveCN106315584ALow costShort production processHydrogen separationTitanium carbideSlagReaction rate

The invention provides a method for preparing carbon-doped titanium oxide or / and titanium carbide from titanium-containing mineral or slag. According to the method, the cheap titanium-containing mineral or slag is adopted as a donor of the titanium element, and hydrogen and methane are selected to serve as a reducing agent and a carbonization agent respectively, so that raw material cost is saved; moreover, the processing only needs to reach the low temperature of 1,200-1,400 DEG C, meanwhile, reforming of methane is realized in the process of preparing carbon-doped titanium oxide or / and titanium carbide, hydrogen and carbon black are obtained through methane splitting, hydrogen and the titanium-containing material are subjected to a gas-solid reduction reaction, and reduction efficiency is high; meanwhile, the carbon black obtained through splitting greatly improves carbonization efficiency, carbonization temperature is low, the carbonization rate is high, energy consumption cost is saved, therefore, production cost is lowered, the production reaction rate is increased, the recovery rate of the titanium element in the raw material is raised, and the problems that in an existing carbon-doped titanium oxide and titanium carbide production process, preparation temperature is high, production efficiency is low, and cost is high are well solved.

Owner:CHONGQING UNIV

Straw carbonization furnace

The invention discloses a straw carbonization furnace. The straw carbonization furnace comprises a control box, a crushing bin, a discharging device, a carbonization furnace, a tar collecting bin, a machine frame, universal wheels and positioning support legs, wherein the control box is respectively control connected with a motor, a vibration motor and the carbonization furnace; a feeding hopper is arranged at the upper end of the right side of the crushing bin; the motor is arranged at the top of the crushing bin, an output end of the motor is connected to a rotating shaft in a driving manner, and a bearing is arranged between the outer wall of the crushing bin and the rotating shaft; and a fixed cutter disc and a rotating cutter disc are connected to the rotating shaft, wherein the fixedcutter disc is arranged below the rotating cutter disc, a plurality of fixed blades are arranged at the edge of the fixed cutter disc, rotating blades are arranged at the outside of the rotating cutter disc, the fixed blades and the rotating blades are arranged in a matching manner, and the fixed blades and the rotating blades are all arranged in a detachable connection manner. According to the straw carbonization furnace, the crushing efficiency is improved, the carbonization efficiency is improved, quality of the carbonization treatment is ensured, tar accumulation is avoided, environment pollution caused by smoke is avoided, and the straw carbonization furnace is easy to move.

Owner:JIANGSU MINHE MACHINERY MFG

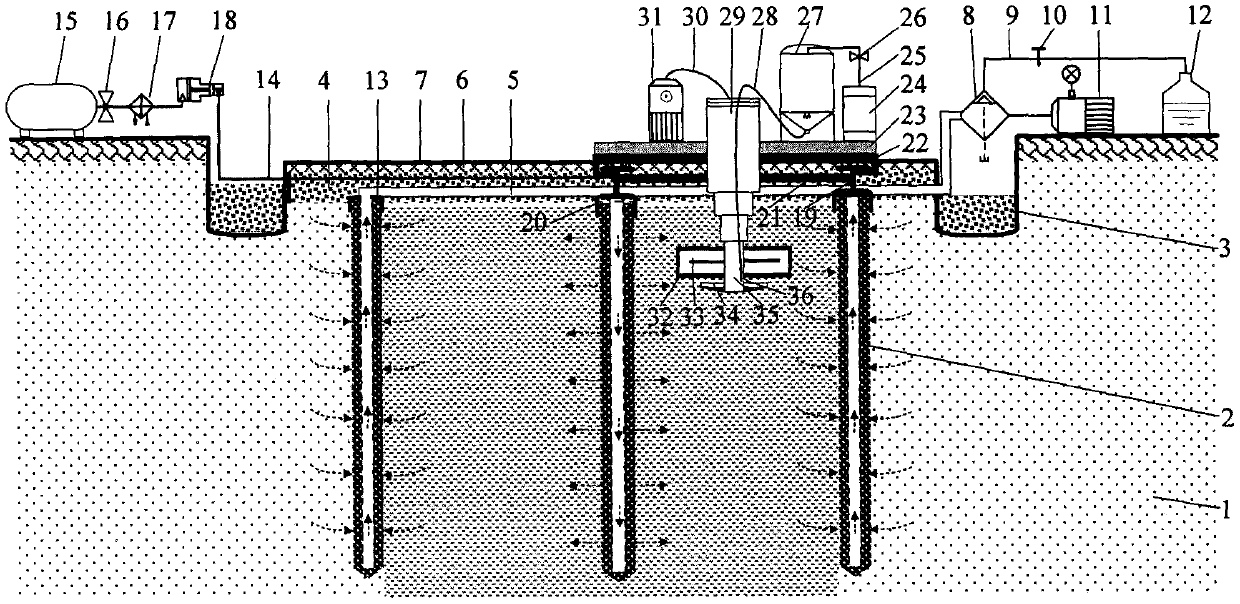

Reinforcing method of vacuum preloading lead pipe pile gas injection carbonized super-soft foundation

ActiveCN110512591AImprove compactionImprove displacement effectSoil preservationSites treatmentResource utilization

The invention discloses a reinforcing method of a vacuum preloading lead pipe pile gas injection carbonized super-soft foundation, and belongs to the technical field of super-soft foundation reinforcing treatment of geotechnical engineering. The reinforcing method comprises the steps of site treatment and exploration, first pile group construction and beating, spraying mixing equipment placement and debugging, curing agent spraying and mixing, first treatment system layout, vacuum preloading-gas injection carbonized treatment, first site treatment completing, continuous construction, final treatment and the like. The reinforcing method has the advantageous of a vacuum preloading method, a magnesium oxide carbonization curing method and a pipe pile composite foundation, the drainage efficiency and the infiltration diffusion efficiency of carbon dioxide are greatly improved through coordination work of vacuum preloading and pipe pile gas injection, the compacting displacement action of apipe pile on soft soil is fully utilized, mud soil is effectively glued through hydration products and carbonization products, thus the intensity of the soft soil composite foundation is enhanced, and the stability is improved. The reinforcing method has the characteristics that the treatment effect is good, the period is short, and low-carbon and environmentally-friendly and economic efficiencyare achieved, and resource utilization of industrial waste in soft foundation treatment is achieved.

Owner:NANJING FORESTRY UNIV

Carbonization reaction device and method for nano calcium carbonate production

ActiveCN104891545AAvoid backmixingGood for pulpingCalcium/strontium/barium carbonatesMaterial nanotechnologyRefluxCarbonization

The invention discloses a carbonization reaction device and a carbonization reaction method for nano calcium carbonate production. The carbonization reaction device comprises a Ca(OH)2 slurry feeding tube, a carbonization tower, a stirrer, an annular gas-liquid distributor, a CO2 gas inlet tube and an emulsion dispersing machine. The carbonization reaction method comprises the following steps: (1) feeding Ca(OH)2 slurry into a reflux area of the carbonization tower; (2) continuously feeding the Ca(IH)2 slurry into the emulsion dispersing machine to mix and react with a CO2 gas, and feeding the obtained product into the reaction area of the carbonization tower; (3) continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for carbonization and emulsion dispersion; (4) adding a dispersing agent, continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for secondary carbonization and emulsion dispersion; and (5) stopping introduction of CO2 for reaction and operation of the emulsion dispersing machine, thereby obtaining prepared nano calcium carbonate slurry. The carbonization reaction device and the carbonization reaction method for nano calcium carbonate production are rapid in carbonization reaction speed, high efficiency, good effect, small investment and low cost.

Owner:FUJIAN HONGFENG NANO TECH

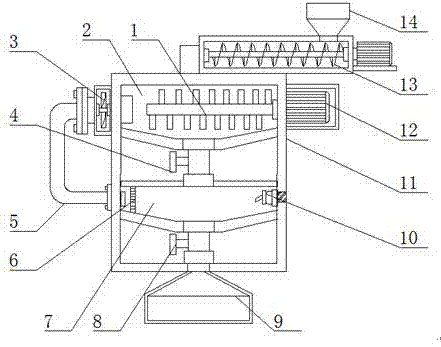

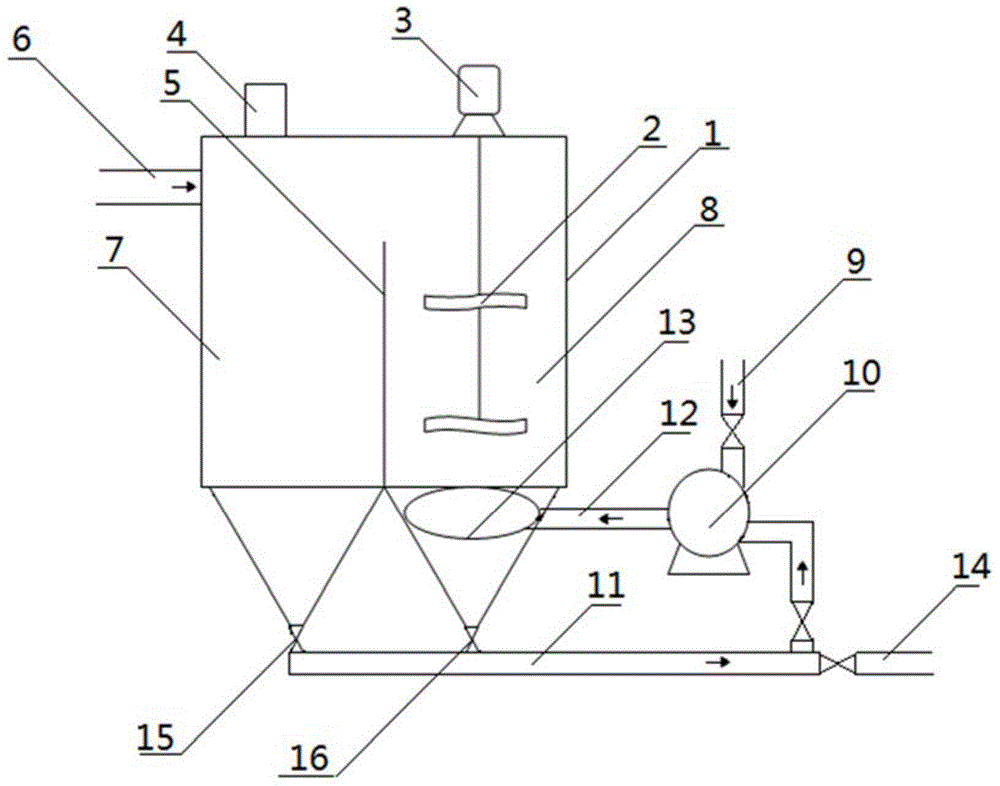

Carbonization device for preparing straw biochar organic fertilizer

InactiveCN110775954AImprove carbonization efficiencyImprove crushing efficiencyCuttersCarbon preparation/purificationAgricultural engineeringCarbonization

The invention relates to the technical field of straw carbonization, in particular to a carbonization device for preparing straw biochar organic fertilizer. The carbonization device comprises a carbonization furnace and microwave generator, wherein a feeding hopper and a first discharging pipe are arranged on the carbonization furnace, and the microwave generator is connected with the carbonization furnace through a microwave guide pipe; a crushing box is arranged on the upper side of the carbonization furnace, an adding hopper is arranged on the top wall of the crushing box, the bottom of thecrushing box is designed to incline, a discharging pipe is arranged at the bottom of the crushing box, and a crushing mechanism for crushing straw is arranged in the crushing box. According to the carbonization device for preparing straw biochar organic fertilizer, a first motor drives a first gear to rotate to drive a second gear and a third gear to rotate so as to drive a first rotating rod anda second rotating rod to rotate, and by cooperation of second crushing teeth and first crushing teeth, straw falling into the crushing box can be crushed; and crushed straw powder enters the carbonization furnace for microwave carbonization, and the carbonization efficiency is effectively improved.

Owner:SHANDONG JIELIER FERTILIZER CO LTD

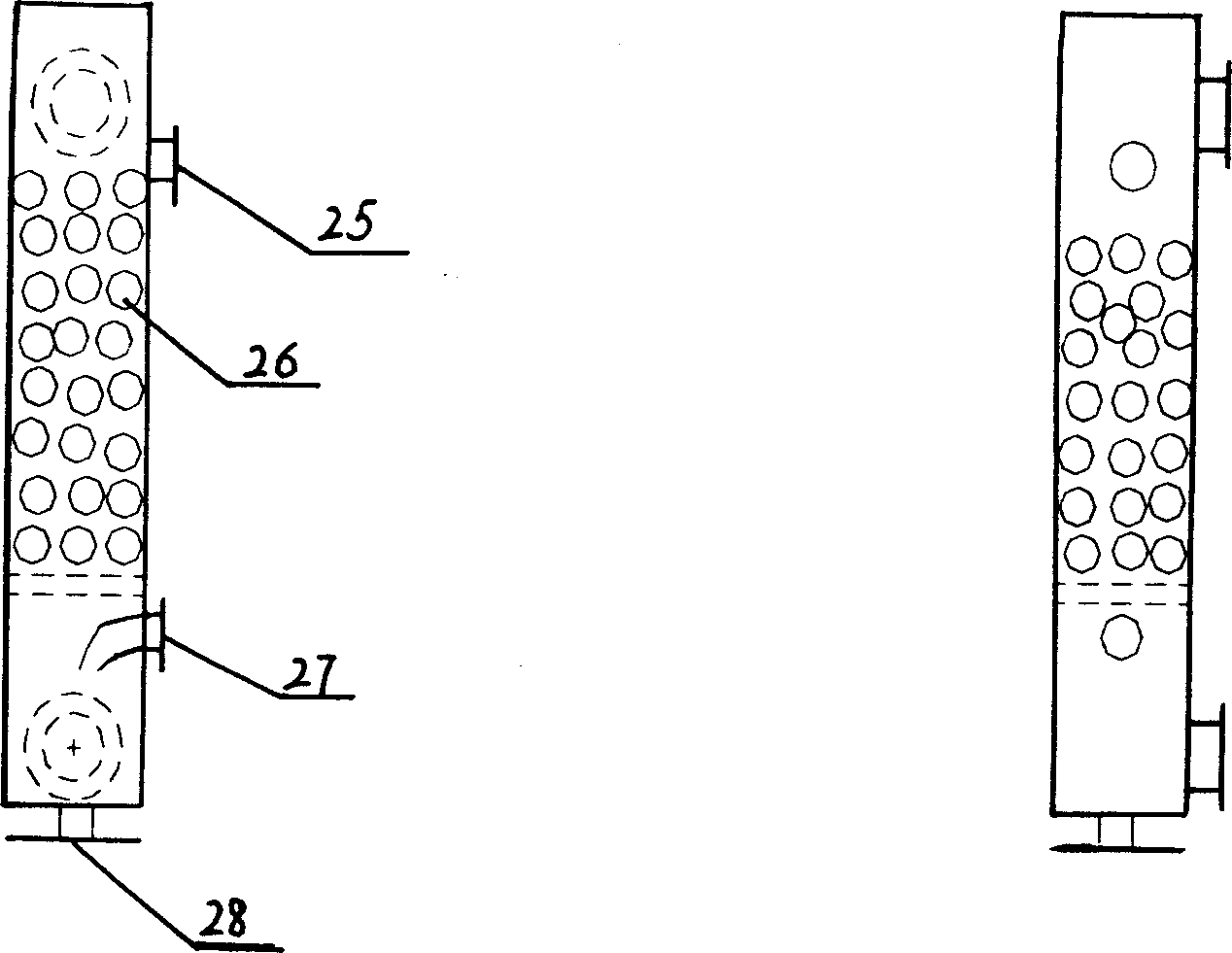

Biomass pyrolytic carbonization system feeding device

InactiveCN105713628AHigh purityImprove carbonization efficiencyBiofuelsSpecial form destructive distillationBiomassEngineering

The invention discloses a biomass pyrolytic carbonization system feeding device. The device comprises a raw material storage bin, a crushing device, an impurity removal device, a drying device and a PLC control system; the crushing device is arranged below the raw material storage bin; the impurity removal device is connected with the crushing device through a conveyor belt; the drying device is arranged below the impurity removal device; the crushing device comprises a crusher and a storage device; the storage device is arranged below the crusher; a collecting device is arranged below a vibration screen; the side of the vibration screen is provided with a conveying channel connected with the drying device; the drying device is connected with a carbonization machine through a transmission device; and the PLC control system is connected with the impurity removal device, the drying device and the transmission device. The feeding device provided by the invention is capable of improving product purity, reducing production time and improving production efficiency.

Owner:泰州瑞沣环保科技有限公司

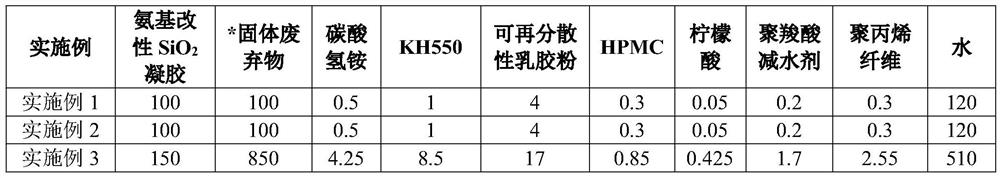

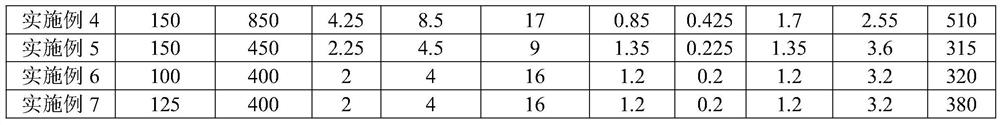

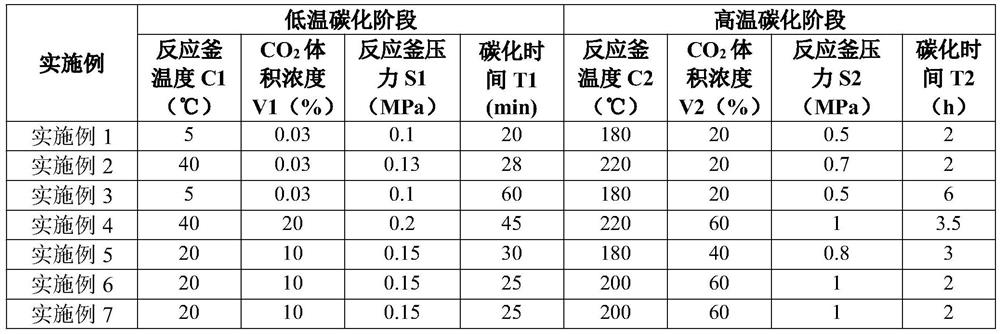

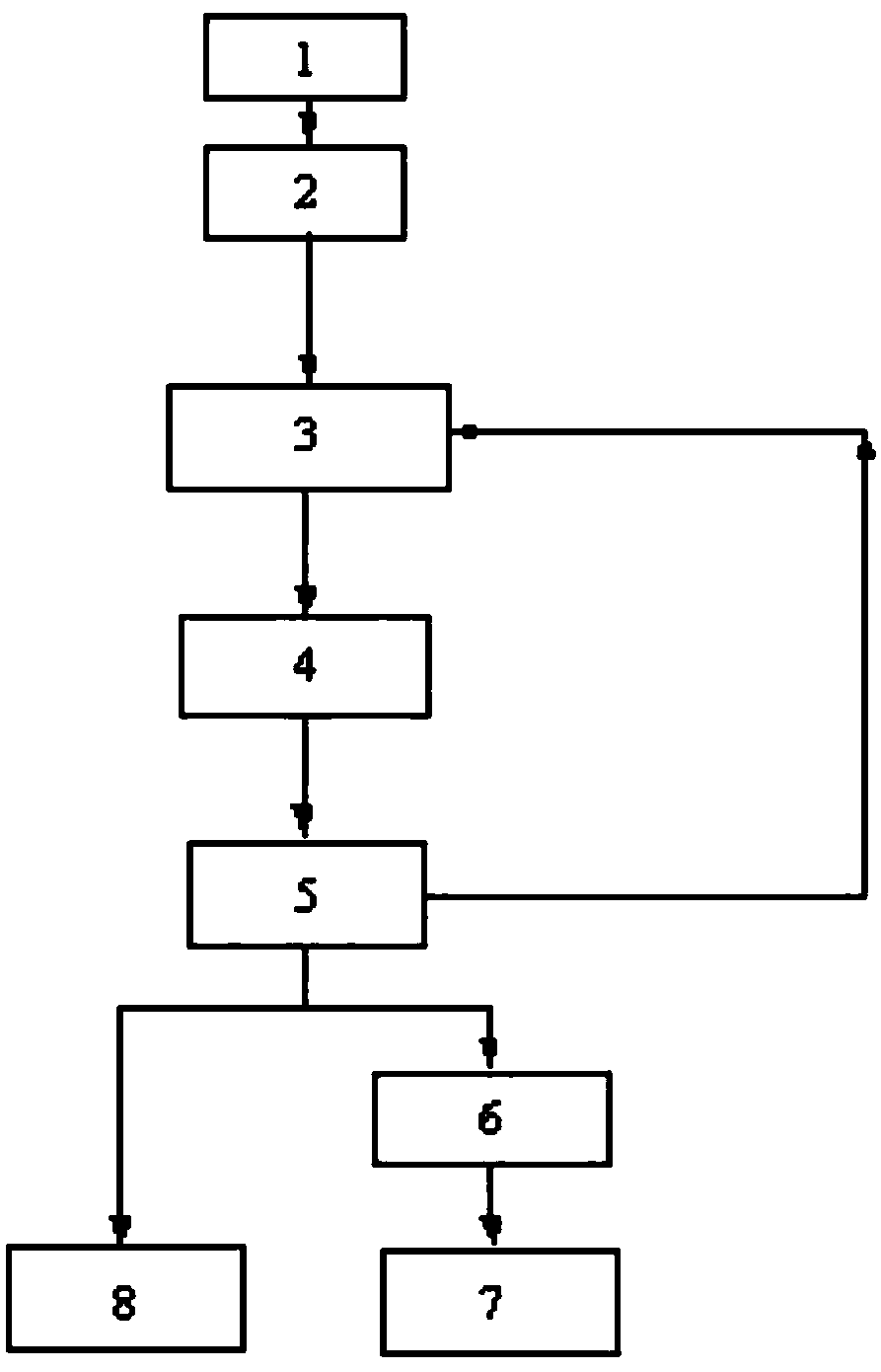

Thermal insulation building material prepared from amino modified SiO2 aerogel in cooperation with solid waste carbonization and method

The invention belongs to the field of building thermal insulation materials, and particularly relates to a thermal insulation building material prepared from amino-modified SiO2 aerogel in cooperationwith solid waste carbonization and a method. The material is prepared from amino-modified SiO2 aerogel, solid waste, a carbonization activator, a silane coupling agent, an organic binder, a thickener, a retarder, a water reducing agent, fibers and water, the raw materials are stirred evenly step by step, an obtained mixture is put into a mold to be formed, the mixture is placed in air at normal temperature and normal pressure for 24 hours, then the mold is removed, and a test piece is obtained. The test piece is put into a CO2 reaction kettle, and the thermal insulation building material is obtained by adopting a low-temperature carbonization curing mode and a high-temperature carbonization curing mode. The method is high in carbonization efficiency and large in solid waste utilization rate, and the prepared building thermal insulation material has a low heat conductivity coefficient and good thermal insulation performance, can be applied to the field of capture of industrial waste gas CO2 to cooperatively prepare thermal insulation building materials, and has the characteristic of green manufacturing of building materials.

Owner:SHANXI UNIV

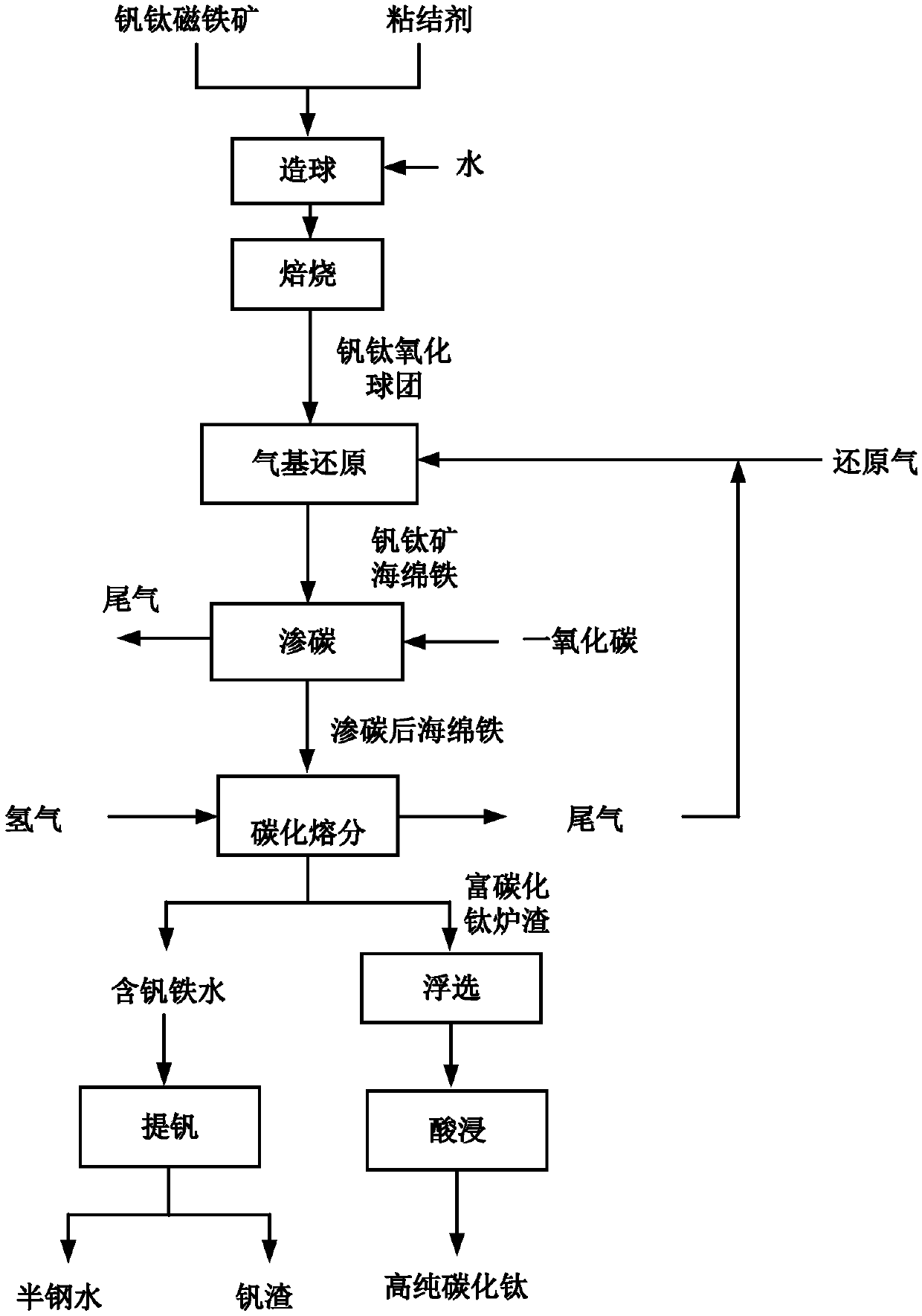

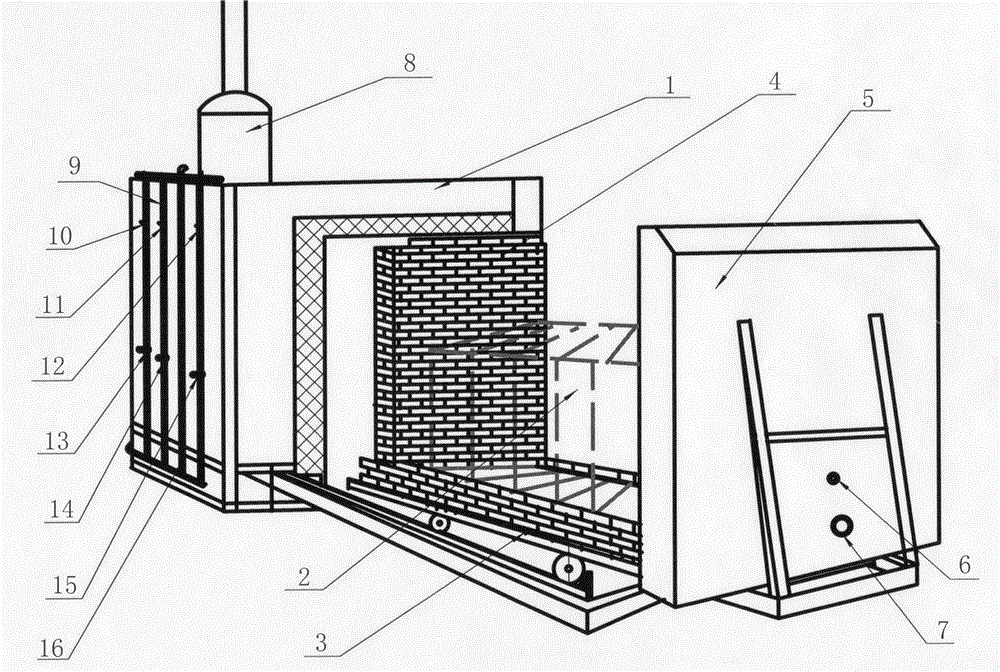

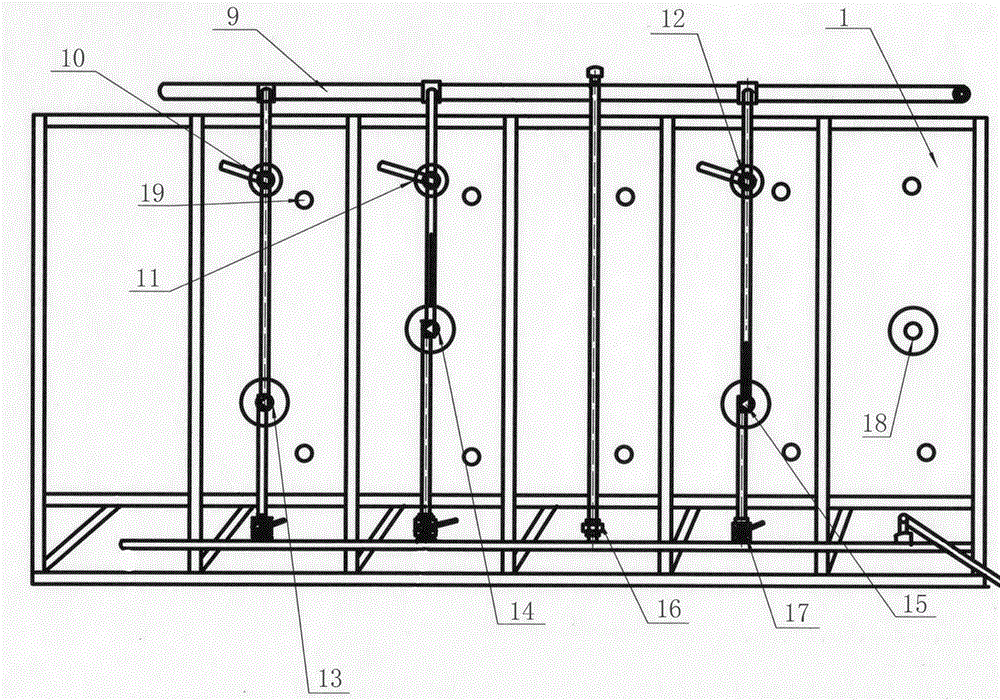

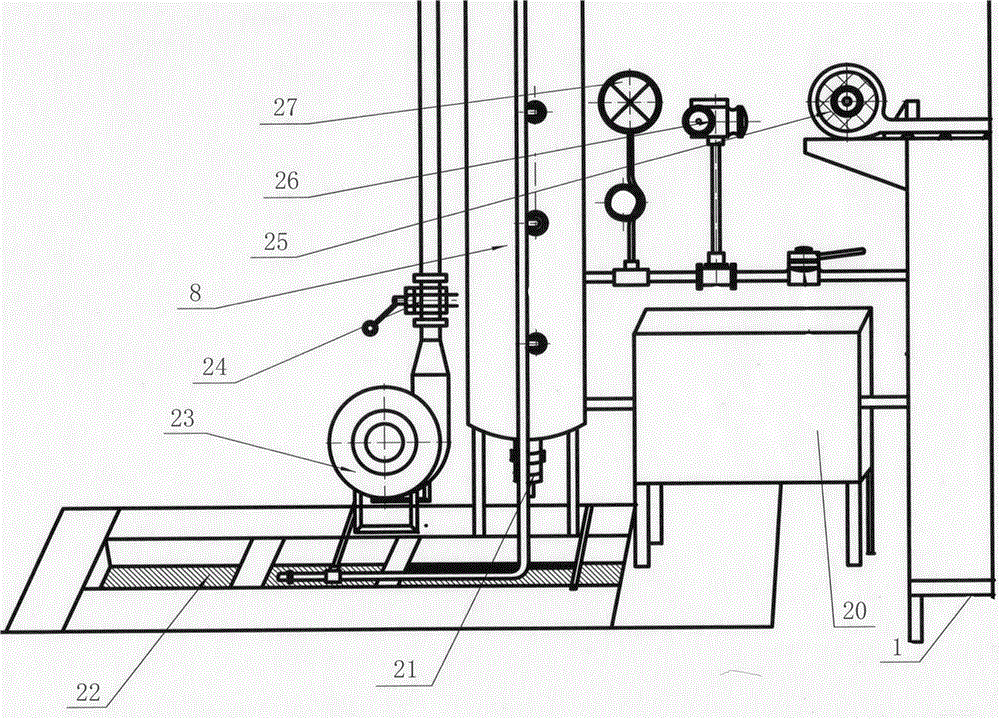

System and method for preparing titanium carbide from vanadium titano-magnetite comprehensively

PendingCN107653353AIncrease product valueEnvironmentally friendlyTitanium carbideShaft furnaceExhaust gasTitanium carbide

The invention relates to a system for comprehensively utilizing vanadium-titanium-magnetite to prepare titanium carbide, wherein the system includes a gas-based shaft furnace, a melting separator and a separation and purification system, and the gas-based shaft furnace includes an inlet of vanadium-titanium-magnetite oxidation pellets , reducing gas inlet and vanadium-titanium ore sponge iron outlet, melting separator includes vanadium-titanium ore sponge iron inlet, hydrogen inlet, tail gas outlet, vanadium-containing molten iron outlet and titanium carbide-rich slag outlet, and the separation and purification system includes titanium carbide-rich slag inlet And the titanium carbide outlet, the vanadium-titanium ore sponge iron outlet of the gas-based shaft furnace is connected to the vanadium-titanium ore sponge iron inlet of the melter, the tail gas outlet of the melter is connected to the reducing gas inlet of the gas-based shaft furnace, and the carbonization of the melter The titanium carbide slag outlet is connected to the titanium carbide-rich slag inlet of the separation and purification system. The invention also relates to a method of producing titanium carbide using the system. The system adopts the short-process smelting process of vanadium-titanium magnetite gas-based direct reduction-melting separation, which can make full use of TiO2 in the slag, and the obtained products have high value and are environmentally friendly.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Device and method for carbonizing straw

ActiveCN102863975AHigh carbonization rateEmission reductionBiofuelsSpecial form destructive distillationTunnel kilnEngineering

The invention relates to a device and a method for carbonizing straw. The device comprises a tunnel kiln type carbonizing furnace body, a heating unit, a smoke dust collecting treatment unit, sintering material boxes and a rail type material carrying cart, wherein the sintering material boxes are arranged in the rail type material carrying cart; the heating unit comprises flame guns, a gas pipeline and a combustion-supporting gas pipeline which are arranged in a hearth; straw devices are arranged in the sintering material boxes in the material carrying cart and are moved to the carbonizing furnace body; after the carbonizing furnace body is closed, gas and combustion-supporting gas are supplied to the flame guns by the gas pipeline and the combustion-supporting gas pipeline in the heating unit, and the flame guns spray flame to heat the hearth; and after the temperature of the hearth is raised to 480 to 550 DEG C and is kept for 5 to 8 hours, the hearth is cooled. According to the carbonizing device, biological straw resources are utilized, and the carbonizing device has the advantages of high carbonizing ratio, low carbon discharge amount, full utilization of resources, high carbonizing efficiency, low energy consumption and the like; and the method for carbonizing the straw is simple in process and environment-friendly and is suitable for large-scale production.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Continuous carbonization apparatus and method

InactiveCN1605797ARapid continuous carbonizationImprove carbonization efficiencyIncinerator apparatusTunnel kilnCarbonization

The present invention provides one kind one continuous carbonizing method and apparatus. The method can treat great amount of matter without generating offensive odor, and has raised carbonizing efficiency, reduced fuel consumption and lowered cost. The continuous carbonizing apparatus includes long horizontal tunnel kiln comprising preparing zone, pre-heating zone, carbonizing zone, cooling zone and conveying zone successively; and re-burning deodorizing furnace performing heat treatment to gas exhausted from the tunnel kiln. The full carbonizing process from loading the matter to be carbonized into the storing boxes to discharging the carbonized matter is completed in the tunnel kiln.

Owner:C Y C +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com