Patents

Literature

569results about How to "Reduce recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

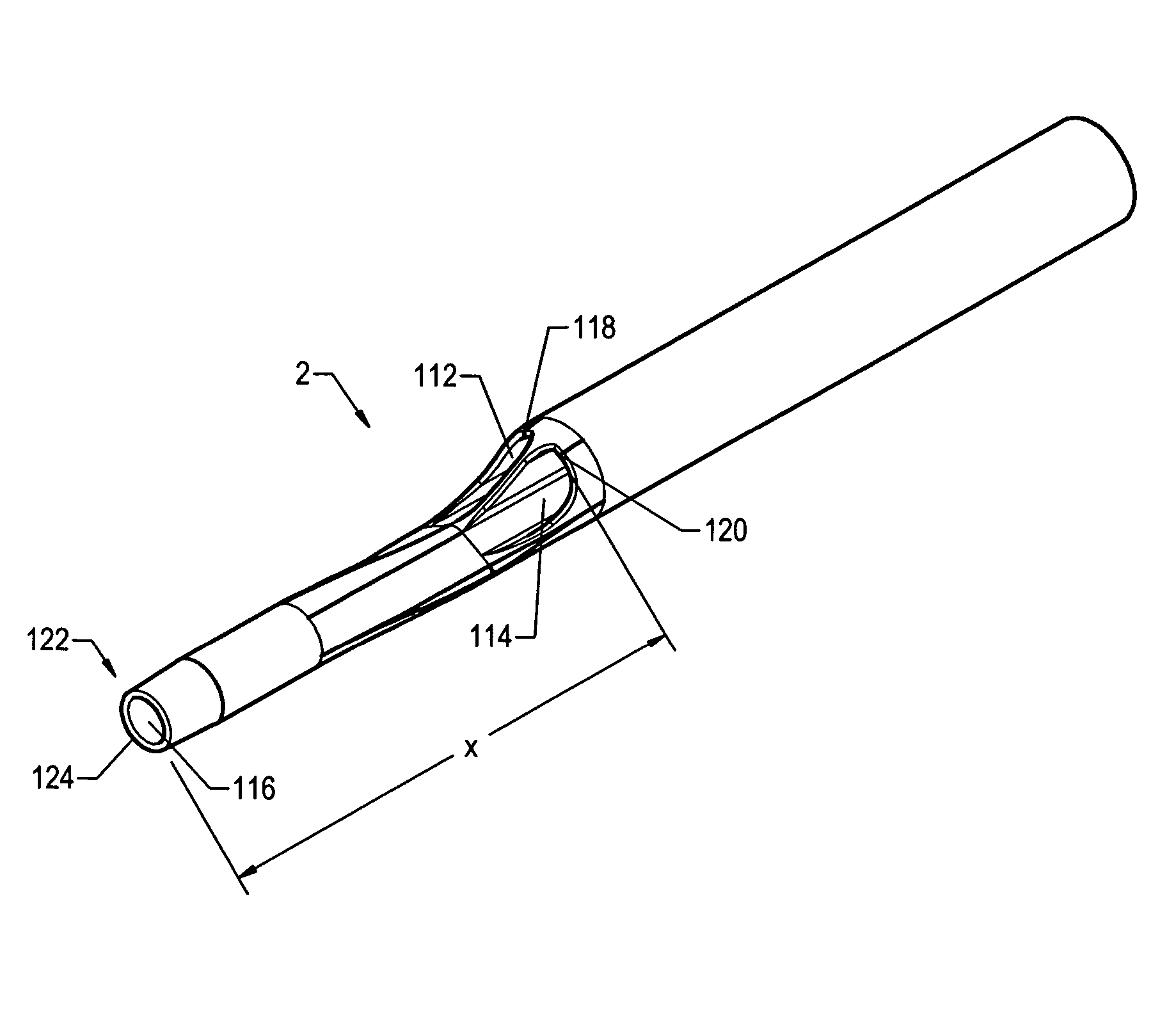

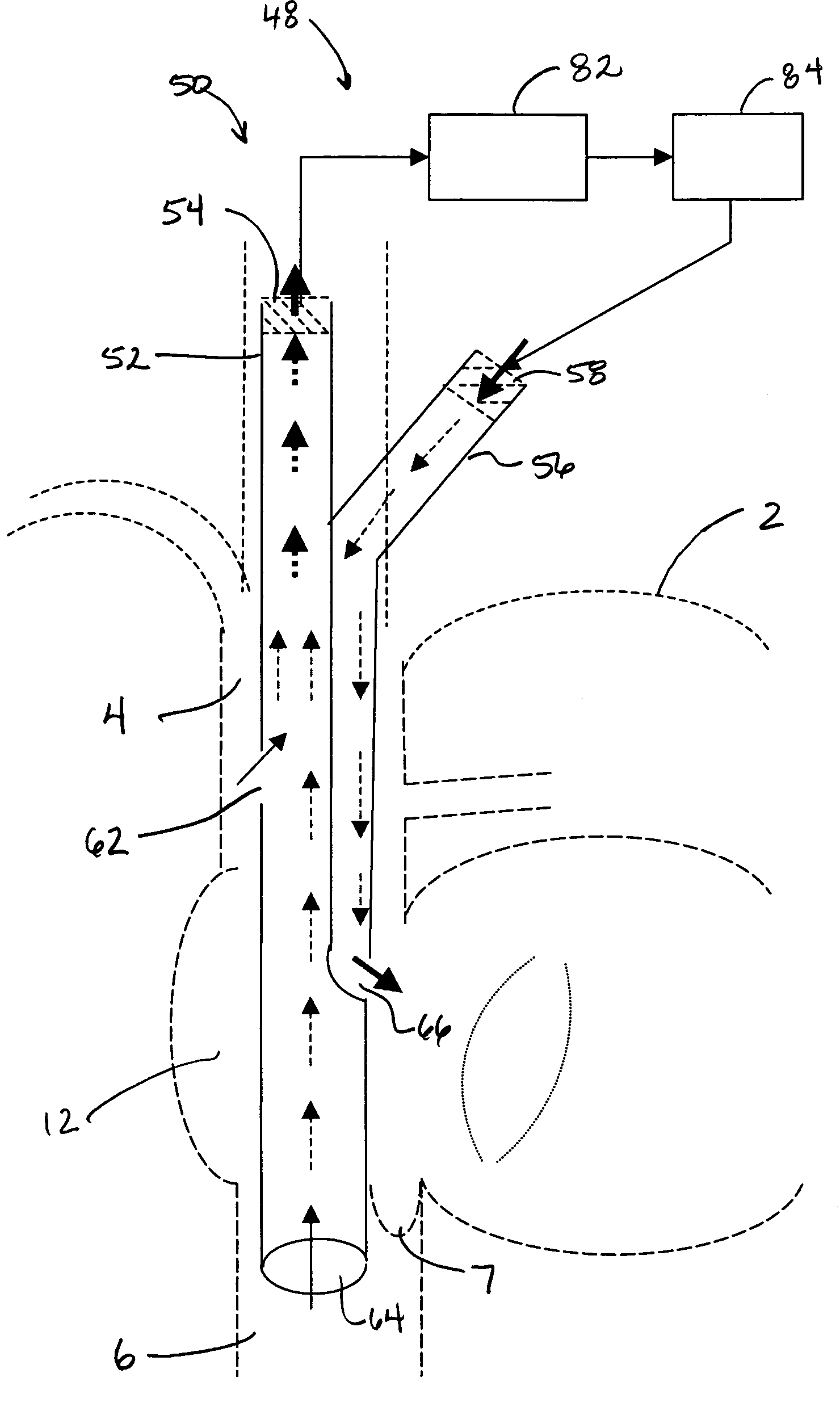

Reduction of recirculation in catheters

InactiveUS20060004316A1Decrease outflow velocity of fluidPrevent sprayingMedical devicesCatheterDistal portionNose

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

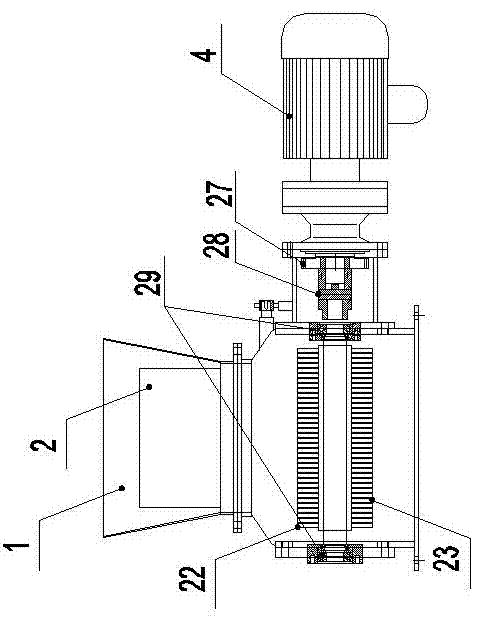

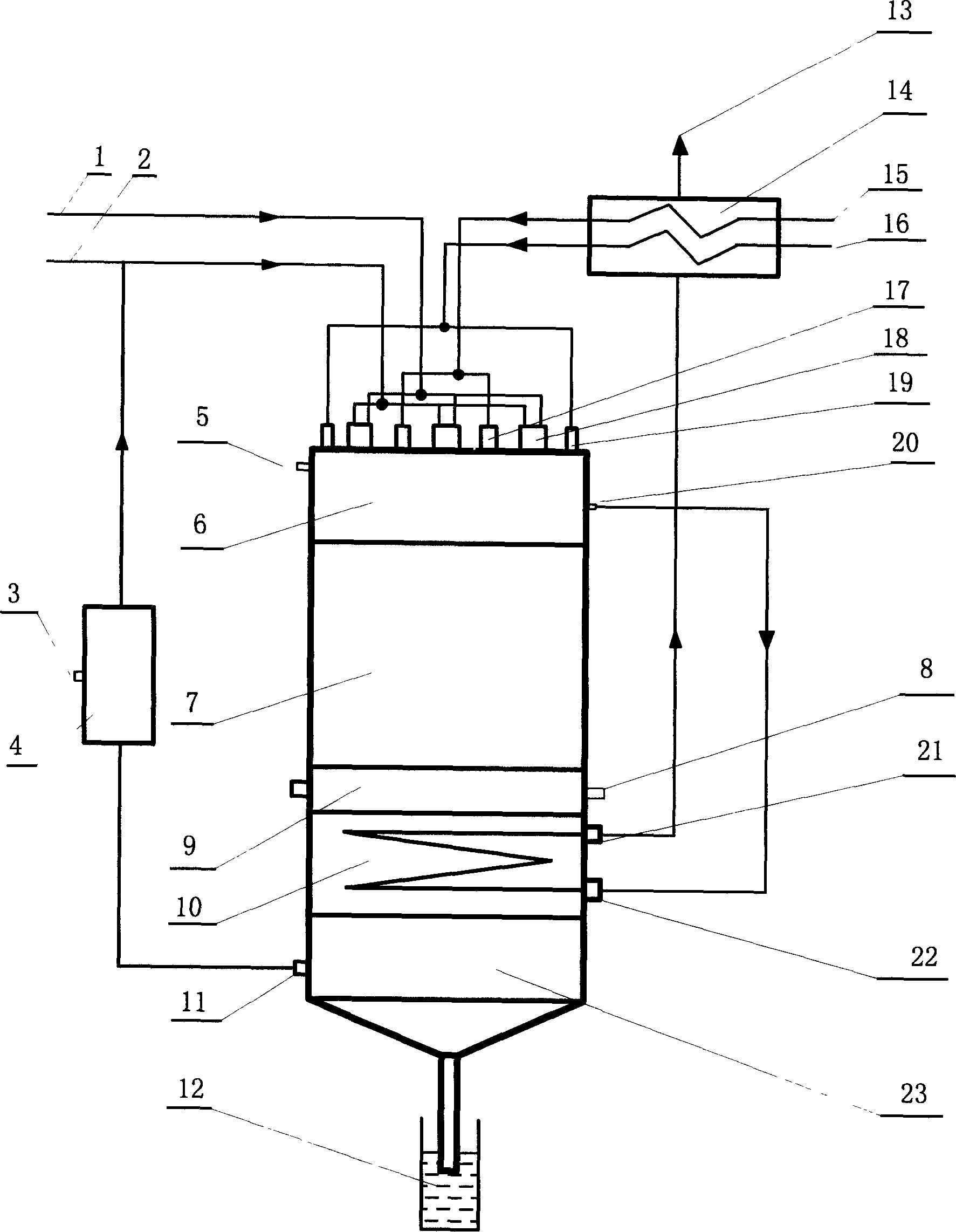

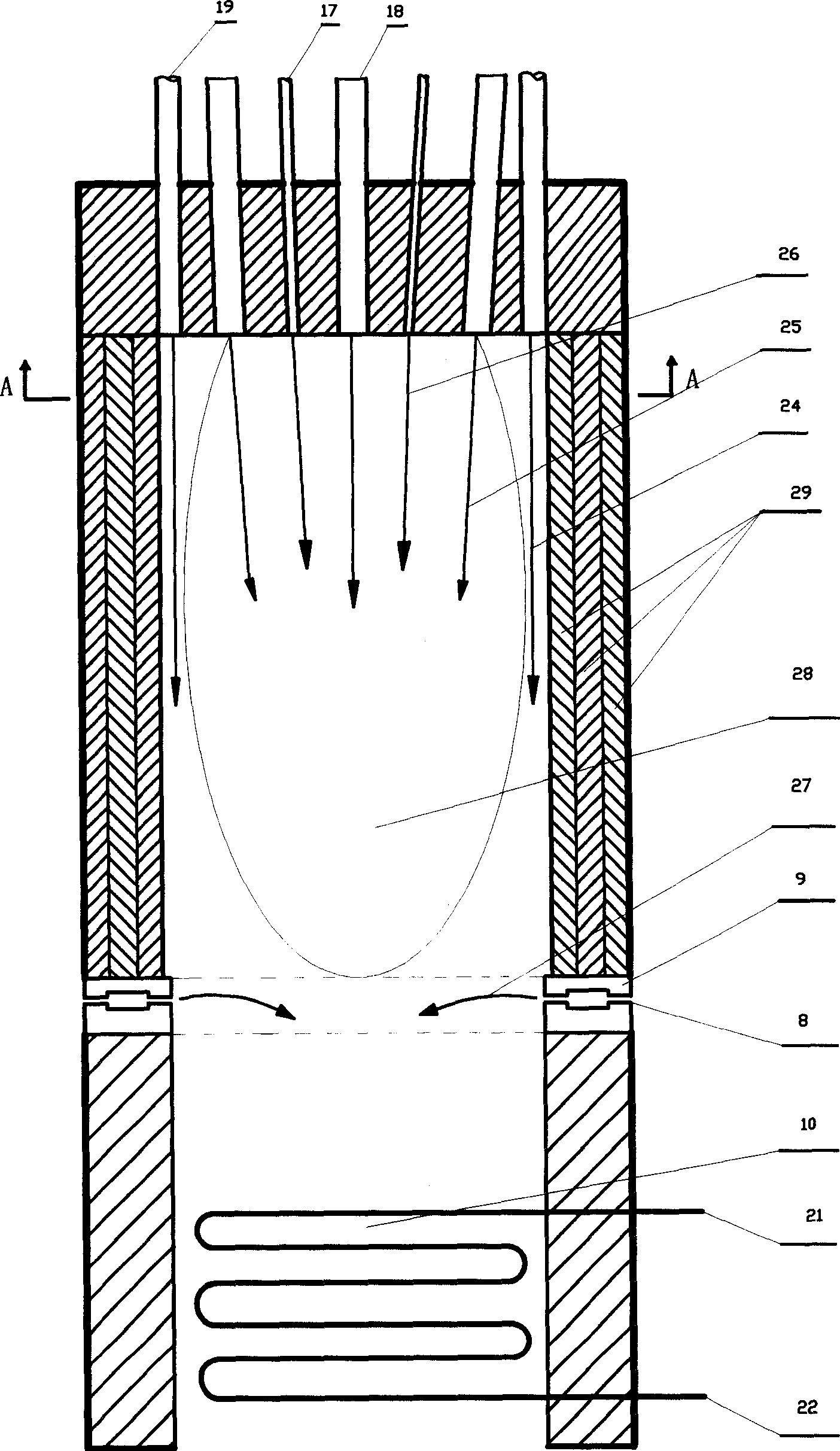

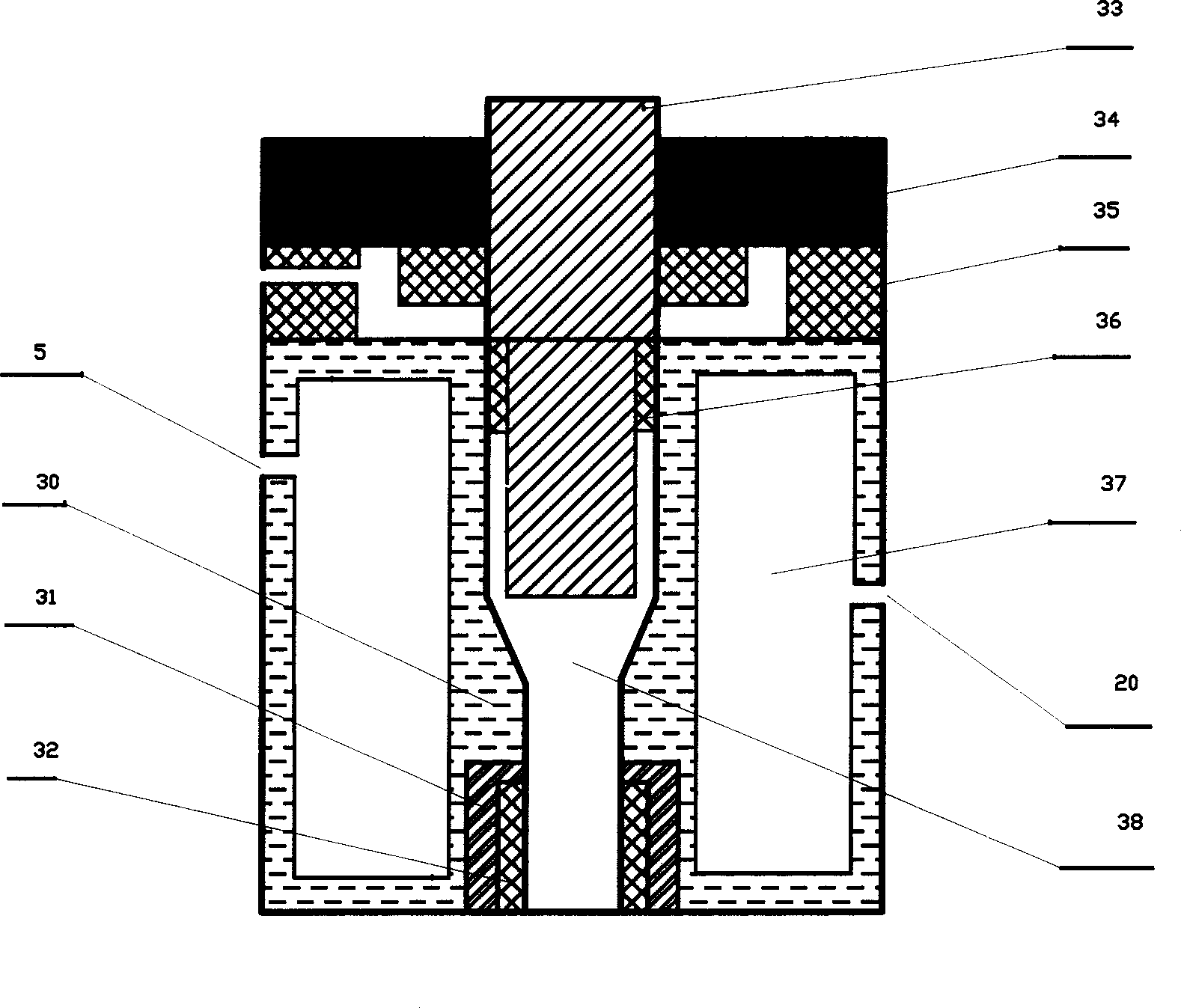

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

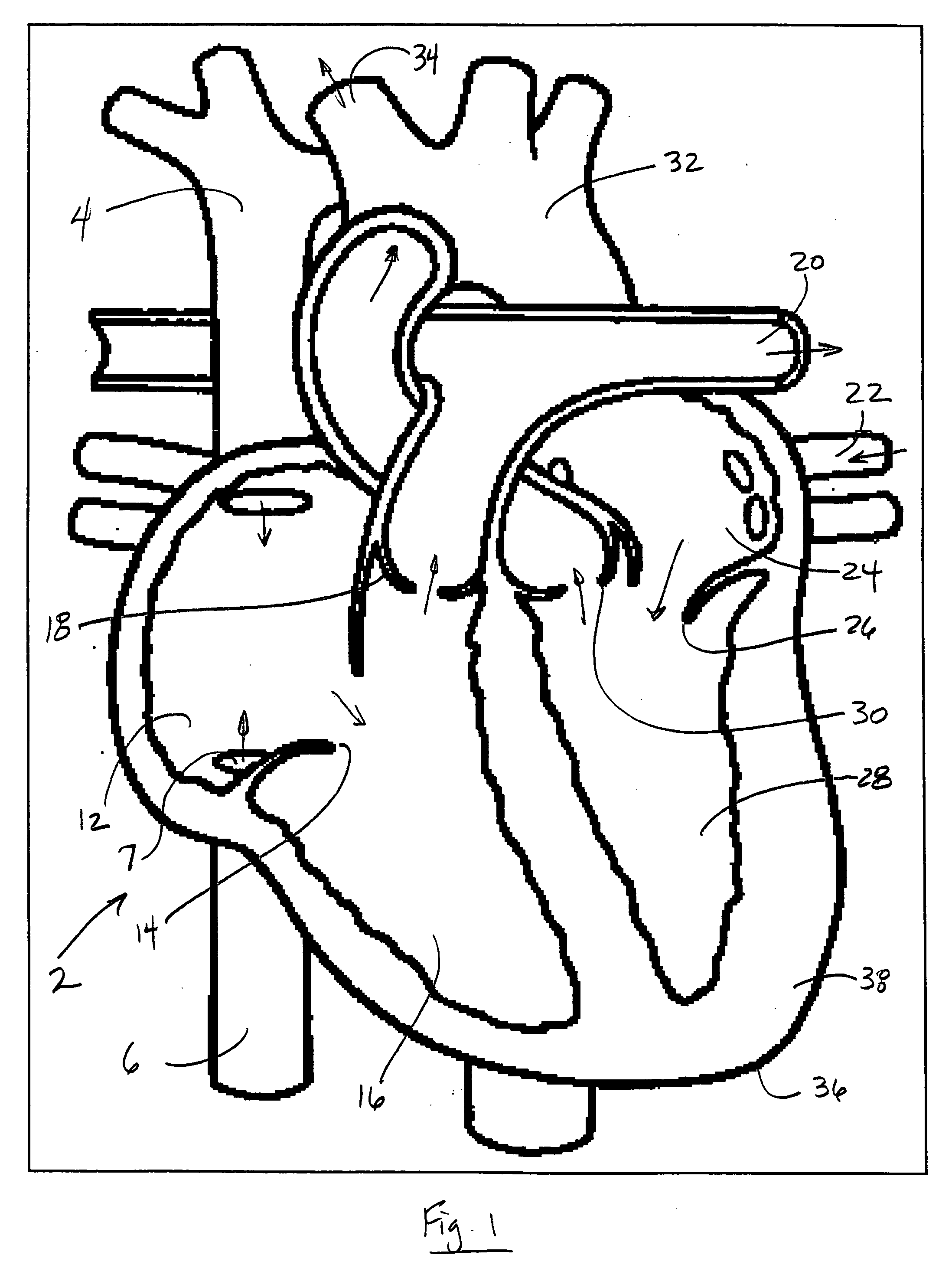

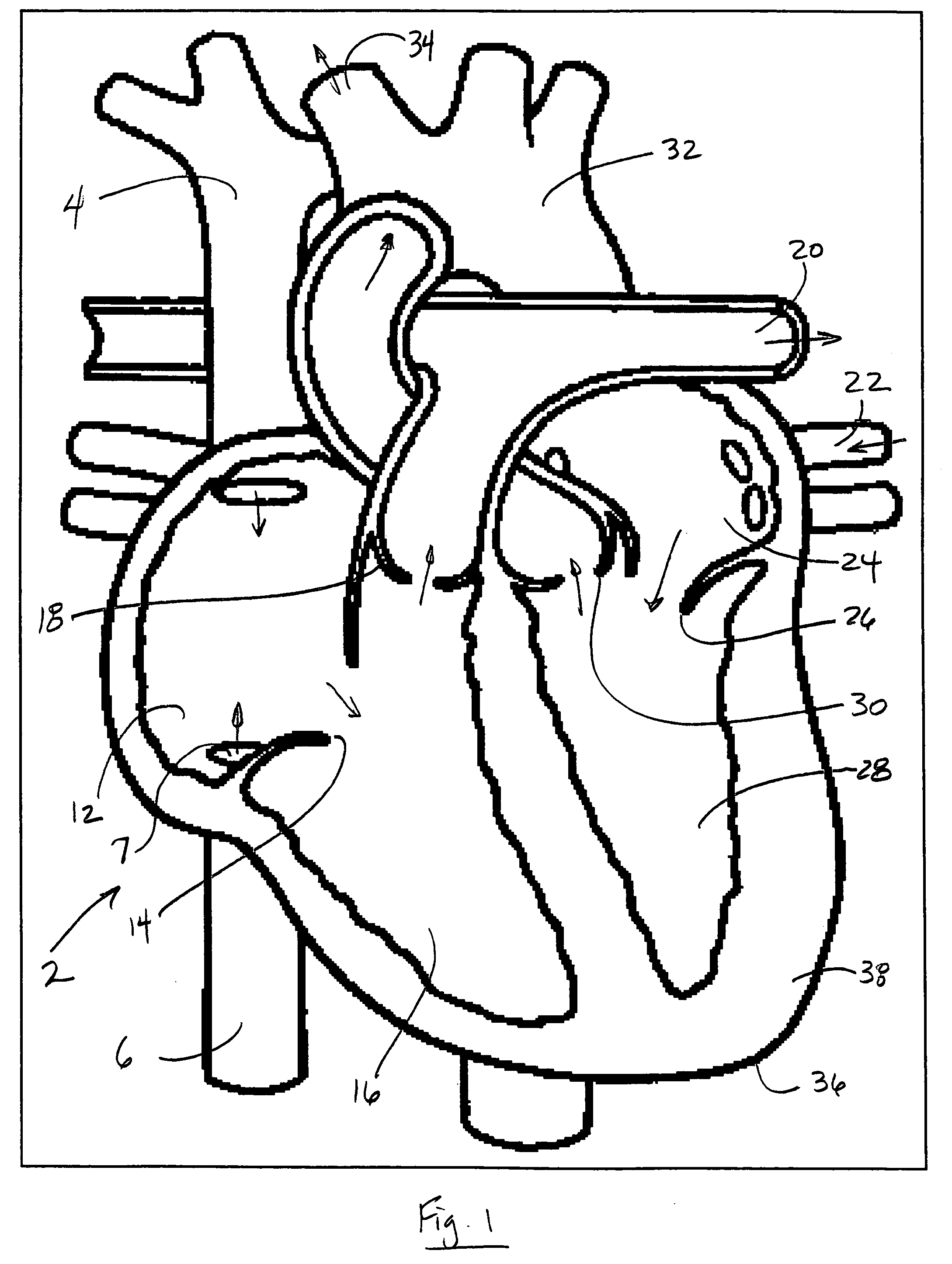

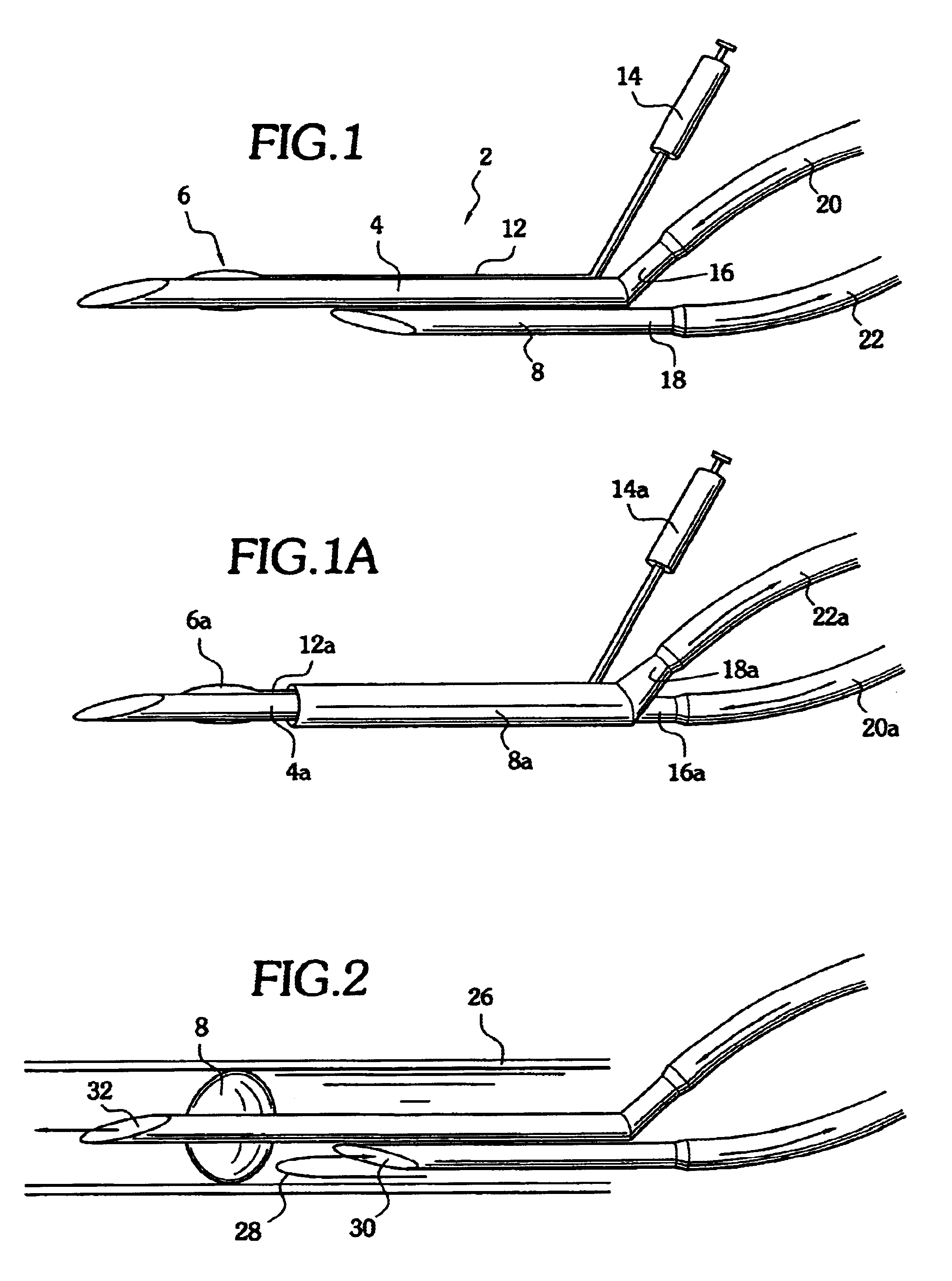

Single expandable double lumen cannula assembly for veno-venous ECMO

ActiveUS20050085761A1Insufficient gas exchangeDecreased surgical and blood traumaMulti-lumen catheterOther blood circulation devicesVeinVenous blood

The present invention provides an apparatus, system, and method of use of a simple, less invasive, self-expandable percutaneous double lumen cannula assembly for VV ECMO that overcomes the limitations and obstacles of the techniques described above. The present invention achieves near theoretical total venous blood drainage, total extracorporeal gas exchange, and prevents recirculation and multiple cannulation, thereby simplifying VV ECMO, decreasing surgical and blood trauma, and expanding its application.

Owner:THE UNIV OF TEXAS SYST

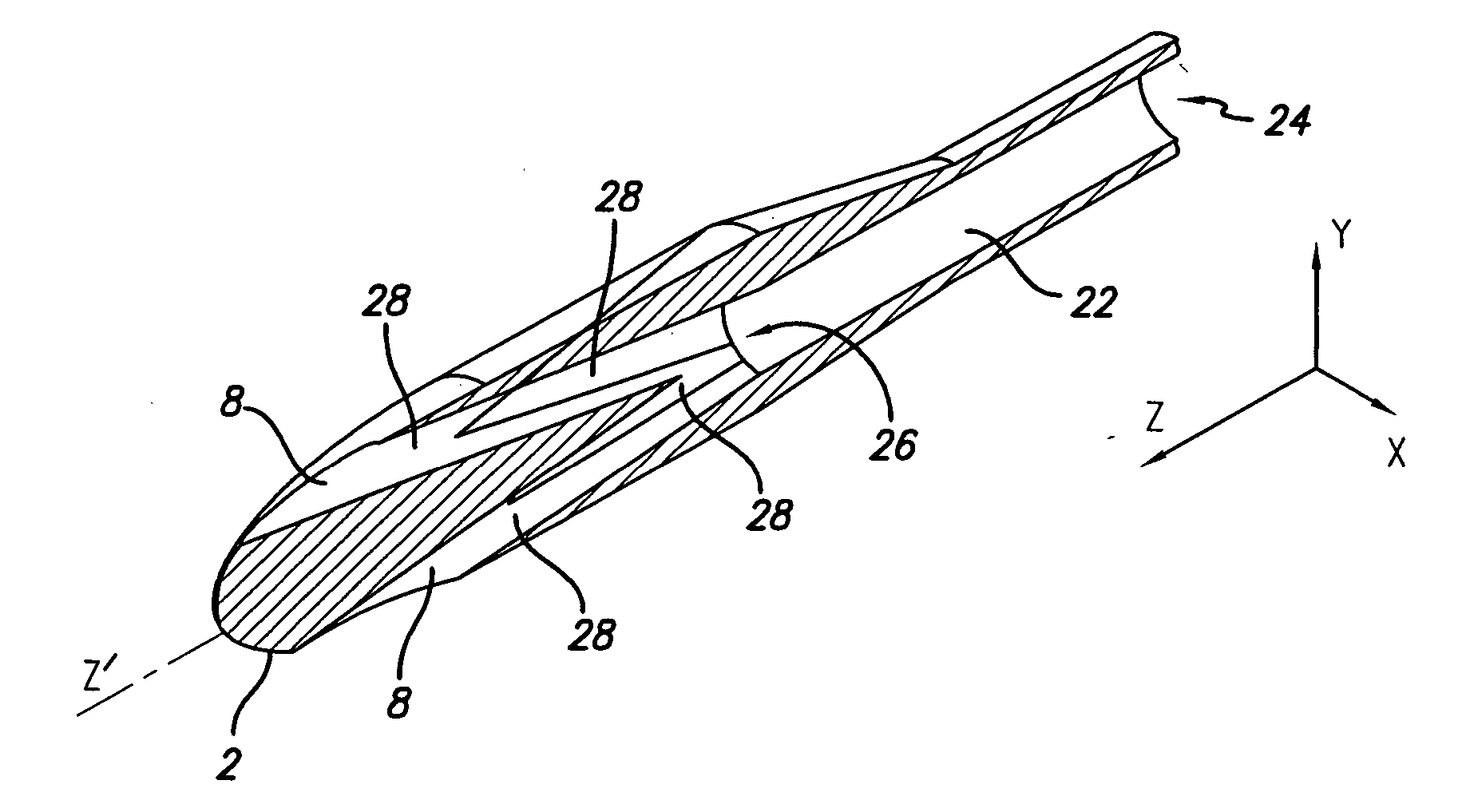

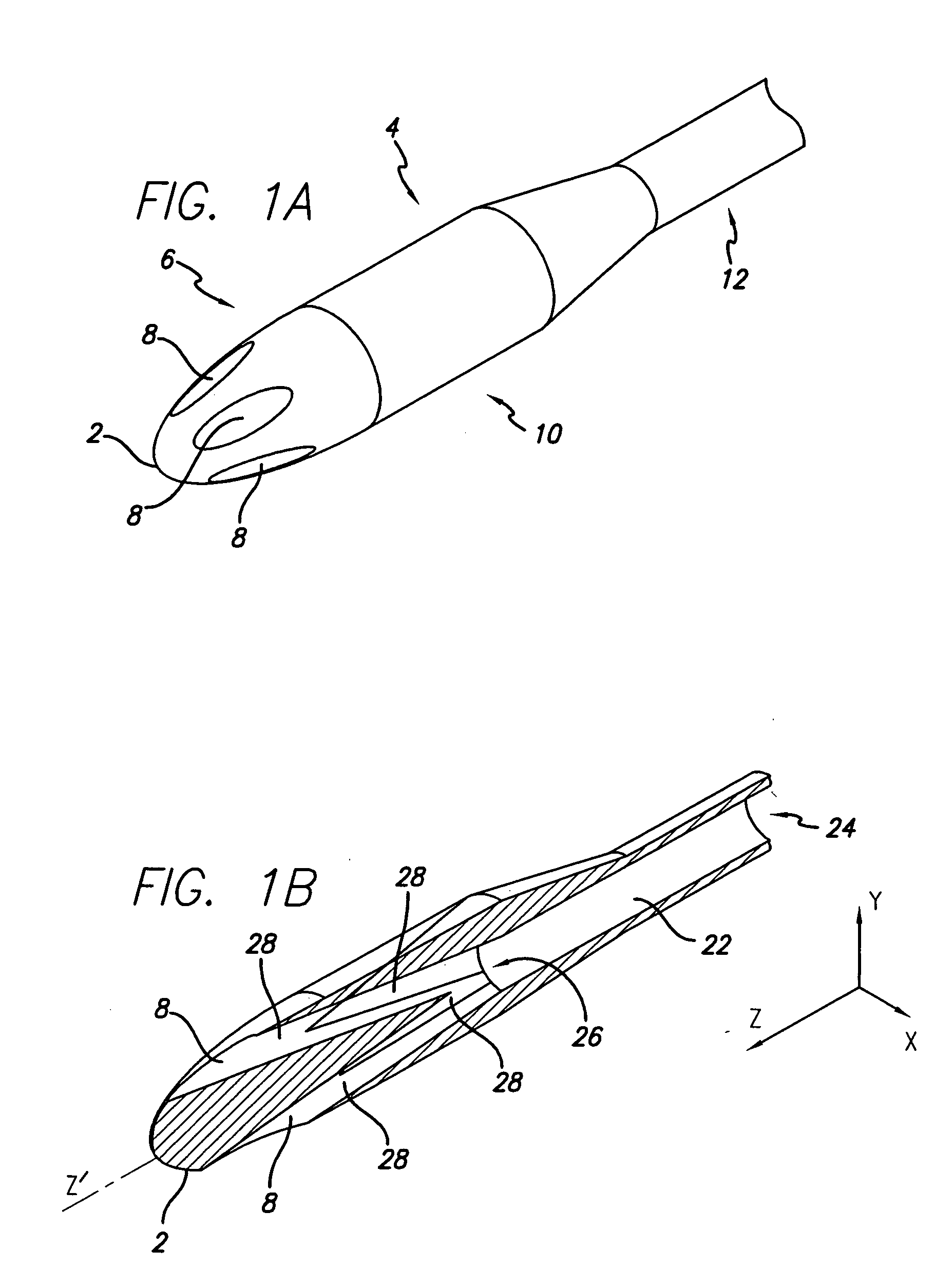

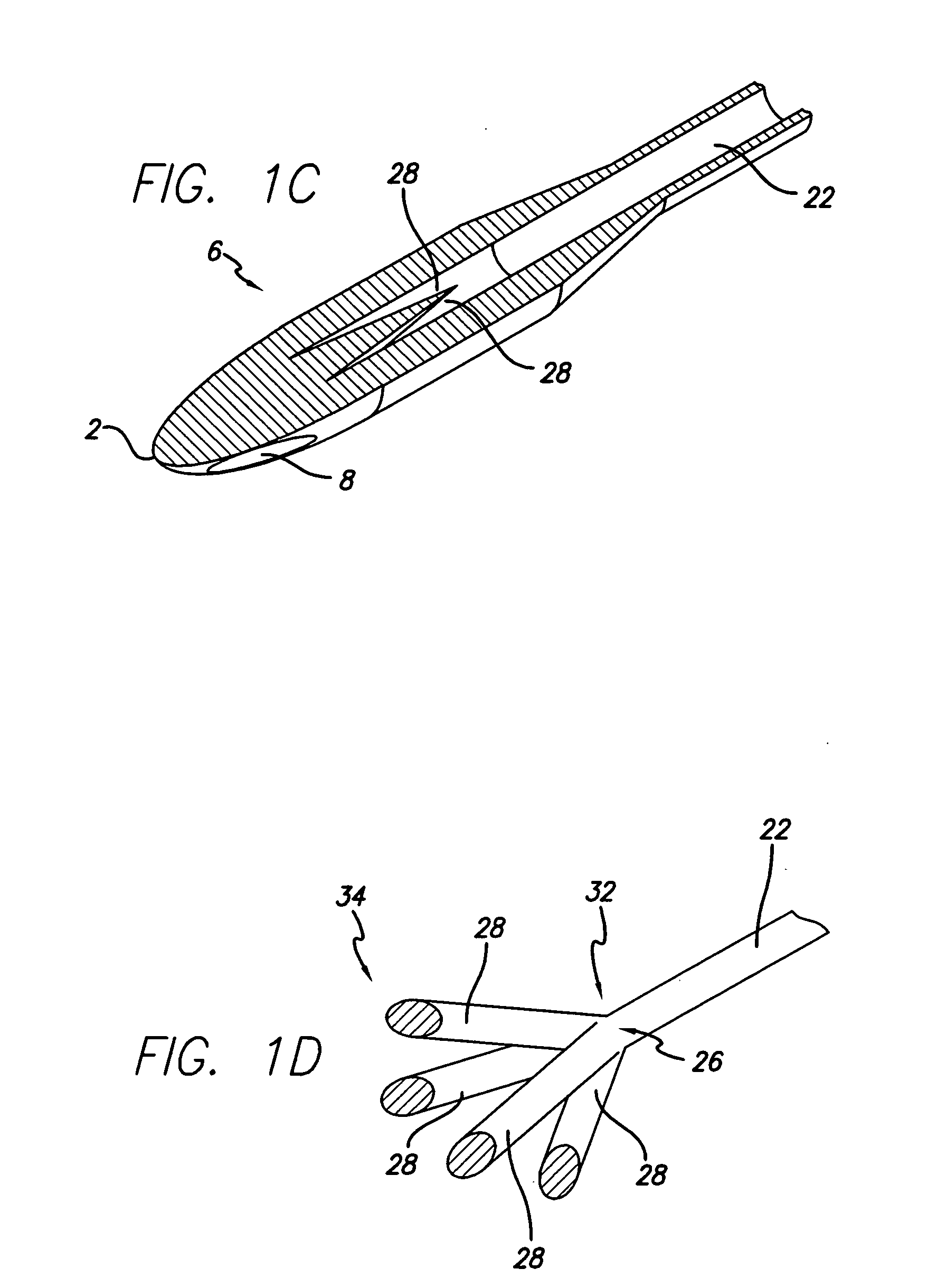

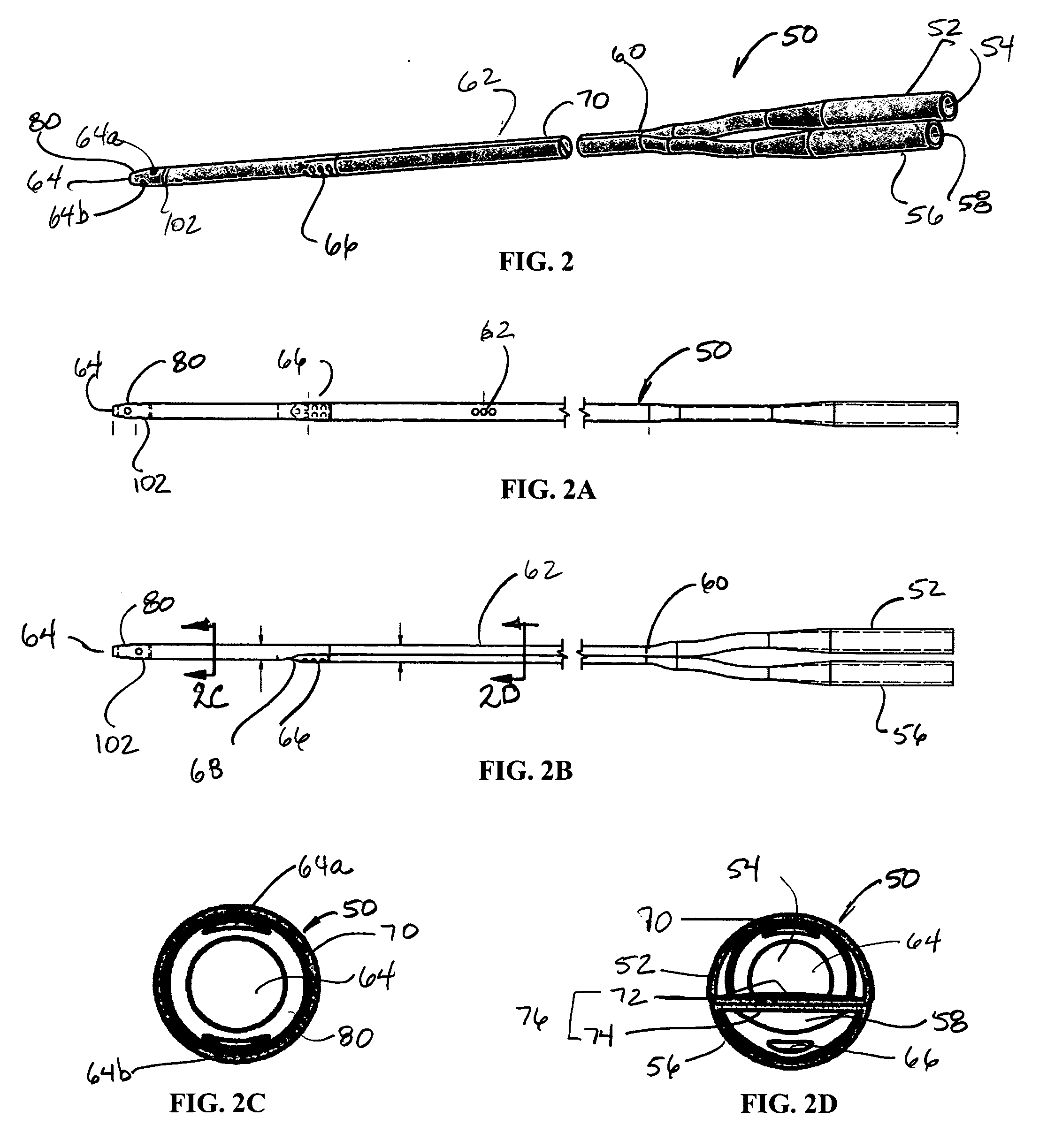

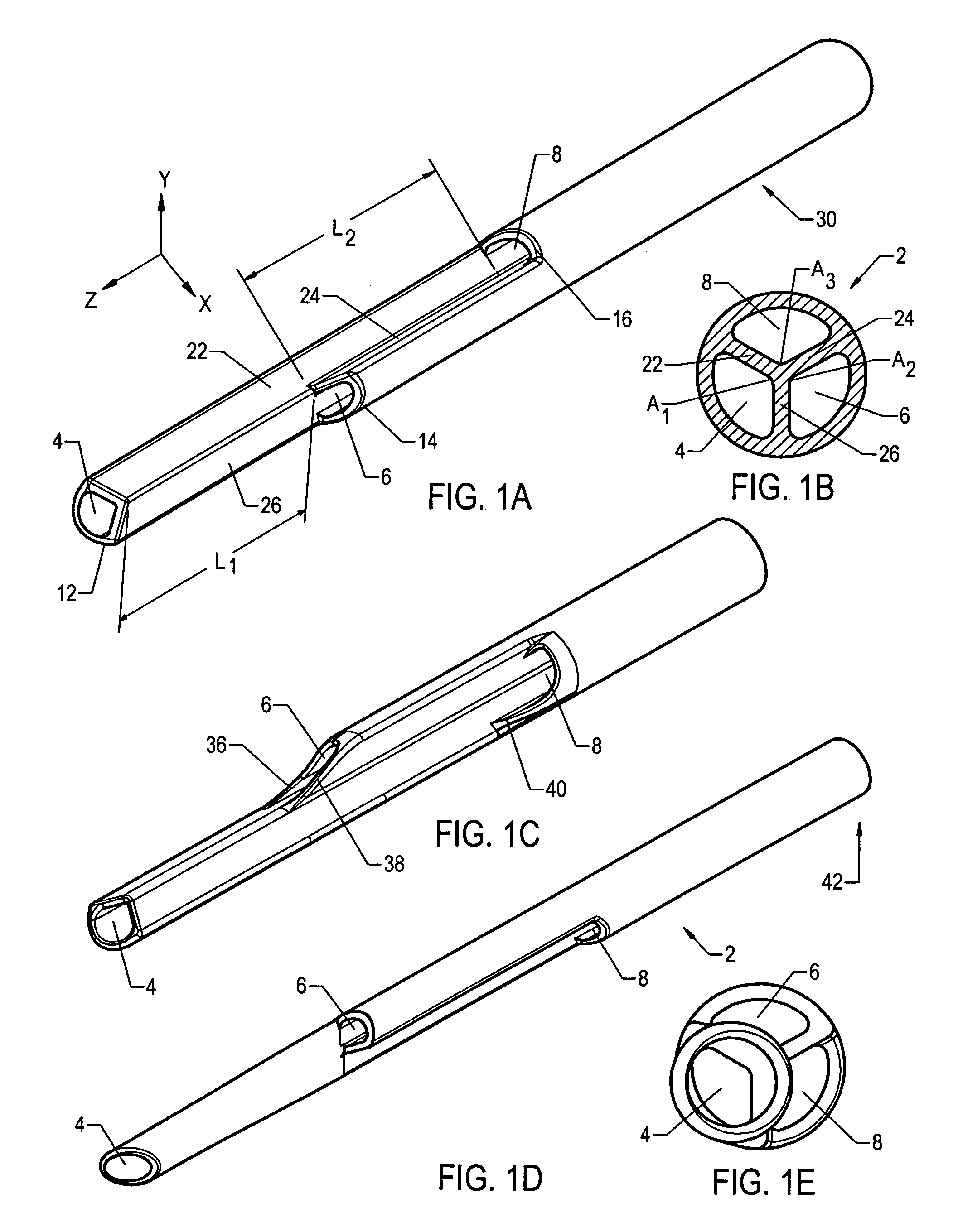

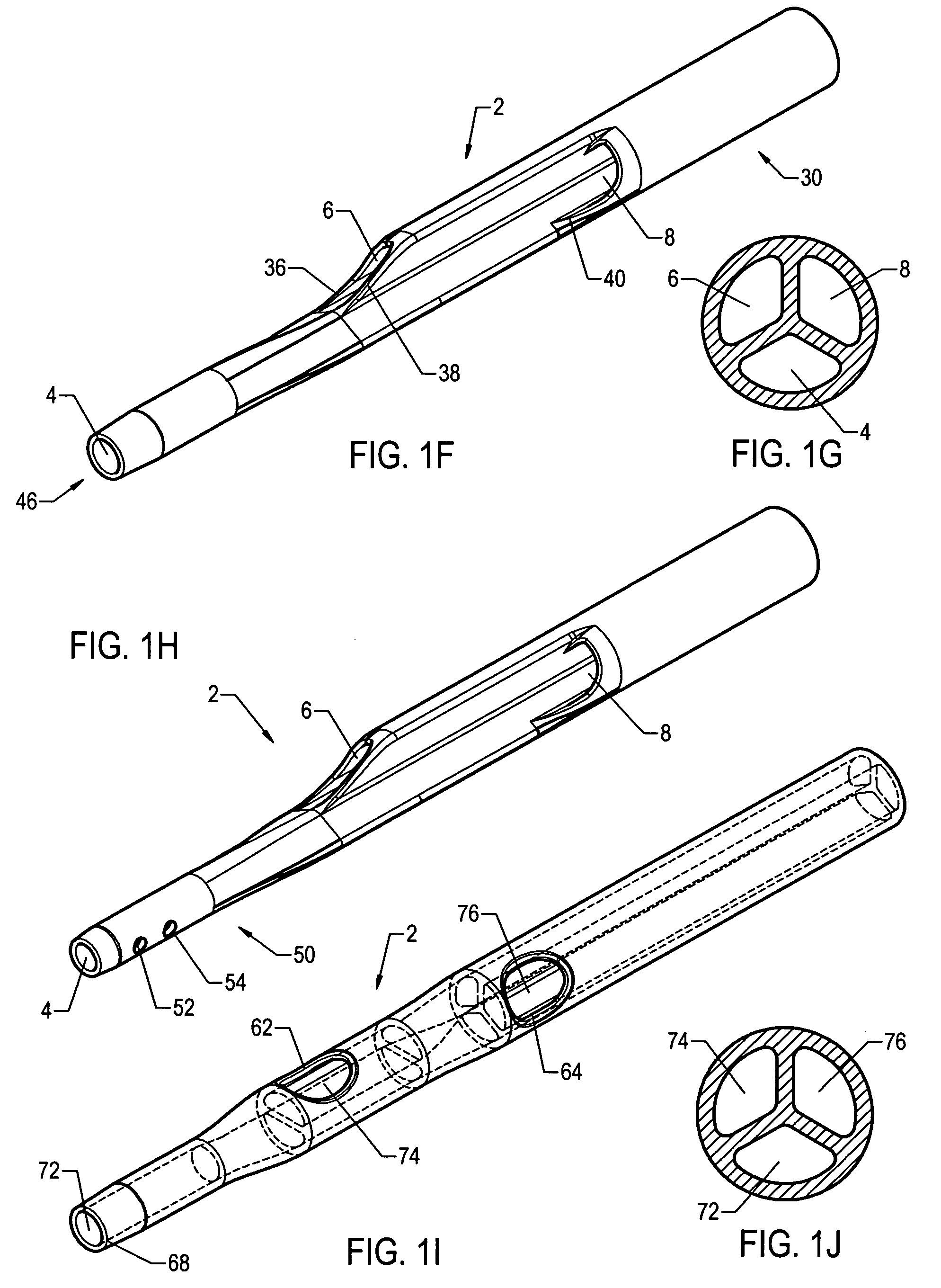

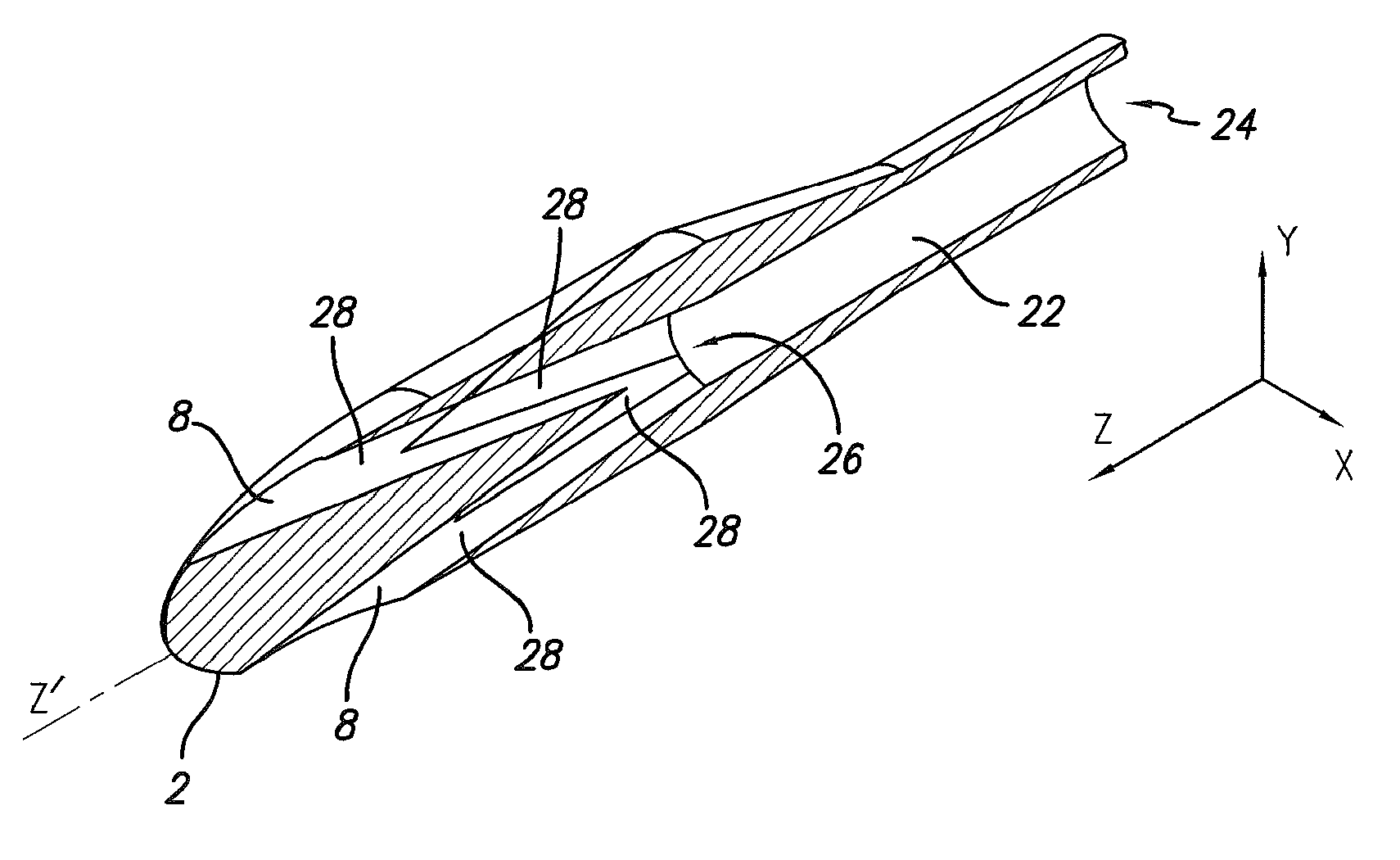

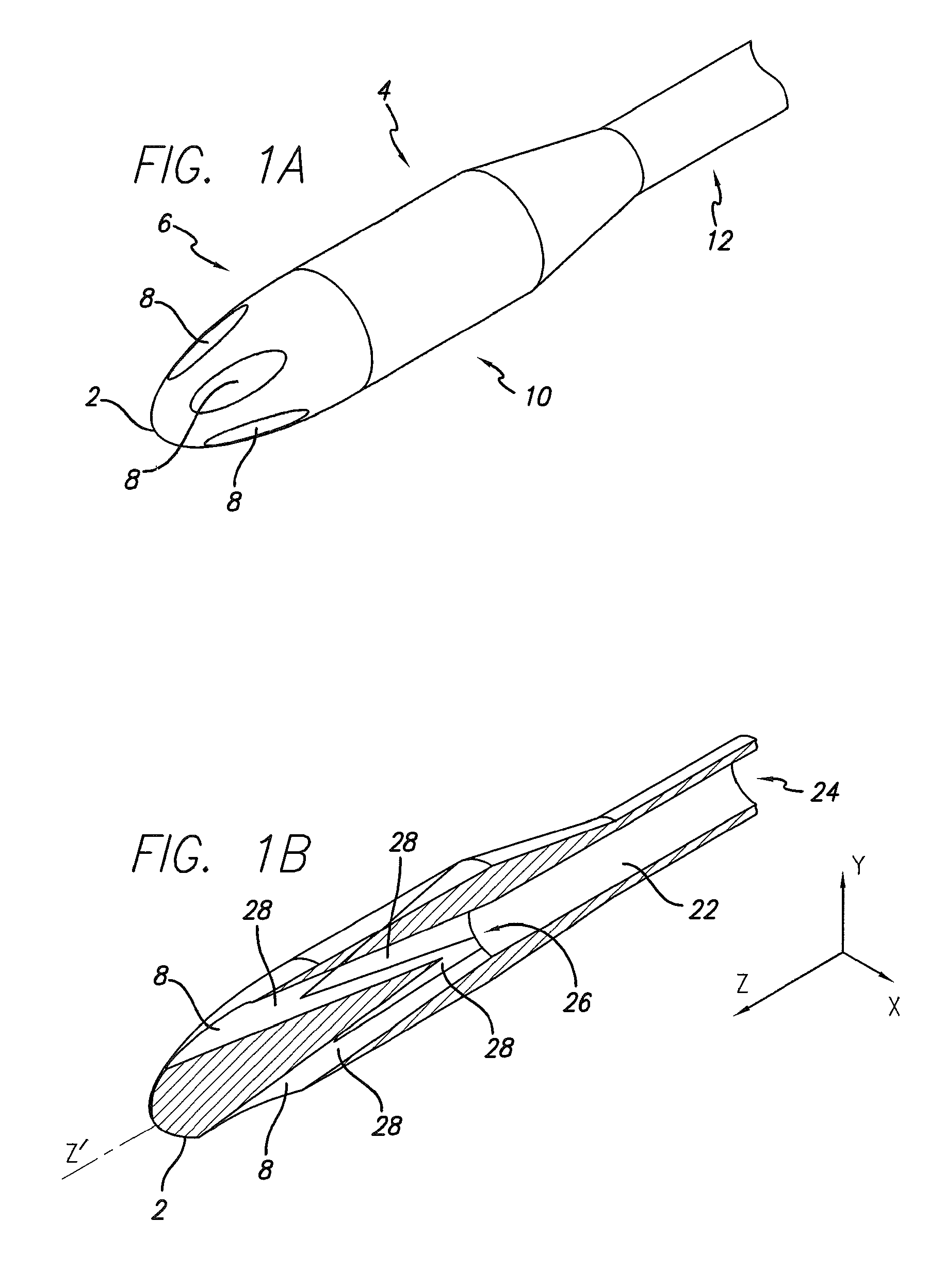

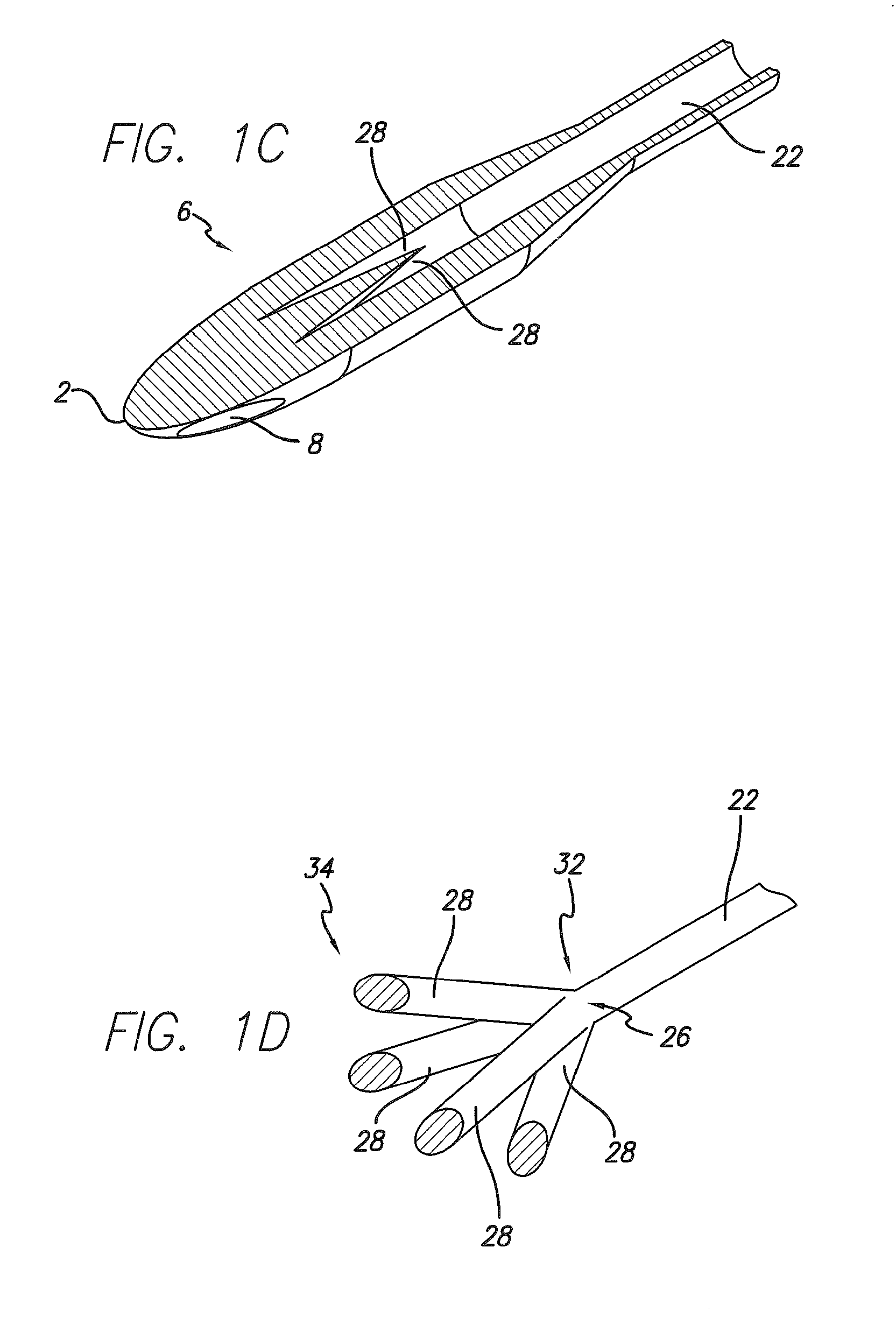

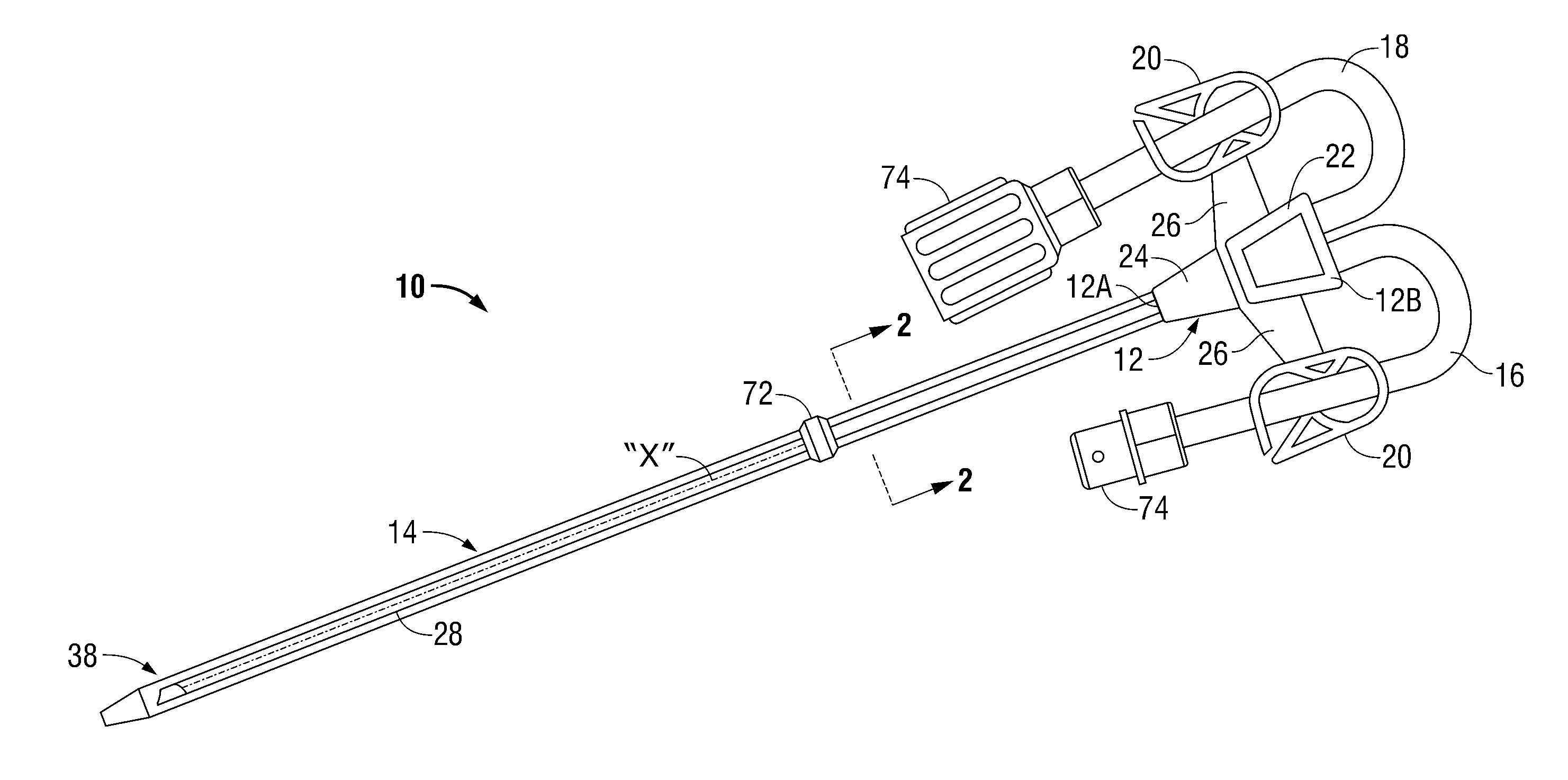

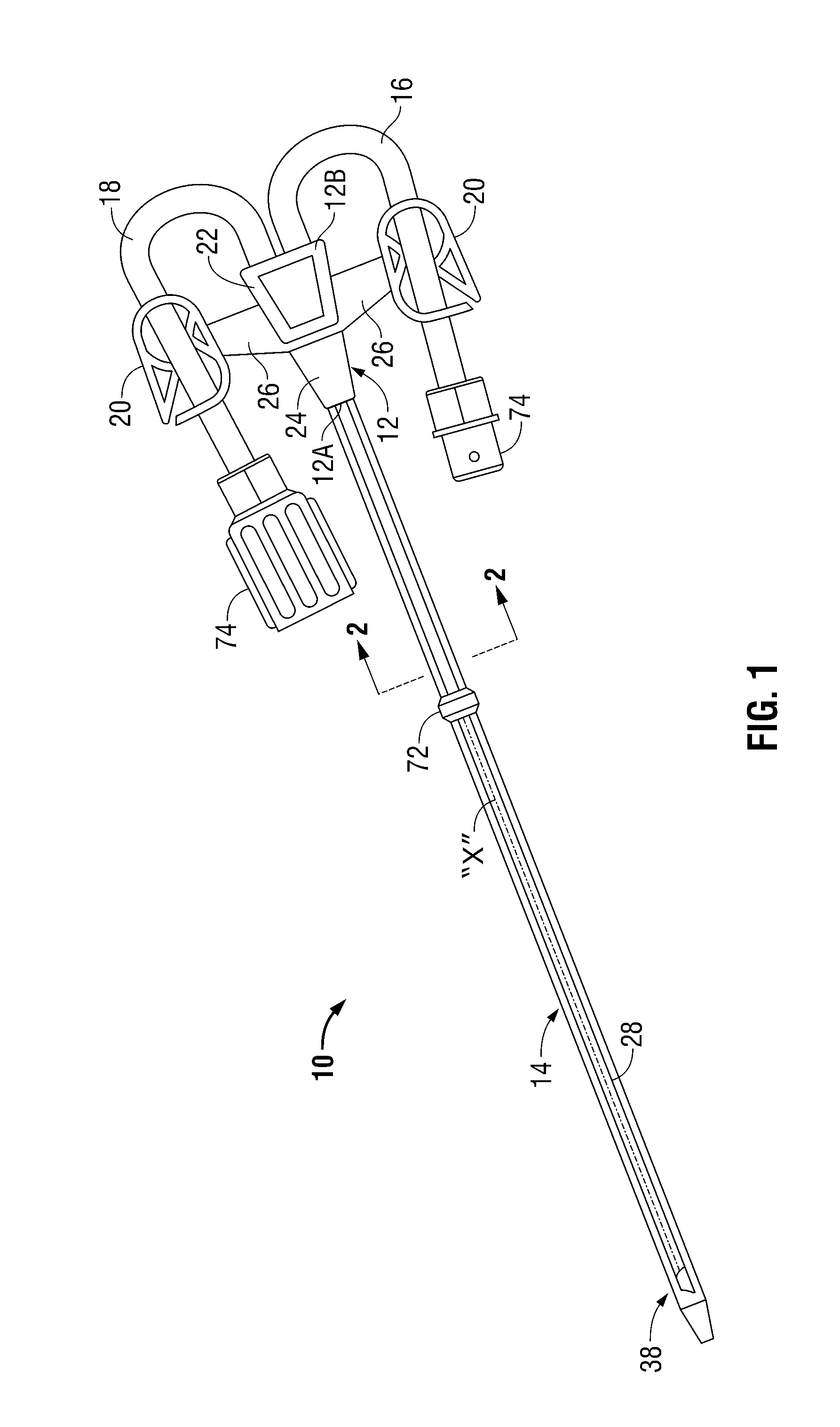

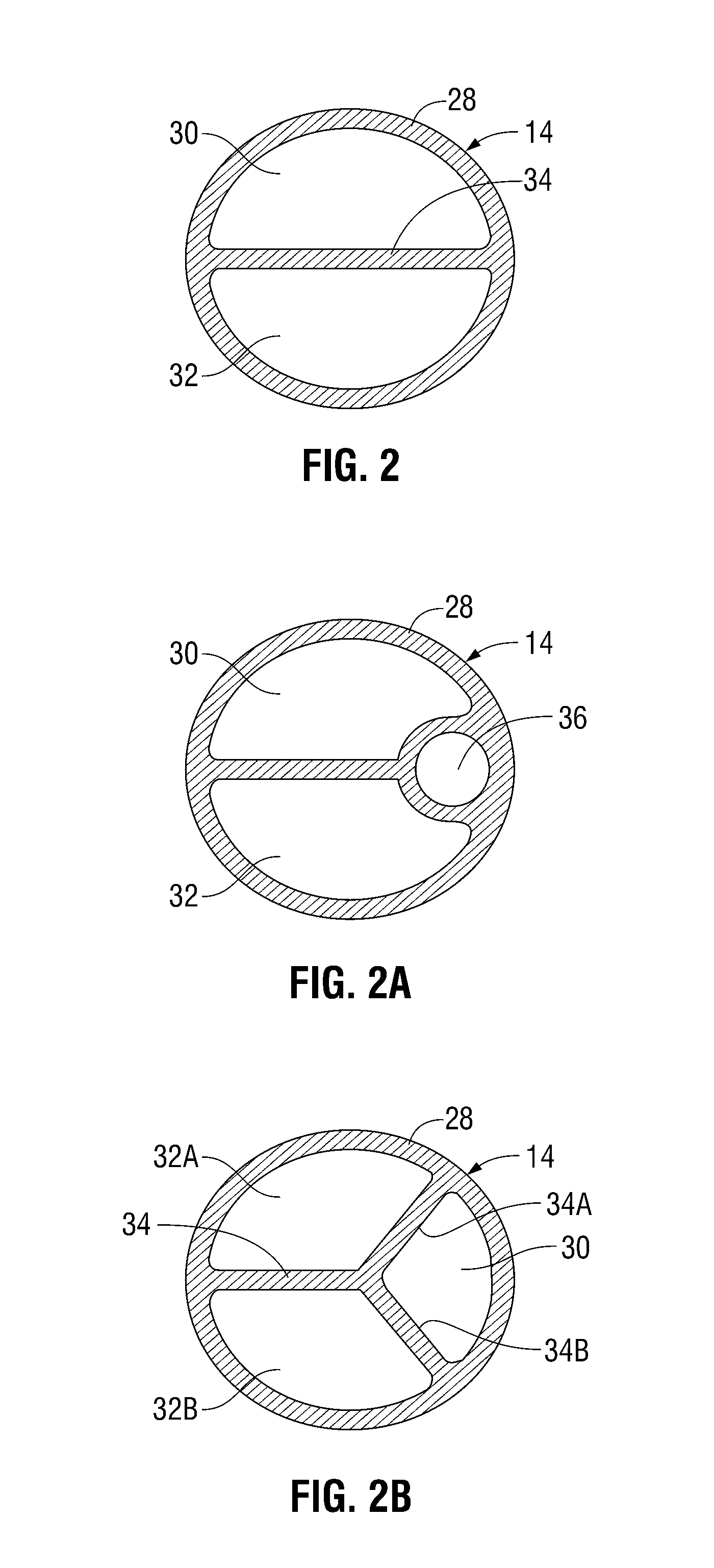

Tip configurations for a multi-lumen catheter

ActiveUS8323227B2Reduce recyclingImprove throughput efficiencyMulti-lumen catheterInfusion devicesTriple lumen catheterCatheter device

Multi-lumen catheters with improved tip configurations, including a triple-lumen catheter which may be useful for apheresis. In one variation, the catheter has three lumens with distal openings angularly spaced apart and staggered axially with respect to one another. In another variation, the catheter has two lumens exiting distally and one centrally positioned lumen exiting proximally. A third variation is a catheter with a single distal opening and two proximal openings. The staggered lumen openings along the axial length of the catheter may decrease recirculation while maximizing flow rates.

Owner:CR BARD INC

Single expandable double lumen cannula assembly for veno-venous ECMO

ActiveUS7473239B2Decreased surgical and blood traumaLess invasiveMulti-lumen catheterOther blood circulation devicesVeinVenous blood

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

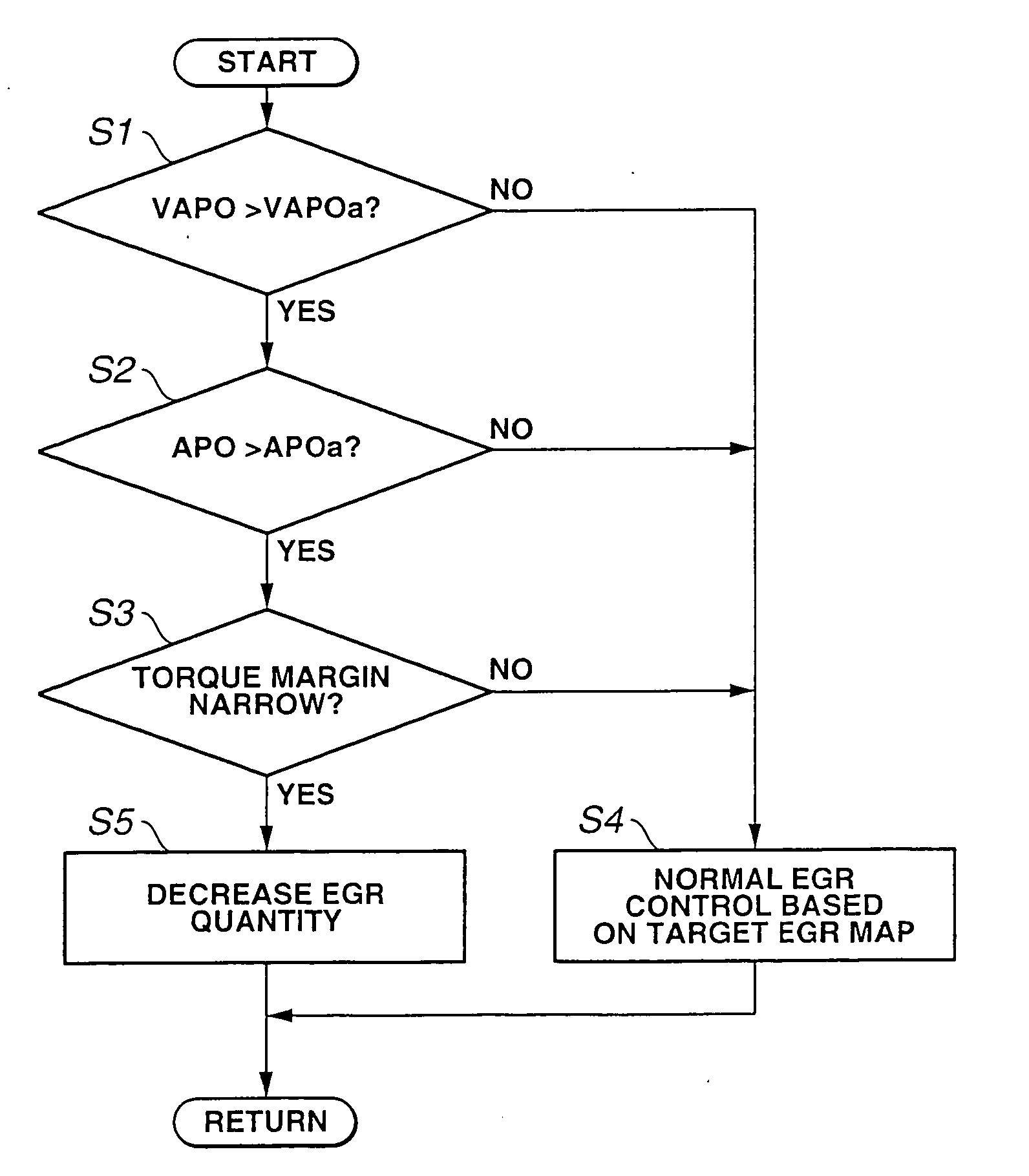

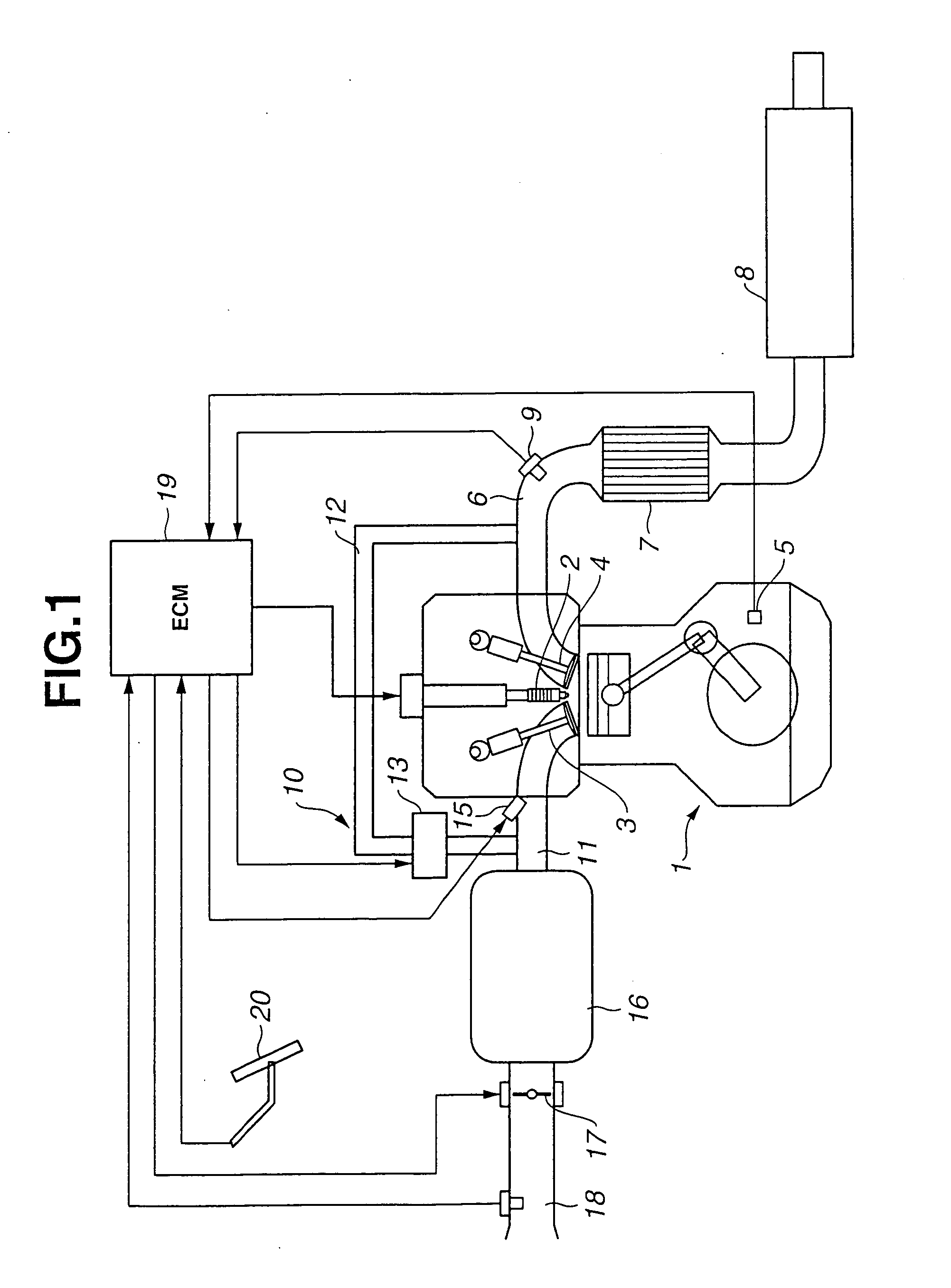

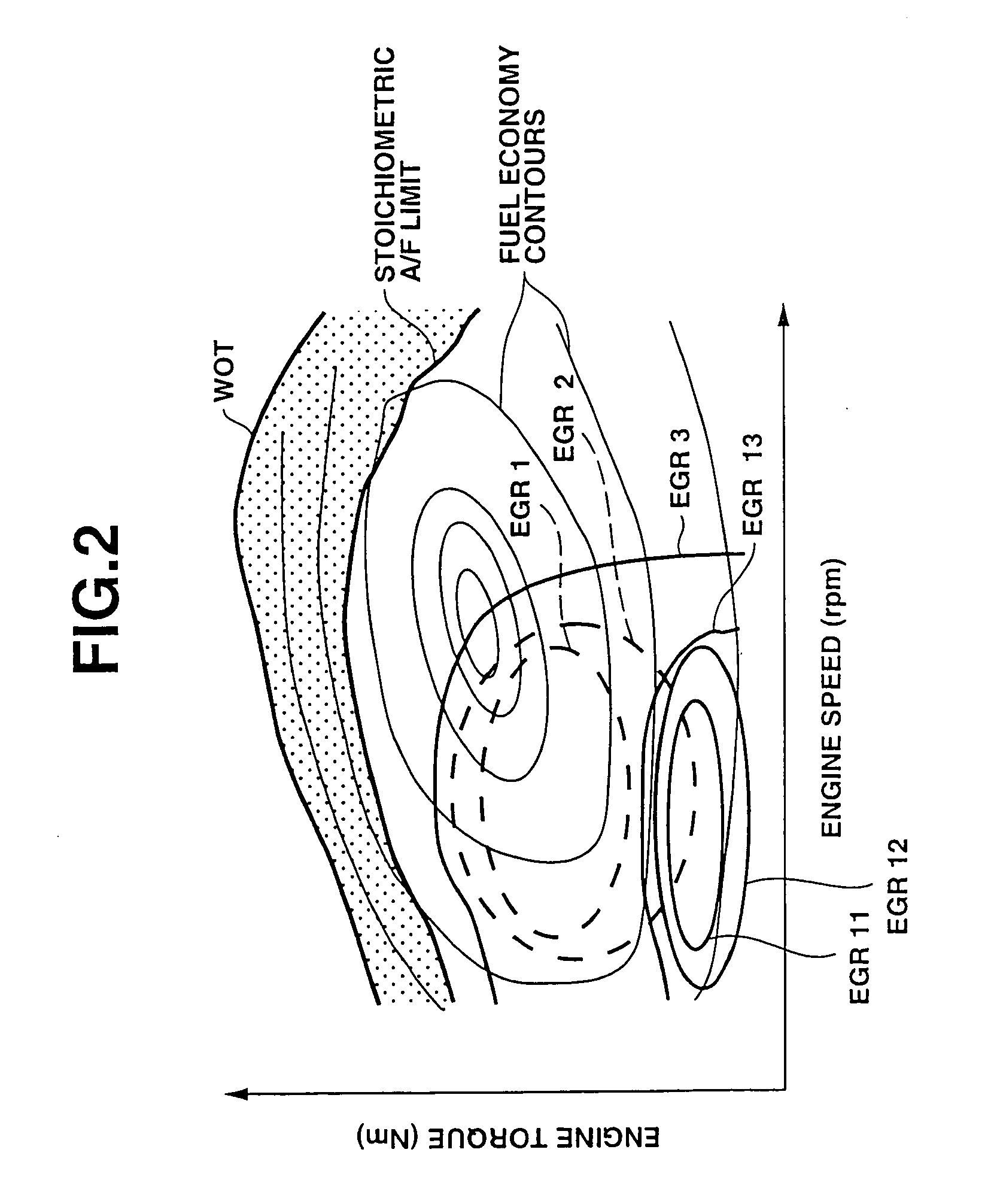

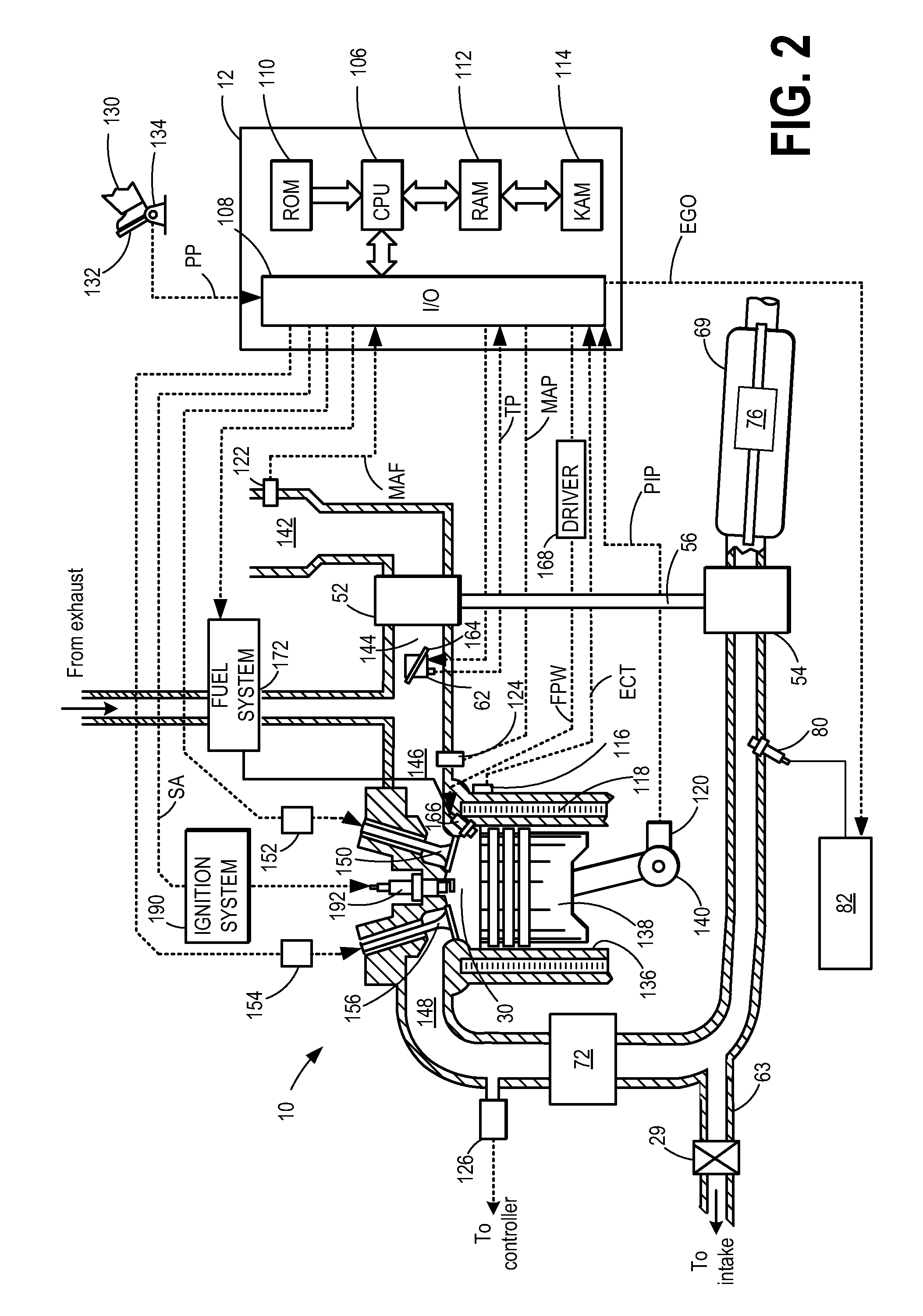

Control apparatus and process for internal combustion engine

ActiveUS20050171670A1Reduce impactIncrease fuel consumptionElectrical controlInternal combustion piston enginesExhaust gas recirculationAcceleration Unit

A control apparatus for an internal combustion engine with an exhaust recirculation system includes an acceleration request sensing section to sense a driver's acceleration request; and an engine operating condition sensing section to sense a current engine operation condition at the time of detection of the driver's acceleration request, to determine a margin from the engine operating condition at the time of detection of the driver's acceleration request, to a fuel economy deterioration region on a higher load side. A controlling section controls the EGR quantity, such as EGR rate, of the exhaust recirculation system in accordance with the margin.

Owner:NISSAN MOTOR CO LTD

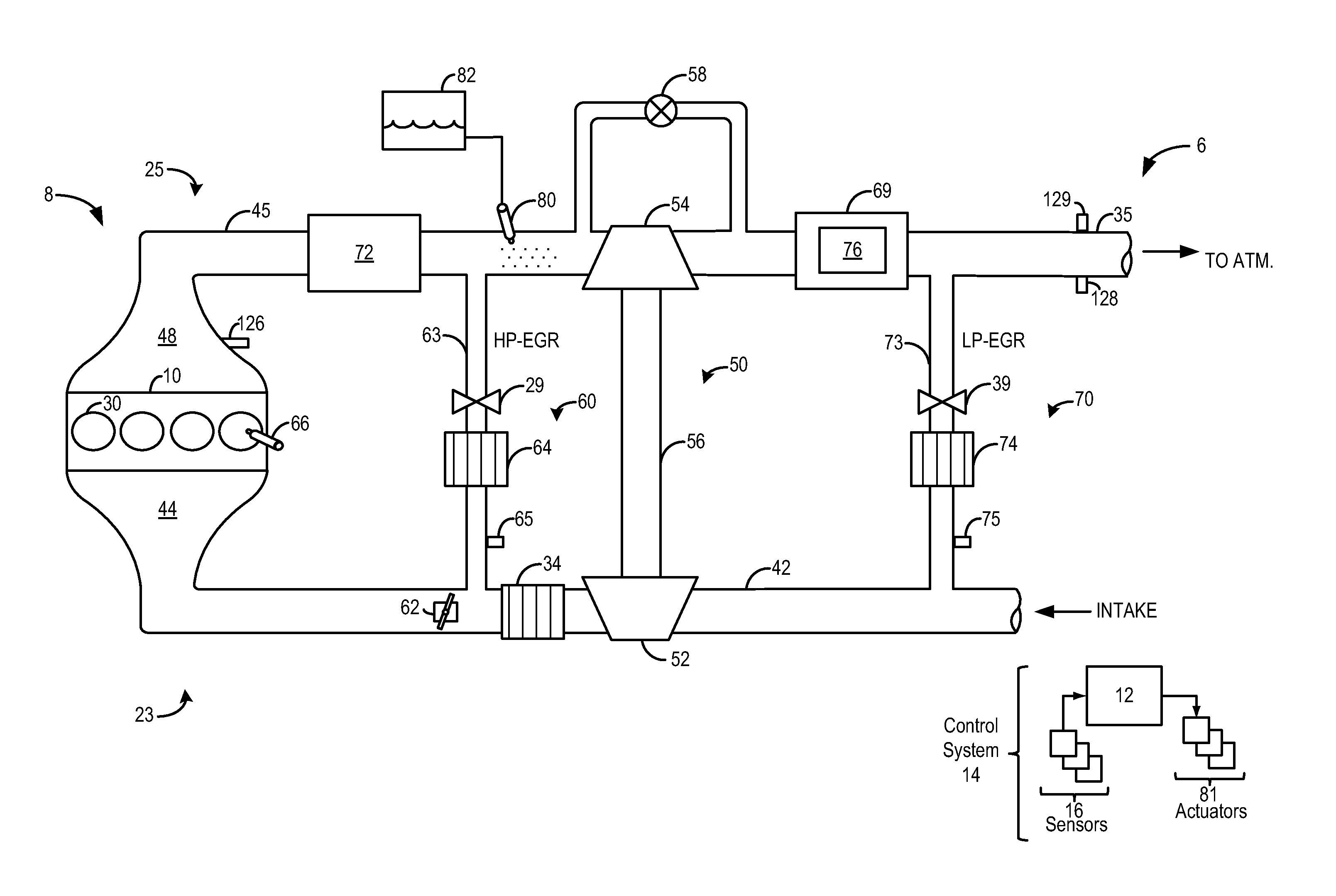

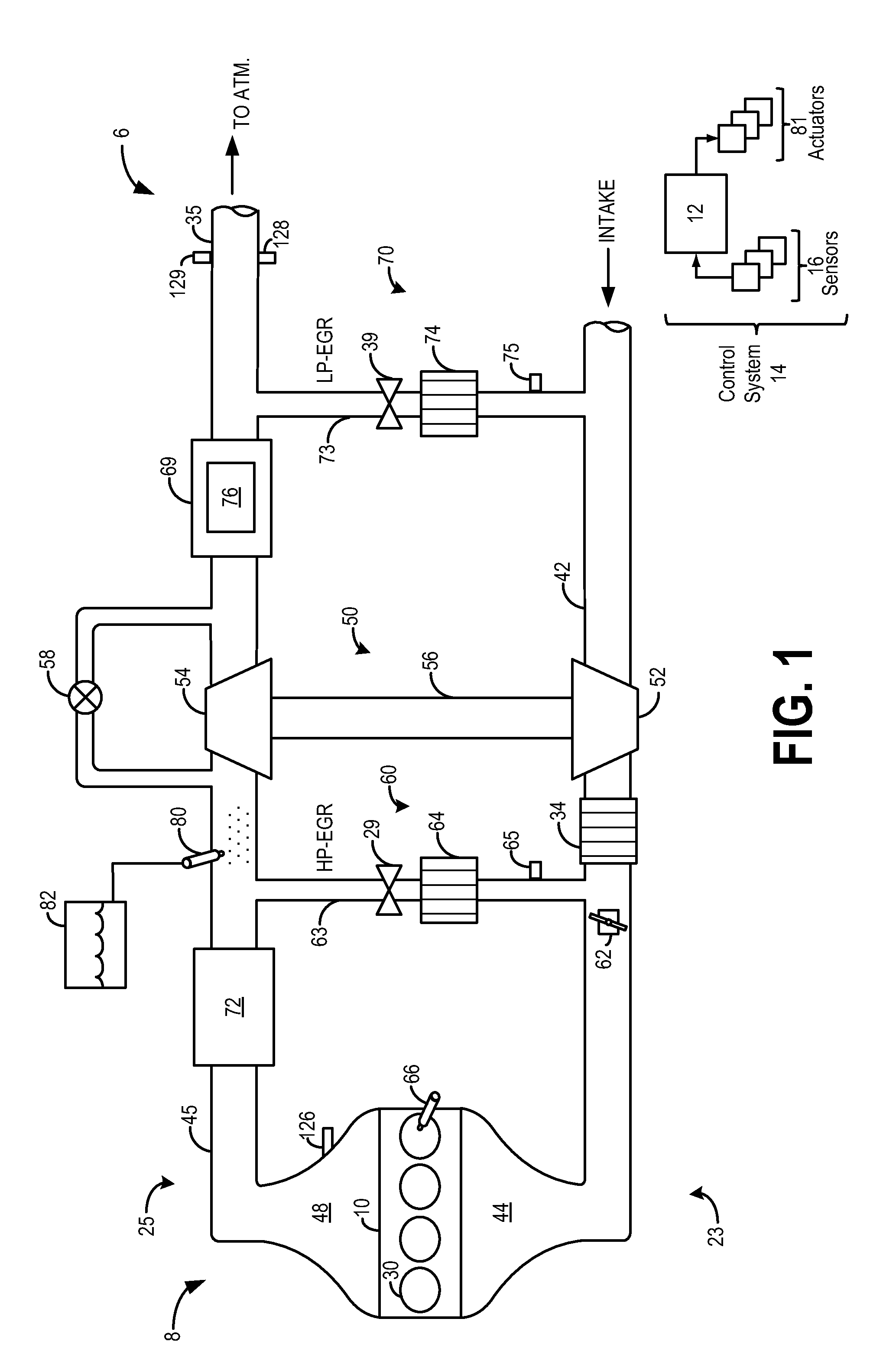

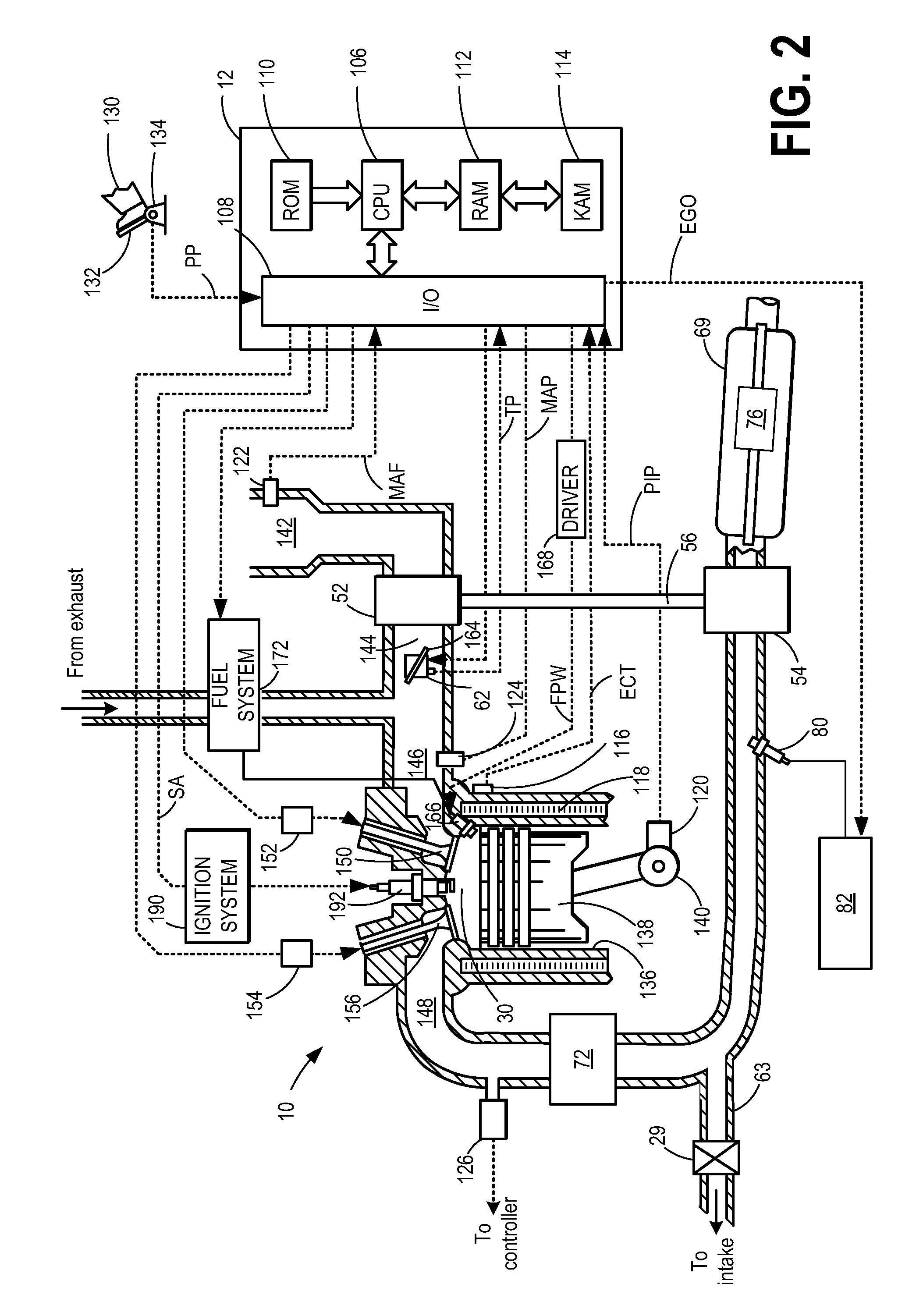

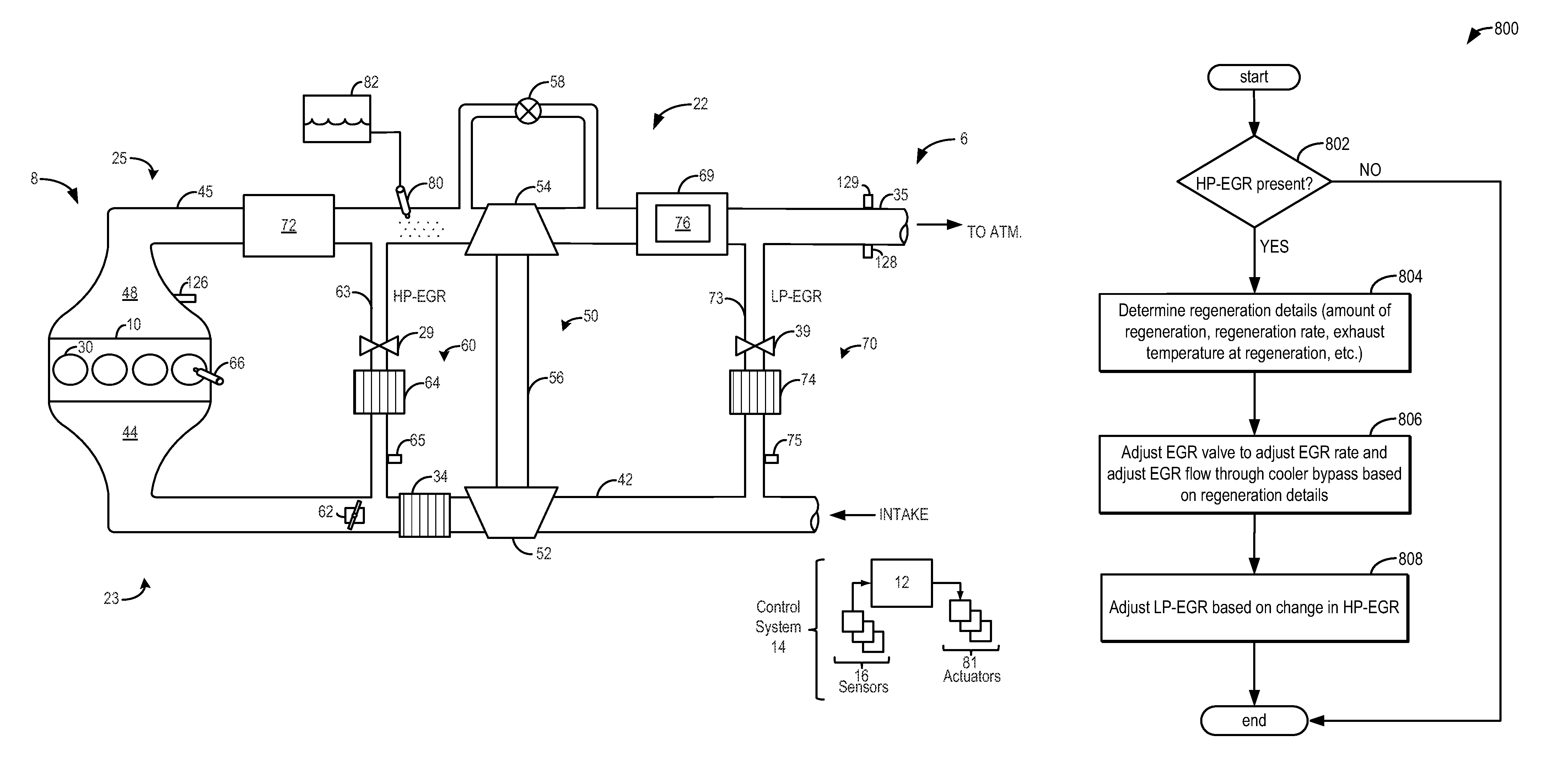

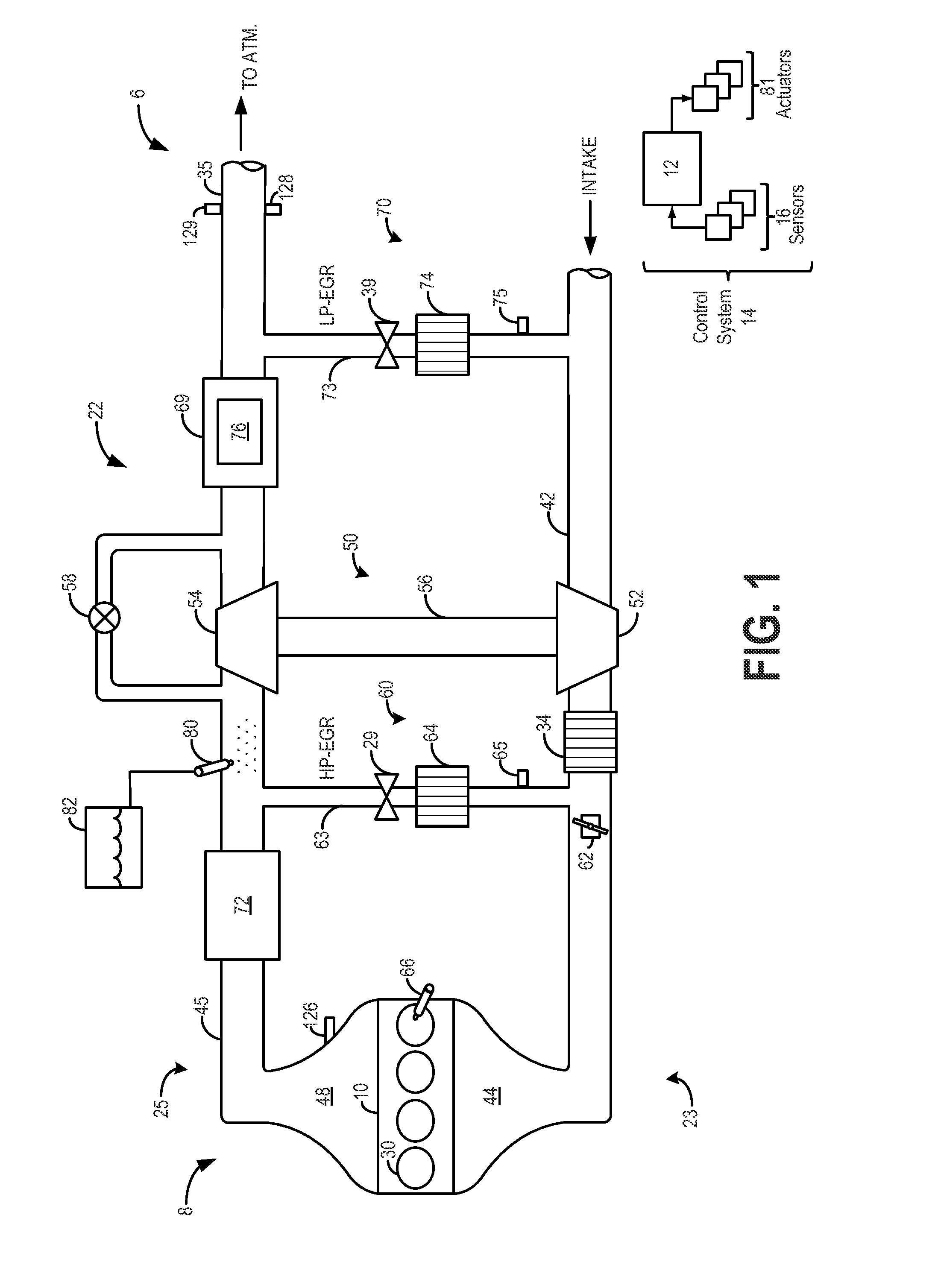

Methods and Systems for Emission System Control

ActiveUS20110131957A1Reduce recyclingReduce degradationElectrical controlInternal combustion piston enginesParticulatesTurbocharger

Methods and systems are provided for operating a turbocharged engine including a particulate filter positioned upstream of a turbocharger turbine, a catalyst positioned downstream of the turbine, and an EGR passage coupled between an engine exhaust and engine intake. In one example, the method comprises, diverting exhaust gas from downstream of the filter to the engine intake via the EGR passage, and adjusting an amount of diverted exhaust gas based on filter operating conditions.

Owner:FORD GLOBAL TECH LLC

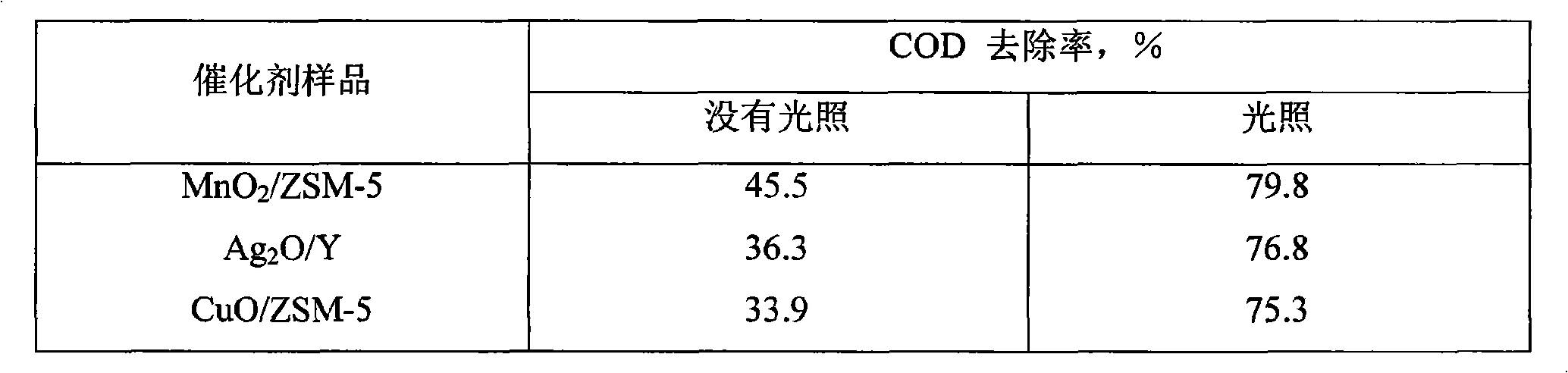

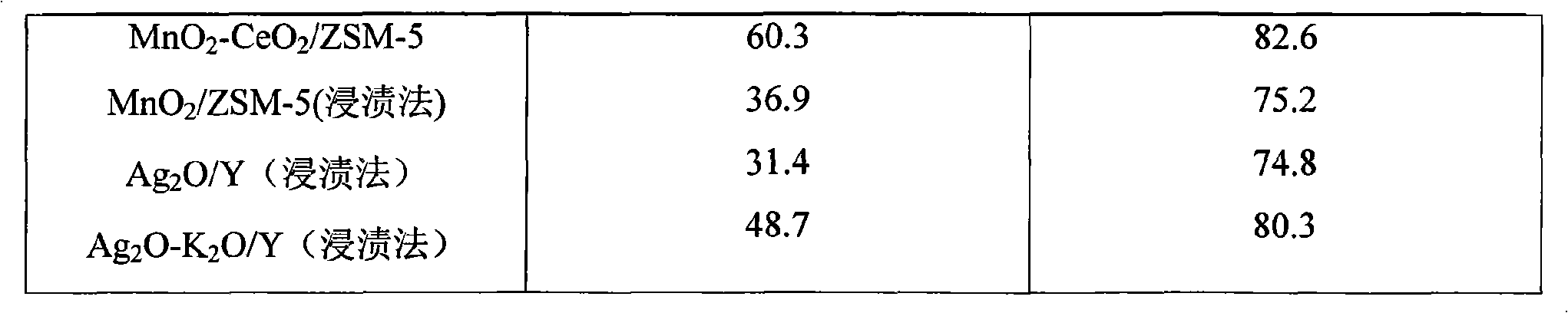

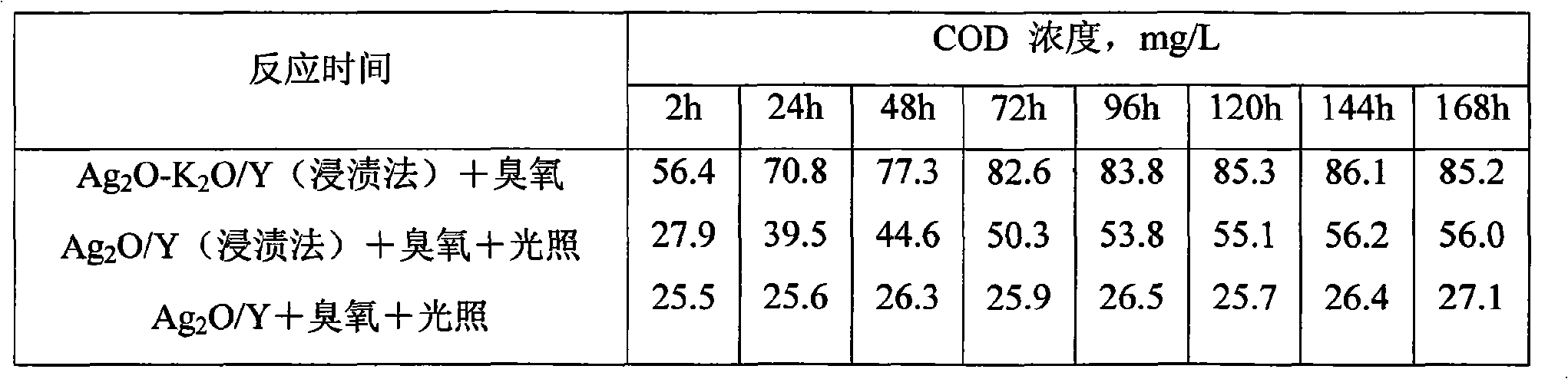

Preparation of catalyst for processing industrial wastewater and using method thereof

ActiveCN101259428AReduce churnHigh bonding strengthMolecular sieve catalystsWater/sewage treatment by irradiationMolecular sieveIndustrial waste water

The invention provides a preparation and application method for treating a catalyst of industrial waste water. The preparation method of the invention adopts a molecular sieve as a carrier, one or a plurality of P-type semiconductor oxides such as MnO2, CeO2, Ag2O, CuO, etc. is / ,are loaded on the molecular sieve in a way of ion-exchange and finally a supported catalyst containing the P-type semiconductor oxides is obtained through molding; and the catalyst is used when ozone and light are coexisted. The preparation and application method of the invention aims at the disadvantages of that active constituents of the catalyst and an addition agent in the combination technique of ozone and catalyst are lost easily, active constituents are loaded on the molecular sieve carrier in the way of ion-exchange so as to improve the combination binding capacity of the active constituents and the carrier; and an electronic addition agent can be substituted through a light electro-donating effect, so as to effectively provide electrons in a long term and promote the catalyst and the ozone to generate active matters; the coaction of the catalyst and the ozone can enhance the activity stability of the catalyst and prolong service life, thus being conducive to industrialization of the technologies.

Owner:FUZHOU UNIV

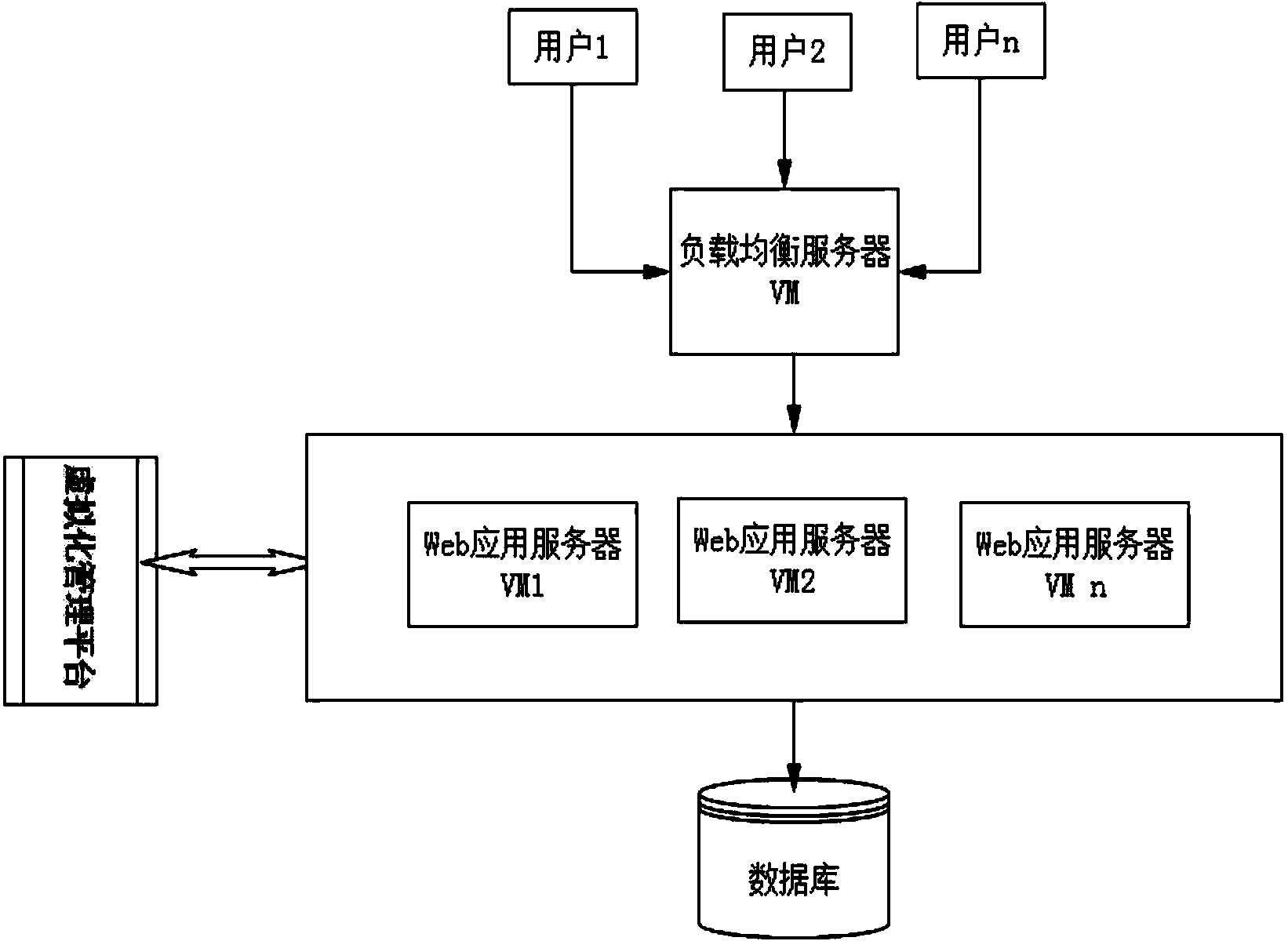

Method and device capable of realizing dynamic expansion of WEB (World Wide Web) application resource

InactiveCN103533063ARealize dynamic expansionEfficient use ofResource allocationTransmissionVirtualizationWeb application

The invention discloses a method and a device capable of realizing dynamic expansion of a WEB (World Wide Web) application resource. The method comprises the following steps of S1, building a virtual management cloud platform which can manage a plurality of physical servers; S2, building a virtual machine and mounting a load balancing server; S3, building a virtual machine and mounting WEB application servers; S4, allocating a load balancing server route on the WEB application servers; S5, dynamically expanding the number of the WEB application servers according to the answer number of a user request by the load balancing server. By the method and the device, when user visits are increased sharply, the number of virtual servers is dynamically and automatically expanded, and when the user visits are reduced, the number of virtual servers is reduced, so that dynamic expansion and effective utilization of the resource are realized.

Owner:BEIJING TEAMSUN TECH

Methods and systems for emission system control

ActiveUS8096125B2Reduce recyclingReduce degradationElectrical controlInternal combustion piston enginesParticulatesTurbocharger

Owner:FORD GLOBAL TECH LLC

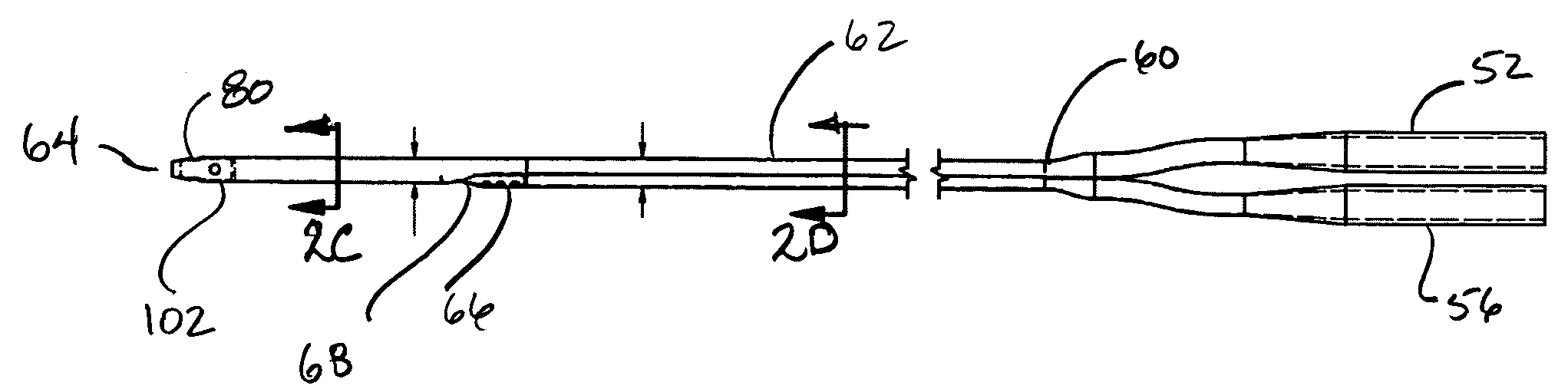

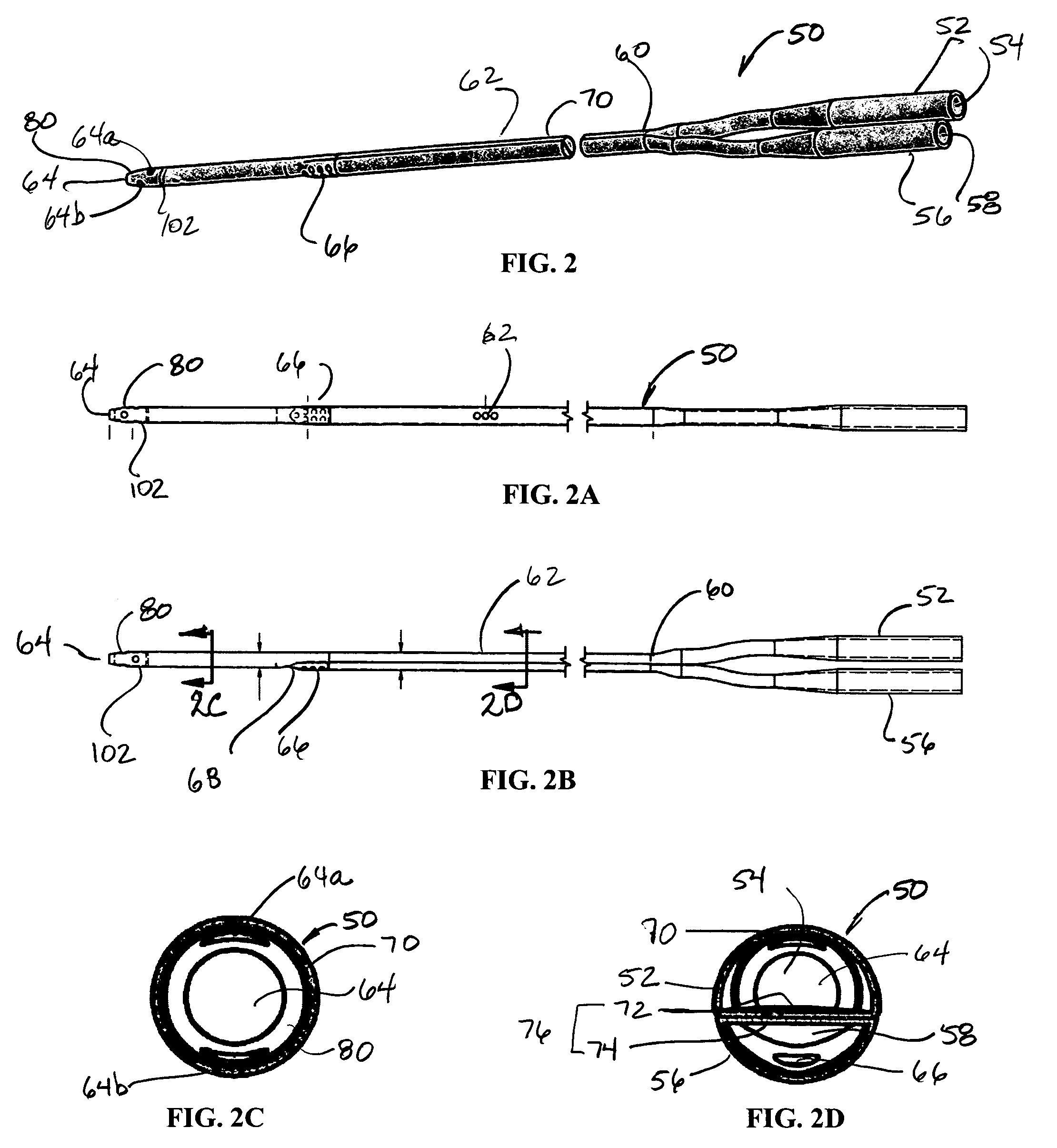

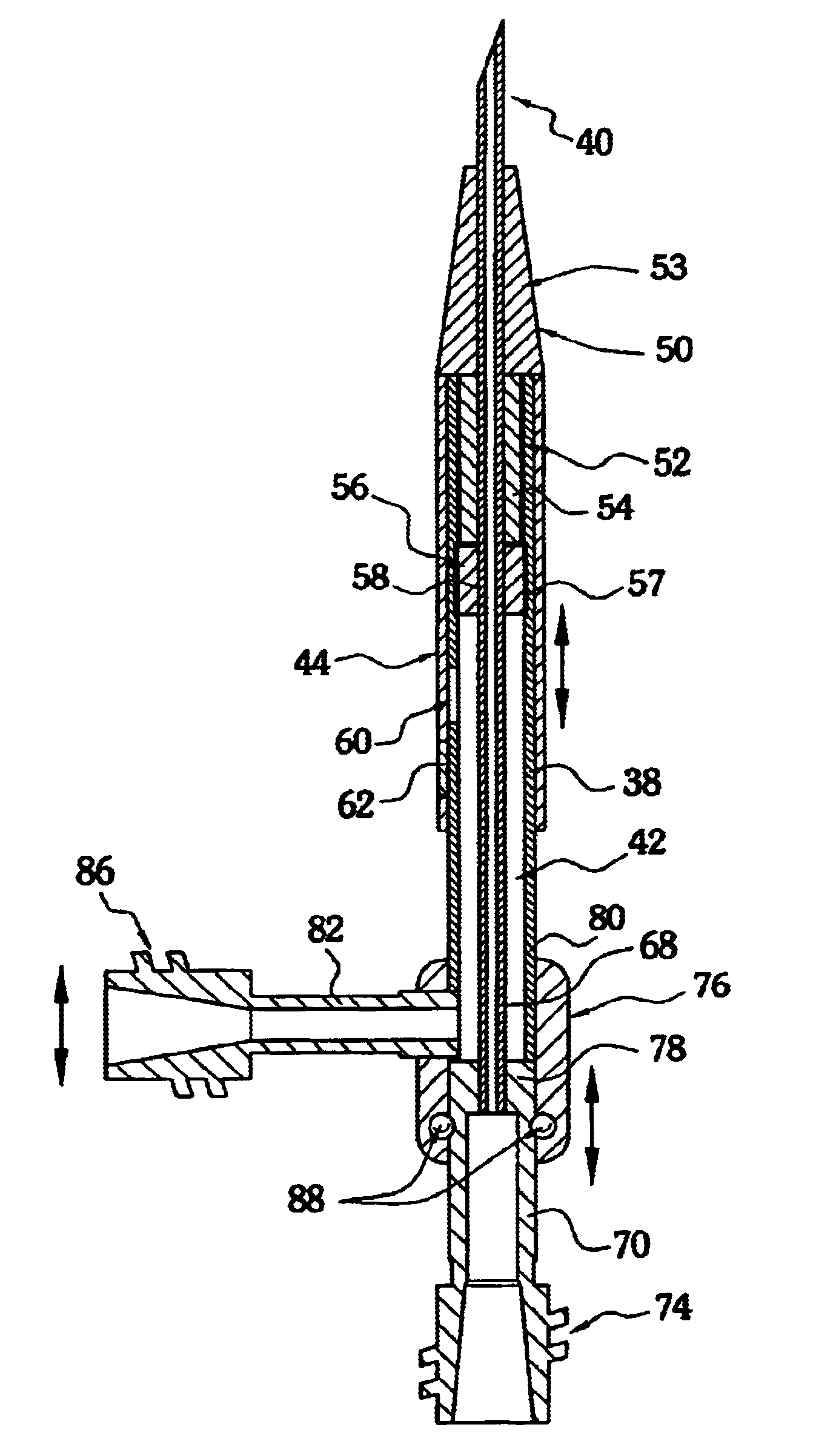

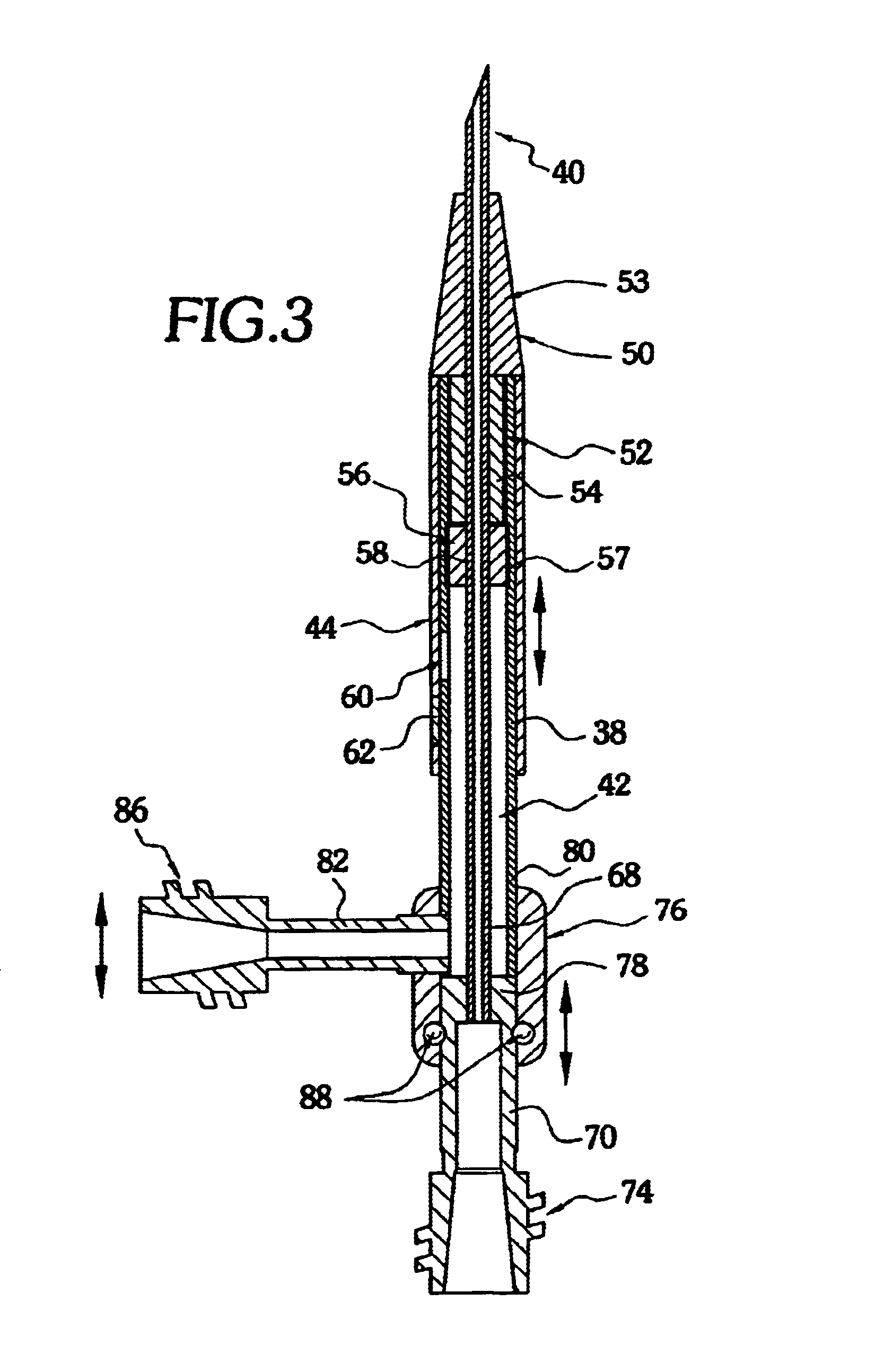

Single access dialysis needle

InactiveUS6962575B2Reduce tissue damageReduce recyclingGuide needlesBalloon catheterDialysisHemodialysis membrane

A single access dialysis needle system comprises a first cannula, a second cannula or sheath, and a barrier arranged on the outer surface of the first cannula. The distal end of the first cannula extends distal to the distal end of the second cannula or outer sheath, and the barrier is positioned between the respective distal ends. When the barrier is inflated or otherwise activated, it prevents or minimizes recirculation.

Owner:YALE UNIVERSITY CORP

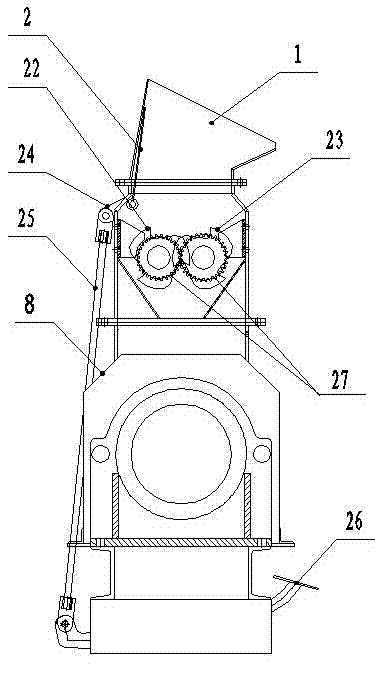

Domestic garbage disposer

InactiveCN102825062ARecycling reducesEasy to recycleSolid waste disposalGrain treatmentsSprocketEngineering

The invention relates to a domestic garbage disposer of which a pulverizer and a squeezer are integrally arranged, wherein the pulverizer part comprises a pair of roller cutters which are arranged in a pulverizing box and are provided with saw-toothed blades respectively; blades of two groups of roller cutters are mutually staggered and engaged and do different-speed opposite rotation through a reducing motor and a transmission gear; the squeezer part comprises a squeezing screw and a pushing screw which are arranged in a stainless steel screen and a squeezing box; pitch of the squeezing screw from a pushing section to a squeezing section is gradually decreased and the diameter of screw shafts is gradually increased; the diameter of the screw shaft of the pushing screw is less than the diameter of the screw shaft of the squeezing screw; the pitch of the pushing screw is the same as the pitch of the squeezing screw; the pushing screw and the squeezing screw are arranged in a staggering way; and the squeezing screw and the pushing screw do equal-speed operation through the reducing motor and a transmission chain wheel. The domestic garbage disposer has the advantages of simple structure, energy saving, high disposal capacity, convenience in maintenance and capabilities of fully removing moisture in domestic garbage, reducing the size of the garbage, facilitating recycling of the garbage material and saving the transportation cost.

Owner:ZUNHUA JIDONG SHENGFANG MACHINERY MFG

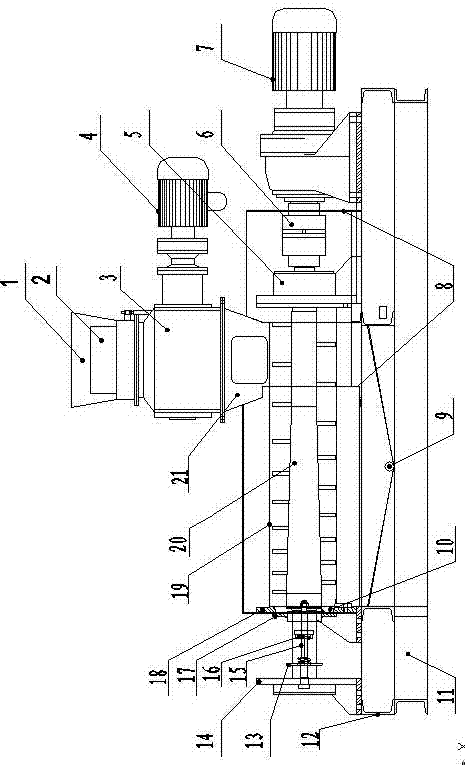

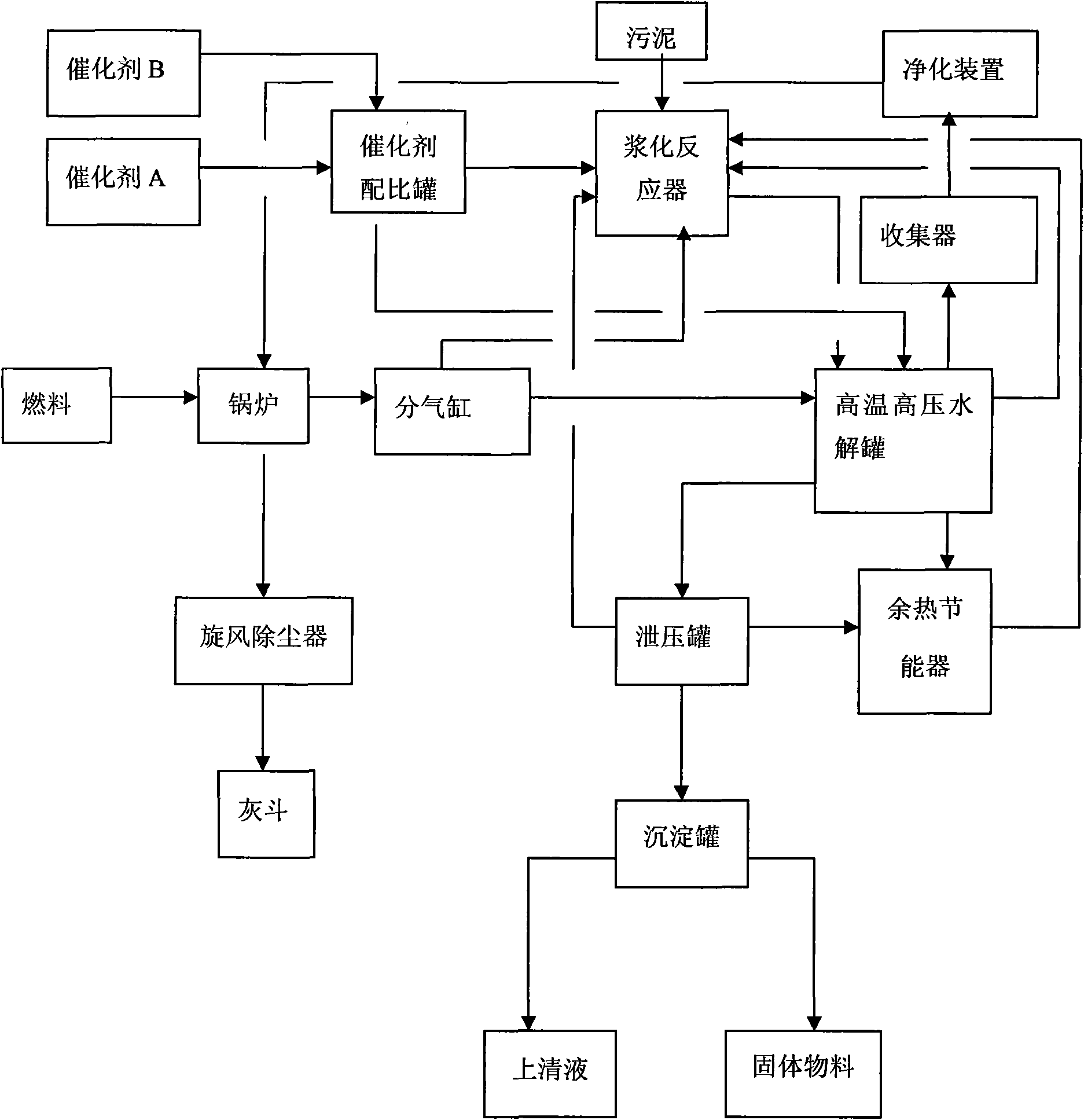

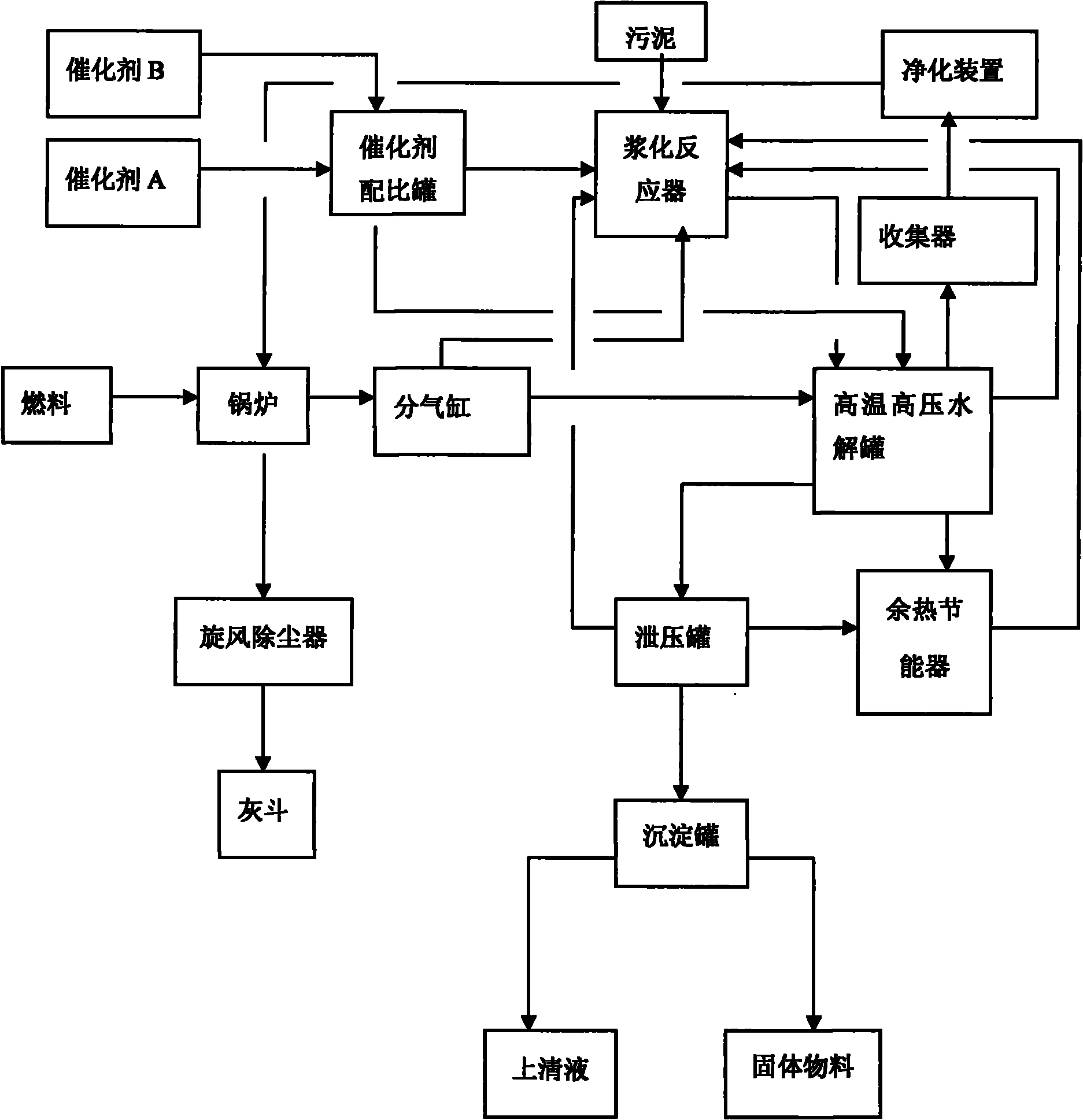

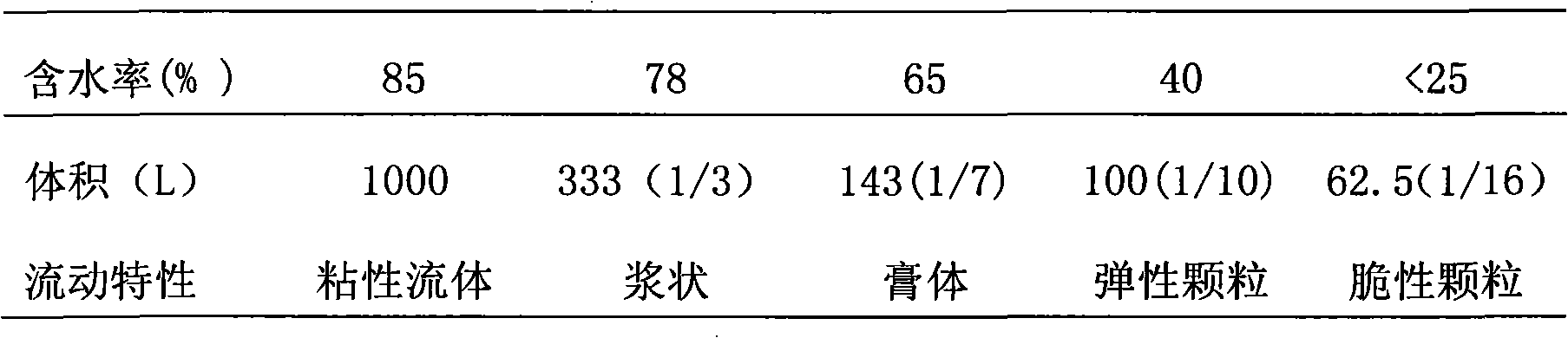

Method and device for rapidly reducing moisture content of sludge

InactiveCN102234170AMake up for the long disposal cycleEase of scalingSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEnvironmental chemistryReclaimed water

The invention provides a rapid, economic and harmless processing method and device for reducing moisture content of sludge. In the invention, hydrolysis by atmospheric steam, hydrothermal dehydration at high temperature and high pressure and solid-liquid separation on materials are carried out to obtain a solid-liquid slurry, high moisture content of 80% can be reduced to low moisture content of 40%, and a hydrothermal separation process in sludge treatment can be rapidly achieved. The form of an organic matter in the sludge is changed, and phase change of water in the sludge can not be caused; compared with the prior art, the method provided by the invention can be used for overcoming the defects that the processing period is long and the processing energy consumption is high, and is easy for realization of large-scale processing and contributes to reducing secondary pollution to the environment and recycling resources; and a new approach is found for processing the sludge.

Owner:安徽合协生态环境科技有限公司

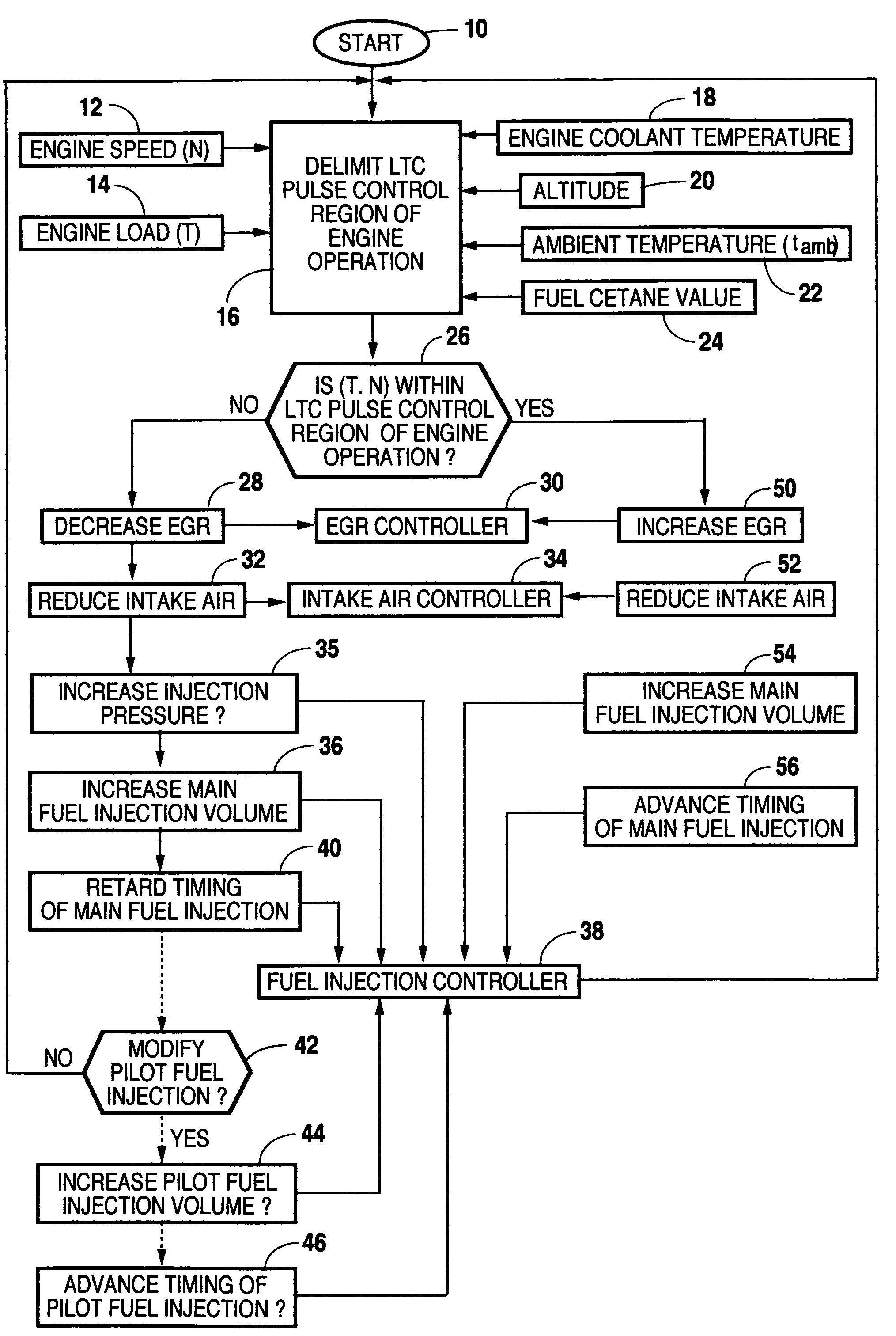

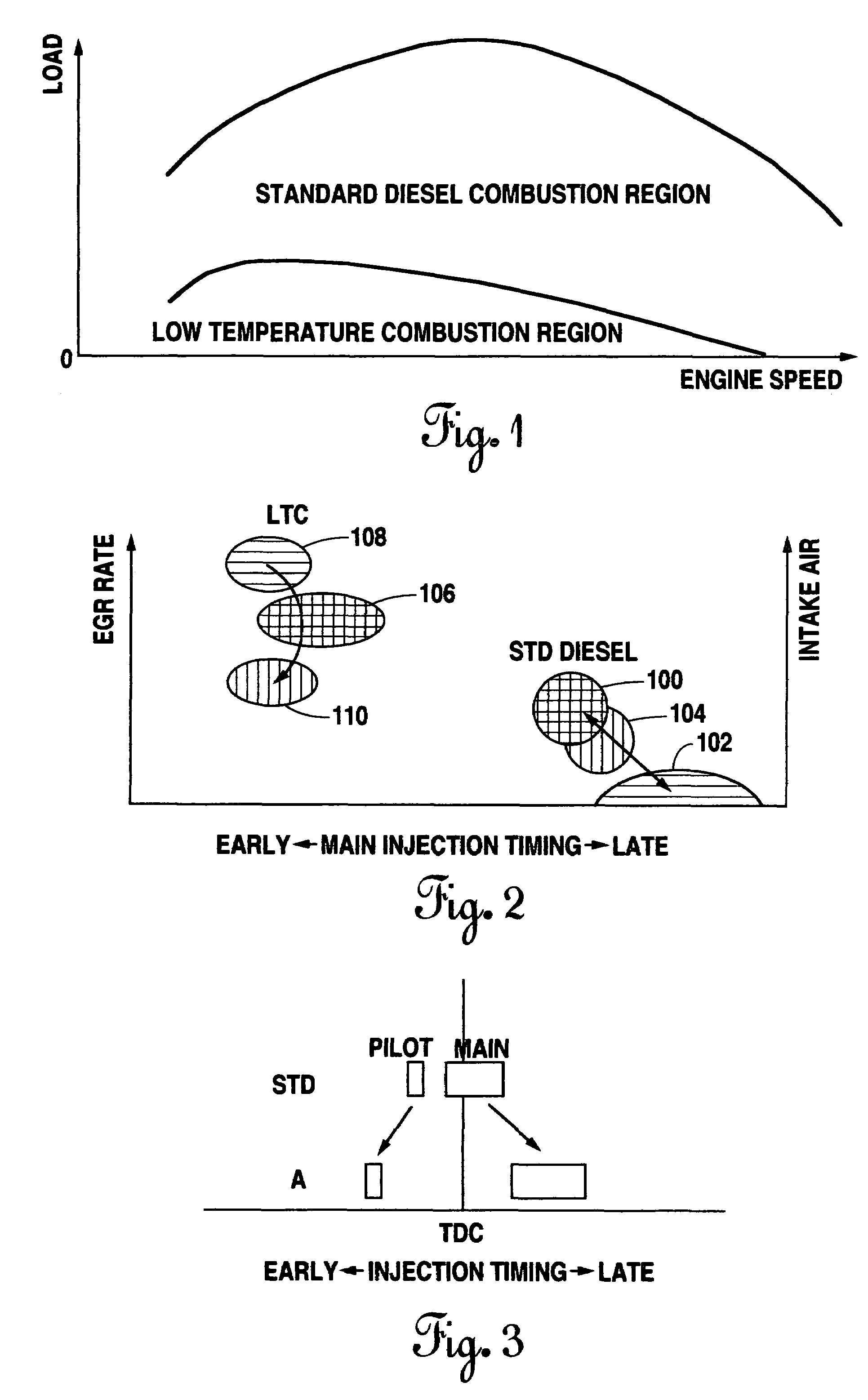

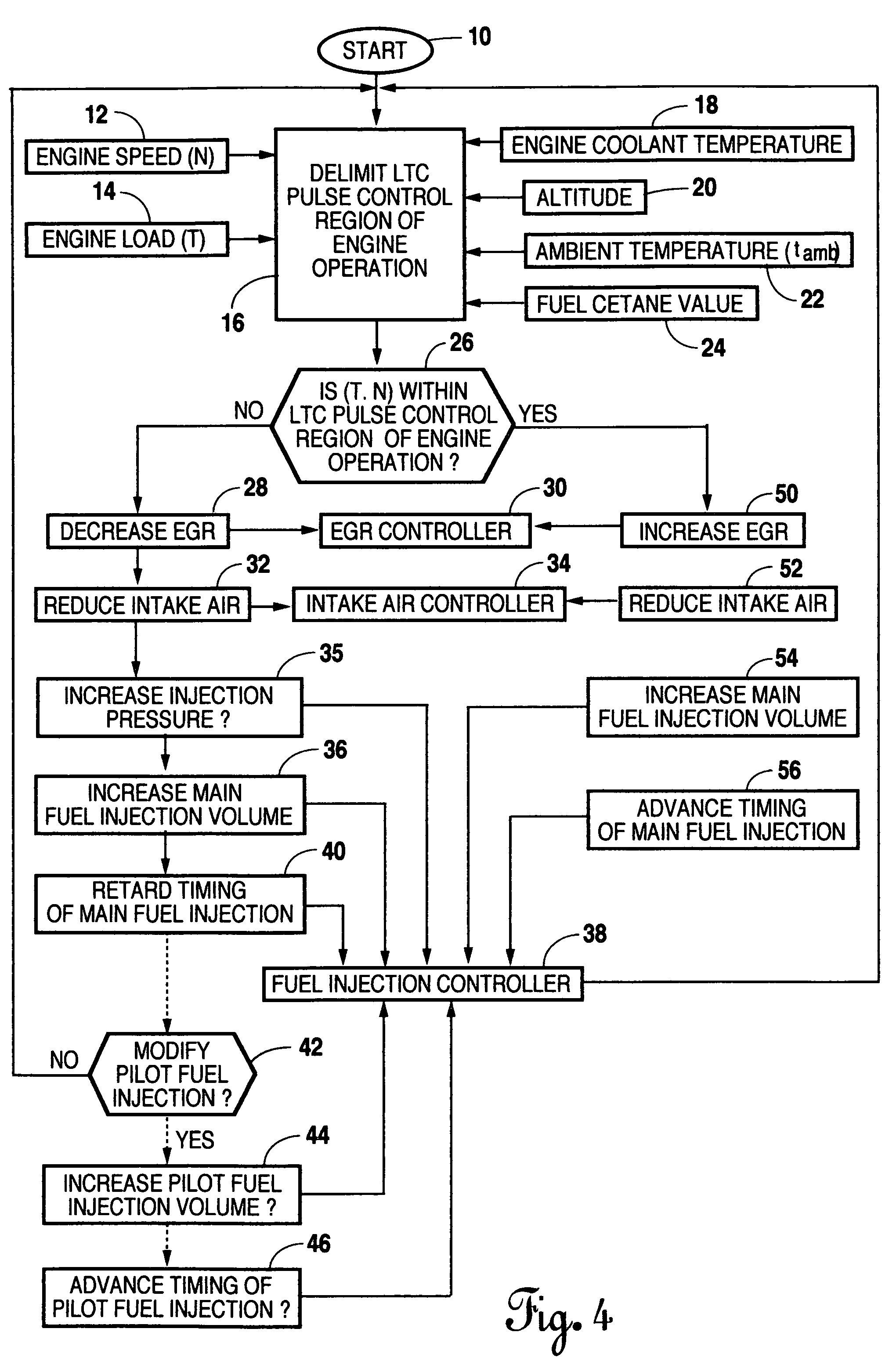

Method for rich pulse control of diesel engines

ActiveUS7137379B2Increased recirculationIntake air is reducedElectrical controlInternal combustion piston enginesPulse controlLow load

A combustion control method for the rich pulse control of Diesel engines with Lean NOX Trap systems includes identifying areas within a Diesel engine operating regime in which reduced recirculated exhaust gas and air with increased pre-mixed combustion is effective in providing fuel rich combustion, and a second, lower load, region in which low temperature combustion is particularly desirable.

Owner:SOUTHWEST RES INST

Apparatus and process for producing acetylene by plasma pyrolysis of coal and natural gas

Production of ethyne by coal and natural gas plasma pyrolyzation and its apparatus are disclosed. It is produced by spraying plasma, buggy steam current and natural gas protective gas in plasma reactor, reacting and generating mixed ethyne gas, cooling, separating, storing ethyne, passing gas into plasma generator and reutilizing, sprayed natural gas forming gas protective layer on plasma reactor wall to prevent carbon fragment from coking, and pyrolytic reacting to obtain mixed ethyne gas. It achieves high converting efficient and reacting efficient.

Owner:TAIYUAN UNIV OF TECH

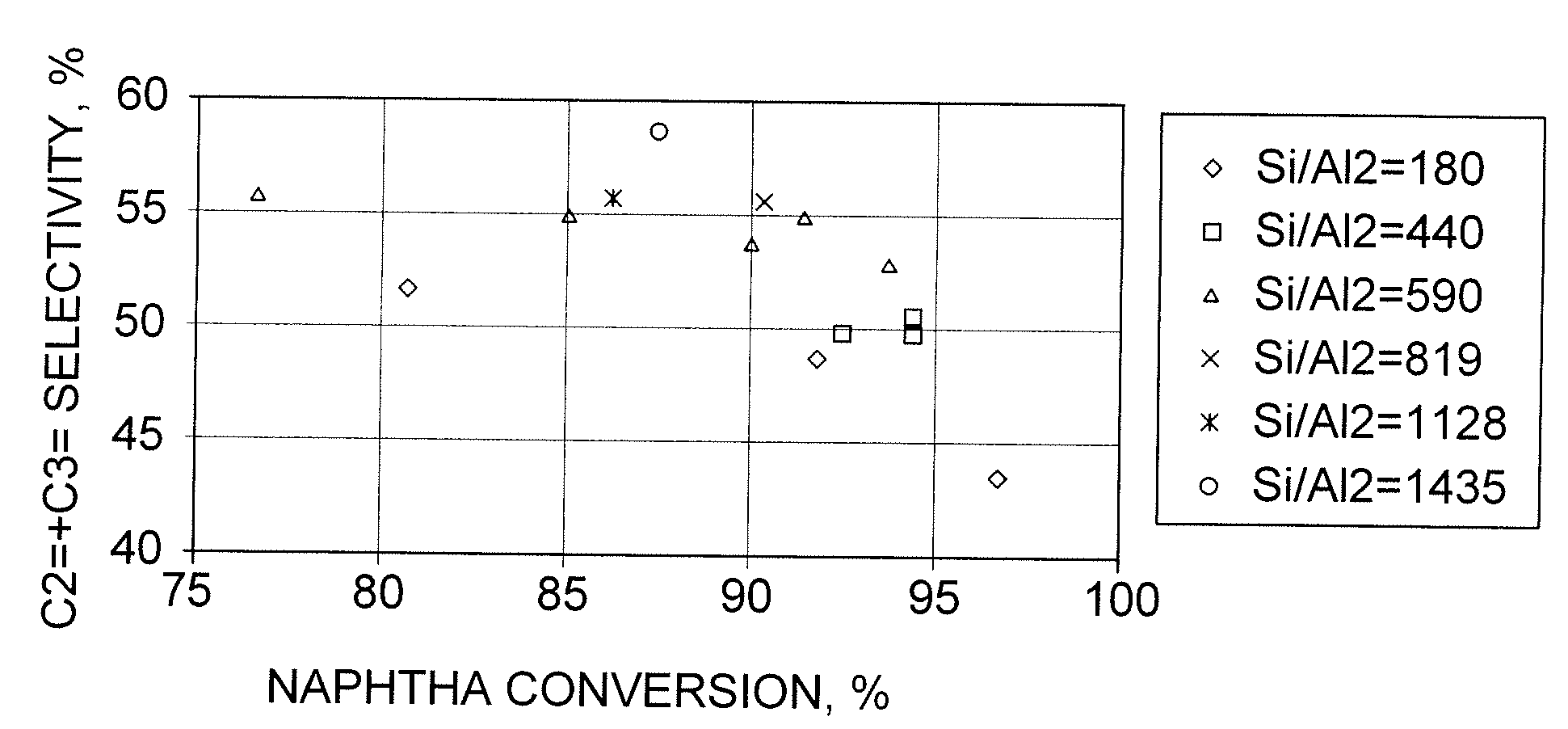

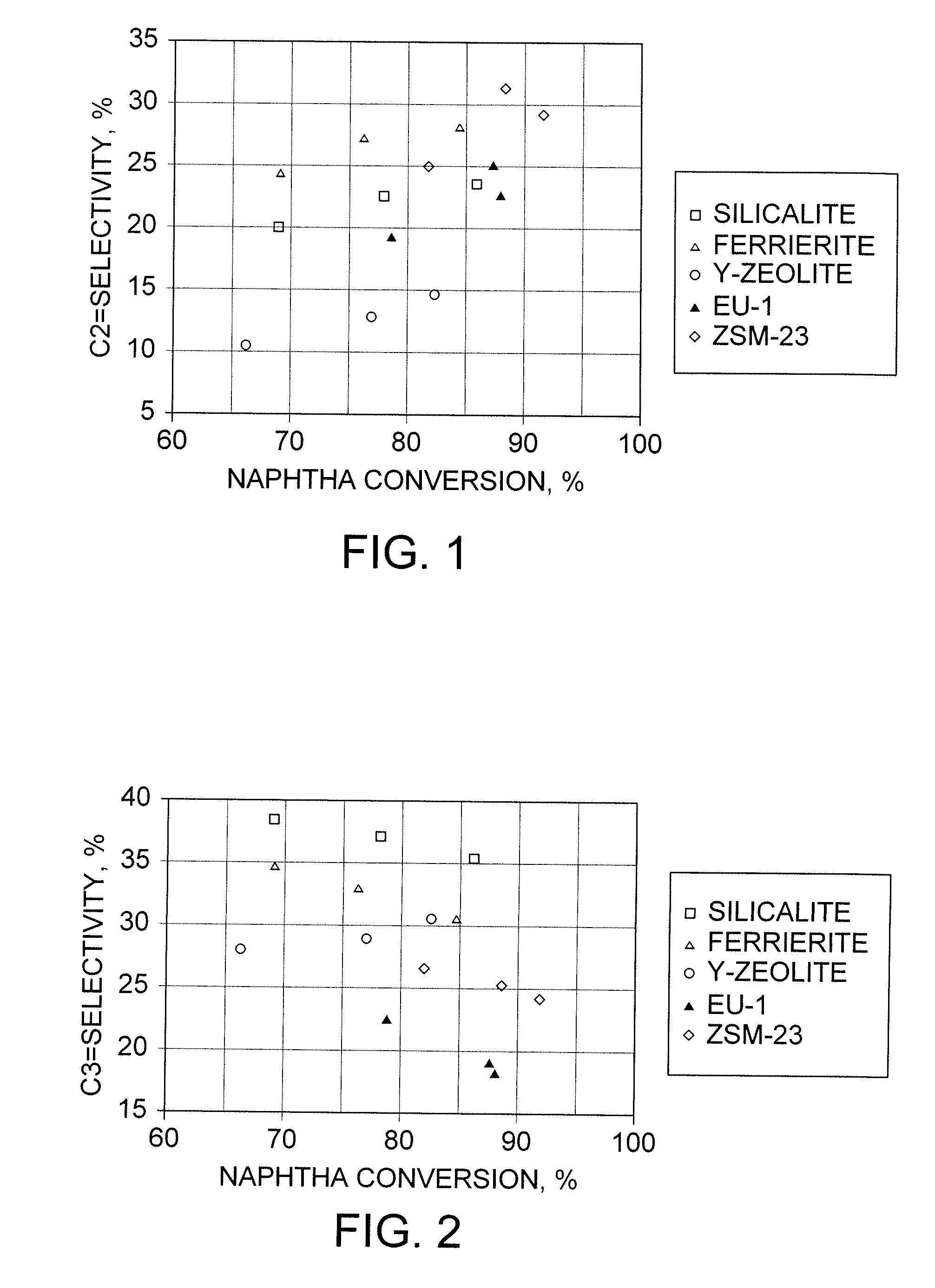

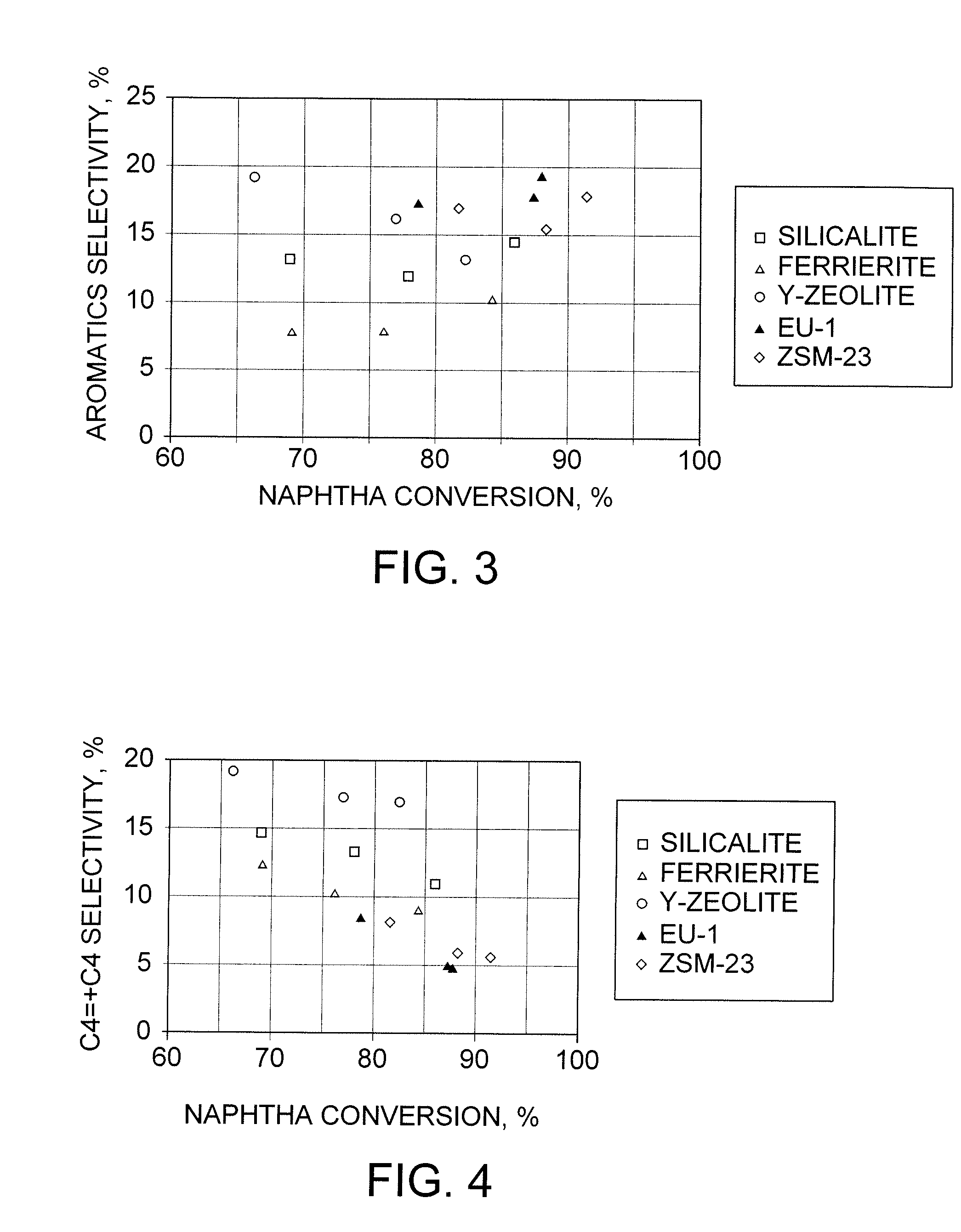

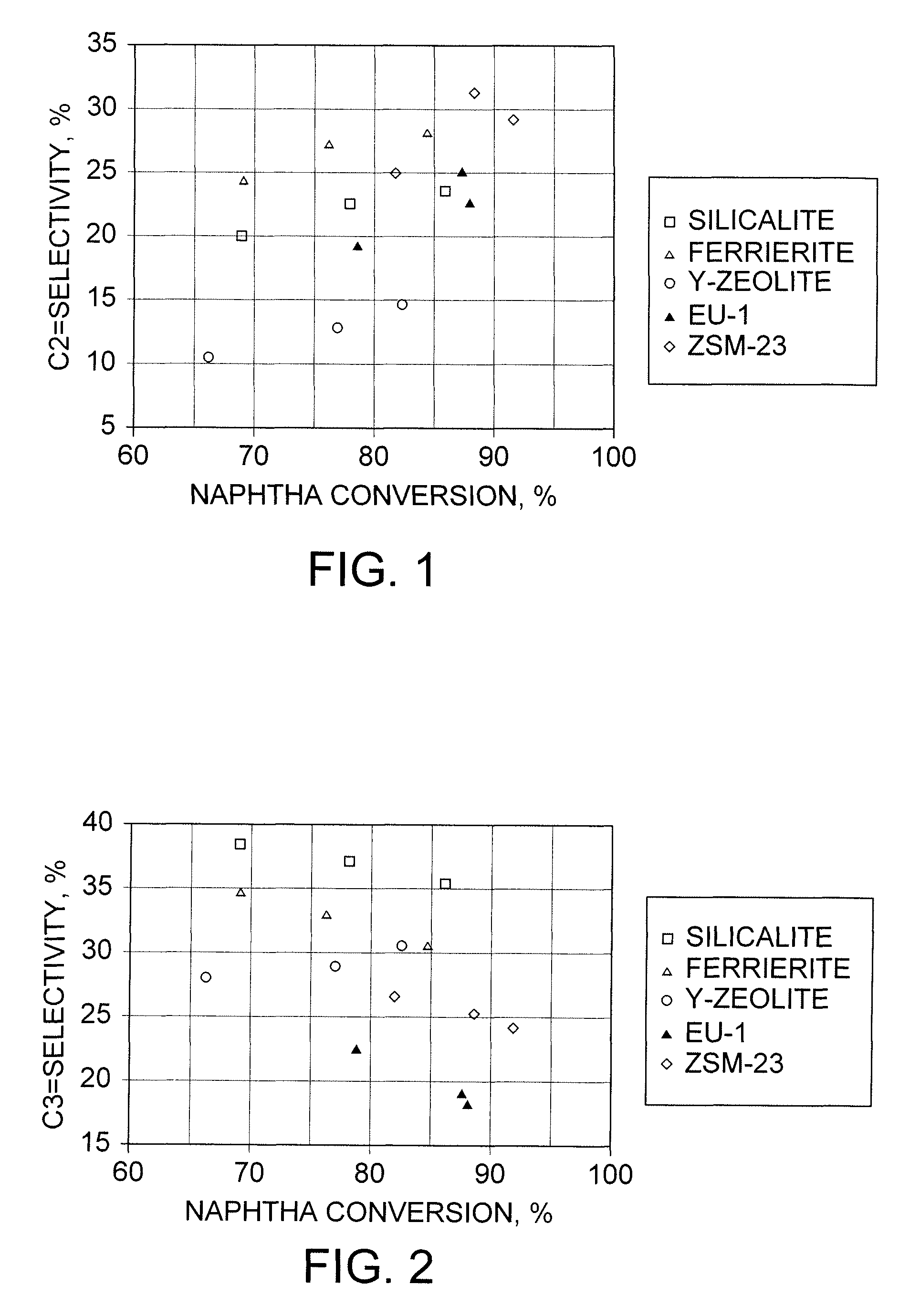

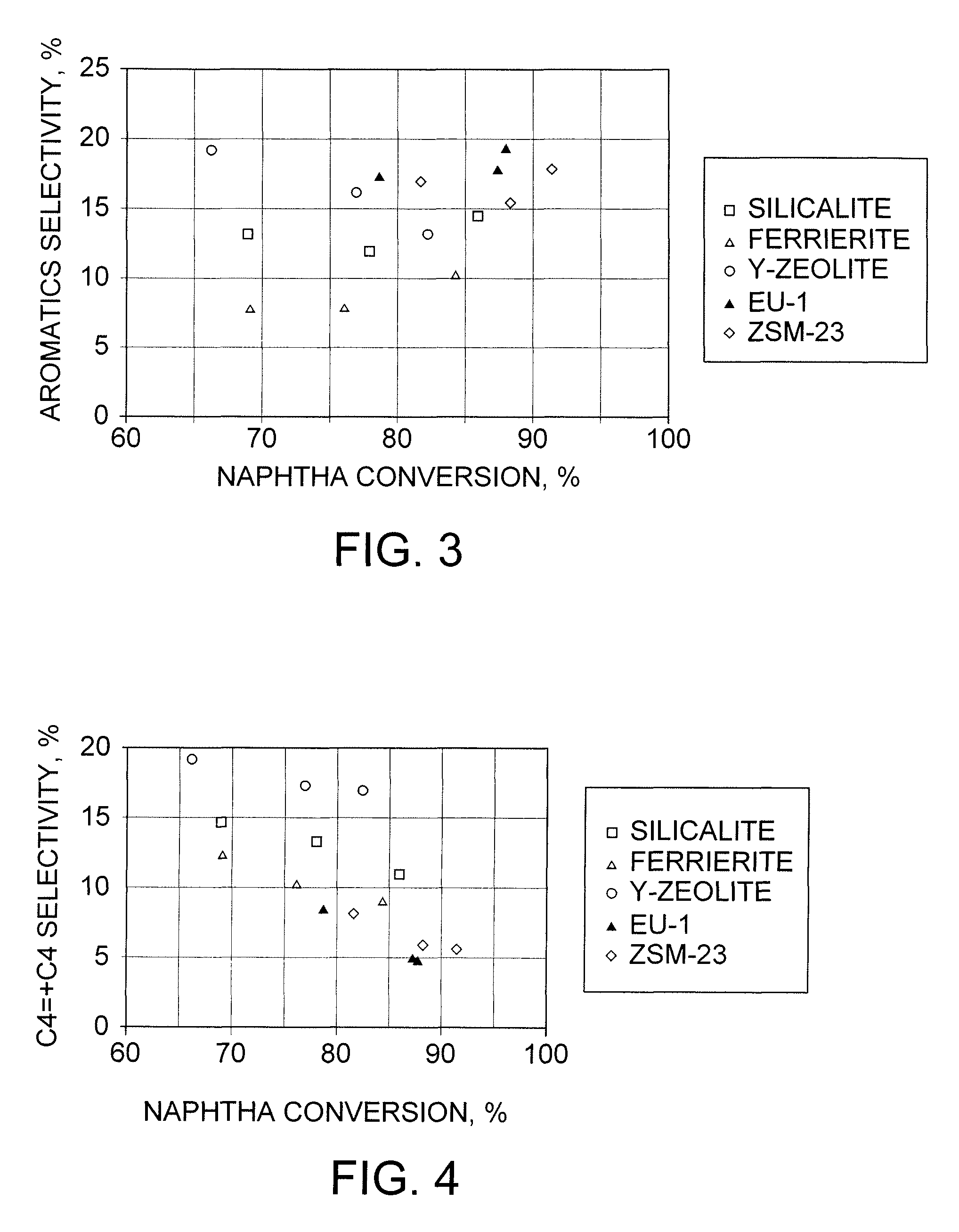

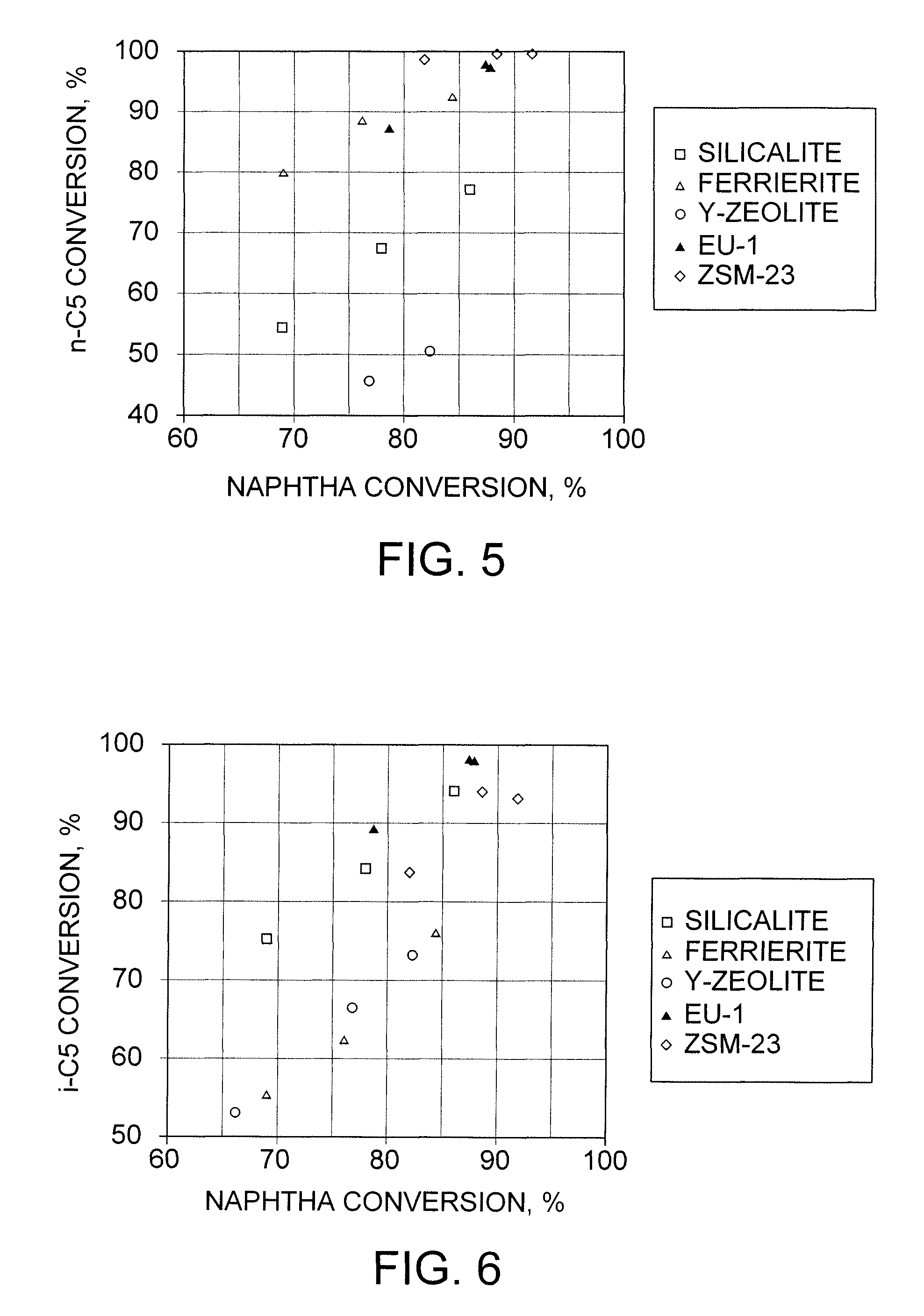

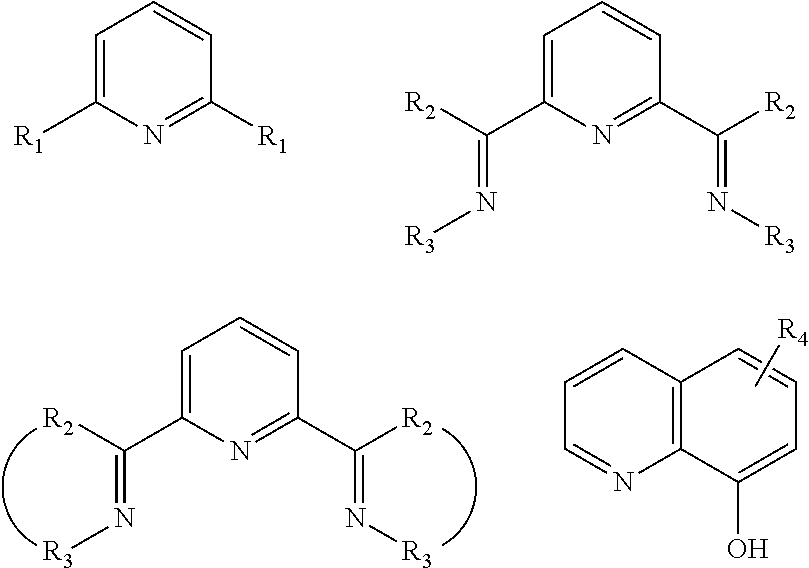

Mixture of Catalysts for Cracking Naphtha to Olefins

ActiveUS20100105974A1Maximize selective yieldReduce the amount requiredCatalytic crackingHydrocarbonsMolecular sieveNaphtha

A process is presented for the selective catalytic cracking of naphtha to light olefins. The process includes contacting a naphtha feedstream with a mixture of catalysts to reduce the amount of recycle, and especially the recycle of light paraffins. The mixture of catalysts includes a first molecular sieve made up from a small pore zeolite having a pore index between 13 and 26, and a second molecular sieve made up from an intermediate pore zeolite having a pore index between 26 and 30.

Owner:UOP LLC

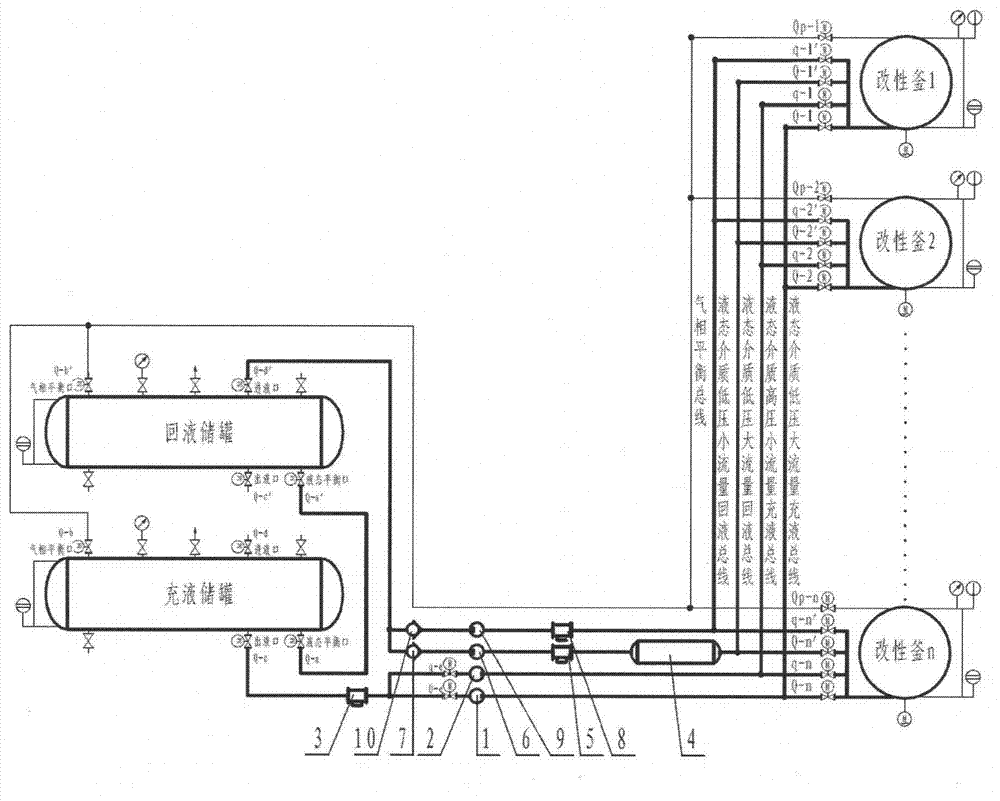

Natural fiber crystal variation modified liquid medium filling and recovery system and method based on paralleled multiple buses and multiple modified kettles

InactiveCN103161046AImprove equipment utilization and production efficiencyReduce equipment cost and production costTextile treatment machine arrangementsTraffic volumeNatural fiber

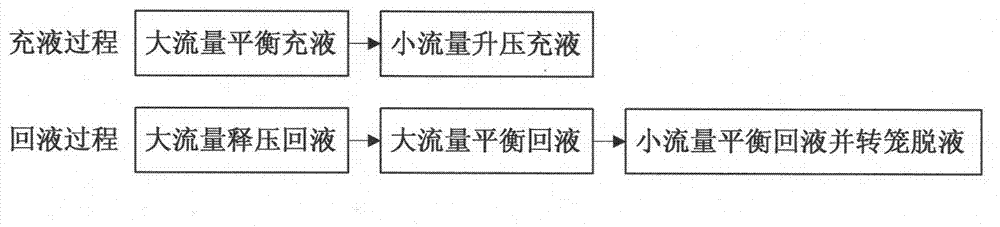

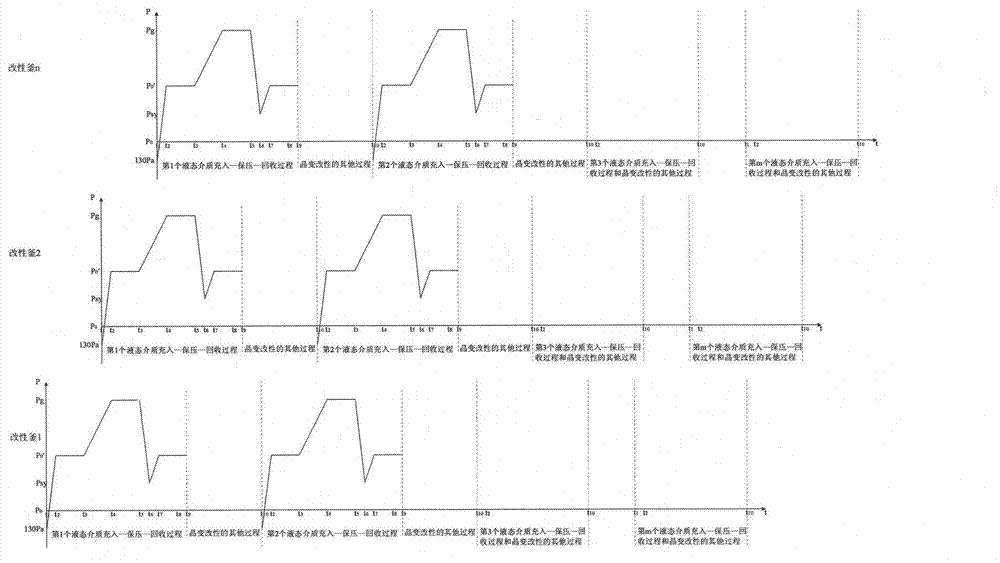

The invention provides a natural fiber crystal variation modified liquid medium filling and recovery system based on paralleled multiple buses and multiple modified kettles. The natural fiber crystal variation modified liquid medium filling and recovery system based on the paralleled multiple buses and multiple modified kettles comprises a liquid medium low-pressure mass flow liquid-filling bus, a liquid medium high-pressure small flow liquid-filling bus, a liquid medium low-pressure mass flow liquid-return bus, a liquid medium low-pressure small flow liquid-filling bus, a gas phase balance bus, and n modified kettles which are in parallel connection on the buses, and n >=1. The invention further provides a natural fiber crystal variation modified liquid medium filling and recovery method based on the paralleled multiple buses and multiple modified kettles. The liquid-filling process comprises mass flow balance liquid filling and small flow pressure boosting liquid filling, and the liquid return process comprises mass flow pressure relief liquid return, mass flow balance liquid return, small flow balance liquid return, and cage shift liquid exhaustion. The natural fiber crystal variation modified liquid medium filling and recovery system and the method based on paralleled multiple buses and multiple modified kettles are good in modified effect, small in system energy consumption, and high in production efficiency.

Owner:DONGHUA UNIV +1

Process and Plant for Substitute Natural Gas

ActiveUS20090264542A1Reduce needCost-effectiveHydrogenHydrocarbon from carbon oxidesChemistryProduct gas

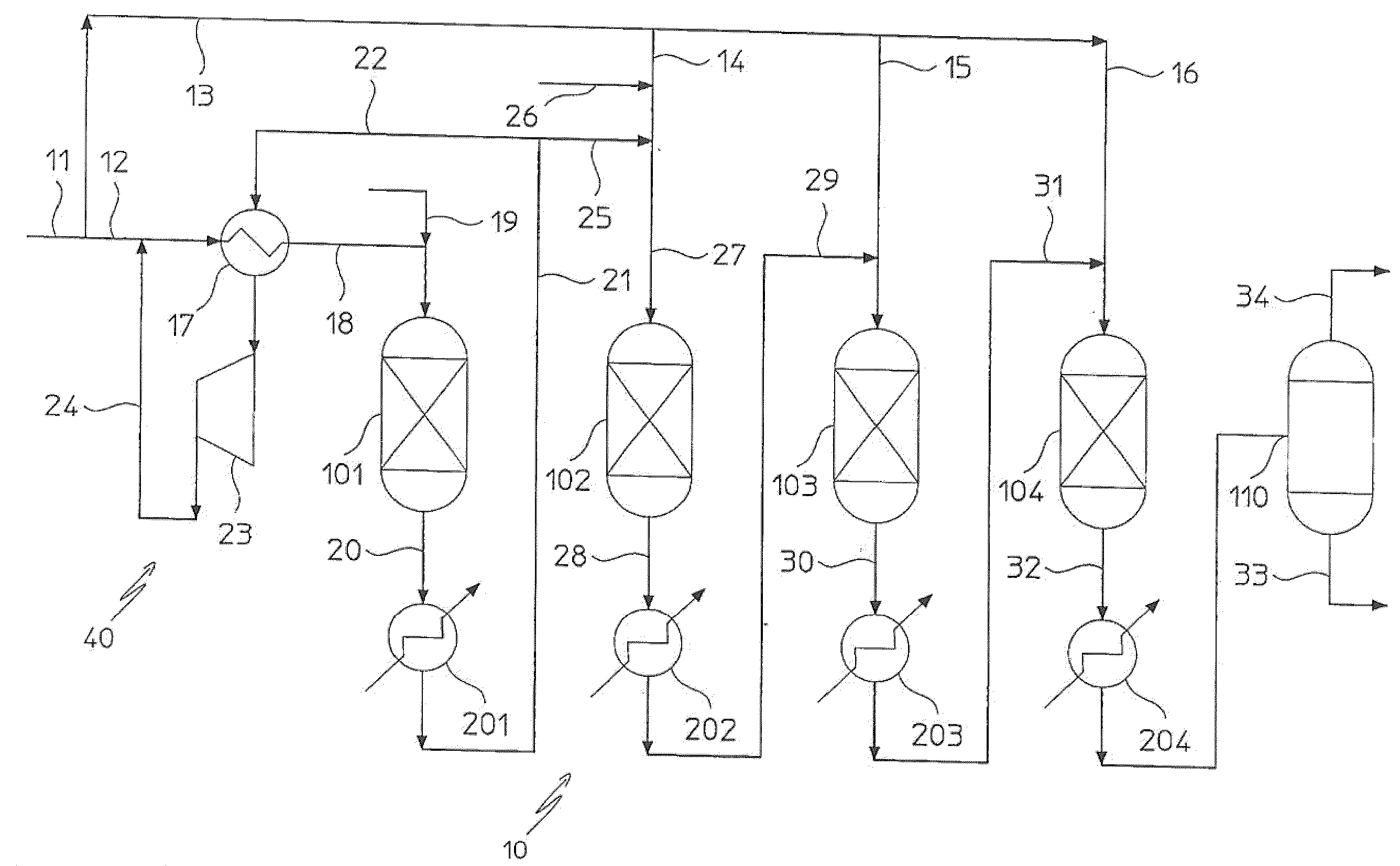

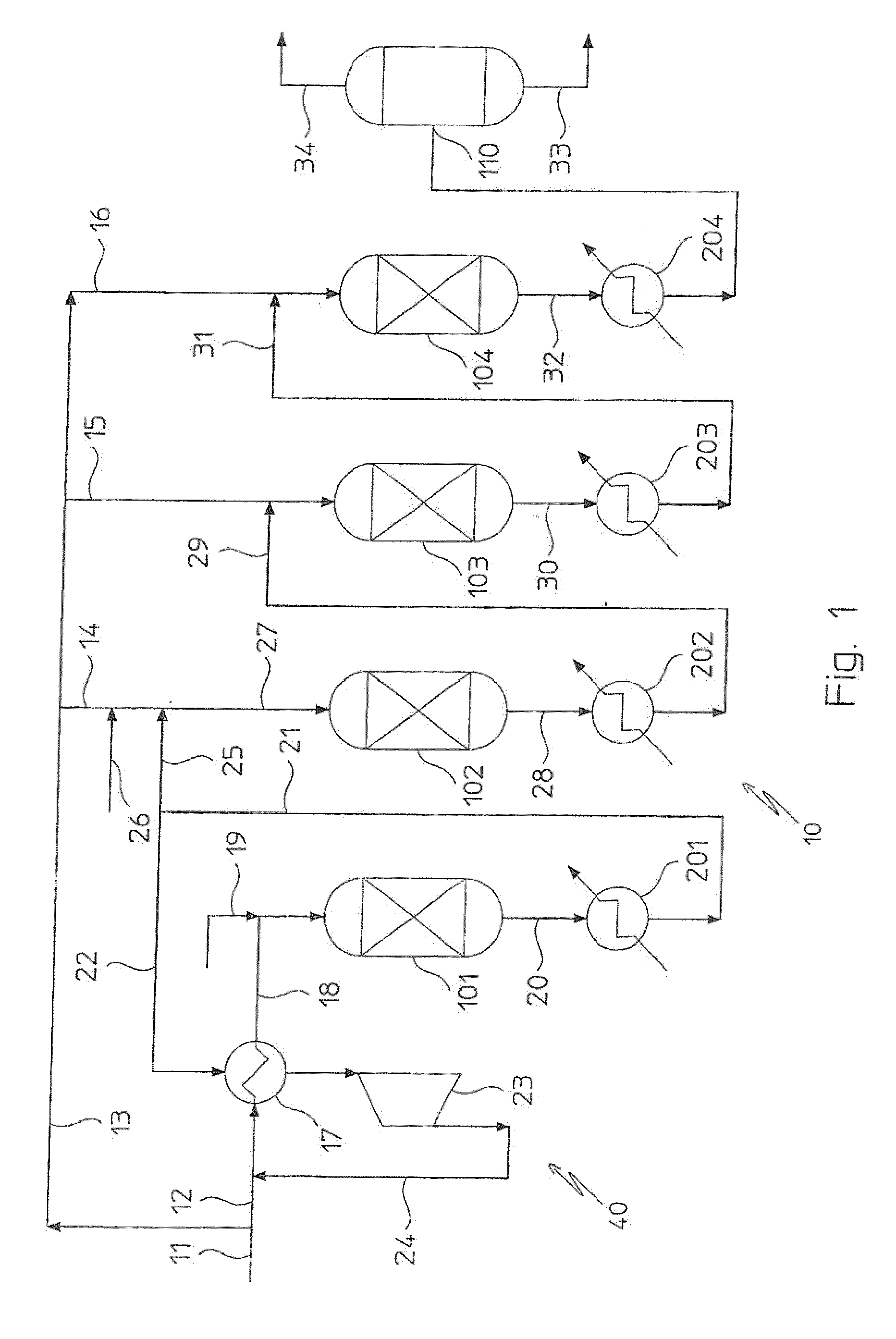

A process for producing substitute natural gas (SNG) comprising the steps of reacting a fresh syngas (11) into a methanation section (10) comprising adiabatic reactors (101-104) connected in series, with heat removal and reacted gas-recirculation, wherein the fresh syngas is fed in parallel to said adiabatic reactors. In a preferred embodiment the reacted gas is recirculated to the first reactor (101) and further dilution of the fresh gas at the inlet of the first and second reactor is achieved by steam addition.

Owner:CASALE SA

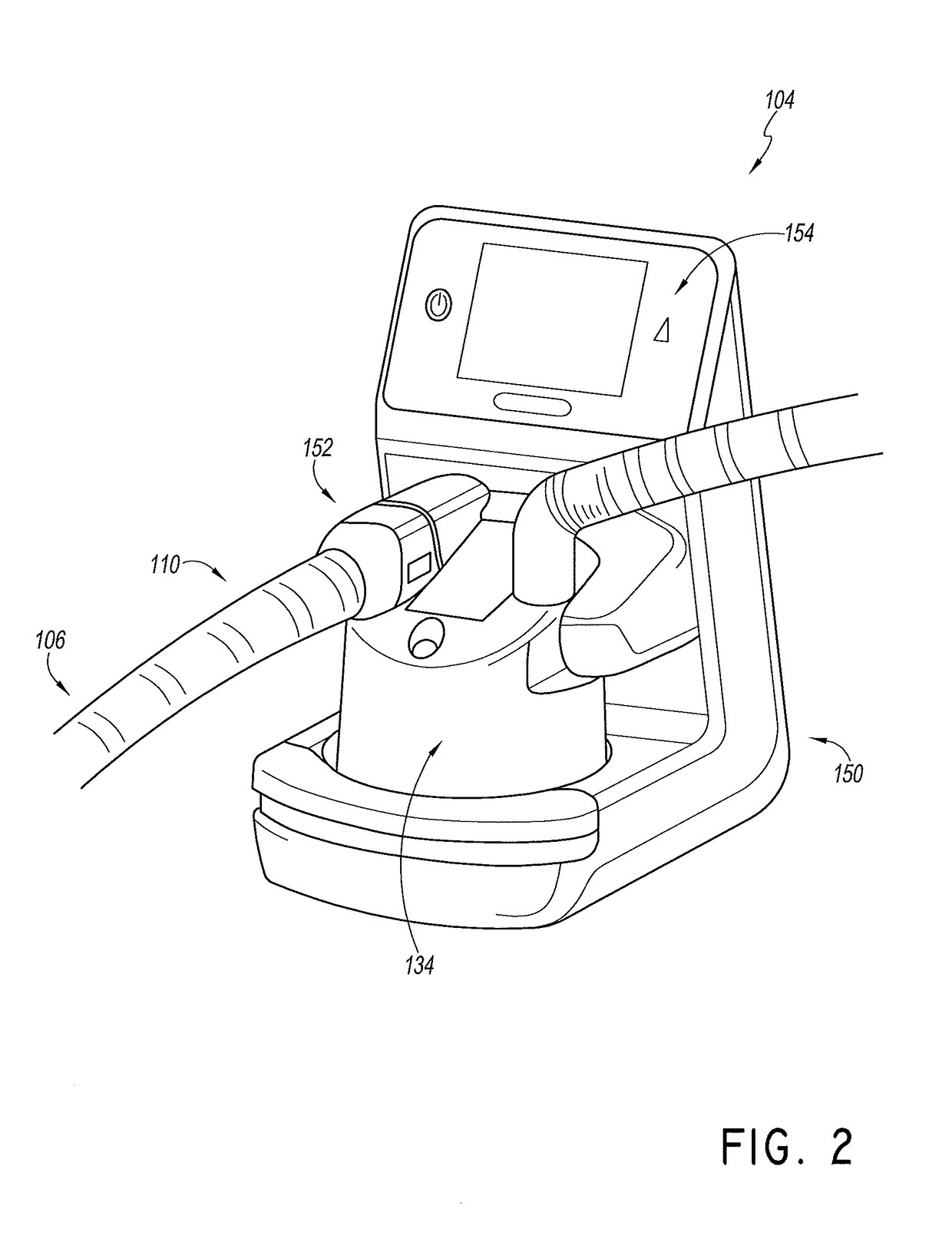

Reduction of recirculation in catheters

ActiveUS8920404B2Reduce the average velocityPrevent sprayingMedical devicesCatheterDistal portionNose

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

Preparation method of 2,4-dichlorin phenoxyacetic acid

ActiveCN101062893AReduce the difficulty of operationReduce unit consumptionOrganic compound preparationCarboxylic compound preparationChlorophenolChemistry

The invention discloses a preparing method of weed killer 2, 4-dichlorobenzene oxide acetic acid, which comprises the following steps: (1) producing bi-chlorophenol sodium solution and sodium monochloracetate solution; (2) putting into bi-chlorophenol sodium solution in condensed still; heating to 90-110 deg. c; dropping sodium monochloracetate solution; reacting for 2-8h; connecting to oil-water separator in reacting period; refluxing; returning water phase to reactor; dividing out of oil phase; setting the mole ratio of bi-chlorophenol sodium and sodium monochloracetate at 1:0. 8-1. 2; disposing; getting the product. This invention possesses low cost, high receiving ratio and simple operation, which can realize self-control.

Owner:SHANDONG WEIFANG RAINBOW CHEM

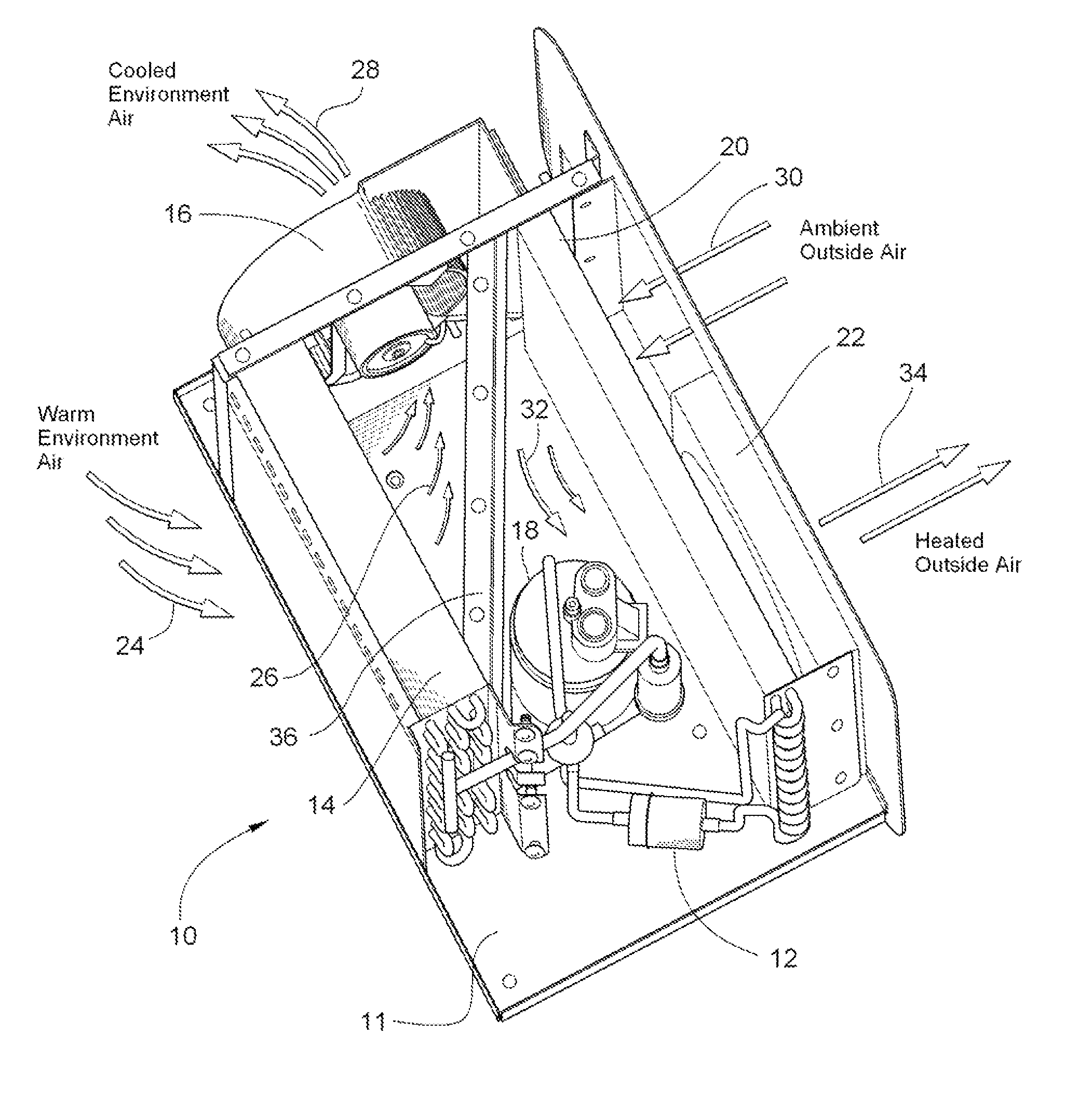

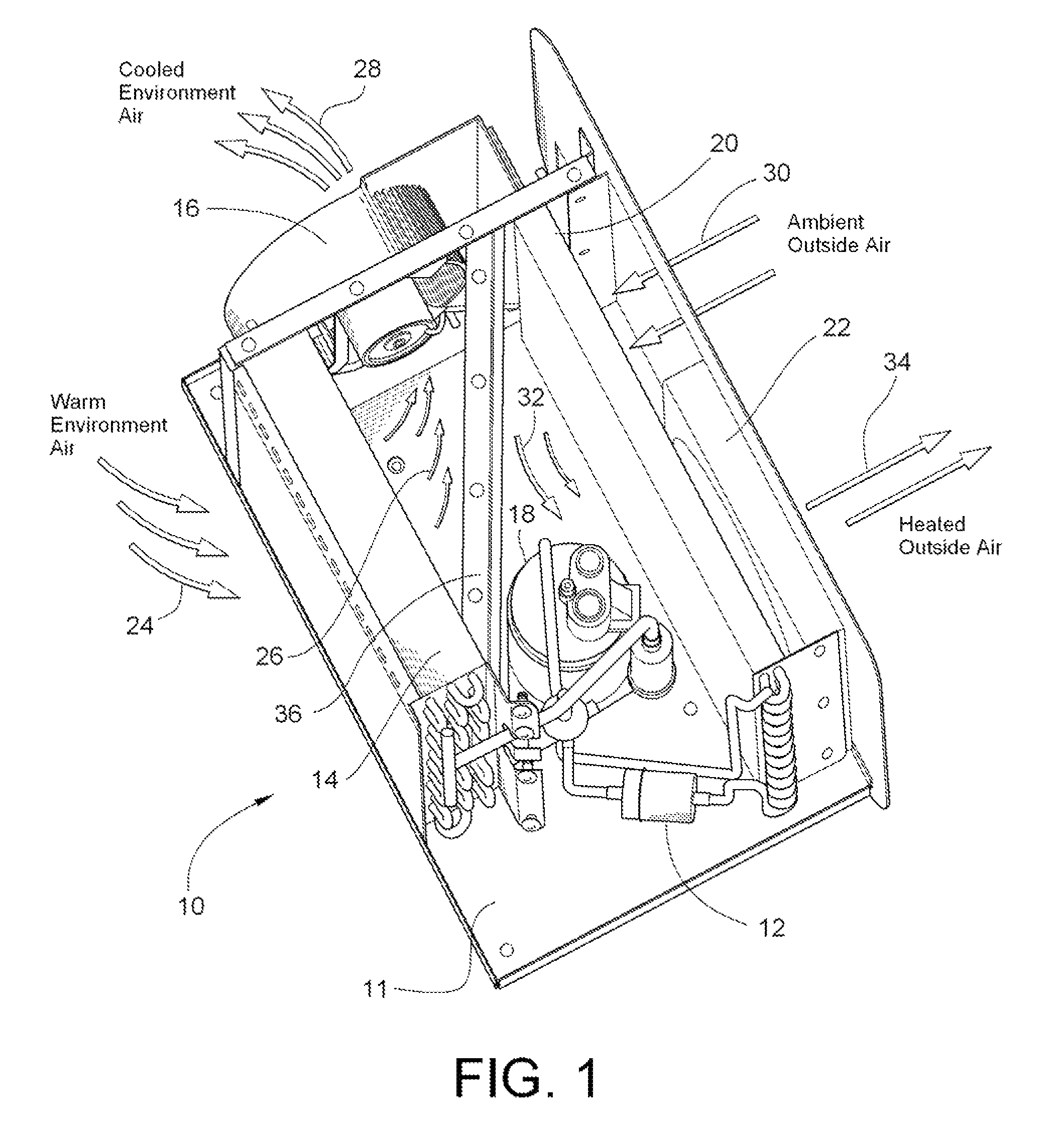

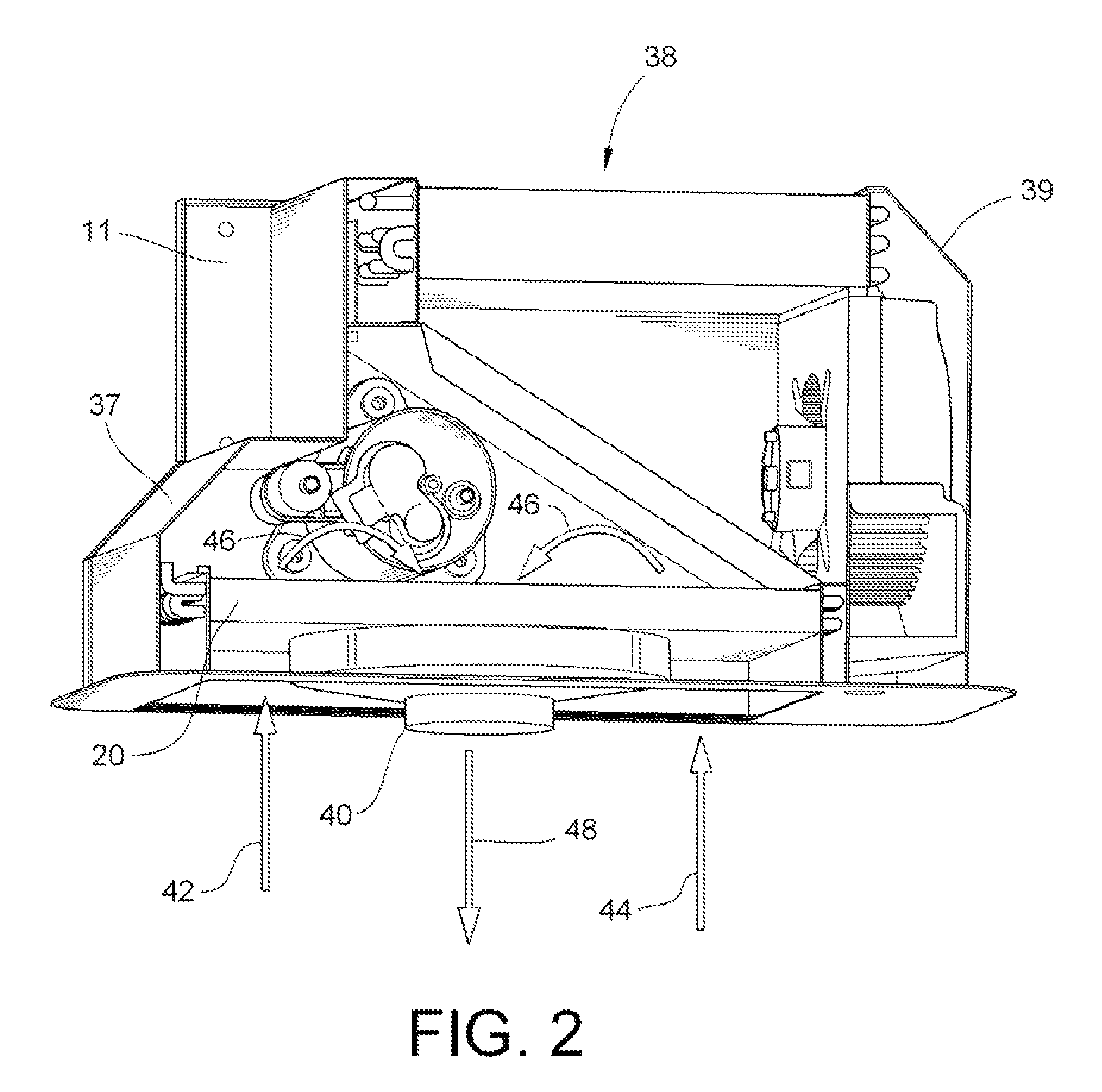

Truck electrified engine-off air conditioning system

ActiveUS8141377B2Reduce recyclingAir-treating devicesVehicle heating/cooling devicesCold airElectricity

An air conditioning system for cooling an environment in an over-the-road vehicle is provided. The air conditioning system includes an electrically driven, variable speed compressor, which enables operation of the system when the engine of the over-the-road vehicle is not running. The system is modular and is adapted to be installed in the side luggage compartment of the vehicle to enable existing vehicles to be retrofitted to provide no-idle air conditioning. The housing of the system defines two flow paths therethrough; one cold air path and one hot air path. The hot air path is configured to intersect the condenser at least two times, and draws and expels the air through the same wall of the housing. An air direction device is used to reduce the amount of air recirculation through the hot air path to increase the efficiency of the system.

Owner:BERGSTROM INC

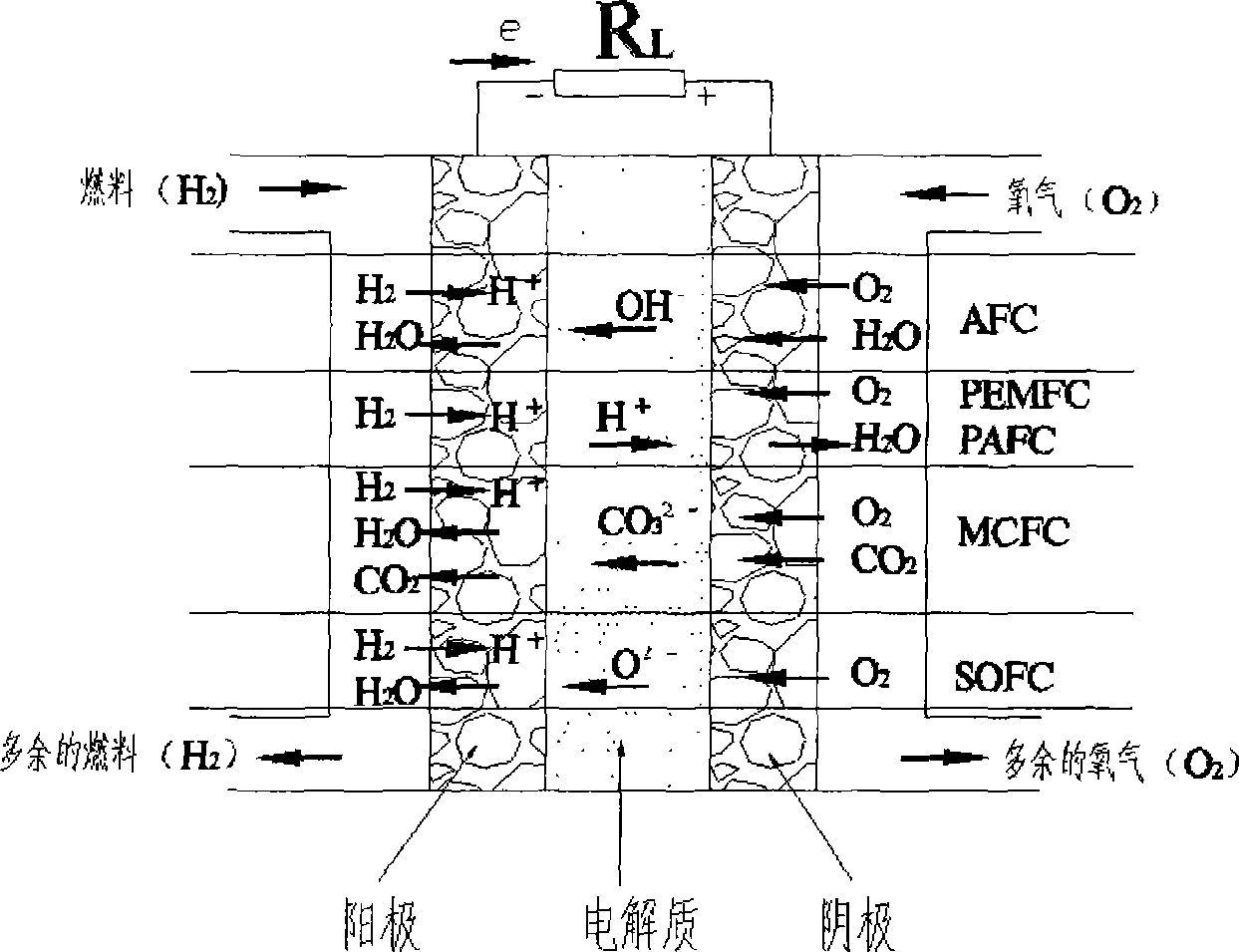

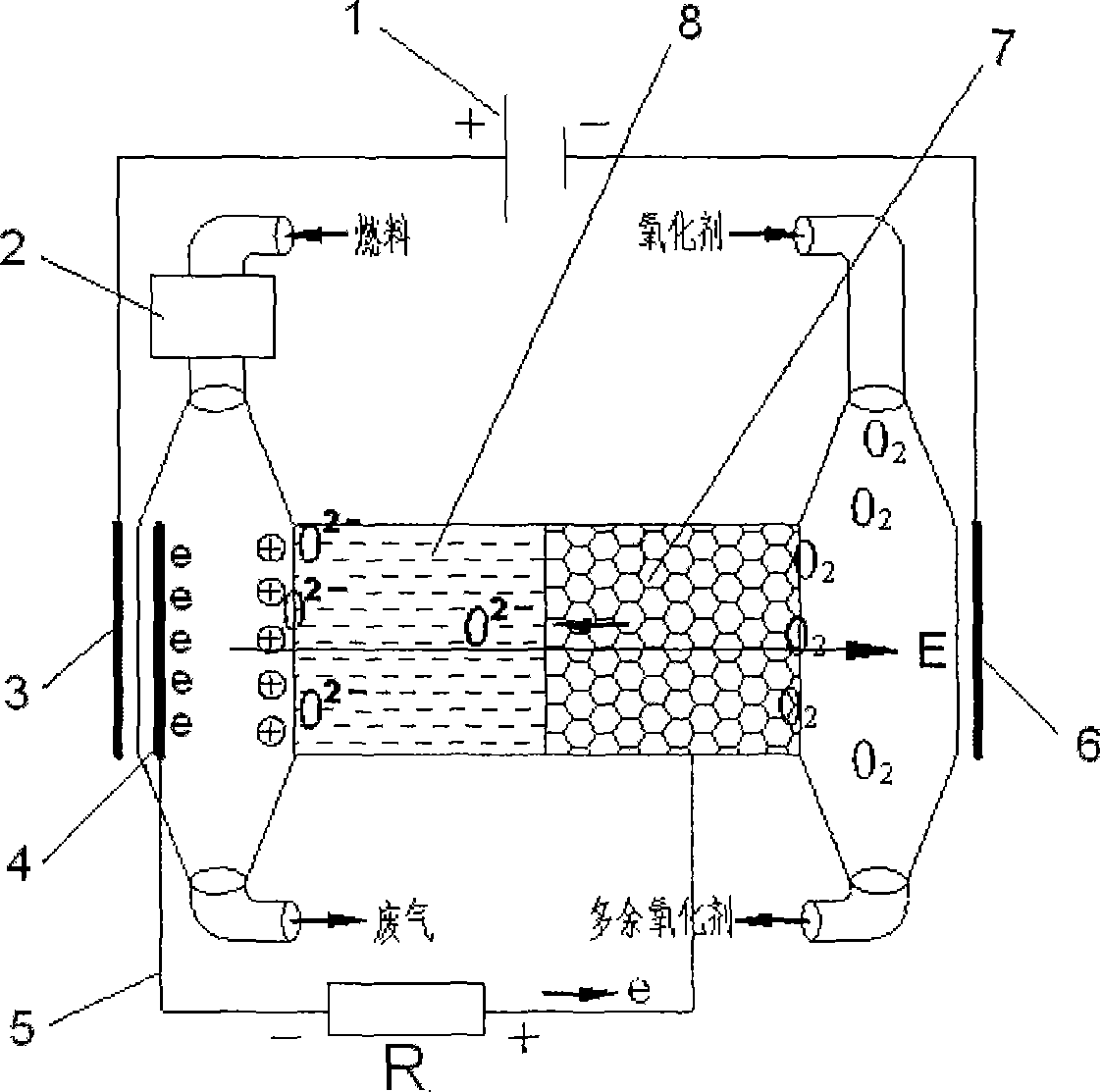

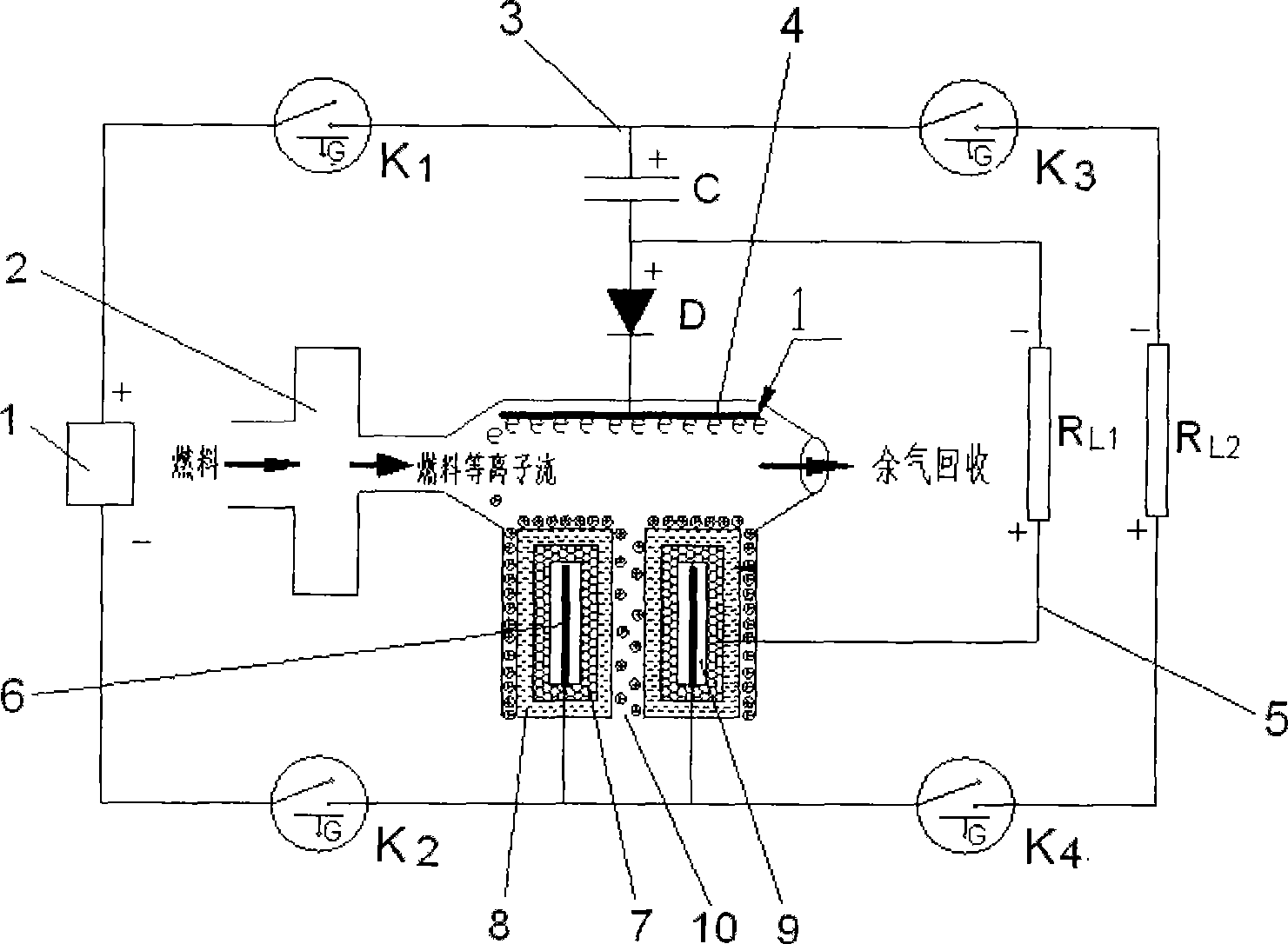

Plasma body fuel cell

InactiveCN101453028AStart fastIncrease powerFinal product manufactureFuel cell auxillariesPlasma jetElectrolysis

The invention provides a plasma fuel cell. An additional ion separation field with field direction which is vertical to running direction is arranged on a plasma flow operating path after a plasma jet generation unit; and corresponding collection structures are arranged on moving directions of separated cation and anion, wherein an electron collection structure is connected with an electric energy output circuit of an electron transfer circuit which is used for moving collected electrons out of the separation field; the electrons are transferred to a porous electrode structure which is on anion collecting side, is communicated with an oxygen introducing structure, and is isolated from the anions by a solid oxide electrolysis isolation structure; oxygen anions reduced by the electrons are combined with cations collected via isolation through the solid oxide electrolysis isolation structure to release converted electric energy to the outside. The cell can break electrostatic balance with feasibility, has a simple structure, can use various fuel gases and effectively recover fuel residual gas, does not need a noble metal catalyst or a biopolar plate so as to reduce the cost, and has the advantages of fast starting, large power and good loading adaptability.

Owner:肖远科 +1

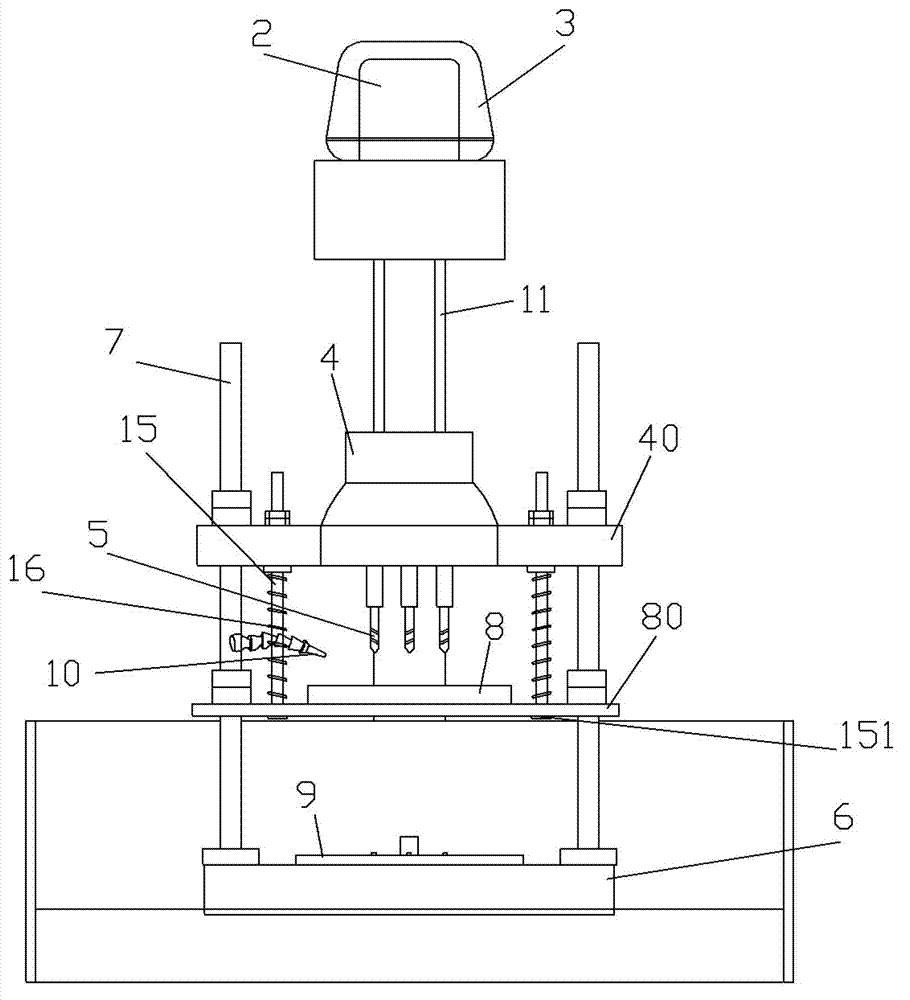

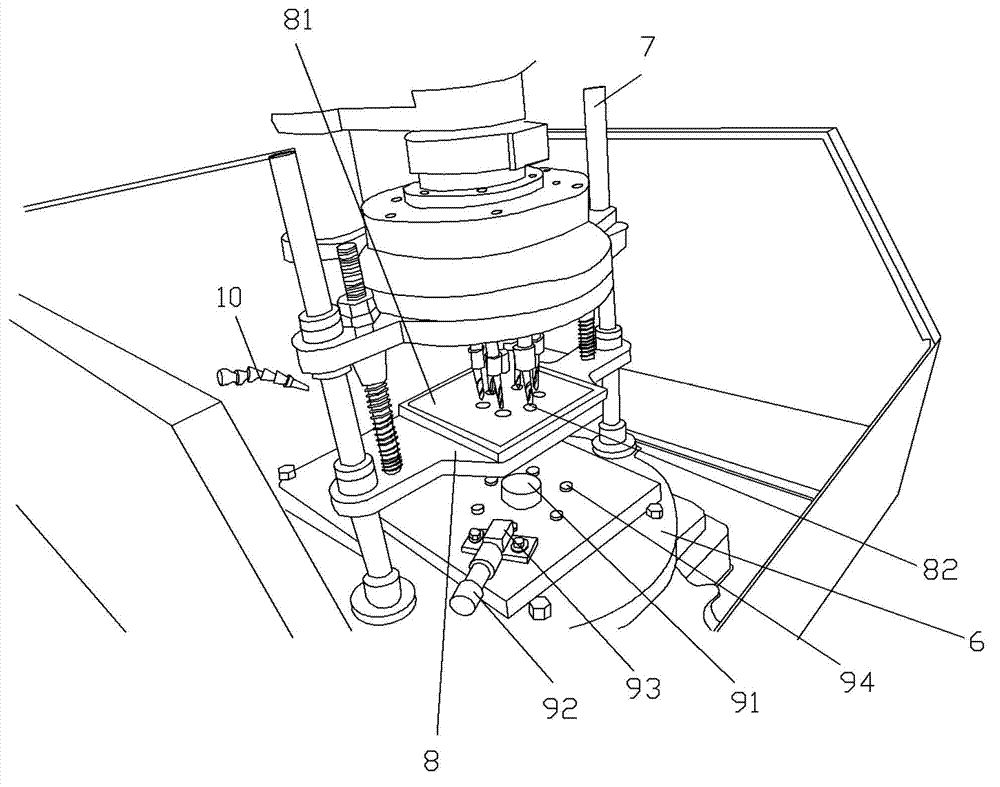

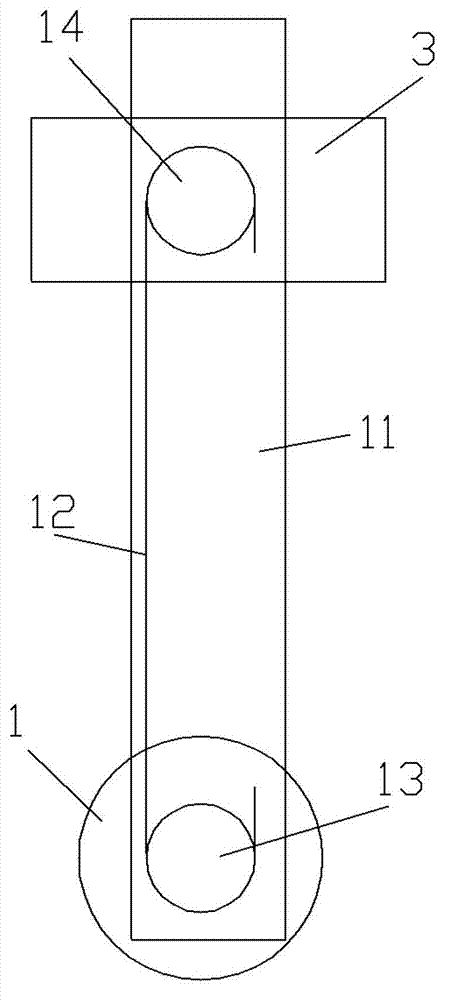

Special drilling machine for processing porous gear

ActiveCN102806371AIncrease productivitySimple structureBoring/drilling componentsMaintainance and safety accessoriesGear wheelMachining process

The invention relates to a special drilling machine for processing a porous gear. A lifting frame can lift; a liquid storing tank is formed in the middle of a cooling bedplate; a through hole is formed at the bottom of the liquid storing tank; a drill bit is aligned with the through hole; the cooling bedplate is sleeved on a slide rod; one end of a spring is pressed on a gearbox sleeve plate; the other end of the spring is pressed on the cooling bedplate; the upper part of the slide rod is fixed on the gearbox sleeve plate; a gear clamp is fixed on an operation platform; the gear clamp is composed of a central positioning pin, a positioning screw rod and a screw rod fixing block; the central positioning pin is located right under a rotating shaft of a drilling motor; the positioning screw rod is screwed on the screw rod fixing block; a plurality of drill bit matched through holes are formed on the periphery of the central positioning pin; the drill bit matched through holes are aligned with the drill bits; and a cooling liquid outlet pipe is aligned with the liquid storing tank. The special drilling machine can be used for drilling a plurality of small holes on a gear at one time; the production efficiency is increased; a gear fixing mode during a processing process and a structure are simple; the use is convenient; the reuse amount of the cooling liquid is reduced; and the production cost is lowered.

Owner:ZHEJIANG ZHONGCHAI MACHINERY

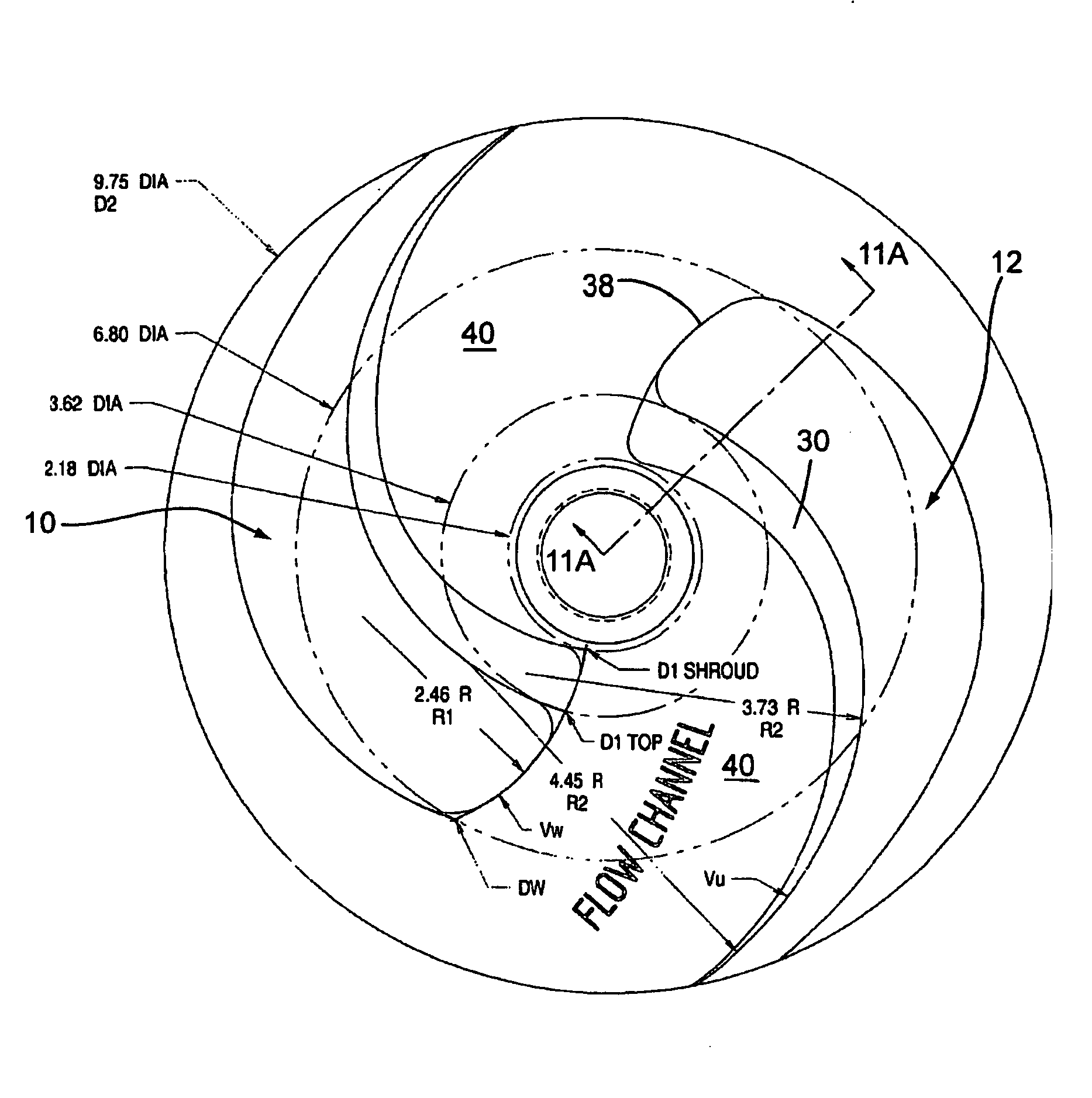

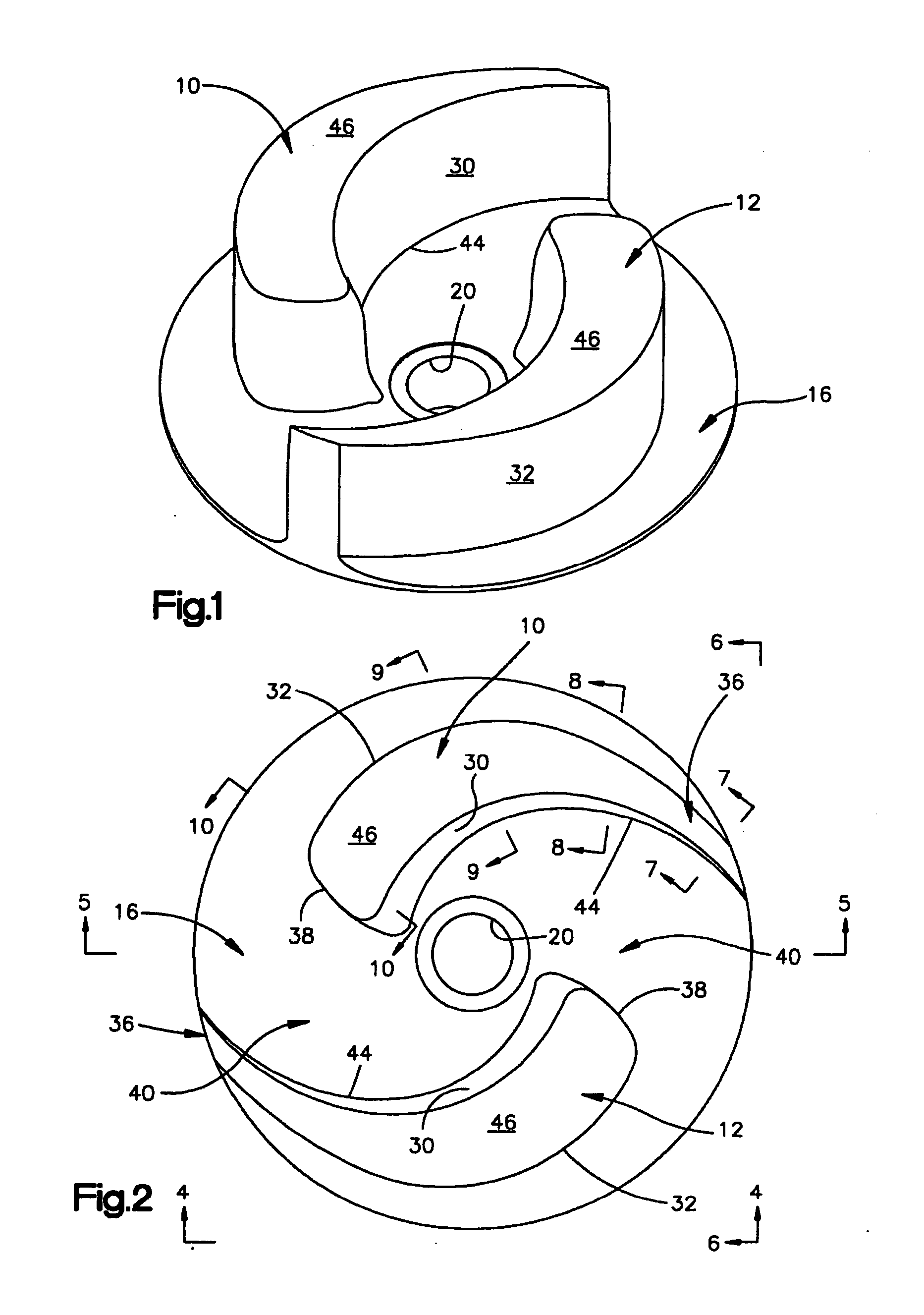

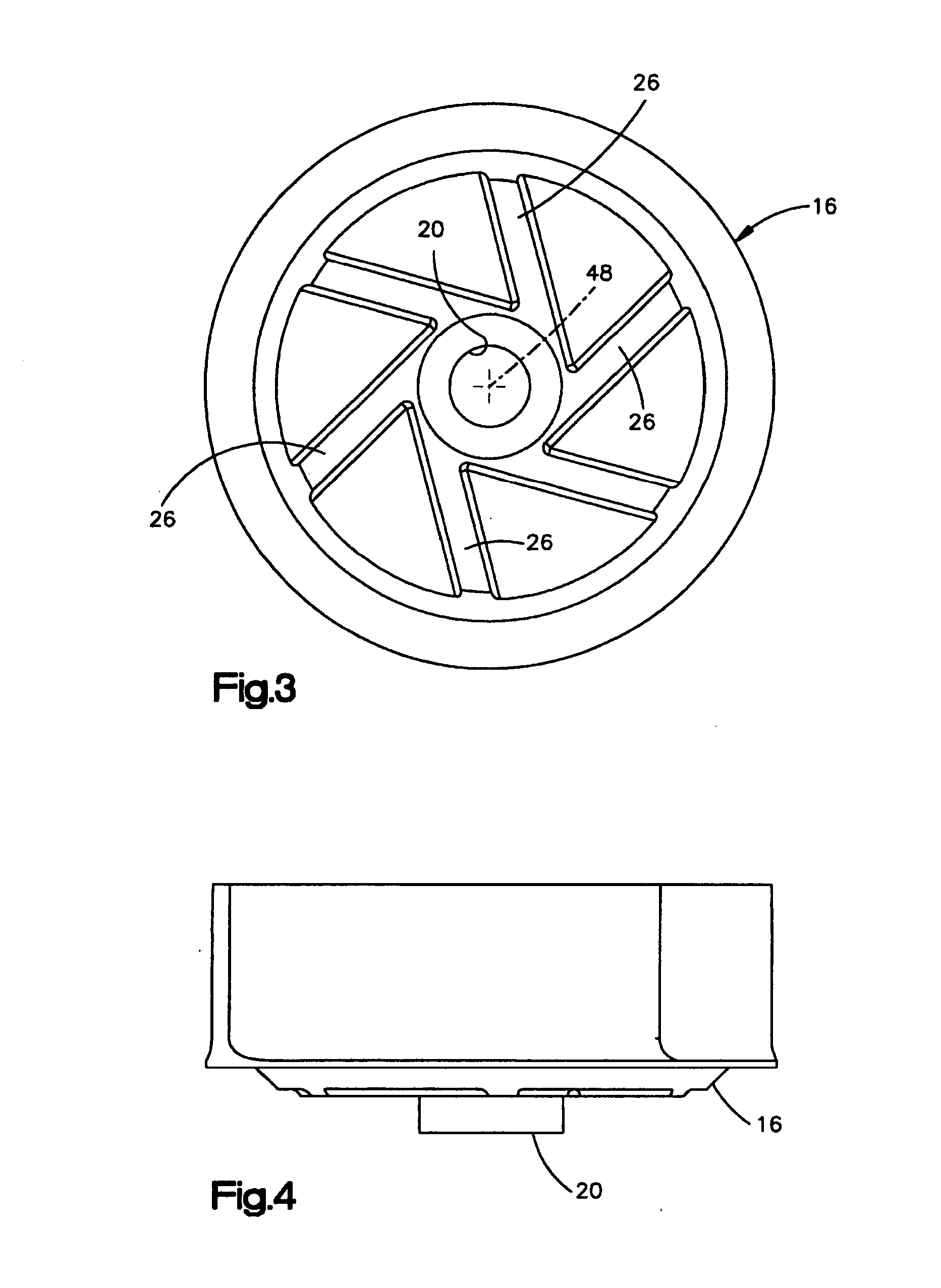

Impeller

ActiveUS20100239417A1Improve hydraulic efficiencyEasy to pumpSpecific fluid pumpsPropellersLeading edgeTrailing edge

A pump impeller for a centrifugal pump The impeller is defined by a shroud rotatable about an axis of rotation At least two pump vanes extend axially from the shroud, each of the vanes configured as a blunted tear drop shape and having an inside wall and an outside wall, the leading edges of which are interconnected by a blunt wall The trailing edges of the inside and outside walls merge together A substantially constant width flow channel is defined between the blunted wall of one vane and a confronting surface defined by an inside wall of the other vane The vanes are tapered in the axial directions by inclining the inside wall of each vane radially outwardly.

Owner:GORMAN RUPP COMPANY

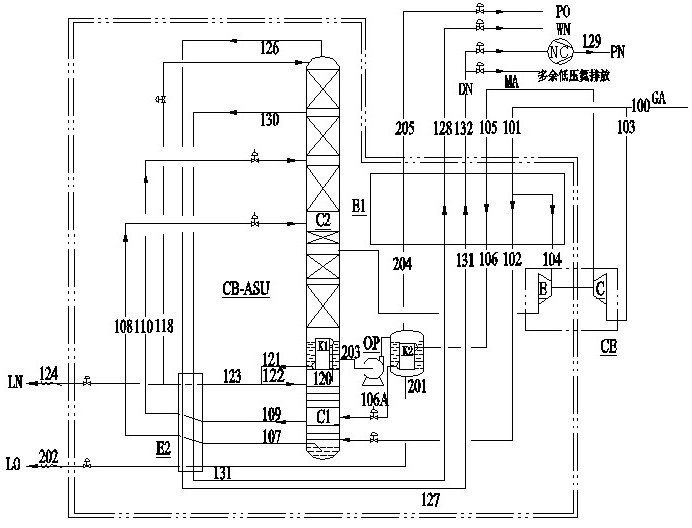

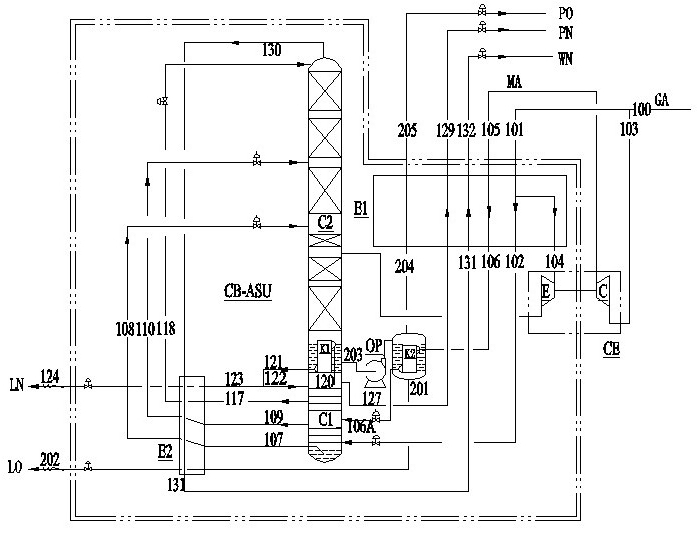

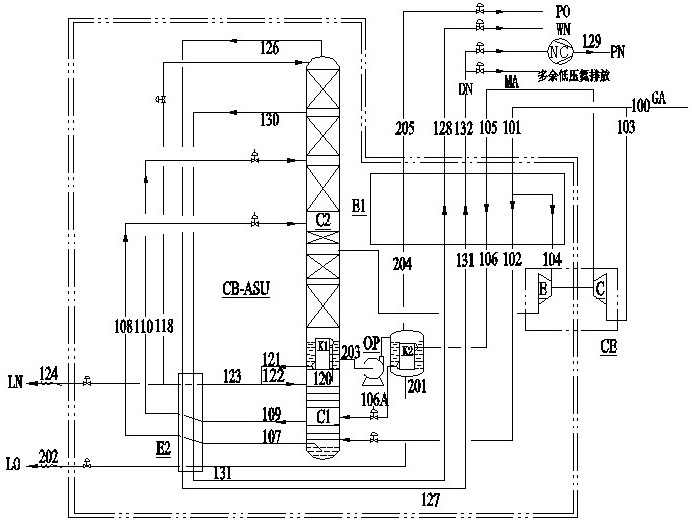

Method and device for producing pressure oxygen by air separation

ActiveCN101886871AReduce exhaust pressureReduce energy consumptionSolidificationLiquefactionLiquid oxygenEvaporator

The invention discloses a method for producing pressure oxygen by air separation. The compressed air is divided into two paths: one path of the compressed air is pressurized to enter a main heat exchanger for cooling, enter an oxygen pressurizer to exchange heat with pressure liquid oxygen to be condensed into a liquid state and enter a lower tower for rectification; and the other path of the compressed air enters the main heat exchanger for cooling and is divided into two parts, and one part of the air is expanded to be fed to an upper tower for rectification. The nitrogen obtained by the lower tower enters a condensing evaporator to be condensed into two parts, namely one part of the nitrogen serving as reflux returns to the lower tower and the other part of the nitrogen is subcooled through a subcooler and divided into two paths. One path of the nitrogen serving as liquid nitrogen is led out, and the other path of the nitrogen enters the top of the upper tower. Dirty liquid air extracted from the lower tower and the obtained liquid air are subcooled through the subcooler, enter the upper tower for rectification once again and pass through the condensing evaporator so as to form liquid oxygen. The liquid oxygen which is pressurized or subjected to liquid oxygen pump pressurization enters the oxygen pressurizer to be evaporated into pressure oxygen and reheated in the main heat exchanger for output. The method for producing the pressure oxygen has the advantages of optimized flow organization, low equipment input cost, and capacity of obviously reducing the energy consumption.

Owner:四川空分设备(集团)有限责任公司

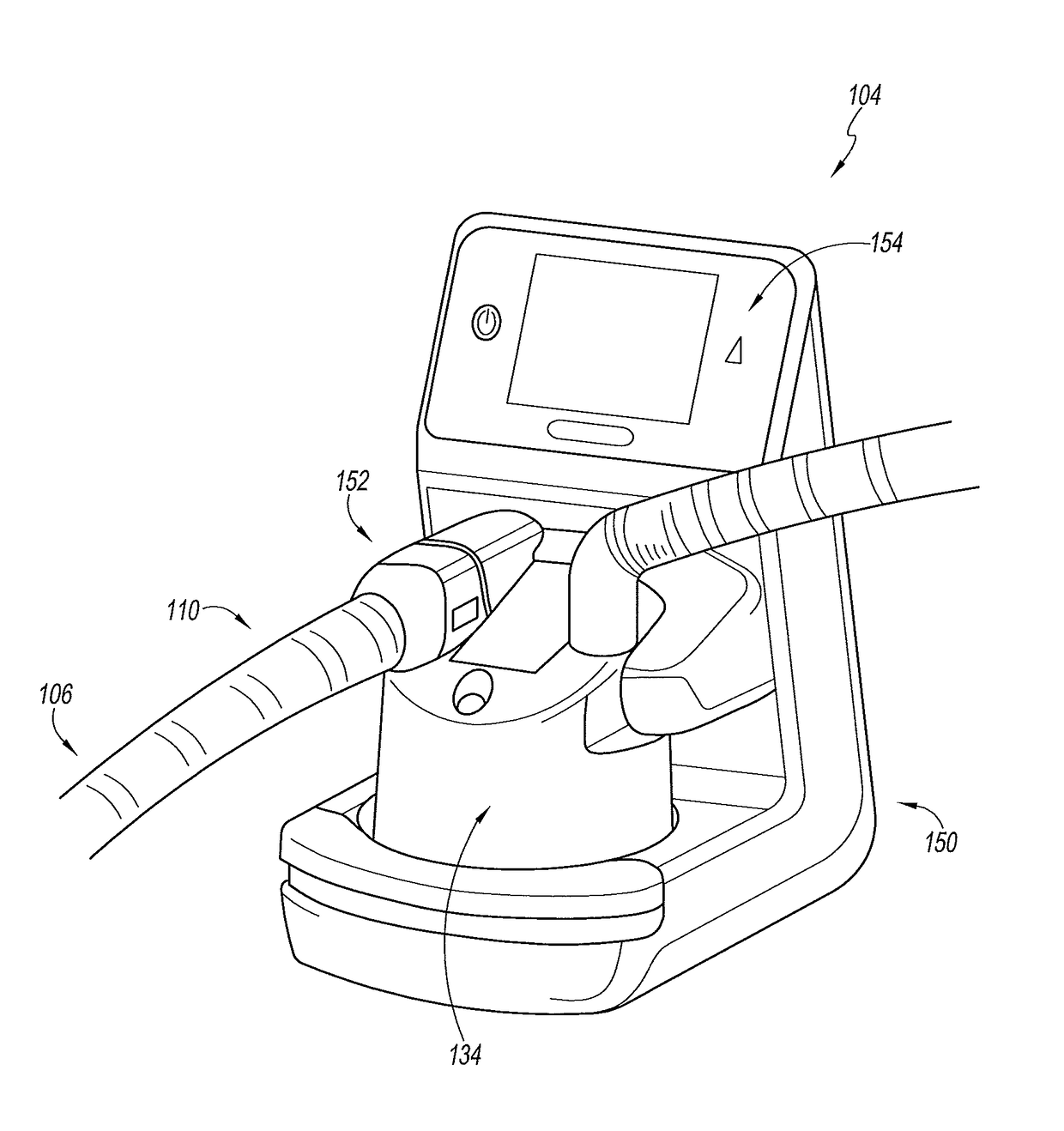

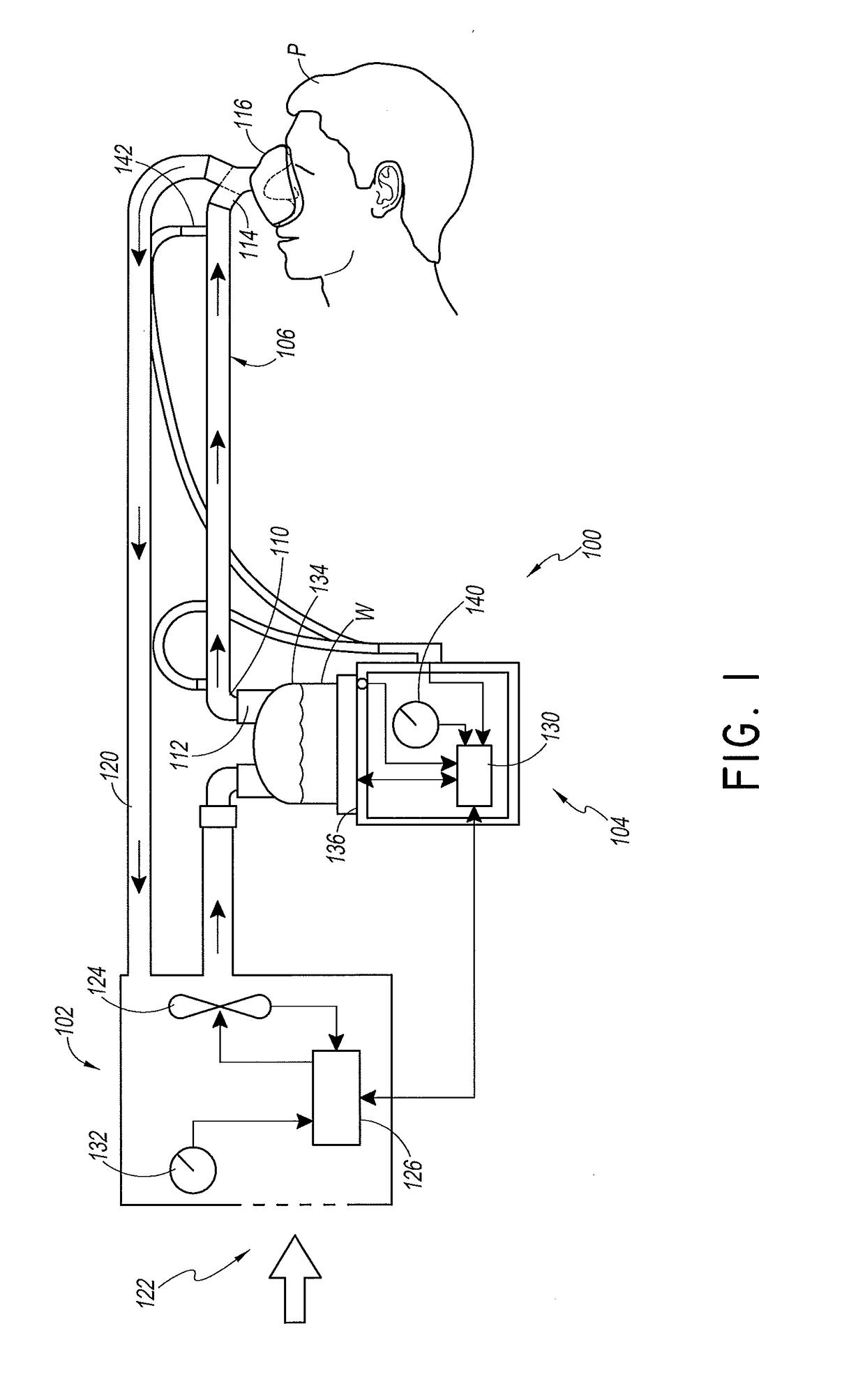

Respiratory humidification system

ActiveUS20170173293A1Improve fluid characteristicReduce recyclingRespiratorsLighting and heating apparatusCatheterEngineering

A system provides warm, humidified gas to a patient via a patient interface. Horizontal connections can be used between the humidification chamber and conduit. To reduce the likelihood of condensate flowing back to the humidification chamber, or dead space or gases recirculation regions occurring within the gases flow path, a raised portion is positioned inside of the flow path to improve flow characteristics and to provide a barrier for condensate back flow. The raised portion also reduces the amount of condensate that is formed in the system and provides better flow characteristics for sensing purposes.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Mixture of catalysts for cracking naphtha to olefins

ActiveUS8137533B2Maximize selective yieldReduce the amount requiredCatalytic crackingHydrocarbonsMolecular sieveNaphtha

Owner:UOP LLC

Medical Catheter Having a Design Providing Low Recirculation and Reversibility

ActiveUS20110077577A1Easy to set upEasy to moveMulti-lumen catheterMedical devicesSurgeryTransverse dimension

The present disclosure relates to a medical catheter including an elongate catheter member defining a longitudinal axis and having a proximal end, a distal end, an outer wall, and first and second internal lumens. The outer wall of the catheter member includes a first opening in fluid communication with the first internal lumen to facilitate the establishment of a first flow stream, and a second opening in fluid communication with the second internal lumen to facilitate the establishment of a second flow stream. Each of the first and second openings includes proximal and distal tapered portions that are connected by an intermediate portion having a constant transverse dimension. The configurations, dimensions, and positioning of the first and second openings optimizes separation of the first flow stream from the second flow stream in order to reduce the likelihood of recirculation between the first and second internal lumens.

Owner:MOZARC MEDICAL US LLC

Process for extracting rare earth from phosphate concentrate

InactiveCN102796888AImprove extraction efficiencyEfficient recyclingProcess efficiency improvementRare-earth elementDecomposition

The invention belongs to the field of rare earth metallurgy, and particularly relates to a full-flow process for extracting a rare earth element from rare earth-containing phosphate concentrate. According to the process, phosphate containing 0.05-0.3 percent of REO (Rare Earth Oxide) is used as a raw material, and decomposition is performed once by using low-concentration hydrochloric acid, so that most of impurities in the phosphate concentrate enter solution and the decomposition of the rare earth is effectively suppressed; primary residue is decomposed by using nitric acid, so that valuable metals such as rare earth enter the solution and secondary decomposition solution which meets a subsequent extraction process is prepared; and rare earth extraction is directly performed in a high-acid phosphate secondary decomposition solution system with complex impurity components by using a neutral extraction agent without adding a salting-out agent, and the rare earth is separated in one step under assistance of a washing measure to further separate phosphorus from the rare earth. The purity of the prepared rare earth enrichment is greater than 90 percent and the total rare earth recovery rate is over 90 percent.

Owner:贵州黔鸿瑞磷稀土分裂开发有限公司 +1

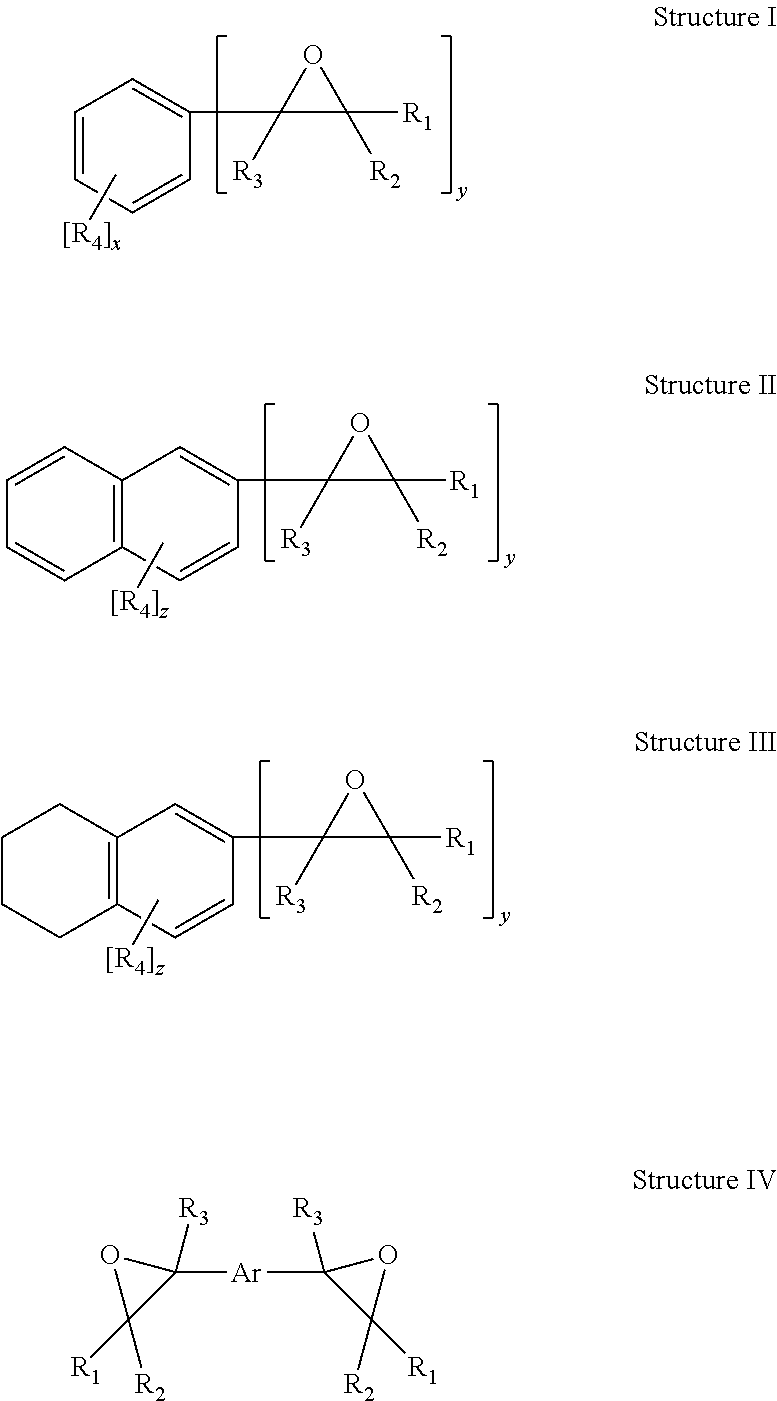

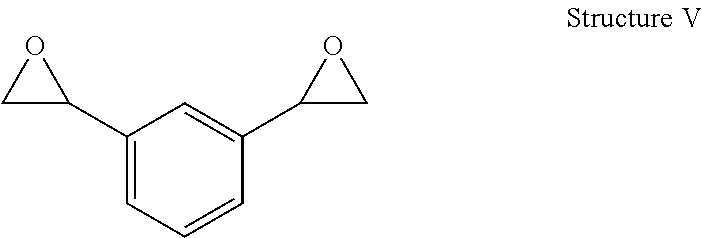

Process for preparing divinylarene dioxides

A process for preparing a divinylarene dioxide comprising reacting a divinylarene, such as divinylbenzene, with hydrogen peroxide in the presence of a solvent and in the presence of a catalyst to from a divinylarene dioxide; wherein the hydrogen peroxide is present in the reaction mixture in an excess or an equivalent mole ratio per mole of divinylarene.

Owner:BLUE CUBE IP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com