Patents

Literature

157results about How to "High char formation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

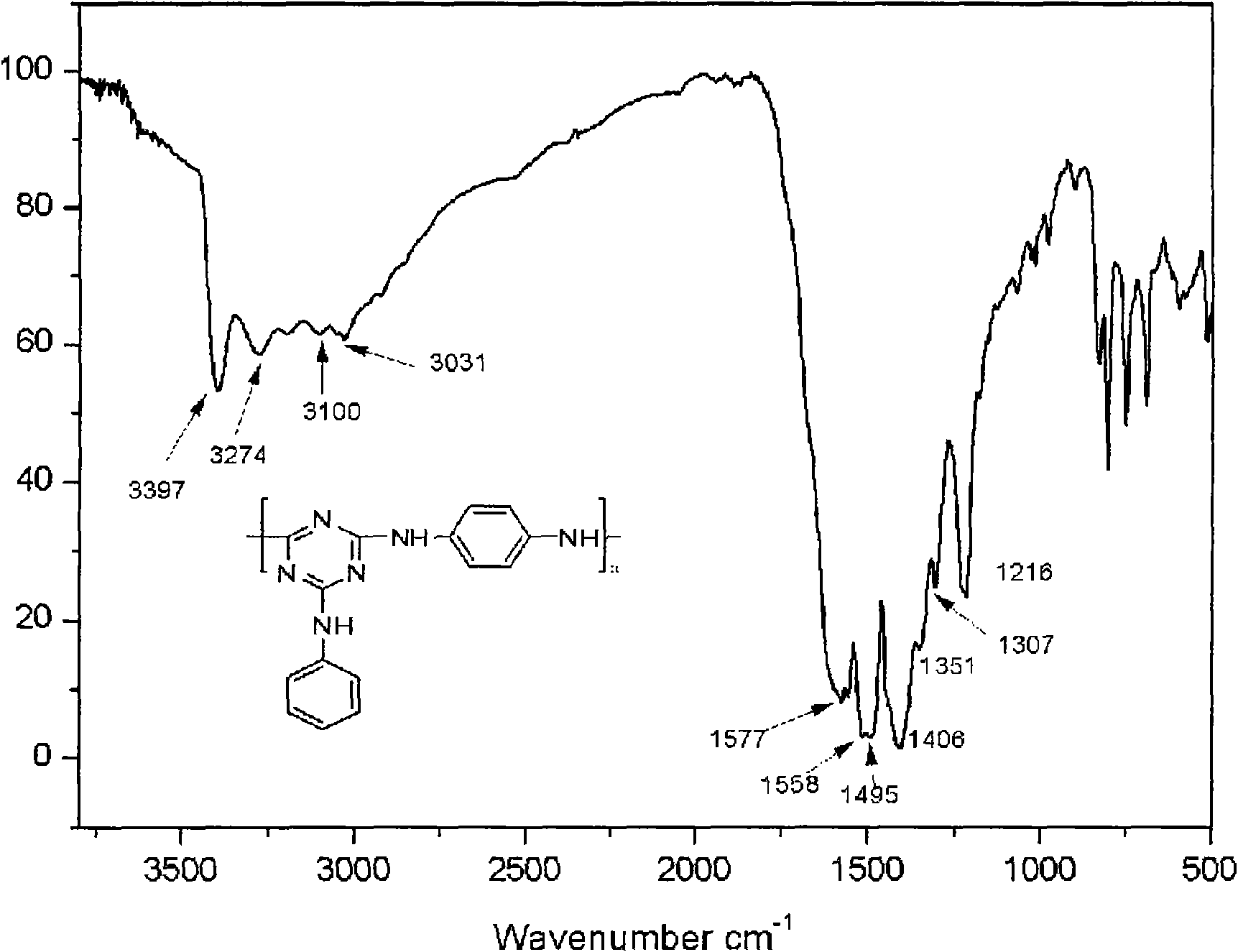

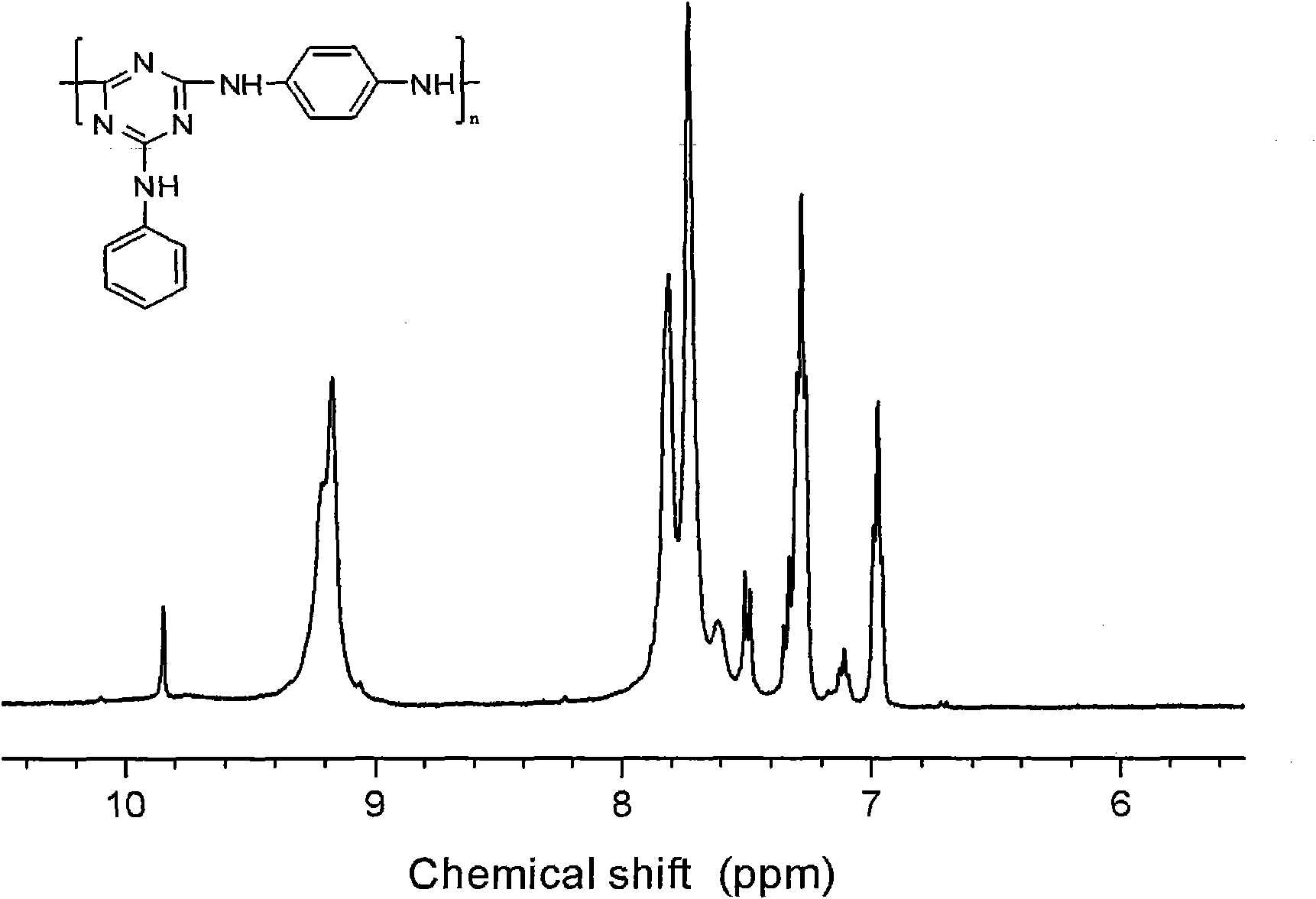

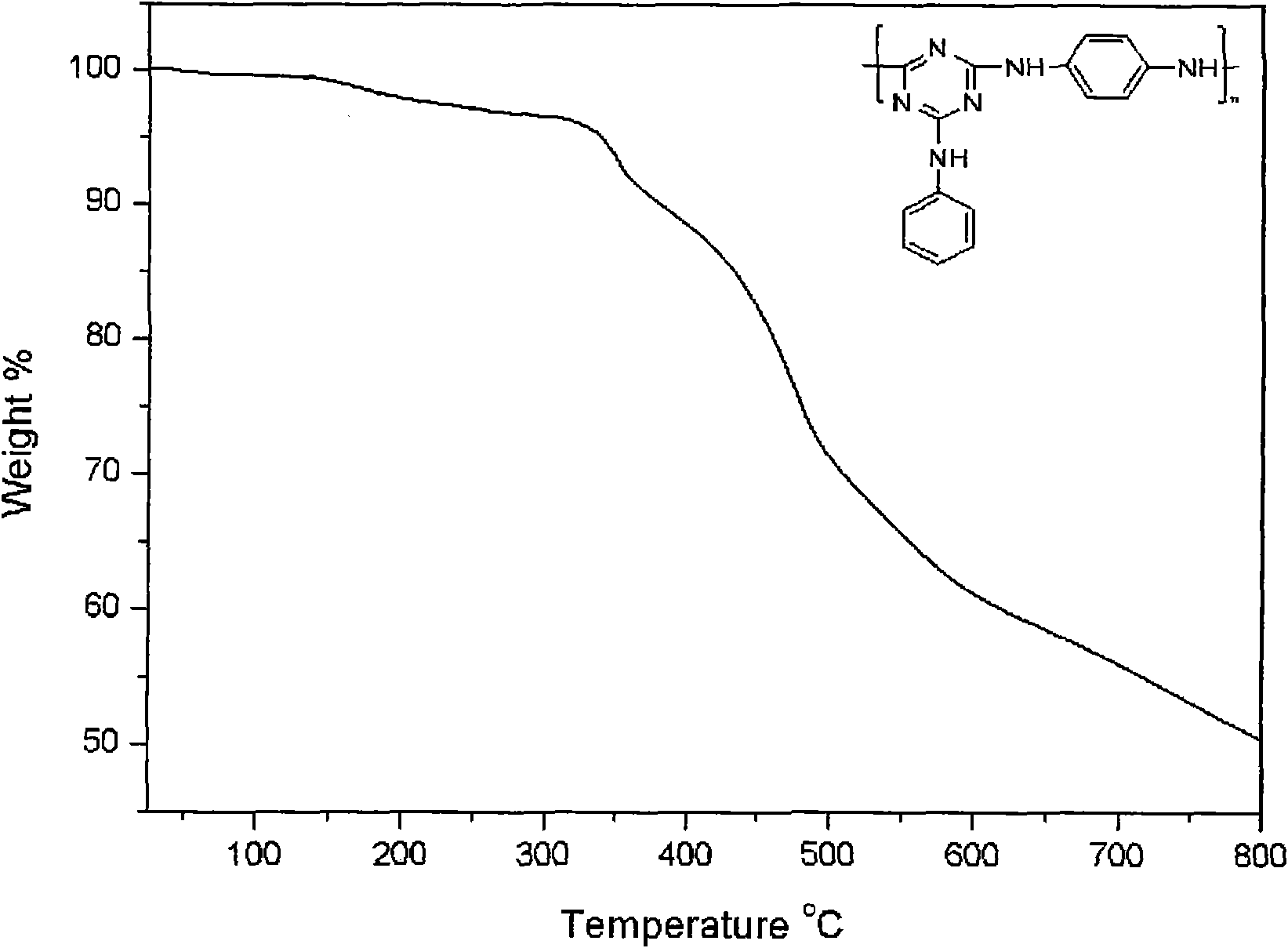

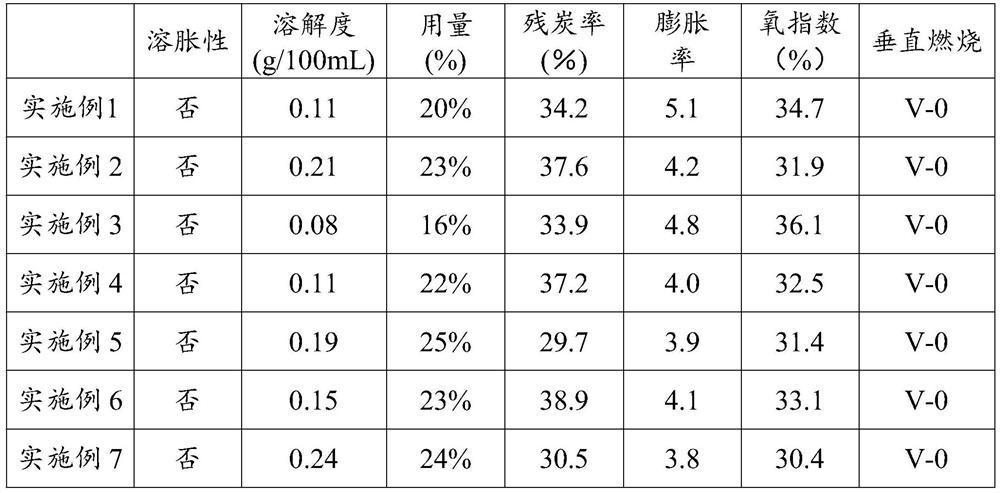

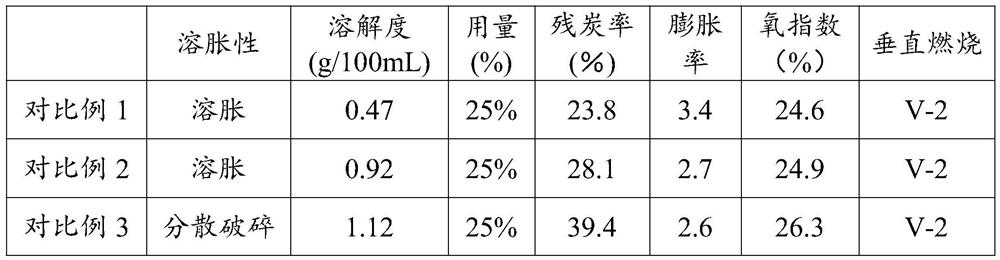

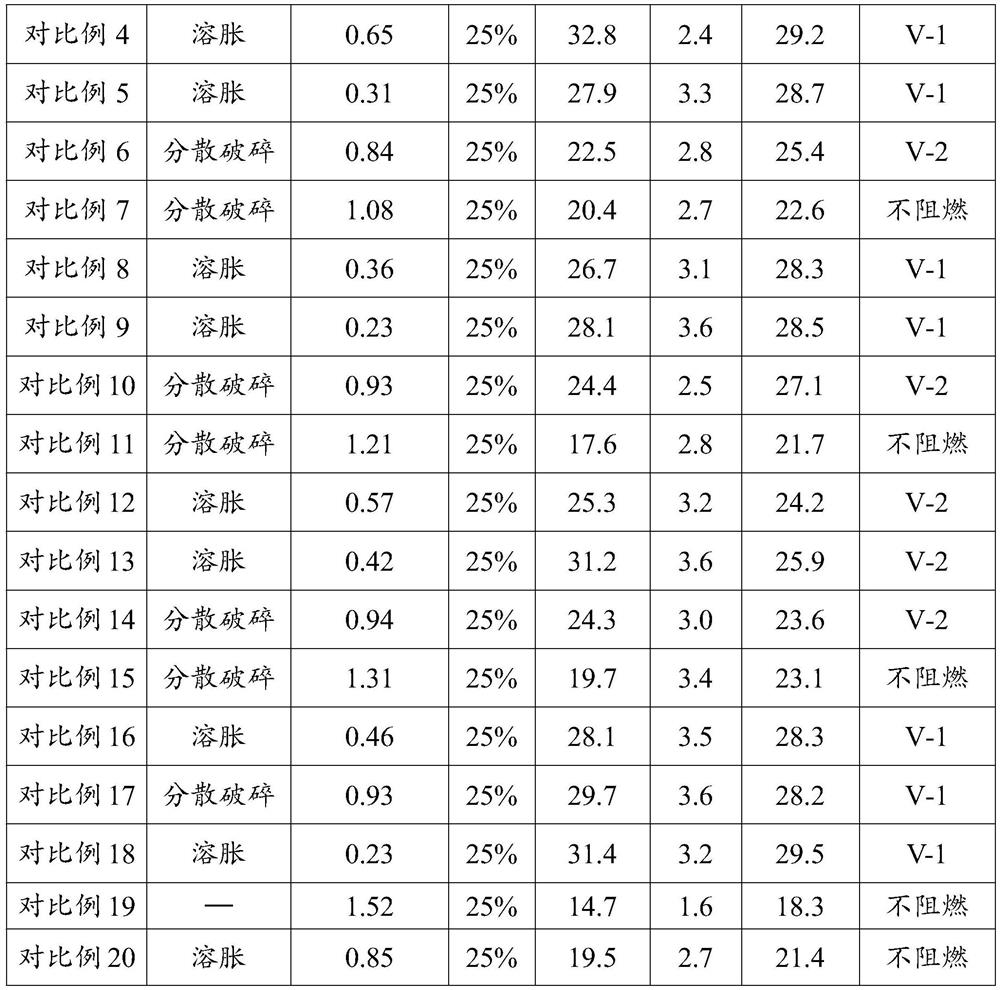

Triazine carbonific containing aromatic chain structure and preparation method

InactiveCN101586033AImprove the defects of poor mechanical behaviorGood foaming effectFireproof paintsChain structureThermal stability

A triazine carbonific containing aromatic chain structure, the carbonific is obtained by aromatic binary compound and monosubstituted cyanuric chloride with structural general formula being NH2-Ar-NH2, HO-Ar-OH or HS-Ar-SH under catalyst action. The invention further claims a method of preparing the triazine carbonific containing aromatic chain structure. Compared with the prior art, the invention has the advantages that: the triazine halogen-free flame retardant obtained by the invention has high thermal stability, high char rate under high temperature; the reaction process is one kettle way continuous reaction, and the preparation process is simple, the intermediate does not need to be processed; the post process method is simple, and the reaction time is short, the yield is high; the invention can effectively save energy consumption, improve the production efficiency and reduce the production cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Soft zero halogen flame retardant thermoplastic elastomers

InactiveUS20090124743A1Desirable vertical burn characteristicDesirable vertical burn characteristicsCoatingsPolyolefinPolymer chemistry

Soft flame retardant thermoplastic compositions that are preferably halogen free and include a styrenic block copolymer having a low modulus, one or more of a polyolefin polymer or copolymer and an acrylate containing polymer or copolymer, one or more of a softener and plasticizer, an inorganic phosphorous-containing flame retardant, and optionally but preferably, a platelet filler such as a nanoclay or an organic modified clay. In a preferred embodiment, the phosphorous-containing flame retardant has a surface coating thereon which reduces sensitivity of the flame retardant to water, and thus reduces the amount of the flame retardant that can leach out in the presence of water, thereby enabling the compositions of the present invention to be utilized outdoors or other environments where exposure to water or high humidity is possible. The hardness of the compositions according to the invention preferably ranges from about Shore A 40 to about Shore A 90. The compositions exhibit high char formation upon burning and also desirable vertical burn characteristics.

Owner:TEKNOR APEX

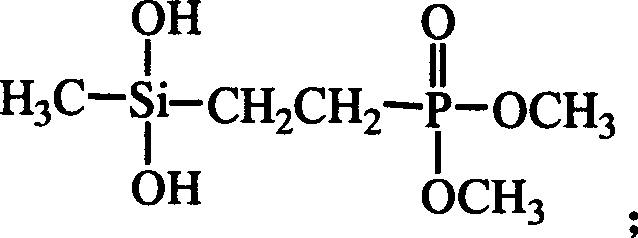

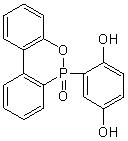

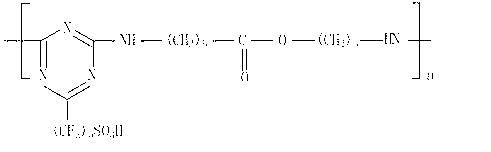

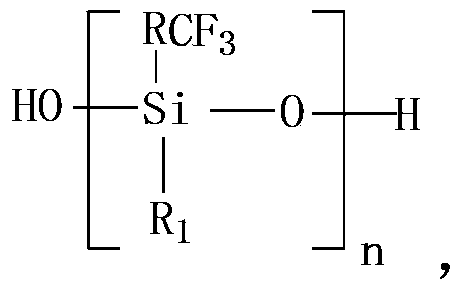

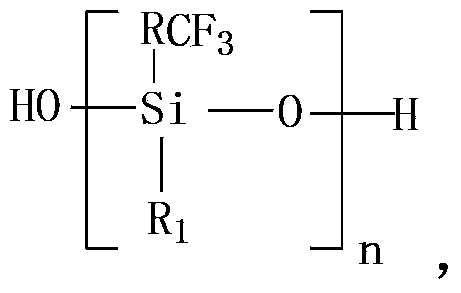

Silicious expanding fire retardant and its prepn process

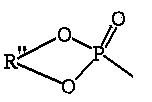

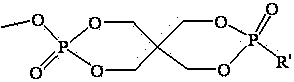

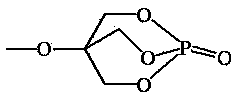

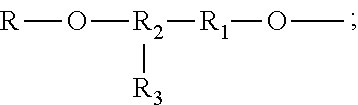

InactiveCN1974721AImprove thermal stabilityImprove flame retardant performanceFireproof paintsHalogenPhosphate

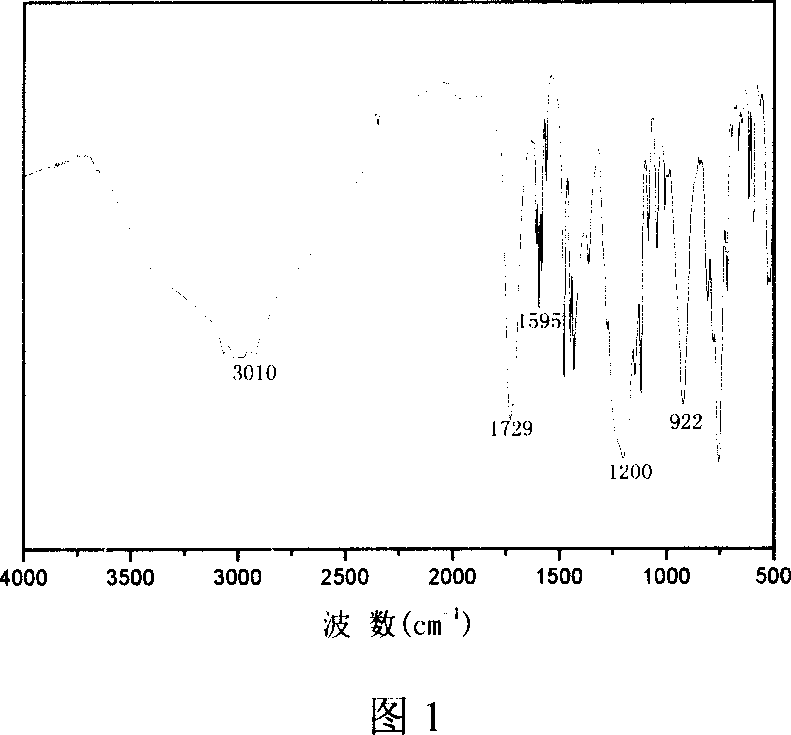

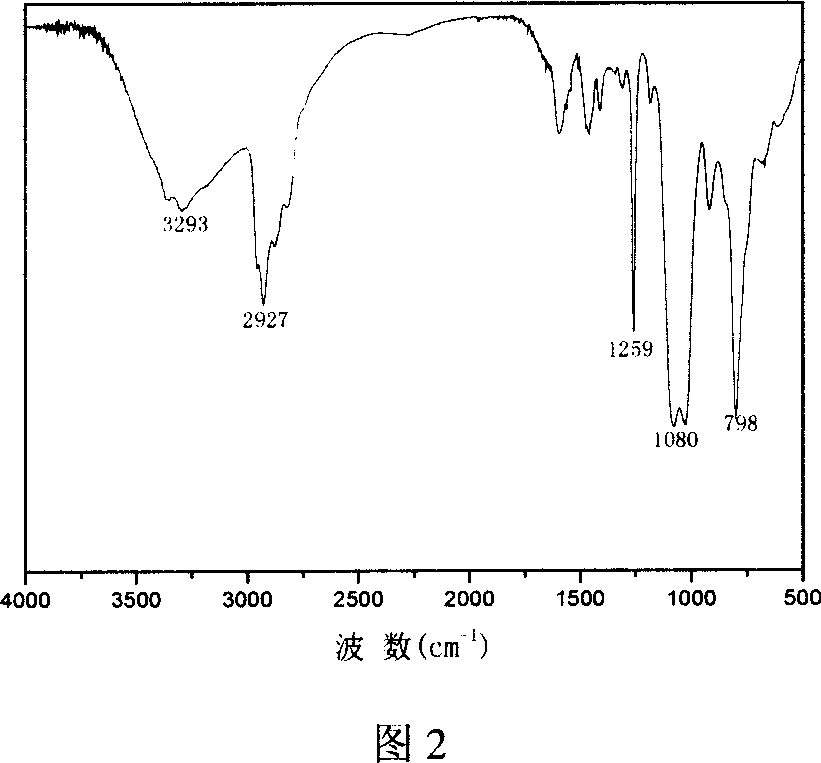

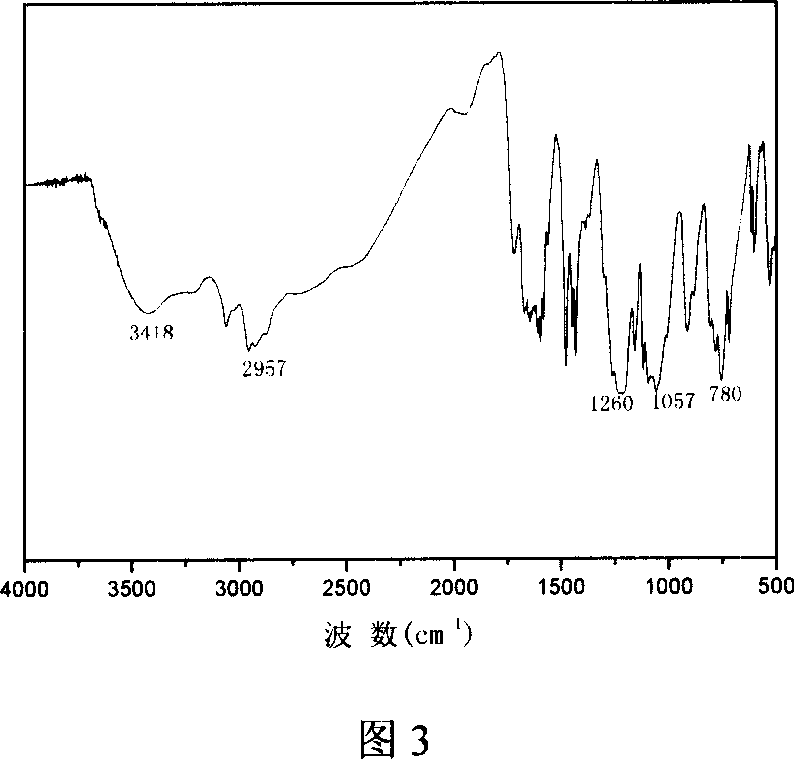

The present invention discloses silicious expanding fire retardant in the structure as shown and its preparation process. Being superior to traditional fire retardant, which contains halogen and hydroscopic, the silicious expanding fire retardant has three essentials as expanding fire retardant, and 9, 10-dihydro-9-oxo-10-phospha phenanthryl-10-oxide without phosphate ester structure as acid source, and possesses excellent fire retarding performance.

Owner:凌庆平

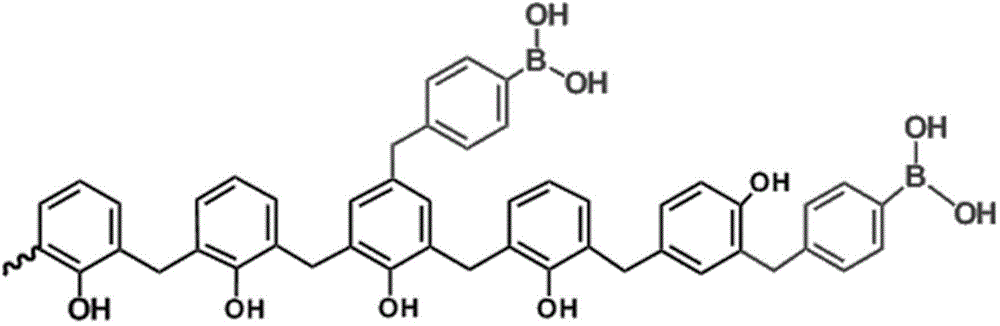

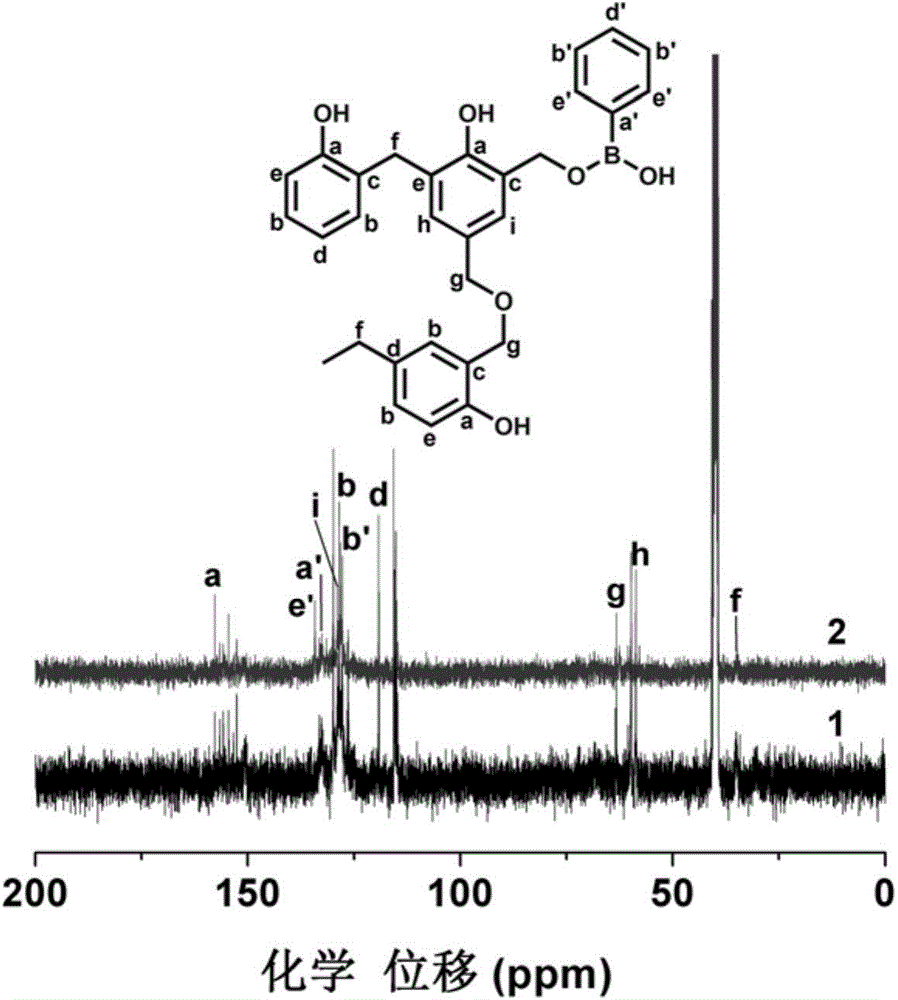

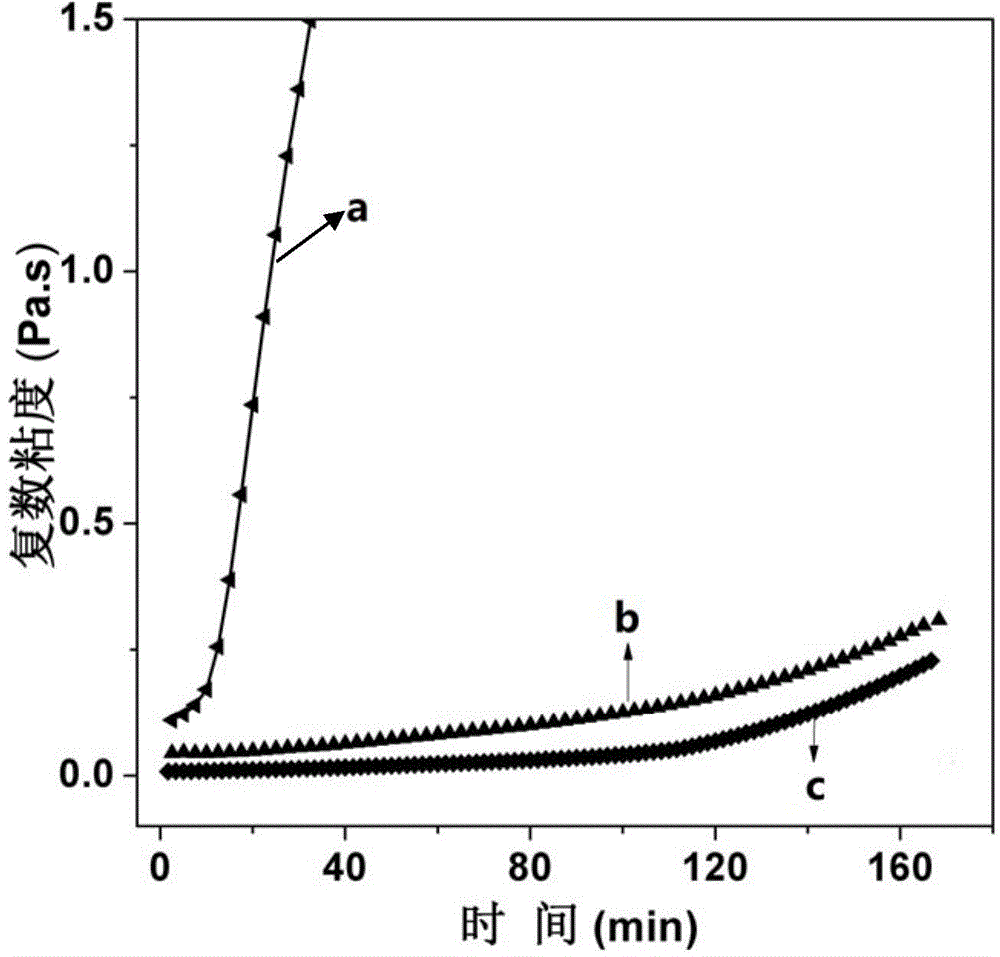

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

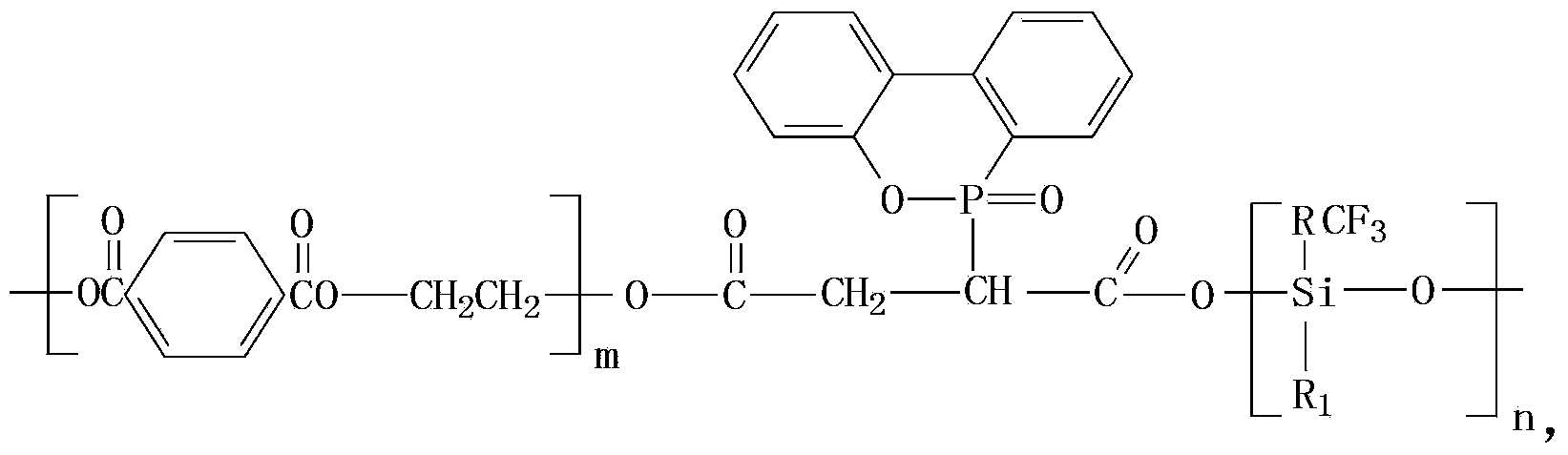

Preparation method of flame-retardant copolyester film of phosphorus, silicon and fluorine

The invention discloses a preparation method of a flame-retardant copolyester film of phosphorus, silicon and fluorine. The preparation method is characterized by comprising the steps of: preparing flame-retardant copolyester sections of phosphorus, silicon and fluorine from maleic anhydride, dihydroxy fluorine silicone, DOPO (9-10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), terephthalic acid and ethylene glycol by addition, esterification and polycondensation reaction in the presence of an esterification catalyst, a polycondensation catalyst and a stabilizing agent; and mixing the prepared flame-retardant copolyester sections of phosphorus, silicon and fluorine with a polyester section, carrying out melt extrusion by an extruder and preparing the flame-retardant copolyester film product of phosphorus, silicon and fluorine by longitudinally drawing, laterally drawing and hot setting treatment. The preparation method disclosed by the invention is simple in reaction process, strong in operability, easy in technological condition control and low in production cost, and shortens the production time and cycle of multivariate copolymerization synthesis; and the flame-retardant property of the product can be up to VTM-0 level.

Owner:四川东方绝缘材料股份有限公司

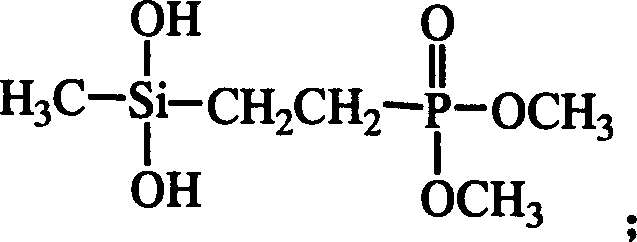

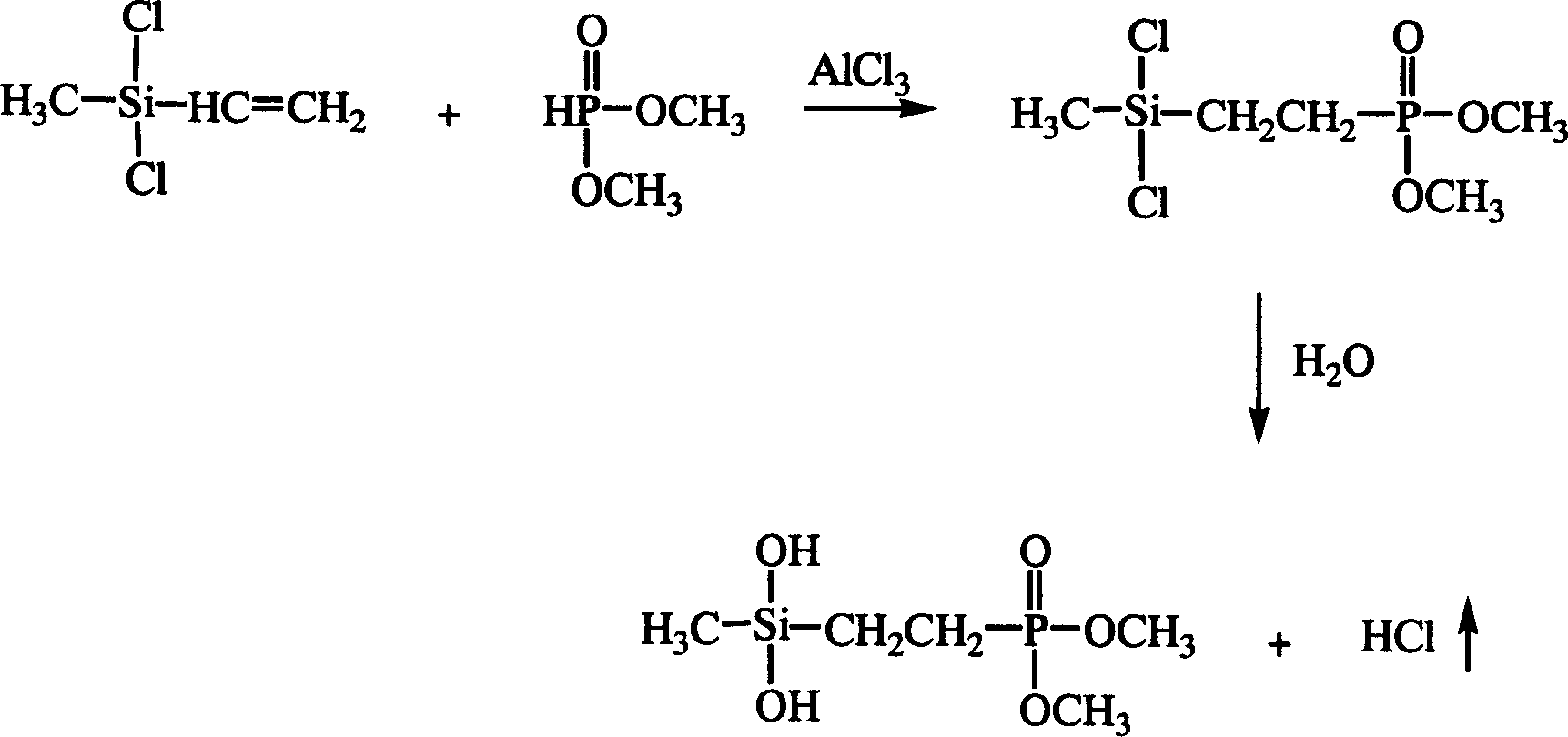

Silicon phosphonate containing fire rotardant and its synthesis method

A Si-contained phosphonate as fire retarding agent used for fabrics is prepared through proportionally mixing methylvinyl dichlorosilane with solvent, stirring, adding dimethyl phosphite and catalyst, stirring under protection of N2, heating, reflux, collecting fraction, cooling, adding water, stirring, oil-water separating, and distilling water phase to obtain fire retarding agent SP.

Owner:ZHEJIANG HENGYI GRP CO LTD +1

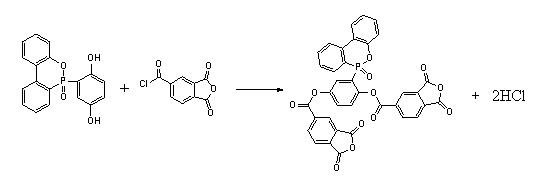

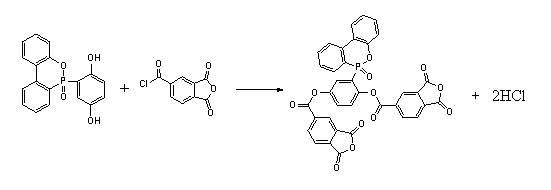

Phosphorous epoxy resin curing agent and preparation method thereof

InactiveCN102070770AImprove thermal stabilityHigh char formation rateGroup 5/15 element organic compoundsEpoxyTrimellitic anhydride chloride

The invention provides a phosphorous epoxy resin curing agent and a preparation method thereof, relating to a curing agent and a preparation method thereof. In the preparation method for synthesizing the phosphorous epoxy resin curing agent BPA-ODOPE, the mole ratio of trimellitic anhydride chloride to ODOPB ranges from (2:1) to (10:1), organic solvents are benzene, toluene and the like, inert gases are nitrogen, argon and helium, and the inert solvents for precipitation and washing are petroleum ether, pentane and the like. The preparation method comprises the following steps of: 1, adding the trimellitic anhydride chloride and the ODOPB in a reactor, adding the organic solvents, stirring under the protection of the inert gases, and obtaining the compound BPA-ODOPE; and 2, cooling the reaction mixing liquid, precipitating in the inert solvents to separate out the BPA-ODOPE, vacuum filtering, washing the precipitate with the inert solvents, drying, and obtaining white or yellowish powder-shaped product. The compound can be used as a curing agent applied in epoxy resin and also as halogen-free fire retardant.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

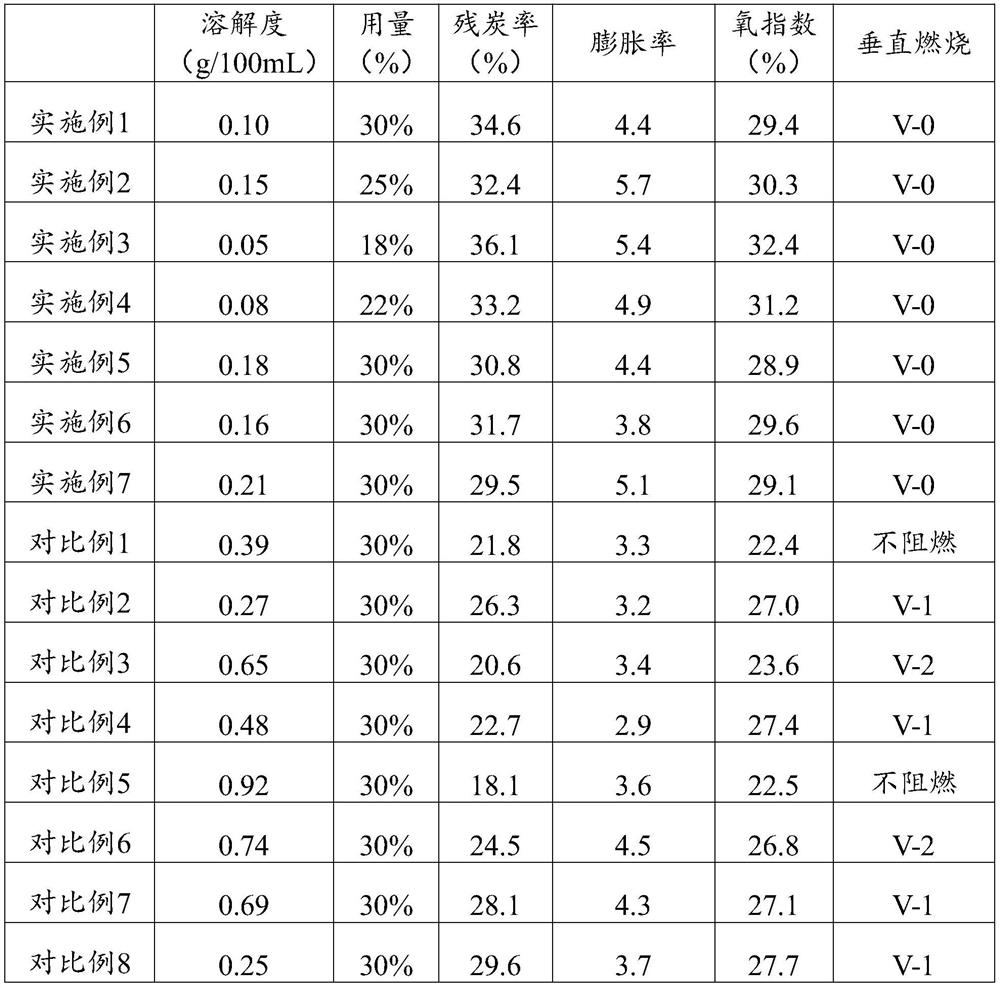

Modified ammonium polyphosphate composite intumescent flame retardant and preparation method and application thereof

The invention discloses a modified ammonium polyphosphate composite intumescent flame retardant and a preparation method and application thereof. According to the intumescent flame retardant, ammoniumpolyphosphate serves as a matrix, chitosan derivatives and phytic acid are used for coating and modifying the ammonium polyphosphate through electrostatic interaction, a chitosan derivative / phytic acid composite layer rich in carbon, nitrogen and phosphorus is formed on the surface of the ammonium polyphosphate, and the three-in-one composite intumescent flame retardant is formed. The modified ammonium polyphosphate composite intumescent flame retardant disclosed by the invention fully utilizes carbon-rich chitosan as a carbon source and phosphorus-rich phytic acid as an acid source to modifyammonium polyphosphate, so that the water resistance and the intumescent flame retardant efficiency of ammonium polyphosphate are improved, and the modified ammonium polyphosphate composite intumescent flame retardant is simple in preparation method, environment-friendly and good in flame retardant property, and can be used for flame retardance of polyolefin.

Owner:HUBEI ENG UNIV

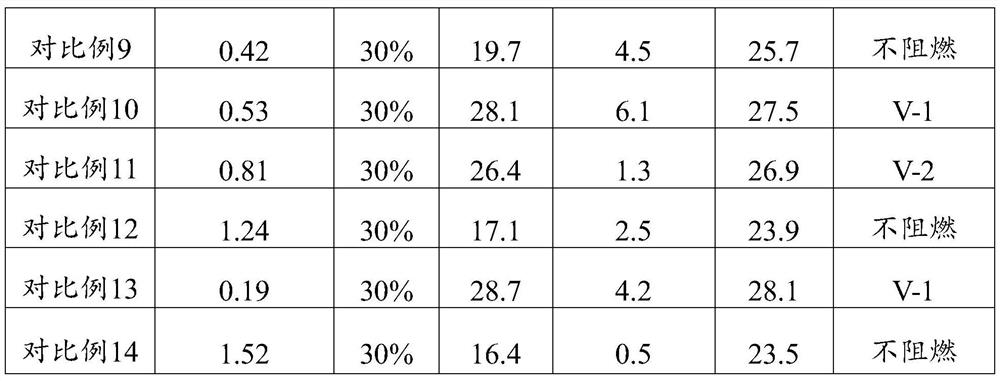

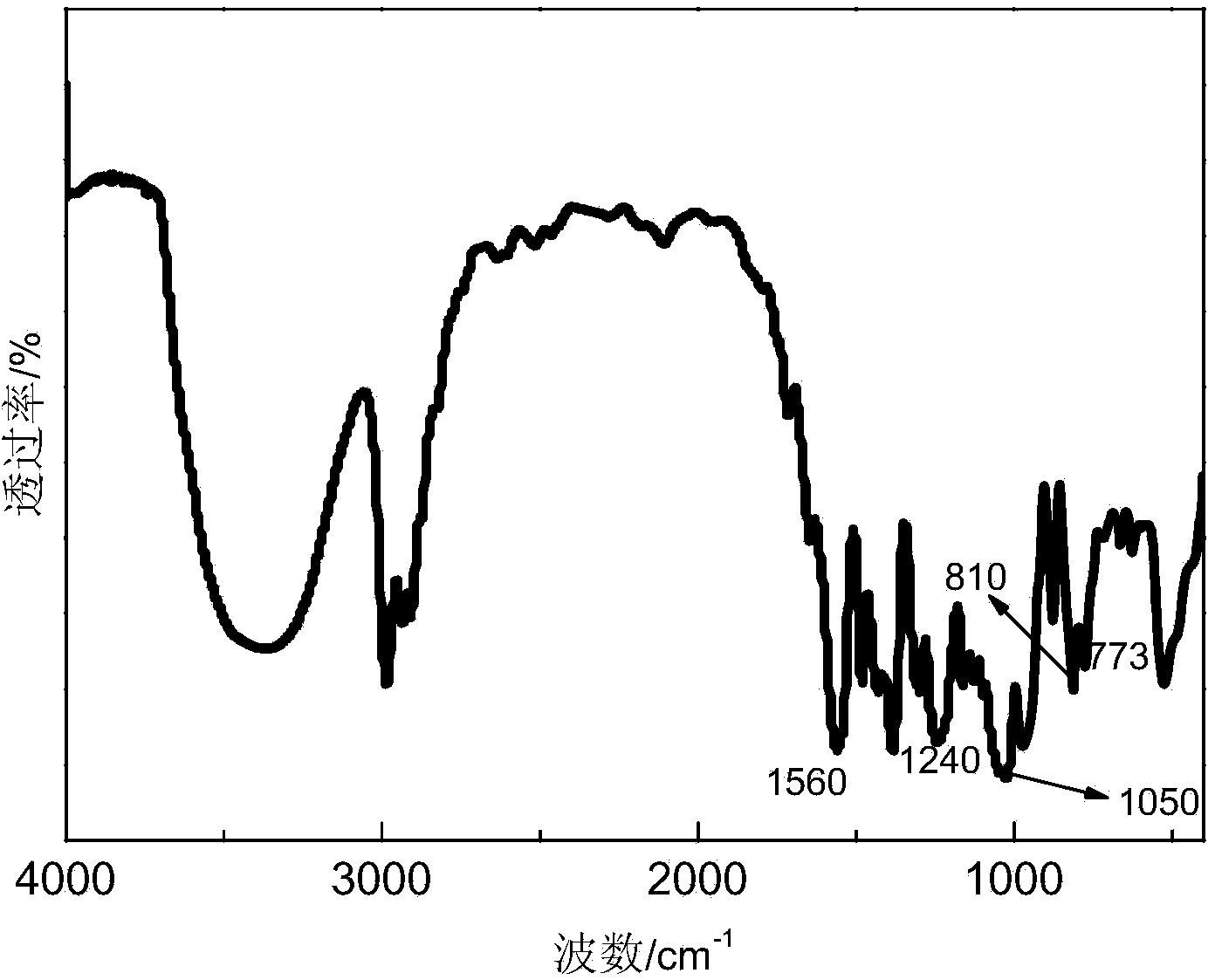

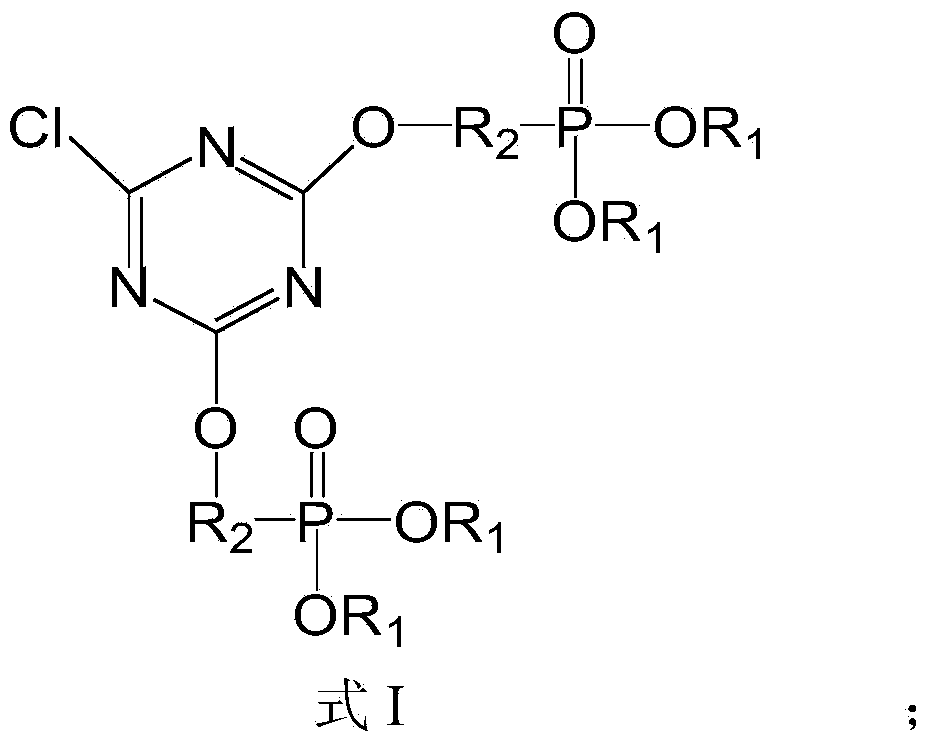

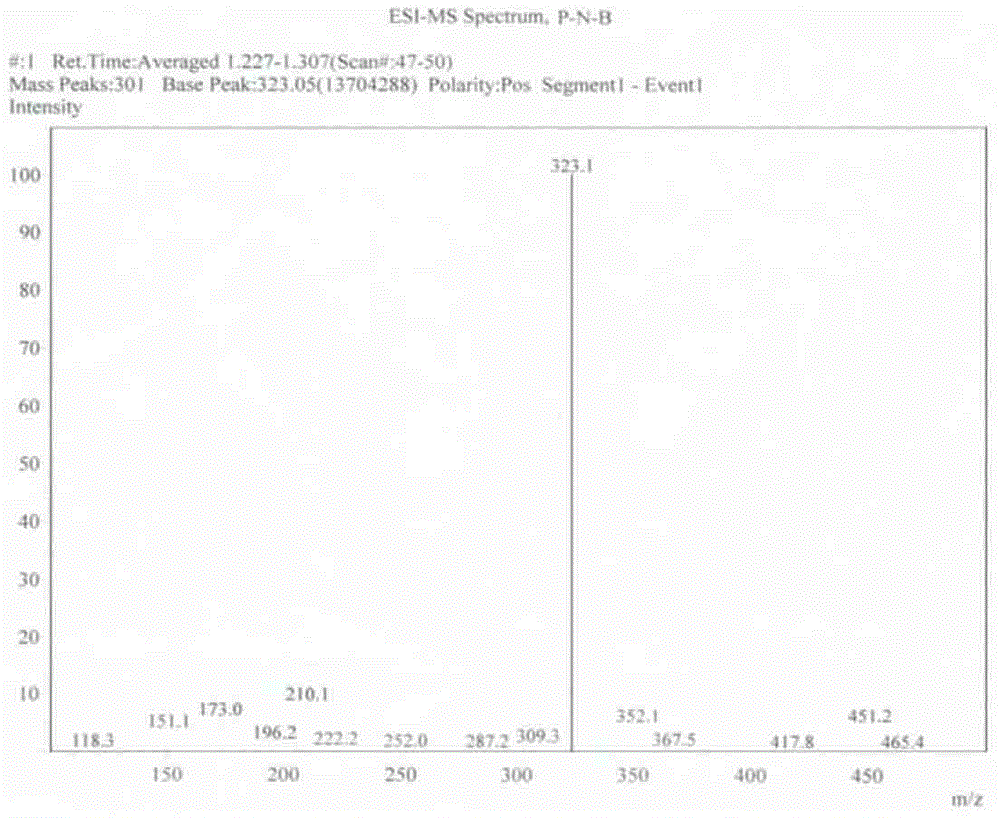

Symtriazine-type flame retardant, preparation method and application of symtriazine-type flame retardant

ActiveCN103882698AWhite colorImprove thermal stabilityGroup 5/15 element organic compoundsVegetal fibresCombustionHeat stability

The invention discloses a smtriazine-type flame retardant, a preparation method and application of the smtriazine-type flame retardant. The structure of the smtriazine-type flame retardant is shown as a formula I, the method is easy in preparation and easy to implement, and the prepared smtriazine-type flame retardant is high in heat stability and excellent in physical and mechanical properties. The method comprises the following steps: mixing and dissolving cyanuric chloride and acetone, reducing the temperature, continuously dripping an aqueous solution of potassium carbonate to regulate the pH to be 5-7, reacting at the temperature of 15-45 DEG C for 15-60 minutes after dripping, and performing aftertreatment to obtain the smtriazine-type flame retardant. In the used method for preparing the smtriazine-type flame retardant, the raw materials are readily available; the obtained smtriazine-type flame retardant is white in color, excellent in heat stability and physical and mechanical properties and high in yield; a fabric finished by the flame retardant is small in combustion smoke amount, high in char yield and environmentally friendly and can obtain long-lasting flame retardant property. The product is high in washing resistance after being applied to the fabric and is ecological, environmentally friendly and convenient to use, and the colored light and handfeel of the fabric are hardly influenced.

Owner:ZHEJIANG SCI-TECH UNIV

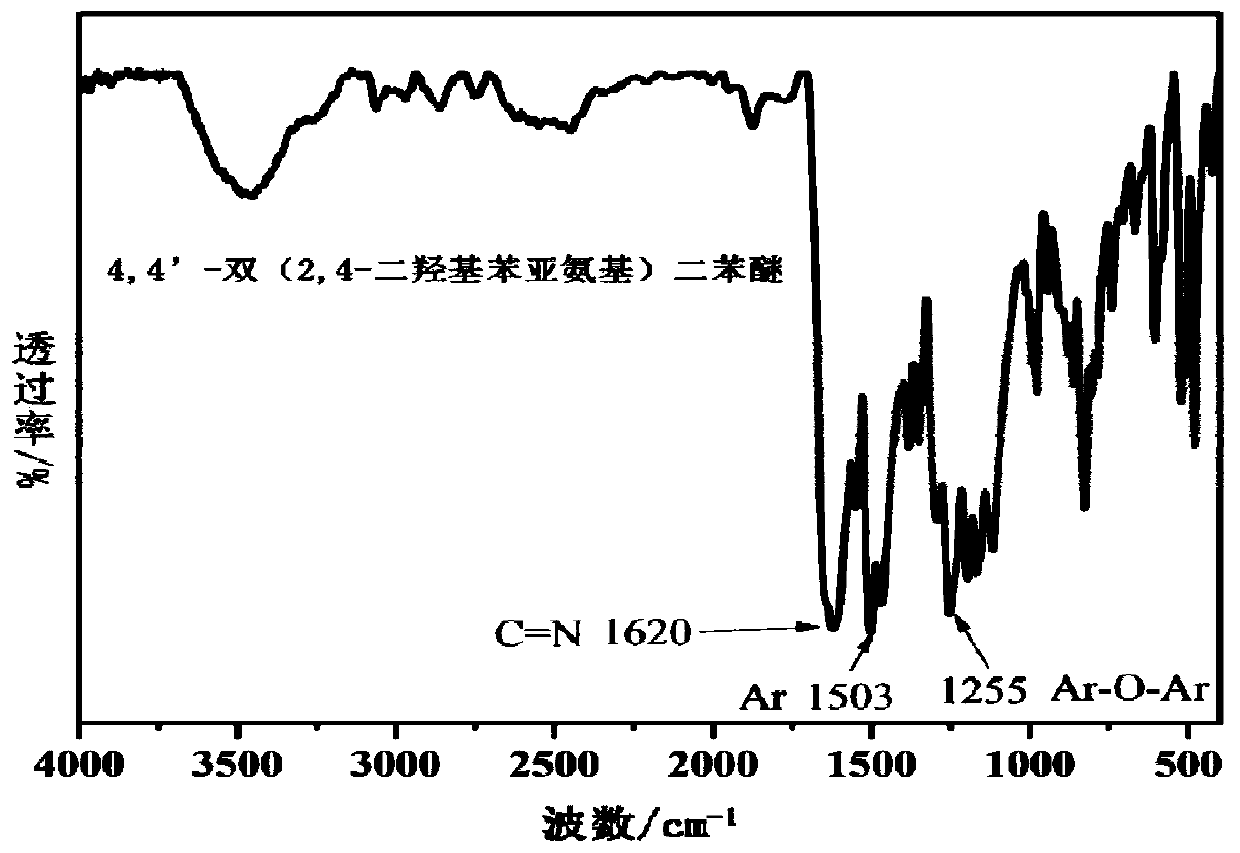

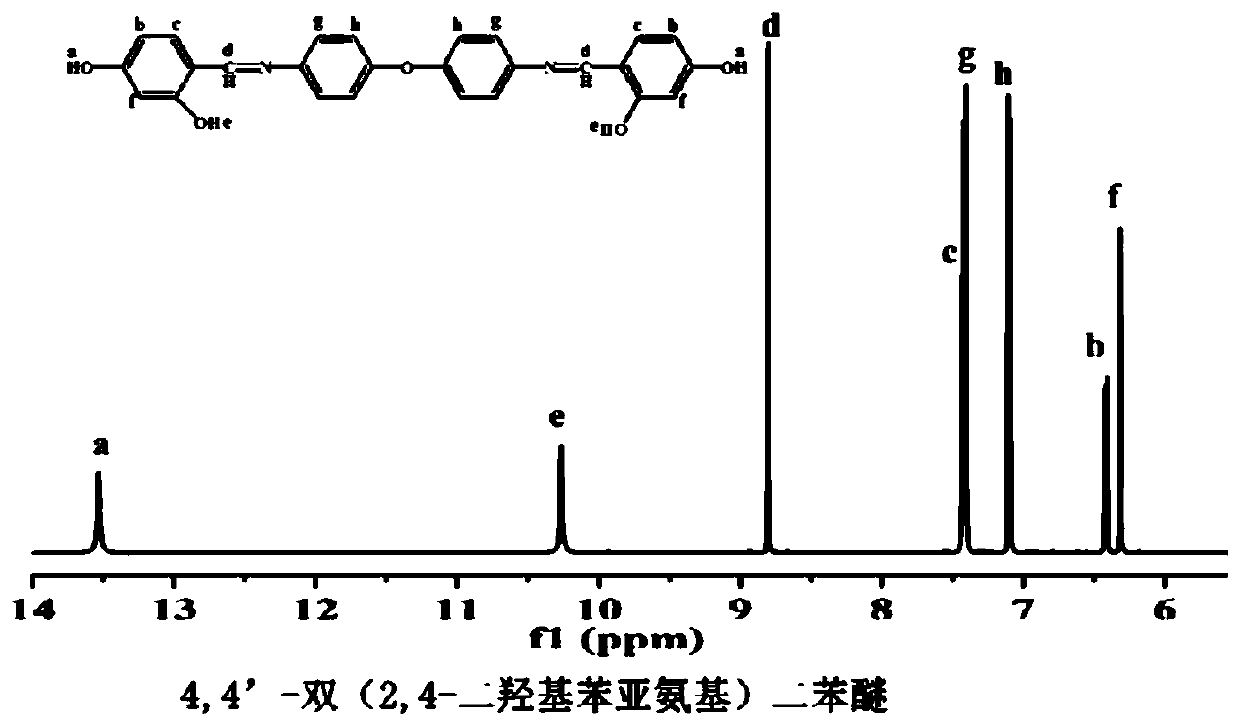

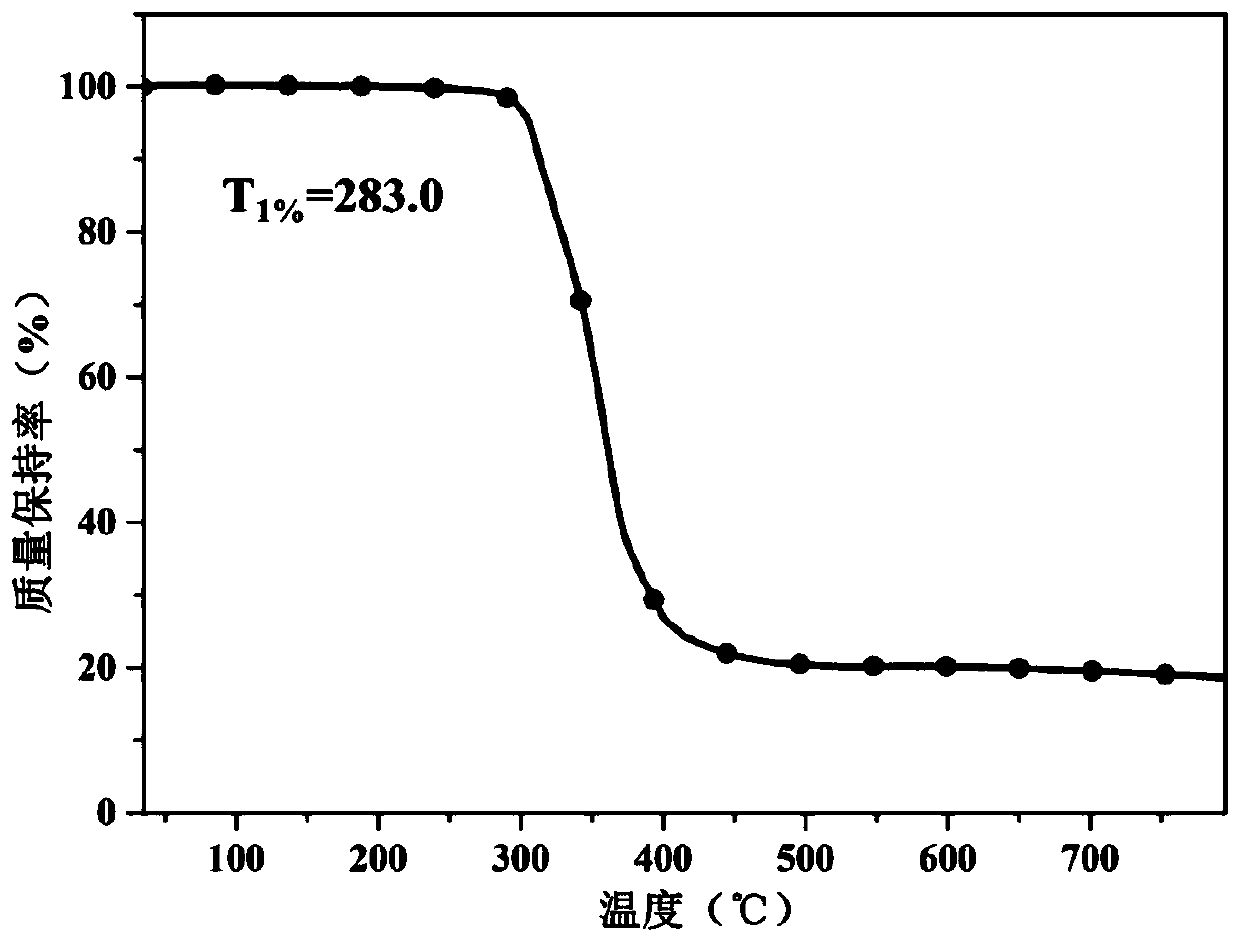

Polyhydroxy-substituted aromatic Schiff base synergistic halogen-free and flame-retardant nylon 6 composition and preparation method thereof

The invention discloses a polyhydroxy-substituted aromatic Schiff base synergistic halogen-free and flame-retardant nylon 6 composition and a preparation method thereof. The raw material formula of the nylon 6 composition comprises, by mass, 68.5-75.8% of nylon 6, 5.0-8.0% of a polyhydroxy-substituted aromatic Schiff base, 12.0-15.0% of ammonium polyphosphate with a high polymerization degree, 3.0-8.0% of a polyolefin grafted maleic anhydride compatibilizer, 0.1-0.3% of an antioxidant and 0.1-0.2% of a lubricant. The flame-retardant nylon 6 is formed by compounding the polyhydroxy-substitutedaromatic Schiff base with the ammonium polyphosphate with the high polymerization degree; and when the total amount of the two components is 20.0 wt%, the nylon 6 can pass UL94V-0@3.2 mm flame-retardant level, is resistant to dripping, and can well keep the rigidity of pure nylon 6 and have good mechanical performances on the premise of achieving the V-0 flame-retardant level.

Owner:SOUTH CHINA UNIV OF TECH

Hyperbranched intumescent flame retardant and preparation method thereof

InactiveCN104262680AHigh flame retardant efficiencyHigh char formation rateGroup 5/15 element organic compoundsFire retardantHyperbranched polymers

The invention relates to the technical field of fire retardants, in particular to a hyperbranched intumescent flame retardant. Hydroxide radical in hydroxyl-terminated hyperbranched polymer is replaced with a phosphorus containing group which is the phosphorus oxychloride group and the like. Through selection of raw materials for preparation of AB2 monomers and variety of the phosphorus containing group, the char yield of the flame retardant in the flame retarding process is increased, further, compatibility can be improved compared with larger molecular weight and high polymer materials, the flame retardant efficiency of the flame retardant can be improved well, the flame retardant effect is increased, and the additive amount is reduced.

Owner:UNIV OF JINAN

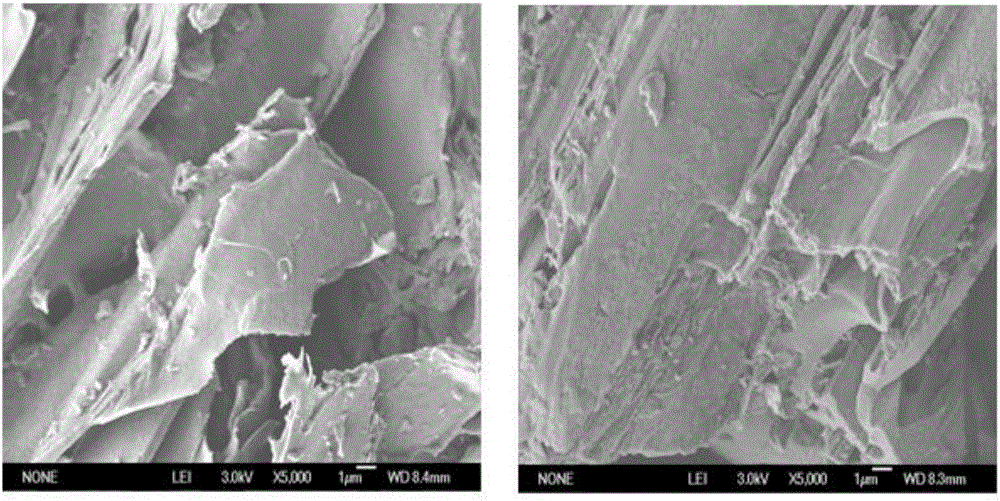

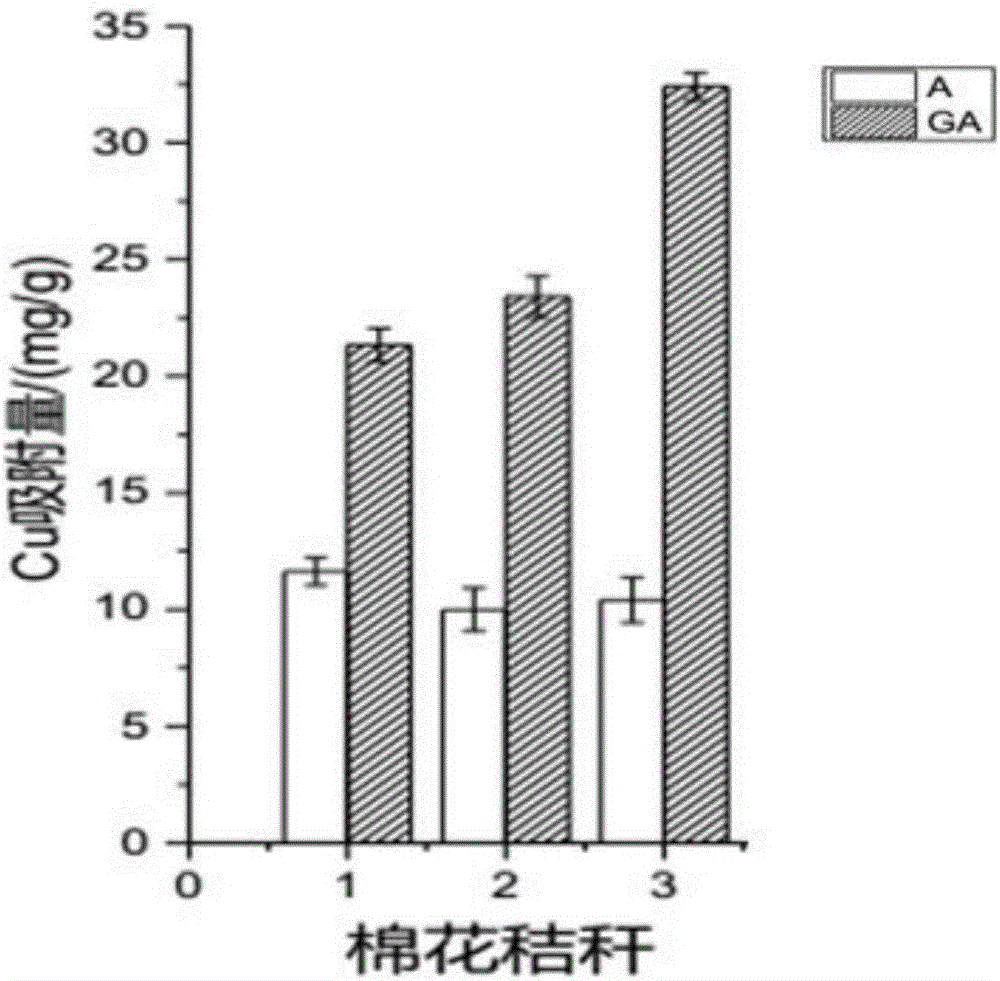

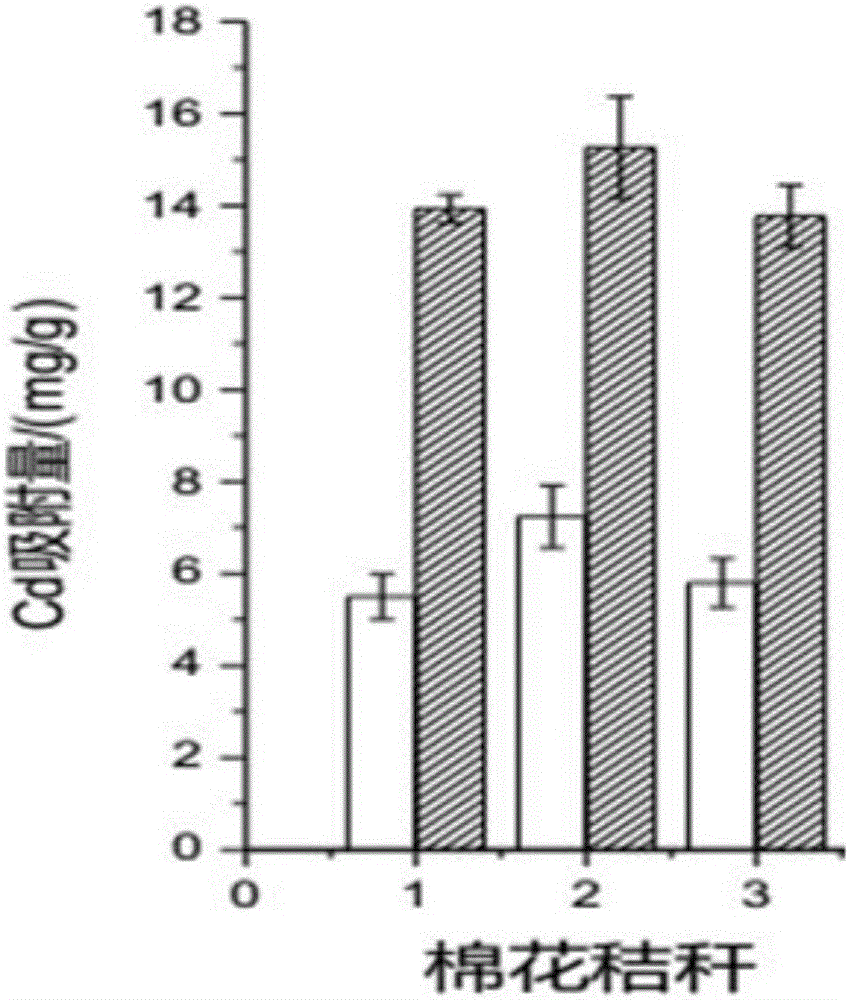

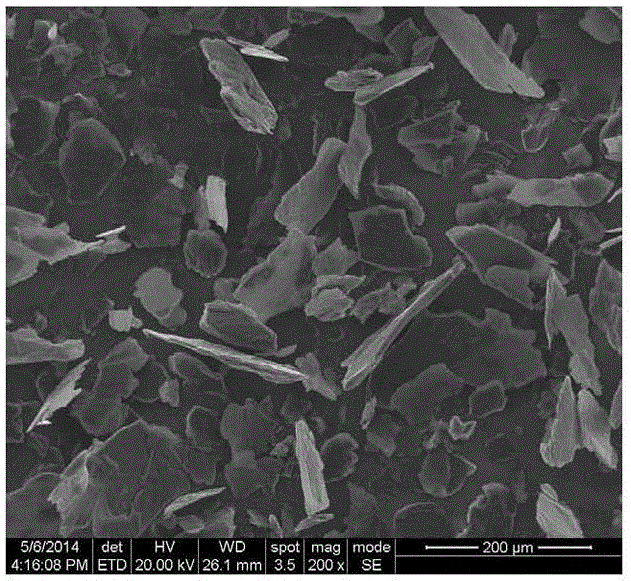

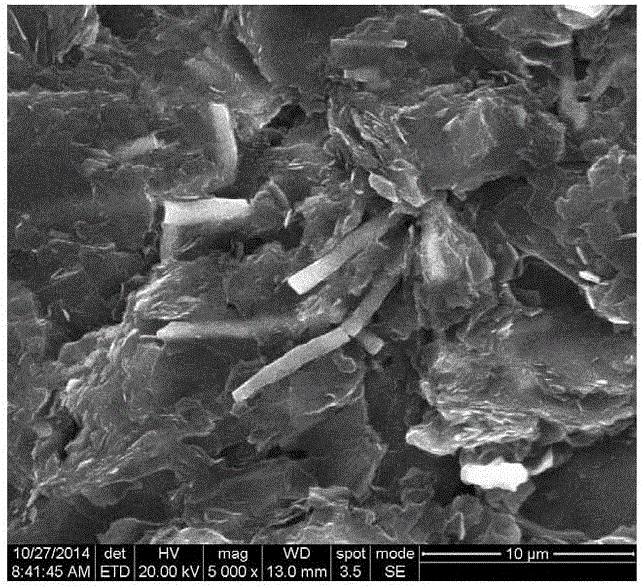

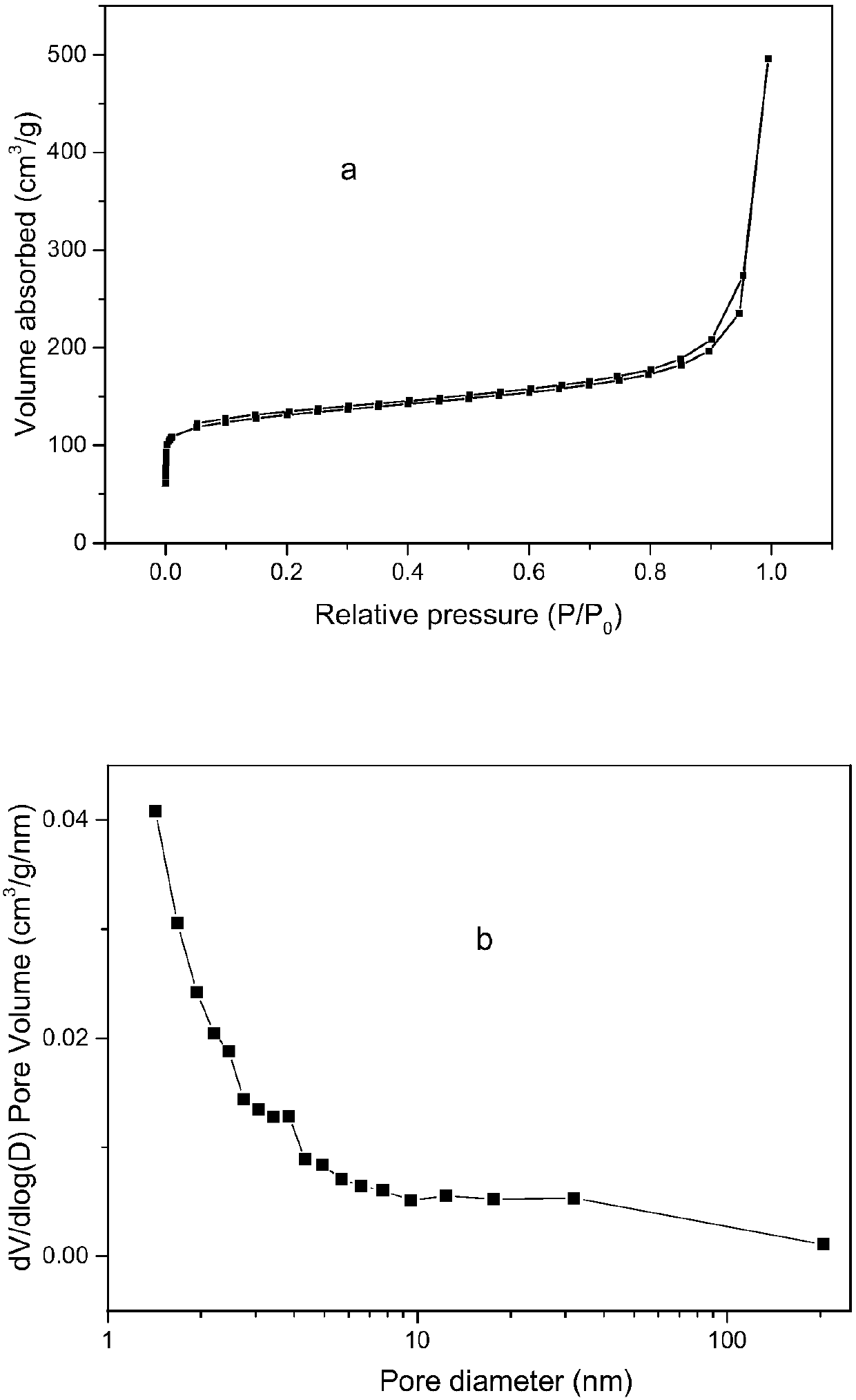

Method for preparing efficient heavy metal adsorbent from modified cotton stalk biomass charcoal

InactiveCN105879838ABiomass carbon pores increaseImprove adsorption capacityOther chemical processesBiomass carbonSorbent

The invention discloses a method for preparing a high-efficiency heavy metal adsorbent by modifying cotton stalk biomass charcoal. Carbonization at 300°C for 3‑6h; (2) Add 0.3mol / L KMnO to the cotton biochar prepared in step (1) 4 solution, and then add a mass fraction of 60% HNO 3 solution, heated at 85-95°C for 2.5-3.5h, filtered, washed, and dried to obtain a modified product, the biochar and KMnO 4 solution and HNO 3 The dosage ratio of the solution is 1g: (7-7.8)ml: (3.3-4.0)ml. The pore volume of the biomass charcoal obtained by carbonizing the cotton stalks prepared by the method of the invention is obviously increased, and can efficiently adsorb heavy metal copper and cadmium at the same time.

Owner:SHANDONG NORMAL UNIV

Strong-laser-ablation-resistant protective coating and preparation method thereof

The invention discloses a strong-laser-ablation-resistant protective coating and a preparation method thereof. The protective coating is prepared from flake graphite, a SiC whisker, an epoxy modified organic silicon resin and a phenolic resin. The preparation method comprises the following steps: dissolving the epoxy modified organic silicon resin and phenolic resin, stirring to obtain a mixed adhesive, and mixing the flake graphite and SiC whisker to obtain mixed powder; (2) mixing the mixed adhesive and mixed powder, and carrying out ball milling to obtain a coating slurry; and (3) coating the coating slurry on a base material, and curing by heating to obtain the strong-laser-ablation-resistant protective coating. The strong-laser-ablation-resistant protective coating has the advantages of low density, high strength, low price, stable performance and the like, and can be sprayed. The preparation method has the advantages of simple technique and low cost.

Owner:NAT UNIV OF DEFENSE TECH

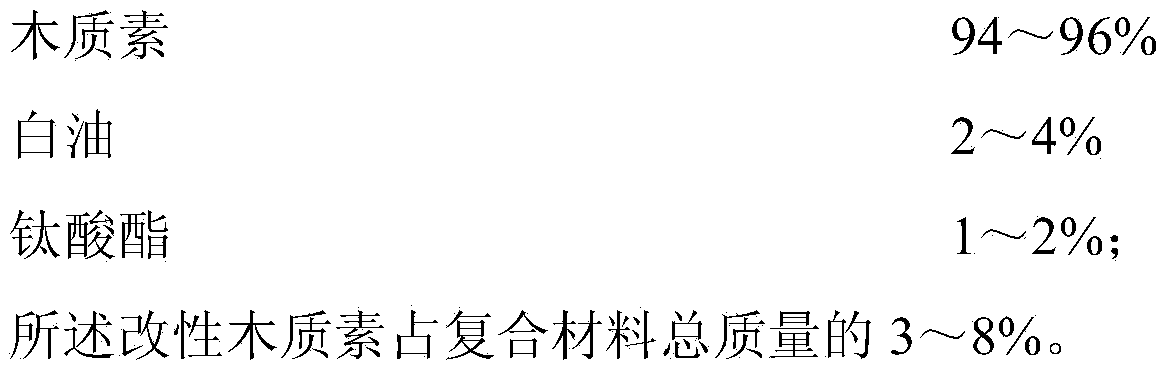

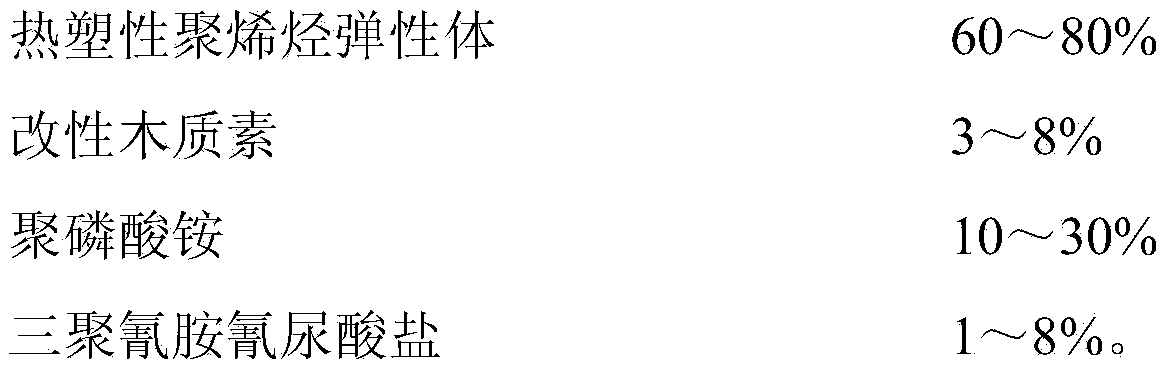

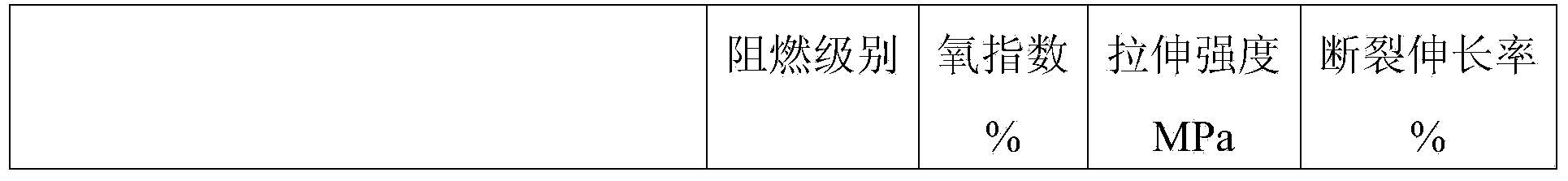

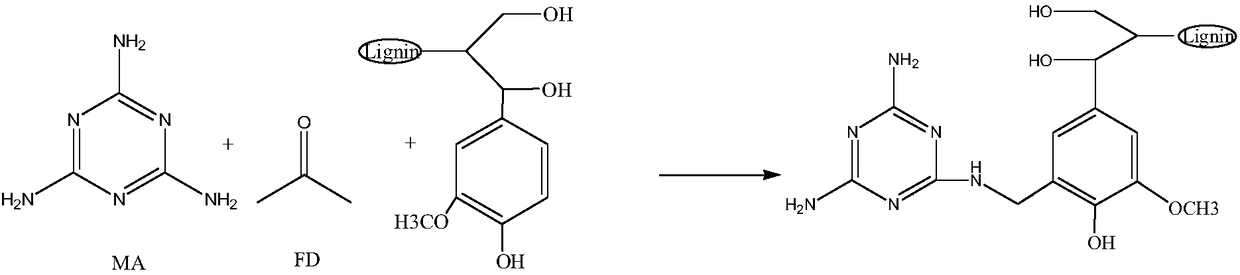

Modified lignin intumescent flame retardant TPO composite material as well as preparation method and application of composite material

InactiveCN103834107APromote environmental protectionHigh char formation ratePolyolefinAging resistance

The invention relates to a modified lignin intumescent flame retardant thermoplastic polyolefin (TPO) composite material as well as a preparation method and an application of the composite material. The composite material contains modified lignin, wherein the modified lignin consists of the following components in percentage by mass: 94-96% of lignin, 2-4% of white oil and 1-2% of titanate; and the modified lignin accounts for 3-8% in terms of total mass of the composite material. The prepared modified lignin intumescent flame retardant TPO composite material disclosed by the invention has the beneficial effects of being high in tensile strength at break, high in elongation at break, low in heating expansion amount, good in low temperature flexibility, good in penetration resistance and strong in chemical corrosion resistance; and the composite material is excellent in weather aging resistance, applicable to damp, hot and cold natural environments in a long term, and low in performance change.

Owner:DALIAN POLYTECHNIC UNIVERSITY

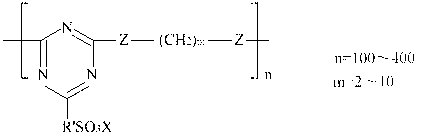

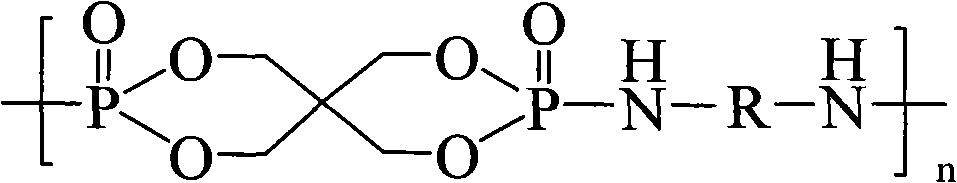

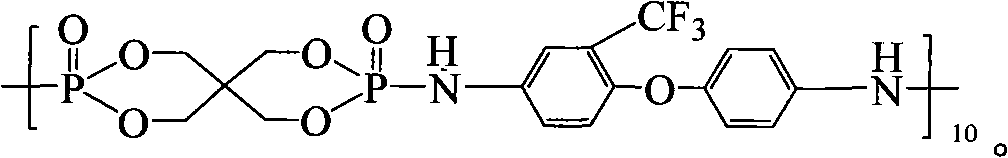

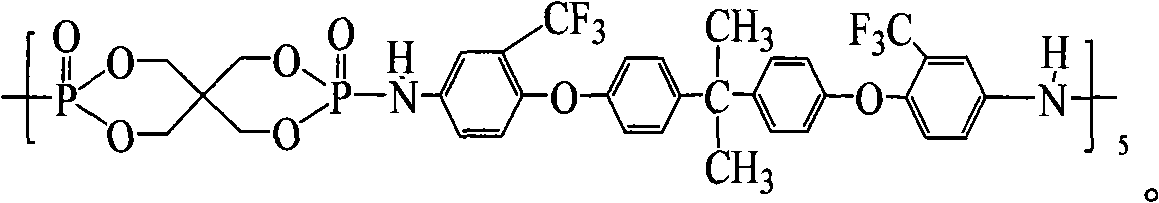

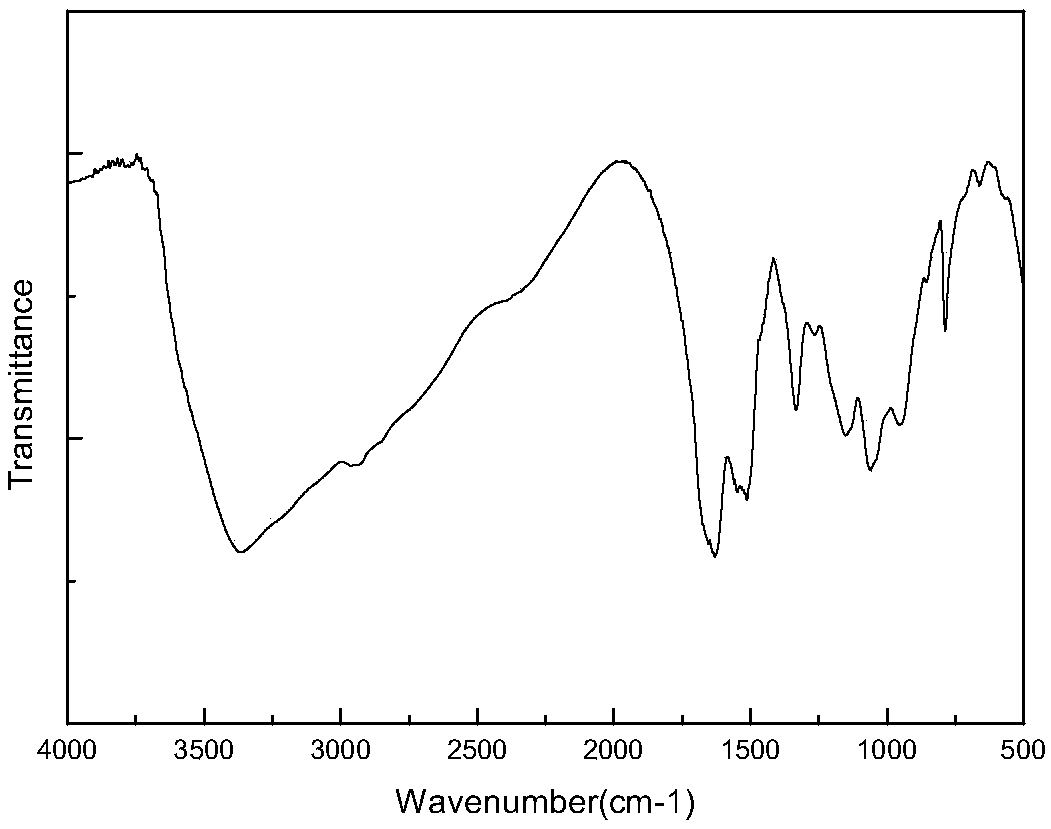

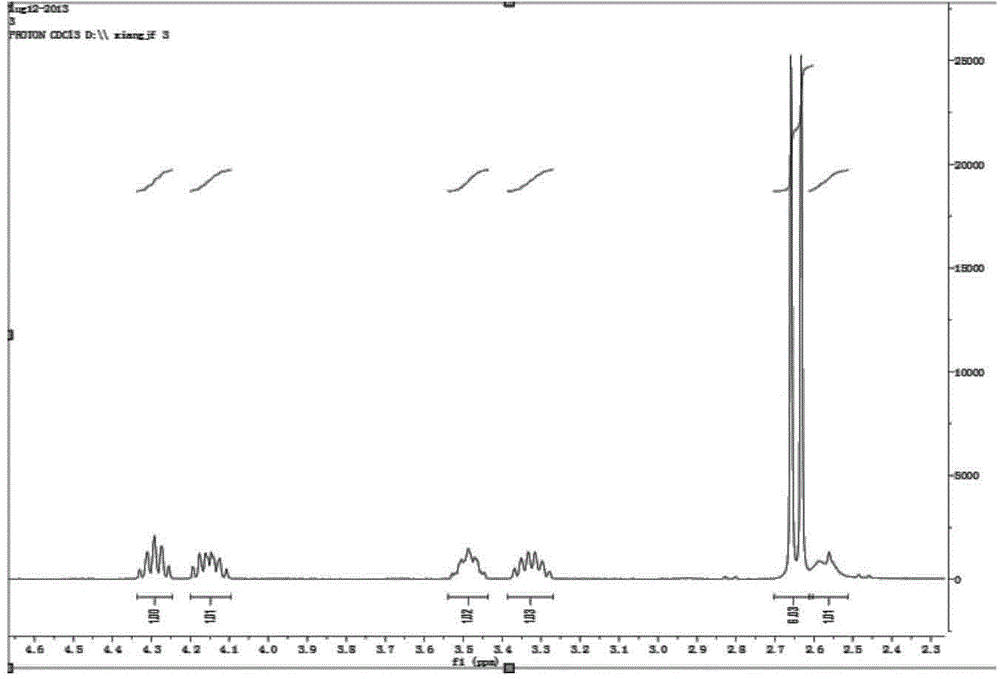

Macromolecule triazine charring agent and preparation method thereof

ActiveCN102702522AHigh char formation rateThe synthesis process is continuousOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventHydrogen

The invention relates to a macromolecule trazine charring agent and a preparation method thereof. According to the invention, a group with the catalytic action is introduced into a triazine macromolecule polymer with the main chains containing the fatty group structures, and is integrated with the charring agent, so as to generate the catalytic action nearby; or, the group with the catalytic action can also be fixed on molecular chains of the polymer, so as to prevent migration and uneven dispersion and greatly improve catalytic efficiency. The specific preparation method is as follows: firstly, a binary substance and an acid-binding agent are mixed, and then are stirred for 0.5 to 1 hour, so as to obtain a compound with bifunctional reactive hydrogen; the compound is added into a cyanuric chloride aprotic organic solvent to react for 4 to 8 hours, and then is added into an aprotic organic solvent containing sulfonic acid group activated monomers to react for 8 to 12 hours by adding the catalytic agent and the acid-binding agent; and finally, the product is obtained through filtering, washing and drying. The method provided by the invention has continuous reaction process, short reaction time and high reaction efficiency.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Flame retardant thermoplastic elastomer compositions

Flame retardant polymeric blend compositions including a synergistic combination of flame retardants, including a halogenated flame retardant and a nanoparticulate, such as an organically modified clay or a natural nanoclay. The compositions are thermoplastic elastomers, include a polyolefin and a styrenic block copolymer, and exhibit high char formation upon burning as well as desirable vertical burn characteristics. In a preferred embodiment, the flame retardants include at least a halogenated flame retardant and a metal oxide.

Owner:TEKNOR APEX

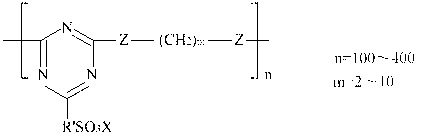

Expansible fire retardant containing fluorine-phosphorus-nitrogen oligomer and preparation method thereof

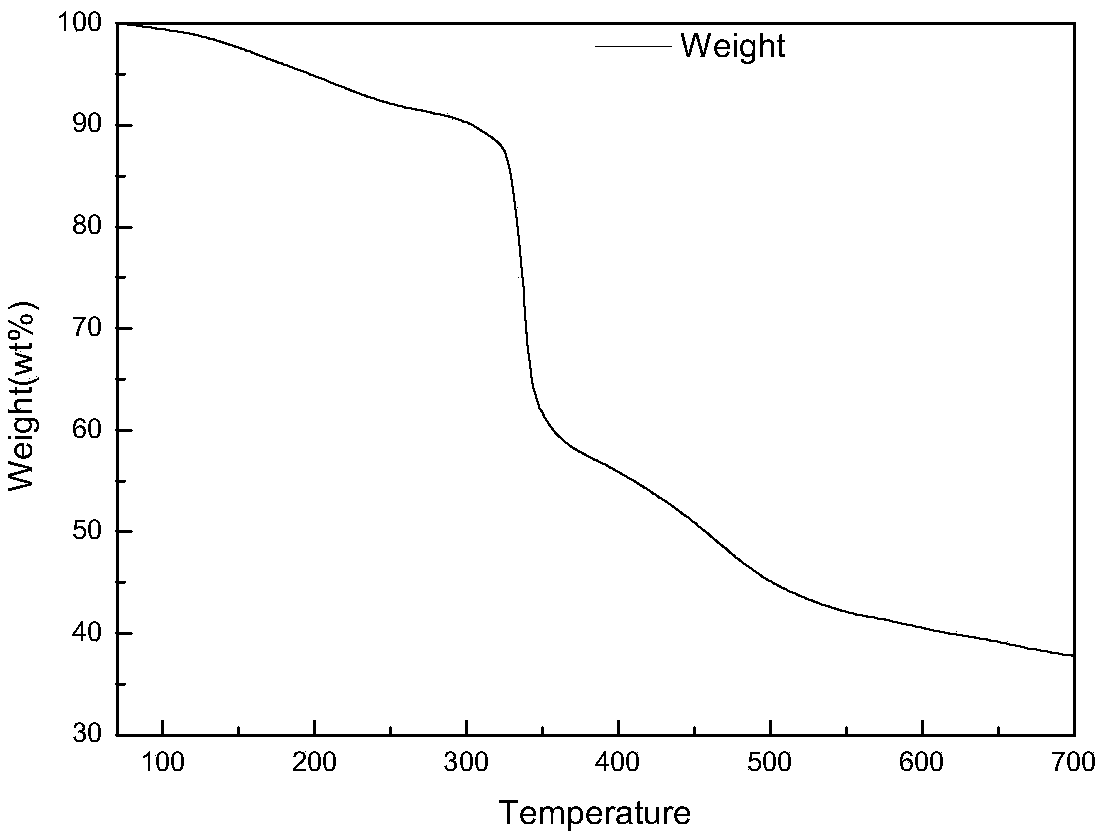

The invention relates to the technical field of fire retardants, particularly relating to an expansible fire retardant containing a fluorine-phosphorus-nitrogen oligomer and a preparation method thereof. The fire retardant is prepared by mixing pentaerythritoldiphosphatediphosphoryl chloride and diamine based on a molar ratio of 1:1-1.5 for reaction, filtering the obtained substance, washing and drying the filter residue. The method is simple and convenient. Meanwhile, the expansible fire retardant containing the fluorine-phosphorus-nitrogen oligomer prepared by the invention is an oligomer type molecule and has large molecular weight and good stability, and solves the problems of shift, precipitation or volatilization and the like which occur in processing and molding the fire retardants and polymer substrates; at the same time, the introduced functional fluorine element greatly improves the water resistance of the substrates; and the fire retardant integrates a carbon source, an acid source and a gas source into a whole, the charcoal yield is high, the carbon residue amount is about 58% at air atmosphere under the temperature of 800 DEG C, and the thermostability is favorable.

Owner:来安县亨通橡塑制品有限公司

Lignin inrumescent flame retardant preparation method

The invention discloses a lignin inrumescent flame retardant preparation method. The alkali lignin is placed in enough water, heating is carried out, melamine is added, stirring and heating are carried out, a formaldehyde solution is added drop by drop for a reaction, a phytic acid solution is added drop by drop in proportion, the product is placed in a centrifuge for centrifugal operation, whiteprecipitate is removed, and residual liquid is dried in a vacuum drying box until the product mass is not changed. While a fire retardant combusts, heavy smoke as well as poisonous and harmful gas having excitant smell are not generated, environment is friendly, the materials for synthesis of the fire retardant are renewable resources, the raw materials are easily available and easy to process, and no burden is generated on environment.

Owner:ZHEJIANG FORESTRY UNIVERSITY

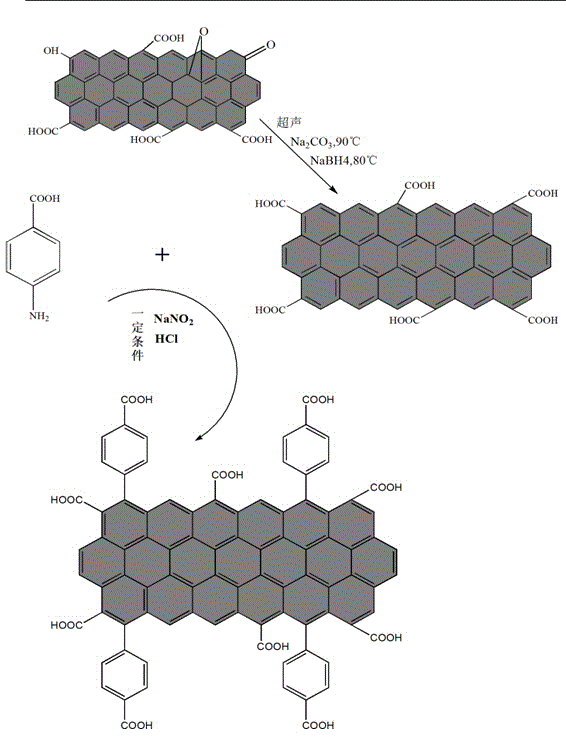

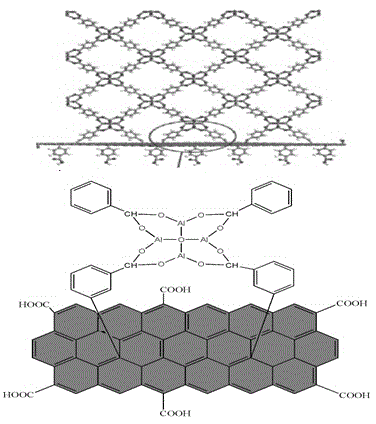

Flame-retardant rubber

The invention relates to a flame-retardant rubber preparation method, wherein the flame-retardant rubber is prepared by mixing the following components by mass fraction: 100 parts of natural rubber, 1.2-1.5 parts of a vulcanizing agent, 0.8-1.0 part of an accelerator CZ, 0.2-0.4 part of an accelerator CZ TMTD, 3.5-4.5 parts of stearic acid, 4.5-5 parts of zinc oxide, 1-2 parts of an an-aging agent 4010, 1-3 parts of liquid paraffin, 30-40 parts of carbon black, 1-5 parts of a flame-retardant synergist, 35-40 parts of ammonium polyphosphate, 10-20 parts of pentaerythrotol, and 10-20 parts of melamine, wherein the flame-retardant synergist is metal organic framework graft functionalized graphene, wherein graphene is functionalized with Benzoic Acid so as to achieve double coordination compounding of the graphene and the metal organic framework. With the flame-retardant rubber of the present invention, the flame-retardant performance of the rubber matrix is significantly improved.

Owner:SHENYANG RUBBER PLANT NO 4 LIAONING PROV

Method for preparing boron-nitrogen co-doped carbon aerogel

ActiveCN107651662ALarge specific surface areaImproves ablation resistanceNanotechnologyNano-carbonFreeze-dryingSolvent

A method for preparing boron-nitrogen co-doped carbon aerogel is disclosed. According to the method, graphene, phenols, aldehydes, a catalyst, boron, amine and a solvent are used as a reaction system,and through reaction crosslinking solidification, organogel is then obtained; the organogel is dried at normal pressure to obtain organic aerogel; and finally, the organic aerogel is carbonized in inert atmosphere to obtain graphene crosslinked boron-nitrogen co-doped carbon aerogel. By the preparation technology, a complex preparation technology of a conventional supercritical or freeze drying method is avoided, and a carbon aerogel material which meets different performance requirements can be prepared by regulating addition amount of B and N elements. In addition, the method of the invention has simple process, has low equipment requirements, is environmentally friendly, can be applied in the fields of energy storage materials, lithium ion batteries, super-capacitors, electro-adsorption materials and the like, and also can realize industrial production of carbon aerogel.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of hyperbranched flame retardant and application of hyperbranched flame retardant in artificial board

ActiveCN107540847AGood compatibilityHigh flame retardant efficiencyDomestic articlesFlat articlesPolymer scienceFire retardant

A phosphorous type hyperbranched flame retardant is disclosed. According to the invention, hydroxyl in a hydroxyl-terminated hyperbranched polymer is replaced by a phosphorus-containing group. By selecting raw materials for preparation of an AB2 monomer and the type of the phosphorus-containing group, char yield of the flame retardant in the flame retardation process is raised; and compatibility of large molecular weight and high polymer materials will be enhanced, flame retardance efficiency of the flame retardant can be greatly improved, flame-retarding effect is increased, and addition amount is reduced.

Owner:UNIV OF JINAN

Reclaimed ABS (acrylonitrile butadiene styrene) environment-friendly modified material and preparation method thereof

The invention relates to the technical field of recycling of ABS reclaimed materials, in particular to a reclaimed ABS (acrylonitrile butadiene styrene) environment-friendly modified material and a preparation method thereof. The material comprises ABS reclaimed materials, flame retardant, flame-retardant synergist, compound antiager, antioxygen, flexibilizer and coupling agent. Environment-friendly modified graphene is adopted as the flame retardant, so that flame retardation of the material is improved, and the material is environmentally friendly; waste nitrile rubber is adopted as the flexibilizer, so that mechanical property of the material is improved, waste turns into wealth, and the requirement on environmental protection is met; being added with the compound antiager, the material is high in ageing resistance. The reclaimed ABS material is equivalent to a new flame-retardant material in flame retardance and mechanical properties, the reclaimed ABS material prepared by the method is excellent in performance, the preparation technique is simple and easy to operate, production cost is low, economic benefit is high, and industrialization is easy to realize.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

Applications of cyclic phosphorus-nitrogen synergic halogen-free flame retardant

The invention relates to applications of cyclic phosphorus-nitrogen synergic halogen-free flame retardant, and particularly relates to applications of 2,7-bis(N,N-dimethylamine)-1,6,3,8,2,7-octahydrodioxadiazole diphosphinic acid, belonging to the field of synthesizing a novel halogen-free high polymer material. As a hard segment chain extender, 2,7-bis(N,N-dimethylamine)-1,6,3,8,2,7-octahydrodioxadiazole diphosphinic acid is applied to halogen-free flame-retardant modification of water-based polyurethane emulsion. Cyclic phosphamide flame retardant 2,7-bis(N,N-dimethylamine)-1,6,3,8,2,7-octahydrodioxadiazole diphosphinic acid as the hard segment chain extender is embedded into a water-based polyurethane macromolecular chain; the research shows that due to the addition of the flame retardant, the limit oxygen index of a polyurethane membrane can be improved to a greater extent, the thermal stability of the polyurethane membrane is enhanced, the carbon residue rate of the material after which is decomposed at high temperature is increased, and the usage amount of the flame retardant is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Composite additive for water mist fire suppression and preparation method and application method thereof

ActiveCN104922848AGood fire extinguishing performanceShorten fire fighting timeFire rescueFire extinguisherPhosphateEnvironmental engineering

The invention discloses a composite additive for water mist fire suppression. The composite additive comprises 1 wt% to 5 wt% of ferrous lactate, 2 wt% to 30 wt% of sylvite, 2 wt% to 30 wt% of phosphate and the balance water. The preparation method of the composite additive comprises the step that the ferrous lactate, the sylvite and the phosphate are sequentially dissolved into the water to obtain the composite additive. The application method of the composite additive comprises the steps that the composite additive and water are diluted according to the proportion of 1:2-1:30; and then a water mist generator is filled with the diluted solution which is sprayed to a fireground for fire extinction. The ferrous lactate, the sylvite and the phosphate in the composite additive have a good synergistic flame retardant effect, so that the fire extinction time is greatly shortened, and the fire extinction and inflaming retarding performance is more excellent.

Owner:STATE GRID CORP OF CHINA +2

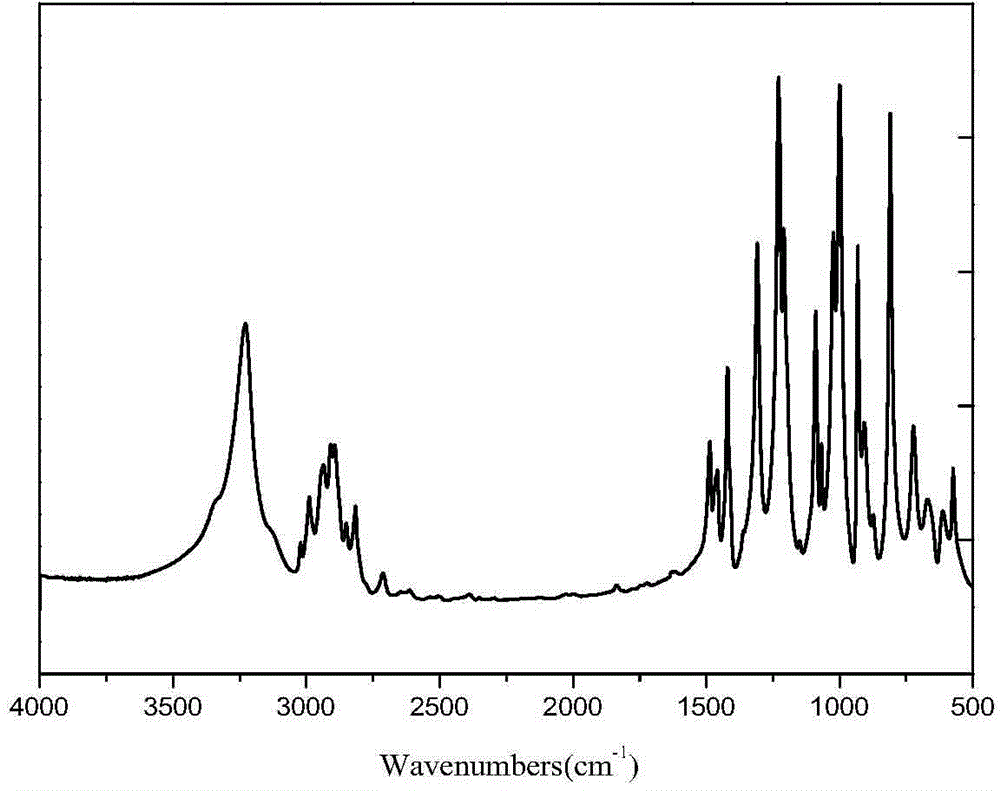

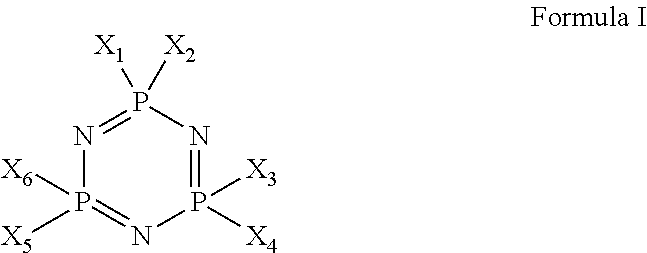

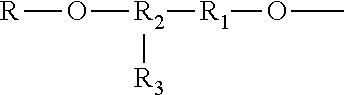

Siloxane-modified cyclotriphosphazene halogen-free flame retardant, preparation process and use thereof

InactiveUS20180112133A1Improve thermal stabilityHigh char formation rateGroup 5/15 element organic compoundsFibre treatmentArylOxygen compound

The present invention provides a siloxane-modified cyclotriphosphazene halogen-free flame retardant, and a preparation method and a use thereof. The siloxane-modified cyclotriphosphazene halogen-free flame retardant has the structural formula as shown in Formula I. In the siloxane-modified cyclotriphosphazene halogen-free flame retardant of the present invention, three kinds of structures of siloxane, aryl phosphorus oxygen compound and cyclotriphosphazene are built in one molecular formula, which combines the advantages of three structures, improves the compatibility between the flame retardant and resins, has a high flame retardant efficiency and a better char formation and can greatly increase the flame retardancy and stability of resin cured products.

Owner:GUANGDONG SHENGYI SCI TECH

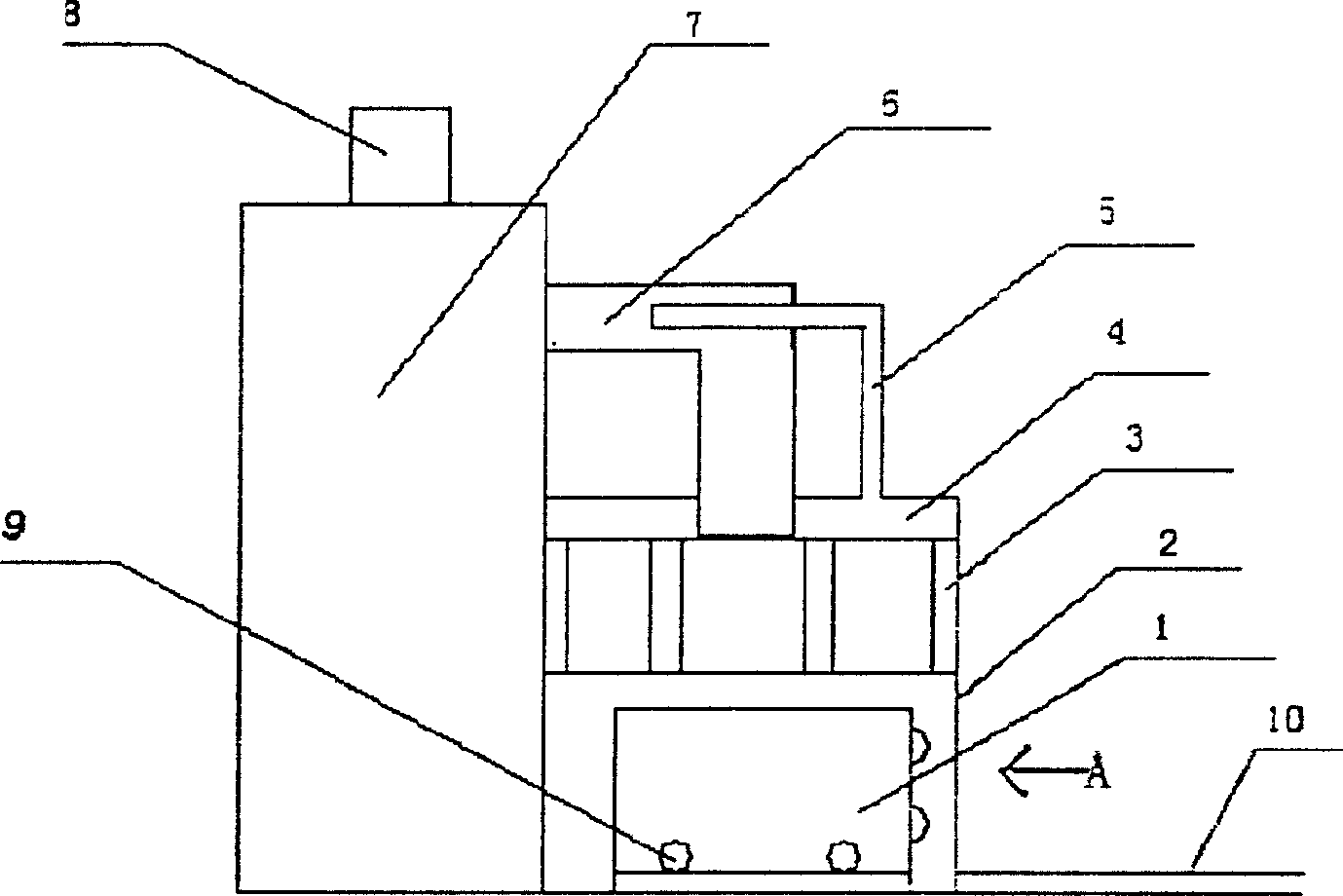

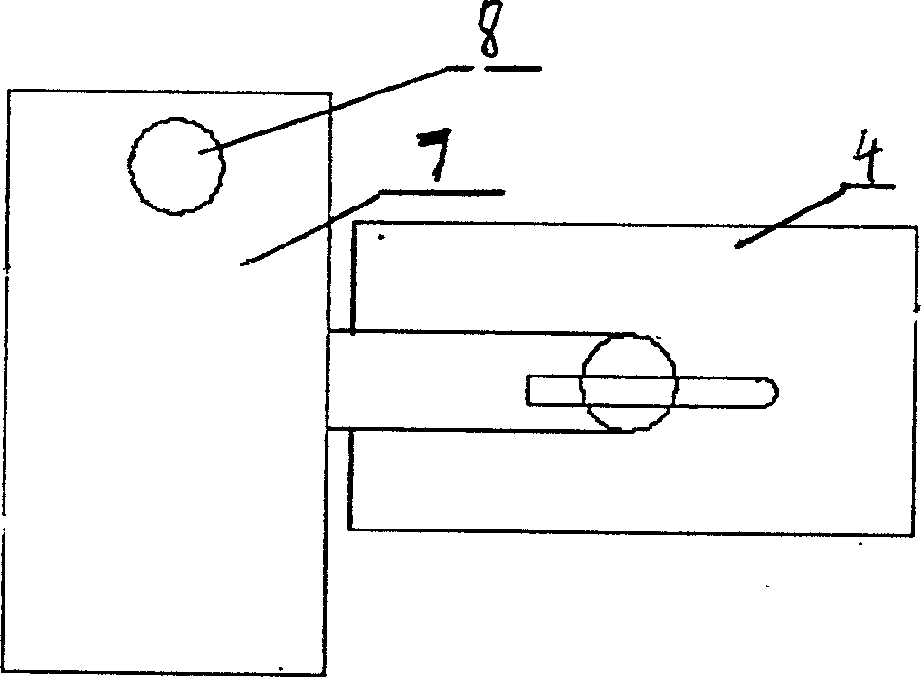

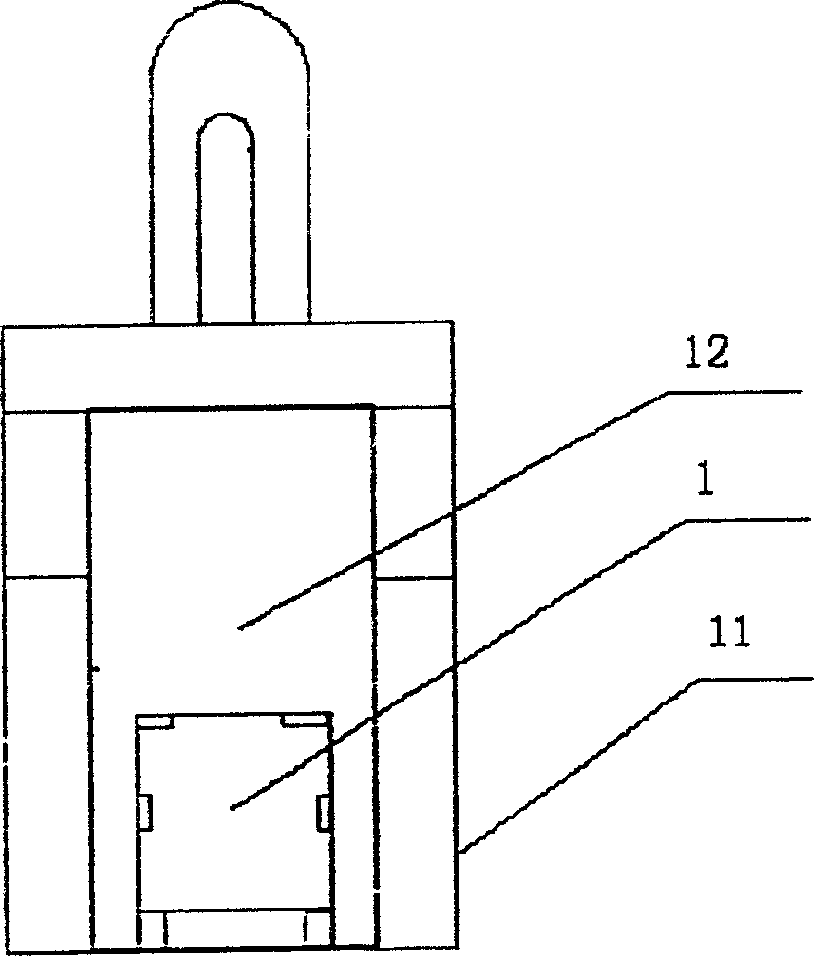

Floating oxygen carbonation technology for grass wood high temperature decomposition

InactiveCN1718677AQuality assuranceNew technologyBiofuelsSpecial form destructive distillationDecompositionEngineering

A high-temp decomposing and floating-oxygen charring process for plant and wood is disclosed. Its apparatus is composed of an internal furnace with open fire hole and bottom wheels and an external furnace with water tank having chimney, vapor tube and gate. Its charring process includes such steps as continuously feeding plant and wood in internal furnace, burning, quick decomposing to educe out high-temp gas, mixing with O2 in air to become flame, continuous charring, and cooling. The CO2 gas is exhausted via chimney.

Owner:杨雪静

Preparation method of compound microcapsule-coated ammonium polyphosphate master batch

InactiveCN105086455AHigh char formation rateImprove flame retardant performanceEpoxyFORMALDEHYDE SOLUTION

The invention discloses a preparation method of a compound microcapsule-coated ammonium polyphosphate master batch. The preparation method comprises that melamine and a formaldehyde solution form a performed polymer, the performed polymer is coated with ammonium polyphosphate in an ethanol aqueous solution, the ammonium polyphosphate-coated performed polymer and epoxy-modified organic silicone resin are mixed and pressed to form the master batch by polymerization. The preparation method improves a processing temperature, widens an application range, utilizes organosilicon to improve a char yield and promotes flame retardation effects.

Owner:ZIBO FUEN CHEM TECH CO LTD

Biomass composite ammonium polyphosphate intumescent flame retardant, preparation method and application thereof

The invention discloses a biomass composite ammonium polyphosphate intumescent flame retardant, a preparation method and application thereof. The biomass composite ammonium polyphosphate intumescent flame retardant comprises the following raw materials in parts by mass: 65-85 parts of ammonium polyphosphate, 10.5-28 parts of starch derivative, and 4-7 parts of biomass, wherein the starch derivative comprises one or a mixture of two of starch phosphate and starch polyphosphate, and the biomass comprises one or a mixture of more of sodium alginate, hyaluronic acid, a chitosan derivative and a cellulose derivative. According to the biomass composite ammonium polyphosphate intumescent flame retardant disclosed by the invention, the starch derivative and the biomass are used as carbon sources,the biomass is compounded and cross-linked with the starch derivative through a high-temperature dry-heat reaction, and a compact coating layer is formed on the surface of ammonium polyphosphate, so that the prepared composite intumescent flame retardant has excellent water resistance and flame retardant efficiency; and the flame retardant of the invention has the advantages of abundant raw material sources, simple production technique, environment friendliness and low preparation cost, and can be widely used for flame retardancy of polar polymer materials.

Owner:HUBEI ENG UNIV

Preparation method of melamine cyanurate (MCA) flame retardant and application of MCA flame retardant in PA6

The invention discloses a preparation method of a melamine cyanurate (MCA) flame retardant and application of the MCA flame retardant in PA6. The invention belongs to the technical field of flame retardant production. The preparation method of the melamine cyanurate (MCA) flame retardant comprises the following steps: adding deionized water into a container, then adding melamine, uniformly stirring, then adding cyanuric acid, sodium dodecyl benzene sulfonate and antimonous oxide, uniformly mixing and stirring, raising the temperature of the materials to 95 DEG C, maintaining the temperature, and reacting for 2 hours to finish the reaction, so as to obtain a viscous paste of melamine cyanurate; and cooling to normal temperature and normal pressure, and then carrying out suction filtration,drying and crushing treatment on the paste to obtain the melamine cyanurate flame retardant. Sodium dodecyl benzene sulfonate and antimonous oxide are added in the synthesis process of melamine and cyanuric acid to serve as modifiers, so that the compatibility of MCA and PA6 is improved, the viscosity of the reaction system is reduced, and the flame retardant efficiency and the thermal stability of the flame retardant can be well improved.

Owner:山东东信新材料科技股份有限公司

Preparation method of flame-retardant copolyester film of phosphorus, silicon and fluorine

The invention discloses a preparation method of a flame-retardant copolyester film of phosphorus, silicon and fluorine. The preparation method is characterized by comprising the steps of: preparing flame-retardant copolyester sections of phosphorus, silicon and fluorine from maleic anhydride, dihydroxy fluorine silicone, DOPO (9-10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), terephthalic acid and ethylene glycol by addition, esterification and polycondensation reaction in the presence of an esterification catalyst, a polycondensation catalyst and a stabilizing agent; and mixing the prepared flame-retardant copolyester sections of phosphorus, silicon and fluorine with a polyester section, carrying out melt extrusion by an extruder and preparing the flame-retardant copolyester film product of phosphorus, silicon and fluorine by longitudinally drawing, laterally drawing and hot setting treatment. The preparation method disclosed by the invention is simple in reaction process, strong in operability, easy in technological condition control and low in production cost, and shortens the production time and cycle of multivariate copolymerization synthesis; and the flame-retardant property of the product can be up to VTM-0 level.

Owner:四川东方绝缘材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com