Flame retardant epoxy prepreg composite material and its preparing method and its use

A technology of composite materials and prepregs, which is applied in transportation and packaging, aircraft floors, hull bulkheads, etc., can solve the problems of poor toughness of composite materials, poor laying process, and large smoke release, so as to improve toughness, physical The effect of performance optimization and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

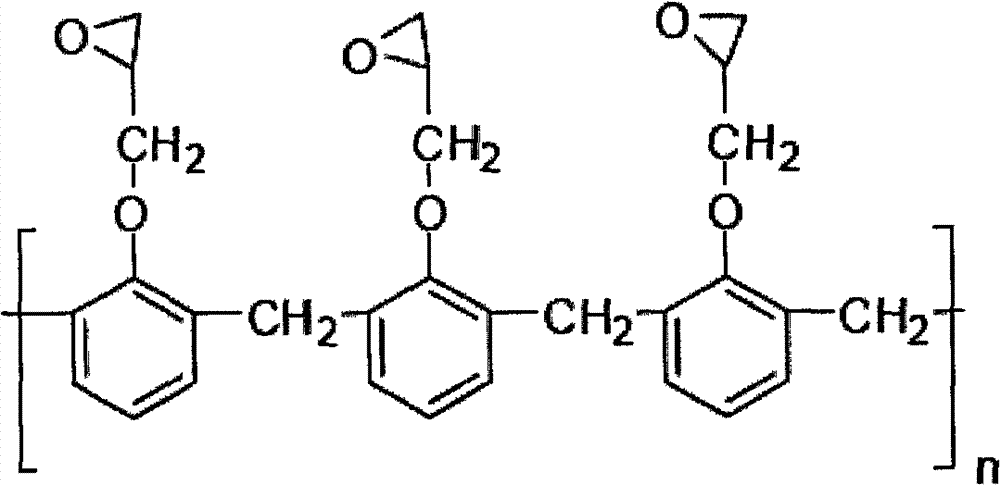

Method used

Image

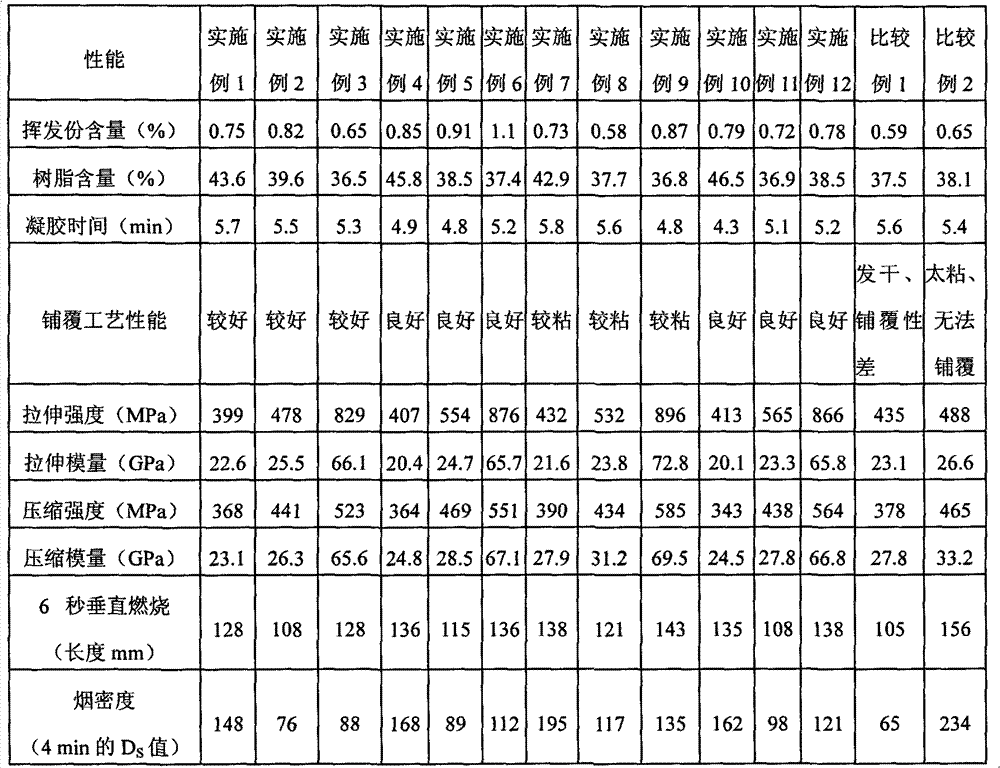

Examples

preparation example Construction

[0067] The preparation method of flame retardant epoxy prepreg composite material of the present invention comprises the following steps:

[0068] Step 1, prepare epoxy resin matrix, specifically as follows:

[0069] Add an organic solvent into the reaction kettle, raise the temperature to 40°C to 80°C, and then add F46 epoxy resin, E-type epoxy resin, toughening agent, tetrabromobisphenol A, curing agent, curing accelerator and three Antimony oxide, fully stirred for 30min~60min, then the epoxy resin matrix was prepared;

[0070] Step 2, prepare flame-retardant epoxy composite material, specifically as follows:

[0071] The epoxy resin matrix and fiber reinforced material are prepared by continuous impregnation, drying and winding processes by solution impregnation method; flame retardant epoxy prepreg is prepared according to the thickness of fiber reinforced material and equipment conditions, and the traction force and rubber extrusion roller are adjusted and optimized. P...

Embodiment 1

[0080] Based on the mass parts of F-type epoxy resin, add 10 mass parts of acetone to a 100L reactor, heat up to 40-60°C, and then add 100 mass parts of F46 (epoxy value 0.46), 10 mass parts of E51 (epoxy value 0.51), 13 parts by mass of carboxyl-terminated nitrile rubber, 5 parts by mass of tetrabromobisphenol A, 8 parts by mass of dicyandiamide, 5 parts by mass of N, N'-dimethyldiphenylurea and 1 parts by mass of antimony trioxide and fully stirred for 30 minutes to obtain a flame-retardant epoxy resin composition.

[0081] With the above epoxy resin as the matrix, EW110C type (four pieces of satin, thickness 0.11mm, surface weight 110g / m 2 ) Glass cloth is used as a reinforcing material, and the flame-retardant epoxy / glass fiber prepreg is obtained through continuous impregnation, drying and winding processes by solution impregnation method. Lay a certain number of layers of epoxy / glass fiber prepreg stacks according to the thickness design requirements, and use a press ho...

Embodiment 2

[0083] Based on the mass parts of F-type epoxy resin, in a 100L reactor, add 10 mass parts of acetone, heat up to 40-60 °C, and then add 100 mass parts of F46 epoxy (epoxy value 0.46), 10 mass parts while stirring. Parts by mass of E51 (epoxy value 0.51), 13 parts by mass of carboxyl-terminated nitrile rubber, 5 parts by mass of tetrabromobisphenol A, 8 parts by mass of dicyandiamide, 5 parts by mass of N,N'-dimethyldiphenylurea and 1 mass part of antimony trioxide, fully stirred for 30 minutes to obtain a flame-retardant epoxy resin composition.

[0084] With the above epoxy resin as the matrix, EW250F type (eight pieces of satin, thickness 0.25mm, surface weight 300g / m 2 ) Glass cloth is used as a reinforcing material, and the flame-retardant epoxy / glass fiber prepreg is obtained through continuous impregnation, drying and winding processes by solution impregnation method. Lay a certain number of layers of epoxy / glass fiber prepreg stacks according to the thickness design r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com