Patents

Literature

509 results about "Tetrabromobisphenol A" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

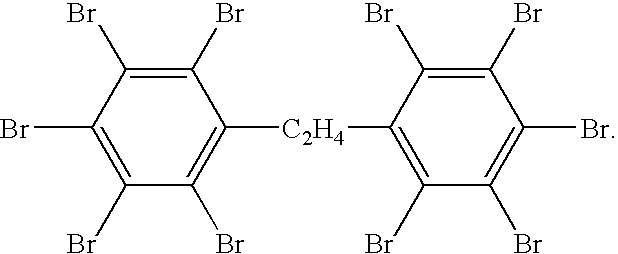

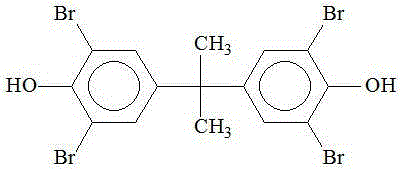

Tetrabromobisphenol A (TBBPA) is a brominated flame retardant. The compound is a white solid (not colorless), although commercial samples appear yellow. It is one of the most common fire retardants.

Thermosetting Resin Composition and Application Thereof

InactiveUS20100240811A1Excellent dielectric propertiesIncrease thermal resistanceBiocideOrganic chemistryTetrabromobisphenol ASolvent

The present invention discloses a thermosetting resin composition including: a bi-functional or multi-functional epoxy resin, a SMA uses as a curing agent, an allyl phenol such as diallyl bisphenol A used as a co-curing agent and a toughening agent a low-bromine or high-bromine BPA epoxy resin or tetrabromobispheno A (TBBPA or TBBA) uses as a flame retardant agent, and an appropriate solvent. After the resin composition of the invention is cured, the resin composition has lower dielectric property and better thermal reliability and tenacity. A copper clad laminate made of an enhanced material such as glass fiber has lower dielectric constant (Dk) and loss tangent (Df), high Tg, high thermal decomposition temperature (Td), better tenacity and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs or applied as a molding resin material for contraction, automobile and air navigation.

Owner:ITEQ DONGGUAN +1

Thermosetting resin composition and use thereof

The present invention discloses a thermosetting resin composition comprising: a bifunctional or multifunctional epoxy resin, a styrene-maleic anhydride (SMA) copolymer with a styrene / maleic anhydride molar ratio of 5-12:1 as a curing agent, a BPA epoxy resin with a low or high bromine content or tetrabromobisphenol A as a flame retardant agent, an accelerator and a solvent. The cured resin composition of the invention has a very low dielectric property, improved thermal reliability and better toughness. A copper clad laminate made of the resin composition and a reinforced material such as glass fiber cloth has a very low dielectric constant and dissipation factor, high Td, better toughness and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs and also applied to the common use of epoxy resins, such as molding resins, and composite materials for construction, automobiles and aviation.

Owner:ITEQ DONGGUAN +1

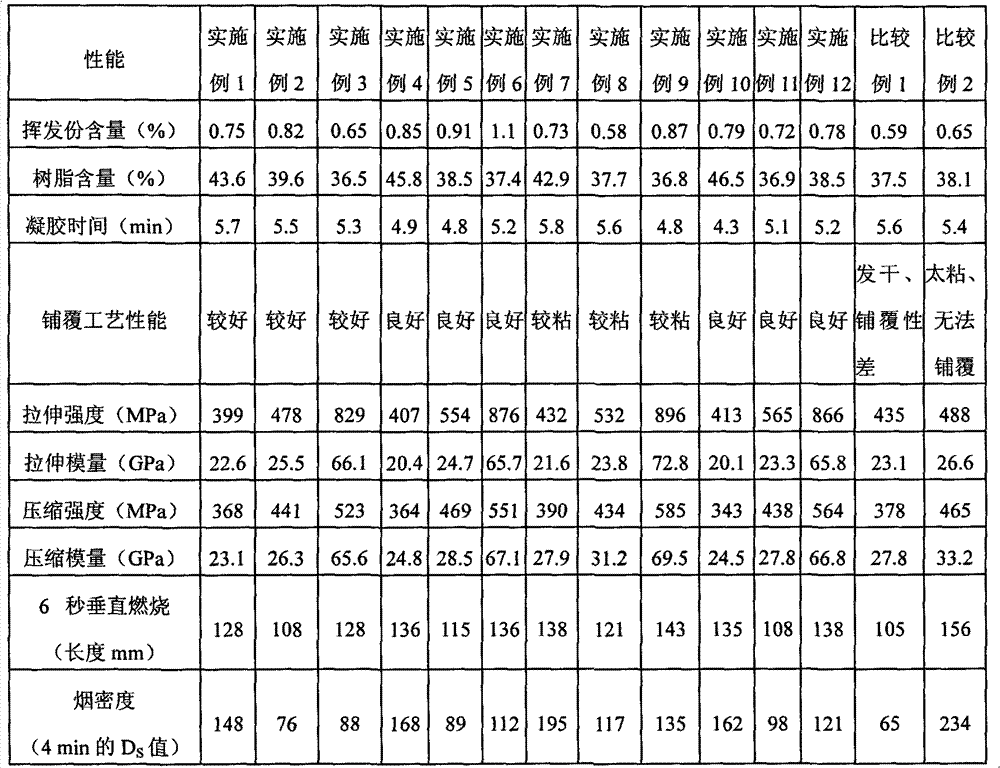

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Thermosetting resin composition and use thereof

ActiveCN102964775AOvercoming the disadvantages of dielectric propertiesReduce the chance of delamination explosionSynthetic resin layered productsMetal layered productsEpoxyTetrabromobisphenol A

The invention discloses a thermosetting resin composition which comprises epoxy resins except brominated epoxy resin, an styrene maleic anhydride copolymer and an additive flame retardant, and further comprises an active ester. The thermosetting resin composition can be used for preparing resin sheet materials, resin compound metal copper foils, prepregs, laminates, copper clad laminates, printed circuit boards, etc. The thermosetting resin composition substantially reduces probability of delamination of PCB substrate, overcomes disadvantages of deterioration of system dielectric properties due to introduction of tetrabromobisphenol A, and has advantages of good heat stability and heat and humidity resistance, low dielectric constant and dielectric loss tangent, and good flame resistance.

Owner:GUANGDONG SHENGYI SCI TECH

Thermosetting resin composition and use

InactiveCN101481490AImprove heat resistanceExcellent dielectric propertiesCircuit susbtrate materialsMetal layered productsGlass fiberTetrabromobisphenol A

The invention discloses a thermoset resin composition, comprising the following ingredients of: bifunctional groups or polyfunctional group epoxy resin, phenylethylene-maleic anhydride copolymer (SMA) as a curing agent, diallyl bisphenol A-like allylphenol as a co-curing agent and a toughening agent, low-bromine or high-bromine BPA-type epoxy resin or tetrabromobisphenol A (TBBPA or TBBA) as a fire retardant, a proper accelerator and a solvent. The inventive resin composition has, after being cured, relatively low dielectric property and superior thermal reliability and toughness, includes, in contrast to a cooper clad laminate manufactured by reinforcing materials such as glass fiber cloth, relatively low dielectric constant (called Dk for short) and electric loss tangent (called Df for short), high Tg, high thermal cracking temperature (called Td for short), excellent toughness and favorable PCB processibility, is quite suitable for manufacturing the cooper clad laminate for PCB and prepreg, and can also applied to general uses of the epoxy resin, such as molding plastics and the like, and to composite materials for construction, automobile and aviation.

Owner:ITEQ DONGGUAN +1

Thermosetting resin composition and application

The invention discloses a thermosetting resin composition, which comprises the following components: bifunctional or multifunctional epoxy resin, styrene-maleic anhydride copolymer SMA as a curing agent with styrene / maleic anhydride molar ratio of 5-12:1, low-bromine or high-bromine BPA type epoxy resin or tetrabromo bisphenol A as a fire retardant, an accelerator and a solvent. The resin composition after curing has quite low dielectric property, higher heat reliability and better toughness, has quite low dielectric constant and dielectric loss coefficient, high Td, better toughness and excellent PCB processability with a copper-clad plate made of glass fiber cloth and other reinforcing materials, is suitable for manufacturing a copper-clad plate and a semi-cured plate for PCB, and can also be used in common application of the epoxy resin, such as molding resin, composite materials for buildings, automobiles and aviation, and the like.

Owner:ITEQ DONGGUAN

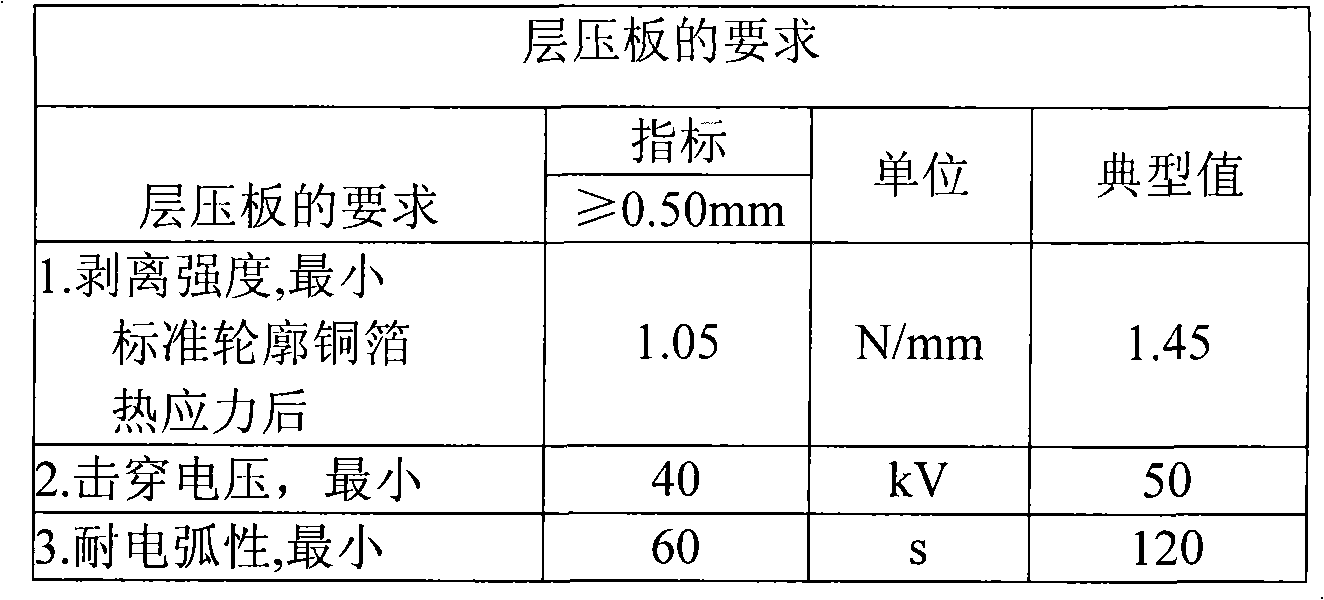

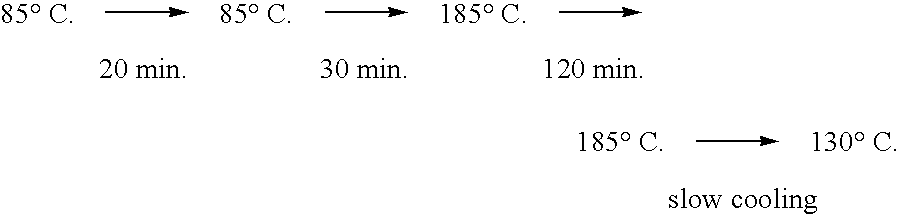

Method for manufacturing CTI copper-clad laminate

ActiveCN101654004AImprove tracking voltage resistanceExtended service lifeLamination ancillary operationsLaminationEpoxyTetrabromobisphenol A

The invention relates to a method for manufacturing a CTI copper-clad laminate. The method is realized by the following steps: glue mixing, sizing, plate arrangement, hot-press molding, disassembly, processing and inspecting, wherein an adhesive system in the step of the 'glue mixing' is composed of the following materials in mass ratio (kg): 125 to 133 kg of low brominated epoxy resin, 2.60 to 3.40 kg of dicyandiamide, 30 to 36 kg of dimethyl formamide, 0.060 to 0.080 kg of dimethyl imidazole, and 10 to 40 kg of aluminum hydroxide, wherein the low brominated epoxy resin belongs to tetrabromobisphenol A type brominated epoxy resin, and the content of bromine accounts for 10 to 14 mass percent of the low brominated epoxy resin. The method has the advantage of improving the tracking voltageresistance of a PCB substrate.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

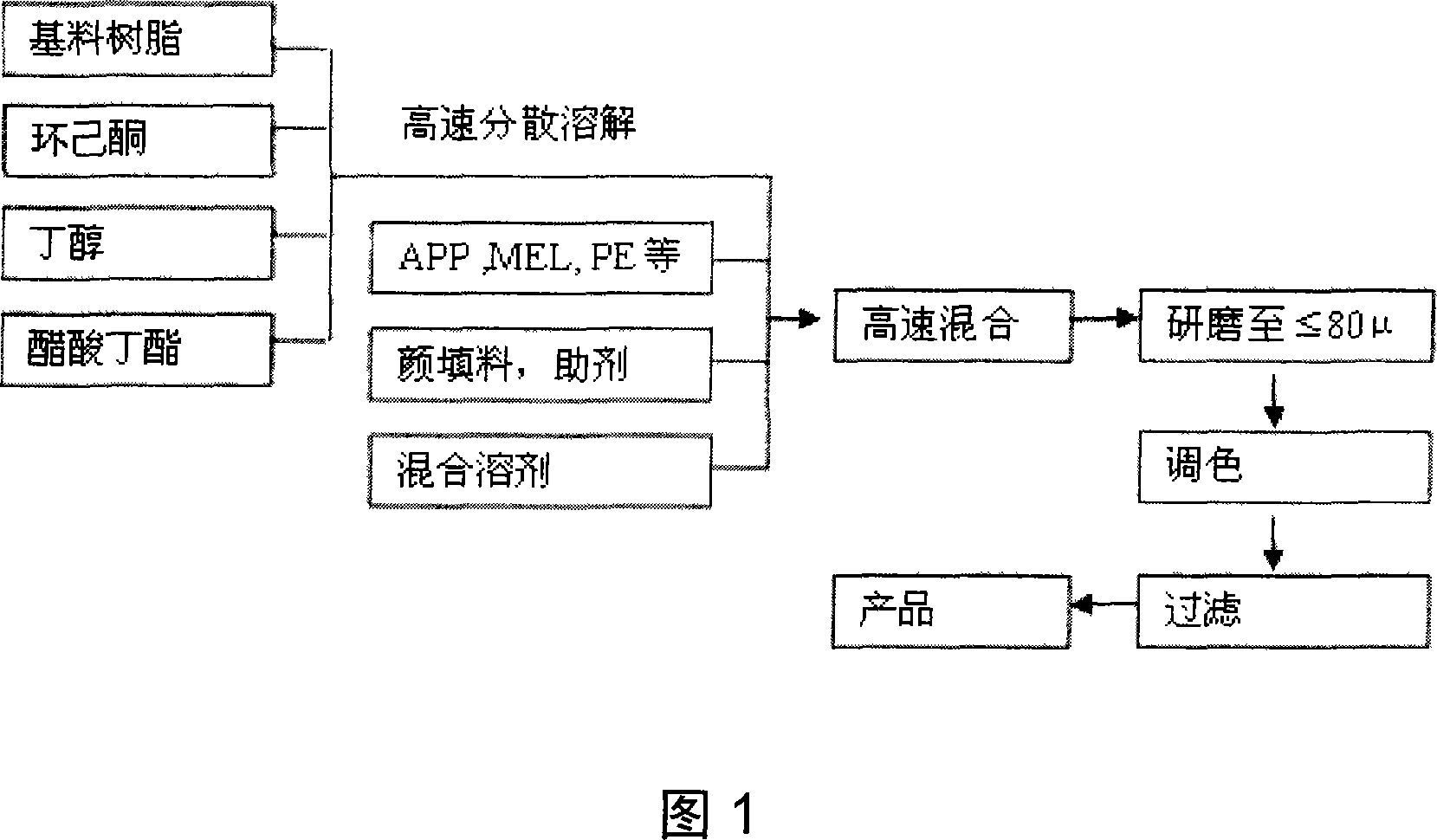

Fireproof paint for super-thin steel structure and preparation method thereof

InactiveCN101058693AStrong adhesionGood film formingFireproof paintsLiquid surface applicatorsTetrabromobisphenol APolyvinyl chloride

The invention discloses a method preparing for an ultra-thin inflatable steel structure fire-proof paint, which is characterized by the following: the allocation of tetrabromo-bisphenol A epoxide resin contains epichlorohydrin and tetrabromo-bisphenol A with weight rate at 1. 3-1. 5:1 and epichlorohydrin and sodium hydroxide with weight rate at 1. 0-1. 05:1; the allocation of fireproof painting is tetrabromo-bisphenol A epoxide resin and hyperchlorinated polyvinyl chloride with weight rate at 3: 1, polyphosphate, melamine, pentaerythritol with weight rate at 3:2:1, antimony trioxide and paraffin chloride with weight rate at 3:7, aluminium hydroxide and zinc borate smoke suppressor with weight rate at 10: 3. The method comprises the following steps: adding epichlorohydrin and tetrabromo-bisphenol A to the autoclave; mixing and heating at 90 Deg. C; adding caustic soda solution; keeping 7. 5 hours; washing and removing thylbenzene by heating;getting tetrabromo-bisphenol A epoxide resin; adding the mixed solvent to tetrabromo-bisphenol A epoxide resin and perchlorinated polyethylene; mixing and dissolving; adding ammonium polyphosphate, melamine, pentaerythrite, titanium dioxide, antimony oxide, aluminum hydroxide, zinc borate separately, adding chlorcosane; grinding after high-speed dispersing uniformly; mixing polyamide uniformly according to 10:1; getting the fire-proof paint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Flame-retardant PBT / PC plastic alloy and manufacturing method thereof

InactiveCN101407621AIncrease productivityAvoid filling mold dissatisfaction and other phenomenaPolytetramethylene terephthalateTetrabromobisphenol A

The invention relates to a flame-retardant PBT / PC plastic alloy and a preparation method thereof. The material components of the flame-retardant PBT / PC plastic alloy comprise main materials and auxiliary materials; wherein, the main materials are polybutylene terephthalate and polycarbonate and the auxiliary materials comprise a compatilizer, a composite flame retardant agent and an antioxidant agent. The plastic alloy is characterized in that the auxiliary materials also comprise a lubricating agent, wherein, the parts by weight of all the components are as follows in sequence: (1) the main material: 30.1 parts to 55 parts of polybutylene terephthalate; 2) 20 parts to 40 parts of polycarbonate; and (2) auxiliary materials: 1) 5 parts to 15 parts of compatilizer; 2) composite flame retardant agent: 8 parts to 16 parts of tetrabromobisphemol A polycarbonate oligomer and 1.5 parts to 6 parts of diantimony trioxide; 3) 0.2 part to 0.4 part of antioxidant agent; and 4) o.2 part to 0.6 part of lubricating agent. The invention has the characteristics of high-effective compatibility, good impact toughness, high-effective flame retardance, high degree of environment protection, excellent processing performance and low cost of materials.

Owner:FOSHAN JINKANGYE PLASTIC

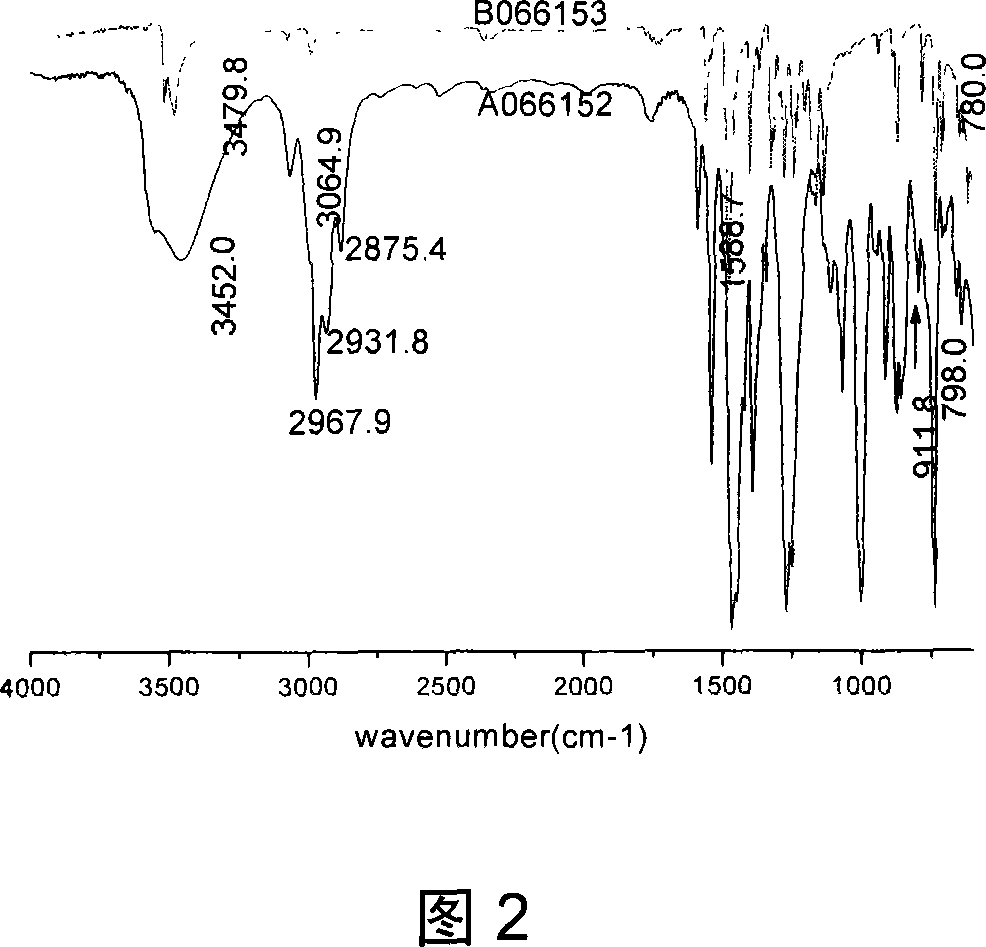

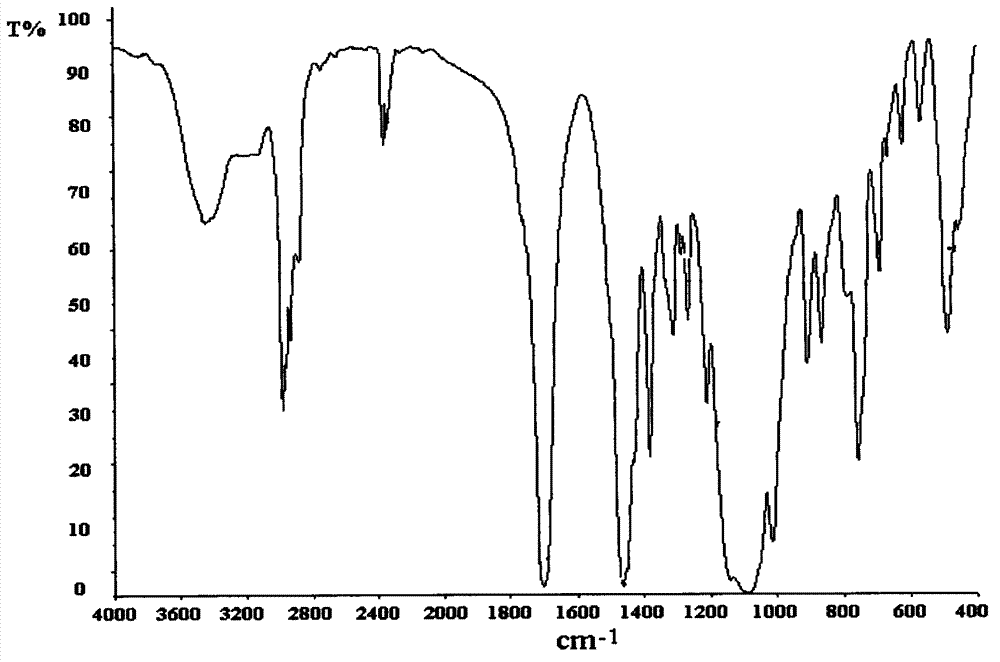

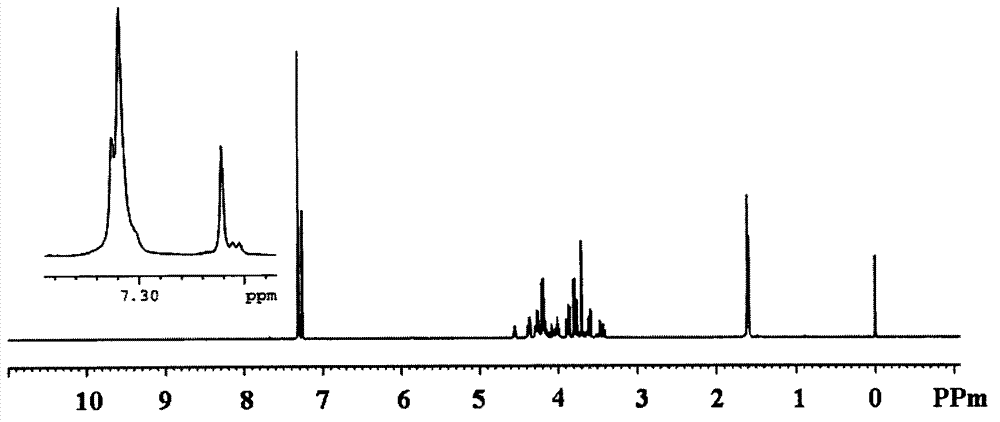

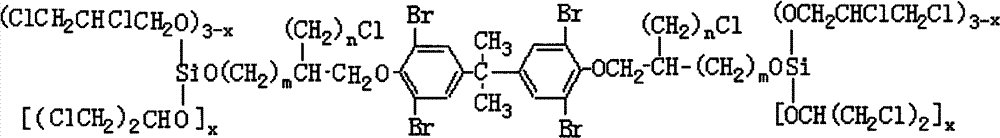

Novel coordinate flame retardant compound of three elements silicon, chlorine and bromine, and preparation method thereof

ActiveCN102775431AGood structural plasticityHigh synergistic flame retardant performanceSilicon organic compoundsTetrabromobisphenol APolyvinyl chloride

The invention relates to a novel coordinate flame retardant compound of three elements silicon, chlorine and bromine, and a preparation method thereof, and in particular relates to a silicon halide coordinate flame retardant plasticizer tetrabromobisphenol A bi[tri(dichloropropoxy) silicon acyloxy chloropropyl] ether compound and a preparation method. The structure of the compound is expressed by the following formula: n is equal to 1 when m is 0, the n is equal to 1 when the m is 1, and x is 0, 1, 2 or 3. The preparation method comprises the following steps of: under stirring, dissolving tetrabromobisphenol A bisepoxy propyl ether in an organic solvent; dropping the mixture in silicon tetrachloride at the temperature of 25 DEG C; after dropping, carrying out insulation reaction for 3-4 hours at the temperature of 70-80 DEG C; dropping epoxychloropropane according to a certain mole ratio; reacting for 7-8 hours at the temperature of 80-100 DEG C; and carrying out purification treatment to obtain the tetrabromobisphenol A bi[tri(dichloropropoxy) silicon acyloxy chloropropyl] ether. The product isa good flame retardant plasticizer, and is suitable for being used as a flame retardant plasticizing additive such as epoxy resin, polyvinyl chloride, unsaturated polyester resin, and polyurethane.

Owner:SUZHOU UNIV OF SCI & TECH

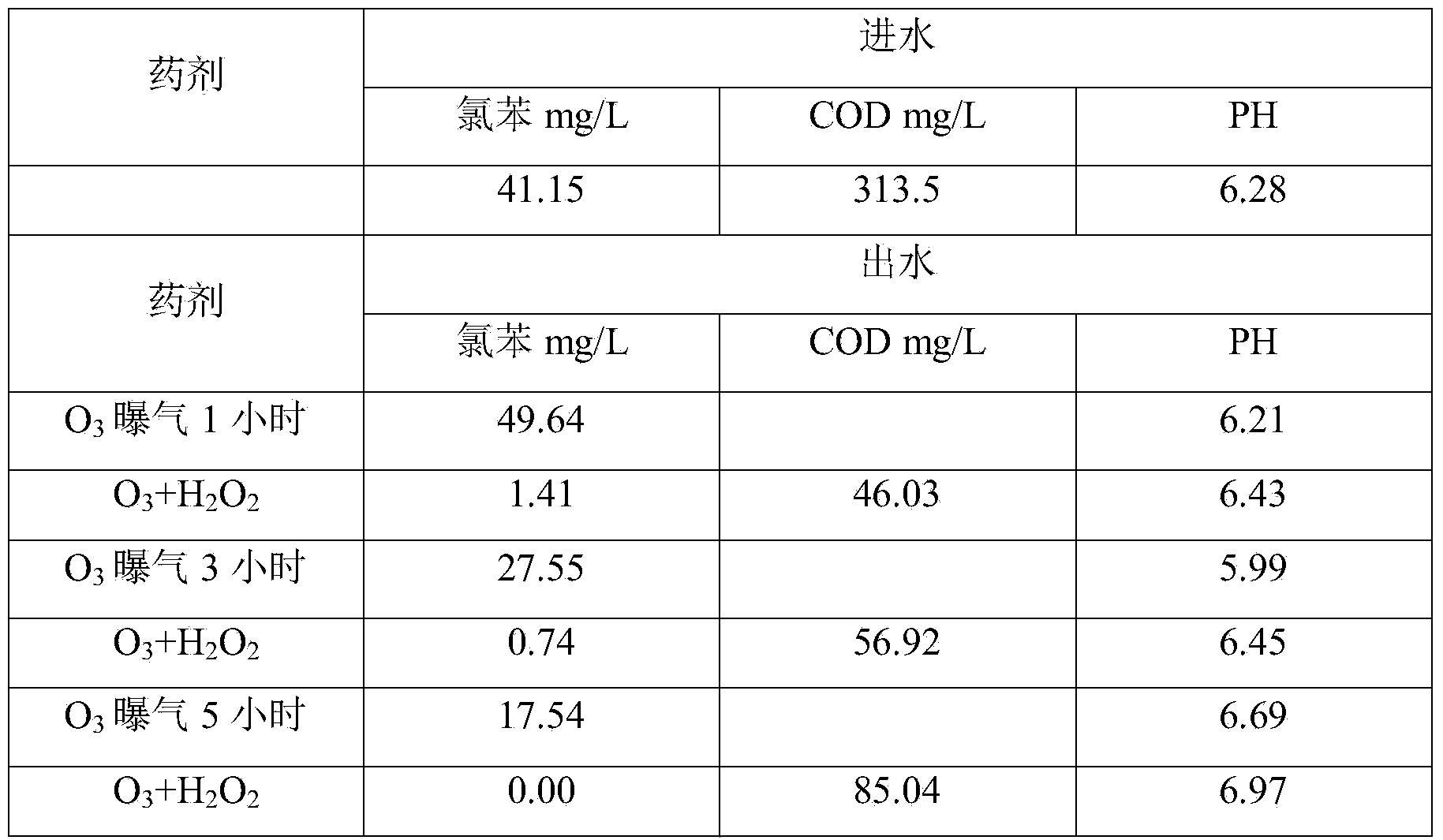

Treatment technique of tetrabromobisphenol A production wastewater

InactiveCN102583849AReduce CODReduce processing loadWater/sewage treatment by electrochemical methodsMultistage water/sewage treatmentTetrabromobisphenol AChlorobenzene

The invention discloses a treatment technique of tetrabromobisphenol A production wastewater, belonging to organic chemical industry wastewater recycling and harmless environmental-protection treatment technologies. The treatment technique of tetrabromobisphenol A production wastewater is an acidification precipitation-resin adsorption-advanced oxidation combined technique, and mainly comprises the following steps: 1. regulating the pH value of the wastewater to recycle the tribromophenol in the wastewater by acidification precipitation; 2. filling the wastewater, in which abundant tribromophenol is removed, into an adsorption column by using a macroporous adsorbent resin subjected to conventional pretreatment, and passing the wastewater through a bed bottom at a certain flow rate so that chlorobenzene is adsorbed by the resin, wherein the resin adsorption is utilized to remove most chlorobenzene, bisphenol A and other nondegradable organic substances in the recycled wastewater, thereby effectively reducing COD (chemical oxygen demand) of the wastewater and relieving the treatment load of the wastewater; and 3. carrying out electrocatalytic oxidation on the wastewater subjected to acidification precipitation-resin adsorption to finally remove harmful and nondegradable substances in the wastewater, thereby achieving the goal of harmless discharge after reaching the standard.

Owner:TIANJIN POLYTECHNIC UNIV

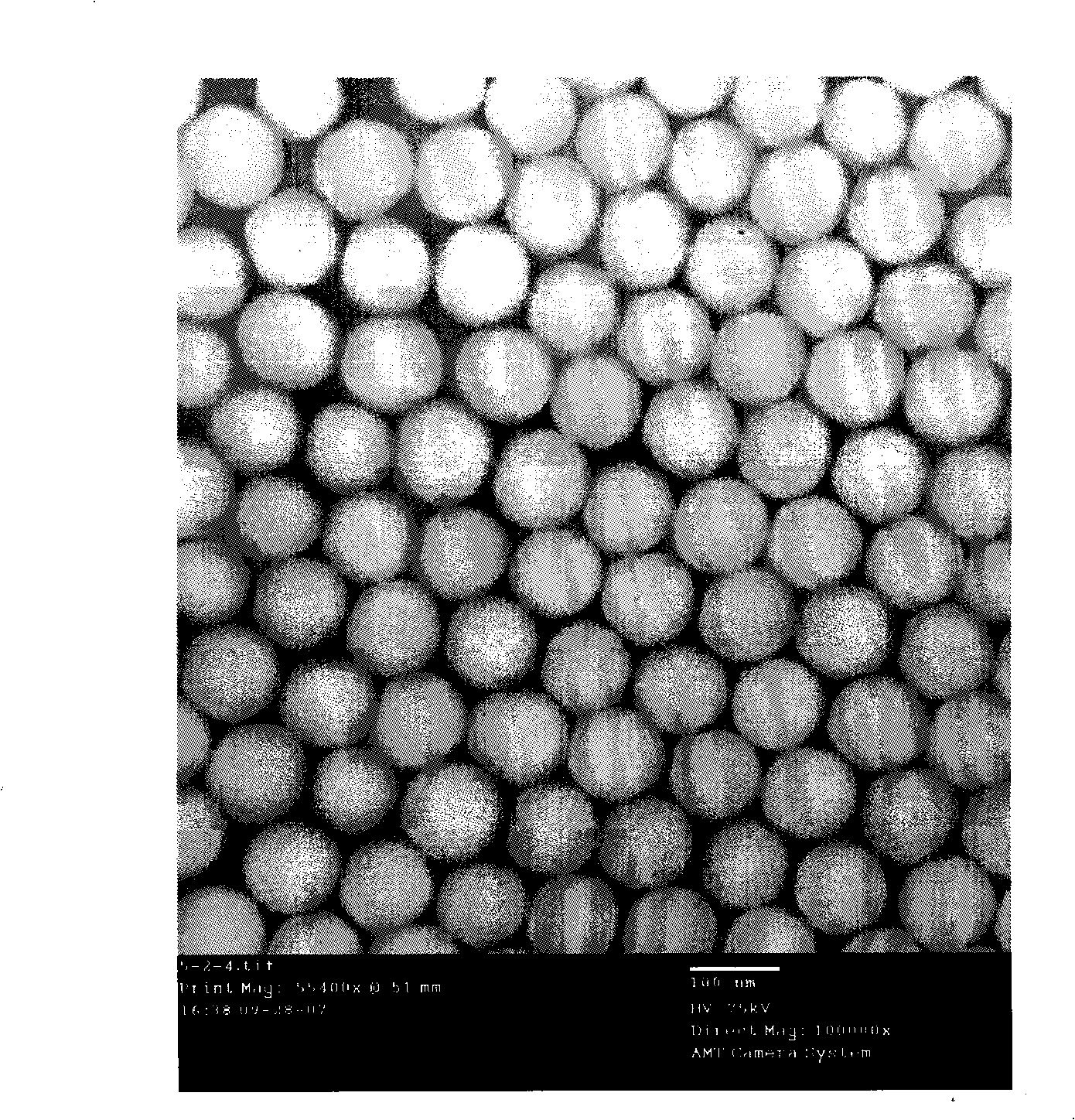

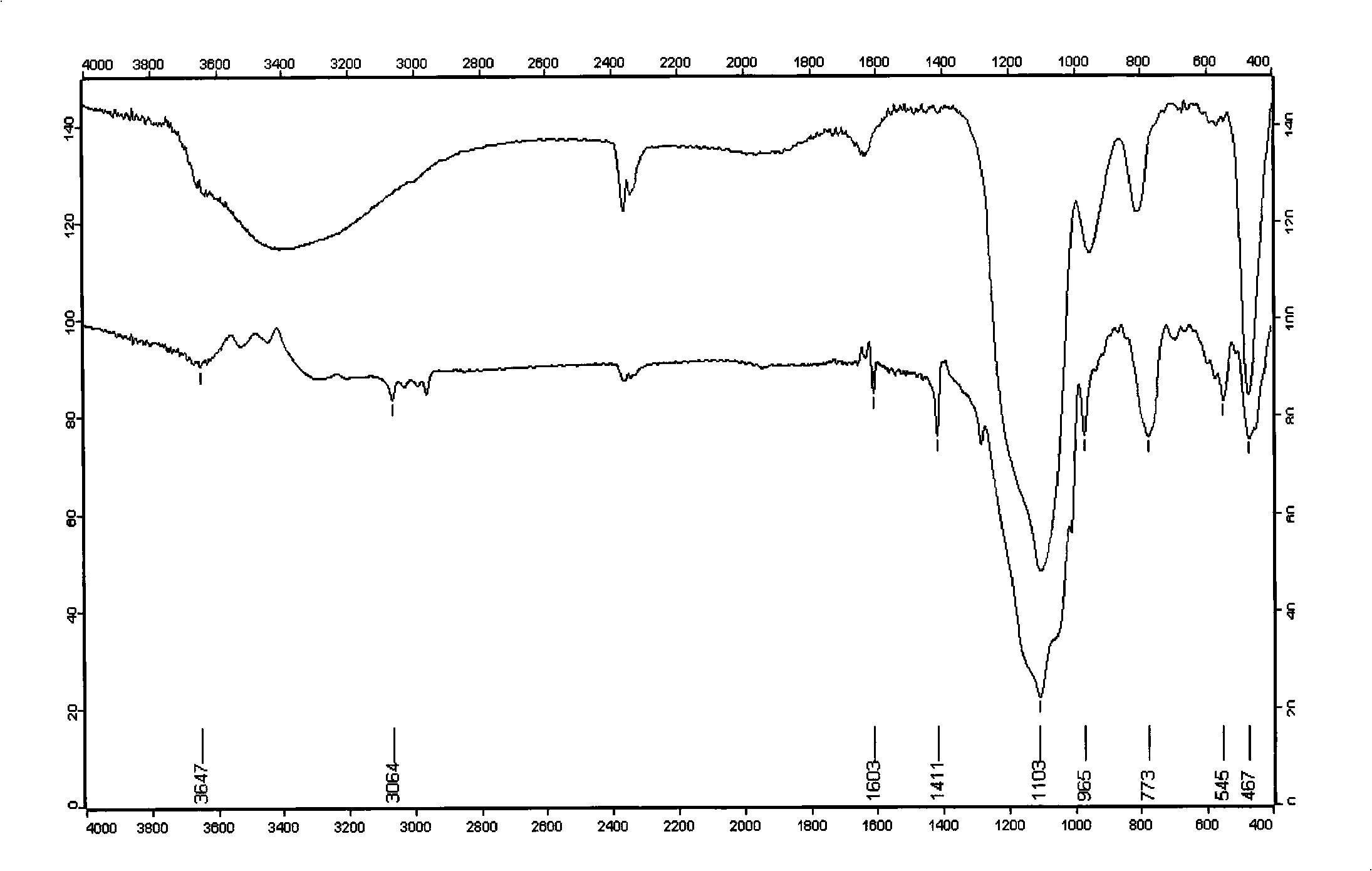

Method for preparing bisphenol A nanometer silicon gel carrier surface molecule print solid phase extraction filling

InactiveCN101524636AImprove bindingEasy to eluteOther chemical processesTetrabromobisphenol AFunctional monomer

The invention discloses a method for preparing bisphenol A nanometer silicon gel carrier surface molecule print solid phase extraction filling. Firstly, silanizing agent containing double bonds is grafted on the surfaces of nanometer silicon dioxide beads; secondly, template molecules, functional monomers and crosslinking agents are added into toluene solution containing proper grafted nanometer silicon and catalytic amount evocating agent according to a certain proportion and stirred for polyreaction at temperature of 60 to 70 DEG C and for 15 to 24 hours to generate light-yellow powdery polymer; and finally, templates are eluted from the polymer, and the bisphenol A nanometer silicon gel carrier surface molecule print solid phase extraction filling which has high special selectivity to bisphenol A is obtained. Because the invention adopts the tetrabromobisphenol A and biphenyl diphenol which are analogues of target molecule BPA of as templates, the problem of template leakage is solved. The prepared bisphenol A nanometer silicon gel carrier surface molecule print solid phase extraction filling has high special selectivity to bisphenol A, can collect bisphenol A molecules in trace amount of water sample, and has high recovery ratio and good reproducibility.

Owner:NANJING MEDICAL UNIV

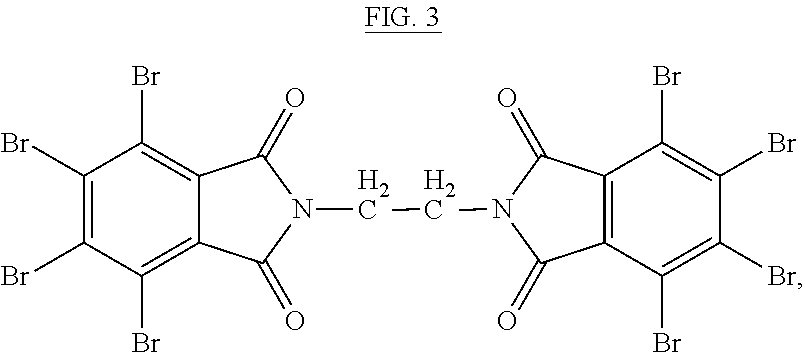

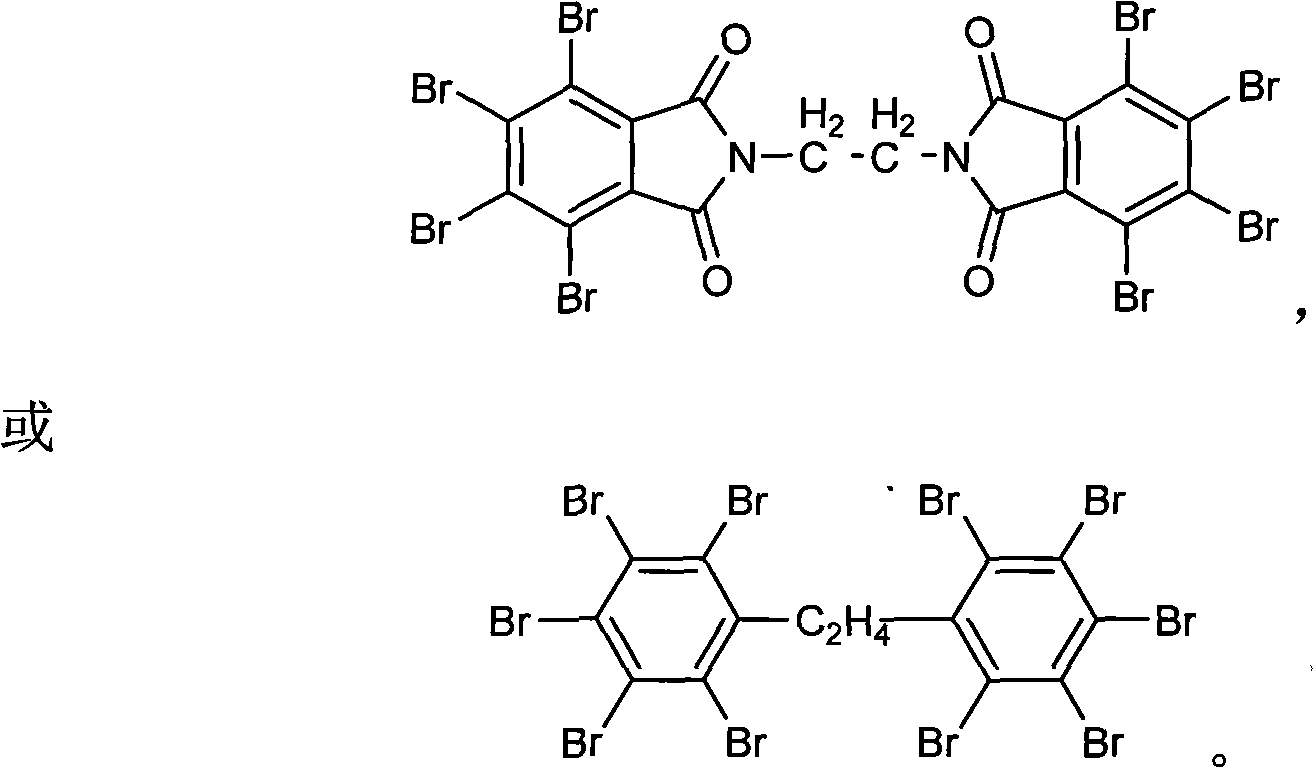

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

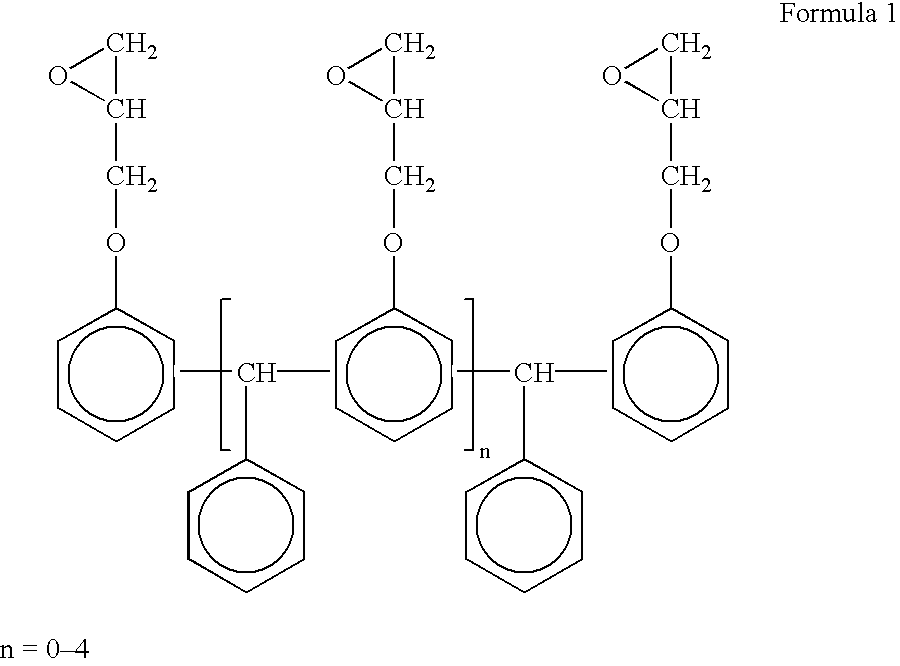

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352ALow costImprove heat resistanceCircuit susbtrate materialsFiberTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

Eco-friendly method of preparation of high purity tetrabromobisphenol-A

InactiveUS6365786B1High yieldMost efficientOrganic chemistryOrganic compound preparationTetrabromobisphenol AOrganic layer

A highly pure and colorless tetrabromobisphenol-A (TBBPA) possessing melting point in the range of 178-182° C. is prepared in yields of 50-70% in first batch and 90-100% when the spent organic layer is recycled. In this method, the corrosive liquid bromine is displaced by sodium bromide / hydrobromic acid as brominating agent. Further, sodium bromate is used as an oxidizing as well as brominating agent to utilize the hydrobromic acid that is produced during the bromination of bisphenol-A (BPA). The reaction is conducted at 10-15° C. in a mixture of methylene chloride-water or carbon tetrachloride-water in the presence of hydrochloric acid and sodium lauryl sulfate. The crystalline product settled at the bottom of the reaction vessel is filtered, washed, dried and weighed. The spent organic layer is recycled in subsequent batches to maximize the overall yield of product recovered directly as solid and to minimize generation of organic effluent.

Owner:COUNCIL OF SCI & IND RES

Flame-retardant ASA material and preparation method thereof

InactiveCN101397391AOvercoming the defect of becoming brittleImprove toughnessSatellite antennasTetrabromobisphenol A

The invention discloses a fire-retardant ASA material and a preparation method thereof. The fire-retardant ASA material is prepared by the following components in accordance with the weight percentage: 72 to 82 percent of ternary graft copolymer which consists of acrylonitrile, styrene, and acrylic ester; 2 to 7 percent of flexibilizer, 12 to 18 percent of tetrabromobisphenol A, 3.0 to 7.0 percent of antimony trioxide, 0.3 to 0.5 percent of UV absorber, 0.1 to 1.0 percent of antioxidant, and 0.3 to 0.7 percent of lubricant. The fire-retardant ASA material not only has good fire-retardant property, but also maintains original toughness and weatherability of the ASA material, and can be widely used in the automotive field, electrical and electronic field, architecture field and other fields, for example, the use in the production of external parts such as automobile exterior mirrors, radiator grilles, tailgates, lampshades and the like, motorcycle panels, camping cars, small hulls, surfboards; all-weather shells such as sewing machines, telephones, kitchen equipment, satellite antennas, and the like; and can also be used in advanced bathrooms, hygiene products, and hot and cold water switches.

Owner:SHENZHEN KEJU NEW MATERIAL

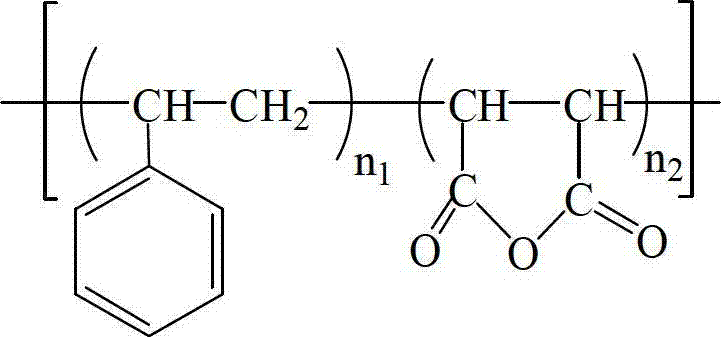

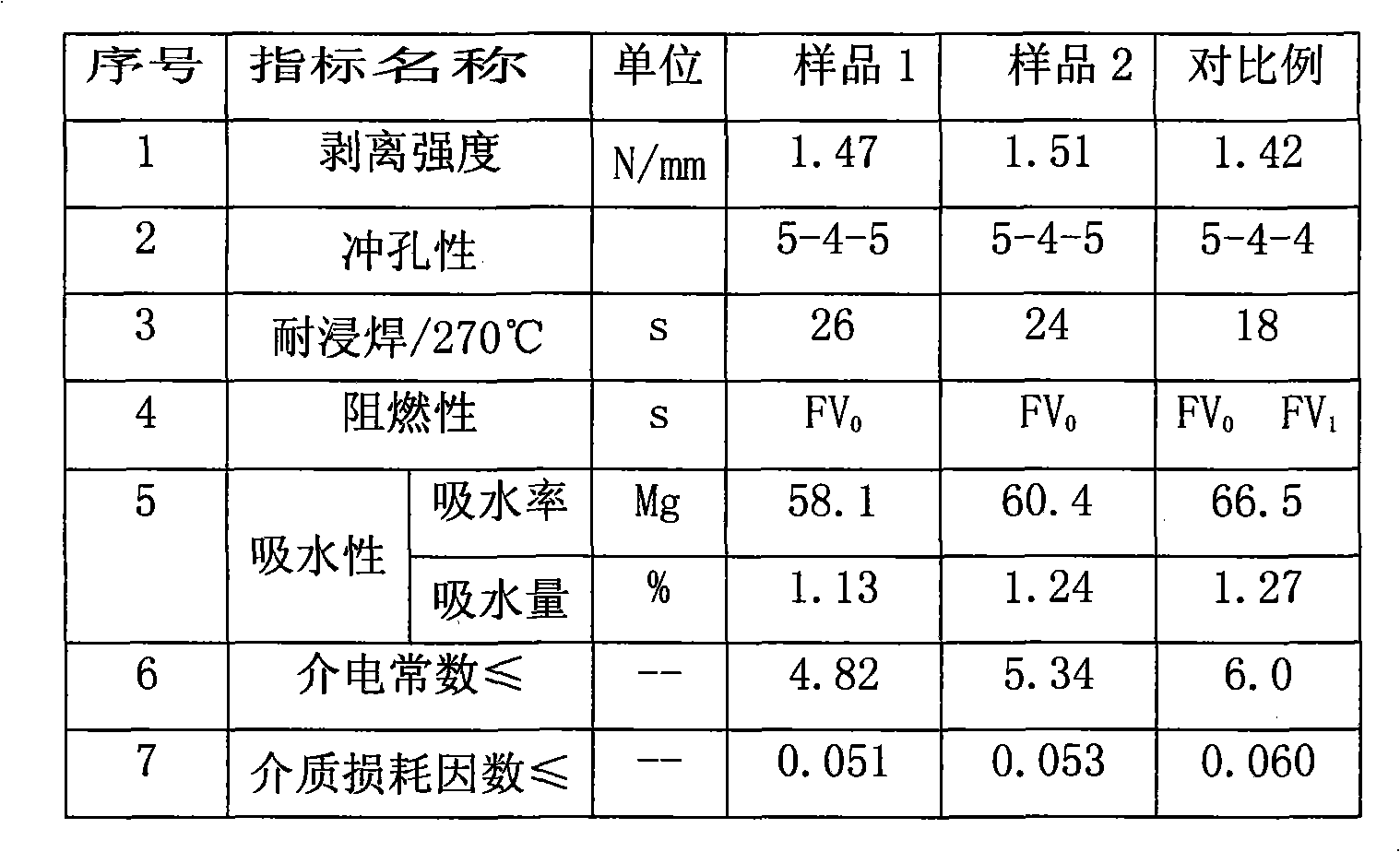

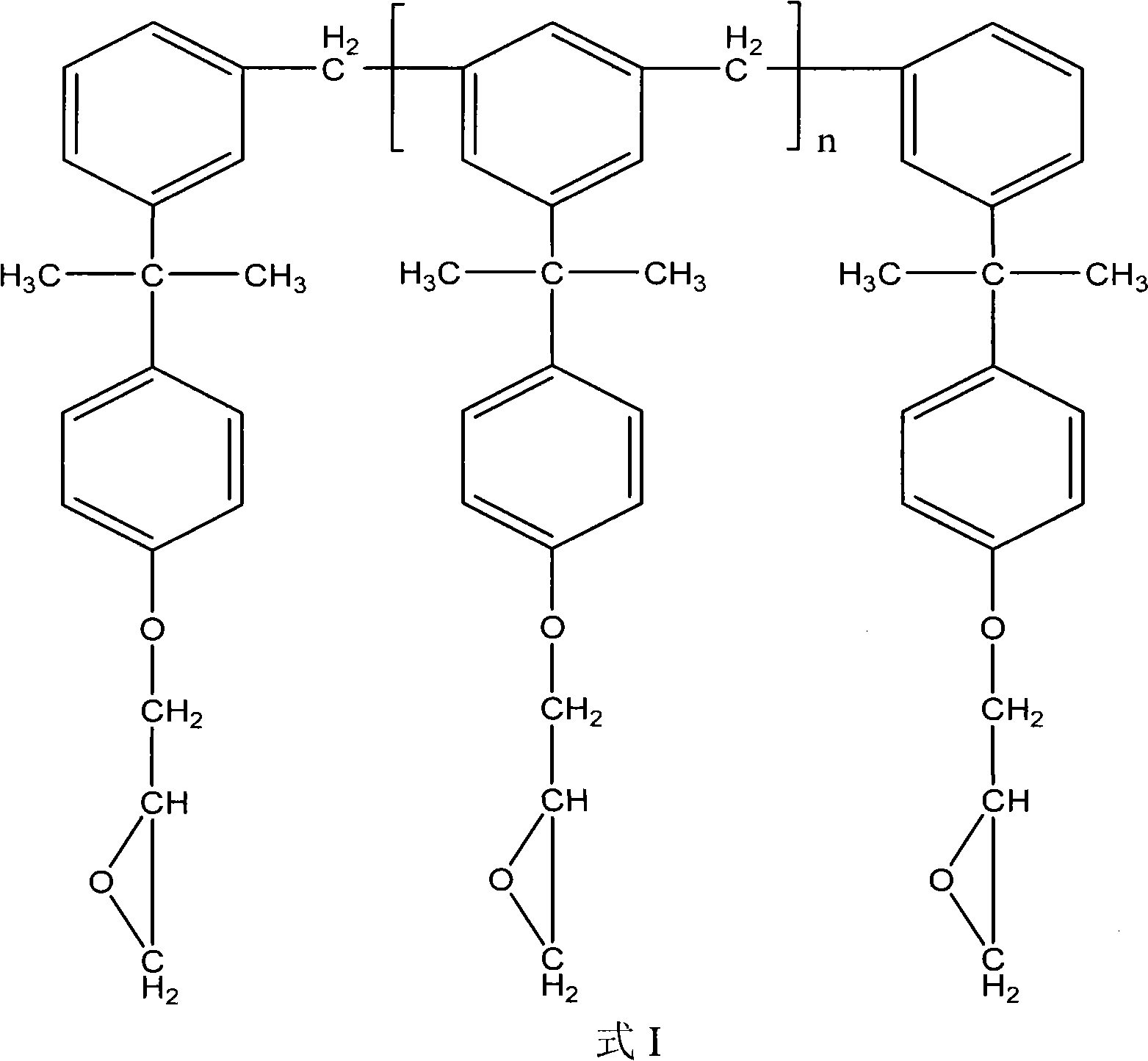

High Tg brominated epoxy resin for glass fiber laminate

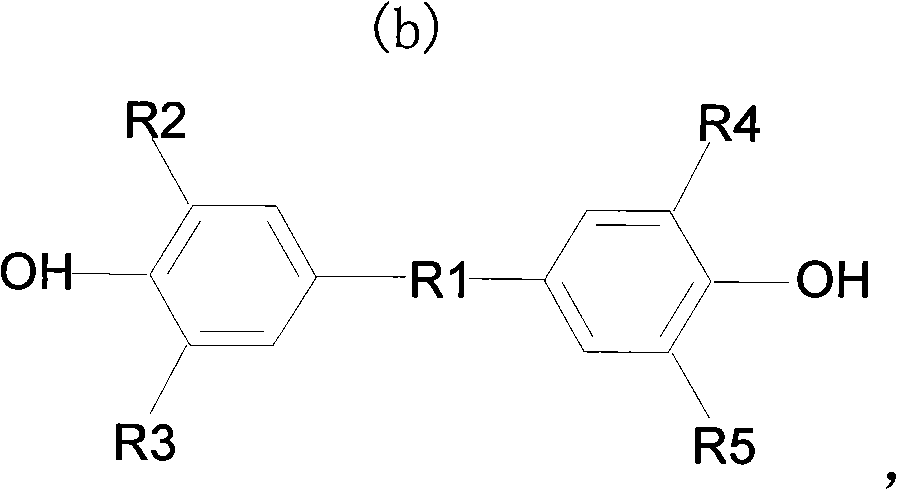

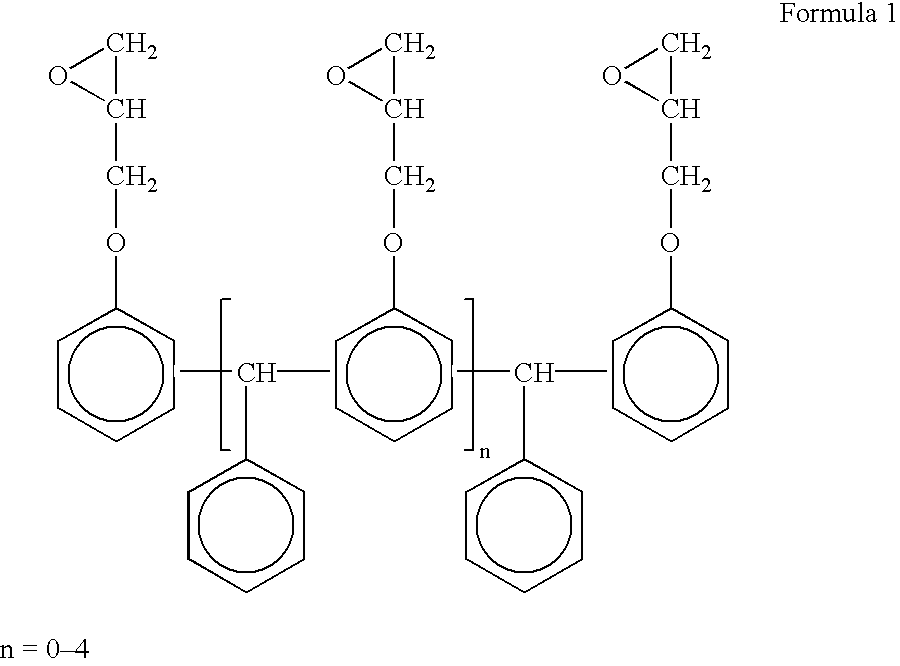

InactiveUS6512075B1Guaranteed uptimeImprove heat resistanceCircuit susbtrate materialsGlass fiberTetrabromobisphenol A

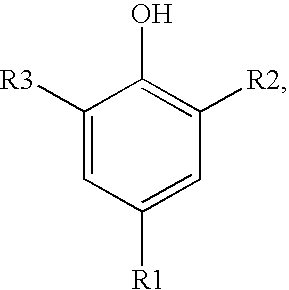

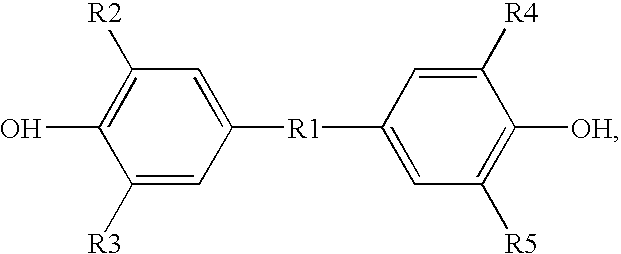

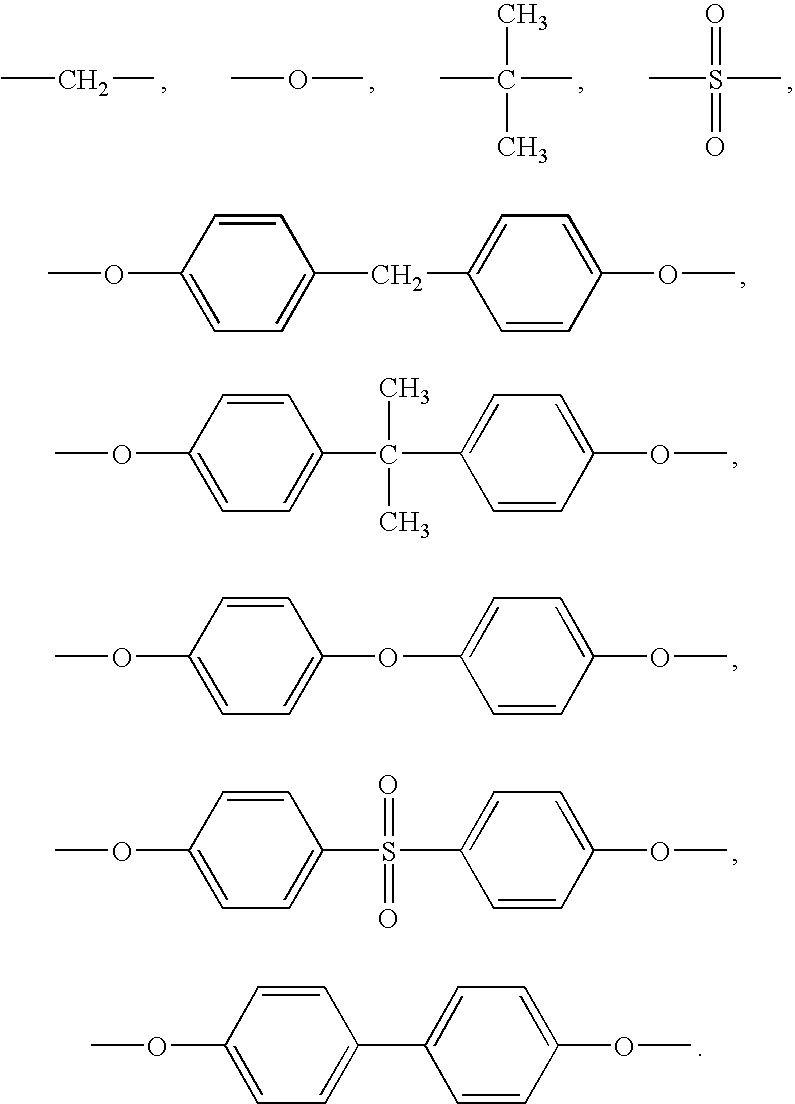

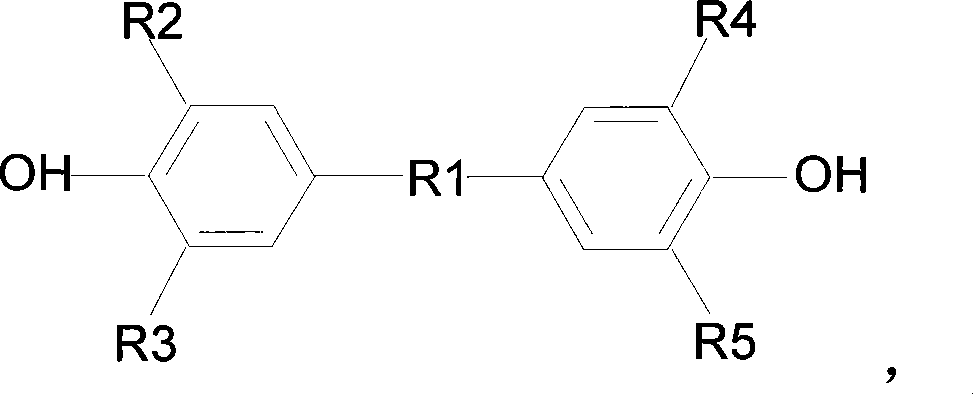

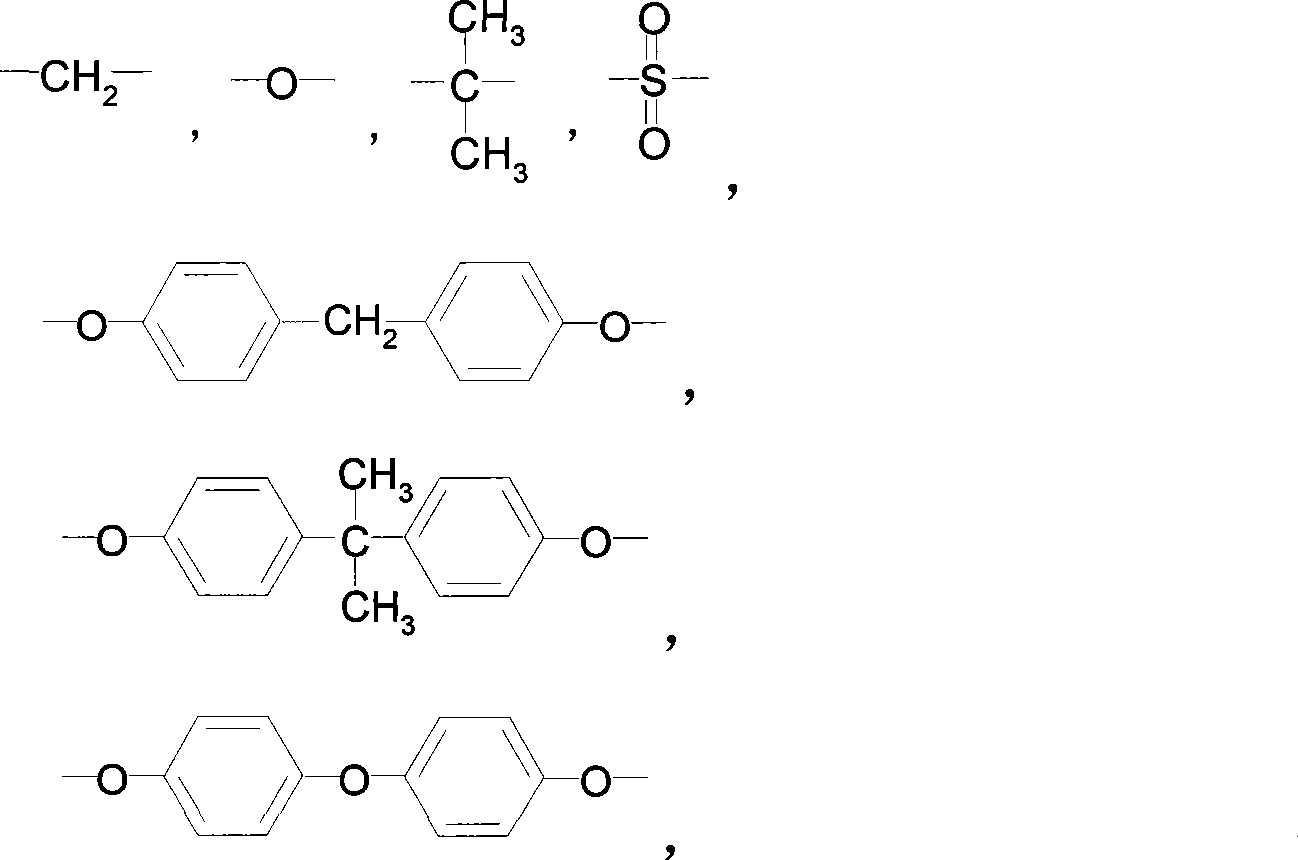

A new brominated epoxy resin has been developed, which consists of following components:A. multifunctional phenol-benzaldehyde epoxy resin (formula 1) 10~70 weight %;B. difunctional epoxy resin 0~55 weight %;C. bromine-containing difunctional epoxy resin 0~20 weight %;D. tetrabromobisphenol-A epoxy resin 15~40 weight %;The synthesis is that (D) tetra bromo bisphenol-A reacts with at least one of (A), (B)and (C), then adding the rest of (A),(B) and (C) and mixing them uniformly, the new brominated epoxy resin produced, which can be applied to glass fiber laminate, and showing proper reactivity and a broad working window. The laminate possesses high Tg and good heat resistance, and applying to electron material with high performance.

Owner:NANYA PLASTICS CORP

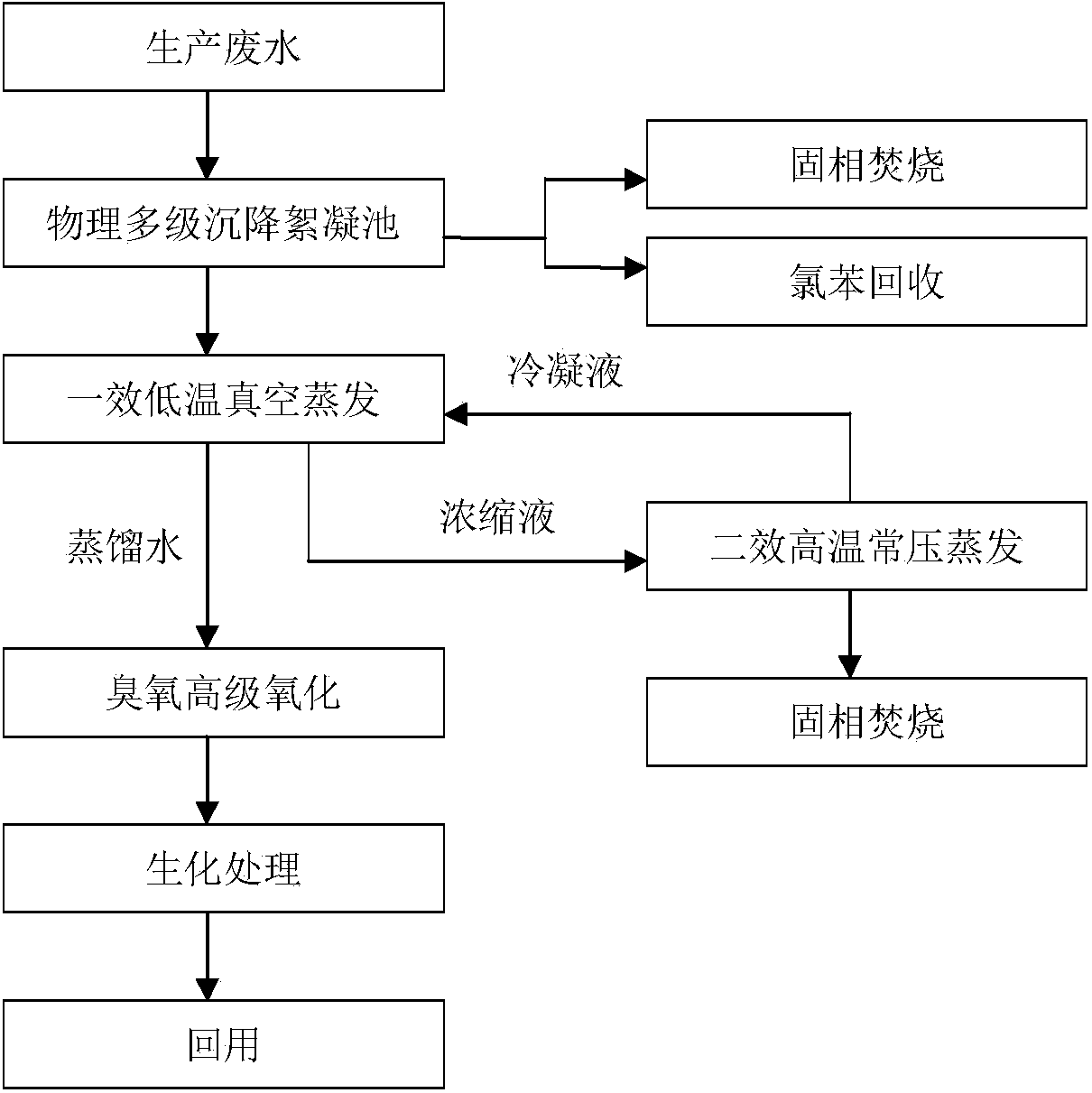

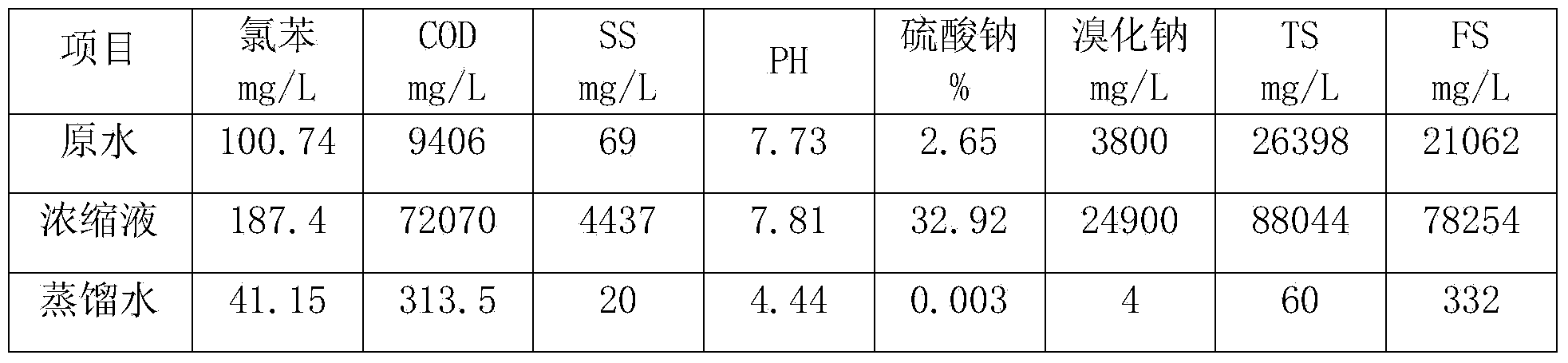

Method for treating and recycling TBBP (tetrabromobisphenol)-A production wastewater

InactiveCN103466894AAchieve removalRealize harmless and up-to-standard dischargeMultistage water/sewage treatmentNature of treatment waterFlocculationChlorobenzene

The invention discloses a method for treating and recycling TBBP (tetrabromobisphenol)-A production wastewater, which comprises the main steps of physical multistage settling, flocculation and recovery, two-effect high / low-temperature evaporative desalination, advanced ozone oxidation and biochemical treatment. According to the invention, the removal of harmful hardly-degradable substances in TBBP-A wastewater is realized, the pH value of wastewater subjected to treatment is neutral, the COD (chemical oxygen demand) can be degraded to below 100 mg / L, and chlorobenzene can be completely decomposed by cutting, thereby reaching reuse and discharge standards, and achieving the purposes of the harmless and up-to-standard discharge of wastewater and the recycling of process water.

Owner:天津长芦汉沽盐场有限责任公司

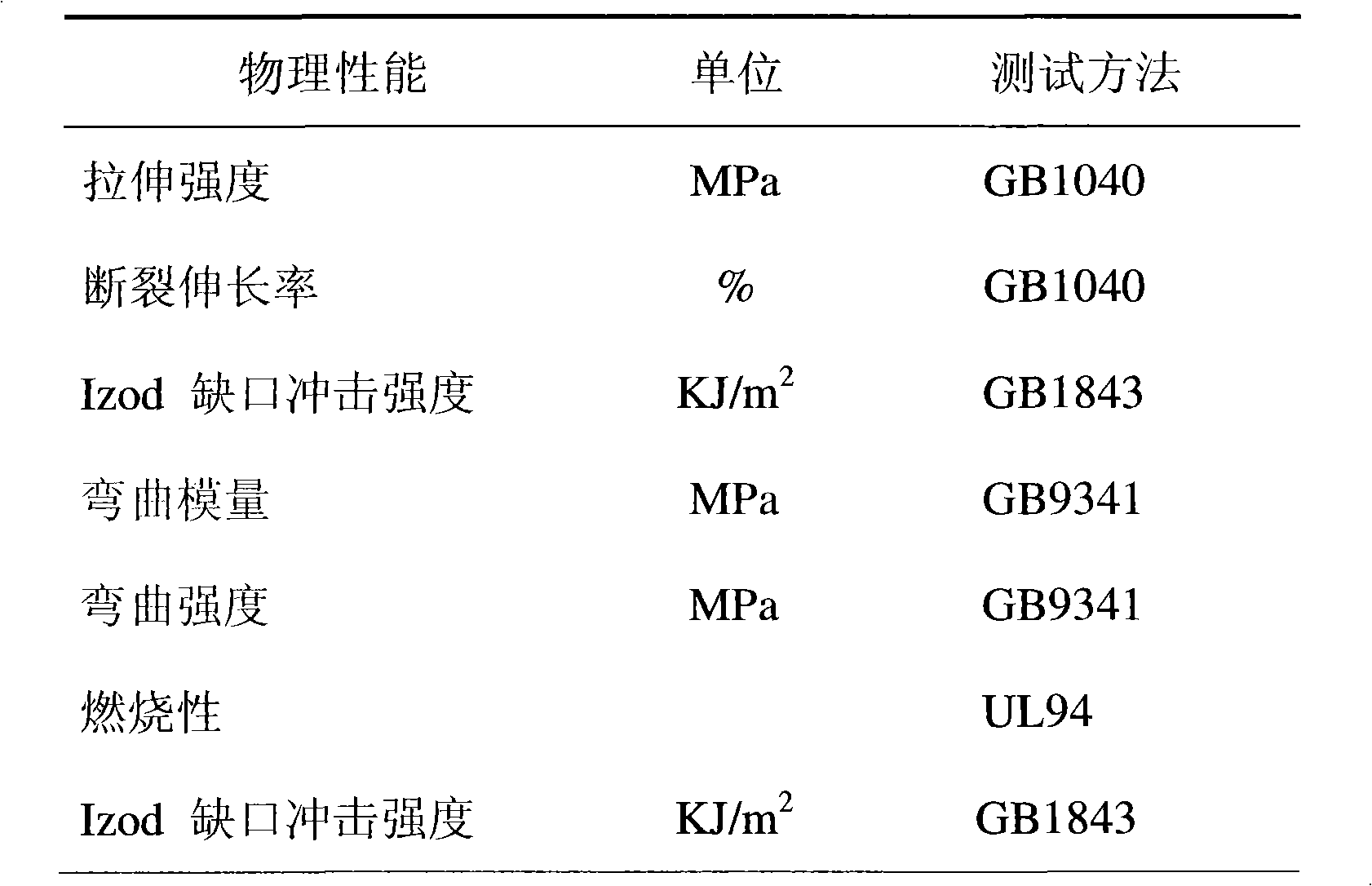

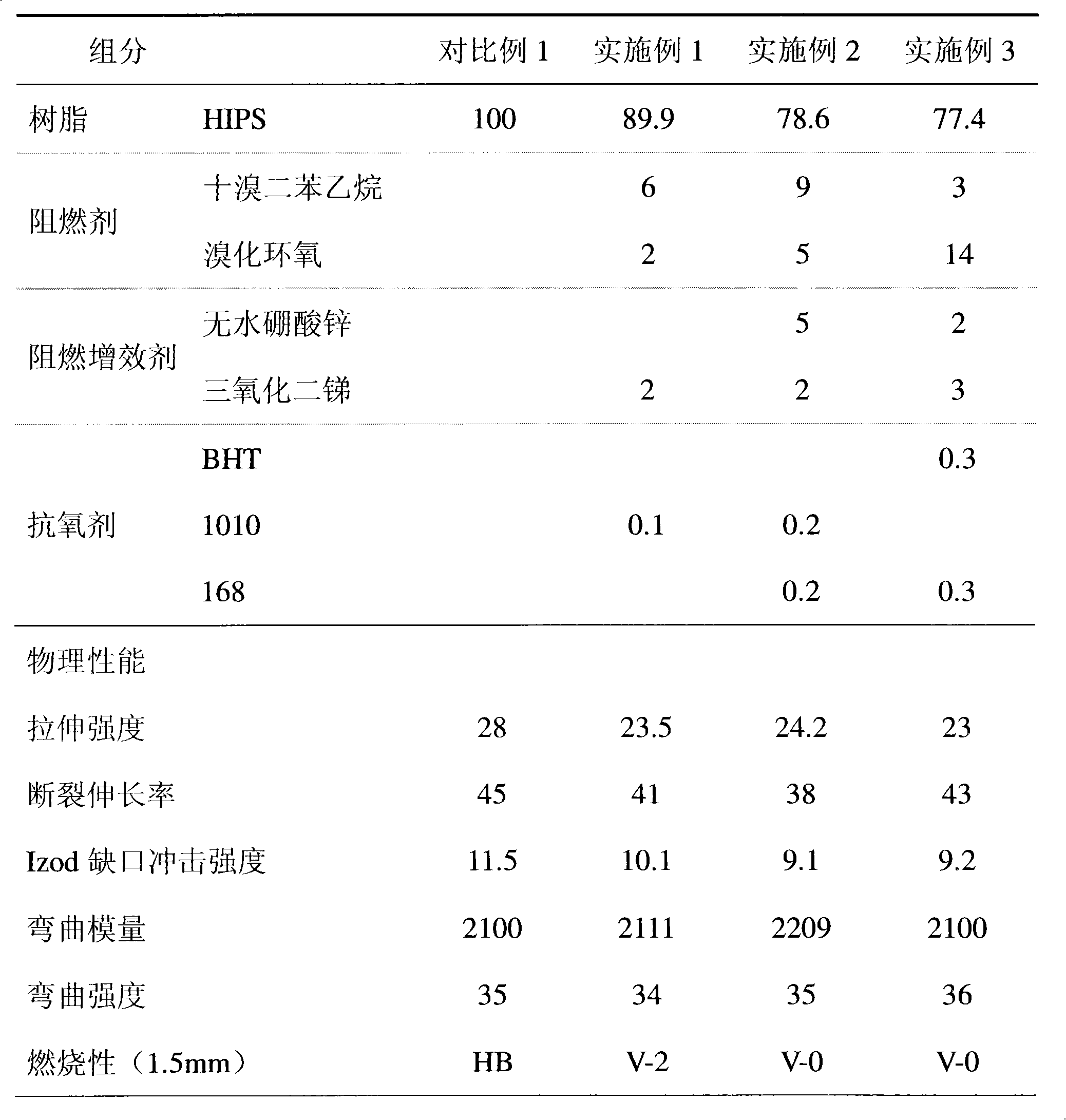

Flame-retardant highly impact resistant polystyrene complex containing decabromodiphenylethane and preparation thereof

The invention discloses a flame-retarding high impact-resistant polystyrene composite containing DBDPE and a preparation method thereof. The composite comprises the components with the following portions: 77 to 89.9 percent of high impact-resistant polystyrene resin, 3 to 10 percent of DBDPE flame retarding agent, 2 to 14 percent of brominated epoxy or tetrabromobisphenol A flame retarding agent, 2 to 7 percent of retardant synergist and 0.1 to 1 percent of antioxidant, which are one-time extruded and processed by a double screw extruder. The composite of the invention has good mechanical performance, unchanged processing performance, high flame retarding efficiency, high-grade flame retarding performance, small environmental pollution and small human harm, can meet the strict requirements for environment protection internationally at present, simultaneously has the advantages of easy forming and good surface glossiness, and is suitable for making shells of various electrical appliances.

Owner:SHANGHAI KINGFA SCI & TECH +1

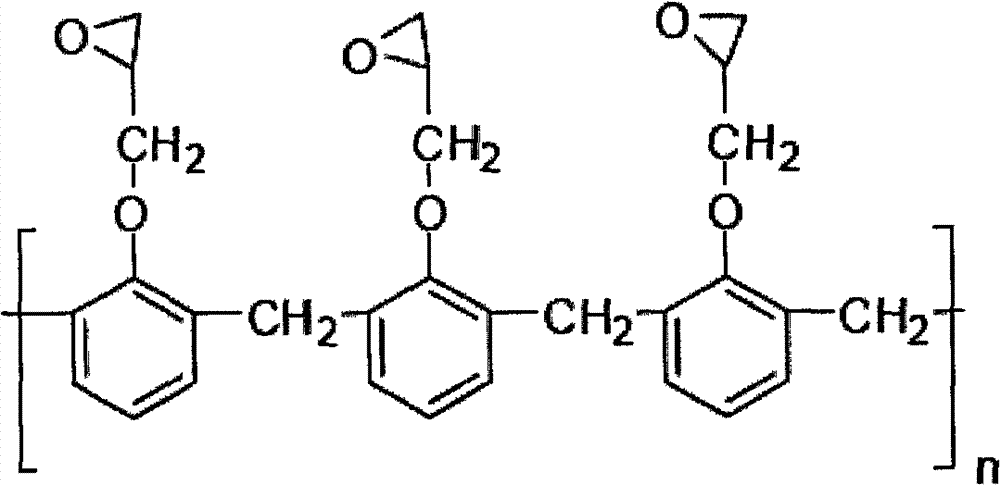

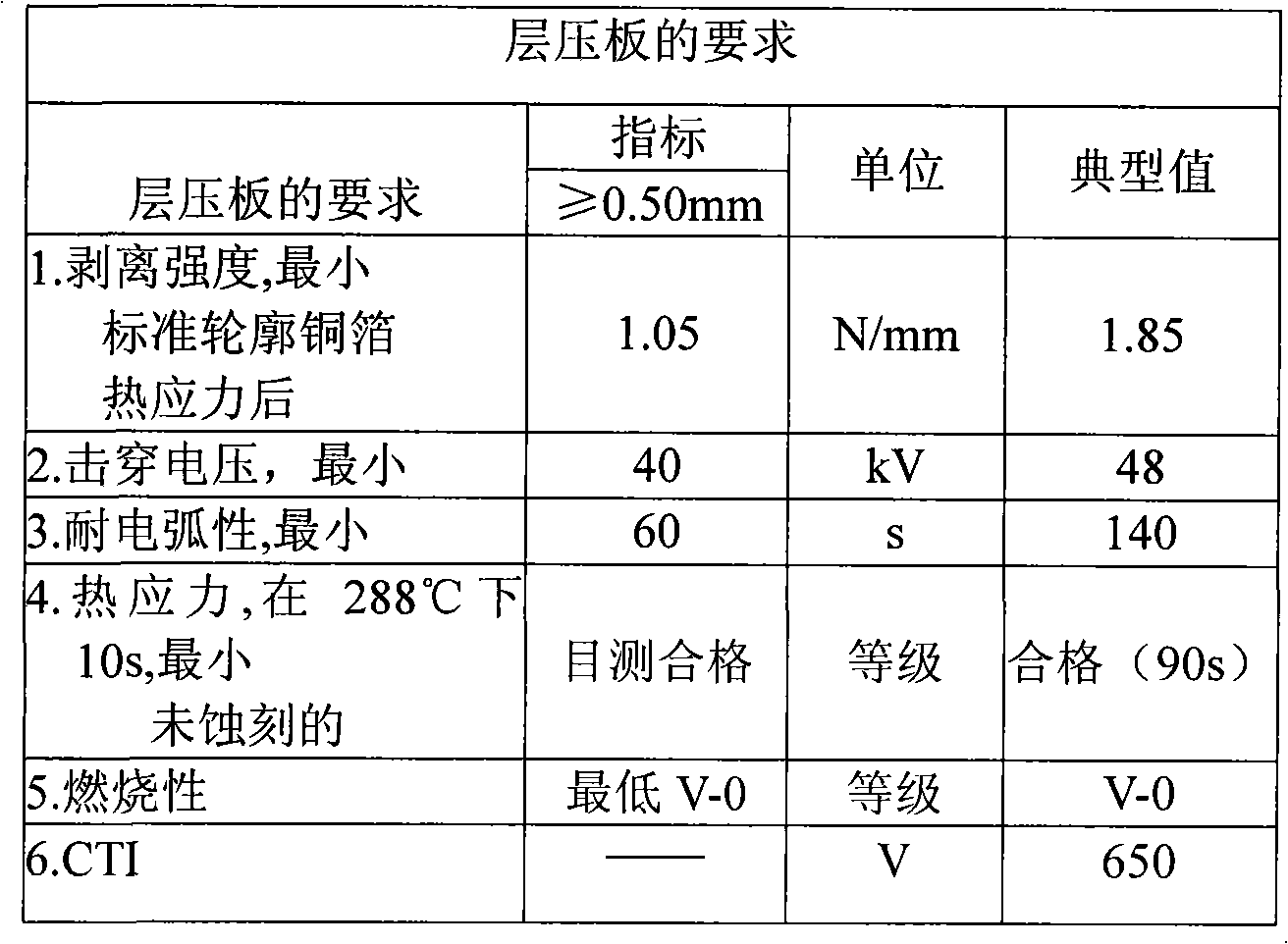

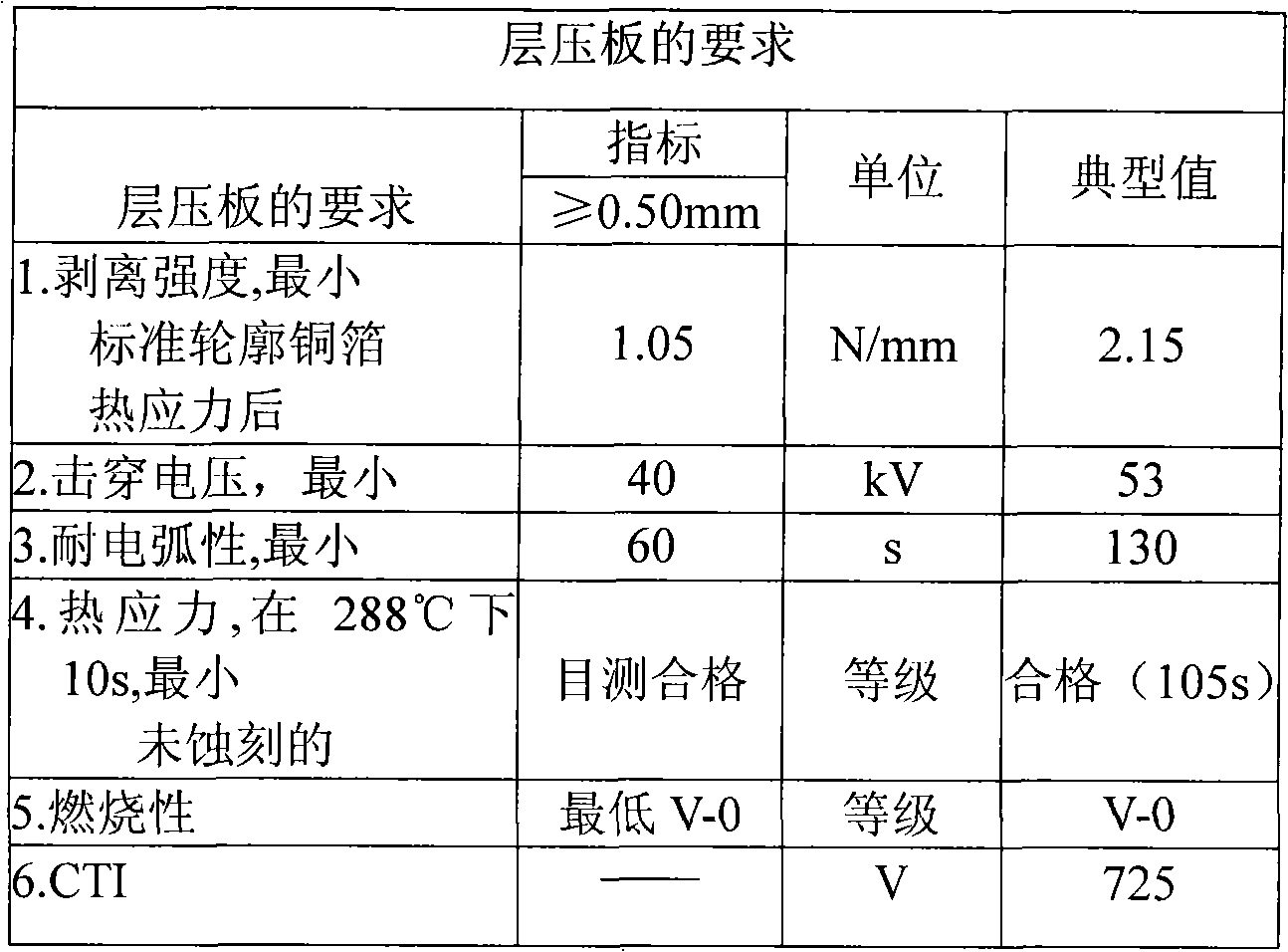

Flame retardant composition copper clad laminate and preparation thereof

ActiveCN101323698AReduce liquidityImprove heat resistanceLiquid surface applicatorsCoatingsTetrabromobisphenol AHeat resistance

The invention discloses a flame retardant compound containing main resin and a curing agent, wherein, the main resin is bisphenol-A phenolic epoxy resin and the curing agent is phenolic resin and the compound also contains tetrabromobisphenol A. The invention also provides a preparation method of the flame retardant compound, a copper clad using the flame retardant compound and a preparation method thereof. The main resin and the curing agent of the flame retardant compound provided by the invention adopt the combination of the bisphenol-A phenolic epoxy resin and the phenolic resin and can effectively improve the heat resistance and lower the water absorption of the copper clad made from the compound. In addition, the tetrabromobisphenol A contained in the flame retardant compound have the effects of flame retarding as well as curing to the bisphenol-A phenolic epoxy resin, thus lowering the mobility of the bisphenol-A phenolic epoxy resin and effectively solving the problem of resin recession during the lamination of a prepreg and a copper foil.

Owner:BYD CO LTD

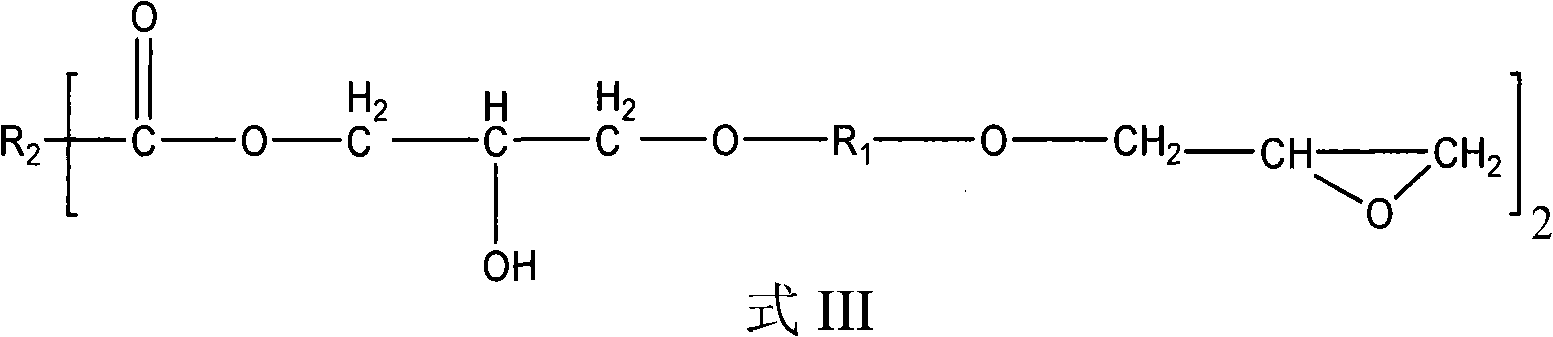

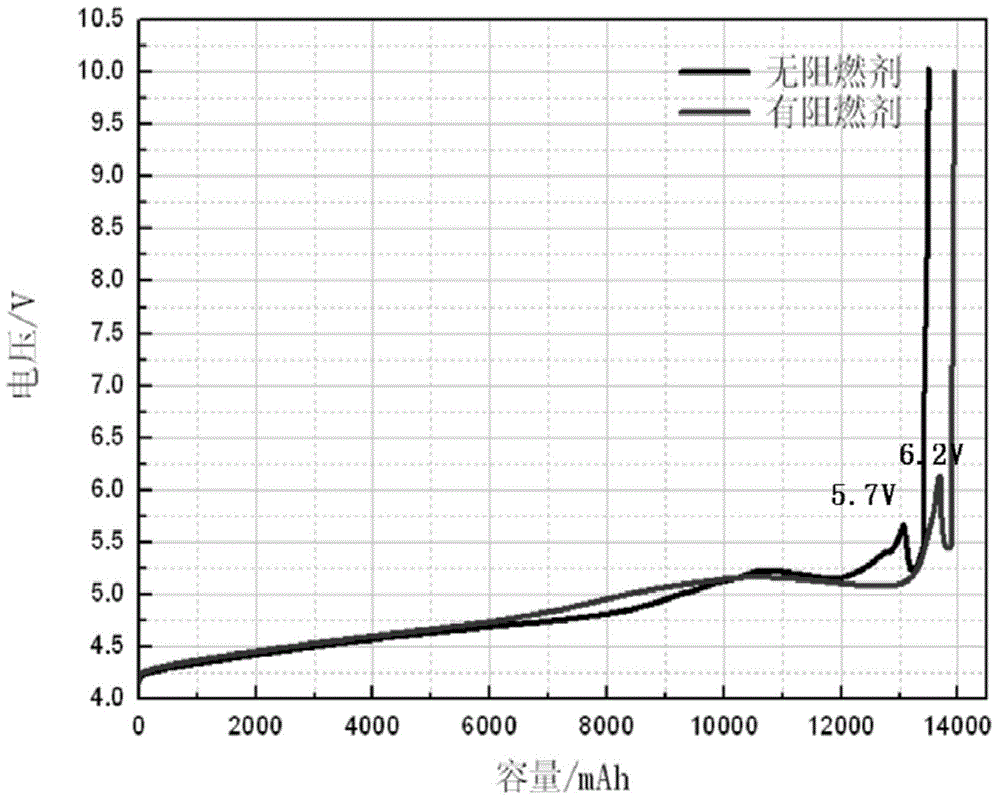

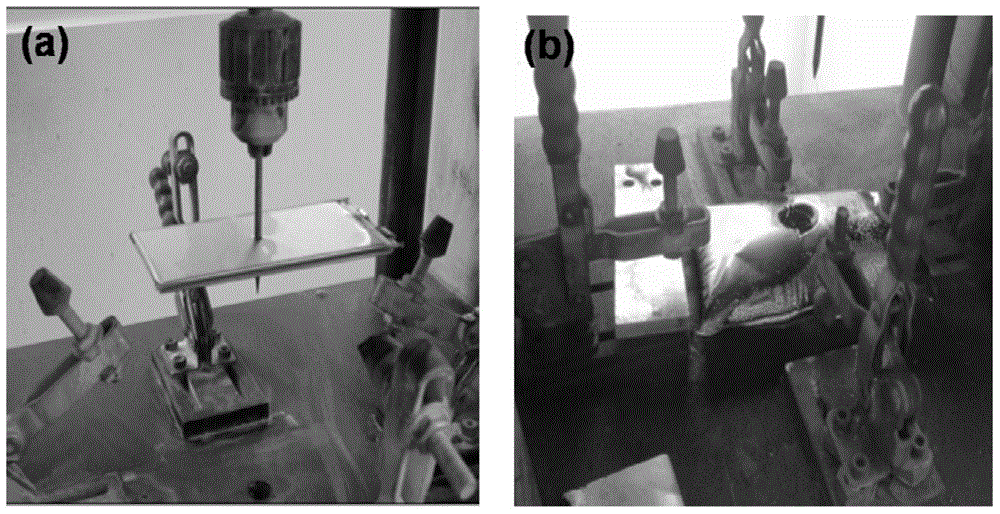

Safe lithium ion battery with anode added with nanometer resinae solid fire retardant, and manufacturing method therefor

ActiveCN104835981AImprove securityAvoid instabilitySecondary cellsNon-aqueous electrolyte accumulator electrodesEpoxyTetrabromobisphenol A

The invention discloses a safe lithium ion battery with an anode added with a nanometer resinae solid fire retardant, and a manufacturing method therefor. As for the structure, the battery comprises four main materials: an anode, a cathode, a diaphragm and an electrolyte. An anode material is added with the nanometer resinae solid fire retardant, wherein the solid fire retardant is a mixture formed by at least one of phenyl silicon resin, epoxy resin and phenolic resin or at least one of phenyl silicon resin, epoxy resin and phenolic resin and ammonium polyphosphate and / or tetrabromobisphenol A. Through adoption of the lithium ion battery with the anode added with the nanometer resinae solid fire retardant, the problem of instability of components of the anode material is thoroughly solved, so that the safety of the battery is improved. The lithium ion battery has low raw material cost, a simple manufacturing method, and good repeatability, and is easy to realize industrial production.

Owner:厦门华理能源股份有限公司

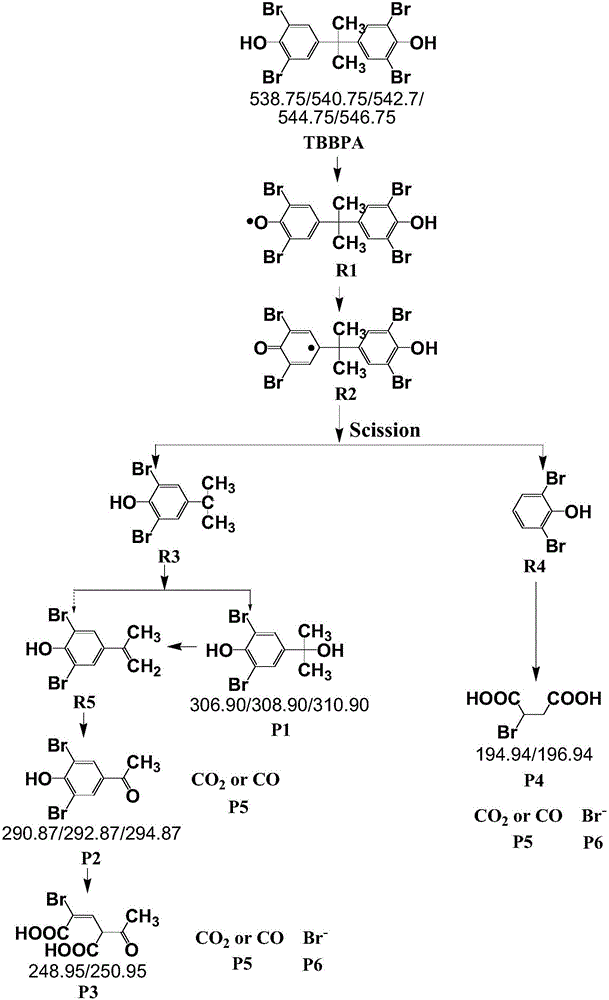

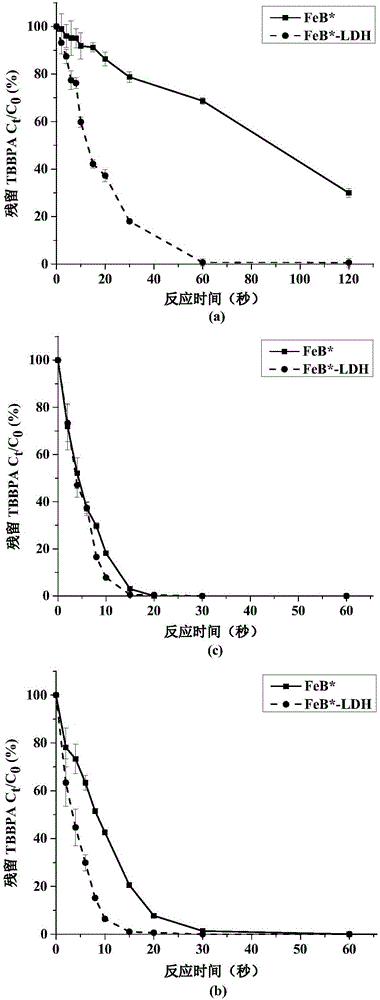

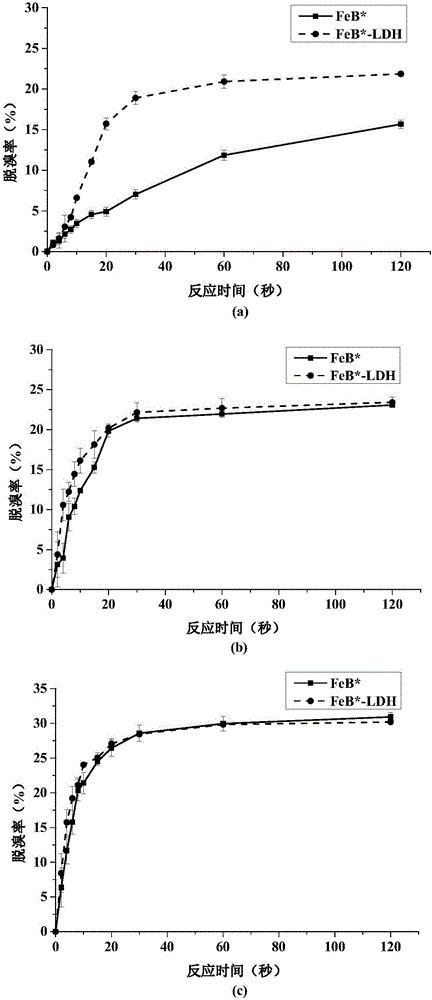

Composite capable of efficiently degrading tetrabromobisphenol A, as well as preparation method and application method of composite

ActiveCN106111204AAchieve debrominationAchieve mineralizationOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsTetrabromobisphenol AIon exchange

The invention discloses a composite capable of efficiently degrading tetrabromobisphenol A, as well as a preparation method and application method of the composite, belongs to the field of degradation of persistent organic pollutants, and solves the problems that the energy consumption is high, the operation is complex and secondary pollution is easy to form existing in a conventional degradation method. According to the composite and the preparation method and application method thereof disclosed by the invention, magnesium-aluminum layered double hydroxide(LDH) is used as a carrier for loading FeB*, and through ion exchange, the loading of the FeB* is realized; when the FeB* is compared with free-state FeB*, the composite FeB*-LDH obtained through ion exchange effects not only promotes the removal of TBBPA, a debromination rate and a mineralization rate, but also realizes the separation of the FeB* from an aqueous solution, so that the recycling properties of the FeB* are increased.

Owner:NANJING UNIV

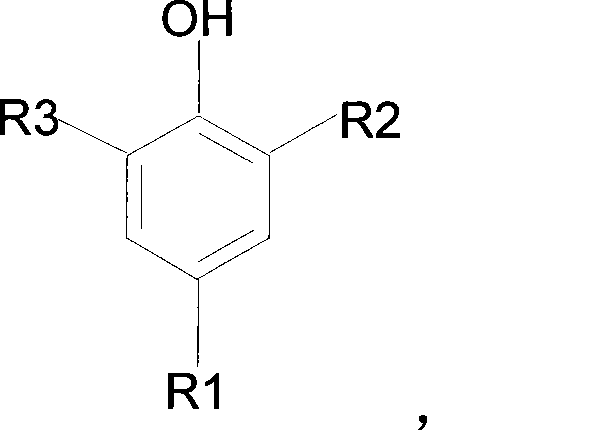

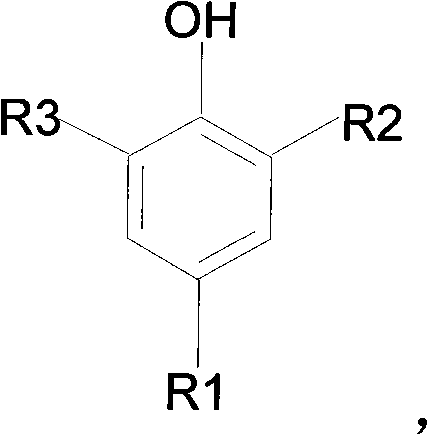

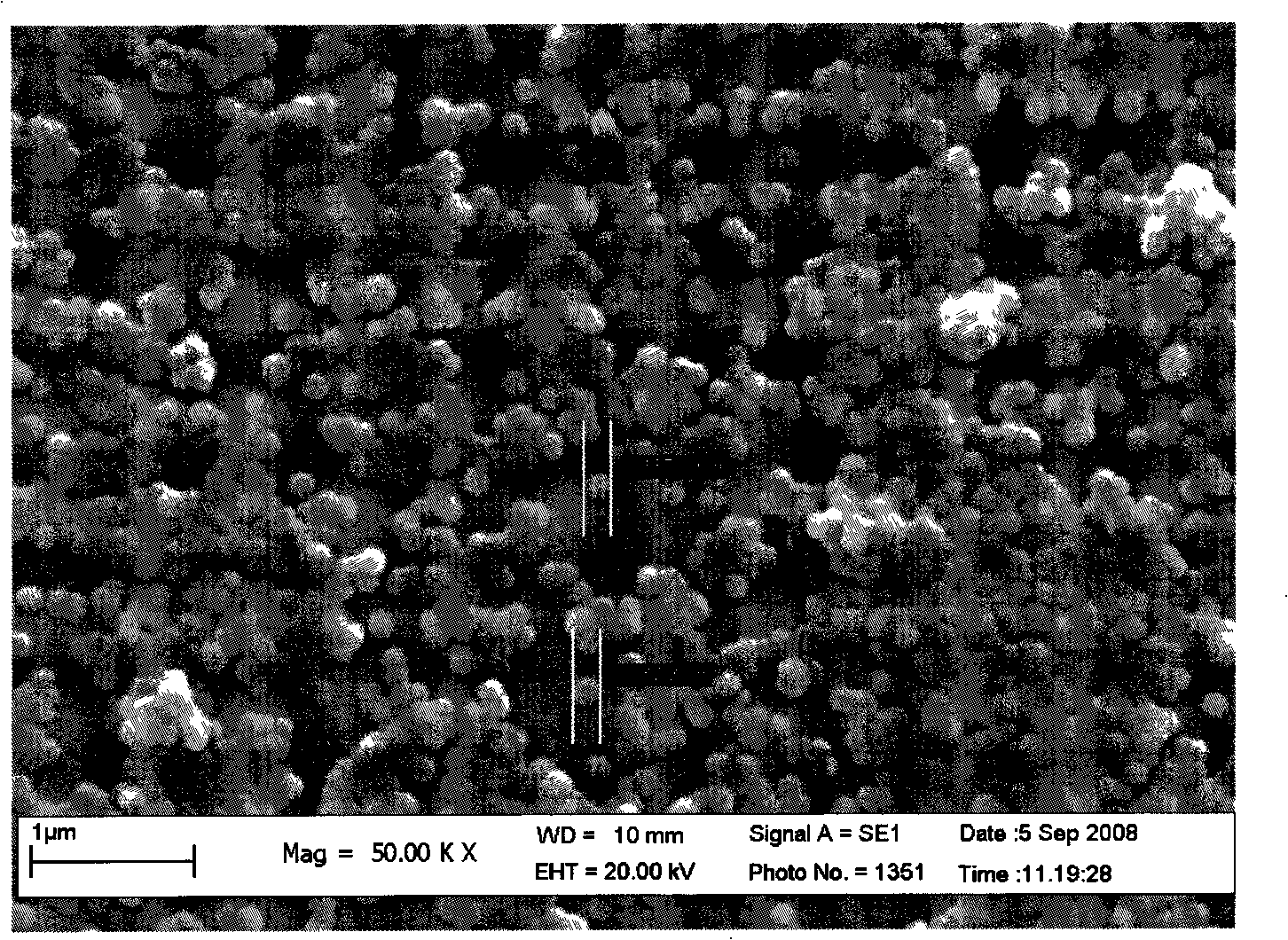

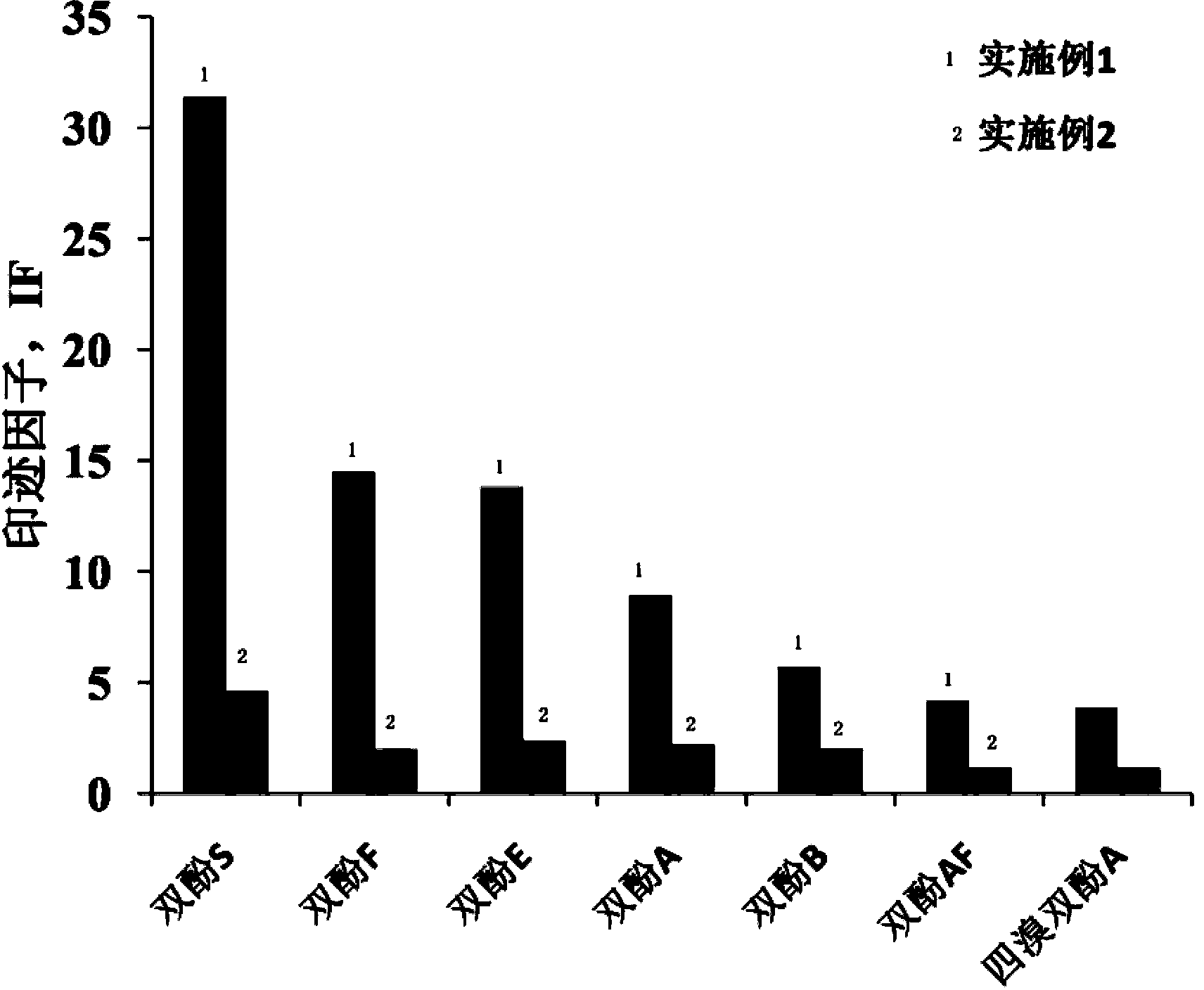

Preparation method and application of dummy template molecularly imprinted polymer

InactiveCN104250349AHigh selectivityHigh specific selectivityOther chemical processesComponent separationPerturbateurs endocriniensFunctional monomer

The invention provides a preparation method and an application method of a dummy template molecularly imprinted polymer selectively enriching bisphenol endocrine disruptors. The preparation method comprises the following steps: dissolving dummy template molecules, a crosslinking agent, a functional monomer and an initiator in a pore forming solvent to prepare a pre-polymerization solution, carrying out a polymerization reaction at 50-70DEG C for 24-48h; and grinding a white block polymer generated through the polymerization reaction, sieving, settling to obtain polymer particles with the particle size of 45-63[mu]m, carrying out soxhlet extraction or ultrasonic extraction with methanol / acetic acid and methanol as an extraction solvent, and removing residual template molecules and unreacted substances in order to obtain the dummy template molecularly imprinted polymer. The invention also provides a solid phase extraction filler. The filler is the dummy template molecularly imprinted polymer. The dummy template molecularly imprinted polymer has very strong specific selectivity and enrichment ability to bisphenol F, bisphenol E, bisphenol A, bisphenol B, bisphenol AF, tetrabromobisphenol A and other bisphenol compounds, solves the template bleeding problem during trace analysis, and realizes the rapid, senseitive, accurate and efficient detection of the bisphenol endocrine disruptors in environment, foods and biological samples.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

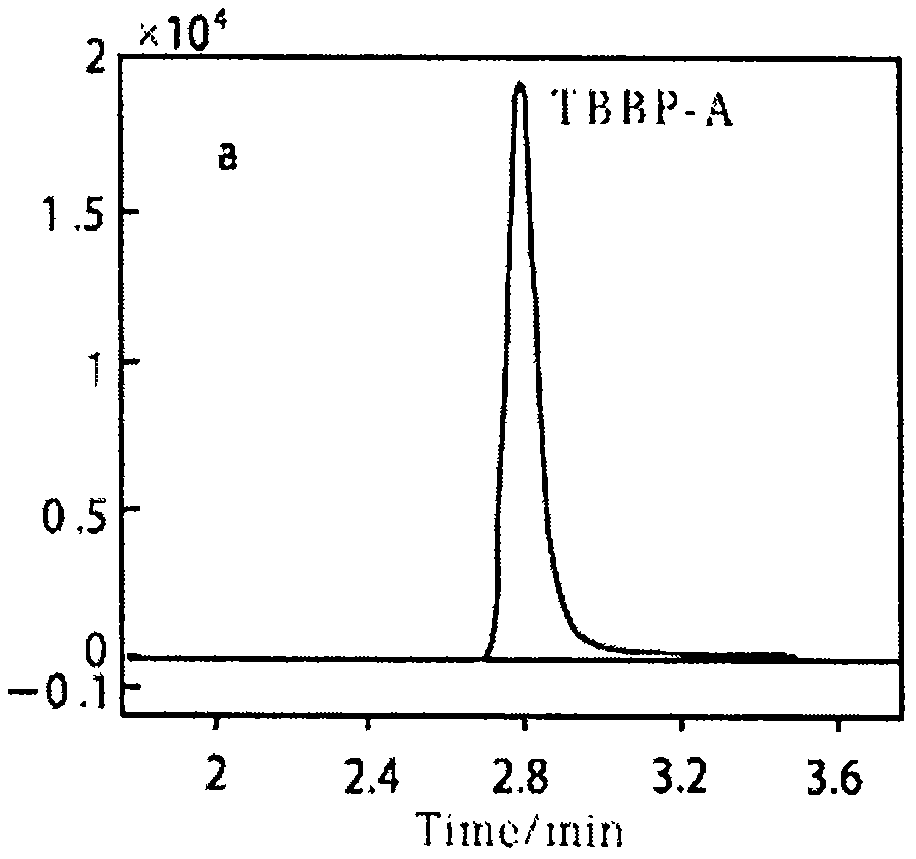

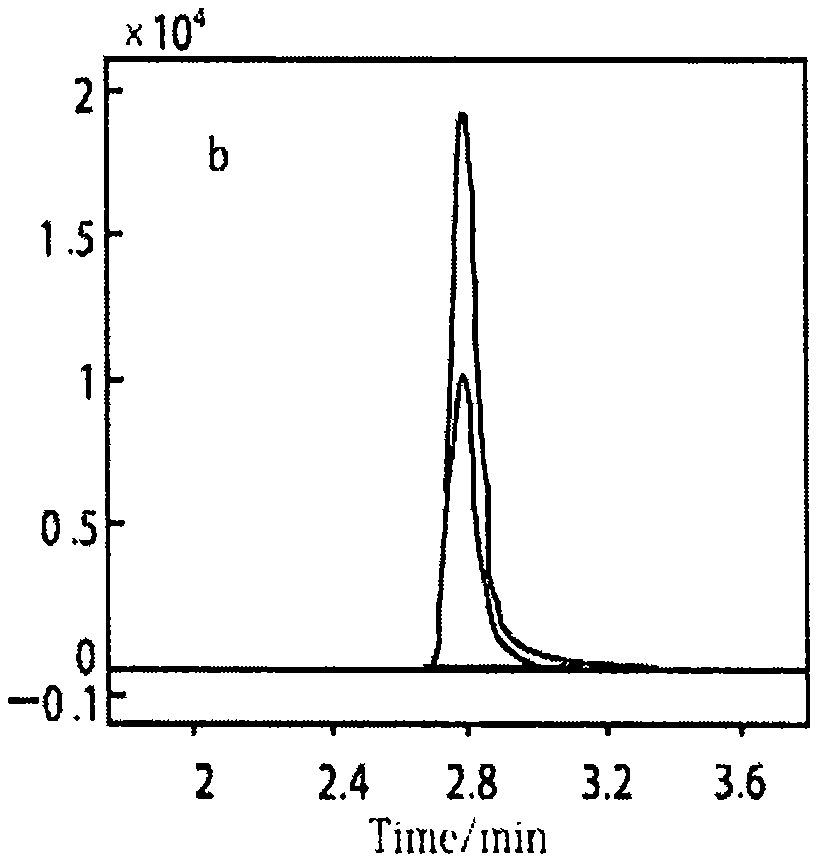

Method for detecting content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in aquatic product

ActiveCN106124643AGuaranteed accuracyGuarantee stabilityComponent separationTetrabromobisphenol ADecabromodiphenyl ether

The invention provides a method for detecting the content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in an aquatic product. The method is characterized by comprising the following steps that the content of the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product is measured by establishing accelerated solvent extraction-fast liquid chromatography-tandem mass spectrometry, an aquatic product sample needing to be detected is separated through a C18 chromatographic column, gradient elution is conducted by taking water and methyl alcohol as mobile phases, detection is conducted in a mass spectrum multi-reaction monitoring mode, the matrix standard is corrected, quantitative determination is conducted through an external standard method, and confirmation is conducted. The detection method has the advantages that operation is easy and convenient, and detection is fast and accurate; by establishing the method for simultaneously detecting the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product, physical health and life safety of consumers are guaranteed, a great practical significance is achieved for promoting sustainable and healthy development of aquatic product processing industry, and a beneficial technical reserve is provided for a food industry supervision department and a detection mechanism.

Owner:ZHOUSHAN INST FOR FOOD & DRUG CONTROL

Fireproof powder paint for super-thin steel structure and preparation method thereof

InactiveCN101058694AExcellent combustion expansionStrong adhesionFireproof paintsPowdery paintsTetrabromobisphenol ABisphenol

The invention discloses a method preparing for an ultra-thin inflatable steel structure fire-proof powder paint; which comprises the following parts: 45%-60% tetrabromo-bisphenol A epoxide resin, 2. 2%-3% dicyandiamide, 15%-21% ammonium polyphosphate, 10%-14% melamine, 5%-7% dipentaerythritol, 0. 5%-2% levelling agent, 0. 3%-0. 5% benzoin, 5%-10% titanium dioxide. The invention comprises the following steps: adding natrium hydroxydatum and water to the autoclave; adding tetrabromo-bisphenol A; mixing and heating at 75 Deg. C; adding colature to the autoclave; cooling to 45-55 Deg. C; adding epichlorohydrin; reacting at 80-85 Deg. C; heating to 90-95 at softening point; adding water; cooling; mixing; washing with the hot water; dewatering at the atmosphere pressure; heating to 125-140 Deg. C; getting the stramineous solid tetrabromo-bisphenol A epoxide resin; Mixing tetrabromo-bisphenol A epoxide resin, dicyandiamide and levelling agent at the high speed; mixing benzoin, titanium dioxide, ammonium polyphosphate, melamine, dipentaerythritol; melting and squeezing the materials after mixing; pelleting the melted materials; disintegrating and grading after cooling and bruising; getting the fire-proof powder paint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

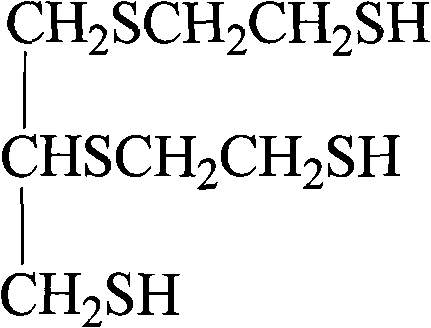

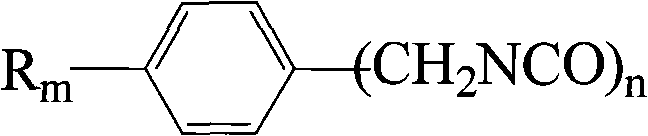

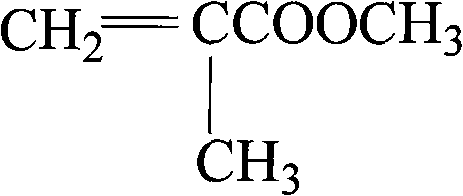

Optical resin monomer material

InactiveCN101665552ALow dispersionHigh refractive indexOptical elementsTetrabromobisphenol ARefractive index

The invention provides an optical resin monomer material. The optical resin monomer material consists of the following components in percentage by weight: 10 to 20 percent of 1,2-bi(2- sulfhydry ethylthio)-3-sulfhydryl propane, 15 to 25 percent of isocyanate compound, 5 to 10 percent of alpha-methyl methacrylate, 10 to 15 percent of tetrabromo bisphenol A, 20 to 30 percent of 2-hydroxyl-3-phenoxycrylic acid propyl ester, and 10 to 20 percent of styrene compound. The optical resin monomer material can be used for producing an ultrathin type high-refractive index optical resin lens of which therefractive index is 1.60 by the conventional process. Compared with the prior art, the invention provides the optical resin monomer material, which can be used for producing the high-refractive indexoptical resin lens and ensure the produced lens is thinner and has high thermal resistance and visible-light transmittance.

Owner:ZHEJIANG OCEAN UNIV

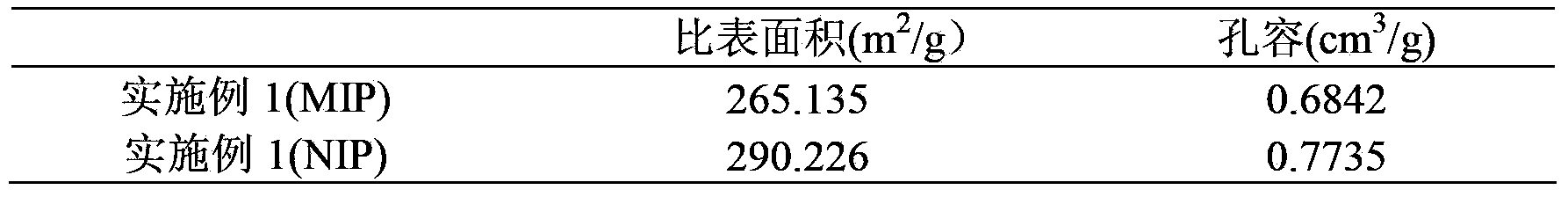

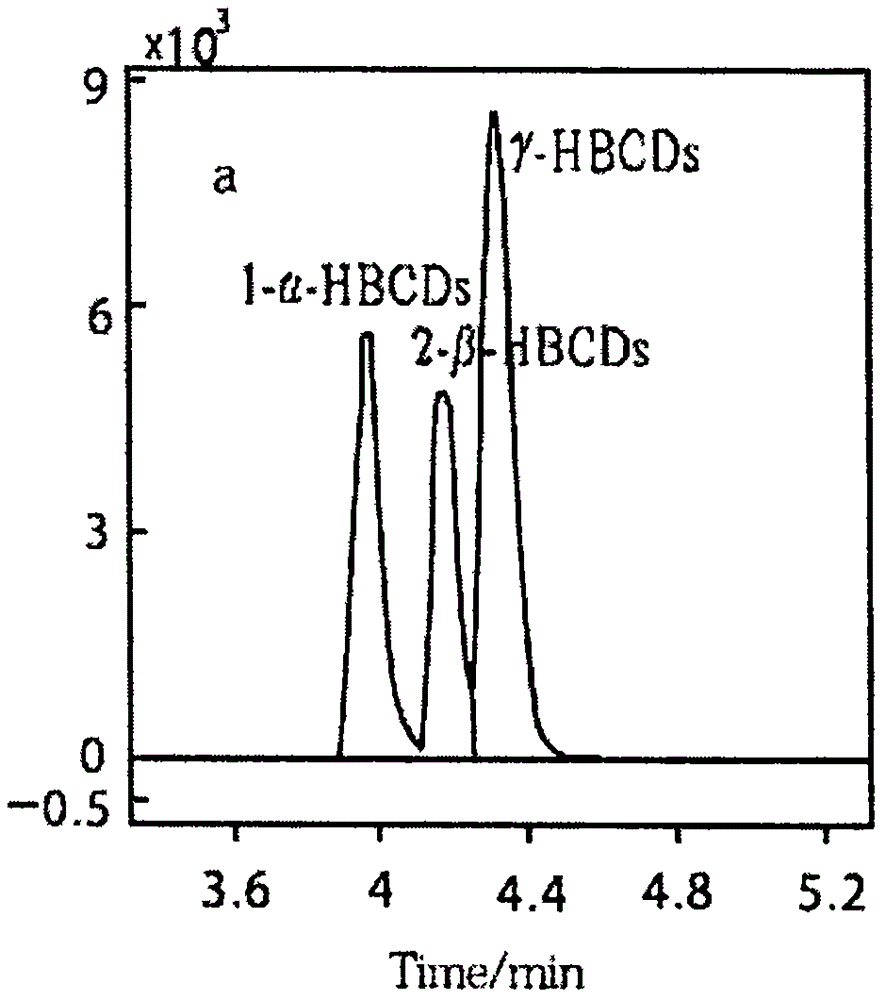

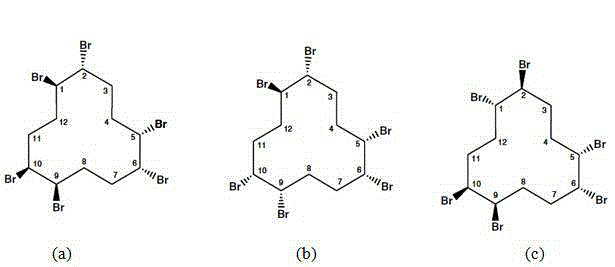

Method for simultaneous determination of hexabromocyclododecane isomer and tetrabromobisphenol A in fat food

InactiveCN105181865AOptimizing pre-processing technologyMeet the requirements for analyzing actual samplesComponent separationTetrabromobisphenol AMicrosphere

The invention provides a method for simultaneous determination of hexabromocyclododecane isomer and tetrabromobisphenol A in fat food. The method is characterized by mainly including sample extraction, extract purification and determination. The extract purification uses mesoporous zirconia hybrid column as a solid phase extraction column containing an anhydrous sodium sulfate layer, a mesoporous zirconia microsphere layer, an acidified silica gel layer, a dielectric hole oxide zirconium microsphere layer and an anhydrous sulfate sodium layer from bottom to top. The recovery rate of hexabromocyclododecane isomer and tetrabromobisphenol A in plant oil, fish, meat, egg, milk and other fat food sample reaches 87.5%-114.4%. The preparation of reusable mesoporous zirconia microsphere optimizes the pretreatment technology, and saves a large amount of solvent; the detection limit, quantification limit, recovery rate and precision can meet the requirements for analysis of real samples; and reliability of the method and result accuracy are verified through the standard substance in international comparison.

Owner:INST OF AGRI QUALITY STANDARDS & TESTING TECH RES HUBEI ACADEMY OF AGRI SCI

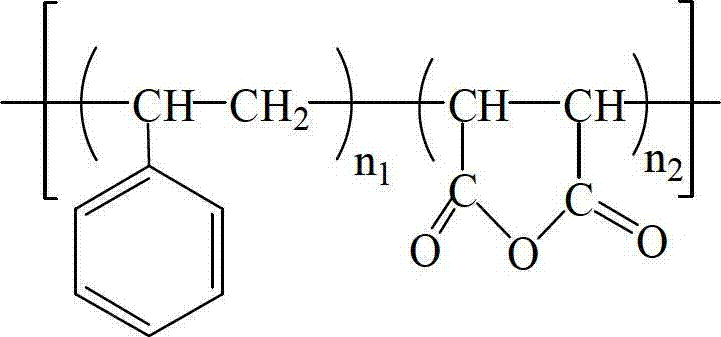

Rubber-modified styrene resin composition

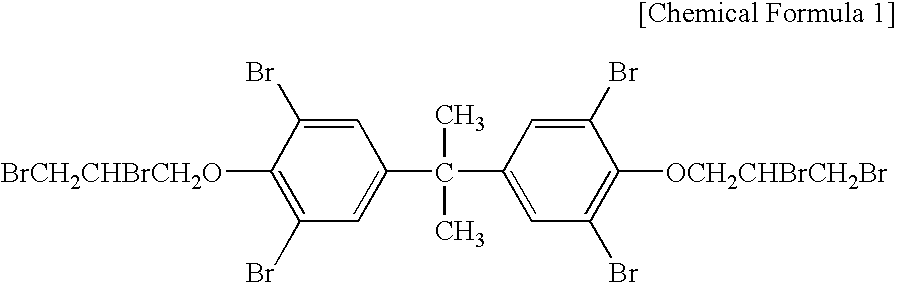

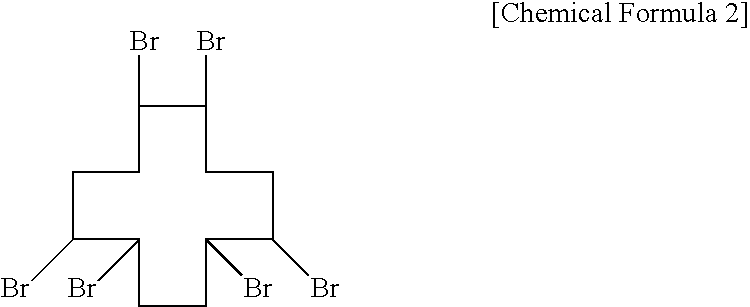

InactiveUS20050020737A1Increase resistanceImprove stabilityOther chemical processesFilm/foil adhesivesEpoxyTetrabromobisphenol A

A rubber-modified flame resistant styrene resin composition, which has superior heat stability and weather resistance to prevent discoloration and deterioration due to heat or light and is processed under various molding condition, is provided. The rubber-modified flame resistant styrene resin composition includes a rubber-modified styrene resin, flame retardant comprising compounds selected from a group consisting of tetrabromobisphenol-A-bis(2,3-dibromopropylether), hexabromocyclododecane and a mixture thereof, and brominated epoxy oligomer, and calcium stearate as a lubricant.

Owner:LG CHEM LTD

Polypropylene anti-flaming foam material and preparation method thereof

ActiveCN105694218AHigh flame retardant levelHigh char formation rateTetrabromobisphenol APolymer science

The invention relates to the technical field of polypropylene foam materials, in particular to a polypropylene anti-flaming foam material and a preparation method thereof. The polypropylene anti-flaming foam material is prepared from, by weight, 100 parts of polypropylene, 0.5-1.5 parts of foaming agent, 0.5-1.5 parts of nucleating agent, 3-6 parts of fire retardant, 0.5-1.5 parts of anti-flaming synergist and 1-2 parts of coupling agent. The fire retardant is formed by compounding magnesium hydroxide and tetrabromobisphenol A. The anti-flaming synergist is formed by compounding kieselguhr and antimonous oxide. The prepared polypropylene anti-flaming foam material is high in anti-flaming grade which can reach the grade V-0, the oxygen index reaches up to 39, the char yield reaches up to 35, processing fluidity is good, the char yield is high after burning, and no melted drop is generated. In conclusion, the prepared polypropylene anti-flaming foam material is high in shock strength, and the fire retardancy of the material is greatly enhanced while the mechanical performance of the material is improved. The preparation method has the advantages that the process is simple, and industrialization is easy.

Owner:DONGGUAN HEYONG PACKING

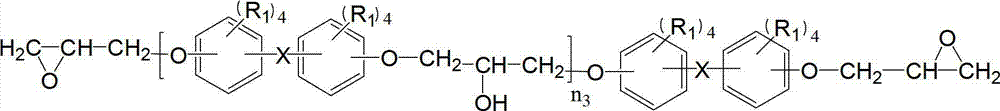

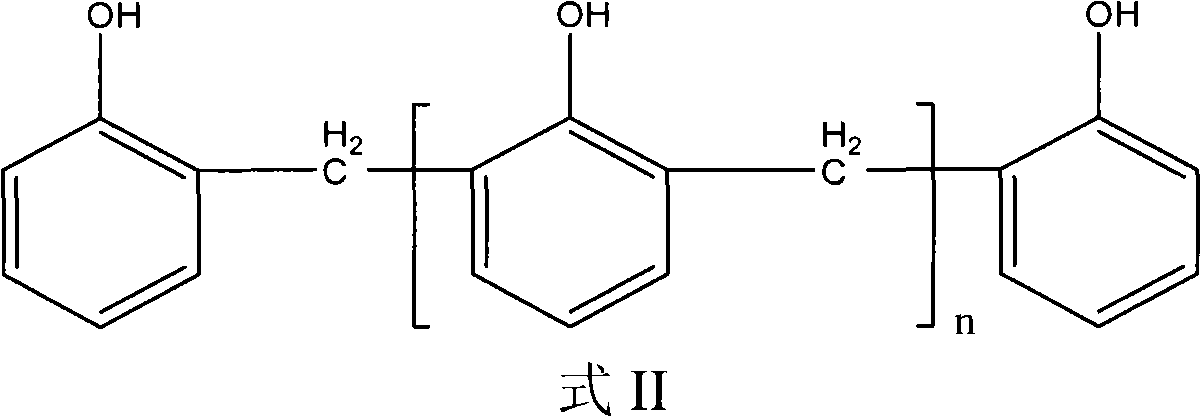

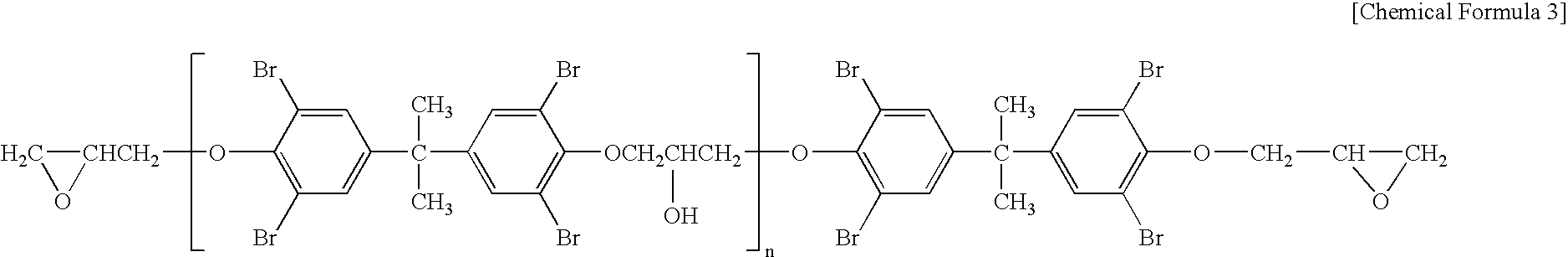

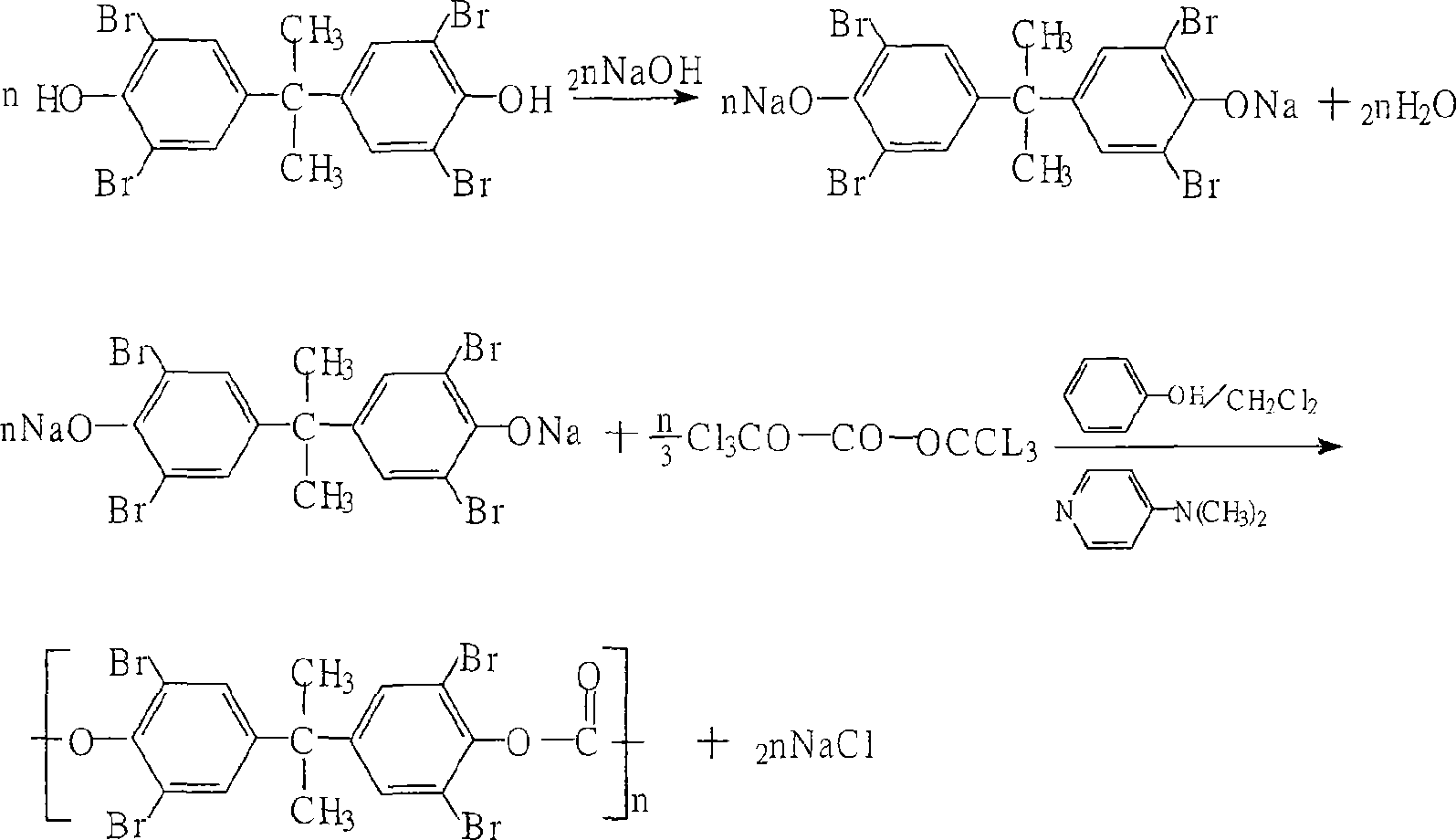

Method for preparing tetrabromo-bisphenol A polycarbonate

The invention relates to a method for preparing molecular tetrabromobisphenol-A polycarbonate. Its character shows as follow: a. it dissolves the tetrabromobisphenol-A and inhibitor in the natrium hydroxydatum, filtering. Then, it dissolves triphosgene in the halogenated alkane, filtring. b. it adds the filtered triphosgene solution to the filtered tetrabromobisphenol-A and inhibitor solution, and then it adds natrium hydroxydatum at room temperature under normal pressure, and maintains the system to be pH9-12, then it stirs the solution for 0.5-1 hours. c. it adds 10%-20% of the natrium hydroxydatum at room temperature under normal pressure, and maintains the system to be pH8-10, then it stirs the solution for 0.5-1 hours. d. it regulates the solution with acid to be neutral and takes out from the organic layer, then it washes the material with deionized water and adds fatty alcohol to precipitate white powder, then it achieves the molecular weight range of 150,000 ~ 250,000 molecular of tetrabromobisphenol-A polycarbonate through filtration and drying.

Owner:TAIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com