Patents

Literature

1384results about How to "Prevent spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

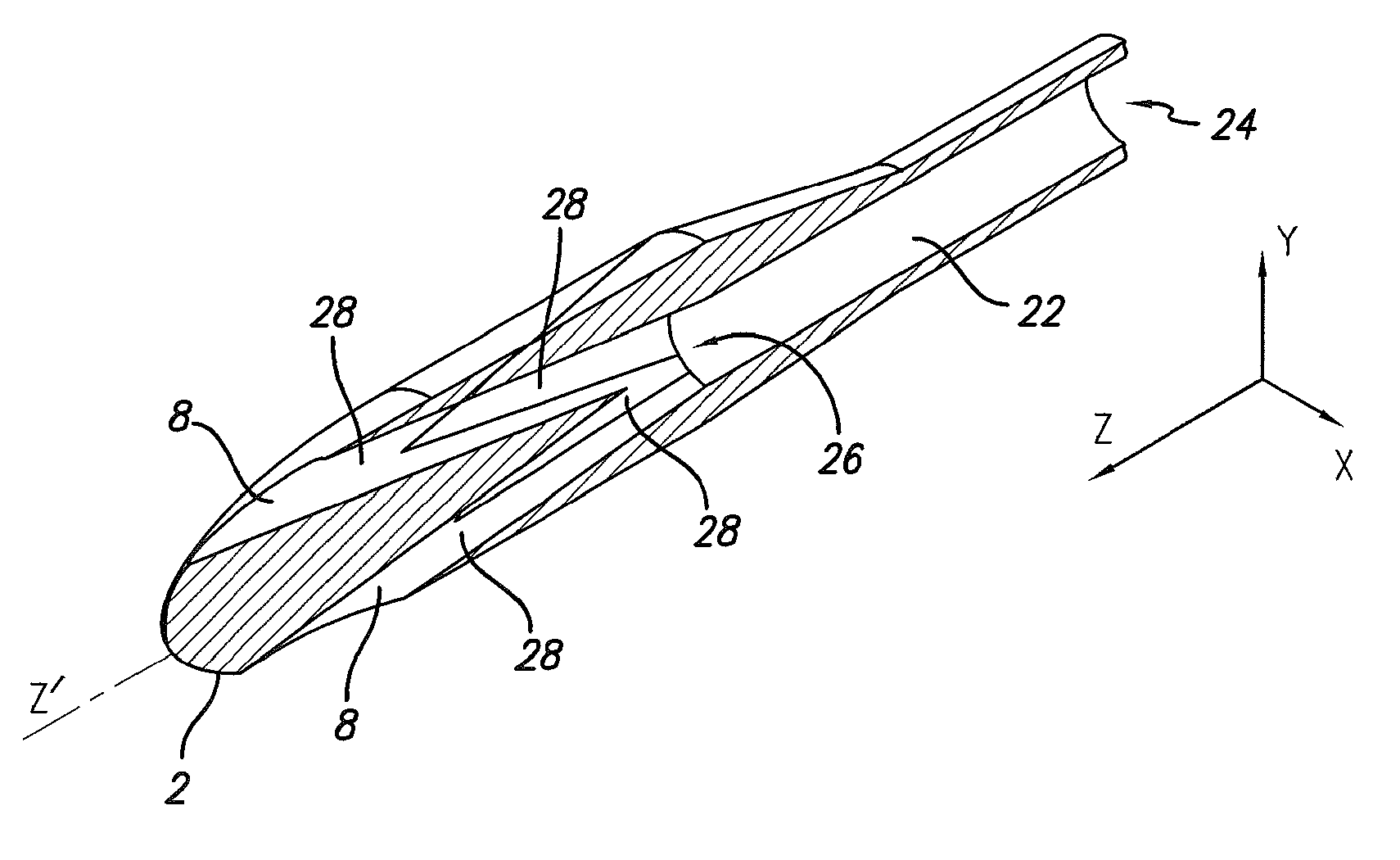

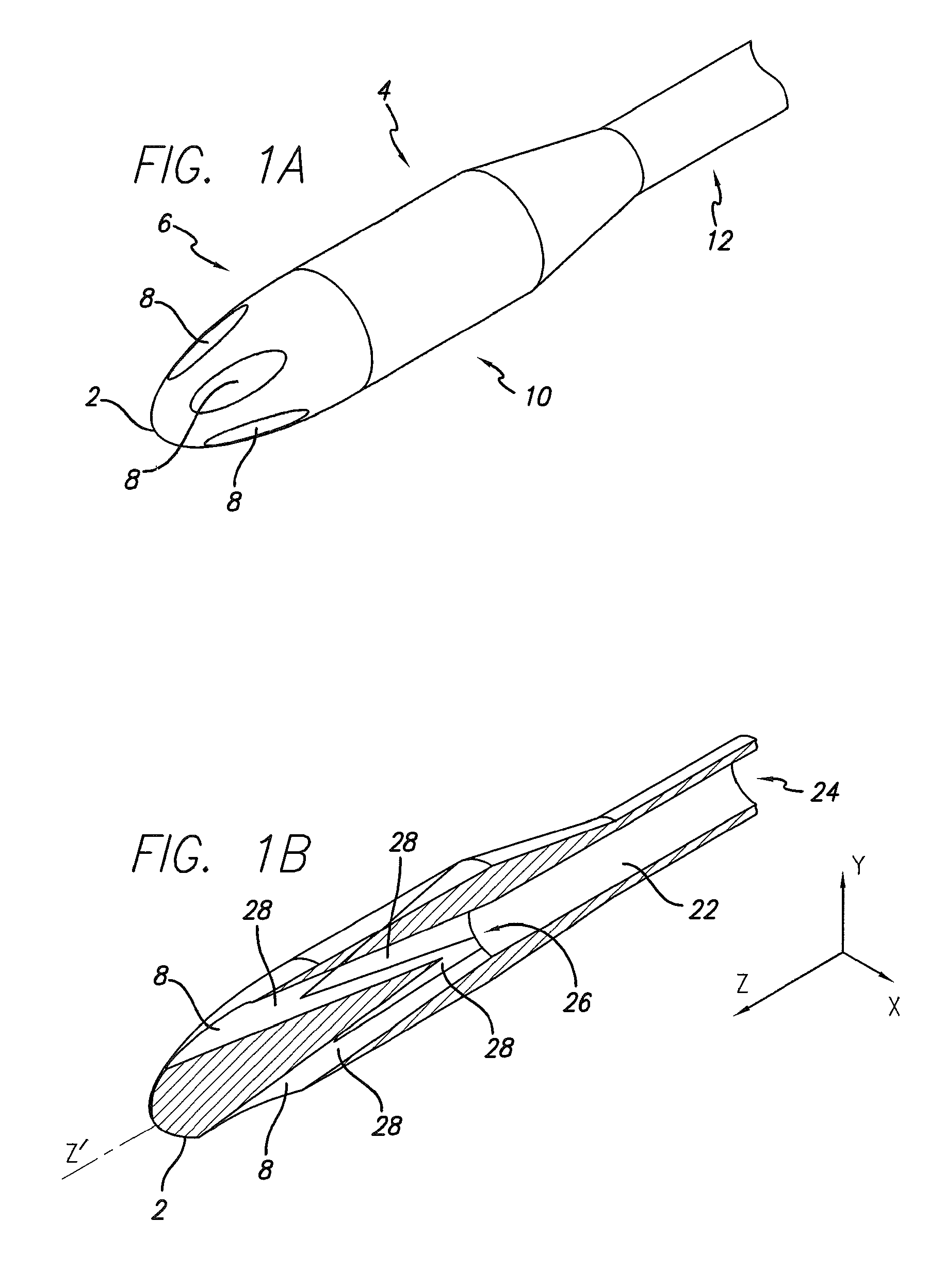

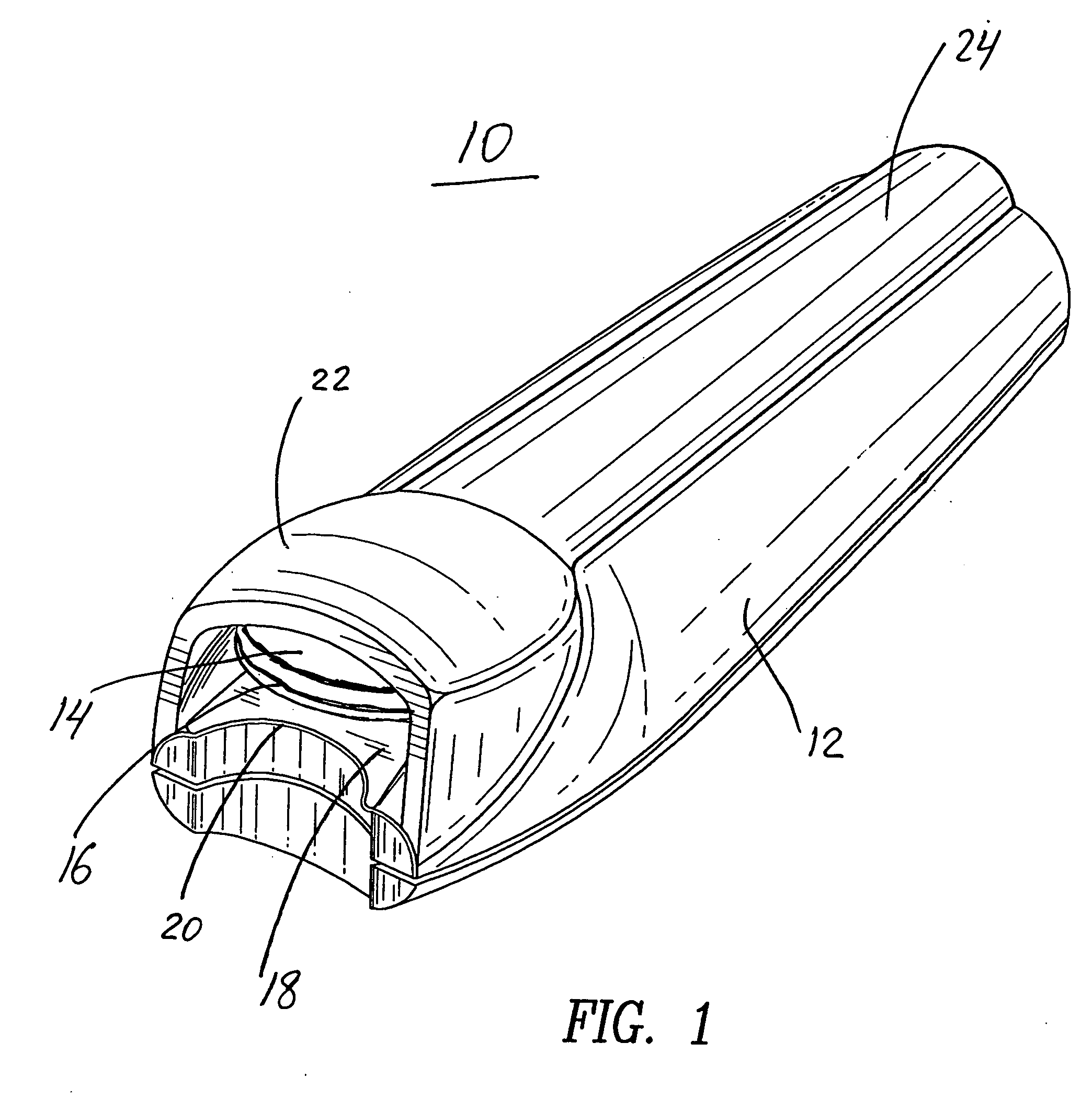

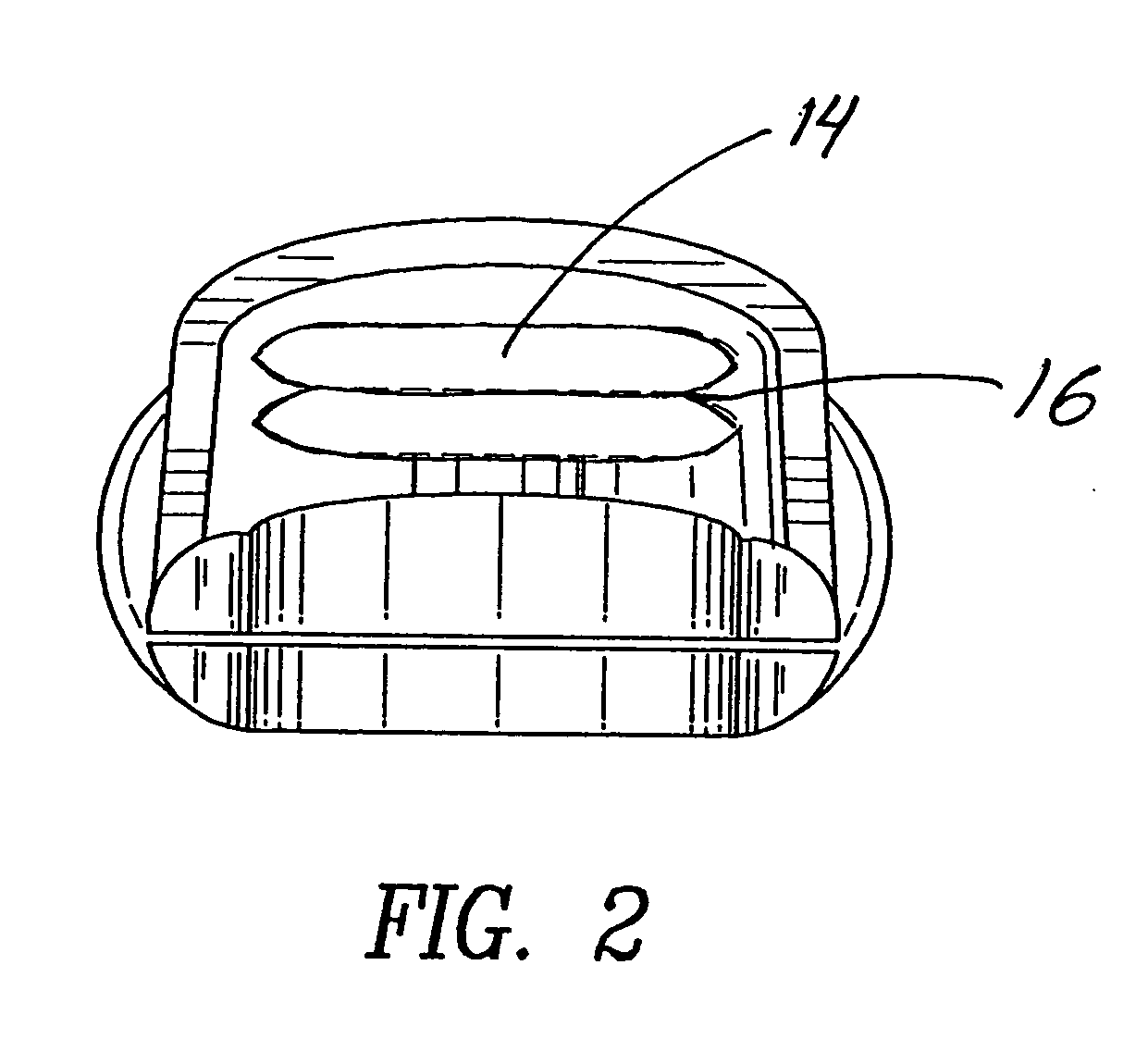

Reduction of recirculation in catheters

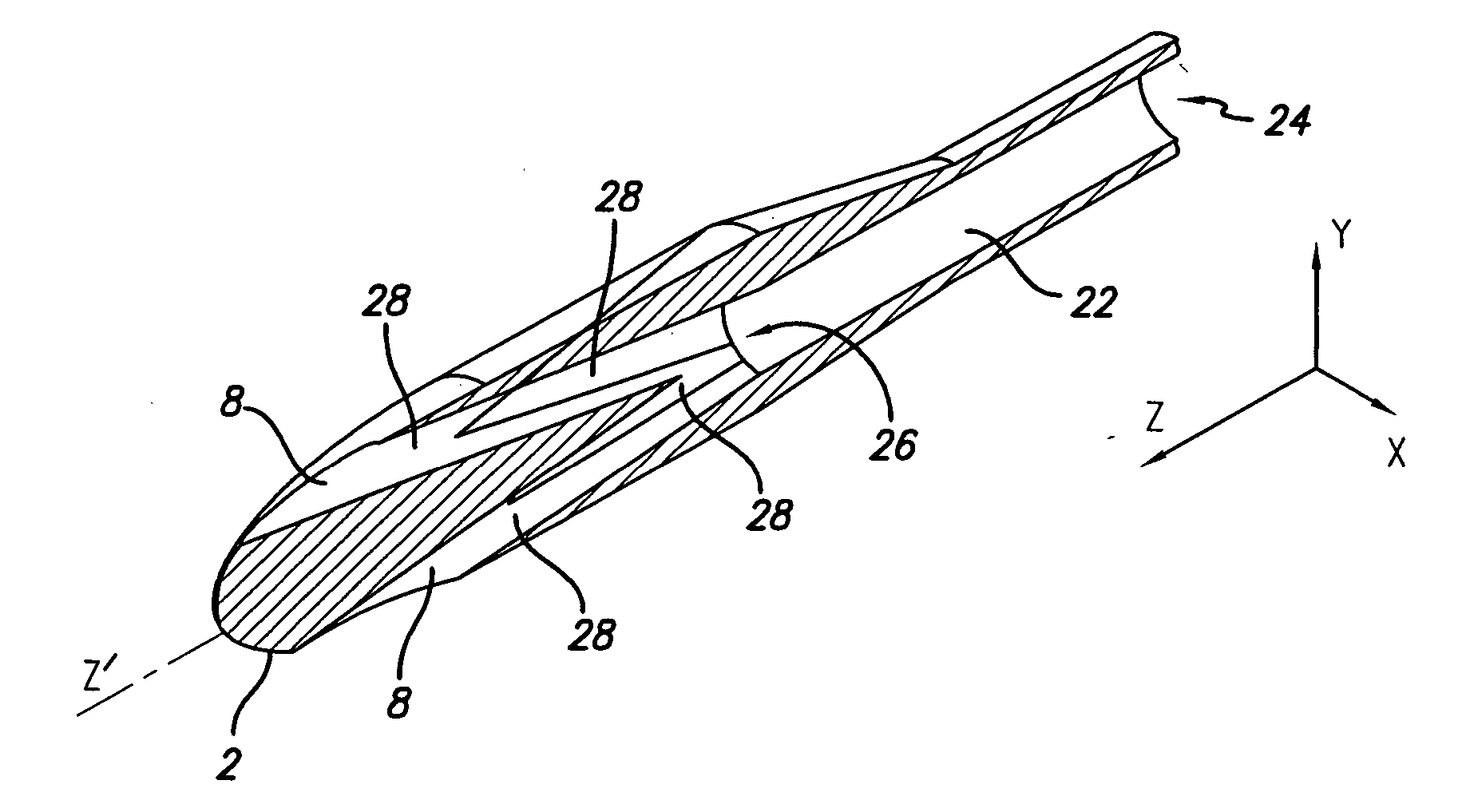

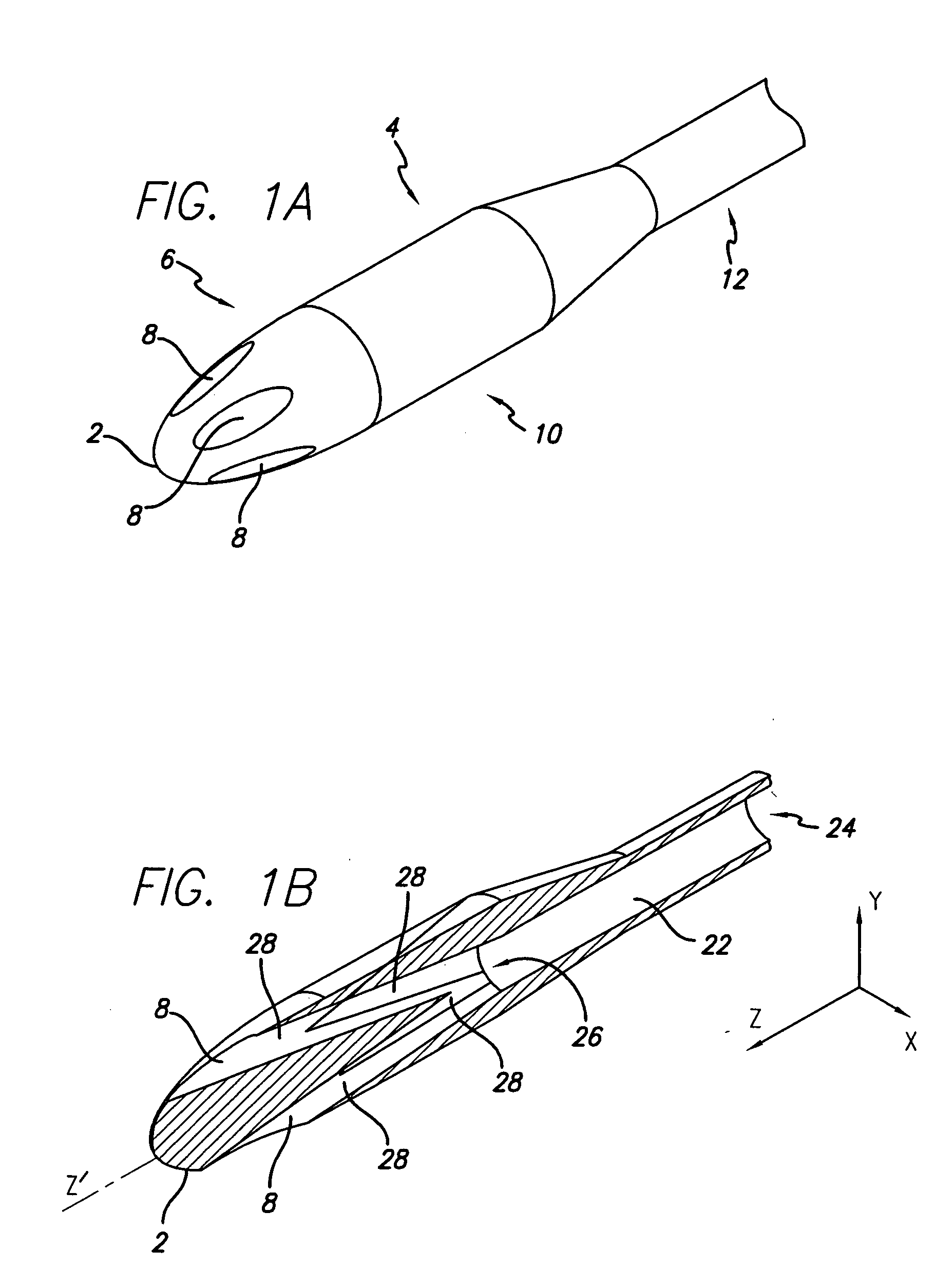

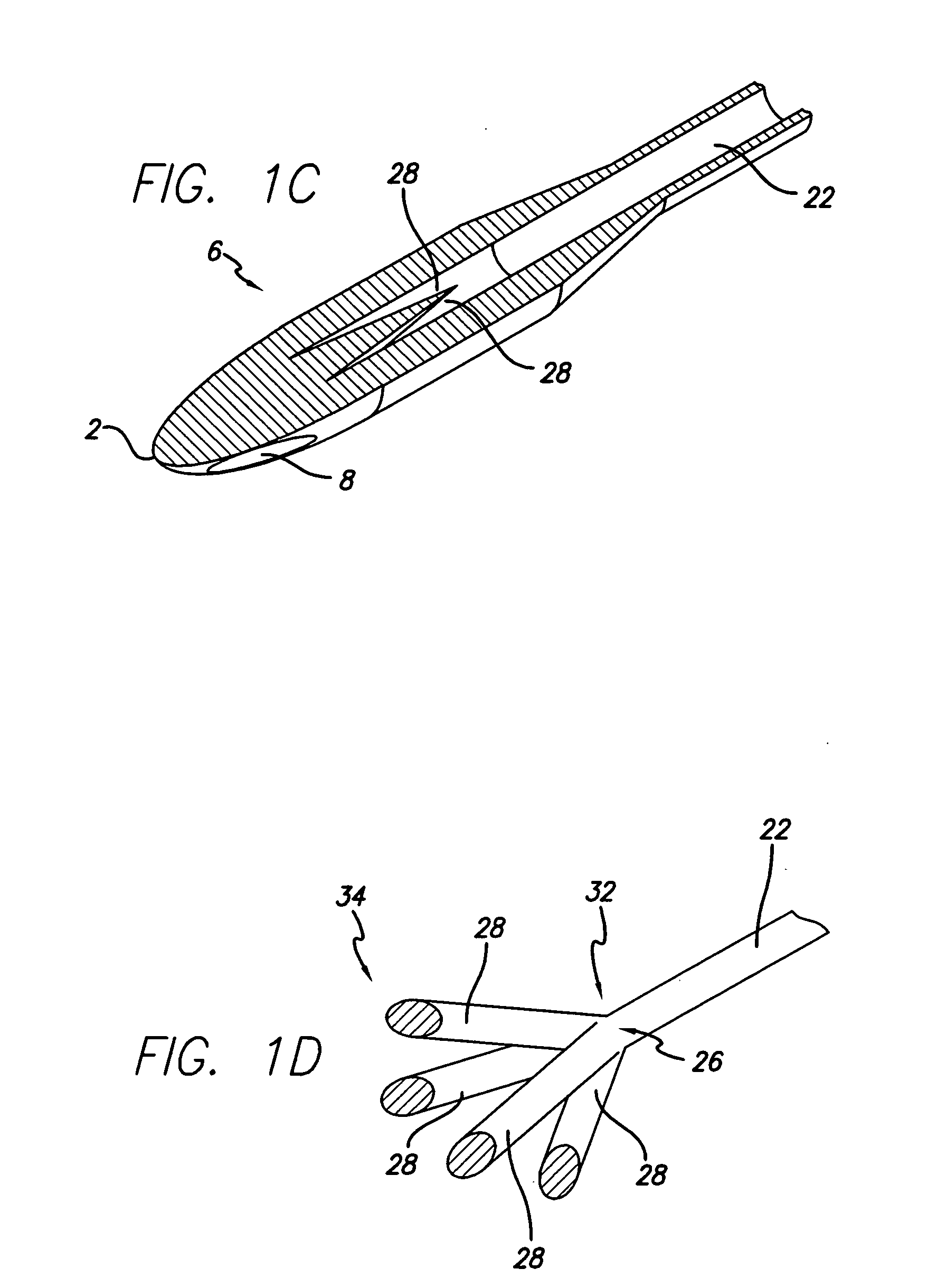

InactiveUS20060004316A1Decrease outflow velocity of fluidPrevent sprayingMedical devicesCatheterDistal portionNose

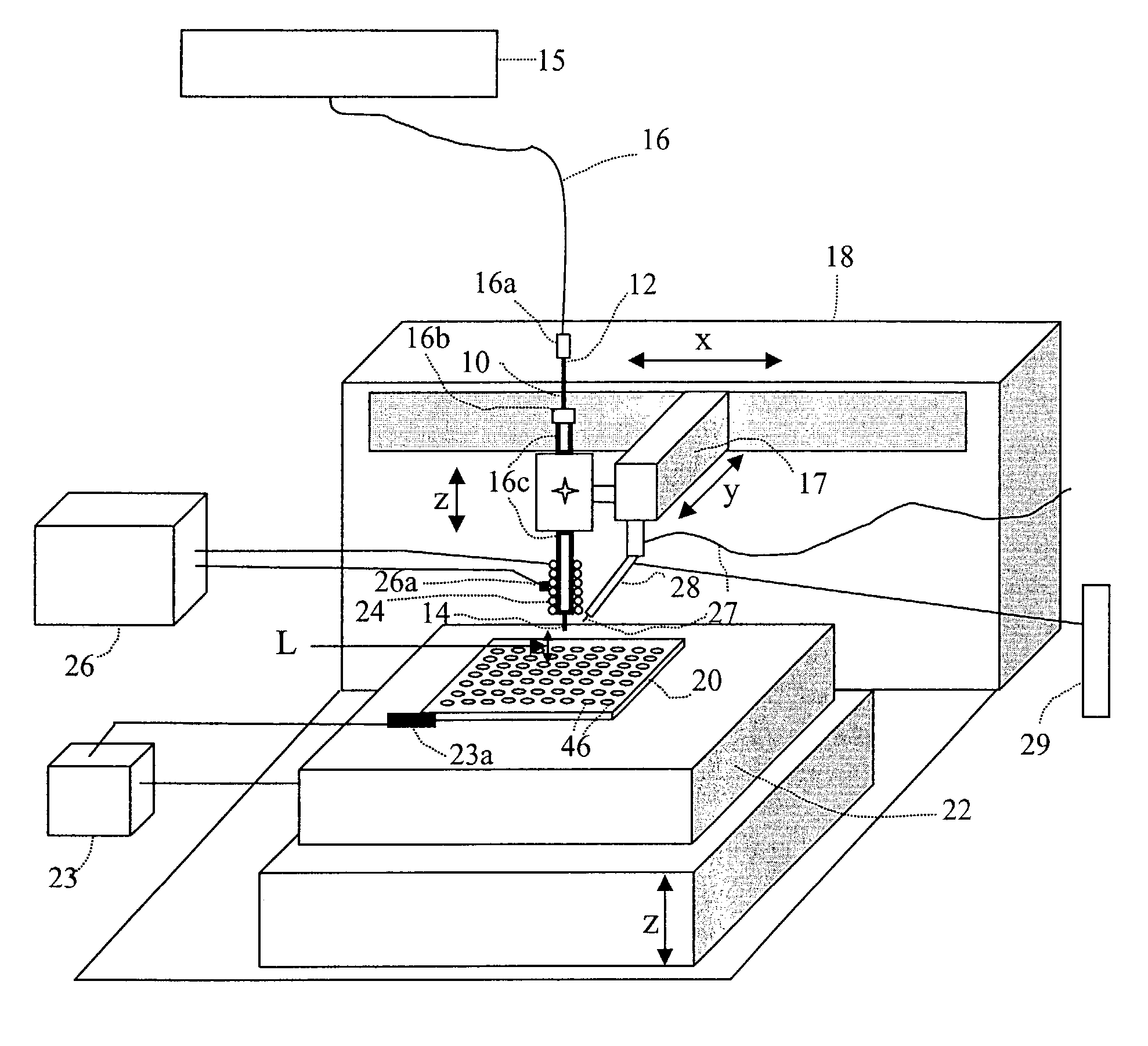

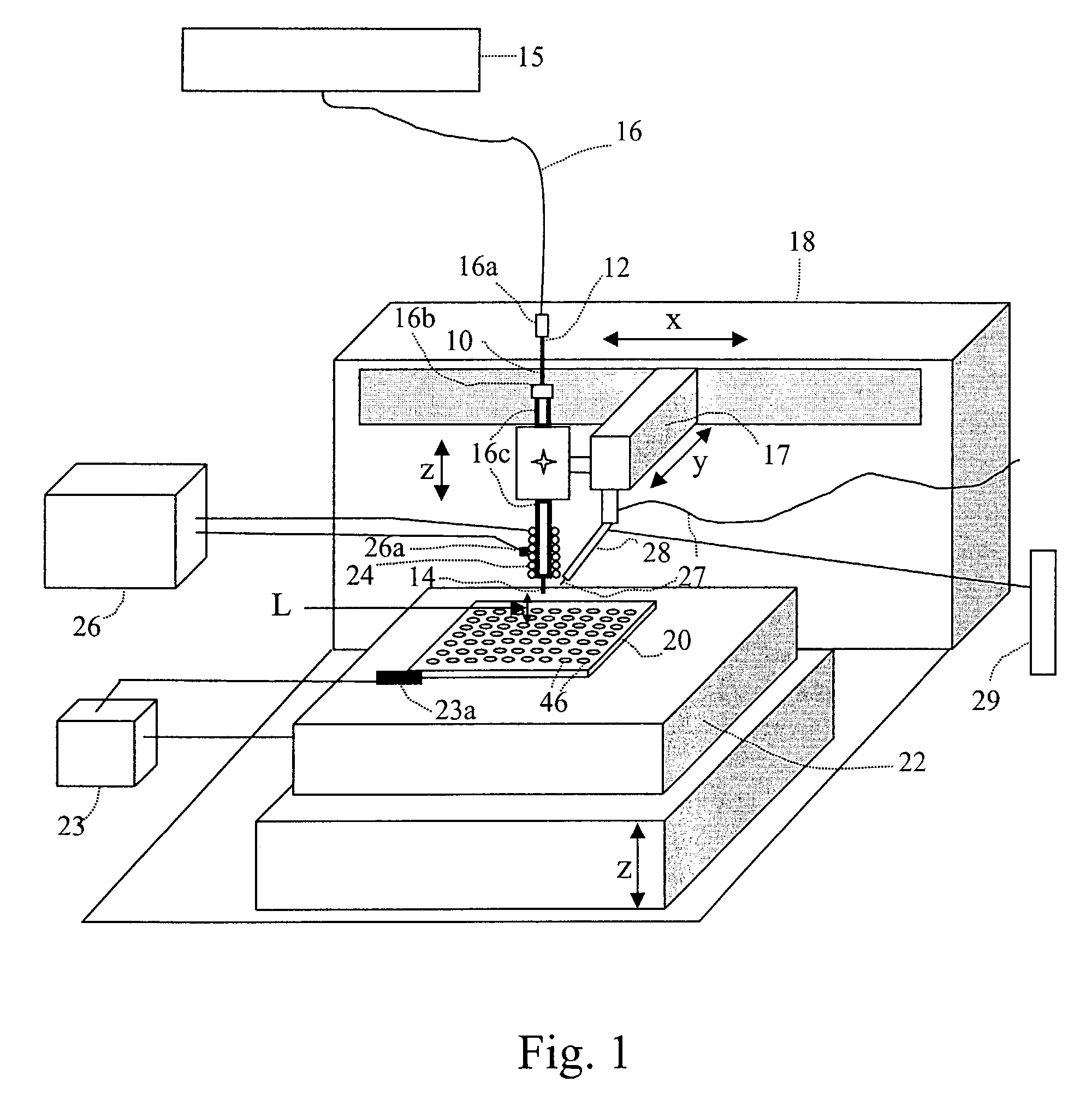

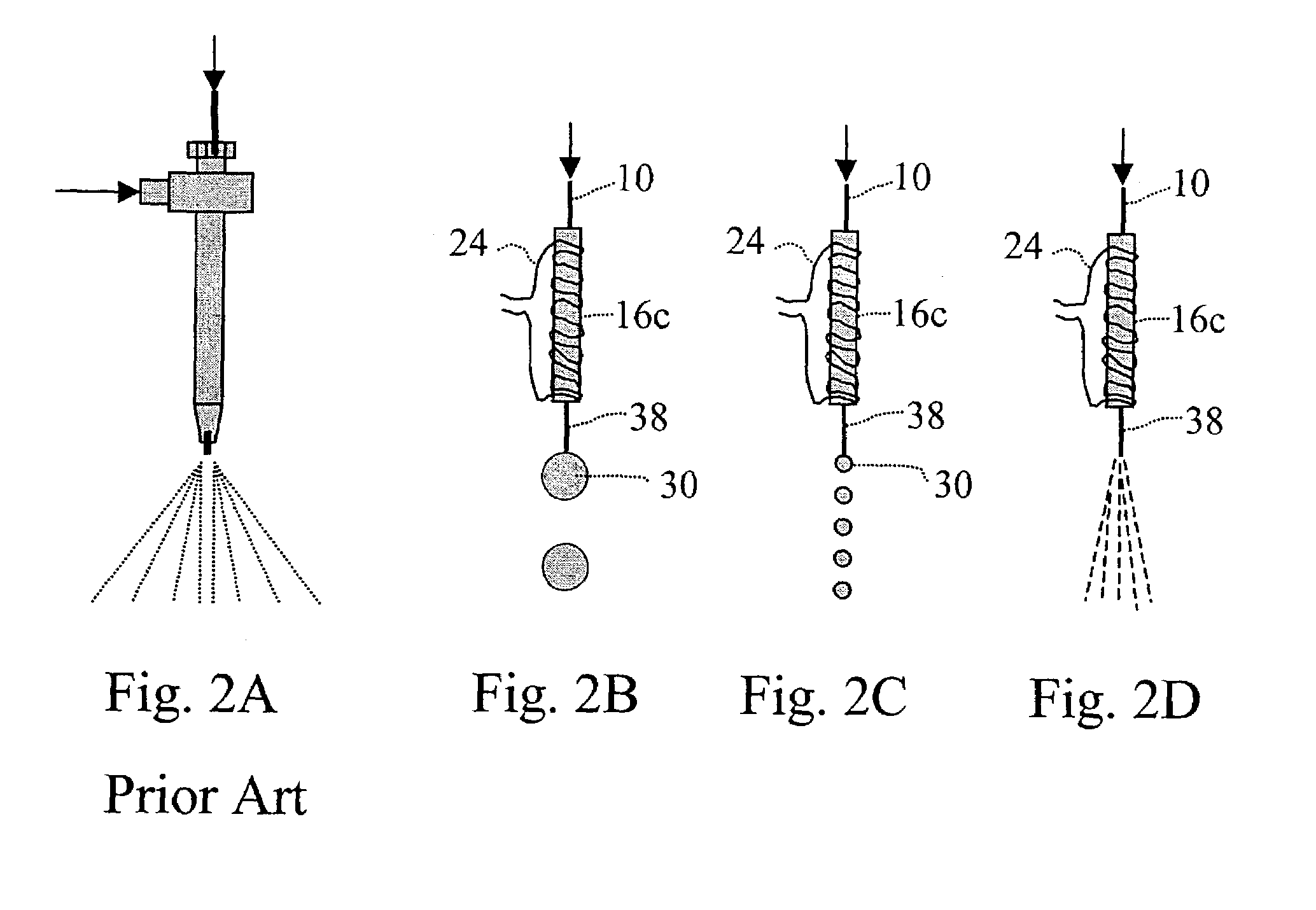

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

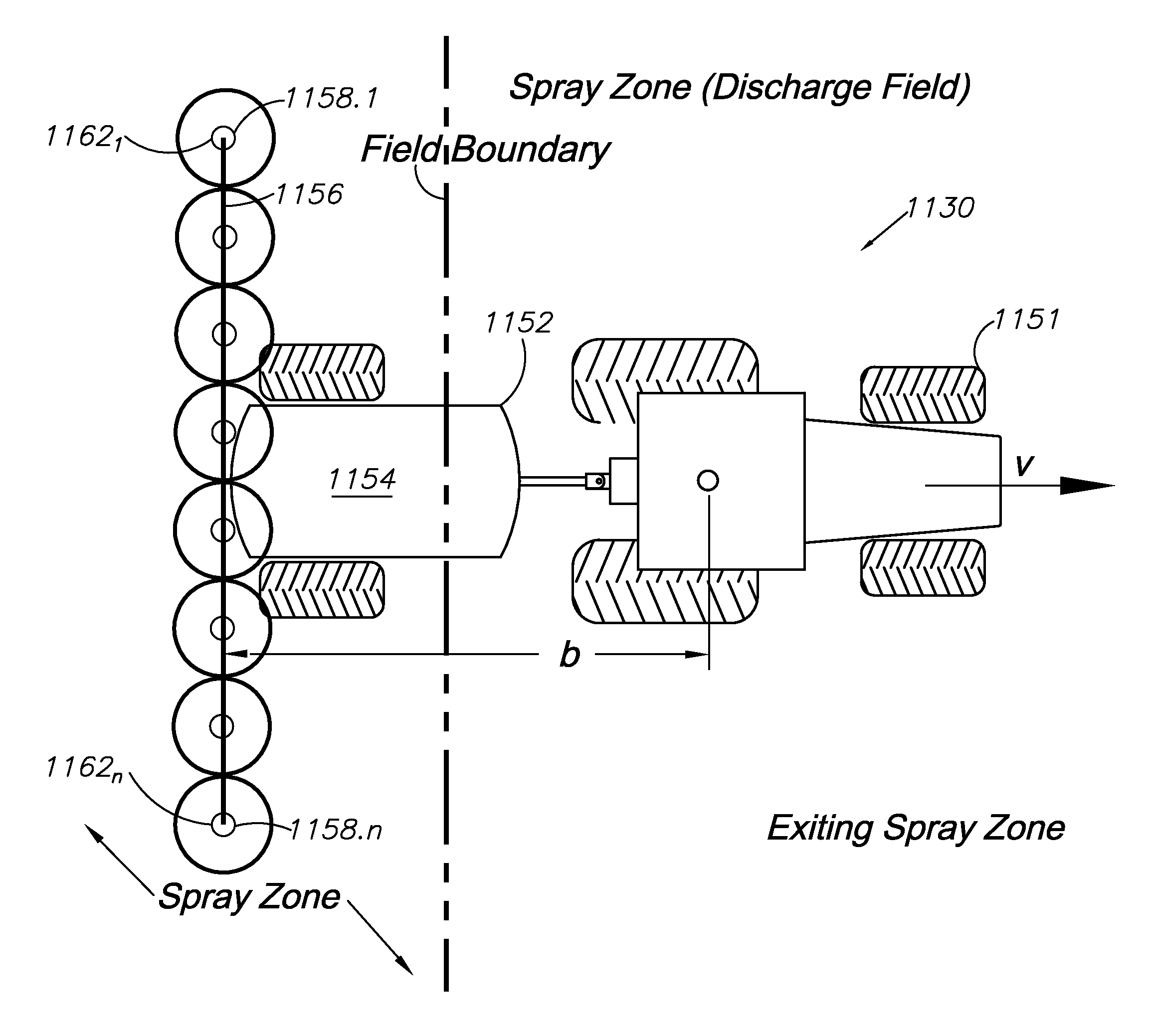

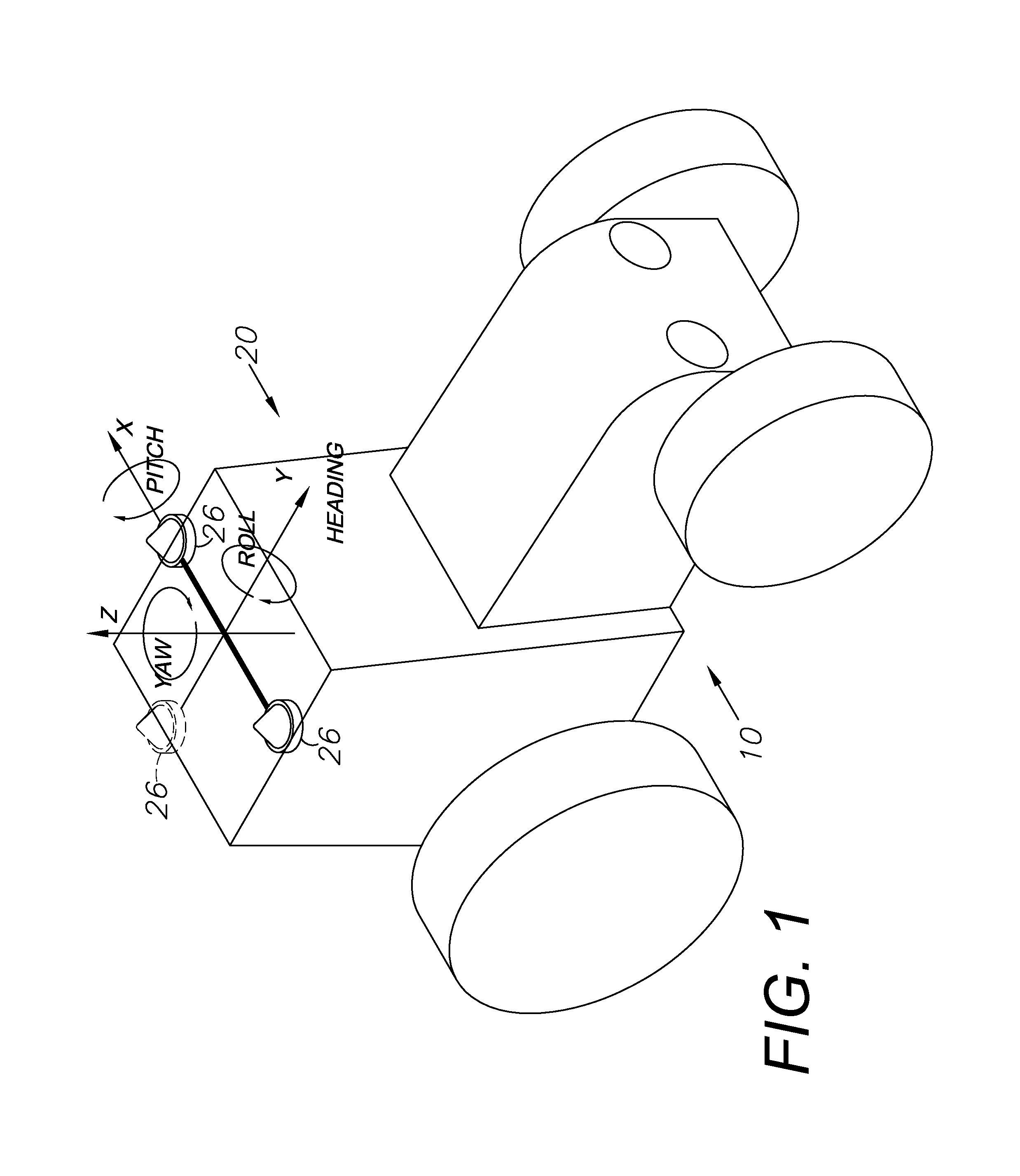

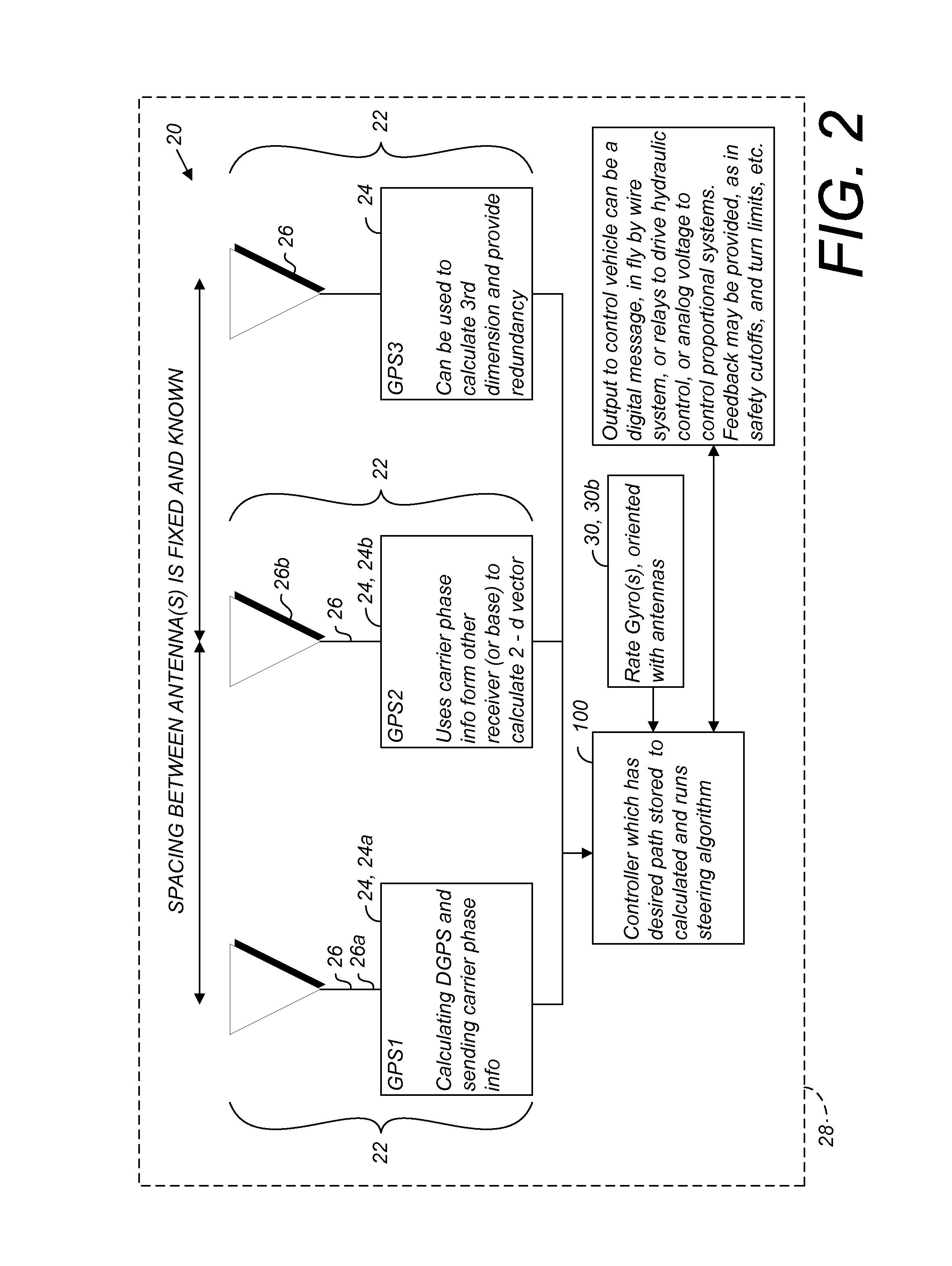

GNSS based control for dispensing material from vehicle

ActiveUS8634993B2Easy to correctEconomical and accurateAnalogue computers for trafficSpraying apparatusSpray nozzleLag

A spray control method employs a spray vehicle including a material tank, a pump communicating with the tank, and nozzles of a spray boom communicating with the pump. A GNSS receiver mounted on the vehicle and interfaced to a controller tracks its position in relation to stored position coordinates of field boundaries separating spray zones from spray exclusion zones. The tank is activated and deactivated by the controller to retain spray of the material within the spray zones and to prevent spray of the material in the exclusion zones, by processing an offset of the spray nozzles from the receiver, the spray range of the nozzles, spray turn-on and turn-off lag times, and the velocity of the spray vehicle, all in relation to the field boundaries. An alternative embodiment individually controls spray from the nozzles by using associated valves interfaced to the controller.

Owner:AGJUNCTION

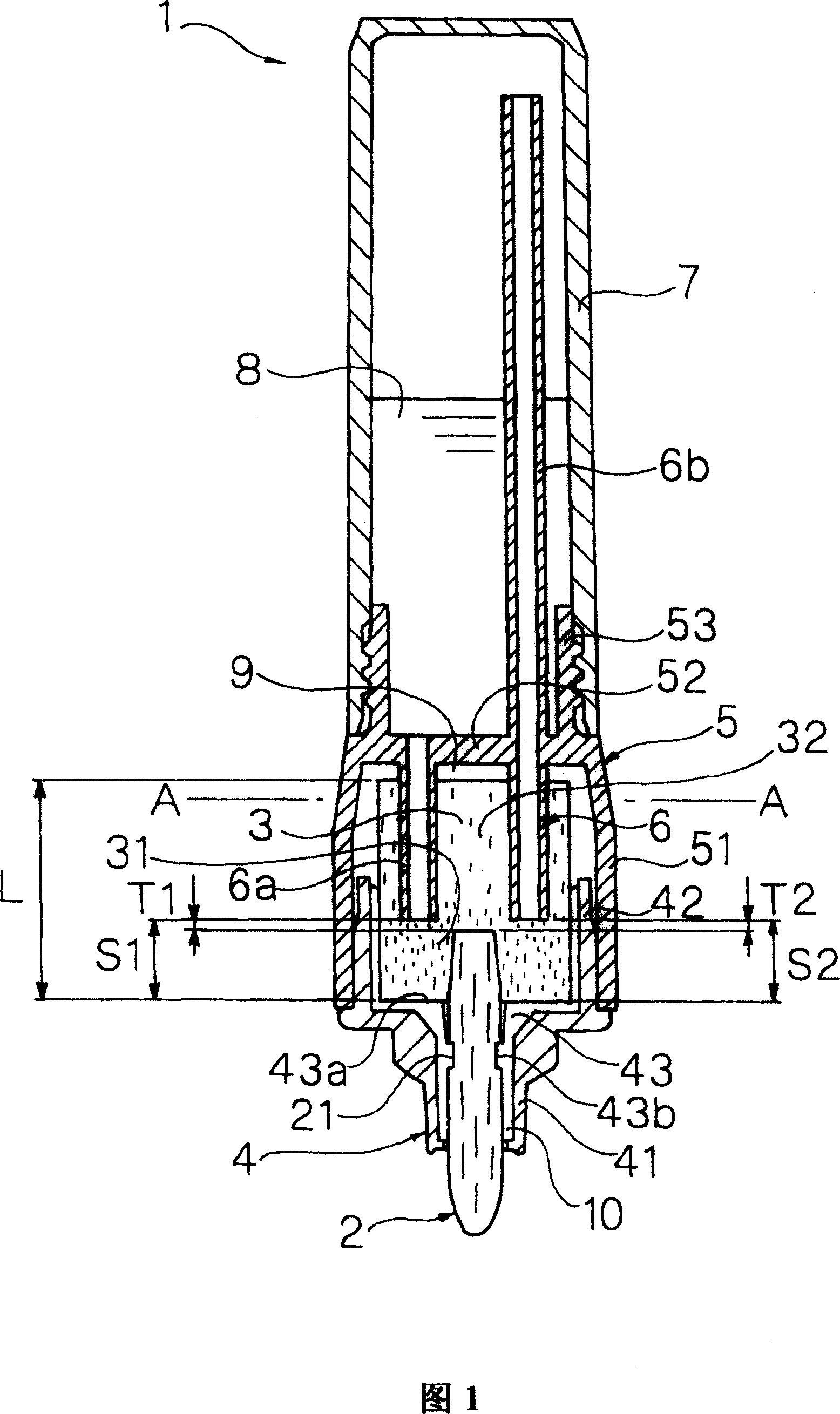

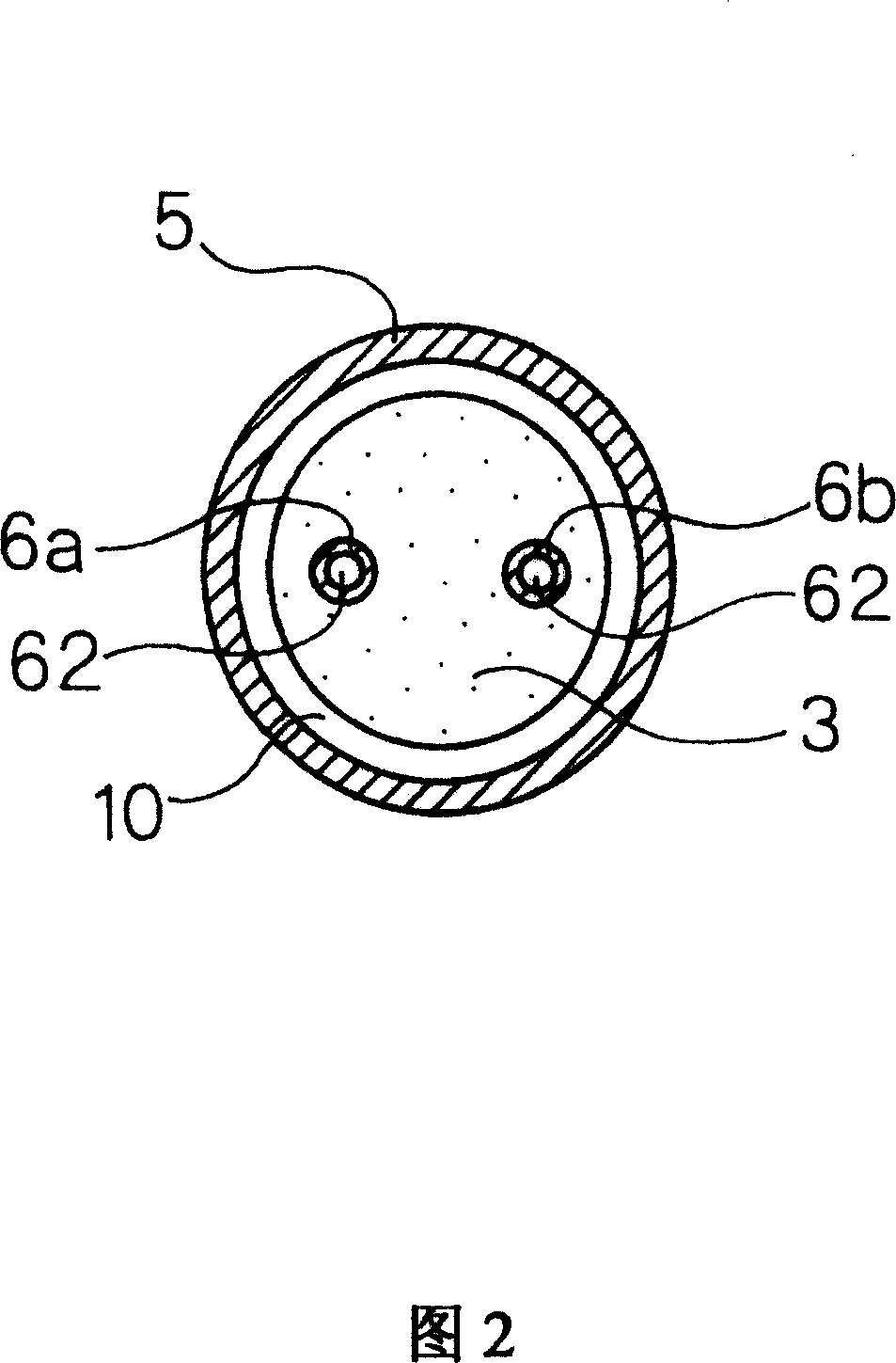

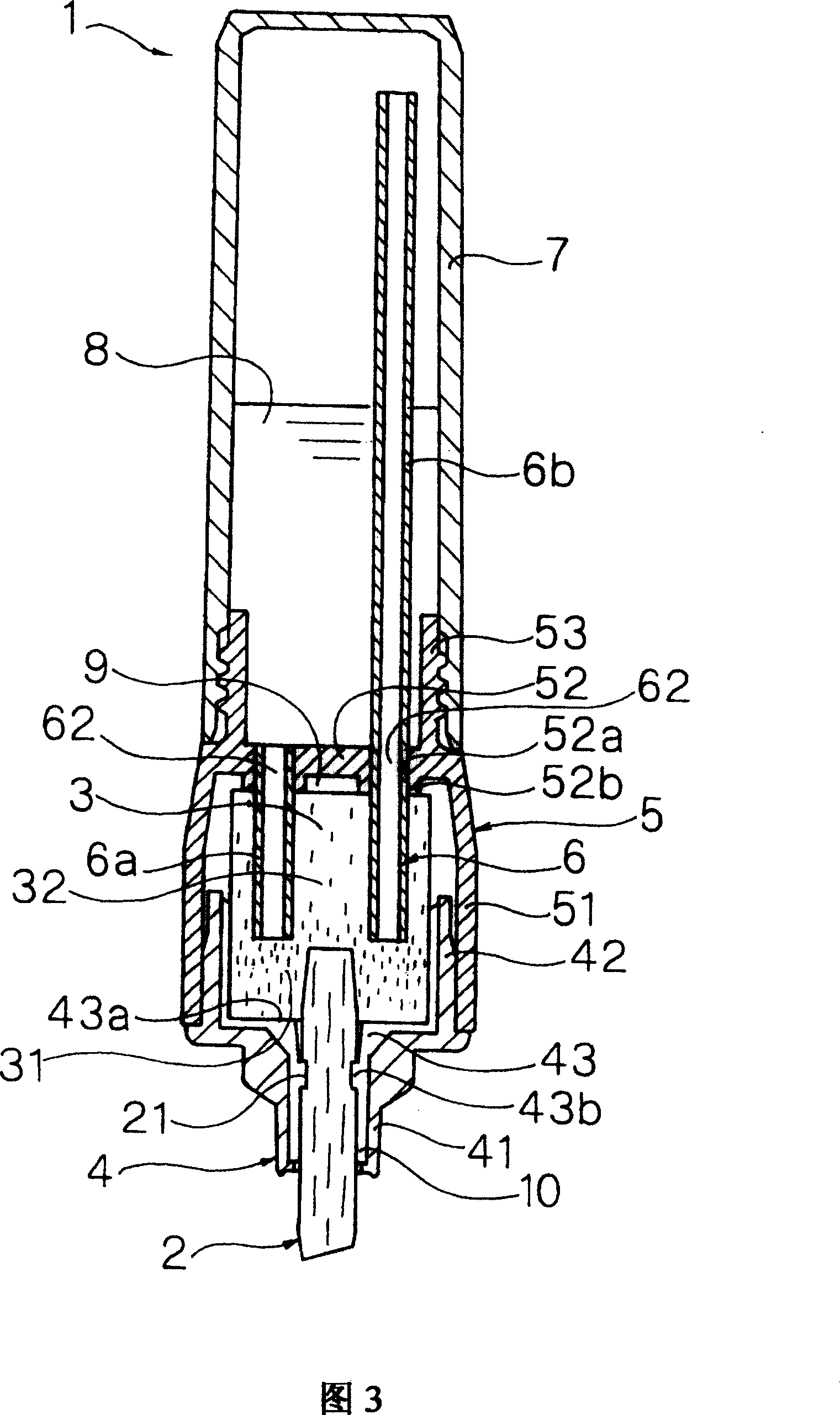

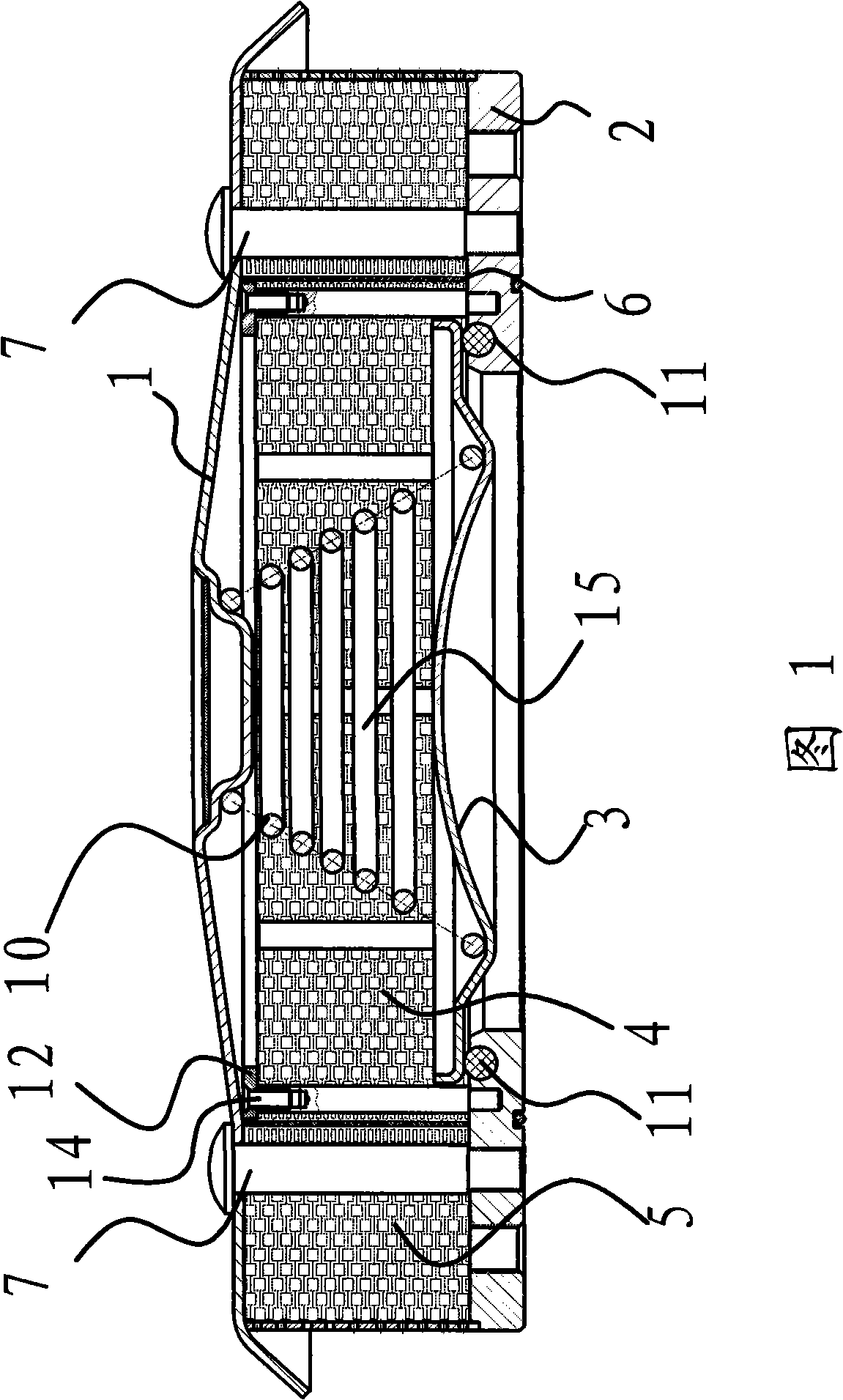

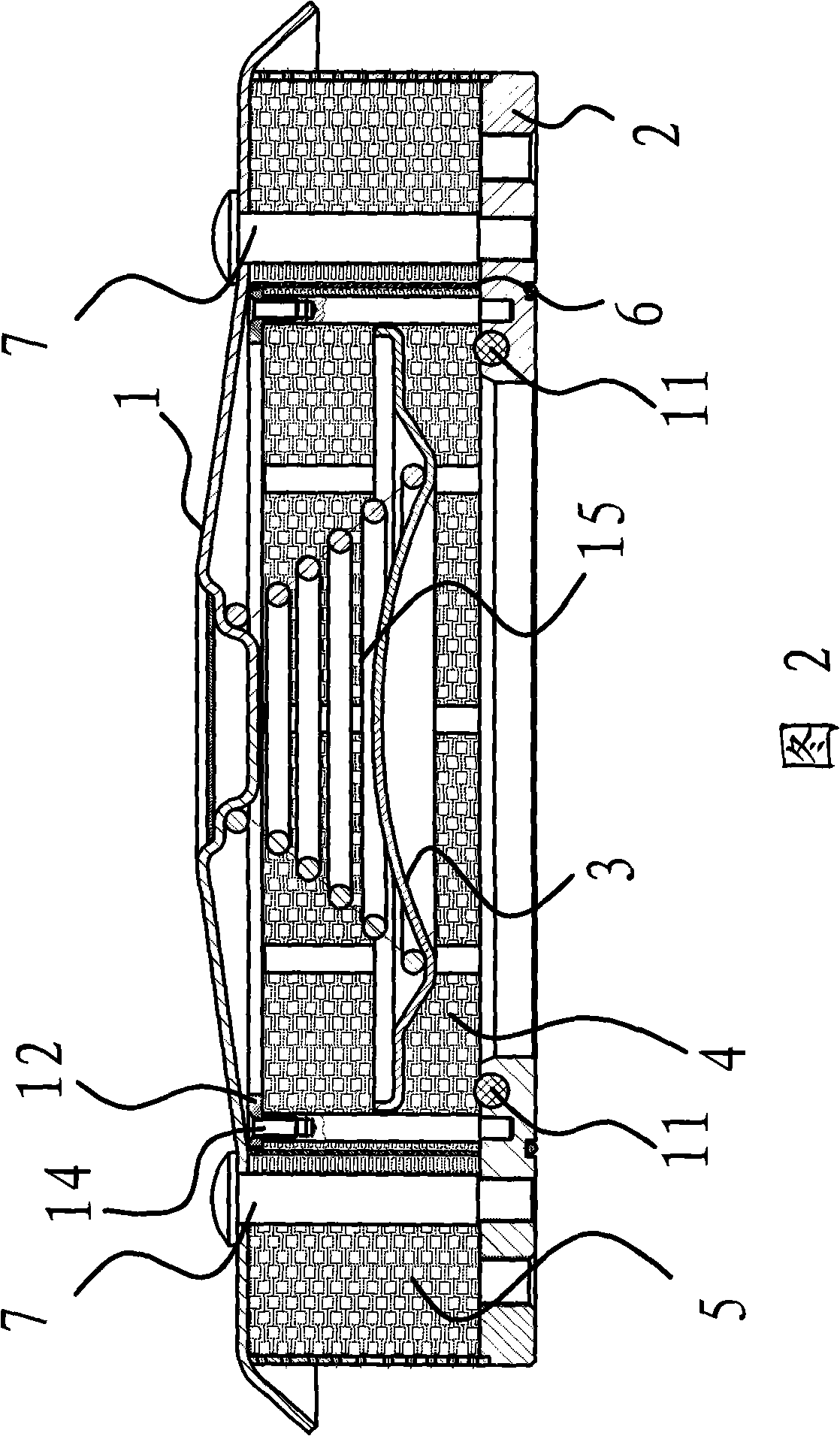

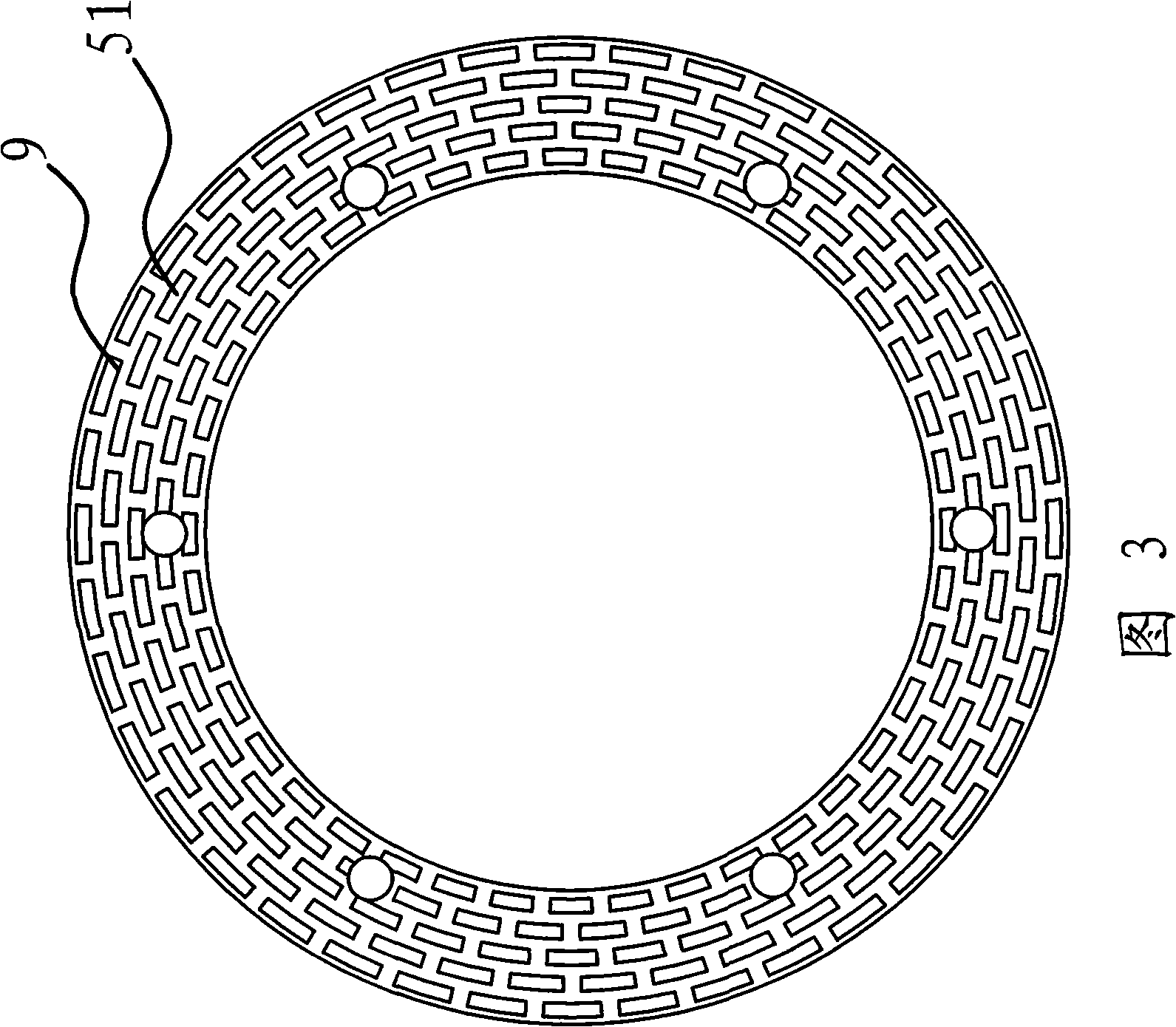

Direct-fluid-supply writing implement

ActiveCN101032905APrevent leakagePrevent sprayingInk reservoir pensOther pensFluid supplyEngineering

A direct-fluid-supply writing implement (1) has a pentip (2), an ink occlusion body (3) connected to a rear end of the pentip (2), an ink tank (7) that directly stores ink (8) and is arranged at a rear of the ink occlusion body (3), a plurality of communication tubes (6) that connects the ink tank (7) to the ink occlusion body (3) and a partition wall (52) provided between the ink occlusion body (3) and the ink tank (7). Forward end portions of the communication tubes (6) are protruded forward from a front face of the partition wall (52), and are located inside the ink occlusion body (3). At least one of the communication tubes (6) is provided such that a rear end of the communication tube (6) is protruded backward from a rear face of the partition wall (52) and is located inside the ink tank (7).

Owner:THE PILOT INK CO LTD

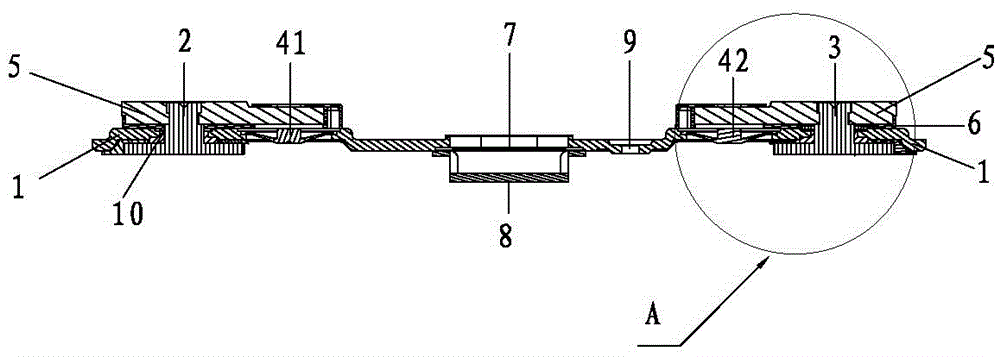

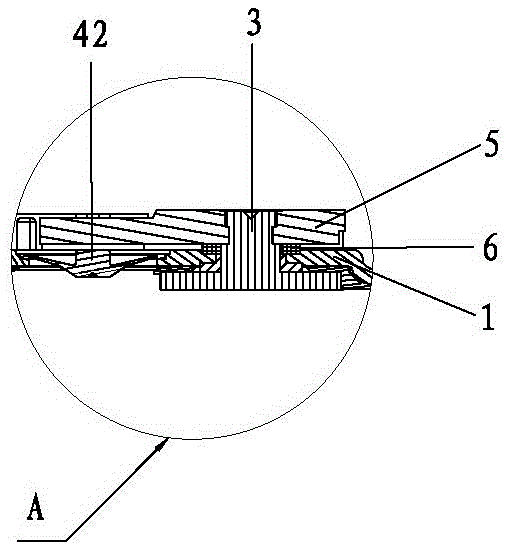

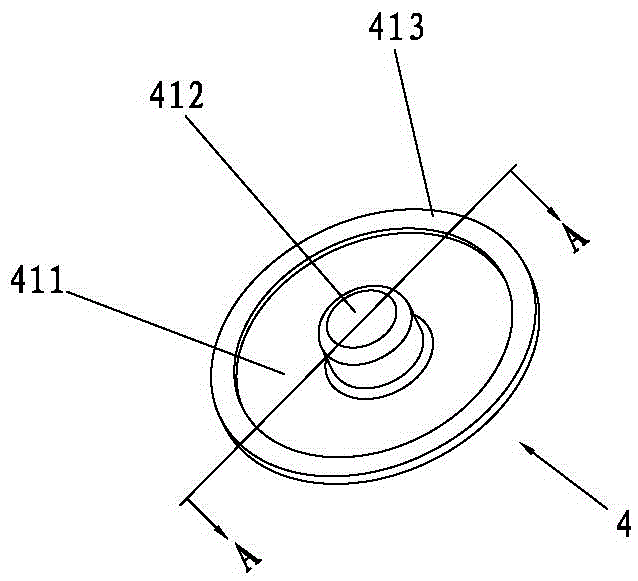

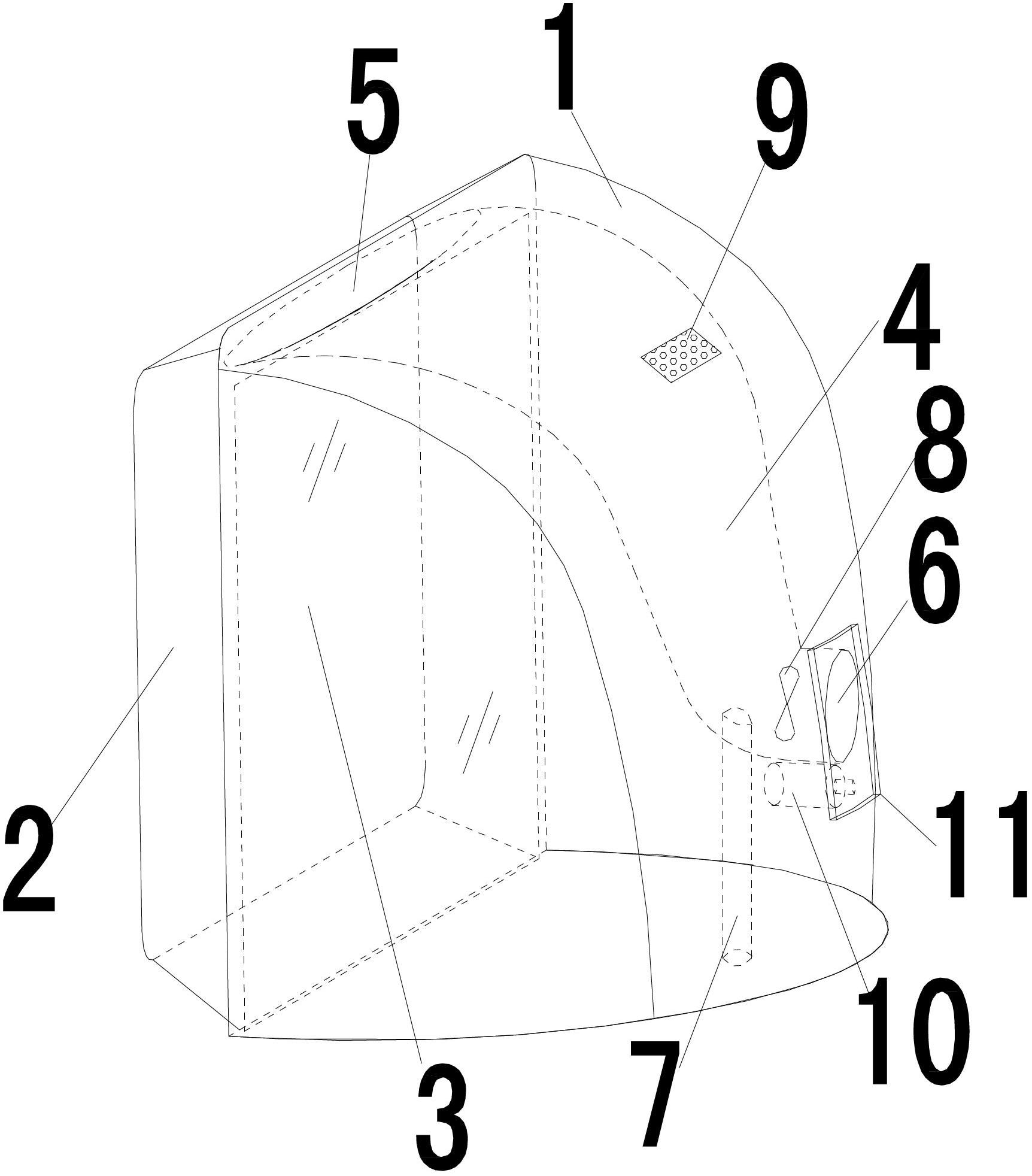

Power battery top cover and power battery using top cover

ActiveCN105932181AOptimized designGood security featuresCell lids/coversBatteriesPower batteryEngineering

The invention belongs to the technical field of power batteries, and especially relates to a power battery top cover and a power battery using the top cover. The power battery top cover comprises a top cover sheet, and a firs pole pillar, a second pole pillar, a pressure release valve, a liquid injection hole, pneumatic overturning sheets and a resistor block, the first pole pillar is in insulation connection with the top cover sheet, the second pole pillar is electrically connected with the top cover sheet through the resistor block, the pneumatic overturning sheets are electrically connected with the top cover sheet, the conductive block is arranged above the pneumatic overturning sheets, a baffle plate is arranged under the pressure release valve, the pneumatic overturning sheets comprise a first pneumatic overturning sheet and a second pneumatic overturning sheet, and the thickness of the first pneumatic overturning sheet is smaller than the thickness of the second pneumatic overturning sheet; and when the pressure in the power battery increases, the pneumatic overturning sheet and the second pneumatic overturning sheet sequentially move upward in order to electrically connect the first pole pillar with the second pole pillar. Compared with power battery top covers in the prior art, the power battery top cover disclosed in the invention makes the power battery have an excellent safety protection function in overcharging, nailing, short circuit and hot box test.

Owner:东莞永蓝电子科技有限公司

Explosion-proof valve

The invention provides an explosion-proof valve, belonging to the field of mechanical technology. The invention solves the problem that a current explosion-proof valve can not extinguish flame completely in the explosion-proof valve. The explosion-proof valve comprises a panel, a base plate and an inner flame retardant device, which form a valve cavity provided with a valve plate forming a sealing space with the seat plate, a spring is arranged between the panel and the valve plate, and an outer flame retardant device is also fixed between the panel and the seat plate, both the outer flame retardant device and the inner flame retardant device are formed by alternatively stacking the front and the back of a plurality of circular sheets of the flame retardant devices, a plurality of channels communicating the valve cavity and the outside are formed by stacking the fronts of the sheets of the flame retardant devices, each channel is provided with at least two bends. The outer flame retardant device and the inner flame retardant device extend the flow route of flame and air flow, the explosion-proof valve has the advantages of safe use, good flame extinguishing property and long service life.

Owner:台州赛特流体控制有限公司

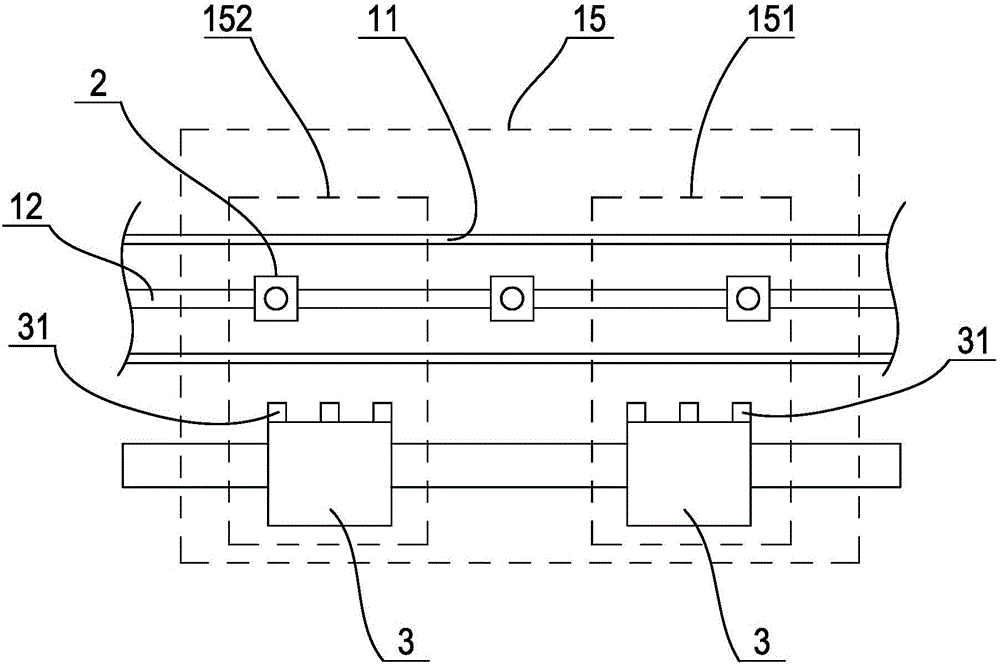

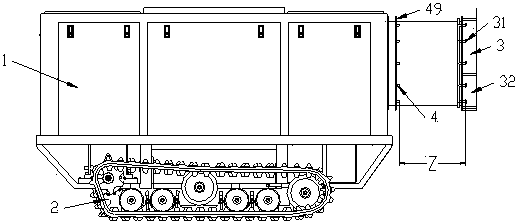

Firefighting monitoring and alarming system

InactiveCN102682561AAvoid sprayingTake advantage ofFire rescueFire alarm smoke/gas actuationElectric machineryWater resources

The invention discloses a firefighting monitoring and alarming system, which comprises smoke sensors, photographic probes, spray heads and a controller, wherein the smoke sensors and the photographic probes are electrically connected with the controller respectively; the spray heads are arranged on trolleys with rollers; the rollers of the trolley are arranged on rails which are arranged on a deck; motors are arranged on the trolleys, take storage batteries as power supplies, and drive the rollers through transmission mechanisms to roll along the rails; and the spray heads are connected with water hoses on which electromagnetic valves are arranged. Due to the adoption of the structure and a working mode, the spray heads can be moved to positions optimal distances away from a fire point, so that an optimal fire suppression effect is achieved, and at least time is gained for the arrival of a special fire brigade; in addition, water resources are fully utilized, and the purposeless spraying phenomenon of the spray heads is avoided; and moreover, the photographic probes can be moved to specified positions along with the trolleys, so that a monitored fire scene can be accurately photographed in real time.

Owner:曾文书

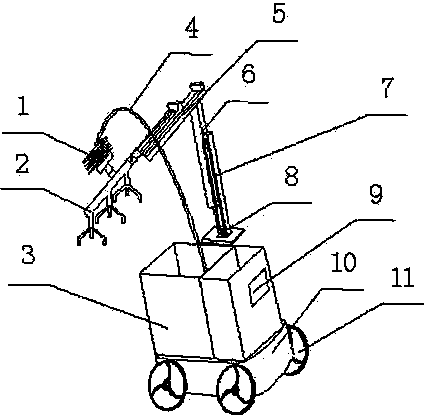

Automatic high-efficiency pesticide spray device

InactiveCN107173373AImprove work efficiencyMention the scope of sprayingInsect catchers and killersEngineeringBevel gear

The invention discloses an automatic high-efficiency pesticide spray device. The device comprises a mobile frame, and a spray tank arranged on the top of the left side of the mobile frame, wherein a pesticide storage cavity is formed in the spray tank, and a stirring mechanism is connected in the pesticide storage cavity in a matched connection manner; a first transmission cavity is formed in the mobile frame at the bottom of the pesticide spray tank; a second transmission cavity is formed in the mobile frame on the right side of the first transmission cavity and extends forward; a guide groove is formed in the mobile frame on the right side of the front extending section of the second transmission cavity, and the top of the guide groove runs through the end face of the top part of the mobile frame; a first rotating shaft is connected into the wall body of the mobile frame between the first transmission cavity and the second transmission cavity in a matched connection manner, and extends toward left and right sides; the left end of the first rotating shaft extends into the first transmission cavity, and a first bevel gear is fixedly arranged at the tail end of the left end of the first rotating shaft; and the right extending section of the first rotating shaft extends into the first transmission cavity, and a second bevel gear is fixedly arranged at the tail end of the right extending section of the first rotating shaft. The automatic high-efficiency pesticide spray device has a simple structure, and can meet the requirement of uniformly spraying crops having different plant heights, so that the spraying efficiency can be improved, and automatic stirring operation can be realized.

Owner:付天龙

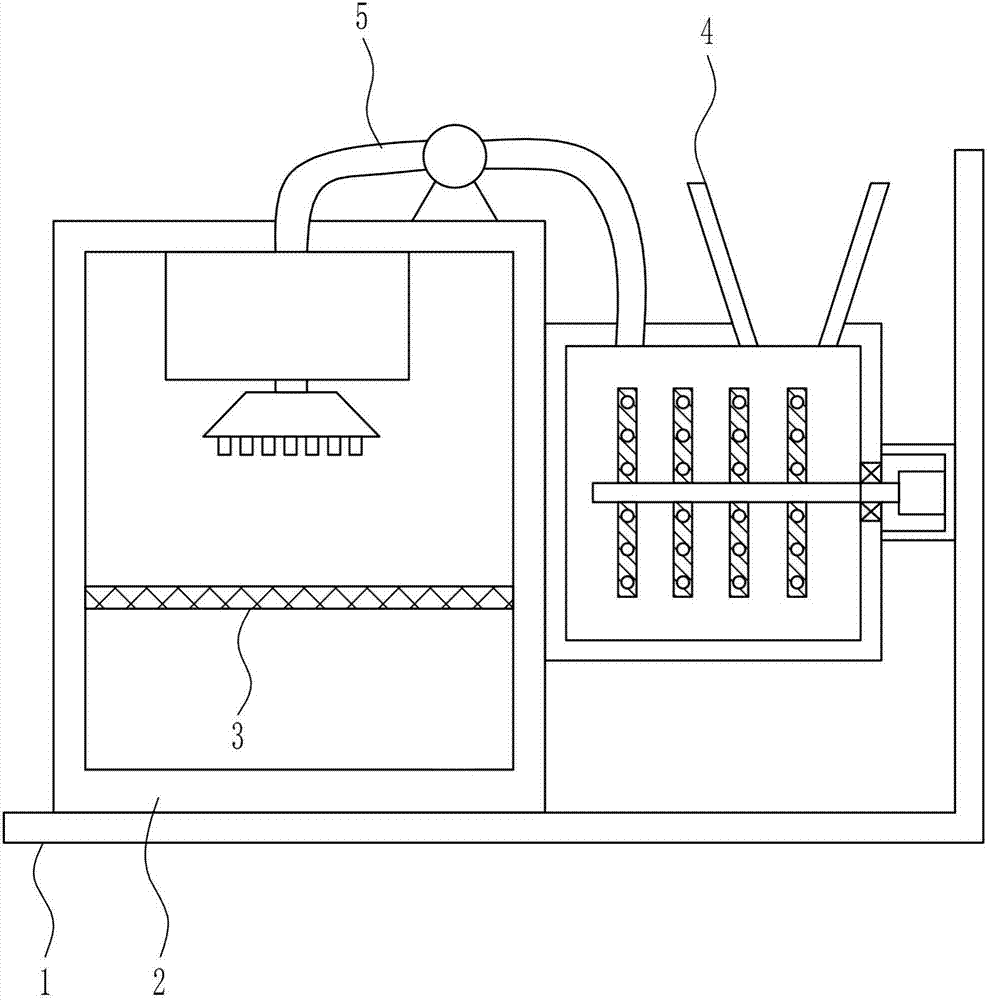

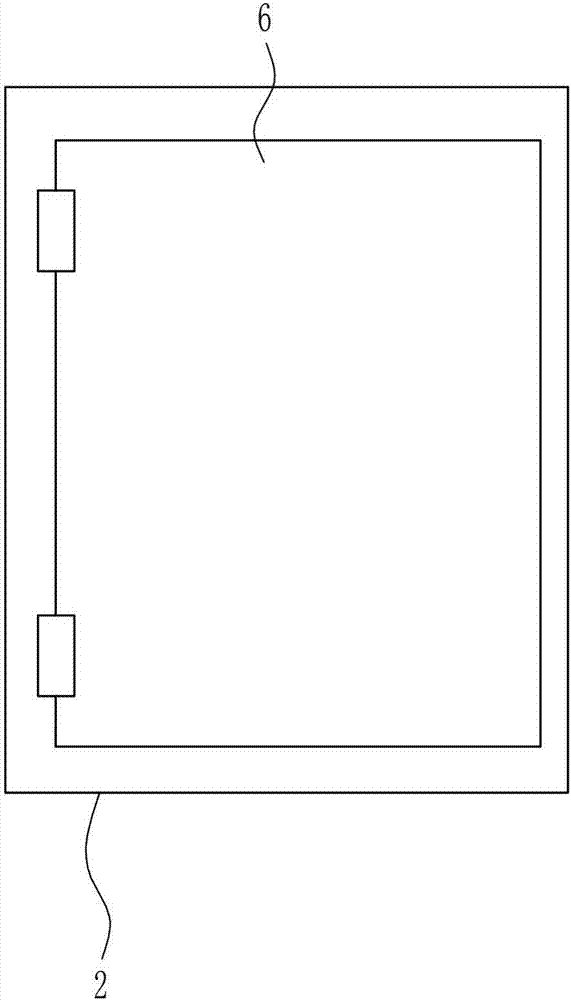

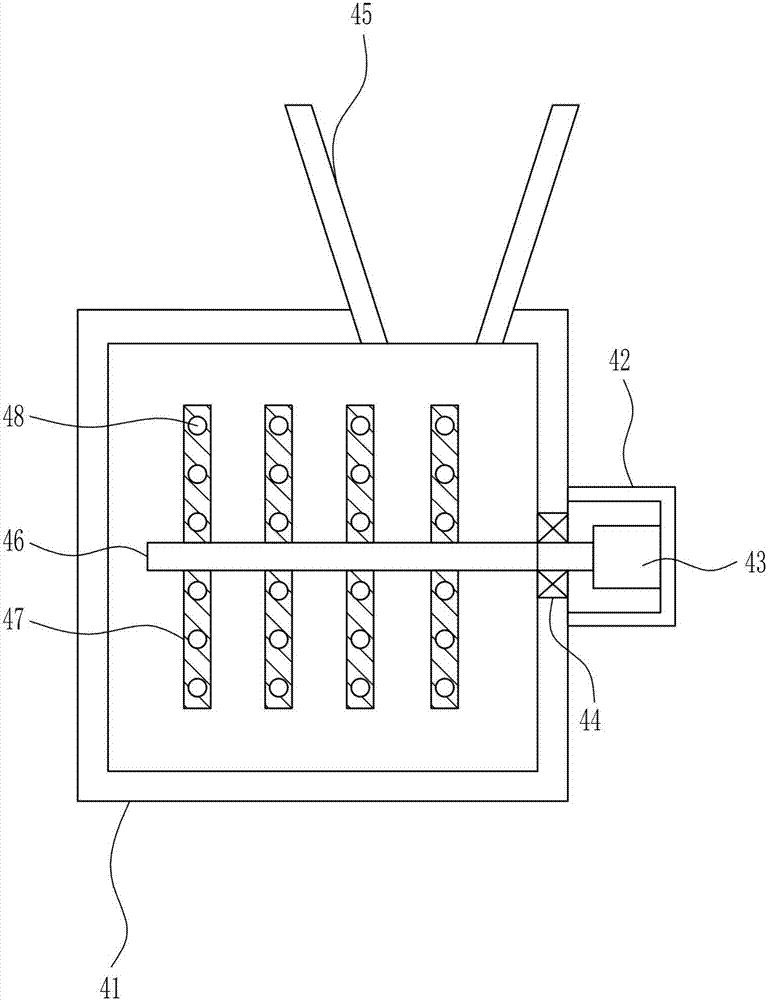

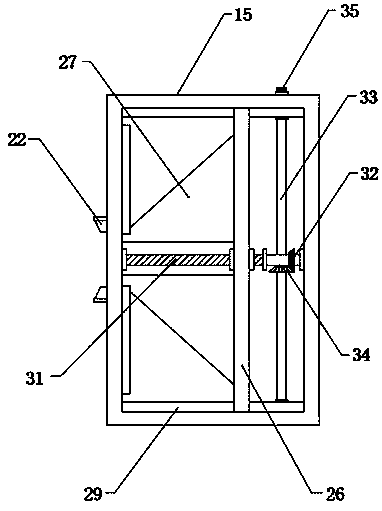

Coating spraying device for parts of agricultural machinery

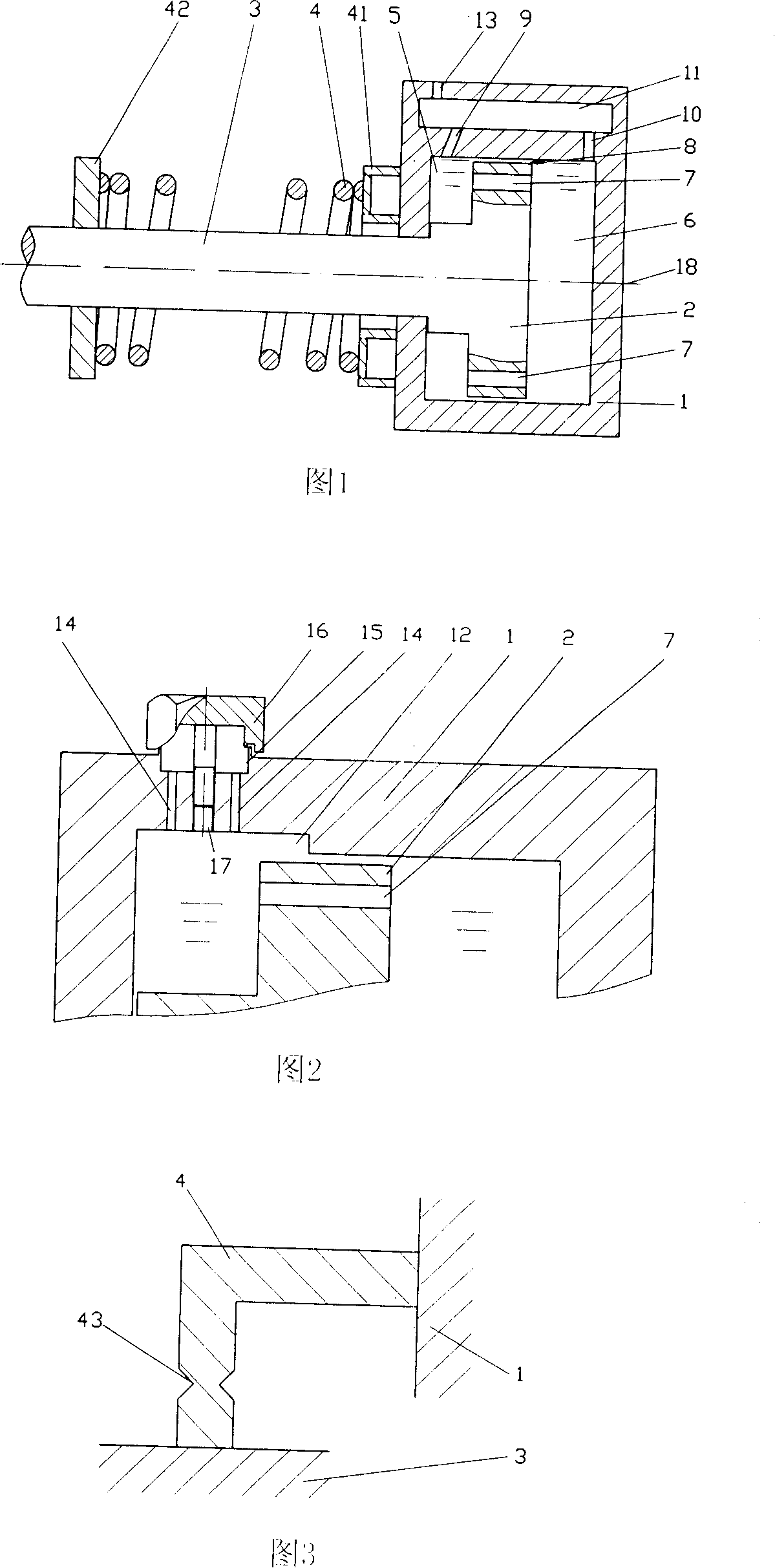

InactiveCN107225065AStir wellImprove spraying effectLiquid surface applicatorsLiquid spraying apparatusAgricultural engineeringAgricultural machinery

The invention relates to a spraying device, in particular to a paint spraying device for parts and components of agricultural machinery. The technical problem to be solved by the present invention is to provide a paint spraying device for parts of agricultural machinery with high efficiency and good spraying effect. In order to solve the above-mentioned technical problems, the present invention provides such a paint spraying device for parts and components of agricultural machinery, including a bracket, etc.; The middle part of the side is connected with a stirring mechanism, the right side of the stirring mechanism is connected with the left wall of the bracket, the upper part of the spraying box is provided with a spraying mechanism, and the left side of the front part of the spraying box is connected with a box door through a hinge connection. The invention designs a paint spraying device for parts of agricultural machinery, which is provided with a stirring mechanism, which can stir the paint more fully, so that the spraying effect of the parts is better, and is provided with a spraying mechanism.

Owner:刘万忠

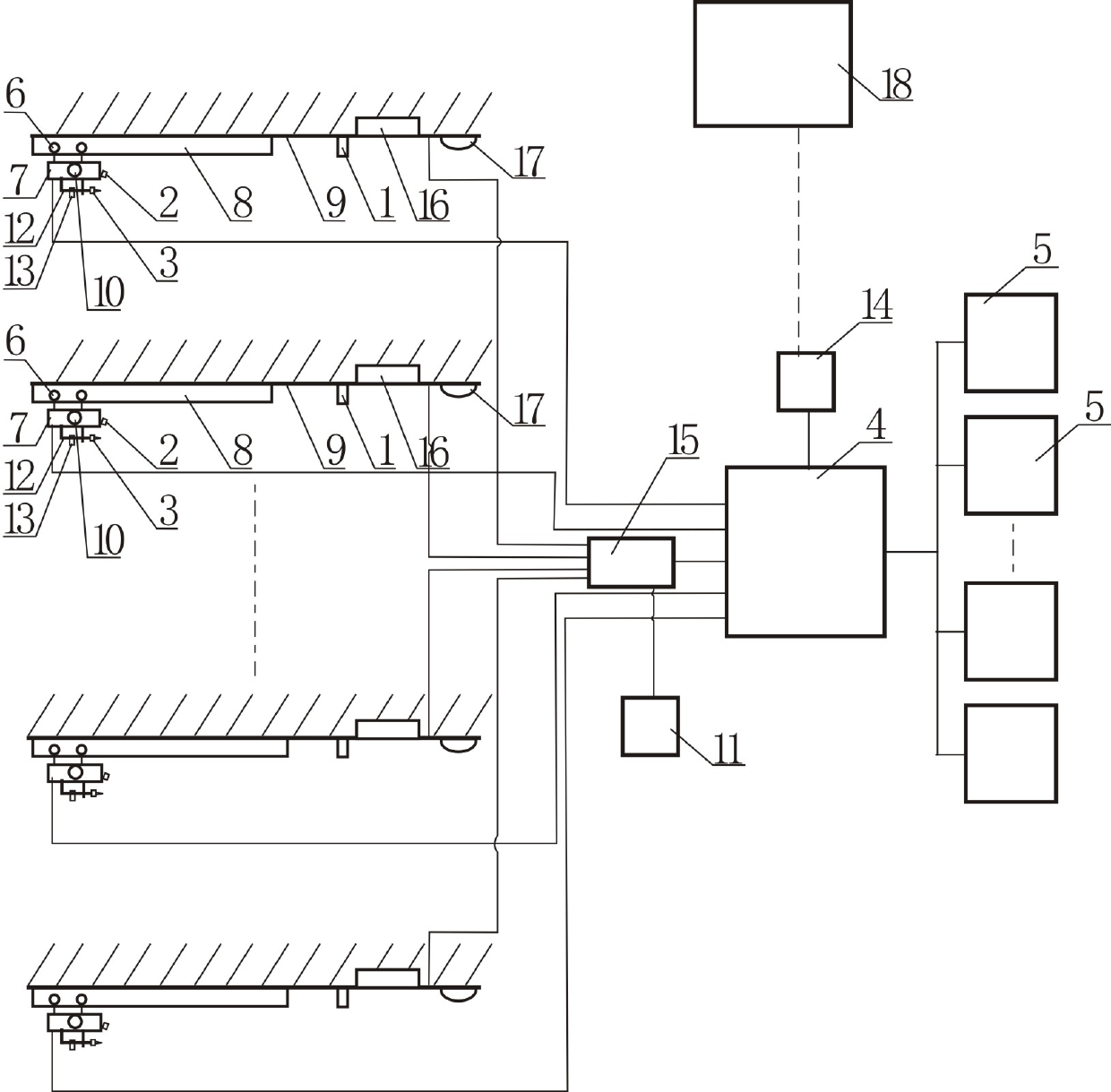

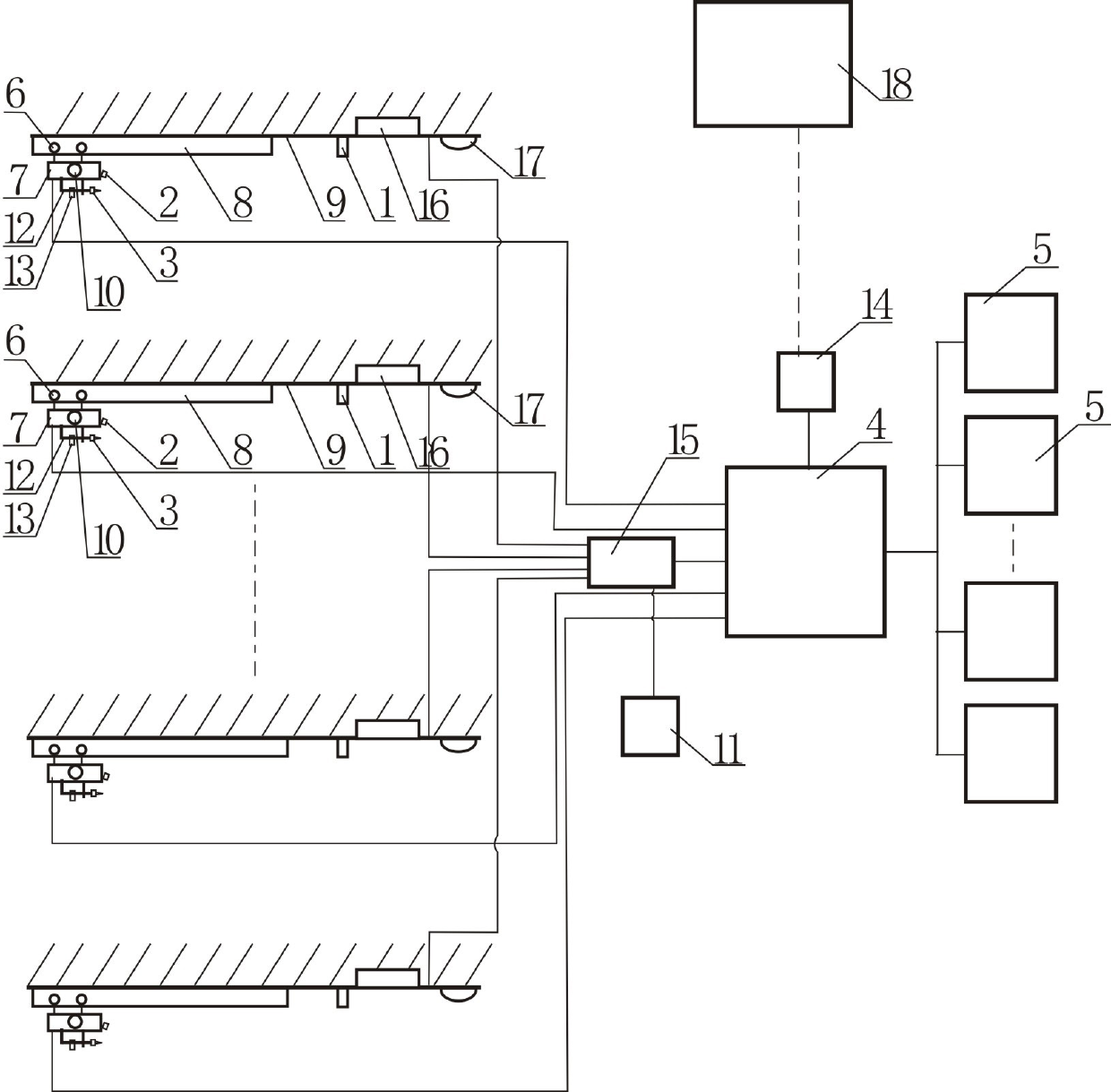

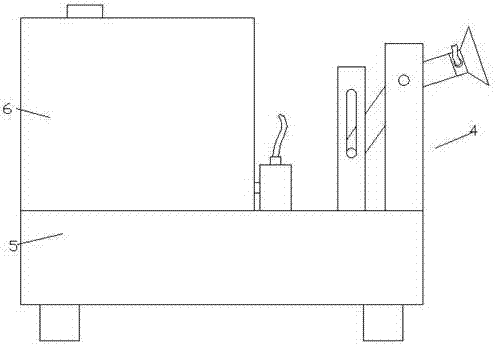

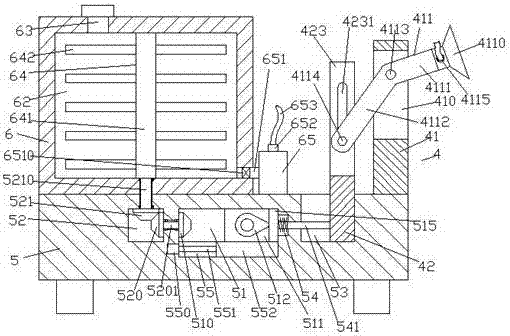

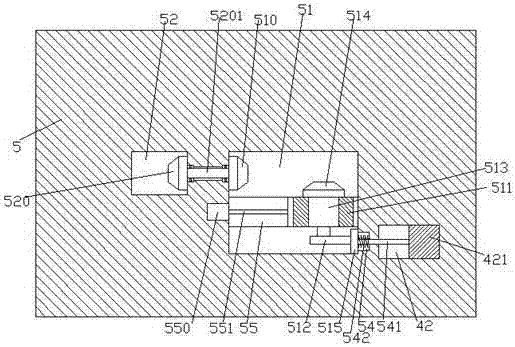

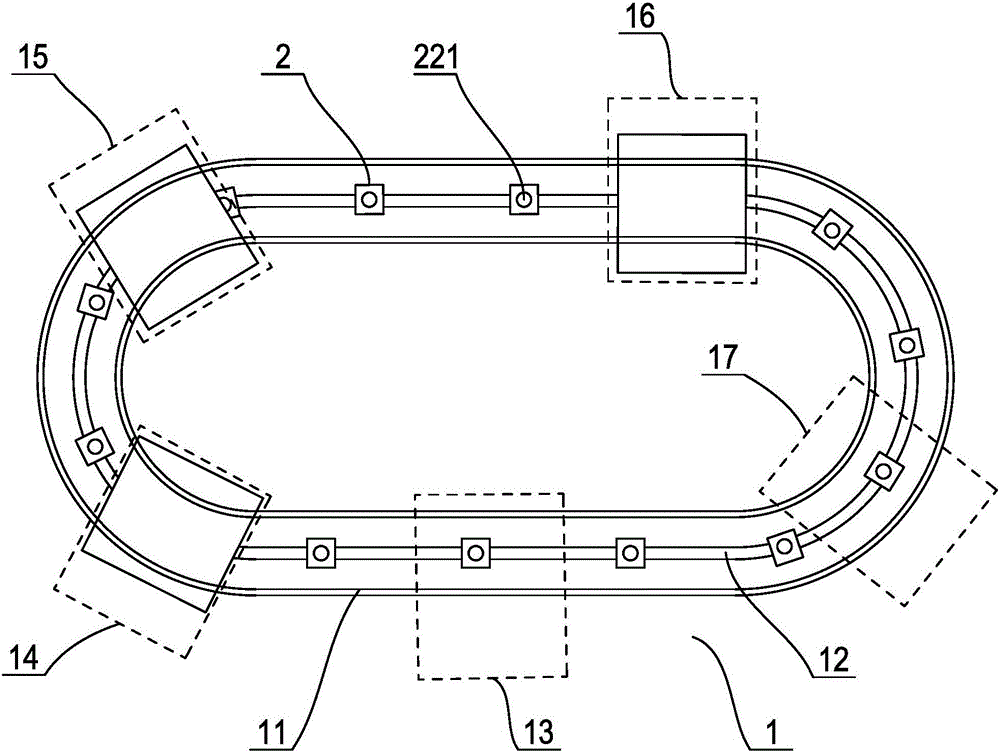

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

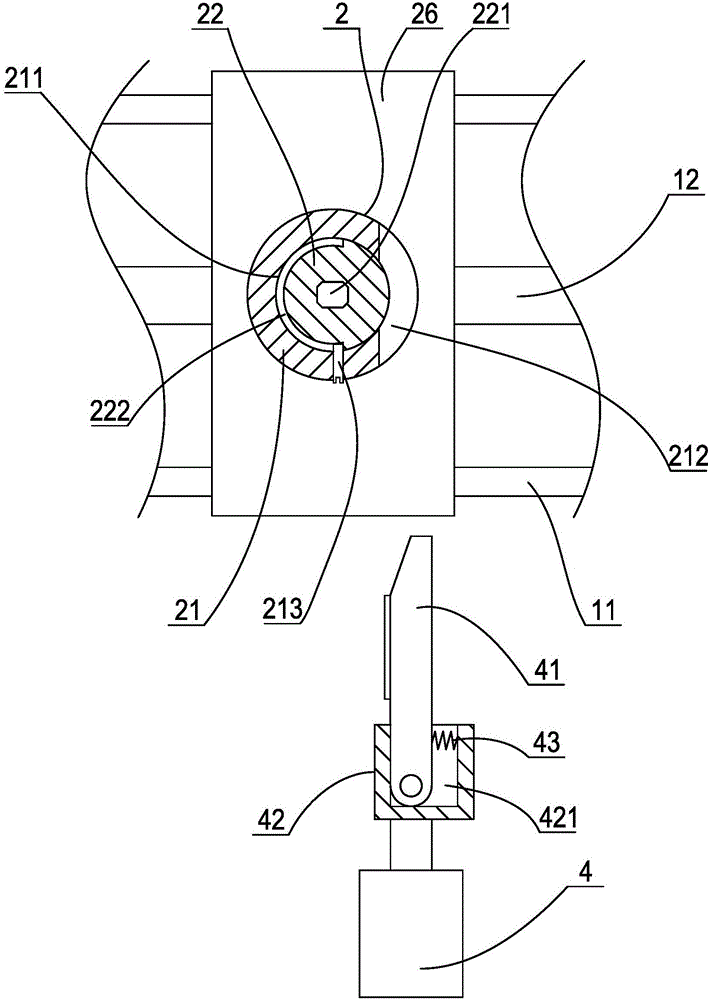

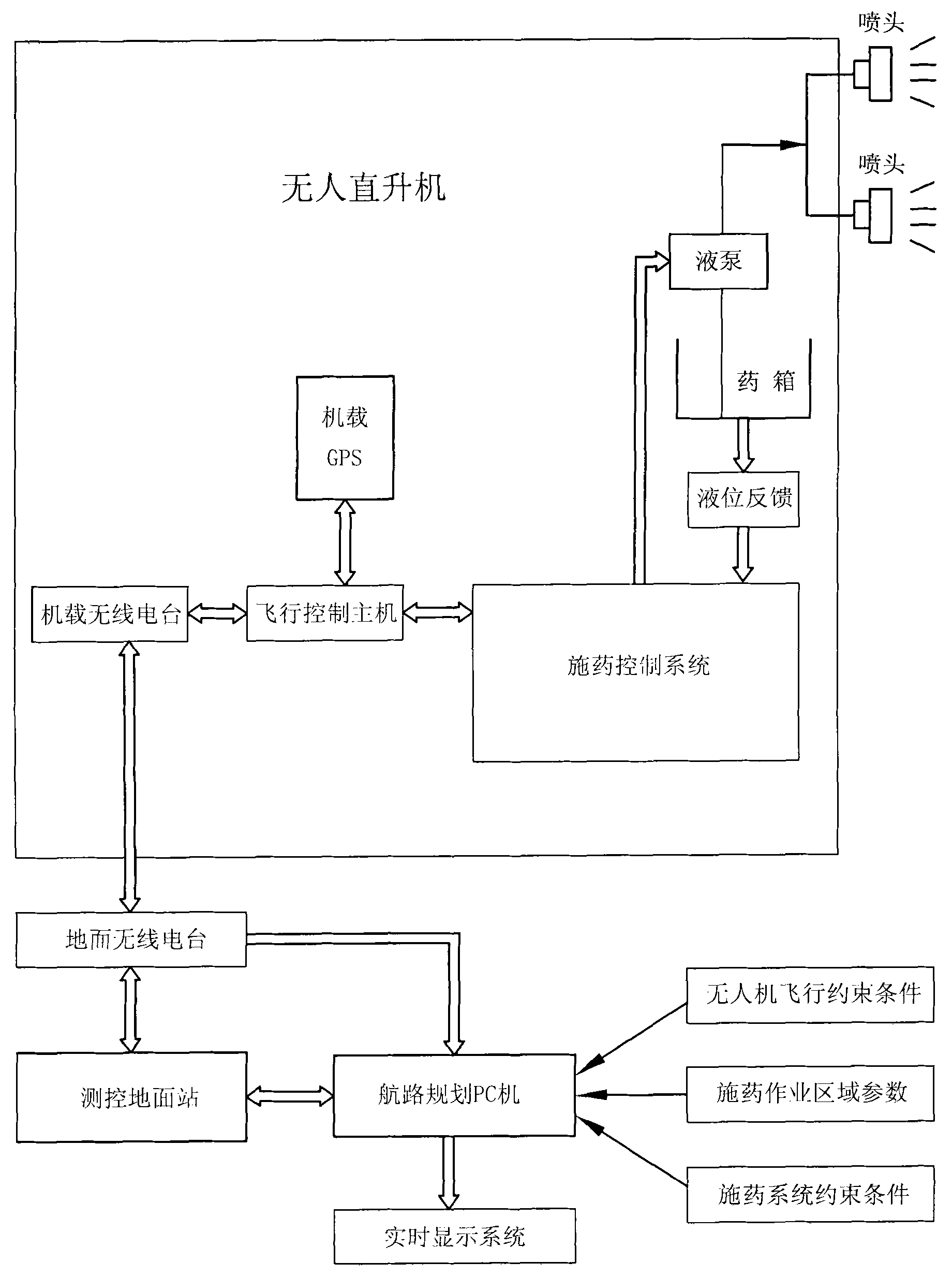

Intelligent pesticide application unmanned helicopter

InactiveCN101979276AAvoid imbalanceAvoid wastingAircraft componentsNavigation instrumentsAutomatic controlControl signal

The invention provides an intelligent pesticide application unmanned helicopter and belongs to the technical field of agriculture. The unmanned helicopter comprises a helicopter body frame, wherein the helicopter body frame is provided with a rotary wing flight system and a undercarriage component which are controlled by a flight control main engine; the communication end of the flight control main engine is communicated with a global position system (GPS), the master control output end of the flight control main engine is connected with the controlled end of the rotary wing flight system and is used for sending a navigation control signal to the flight system according to a contemplated route and real-time position information transmitted from the GPS; the central part below the helicopter body frame is also provided with a pesticide application device consisting of a pesticide chest, a liquid pump, a spray beam and a spray nozzle; the liquid outlet of the pesticide chest is communicated with the spray beam with the spray nozzle through a liquid infusion pipeline and the liquid pump; the flight control main engine also comprises an auxiliary control output end; and the auxiliary control output end is connected with the controlled end of the liquid pump and is used for sending a pesticide application control signal to the liquid pump according to the preset pesticide application sites and the real-time position information transmitted from the GPS. The unmanned helicopter can realize automatic navigation flight and can automatically control the pesticide application operation.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

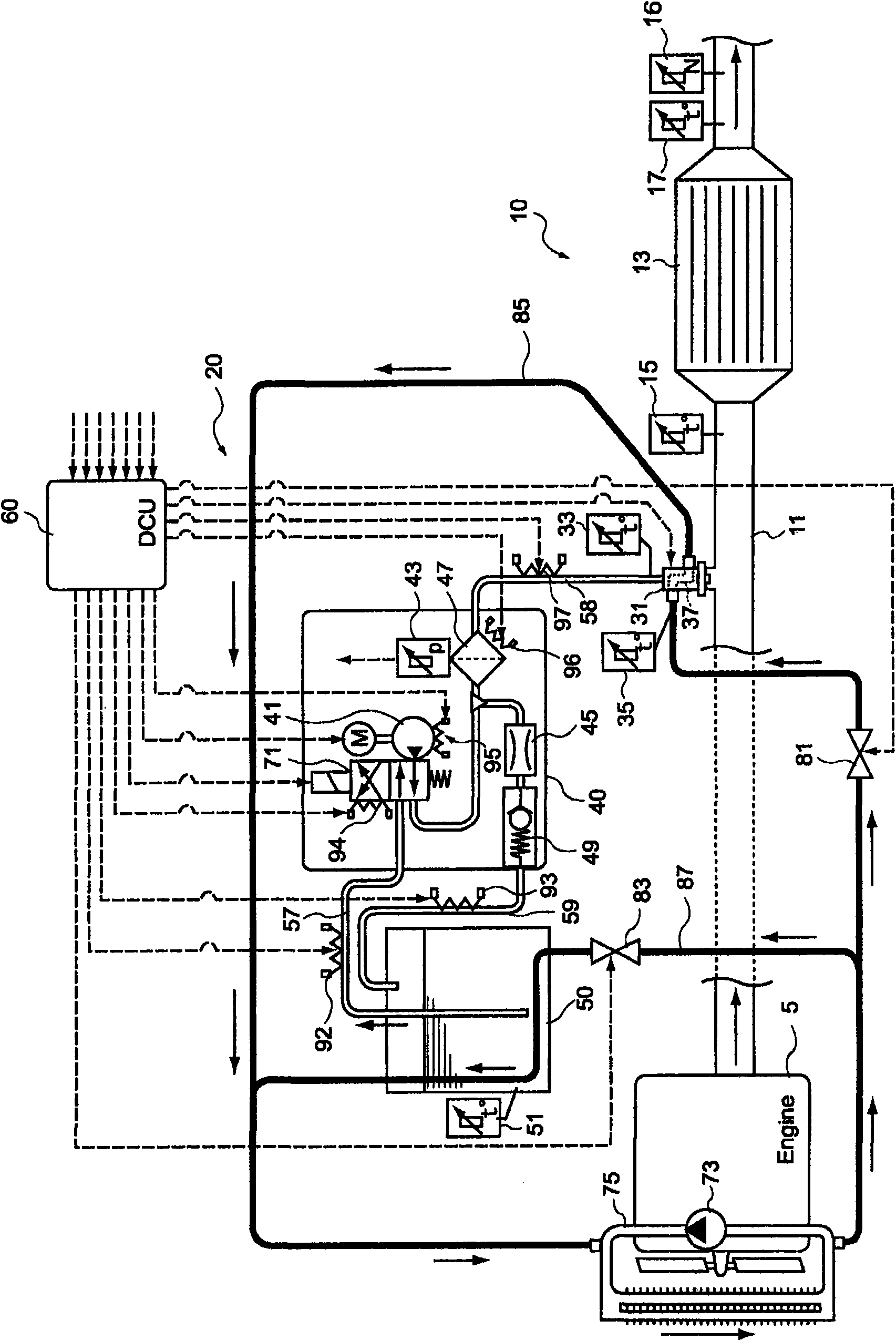

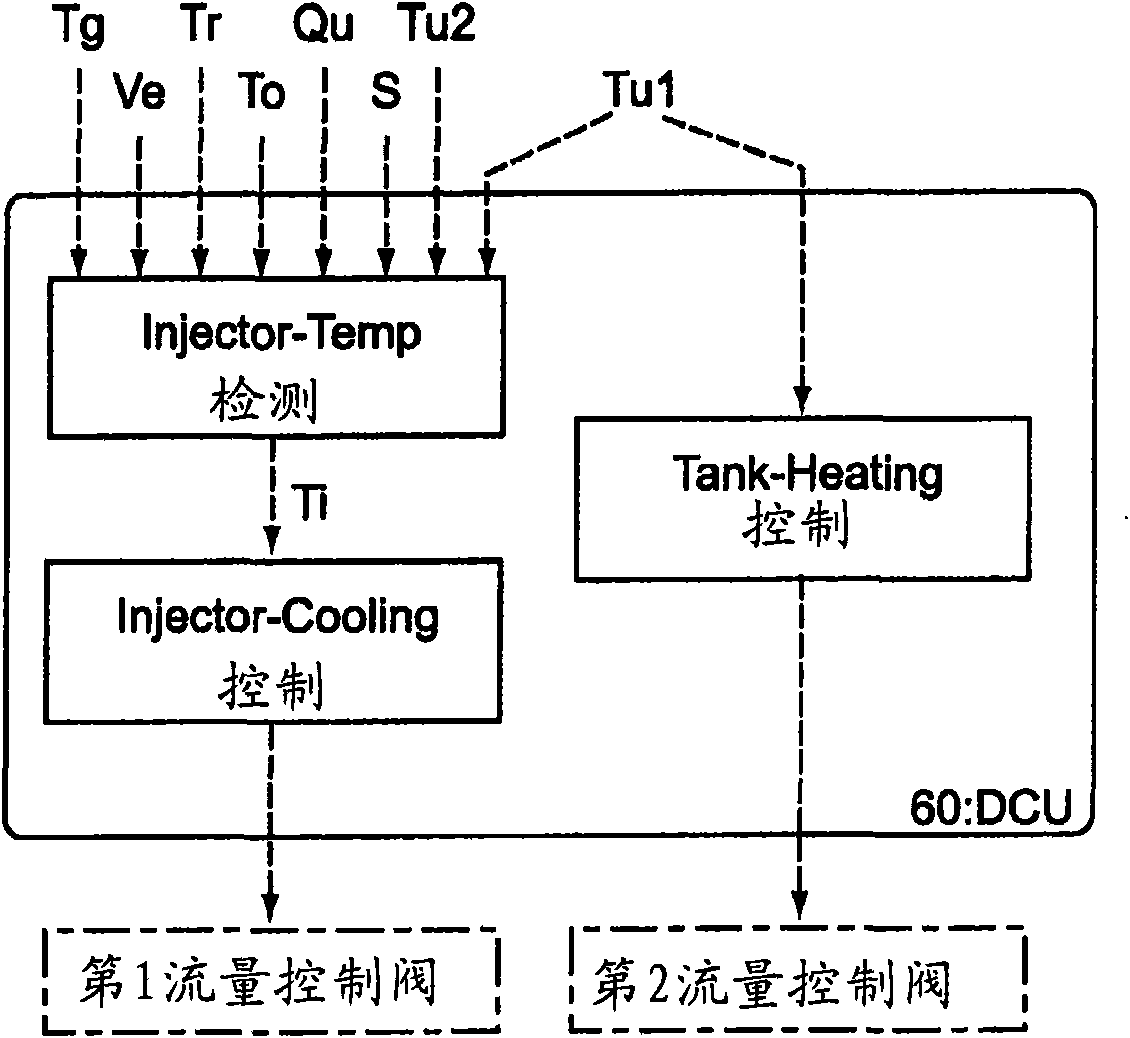

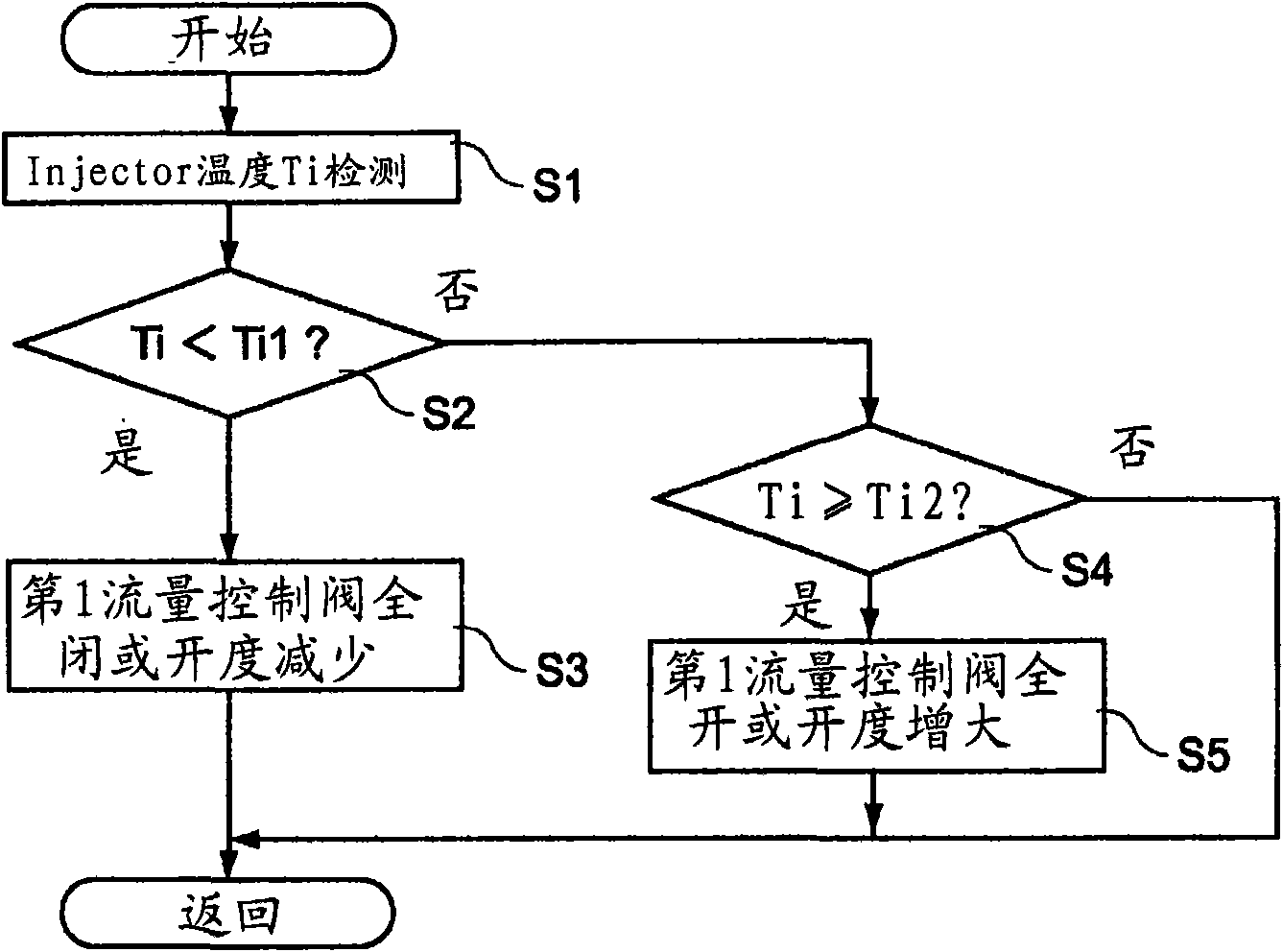

Controller of reducing agent supply unit and method of controlling the same

InactiveCN101828011APrevent crystallizationPrevent sprayingLiquid coolingInternal combustion piston enginesTemperature controlNitrogen oxides

A reducing agent supply unit that prevents any heat damaging of reducing agent injection valve and also prevents any crystallization of urea solution by excessive cooling of liquid reducing agent; and a method of controlling the same. There is disclosed a reducing agent supply unit for use in an exhaust purification apparatus capable of feeding by injection a urea solution as a reducing agent on the along-exhaust upstream side of a reduction catalyst disposed along an exhaust path of internal combustion engine so as to attain reduction purification of any nitrogen oxides contained in exhaust gas by the reduction catalyst, which reducing agent supply unit has a reducing agent injection valve fixed to an exhaust pipe on the along-exhaust upstream side of the reduction catalyst. The reducing agent supply unit comprises a cooling water circulation path for circulating at least a portion of the cooling water of the internal combustion engine in order to cool the reducing agent injection valve; flow rate control means for regulating the flow rate of cooling water through the cooling water circulation path; temperature detection means for detecting the temperature of the reducing agent injection valve; and control means for controlling the flow rate control means on the basis of the temperature of the reducing agent injection valve.

Owner:BOSCH CORP

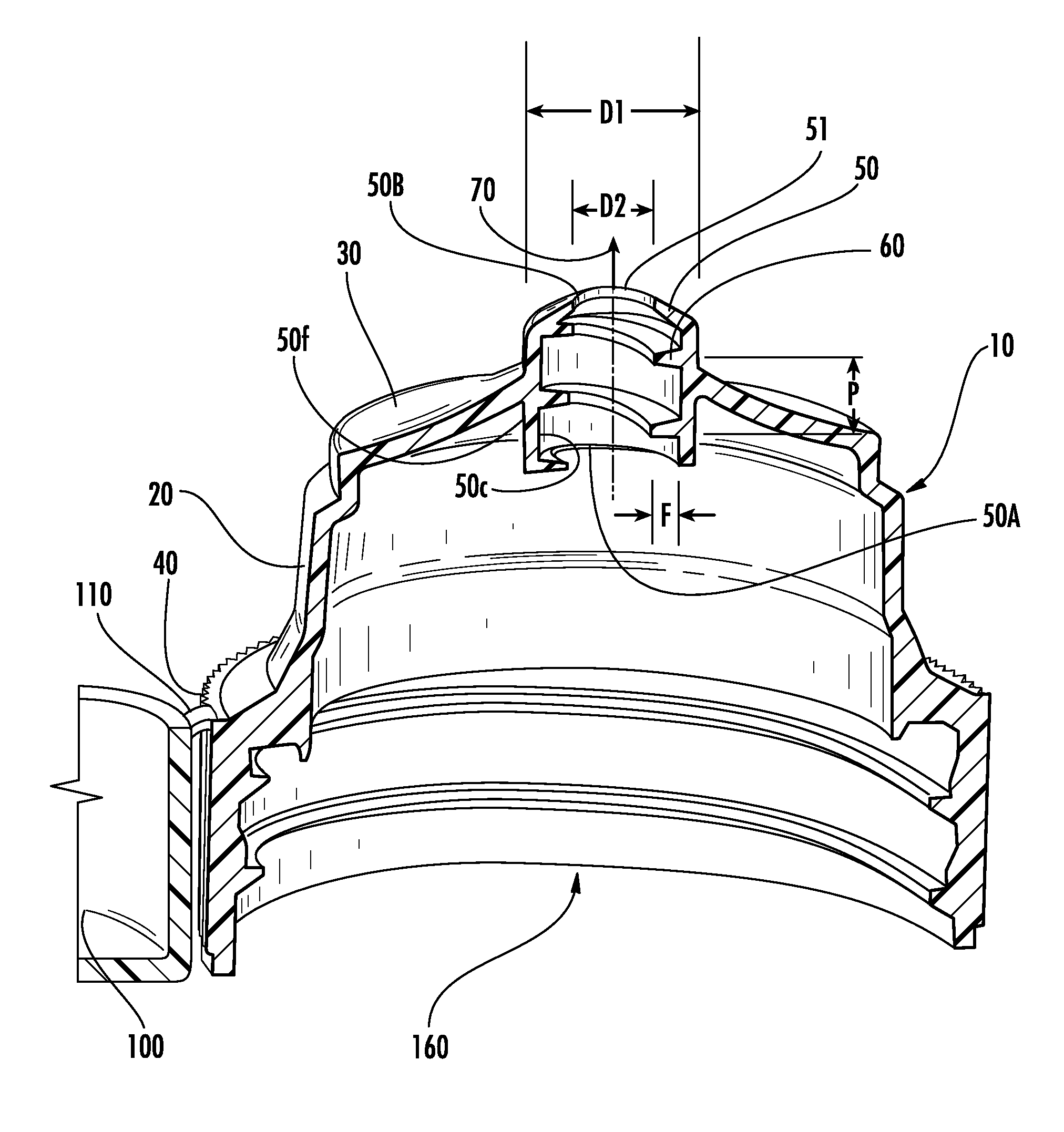

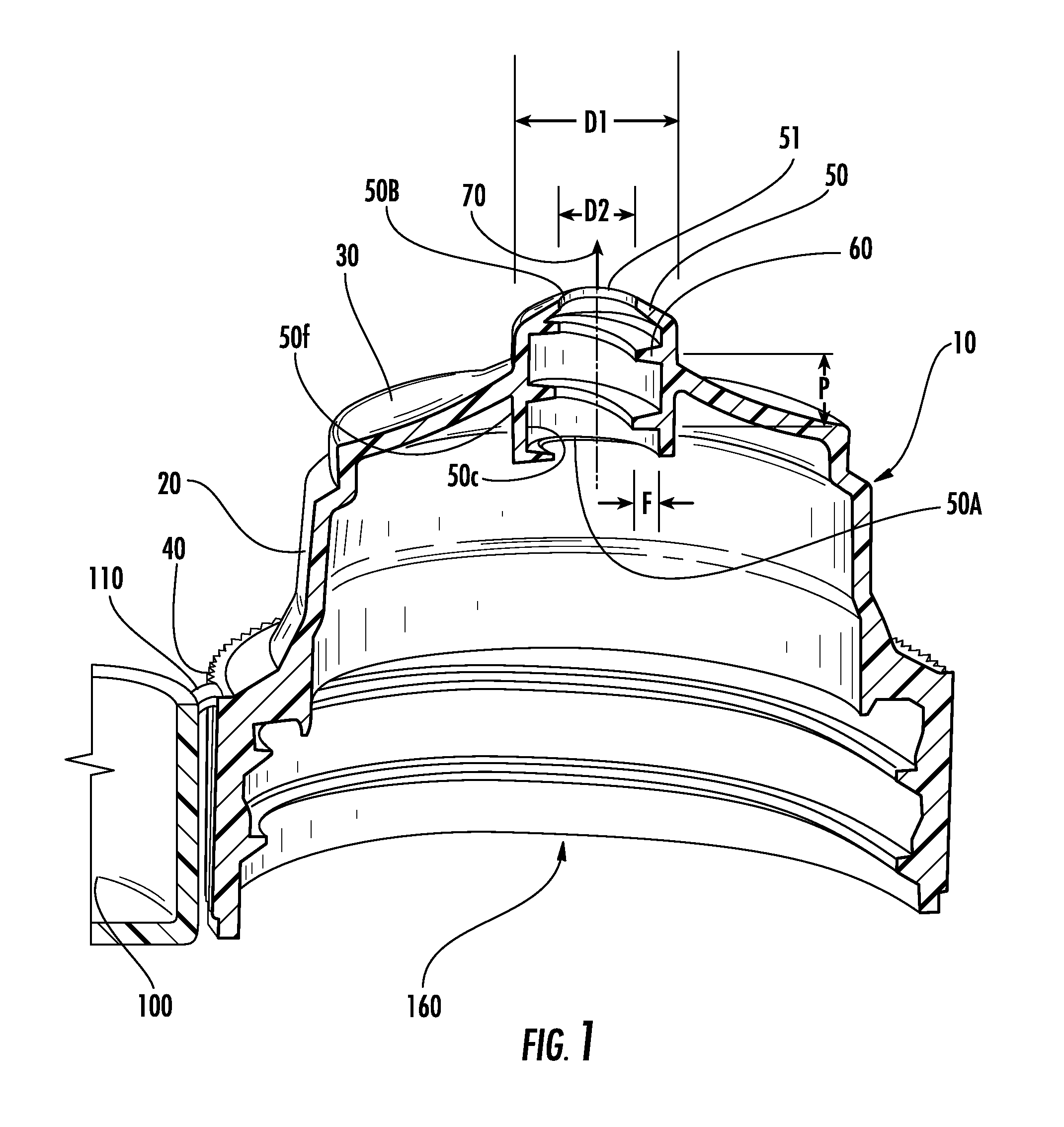

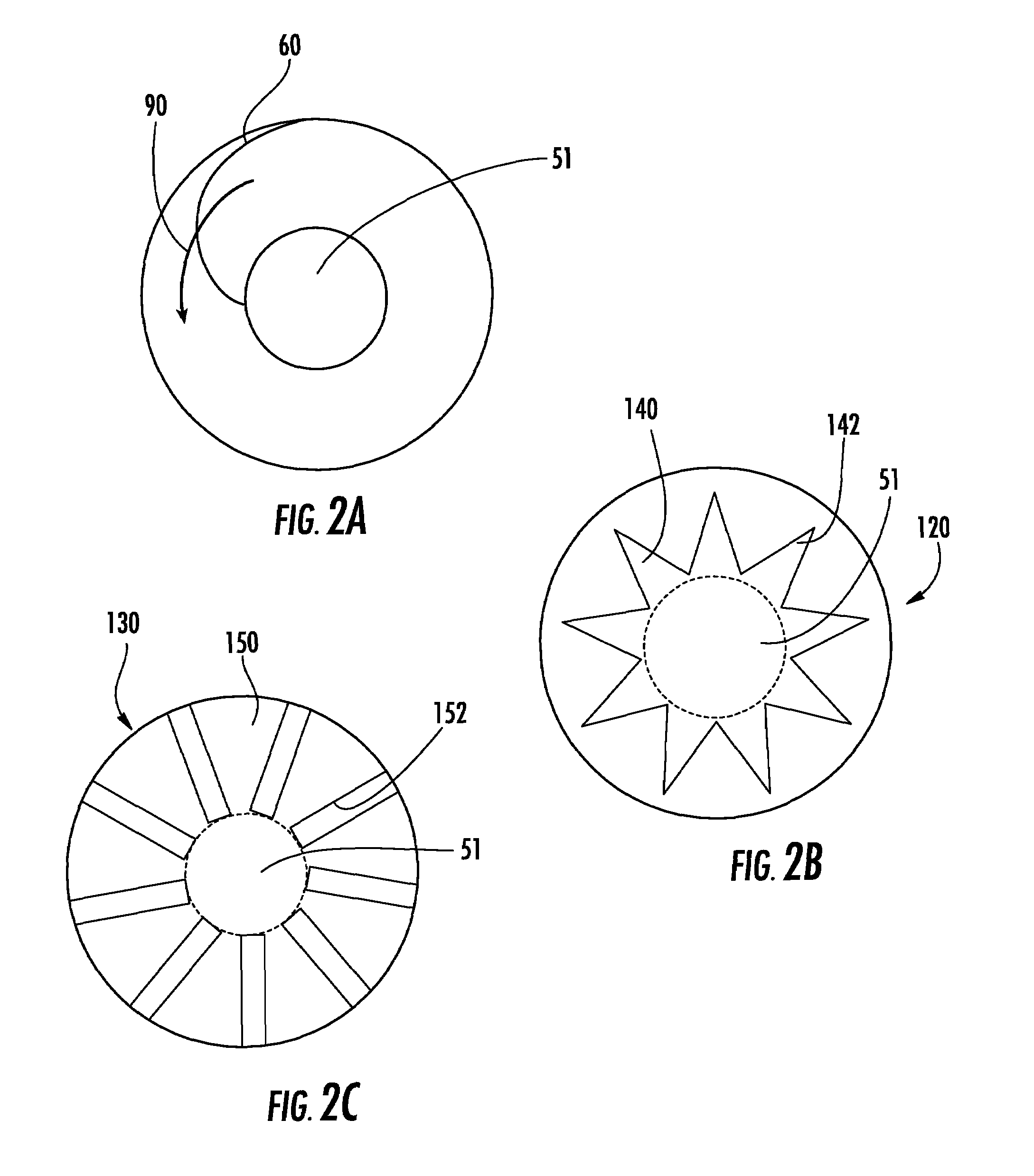

Dispensing cap with center channel and helical flow profile

A dispensing closure for viscous fluids contains a closure body, a closure lid and a living hinge structure hingeably connecting the closure lid to the closure body. The closure body includes an upper deck, a skirt configured and arranged to mount to a product container, and a flow conduit extending through the upper deck to provide a flow path from an interior of the closure to an exterior of the closure. The flow conduit includes an entrance orifice and an exit orifice, and an inner wall extending between the entrance orifice and the exit orifice. To provide the desired flow effect, the inner wall includes at least one flow inhibitor structure, such as helically threaded flights extending at least partially inwardly from the inner wall into the flow path to define an unobstructed central flow path and a partially obstructed peripheral flow path.

Owner:WESTROCK SLATERSVILLE

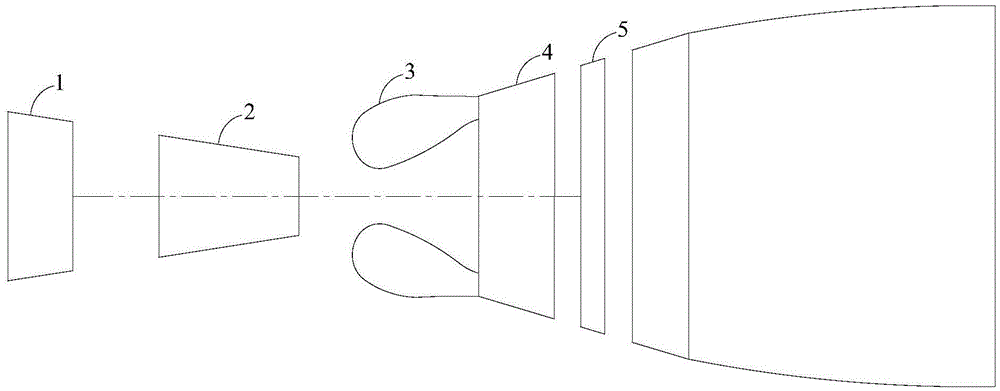

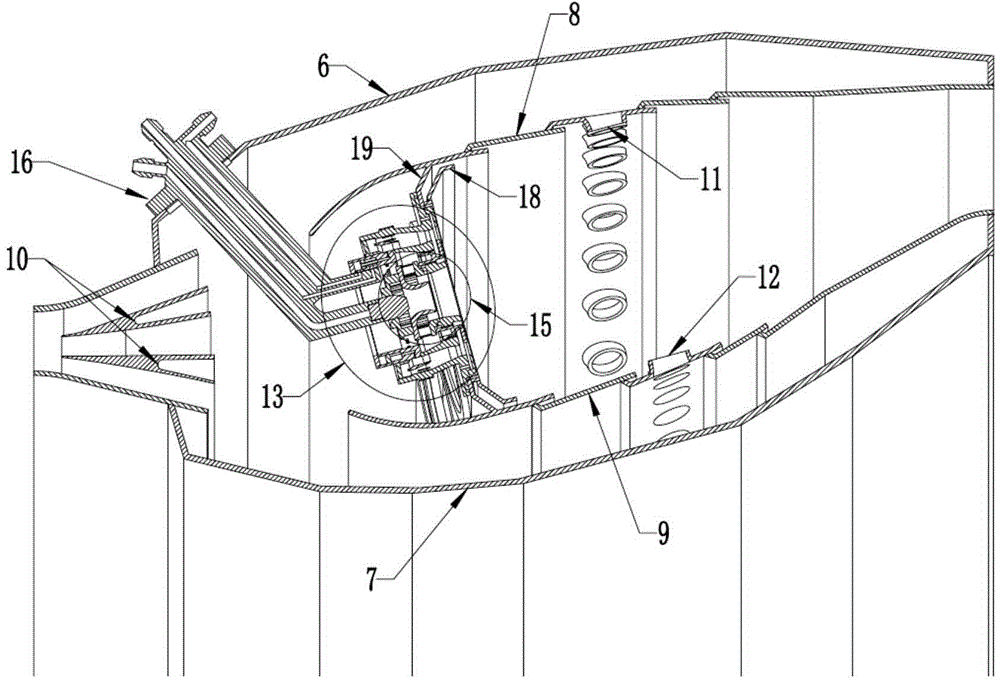

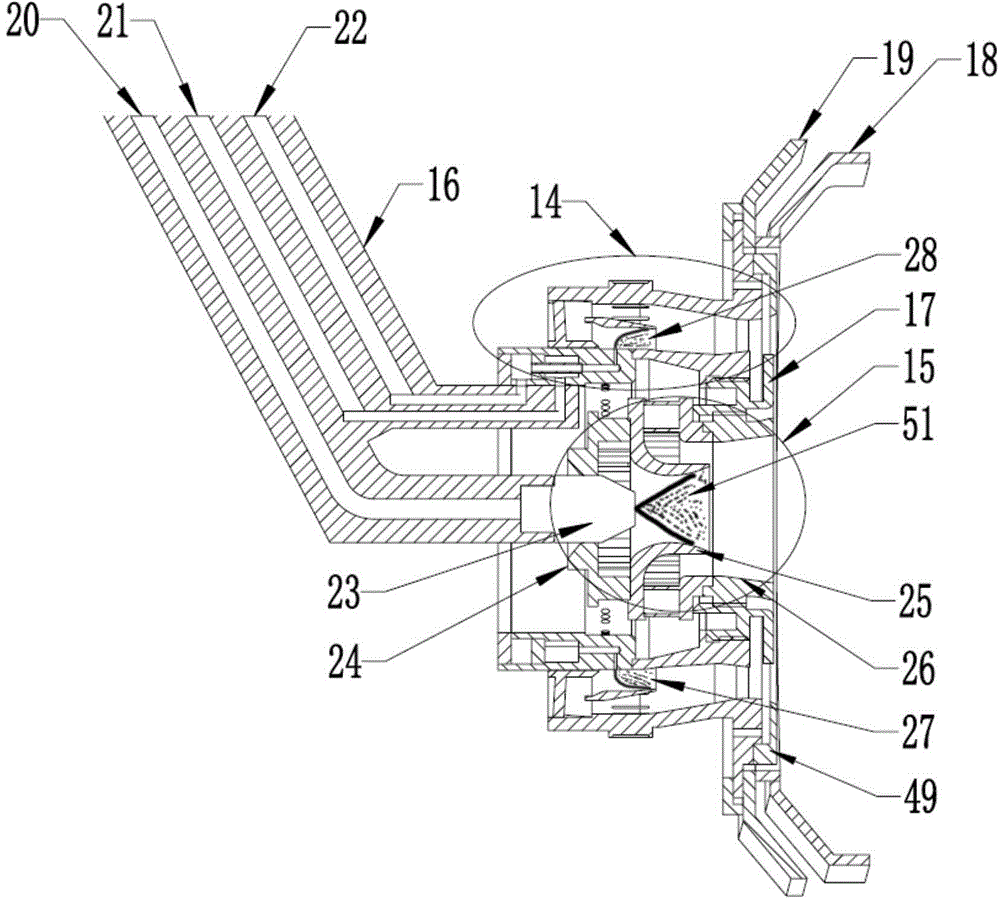

Lean oil premixing and pre-evaporating combustion chamber head structure with cyclone/pre-film plate integrated primary combustion stage

The invention relates to a lean oil premixing and pre-evaporating combustion chamber head structure with a cyclone / pre-film plate integrated primary combustion stage. A central staged combustion mode is adopted for the head structure and divided into a pre-combustion stage and the primary combustion stage, the mode of combining diffusive combustion and cyclone premixing combustion is adopted for the pre-combustion stage, the mode of premixing and pre-evaporating combustion mode is adopted for the primary combustion stage, and combustion pollutants can be effectively reduced. A cyclone / pre-film plate integrated structure is adopted for the primary combustion stage, the structure is simple and reliable, first-stage fuel and second-stage fuel form oil films on the same pre-film plate and are atomized, evaporated and mixed under the action of two strands of cyclones, an even oil and gas mixture can be easily formed at an outlet of the primary combustion stage, and the combustion pollutants are reduced. The design of dual oil paths of the primary combustion stage is beneficial to oil and gas matching of the combustion chamber under different working conditions, and the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aero-engine is further lowered. By means of the micro shrinkage type design of a primary combustion stage channel and the design of a backfire prevention ring, the backfire problem can be effectively solved, and the safety of the head of the combustion chamber is ensured.

Owner:BEIHANG UNIV +1

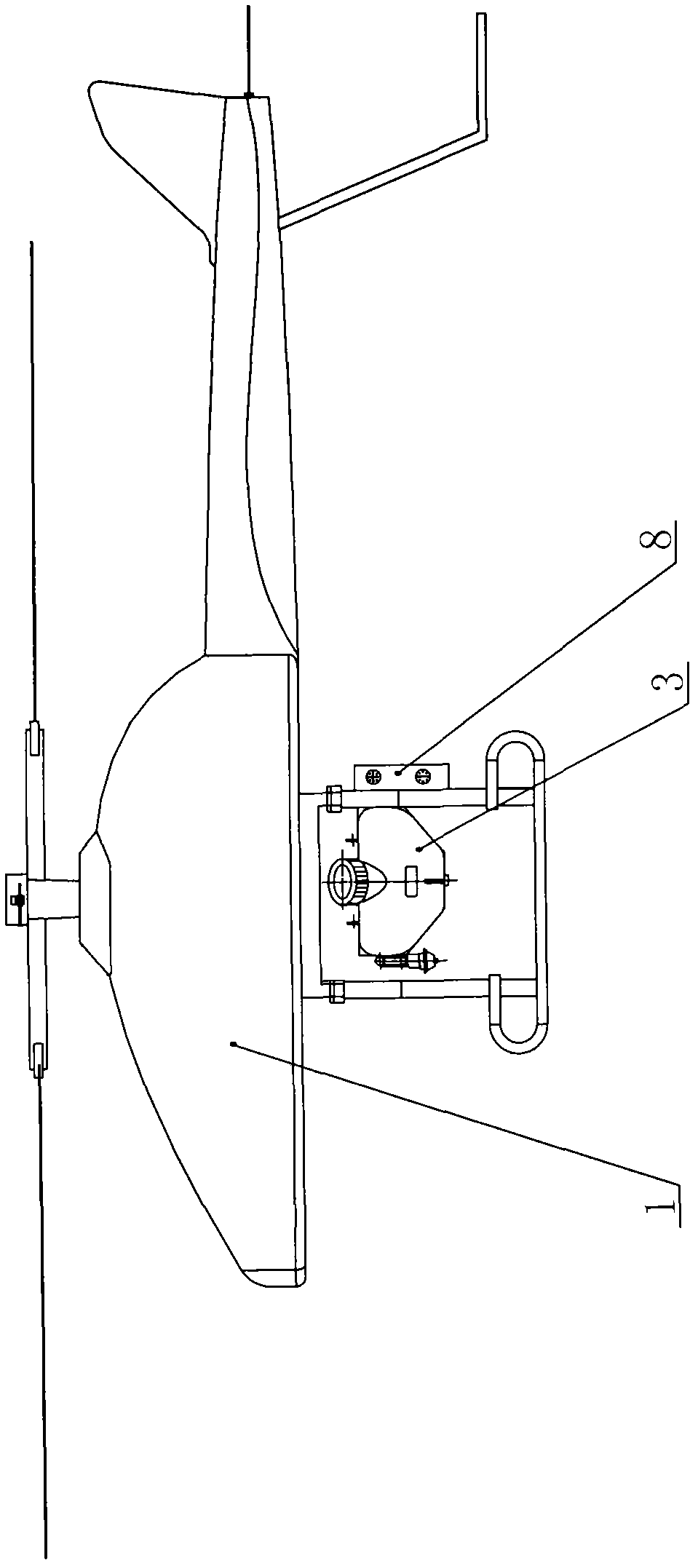

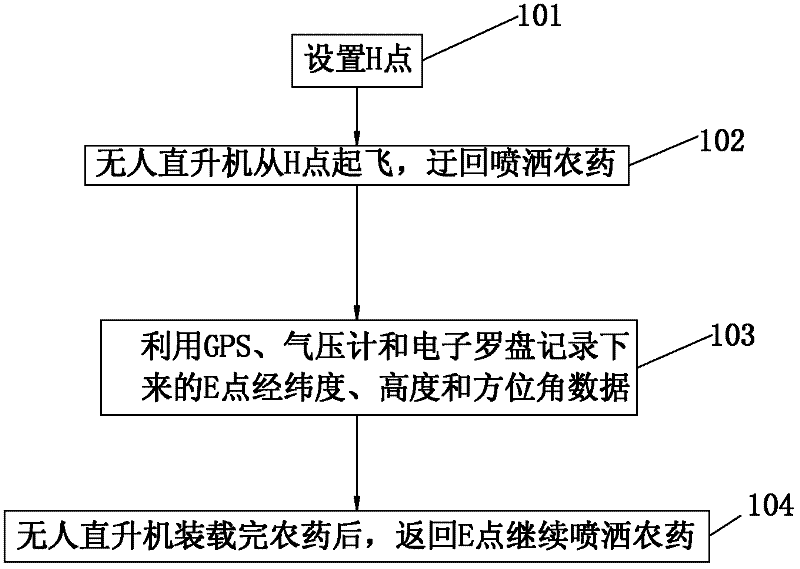

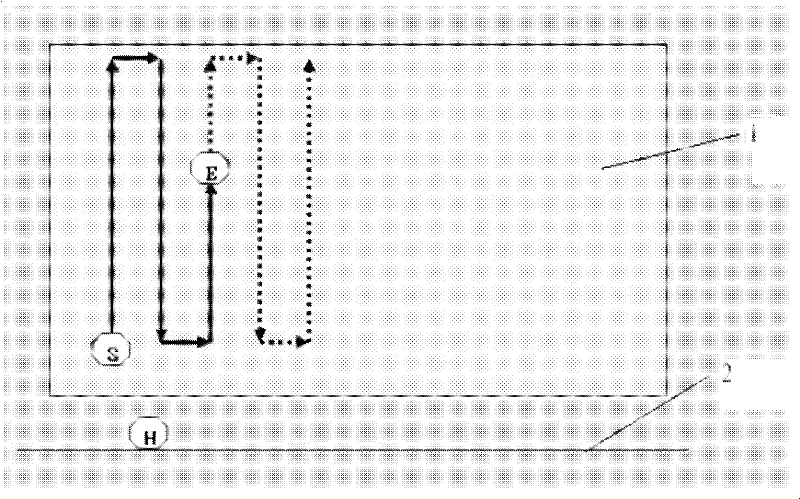

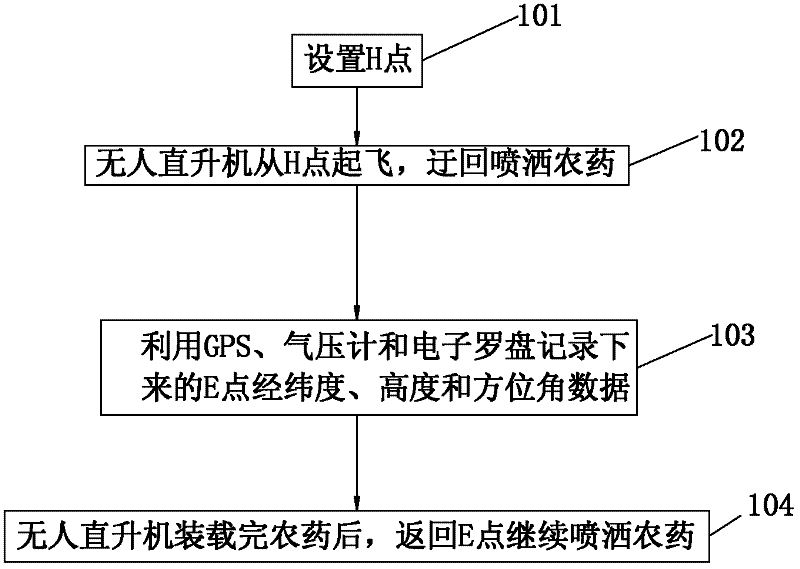

Method for continuously spraying pesticide by unmanned helicopter

ActiveCN102360219APrevent sprayingAvoid duplicationPosition/course control in three dimensionsLongitudeGlobal Positioning System

The invention discloses a method for continuously spraying pesticide by an unmanned helicopter, which comprises the following steps that: one edge of a piece of land is provided with a moving point H; the unmanned helicopter takes off from the point H and sprays the pesticide along parallel straight lines; after the pesticide spraying completion by the unmanned helicopter at a point E, the longitude and latitude of the point E are recorded by a global positioning system (GPS), the height of the point E is recorded by a barometer, and the azimuthal angle data of the point E is recorded by an electronic compass; and the unmanned helicopter automatically flies back to the point E for continuously spraying the pesticide according to the longitude and latitude, the height and the azimuthal angle data of the point E recorded by the GPS, the barometer and the electronic compass after the unmanned helicopter returns to the point H to load the pesticide. The goal of preventing missed spraying or repeated spraying is realized, and the continuous pesticide spraying operation is formed.

Owner:WUXI HANHE AVIATION TECH

Reduction of recirculation in catheters

ActiveUS8920404B2Reduce the average velocityPrevent sprayingMedical devicesCatheterDistal portionNose

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

Hydraulic buffering device when automobile being bounced

InactiveCN101125539AIncrease impact forcePrevent sprayingLiquid based dampersBumpersEngineeringPiston cylinder

The present invention relates to a hydraulic buffering device when the car is hit and consists of a piston cylinder, a piston, a piston rod and a buffering starting device. The coordination of the piston cylinder and the piston rod and the piston are movable fit. The piston cavity that is filled with oil is divided into a front cavity and a back cavity that are communicated by the piston. The oil can not fill the whole space that is communicated with the piston cavity before buffering force of the hydraulic buffering device reaches the maximum design buffering force. The buffering starting device is used for fixing the relative positions of the piston and the piston cylinder. The hydraulic buffering device is actuated and starts the buffering action when the impact of the vehicle reaches a certain design value. The discharged oil in the rear cavity can automatically flow back after the buffering is reset. Better buffering effect can be achieved when the piston cylinder is provided with a vent hole that is communicated with the front cavity and the outside and measures are taken to prevent the oil being discharged out from the vent hole; utilizing spring as the buffering actuating device can realize slow reset of the hydraulic buffering device and the second buffering of the spring.

Owner:李正才

Device for measuring droplet charge-mass ratio of electrostatic spraying droplets

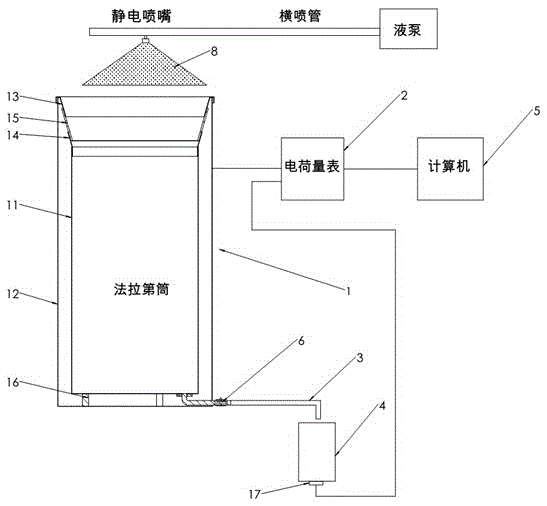

InactiveCN105676010AReduce churnPrevent sprayingElectrical measurementsMass ratioMovement measurement

The invention relates to the field of agriculture and forestry plant protection technology, and more particularly relates to a device for measuring the droplet charge-mass ratio of electrostatic spraying droplets. The device is characterized by comprising a faraday cylinder (1), a coulometer (2), a water outlet pipe (3), a liquid collecting barrel (4) and a computer (5). The faraday cylinder (1) and the coulometer (2) are connected. The coulometer (2) and the computer (5) are connected. The water outlet pipe (3) is communicated with the bottom of the faraday cylinder (1). The bottom of the liquid collecting barrel (4) is provided with a weight sensor (17). The weight sensor (17) and the coulometer (2) are connected. The liquid collecting barrel (4) is used for collecting the liquid that flows out of the water outlet pipe (3). Compared with the prior art, the technical effects of small charge loss between sealed inner and outer cylinders, easy operation, good measurement real-time performance, high accuracy, high cost performance, convenient movement measurement and the like are realized.

Owner:SOUTH CHINA AGRI UNIV

Liquid food cooking method and cooking device

InactiveCN1973738AImprove qualityGuaranteed air tightnessBeverage vesselsFood preparationProper timeFood material

The invention provides an apparatus and method for cooking liquid food, which comprises a heating mechanism, a pressure vessel heated by the heating mechanism, a extracting vessel having a connected pipe extending from the bottom of a receiving-filtration mechanism into the pressure vessel and arranged on an opening of the pressure vessel for sealing the opening, a disintegrator inserted into the inner of the extracting vessel. The extracting vessel is filled with food material and cooking water, then the disintegrator is turned on for smashing the food material in the cooking water left in the extracting vessel. After smashed, the food material is heated by boiled cooking water for extracting available component. Stop heating by the heating mechanism in proper time after extracting, then filtrate the extracting liquid form the extracting vessel using the filtrating mechanism, pump the extracting liquid to the pressure vessel for reclaiming employing the pressure decline, caused by heating stop, though the connected pipe.

Owner:YAMAMOTO ELECTRIC

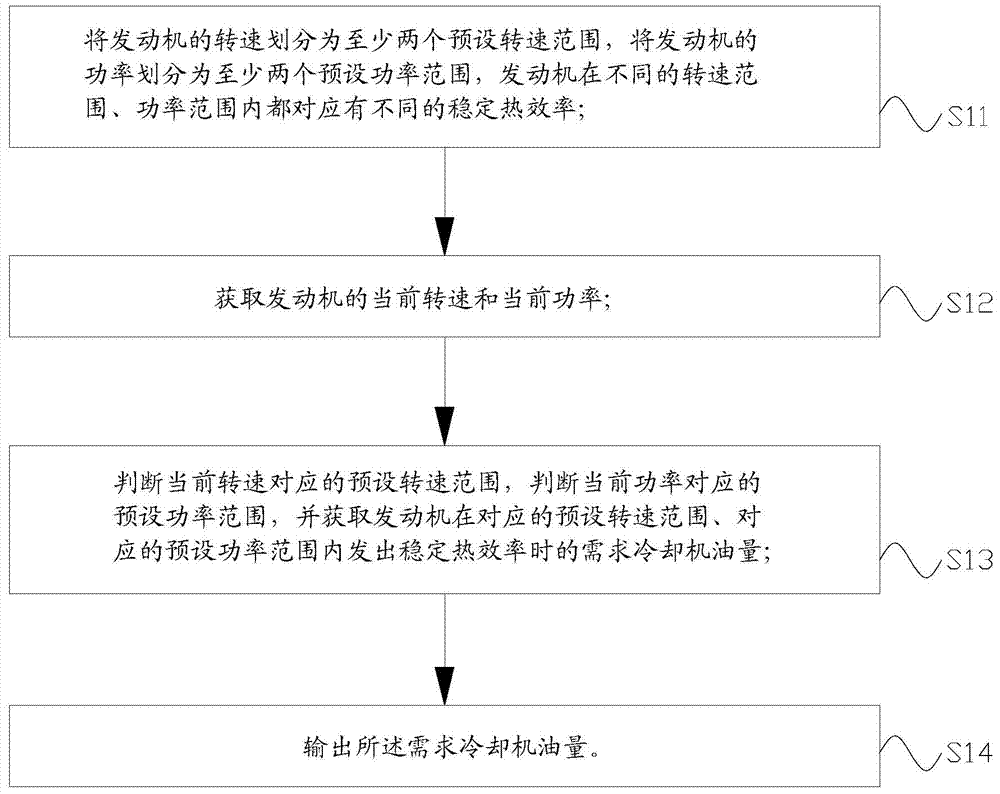

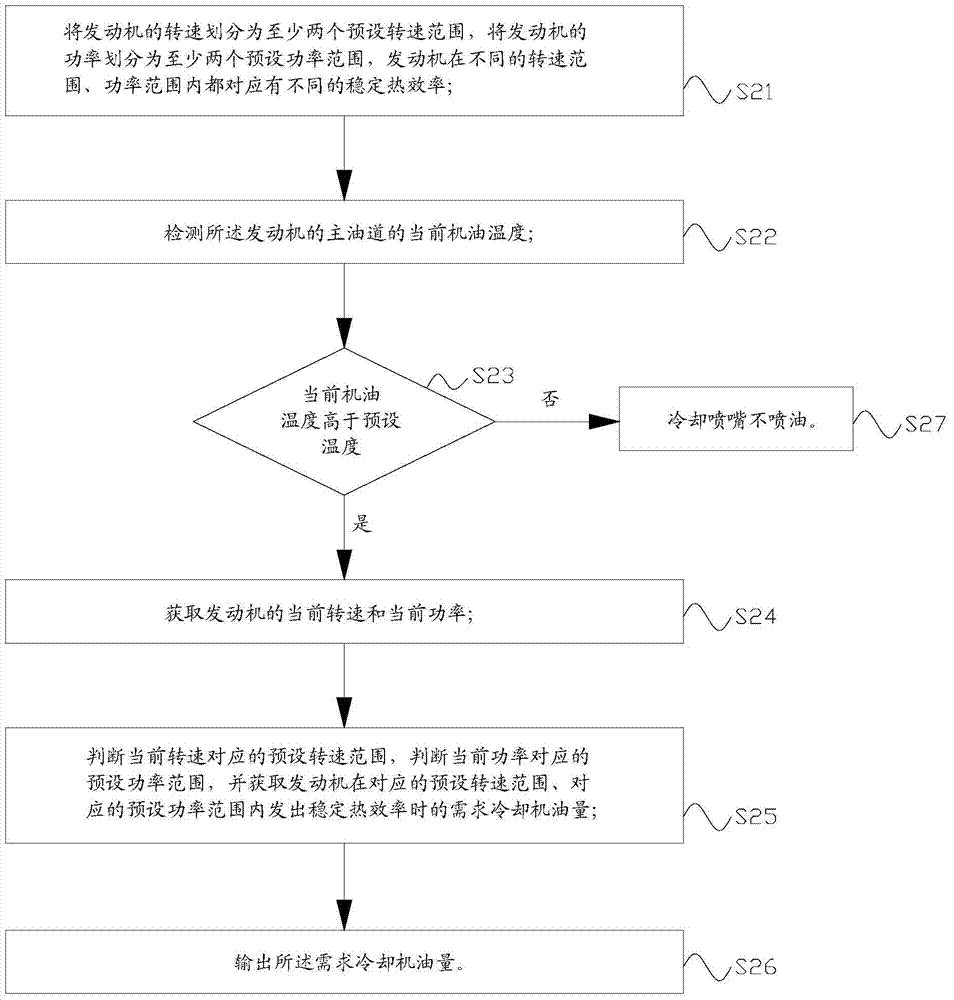

Engine and control method and system for cooling jet of engine

ActiveCN103790688APrevent sprayingGuaranteed thermal efficiencyLiquid coolingCoolant flow controlControl systemSpray nozzle

The invention discloses a control method for a cooling jet of an engine. The control method for the cooling jet of the engine comprises the following steps that the rotating speed of the engine is divided to be within at least two preset rotating speed ranges, the power of the engine is divided to be within at least two preset power ranges, and the engine has different levels of stable heat efficiency when the rotating speed of the engine is within different preset rotating speed ranges and the power of the engine is within different preset power ranges; the current rotating speed and the current power of the engine are obtained; the preset rotating speed range corresponding to the current rotating speed is judged, the preset power range corresponding to the current power is judged, and the quantity of cooling machine oil needed by the engine is obtained when the engine has the stable heat efficiency within the corresponding preset rotating speed range and the corresponding preset power range; the quantity of the needed cooling machine oil is output. According to the control method for the cooling jet of the engine, distribution of the quantity of the cooling machine oil according to the needs is achieved, the phenomenon that when an engine is in idling and is low in load, the quantity of output cooling machine oil is large is avoided, and heat efficiency of the engine is ensured. The invention further discloses a control system for the cooling jet of the engine, and the engine with the control system.

Owner:WEICHAI POWER CO LTD

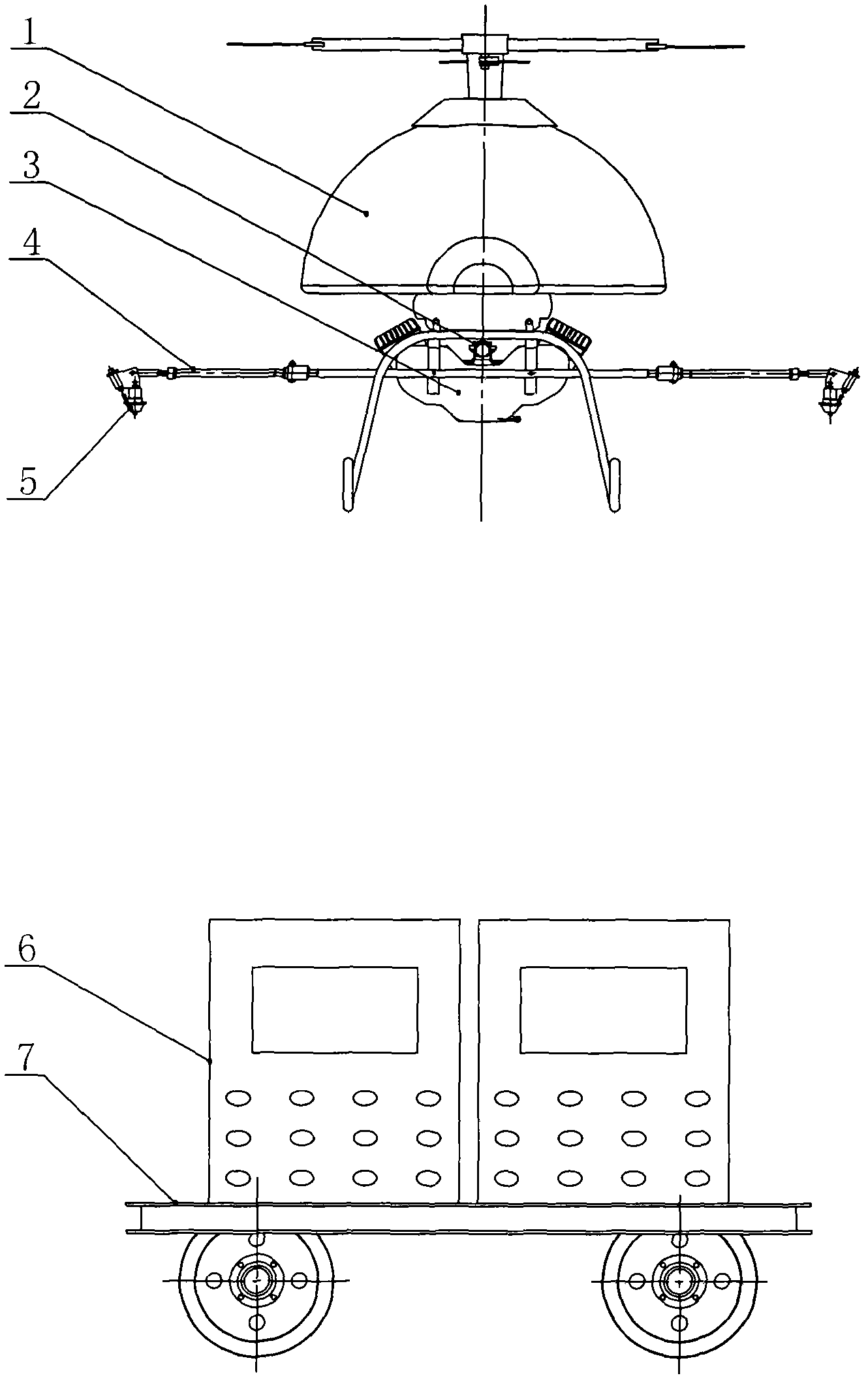

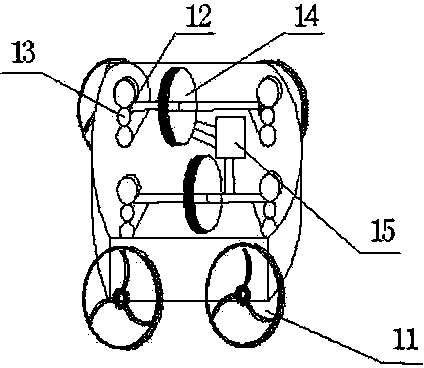

Full-automatic watering vehicle

InactiveCN105248256ALow energy consumptionReduce labor intensityWatering devicesCultivating equipmentsElectric machineryPiping

The invention discloses a full-automatic watering vehicle. The full-automatic watering vehicle is characterized in that a water storing tank and a storage cabinet are arranged over a lower vehicle body; a vertical telescopic assembly is arranged beside the water storage tank; a telescopic rod of the vertical telescopic assembly is provided with a chain; the chain is driven by a motor; a horizontal driving slide block of a horizontal telescopic assembly is engaged with a horizontal driving screw rod; the end part of the horizontal driving screw rod is provided with a pressing device; the pressing device is installed over a supporting water pipe; a water spraying head is installed under the supporting water pipe; the lower vehicle body is provided with a worm gear rod and a damping wheels; the worm gear rod is engaged with a turning gear via a driving motor; the turning gear is engaged with a wheel driving shaft; and the worm gear rod and the turning gear transmit power to damping wheels, so the damping wheels can rotate and drive the lower vehicle body to move forward, backward and steer. Watering load can be reduced for workers, so less labor and time can be achieved for flower planting workers; and the full-automatic watering vehicle benefits people.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

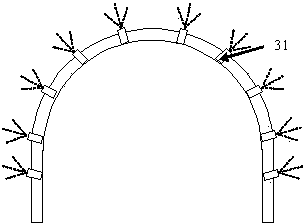

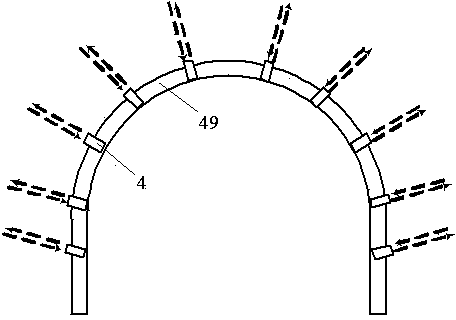

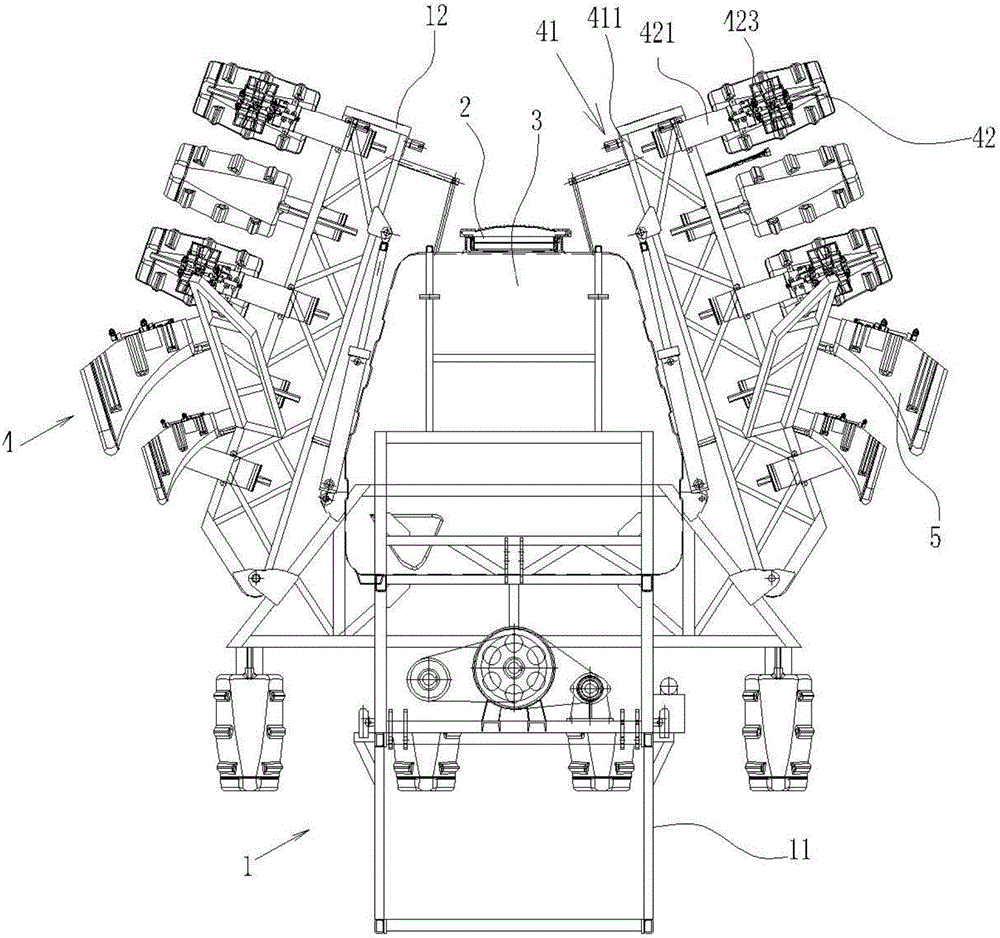

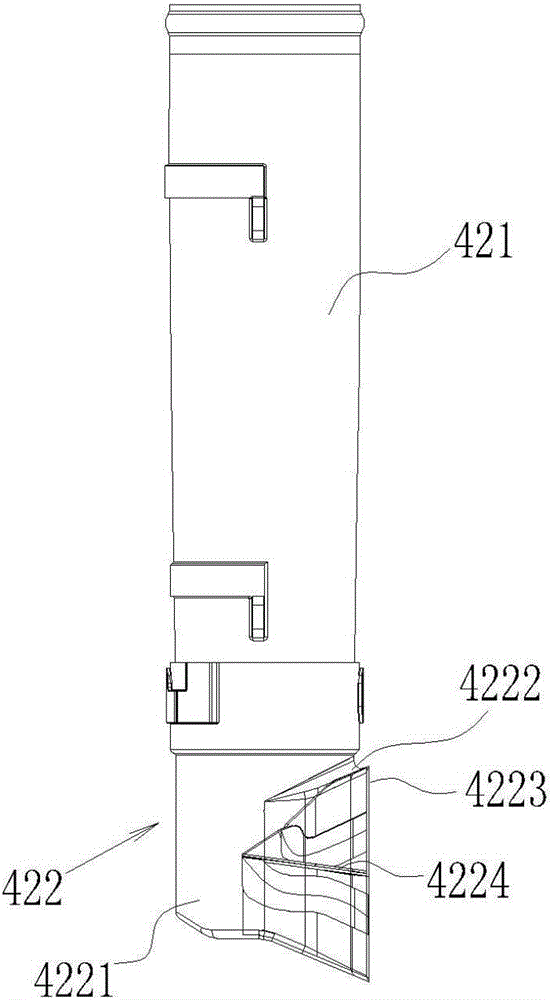

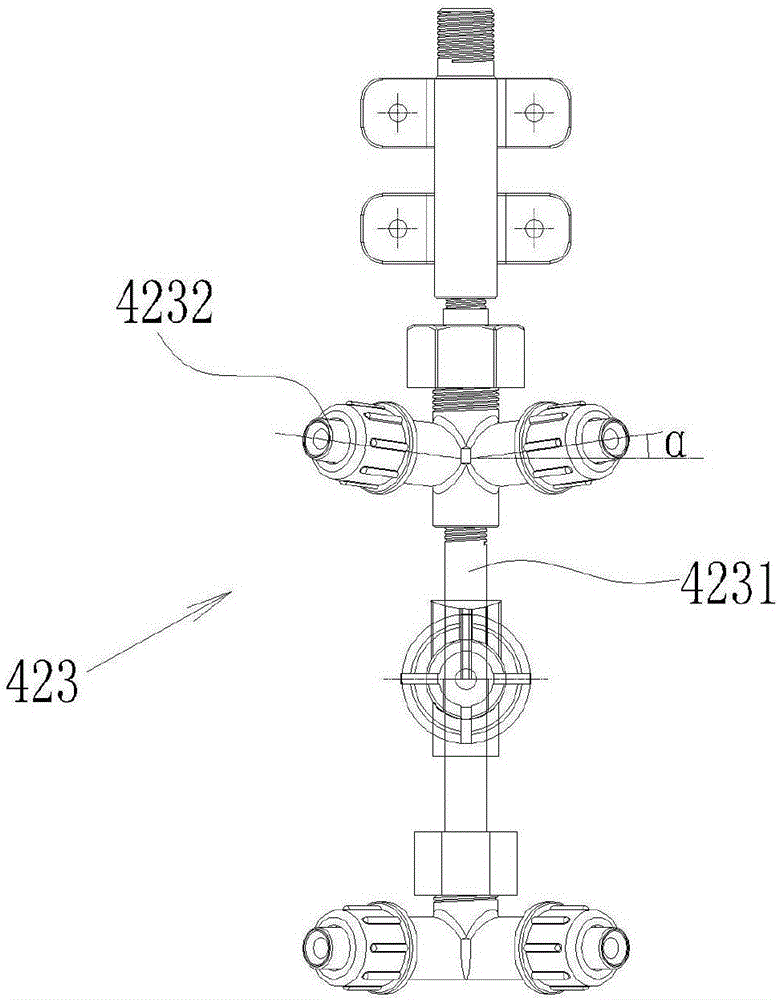

Self-propelled spraying machine with automatic targeting in orchard and spraying method thereof

ActiveCN103548802AStrong laser directionalityFree from environmental interferenceInsect catchers and killersSet distanceSpray nozzle

The invention discloses a self-propelled spraying machine with automatic targeting in an orchard and a spraying method thereof. According to the self-propelled spraying machine, the automatic targeting is realized, the influence by the environment is less, the response time is fast, no leaked spraying or more spraying is caused and the waste of pesticide is prevented. The spraying machine comprises a rack, a traveling device, a spraying device with a plurality of spraying nozzles, laser detecting devices and a central processor; the laser detecting devices correspond to the spraying heads in a one-by-one manner; each laser detecting device comprises a laser generator, a laser receiver, a signal processor and a controller; the spraying heads and the laser detecting devices are distributed on the rack at the same corresponding angle; the central processor is connected with all spraying-nozzle control devices. The spraying method disclosed by the invention comprises the steps that the laser generator generates laser transmitting signals, the laser receiver receives reflecting signals, and if the target distance is in the set distance range, the target is the current target; if the former signal does not detect the current target, the latter reflecting signal detects the current target, and then the spraying is carried out; if the three continuous reflecting signals do not detect the target, the spraying is stopped; the other states are maintained to be the original states.

Owner:NANTONG GUANGYI ELECTROMECHANICAL CO LTD

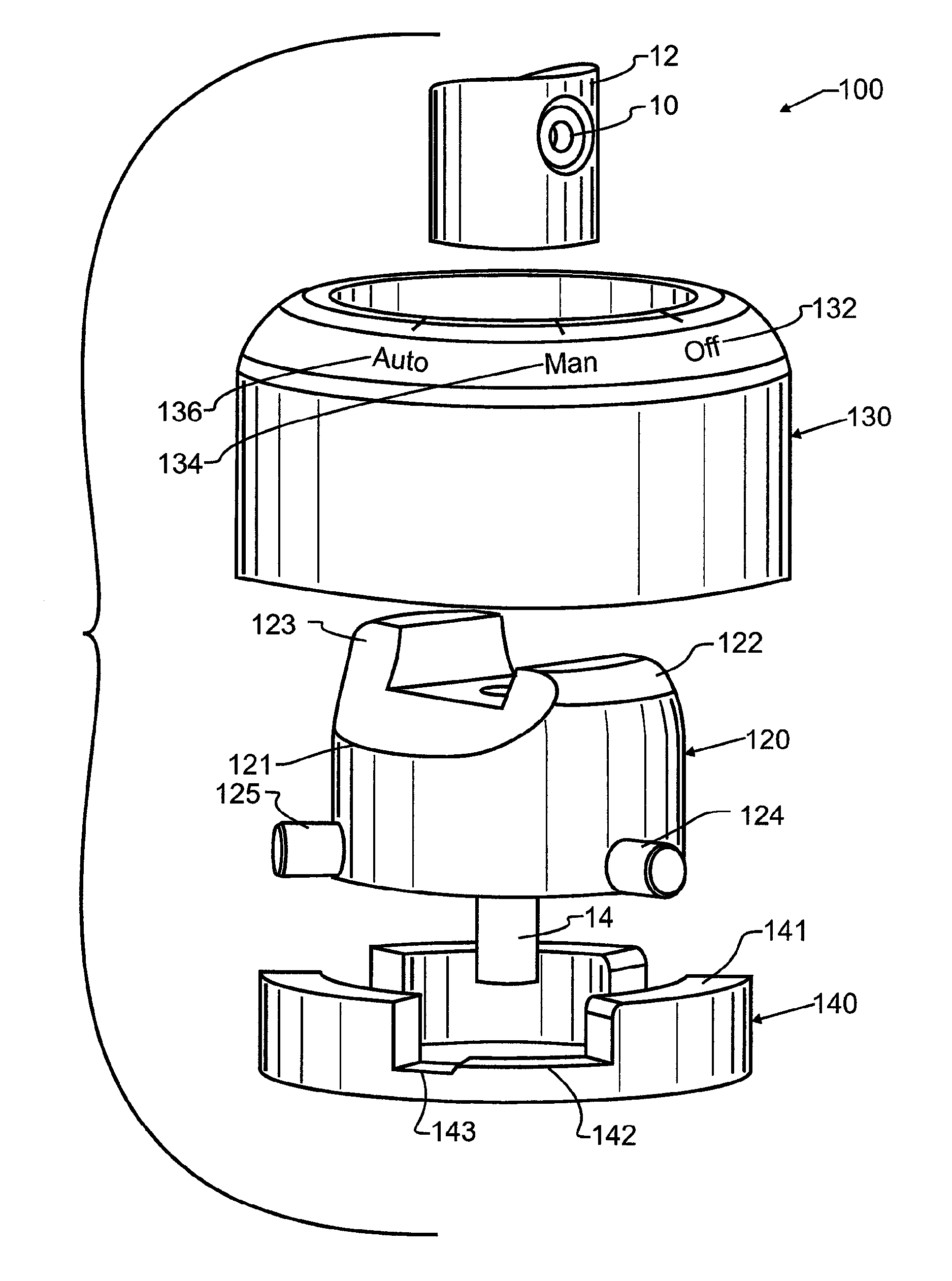

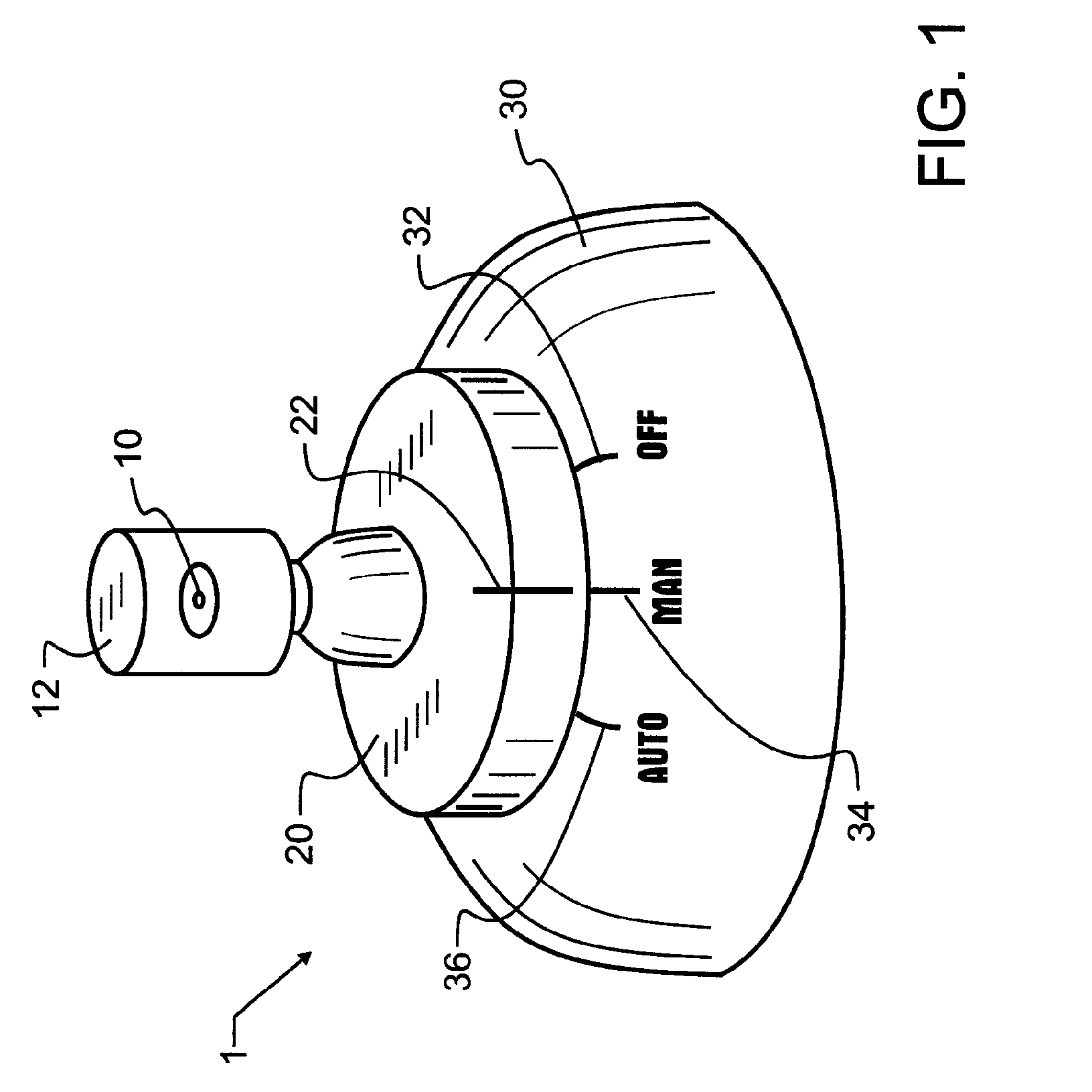

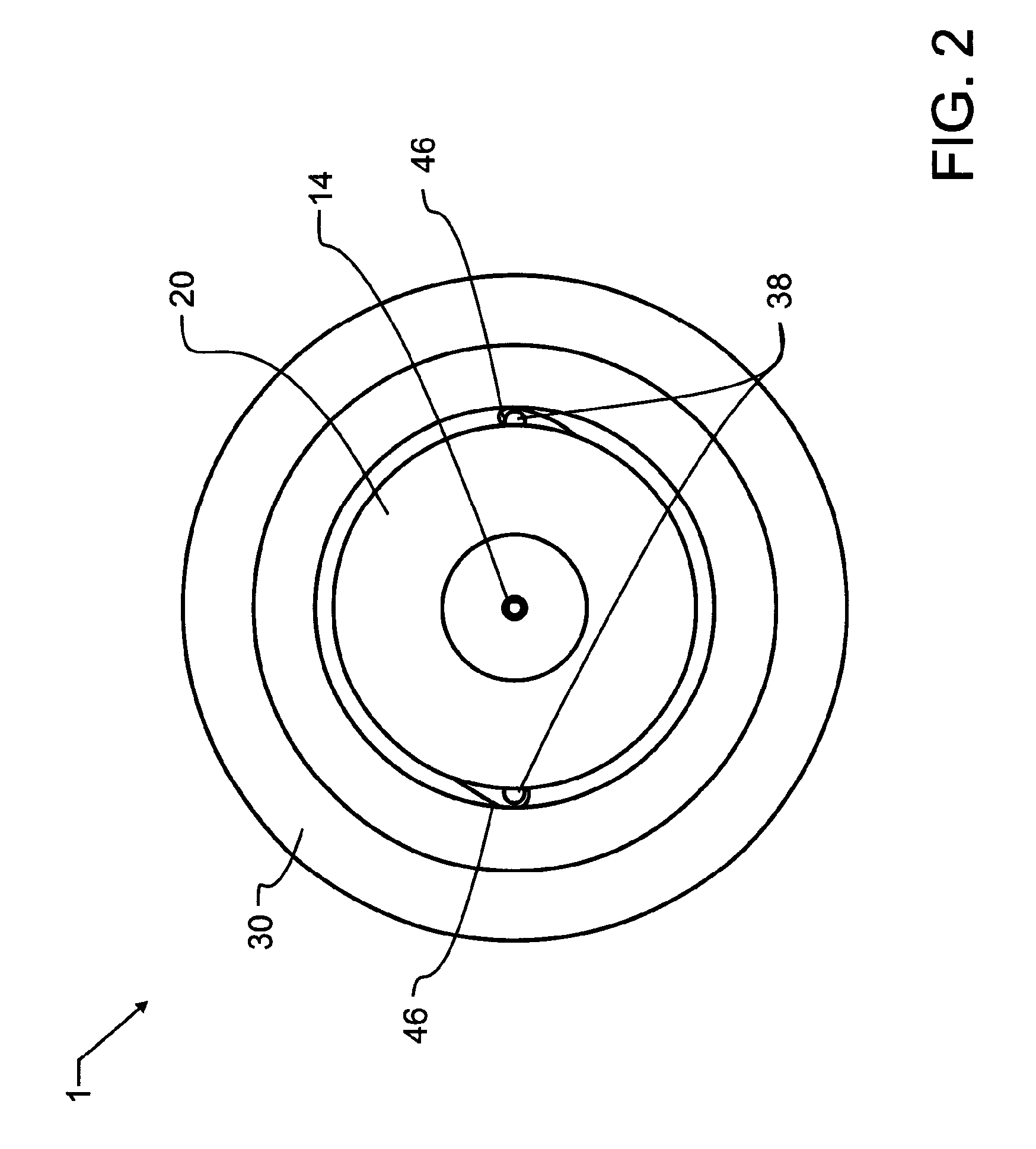

Select-a-spray

ActiveUS8333304B1Prevent sprayLow cost and intuitive to useLiquid transferring devicesLiquid spraying apparatusEngineeringPush-button

A spray control device for aerosol cans is provided having three or more dispensing positions. The positions in the preferred embodiment include “automatic” for continuous spray, “manual” for normal push-button control, and “off” to prevent spraying. Adjustment between the various positions is achieved by rotation of a centrally located, floating spray button device that nests on top of an aerosol can. The central spray button device floats within a can coupling ring to accommodate any misalignment between the spray control device and spray can, and movement of the central spray button device is guided by a pin and track combination for predictable and repeatable control over paint or other fluid application. A guide ring is press-fit into the can coupling ring, and both act as a part of the guide track for the central spray button device. The guide ring may optionally be removable to permit complete disassembly and cleaning.

Owner:HAAGE GREGORY A

Apparatus and method for concentrating and collecting analytes from a flowing liquid stream

InactiveUS7332347B2Optimizes analyte enrichmentPrevent sprayingComponent separationWithdrawing sample devicesSolventBoiling point

An apparatus for concentrating and collecting one or more analytes in a flowing liquid stream of a carrier solvent composed of one or more solvent components is provided, which includes a transfer tube which forms a bore having an inlet and an outlet, the inlet being adapted to accept the flowing liquid stream, and the outlet being adapted to form continuously replaced, hanging droplets of the liquid stream, and a collection device mounted below the outlet of the transfer tube for collecting the droplets. The apparatus includes a device for heating the liquid stream in the transfer tube to a temperature sufficient to cause partial evaporation of the carrier solvent from the hanging droplets but not exceeding the boiling point of the carrier solvent, and a device for heating the collection device to a temperature sufficient to cause further evaporation of the carrier solvent from the collected droplets. Also provided is a method for concentrating and collecting one or more analytes in a flowing liquid stream of a carrier solvent composed of one or more solvent components. The method includes the steps of introducing the liquid stream into a transfer tube which forms a bore having an inlet and an outlet, the inlet being adapted to accept the flowing liquid stream, and the outlet being adapted to form continuously replaced, hanging droplets of the liquid stream, and heating the liquid stream in the transfer tube while controlling the temperature of the liquid stream in the transfer tube to be sufficient to cause partial evaporation of the carrier solvent from the hanging droplets without exceeding the boiling point of the carrier solvent. The method allows the droplets to dislodge from the outlet, and the droplet is collected on a collection device mounted below the outlet of the transfer tube. The collection device is also heated to a temperature sufficient to cause further evaporation of the carrier solvent from the collected droplets.

Owner:LI LIANG

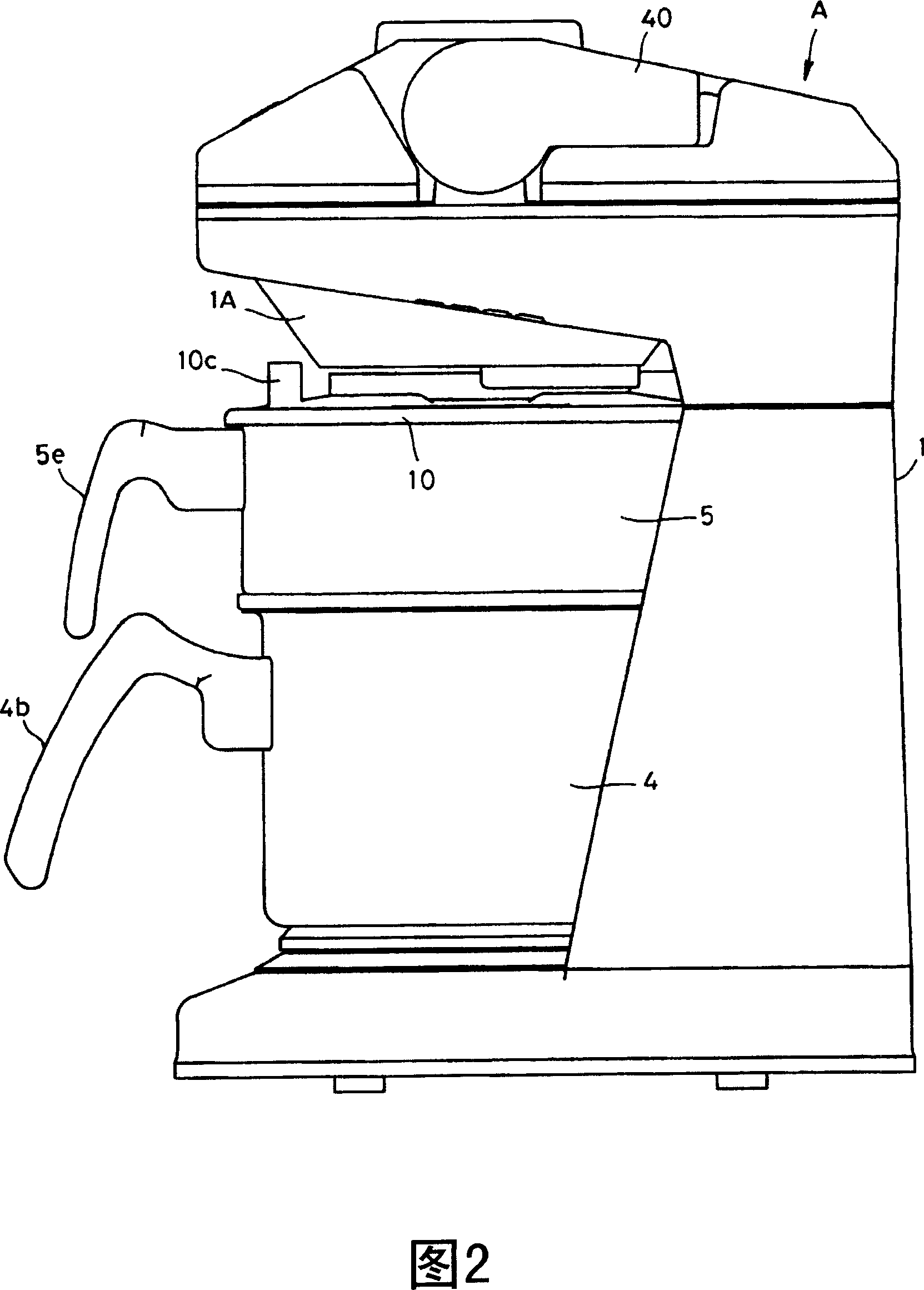

Nail care device

A personal nail care device comprises an elongate housing, a disk having a surface adapted to contact a nail of a user of the device, the disk made to rotate when the device is in an on condition and a catcher having a cavity extending therein for receipt within the cavity of nail dust and / or clippings created during the contact of the nail and the disk during the on condition, the catcher being selectively, removably attached to the housing for emptying the catcher of the dust and / or clippings. The catcher is removable from the housing using any known construction, including but not limited to rails and channel guides and / or protrusions and openings. The device also has a hood to substantially cover the top and sides of the disk to help prevent spraying of the dust and / or clippings during use of the device. The hood may consist of just a top and / or a top and sides and may be pivotally openable and / or fully removable from the housing.

Owner:KRISER GREGORY A

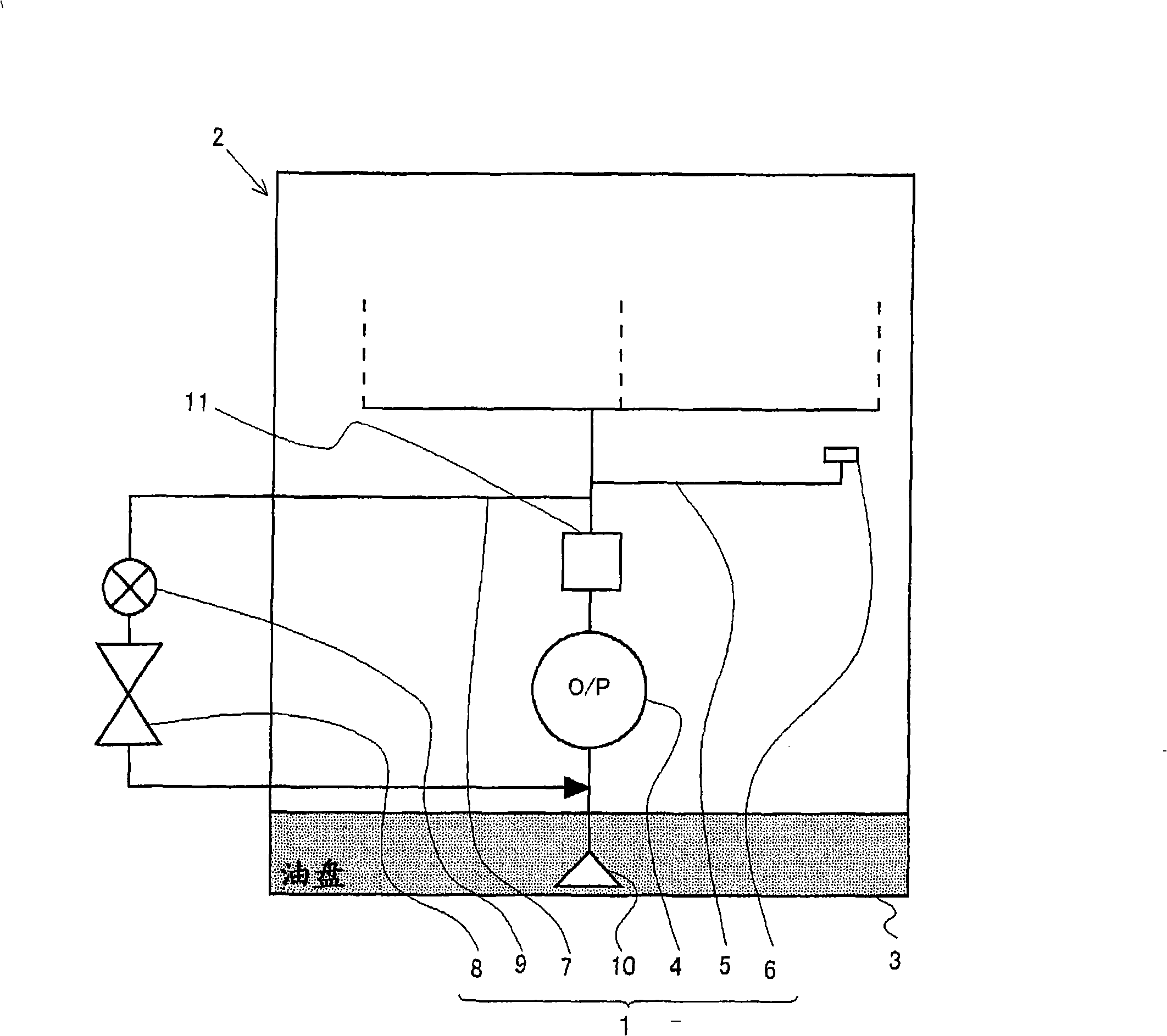

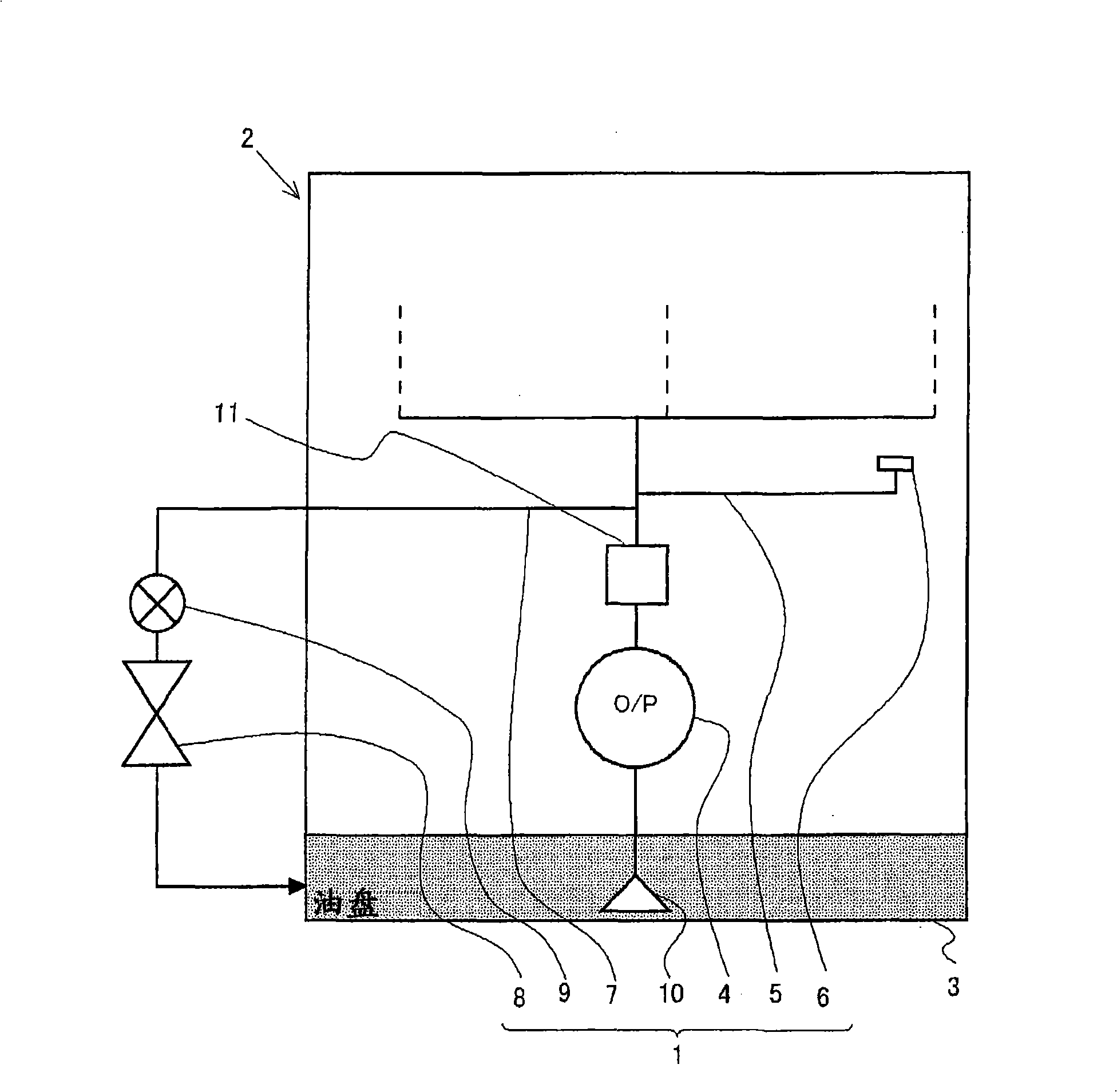

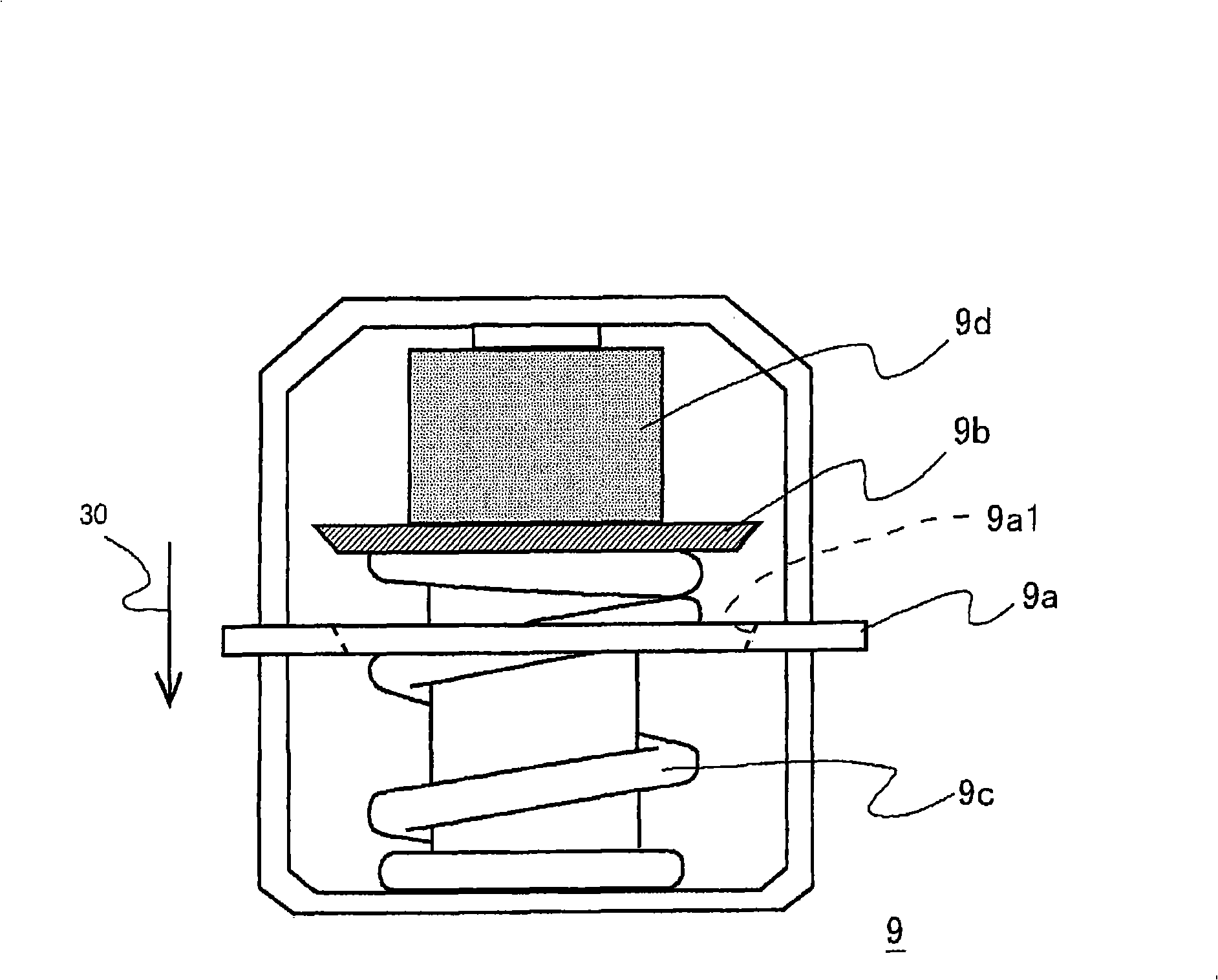

Hydraulic control device for engine

InactiveCN101287895APrevent sprayingReduce loadMachines/enginesLubrication pressure controlCrankshaftPiston

The present invention relates to a hydraulic control device (1) having an oil pump (4) for sucking oil from an oil pan (3) by rotation of a crankshaft, a piston jet (6) opened when the pressure of the oil sucked by the oil pump (4) reaches a valve opening pressure Qa and ejecting the oil through a oil ejection route (5) toward a piston, a relief valve (8) placed in an oil return route (7) and opening when the pressure of the oil sucked by the oil pump (4) reaches a valve opening pressure Qb, and a switchover valve (9) placed in the oil return path (7). The valve opening pressure Qb is set lower than the valve opening pressure Qa.

Owner:TOYOTA JIDOSHA KK

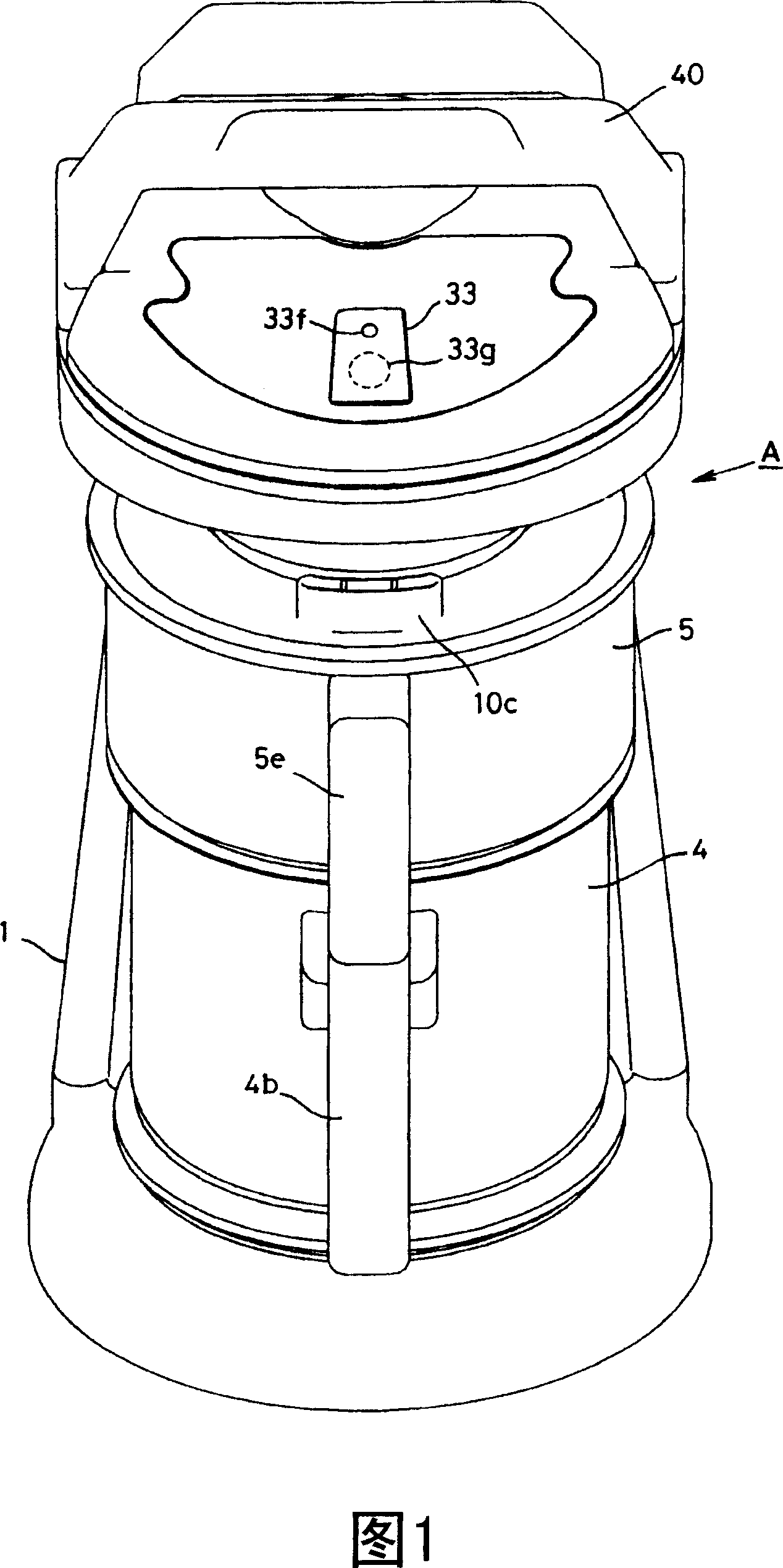

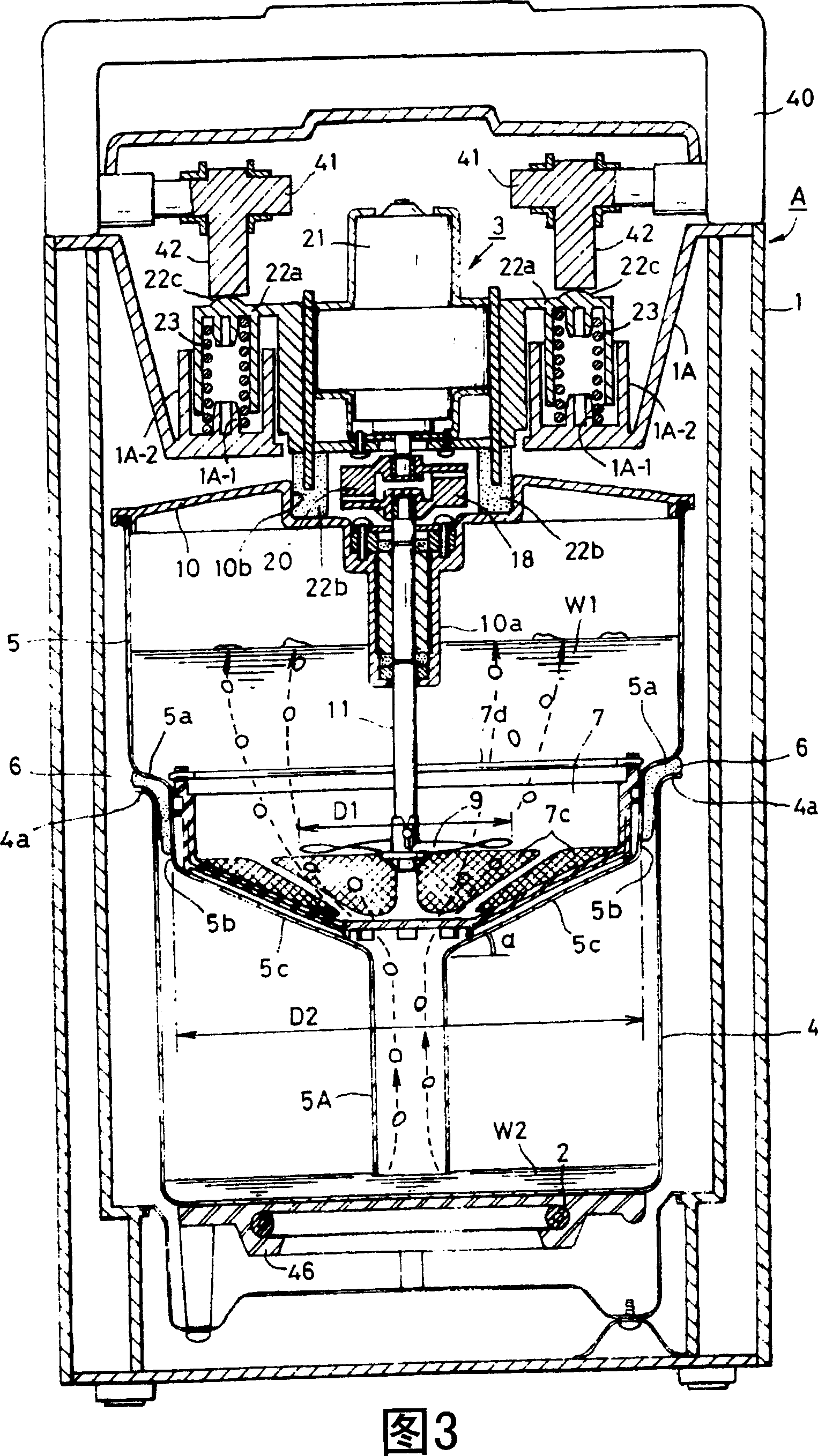

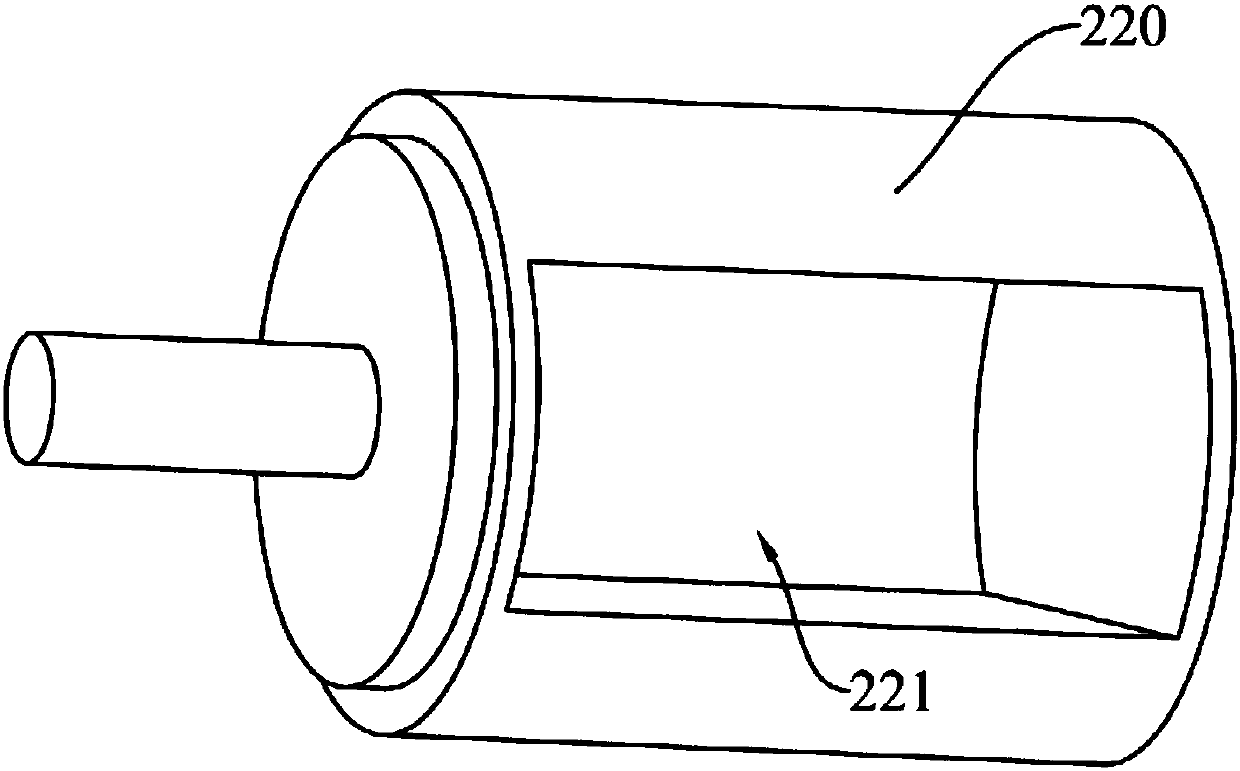

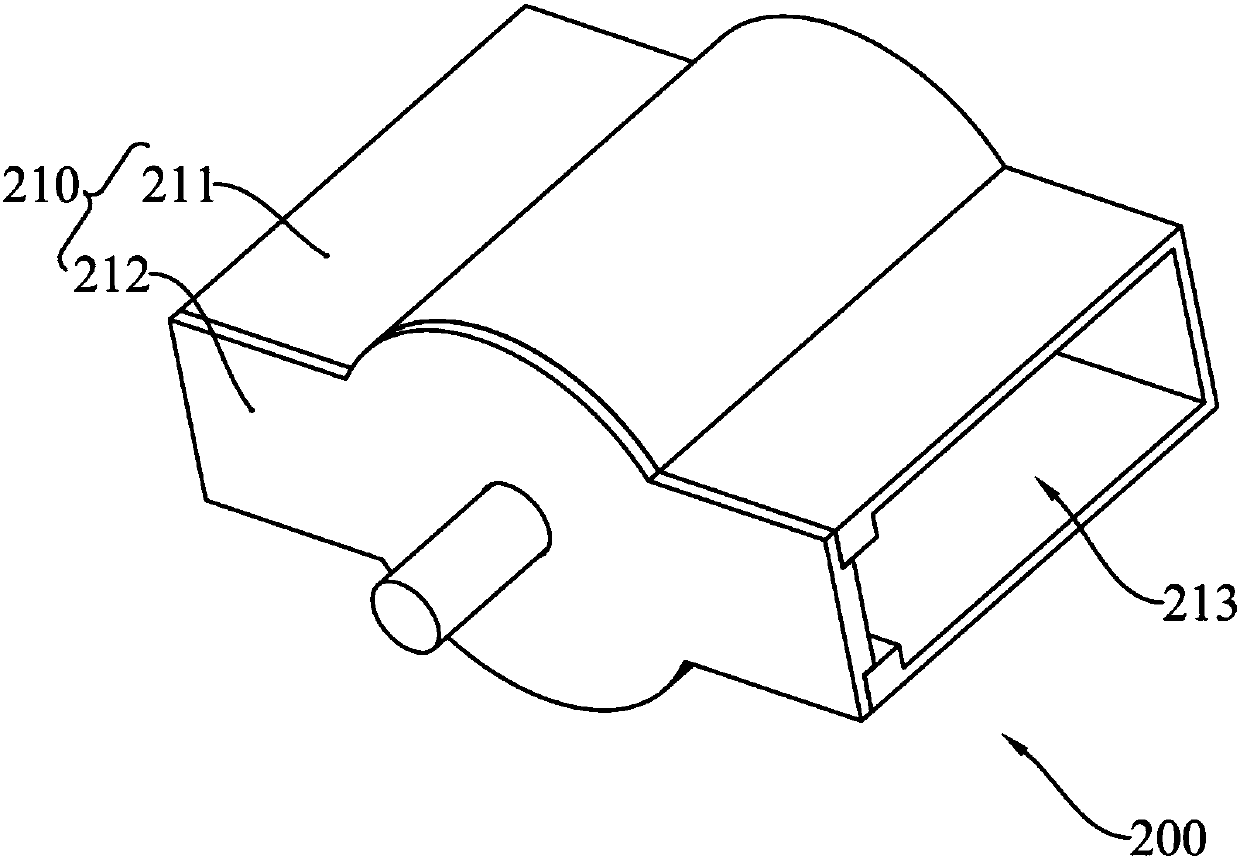

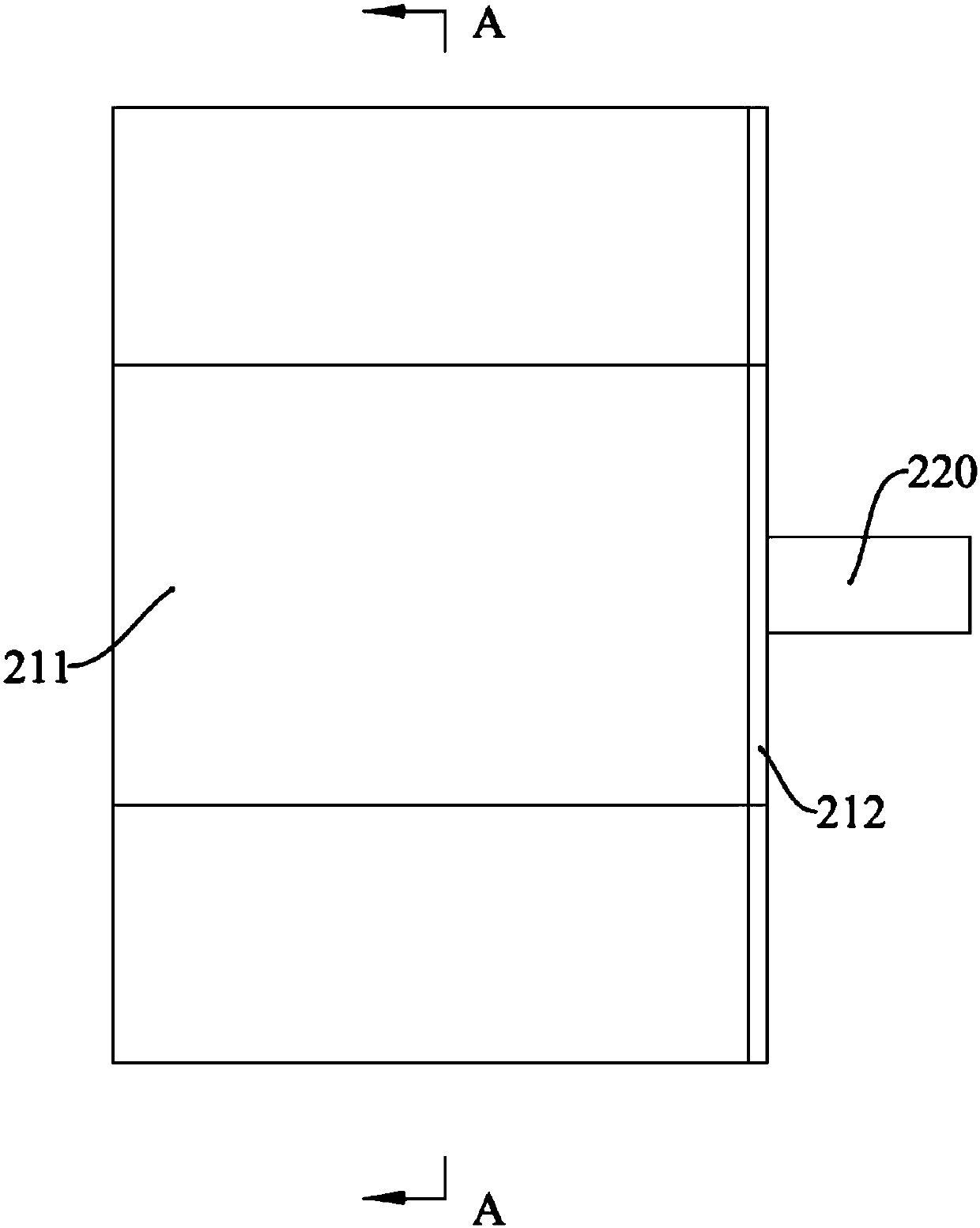

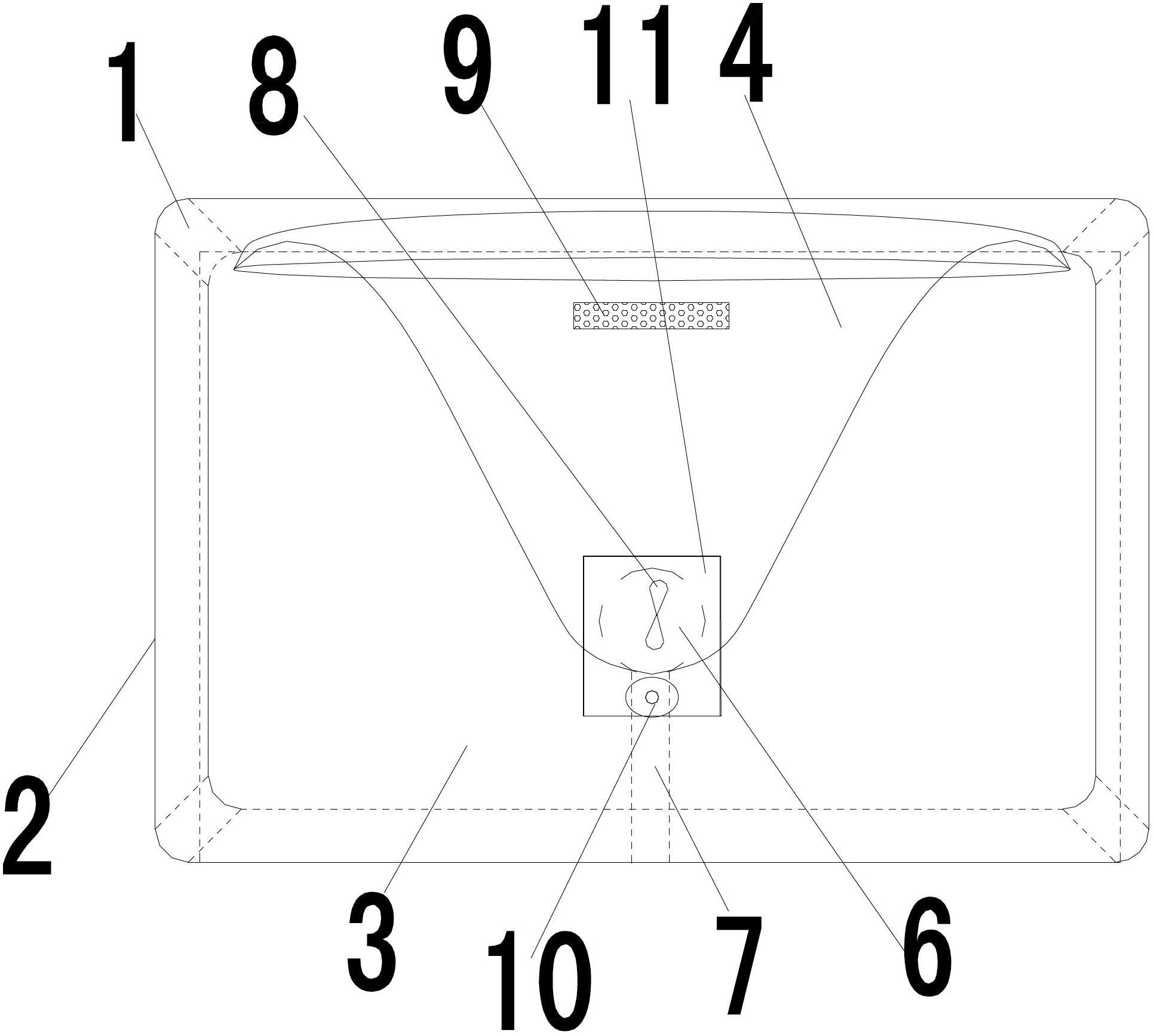

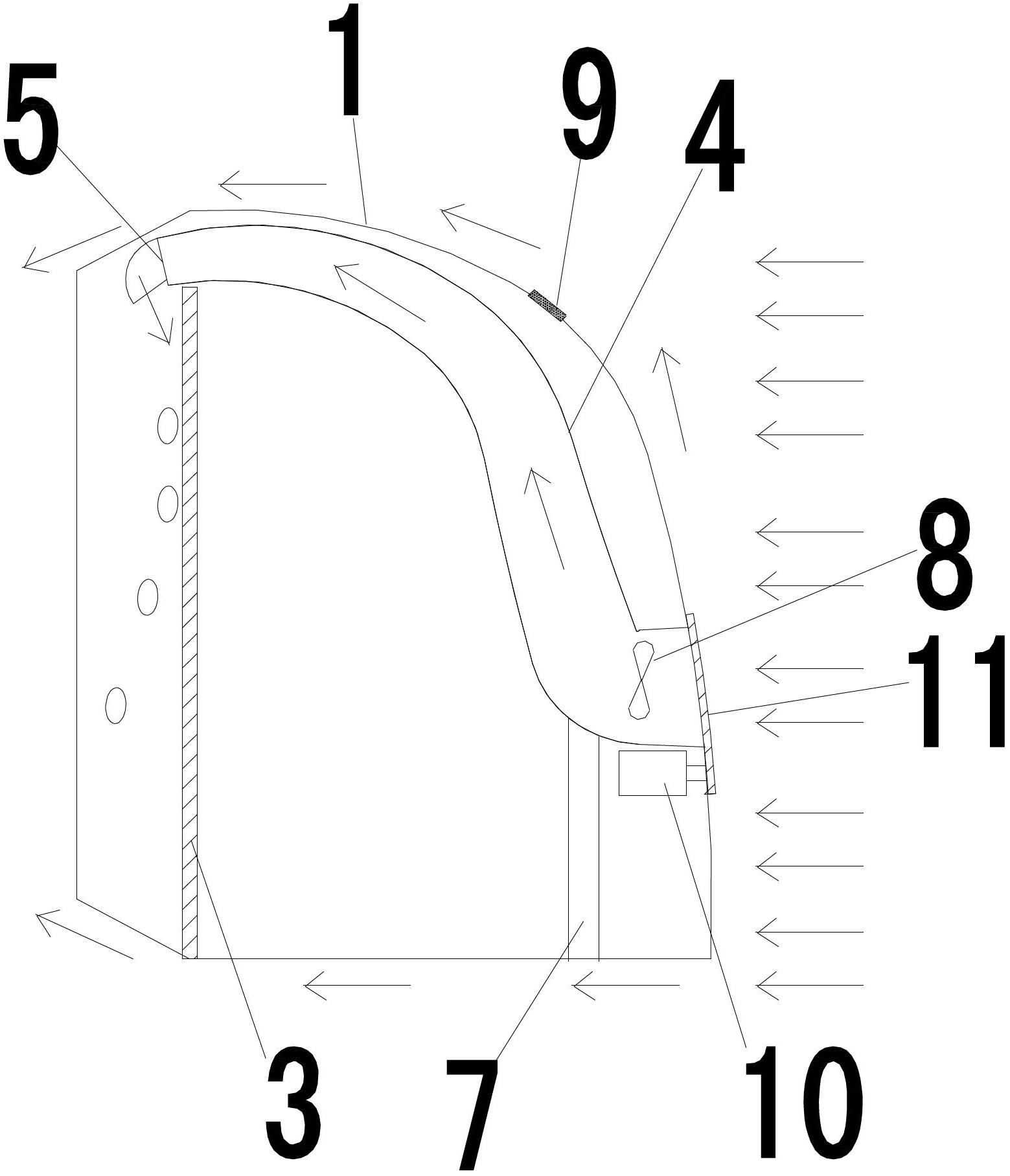

Vent structure, washing machine and control method

PendingCN110130053APrevent sprayingAvoid burnsOther washing machinesControl devices for washing apparatusPulp and paper industryHeat losses

The invention discloses a vent structure, a washing machine and a control method, and relates to the technical field of washing machines. The vent structure comprises a vent and a rotating body, wherein the vent is formed in a to-be-vented device and communicated with a chamber in the to-be-vented device; the rotating body is rotationally arranged at the vent, and a first connecting hole is formedin the rotating body in the radial direction in a penetrating manner and can be selectively communicated with the vent. According to the vent structure, the vent can be blocked or the connecting holein the rotating body can be communicated with the vent through rotation of the rotating body, so that the vent is selectively opened or closed; when the washing machine is in a washing state, the rotating body blocks the vent to prevent heat or washing water from being sprayed out of the vent, so that heat loss is prevented and burning of users is avoided; after washing of the washing machine iscompleted, the rotating body rotates to enable the connecting hole to be communicated with the vent, the inside and outside of the washing machine are communicated, moisture is discharged from the vent, and accordingly, mildew and peculiar smell of the washing machine or clothes in the washing machine are prevented.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

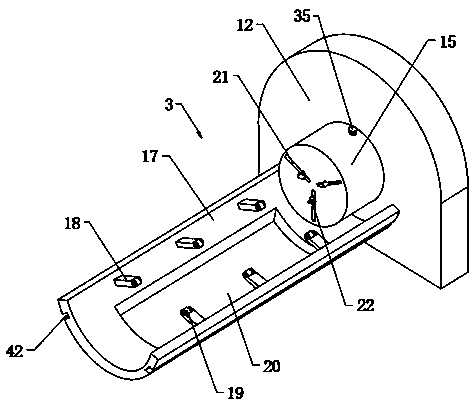

Separating walking device and special cotton chemical-applying machine with same

The invention provides a separating walking device and a special cotton chemical-applying machine with the same. The separating walking device comprises a separating walking shell which comprises a boot-shaped guiding assembly and connecting rods connected with the guiding assembly, the cross section of the guiding assembly is in a V shape, and the connecting rods are connected to the upper portion of the guiding assembly and arranged vertically. The separating walking device is in a V-type structure, and therefore crossed and complex cotton branches and leaves in the growth process are sequentially and conveniently separated backwards and upwards; the separated branches and leaves pass through the separating walking device and then rapidly and sequentially close, the cotton branches and leaves pass through an atomizing region during closing to be sufficiently stained with medicinal liquid droplets, and therefore the chemical-applying effect is improved.

Owner:NANTONG HUANGHAI CHEM MACHINERY

Rainproof rearview mirror

InactiveCN102689622ASimple structureLow failure rateVehicle cleaningOptical viewingTraffic accidentDrainage tubes

The invention discloses a rainproof rearview mirror which comprises a rearview mirror shell, a lens, an accelerating air duct, a water removal starting system and a water drainage tube. The lens is arranged on the front side of the rearview mirror shell, an air outlet of the accelerating air duct is arranged on the top of the lens, an air inlet of the accelerating air duct is arranged on the rear side of the rearview mirror shell, the water removal start system corresponds to the air inlet of the accelerating air duct, and the accelerating air duct is communicated with the bottom of the rearview mirror shell via the water drainage tube. The rainproof rearview mirror solves problems that a rainproof system in the prior art is complicated, is high in production cost and easy to cause mechanical faults, and the like, and has the advantages of simple structure, low production cost and fault rate, good rainproof effect, capabilities of saving energy and effectively reducing traffic accidents, and the like.

Owner:SOUTH CHINA AGRI UNIV

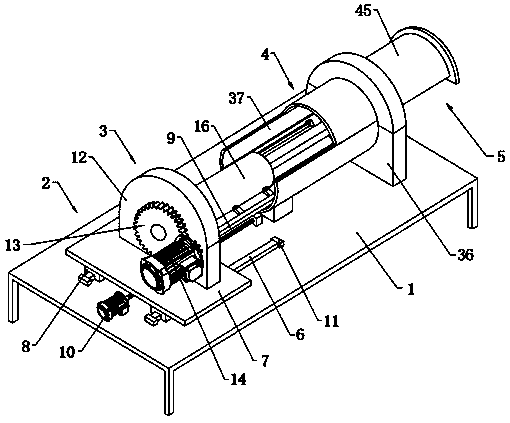

Automatic spraying machine for steel pipe

The invention discloses an automatic spraying machine for a steel pipe. The automatic spraying machine comprises a workbench, wherein a conveying mechanism and an in-pipe spraying mechanism are arranged at the two ends of the top of the workbench correspondingly; the conveying mechanism comprises a first sliding rail fixed to the top of the workbench, a bearing plate is arranged above the first sliding rail, and a sliding block matched with the first sliding rail is arranged at the bottom of the bearing plate; a first threaded rod and a first motor are further arranged at the top of the workbench, the bottom of the bearing plate is in threaded connection with the first threaded rod, and the first threaded rod is connected with the output end of the first motor; and a clamping rotating mechanism is arranged above the conveying mechanism, an out-pipe spraying mechanism is arranged above the in-pipe spraying mechanism, the steel pipe is clamped on the clamping rotating mechanism, and theclamping rotating mechanism is connected with the in-pipe spraying mechanism. According to the automatic spraying machine, the overall structure is arranged, so that the inner wall and the outer wallof the steel pipe can be automatically and uniformly sprayed, and the rust prevention capacity of the steel pipe can be improved; and meanwhile, the workload is greatly saved, the production cost is reduced, and the production efficiency is improved.

Owner:上海翎航动力科技有限公司

Degreasing agent used for workpieces, preparation method and workpiece surface spraying pretreatment method

ActiveCN108384645AGood degreasingImprove washing effectInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholPretreatment method

The invention relates to a degreasing agent used for workpieces, a preparation method and a workpiece surface spraying pretreatment method. The degreasing agent includes 3-5% by mass of a component A,3-5% by mass of a component B and the balance of tap water or deionized water, wherein the component A includes deionized water, an inorganic base, a complexing agent and a compounded low-foam solubilizing surfactant, and a mass ratio of the deionized water to the inorganic base to the complexing agent to the compounded low-foam solubilizing surfactant is (65-70):(15-25):(1-2):(8-14); and the component B includes deionized water, a complexing dispersant, a corrosion inhibitor, a low-foam solubilizer, an end-capped / modified isomeric alcohol ether surfactant and a modified polyether, and a massratio of the deionized water to the complexing dispersant to the corrosion inhibitor to the low-foam solubilizer to the end-capped / modified isomeric alcohol ether surfactant to the modified polyetheris (50-70):(1-2):(0-5):(5-10):(8-15):(8-25). The degreasing agent provided by the invention can be used at room temperature during spraying, has an excellent degreasing effect, and does not generatea large amount of foam; and the method for preparing the degreasing agent and the workpiece surface spraying pretreatment method which uses the degreasing agent have simple operation, and are suitablefor mass production.

Owner:佛山科富科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com