Patents

Literature

447results about How to "Improve equipment utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

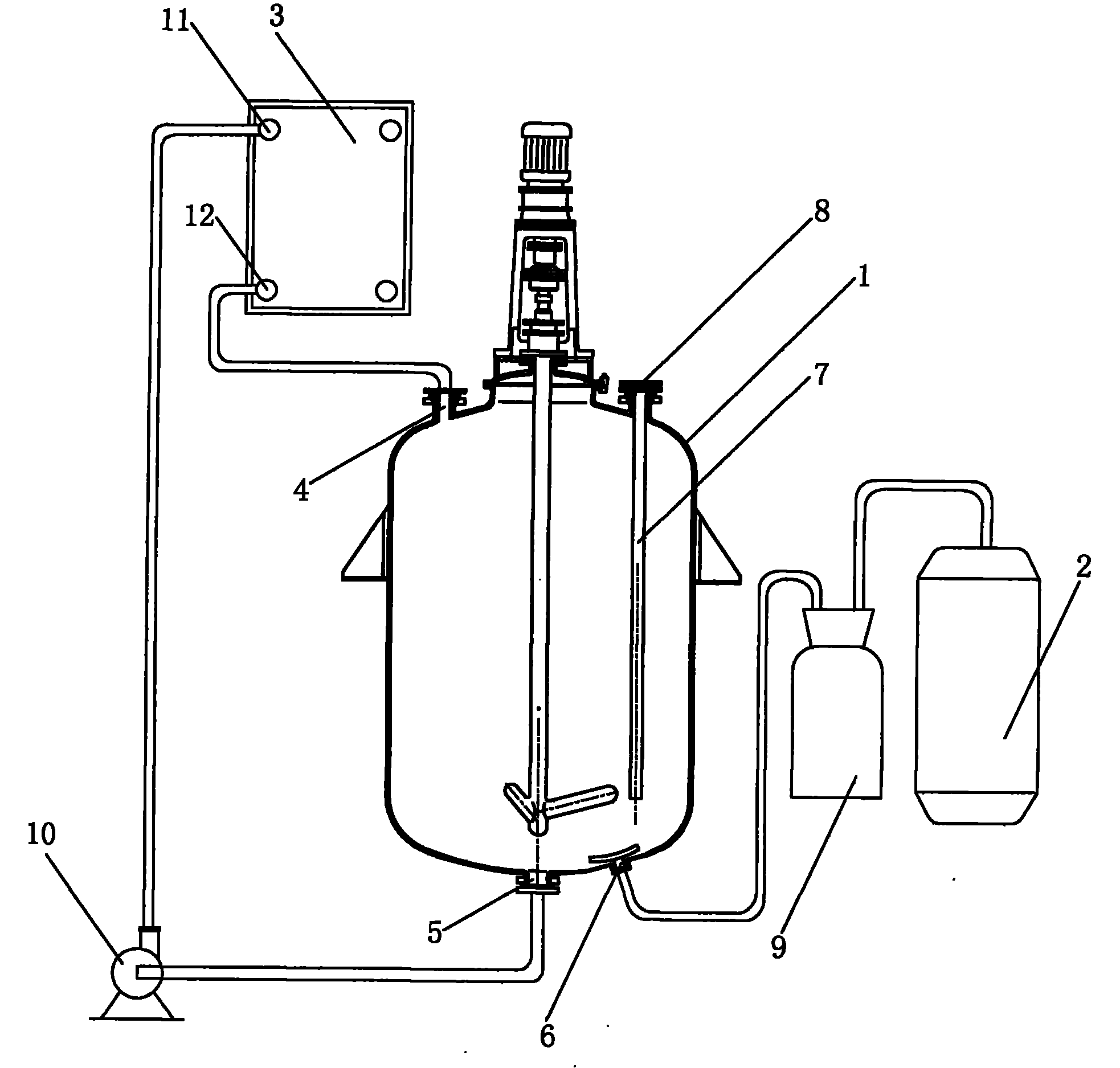

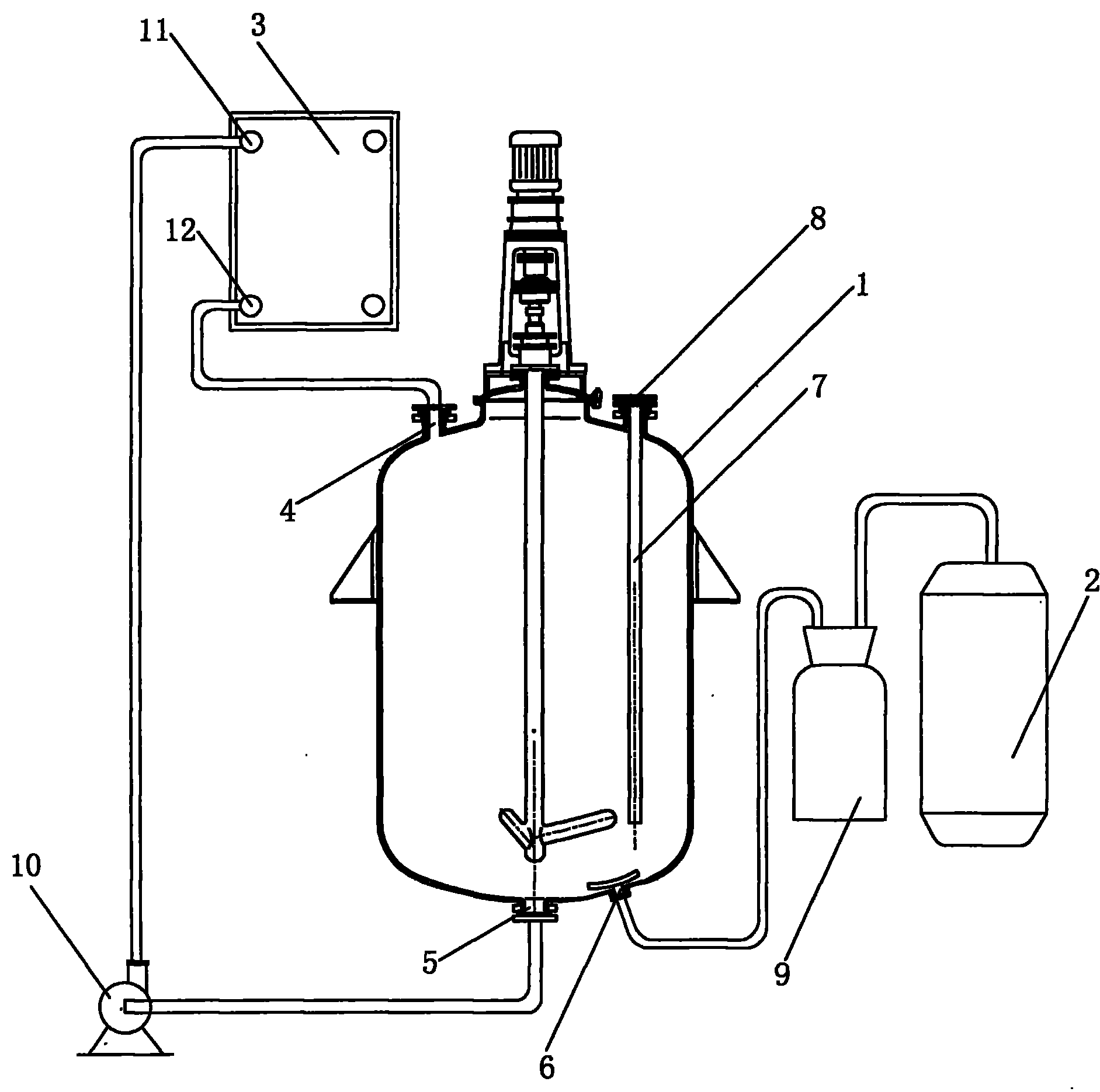

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

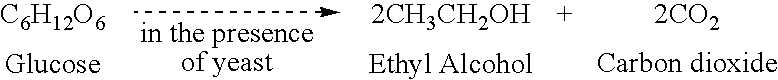

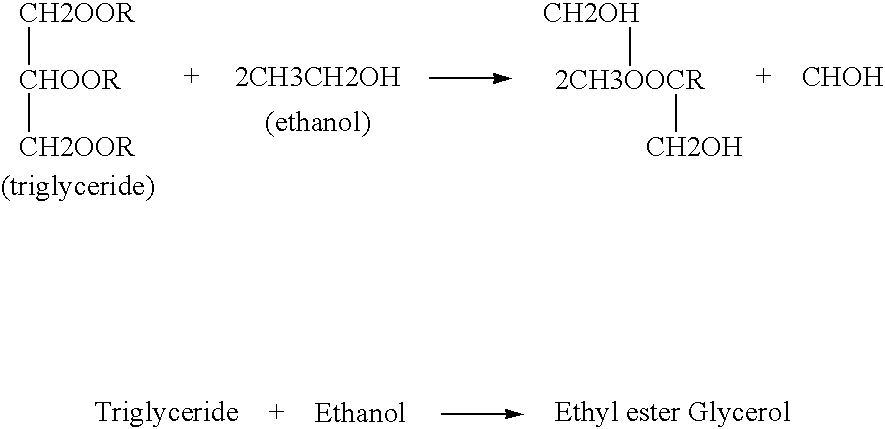

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

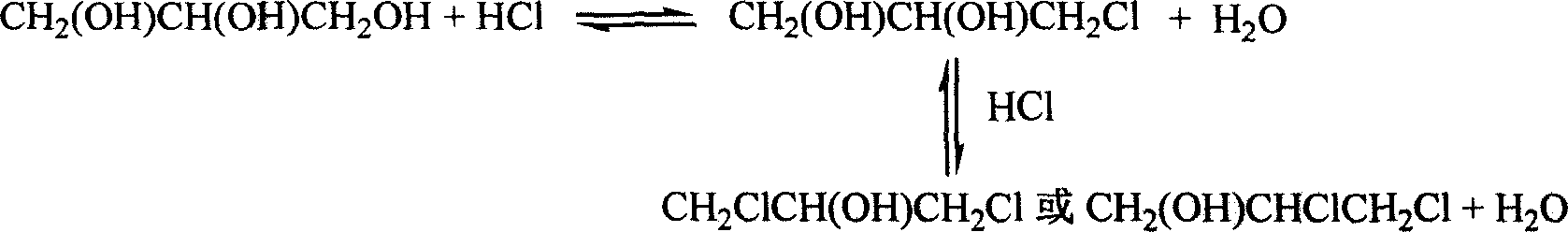

Preparation method of dichloro propanol from glycerin

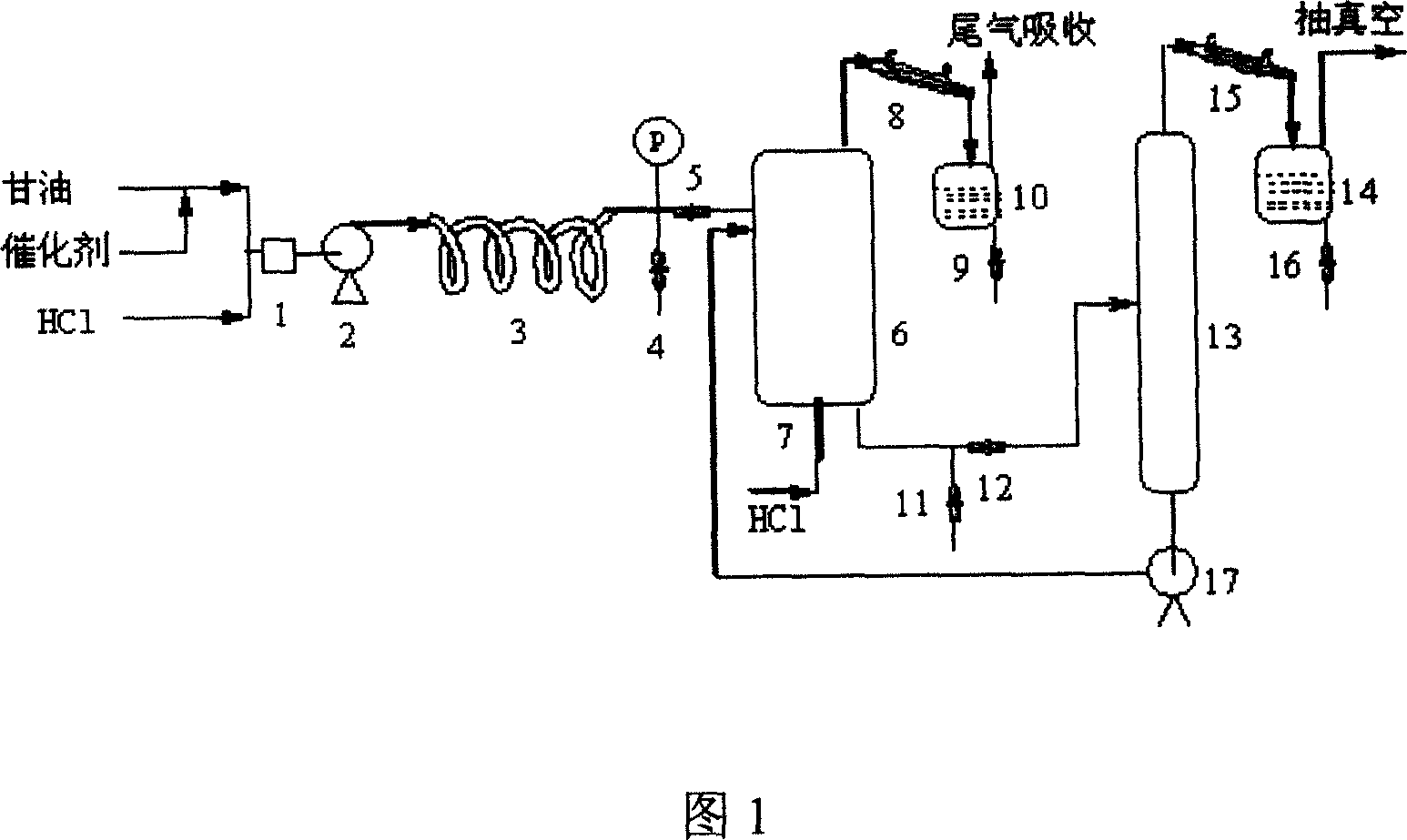

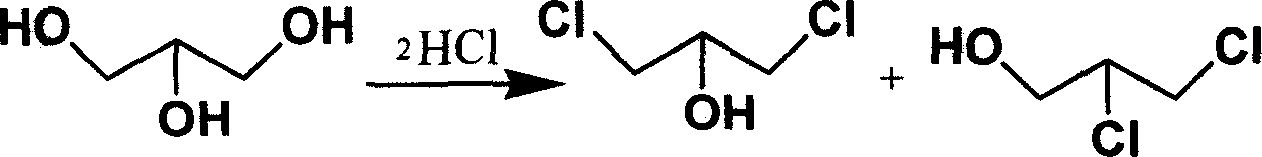

ActiveCN101007751AIncrease reaction rateImprove equipment utilizationOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by halogen introductionPropanolGlycerol

The invention discloses a preparing method of dichlorohydrin from glycerol, which comprises the following steps: adding glycerol and HCl and carboxyl acid activator into mixer; charging into tubular reactor continually to proceed chlorination reaction; reacting through chlorination reaction; transforming glycerol swiftly; entering into HCl bubbling still to react continually; evaporating azeotropic material comprised by water through reaction, dichlorohydrin, HCl and part of activator from the top of bubbling still; recycling product through condensation; separating liquid of bubbling still in the fractionating tower; getting dichlorohydrin from the top of fractionating tower; delivering liquid of fractionating tower to proceed circular response.

Owner:溧阳常大技术转移中心有限公司

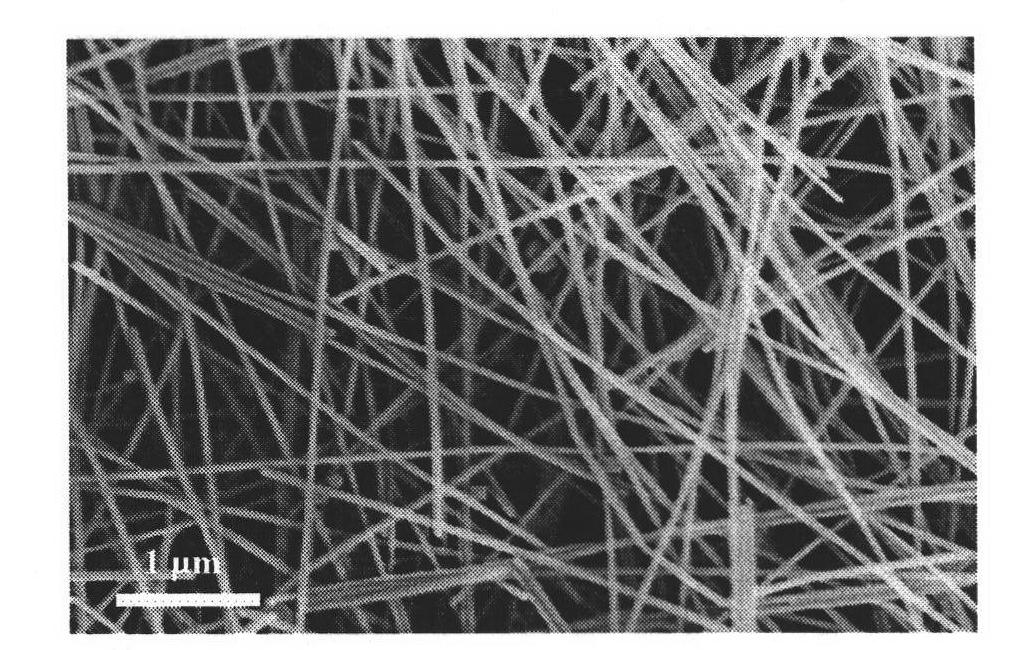

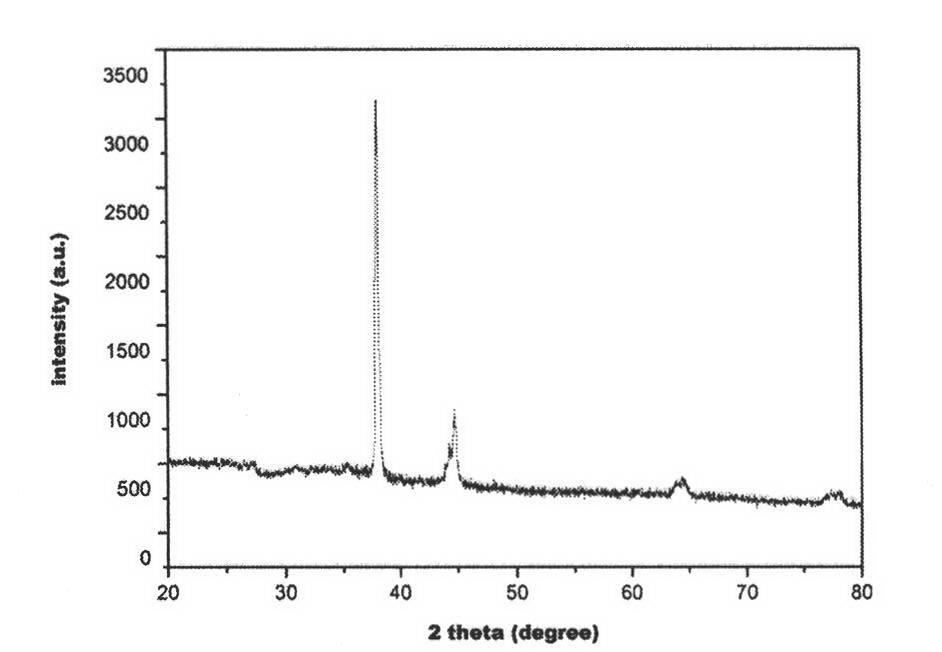

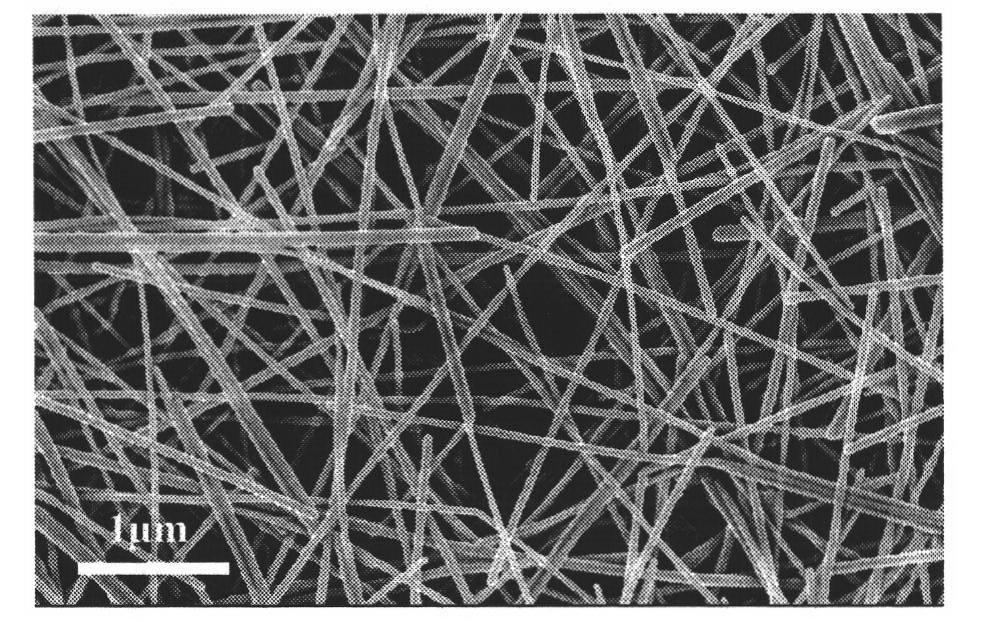

High-concentration fast preparation method for silver nanowires

InactiveCN101934378AShort reaction timeImprove reaction efficiency and equipment utilizationCopper chlorideMother liquor

The invention discloses a high-concentration fast preparation method for silver nanowires. The method comprises the following steps of: under the protection of inert gas, adding high-concentration silver nitrate glycol solution and polymer glycol solution into pre-heated glycol solution, and adding copper chloride serving as control agent at the same time so as to obtain mother liquor of the silver nanowires; and performing centrifugal separation and purification on the mother liquor so as to obtain pure silver nanowires diffused in ethanol solution. The high-concentration fast preparation method for silver nanowires has the advantages of high efficiency, low cost, simple process, high repeatability, high stability, fast reaction, high yield and adjustable and controllable shape and size of the silver nanowires, and makes the large-scale fast preparation and the application and research of the silver nanowires possible.

Owner:ZHEJIANG UNIV

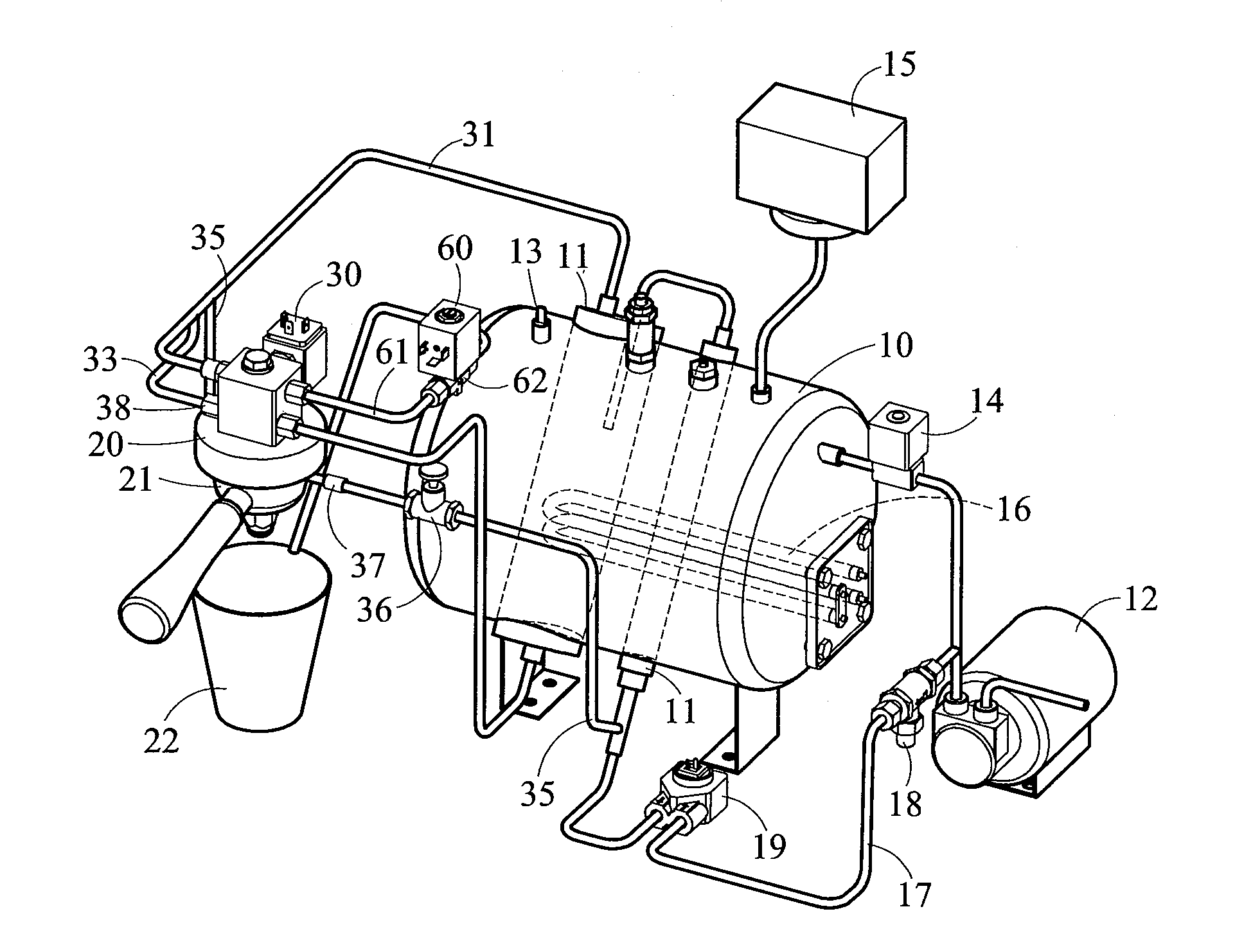

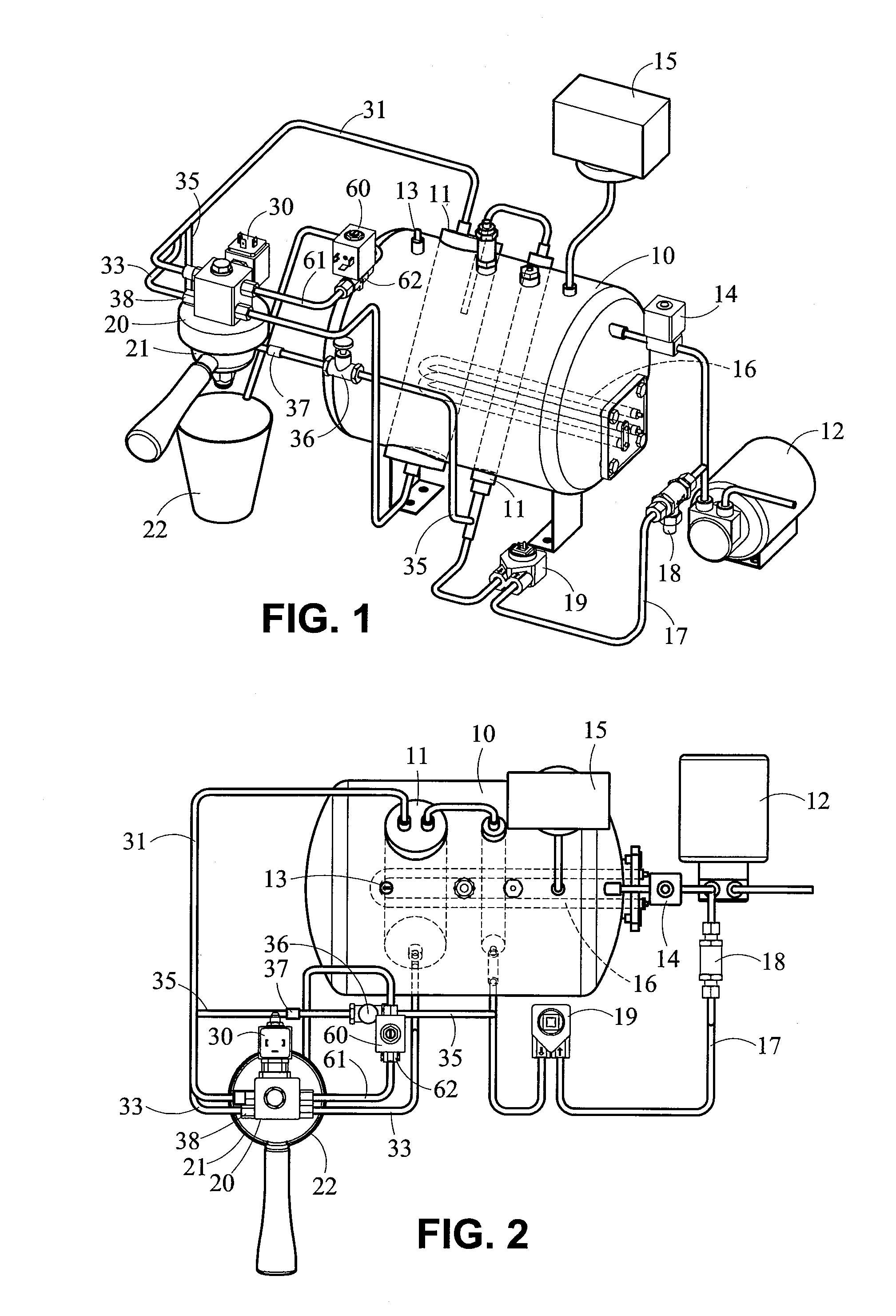

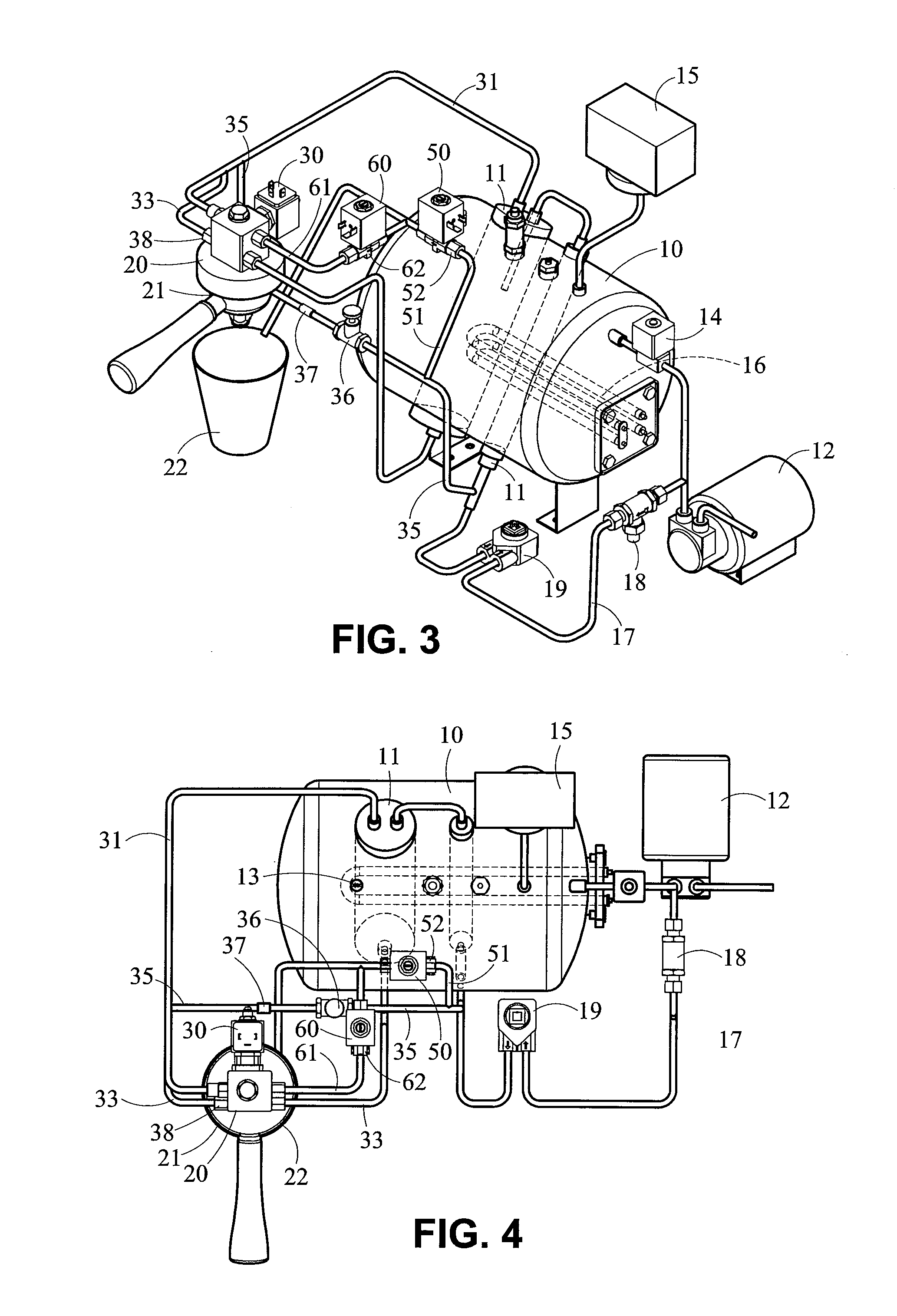

Beverage preparing apparatus

A beverage preparing apparatus mixes hot water from a hot water pipe with cold water from a cold water pipe to produce a mixed water flow with an appropriate temperature to be delivered to a liquid dispenser. When a brewing solenoid valve is opened, the liquid dispenser delivers the mixed water flow to a preparing container that contains a beverage composition to prepare a beverage. When the brewing solenoid valve is shut, the liquid dispenser delivers the mixed water flow into a hot water inlet pipe. When a hot water inlet solenoid valve is opened, the mixed water flow is added into the beverage directly. When the brewing solenoid valve and hot water inlet solenoid valve are shut, the hot water in the heat exchanger is vaporized and passed through a pre-heating circulation pipeline to pre-heat the liquid dispenser and returned to a heat exchanger to constitute a pre-heating circulation.

Owner:LIU TSUNG HSI

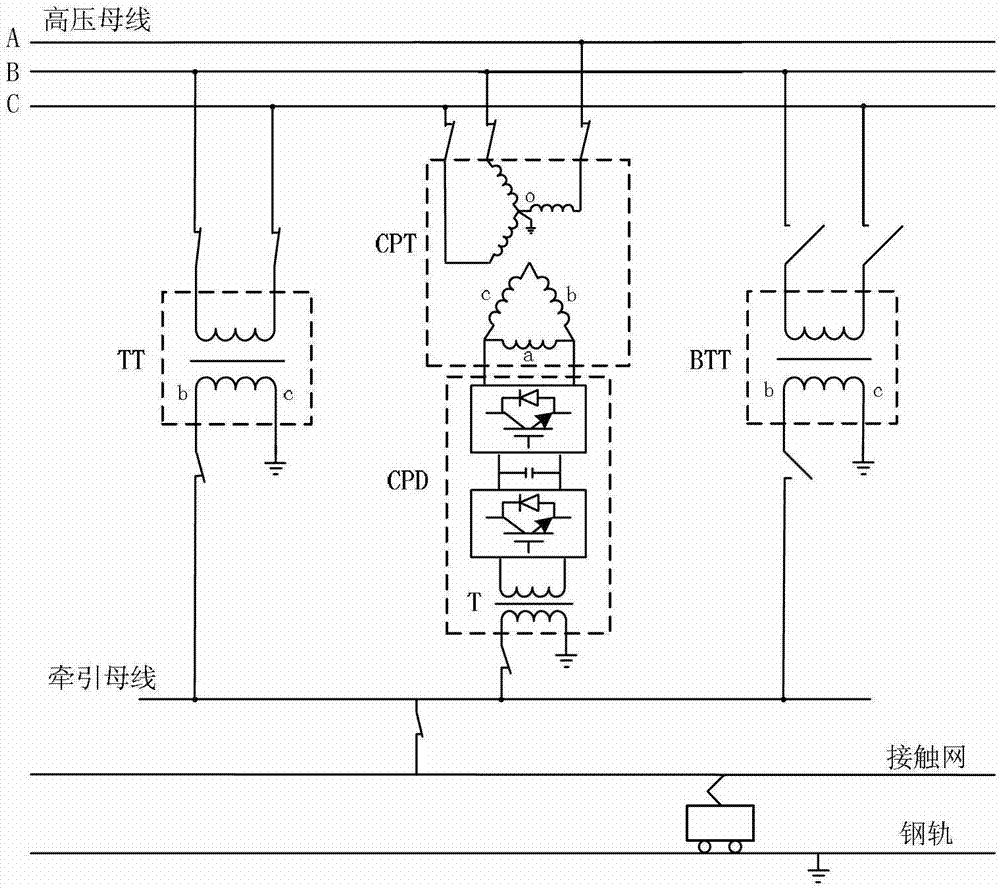

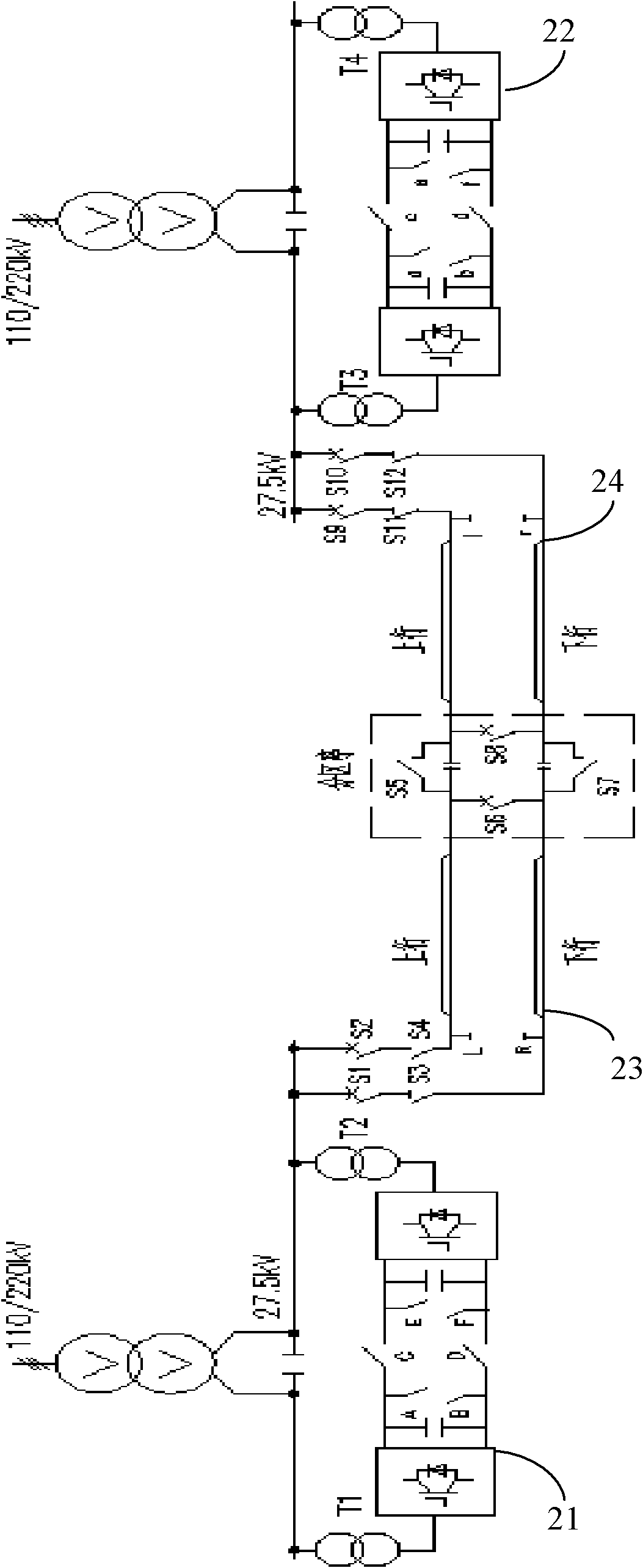

Single-phase and three-phase combined in-phase power supply and transformation device

ActiveCN103078315AReduce capacityReduce its proportionPolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionPower qualityEngineering

The invention discloses a single-phase and three-phase combined in-phase power supply and transformation device which comprises a single-phase traction transformer, a three-phase YNd11 grounding compensation transformer and a single-phase in-phase compensation device thereof; the in-phase compensation device comprises an alternating current-direct current-alternating current (AC-DC-AC) converter; the traction transformer and the compensation transformer have equal effect to a three-phase and two-phase balance transformer with the phase of secondary side voltage being vertical; when in a normal state, the traction transformer, the compensation transformer and the in-phase compensation device jointly supply power for a transaction load by a specified proportion; when the compensation transformer or the in-phase compensation device exit the operation, the traction transformer can work independently in a short time; and a backup traction transformer can replace the traction transformer to work and can work on linear voltage different from that of the traction transformer. According to the device, the electric phase at the exit of a traction transformer substation can be canceled, so that the electric energy quality requirements mainly comprising the unbalance of three-phase voltage can be met, and the optimal configuration of traction power supply resources can be realized.

Owner:CHENGDU SHANGHUA ELECTRIC CO LTD

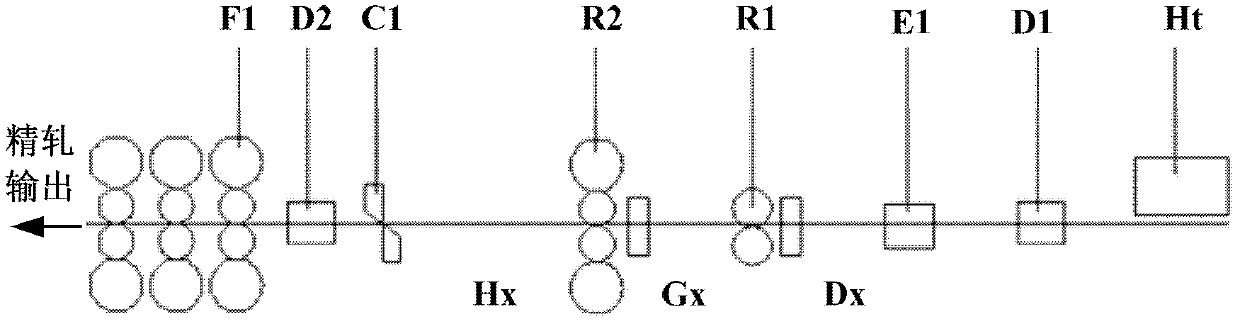

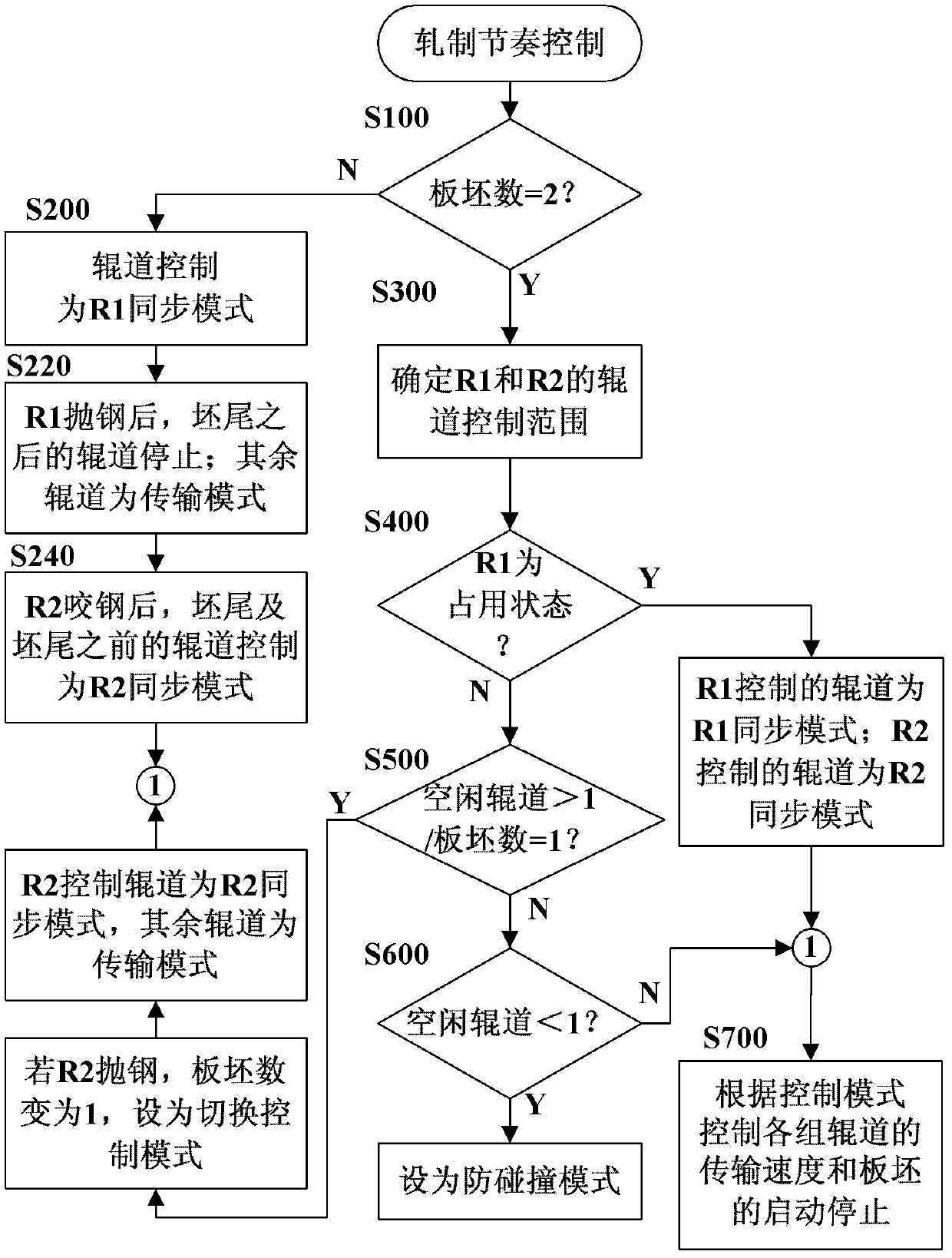

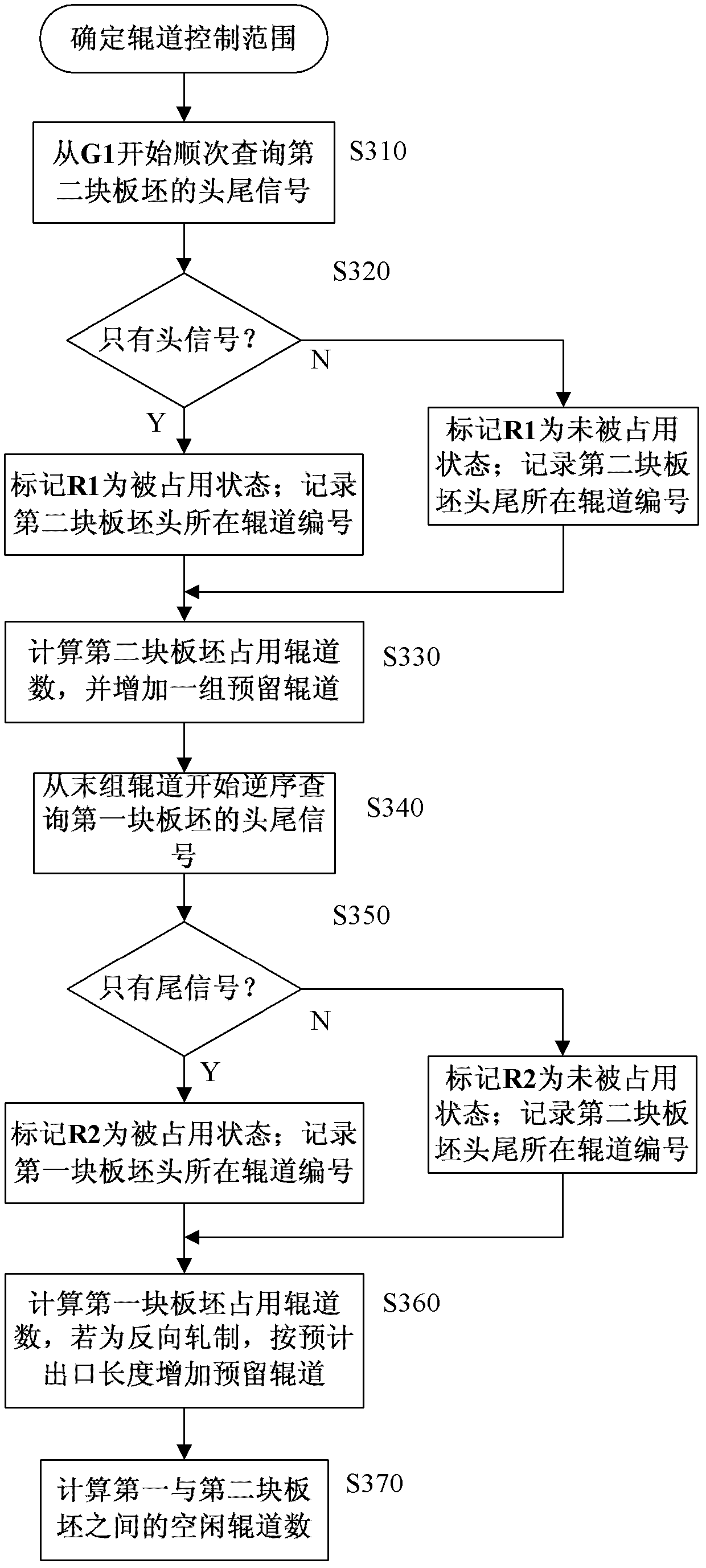

Control method for improving rolling pace of roughing mill

ActiveCN103372572AImprove rolling rhythmImprove equipment utilizationRoll mill control devicesMetal rolling arrangementsStrip millEngineering

The invention discloses a control method for improving rolling pace of a roughing mill and relates to a control device or method which is specially applicable to a metal rolling mill or machined products of the metal rolling mill. Plate blank head and plate blank tail detection devices are arranged on all groups of roller beds; according to detected plate blank head and plate blank tail signals, plate blank collision prevention conditions are set, and the occupancy state of a rack and the number of the idle roller beds are determined; according to the occupancy state of the rack and the number of the idle roller beds, control modes of the groups of roller beds are set; according to the plate blank collision prevention conditions and the control modes of the groups of roller beds, transmission speeds of the groups of roller beds are controlled respectively, and starting and stopping of a second plate blank are controlled to minimize the distance between a first plate blank and the second plate blank, so that the transmission time interval between the two plate blanks is minimized. By the aid of the method, the distance between the two adjacent machined plate blanks can be greatly shortened, so that the front and back rack production is closely connected, and the rolling pace of the rolling mill and the device utilization rate can be greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

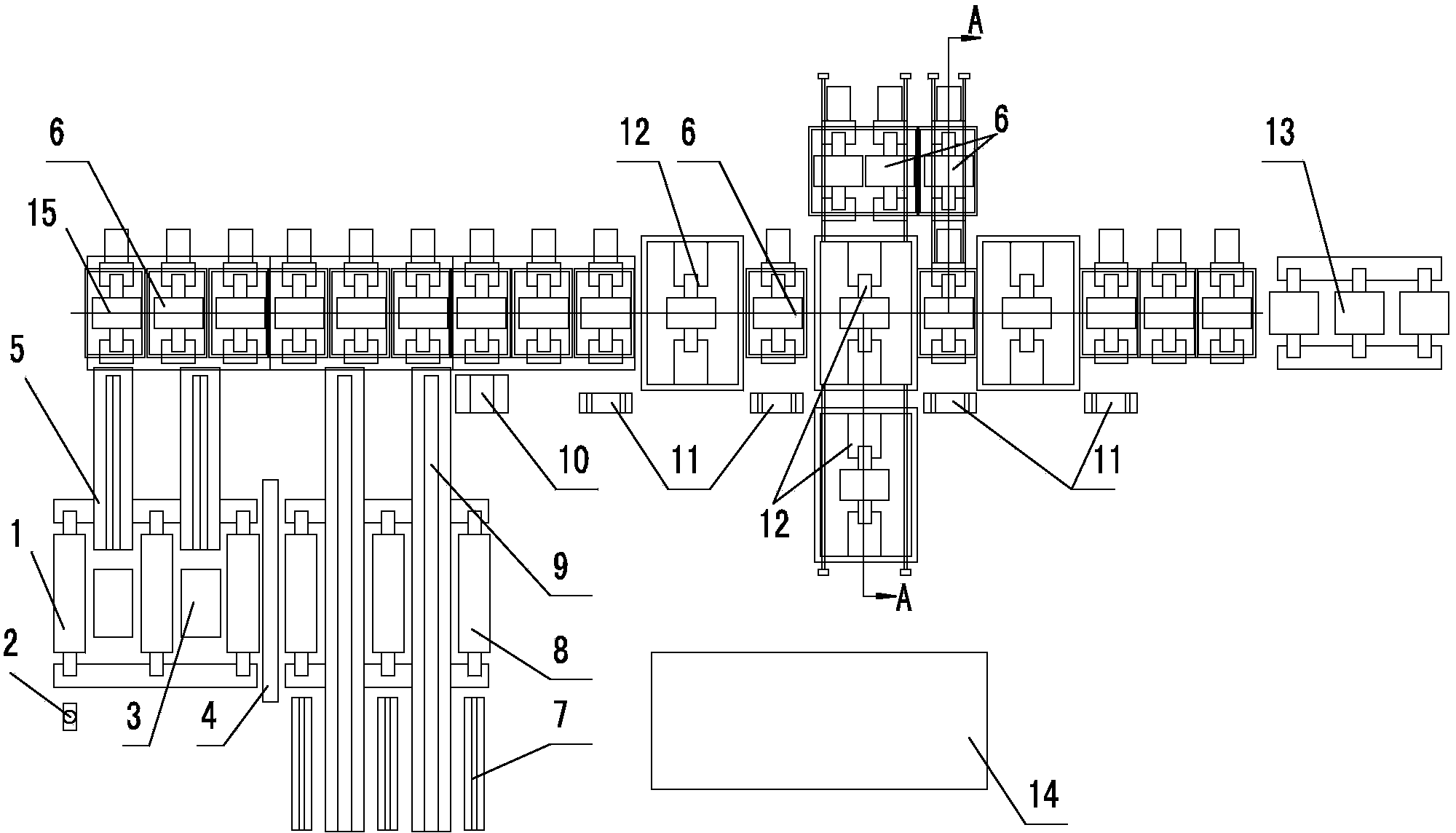

Continuous-casting and continuous-rolling integrating device and process

ActiveCN103464463AReduce heat lossIncrease profitTemperature control deviceMetal rolling arrangementsHeating timeEngineering

The invention relates to a continuous-casting and continuous-rolling integrating device and a continuous-casting and continuous-rolling integrating process. An ejection roller way in an ejection roller way ejection area and a transition roller way are linearly and continuously jointed and a moveable baffle plate which can automatically lift is arranged at the joint; the ejection roller way and a heat conveying roller way are jointed through a casting blank separating device with a heat-preserving device; a set of blank-separating collecting device which can move bi-directionally is jointly used between a cooling bed and the transition roller way as well as between the transition roller way and the heat conveying roller way and can drive casting blanks to bi-directionally move between the cooling bed and the transition roller way; a heater is arranged on the heat conveying roller way; the tail end of the heat conveying roller way is jointed with a rolling machine. According to heat conveying and rolling requirements, the casting blanks are selected, separated and collected, according to casting blank temperature data which is detected in real time, the heating temperature and the heating time are automatically adjusted, the casting blanks are heated to the temperature meeting the rolling requirement and are fed into the rolling machine to be rolled, the metal yield can be increased, the continuous-casting blank quality can be improved, the energy consumption can be reduced, the utilization efficiency, the maintenance rate and the production efficiency of equipment are improved, and the investment cost and the operation cost are reduced.

Owner:HUBEI CENT STEEL UNION METALLURGICAL ENG

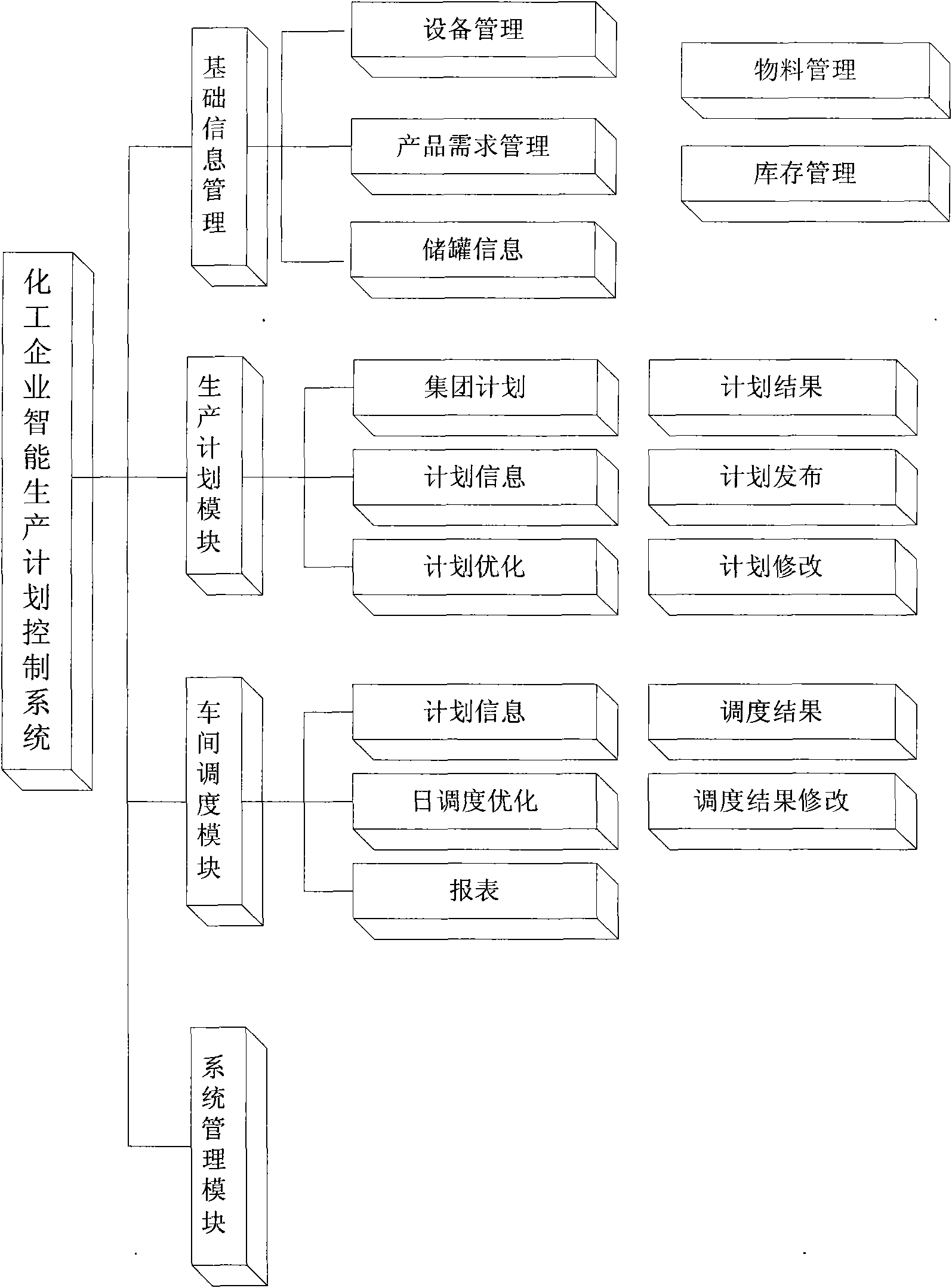

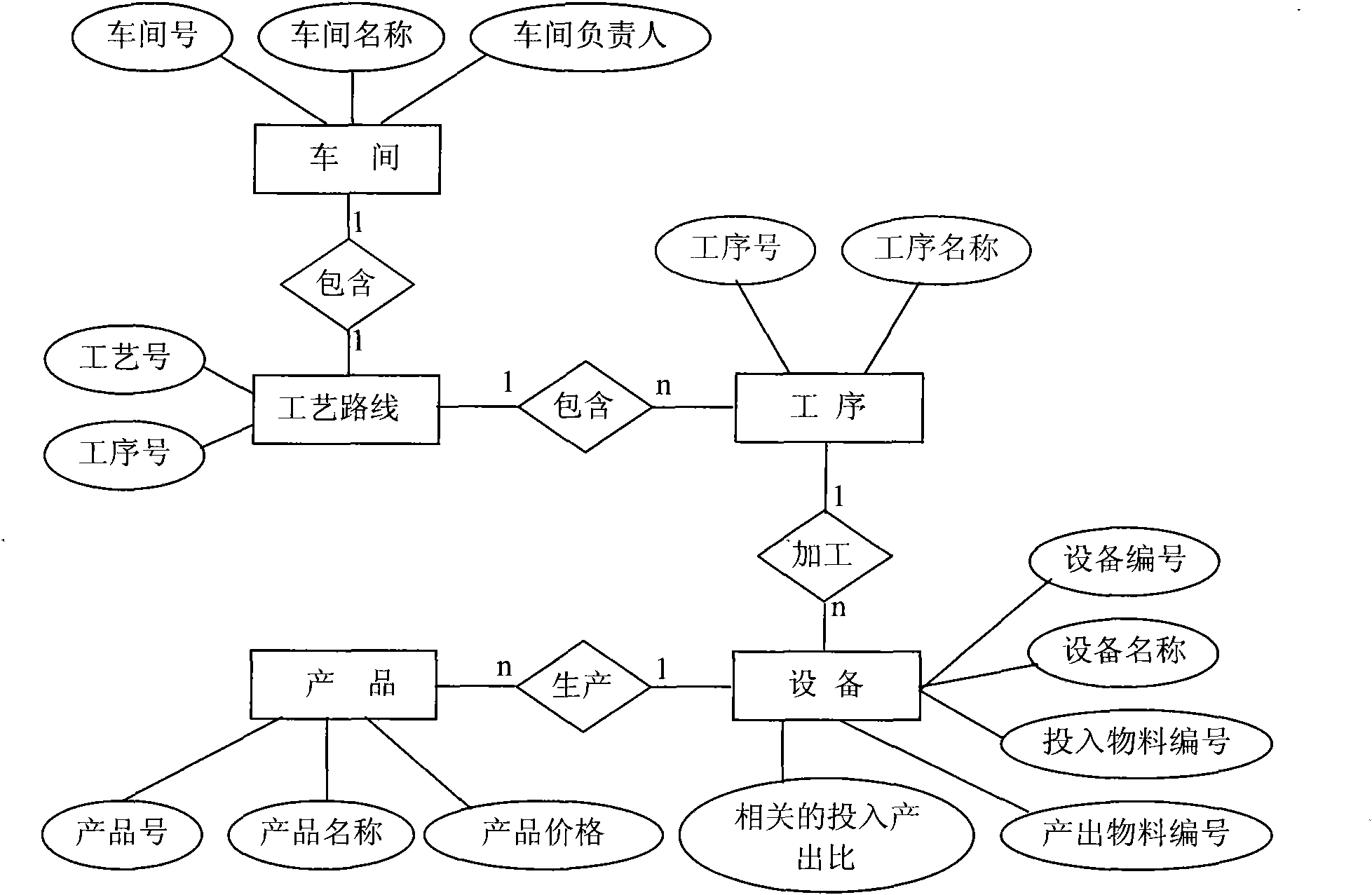

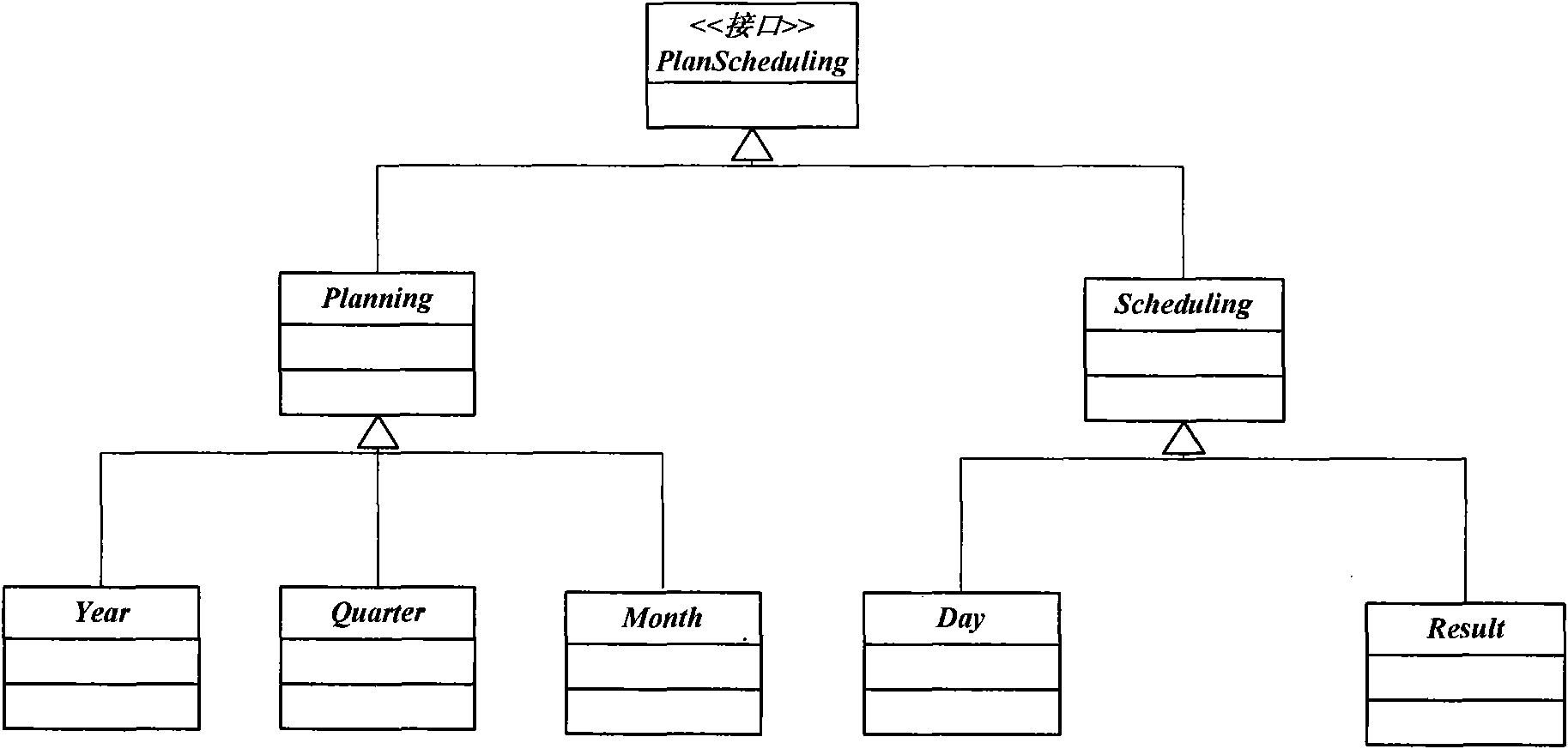

Chemical enterprise intelligent production plan control system based on quantum particle swarm algorithm

InactiveCN101604418AImprove efficiencyImprove resource utilizationComputing modelsResourcesProduction lineHypothesis

The invention relates to a chemical enterprise intelligent production plan control system based on quantum particle swarm algorithm. The control system comprises a production plan optimization module, a workshop intelligent dispatching module, a basic information management module, a system management module and a database. According to the characteristics of the production plan problems of a multistage multi-product multi-restriction mixed production line in a chemical enterprise, a model adopts the following hypotheses: (1) no permission of out of stock; (2) infinite product stock capacity; (3) raw material arrival date occurring at the beginning of each period of time, and product delivery date occurring at the end of each period of time; (4) stable production state, namely outputting products as long as raw materials are input during each working procedure; (5) selling surplus products at the current period of time when products meeting the demands; moreover, setting an objective function and calculating product output; and finally, and adopting quantum particle swarm algorithm to carry out model solution. The chemical enterprise intelligent production plan control system effectively combines various constraint conditions in a chemical enterprise and has high efficiency; moreover, the control system realizes effective sharing of the prior enterprise coordination production workshop to increase resource and equipment utilization rate.

Owner:ZHEJIANG UNIV OF TECH

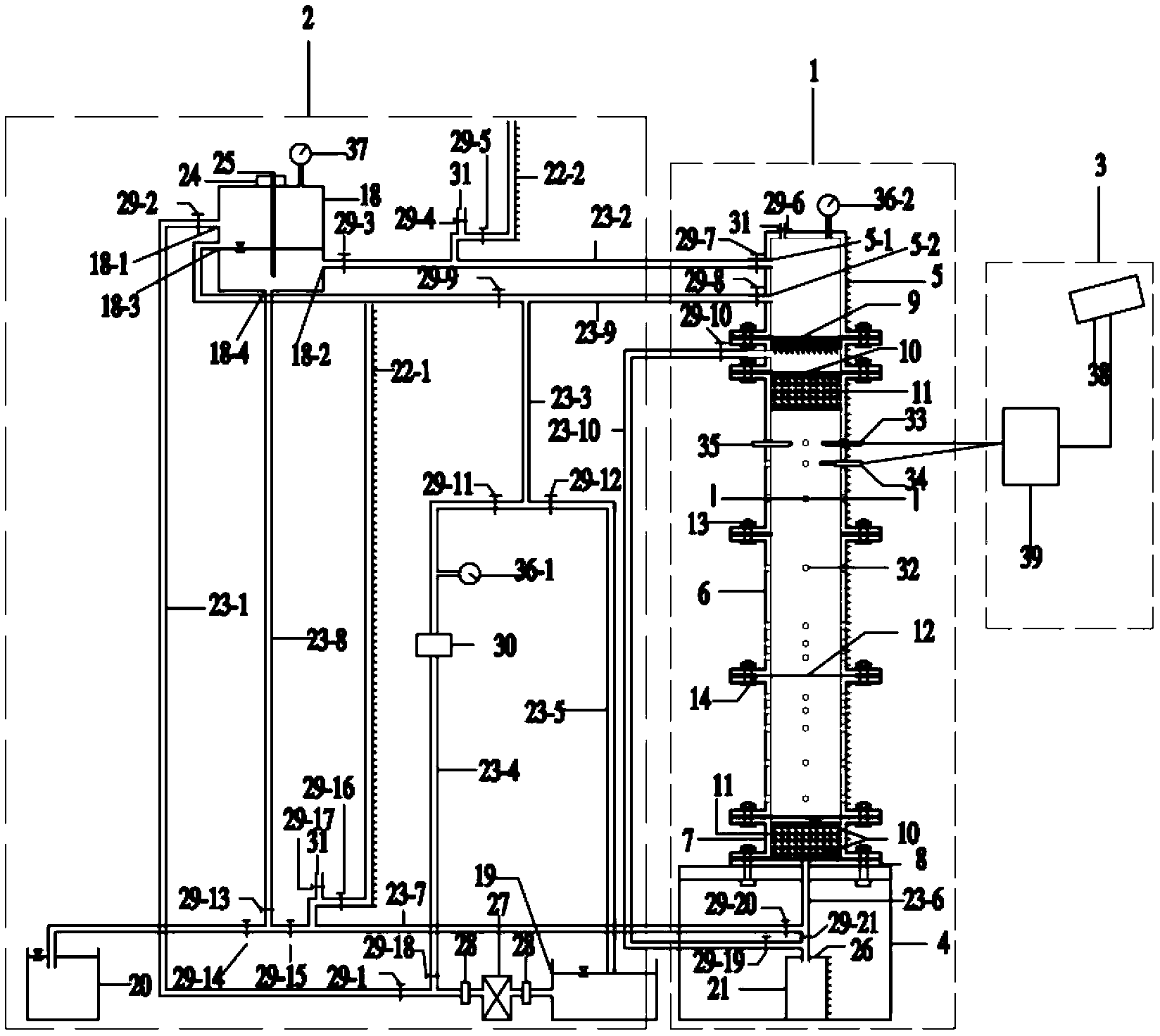

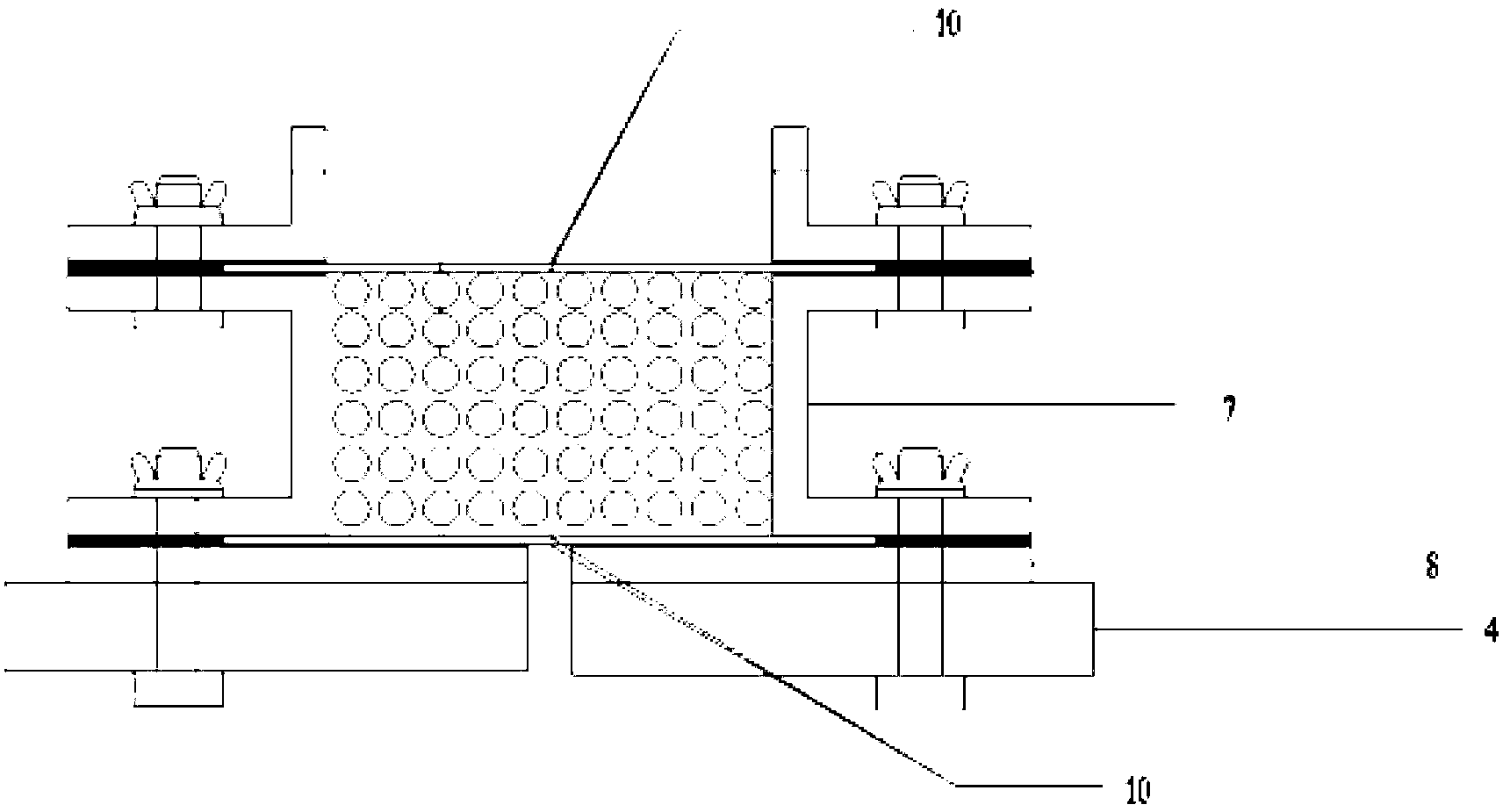

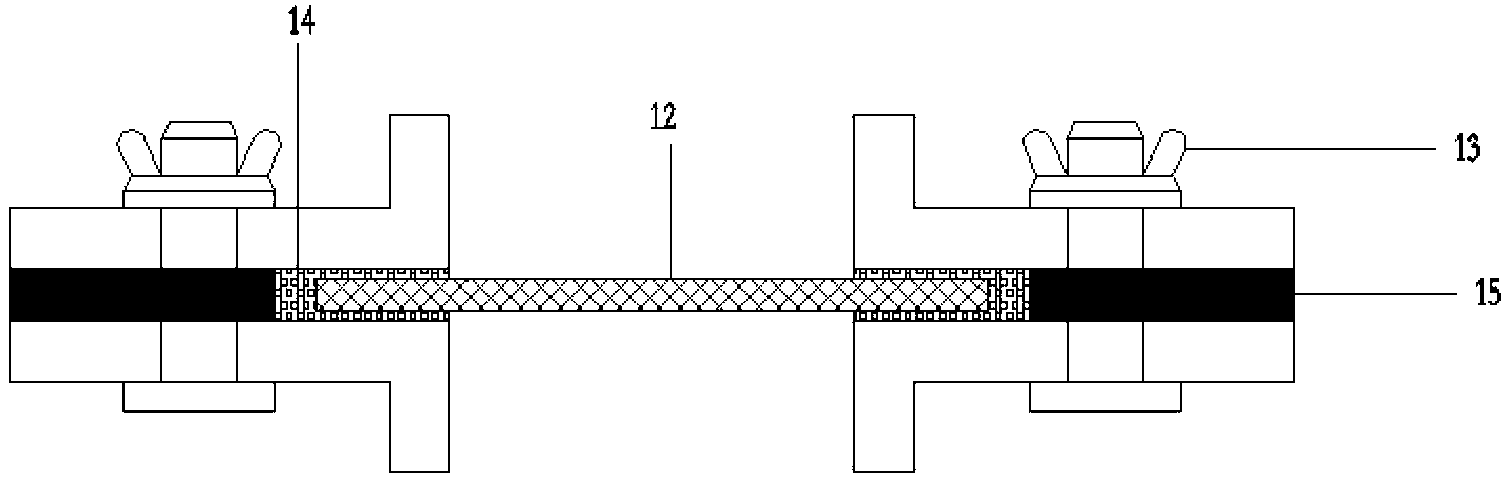

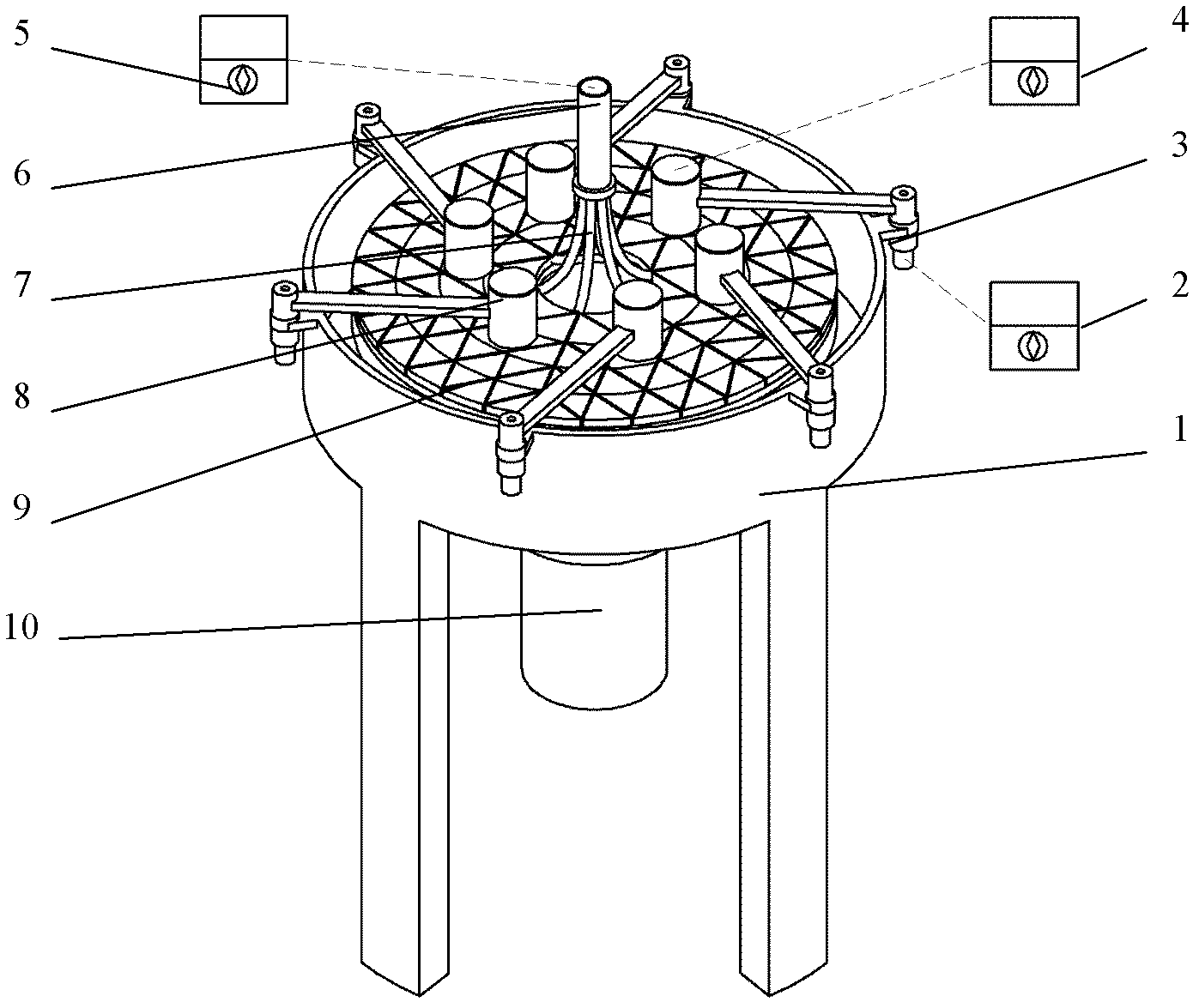

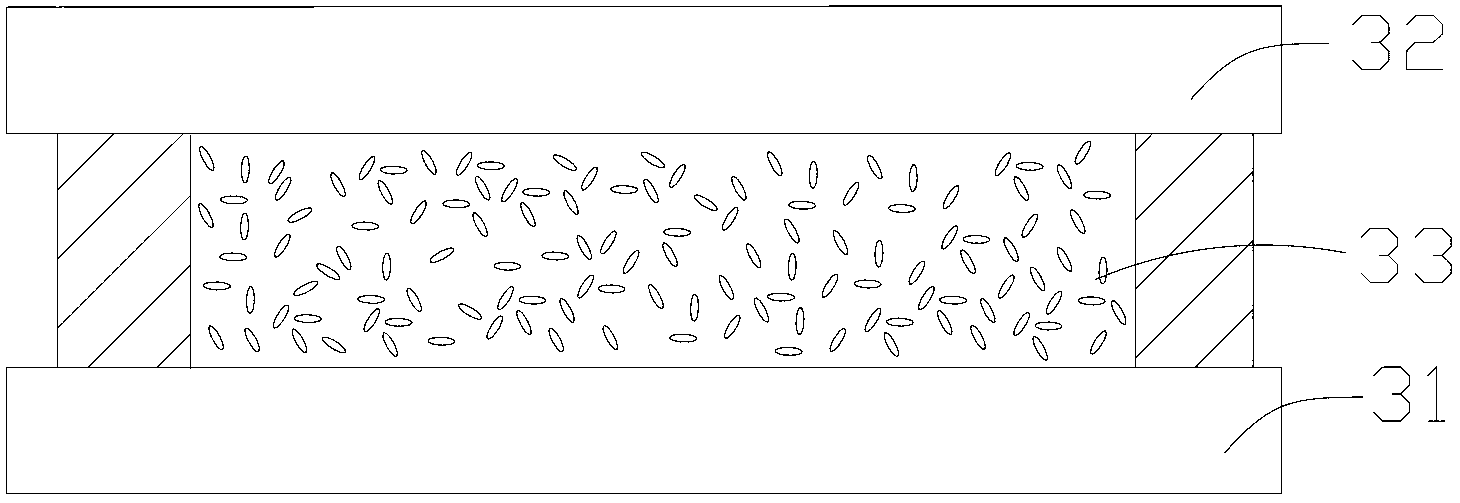

Modular soil body permeability tester

ActiveCN103308438AImprove equipment utilizationMedium sizePermeability/surface area analysisModularityWater cycle

The invention discloses a modular soil body permeability tester. The modular soil body permeability tester comprises a soil body seepage system, a seepage condition control system and a data acquisition system. According to the modular soil body permeability tester, different modular components are assembled to simulate various test conditions so as to scientifically and effectively research the seepage characteristics of a soil body. The modular components include a top box, an organic glass cylinder, a bottom box, an artificial rainfall module, a reversed filter component and the like. According to the modular soil body permeability tester, the mounting and the detaching are convenient, the preparation of samples is facilitated, and water is recycled in a seepage process, so that the water resource can be saved; besides, each modular component can be freely selected and arranged aiming at different research purposes, so that the tester has height expandability and can meet various test requirements; by utilizing a modular design idea, the tester has the advantages of diversity, economy, high efficiency, expandability and the like, and measured test parameters are accurate.

Owner:CHANGAN UNIV

Process for extracting heparin sodium from pig lung and co-producing polypeptide protein powder

InactiveCN102295711AImprove equipment utilizationSave raw materialsFermentationUltrafiltrationChemistry

A process for extracting heparin sodium from pig lungs and co-producing polypeptide protein powder. Two products of heparin sodium and polypeptide protein powder can be obtained at the same time with one feeding. It includes the following steps: (1) raw material pretreatment; (2) enzymatic hydrolysis; (3) salt hydrolysis twice; (4) slag (protein) removal and clear liquid collection; (5) ultrafiltration and concentration to remove ash; (6) Ammonium salt precipitation; (7) precipitation of heparin sodium, and vacuum drying to obtain crude heparin sodium; (8) enzymatic precipitation; (9) decolorization; (10) pressure filtration; (11) spray drying. The process is co-production, which has a higher utilization rate of equipment than a single production process, saves raw materials, auxiliary materials, and manpower, and can reduce the production cost of heparin sodium and polypeptide protein powder; make full use of my country's pig lung resources to increase the added value of pig lung; reduce protein-containing waste Liquid waste slag pollutes the environment, and turning waste into treasure is an effective way to supplement the shortage of protein feed resources in our country.

Owner:HUBEI BAODI AGRI TECH

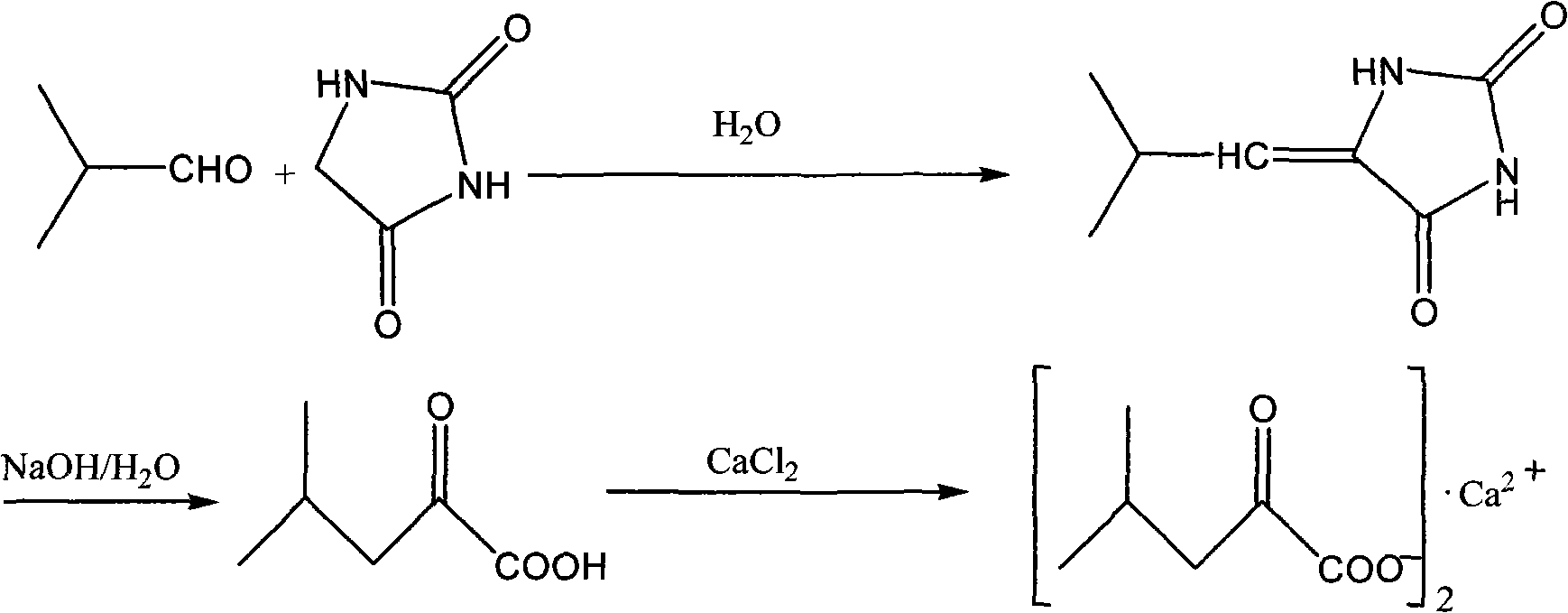

Alpha-keto-leucine-calcium preparation method

ActiveCN101607888AImprove equipment utilizationMild reaction conditionsOrganic compound preparationCarboxylic acid salt preparationSolventCalcium

The invention discloses an alpha-keto-leucine-calcium preparation method, comprise the following steps: mixing hydantoin, alkali and water and heating the solution, then dripping isobutylaldehyde to perform reflux reaction, cooling the solution after reflux reaction, adding strong alkali liquid and cooling the solution after reflux reaction, extracting and concentrating to obtaining raw liquid alpha-keto-leucine, dripping the raw alpha-keto-leucine in the alcoholic solution of calcium chloride to react and filtrating to obtain alpha-keto-leucine-calcium. The reaction mechanism is as follows: adopting hydantoin to perform condensation reaction with isobutylaldehyde in the presence of catalyst, namely alkali to obtain isobutylidene hydantoin, generating alpha-keto-leucine through hydrolysis in the presence of strong alkali and salifying to obtain alpha-keto-leucine-calcium. The invention adopts condensation reaction so that hydrolysis can be directly realized without separating isobutylidene hydantoin, the equipment utilization can be improved by 30%, the reaction condition is mild and the operation is easier; water is adopted as solvent, thus lowering the cost and waste water and reducing the pollution to the environment; in addition, the invention has accessible raw materials and stable product quality, the reaction yield is increased by 10% compared with that of the prior art, and the invention has no special requirement on the equipment, thus being applicable to the industrial production.

Owner:HEBEI YIPIN PHARMA

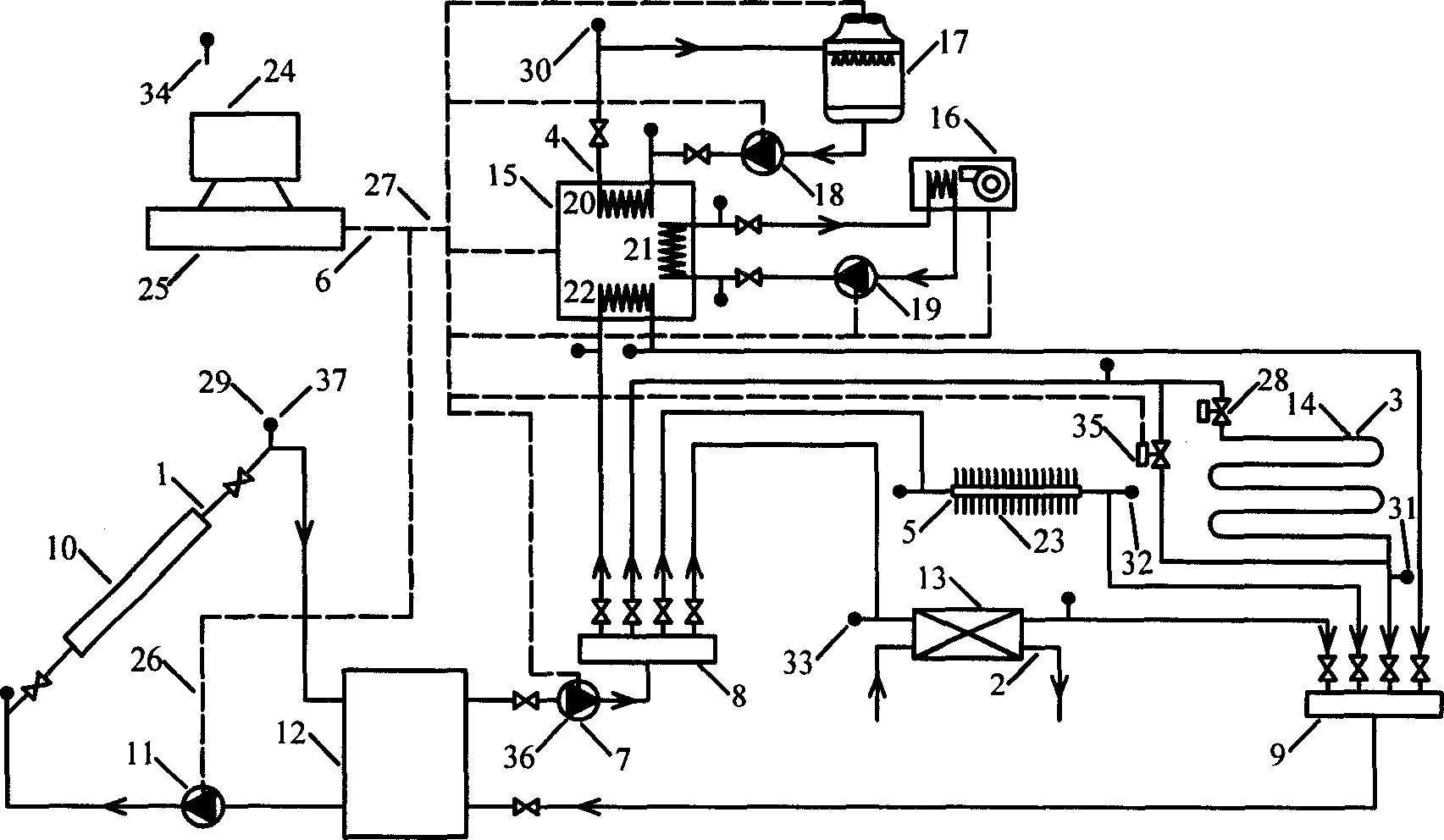

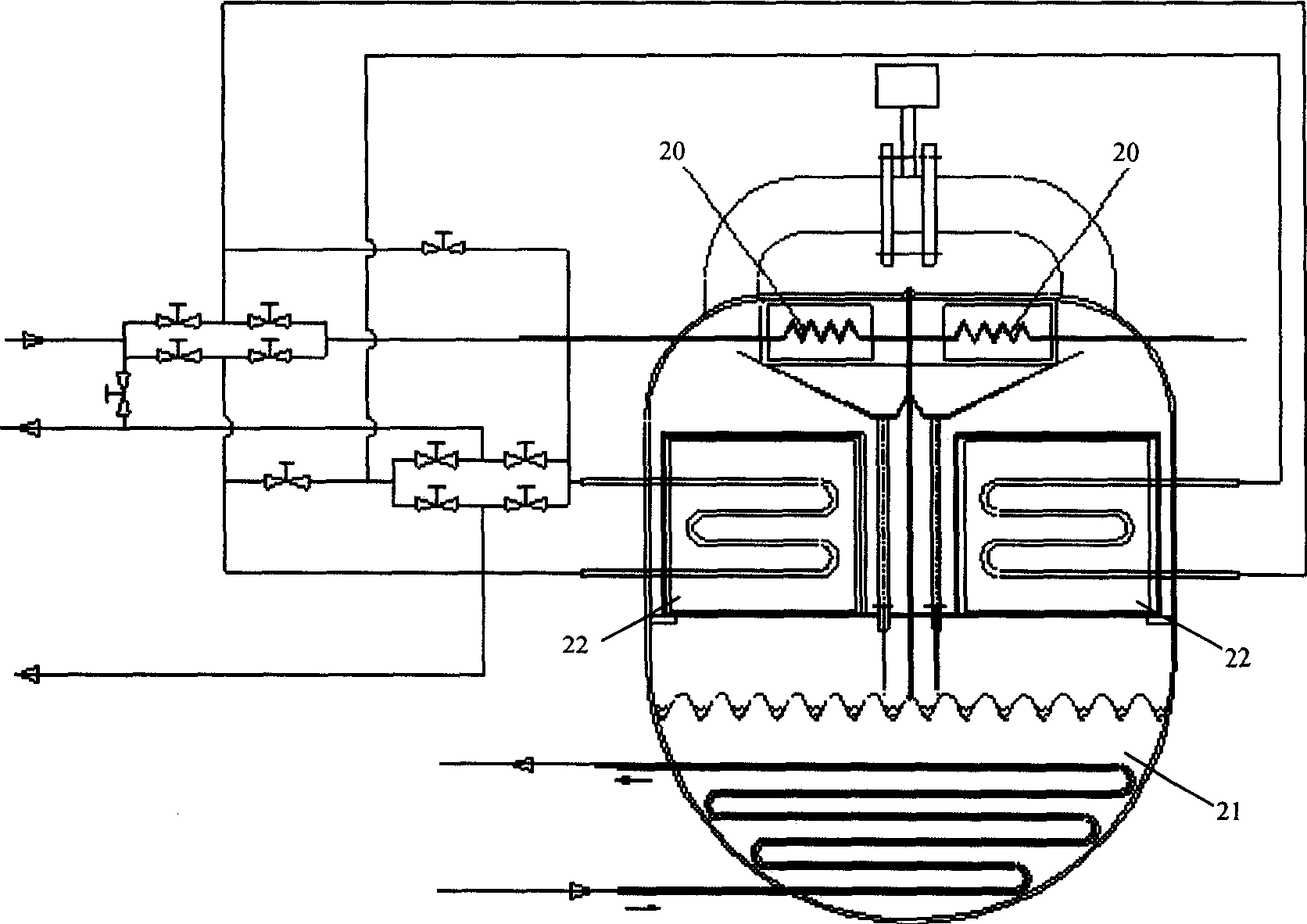

Solar energy composite energy system based on solid adsorption refrigerator

InactiveCN1719158AImprove equipment utilizationImprove solar utilizationSolar heat devicesEnergy efficient heating/coolingAutomotive engineeringHeating system

The present invention relates to a solar composite energy system based on solid adsorption refrigerating machine in the energy-saving field. Said system includes solar collection system, solar hot water supply system, solar floor heating system, solar air-conditioning system, solar natural ventilation system and control system.

Owner:SHANGHAI JIAO TONG UNIV

Brown fermented milk base material, brown milk beverage and preparation method of brown fermented milk base material

The invention discloses a brown fermented milk base material and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing raw materials to obtain a material liquid, wherein the material liquid comprises following components except for skimmed milk: 0.5-2g / L of low-poly xylose, 0.3-1g / L of sodium bicarbonate and 60-100g / L of fructose syrup; (2) sterilizing the material liquid at 115-123 DEG C for 300 seconds, performing Maillard reaction, cooling to 41-43 DEG C and pouring into a fermentation tank; (3) grafting a yogurt starter, wherein the yogurt starter includes 15-23g / T of Danisco 528, 11-13.7g / T of DSM1821 and 6-8mL / T of lactobacillus plantarum with the CGMCC No. 9405, and fermenting until the acidity is up to 70 degrees to obtain the brown fermented milk base material. A brown milk beverage prepared from the fermented milk base material has the comparable browning effect to similar products in the market and has better flavor, taste and nutrients compared with the similar products in the market; moreover, the production efficiency is greatly improved and the equipment utilization ratio is greatly increased.

Owner:河北新希望天香乳业有限公司

Novel method for preparing battery grade lithium carbonate by using tantalum niobium tailings lithium mica

InactiveCN102139894AImprove utilization efficiencyReduce the impactCell electrodesLithium carbonates/bicarbonatesRubidiumNiobium

The invention provides a novel method for preparing battery grade lithium carbonate by using tantalum niobium tailings lithium mica. The method is characterized by comprising the following steps of: crushing lithium mica powder until granularity is 100 to 200 meshes, adding the crushed lithium mica powder and 30 to 70 percent sulfuric acid solution in a solid and liquid mass ratio of 1:(2-8) into a reaction device, reacting at the temperature of between 60 and 200 DEG C for 3 to 10 hours to obtain the sulfuric acid solution which contains Li<+>, and separating to remove fluorine-containing solution; performing filtering separation on the sulfuric acid solution which contains the Li<+>, and fully washing the filter residue with water to remove the filter residue and obtain filtrate which serves as mother liquor 1; changing the temperature of the mother liquor to be between 10 and 100 DEG C with stirring, separating solids, namely rubidium, caesium and alum, performing filtering separation, washing the filter residue, and recovering the filtrate as mother liquor 2; adding calcium hydroxide into the mother liquor 2, and controlling the pH value of the solution to between 2 and 7 to obtain solid and liquid mixed solution of neutralization reaction; performing filtering separation on the solid and liquid mixed solution, washing and filtering the filter residue, and recovering the filtrate as mother liquor 3; performing evaporation concentration on the mother liquor 3, controlling the concentration of the Li<+> in the solution to be between 40 and 65g / l, and filtering to obtain the filtrate serving as mother liquor 4; and blowing carbon dioxide into the mother liquor 4 at the temperature of between 95 and 105 DEG C under 2 atmospheres and performing lithium-sinking reaction for 40 to 100 minutes, filtering and mechanically separating to obtain lithium carbonate, washing with water, and drying to obtain the battery grade lithium carbonate product.

Owner:宜春银锂新能源有限责任公司

Method for preparing gelatin with protease degradation ossein

InactiveCN102051130AHigh purityEmission reductionGlue/gelatin preparationInorganic saltsNeutral protease

The invention discloses a method for preparing gelatin with protease degradation ossein. The method is characterized in that derosination and demineralization ossein is mainly adopted as the raw material, and acidic or neutral protease degradation ossein is used for preparing gelatin. Compared with the traditional technology, the method has the advantage that long liming period and complicated neutralization washing process are omitted, so that the production period of gelatin is shortened, and a great amount of water resource and manpower cost are saved; and compared with the new technology of preparing gelatin with skeleton grains, and the content of foreign protein and inorganic acid in gelatin is greatly reduced, so that freezing strength and viscosity of the product are improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing n-phenylglycinonitrile

ActiveCN101514170ARapid responseModerate responseCarboxylic acid nitrile preparationOrganic compound preparationAutomatic controlAcetonitrile

The present invention provides a method for preparing n-phenylglycinonitrile, wherein the method comprises a step of executing condensation reaction for generating n-phenylglycinonitrile when the phenylamine and glycolonitrile are used as raw materials. The invention is characterized in that according to the continuous production method, the raw materials continuously pass through a pipe type preheater, a pipe type mixer, a pipe type reactor and a reaction still for executing condensation reaction for generating the n-phenylglycinonitrile. The method of the invention has the advantages of fewer devices, simple and brief technical route, saved costs of man power, device, raw materials, energy, etc., improved operating environment, extraordinary automatic control realization, excellent guaranteed safety production operability and continuity, equitability and stability of production thereby guaranteeing the stability of product quality, increasing the product purity and yield. The product purity in the invention is above 95.5%, and the product yield is above 99.8%.

Owner:重庆渝化新材料有限责任公司

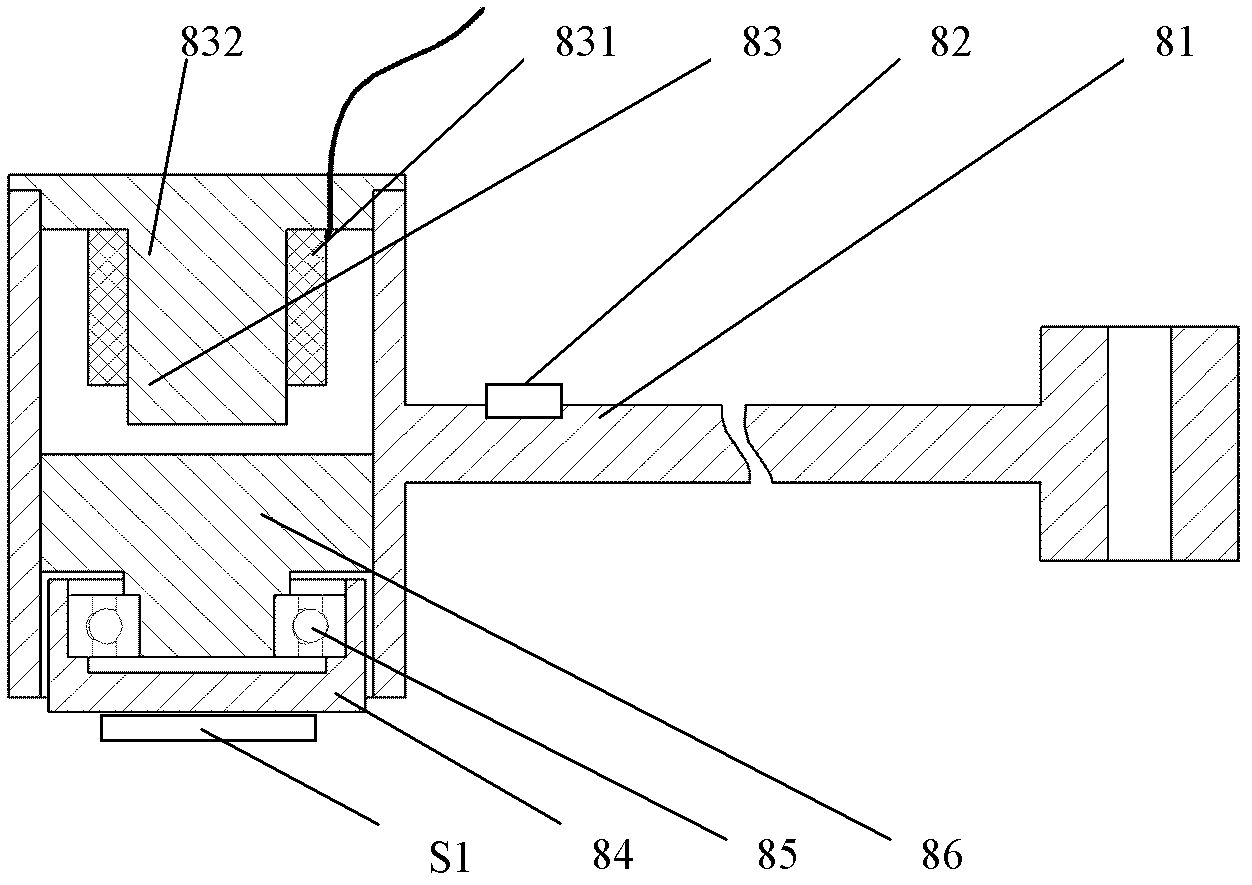

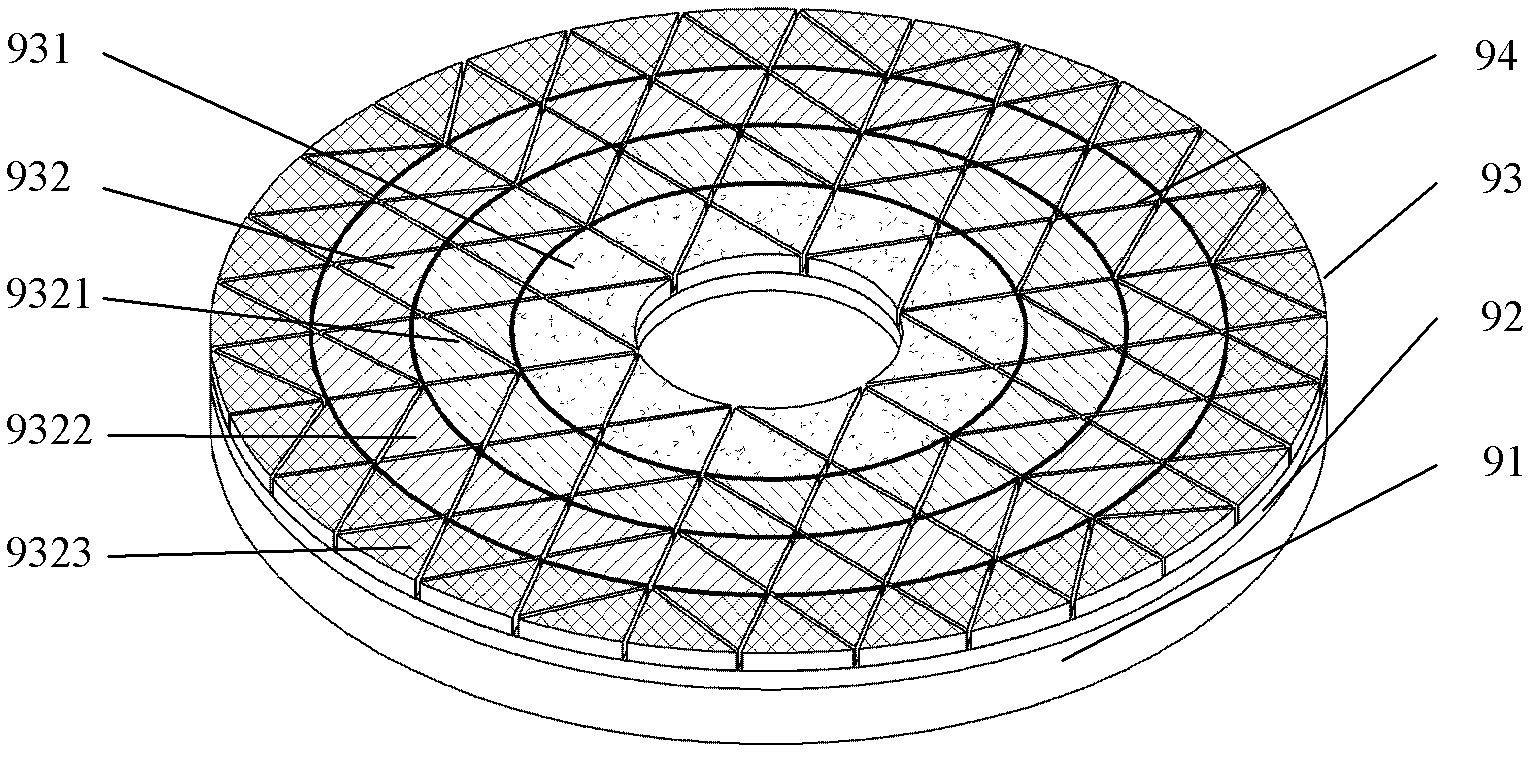

Dynamic pressure finishing system based on hierarchical structured composite elastic abrasive disk

InactiveCN102658520AImprove processing qualityImprove efficiencyLapping machinesLapping toolsReduction driveReducer

Disclosed is a dynamic pressure finishing system based on a hierarchical structured composite elastic abrasive disk, including a working table and an abrasive disk erected on the working table. The abrasive disk is connected with an abrasive disk driving device, which is composed of a motor and a reducer, and is used to control rotation of the abrasive disk provided with a bull ring and a polishing inner ring. A runner though which polishing fluid circulates is arranged on the surface of the abrasive disk, on which dynamic pressure adjusting devices presses a work piece. The system provided by the invention has the beneficial effects that: the system has a high degree of automation, can realize stepless pressure change by dynamically adjusting the pressure applied to the work piece with an electromagnetic device, and can adjust the applied pressure according to different processing stages of the work piece, improve work piece processing quality and reduce influence of human factors.

Owner:嘉兴花汇红园林有限公司

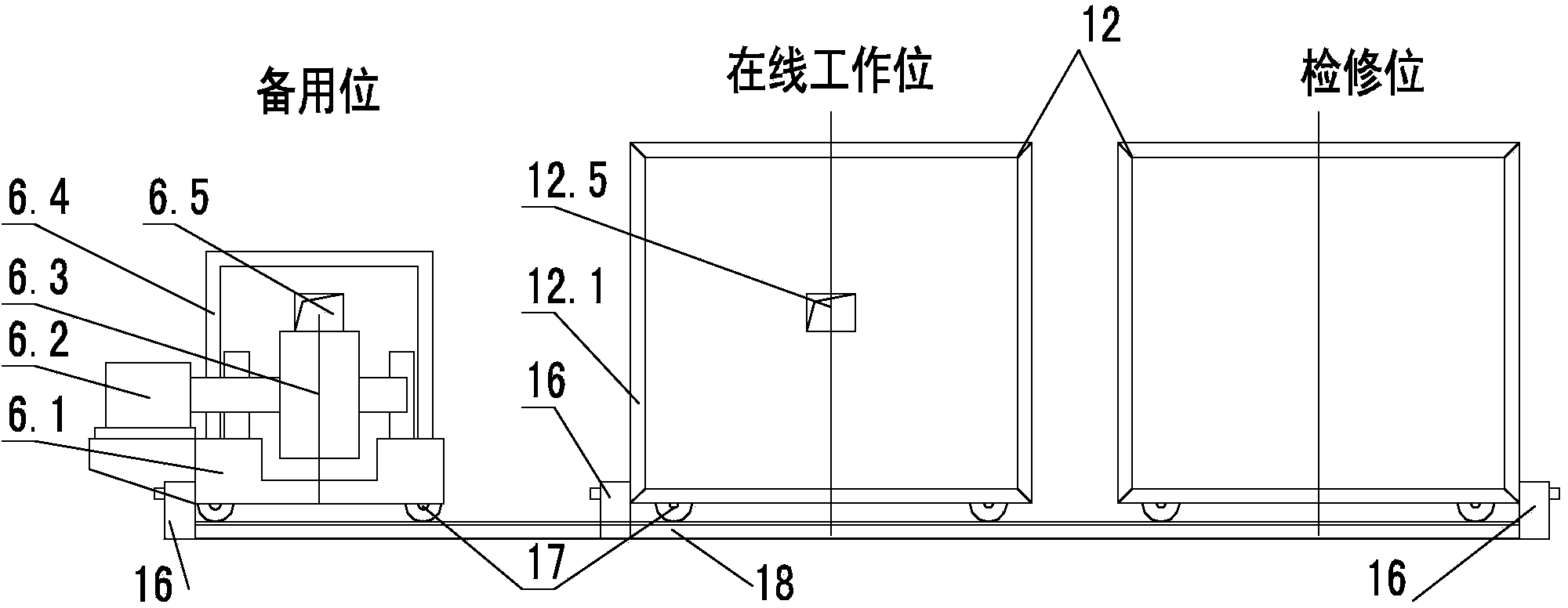

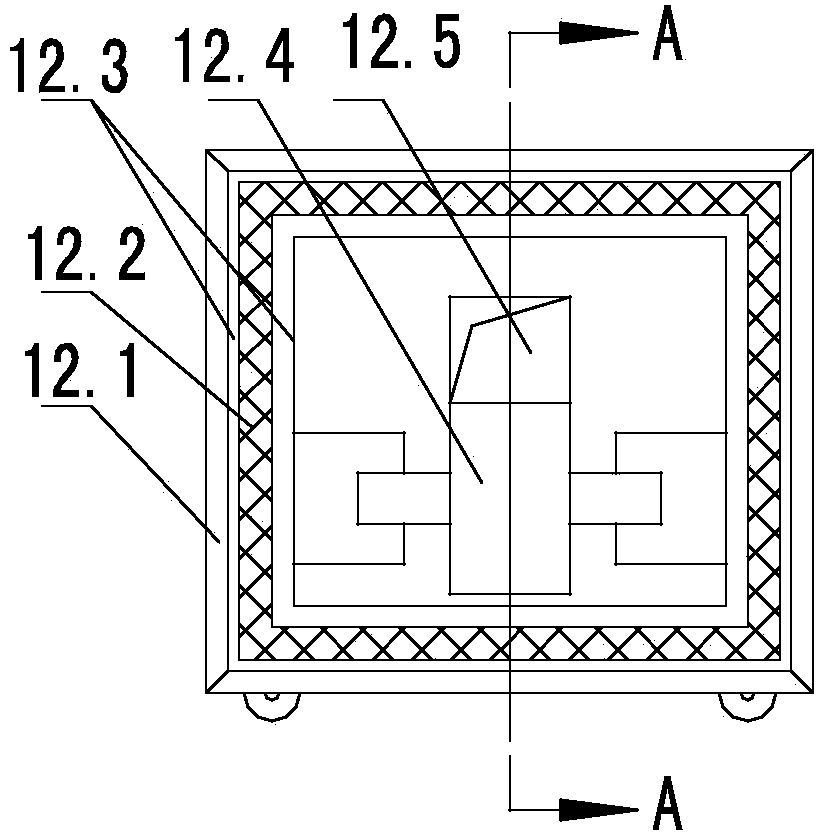

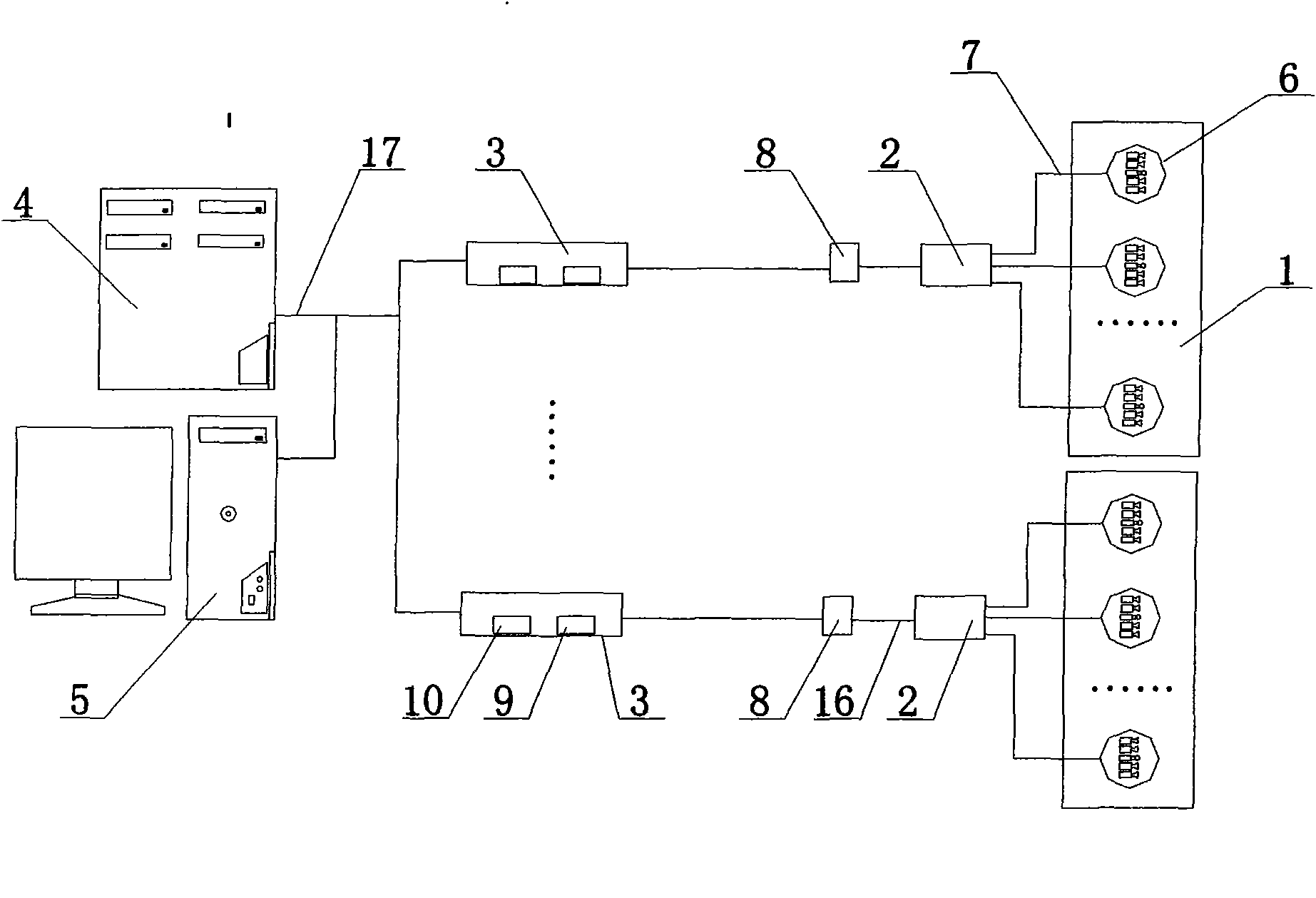

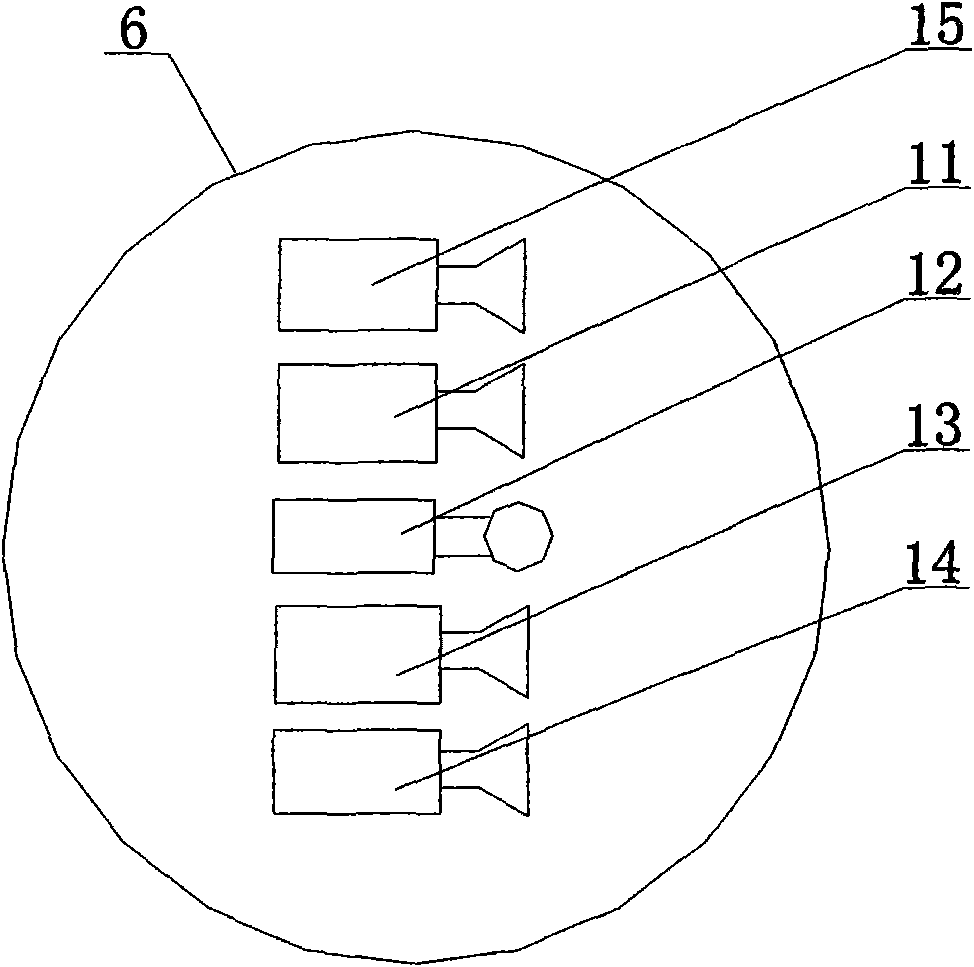

Internal operation image real-time monitoring system for high-voltage electric apparatus

ActiveCN101644736AGuaranteed uptimeImprove power supply reliabilityTesting dielectric strengthRadiation pyrometryInfraredData information

The invention discloses an internal operation image real-time monitoring system for high-voltage electric apparatus, which mainly comprises a high-voltage apparatus, an optical cable hub, an industrial computer, a computer server and a computer terminal, wherein the inner wall of the cavity of the high-voltage apparatus is provided with a monitoring point; the monitoring point mainly comprises a high-resolution optical-fiber lens, an infrared optical-fiber lens, an ultraviolet optical-fiber lens, an optical-fiber lamp and an optical-fiber sensor; the monitoring point is provided with a high-voltage insulating optical cable and an afflux optical cable hub; an optical cable outlet sleeve is arranged behind the optical cable hub; and the high-voltage insulating optical cable is led out of thehigh-voltage apparatus through the optical cable outlet sleeve and connected with the computer server of the main control room of a transforming plant through the industrial computer. The system canmonitor data information in an apparatus in real time, such as electrical quantities and the like, and has the advantages of high precision, strong disturbance resisting capacity and high response speed. When apparatus abnormalities and faults happen, the system can provide detailed information before and after the abnormality or fault, which is helpful to analyze the accident and make the corresponding measures, and enhance the operation level and the power supply reliability of the electric apparatus.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN +1

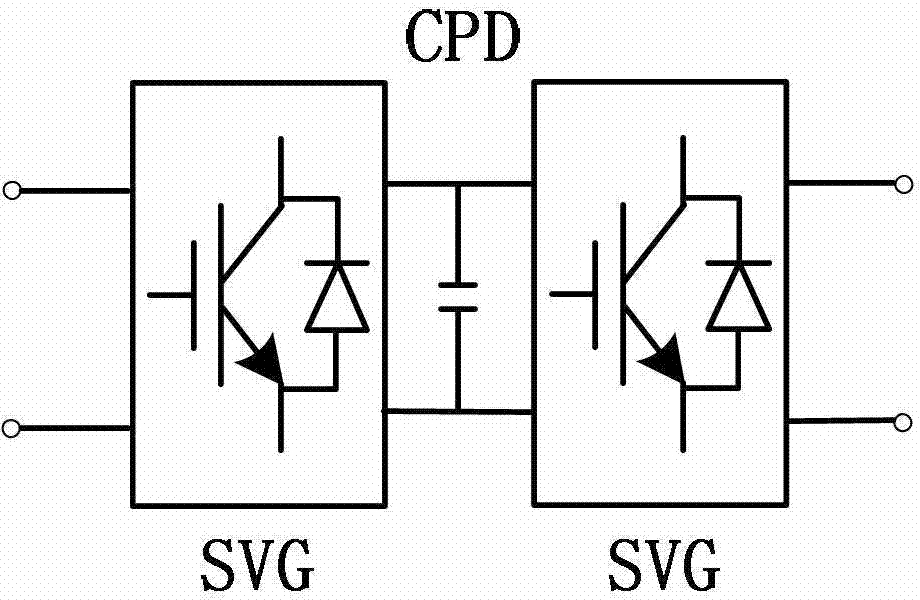

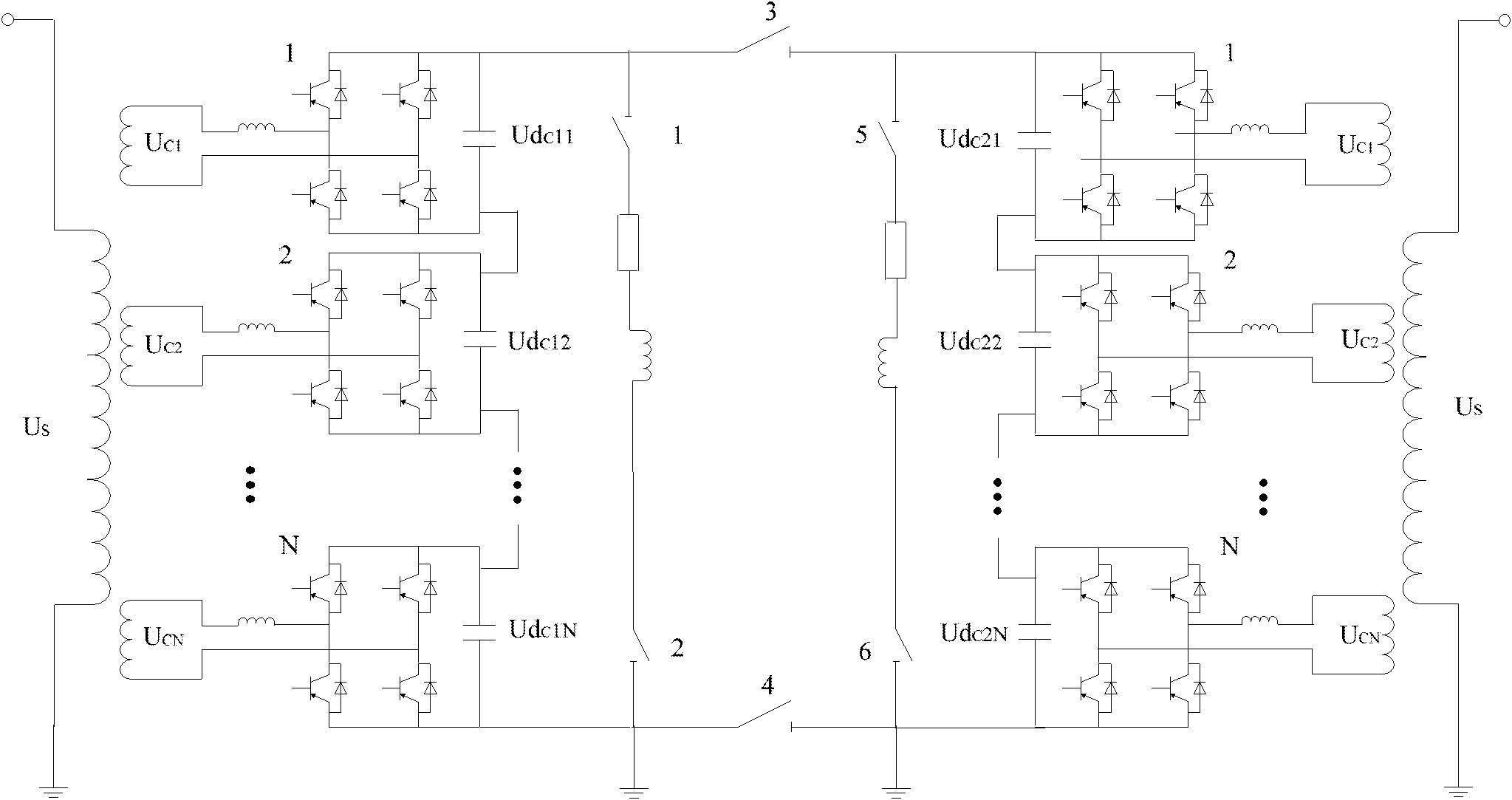

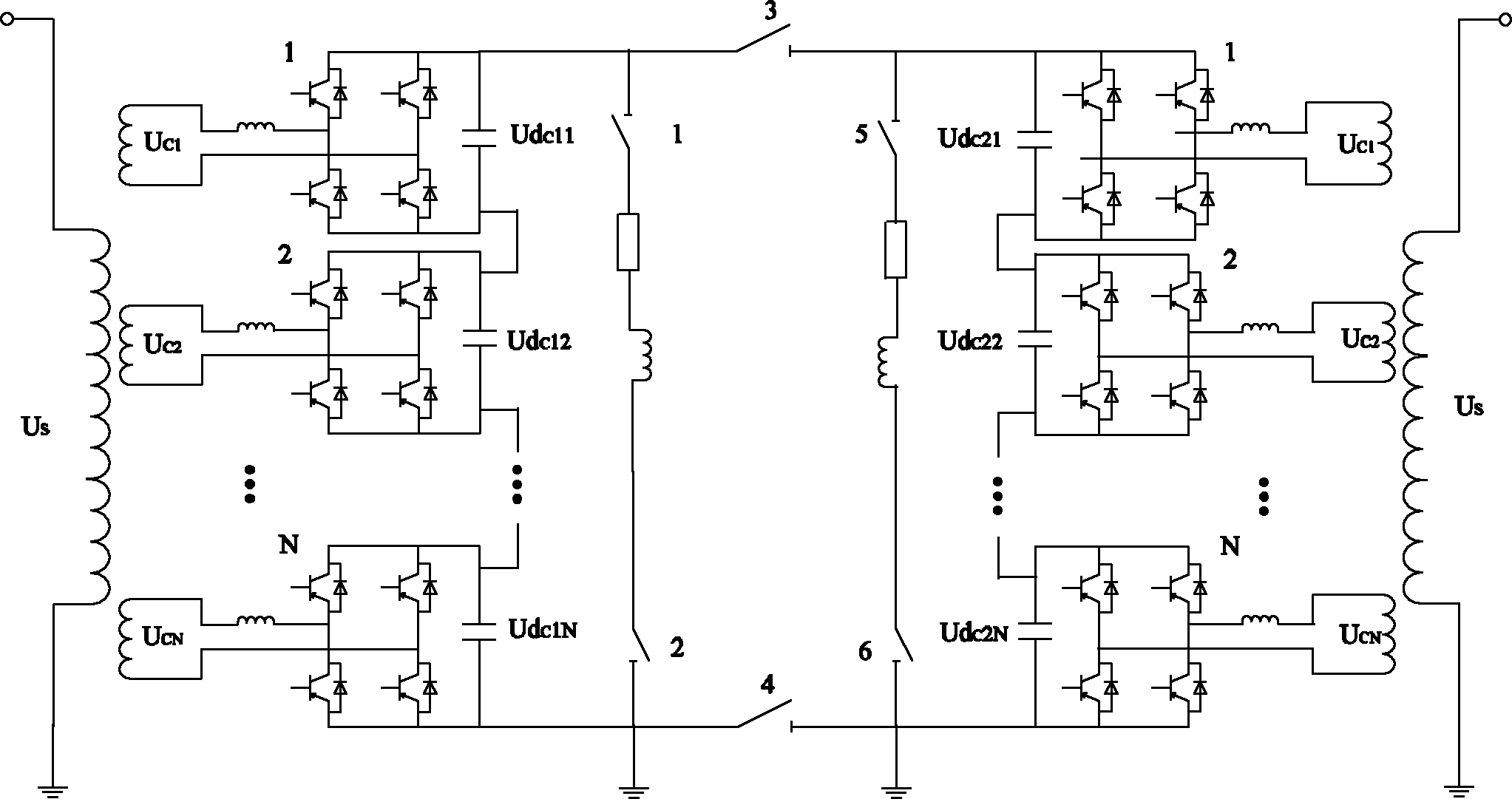

Electricity energy regulating-ice melting device and method for railway traction network

ActiveCN102642481ALess investmentImprove equipment utilizationOverhead installationTrolley linesSingle phaseUtilization factor

The invention relates to a power regulating-ice melting device for a railway traction network. The device comprises two converter devices at left and right, which are same in structure, wherein direct-current sides of the two converter devices at left and right are connected through a switch; each converter device comprises a multiplied winding transformer and a plurality of H-bridge modules which are same in structure; the transformer consists of a primary winding and a plurality of secondary windings; the primary winding is connected with a single-phase alternating current of a power supply arm of a traction network substation; each secondary winding is connected with an H-bridge module; and direct-current sides of all the H-bridge modules are connected in series. The invention also relates to a power regulating-ice melting method for the railway traction network. According to the invention, an H-bridge direct-current side serial based topological structure is adopted, not only can high-capacity direct-current ice melting requirement be met, but also the electricity energy quality management of an electrified railway also can be satisfied so as to implement ice melting in ice covering, the electricity energy quality management of the traction substation can be carried out when ice is not melt, so that the investment is reduced, and the device utilization ratio is improved.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

A MES-based Kneading Single Scheduling Algorithm for Plate Customized Furniture

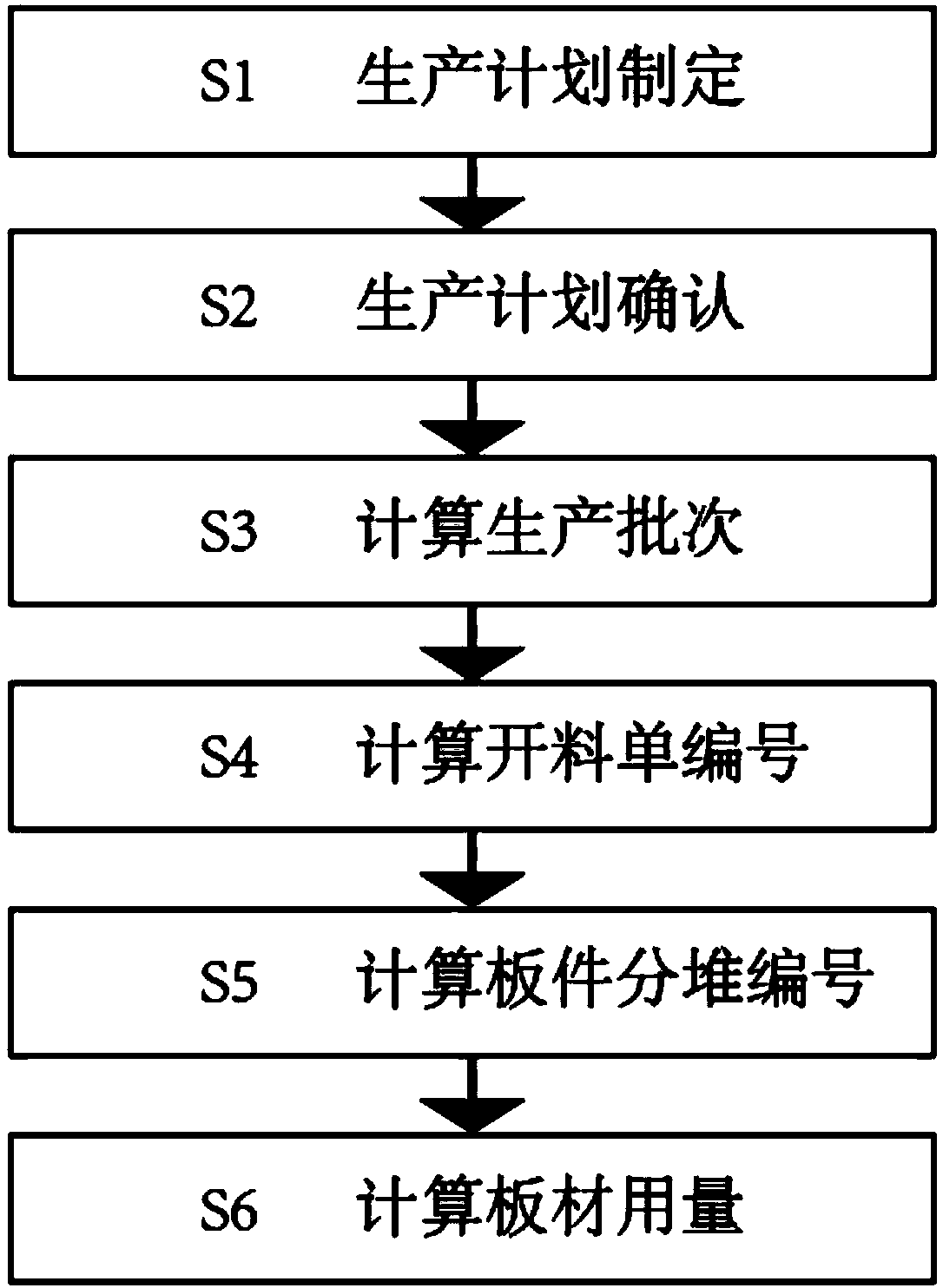

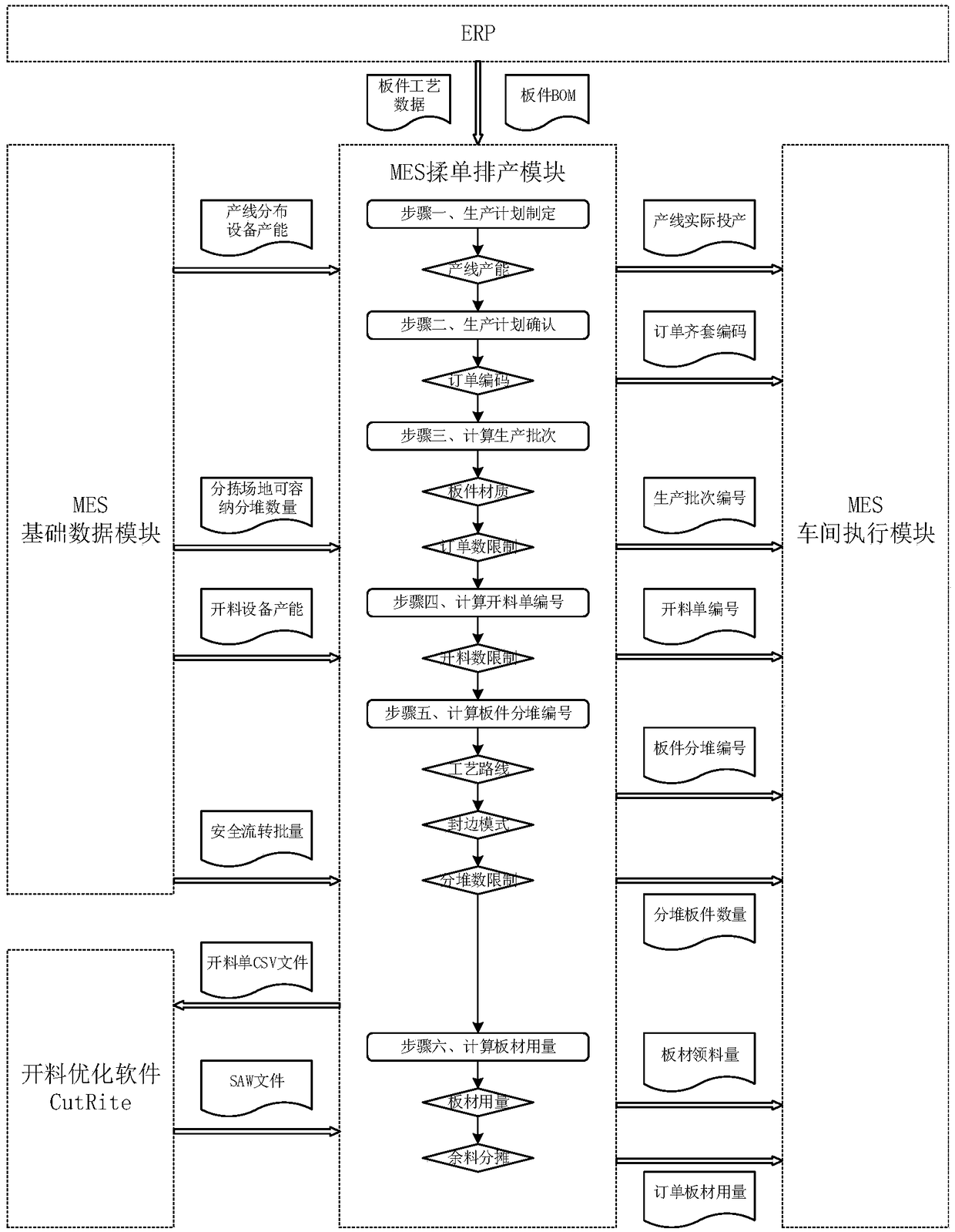

InactiveCN109460931AImprove efficiencyReduce frequency and timeForecastingResourcesMaterial DescriptionProduction planning

The invention relates to the field of intelligent production scheduling, in particular to a MES-based plate customized furniture kneading single production scheduling algorithm, comprising the following steps: according to the production line capacity and the plate BOM data, the system calculates the actual production line input output; the MES-based plate customized furniture kneading single production scheduling algorithm comprises: Scheduler confirms the production plan, and the system automatically generates a unique set of order codes for each order randomly; The system classifies the plates on different production lines according to the material description; The system divides the sheets in the same batch into different sheets according to the limit value of the number of sheets in the sheet. The system obtains the process route data, the edge sealing mode data and the stack number limit of the plate, and forms the stack number and the number of the plate. The system obtains theSAW file optimized by CutRite, calculates the actual plate quantity and the remaining material data of the opening list, and forms the plate picking list and the order plate quantity. The invention improves the scheduling efficiency, the accuracy of the production data, the production efficiency and the utilization rate of the equipment of the plate-type customized furniture kneading sheet production.

Owner:广州市酷匠信息科技有限公司

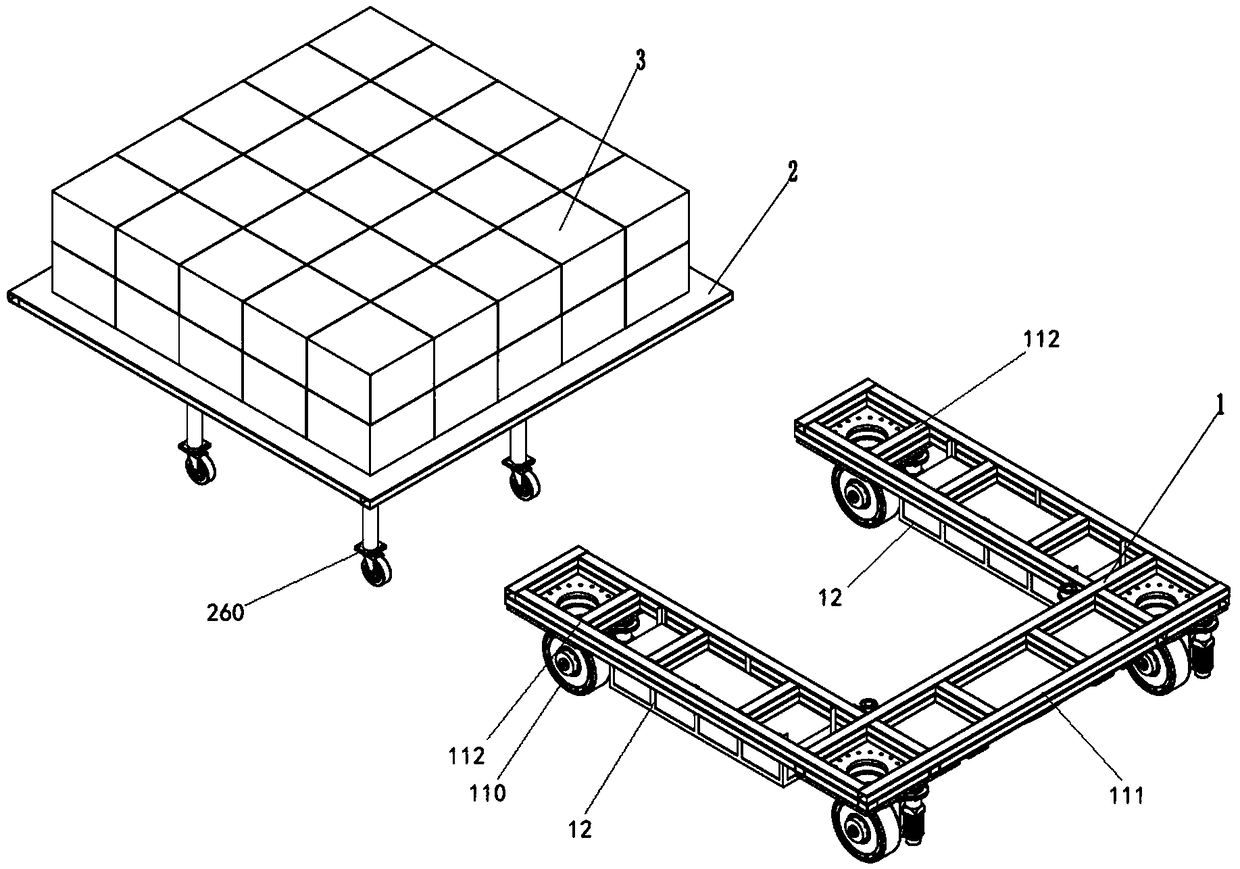

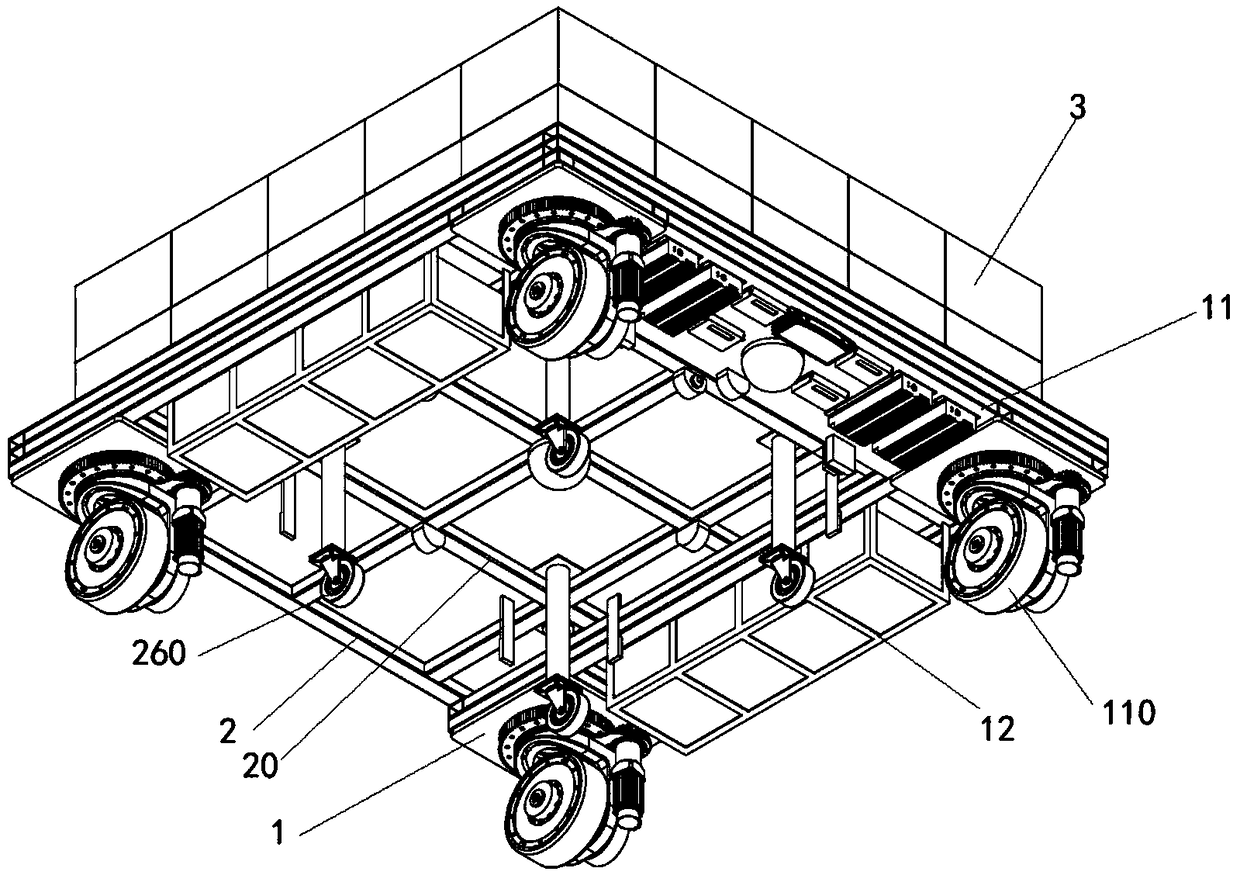

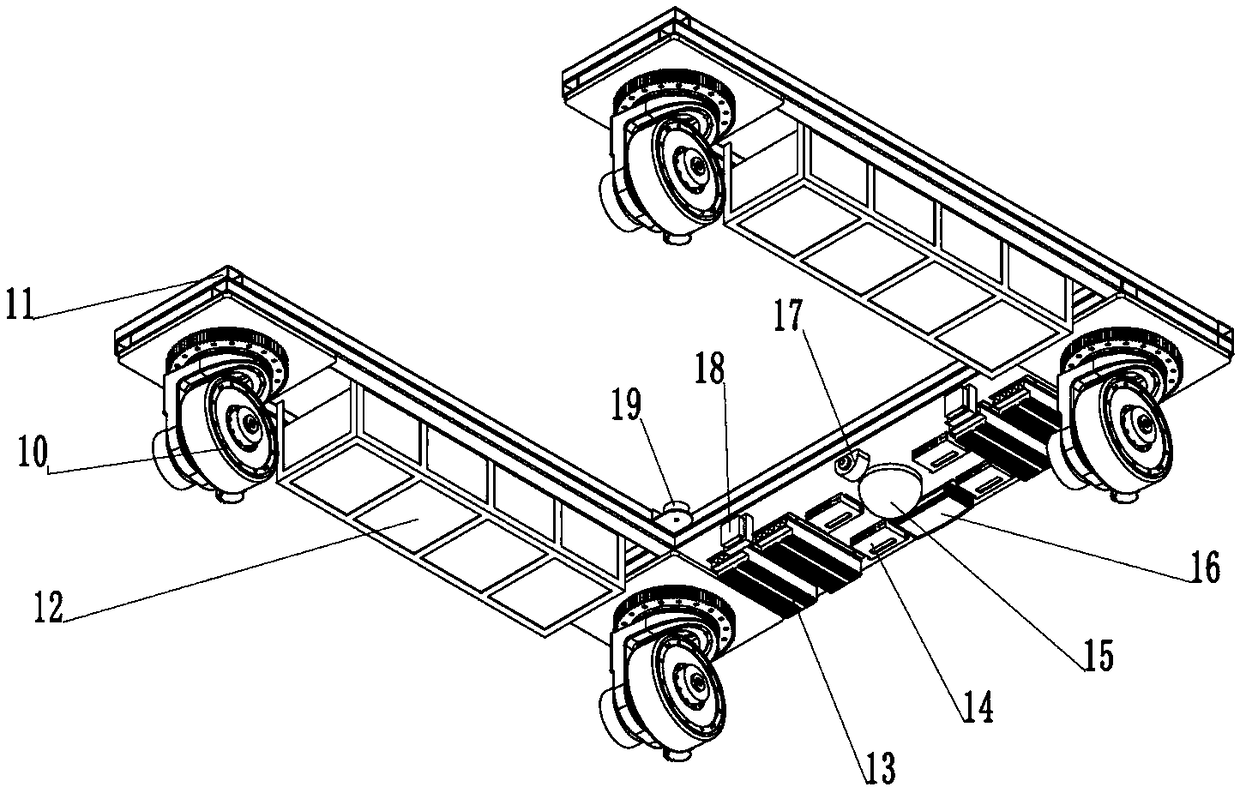

Hub-motor-driven convey device and conveying system, and convey method

ActiveCN109080444AImprove equipment utilizationLow costMotor depositionElectrical steeringTruckMotor drive

The invention is applicable to the technical field of new energy vehicles and ground transportation equipment, and discloses a conveying device and a conveying system driven by a hub motor, and a conveying method. The transporting device comprises a transporting truck which can be used for locking and driving with a truck, and the transporting truck comprises a transporting truck frame which is connected with an energy storage device, a steering device, an alignment device, a transporting truck docking locking device, a transporting truck positioning device, a driving wheel driven by a hub motor, and a whole truck controller which can plan a moving path or receive a moving path. The transporting truck frame is connected with an energy storage device, a steering device, an alignment device,a transporting truck docking locking device, and a transporting truck positioning device. The handling system comprises the handling device and the dispatching control center. The conveying method uses the conveying device and the conveying system. The invention provides a conveying device and a conveying system driven by a wheel hub motor, and a conveying method thereof. The conveying device hashigh equipment utilization ratio, and the conveying vehicle can be flexibly turned in a narrow space and can realize multi-purpose of one vehicle, so that the conveying device can replace manual conveying, save energy and environmental protection, and has high efficiency and low cost.

Owner:SHANDONG INST OF ADVANCED TECH CHINESE ACAD OF SCI CO LTD

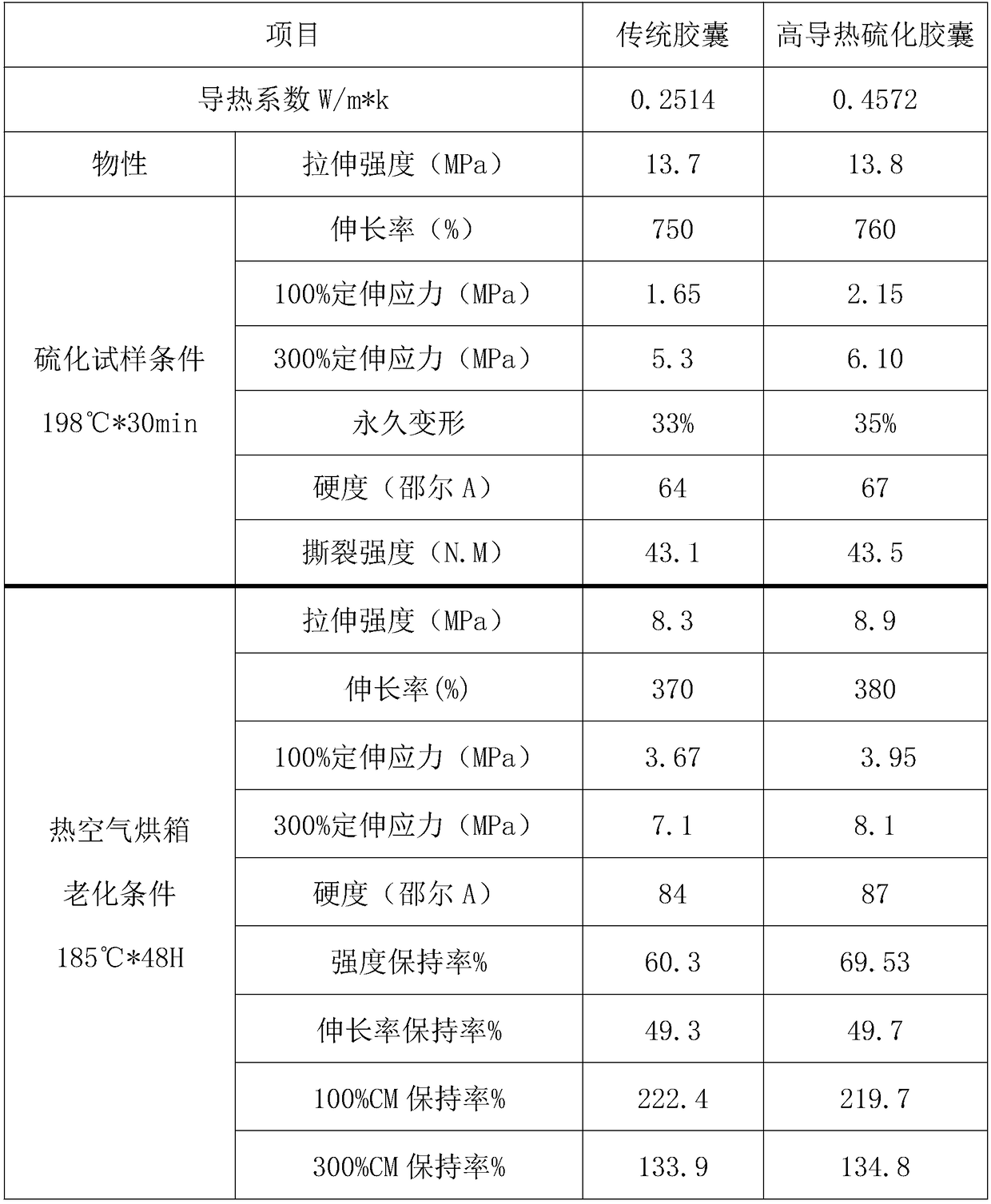

Preparation method of high-heat-conductivity type tire vulcanization capsule

The invention discloses a preparation method of a high-heat-conductivity type tire vulcanization capsule. The preparation method of the high-heat-conductivity type tire vulcanization capsule belongs to the technical field of tires, and comprises the following steps of (1) compounding the components according to the matching ratio: 95 parts of butyl rubber, 4 to 5 parts of chloroprene rubber, 15 to20 parts of N375 carbon black, 35 to 45 parts of acetylene black, 7 to 15 parts of graphene, 7 to 10 parts of alkane oil, 0.5 to 1.5 parts of stearic acid, 5 to 7 parts of zinc oxide, and 8 to 10 parts of resin; (2) primarily mixing; (3) filtering rubber; (4) secondarily mixing; (5) forming; (6) vulcanizing; (7) polishing; and (8) inspecting a finished product. According to the preparation methodof the high-heat-conductivity type tire vulcanization capsule provided by the invention, on the basis of ensuring the stability of various physical and mechanical properties, a heat conductivity coefficient is further improved, so that the aims of saving energy and reducing cost are achieved.

Owner:YONGYI RUBBER CO LTD

Chlorination method and device used in ethyl maltol production

InactiveCN102060821AOperational securityImprove equipment utilizationOrganic chemistryChemistryLiquid chlorine

The invention discloses a chlorination method and device used in ethyl maltol production. The chlorination device comprises a reactor, a circulating pump and a plate type heat exchanger. The chlorination method comprises the steps of: firstly, pumping a methanol solution into a chlorination kettle for freezing to be below -18 DEG C, then dropping furfuryl alcohol, introducing chlorine in a steel liquid chlorine cylinder into the chlorination kettle through a buffering tank, cyclically cooling materials by the plate type heat exchanger, and controlling the reaction temperature to be lower than -8 DEG C. The method is safe and convenient to operate; the device has simple structure; and the utilization rate of the raw materials and the yield of products are improved.

Owner:ANHUI JINGHE IND

Method for preparing CO2-N2 mixed gas from boiler flue gas to be used for clarification process of sugar production

InactiveCN101805804AGood clarificationHigh purityPurification using alkaline earth metal compoundsDispersed particle separationEcological environmentAir blower

The invention discloses a method for preparing CO2-N2 mixed gas from boiler flue gas to be used for a clarification process of sugar production. The method of the process comprises the following steps of: collecting the boiler flue gas by an air blower, making the boiler flue gas pass through a dust catcher, a heat exchanger and a gas-water separator; desulfurizing by alkaline water or in a pressure-swing adsorption tower to obtain pretreated gas; and adsorbing and desorbing the pretreated gas in the adsorption tower of a pressure-swing adsorption system to obtain the mixed gas containing 18%-40% of CO2 and 54%-74% of N2 in percentage by volume. The mixture is delivered into a mixed juice carbonating tower and an upward-floating clarifier or a syrup carbonating tank and the upward-floating clarifier, and the mixed juice or syrup is clarified by a clarifying method of half carbon and half sulfur. The invention is used for the clarification process of sugar production by a sulfurous method, and the clarification effect of the mixed juice or the syrup is good. By adopting the invention, CO2 discharged from the boiler flue gas is reduced, and the ecological environments are protected; meanwhile, filter mud generated in the production process can be used as a fertilizer for crops, thus the invention has an important meaning for making full use of resources and protecting environments.

Owner:GUANGXI UNIV +1

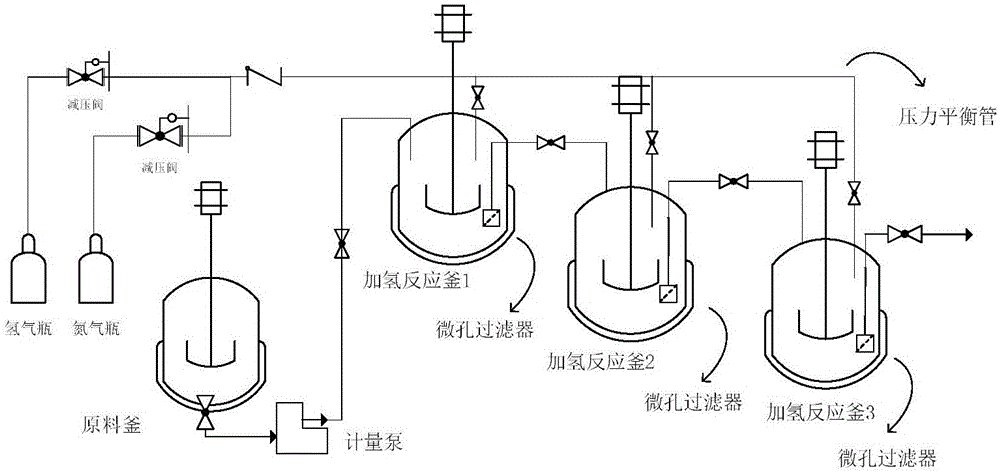

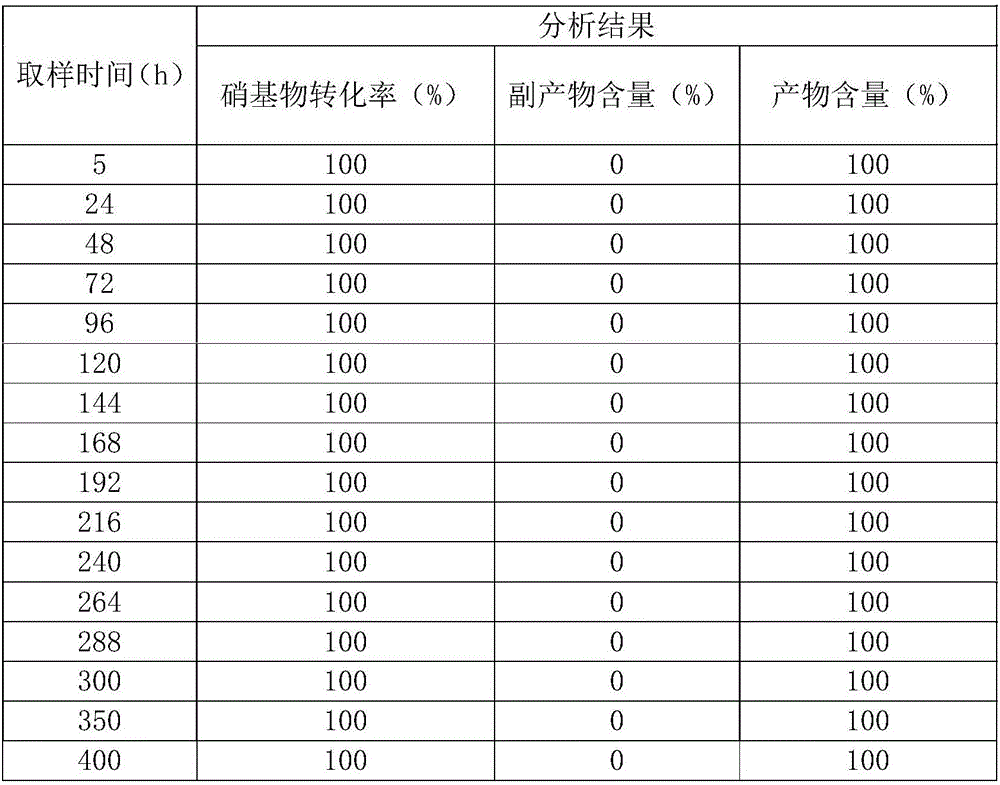

Production method for preparing sodium m-aminobenzene sulfonate by means of continuous hydrogenation reduction

ActiveCN106699611AProduce pollutionImprove energy utilizationSulfonic acids salts preparationMetal/metal-oxides/metal-hydroxide catalystsAzoxyHigh concentration

The invention belongs to the field of fine chemical engineering, and in particular relates to a production method for preparing sodium m-aminobenzene sulfonate by means of continuous hydrogenation reduction. The method is characterized in that a sodium m-nitrobenzene sulfonate solution is pumped into multiple stages of hydrogenation reaction kettles which are in series connection, and a multi-element catalyst is added into all the reaction kettles; overflow pipes used for conveying a reaction solution are arranged among all the hydrogenation reaction kettles, and a microporus filter used for filtering the catalyst is installed at the front end of each overflow pipe; the reaction solution enters the next kettle by means of liquid level difference after being filtered by the microporus filter; furthermore, balance pipes used for transmitting hydrogen are arranged among all the hydrogenation reaction kettles so as to maintain all the hydrogenation reaction kettles to be communicated with one another in a pressure balance way; therefore, the sodium m-aminobenzene sulfonate can be prepared by means of continuous hydrogenation reduction. After the catalyst provided by the invention is adopted, a condensation side reaction producing azo compounds and oxidized azo compounds is effectively avoided in a high concentration hydrogenation process, dimer and polymer side reactions caused by a deamination reaction can be avoided, and the problem that tarry matters, formed in the side reactions, cover the surface of the catalyst and become catalyst poisons can be solved.

Owner:SHENYANG RES INST OF CHEM IND

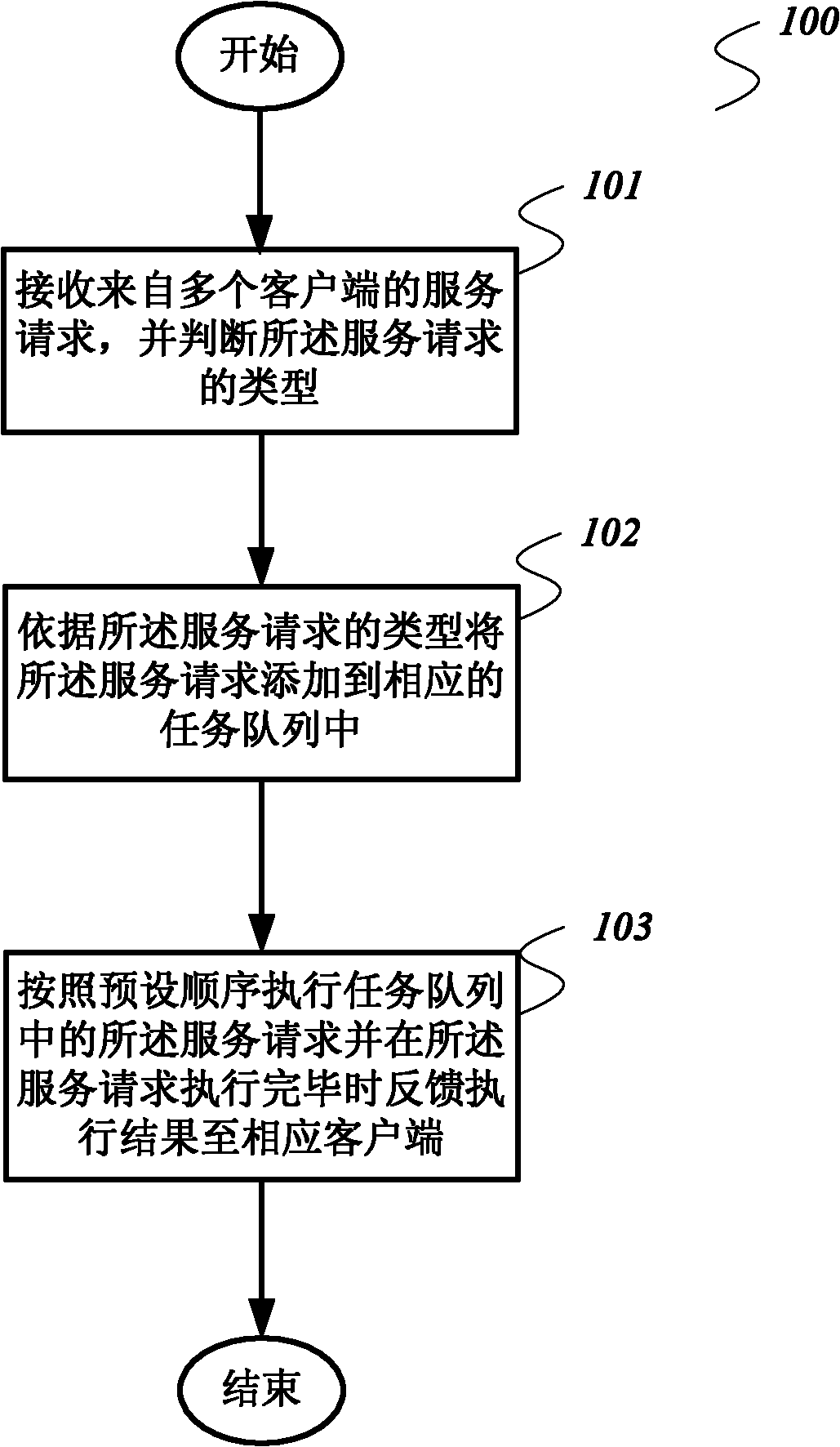

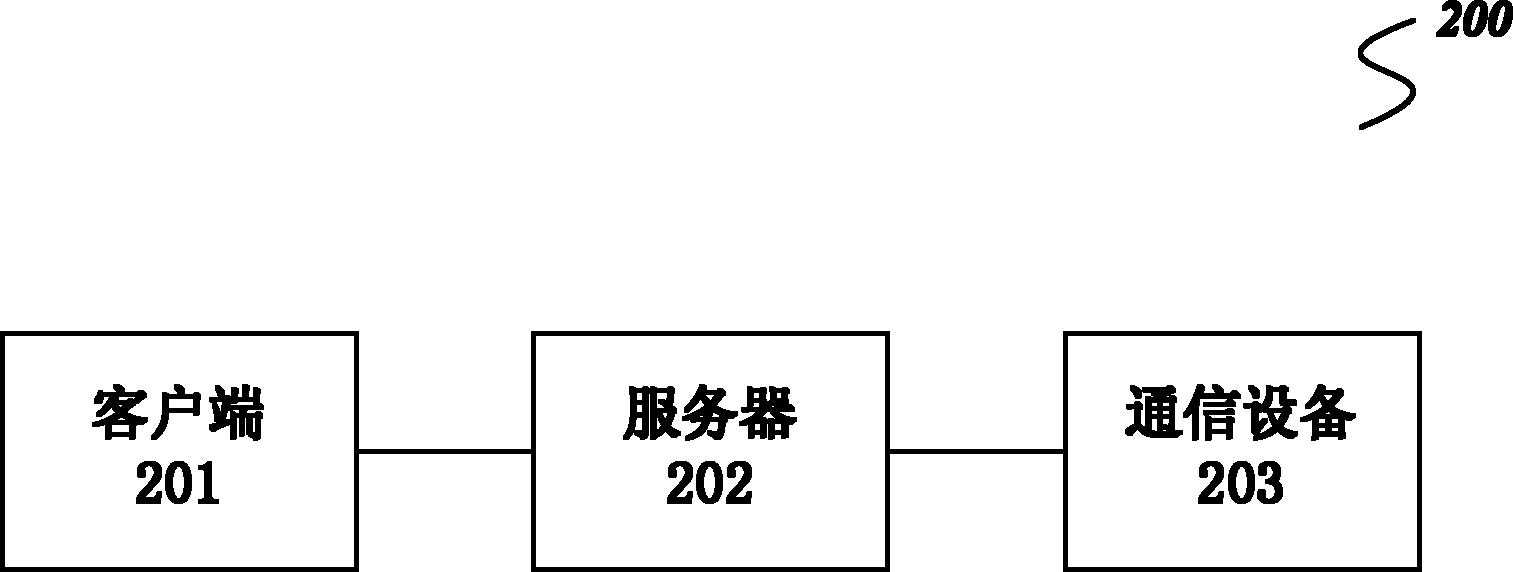

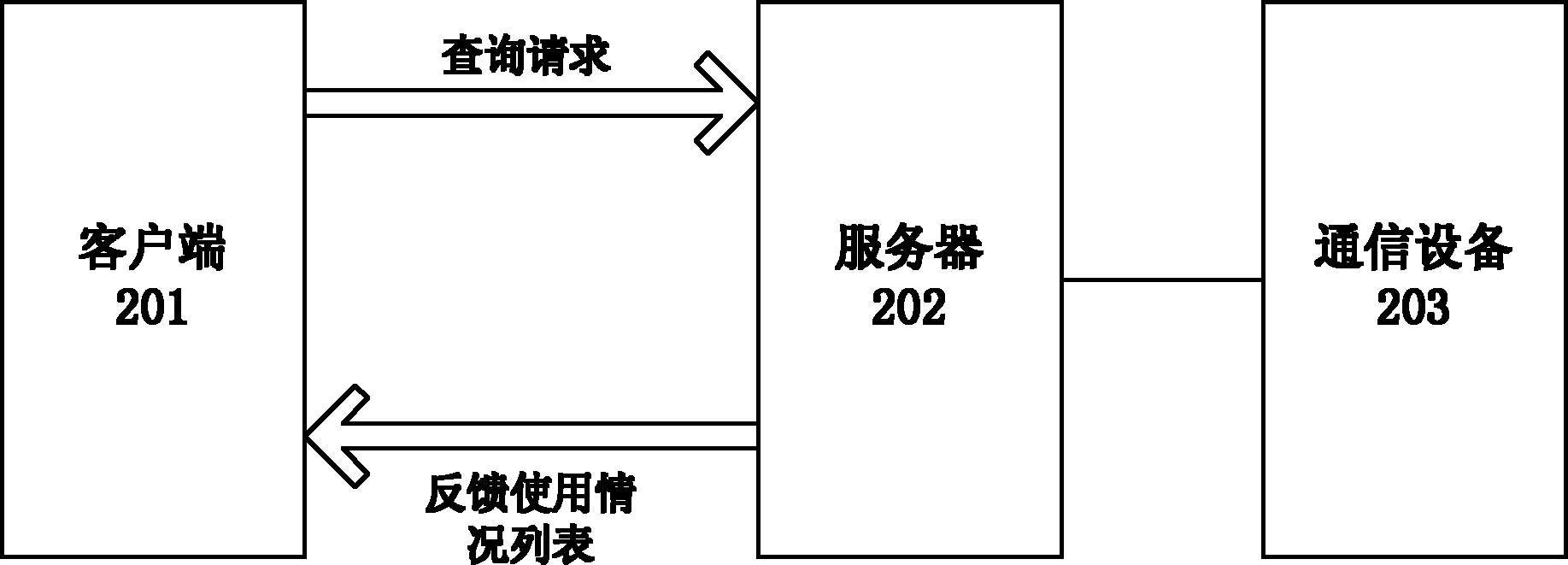

Multi-user control method and multi-user control system for communication equipment and server

ActiveCN101895544ARealize centralized controlImprove execution efficiencyTransmissionControl systemClient-side

The invention relates to a multi-user control method and a multi-user control system for communication equipment and a server. The method comprises the following steps of: receiving service requests from a plurality of clients, and judging the types of the service requests; adding the service requests into corresponding task queues according to the types of the service requests; and executing the service requests in the task queues according to a preset rule, and feeding the execution results back to the corresponding clients when the execution of the service requests is finished. The invention also relates to the multi-user control system and the server. The technical scheme of the invention can realize simultaneous control of multiple users, does not need direct operation equipment for control and operation of the communication equipment, improves the operation efficiency, and also improves the execution efficiency of instructions and the utilization rate of the equipment.

Owner:TP-LINK

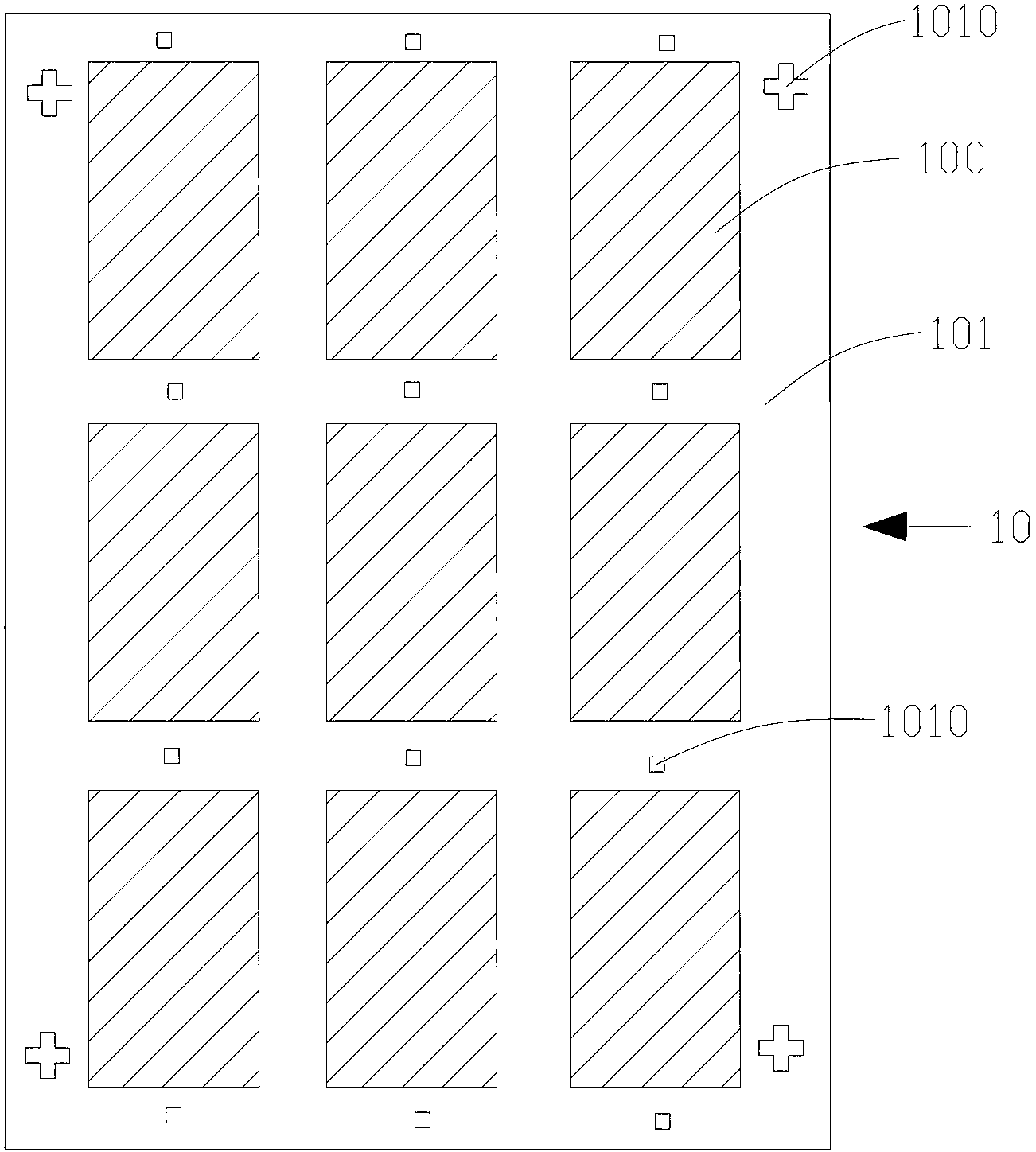

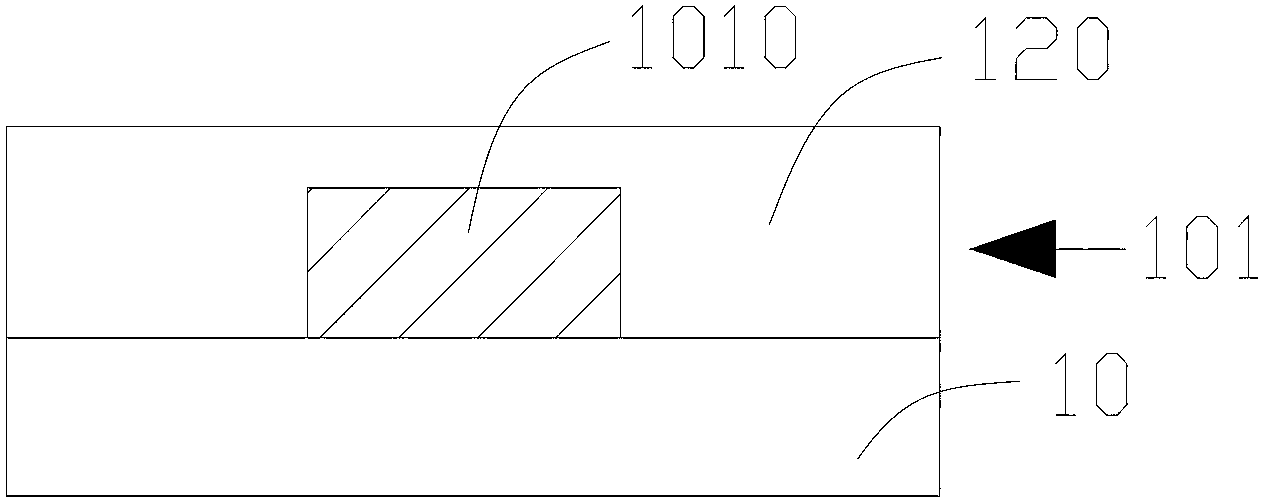

Color filter substrate and manufacturing method for same

ActiveCN102707486AEnhanced Optical DistinctionIncrease success rateOptical filtersNon-linear opticsCamera lensOptical pickup

The invention discloses a color filter substrate and a manufacturing method for the same. The method comprises the following steps of: forming a black matrix pattern in a pixel ineffective area of a transparent substrate to form a mark; coating a transparent conductive layer on the pixel inactive area to cover the mark; and patterning the transparent conductive layer to make the covering characteristics of the transparent conductive layer at the mark and the peripheral zone of the mark different. Optical differences of the mark and the peripheral zone of the mark under a charge coupled device (CCD) optical pickup lens are effectively enhanced, and the success rate of the pickup of the mark is increased, so that production efficiency is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

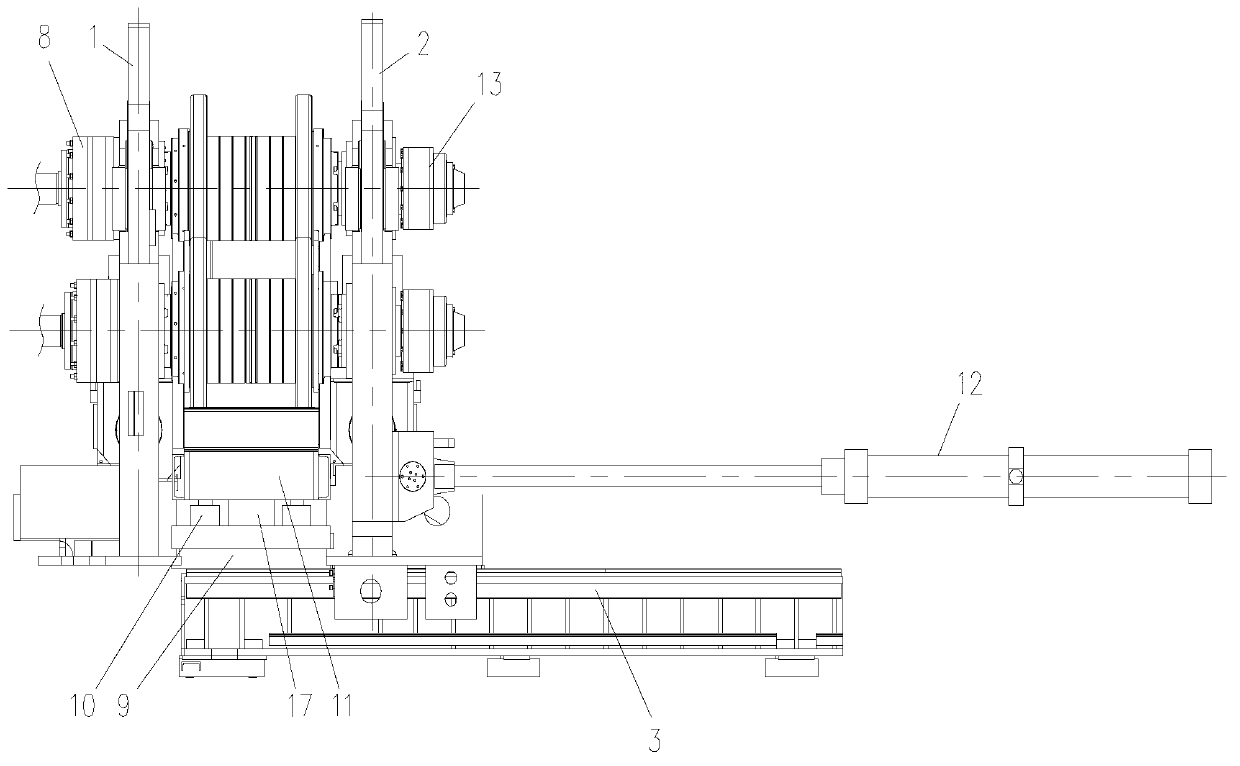

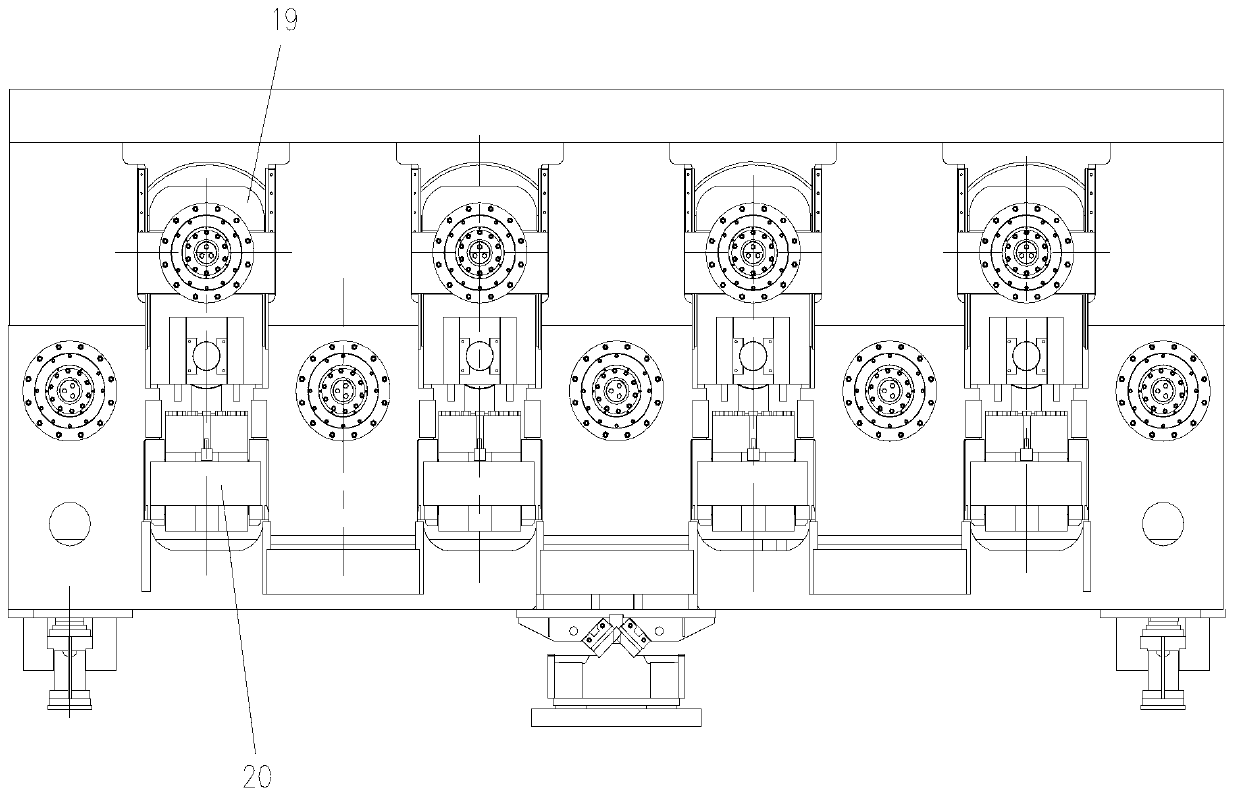

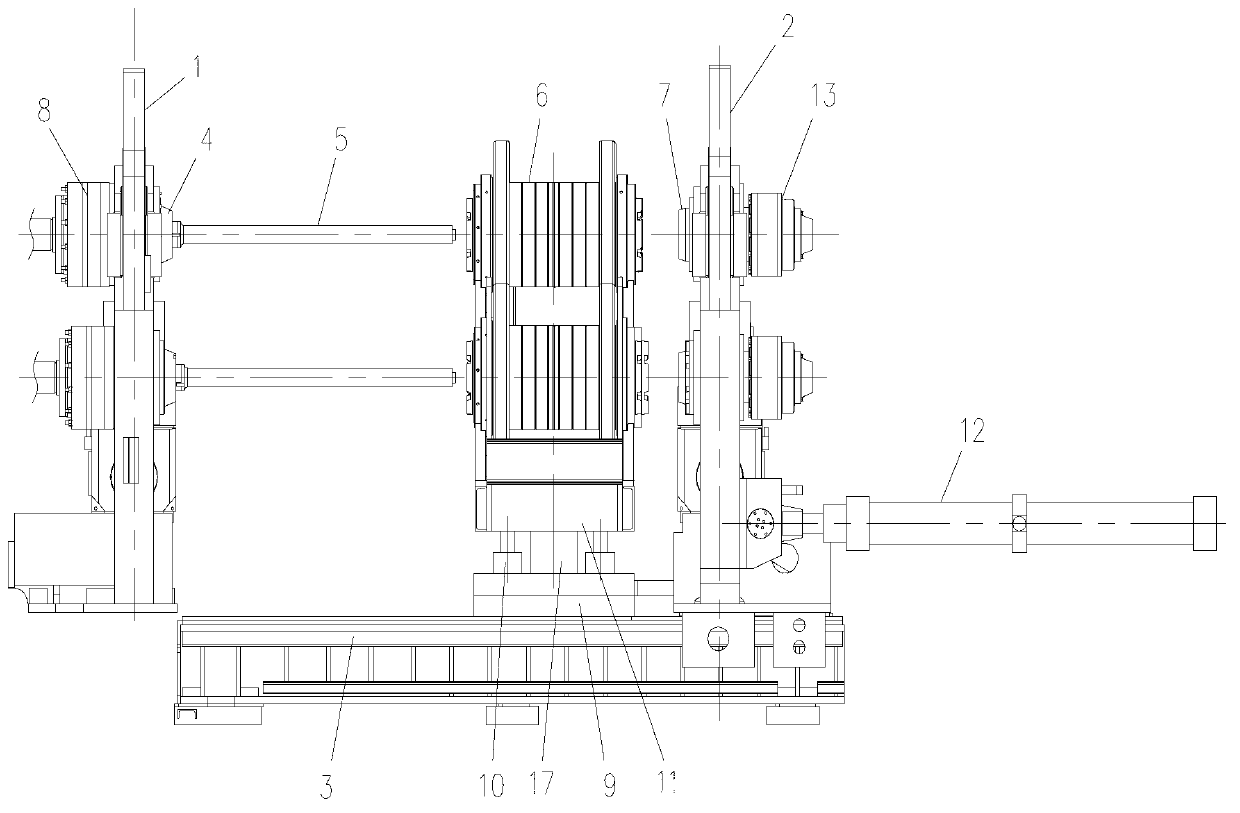

Straightener capable of changing rolls quickly

ActiveCN103272892AEasy to operateSimple and convenient operation of changing rollsMetal working apparatusOn boardEngineering

The invention discloses a straightener capable of changing rolls quickly. The straightener comprises a driving side frame, a rolling ring assembly, a sliding seat, an operation side frame, a transverse shifting device and an onboard roll changing device, and the on-board roll changing device comprises a roll changing trolley, a lifting device and a rolling ring storage table. The rolling ring storage table is arranged on a lifting device, and the roll changing trolley matches with the sliding seat in a reciprocating slide manner and is arranged on the sliding seat. The onboard roll changing device further comprises a positioning rolling ring storage table and a storage table positioning device opposite to the roll changing trolley in the horizontal direction. When rolls are changed, the rolling ring storage table is lifted to contact with the rolling ring assembly, then a locking device is released from a dragging rod, and the rolling changing trolley and the operation side frame are dragged by the transverse device to move horizontally to separate the rolling ring assembly from the dragging rod, so that the rolling ring assembly and the rolling ring storage table can be hoisted away in one piece. The straightener is simple and convenient in roll changing operation, and short in roll changing time; working efficiency of roll changing and device utilization efficiency can be improved; and the straightener has the advantages of small size, low cost and the like.

Owner:CISDI ENG CO LTD

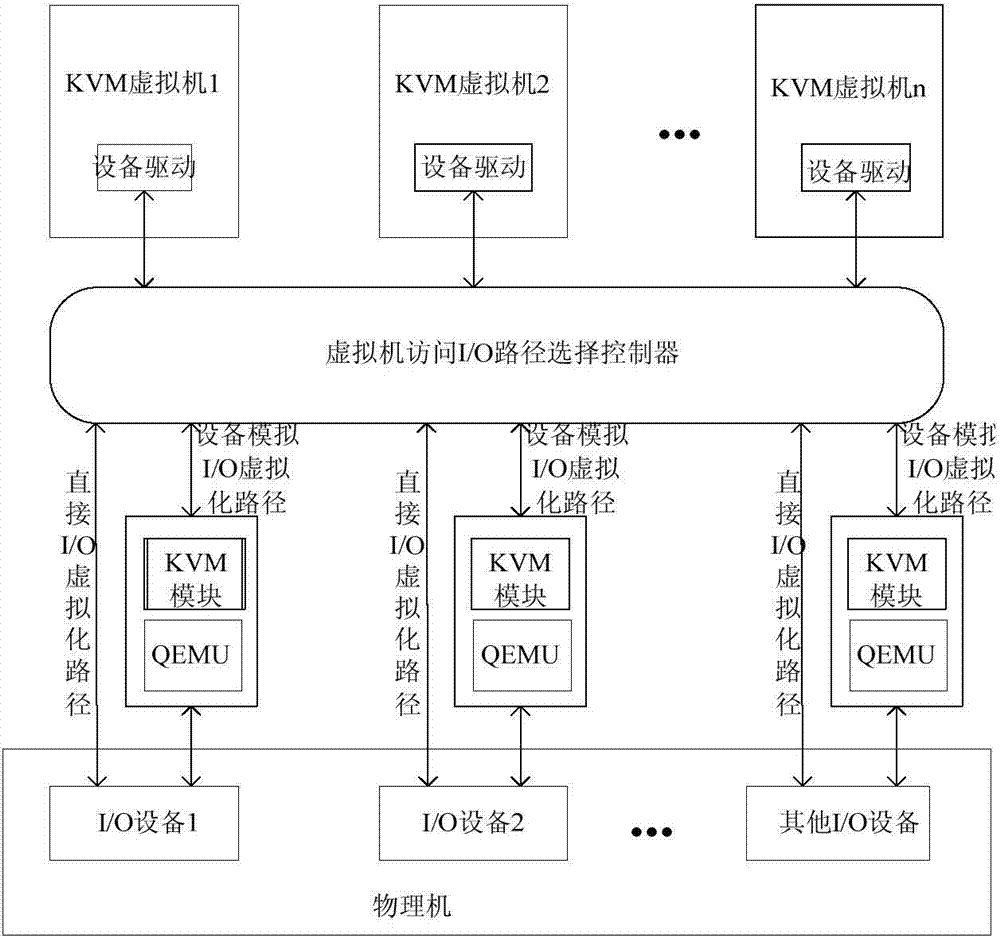

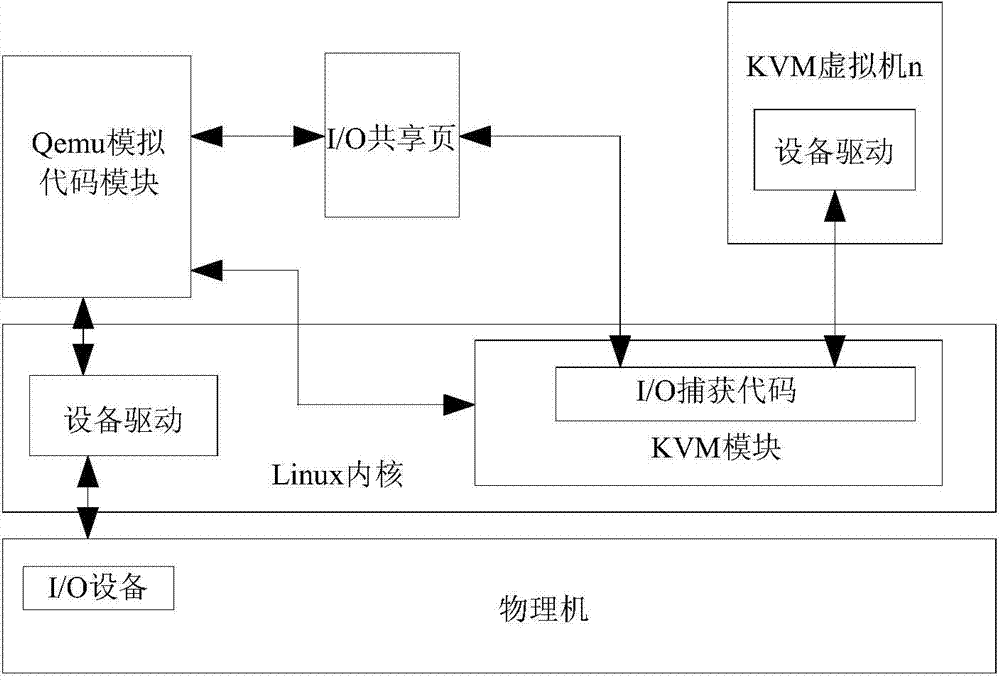

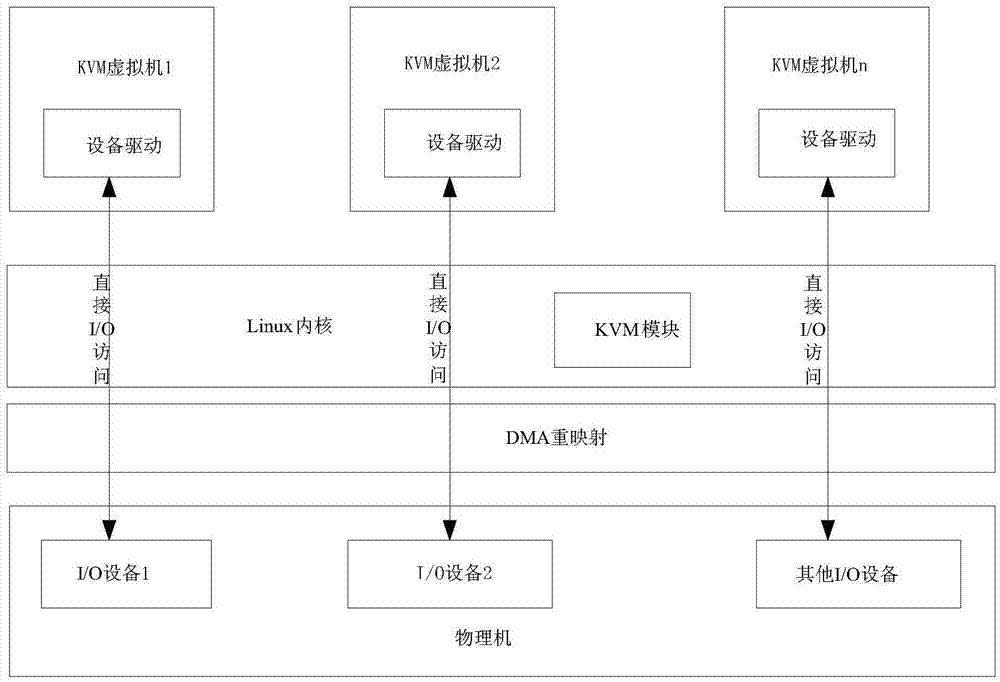

Mixed type equipment virtualization method based on KVM (Kernel-based Virtual Machine)

ActiveCN104503825ALower Average Access LatencyImprove equipment utilizationProgram initiation/switchingSoftware simulation/interpretation/emulationTime delaysVirtualization

The invention discloses a mixed type equipment virtualization method based on a KVM. An existing equipment virtualization model is additionally provided with a virtual machine access I / O (Input / Output) route selection controller; when the quantity of virtual machines which are to access I / O equipment is larger than the quantity of the I / O equipment on a physical machine, the virtual machines access the I / O equipment by adopting an equipment simulation I / O virtual route; when the quantity of the virtual machines which are to access the I / O equipment is smaller than the quantity of the I / O equipment on the physical machine, the virtual machines access the I / O equipment by adopting a direct I / O virtual route. The method disclosed by the invention has the advantages of reducing the average time delay for the virtual machines to access the I / O equipment and simultaneously increasing the utilization rate of the equipment.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com