Patents

Literature

478results about How to "Tight texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Various grains nutritious vermicelli produced with dual-extrusion pressing and compound steam combined method

InactiveCN101366479AImprove qualityGreat tasteDough extruding machinesFood preparationCombined methodThermal stability

The invention relates to flour food, in particular to a minor cereal nutrient dried noodle produced by a double extrusion and secondary steaming combination method and a preparation method thereof. The invention is characterized in that the minor cereal nutrient dried noodle is prepared through the following steps: five cereals are taken as main raw materials, cucurbits, vegetables and potatoes are added or are not added, an auxiliary material capable of improving and enhancing the quality of a product and a complex quality improvement liquid are added, and processes such as raw material pretreatment, mixing and stirring, noodle-making molding by the double extrusion and secondary steaming combination method, drying, cutting, packing and so on, are performed. The reasonable formula design and the noodle-making molding process by the double extrusion and secondary steaming combination method, namely a process of steaming and cooking once again after two-stage extrusion molding, assure the balanced nutrition and the strong health care function of the product, and the minor cereal nutrient dried noodle has the advantages of long storage period, steady quality, no turbid soup during the cooking, boiling fastness, good thermal stability, smooth appearance, and chewy taste, and can be eaten as staple food like ordinary dried noodles.

Owner:奥生平 +1

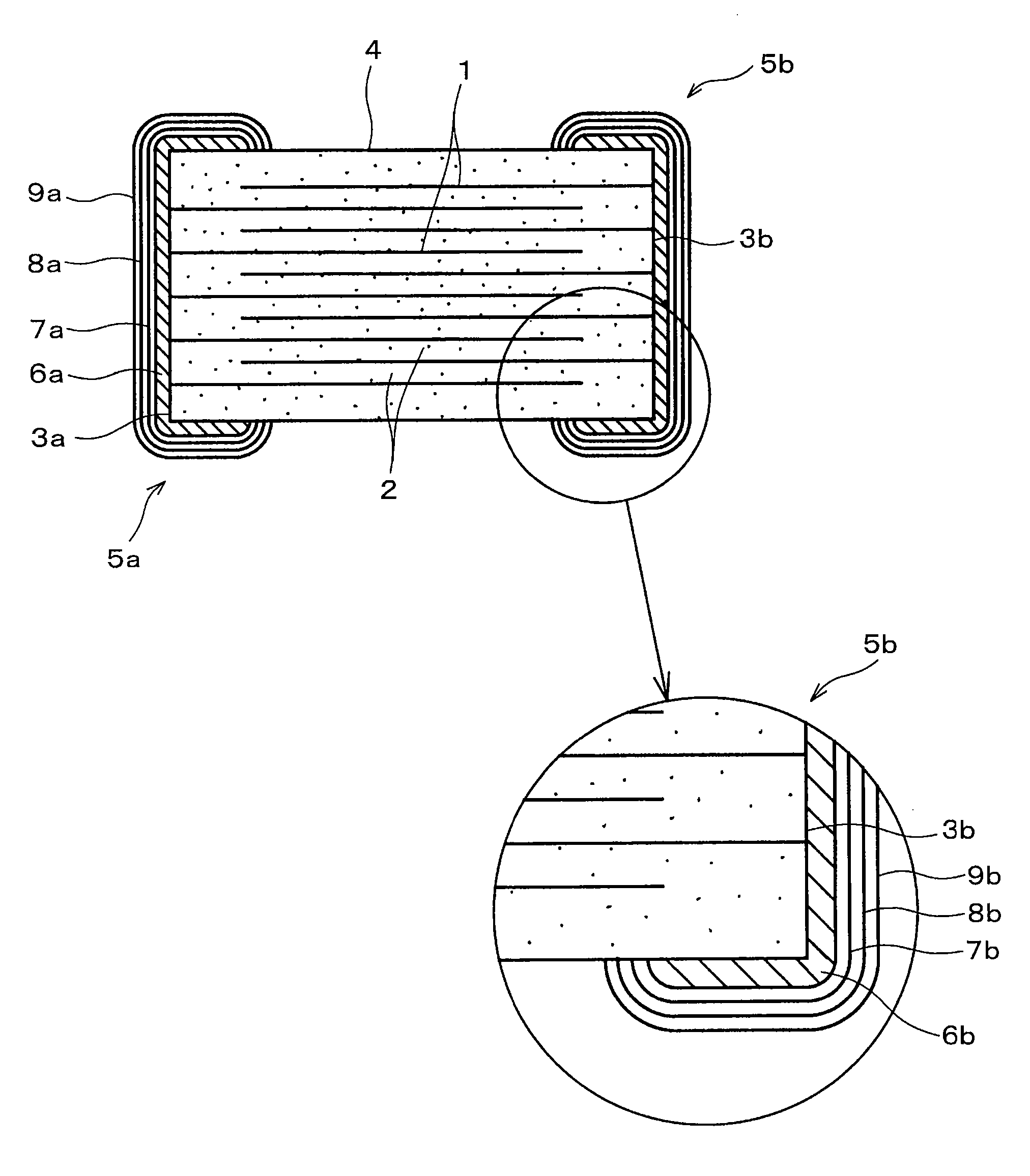

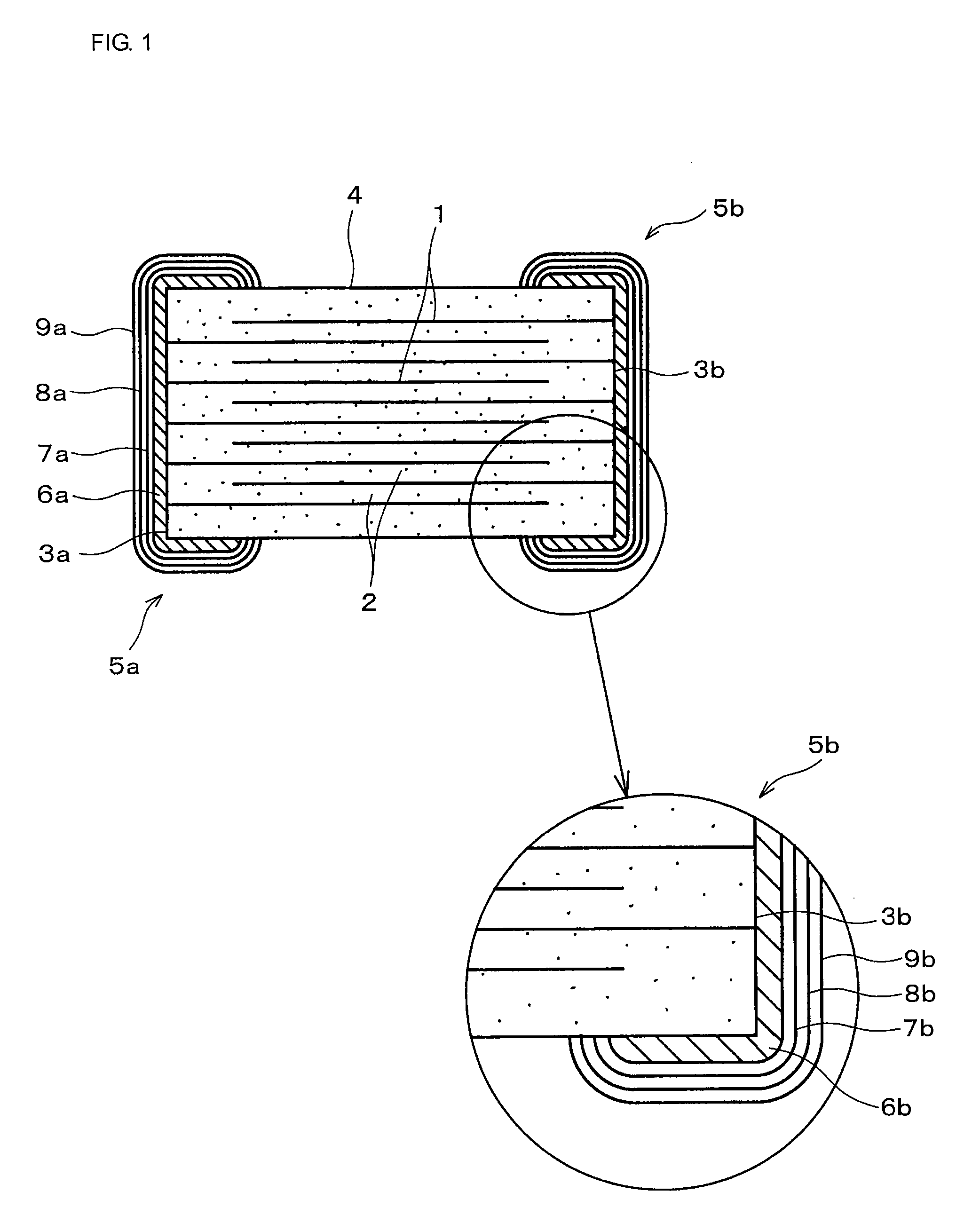

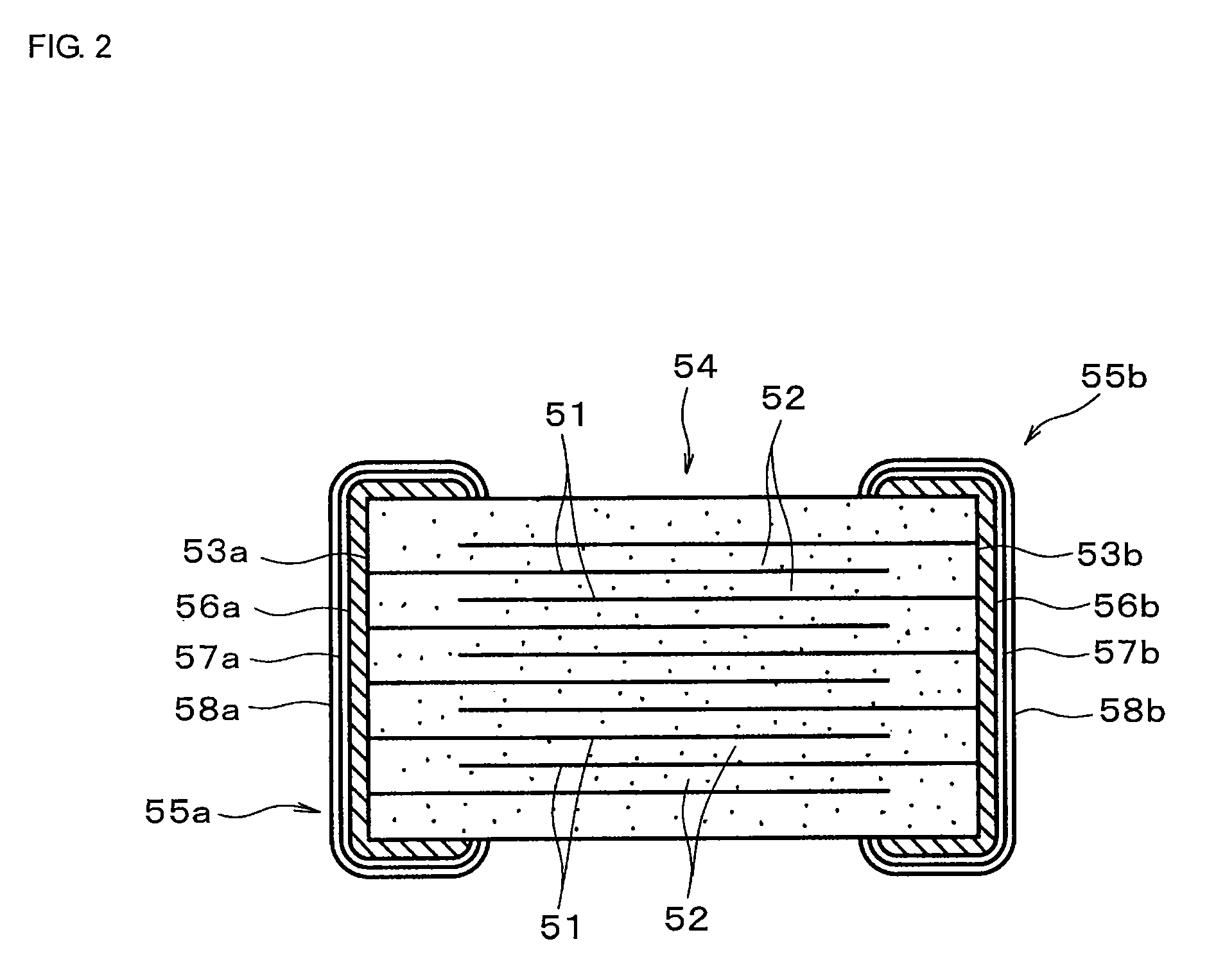

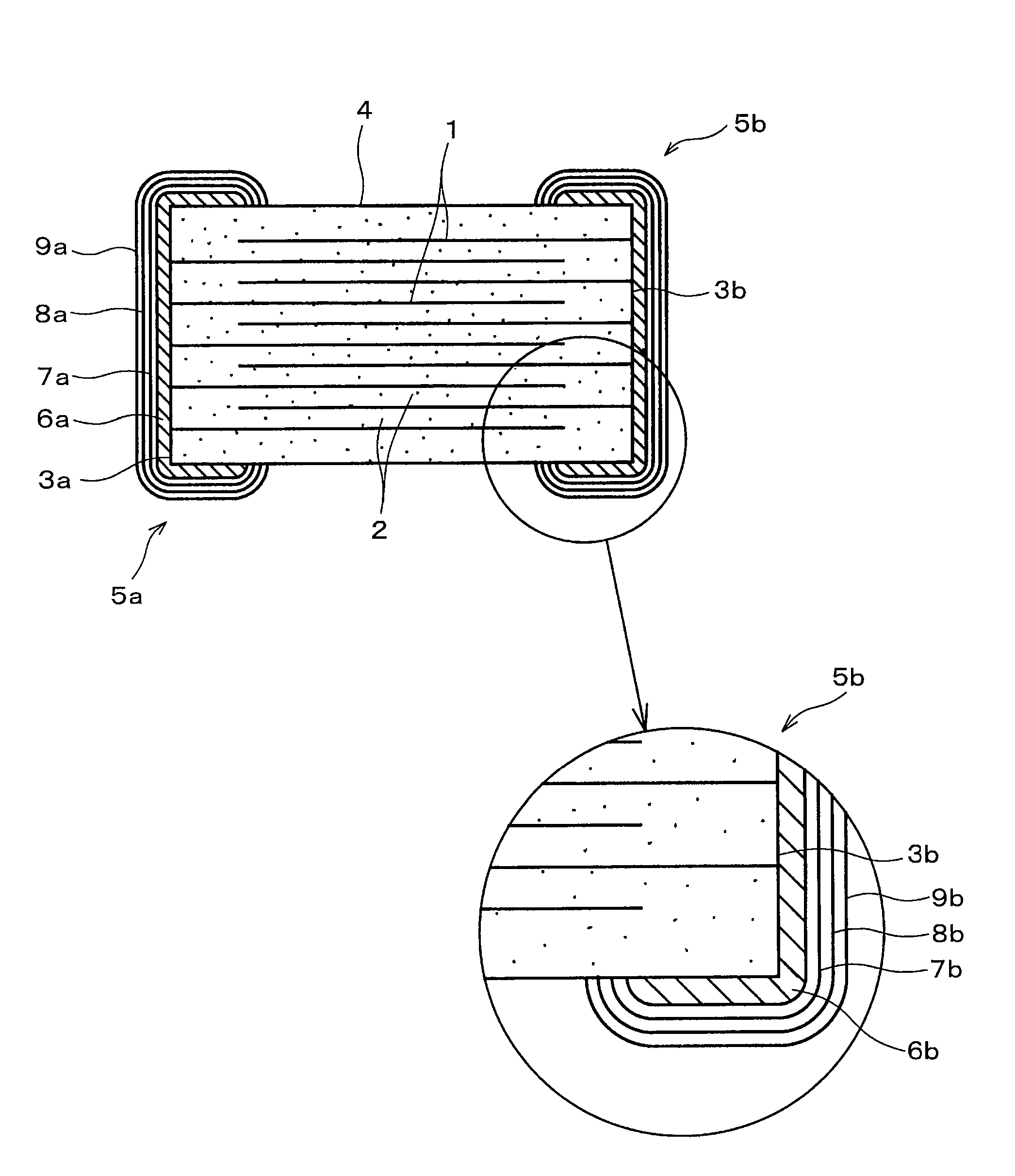

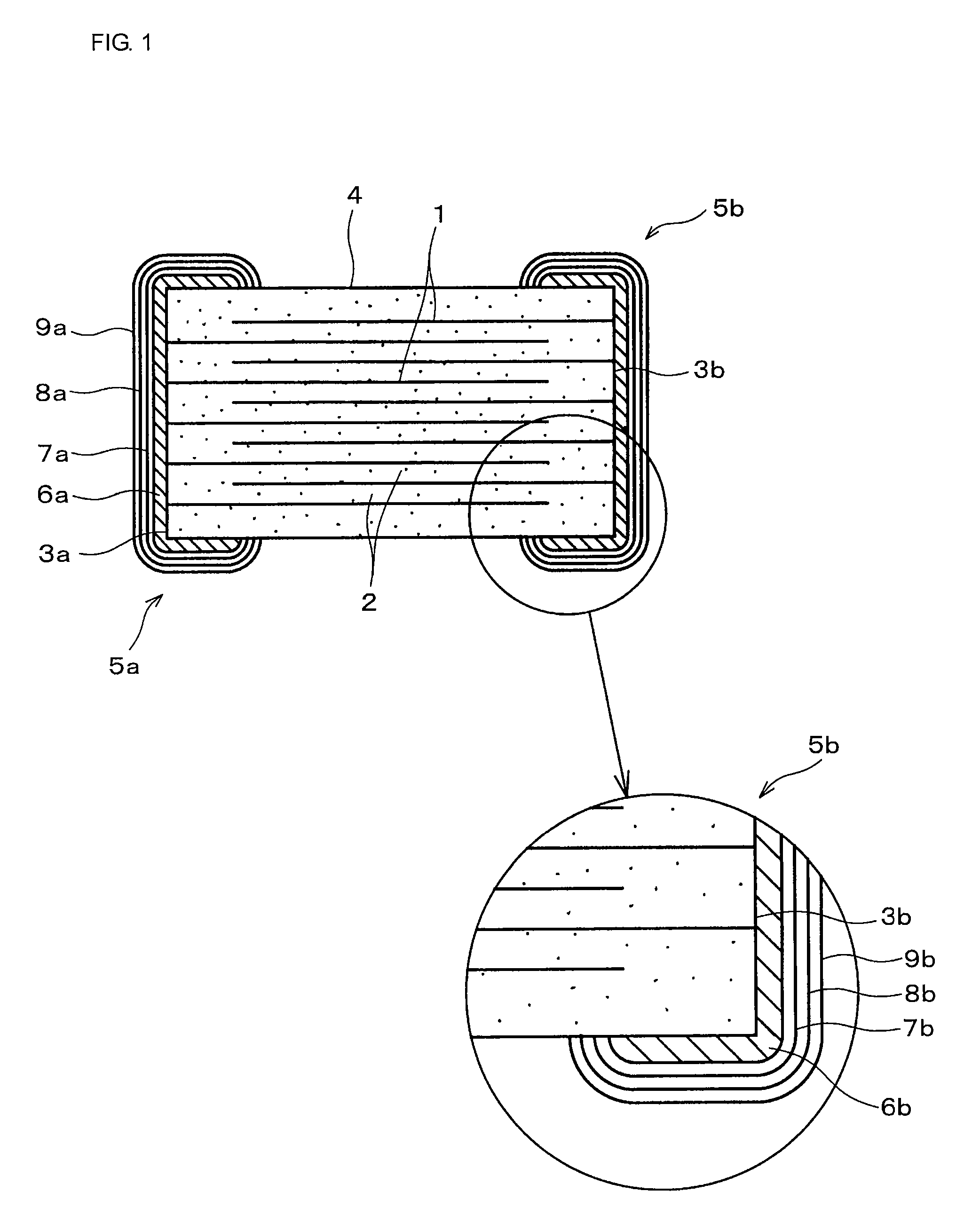

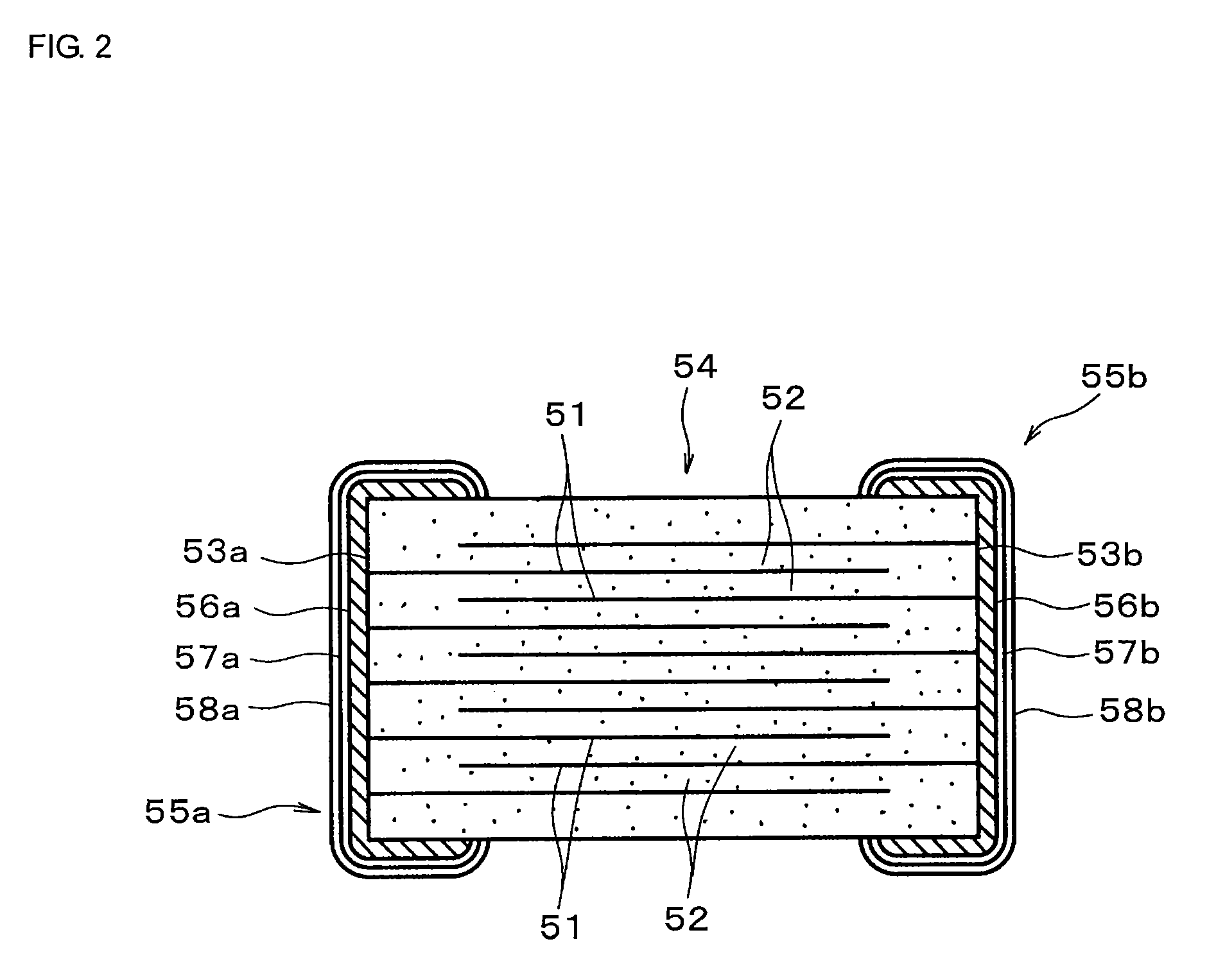

Electronic Device and Method for Manufacturing the Same

ActiveUS20080081200A1Suppress generationHigh reliabilityLiquid surface applicatorsFixed capacitor dielectricMoistureCopper

A highly reliable electronic device and a method for manufacturing the same are provided, the electronic device preventing entry of a plating solution via an external electrode and entry of moisture of external environment inside thereof, and generating no soldering defects nor solder popping defects which are caused by precipitation of a glass component on a surface of the external electrode. The structure is formed of Cu-baked electrode layers 6a and 6b primarily composed of Cu, Cu plating layers 7a and 7b which are formed on the Cu-baked electrode layers 6a and 6b and which are processed by a recrystallization treatment, and upper-side plating layers 9a and 9b formed on the Cu plating layers 7a and 7b. After the Cu plating layers 7a and 7b are formed, a heat treatment is performed at a temperature in the range of a temperature at which the Cu plating layers 7a and 7b are recrystallized to a temperature at which glass contained in a conductive paste is not softened (both inclusive), so that the Cu plating layers 7a and 7b are recrystallized.

Owner:MURATA MFG CO LTD

Processing method for rolling scissors with high abrasion resistance and strong shock resistance

InactiveCN103009026AImprove wear resistanceImprove impact resistanceFurnace typesHeat treatment furnacesEngineeringShock resistance

The invention discloses a processing method for rolling scissors with high abrasion resistance and strong shock resistance, belonging to the technical field of cutter processing. The processing method comprises the following steps of: (1) preparing the raw materials of rolling scissors; (2) carrying out annealing treatment of a forged blank at the annealing temperature of 940-960 DEG C; (3) rough processing of the forged blank; (4) heat processing which comprises annealing, quenching and tempering of the rolling scissors; (5) rough abrasion of the rolling scissors; (6) deep cooling of the rolling scissors, placing the rolling scissors in a liquid nitrogen deep cooling low temperature box at a temperature of minus 80 DEG C to minus 90 DEG C to be subjected to cooling treatment, and carrying out heat preservation for 1-1.5 hours; (7) secondary tempering of the rolling scissors at the tempering temperature of 500 DEG C, and carrying out heat preservation for 2 hours; and (8) fine processing of the rolling scissors. The rolling scissors prepared by the processing method are provided with a two-sided cutter point, the abrasion resistance and the shock resistance of the rolling scissors are further improved on the basis of material selection and processing technology, thus the rolling scissors are enabled to have remarkable performances of high abrasion resistance and shock resistance, and the requirement on cutting a hard board of a user is met.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

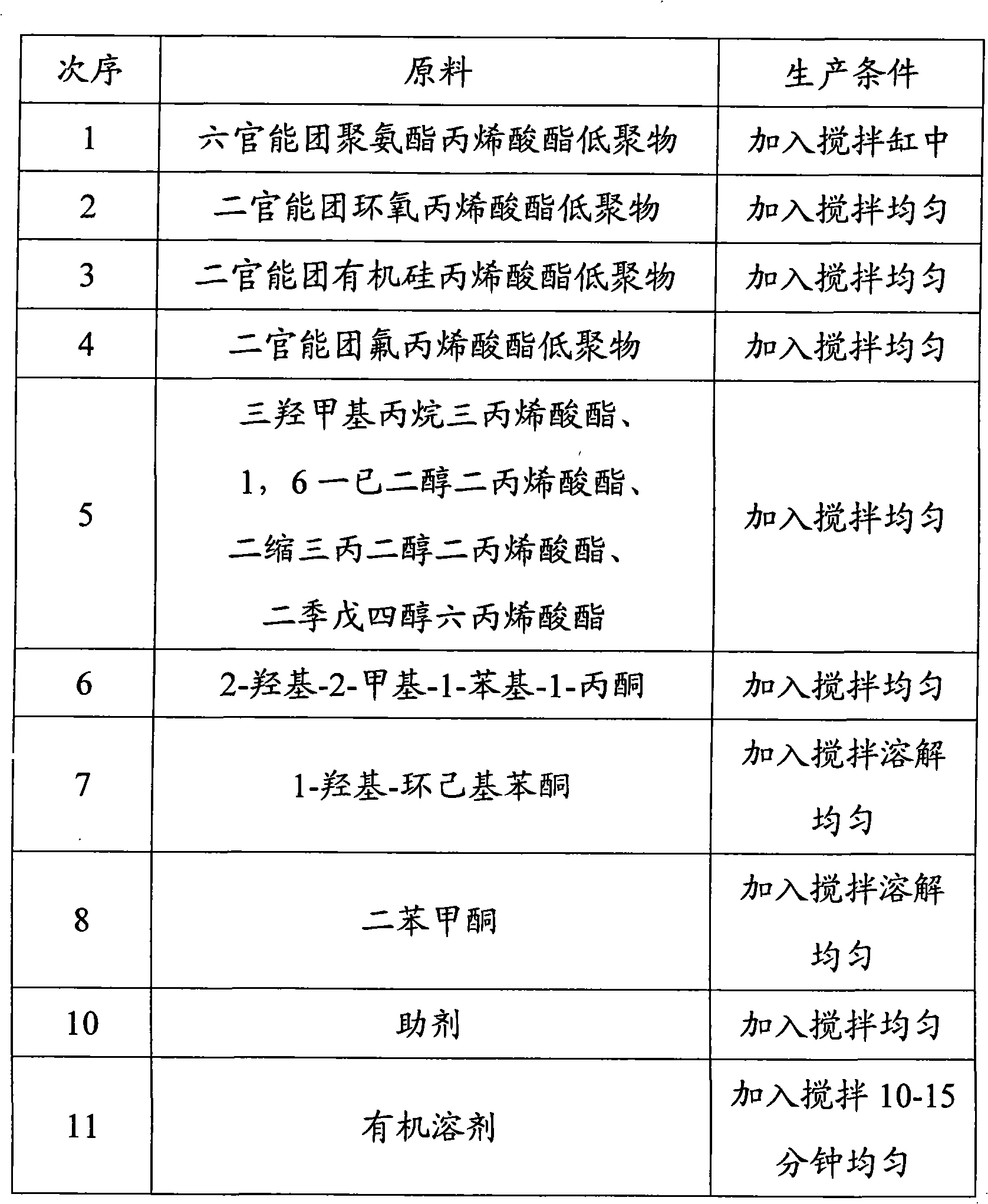

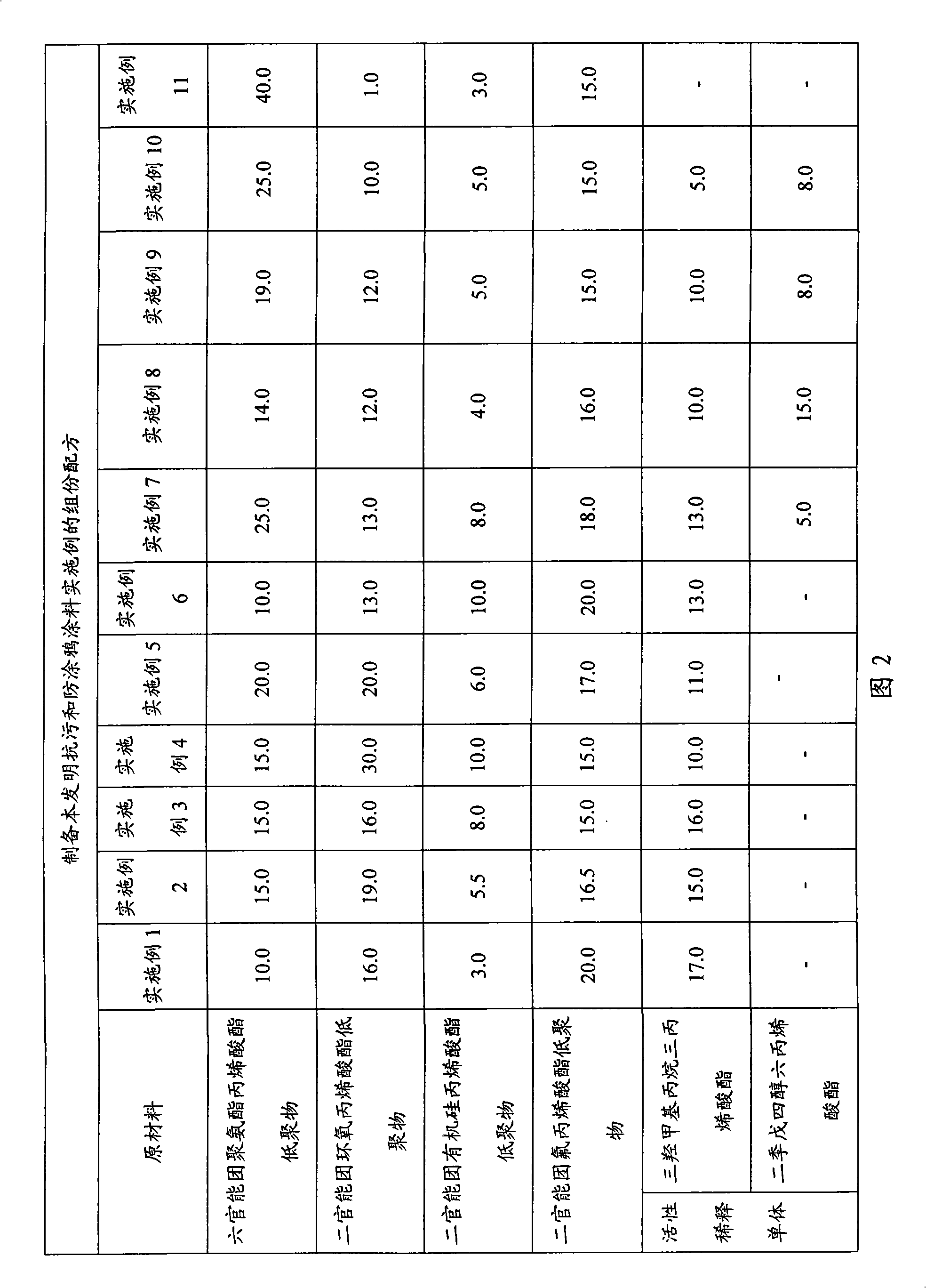

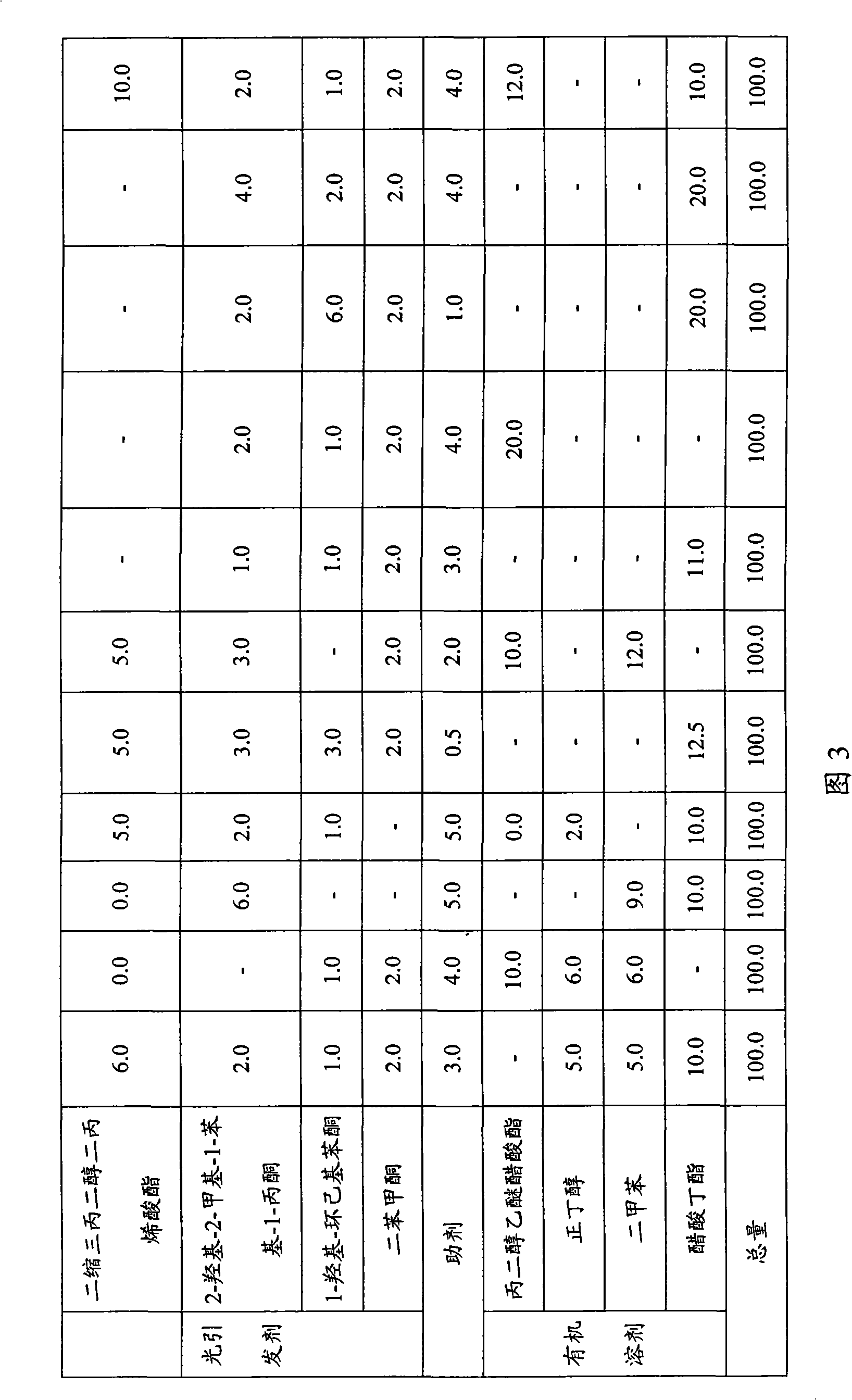

Antisoil and anti-graffiti coatings and method for preparing same

ActiveCN101333347ADissolve evenlyStir wellAntifouling/underwater paintsPaints with biocidesOligomerOrganic solvent

The invention discloses an anti-fouling and anti-doodling dope and a preparation method. The dope contains the following ingredients(based on weight portions): 15-20 portions of biradical fluoro-acrylate oligomer, 3-10 portions of biradical silicone acrylate oligomer, 10-40 portions of 6-radical polyurethane acrylate oligomer, 1-30 portions of biradical epoxy acrylate oligomer, 1-10 portions of photoinitiator, 10-25 portions of reactive diluted monomer, 0.5-5 portions of addition agent and 10-25 portions of organic solvent. Paint film made from the anti-fouling and anti-doodling dope is structurally compact, with surface tension reaching 27-33dyne / centimeter and effectively prevents various doodling materials, such as oil pen, waterborne pen, ink jet and pollutant from infiltrating to the dope or the substrate, thus reducing cleaning difficulties; meanwhile, the dope is good in dirt resistance and doodling resistance and long in service life. The dope can be prepared by mixing the ingredients of the dope to be even, so the preparation method is economic and simple.

Owner:CHINA PAINT MFG CO SHENZHEN

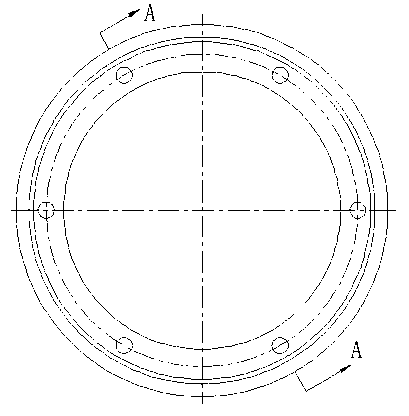

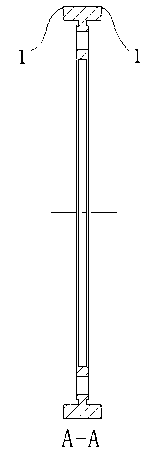

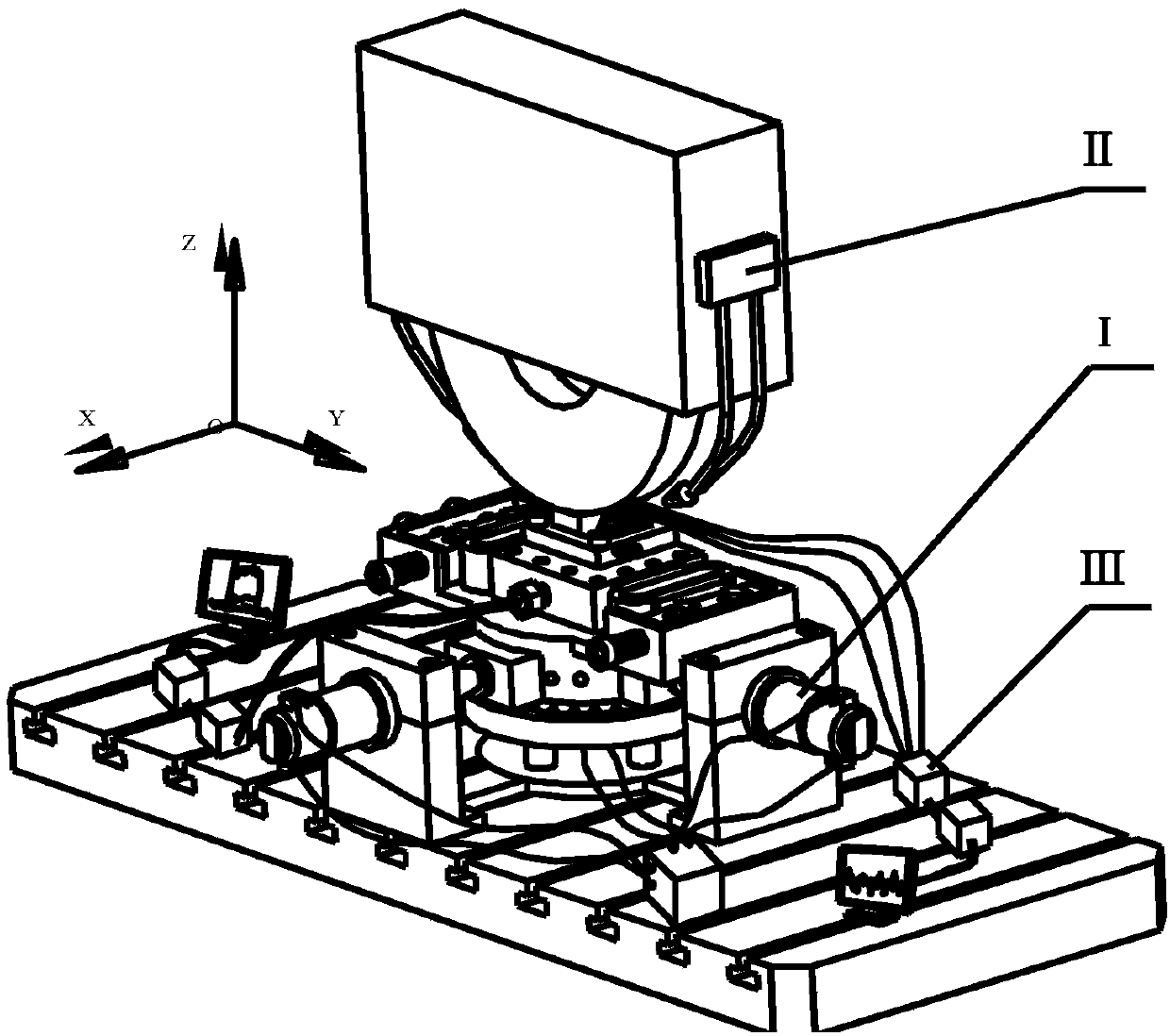

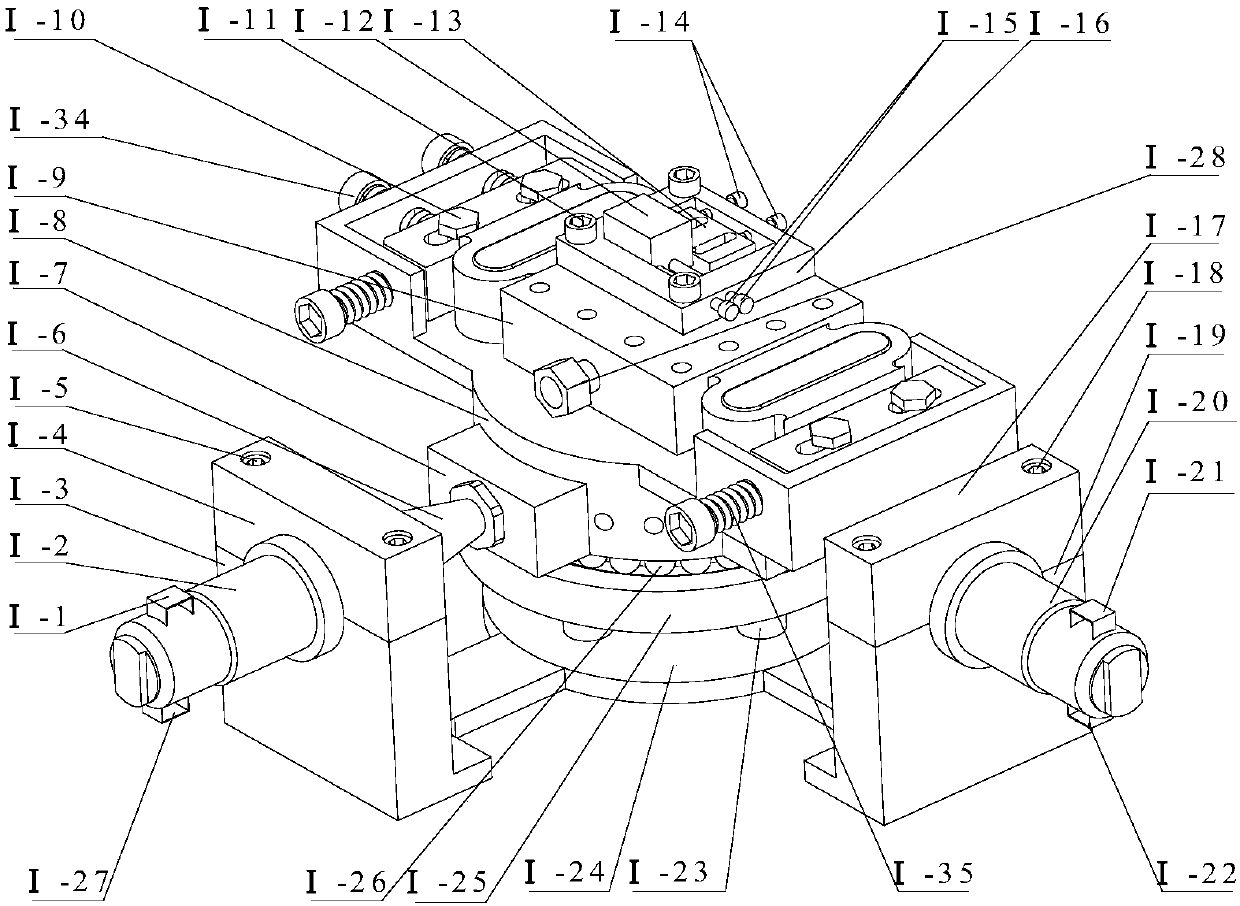

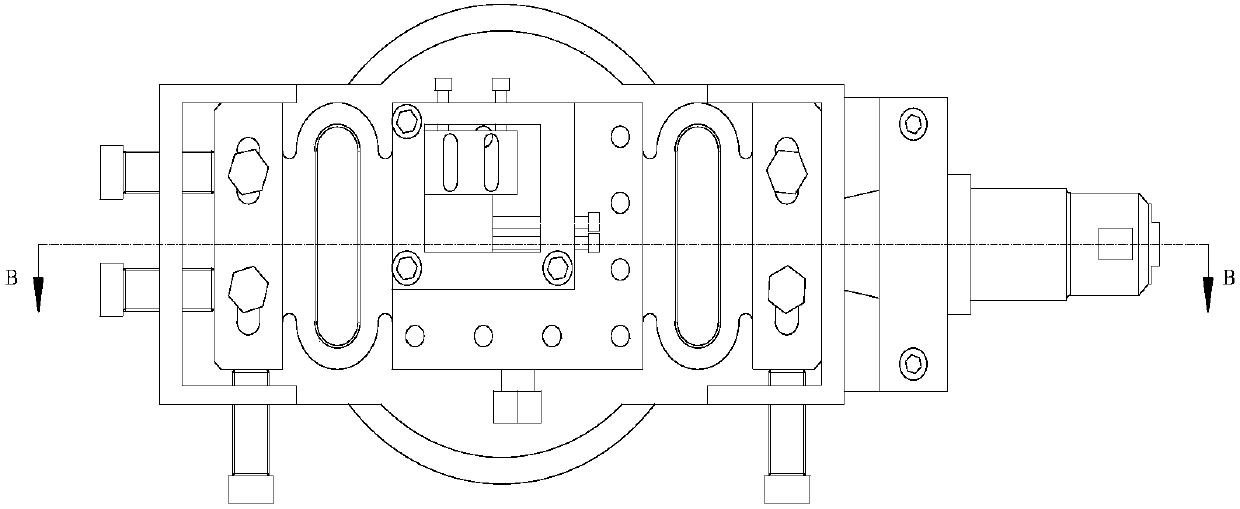

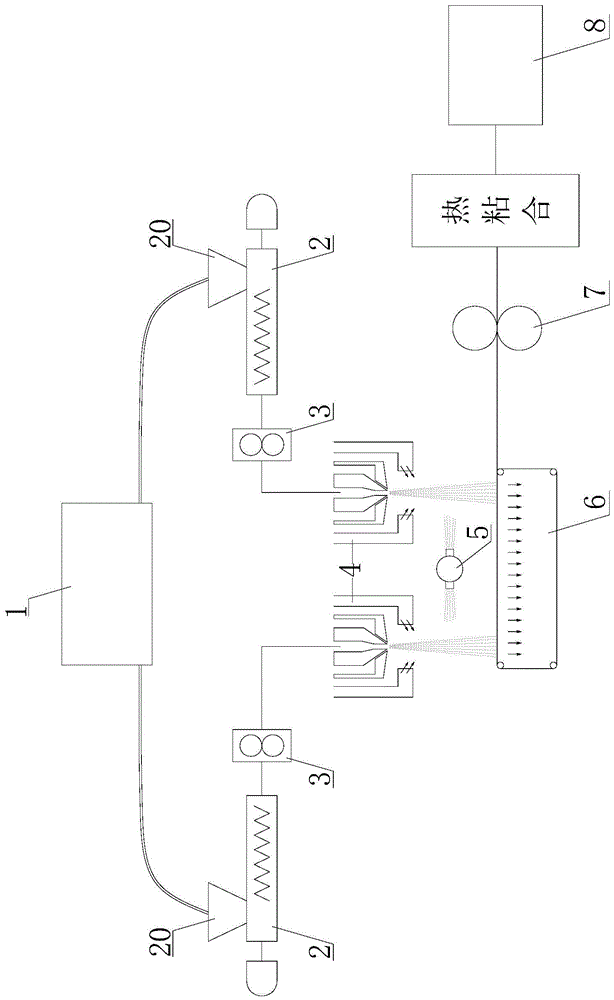

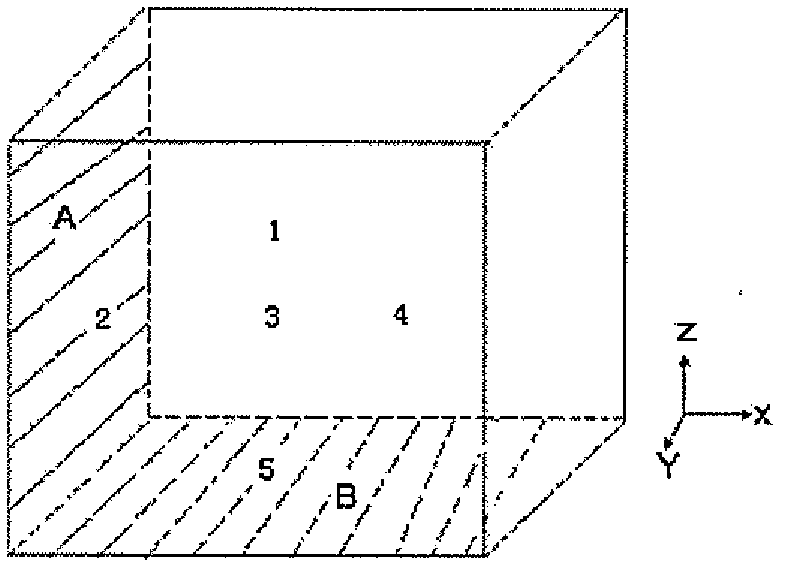

Nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding

InactiveCN107336086AImprove surface qualityDifferent grinding effectsUltrasonic vibrationLubrication

The invention discloses a nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding. The system comprises a magnetism worktable, a workpiece clamp, a measuring cell and an ultrasonic vibration device; the ultrasonic vibration device comprises a tangential ultrasonic vibration device, an axial ultrasonic vibration device, a vibrating base and radial piezoelectric ceramic pieces fixed on the vibrating base; the tangential ultrasonic vibration device and the axial ultrasonic vibration device are respectively fixed on the vibrating base and meanwhile, are respectively fixed on the magnetism worktable by supports, the measuring cell is fixed on the vibrating base and the workpiece clamp is fixed on the measuring cell. The nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding have the advantages that simultaneous online detection of a grinding force and a grinding temperature are realized, time is saved, and the machining errors caused by assembling for multiple times are also avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Super-soft skin-close mask specific non-woven fabric and manufacturing method for same

ActiveCN105463699ANon-toxic, tasteless and odorlessLow densityCosmetic preparationsToilet preparationsElastomerFiber

The invention discloses a super-soft skin-close mask specific non-woven fabric comprising the following components by parts: 35 to 105 parts of propylene based elastomer, 12 to 36 parts of polypropylene resin, 2.5 to 7.5 parts of hydrophilic master batches and 0.5 to 1.5 parts of soft master batches. The invention further provides a manufacturing method for the super-soft skin-close mask specific non-woven fabric. The manufacturing method comprises the following steps of preparing raw material, mixing and stirring raw material, conveying raw material, fusing and extruding, extruding spinning filaments, forming a net via air flows, conducting a heat bonding technology and cutting and packing. The manufacturing method for the super-soft skin-close mask specific non-woven fabric has simple steps; Vistamaxx 7050 type propylene based elastomer and S2040 type polypropylene resin are raw material for the non-woven fabric fibers and have great softness, small density and great skin-close property; a technical problem of decreased skin-close property of mask base cloth due to low density of the mask base cloth in the prior art can be solved; and mask base cloth quality and practicality can be enhanced.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

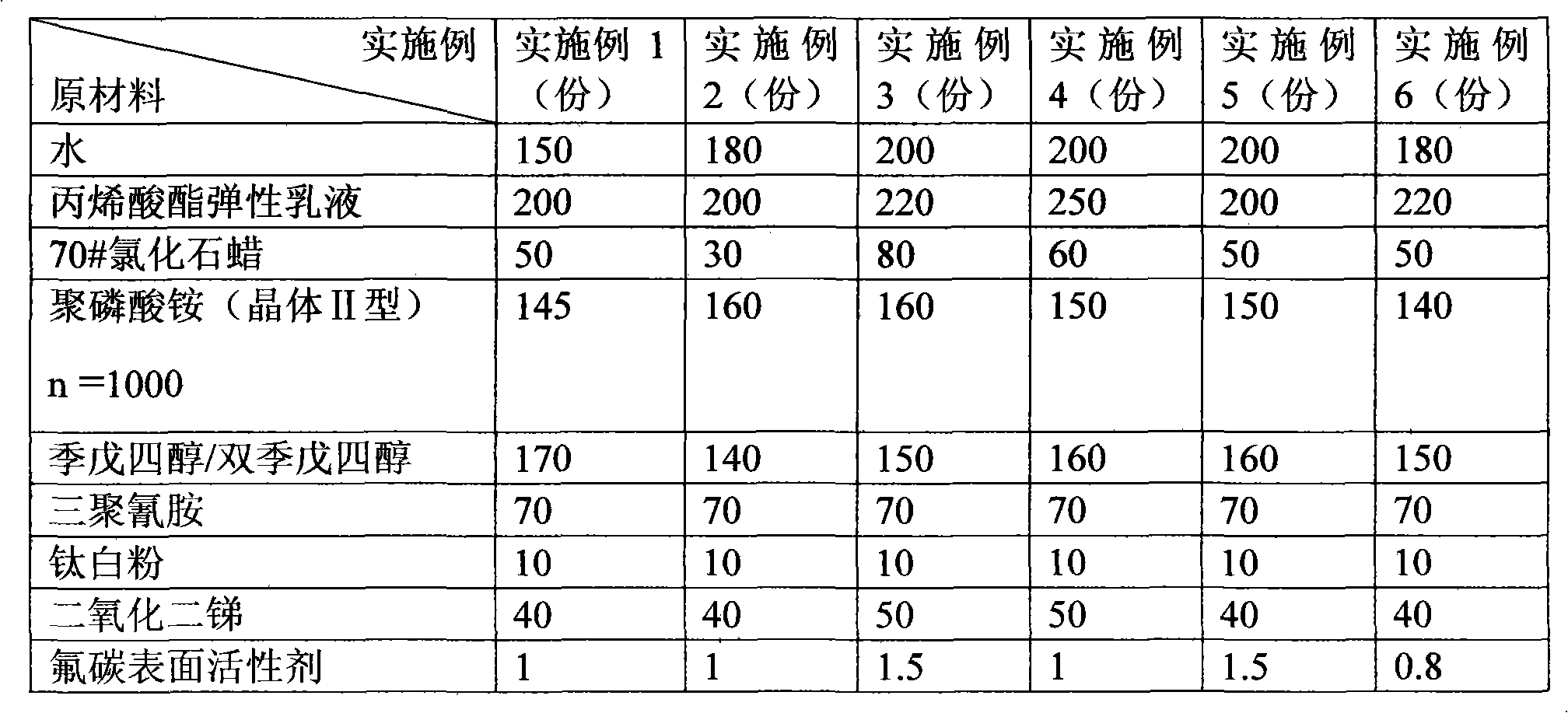

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

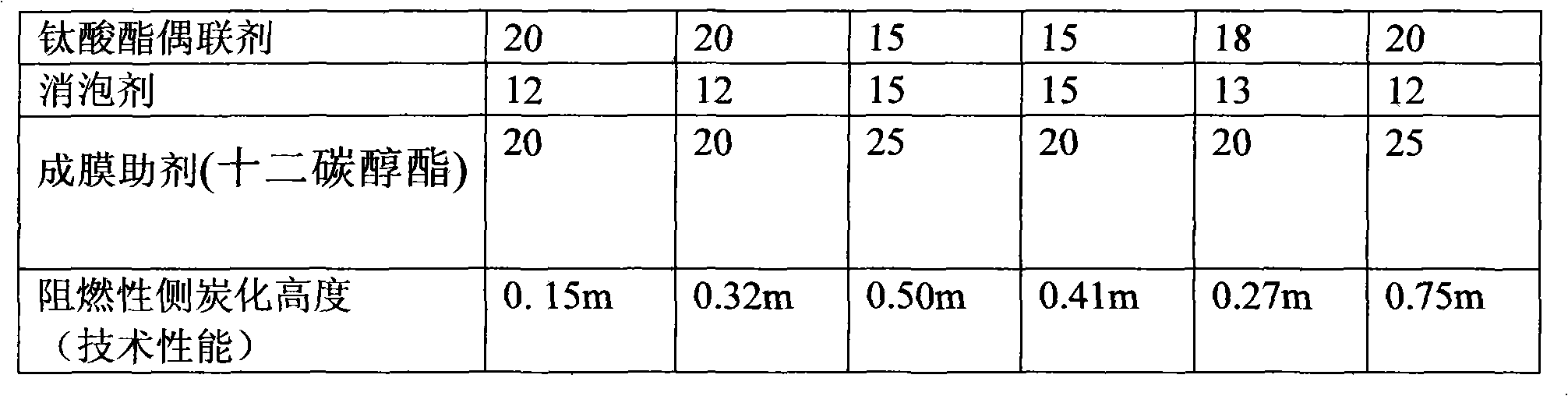

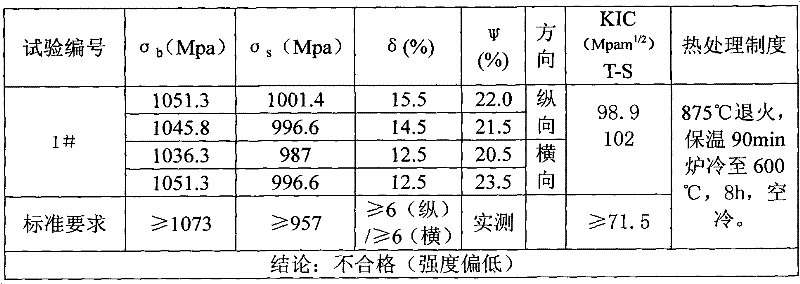

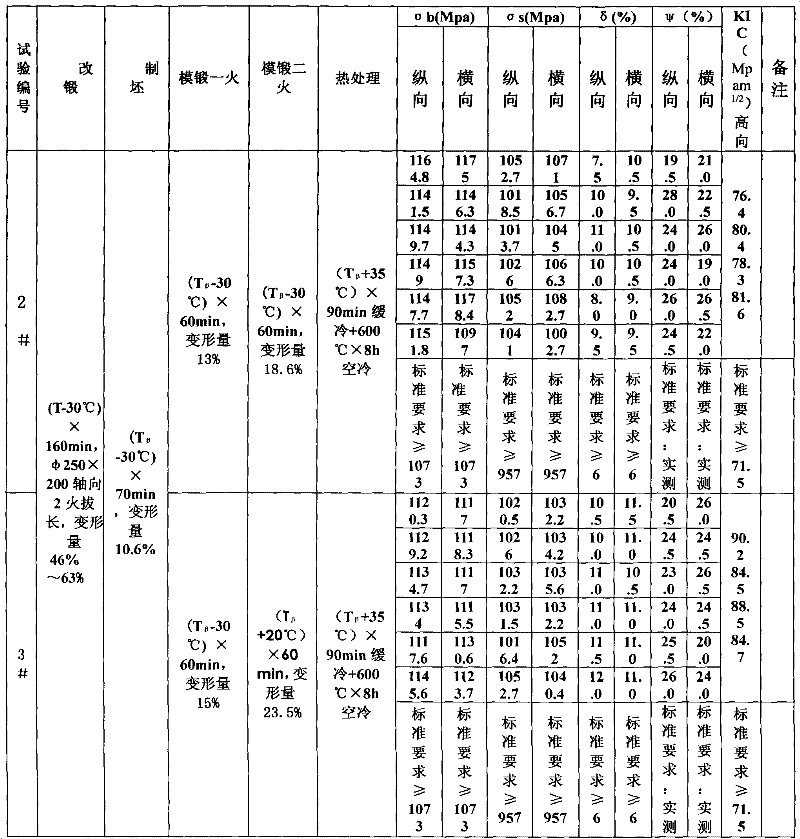

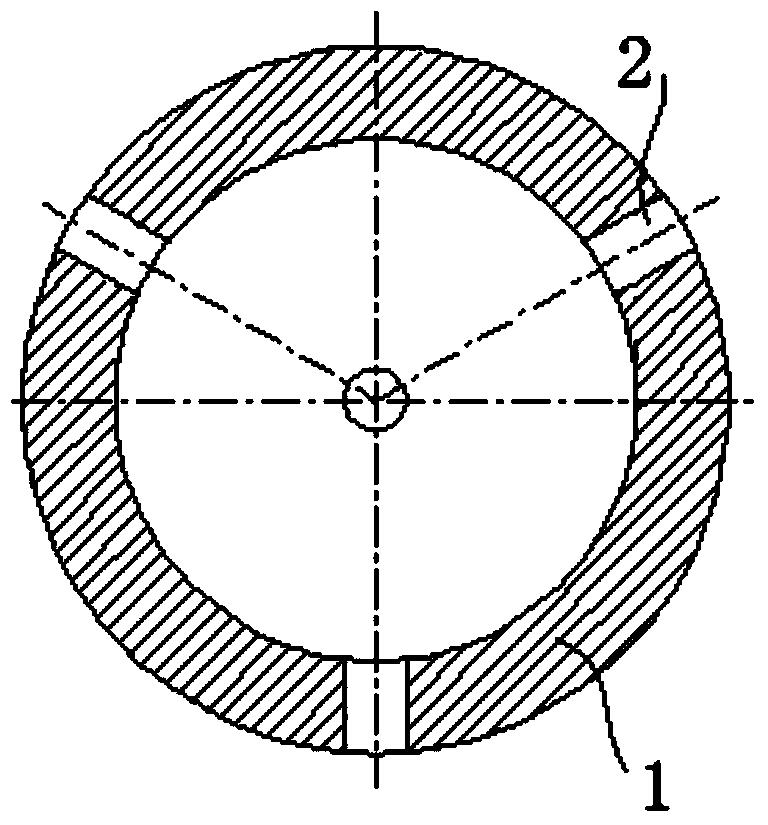

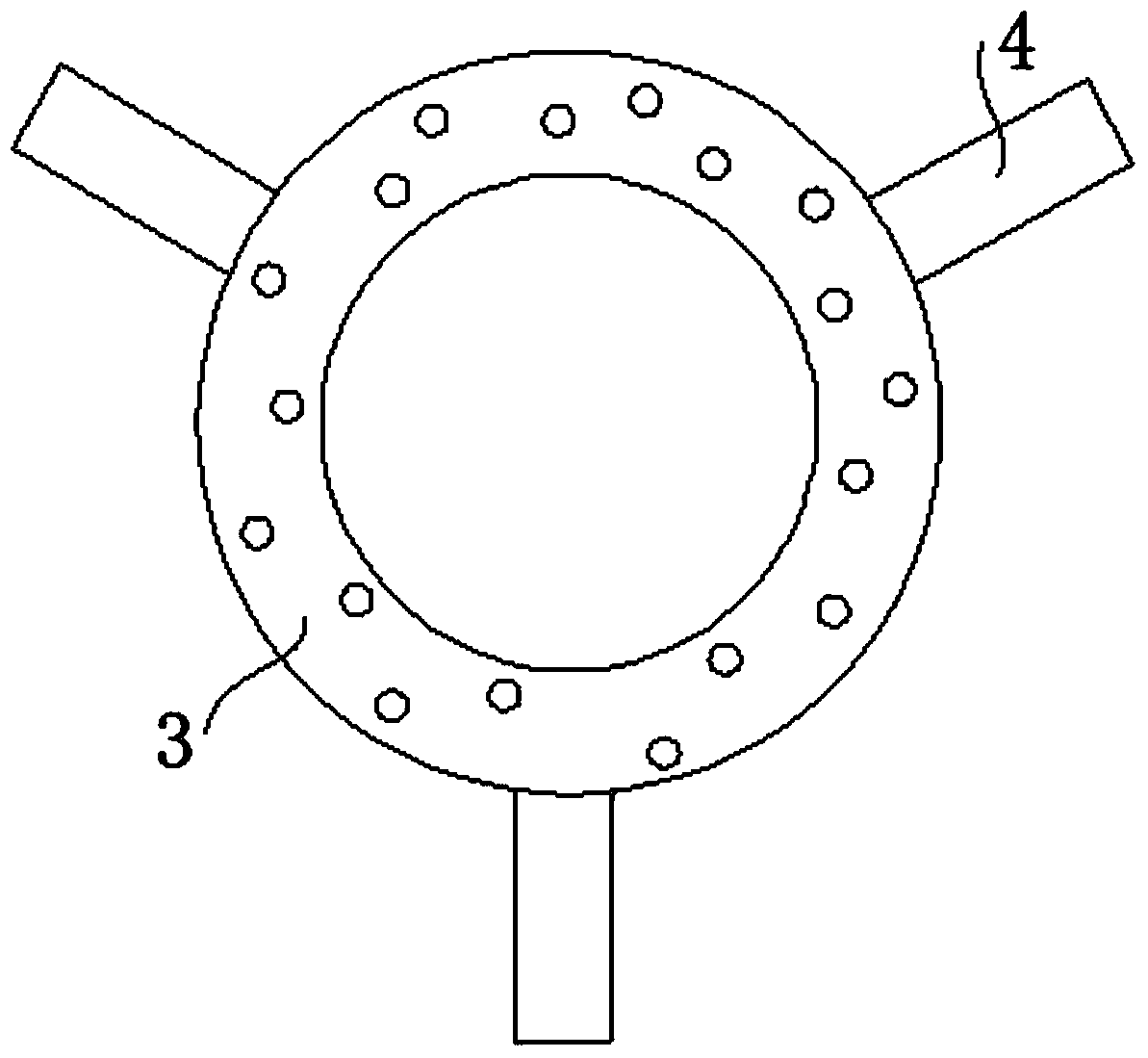

Hot working method for improving structure property of Ti5553 titanium alloy

The invention discloses a hot working method for improving structure property of Ti5553 titanium alloy, which comprises the steps of: firstly, performing two-phase region re-forging (alpha equiaxial+ beta transformation) on a titanium alloy blank; and then, performing beta forging on the re-forged blank (the beta forging is a forging method of heating above phase transformation point); and finally, performing beta thermal treatment to primarily form a fine and dense net basket structure after the re-forging operation; and a fine flaky alpha phase inversion in beta crystal grain and a fine, disperse and discontinuous alpha phase inversion at the crystal boundary are generated during the final beta thermal treatment process to improve the comprehensive structure property of the beta titanium alloy. By means of the heating re-forging in two-phase region (alpha equiaxial+ beta transformation) and the beta forging, nucleation energy and broken crystal structures formed by relatively large deformation quantity lay a good foundation for improving the flaky alpha phase inversion and the granular beta phase inversion in the successive beta thermal treatment, so as to obtain a member with uniform, fine and dense structure and good comprehensive performance indexes.

Owner:SHAANXI HONGYUAN AVIATION FORGING

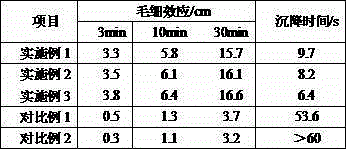

Multifunctional ore dressing chemical, synthesis method thereof and using method thereof

ActiveCN101890398AImprove protectionIncrease productivityFlotationSynthesis methodsOrganic synthesis

The invention discloses a multifunctional ore dressing chemical, and a using technique thereof. The chemical can be widely used for treating various ore resources. A synthesis method of the multifunctional ore dressing chemical comprises the following steps: preparing colloidal solution of an inorganic oxide and a hydroxide; dissolving an organic monomer in the colloidal solution of the inorganicoxide and the hydroxide; adding an initiator into the solution to complete organic synthesis a reaction kettle. The obtained multifunctional ore dressing chemical which has a selective flocculation function is added into the flotation pulp to help ore separation in ore flotation and solid-liquid separation in tailing processing. The using technique comprises: the flotation and tailing processing.The multifunctional ore dressing chemical also can be used in tailing processing alone. The multifunctional ore dressing chemical can improve production efficiency, improve mine environmental protection, greatly improve the economic benefits of the mine, improve the return water recovery effect and reduce mine environment pollution.

Owner:李海红

Preparation method of large abrasion-proof hollow grinding ball

ActiveCN103639363AImprove organizationImprove hardenabilityFoundry mouldsFoundry coresSmelting processRare earth

The invention discloses a preparation method of a large abrasion-proof hollow grinding ball, and belongs to the technical field of metal abrasion-proof materials. The preparation method comprises the following steps: step 1, preparing a casting shape, wherein an air extraction support mechanism is prearranged in the core part of a foam plastic die sample, and comprises a support part and an extraction branch tube; step 2, performing a smelting process, wherein pouring molten steel comprises the following components in percentage by mass: 0.3-0.5% of C, 0.5-1.5% of Si, 0.5-2% of Mn, 1.0-3.0% of Cr, 1.0-3.0% of Ni, 0.5-2% of Mo, 0.24-0.32% of B, 0.28-0.35% of V, 0.08-0.13% of Ti, 0.8-1.2% of rare earth, less than or equal to 0.02% of P, less than or equal to 0.02% of S, the balance being Fe and inevitable impurities, and C% is equal to 1.2*B%+(0.06 to 0.13); step 3, performing a pouring process; and step 4, performing heat treatment. Through the preparation method of the large abrasion-proof hollow grinding ball, the problems of poor tenacity of the hollow grinding ball, the offset of a conventional sand type casting sand core and uneven ball wall can be solved.

Owner:马鞍山市海天重工科技发展有限公司

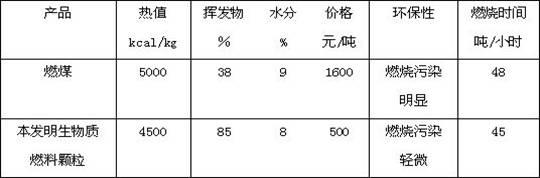

Biomass fuel with good formability

InactiveCN103666620AStrong coagulationCompact structureSolid fuelsWaste based fuelFiberEnvironmental resistance

The invention relates to environment-friendly biomass fuel with good formability. The biomass fuel is renewable biomass fuel free of any harmful substance, which is prepared by mixing wood dust powder and an additive, wherein the additive is high clay having high viscosity and strong adsorptive power; and the biomass fuel is prepared by mixing the wood dust and the additive according to a ratio of 9:1. The high clay additive is beneficial to formation of wood dust particles, and the multiporous fiber-like structure of the high clay additive can adsorb tar in flue gas from a heating system in the biomass fuel processing course, thereby preventing the tar from being attached to a granulator and a chimney and further avoiding influencing the granulating effect. Besides, the additive also solves the problem that the tar is difficult to remove and clean.

Owner:广州金安源节能科技股份有限公司

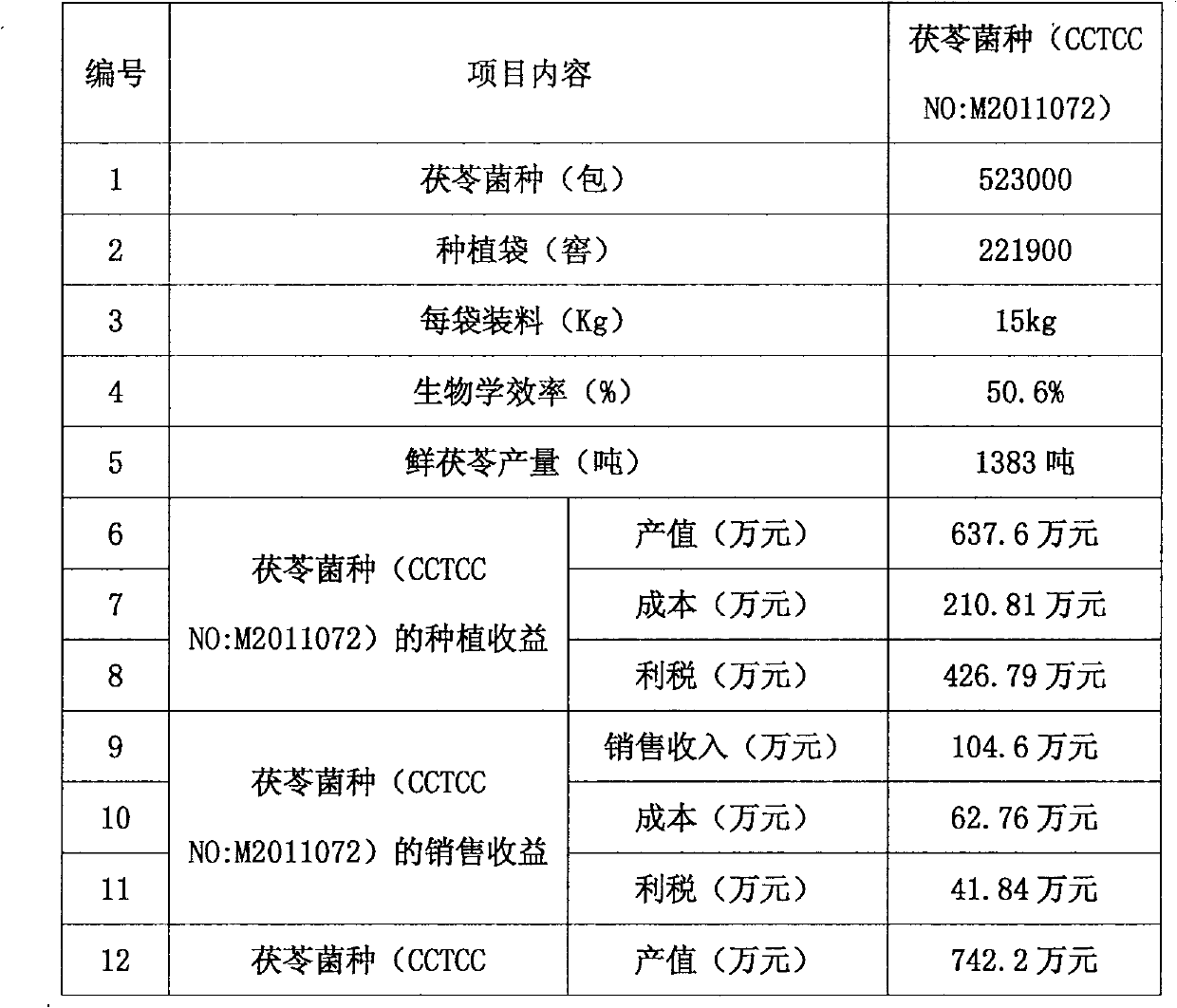

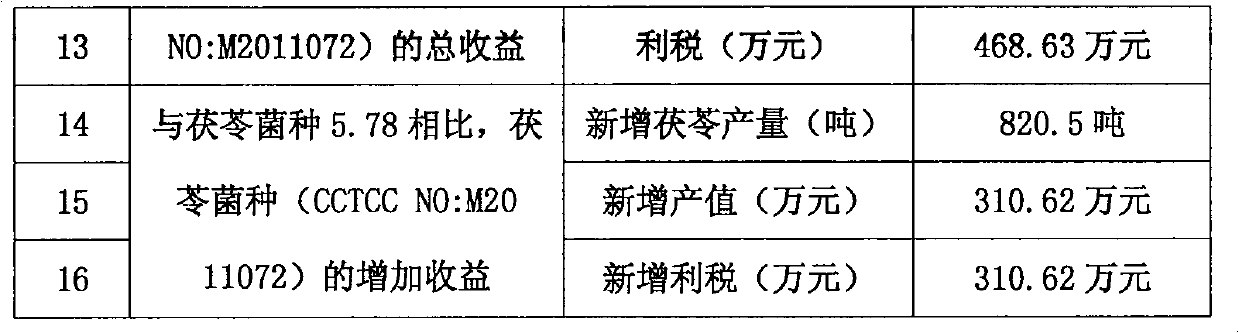

Novel tuckahoe strain and efficient cultivation technology thereof

The invention discloses a novel tuckahoe strain (china center for type culture collection (CCTCC) M2011072) and bag-material efficient cultivation technology. The novel tuckahoe stain is applied to cultivation by adopting the bag-material efficient cultivation technology. The novel tuckahoe stain is mainly characterized in that 1) a mycelium is strong, white, obvious in clamp connection; and hypha is spread quickly in a cultivation process; 2) the tuckahoe fruits earlier, the fruit body is even and strong, the color of pulp is white or light yellow, and the skin of tuckahoe is thin and presents purplish red color; 3)the novel tuckahoe strain has the advantages of being stable inheritable characteristics, strong in anti-bacteria infection capacity, high in biological efficiency and yield, good in quality and the like; and 4) the novel tuckahoe strain remarkably improves content of effective components of amino acid, pachymaran and the like in the tuckahoe.

Owner:HUNAN BUTIAN PHARMA

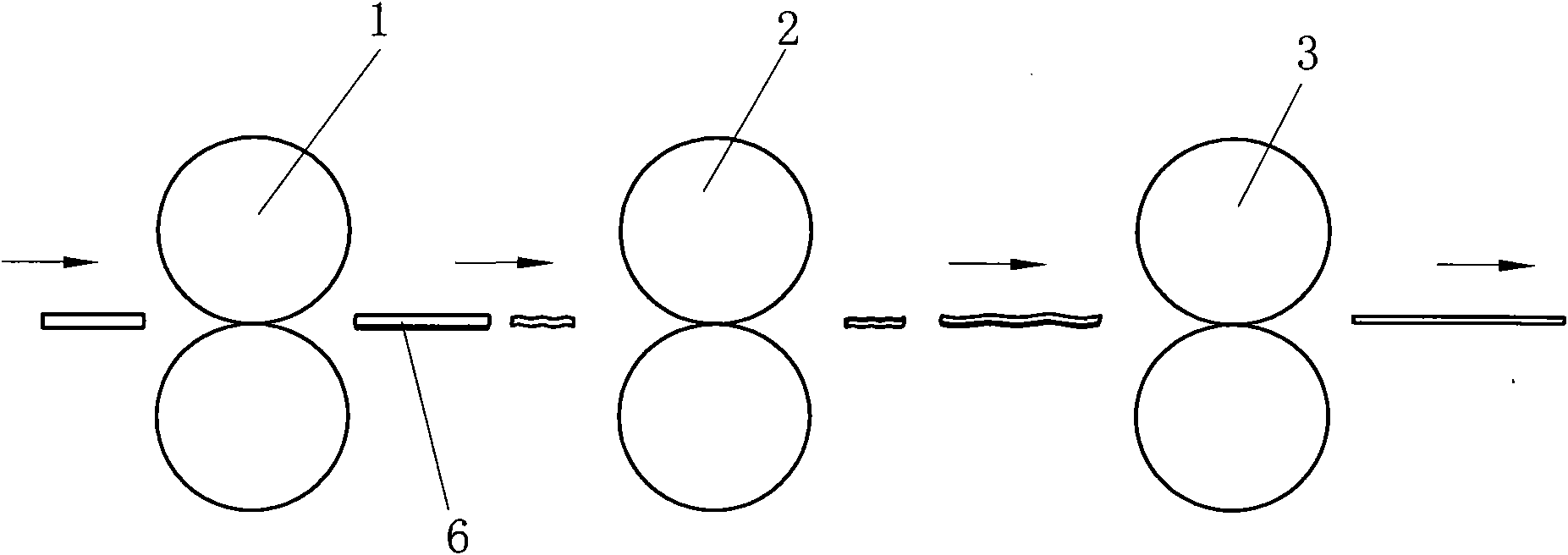

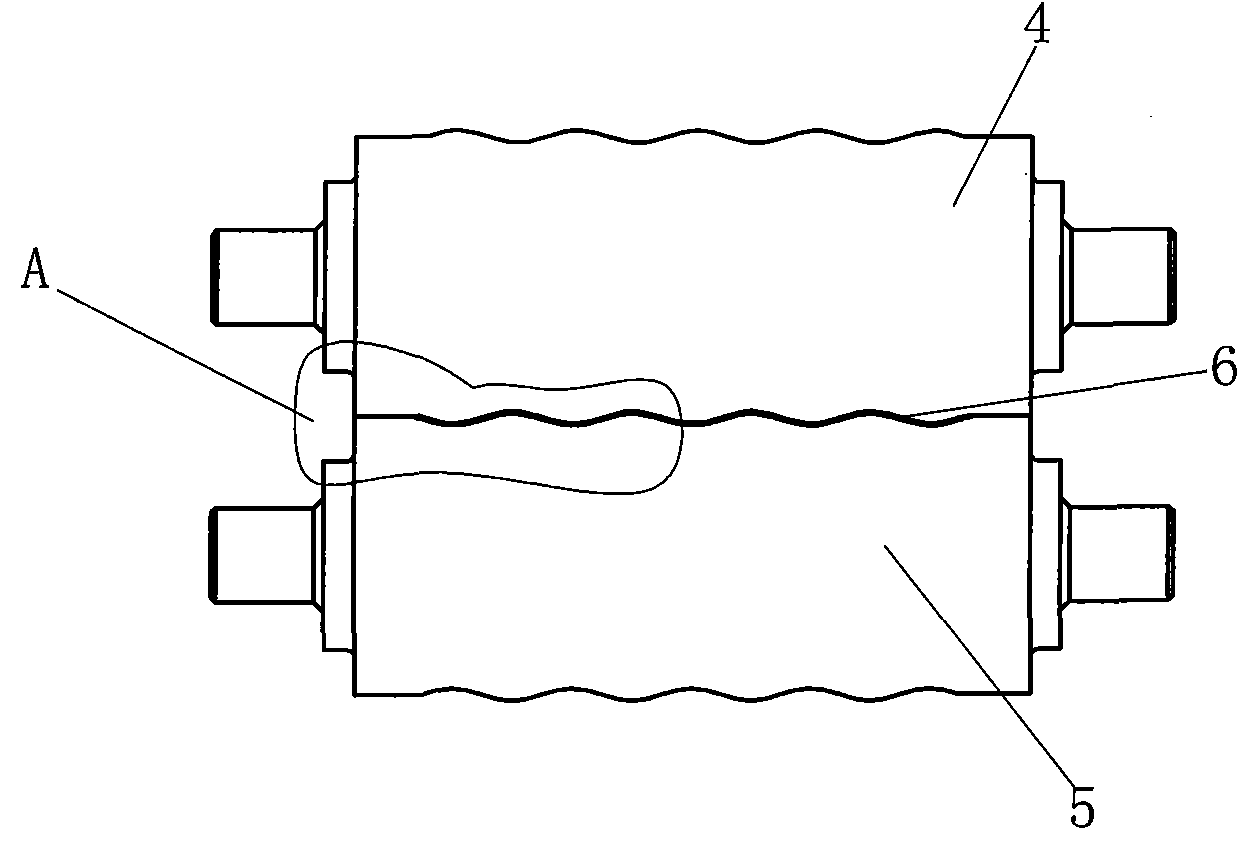

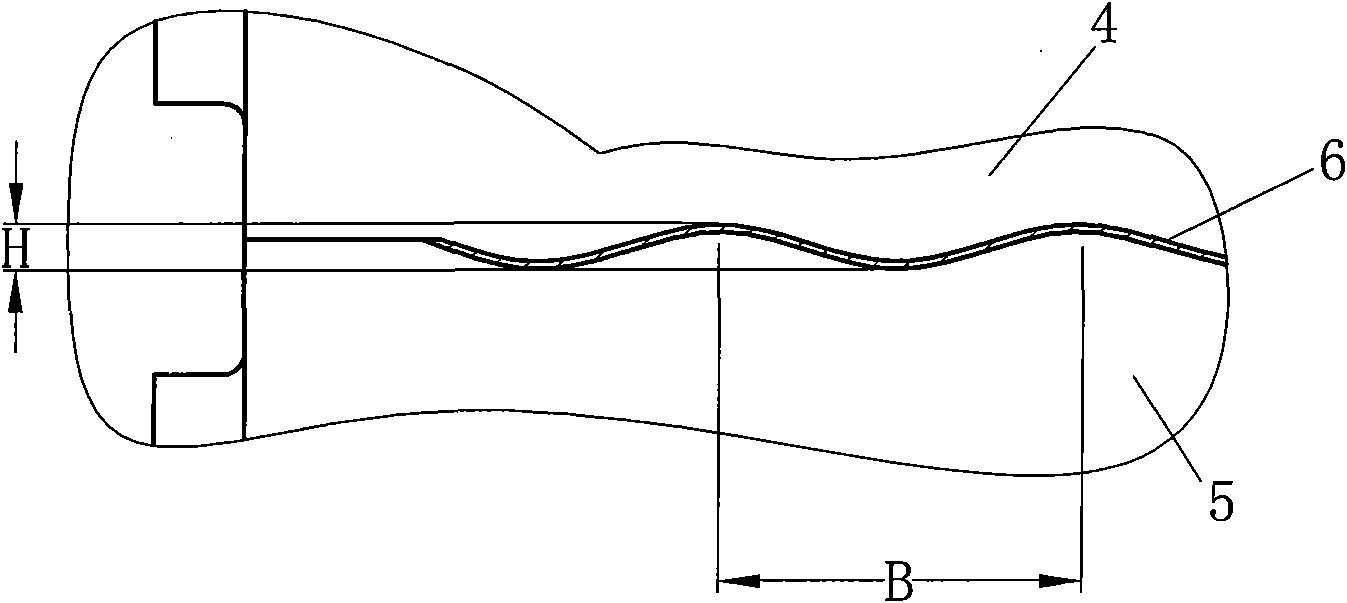

Rolling process for molybdenum billet plate

InactiveCN101829676ATight textureImprove machinabilityTemperature control deviceMetal rolling arrangementsPowder metallurgyMachining

The invention relates to a method for manufacturing a molybdenum billet plate, in particular to a rolling process for the molybdenum billet plate. In the invention, the molybdenum billet obtained by powder metallurgy is subjected to hot rolling and calendering through a plurality of wavelike rollers and at last one cylindrical roller to undergo three-way compression stress, so that the molybdenum billet plate has a close texture, the machining performance, the wear resistance and the conductivity are improved, cracking and delaminating phenomena of the molybdenum billet plate during the rolling process are avoided and the production cost of the molybdenum billet plate is reduced.

Owner:江苏时代华宜电子科技有限公司

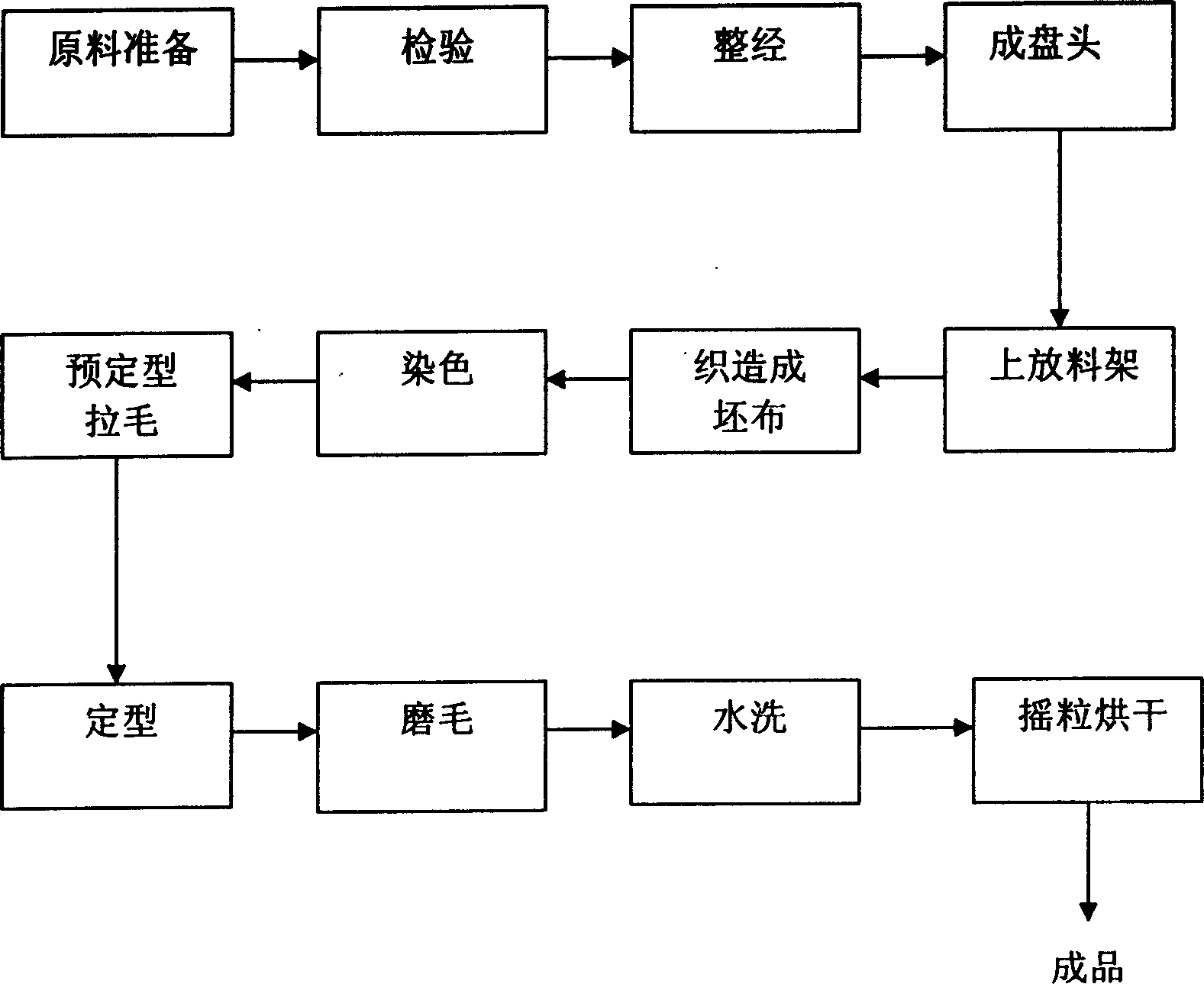

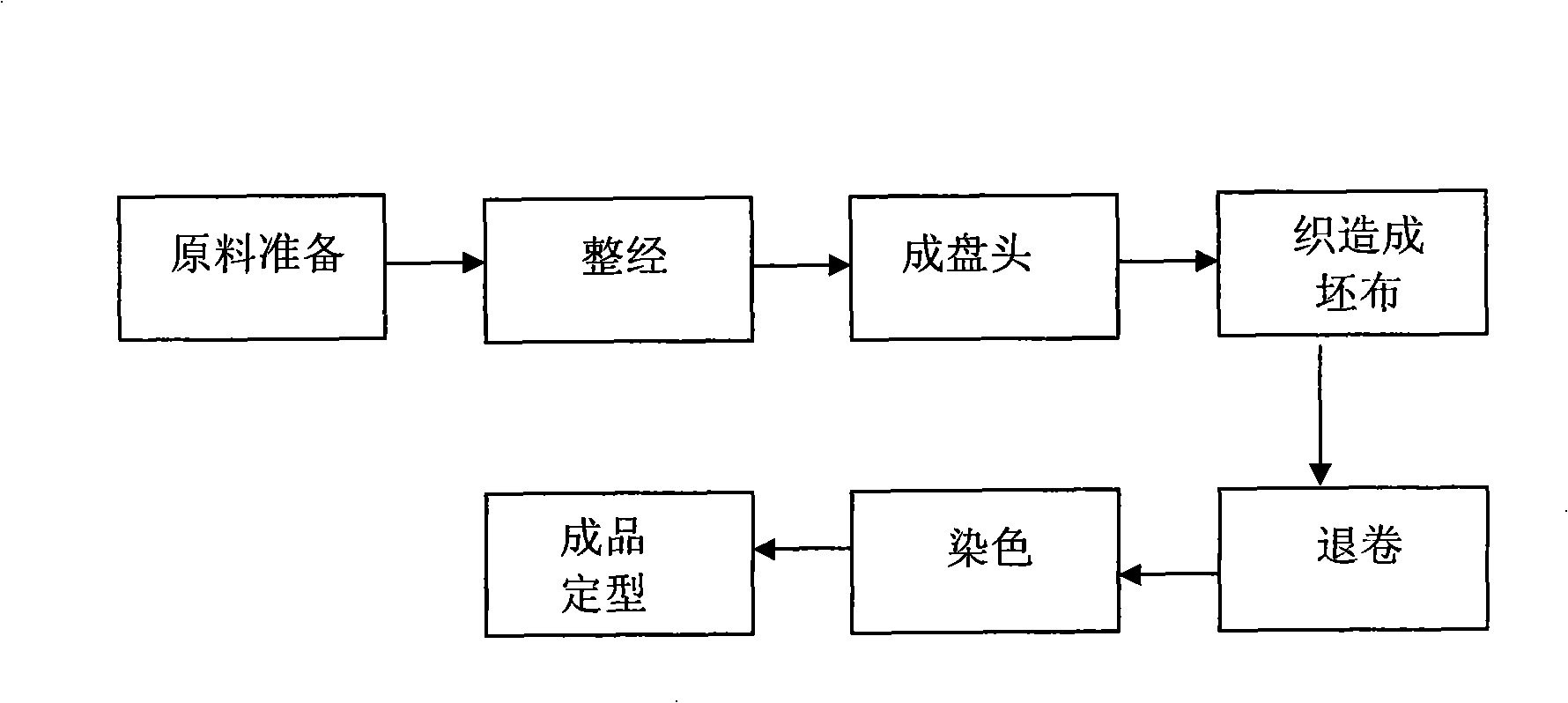

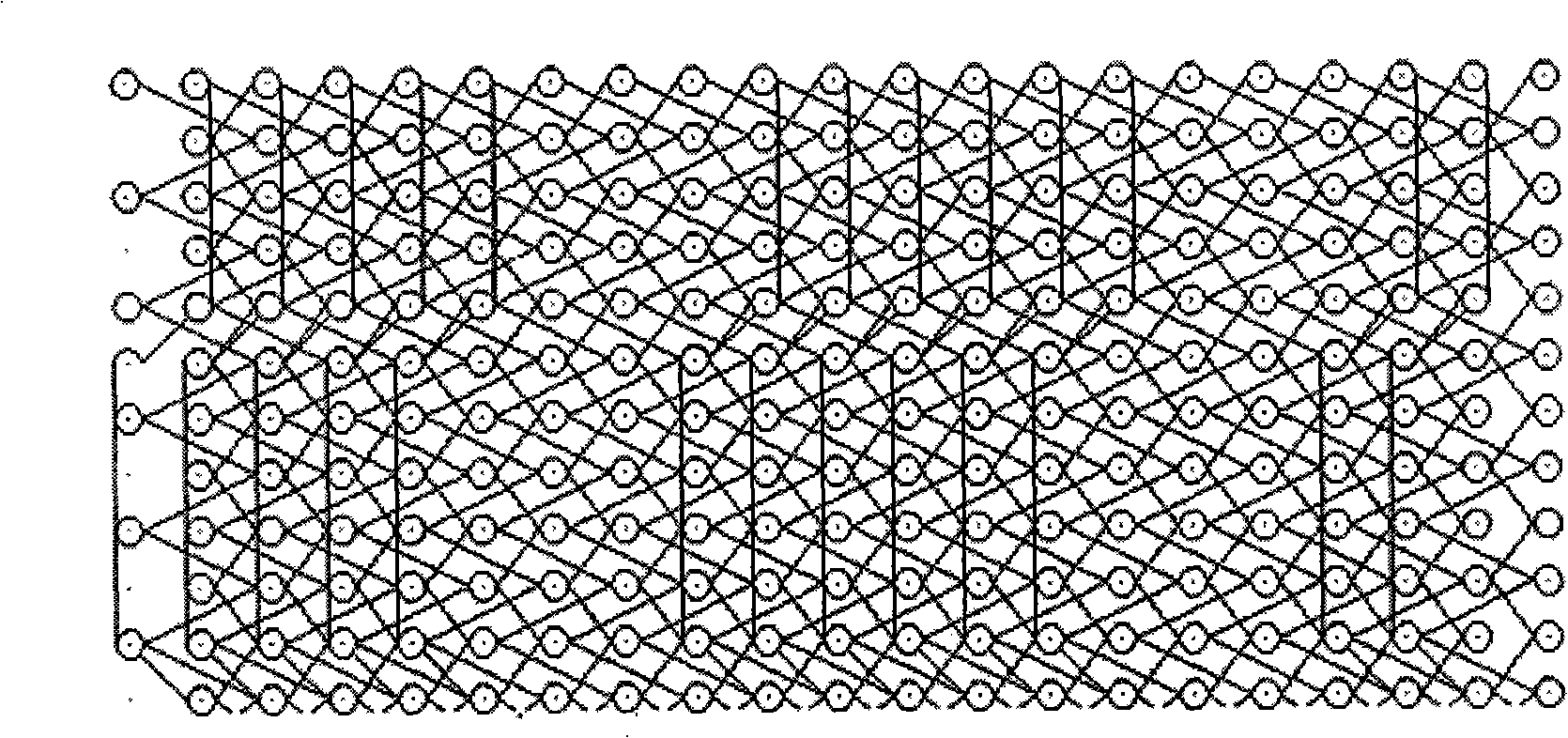

Production process of highly-compacted tricot-knitting sanded fabric

The invention relates the manufacturing technique of high sley abrasive material, comprising preparation of raw material, certification, warping, making grey cloth, dyeing, preboarding plucking, shaping, grinding hair, water scrubbing and drying. The face fabric made with the said technology is tight, thick, novel style, cubic effect, fashion and good hand feeling.

Owner:HAINING CHAODA WARP KNITTING

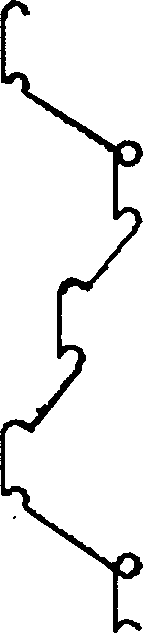

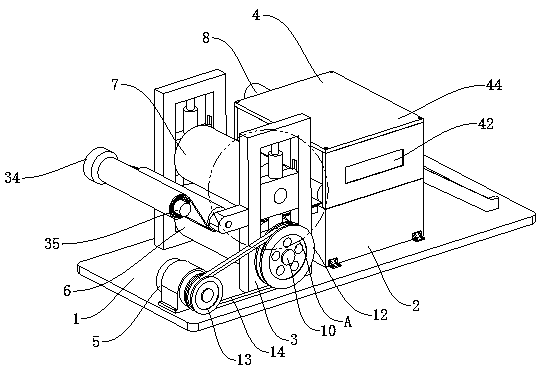

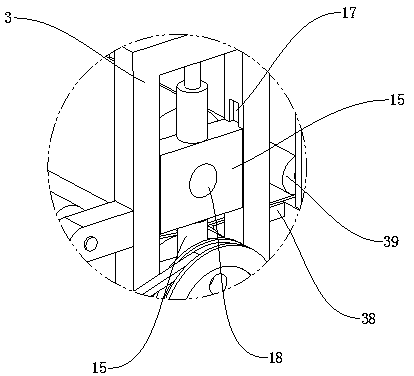

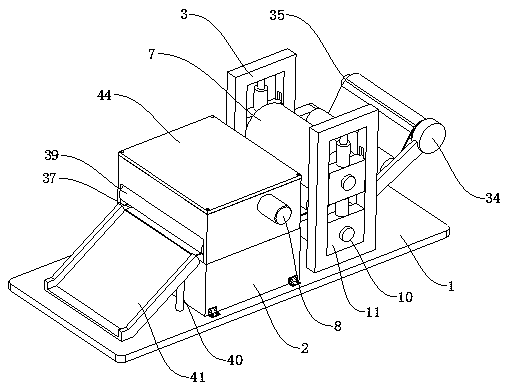

Cloth leveling and shearing equipment for garment manufacturing

ActiveCN110117897ATight textureImprove textureSevering textilesArticle deliveryAssistive device/technologyEngineering

The invention relates to the technical field of garment manufacturing auxiliary equipment, in particular to cloth leveling and shearing equipment for garment manufacturing. The equipment comprises a base seat, a supporting table, two supporting frames, a compacting mechanism and a shearing mechanism, wherein the compacting mechanism is arranged between the two supporting frames to feed cloth ontothe supporting table and compact the cloth; the shearing mechanism is arranged above the supporting table through a protective outer cover to shear the cloth; the compacting mechanism comprises a first motor, a first pressing roller and a second pressing roller; and the shearing mechanism comprises a second motor and a cutter. The cloth leveling and shearing equipment for garment manufacturing hasthe functions of feeding and blanking, and is convenient to use; the designed compacting mechanism can compact the cloth to make the texture more compact, and thus the texture of the cloth is improved; and meanwhile, a designed observation window can watch the operation of the cutter in real time, and thus the occurrence of faults is prevented, and the cloth processing process is transparent andefficient, so that the shearing efficiency of the cloth is improved, and corporate earnings are increased.

Owner:浙江新衣诚服装有限公司

Method for generating electricity using cow dung as fuel

InactiveCN102444435AHigh combustion valueHigh densityBiofuelsSolid fuelsCombustion chamberFuraldehyde

The invention discloses a method for generating electricity using cow dung as fuel. The method comprises the following steps of: burning the cow dung in a steam boiler to prepare high-pressure steam; using the high-pressure steam to drive a steam turbine to rotate; and using the steam turbine to drive an electric generator to rotate for generating electric current, wherein the cow dung needs pre-treatment before being fed to a boiler furnace, and the pre-treatment comprises the following steps of: carrying out solid-liquid separation to fresh cow dung, so that the moisture content of the cow dung is smaller than or equal to 55%, and then wet cow dung is obtained; mixing and uniformly stirring the wet cow dung with furaldehyde residue to acquire the dung residue mixture; drying the dung residue mixture to acquire the dry dung residue mixture; thermoforming the dry dung residue mixture to acquire the cow dung electricity-generating fuel. The method uses the cow dung as the fuel to produce high-temperature and high-pressure steam which drives the steam turbine to rotate, so that the steam turbine drives the electric generator to rotate and generate electricity, thus the purpose of using cow dung to replace non-renewable resources such as coal or petroleum and the like to generate electricity is achieved.

Owner:刘明全

Chinese medicinal herb fragrant bath formula for nursing and caring skin and resisting aging

InactiveCN103054780ANo side effectsGood effectCosmetic preparationsToilet preparationsMedicinal herbsSide effect

The invention relates to a Chinese medicinal herb fragrant bath formula for nursing and caring skin and resisting aging, wherein cinnamon, radix angelicae, Sichuan lovage rhizome, angelica sinensis, ginger and folium artemisiae argyi are cut into pieces or sections which are about 1-2 cm long; grinding folium syringae, rosemary and radix paeoniae alba into coarse powder; and then proportionally mixing the coarse powder with rose flowers dried in the shade, and then packaging the mixture in a small gauge bag. The Chinese medicinal herb fragrant bath formula provided by the invention employs Chinese medicinal herbs and realizes scientific compatibility thereof, and thus has good effects on improving the human body immunity and delaying skin aging and are suitable for the symptoms of skin aging of various features; after the Chinese medicinal herb fragrant bath formula is used, no any anaphylactic reaction and no any toxic and side effect are caused; if the Chinese medicinal herb fragrant bath formula is taken for a long time, the active substances of the medicinal herbs penetrate into the skin and thus are absorbed by the skin, so that the purposes of nursing the skin, softening cutin, resisting aging and the like are achieved; and the Chinese medicinal herb fragrant bath formula is quick in effect taking and good in effect.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI HAINAN BRANCH +1

Emulsified asphalt and preparation method thereof

The invention discloses an emulsified asphalt and a preparation method thereof. A formula of the emulsified asphalt comprises asphalt, a cationic emulsifier, an anionic emulsifier, a thickener, a stabilizer, a water reducing agent and water. According to the invention, the water reducing agent is added to asphalt emulsion as a component for not only playing the role of the reducing agent itself, reducing operation steps during construction, but also for cooperating with the cationic surfactant and the anionic surfactant, thus obviously improving sieve residual amount, storage stability and especially indexes of cement miscibility of the emulsified asphalt. The emulsified asphalt provided by the invention is used for cement asphalt mortar pouring of a plate-type ballastless track during construction of a high-speed railway.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electronic device and method for manufacturing the same

ActiveUS8179660B2Improve reliabilityAvoid enteringLiquid surface applicatorsFixed capacitor dielectricConductive pasteMoisture

A highly reliable electronic device that prevents entry of a plating solution via an external electrode and entry of moisture of external environment inside thereof, and generates no soldering defects or solder popping defects which are caused by precipitation of a glass component on a surface of the external electrode. The electrode structure of the electronic device is formed of Cu-baked electrode layers primarily composed of Cu, Cu plating layers formed on the Cu-baked electrode layers and which are processed by a recrystallization treatment, and upper-side plating layers formed on the Cu plating layers. After the Cu plating layers are formed, a heat treatment is performed at a temperature in the range of a temperature at which the Cu plating layers are recrystallized to a temperature at which glass contained in a conductive paste is not softened, so that the Cu plating layers are recrystallized.

Owner:MURATA MFG CO LTD

Preparation method of artificial stone with marble-imitated Sha Anna high-grade variety pattern and artificial stone prepared thereby

The invention discloses a preparation method of an artificial stone with a marble-imitated Sha Anna high-grade variety pattern, which comprises the following steps of: (1) preparing artificial stone pug in a stirring way; (2) vacuumizing to be more than -0.077MPa to perform the following steps of: 1. prefabricating and tabletting the artificial stone pug; 2. spraying color paste to the surfaces of the prefabricated and tabletted pug pieces; 3. accumulating and overlapping the cloth of the pug pieces; and 4. pressing in a forming way; and (3) solidifying a pressed forming body under the normal temperature. As the step of prefabricating and tabletting is increased before the step of spraying the color paste, the streak of the pattern on the surface of the marble-imitated Sha Anna high-grade variety artificial stone prepared by the method is thinner and longer, has a certain trend regularity, and avoids the coarse streak and the unordered trend of the product which is correspondingly prepared by existing working procedures without the step of tabletting, thereby more realistically reappearing the delicate grain of the marble Sha Anna high-grade variety and bringing greater upvaluation space to the product.

Owner:WANFENG COMPOUND STONE TECH

Biomass fuel particle and preparation method thereof

The invention discloses a biomass fuel particle. 70-80 percent by weight of biomass fuel raw material, 5-20 percent by weight of palm meal and 5-20 percent by weight of chemical mud alcohol-precipitation substance which are used as raw materials are uniformly mixed and are compressed into square or cylindrical biomass fuel particle by using a special press block complete machine. The biomass fuel particle has the advantages of smoothness in surface, tight texture, low breaking rate, remarkably-improved production efficiency and less wear on a mechanical die.

Owner:天津市施乐德科技有限公司

Production method of machine-made charcoal

InactiveCN105349212AWide choiceLow cost of preparationBiofuelsSolid fuelsComposite materialCombustion

The invention provides a production method of machine-made charcoal and relates to the technical field of charcoal processing. The machine-made charcoal is prepared from 90 parts by weight of sawdust, 15 parts by weight of bamboo powder, 20 parts by weight of levant cotton exocarp powder, 15 parts by weight of peanut shell powder, 20 parts by weight of corn straw powder, 25 parts by weight of Artemisia argyi powder, and 6 parts by weight of diatomite. The sawdust, bamboo powder, levant cotton exocarp powder, peanut shell powder, corn straw powder and Artemisia argyi powder have particle diameters of 0.5-0.8mm and are obtained by drying, crushing, centrifugation screening and rough impurity removal. The production method has a wide raw material selection range, a low preparation cost and simple and easy processes. The machine-made charcoal has good density and long combustion time, contains diatomite for improving raw material viscosity, can be molded easily, does not easily crack and has high product quality.

Owner:和县伊迈炭业有限责任公司

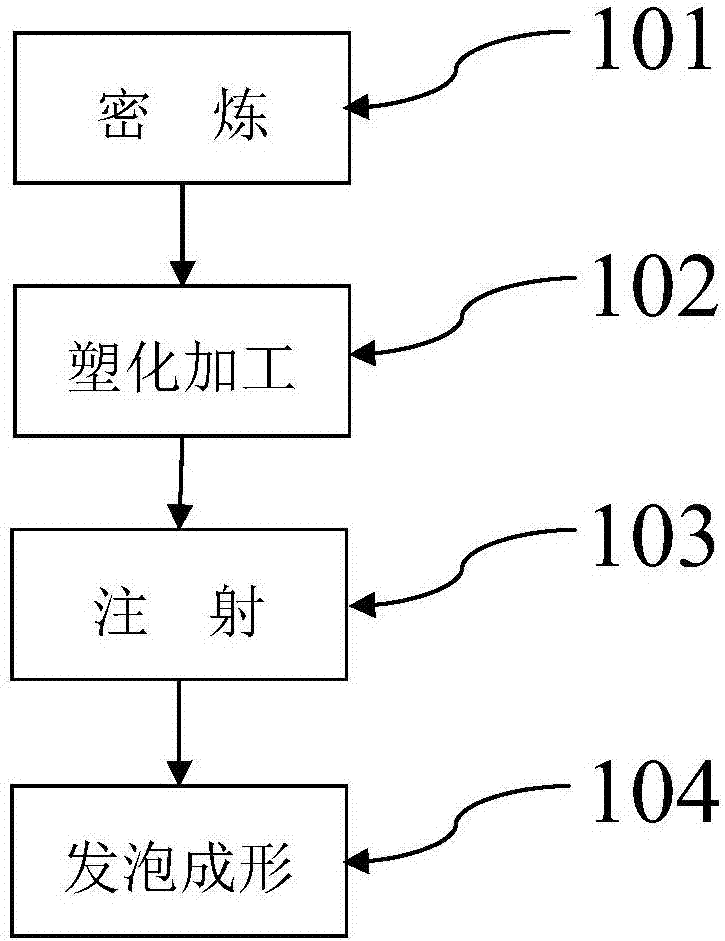

Production formula and preparation method for elastic rotator

The invention discloses a production formula and a preparation method for an elastic rotator, which belong to the technical field of road transportation equipment. The formula comprises the following specific components: 10 to 20 percent of ethylene-octene copolymer (POE), 40 to 60 percent of EVA (ethylene-vinyl acetate copolymer), 10 to 20 percent of ethylene-propylene-diene monomer, 5 to 10 percent of anti-shrinking agent, 1 to 3 percent of filler, 0.6 to 1.6 percent of dispersed lubricant, 1 to 2 percent of zinc oxide, 0.7 to 1.2 percent of cross-linking agent, 1.5 to 2.5 percent of foaming agent, 1.5 to 2.5 percent of flowable agent and 2 to 4 percent of color masterbatch pigment, and the total weight is 100 percent. The POE, the ethylene-propylene-diene monomer and the EVA are mixed and refined, and are added with a variety of additives, so that the three types of materials keep respective properties and complement one another, the elasticity of the prepared elastic rotator is high, moreover, after foaming, the texture is dense, the weight is light, the good anti-aging property of the elastic rotator is ensured, the elastic rotator cannot be easily cracked when receiving impact force, and the service life of the elastic rotator is effectively prolonged.

Owner:江苏恪铭智慧交通科技有限公司

Super-power moisture-absorbing towel and preparation method for same

The invention discloses a super-power moisture-absorbing towel and a preparation method for the same. Base material is formed by 45% to 50% of bamboo fibers, 40% to 45% of combed cotton, 10% to 20% of superfine fibers, 0.3% to 0.7% of resin fibers in a blending way, so the base material possesses strong moisture absorbing property, bacteria resistance, tight and soft texture, great strength and deformation prevention; a wool loop is an untwisted yarn blended by 60% of bamboo fibers, 20% of superfine fibers, 5% of milk fibers, 5% of alginate fibers, 5% of modal fibers and 5% of tea fibers; and the wool loop is naturally bacteria-resistant, fine and smooth, has strong moisture-absorbing capability and great ventilating capability. With the tea fibers added to the towel, the towel has natural colors, so dyeing is prevented; and body microcirculation can be improved during the use of the towel, so body function can be enhanced. The towel has strong moisture-absorbing property, great ventilating property, softness, washing resistance, natural bacteria resistance and safety as well as skin care.

Owner:JIESHOU SHUANGXIN TEXTILE

Anti-freezing emulsified asphalt and preparation method thereof

ActiveCN103059581AImproved sieve residueGood storage stabilityBuilding insulationsPolymer scienceAlcohol

The invention discloses an anti-freezing emulsified asphalt and a preparation method thereof. A formula of the emulsified asphalt comprises asphalt, an anionic emulsifier, a cationic emulsifier, a thickener, a stabilizer, a water reducing agent, alcohol and water. The method provided by the invention comprises steps of: dissolving the water reducing agent and the thickener in alcohol at room temperature to prepare a paste, and adding a defoaming agent into the paste; and then participating the paste in the emulsion as a whole. The paste is combined with the cationic emulsifier and the anionic emulsifier emulsifier, so as to reduce usage amount and cost of emulsifier, and obviously improve sieve residue, storage stability, cement miscibility and frost resistance of the emulsified asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biomass briquette fuel

InactiveCN104745266AReduce sulfur contentReduce nitrogen contentBiofuelsSolid fuelsCombustionEngineering

The invention provides a biomass briquette fuel. The biomass briquette fuel is formed by mixing biomass raw material particles with fuel additives, and then crushing, mixing, drying, extruding and granulating; the weight percentage of the biomass raw material particles is 90-95%; the weight percentage of the fuel additive is 5-10%; the biomass raw material particles are composed of saw dust, bamboo dust, straws and rice straws; and the fuel additives are composed of quick lime, a combustion improver and high clay. The biomass briquette fuel is low in dust content which is greatly lower than the dust content of the fuel coal, and also high in combustion value and advantageous for improving the efficiency and the output of a boiler.

Owner:LINAN JICHEN BIOMASS ENERGY TECH CO LTD

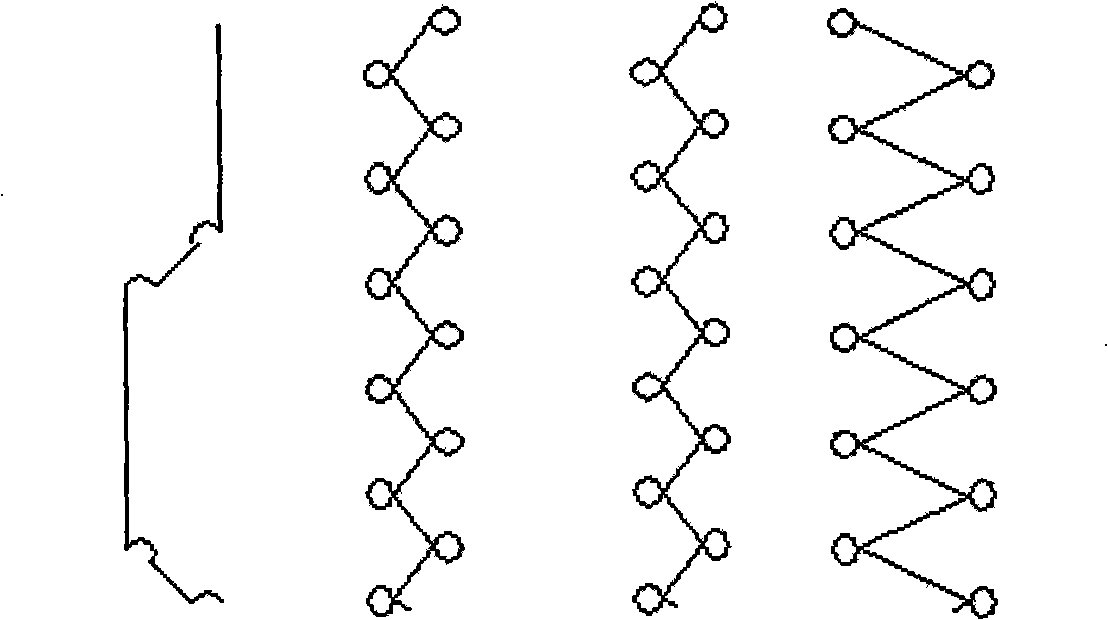

Production process of polyester-cotton gathering warp knitting uniform fabric

The invention relates to a manufacturing technique of fabrics of polyester-cotton plisse warp knitting western-style clothes, comprising the steps of the preparation of raw materials, warping, complete hair-coiling, the fabric manufacture of grey cloth, unwinding, dyeing and the typing of finished products. The step of the fabric manufacture of the grey cloth adopts four stripping combs for weaving, wherein, the first stripping comb adopts polyester filament in a way of 6 being penetrated and 3 being hollow, and crossband plisses are formed by a manner of combining woven flatness and pad lack; the second stripping comb adopts compact spinning cotton yarn in the way of 1 being penetrated, 6 being hollow, 1 being penetrated and 1 being hollow, and straight strips are formed in a manner of woven flat double stranded weaving; the third stripping comb adopts polyester low stretch yarn in the way of 1 being hollow, 6 being penetrated, 1 being hollow and 1 being penetrated, the blank penetrating part of the second stripping comb is filled up in the manner of woven flat weaving, and straight twin color effect is formed after dyeing; the fourth stripping comb also adopts the polyester low stretch yarn in the manner of symmetrical double needle woven flat weaving, mainly playing the role of solidification so as to cause the fabrics to be more compact. The fabrics have compact texture, novel style, and stereoscopic impression, and are rough while maintaining softness, and the application of the cotton yarn causes the fabrics to have the twin color effect, and enhances the wearing comfort of the fabrics.

Owner:HAINING CHAODA WARP KNITTING

Duplex blended weaving comfortable and durable yarn

The invention discloses a duplex blended weaving comfortable and durable yarn, which is formed by moisture absorption yarns, ventilation yarns and health care yarns through blending weaving, wherein the moisture absorption yarns are formed by copper ammonia silk fiber and spandex fiber through blending weaving, the ventilation yarns are formed by modal fiber and polynosic fiber through blending weaving, the health care yarns are formed by viscose chitin fiber and polyvinyl chloride fiber through blending weaving, the weight percentage of the moisture absorption yarns in the duplex blended weaving comfortable and durable yarn is 27 to 36 percent, the weight percentage of the ventilation yarns in the duplex blended weaving comfortable and durable yarn is 52 to 57 percent, and the weight percentage of the heath care yarns in the duplex blended weaving comfortable and durable yarn is 12 to 16 percent. The duplex blended weaving comfortable and durable yarn is woven through duplex blending, and the woven yarn has tight and compact texture and has the characteristics that the moisture absorption performance and the ventilation performance are good, the wearing is comfortable, the health care effect is realized, and firmness and durability are realized.

Owner:ZHONGSHAN XINTAI TEXTILE

Composite multifunctional health paint mate and preparation method thereof

InactiveCN102532977AAnti-mildewHas bactericidal and anti-mildew effectAntifouling/underwater paintsPaints with biocidesEmulsionZinc compounds

The invention provides a composite multifunctional health paint mate and a preparation method thereof, which relate to a paint mate and a preparation method thereof. According to the invention, the problems of complicated preparation process, single function and no environment protection of the traditional paint. The product comprises environment friendly functional material negative ion element, nano-zinc compound, nano-titanium dioxide, nano-silver solution, nanometer calcium carbonate and substrate emulsion paint. The method comprises the following steps of: 1) weighing raw materials; 2) mixing and stirring the nano-zinc compound, nano-titanium dioxide, nano-silver solution and nanometer calcium carbonate, and then adding the environment friendly functional material negative ion element to the mixed material, and continuing to stir the mixture so as to obtain a slurry; and 3) adding the substrate emulsion paint to the slurry and stirring the mixture so as to obtain the composite multifunctional health paint mate. The composite multifunctional health paint mate and the preparation method thereof, provided by the invention, have the advantages of simplicity and convenience in operation, multiple product functions, environment friendliness, health, capability of resisting disoperations from atmosphere and ultraviolet rays, durability, scrub resistance, alkali resistance, mildew resistance and good air permeability; and negative ions are continuously released into the air so that the paint mate can be mixed with the emulsion paint to improve the painting texture of the common emulsion paint and stop the penetrations of water and salt.

Owner:黑龙江省玉琦装饰涂料有限公司

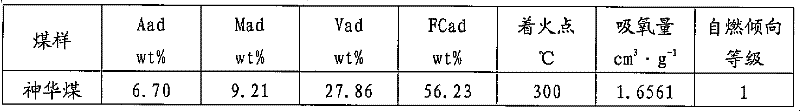

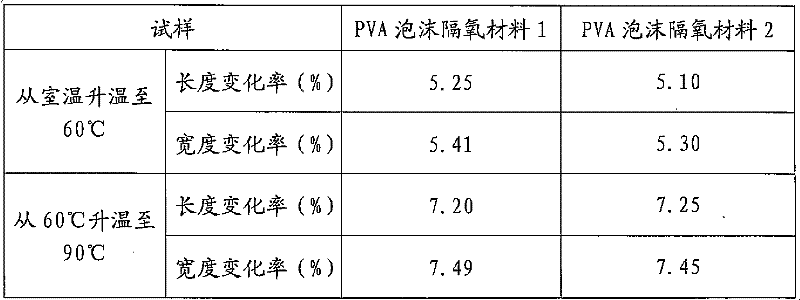

Polyvinyl alcohol foam oxygen insulation material and preparation method and application thereof

ActiveCN102336994AGood oxygen barrier effectSmall oxygen permeability coefficientDust removalFire preventionFoaming agentAlcohol

The invention discloses a polyvinyl alcohol foam oxygen insulation material, which comprises a component (A) and a component (B), wherein the component (A) comprises a solvent, and 3-8 percent by weight of polyvinyl alcohol, 0.5-1.5 percent by weight of linear hydrocarbon organic alcohol or ester and 0.04-0.10 percent by weight of foaming agent based on the total amount of the solvents contained in the component (A) and the component (B); the component (B) comprises 0.1-0.3 percent by weight of borate based on the total amount of solvents contained in the component (A) and the component (B); and the mass ratio of the solvent contained in the component (A) to the solvent contained in the component (B) is (5-9):1. A method for preparing the polyvinyl alcohol foam oxygen insulation material comprises the following steps of: dissolving polyvinyl alcohol into the solvent at constant temperature 70-95 DEG C, performing return flow agitation for 30-60 minutes, cooling to room temperature, and adding the linear hydrocarbon organic alcohol or ester and the foaming agent to obtain the component (A); adding borate into the solvent to obtain the component (B); and foaming the component (A), spraying onto a coal surface and spraying the component (B) to form a foam gel oxygen insulation material layer which plays a good role in sealing and insulating oxygen on the coal surface.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com