Biodegradable plastic film

A plastic film and raw material technology, applied in the field of degradable plastic film, can solve problems such as difficult to guarantee the fixing conditions of plastic film, and achieve the effect of easy industrial implementation, high production efficiency and improved compatibility

Inactive Publication Date: 2015-04-08

TIANJIN KAIXUAN PLASTIC PROD

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In addition, the degradation of this degradable plastic film requires certain fixed conditions, and the environment after the plastic film is discarded is either placed in a closed garbage disposal system or exposed to a natural environment with unstable conditions. The fixed conditions required for the degradation of this plastic film, these degradable plastics in most cases, whether in the garbage disposal system or in the natural environment, cannot be degraded well due to limited conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

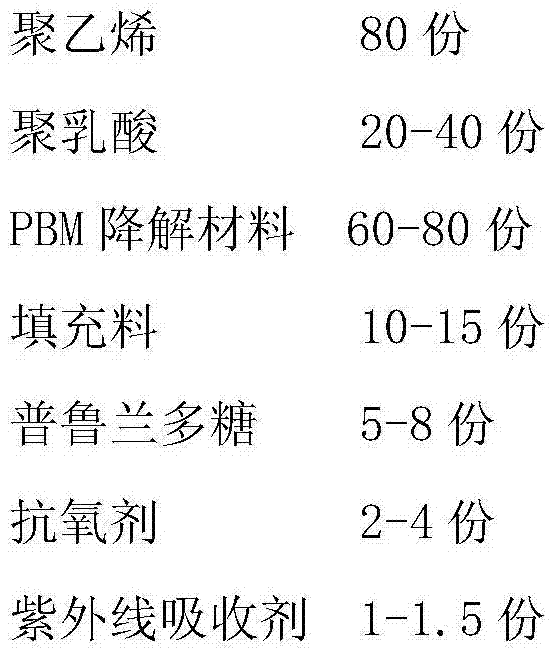

[0023] A degradable plastic film is characterized in that: its raw material components and parts by weight are respectively:

[0024]

[0025]

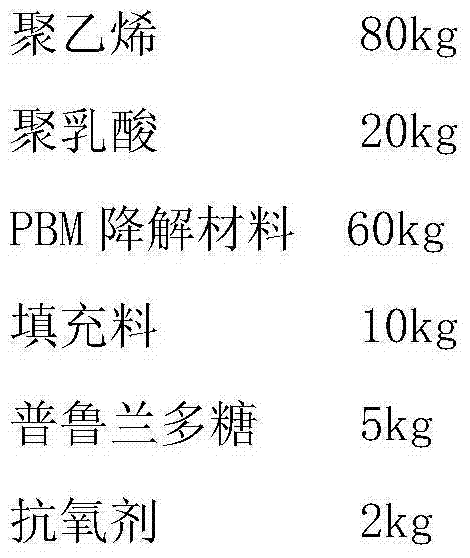

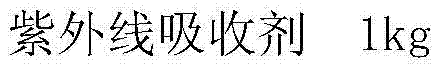

Embodiment 2

[0027]

Embodiment 3

[0029] .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a biodegradable plastic film which respectively comprises the following raw material components in parts by weight: 80 parts of polyethylene, 20-40 parts of polylactic acid, 60-80 parts of a PBM degradable material, 10-15 parts of a filling material, 5-8 parts of Pullulan, 2-4 parts of an antioxidant and 1-1.5 parts of an ultraviolet light absorber. The oxygen-isolating and biodegradable plastic film provided by the invention has the advantages that the mature modified starch biodegradable plastic master batch PBM, the Pullulan and film-level LDPE in the market are selected to be subjected to blending extrusion and film blowing in the preparation method at present, the characteristics of LDPE are utilized, and good mechanical property of the film is guaranteed; by utilizing the biodegradability of PBM and Pullulan, the environment friendliness of the film material is realized; by utilizing high oxygen isolating property of the Pullulan, the oxygen isolation property of the film material is improved; by utilizing the structural similarity of the starch and Pullulan serving as saccharides, the overall compatibility of the plastic film material is improved; and moreover, the blending ratio of the LDPE / PBM / Pullulan system is controlled, so that the oxygen isolation property, the biodegradability and the like can be regulated.

Description

technical field [0001] The invention relates to a plastic film, in particular to a degradable plastic film. Background technique [0002] As we all know, the plastic bag made of plastic film is light, thin, impermeable, strong, and low in cost. It is a good packaging material. The amount of bags is increasing, and the waste plastic bags after use are not easy to recycle and degrade. A large number of waste plastic bags have become a serious problem that pollutes the environment. In order to reduce the pollution of plastic films to the environment, people have developed some environmentally friendly green degradable plastic films, methods that can completely biodegrade plastic resins and film products. This type of degradable plastic film is composed of film-grade plastics and components that can cause plastic degradation, such as starch and calcium carbonate. This kind of degradable plastic film is an additive degradable plastic film. Thin films play a positive role in imp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/06C08L67/04C08L5/00C08L3/04C08K13/02C08K3/26C08K5/134C08K5/526C08J3/22B29C55/28

CPCC08L23/06B29C55/28C08J5/18C08J2323/06C08J2403/02C08J2405/00C08J2423/06C08J2467/04C08J2491/00C08L2201/06C08L2201/14C08L2203/16C08L2205/035C08L2207/062C08L2207/066

Inventor 郝永强

Owner TIANJIN KAIXUAN PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com