Polyvinyl alcohol foam oxygen insulation material and preparation method and application thereof

A technology of polyvinyl alcohol and foam, which is applied in mining equipment, earth square drilling, dust prevention, etc. It can solve problems such as the inability to use coal for long-term storage and long-distance transportation, the use of a large amount of oxygen barrier materials, and the instability of foam materials, etc., to achieve Eliminate the effects of unstable performance, good film-forming properties, and small oxygen permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

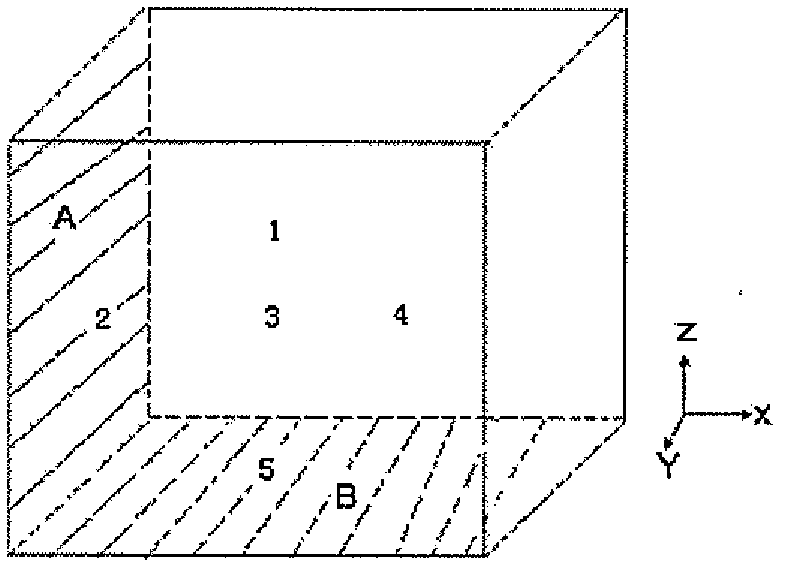

Method used

Image

Examples

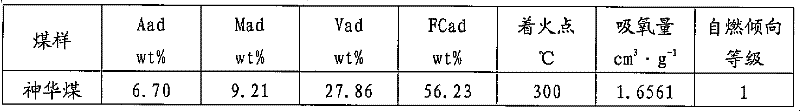

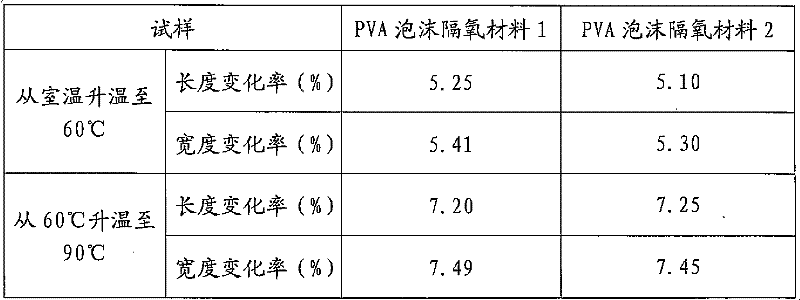

Embodiment 1

[0042] At a constant temperature of 90°C, add 8 kg of polyvinyl alcohol particles into 160 kg of deionized water stirred at high speed to dissolve completely, and prepare a homogeneous aqueous solution of polyvinyl alcohol. After cooling down to room temperature, add 2 kg of glycerol and stir to make it Dissolve completely, add 0.08kg sodium dodecylsulfonate, stir slowly and evenly, and prepare polyvinyl alcohol modified foaming solution; add 0.3kg sodium borate in 30kg deionized water, stir until uniform, and prepare sodium borate aqueous solution. The prepared polyvinyl alcohol modified foaming solution is foamed in the foaming device, and it is transported and sprayed to the surface of the coal pile through a pump and a steel pipe with a diameter of 80 mm to form a foam surface, and then the sodium borate aqueous solution is pumped through the pump Spray evenly to the foam surface, form a layer of PVA oxygen barrier foam material 1 with a thickness of about 5mm on the surfac...

Embodiment 2

[0044] At a constant temperature of 80°C, in 160kg of deionized water stirred at high speed, add 8kg of polyvinyl alcohol particles to dissolve them completely, and prepare a homogeneous aqueous solution of polyvinyl alcohol. After cooling down to room temperature, add 2kg of glycerol and stir Make it dissolve completely, add 0.1kg sodium lignosulfonate, stir slowly and evenly, and prepare polyvinyl alcohol modified foaming solution; add 0.6kg sodium borate in 30kg deionized water, stir until uniform, and prepare sodium borate aqueous solution. The prepared polyvinyl alcohol modified foaming solution is foamed in the foaming device, and it is transported and sprayed to the surface of the coal pile through a pump and a steel pipe with a diameter of 80 mm to form a foam surface, and then the sodium borate aqueous solution is pumped through the pump Spray evenly onto the foam surface, form a layer of PVA foam oxygen barrier material 2 with a thickness of about 5mm on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com