Patents

Literature

112 results about "Cohesive energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cohesive energy is the energy gained by arranging the atoms in a crystalline state, as compared with the gas state. Insulators and semiconductors have large cohesive energies; these solids are bound together strongly and have good mechanical strength. Metals with electrons in sp -bonds have very….

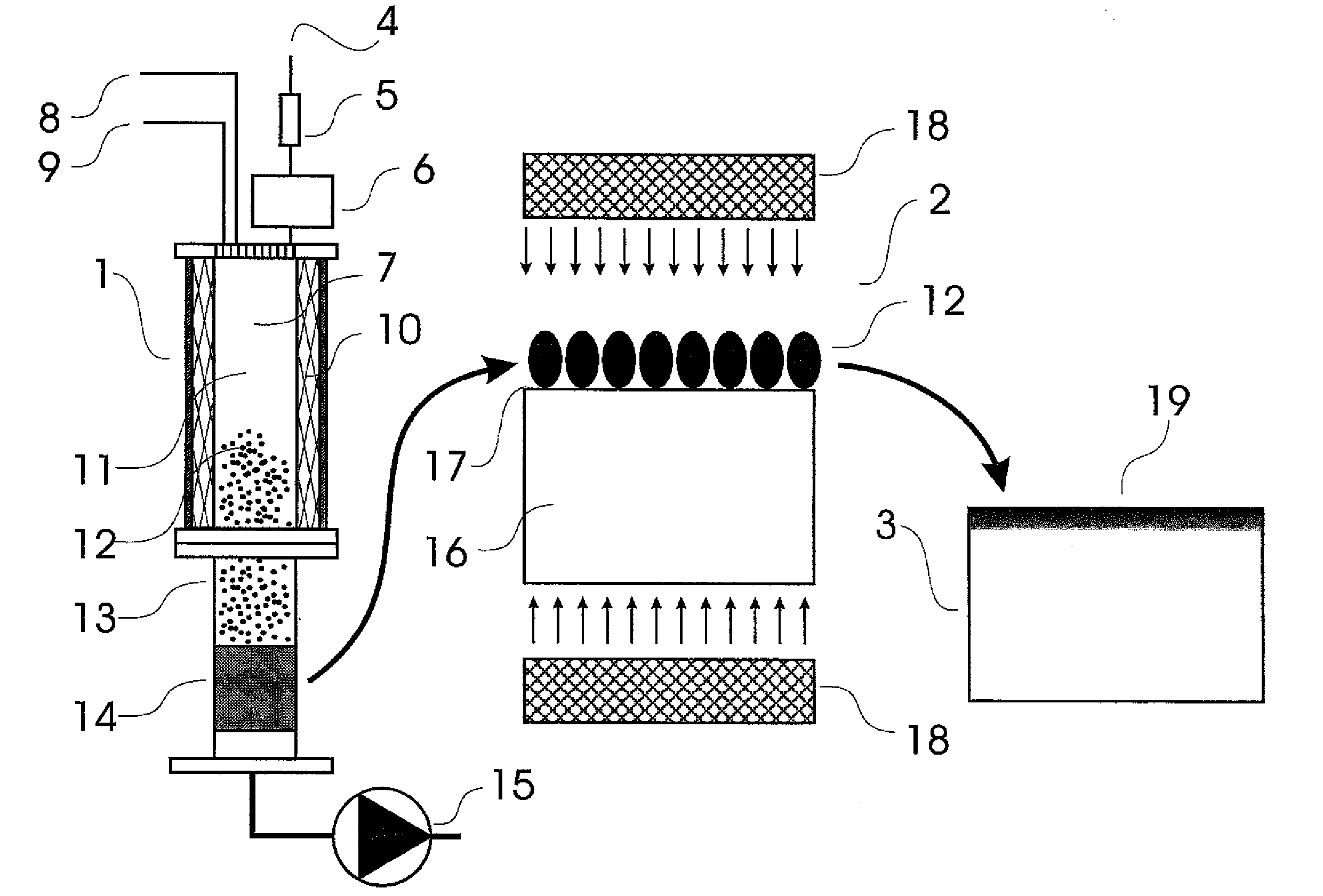

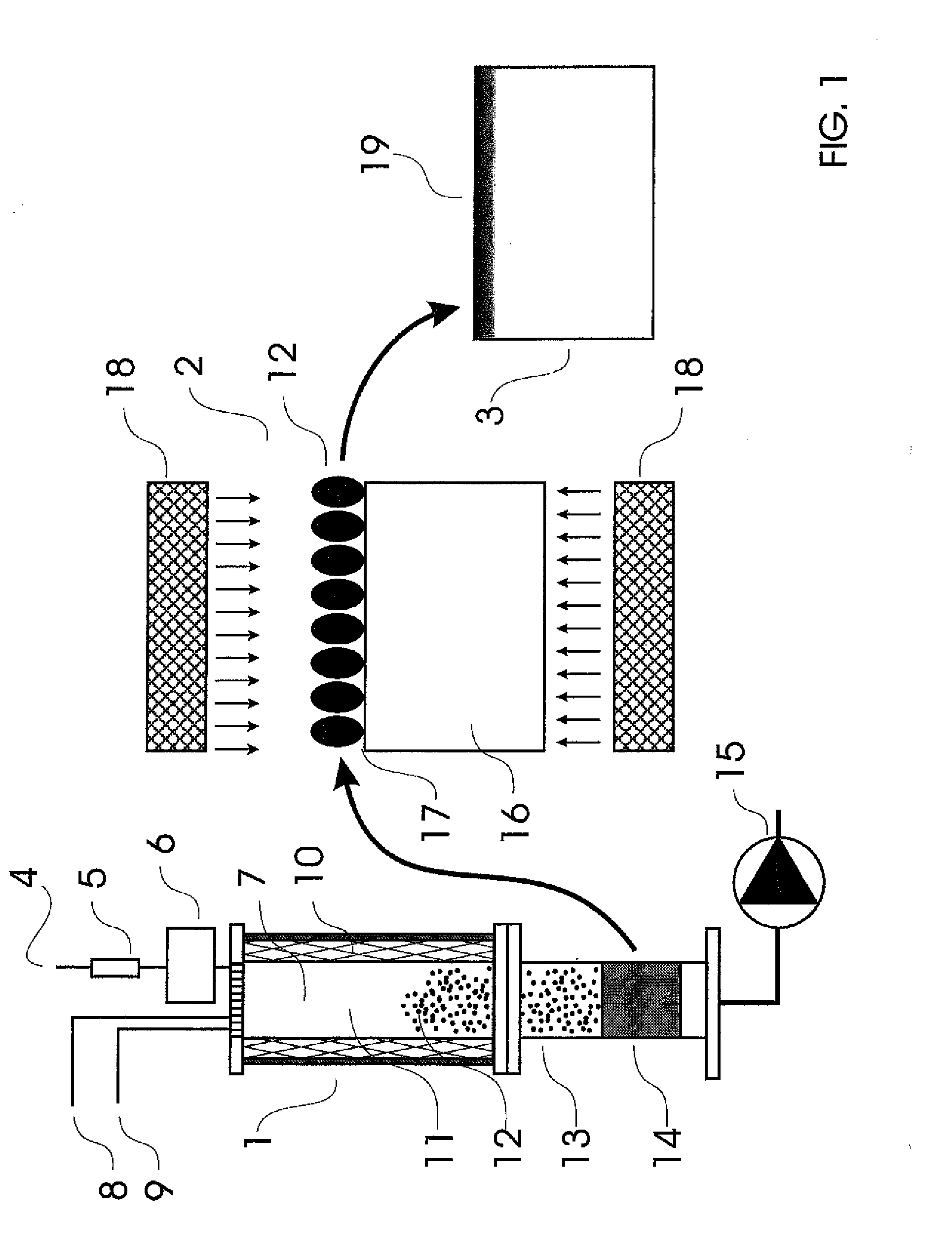

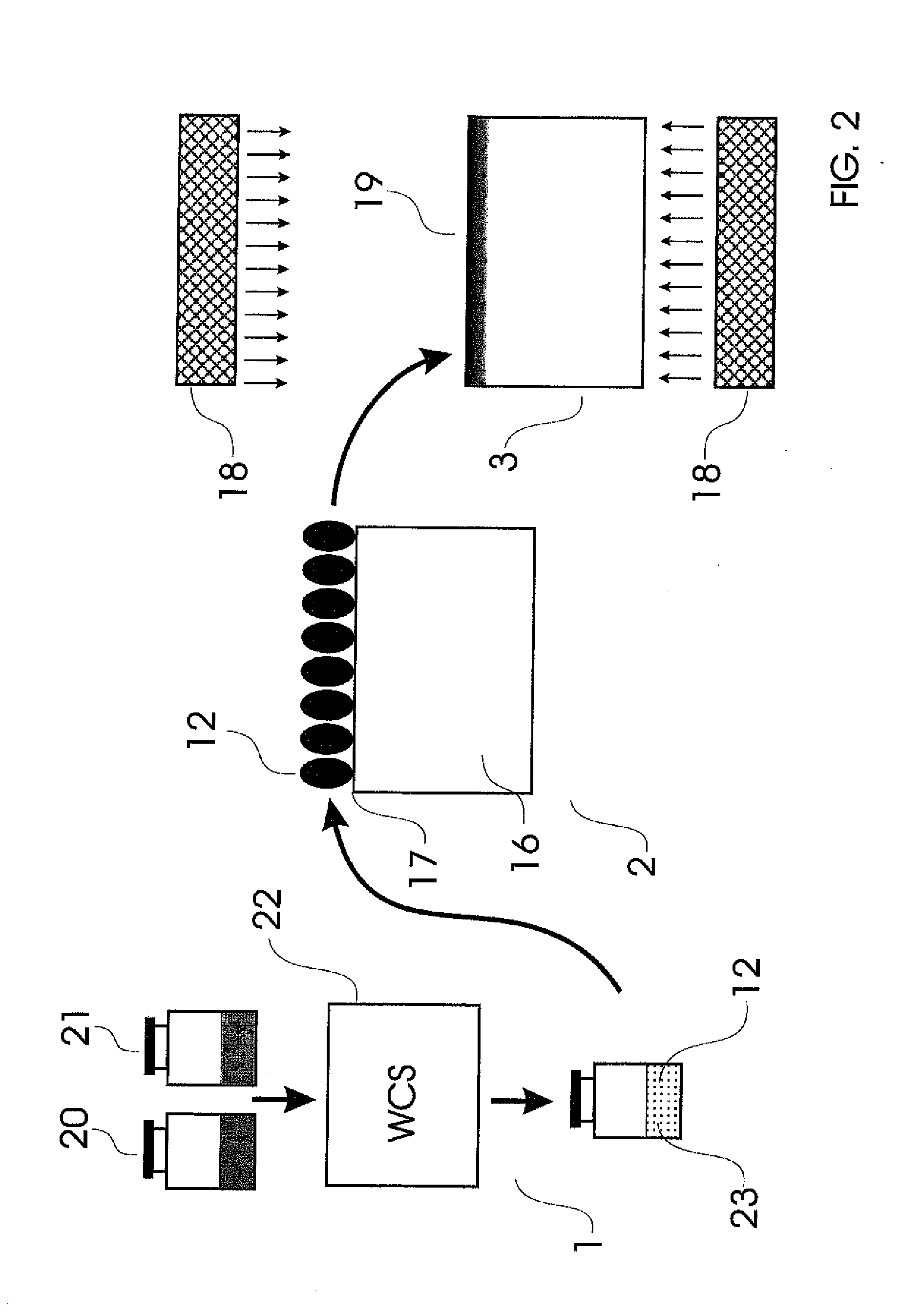

Method for producing functional glass surfaces by changing the composition of the original surface

InactiveUS20090104369A1Change the functionality of glassSpecial surfacesCoatingsNanometreMaterials science

A method for modifying glassy surfaces including: producing nanoparticles; depositing the said nanoparticles on a surface; providing energy to the particles and / or surface so that the nanoparticles are at least partly diffused / dissolved into the glassy surface; and reducing the cohesive energy of the nanoparticles during the production of the nanoparticles or after the production of the nanoparticles.

Owner:BENEQ OY

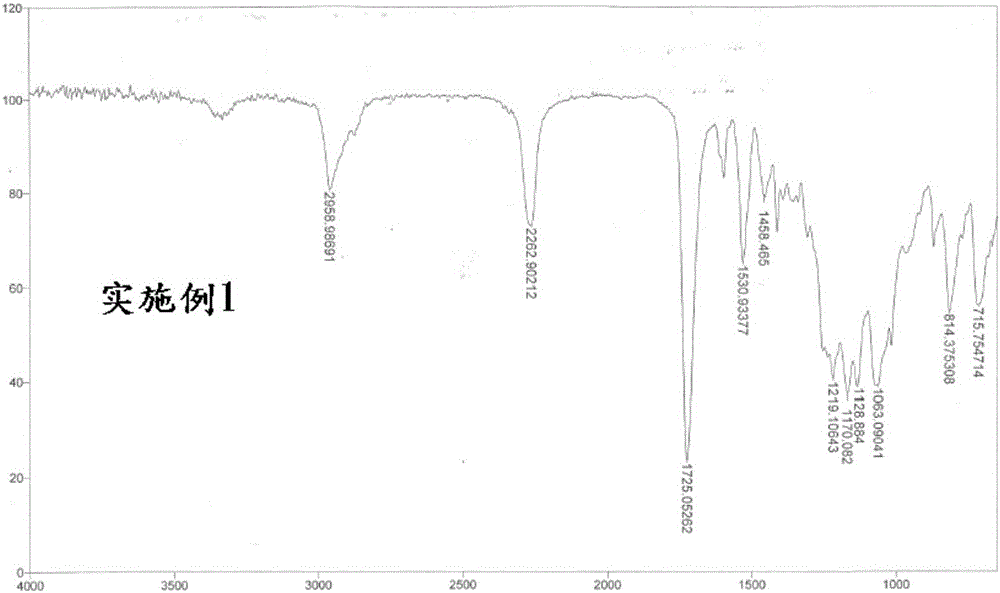

Preparation method of waterborne resin and water-based paint composite

ActiveCN102020759AImprove water resistanceImprove wear resistancePolyurea/polyurethane coatingsWater basedPolyester

The invention discloses a preparation method of waterborne resin and a water-based paint composite. The waterborne resin prepared with the preparation method of the invention contains various functional groups, such as a polyester group, a polypropylene resin group, an organic siloxane group, a polyurethane group and the like, and is acrylic ester graft modified polyester-type polyurethane water dispersion containing siloxane structure, and the siloxane structure can be hydrolyzed to form inorganic-organic crosslinking structure so as to improve the water resistance and the abrasive resistance of waterborne resin. The acrylic acid functional group structure improves the gloss and the weather fastness of a paint film; meanwhile, the polyester-type polyurethane structure ensures high hardness of the paint film because of larger cohesive energy. The water-based paint composite takes the waterborne resin as the main material for forming films, does not contain toxic and harmful substances of toluene and dimethylbenzene, has excellent gloss, good abrasive resistance, and excellent waterproof property and anti-ageing property and is an environmentally-friendly water-based paint with excellent comprehensive performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

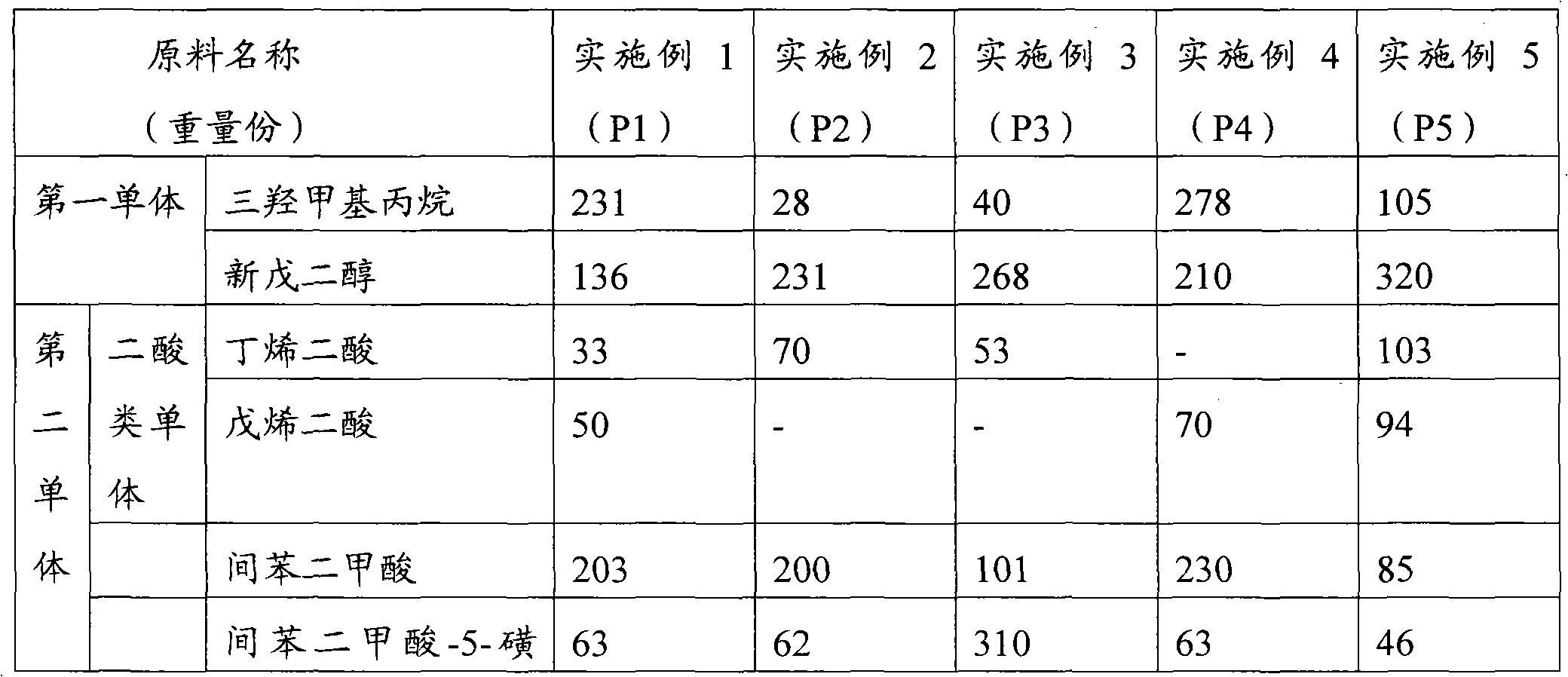

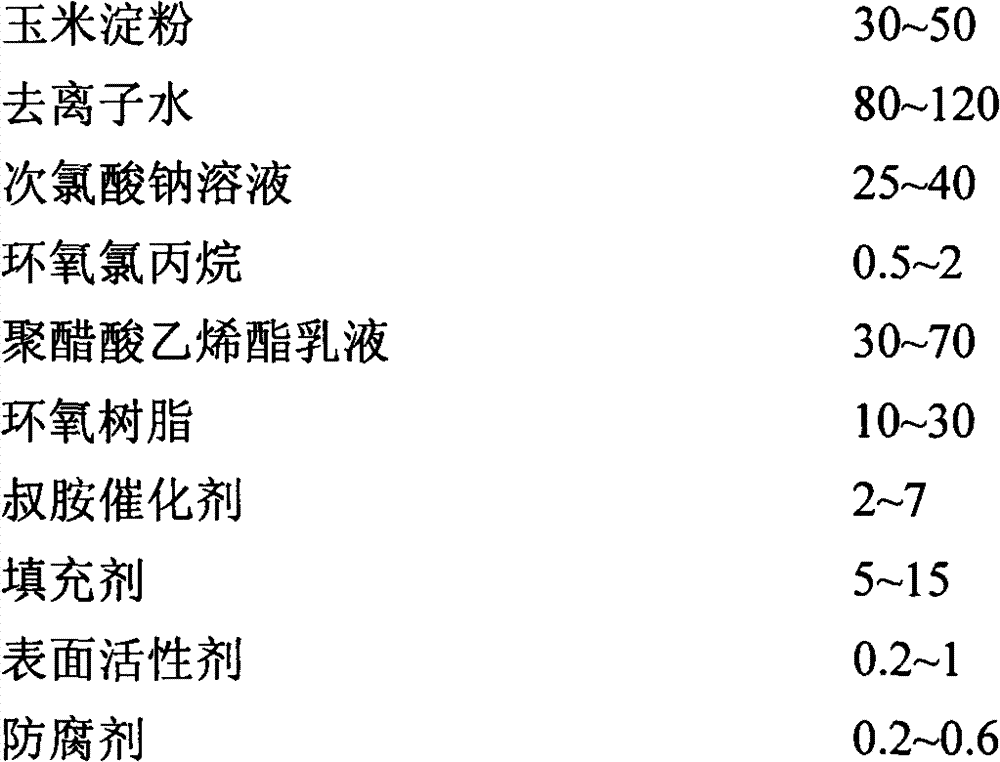

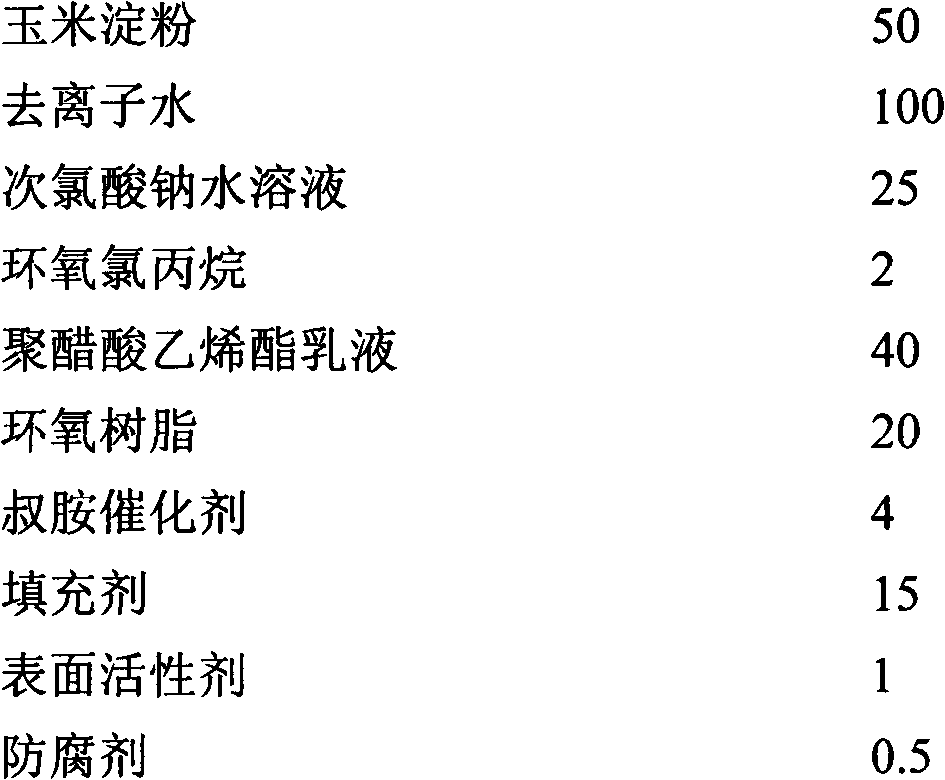

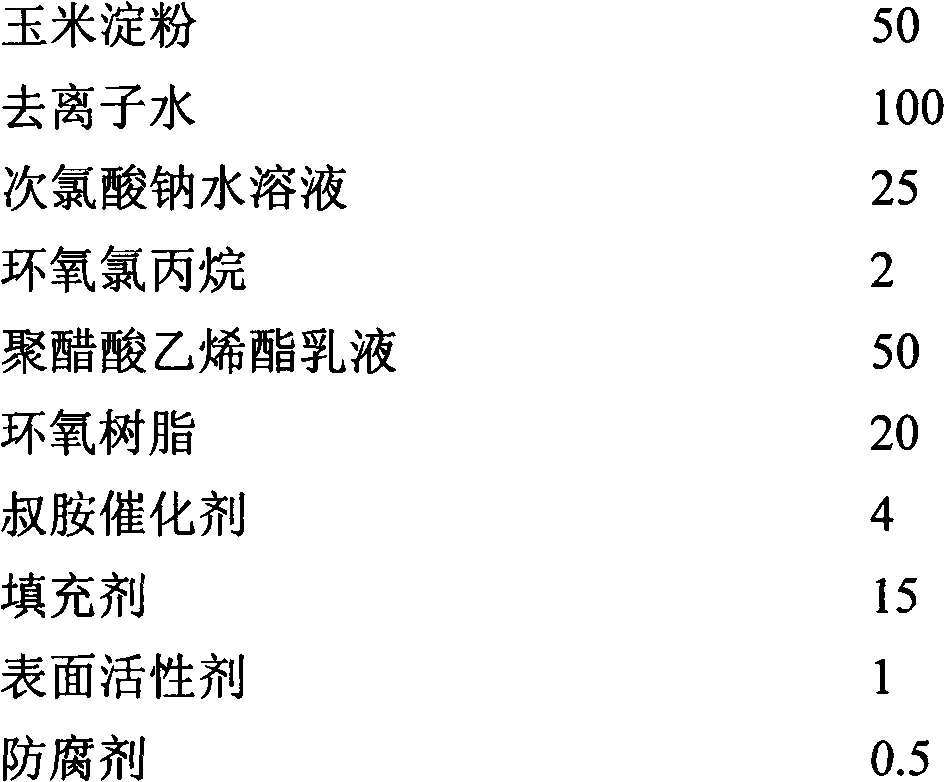

Modified starch adhesive and method for preparing same

InactiveCN102732186AGood compatibilityRaw materials are cheap and easy to getMonocarboxylic acid ester polymer adhesivesStarch derivtive adhesivesEpoxyAdhesive

The invention discloses a modified starch adhesive and a method for preparing the same. The modified starch adhesive comprises the following components by weight: 30-50 parts of corn starch, 80-120 parts of deionized water, 25-40 parts of sodium hypochlorite solution, 0.5-2 parts of epichlorohydrin, 30-70 parts of polyvinyl acetate emulsion, 10-30 parts of epoxy resin, 2-7 parts of tertiary amine catalyst, 5-15 parts of filler, 0.2-1 part of surfactant, and 0.2-0.6 part of preservative, wherein the sodium hypochlorite solution serves as the oxidant, the polyvinyl acetate emulsion serves as the high-cohesive-energy reinforcement component, and the epoxy resin servers as the water-tolerant modified component. The method for preparing the modified starch adhesive comprises the following steps: mixing the oxidized starch emulsion prepared in advance, the polyvinyl acetate emulsion and the epoxy resin according to proportion uniformly, adding the catalyst, the filler and the preservative, and stirring quickly and uniformly. The modified starch adhesive disclosed by the invention has the advantages of high shear strength, high water-tolerant shear strength, moderate viscosity, good liquidity, moderate primary drying time, low cost and excellent integrated performance.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing melt spun chlorine-resistance high resilient polyurethane fiber

InactiveCN102011211AIncrease elasticityGuaranteed physical propertiesFilament/thread formingArtificial filament heat treatmentFiberCross-link

The invention discloses a method for preparing melt spun chlorine-resistance high resilient polyurethane fiber, comprising the following steps: 1) a thermoplastic polyurethane slice is prepared by a one-step method; 2) the slice is uniformly mixed with chlorine-resistance cross-linking agent; 3) melt extrusion is carried out; 4) spinning moulding is carried out; and 5) post curing is carried out. By utilizing the invention, the requirement on higher chlorine resistance and resilience in special fields is met, combination of the chlorine-resistance cross-linking agent and polyurethane fiber is good, and the physical performance of fiber can be effectively maintained when being used in a chlorine-containing environment; and besides, diamine is adopted as chain extension agent, the hard section of the formed polyurethane urea has higher cohesive energy, three-dimensional hydrogen bonds can be formed, and the microphase separation degree is improved, thus improving the resilience of fiber.

Owner:奥斯汀新材料(张家港)有限公司

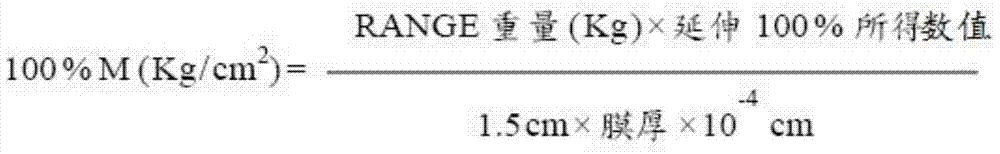

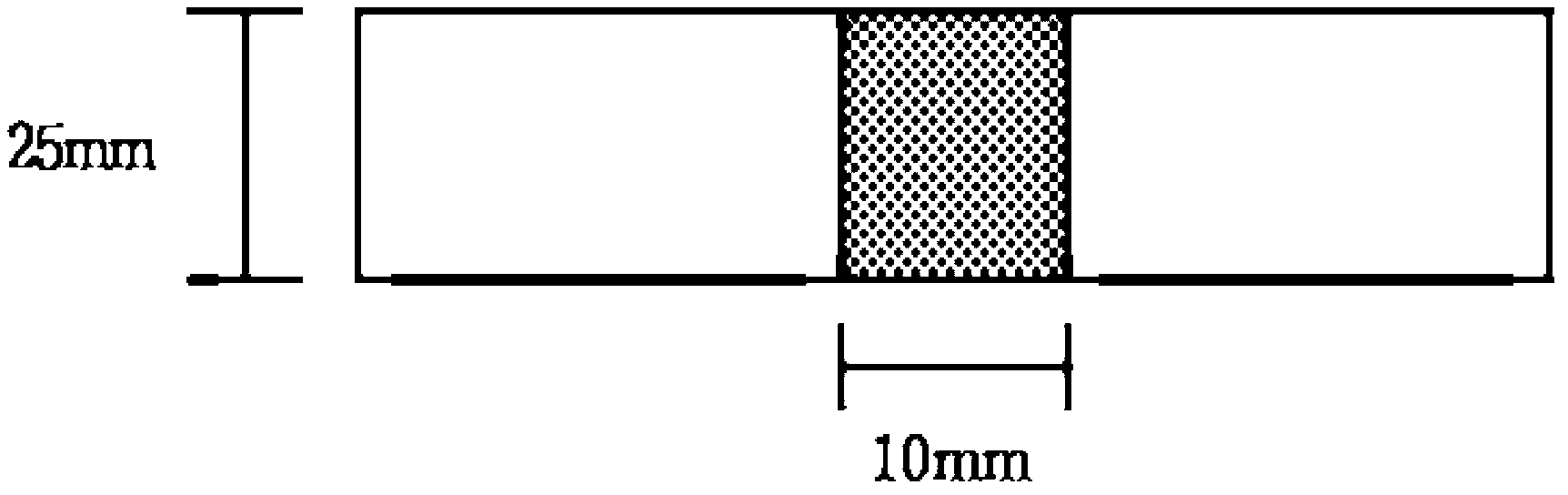

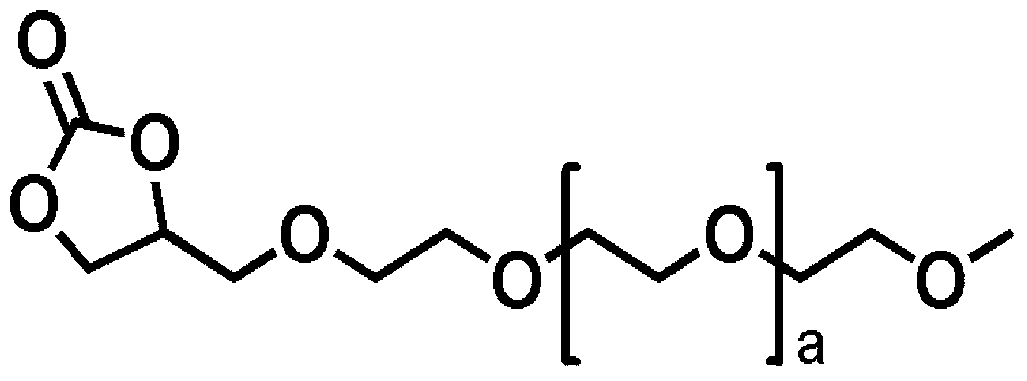

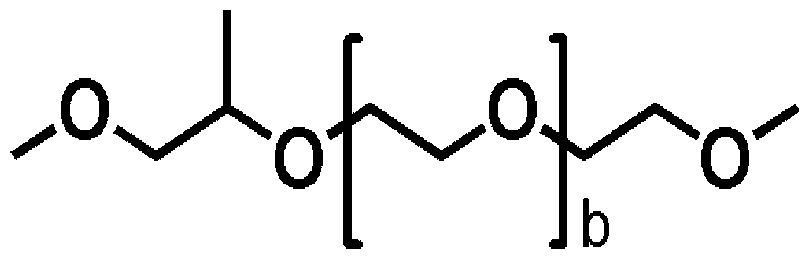

Wet-type high cracking resistance, high wear resistance and high peel strength polyurethane resin and preparation thereof

The invention discloses a wet polyurethane resin with high flexing resistance, high wear resistance and high peeling strength, and a preparation method thereof. During a synthetic process of the polyurethane (PU) resin, proper soft polyurethane segment and hard polyurethane segment materials and a brand-new synthesis process route by quasi prepolymerization are selected to prepare the wet polyurethane resin based on fully considering effect of separate soft and hard segment structure, crystallinity and intermolecular cohesive energy density distribution of the PU resin on aggregation structure relationship formed by coagulation of PU resin solution in dimethylformamide (DMF) aqueous solution. The wet PU resin with high flexing resistance, high wear resistance and high peeling strength fully solves the defect that the existing common PU resin can not reach three performance indexes which are high flexing, high wear resistance, high peeling strength at the same time. Synthetic leather made from the wet PU resin with high flexing resistance, high wear resistance and high peeling strength can meet three performance indexes of high flexing resistance, high wear resistance, high peeling strength at the same time, and can greatly improve durability of shoes products.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

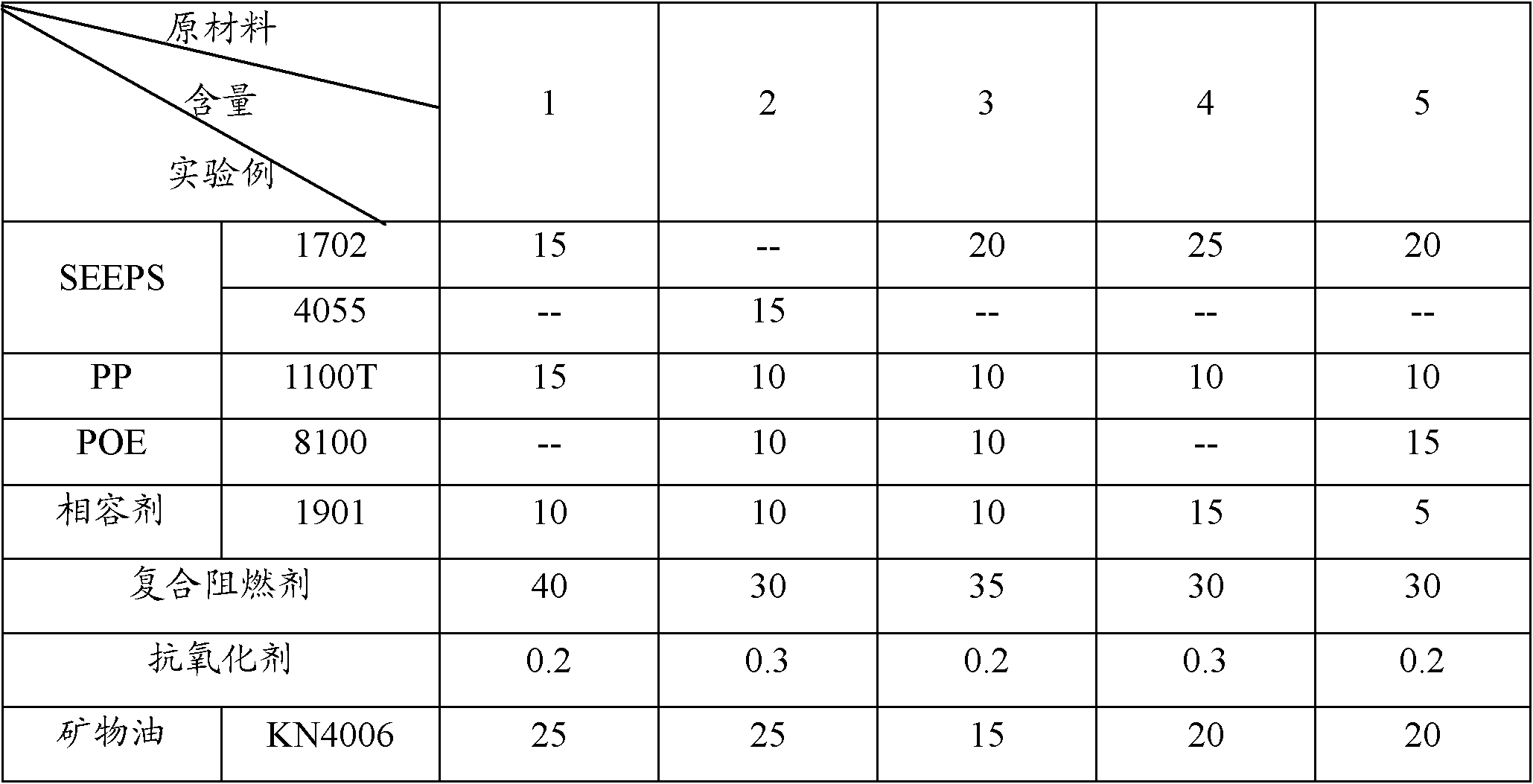

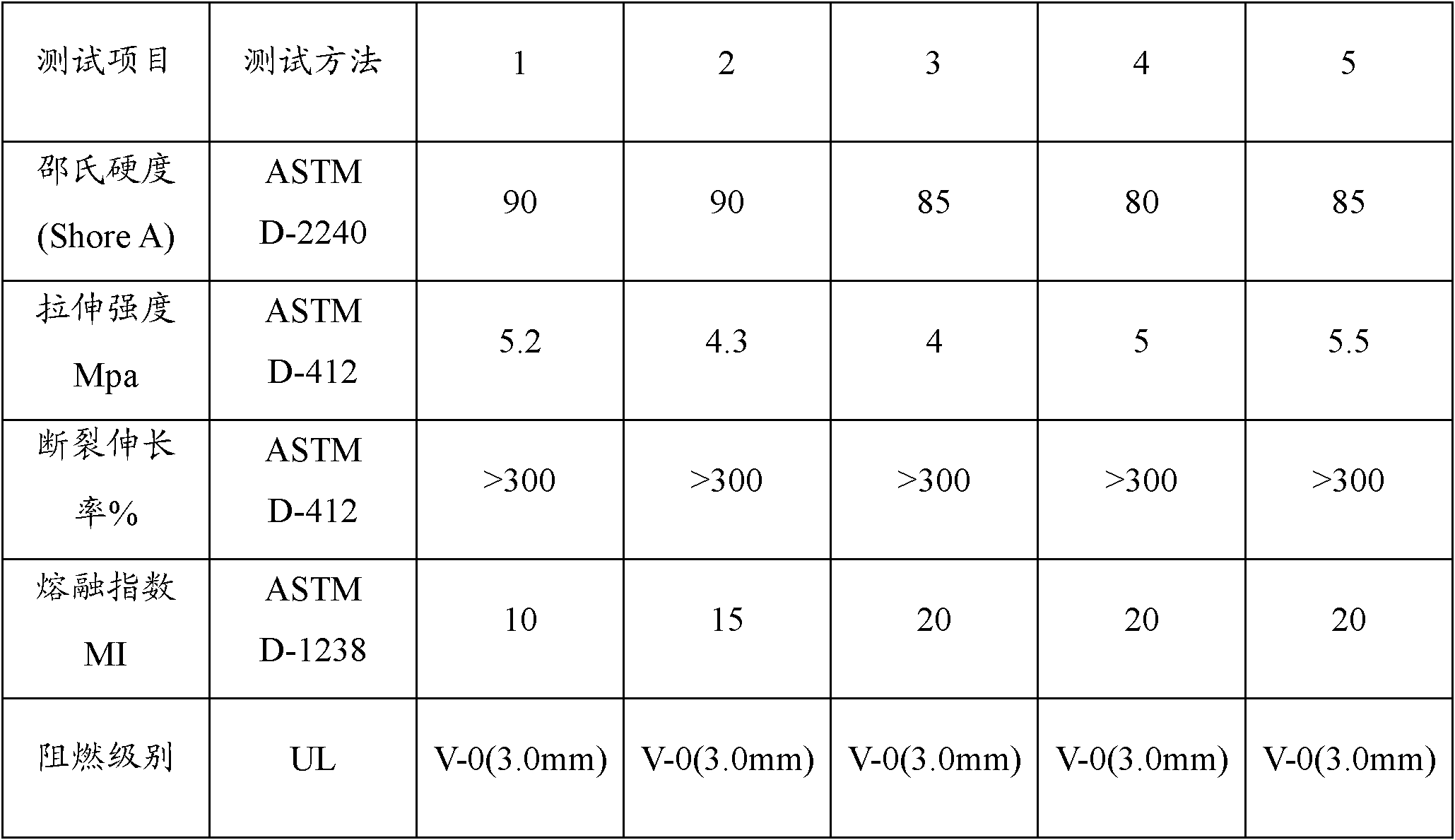

Halogen-free fire-retardant thermoplastic elastomer material and preparation method thereof

The invention provides a halogen-free fire-retardant thermoplastic elastomer and a preparation method thereof. The halogen-free fire-retardant thermoplastic elastomer material comprises the following raw materials in part by weight: 15 to 25 parts of styrene-ethylene-ethylene / propylene-styrene (SEEPS), 10 to 20 parts of polypropylene, 10 to 15 parts of polyolefin elastomer (POE), 30 to 40 parts of halogen-free fire retardant, 10 to 15 parts of compatilizer, 0.1 to 0.3 part of antioxidant and 15 to 25 parts of mineral oil. The SEEPS with larger cohesive energy is taken as a modification base material and is matched with low-hardness polypropylene and the compatilizer, the halogen-free fire-retardant thermoplastic elastomer material is low in hardness, is high in elastic resilience, tensile strength and elongation at break, and has a smooth surface.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

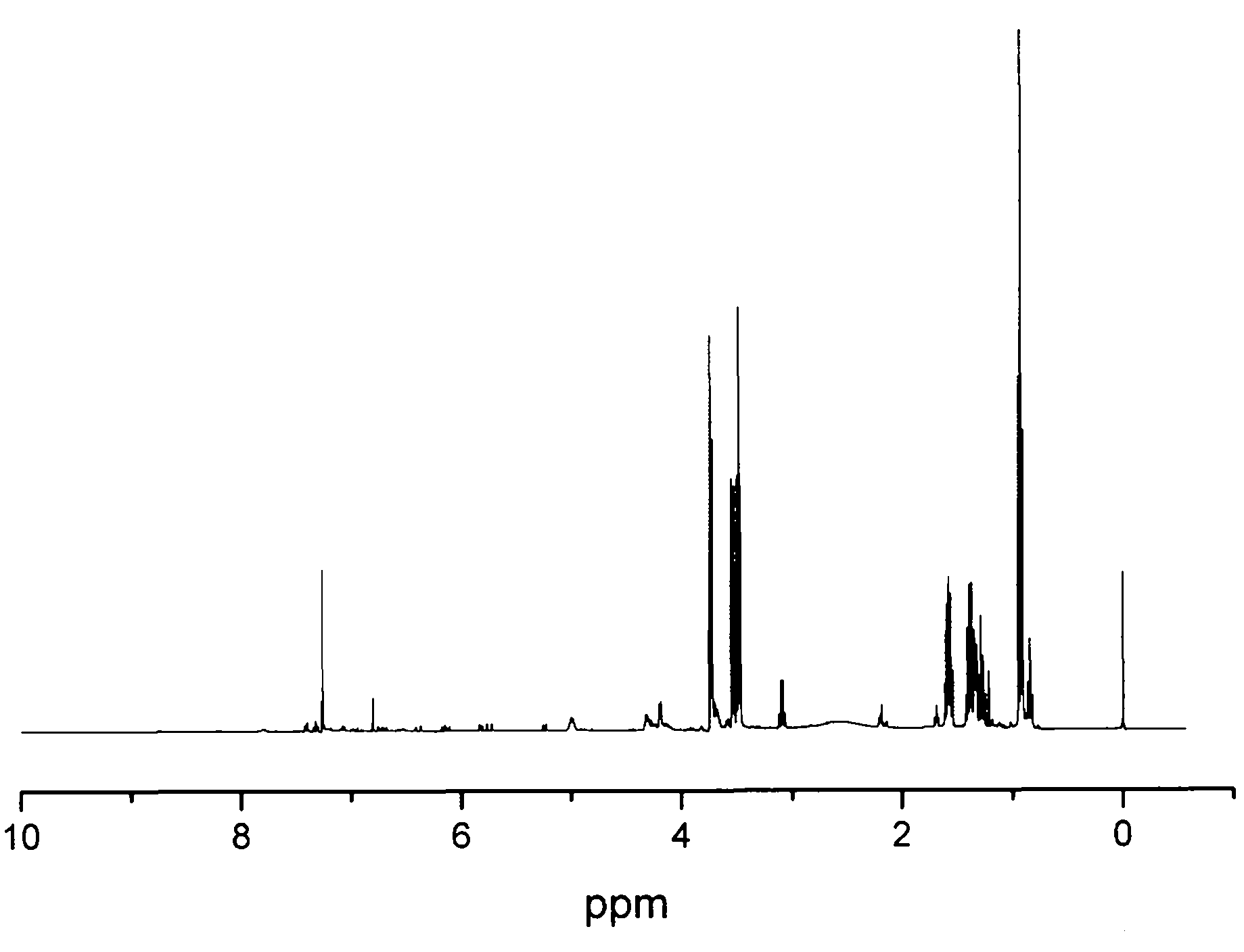

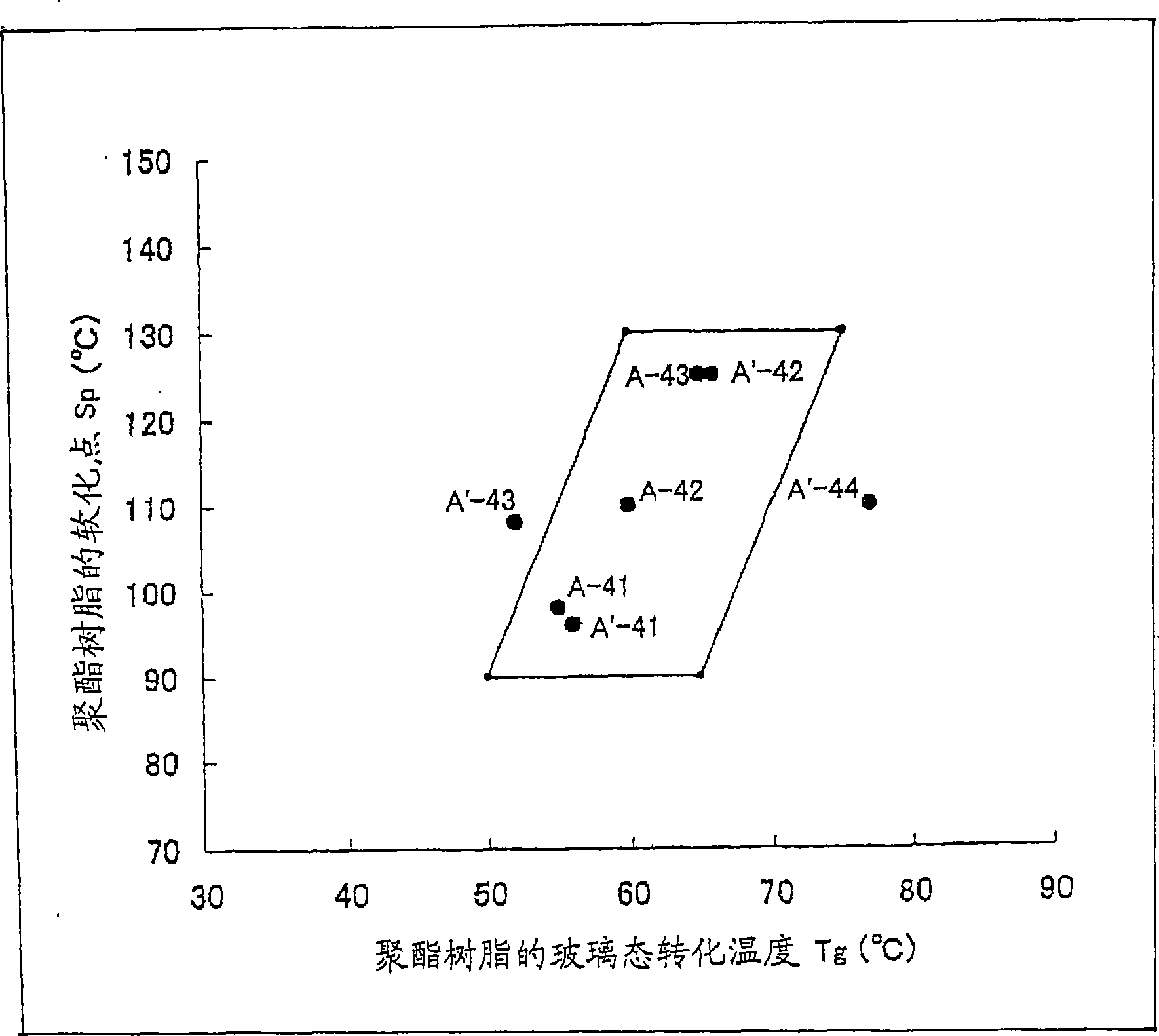

Polyester resin for toner, toner composition and resin particles

Disclosed is a heat-fusible electrostatic image developing toner which has an excellent balance between fixability at low temperatures and grindability and is excellent in glossiness after fixation. Also disclosed is a resin for toners. A polyester resin for toners which is obtained by polycondensing a polyol component and a polycarboxylic acid component is characterized by containing 20-100 weight% of one or more polyester resins (A1) having a storage elastic modulus from 2.5 x 10<3> Pa to 5 x 10<6> Pa at 150 1 / 2 C wherein the molar average cohesive energy of the polyol component is between 7.0 x 10<4> and 1.4 x 10<5> J.

Owner:SANYO CHEM IND LTD

Lubricating oil composition for continuously variable transmission

InactiveUS20070155632A1Increase coefficient of frictionImprove wear resistanceOrganic chemistryAdditivesPhosphoric Acid EstersEngineering

Owner:IDEMITSU KOSAN CO LTD

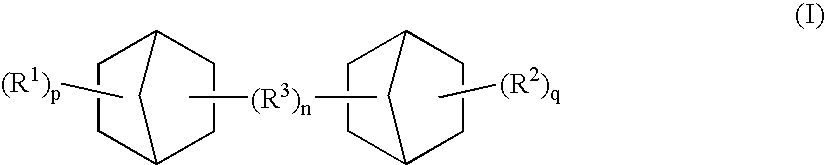

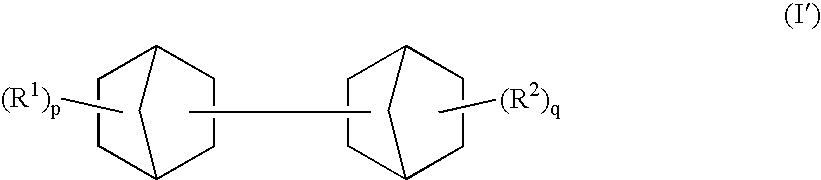

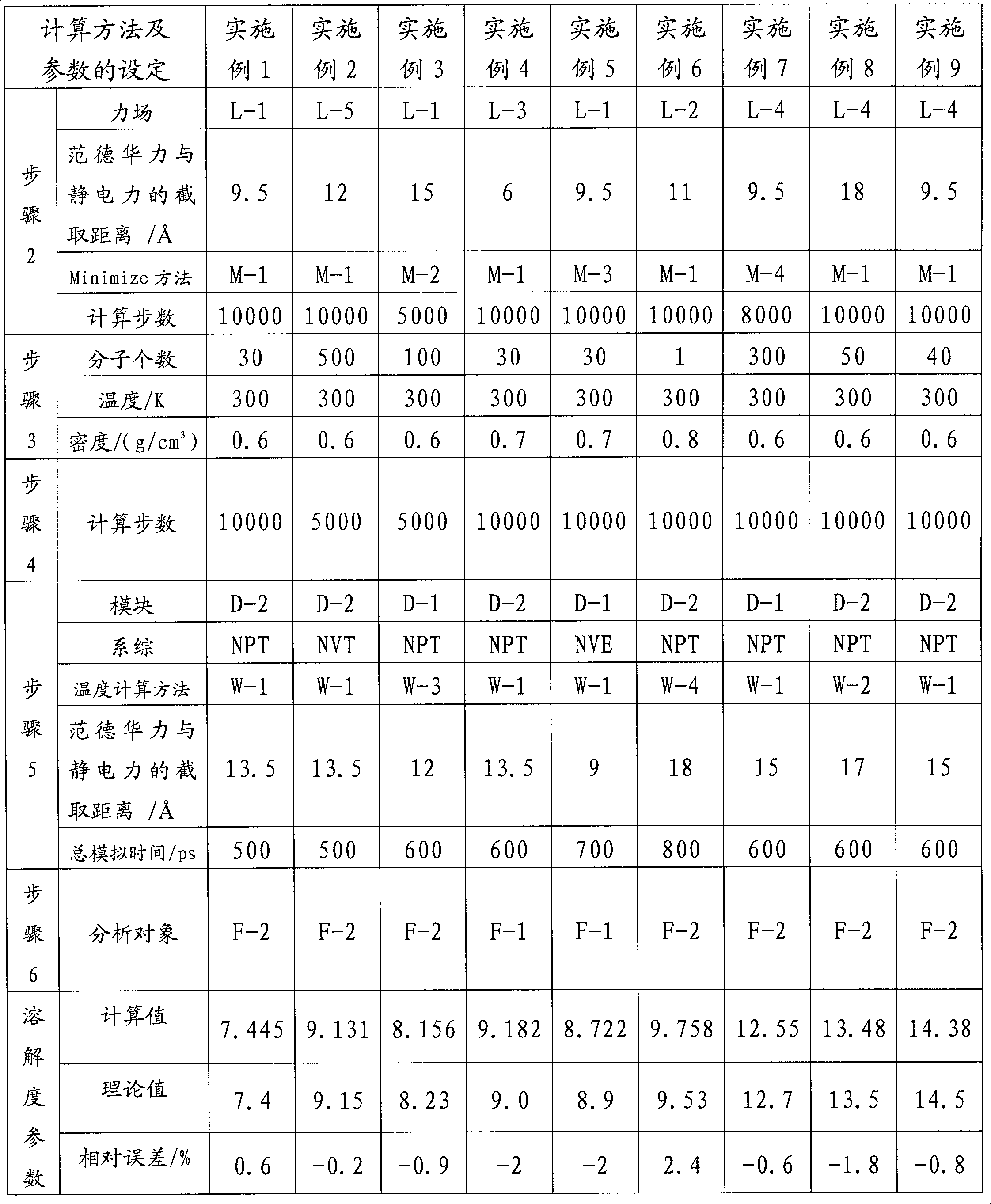

Method for calculating chemical substance solubility parameter by using computer simulation

InactiveCN102831256AWide measurement rangeSolve impossible puzzlesSpecial data processing applicationsSolubilityPetrochemical

The invention provides a method for calculating a chemical substance solubility parameter by using computer simulation. The method comprises the following steps: constructing a molecular model of a chemical substance to be calculated and performing energy minimization calculation; constructing a unit cell structure of an amorphous aggregate of the chemical substance to be calculated; performing energy minimization calculation and molecular dynamics calculation on the unit cell structure, to obtain the cohesive energy density of the chemical substance from the calculation; and calculating the square root of the cohesive energy density to obtain the solubility parameter. The method for calculating the chemical substance solubility parameter by using computer simulation provided by the invention has the advantages of fast calculation and accurate result, and is applicable to solving the technical problem that the compatibility of different substances is difficult to judge in the petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

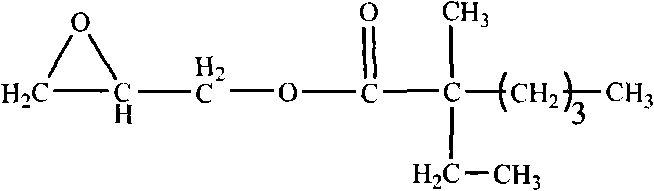

Adhesive for light-reflecting particles and preparation method thereof

ActiveCN101698788AFeel goodSoft touchPolyureas/polyurethane adhesivesFunctional monomerPolymer science

The invention discloses adhesive for light-reflecting particles and a preparation method thereof, which belongs to the technical field of adhesive preparation. The adhesive comprises a component A and a component B which are mixed in a weight ratio of 100:5-9, wherein the component A comprises the following raw materials in percentage by mass: 30 to 55 percent of acrylate soft monomer, 0.2 to 5 percent of functional monomer containing carboxyl or hydroxyl groups, 0.5 to 10 percent of crosslinking monomer containing hydroxyl groups, 40 to 60 percent of non-alcohol solvent, 0.2 to 5 percent of oil-soluble initiator and 0.05 to 0.2 percent of thiol chain transfer agent; and the component B adopts low-molecular polymer with the content of NCO between 10 and 14 percent. The crosslinking monomer containing hydroxyl groups in the component A of the adhesive undergoes crosslinking reaction with NCO in the component B to increase the cohesive energy and polarity of an adhesive system, thereby increasing the adhesive bonding action of the system on base materials and inorganic light-reflecting particles.

Owner:NANTONG GAOMENG NEW MATERIAL

Dispersing type anti-agglomeration polyurethane coating and preparation method thereof

InactiveCN104893552AEasy reunionGood dispersionPolyurea/polyurethane coatingsPolymer scienceHeat resistance

The invention discloses a dispersing type anti-agglomeration polyurethane coating. Firstly, a castor oil crosslinking prepolymer is adopted, wherein a multifunctional group structure of castor oil can endow a polymer with certain crosslinking, accordingly, the crosslinking degree of the polymer is improved, the interaction force of molecular chains is increased, movement of the molecular chains is blocked, water molecules cannot easily enter the molecular chains to swell the polymer, and the water absorption of the coating is reduced; meanwhile, the castor oil is triglycerin of fatty acid, nonpolar fatty acid chains of medium-long chains in molecules of the castor oil enable the coating to have excellent hydrophobicity, and the water absorption is further reduced; besides, ester in the castor oil has higher cohesive energy and can improve the tensile strength of the coating; ethyl cellulose has better heat resistance and thermoplasticity and has good compatibility with polyurethane, and the comprehensive performance of the prepolymer can be improved; the polyurethane prepolymer and polysilsesquioxane are subjected to blending modification.

Owner:HEFEI JIKE NEW MATERIALS

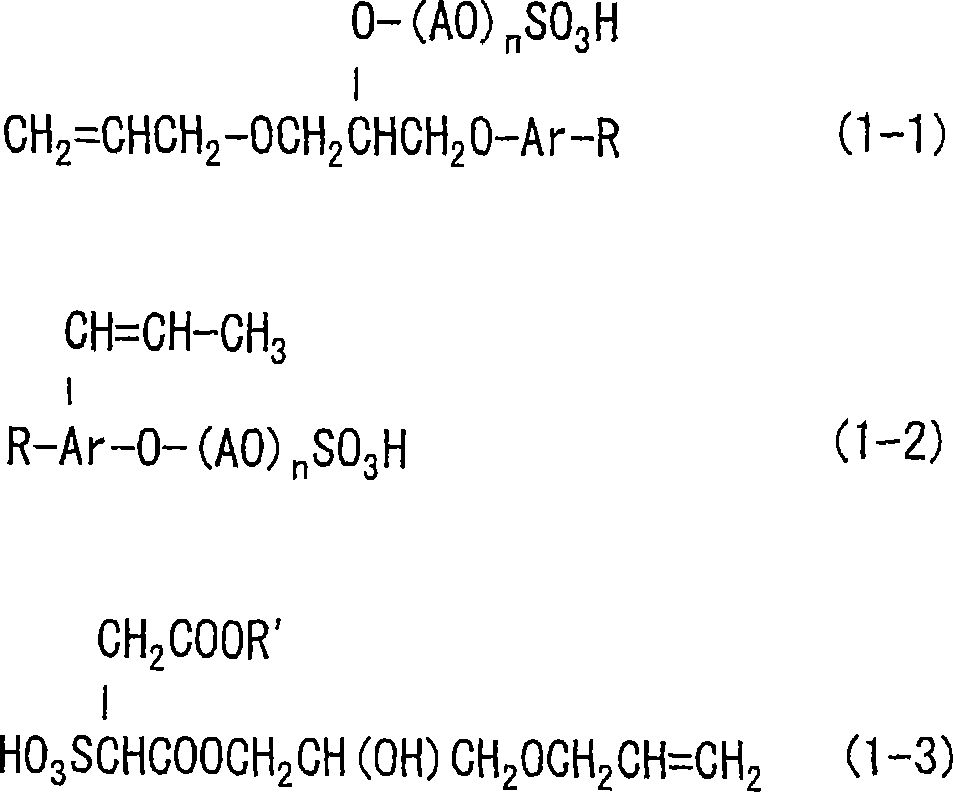

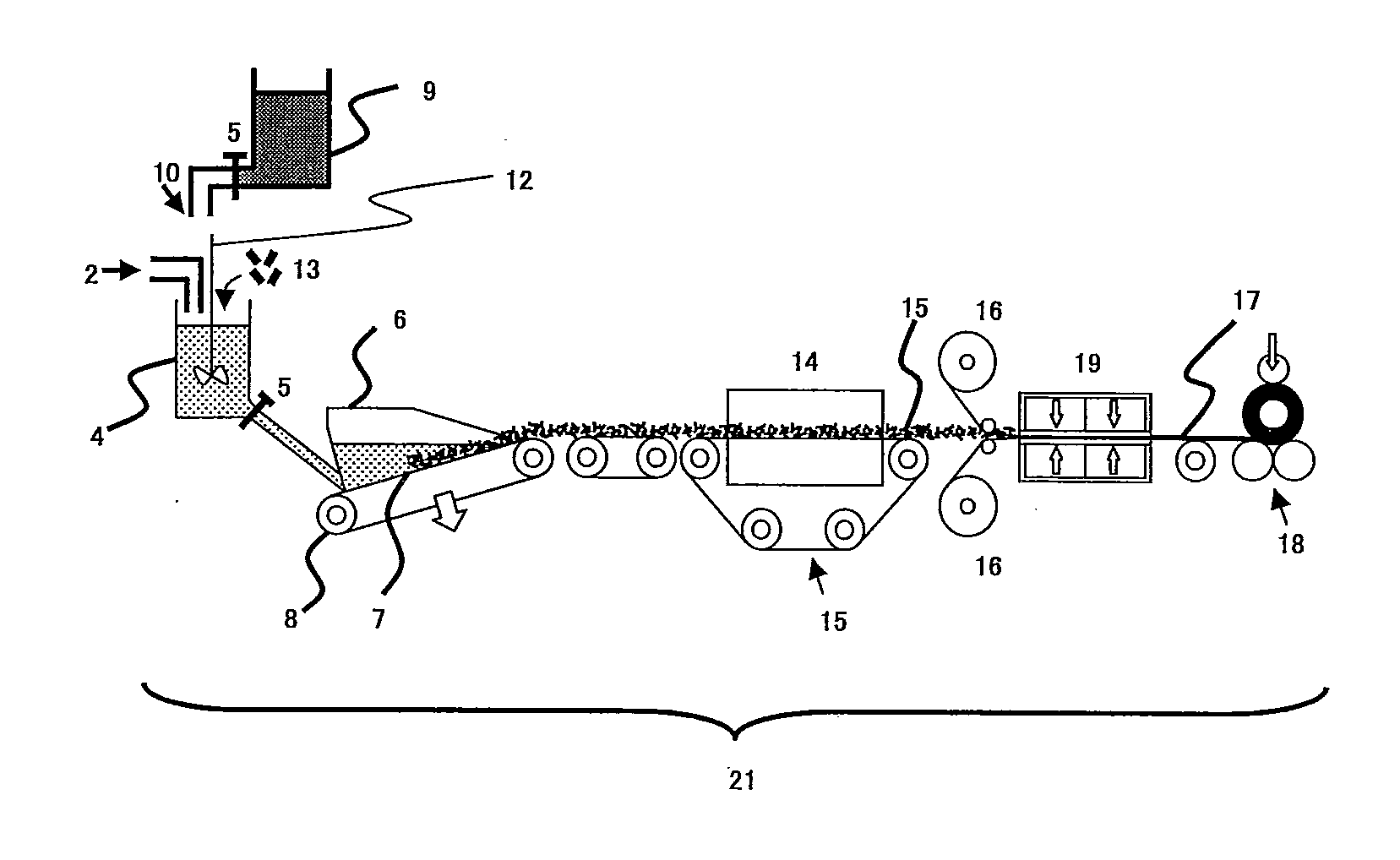

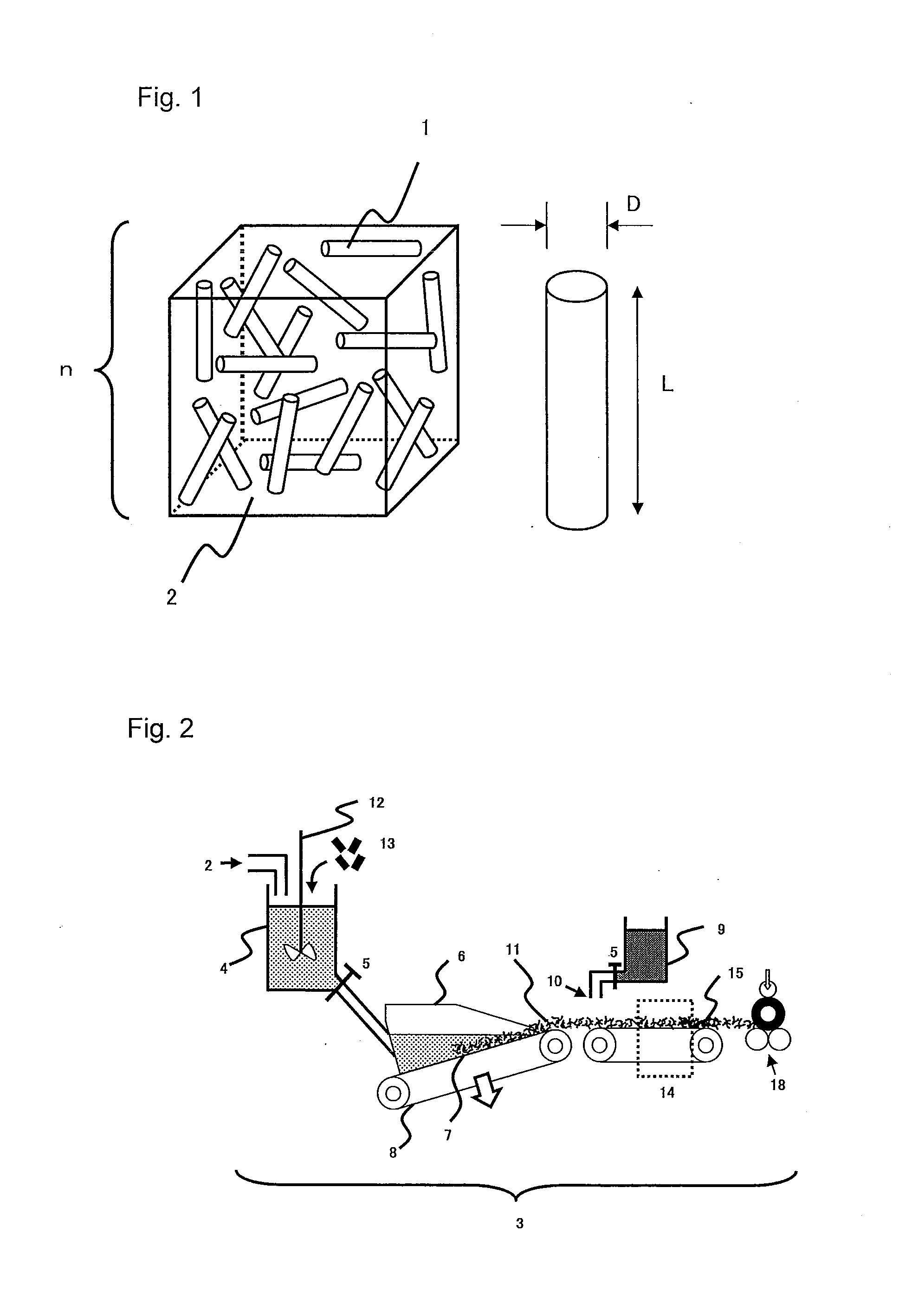

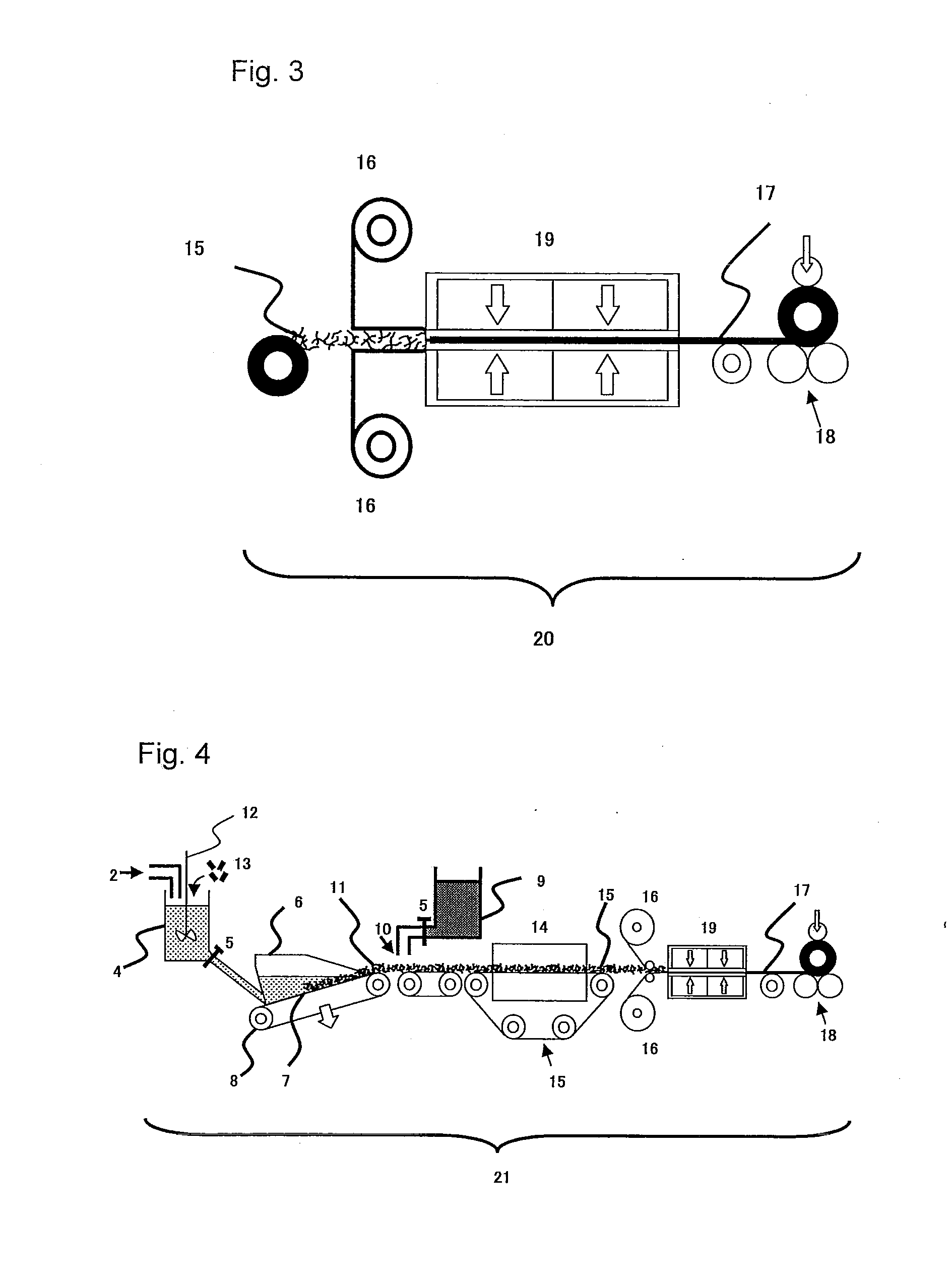

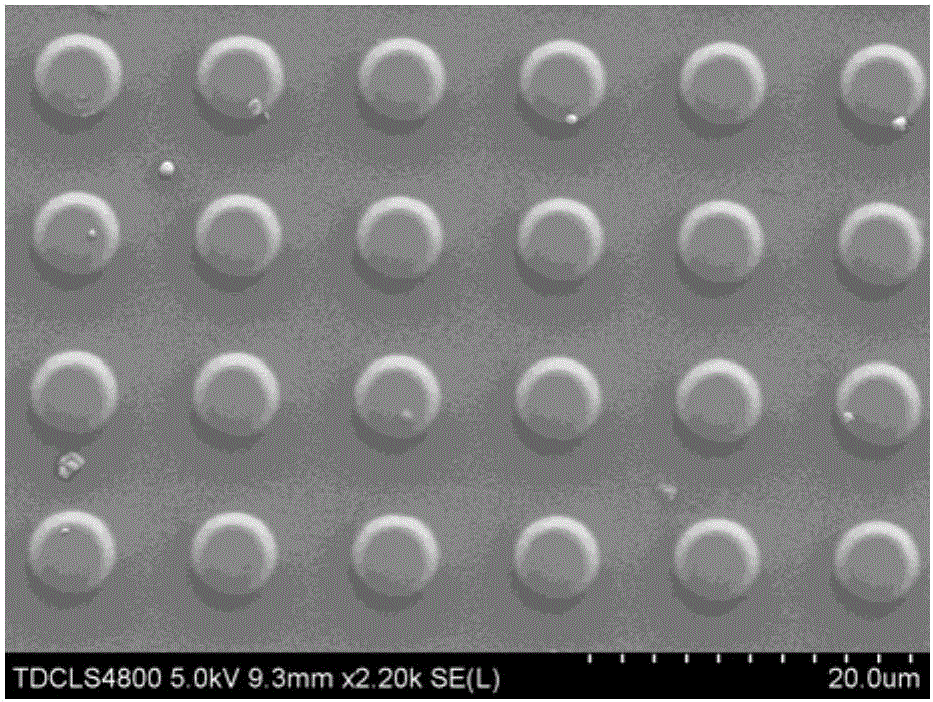

Fiber-reinforced thermoplastic resin composition, reinforcing fiber bundle, and process for production of fiber-reinforced thermoplastic resin composition

ActiveUS20130234361A1Improve interfacial adhesionExcellent mechanical propertiesLiquid surface applicatorsWood working apparatusPolyolefinMeth-

The present invention relates to fiber-reinforced thermoplastic resin composition comprising 0.1 to 10 mass % of a (meth)acrylic-based polymer, 1 to 70 mass % of reinforcing fiber, and 20 to 98.9 mass % of thermoplastic resin, wherein the (meth)acrylic-based polymer has, in a side chain, at least one functional group selected from a hydroxyl group, a carboxyl group, an amide group, and an urea group, and has a cohesive energy density (CED) of 385 to 550 MPa. The present invention provides, particularly in the case of using a polyolefin-based resin as matrix resin, a fiber-reinforced thermoplastic resin composition and a reinforcing fiber bundle which have high adhesiveness and good mechanical characteristics.

Owner:TORAY IND INC

Freeze-tolerant acrylate pressure-sensitive adhesive, preparation method thereof, and application thereof in production of freeze-tolerant acrylate pressure-sensitive labels

ActiveCN105400464AImprove performanceMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention discloses a freeze-tolerant acrylate pressure-sensitive adhesive, a preparation method thereof, and an application thereof in the production of freeze-tolerant acrylate pressure-sensitive labels. The adhesive is prepared through free radical polymerization of copolymerization monomers, and the copolymerization monomers comprise, by weight, 20-50 parts of iso-octyl acrylate, 150-200 parts of butyl acrylate, 50-100 parts of acrylic acid, 10-70 parts of 2-ethylhexyl acrylate, 100-200 parts of ethyl acetate, 300-450 parts of toluene and 3-5 parts of benzoyl peroxide. The problems of low molecular weight, insufficient cohesive energy and adhesive overflow due to softness are solved through improving a formula and combing a new label production technology; and the freeze-tolerant acrylate pressure-sensitive adhesive labels disclosed in the invention have the advantages of soft adhesive, stable performances, avoiding of warping, opening and other phenomena when used to label refrigerated blood bags and other refrigerated products, and solving of the problem of difficult automatic labeling of -30DEG C blood bags with present blood bag labels.

Owner:GUANGZHOU JINWANZHENG PRINTING MATERIAL CO LTD

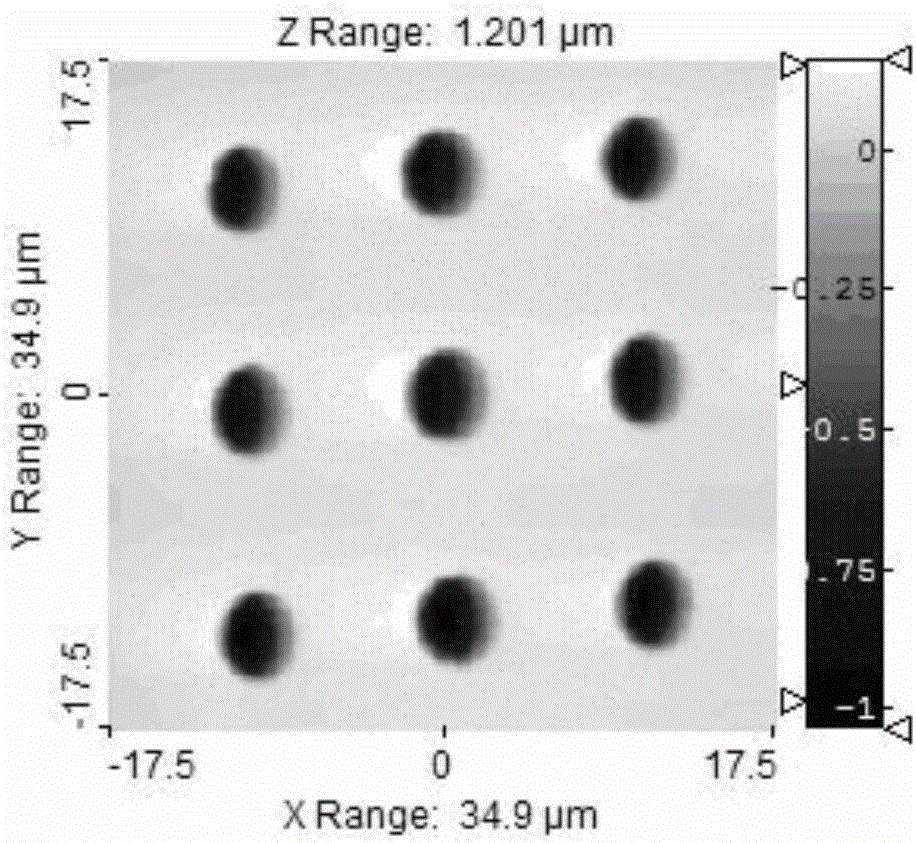

PDMS elastomer micro-nano processing method based on surface oxidation control transfer printing

InactiveCN105731364AAchieve controllable patterningRealize fine controlDecorative surface effectsChemical vapor deposition coatingElastomerMicro nano

The invention discloses a PDMS elastomer micro-nano processing method based on surface oxidation control transfer printing. The PDMS elastomer micro-nano processing method comprises the following steps: preparing a PDMS film with an adjustable thickness to serve as a transfer printing substrate by using a pouring method or a spin coating method; preparing a PDMS film with a surface microstrucutre to serve as a transfer printing stamp by using a replica casting method; carrying out a surface oxidation treatment on the substrate or the stamp, importing a cohesive energy difference between the PDMS stamp and the planar PDMS substrate to obtain a hard / soft or soft / hard stamp-substrate combination, and simultaneously carrying out a surface activation treatment and a heating treatment on the combination to improve the contact adhesion of the two; taking off the stamp, generating cohesive energy breakage on the soft party during the separation to transfer PDMS ink to the hard party, so as to obtain a PDMS film with complex, precise and controllable concave or convex patterns on the surface. The PDMS elastomer micro-nano processing method disclosed by the method is simple and convenient to operate, low in cost, and is used for avoiding the defects of limited applicable range of other related technology and simple processing patterns.

Owner:TIANJIN UNIV

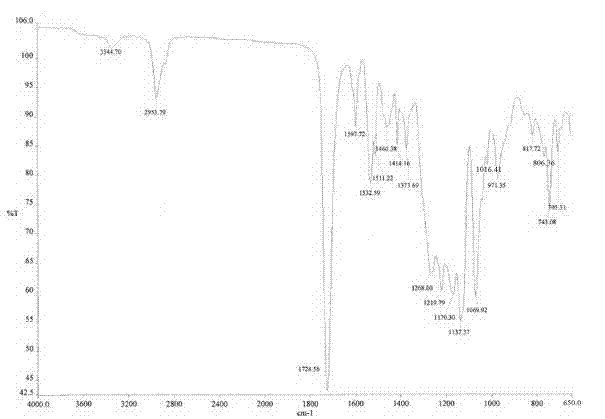

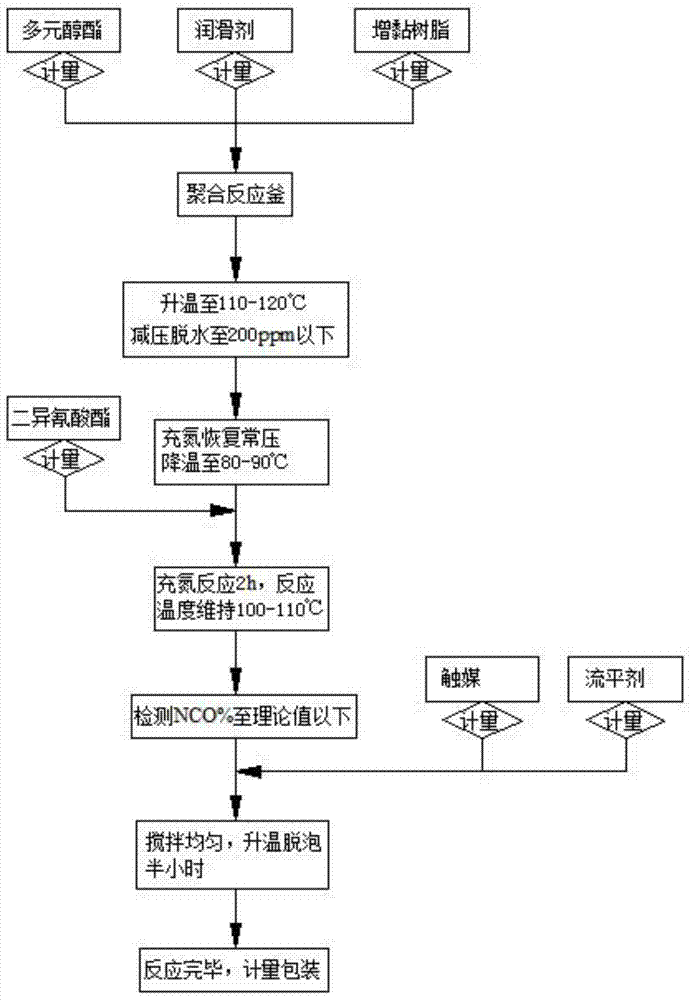

Preparation method and use of moisture-curable polyurethane hot melt adhesive for special-shaped material coating

ActiveCN104497947ASimple processReduce manufacturing costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceWeather resistance

The invention discloses a preparation method and a use of a moisture-curable polyurethane hot melt adhesive for special-shaped material coating. The preparation method comprises that a NCO functional group and air or vapor on the base surface undergo a reaction to produce an amido group and simultaneously release CO2, the amido group and other NCO group undergo a reaction to produce a structure with a urea functional group, and reactive hydrogen in the urea structure and unreacted NCO groups undergo further reaction to produce a biuret structure so that a crosslinking reaction is finished, wherein in the reaction, through detection of isocyanate group NCO%, a reaction degree is monitored. The preparation method is free of a solvent and thus a drying process is avoided, processes are simplified and a production cost is reduced. The moisture-curable polyurethane hot melt adhesive obtained by the preparation method has high cohesive energy, good initial adhesion, and excellent heat, water and weather resistance after curing, and is especially suitable for coating of outdoor door and window section bars.

Owner:高鼎精细化工(昆山)有限公司

Composition of eco-friendly hot melt adhesive

ActiveCN103261354AGood compatibilityImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesHot-melt adhesiveHigh adhesion

Provided is a polypropylene carbonate based resin composition used as a hot melt adhesive. In detail, the present invention is to provide a composition of the hot melt adhesive having high adhesion to a polar surface of the polypropylene carbonate resin based hot melt adhesive and adhesion to a non-polar surface. The composition of hot melt adhesive according to the present invention has excellent compatibility between raw materials so as to have a completely uniform phase, thereby increasing cohesive energy as the adhesive and having the excellent adhesion to the polar or non-polar surface.

Owner:SK INNOVATION CO LTD

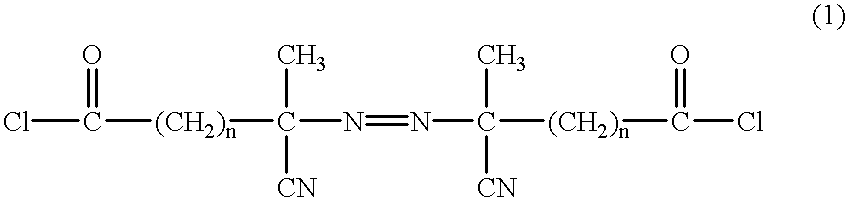

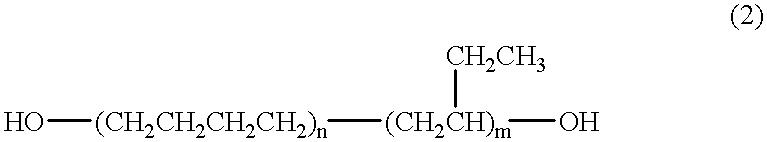

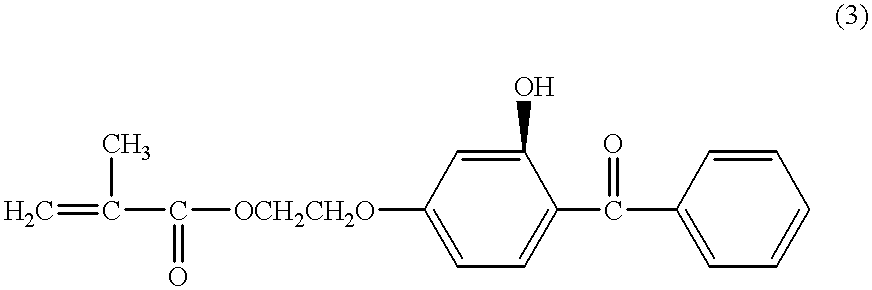

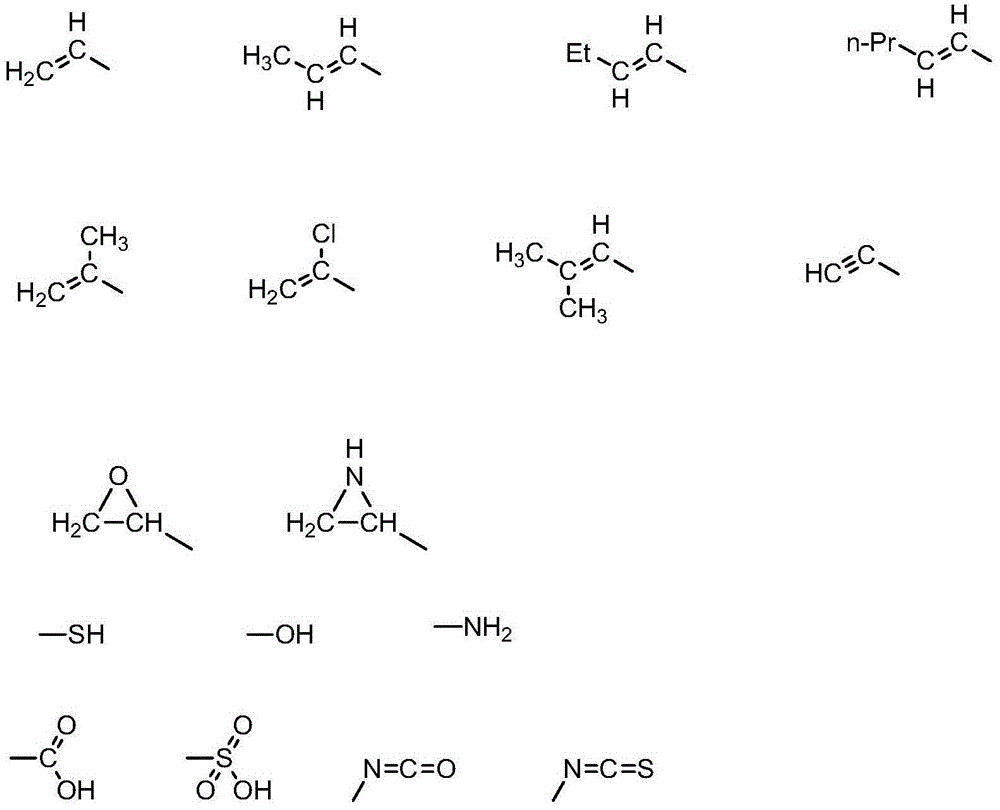

Block copolymer with condensation or vinyl polymer, functions imparting, and lower cohesive E segments

A functional block copolymer useful as a compatibilizing agent for a blend of a condensation polymer and vinyl polymer comprises segments of a condensation polymer and a vinyl polymer derived from a reactive functional group-containing monomer or a functions-imparting monomer such as ultraviolet absorption or flame retardant functions. The block copolymer can further include a segment of a lower cohesive energy polymer. The condensation or vinyl polymer segment, or the lower cohesive energy polymer segment contains azo or peroxide groups which act as a polymerization initiator for the copolymerization of the vinyl monomer forming the vinyl polymer segment.

Owner:OSAKA MUNICIPAL TECHN RES INST

Preparation method for nano calcium carbonate special for low modulus silicone adhesive

ActiveCN107118590AGood compatibilityReduce reunionNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsCarbonizationSlurry

The invention discloses a preparation method for nano calcium carbonate special for low modulus silicone adhesive. The preparation method is implemented according to the following steps: 1) preparing Ca(OH)2 slurry; 2) carrying out carbonization; 3) adding a crystal form conditioning agent; 4) carrying out surface treatment; 5) adding a modulus conditioning agent; 6) carrying out filter pressing, drying and smashing on calcium carbonate boiled size in after the modulus conditioning agent is added to prepare the nano calcium carbonate special for the low modulus silicone adhesive, wherein the moisture of the nano calcium carbonate is less than or equal to 0.3%. The nano calcium carbonate prepared by the preparation method has good compatibility with polydimethylsiloxane, and cohesive energy is reduced after the nano calcium carbonate and the polydimethylsiloxane are mixed so as to achieve an effect of lowering silicone adhesive product modulus.

Owner:FUJIAN HONGFENG NANO TECH

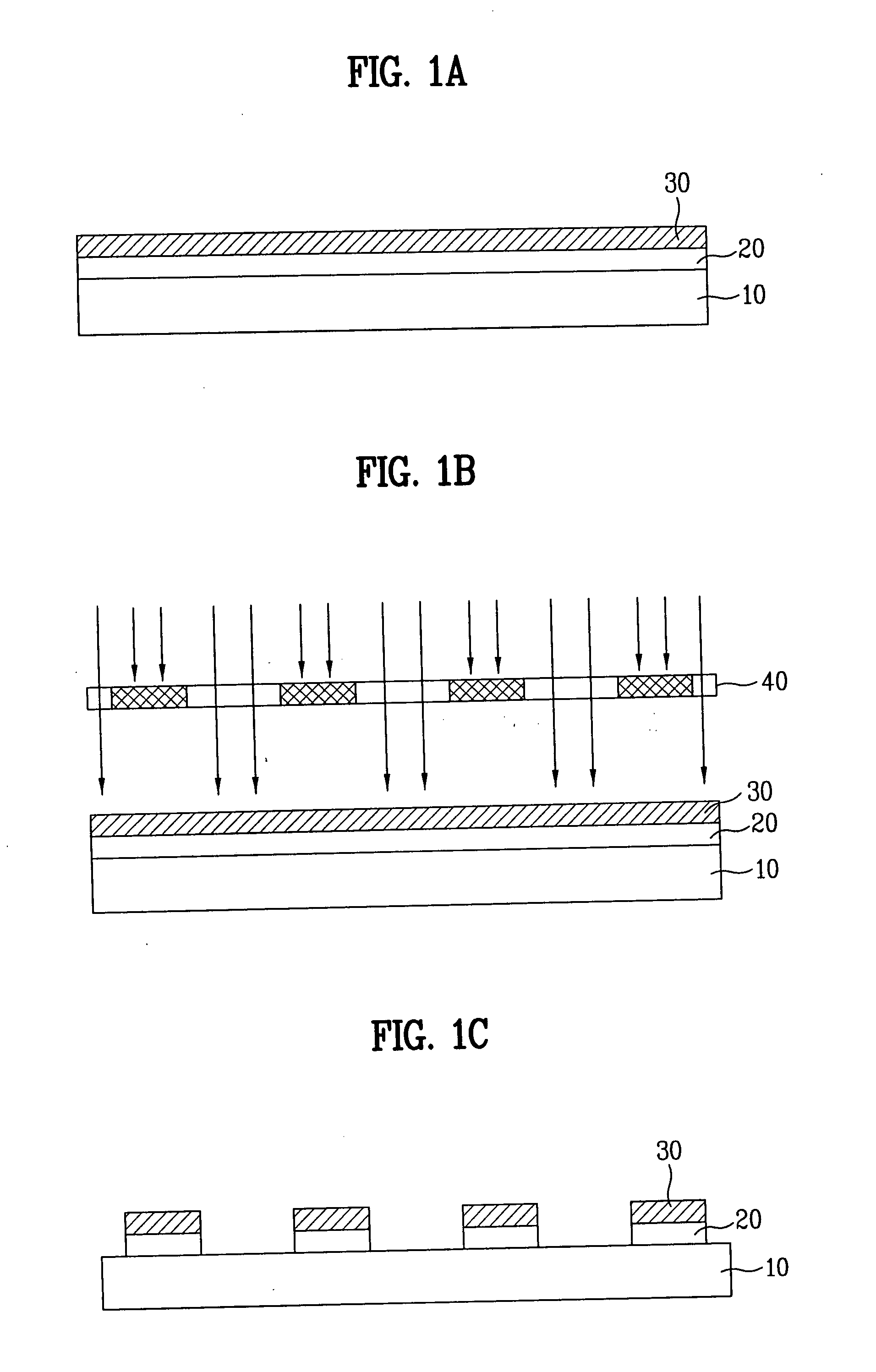

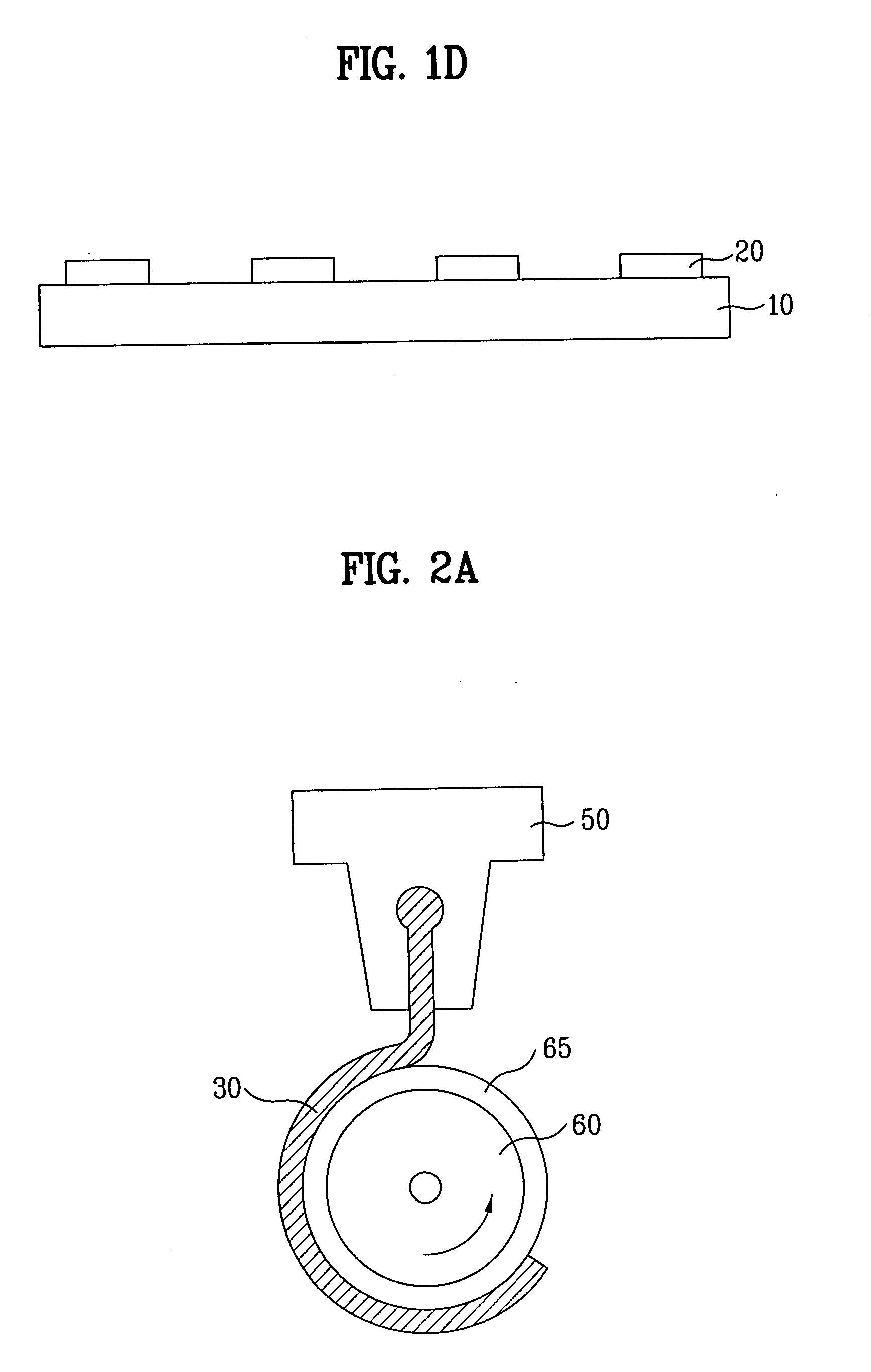

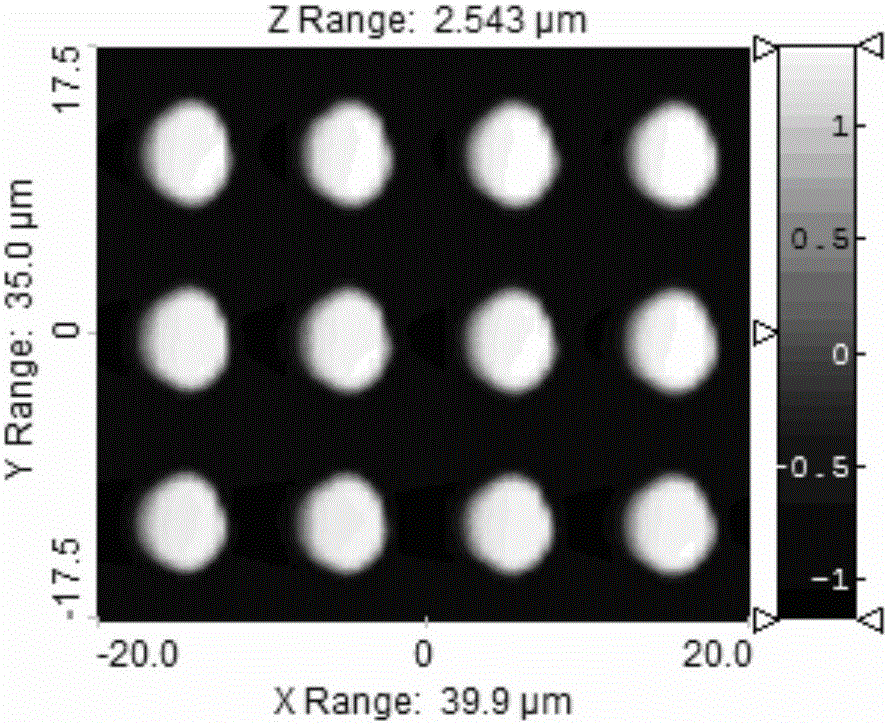

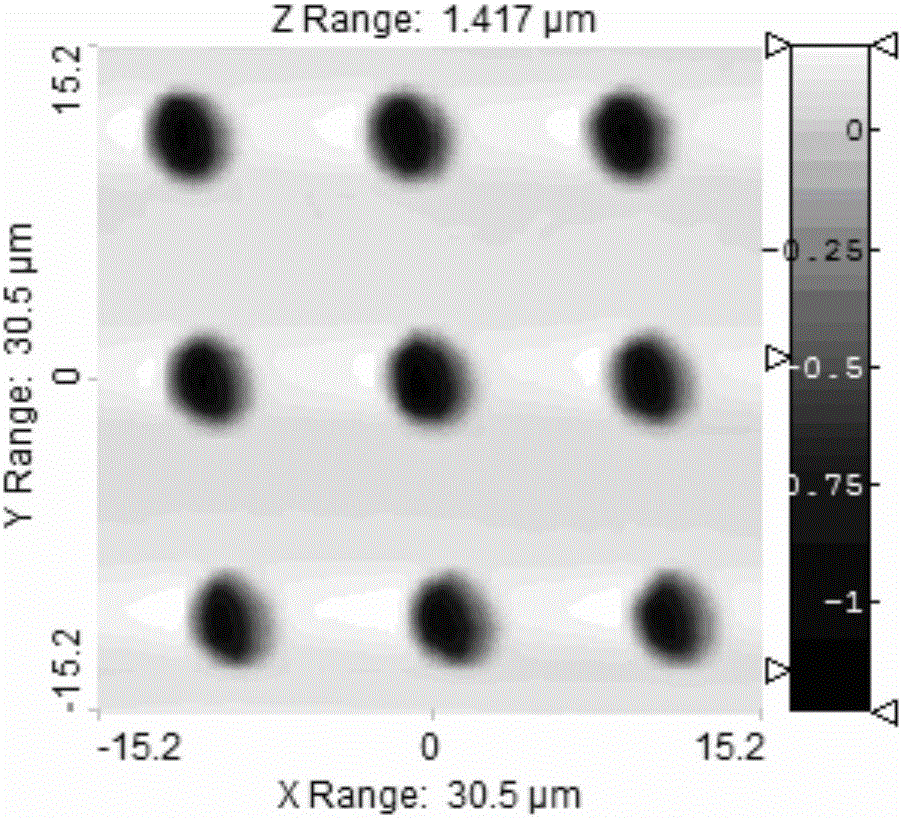

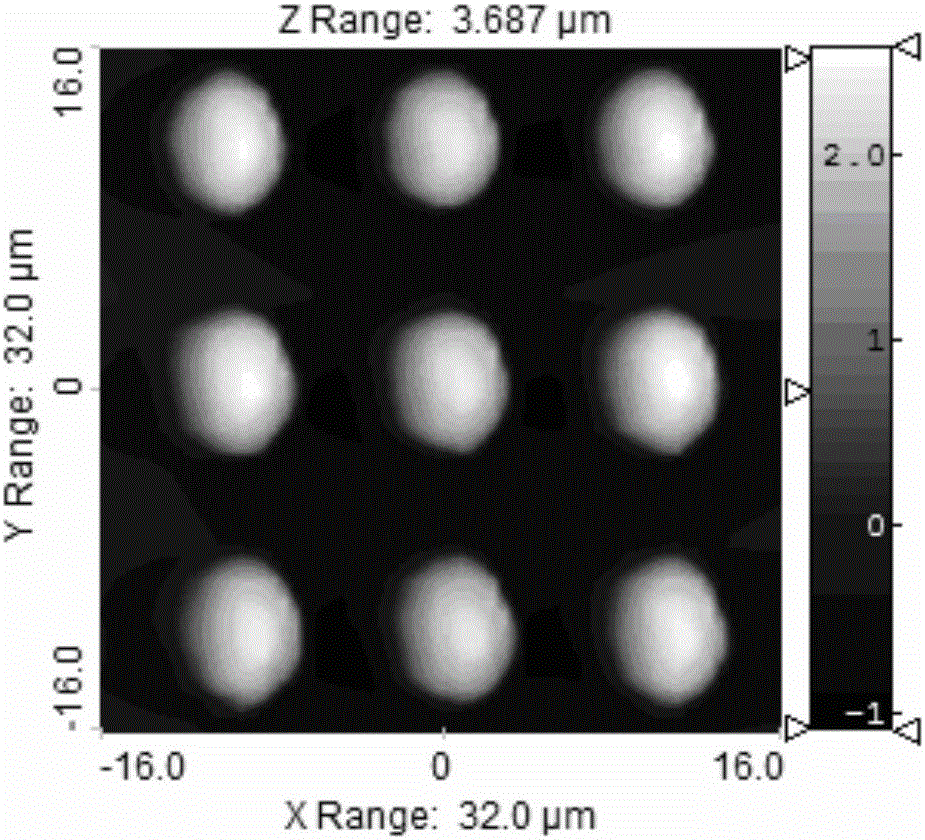

Resist for printing and patterning method using the same

ActiveUS20070254239A1Large energyPrecise pattern of resistPhotosensitive materialsPhoto-taking processesResistEngineering

A resist for printing that is coated on a printing roll and is then sequentially transcribed on a printing plate and a substrate including: a material wherein a cohesive energy between the resist and the printing plate is larger than a cohesive energy between the resist and a blanket formed on the surface of printing roll, and wherein a cohesive energy between the resist and the substrate is larger than the cohesive energy between the resist and the blanket formed on the surface of printing roll.

Owner:LG DISPLAY CO LTD

Polyurethane modifier, preparation method thereof, and preparation method of nanometer calcium carbonate

InactiveCN106366287AFlexibleElasticCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarbamatePliability

The invention discloses a polyurethane coupling agent used for synthesizing polyurethane-containing groups and long-chain fatty alcohols. The main chain of the polyurethane coupling agent contains a carbamate group, an isocyanate group and long-carbon chain fatty acid, has the characteristics of possessing of the large polarity of an ester group and an isocyanate group, high cohesive energy, large intermolecular action force, high activity and polarity, excellent chemical bonding force with nanometer calcium carbonate, possessing of the flexibility and the elasticity of the long-chain fatty acid, and increase of the nanometer calcium carbonate filler and substrate silicone adhesive resin interface combination force. Compared with common fatty acid surface-treated calcium carbonate surface, nanometer calcium carbonate treated with the polyurethane modifier has the advantages of increase of the tensile strength, the elongation at break and the elastic modulus, good mechanical performances and wide application prospect when applied to plastics, rubbers and sealants.

Owner:连州市万仕达新材料有限公司

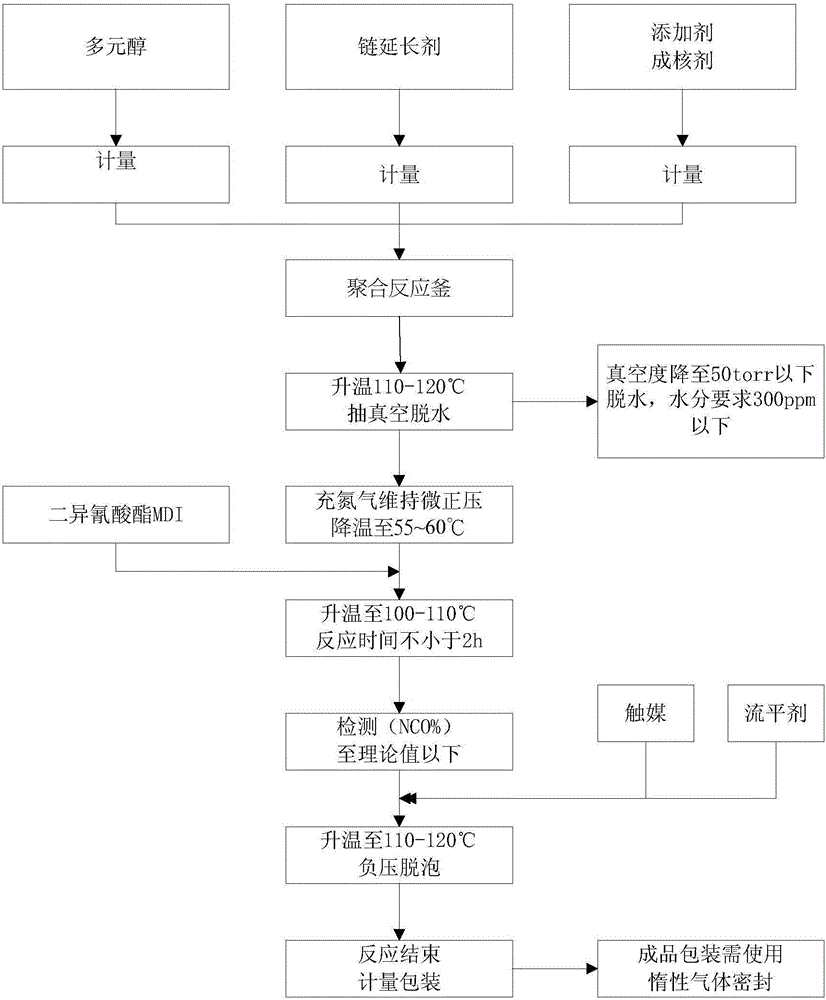

Preparation method and application of moisture reaction type polyurethane hot-melt adhesive for composite floor

The invention disclose a preparation method and application of moisture reaction type polyurethane hot-melt adhesive for a composite floor and belongs to the technical field of macromolecule material preparation .According to the method, polyester polyol, diisocyanate and chain extender are adopted as basic raw materials, auxiliary agents such as accelerant, a flatting agent and a nucleating agent are combined, and a high temperature polymerization reaction is conducted, so that the moisture reaction type polyurethane hot-melt adhesive (PUR) is obtained .A product prepared through the method is the one-component moisture reaction type polyurethane hot-melt adhesive, no cross-linking agent is used for hardening, and instead, an NCO functional group with the resin molecular chain tail end reactive is adopted for reacting with moisture to achieve cross-linking .The solid content of the product is 100%, no solvent is contained, no solvent is used in the technological process, a baking channel does not need to be arranged, cost is lowered, and no safety or environmental protection problem exists .In addition, the polyurethane adhesive product produced through the method is high in cohesive energy, good in initial adhesion and excellent in heat resistance, weather resistance, hydrolysis resistance and aging resistance after being cured and can be widely applied to processing of building decorative materials.

Owner:高鼎精细化工(昆山)有限公司

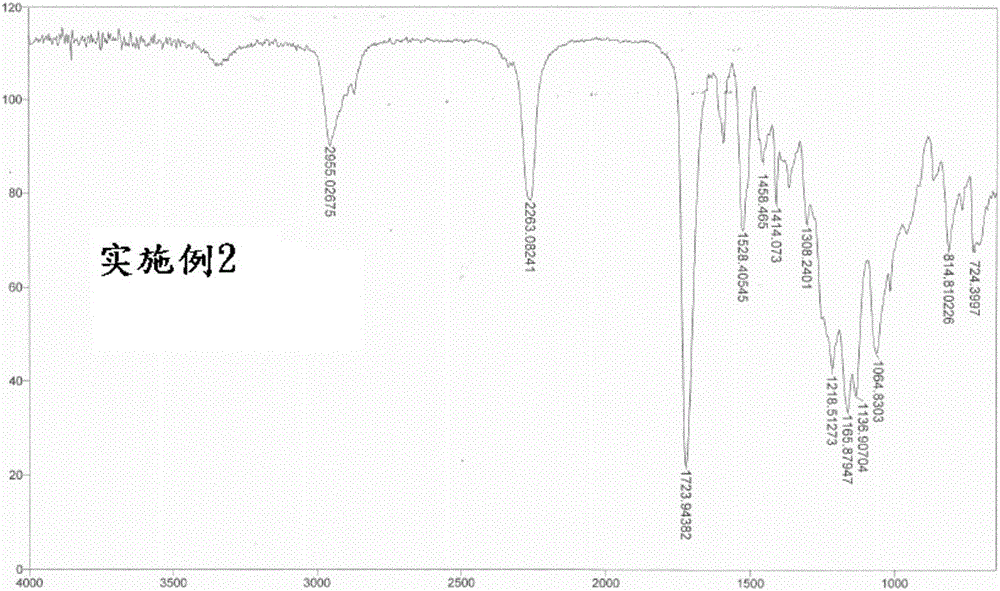

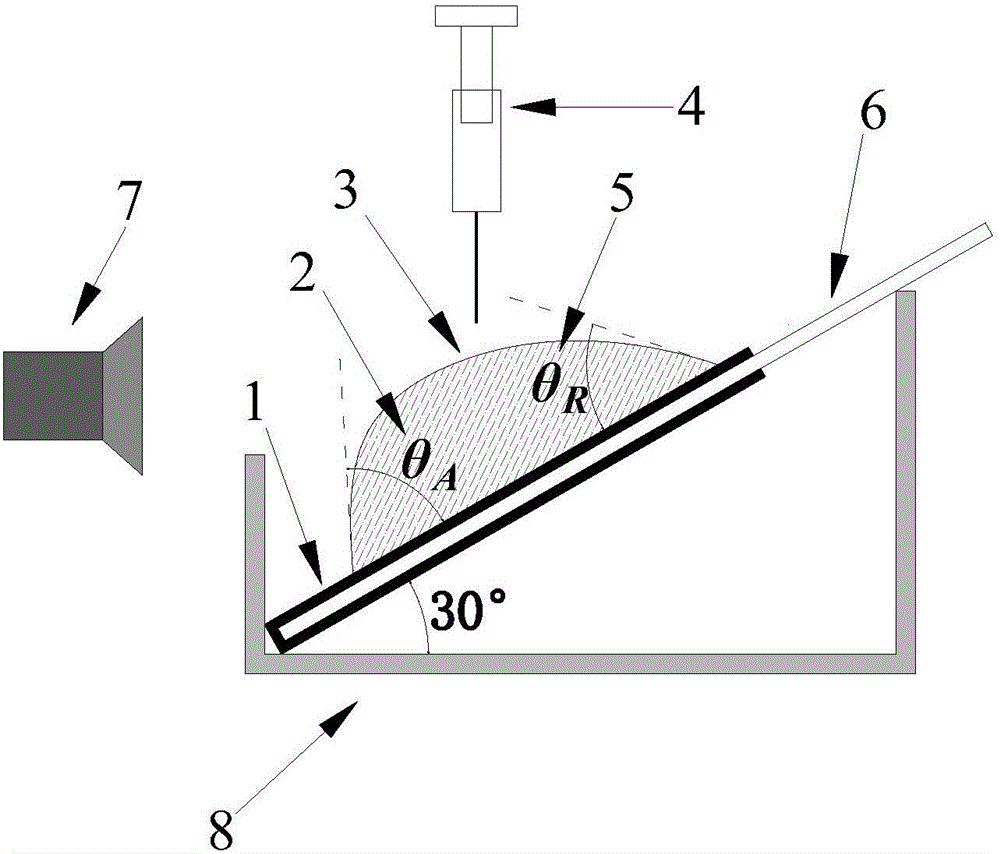

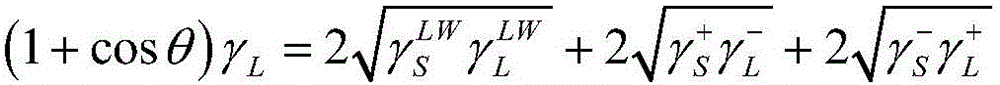

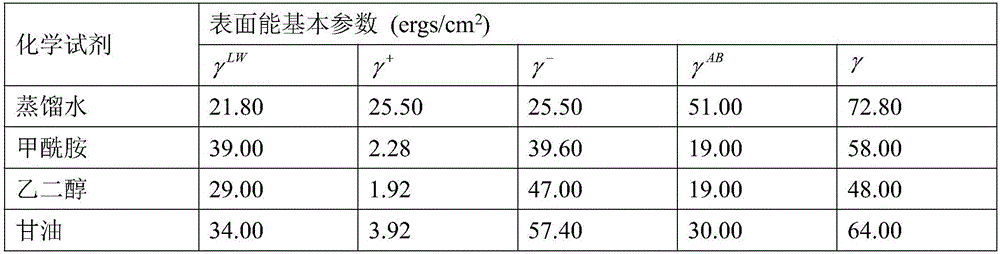

Method for testing dynamic surface energy parameters of asphalt material

The invention discloses a method for testing dynamic surface energy parameters of an asphalt material. The method comprises the following steps: selecting four chemical reagent with known surface energy parameters, and respectively dropwise adding the four chemical reagents on the surface of an asphalt membrane; recording an advancing contact angle and a receding contact angle at the moment nearby a limit which tends to slide but is in a static state; solving cohesive energy of the asphalt in an advancing and receding process, and solving adhesional energy of the asphalt and aggregates in the advancing and receding process by combining with surface energy parameters of the aggregates; evaluating the healing performance and the water stability of an asphalt mixture by using the surface energy in the advancing process, evaluating the cracking performance of the asphalt mixture by using the surface energy in the receding process, quantizing the adhesion performance, and preferring a road material. The dynamic surface energy parameters of the asphalt are tested by adopting a static drop tilting method provided by the invention, and are enabled to correspond to healing and cracking performances and the water stability of the asphalt mixture; the method disclosed by the invention has certain advantages compared with an existing test method in aspects of reasonability and error control of a testing method and test operations.

Owner:WUHAN UNIV OF TECH +1

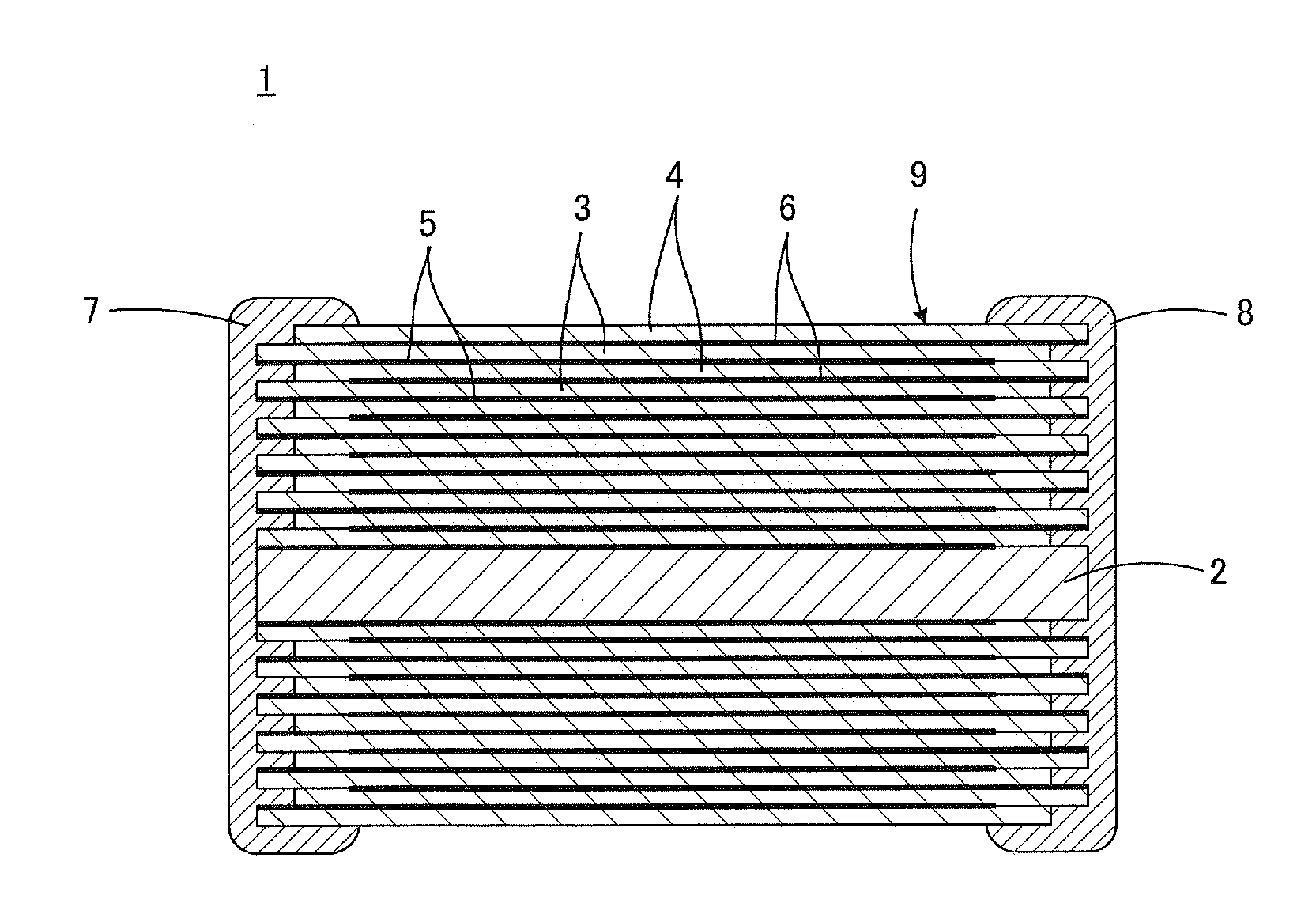

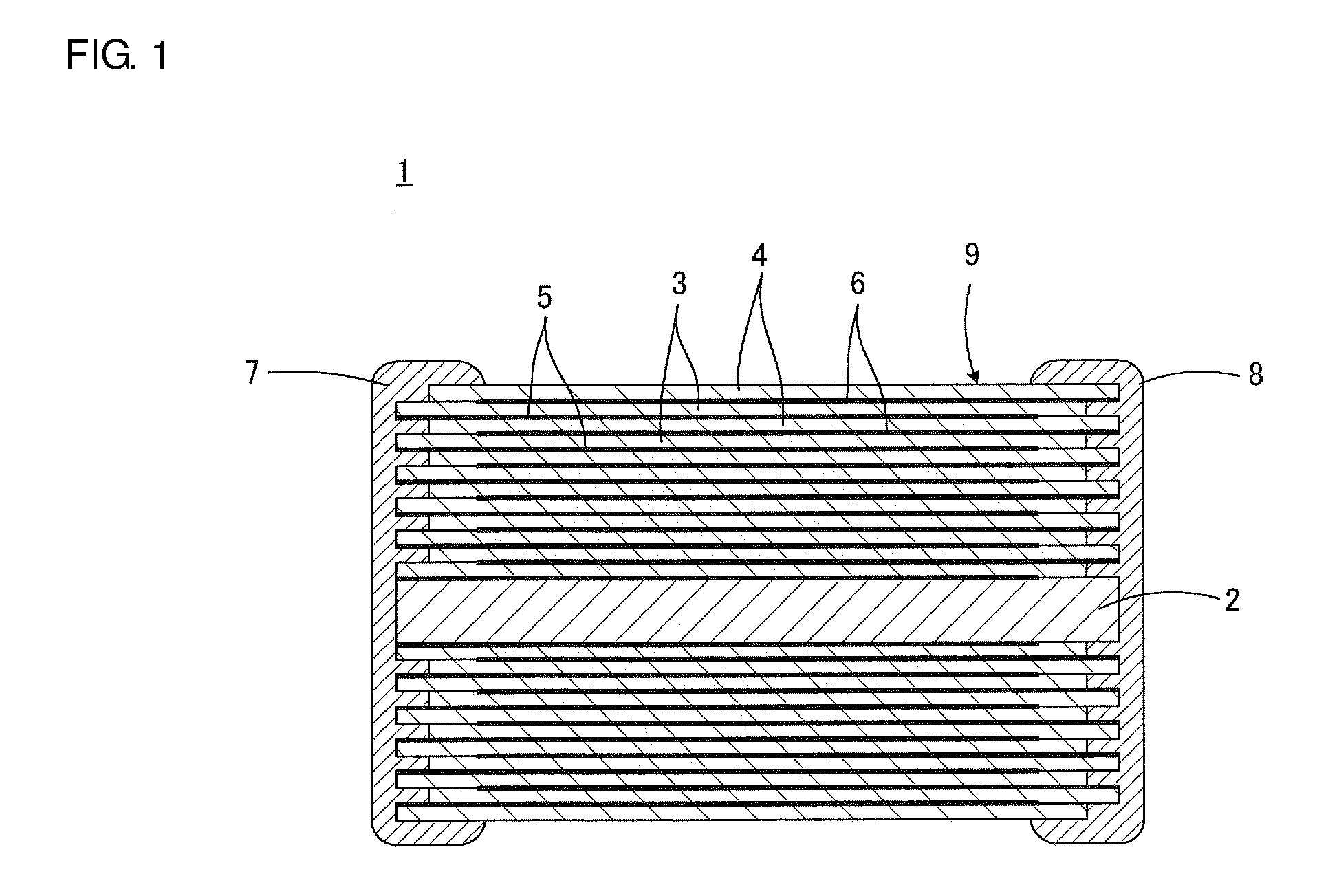

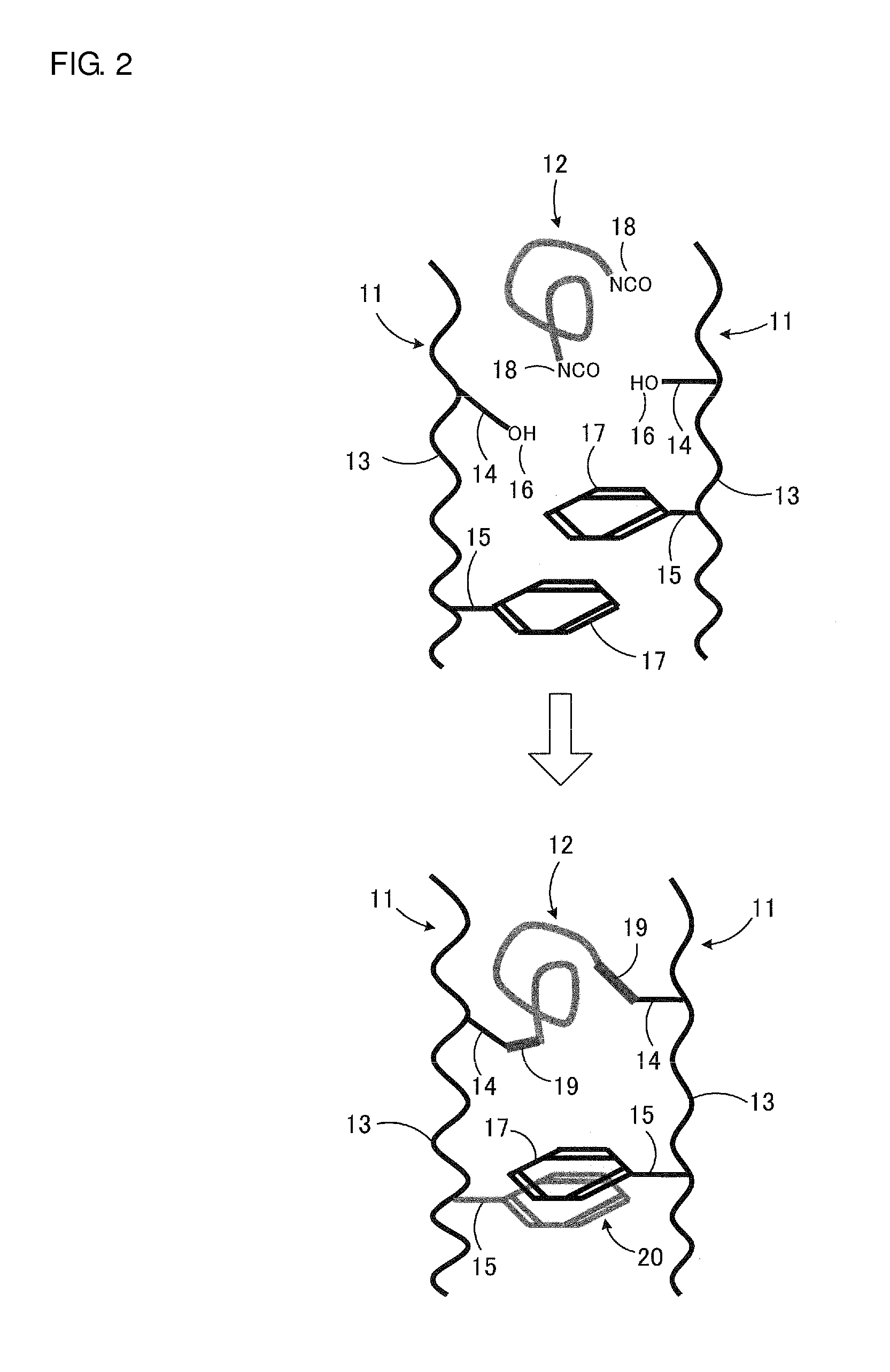

Dielectric resin composition for film capacitor and film capacitor

ActiveUS20120008250A1Improve heat resistanceHigh energyFixed capacitor electrodesFixed capacitor dielectricAtomic groupHeat resistance

To increase the heat resistance of a film capacitor, a dielectric resin composition is used as a material for a dielectric resin film used in a film capacitor, the dielectric resin composition being cured by mixing and crosslinking two or more organic materials having functional groups that react with each other to provide a cured article. At least one pair highly cohesive atomic groups which has a molecular cohesive energy equal to or higher than that of a methyl group and capable of cohering with each other due to the molecular cohesive energy is linked to the organic material. The highly cohesive atomic groups form a cohesive portion serving as pseudo-crosslinking.

Owner:MURATA MFG CO LTD

Antibacterial and anticorrosive coating and preparation method thereof

InactiveCN104893548AImprove antibacterial and antiseptic effectAntifouling/underwater paintsPaints with biocidesCross-linkPolymer science

Owner:HEFEI JIKE NEW MATERIALS

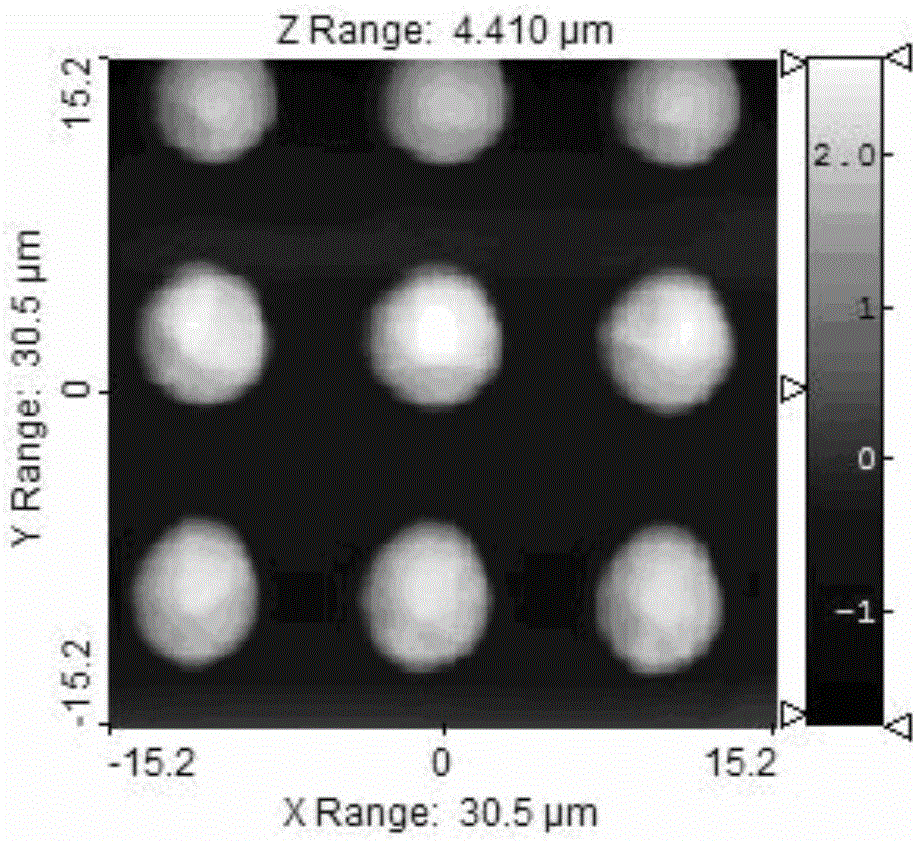

PDMS elastomer micro-nano processing method based on crosslinking control control transfer printing

InactiveCN105731365AAchieve controllable patterningRealize fine controlDecorative surface effectsChemical vapor deposition coatingElastomerMicro nano

The invention discloses a PDMS elastomer micro-nano processing method based on crosslinking control control transfer printing. The PDMS elastomer micro-nano processing method comprises the following steps: preparing a PDMS film to serve as a transfer printing substrate by using a pouring method; preparing a PDMS film with a surface microstrucutre to serve as a transfer printing stamp by using a replica casting method; importing a cohesive energy (soft / hard) difference between the PDMS stamp and the planar PDMS substrate by different crosslinking agent contents in the process of preparing the substrate and the stamp; and simultaneously carrying out an OP treatment on the prepared substrate and the stamp for 0.5 min, immediately adhering the substrate and the stamp, and carrying out a heating treatment to improve the contact adhesion of the substrate and the stamp, taking off the stamp, generating cohesive energy breakage on the soft party during the separation to transfer PDMS ink to the hard party, so as to obtain a PDMS film with concave or convex patterns on the surface. The PDMS elastomer micro-nano processing method disclosed by the method is simple and convenient to operate, low in cost, and is used for avoiding the defects of limited applicable range of other related technology and simple processing patterns.

Owner:TIANJIN UNIV

Frosting coating and preparation method thereof

InactiveCN104893530ATight textureUniform and fine grainPolyurea/polyurethane coatingsCross-linkPolymer science

The invention discloses a frosting coating. Firstly, a castor oil is used for cross-linking a prepolymer: the multifunctional-group structure in the castor oil can cross-link a polymer to a certain extent, the cross-linking degree of the polymer is increased, the interaction force among molecular chains is increased, molecular chain movement is resisted, water molecules cannot enter the molecular chains to swell the polymer, and the water absorption of an adhesive film is decreased; meanwhile, the castor oil is a triglyceride of fatty acid, due to long nonpolar fatty acid chains in molecules, the adhesive film has good hydrophobicity, and the water absorption is further reduced; meanwhile, ester groups in the castor oil have higher cohesive energy and can improve the tensile strength of the adhesive film; ethyl cellulose has better heat resistance and thermal plasticity, has good compatibility with polyurethane and can improve the comprehensive property of the prepolymer; then the polyurethane prepolymer is mixed with polysilsesquioxane for modification.

Owner:HEFEI JIKE NEW MATERIALS

High-viscosity double-component polyurethane coating and preparation method thereof

InactiveCN104893549AIncrease the degree of cross-linkingRestricted movementPolyurea/polyurethane coatingsPolymer scienceFatty acid

The invention discloses a high-viscosity double-component polyurethane coating. Firstly, a castor oil crosslinking prepolymer is adopted, wherein a multifunctional group structure of castor oil can endow a polymer with certain crosslinking, accordingly, the crosslinking degree of the polymer is improved, the interaction force of molecular chains is increased, movement of the molecular chains is blocked, water molecules cannot easily enter the molecular chains to swell the polymer, and the water absorption of the coating is reduced; meanwhile, the castor oil is triglycerin of fatty acid, nonpolar fatty acid chains of medium-long chains in molecules of the castor oil enable the coating to have excellent hydrophobicity, and the water absorption is further reduced; besides, ester in the castor oil has higher cohesive energy and can improve the tensile strength of the coating; ethyl cellulose has better heat resistance and thermoplasticity and has good compatibility with polyurethane, and the comprehensive performance of the prepolymer can be improved; the polyurethane prepolymer and polysilsesquioxane are subjected to blending modification.

Owner:HEFEI JIKE NEW MATERIALS

Optical interference pigment and method for producing same

InactiveCN105073907AExcellent light reflectivityHigh light reflectivityOrganic dyesPigment physical treatmentSolubilityOrganic solvent

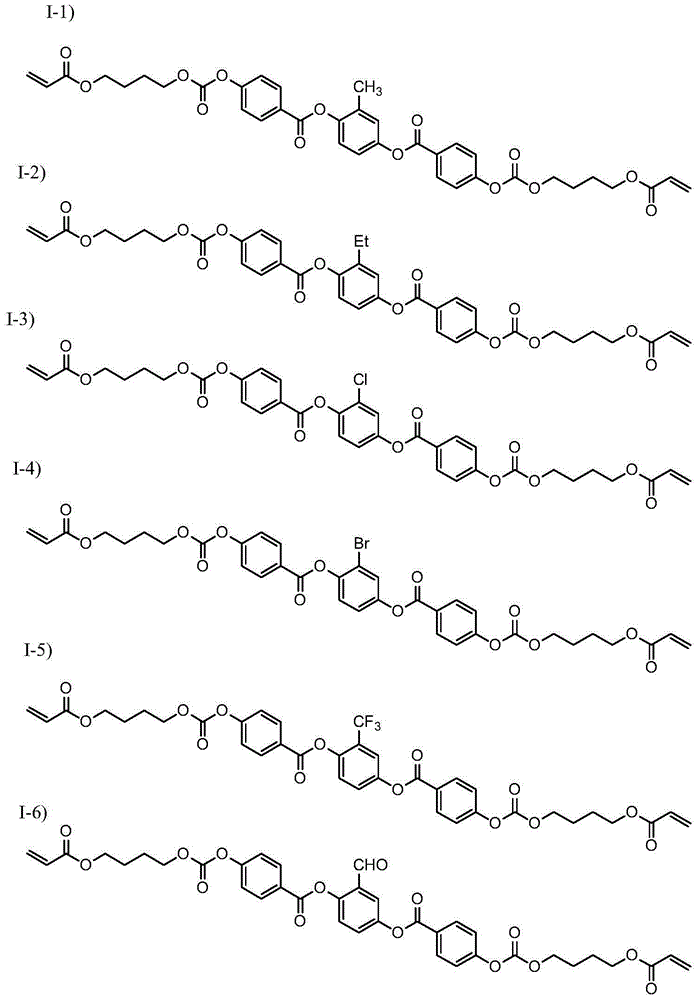

The present invention provides a method for producing an optical interference pigment, said method being characterized by comprising a step of hardening the alignment state of a polymerizable liquid crystal compound to produce a film having a fixed cholesteric liquid crystal structure, a step of crushing the film having a cholesteric liquid crystal structure to produce optical interference particles, and a step of washing the optical interference particles at a temperature of 35˚C or higher using at least an organic solvent having an SP value of 8.5 to 12 (cal / cm3)1 / 2, wherein the SP value represents a solubility parameter (δ) as measured by a Hoy method and is represented by formula (1): δ = (ΔE / V)1 / 2 (wherein V represents the molar molecular volume of the solvent; and ΔE represents a cohesive energy). The production method enables the provision of an optical interference pigment that has good light reflection performance at a selective reflection wavelength when being dispersed in a dispersion medium.

Owner:FUJIFILM CORP

Wound healing promoting gel and preparation method thereof

InactiveCN107049930APromote healingIncrease infectionOrganic active ingredientsAerosol deliveryCross-linkIn vivo

The invention relates to wound healing promoting gel and a preparation method thereof. The wound healing promoting gel is prepared by forming a gel matrix by oxidized alginate and diamine or diamidogen matters through a cross-linking reaction and compounding the following components in parts by weight: 5 to 10 parts of carbomer, 10 to 20 parts of isomalto-oligosaccharide, 0.1 to 10 parts of a wound healing promoting drug, 5 to 20 parts of a skin penetration enhancer and 40 to 70 parts of purified water. According to the wound healing promoting gel disclosed by the invention, after alginate is partially oxidized by sodium periodate which is subjected to a specific technology, carboxyl active genes in alginic acid can be activated, occurrence of the cross-linking reaction can be quickened, and the production efficiency of the gel is increased; alginate gel prepared by the invention has higher cohesive energy, is easy to form and not easy to crack, can be suitable for wounds in any parts, and is also capable of inhibiting reproduction of in-vivo harmful bacteria and generation of poisonous corrupt matters, expressing the effects of stopping bleeding, resisting bacteria, clearing wounds and promoting wound healing, and greatly shortening the healing time of the wounds.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

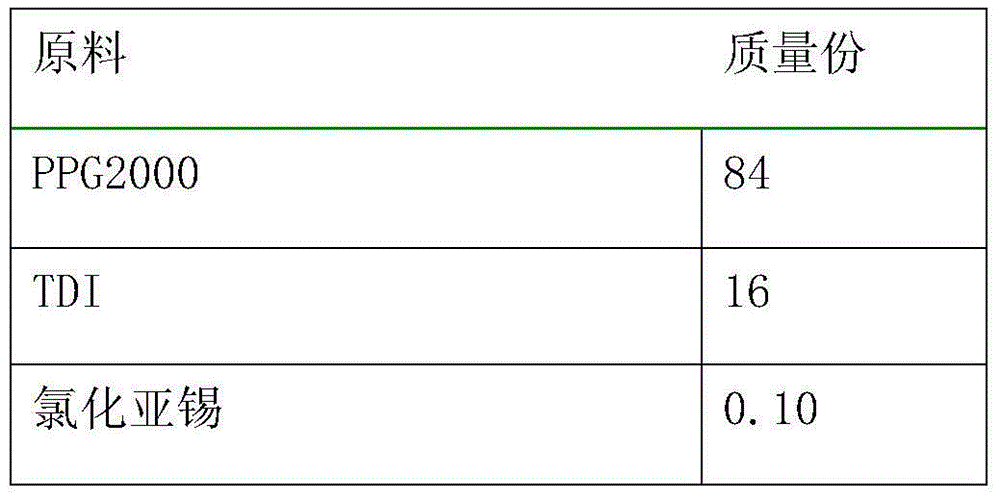

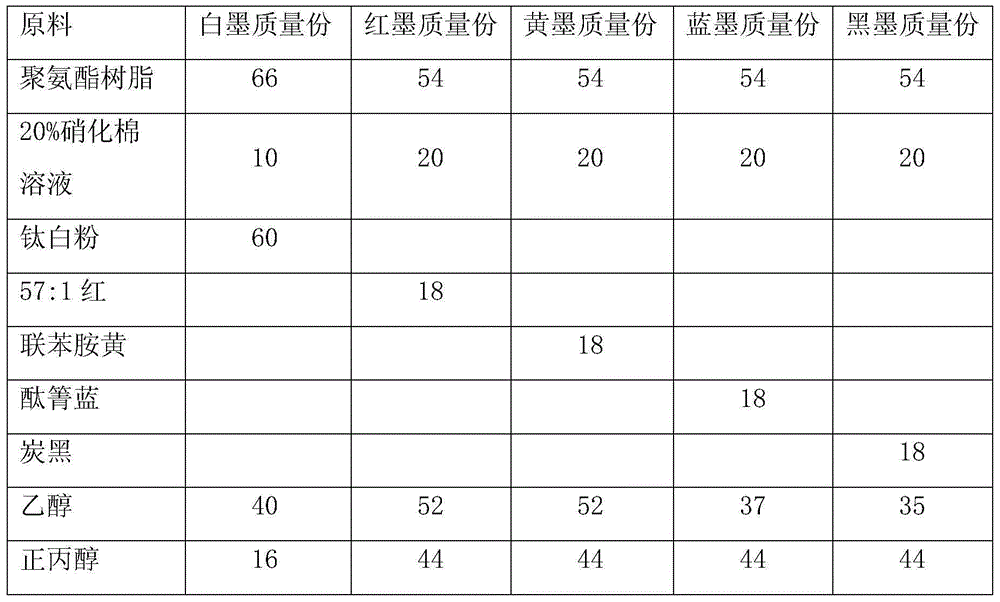

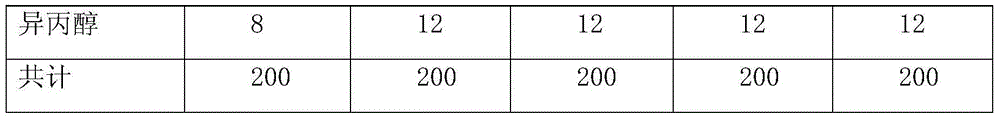

Method for preparing polyurethane binder for flexible printing composite ink

The invention discloses a method for preparing a polyurethane binder for flexible printing composite ink. The method comprises the following steps: preparing a terminal-NCO group prepolymer, namely, mixing polyether glycol, a catalyst and diisocyanate, reacting for 2-4 hours at 50-120 DEG C to obtain a reaction product, namely, the terminal-NCO group prepolymer; and carrying out chain extension synthesis, namely, adding an amine chain extender and an alcohol solvent into an another container to form a mixed solution, feeding the prepared terminal-NCO group prepolymer to the mixed solution within 5-50 minutes and carrying out chain extension reaction for 2-3 hours to obtain polyurethane resin, namely, polyurethane binder for flexible printing composite ink, wherein the reaction temperature is controlled at 30-50 DEG C. The prepared resin has the advantages of good solubleness in alcohol, high cohesive energy, excellent dryness and adhesion force, high composite strength, excellent printability, no foreign smell, no residue, safety and environmental friendliness after printing.

Owner:BEIJING COMENS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com