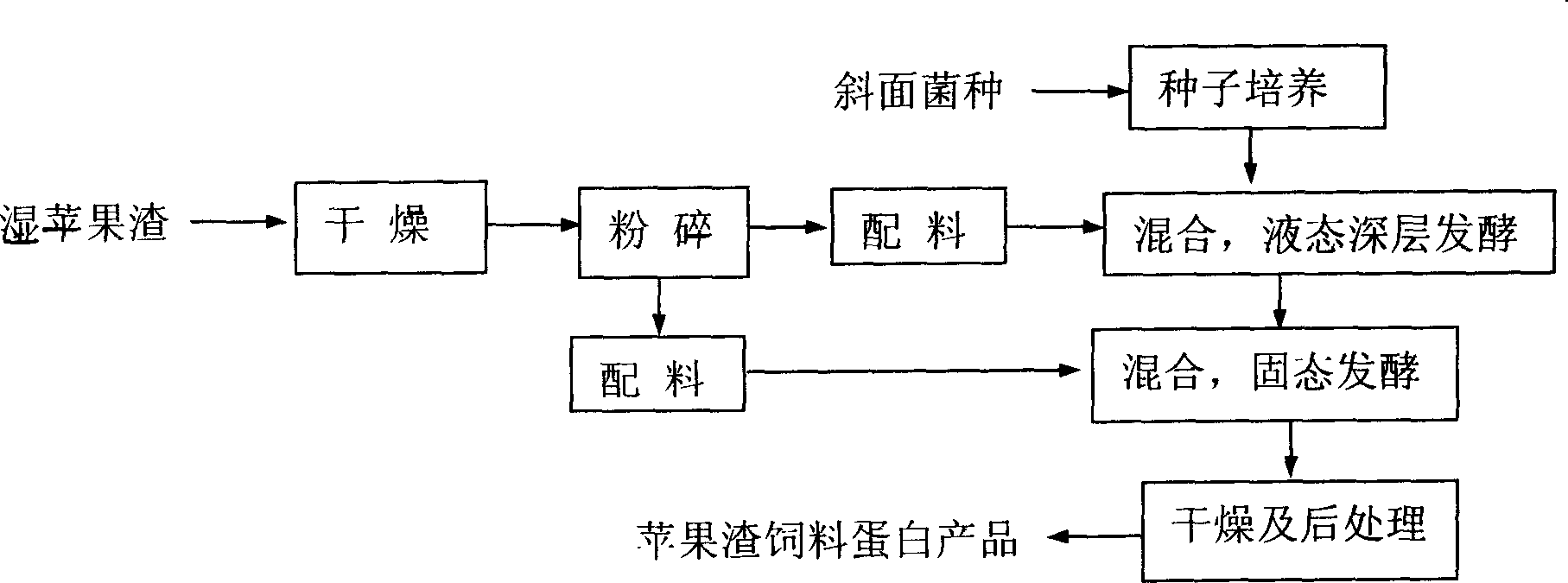

Method for manufacturing feedstuff protein by solid state fermentation of apple dregs liquid

A feed protein and solid-state fermentation technology, applied in animal feed, animal feed, application, etc., can solve the problems of high equipment investment and production costs, large amount of seed medium consumption, complicated pure culture of bacteria, etc., and achieve high equipment utilization rate , shorten the fermentation time and production cycle, and reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Seed medium: 200g of potatoes, 20g of sucrose, some water; the production method is as follows: cut the potatoes into small pieces, add an appropriate amount of tap water to boil for 20-30min, filter, take the filtrate and add tap water to 1000mL.

[0035] Cultivation of seed strains: Take 300mL seed culture medium and put it into a 500mL conical flask and keep it at 121°C for 20min to sterilize. Cultivate at 140 rpm for 36-54 hours to obtain mature seed strains.

[0036] The liquid submerged fermentation medium consists of: dry apple pomace 90%, sucrose 5%, urea 2%, (NH 4 ) 2 SO 42%, KH 2 PO 4 1%. And add 10 times the water of solid material.

[0037] The mixed strains and ratios of the access: Candida utilis: Trichoderma viride: Saccharomyces cerevisiae=4:3:1.5,

[0038] The solid medium consists of: dry apple pomace 75%, bran 20%, urea 2%, (NH 4 ) 2 SO 4 2%, KH 2 PO 4 1%, add water to adjust the initial water content to 60%.

[0039] Fresh and wet app...

Embodiment 2

[0067] Fresh and wet apple pomace is dried at 65°C by a hot air drying line, crushed and sieved, and the 40-mesh raw material is put into a large-scale fermentation tank according to a liquid fermentation medium. The composition of the liquid fermentation medium is: 90% dried apple pomace, 4% sucrose , urea 2%, (NH 4 ) 2 SO 4 2%, KH 2 PO 4 2%, and add 12 times the moisture of the solid material. Simultaneously by the amount of 8% (v / v) access seed tank to cultivate mature mixed strains, the strain ratio of its access: Candida utilis: Trichoderma viride: Fruit wine yeast: Trichoderma korning=2: 1.5 : 6: 3, under 33 ℃, liquid submerged fermentation 36h, then the fermented liquid is poured into the prepared apple pomace solid medium by the amount of 20mL / 100g solid substrate, the composition of culture medium is: dried apple pomace 84% , bran 10%, urea 3%, (NH 4 ) 2 SO 4 2%, KH 2 PO 4 1%. Under the condition of non-sterile water content of 70%, solid-state culture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com