Applications of cyclic phosphorus-nitrogen synergic halogen-free flame retardant

A flame retardant, phosphorus nitrogen technology, applied in the field of new halogen-free flame retardant polymer material synthesis, can solve the problems of affecting the immune and regeneration system, secondary pollution, more smoke and toxic corrosive gases, etc., to achieve market application prospects Wide, good symmetry, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A cyclic phosphorus-nitrogen synergistic halogen-free flame retardant, the name is: 2,7-bis(N,N-dimethylamino)-1,6,3,8,2,7-octahydrodioxin Azole diphosphonic acid; the structure of this compound is shown below:

[0043]

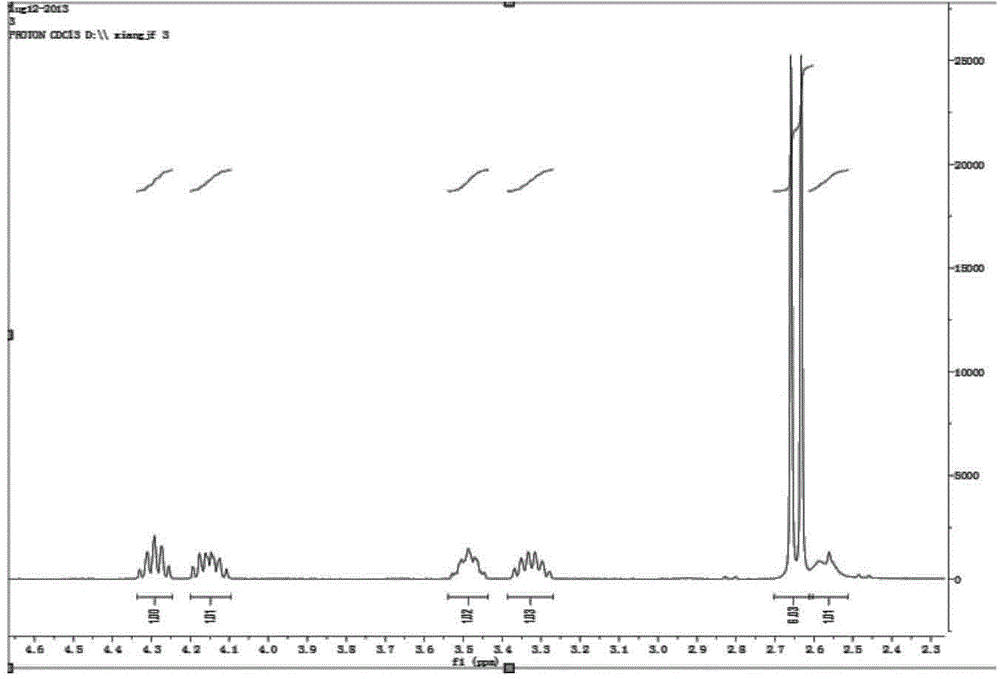

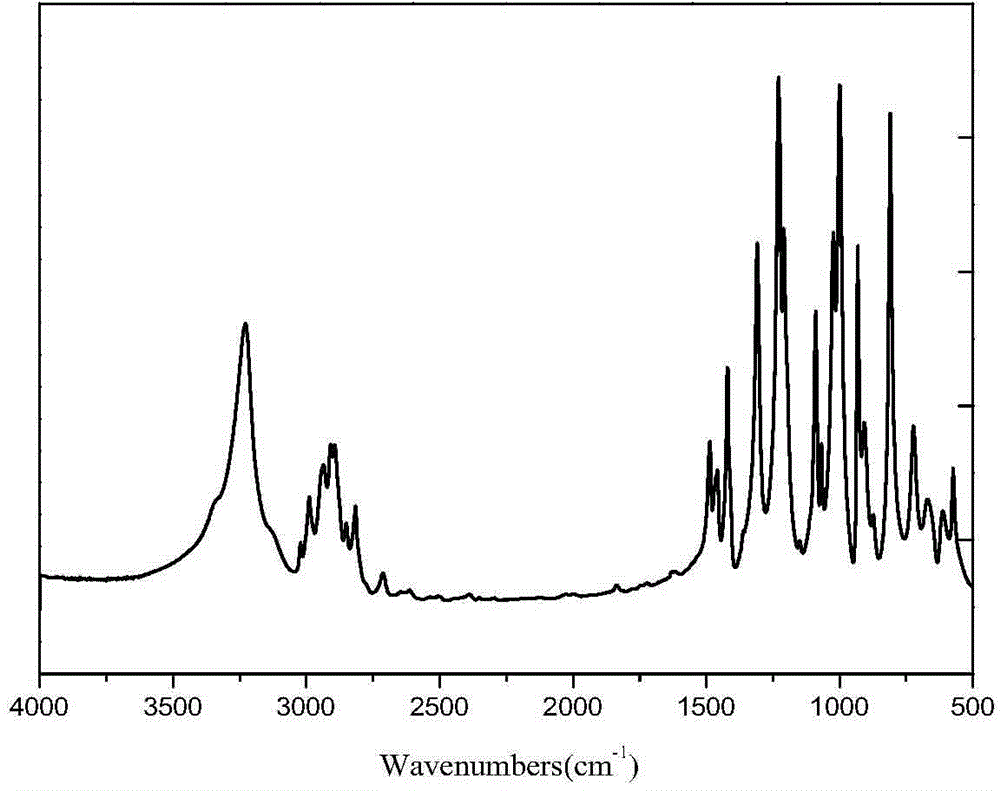

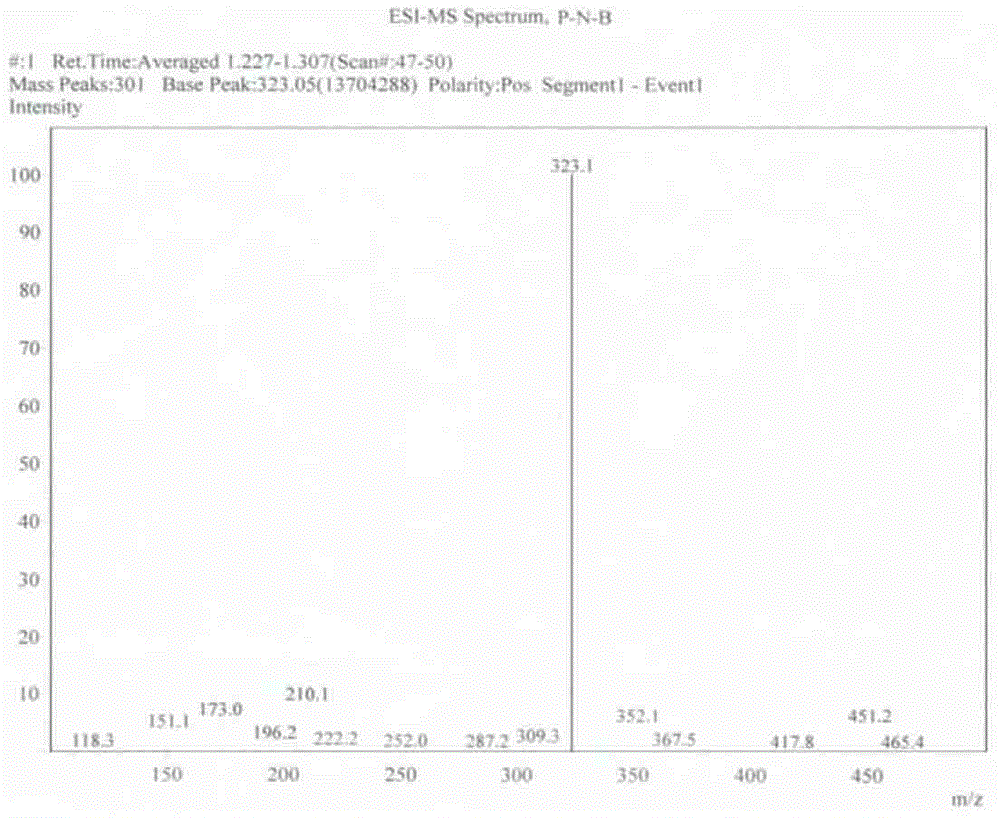

[0044] 2,7-bis(N,N-dimethylamino)-1,6,3,8,2,7-octahydrodioxadiazole diphosphonic acid is a white or light yellow solid, and the product yield is 35 %~50%, the melting point is 88,7℃, the temperature at the maximum decomposition rate of thermal weight loss is 198.14℃, the percentages of P, N, H, and C in the molecular structure are 20.66%, 18.66%, 7.33% and 32%, respectively , It is suitable as flame retardant or chain extender for polymer materials. Such as figure 1 , figure 2 , image 3 Shown figure 1 Said, 3264cm -1 N-H stretching vibration absorption peak at the place; 2930~2894cm -1 At -CH 2- CH 2 Absorption peak of stretching vibration; 1394cm -1 The stretching vibration absorption peak of -P-NH; 1213.99cm -1 , 1310.41cm -1 , 1004cm -1 They are th...

Embodiment 2

[0048] A cyclic phosphorus-nitrogen synergistic halogen-free flame retardant, the name is: 2,7-bis(N,N-dimethylamino)-1,6,3,8,2,7-octahydrodioxin Azole diphosphonic acid; the structure of this compound is shown below:

[0049]

[0050] 2,7-bis(N,N-dimethylamino)-1,6,3,8,2,7-octahydrodioxadiazole diphosphonic acid is a white or light yellow solid, and the product yield is 35 %~50%, the melting point is 88,7℃, the temperature at the maximum decomposition rate of thermal weight loss is 198.14℃, the percentages of P, N, H, and C in the molecular structure are 20.66%, 18.66%, 7.33% and 32%, respectively It is suitable as flame retardant or chain extender for polymer materials.

[0051] In a reactor equipped with an argon protection device, a thermometer, and a feeder, add 0.15 mol of phosphorus oxychloride and 0.1 mol of dimethylamine hydrochloride, while adding 150 ml of toluene as a solvent, and 0.25 mol of triethylamine to the feeder Under magnetic stirring, triethylamine was slowl...

Embodiment 3

[0054] A cyclic phosphorus-nitrogen synergistic halogen-free flame retardant, the name is: 2,7-bis(N,N-dimethylamino)-1,6,3,8,2,7-octahydrodioxin Azole diphosphonic acid; the structure of this compound is shown below:

[0055]

[0056] 2,7-bis(N,N-dimethylamino)-1,6,3,8,2,7-octahydrodioxadiazole diphosphonic acid is a white or light yellow solid, and the product yield is 35 %~50%, the melting point is 88,7℃, the temperature at the maximum decomposition rate of thermal weight loss is 198.14℃, the percentages of P, N, H, and C in the molecular structure are 20.66%, 18.66%, 7.33% and 32%, respectively It is suitable as a flame retardant or chain extender for polymer materials.

[0057] With N 2 In the reactor of the protective device, thermometer, and feeder, add 0.6 mol of phosphorus oxychloride and 0.4 mol of dimethylamine hydrochloride, while adding 300 ml of ethyl acetate as a solvent, and put 0.9 mol of triethylamine in the feeder. Under magnetic stirring, triethylamine was slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com